Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2041results about How to "Fine foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

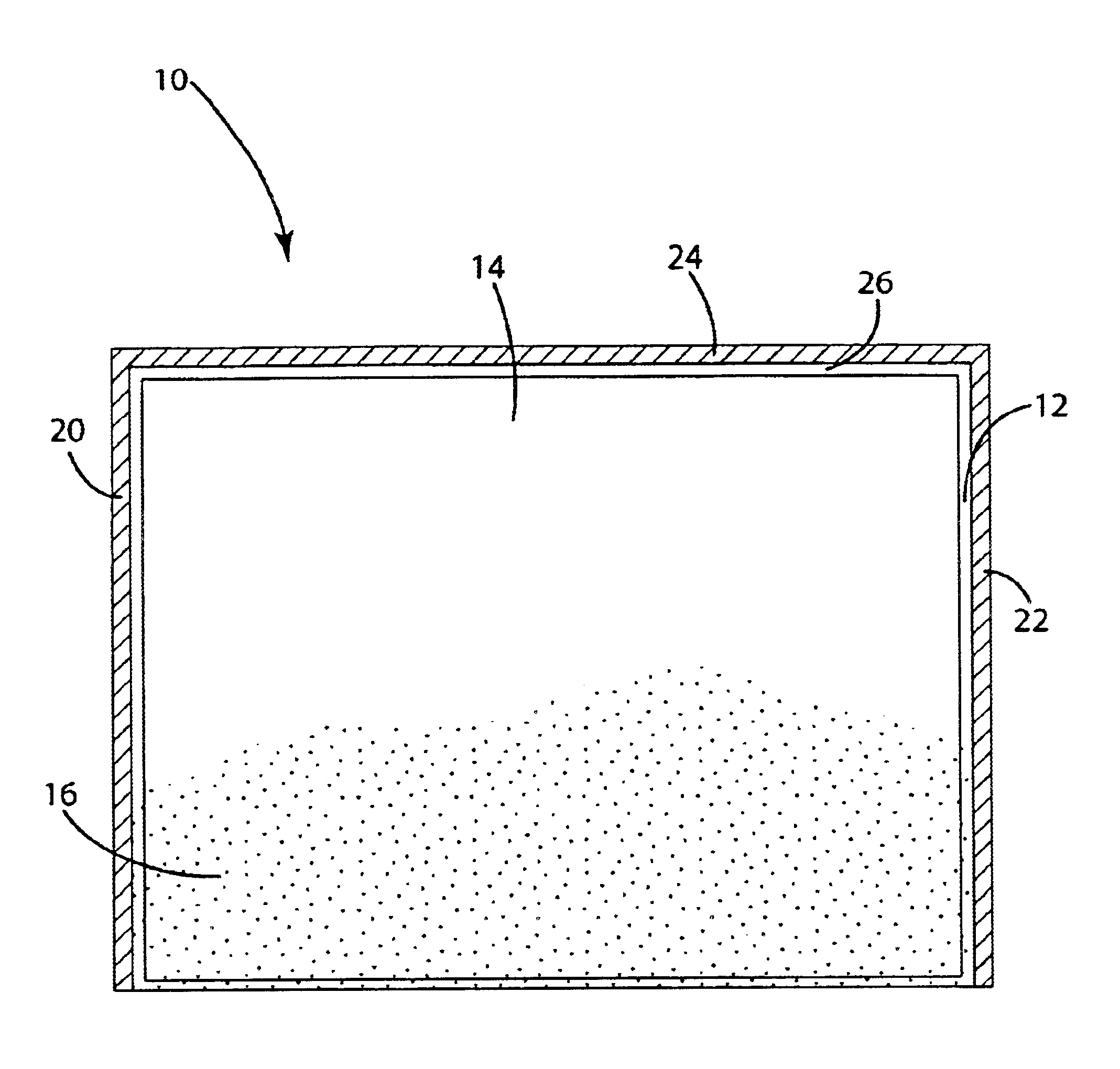

In vivo tissue engineering with biodegradable polymers

The present invention relates generally to the utilization of in situ polymers or copolymers to form a porous microcellular scaffold for the delivery, attachment, housing, protection, multiplication and growth of encapsulated cells. More particularly, the present invention relates to cells delivered using such a scaffold to augment, repair or replace in vivo diseased, damaged or otherwise compromised tissues or organs of a living body.

Owner:DERMAGENESIS

Foam including surface-modified nanoparticles

InactiveUS20020128336A1Improves foamIncrease in numberMaterial nanotechnologyNon-macromolecular adhesive additivesNanometreNanoparticle

A foam composition that includes a vehicle and surface-modified nanoparticles disposed in the vehicle. The individual nanoparticles having a particle diameter of less than about 100 nanometers.

Owner:3M INNOVATIVE PROPERTIES CO

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

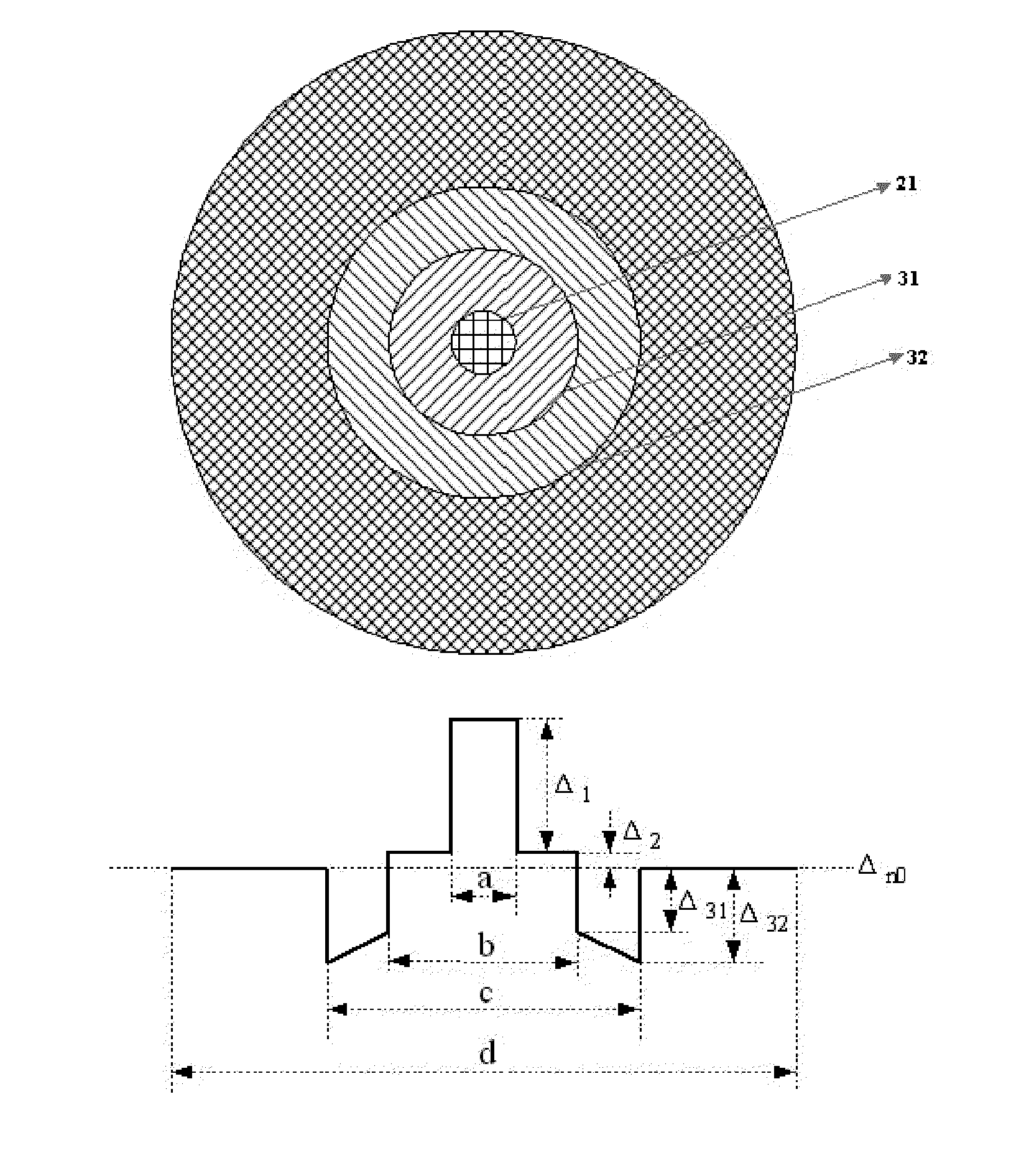

Single-mode fiber and production method thereof

ActiveUS20110058780A1Prevent viscosity being lowIncrease refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingSingle-mode optical fiberUltrasound attenuation

A single mode fiber having a core, an inner cladding, a depressed cladding, and an outer cladding composed of pure silica glass. The core is surrounded in sequence with the inner cladding and the depressed cladding. The core has silica glass doped with germanium and fluorine, with a diameter (a) of 8.0-8.8 μm, a relative refractive index difference (Δ1) of 0.35-0.38%, and the contribution of fluoride (ΔF) is −0.09±0.02%. The inner cladding has silica glass doped with germanium and fluorine, with a diameter (b) of 18-21 μm and a relative refractive index difference (Δ2) of 0±0.02%. The depressed cladding has silica glass doped with fluorine, with a diameter (c) of 26-36 μm and a relative refractive index difference (Δ32) at the external interface thereof is between −0.22 and −0.35%, and a relative refractive index difference (Δ31) at the internal interface thereof is between −0.20 and −0.35%, and Δ32≦Δ31. The fiber has a good bending resistance, good mechanical properties, and extended service lifetime, and prevents the additional stresses generated by bending from passing on to the core, thereby reducing attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

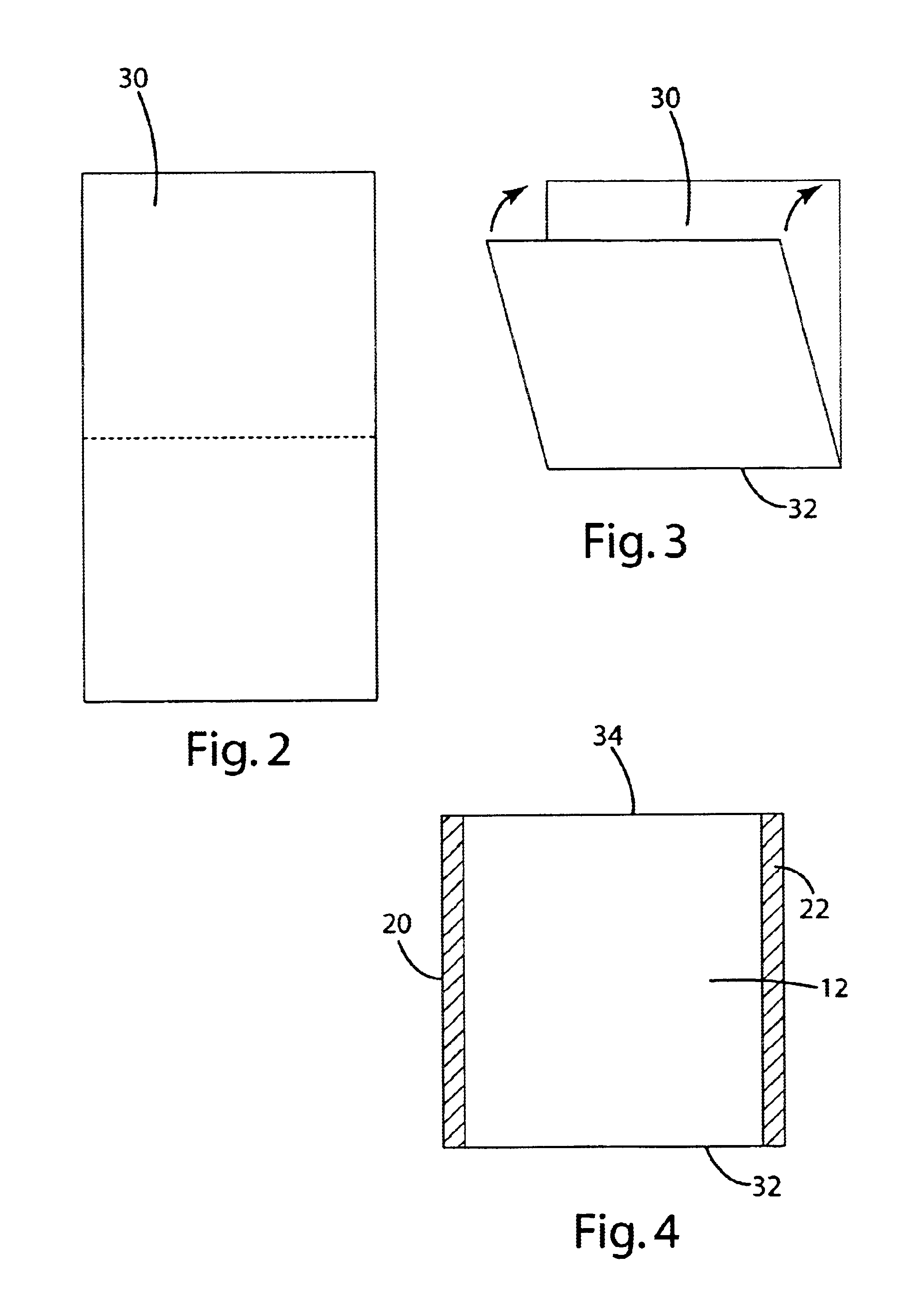

Water soluble pouch package

InactiveUS6846784B2Fine foamSimple and inexpensiveInorganic/elemental detergent compounding agentsBiocideWater solubleCleansing Agents

A unit-dose personal care product including a cleansing agent and a cleansing pad wrapped in a film of water-soluble material. The water-soluble material protects the cleansing pad and cleansing agent until the package is exposed to water, at which time the film dissolves and the user is left with a cleansing product comprised of the pad, cleansing agent and water. Also disclosed is a method of manufacturing the personal care product.

Owner:ACCESS BUSINESS GRP INT LLC

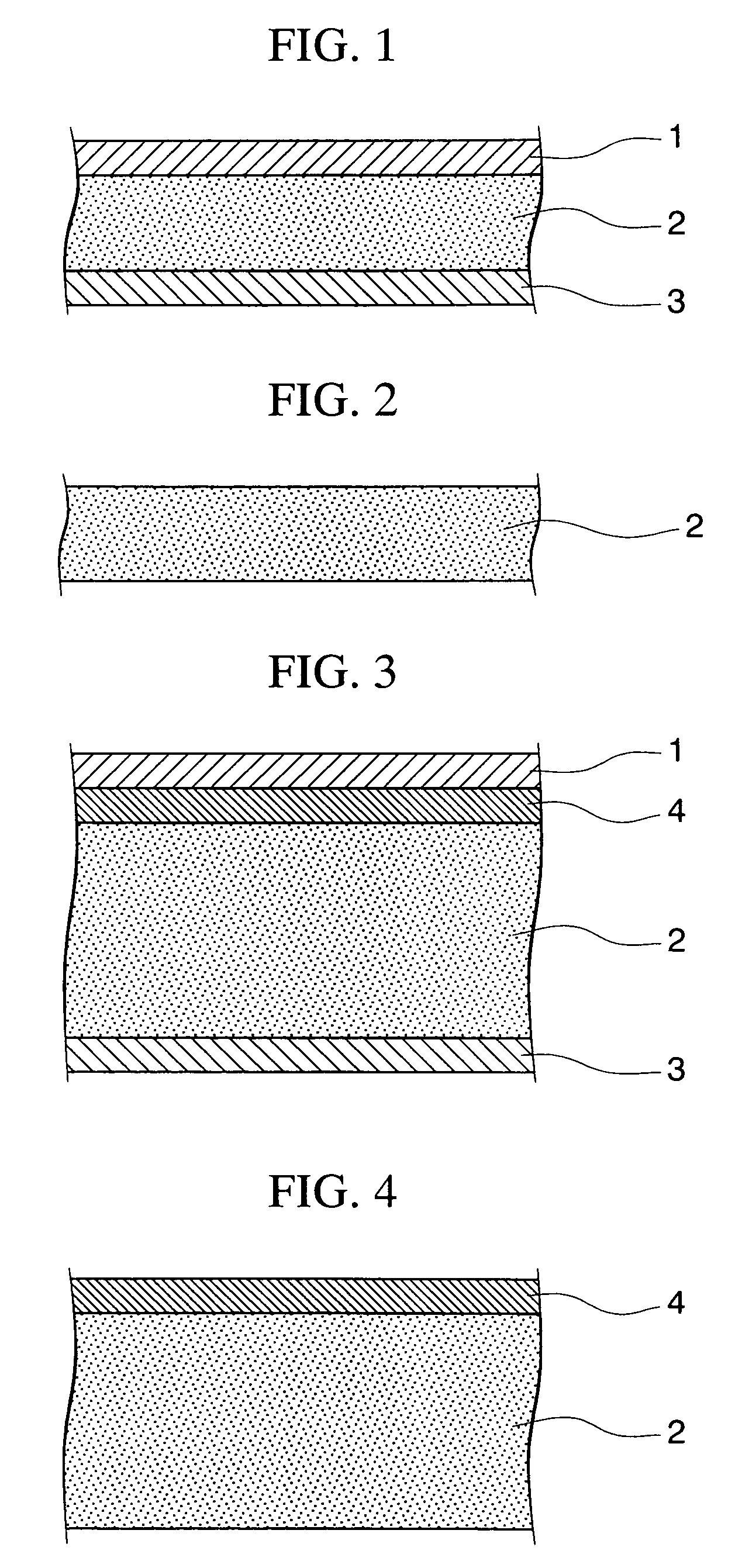

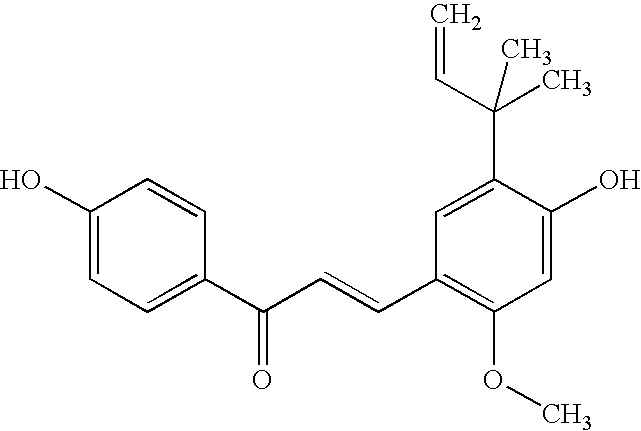

Pressure-sensitive adhesive composition, and pressure-sensitive adhesive product and display using the same

InactiveUS20080281047A1High transparencyFine foamAcid polymer adhesivesEster polymer adhesivesPolymer scienceMeth-

The present invention provides a pressure-sensitive adhesive composition comprising an acrylic polymer (a), an acrylic oligomer (b), a silane coupling agent having an amino group, and a cross-linking agent, the acrylic polymer (a) containing, as a main monomer component, at least one of a (meth)acrylic acid alkyl ester containing an alkyl group having a number of carbons of from 4 to 12 and a (meth)acrylic acid alkoxyalkyl ester, and containing 1 to 10 parts by weight of a carboxyl group-containing monomer as a monomer component based on 100 parts by weight of the total monomer components constituting the acrylic polymer (a), the acrylic polymer (a) having a weight-average molecular weight of from 400,000 to 1,500,000; and the acrylic oligomer (b) containing a (meth)acrylic acid ester as a main monomer component, and containing 1 to 10 parts by weight of a carboxyl group-containing monomer as a monomer component based on 100 parts by weight of the total monomer components constituting the acrylic oligomer (b), the acrylic oligomer (b) having a weight-average molecular weight of 3,000 or more but less than 6,000, in which the pressure-sensitive adhesive composition contains 10 to 35 parts by weight of the acrylic oligomer (b) and 0.01 part by weight or more but less than 1.0 part by weight of the silane coupling agent having an amino group, based on 100 parts by weight of the acrylic polymer (a). The pressure-sensitive adhesive composition is excellent in transparency and foaming and separation resistances, does not cause periodical reduction of adhesiveness and dramatically improves adhesion reliability.

Owner:NITTO DENKO CORP

Expandable polypropylene beading, preparation method thereof, and its foaming beading and foaming molding products

The invention provides an expandable polypropylene bead and a preparation method of the expandable polypropylene beads, and also provides foaming beads and foaming molding products of the expandable polypropylene beads, which relates to the resin expandable beads technical field. Random copolymerized polypropylene is used as basic resin, so that melting intensity can reach to an ideal range when in foaming with high melting intensity polypropylene and low density polyethylene resin being added. Expandable beads are prepared in a closed reactor without external pressure with pentane being used as foaming agent. The expandable beads contain 1 to 15 parts by weight of the high melting intensity polypropylene, 1 to 10 parts by weight of the low density polyethylene, 1.0 to 3.8 parts by weight of the foaming agent and 0.1 to 10 parts by weight of nucleating agent on the basis of 100 parts by weight of the random copolymerized polypropylene. The expandable polypropylene beads are easy to foam, whose foaming rate can reach to 16 times with uniform cells and whose foam volume weight is about 0.05 to 0.12g / cm3. The invention adopts a low-pressure method to produce the polypropylene foaming products in different shapes according to the requirement with low equipment requirement and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

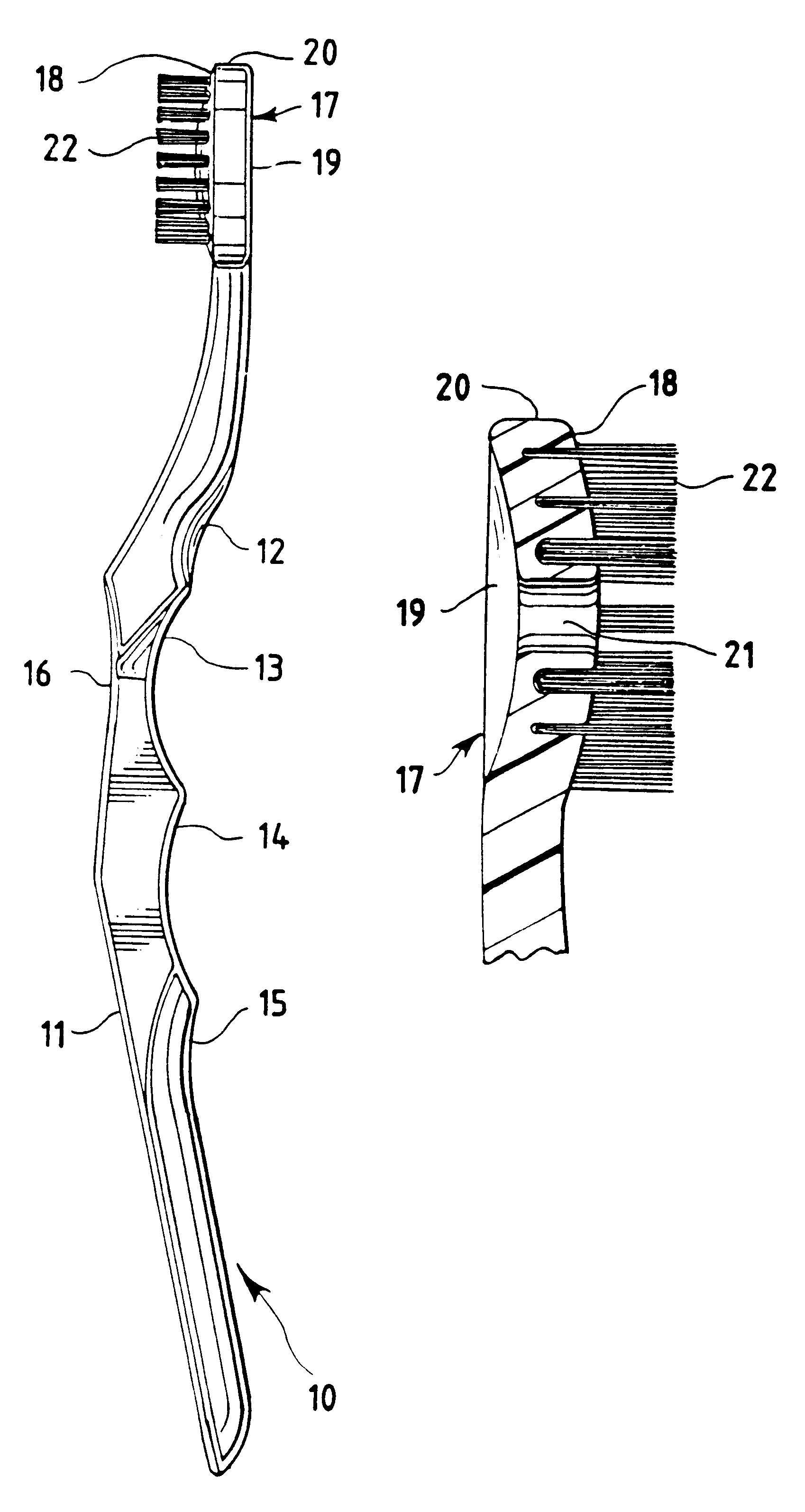

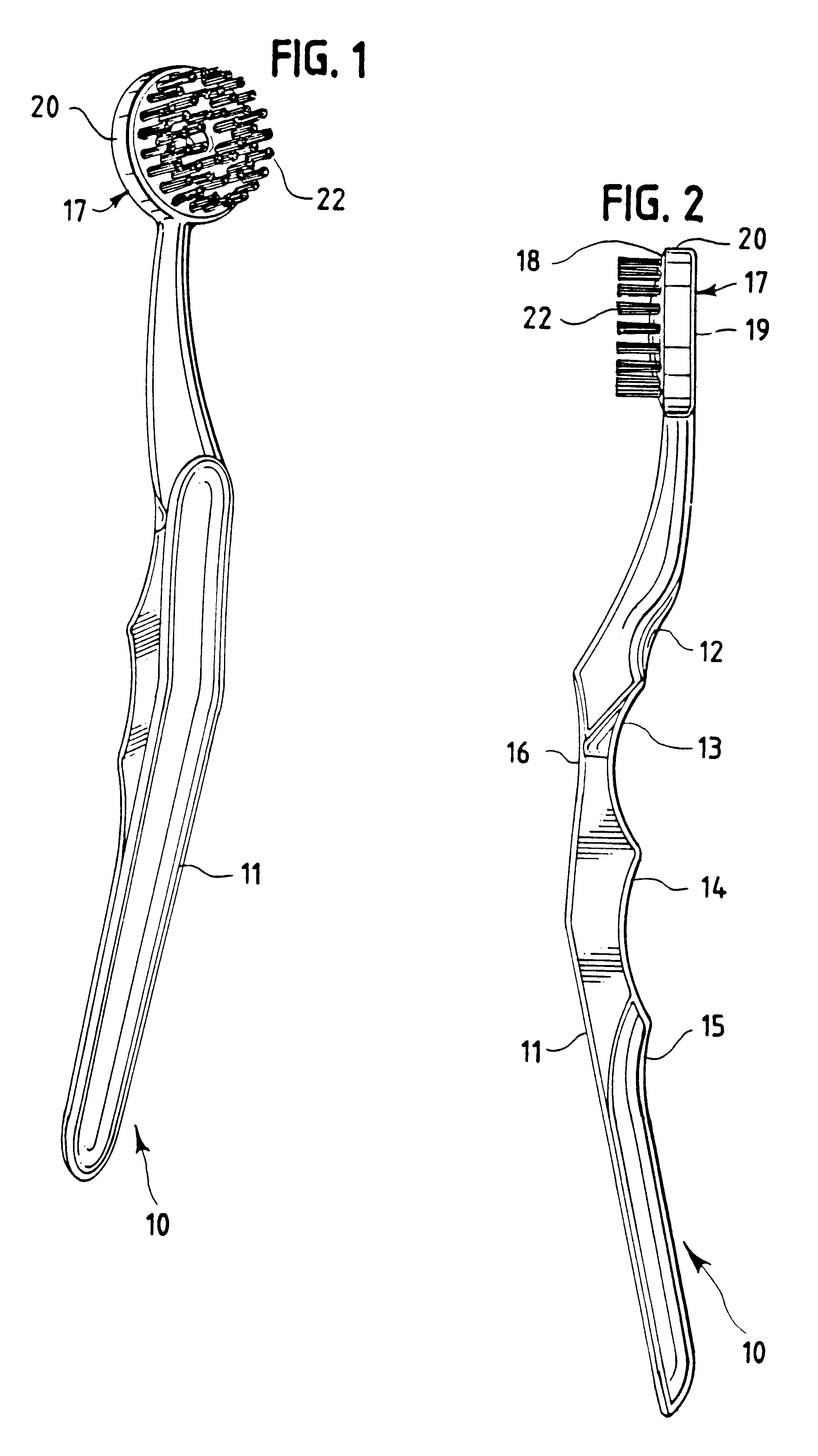

Tongue hygiene device

A tongue hygiene device to be used with a mildly abrasive cleanser, the tongue hygiene device having a generally elongate handle section and a generally disk-shaped cleansing section. The handle section is ergonomically designed to allow the user to effectively and comfortably hold the tongue hygiene device in proper cleansing alignment with the tongue. The cleansing section includes three generally parallel, circular patterns of medium-length bristles of medium stiffness, protruding from a generally disk-shaped cleansing head, the cleansing head having a top face, and a bottom face from which the bristles protrude, and a large aperture extending between the centers of the bottom and top faces which is surrounded by the bristles on the bottom face. The bristles allow the tongue hygiene device to cleanse the tongue by brushing bacteria and food buildup from the tongue using a mildly abrasive cleanser. The aperture allows air and the lather formed by brushing with a cleanser to pass through the head element, thereby increasing the lather and facilitating the passage of bacteria and food buildup away from the surface of the tongue, and provides a conduit for the passage of air and water through the head element during cleaning of the tongue hygiene device, expediting and simplifying cleaning of the tongue hygiene device and hastening drying of the bristles.

Owner:PEAK ENTERPRISES

Textured film devices

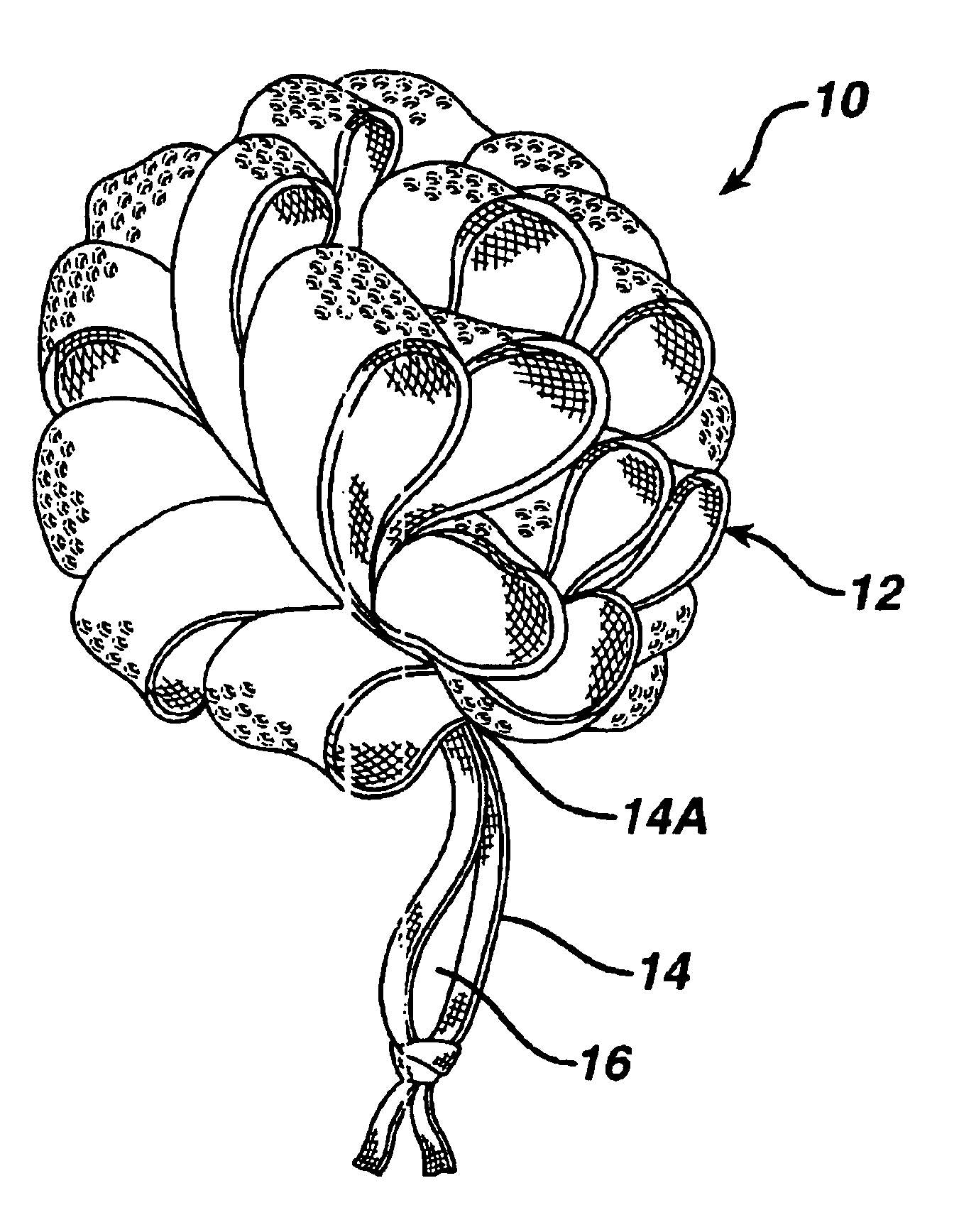

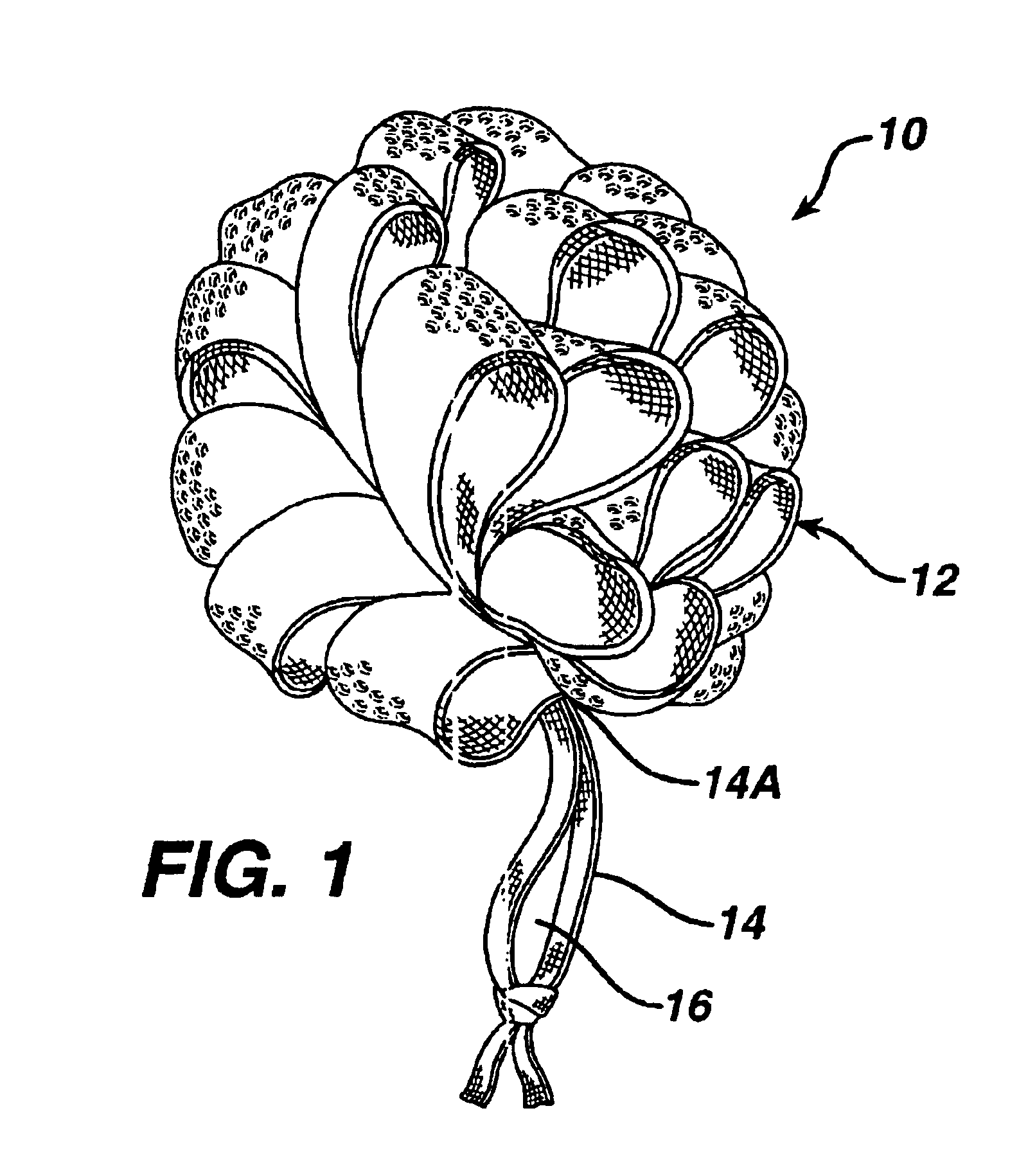

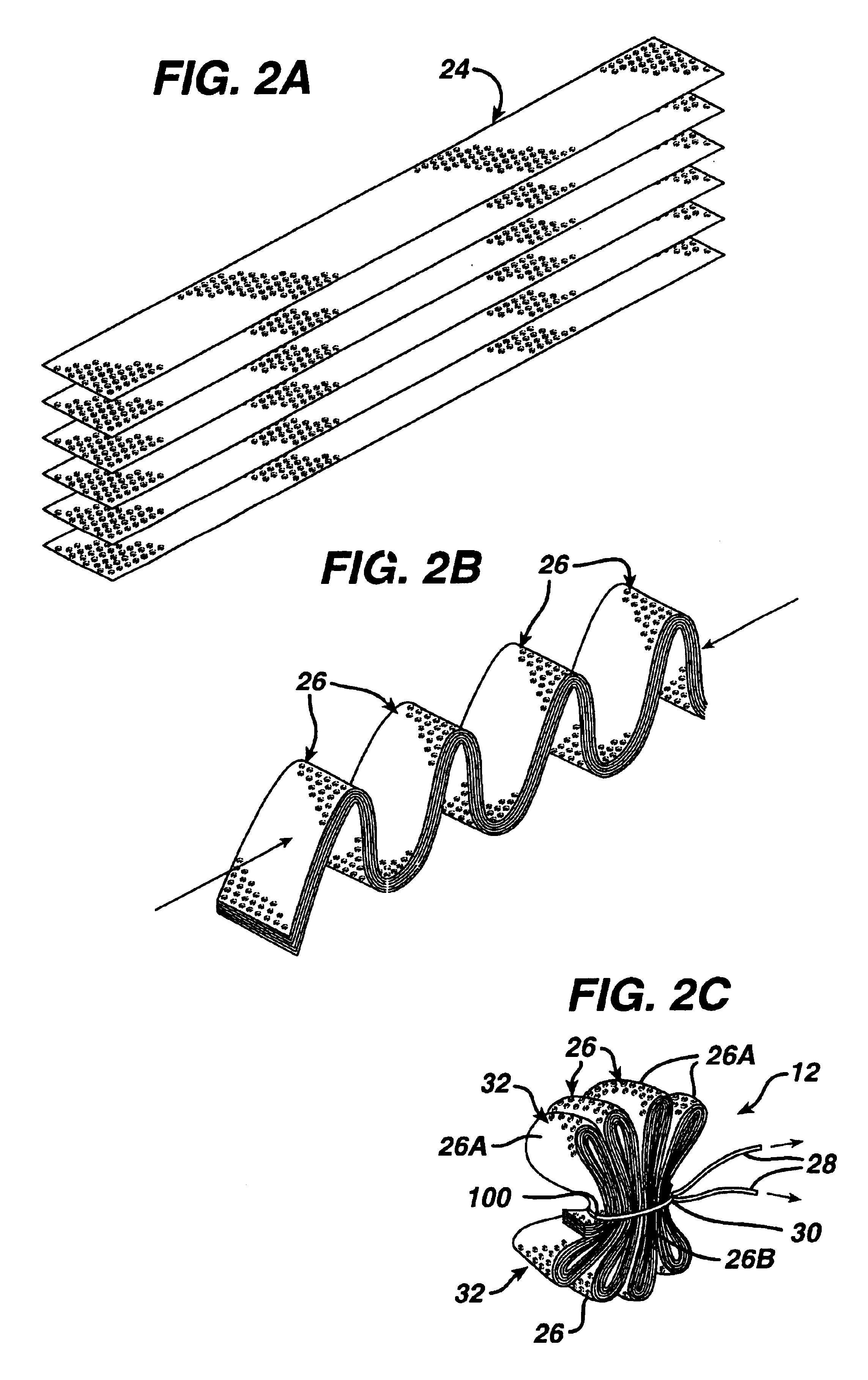

InactiveUS6957924B1Gentle on skinFine foamCosmetic preparationsKitchenware cleanersDevice formEngineering

A textured film device formed from at least one layer of gathered textured film. These devices are capable of producing excellent lather when used with a cleanser and are soft to the touch. Other textured film devices include mitts, gloves, washcloths, and the like formed from at least one layer of textured film.Also provided are systems comprised of the textured film devices and at least one active material selected from cleansers; moisturizers, conditioners; sunscreens; shaving foams; tanning agents; anti-acne agents; anti-aging agents; anti-irritant agents; perfumes / fragrances; and mixtures thereof.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Low-irritation and high-foaminess fancy soap formula

The invention discloses a low-irritation and high-foaminess fancy soap formula, which is composed of the following components by mass percentage: 2%-10% of alpha-lauryl betaine ampholytic surfactant, 20%-30% of coconut oil sodium salt, 50%-70% of sodium palmitate, 2%-5% of sorbic alcohol, 0.1%-1.5% of antioxidant, 0.05%-0.15% of Kathon, 0.05%-0.2% of chelant, 0.5%-1% of titanium white powder, 0.5%-1.0% of essence and water (the rest). In the fancy soap, the alpha-lauryl betaine ampholytic surfactant is used as additive, which can reduce the irritation of the fancy soap taking the normal sodium soap as the soap base and improve the foaminess of the fancy soap.

Owner:JIANGNAN UNIV +1

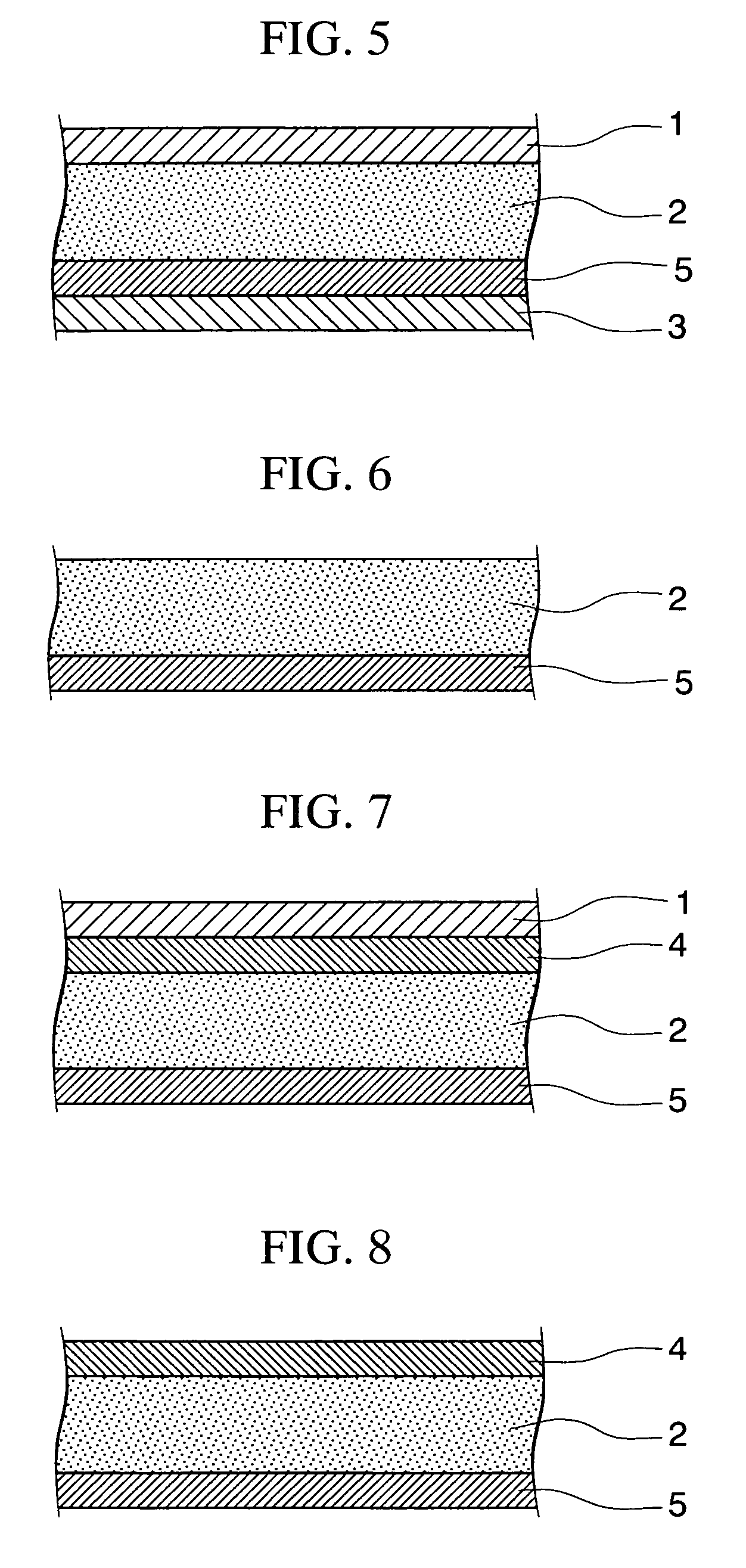

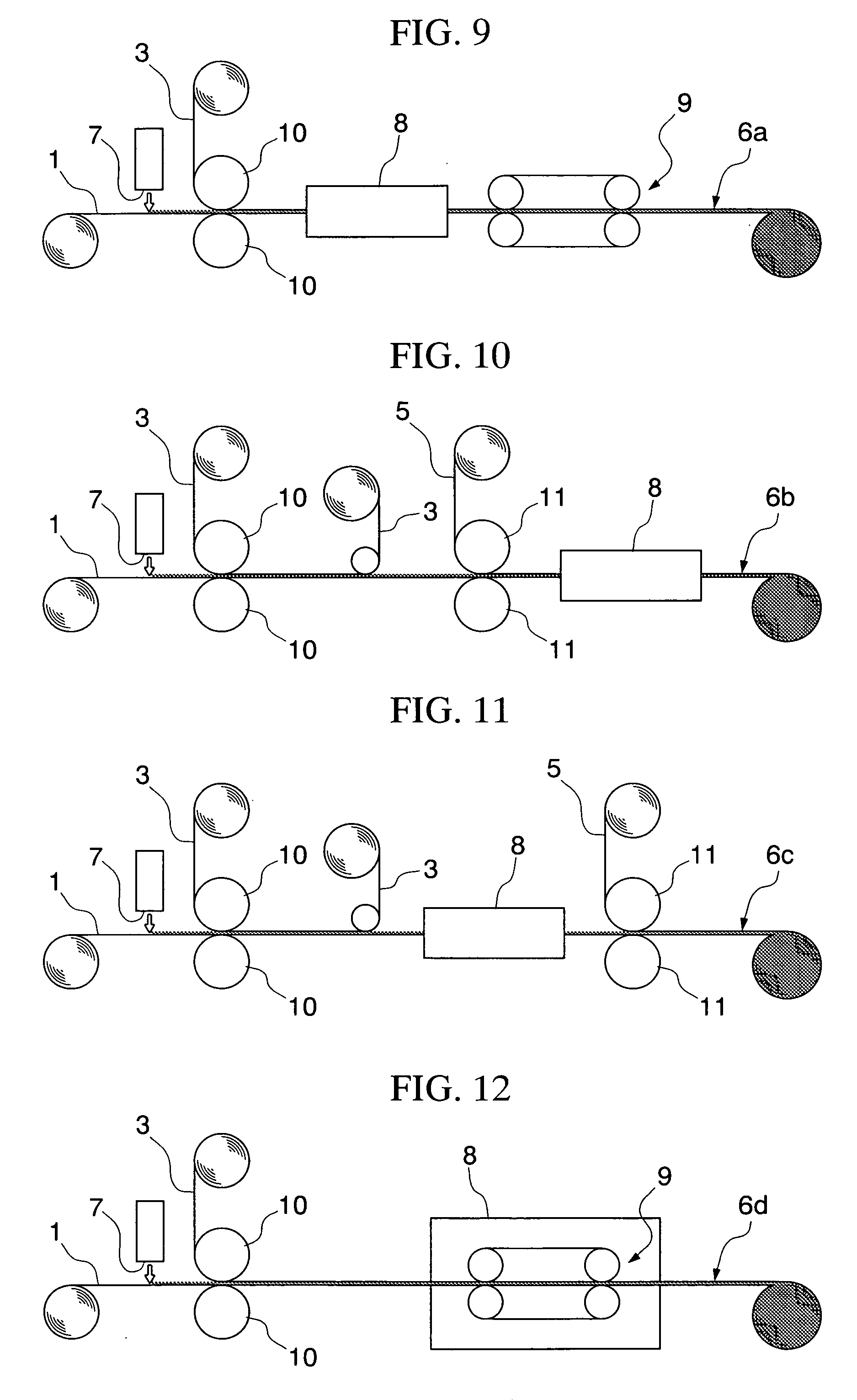

Polyurethane foam sheet and process for layered sheet with the same

ActiveUS20060079589A1Easy to controlReduce energy consumptionAdhesive articlesSynthetic resin layered productsCushioningPolymer science

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DAINIPPON INK & CHEM INC

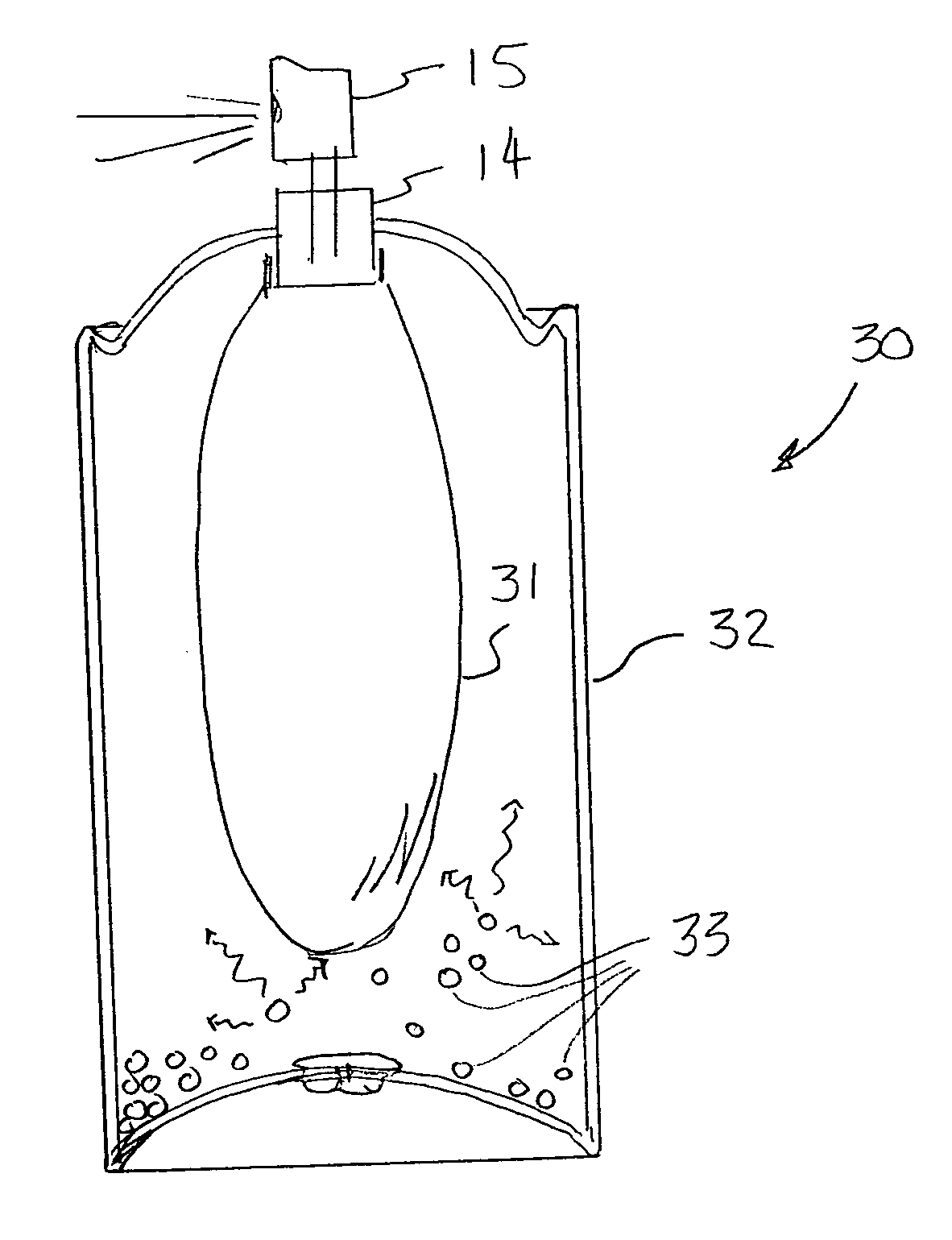

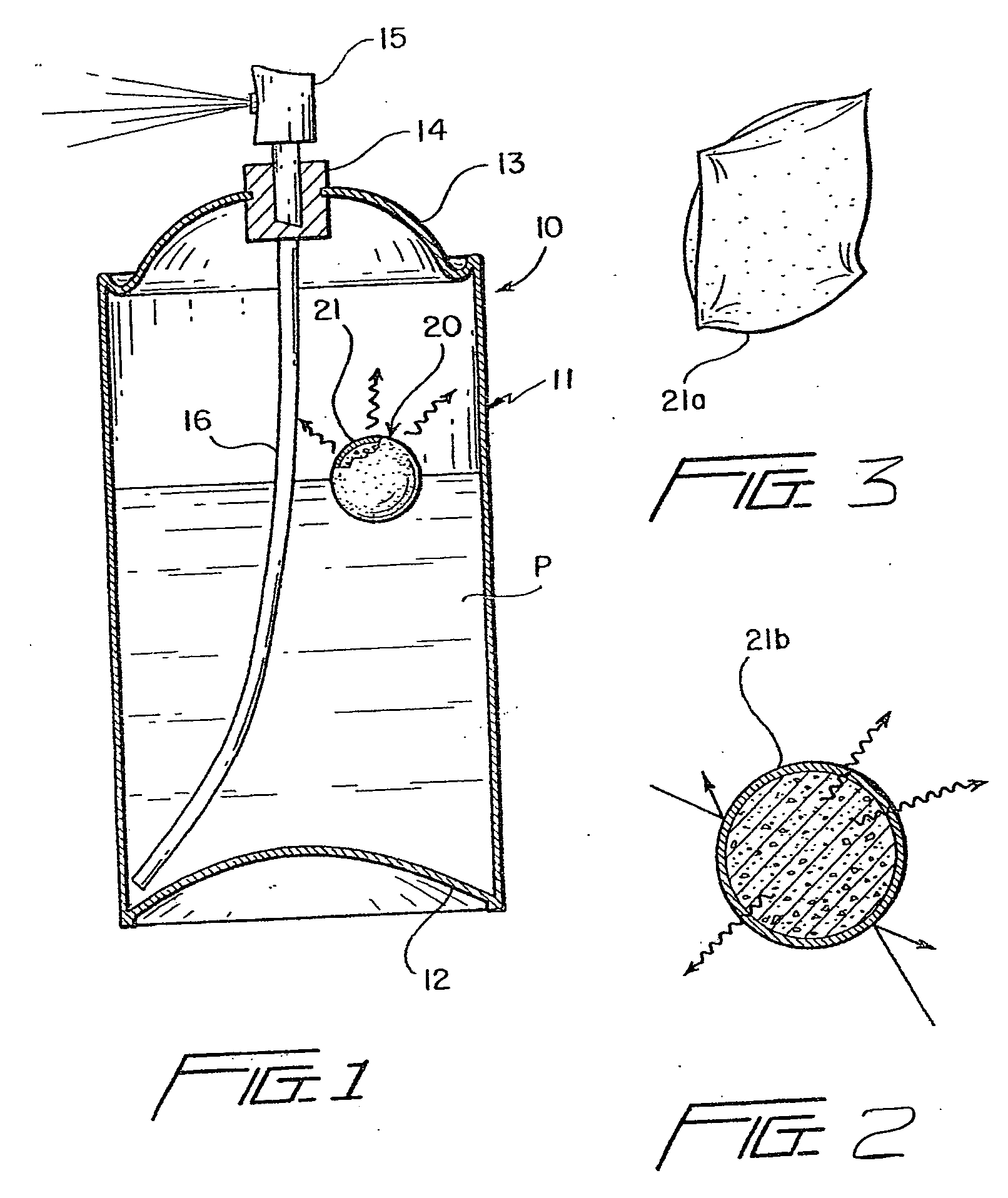

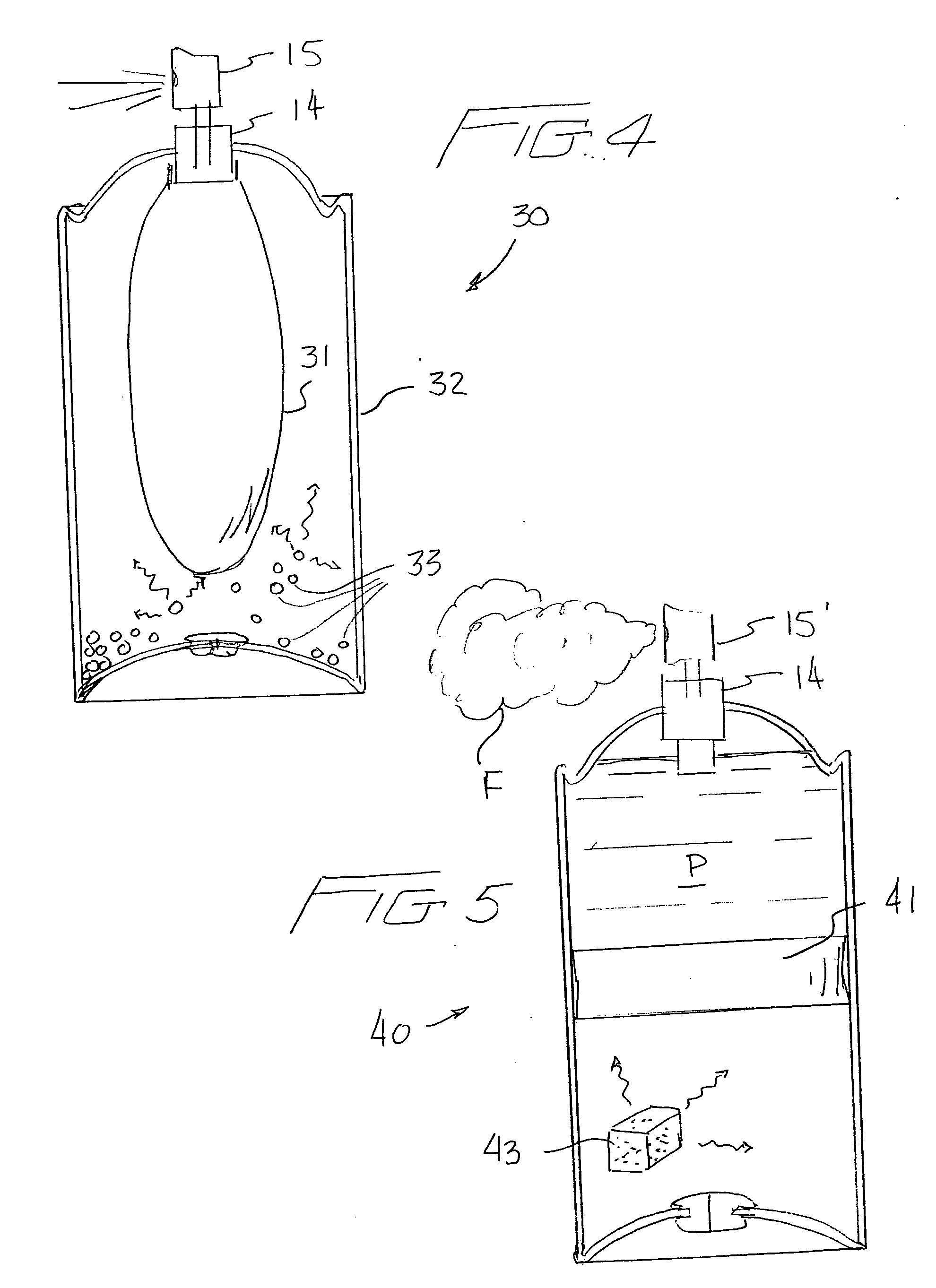

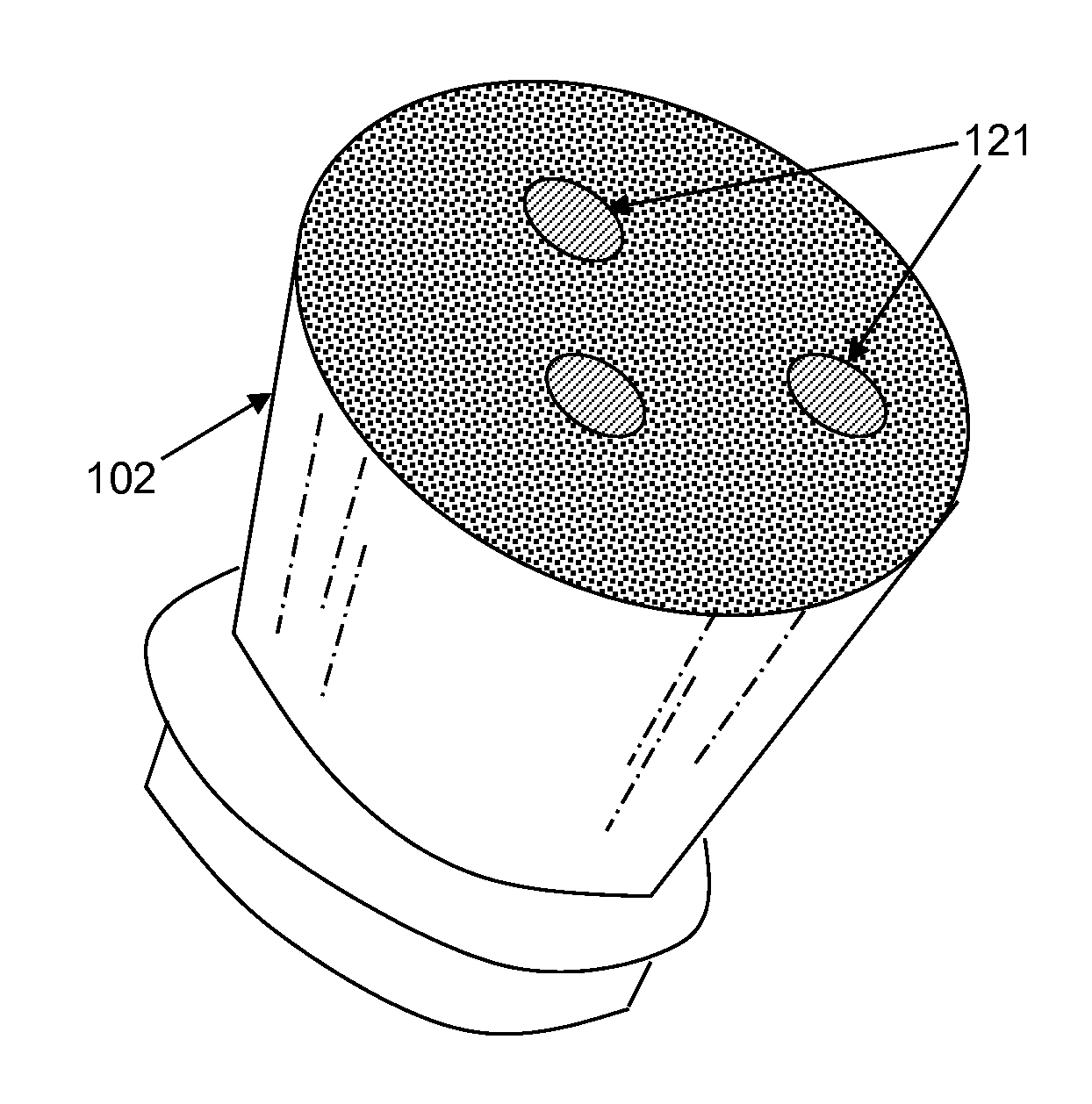

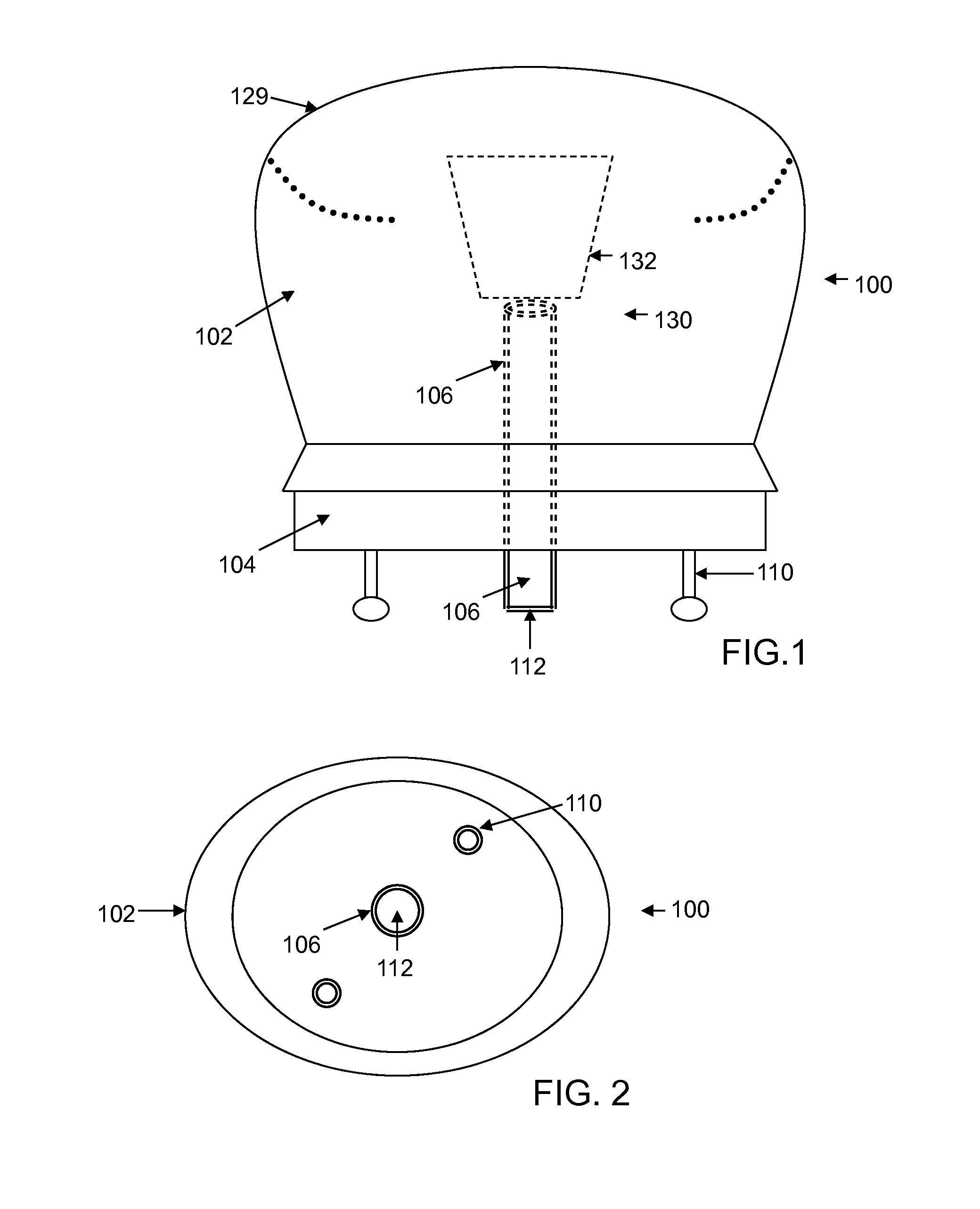

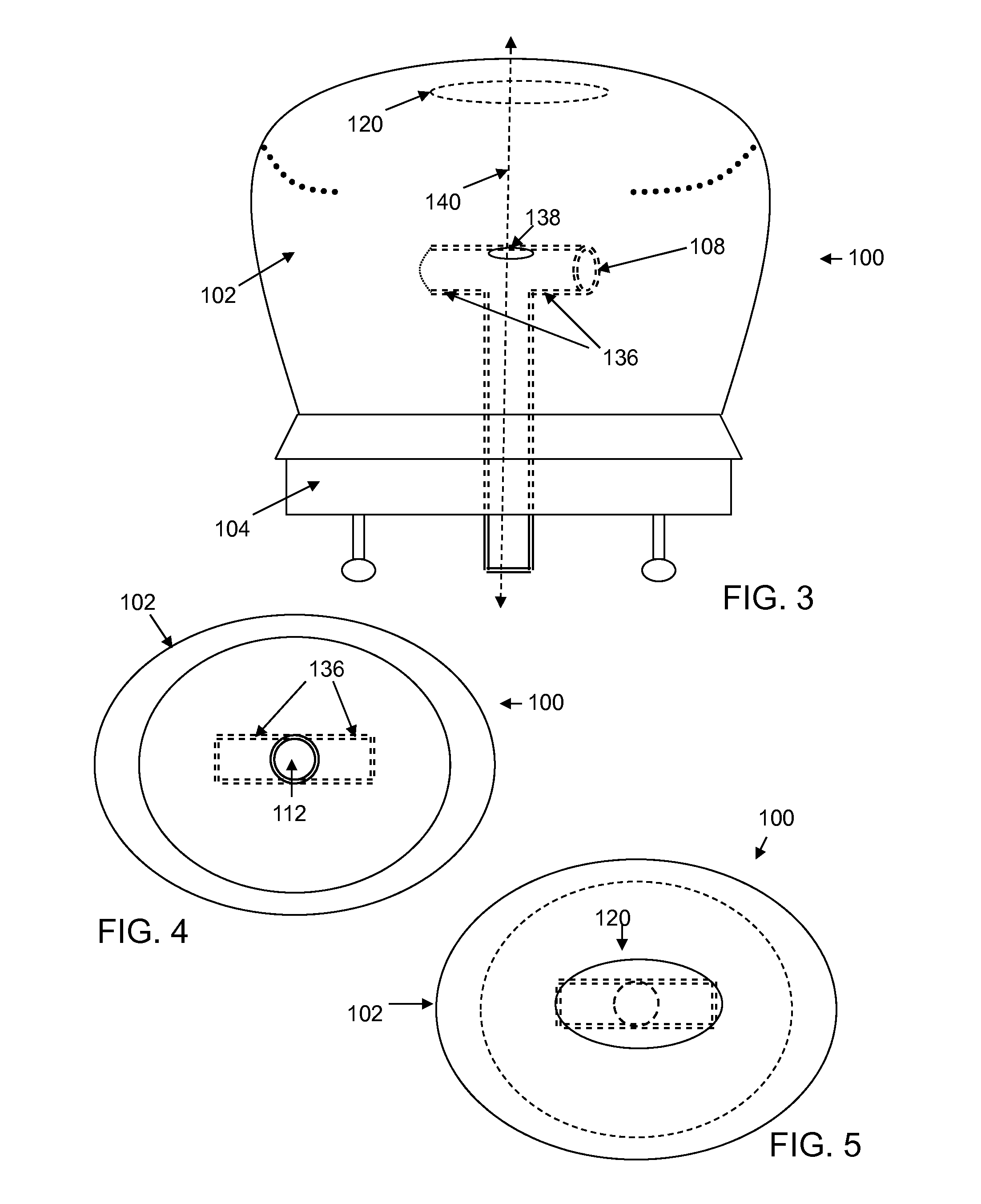

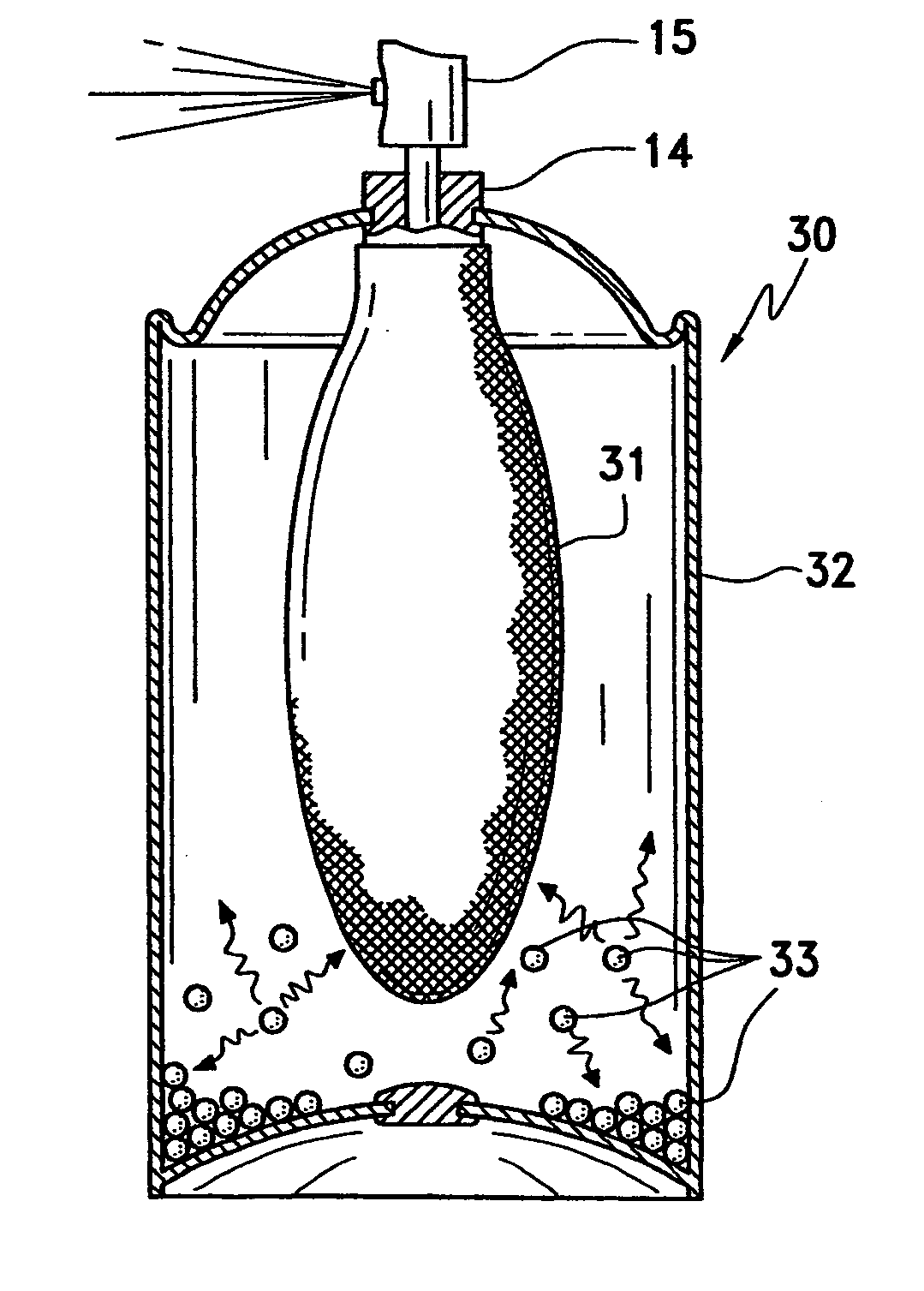

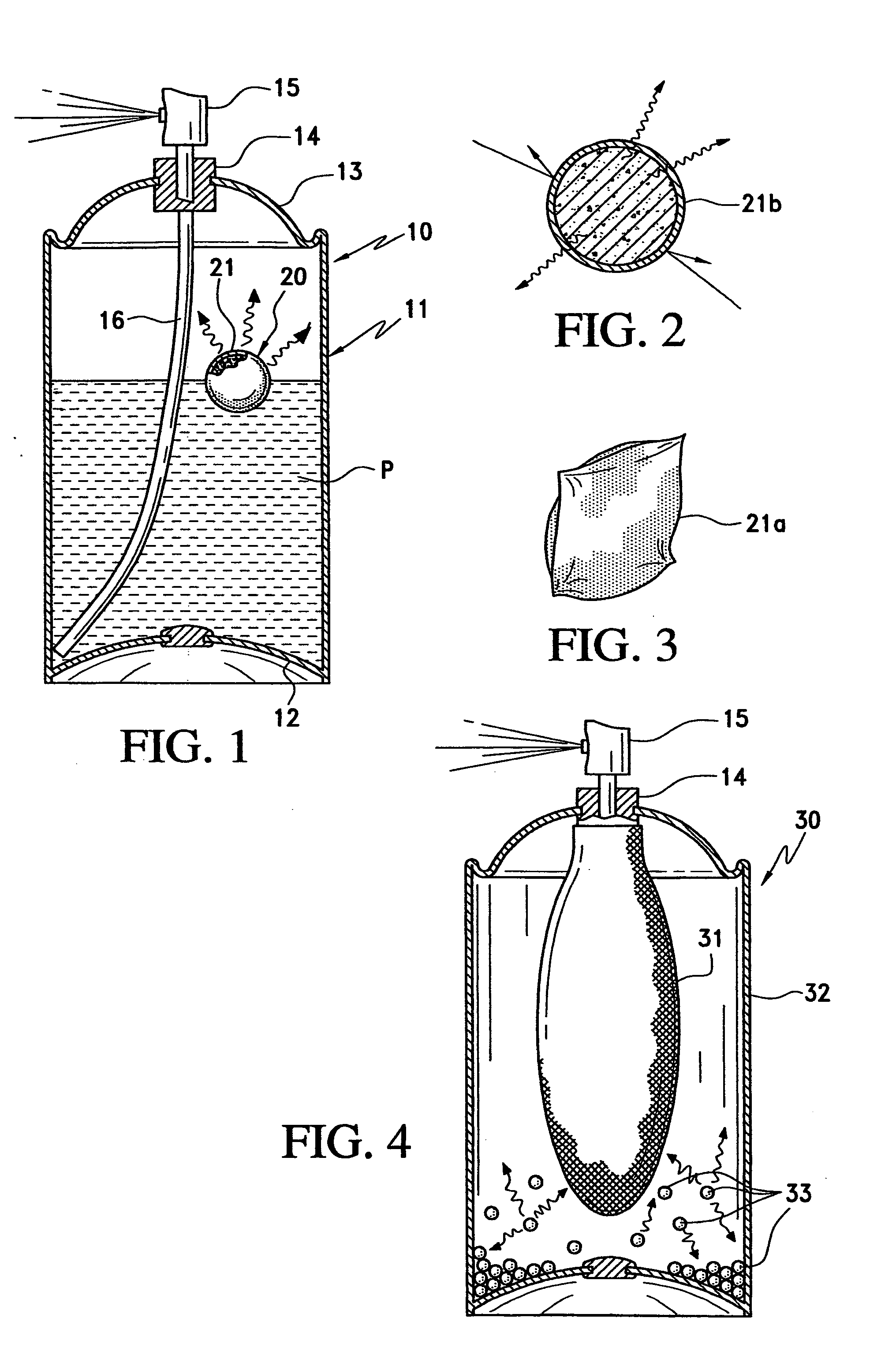

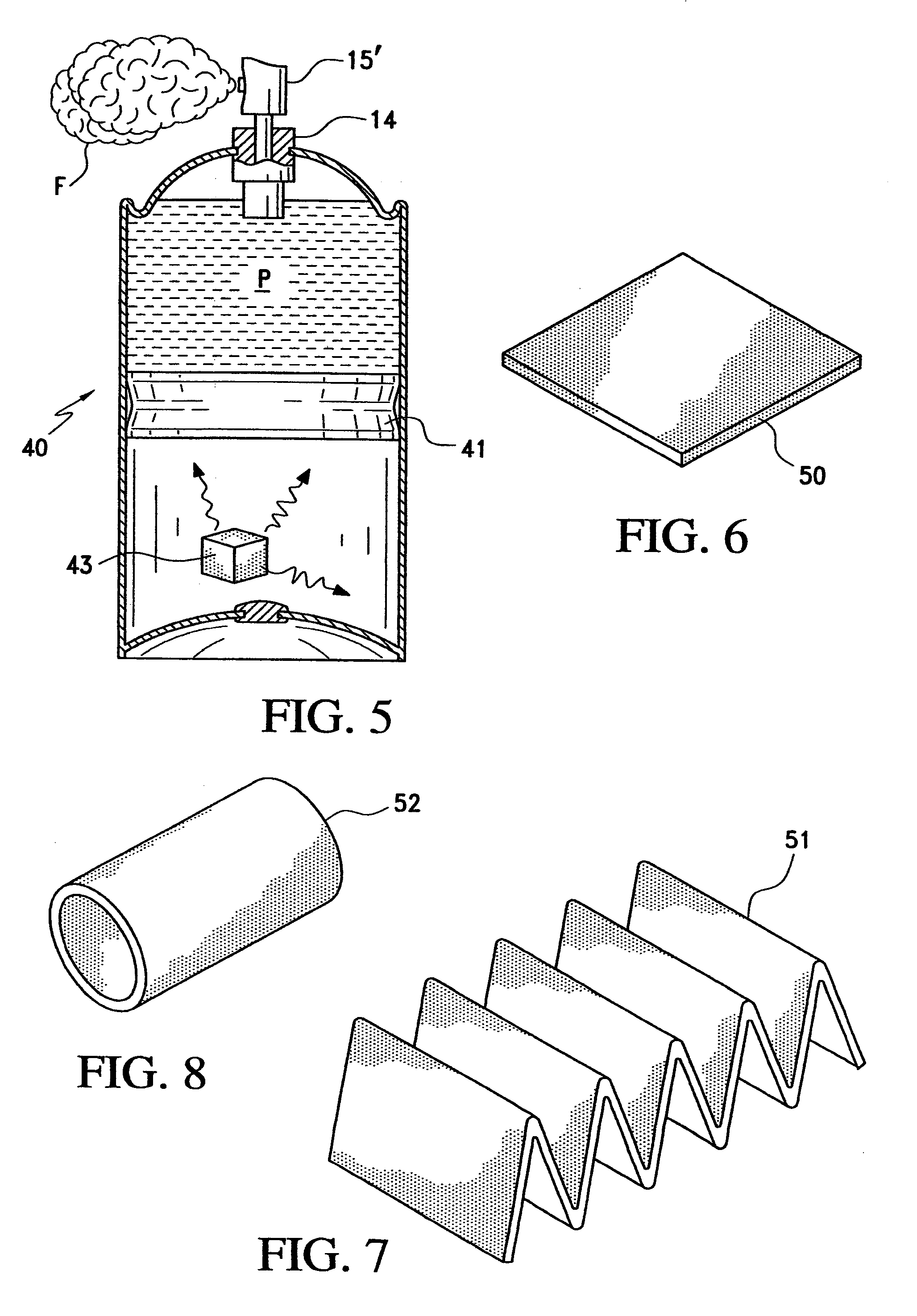

Gas storage and delivery system for pressurized containers

InactiveUS20050274737A1Consistent and uniform and acceptable spray patternFine foamOpening closed containersBottle/container closureSodium bicarbonateDesorption

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

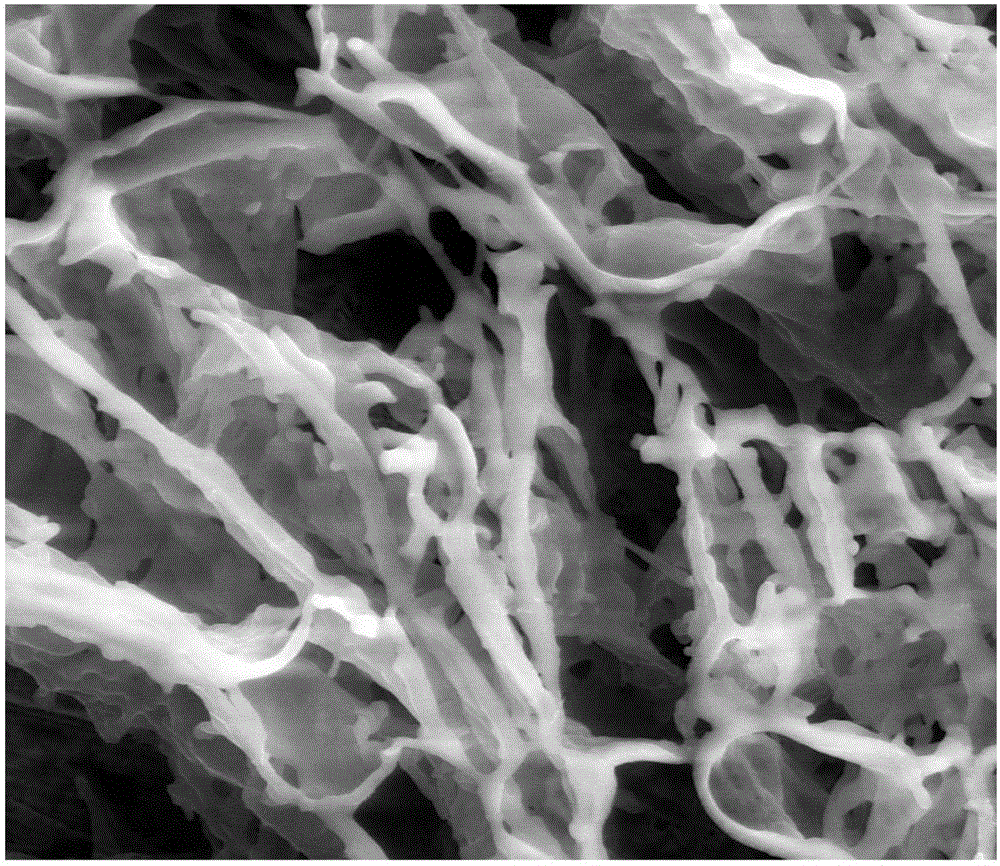

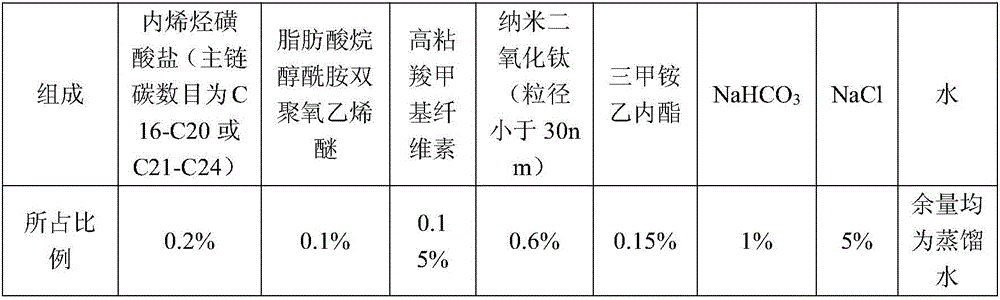

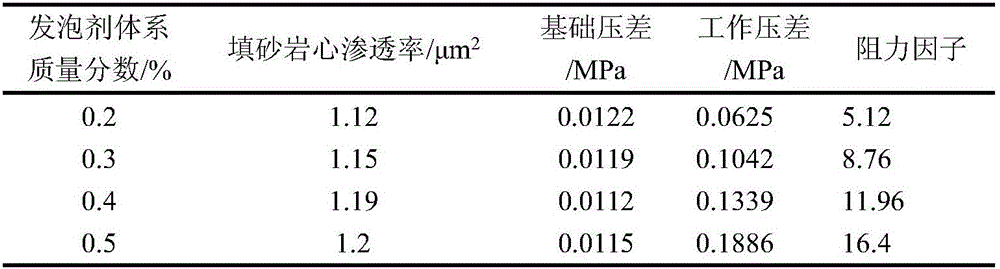

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

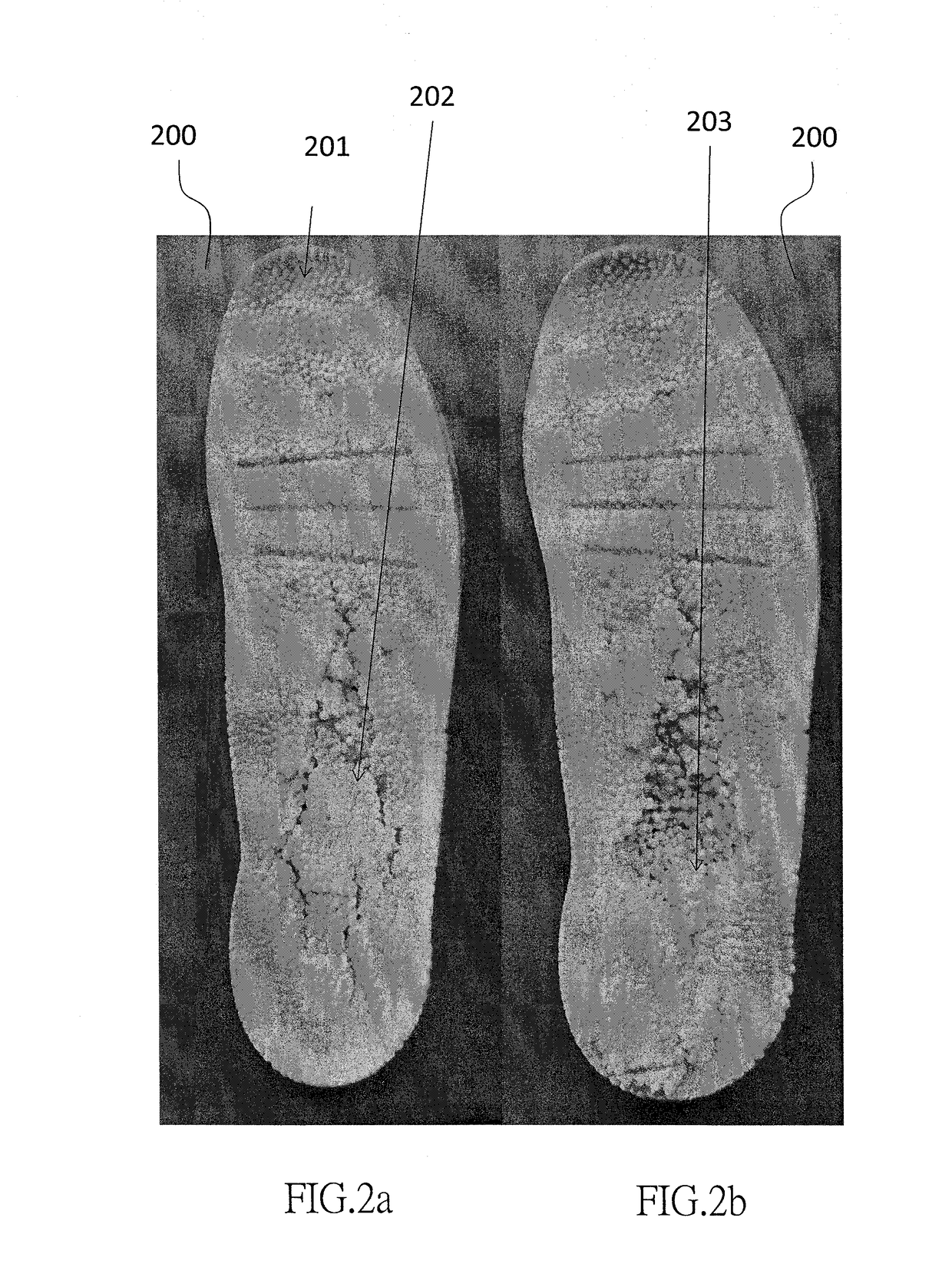

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

Mining foam paste filling material prepared by utilizing synergistic foaming method and preparation method thereof

ActiveCN103449837AReasonable allocation of resourcesLower filling costsCeramicwareFoaming agentActive component

The invention discloses a mining foam paste filling material prepared by utilizing a synergistic foaming method and a preparation method thereof, which are widely suitable for filling of coal mine gob areas, closure of laneways and construction of underground firewalls. The filling material comprises a component A and a component B, wherein the component A comprises an active component, a fine aggregate, a mineral foaming agent, an activating agent, a coagulant and the like; and the component B comprises a foaming agent, a foam stabilizing agent, a water reducing agent and the like. The key point is as follows: after fly ash is activated, the fly ash can be used for replacing part of cement for being used as a cementing material; and in addition, a concrete foaming technology is applied to the filling material, and the mineral foaming agent is innovatively applied to work in coordination with a concrete foaming agent for foaming, so that the foaming expansion performance, pumping performance and anti-seepage performance of the filling material are improved on the original basis, a gob area with a larger space can be filled under the condition of low cement consumption, and low consumption, environmental friendliness, energy conservation and easiness in pumping are realized.

Owner:ANHUI UNIV OF SCI & TECH

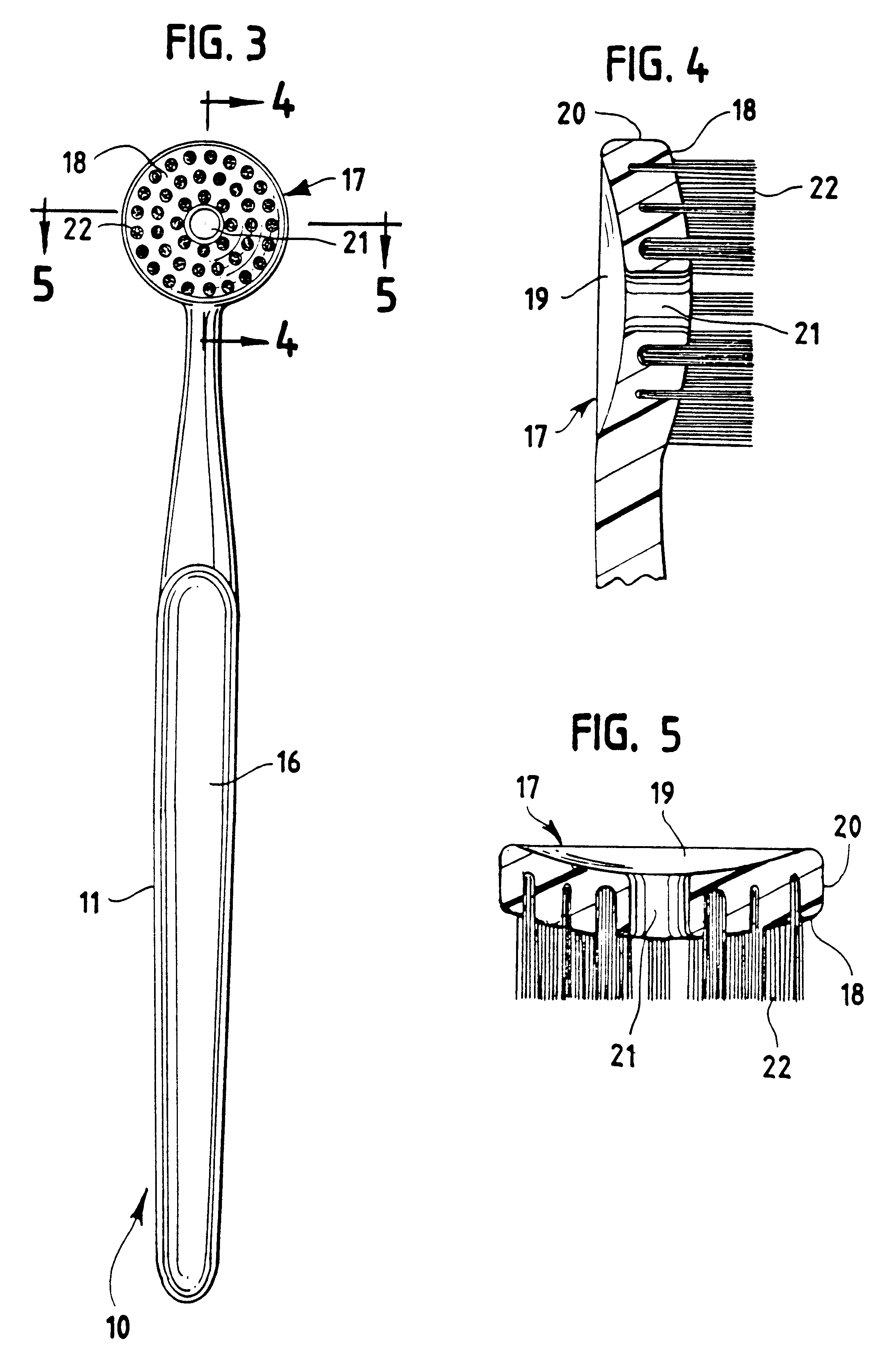

Brush for use with a composition

A brush suitable for use as part of a product dispensing container which includes various characteristics which provide desirable product performance during use.

Owner:THE GILLETTE CO

Displacement developing method for artificial foamed oil of heavy oil reservoir

ActiveCN104265252AViscosity reduction by a large marginNot easy to degasFluid removalDrilling compositionFoaming agentHorizontal wells

The invention provides a displacement developing method for artificial foamed oil of a heavy oil reservoir. The method comprises the following steps: adopting a vertical well or a horizontal well to displace a well pattern; injecting an oil soluble viscosity reducer and a solvent based foaming agent in an injection well repeatedly and alternatively, or injecting an oil-in-water emulsified viscosity reducer solution and a high oil-resisting foaming agent in an injection well repeatedly and alternatively, wherein during the injection process, a producing well produces continuously. With the adoption of the method, the purposes that the heavy oil reservoir mined through steam injection and the heavy oil reservoir difficulty produced by a conditional mining method can be effectively produced and developed, heavy oil is economically and efficiently developed and the recovery efficiency is improved greatly are achieved.

Owner:PETROCHINA CO LTD

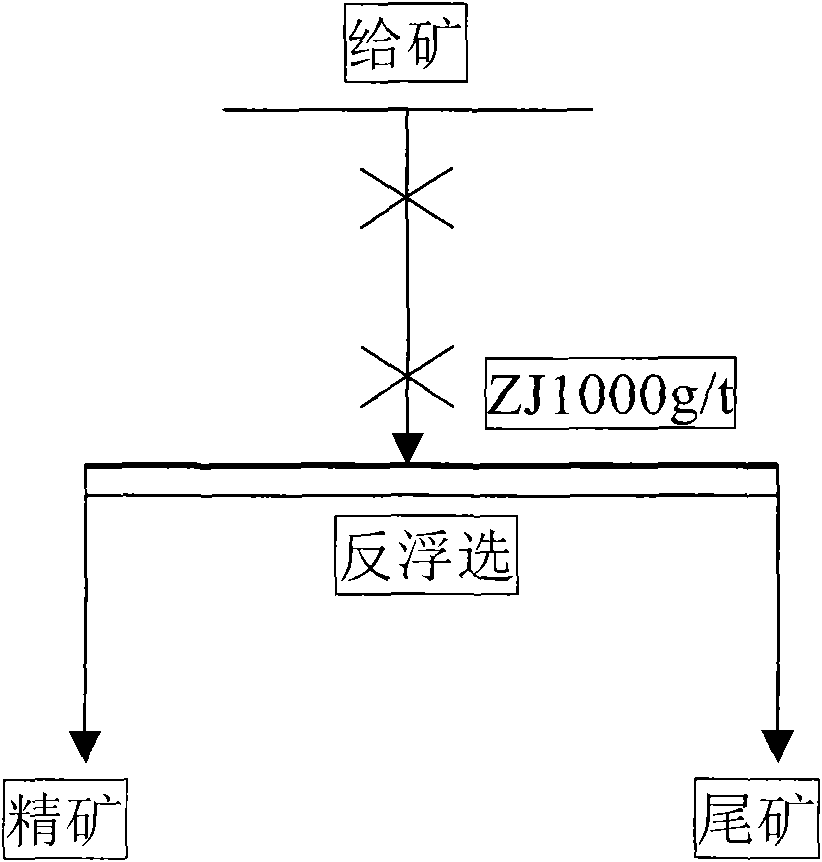

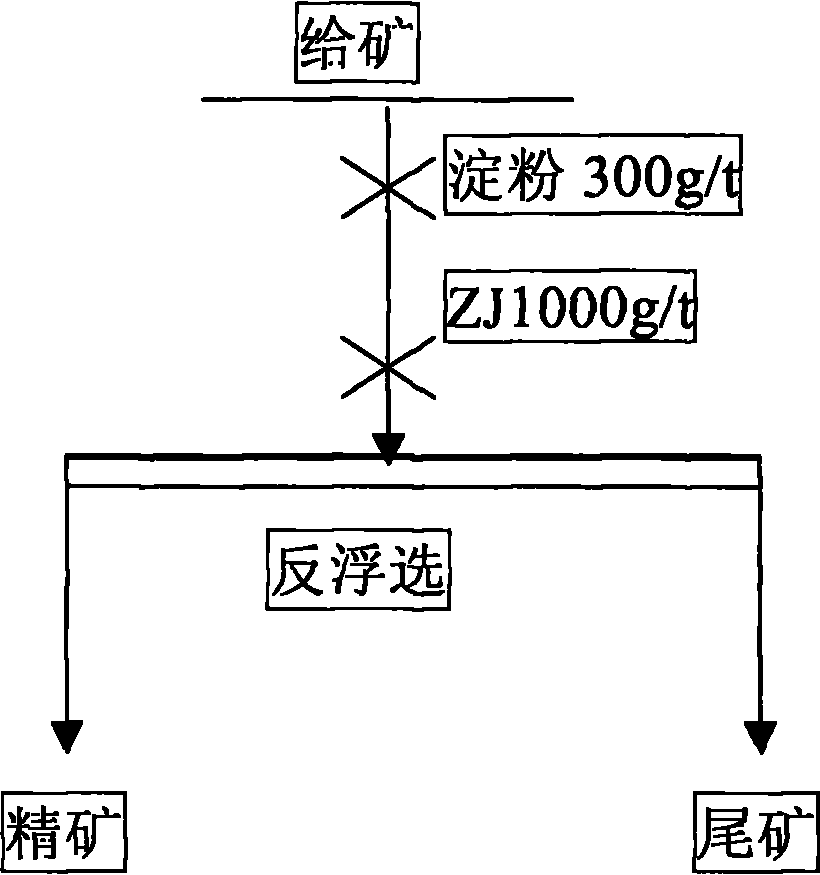

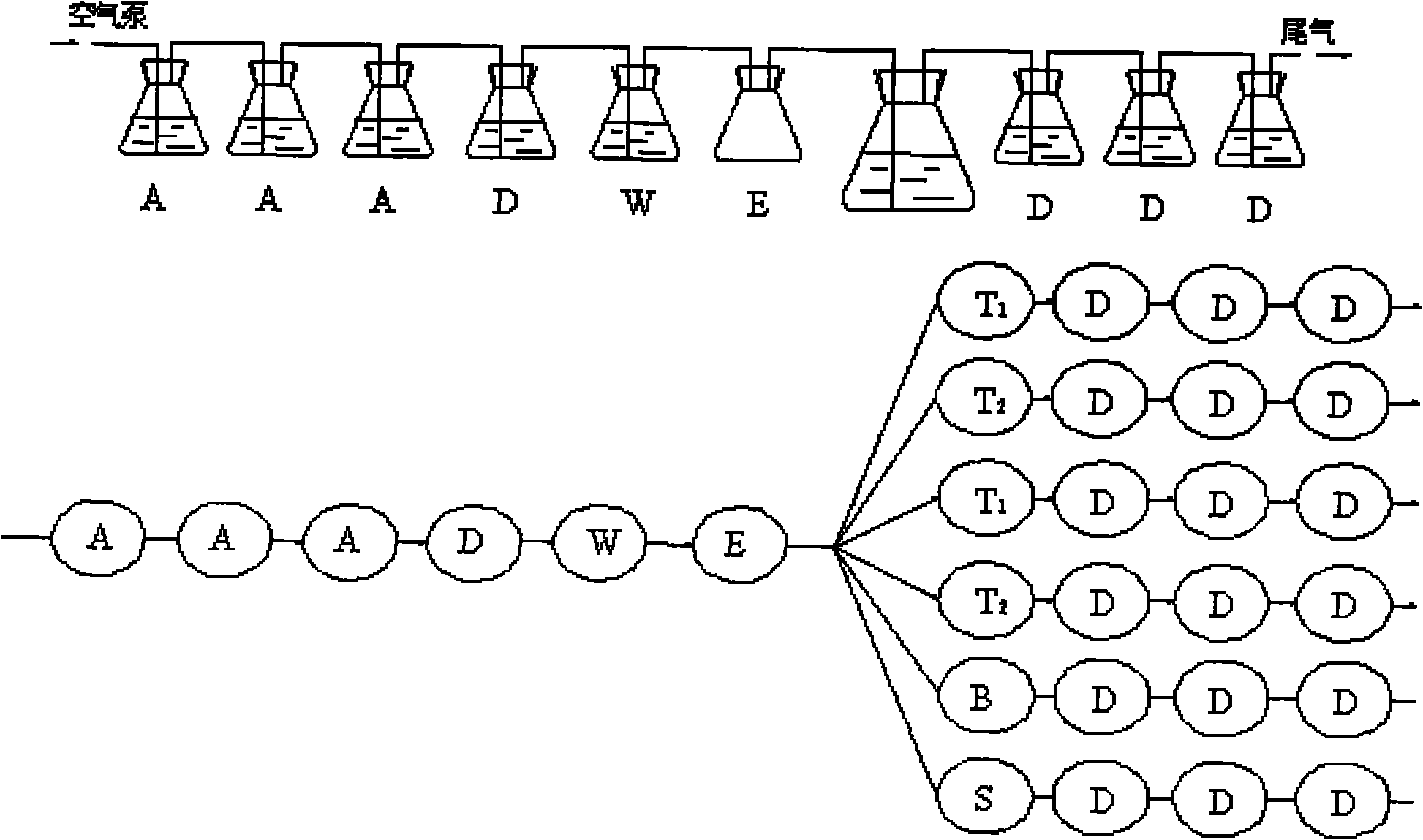

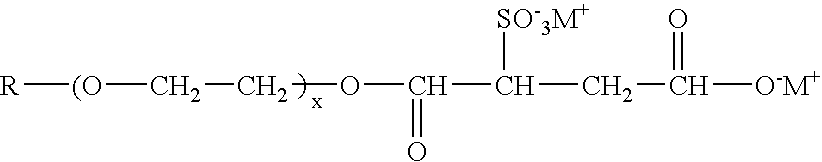

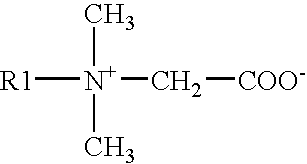

Environmentally-friendly amine cationic collector and using method thereof

InactiveCN101816981ASave on heating costsPracticalOrganic compound preparationFlotationSURFACTANT BLENDToxicity

The invention discloses an environmentally-friendly amine cationic collector and a using method thereof. The collector ZJ is ester group-containing quaternary ammonium salt cationic surfactant and has a plurality of alkyl groups, wherein an R alkyl group has 6 to 18 carbon atoms; an R1 alkyl group has 1 to 4 carbon atoms; the number of ester groups is 1 or two; and the number of the quaternary ammonium group is 1. The collector is obtained by esterification and quaternarization. As a hydrophobic chain has a carbonyl structure, the collector can hydrolyze easily into nonsurfactant fragments, and is a surfactant with high biodegradability, small toxicity and high performance. The collector is used in ore flotation for the first time and demonstrates high collecting capacity and selectivity.The collector forms fine and fragile foam that is low temperature resistant. The collector can be used under the condition that the pH value of ore pulp is 7 without corroding equipment. The preparation process of the collector is simple and easy in operation. And the collector is easy to biodegrade and is environmentally-friendly.

Owner:WUHAN UNIV OF TECH

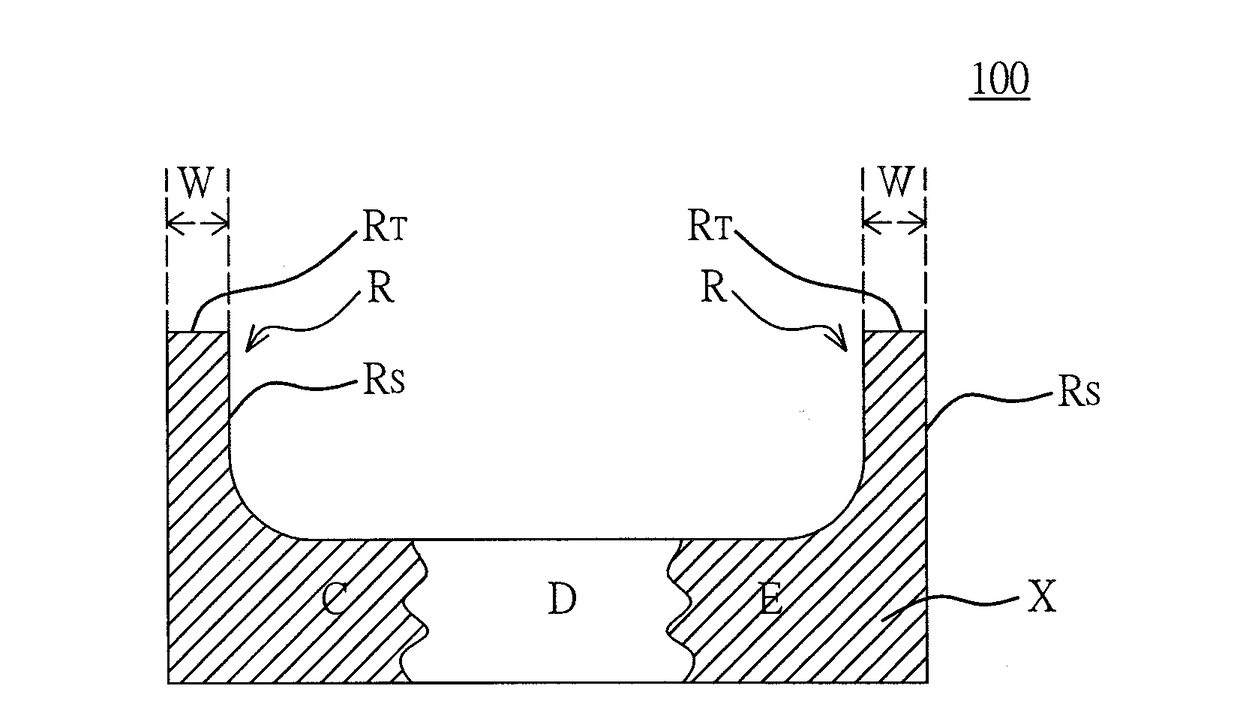

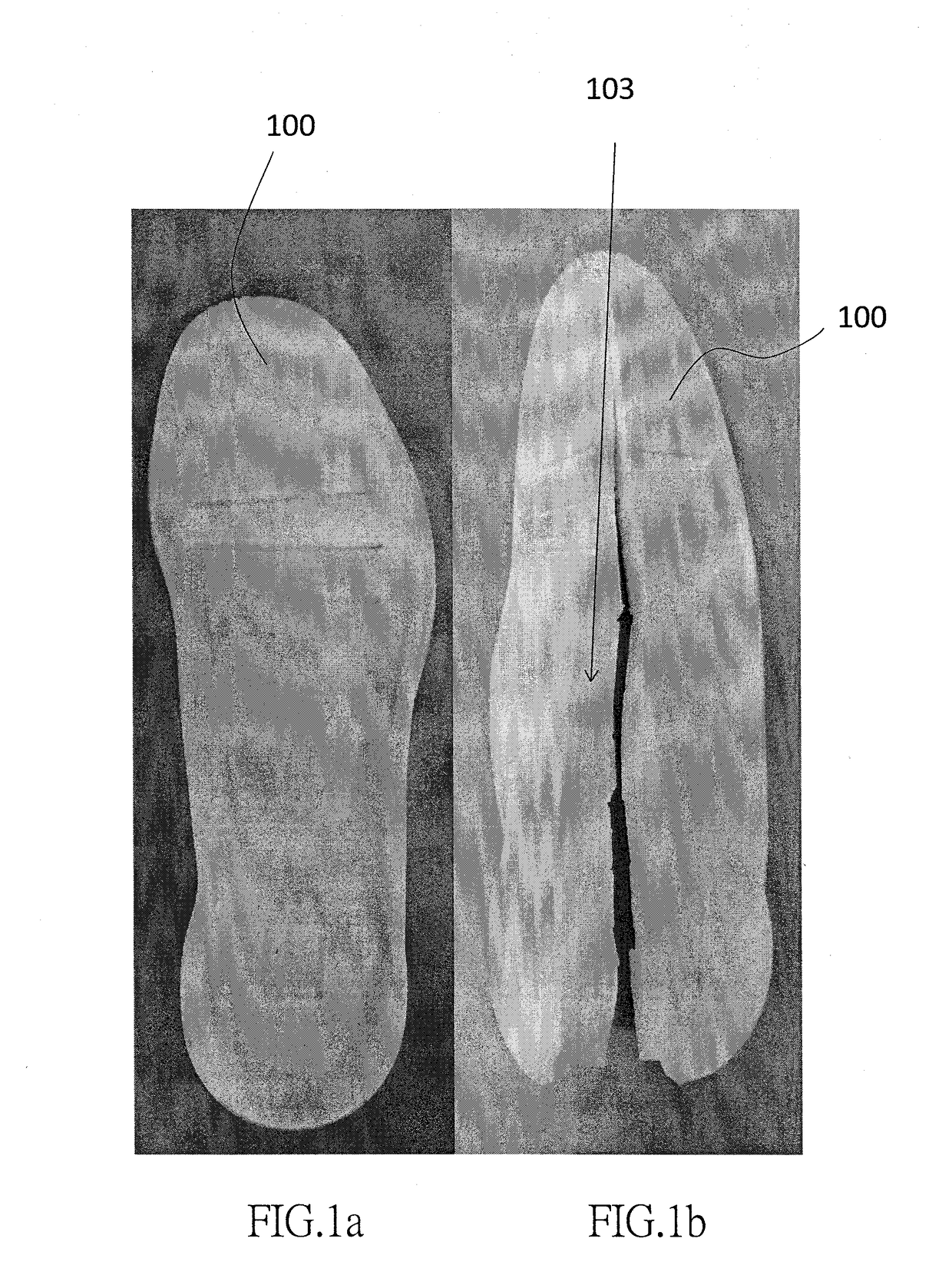

Microwave molded article and method thereof

The present invention disclosures microwave molded articles, including molded articles having portions with different hardness; molded articles having sharp flanges; molded articles having portions with different colors; molded articles with designed pattern; molded articles made of plastic particles with hollow tubes; molded articles made of plastic and rubber particles composition; molded articles made of plastic particles in combination of pre-molded rubber blocks; a molded article made of plastic particles in combination of textile; and a molded article made of non-spherical type plastic particles. The manufacturing methods for the above molded articles are also provided.

Owner:TAYIN RES & DEV +1

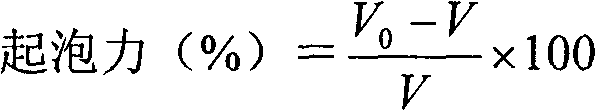

Egg white powder with high foamability and preparation method thereof

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

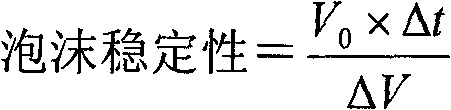

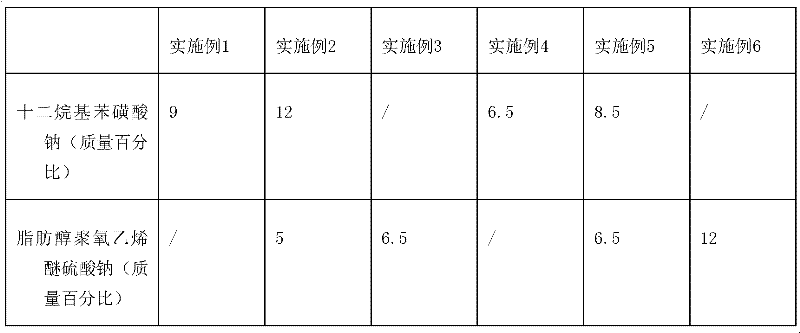

Compound type cleaning solution

InactiveCN102559406AExcellent decontamination synergisticGood thickeningAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid stateWater soluble

The invention relates to a compound type cleaning solution which comprises a component A, a component B and pure water, wherein the component A is composed of at least one amphoteric surfactant with 8 or more carbon atoms, and accounts for 0.1-15% of the cleaning solution by mass; the component B is at least one anionic surfactant, non-ionic surfactant or cationic surfactant with 8 or more carbon atoms, and accounts for 1-30% of the cleaning solution by mass; and the balance is pure water. In the invention, the amphoteric surfactant and other surfactants are compounded to prepare a dish hand-washing detergent which has excellent functions of cleaning, efficacy enhancing, thickening, foaming, foam stabilizing and the like and is very favorable for improving the performance of the product such as detergency, viscosity, storage stability and the like. Moreover, the amphoteric surfactant is generally in a water-soluble liquid state and can be easily mixed in a formula solution, thus the industrialization of the product provided by the invention can be easily realized.

Owner:WALCH GUANGZHOU COMMODITY

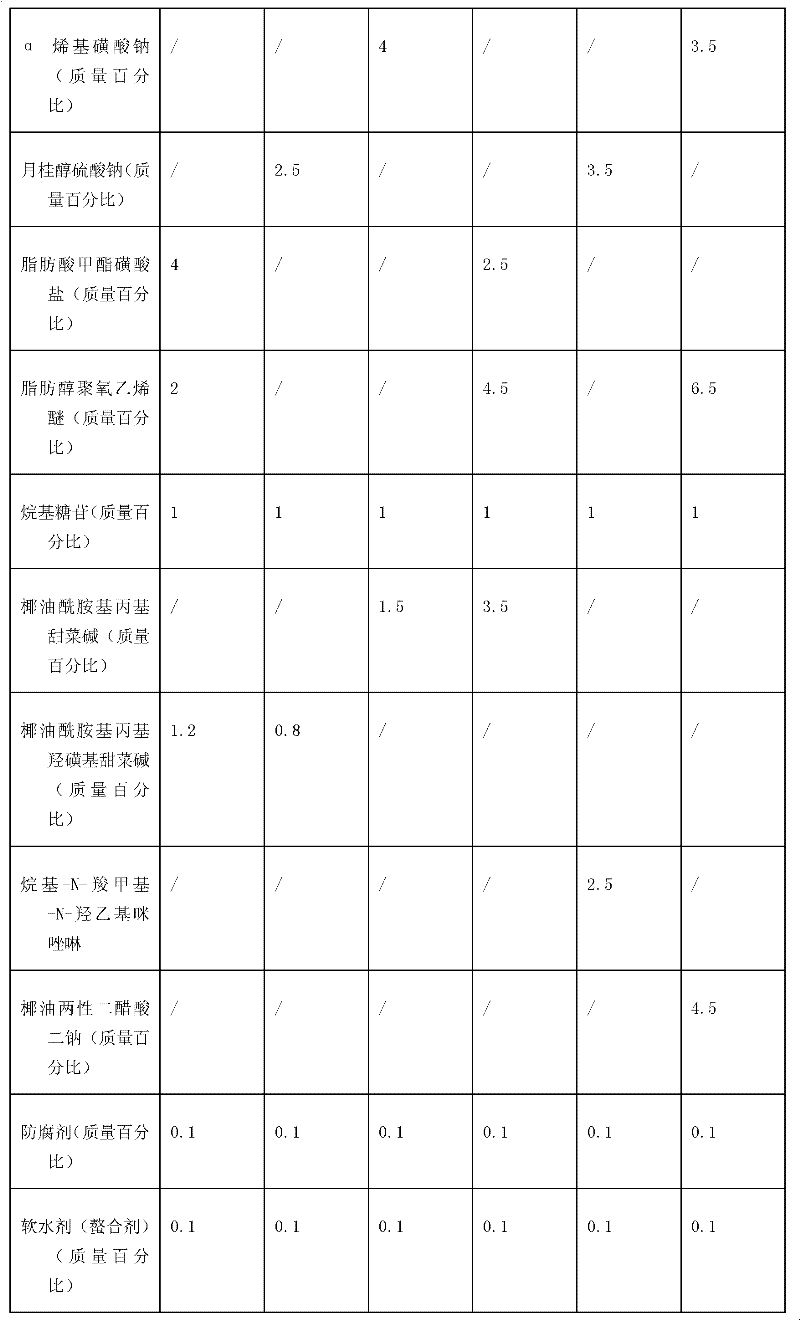

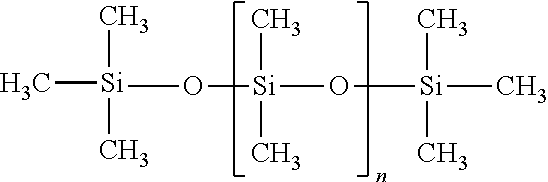

Surfactant-containing preparation comprising licochalcone A

ActiveUS8741363B2Improve the situationOvercome disadvantagesBiocideCosmetic preparationsLicochalcone ABULK ACTIVE INGREDIENT

Cosmetic hair- and / or body-cleansing compositions comprising licochalcone A or an extract of Radix Glycyrrhiza inflata and one or more surfactants and, optionally, further comprising cosmetic and / or dermatological active ingredients, auxiliaries and additives.

Owner:BEIERSDORF AG

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499AIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life is moderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

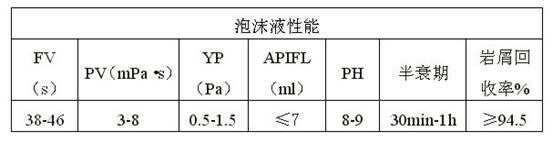

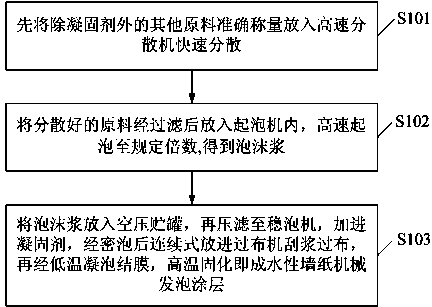

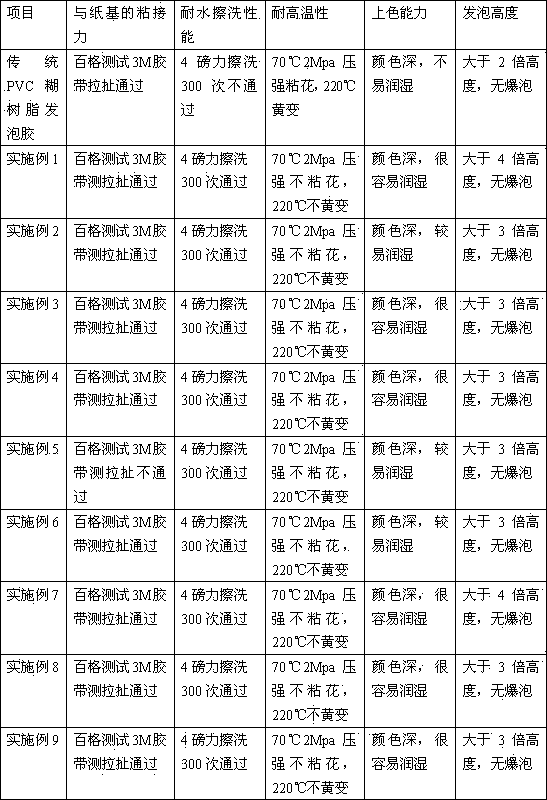

Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

InactiveCN104004473AImprove adhesionGood flexibilitySpecial visual effect coatingsSpecial paperWater basedPolymer science

The invention discloses a foam coating glue of water-based wallpaper. The foam coating glue includes 40-60% of a main body emulsion resin, 35-55% of a compounding agent and 1-10% of water. The main body emulsion resin is selected from one or more of neoprene latex, nitrile rubber latex, styrene-butadiene latex, water-based acrylate resin, water-based polyurethane resin and ethylene-vinyl acetate resin. The compounding agent includes a dispersing agent, an emulsifier, a thickening agent, a foam-starting agent, a foam-stabilizing agent, a foaming agent, a coagulating agent and a foam-densifying agent. Correspondingly, the invention discloses a preparation method of the foam coating glue of the water-based wallpaper and wallpaper prepared by using the foam coating glue of the water-based wallpaper. Through the preparation method, the foam coating glue of the water-based wallpaper is environmental-friendly and energy-saving, has an excellent foaming effect and can form an excellent-performance foam coating on the water-based wallpaper.

Owner:佛山市三水灏诚合成树脂有限公司

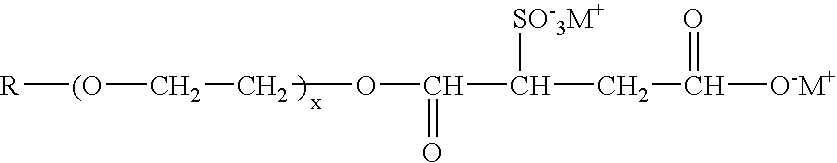

Mild, moisturizing cleansing compositions with improved storage stability

InactiveUS20060019847A1Mild to hair and skinExcellent latherCosmetic preparationsHair cosmeticsIonChemistry

Compositions used for cleansing hair and skin based on the combination of a sulfosuccinate surfactant and an amphoteric surfactant are described that are very mild but do not compromise in-use properties such as lather and are economical. A route to solve the intrinsic instability of such aqueous compositions in storage has been developed based on the use of electrolytes. The electrolytes are present at a level sufficient to provide at least about 0.1 equivalents of cationic ions per Kg of composition and maintains a viscosity of the composition at its initial value after storage for 4 weeks at 49° C.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

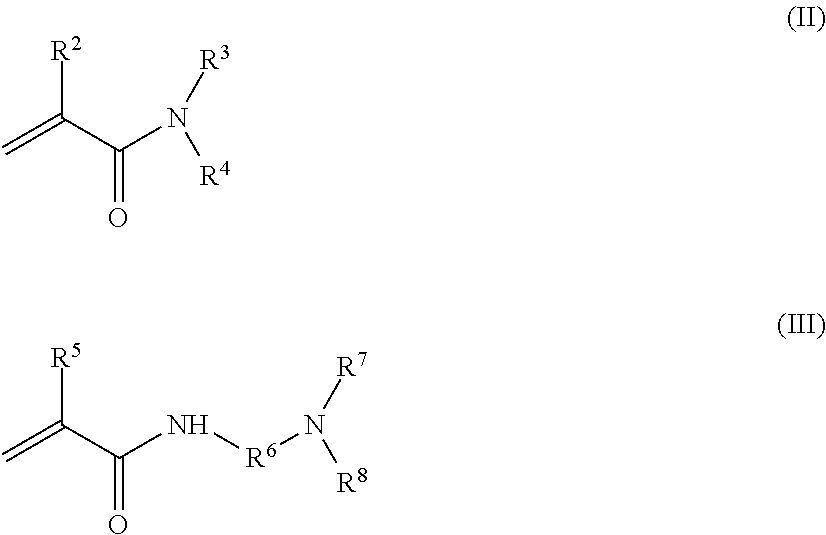

Improved foaming performance in cleansing compositions through the use of nonionic, amphiphilic polymers

ActiveUS20160022566A1Good foaming effectExcellent detersive and foaming propertyCosmetic preparationsHair cosmeticsHydrophilic monomerMonomer composition

The invention relates to a method for improving the foaming and / or yield value properties associated with surfactant containing compositions comprising at least one anionic surfactant, the method comprises combining an effective amount of at least one nonionic, amphiphilic polymer with at least one anionic detersive surfactant in combination with an optional surfactant selected from amphoteric surfactants, nonionic surfactants and combinations of two or more thereof. The at least one nonionic amphiphilic polymer is prepared from a free radically polymerizable monomer composition comprising at least one hydrophilic monomer and at least one hydrophobic monomer, wherein said hydrophilic monomer is selected from a N-vinyl lactam and wherein said hydrophobic monomer is selected from a vinyl ester of a C1-C22 carboxylic acid or at least one monomer selected from a C5-C22 alkyl (meth)acrylate an associative monomer, a semi-hydrophobic monomer, or mixtures thereof, and an optional crosslinking monomer.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Mild, moisturizing sulfosuccinate cleansing compositions

InactiveUS20060019858A1Mild to hair and skinFine foamCosmetic preparationsHair removalSulfosuccinic acidSURFACTANT BLEND

Compositions used for cleansing hair and skin based on the combination of an ethoxy sulfosuccinate surfactant and an amphoteric surfactant are described that are very mild but do not compromise in-use properties and economy. It has been found desirable to utilize a mixture of a Mid-Chain alkyl ethoxy sulfosuccinate and a Long-Chain alkyl ethoxy sulfosuccinate wherein the Long-Chain component is present in the composition at a level from about 0.1% to about 6% based on the total weight of the Mid-Chain component.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

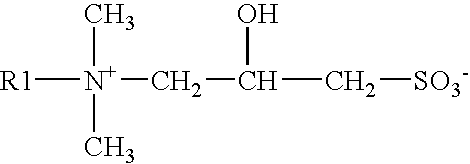

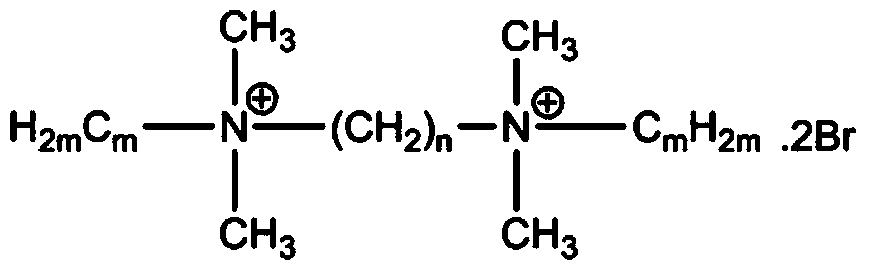

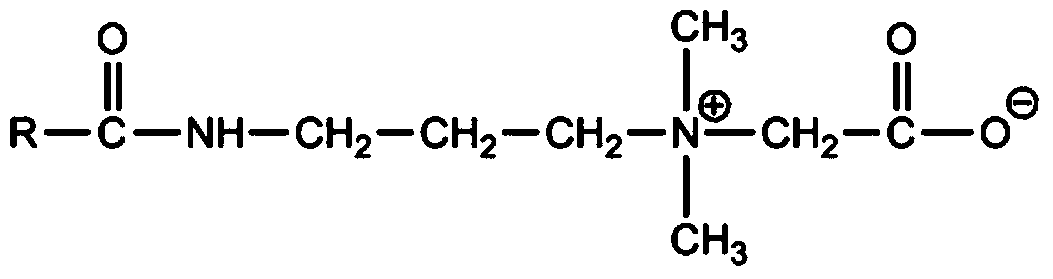

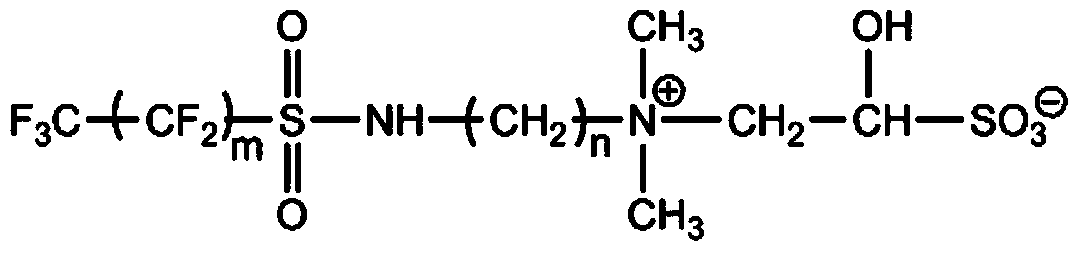

Foam drainage agent for gas well drainage gas recovery

ActiveCN104140802AImprove stabilityGood water carrying effectDrilling compositionBond energyChemical agent

Belonging to the technical field of oil-gas field chemical agents, the invention relates to a foaming drainage agent for gas well drainage gas recovery. The foaming drainage agent for gas well drainage gas recovery is formed by mixing of a gemini surfactant, a zwitterionic surfactant, a high-bond energy surfactant and a macromolecular polymer. The foaming drainage agent provided by the invention has high temperature environment resistance (up to 180DEG C), suitability to environment with wide pH value (of 1-10), high mineralization degree resistance (greater than or equal to 320000mg / L), and resistance to hydrogen sulfide and carbon dioxide atmosphere (with the hydrogen sulfide partial pressure being greater than or equal to 25% and the carbon dioxide partial pressure being greater than or equal to 20%). And the foaming drainage agent also has the advantages of excellent foaming performance, good foam stability, good water-carrying effect, low surface tension, and foam volume mostly higher than 8 times.

Owner:CHINA PETROLEUM & CHEM CORP +1

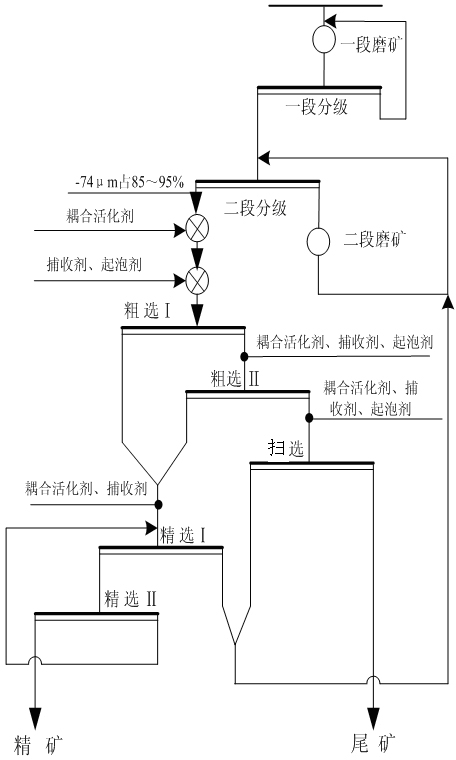

Ammonium-amine coupling activation method based on copper mineral sulfurization floatation system

Owner:KUNMING UNIV OF SCI & TECH

Gas storage and delivery system for pressurized containers

InactiveUS7185786B2Consistent, uniform and acceptable spray patternBetter aerosolize the productOpening closed containersBottle/container closureSodium bicarbonateDesorption

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com