Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Uniform cell distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing TPU foamed beads by continuous extrusion foaming

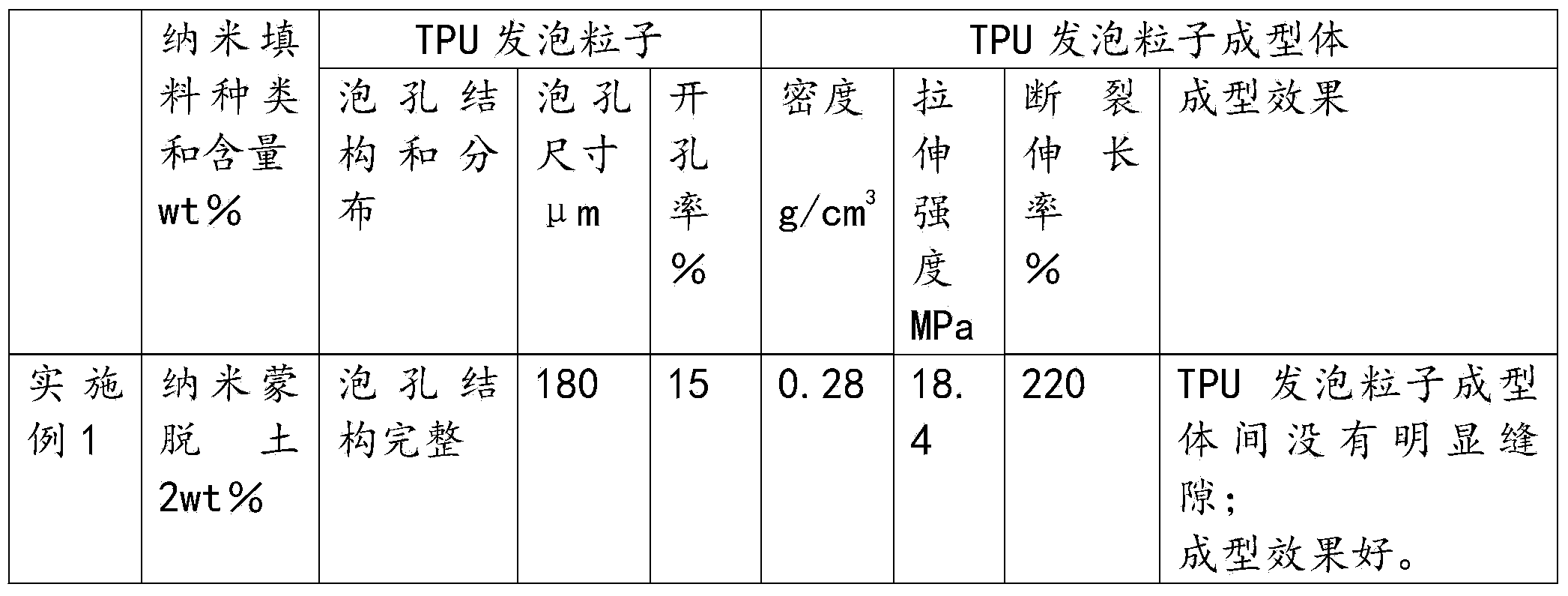

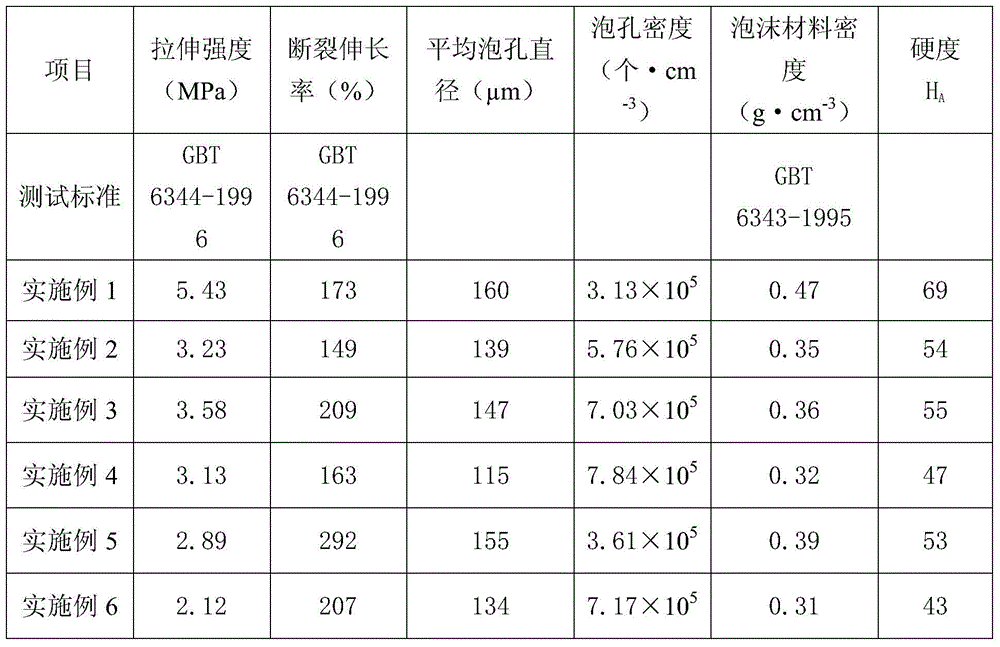

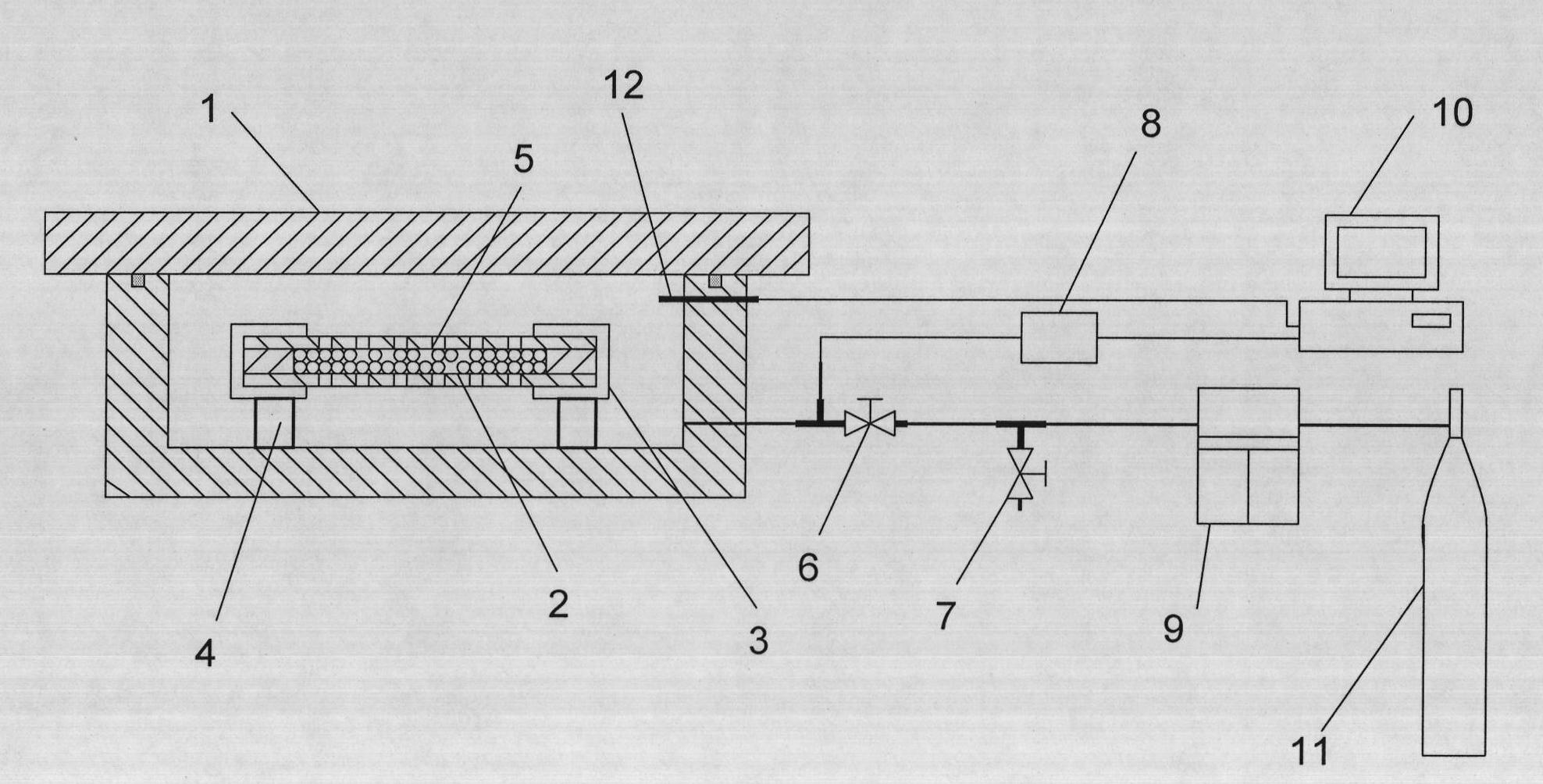

The invention discloses a method for preparing TPU (Thermoplastic Polyurethane) foamed beads by continuous extrusion foaming. The method comprises the steps of (1) mixing TPU particles with inorganic nano-particles which are organically modified, adding the mixed TPU particles into a material barrel of a first extruder, melting the TPU particles into a polymer melt by screw heating, and injecting a supercritical fluid into the tail end of the first extruder to mix the supercritical fluid with the polymer melt; (2) injecting a mixed polymer / high-pressure fluid melt into a second extruder through a melt pump, and gradually reducing the temperature of a heating area of the second extruder to obtain a polymer / supercritical fluid melt which is cooled and uniformly mixed; (3) extruding the polymer / supercritical fluid melt from an opening mold of the second extruder, and performing underwater ring cutting to obtain TPU foamed particles. According to the method, a TPU foamed particle molding body material which enables the foamed particles to be well bonded after steam molding can be quickly prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

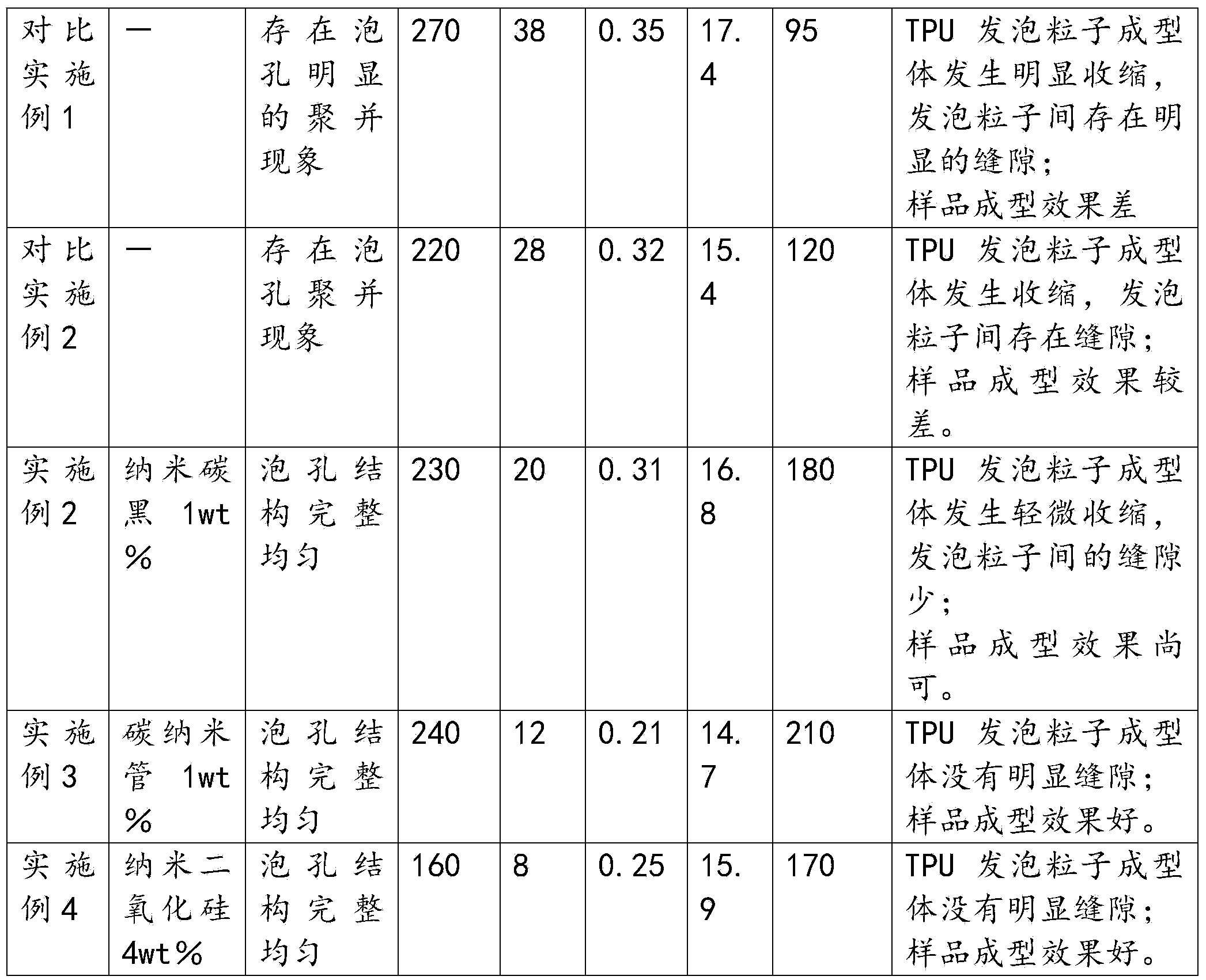

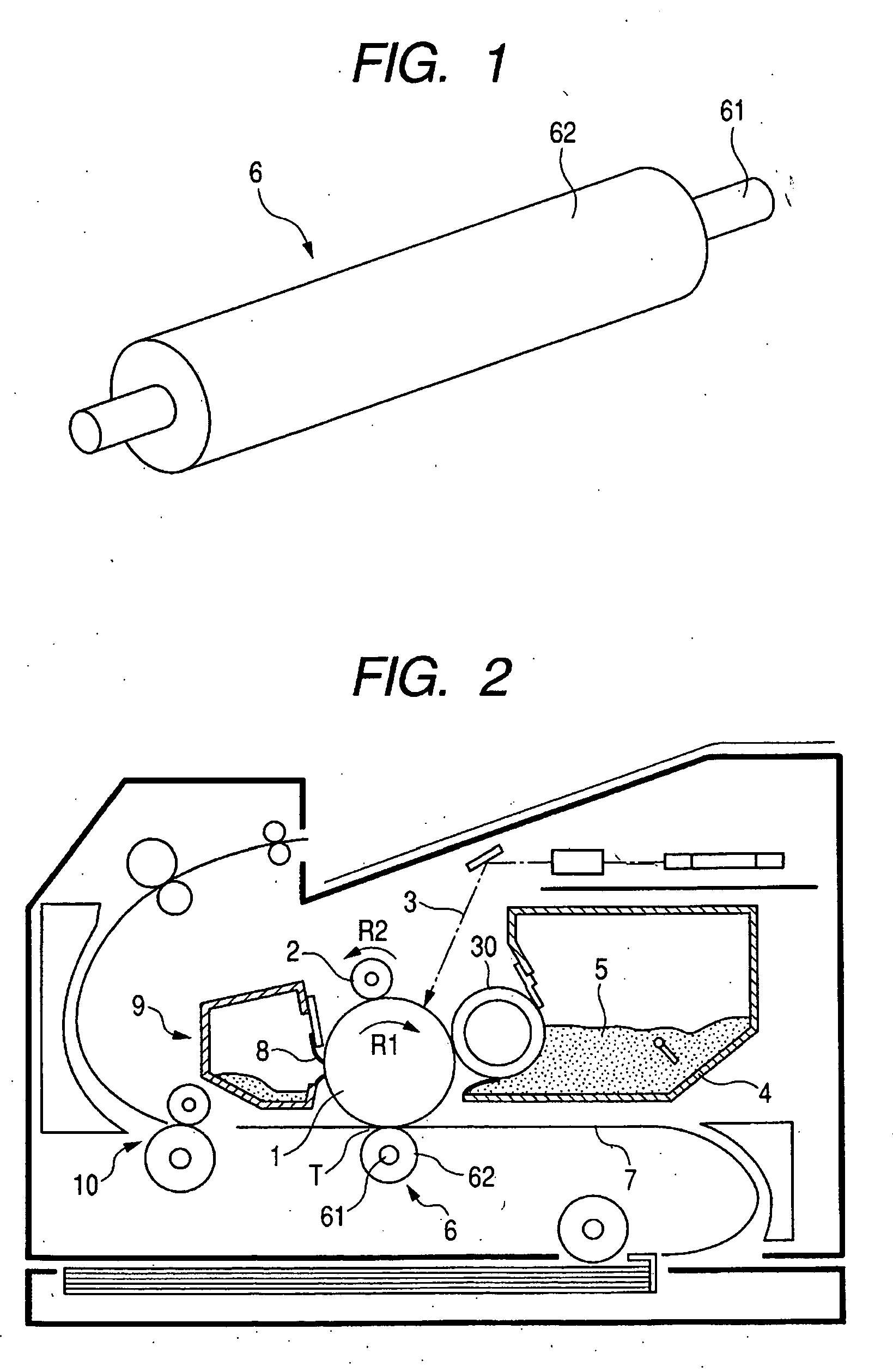

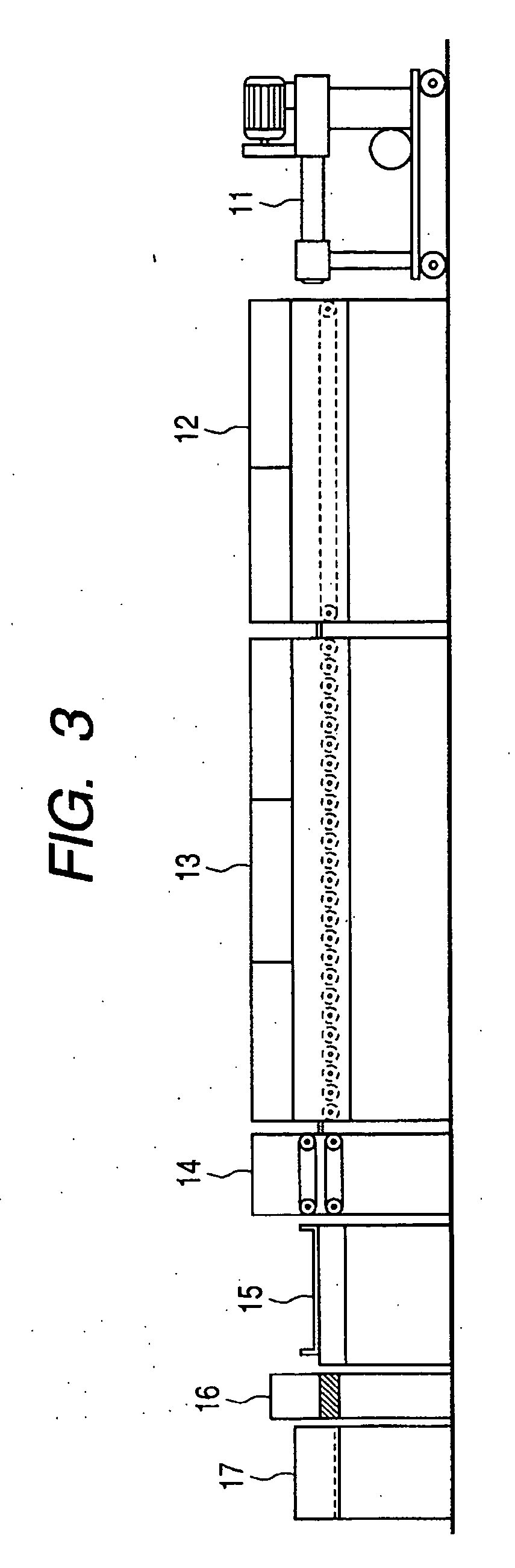

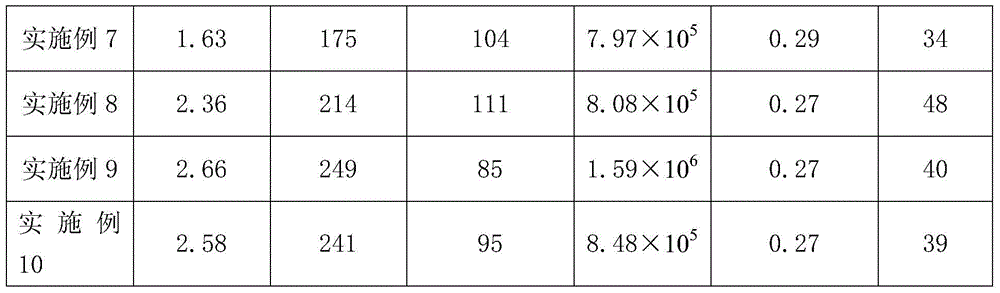

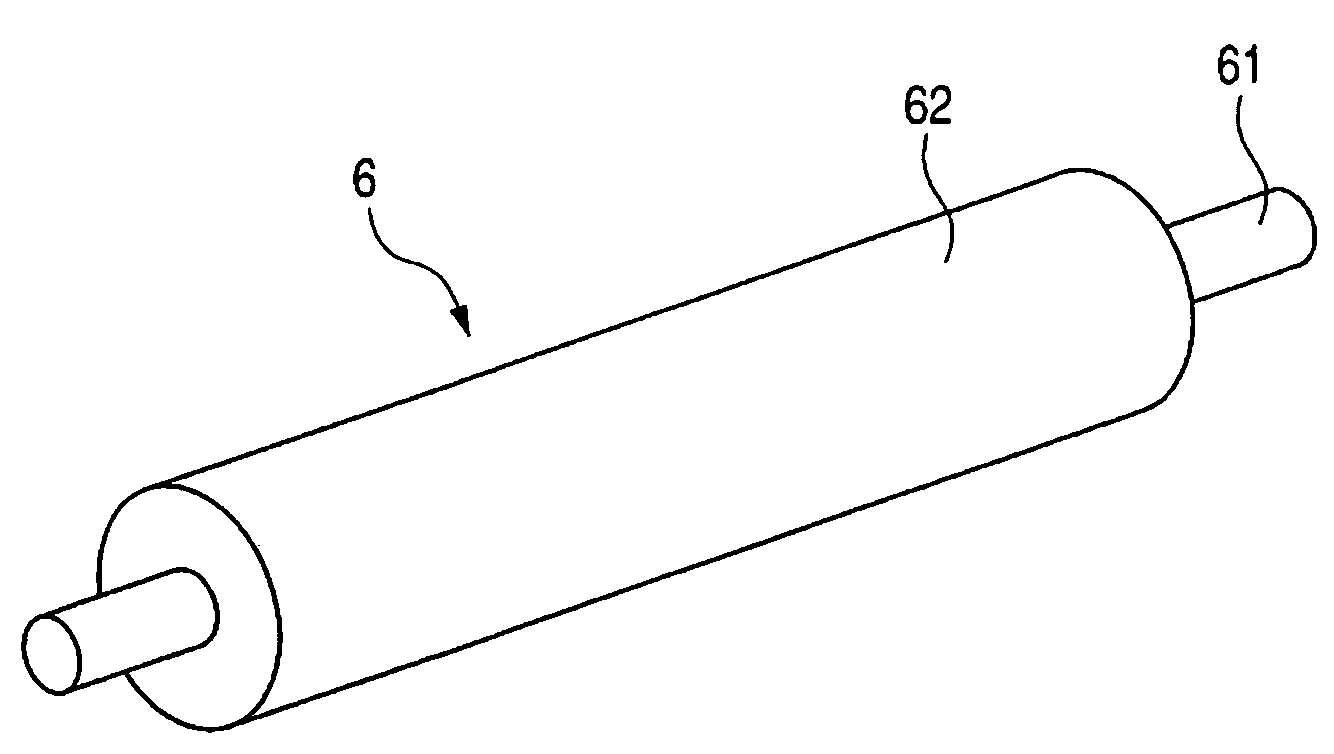

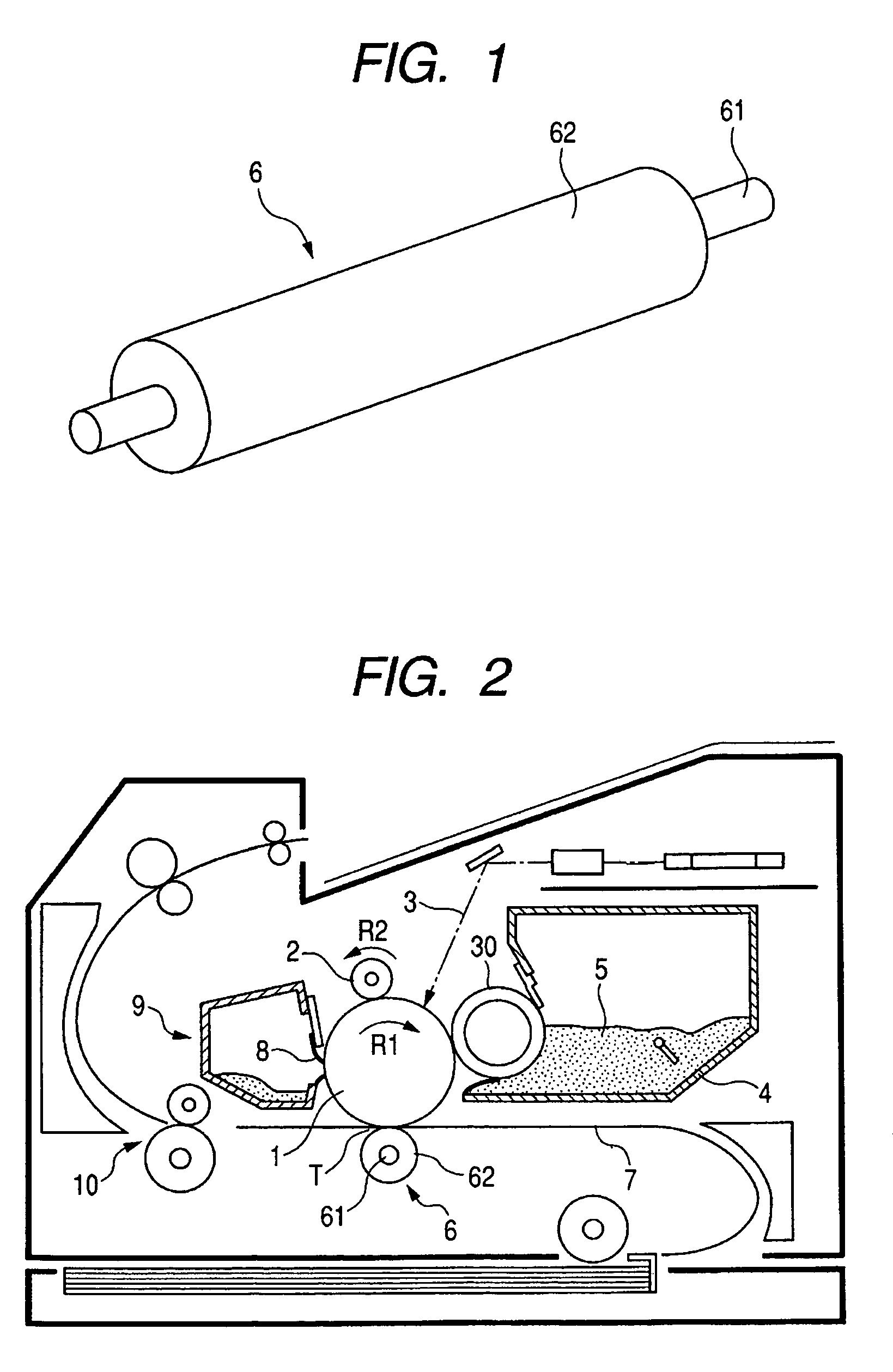

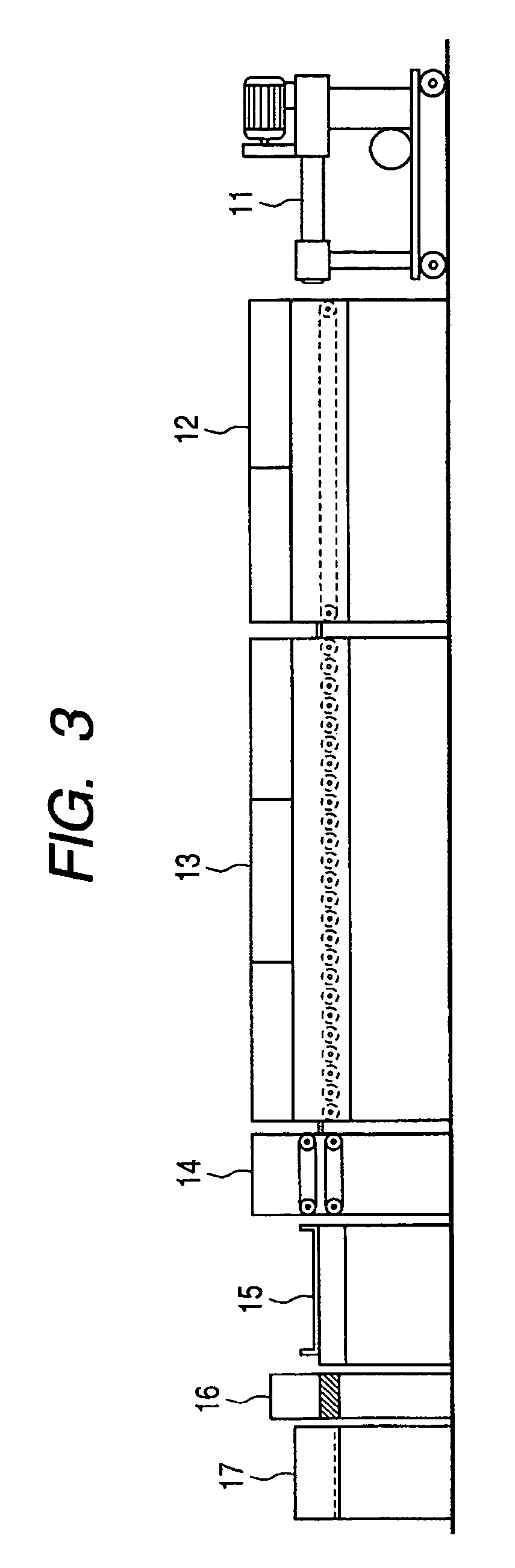

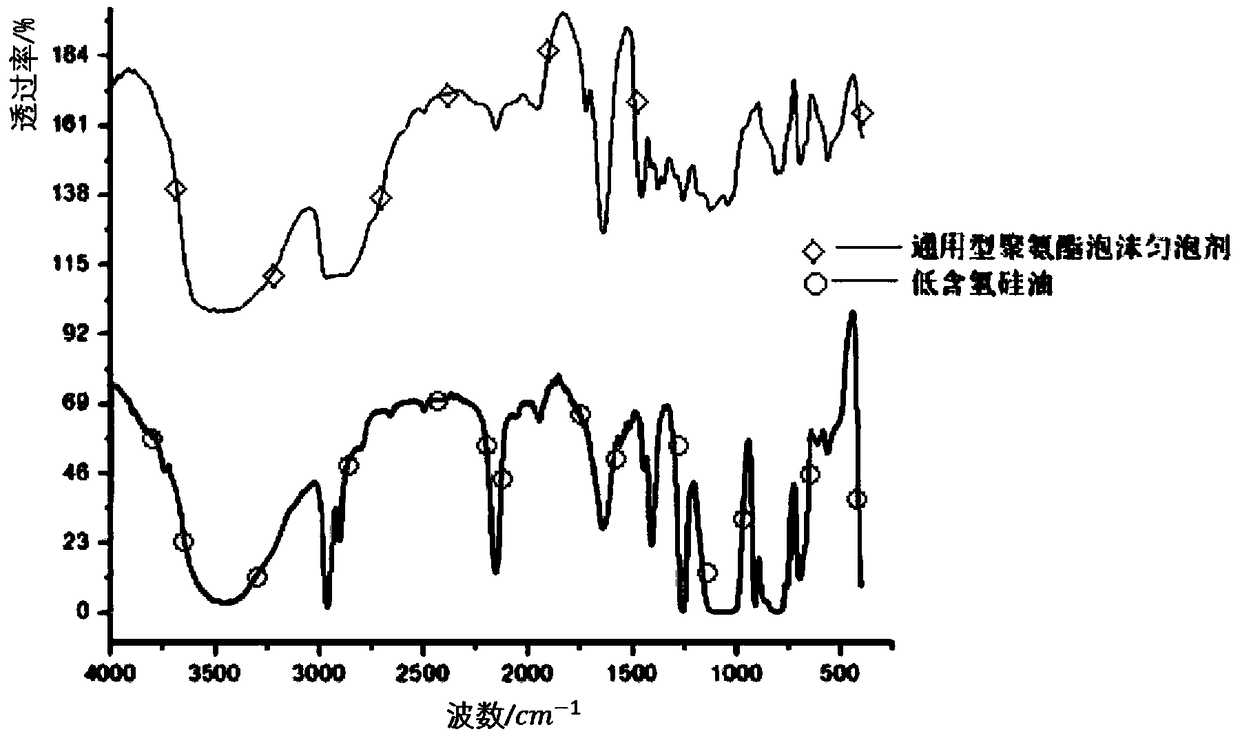

Process for producing conductive rubber roller, and roller for electrophotographic apparatus

InactiveUS20060280928A1Uniform hardnessUniform resistivityShaft and bearingsHollow filament manufactureElectrical resistance and conductanceAdhesive

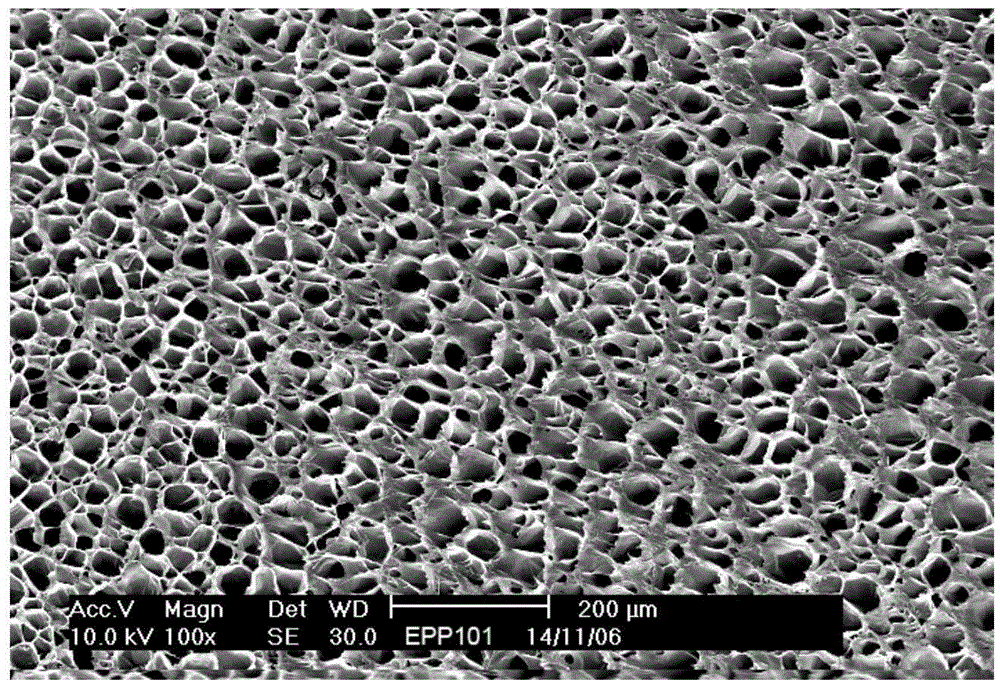

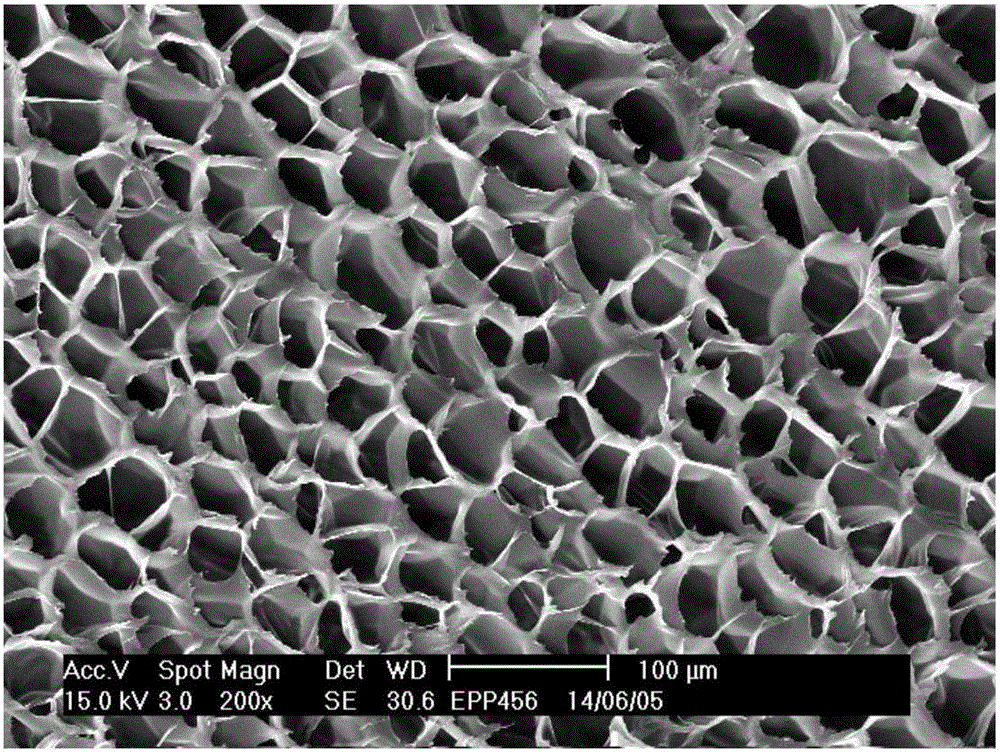

This invention provides a process for producing a conductive rubber roller having small aspect ratios of inner and outer diameters, having a stable measure of its inner diameter, having uniform cell distribution and being free from non-uniformity of hardness and electrical resistance in the peripheral direction. The process has a step of continuously extruding a tube composed of a specific unvulcanized rubber composition from a rubber extruder in a microwave vulcanizing unit, and a step of foaming and vulcanizing the tube by using a microwave irradiator having a microwave irradiation zone 4 m or less in length while being transported at given speed. The foamed rubber tube has an inner diameter 20 to 35% smaller than the outer diameter of the conductive core material over the whole region in the lengthwise direction, and the conductive core material is press-fitted into the foamed rubber tube without using any adhesive.

Owner:CANON KK

Heat-insulating fireproof material based on phenolic aldehyde hollow microspheres and preparation method thereof

Provided are a heat-insulating fireproof material based on phenolic aldehyde hollow microspheres and a preparation method thereof. The heat-insulating fireproof material comprises, by weight ratio, 45-60 wt% of liquid thermosetting phenol resin, 5-20 wt% of phenolic aldehyde hollow microspheres, 5-20 wt% of light filling and 5-15 wt% of flame retardant. The sum of mass percents of all the ingredients is 100 wt%, wherein the phenolic aldehyde hollow microspheres are spherical blind hole phenolic aldehyde hollow microspheres with a diameter of 0.1-500 um and a stacking density of 50-200 kg / m<3>. The invention further comprises the method for preparing the heat-insulating fireproof material based on the phenolic aldehyde hollow microspheres. The product has the advantages that the material is large in foam intensity, good in toughness and low in electrical conductivity, foam holes are uniform, the residual acidity is small and even neutral, and the material is green, environmentally friendly and high in fireproof grade. The preparation forming process is simple.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Radiated crosslinking PVC (Polyvinyl Chloride) rigid foaming material

The invention discloses a PVC (Polyvinyl Chloride) rigid foaming material and a preparation method thereof. The PVC rigid foaming material has a crosslinking structure formed by the PVC self and does not have the crosslinking structure formed by network systems of other high polymers. The PVC rigid foaming material is formed by heating and foaming a blending modified PVC resin and various auxiliary agents after electron irradiation. Because the PVC forms the crosslinking structure per se by an irradiation method, the network structure of other polymer systems is not needed to be introduced, thereby reducing material costs, simplifying production process and improving production efficiency.

Owner:FSPG HI TECH

Polybutylene foam material and preparing method thereof

The invention provides a polybutylene foam material and a preparing method thereof. According to the foam material, by means of a chemical foaming method, an extruder is used for carrying out extruding foaming, an injection molding machine is used for carrying out injection molding foaming, and a double-roller mixing mill is used for carrying out mould pressing foaming after blending. The situation that melt indexes and melt strength corresponding to polybutylene of different and identical contents are different is taken into consideration, and the influence on the foaming behavior from polybutylene of the different and identical contents is explored. The influence on the cellular structure and mechanical properties of the foam material from different addition quantities of foaming agents is studied. The influence on the polybutylene cross-linking degree and the material melt strength from different addition quantities of cross-linking agents is studied, so that the foam material with cells distributed uniformly and good mechanical properties is obtained. In addition, different kinds of nucleating agents and the addition quantity of the different nucleating agents are considered according to the classic nucleating theory, and a balance point is found between the cellular structure and the mechanical properties of the foam material. The foam material can be applied to automotive upholstery parts, food packages, biological medicine materials and pipe heat insulation and heat preservation cannulas.

Owner:BEIJING UNIV OF CHEM TECH

Process for producing conductive rubber roller, and roller for electrophotographic apparatus

InactiveUS7520057B2Uniform cell distributionUniform cellsHollow filament manufactureShaft and bearingsElectrical resistance and conductanceAdhesive

Owner:CANON KK

Method for forming thermoplastic polyester elastomer closed pore micro-foaming product

The invention discloses a method for forming a thermoplastic polyester elastomer closed pore micro-foaming product, which comprises the following steps of: filling a thermoplastic polyester elastomer into a forming die with capillary through holes, putting the forming die into a high-pressure container, injecting a gas into the high-pressure container to displace air in the high-pressure container, adjusting the temperature of the high-pressure container to between 160 and 220 DEG C and adjusting the pressure to between 8 and 30MPa, keeping the high-pressure container for 10 to 50 minutes at a constant temperature under a constant pressure, then reducing the pressure of the high-pressure container to the atmospheric pressure at the speed of 200 to 700MPa / s, taking the forming die out, and cooling and removing the forming die to obtain the thermoplastic polyester elastomer closed pore micro-foaming product, wherein the gas is nitrogen or carbon dioxide. The method has simple process, is convenient to operate and control, and can obtain the micro-foaming polyester elastomer product with smaller foam pore size, higher foam pore density, more uniform foam pore structure and more excellent damping impact resistance.

Owner:中广核俊尔(上海)新材料有限公司 +1

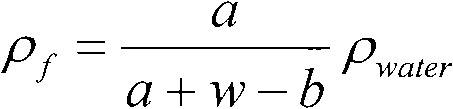

Universal polyurethane foam stabilizer and preparation method thereof

The invention discloses a universal polyurethane foam stabilizer and a preparation method thereof. According to the present invention, the hydrosilylation reaction of low-hydrogen-content silicone oiland allyl polyether is performed with a solvent-free method, such that the obtained product does not require solvent remove, and does not contain inorganic acids, the process is simple and environmentally friendly, and the cost is saved; the special molecular weights and the ratio of low-hydrogen-content silicone oil and allyl polyether are designed, and the conversion rate of the C=C reaction between Si-H and allyl polyether is controlled, such that the universal polyurethane foam stabilizer can simultaneously meet the foaming requirements of hard foam polyurethane foam and soft foam polyurethane foam, and has good actual foaming effect, the obtained polyurethane soft foam and the obtained polyurethane hard foam have characteristics of uniform pore size and uniform foam distribution, each surface of the obtained soft foam and the obtained hard foam approximately comprises five edges, and the pore size of the foam body is 100-1000 [mu]m; and the universal polyurethane foam stabilizeris a polymer having a structural fragment represented by a formula (1) defined in the specification.

Owner:SHANGHAI RESIN FACTORY

EVA foam material taking four components as base material and preparation method of EVA foam material

The invention provides an EVA foam material taking four components as base materials and a preparation method of the EVA foam material. The foam material comprises the following substances in parts by mass: 70-90 parts of ethylene-vinyl acetate copolymer, 10-30 parts of rubber, 1-9 parts of starch, 1-9 parts of calcium carbonate, and 4.6-7.3 parts of an additive, wherein the additive comprises a foaming agent, a cross-linking agent and a combined foaming aid. The foam material has the characteristics of being excellent in mechanical property, uniform in foam hole distribution, capable of realizing natural degradation, and the like, can be widely applied to shoe materials, jigsaw puzzle for kids, foamed floors, precise electronic instruments, electrical equipment, packing materials of medical instruments, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

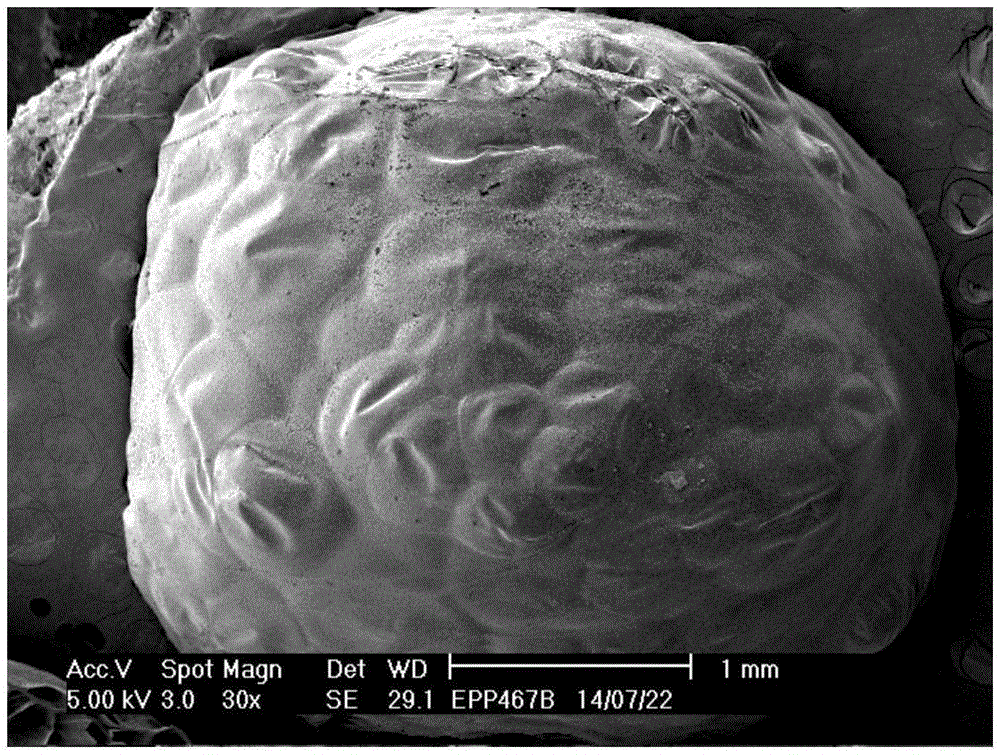

High-melt strength high-impact polypropylene foaming expanded beads and preparation method thereof

The invention provides polypropylene foaming expanded beads and a preparation method thereof. The foaming expanded beads take high-melt strength high-impact polypropylene as a basic resin, and are prepared by foamed impregnation; wherein, the high-melt strength high-impact polypropylene comprise a propylene homopolymer component and a propylene-ethene copolymer component, molecular weight distribution ratio of Mw to Mn is less than or equal to 10 and greater than or equal to 4; the ratio of Mz+1 to Mw is greater than 10 and less than 20; the content of a room temperature xylene soluble substance is greater than 10 weight% and less than 30 weight%; and the ratio of Mw of a room-temperature trichloro-benzenes soluble substance to Mw of a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less or equal to 1 The polypropylene foaming expanded beads have the advantages of uniform size and distribution of foaming pore and aperture, high percentage of close area, good high / low temperature high-impact performance, and high melt-strength; and can be widely used for the fields of automobile part, food, electronic package and building decoration; the preparation method is simple, operation is easy, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

EVA large hole composite foam material and preparation method

The invention discloses an EVA large hole composite foam material and a preparation method thereof. The composite foam material is prepared by mixing, granulation and foaming of materials, and the materials include: 40-60 mass parts of an ethylene-vinyl acetate copolymer, 10-20 mass parts of graphene modified isotactic polybutene, 10-15 mass parts of a polyolefin thermoplastic elastomer, 10-20 mass parts of a polyester elastomer, 0.4-0.8 mass part of an active agent, 0.7-1.5 mass parts of a cross-linking agent, 2.5-3.5 mass parts of a foaming agent and 0.1-0.3 mass part of an assistant. The mass content of vinyl acetate in the ethylene-vinyl acetate copolymer is 26%-40%. The preparation method of the EVA large hole composite foam material includes: weighing a certain amount of isotactic polybutene-1 for melting, adding 0.05%-0.2% by mass of graphene when the melting temperature of the isotactic polybutene-1 is 140-170DEG C, and mixing the two substances to obtain graphene modified isotactic polybutene. The large holes in the EVA large hole composite foam material has good foaming effect, the compression resistance and resilience are enhanced, and also the softness and wear resistance are also improved. The preparation method is simple and easy to operate.

Owner:ANTA CHINA

Palm wax-silicon resin compound high-resilience polyurethane foaming product release agent

The invention relates to a release agent and discloses a palm wax-silicon resin compound high-resilience polyurethane foaming product release agent. The release agent is prepared from palm wax and silicon resin through compounding. In the invention, the palm wax is first introduced into the high resilience polyurethane release agent, and the compound polyurethane release agent has the release effect reaching to level 1 on the high resilience polyurethane product in a mold of casting aluminum, has release frequency of 12 or more, can effectively improve the traditional high resilience polyurethane release agent-caused cell uneven phenomenon and reduce the defect rate, is prepared through simple processes easy to control, and meets release agent use requirements of the complex high-resilience polyurethane products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Preparation method of carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure

The invention relates to a preparation method of a carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure. The preparation method is implemented through the following steps of preparing composite powder uniformly loaded with carbon nano-tubes on the surface of aluminum powder; conducting mechanical ball milling; evenly mixing the ball-milled composite powder with urea and then conducting cold press molding; conducting water bathing on a cold pressed sample under 60-80 DEG C for 6-8 h to remove urea and then putting the sample in a drying oven to be dried after water bathing; putting the dried sample in a tube furnace to be heated to 650 DEG C under argon shielding of 200-300 ml / min at the rate of 5 DEG C / min, conducting sintering for 2-4 h, and then conducting furnace cooling to the indoor temperature after completion of sintering to obtain the carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure.

Owner:TIANJIN UNIV

3D printing foaming shoe material and preparation method thereof

The invention provides a 3D printing foaming shoe material and a preparation method thereof, and belongs to the technical field of 3D printing materials. The foaming shoe material is prepared from thefollowing raw materials in parts by weight: 80-100 parts of ethylene-vinyl acetate copolymer, 30-40 parts of ethylene-propylene-diene monomer rubber, 40-50 parts of glass fibres, 5-8 parts of a wear-resistant agent, 6-10 parts of a foaming agent, 4-6 parts of gamma-chloropropyl triethoxysilane, 15-20 parts of a flame retardant, 3-5 parts of a flame retardant synergist, 3-5 parts of a lubricatingagent, 3-5 parts of a foaming auxiliary agent and 1-2 parts of an antioxidant; the flame retardant is a layered double hydroxide; the flame retardant synergist is prepared from graphene and isopropyltris(dioctyl pyrophosphate) titanate which are in the weight ratio of (3-4):1. The 3D printing foaming shoe material prepared with the preparation method has relatively high wear resistance, flame resistance, good elasticity and moderate hardness.

Owner:广西景康商贸有限公司

High-melt-strength impact-resistant polypropylene foamed beads and preparation method thereof

The invention provides high-melt-strength impact-resistant polypropylene foamed beads and a preparation method thereof. The foamed beads are prepared by dipping and foaming high-melting-strength impact-resistant polypropylene serving as base resin; the high-melting-strength impact-resistant polypropylene comprises an atactic copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber dispersion phase; the room-temperature xylene dissolved substance content is more than or equal to 10 percent by weight and less than or equal to 35 percent by weight; the ratio of the Mw of room-temperature trichlorobenzene dissolved substance to the Mw of room-temperature trichlorobenzene undissolved substance is more than 0.4 and less than or equal to 1. The polypropylene foamed beads provided by the invention has the advantages of foam pore and pore diameter distribution uniformity, high closed pore rate, good high-temperature and low-temperature impact resistance, high melt strength and the like, and can be widely applied in the fields of automobile parts, food, electronic package, building decoration and the like; the preparation method is simple, easy to operate and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Material for manufacturing modified phenolic fireproof insulating plate

The invention relates to the technical field of building materials, in particular to a material for manufacturing a modified phenolic fireproof insulating plate. The material comprises the following components in part by weight: 100 parts of expandable phenolic resin, 6 to 8 parts of composite surfactant, 5 to 7 parts of foaming agent and 8 to 10 parts of curing agent. Due to the adoption of the technical scheme, the material has the advantages of large foam expansion rate, small apparent density, uniform cell distribution, high closed porosity, low hygroscopicity, large compressive strength, good foaming effect, most excellent comprehensive performance of foam, and capability of being applied to outer wall construction (an insulation system) of buildings.

Owner:上海雅达特种涂料有限公司 +1

Microfoamed polypropylene and plant-fiber composite material and preparation method thereof

The invention discloses a microfoamed polypropylene and plant-fiber composite material and a preparation method thereof. The microfoamed polypropylene and plant-fiber composite material and the preparation method disclosed by the invention have the beneficial effects that by adoption of high-strength and high-fluidity PP for complexing, the melt strength and the fluidity of a base material are effectively ensured, not only can the technical defects of the existing PP foaming be overcome, but also the benefit for forming and processing of products can be achieved meanwhile; a foaming product with uniform foam-hole distribution, high foaming ratio and excellent property can be prepared by adopting NaHCO3 is adopted as a foaming agent and under the condition of adopting an injection process for processing; meanwhile, plant fiber has the advantages of rich source, low cost, easiness in processing and dyeing, complete waste degradation and the like; in addition, the plant fiber has unique wheat fragrance, and by matching with mold patterns, a unique surface sensing effect and and good apparent quality can be obtained, so that the microfoamed polypropylene and plant-fiber composite material has good development prospect in the fields of automobile interior and exterior decorations, packs, foaming tableware and the like.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Foamable composition for electric cable

InactiveCN104672690AStable production processUniform cell distributionPlastic/resin/waxes insulatorsInsulated cablesFoaming agentPlasticizer

The invention discloses a foamable composition for an electric cable. The foamable composition comprises the following components in parts by weight: polyvinyl chloride, a foaming agent, a stabilizer, a plasticizer, filler, an antioxidant and a lubricating agent, wherein the components are mixed by a high-speed mixer, discharged and then extruded by a screw extruder to obtain the foamable composition. The electric cable prepared from the foamable composition is uniform in foam hole distribution by adopting a foamed polymer material, satisfies the required specifications of the electric cable in electric performance and mechanical properties and can save more than 10% of used materials in comparison with an unfoamed material, so the cost is effectively lowered and social resources are saved.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Degradable starch-fiber composite foam material and preparation method thereof

A degradable starch fiber composite foam material and a preparation method thereof are disclosed. According to the material, fibers and starch are mixed. Compared with traditional petroleum-based rawmaterials, the used raw materials are environmentally friendly, degradable, safe and non-toxic; compared with extrusion and mould pressing process methods, the method adopts a freezing replacement method, has low requirements on operation equipment, and is simple and safe to operate. A gradient ethanol replacement method is used in a drying mode, after starch paste is frozen, water in a system isreplaced with a volatile solvent with low surface tension, so that surface structure change caused by sudden loss of material moisture can be avoided, and foam holes are protected against collapse. The prepared starch-fiber composite foam material is uniform in foam hole distribution, high in porosity, good in rebound resilience, high in mechanical property and low in density.

Owner:SHAANXI UNIV OF SCI & TECH

Wet hard fine polishing wheel polishing material and preparation method thereof

InactiveCN106977685AAvoid large differences in cell distributionAvoid the problem of brittle properties of polishing materialsPolishing compositions with abrasivesFoaming agentPolyol

The invention relates to a wet hard fine polishing wheel polishing material, which is prepared from the following ingredients in parts by weight: 90 to 100 parts of polyether polyol, 40 to 60 parts of polyisocyanates, 30 to 40 parts of abrasive materials, 6 to 10 parts of coupling agents, 8 to 10 parts of chain expanding agents, 3 to 6 parts of foaming agents, 0.1 to 0.5 part of catalysts and 1 to 2 part of water. Through a two-step method, polyurethane prepolymers and modified grinding materials are firstly prepared respectively and are then mixed to perform a foaming reaction; the problems of great foam hole distribution differences and polishing material property brittlement due to serious heat release of the one-step integrated reaction are solved. The prepared wet hard fine polishing wheel polishing material has the advantages that the foam hole distribution is uniform; the texture is soft and elastic; the fine gap grinding of objects can be realized; the contact area between the grinding materials and a workpiece can be increased; the grinding efficiency is improved; meanwhile, good heat radiation performance is realized.

Owner:台山市远鹏研磨科技有限公司

Polyformaldehyde foam composition, preparation method thereof, and structural foam material containing polyformaldehyde foam composition

The invention relates to a polyformaldehyde foam composition, a preparation method thereof, a structural foam material containing the polyformaldehyde foam composition, and a use of the polyformaldehyde foam composition and the structural foam material. The polyformaldehyde foam composition mainly includes polyformaldehyde, a foamable polymer and a foaming agent. The polyformaldehyde foam composition has the advantages of uniform distribution of cells, light weight, excellent comprehensive mechanical performances and high thermal deformation temperature.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

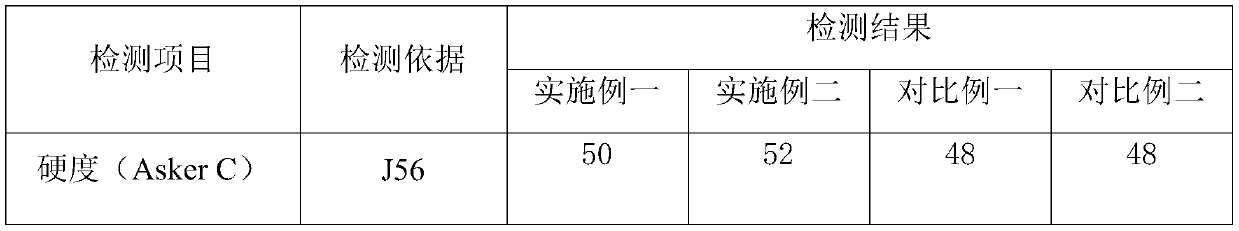

PU formula and PU technology for uniform foaming

The invention discloses a PU formula and a PU technology for uniform foaming. The PU formula, that is a polyurethane formula, comprises a component A and a component B, wherein the component A comprises, by weight, 60-80 parts of polyester polyol, 10-30 parts of polyether polyol, 10-20 parts of water, 0.2-0.5 part of a catalyst, 0.1-0.2 part of a foam stabilizer, 4-8 parts of a foaming agent, 14-18 parts of a chain extender, 3-6 parts of a fire retardant and 2-3 parts of an antioxidant, and the component B comprises 30-60 parts by weight of isocyanate. Polyurethane foam prepared in the invention has the characteristics of uniformity in foaming, uniform distribution of foam holes, stable size, and good resistance to high temperature, low temperature, wear and ageing.

Owner:江苏唯源橡塑制品有限公司

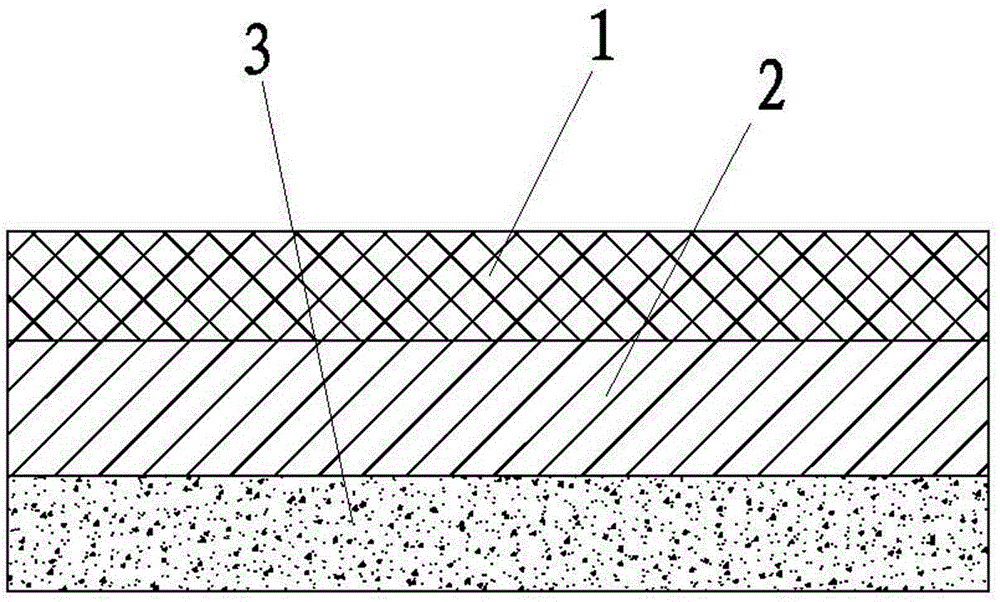

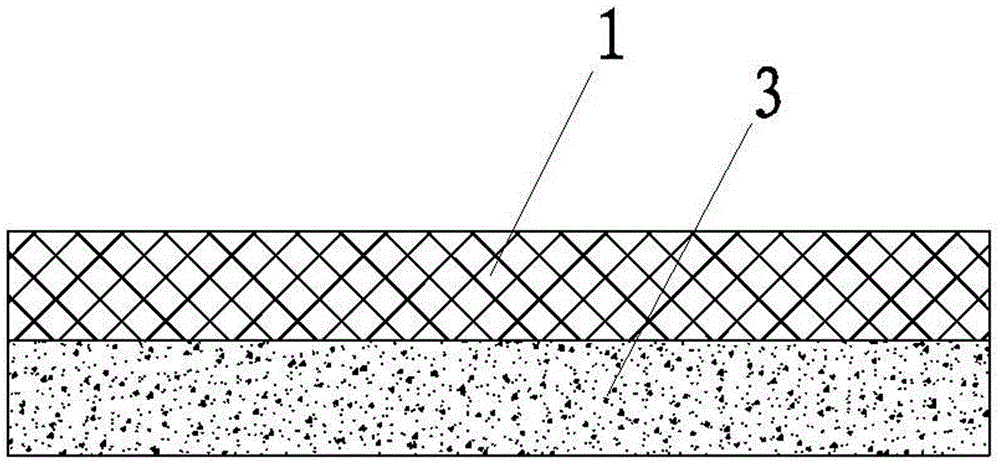

Polyvinyl chloride slurry and a coating, scraping and foaming process thereof

InactiveCN109722919AUniform foamingUniform cell distributionTextiles and paperMetallurgyPolyvinyl chloride

The invention discloses polyvinyl chloride slurry. The polyvinyl chloride slurry comprises primary coating slurry and secondary coating slurry, and the invention further provides a coating, scraping and foaming process of the polyvinyl chloride slurry. The coating, scraping and foaming slurry comprises the primary coating slurry and the secondary coating slurry, the screen cloth is coated with theprimary coating slurry, then the primary coating slurry is coated with the secondary coating slurry, and the obtained foaming product is uniform in foaming, uniform in foam hole distribution, environmentally friendly and good in quality.

Owner:广东远华新材料股份有限公司

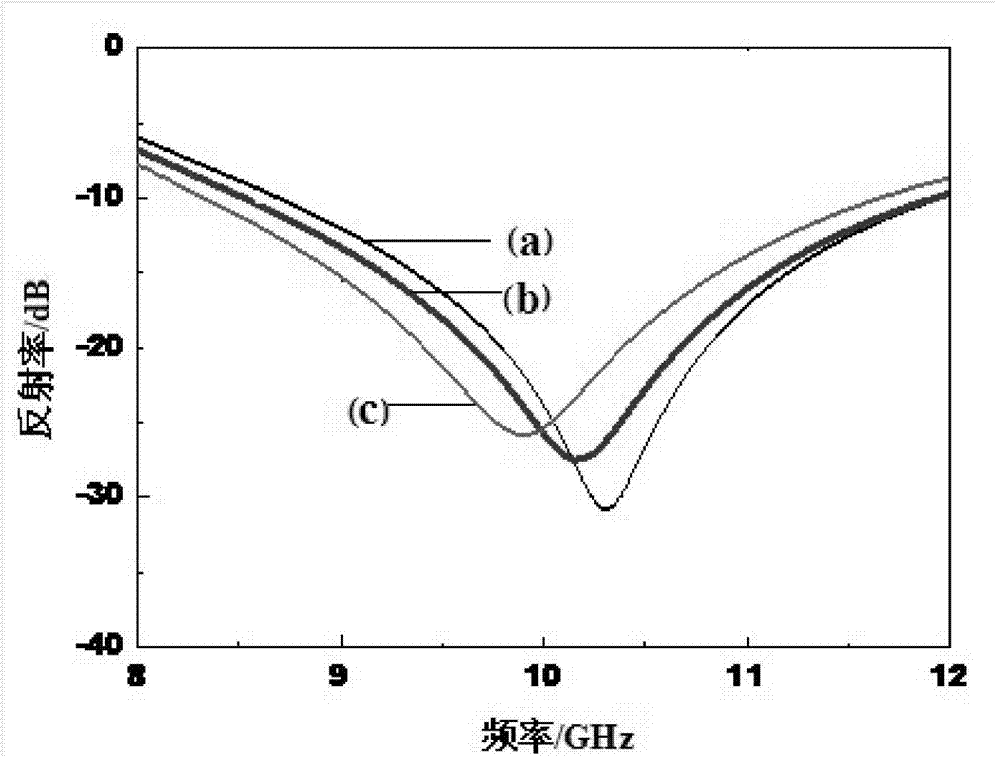

Microporous wave-absorbing material with low surface density and high tensile strength and preparation method

ActiveCN103589010AImprove absorbing performanceLow areal densityOther chemical processesResistPolymer science

The invention discloses a microporous wave-absorbing material with low surface density and high tensile strength and a preparation method and belongs to the technical field of wave-absorbing material. According to the invention, problems of high density, low mechanical properties and poor temperature resistance of a present microwave material are solved. The preparation method comprises steps of: uniformly stirring rubber, zinc oxide, eleaostearic acid, an anti-aging agent, a flow promoter, sulphur, a promoter, a foaming agent, a plasticiser and an absorbent, banburying, open-milling, vulcanizing at 150-160 DEG C and simultaneously foaming for 25-35min so as to obtain the microporous wave-absorbing material. The total thickness of the prepared microporous wave-absorbing material is between 1.4mm and 2.0mm, and its surface density is less than 1.7kg / m<2>. The material has good wave-absorbing performance at specific wavelengths. Meanwhile, the material has good temperature resistance and mechanical property. The temperature that the material resists can reach 150 DEG C. Average value of tensile strength is greater than 8.5MPa, and the minimum elongation at break is 360%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

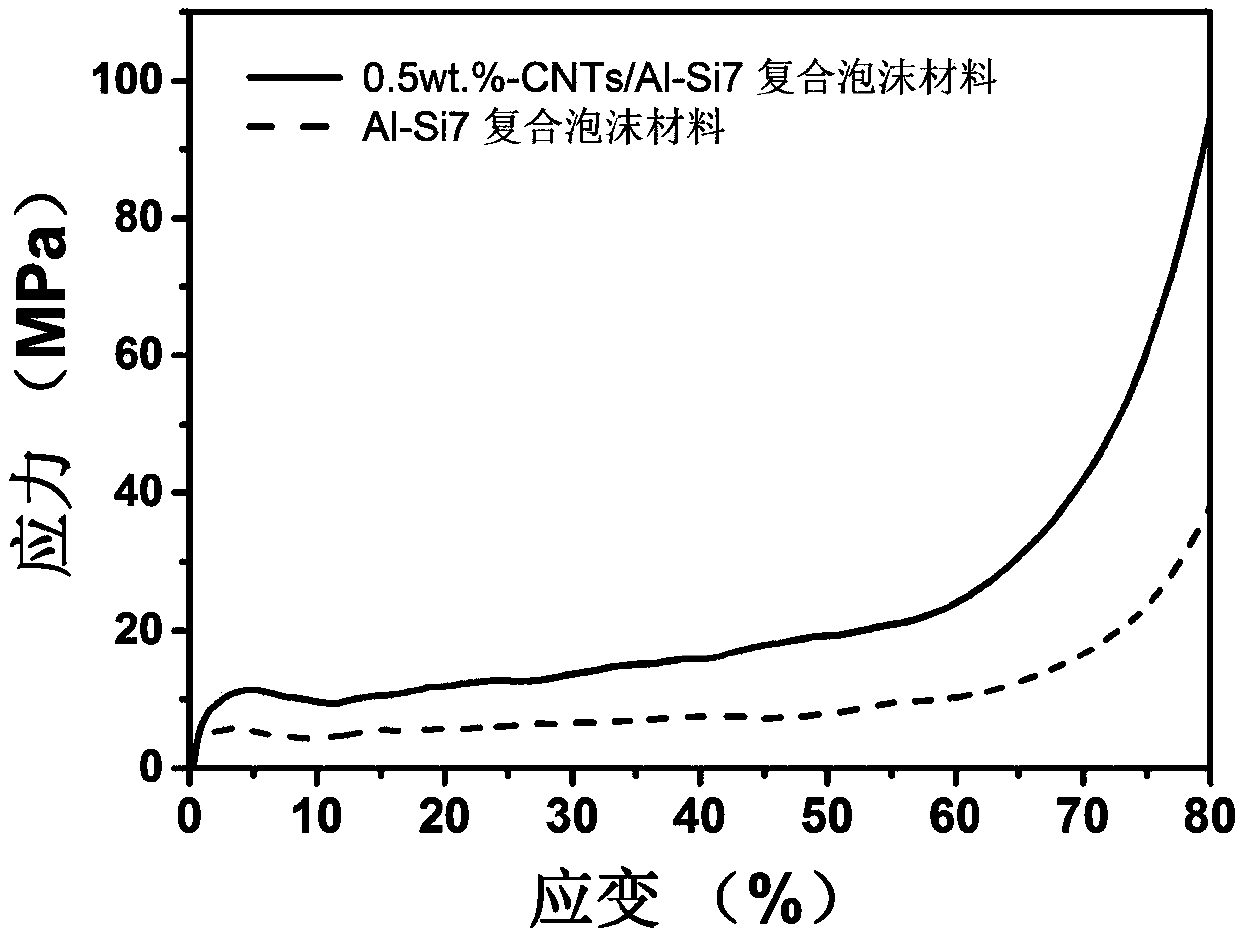

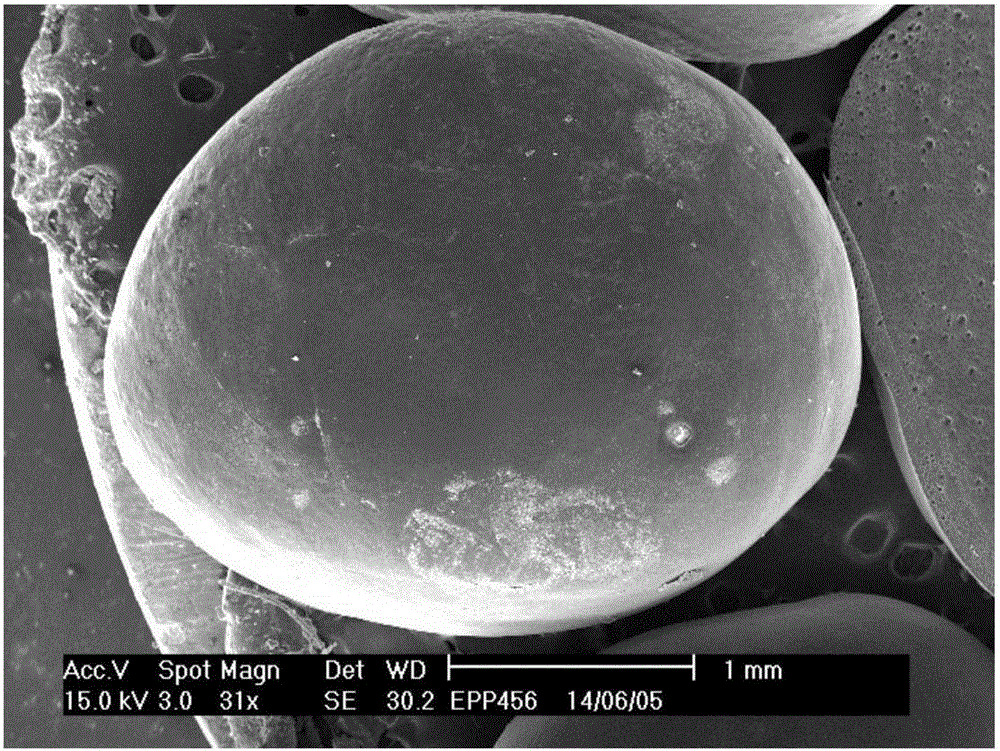

Closed pore CNTs/Al-Si composite foamed material and preparation method thereof

The invention relates to a closed pore CNTs / Al-Si composite foamed material. The closed pore CNTs / Al-Si composite foamed material comprises, by weight, 5%-25% of silicon powder, 0-5% of magnesium powder, 0.15%-1.5% of TiH2 powder and the balance CNTs / Al powder obtained through in-situ chemical vapor deposition. The preparation method includes the steps that the in-situ CNTs / Al powder is subjectedto mechanical ball milling; the CNTs / Al powder obtained through ball grinding is mixed with the silicon powder, the magnesium powder and a foaming agent in a stirring machine; the mixed powder is subjected to cold-press molding, so that a cylindrical precast block is obtained; and the precast block is put into a cylindrical steel mold of a resistance furnace for fast foaming, and accordingly the closed pore CNTs / Al-Si composite foamed material can be obtained. According to the closed pore CNTs / Al-Si composite foamed material, foam pores are evenly distributed, and the size dimensions are uniform; and full-closed holes are formed, the strain rate sensitive effect is low, and the compression stress-strain curve has an obvious platform region. The foamed aluminum material product prepared through the method is stable in quality and excellent in performance, the preparation process is simple and the technological process is fast.

Owner:CIVIL AVIATION UNIV OF CHINA

High-strength polylactic acid foamed plastic and preparation method thereof

PendingCN110483962AImprove mechanical propertiesNo pollution in the processSodium bicarbonatePolymer science

The invention relates to the technical field of foamed plastic, particularly to high-strength polylactic acid foamed plastic including, by mass, 38-46% of polylactic acid, 1.2-3% of a chain extender,6-8% of a plasticizer, 2-3% of azodicarbonamide, 1.6-2.2% of sodium bicarbonate, 0.1-3.2% of zinc oxide, 6-8% of talcum powder, 8-12% of nano aluminum dioxide, and 9-14% of atactic polypropylene, withthe balance being deionized water. The invention further discloses a preparation method of the high-strength polylactic acid foamed plastic. The preparation method comprises the following preparationsteps: S1, weighing and proportioning; S2, dehydrating the polylactic acid; S3, modifying and mixing; S4, extruding and granulating; S5, cooling and shaping. The plastic has the beneficial effects that the formula is more scientific and reasonable, the polylactic acid is filled with the nanometer aluminum dioxide, and the chemical bond effect between the nanometer aluminum dioxide and the polylactic acid is utilized, so that the plastic has good mechanical performance, can be completely biodegraded, does not pollute the environment, is higher in functionality and is beneficial to popularization.

Owner:HUBEI UNIV OF ARTS & SCI

High-melt strength high-impact polypropylene foaming expanded beads and preparation method thereof

The invention provides polypropylene foaming expanded beads and a preparation method thereof. The foaming expanded beads take high-melt strength high-impact polypropylene as a basic resin, and are prepared by foamed impregnation; wherein, the high-melt strength high-impact polypropylene comprise a propylene homopolymer component and an ethane-1-butylene copolymer, the ratio of Mw of a room-temperature trichloro-benzenes soluble substance of high-melt strength high-impact polypropylene to Mw of a room-temperature trichloro-benzenes insoluble substance is greater than 0.5 and less or equal to 1; and the content of a room temperature xylene soluble substance is greater than 10 weight% and less than 30 weight%. The polypropylene foaming expanded beads have the advantages of uniform size and distribution of foaming pore and aperture, high percentage of close area, good high / low temperature high-impact performance, and high melt-strength; and can be widely used for the fields of automobile part, food, electronic package and building decoration; the preparation method is simple, operation is easy, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

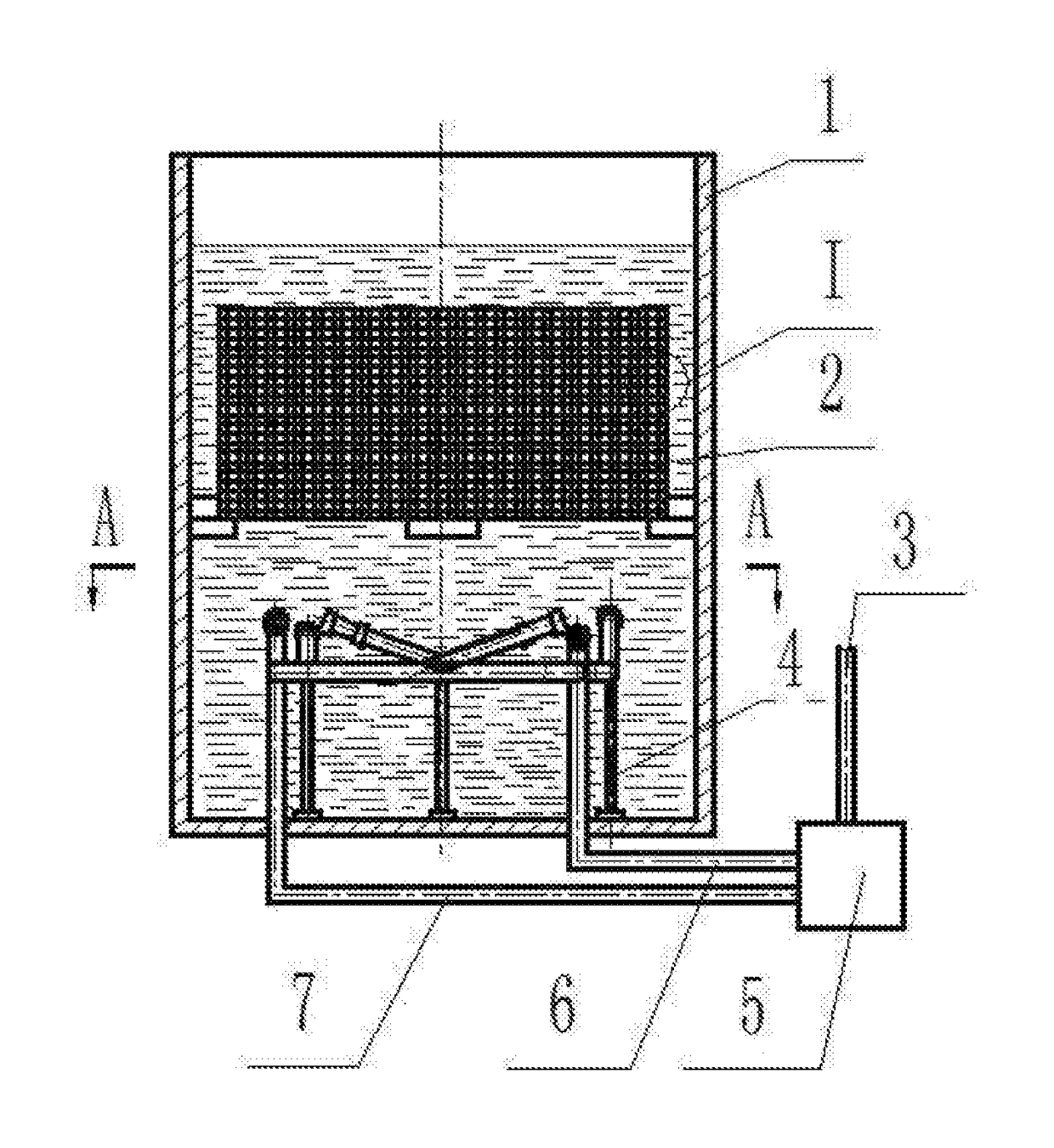

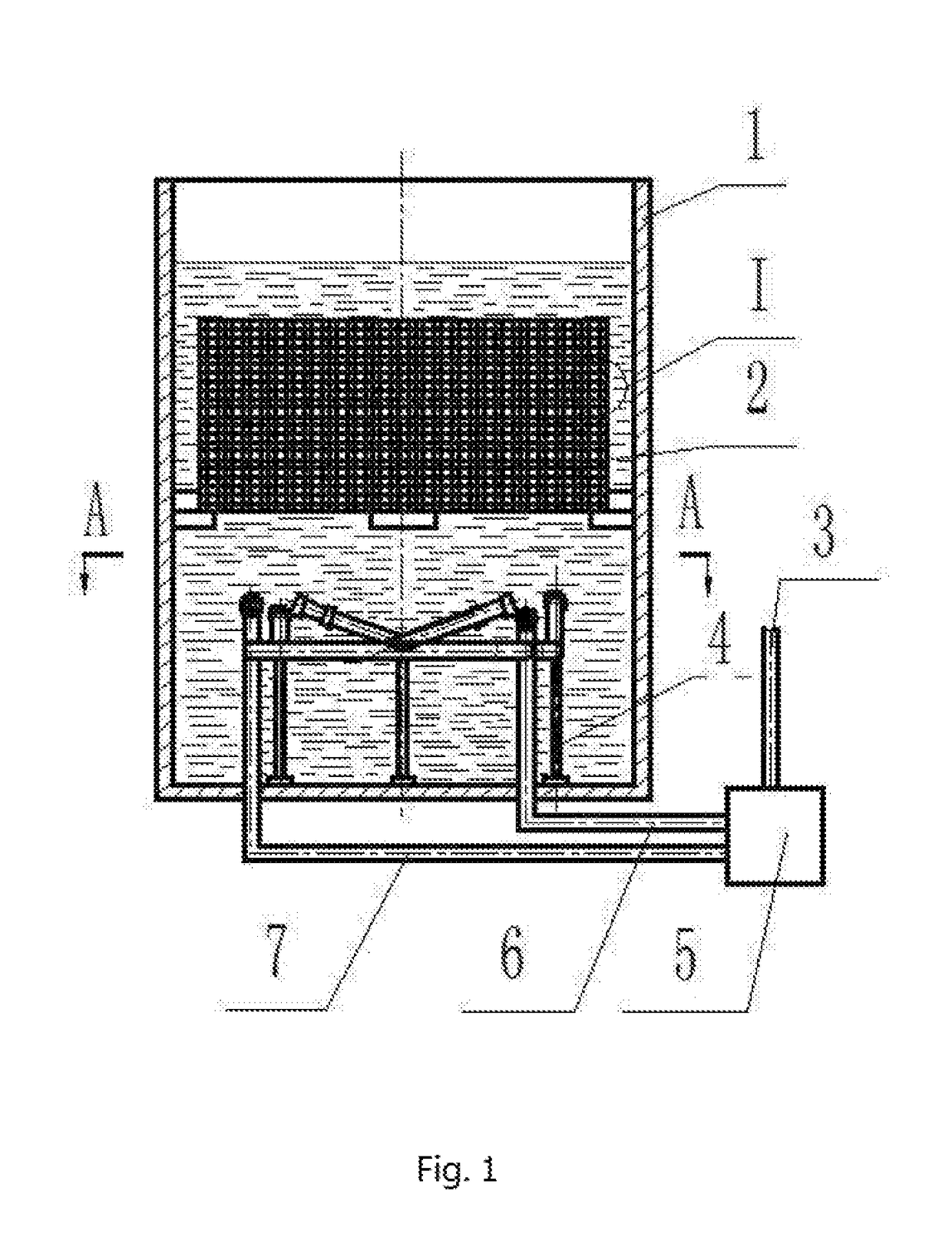

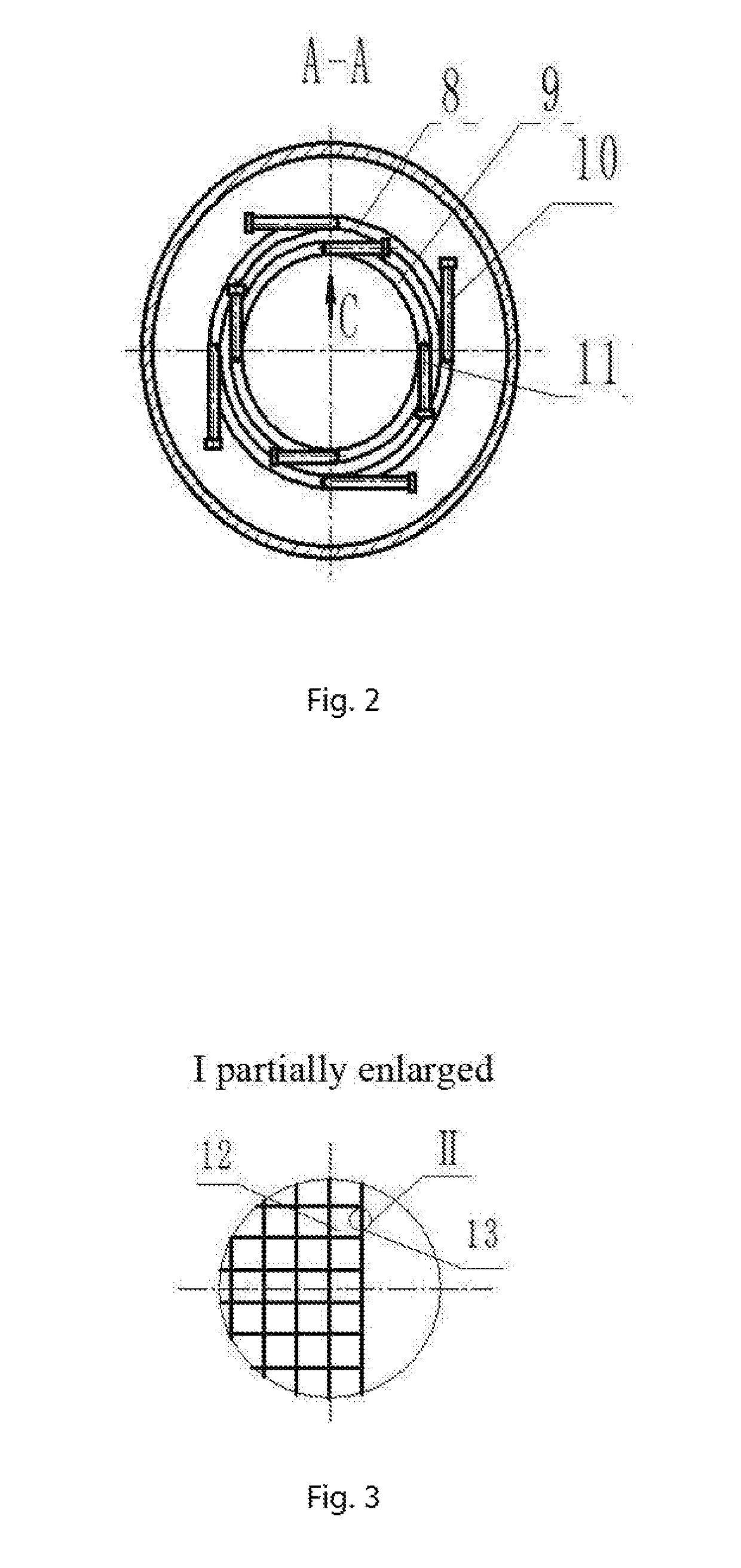

Culture device for tissue cell suspension

InactiveUS20180237733A1Promote tissue growthUniform cell distributionBioreactor/fermenter combinationsBiological substance pretreatmentsCavity wallBiomedical engineering

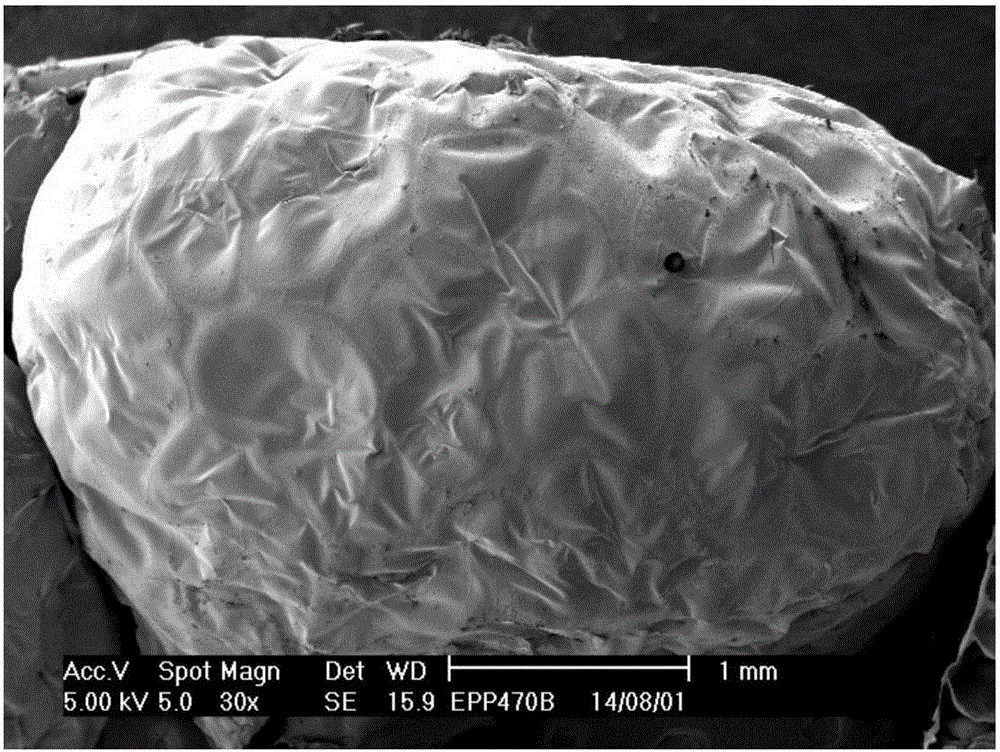

The present invention relates to a culture device for tissue cell suspension. The culture device includes a tissue cell culture body. The tissue cell culture body is a porous material. The porous material is formed by cavities classified into different levels according to the pore size of material and cavity walls surrounding to form the cavities. A lower level of small cavities is provided to surround the cavity wall which forms the upper level of large cavity. Cavities of each level are in communication with each other, and cavities between respective levels are also in communication with each other. The culture device further includes a swirler device provided therein. Such culture device can particularly facilitate normal and unrestricted growth of the suspension of cells in three-dimensional space, obstructing the formation of over-dense cell region or nutrient-rich region during the cell culturing.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of biodegradable poly butylene succinate (PBS) foam materials

The invention provides a preparation method of biodegradable poly butylene succinate (PBS) foam materials, which adopts a traditional chemical foaming method, improves and controls raw materials formula and technological conditions, and adds a cross-linking agent, a cross-linking auxiliary agent, a blowing promoter, a tackifier, an oxidation inhibitor, a foam stabilizer, a plasticizer and a release agent into raw materials except the PBS and the foaming agent so as to change fusant property of the PBS and adjust decomposition temperature of the foaming agent. The method comprises the following steps: firstly, evenly mixing various raw materials in a high-speed stirring machine; then carrying out plasticization in a mixing machine to obtain granules or sheets and carrying out chemical foam; and finally, obtaining PBS foaming materials. The PBS foaming materials have the advantages of controllable density, good mechanical proportionality, anti-chemical corrosion, easy processing, anti-vibration, heat insulation, biodegradation and the like, can replace polystyrene rigid foam, and are widely applied to the fields, such as various food packaging, medicines, medical apparatus and instruments or packaging manufacturing industry and the like.

Owner:SHANGHAI JIAOTONG UNIV

Photovoltaic thin film backboard

InactiveCN103337539AWarpage suppressionAvoid deformationSynthetic resin layered productsPhotovoltaic energy generationEngineeringDiffuse reflection

The invention relates to a component, particularly to a photovoltaic thin film backboard. The technical purpose of the invention is realized through the following technical scheme: the photovoltaic thin film backboard comprises a multi-microvesicle polymer film layer. The photovoltaic thin film backboard has high diffuse reflection performance to increase the use ratio of sunlight in unit area, to improve the integral photovoltaic conversion efficiency of a battery pack, particularly a crystal silicon battery pack; in addition, the photovoltaic thin film backboard is lower in cost and light in weight, and can effectively reduce the consumable items and weight ratio of photovoltaic backboards.

Owner:中国科学院宁波材料技术与工程研究所湖州新能源产业创新中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com