Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

A composite material and carbon fiber technology, applied in the direction of railway car bodies, railway car body parts, railway roofs, etc., can solve the problems of non-metallic materials and metal materials deformation mismatch, commercial operation difficulties, and weight loss are not obvious, etc., to avoid Welding defects, good sound insulation and heat insulation effect, the effect of improving bending stiffness and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

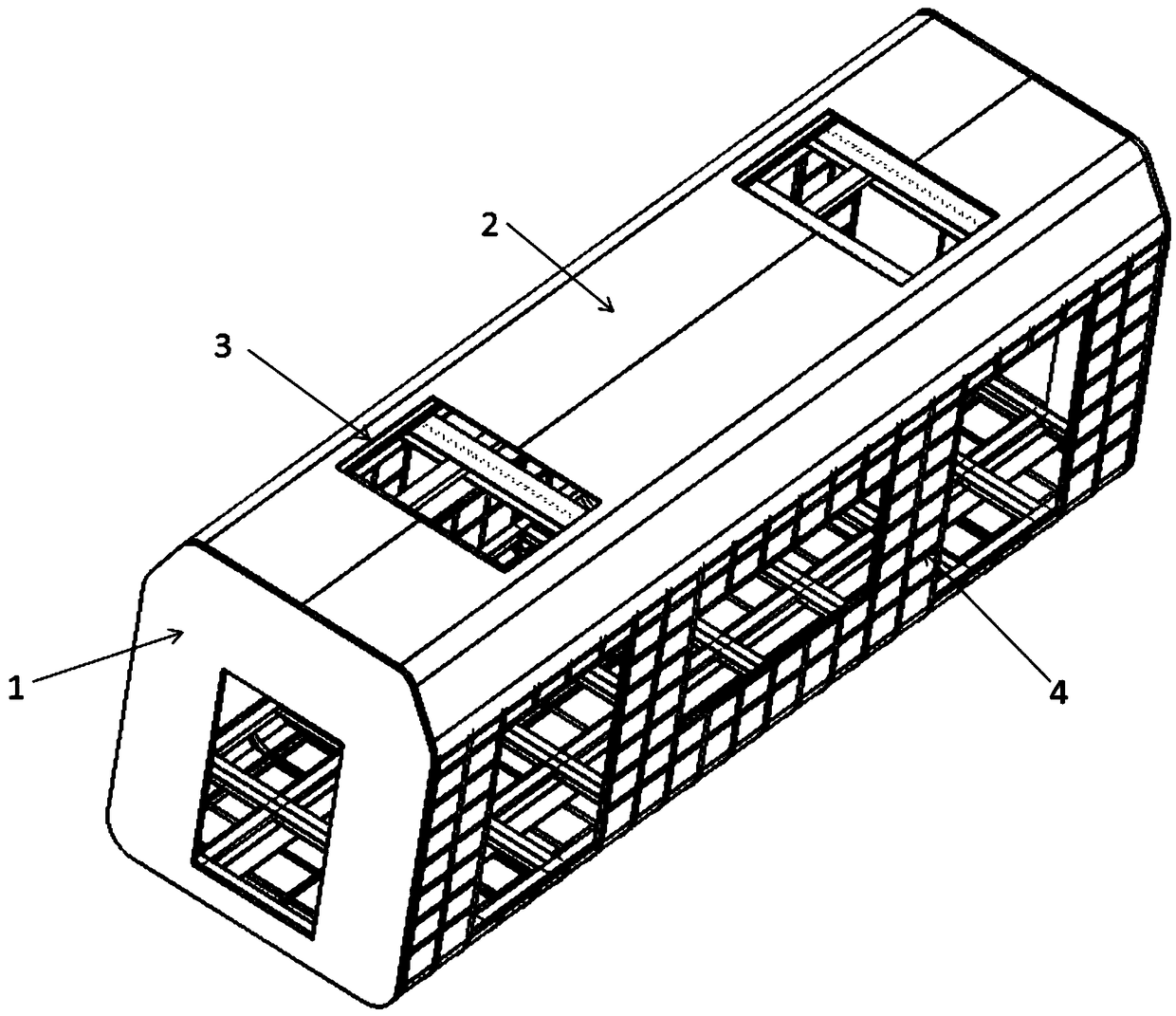

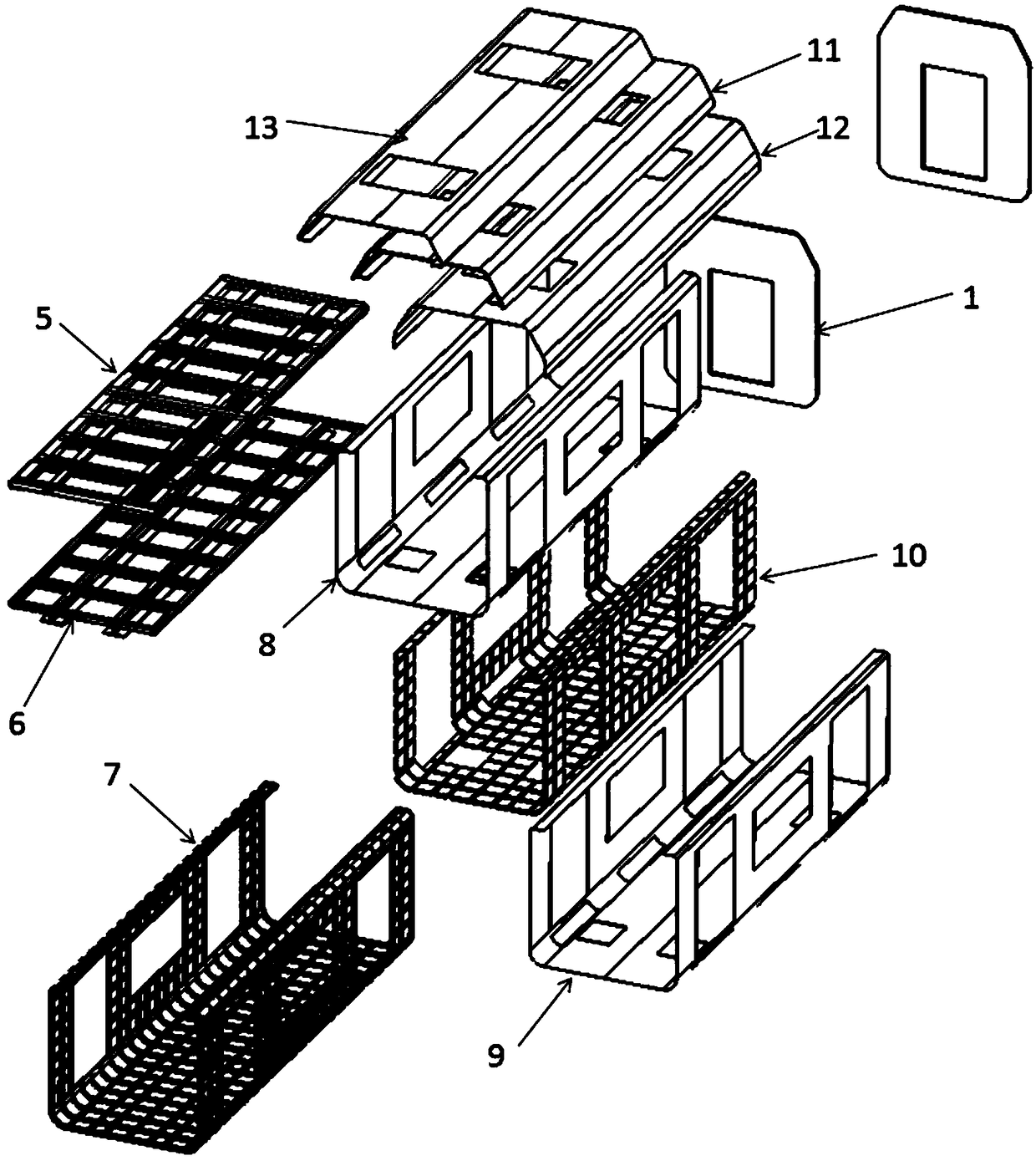

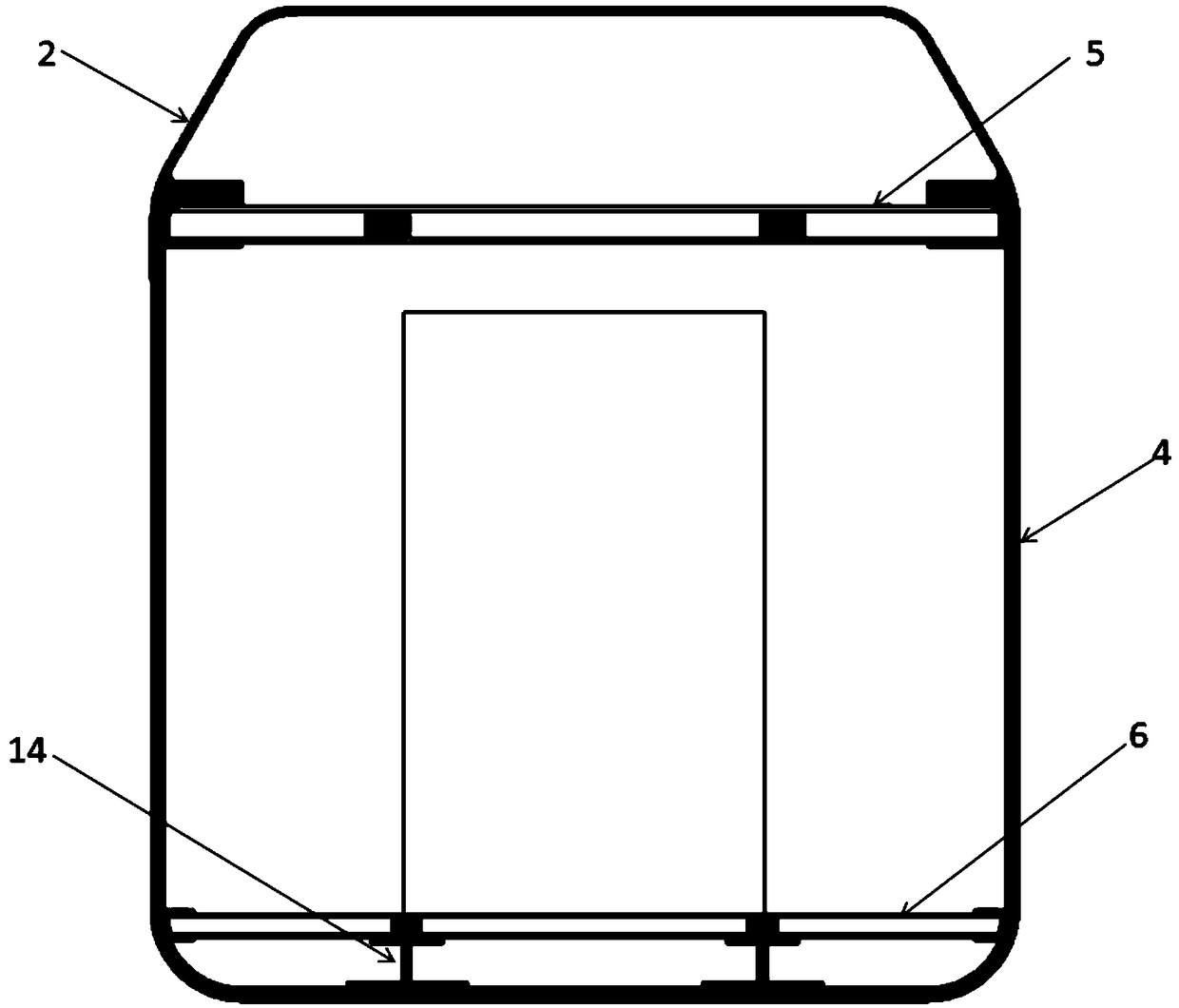

[0046] Such as Figure 1-Figure 9 As shown, the present invention provides a structure of a low-cost carbon fiber composite empty iron car body, which includes a U-shaped groove-shaped car body side wall 4, and both ends of the car body side wall 4 are assembled and connected with end The wall 1 and the end wall 1 are used to seal the openings at both ends of the side wall 4 of the car body, and the inner wall on the opening side of the side wall 4 of the car body is provided with an inner edge, and the two sides of the inner edge are respectively the inner top surface of the side wall 4 of the car body and the outer top surface of the vehicle body side wall 4, the inner top surface and the inner bottom surface of the vehicle body side wall 4 are respectively assembled and connected with a top frame 5 and an underframe 6, that is, the top fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com