Method for manufacturing carbonyl iron foam wave-absorbing material

A wave absorbing material, carbonyl iron technology, applied in the fields of radar wave absorption and functional materials, can solve the problems of large thickness, and achieve the effect of low surface density, good overall performance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Accurately weigh 74g of carbonyl iron, 14g of acrylic resin, 8g of titanate coupling agent and 100g of absolute ethanol; dissolve the acrylic resin in absolute ethanol, and stir until it dissolves into a transparent and uniform solution;

[0022] Step 2: Add carbon black and titanate coupling agent to the above-mentioned adhesive glue, mechanically stir and sonicate for 30 minutes to prepare absorbent glue;

[0023] Step 3: Immerse soft polyurethane with a thickness of 4mm in the above glue, pull the filtrate, then soak again, repeat 3 times, finally drain the excess glue, and dry in a vacuum oven at 40°C ;

[0024] Step 4: Process the dried carbonyl iron foam absorbing material according to the specified size to obtain the finished product.

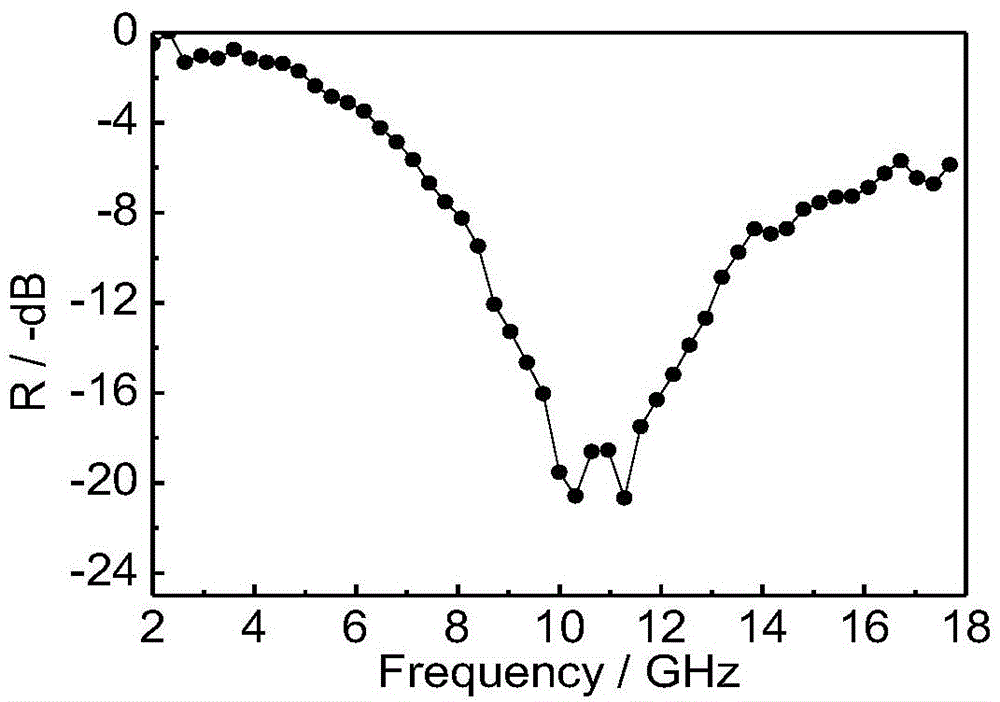

[0025] Depend on figure 1 It can be seen that the carbonyl iron in the carbonyl iron foam absorbing material prepared in this example is evenly distributed and is effectively compounded with soft polyurethane. Depend on...

Embodiment 2

[0027] Step 1: Accurately weigh 74g of the mixture of carbon black and carbonyl iron, 18g of acrylic resin, 8g of titanate coupling agent and 100g of absolute ethanol; dissolve the acrylic resin in absolute ethanol, and stir until it dissolves into a transparent homogeneous solution;

[0028] Step 2: Add carbon black and titanate coupling agent to the above-mentioned adhesive glue, mechanically stir and sonicate for 45 minutes to prepare absorbent glue;

[0029] Step 3: Immerse soft polyurethane with a thickness of 3mm in the above glue, pull the filtrate, then dip again, repeat twice, finally drain the excess glue, and dry it in a vacuum oven at 40°C ;

[0030] Step 4: Process the dried carbonyl iron foam absorbing material according to the specified size to obtain the finished product.

[0031] Depend on image 3 It can be seen that the carbonyl iron foam absorbing material prepared in this example has good absorbing performance. The thickness is 3mm. When impregnated twic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com