Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve pilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

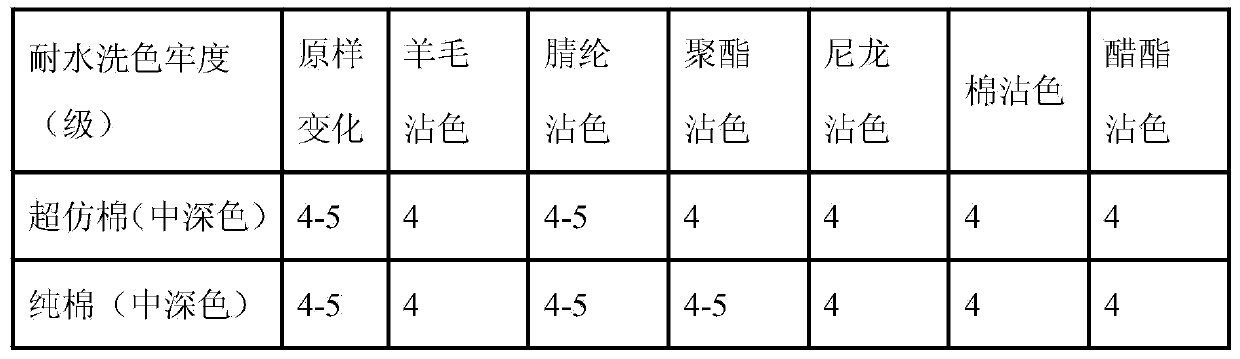

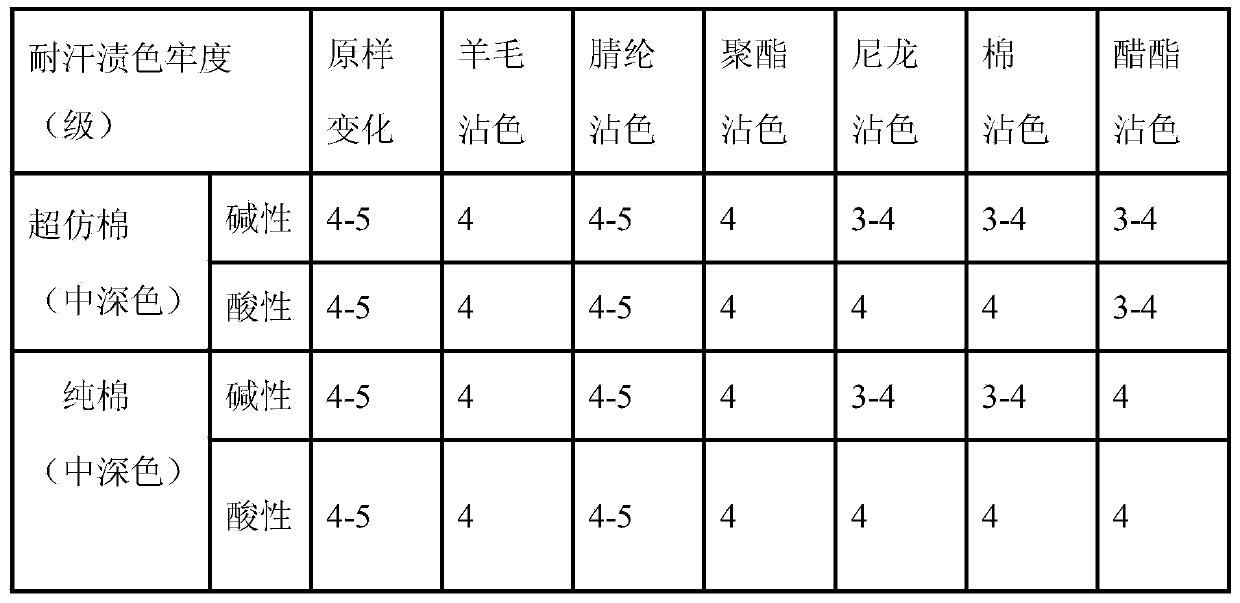

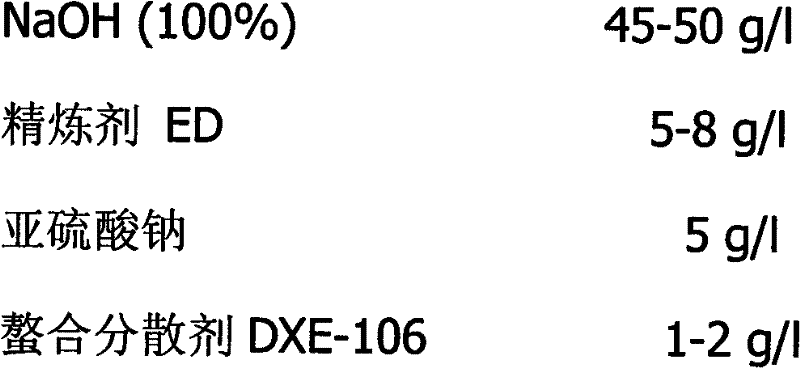

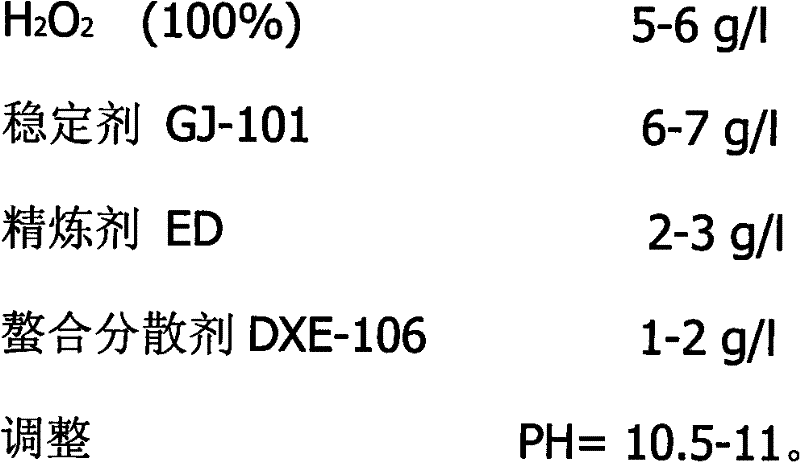

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

New anti-fluffing and anti-pilling technology for polyester-cotton fabric under special standards

ActiveCN102561040AImprove refining effectReduce slipMercerising of indefinite length fabricsFibre treatmentPolyesterEngineering

The invention relates to the technical field of dyeing and finishing production of polyester-cotton anti-fluffing and anti-pilling fabrics. A new anti-fluffing and anti-pilling technology for a polyester-cotton fabric under special standards comprises the following steps of: (1) grey cloth seam turning, (2) primary singeing, (3) flat bleaching, (4) secondary singeing, (5) sizing, (6) mercerizing, (7) dyeing (dispersion / reduction), (8) finishing with a compound solution of ironing-free resin and an anti-fluffing and anti-pilling agent, (9) baking, (10) tentering, (11) pre-shrinking, (12) inspection, and (13) formation of a finished product. The product prepared by the technology meets the special quality requirement of customers for washing for 5 times, 30 minutes in each time, in hot water at 92 DEG C, the anti-fluffing and anti-pilling quality index of the fabric is detected, and the anti-fluffing and anti-pilling quality index of the product for clothes reaches the export standard, namely level 3-4.

Owner:辽宁宏润源印染有限公司

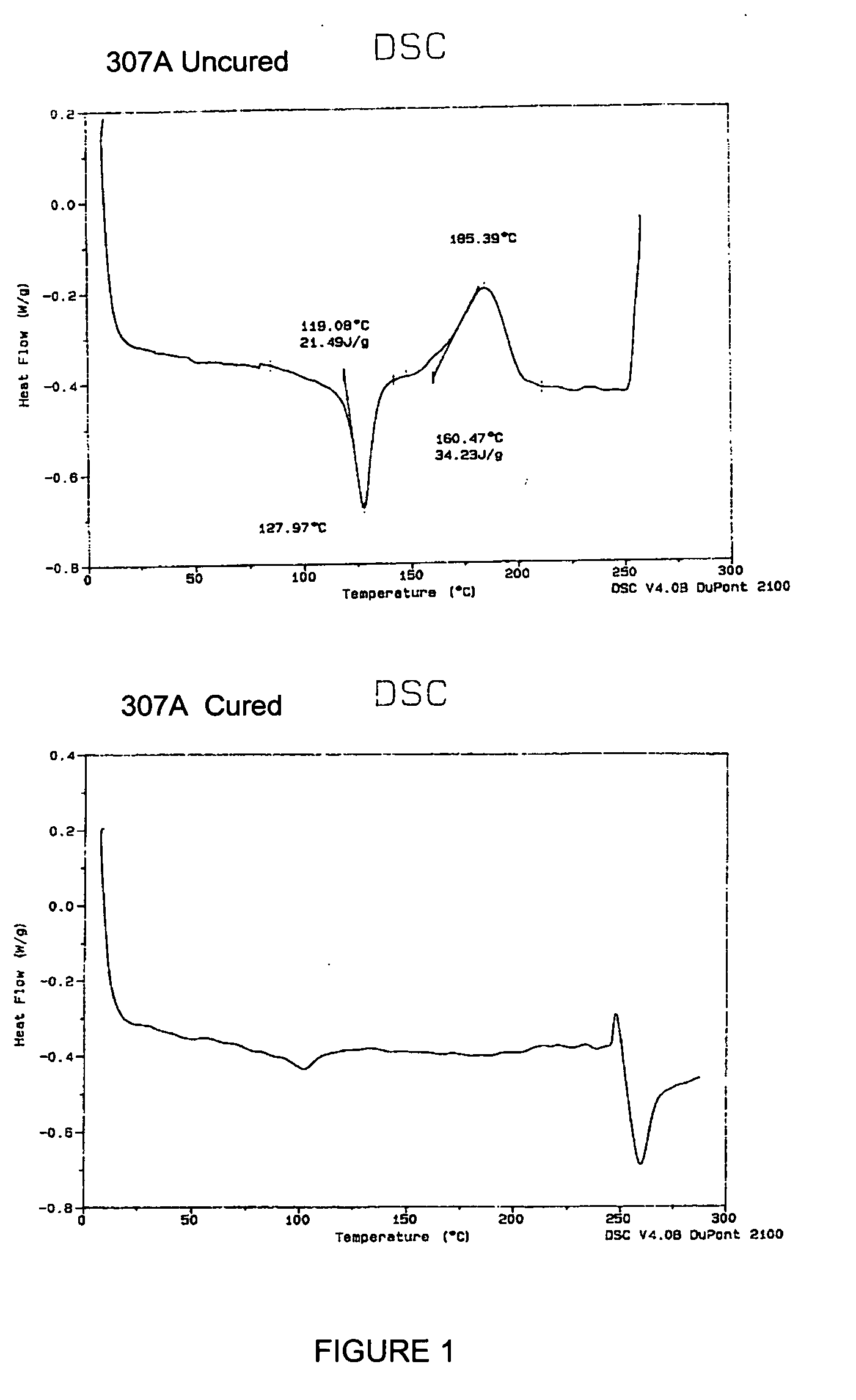

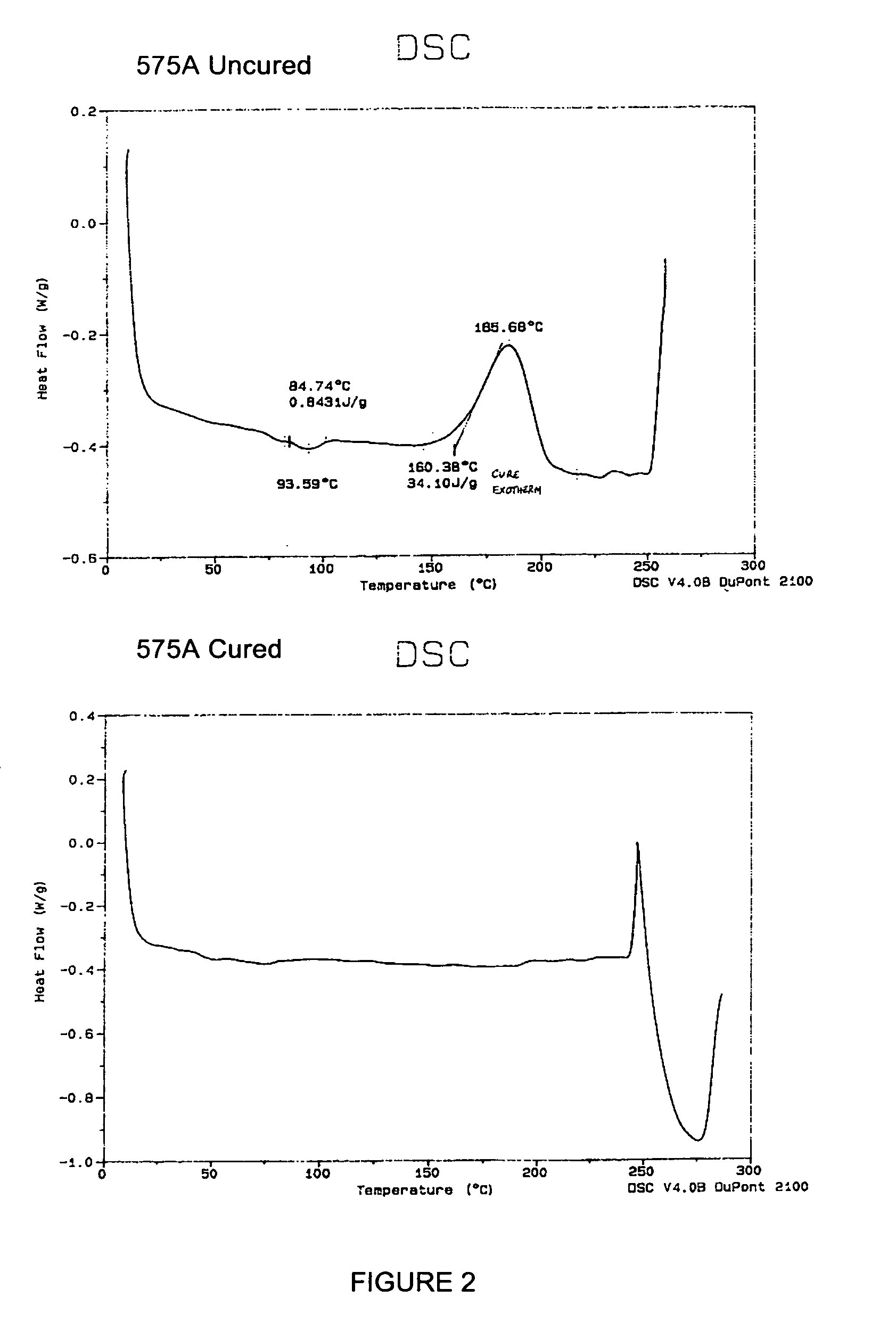

Power transmission products having enhanced properties

ActiveUS20060148990A1Improved compositionImprove pillingV-beltsFilm/foil adhesivesElastomerAlpha-olefin

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers , such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

Zelkova serrata clump culture method

ActiveCN105850647AReduce spacingAvoid bendingCultivating equipmentsHorticulture methodsZelkova serrataAgroforestry

The invention discloses a zelkova serrata clump culture method and belongs to the field of plant clump culture. The method has the advantages that great bending of nursery stock is avoided during clump planting. According to the technical scheme, the zelkova serrata clump culture method comprises the methods of seed selection, seedling culture, primary seedling selection, root rearing, secondary seedling selection, nursery stock digging, nursery stock treatment, nursery stock clump planting, adult plant culture and adult plant transplanting. Growth of the roots of nursery stock is ensured, branch gaps are reduced after nursery stock clump planting, branch bending is avoided, and the landscape effect is improved.

Owner:NANJING HONGSEN SEEDLINGS CO LTD

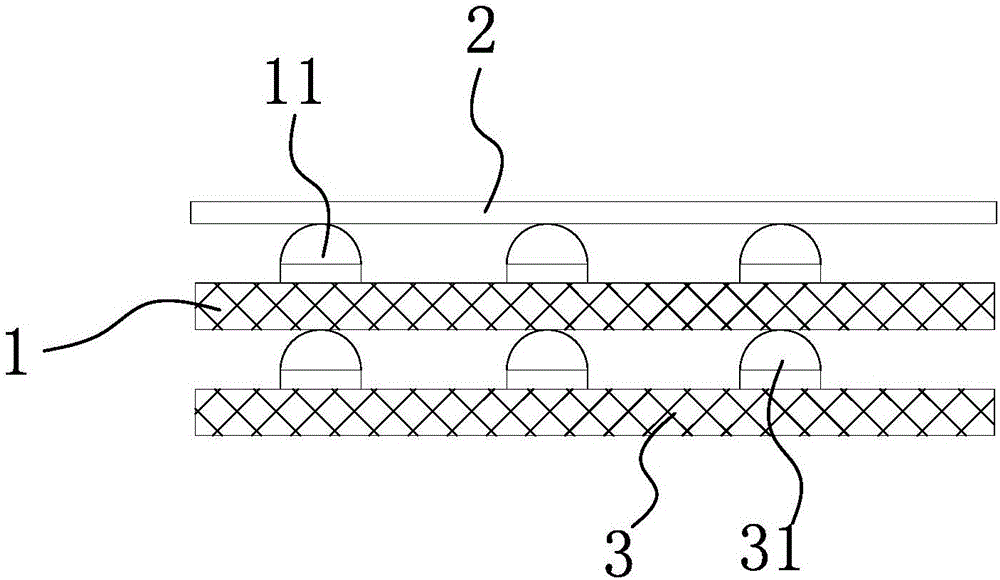

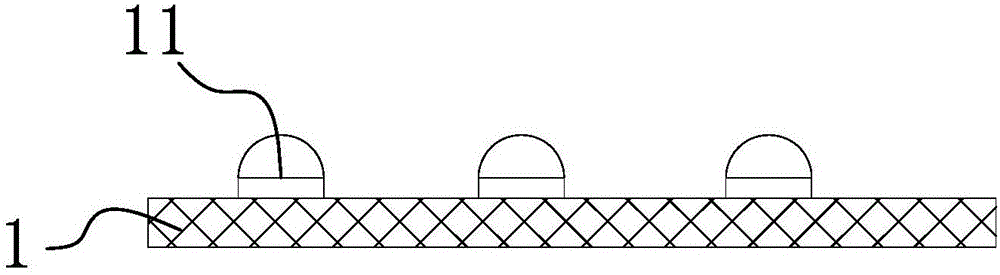

Three-layer knitted composite fabric and production technology thereof

ActiveCN106183119AImprove mechanical propertiesThick textureLaminationLamination apparatusEngineeringCoating

The invention belongs to the technical field of clothing materials, particularly relates to three-layer knitted composite fabric and a production technology thereof, and solves the technical problems of poor wearing comfort, poor shape maintenance performance, small application range and the like in the prior art. The three-layer knitted composite fabric comprises wrap-weft insertion warp knitted fabric, outer fabric and inner fabric, wherein a first double-dot coating is arranged on one surface of the wrap-weft insertion warp knitted fabric; the outer fabric is connected with one surface of the wrap-weft insertion warp knitted fabric through the first double-dot coating; a second double-dot coating is arranged on one surface of the inner fabric, and the other surface of the wrap-weft insertion warp knitted fabric is connected with the inner fabric through the second double-dot coating. The production technology of the three-layer knitted composite fabric comprises steps as follows: A, preparation of materials; B, compositing. The three-layer knitted composite fabric and the production technology thereof have the advantages that the technology is simple, good balance between the wearing comfort and the shape maintenance performance can be kept, and the application range can be enlarged.

Owner:CPL NEW MATERIAL TECH CO LTD

One-way moisture conducting fabric and production process thereof

ActiveCN107034692AImprove hydrophilicityIncrease moisture contentWeft knittingSynthetic resin layered productsFiberColour fastness

The invention relates to a one-way moisture conducting fabric by means of a textile material characteristic and a knitted fabric specific structure and a production process thereof. The one-way moisture conducting fabric comprises 35-45% of cotton fibers, 45-55% of polyester fibers and 5-15% of hydrophilic polyester fibers. The one-way moisture conducting fabric produced through the process can bring water absorbed by a base shirt to the surface of a jacket, the closed-fit inner layer is kept dry and comfortable, and the comfort of the human body during exercise is effectively improved; the phenomena of static, hair shedding and hair staining during kinetic friction and the pilling problem during washing and friction are relieved; no waterproof agent is used during after-finishing processing, environmental protection is promoted, the manufacturing process is simple, low carbon and environmental protection are achieved, the cost is low, the color and the color fastness are not affected, one-way moisture conducting performance is permanent, and the fabric is washable, soft in hand feeling, comfortable and breathable. The fabric has the advantages of being excellent in performance and low in cost.

Owner:广州锦兴纺织漂染有限公司

Permanent-flame-retardant multicomponent blended yarn, fabric, fabric making process and molten metal splashing resistant protection garment

InactiveCN110359148AImprove securityImprove flame retardant performanceWoven fabricsYarnYarnColour fastness

The invention discloses permanent-flame-retardant multicomponent blended yarn, fabric, a fabric making process and a molten metal splashing resistant protection garment and belongs to the technical field of protection garment fabric. The blended yarn comprises, by weight, 64-75% of Lenzig flame-retardant viscose fiber, 15-30% of aramid fiber, 1-5% of polyimide fiber and 5-8% of nylon fiber. Consumption of intrinsically flame-retardant fiber is lowered, and consumption of the flame-retardant viscose fiber is increased; by adding the polyimide fiber and the nylon fiber, strength of the fabric isimproved, and the fabric has excellent permanent flame retardance and metal molten splashing resistance; the fabric has the advantages of being high in strength, moisture permeability and color fastness, comfortable to wear, environment-friendly and basically degradable.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Production method and home-textile application of wool-tencel bi-component blended yarns

The invention discloses wool-tencel bi-component blended yarns which are formed by blending 25-35% of wool and 65-75% of tencel fiber. According to the arrangement, by adding the tencel in wool fibers, inter-friction of the wool fibers is reduced, the product is prevented from shrinkage and pilling in use, and wool fabric intensity is improved; the product, made of the fabric formed by blending the tencel and the wool, is excellent in hand feeling and surface smoothness, allows people to rarely feel the special wool itchy and meets needs to the healthy and comfortable green products of customers; besides, the tencel is so glossy as real silk and colorful, bright and soft after easily dyed. The invention further discloses a production method of the wool-tencel bi-component blended yarns and solves the key problem of the wool and tencel spinning. The production method lowers cost, maintains yarn finishing performance and has favorable properties of the wool and the tencel.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Rabbit tomentum blanket and production process thereof

The invention relates to a rabbit tomentum blanket and a production process thereof. The rabbit tomentum blanket comprises a blanket liner, wherein fillers are filled in the blanket liner, and a depilation preventing isolated layer is arranged between the fillers and the blanket liner. The fillers comprise the following raw materials in part by weight: 60 to 80 parts of rabbit tomentum, 10 to 30 parts of cashmere and 10 to 15 parts of low-melting point chemical fibers. The rabbit tomentum blanket has the advantages that: the problem of hair slip of the rabbit tomentum blanket is radically solved by improving the production process and production technology of the rabbit tomentum blanket, the rabbit tomentum blanket have good effects of hair slip prevention, depilation prevention and pilling prevention, excellent heat retention performance and remarkable health-care function; and the process develops and utilizes the rabbit tomentum widely, liberates and develops the breeding industry of long hair rabbits, elongates the breeding industry chain of the long hair rabbits, and improves additional values of rabbit hair products, so that the rabbit hair products begin to walk into thousands of households and serve the home life of people.

Owner:枣庄甘霖实业有限公司

Anti-static silk fabric

InactiveCN106666885ALow costImprove gloss and skin-friendlyProtective garmentSpecial outerwear garmentsElectromagnetic fieldEngineering

The invention discloses an anti-static silk fabric. The anti-static silk fabric is a blended product of cotton fiber, silk fiber, bamboo charcoal fiber, carbon conductive fiber and coffee carbon fiber. The anti-static silk fabric has the advantages that according to the fabric prepared through the method, the cost of a silk fiber product can be reduced, light, luster, a skin-friendly property, fabric balling up and sagging can be improved, and the fabric is smooth, neat, anti-static, soft and comfortable in hand feeling, light in texture, solid and durable. The carbon conductive fiber in the silk fabric can effectively prevent the accumulation of electrostatic charges, is washing resistant, has a certain shielding effect on an electromagnetic field, thus the anti-static silk fabric has good and durable anti-static performance, reduces harm of electromagnetic radiation to the human body, and has a health care effect. The fabric effectively prevents adsorption on dust in the wearing process, and keeps the attractiveness of the clothes.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Antibacterial fiber and preparation technology thereof

InactiveCN108642872AAntibacterial hasWith slipperyBiochemical fibre treatmentGrip property fibresCross-linkTextile fiber

The invention discloses an antibacterial fiber and a preparation technology thereof. The preparation technology of the antibacterial fiber comprises the following steps of a, fiber pretreatment; b, silver ammonia solution preparation; c, nano-PU microsphere adding; d, fiber soaking; e, drying for the first time; f, reduction reaction; g, drying for the second time to obtain the antibacterial fiber. According to the antibacterial fiber and manufactured antibacterial fabric, a fiber texture itself adsorbs the silver ammonia solution, and nano-PU is cross-linked on the surface of a textile fiber;nano-elemental silver is firmly adsorbed on the textile fiber through haptoreaction, an adhering layer of nano-spandex is formed on the surface of the textile fiber so that the antibacterial, smoothand elastic properties of the fabric are increased, and the anti-fuzzing and piling properties and the antistatic property are improved.

Owner:JOES HOME TEXTILE CO LTD

Processing method of mothproof, anti-mite, moisture-absorption and heat-generating wool yarn

The invention provides a processing method of a mothproof, anti-mite, moisture-absorption and heat-generating wool yarn. The processing method comprises the following steps: firstly, making wools intowool tops; secondly, mixing moisture-absorption and heat-generating acrylic fibers with PLA fibers to form blended strips; thirdly, mixing the wool tops with the blended strips to form rough yarn strips; and fourthly, twisting two rough yarn strips to form a wool yarn. The processing method provided by the invention has the advantages that wool fibers with high moisture regain and the moisture-absorption and heat-generating acrylic fibers are smartly combined, moisture in human body or environment can be continuously absorbed, heat is released, moisture absorbing and heat generating effects are realized, and the processed wool yarn is especially applicable to development of winter warm clothing products.

Owner:TONGXIANG GRANDSMARK TEXTILE

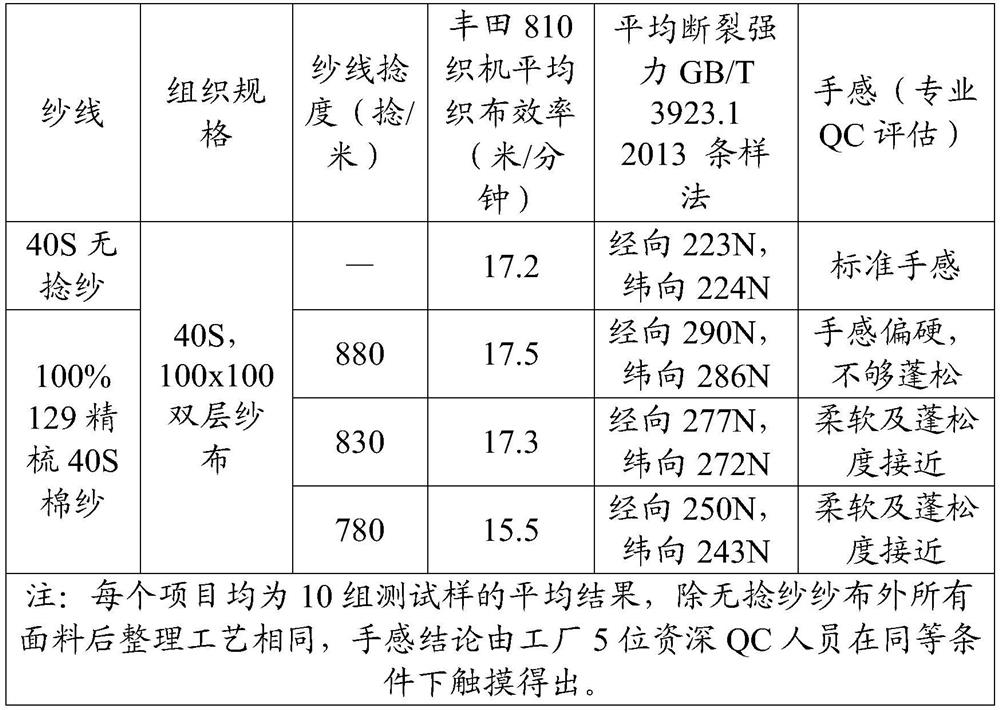

Pure cotton imitation untwisted yarn super-soft gauze and preparing method thereof

InactiveCN111764027AFluffy and softEmission reductionFabric breaking/softeningWoven fabricsYarnFiber

The invention discloses pure cotton imitation untwisted yarn super-soft gauze and a preparing method thereof. The preparing method of the pure cotton imitation untwisted yarn super-soft gauze comprises the following steps of cotton bale flock yarn spinning, slashing, weaving, loose type water washing, dehydration drying, dying or printing, air flapping, sizing, preshrinking and finished product forming. As cotton bale flock yarns are adopted for weaving and fluffiness is achieved through air flapping, the strength of yarns does not need to be improved through water soluble fibers, weaving efficiency is ensured, and pollutant emission is reduced. The preparing method adopts a physical method to soften the textiles, no softening agent or a little of a softening agent is added, and high efficiency and environment friendliness are achieved; the pure cotton imitation untwisted yarn super-soft gauze prepared with the method is quite soft and fluffy in hand touch, and the issues that fuzz balls and lint are likely to occur are relieved compared with untwisted gauze.

Owner:SHENZHEN PURCOTTON TECH

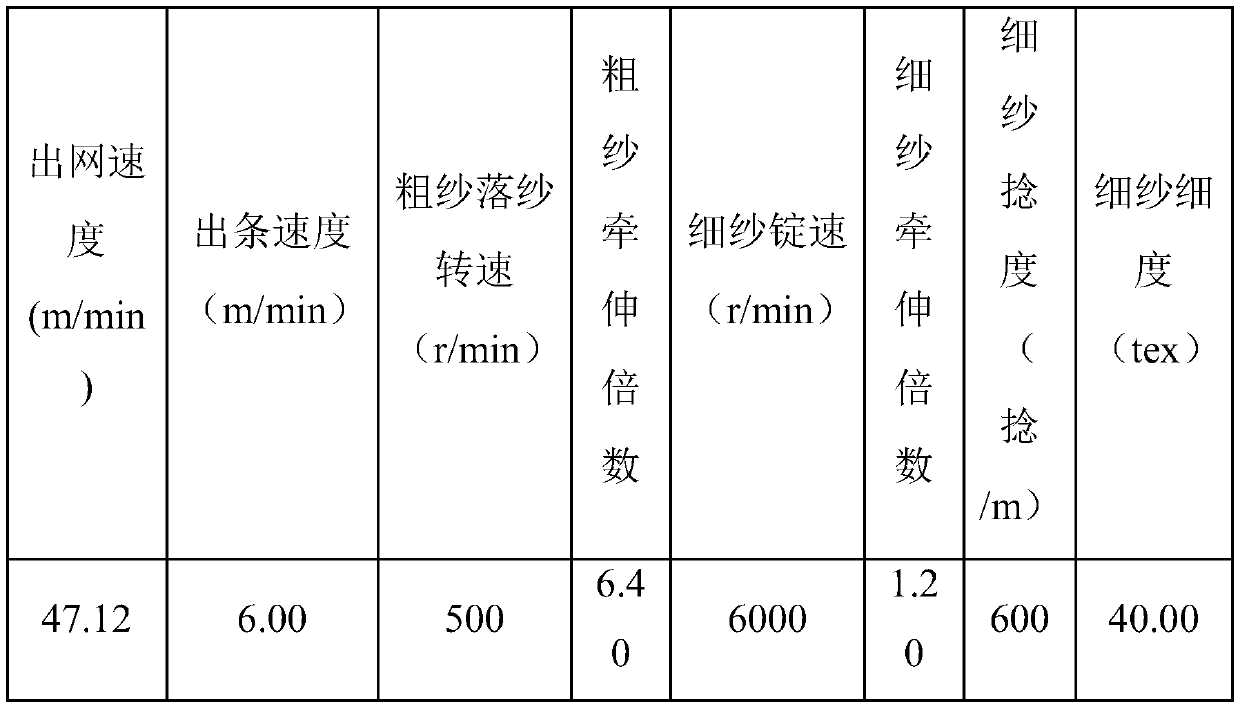

Production method for spinning high count cashmere yarns with wool-cotton type mixed technology route

The invention provides a production method for spinning high count cashmere yarns with a wool-cotton type mixed technology route. The method comprises the following steps: 1) wool blending: adopting awool-type wool blending machine; 2) carding: utilizing a roller-type and cover plate-type wool-cotton mixed type combined carding machine; 3) first gilling-secondary gilling-third gilling-fourth gilling-fifth gilling; 4) first roving-secondary roving; employing a wool-type twistless roving machine to perform secondary roving operation; 5) spinning: adopting a cotton-type compact spinning machineand remoulding a draft rocking rack into a slip draft rack; 6) spooling-doubling-twisting; 7) yarn steaming: forbidding to steam stocking yarns and allowing to steam machine-woven yarns. The damage tocashmere fibers is reduced. A part of shorter fibers is removed. Therefore, cashmere fibers are more easily carded, drawn and controlled. Yarn evenness and strength are enhanced. Yarn hairiness is reduced. wear resistance of yarns is enhanced. Fuzzing and pilling occurrences of fabric are decreased.

Owner:JIANGSU DANMAO TEXTILE

Method of using air-jet vortex spinning for spinning polysulfonamide yarns

InactiveCN101671874AEasy to organizeReduce defectsContinuous wound-up machinesOpen-end spinning machinesYarnPetroleum engineering

The invention relates to a method of using air-jet vortex spinning for spinning polysulfonamide yarns, which comprises that air-jet vortex spinning is used, and the technical parameters are as follows: nozzle pressure P=0.42 to 0.68 MPa, spindle distance L=16 to 20mm and V=330 to 360m / min. The invention has simple operation and high production efficiency, and can improve yarn evenness and reduce yarn defects.

Owner:DONGHUA UNIV

Woolen cloth fabric easy to maintain

InactiveCN104783356ALow costConvenient careProtective garmentSpecial outerwear garmentsPolymer scienceEngineering

The invention discloses woolen cloth fabric easy to maintain. The woolen cloth fabric easy to maintain mainly comprises, by mass fraction ratio, 50-60 parts of wool fibers, 30-40 parts of improved polypropylene fibers, 20-30 parts of soybean fibers, 25-35 parts of viscose fibers, 15-30 parts of polyamide fibers and 15-30 parts of polyester fibers. The woolen cloth fabric easy to maintain has the advantages that the fabric prepared through the method can lower the cost of woolen cloth products, and improve the glossiness and the skin-friendly performance of products, fabric pilling is relieved, and the drapability of the fabric is improved; the fabric is smooth, easy to maintain, soft and smooth in hand feeling, light in weight, firm and durable. The prodding and itching feeling of traditional woolen type shirt fabric is eliminated, and the fabric has soft hand feeling and skin-friendly performance. The fabric has the performance of antibiosis, deodorization, warm keeping and pilling resistance, the cost of raw materials is low, the manufacturing method is easy, operation is easy, and the effect is remarkable.

Owner:RUGAO SANFEI FASHION CO LTD

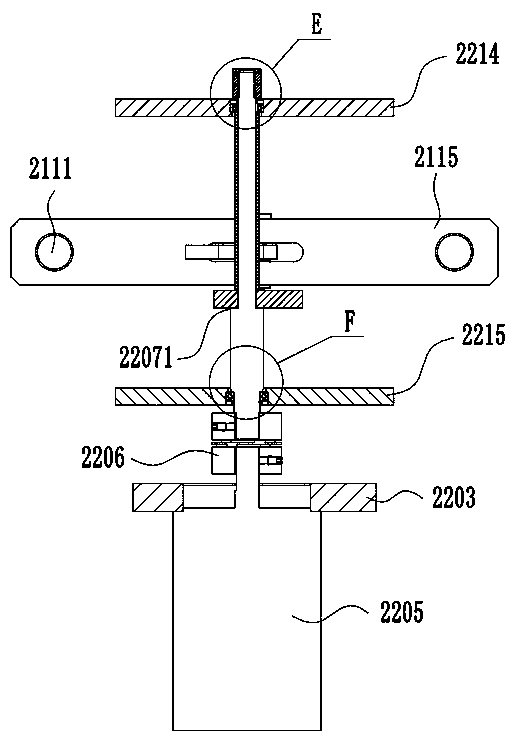

Test equipment for fabric fuzzing and pilling

InactiveCN111441163ASatisfy the pursuitImprove test efficiencyInspecting textilesStructural engineeringTest equipment

The invention provides test equipment for fabric fuzzing and pilling and belongs to the technical field of textile machinery. The test equipment comprises a rack device, a fabric unwinding device, a fabric winding device, a guide device, an electrostatic generator, a double-side fuzzing and pilling device, a perpendicularity adjusting device, a fuzz ball scraping device and a fuzz ball conveying and weighing device, wherein the double-side fuzzing and pilling device comprises a sliding double-side fuzzing and pilling mechanism and a double-side fuzzing and pilling drive mechanism; the fuzz ball scraping device comprises an upper fuzz ball scraping mechanism, a lower fuzz ball scraping mechanism and a fabric guide mechanism; and the fuzz ball conveying and weighing device comprises a firstfuzz ball conveying mechanism, a second fuzz ball conveying mechanism and a weighing mechanism. The test equipment can achieve synchronous fuzzing and pilling testing on double sides of a textile fabric, is high in testing efficiency, and achieves weighing of fuzz balls on the double sides of the textile fabric, so that quantitative evaluation is achieved, and the fabric fuzzing and pilling testing accuracy is greatly improved.

Owner:全彬强

Blended yarn, preparation method of blended yarn and method for preparing fabric by adopting blended yarn

InactiveCN111118683ALow costOvercome PillingGrip property fibresAbrasion resistant fibresYarnPolymer science

The invention relates to a blended yarn, a preparation method of the blended yarn and a method for preparing a fabric by adopting the blended yarn. The blended yarn is prepared by taking mink cashmereas a main raw material and chinlon, acrylic fiber and aloe fiber as auxiliary raw materials. The preparation method of the blended yarn comprises the steps of treating the main raw material with wooloil, wherein the wool oil comprises spindle oil, sulfated castor oil, triethanolamine oleate, an emulsifier and glycerin; after wool oil and wool treatment, opening the main raw material; mixing themain raw material with chinlon, acrylic fiber and aloe fiber to obtain mixed fibers, and opening the mixed fibers; sequentially carrying out cotton carding, drawing, roving, spinning and spooling on the mixed fibers so as to obtain the finished blended yarn. The blended yarn adopted in the invention is applied to weaving of special fabric, and the prepared fabric has the advantages of being high in firmness, resistant to pilling, resistant to static electricity and the like.

Owner:GUIZHOU WANGFENGLIN TEXTILE TECH CO LTD

Stain-resistant and easy-to-clean yarn and production process thereof

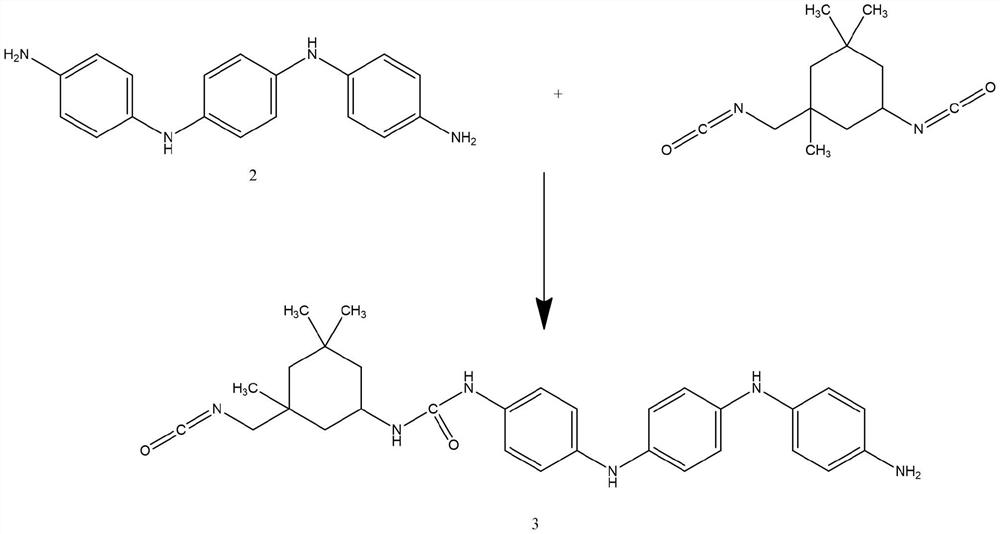

PendingCN113481729AImprove wrinkle resistanceImprove pillingStain/soil resistant fibresLiquid repellent fibresFiberPolymer science

The invention discloses a stain-resistant and easy-to-clean yarn and a production process thereof, and relates to the technical field of textile yarns. An emulsifier and deionized water are used for shearing at a high speed, then glycidyl methacrylate, hydroxyethyl methacrylate, an anti-wrinkle monomer and a stain-resistant monomer are added for continuous shearing, emulsifying is performed to form a pre-emulsion, and an initiator is added into the pre-emulsion, so that the glycidyl methacrylate, the hydroxyethyl methacrylate, the anti-wrinkle monomer and the stain-resistant monomer are polymerized to form a polymer; after the polymer treats yarn, isocyanate is cross-linked with hydroxyl and amino on fiber to form a network-shaped polymer, so that the wrinkle resistance and the fuzzing and pilling performance of the yarn are improved, and the situation that dust is accumulated and difficultly cleaned is avoided; and a modifier is endowed with excellent hydrophobic and waterproof performance through a large number of existing C-F bonds, so that the yarn is prevented from being polluted by stains such as water, oil and dust, and the stain-resistant and self-cleaning effects of the yarn are greatly improved.

Owner:JIESHOU HUAYU TEXTILE

Continuous processing technology for improving fuzzing and pilling of dope-dyed fabric

ActiveCN114411423AContinuityRealize continuous productionSingeingDry-cleaning apparatus for textilesTextile printerPolymer science

The invention relates to a continuous processing technology for improving fuzzing and pilling of a dope-dyed fabric, and belongs to the technical field of textile printing and dyeing. The continuous processing technology for improving fuzzing and pilling of the dope-dyed fabric adopts the following processing flow: singeing, cold batching, washing, tentering and preshrinking, and self-crosslinking polyether polyurethane and a silicon softening agent are adopted in the tentering process. By adopting the process disclosed by the invention, the fuzzing and pilling of the dope-dyed fabric are improved from 2.5 level to 3.5 level, and the improved process is green and environment-friendly; by optimizing the dyeing and finishing process flow and process parameters, the produced dope-dyed fabric has excellent anti-pilling ability and soft hand feeling.

Owner:鲁丰织染有限公司

Production process of pure viscose fabric

PendingCN110725123AStay hygroscopicGuaranteed skin-friendly comfortLiquid/gas/vapor treatment of propelled fabricsHeating/cooling textile fabricsHydroxide potassiumPulp and paper industry

The invention discloses a production process of a pure viscose fabric. The production process of the pure viscose fabric comprises the following steps: first step, mercerizing viscose fabric bleachingcloth by using a potassium hydroxide solution to obtain a product A; second step, performing overflow dyeing on the product A to obtain a product B; third step, carrying out after-finishing on the product B to obtain a product C; and fourth step, preshrinking the product C to obtain a finished product. Viscose fibers can be protected effectively, and furthermore, the phenomena of easiness in wrinkling and pilling of the pure viscose fabric can further be improved effectively.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Three-layer Knitted Composite Fabric and Its Production Technology

ActiveCN106183119BImprove mechanical propertiesThick textureLaminationLamination apparatusEngineeringCoating

The invention belongs to the technical field of clothing materials, particularly relates to three-layer knitted composite fabric and a production technology thereof, and solves the technical problems of poor wearing comfort, poor shape maintenance performance, small application range and the like in the prior art. The three-layer knitted composite fabric comprises wrap-weft insertion warp knitted fabric, outer fabric and inner fabric, wherein a first double-dot coating is arranged on one surface of the wrap-weft insertion warp knitted fabric; the outer fabric is connected with one surface of the wrap-weft insertion warp knitted fabric through the first double-dot coating; a second double-dot coating is arranged on one surface of the inner fabric, and the other surface of the wrap-weft insertion warp knitted fabric is connected with the inner fabric through the second double-dot coating. The production technology of the three-layer knitted composite fabric comprises steps as follows: A, preparation of materials; B, compositing. The three-layer knitted composite fabric and the production technology thereof have the advantages that the technology is simple, good balance between the wearing comfort and the shape maintenance performance can be kept, and the application range can be enlarged.

Owner:CPL NEW MATERIAL TECH CO LTD

Shrink-proof fabric and preparation method thereof

InactiveCN110965338ASmall shrinkageGood dimensional stabilityHeating/cooling textile fabricsGrip property fibresPolymer scienceAqueous ethanol

The invention discloses shrink-proof fabric and a preparation method thereof. The shrink-proof fabric is prepared from borane coupling agent modified silica sol finished fiber fabric, and the preparation method comprises the steps of adding silica sol and a borane coupling agent into a 50%-60% ethanol water solution according to the mass ratio of 1: (0.05 to 0.1), heating to 55+ / -5 DEG C at the heating speed of 2 to 3 DEG C / min, and reacting for 4 to 5 h; and performing fiber spinning, weaving, grey cloth desizing, scouring, oxygen bleaching, tentering and whitening, printing and dyeing processing, soft setting, calendering and preshrinking, wherein the weaving adopts a warp and weft interweaving mode, and the concentration of the modified silica sol in the soft shaping working solution is40 to 60 g / L. The shrink-proof fabric can effectively reduce the shrinkage rate of the fabric and improve the dimensional stability of the washed fabric, meanwhile, the hand feeling of the fabric isnot influenced, and the fuzzing and pilling performance of the fabric further can be improved.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for producing variable satin weave fabric

InactiveCN110820121AImprove tightness and smoothness of cloth surfaceImprove pillingSwivel-woven fabricsLappet-woven fabricsWoven fabricPolymer chemistry

The invention relates to a method for producing a variable satin weave fabric; the method includes: twisting warp yarns and weft yarns, drafting, carrying out satin weaving to obtain a fabric, desizing, coloring, washing, finishing, and setting to obtain the finished fabric. Compared with the prior art, the satin fabric woven herein has uniform warp and weft compactness, elegant surface gloss, high texture grade and the like.

Owner:劲霸男装(上海)有限公司

Process for reducing fabric hairiness shedding, fuzzing and pilling

InactiveCN113699645APromote sheddingImprove pillingLiquid/gas/vapor removalWoven fabricsTextile technologyFiber

The invention relates to the technical field of textiles, in particular to a process for reducing fabric hairiness shedding, fuzzing and pilling. The process comprises spinning, weaving and after-finishing. Low-melting-point fibers are added in the spinning process, the adding amount of the low-melting-point fibers accounts for 1%-5% of the total amount of the fibers, and the melting point of the low-melting-point fibers is less than or equal to the baking temperature in the after-finishing process. The process is applicable to fabrics with different components and different proportions, special textile dyeing and finishing equipment is not needed, the hand feeling of the fabrics is not changed, and the purposes of reducing fabric hairiness falling, fuzzing and pilling can be achieved according to a normal processing process.

Owner:HUAFANG +1

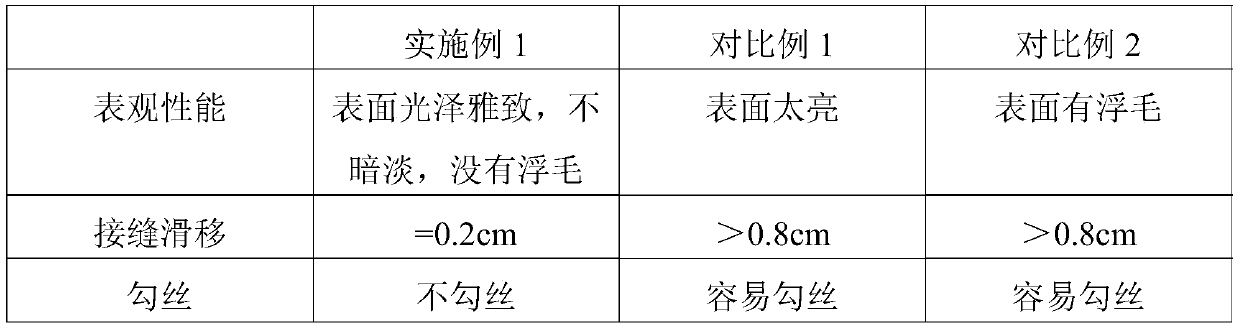

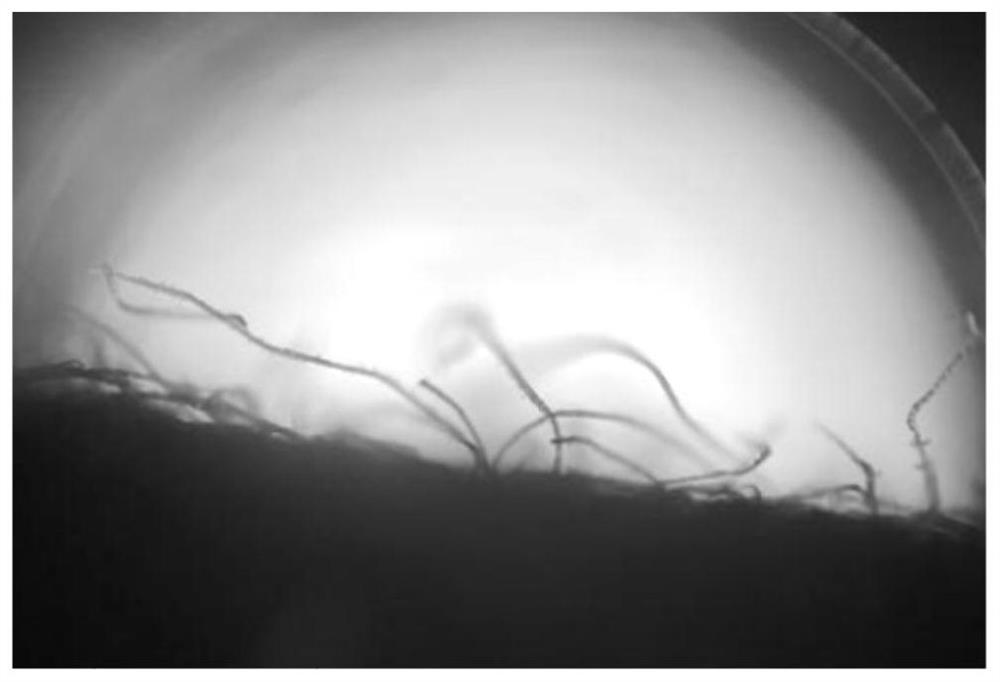

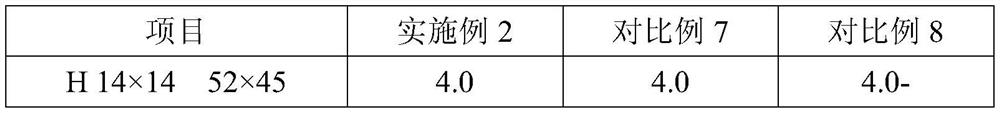

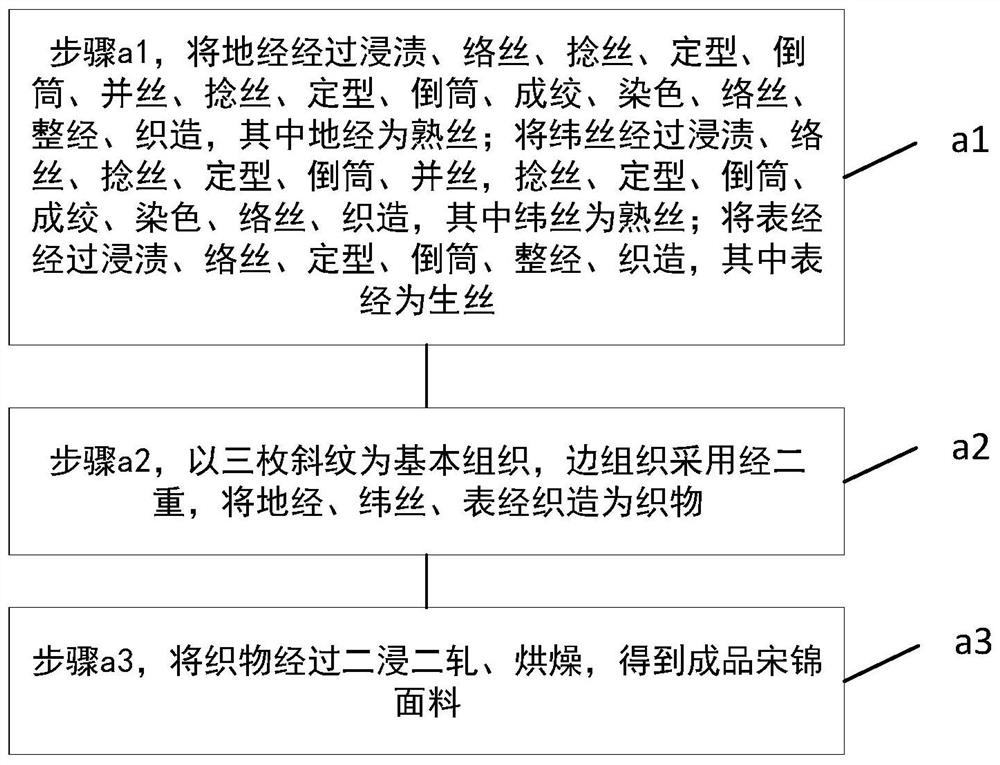

Preparation method of song brocade fabric

ActiveCN108456970BRich organizational structureImprove wear resistanceLiquid/gas/vapor textile treatmentSwivel-woven fabricsMechanical engineeringManufacturing engineering

The invention discloses a preparation method of a brocade fabric. The warp and the weft are processed, the warp and the weft are woven into a fabric, and the fabric is subjected to two dipping, two rolling and drying to obtain a finished Song brocade fabric. Based on Song Brocade's exquisite manufacturing technology and rich and colorful organizational structure, by changing the fabric raw materials, increasing the warp and weft density, and adopting multiple weft, weft pattern and other organizational structures and post-finishing processes to improve the wear resistance and pilling properties of the fabric , making the fabric thick and firm, especially suitable for wide application in the field of luggage, broadening the scope of use of Song Brocade; enriching the organizational structure of Song Brocade, enhancing the use value of Song Brocade fabrics in high-end luggage fabrics; reflecting traditional Chinese culture Features, broad market prospects.

Owner:DING SHENG SILK

A kind of unidirectional wet fabric and its production process

ActiveCN107034692BAvoid stuffinessImprove comfortWeft knittingSynthetic resin layered productsPolyesterFiber

Owner:广州锦兴纺织漂染有限公司

Device for simulating fuzzing and pilling of fabric

InactiveCN111398160APilling RealizationImprove pillingUsing mechanical meansMaterial analysisBilateral symmetryTextile

The invention provides a device for simulating fuzzing and pilling of a fabric. The device belongs to the technical field of textile machinery, which comprises a double-sided fuzzing and pilling module and a double-sided rolling ball module, wherein the double-sided fuzzing and pilling module comprises a sliding double-sided fuzzing and pilling mechanism and a double-sided fuzzing and pilling driving mechanism; the sliding double-sided fuzzing and pilling mechanism comprises a first fuzzing and pilling assembly and a second fuzzing and pilling assembly; fuzzing and pilling broaching teeth arearranged on the first fuzzing and pilling device and the second fuzzing and pilling device; a transmission roller of the double-sided fuzzing and pilling driving mechanism is attached to a double-sided fuzzing and pilling driving cam under the action of an upper torsional spring and a lower torsional spring of a swing base; the double-sided rolling ball module comprises a left rolling ball deviceand a right rolling ball device; and the left rolling ball device and the right rolling ball device are arranged in a bilateral symmetry mode. According to the device, the fuzzing and pilling processof the fabric can be simulated, the anti-fuzzing and anti-pilling performance of the fabric can be conveniently tested, the simulation conditions are variable, and the device is suitable for simulating fuzzing and pilling of different fabrics.

Owner:全彬强

Antistatic coral fleece fabric

The antistatic coral fleece fabric of the present invention is a blended product of wool fiber, cotton fiber, seaweed charcoal fiber, aloe fiber, viscose fiber, conductive fiber and conductive filament fiber. The advantages of the present invention are: the fabric prepared by this method can reduce the cost of coral fleece products, improve product gloss and skin-friendly properties, improve fabric pilling and drapability, smooth and smooth, antistatic, soft and smooth, and light in texture , strong and durable. The conductive filaments and conductive fibers in the coral fleece fabric can effectively prevent the accumulation of static charges, and are resistant to washing, and have a certain shielding effect on the electromagnetic field, so the antistatic coral fleece fabric of the present invention has excellent and long-lasting antistatic properties. And can reduce the harm of electromagnetic radiation to the human body, and has the function of health care.

Owner:南通三荣实业有限公司

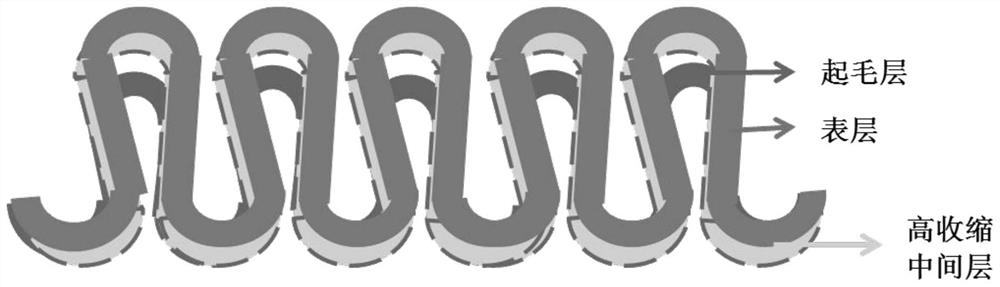

A kind of anti-pilling fabric and its preparation process

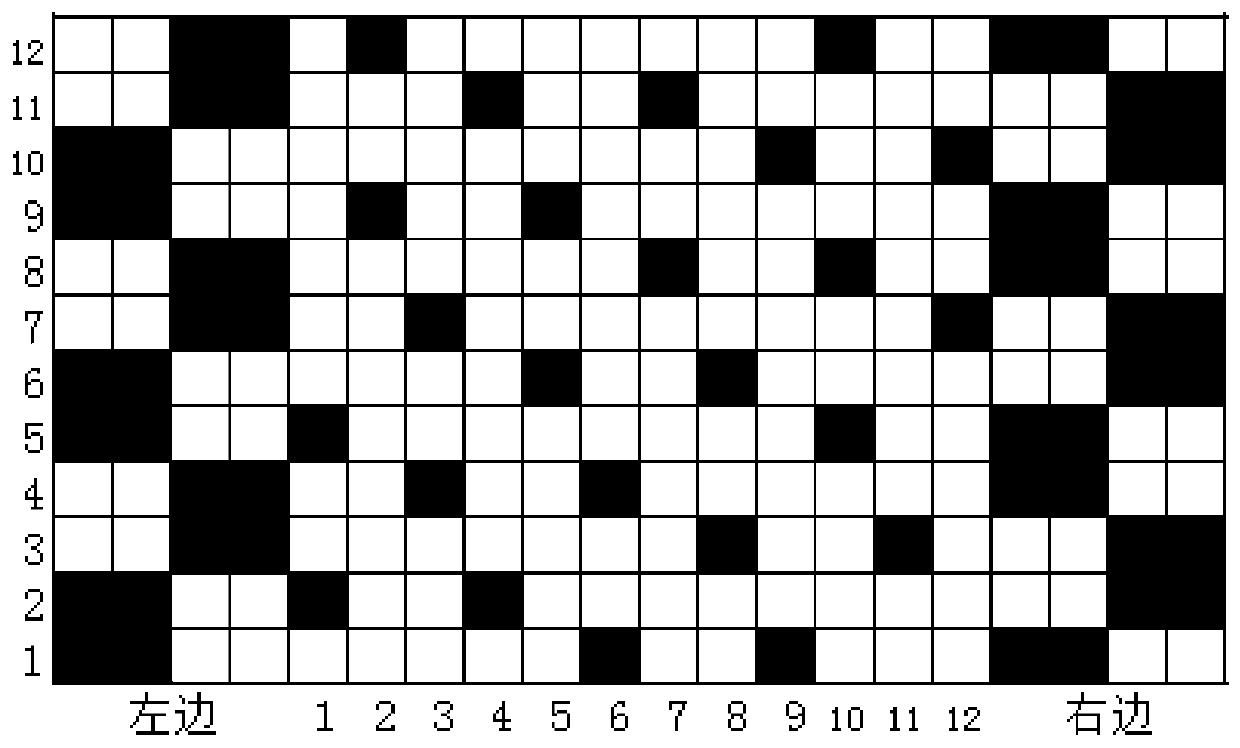

ActiveCN108221152BDoes not affect organizational structureImprove surface propertiesWeft knittingFibre treatmentYarnPolymer science

The invention discloses an anti-pilling fabric and a preparation process thereof. The anti-pilling fabric is a single-sided fabric, and the single-sided fabric is composed of surface yarn, raised yarn and isolation yarn; the described The isolation yarn connects the surface yarn and the raising yarn, and is used to separate the surface yarn and the raising yarn; the isolation yarn is a high-shrinkage elastic yarn. The preparation process of the present invention is obtained by adding locking layer weaving, and using special elastic high-shrinkage yarn and ultra-fine yarn matching weaving, then going through fluffing processing, and finally performing post-finishing processing under appropriate tension conditions. . In terms of structure, the present invention isolates the veil from the inner yarn by using an isolated yarn, so that the surface is not affected by the pulling of the raised surface, and the original style and physical properties are retained. The snagging and pilling on the surface of the fabric meet the requirements of The national standard requires that it is thicker than ordinary fabrics of the same weight and has a certain degree of warmth retention.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com