Artificial heart valve pyrolytic carbon and testing method for fracture toughness of pyrolytic carbon composite material

A technology of artificial heart valve and composite material, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of small sample size, thin thickness, and no method for testing the fracture toughness of artificial heart valve pyrolysis carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation steps of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0026] The method for testing the fracture toughness of artificial heart valve pyrolytic carbon and its composite materials, the specific steps are:

[0027] Step (1). Prepare the artificial heart valve pyrolytic carbon or its composite material to be tested into n (n ≥ 3) compact tensile C (T) samples, and then on each compact tensile C (T) sample Prefabricated sharp cracks;

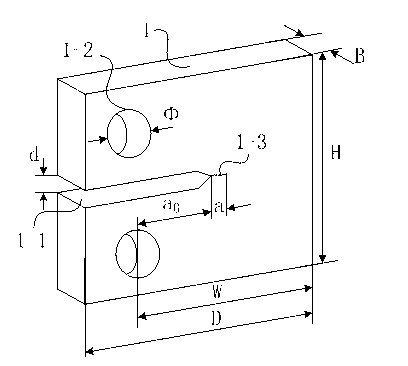

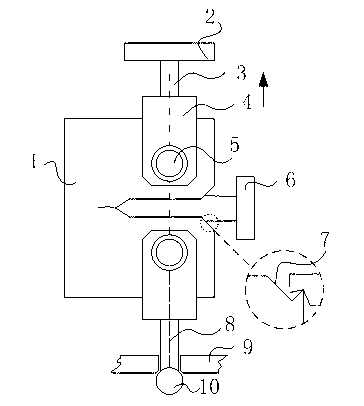

[0028] Such as figure 1 As shown, the compact tensile C(T) sample is in accordance with the American ASTM standard E399 recommended specifications, sample 1 is a cube, the middle part is machined with a notch 1-1, and the upper and lower ends of the notch 1-1 are respectively provided with loading holes 1-2. The notch 1-1 is a straight-through notch, one end is set on the side of sample 1, and the other end is the tip; the effective width W of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com