Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229results about How to "Low areal density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

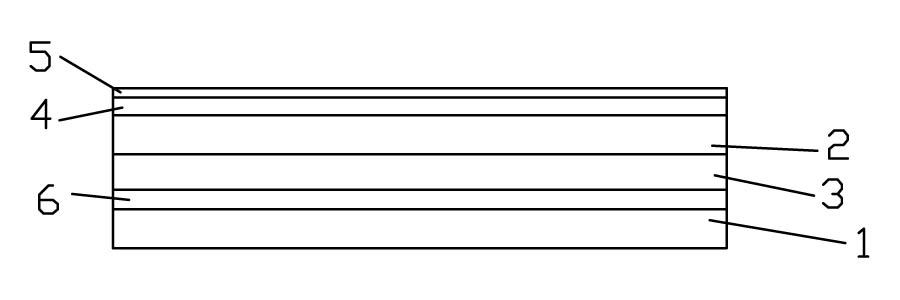

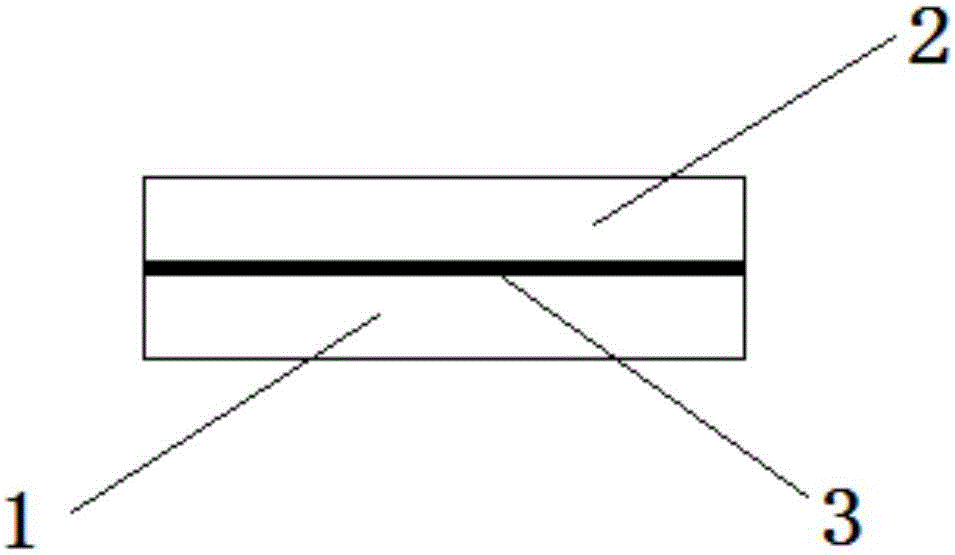

Anode or cathode pole piece of lithium ion battery and coating method thereof

InactiveCN101174685ALower surface energyLow densityElectrode manufacturing processesActive material electrodesCyclic processPole piece

The present invention relates to a lithium-ion battery anode or cathode pole piece and a spreading method of the anode pole piece or the cathode pole piece, wherein, the anode pole piece and the cathode pole piece consists of a foil, a conducting adhesive thin layer and an electrode active material layer in turn; the thickness of the conducting adhesive thin layer is five to ten microns. The electrode pole piece is made in the procedures that a layer of conducting adhesive thin layer in the thickness of five to ten microns are pre-coated on the surface of the foil before the sizing agent is spread, so that a conducting adhesive thin layer having good adhesive force, good conductivity and compact structure is formed on the surface of the foil. Then the electrode active material sizing agent is spread on the conducting adhesive thin layer, and is dried under an appropriate temperature to produce a required pole piece. The present invention can reduce the surface of the foil, and can improve the wetting quality of the sizing agent, thereby improving the adhesion performance of the anode material and the collecting body (aluminum foil) so as to reduce the powder-dropping of the battery during the cycling process, and to prolong the cycling service life of the battery; moreover, the present invention can reduce the content of the adhesive agent in the sizing agent, and improve the utilization rate of the active substance, and the method of the present invention does not produce negative influence on the performance of the battery.

Owner:CENT SOUTH UNIV

Anti-ballistic protective composite fabric

InactiveUS6127291ALoss of flexibilityReduce in quantitySynthetic resin layered productsPersonal protection gearMechanical engineeringProjectile

A composite woven fabric made up of at least two plies of individual woven fabrics bonded together by a layer of flexible bonding resin disposed on juxtaposed surfaces of the individual woven fabrics. The bonding agent covers at least about 75%, preferably 100%, of the juxtaposed individual fabric surfaces and does not exude through the interstices of the woven fabric. The thus constituted fabric material is very good for use in making an anti-ballistic composite fabric. An anti-ballistic composite fabric is made up of at least one of these bonded woven fabrics sub-composites, preferably in combination with conventional non-woven fabric layers. This composite product has an exceptionally low areal density but still can withstand the impact of a 44 magnum projectile. It also offers excellent protection against knife and ice pick threats. One attribute of this composite fabric is its ability to reduce the trauma conventionally caused by the impact of a ballistic projectile, even though the projectile is stopped from penetrating the fabric.

Owner:HPT INC +1

Continuous tow dispersing device

InactiveCN1811025AAvoid damageEvenly distributedFilament handlingFibre rougheningEngineeringMechanical engineering

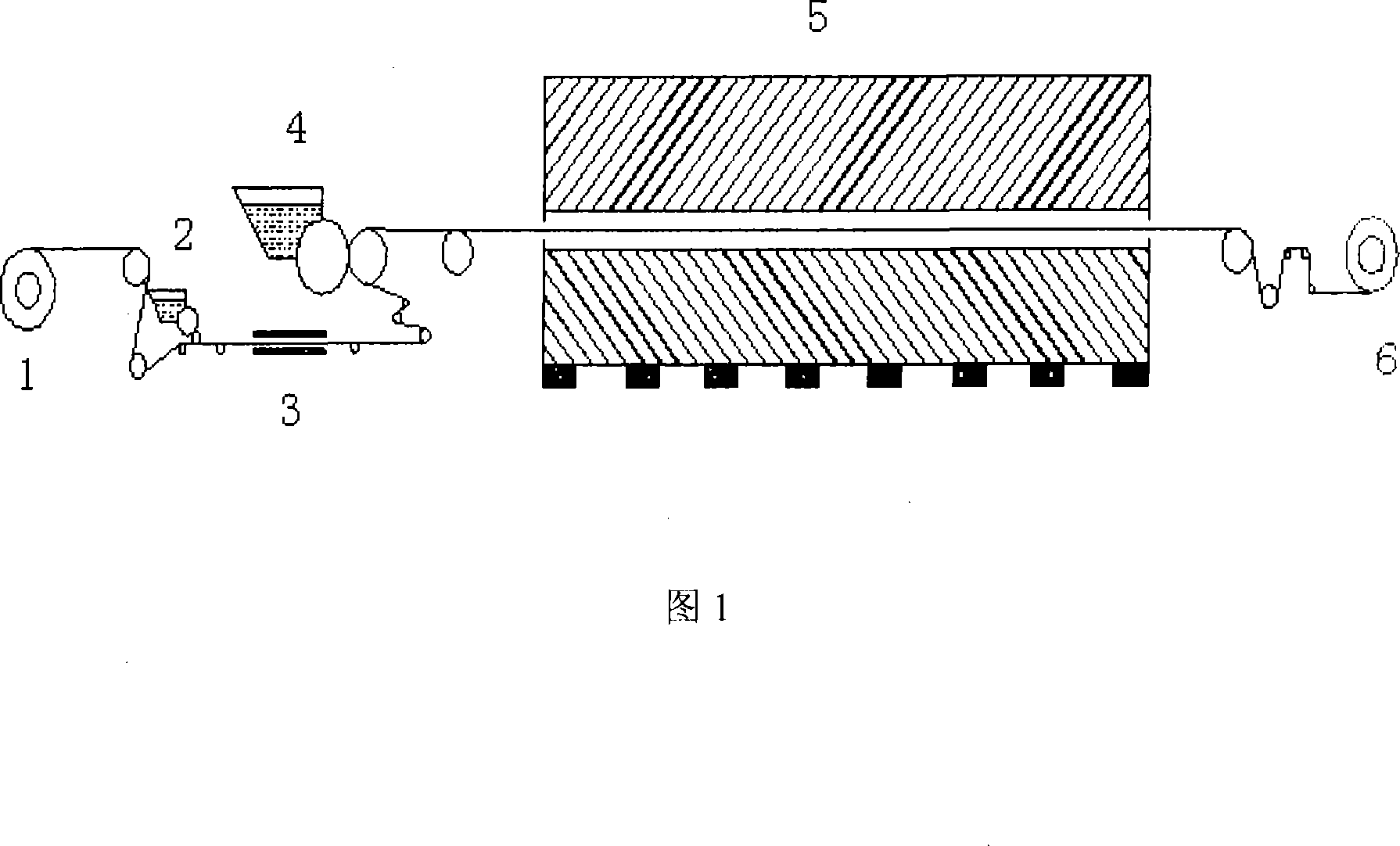

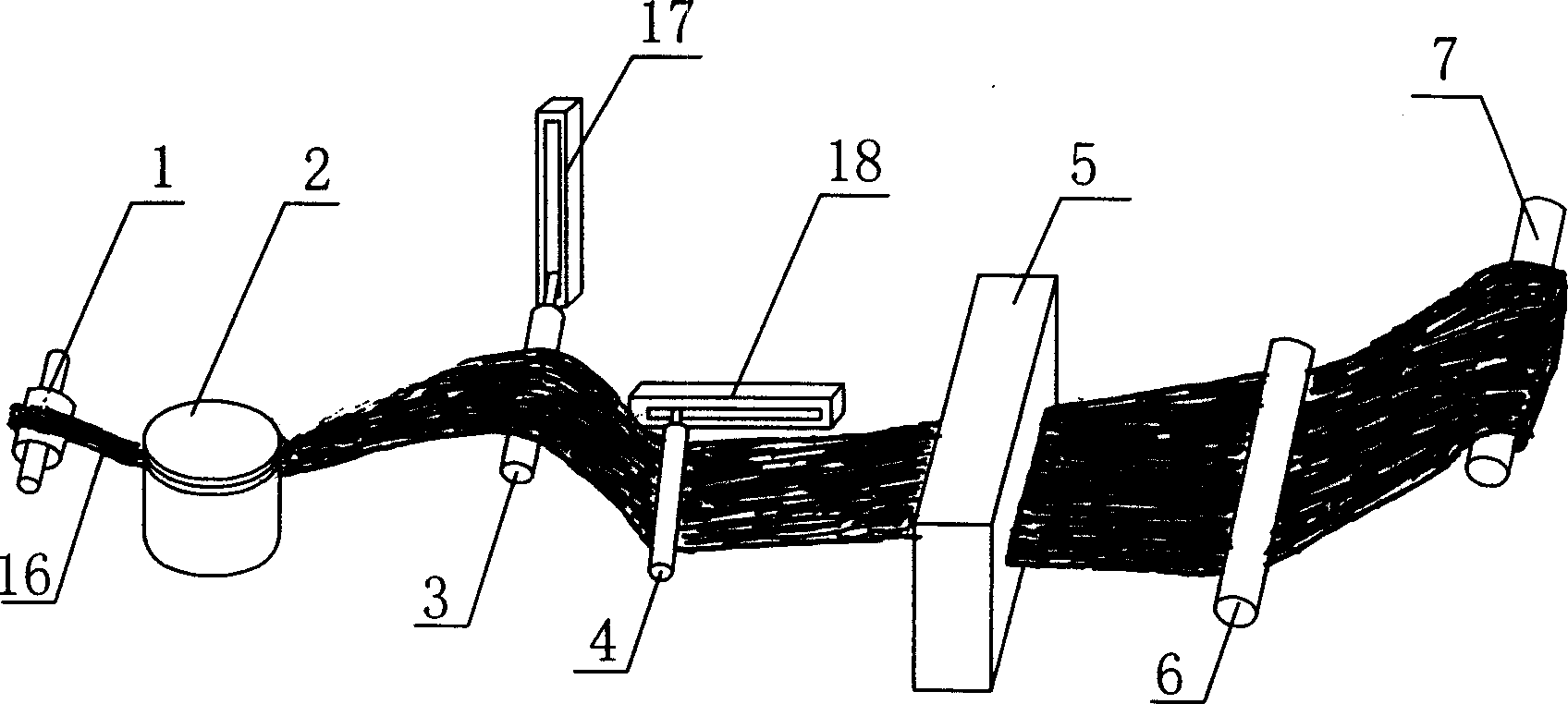

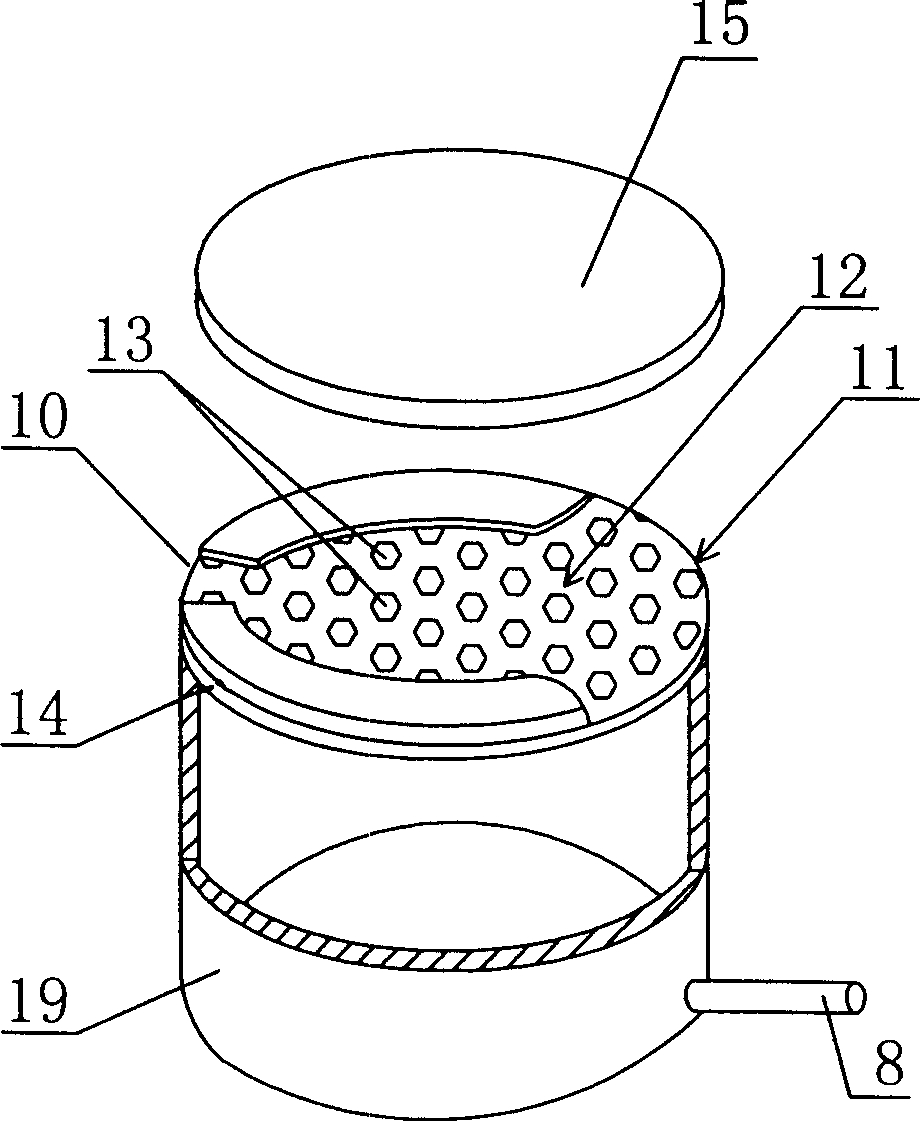

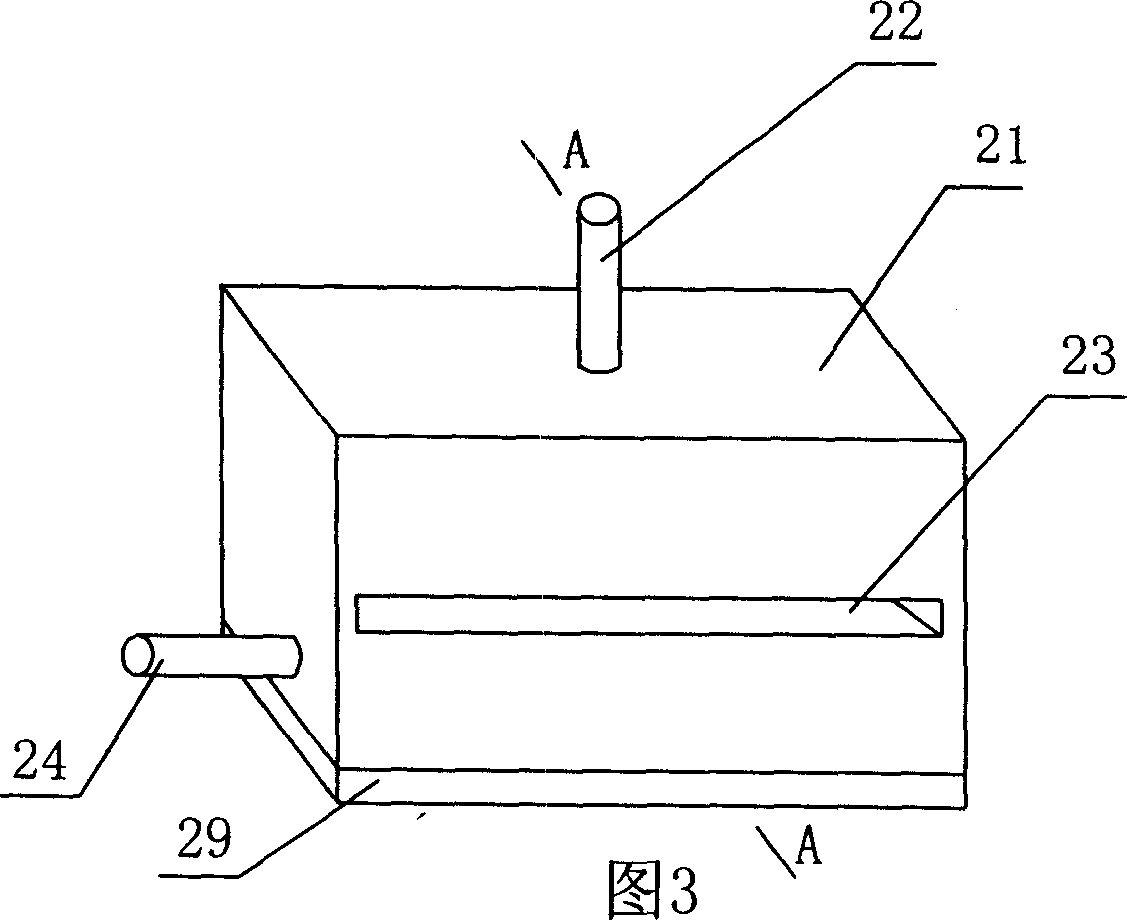

The continuous tow dispersing device includes unwinding roller, winding roller and tightening roller, as well as air separator and carding unit set successively between the unwinding roller and the winding roller. The air separator has a hollow barrel, and a tow separating cavity in the upper port of the hollow barrel with a tow separating plate with ventilating holes in the bottom and a closing cover plate in the top. The carding unit has a box; inside the box, there are horizontal upper plate with at least two parallel air slots, lower plate with air holes and carding groove between the upper plate and the lower plate; and on the box, there is mechanical vibrator. The device has simple structure, no need of outer power, tow dispersing action completed with air pressure, good tow dispersing effect, low tow damage and other advantages.

Owner:HUNAN UNIV

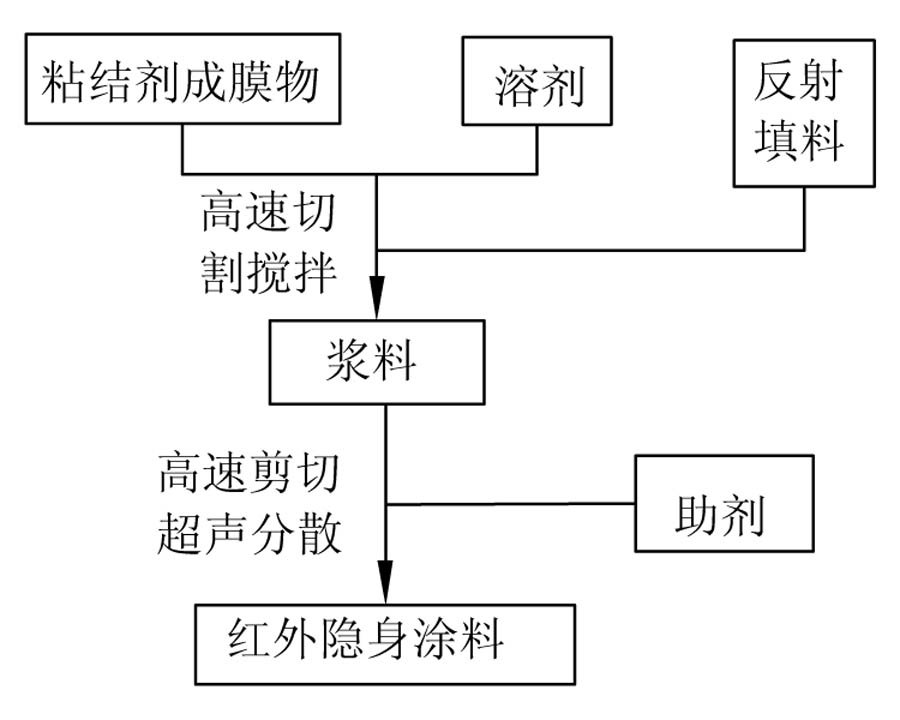

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

Ceramic-rich composite armor, and methods for making same

InactiveUS7104177B1Reduce manufacturing costHighly dimensionally accurate shaped articleCeramic layered productsArmour platesReaction bonded silicon carbideGrain growth

Silicon infiltration technology, e.g., siliconizing or reaction-bonding, is used to produce ceramic-rich composite bodies having utility as ballistic armor. In the main embodiment of the invention, the ballistic armor includes a reaction-bonded silicon carbide body (RBSC). Good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers, and by limiting the size of the morphological features making up the composite body. This control of “grain size” can be accomplished by controlling the size of the largest particles making up the porous mass to be infiltrated, but also of importance is controlling the processing conditions, particularly by controlling the factors that cause grain growth, coarsening of microstructure, and / or grain coalescence.

Owner:II VI DELAWARE INC

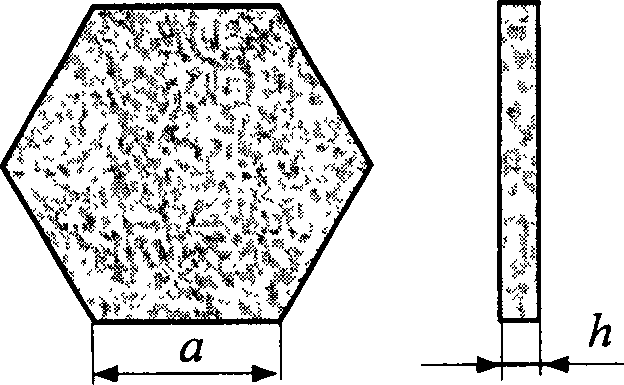

Composite bulletproof armour with steel honeycomb ceramic sandwich and manufacture thereof

In the invention, the composite bullet-proof armour plate consists of a metal panel, a honeycomb core board, a ceramic wafer core and a metal rear panel bonded with the metal brazing layer via the organic adhesive layer. The preparing method is that using the brozing and the line-cutting method are finished the honeycomb core board and the plain or curved ceramic wafer core, whose size must fit in that of the honeycomb hole of the honeycomb core board. The panel and the rear panel must be made of the bullet-proof steel plate through heat treating after cold rolling. The Ag72Cu metal brazing material and the epoxy resin group high strength structural sizing for connecting the interface are assembly welded.

Owner:UNIV OF SCI & TECH BEIJING

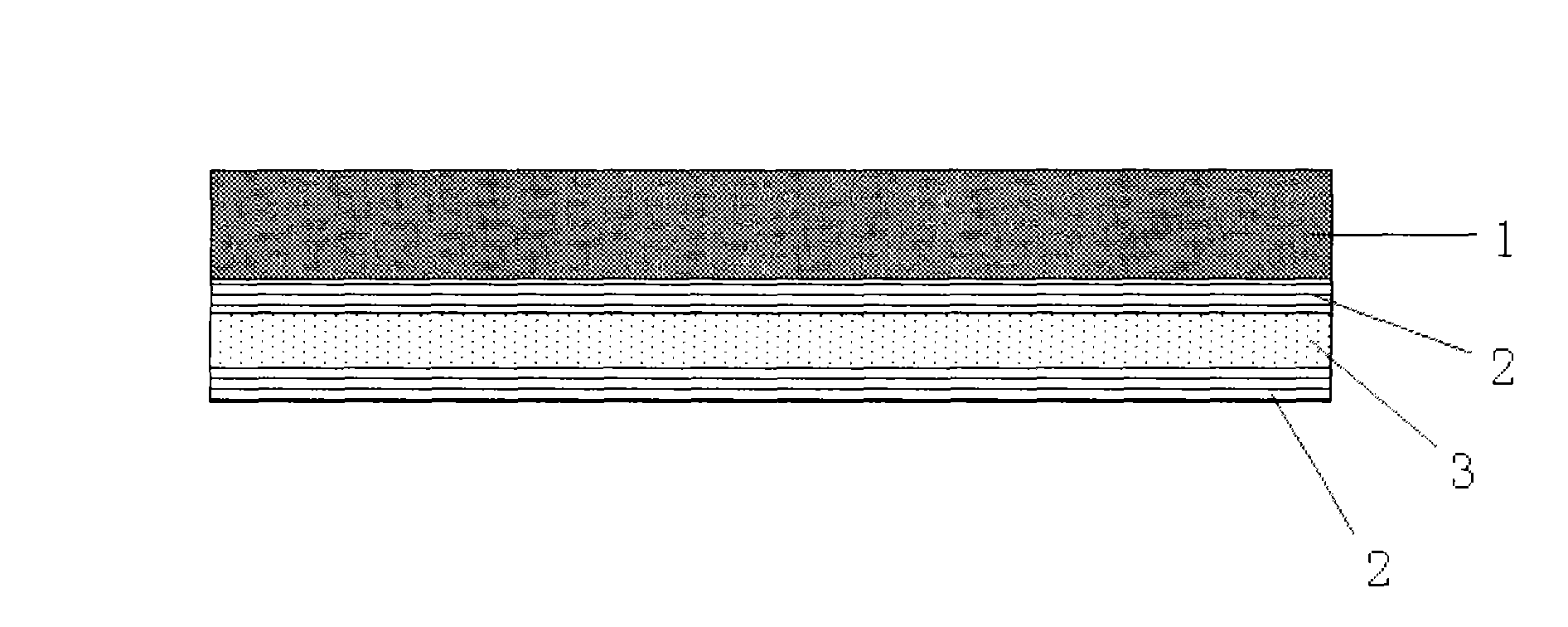

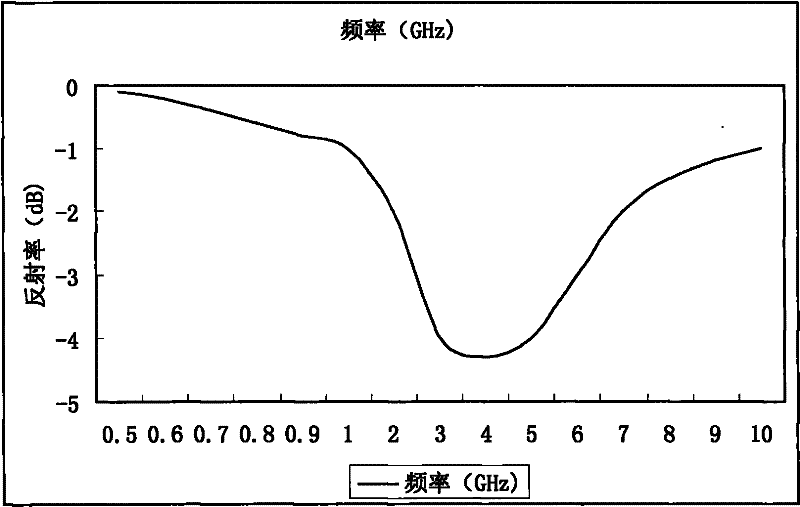

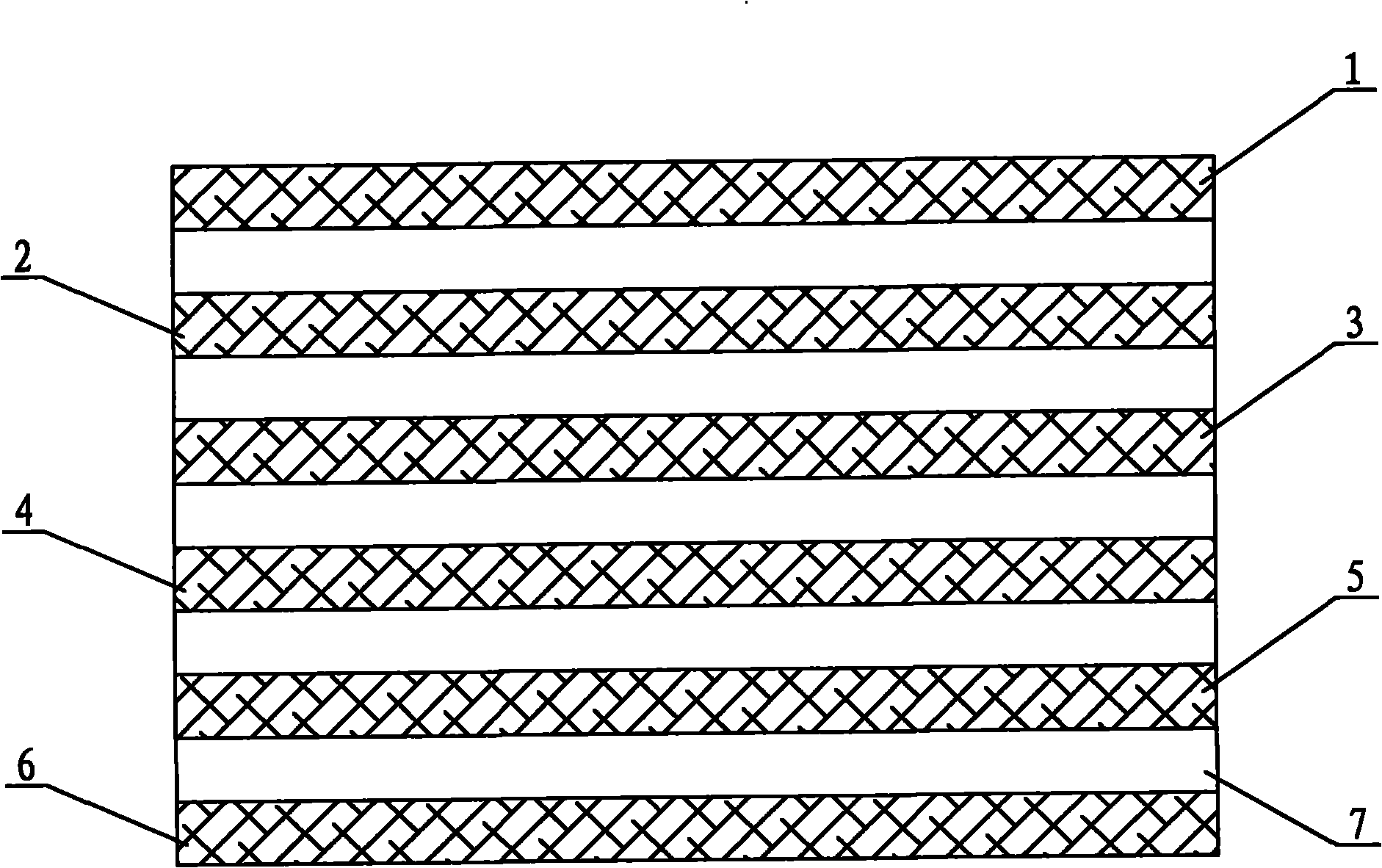

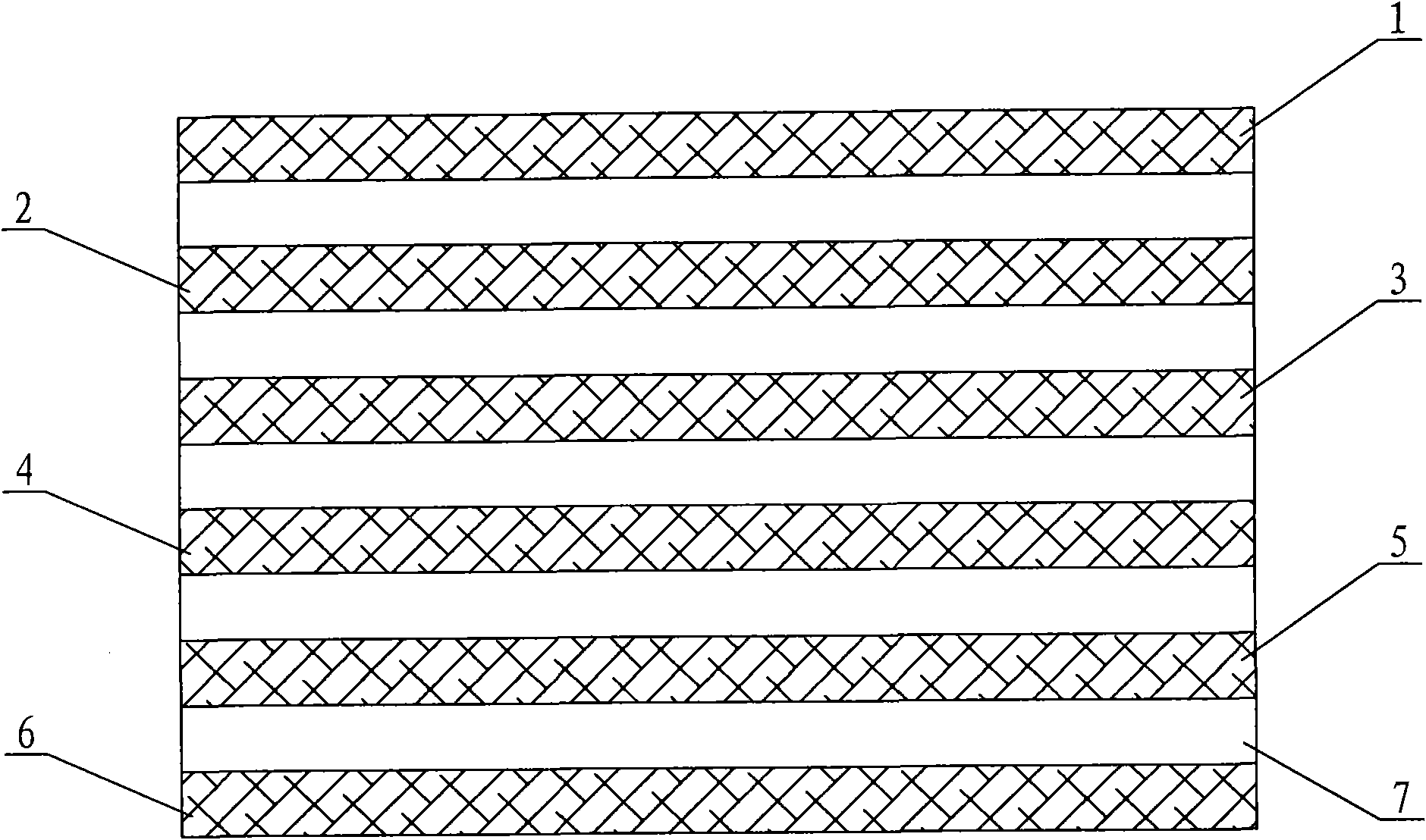

Broadband multi-layer structured wave absorbing composite material and preparation thereof

InactiveCN101434134AWith electrical lossWith magnetic lossLamination ancillary operationsSynthetic resin layered productsGlass fiberSurface layer

The invention relates to a broadband wave absorption composite material with a multilayer structure and a preparation method thereof. The broadband wave absorption composite material is characterized in that the material comprises three parts, namely a surface layer, a sandwich layer and a bottom layer; the surface layer comprises, by mass percentage, 20 to 50 percent of carbonyl iron dust, 30 to 48 percent of polymer and 20 to 32 percent of fiberglass cloth; the sandwich layer comprises, by mass percentage, 2 to 6 percent of carbon nanometer tube, 56.4 to 58.8 percent of polymer and 37.6 to 39.2 percent of fiberglass cloth; and the bottom layer comprises, by mass percentage, 50 to 80 percent of carbonyl iron dust, 12 to 30 percent of polymer and 8 to 20 percent of fiberglass cloth. The broadband wave absorption composite material has the advantages of low surface density, thin thickness and high mechanical strength, and improves the bearing performance and the engineering application value.

Owner:BEIJING UNIV OF CHEM TECH

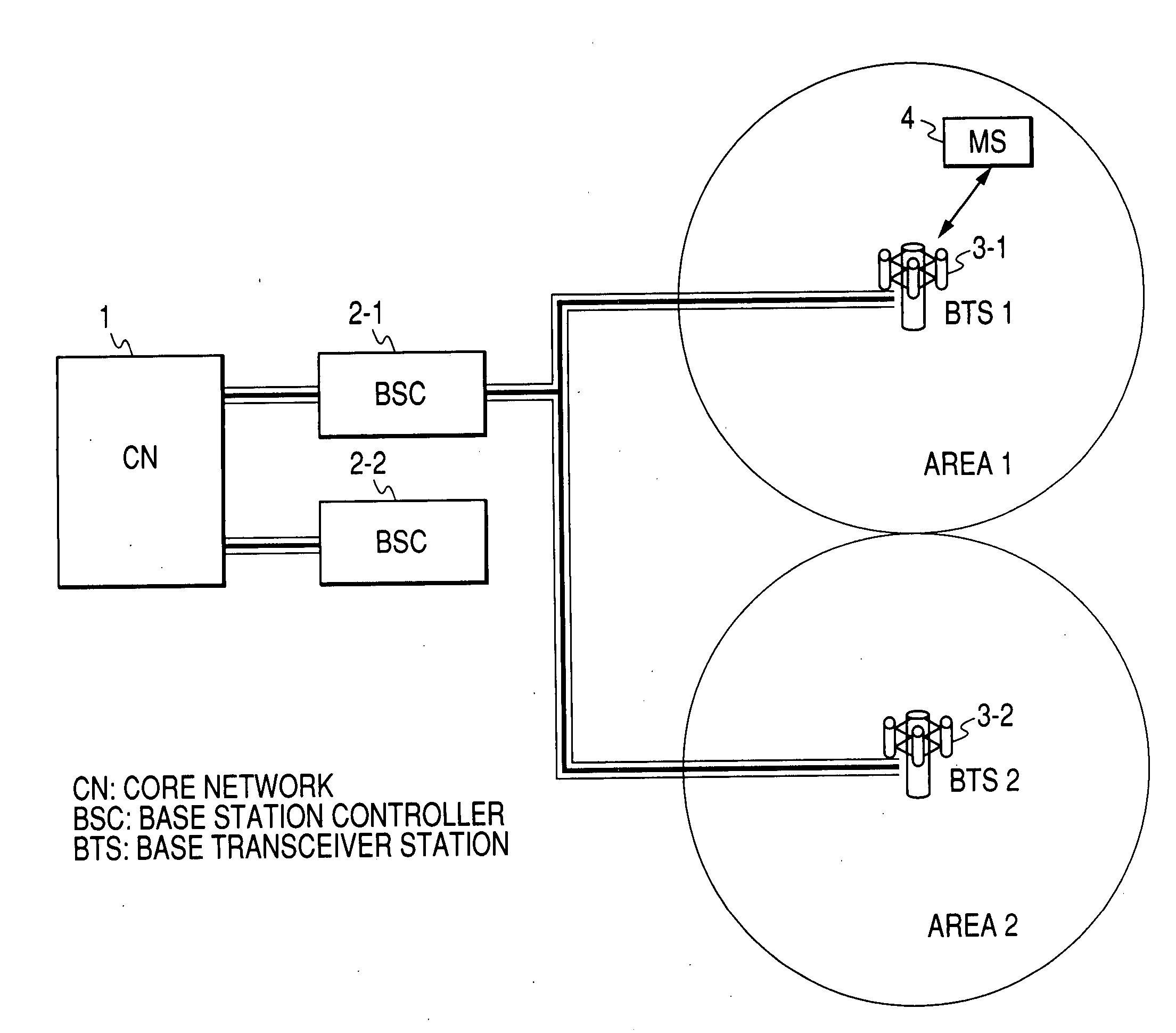

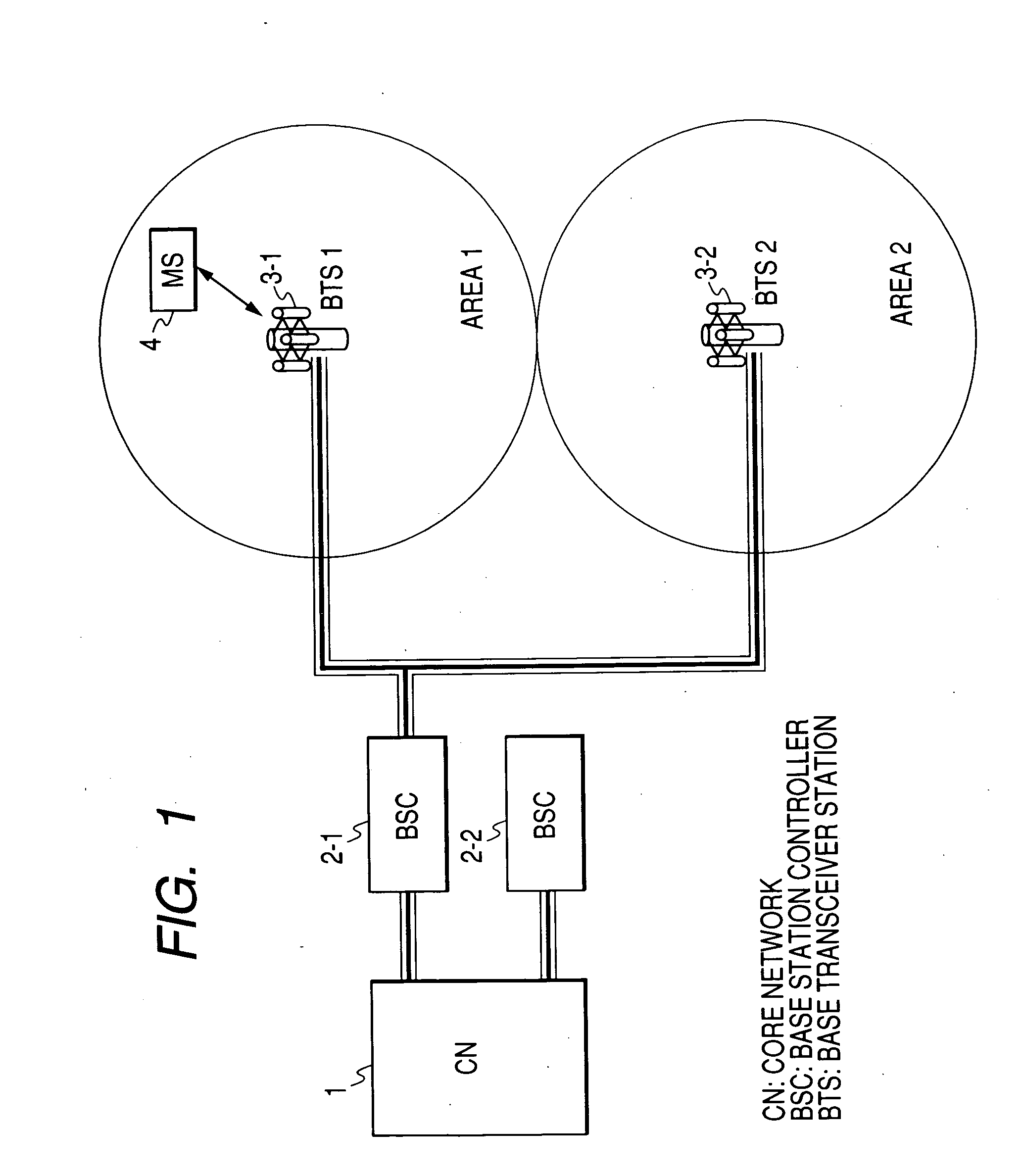

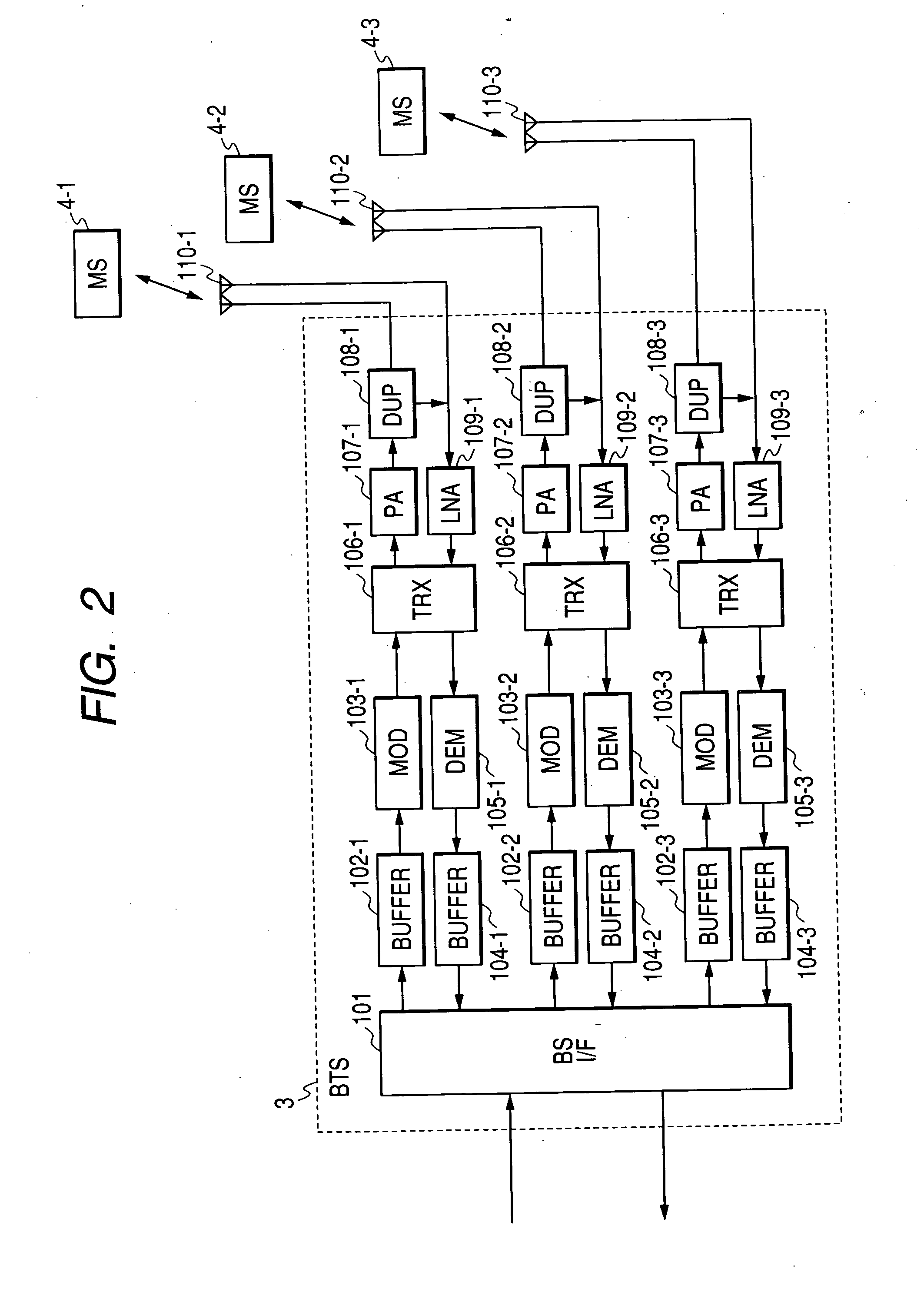

Base station apparatus and control method for controlling channel density

InactiveUS20060189353A1Increase the number ofLow costSpatial transmit diversityConnection managementChannel densityControl channel

A base station apparatus is provided for adaptively controlling a maximal accommodation channel number per unit area (for example, the coverage area of a cell or sector) in accordance with a traffic quantity without relying upon detachment of a mobile base station and installation of a repeater. Upon inputting of a plurality of baseband signals of a user channel-multiplexed channel group, linear coupling is performed by a weight which is different per area that outputs it, thereby enabling control of the channel density. Additionally, a per-group available channel number is constantly monitored to control the weight while using threshold judgment for the available channel number as a trigger, thus achieving situation-sensitive prompt handleability.

Owner:HITACHI LTD

Preparation method of lightweight composite wallboard

InactiveCN102888943AWith adjustable performanceRealize gapless compoundingConstruction materialMouldsFiberSurface layer

The invention provides a preparation method of a lightweight composite wallboard and belongs to the technical field of lightweight composite wallboard manufacturing. The method comprises the following steps: assembling a flat slab for flat-die roller forming and a combined type baffle into a set of forming mould, wherein a wallboard body with tenons and notch shapes at the two sides can be formed by the set of forming mould; when the forming mould moves along the preparation flow line, finishing a series of operations for forming the wallboard body, such as placing a bottom layer cement fiber face plate, paving and rolling a bottom layer light aggregate concrete layer, placing a reinforcement rib net, paving and rolling an upper layer light aggregate concrete layer, paving a surface layer mortar layer, paving glass gridding cloth, rolling a surface mortar layer, paving a plastic film, and preparing the lightweight composite wallboard after the wallboard body with the forming mould gets down a flow line delivering platform. The lightweight composite wallboard prepared by the preparation method has ideal overall mechanical strength, and is particularly suitable to be used for constructing insulation and sound-proof walls of housing industrialized buildings.

Owner:MAANSHAN MCC17 ENG TECH CO LTD +1

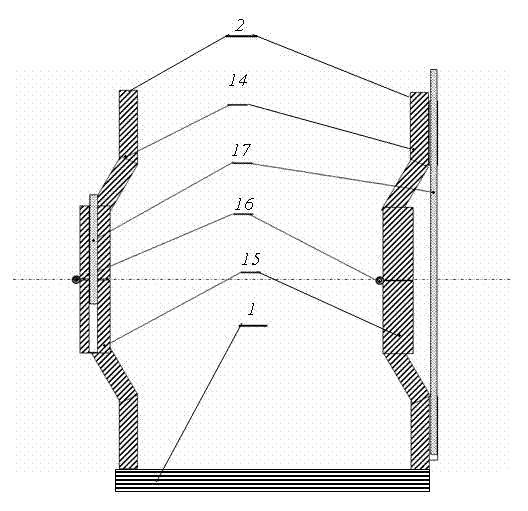

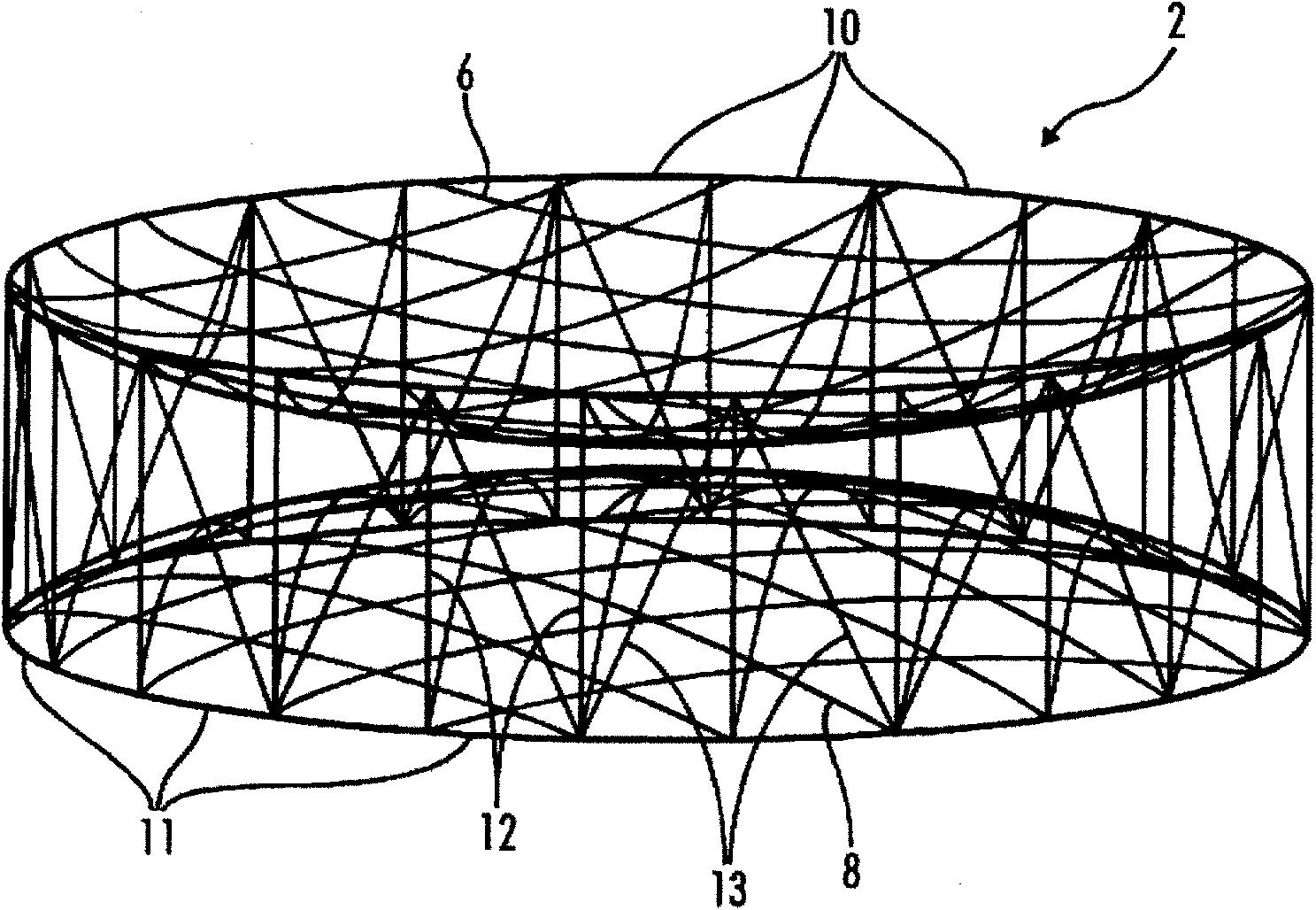

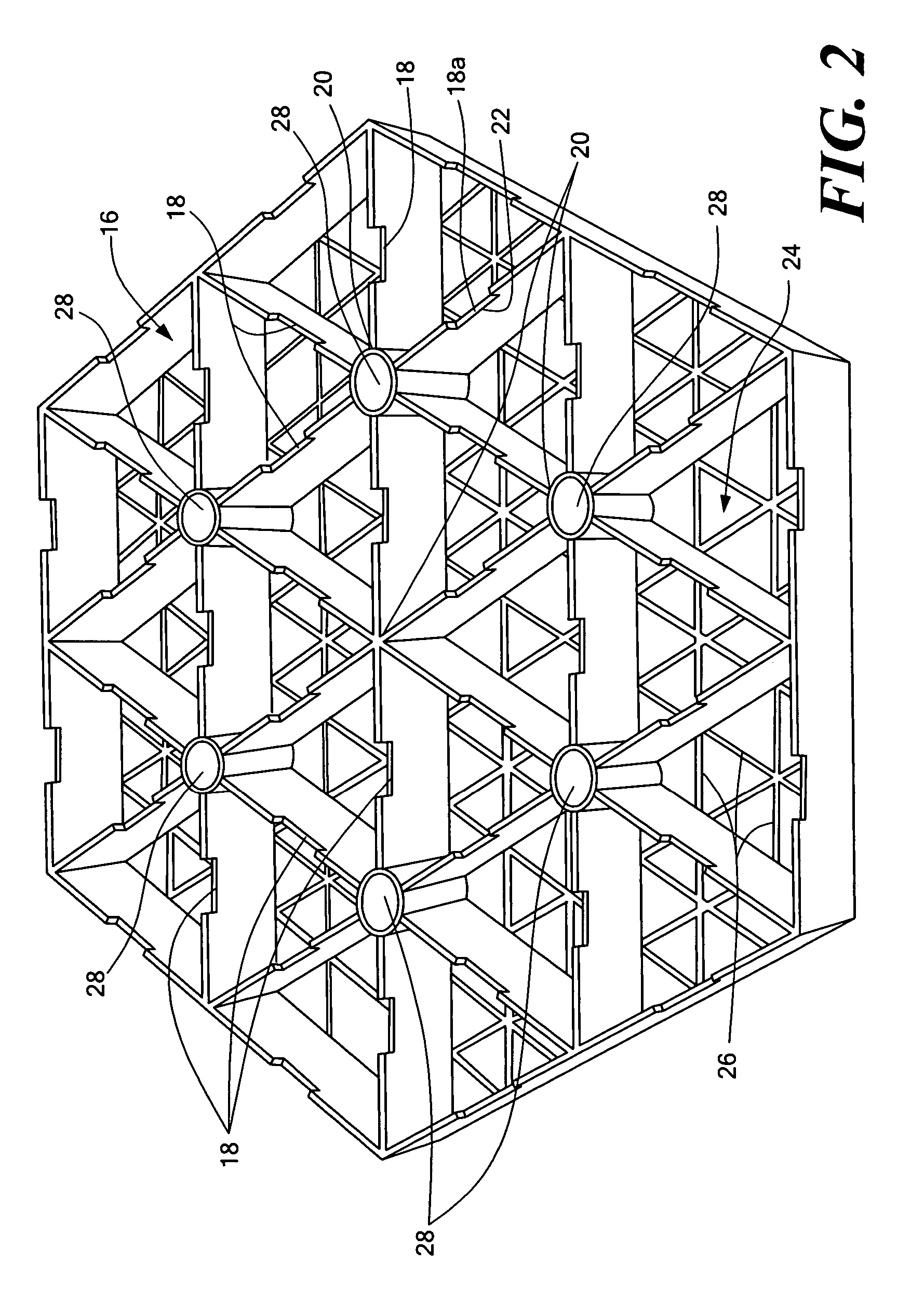

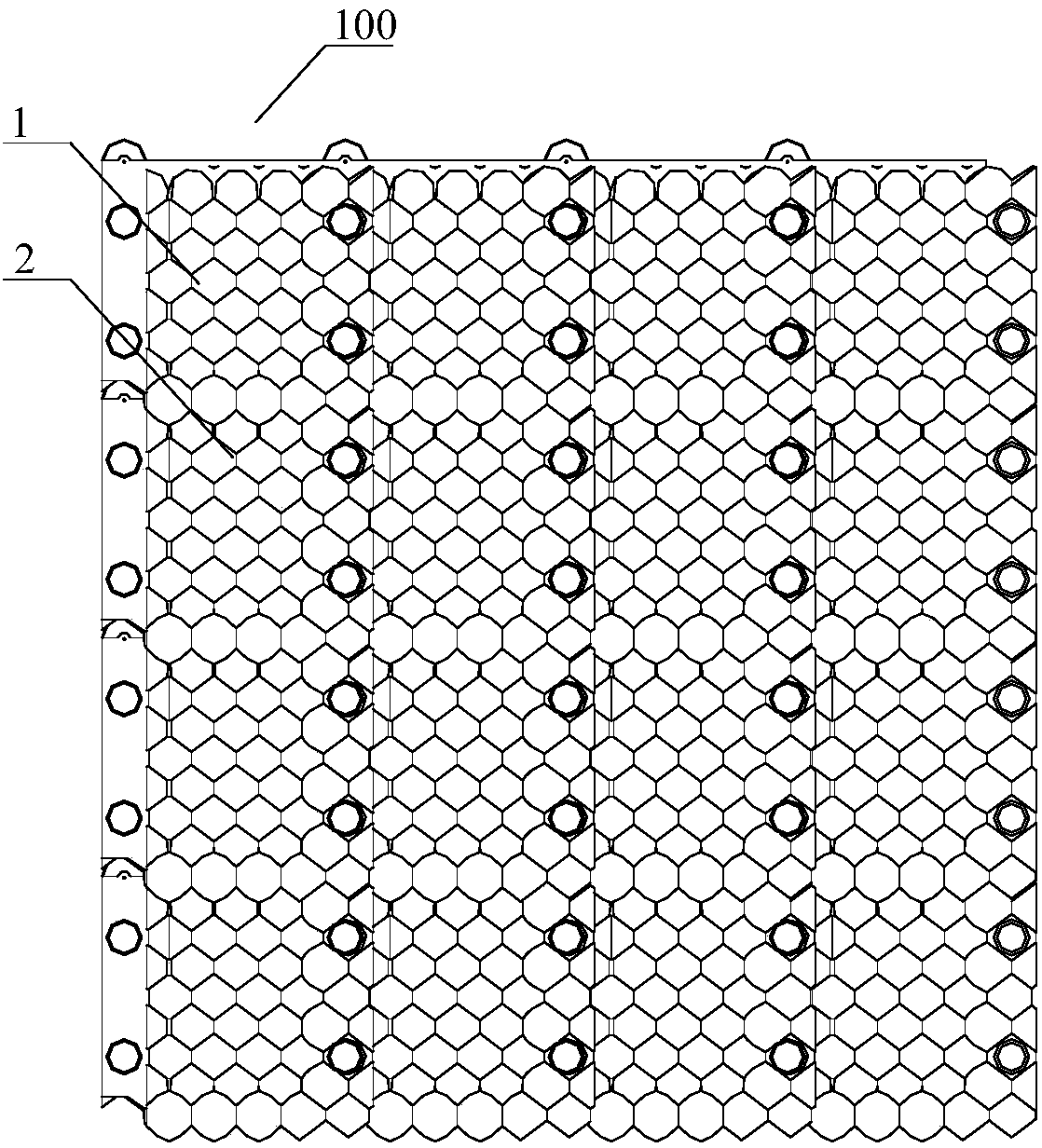

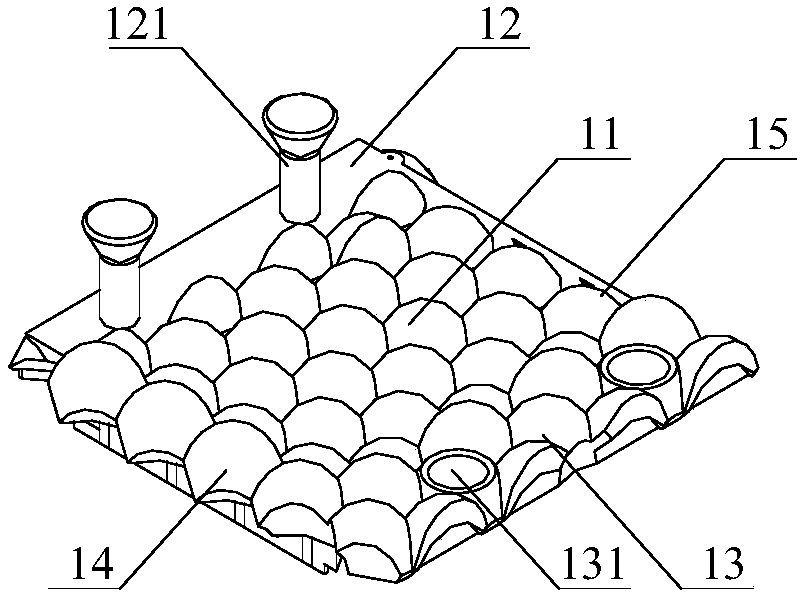

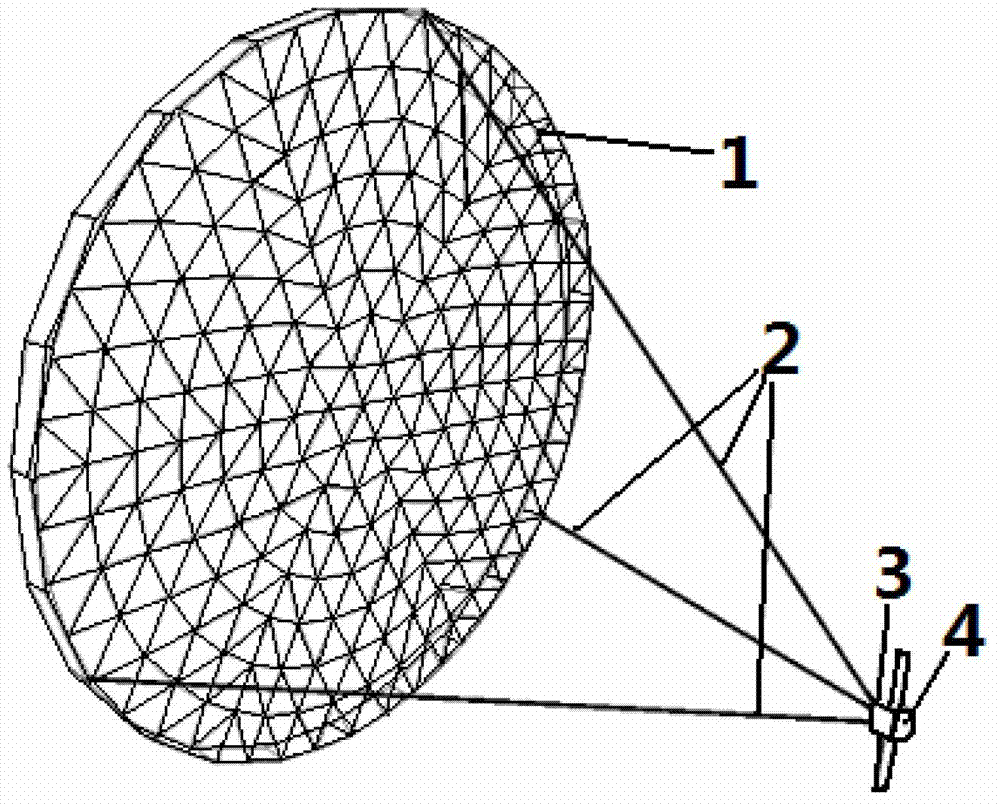

Deployable surface device with fixed truss structure

InactiveCN102011922ALight in massLow areal densityCollapsable antennas meansCosmonautic power supply systemsSacroiliac jointElectrical and Electronics engineering

The invention discloses a deployable surface device with a fixed truss structure, which mainly aims to solve the problems of high areal density, complicated structure, low deployable reliability and the like in the prior art. The device comprises a plurality of folded rings and connection joints, wherein every two folded rings (2) are connected by one ring connection joint (1) so as to form a circular foldable and deployable ring structure; each folded ring adopts a rectangular or regular triangle hollow straight bar single-rowed truss structure; driven or locked by the ring connection joints, the folded rings are unfolded into an approximately curve working state from a vertically folded state; staggered flexible pulling ropes are arranged on the folded rings; and a wire mesh or a film of which the surface is coated with aluminum is bound to the pulling ropes, so that the deployable surface device with the fixed truss structure is formed. The deployable surface device with the fixed truss structure has high composite performance indexes such as low areal density, simple structure, high deployable reliability, capacity of transmitting or converging electromagnetic waves in a long distance and the like, and can be used as a reflector or a converging device in space or on the ground.

Owner:XIDIAN UNIV

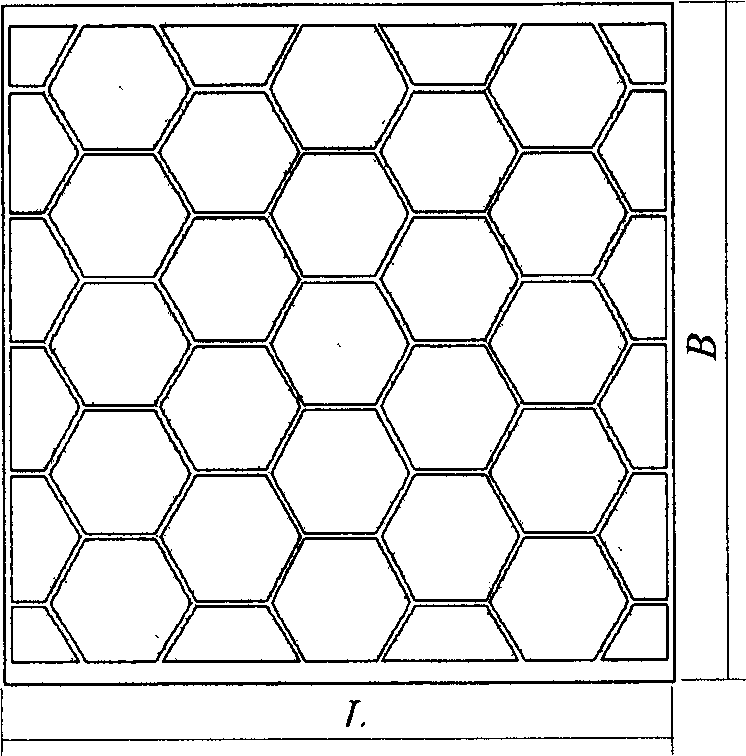

Integrated actuator meniscus mirror

An integrated actuator meniscus mirror includes an optical substrate having a mirror surface on one side and a support structure on the other and a plurality of actuators embedded in the support structure, spaced from and generally parallel to the mirror surface for applying bending moments to the mirror surface for controllably altering the shape of the mirror surface.

Owner:NORTHROP GRUMMAN SYST CORP

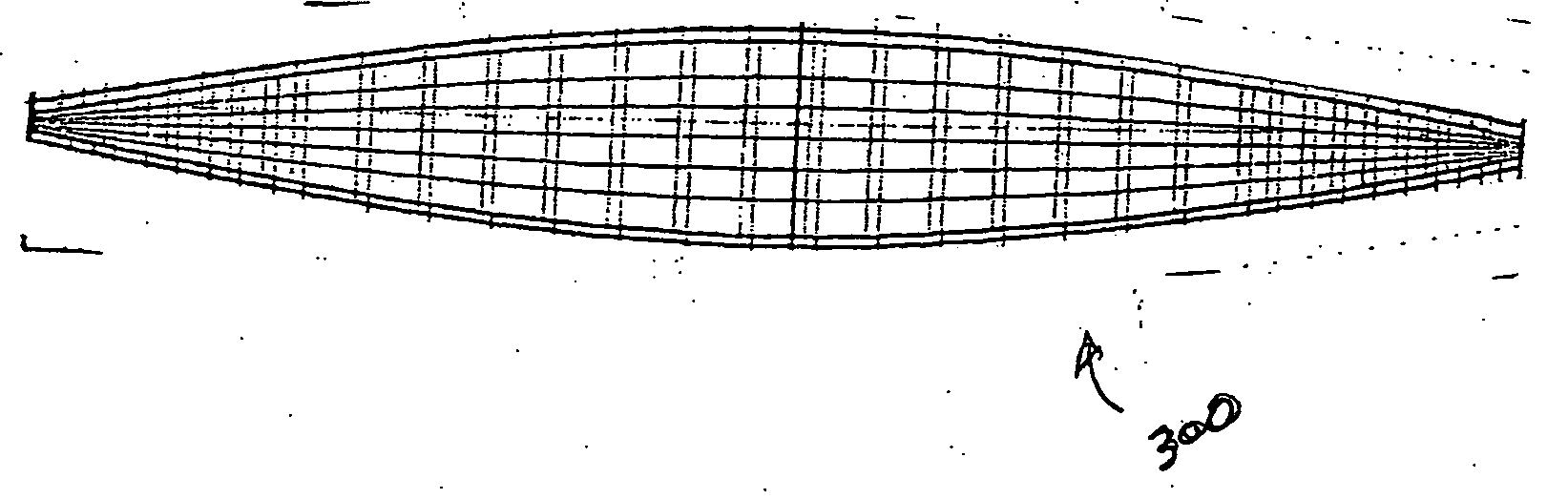

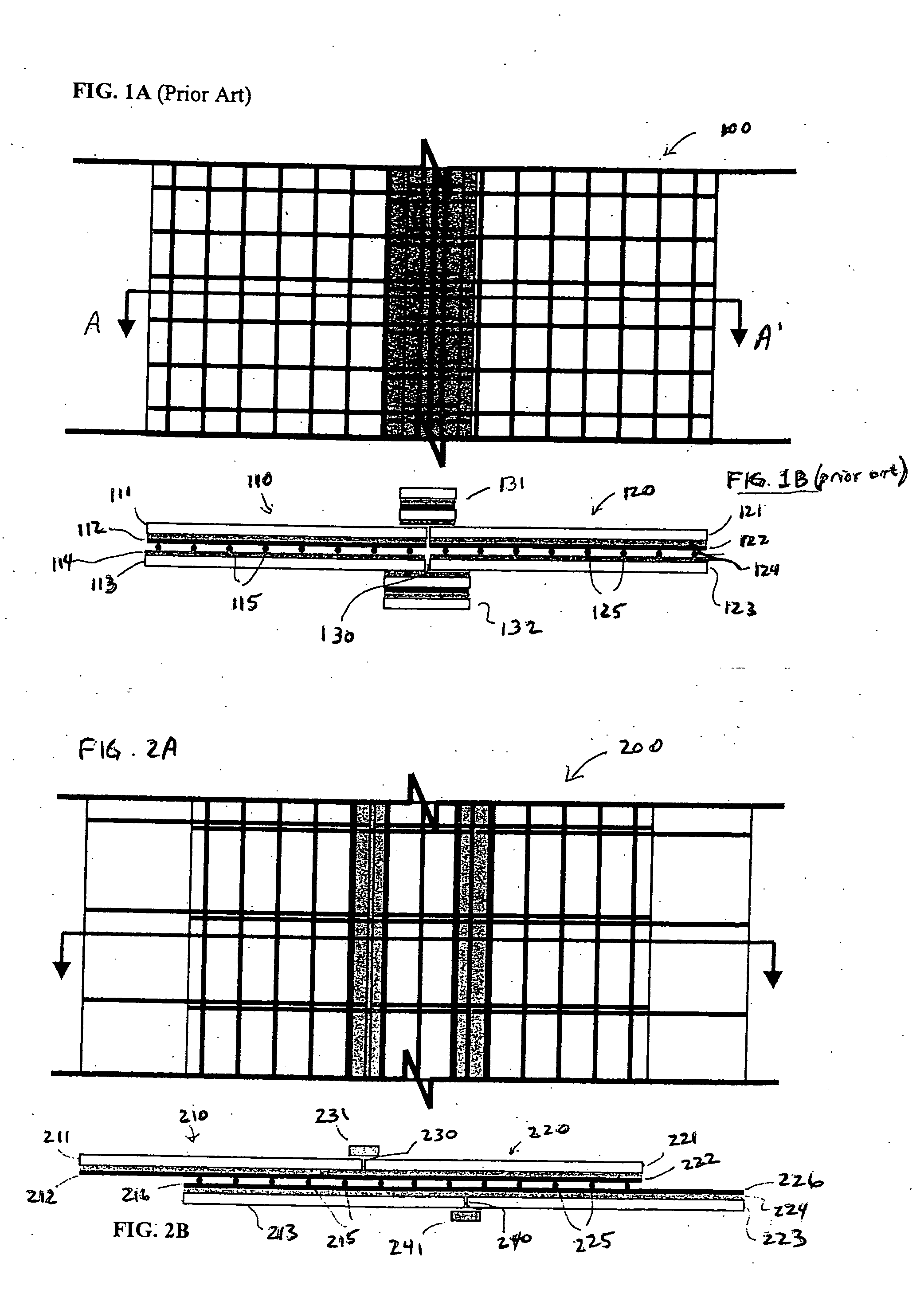

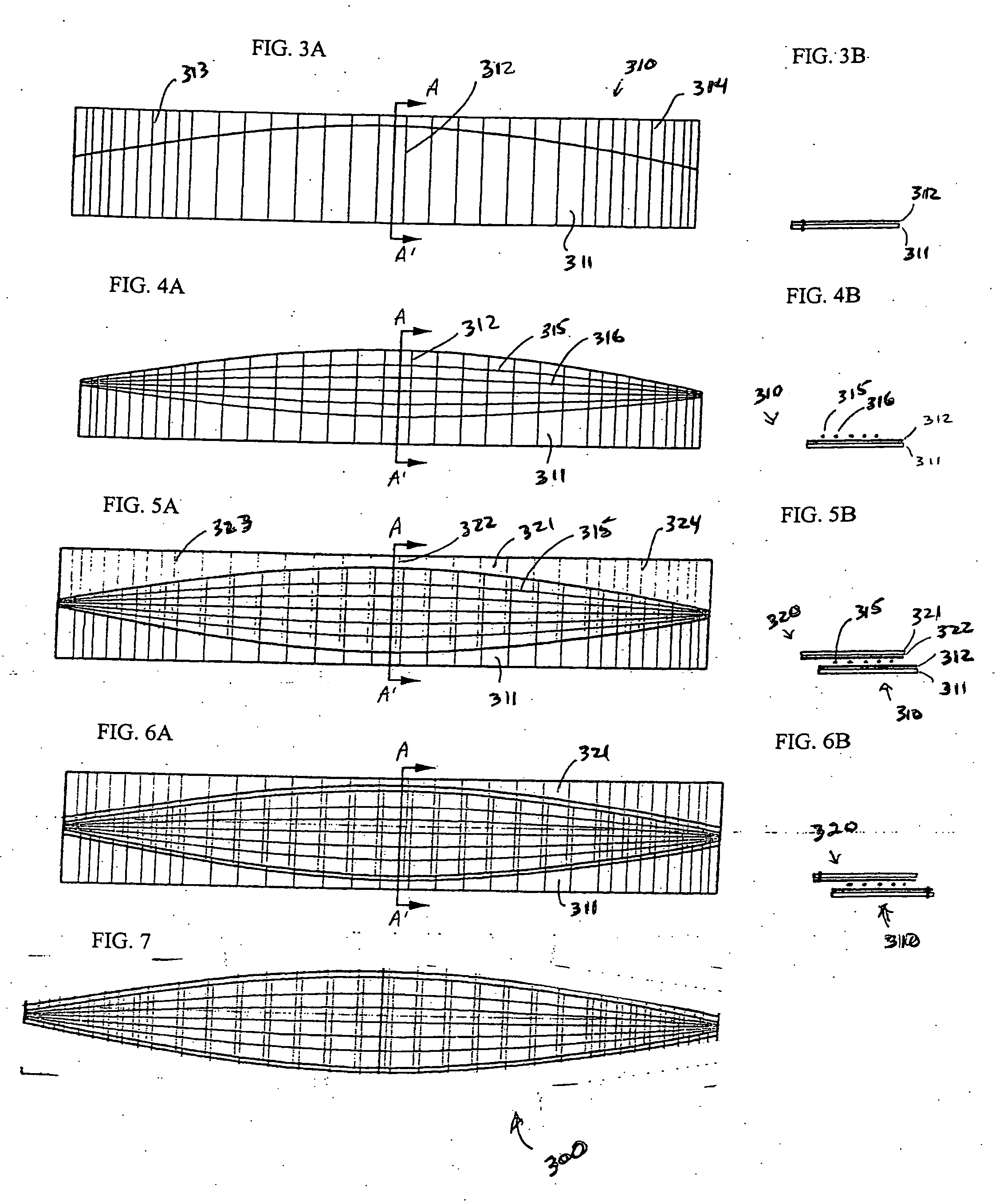

Inflatable and deployable systems with three dimensionally reinforced membranes

InactiveUS20060192054A1Improve performanceMinimize seamCosmonautic vehiclesParachutesState of artThree dimensional shape

An illustrative embodiment of the invention includes an apparatus and method for making air and space inflatables and deployables using three dimensionally reinforced (3DR) membranes. A 3DR process preferably takes plural substantially flat gore segments, each segment made of plural membranes and reinforcing fibers, and joins adjacent gores so the seams on opposite sides are offset. Single ply seam tape may be used. When all gores are joined, a three dimensional deployable or inflatable (e.g., balloon) structure with a minimized seam is produced. Further, localized fiber reinforcement may be used, with different characteristics depending on the desired placement in the gore, allowing the substantially flat gores, when joined and loaded, to strain to the desired three dimensional shape. In doing so, the required number of gores and seams may be reduced, while using materials with significantly lower areal densities. Thus, the 3DR process allows one to make locally reinforced materials that optimize strength to weight ratios; permits single ply and sub-gore width seam tapes; permits multi-phase optimized envelope shapes, designed to efficiently handle multiple loading conditions; and provides increased design flexibility for a wide range of shapes and characteristics impractical or unavailable under prior techniques.

Owner:LACHENMEIER TIMOTHY T

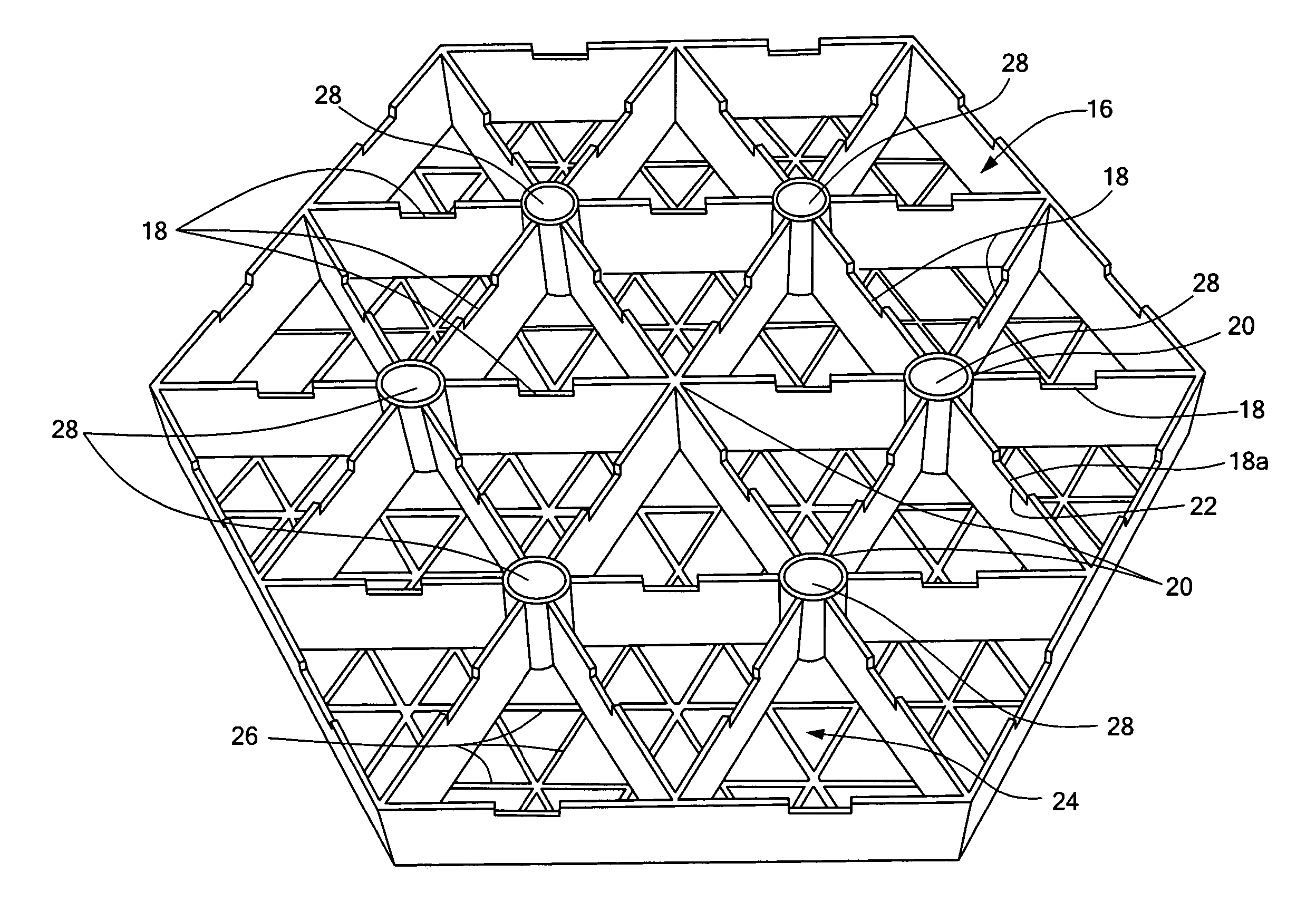

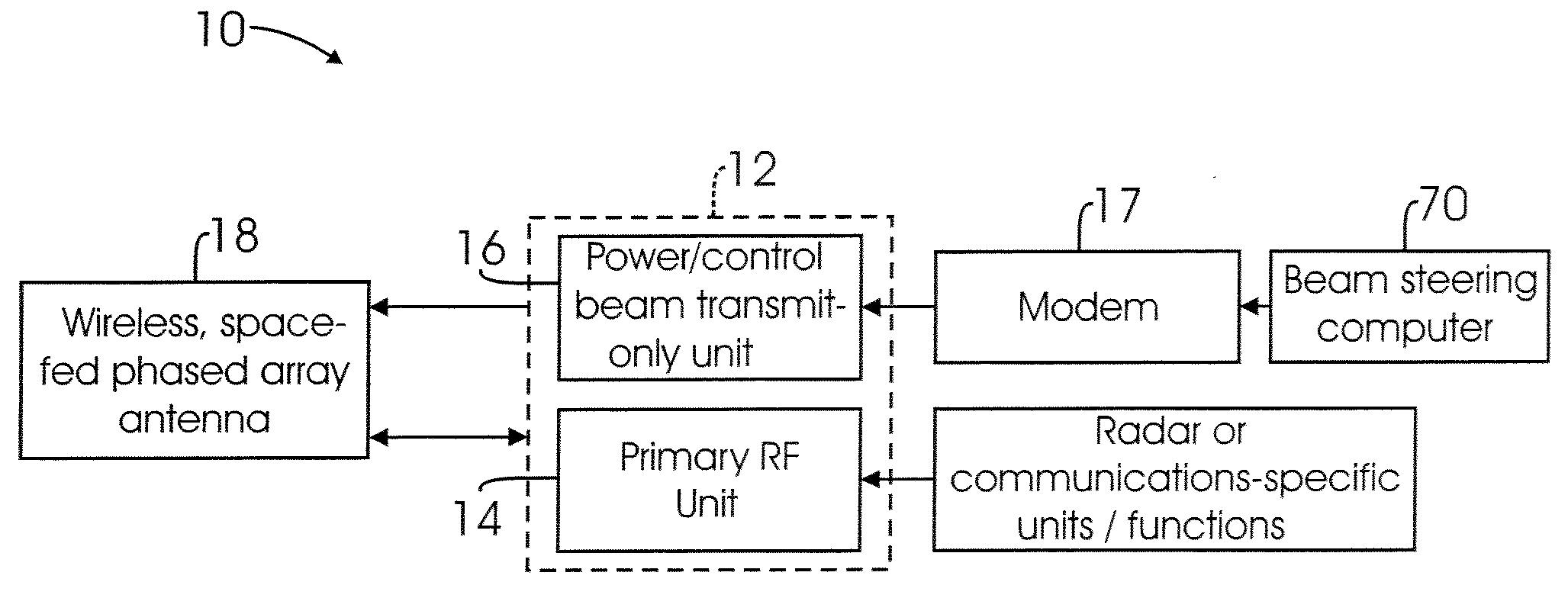

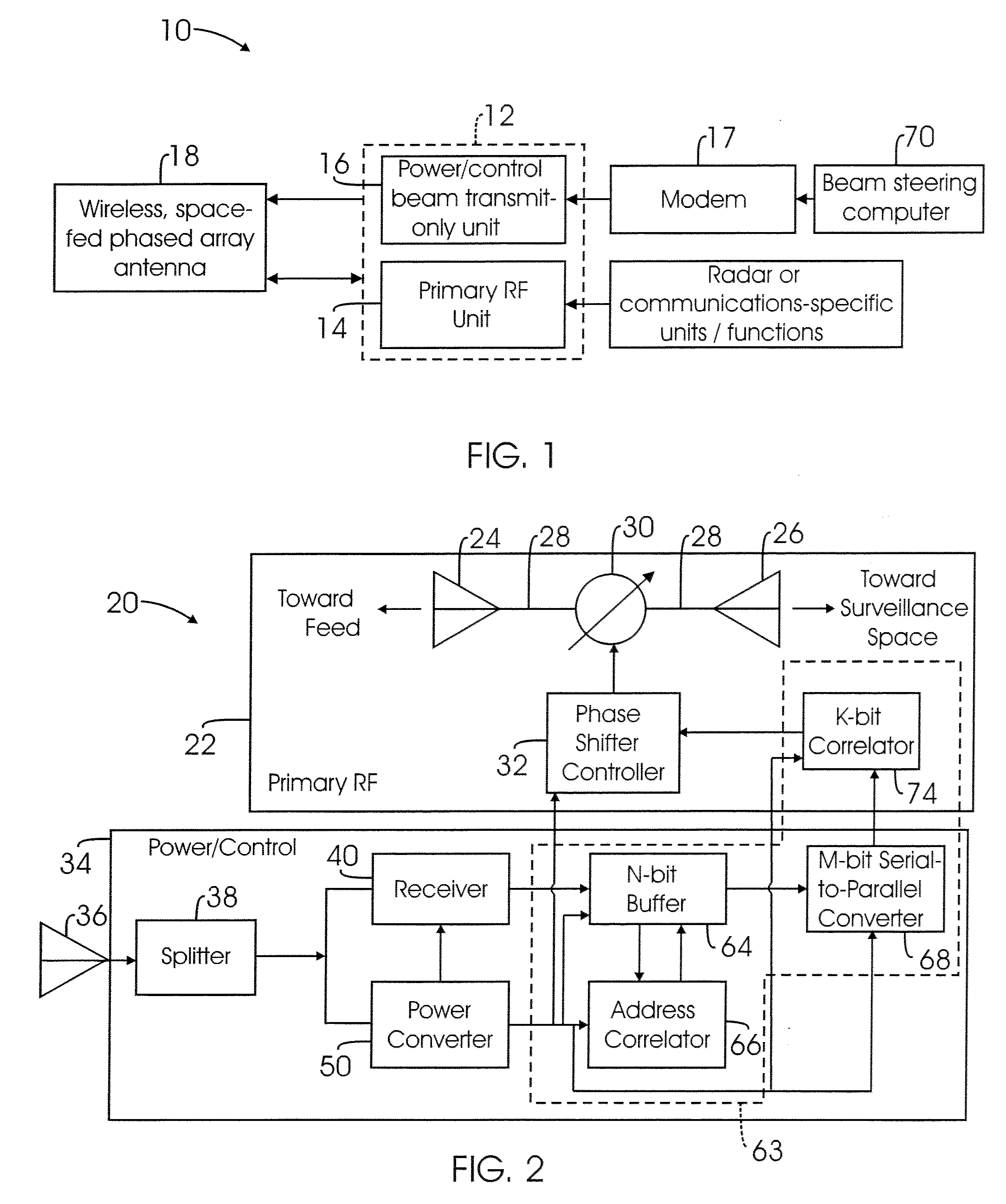

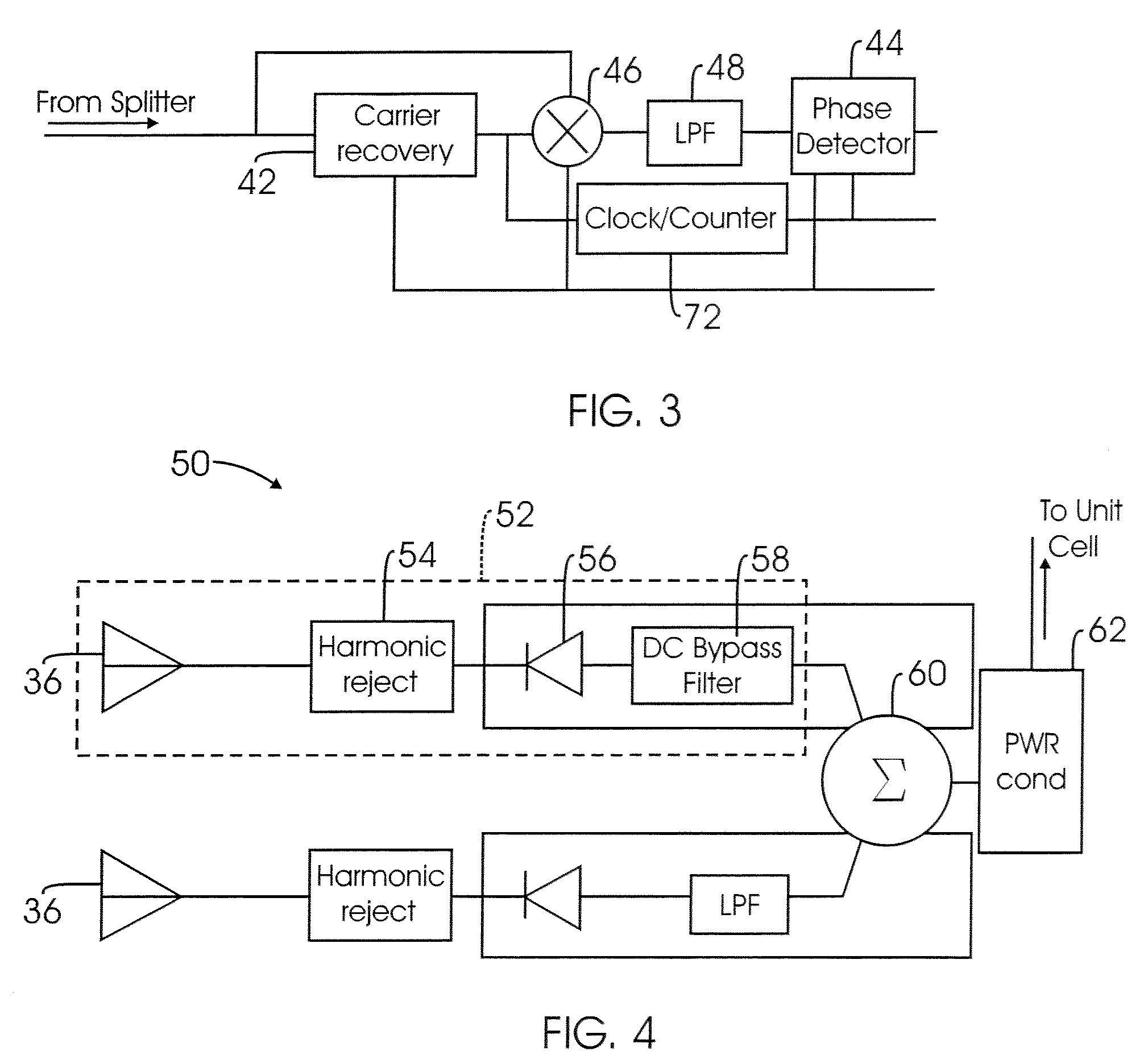

System and methods for radar and communications applications

ActiveUS20090102716A1Low areal densitySimultaneous aerial operationsRadiating elements structural formsPhase shiftedPresent method

A system and methods for radar and communications applications. In one embodiment the present system comprises a wireless, space-fed, phased array of antennas including a plurality of unit cells. A first one of the unit cells includes a first one of the antennas and a unit cell command interpreter configured to receive a command, determine whether the command is intended for the first unit cell, and relay the command to logic for enabling a phase shift controller of the first antenna. In one embodiment the present methods comprise the step of wirelessly beaming microwave power from a power and control beam transmit unit to illuminate a wireless, space-fed, phased array of antennas including a plurality of unit cells. The method further comprises the steps of beaming a command to the array and converting the microwave power into direct current within a first one of the unit cells. The first unit cell includes a first one of the antennas. The method further comprises the steps of supplying the direct current to components of the first unit cell to power the first unit cell, receiving the command within the first unit cell, determining whether the command is intended for the first unit cell, and relaying the command to logic for enabling a phase shift controller of the first antenna.

Owner:THE BOEING CO

Armour splicing-type stab-proof vest based on hollow micro-egg shell structure

PendingCN108095222AIncrease flexibilityReduce heat and moisture resistanceProtective garmentPlastic materialsMoisture permeability

The invention discloses an armour splicing-type stab-proof vest based on a hollow micro-egg shell structure. The stab-proof vest comprises a plurality of stab-proof sheet sets, each stab-proof sheet set comprises a first stab-proof base plate and a second stab-proof base plate connected with the first stab-proof base plate, the first stab-proof base plate and the second stab-proof base plate are made of a plastic material by means of a 3D printing-laser sintering technology, and the first stab-proof base plate in each stab-proof sheet set is connected with the first stab-proof base plate and the second stab-proof base plate in adjacent stab-proof sheet set. Compared with an existing stab-proof vest, the armour splicing-type stab-proof vest uses an arrangement mode of hierarchical overlapping of animal scales and shells for reference, all the stab-proof base plates are horizontally arranged according to the arrangement of upper-lower layering, overall surface density is reduced, overallcomfort and flexibility are improved, and diathermanous effects and moisture permeability effects are improved; a plurality of hollow semi-ellipsoidal shells are sequentially arranged in a staggeredmanner to effectively disperse the impact force of sword stabbing, and the stab-proof performance of the stab-proof base plates can be enhanced; the stab-proof vest has the advantages of simple production process, high efficiency, light weight, raw materials savings, low cost and good market competitiveness.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

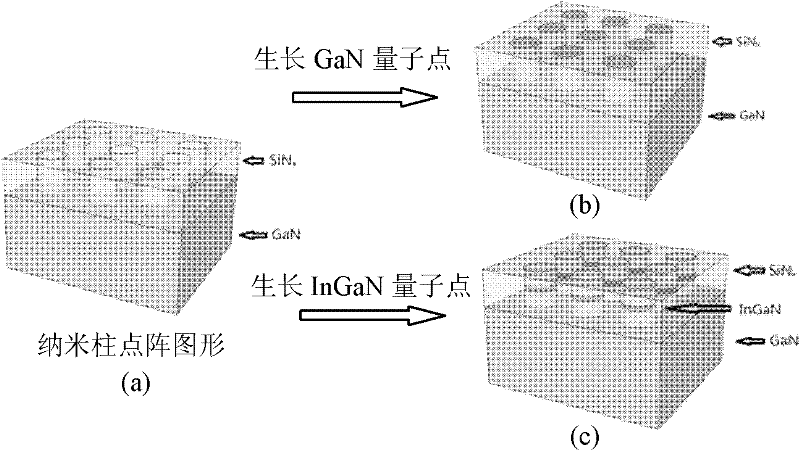

Method for preparing active layer structure with high-density gallium nitride quantum dots

ActiveCN102420277AHigh densityIncrease areal densityLaser detailsSemiconductor lasersMethacrylateNanopillar

The invention relates to a method for preparing an active layer structure with high-density gallium nitride quantum dots; the method comprises the following steps of: (1). depositing a layer of SiO or SiNx dielectric thin film material with the thickness of 10-50nm on a GaN template or surfaces of other semiconductor films, painting a mixing copolymer of PS (Polystyrene) and PMMA (Polymenthyl Methacrylate) on the surface of the dielectric thin film, obtaining a PS nanometer column graph after cleaning the PMMA, transferring the PS nanometer column graph to the dielectric thin film layer by adopting plasma etching, wherein the PS nanometer column graph is prepared according to the following parameters: (1) the surface density reaches 0.8-1.0*1011cm<-2>; (2) the PS nanometer column graph istransferred to the SiNx or SiO2 dielectric thin film layer by adopting reactive ion etching, the PP is removed to obtain a template on which a GaN nanometer point structure grows for the second time through MOCVD (Metal-organic Chemical Vapor Deposition); and (3) a GaN-base quantum dot structure grows, emits strong royal purple light and is used for manufacturing the active layer structure in a light-emitting diode (LED) with high efficiency and a laser device (LD) optoelectronic device.

Owner:NANJING UNIV

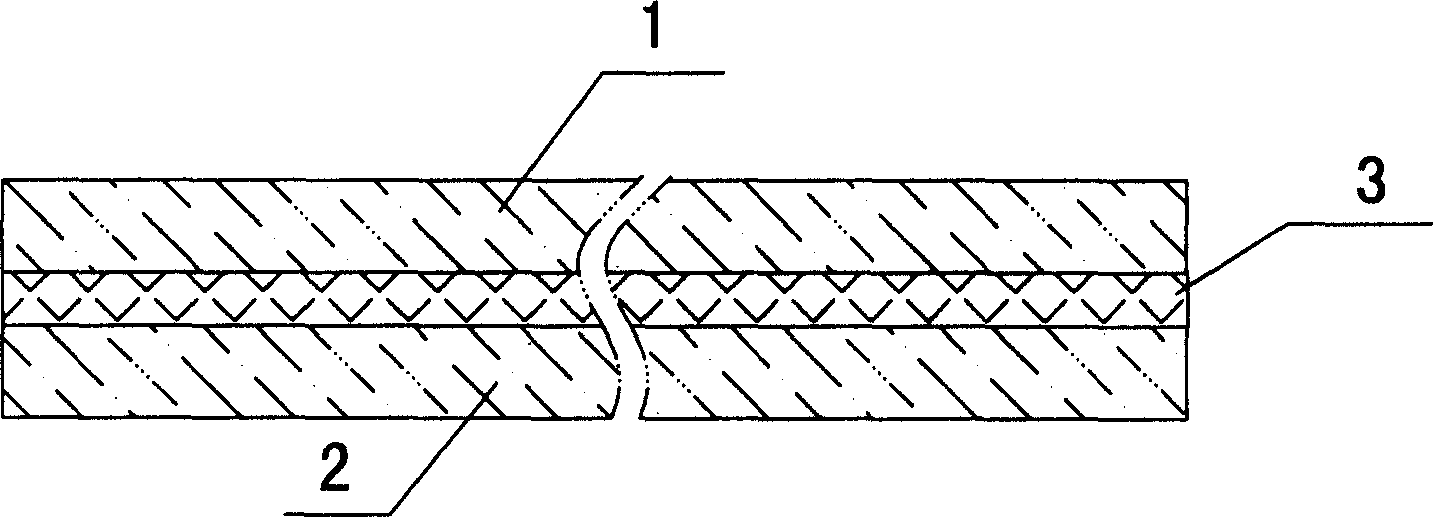

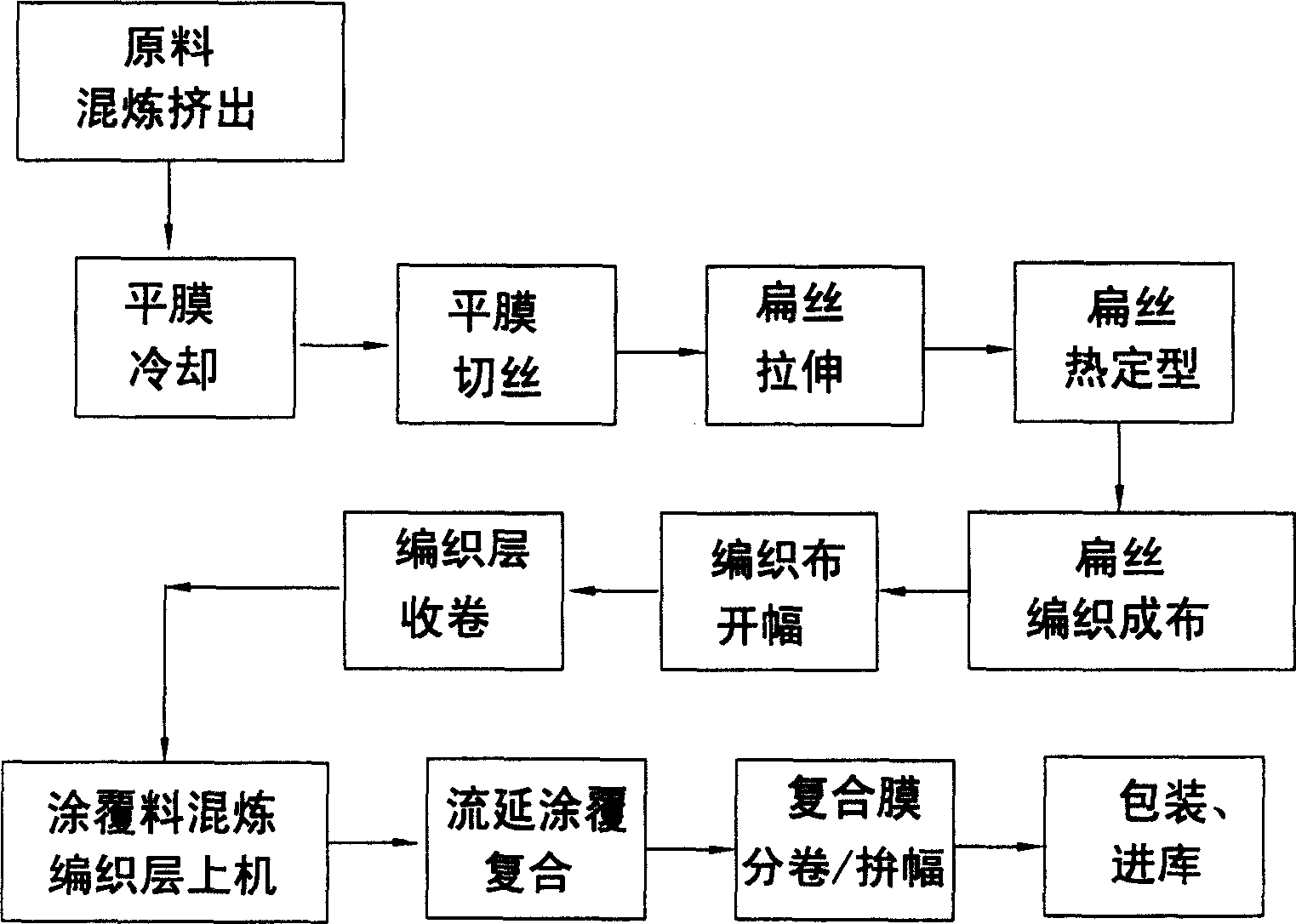

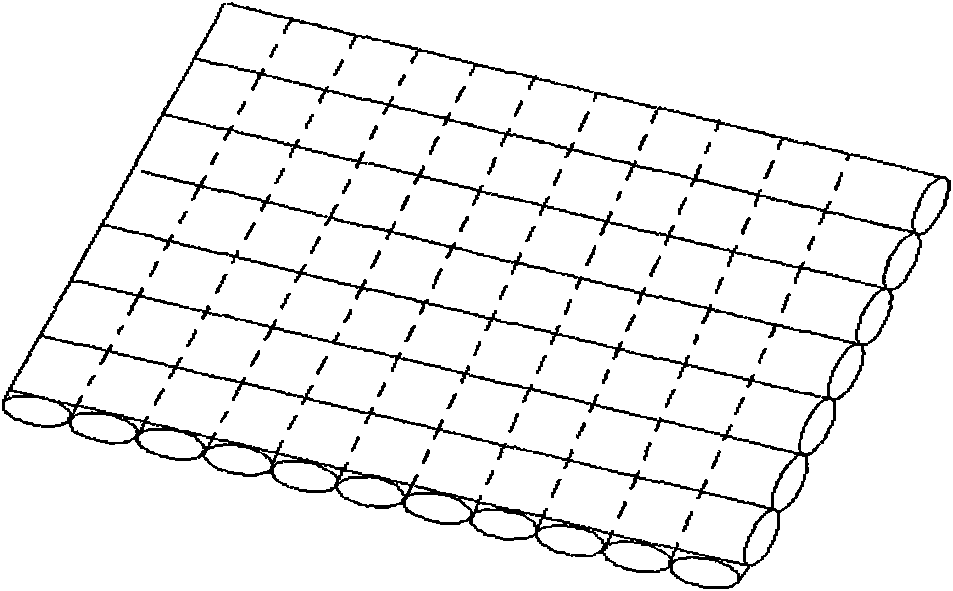

Anti-leakage earth work film reinforced with fiber knitting layer and its preparing process

ActiveCN1616222AMeet engineering requirements such as anti-seepageLow areal densitySynthetic resin layered productsFiberGeomembrane

The anti-leakage earth work film reinforced with fiber knitting layer includes an upper film layer, a lower film layer and a core layer in between, with the three layers being of the same or different material. The present invention features that the core layer includes at least one fiber knitting layer with cross knitted fiber material and the fiber knitting layer has its two sides adhered to other core layers or the upper film layer and the lower film layer. The fiber knitting layer reinforced anti-leakage earth work film has high mechanical strength, reliable anti-leakage characteristic and high durability.

Owner:FSPG HI TECH

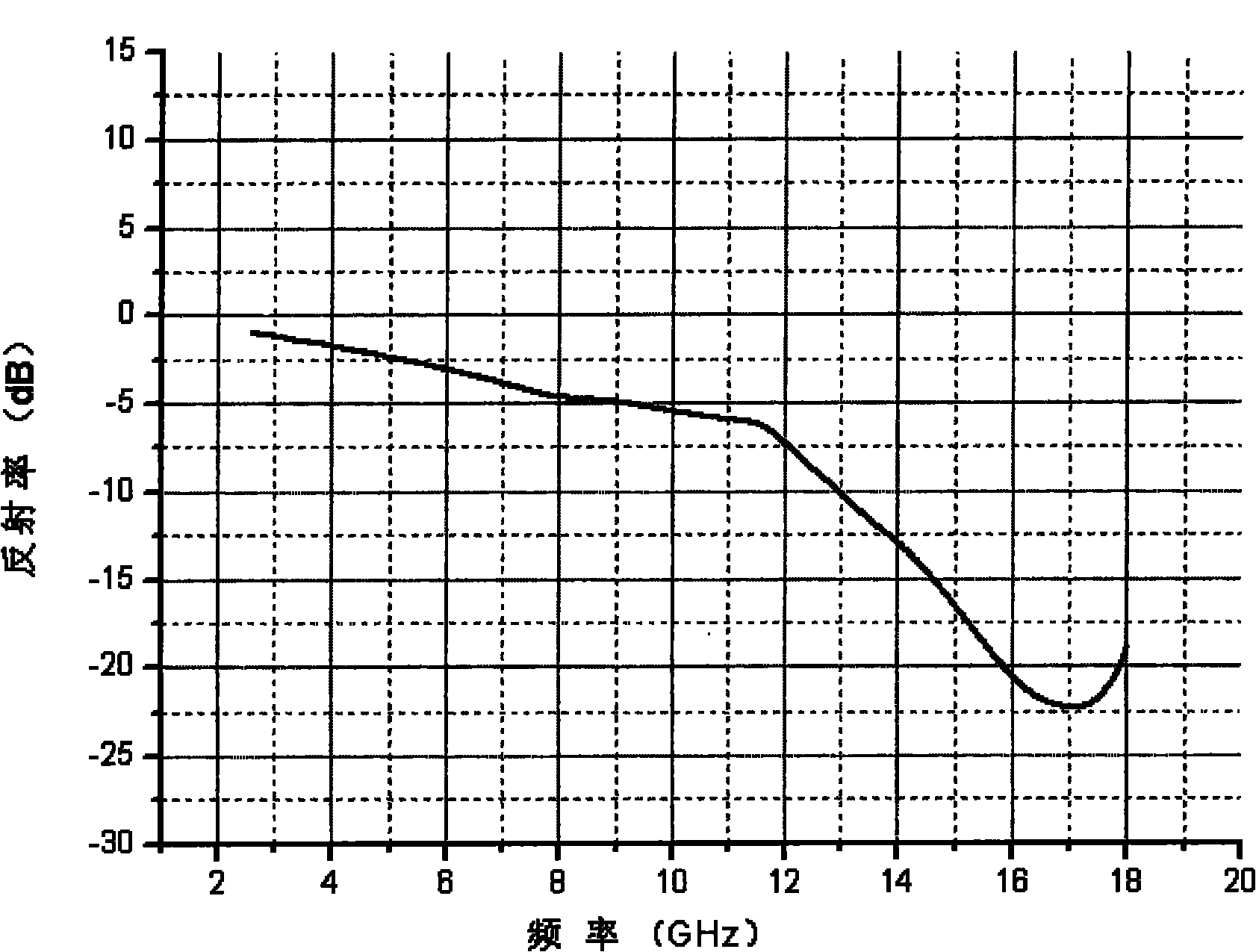

Centimeter wave-millimeter wave compatible absorbing composite material

ActiveCN102504659AGood impedance matching effectReduce reflectionPolyurea/polyurethane coatingsRadiation-absorbing paintsPolyurethane adhesiveWave band

The invention discloses a centimeter wave-millimeter wave compatible absorbing composite material. The material has a five-layer structure including a substrate which is an irregular surface made of a random material, a topmost first layer which is composed of a W-shaped hexagonal ferrite absorbent and a acrylic resin adhesive, a second layer which is composed of a carbonyl iron powder absorbent and an epoxy resin adhesive, a third layer which is composed of an Fe85Si1Al6Cr8 nanocrystalline sheet-like absorbent and an epoxy resin adhesive, a fourth layer which is composed of a polycrystallineiron fiber absorbent and an epoxy resin adhesive, and a fifth layer which is composed of a short carbon fiber / carbon black mixed absorbent and a polyurethane adhesive. The material can well solve theproblem of poor centimeter wave-millimeter wave compatible absorbing performance in the prior art, and is a composite wave-absorbing material compatible with electromagnetic waves of centimeter wave-millimeter wave bands.

Owner:HUNAN JINGE NEW MATERIAL

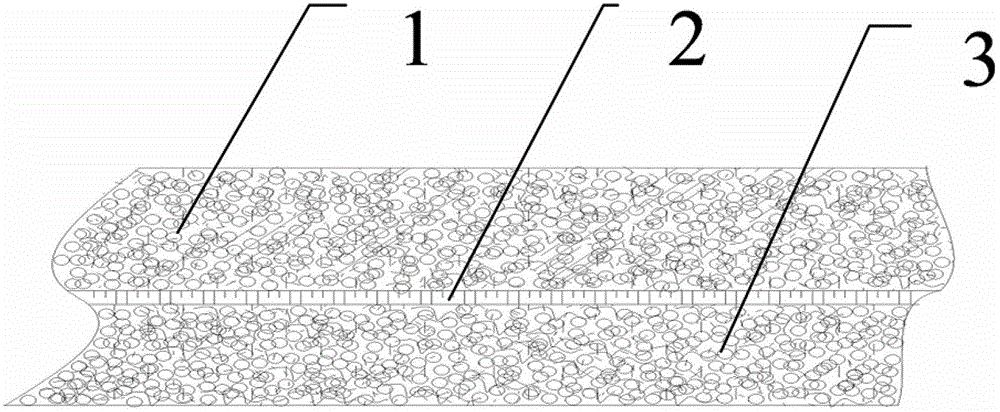

Ceramic/composite material interlayer protecting structure

InactiveCN101650148AImprove rigidityTo make up for the shortcomings of low bending strengthSynthetic resin layered productsCeramic layered productsShock waveVolumetric Mass Density

The invention belongs to a design technology of protecting structures and relates to an improved / composite material protecting structure, which comprises a ceramic panel (1) and a rear panel bonded with the ceramic panel (1). The ceramic / composite material interlayer protecting structure is characterized in that the rear panel is an interlayer panel which comprises two fiber reinforced resin base composite material plates (2) and a foam aluminum plate (3) clamped between the two fiber reinforced resin base composite material plates, and the fiber reinforced resin base composite material plates (2) and the foam aluminum plate (3) are formed into the interlayer plate bonded by plate cores. The interlayer structural rear panel provides support with greater rigidity for the ceramic panel under the condition of same planar density and fully plays a role of high compression strength of ceramic materials. Closed cell aluminum in the interlayer structure can also delay the transmission of shock waves along the thickness direction when a bullet is shocked, delays the damage of the shock waves to the ceramic panel, and improves the ballistic curve limit speed of an integral protecting structure.

Owner:HARBIN

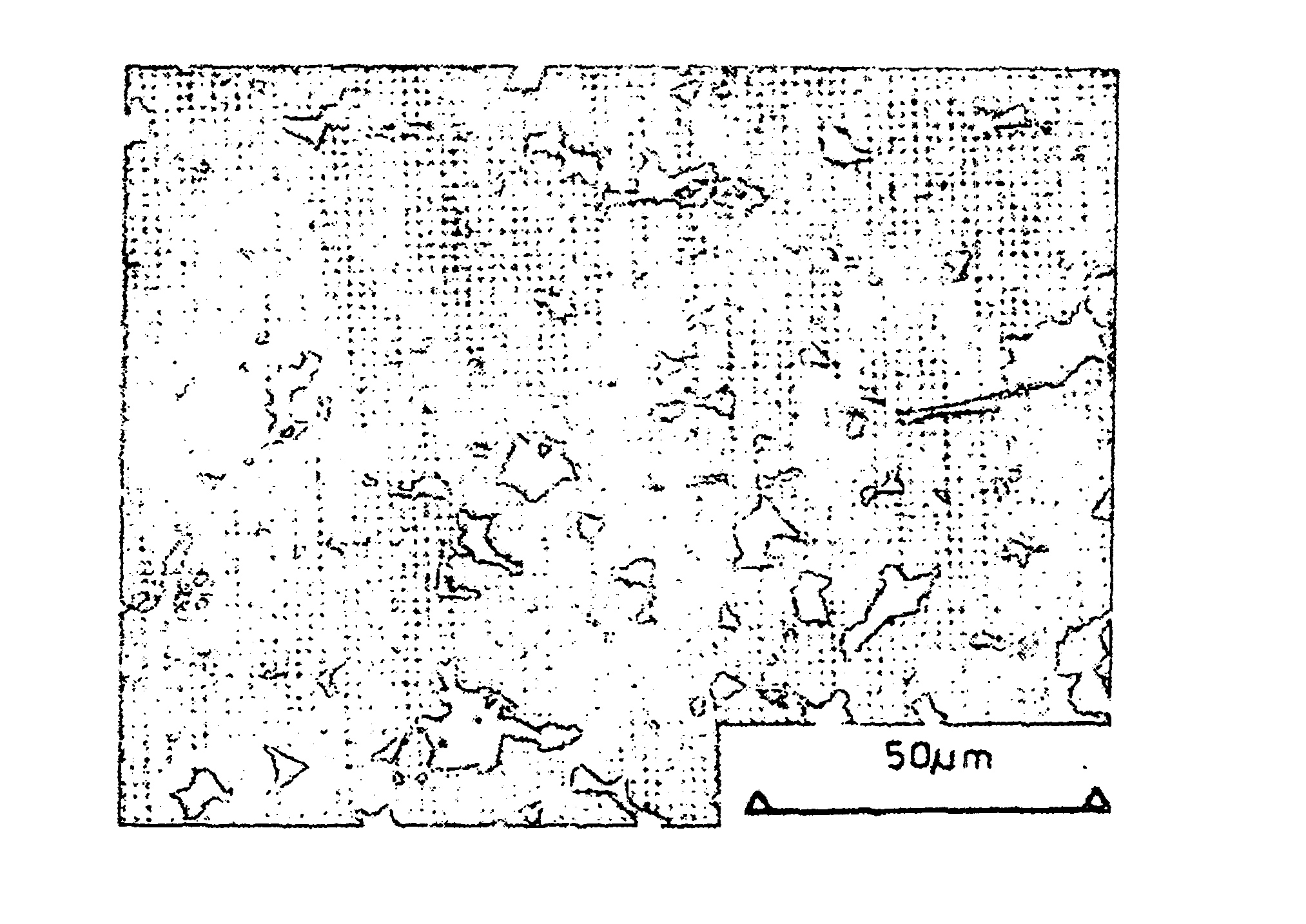

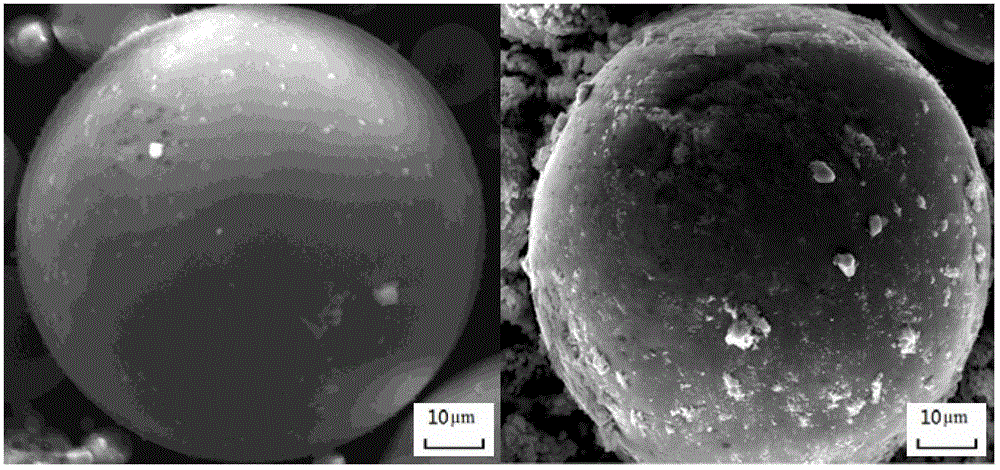

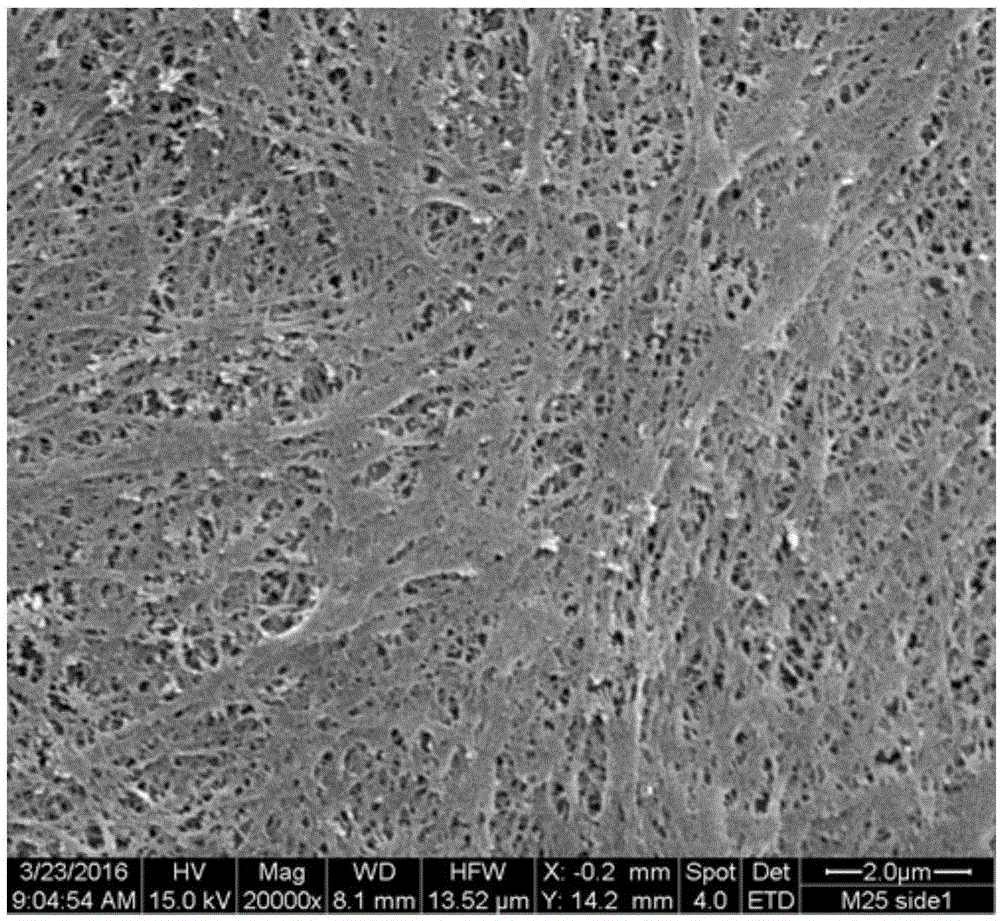

Ferrite wave-absorbing material used for injection moulding, preparation method thereof and magnetic wave-absorbing element

InactiveCN102173762ALow areal densityOrderly rowsMagnetic/electric field screeningCeramic shaping apparatusElectromagnetic environmentInjection moulding

The invention discloses a ferrite wave-absorbing material used for injection moulding, a preparation method thereof and a magnetic wave-absorbing element. The molecular formula of the wave-absorbing material is A2(Bx+C2-x)Fe12O22, wherein A is Sr or Ba, B and C are selected from Mn, Ni, Zn, Mg, Co, Cu or Ca, x is no less than 0 and no more than 2. The invention also provides the preparation method of the wave-absorbing material and the magnetic wave-absorbing element. A fluxing agent is introduced in the preparation of the ferrite wave-absorbing material, thus the free growth of crystal particles can be ensured, the bond strength between crystal particles can be reduced simultaneously, ideal hexagonal flaky crystal particles can be obtained, and the surface density of the wave-absorbing material can be effectively reduced; and injection moulding is utilized for moulding, thus the wave-absorbing element with order crystal particles and complex shape can be prepared. The wave-absorbing material disclosed by the invention can be used in different electromagnetic environments and have wide application value in the aspects for preventing the influences of electromagnetic radiation on a human body and equipment, improving the pollutions of the space electromagnetic environment and the like.

Owner:BGRIMM TECH CO LTD

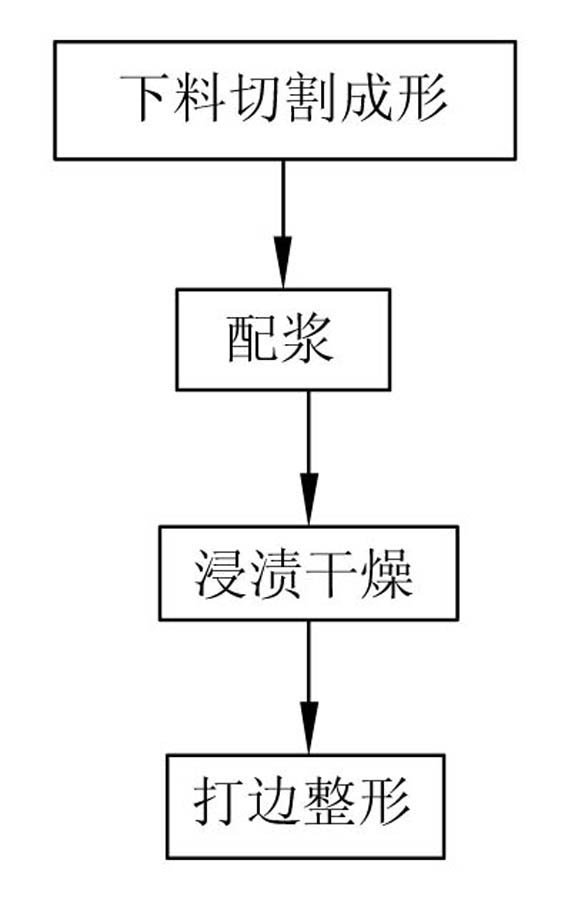

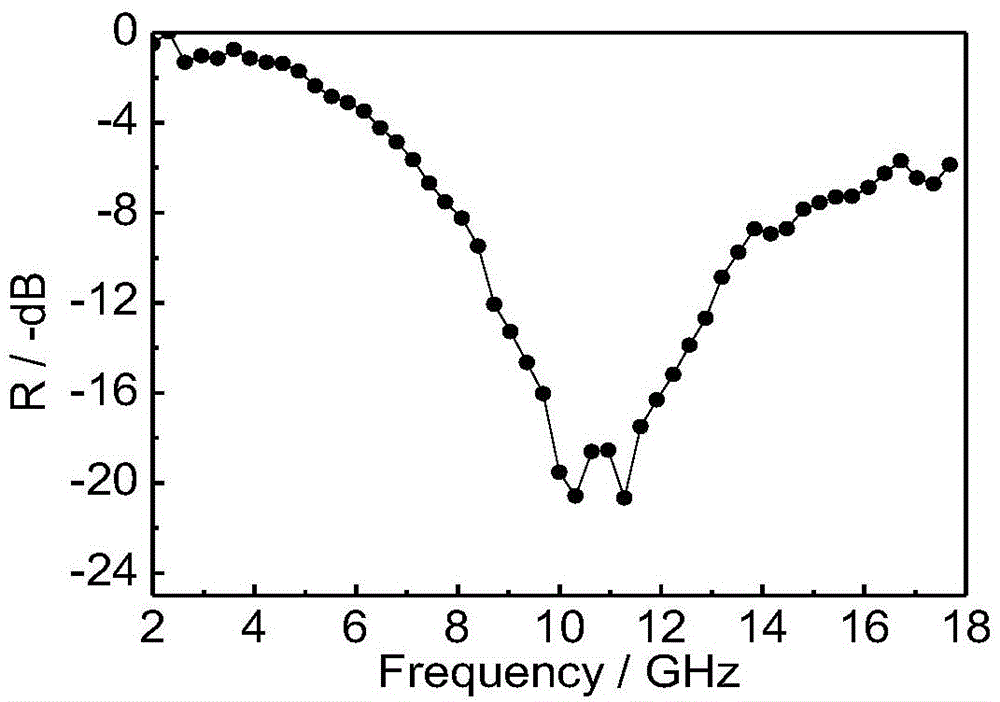

Method for manufacturing carbonyl iron foam wave-absorbing material

The invention relates to a carbonyl iron foam wave-absorbing material. Carbonyl iron which is large in magnetic loss, wave-absorbing strength and density is used as an absorbent to be added into a soft polyurethane foam base body, and the density and the mass of the carbonyl iron foam wave-absorbing material can be effectively reduced; the wave-absorbing performance of the material can be adjusted by changing the dipping times and the thickness of the base body, and the wave-absorbing material excellent in whole performance can be obtained. A method for manufacturing the carbonyl iron foam wave-absorbing material comprises the steps of preparing an adhesive glue solution, preparing an absorbent glue solution, dipping the soft polyurethane foam base body into the absorbent glue solution at multiple times repeatedly, removing an excess glue solution, placing the base body into a vacuum drying box to be dried, carrying out machining according to the specified dimension, and obtaining a finished product of the carbonyl iron foam wave-absorbing material. The overall wave-absorbing performance of the carbonyl iron foam wave-absorbing material is good, the surface density is low, the absorbed frequency is wide, the technology is simple and efficient, the repeatability is good, the radar wave absorbing effect is obvious, and the wide application prospect of the method in the radar camouflage field and the electromagnetic shielding field is displayed.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

Invisible coating material and preparation method thereof

ActiveCN103013256AImprove absorbing performanceLow areal densityCoatingsAcrylic resinCarbon nanotube

The invention discloses an invisible coating material and a preparation method thereof. The invisible coating material comprises a component A and a component B in a weight ratio of (10-15): 1, wherein the component A is prepared from the following raw materials in weight percentage: 40-60% of hydroxyl acrylic resin, 10-15% of carbon nanotube, 5-10% of ceramic powder, 5-8% of vacuum glass microbead, 1-5% of siloxane coupling agent, 1-10% of nano-sized barium sulphate, 1-10% of nano-sized titanium dioxide and 5-10% of dimethylbenzene and butyl acetate mixture; and the component B is prepared from the following raw material in weight percentage: 100% of biuret. The invention provides the invisible coating material with good invisible effect, high wave-absorbing capacity, small surface density, light weight and high bonding strength and the preparation method thereof.

Owner:山东孚日宣威新材料科技有限公司

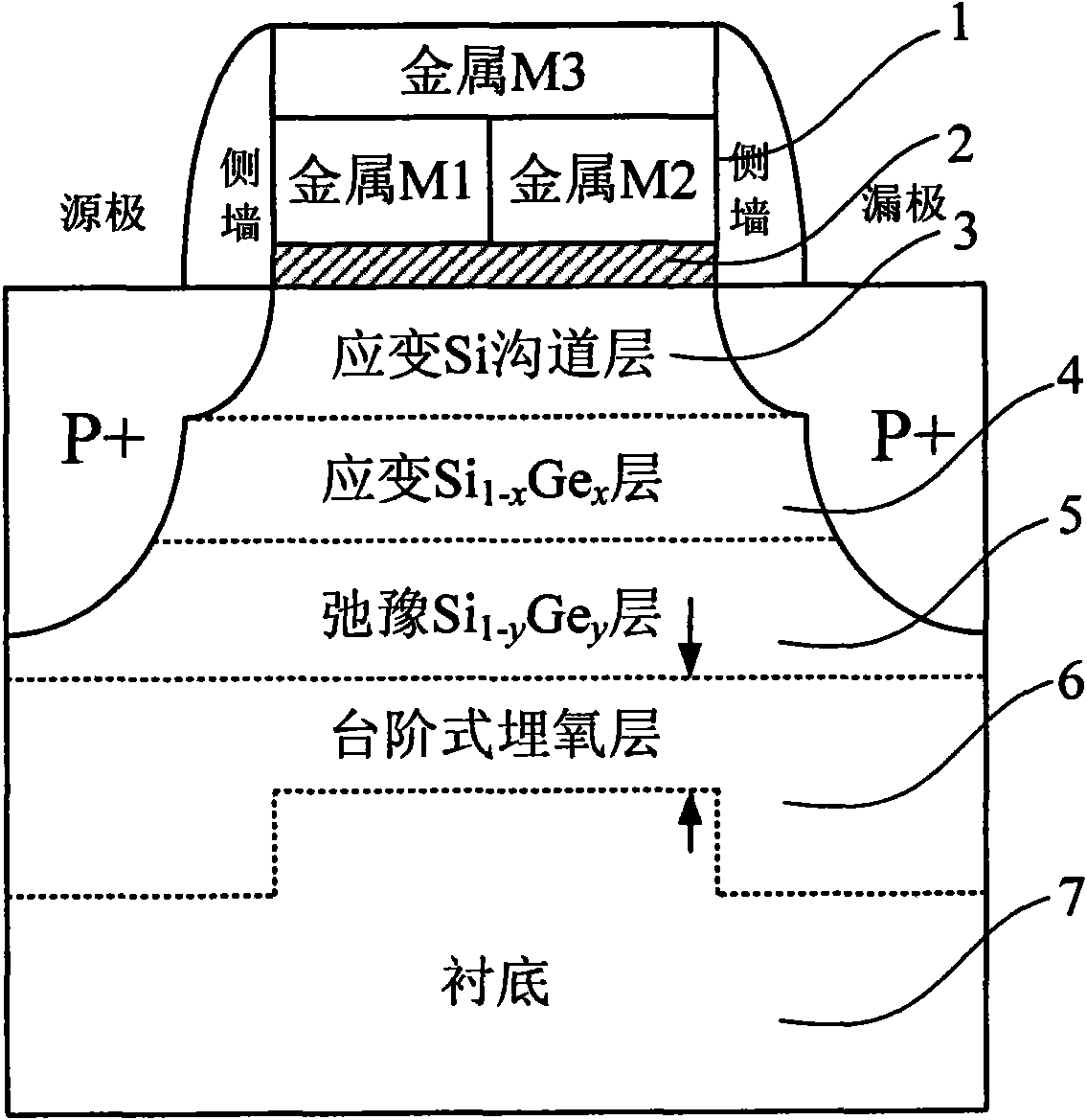

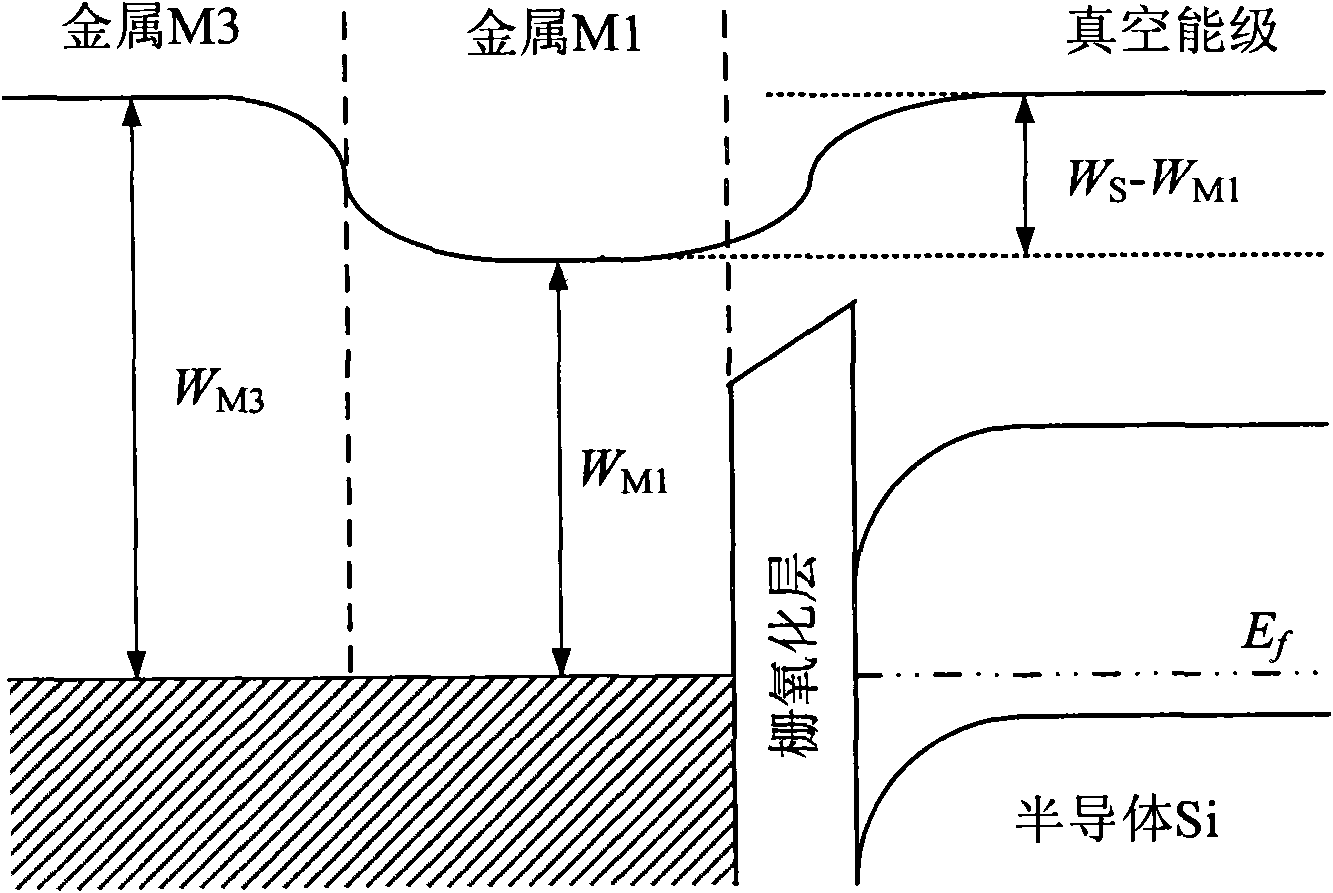

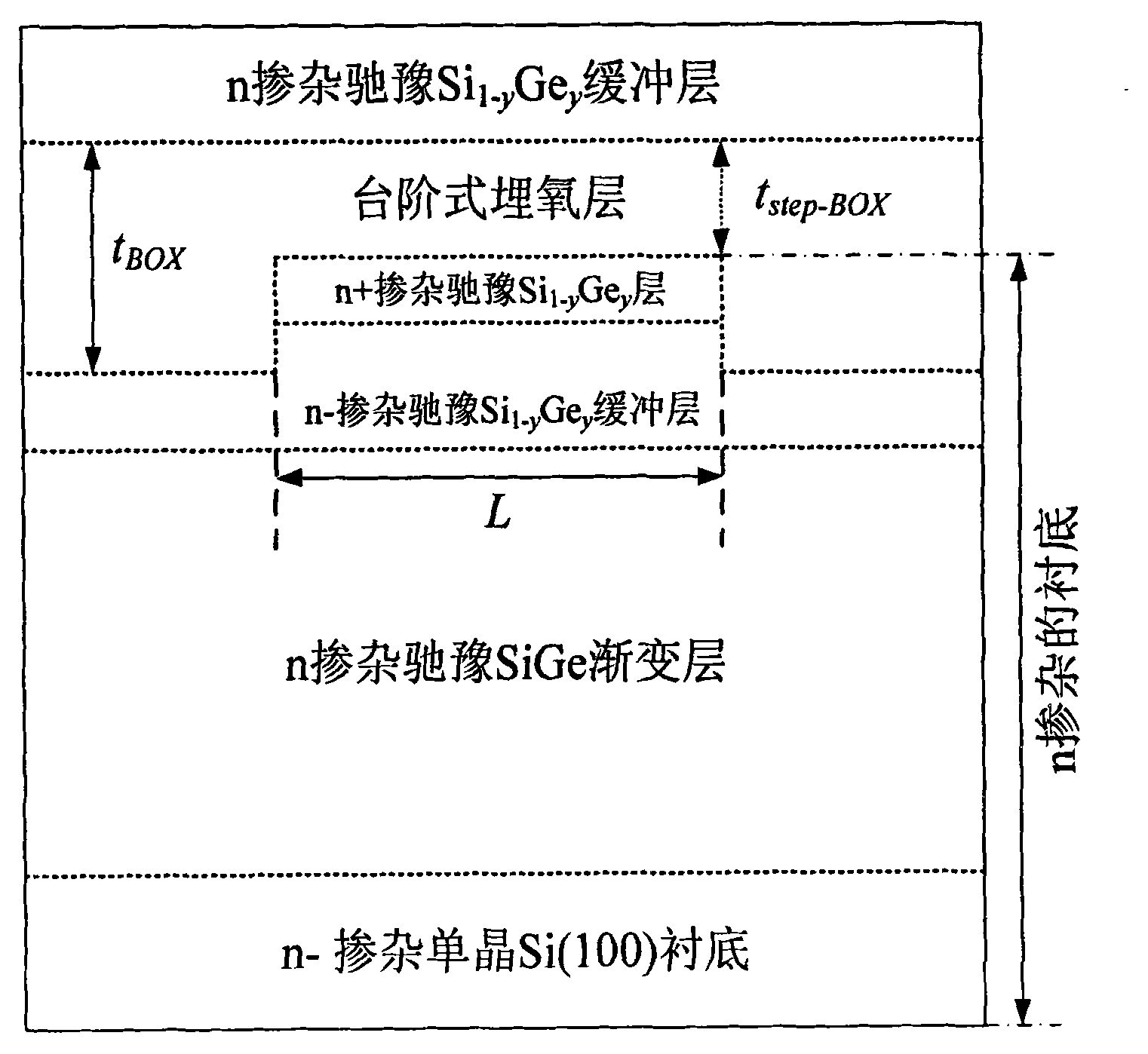

Heterogeneous metal stacked grid strained silicon-germanium on insulator p-channel metal oxide semiconductor field effect tube (SSGOI pMOSFET) device structure

InactiveCN102214694AImprove shipping speedImprove transmission efficiencySemiconductor devicesInsulation layerOxygen

The invention discloses a heterogeneous metal stacked grid strained silicon-germanium on insulator p-channel metal oxide semiconductor field effect tube (SSGOI pMOSFET) device structure, which comprises a heterogeneous metal stacked grid structure, a grid insulation layer, an intrinsic or n-doped strained Si channel layer, a strained Si1-xGex layer of which an intrinsic or n-doped component is changed gradually, an n-doped relaxation Si1-yGey layer, a stepped oxygen buried layer and an n-doped substrate part sequentially from top to bottom, wherein the n-doped substrate part consists of four parts, namely an n<+>-doped relaxation Si1-yGey layer, an n<->-doped relaxation Si1-yGey buffer layer, an n-doped relaxation SiGe gradient layer and an n<->-doped monocrystal Si(100) substrate. The device has a simple structure, can be totally compatible with the conventional Si silicon on insulator (SOI) process, is integrated with the advantages of grid engineering, strain engineering and substrate engineering, and makes a complementary metal-oxide-semiconductor structure process simply integrated.

Owner:XIDIAN UNIV

Material with characteristics of fire retardation, thermal insulation and wave absorption, and preparation method thereof

InactiveCN102746823AImprove flame retardant and heat insulation effectEvenly dispersedOther chemical processesFibre treatmentThermal insulationAdhesive

The present invention provides a material with characteristics of fire retardation, thermal insulation and wave absorption. The material comprises a base layer, wherein the base layer is mesh fabric, both sides of the mesh fabric are coated with an adhesive coating layer, and the adhesive coating layer is a polyvinylchloride adhesive coating layer. The adhesive coating layer comprises a wave absorption agent, wherein the wave absorption agent comprises nickel-plated glass beads, and a mass ratio of the wave absorption agent powder to the adhesive is 0.17-1.85:1. The present invention further provides a preparation method for the material. According to the material with characteristics of fire retardation, thermal insulation and wave absorption in the present invention, the polyvinylchloride adhesive is added with the wave absorption agent, such that functions of fire retardation, thermal insulation and wave absorption can be concurrently provided; the material of the present invention can concurrently has functions of fire retardation and thermal insulation, and characteristics of high wave absorption strength, wide wave absorption frequency band, and small surface density; and the material of the present invention can be used for wave absorption defilading, electromagnetic shielding, and the like.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Ceramic membrane with improved adhesion to plasma-treated polymeric support material and the manufacture and usage thereof

ActiveCN101301586APrecisely defined pore size distributionWeakened ionic conductivitySemi-permeable membranesMembranesCeramic membranePolymer

The invention relates to a flexible ceramic membrane which is suitable for batters as a spacer according to different embodiment manners, in particular for lithium battery. The invention further relates to the preparation method thereof, wherein plasma processing is carried out to the polymer nonwovens.

Owner:EVONIK DEGUSSA GMBH

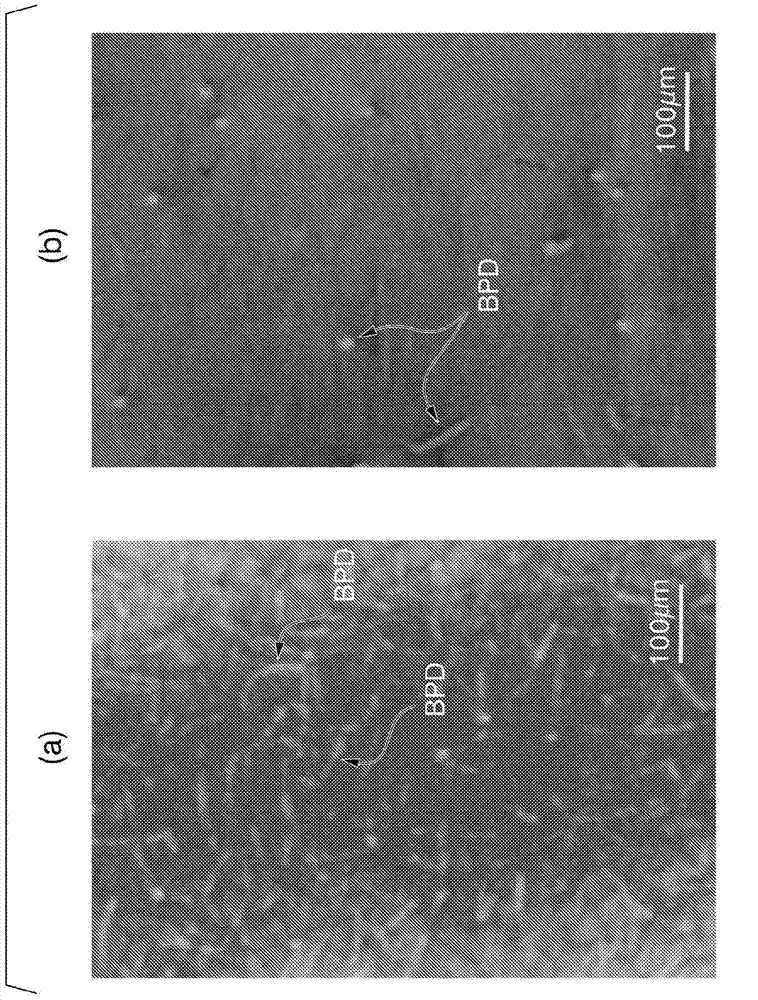

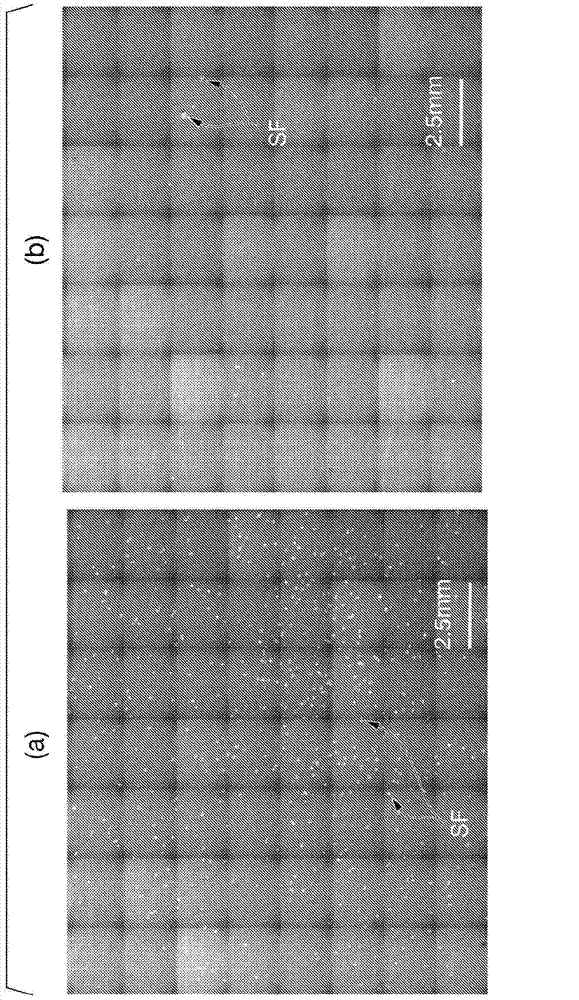

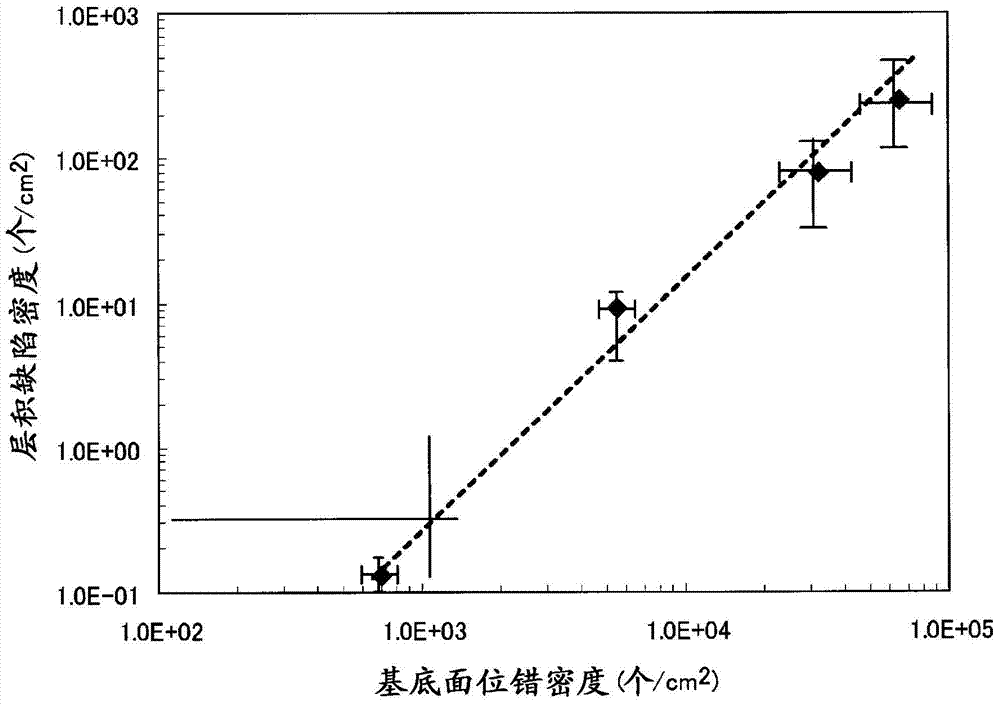

SiC epitaxial wafer and method for manufacturing same

ActiveCN103765559ALow areal densityPolycrystalline material growthSemiconductor/solid-state device manufacturingMaterials scienceEpiwafer

The present invention relates to a SiC epitaxial wafer with a reduced surface density of a stacking fault, and a method for manufacturing the same. The method of the present invention comprises determining a stacking fault ratio at a SiC epitaxial membrane having a predetermined thickness formed on a SiC single crystal substrate in a basal plane dislocation (BPD) present at a growth plane of the SiC single crystal substrate having an off angle, determining an upper limit of a surface density of the BPD at the growth plane of the SiC single crystal substrate in use based on the ratio, and forming the SiC epitaxial membrane on the SiC single crystal substrate by using the SiC single crystal substrate below the upper limit in the same condition as a growth condition of the epitaxial membrane used when determining the ratio.

Owner:SHOWA DENKO KK

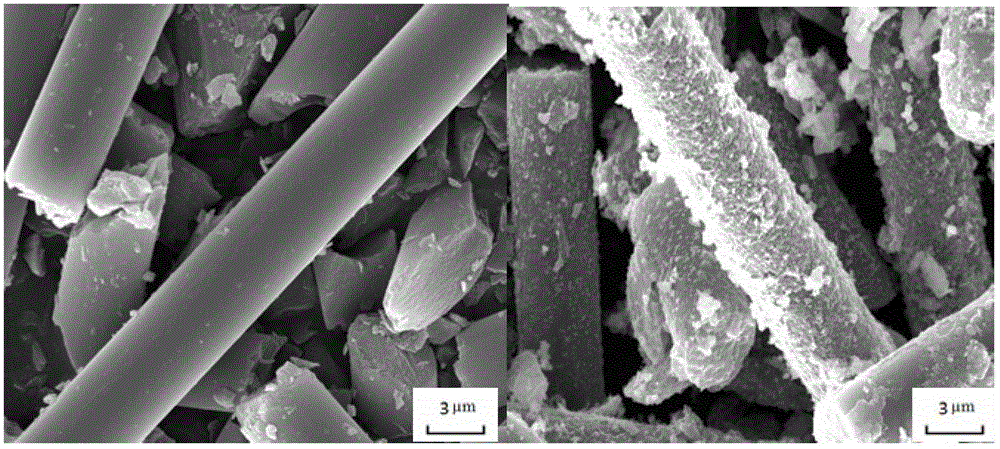

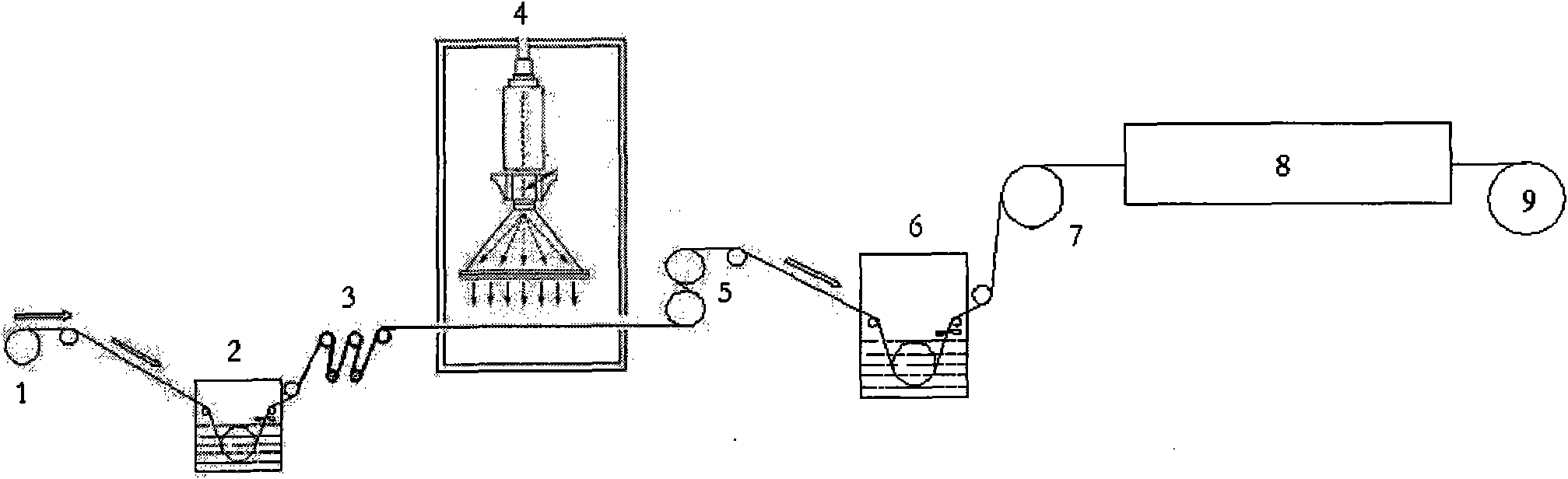

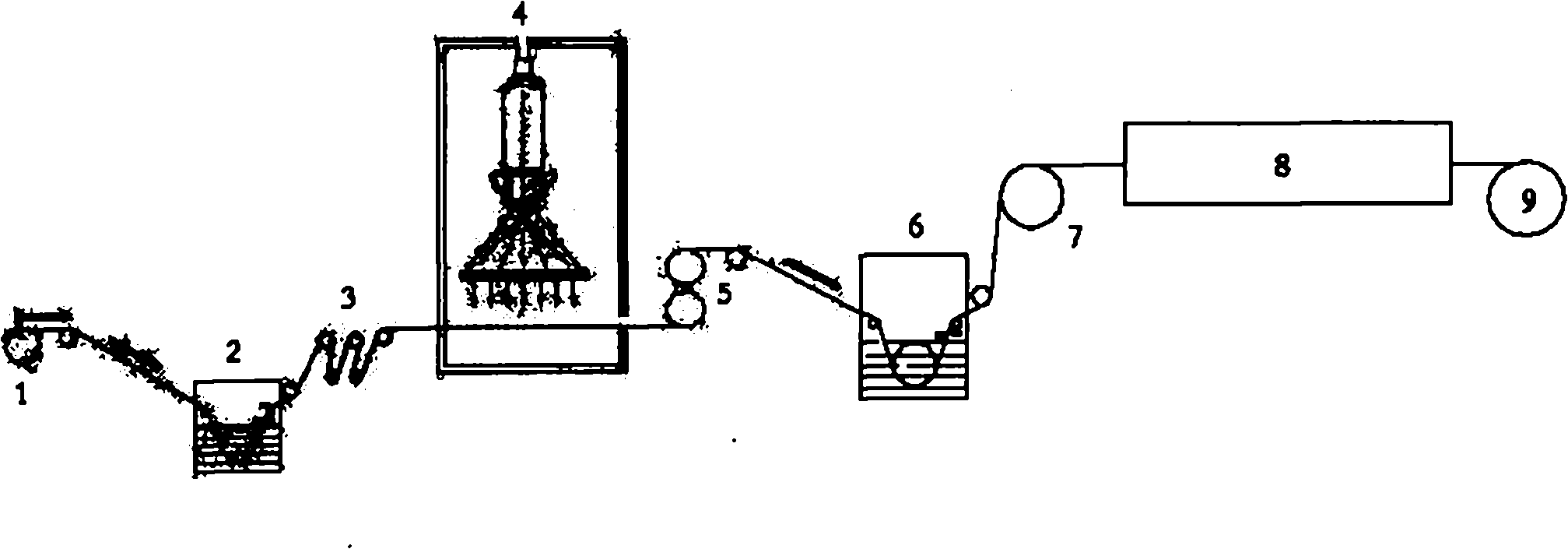

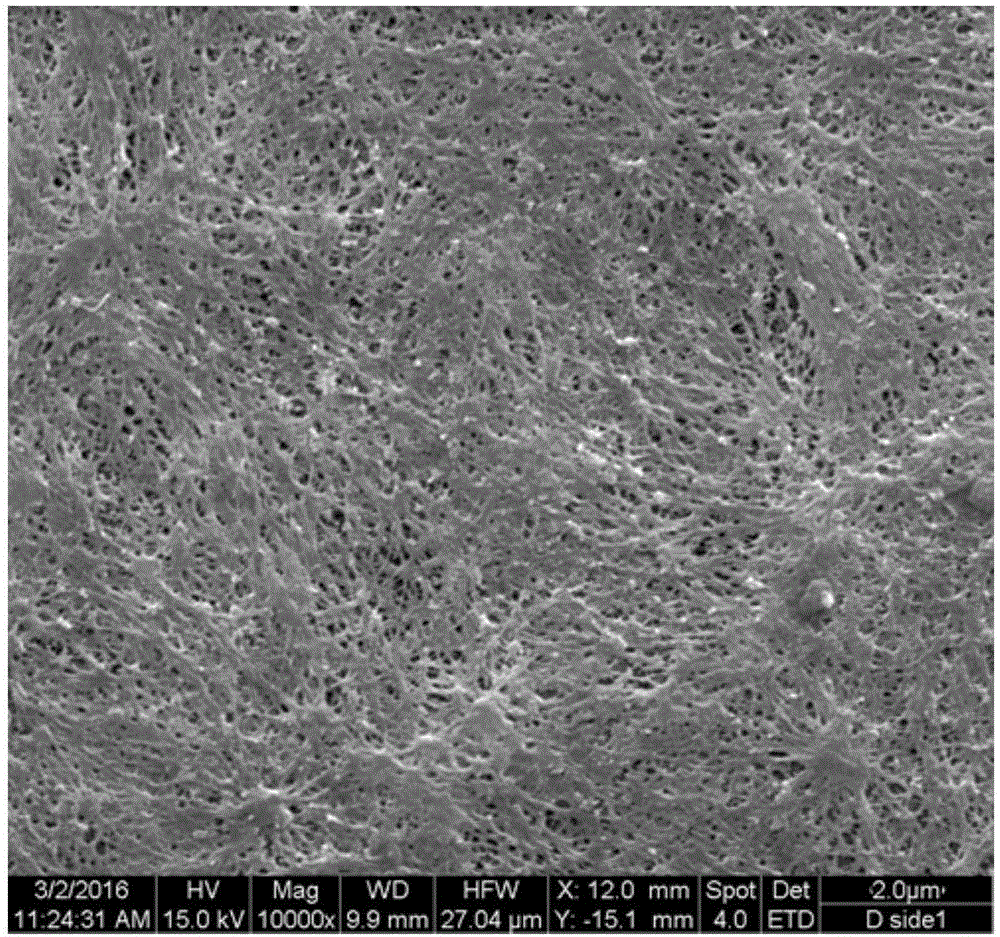

Method for producing composite non-woven cloth material from irradiated ultrahigh molecular weight polyethylene fiber

InactiveCN102400284AImprove interface bonding performanceReduce dosageFibre typesNon-woven fabricsTectorial membraneFiber

The invention relates to a method for producing a composite non-woven fabric material from irradiated ultrahigh molecular weight polyethylene (UHMWP) fiber. The method comprises the following steps of: (1) spreading a plurality of strands of ultrahigh molecular weight polyethylene fiber in parallel by using a guide roller after passing through a buncher, and impregnating the fiber in a grafting liquid; (2) irradiating the fiber impregnated in the grafting liquid to realize grafting, and sending the fiber into a glue dipping groove; (3) processing glue on double surfaces of adhesive-containing filament bundles by using parallel scrappers, and drying the filament bundles to obtain a one-way non-woven fabric; (4) producing composite non-woven fabric sheets or coils to obtain a composite non-woven fabric material. Compared with the prior art, the method has the advantages that an electron beam irradiation grafting technology is introduced into a UD cloth production method in the invention, so that the UHMWP fiber can be grafted and modified through mutual irradiation, and interfacial adhesive performances of the fiber and the adhesive can be improved; and therefore, the consumption of the adhesive is reduced during the production of the one-way non-woven fabric, application of a protective film is eliminated, and finally surface density of the composite non-woven fabric material is reduced.

Owner:SURREY HI TECH INC +1

Stab-resisting cloth with inorganic powder coating and preparing method of stab-resisting cloth

InactiveCN106767165AGood flexibilityExcellent comfort and flexibilityPersonal protection gearFiberPolyresin

The invention discloses stab-resisting cloth with an inorganic powder coating and a preparing method of the stab-resisting cloth. The stab-resisting cloth comprises the inorganic powder coating and base cloth. The inorganic powder coating and the base cloth are stuck through an adhesive layer. Inorganic powder in the inorganic powder coating is ceramic powder. The prepared finished slab-resisting cloth with the inorganic powder coating is a soft non-metal stab-resisting product and has good stab-resisting performance, the face density of a stab-resisting material of the stab-resisting cloth is reduced by 20% than that of a resin fiber composite material of the same base cloth, the overall thickness and weight are reduced to a great degree, and the service life of the stab-resisting material of the stab-resisting cloth is prolonged by 50% or above than that of a stab-resisting material containing metal. In addition, the prepared stab-resisting cloth has better softness, and the comfortable and flexible degree is better when the stab-resisting cloth is made into stab-resisting clothes to be worn.

Owner:江苏安卡新材料科技有限公司

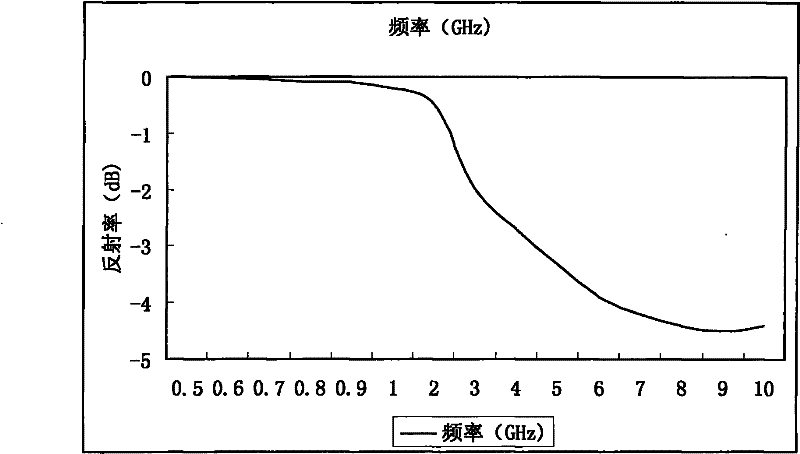

Waves-absorbing material for Ku waveband radar with film structure

ActiveCN101817248AGood absorptionLow areal densitySynthetic resin layered productsWave bandFilm structure

The invention relates to a wave-absorbing material for a Ku waveband radar with a film structure, mainly comprising six wave-absorbing material layers and five plastic films, wherein the plastic films are arranged between every two wave-absorbing material layers of the six wave-absorbing material layers; the first wave-absorbing material layer is a mixture of 1.50 parts of coupling agents, 50 parts of diluents, 150 parts of ferrites and 53.67 parts of 60% epoxy resins; the second wave-absorbing material layer is a mixture of 1.50 parts of the coupling agents, 50 parts of the diluents, 150 parts of carbonyl iron absorbents, 39.83 parts of the 60% epoxy resins and 12.93 parts of curing agents; the third wave-absorbing material layer is a mixture of 1.50 parts of the coupling agents, 50 parts of the diluents, 150 parts of the carbonyl iron absorbents, 109.02 parts of the 60% epoxy resins and 33.10 parts of the curing agents; and the fourth wave-absorbing material layer, the fifth wave-absorbing material layer and the sixth wave-absorbing material layer are mixtures of 1.50 parts of the coupling agents, 50 parts of the diluents, 150 parts of the carbonyl iron absorbents, 39.83 parts of the 60% epoxy resins and 12.93 parts of the curing agents. The wave-absorbing material combines an impedance gradual change principle with an electromagnetic wave trap principle, has high wave-absorbing property within a Ku waveband range, little thickness, low surface density, light weight and good mechanical property and is suitable for resisting the Ku waveband radar.

Owner:江苏万华拓谷新材料科技有限公司

Lithium battery composite membrane and preparation method thereof

InactiveCN106299220AAchieve lightweightHigh densityMaterial nanotechnologyCell component detailsHigh energyThermal stability

The invention discloses a lithium battery composite membrane which is formed by coating a porous base membrane with nano sol and then drying the sol. The lithium battery composite membrane has the following performances: the surface density is 10.04-12.70g / m<2>, the thickness is 15.3-16.6 microns, and the gas permeability is 140-696s / 100cc. If the discharged membrane is put into an oven, the temperature is set to be 105 DEG C or 130 DEG C and the set temperature is kept for one hour, the thermal shrinkage rate is 2.5-3.5 105 DEG C / TD, 2.5-3.0 105 DEG C / MD and 3.3-10 130 DEG C / TD, and 3.5-8.5 130 DEG C / MD. The composite membrane consists of the porous base membrane and an inorganic material high-temperature coating coated between the surface and holes of the base membrane, has good thermal stability, good quality and less thickness increase, can be used for preparing high-energy density lithium batteries and also has the characteristics of simple preparation process, low cost and the like.

Owner:SHANGHAI SHUANGAO ENERGY TECH

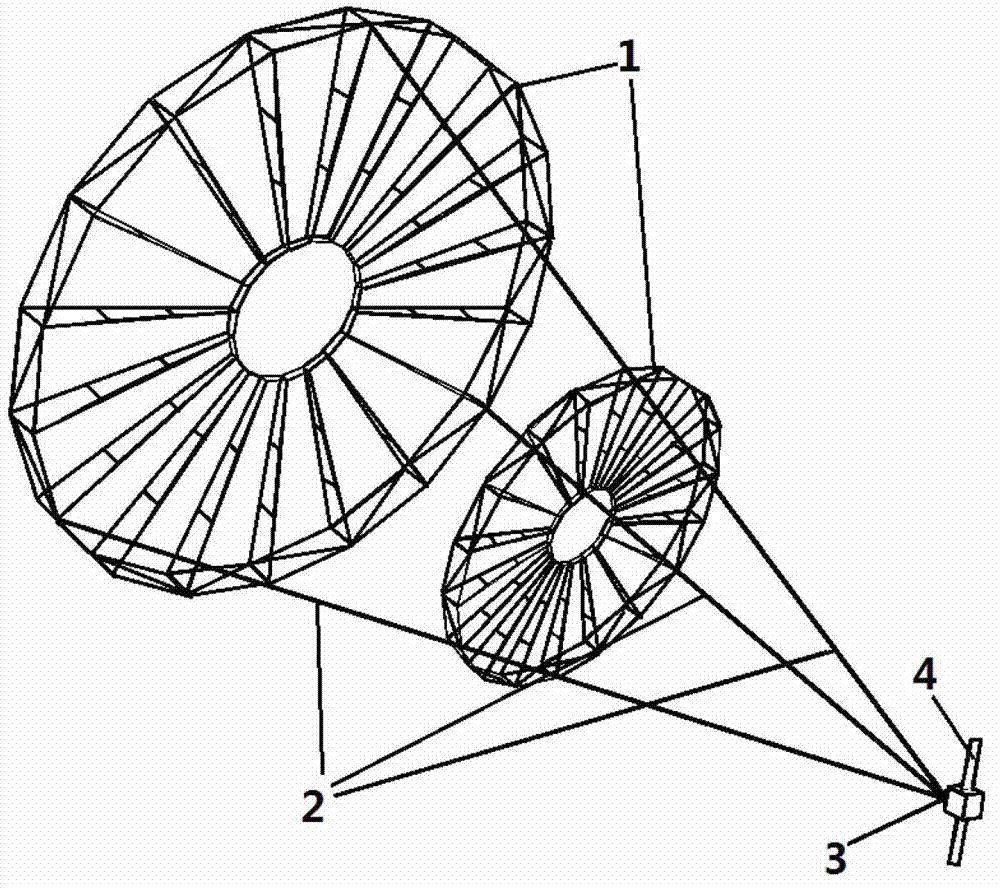

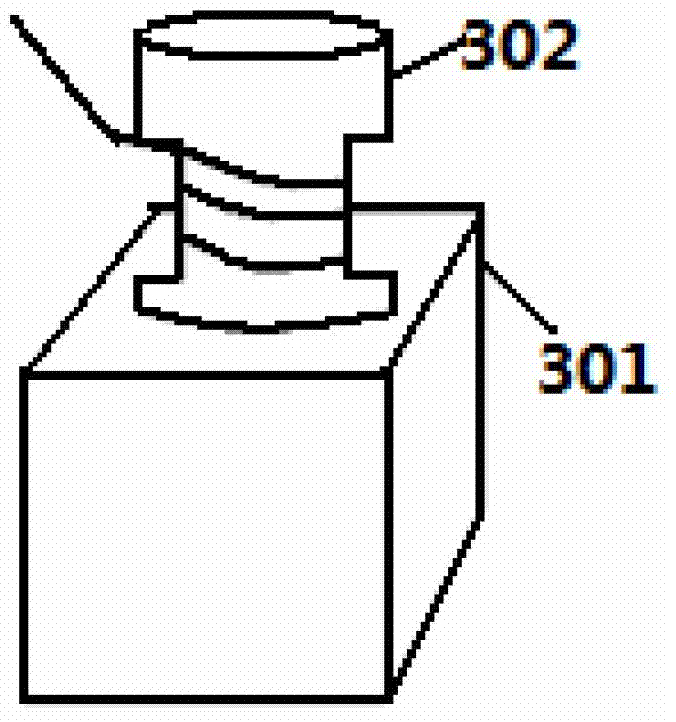

Device for unfolding surface of space rope system

The invention discloses a device for unfolding a surface of a space rope system, and is mainly used for solving the problems that the prior art is difficult to mold and has bad stability. The device comprises a plurality of reflectors or transmission surfaces (1), a plurality of flexible pulling cables (2), a satellite platform (4) and a plurality of control mechanisms (3) of the pulling cables, wherein each reflector or transmission surface (1) is composed of a folding ring (4) and a ring connecting joint (5), and is stacked according to the caliber size; one end of each flexible pulling cable (2) penetrates through a corresponding hole of the folding ring (4) of the reflector or transmission surface with the biggest caliber to be tied fixedly, and then penetrates through the folding ring (4) of the other reflector or transmission surface to be tied fixedly; the other end of each flexible pulling cable (2) is connected with the control mechanisms (3) on the satellite platform; and the reflectors or transmission surfaces are connected hierarchically to form a stacked structure composed of the satellite platform and all reflectors or transmission surfaces so as to form a space rope system. The device can achieve effective molding structure, autonomous orbit and pose stability of the whole system, so that the device can be applied in a large antenna or telescope in space.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com