Lithium battery composite membrane and preparation method thereof

A composite diaphragm and lithium battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of occupying the internal space of the battery, increasing the weight and thickness of the diaphragm, and not conducive to improving the volumetric energy density of lithium-ion batteries. Realize the effects of lightweight battery, increased capacity per unit volume, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of a kind of lithium battery composite membrane that the present invention proposes comprises the following steps:

[0028] Step 1, preparation of nano-sol:

[0029] The nano sol is a mixture of one or more of silica sol, titanium sol, aluminum sol and zirconium sol, and its preparation steps are as follows:

[0030] Dissolving the compound of silicon, titanium, aluminum and zirconium which can be hydrolyzed in an organic solvent, adjusting the pH value to 2-4 or 8-10, adding high-purity water and hydrolyzing it to form a mixed solution A is obtained;

[0031] The compound of silicon, titanium, aluminum and zirconium that can be hydrolyzed is at least one of organic alcohol compounds, halides and organic esters, and can be divided into class A hydrolyzable compounds and class B hydrolyzable compounds; class A Hydrolyzable compounds include tetraethoxysilane, diethyl titanate, tetraisopropanol titanate, tetraethyl titanate, tetrabutyl titanate, ti...

Embodiment 1

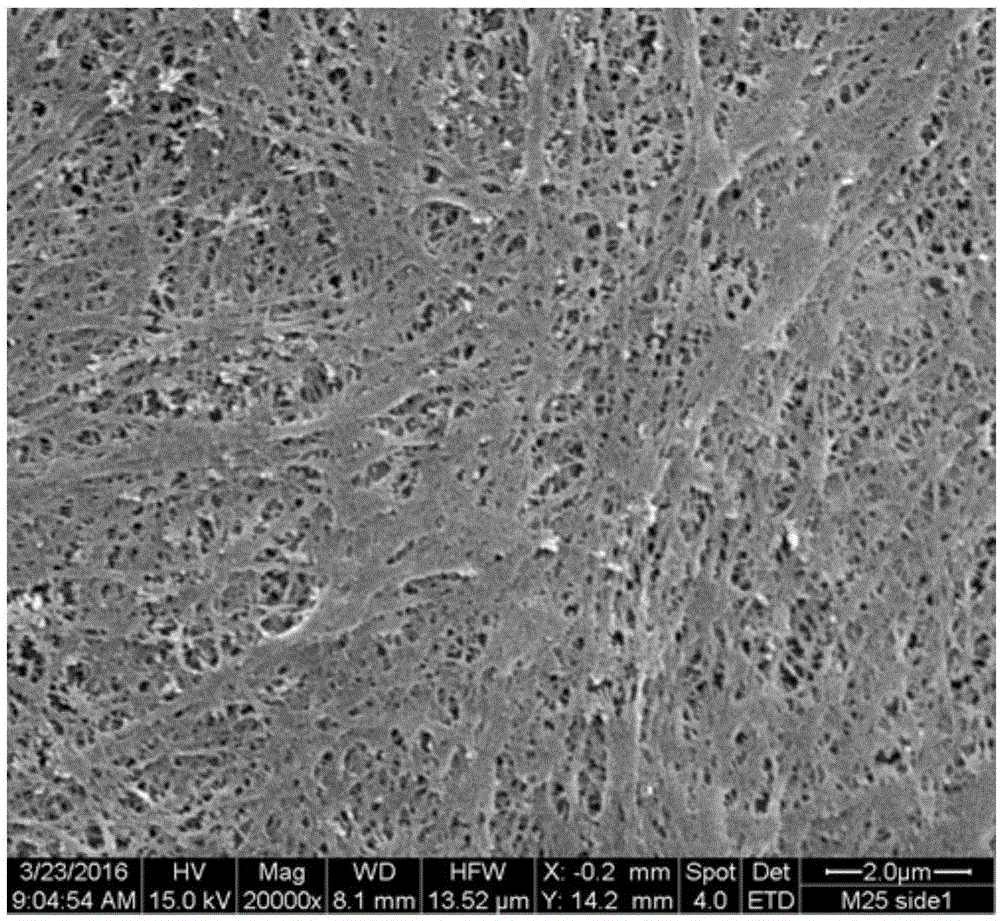

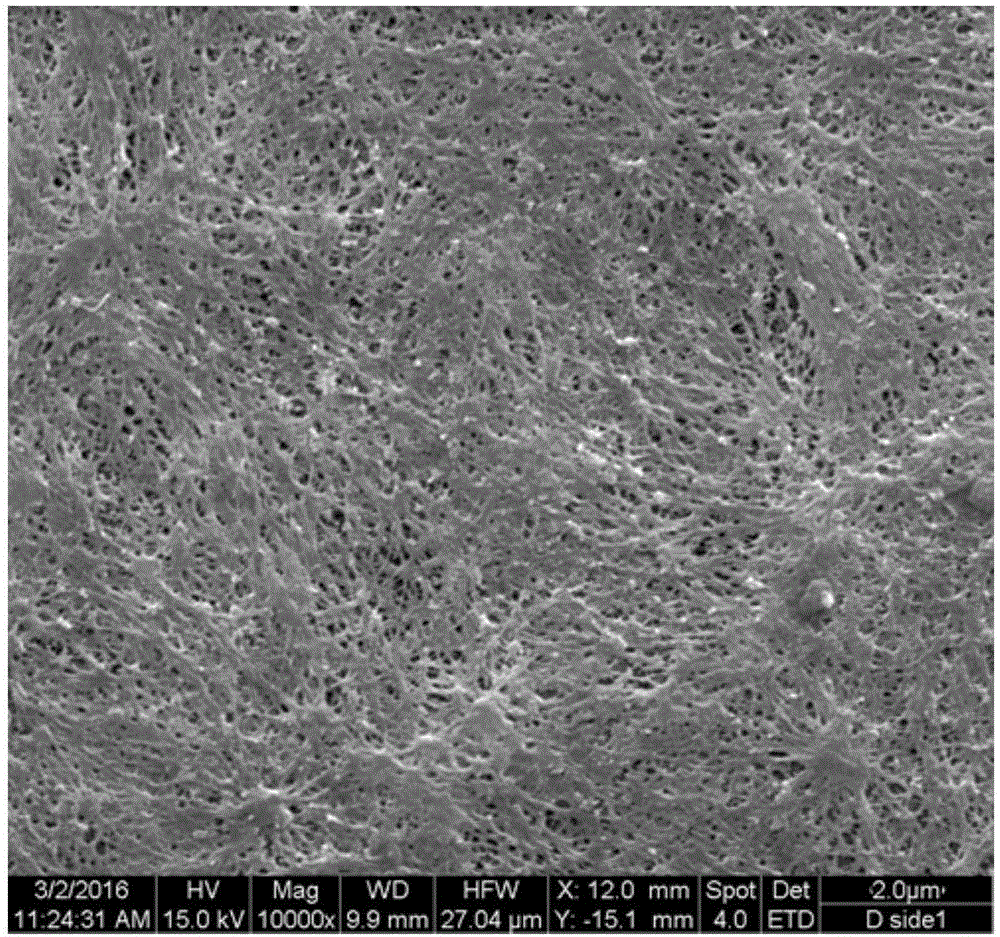

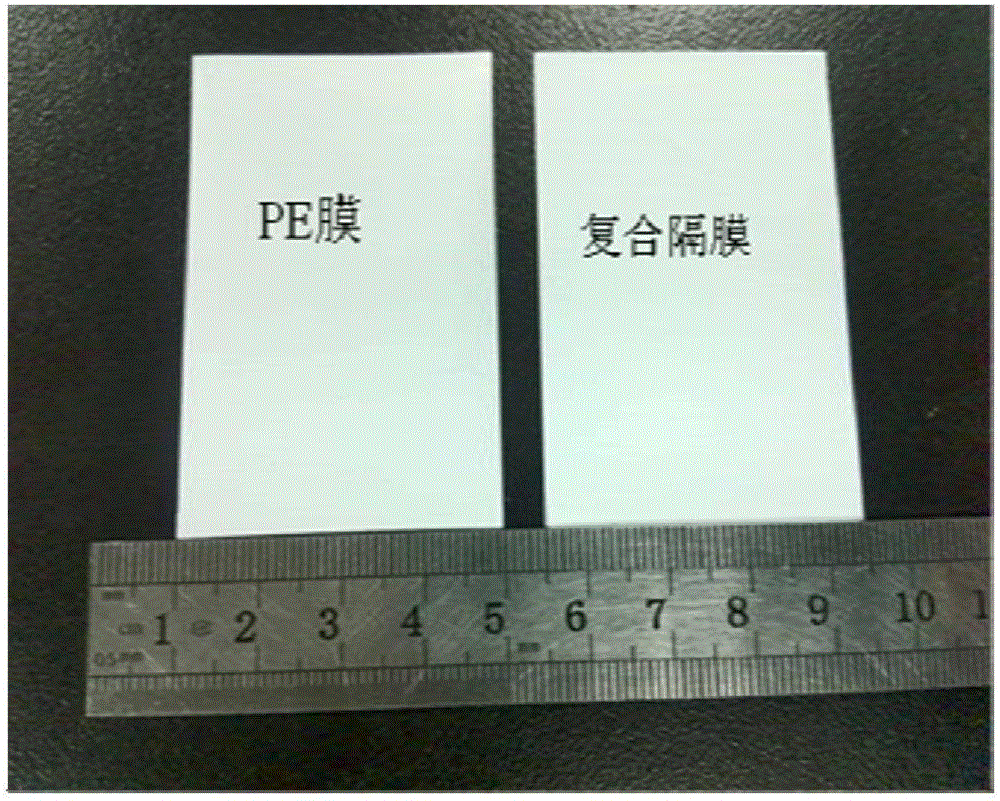

[0042] Embodiment 1. Mix 20 g of tetraethoxysilane and 172 g of ethanol to form a uniform solution, add hydrochloric acid to adjust the pH value to 4, and slowly add high-purity water dropwise. The molar ratio of high-purity water to tetraethoxysilane was 8:1, stirred evenly, heated to reflux at 50° C. for 7 hours, and cooled to room temperature to obtain a nano-sol. During the experiment, a PE diaphragm with a thickness of 16 μm and a porosity of 60% was selected as the porous base film, and the nano-sol was coated on the PE diaphragm by dip-coating at a speed of 10 m / min, and dried at 15 °C. Dry.

Embodiment 2

[0043] Example 2 is basically the same as Example 1, the only difference is that in the preparation of nano-sol, tetraethoxysilane is replaced by tetraethyl titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com