Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329results about How to "Uniform cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

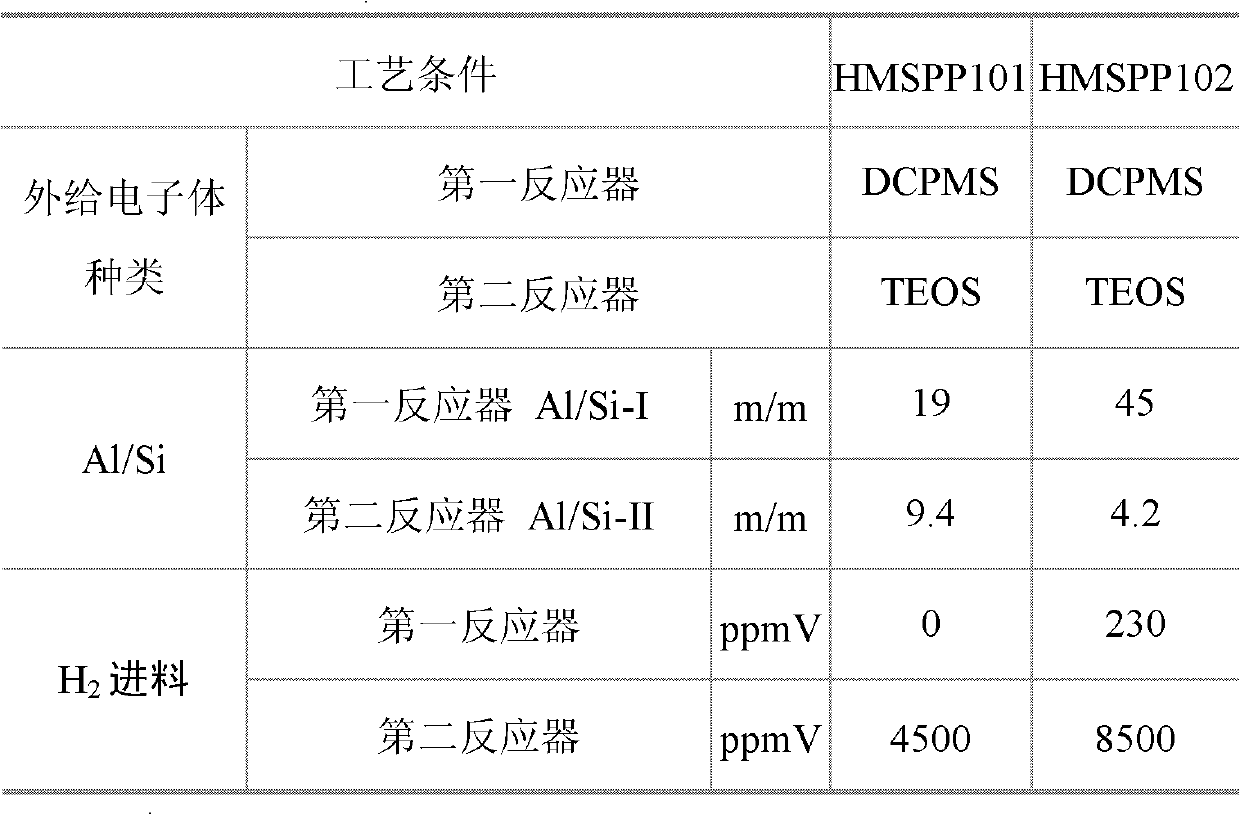

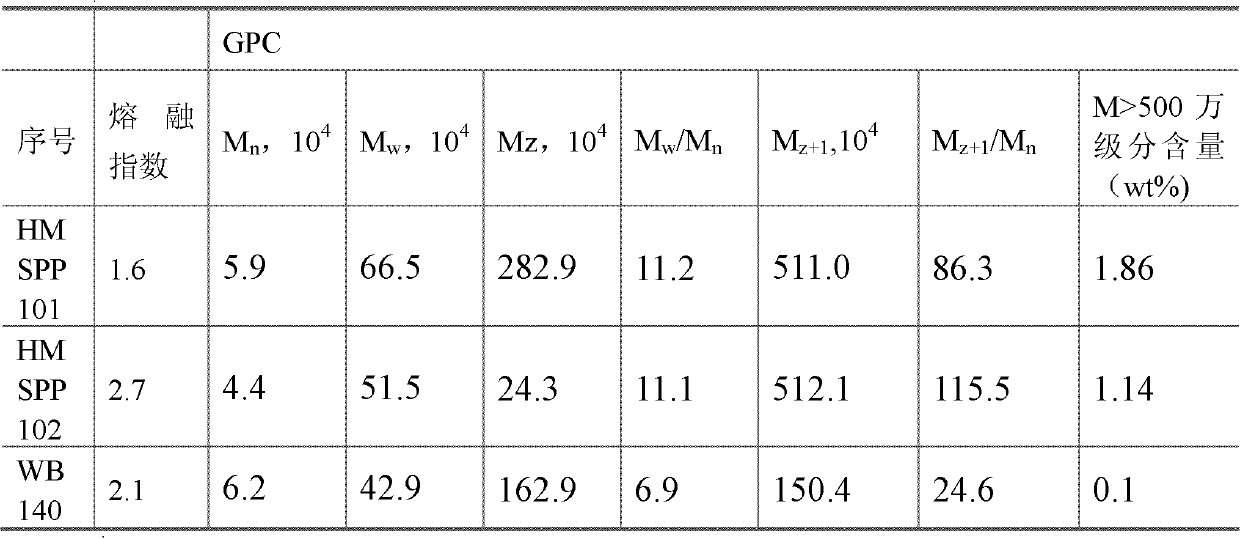

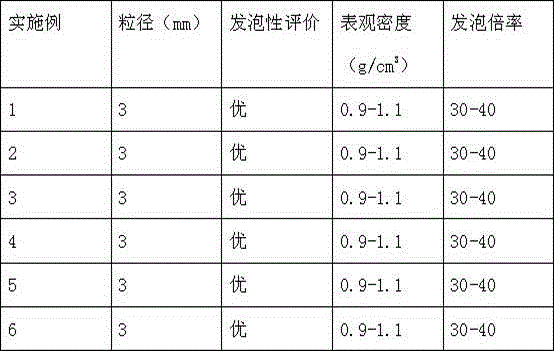

Expandable polypropylene beading, preparation method thereof, and its foaming beading and foaming molding products

The invention provides an expandable polypropylene bead and a preparation method of the expandable polypropylene beads, and also provides foaming beads and foaming molding products of the expandable polypropylene beads, which relates to the resin expandable beads technical field. Random copolymerized polypropylene is used as basic resin, so that melting intensity can reach to an ideal range when in foaming with high melting intensity polypropylene and low density polyethylene resin being added. Expandable beads are prepared in a closed reactor without external pressure with pentane being used as foaming agent. The expandable beads contain 1 to 15 parts by weight of the high melting intensity polypropylene, 1 to 10 parts by weight of the low density polyethylene, 1.0 to 3.8 parts by weight of the foaming agent and 0.1 to 10 parts by weight of nucleating agent on the basis of 100 parts by weight of the random copolymerized polypropylene. The expandable polypropylene beads are easy to foam, whose foaming rate can reach to 16 times with uniform cells and whose foam volume weight is about 0.05 to 0.12g / cm3. The invention adopts a low-pressure method to produce the polypropylene foaming products in different shapes according to the requirement with low equipment requirement and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

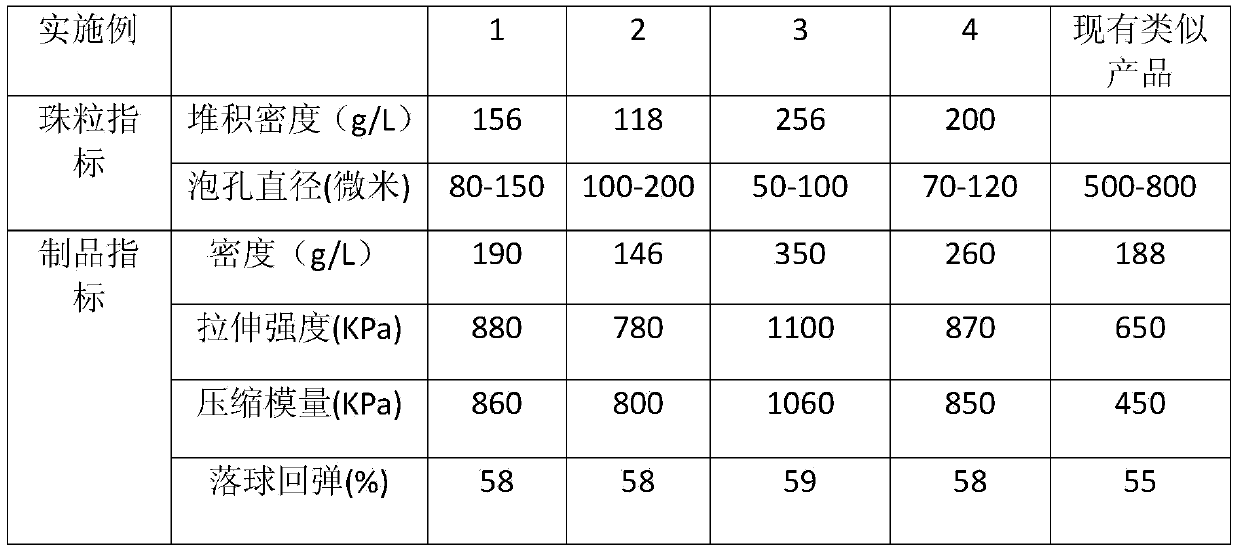

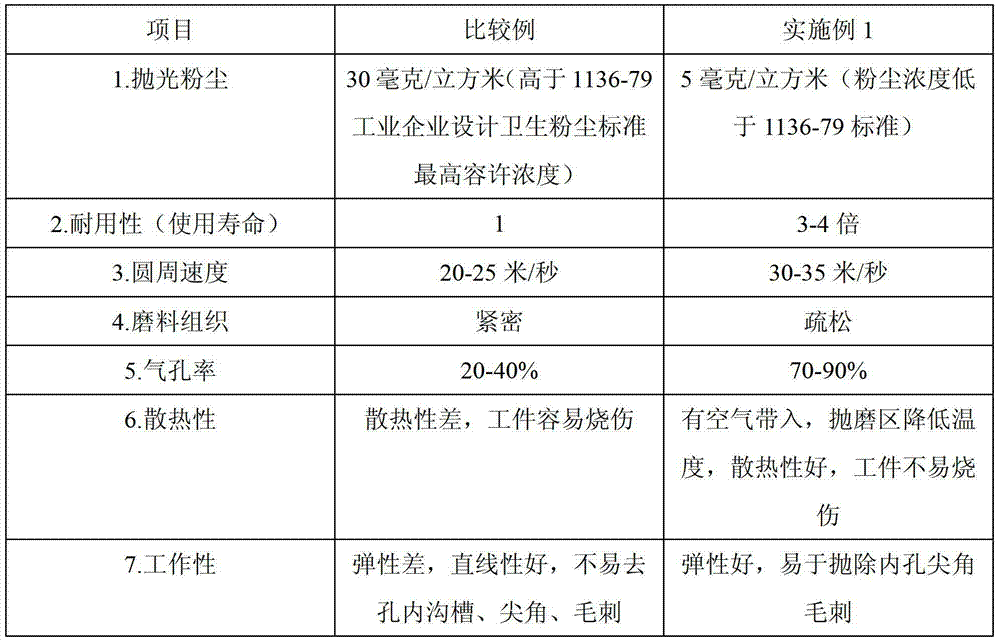

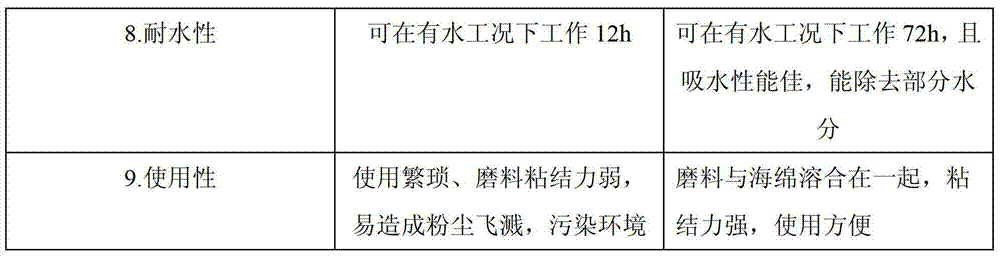

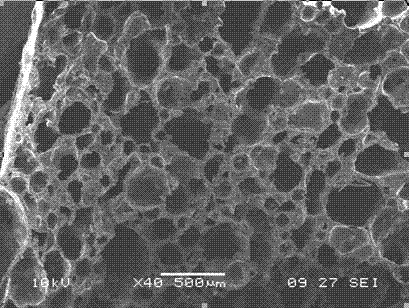

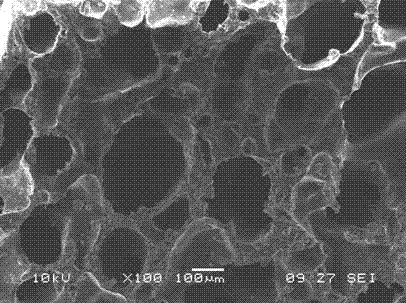

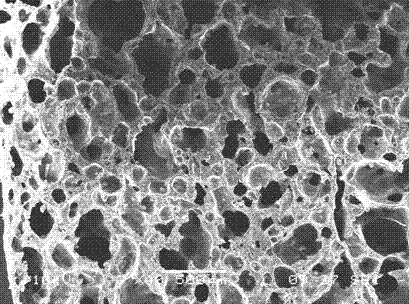

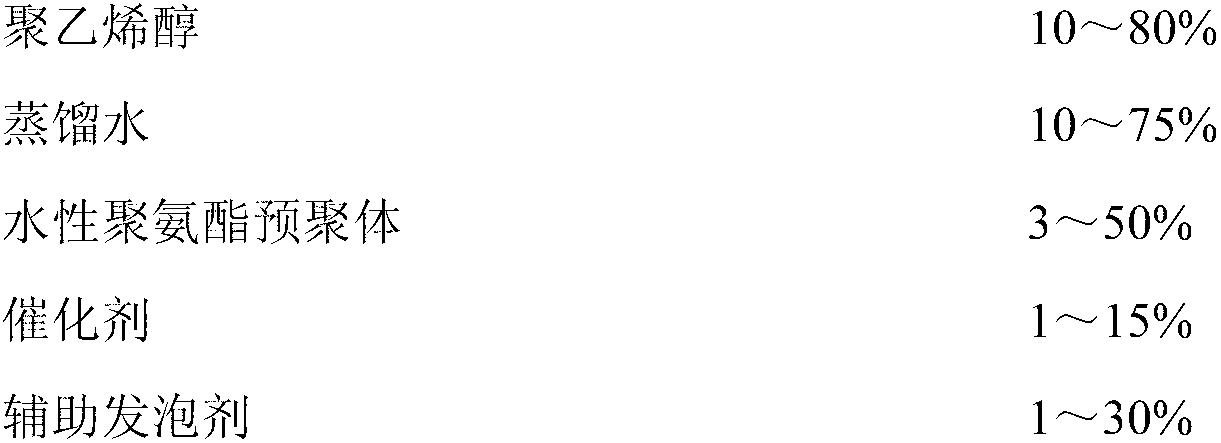

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

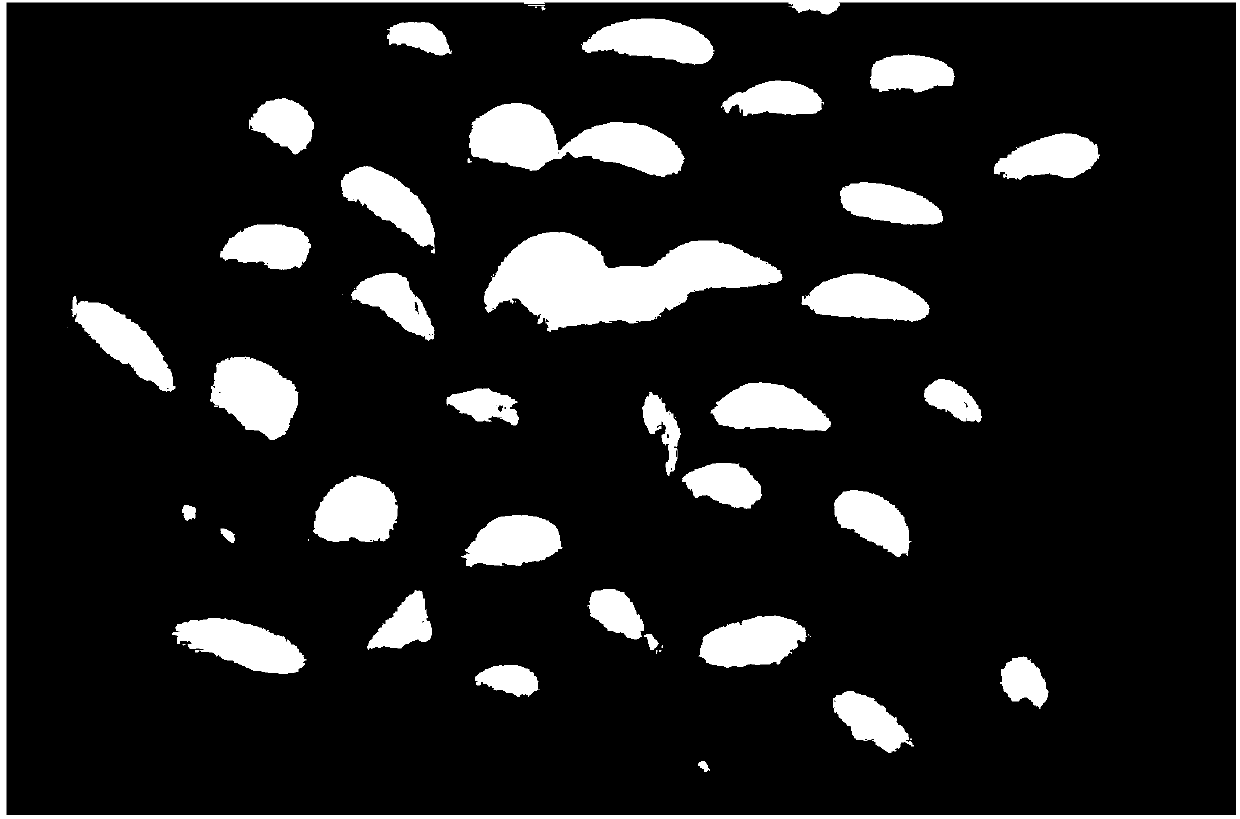

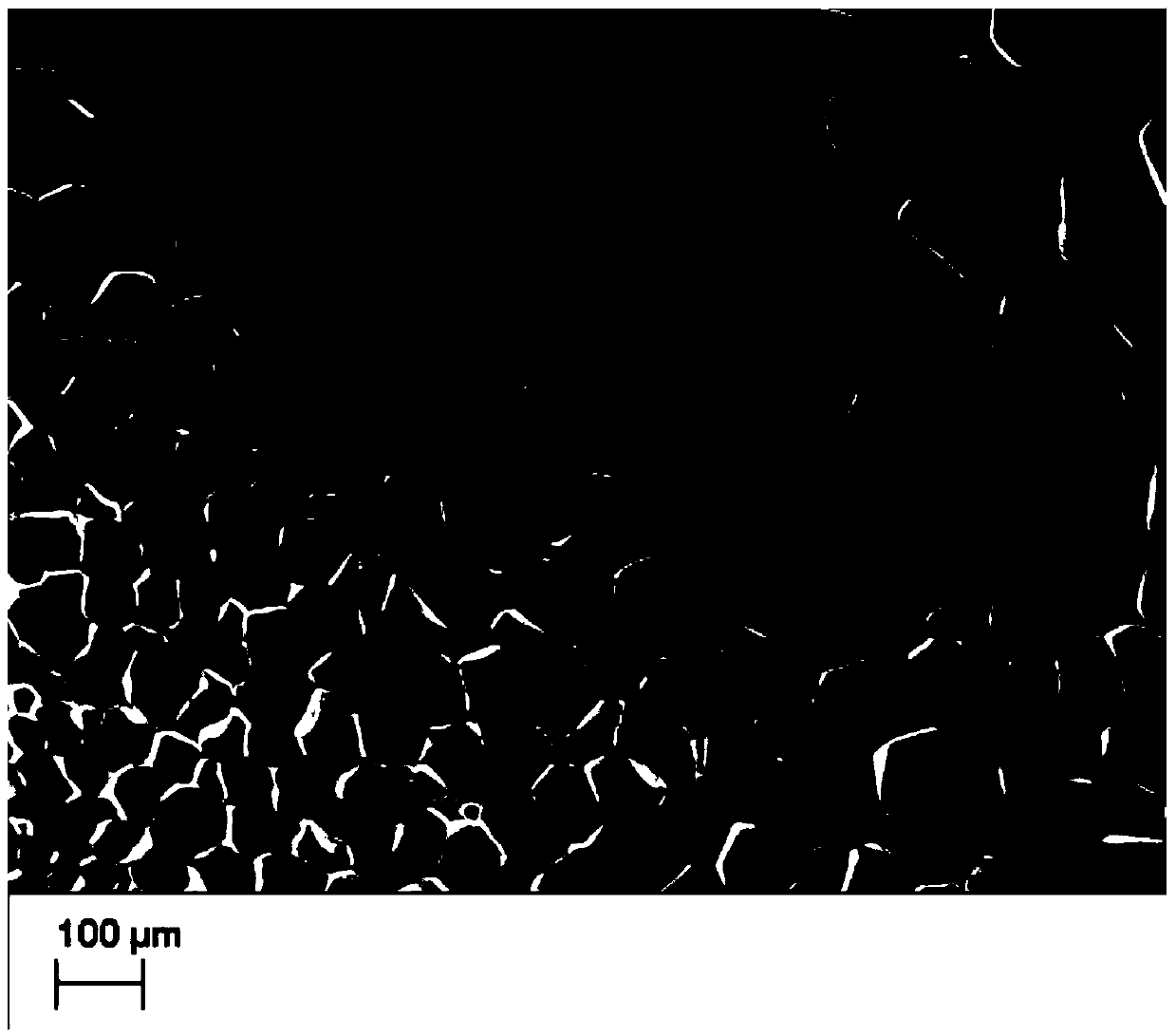

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

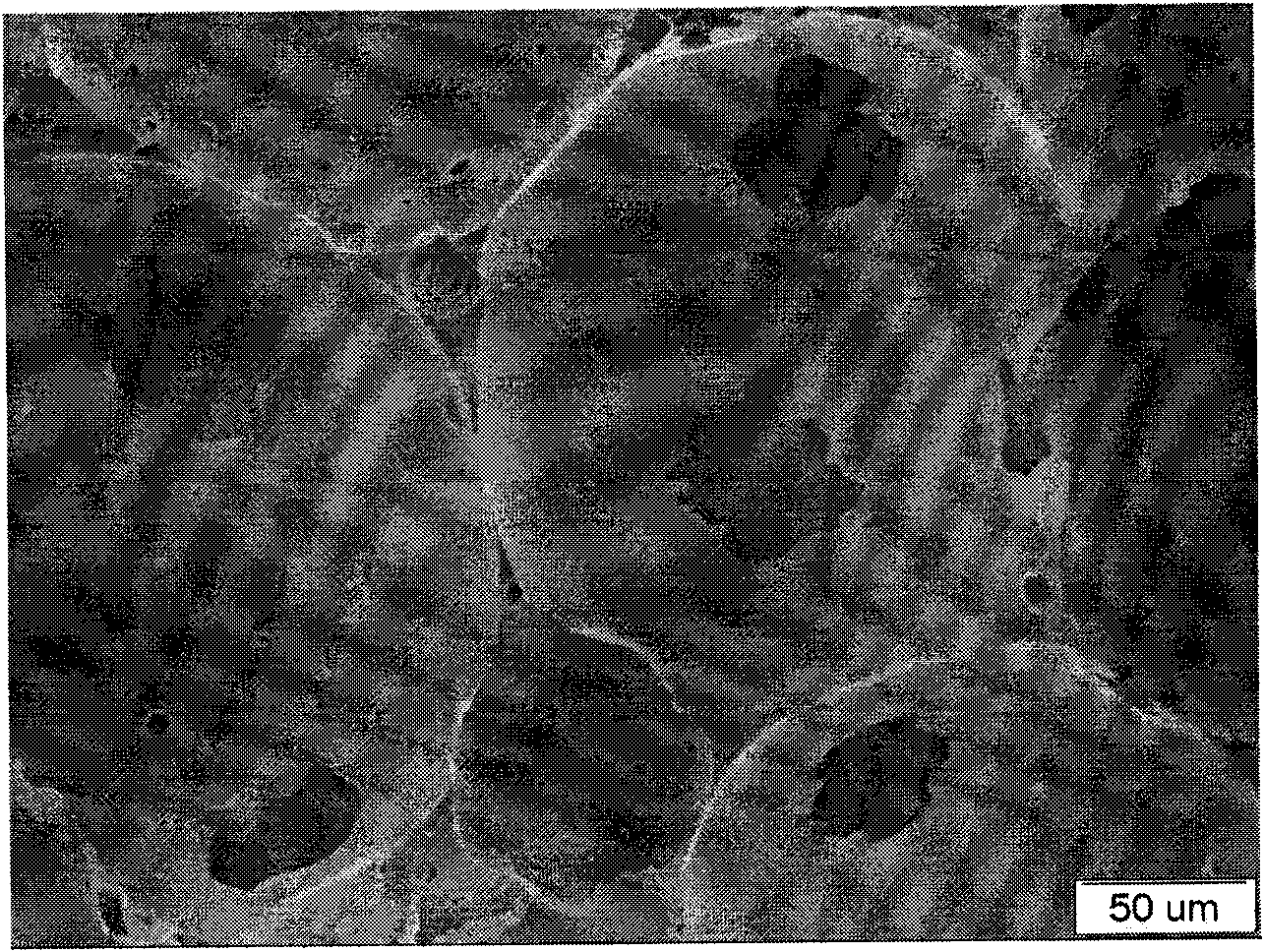

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

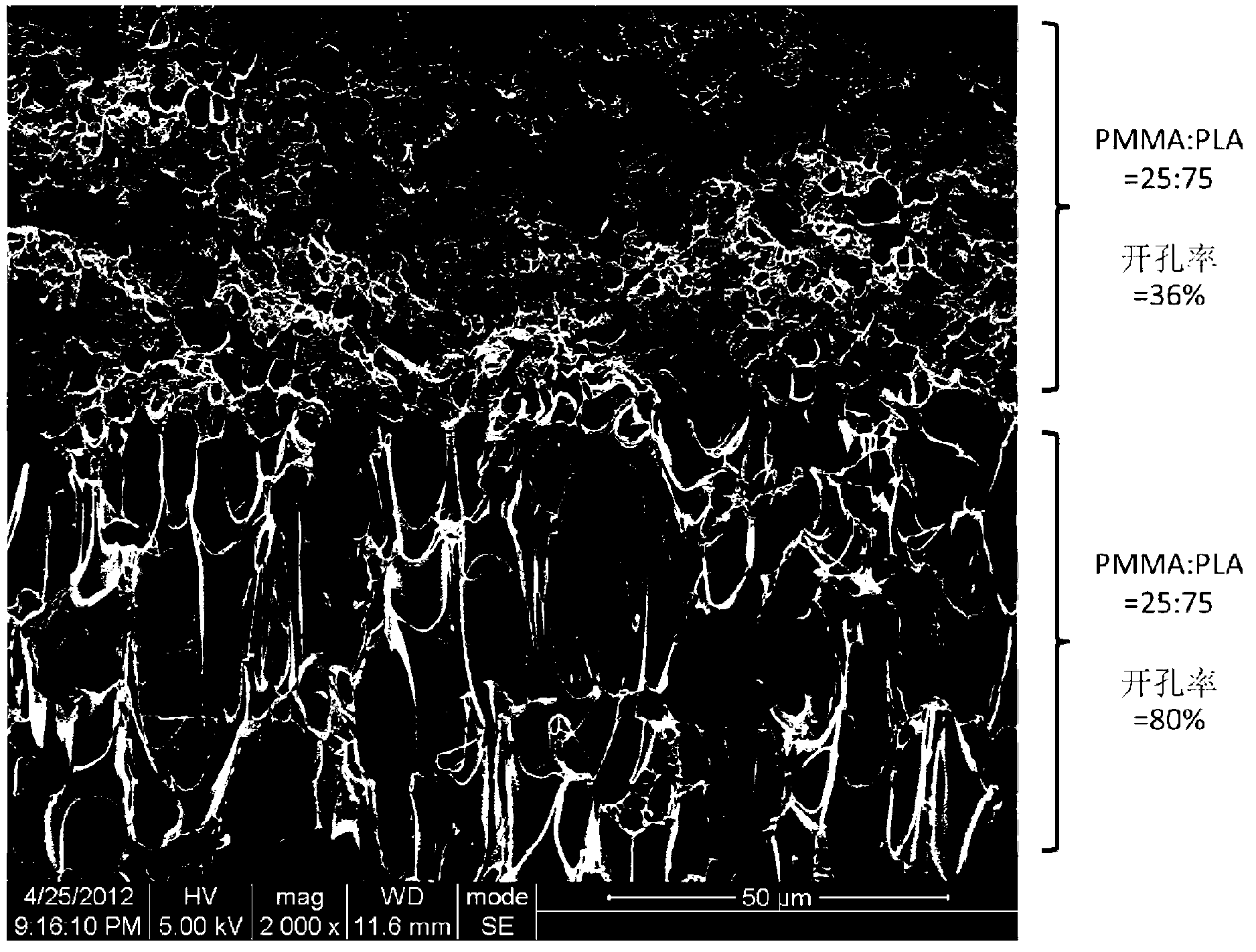

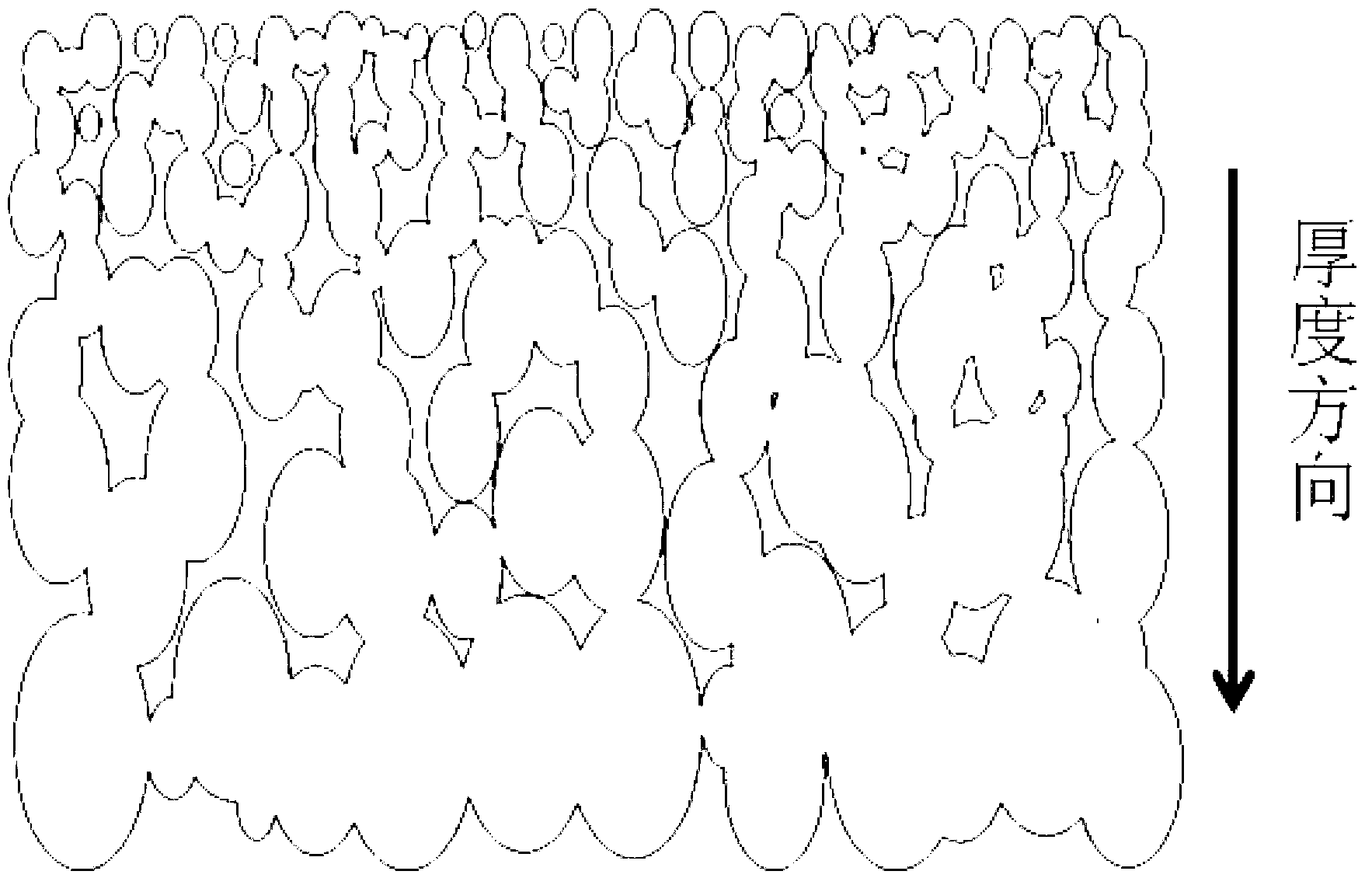

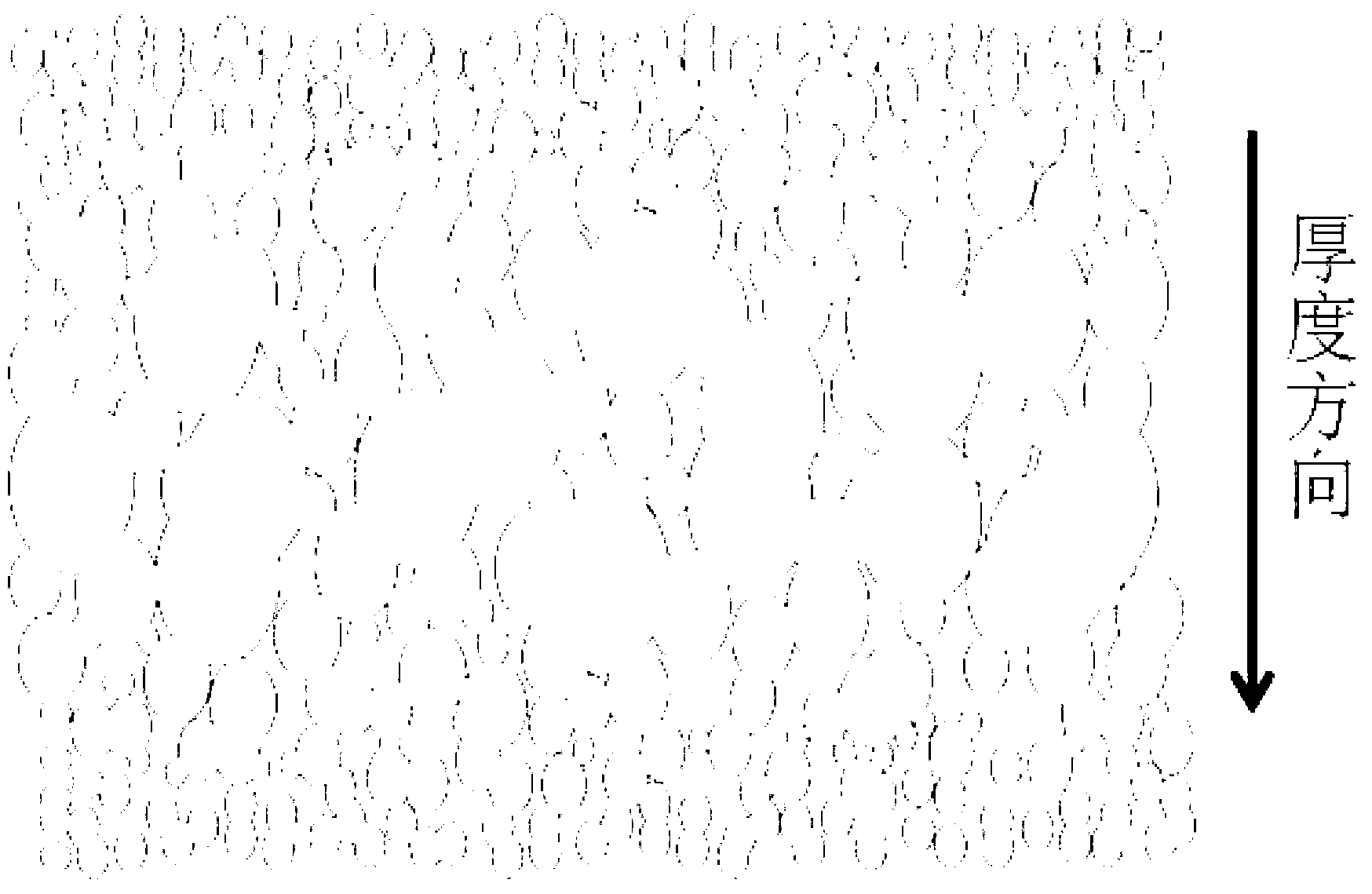

Gradient biocompatible polymer foaming material with opening structure and preparation method thereof

The invention provides a gradient biocompatible polymer foaming material with an opening structure, and the gradient biocompatible polymer foaming material comprises at least two biocompatible polymers, wherein the content of the biocompatible polymer in the foaming material as well as the cell size and aperture ratio of the foaming material change in gradient along the thickness direction of a flat shaped foaming material or the radial direction of a cylindrical foaming material. The preparation method of the gradient biocompatible polymer foaming material with the opening structure comprises the following steps of: preparing a gradient parison and foaming the gradient parison.

Owner:SICHUAN UNIV

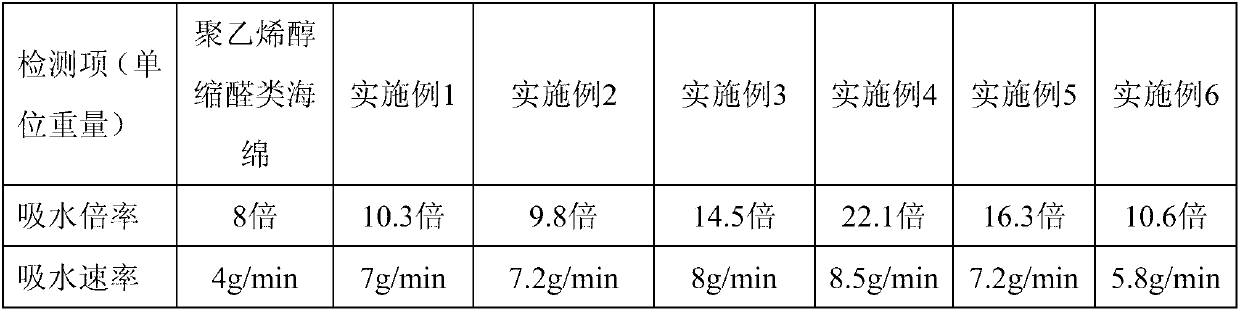

Method for preparing polyvinyl alcohol and polyurethane super absorbent sponge

The invention discloses a method for preparing a polyvinyl alcohol and polyurethane super absorbent sponge. The method includes mixing polyvinyl alcohol with distilled water at first, dissolving the polyvinyl alcohol for 20 to 30 minutes under the condition that the water bath temperature ranges from 50 DEG C to 95 DEG C and rotational speed ranges from 400r / min to 600r / min to obtain polyvinyl alcohol aqueous solution; and then heating the polyvinyl alcohol aqueous solution until the temperature of the polyvinyl alcohol aqueous solution ranges from 30 DEG C to 100 DEG C, adding water-based polyurethane prepolymer, catalysts and auxiliary foaming agents into the polyvinyl alcohol aqueous solution, stirring and uniformly mixing the mixture under the condition of rotational speed ranging from 400r / min to 600r / min, enabling the mixture to react for 5 minutes to 10 minutes, and solidifying the mixture for 2 to 4 hours at the temperature ranging from 30 DEG C to 100 DEG C to obtain the sponge with the water absorbent rate higher than 9.8. The water absorbent rate of the obtained sponge is increased to 10-20 times from the original 6-8 times of an existing polyvinyl acetal sponge, the water absorbing velocity of the sponge is increased to 8g / ming from the original 4g / ming, and the polyvinyl alcohol and polyurethane super absorbent sponge has a broad development prospect in fields of aquatic product processing, food, clinical medicine, water treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of graphene oxide and polyvinyl alcohol hybrid aerogel

InactiveCN105521770AUniform cellsStrong water absorptionOther chemical processesWater contaminantsCross-linkPolyvinyl alcohol

The invention belongs to the technical field of preparation of aerogel having a water treatment function, in particular relates to a preparation method of graphene oxide and polyvinyl alcohol hybrid aerogel. The preparation method comprises the following five processing steps: preparing a graphene oxide dispersing solution; preparing a graphene oxide / chitosan mixed solution; preparing a self-foaming solution; preparing a gel solution; preparing graphene oxide / chitosan and polyvinyl alcohol hybrid aerogel. The preparation method is characterized in that the graphene oxide and polyvinyl alcohol hybrid aerogel is prepared by fully mixing the graphene oxide dispersing solution with distilled water, glacial acetic acid and chitosan powder and then adding polyvinyl alcohol, a filling agent, a cross-linking agent, a foaming agent and a catalyst in the mixture. The graphene oxide and polyvinyl alcohol hybrid aerogel prepared by the invention is strong in water absorbing capacity, high in hydrophily and quick in adsorption rate and can be reused after regeneration and can be used for industrial wastewater treatment. The preparation method of the graphene oxide and polyvinyl alcohol hybrid aerogel, disclosed by the invention, has the advantages that the principle is simple, the operation is easy, processing equipment is simple, the cost of raw materials is low, and the preparation method is beneficial for industrialization.

Owner:QINGDAO UNIV

Antistatic polypropylene foam material and preparation method thereof

The invention discloses an antistatic polypropylene foam material and a preparation method thereof. The foam material comprises the following blended components in parts by weight: 100 parts of high-melt-strength polypropylene, 0.1-2 parts of grapheme, 5-15 parts of a foaming agent, 0.125-0.25 parts of a compatilizer and 0.05-0.15 parts of a coupling agent. The method for preparing the antistatic polypropylene foam material comprises the following steps of: melting and blending according to the using amounts; molding and foaming.

Owner:CHINA PETROLEUM & CHEM CORP +1

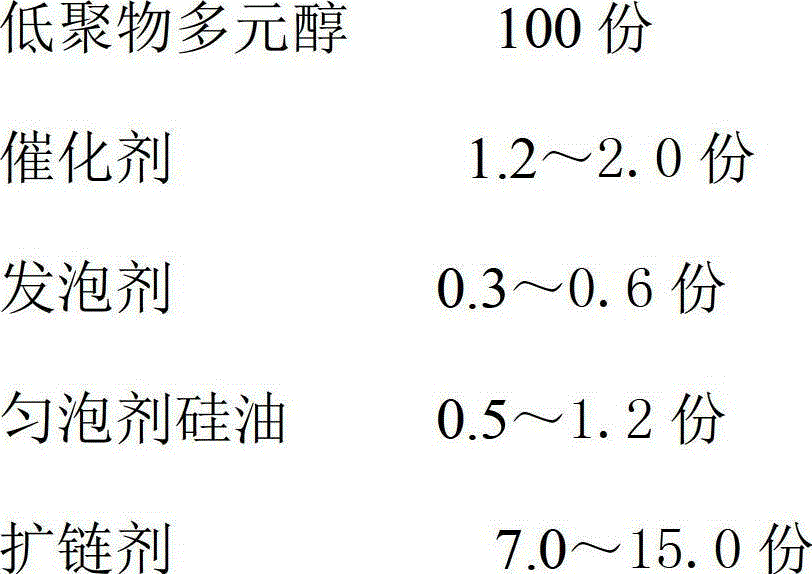

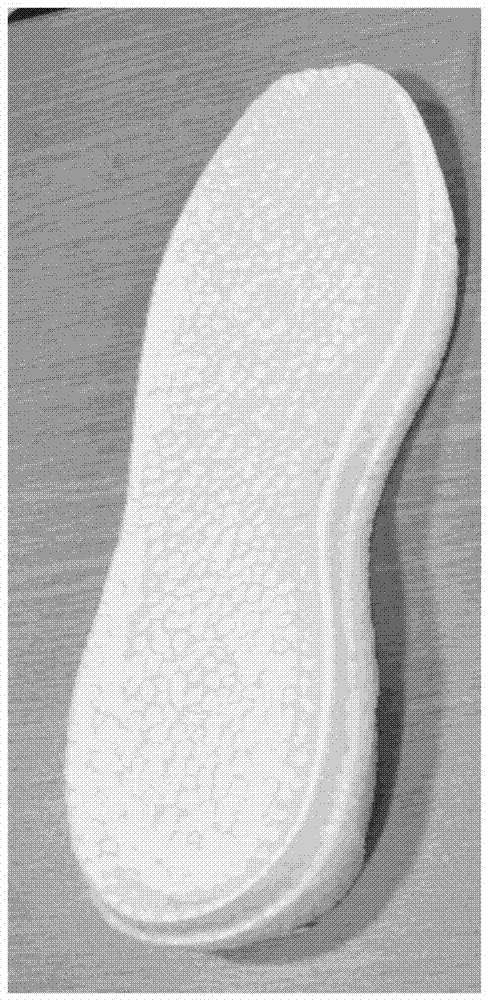

Method for filling polyurethane sole with waste rubber

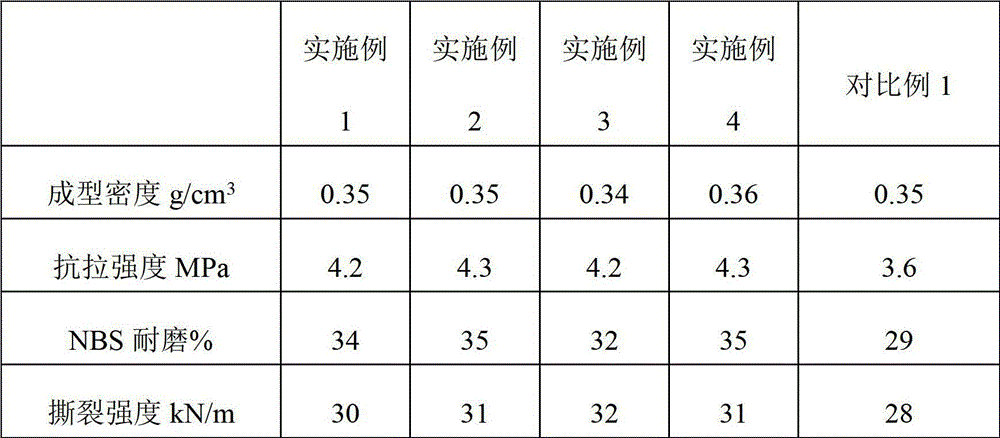

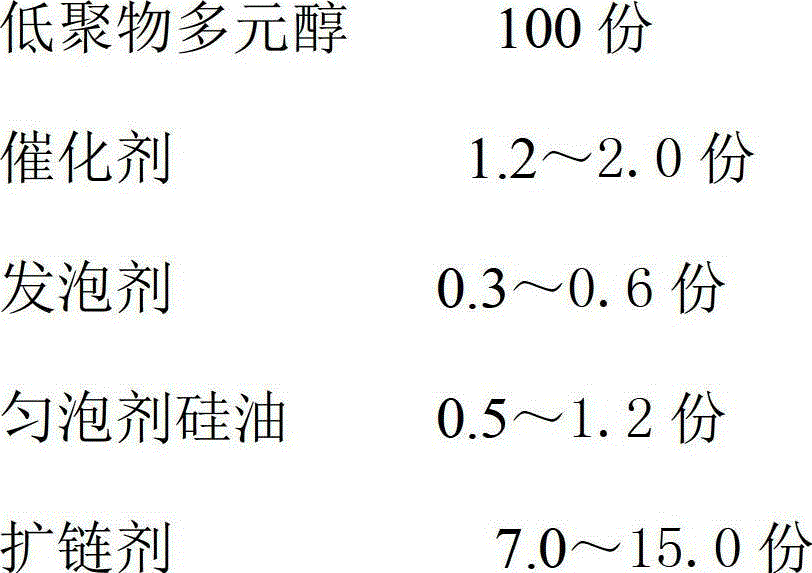

The invention provides a method for filling a polyurethane sole with waste rubber. The method comprises the following steps that A components, B components and rubber particles are mixed to be poured into a sole mold to be in reaction forming, demolding is carried out, and curing is maintained in a 60-70 DEG C drying oven for 22-24 hours to obtain the polyurethane sole filled with the waste rubber particles; the A components comprise, by weight, 100 parts of low polymer polyhydric alcohols, 1.2-2.0 parts of catalytic agents, 0.3-0.6 part of foaming agents, 0.5-1.2 parts of foam stabilizer silicone oil, and 7.0-15.0 parts of chain extender; and the B components comprise, by weight, 30-90 parts of the low polymer polyhydric alcohols, and 100 parts of diisocyanate. According to the method, the obtained polyurethane sole is uniform in foam holes, smooth in surface, and higher than a common polyurethane sole in tensile strength, abrasion resistance and tearing strength, the problem of reuse of rubber waste is resolved, and the technological process is simple and efficient.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

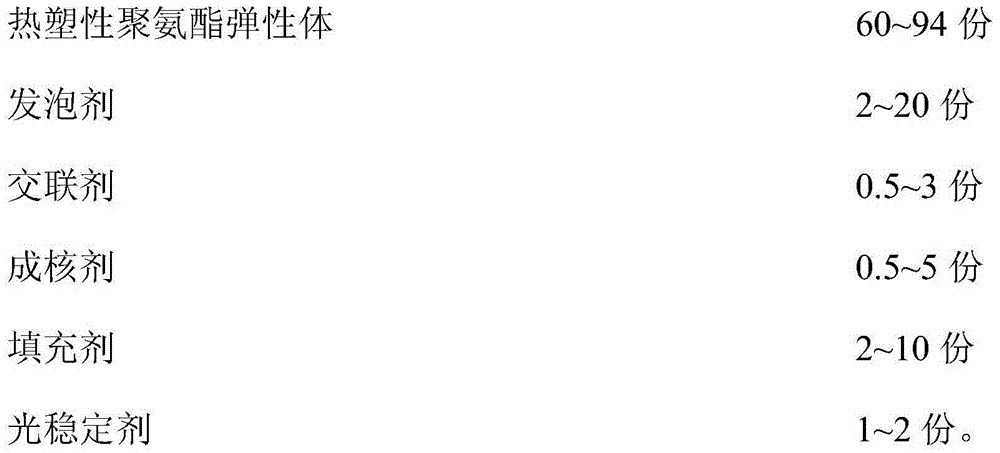

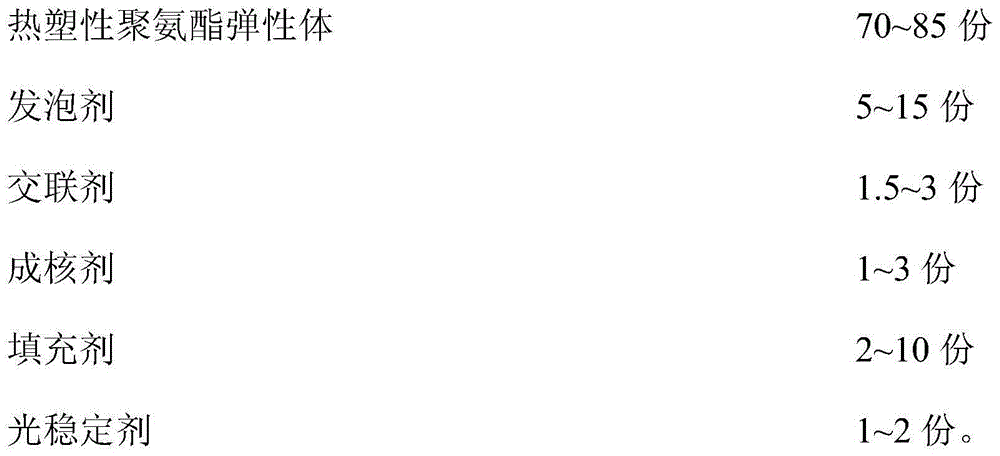

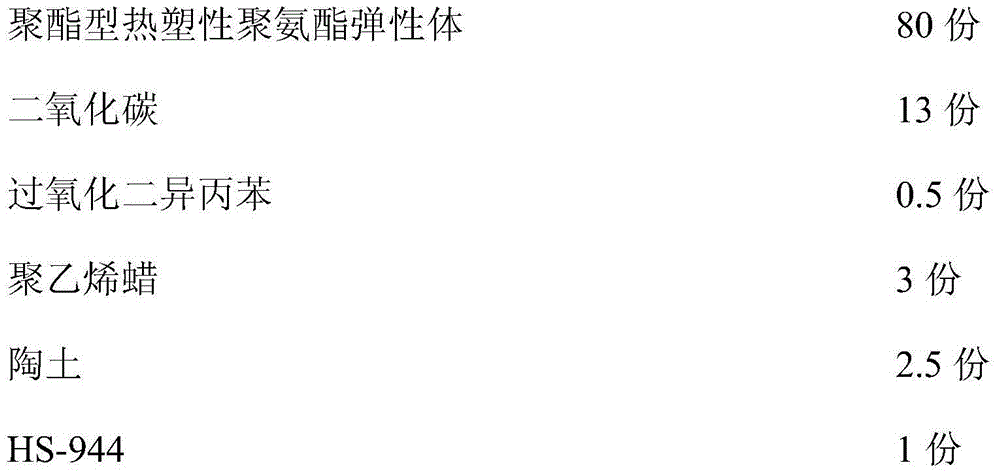

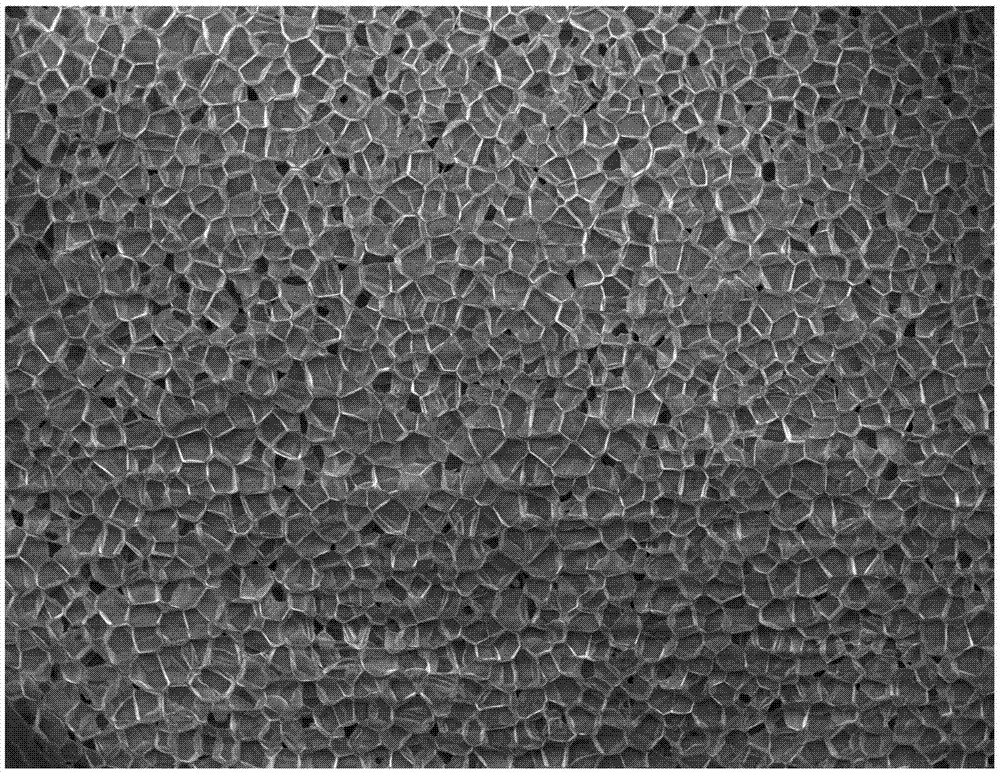

Thermoplastic polyurethane elastomer foamed bead and preparation method thereof

The invention provides a thermoplastic polyurethane elastomer foamed bead and a preparation method thereof. The thermoplastic polyurethane elastomer foamed bead is mainly prepared from the following raw materials in parts by weight: 60-94 parts of thermoplastic polyurethane elastomer, 2-20 parts of foaming agent, 0.5-3 parts of crosslinking agent, 0.5-5 parts of nucleator, 2-10 parts of filler and 1-2 parts of light stabilizer. The thermoplastic polyurethane elastomer foamed bead has the advantages of uniform particle size, high closed-cell rate, uniform pores and high strength. The preparation method is simple, has the advantages of fewer production steps, low required equipment investment, safe and environment-friendly production process and controllable foaming density, and is suitable for all thermoplastic polyurethane elastomers.

Owner:丁钰

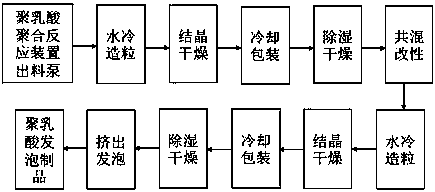

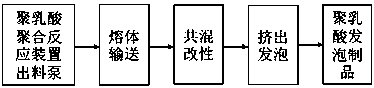

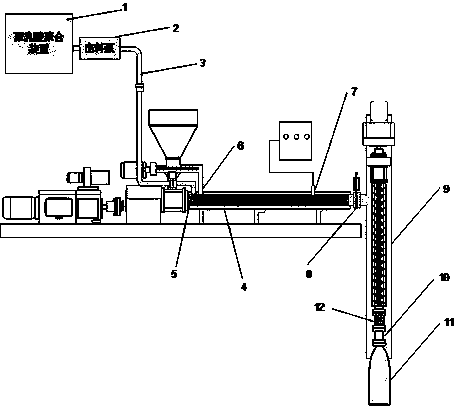

Method and device for directly preparing polylactic acid foam product from polylactic acid polymer melt

The invention provides a method and a device for directly preparing a polylactic acid foam product from a polylactic acid polymerization melt. The method and the device for directly preparing the polylactic acid foam product from the polylactic acid polymerization melt comprises the steps of polylactic acid melt preparation, material feeding and secondary extruding treatment. In the secondary extruding treatment, the outlet pressure of a first-stage double-screw extruder is 15-17 MPa, the material feeding speed of the polylactic acid polymerization melt is 250 kg / h, the foam auxiliary feedingspeed is 7.5-10 kg / h, and the foaming gas feeding speed is 2.8-7.5 L / h. The method and the device for directly preparing the polylactic acid foam product from the polylactic acid polymerization melt,provided by the invention, have the advantages that an influence on the foaming performance is avoided due to no need of processes such as water cooled pelletizing, repeated drying cooling and heating, melting and mixing; the foaming performance can be guaranteed; the quality can also be guaranteed; the energy consumption is saved by about 1 / 3 or above; the foaming multiplying power of an obtainedproduct is adjusted by 3-25 times; the degree of crystallinity is 40.3-48.5%; the tensile strength is 8.7-19.6 MPa; and the apparent density is 0.05-0.4 g / cm<3>.

Owner:CHTC BIO BASED MATERIAL ENG & TECH NINGBO CO LTD

Antibacterial and mildewproof latex foam material and preparation method thereof

The invention provides an antibacterial and mildewproof latex foam material and a preparation method thereof. The foaming material comprises, by weight, 100 parts of latex (based on dry weight), 0.58 parts of potassium hydroxide, 2-5 parts of potassium vegetable oleate, 1-2 parts of potassium ricinate, 4-6 parts of sulfur, 1-2 parts of an antiager, 1-2 parts of sodium silicofluoride, 1-1.5 parts of bentonite, 4-6 parts of a vulcanization accelerator nanometer zinc oxide, and 0.5-1 part of an inorganic silver-carrying zinc-carrying antibacterial agent. The preparation method comprises removing ammonia, stirring ingredients, aging the mixture, and carrying out foaming, material filling, setting, vulcanization, cleaning and drying setting. The antimicrobial efficiency of the antibacterial and mildewproof latex foam material is 99% or more. The anti-mildew performance of the antibacterial and mildewproof latex foam material reaches the level 0-1. The elasticity, rebound resilience, strength and hardness of the foam material are excellent.

Owner:福家汇(北京)电子商务有限公司

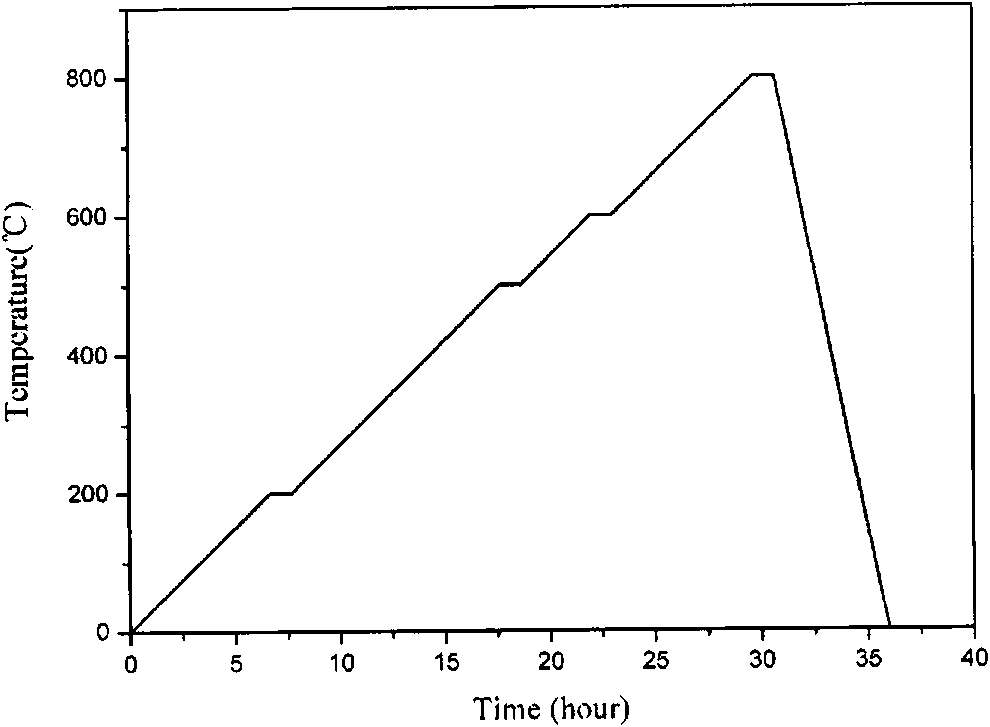

Preparation method of carbon foam heat insulation material added with hollow ceramic balls

The invention relates to a preparation method of carbon foam heat insulation material added with hollow ceramic balls. The method includes the following steps: (1) uniform mixing of raw materials: thefoaming formula of phenolic foam comprises the steps: adding 3-5 parts of surfactant, 1-3 parts of foaming agent and 0-2wt% of hollow ceramic microballs to 100 parts of phenolic resin sequentially and uniformly dispersing the mixture by means of combining mechanical stirring and ultrasonic oscillation; (2) adding 5-9 parts of curing agent to the uniformly dispersed mixture of step (1) and after stirring, casting the mixture to a mold to be foamed and solidified, thus obtaining phenolic foam; and (3) carbonized heat treatment: after shelling treatment, putting the phenolic foam in a vacuum carbonization furnace to be heated to the temperature of 800 DEG C at the average rate of 0.5 DEG C / min under vacuum condition, thus obtaining the carbon foam heat insulation material. The high temperature heat insulation material has the advantages of light weight, high strength, low thermal conductivity, low coefficient of heat expansion, low cost, designability and the like.

Owner:BEIHANG UNIV

Method for preparing polyether amine modified isocyanate group polyimide foam

The invention relates to a method for preparing polyether amine modified isocyanate group polyimide foam. Preparation equipment and chemical raw materials are used for preparing the foam, foam precursor solution of the prepared foam is stable in storage, the foam is provided with uniform holes and has flexibility, and rigidity and brittleness are reduced. The method is simple in preparation technology, low in preparation cost, easy in industrial production and convenient in popularization and application.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Preparation method for thermoplastic polyurethane elastomer foaming material

The invention discloses a preparation method for a thermoplastic polyurethane elastomer foaming material. The method comprises the following steps: (1) stirring and mixing 100 parts of TPU material, 0.5-10 parts of graphene material and 0.05-3 parts of lubricating agent, thereby acquiring a mixture; (2) adding the aggregates acquired in the step (1) and water into a reaction kettle and starting to stir; (3) introducing carbon dioxide or / and nitrogen into the reaction kettle, controlling the pressure and temperature in the reaction kettle and keeping the carbon dioxide or / and nitrogen in the reaction kettle under a super-critical state; (4) heating the reaction kettle and dissolving the super-critical carbon dioxide or / and nitrogen in thermoplastic polyurethane with uniformly doped graphene under the temperature of the reaction kettle; (5) continuously adding a foaming agent, a cross-linking agent, a lubricating agent and cross-linking auxiliaries into the reaction kettle, continuously stirring for 1-5h, and then connecting the reaction kettle with a pressure tank and enabling the materials in the reaction kettle to enter into the pressure tank under the pressure effect; and (6) foaming the materials in the pressure tank for 30-90min, and then reducing the pressure and reducing the temperature to below 70 DEG C, thereby acquiring the TPU foaming material.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

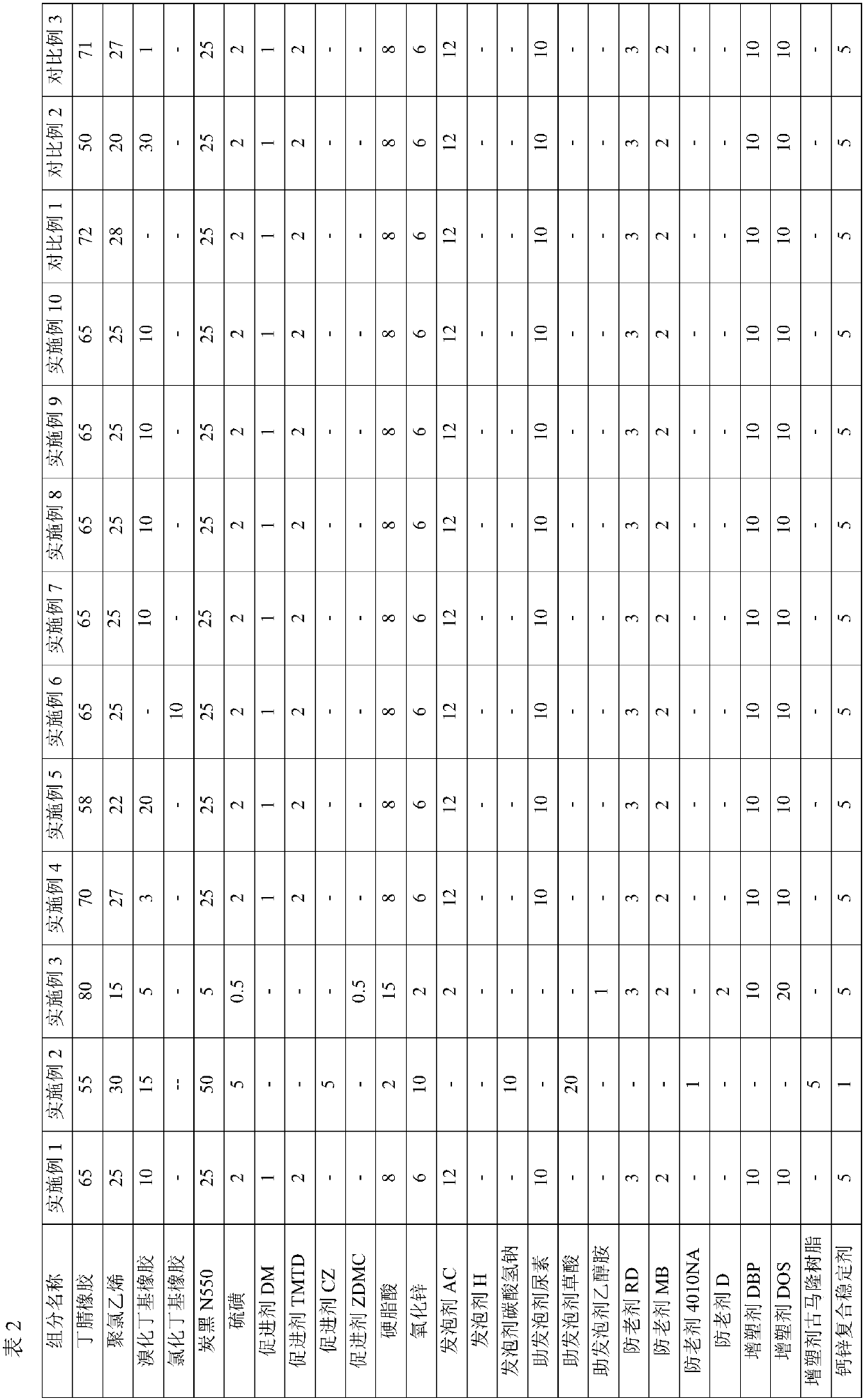

Foam rubber composition, vulcanized rubber and preparation method and application thereof

The invention relates to the field of rubber and discloses a foam rubber composition, vulcanized rubber and a preparation method and application thereof. The foam rubber composition contains a rubbermatrix, a reinforcing agent, a vulcanizing agent, a vulcanization accelerator, a vulcanization activator and a foaming agent, wherein the rubber matrix contains nitrile-butadiene rubber, polyvinyl chloride and halogenated butyl rubber, and every 100 parts of rubber matrix contains 3-20 parts of halogenated butyl rubber. The preparation method of the vulcanized rubber includes: mixing various components in the foam rubber composition, and vulcanizing the obtained mixed rubber. The vulcanized rubber is low in density, uniform in foam pores and evident in low-temperature resistance while the mechanical performance is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

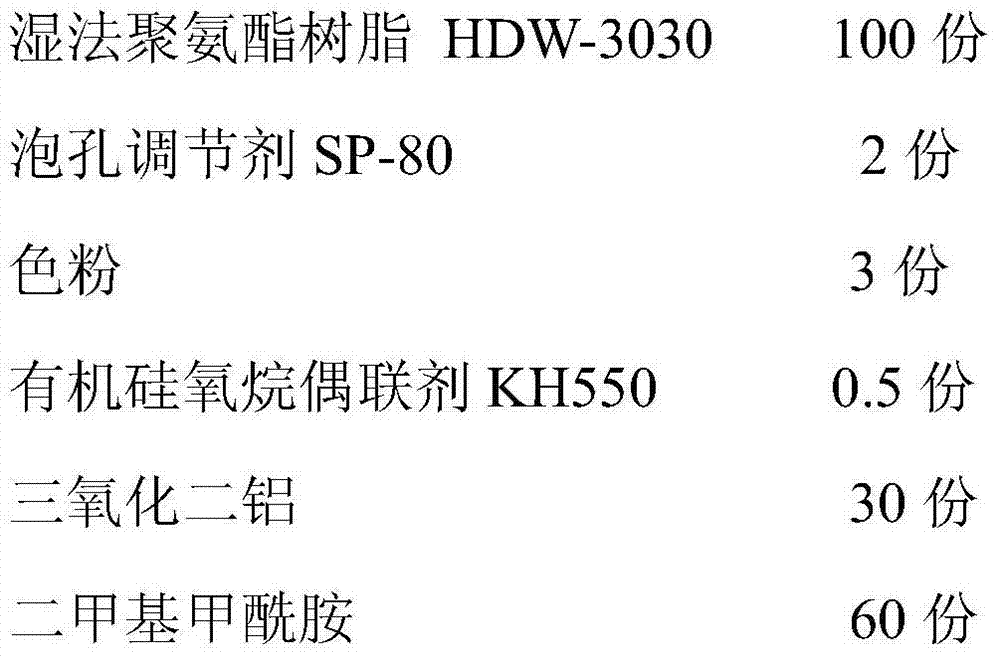

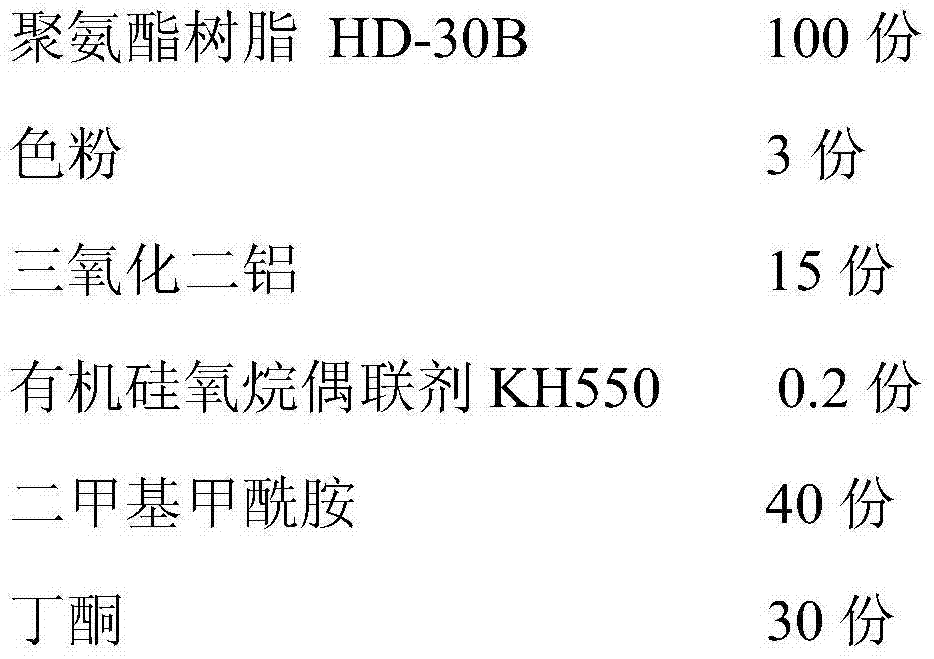

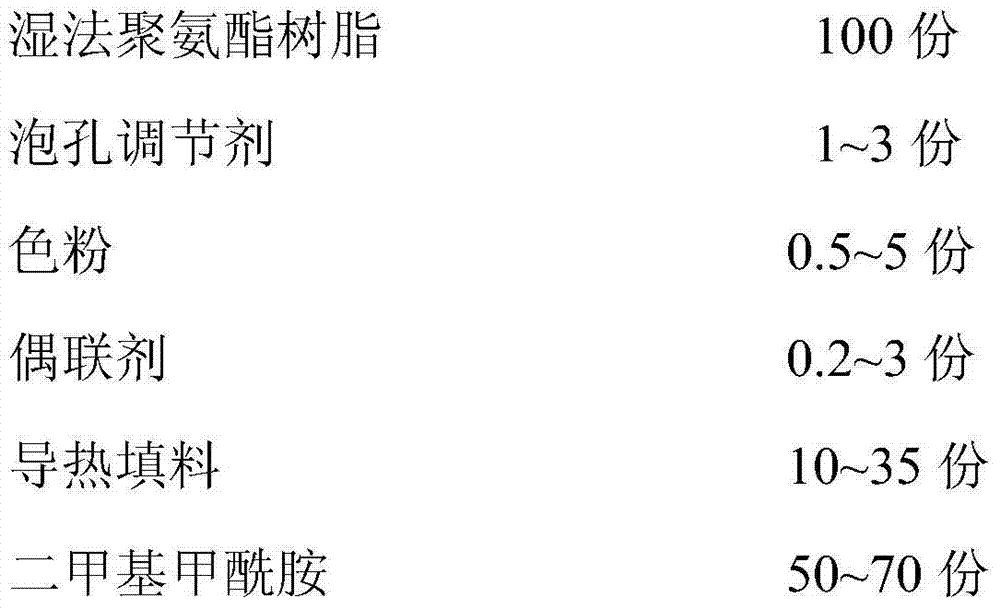

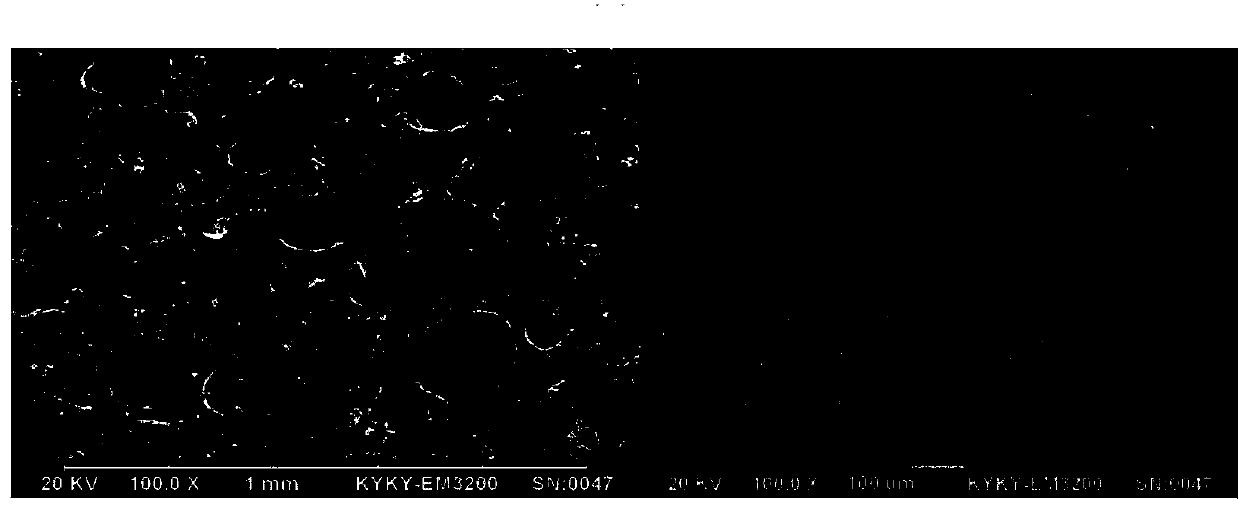

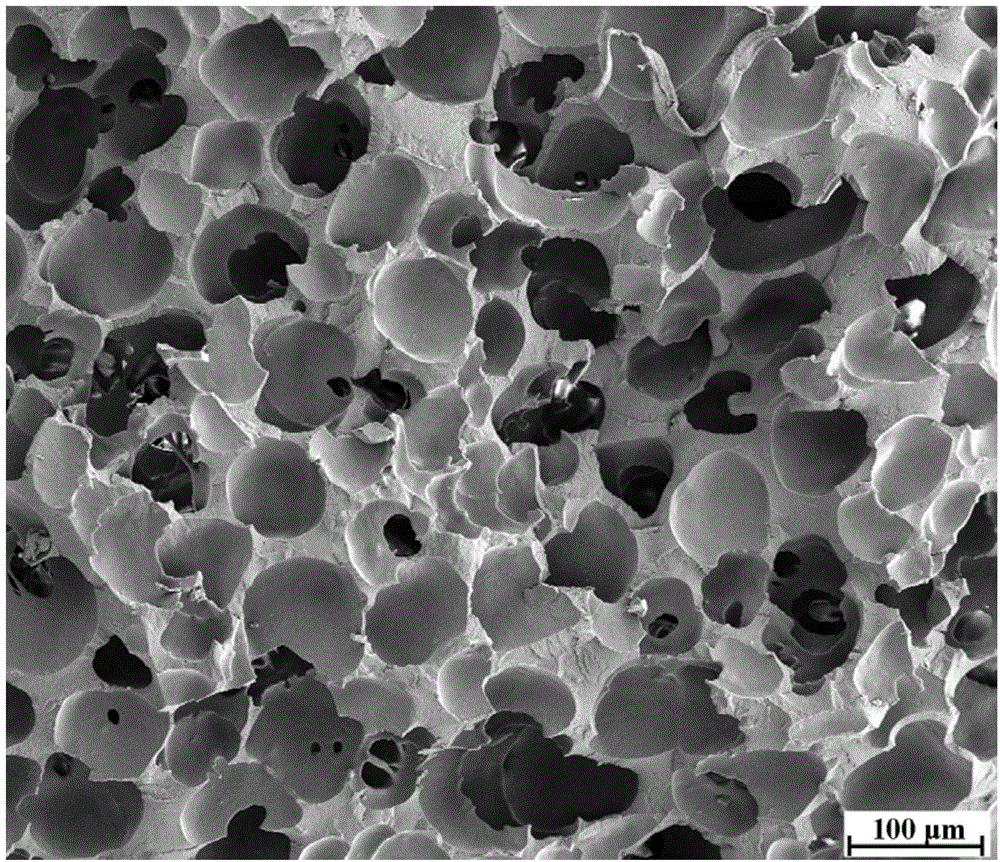

Thermal conductive polyurethane synthetic leather production method

InactiveCN104328690AImprove thermal conductivityImprove wear resistanceSynthetic resin layered productsTextiles and paperMoisture permeabilitySlurry

The invention discloses a thermal conductive polyurethane synthetic leather production method which comprises the following process: selecting base cloth, coating with wet process polyurethane slurry, solidifying, washing with water, expanding and drying, veneering by dry method, and finishing the surface; first of all, the base cloth is coated with the wet process polyurethane slurry with conductive filler; then, the coated substrate is solidified by wet method for adjusting of bubble hole structure and expanding and drying for production of thermal conductive and breathable Base; finally thermal conductive breathable polyurethane synthetic leather is produced by veneering by dry method and finishing the surface of the thermal conductive and breathable Base. The thermal conductive polyurethane synthetic leather prepared by the method is relatively high in thermal conductivity coefficient, the thermal conductivity coefficient reaches 0.06-0.09W .M <-1> .K <-1>, compared with traditional synthetic leather, the thermal conductivity is increased by more than 30%, and the bubble hole is even, delicate, soft in hand feeling, good in drapability, air and moisture permeability, similar to natural leather in apparent and hand feeling, and simple in manufacturing process.

Owner:SHAANXI UNIV OF SCI & TECH

Adhesive and modified EVA (ethylene vinyl acetute) foaming composite for automobiles

The invention discloses adhesive and modified EVA (ethylene vinyl acetute) foaming composite for automobiles. The foaming composite consists of the following components in parts by weight: 60-80 parts of EVA resin; 5-15 parts of epoxy resin; 5-25 parts of foaming agent; 0.1-5 parts of foaming accelerator; 0.1-5 parts of cross-linking agent; 0.1-5 parts of curing agent; 0.1-5 parts of curing accelerator; 0.1-5 parts of tackifier and 0.1-20 parts of filler. The obtained foaming composite can foam at the temperature range of 140-210 DEG C; and with uniform foam holes, high volume expansion ratioand excellent adhesive force with steel sheets or galvanized steel sheets, the adhesive and modified EVA (ethylene vinyl acetute) foaming composite can fill or seal the cavity of an automobile body and play sound-insulation and vibration-reduction roles.

Owner:广东时利和汽车材料有限公司

Compact/foamed rubber sole and its special foaming rubber

The invention discloses a compact / foamed rubber sole and its special foaming rubber. The foaming rubber is prepared by using the following parts, by mass, 60.0-80.0 parts of natural rubber, 20.0-40.0 parts of chloroprene rubber, 50.0-100.0 parts of a reinforcing filler, 5.0-10 parts of zinc oxide, 1.0-2.5 parts of a vulcanization accelerant, 0.5-2.0 parts of sulfur, and 0.5-5.0 parts of a foaming agent. The invention further provides the compact / foamed rubber sole. The compact / foamed rubber sole is composed of a solid layer and a foaming layer; and the foaming layer is made by using the foaming rubber. The foaming rubber has the advantages of good thermal stability, uniform foam hole, good dimension stability, low density, softness, good elasticity, flame retardation and the like. The foaming rubber can be used in the sole to effectively reduce the weight, improve the elasticity and increase the comfortableness of the sole.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method for preparing rubber-toughened PS foam material through extrusion of supercritical fluid

ActiveCN104877245AImprove mechanical propertiesIncrease productivityThermoplastic elastomerPolystyrene

The invention discloses a method for preparing rubber-toughened PS foam material through extrusion of a supercritical fluid. The rubber-toughened PS foam material is prepared from the following raw materials in parts by weight: 80-95 parts of polystyrene, 5-20 parts of a thermoplastic elastomer and 1-10 parts of one or more nucleating agents. The method comprises the following steps: mixing such raw materials according to a proportion; feeding the mixed raw materials into a first extruder for melt-blending and extrusion pelletization to obtain a rubber-toughened polystyrene-based blend containing the nucleating agents; feeding the rubber-toughened polystyrene-based blend into a second extruder for heating and melting; meanwhile, injecting the supercritical fluid into a plasticization section of the second extruder to ensure that a homogeneous phase system is formed between the supercritical fluid and a melt of the rubber-toughened polystyrene-based blend under the shearing action of a threaded rod of the second extruder; continuously extruding the supercritical fluid for foaming. The rubber-toughened PS foam material prepared according to the method is uniform in cell, small in cell size, high in processing operability and anti-impact property, and suitable for industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

Low density silicone rubber and preparation method thereof

The invention relates to the field of silicone rubber, in order to solve the matching problem of sulfuration rate and foaming rate in the prior art, and provides low density silicone rubber and a preparation method thereof. At a room temperature, a component A and a component B are mixed according to a ratio 1:1, the materials are permitted to stand, foaming and solidification are carried out for5-20 minutes, and the product is obtained. The low density silicone rubber has the characteristics of low density, uniform bubble apertures, excellent elasticity, and low cost.

Owner:HANGZHOU RIYAO TECH

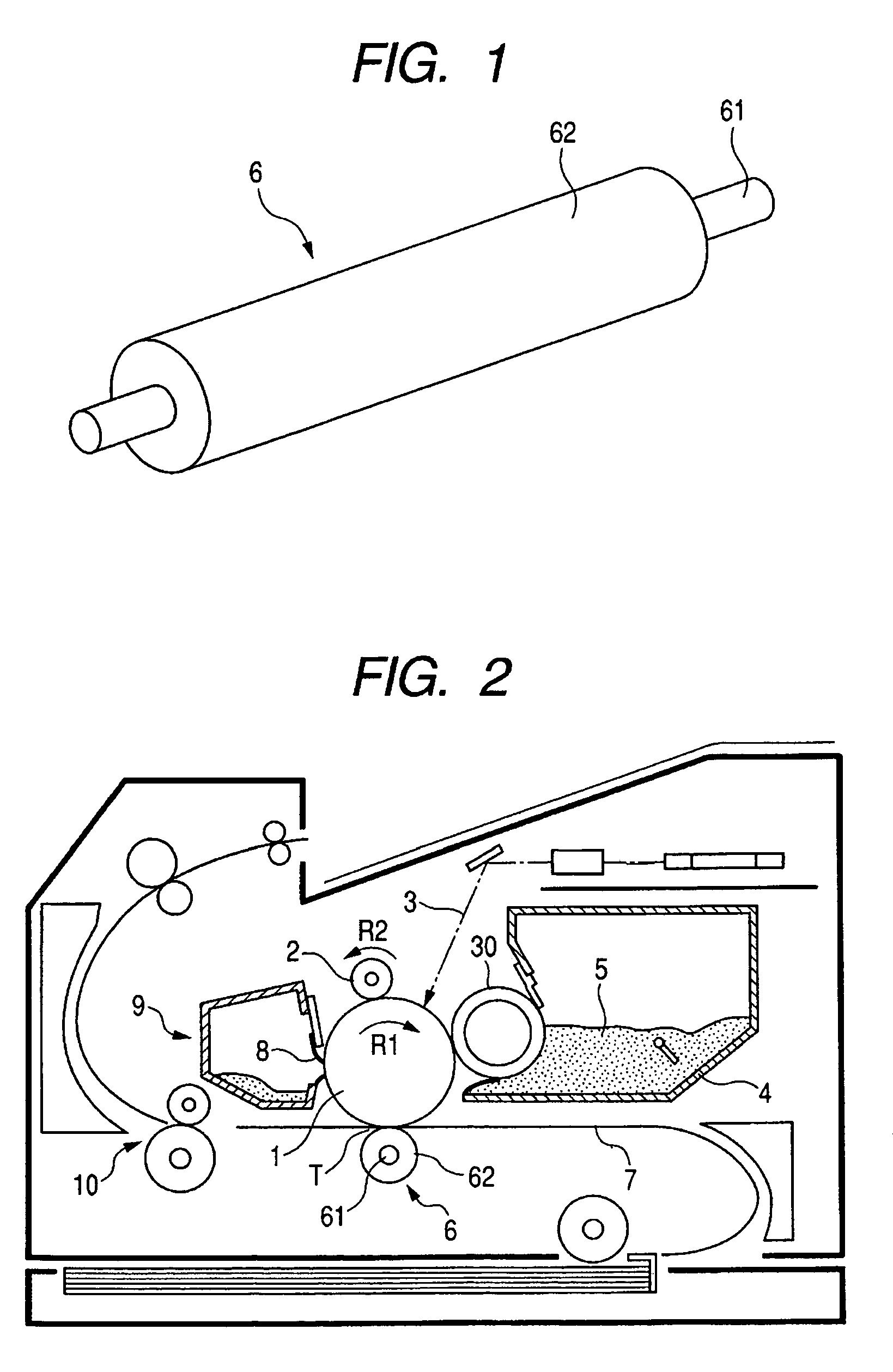

Process for producing conductive rubber roller, and roller for electrophotographic apparatus

InactiveUS7520057B2Uniform cell distributionUniform cellsHollow filament manufactureShaft and bearingsElectrical resistance and conductanceAdhesive

Owner:CANON KK

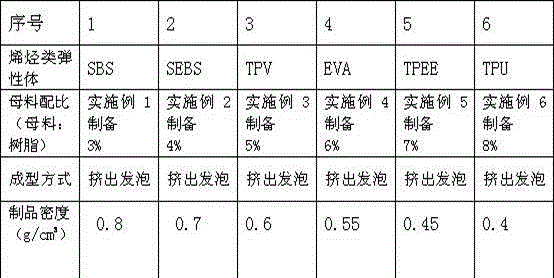

TPE (thermoplastic elastomer) foamed master batch and preparation method thereof

The invention relates to TPE (thermoplastic elastomer) foamed master batch and a preparation method thereof and belongs to the field of new chemical materials. The TPE foamed master batch is prepared from raw materials in parts by weight as follows: 10-30 parts of a styrene-butadiene block copolymer, 10-30 parts of an ethylene-octylene block copolymer, 30-80 parts of white oil, 20-80 parts of a microsphere foaming agent, 10-50 parts of a chemical foaming agent, 1-3 parts of a lubricating agent and 1-3 parts of a dispersing agent. The prepared TPE foamed master batch has high modulus, fine and uniform foam holes and adjustable density.

Owner:FUZHOU HAOWANG MATERIALS TECH CO LTD

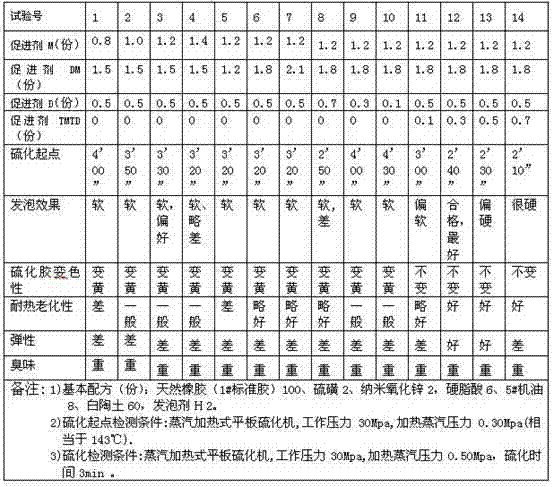

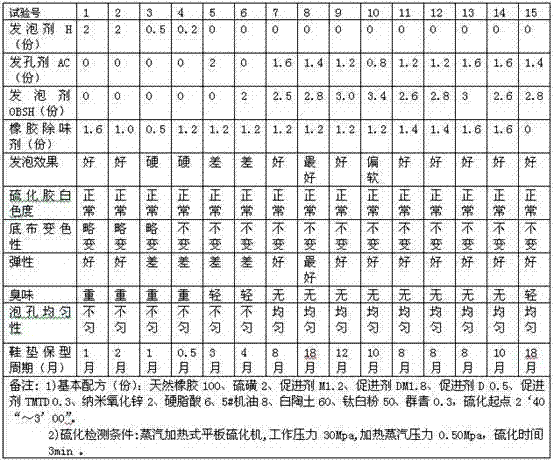

Natural rubber white odorless spongy cushion for in situ color-protecting shoes and preparation method thereof

ActiveCN102391550APrevent high temperature agingShort vulcanization timeInsolesLaminationActivated carbonPolymer science

The invention discloses a natural rubber white odorless spongy cushion for in situ color-protecting shoes and a preparation method thereof. The raw materials of the spongy cushion comprises natural rubber, sulfur, an accelerating agent, a vulcanizing active agent, a hole-forming agent AC (activated carbon), titanium white, 5# engine oil, kaolin, a rubber odor-removing agent and a foaming agent OBSH (oxybis(benzenesulfonyl hydrazide)). In the invention, the odorless spongy for shoes is prepared by utilizing the natural rubber as a main body; vulcanization is promoted by using a thiuram accelerating agent TMTD (tetramethyl thiuram disulfide) to inhibit the high-temperature ageing of the natural rubber, thereby ensuring that titanium white and kaolin filled white spongy rubber do not generate high yellowing to discolor the bottom surfaces in the shoes; the foaming agent AC and OBSH are jointly used, so as to achieve the shape keeping property and even bubbles and low odor of the inner bottoms of the spongy shoes; because no water gas is generated in the foaming process of spongy, heterochromatic substances are not dissolved and transported to cause the yellowing and discoloring of white soft goods of the inner bottoms of the shoes, thus the spongy cushion has abundant white keeping capacity; and the odor generated in the process of vulcanizing the spongy rubber can be effectively removed through the rubber odor-removing agent.

Owner:际华制鞋工业有限公司

Preparation method of hydrotalcite and polyimide composite foam material

The invention provides a preparation method of a hydrotalcite and polyimide composite foam material. Aromatic dianhydride is heated and dissolved in a polar solvent to react with fatty alcohol to obtain an aromatic dianhydride derivative diacid diester liquor; the diacid diester liquor is compounded with a foam stabilizer to form combined liquor; hydrotalcite is filled in and sufficiently stirred to form a uniform milk white material; polyisocyanates are added and quickly stirred uniformly to form mixed liquor, and the mixed liquor is quickly poured into a mould for freely foaming to obtain a foam plastic intermediate; the foam intermediate is prepared into the hydrotalcite and polyimide composite foam material by electric-heating and curing. The foam plastic prepared by the preparation method has a semi-closed structure, is uniform in foam holes and is soft in texture; the hydrotalcite achieves smoke inhibition effect while improving material flame resistance. The preparation method disclosed by the invention is simple in process, low in cost and easy to industrially produce. Besides, the product is excellent in flame resistance, and can satisfy fireproof safety requirements in a using process of a thermal-insulation heat insulating material.

Owner:HARBIN ENG UNIV

Low temperature resistant LNG thermal insulation material and preparation method thereof

The invention discloses a low temperature resistant LNG heat insulating material and a preparation method thereof. The material is prepared as follows: a component A consists of 60 to 97 percent of mixed polyhydric alcohols, 0.1 to 2 percent of a catalyzer, 0.5 to 10 percent of a foam homogenizer, 2 to 15 percent of a foaming agent, 2 to 15 percent of a fire retardant and 0.1 to 5 percent of a chain extendor; the component A reacts with a component B in isocyanate series to prepare and get the low temperature resistant LNG heat insulating material. The material can be used for long term at low temperature above 220 DEG C below zero, which has excellent cold insulativity and mechanical properties. The material can be adaptable to the quick change of temperature above 300 DEG C, and has high fire resistance and small coefficient of heat conductivity, which can effectively prevent the thermal loss of ultra-low temperature fluid and is a pollution-free energy-saving thermal insulative cold insulating material with high performance.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com