Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Astm standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strengthened borosilicate glass containers with improved damage tolerance

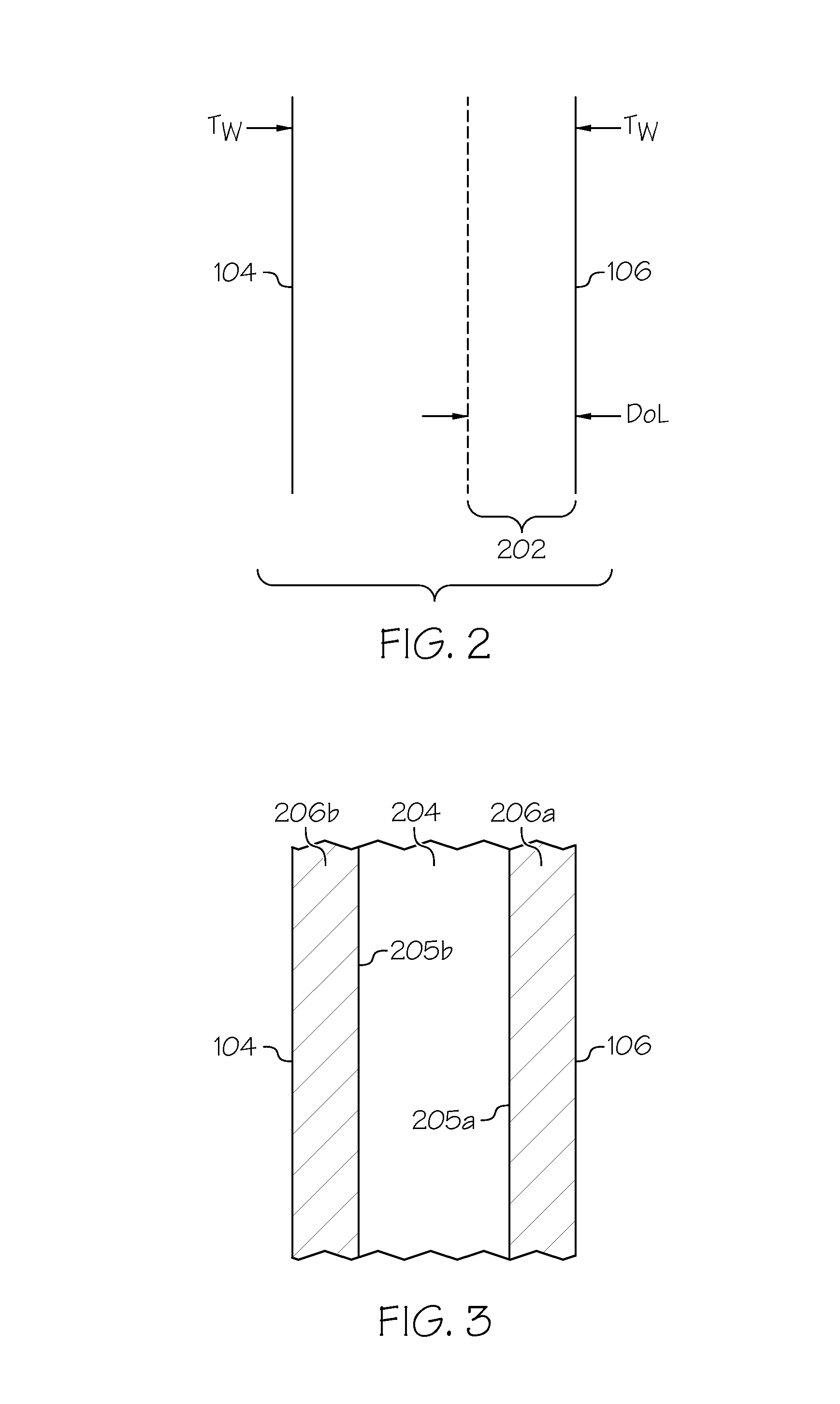

According to one embodiment, a glass container may include a body formed from a Type I, Class B glass composition according to ASTM Standard E438-92. The body may have an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. The body may also include a compressively stressed layer extending into the wall thickness from at least one of the outer surface and the inner surface. A lubricous coating may be positioned on at least a portion of the outer surface of the body, wherein the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

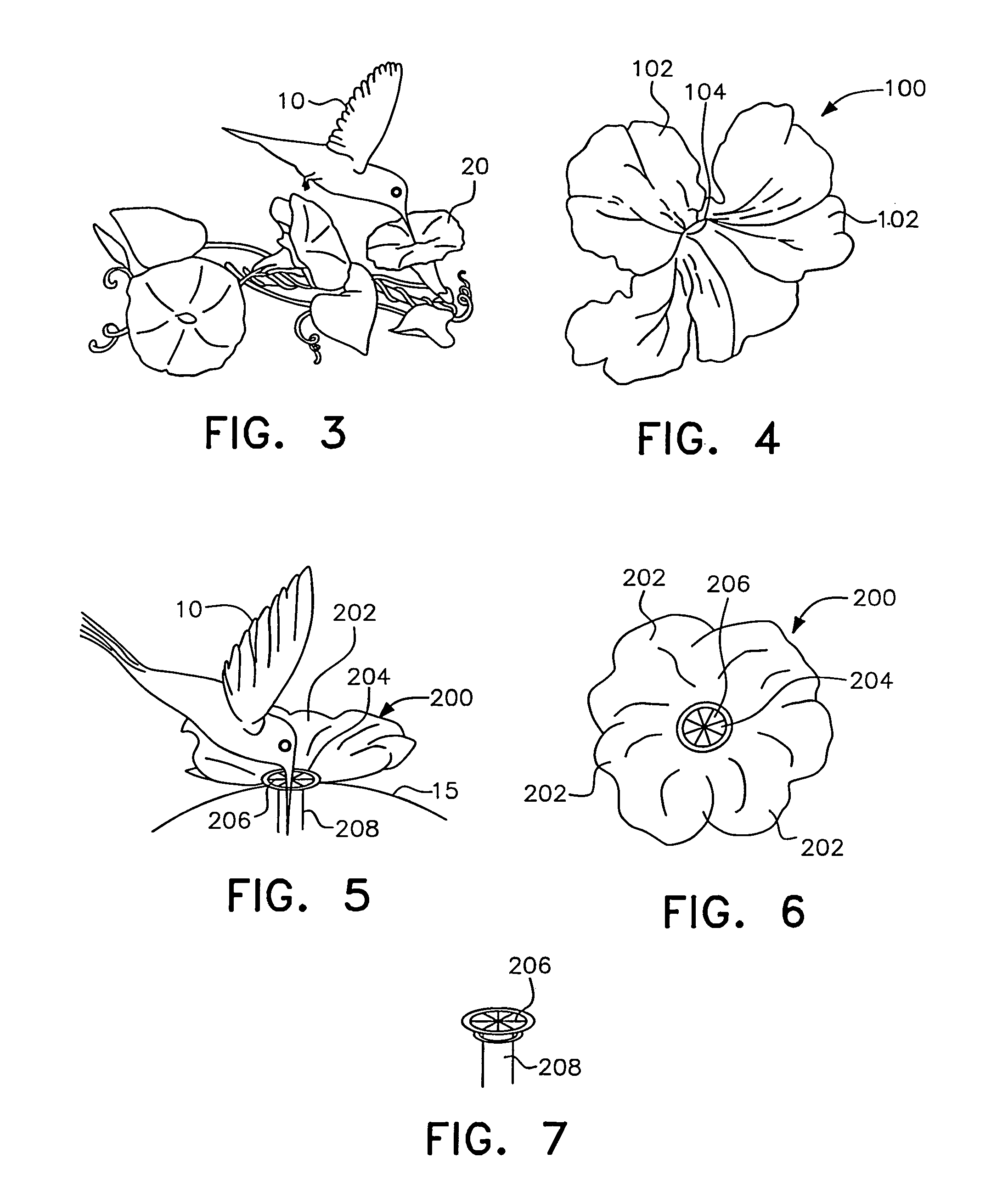

Soft petal flower port for hummingbird feeders

ActiveUS8763556B1Easy to bendEnsure safetyAnimal watering devicesPisciculture and aquariaPetalEngineering

A hummingbird feeder having one or more soft petal feeding ports, each port having a three-dimensional simulated flower made of a soft, flexible plastic or rubber-type material having a durometer reading not to exceed 50A based on ASTM standard D2240 is provided. The petals are pliable so as to be easily manipulated by a hummingbird coming into contact with them, and provide a texture and resistance comparable to that of natural flower petals.

Owner:WOODSTREAM CORP

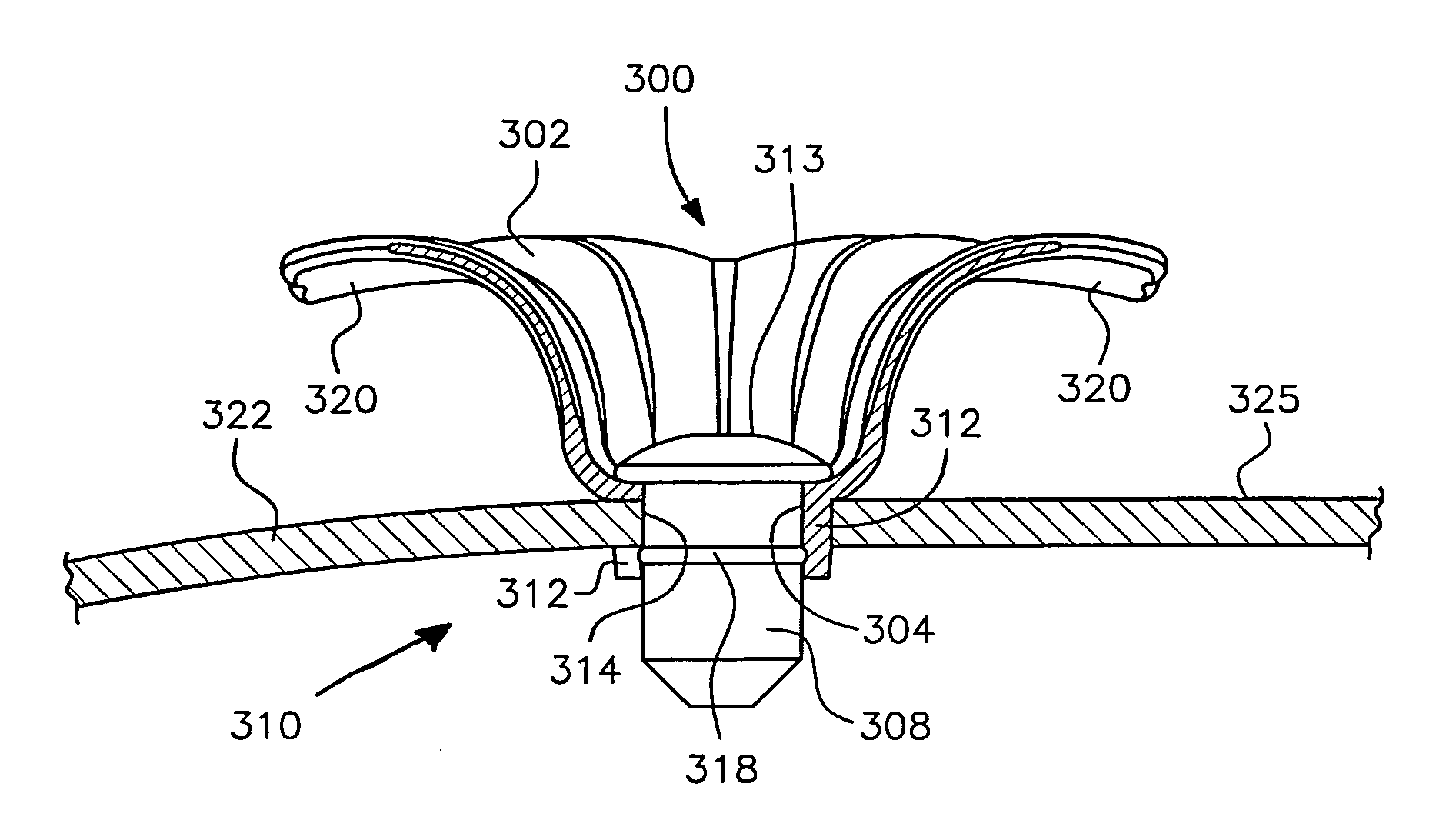

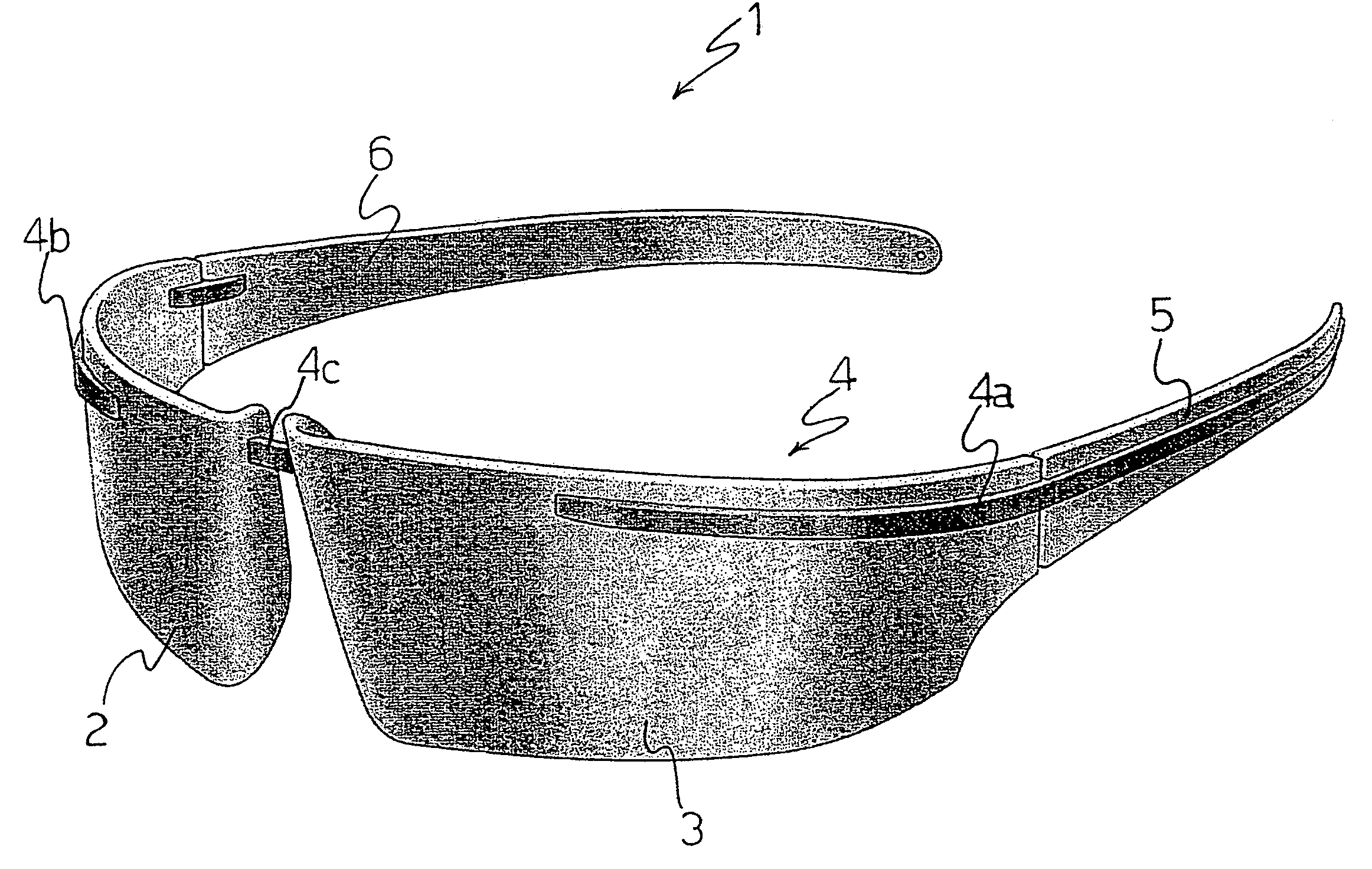

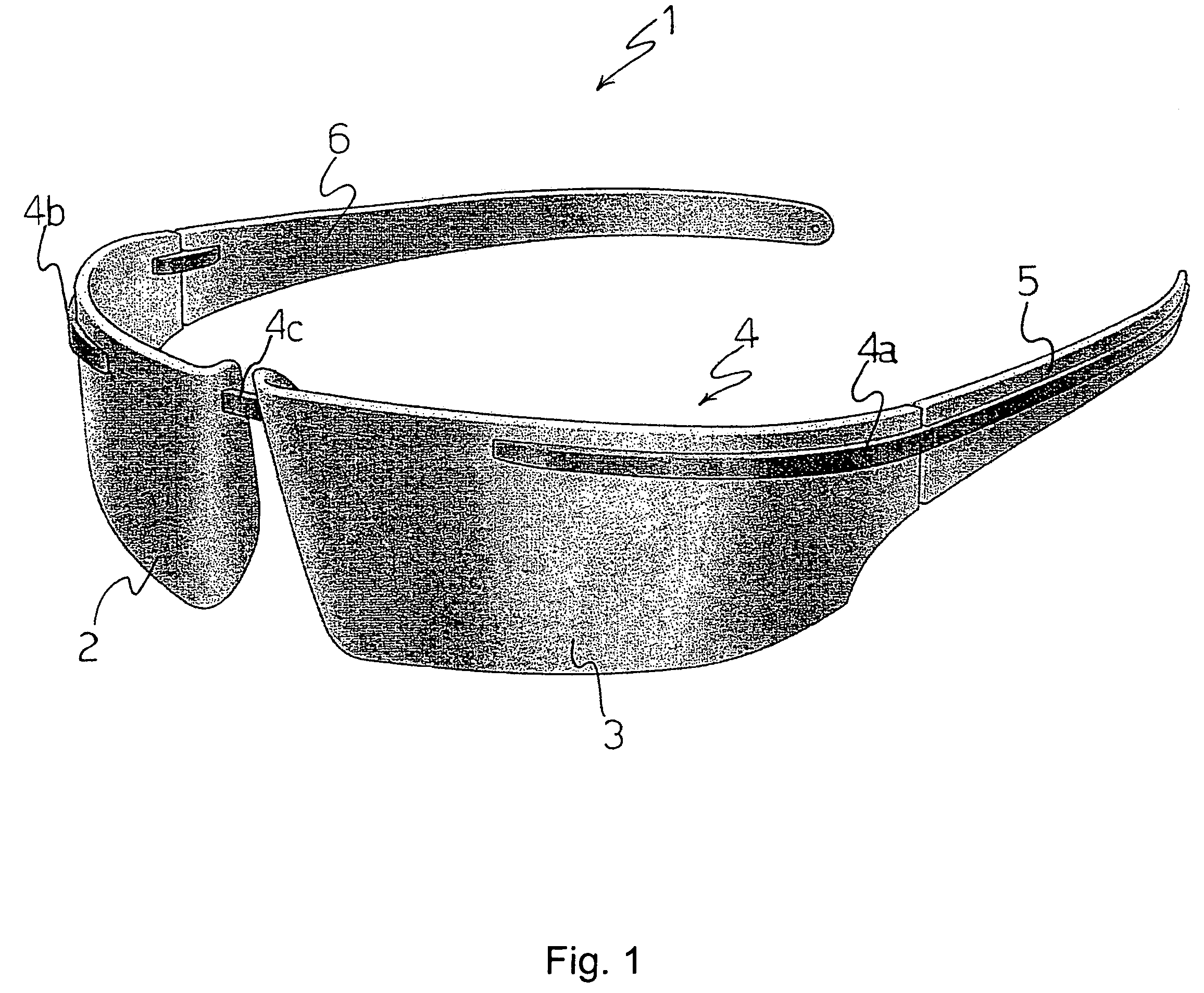

Soft optical element for use in eye-protecting devices

ActiveUS7014315B2Improve securityImproving the comfort of the wearerGogglesNon-optical partsPlastic materialsHardness

An optical element is disclosed comprising at least one transparent eye-protecting portion comprising a plastic material, preferably having a hardness within a range of about 40 Shore A to about 77 Shore D, as measured according to ASTM Standard D2240, and an elongation at break within a range of about 200% to about 700%, as measured according to ASTM Standard D638.

Owner:INTERCAST EURO

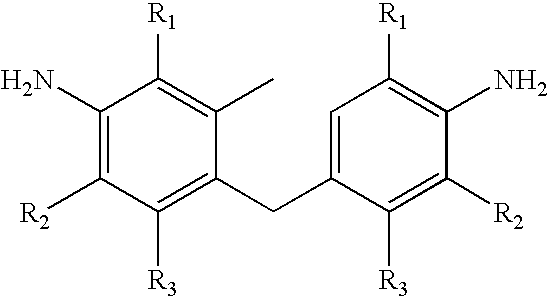

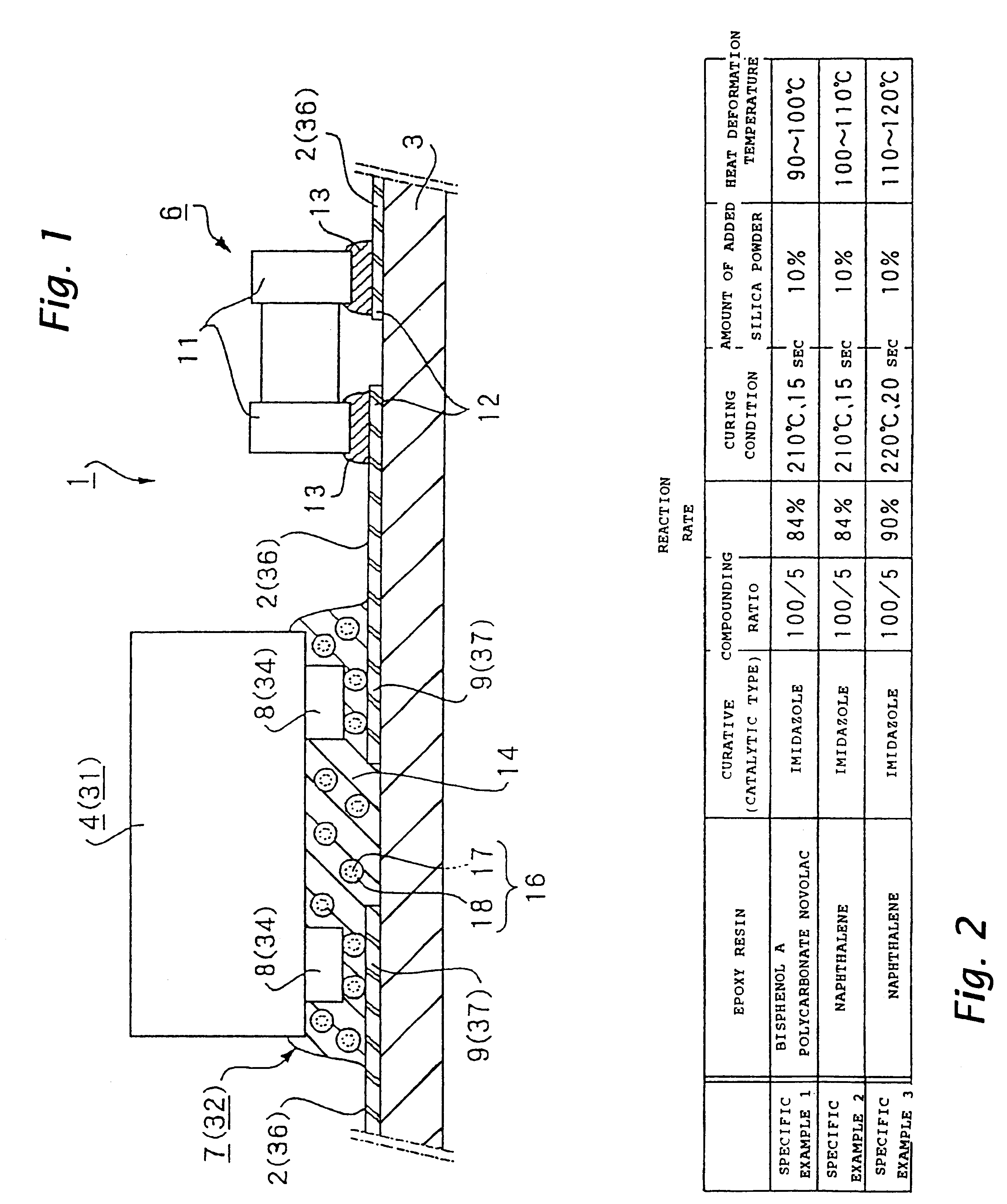

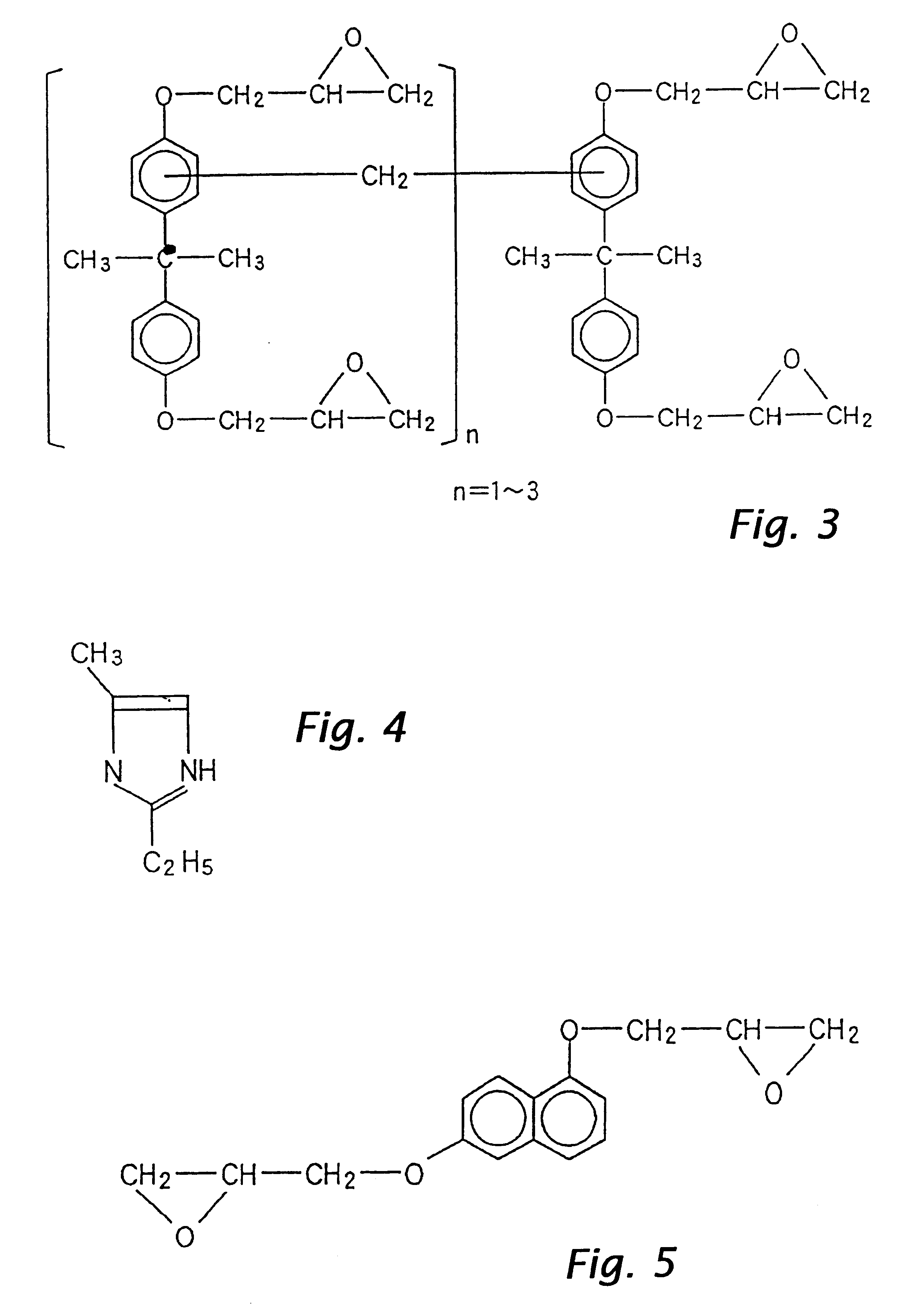

Conductive adhesive with conductive particles, mounting structure, liquid crystal device and electronic device using the same

InactiveUS6356333B1Improve heat resistancePrinted circuit assemblingSemiconductor/solid-state device detailsAdhesiveThermal deformation

A conductive adhesive which can withstand exposure to high temperature during a solder reflow process comprises an adhesive resin and a plurality of conductive particles mixed in the adhesive resin. The conductive particles each include a core formed of a synthetic resin and a conductive material coated around the core. The cores are each formed of a material having a thermal deformation temperature higher than that of the adhesive resin, and more preferably formed of a material having a thermal deformation temperature (18.6 kg / cm2) higher than 120° C. as measured according to the measuring method defined in the ASTM standard D648, and still more preferably formed of a material selected from the group consisting of polyphenylene oxide, polysulfone, polycarbonate, polyacetal, and polyethylene terephthalate.

Owner:BOE TECH GRP CO LTD

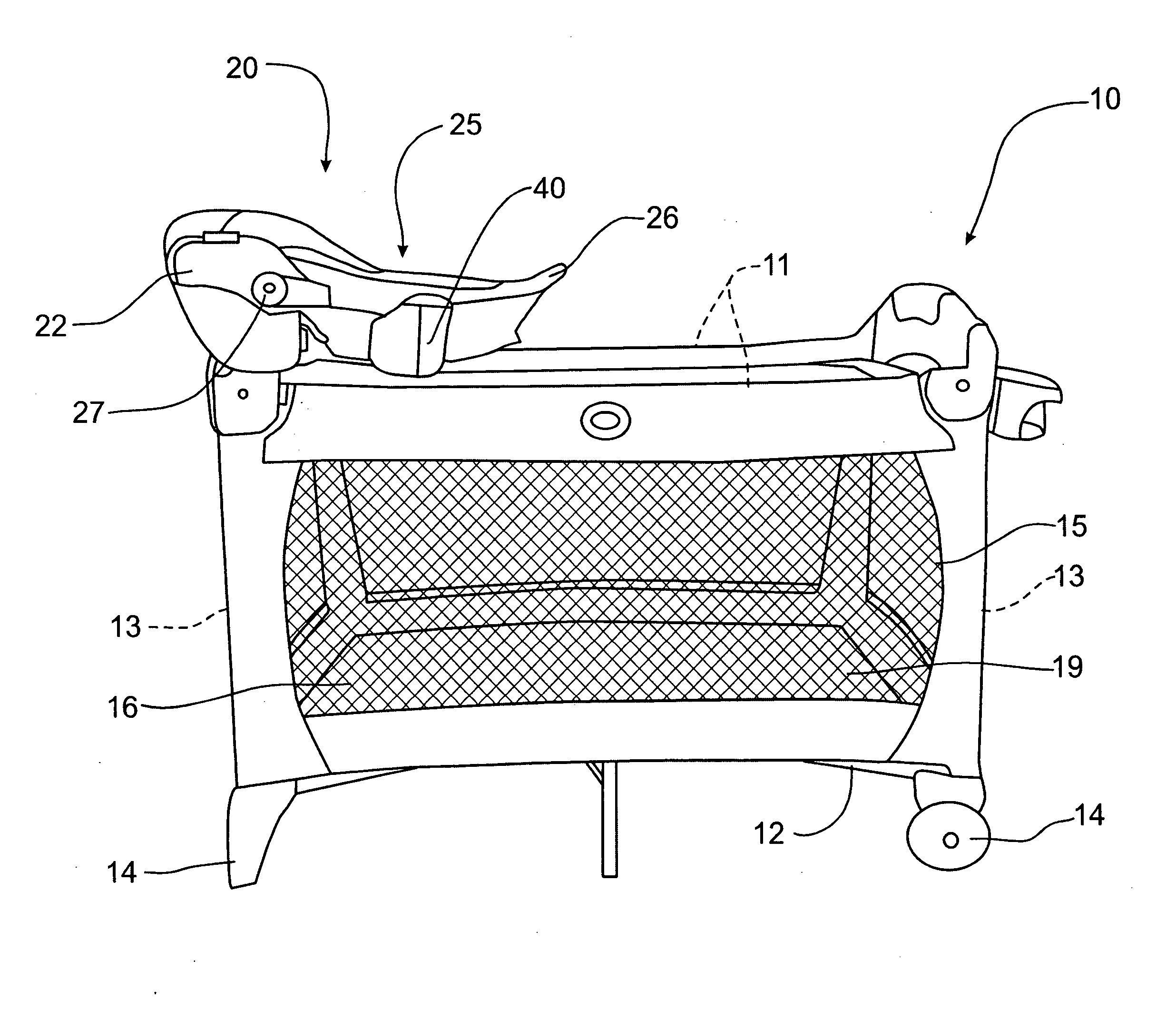

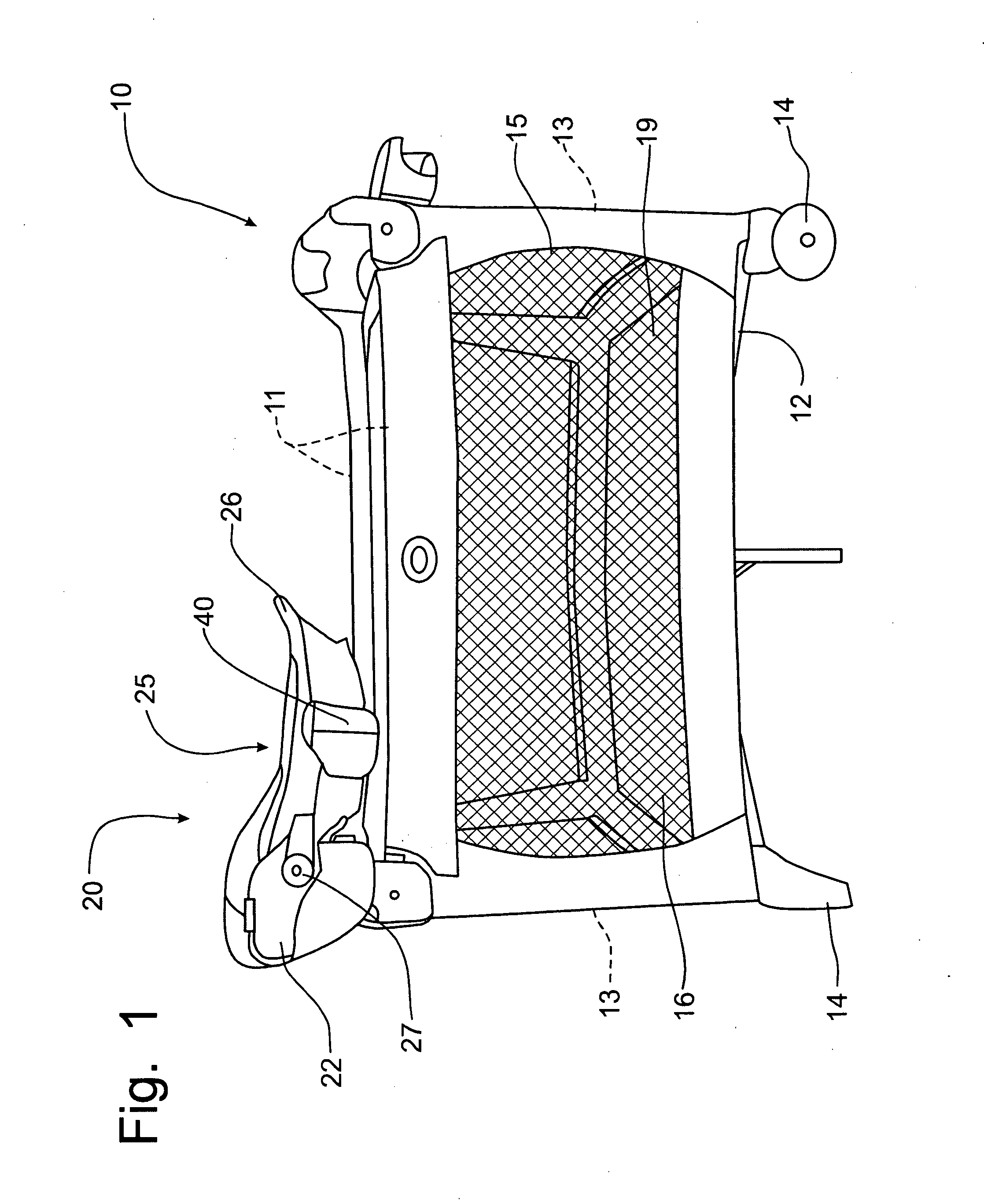

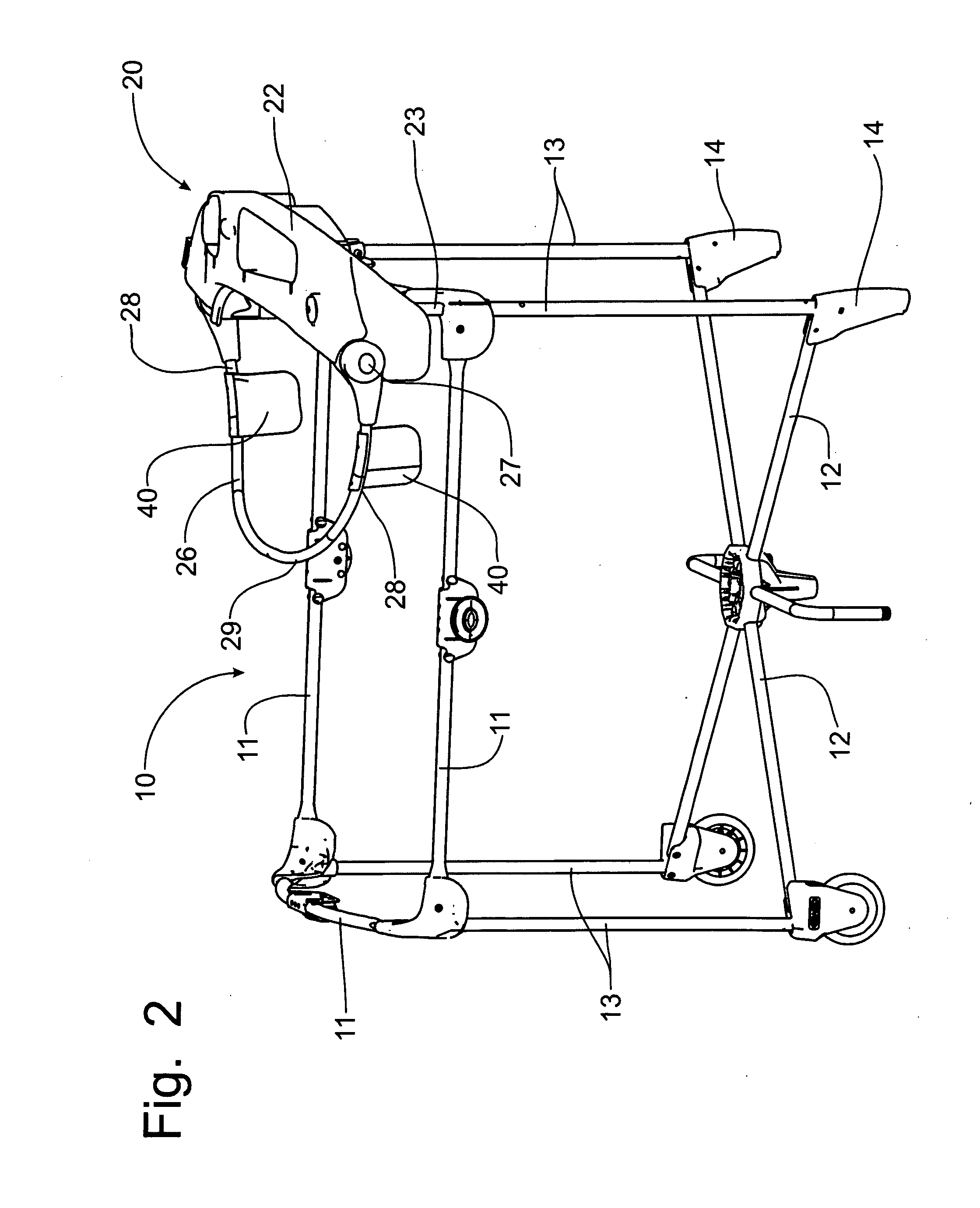

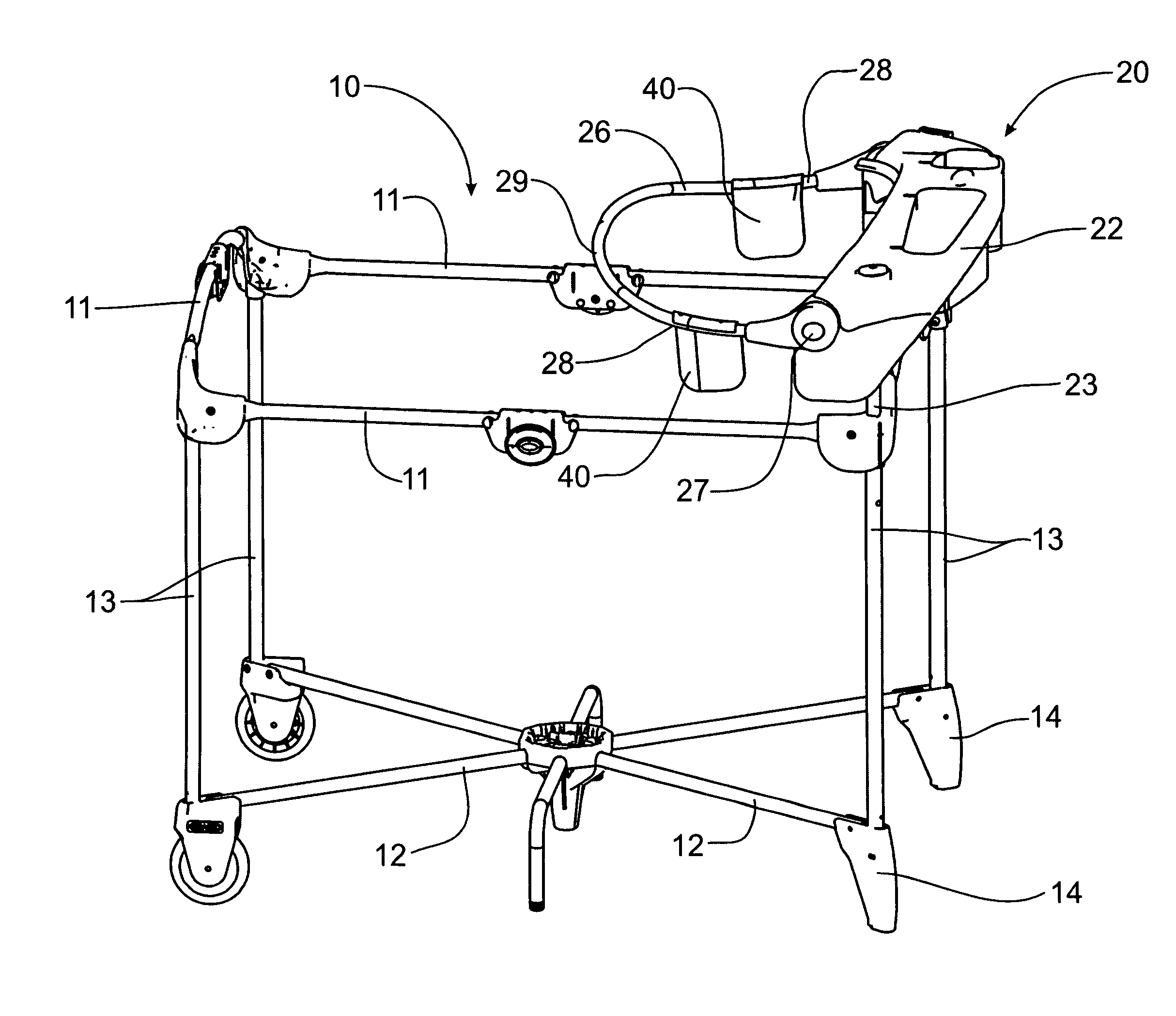

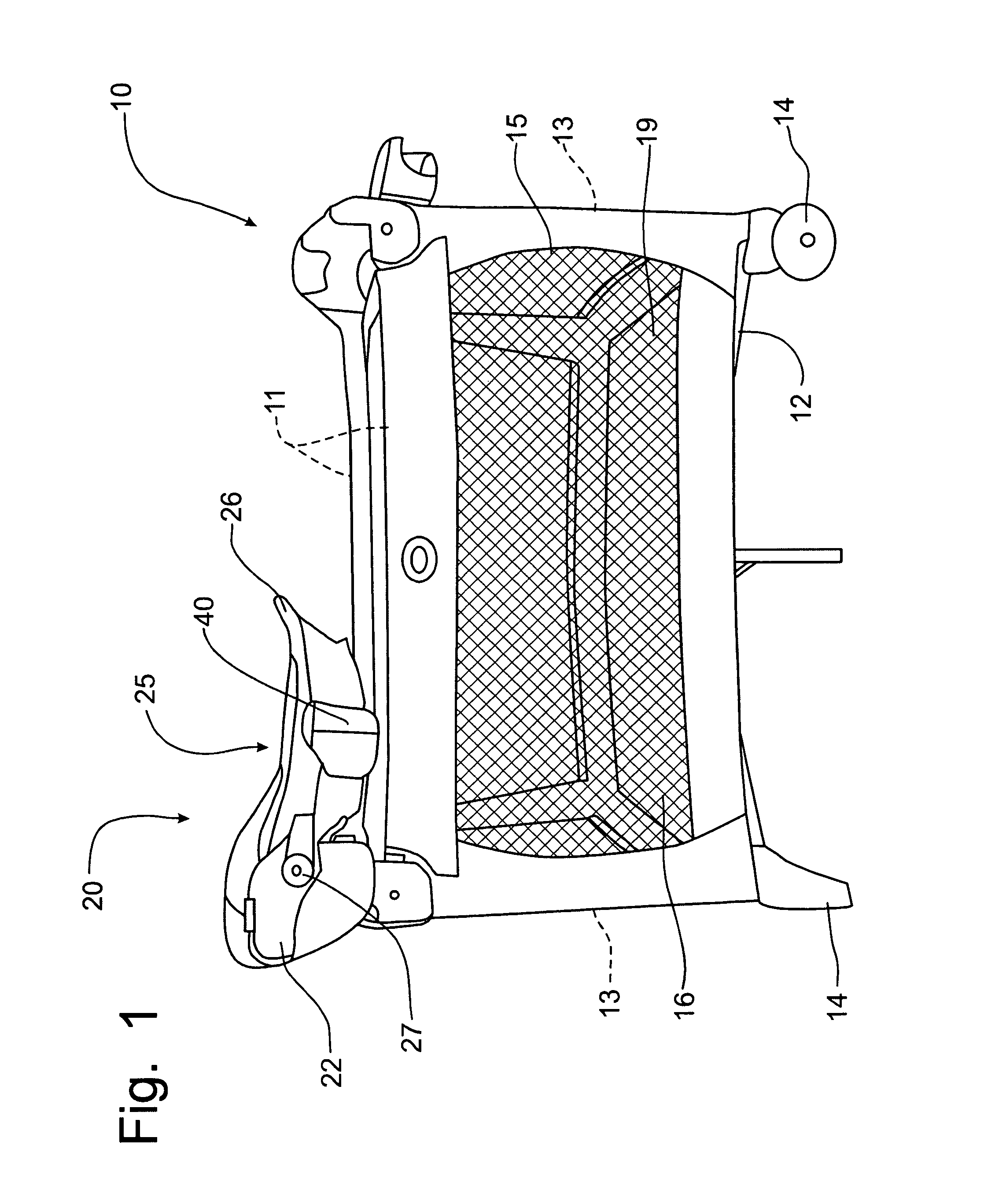

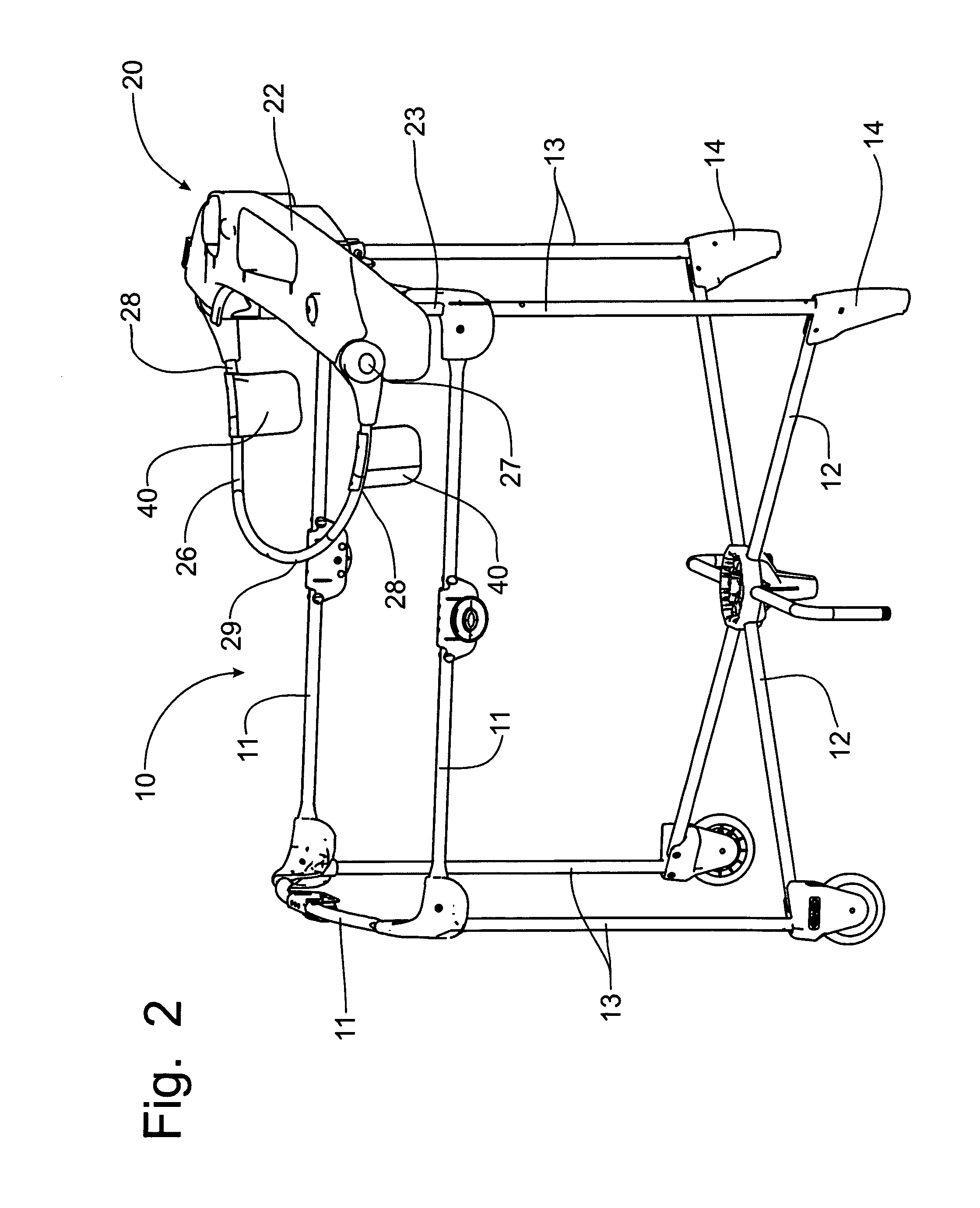

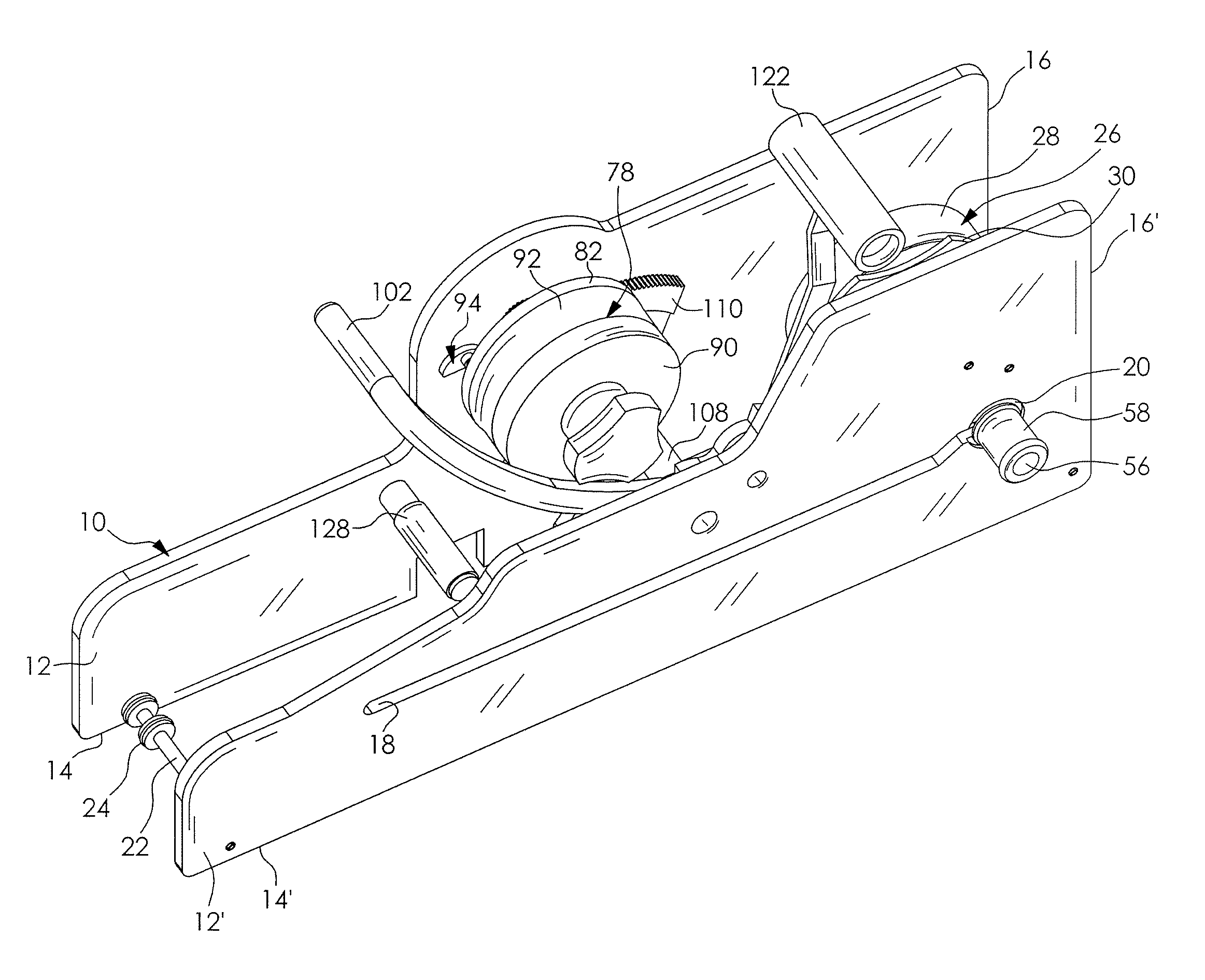

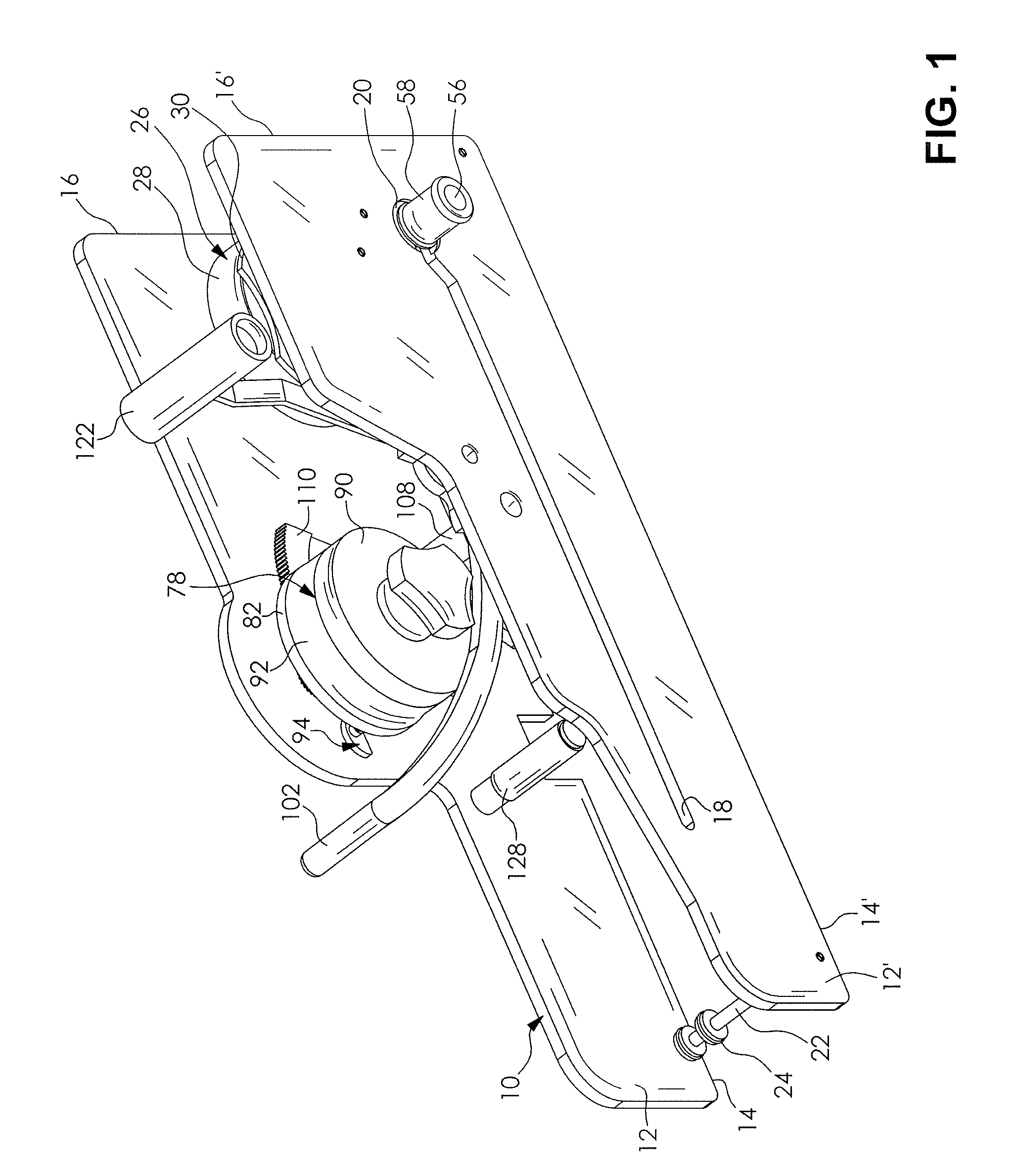

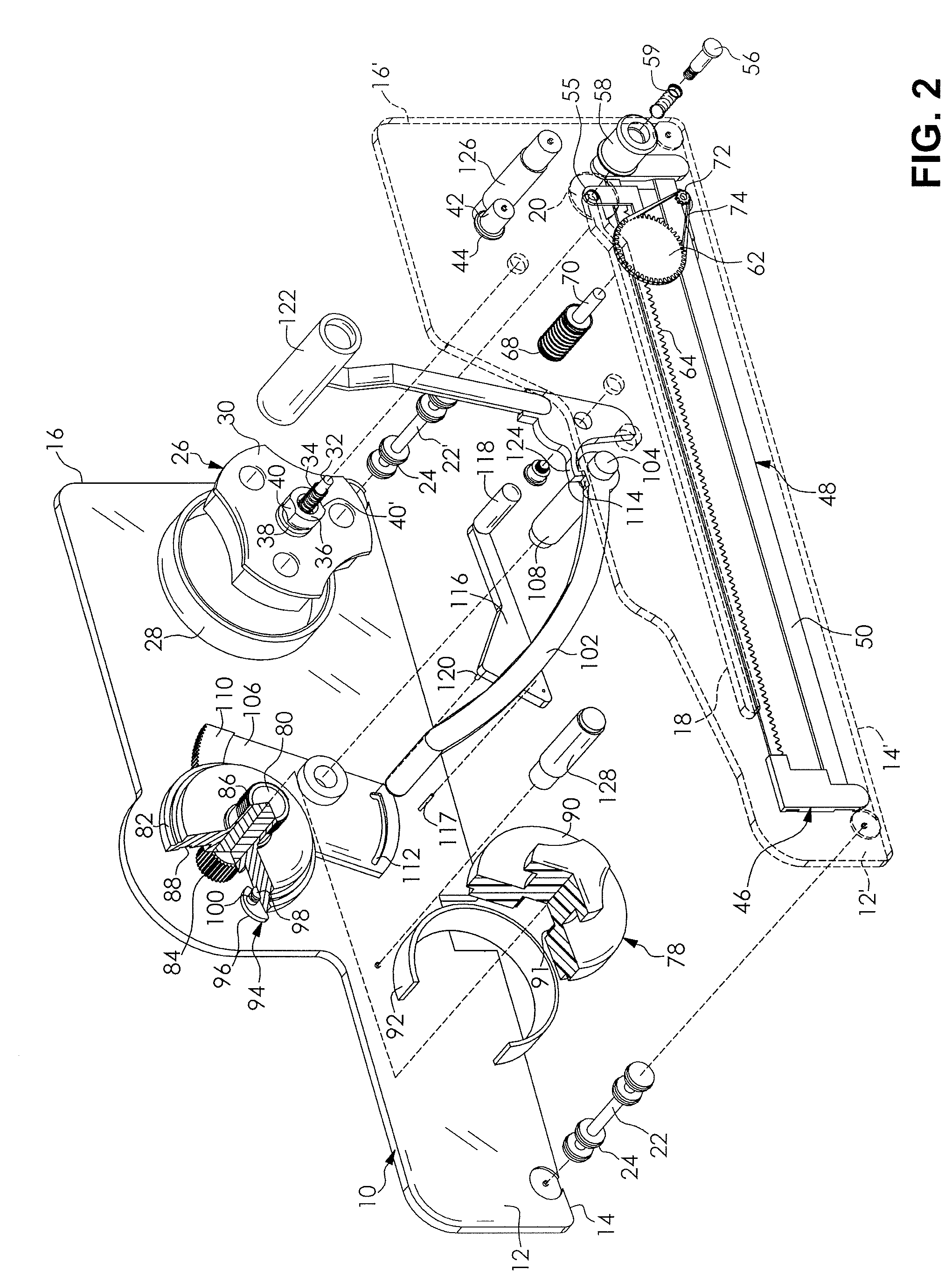

Play Yard with Height Adjustable Changing Table

ActiveUS20090113624A1Effective and conveniently stationDressing tableKids bedsYardMechanical engineering

A changing table is mounted on the frame of a play yard to be vertically adjustable in operative height and pivotally movable between operative and inoperative positions. The frame of the changing table is provided with a downwardly extending guard member that extends across the opening between the frame of the changing table and the frame of the play yard to prevent a child's head from being trapped in the opening. The use of the guard member enables the changing table to be moved through a greater vertical range of operative positions without violating ASTM standards regarding the passage of probes through frame openings. The height adjustment mechanism is mounted within the vertical frame member of the play yard and the vertical mounting member of the changing table to allow the changing table to be raised and lowered with respect to the upper frame members of the play yard.

Owner:WONDERLAND NURSERYGOODS CO LTD

Aviation gasoline for aircraft piston engines, preparation process thereof

InactiveUS20110114536A1Reduce sulfur contentImprove the immunityLiquid carbonaceous fuelsFuel additivesAviationGasoline

The subject of the present disclosure is an aviation gasoline composition that is lead-free and free of oxygenated compounds meeting the specifications of the ASTM standard comprising isopentane, isooctane, and (alkyl)aromatics. The aviation gasoline composition according to the disclosure may be obtained simply and economically from a mixture of hydrocarbon bases usually available in a refinery.

Owner:TOTAL MARKETING SERVICES

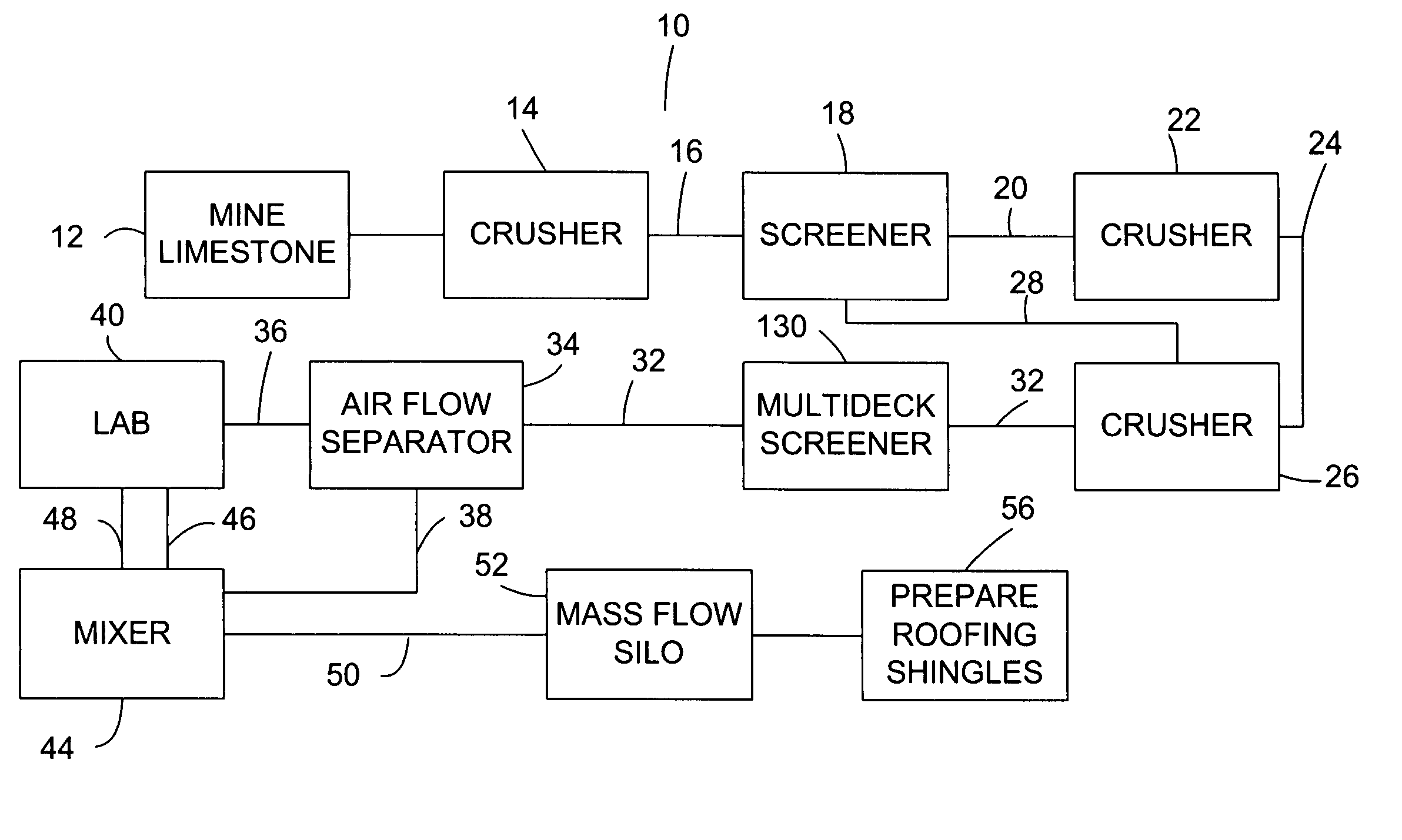

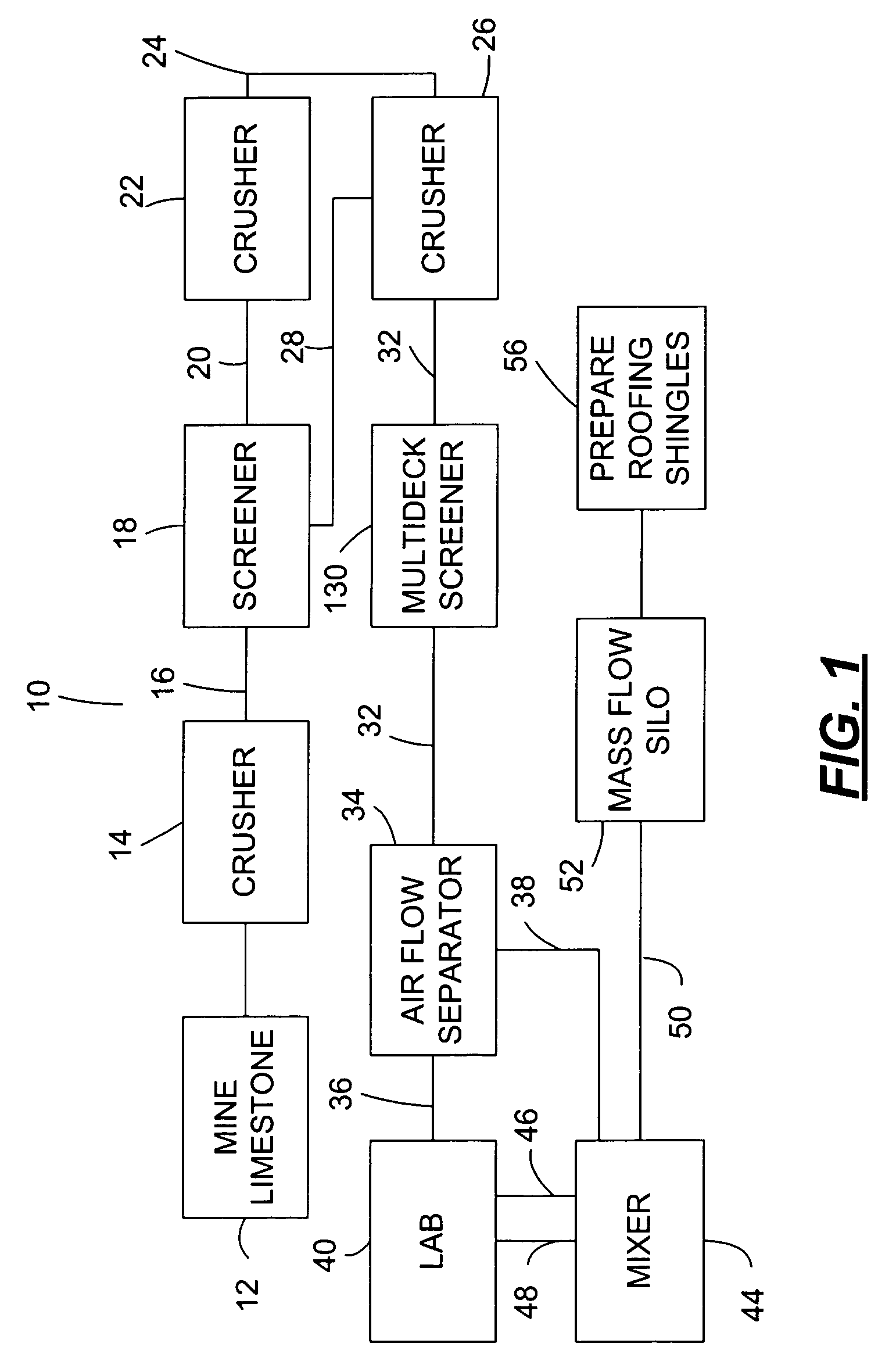

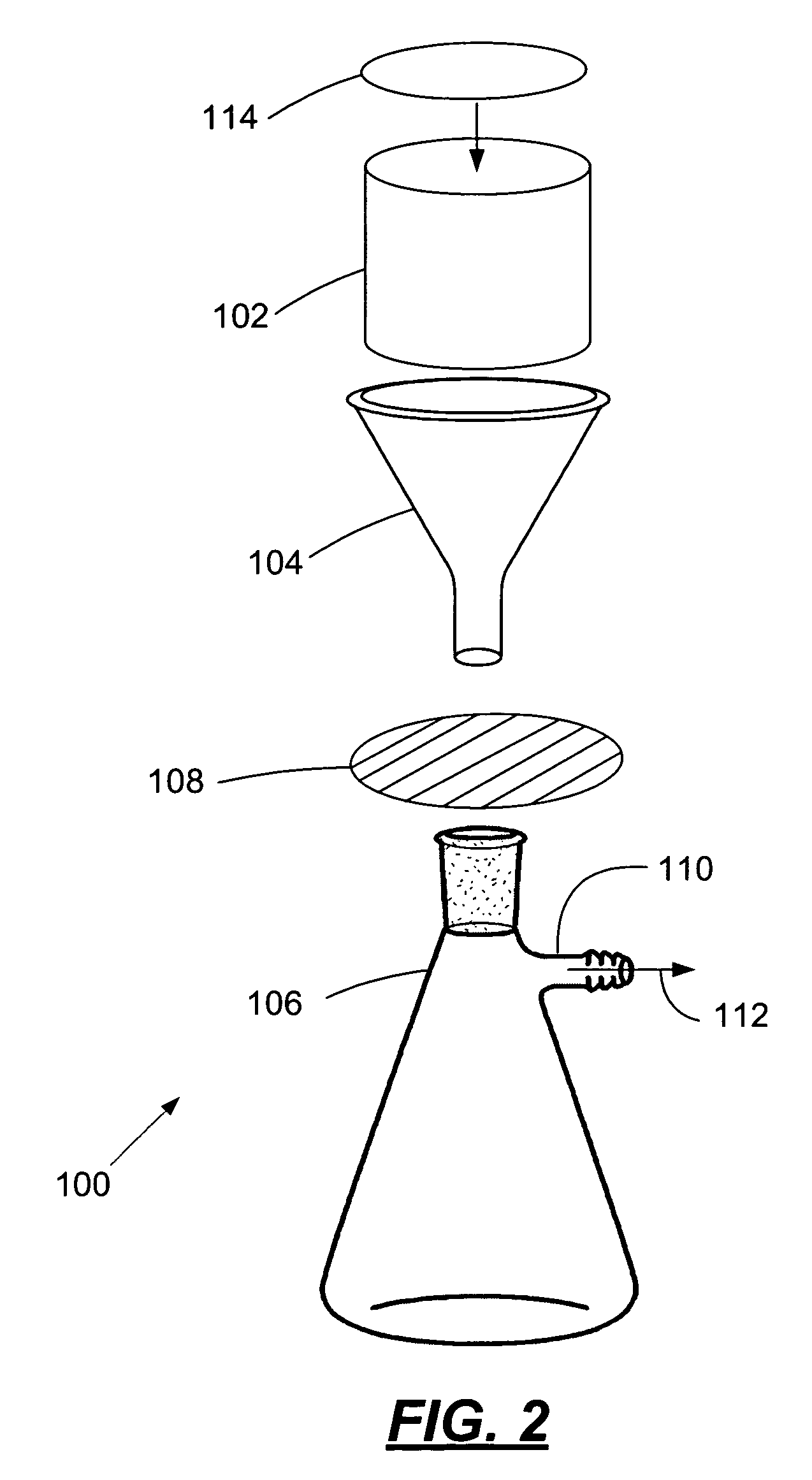

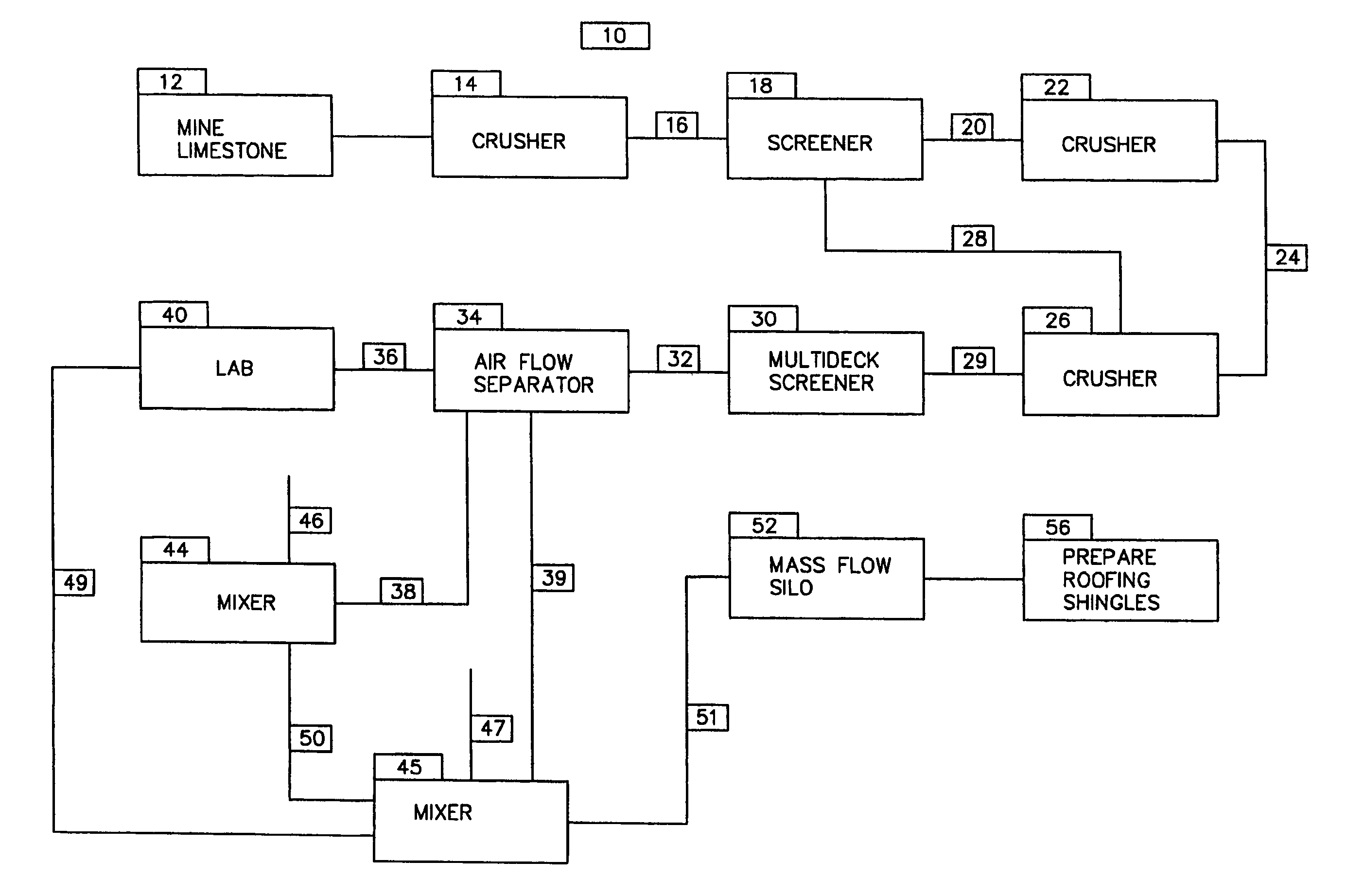

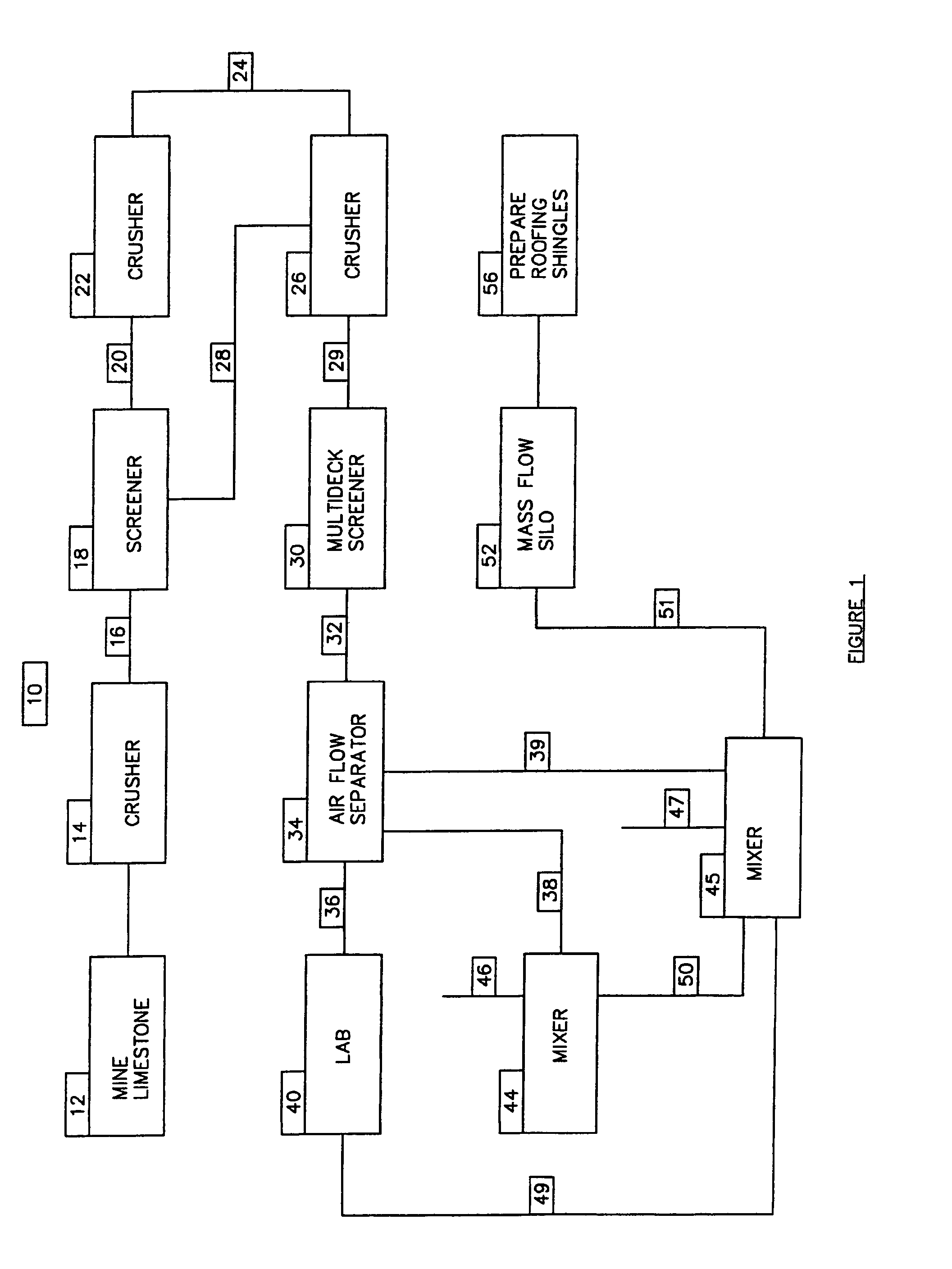

Novel mineral composition

InactiveUS20070104923A1Lose materialRoof covering using sealantsTextiles and paperGramPolymer chemistry

A mineral composition that contains at least about 90 weight percent of headlap granules, at least about 50 weight percent of calcium carbonate, and from about 0.1 to about 1.0 weight percent of a pigmented material. The pigmented material contains from about 10 to about 35 weight percent of pigment and from about 90 to about 65 weight percent of a resin. The mineral composition has superior adhesion properties; when it is tested in accordance with ASTM Standard Test D 4977-03, it loses less than 5 grams of material.

Owner:WHITAKER ROBERT H +1

Play yard with height adjustable changing table

A changing table is mounted on the frame of a play yard to be vertically adjustable in operative height and pivotally movable between operative and inoperative positions. The frame of the changing table is provided with a downwardly extending guard member that extends across the opening between the frame of the changing table and the frame of the play yard to prevent a child's head from being trapped in the opening. The use of the guard member enables the changing table to be moved through a greater vertical range of operative positions without violating ASTM standards regarding the passage of probes through frame openings. The height adjustment mechanism is mounted within the vertical frame member of the play yard and the vertical mounting member of the changing table to allow the changing table to be raised and lowered with respect to the upper frame members of the play yard.

Owner:WONDERLAND NURSERYGOODS CO LTD

Mineral composition

A mineral composition comprised of at least about 90 weight percent of roofing granules, at least about 50 weight percent of calcium carbonate with a hardgrove grindability index of less than about 70, from about 0.1 to about 1.0 weight percent of a pigmented material, from about 0.1 to about 1.0 weight percent of a composition for inhibiting the growth of an organism selected from the group consisting of algae, bacteria, and mixtures thereof, and less than about 100 parts per million of a metal selected from the group consisting from the group consisting of arsenic, barium, cadmium, chromium, lead, mercury, selenium, and silver, and less than about 100 parts per million of a polycyclic aromatic hydrocarbon. The mineral composition, when tested in accordance with by ASTM Standard Test D 4977-03, loses less than 5 grams of material.

Owner:LHOIST NORTH AMERICA INC

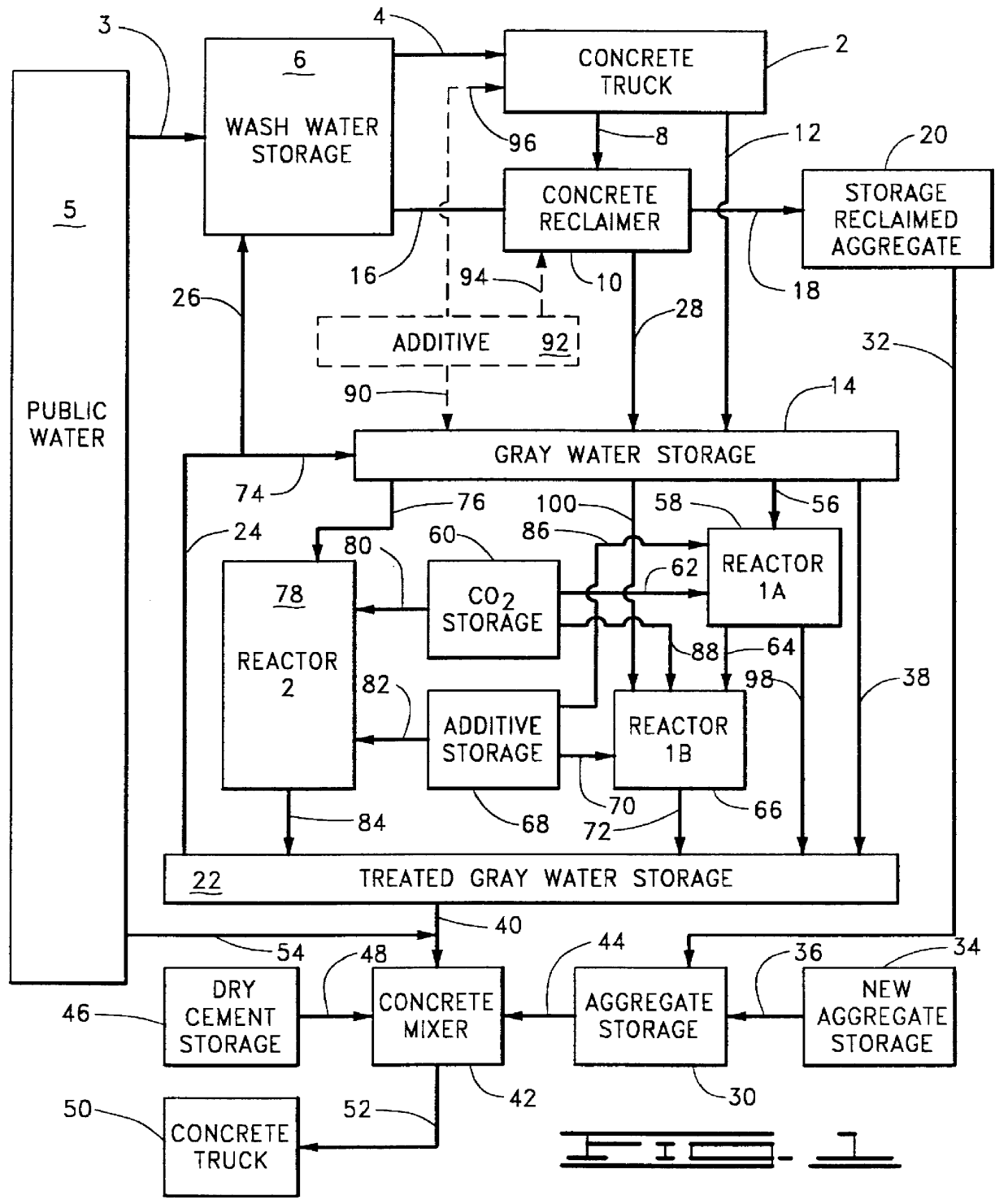

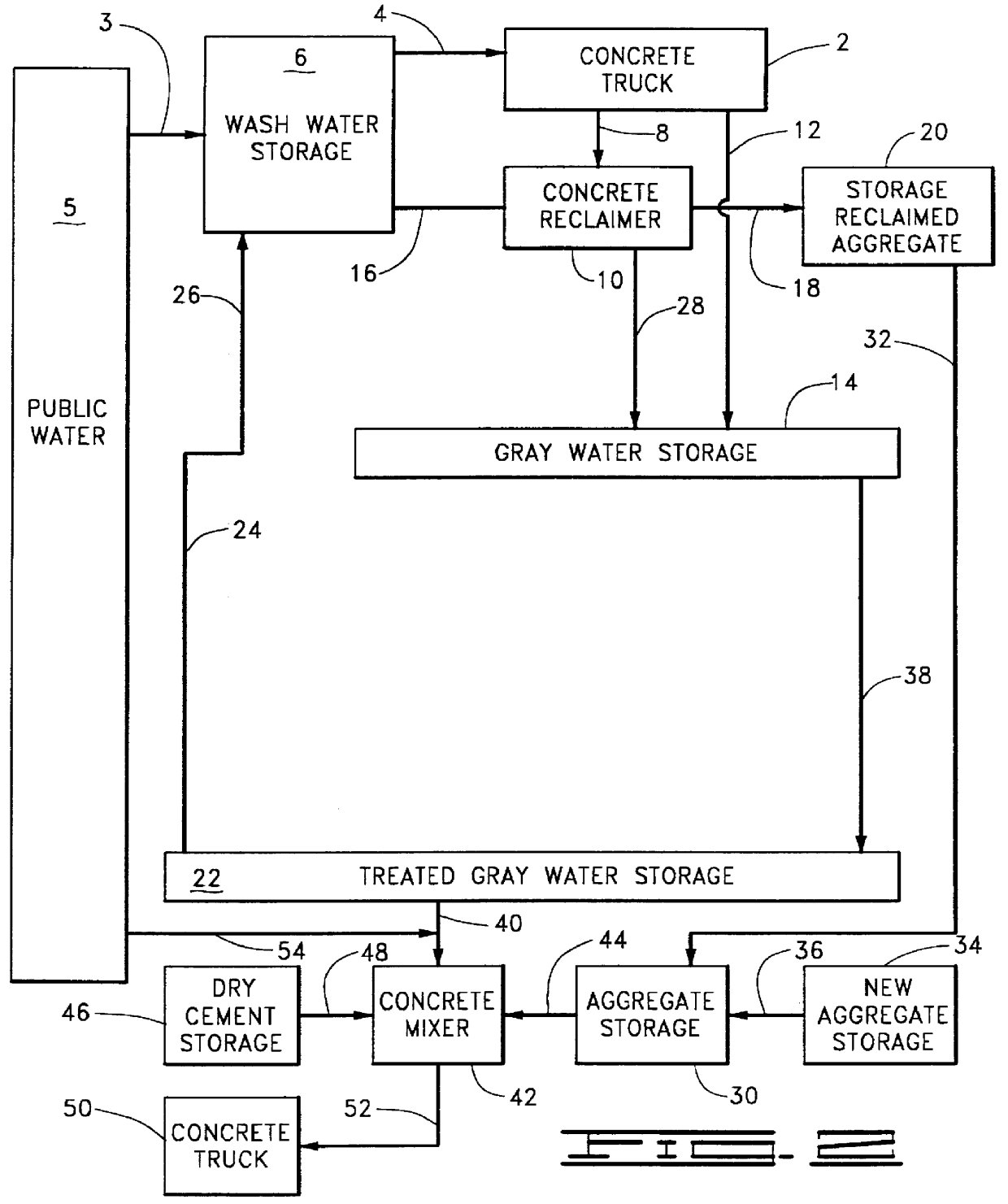

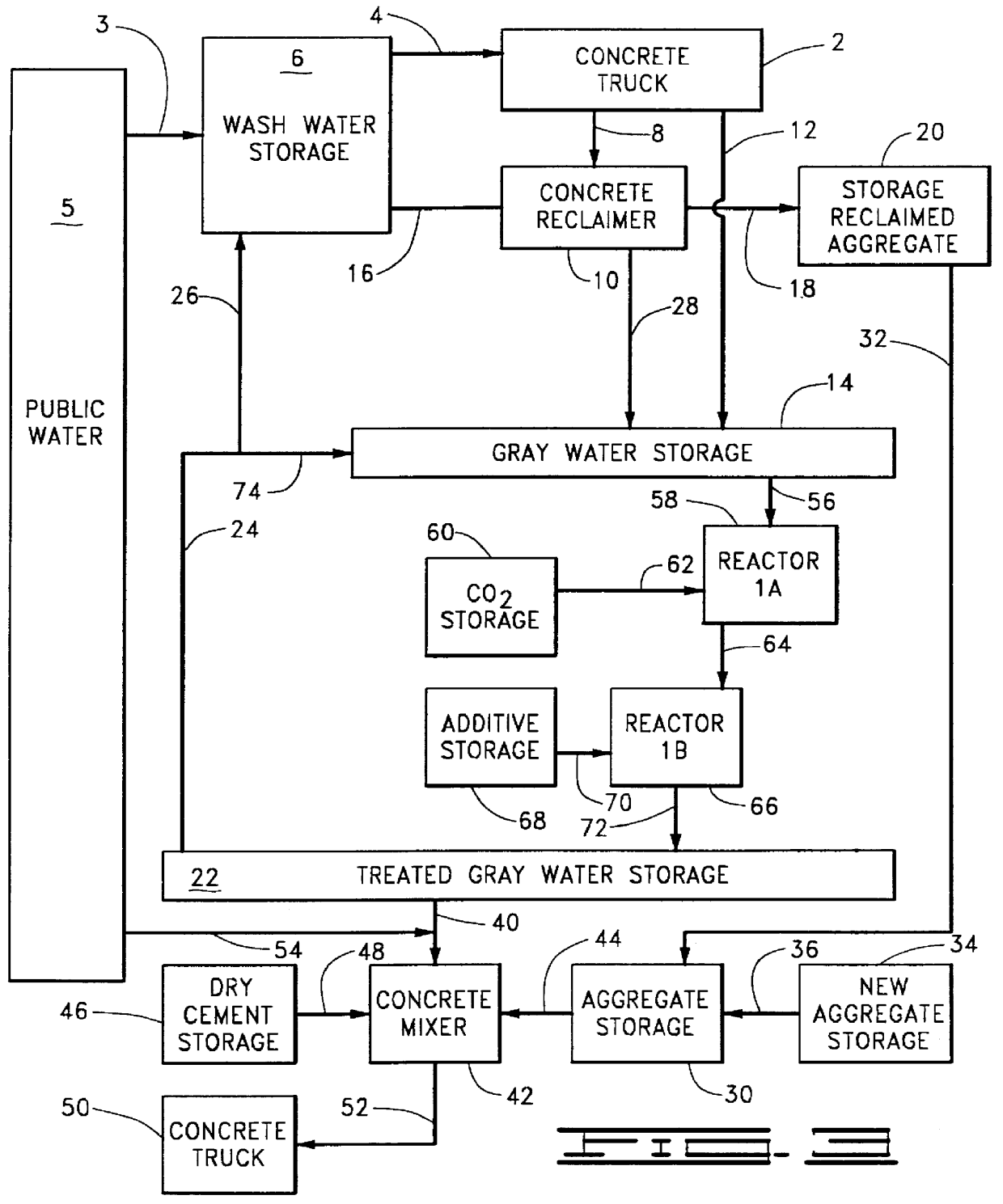

Concrete mix water

InactiveUS6066262ASolid waste managementWater/sewage treatment by neutralisationLithium carbonatePotassium

Water having alkalies selected from sodium, potassium and mixtures thereof dissolved therein is treated with a composition to reduce the concentration of the alkalies whereby the water is rendered usable according to ASTM standards to render the water usable as concrete mix water. The composition and the method of its use is disclosed herein, wherein the composition is selected from compounds in the group consisting of lithium carbonate, acid zirconium phosphate, carbon dioxide and mixtures thereof.

Owner:FRITZ INDS

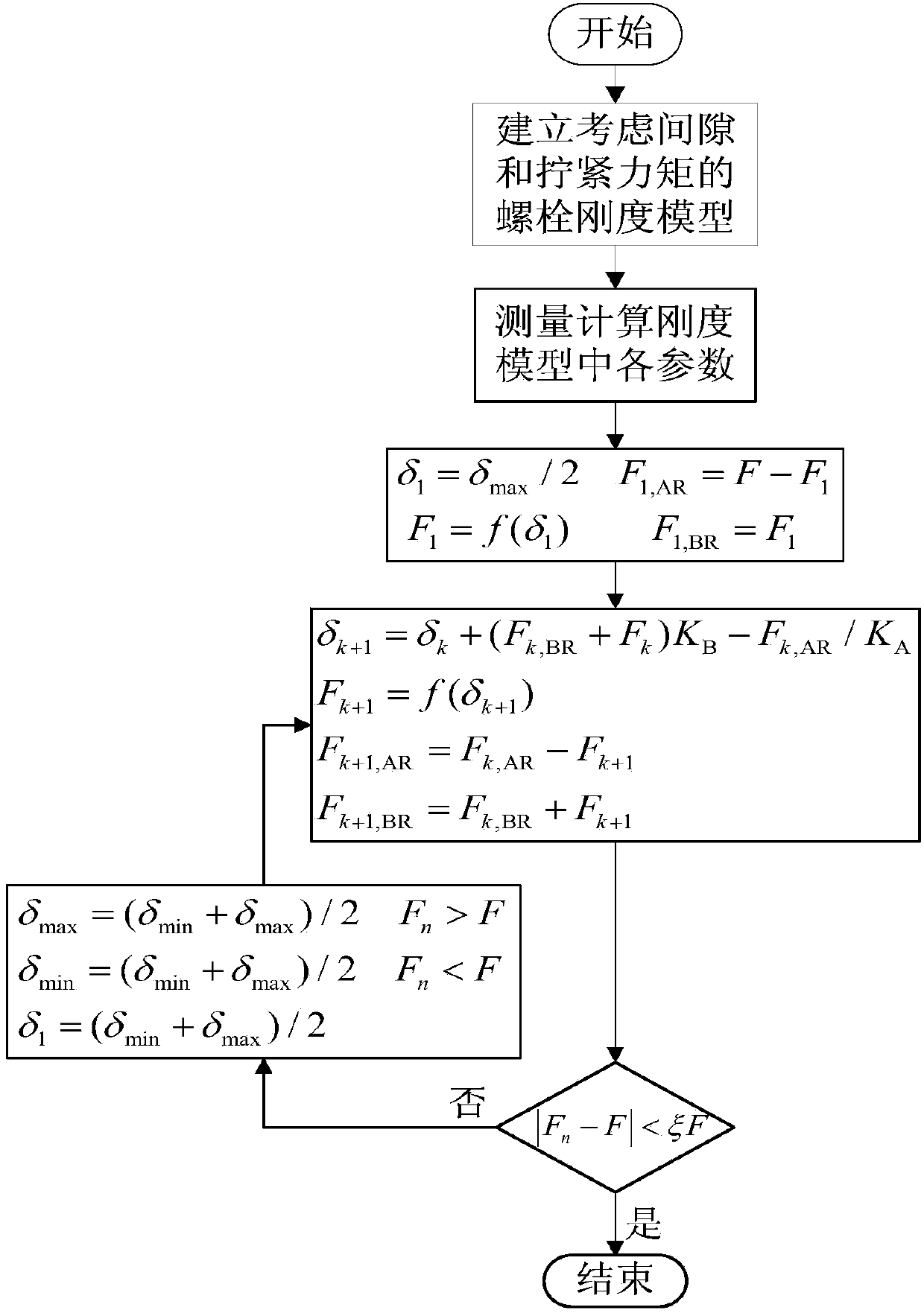

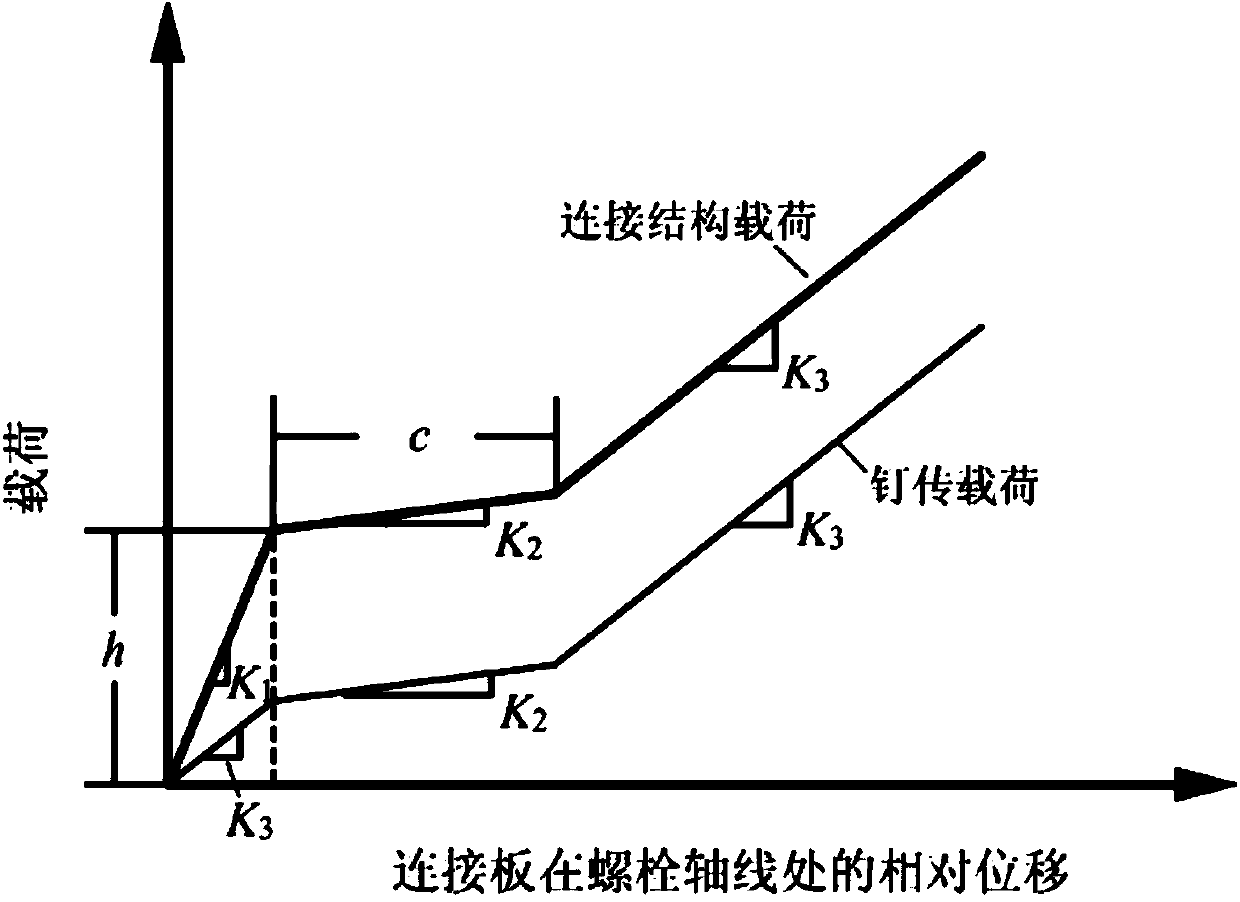

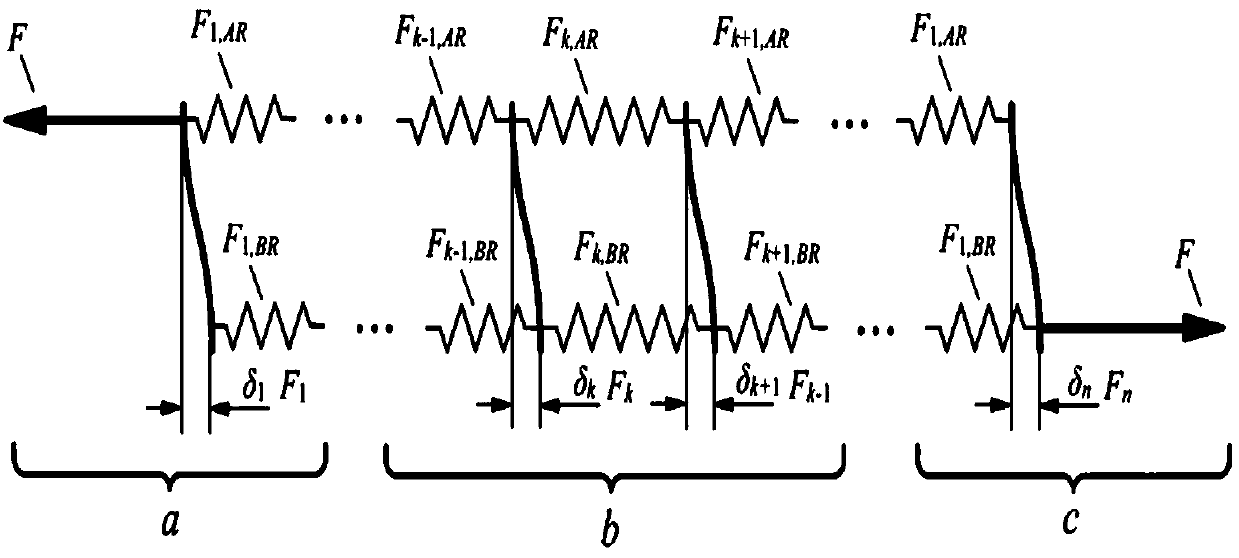

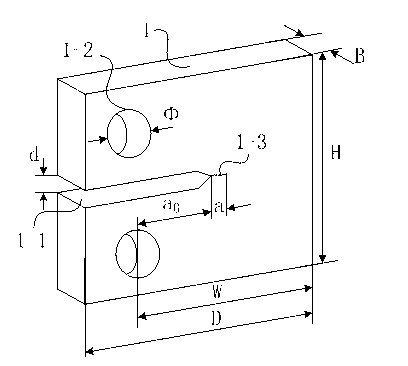

Composite bolt connection structure pin load distribution determination method in consideration of intervals and tightening torque

InactiveCN103593542AAchieve allocation determinationAllocation is determined preciselySpecial data processing applicationsStructural deformationLoad distribution

The invention relates to a composite bolt connection structure pin load distribution determination method in consideration of intervals and tightening torque. The method includes the following steps that firstly, a bolt rigidity model in consideration of the intervals and the tightening torque is built; secondly, a structural deformation-pin load relation at the positions of bolts when the intervals and the tightening torque exist is experimentally studied through an ASTM standard mesopore displacement measuring method, and then parameters of the bolt rigidity model are acquired; thirdly, a pin load distribution determination formula in a recursion mode is built according to the bolt rigidity model; fourthly, a pin load distribution rule when the intervals and the tightening torque exist is calculated according to a univariate iterative bisection method. The method is suitable for pin load distribution analysis of a composite bolt connection structure, the influences of the intervals and the tightening torque are taken into consideration, and the pin load distribution problem of the bolt connection structure can be accurately predicted and studied.

Owner:BEIHANG UNIV

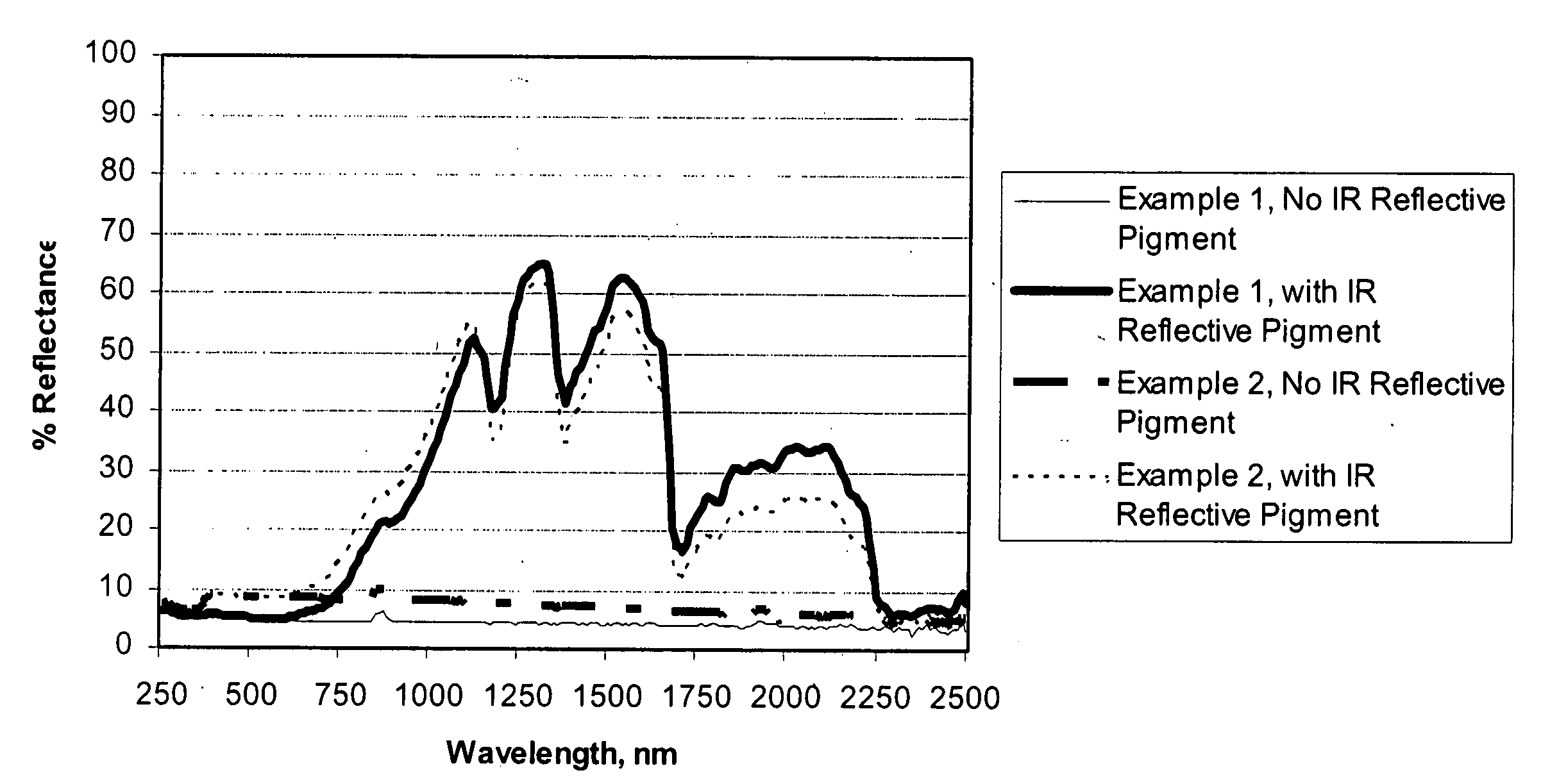

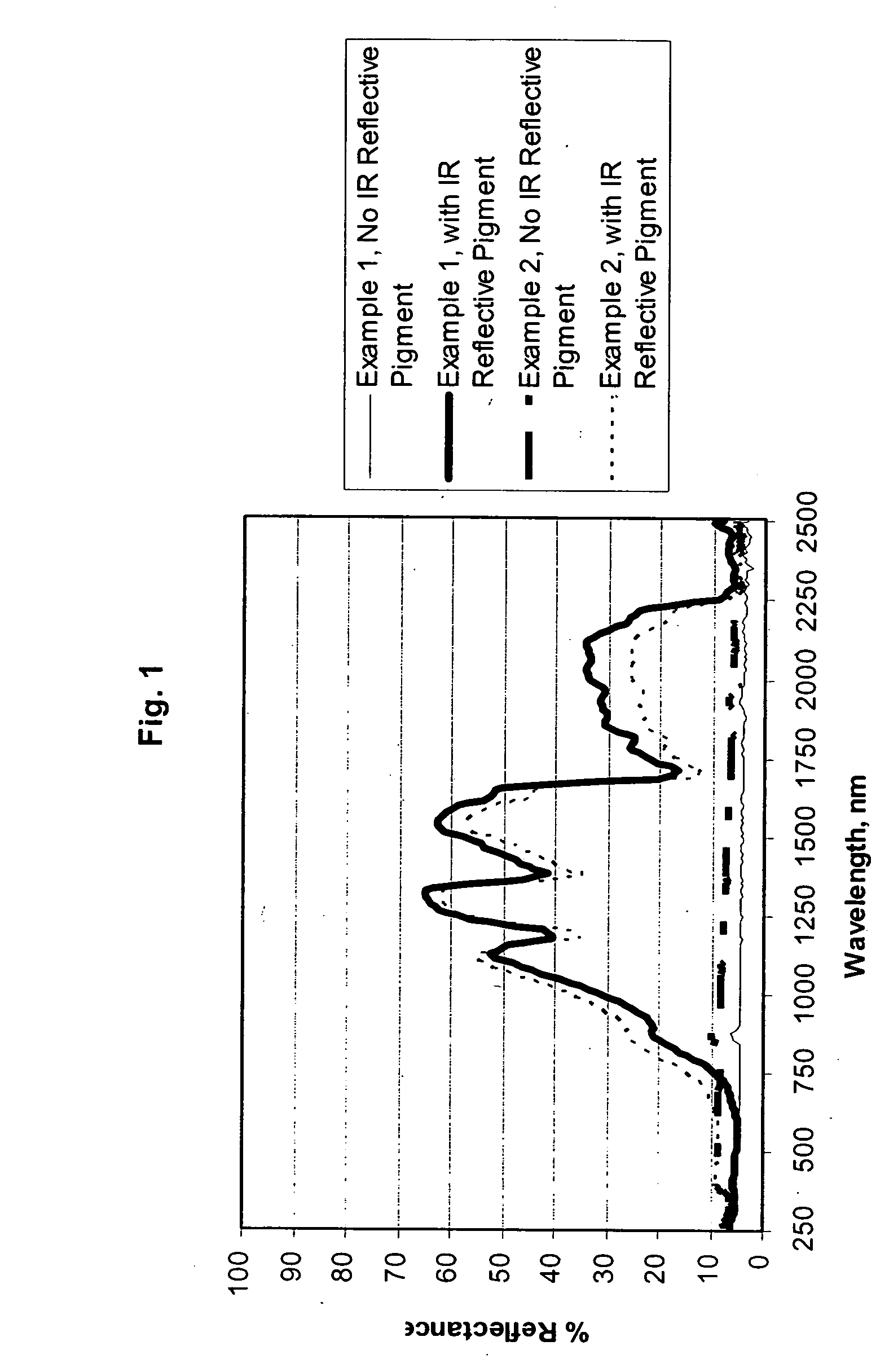

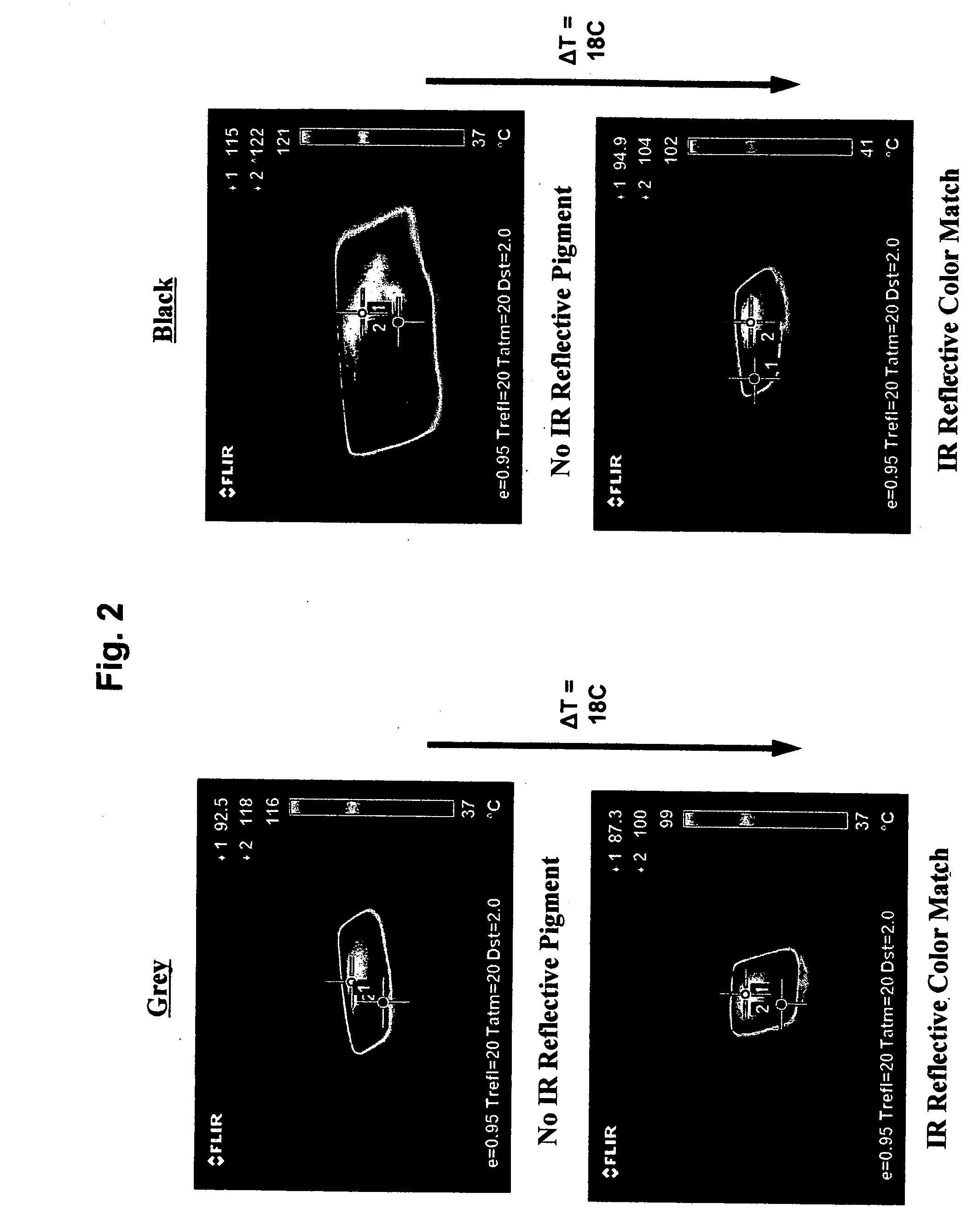

Infrared reflective pigments in unpainted automotive plastics

InactiveUS20080138609A1Improve heat resistanceReduce heat buildupPigmenting treatmentLiquid surface applicatorsLength wavePigment

This disclosure is directed to a plastic composition for use on an automotive vehicle including an infrared reflective pigment, and a thermoplastic component. The plastic composition with the infrared reflective component therein increases reflectance by at least about 300% in the spectrum between about 750 nm and about 2500 nm wavelength over a color matched plastic composition containing no infrared reflective pigment, and provides a delta T of at least about 15 C. over a color matched plastic composition containing no infrared reflective pigment under the procedures set forth in the ASTM Standard D 4803-97 test method. The plastic composition also provides a method of reducing the heat build-up of a plastic automotive vehicle part when the plastic automotive vehicle part is exposed to an infrared radiation source.

Owner:HONDA MOTOR CO LTD

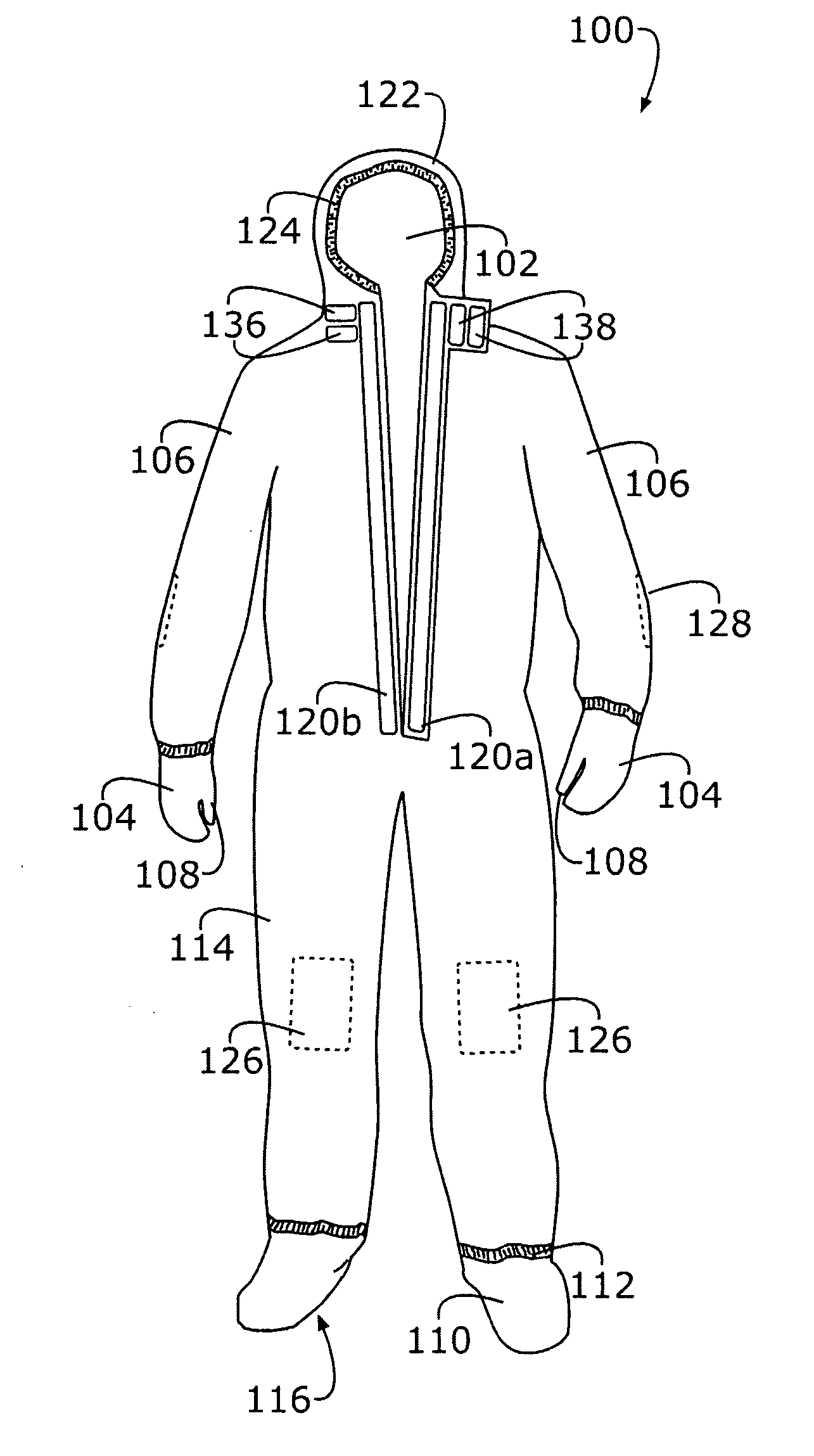

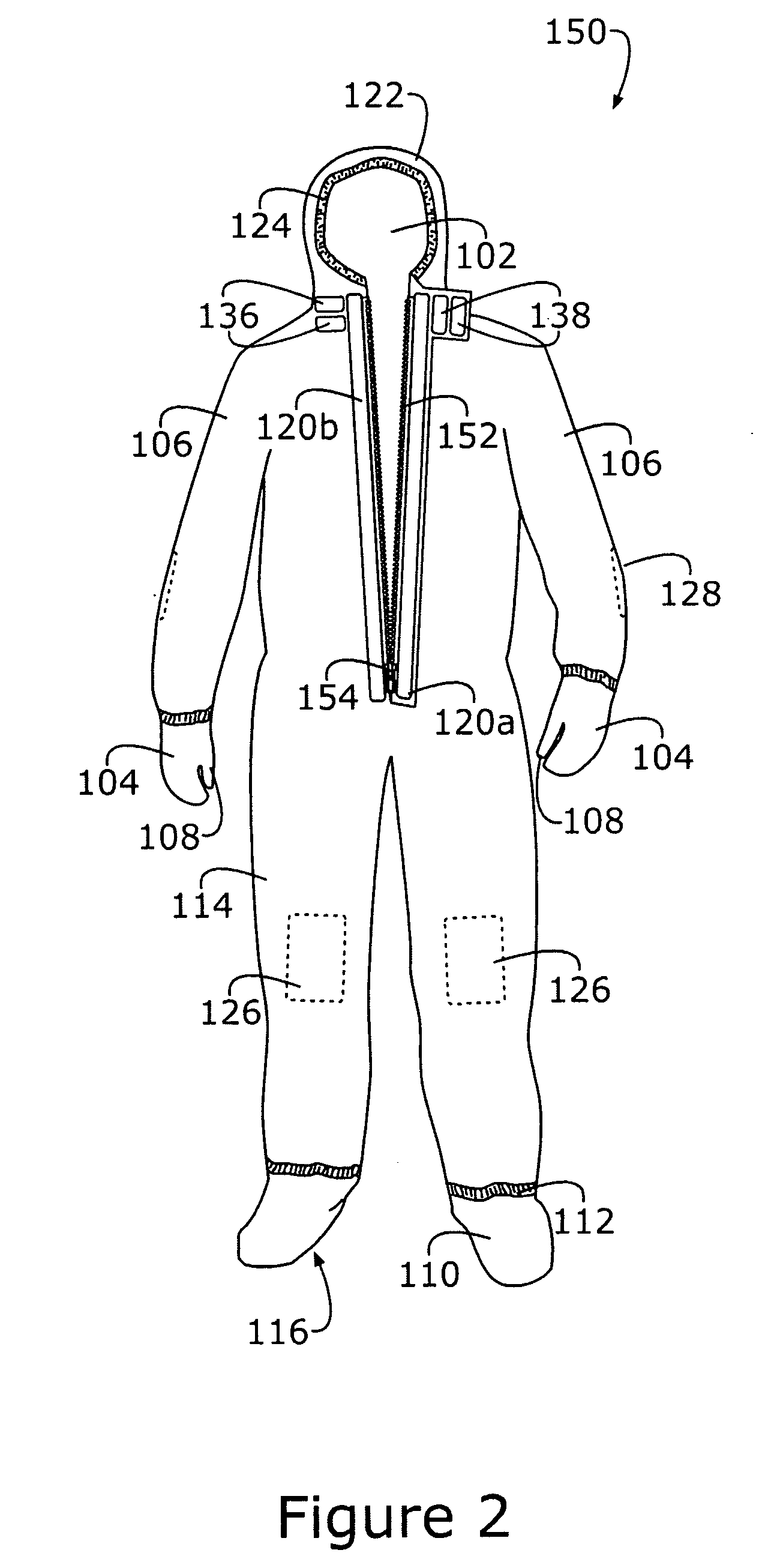

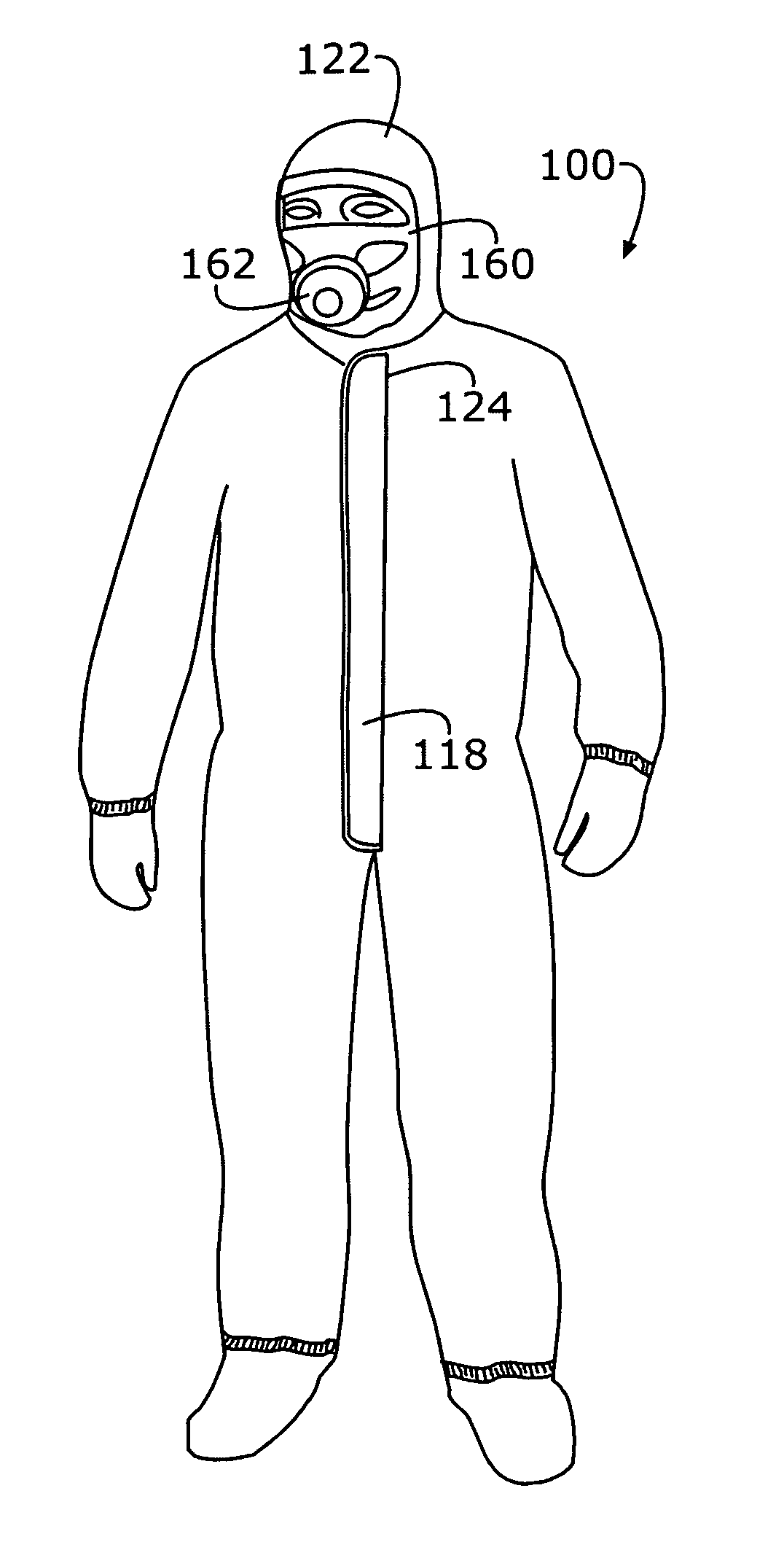

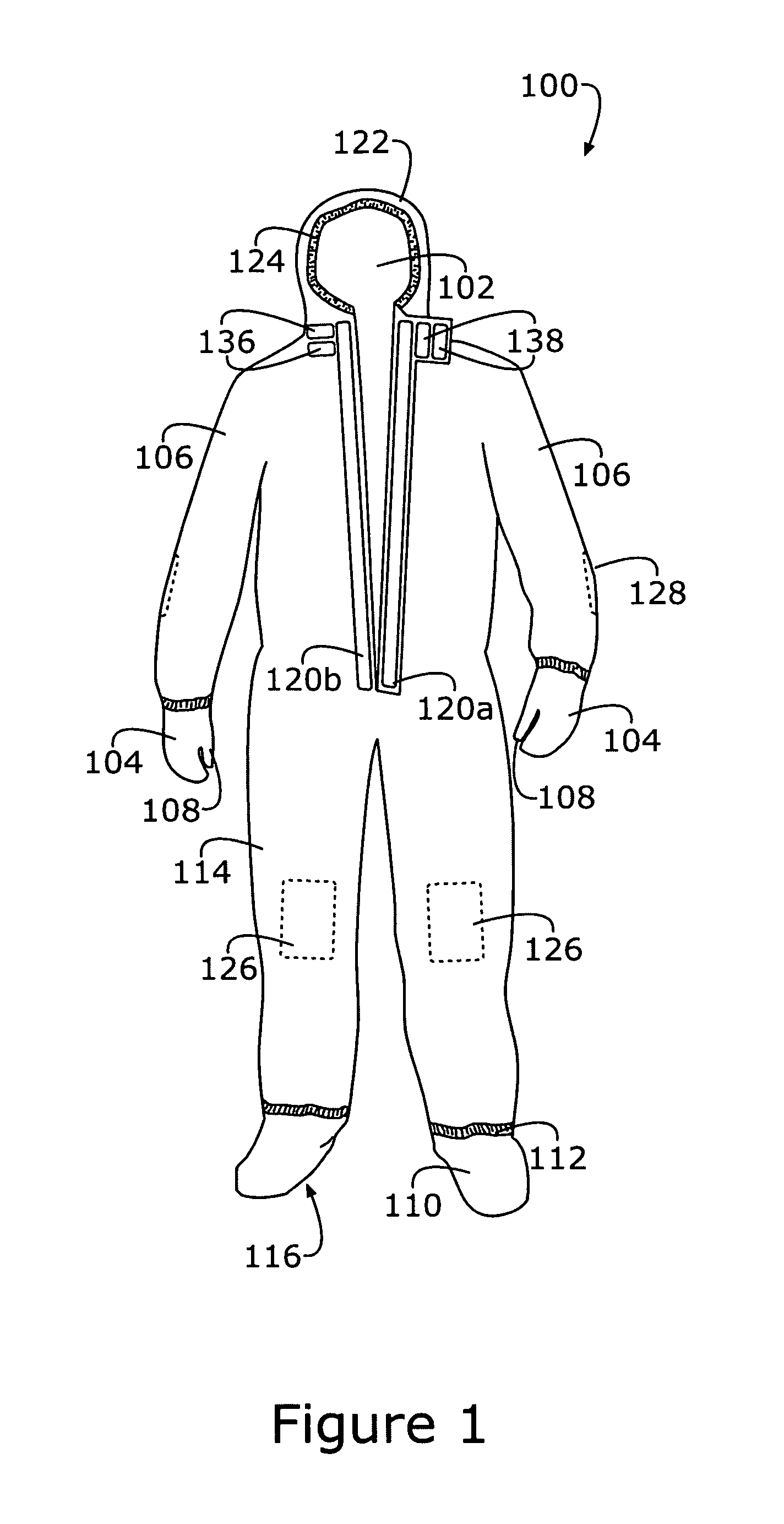

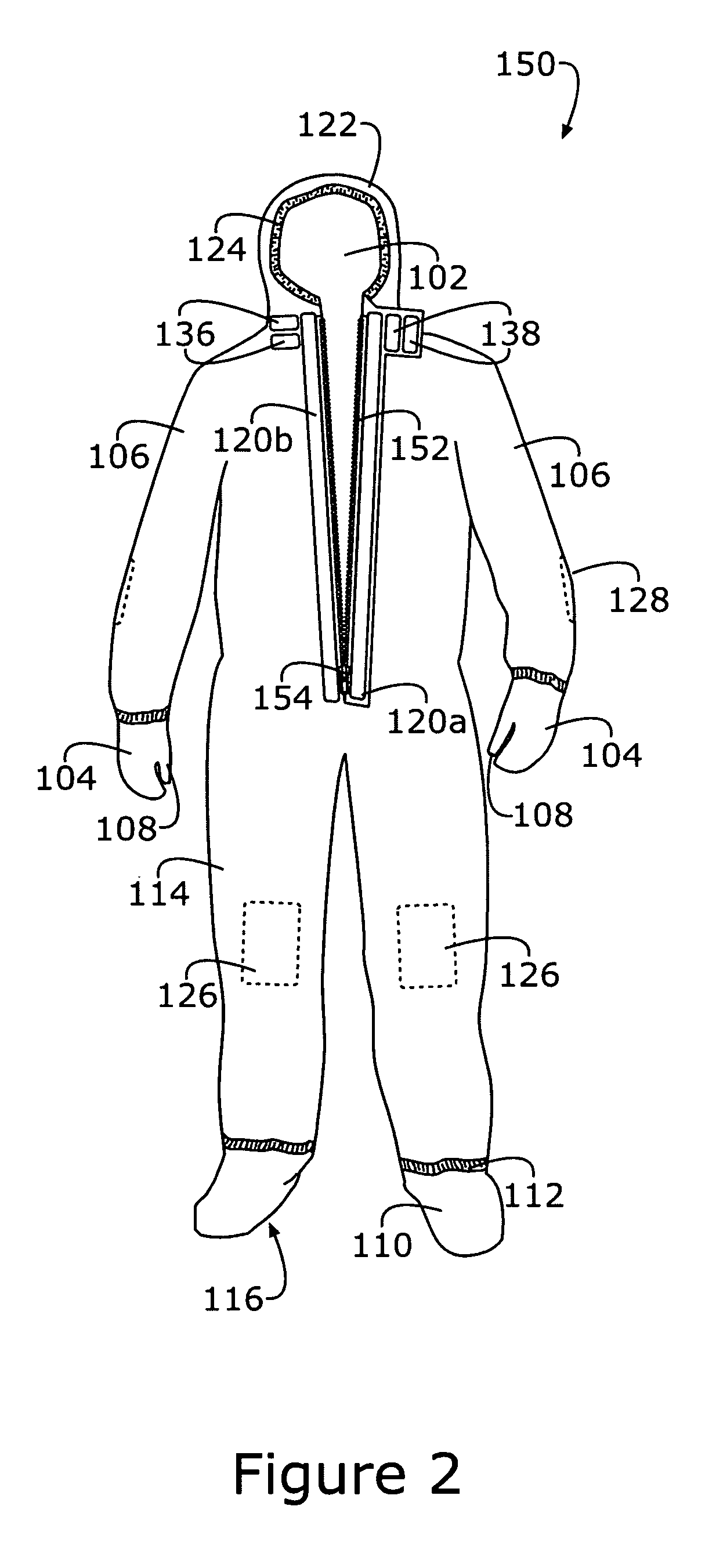

Flameproof, heat resistant, one-piece escape suite

ActiveUS20080276357A1Low enough in costLow costChemical protectionHeat protectionEngineeringSmoke hood

A flameproof, heat resistant, lightweight, one-piece escape suit which includes attached integral mitts or gloves, covered footing, and a hood. The fire and heat resistant one piece suit is designed to be worn over a commercial smoke hood, is formed from a metalized fabric, and meets the requirements of ASTM standard D6413. The suit is designed to be easily slipped onto a wearer's body over typical street clothing, and allows a wearer to wear his or her accustomed footwear for improved safety and comfort. The durable fabric provides protection to a wearer when crawling low to the ground on his or her knees and elbows as is often recommended as a preferred escape posture. The fire and heat resistant one piece suit may be provided in multiple sizes to fit adults and children. The fire and heat resistant one piece suit, as well as a smoke hood, may be packaged into compact, lightweight emergency escape kit bag with unique “glow in the dark” lettering; FIRE ESCAPE KIT suitable for carrying between home and work, etc.

Owner:SIGMON KENNIS L

Artificial heart valve pyrolytic carbon and testing method for fracture toughness of pyrolytic carbon composite material

InactiveCN103234823AGuaranteed feasibilityGuaranteed reliabilityMaterial strength using tensile/compressive forcesCritical loadPyrolytic carbon

The invention relates to an artificial heart valve pyrolytic carbon and a testing method for the fracture toughness of a pyrolytic carbon composite material. A testing method for the fracture toughness of the pyrolytic carbon composite material has not been brought forward yet. The testing method provided by the invention comprises the following steps: preparing a plurality of compact tension C(T) specimens from heart valve pyrolytic carbon or a composite material thereof and prefabricating sharp cracks on each specimen, wherein the specimen is of a specification as recommended by American ASTM standard E399, a gap is processed at the central part of the specimen, and upper and lower ends of the gap are respectively provided with a loading hole; then respectively clamping the two loading holes of the gap by using clamps and erecting an extensometer on an open end of the gap; and starting a loading platform to apply an upward load increasing at a uniform speed until the specimens fracture, determining critical load and effective crack length of each specimen, calculating fracture toughness according to the critical load and the effective crack length and taking a mean value as a fracture toughness test value of the heart valve pyrolytic carbon or the composite material thereof. The method provided by the invention can accurately determine fracture toughness of pure pyrolytic carbon and a pyrolytic carbon composite material.

Owner:HANGZHOU DIANZI UNIV

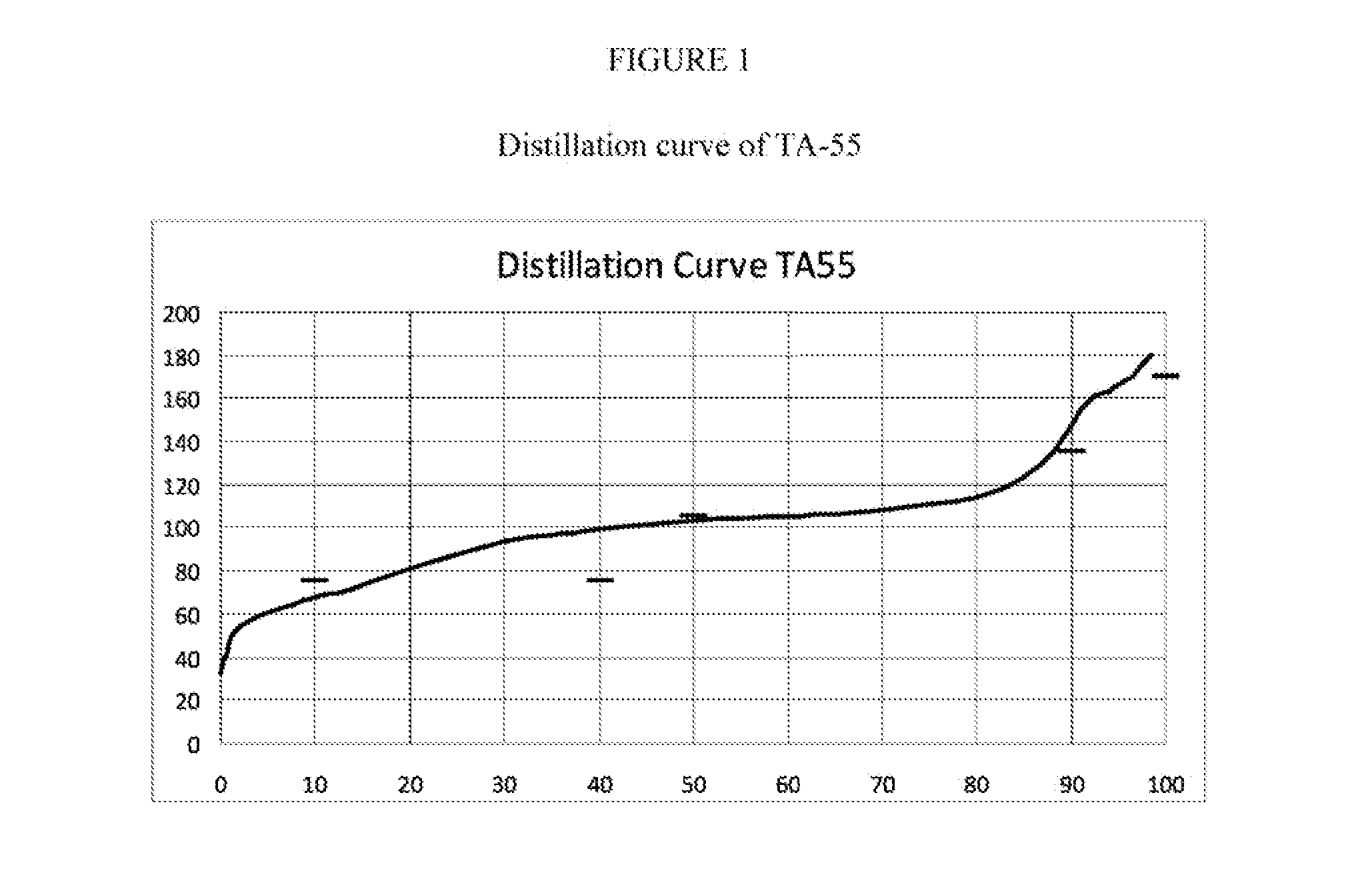

Aviation gasoline for aircraft piston engines, preparation process thereof

The subject of the present disclosure is an aviation gasoline composition that is lead-free and free of oxygenated compounds meeting the specifications of the ASTM standard comprising isopentane, isooctane, and (alkyl)aromatics. The aviation gasoline composition according to the disclosure may be obtained simply and economically from a mixture of hydrocarbon bases usually available in a refinery.

Owner:TOTAL MARKETING SERVICES SA

Hydrodewaxed hydrocarbon fluid used in the manufacture of fluids for industrial, agricultural, or domestic use

ActiveUS8785354B2Solution to short lifeReduce sulfur contentBiocideRefining to change hydrocarbon structural skeletonAlkanePolymer science

Hydrocarbon fluid which can be used in the composition of industrial, agricultural and household products, with a pour point of less than −15° C. according to ASTM standard D97, initial and final boiling points between 200 and 450° C., containing more than 50% by weight of isoparaffins and naphthenes up to at most 40% by weight, and constituted by a mixture of hydrocarbons obtained by distillation of hydrodewaxed gas-oil cuts with a boiling point greater than 200° C.

Owner:TOTAL MARKETING SERVICES

Method for forging bearing support forge piece

ActiveCN101767177AMeet the use requirementsMeet technical needsFurnace typesEngine componentsNuclear reactorIngot

The invention relates to the technical field of forging, in particular to a method for forging a bearing support forged piece for a nuclear reactor pressure vessel. The method comprises the following steps: repeatedly performing upsetting-stretching on a suitable steel ingot at the temperature of between 1,200 and 800 DEG C to ensure that the forging ratio is no less than 4; and then sequentially performing heat treatment after forging, rough machining before the heat treatment, property heat treatment and machining after the heat treatment on the steel ingot to obtain the bearing support forge piece. The method has the advantages that: the actual grain size of the bearing support is less than 5; performance indexes of the bearing support forge piece meet requirements of RCC-M and an ASTM standards; using requirements of the bearing support forge piece for the nuclear reactor pressure vessel are met; the safety and the reliability are greatly improved; and technical requirements of the products are met.

Owner:上海新闵重型锻造有限公司

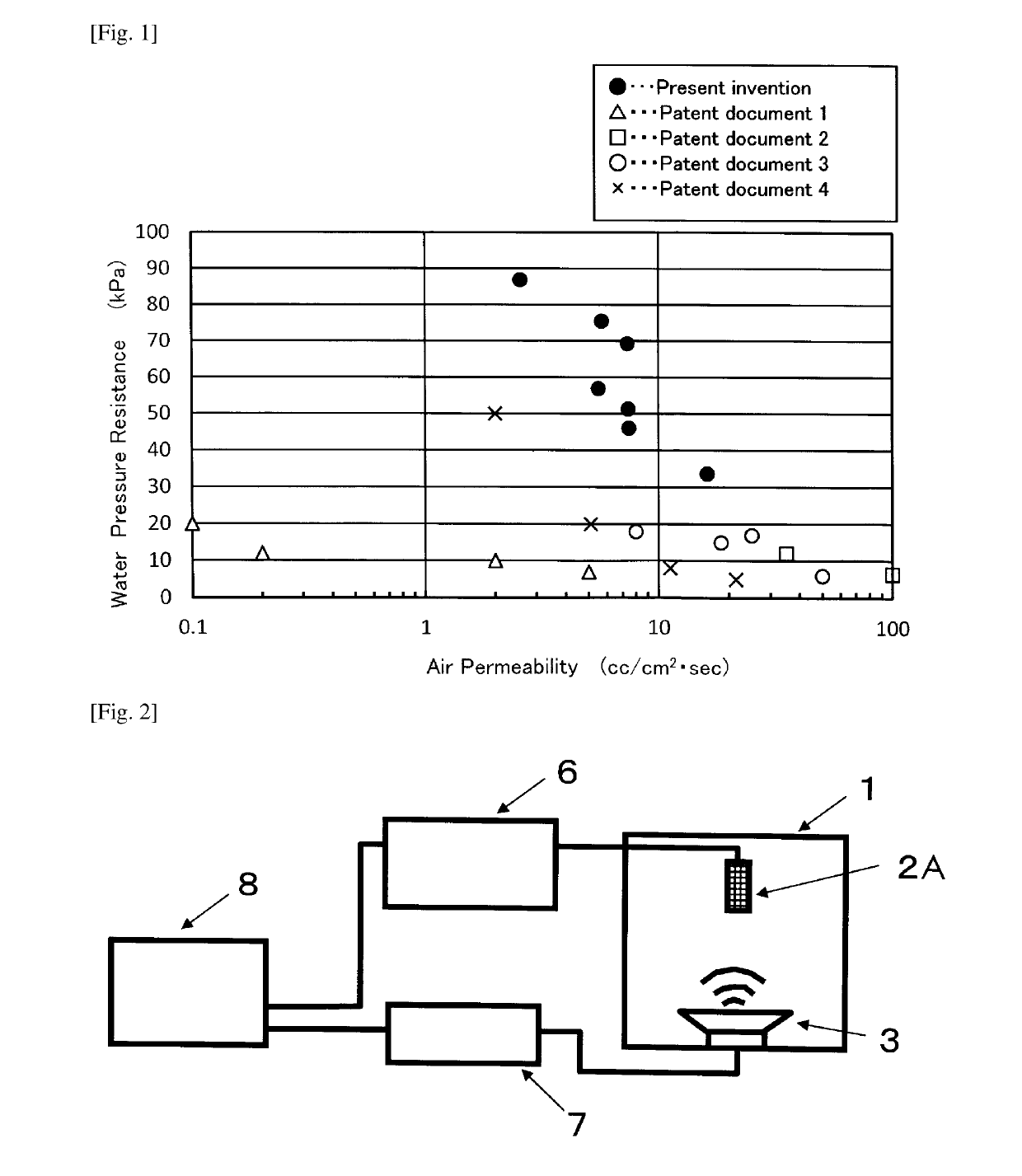

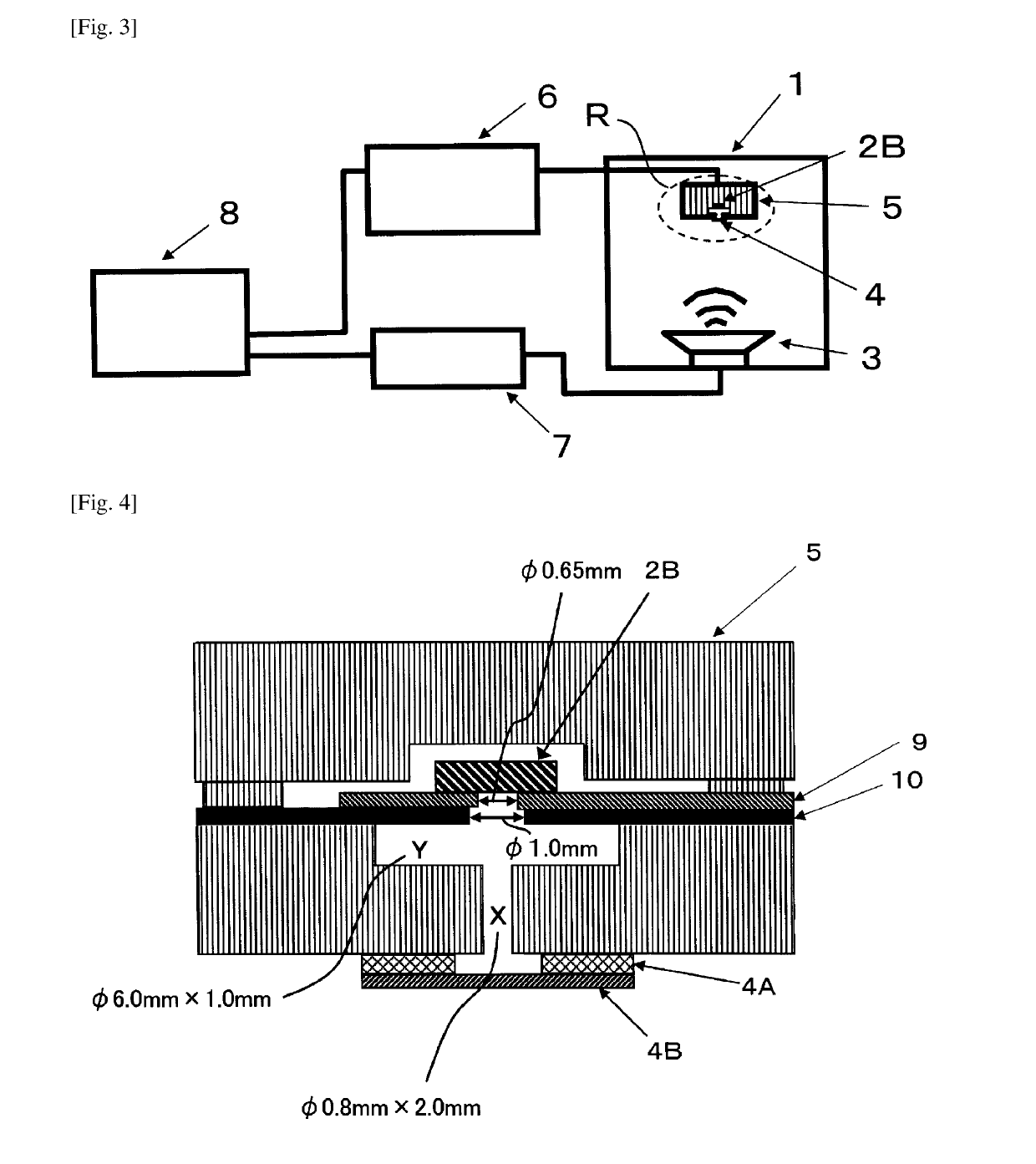

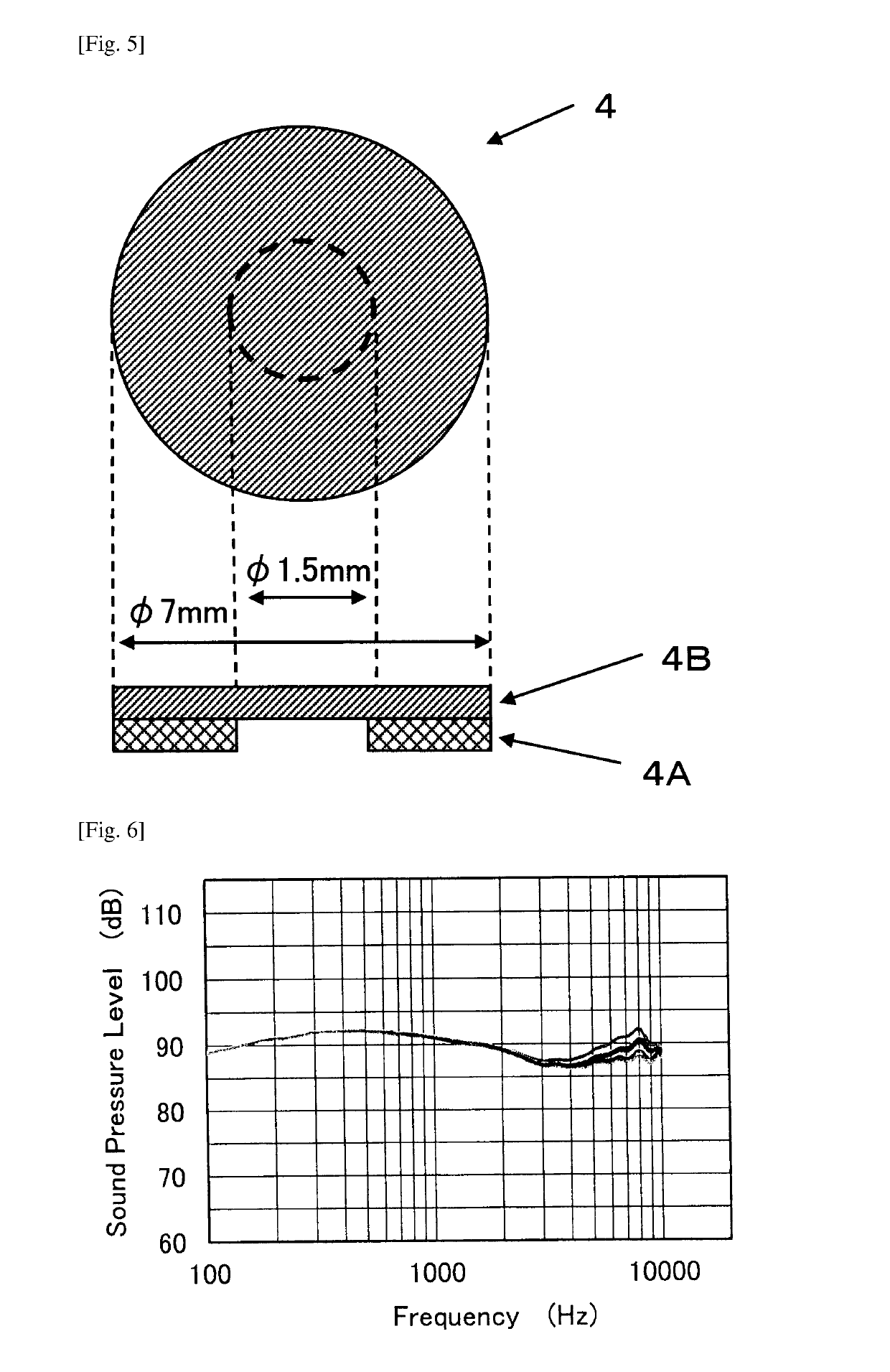

Waterproof sound-transmissive cover, waterproof sound-transmissive cover member and acoustic device

ActiveUS20190268679A1Improve breathabilityImprove waterproof performanceLoudspeaker screensMouthpiece/microphone attachmentsEngineeringHigh pressure

The waterproof sound-transmissive cover is characterized by providing a frequency response curve with a difference between a maximum sound pressure level and a minimum sound pressure level of 13.0 dB or less in the range of frequencies from 3 kHz to 8 kHz, and an insertion loss at 1 kHz of less than 14.0 dB, and said cover comprising: a porous film having (1) a water pressure resistance measured according to JIS L1092 water penetration test method B (high pressure method) of 20 kPa or more, and air permeability measured according to JIS L1096 method A (Frazier type method) of 3.0 cc / cm2·sec or more, and (2) a tensile strength measured according to ASTM standards D412 of 5.5N or more.

Owner:W L GORE & ASSOC GK

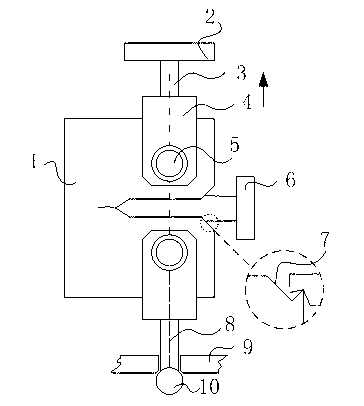

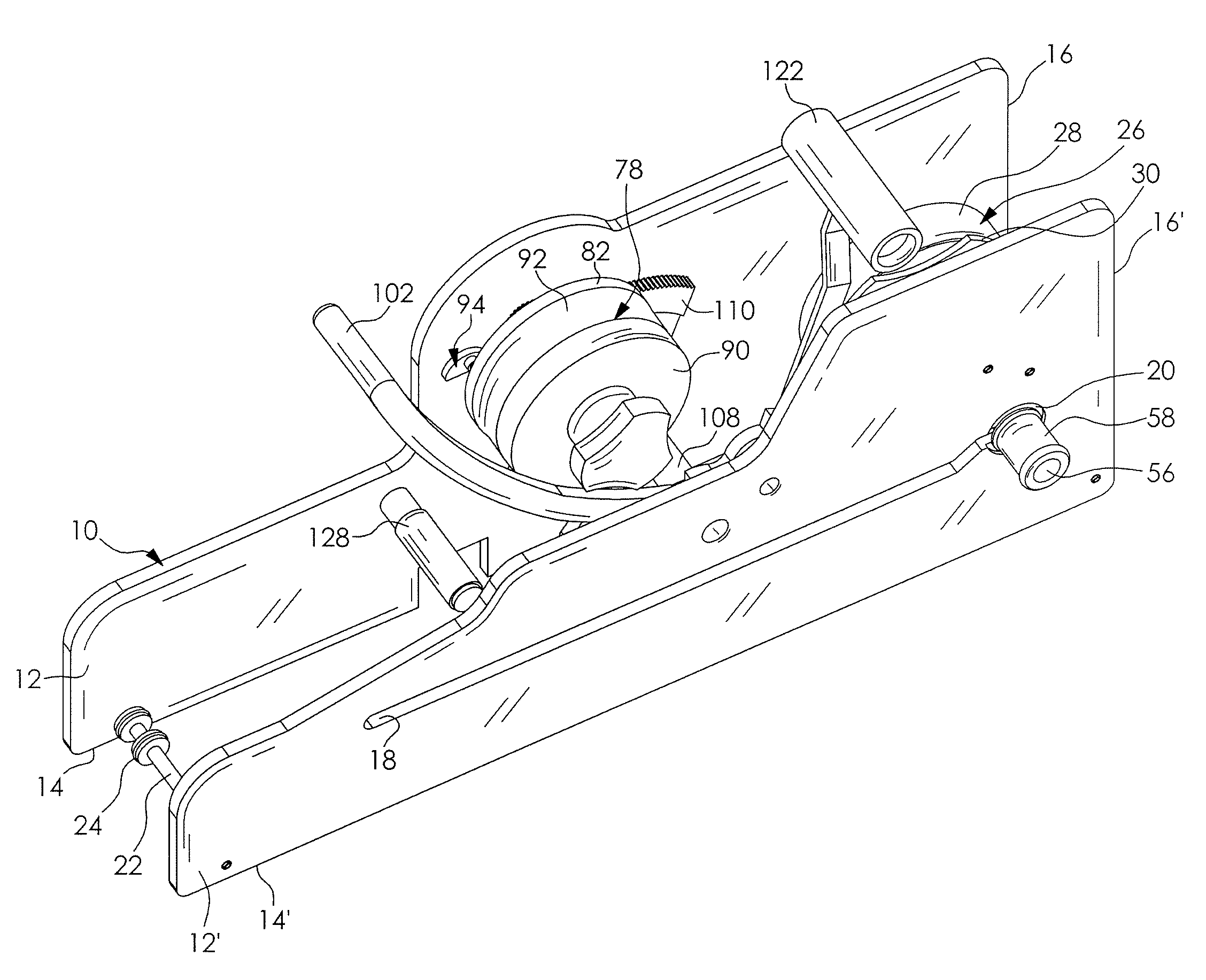

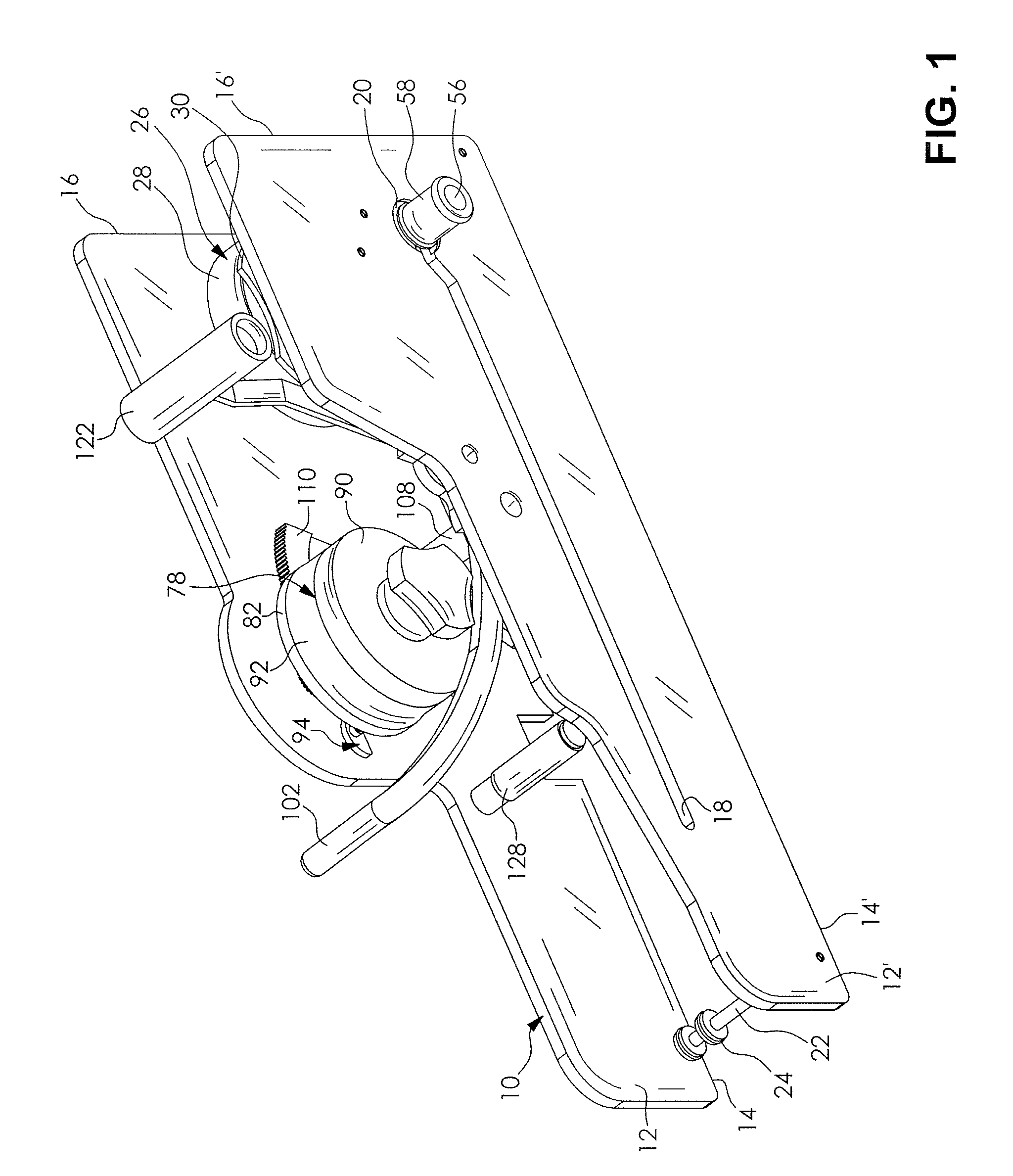

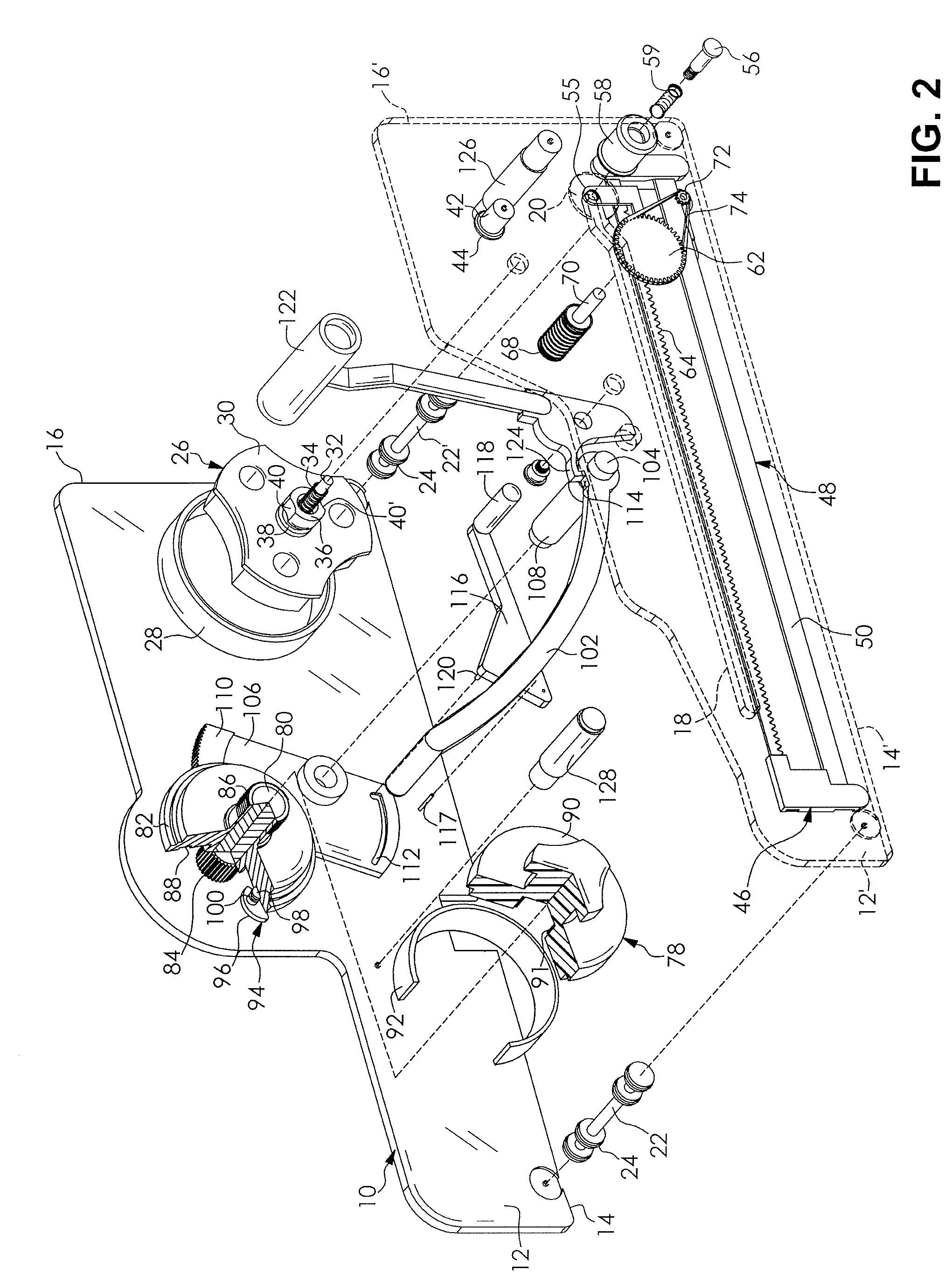

Device for testing the adhesion of a coating to a substrate and method of using same

InactiveUS7913552B2Facilitates consistently applying a tapeUsing mechanical meansMaterial analysisContact testTest procedures

A device for testing the adhesion of a coating to a substrate and a method of using the device are disclosed. The device is adapted to substantially replicate and consistently conduct the adhesion test procedure described in ASTM standards D3359 and F1842. The device includes a support with a source of a pressure sensitive adhesive tape rotatably mounted to the support. A tape dispenser and means to cause the tape to contact a test surface are mounted to the support. Means to remove the tape from the test surface is provided that includes a take-up spool adapted to receive the tape removed from the test surface.

Owner:RANDOM LOGIC

Conductive connecting material, method for connecting terminals and method for producing connection terminal

InactiveUS20120183781A1Promote aggregationReliable electrical connectionPrinted circuit aspectsSynthetic resin layered productsElectricityMetal foil

The present invention provides a conductive connecting material having a multi-layered structure comprising a resin composition and a metal foil selected from a solder foil or a tin foil, wherein the minimum ion viscosity value of the resin composition is 4-9 when measured in accordance with ASTM standard E2039 by applying a frequency of 10000 Hz at the melting point of the metal foil. The present invention further provides a method for connecting terminals and a method for producing a connection terminal using the conductive connecting material. By using the conductive connecting material of the present invention, good electric connection between connection tell finals as well as highly-reliable insulation between adjacent terminals can be achieved.

Owner:SUMITOMO BAKELITE CO LTD

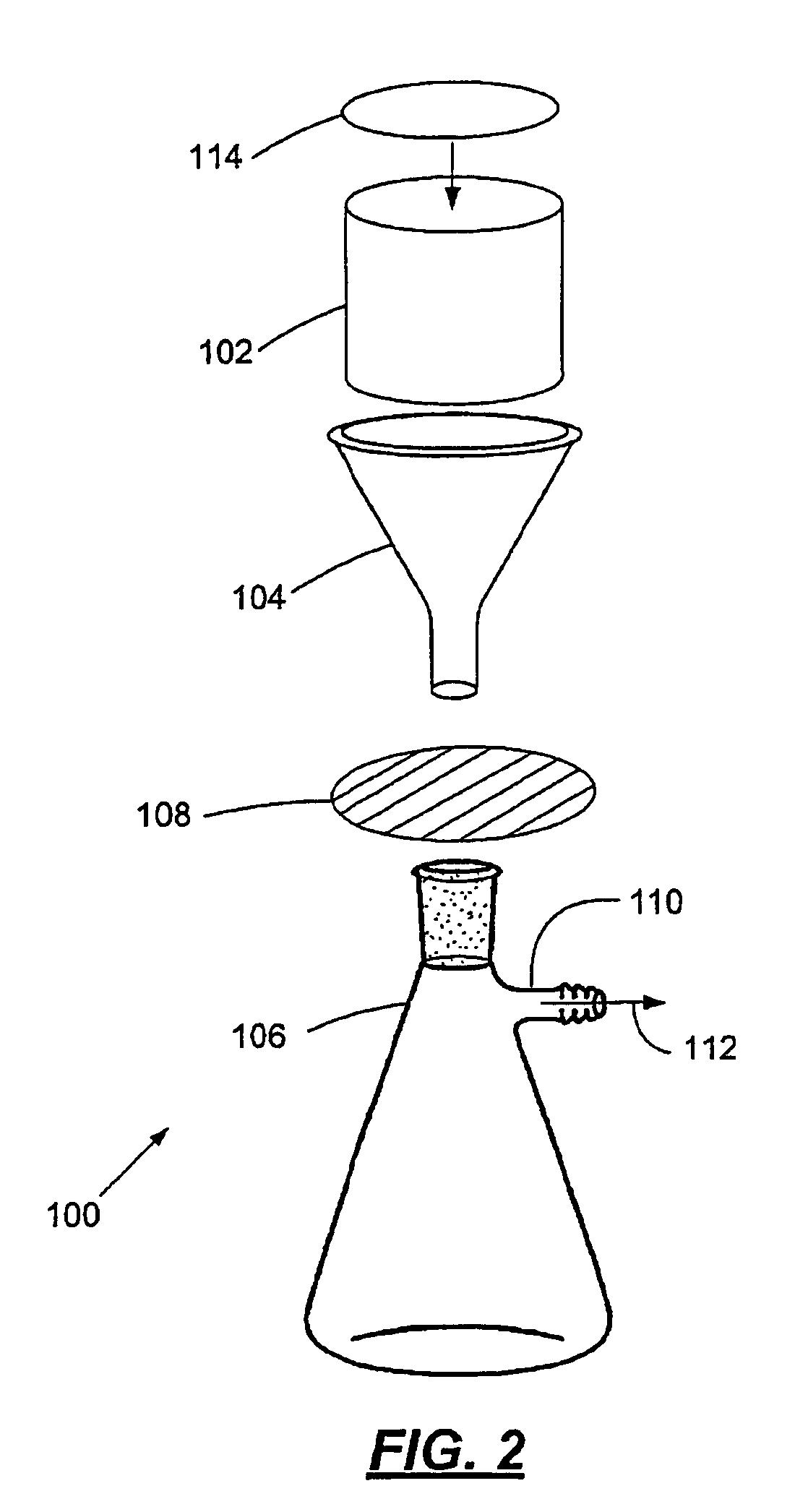

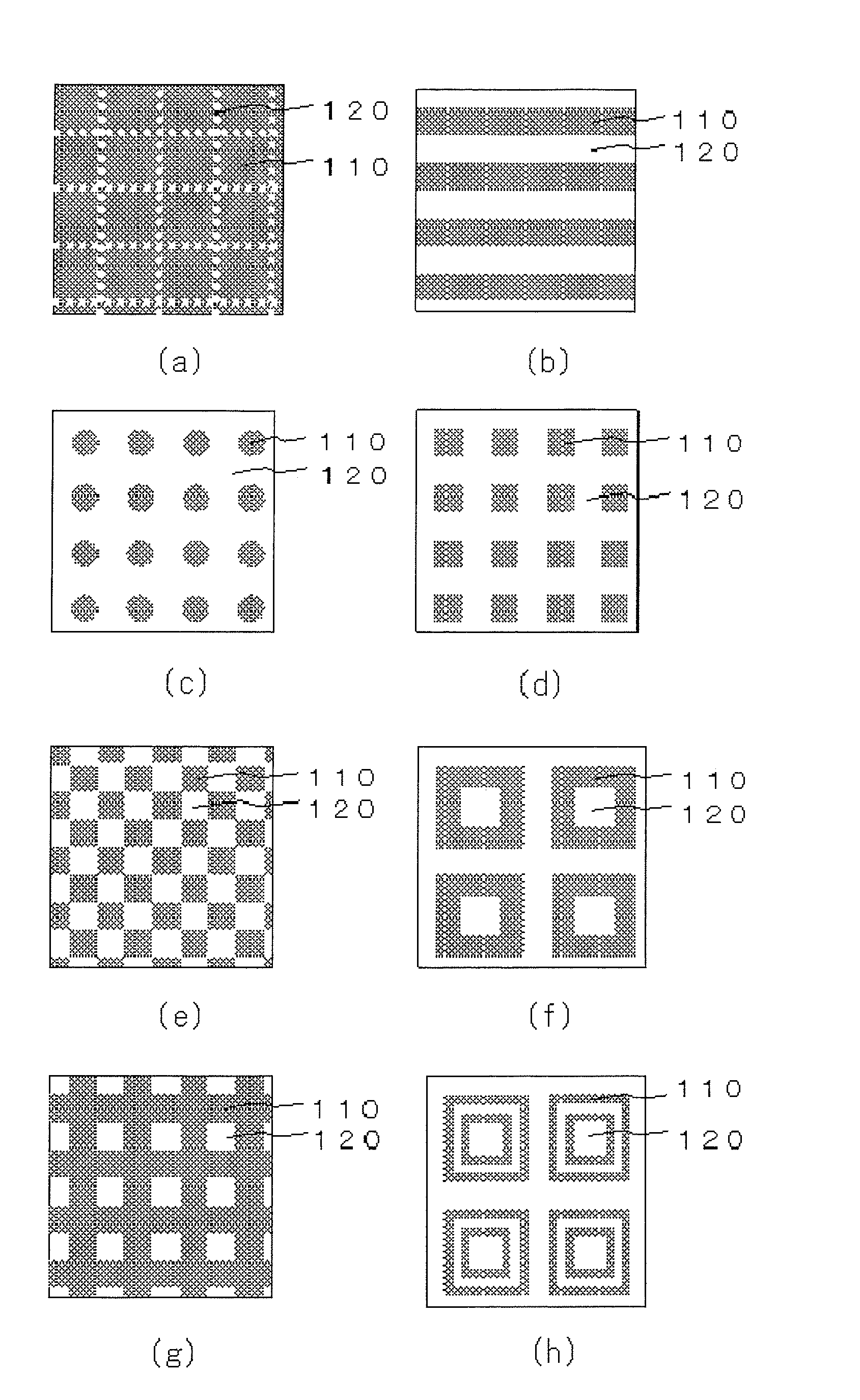

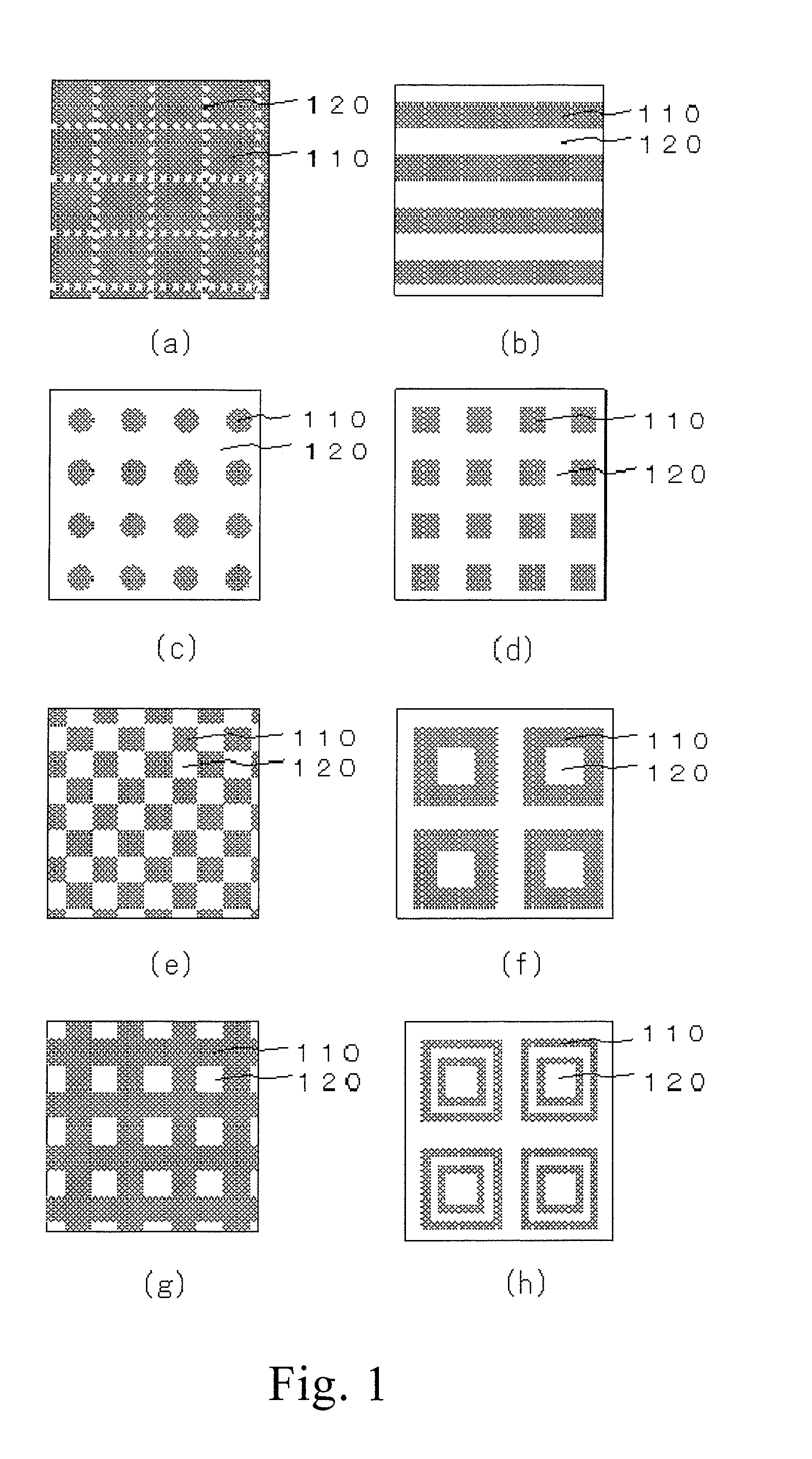

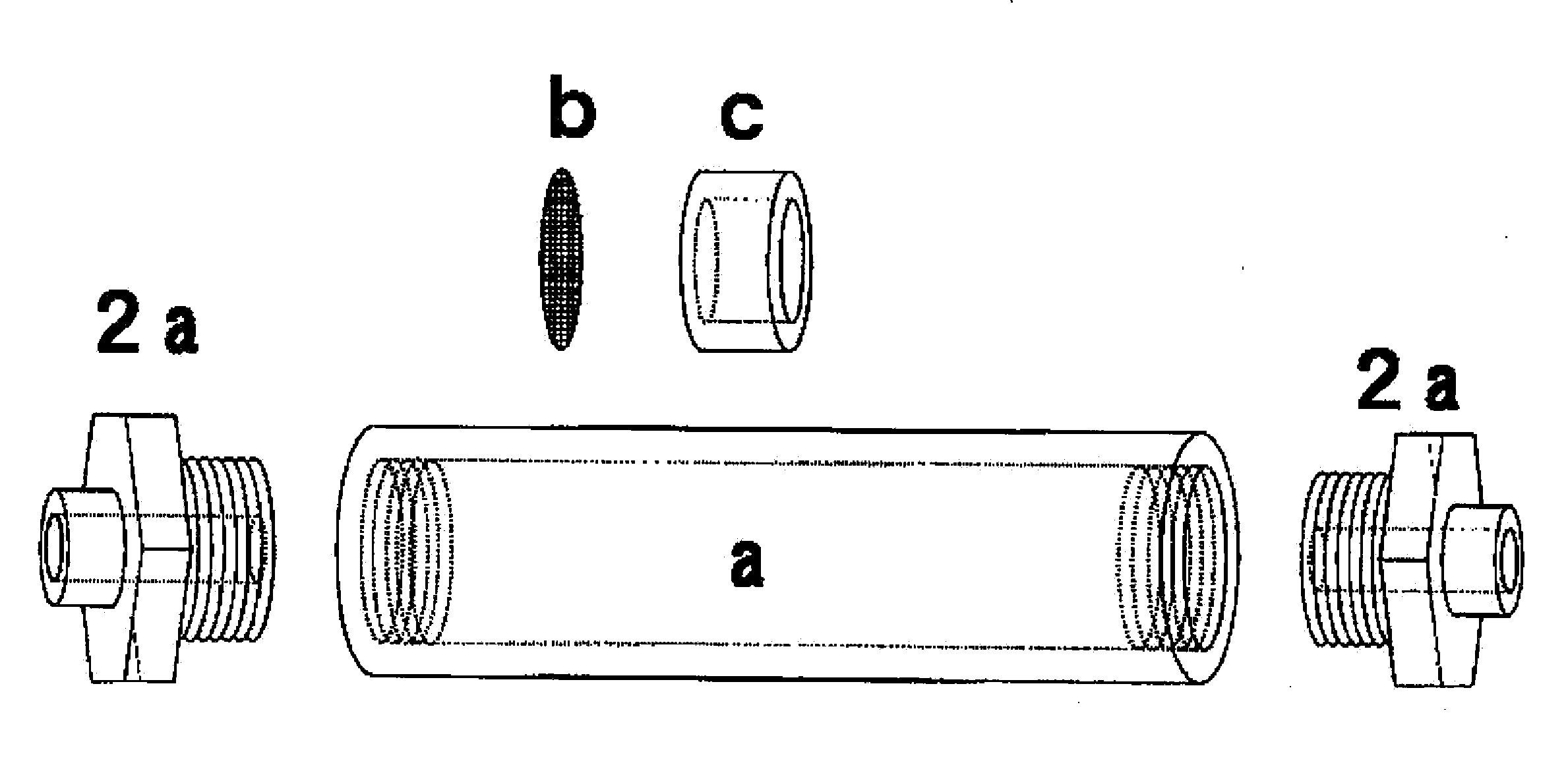

Method and apparatus for controlling particle diameter and particle diameter distribution of emulsion particles in emulsion

InactiveUS20110135933A1Easy to controlSimple structureLiquid surface applicatorsFlow mixersFeeding pumpsMaterials science

A method for controlling a particle diameter and a particle diameter distribution of emulsion particles during manufacturing of an emulsion dispersion is provided. The method includes causing two or more types of liquids substantially immiscible with each other to continuously and sequentially pass through net bodies. The net bodies are disposed in a cylindrical flow passage at intervals of 5 to 200 mm, and the number of the net bodies is more than 50 and 200 or less. Each of the net bodies is equivalent to a gauze having a mesh number of 35 mesh to 4000 mesh in accordance with an ASTM standard and has a surface that intersects the direction of the flow passage. An emulsification apparatus used for the method includes a feed pump for feeding two or more types of liquids substantially immiscible with each other; and a cylindrical flow passage to which the two or more types of liquids fed by the feed pump are delivered. A predetermined number of net bodies are disposed in the cylindrical flow passage at predetermined intervals, and each net body has a surface intersecting the direction of the flow passage.

Owner:NIPPON OIL CORP

Free-Machining Powder Metallurgy Steel Articles and Method of Making Same

ActiveUS20100068547A1Improve surface qualitySmall diameterThin material handlingMetal layered productsCarbideMetal powder

A small diameter, elongated steel article, comprising fully consolidated, prealloyed metal powder is disclosed. The consolidated metal powder has a microstructure that has a substantially uniform distribution of fine grains having a grain size of not larger than about 9 when determined in accordance with ASTM Standard Specification E 112. The microstructure of the consolidated metal powder is further characterized by having a plurality of substantially spheroidal carbides uniformly distributed throughout the consolidated metal powder that are not greater than about 6 microns in major dimension and a plurality of sulfides uniformly distributed throughout the consolidated metal powder wherein the sulfides are not greater than about 2 microns in major dimension. A process for making the elongated steel article is also disclosed.

Owner:CRS HLDG LLC

Device for testing the adhesion of a coating to a substrate and method of using same

InactiveUS20090114006A1Facilitates consistently applying tapeFacilitates consistently applying a tapeUsing mechanical meansMaterial analysisTest proceduresBiomedical engineering

A device for testing the adhesion of a coating to a substrate and a method of using the device are disclosed. The device is adapted to substantially replicate and consistently conduct the adhesion test procedure described in ASTM standards D3359 and F1842. The device includes a support with a source of a pressure sensitive adhesive tape rotatably mounted to the support. A tape dispenser and means to cause the tape to contact a test surface are mounted to the support. Means to remove the tape from the test surface is provided that includes a take-up spool adapted to receive the tape removed from the test surface.

Owner:RANDOM LOGIC

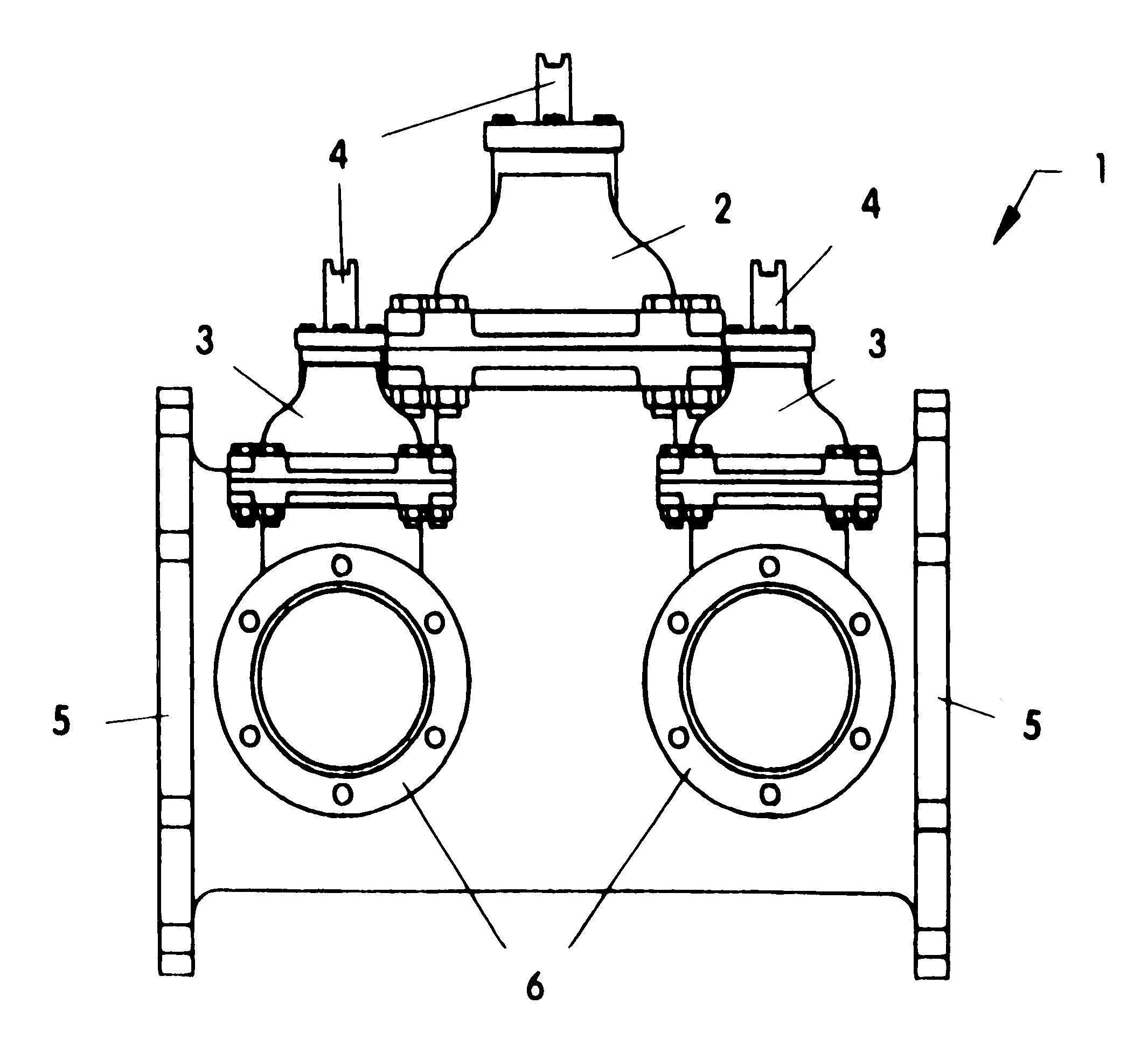

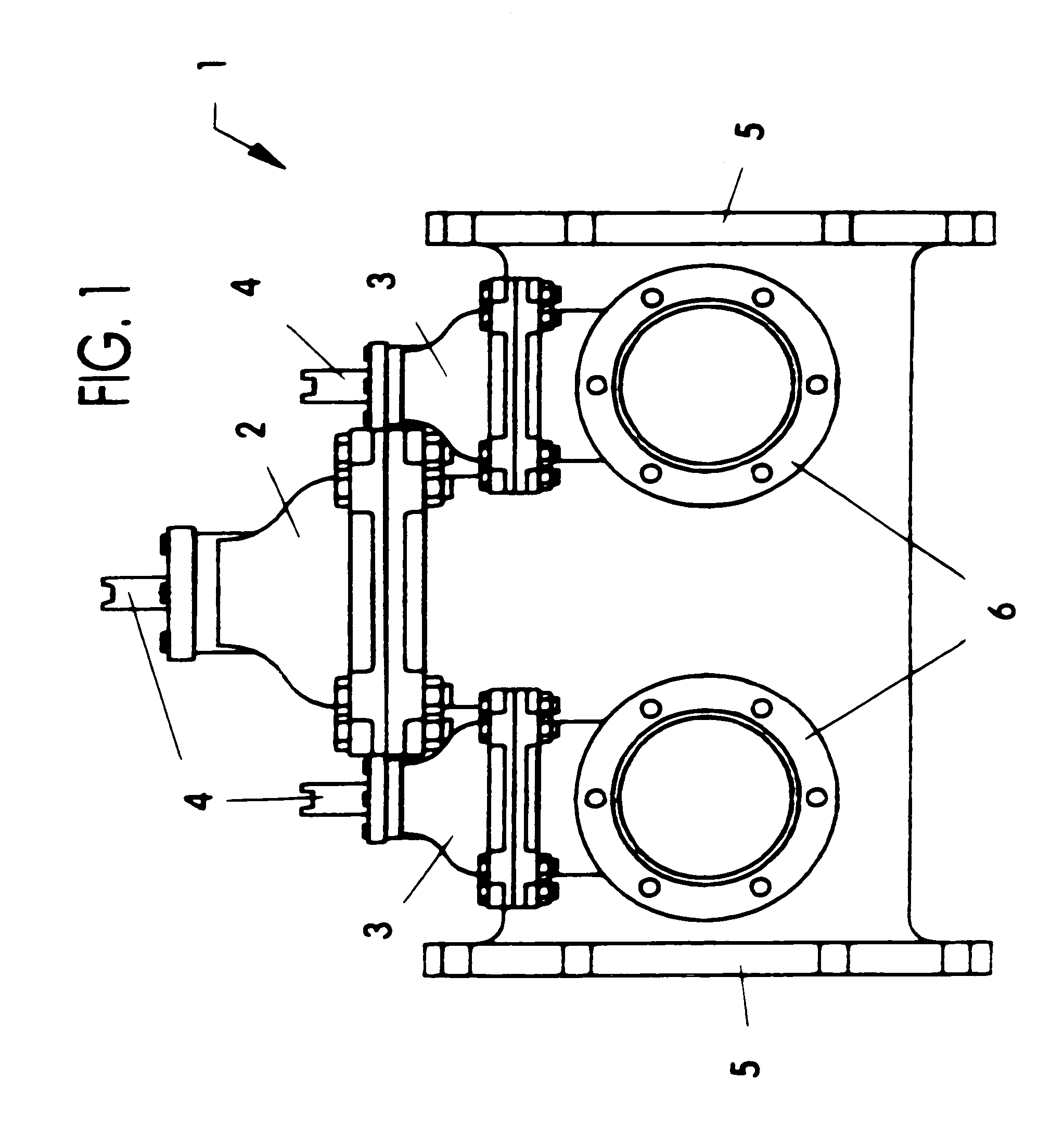

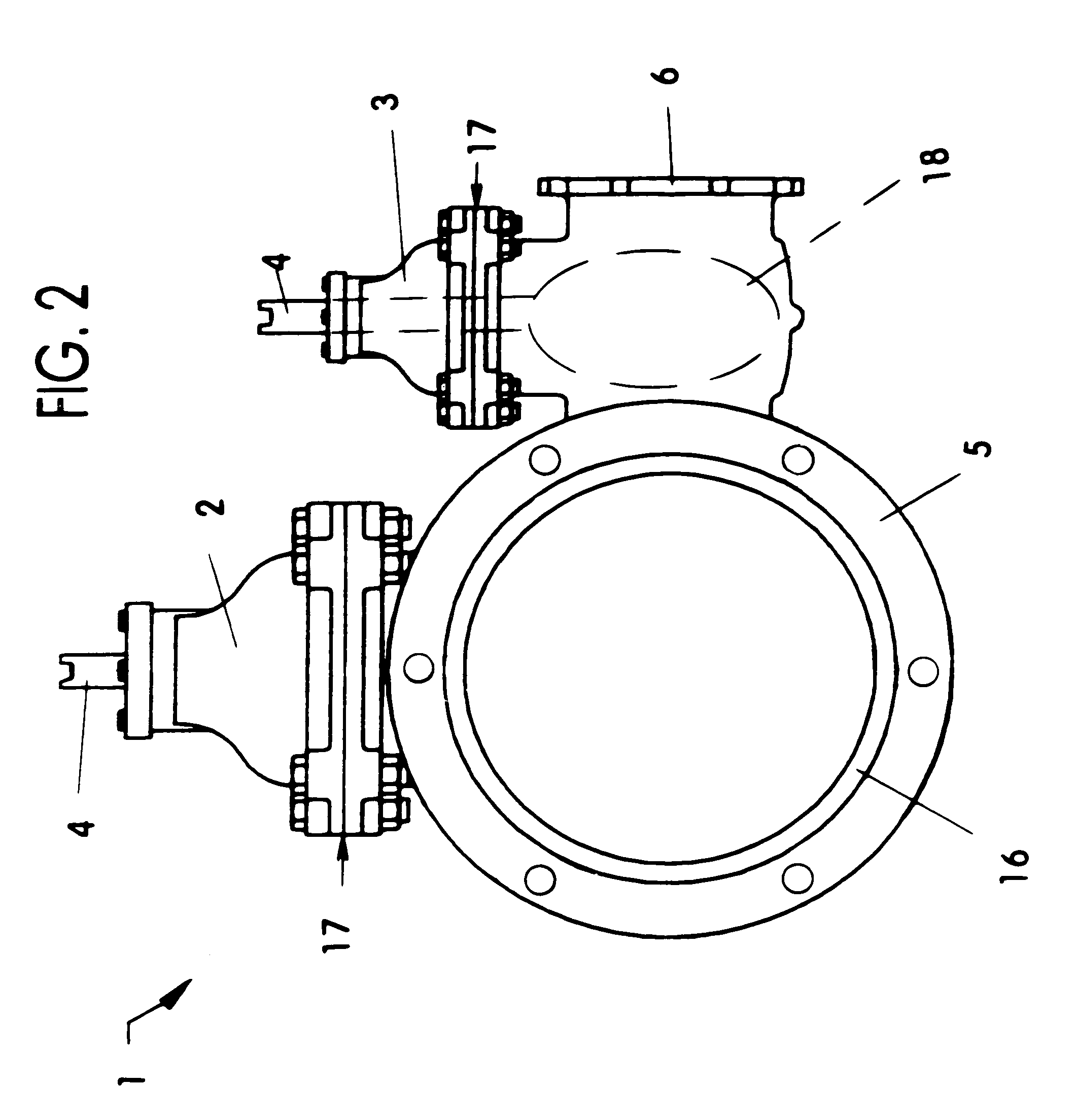

Tri valve backflow preventer

InactiveUS7121293B2Reduce equipment timeReduce usageCheck valvesCombustion enginesMan-hourEPDM rubber

A tri valve backflow preventer having parts and materials preferably consisting of steel nuts and bolts, ductile iron operating nuts, nitrile rubber O-rings, nitrile rubber gaskets, manganese bronze valve adjusting stems, valve wedge gates made of ductile iron encapsulated with EPDM rubber, and ductile iron valve bodies. Material and parts are constructed in accordance with ASTM standards and the requirements of the AWWAC-509 and AWWAC-504 for gate valves and butterfly valves. The tri valve backflow preventer is used with a temporary conventional backflow assembly between existing water main pipe and new / upgraded sections of water main pipe while they are under construction. It is left in place when the temporary backflow assembly is removed. Its use saves extra inspection hours, extra man hours, extra equipment hours, conserves large amounts of good water otherwise needed for flushing, and reduces the safety risk to the public during activation of new water lines.

Owner:WALTER GUY ROBERT +1

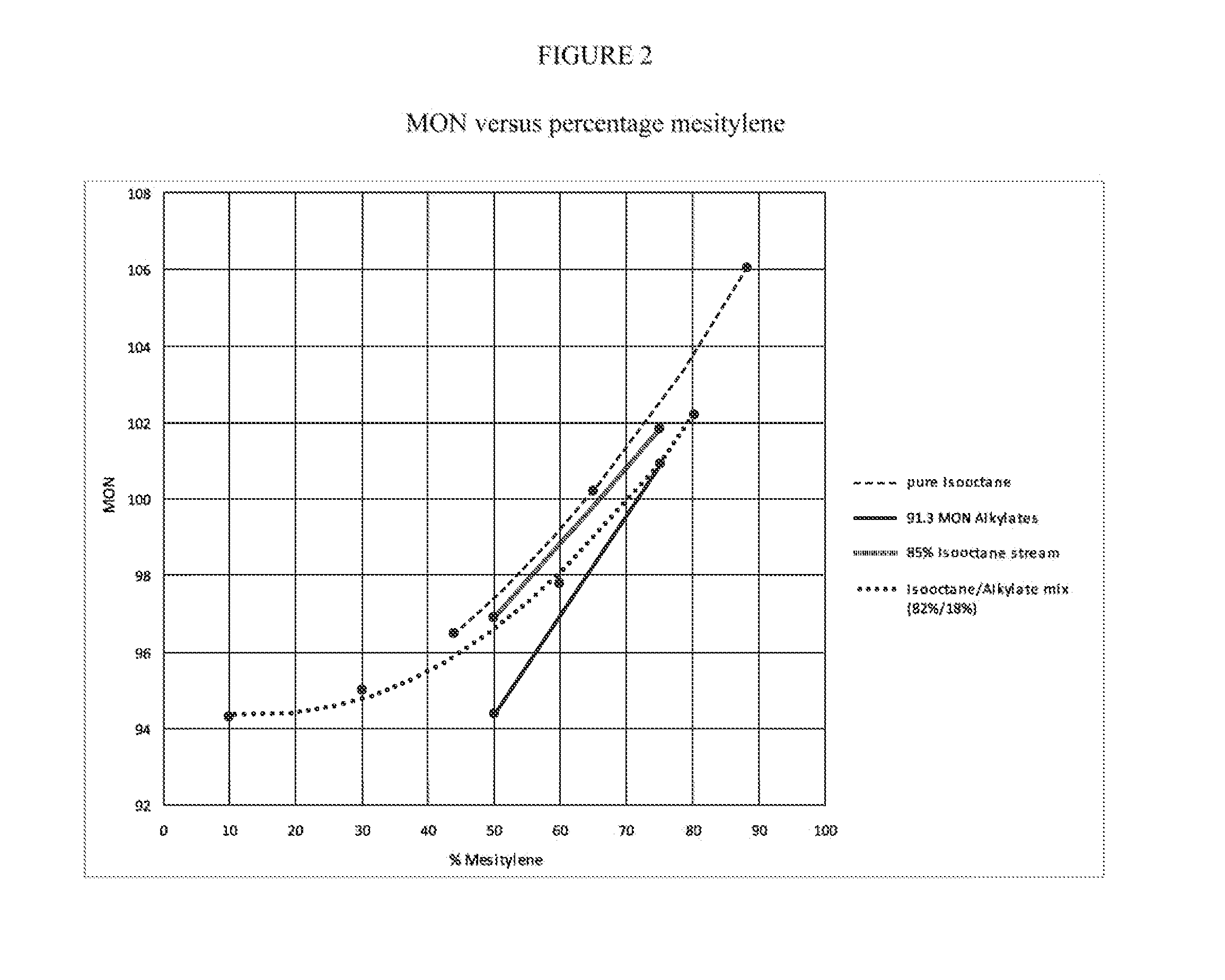

Aviation gasolines containing mesitylene and isopentane

Describe are preferred formulations for Avgas meeting the requirements for use in aircraft, including requirements established under ASTM standards and by the Federal Aviation Administration. In one embodiment, a binary mixture of 1,3,5-trimethyl benzene (mesitylene) and isopentane is used to provide a MON of at least 100, and more preferably at least 102. In other embodiments, the amounts of mesitylene and / or isopentane may be changed, and other fuel components are included. These various Avgas formulations are thereby adjusted to meet a variety of requirements as to octane rating, RVP, cold start, and other fuel characteristics.

Owner:SWIFT FUELS

Free-machining powder metallurgy steel articles and method of making same

A small diameter, elongated steel article, comprising fully consolidated, prealloyed metal powder is disclosed. The consolidated metal powder has a microstructure that has a substantially uniform distribution of fine grains having a grain size of not larger than about 9 when determined in accordance with ASTM Standard Specification E 112. The microstructure of the consolidated metal powder is further characterized by having a plurality of substantially spheroidal carbides uniformly distributed throughout the consolidated metal powder that are not greater than about 6 microns in major dimension and a plurality of sulfides uniformly distributed throughout the consolidated metal powder wherein the sulfides are not greater than about 2 microns in major dimension. A process for making the elongated steel article is also disclosed.

Owner:CRS HLDG LLC

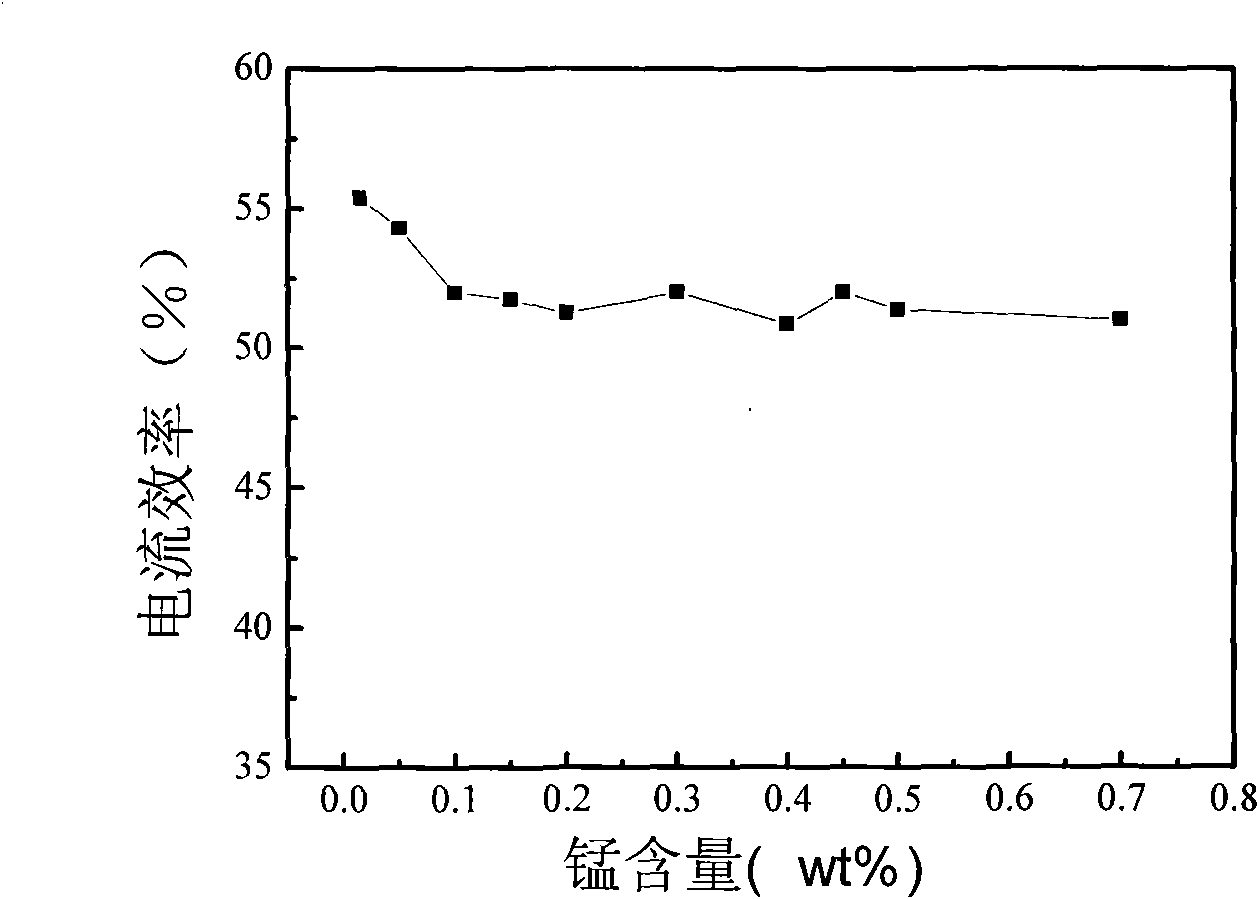

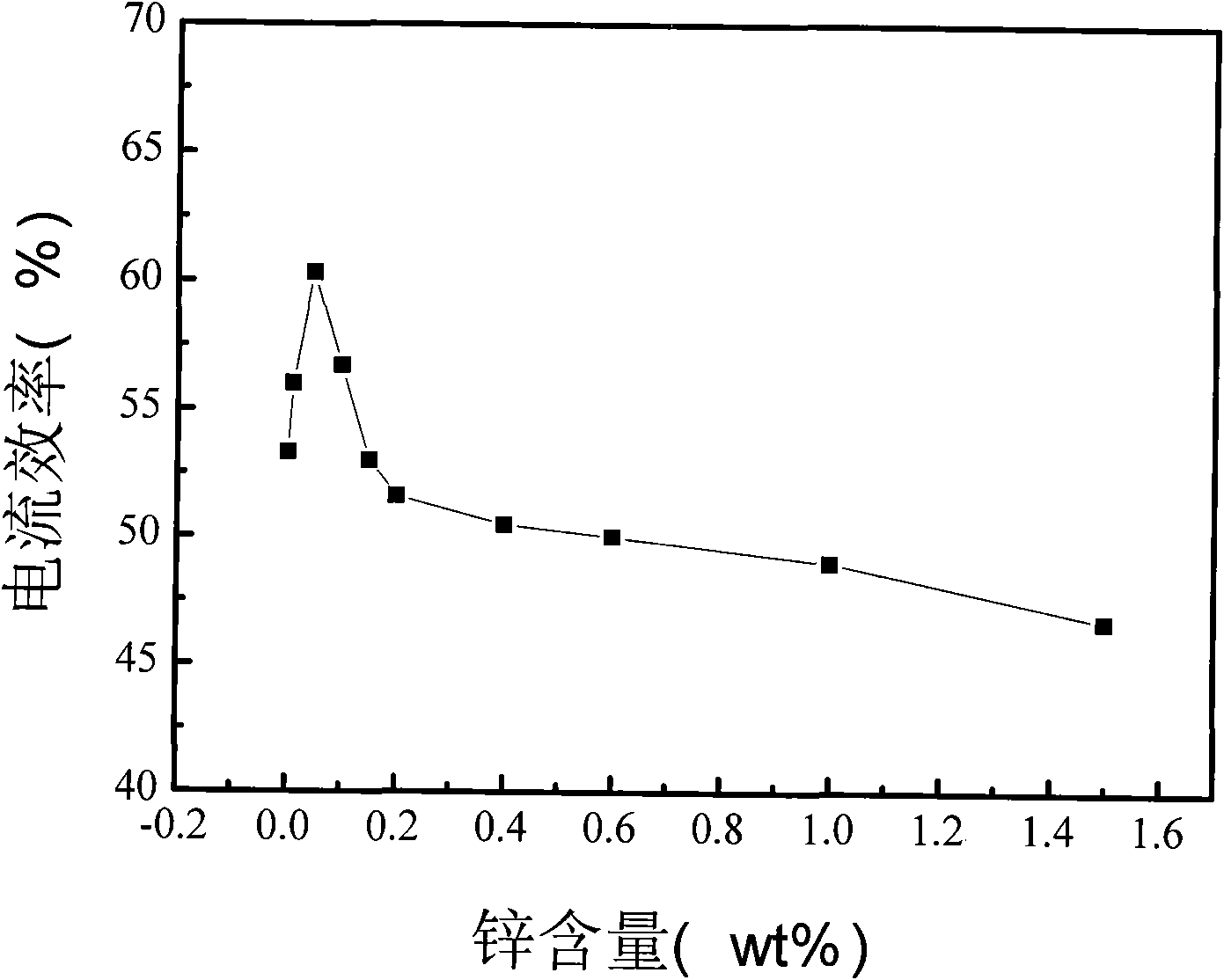

High-potential sacrificial magnesium alloy anode and manufacturing method thereof

The invention provides a high-potential sacrificial magnesium alloy anode and a manufacturing method thereof. The high-potential sacrificial magnesium alloy anode comprises the following chemical components in percentage by weight: 0 to 0.4 percent of Zn, less than or equal to 0.01 percent of Al, less than or equal to 0.02 percent of Si, less than or equal to 0.05 percent of Mn, less than or equalto 0.03 percent of Fe, less than or equal to 0.003 percent of Ni, less than or equal to 0.005 percent of Cu, and the balance of Mg; besides, the potential of the high-potential sacrificial magnesiumalloy anode is more than -1.70 volts, and the current efficiency is over 50 percent. The high-potential sacrificial magnesium alloy anode has a simple manufacturing process and low cost, and has the electrical property in accordance with the prescriptions of an ASTM standard.

Owner:HEBI WONDERFUL MAGNESIUM TECH

Hydrocarbon diluent with a low VOC level for construction materials

ActiveUS20110319539A1Low viscosityEasy to handlePlastic/resin/waxes insulatorsRefining to change hydrocarbon structural skeletonAlkanePolymer science

A hydrocarbon diluent for the dilution of polymer with a pour point below −15° C. according to ASTM standard D97, with a boiling point comprised between 280 and 450° C., including more than 50% by weight of isoparaffins, and naphthenes up to at most 40% by weight, and constituted by a mixture of hydrocarbons with a boiling point above 200° C., obtained by distillation of hydrodewaxed gas-oil cuts.

Owner:TOTAL MARKETING SERVICES SA

Flameproof, heat resistant, one-piece escape suit

A flameproof, heat resistant, lightweight, one-piece escape suit which includes attached integral mitts or gloves, covered footing, and a hood. The fire and heat resistant one piece suit is designed to be worn over a commercial smoke hood, is formed from a metalized fabric, and meets the requirements of ASTM standard D6413. The suit is designed to be easily slipped onto a wearer's body over typical street clothing, and allows a wearer to wear his or her accustomed footwear for improved safety and comfort. The durable fabric provides protection to a wearer when crawling low to the ground on his or her knees and elbows as is often recommended as a preferred escape posture. The fire and heat resistant one piece suit may be provided in multiple sizes to fit adults and children. The fire and heat resistant one piece suit, as well as a smoke hood, may be packaged into compact, lightweight emergency escape kit bag with unique “glow in the dark” lettering; FIRE ESCAPE KIT suitable for carrying between home and work, etc.

Owner:SIGMON KENNIS L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com