Method for knitting 2.5-dimension integral knit multiple-pass fabric

A technology of integral weaving and multi-way pipe, which is applied in the direction of braids, fabrics, textiles, etc., can solve the problems of weak mechanical properties at the intersection of fabric interfaces, difficult control of fabric uniformity and consistency, and difficult quality assurance, etc., to achieve Effect of improving void phenomenon, ensuring overall density uniformity, and high damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: The fabric adopts a 2.5-dimensional shallow cross-bending structure

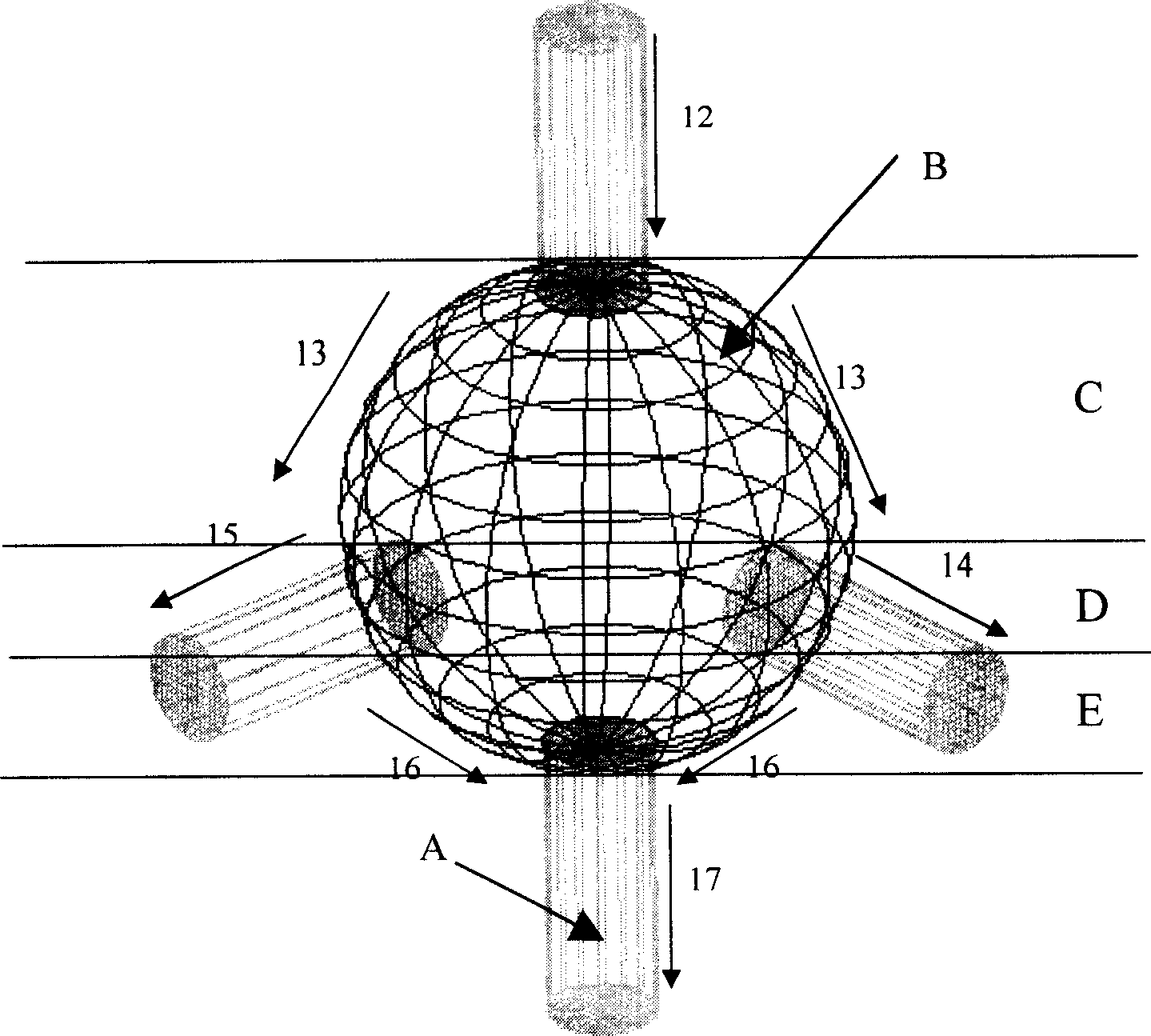

[0027] refer to figure 1 , the following takes the 2.5-dimensional four-way pipe as an example to describe the process implementation method in detail. like figure 1 We divide the fabric into two parts: connecting body B and through pipe A; according to the weaving process, the sphere part is divided into three parts (such as figure 1 Middle C, D, E): the upper hemisphere part, the arc section between the tubes and the lower hemisphere part. The weaving sequence is as figure 1 Display: 12→13→14→15→16→17.

[0028] The present invention is described in further detail below.

[0029] The upper hemisphere of the fabric realizes the increase of the warp by shifting and adding yarns. We assume that the number of warp layers of the fabric is 8 layers. The specific operation is as follows:

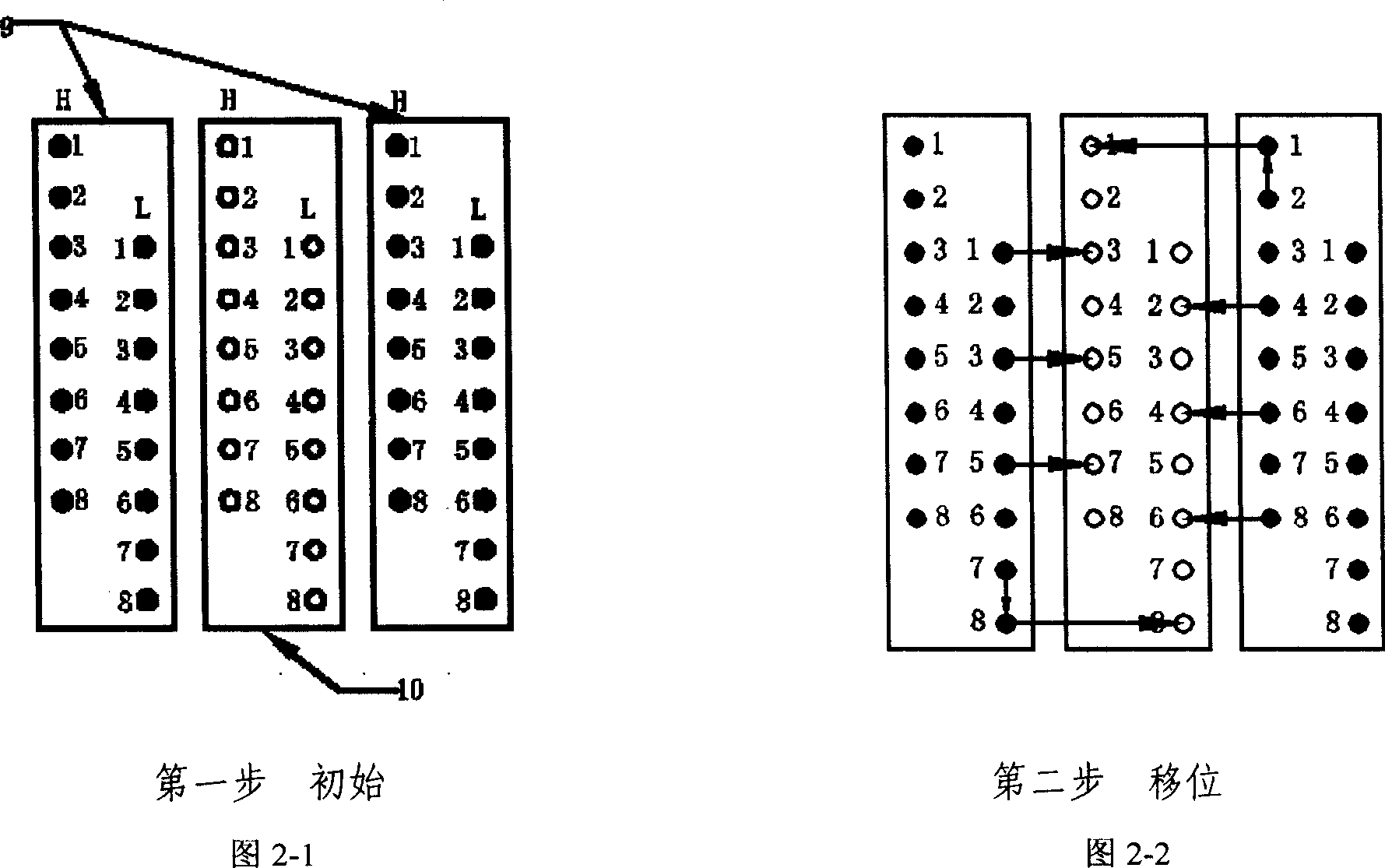

[0030] (1) see figure 2 , in the shallow cross-bending structure of 2.5-dimensional fabrics, two adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com