High-efficiency multifunctional foliage fertilizer and production method thereof

A production method and foliar fertilizer technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of high production cost, incomplete nutrition, and large amount of acid and alkali consumption of chitosan and chitosan oligosaccharides, and achieve improved resistance The ability of diseases and insect pests, improving the utilization rate of fertilizer, and improving the effect of absorption and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

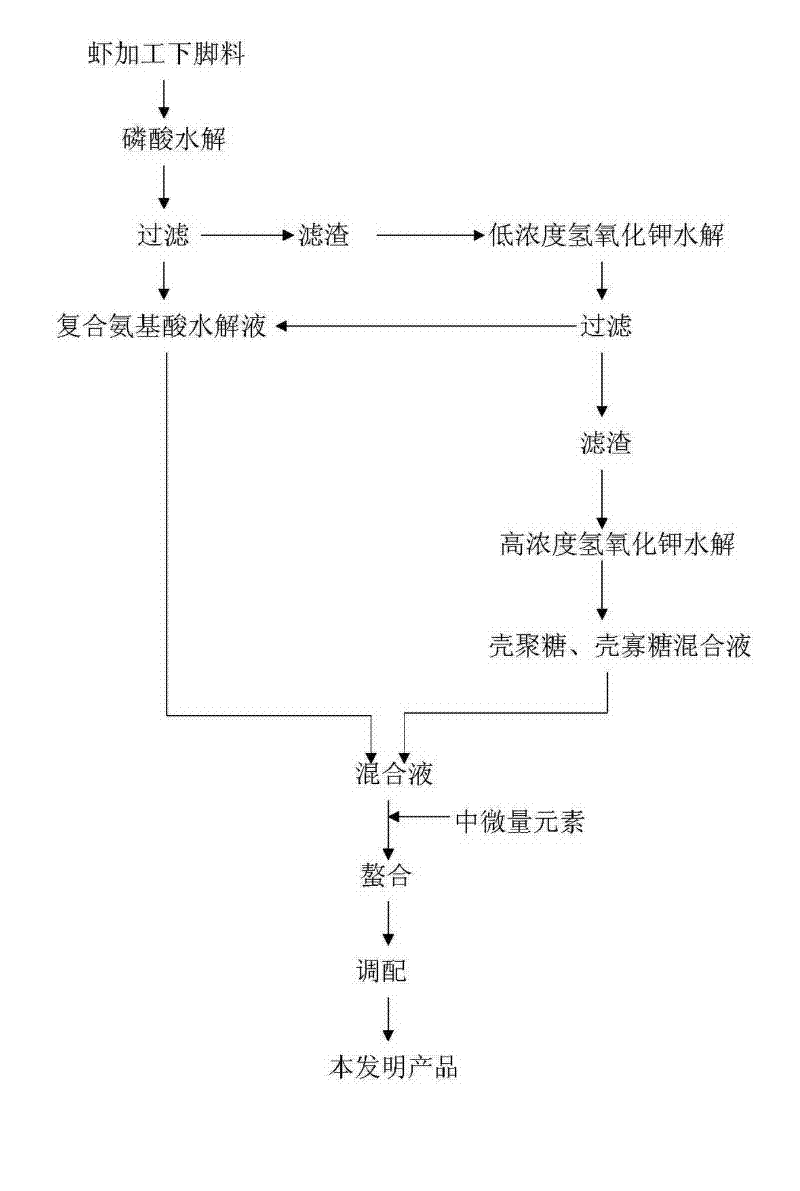

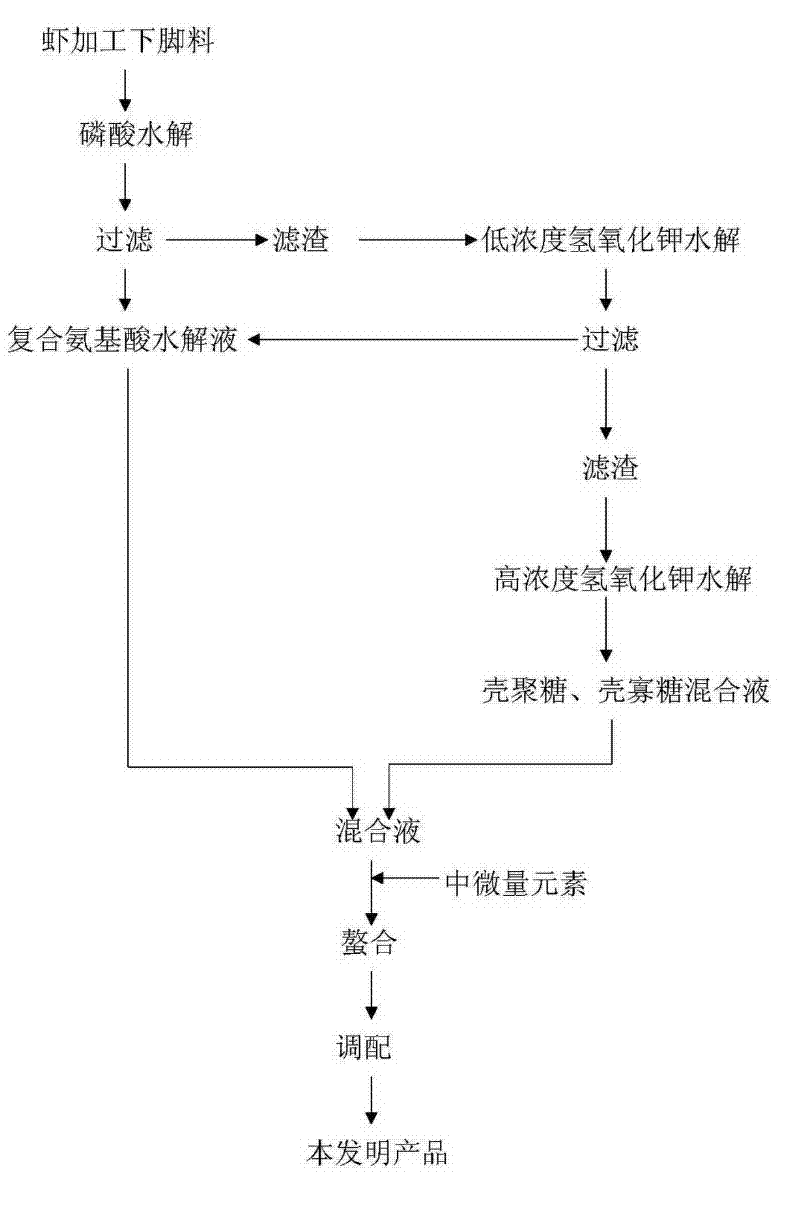

Method used

Image

Examples

Embodiment 1

[0030] Take 1 ton of fresh shrimp processing waste, place it at 25°C for 24 hours for autolysis, and ferment. Crush the fermented shrimp processing waste, pass through a 40-mesh sieve, put it into a reaction tank, add 3 times the amount of 20% phosphoric acid, stir evenly, hydrolyze at 100°C for 24 hours, and stir for 5 minutes every 2 hours. After hydrolysis, squeeze and filter, and collect the acidic filtrate. Add 2 times the amount of 20% potassium hydroxide to the filter residue, stir evenly, hydrolyze at 100°C for 4 hours under normal pressure, stir for 5 minutes every 2 hours, squeeze and filter after hydrolysis, and collect the alkaline filtrate of the first stage. Then add an appropriate amount of potassium hydroxide to the remaining filter residue to make its concentration in the filter residue reach 45%, stir evenly, react at 110°C under normal pressure for 6 hours, and stir for 5 minutes every 2 hours. The acidic filtrate is mixed with the basic filtrate, and the p...

Embodiment 2

[0032] Take 1 ton of fresh shrimp processing waste, place it at 25°C for 24 hours for autolysis, and ferment. Crush the fermented shrimp processing waste, pass through a 40-mesh sieve, put it into a reaction tank, add 5 times the amount of 10% phosphoric acid, stir evenly, hydrolyze at 90°C for 24 hours, and stir for 5 minutes every 2 hours. After hydrolysis, squeeze and filter, and collect the acidic filtrate. Add 3 times the amount of 10% potassium hydroxide to the filter residue, stir evenly, hydrolyze at 100°C under normal pressure for 4 hours, stir for 5 minutes every 2 hours, squeeze and filter after hydrolysis, and collect the alkaline filtrate of the first stage. Then add an appropriate amount of potassium hydroxide to the remaining filter residue to make the concentration in the filter residue reach 30%, stir evenly, hydrolyze at 110°C under normal pressure for 6 hours, and stir for 5 minutes every 2 hours. The acidic filtrate is mixed with the basic filtrate, and th...

Embodiment 3

[0034] Take 1 ton of fresh shrimp processing waste, place it at 25°C for 24 hours for autolysis, and ferment. Crush the fermented shrimp processing waste, pass through a 40-mesh sieve, put it into a reaction tank, add 1 times the amount of 30% phosphoric acid, stir evenly, hydrolyze at 90°C for 8 hours, and stir for 5 minutes every 2 hours. After hydrolysis, squeeze and filter, and collect the acidic filtrate. Add 1 times the amount of 20% potassium hydroxide to the filter residue, stir evenly, hydrolyze at 100°C for 2 hours under normal pressure, stir for 5 minutes every 2 hours, squeeze and filter after hydrolysis, and collect the alkaline filtrate of the first stage. Add an appropriate amount of potassium hydroxide to the remaining filter residue to make the concentration in the filter residue reach 40%, stir evenly, hydrolyze at 100°C for 3 hours under normal pressure, and stir for 5 minutes every 2 hours. The acidic filtrate is mixed with the basic filtrate, and the pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com