Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

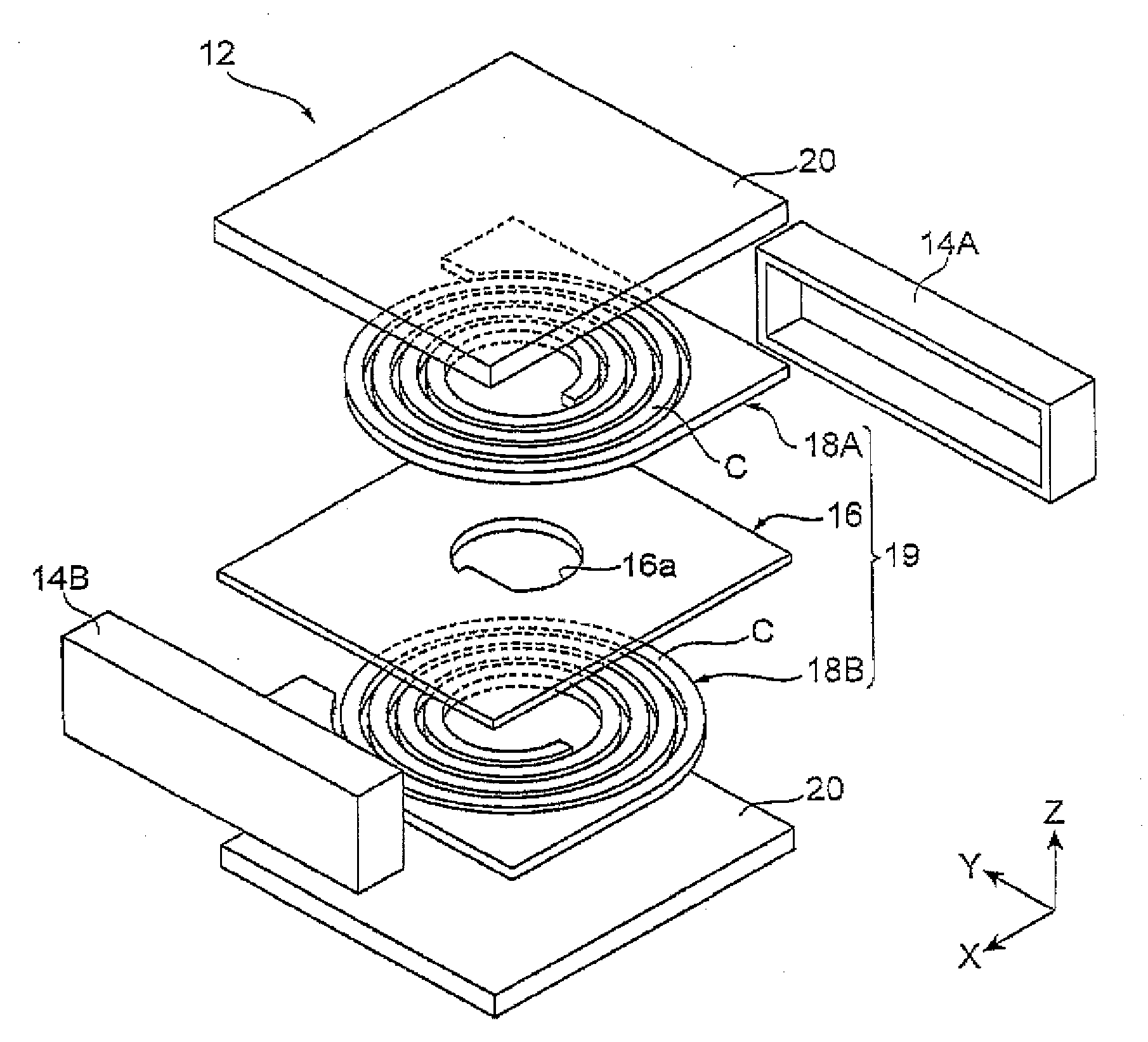

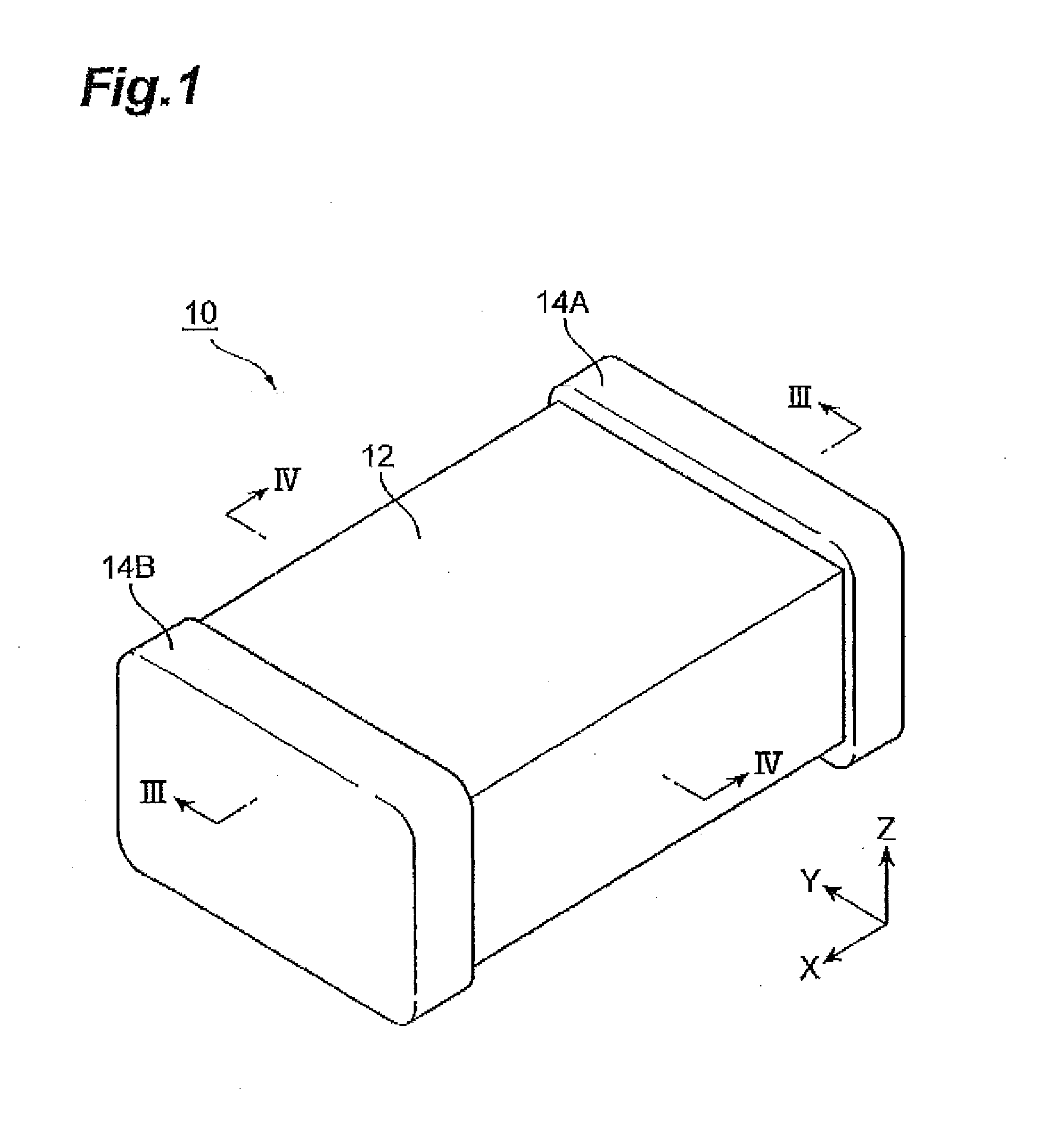

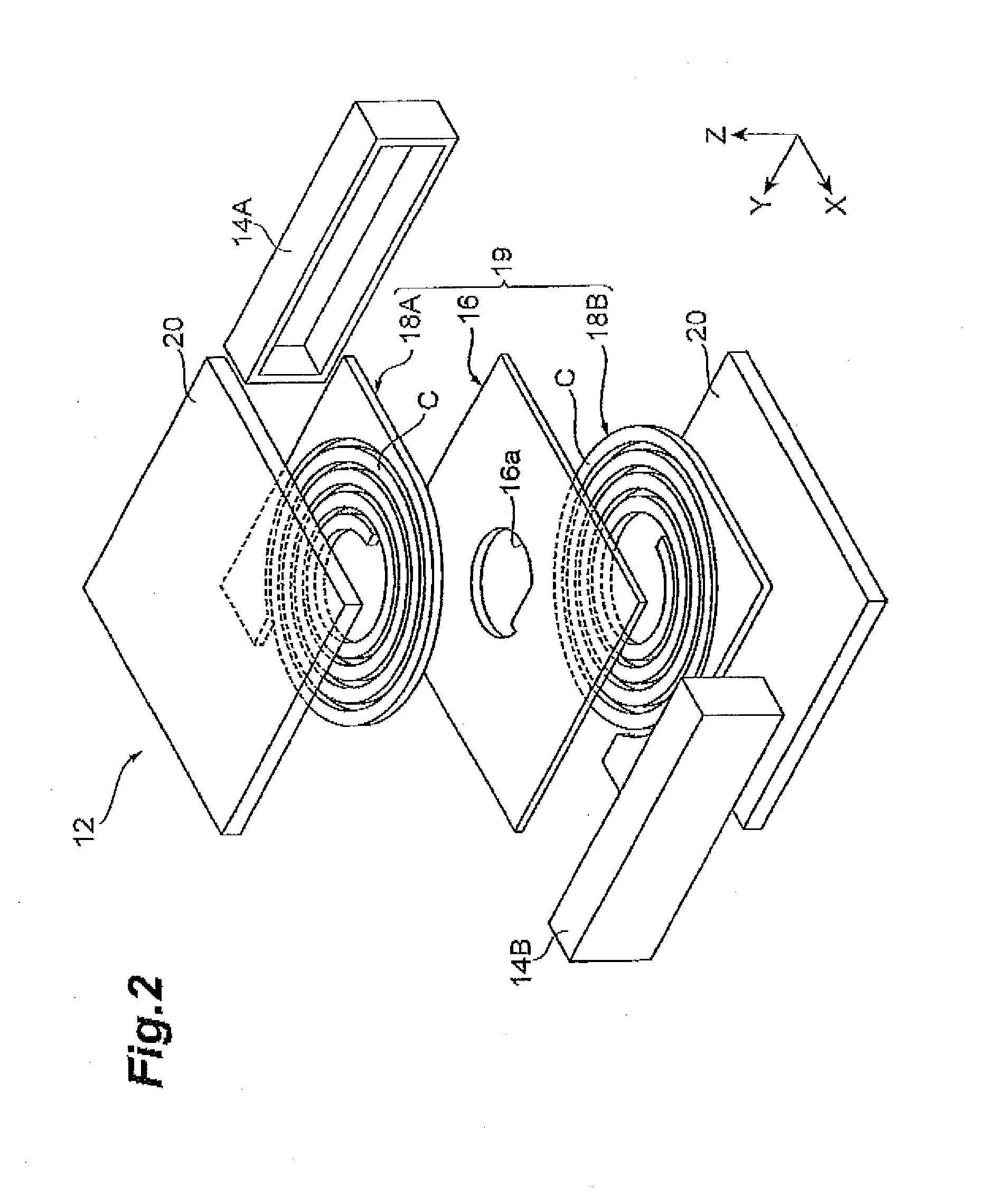

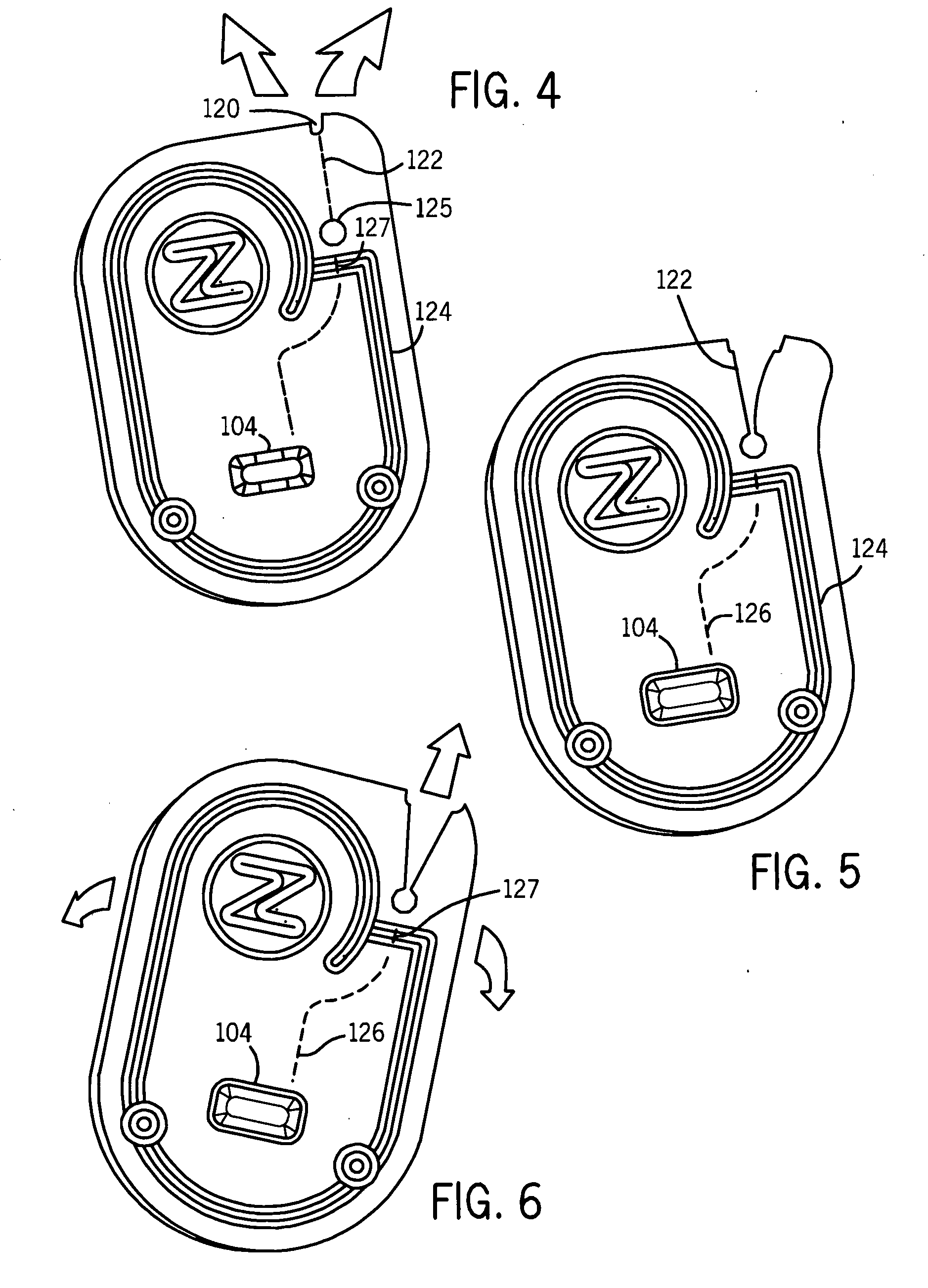

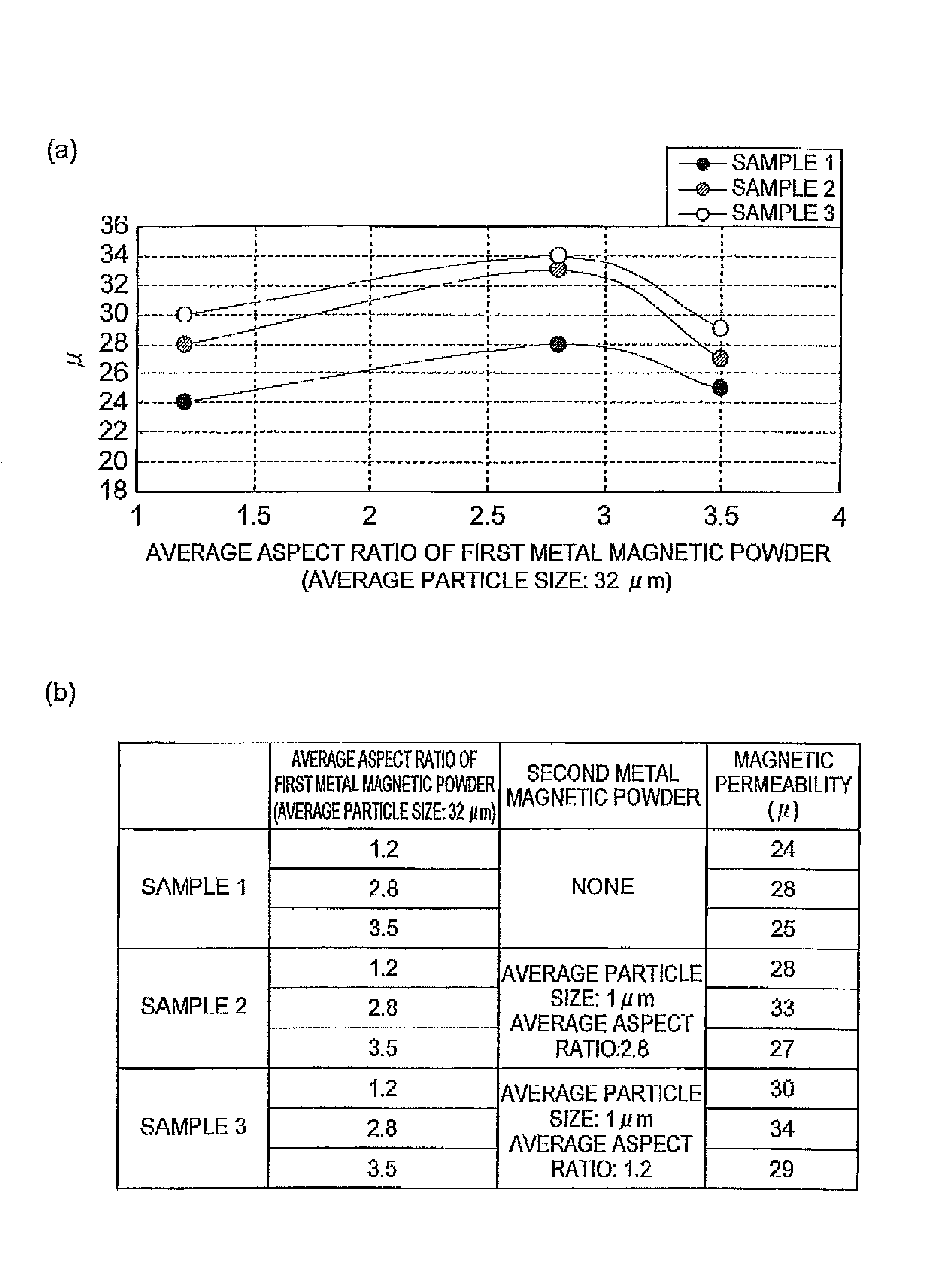

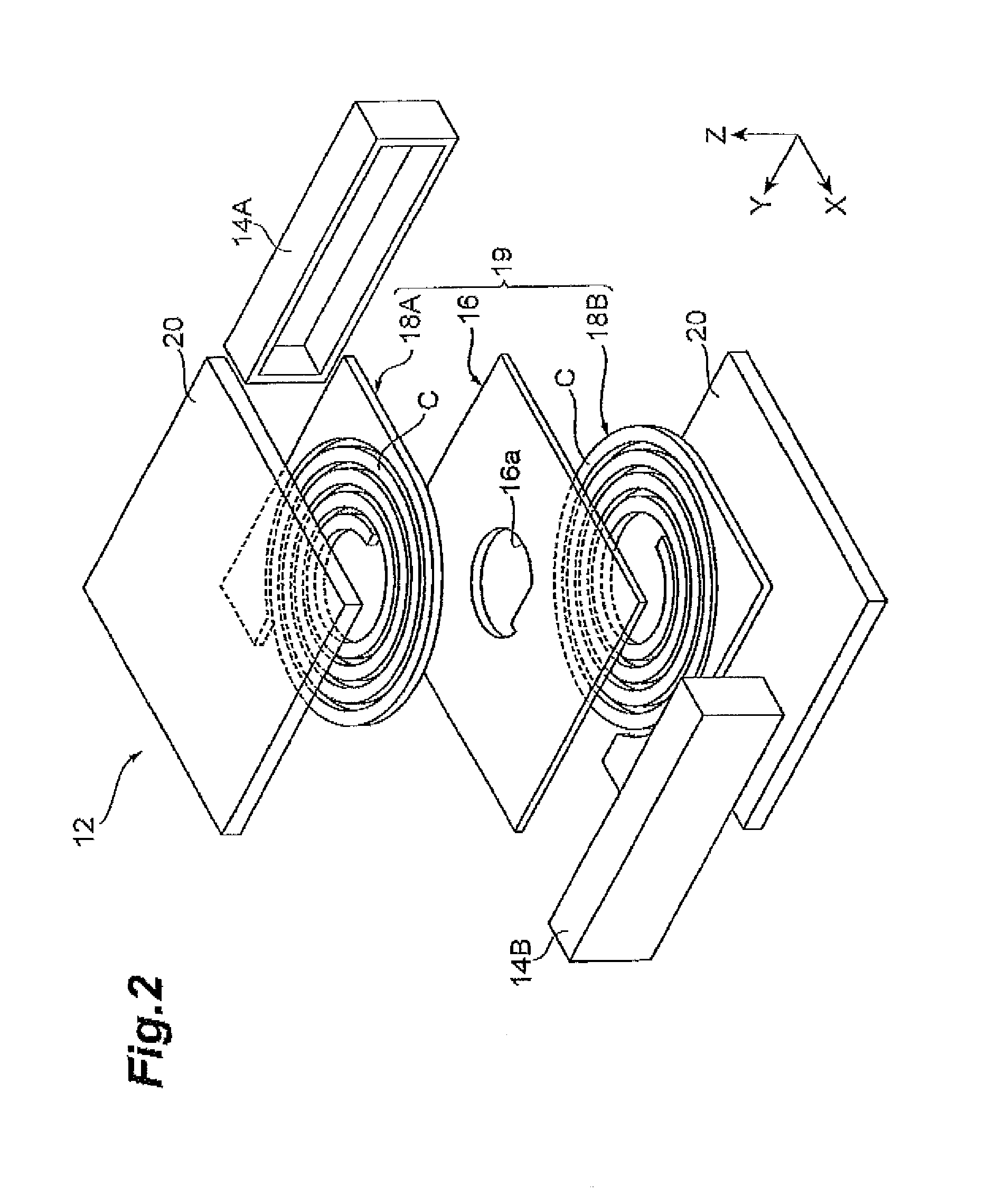

Planar coil element

ActiveUS20130249662A1Improve permeabilitySmall particle sizeInorganic material magnetismTransformers/inductances detailsMetalMaterials science

In a planar coil element, the quantitative ratio of inclined particles to total particles of a first metal magnetic powder contained in a metal magnetic powder-containing resin provided in a through hole of a coil unit is higher than the quantitative ratio of inclined particles to total particles of the first metal magnetic powder contained in the metal magnetic powder-containing resin provided in other than the through hole, and many of particles of the first metal magnetic powder in the magnetic core are inclined particles whose major axes are inclined with respect to the thickness direction and the planar direction of a substrate. Therefore, the planar coil element has improved strength as compared to a planar coil element shown in FIG. 9A and has improved magnetic permeability as compared to a planar coil element shown in FIG. 9B.

Owner:TDK CORPARATION

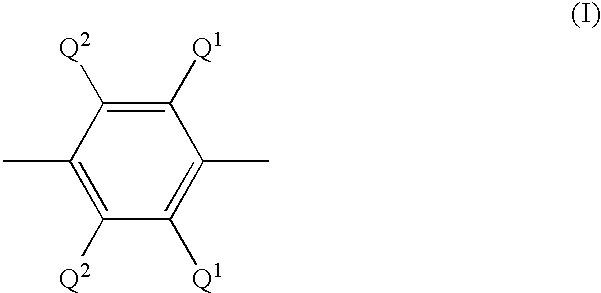

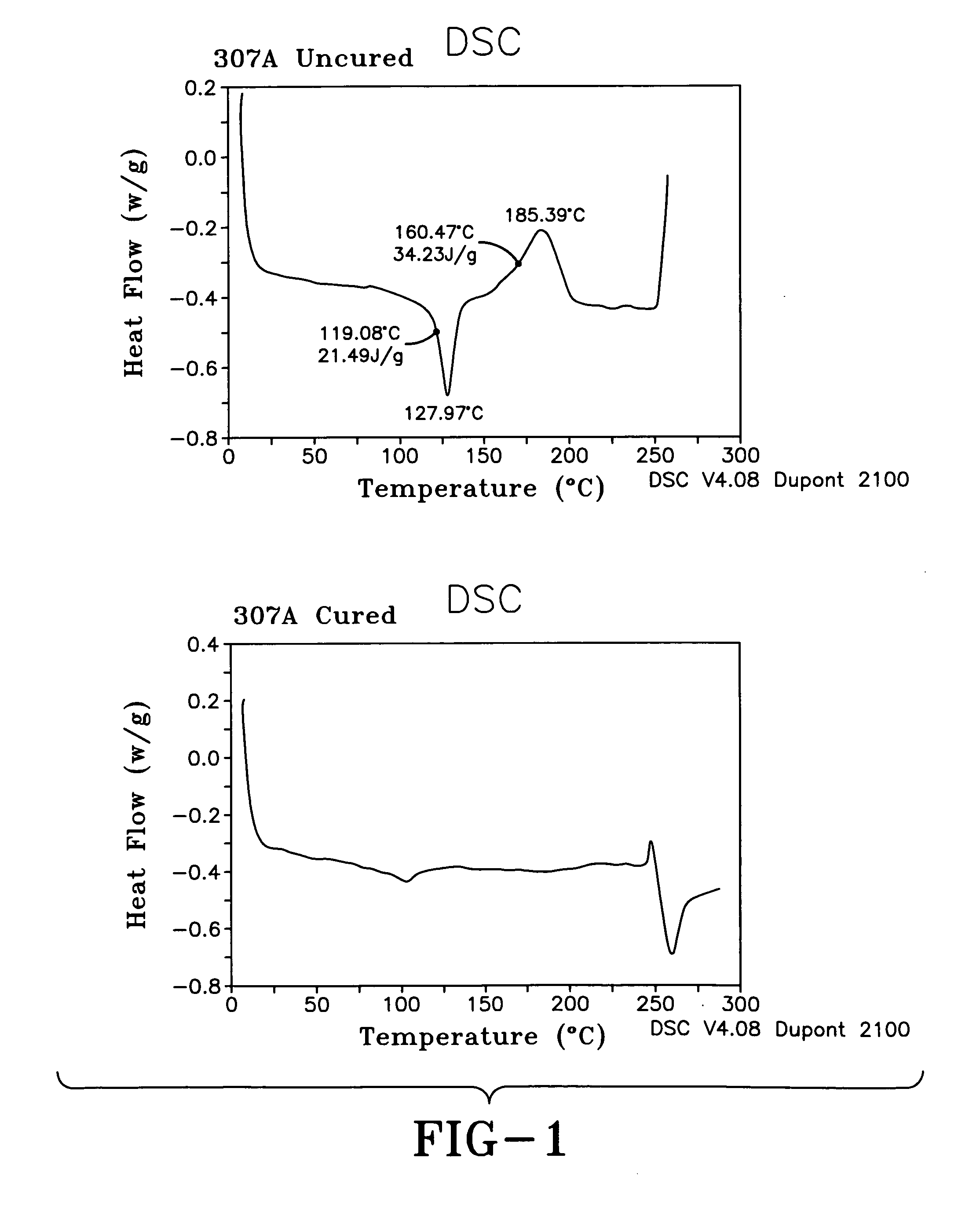

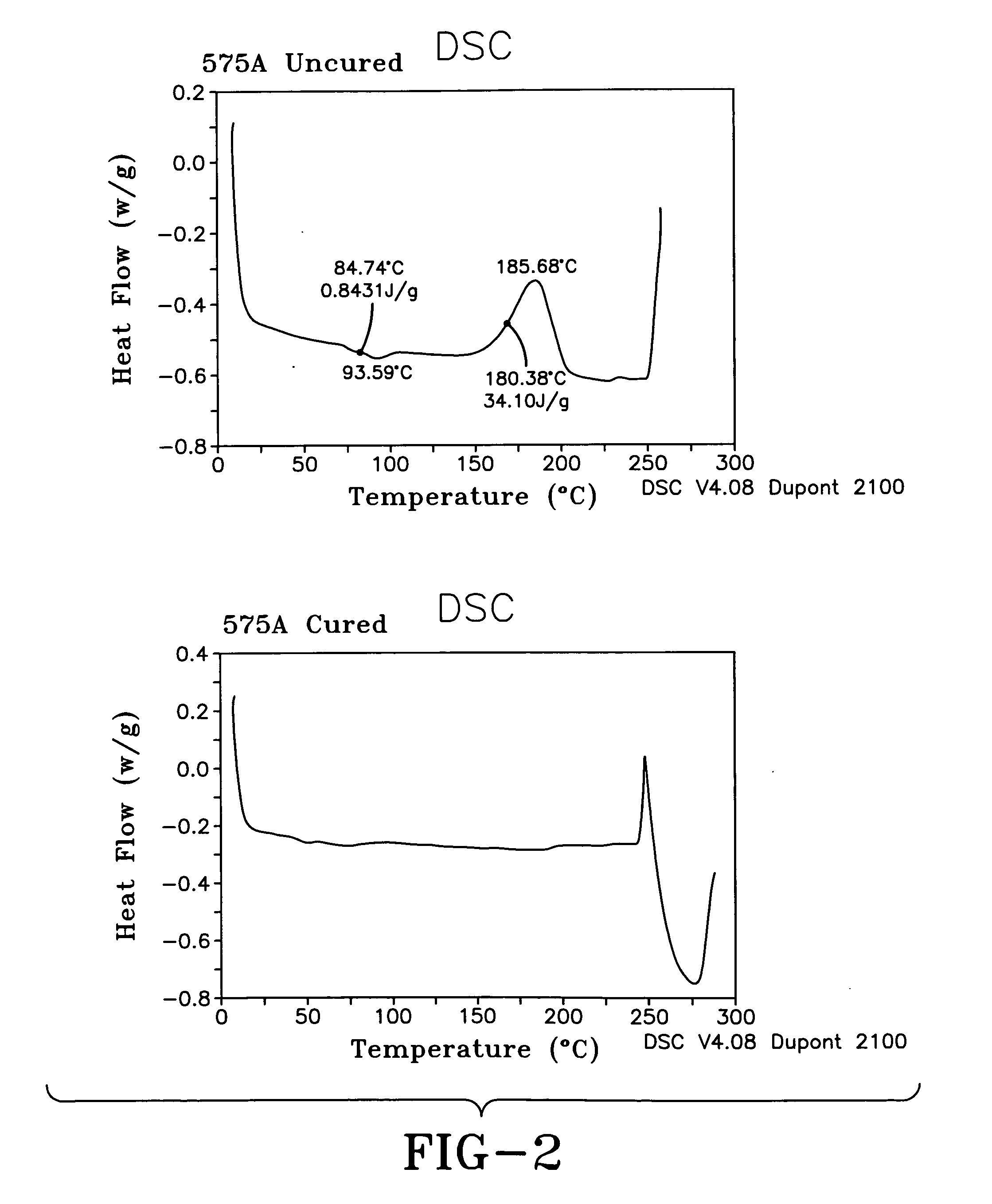

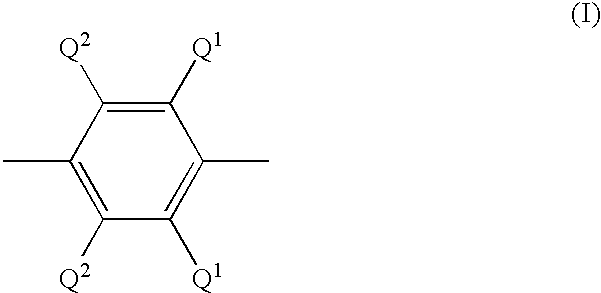

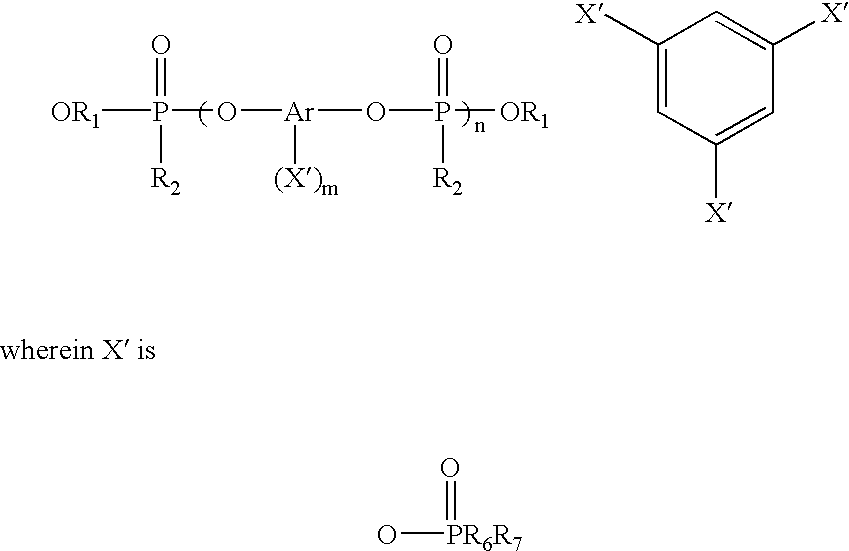

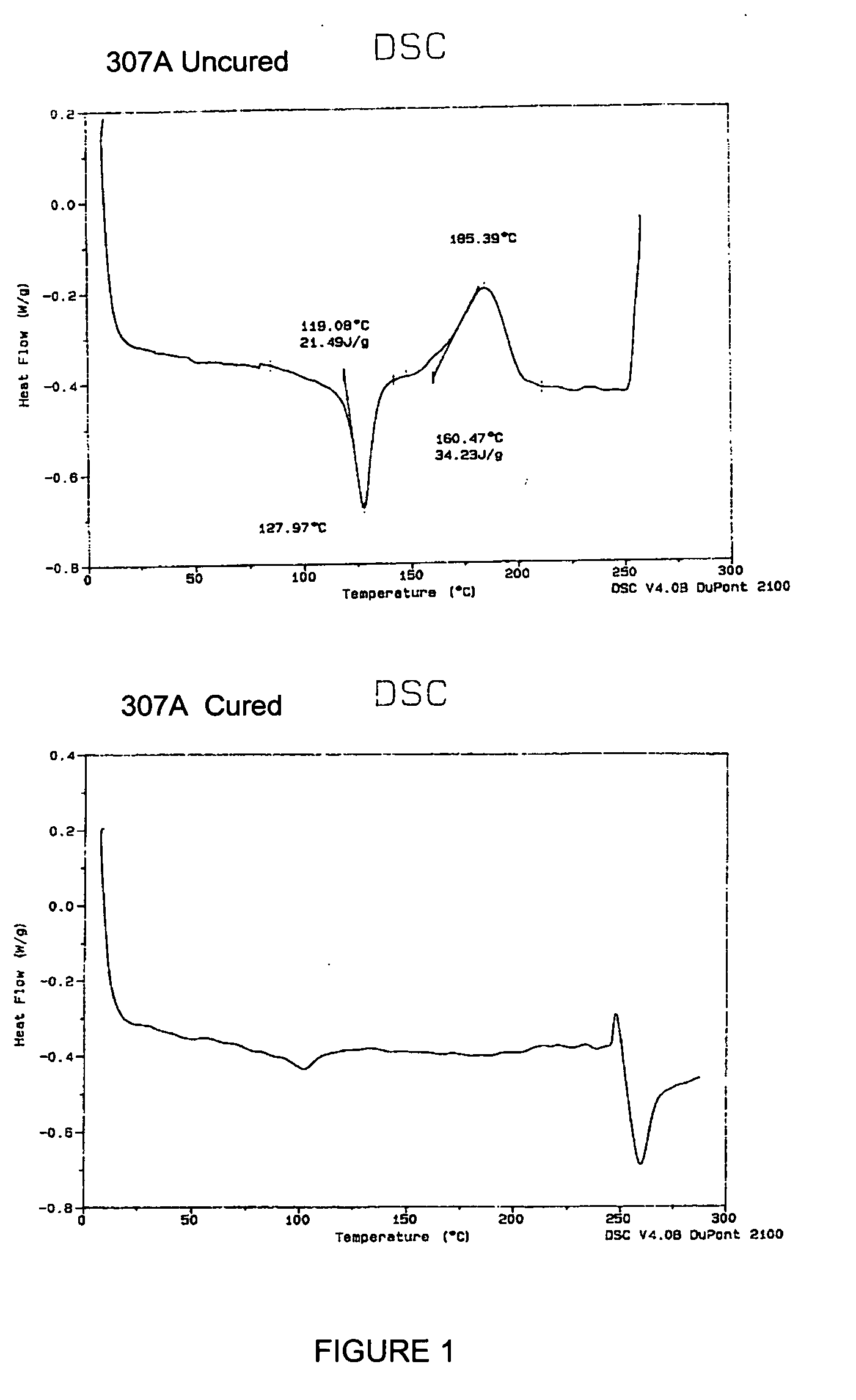

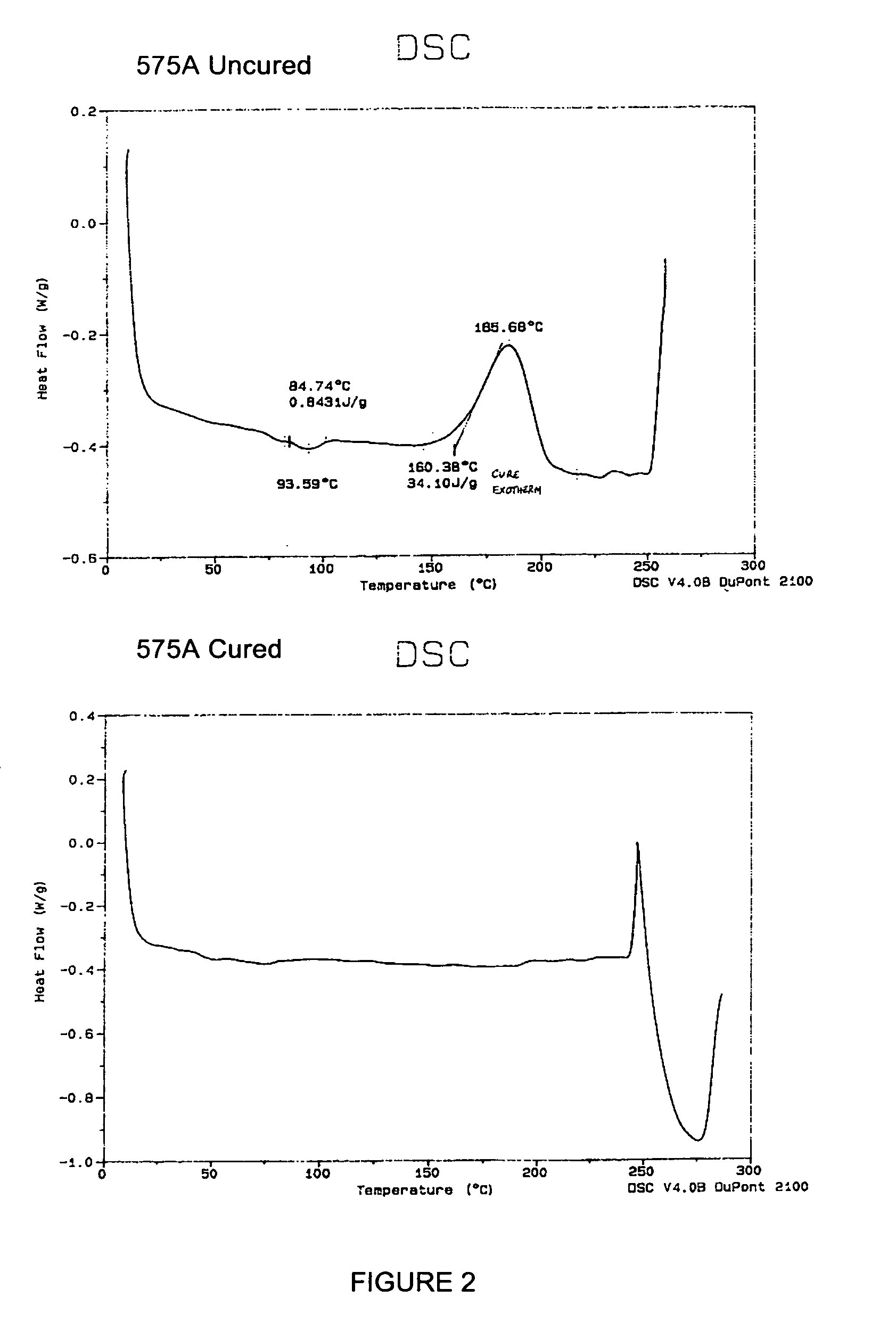

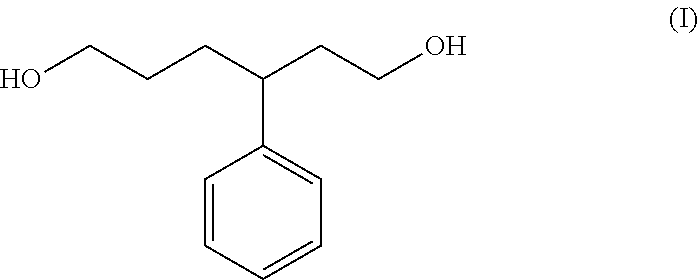

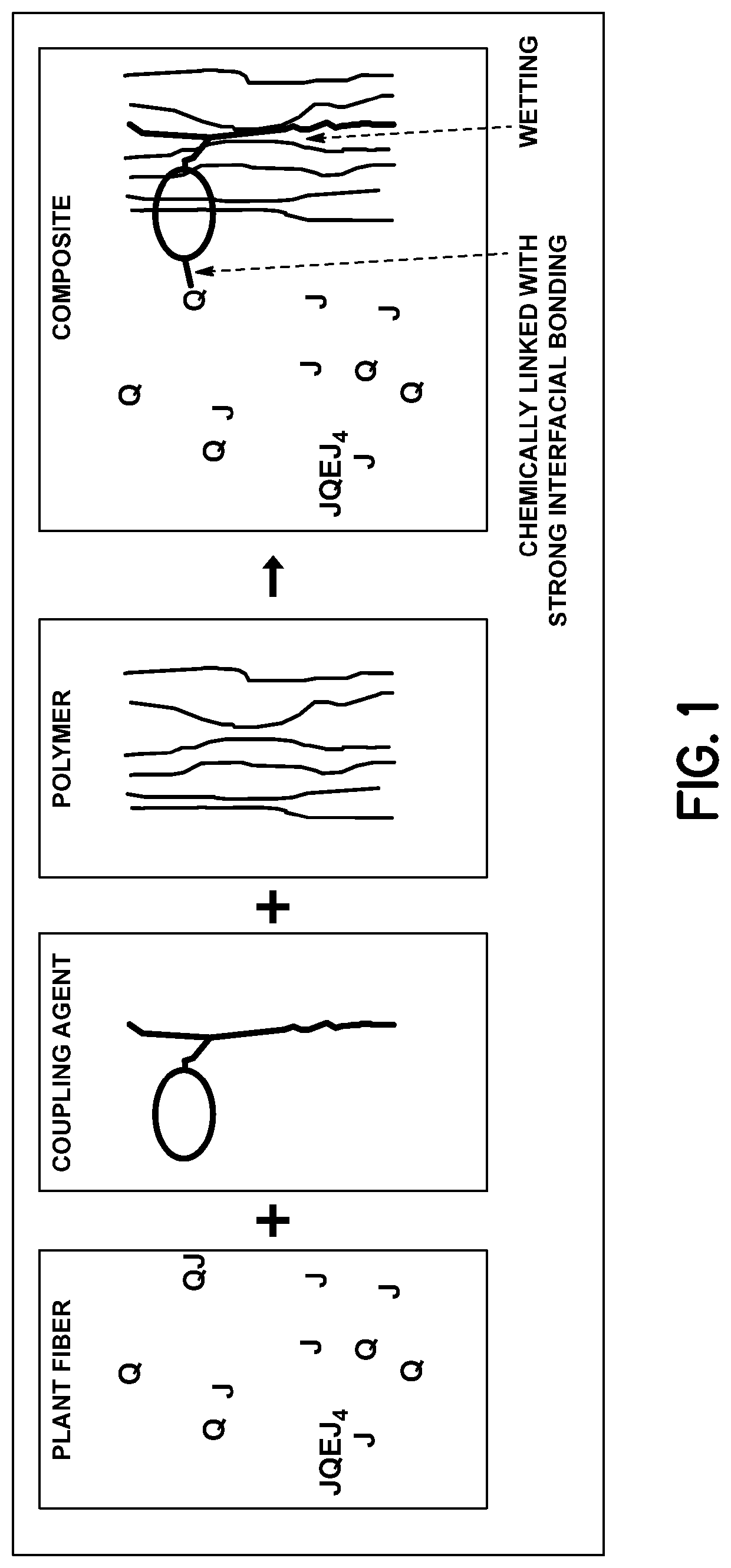

Pre-impregnated composite materials with improved performance

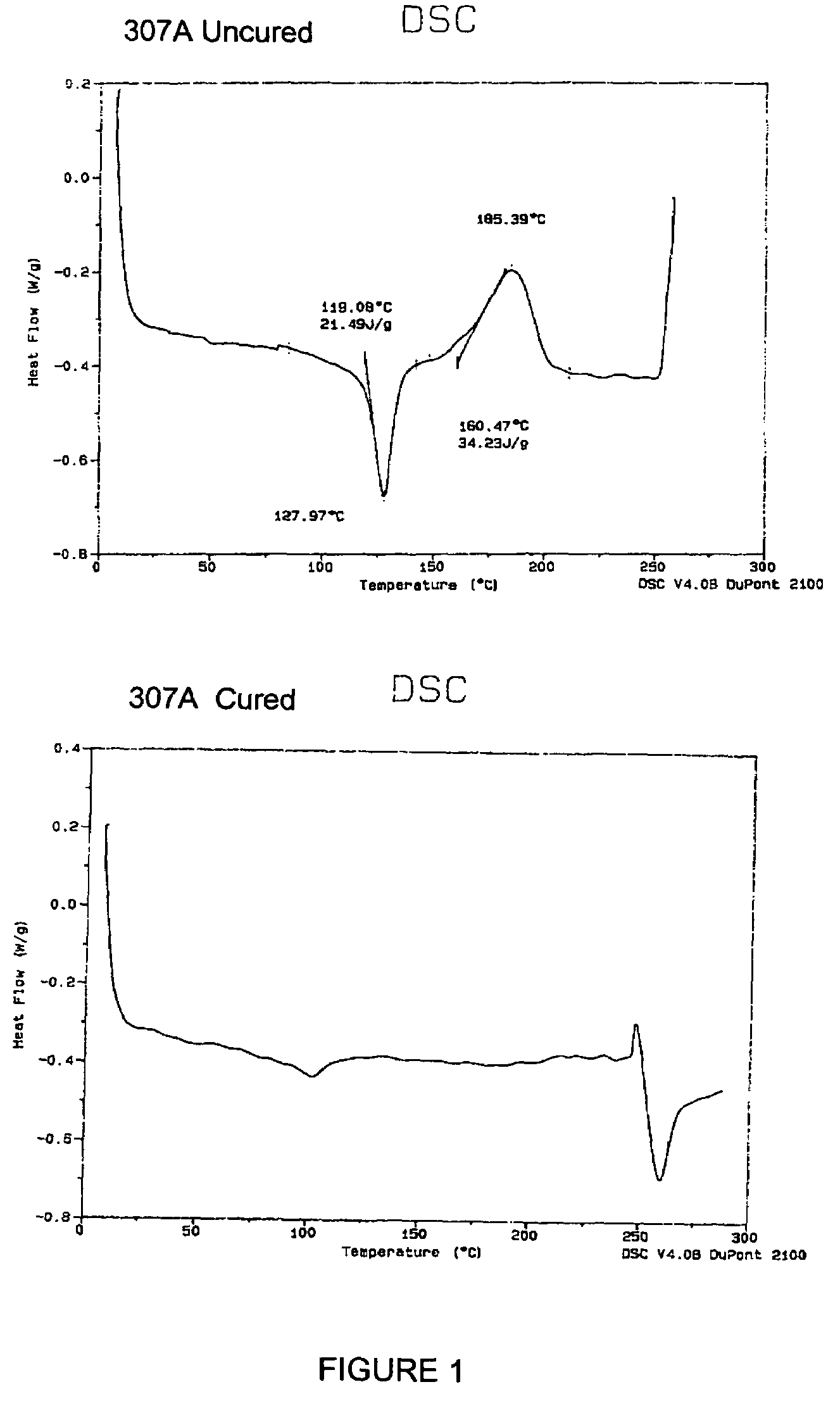

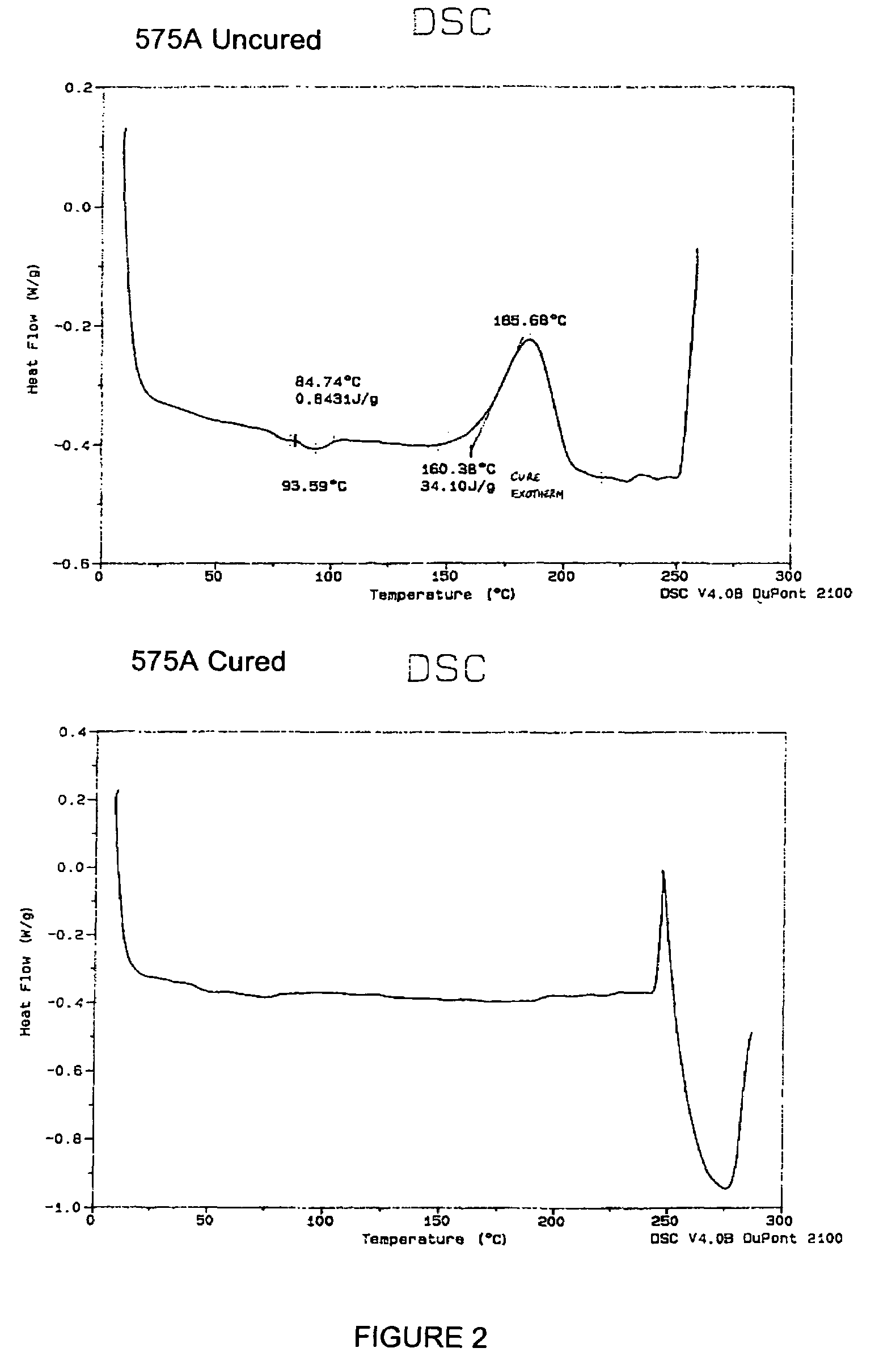

ActiveUS20080081170A1High of damageHigh of strengthSynthetic resin layered productsGlass/slag layered productsEpoxyShell molding

Pre-impregnated composite material (prepreg) is provided that can be molded to form composite parts that have high levels of both strength and damage tolerance without causing any substantial negative impact upon the physical or chemical characteristics of the uncured prepreg or cured part. This is achieved by including in the matrix resin a substantial amount of a multifunctional aromatic epoxy resin that has at least one phenyl group that is meta-substituted.

Owner:HEXCEL +1

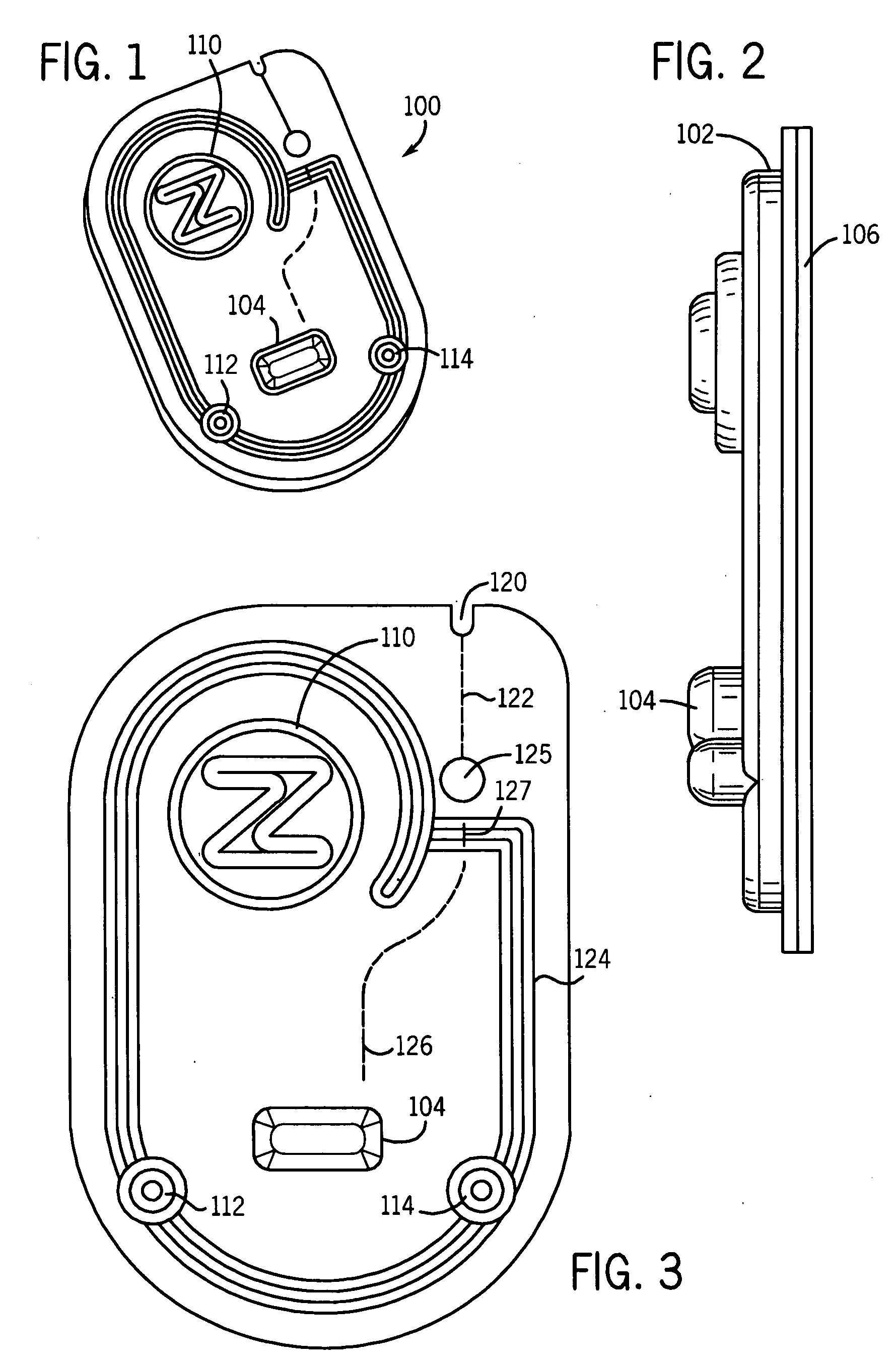

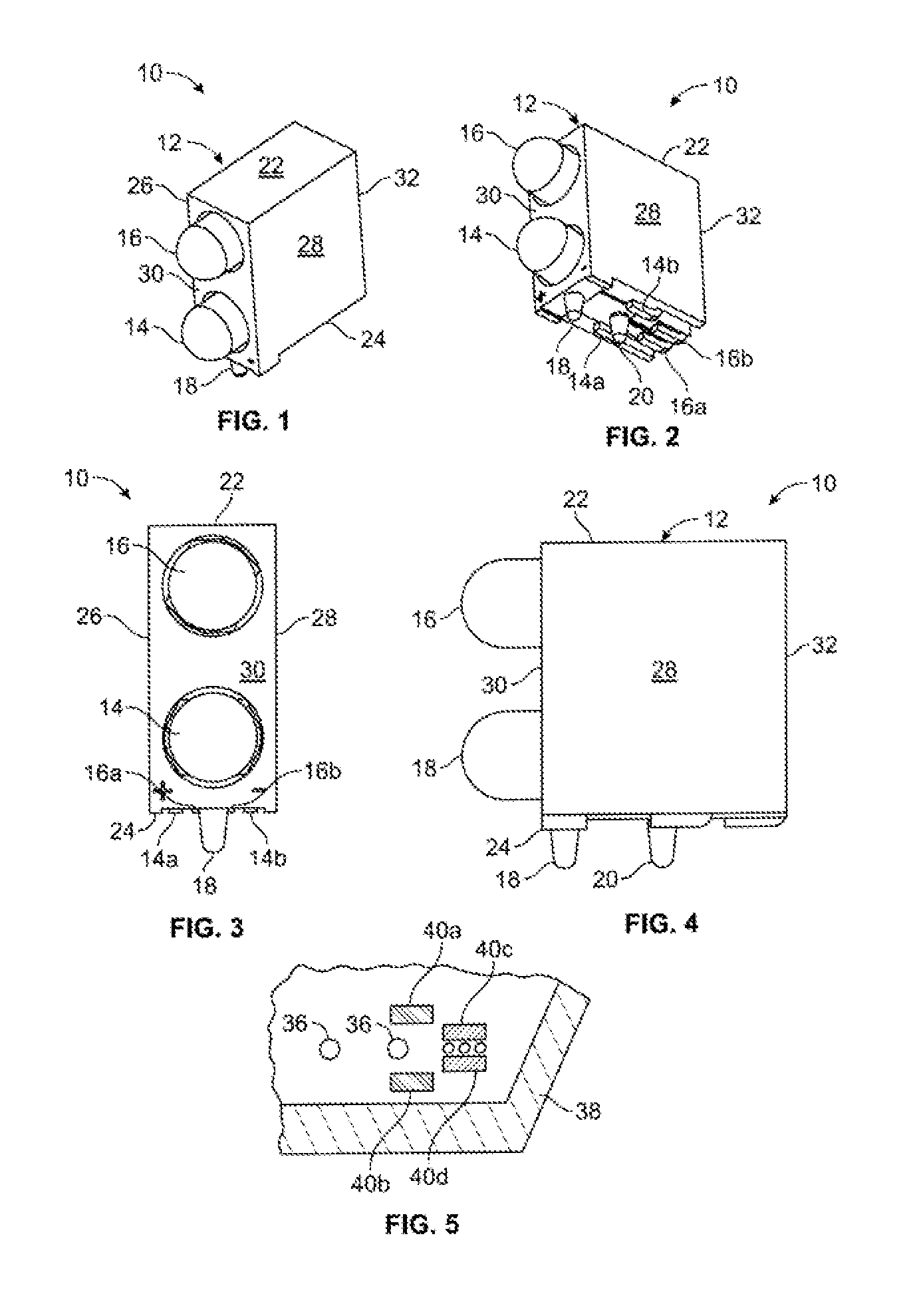

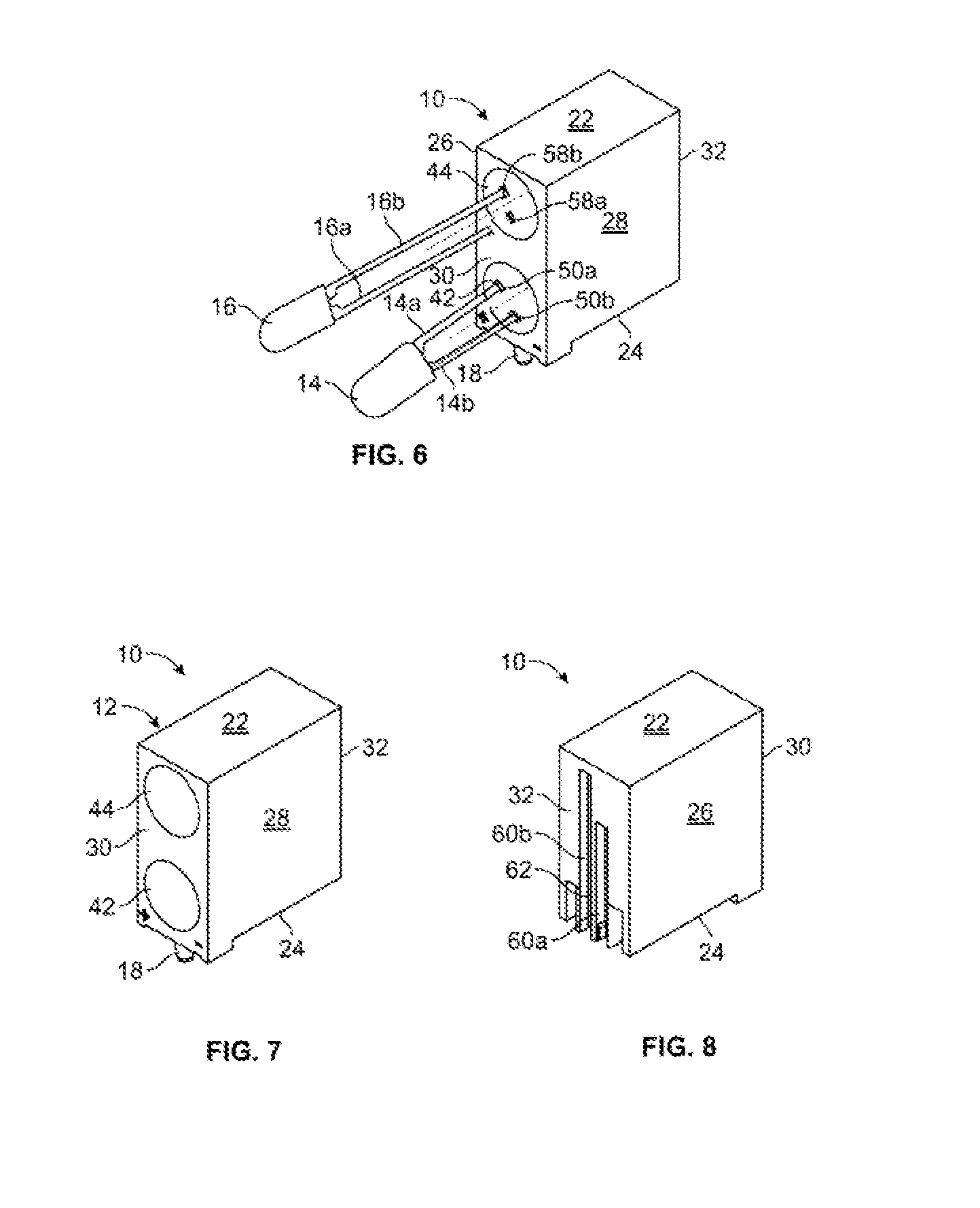

Blister package

ActiveUS20070284279A1Improve the level ofHigh degree of forceSmall article dispensingOther accessoriesEngineeringBlister pack

A child-resistant multi-step tear-access blister package having at least one product well containing a product. The product is accessed by tearing the blister package from a peripheral edge toward the product well. A step in addition to tearing is required to access the product, thereby elevating the cognitive skill necessary to access the product above those of a typical small child. In the disclosed exemplary embodiment, the additional step involves weakening a tear-resistant channel blocking a tear path from the peripheral edge of the package to the product well. More particularly, initial tearing of the package toward the product well is interfered with by the presence of the tear-resistant channel interrupting the tear path. The tear-resistant channel may be bent or snapped to permit tearing therethrough and to permit continued tearing of the blister package toward the product well to access the product.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Planar coil element

ActiveUS8975997B2High strengthImprove permeabilityTransformers/inductances coils/windings/connectionsInorganic material magnetismUltimate tensile strengthMetal

In a planar coil element, the quantitative ratio of inclined particles to total particles of a first metal magnetic powder contained in a metal magnetic powder-containing resin provided in a through hole of a coil unit is higher than the quantitative ratio of inclined particles to total particles of the first metal magnetic powder contained in the metal magnetic powder-containing resin provided in other than the through hole, and many of particles of the first metal magnetic powder in the magnetic core are inclined particles whose major axes are inclined with respect to the thickness direction and the planar direction of a substrate. Therefore, the planar coil element has improved strength as compared to a planar coil element shown in FIG. 9A and has improved magnetic permeability as compared to a planar coil element shown in FIG. 9B.

Owner:TDK CORPARATION

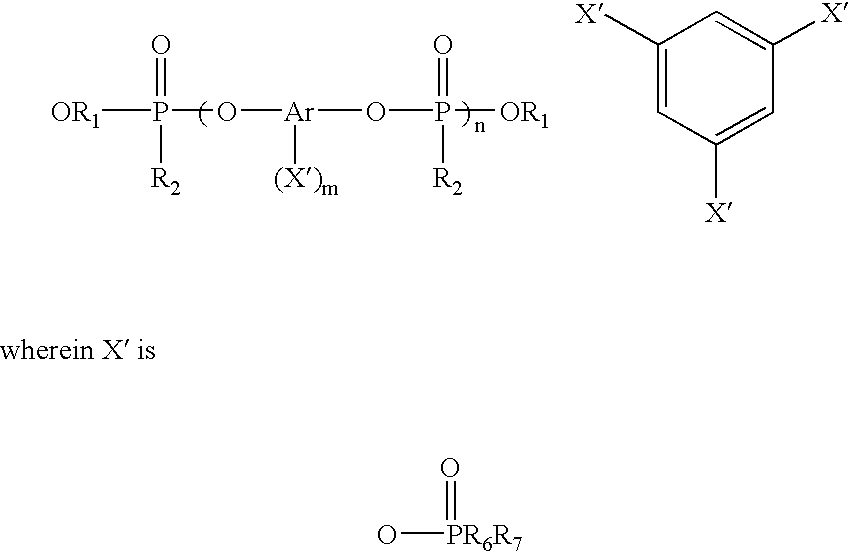

High flow polyphenylene ether formulations with dendritic polymers

High flow polyphenylene ether formulations are obtained with the addition of dendritic polymers. High flow is also obtained with the addition of dendritic polymers to flame retardant polyphenylene ether formulations.

Owner:SABIC INNOVATIVE PLASTICS IP BV

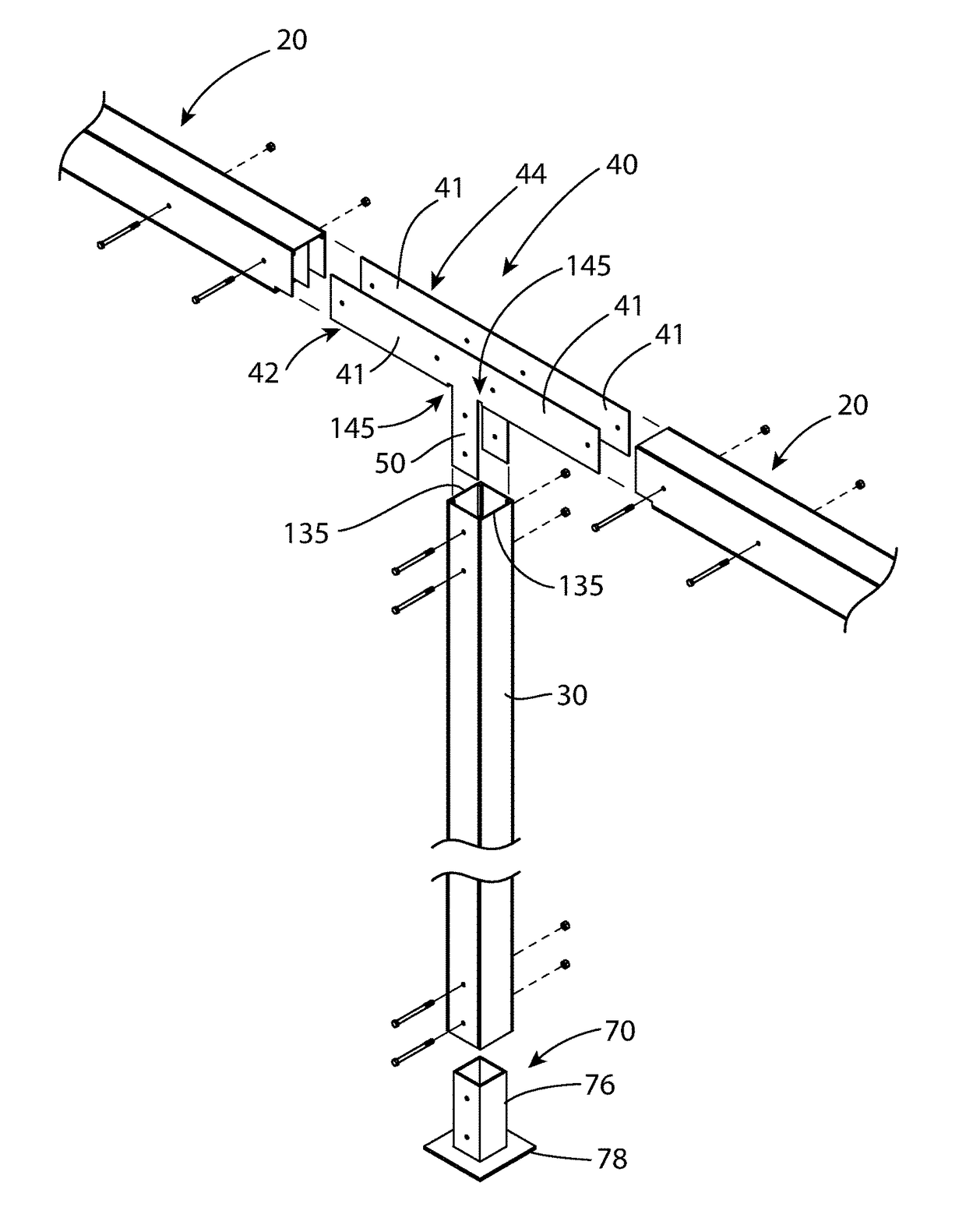

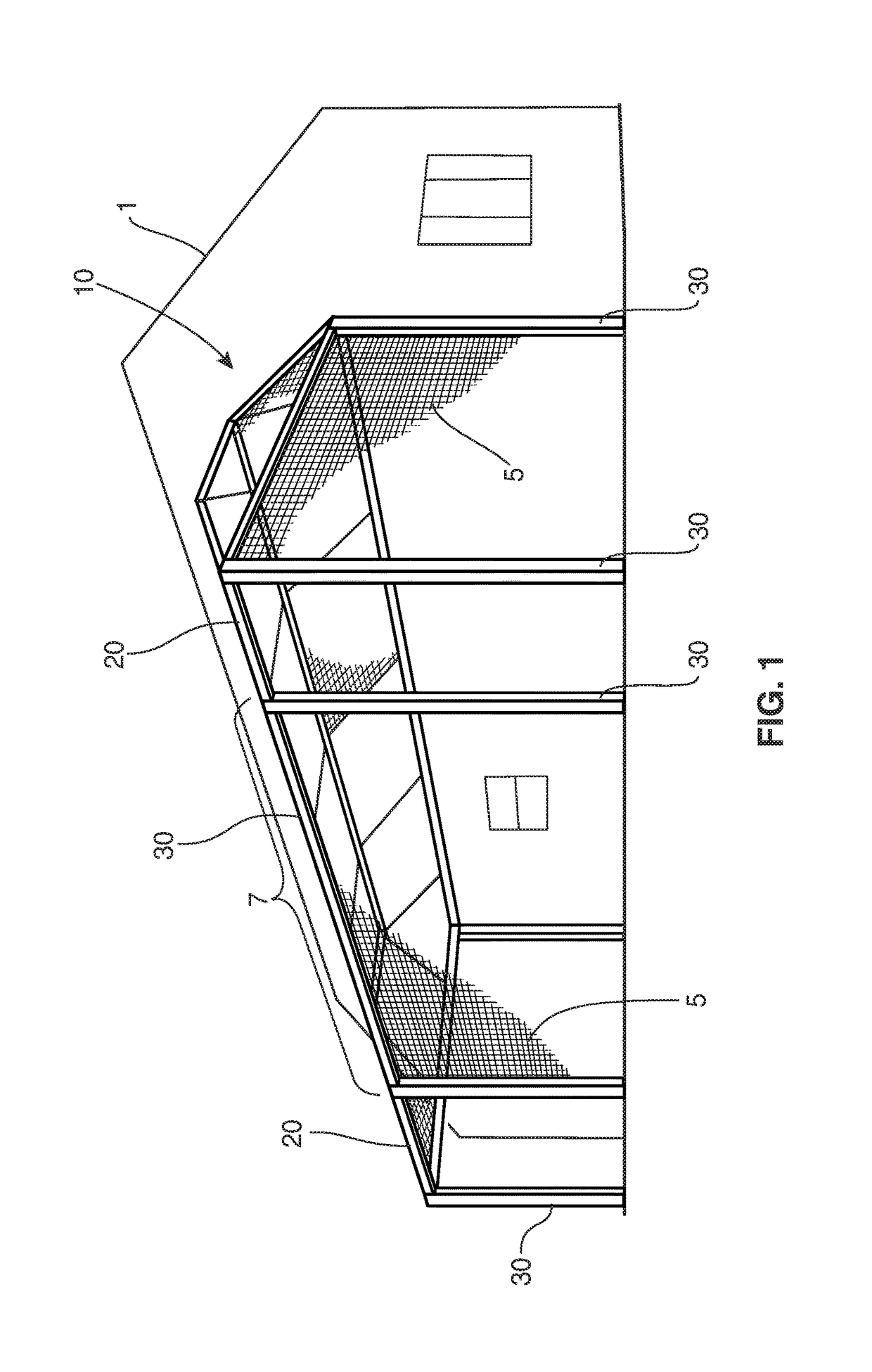

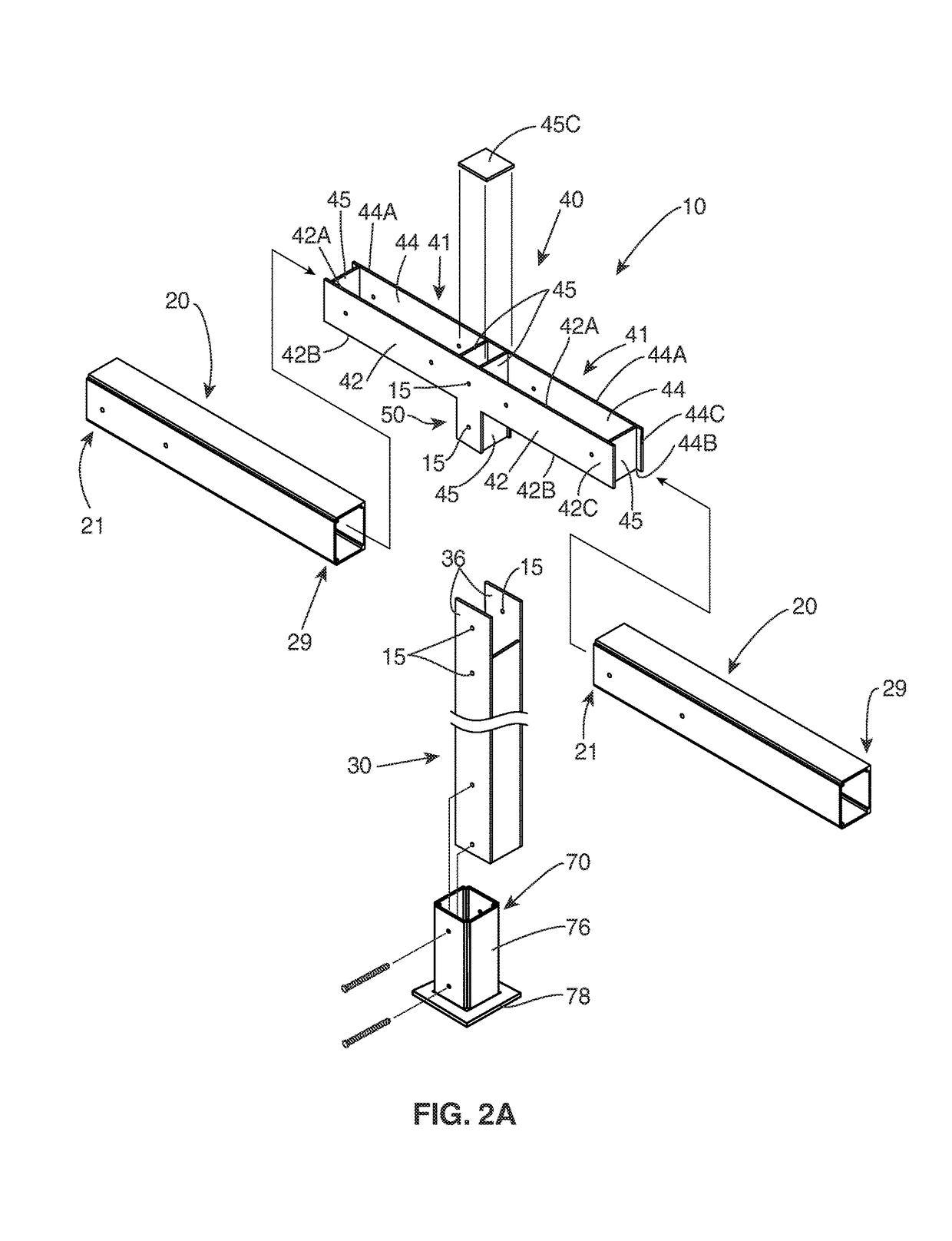

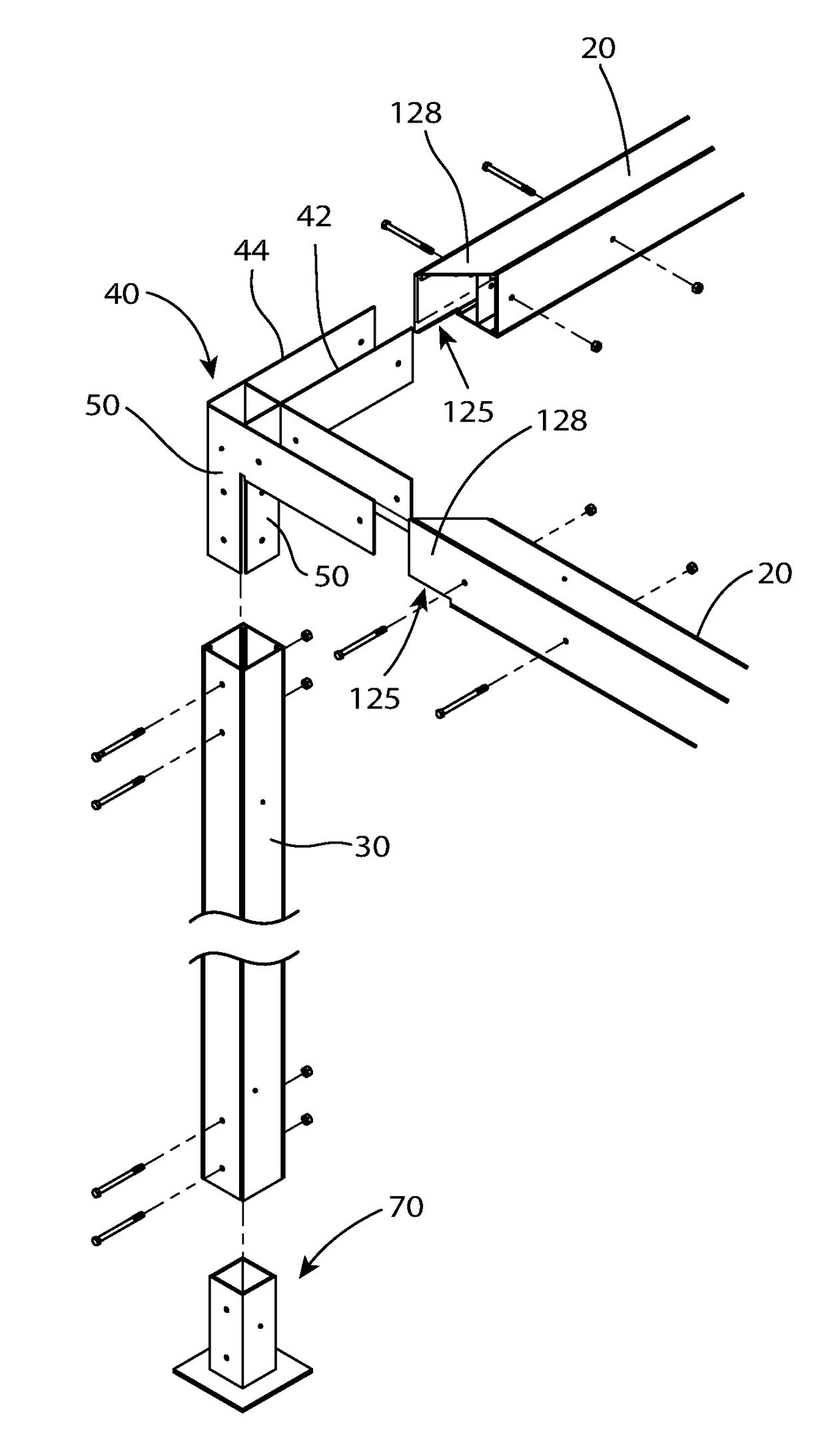

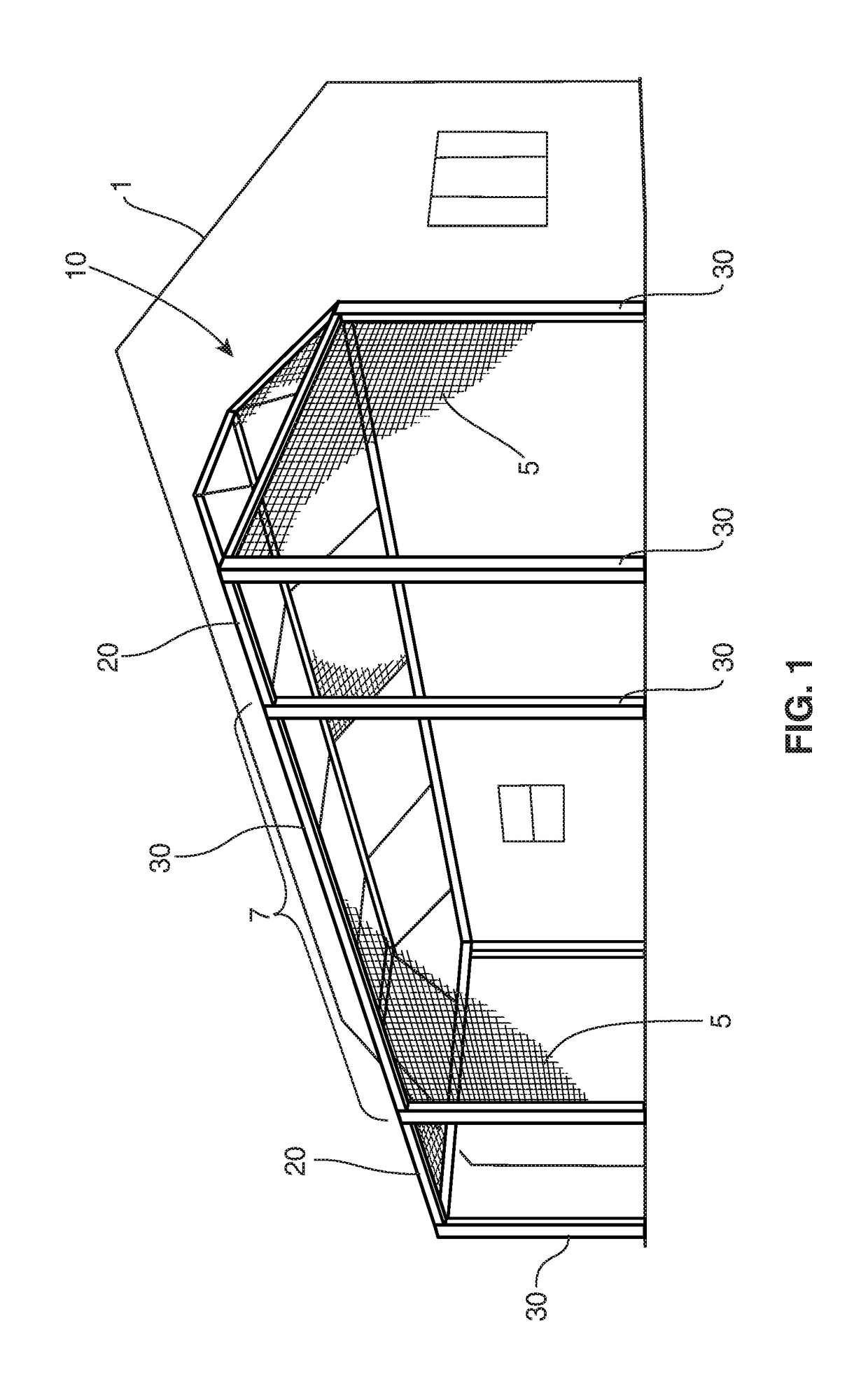

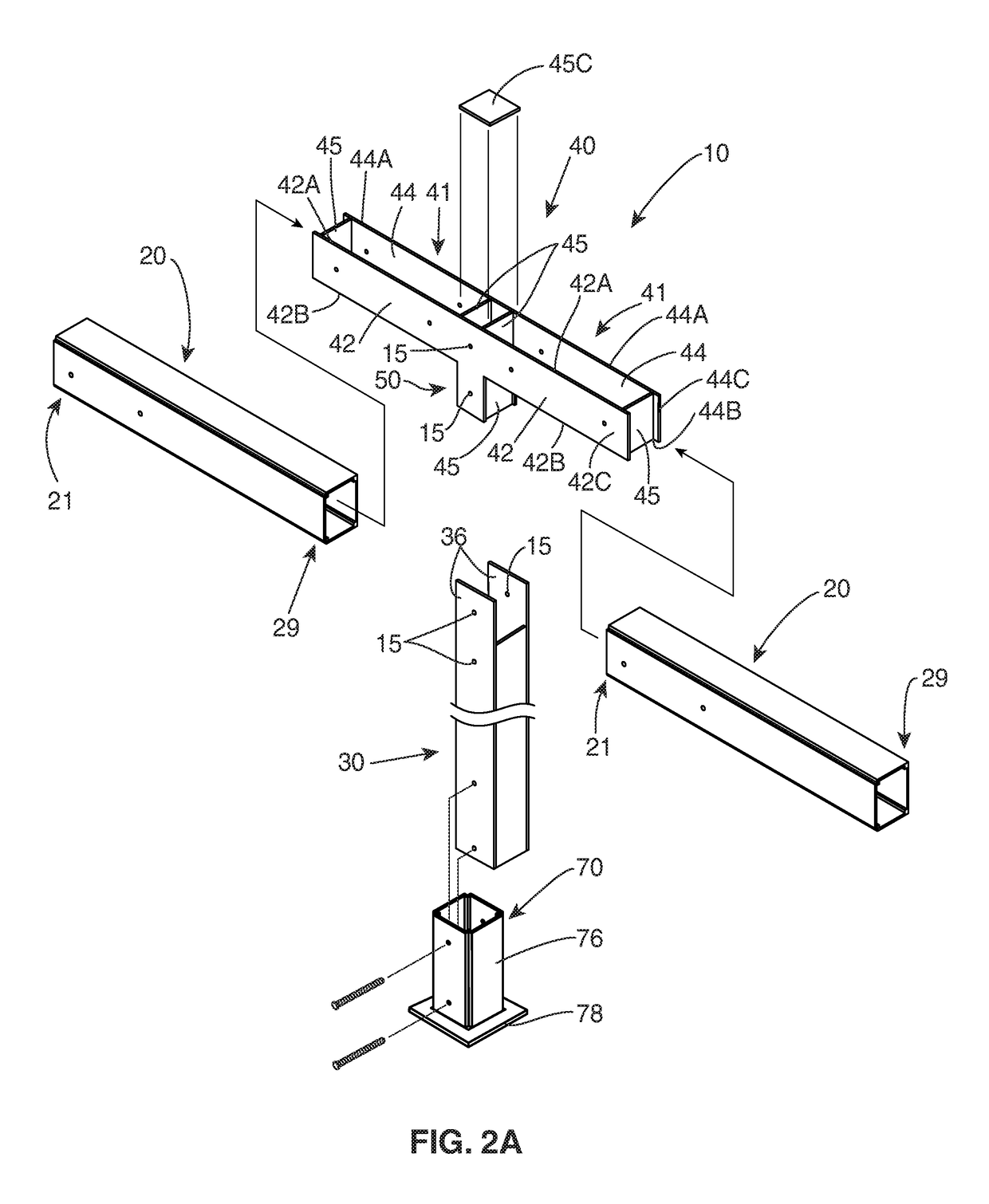

Screen support assembly with wide lateral support efficiency

ActiveUS9605425B1Improve integrityOpen spaceInsect protectionTowersEngineeringUltimate tensile strength

A support assembly for providing a high degree of lateral strength and integrity is presented herein. The support assembly includes a beam support bracket having at least one laterally disposed elongated portion that is slidingly engaged with a corresponding lateral beam. The elongated portion of the beam support bracket is defined by spaced apart first and second support plates each including oppositely disposed edges which will mate with corresponding ledges, protrusion or reinforced corners within the lateral beam.

Owner:HENDRY THOMAS G

Power transmission products having enhanced properties

ActiveUS20100190914A1Improved compositionImprove pillingV-beltsRopes and cables for vehicles/pulleyElastomerHardness

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers, such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

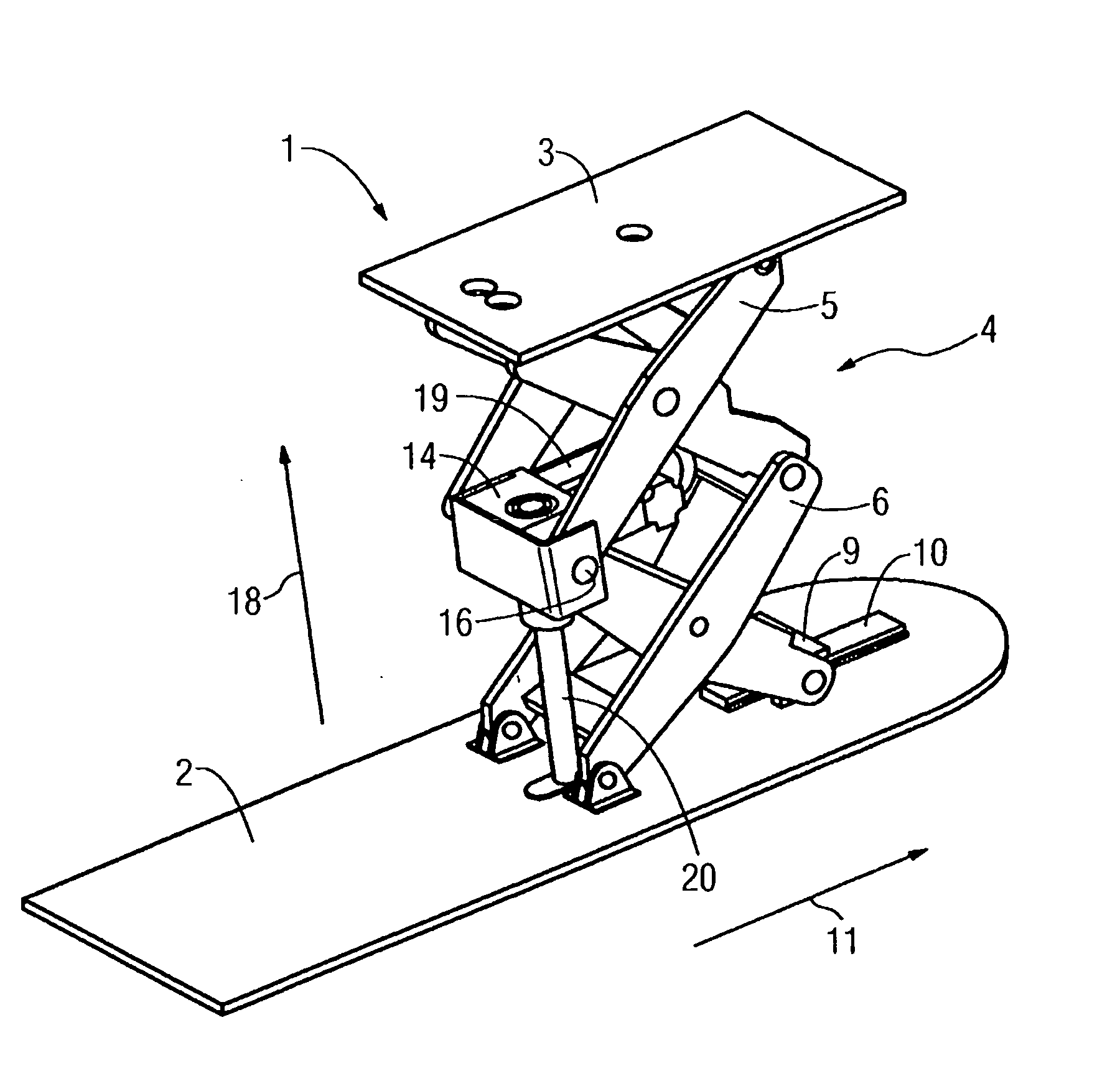

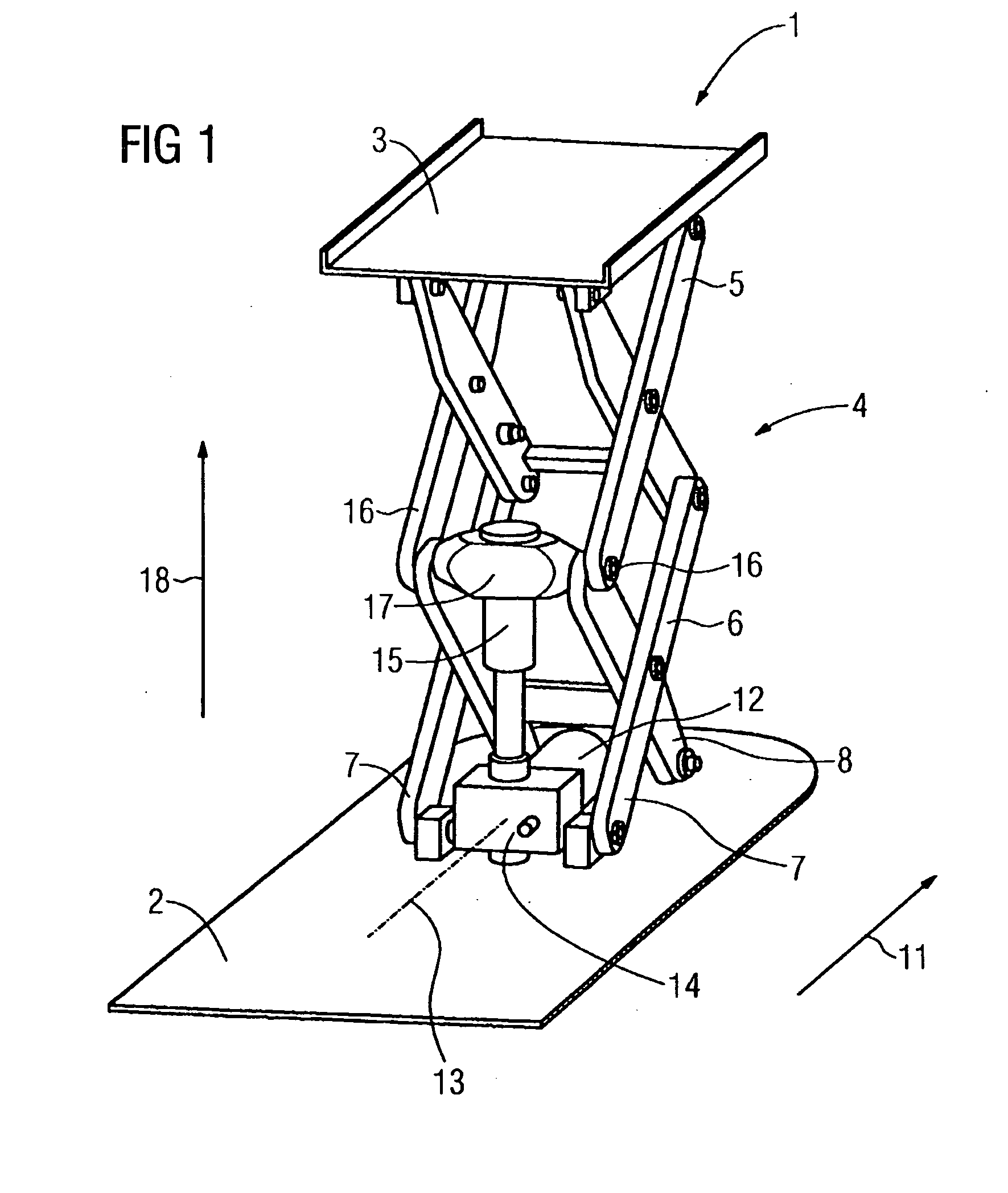

Lifting Device

InactiveUS20070221895A1Reduce maintenanceSave building spaceLifting framesIndustrial engineeringLinkage concept

Owner:SIEMENS AG

High flow polyphenylene ether formulations with dendritic polymers

High flow polyphenylene ether formulations are obtained with the addition of dendritic polymers. High flow is also obtained with the addition of dendritic polymers to flame retardant polyphenylene ether formulations.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Power transmission products having enhanced properties

ActiveUS20060148990A1Improved compositionImprove pillingV-beltsFilm/foil adhesivesElastomerAlpha-olefin

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers , such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

Screen support assembly with wide lateral support efficiency

InactiveUS10066384B1Improve integrityHigh of strengthInsect protectionTowersClassical mechanicsEngineering

A support assembly for providing a high degree of lateral strength and integrity is presented herein. The support assembly includes a beam support bracket having at least one laterally disposed elongated portion that is slidingly engaged with a corresponding lateral beam. The elongated portion of the beam support bracket is defined by spaced apart first and second support plates each including oppositely disposed edges which will mate with corresponding ledges, protrusion or reinforced corners within the lateral beam.

Owner:HENDRY THOMAS G

TiAl-BASED ALLOY, PROCESS FOR PRODUCING SAME, AND ROTOR BLADE USING SAME

InactiveUS20100316525A1Improve high temperature strengthImprove oxidation resistanceEngine manufactureMetal-working apparatusAlloyImpurity

A hot-forged TiAl-based alloy having excellent oxidation resistance and high strength at high temperatures, and a process for producing such an alloy. A TiAl-based alloy comprising Al: (40+a) atomic % and Nb: b atomic %, with the remainder being Ti and unavoidable impurities, wherein a and b satisfy formulas (1) and (2) below.0≦a≦2 (1)3+a≦b≦7+a (2)Also, a TiAl-based alloy comprising Al: (40+a) atomic % and Nb: b atomic %, and further comprising one or more elements selected from the group consisting of V: c atomic %, Cr: d atomic % and Mo: e atomic %, with the remainder being Ti and unavoidable impurities, wherein a to e satisfy formulas (3) to (9) shown below.0≦a≦2 (3)3+a≦b+1.0c+1.8d+3.8e≦7+a (4)b≧2 (5)c≧0 (6)d≧0 (7)e≧0 (8)c+d+e>0 (9)

Owner:MITSUBISHI HEAVY IND LTD +1

Rubber Composition and Pneumatic Tire Using Same

ActiveUS20180298164A1Enhance wear resistanceExcellent rubber hardnessSpecial tyresButadiene-styrene rubberStyrene-butadiene

The present technology provides a rubber composition containing a diene rubber including a styrene-butadiene copolymer component including at least one type of styrene-butadiene copolymer and a reinforcing filler. The bonded styrene content is from 5 to 50 wt. %. The total amount of styrene of an ozone decomposed component S1 including one styrene-derived unit and an ozone decomposed component S1V1 including one styrene-derived unit and one 1,2-bonded butadiene-derived unit is less than 80 wt. % of the amount of bonded styrene. The total amount of styrene of the decomposed component S1V1 is not less than 10 wt. % of the amount of bonded styrene. The integrated intensity of an ozone decomposed component S1V2 including one styrene-derived unit and two 1,2-bonded butadiene-derived units is less than 15% of the integrated intensity of all decomposed components including styrene-derived units. The vinyl content of a butadiene portion is not less than 50%.

Owner:YOKOHAMA RUBBER CO LTD

Power transmission products having enhanced properties

ActiveUS7655729B2Low viscosityHigh hardnessV-beltsRopes and cables for vehicles/pulleyElastomerHardness

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers, such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

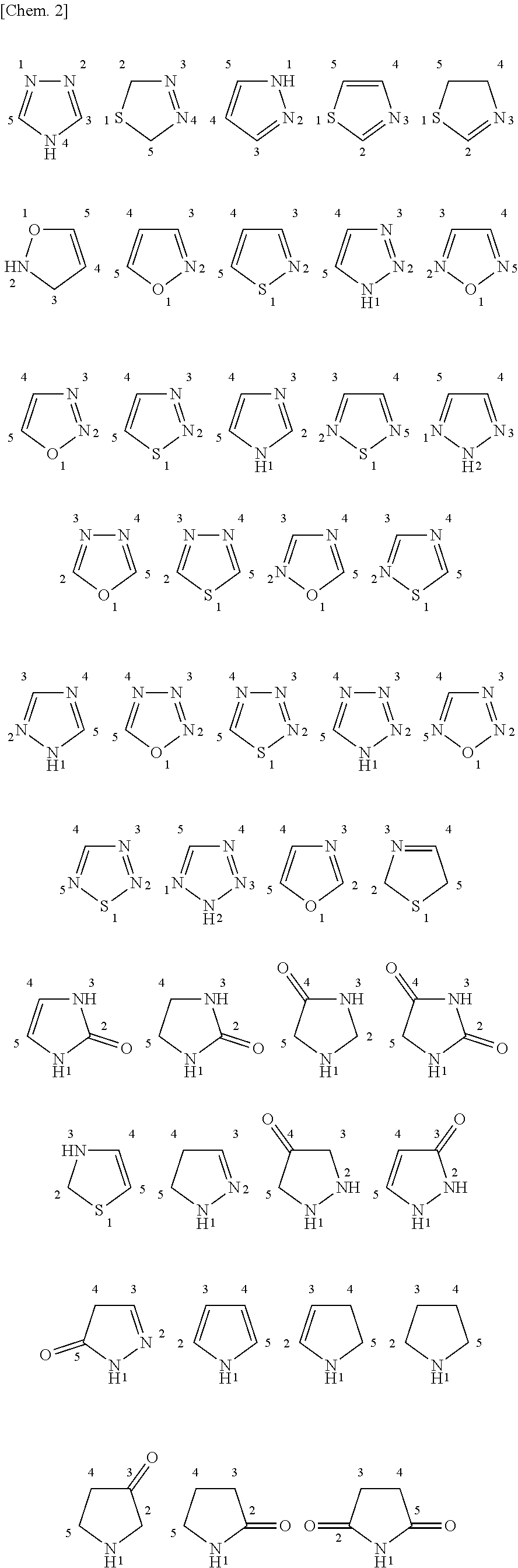

Thermoplastic elastomer composition and method for producing the same

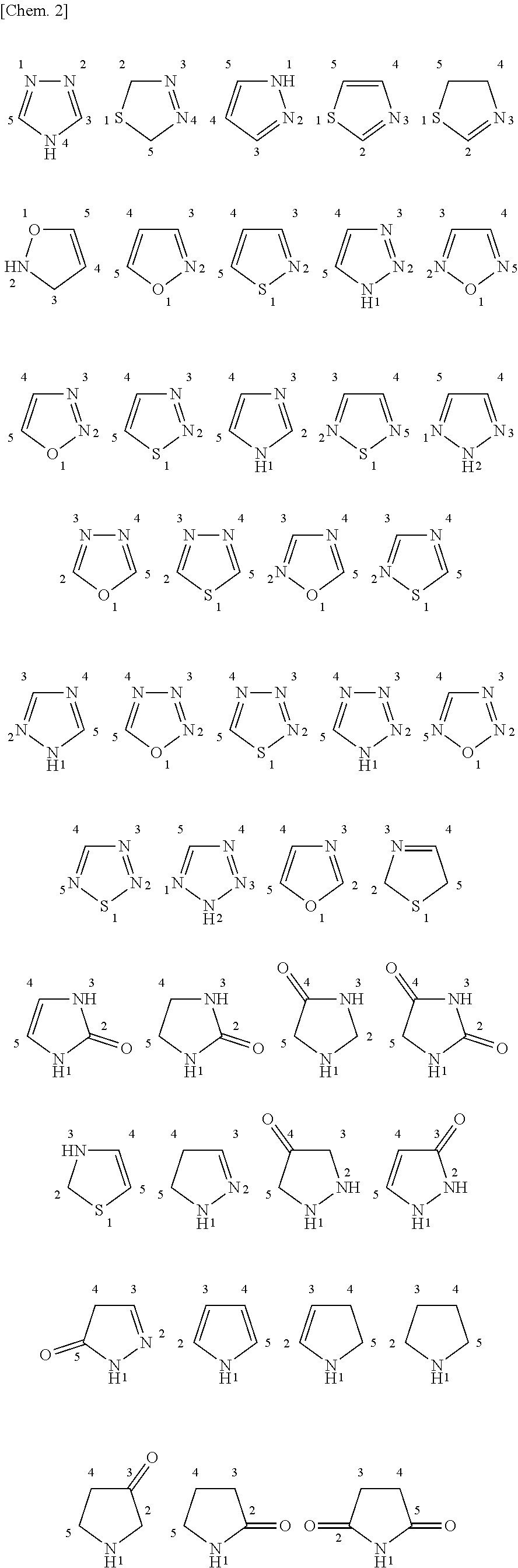

A thermoplastic elastomer composition includes: at least one elastomer component selected from the group consisting of elastomeric polymers each of which has a side chain containing a hydrogen-bond cross-linkable moiety having a carbonyl-containing group and / or a nitrogen-containing heterocycle and has a glass-transition point of 25° C. or below, and elastomeric polymers each of which contains a hydrogen-bond cross-linkable moiety and a covalent-bond cross-linking moiety in a side chain and has a glass-transition point of 25° C. or below; a clay, a content ratio of which is 20 parts by mass or less relative to 100 parts by mass of the elastomer component; and an α-olefin-based resin having no chemical-bond cross-linking moiety.

Owner:ENEOS CORP

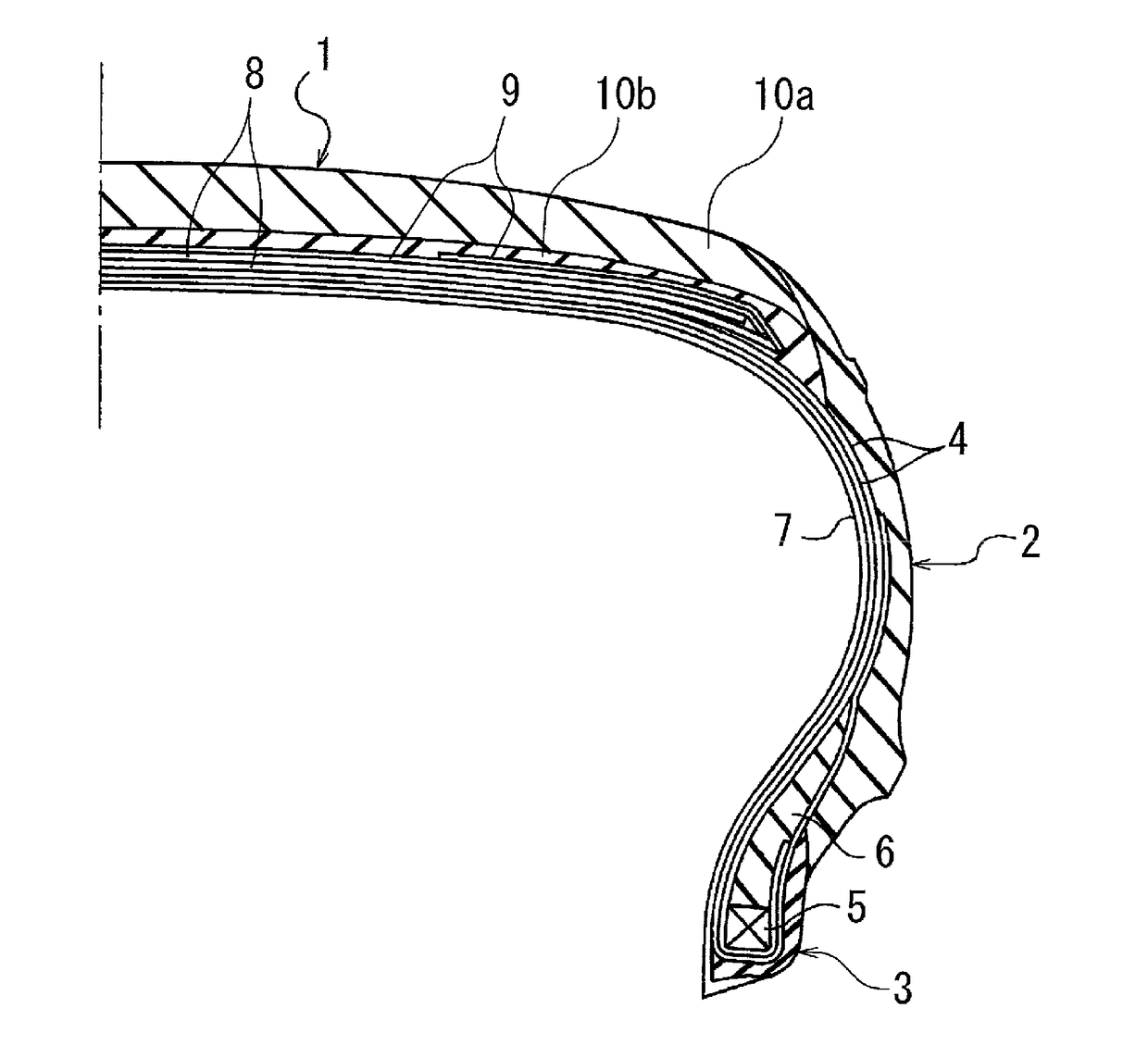

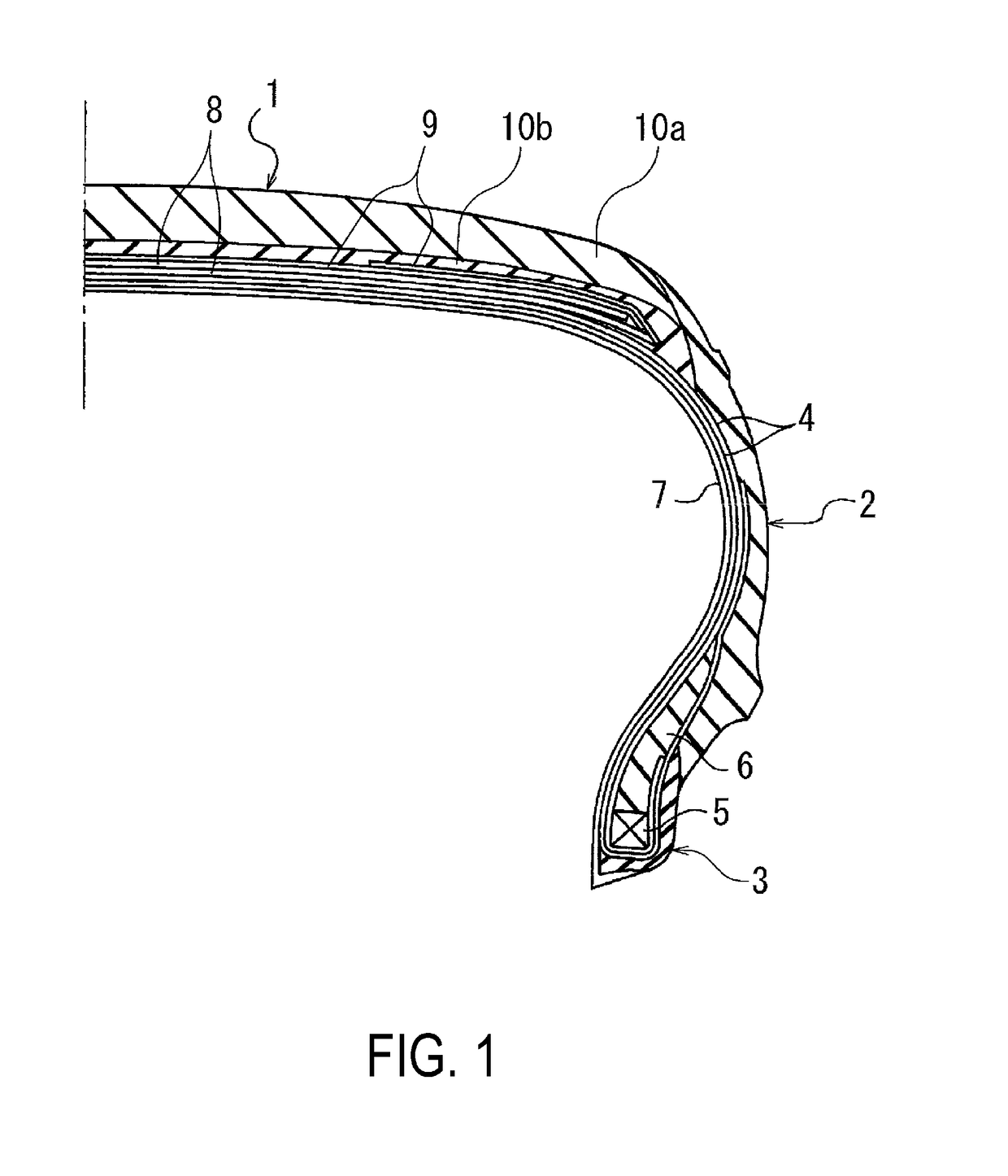

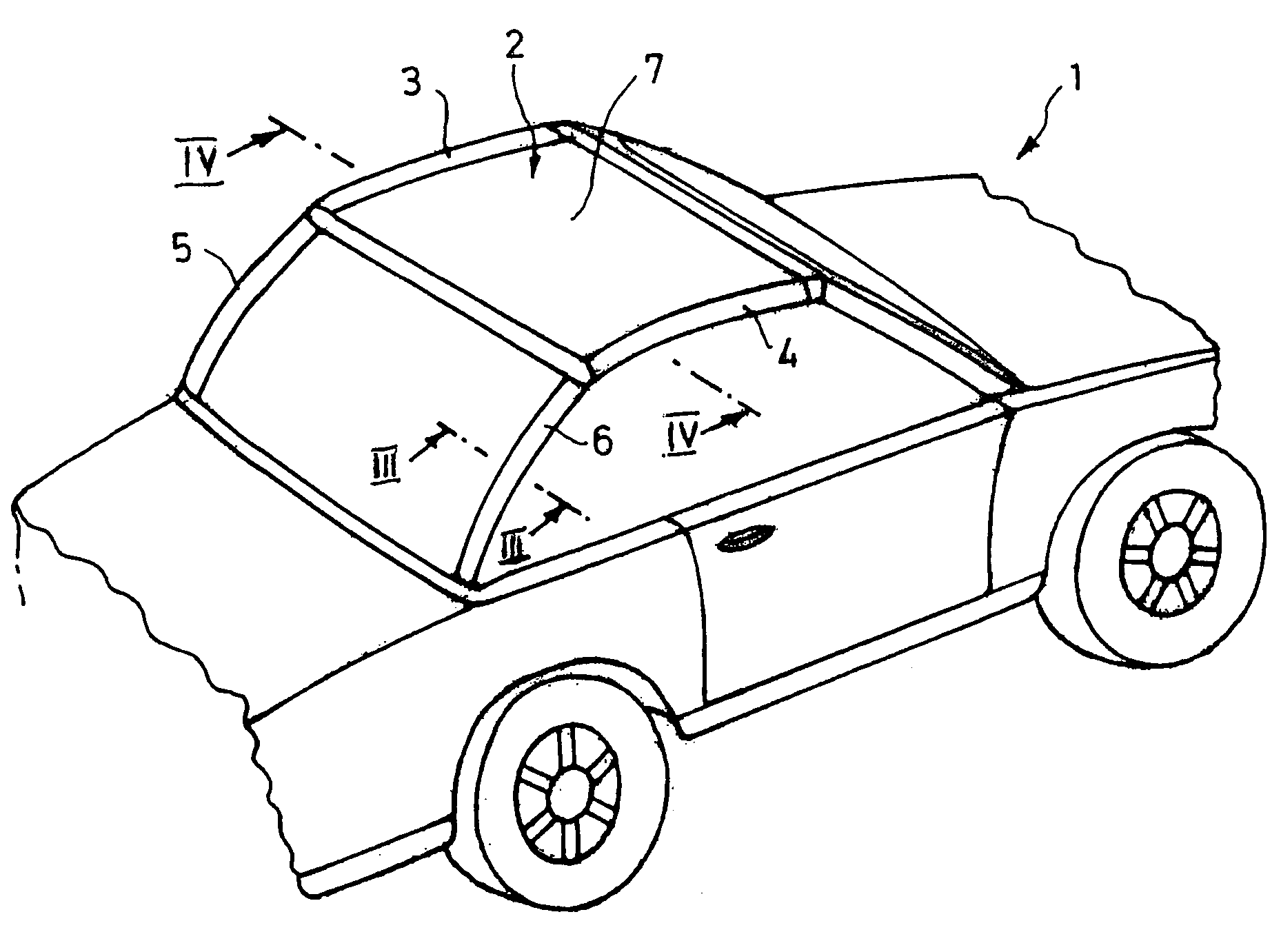

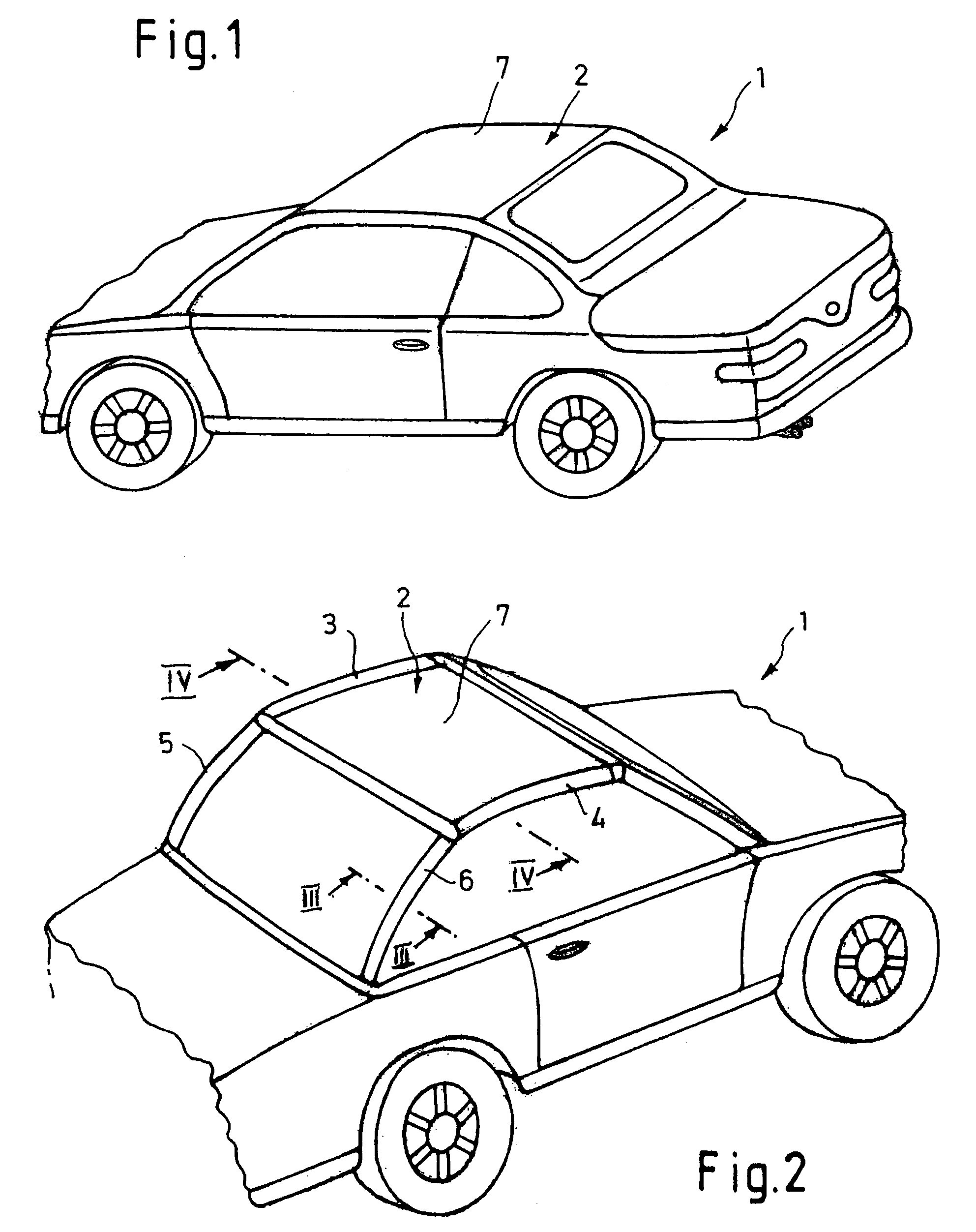

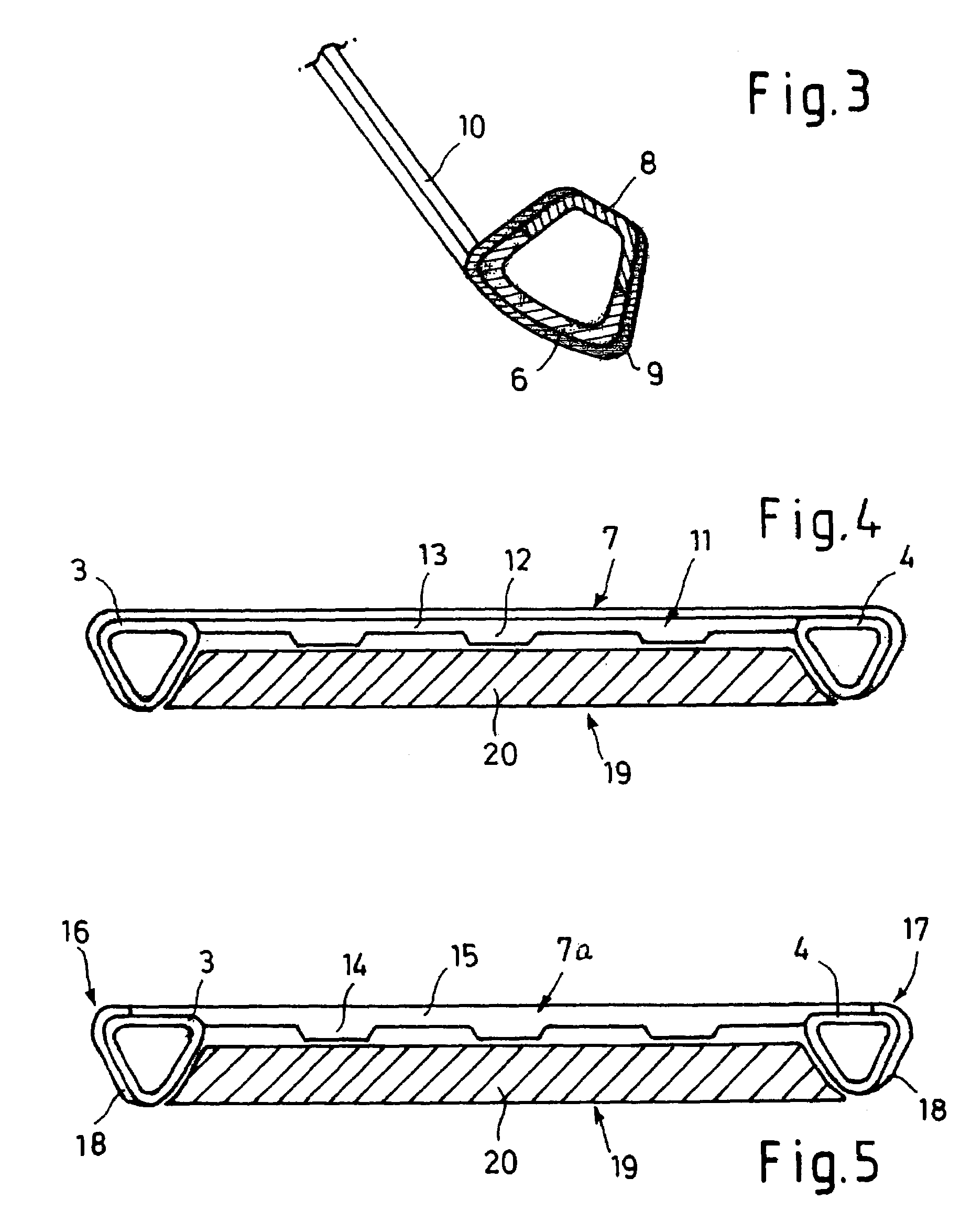

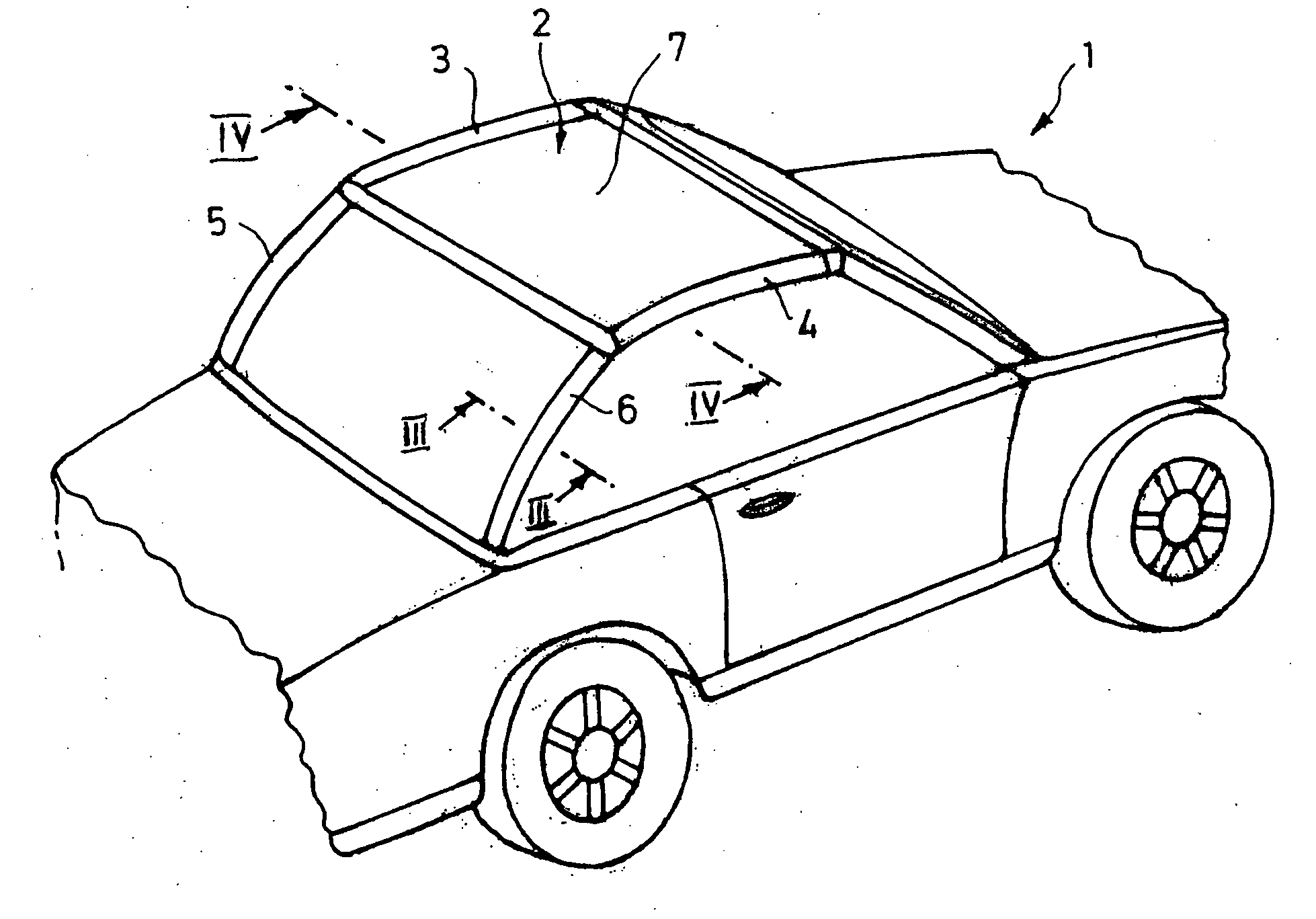

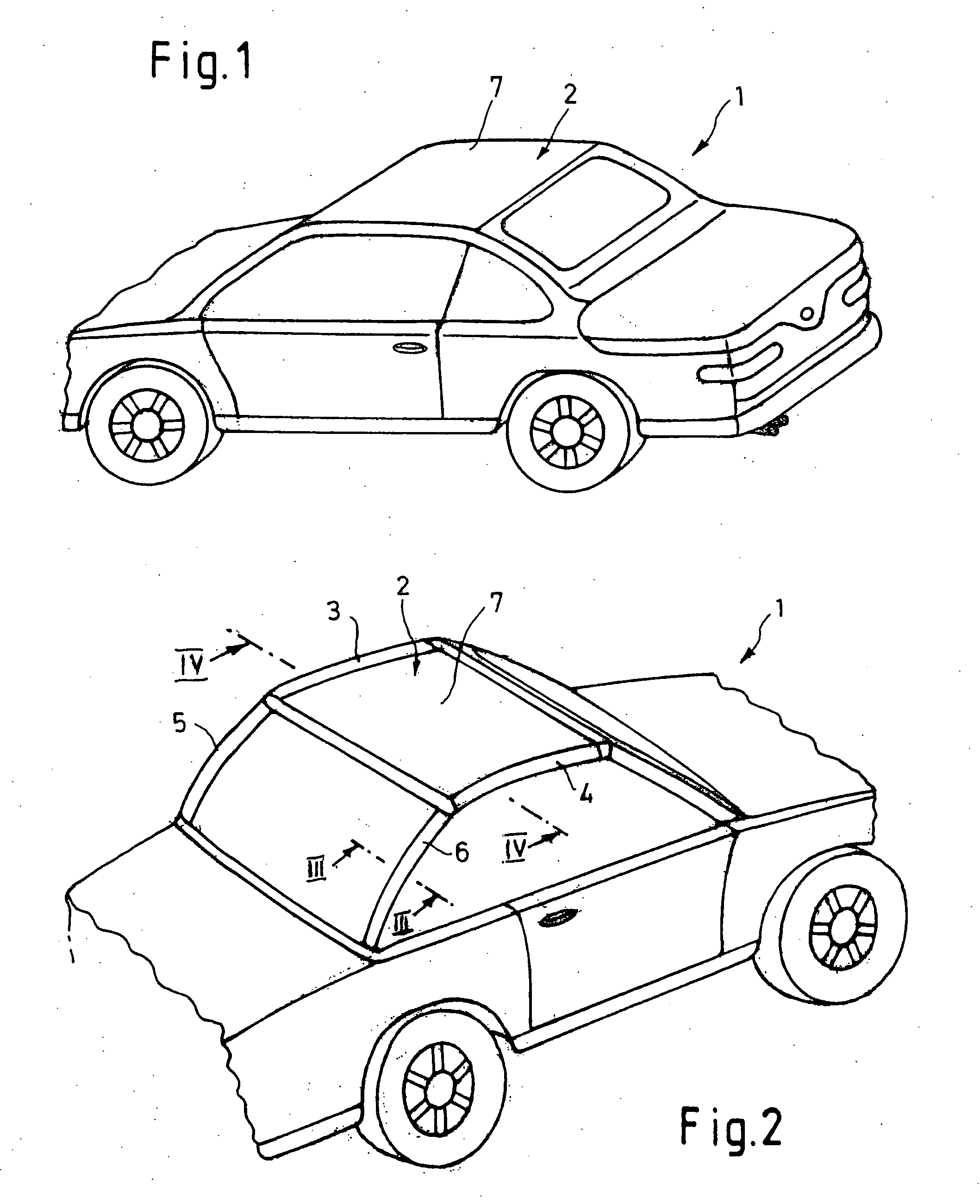

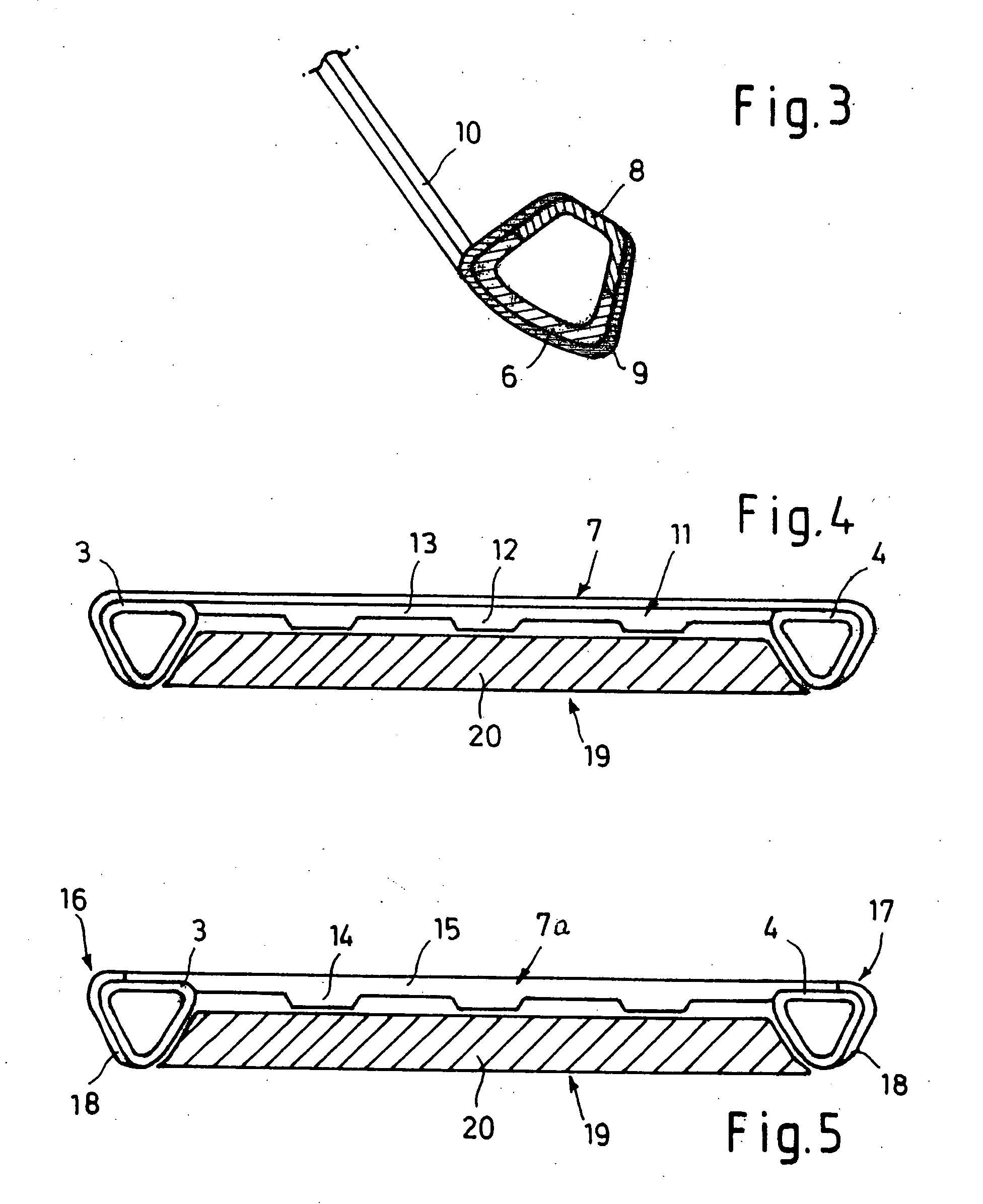

Folding top of a convertible automobile

InactiveUS7163254B2High degreeHigh of strengthEngine sealsVehicle sealing arrangementsEngineeringHigh intensity

A convertible includes a folding top having side beams, which are articulated to one another, and a roof structure, which is connected to the side beams and made at least partially of high-strength hot-formed steel material. Hereby the roof structure may include a roof member which is made of high strength hot formed steel material, or the roof structure may include a roof member and a reinforcement member which is made of high strength hot formed steel material and extends between the side beams, for support of the roof member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

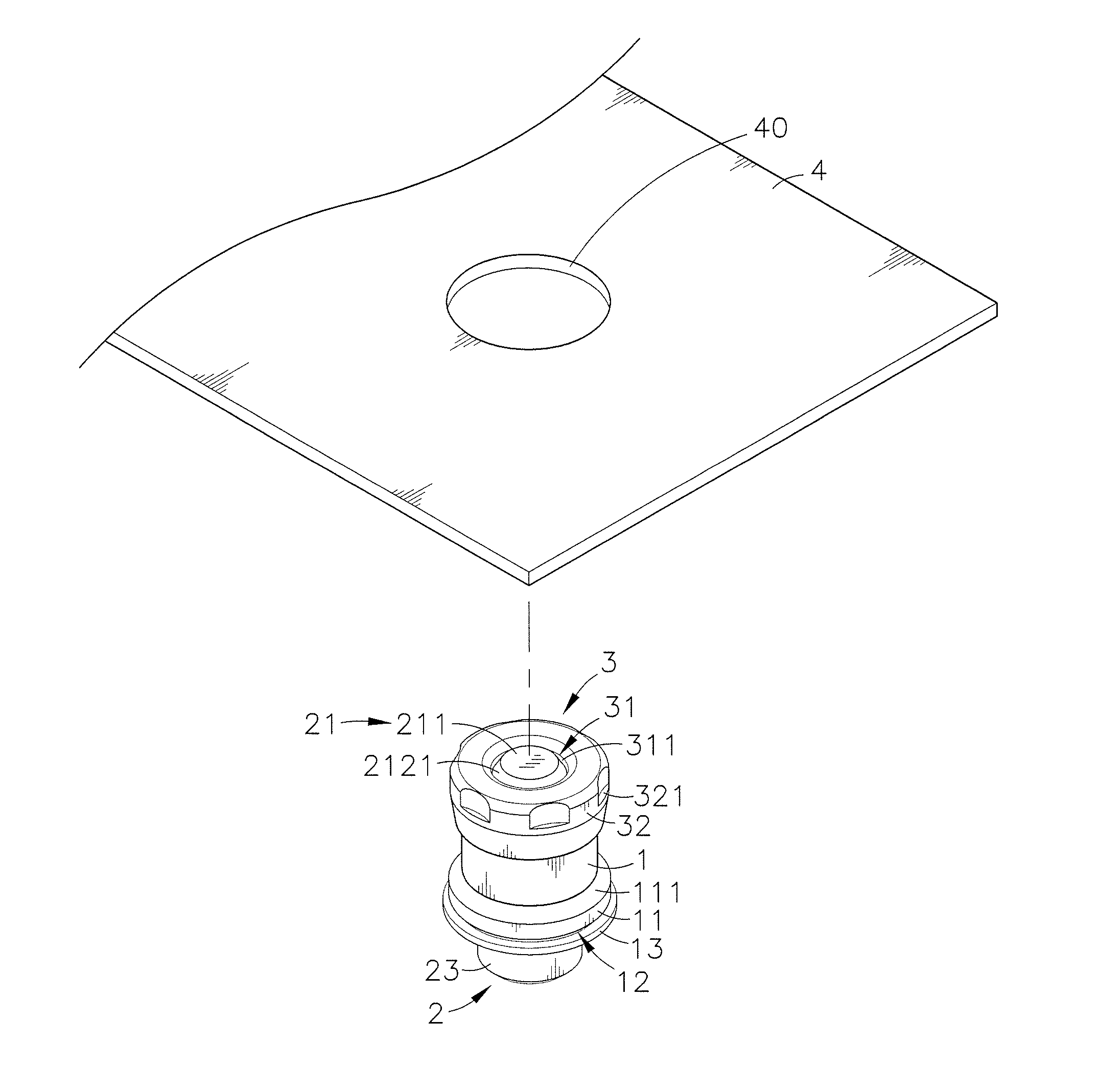

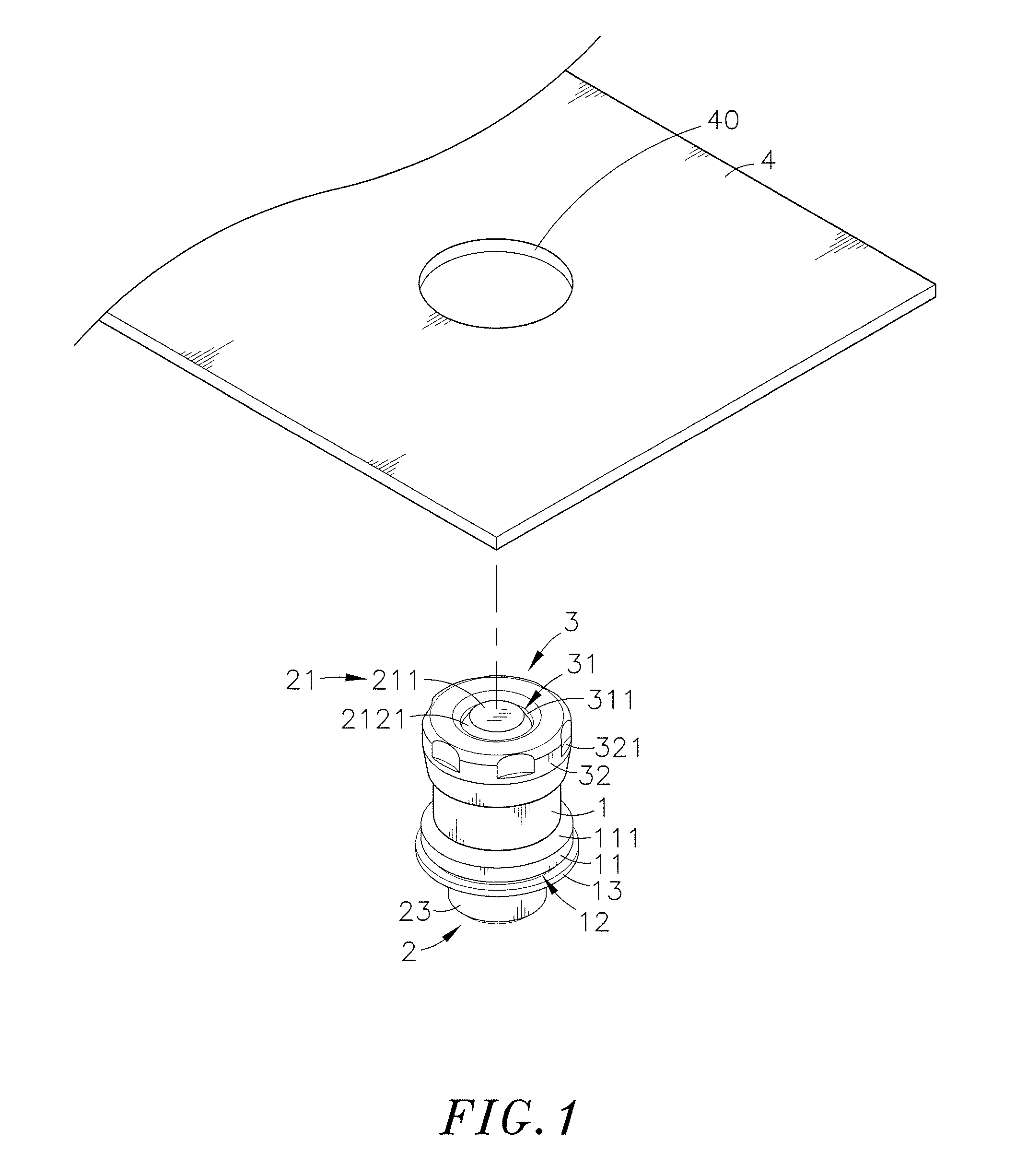

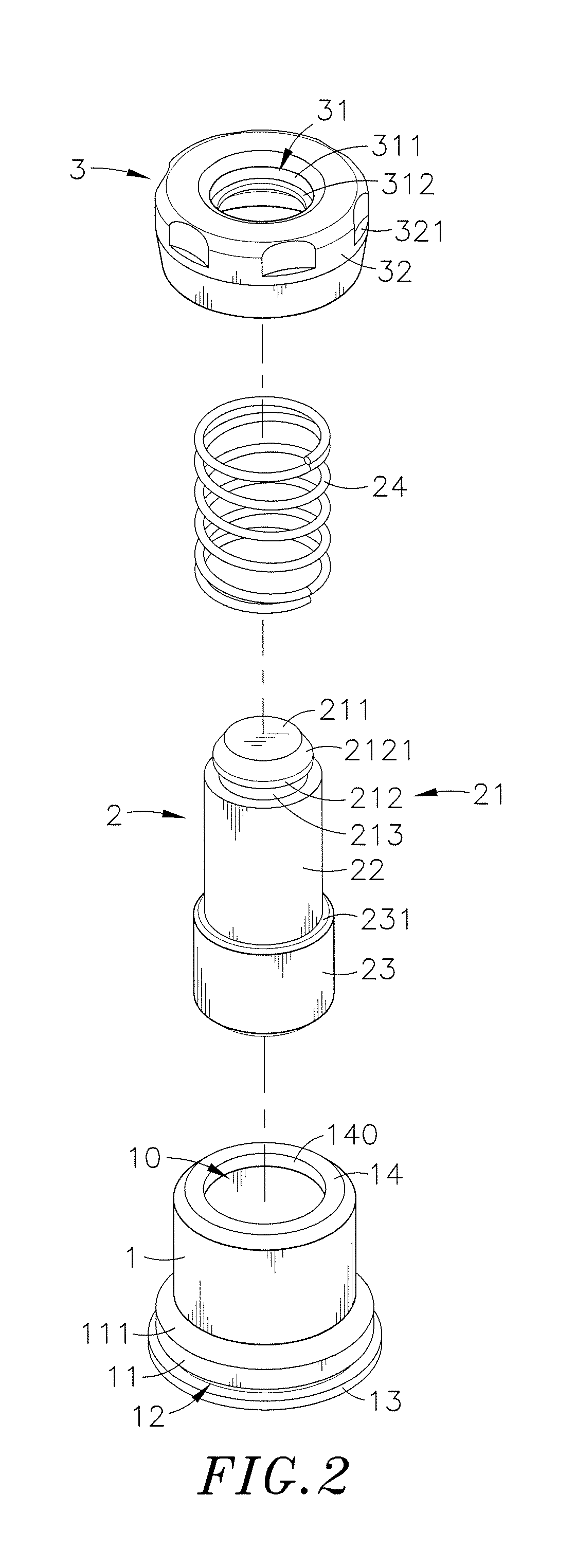

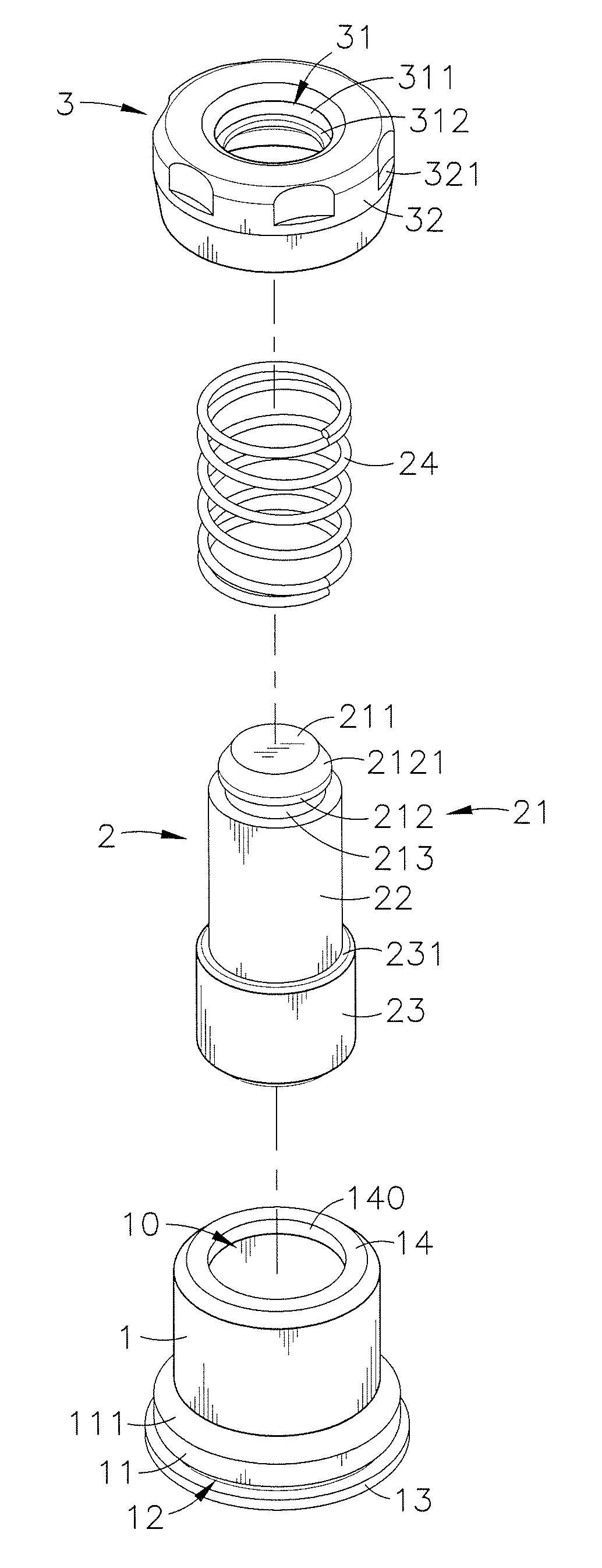

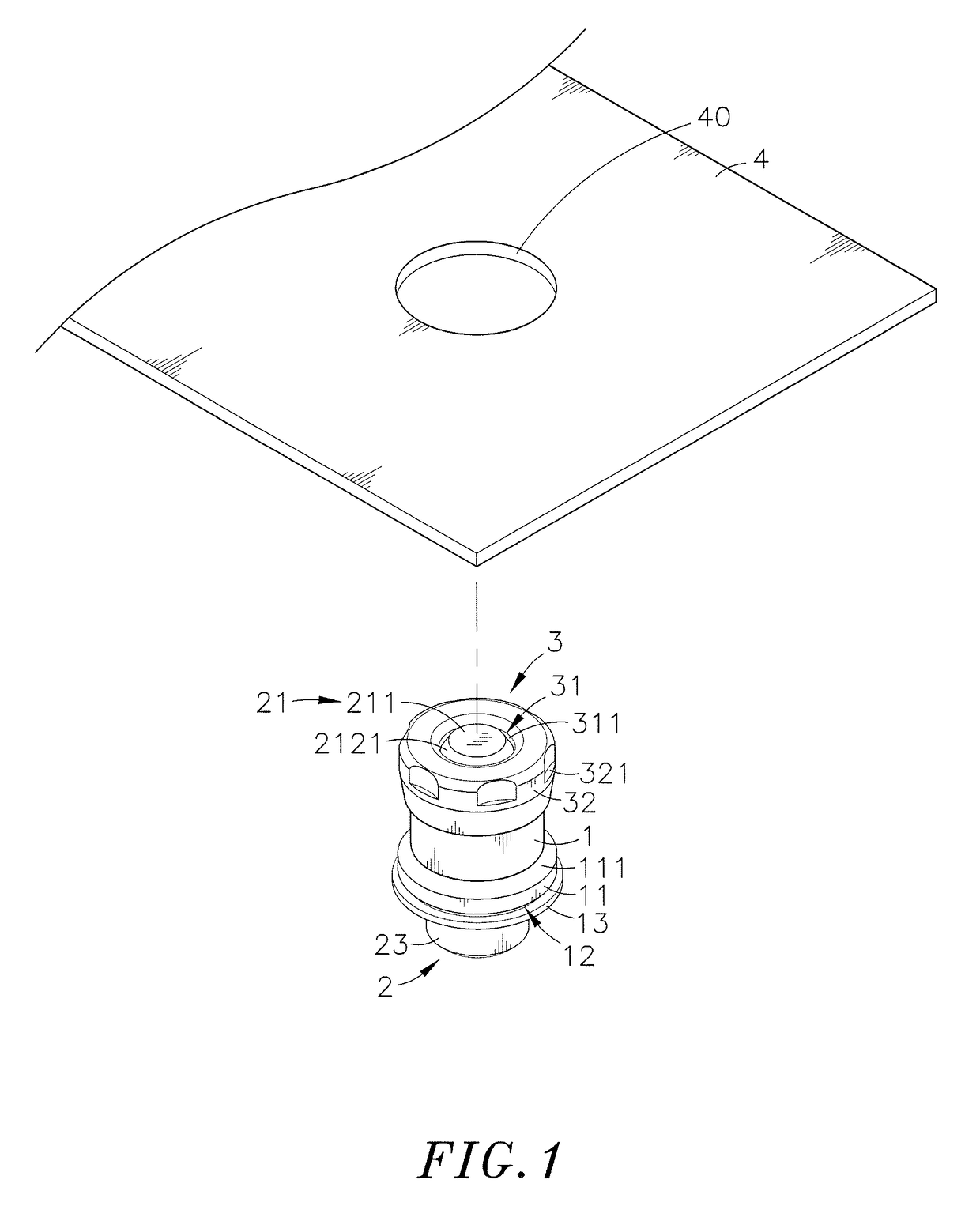

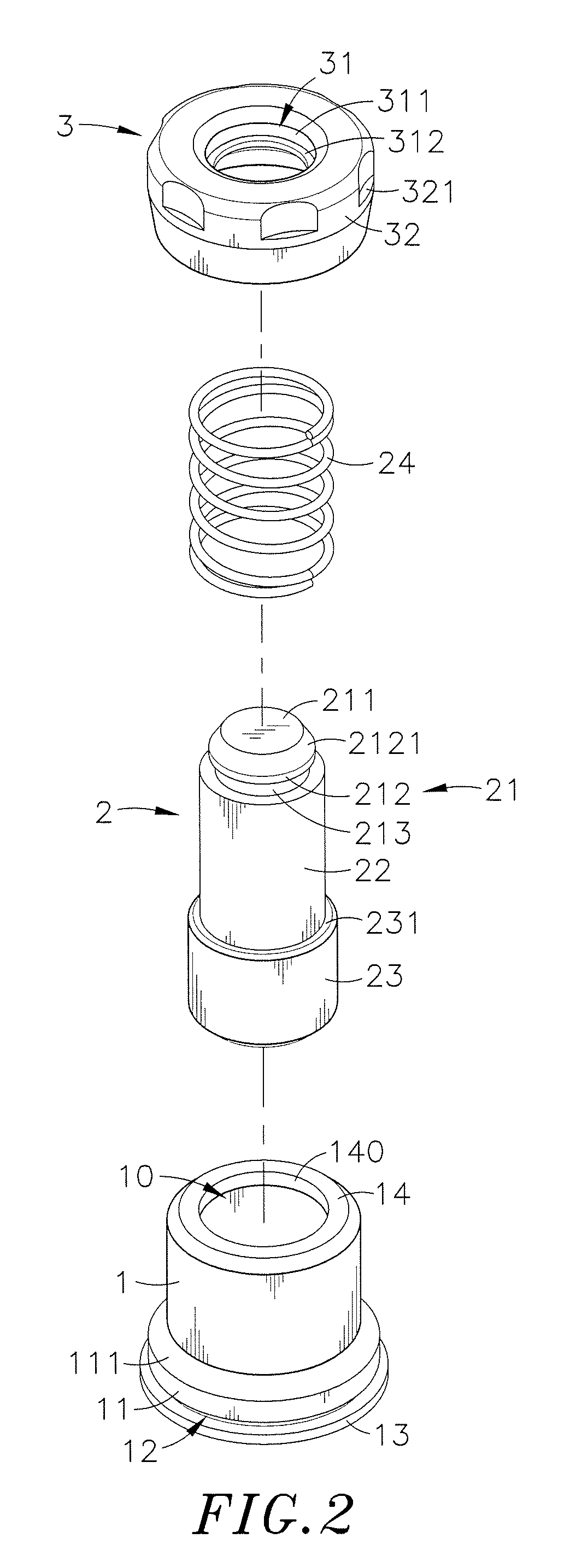

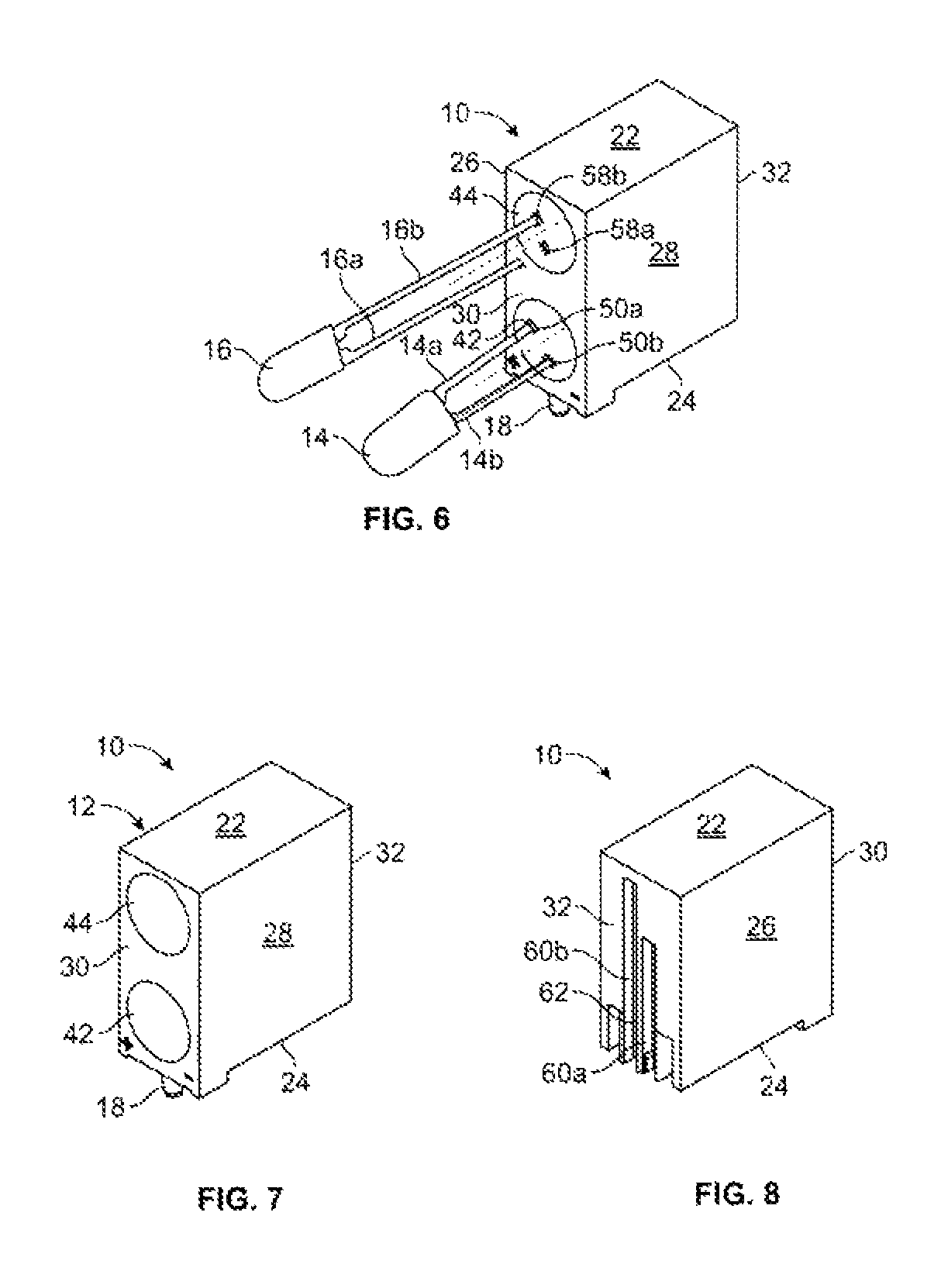

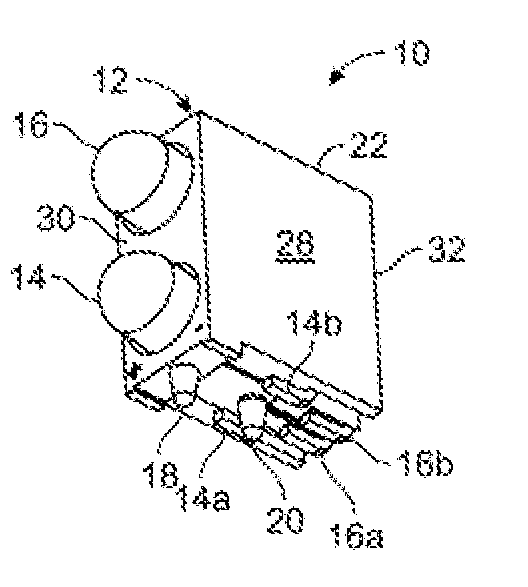

Floating fastener mounting structure

A floating fastener mounting structure includes a mounting socket having a locating groove extending around the periphery and defined between a relatively smaller annular step and a relatively larger stop flange thereof, a metal panel member having a mounting through hole attached to the mounting socket and stopped above the stop flange and stamped by a stamping press to provide a riveting portion and to force the riveting portion to engage into the locating groove and to wrap about the stop flange of the mounting socket, a spring-loaded locking member axially slidably mounted in the mounting socket for detachably locking the metal panel member to an external metal panel member, and a cap member capped on a mounting head of the locking member and affixed to the mounting head during the operation of the stamping press to stamp the metal panel member. Affixing the mounting socket to the metal panel member by riveting greatly enhances the shearing strength of the floating fastener mounting structure.

Owner:HANWIT PRECISION IND LTD

Metal preservative coating composition and method

InactiveUS20100075163A1Suitable protectionIncrease flexibilitySynthetic resin layered productsPretreated surfacesCross-linkOrganic solvent

An invention discloses an ambient or online heat curing chromate free, corrosion resistant coating composition comprising (a) a linear vinyl terpolymer having three randomly distributed functional groups comprising acetyl, formal and hydroxy! groups along the vinyl backbone that offers cross-linking sites through the hydroxyl groups during cure; (b) one or more alkoxy amino resin(s); (c) a mineral acid catalyst; (d) a blend of organic solvents and optionally (e) one or more chromate free inorganic pigment and / or organic dyes.

Owner:ROTOMAC ELECTRICALS PVT

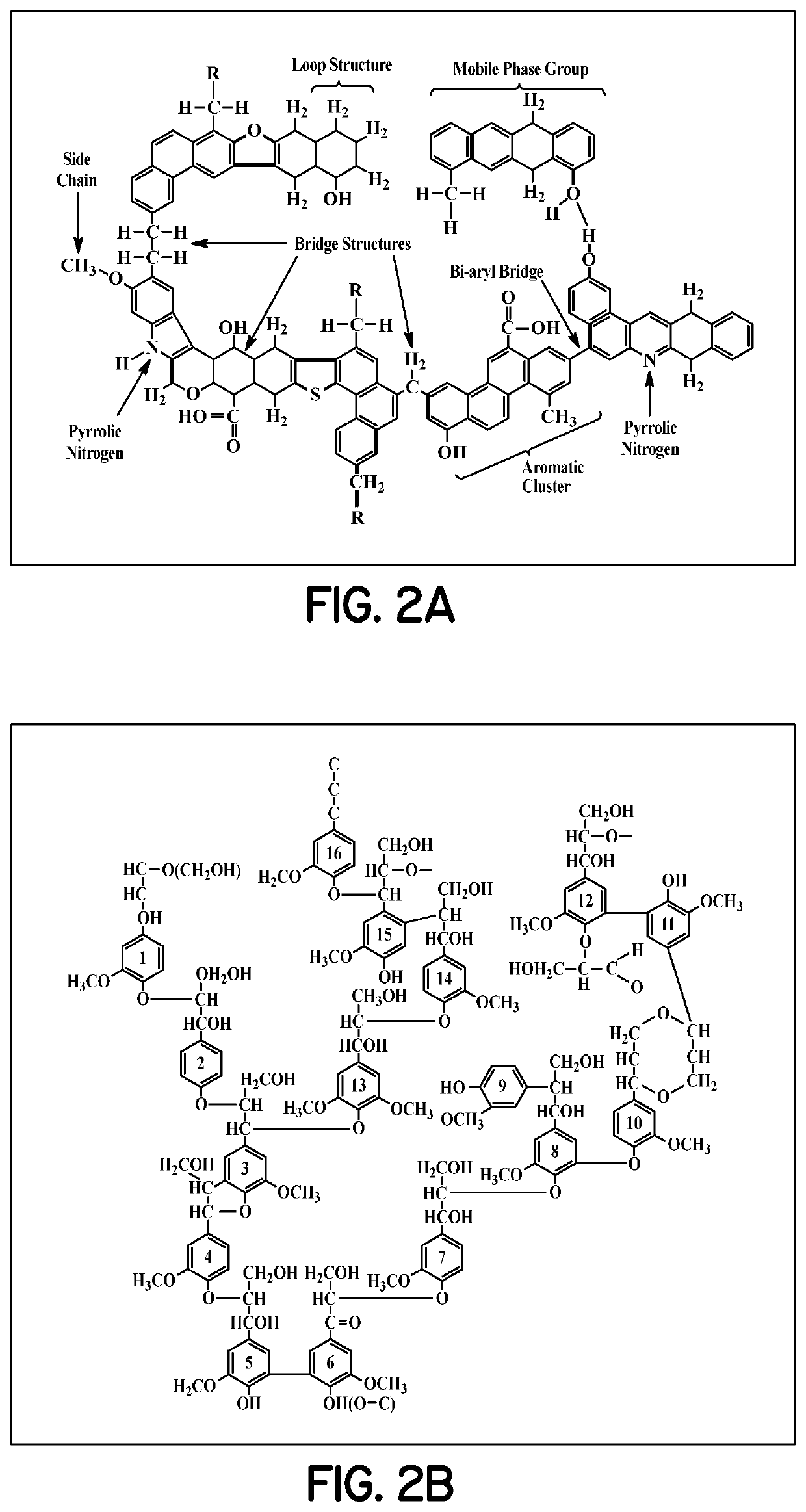

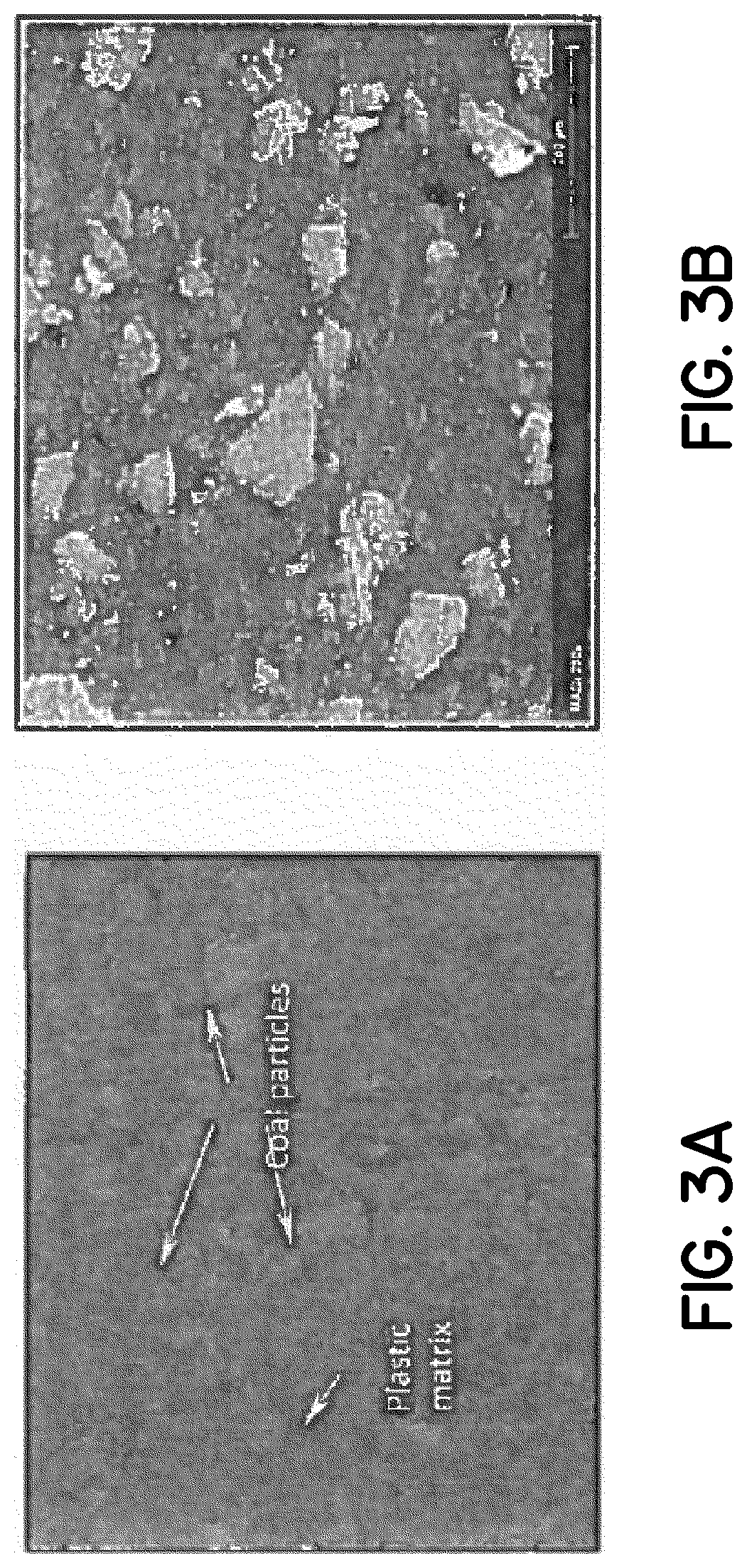

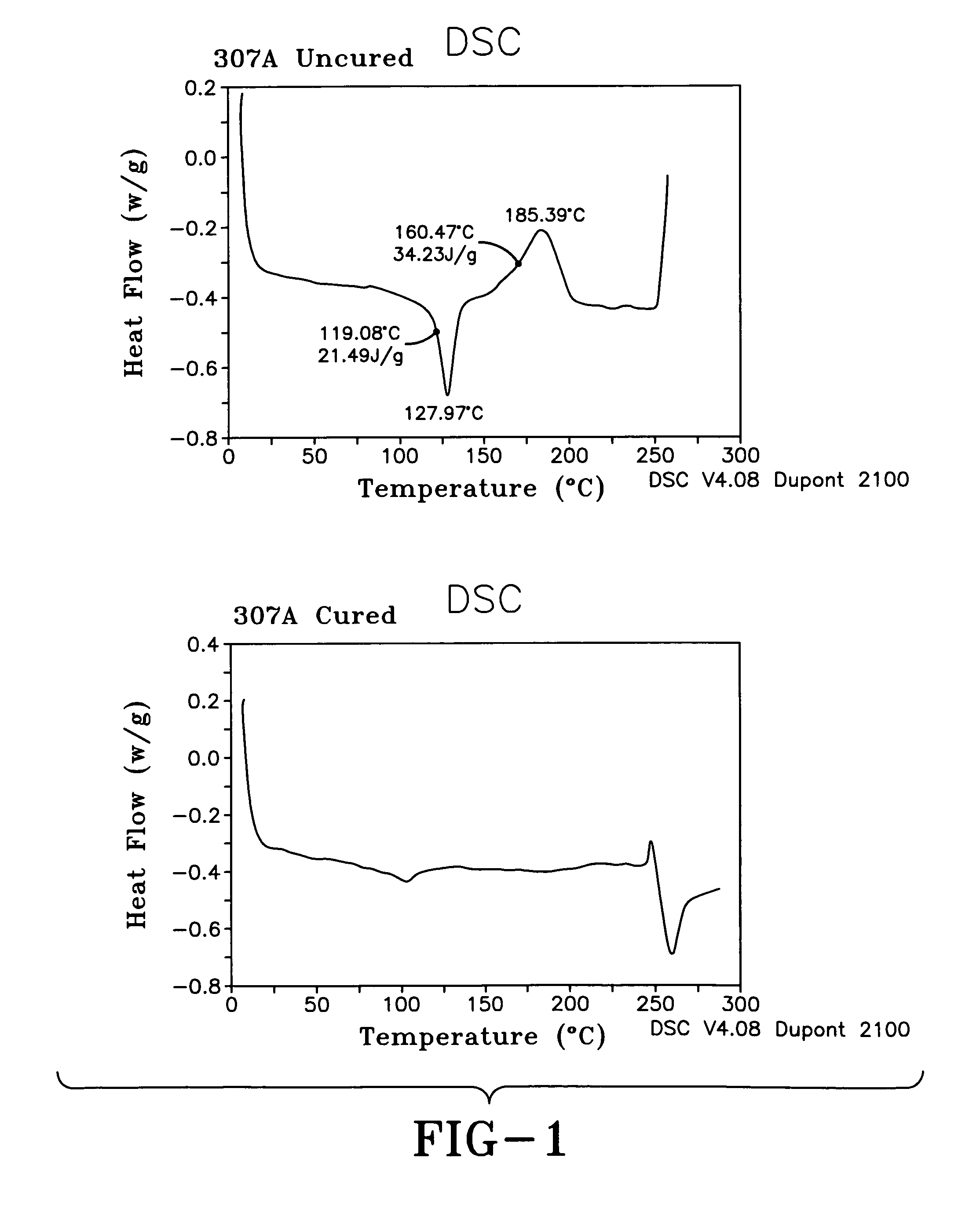

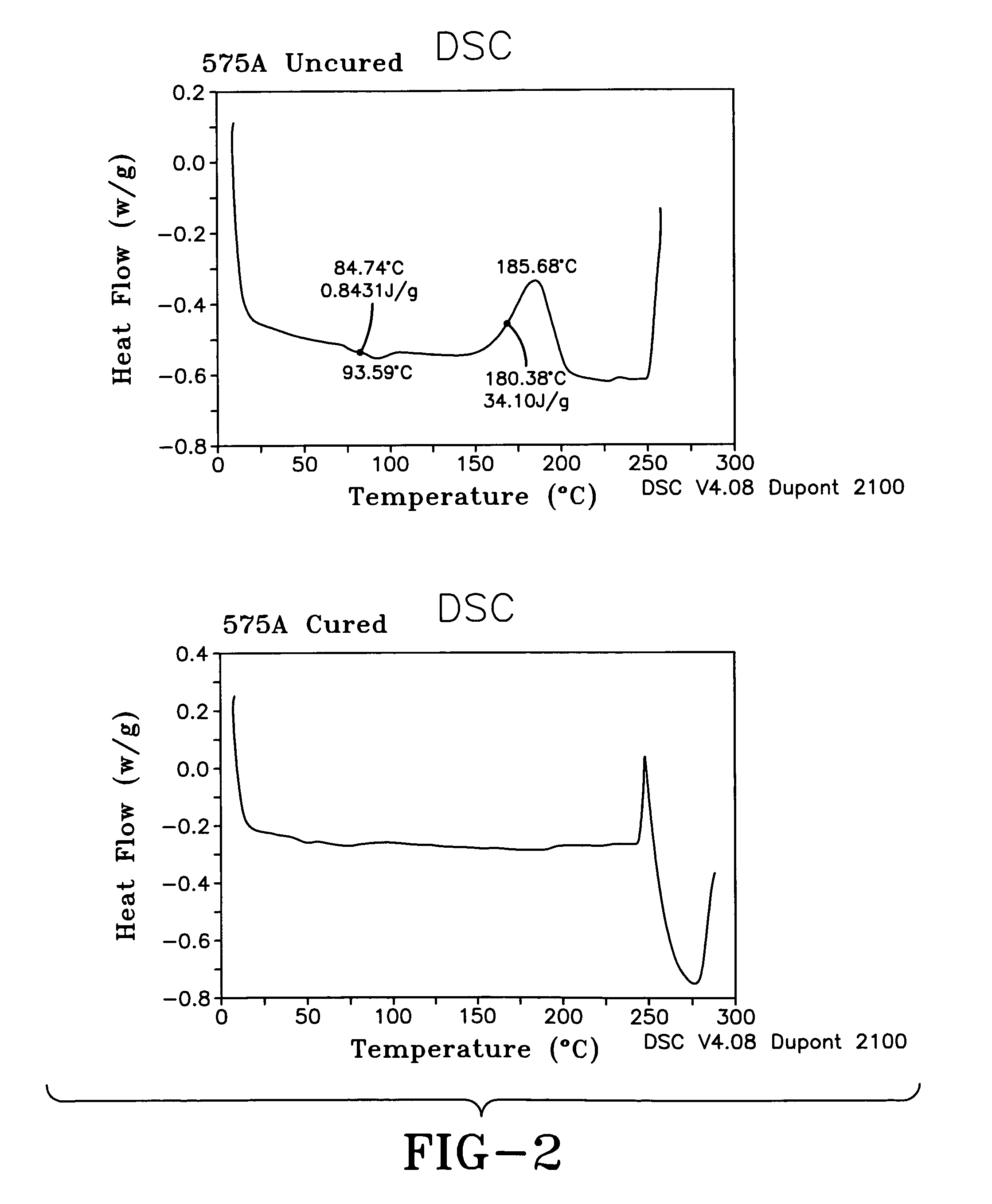

Coal plastic composites

PendingUS20210102071A1High degreeHigh of flexural strengthBuilding insulationsPolymer sciencePolymer chemistry

Owner:OHIO UNIV

Power transmission products having enhanced properties

ActiveUS8030404B2Low viscosityHigh hardnessV-beltsRopes and cables for vehicles/pulleyElastomerHardness

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers, such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

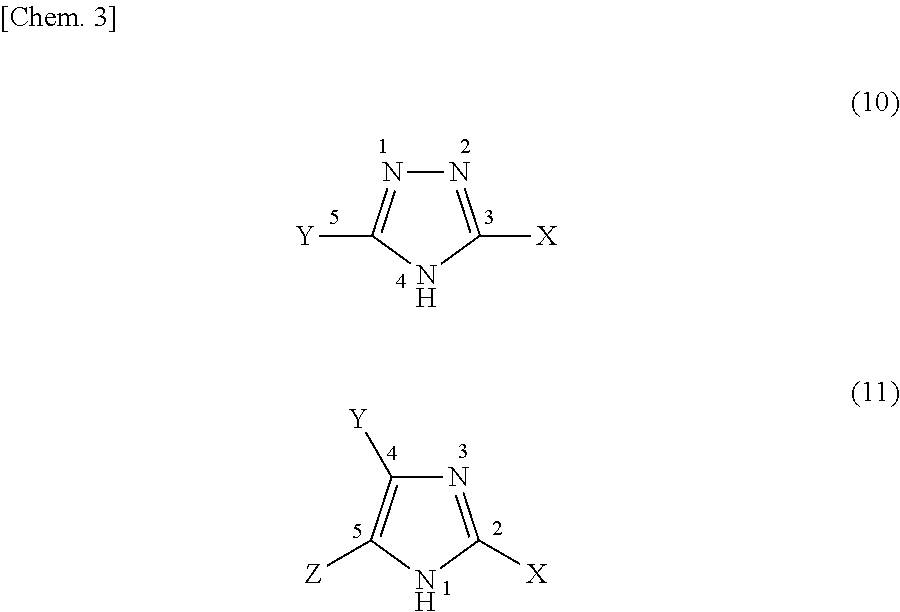

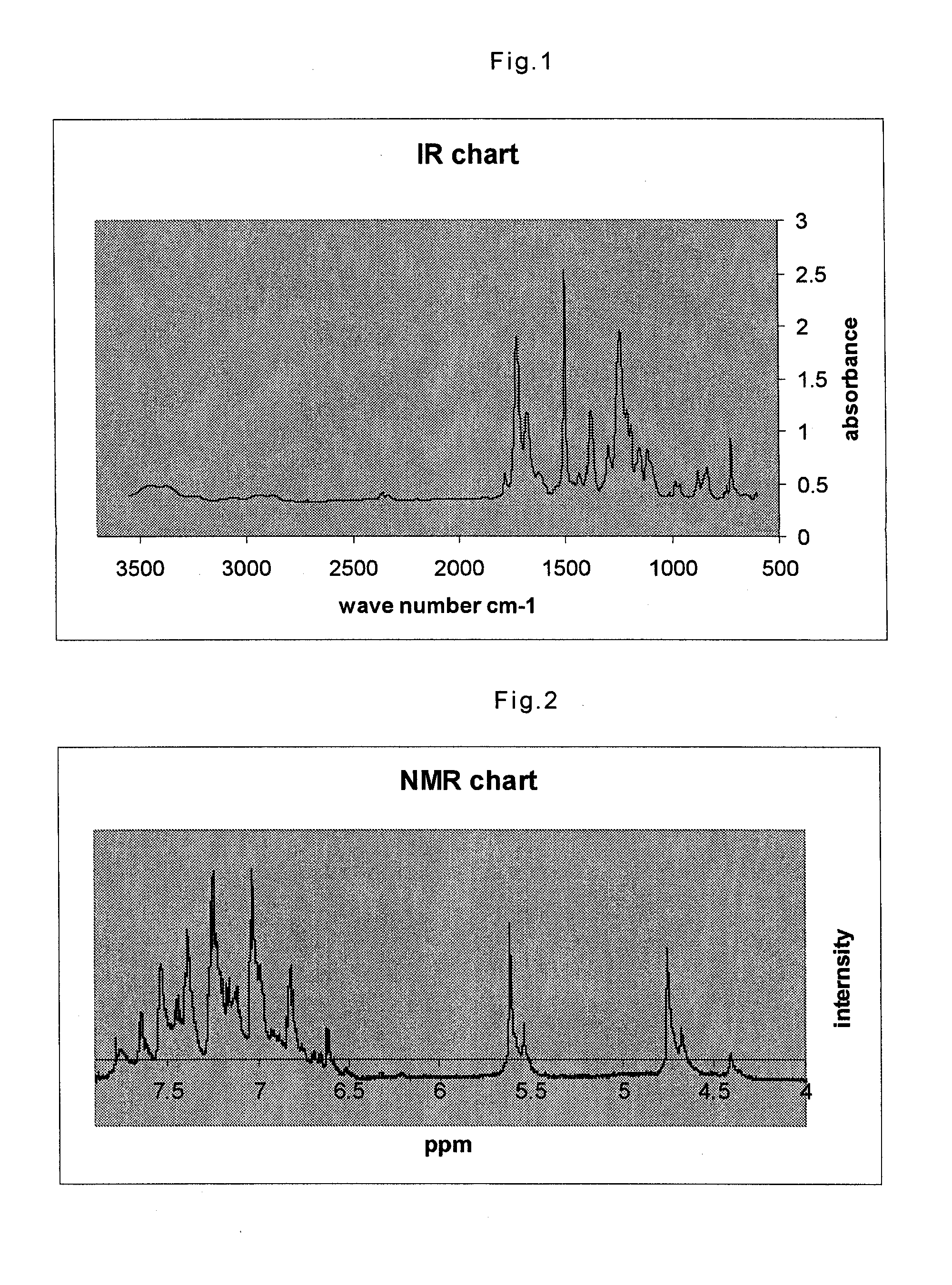

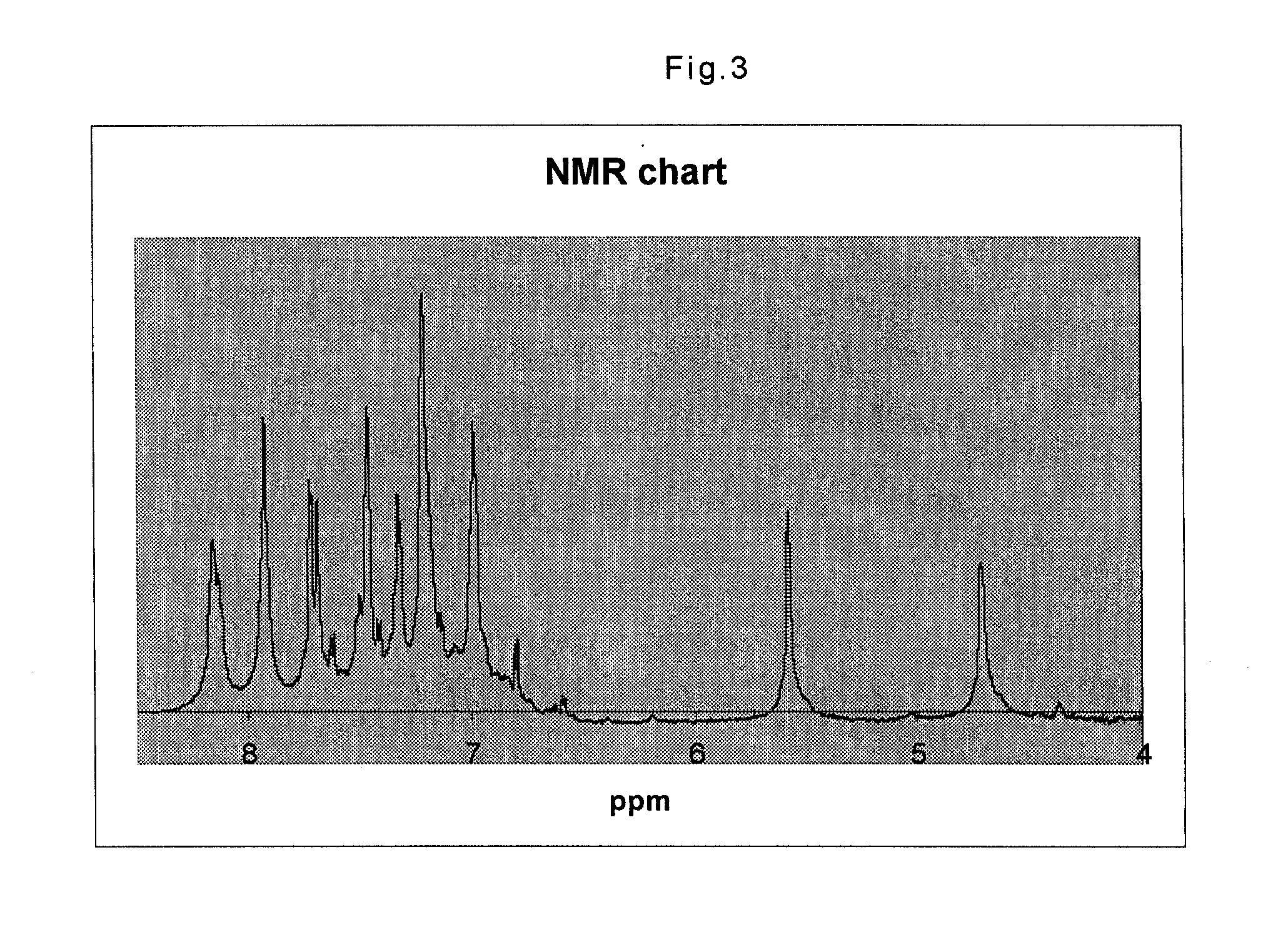

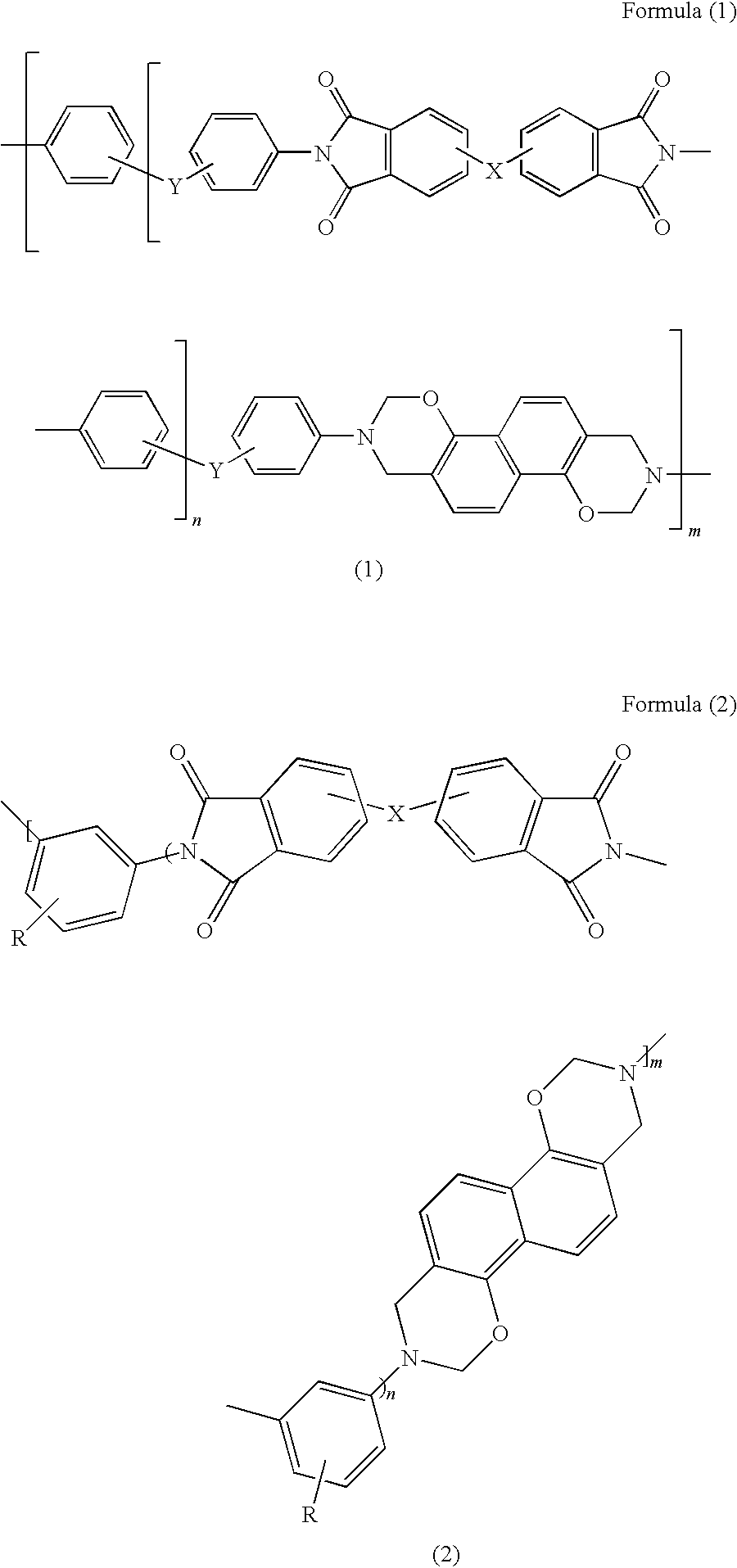

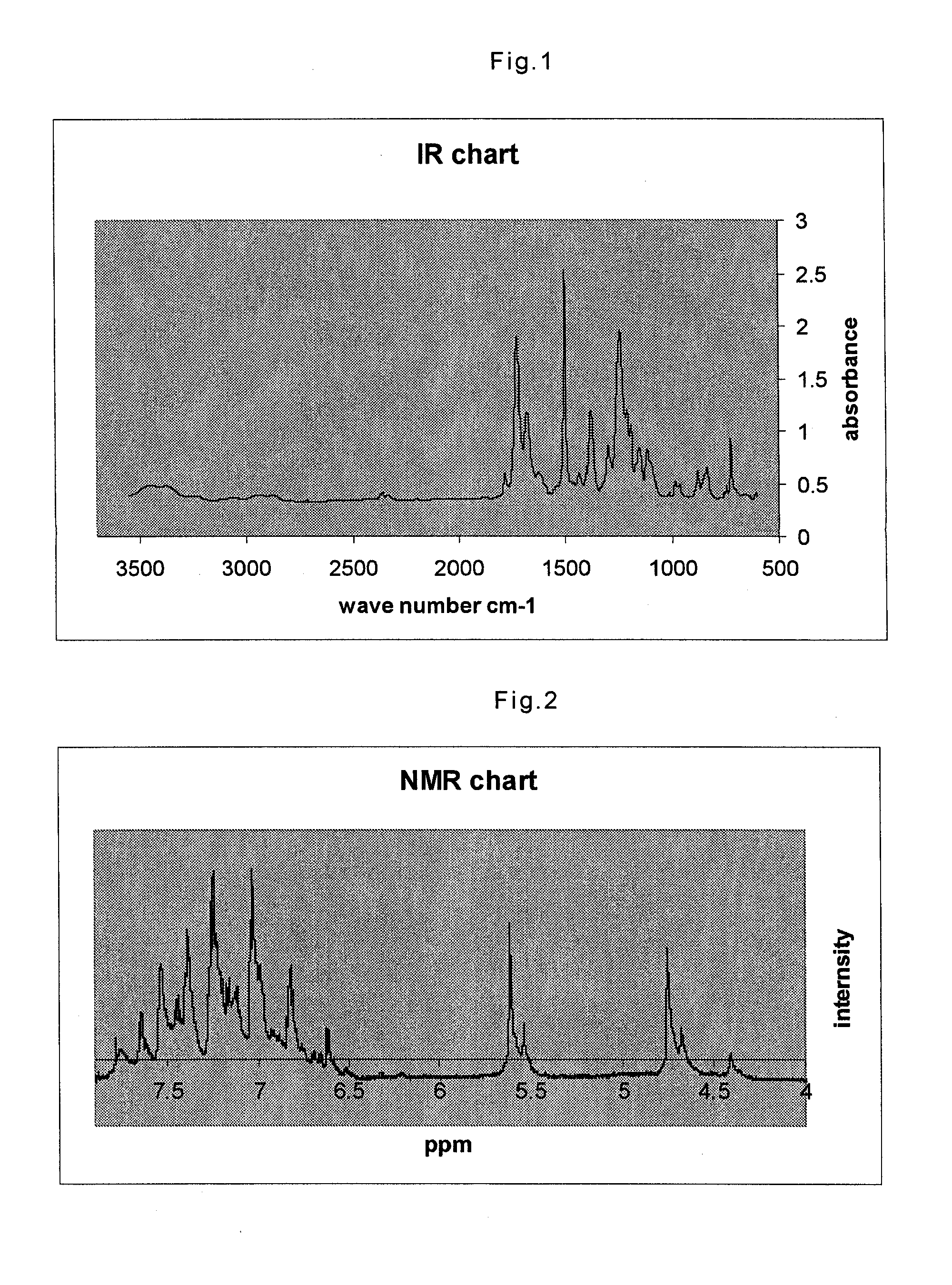

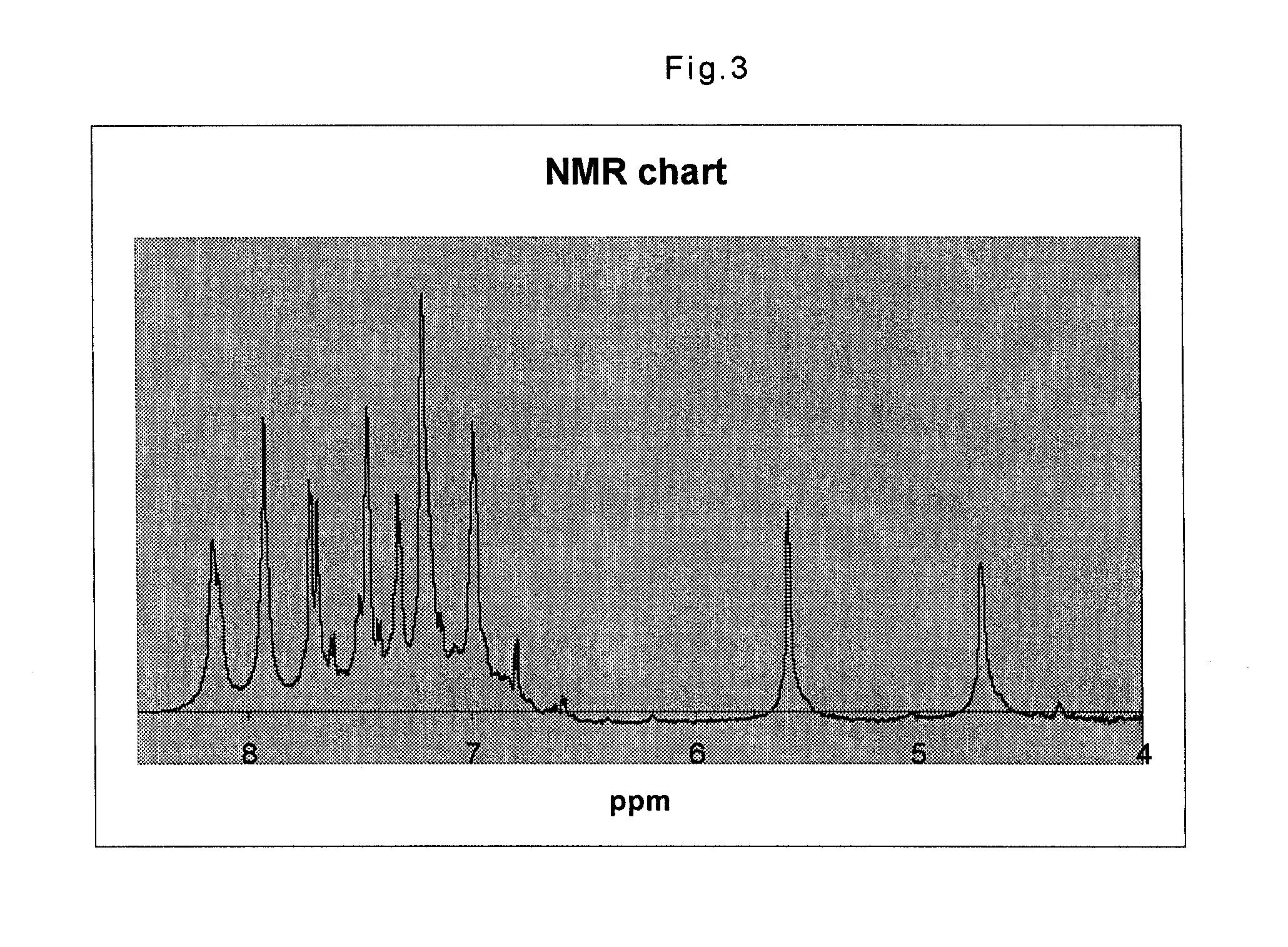

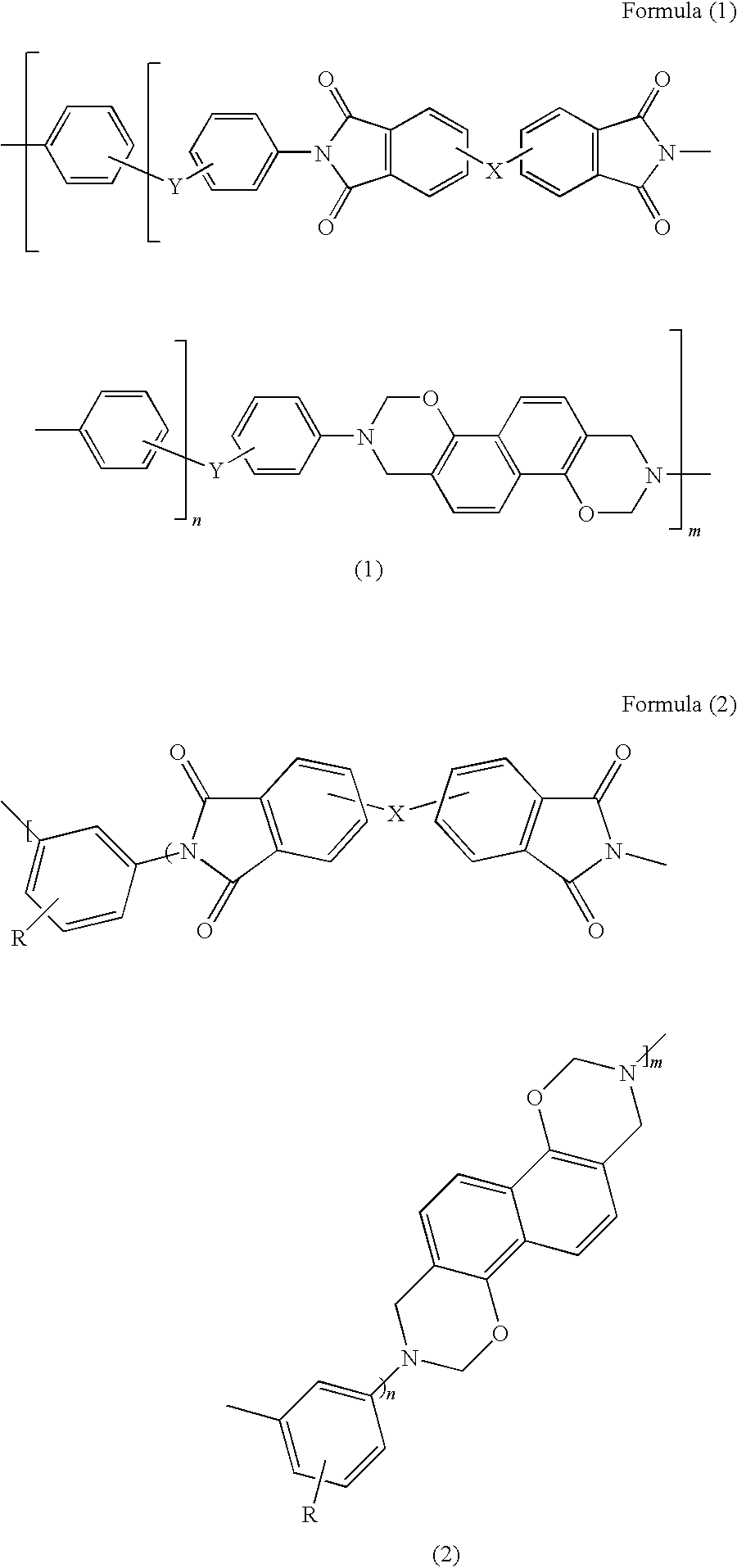

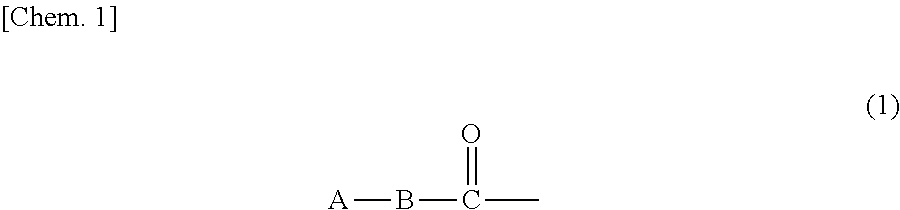

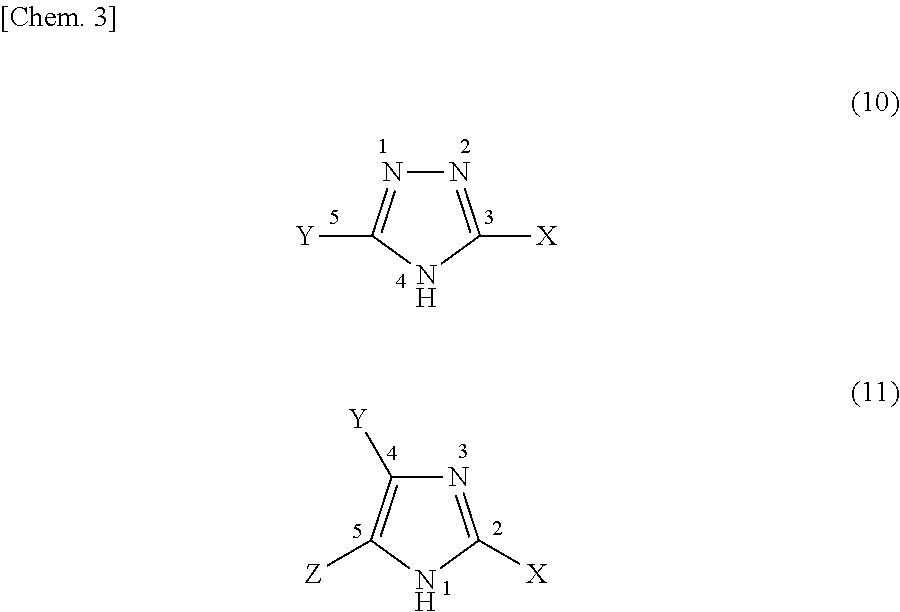

Imide-naphthoxazine copolymer

An imide-naphthoxazine copolymer comprising a repeating unit represented by General Formula (1) below:(wherein X and Y independently represent a single bond, an oxygen atom, a carbonyl group, or an organic group which may be substituted by a heteroatom;R represents CH3 or H,n represents an integer from 1 to 10; and m represents an integer from 1 to 20).

Owner:SEKISUI CHEM CO LTD +1

Floating fastener mounting structure

A floating fastener mounting structure includes a mounting socket having a locating groove extending around the periphery and defined between a relatively smaller annular step and a relatively larger stop flange thereof, a metal panel member having a mounting through hole attached to the mounting socket and stopped above the stop flange and stamped by a stamping press to provide a riveting portion and to force the riveting portion to engage into the locating groove and to wrap about the stop flange of the mounting socket, a spring-loaded locking member axially slidably mounted in the mounting socket for detachably locking the metal panel member to an external metal panel member, and a cap member capped on a mounting head of the locking member and affixed to the mounting head during the operation of the stamping press to stamp the metal panel member. Affixing the mounting socket to the metal panel member by riveting greatly enhances the shearing strength of the floating fastener mounting structure.

Owner:HANWIT PRECISION IND LTD

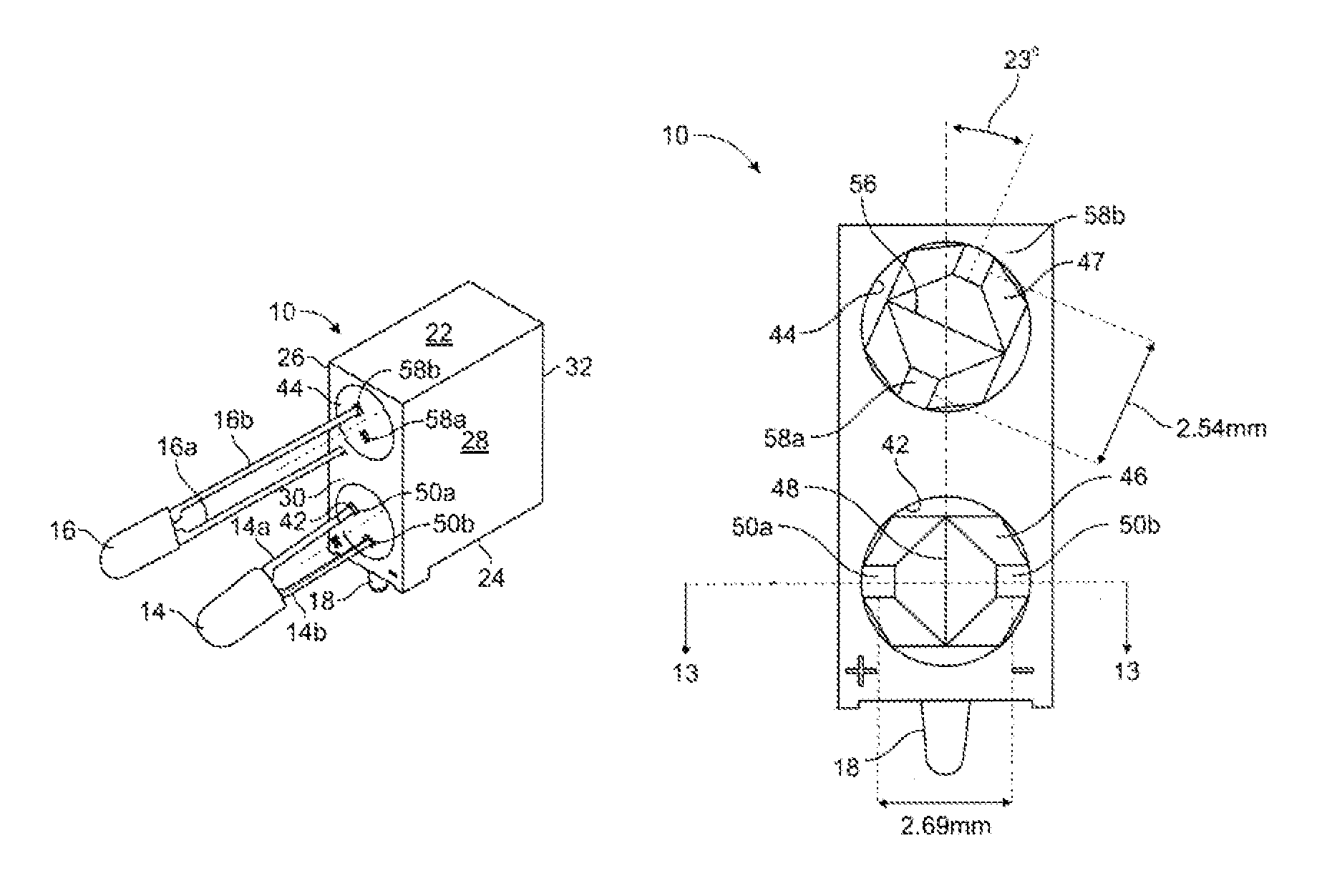

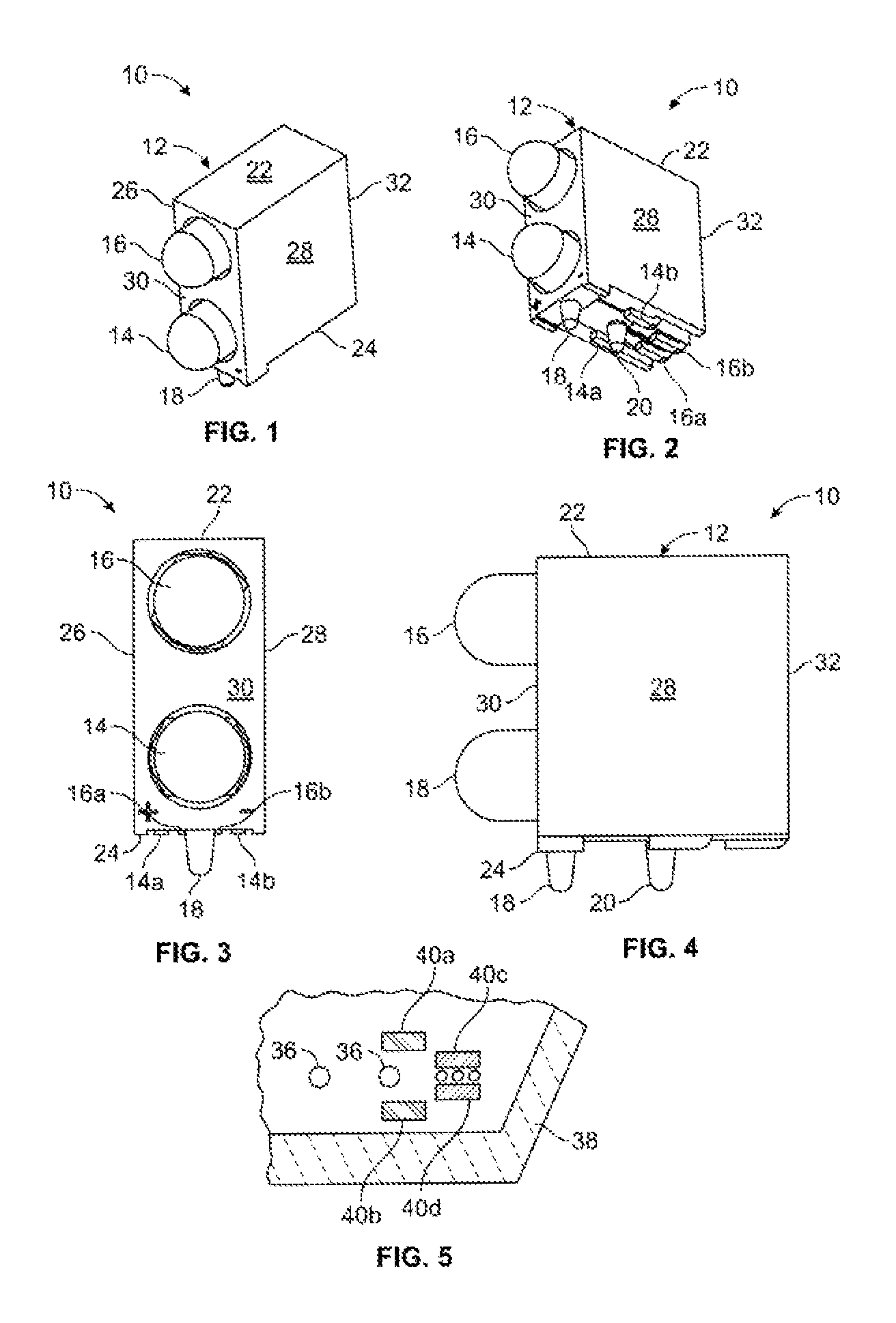

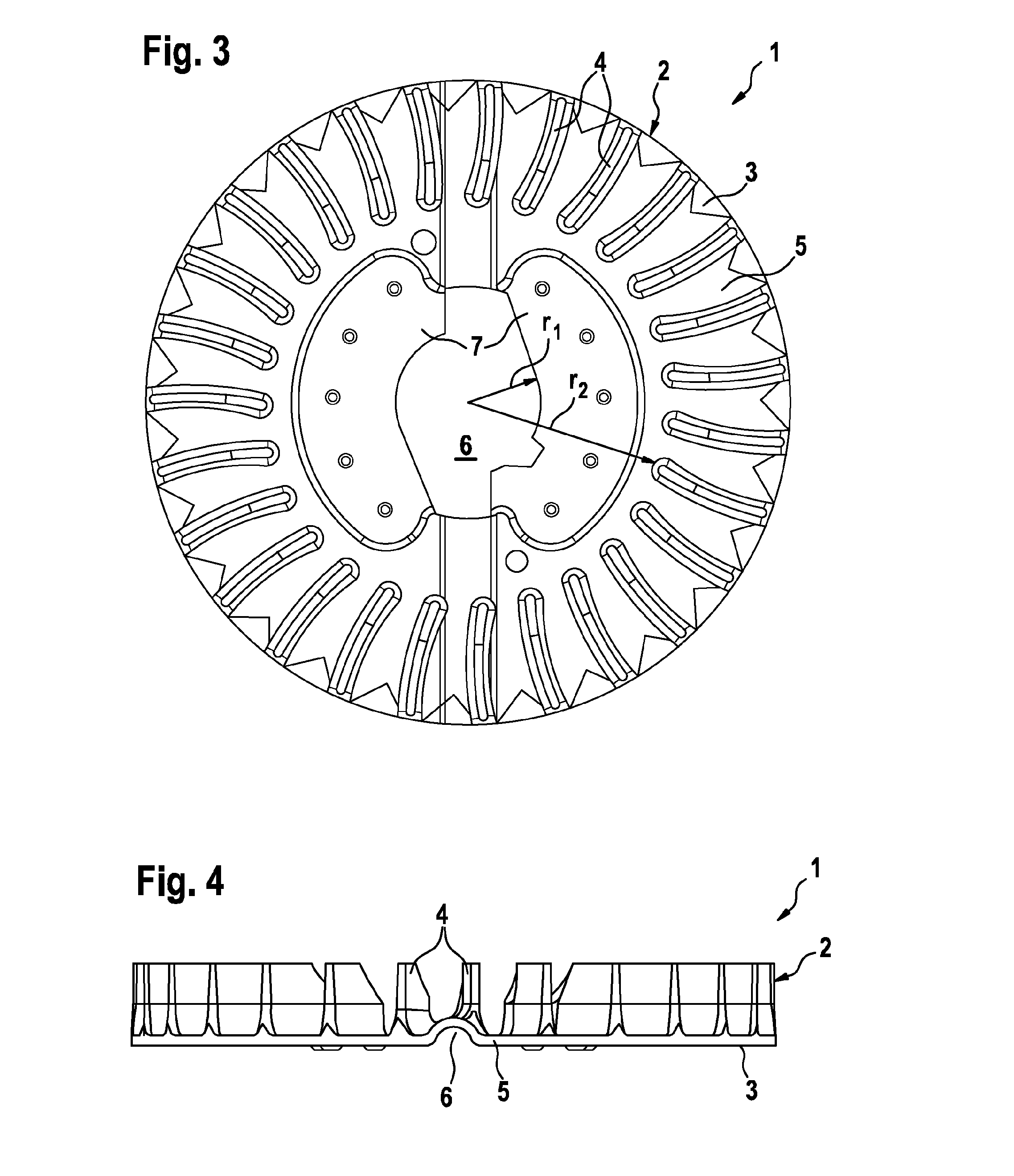

Two-high light-emitting diode holder structure

ActiveUS9562675B2Easy to viewImprove accuracyLighting applicationsPrinted circuit assemblingVertical planeEngineering

A holder structure for mounting light indicators on printed circuit boards using surface mount technology at a position elevated above the surface of the board is provided with a body member including a top wall, a bottom wall, opposed sidewalls, a front wall, and a rear wall, all being formed integrally together. Two spaced-apart recesses are formed and aligned vertically in the front wall of the body member terminating in respective first and second interior wall portions. The first interior wall portion has openings formed on diametrically opposed sides of a vertical partition and lying in a horizontal plane parallel to the bottom wall. The second interior wall portion has openings formed on diametrically opposed sides of a transverse partition and lying in a plane which is rotated a predetermined number of degrees from a vertical plane perpendicular to the bottom wall.

Owner:ILLINOIS TOOL WORKS INC

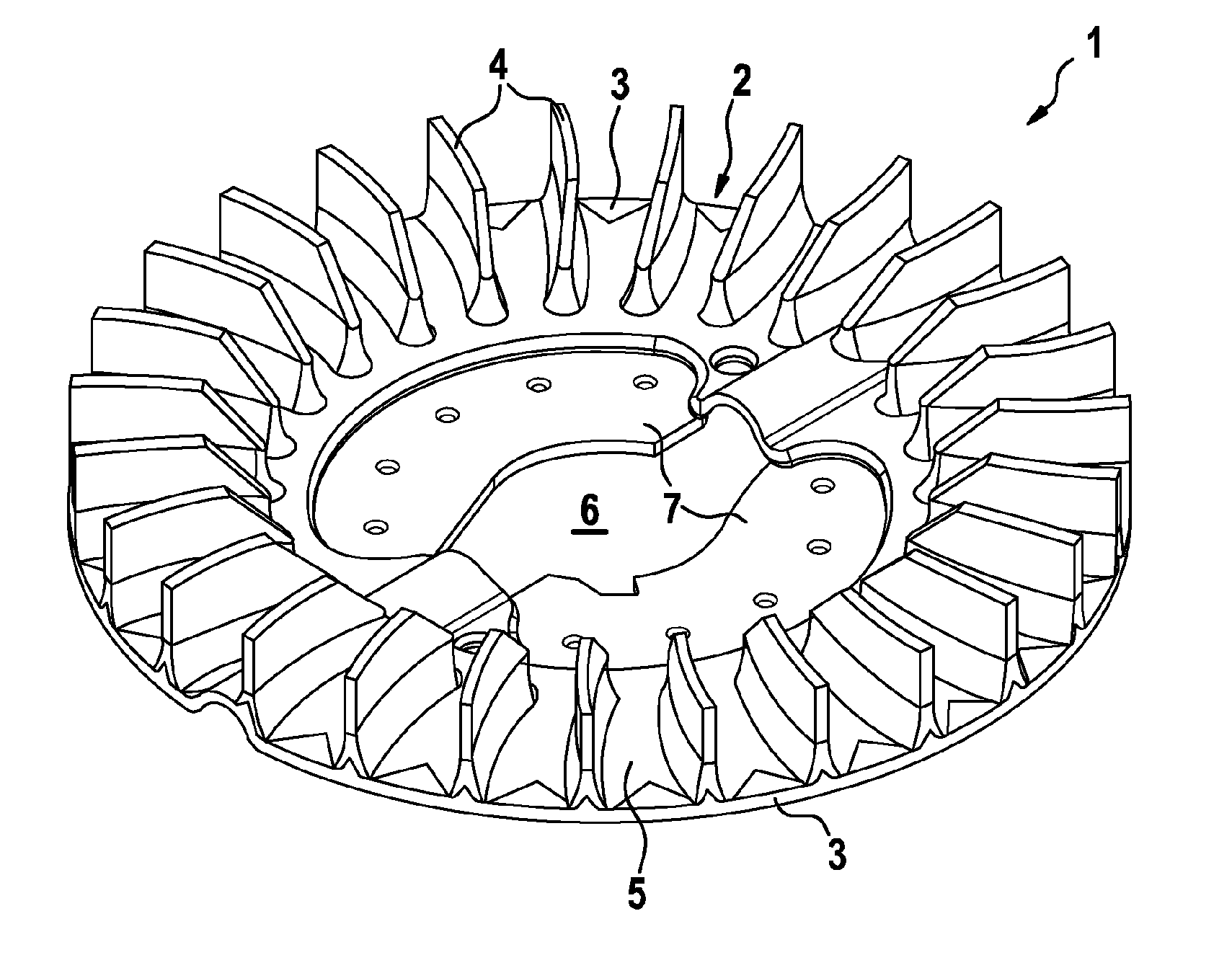

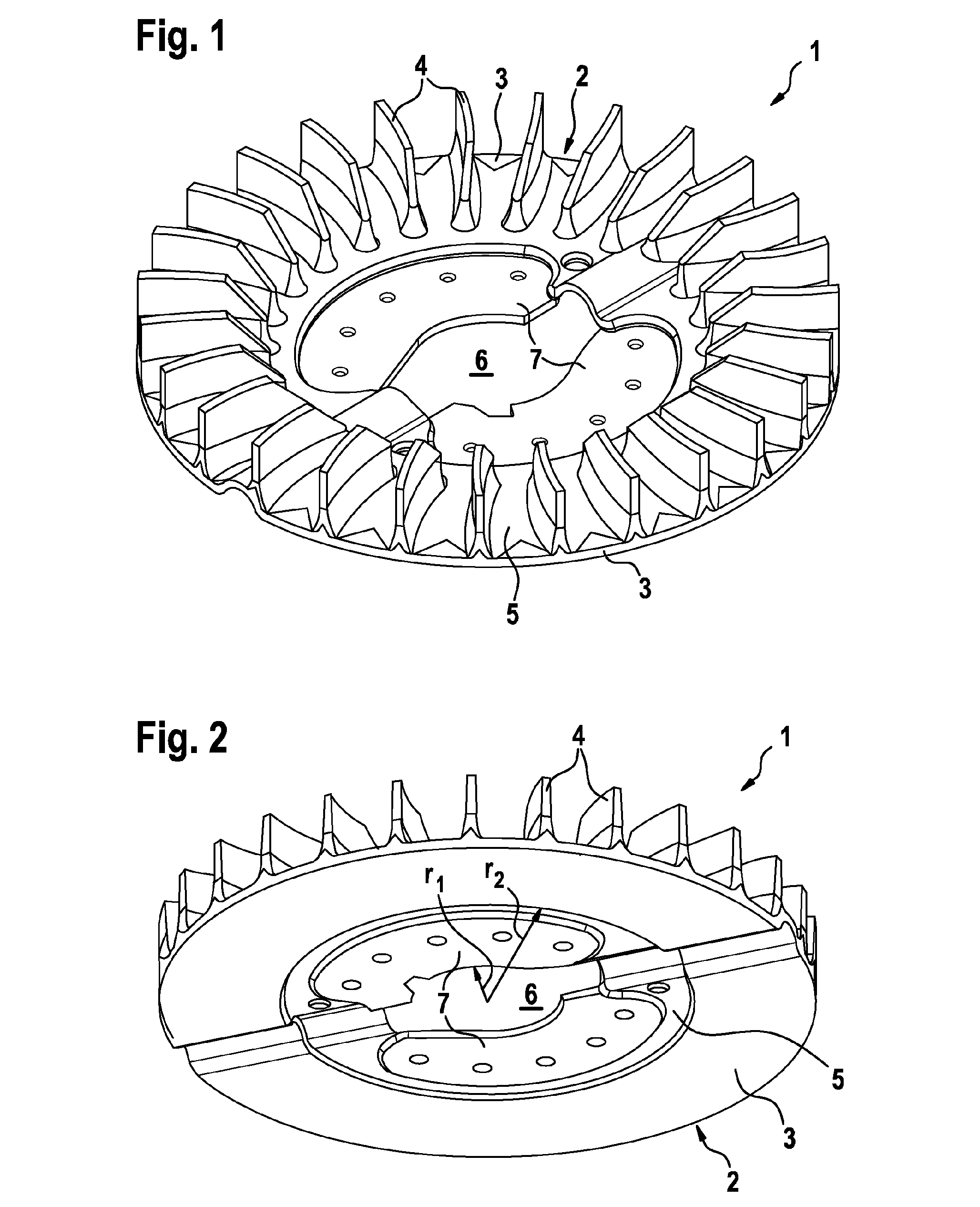

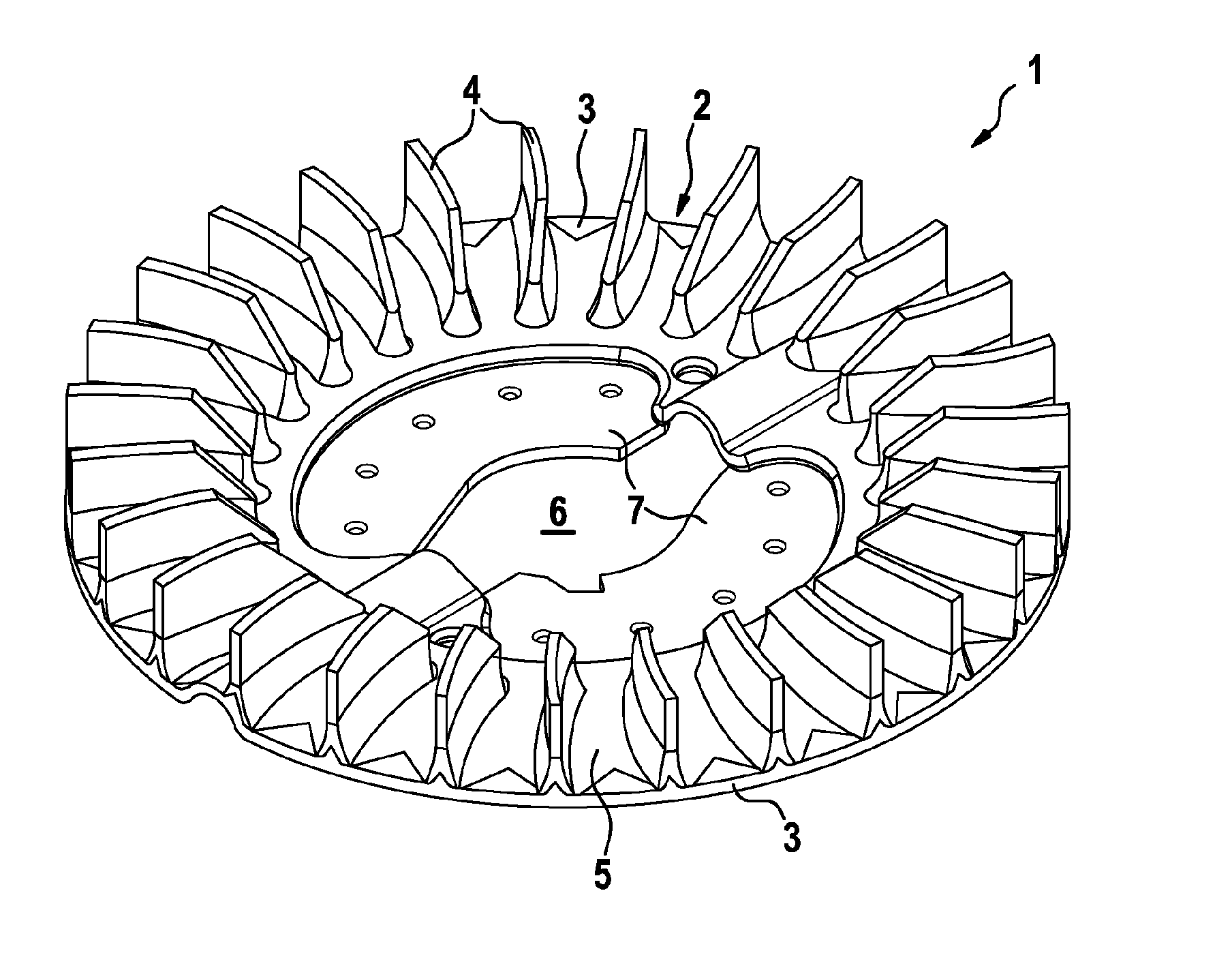

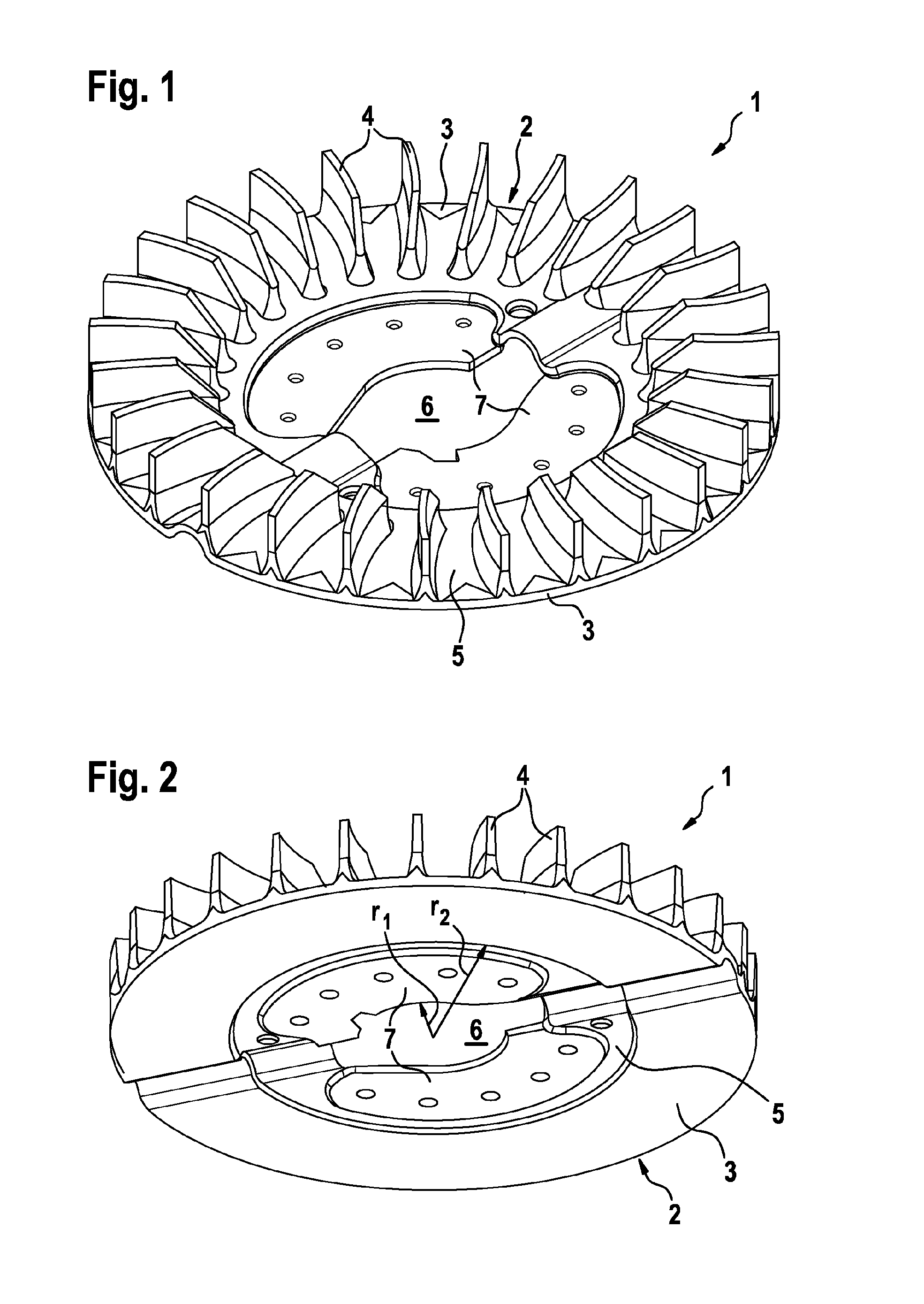

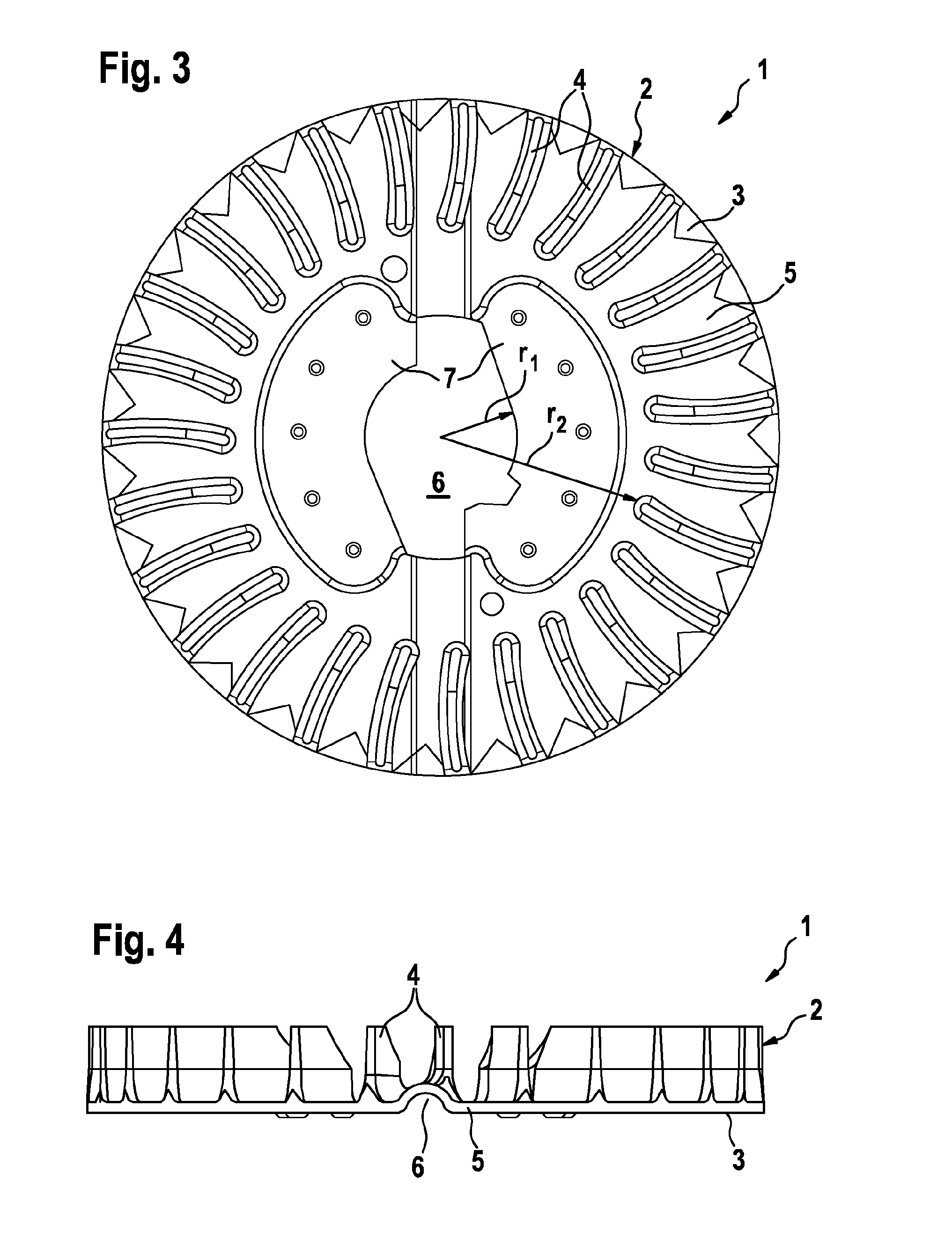

Electrical machine having a fan wheel

ActiveUS20130078102A1Improve heat dissipationImprove stabilityPropellersRotary propellersImpellerEngineering

The invention relates to an electrical machine having a fan wheel which comprises an injection-moulded blade carrier ring with fan blades as well as an annular insertion part which is integrated into the blade carrier ring and which comprises passage openings via which the blade carrier ring is connected to the fan blades.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Electrical machine having a fan wheel

ActiveUS9416792B2Improve stabilityHigh degreePump componentsMetal-working apparatusImpellerEngineering

The invention relates to an electrical machine having a fan wheel which comprises an injection-moulded blade carrier ring with fan blades as well as an annular insertion part which is integrated into the blade carrier ring and which comprises passage openings via which the blade carrier ring is connected to the fan blades.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Folding top of a convertible automobile

InactiveUS20050194812A1High degreeHigh of strengthEngine sealsVehicle sealing arrangementsHigh intensityMechanical engineering

A convertible includes a folding top having side beams, which are articulated to one another, and a roof structure, which is connected to the side beams and made at least partially of high-strength hot-formed steel material. Hereby the roof structure may include a roof member which is made of high strength hot formed steel material, or the roof structure may include a roof member and a reinforcement member which is made of high strength hot formed steel material and extends between the side beams, for support of the roof member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

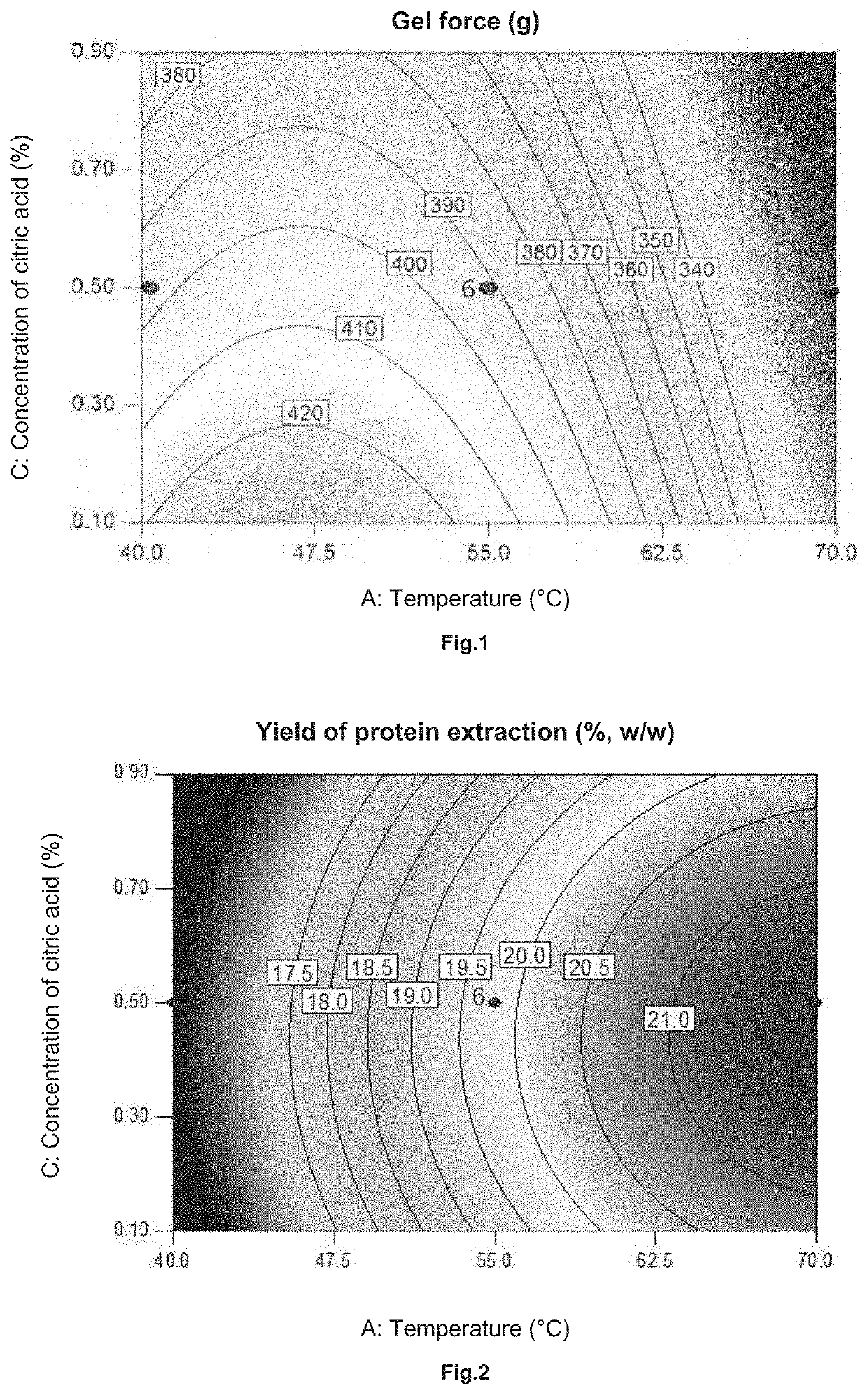

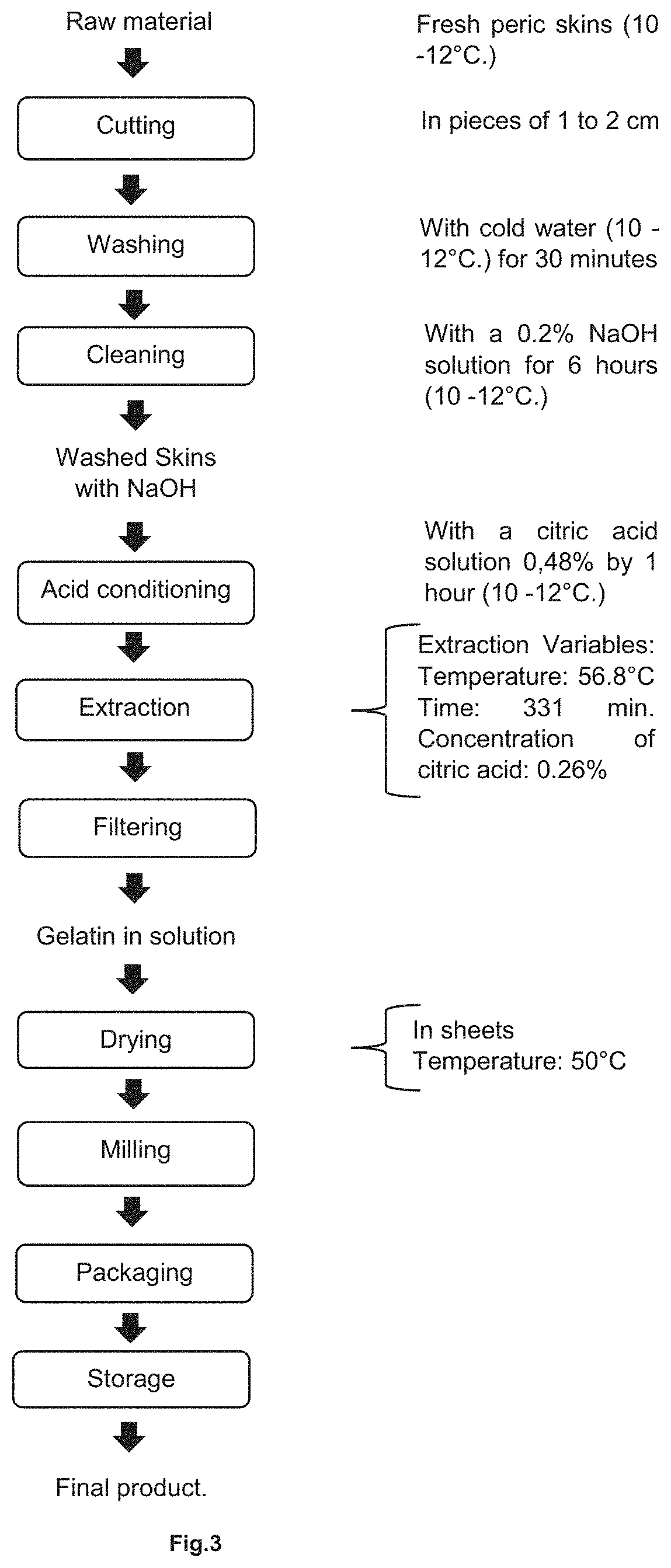

Process for producing gelatin from fish skin by optimisation of the extraction conditions

InactiveUS20200165488A1Increase valueSolution value is not highProtein composition from fishGlue/gelatin preparationOrganic acidWash water

A process for obtaining fish gelatin characterized because it comprises: (a) cleaning of fish skins; (b) washing of skins with water; (c) treating with diluted alkali solution with constant agitation; (d) washing of skins with water until the wash water is in a pH range between 6.8 and 7.2; (e) treating with diluted organic acid solution with constant agitation; (f) washing of skins with water until the wash water is in a pH range between 6.8 and 7.2 and subsequent runoff; (g) extracting gelatin by mixing the skins in an organic acid solution with a concentration of 0.2 to 0.3 weight percent by volume at a temperature of 55 to 65° C. and for 260 to 340 minutes; (h) filtering to remove skin debris and impurities; (i) drying; and (j) grinding.

Owner:INST TECHCO DE LA PRODUCCION

Imide-naphthoxazine copolymer

Owner:SEKISUI CHEM CO LTD +1

Two-high light-emitting diode holder structure

ActiveUS20150369458A1Easy to viewImprove accuracyLighting applicationsPoint-like light sourceVertical planeEngineering

A holder structure for mounting light indicators on printed circuit boards using surface mount technology at a position elevated above the surface of the board is provided with a body member including a top wall, a bottom wall, opposed sidewalls, a front wall, and a rear wall, all being formed integrally together. Two spaced-apart recesses are formed and aligned vertically in the front wall of the body member terminating in respective first and second interior wall portions. The first interior wall portion has openings formed on diametrically opposed sides of a vertical partition and lying in a horizontal plane parallel to the bottom wall. The second interior wall portion has openings formed on diametrically opposed sides of a transverse partition and lying in a plane which is rotated a predetermined number of degrees from a vertical plane perpendicular to the bottom wall.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com