Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Reduce mutual friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone master batch with long-lasting scratch resistance, and preparation method thereof

The invention discloses a silicone master batch with long-lasting scratch resistance, and a preparation method thereof. The raw materials of the master batch contain modified silicone, the modified silicone is an active group-containing long side chain-grafted high molecular weight polysiloxane, and the raw materials also contain polypropylene, a reinforcing agent, an anti-aging agent and other assistants. The raw materials are internally mixed at 200-220 DEG C, and then are extruded and granulated under certain conditions by a twin-screw extruder to obtain the silicone master batch with long-lasting scratch resistance. The silicone master batch prepared by the invention contains the active group-containing long side chain-grafted high molecular weight polysiloxane, so the problems of unabiding scratch resistance and stress whitening of common silicone are well solved, the plastic processing performance is improved, and the device wearing is reduced. The preparation method of the invention has the advantages of simple process, environmental protection, safety, good repeatability, and easiness in industrialization. The silicone masterbatch prepared in the invention is mainly used for preparing a scratch-resistant automotive interior polypropylene composite material.

Owner:CHENGDU GUIBAO SCI & TECH

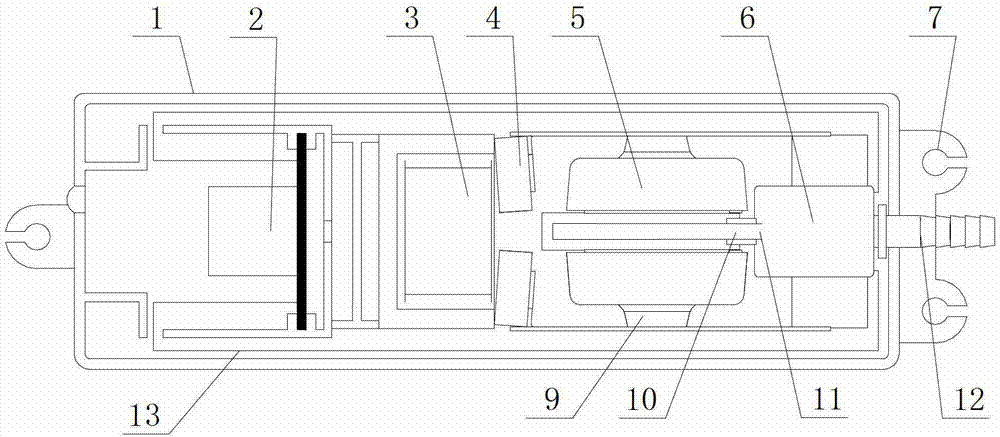

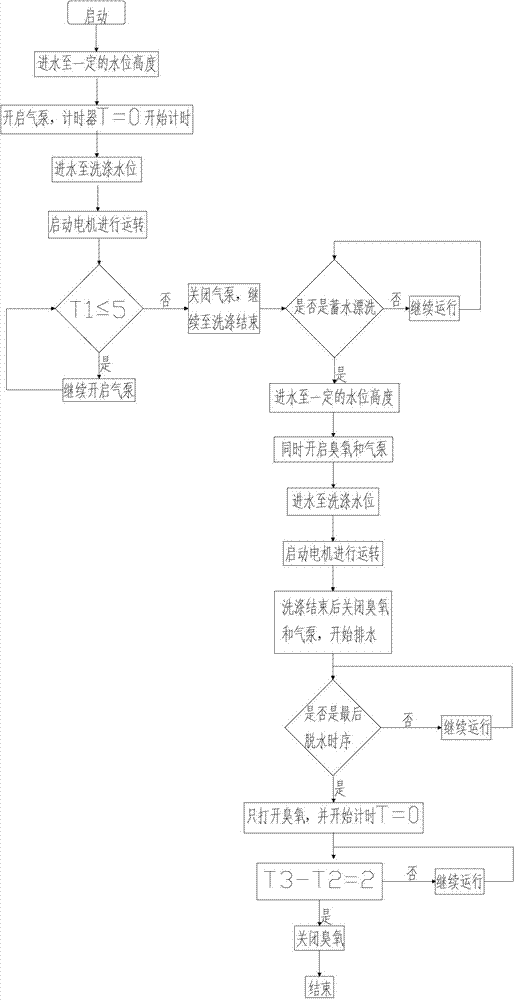

Cleaning sterilizing device for washing machine, washing machine using cleaning sterilizing device and control method thereof

InactiveCN102877271AReduce usageImprove cleaning ratioOther washing machinesControl devices for washing apparatusWater storageOzone generator

The invention relates to a cleaning sterilizing device for a washing machine, a washing machine using the cleaning sterilizing device and a control method thereof, wherein the cleaning sterilizing device comprises an ozone bubble generating device, a bubble generator and a control device; the ozone bubble generating device comprises an ozone generator and an air pump; the ozone bubble generating device is connected with the bubble generator; and the control device can control the ozone bubble generating device and the bubble generator to individually form air bubbles or ozone bubbles or control the ozone bubble generating device and the bubble generator to simultaneously generate air bubbles and ozone bubbles. Through a corresponding control method, only air bubbles are injected in the water cleaning process of the washing machine to reduce the mutual friction of clothes in the washing process; the air bubbles and the ozone bubbles are simultaneously injected in the water storage and rinsing process; and only the ozone bubbles are injected in the final dewatering procedure to sterilize the clothes. The washing machine using the cleaning sterilizing device has the advantages of high clean ratio, high sterilizing capability, low ozone consumption and low energy consumption, and is helpful for realizing energy conservation and discharge reduction.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Non-cutting variable cross-section steel plate spring and end forming manufacturing technology and device thereof

InactiveCN101561023AImprove fatigue lifeImprove noiseLeaf springsManufacturing technologySheet steel

The invention discloses a non-cutting variable cross-section steel plate spring, which is an arc-shaped plate spring and consists of a plurality of variable cross-section steel plate spring strips overlapped mutually. The radian of each steel plate spring strip takes a steel plate center as a symmetric point and the arcs of both ends are completely same. A straight section is arranged in the middle part of each steel plate spring strip, the exterior at the end of the steel plate spring strip presents a convex arc and both sides thereof present a concave arc. The invention further discloses a manufacturing technology and a manufacturing device of the steel plate spring. The steel plate spring and the technology thereof, on the basis of keeping the property of an original variable cross-section steel plate, can effectively reduce the generation of early fatigue sources at ends among steel plate spring strips due to corner cut burr, increase the anti-fatigue life of the plate spring, improve the utilization rate of materials, reduce mold consumption during the plate manufacturing process, reduce the labor quantity of operators and effectively reduce the production cost of the plate spring.

Owner:QINGDAO SHUAICHAO IND

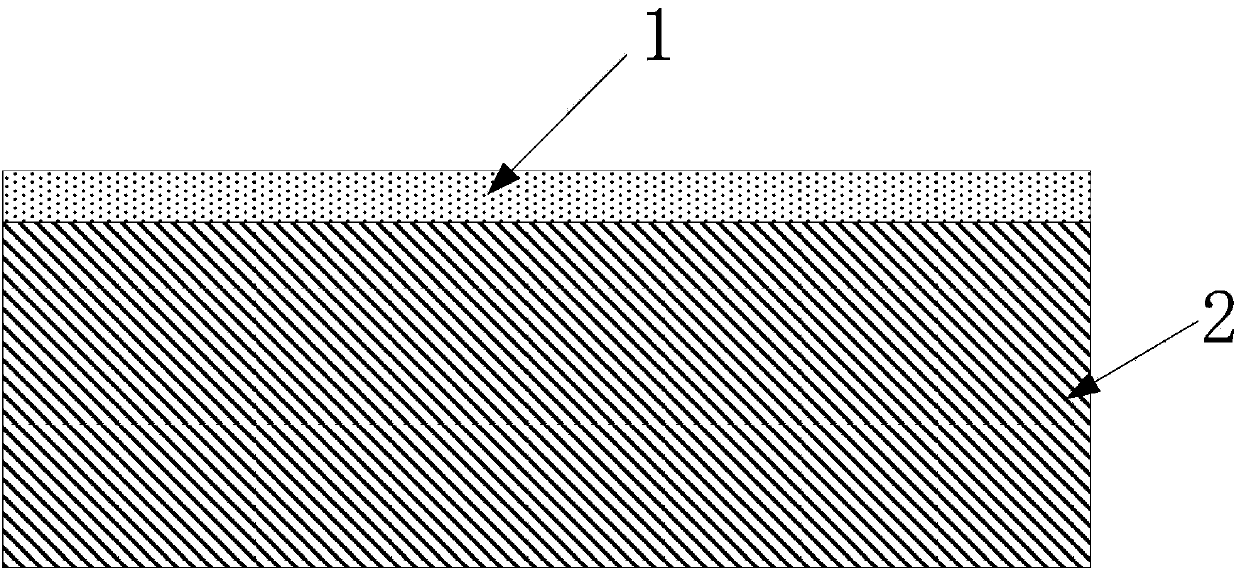

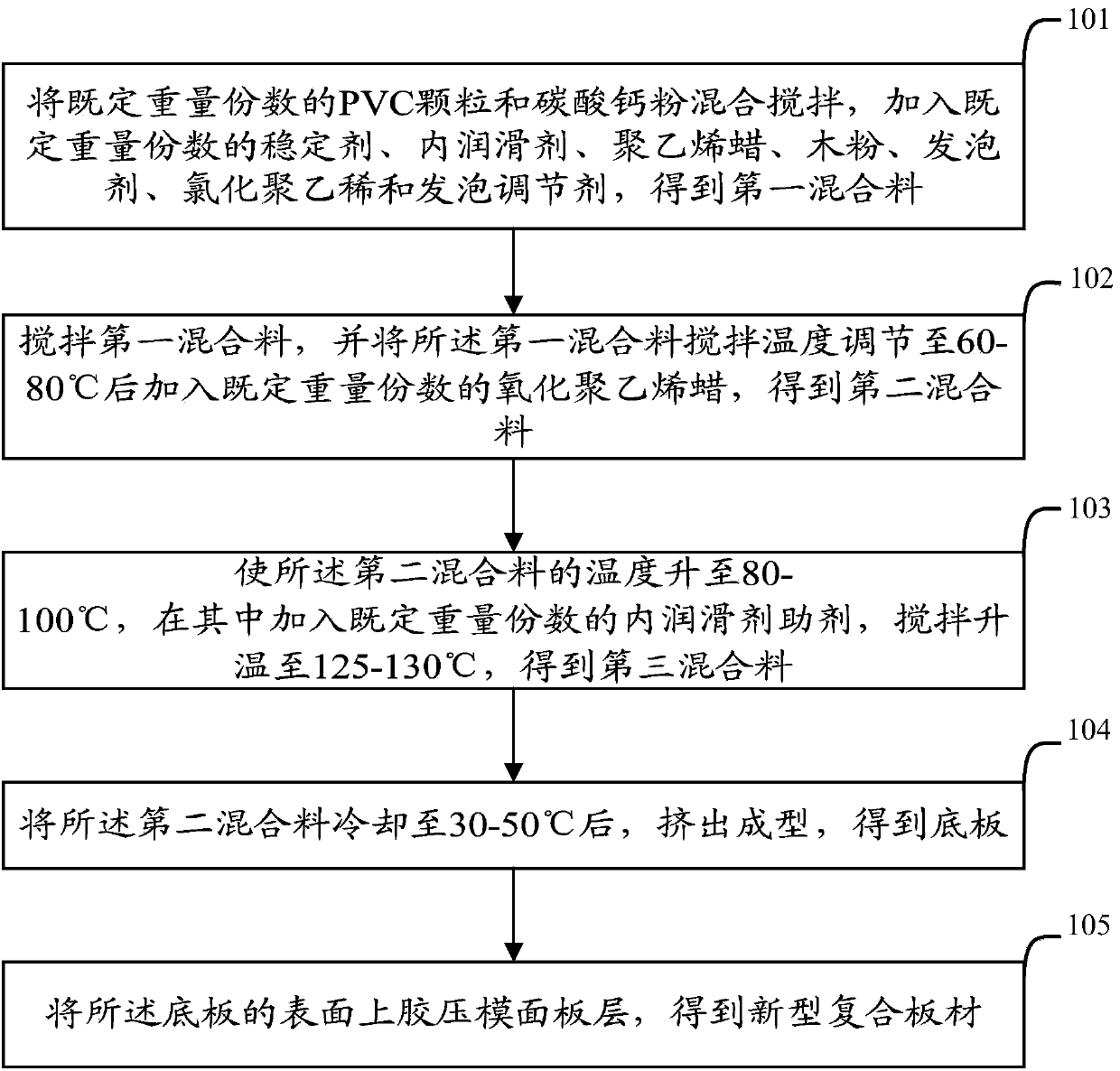

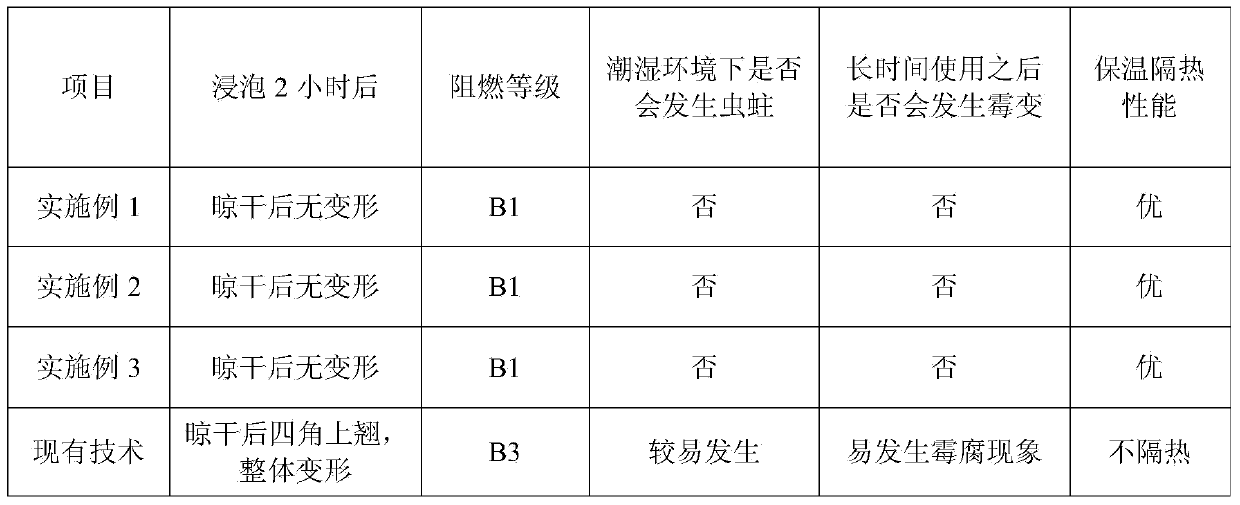

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

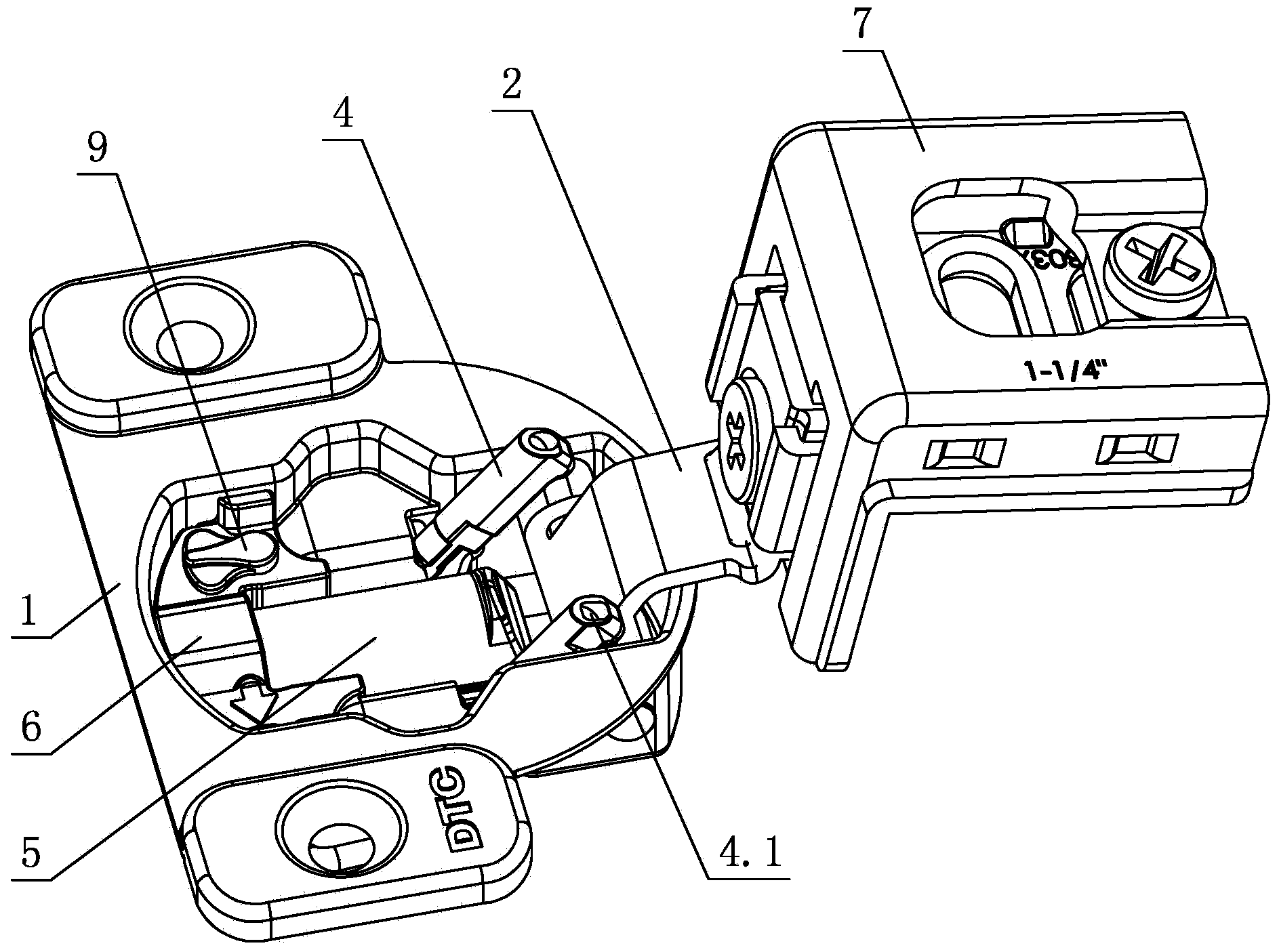

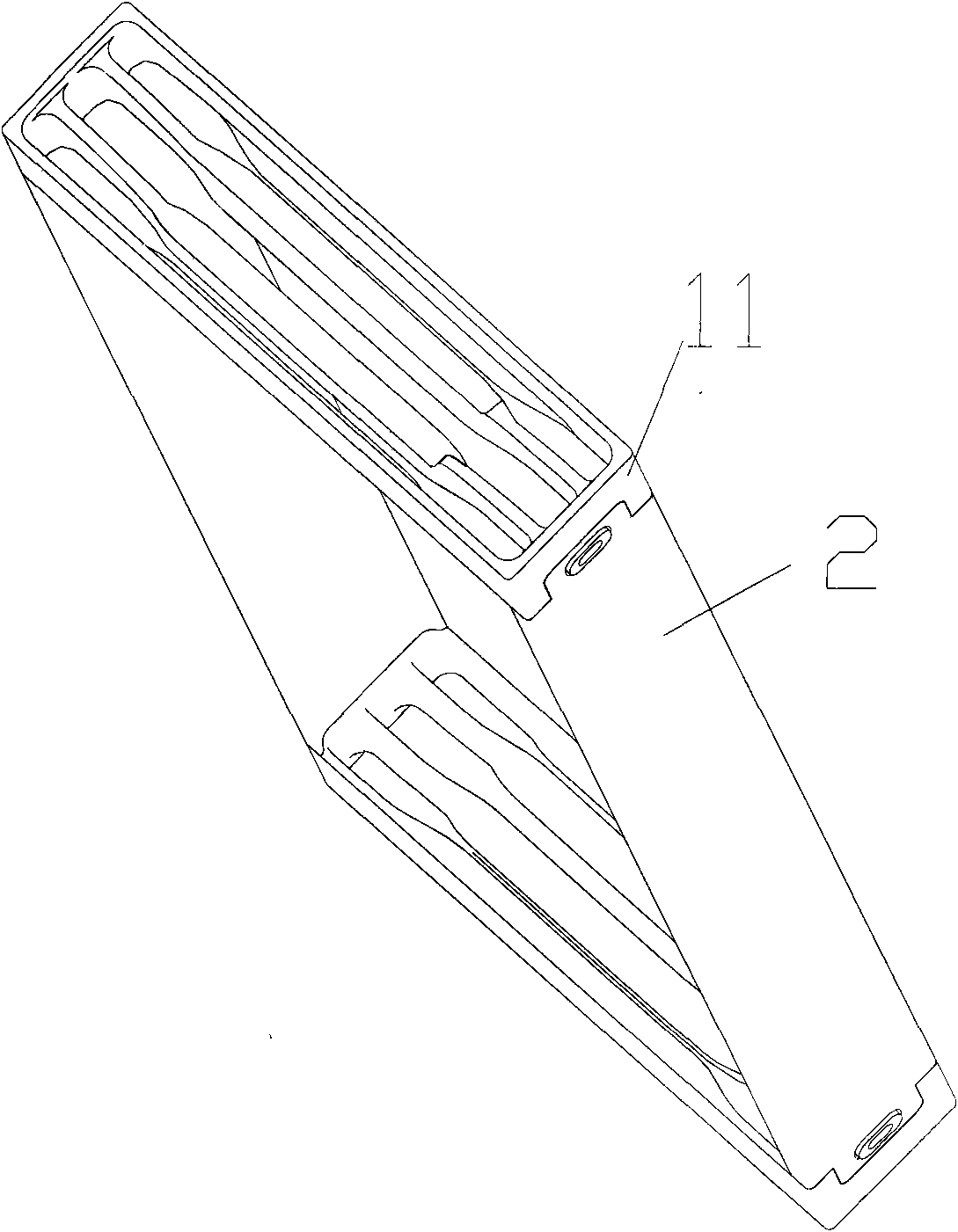

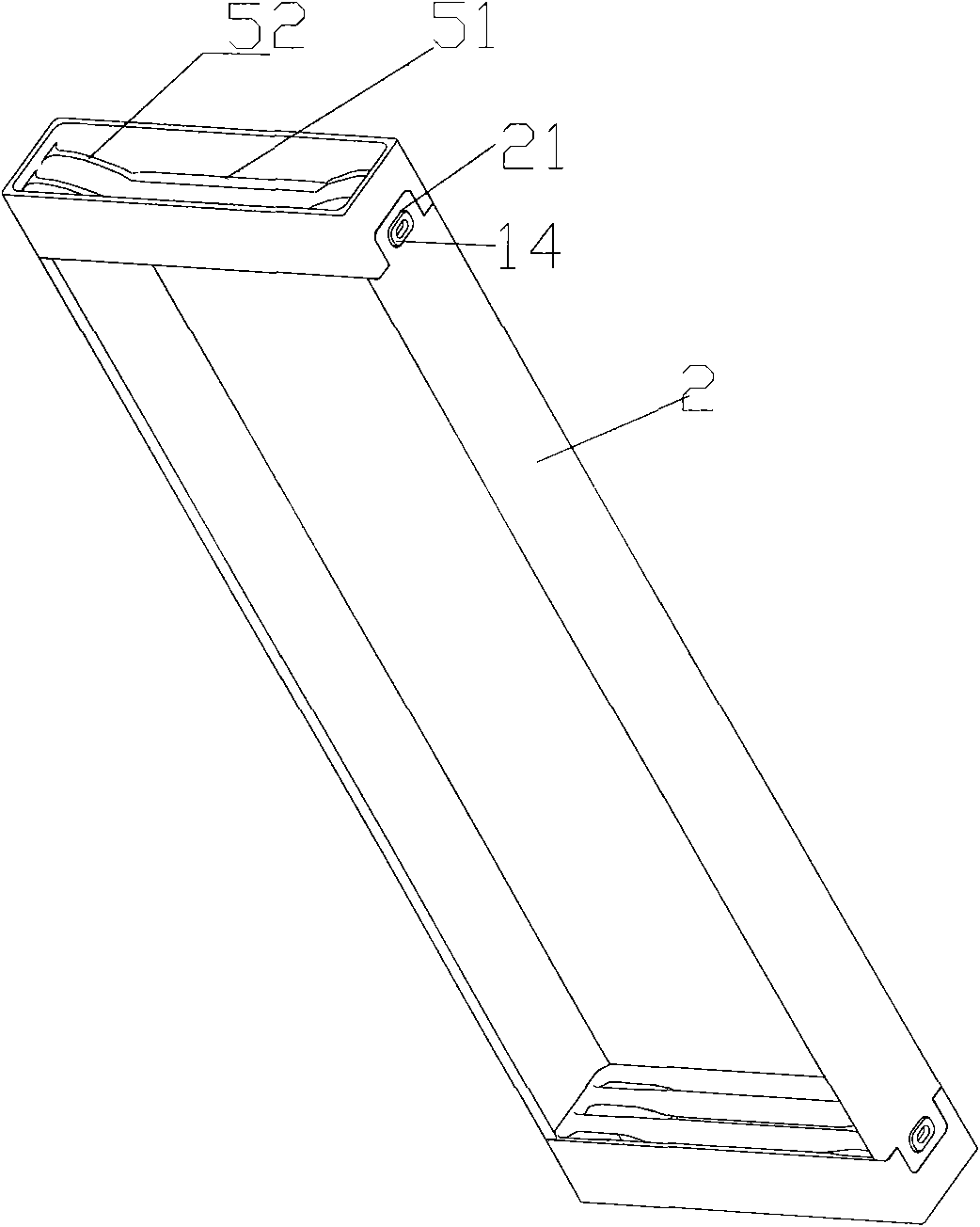

Silent hinge for furniture

InactiveCN103953236AReduce noiseOpen and close smoothlyBuilding braking devicesPin hingesEngineeringMechanical engineering

The invention relates to a silent hinge for furniture, which comprises a movable hinged cup connected with a door plate, a fixed piece connected with a wall plate and a hinged arm connected with the movable hinged cup and the fixed piece; a damper is arranged on the movable hinged cup and at least acts on the hinged arm when the hinge is closed, springs which can generate opening and closing action force to the movable hinged cup at least is arranged on the hinge, and one end of the hinged arm is hinged with the movable hinged cup through a connecting unit; the cross section of at least one ends of the springs are non-circular, a sliding piece is arranged on the spring; a concave cavity is formed in the sliding piece, and at least one end of the spring is arranged in the concave cavity; the bottom surface of the sliding piece acts on a rotating part of the hinged arm through the elasticity of the springs, and the sliding piece moves relative to the rotating part when the hinge is opened and / or closed and generates an opening force or a closing force. Through an improved structure, the silent hinge has the characteristics of simple and reasonable structure, reliable performance, flexibility in operation, long service life, stable and smooth opening and closing process, less effort, low noise and the like, thereby having high practicability.

Owner:伍志勇

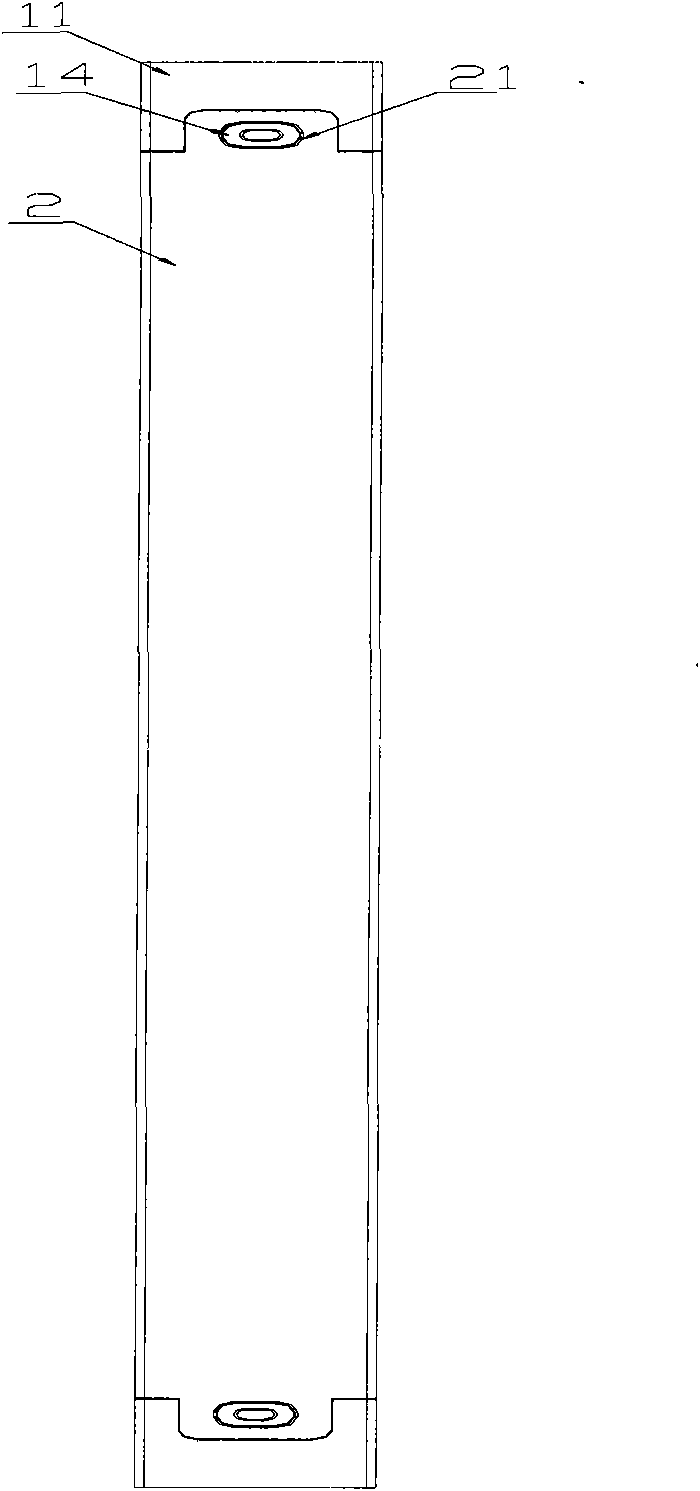

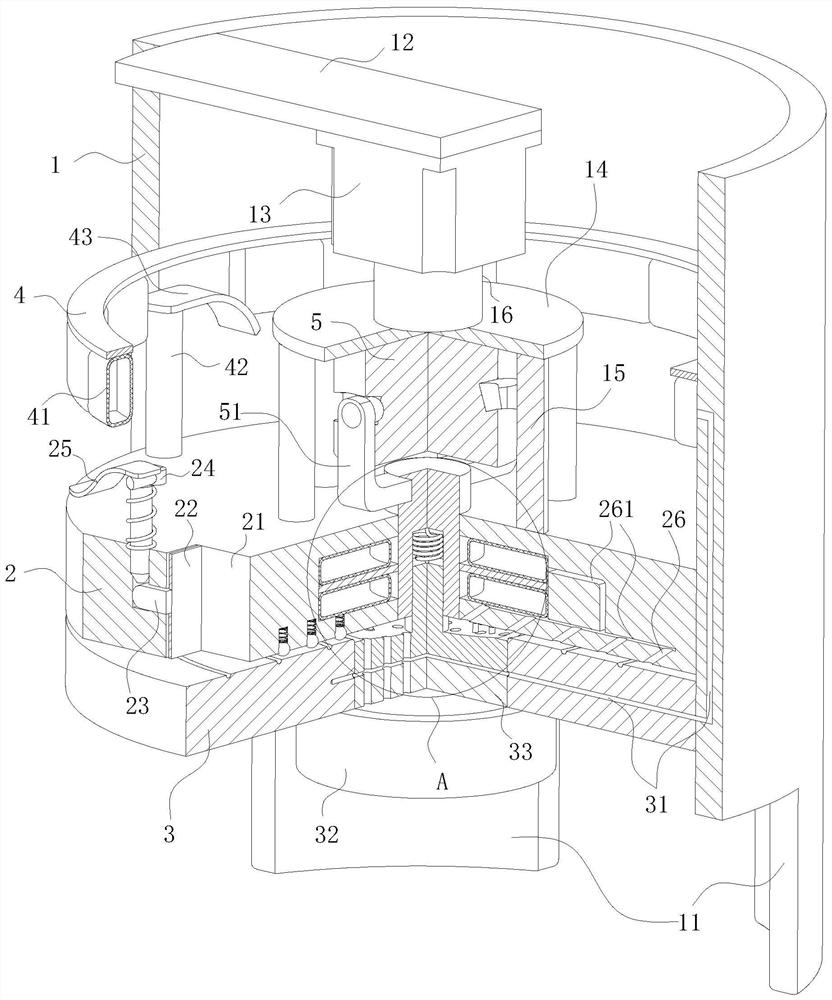

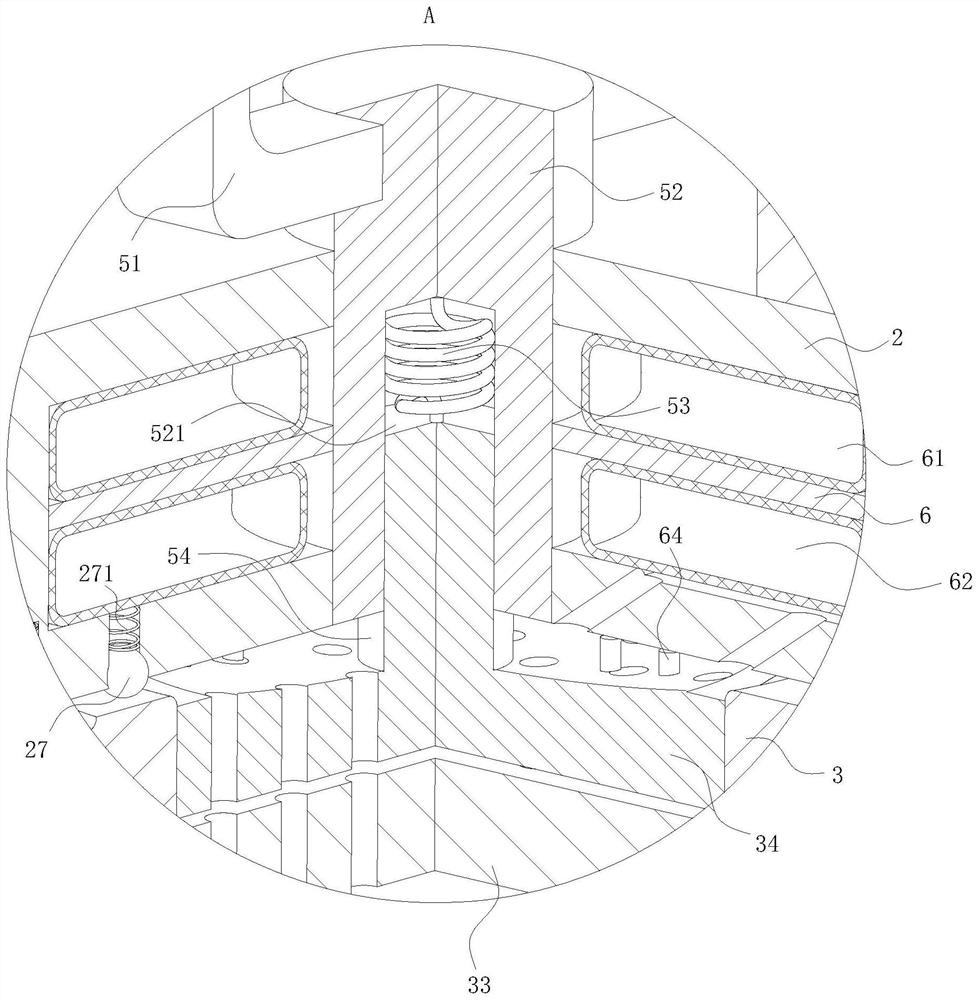

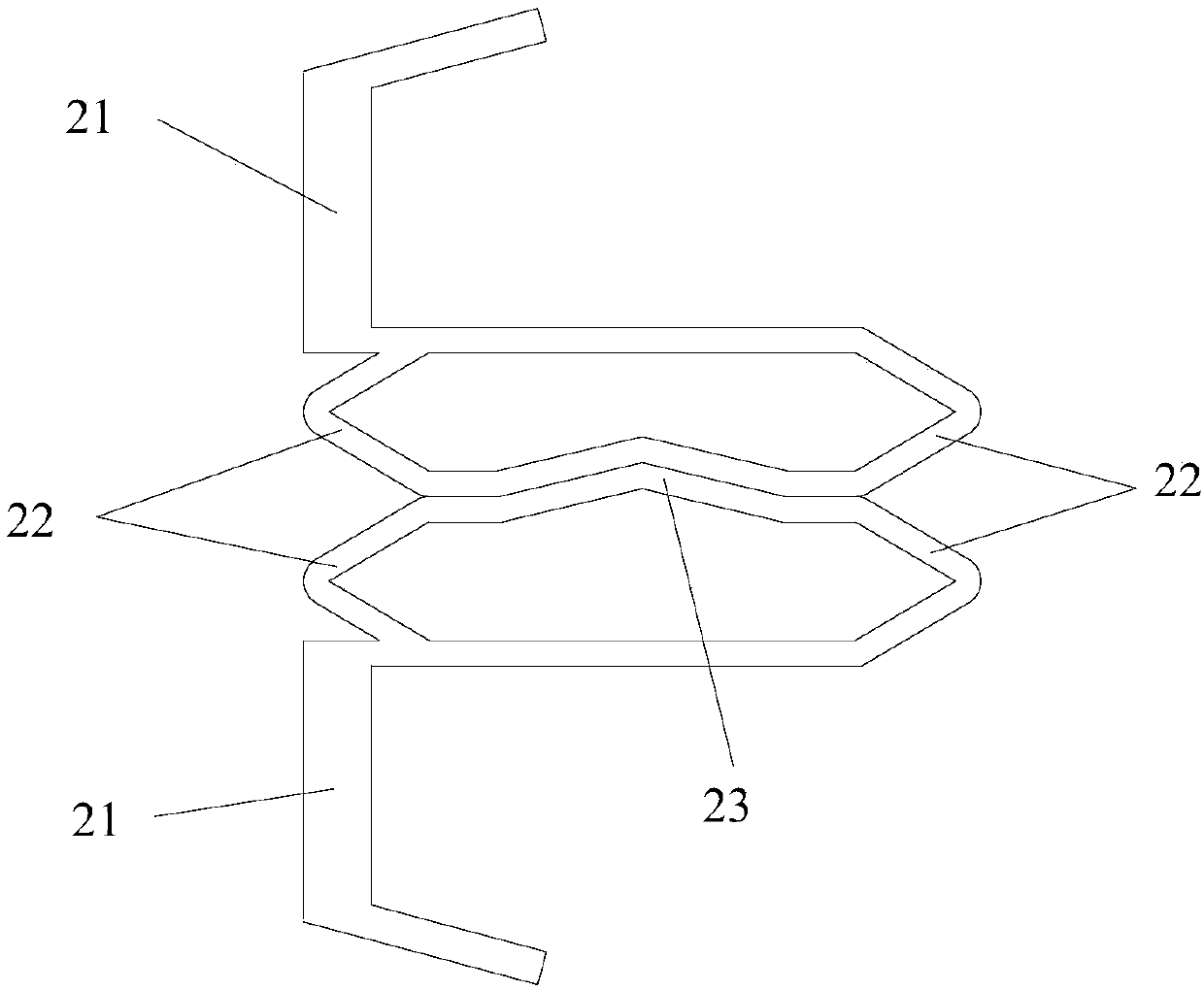

Electrode core assembly and battery containing same

ActiveCN101662045APrecise positioningReduce mutual frictionFinal product manufactureSecondary cellsRelative displacementPower battery

The invention provides an electrode core assembly comprising at least one electrode core, one space ring and one baffle, wherein the electrode core comprises an upper end surface, a lower end surface, two small side surfaces and two big flat side surfaces; the space ring is positioned at the end face of the electrode core, the baffle is positioned at the small side surface of the electrode core, and the space ring and the baffle are fixedly connected. The electrode core assembly can enable the electrode core to be positioned and fixed well so as to prevent the electrode core from shifting in the battery, especially prevent the relative displacement among the small electrode cores in a power battery pack, and reduces circumstances of current collector breakage, septum wrinkle, pole piece fall and the like, and thereby, the service life of the battery is prolonged, and the safety performance of the battery is improved. Moreover, a plurality of electrode cores of the power battery pack are easy to position, combine and assemble, thereby improving the production efficiency. Meanwhile, the invention reduces the mutual friction between the shell of the battery and the electrode core of the arc-shaped side surface, thereby reducing the damage on the electrode core, prolonging the service life of the battery and improving the battery performance.

Owner:BYD CO LTD

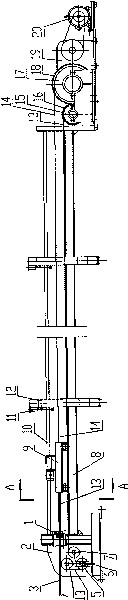

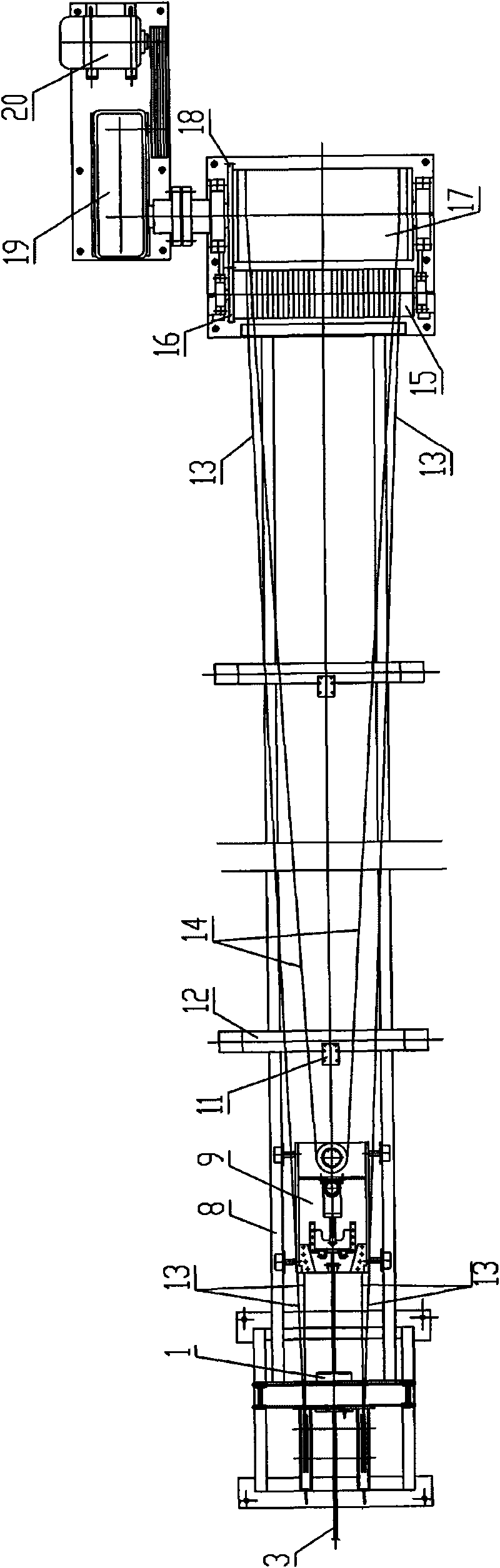

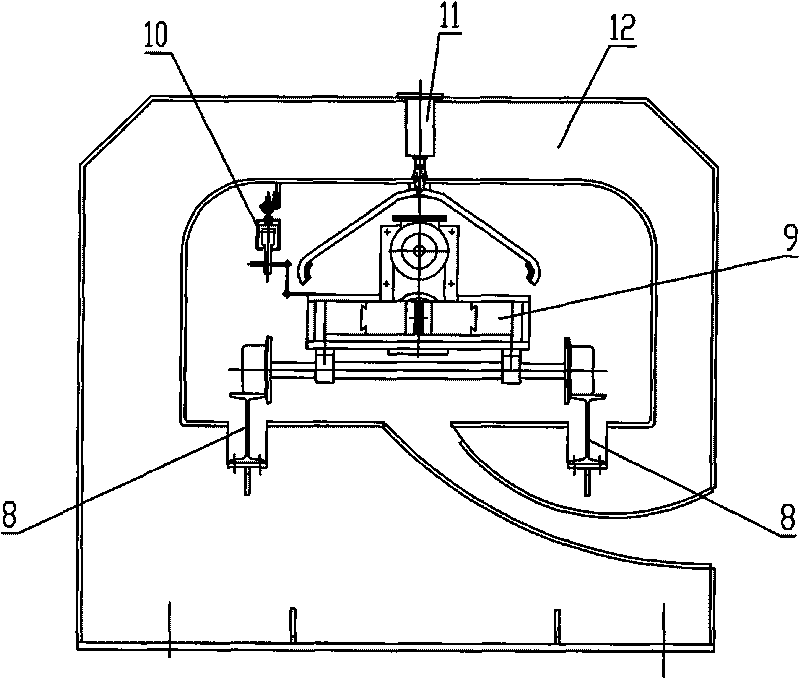

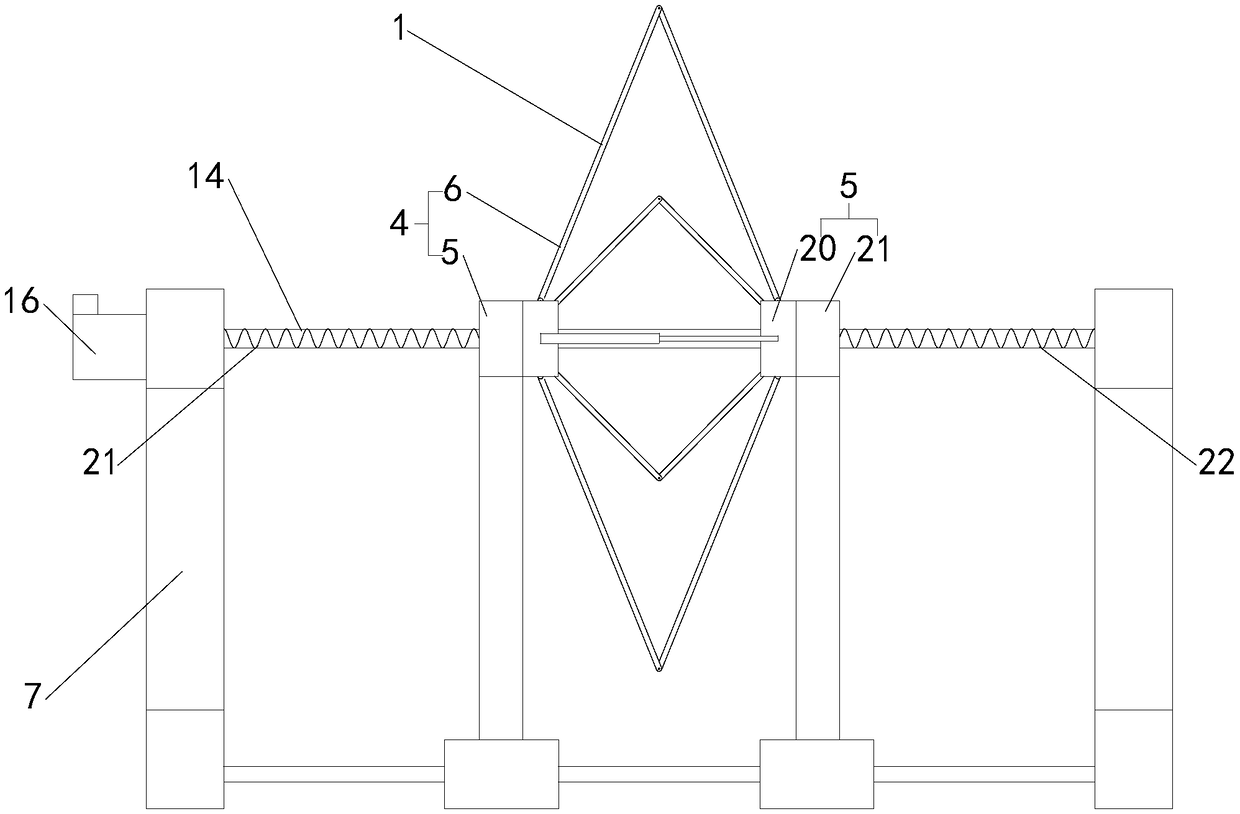

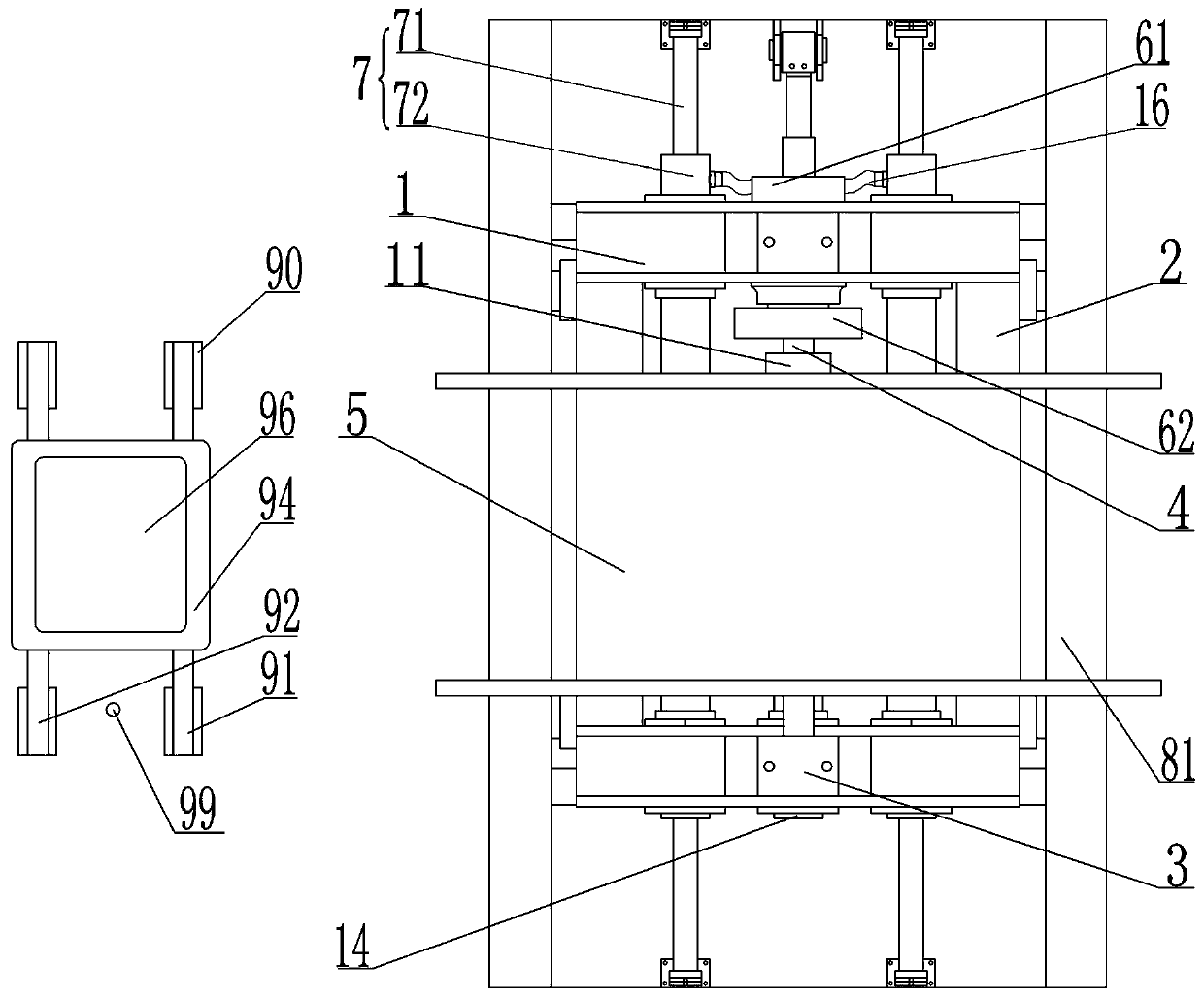

Overlength tube cold-drawing machine

ActiveCN101690956AImprove surface qualityEasy and flexible operationDrawing diesGear wheelReduction drive

The invention relates to a tube cold-drawing processing device, in particular to an overlength tube cold-drawing machine. The invention comprises a drawing die arranged on a headstock, drawing trolley capable of moving along the rail and a dragging device connected with the drawing trolley; the dragging device comprises a pulley block arranged on a headstock, a motor and a retarder connected with the motor; the rail is provided with a clamping device; the pulley block is winded with a thin steel wire rope; one end of the thin steel wire rope is connected to the back end of the drawing trolley and the other end thereof is connected to a small winding drum arranged at the front end of rail; the front end of the drawing trolley is connected to a large winding drum arranged at one side of the small winding drum by a wide steel wire rope; the small winding drum is provided with a small gear; the large winding drum is provided with a large gear meshed with the small gear; and the large gear is connected with the retarder. The invention has the beneficial effects of simple and convenient operation, small error, time-saving, labor-saving, tube material-saving, good quality of tube drawing, and high processing efficiency.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD +1

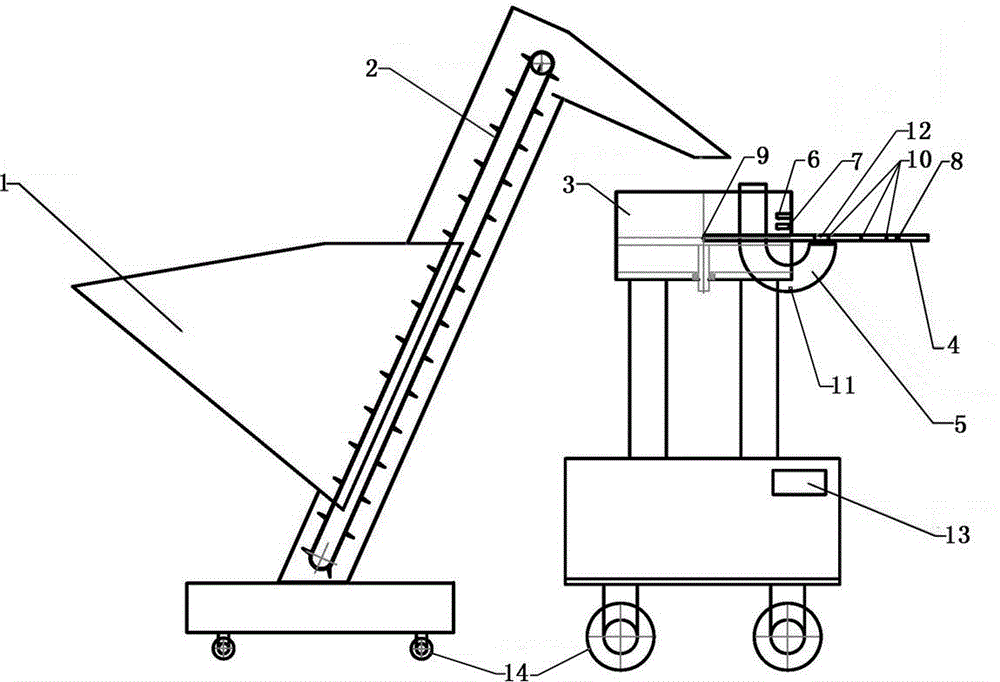

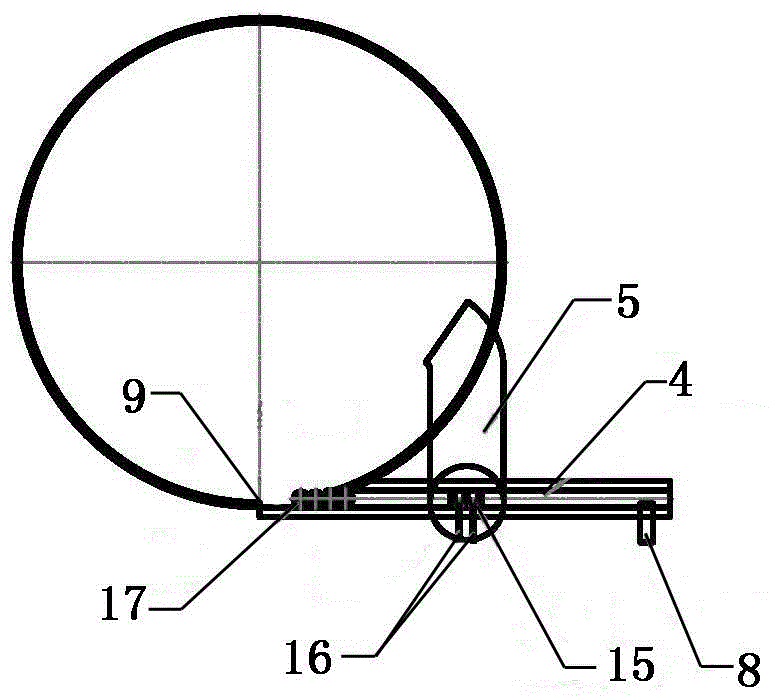

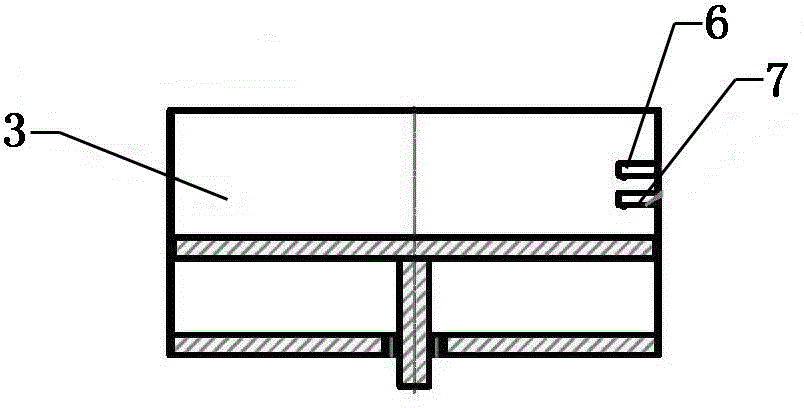

Feeding and finishing system and process of aluminum and plastic caps

ActiveCN104444292AAchieve the purpose of organizingReduce mutual frictionConveyor partsEngineeringHigh pressure

The invention discloses a feeding and finishing system of aluminum and plastic caps. The system comprises an aluminum cap feeding and finishing portion, a plastic cap feeding and finishing portion, a pneumatic control portion, a photoelectric control portion and an automatic controller. The invention further discloses a feeding and finishing process of aluminum and plastic caps employing the system. By the use of the centrifugal separation mode with a unique tray structure, friction of the aluminum or plastic caps is greatly reduced, and loss is reduced; by the use of a pneumatic mode with a unique screening rail and the use of high-pressure air as power to finish the caps, the caps run faster on the rail, the cap finishing process is stable and is better than mechanical finishing, product yield can be evidently increased, the surfaces of the caps have no scratch or deformation after finishing, and fewer caps are jammed or deformed; the fishing and moving speeds are higher, above 900 caps per minute; finishing and arrangement of the aluminum and plastic caps is achieved, and feeding for a next procedure is achieved.

Owner:HEBEI JINHUAN PACKAGING

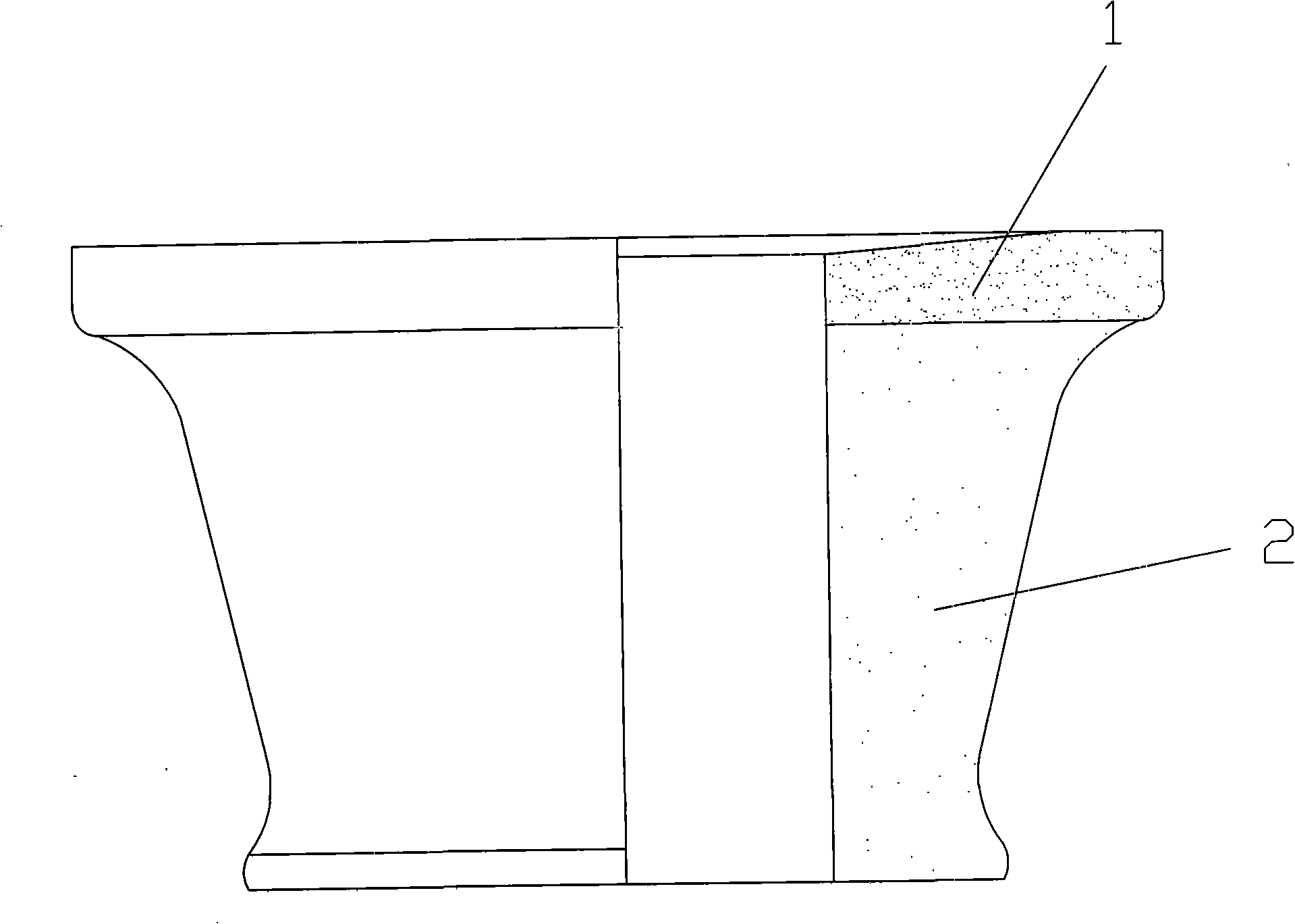

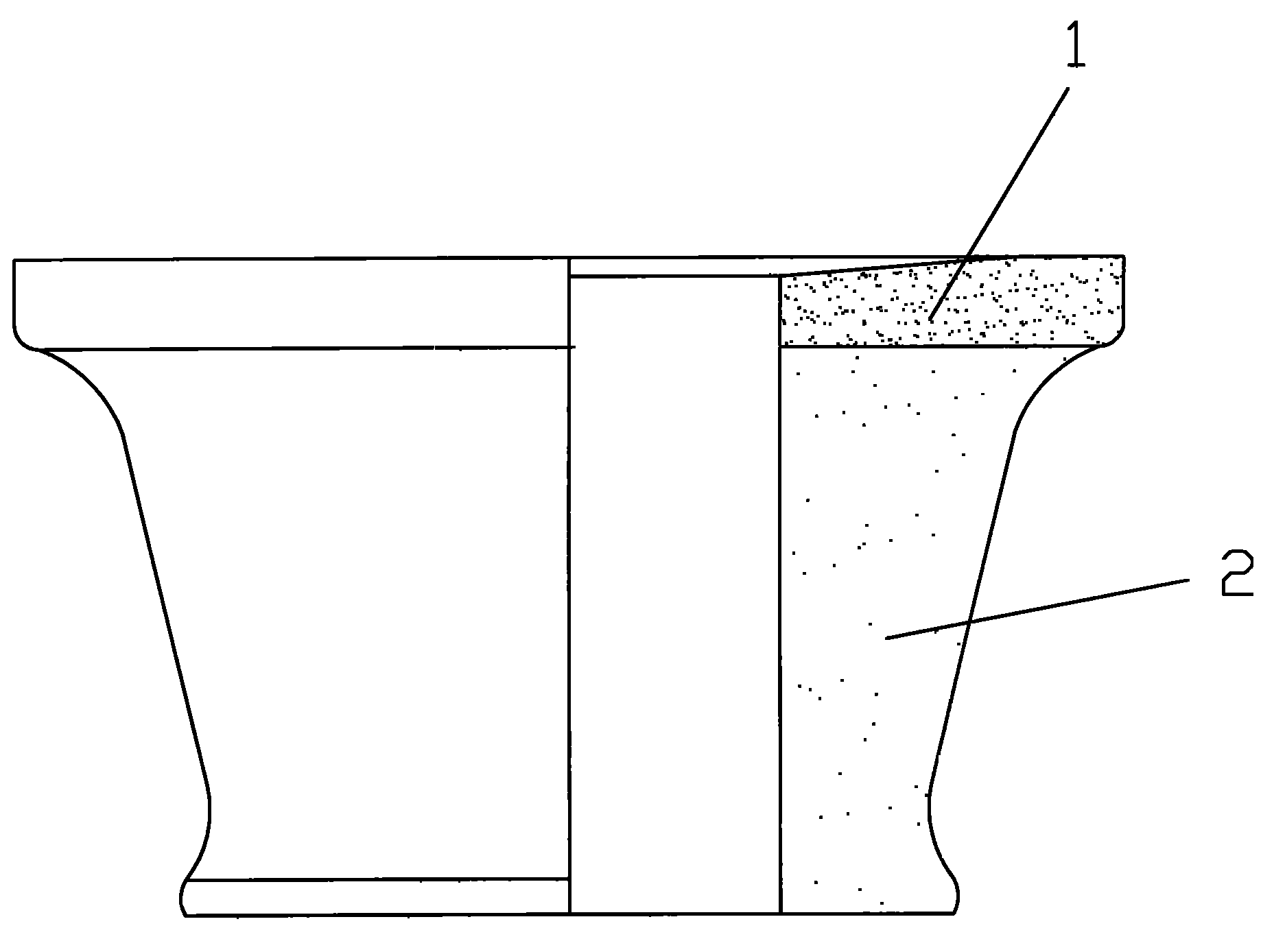

Powder alloy smithing float grease seal ring with upper and lower double-layer and method of producing the same

InactiveCN101402138AReduce wearSelf-lubricatingEngine sealsFurnace typesIron powderChemical composition

The invention relates to a floating oil-seal ring which has an upper layer and a lower layer and is forged by powder alloy. The floating oil-seal ring comprises the upper layer and the lower layer, wherein the upper layer is made of rare alloy powder materials, and chemical compositions in weight percentage of the upper layer are as follows: 0.5 to 3 percent of Cu, 0.5 to 1 percent of C, 0.5 to 2 percent of Cr, 0.5 to 1.5 percent of MoS2, and the balance being Fe; the lower layer is made of ordinary iron powder materials, and chemical compositions in weight percentage of the lower layer are as follows: 0.5 to 3 percent of Cu, 0.5 to 1 percent of C, and the balance being Fe; and the upper layer and the lower layer are sintered into an integrated floating oil-seal ring through pressing and high-temperature sintering. The upper layer of the floating oil-seal ring is made of high alloy powder, the lower layer is made of ordinary iron-based powder, and then the heat treatment process is performed, thereby assuring reasonable quenching depth as well as higher wear resistance and anti-fatigue performance; and the floating oil-seal ring has steady working performance, the service life is improved by 50 to 100 times, and the production cost is greatly reduced.

Owner:韶关市富洋粉末冶金有限公司

PVC (polyvinyl chloride) home decorative sheet and preparation method thereof

InactiveCN106380738AInhibition of premature decompositionAvoid breakingWeather resistanceFoaming agent

The invention discloses a PVC (polyvinyl chloride) home decorative sheet which is prepared from the following raw materials according to a weight proportion: 20 to 30 of PVC resin powder; 10 to 30 of colloidal calcium carbonate; 90 to 150 of PVC recycled materials; 1.5 to 2.0 of composite stabilizer; 6 to 9 of foaming control agent; 1 to 1.8 of composite foaming agent; 0.2 to 0.5 of plasticizer, 0.5 to 0.7 of internal lubricant, 0.1 to 0.3 of external lubricant, and 0.025 to 0.035 of whitening agent. The PVC recycled materials comprise a PVC decorative template recycled material, a white PVC plastic steel window recycled material and a white PVC pipe recycled material; the composite foaming agent is formed by mixing a white foaming agent and a yellow foaming agent. The invention further discloses a preparation method of the PVC home decorative sheet. According to the PVC home decorative sheet and the preparation method thereof, which are disclosed by the invention, the PVC recycled materials are used as one of the main raw materials, wastes are changed into treasures, production cost is reduced, energy is saved, hardness and weather resistance of the product are improved, recycling times are increased, the recycling times can reach 35 times or above, moreover, the preparation method is easy to operate, and the prepared product is smooth and attractive in surface. The PVC home decorative sheet disclosed by the invention is energy-saving, environmental-friendly, low in production cost and long in service life.

Owner:江苏旺科新材料有限公司

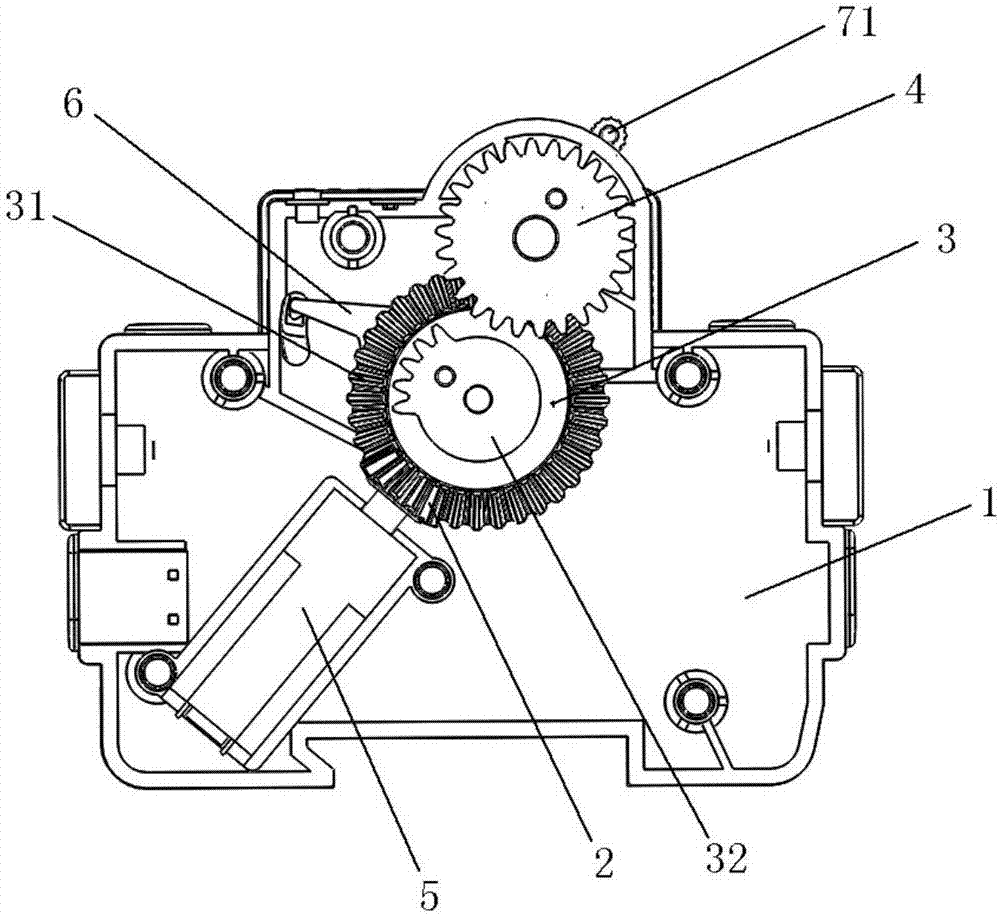

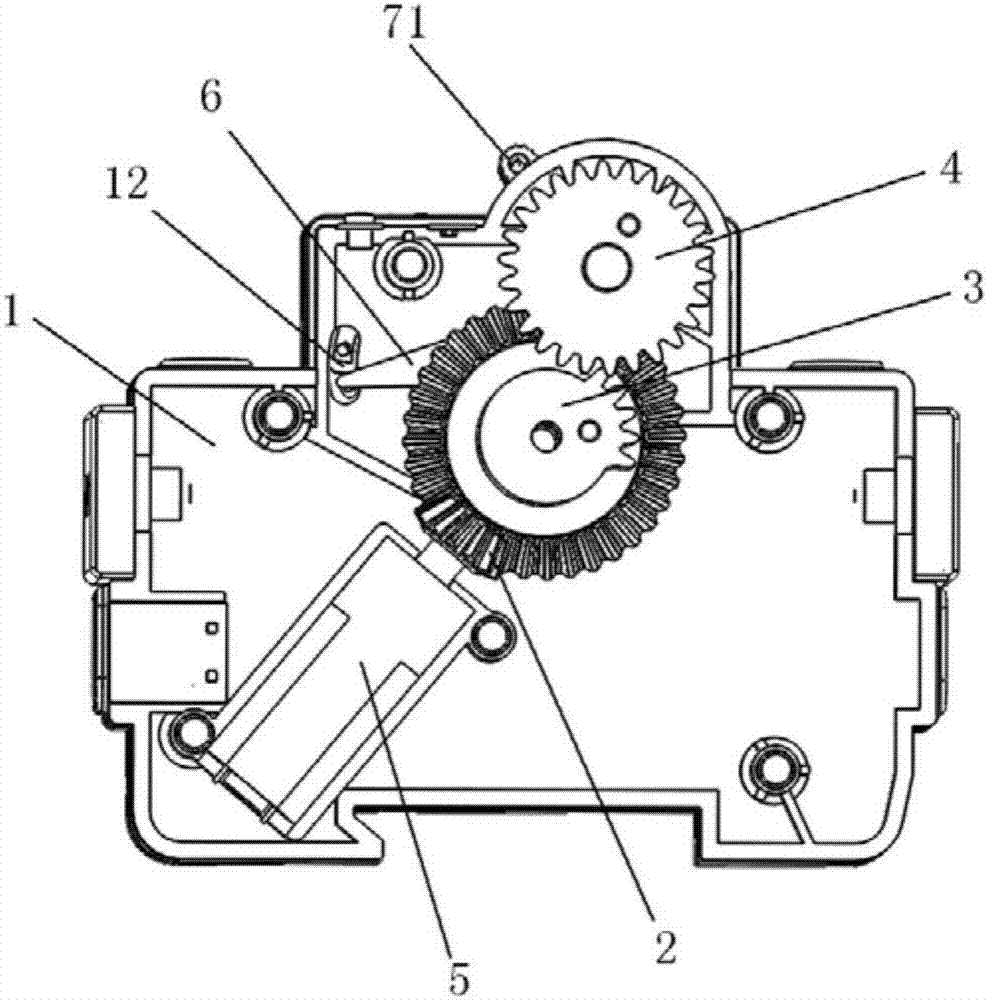

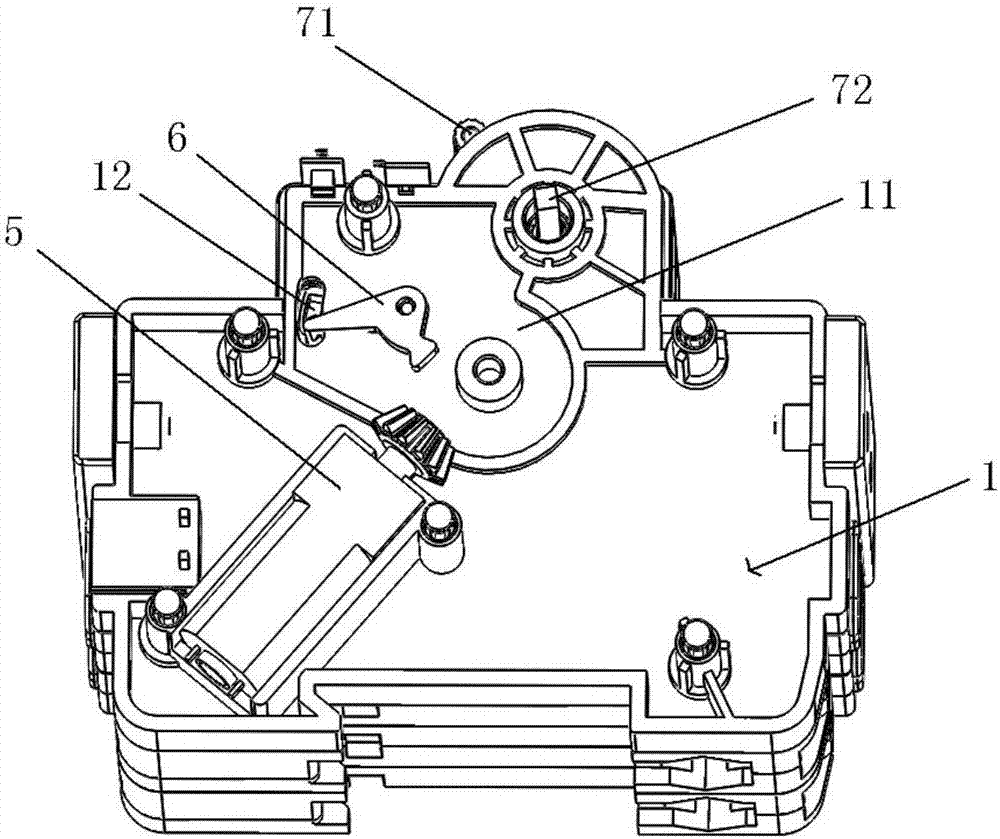

Automatic opening/closing control device and circuit breaker

InactiveCN107068503AStable structure and performanceIncrease the transmission ratioProtective switch operating/release mechanismsGear transmissionDrive motor

The invention discloses an automatic opening / closing control device and a circuit breaker. The automatic opening / closing control device comprises a housing, a driving motor arranged in the housing, a control module, a circuit breaker handle mechanism, a gear drive mechanism and a linkage locking piece. The gear drive mechanism is formed by a drive gear, a transmission gear and a handle gear, which are engaged. Through forward rotation or backward rotation of the motor, a driven gear in the transmission gear drives the handle gear to carry out forward or backward transmission, and the handle gear drives the circuit breaker handle to realize opening / closing; after arrearage opening, the linkage locking piece and a locking component keep in a locked state, so that the circuit breaker cannot be closed; and after payment closing, the circuit breaker can be subjected to free opening / closing operation. According to the technical scheme, gear transmission transformation ratio is improved greatly, transmission efficiency is improved, service life of the motor can be prolonged favorably, a transmission mode of mutual pushing is prevented, structure performance is stable, cooperation is reliable, transmission efficiency is high, and use performance of the product is improved.

Owner:浙江智美电气有限公司

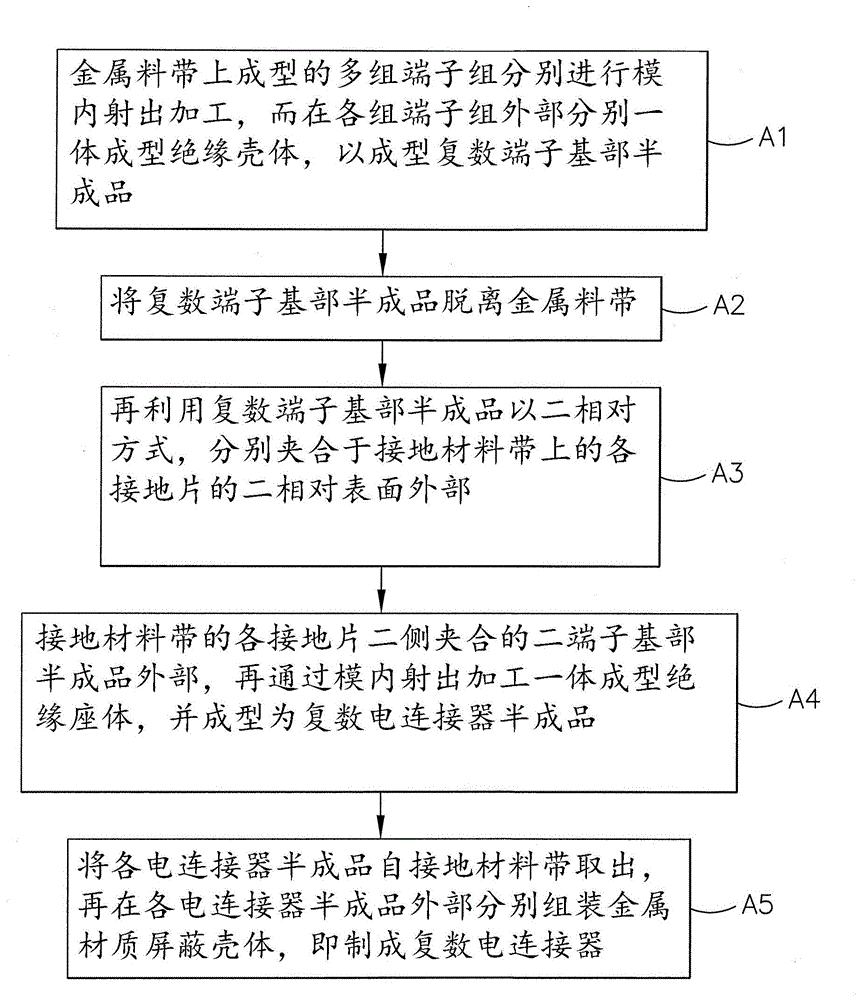

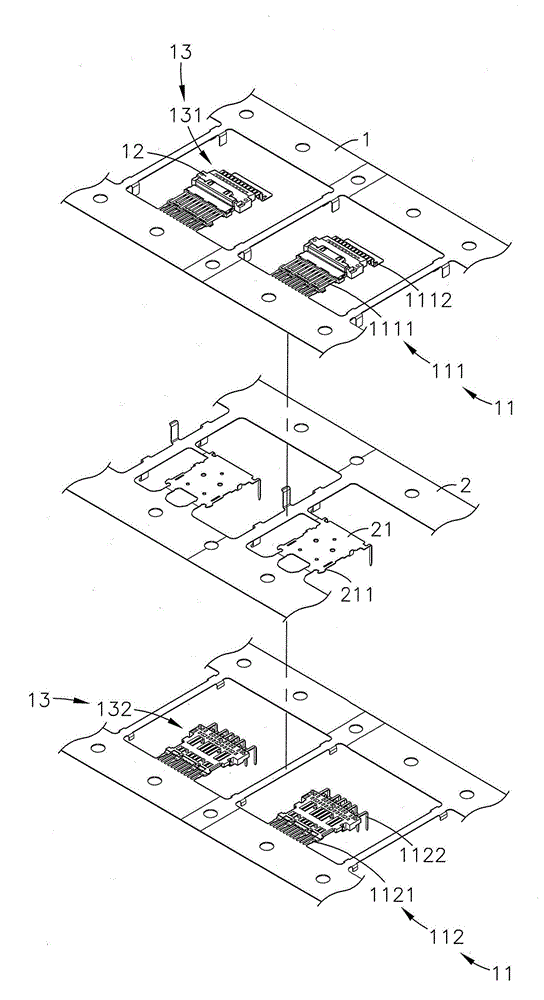

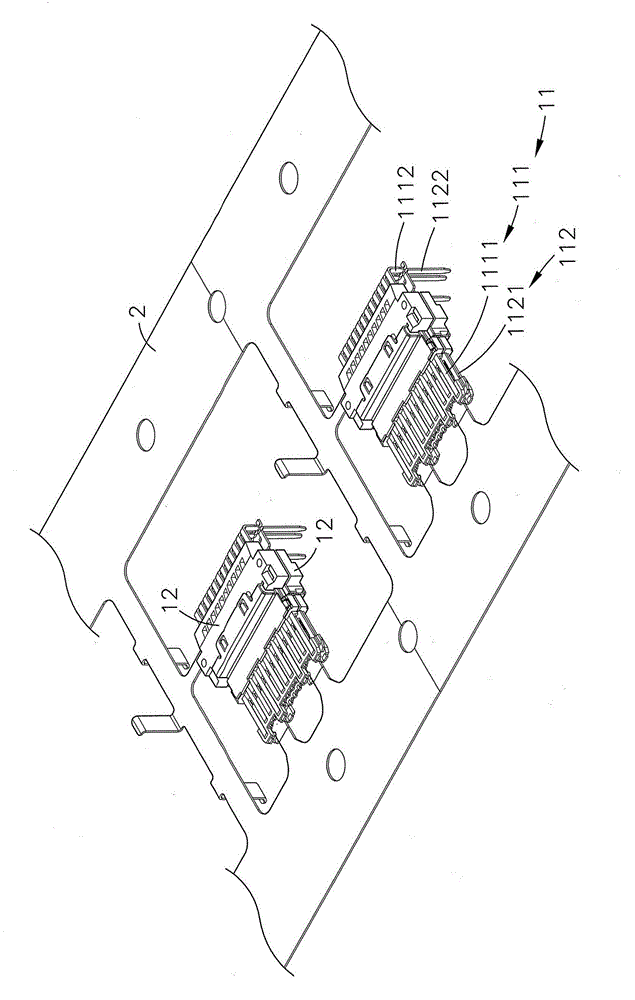

Manufacturing method of electric connectors

ActiveCN105990785AReduce volumeFast productionContact member manufacturingContact member assembly/disassemblyMetal stripsEngineering

The invention relates to a manufacturing method of electric connectors. The manufacturing method comprises the steps of: carrying out in-mold ejection processing respectively on a plurality of terminal groups formed on a metal strip, forming an insulating housing outside each terminal group in an integrated manner, forming a plurality of terminal base semi-finished products after separation from the metal strip, utilizing two opposite terminal base semi-finished products to clamp the outer parts of two opposite surfaces of each grounding sheet on a grounding material strip, forming an integrated insulating seat body by means of in-mold ejection processing outside the two terminal base semi-finished products clamping each grounding sheet, taking each electric connector semi-finished product out from the grounding material strip out after forming the plurality of electric connector semi-finished products, externally assembling the metal shielding housings, and namely manufacturing a plurality of electric connectors. According to the invention, the purposes of high production speed and stable quality are reached.

Owner:ACES ELECTRONICS CO LTD

Flame-retardant elastic rubber-plastic wave insulation board and preparation method thereof

The invention relates to a flame-retardant elastic rubber-plastic wave thermal insulation material and a preparation method thereof. The flame-retardant elastic rubber-plastic wave thermal insulationmaterial comprises the following raw materials: an ethylene propylene diene monomer, butadiene styrene rubber, high styrene resin, dioctyl sebacate, a vulcanization accelerator, an active agent, an anti-scorching agent, a foaming agent, sulfur, an antioxidant, a light stabilizer and a composite flame retardant. Ethylene-propylene-diene monomer and a composite flame retardant are added; no polar substituent exists in the molecular structure of the ethylene propylene diene monomer; the molecular cohesion is low, a molecular chain can keep flexibility in a relatively wide range, and the flexibility and elasticity of the material are improved; by adding the composite flame retardant, heat can be absorbed to generate a thermal decomposition reaction, the temperature in a condensed phase can bereduced, the thermal decomposition speed of the material can be reduced, and a large number of active hydroxyl free radicals generated in the combustion process can be isolated, so that the flame retardant effect is achieved, and the elasticity and flame retardant property of rubber and plastic products are effectively improved.

Owner:WINCELL INSULATION CO LTD

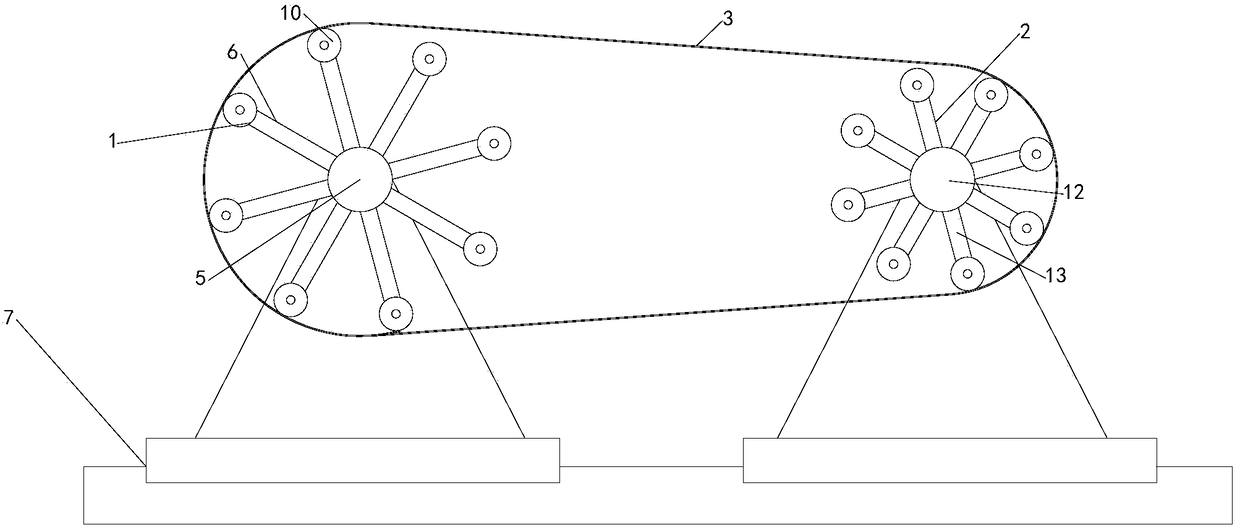

New energy automobile single-double speed changer

The invention provides a new energy automobile single-double speed changer. The new energy automobile single-double speed changer comprises a first driven wheel, a second driven wheel and a transmission belt. The first driven wheel comprises two first umbrella-type units. The two first umbrella-type units are arranged in the axial direction and symmetrically arranged. Each first umbrella-type unitcomprises a first driven block and first connecting rods, wherein one ends of the first connecting rods are rotationally connected with the first driven block, and the multiple first connecting rodsare arranged and are arranged in the circumferential direction and are distributed at intervals in an umbrella shape. The first connecting rods of the two first umbrella-type units are in one-to-one correspondence, the other ends of the first connecting rods can be rotationally connected, and therefore the two first umbrella-type units can be combined to form a diameter changeable wheel shape. Thespeed changer further comprises a sliding table. The sliding table comprises a first drive unit and a second drive unit, wherein the first drive unit is connected with the two first driven blocks, and the second drive unit is connected with the first driven wheel. The new energy automobile single-double speed changer is long in service life, high in transmission efficiency and high in load bearing capability.

Owner:王磊仪 +1

Non-damage conveying, cutting and washing system of bananas

ActiveCN103662573AReduce vibration damageReduce mutual frictionManual conveyance devicesFood treatmentEngineeringPulley

The invention discloses a non-damage conveying, cutting and washing system of bananas. The system mainly comprises a conveying device, a cutting knife and a washing device. The conveying device comprises an annular track, a track support, a guide rail, a guide rail seat, a pulley block and a fixing device. A banana stem of harvested bananas is fixed by the fixing device and conveyed to the washing device along the track, so that the bananas are cut and washed at the same time. The non-damage conveying, cutting and washing system of bananas solves the problem that mechanical collision is caused in the harvesting process of bananas, labor is saved, and the appearance quality of bananas is greatly improved.

Owner:GUANGXI JINSUI AGRICULTURE GROUP CO LTD

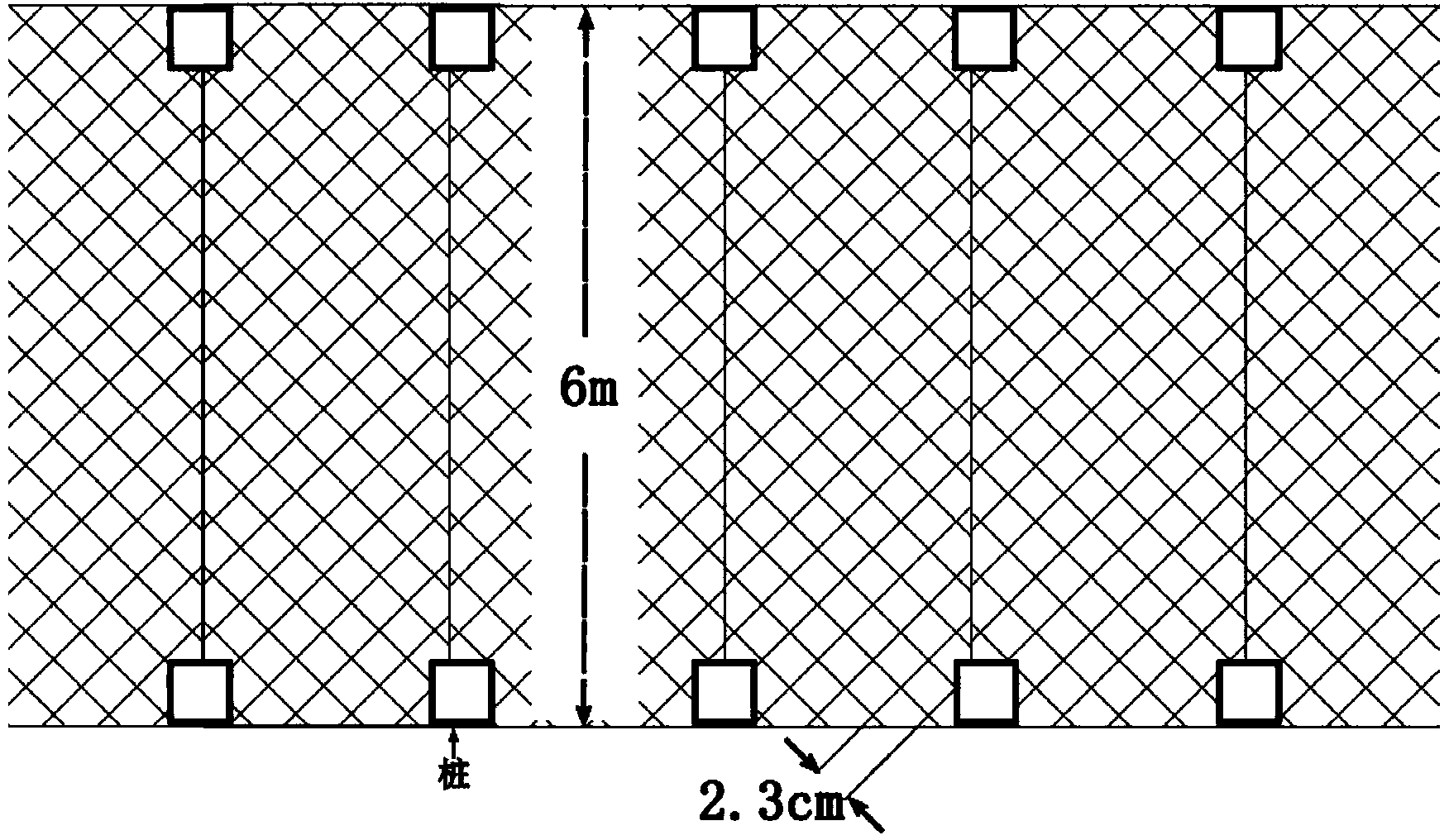

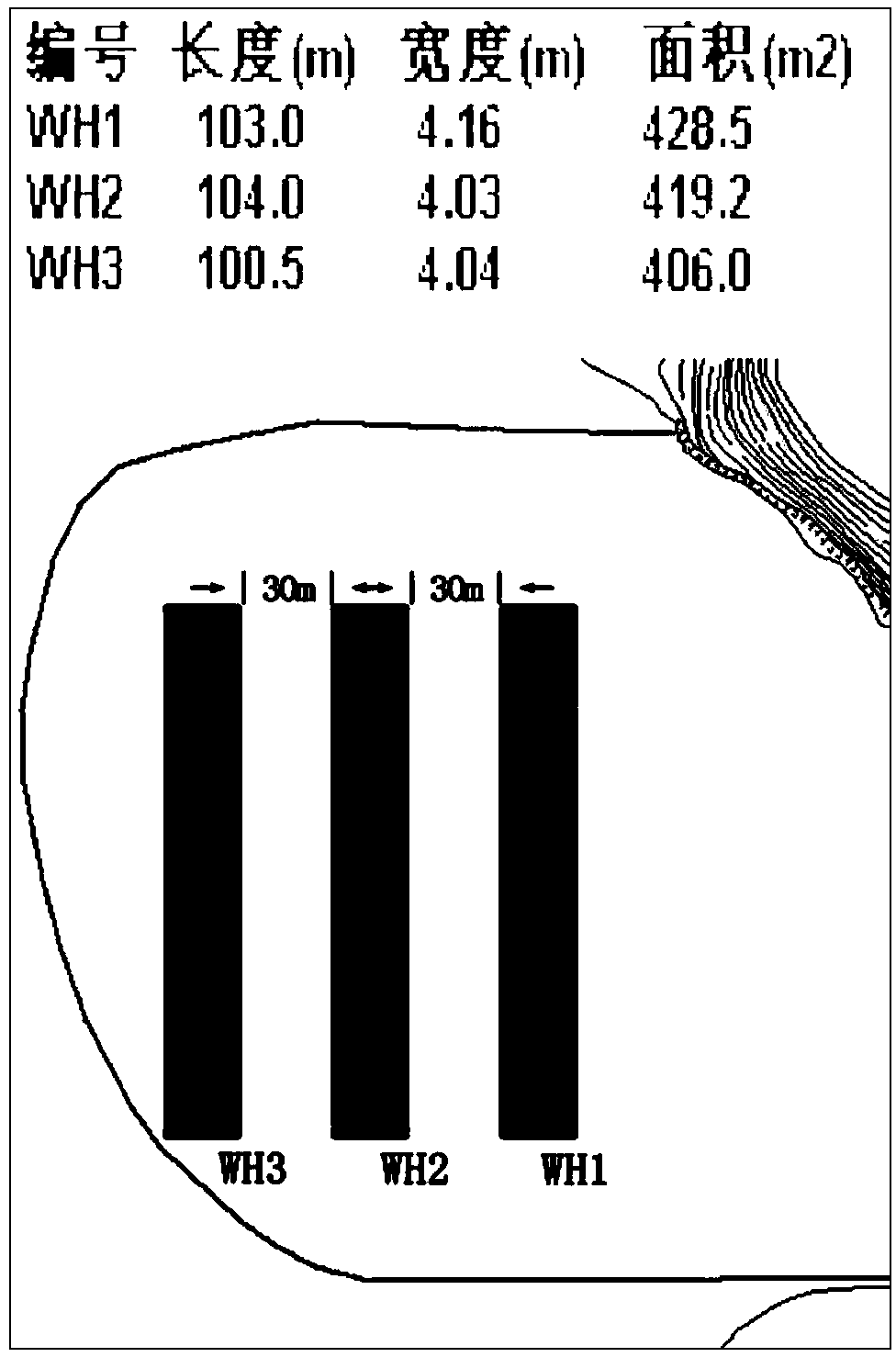

Method for purifying water by using aquatic-floating-plant floating bed

ActiveCN104129859AHigh transparencyIncrease growth rateSustainable biological treatmentBiological water/sewage treatmentBiocoenosisWind wave

The invention belongs to the technical field of ecological restoration and relates to a technology for purifying water of large-wind-wave water areas by using an aquatic-floating-plant floating bed. The technology comprises the steps of adopting a structured floating bed, so as to improve environmental conditions, such as wind wave and transparency, lower the root-stem-leaf relative motion, mutual friction and drift among floating plants and construct habitat conditions suitable for the floating plants, carrying out child care on the floating plants, and exerting the pioneering effect of floating plant biocoenosis, so as to improve the water quality of lakes and provide favorable conditions for the resumption of submerged plants. According to the technology, network-structured floating beds made from special mesh bags and bamboo-rafted floating beds made from wave-dissipating bamboo rafts are taken as a carrier, so as to lower wind wave disturbance and drift caused by the wind wave disturbance and improve basic environmental conditions; dominant floating plants are screened through integrating the characteristics of water purification time, purification effect, wind wave resistance, easiness in maintenance and the like and are subjected to floating bed cultivation; for floating plant resumed water areas, hibernation protection and removal techniques are adopted, so as to prevent secondary pollution caused by plant residues.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

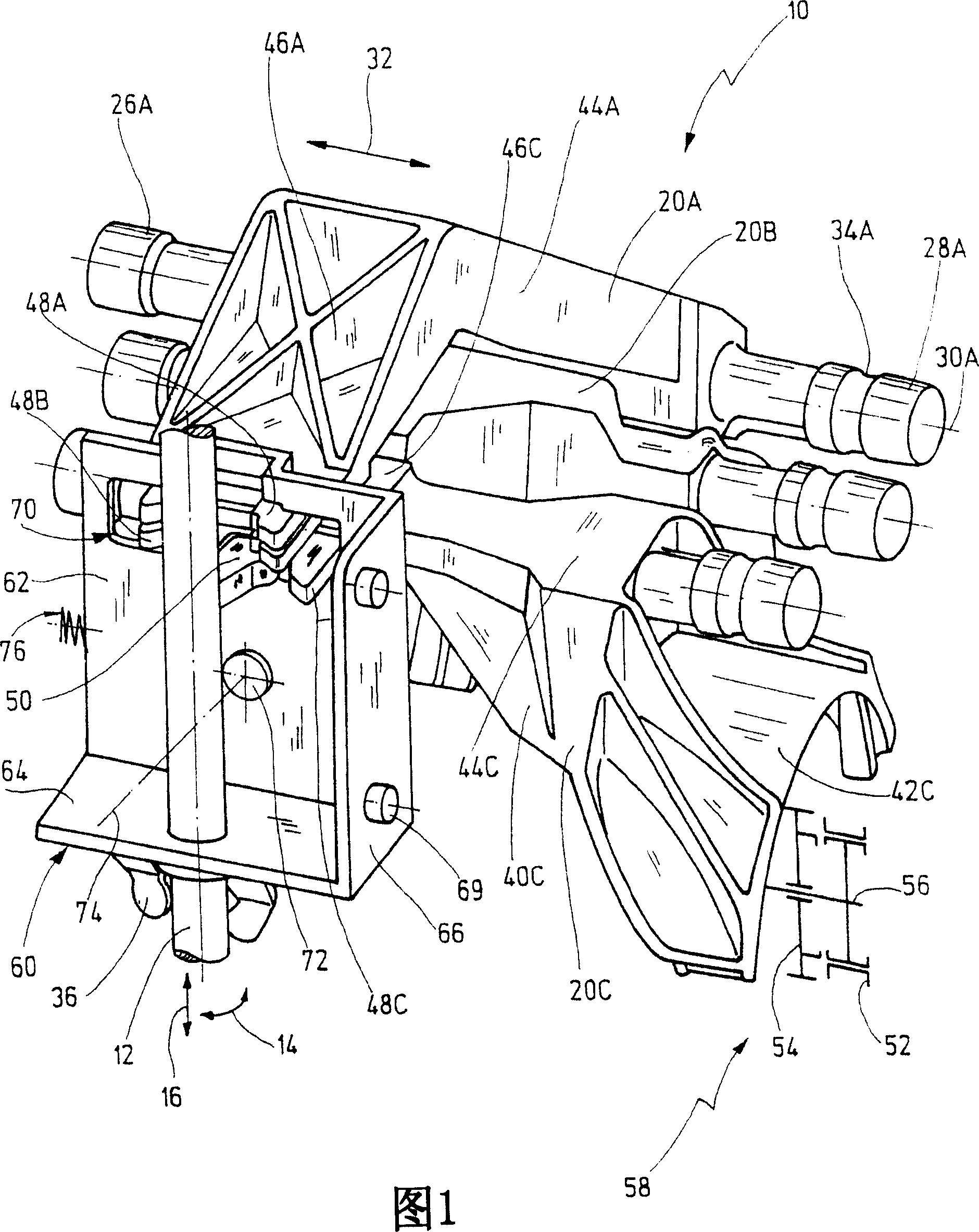

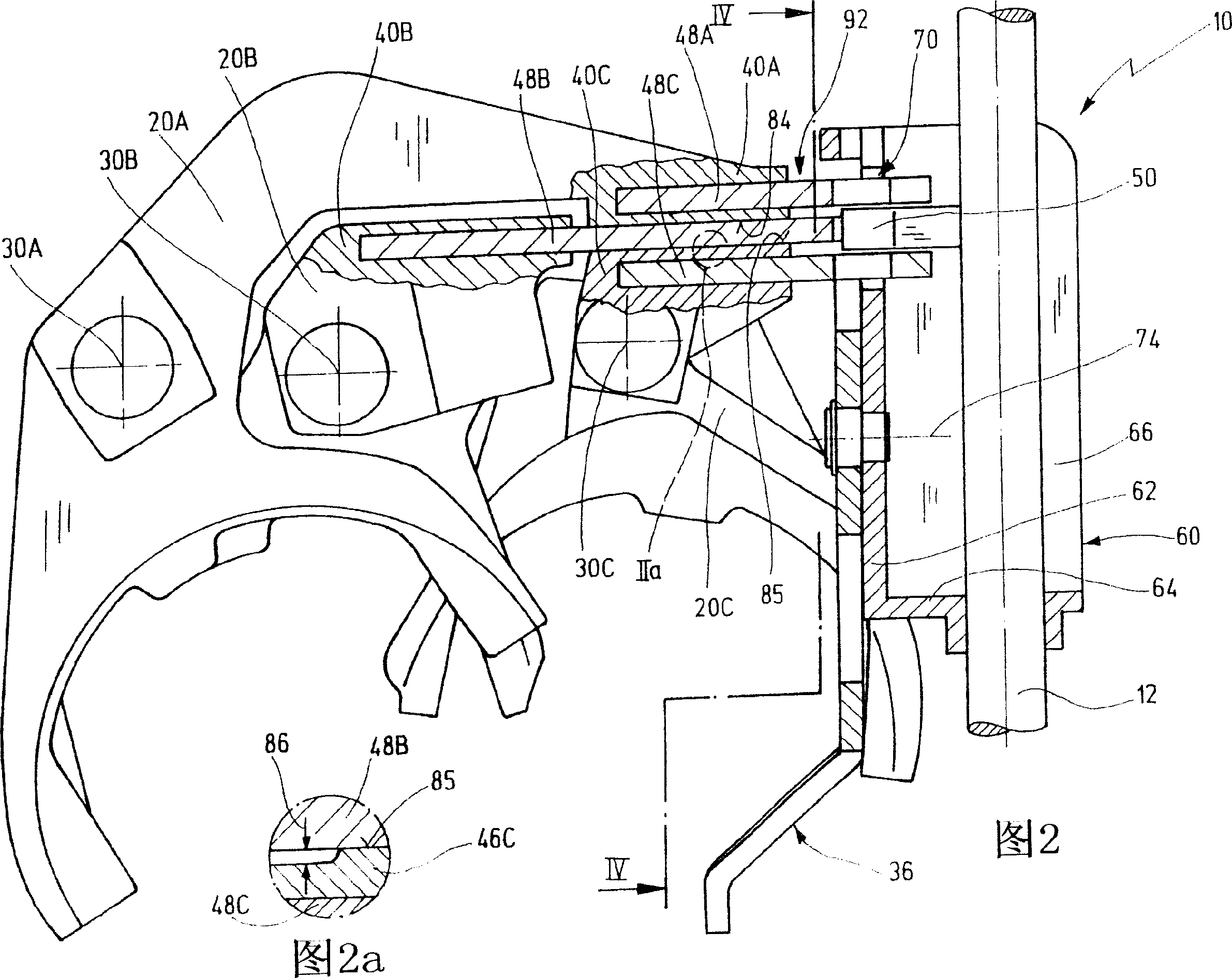

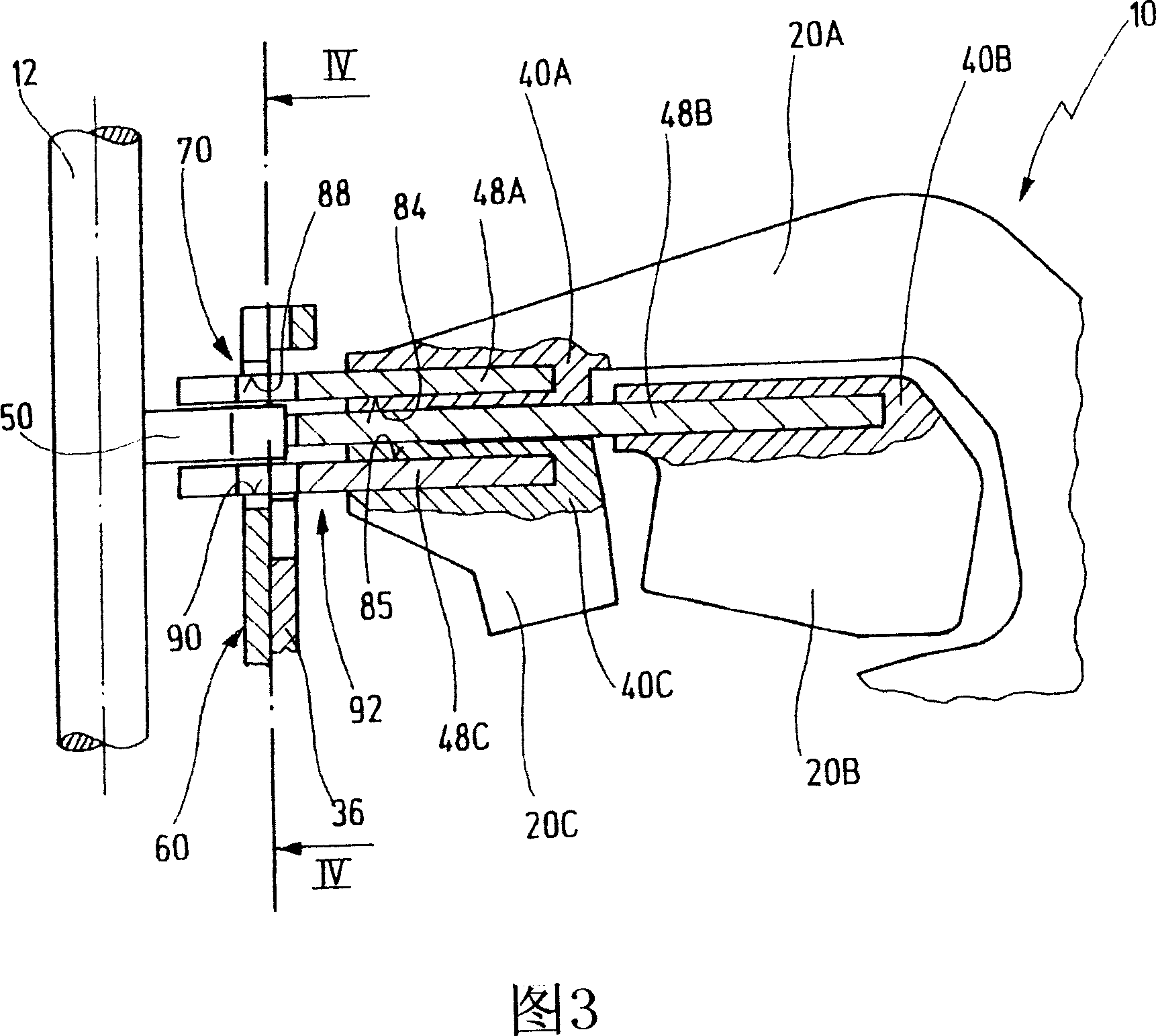

Gear-shifting device

ActiveCN1942694AEnsure precise guidanceNot negatively affectedGearing controlDriven elementMechanical engineering

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Production method and home-textile application of wool-tencel bi-component blended yarns

The invention discloses wool-tencel bi-component blended yarns which are formed by blending 25-35% of wool and 65-75% of tencel fiber. According to the arrangement, by adding the tencel in wool fibers, inter-friction of the wool fibers is reduced, the product is prevented from shrinkage and pilling in use, and wool fabric intensity is improved; the product, made of the fabric formed by blending the tencel and the wool, is excellent in hand feeling and surface smoothness, allows people to rarely feel the special wool itchy and meets needs to the healthy and comfortable green products of customers; besides, the tencel is so glossy as real silk and colorful, bright and soft after easily dyed. The invention further discloses a production method of the wool-tencel bi-component blended yarns and solves the key problem of the wool and tencel spinning. The production method lowers cost, maintains yarn finishing performance and has favorable properties of the wool and the tencel.

Owner:SHANGHAI SHUIXING HOME TEXTILE

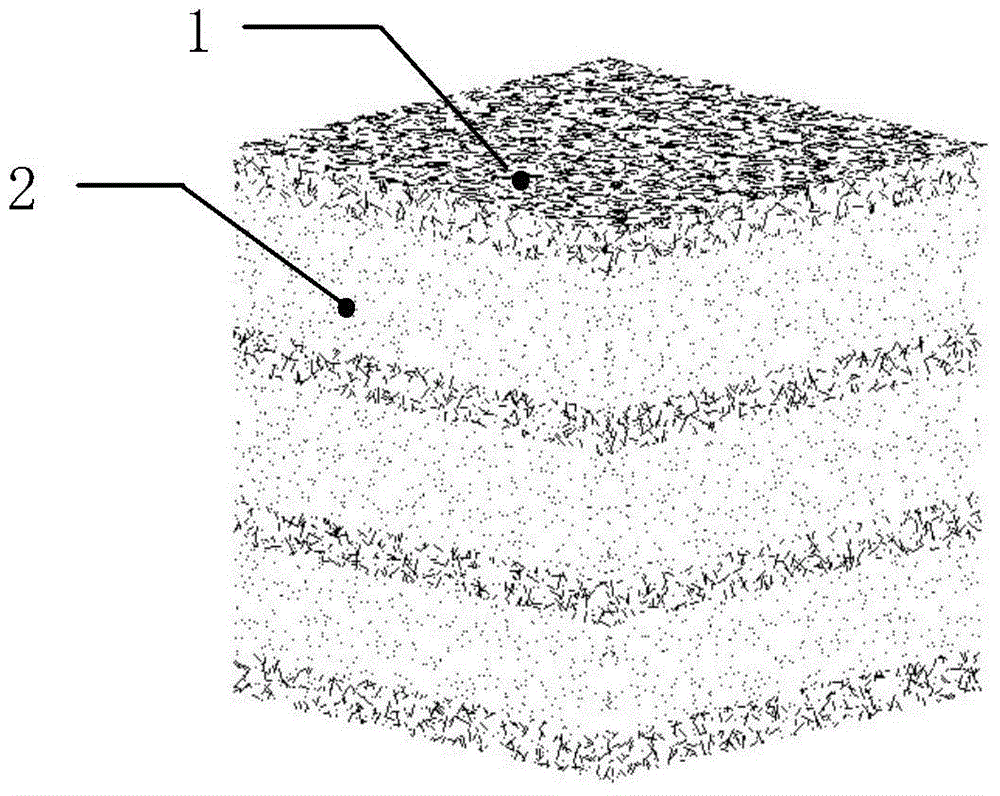

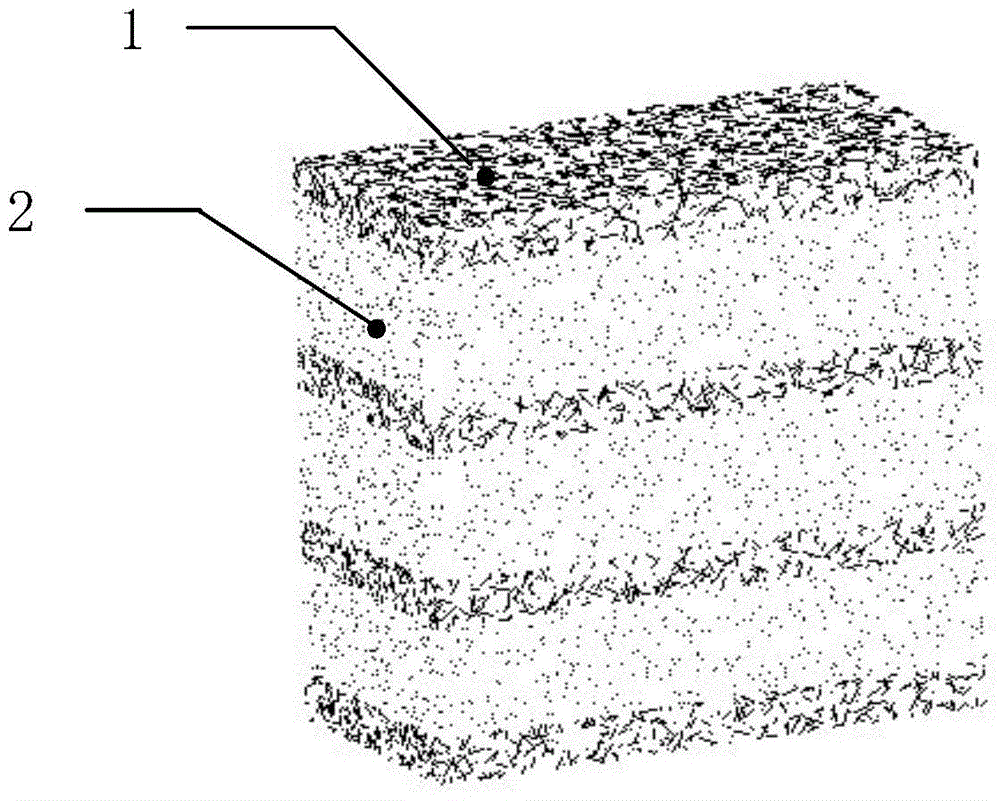

Preparation and application of sandwich-type multilayer immobilized bioactive filler

ActiveCN103951041AStable structureGuaranteed uptimeSustainable biological treatmentOn/in organic carrierSandwich likeYarn

The invention discloses preparation and an application of a sandwich-type multilayer immobilized bioactive filler, and belongs to the technical field of water treatment. The bioactive filler is composed of two parts: embedding bodies and non-woven carriers; the embedding bodies are obtained by boric acid secondary cross-linking curing of an embedding liquid; the embedding bodies and the non-woven carriers are in alternative arrangement; fiber yarns of the non-woven carriers and the embedding bodies are combined into a stable organic whole; the embedding liquid formed by mixing a bacteria concentrated solution and a polyvinyl alcohol solution evenly coats the non-woven carriers, multiple layers of carriers are overlaid together, a layered filler having a sandwich-like structure is formed after boric acid secondary cross-linking curing, and then the granular bioactive filler is prepared through cutting the layered filler. The problems that bacteria in a traditional biochemical method are low in concentration, easy to lose and the like are solved, and moreover, the sandwich-like layered structure formed by the non-woven fabrics and the embedding bodies improves the stability of the bioactive filler, and the bioactive filler has a good application prospect.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Production system of waterproof agent

ActiveCN112517140AImprove quality levelExtension of timeCocoaGrain treatmentsElectric machineryIndustrial engineering

The invention belongs to the technical field of waterproofing agents, and particularly relates to a production system of a waterproof agent. The production system comprises a fine grinding device, thefine grinding device comprises a shell, an installing plate is fixedly installed at the upper end of the shell, a motor I is fixedly installed on the installing plate, an output shaft of the motor Iis fixedly connected to a connecting plate, the connecting plate and an upper grinding plate are fixedly connected to each other through a fixing column, a lower grinding plate is fixedly installed inthe shell, a feeding groove is formed in the edge of the upper grinding plate, a sieve plate is fixedly installed in the middle position of the lower grinding plate, a spiral groove is formed in thelower grinding plate, a collecting cylinder is fixedly installed on the lower grinding plate, and the collecting cylinder is over against a sieve plate on the lower grinding plate. The production system is simple in structure and convenient to use, raw materials can be automatically ground and screened, the fineness of products is improved, and the performance and quality grade of the products areimproved.

Owner:GUANGDONG GUANHAO HIGH TECH

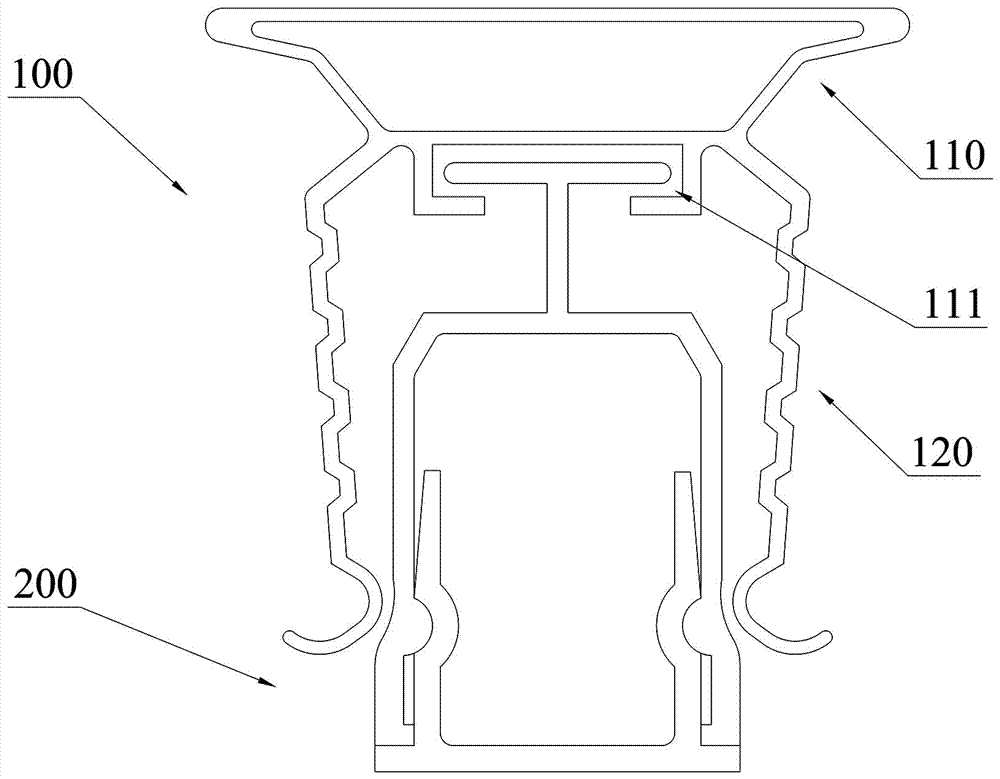

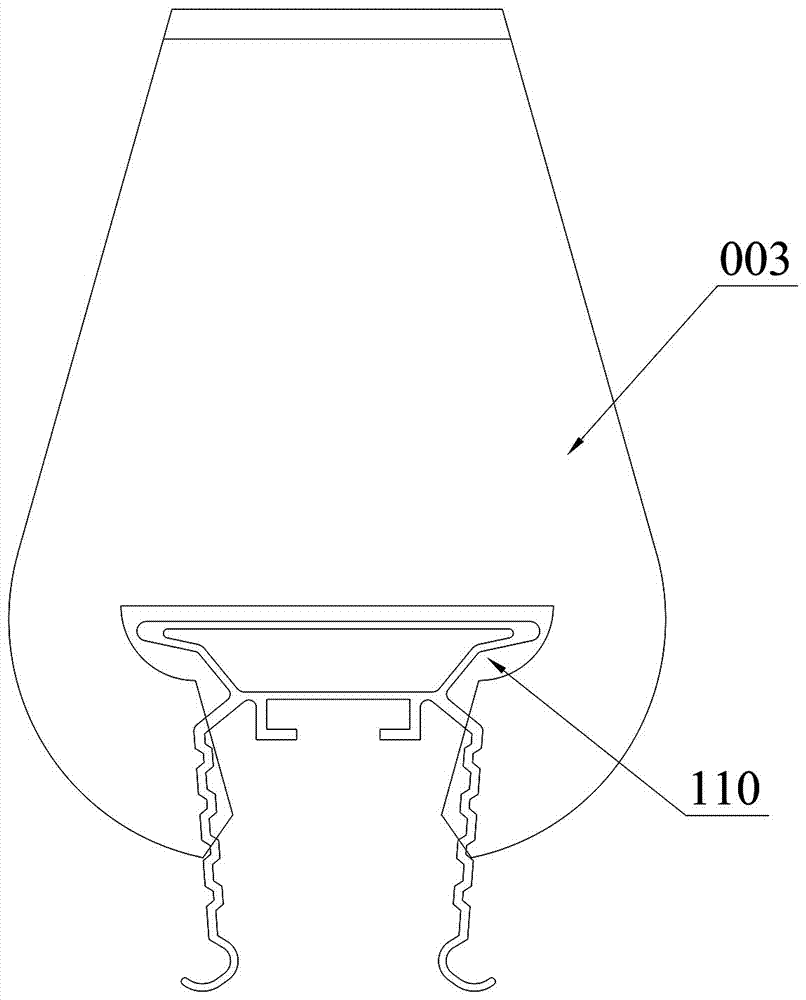

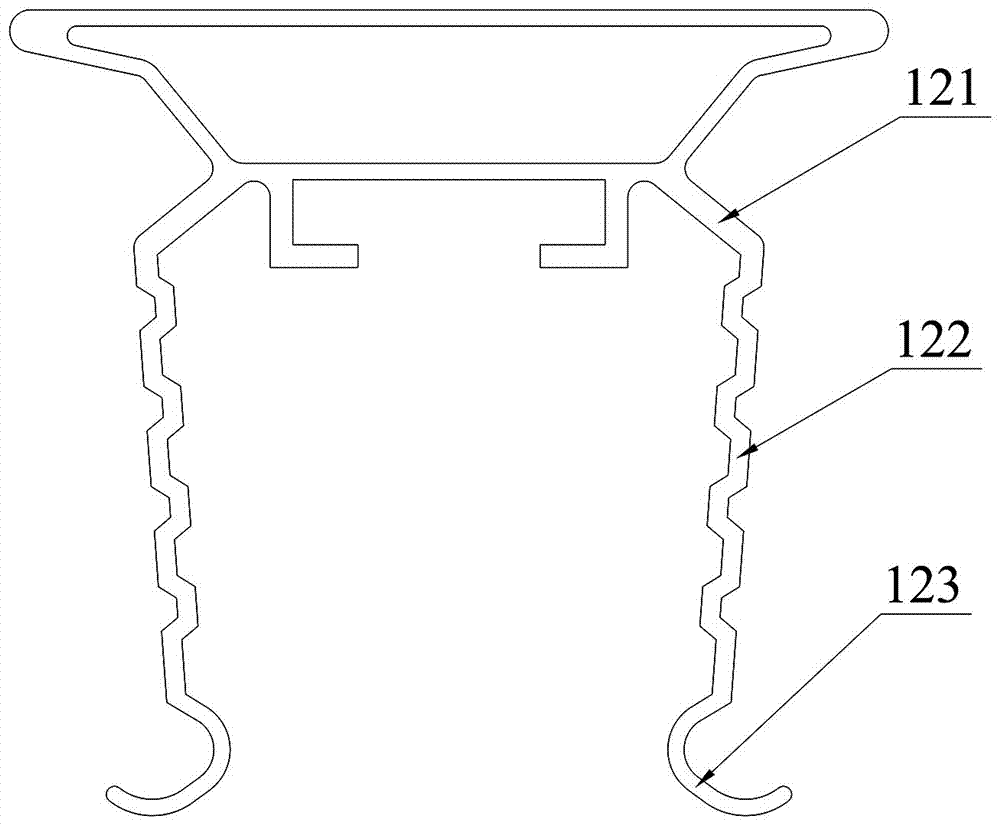

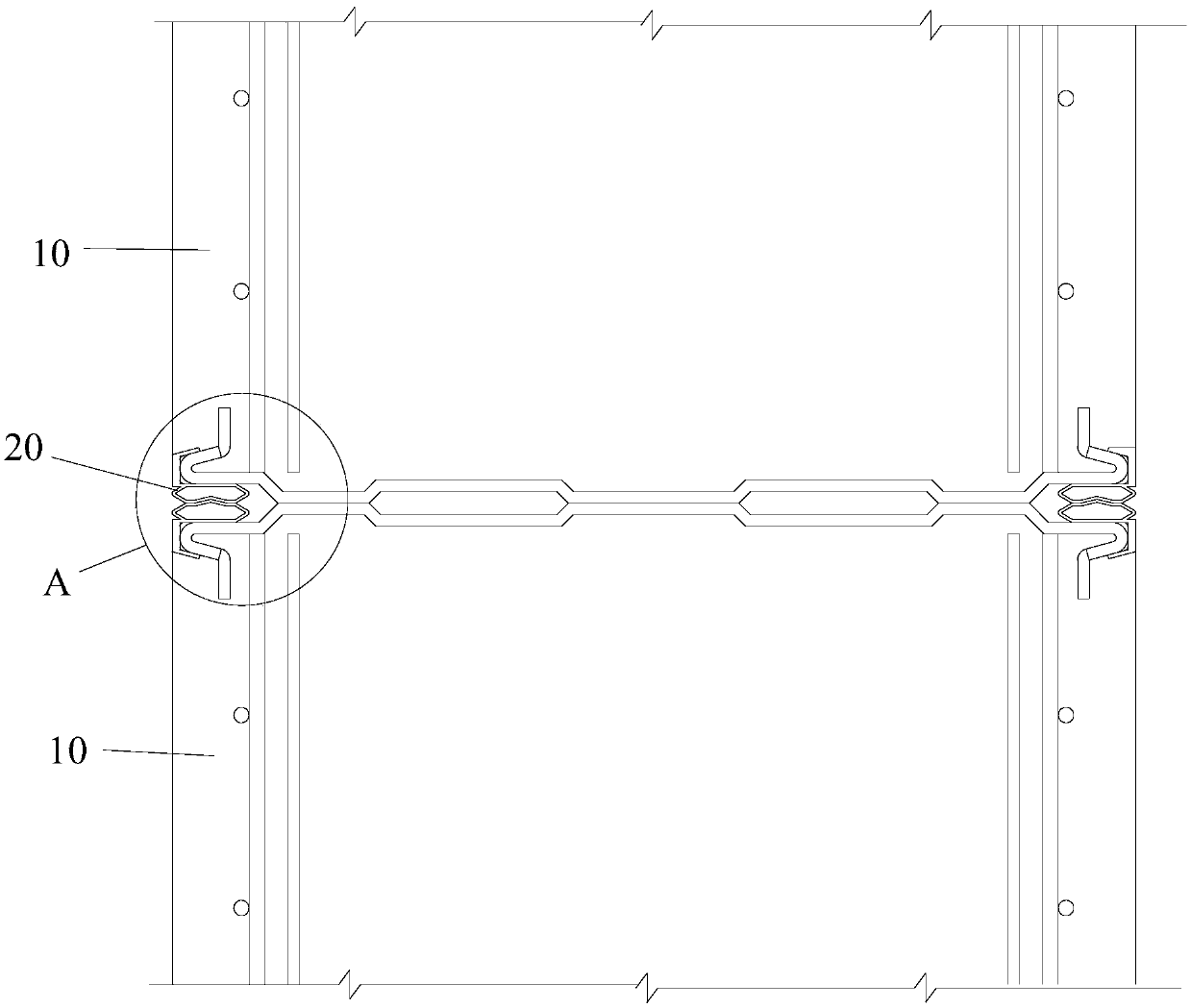

Decorative rib keel

ActiveCN107268867AGuaranteed stabilityGuaranteed reliabilityCeilingsPhotovoltaic energy generationStructural engineeringMechanical engineering

Owner:佛山市志联永道铝业有限公司

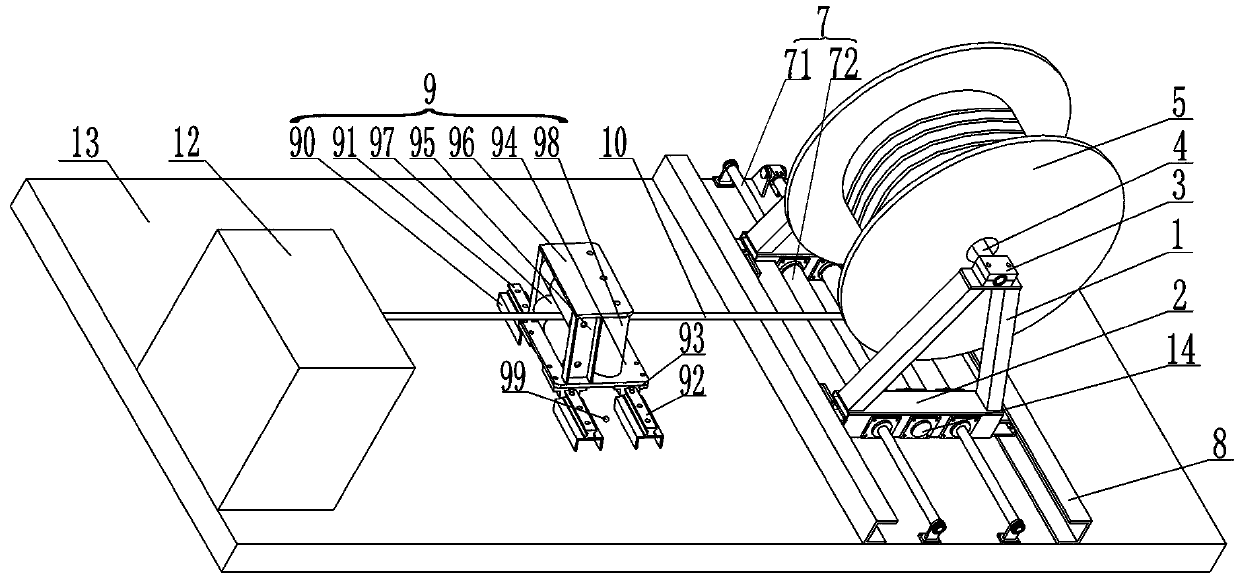

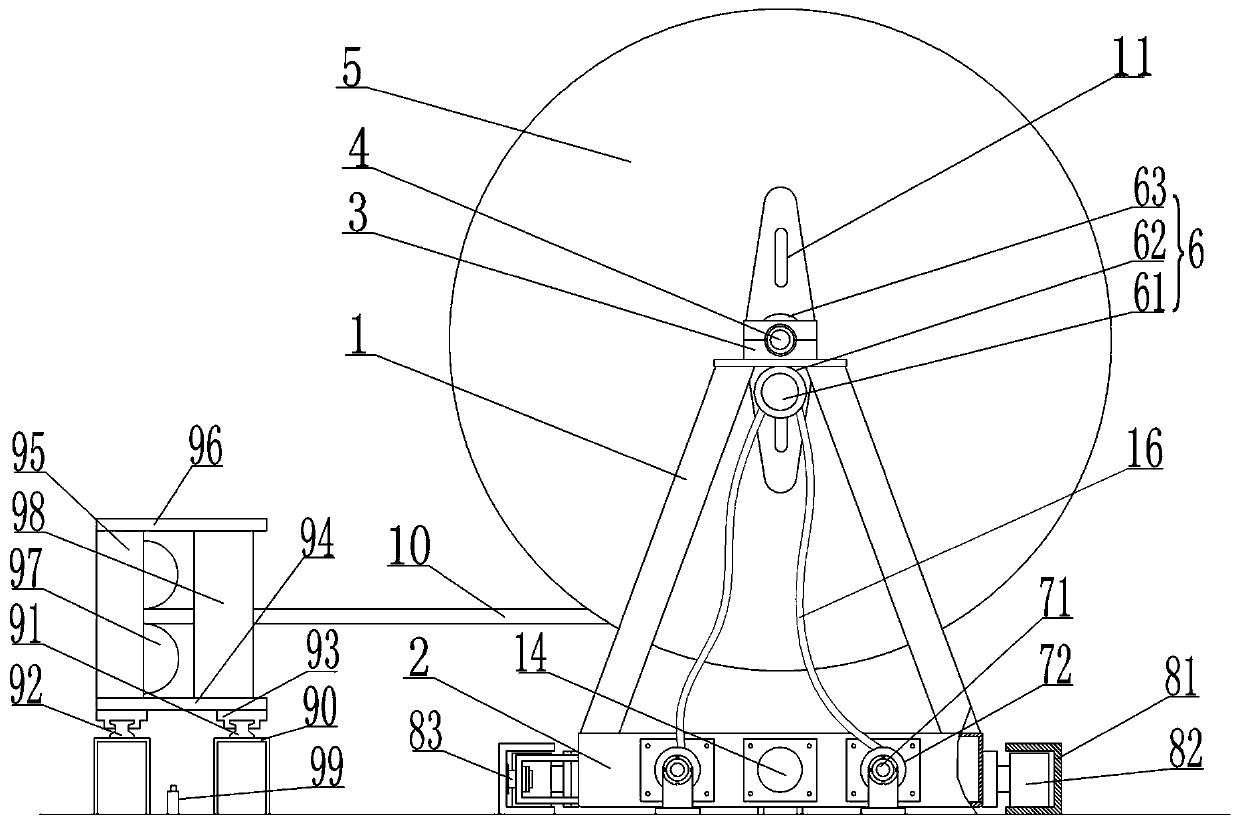

Constant-tension pay-off device

PendingCN111532894AConstant tensionStable tensionFilament handlingTrolley linesControl theoryWire wrap

The invention discloses a constant-tension pay-off device and belongs to the technical field of railway bearing conductor erection. The constant-tension pay-off device comprises a support, a rotary shaft rotationally connected to the support, and a winding device which is fixedly arranged on the rotary shaft and used for winding a bearing conductor. The support is connected to a car body, used forbearing the support, in a sliding mode through sliding rail devices. Moving devices and driving devices are fixedly arranged on the support, the moving devices enable the support to move along the sliding rail devices, the driving devices are used for driving the rotary shaft to rotate and provide tension for the winding device, and the force application direction of the driving devices is opposite to the pay-off direction of the winding device. The constant-tension pay-off device further comprises a guide device used for detecting the position of the bearing conductor and providing an actuating signal for the moving devices, and a control device. The constant-tension pay-off device provided by the invention is high in automation degree can be automatically aligned with a tension application device during paying-off, the tension is constant and can be automatically adjusted, friction between the bearing conductor and the ground and dragging are reduced during paying-off, the service life is long, dismounting and mounting are convenient, guiding is stable, and the device is applicable to all pay-off devices.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

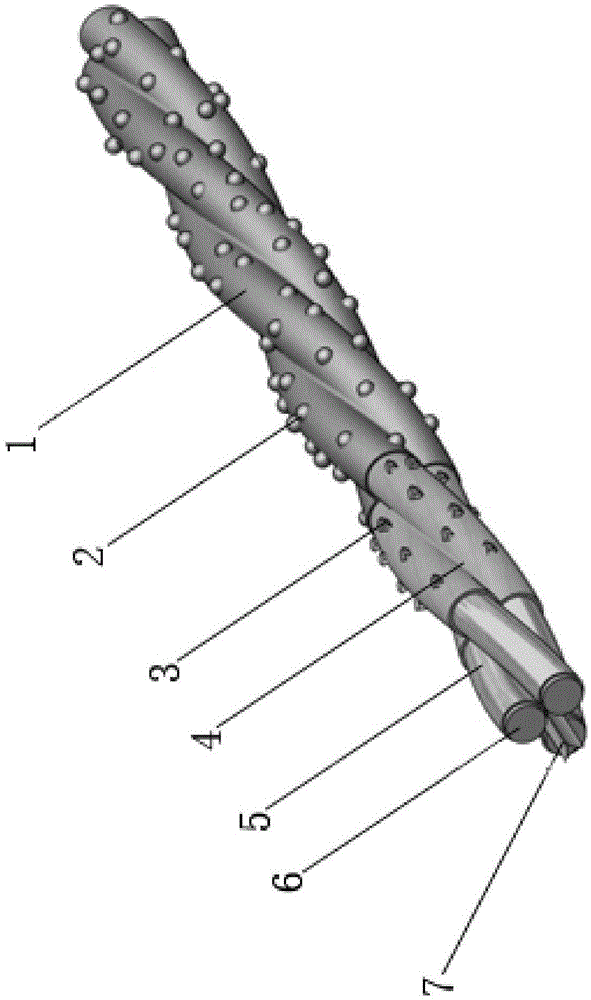

Novel composite metal fixed abrasive diamond rope and production process thereof

InactiveCN105459281AReduce mutual frictionLimit slipFine working devicesCoatingsCopper platingPre treatment

The invention relates to the technical field of diamond ropes, in particular to a novel composite metal fixed abrasive diamond rope. The novel composite metal fixed abrasive diamond rope comprises a core rope which is prepared by twisting a plurality of copper-plated steel wires and a soft polymer filling strip, wherein an attaching nickel layer for attaching diamond particles is deposited at the outer side of the core rope; the diamond particles are deposited on the attaching nickel layer on the surface of the core rope; and a packaging nickel layer for covering the diamond particles is deposited on the surfaces of the diamond particles. The invention further discloses a production process for the novel composite metal fixed abrasive diamond rope, wherein the production process comprises the following steps: compounding the core rope; carrying out surface pre-treatment; depositing the attaching nickel layer; attaching diamond; and depositing the packaging nickel layer. After the process is adopted, the core part of the core rope is free of a remarkable gap, so that a water-phase electrolyte solution is not remained in the space of the rope core, and therefore, corrosion is avoided; after the rope core is filled with soft stuffing, the diamond rope fracture risk is reduced; besides, by virtue of a buffer layer, slippage among steel wires is restricted, and coating is integrated, so that the coating fracture risk is reduced, and therefore, the line breakage risk in use is further reduced.

Owner:盛利维尔(常州)金属材料有限公司

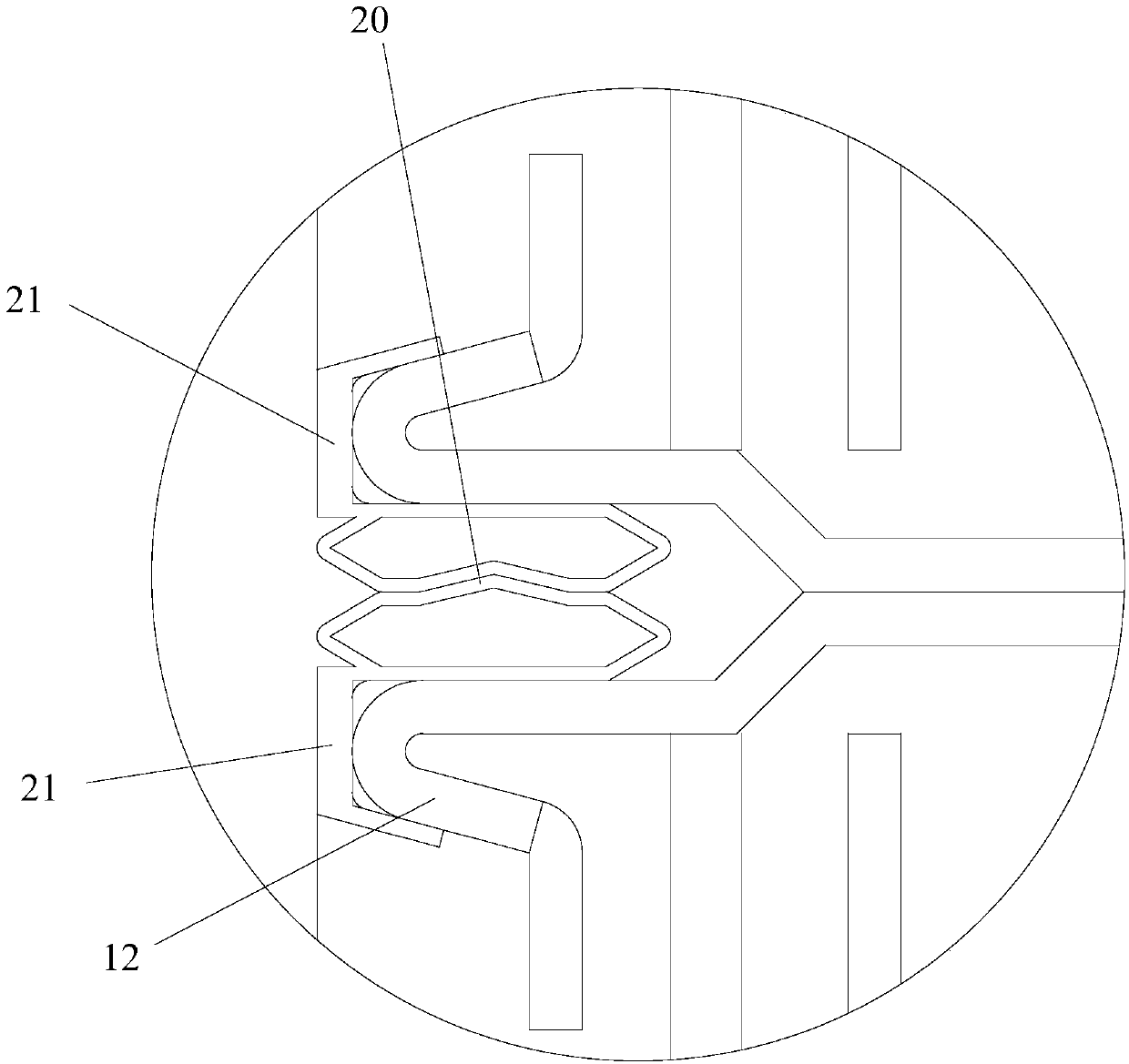

Building component sealing component and structure

PendingCN107829501AReduce mutual frictionExtended service lifeBuilding constructionsEngineeringStructural engineering

Owner:NENGCHENG GRP

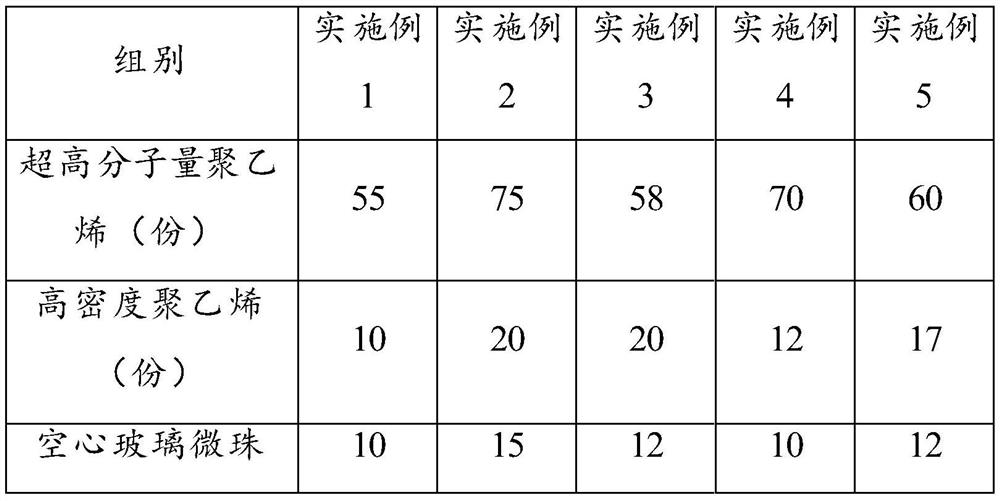

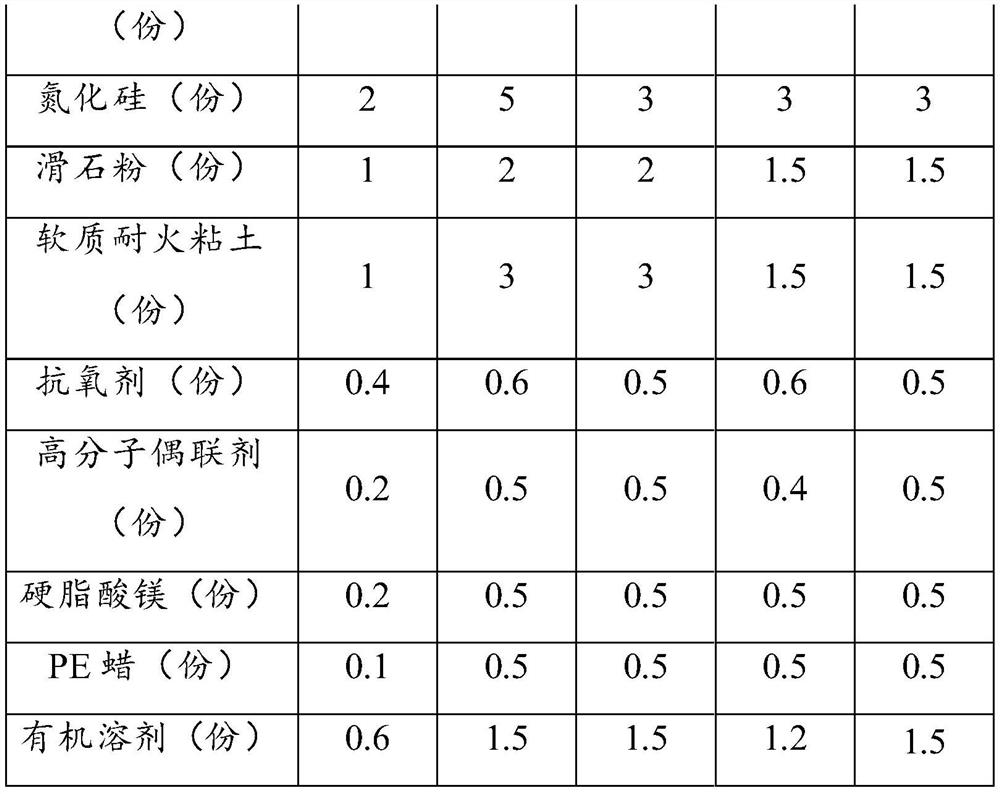

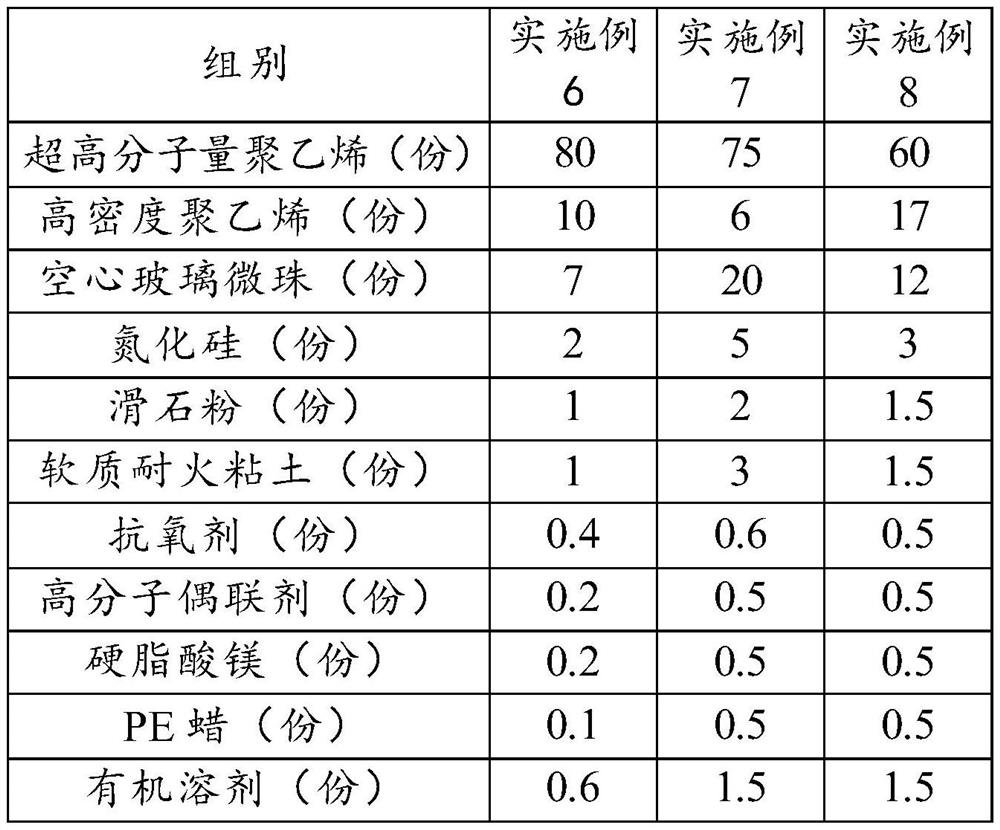

Polyethylene composite material and application thereof in preparation of high-temperature-resistant lining oil pipe

The invention provides a polyethylene composite material and application thereof in preparation of a high-temperature-resistant lining oil pipe, and relates to the technical field of special pipes. The polyethylene composite material is mainly prepared from ultra-high molecular weight polyethylene, high-density polyethylene, a heat-resistant filler and auxiliaries, wherein the heat-resistant filler comprises hollow glass beads, silicon nitride, talcum powder and soft refractory clay; the auxiliaries comprise an antioxidant, a macromolecular coupling agent, magnesium stearate, PE wax and an organic solvent. According to the polyethylene composite material prepared by compatibility of the raw materials, all the raw materials achieve a synergistic compounding effect, and the polyethylene composite material has good temperature resistance and aging resistance, is stable in mechanical property and can cover basic characteristics of a conventional lining oil pipe product. Experiments verify that the composite material can resist high temperature of 150 DEG C effectively, and the technical requirements for use in a deep well oil extraction environment are fully met.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

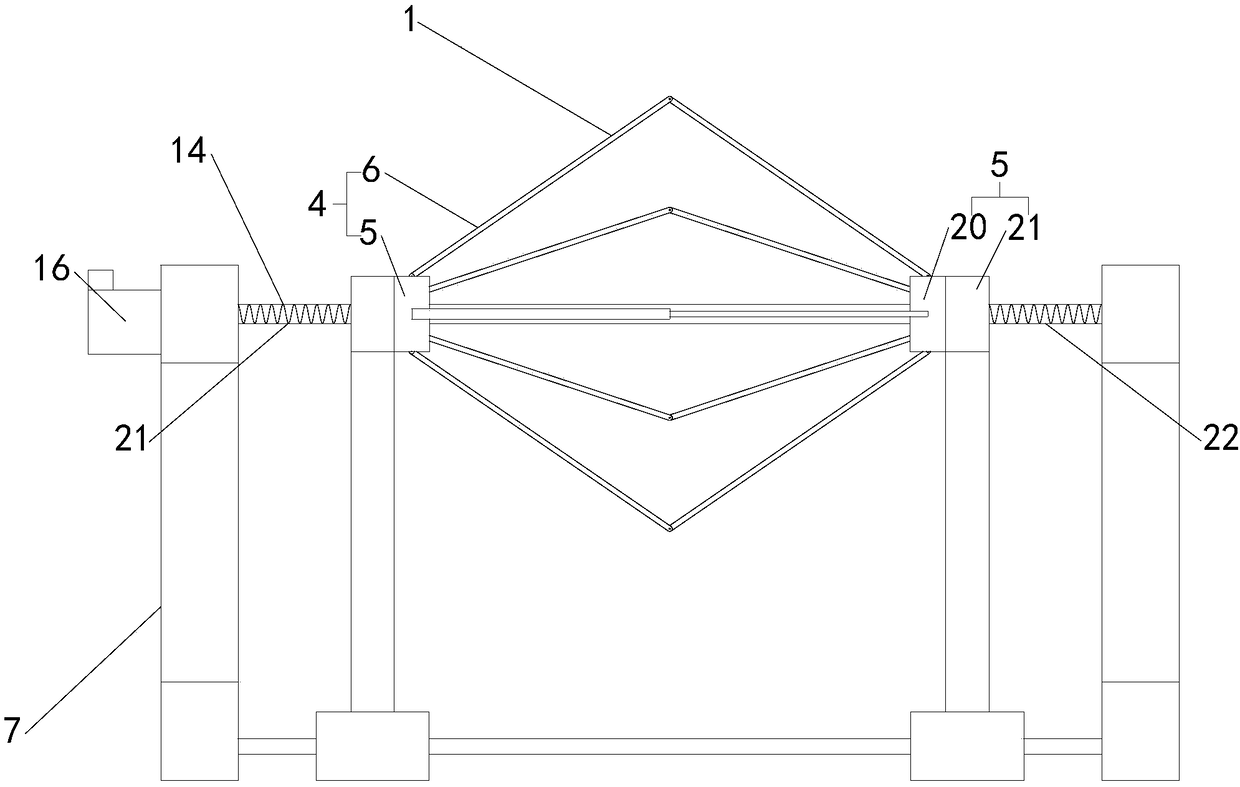

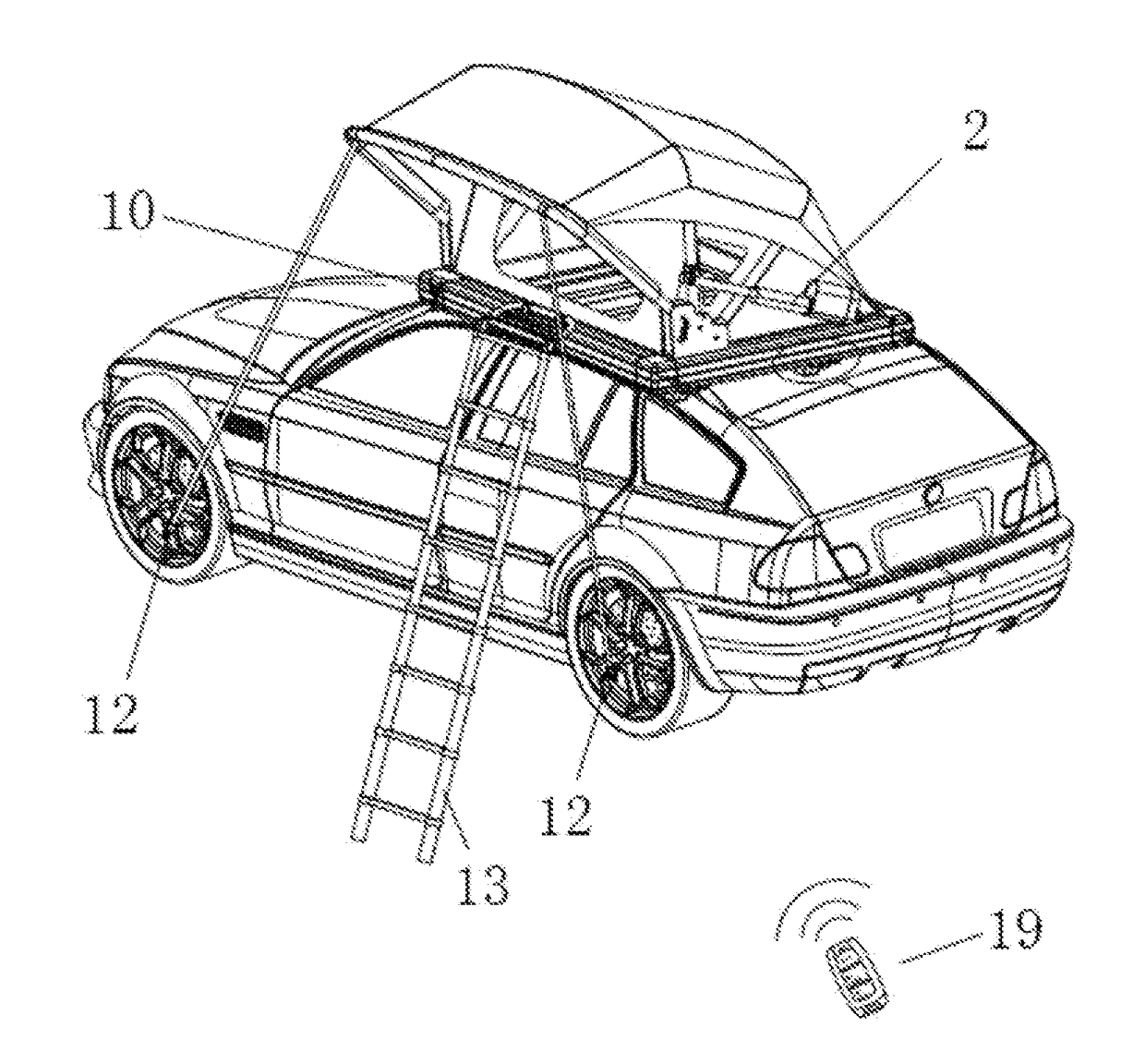

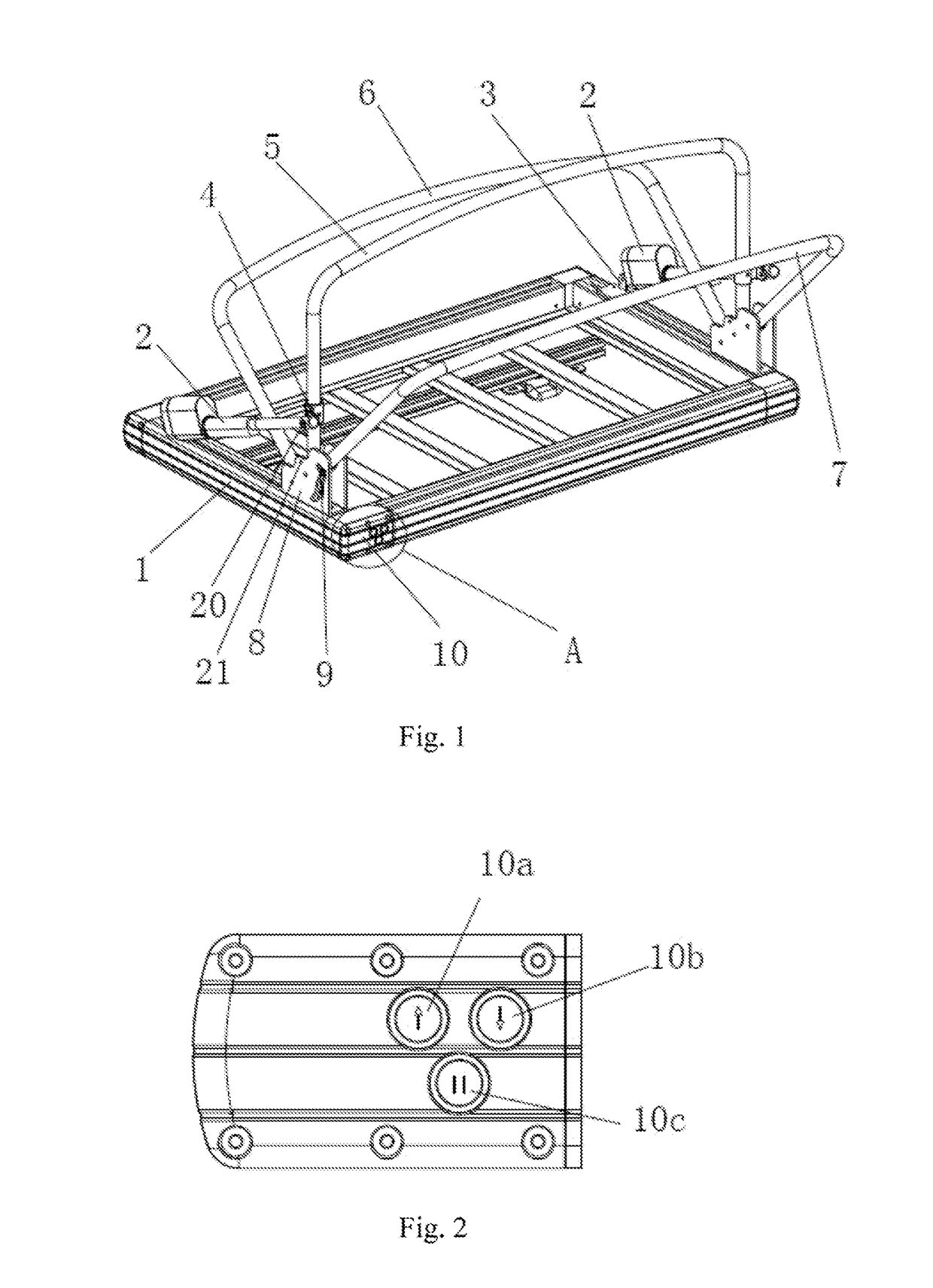

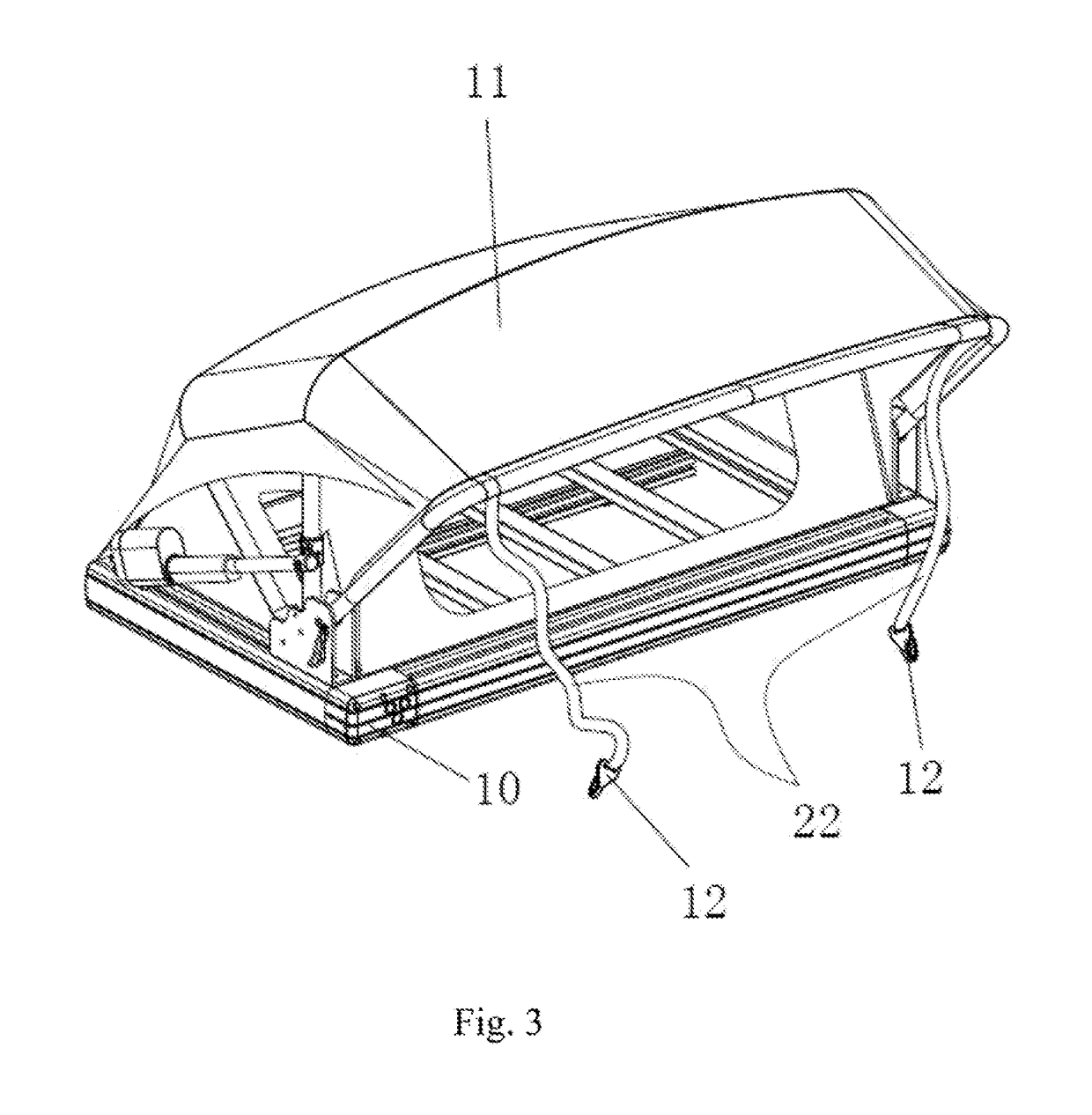

Folding vehicle roof top tent under manual and electric control

InactiveUS20180112432A1Rapid switchPrevent be damageTents/canopiesVehicle with living accommodationHinge angleEngineering

A folding vehicle roof top tent under manual control and electric control, which comprises ejector rods consisting of a front ejector rod, a middle ejector rod and a rear ejector rod, a bed frame and tent cloth, the one ends of two electric ejectors are respectively hinged to a middle-lower part of two side walls of the middle ejector rod, the other ends of the two electric ejector rods are respectively hinged to two sides of the other end of the bed frame, a press button control panel provided on a side of the bed frame, the electric ejector rods drive the middle ejector rod to rotate, an adapter is fixed in the middle-lower part of the middle ejector rod, and the electric ejector rods realize the hinge / unhinge between the electric ejector rods and the middle ejector rod.

Owner:YUAN CHENG AUTO ACCESSORIES MFGR CO LTD

PVC building formwork and preparation method thereof

The invention discloses a PVC building formwork which is characterized by being prepared from, by weight, 150-200 parts of PVC recycled material, 1-4 parts of composite stabilizer, 4-9 parts of foaming regulator, 1-1.5 parts of composite foamer, 0.1-0.5 part of plasticizer, 0.3-0.9 part of inner lubricant, 0.1-0.4 part of outer lubricant and 1.5-4 parts of toughening agent, wherein the composite foamer is formed by mixing a white foamer with a yellow foamer. The invention further discloses a preparation method of the PVC building formwork. The PVC recycled material is used as a main raw material, so that waste is turned into valuable things, production cost is lower, energy resources are saved, weatherability and aging resistance of the PVC building formwork are improved, and number of circulating use times is increased and can reach higher than 35. The preparation method is simple and easy to operate, and the PVC building formwork is smooth and attractive in surface. The PVC building formwork is energy-saving, environment-friendly, low in production cost and long in service life.

Owner:江苏旺科新材料有限公司

Method for processing curling spinning cakes

The invention discloses a method for processing curling spinning cakes, which comprises the following process steps: sorting, namely selecting severe wool curling cakes selected in a tubing process; oil immersion, namely immersing the selected severe wool curling cakes in 2.0 to 5.0g / l oiling agent for 20 to 40 minutes; dehydration, namely dehydrating the immersed wool curling cakes; airing, naturally airing the dehydrated wool curling cakes at a temperature of between 30 and 75 DEG C for 2.5 to 5.5 hours; and tubing, tubing the aired wool curling cakes on a spooler. The method can process the severely-curly spinning cakes, and the processed spinning cakes can be unwounded to form a tube or a ternary tube, so that the product added value of the severely-curly wool curling cakes is increased, the yield is improved, and the economic benefits are increased.

Owner:YIBIN HIEST FIBER +1

Powder alloy smithing float grease seal ring with upper and lower double-layer and method of producing the same

InactiveCN101402138BReduce wearSelf-lubricatingEngine sealsFurnace typesIron powderChemical composition

The invention relates to a floating oil-seal ring which has an upper layer and a lower layer and is forged by powder alloy. The floating oil-seal ring comprises the upper layer and the lower layer, wherein the upper layer is made of rare alloy powder materials, and chemical compositions in weight percentage of the upper layer are as follows: 0.5 to 3 percent of Cu, 0.5 to 1 percent of C, 0.5 to 2percent of Cr, 0.5 to 1.5 percent of MoS2, and the balance being Fe; the lower layer is made of ordinary iron powder materials, and chemical compositions in weight percentage of the lower layer are as follows: 0.5 to 3 percent of Cu, 0.5 to 1 percent of C, and the balance being Fe; and the upper layer and the lower layer are sintered into an integrated floating oil-seal ring through pressing and high-temperature sintering. The upper layer of the floating oil-seal ring is made of high alloy powder, the lower layer is made of ordinary iron-based powder, and then the heat treatment process is performed, thereby assuring reasonable quenching depth as well as higher wear resistance and anti-fatigue performance; and the floating oil-seal ring has steady working performance, the service life is improved by 50 to 100 times, and the production cost is greatly reduced.

Owner:韶关市富洋粉末冶金有限公司

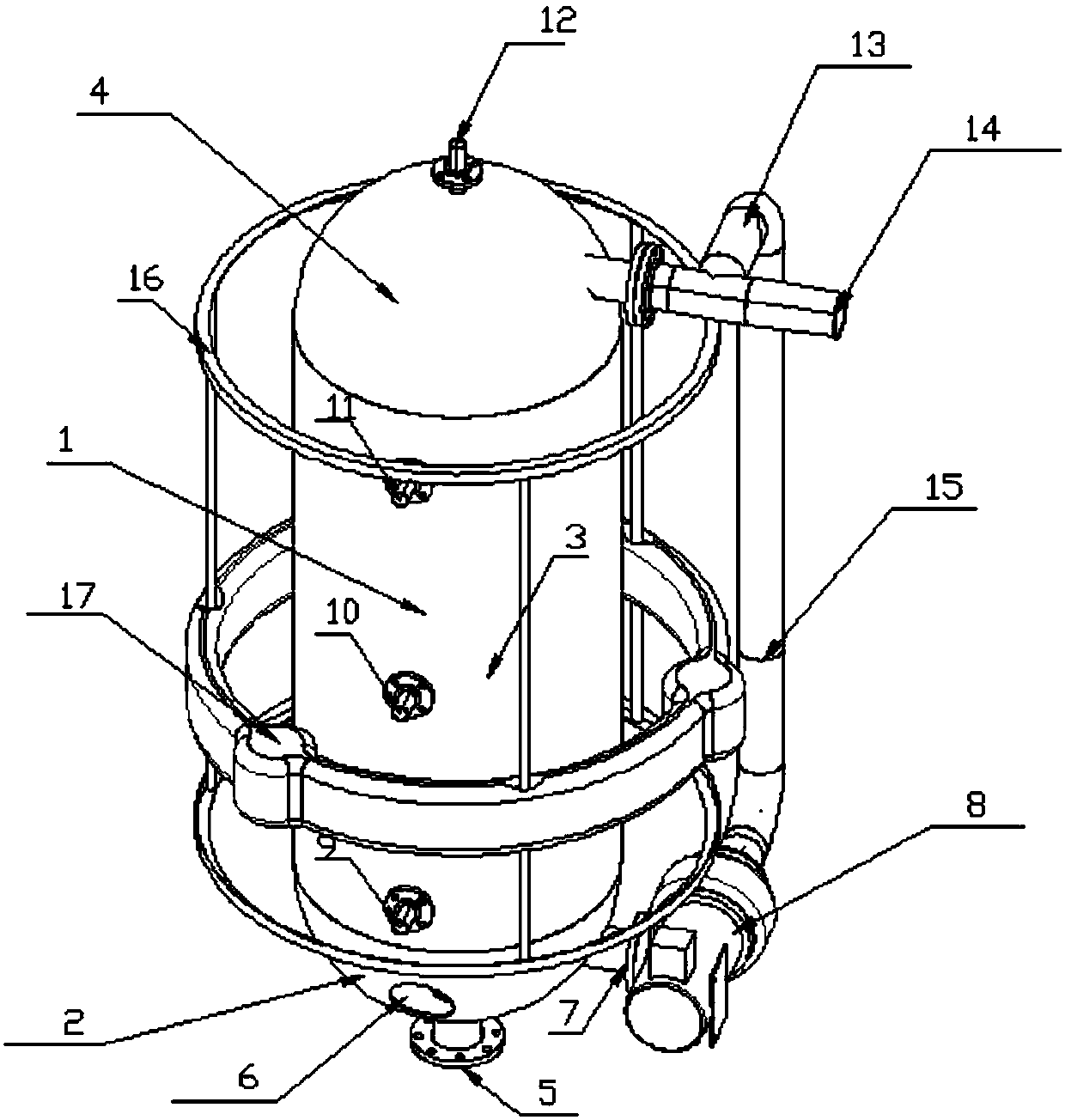

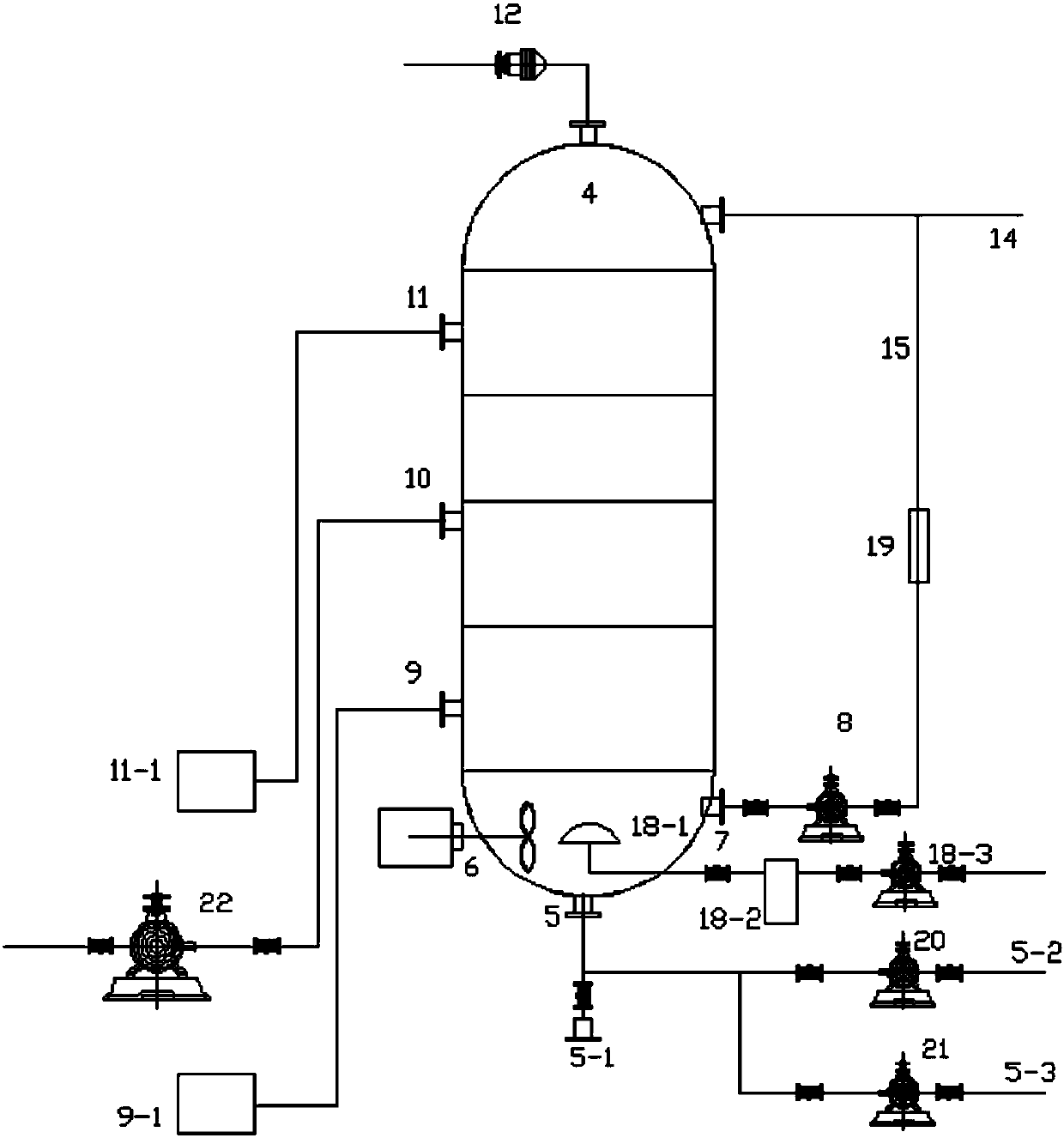

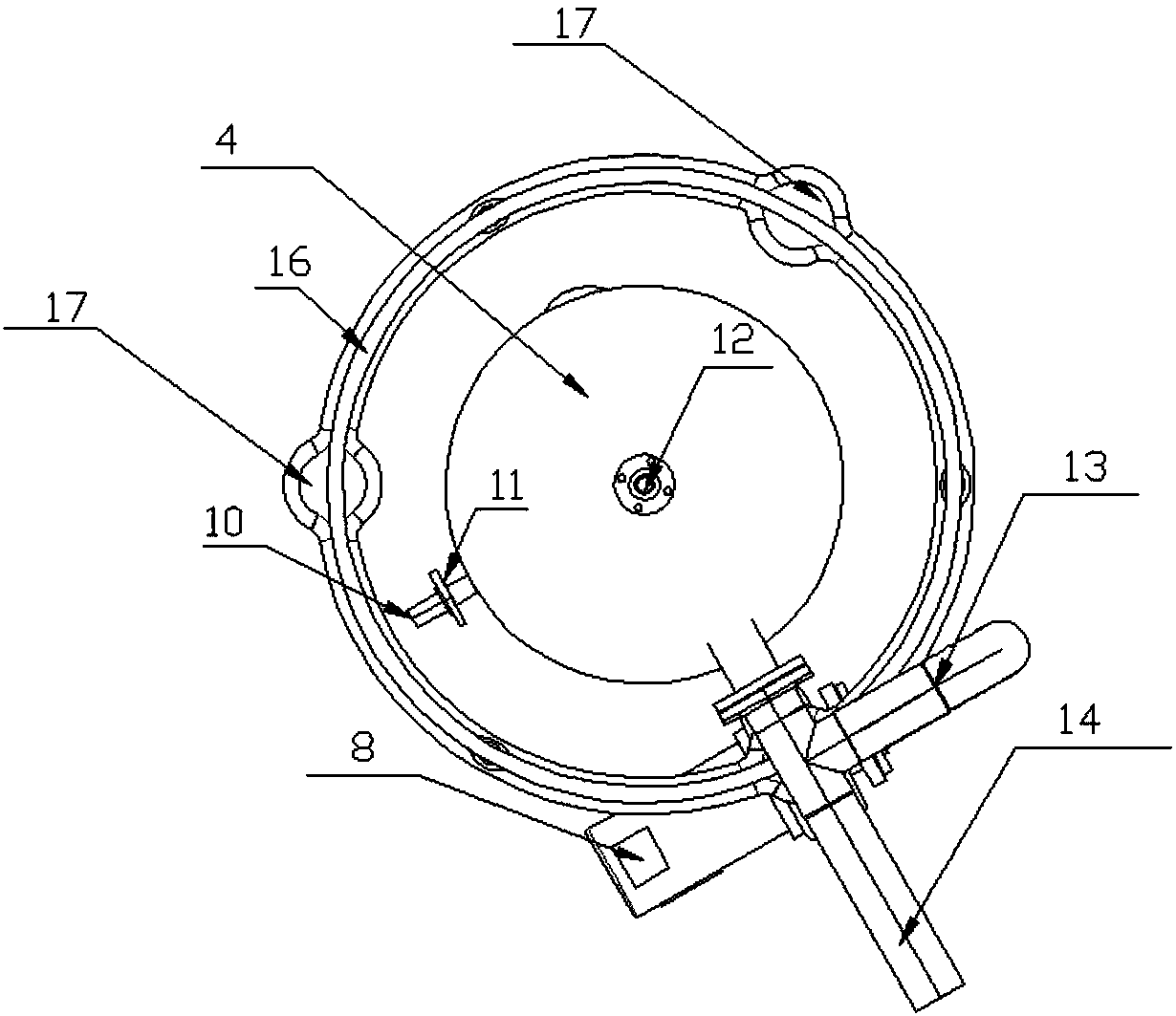

Sewage treatment method of magnetic three-phase Fenton reactor and equipment thereof

PendingCN107827222AReduce dosageSave the dosing adjustment processWater treatment compoundsWater/sewage treatment apparatusPtru catalystWater production

The invention discloses a sewage treatment method of a magnetic three-phase Fenton reactor and equipment thereof. The sewage treatment method comprises the following steps: (A), sewage to be treated enters the bottom of a reactor through a water inlet hole, and the sewage to be treated is mixed with hydrogen peroxide at the bottom of the reactor; (B), after mixing, the mixed solution undergo uniform water distribution in a water intake area and then enters a Fenton reaction area to undergo a Fenton reaction, and iron mud sediment and carrier particles generated during the reaction process enter a water production area under the action of current; and (C), gas generated by a reaction at the top of the water production area is discharged out of the reactor through an exhaust valve at the topof the water production area. The equipment of the magnetic three-phase Fenton reactor is composed of a reactor, a water intake area, a Fenton reaction area, a water outlet area, a stirring device, areflux pump, a pH monitor, an exhaust valve, a return pipe, a support, aeration equipment, an aeration disc, an air compressor, a flowmeter, a sewage intake pump, a dosing pump and the like. According to the invention, hardly-degradable organic wastewater can be treated effectively, and chroma of sewage is removed. The equipment of the invention has a simple structure and is convenient to use. Bythe sewage treatment method and the equipment, use efficiency of a catalyst is raised, and sedimentation of iron mud is reduced.

Owner:王黎明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com