Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

275 results about "Damage tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Damage tolerance is a property of a structure relating to its ability to sustain defects safely until repair can be effected. The approach to engineering design to account for damage tolerance is based on the assumption that flaws can exist in any structure and such flaws propagate with usage. This approach is commonly used in aerospace engineering, mechanical engineering, and civil engineering to manage the extension of cracks in structure through the application of the principles of fracture mechanics. In engineering, a structure is considered to be damage tolerant if a maintenance program has been implemented that will result in the detection and repair of accidental damage, corrosion and fatigue cracking before such damage reduces the residual strength of the structure below an acceptable limit.

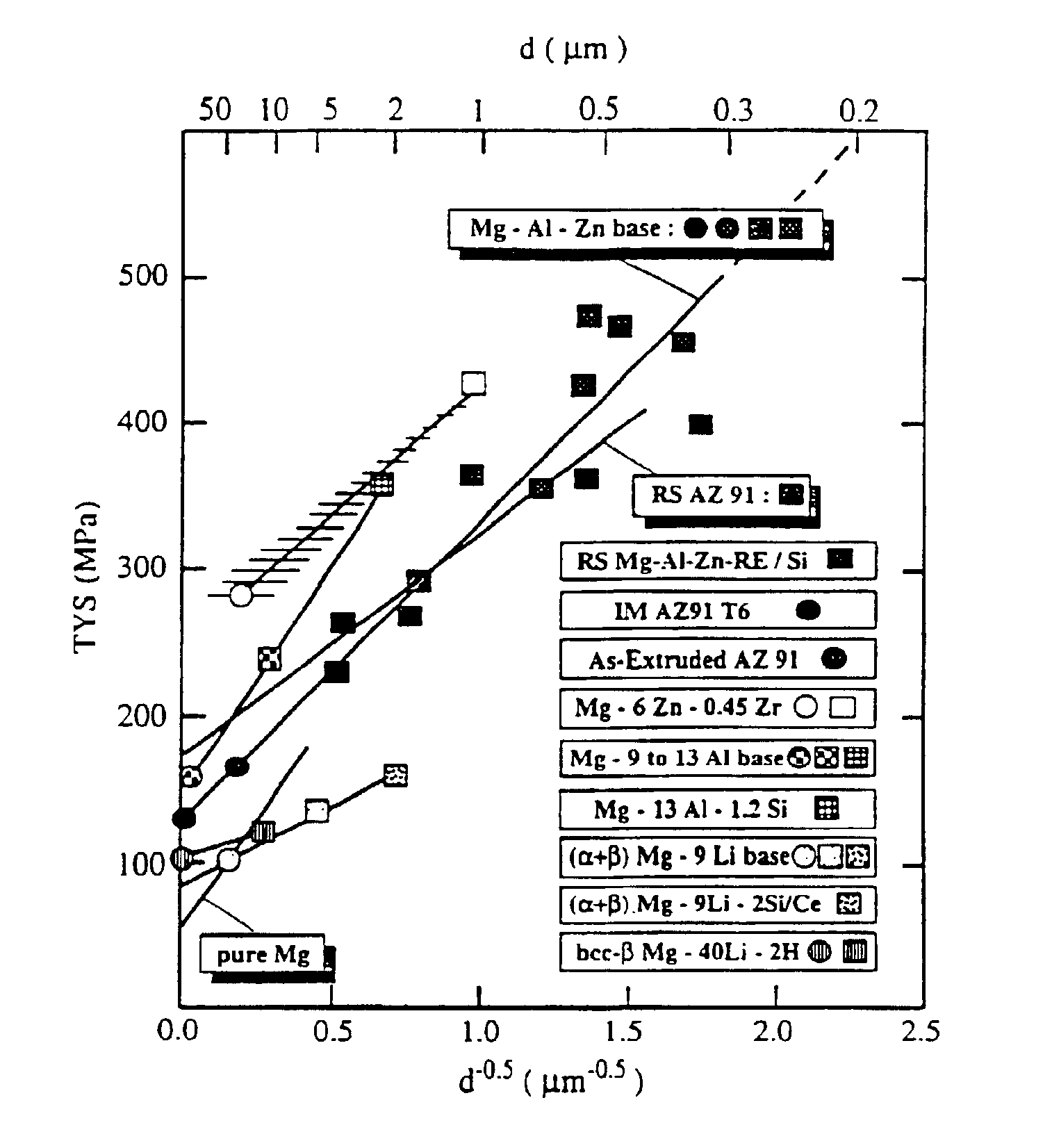

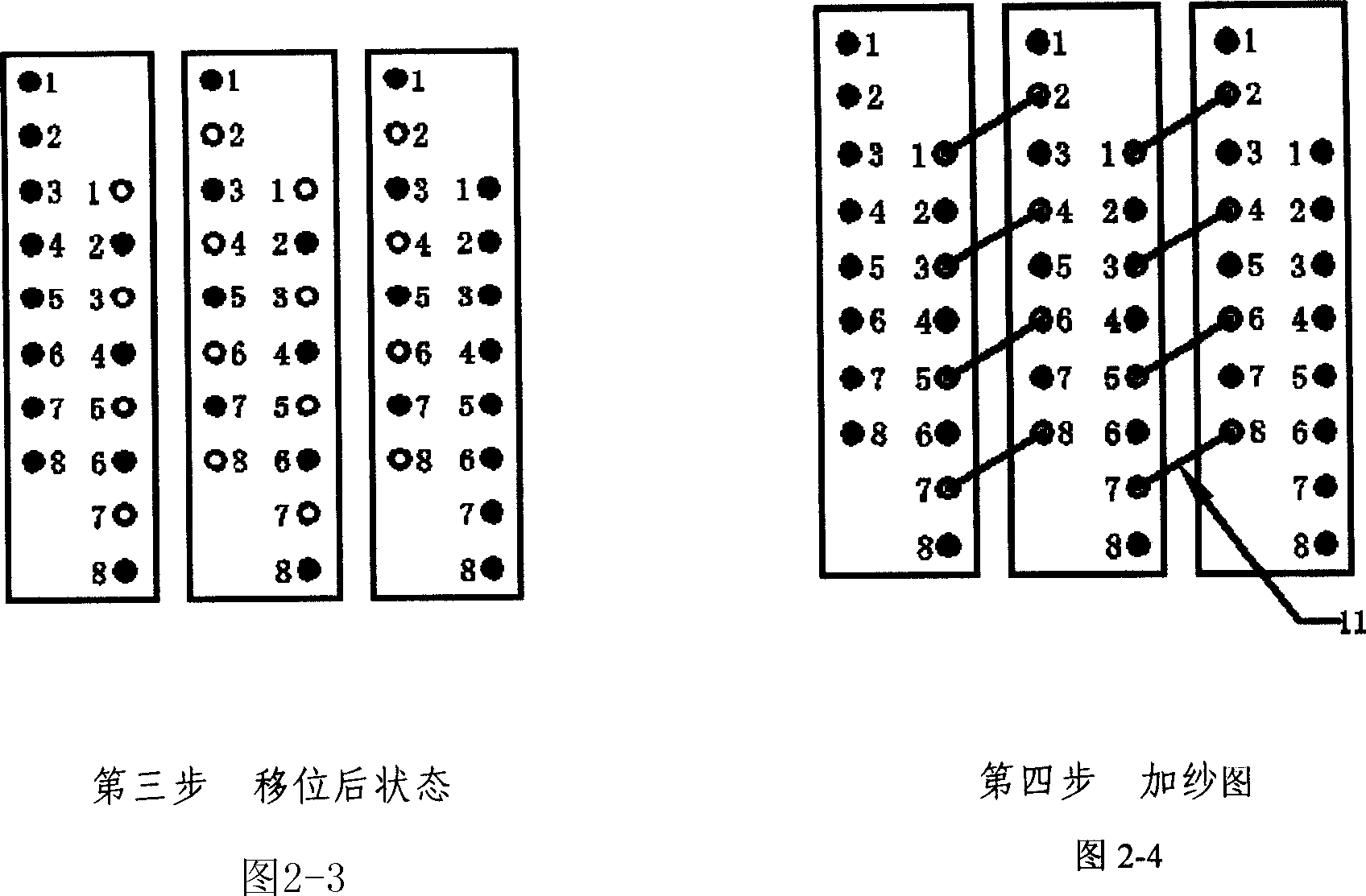

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

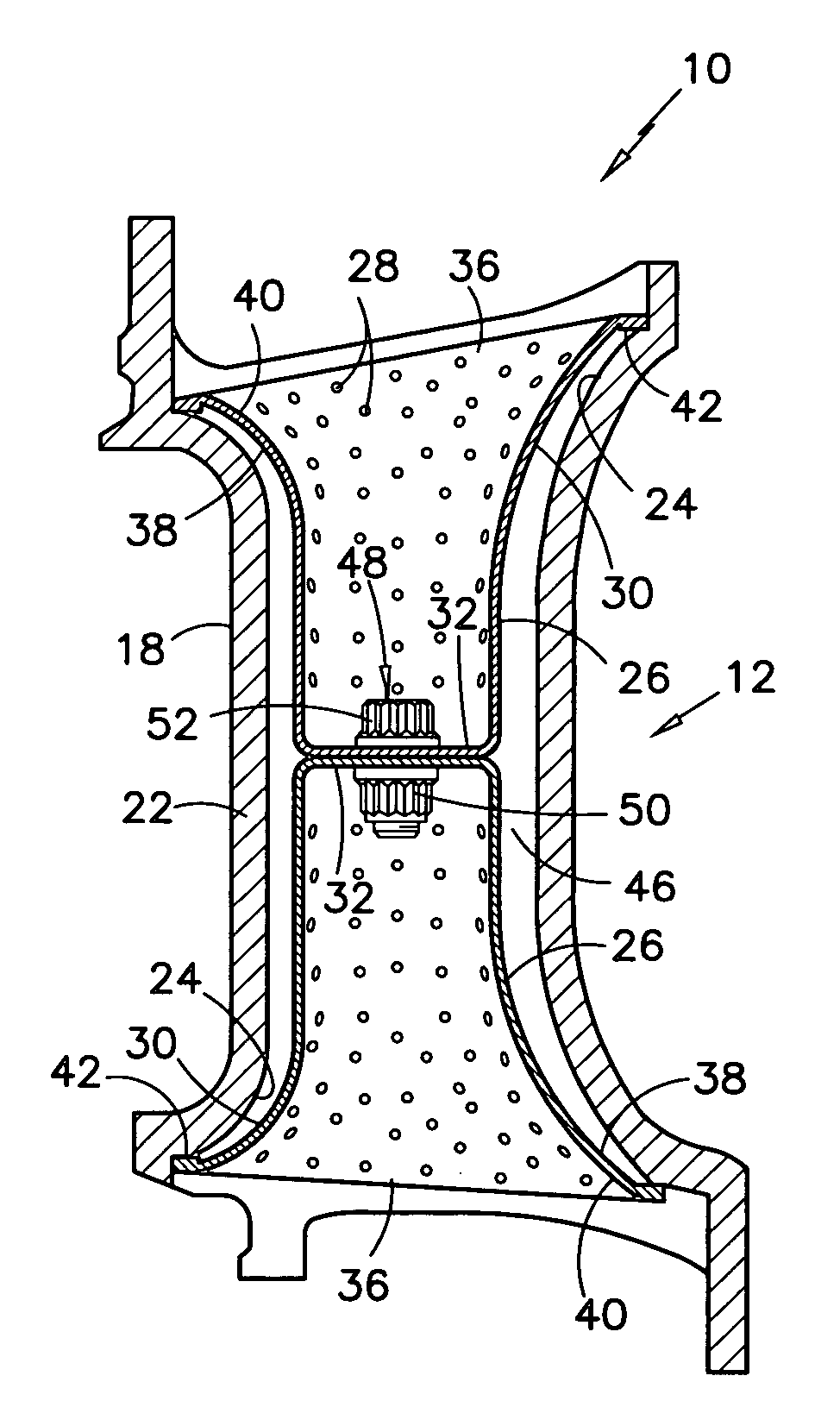

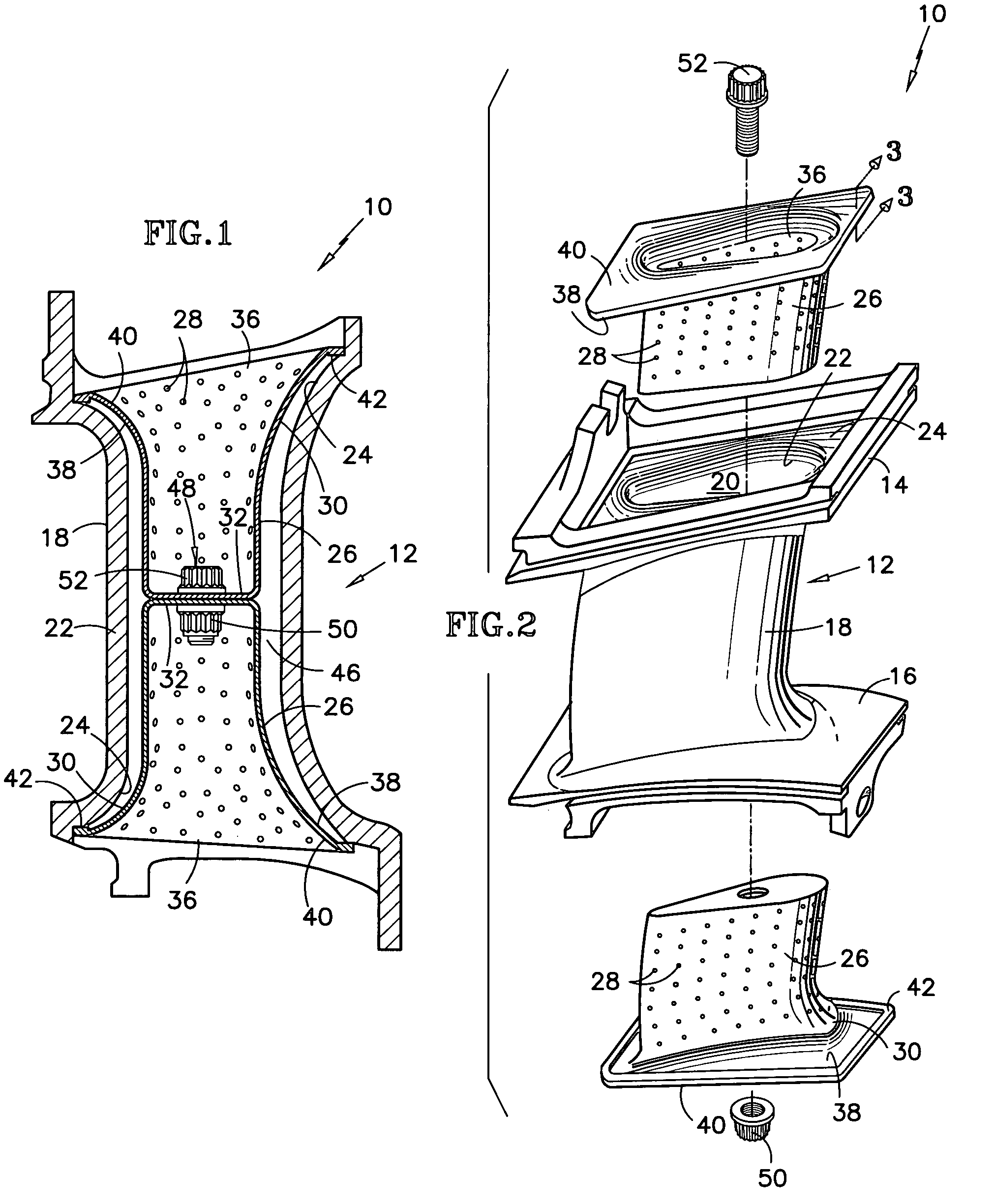

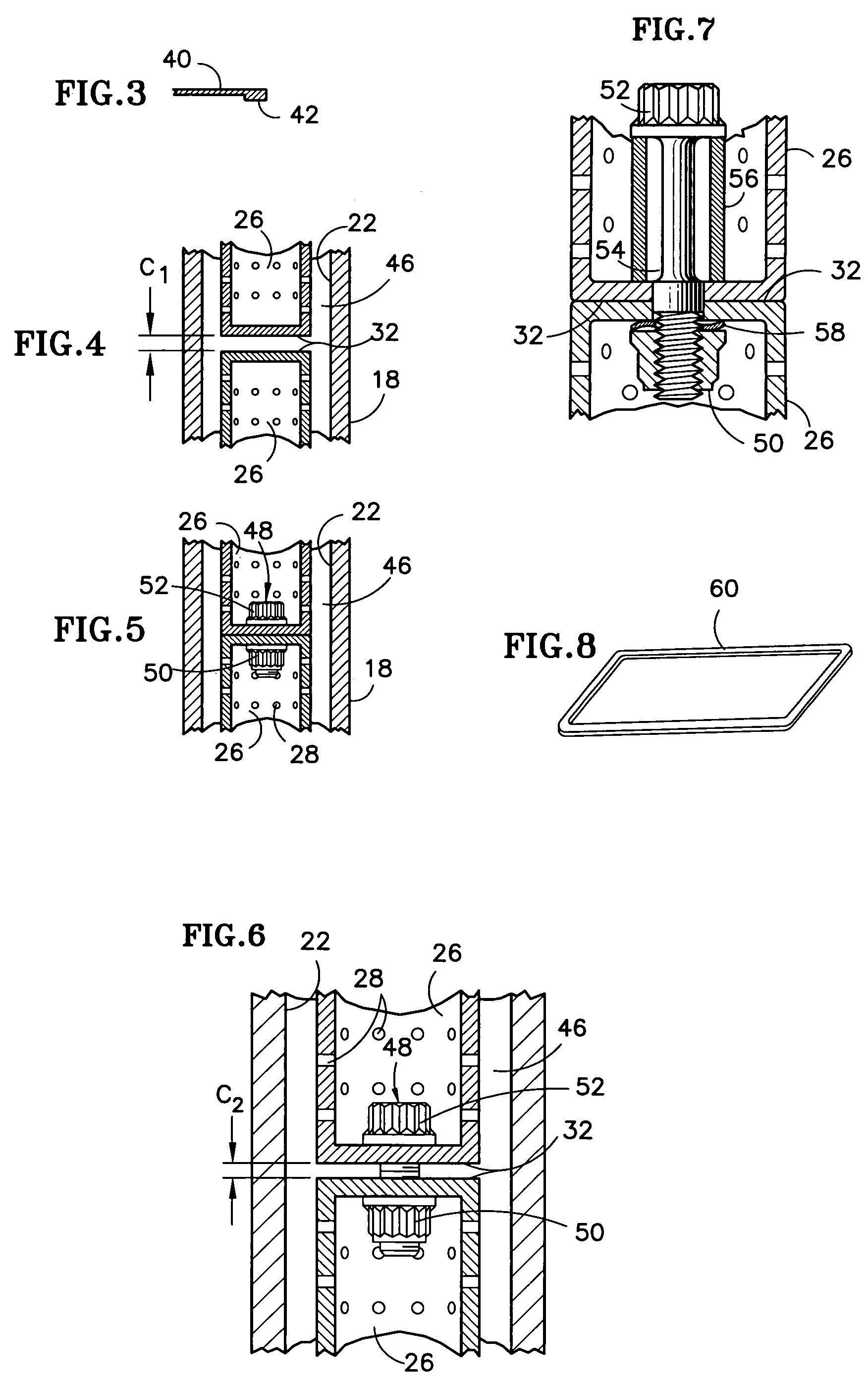

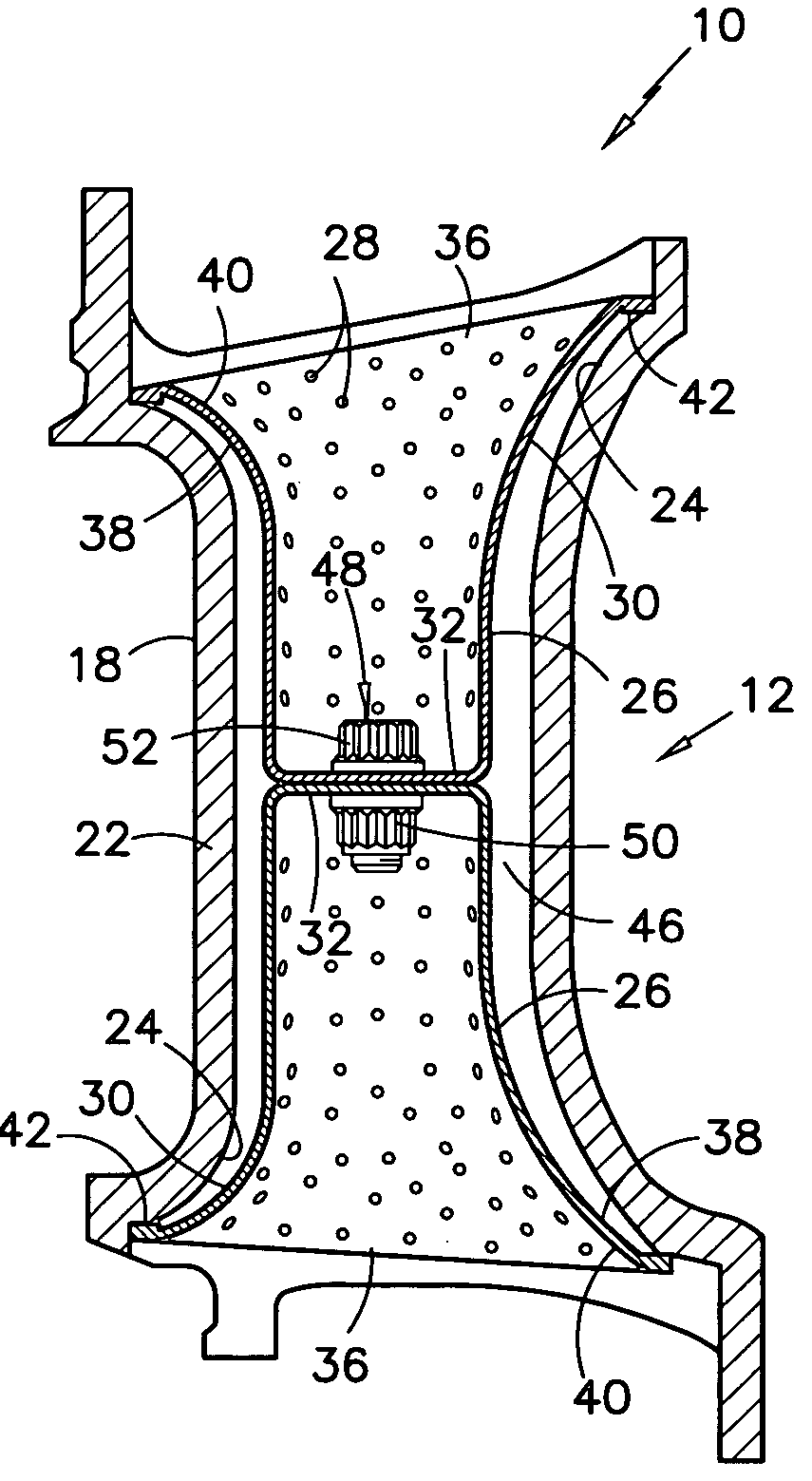

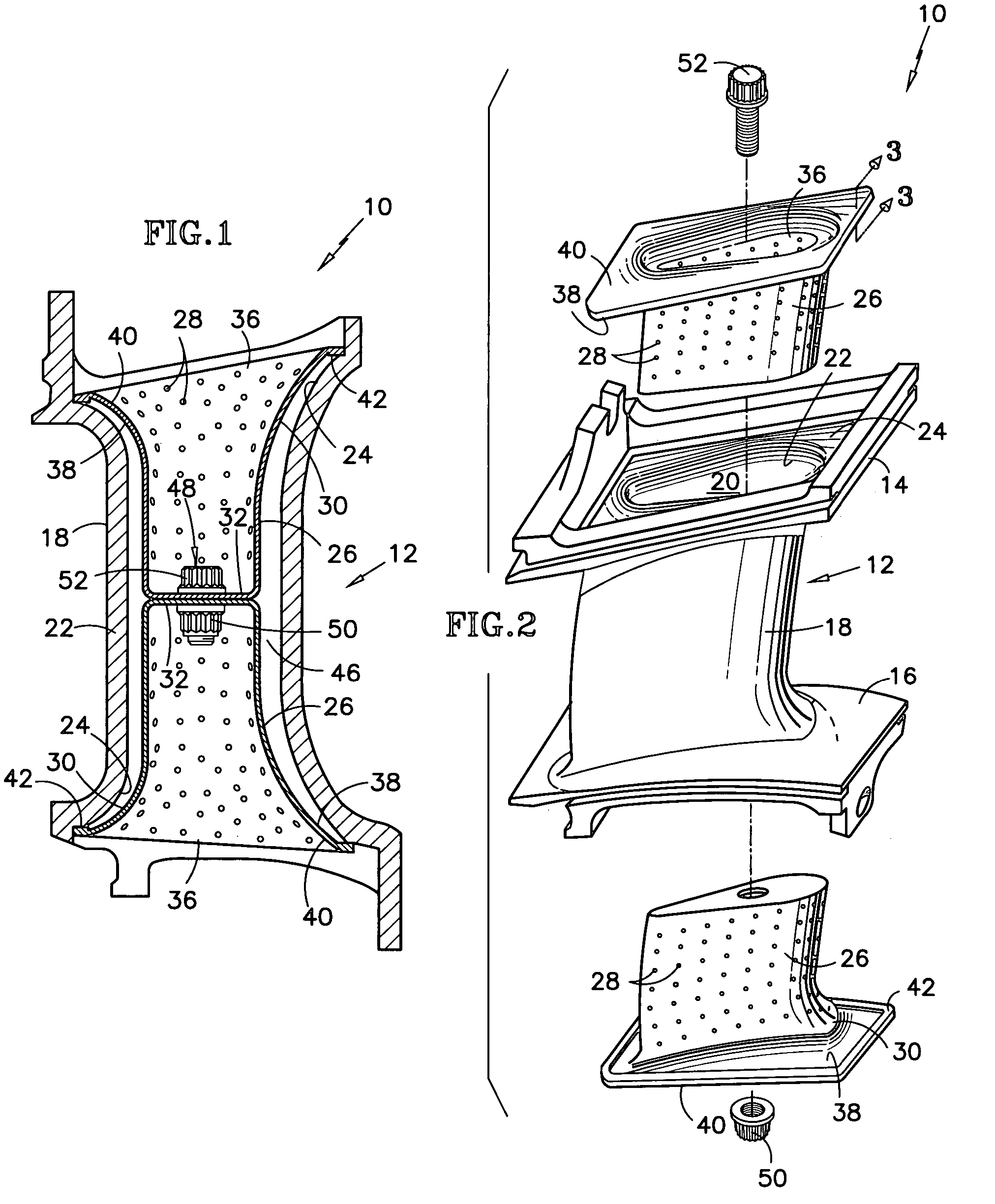

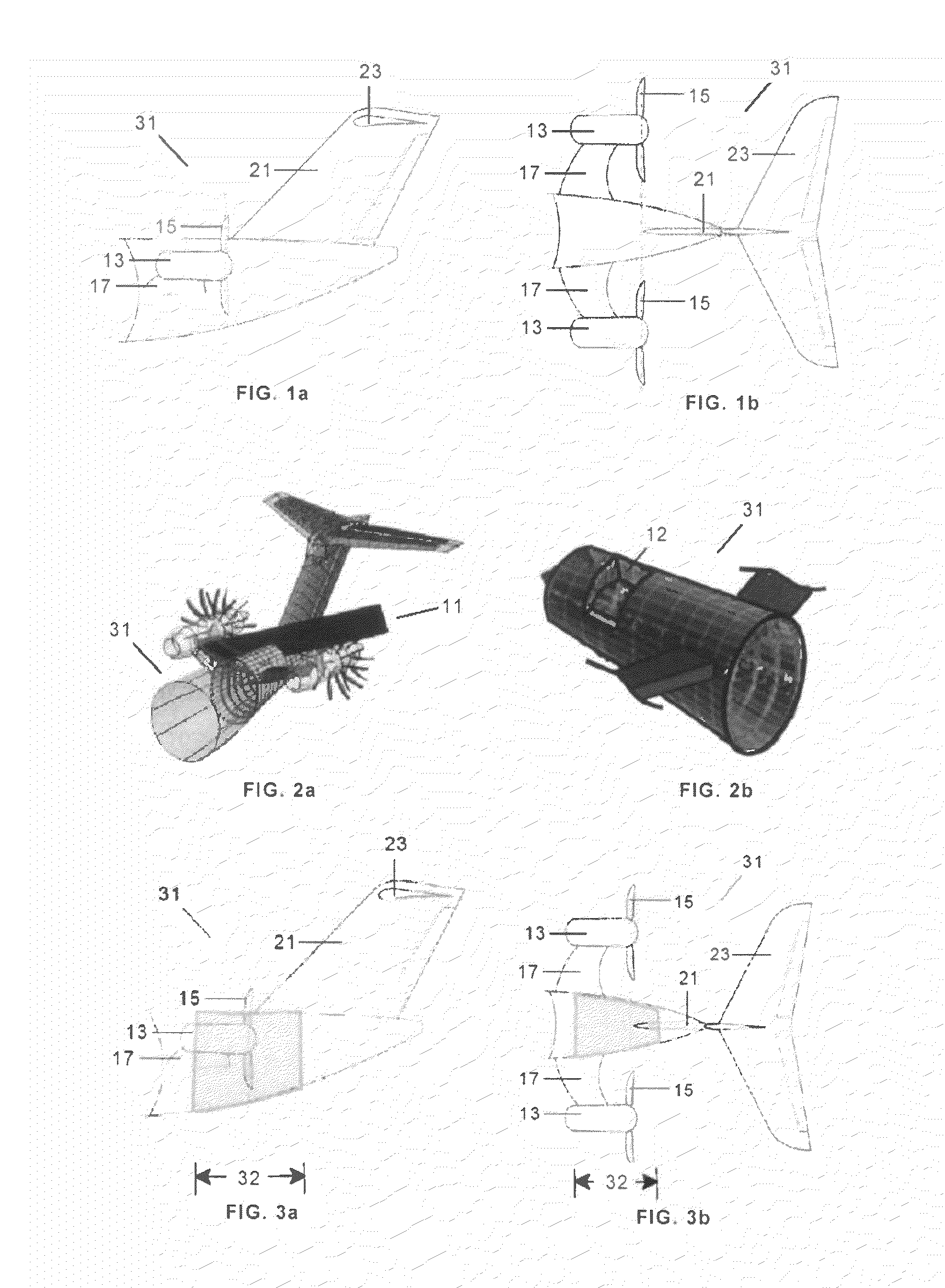

Temperature tolerant vane assembly

A vane assembly 10 suitable for a turbine engine features a refractory vane 12 with an internal cavity 20 and a pair of flexible metallic baffles 26 extending into the cavity from spanwisely opposite ends of the vane. A rigid fastener 48, such as a nut and bolt assembly applies a tensile load to the baffles. The tensile load is reacted out as a compressive load applied to the vane. In another embodiment, the baffle is relatively rigid but the fastener is flexible. The compressive loading exerted on the vane counteracts the brittleness customarily exhibited by refractory materials and imparts damage tolerance to the vane. The arrangement also allows the use of a metal baffle that can be easily secured to the vane and dispenses with any need for a potentially troublesome seal between the baffles and the spanwise extremities of the vane.

Owner:RTX CORP

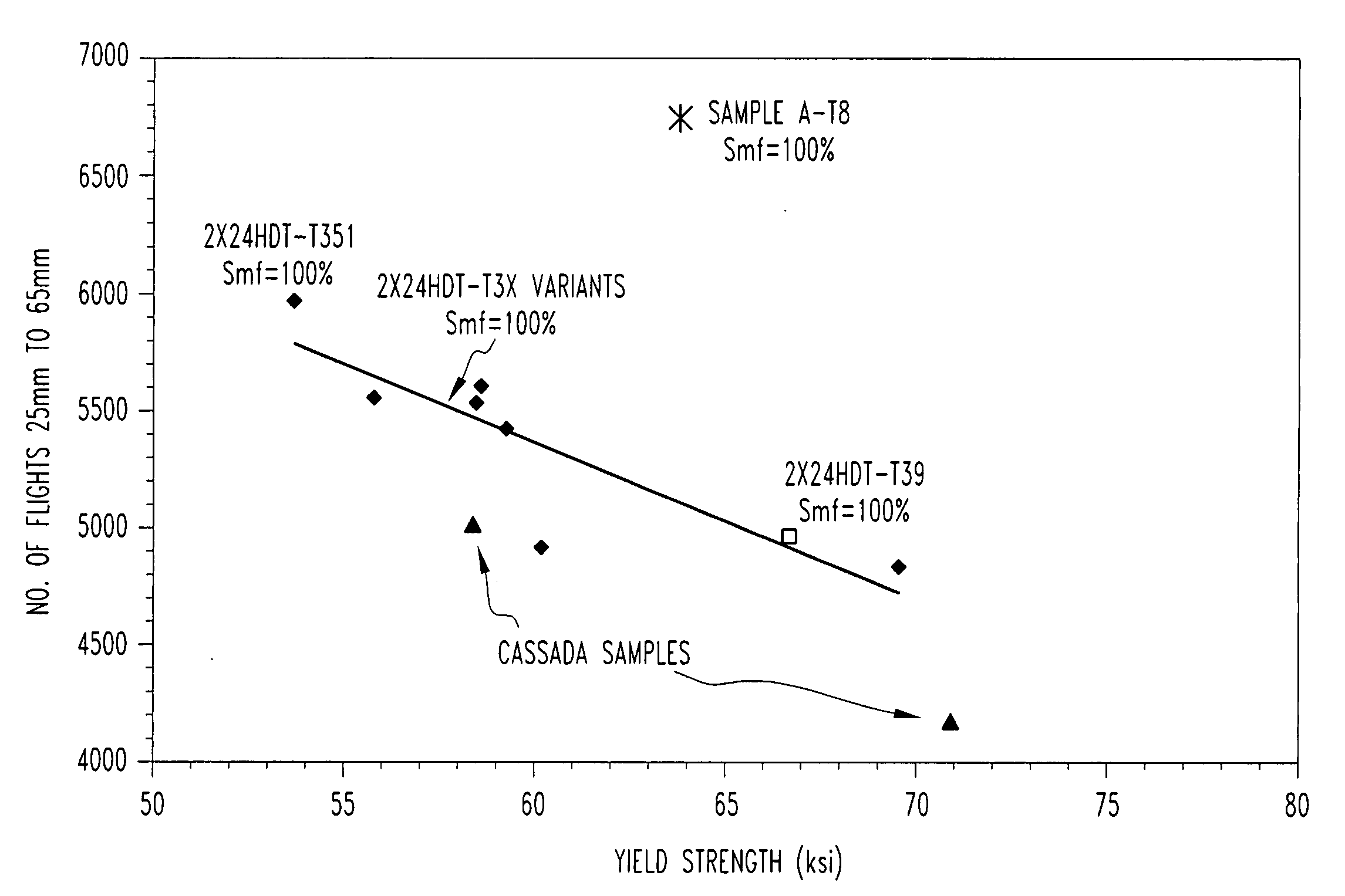

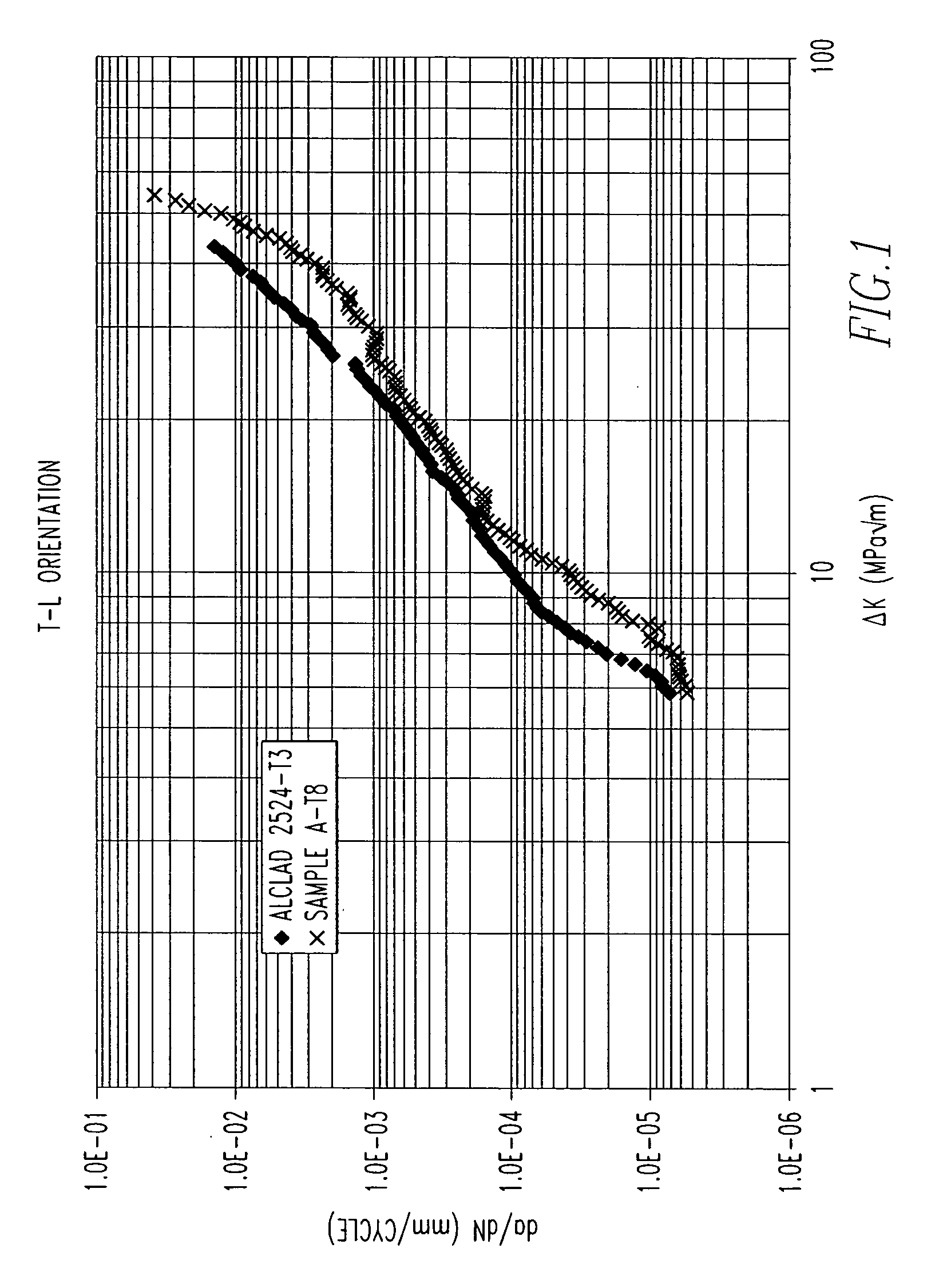

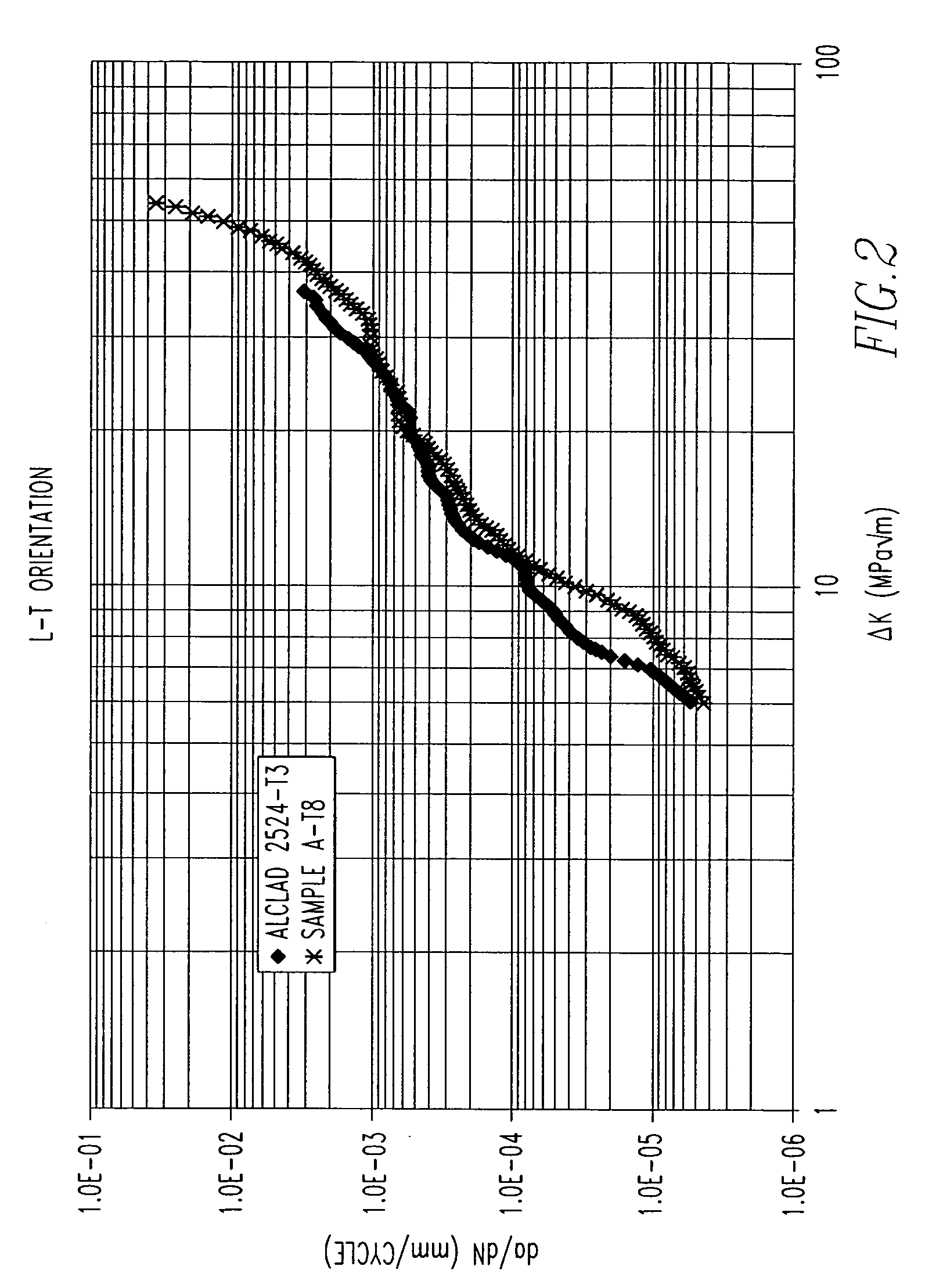

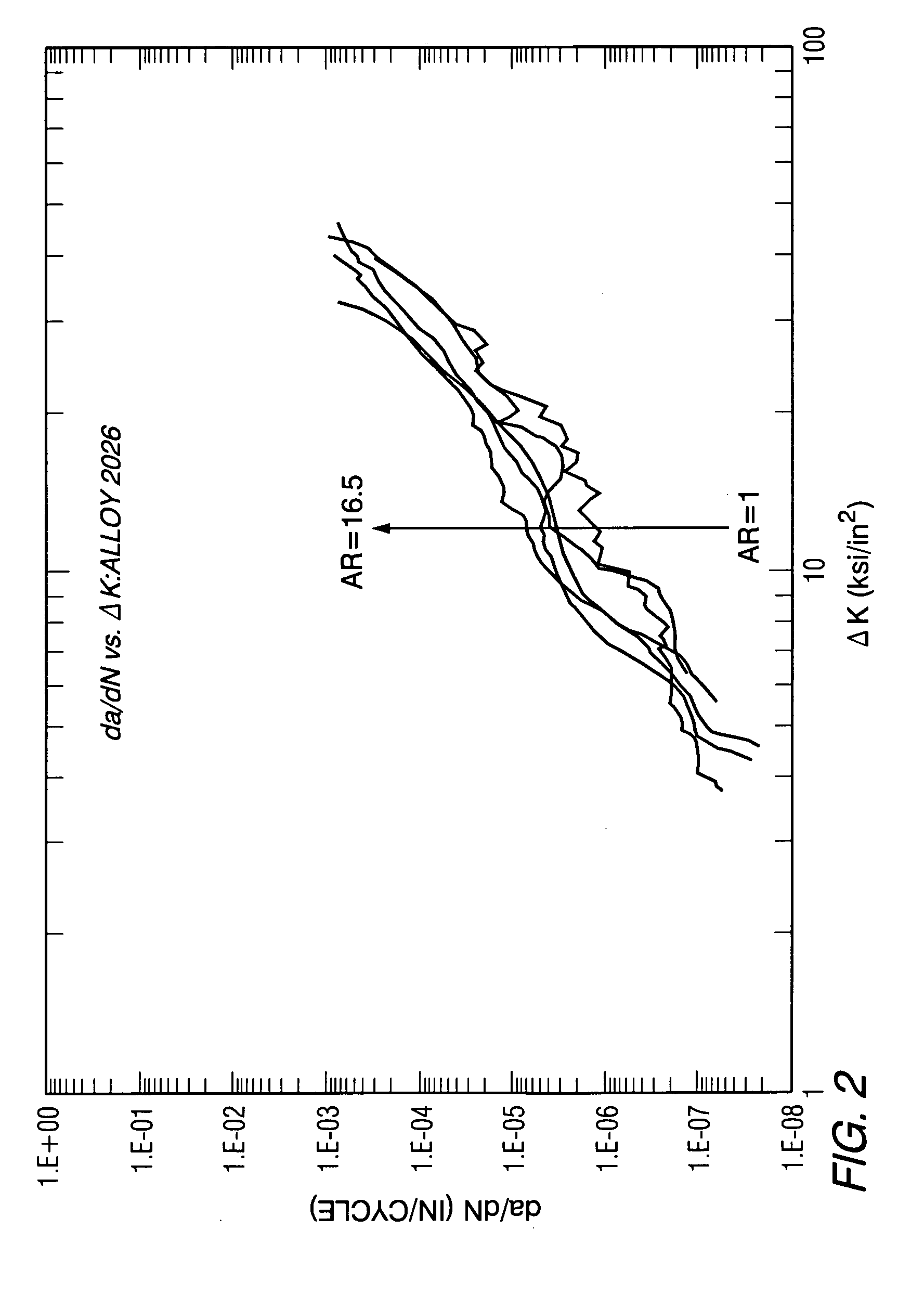

2000 Series alloys with enhanced damage tolerance performance for aerospace applications

The invention provides a 2000 series aluminum alloy having enhanced damage tolerance, the alloy consisting essentially of about 3.0-4.0 wt % copper; about 0.4-1.1 wt % magnesium; up to about 0.8 wt % silver; up to about 1.0 wt % Zn; up to about 0.25 wt % Zr; up to about 0.9 wt % Mn; up to about 0.5 wt % Fe; and up to about 0.5 wt % Si, the balance substantially aluminum, incidental impurities and elements, said copper and magnesium present in a ratio of about 3.6-5 parts copper to about 1 part magnesium. The alloy is suitable for use in wrought or cast products including those used in aerospace applications, particularly sheet or plate structural members, extrusions and forgings, and provides an improved combination of strength and damage tolerance.

Owner:ARCONIC TECH LLC

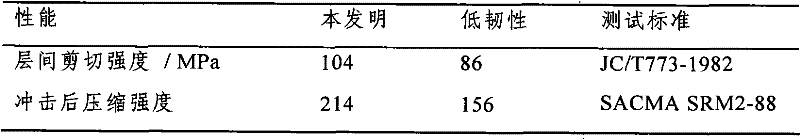

Pre-impregnated composite materials with improved performance

ActiveUS20080081170A1High of damageHigh of strengthSynthetic resin layered productsGlass/slag layered productsEpoxyShell molding

Pre-impregnated composite material (prepreg) is provided that can be molded to form composite parts that have high levels of both strength and damage tolerance without causing any substantial negative impact upon the physical or chemical characteristics of the uncured prepreg or cured part. This is achieved by including in the matrix resin a substantial amount of a multifunctional aromatic epoxy resin that has at least one phenyl group that is meta-substituted.

Owner:HEXCEL +1

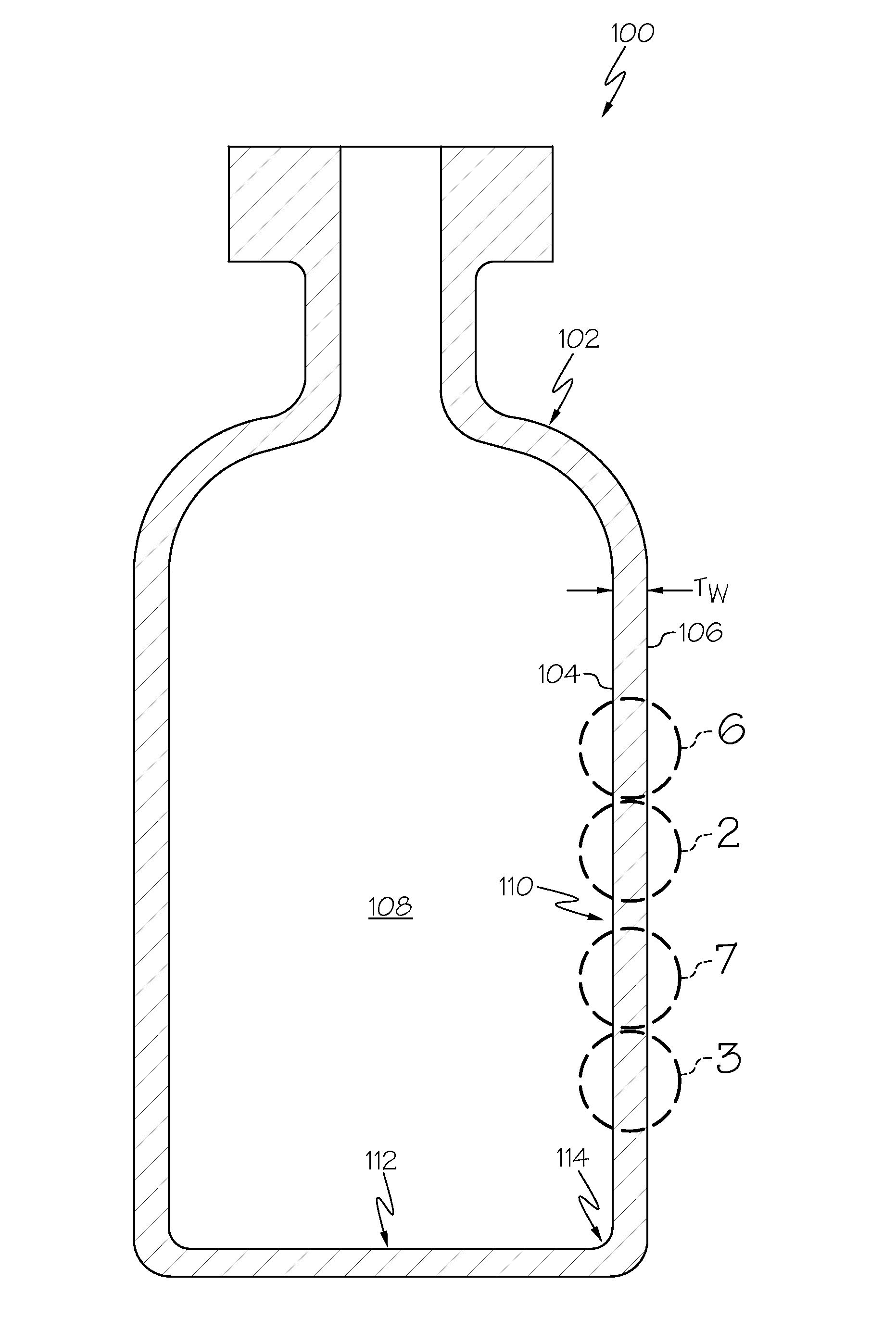

Glass containers with delamination resistance and improved damage tolerance

The glass containers described herein have at least two performance attributes selected from resistance to delamination, improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. A tenacious inorganic coating may be positioned around at least a portion of the outer surface of the body. The outer surface of the body with the tenacious inorganic coating may have a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

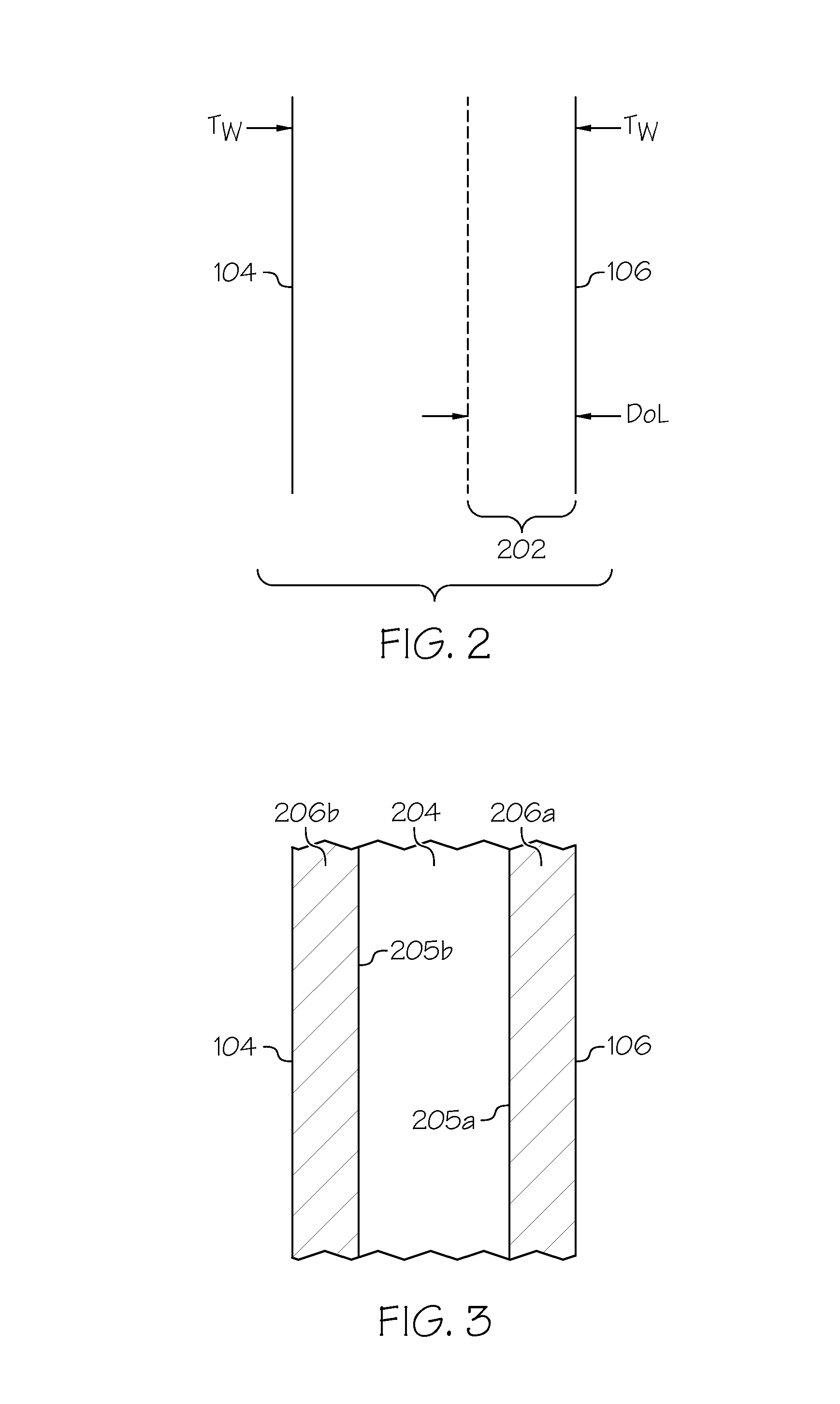

Strengthened borosilicate glass containers with improved damage tolerance

According to one embodiment, a glass container may include a body formed from a Type I, Class B glass composition according to ASTM Standard E438-92. The body may have an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. The body may also include a compressively stressed layer extending into the wall thickness from at least one of the outer surface and the inner surface. A lubricous coating may be positioned on at least a portion of the outer surface of the body, wherein the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

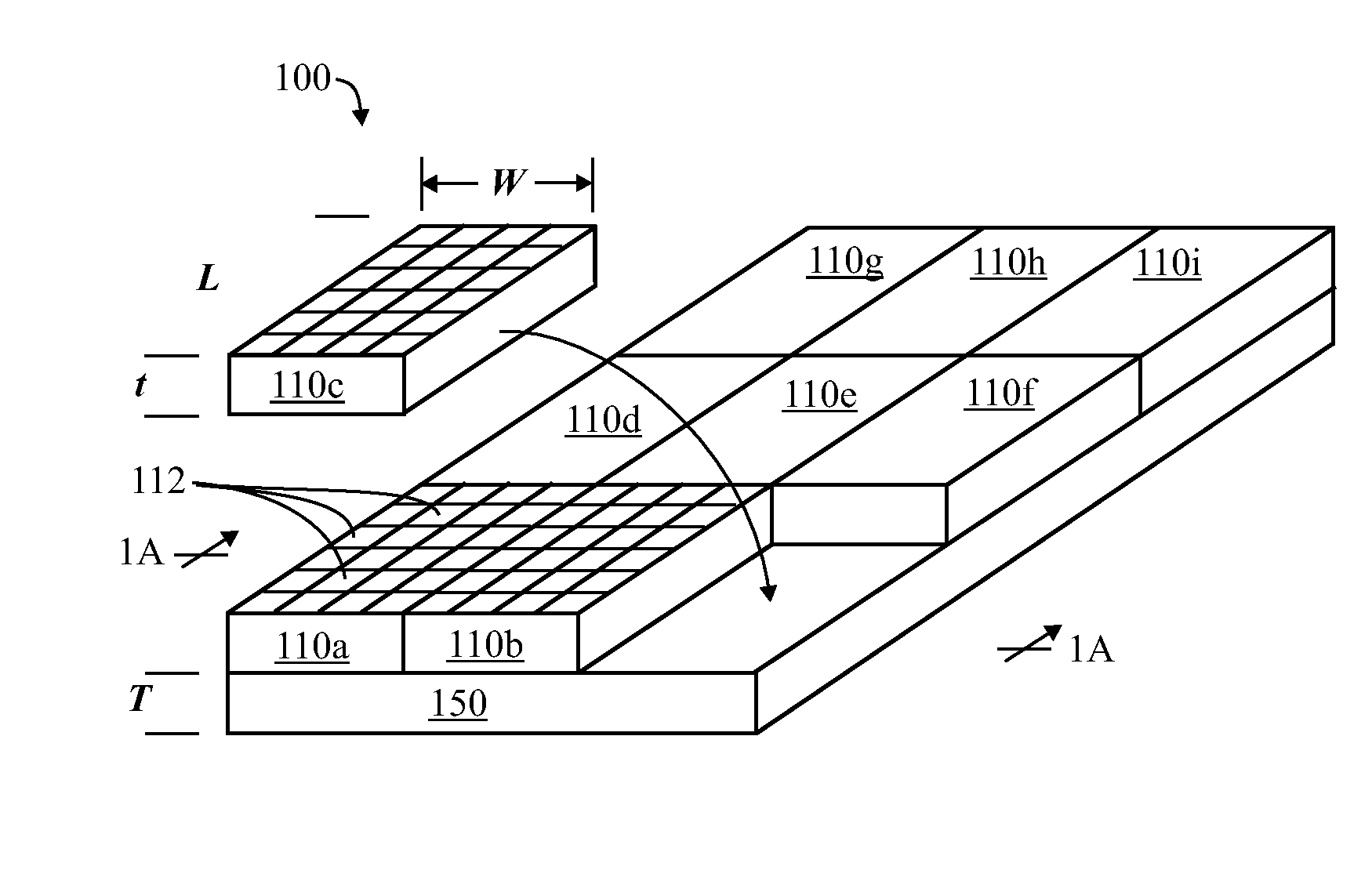

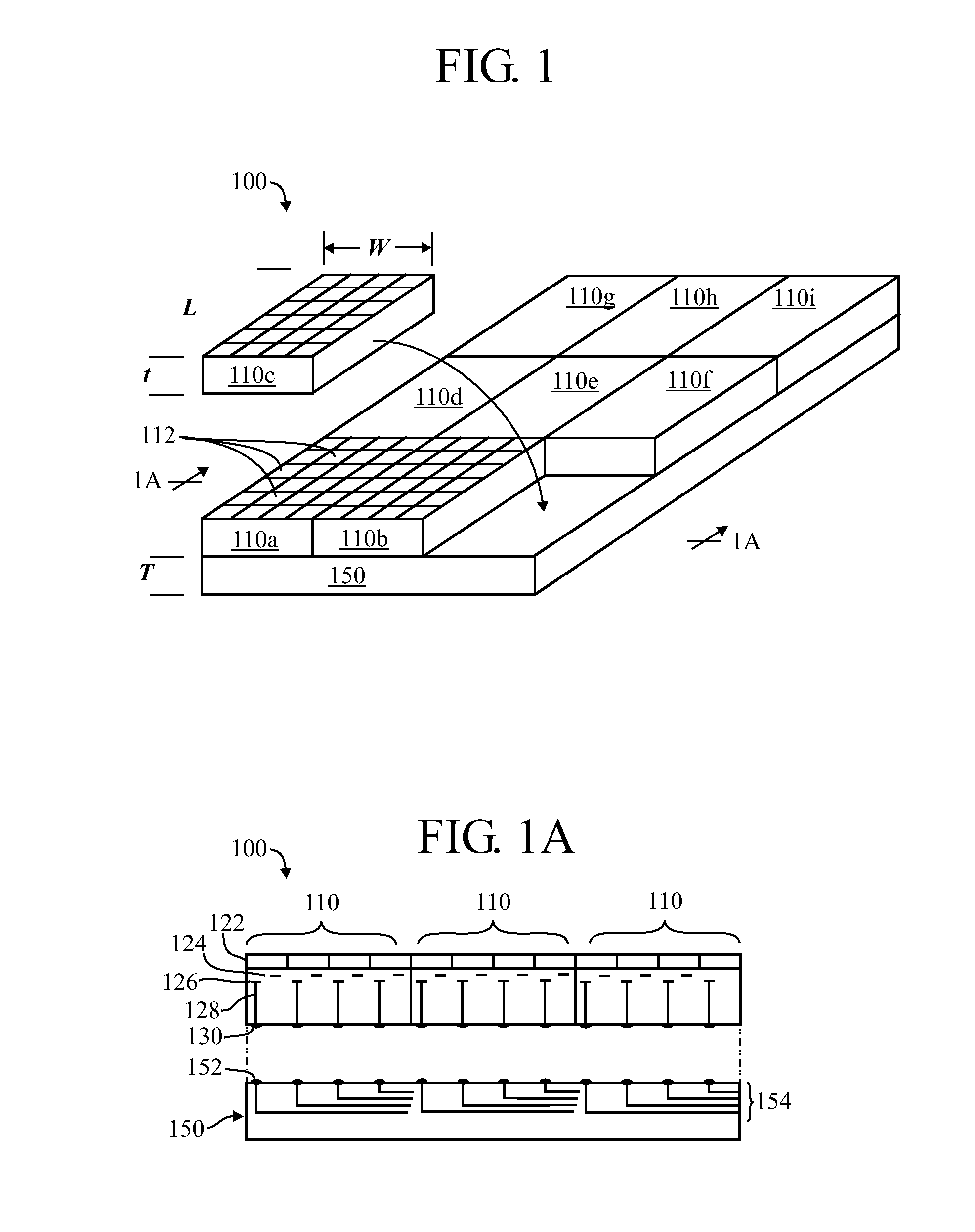

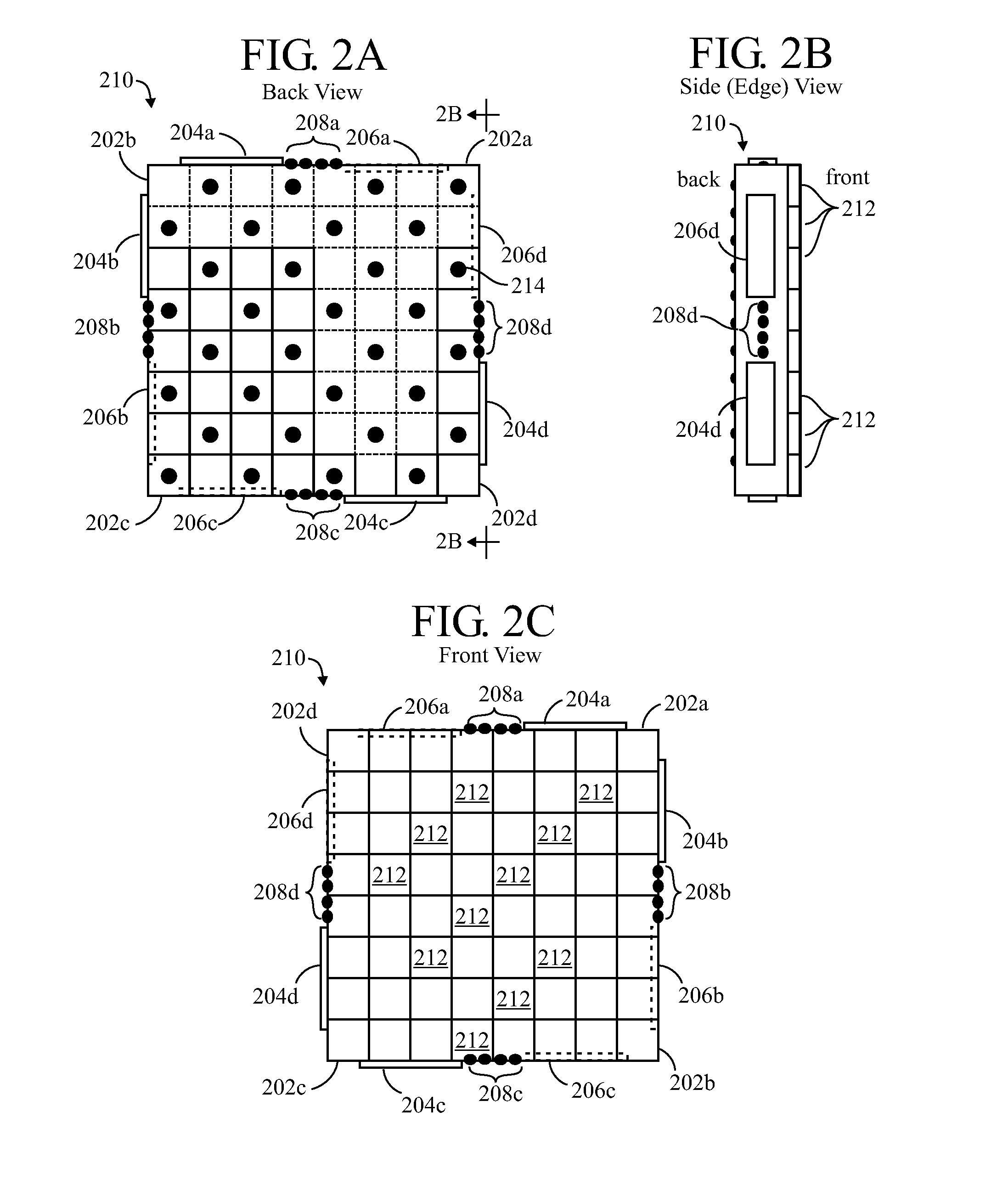

Techniques for Tiling Arrays of Pixel Elements

ActiveUS20140138543A1Remove complexitySimple technologyLine/current collector detailsWave amplification devicesMicrobolometerDamage tolerance

Sub-arrays such as tiles or chips having pixel elements arranged on a routing layer or carrier to form a larger array. Through-chip vias or the like to the backside of the chip are used for connecting with the pixel elements. Edge features of the tiles may provide for physical alignment, mechanical attachment and chip-to-chip communication. Edge damage tolerance with minimal loss of function may be achieved by moving unit cell circuitry and the electrically active portions of a pixel element away from the tile edge(s) while leaving the optically active portion closer to the edge(s) if minor damage will not cause a complete failure of the pixel. The pixel elements may be thermal emitter elements for IR image projectors, thermal detector elements for microbolometers, LED-based emitters, or quantum photon detectors such as those found in visible, infrared and ultraviolet FPAs (focal plane arrays), and the like. Various architectures are disclosed.

Owner:SANTA BARBARA INFRARED +2

Fiber-toughened ceramic-based composite material with ternary-layer-shaped MAX phase interface layer and preparation method of composite material

InactiveCN106083117AImprove antioxidant capacityImprove radiation resistanceHeat conductingMaterials science

The invention provides a fiber-toughened ceramic-based composite material with a ternary-layer-shaped MAX phase interface layer. A ternary-layer-shaped MAX phase material is introduced to serve as an interface layer, and therefore the anti-irradiation property, the heat-conducting property and the anti-oxidation property of the ceramic-based composite material can be effectively improved; in addition, through multiple fracture energy absorbing mechanisms of the MAX phase material, fracture energy can be effectively absorbed, extension of cracks in the ceramic-based composite material is hindered, and therefore the toughness and the damage tolerance of the ceramic-based composite material are improved. Accordingly, the application fields of the composite material are effectively widened, and the composite material has good application prospects in the fields of aerospace thermal structure materials, nuclear energy structural materials and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Polymer composite structure reinforced with shape memory alloy and method of manufacturing same

ActiveUS6989197B2Improve resistance to damageIncrease damage toleranceRecord information storageLight beam reproducingPolymer scienceResin matrix

A polymer composite structure having resin matrix interlayers reinforced with shape memory alloy (SMA) particles. In one preferred form Nitinol® alloy particles are used for the SMA particles. The Nitinol® alloy particles may comprise cylindrical, oval or spherical shaped particles and are intermixed in the resin of the resin matrix interlayer(s) of the composite structure. The SMA particles provide superelastic, reversible strain properties that significantly improve the damage resistance, damage tolerance (e.g. compression-after-impact (CAI) strength) and elevated temperature performance of the composite structure without negatively affecting the hot-wet compression strength of the composite structure. The polymer composite structure is ideally suited for aerospace and aircraft applications where lightweight and structurally strong materials are essential.

Owner:THE BOEING CO

Preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials

InactiveCN102516569AInhibition formationPrevent scalabilityCarbon nanotubeFiber-reinforced composite

The invention belongs to the advanced composite material preparing technology and relates to a preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials. The method includes: enabling carbon nanotube non-woven fabric to enter resin rich areas of the layers of fiber reinforced thermosetting resin base composite materials in direct intercalation mode, using an autoclave molding process or a liquid forming process, and preparing interlayer the interlayer modified composite materials according to an original curing process of matrix resin. The carbon nanotube non-woven fabric can enter weak interlayer areas of the composite materials through direct intercalation mode, has no influence on flow of the resin in the curing process and a liquid forming process of the matrix resin, and simultaneously a network structure formed by carbon nanotubes in an interlayer can effectively prevent interlayer microcracks from being formed and extending, thereby improving strengthening-toughening performance of interlayer of the composite materials, obtaining high impact damage resistance and high damage tolerance, and covering a temperature range of typical aerospace composite structure application, in particular to a more than 300 DEG C high temperature range.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

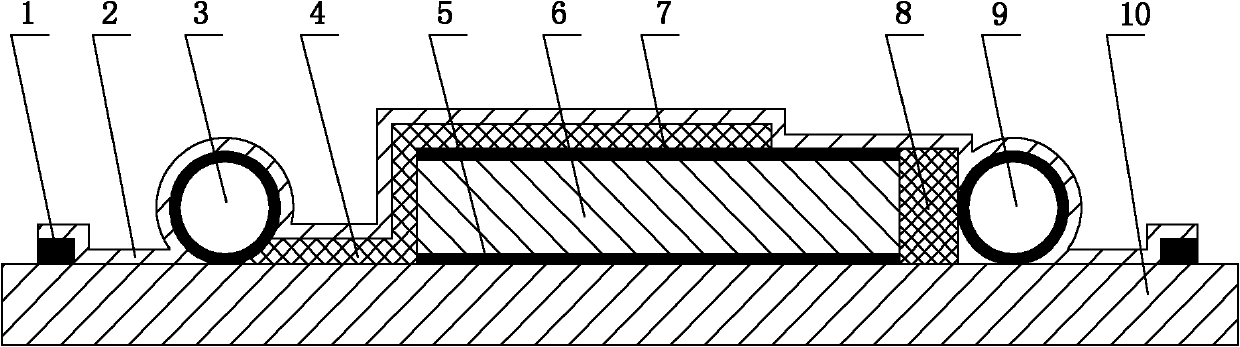

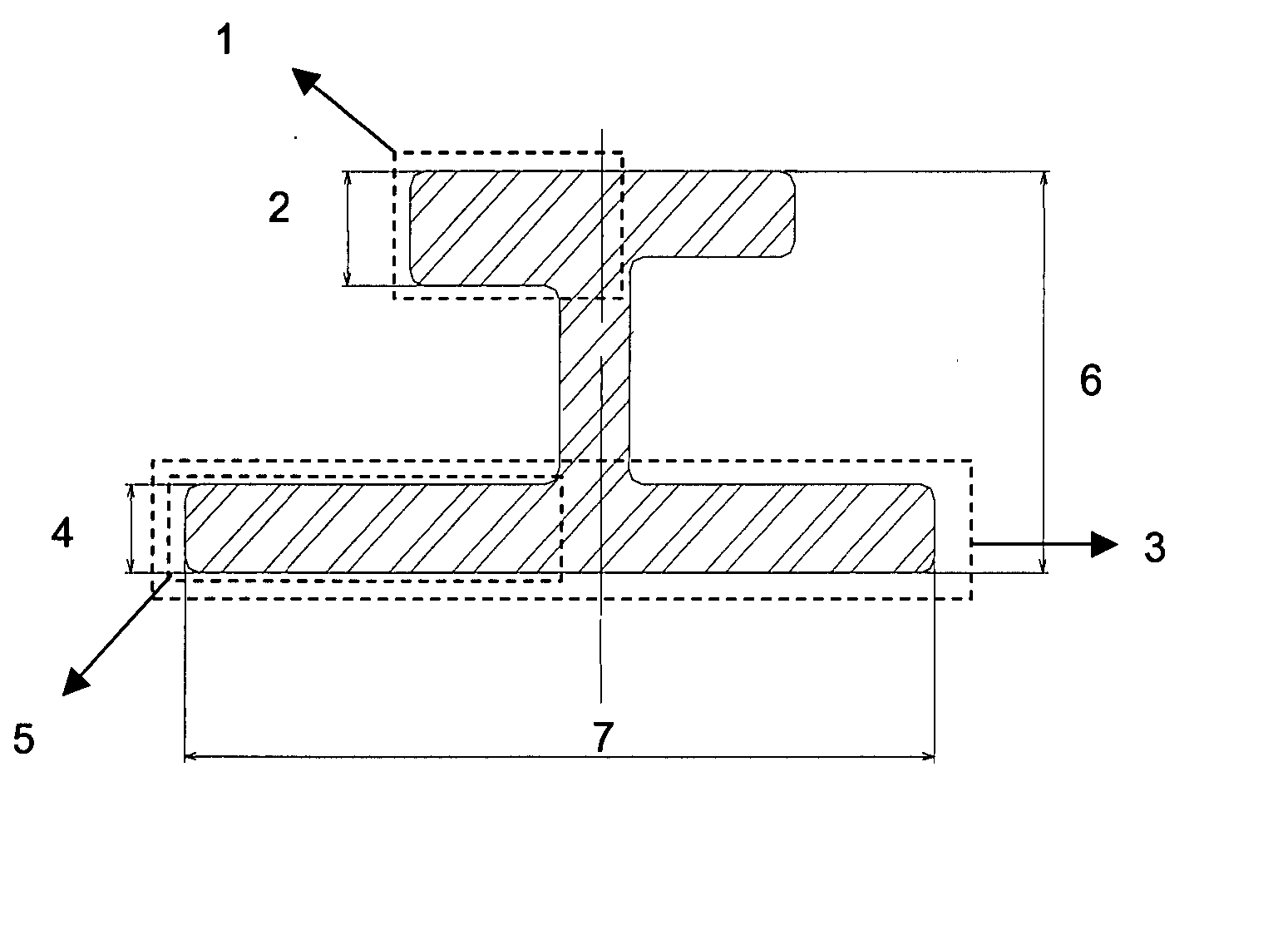

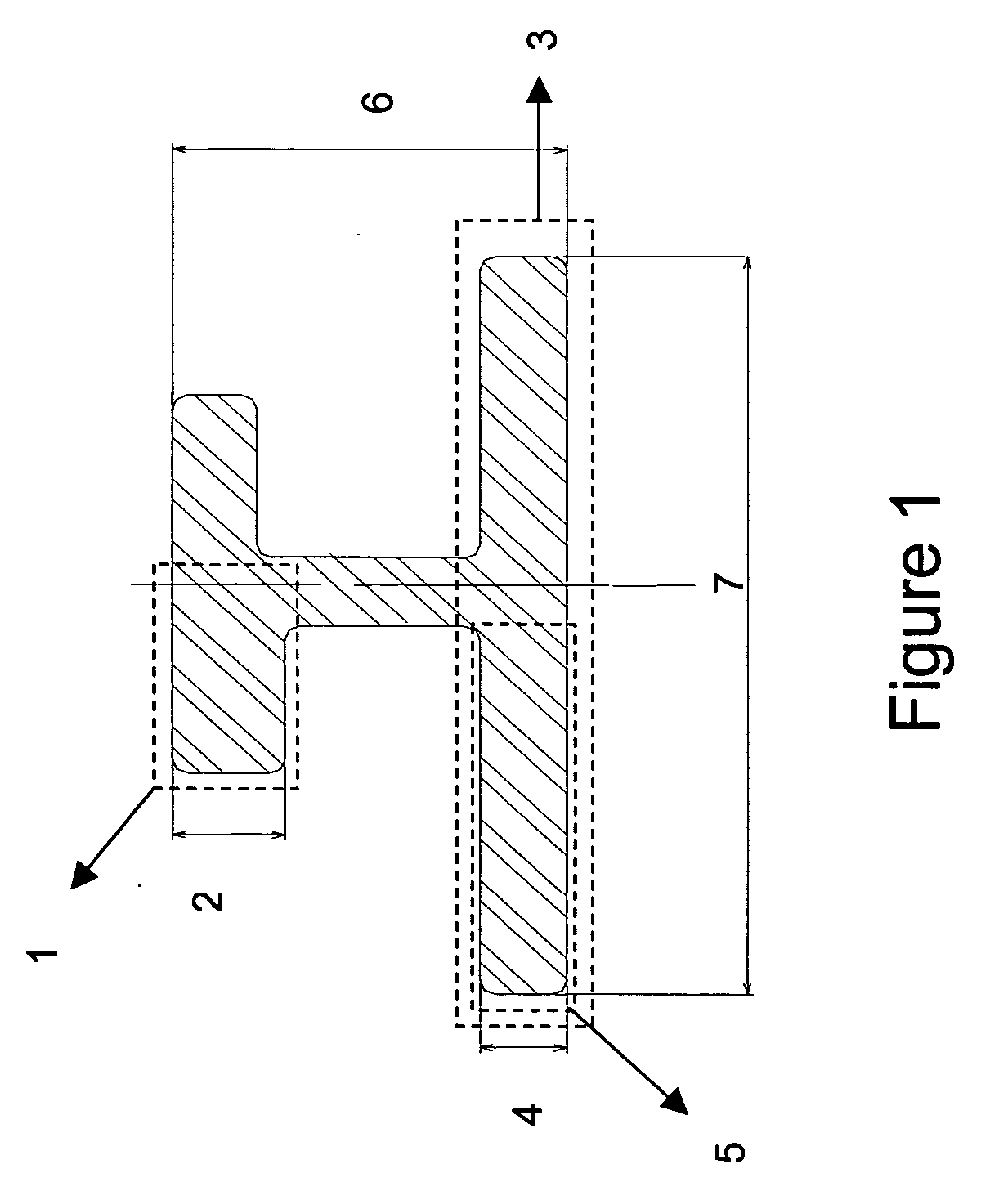

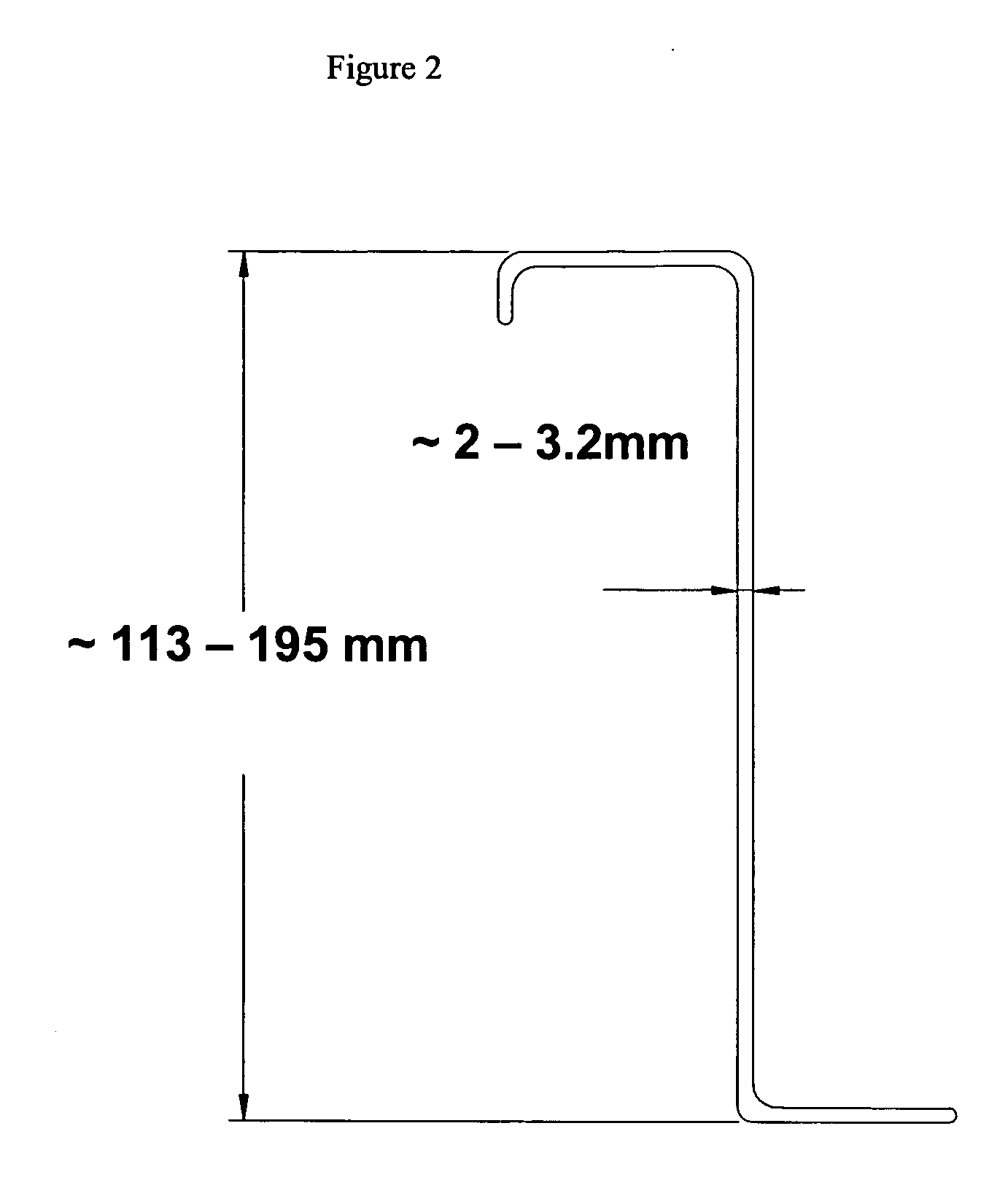

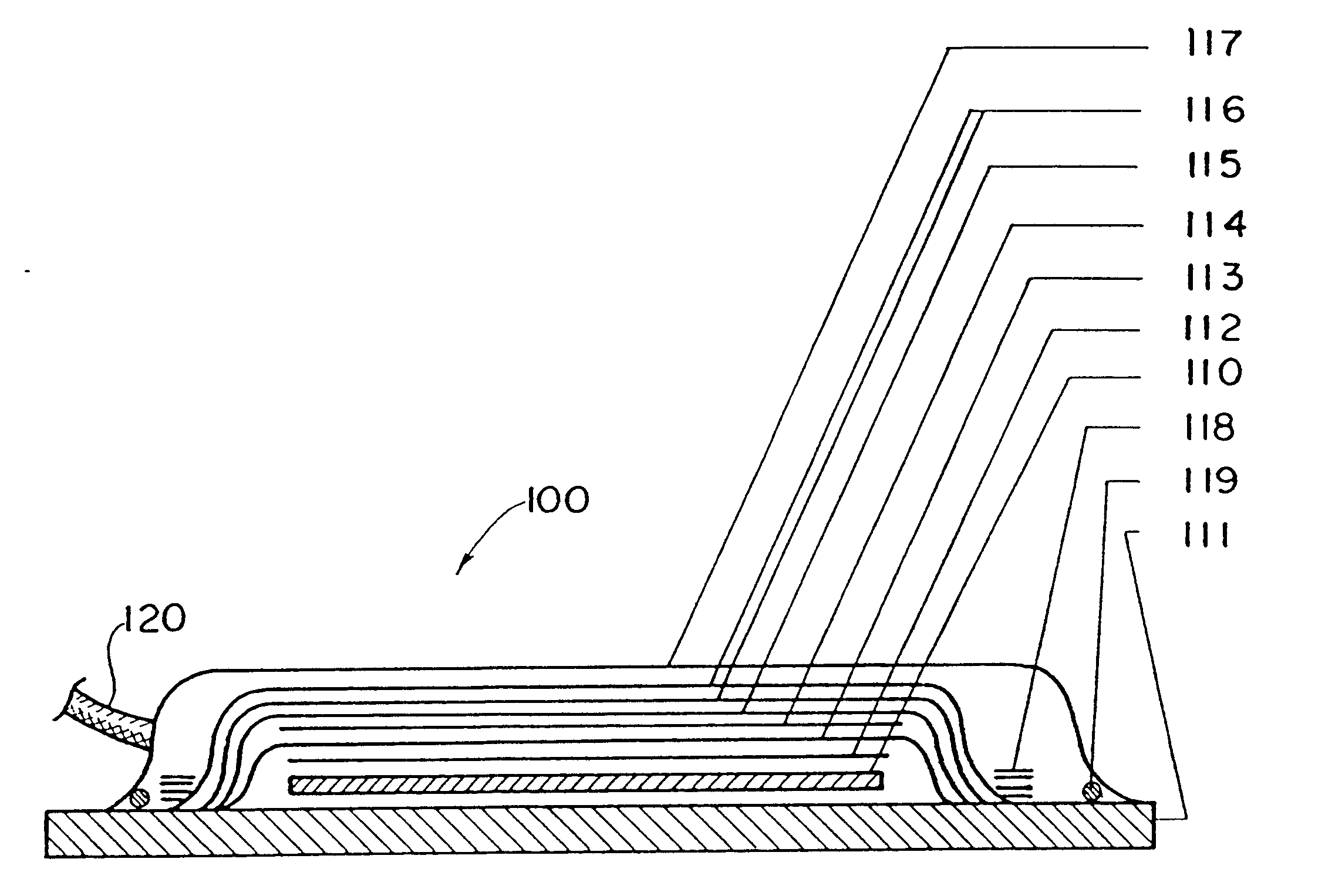

Structural members having improved resistance to fatigue crack growth

InactiveUS20050241735A1High damage toleranceReduce rate of fatigue crack growthLayered productsExtrusion containersFiberDamage tolerance

An extruded structural member having improved damage tolerance containing a base section (6); a stiffening section having at least one pair of structural stiffeners (10), the structural stiffeners integral with the base section (6) and projecting outwardly thereof; and at least one intra-stiffener (90) area positioned between the pair of structural stiffeners (10), the intra-stiffener area (90) having a microstructure with intentionally increased amounts of fiber texture to reduce the rate of fatigue crack growth in the extruded structural member.

Owner:ARCONIC INC

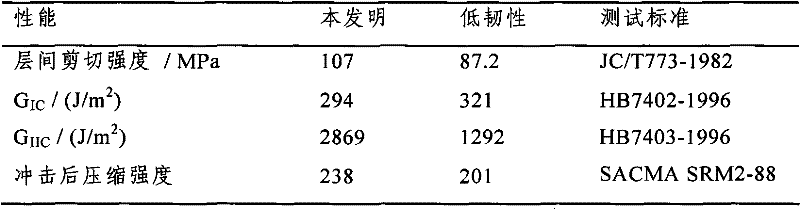

Composite material with polyamide particle mixtures

ActiveUS20140163139A1High level of strengthHigh level of damage toleranceSemiconductor/solid-state device detailsSolid-state devicesPolyamideDamage tolerance

Pre-impregnated composite material (prepreg) is provided that can be cured / molded to form composite parts having high damage tolerance and interlaminar fracture toughness. The matrix resin includes a thermoplastic particle component that includes a mixture of polyamide 12 particles and polyamide 11 particles.

Owner:HEXCEL

High-damage tolerance type ultrahigh strength aluminum alloy and preparation method thereof

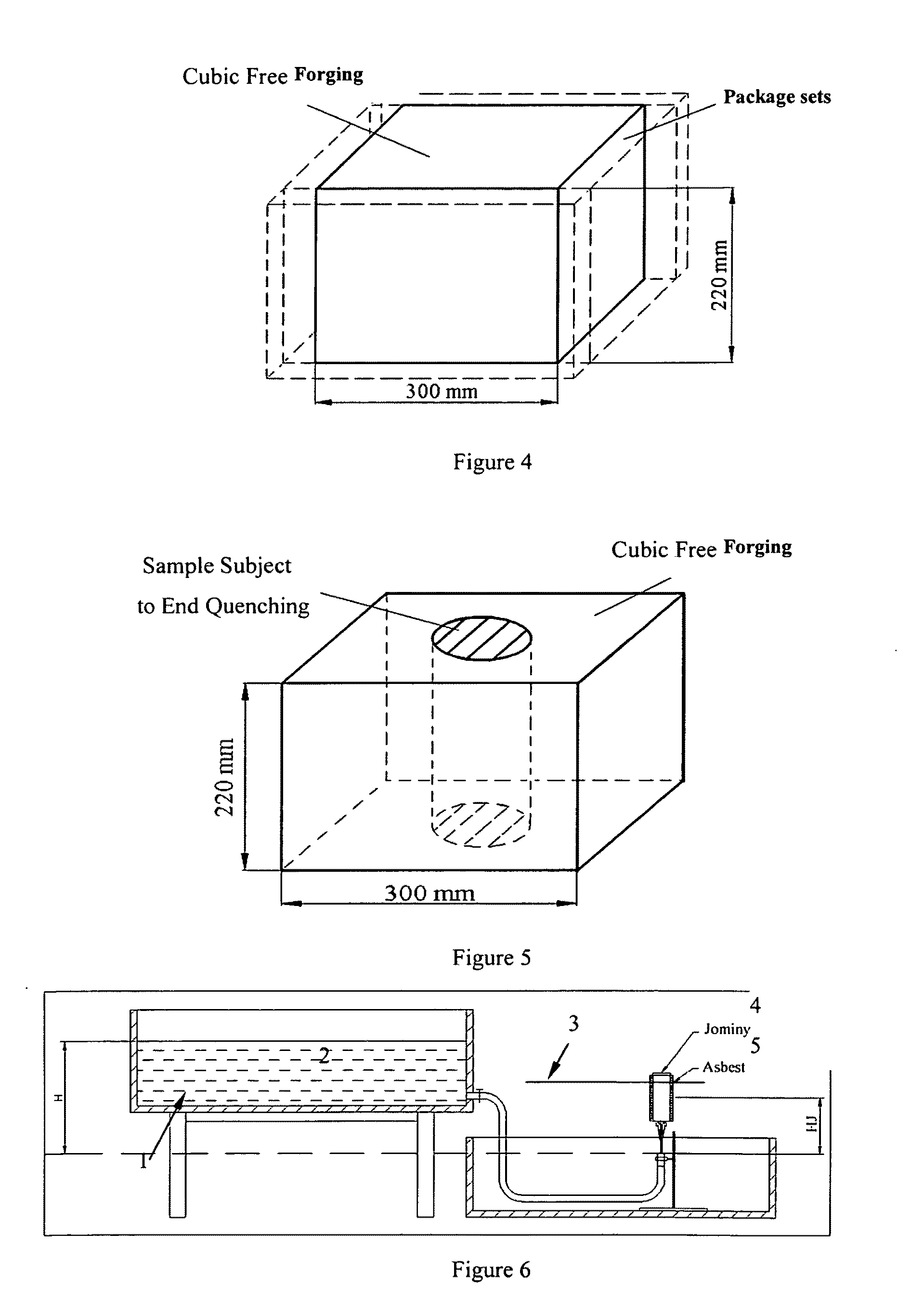

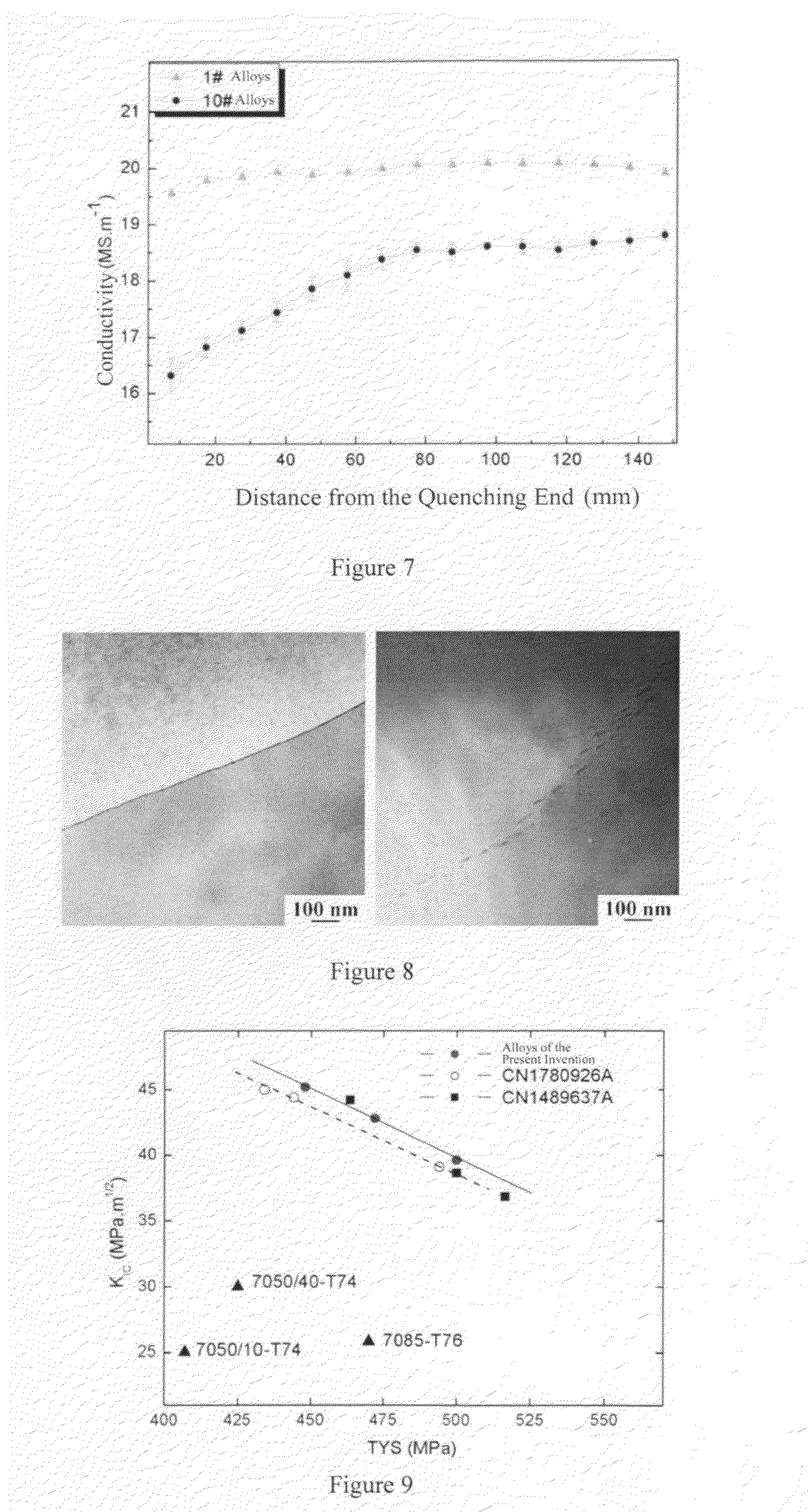

The invention relates to a high-damage tolerance type ultrahigh strength aluminum alloy and a preparation method thereof. The high-damage tolerance type ultrahigh strength aluminum alloy comprises the following components in percentage by weight: 8.5-10.0 percent of Zn, 1.0-2.5 percent of Mg, 1.0-2.0 percent of Cu, 0.06-0.20 percent of Zr, 0.02-0.05 percent of Ti, not more than 0.08 percent of Fe, not more than 0.06 percent of Si and the balance of Al and unavoidable impurities, wherein the Fe content is larger than Si content. The method comprises the following steps: firstly, smelting and casting; then carrying out homogenization on an alloy casting blank by stages, carrying out hot rolling on the homogenized casting blank and carrying out solid dissolution on a hot rolled plate; prestretching the plate in four hours after quenching; and finally immediately carrying out double-stage ageing processing on the prestretched plate. The obtained alloy has higher strength and damage tolerance and is suitable for being applied in an airplane part exposed in the atmospheric environment for a long time.

Owner:CHINA ALUMINUM INT ENG CORP

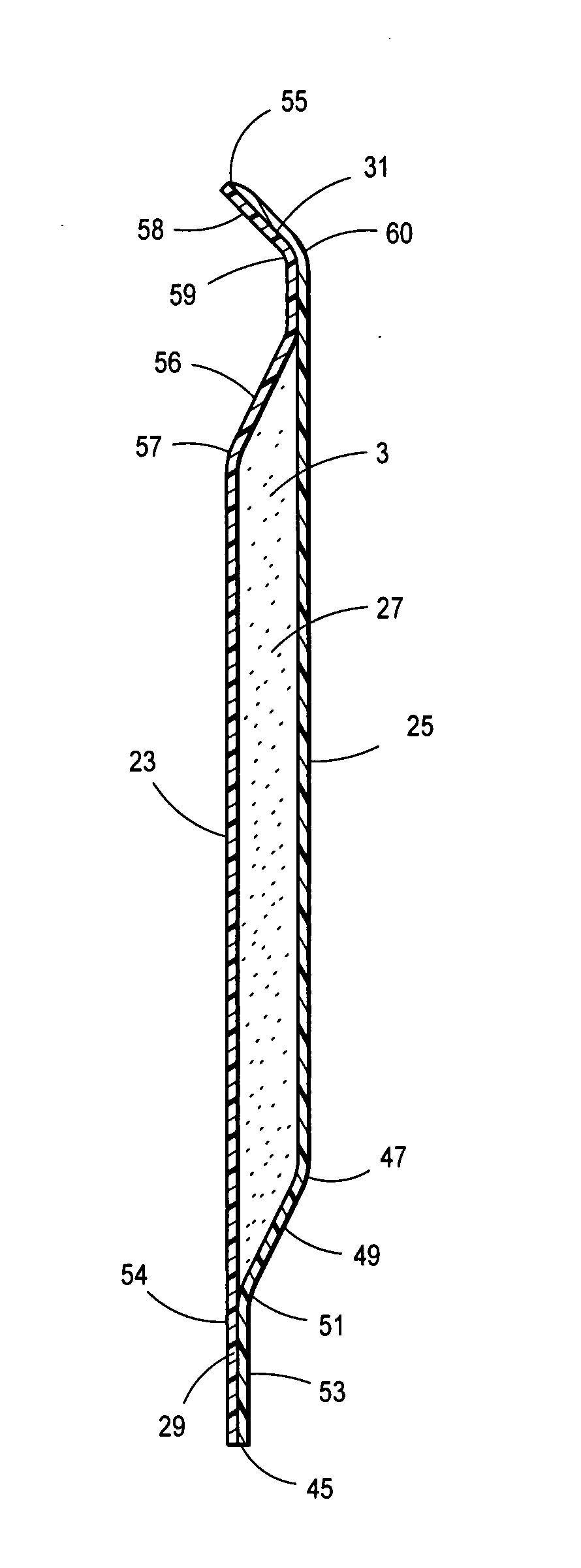

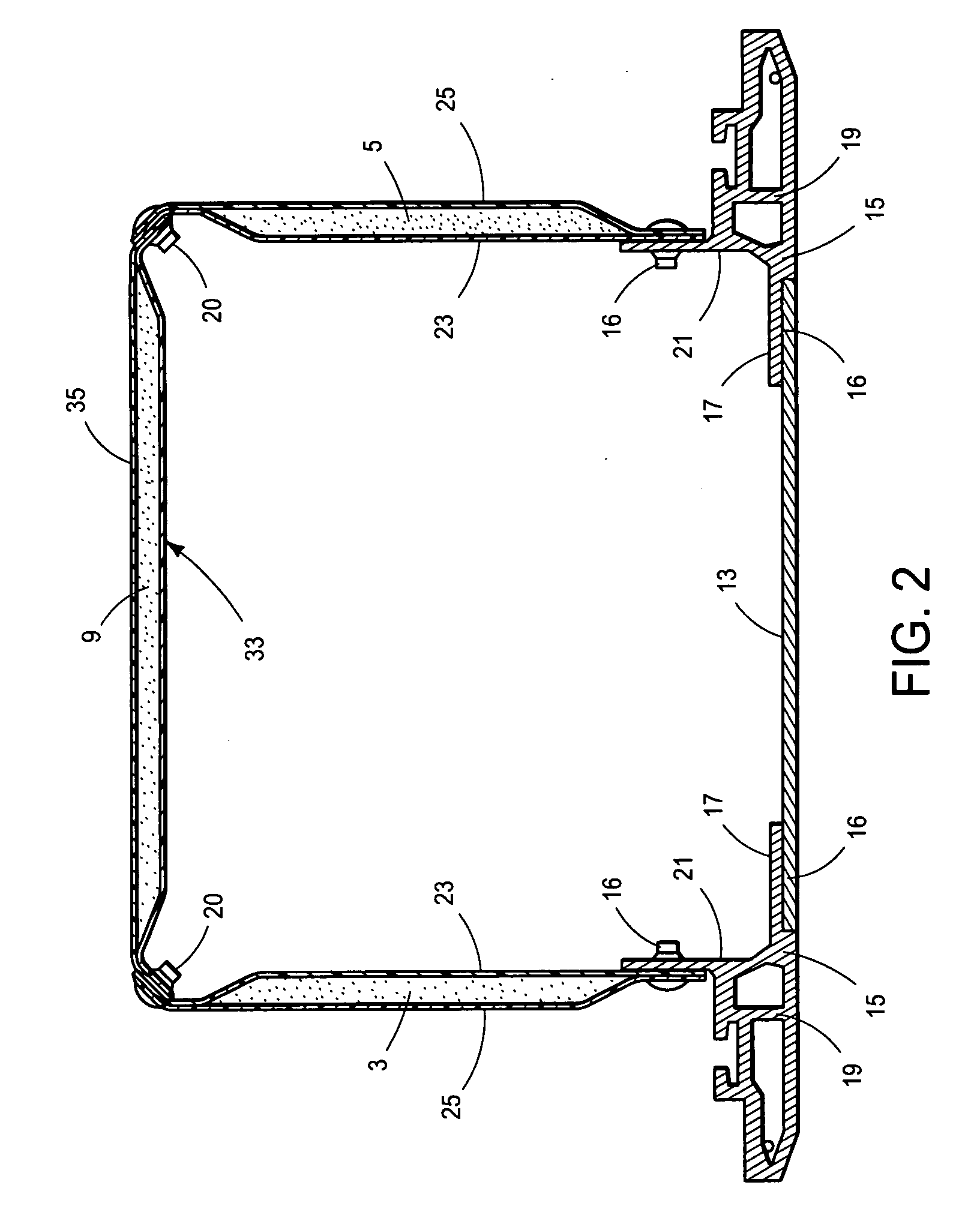

Temperature tolerant vane assembly

ActiveUS20060034679A1Improve stress distributionPropellersPump componentsDamage toleranceEngineering

A vane assembly 10 suitable for a turbine engine features a refractory vane 12 with an internal cavity 20 and a pair of flexible metallic baffles 26 extending into the cavity from spanwisely opposite ends of the vane. A rigid fastener 48, such as a nut and bolt assembly applies a tensile load to the baffles. The tensile load is reacted out as a compressive load applied to the vane. In another embodiment, the baffle is relatively rigid but the fastener is flexible. The compressive loading exerted on the vane counteracts the brittleness customarily exhibited by refractory materials and imparts damage tolerance to the vane. The arrangement also allows the use of a metal baffle that can be easily secured to the vane and dispenses with any need for a potentially troublesome seal between the baffles and the spanwise extremities of the vane.

Owner:RTX CORP

Forming process of fiber reinforced thermoplastic composite material

The invention discloses a low-cost high-efficiency forming process of a fiber reinforced thermoplastic composite material, comprising the following steps of: arranging a workpiece to be formed, which is prepared by laying fiber reinforced materials, in a closed space containing a mold template; laying demolding cloth and a diversion grid in sequence on the workpiece; laying or coating a demolding material under the workpiece; arranging an impregnating pipe on one side of the width direction of the workpiece; arranging a vacuum pipeline on the other side along the length direction of the workpiece and parallel to the side surface; arranging a breathable material between the vacuum pipeline and the workpiece; then pumping vacuum in the closed space through the vacuum pipeline, simultaneously raising the temperature of the mold template to the impregnating temperature of 50-250 DEG C; and finally filling molten thermoplastic resin or the precursor of the thermoplastic resin of which the temperature is 50-250 DEG C and the viscosity is 0.15-1.0Pa.s into the workpiece from the impregnating pipe, and then insulating for polymerization or reducing the temperature for cooling and forming. The forming process needs not to prepare a pre-impregnated belt in advance and has low cost and high efficiency, and the workpiece can be formed easily and has superior toughness and damage tolerance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

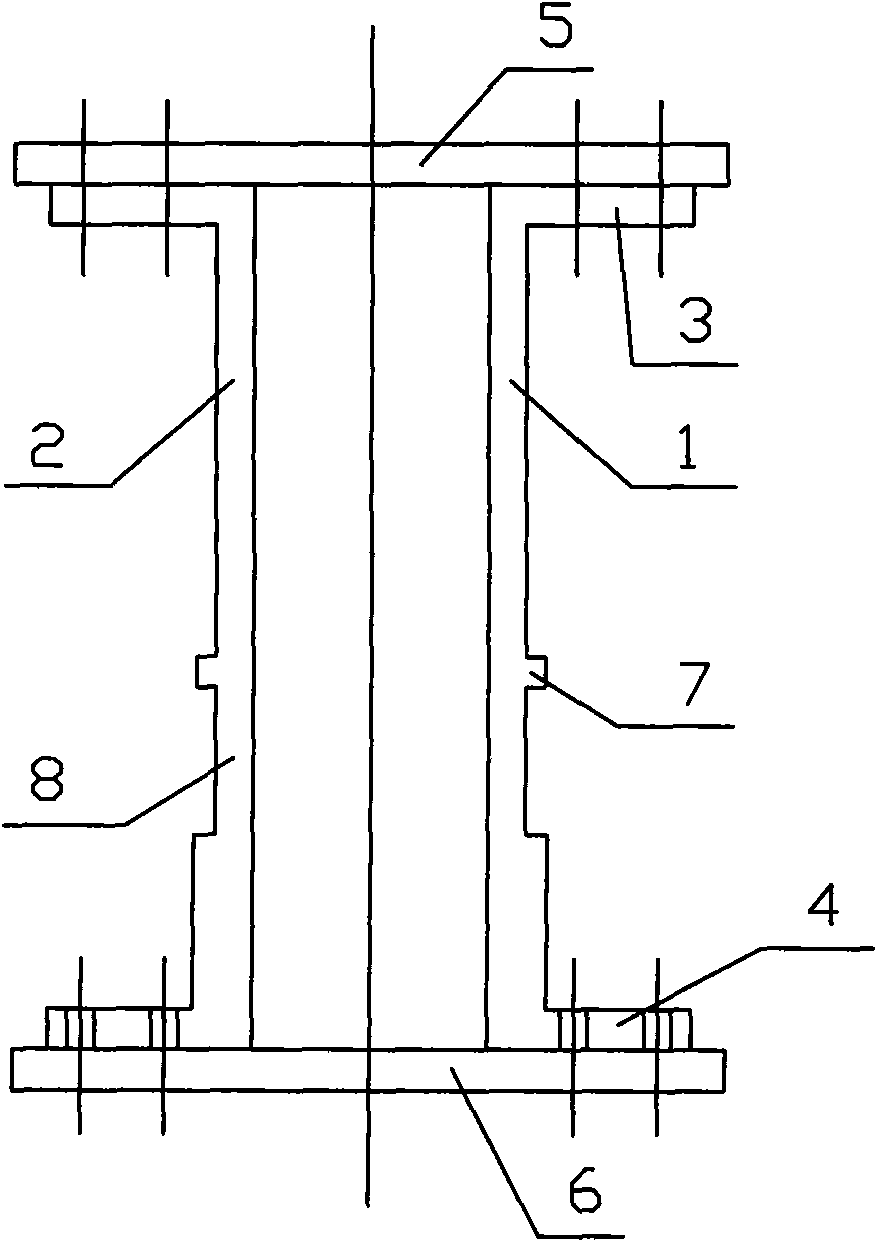

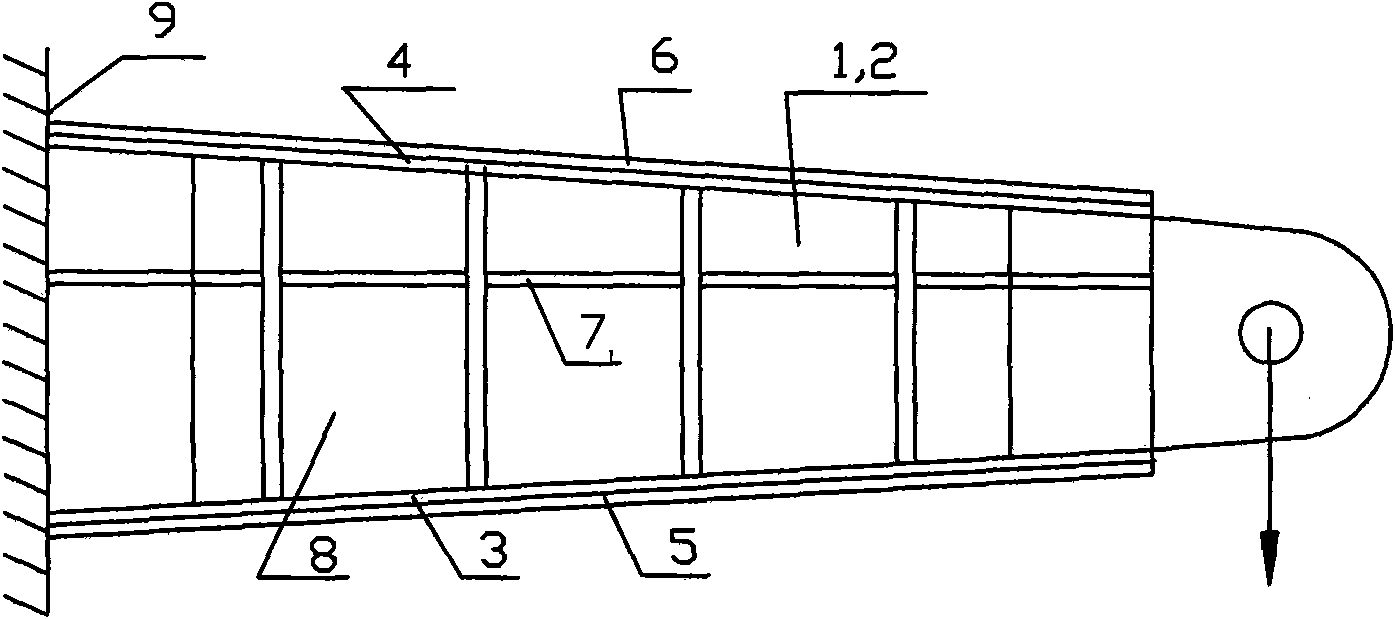

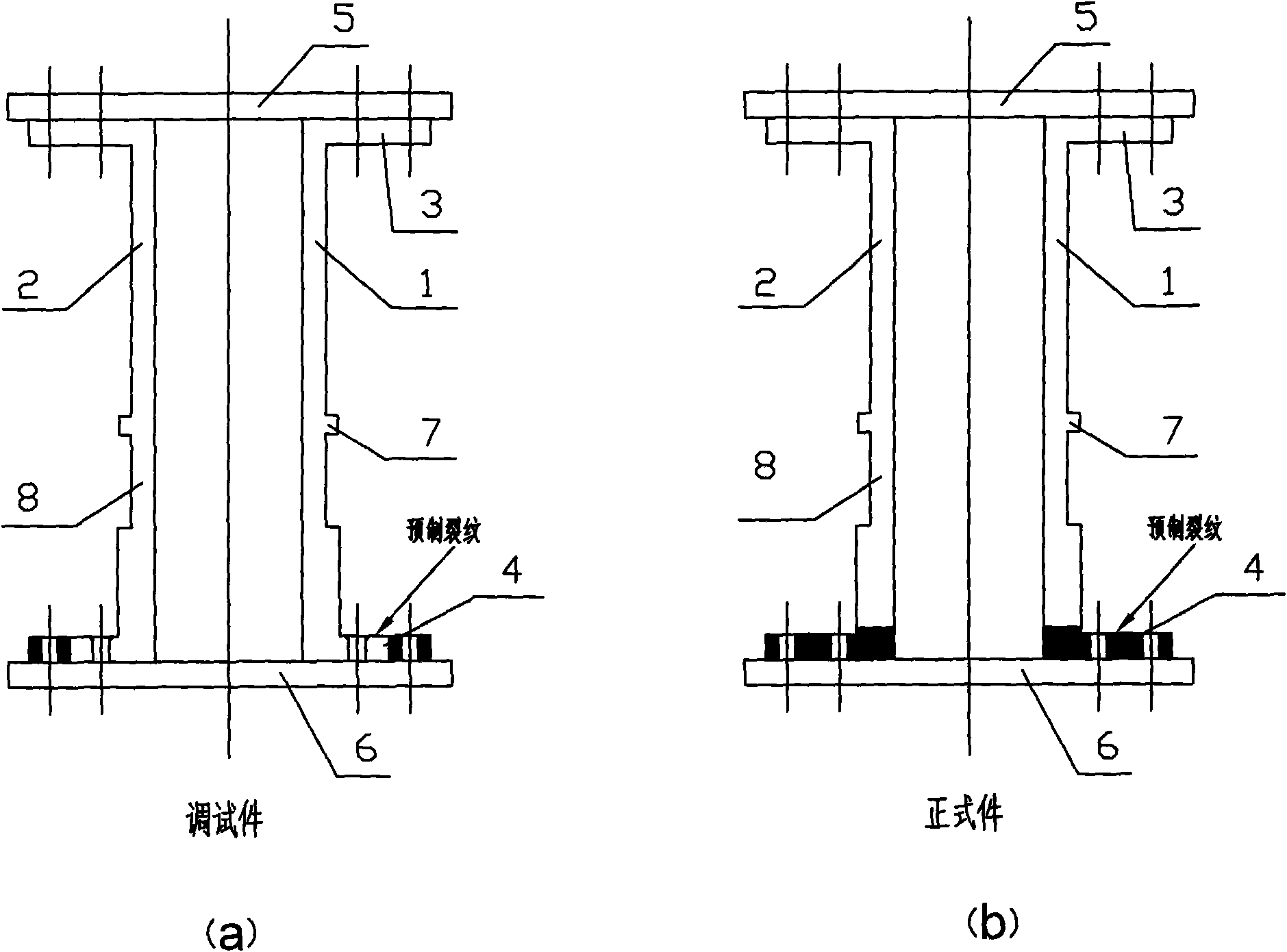

Damage-tolerance testing method for whole wing spar of airplane

InactiveCN101561365ASolve scalabilitySolve the strength problemStructural/machines measurementJet aeroplaneResidual strength

The invention pertains to airplane fatigue and damage-tolerance testing technologies, and relates to a damage-tolerance testing method for the whole wing spar of an airplane. The method comprises the steps of: (I) choosing a part with large load from the whole wing spar for serving as a testing part examining segment, (II) producing two same testing parts according to the examining segment, (III) reserving an interval of 20 to 30mm between the two back-to-back testing parts which are respectively provided with a coating in the upper part and the lower part (the coating is connected with an upper spar edge strip and a lower spar edge strip to form a case segment), (IV) fixing the root of the testing case segment completing assembly on a load-bearing wall, (V) exerting concentrated load at one end of the testing parts to simulate the bending moment of the spar at the testing segment and the shearing force of a web, without considering the influence of the shearing flow of the coating and (VI) using a finite element method to conduct damage tolerance analysis on the testing parts and comparing testing results. The method solves the difficulty that the crack expansion and remaining strength of the present airplane whole wing spar structure lack theoretical evidence; and the design of the testing parts adopts a method of simultaneously conducting tests to the two back-to-back testing parts, thereby eliminating the distortion of a single spar.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

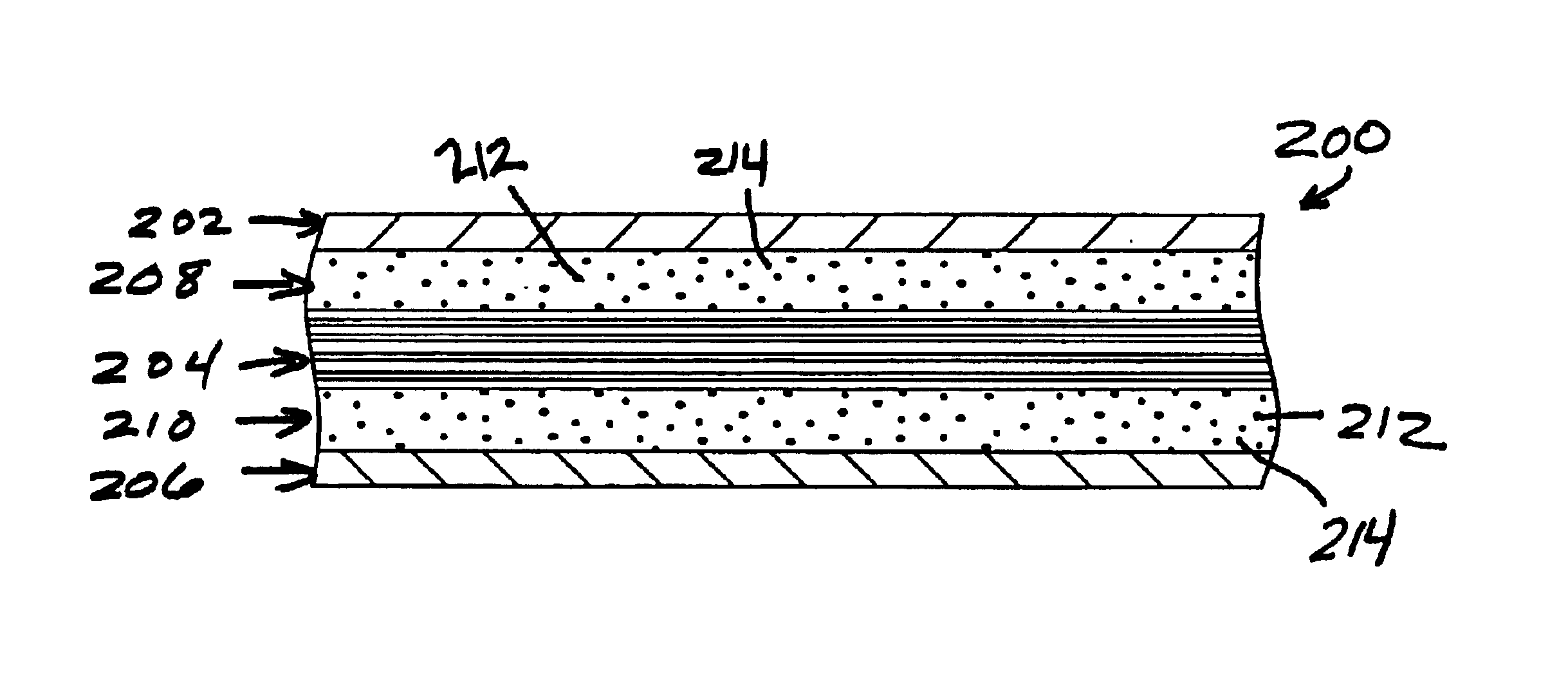

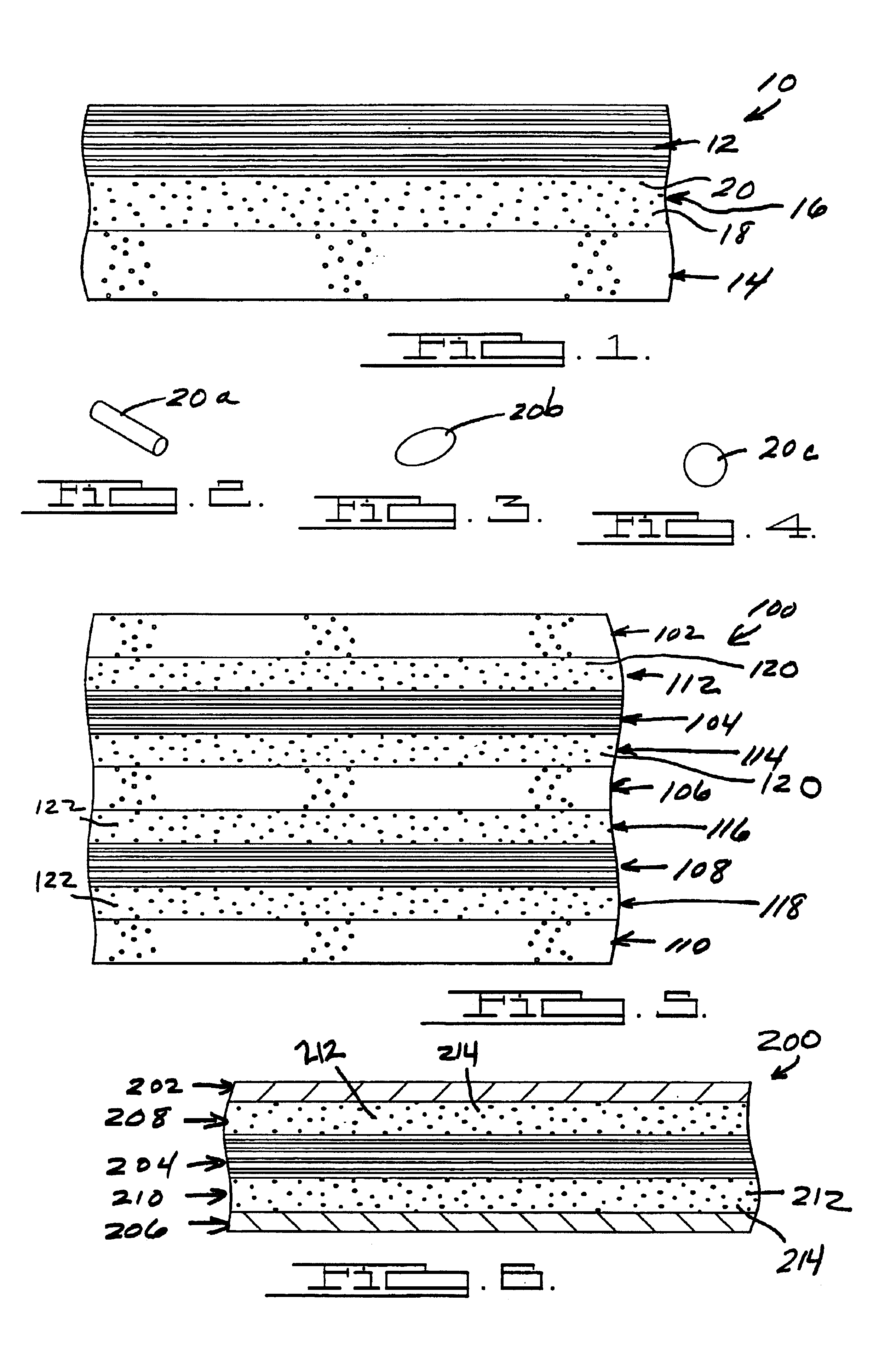

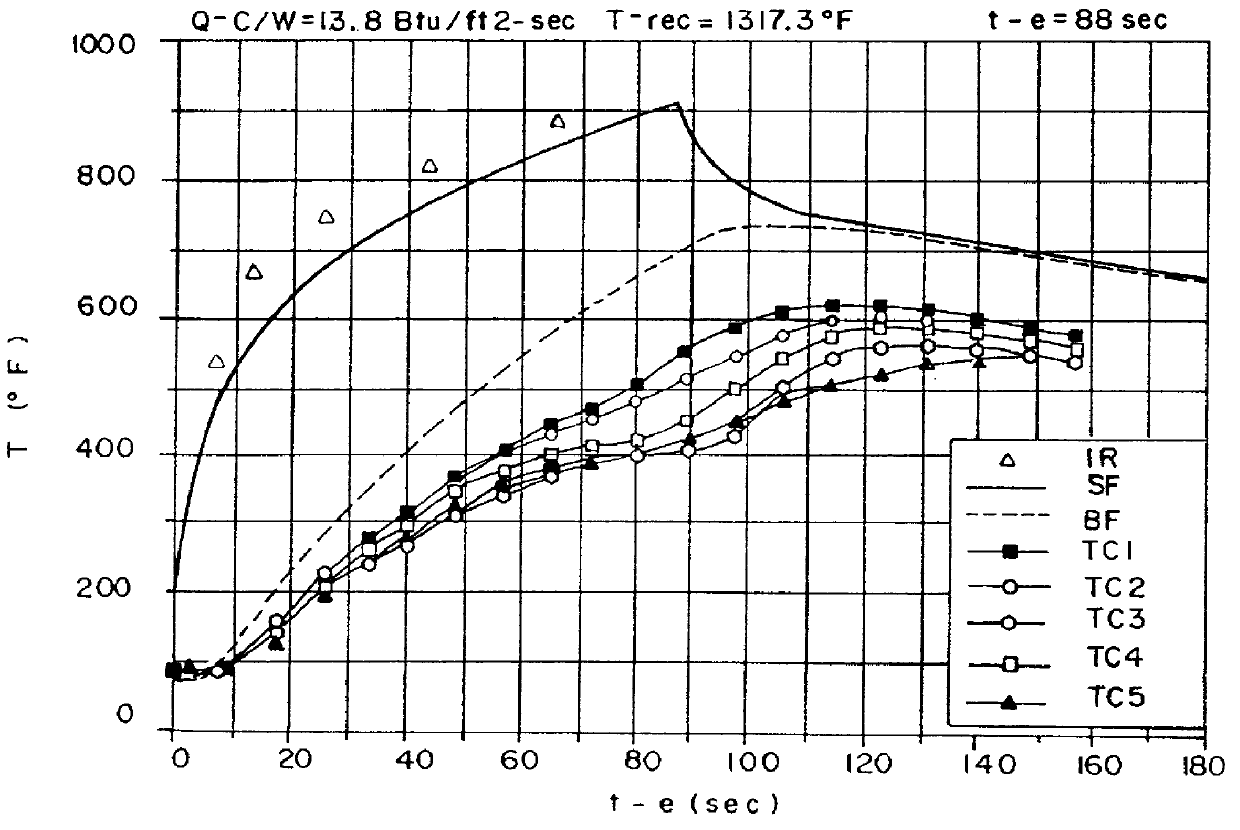

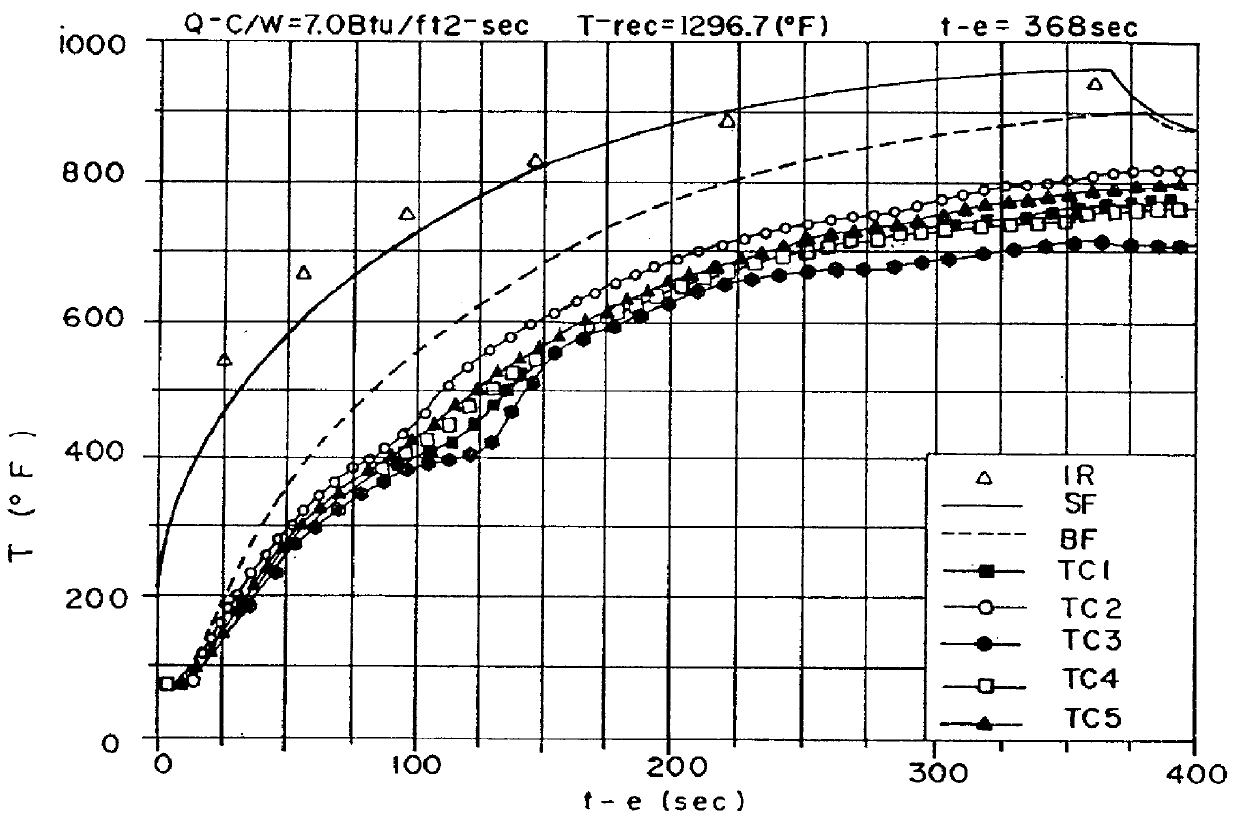

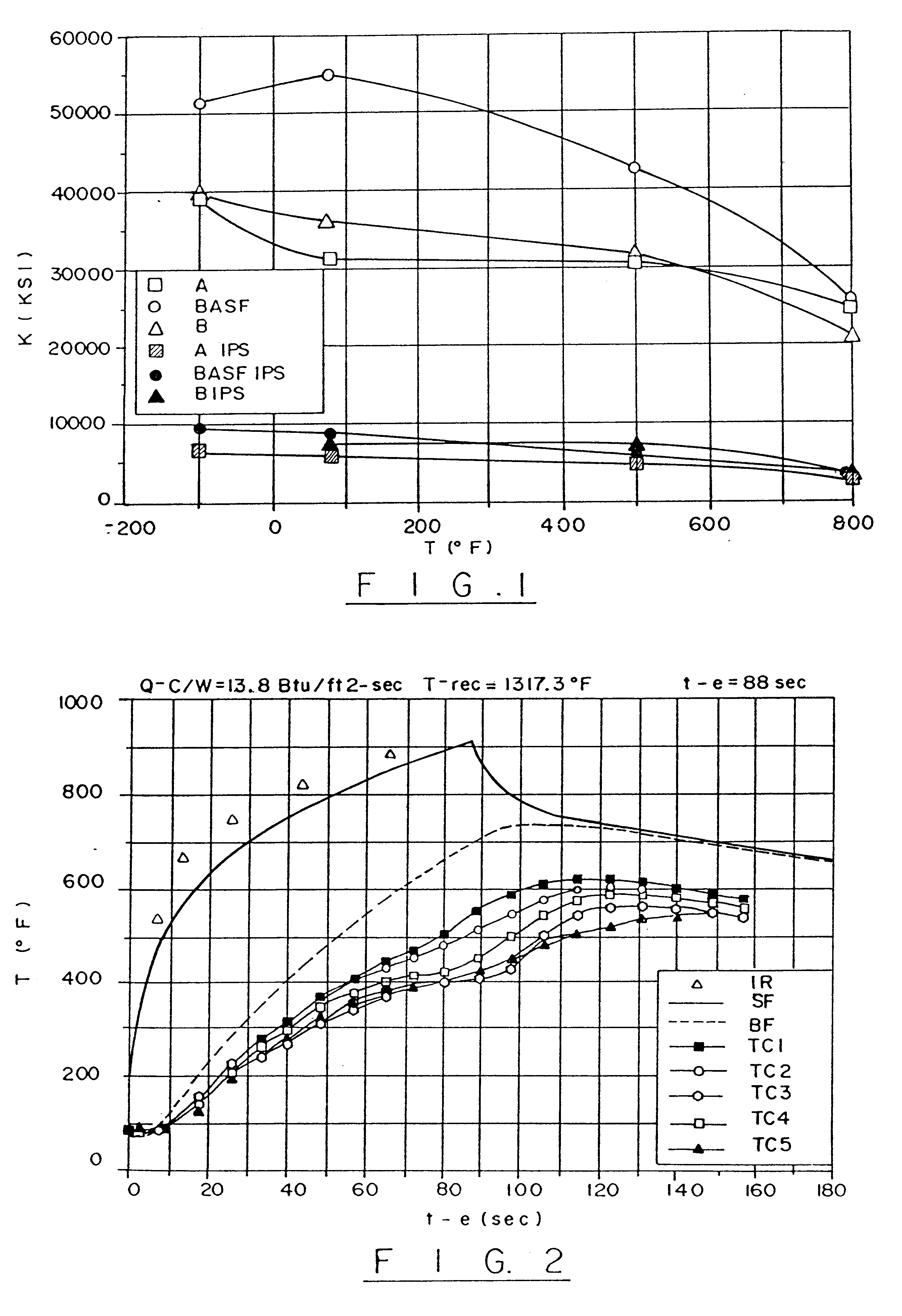

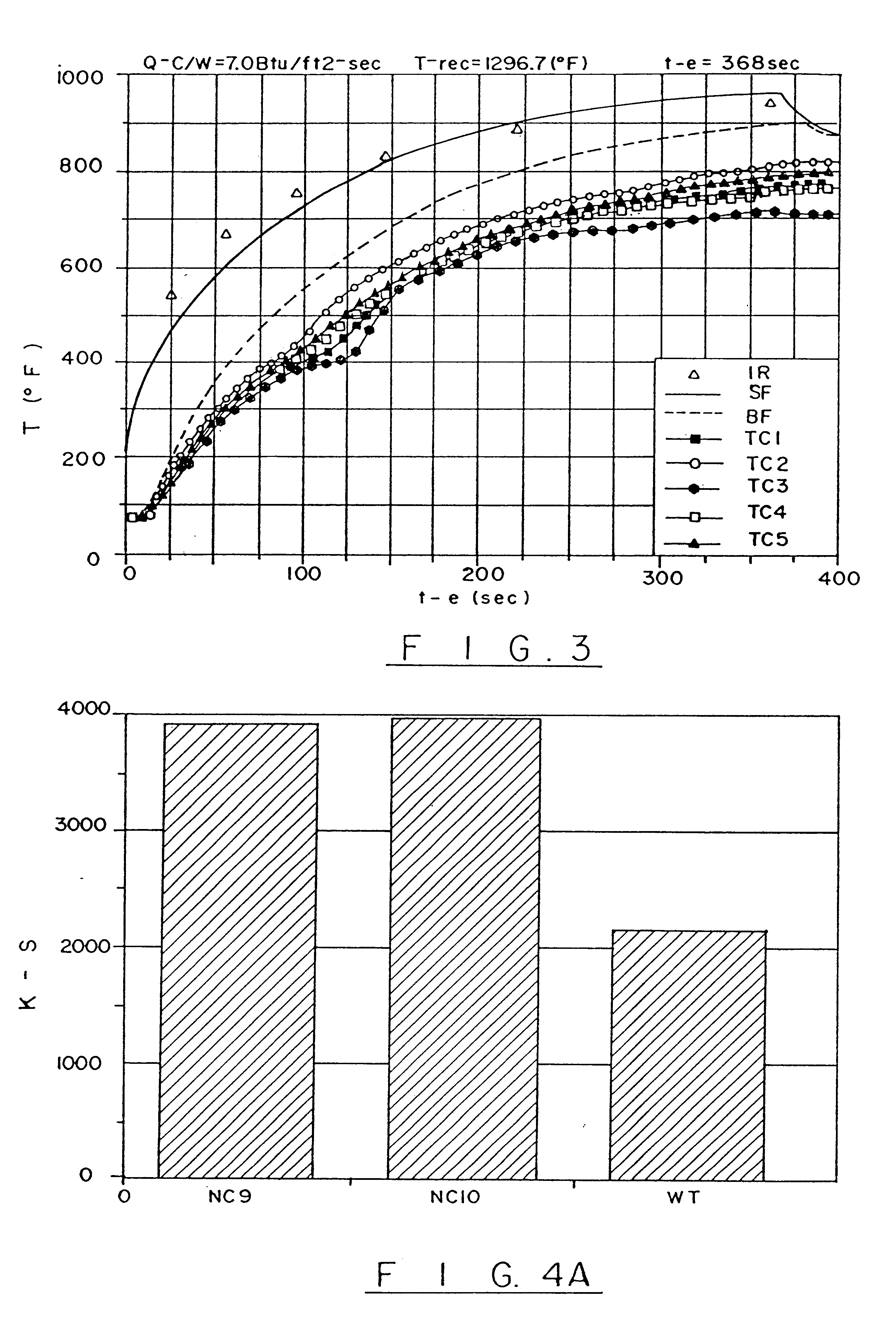

High performance structural laminate composite material for use to 1000 DEG F and above, apparatus for and method of manufacturing same, and articles made with same

InactiveUS6013361ASufficient permeabilityReduce weightCosmonautic vehiclesCosmonautic partsDamage toleranceRefractory

A novel materials technology has been developed and demonstrated for providing a high modulus composite material for use to 1000 DEG F. and above. This material can be produced at 5-20% of the cost of refractory materials, and has higher structural properties. This technology successfully resolves the problem of "thermal shock" or "ply lift," which limits traditional high temperature laminates (such as graphite / polyimide and graphite / phenolic) to temperatures of 550-650 DEG F. in thicker (0.25'' and above) laminates. The technology disclosed herein is an enabling technology for the nose for the External Tank (ET) of the Space Shuttle, and has been shown to be capable of withstanding the severe environments encountered by the nose cone through wind tunnel testing, high temperature subcomponent testing, and full scale structural, dynamic, acoustic, and damage tolerance testing.

Owner:LOCKHEED MARTIN CORP

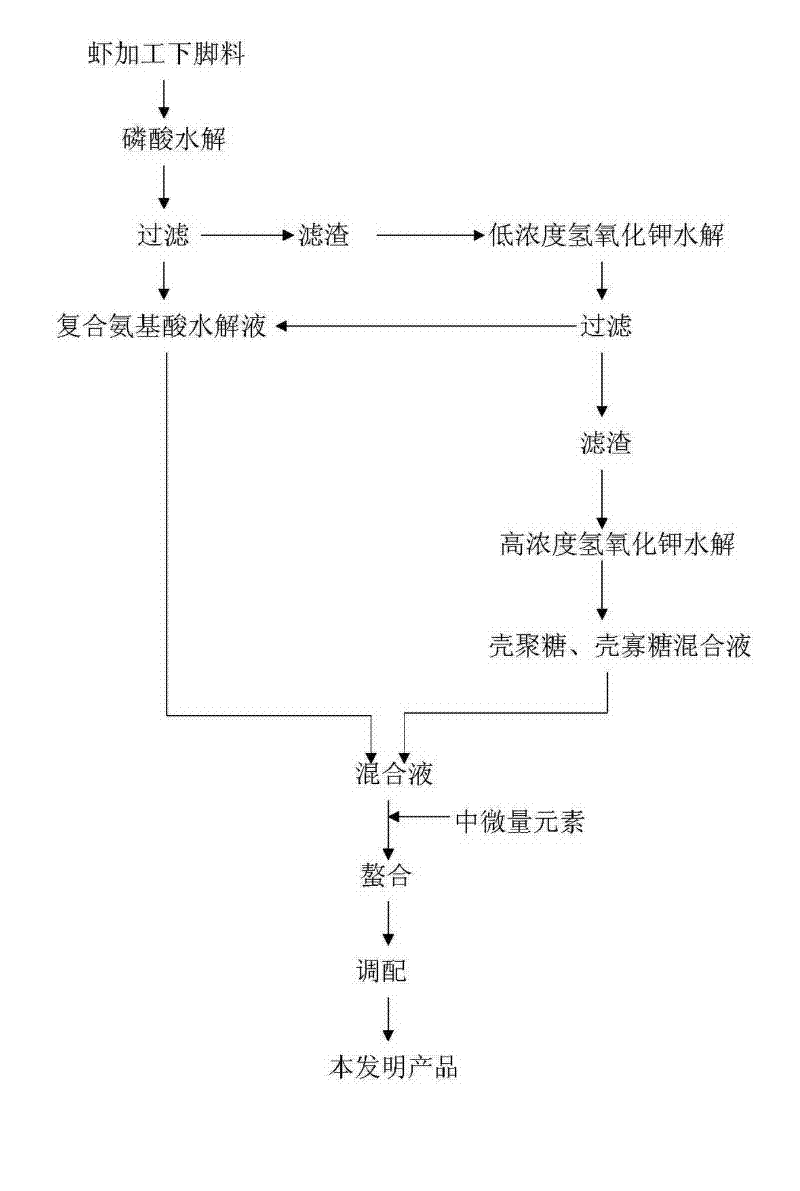

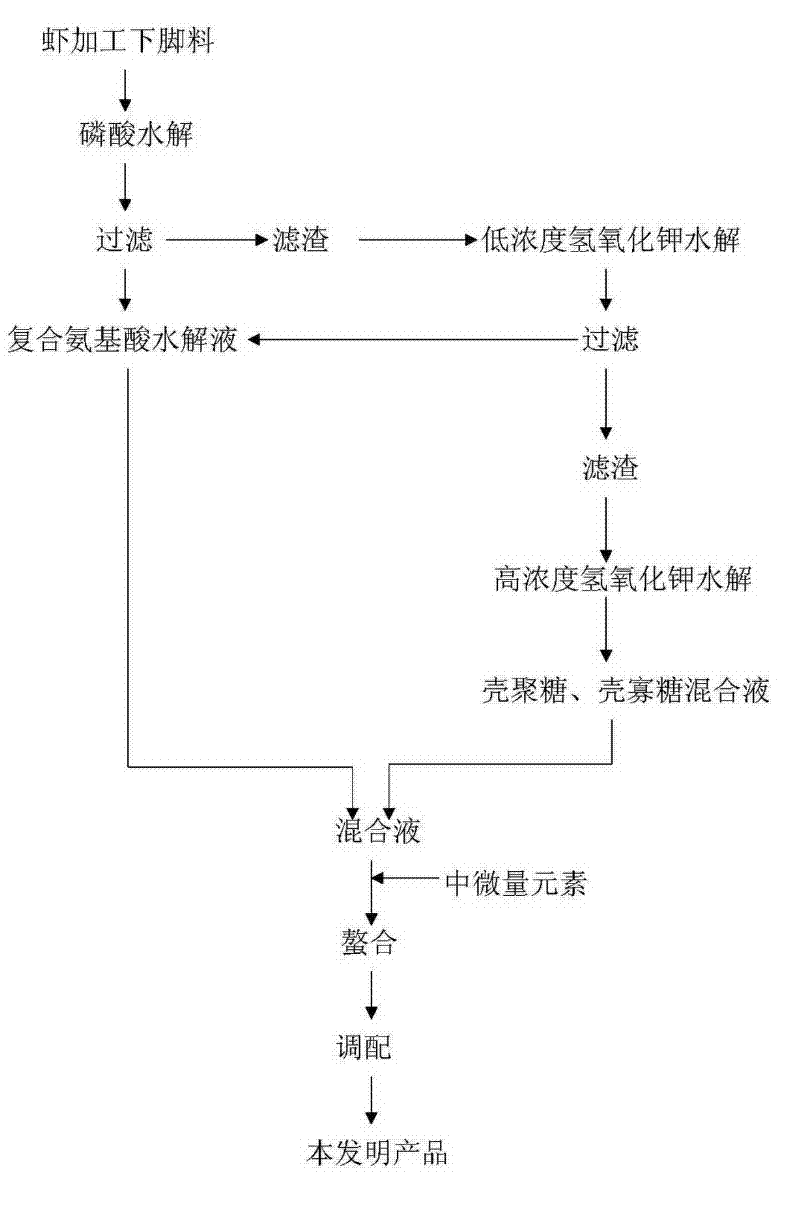

High-efficiency multifunctional foliage fertilizer and production method thereof

The invention discloses a high-efficiency multifunctional foliage fertilizer and a production method thereof. The foliage fertilizer is prepared by chelating shrimp processing leftovers, which serve as the main raw material, with medium and minor elements. The foliage fertilizer is prepared from 10-30% of amino acids, 2-8% of medium and minor elements, 10-30% of organic nitrogen, 3-20% of phosphorus, 3-20% of potassium, and 10-30% of shrimp peptide protein, chitosan, chitosan oligosaccharide, chitin, glucosamine hydrochloride, astacin and shrimp cephalin. The foliage fertilizer disclosed by the invention enhances the low-temperature tolerance, drought tolerance, salt damage tolerance, chemical damage tolerance and other stress tolerances of crops on the premise of comprehensively and efficiently supplementing necessary nutrients for crops, and has the functions of restoring the wound in the root system, enhancing the disease resistance of the crops, inhibiting disease and pest and the like. The production technique can reduce the acidolysis consumption, avoids introducing abundant inorganic salts and chloride ions to destroy soil ecological equilibrium and influence plant growth, lowers the energy consumption and requirements for equipment strength, and can implement the clean production of complete utilization and zero pollution discharge.

Owner:ZHANJIANG BOTAI BIOCHEM IND

Products made of Al-Zn-Mg-Cu alloys with an improved compromise between static mechanical characteristics and damage tolerance

The present invention relates to an extruded, rolled and / or forged product made of an aluminium alloy. Alloys of the present invention may comprise (by mass): Zn 6.7-7.5% Cu 2.0-2.8% Mg 1.6-2.2% at least one element selected from the group composed of: Zr 0.08-0.20% Cr 0.05-0.25% Sc 0.01-0.50% Hf 0.05-0.20% and V 0.02-0.20% Fe+Si<0.20% other elements ≦0.05 each and ≦0.15 total, balance aluminium. Products of the present invention in some embodiments have an improved compromise between static mechanical strength and damage tolerance.

Owner:RHENALU ALCAN

Metal structure fatigue crack propagation life prediction method based on material R curve

InactiveCN102778404APredicted Extended LifeStrength propertiesFatigue loadingCrack growth resistance curve

The invention relates to a metal structure fatigue crack propagation life prediction method based on a material R curve and is technically characterized in that based on the material crack propagation resistance curve (R curve) and crack propagation energy release rate theory, the effective energy release rate under fatigue load is defined as energy for crack propagation after a fatigue crack is completely expanded, the energy is equal to the consumed energy characterized by the crack propagation resistance curve in the same loading cycle, so that a fatigue crack propagation life prediction model capable of reflecting the physical nature of the crack propagation is proposed. By adopting the model, the crack propagation amount in each loading cycle can be calculated, the crack propagation life can be predicated through the accumulative calculation of the crack propagation amount, and the metal structure fatigue crack propagation life prediction method is suitable for predicting the fatigue crack propagation life of a metal structure in engineering and provides a reference method for tolerance evaluation of a structural damage.

Owner:AIR FORCE UNIV PLA

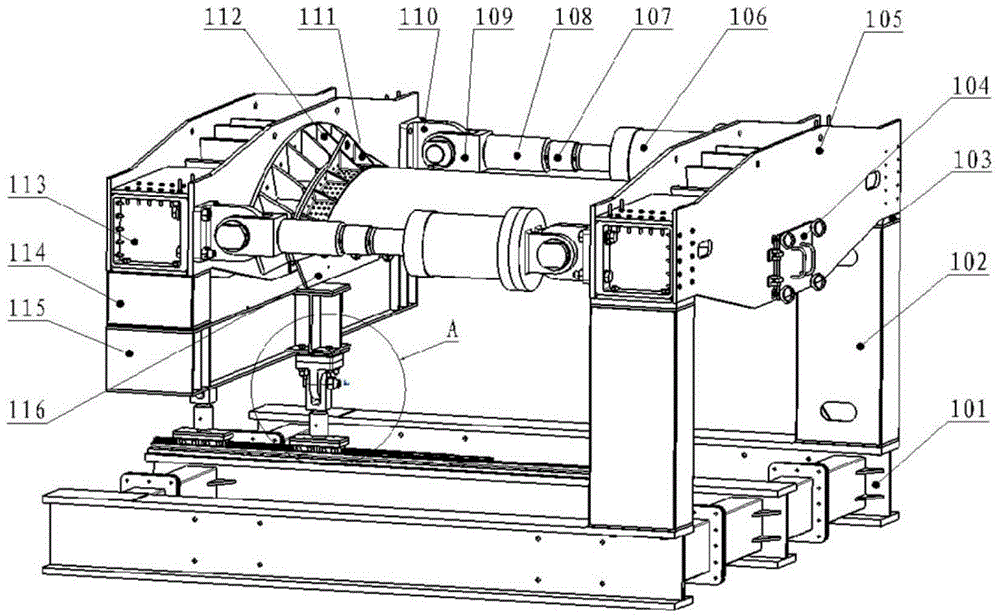

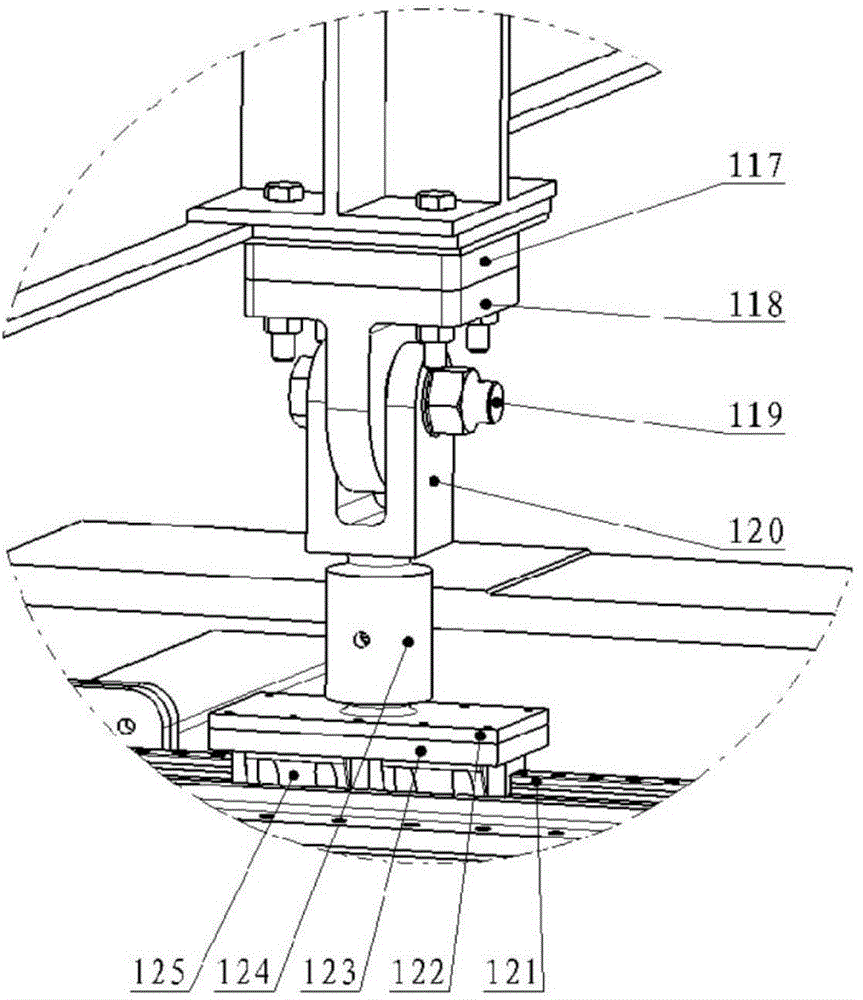

Fuselage panel combined load test device

ActiveCN104807694AImprove the design levelShorten the design cycleStrength propertiesDamage toleranceEngineering

The invention relates to an aircraft fuselage panel test device, in particular to a fuselage panel combined load test device. The fuselage panel combined load test device comprises an axial load applying assembly (100), a shear load applying assembly (200), an air pressure and circumferential load balance assembly (300) and a counterweight assembly (400), wherein single load can be applied among the assemblies, and the assemblies can be freely combined to apply load. Stretching / compressing, shearing and airtight load can be applied to a fuselage panel at the same time for static force and fatigue experiments, and static force, fatigue and damage tolerance tests related to the fuselage panel can be performed, so that the design level is promoted, and the design period is shortened.

Owner:CHINA AIRPLANT STRENGTH RES INST

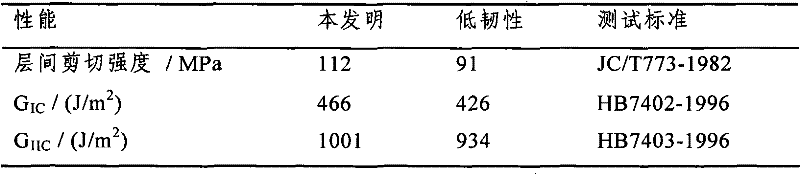

Composite materials with blend of thermoplastic particles

ActiveUS20080286578A1High level of strengthImprove toleranceSynthetic resin layered productsSolid ballsDamage toleranceMaterials science

Pre-impregnated composite material (prepreg) is provided that can be cured to form composite parts that have high levels of damage tolerance. The matrix resin includes a thermoplastic particle component that is a blend of particles that have a melting point above the curing temperature and particles that have a melting point at or below the curing temperature.

Owner:HEXCEL COMPOSITES LTD (GB)

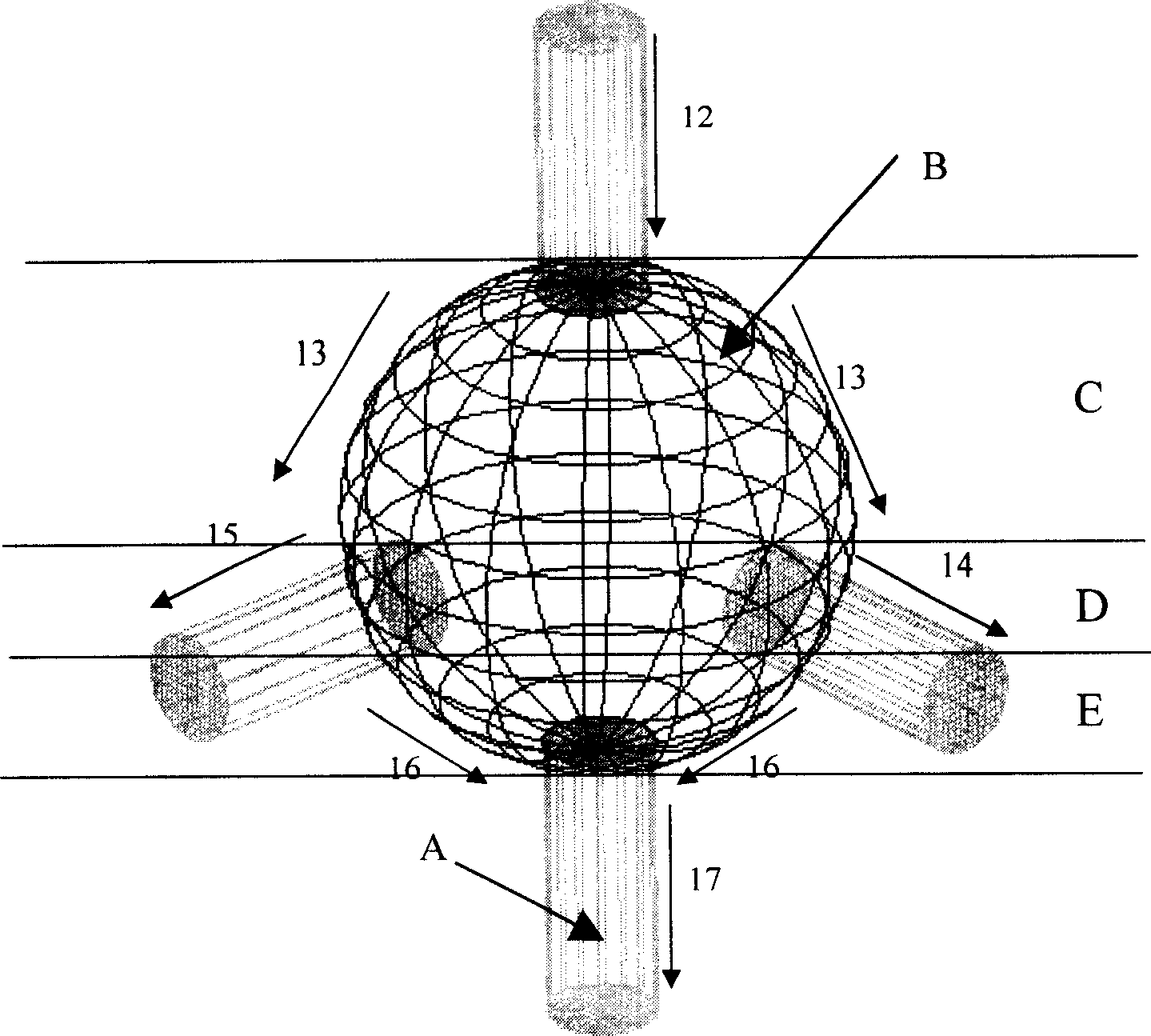

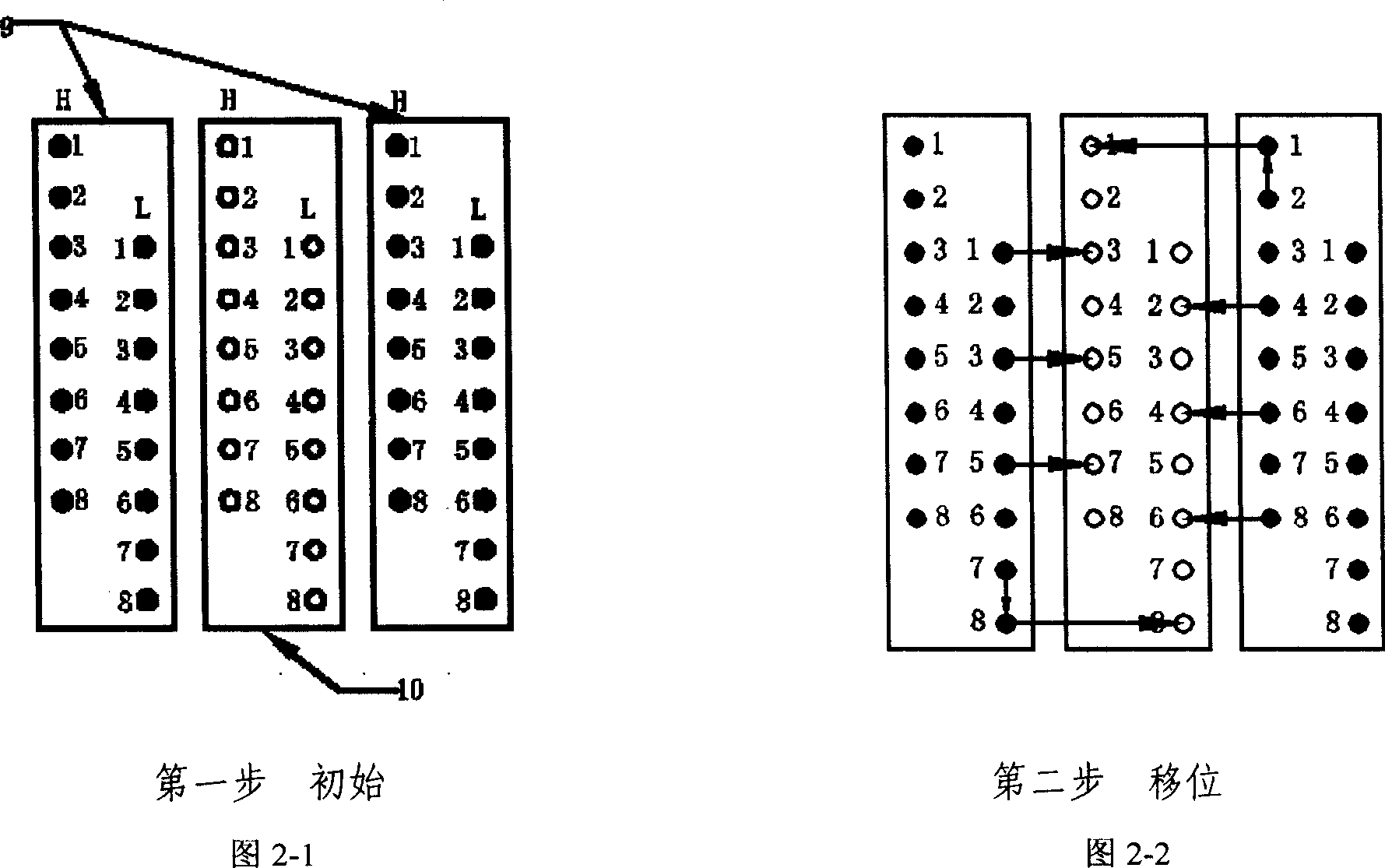

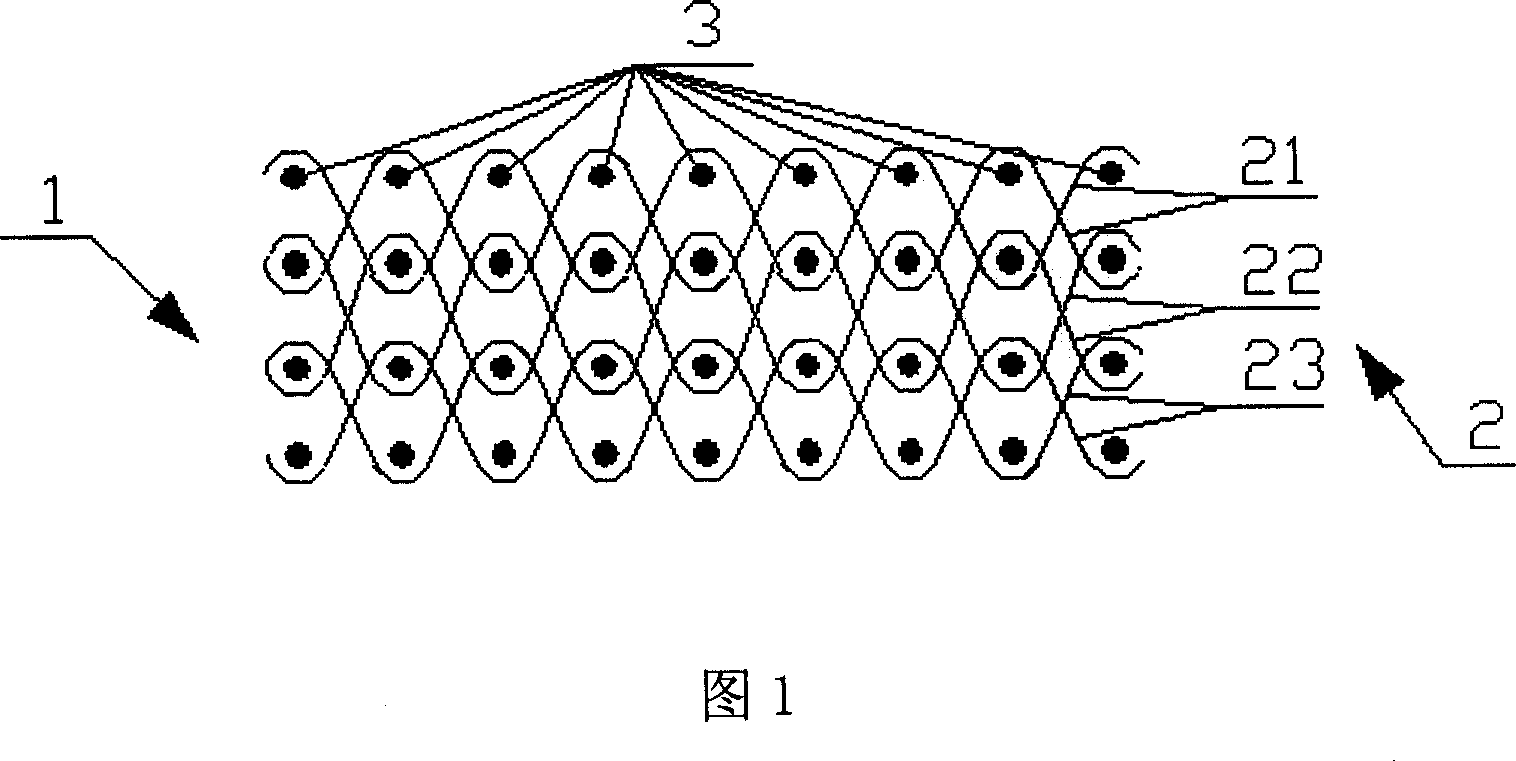

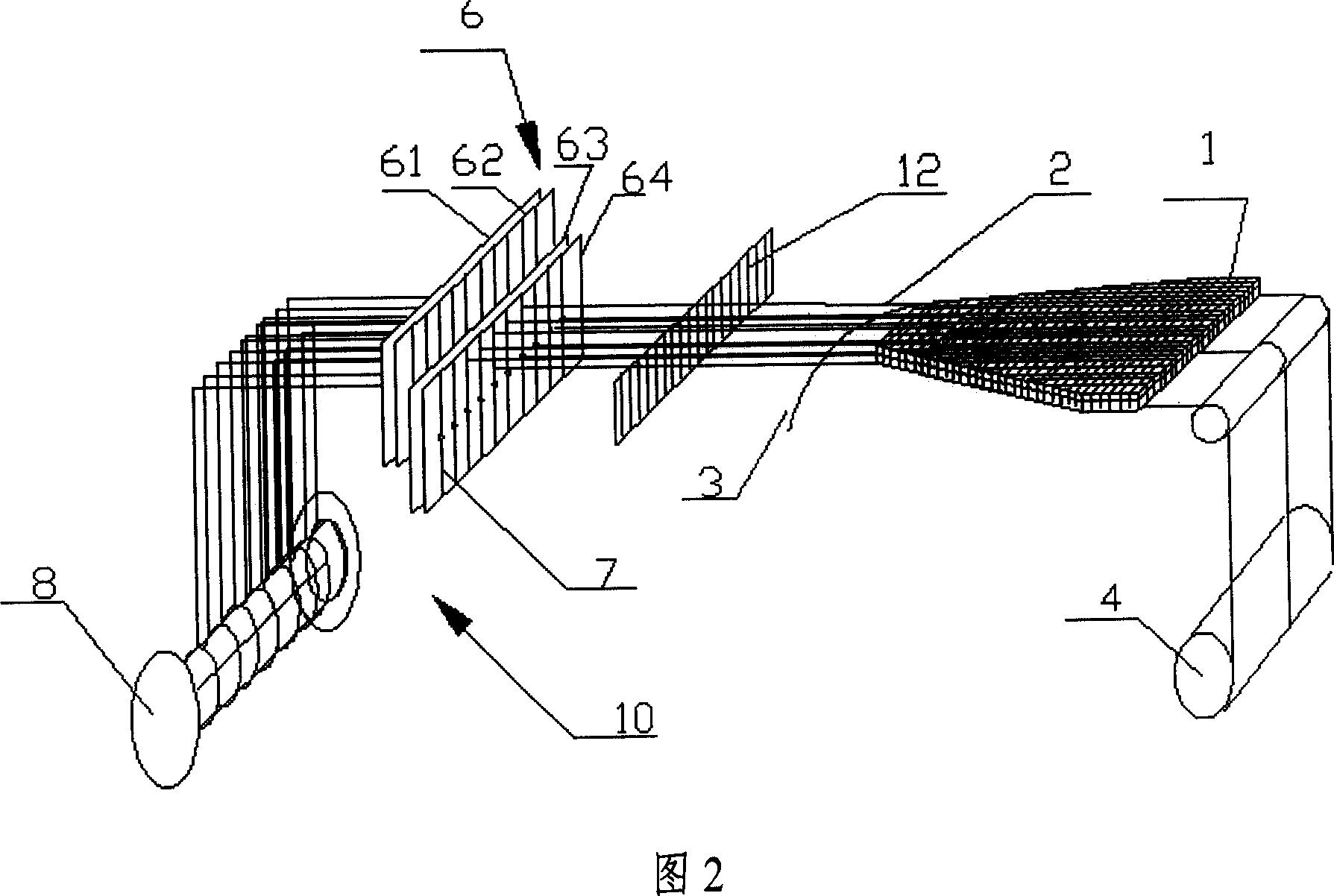

Method for knitting 2.5-dimension integral knit multiple-pass fabric

The invention relates to a weave method of 2.5-dimensional overall braided multi-through pipe fabric. The weave method is characterized in that (1) the structure of the fabric adopts a 2.5-dimensional shallow-cross bended-connection structure; (2) the overall weaving of the fabric adopts core imitation-shaped weaving to ensure the internal molded surface dimension of the fabric; (3) the fabric is divided into two parts, namely a connecting body part and a through pipe part, wherein the connecting body is a part connected with the through pipes, while the through pipes are connected through the same connecting body; (4) the lower section of each through pipe is provided with warp yarns of the part in advance; (5) weft yarns between through pipes in the same plane are lined between the warp yarns layer by layer through adopting a weft insertion process; (6) when the horizontal section of the connecting body increases, warp yarns are increased through adopting a shift yarn adding method, and the method can effectively improve the hole phenomenon in yarn-adding points; and (7) when the horizontal section of the connecting body decreases, warp yarns are reduced through adopting a shift yarn reduction method. The 2.5-dimensional multi-through pipe fabric woven by the weave method has the advantages of better overall property, controllable shaping, high damage tolerance, excellent performances of impact resistance, delamination resistance, fatigue resistance, and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Aluminum alloy products for manufacturing structural components and method of producing the same

ActiveUS20110297278A1Improve performanceLarge thicknessHeat treatment process controlDamage toleranceDirect chill casting

An aluminium alloy product for manufacturing structural components, made from direct chill casting ingots comprises, based on wt %: Zn 7.5˜8.7, Mg 1.1˜2.3, Cu 0.5˜1.9, Zr 0.03˜0.20, the balance being Al, incidental elements and impurities. The levels of Zn, Mg, Cu, and Zr in the aluminum alloy products satisfy the expressions of (a) 10.5≦Zn+Mg+Cu≦11.0; (b) 5.3≦(Zn / Mg)+Cu≦6.0; and (c) (0.24−D / 4800)≦Zr≦(0.24−D / 5000). D is the minimum length of a line section connecting any two points on the periphery of the cross section of the ingot and passing through the geometrical center of the cross section. 250 mm≦D≦1000 mm. The aluminum alloy products have a superior combination of strength and damage tolerance, and exhibit homogeneous and consistent performance on the surface, at various depths under the surface, and in the core of the product. A method of producing the aluminum alloy products is also provided.

Owner:GRIMAT ENG INST CO LTD

Method of thermoforming fiber reinforced thermoplastic sandwich panels, thermoformed articles, and modular container structure assembled therefrom

InactiveUS20110180959A1Eliminate the problemIncrease stiffnessLarge containersCeramic shaping apparatusThermoplasticOff the shelf

A method is disclosed utilizing off the shelf constant cross section thickness sandwich panels comprised of Fiber Reinforced Thermoplastic (FRTP) resin skins and low density thermoplastic (TP) core material wherein the steps of selectively and controllably exposing the panels to heat and incrementally thermoforming the skin-core into a consolidated composite edge or intra-panel area in consideration of subsequent mating and attachment of the FRTP sandwich panel to other structures is achieved. The exact configuration of articles so thermoformed is design optimized to overcome manufacturing, assembly, weight, in-service and structural performance shortcomings of prior art and FRP sandwich panel structures. Further disclosed is an improved, load-bearing, modular design container structure assembled from such thermoformed FRTP sandwich panels in which is utilized the unique core-skin edge configuration of the present invention in consideration of improved: load bearing performance, useful load volume, reduced manufacturing costs, structural weight savings, impact and damage tolerance and repair and replace issues.

Owner:DONNELLY MATTHEW WILLIAM +3

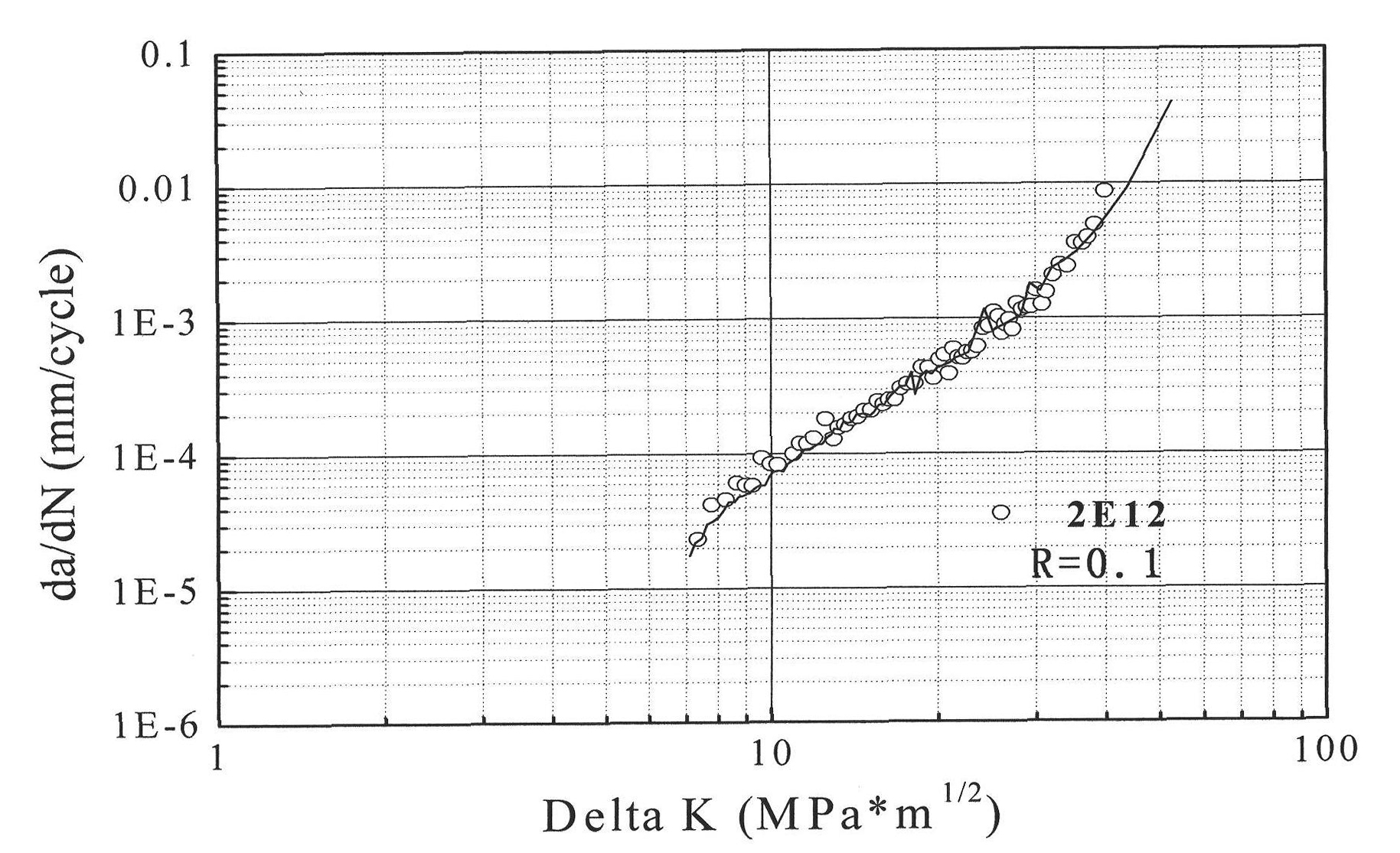

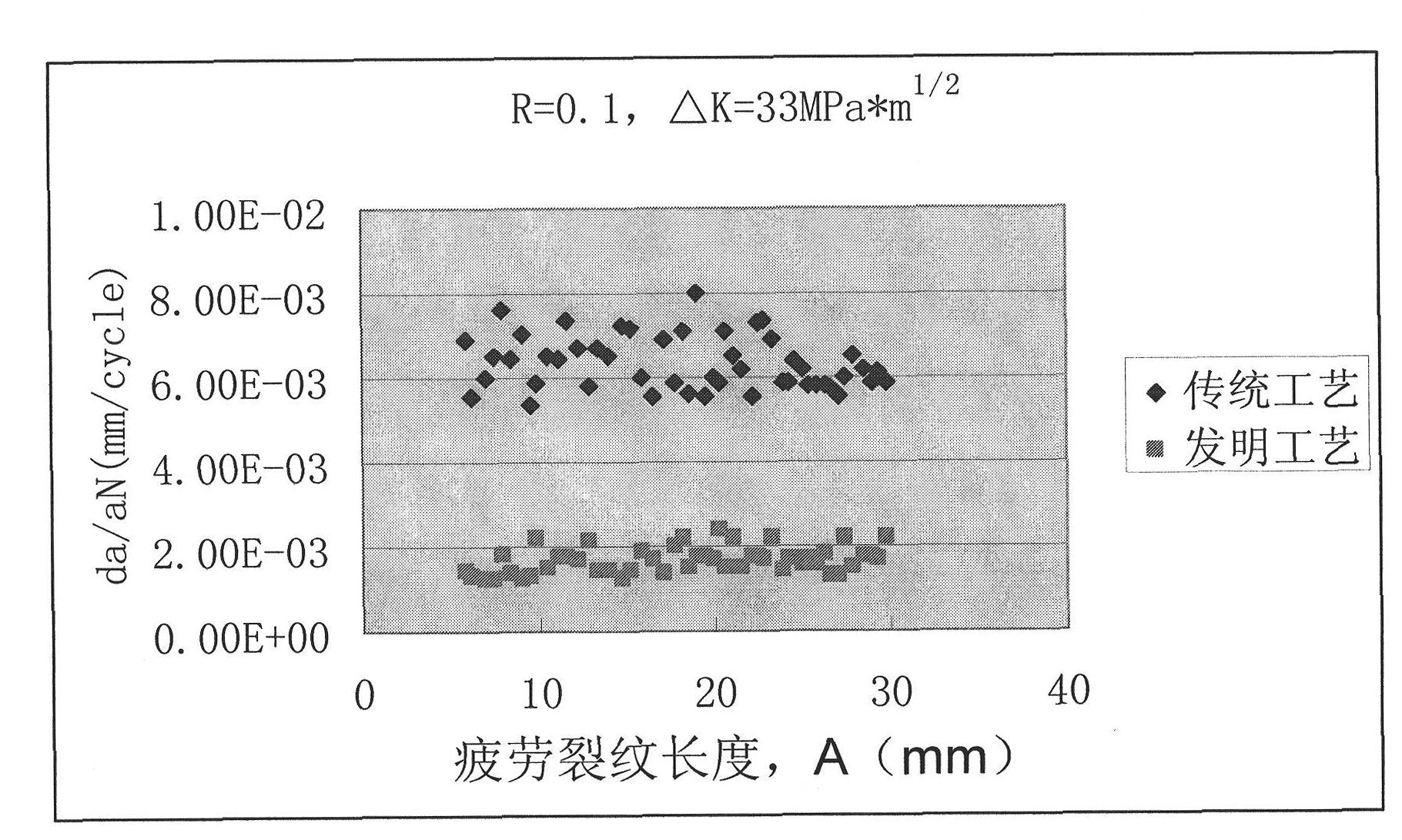

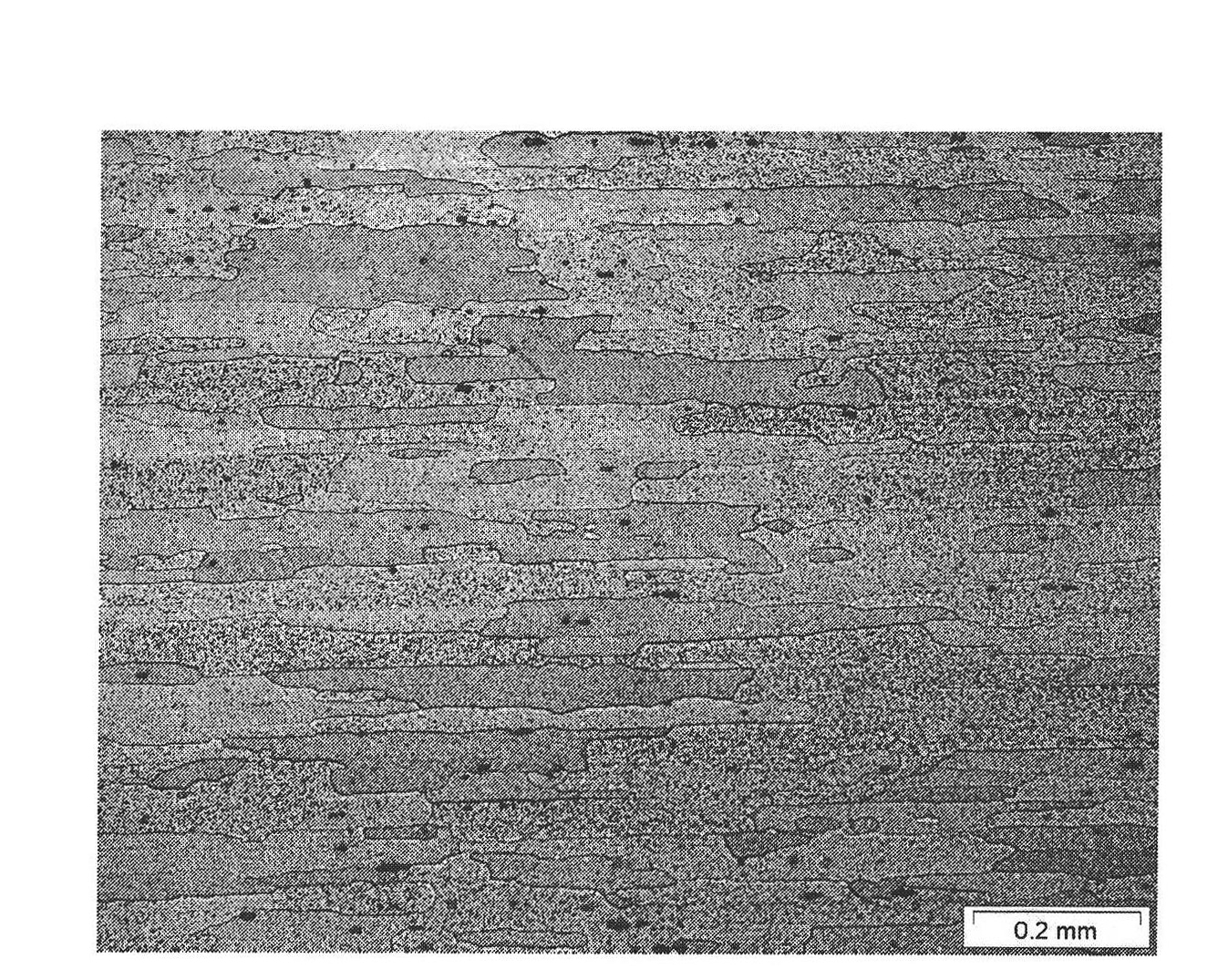

Method for improving damage-tolerance property of 2,000-type aluminium alloy plate material

ActiveCN101967615AEase of production implementationReduce fatigue crack rateMetallurgyDamage tolerance

The invention relates to a method for improving the damage-tolerance property of a 2,000-type aluminium alloy plate material. In the method, preferable hot-rolling outlet temperature, high-temperature softening treatment and smaller cold-rolling deformation in softening treatment process can be controlled, so that intercrystalline energy storage of the material is reduced, recrystallization degree is controlled and a malleableized texture is formed. By the method, the service life of the 2,000-type material such as 2,024, 2E12 and the like is prolonged by 2 to 4 times; the crack propagation rate is reduced to 1 / 4 to 1 / 2 of the original crack propagation rate; the production efficiency is improved; and the energy is further saved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High performance structural laminate composite material for use to 1000° F. and above, apparatus for and method of manufacturing same, and articles made with same

InactiveUS6521296B1Improve structural performanceHigh modulusPretreated surfacesWood working apparatusDamage toleranceRefractory

A novel materials technology has been developed and demonstrated for providing a high modulus composite material for use to 1000° F. and above. This material can be produced at 5-20% of the cost of refractory materials, and has higher structural properties. This technology successfully resolves the problem of "thermal shock" or "ply lift," which limits traditional high temperature laminates (such as graphite / polyimide and graphite / phenolic) to temperatures of 550-650° F. in thicker (0.25'' and above) laminates. The technology disclosed herein is an enabling technology for the nose for the External Tank (ET) of the Space Shuttle, and has been shown to be capable of withstanding the severe environments encountered by the nose cone through wind tunnel testing, high temperature subcomponent testing, and full scale structural, dynamic, acoustic, and damage tolerance testing.

Owner:LOCKHEED MARTIN CORP

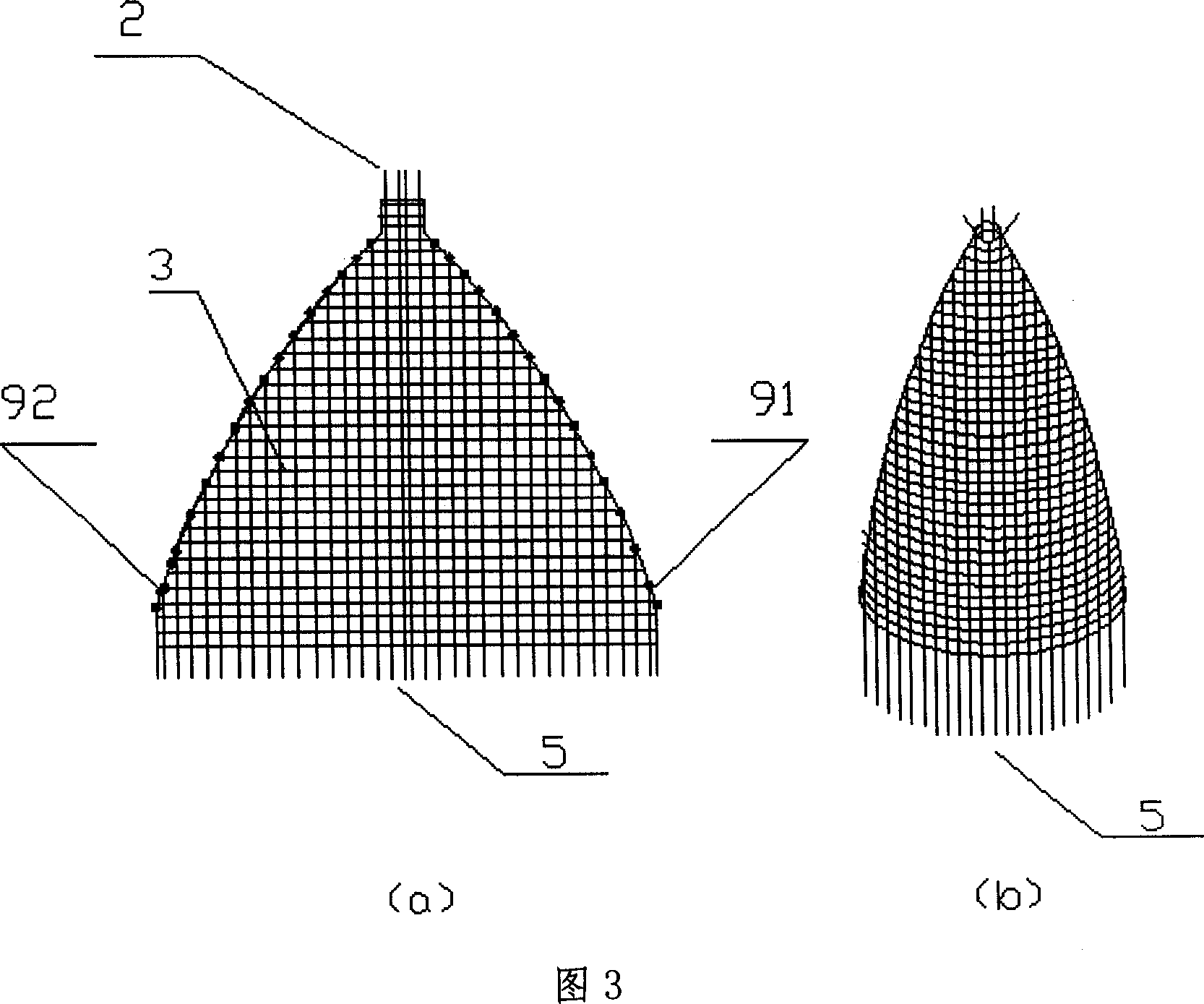

Weaving process in three-dimensional conic-casing loom and its product

InactiveCN1932102ARealize planar overall weavingImprove integrityWoven fabricsDamage toleranceEngineering

The present invention is weaving process of three-dimensional conic-casing fabric and its product. The weaving process includes the following steps: 1. pre-setting warp yarns based on the fabric structure and in tubular fabric weaving process; 2. introducing weft yarns in planar helical wefting method and interweaving with preset warp yarns; 3. setting warp cutting points on two sides based on the planar shape of the fabric and performing copying warp cutting operation; and 4. repeating the steps 2 and 3 until finishing the weaving of the three-dimensional conic-casing fabric. The present invention has short weaving period, low cost, simple operation, high efficiency, high adaptability and other features, and the fabric has high integrality, high damage tolerance, high impact resistance and other advantages.

Owner:TIANJIN POLYTECHNIC UNIV

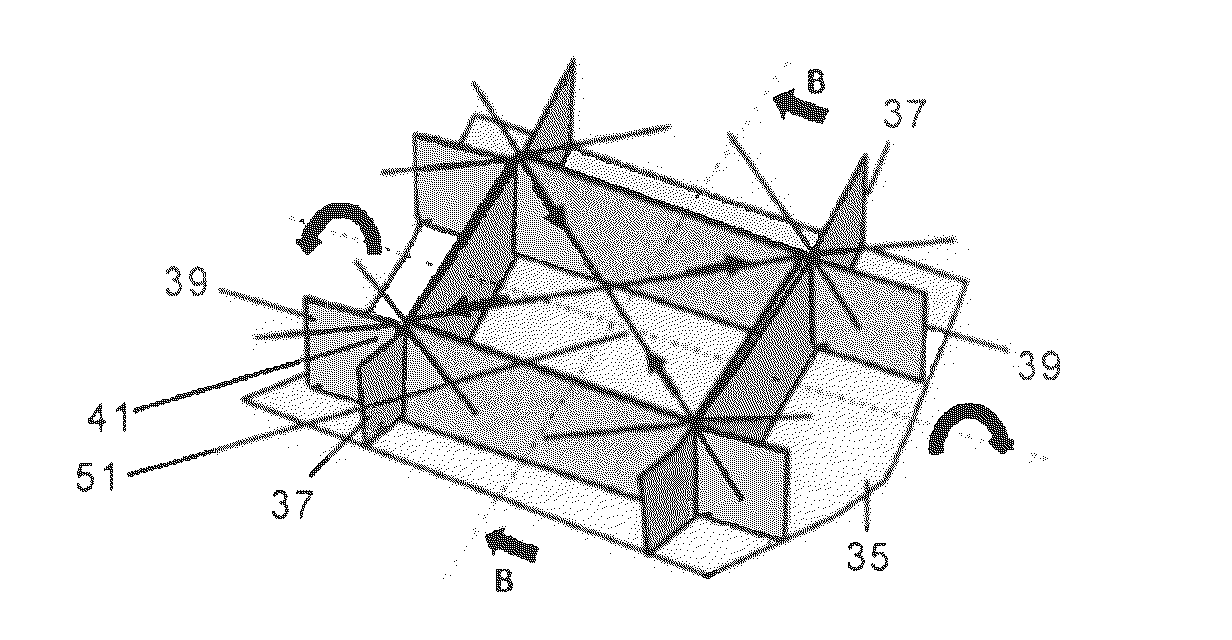

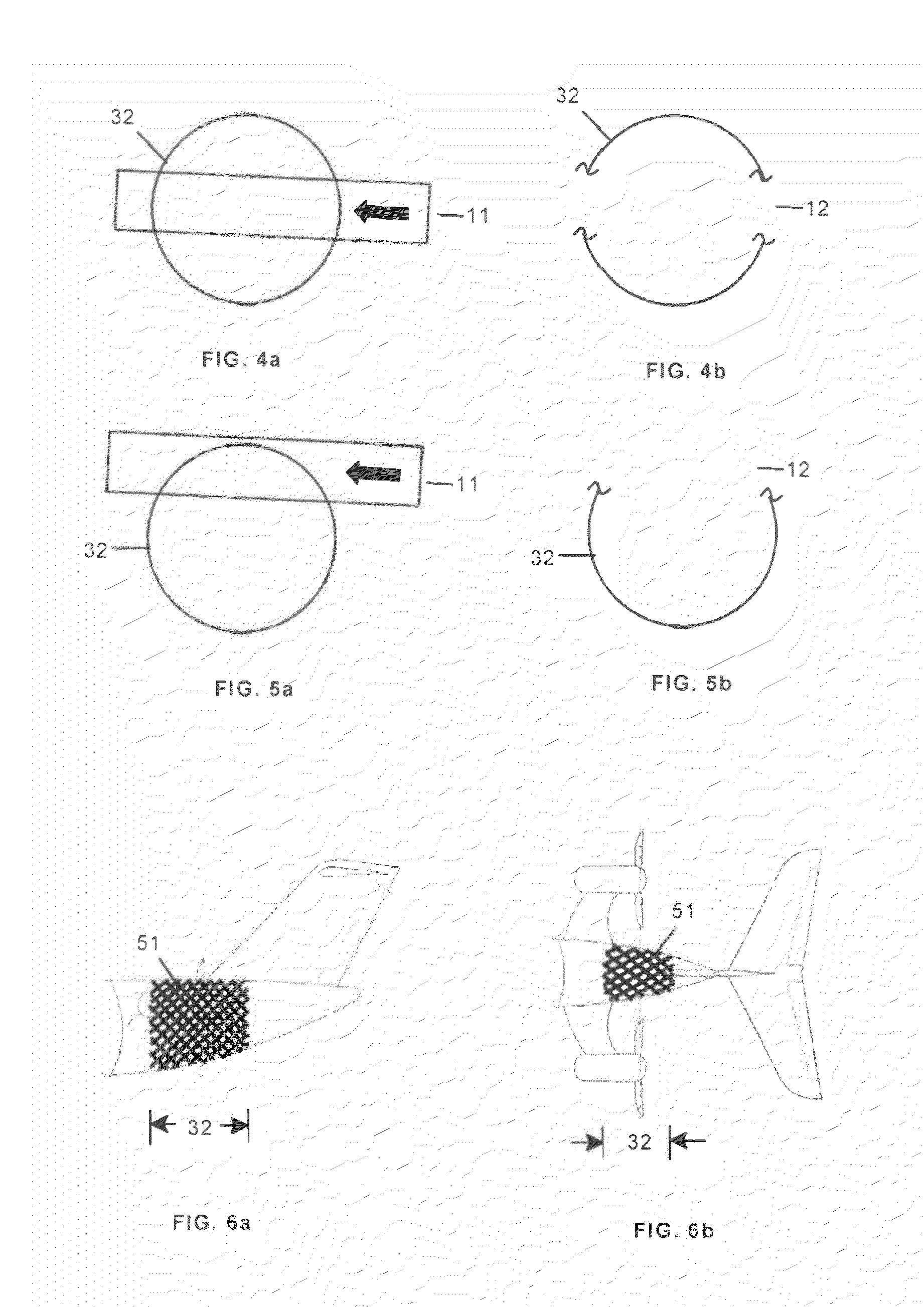

Impact resistant and damage tolerant aircraft fuselage

ActiveUS20130099057A1Convenience to mergeEasy to implementFuselage framesGas turbine type power plantsCurve shapeDamage tolerance

Aircraft fuselage section (32) subjected to impacts of external bodies, the aircraft fuselage having a curved shape with at least a vertical symmetry plane (A-A) and a central longitudinal axis and comprising a skin (35) and a plurality of frames (37) arranged perpendicularly to said longitudinal axis (33), the aircraft fuselage section also comprising at least an inner reticular structure (51, 53) mounted on a supporting structure (41, 43) comprising longitudinal beams (39) attached to the skin (35) and interconnected with said frames (37), said inner reticular structure (51, 53) being arranged for creating at least one closed cell (75) with the skin (35) for improving its resistance and its damage tolerance to said impacts. Said inner reticular structure (51, 53) can be formed by panels (61), rods (65, 65′), cables (67, 67′) or belts (69, 69′).

Owner:AIRBUS OPERATIONS SL +1

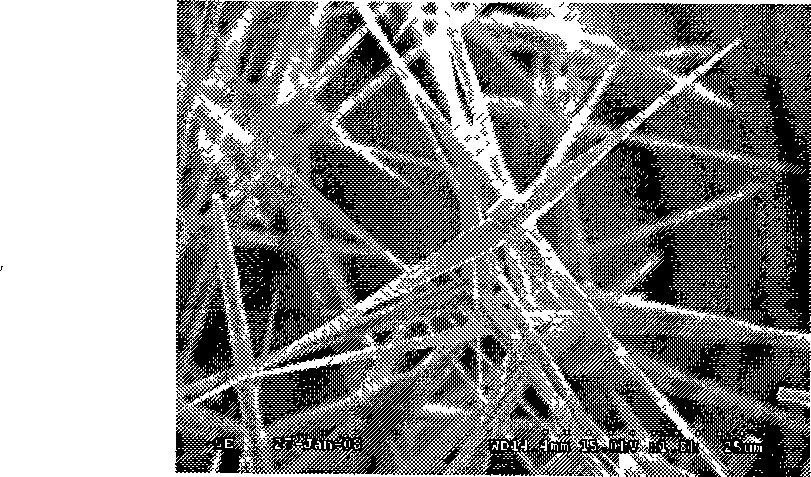

Method for preparing rigid three-dimensional crystal whisker interlayer modified continuous fiber composite material

ActiveCN101423618AImprove the strength-toughness performanceAvoid difficultiesMicron scaleTransfer molding

The invention belongs to a technology for preparing composite materials and relates to a method for preparing rigid three-dimensional crystal whisker interlaminar modified continuous fiber composite materials. The interlaminar modified thermosetting resin composite materials are prepared by the following method by adoption of a micron-scale heteropical rigid micro 3-3 structure and adoption of a four-pin zinc oxide crystal whisker as an interlaminar reinforcement: firstly, the four-pin zinc oxide crystal whisker which is subjected to vacuum drying for 2 hours at a temperature of 100 DEG C is deposited on the surface of fabrics by means of a mechanical vibrating screen or electrostatic adherence or deposition through a fluidized bed or powdering through a drum-type silk screen, and modified fabrics are obtained; and secondly, after the modified fabrics are laid as required, the resin transfer molding technology or the resin membrane permeation technology is utilized for preparing the composite materials by the prior matrix resin solidifying technology. The method can improve the strong interlaminar toughening performance of the composite materials, obtain high surge impedance and high damaged tolerance, and cover the temperature range of structural application of typical aerospace composite materials and particularly cover the high temperature range of more than 300 DEG C.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com