Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253results about How to "Avoid Welding Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

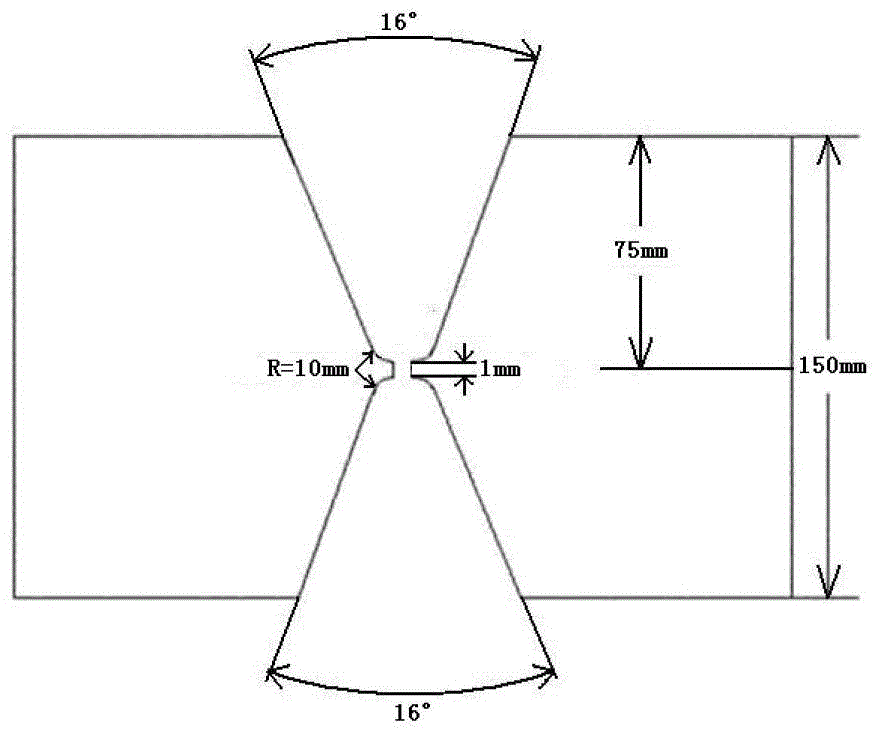

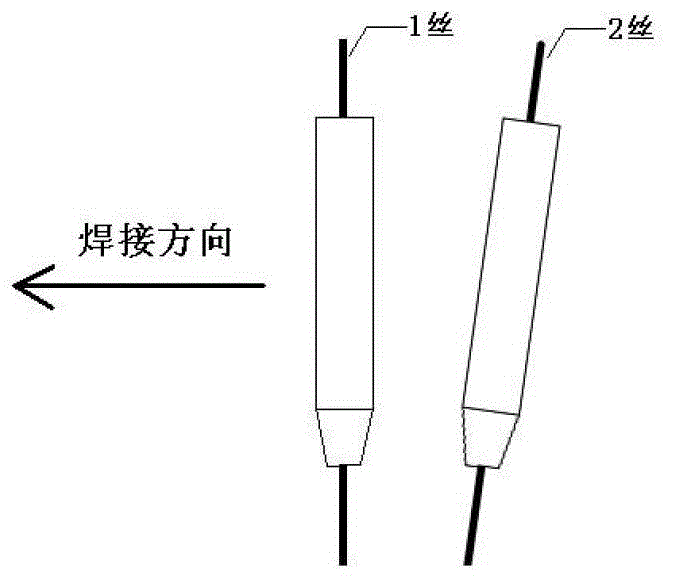

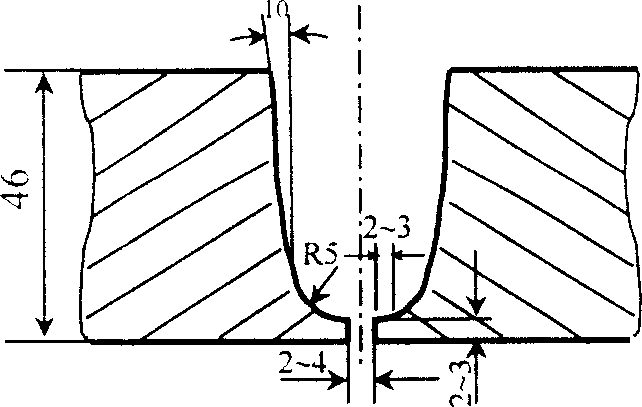

Method for welding specially-thick high-strength bridge steel plate

InactiveCN102744498AImprove welding efficiencyReduce manufacturing costArc welding apparatusWorkpiece edge portionsSteel platesSubmerged arc welding

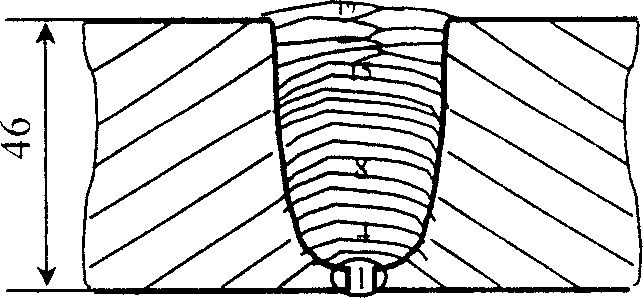

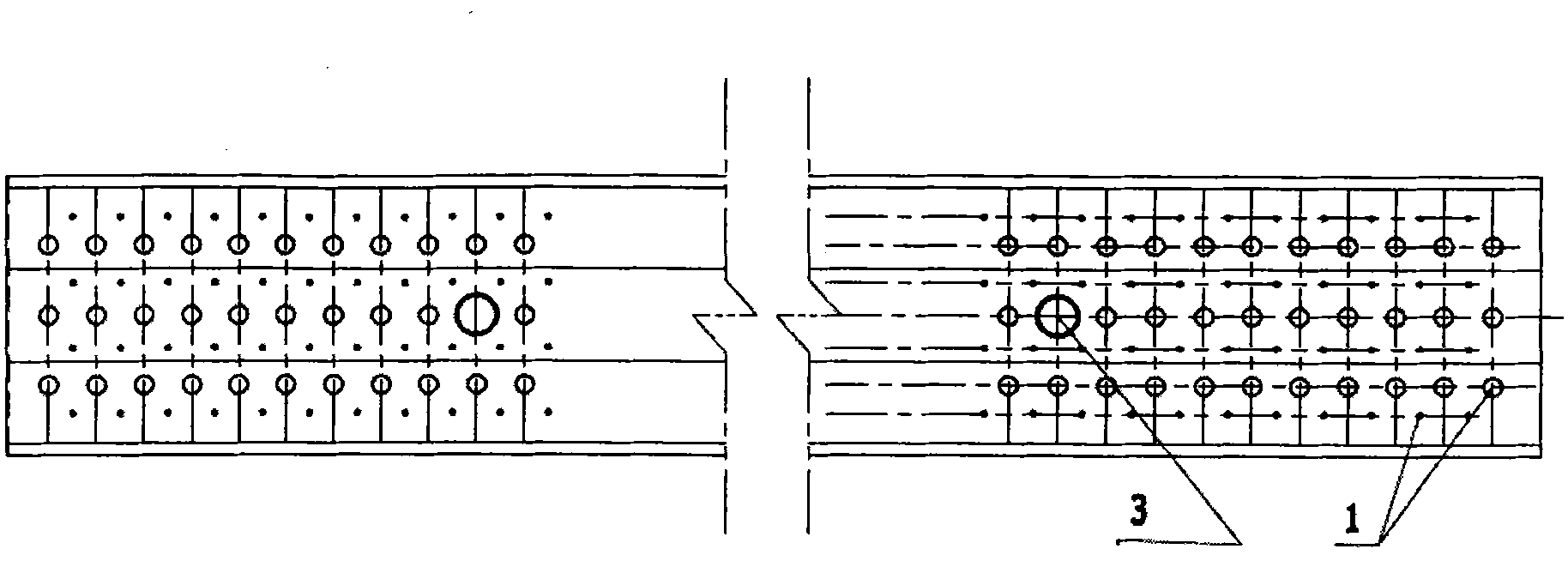

The invention provides a method for welding a specially-thick high-strength bridge steel plate and belongs to the technical field of specially-thick plate welding. The test plate of the method adopts a symmetric narrow gap U-shaped groove form, is combinedly welded by using two efficient welding methods, namely gas shielded welding for priming and bottom filling, and double-wire submerged arc welding for continuous filling and finishing, so as to achieve the purposes of reducing filling level and giving full play to the efficient double-wire submerged arc welding and high automation degree. The method has strong operability, greatly improves the welding efficiency of the specially-thick bridge steel plate, and significantly reduces manpower cost. Furthermore, by selecting a proper welding sequence, the method solves the problem that the welding deformation of the specially-thick steel plate is hard to control.

Owner:SHOUGANG CORPORATION

Submerged-arc welding process for T-type joint for extra thick steel plate

ActiveCN102240841AImprove welding qualityReduce the deterioration of mechanical propertiesArc welding apparatusCrazingThick plate

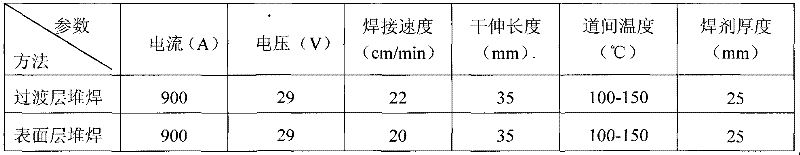

The invention discloses a submerged-arc welding process for a T-type joint for an extra thick steel plate and belongs to the technical field of welding of extra thick plates. The process comprises the following steps of: before welding, pre-heating the extra thick steel plate to 100 to 150 DEG C; removing pollutants of oxides, greasy dirt and the like on the surface of the groove of the extra thick steel plate; bottoming the extra thick steel plate by submerged-arc welding; forming systematical grooves and after the front face of the extra thick steel plate is bottomed, welding and filling; performing back gouging on the reverse side of the extra thick steel plate and welding and filling the reverse side; and filling welding wires on the front side of the extra thick steel plate and covering the side. The problems that manual bottoming efficiency is low, labor intensity is high, and heat cracking, undercutting, mechanical slag inclusion, large working amount of back gouging of the reverse side and the like are easily caused by submerged-arc welding bottoming when the T-type joint of the extra thick plate of which the thickness is 50 to 150mm is welded are solved; by the selection of an appropriate groove form, the welding sequence, and welding process parameters, and slow cooling measures, slag is easy to clean in a filling weld pass, the working amount of back gouging is reduced, the welding deformation is reduced, the welding residual stress is reduced and the quality of a weld joint is guaranteed; and the submerged-arc welding process is easy to operate and implement, and is convenient to popularize.

Owner:SHOUGANG CORPORATION

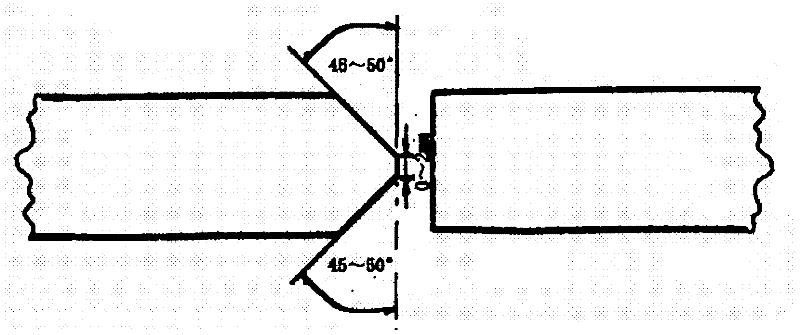

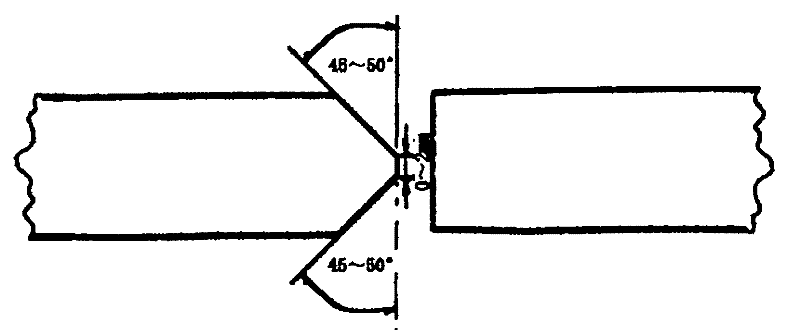

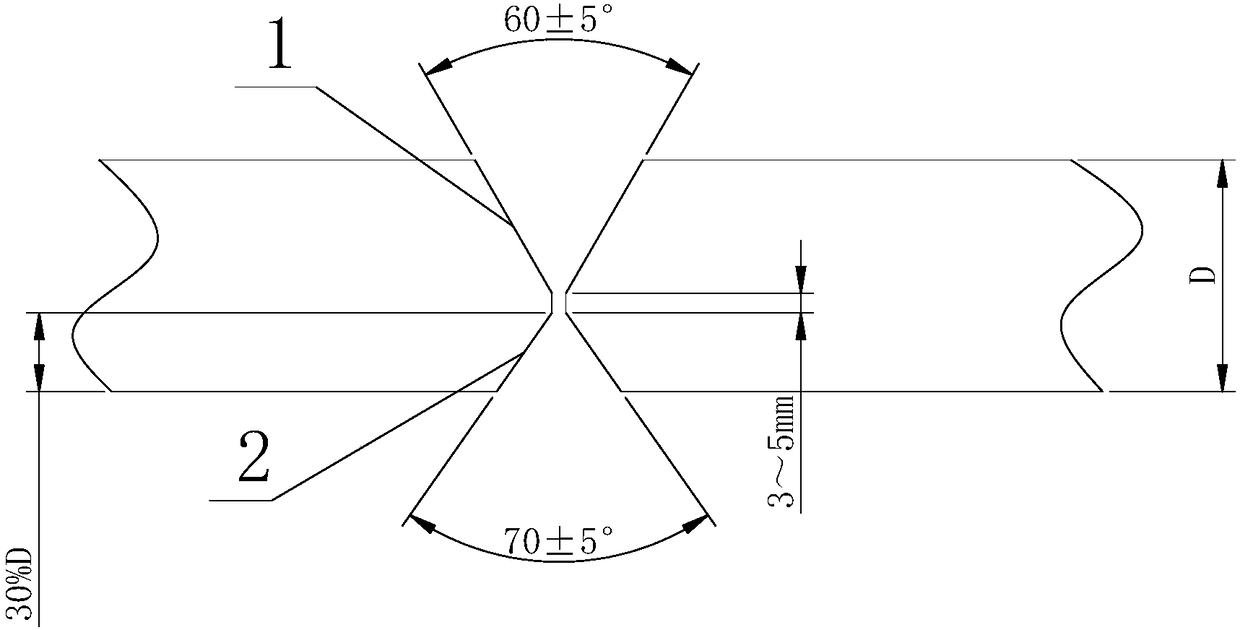

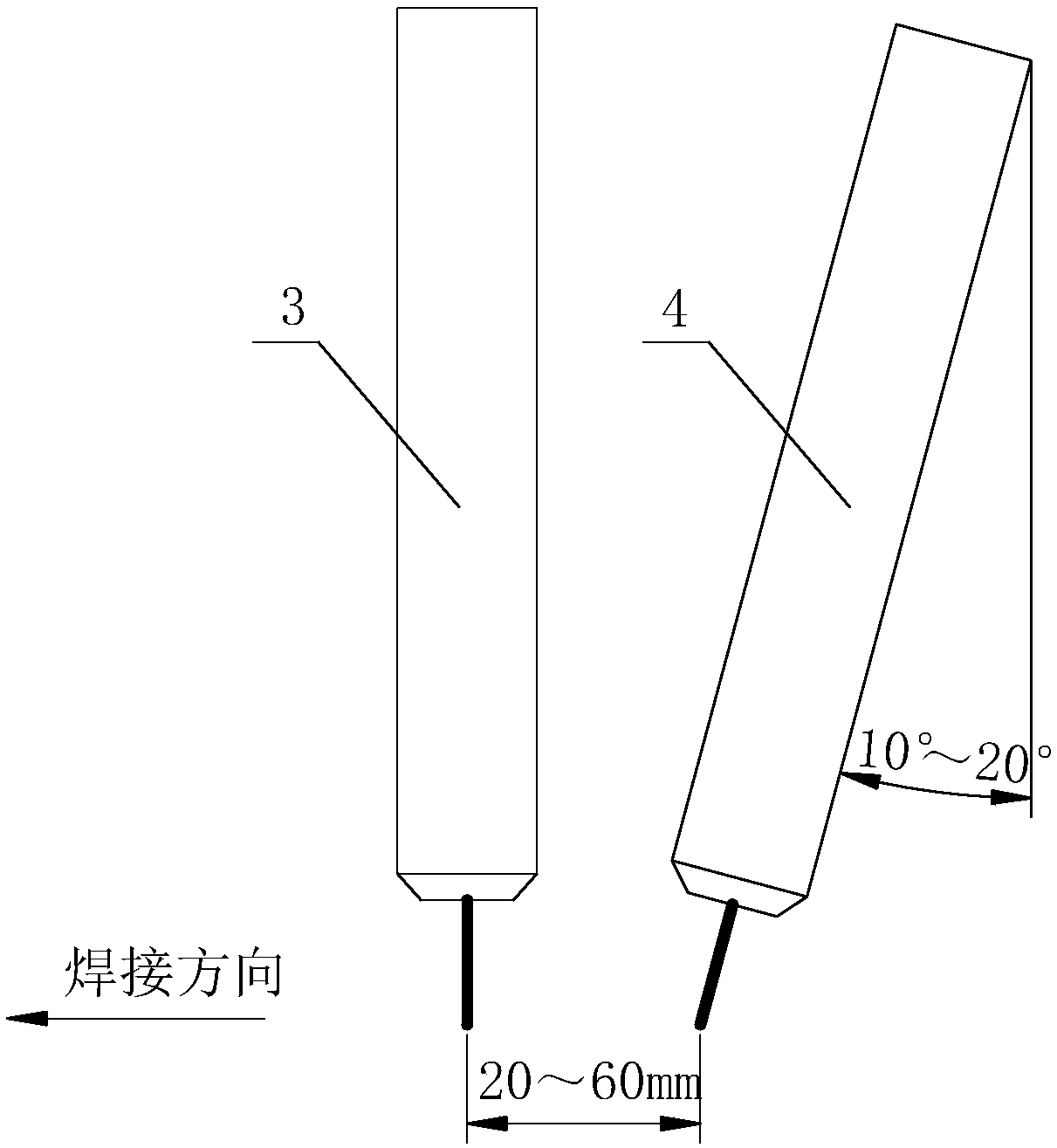

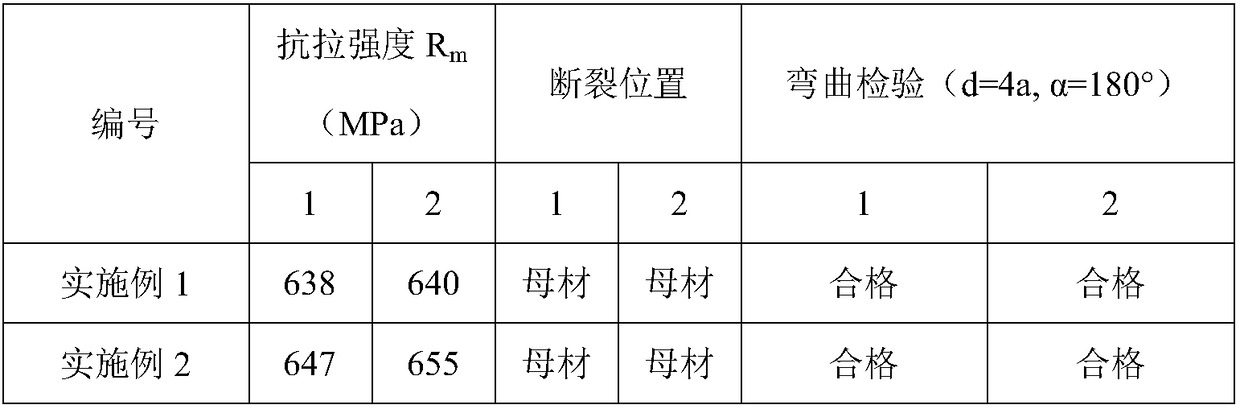

Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

InactiveCN109014513AImprove performanceSimple methodArc welding apparatusWelding/cutting media/materialsSheet steelEngineering

The invention relates to a double-wire submerged arc welding method for the high heat input energy welding of high-strength super-thick steel plates. Double-wire submerged arc welding is carried out on the steel plates of which the thickness is larger than 50mm without carrying out preheating before welding or carrying out heat treatment after welding. The total welding heat input energy of double-wire submerged arc welding is controlled at 100+ / -5kJ / cm, interlayer temperature is controlled between 100DEG C and 150DEG C, and the welding groove type belongs to a non-symmetrical X type. The double-wire submerged arc welding method has the advantages that the method is simple, easy to operate and efficient, saves energy and is particularly suitable for guiding the building construction of a large steel structure; and the quality of welding joints is excellent, the deformation degree of the welded plates is very small, welding defects are effectively avoided, welding deformation is controlled, the welding efficiency is increased, and the welding operation intensity is reduced.

Owner:ANGANG STEEL CO LTD

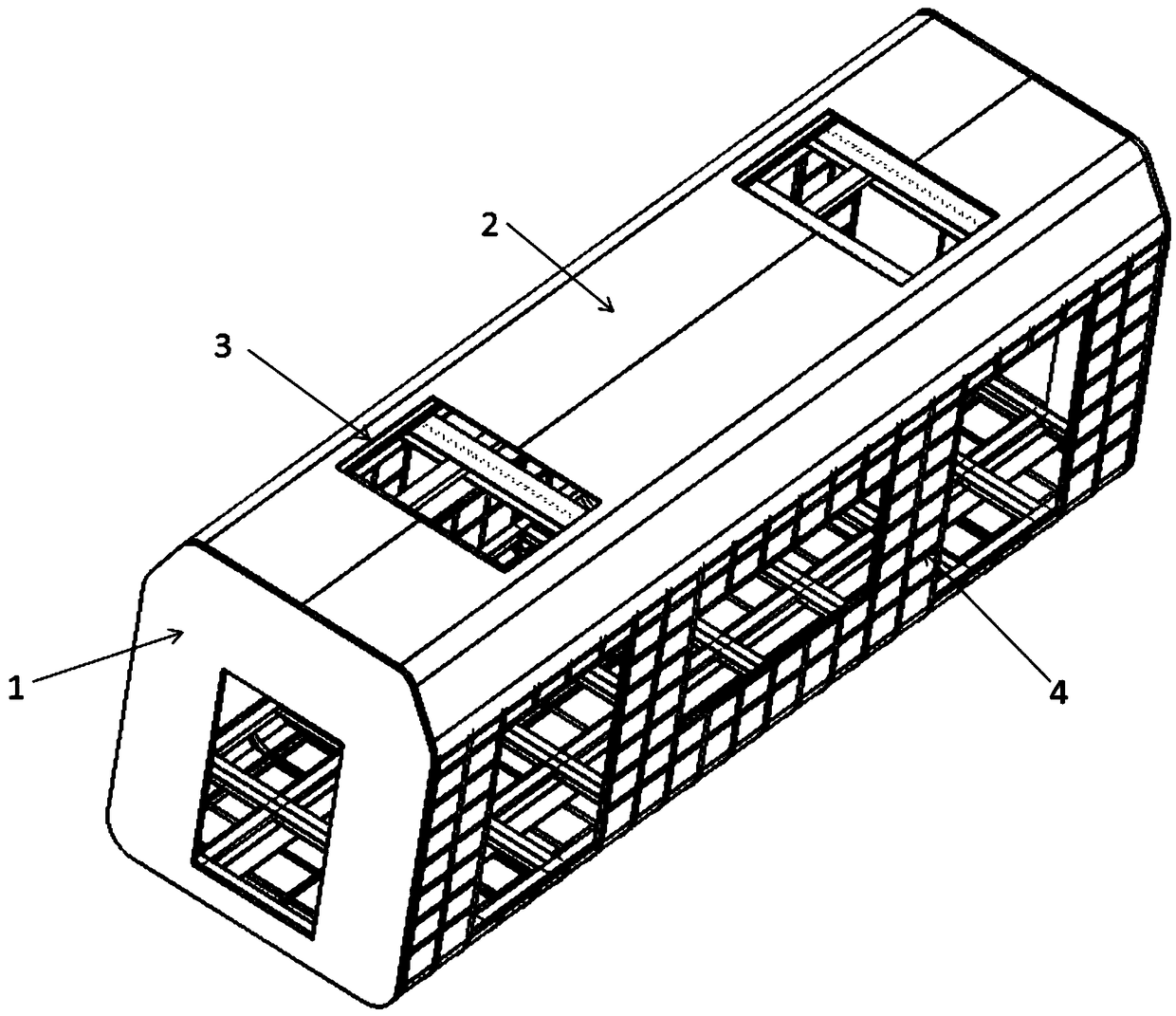

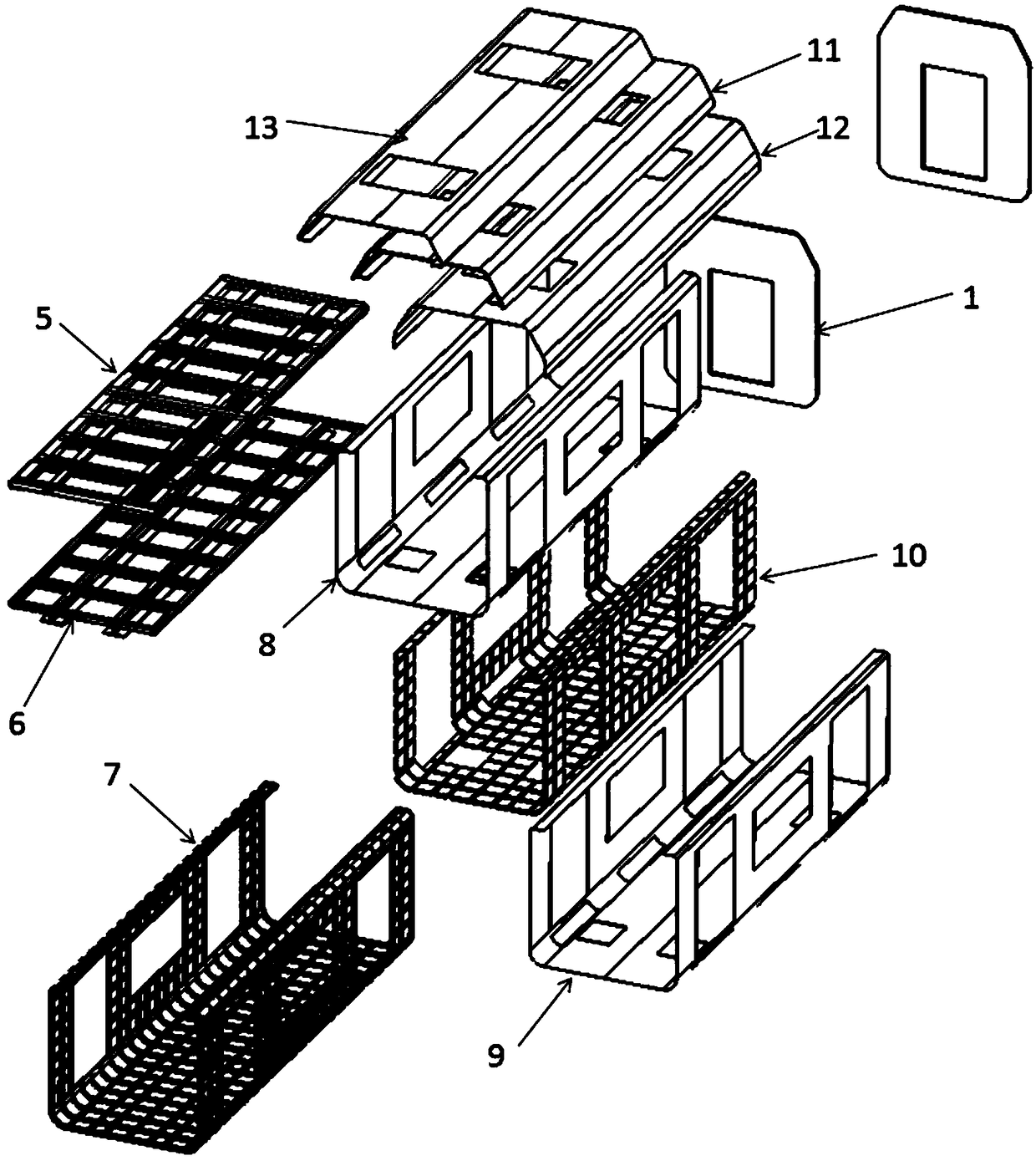

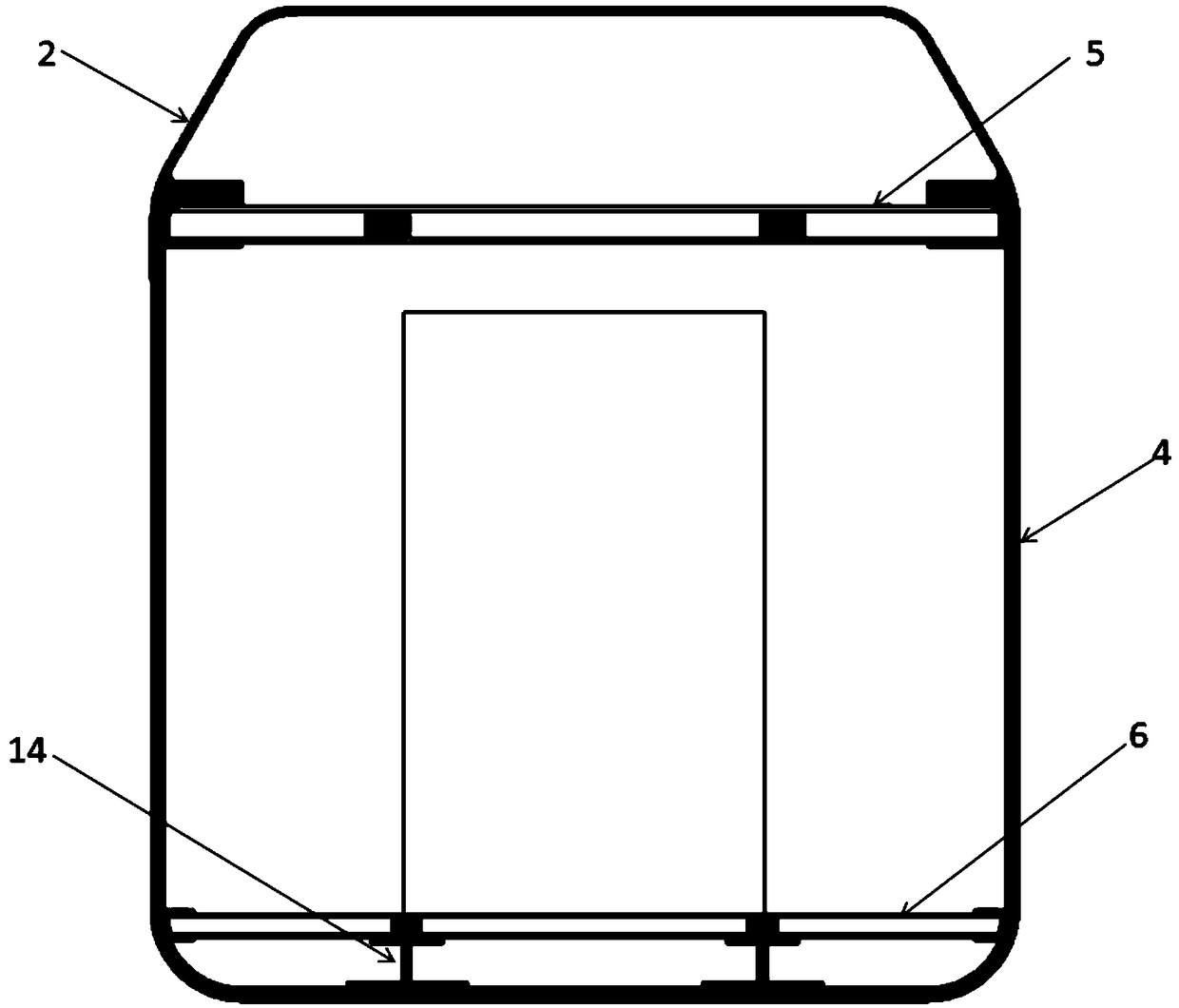

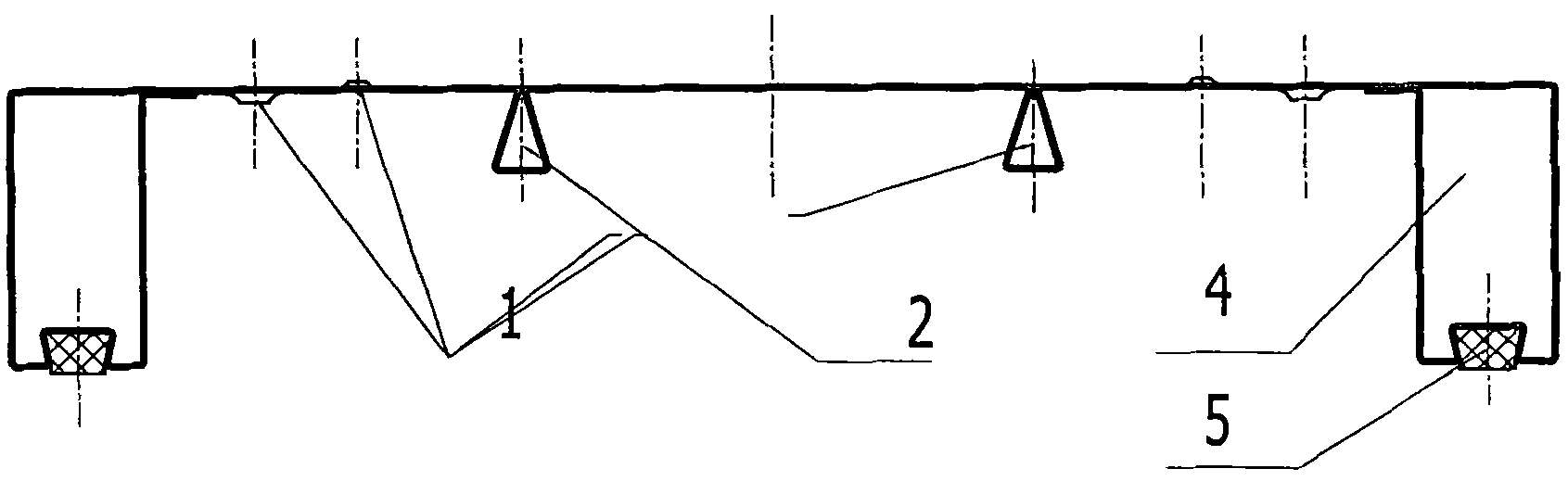

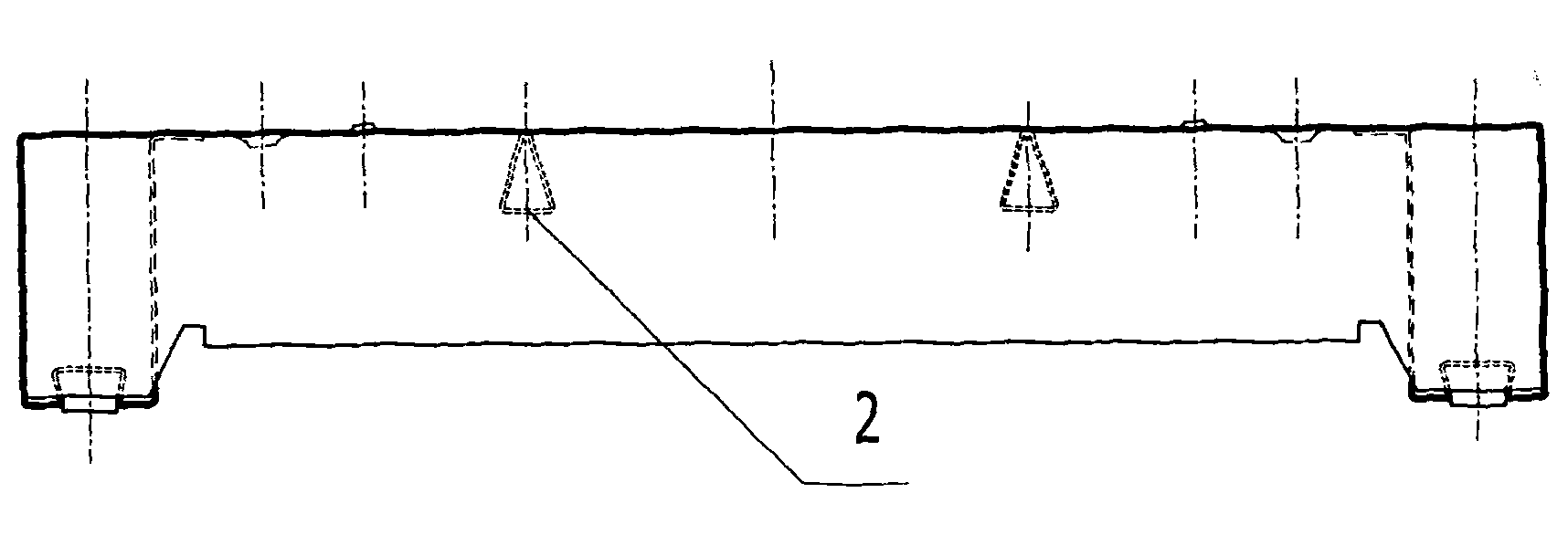

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

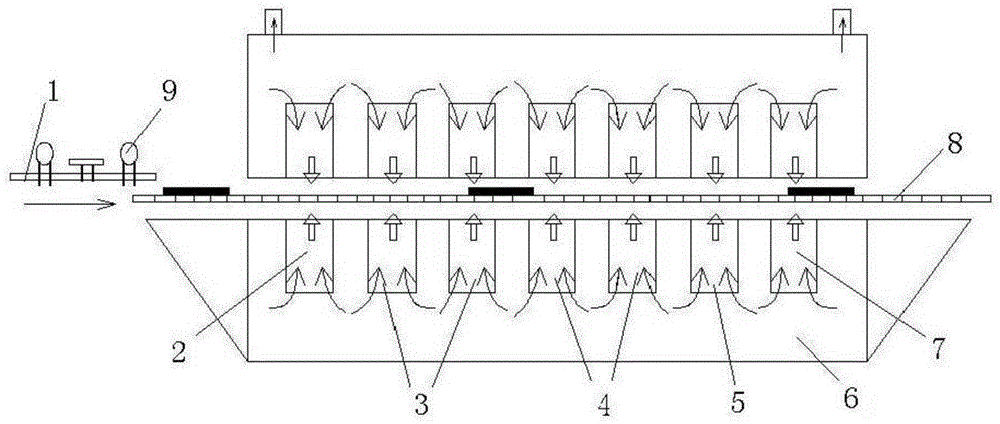

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Manufacture method of ultra-low-temperature, high-strength and long-fatigue life automobile bridge seamless heterotype axle steel tube

The invention relates the method for producing seamless axle steel pipe. The method uses seamless steel pipe billet, and the billet adopts low-alloy high-strength steel, which comprises C 0.14-0.18%, Si 0.3-0.55%, Mn 1.4-1.8%, V 0.02-0.08%, Nb 0.02-0.08%, Ti 0.02-0.08%, and Al 0.015-0.03%. The method comprises the following steps: 1 normalization heat trematment; 2 acid cleaning and lubricating; 3 fluid pressure shaped cold-drawing, thickening four corners of the steel pipe, the rate of the wall thickness and the corner thickness being 1:1.15-1.2; 4 heat treating product. The hardening temperature is 880-950Deg.C, keeping temperature is 20-30min, the cooling temperature is 350-450Deg.C, drawing temperature is 500-600Deg.C, and keeping temperature is 40-60min. The invention has homogeneous integral structure property and strong combination mechanics property.

Owner:江苏界达特异新材料股份有限公司

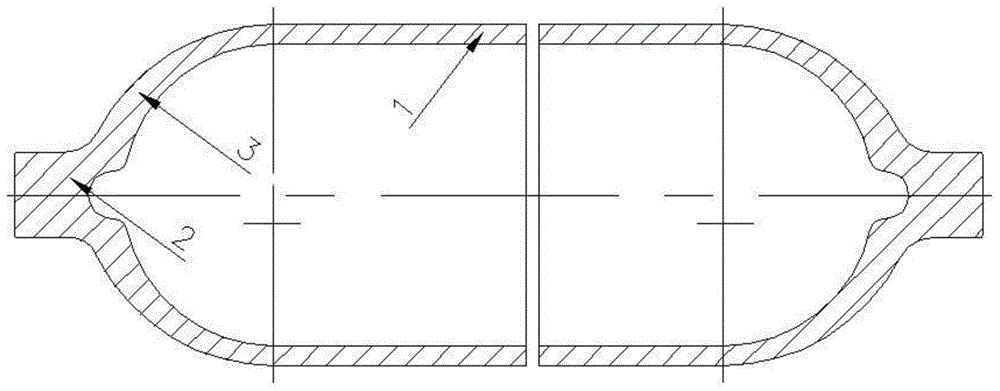

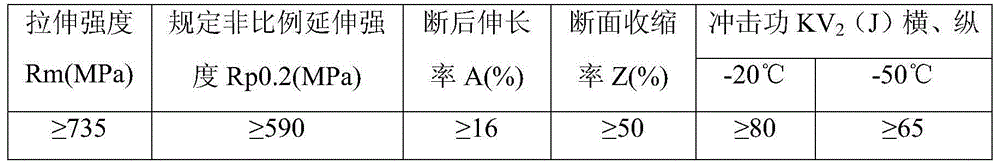

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

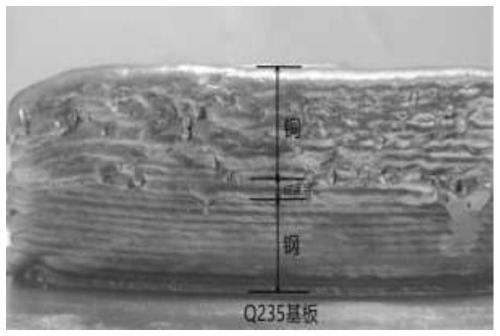

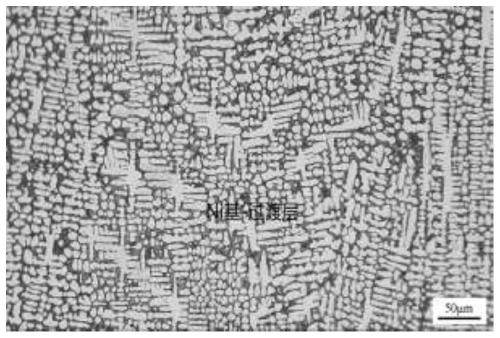

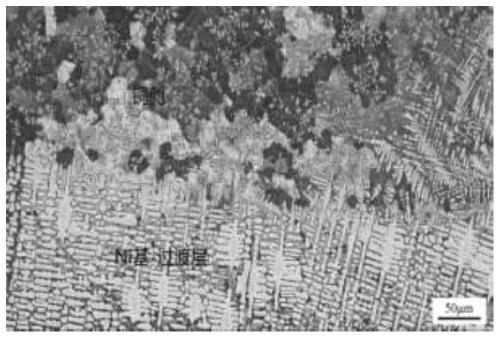

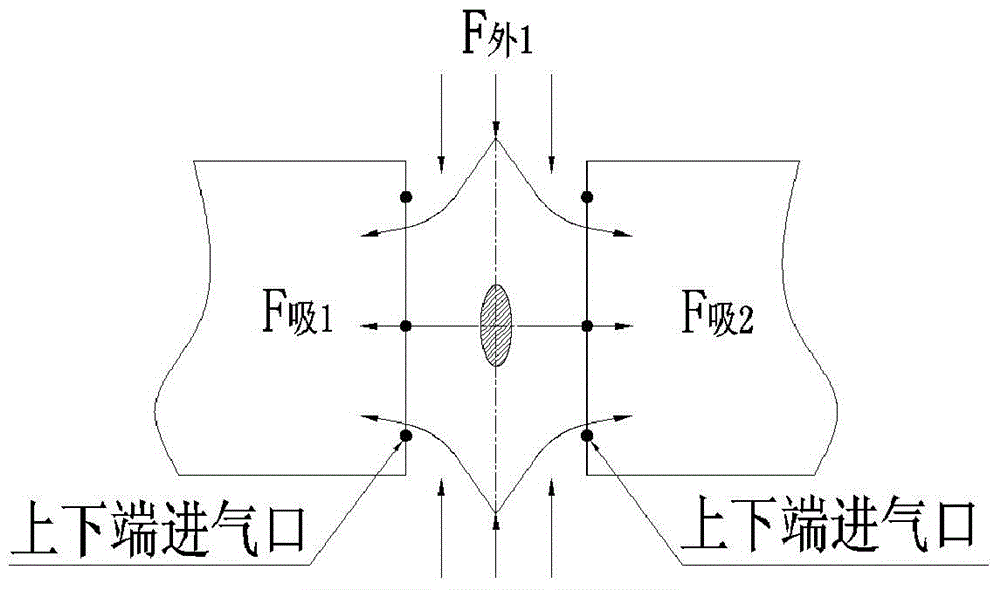

Ni based-flux-cored wire and method for preparing copper-steel base gradient composite

ActiveCN111558793AAvoid Welding DefectsImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsCopperWelding defect

The invention discloses a Ni based-flux-cored wire. The Ni based-flux-cored wire comprises a flux core and a welding scale, wherein the flux core is prepared from the following components in percentage by mass: 86%-90% of Ni powder, 3%-5% of Mn powder, 6%-7% of Si powder, the balance of Cu powder, and the sum of the mass percentage of the components is 100%. The Ni based-flux-cored wire is used asa transition layer to avoid welding defects caused by thermophysical parameter difference of two types of materials during direction connection of copper-steel. The invention further provides a method for preparing copper-steel base gradient composite based on the Ni based-flux-cored wire used as the transition layer. The problem of the welding defects caused by direct connection in existing copper / steel composite is solved, parts can be combined from the steel side to the copper side to reach a gradient mode, so that the combining capacity of a heterogeneous material interface is enhanced, and the mechanical properties of composite members are improved.

Owner:XIAN UNIV OF TECH

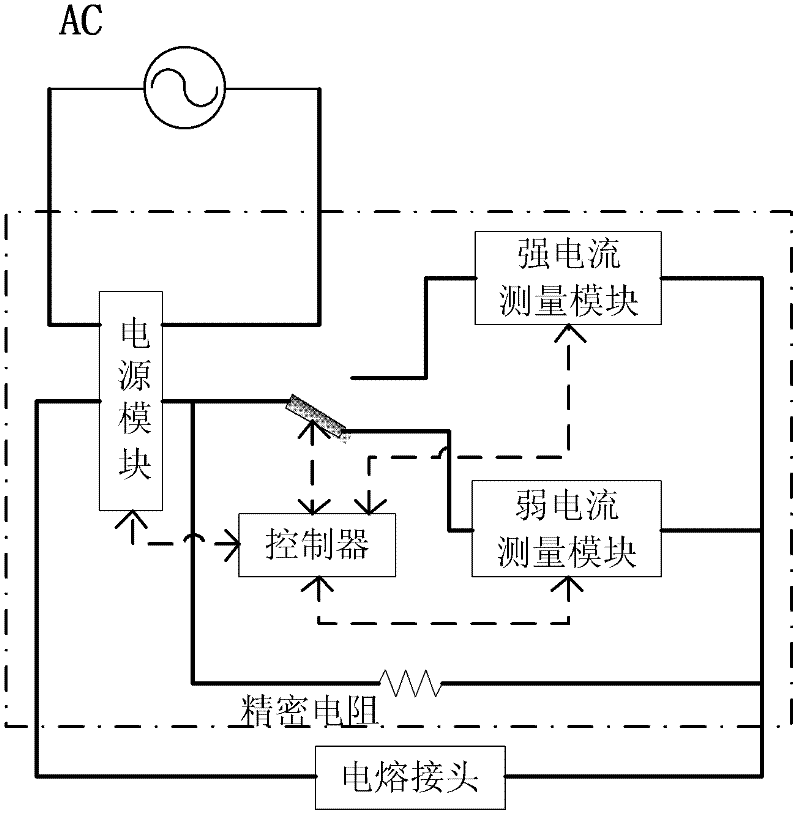

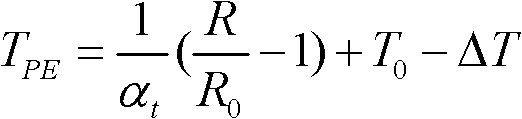

Electrofusion welding process for preventing generation of cold welding and over welding defects and electrofusion welder

The invention which relates to an electrofusion welder technology aims to provide an electrofusion welding process for preventing the generation of cold welding and over welding defects and an electrofusion welder. The process comprises the following steps: 1, measuring the current and the voltage of a welding circuit in real time in the welding process to obtain the resistance value change case of a resistance wire, controlling the voltage of the welding circuit to realize the control on the resistance value of the resistance wire and the welding power, and simultaneously controlling the temperature of a polyethylene material around the resistance wire in the welding process; and 2, recording the real-time welding power of the resistance wire in the welding process, carrying out accumulating calculation to obtain welding input heat, and ending the welding when the welding input heat reaches the value of total heat Q needed by the welding completion through an electrofusion sleeve. According to the invention, the electrofusion welder can automatically determine a reasonable welding technology only through giving the needed welding input heat. A present digital welder which can be conveniently added with the control forms the novel electrofusion welder with the cold welding and over welding prevention functions.

Owner:ZHEJIANG UNIV

P91 steel welding method

InactiveCN1721118AIncreasing the thicknessReduce thicknessArc welding apparatusBack-fireThermal insulation

This invention provides welding method for P91 steel with basic steps of preheating, back welding with TGS-9CbªŽ2.4 solder wire, filler welding with C9MVªŽ2.5, C9MVªŽ3.2 welding rod and parameters of current 75-140A, welding time for every layer 6-21min, welding preheating temperature 150Deg and welding layer-to-layer temperature 200-300Deg, thermal insulation and thermal treatment. The technique progress can be found from: 1. increase welding current and speed about one times compared with generated method; 2. change layer bead arrangement, decrease welding bead and welding layer thickness convenient to operate, avoid dead angle, prevent welding bug; use layer-to-layer back fire effect to improve metal structure and performance of welding line; 3. come to welding operation standardization and process programming benefit for training and management to workers.

Owner:石家庄电力工业学校焊接培训中心

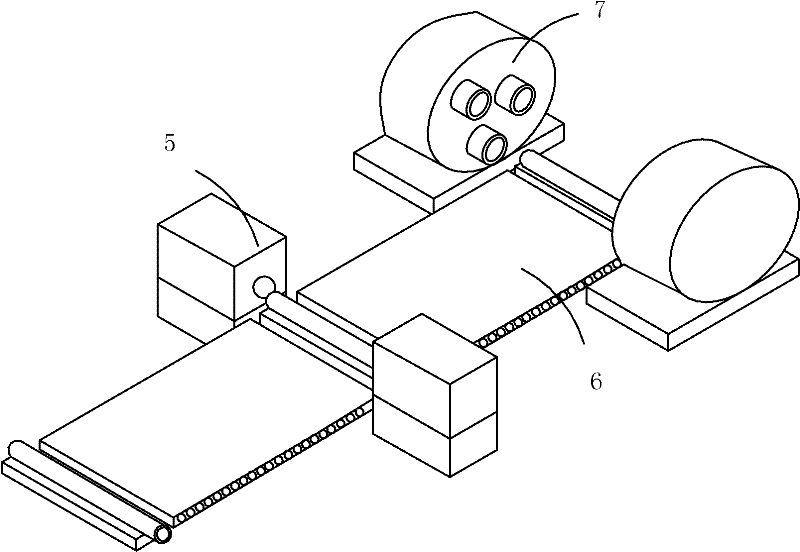

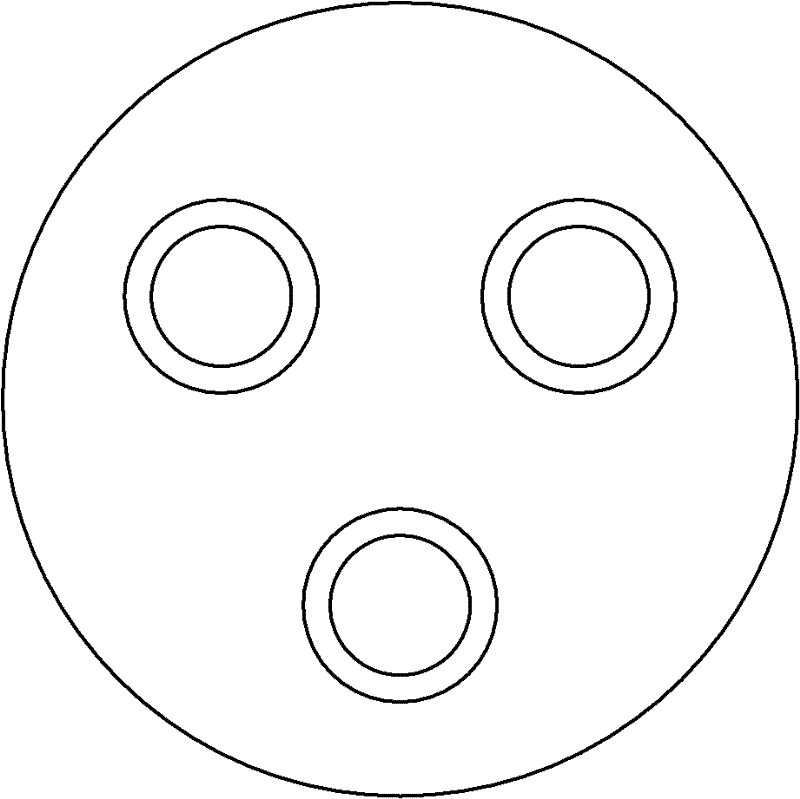

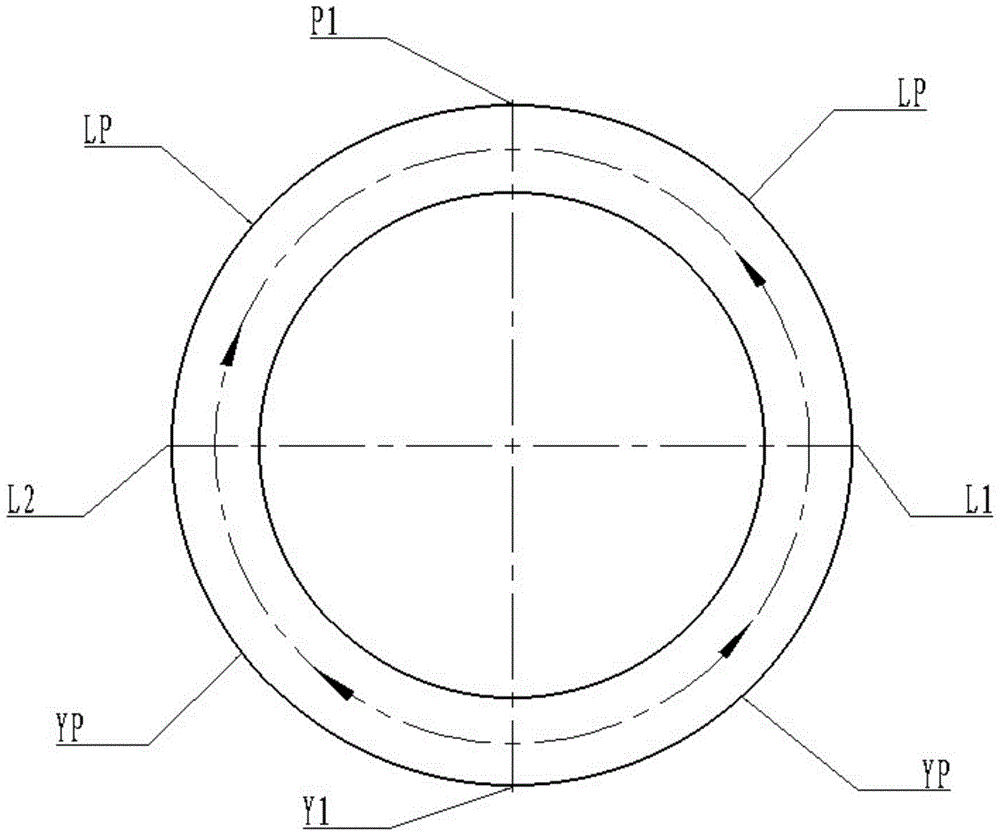

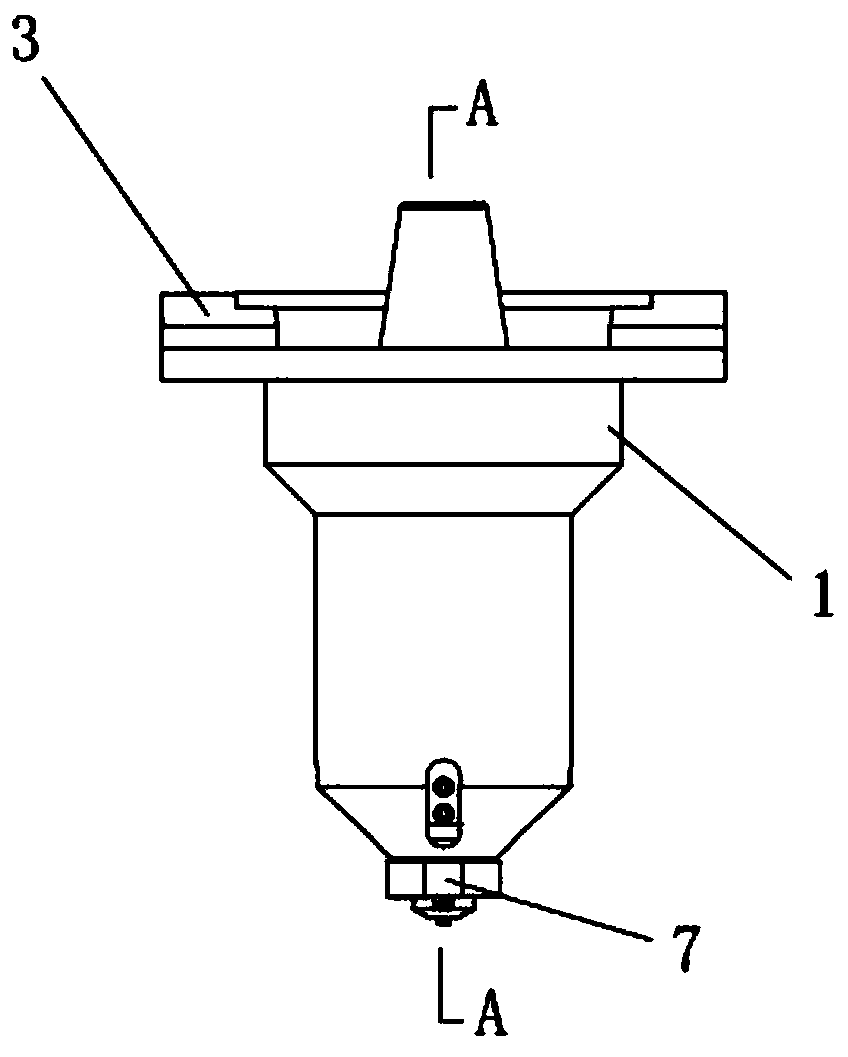

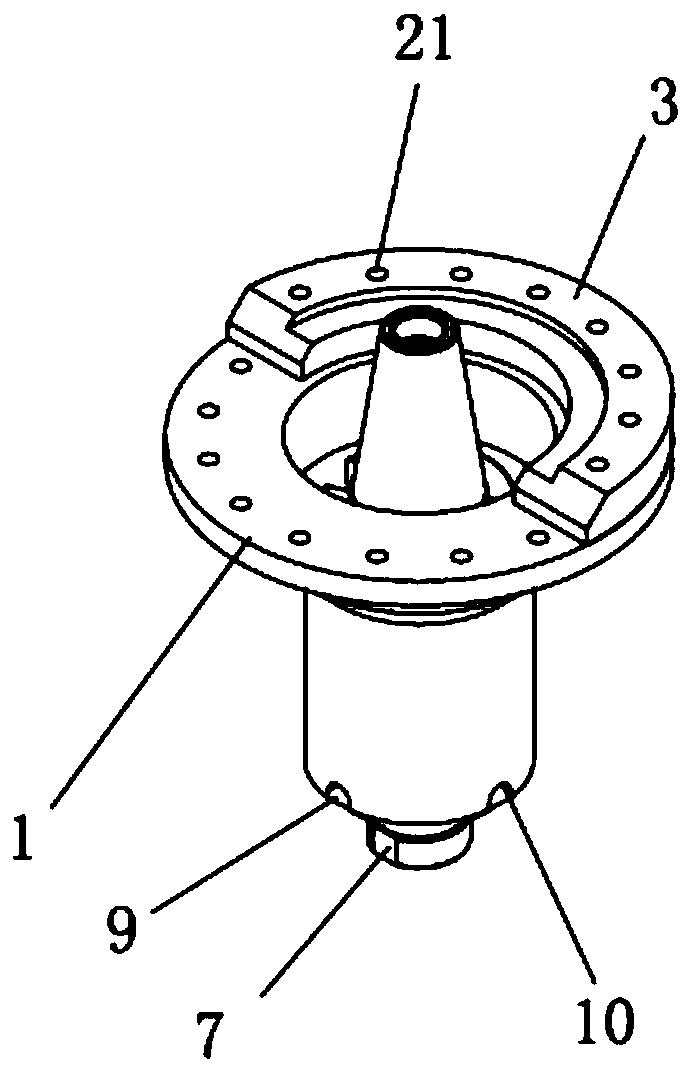

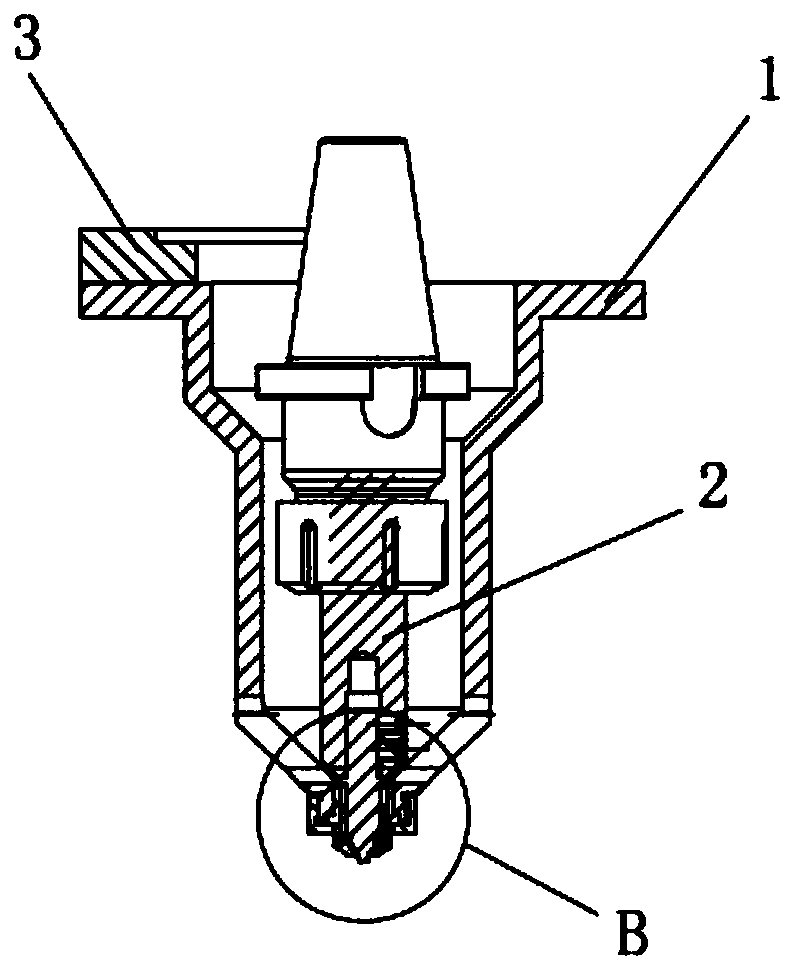

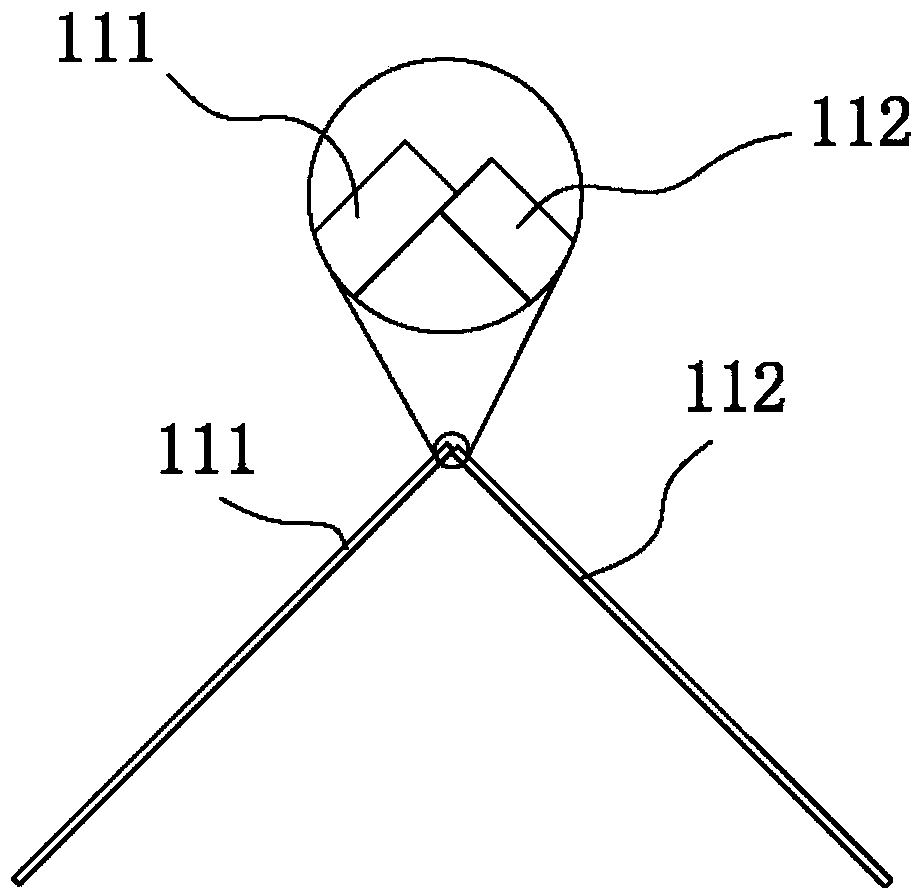

Special annular welding machine for thin wall of stainless steel kettle

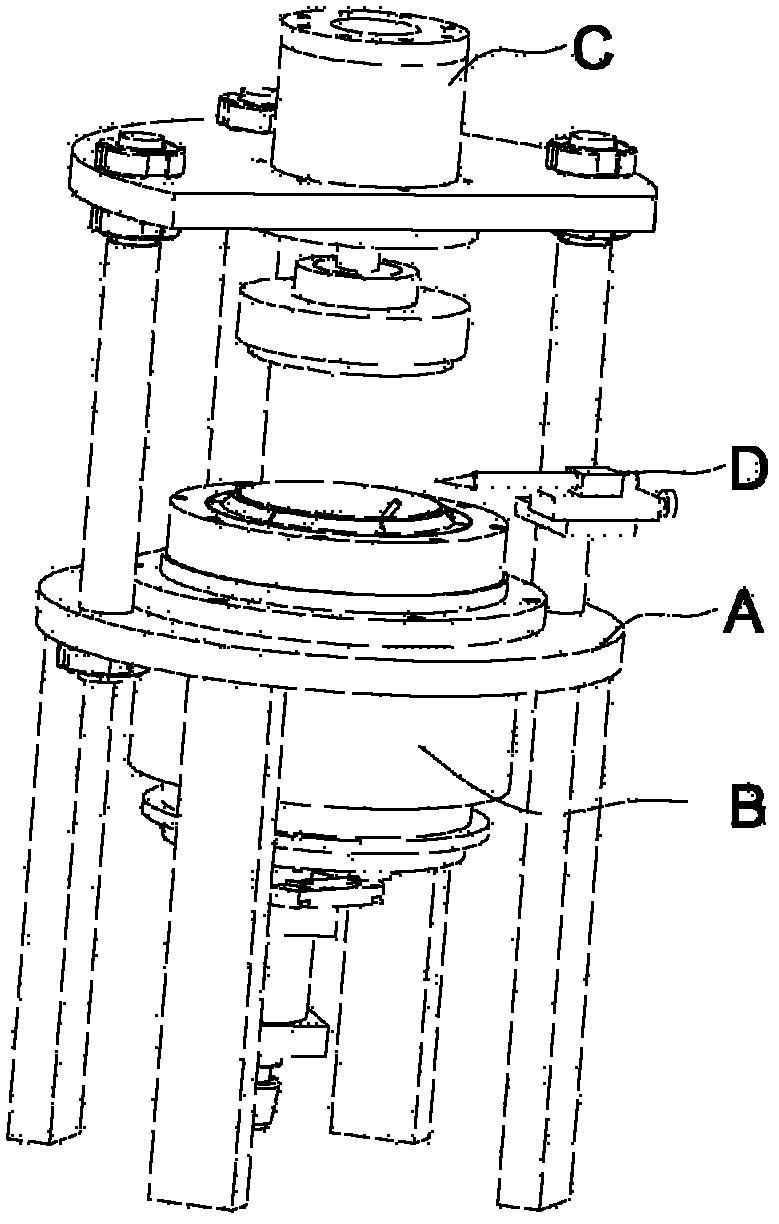

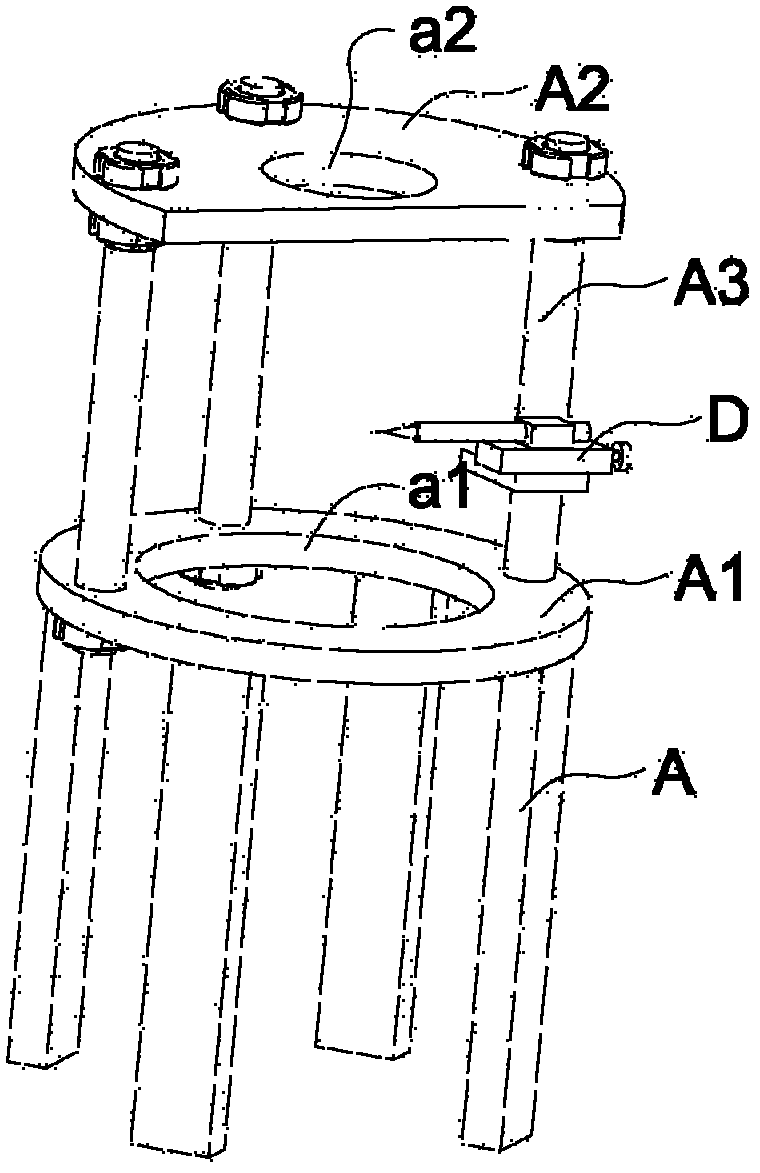

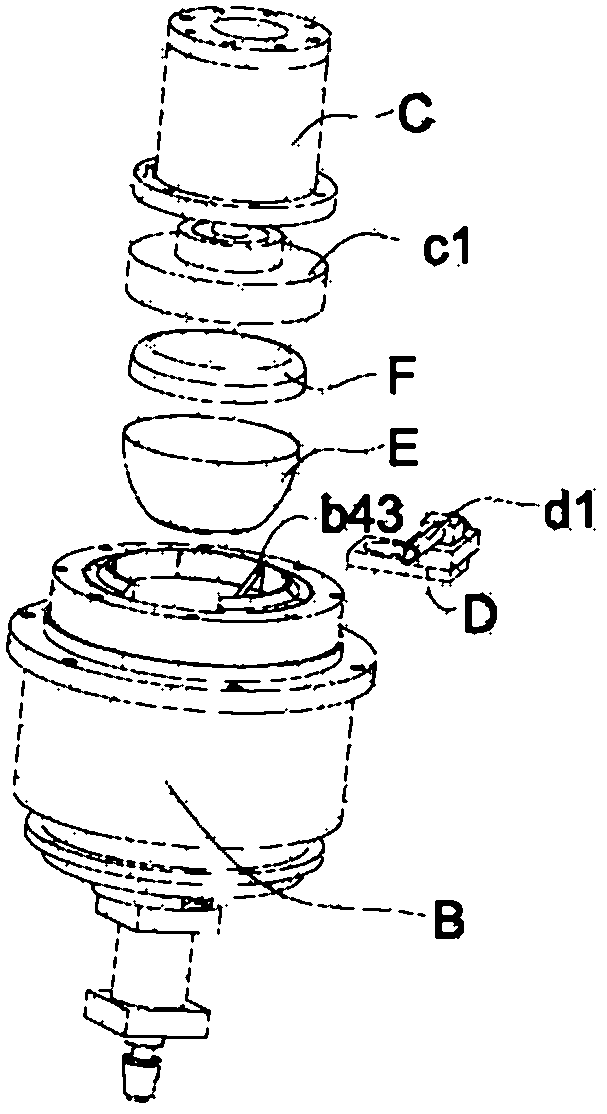

InactiveCN102615397ASolve the problem of secondary out-of-roundnessAvoid Welding DefectsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingShielding gas

The invention discloses a special annular welding machine for the thin wall of a stainless steel kettle, which is characterized by comprising a stand, a round mechanism, an ejection mechanism and a welding gun mechanism, wherein a lower stand surface and an upper stand surface in different heights are arranged on the stand in a perpendicular direction, respectively; the same center axis of the lower stand surface and the upper stand surface is provided with a first round hole and a second round hole, respectively; the round mechanism is fixed in the first round hole of the lower stand surface; the ejection mechanism is fixed above the second round hole of the upper stand surface; and the welding gun mechanism is fixed on a stand strut of the stand. The special annular welding machine has the advantages that the out-of-round problem of a circular weld surface of a drawing workpiece is solved, the upper and the lower parts of the workpiece are in butt welding; meanwhile, the secondary out-of-round problem generated by stress release due to high temperature in a welding process is solved. The welding position is protected by internal protection gases in the whole process, therefore, the welding defect caused by oxidization of stainless steel in the welding process is overcome.

Owner:GUANGDONG ZHONGBAO KITCHENWARE

Semitrailer integral axle tube extrusion moulding equipment and method

InactiveCN102172658AIncrease productivityReduce manufacturing costExtrusion profiling toolsIntermediate frequencyPulp and paper industry

The invention relates to semitrailer integral axle tube extrusion moulding equipment, comprising a hydraulic machine and an intermediate frequency heating furnace, wherein the two ends of the rack of the hydraulic machine are respectively provided with a first slide seat and a second slide seat, the first slide seat is connected with a first cylinder of the hydraulic machine, the second slide seat is connected with a second cylinder of the hydraulic machine, and the first and second slide seats are provided with mould replacing wheel discs; and the top of the rack of the hydraulic machine is also provided with a clamping device for an axle tube. The axle tube extrusion moulding equipment provided by the invention has high production efficiency and has the advantages of high product processing accuracy, good integral mechanical property and stable product quality compared with the traditional hot spinning process. A steel pipe blank is directly moulded at axle heads at the two ends in an extruding way by virtue of the hydraulic machine, and various welding defects existing in subsection moulding are avoided, thus the bearing capacity of a car axle is greatly improved.

Owner:GUANGDONG FUWA HEAVY IND

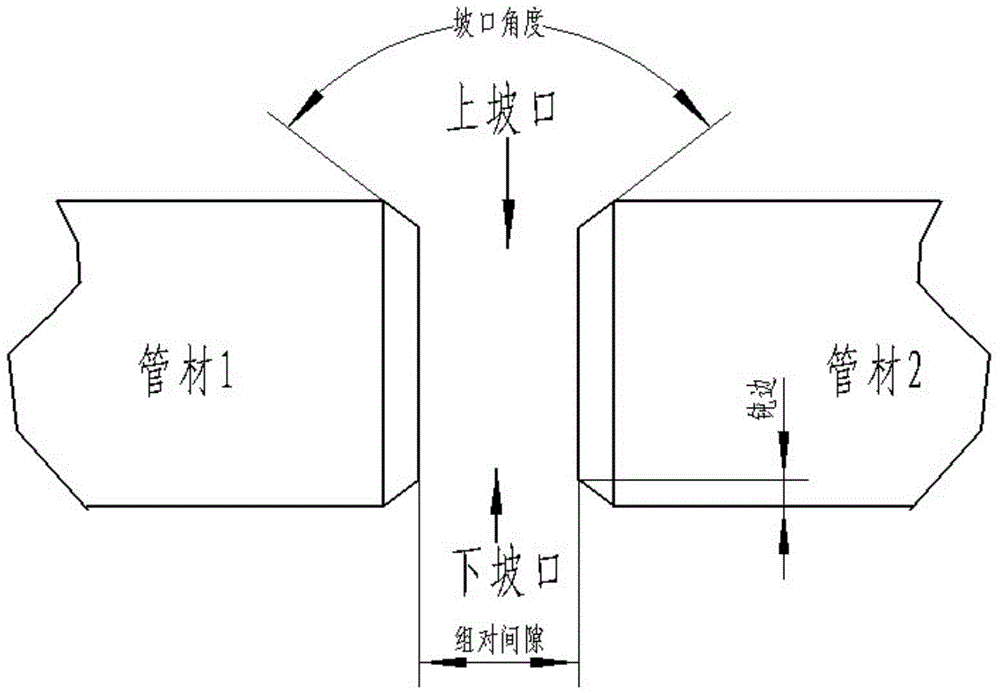

Pipeline welding method

ActiveCN104014909APrevent intrusionStrong penetrating powerArc welding apparatusPipeline systemsPower flowEngineering

The invention provides a pipeline welding method which comprises the following steps: carrying out pre-welding preparation, namely pairing all pipes according to a gap requirement and machining pipe grooves according to a groove angle requirement; choosing welding rods and electric currents, namely choosing proper welding rods and electric currents according to the diameters of the pipes, the thicknesses of pipe walls and welding skill proficiencies; carrying out backing welding by using argon arc welding; filling and welding cover surface by using electric covering surface large current interruption welding method. As the current interruption welding method controls welding sequences, welding current, welding rod angles, arc-starting points and arc-stopping points, the qualification rate of pipeline welding can be effectively increased.

Owner:CHINA HUAYE GROUP

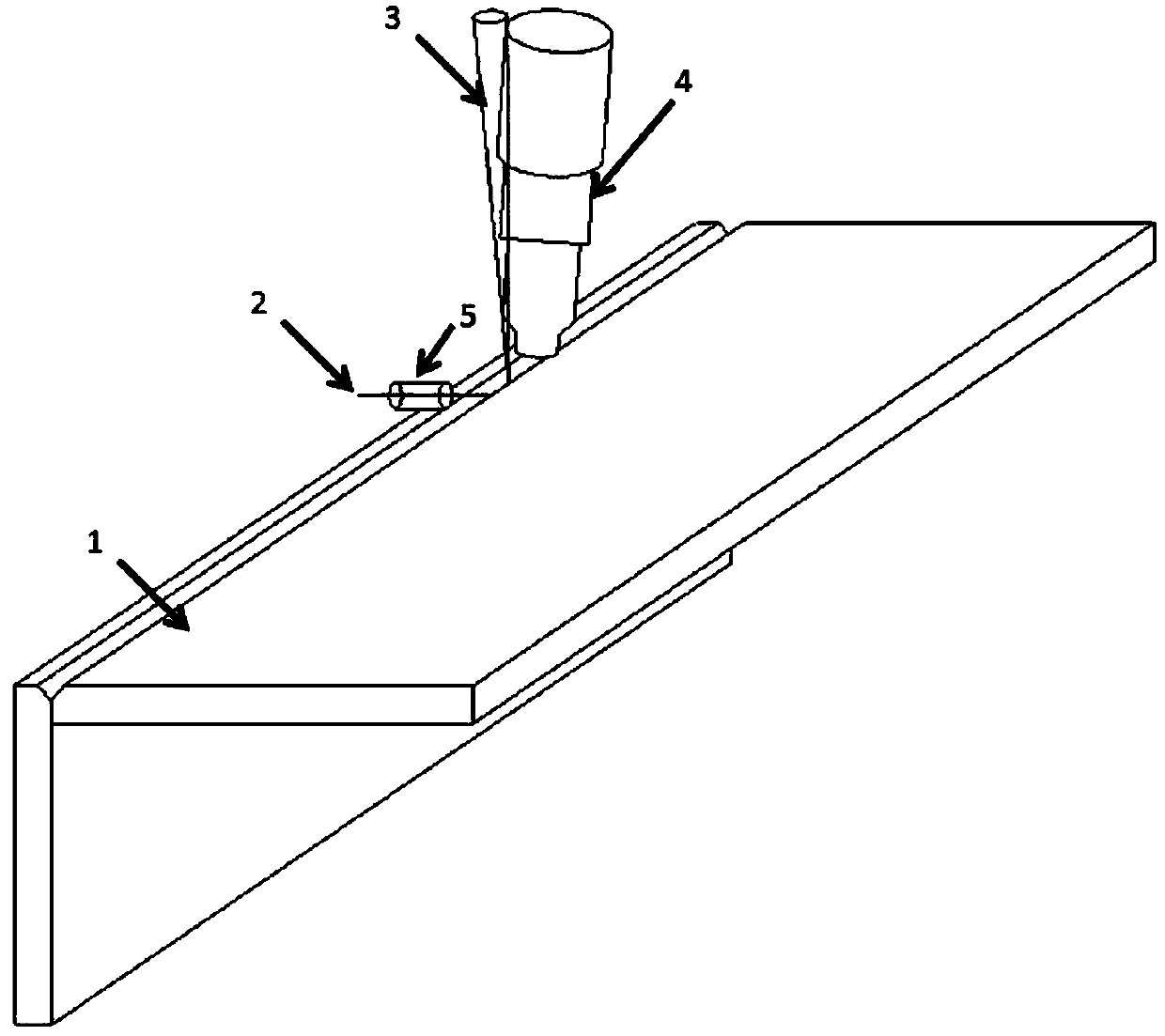

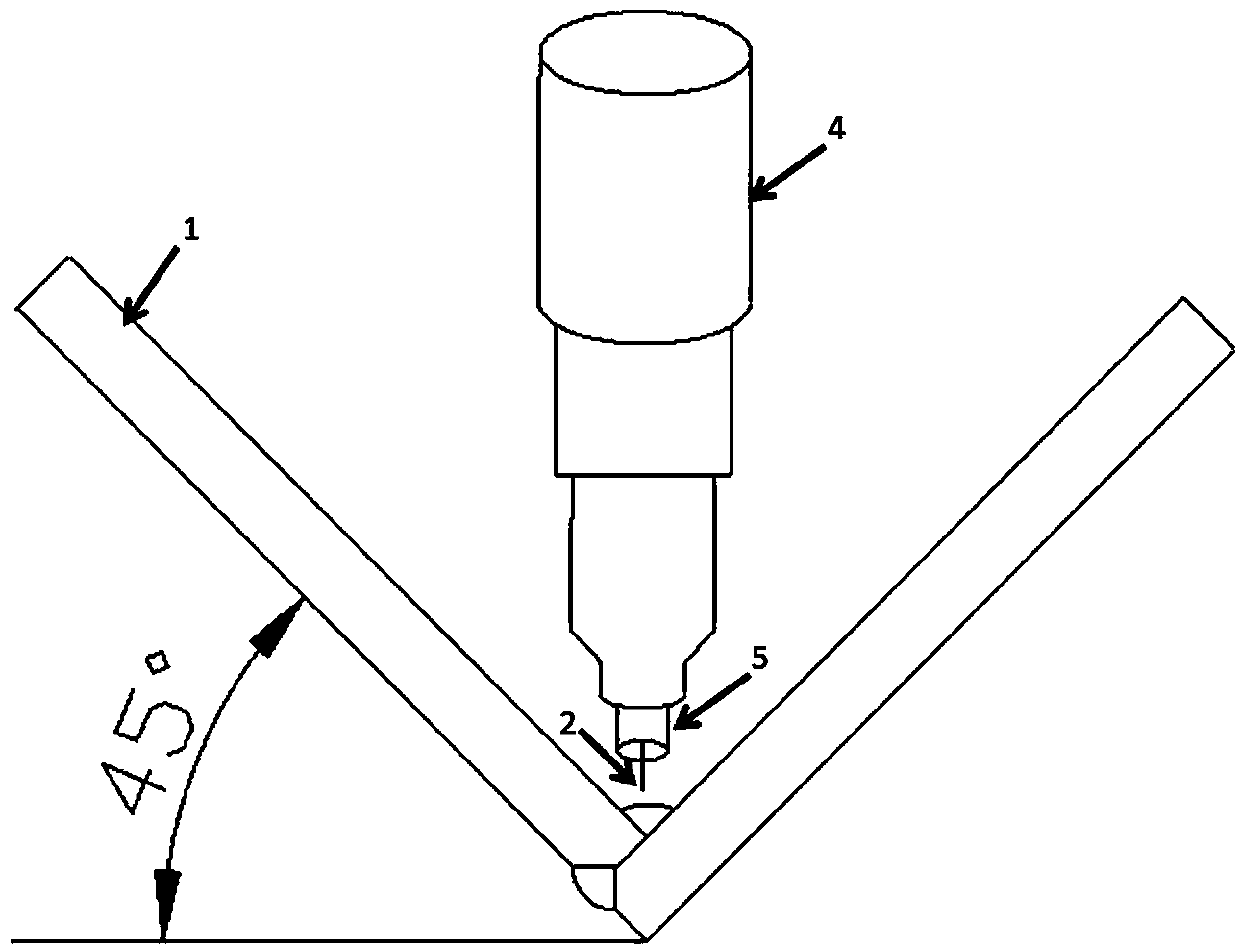

Laser-TIG composite wire filling seal welding method for L-shaped aluminum alloy structure

ActiveCN104191092AReduce linear energy densityLow heat inputWelding/soldering/cutting articlesMetal working apparatusStructural deformationWelding process

The invention discloses a laser-TIG composite wire filling seal welding method for an L-shaped aluminum alloy structure. The method comprises the steps that aluminum alloy is fixed in a gapless mode according to an L-shaped structure before welding, and a V-shaped groove is formed in the outer side of the L-shaped aluminum alloy structure after fixing; a laser, a TIG weld gun and a wire feed nozzle are elevated at the same time during welding, the outer side of the L-shaped aluminum alloy structure is horizontally placed, welding technology parameters of a first layer and a second layer are controlled to be the same, welding technology parameters of layers from a third layer to the last layer are controlled to be the same, and wire filling welding is carried out on a fourth layer and a fifth layer; after the outer side is welded, the inner side of the L-shaped aluminum alloy structure is placed upwards by 45 degrees, and wire filling welding is carried out on the fifth layer and a sixth layer. Multi-layer wire filling is carried out, the interlayer temperature and the laser defocusing amount are accurately controlled, and therefore the deformation, caused by excessively large thermal input, of the L-shaped structure is avoided to the greatest extent; the inner side and the outer side are welded in sequence, the deformation tendency in the welding process is restrained to the greatest extent, and the laser-TIG composite wire filling sealing welding efficiency is guaranteed.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

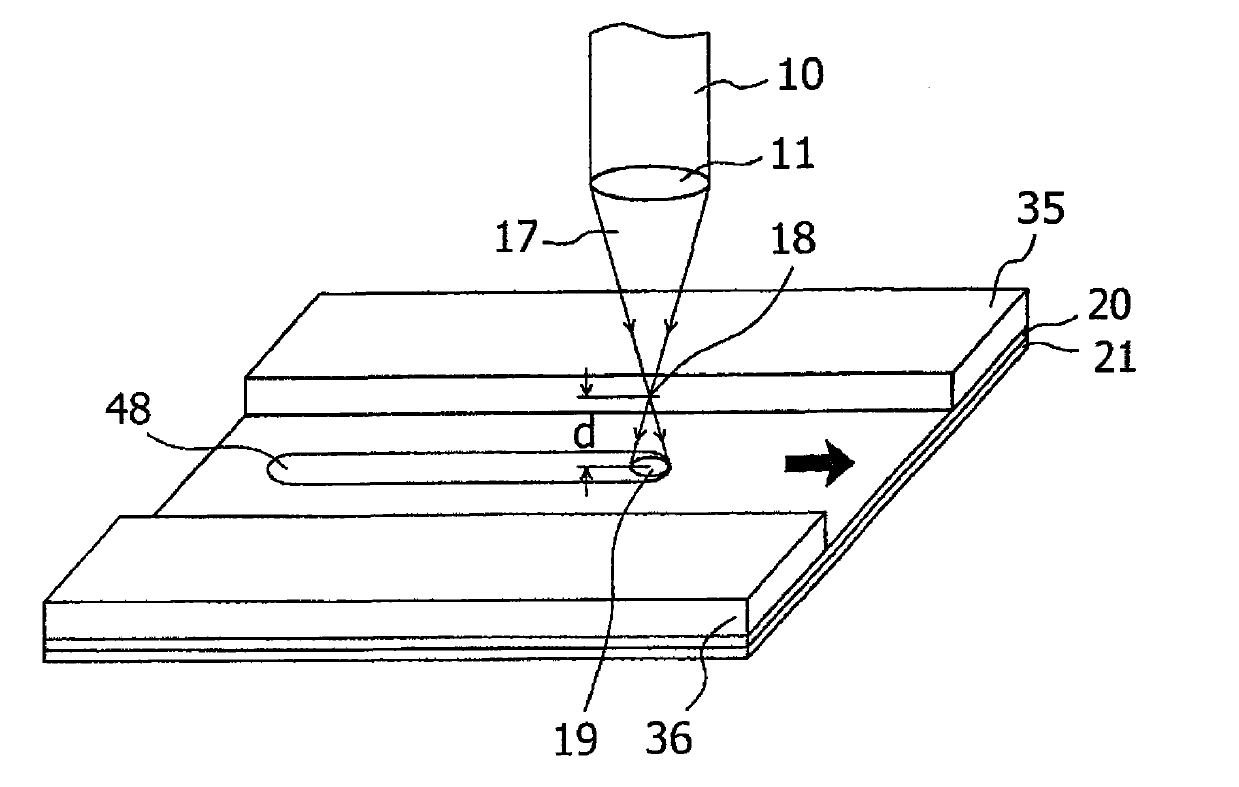

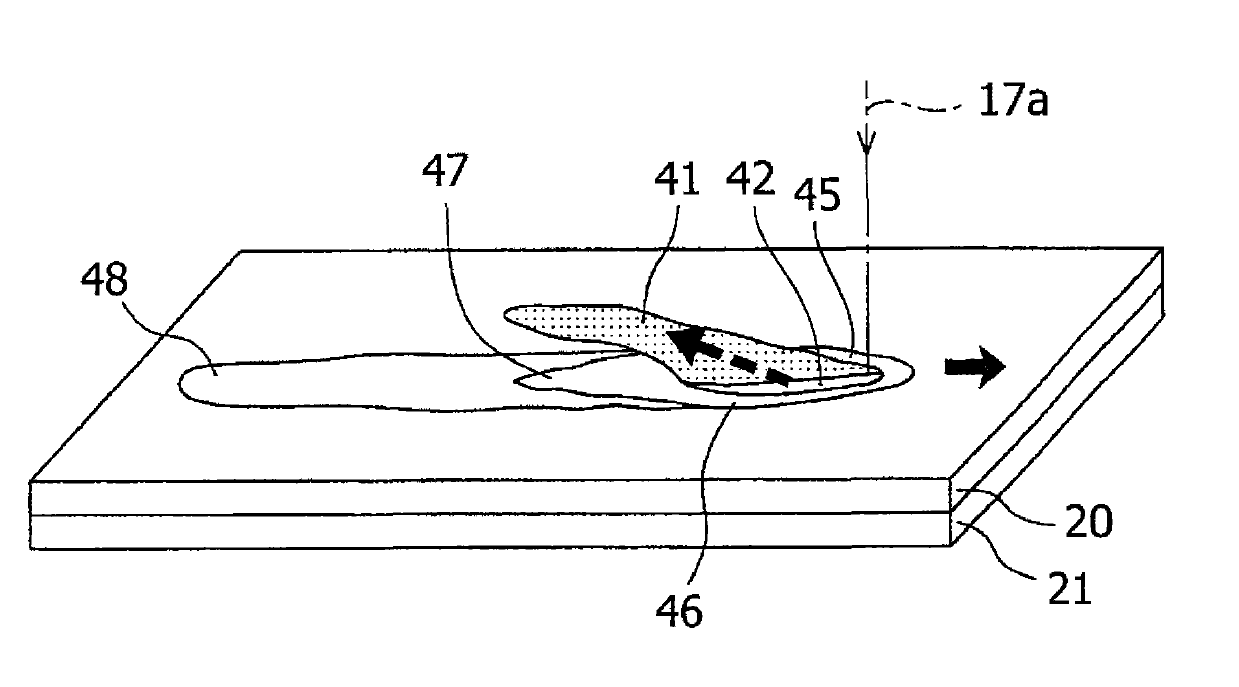

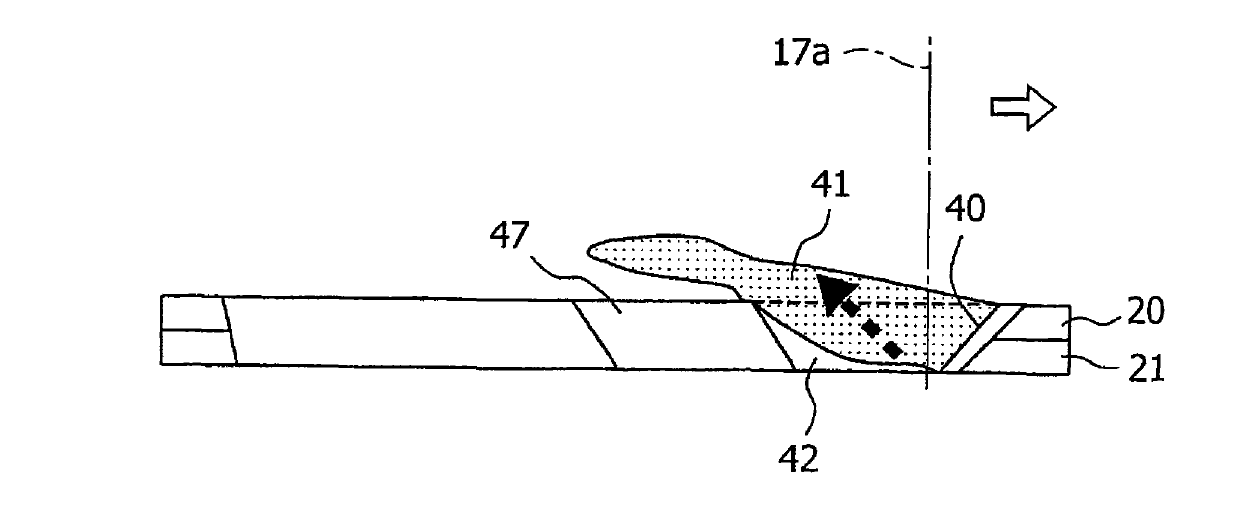

Laser lap welding method for galvanized steel sheet

InactiveCN102120288AAvoid Welding DefectsImprove process managementWelding/soldering/cutting articlesMetal working apparatusSheet steelLight beam

A laser lap welding method, for a galvanized sheet, includes, irradiating a laser beam while traveling at a laser traveling speed (v) mm / sec which leads a power per volume in unit time of the laser beam within a range from 0.07 to 0.11 kWsec / mm3 when the laser beam has a power (P) which is not less than 7 kW and an irradiation spot diameter which is not less than 0.4 mm and a galvanized steel sheet has a thickness (t) mm, so that an elongated hole is formed in a molten pool extending backward from a laser irradiation spot at least in the steel sheet on the outer surface side, whereby metal vapor produced by laser irradiation is vented through the elongated hole backward in a laser traveling direction and in a direction towards a laser irradiation source.

Owner:SUZUKI MOTOR CORP

Micro arc spot welding power supply and micro arc spot welding method

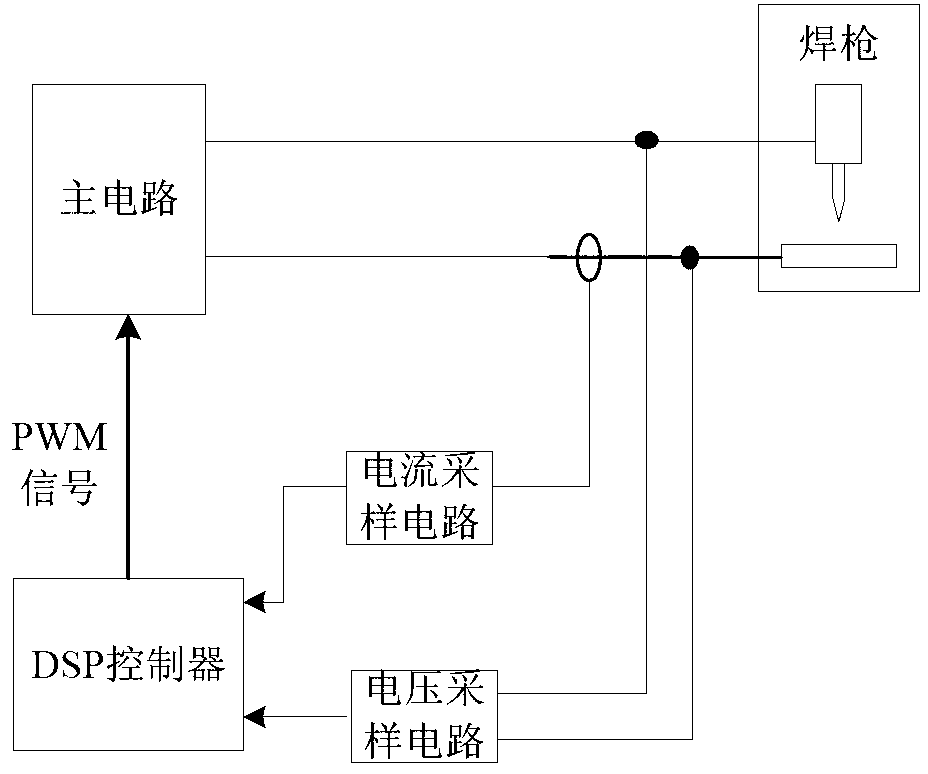

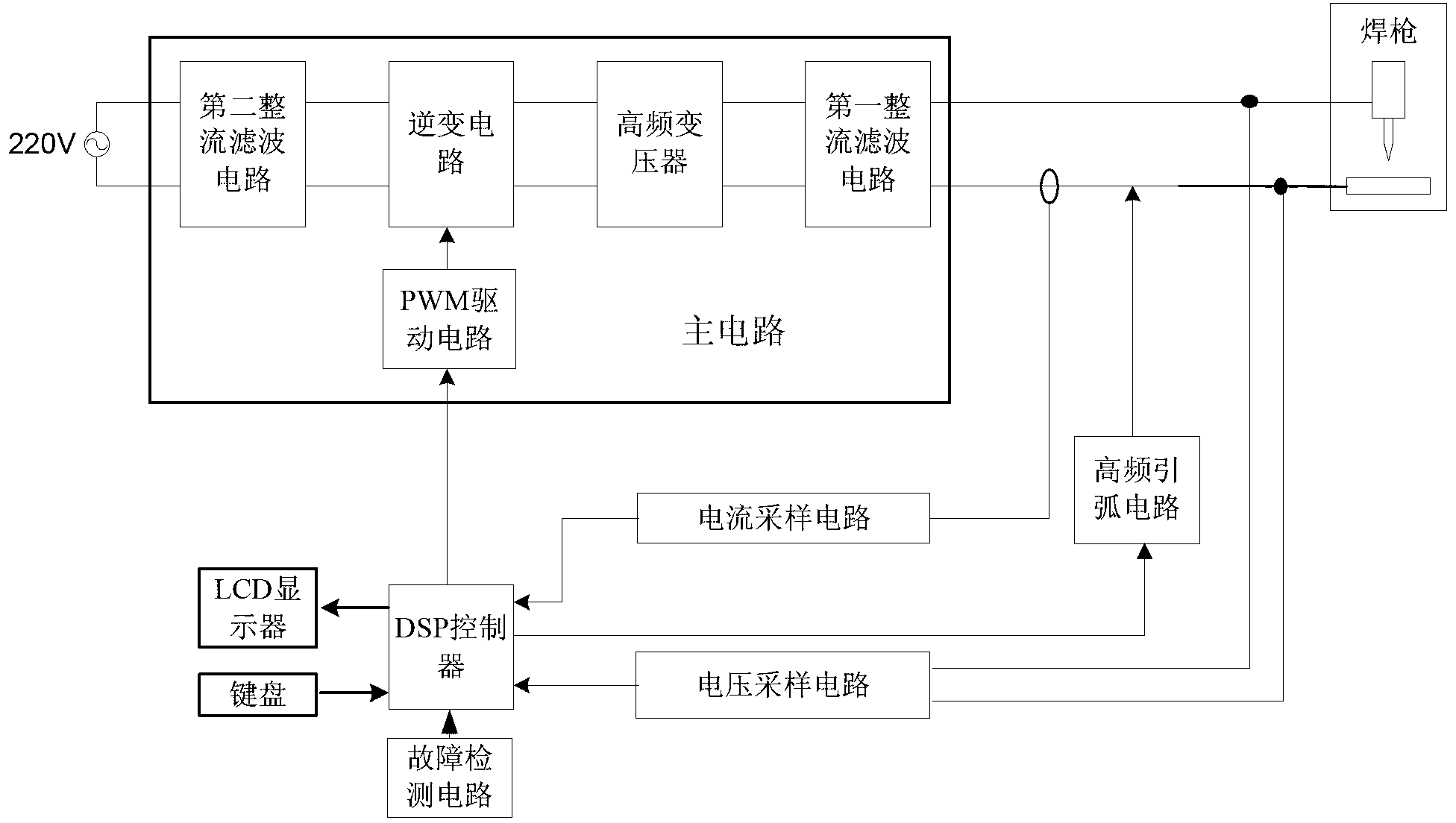

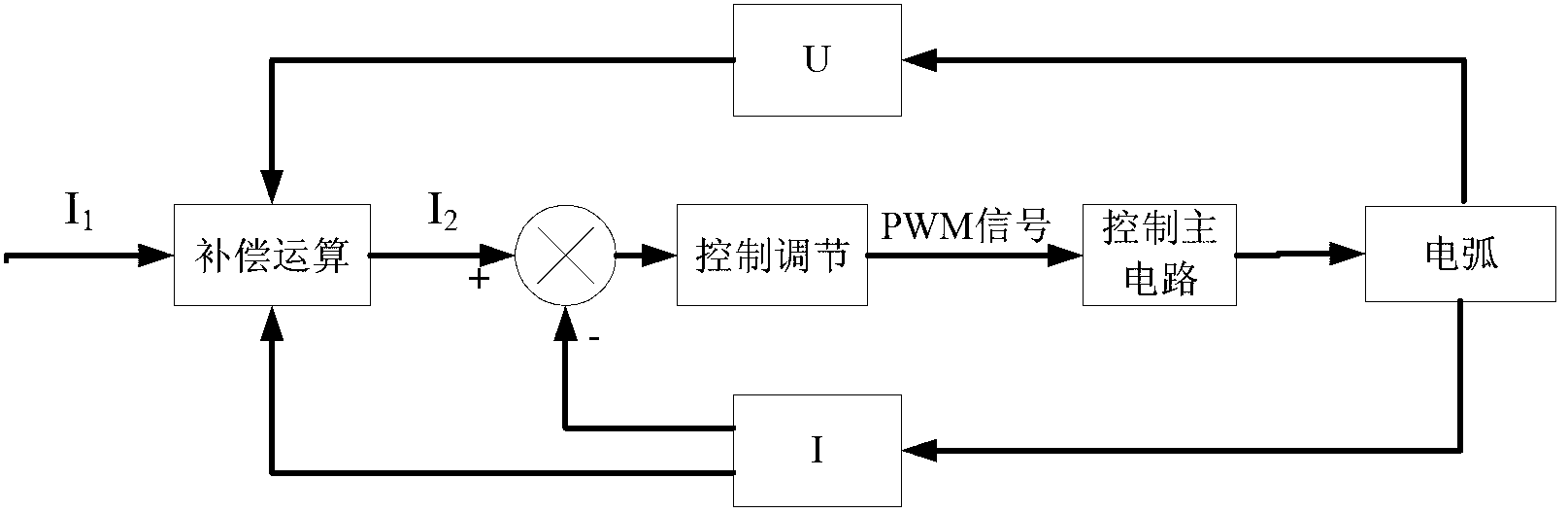

ActiveCN103182582AAvoid Ripple OscillationAvoid Welding DefectsArc welding apparatusHigh frequency powerPower flow

The invention discloses a micro arc spot welding power supply. The micro arc spot welding power supply comprises a main circuit for outputting high-frequency power to a welding gun, a digital signal processing (DSP) controller, and a current sampling circuit and a voltage sampling circuit which are connected to the output ends of the DSP controller and the main circuit respectively; the current sampling circuit is used for acquiring the current value output by the main circuit to obtain a feedback current and outputting the feedback current to the DSP controller; the voltage sampling circuit is used for acquiring the voltage value output by the main circuit to obtain a feedback voltage and outputting the feedback voltage to the DSP controller; and the DSP controller is used for controlling and adjusting the duty ratio of pulse width modulation (PWM) signals according to the set first current value, the feedback current and the feedback voltage and outputting the PWM signals to control the current output by the main circuit. By adopting the power supply, the melting quantity of workpieces is accurately controlled. The control precision of the power supply is high, and formed joints are uniform, beautiful and high in consistency. In addition, the invention also provides a micro arc spot welding method for overcoming the defects that the quality of the welded joints is instable and the outer parts of the welded joints are not smooth enough.

Owner:广州市精源电子设备有限公司 +1

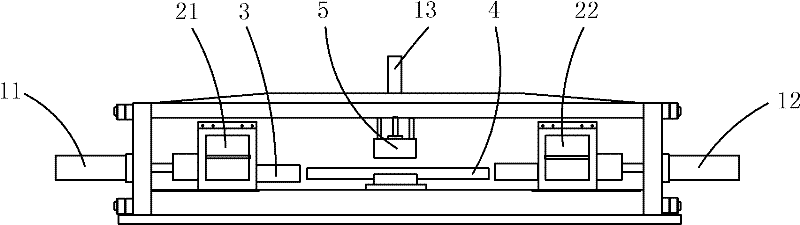

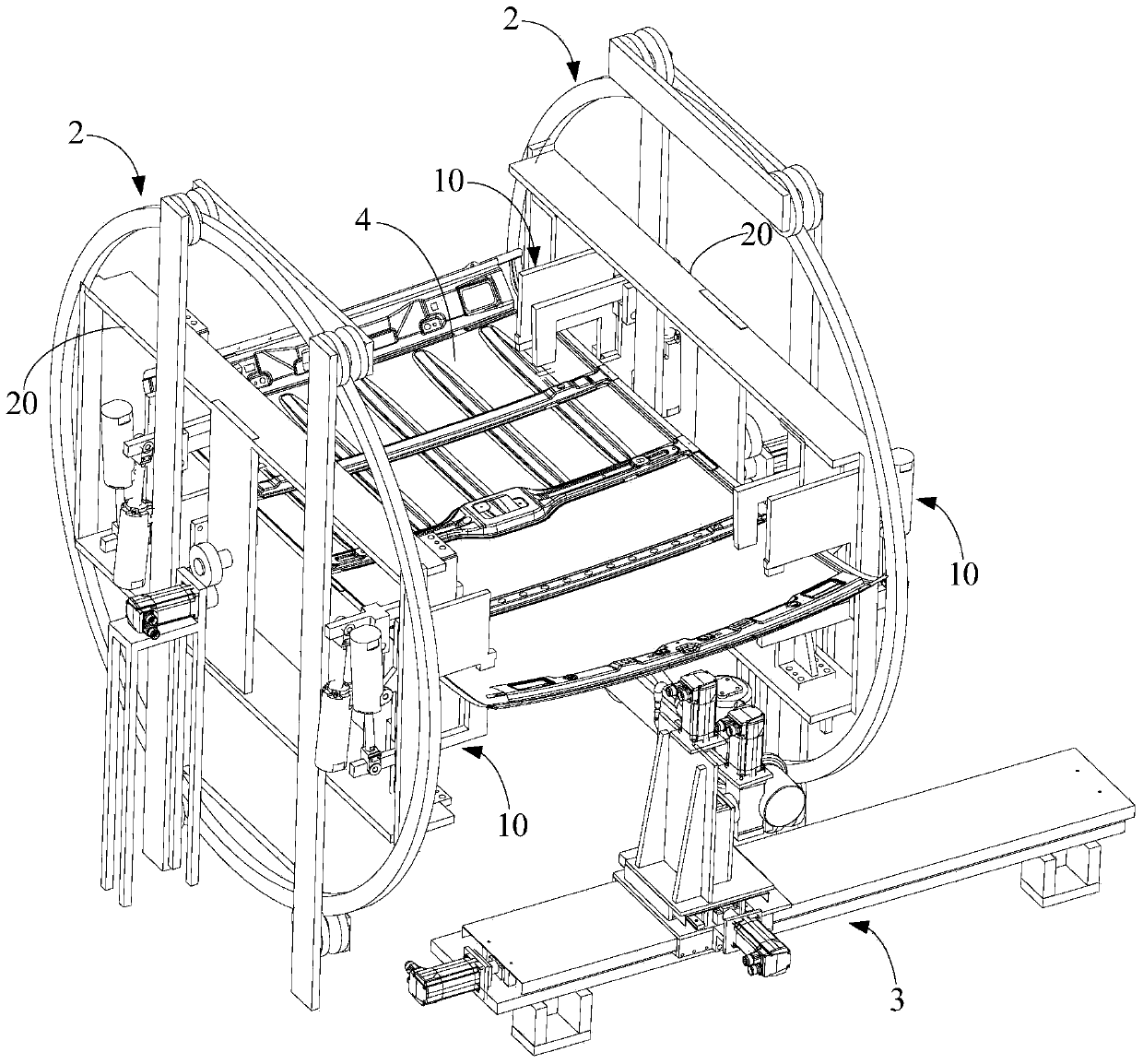

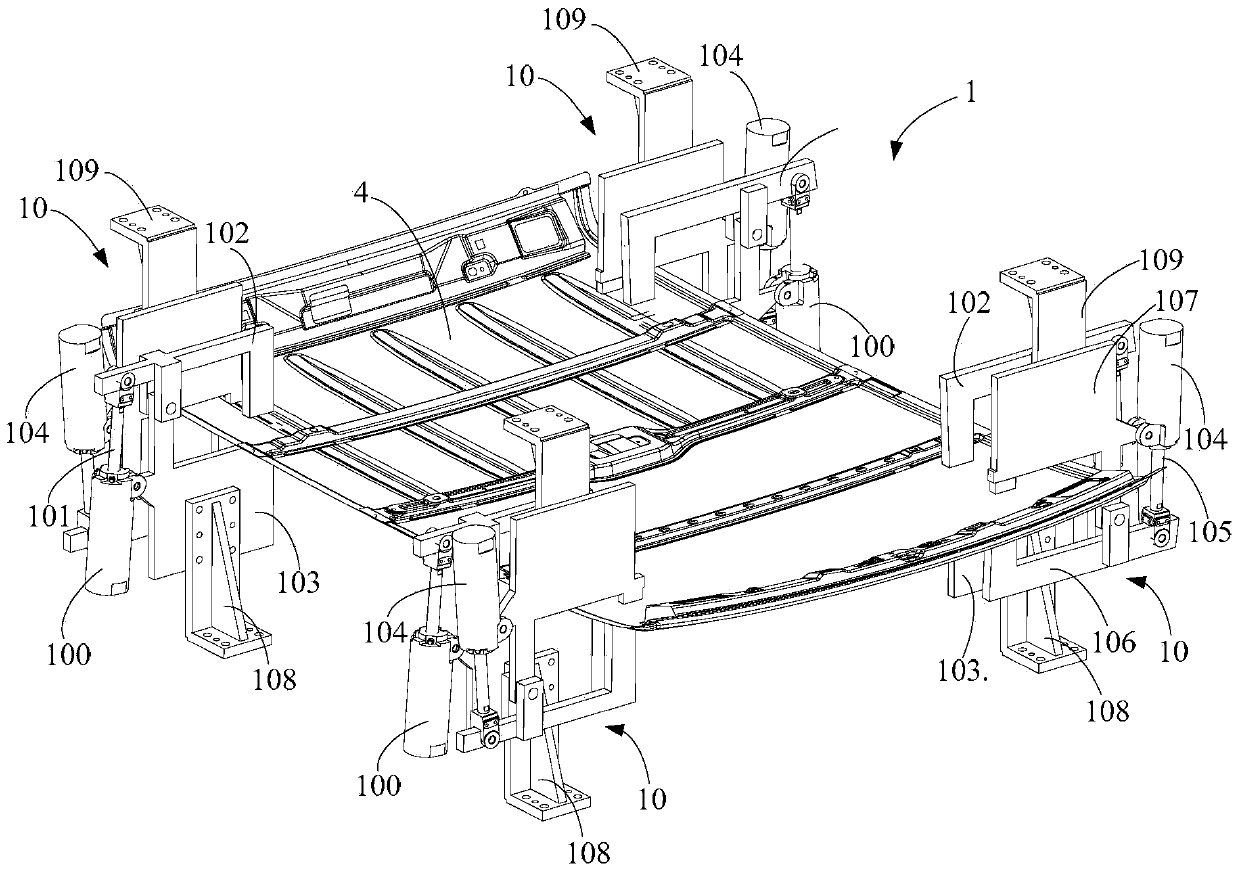

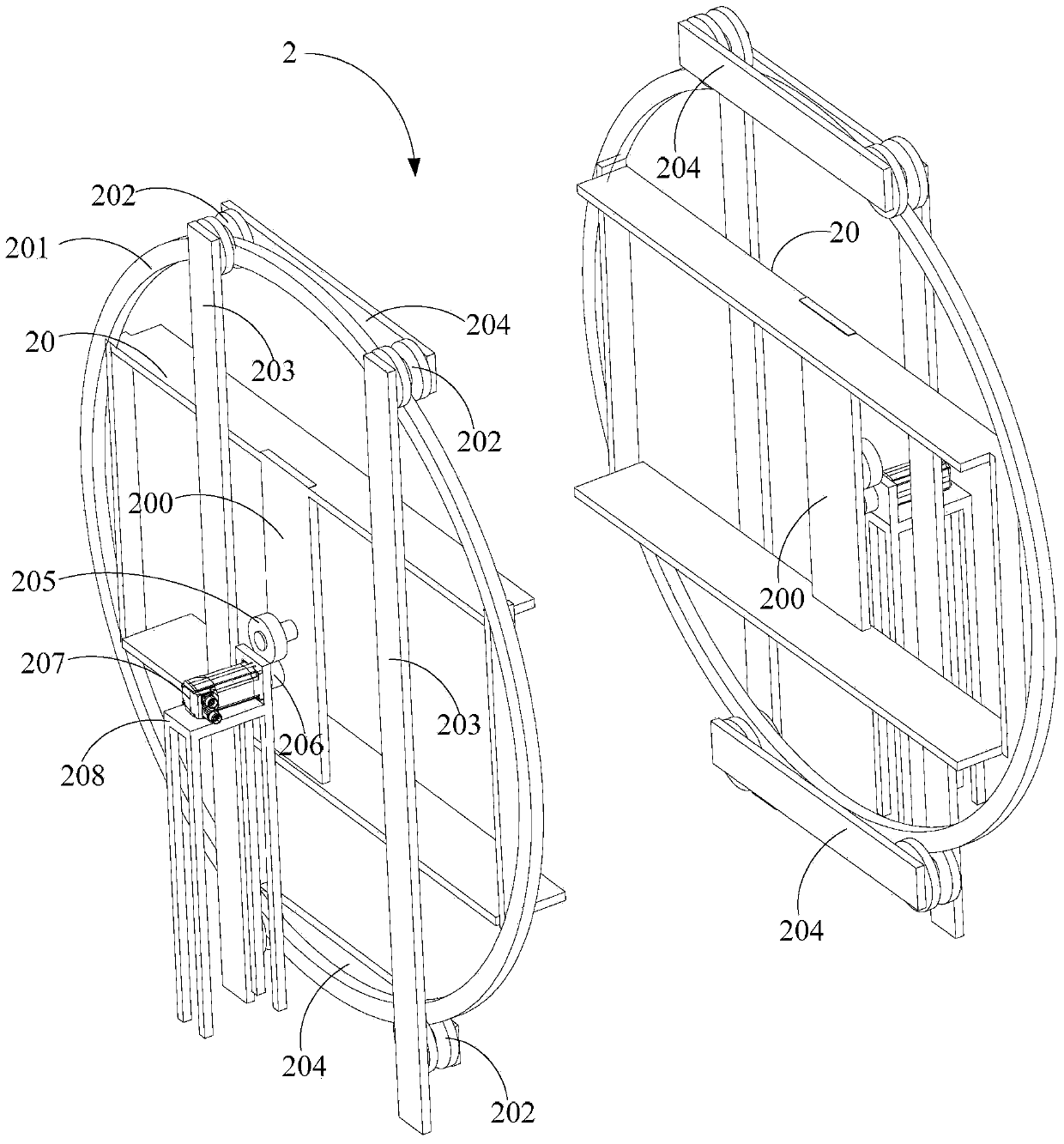

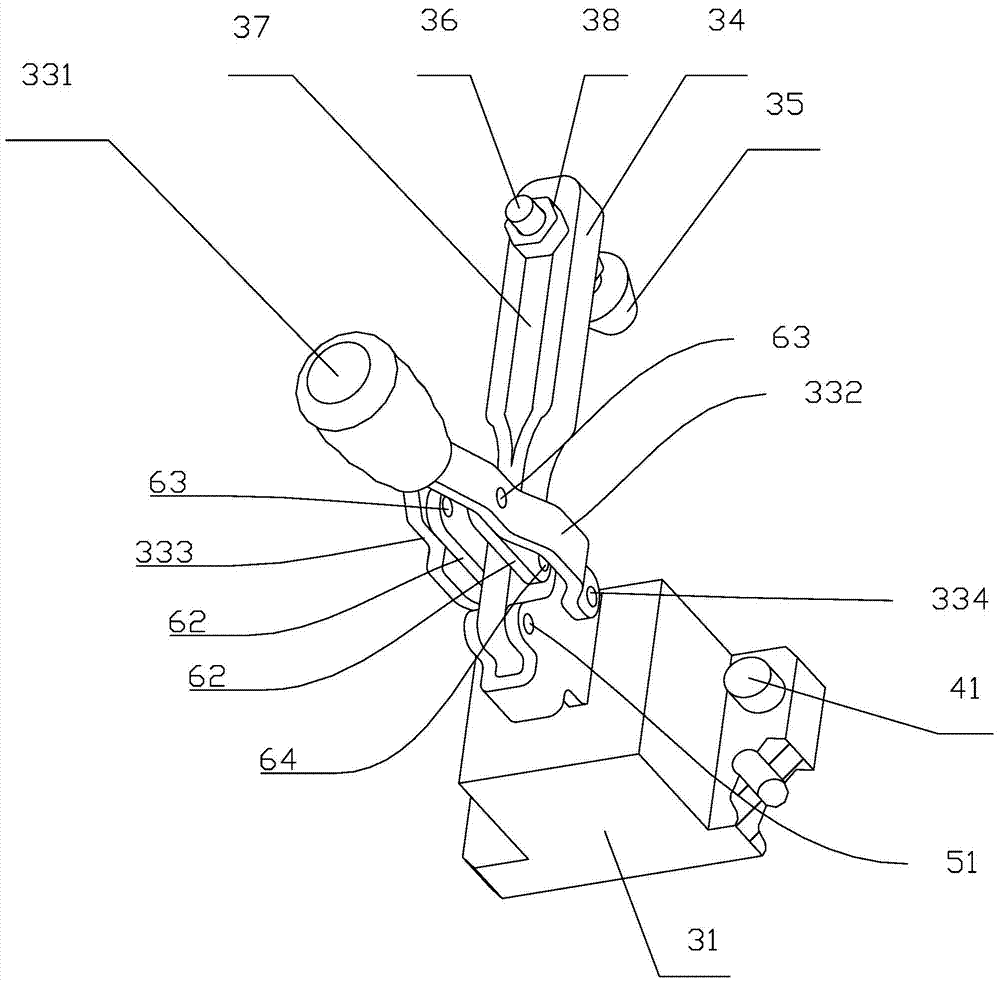

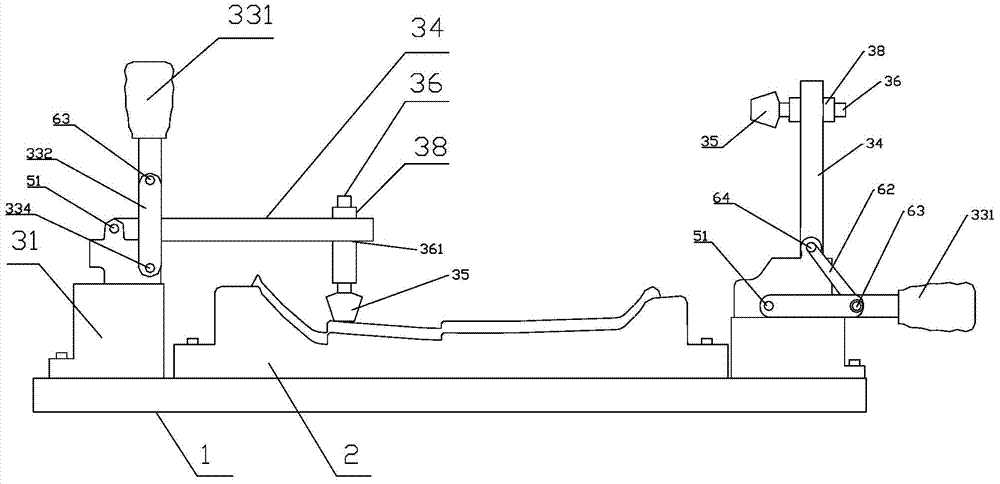

Car roof welding equipment

ActiveCN103692139AAvoid Welding DefectsAvoid bruisesWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringManufacturing engineering

The invention discloses car roof welding equipment, and relates to mechanical welding equipment. The car roof welding equipment is invented, in order to guarantee welding quality, reduce labor intensity and lower cost input. The car roof welding equipment comprises a clamping mechanism, a welding mechanism, turnover mechanisms and a control unit, the clamping mechanism is used for clamping a roof to enable the top surface and the bottom surface of the roof to face downwards and upwards respectively, the welding mechanism is located on one sides of clamping units and used for welding the front end of the clamped roof, the turnover mechanisms are connected with the clamping units and used for turning over the clamped and welded roof, and the clamping mechanism, the welding mechanism and the turnover mechanisms are all electrically connected with the control unit, and the control unit is used for controlling clamping action of the clamping mechanism, welding action of the welding mechanism and turnover actions of the turnover mechanisms. The car roof welding equipment is mainly used for welding production.

Owner:长城汽车股份有限公司平湖分公司

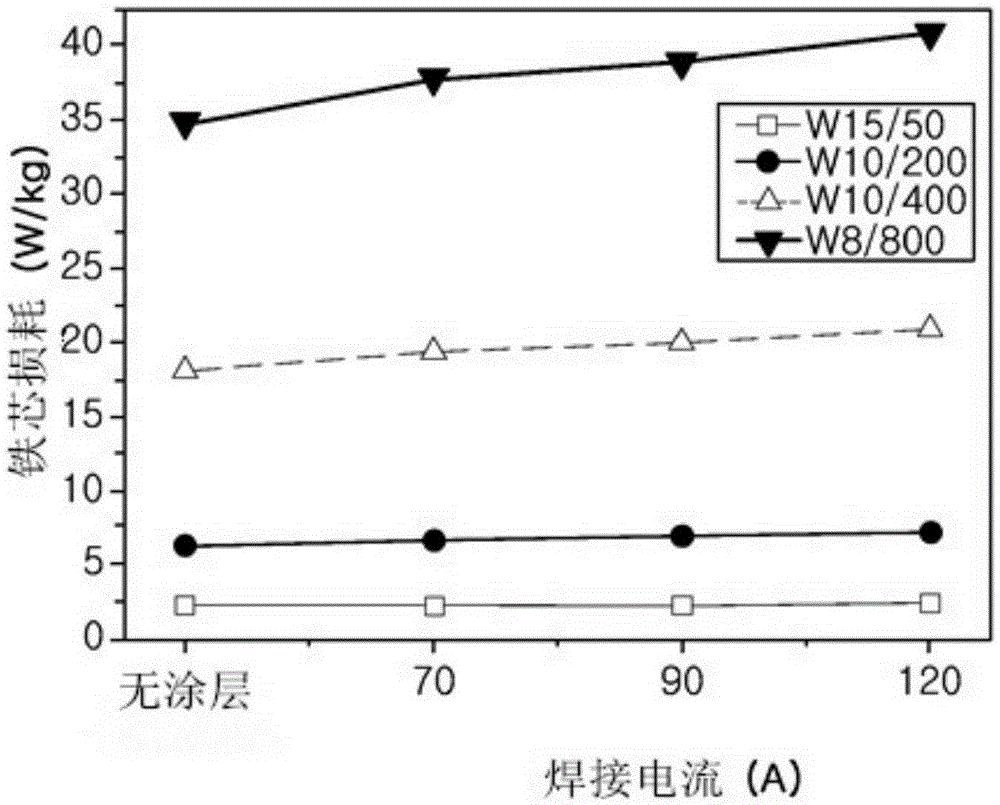

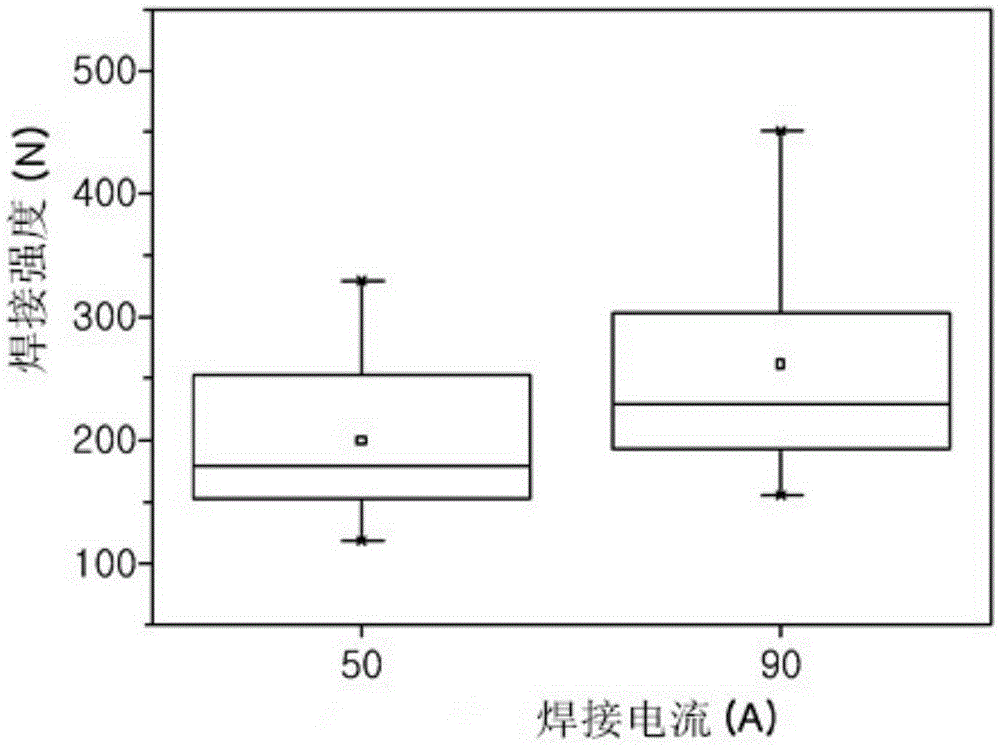

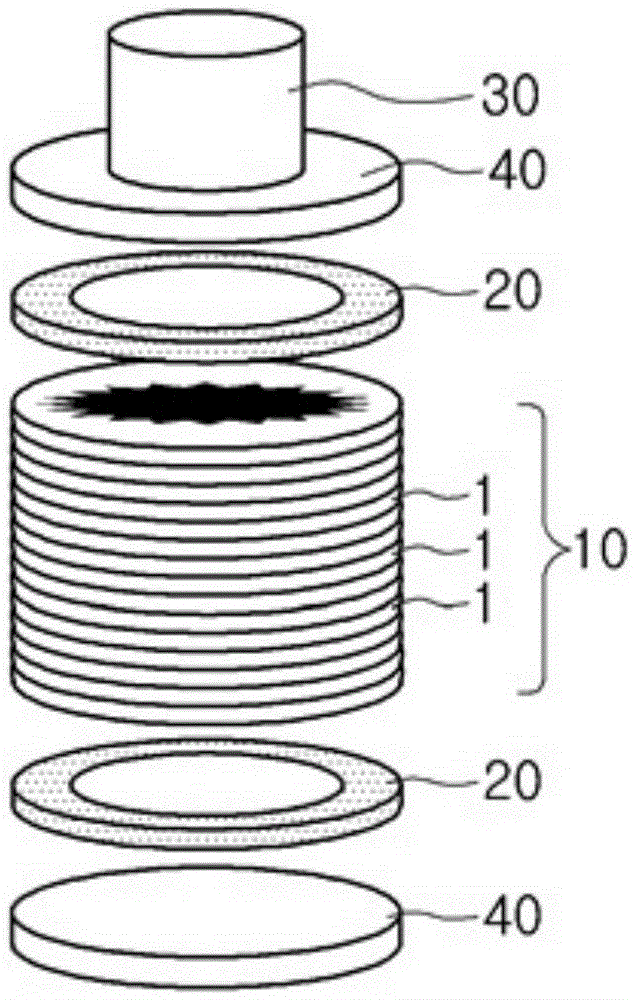

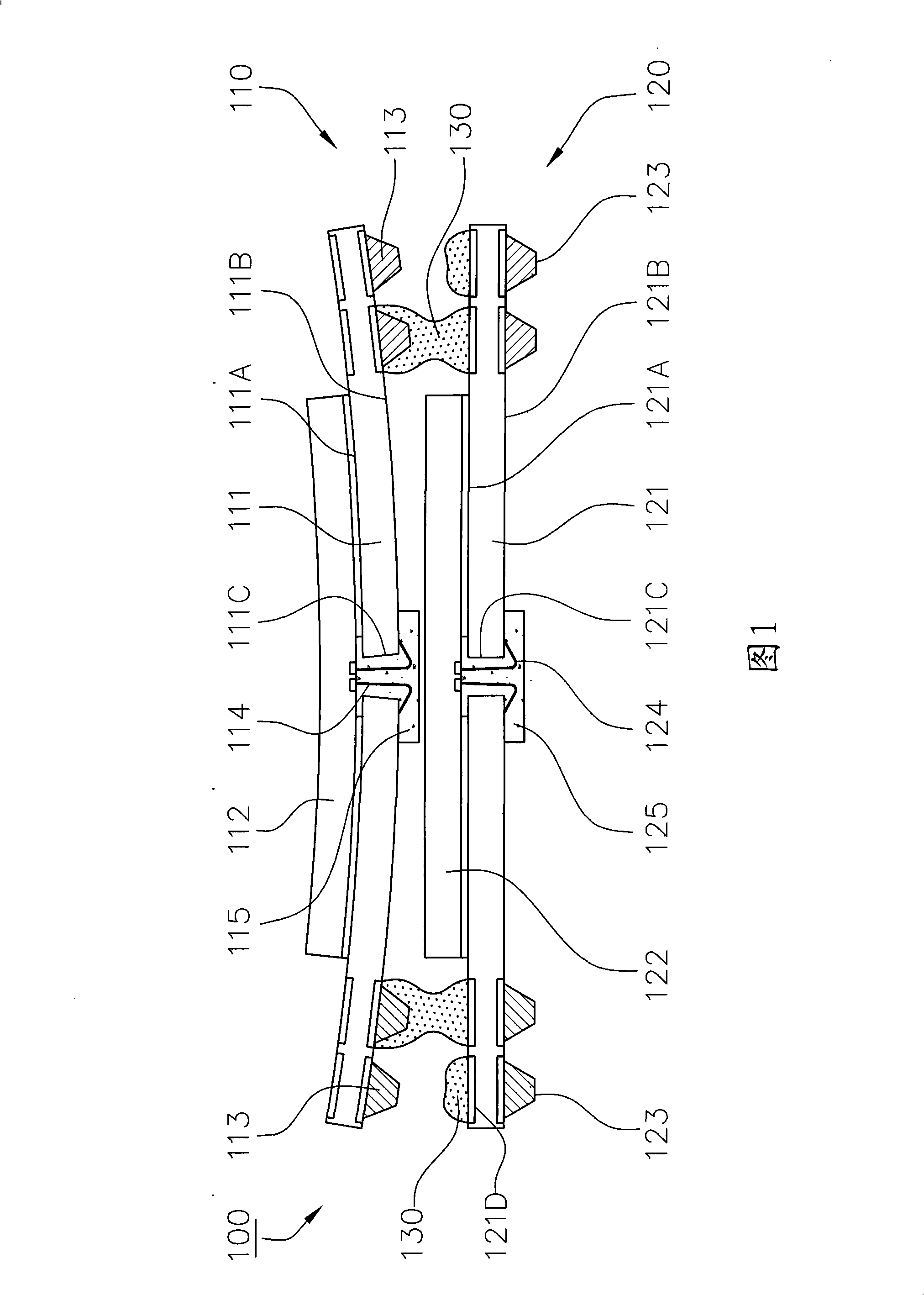

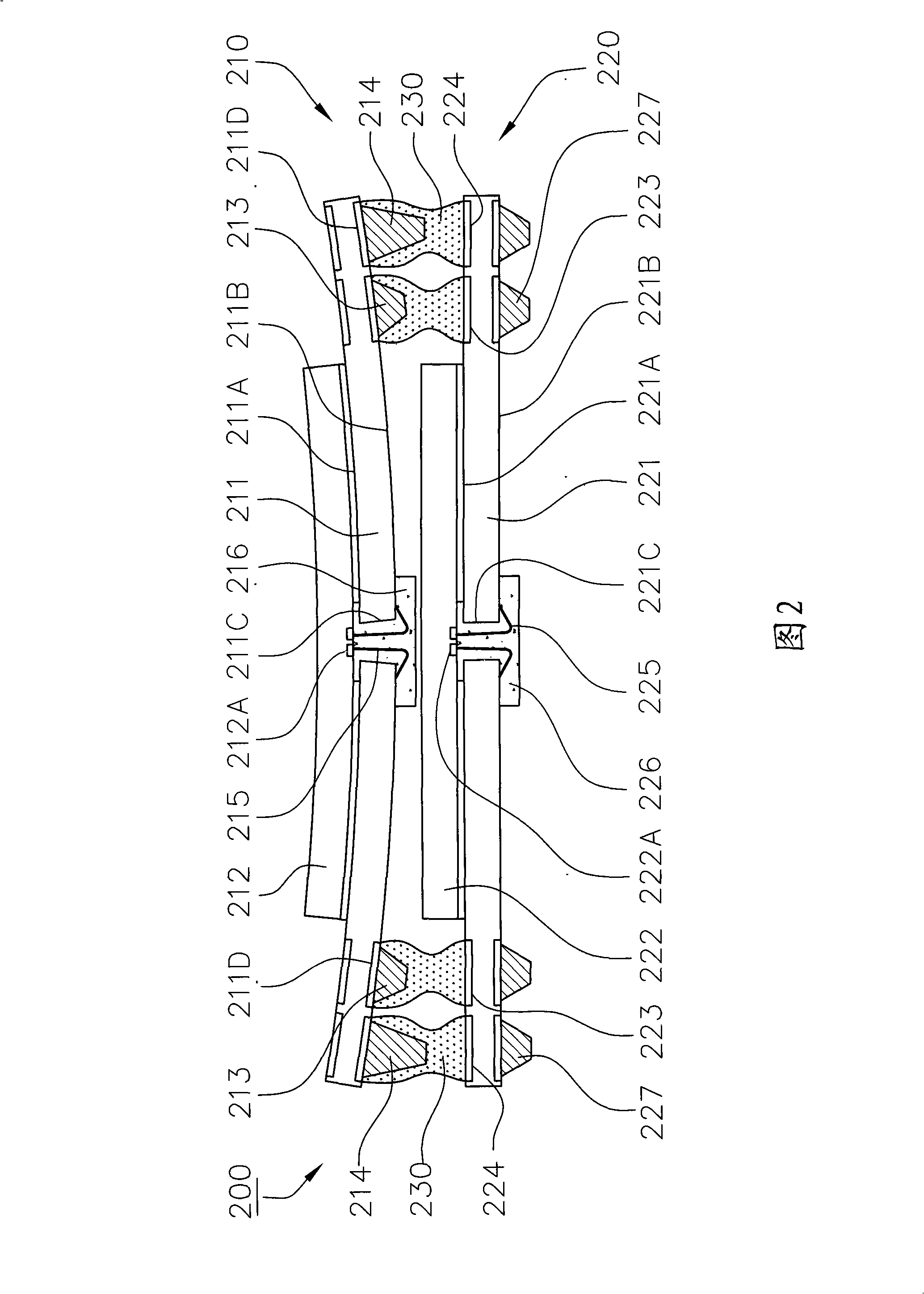

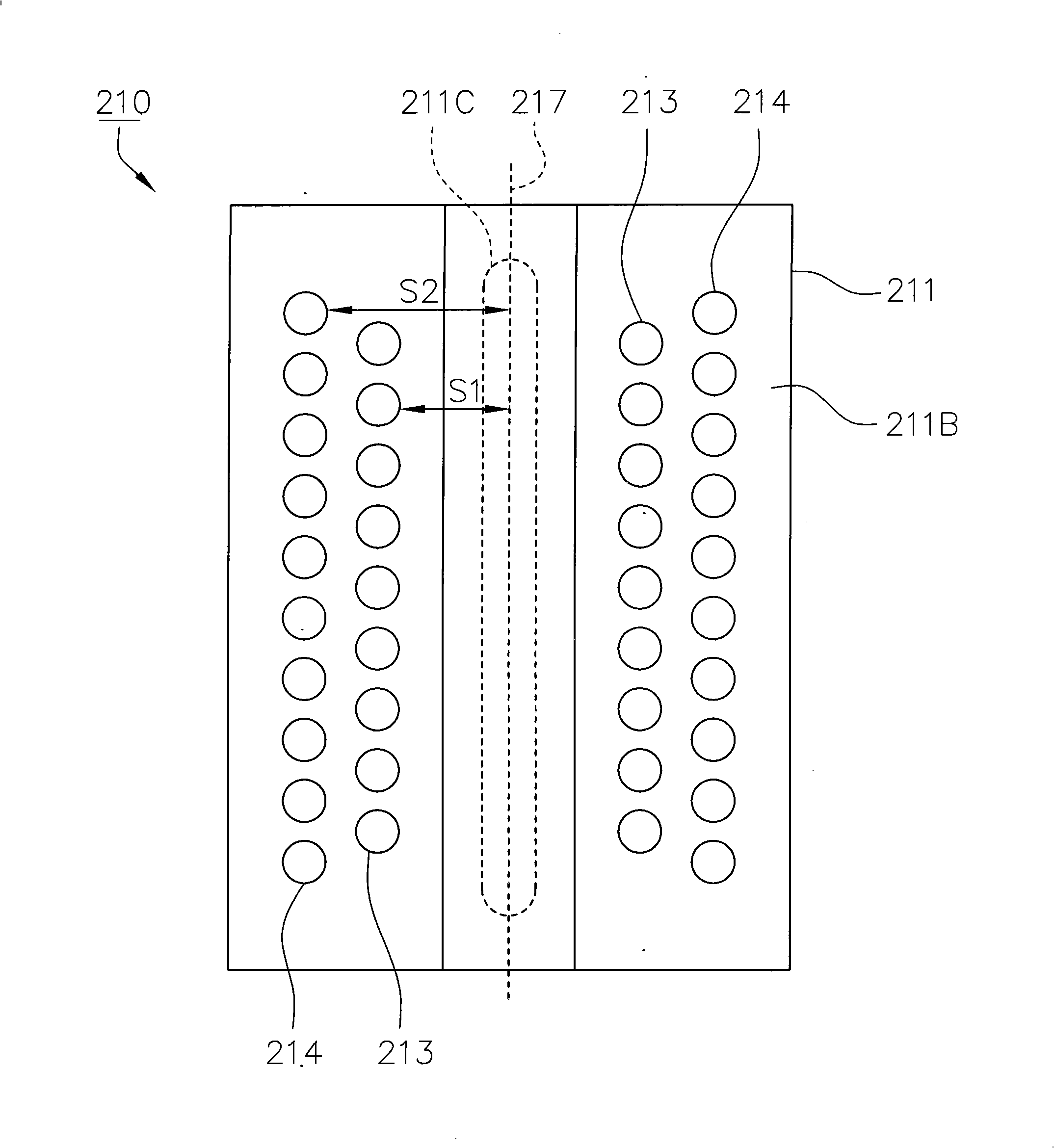

Method for manufacturing electrical steel sheet laminated core having reduced core loss and increased strength, and laminated core produced by the same

InactiveCN105324204AImprove magnetismReduce joint forceMagnetic circuitWelding/cutting auxillary devicesElectrical steelRelative permeability

There are provided a method for manufacturing an electrical steel sheet laminated core having reduced core loss and improved strength, and a laminated core produced by the manufacturing method. The method includes: stacking electrical steel sheets to obtain a lamination; and welding an outer surface of the lamination, wherein during the welding, a welding wire having a resistivity of 6.5 x 10-7 Omegam or greater, a relative permeability of less than 1.02, and a melting point lower than that of the electrical steel sheets is used as a welding material.

Owner:POHANG IRON & STEEL CO LTD

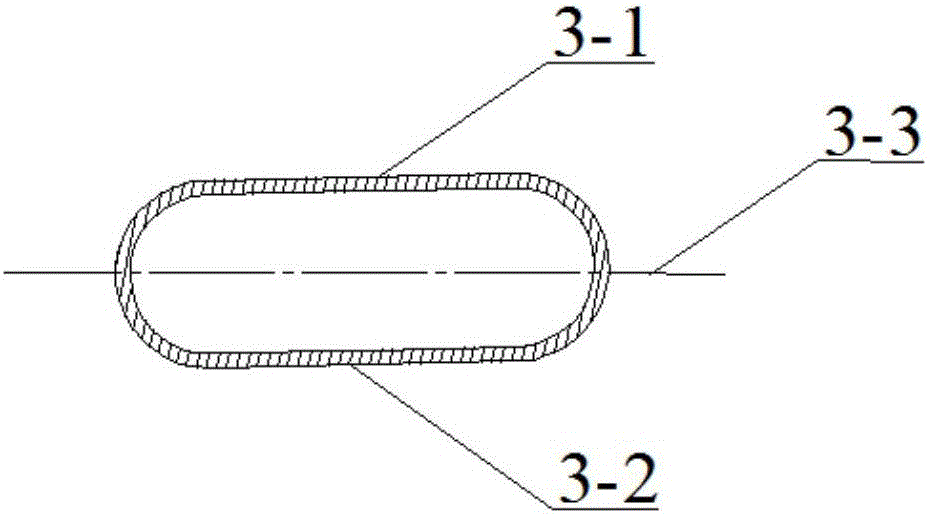

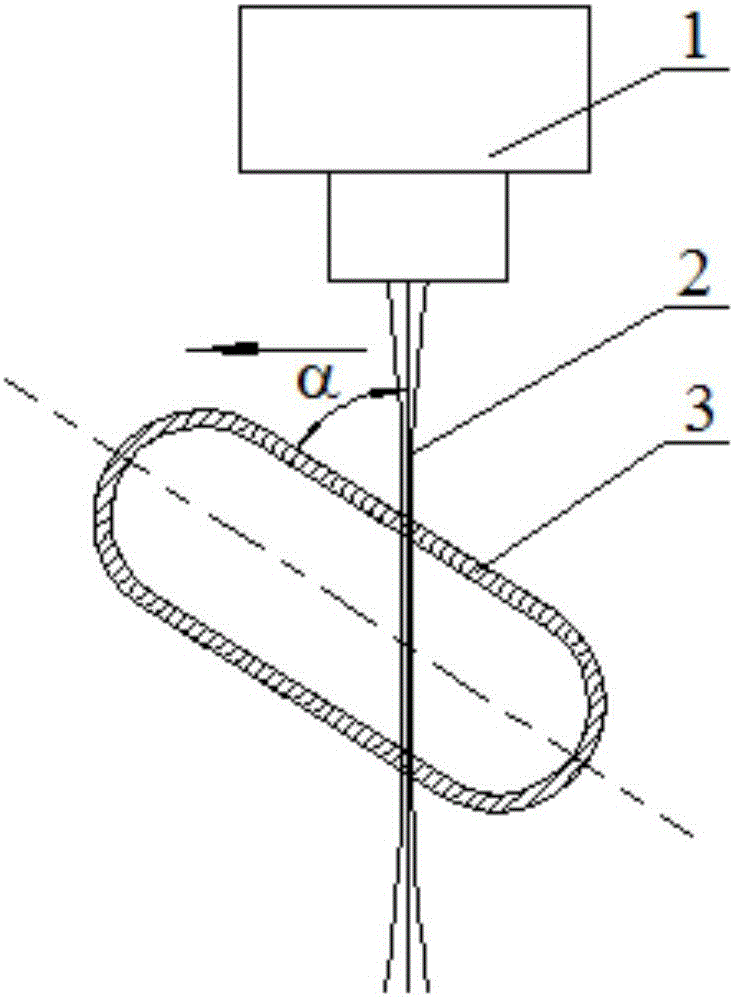

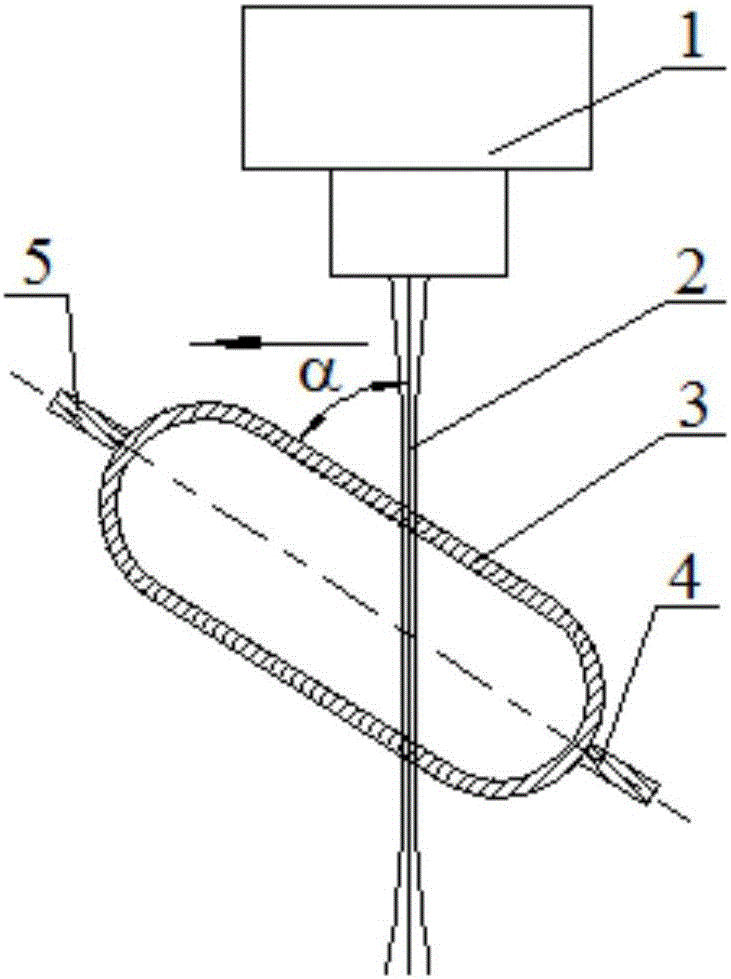

Method for electron beam welding of hollow flat tube type parts

ActiveCN106624320AImprove welding efficiencySolving Difficult-to-Solder ProblemsElectron beam welding apparatusMetal working apparatusLong axisTubes types

The invention discloses a method for electron beam welding of hollow flat tube type parts. Firstly, two hollow flat tube type parts are installed on a welding worktable in an electron beam welding machine vacuum chamber, the installing positions of the two hollow flat tube type parts are adjusted to make included angles formed by the upper side faces of their hollow flat tubes and an electron beam emitted by an electron beam generator range from 45 degrees to 90 degrees; vacuumizing is performed to make the pressure intensity in the electron beam welding machine vacuum chamber smaller than or equal to 1.0*3 mbar; finally, the welding worktable or the electron beam generator is moved at a constant speed to introduce the electron beam from a welding part on one side of the long axes of the hollow flat tubes and is moved to the tail end of the welding part on the other side of the long axes of the hollow flat tubes in the long-axis direction, namely welding of the two hollow flat tube type parts is completed. The welding of two faces of the hollow flat tubes is achieved and the welding efficiency is improved by at least one time by adopting the method, the problem that shielded portion parts are difficult to weld is solved, and the method has wide application prospect in the field.

Owner:AECC AERO SCI & TECH CO LTD

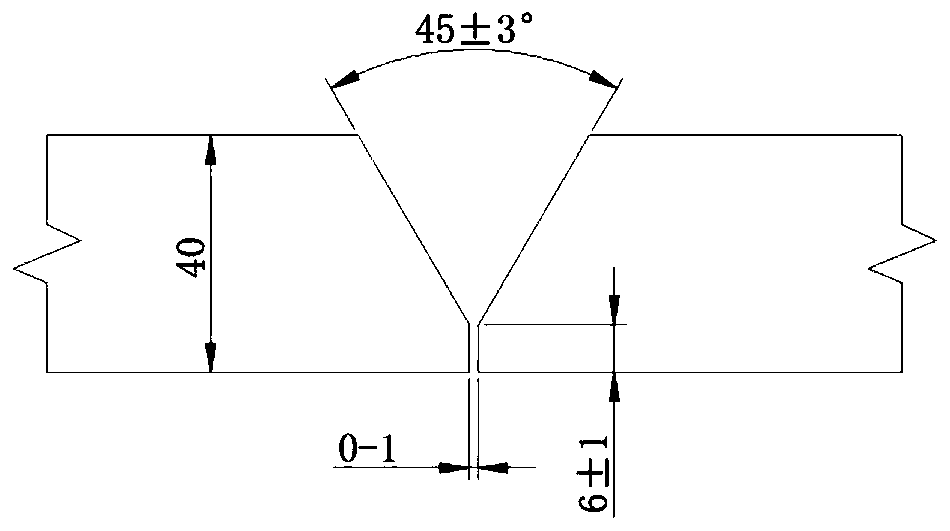

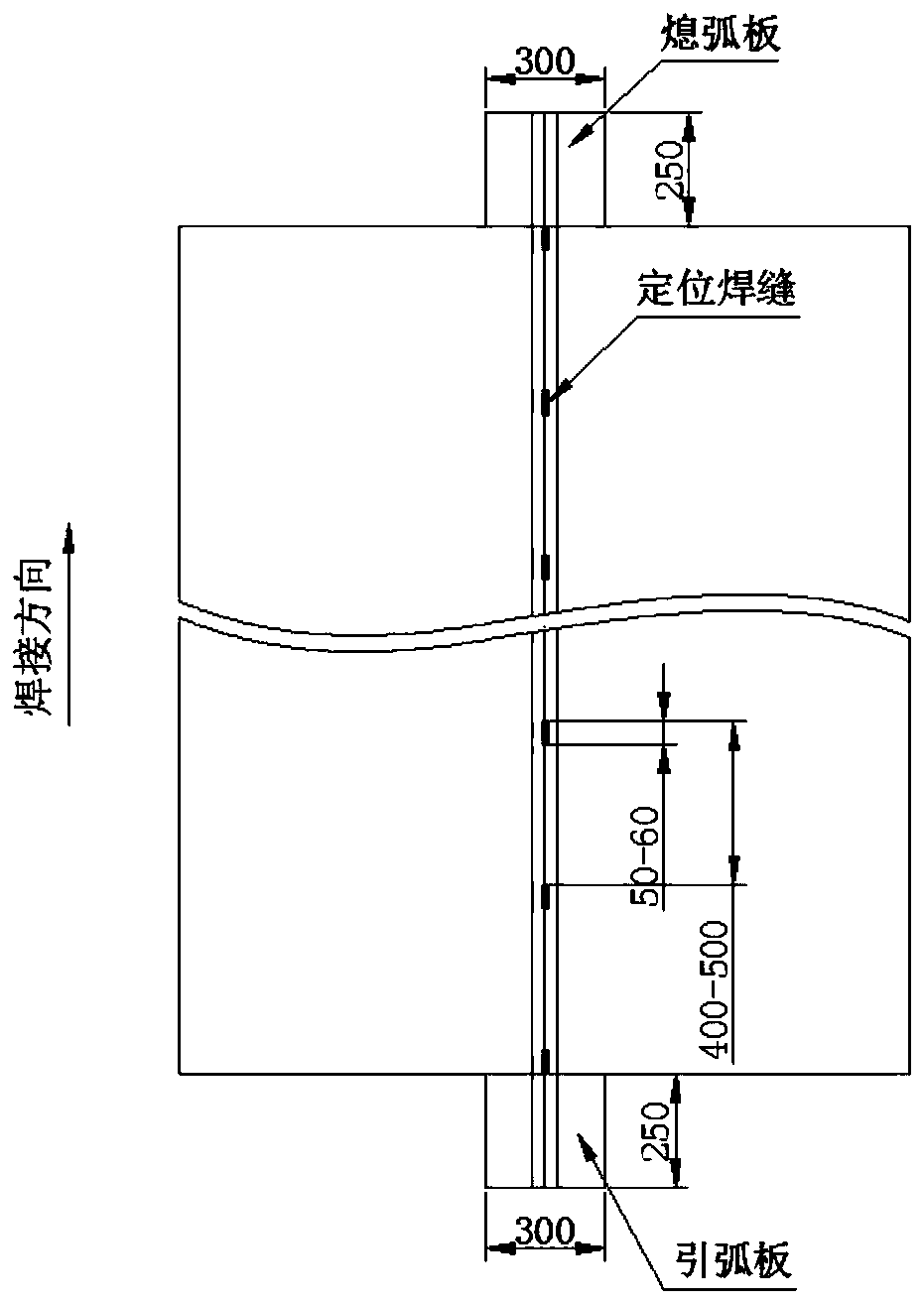

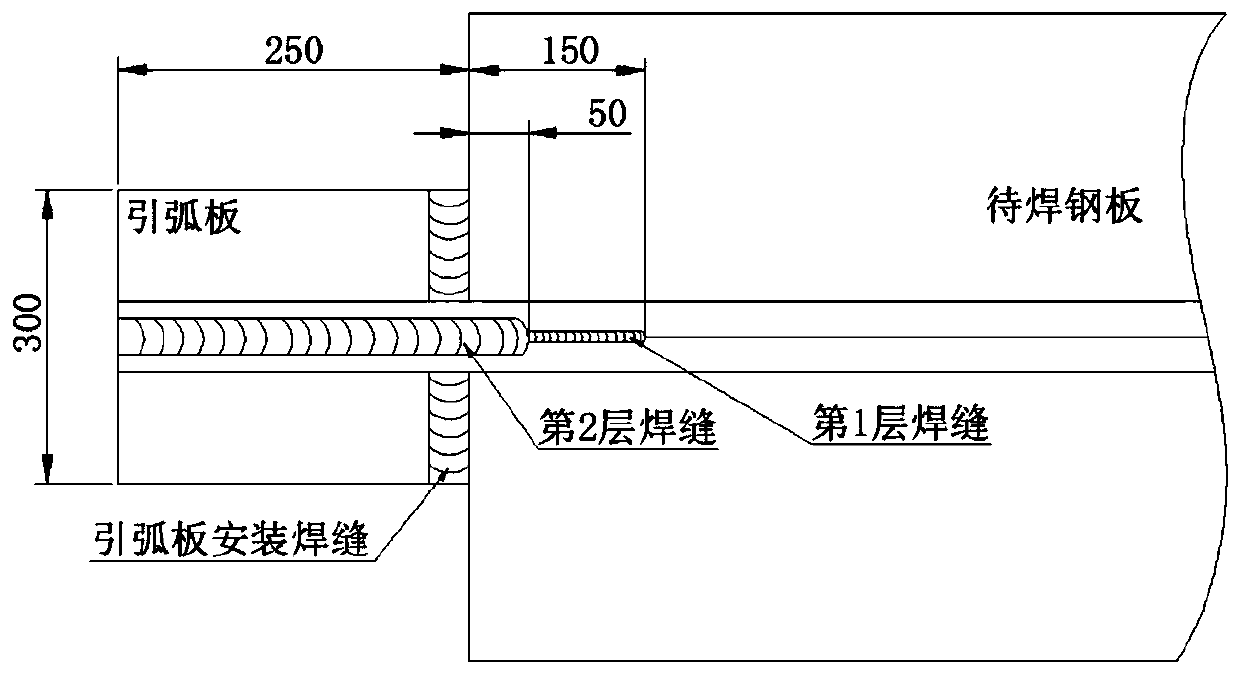

Flux copper gasket method submerged arc welding technology of Q420 high-strength steel thick plate

ActiveCN110640279AImprove efficiencyImprove welding efficiencyArc welding apparatusWelding/soldering/cutting articlesSlag (welding)Thick plate

The invention provides a flux copper gasket method submerged arc welding technology of a Q420 high-strength steel thick plate. The technology is characterized by comprising the following steps that aY-shaped welding groove is machined in a welding position of the to-be-welded Q420 high-strength steel thick plate; a tack weld is welded; a run-on plate and a run-off plate are welded at the two endsof the Y-shaped welding groove respectively; step type restraining weld joints are welded at the two ends of the welding groove; slag and impurities on the surface of a copper gasket are removed, then back flux is spread on the copper gasket, and then the copper gasket is tightly attached to the back surface of the welding groove after the copper gasket is aligned to the center of the welding groove; a proper welding material and suitable electrode welding parameters are selected for welding; and after welding is completed, gouging cleaning is conducted on non-welded defects at the restraining weld joints of the arcing end and the arc extinguishing end, and the gouged groove is subjected to repair welding. The technology can effectively solve the problem that the mechanical property of awelding joint of the Q420 high-strength steel thick plate is severely weakened under a large-heat input welding technology, and application of the flux copper gasket method submerged arc welding efficient welding technology on the Q420 high-strength steel thick plate can be realized.

Owner:广州黄船海洋工程有限公司

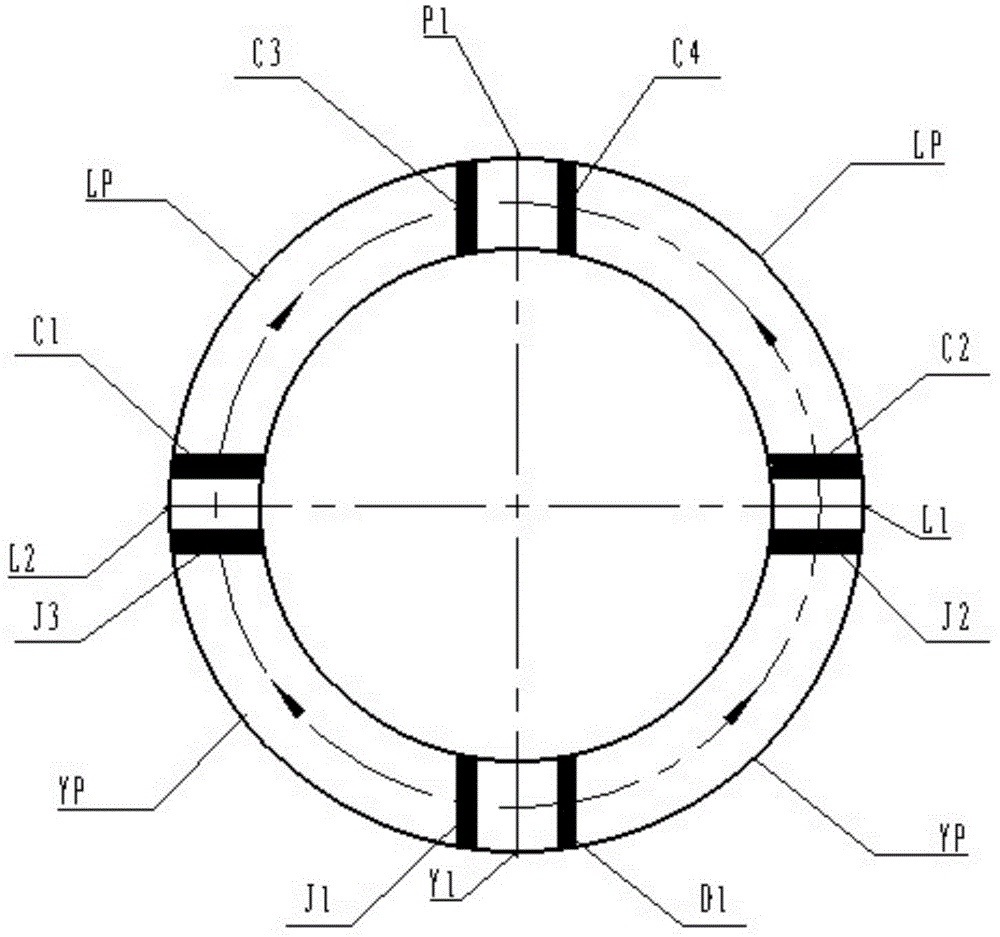

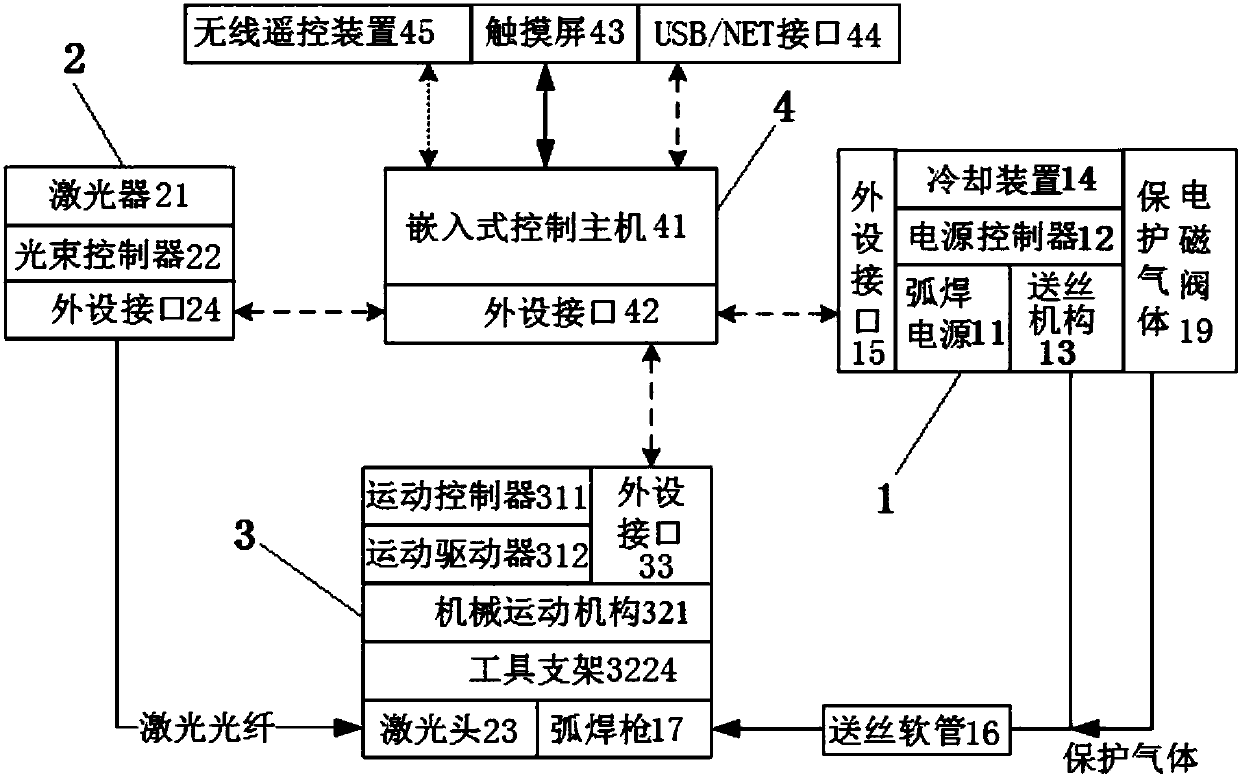

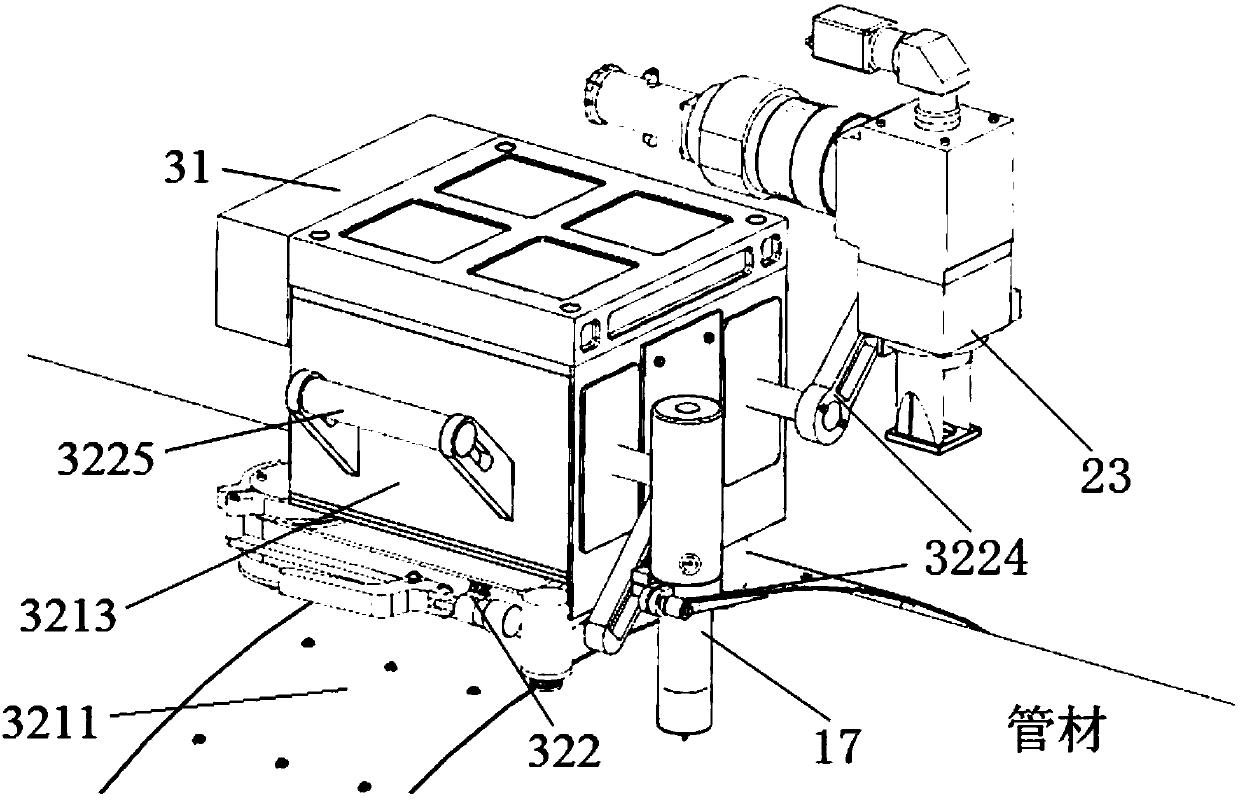

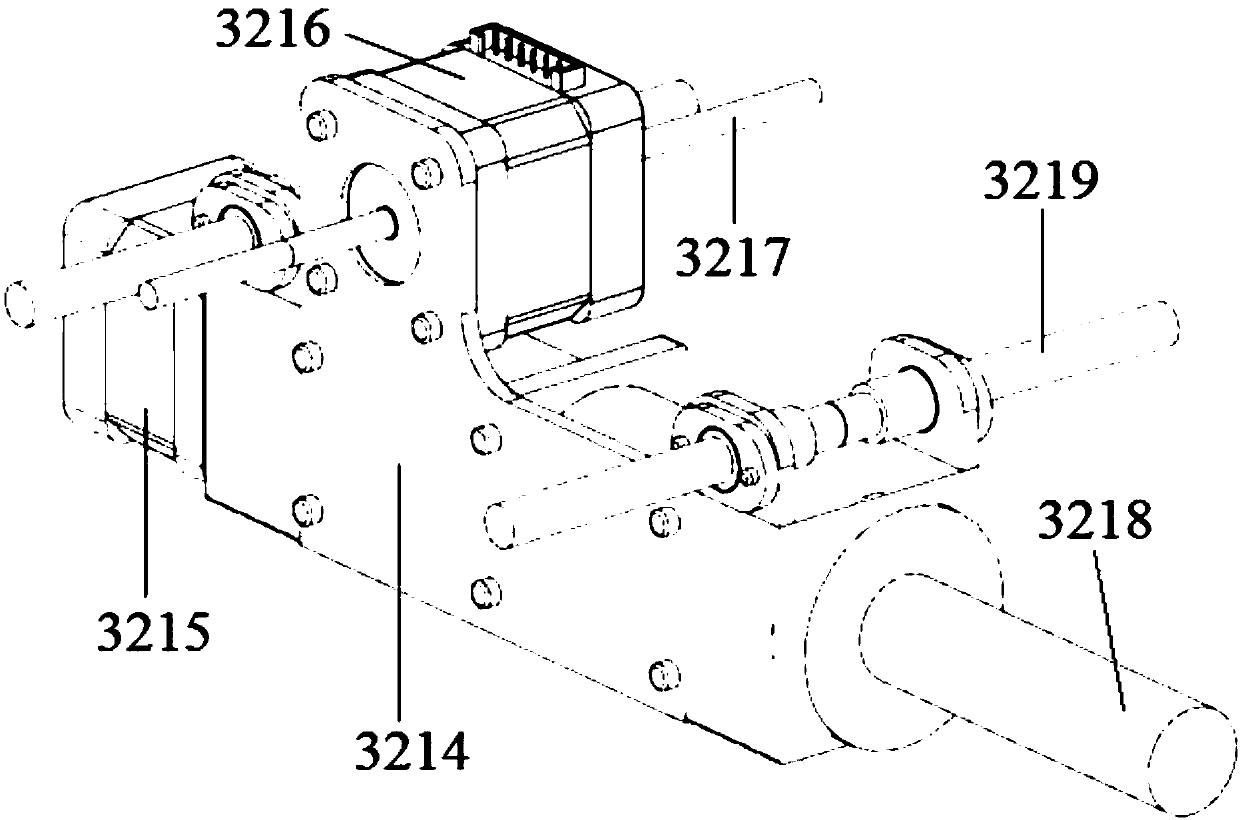

Pipe material full position laser-electric arc composite welding system

ActiveCN107755912ACompact designImprove stabilityWelding apparatusTubular articlesEngineeringElectric resistance welding

The invention provides a pipe material full position laser-electric arc composite welding system. The pipe material full position laser-electric arc composite welding system comprises a full positionlaser and electric arc composite welding device and a full position laser and electric arc composite welding control system used for controlling the full position laser and electric arc composite welding device; the full position laser and electric arc composite welding device comprises an electric arc welding system, a laser welding system, a laser and electric arc composite welding movement system and a laser and electric arc composite welding embedded type control system; the electric arc welding system, the laser welding system, the laser and electric arc composite welding movement systemand the laser and electric arc composite welding embedded type control system perform data transmission and coordinated control through a field control bus; the full position laser and electric arc composite welding control system comprises an arc welding power source wave shape controller and a laser energy time sequence controller; the arc welding power source wave shape controller is used for controlling the electric arc welding system; and the laser energy time sequence controller is used for controlling the laser welding system. The pipe material full position laser-electric arc compositewelding system can improve the quality and the efficiency of large diameter and large wall thickness pipe material full position welding.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

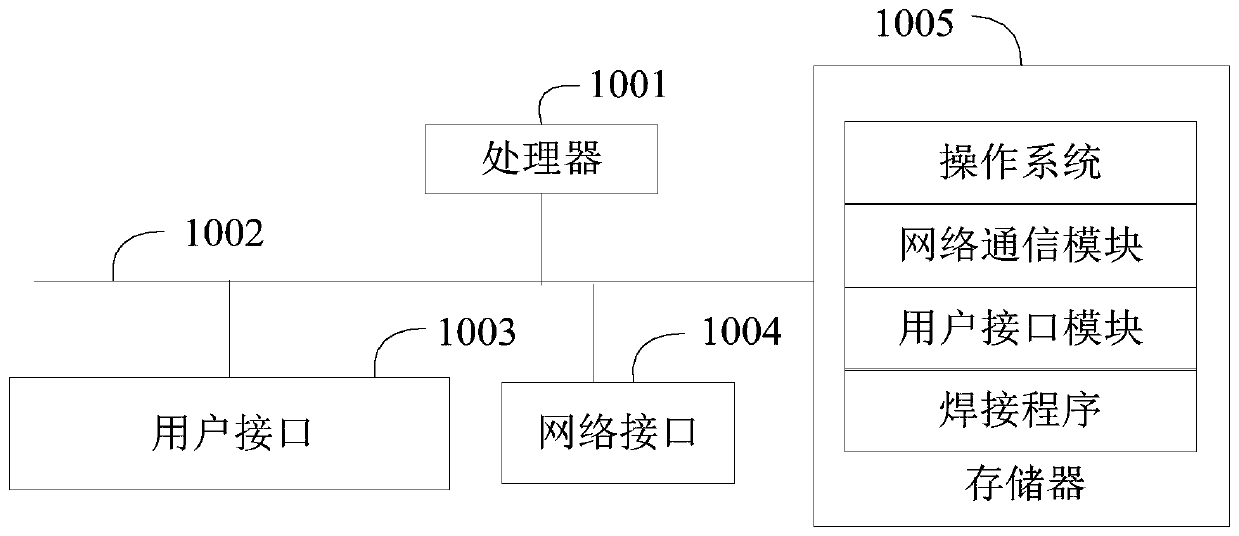

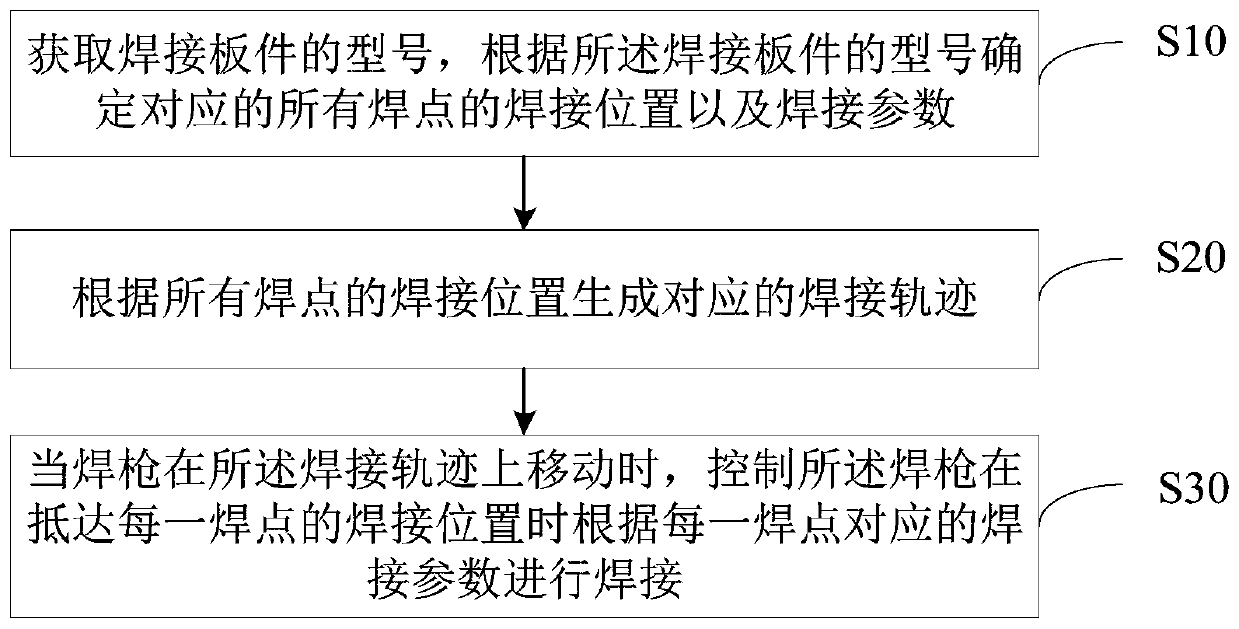

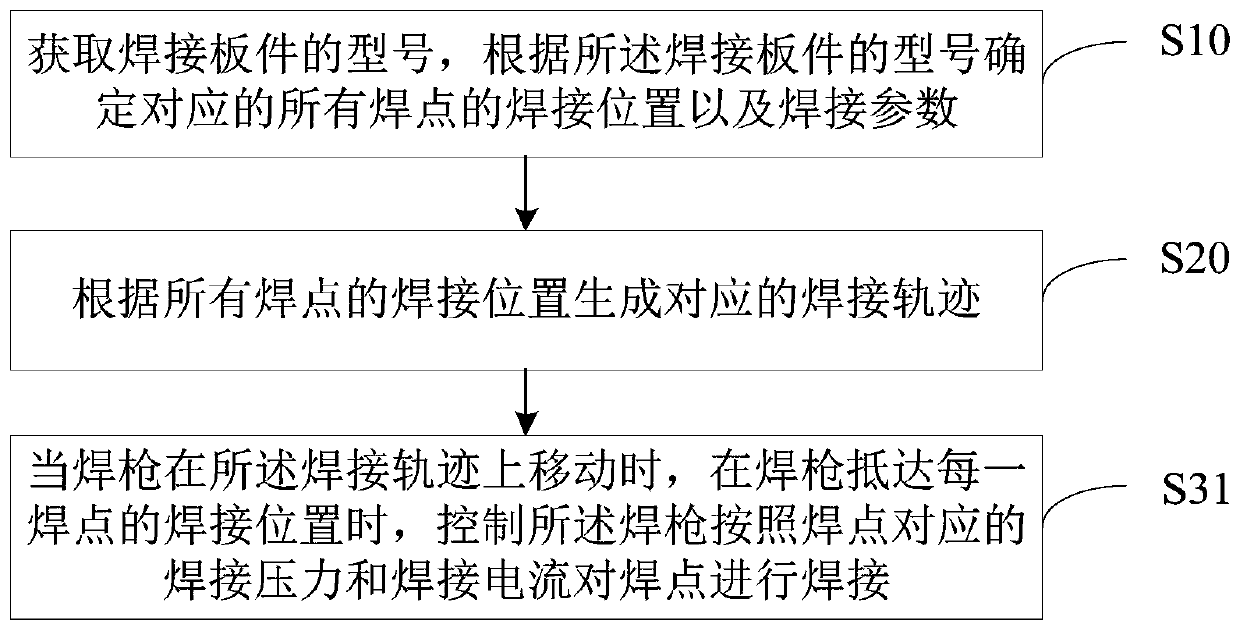

Welding method, automatic welding device and storage medium

ActiveCN110666321AAvoid Welding DefectsResistance electrode holdersWelding electric supplyWelding defectMaterials science

The invention discloses a welding method, an automatic welding device and a storage medium. The welding method comprises the steps: acquiring model of a welding plate, and determining corresponding welding positions and welding parameters of all welding spots according to the model of the welding plate; generating corresponding welding tracks according to the welding positions of all welding spots; and when a welding gun moves on the welding tracks, controlling the welding gun to carry out welding according to the welding parameter corresponding to each welding spot when reaching the welding position of each welding spot. In the process that the welding gun moves and carries out welding through the preset welding tracks, a welding mode corresponding to each welding spot can be adopted forwelding when each welding spot is welded, therefore, the welding spots at the different positions on the welding plate are correspondingly welded, and welding defects of the welding spots caused by single welding mode are prevented.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

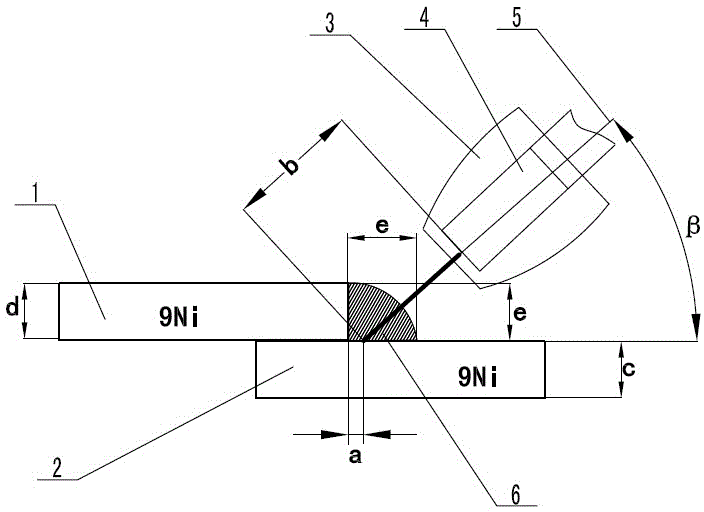

Welding technique for base plate of LNG low-temperature tank

InactiveCN104625359ASatisfy the pressure bearing capacity requirementsHigh hardnessArc welding apparatusDomestic vesselsFillet weldCurrent range

The invention discloses a welding technique for a base plate of an LNG low-temperature tank and belongs to the technical field of welding of LNG low-temperature tanks. According to the welding technique, two 9Ni steel plates with the thicknesses ranging from 6 mm to 9 mm are made to be in lap joint in the horizontal direction and overlap to form an overlap joint, the end face is cleaned, a preparation for welding is made, and then submerged-arc welding is conducted by means of alternating current, wherein the arc voltage ranges from 25 V to 29 V, the welding current ranges from 260 A to 290 A, the wire extension length ranges from 25 mm to 35 mm, the welding speed ranges from 22 in / min to 25 in / min, the welding wire angle ranges from 55 degrees to 65 degrees, and a full fillet weld with a welding foot with the length ranging from 6 mm to 9 mm is formed. By the adoption of the welding technique, submerged-arc welding of the base plate of the LNG low-temperature tank can be achieved, the problems that during submerged-arc welding, a lap fillet weld is poorly formed, hot cracks are formed during welding, and burning through occurs easily during welding are solved, the two 9Ni steel plates with the thicknesses ranging 6 mm to 9 mm can be welded in a single-pass mode at a time during actual operation, and welding efficiency is remarkably improved.

Owner:SINOPEC TENTH CONSTR

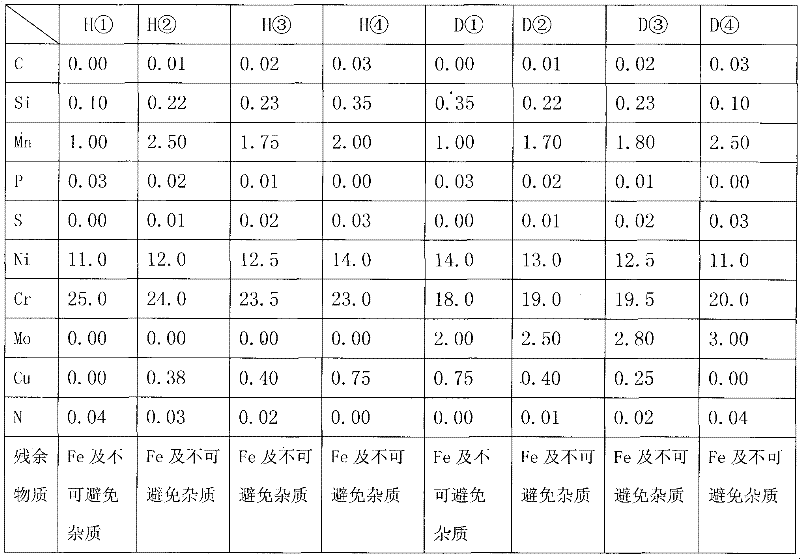

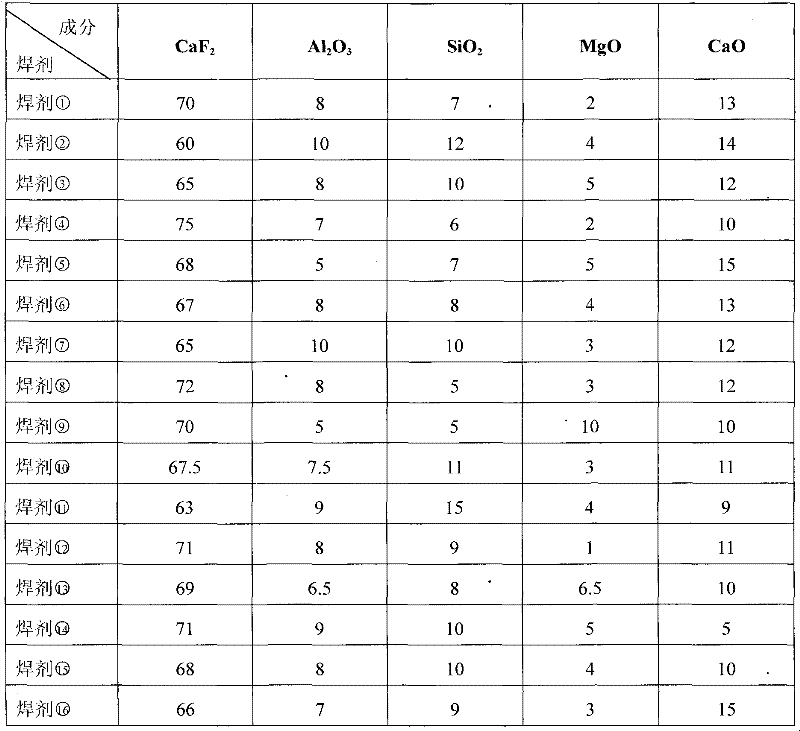

Stainless steel band electrode electroslag surfacing welding strip and welding flux

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

Reflow welding process of DIP through-hole part

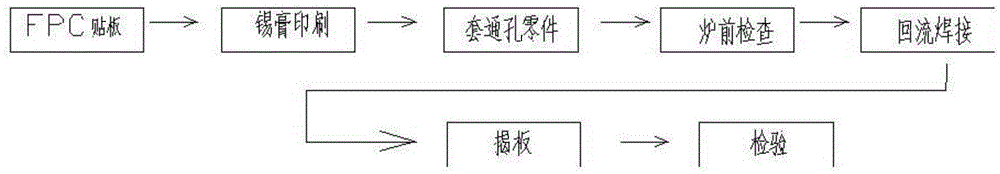

InactiveCN104308314AQuality assuranceReduce thermal shockPrinted circuit assemblingSoldering apparatusEngineeringAlloy

The invention discloses a reflow welding process of a DIP through-hole part and belongs to the technical field of manufacturing of printed circuit boards. The reflow welding process relates to an automatic printing machine, a hot air reflow welding machine and matched welding equipment, and comprises the following steps of (1) pre-welding preparation, (2) tin printing and mounting, (3) pre-welding assembly, (4) in-furnace welding and (5) post-welding test, wherein Sn96.5Ag3.0Cu0.5 tin paste alloy is adopted as tin paste in the step (1). Compared with a conventional DIP process product, the reflow welding process has the advantages that the cleaning time of a flux is eliminated, the risks of residue of the flux and pollution of the product are zero, the production efficiency is improved by 50 percent; the one-time welding yield can exceed 99.5 percent, the welding quality of a welding point is effectively improved, the production efficiency is improved, the cost is reduced, and the labor time is shortened.

Owner:昆山圆裕电子科技有限公司

Inner decoration piece fixing device

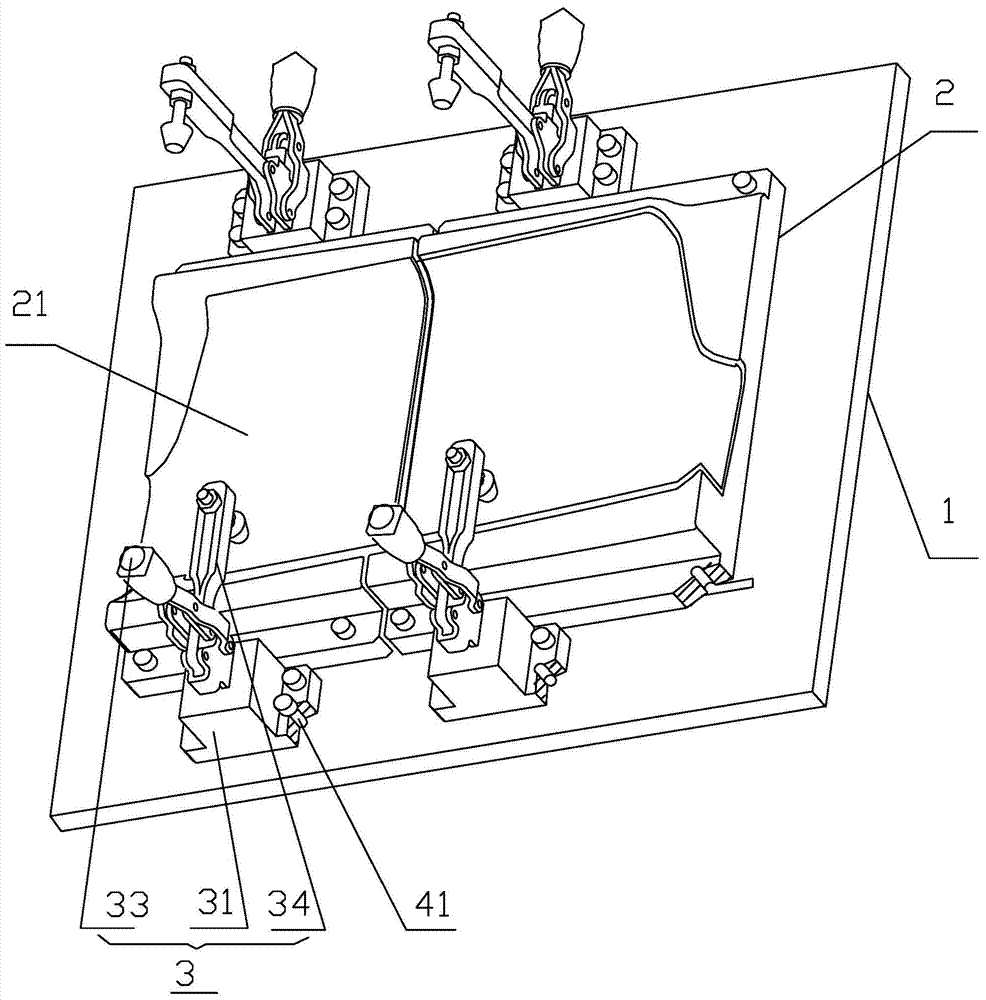

ActiveCN103753004AEasy to processImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention provides an inner decoration piece fixing device which is characterized by comprising a support plate and at least two abutting pressing devices. Each abutting pressing device comprises a base, a press head and a handle, one end of the press head is installed on the base in a rotating mode, and the handle is connected with the press head and is installed on the base in a rotating mode. The handles can drive the press heads to rotate in the identical direction or in the reverse direction to enable the other ends of the press heads to press inner decoration pieces in an abutting mode. The support plate is provided for the inner decoration pieces to be welded, the inner decoration pieces are fixed through the abutting pressing devices and are accurately aligned, welding accuracy and inner decoration piece stability are improved, welding shortcomings in the traditional welding process are overcome, the welding quality is greatly improved, the inner decoration piece welding safety coefficients are improved, and the danger that an operator is scalded by welding materials is removed.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

Semi-conductor encapsulation connecting construction avoiding welding defect induced by warp of substrate

InactiveCN101339942AAvoid Welding DefectsMinimize Solder Gap DifferencesSemiconductor/solid-state device detailsSolid-state devicesWelding defectRadiation

The invention relates to a semiconductor packaging and jointing structure, in particular to a semiconductor packaging and jointing structure for preventing welding defects caused by substrate warping, which mainly comprises at least a semiconductor packaging component, a package carrier and a solder. The solder is used for welding external terminals of the semiconductor packaging component to the package carrier. The external terminals of the semiconductor packaging component are at least divided into two groups according to different distances from the substrate centerline. In one embodiment, the external terminals of different groups contain bumps with different heights, the bumps are used for compensating solder clearance difference between connection end points of the external terminals and the package carrier caused by a preset warpage of the substrate, and the welding defects can not occur under the situation that the warpage of the substrate is predictable. In another embodiment, a compensation bump can be arranged between larger solder clearances. The semiconductor packaging and jointing structure can shorten the solder clearance difference caused under a predictable warpage of the substrate, can prevent the welding defects caused by substrate warping; and can integrate the functions of heat radiation and micro distance maintenance.

Owner:POWERTECH TECHNOLOGY

Friction stir welding structure applied to robot and working method thereof

PendingCN110102868AAvoid Welding DefectsReduce control difficultyNon-electric welding apparatusEngineeringRobot control

The invention discloses a friction stir welding structure applied to a robot and a working method thereof, and relates to the technical field of friction stir welding equipment. The friction stir welding structure a shaft shoulder sleeve, a shaft shoulder, a main shaft connecting plate, a moving shaft connecting block, a stirring needle, an extension rod and a shaft shoulder locking nut, wherein the upper surface of the shaft shoulder sleeve is provided with the main shaft connecting plate, the shaft shoulder sleeve is connected with a robot friction stir welding main shaft through the main shaft connecting plate, the extension rod is arranged inside the shaft shoulder sleeve, a mounting hole is formed in the middle of the lower surface of the extension rod, the stirring needle is arrangedin the mounting hole, the lower end of the stirring needle protrudes downwards out of the shaft shoulder sleeve, a welding end is arranged at the lower end of the stirring needle, the shaft shoulderis arranged inside the lower end of the shaft shoulder sleeve, the lower end of the stirring needle penetrates through the shaft shoulder, a shaft shoulder pre-tightening hole position is formed in the lower end of the shaft shoulder sleeve, the shaft shoulder pre-tightening hole position is opposite to the shaft shoulder, and the locking nut is arranged in the shaft shoulder pre-tightening hole position. The friction stir welding structure has the characteristics of reducing the robot control difficulty, reducing the cost and improving the efficiency.

Owner:SHANGHAI FANUC ROBOTICS

Lightweight galvanized steel springboard and processing process thereof

InactiveCN101956453AReasonable structureGood strengthVessel partsScaffold accessoriesWeld strengthGalvanization

The invention discloses a lightweight galvanized steel springboard and a processing process thereof, relating to the fields of building construction and ship building devices. The lightweight galvanized steel springboard of the invention uses steel SGC570, the steel springboard has a reverse-concave cross section, supporting feet at both sides are in a box-shaped structure, grooves are arranged at the bottoms of the supporting feet, end plates are arranged at both ends of the steel springboard, transverse rib plates are alternately arranged on the bottom of the steel springboard, and cold-extrusion punch holes are arranged on the surface of the steel springboard. The supporting feet and longitudinal ribs of the lightweight galvanized steel springboard of the invention are formed together with the body through once cold bending and pressing, which avoids the processing defects of the product, avoids the welding strength requirement, increases the strength, ensures the sheet smoothness and improves the whole bearing capability. According to the invention, the steel thickness can be reduced to 1 / 2.4 by substituting steel SGC570 for steel Q235, thus the consumption of iron ore and the waste of energy are reduced, the needs of practical use by reasonable design can be met.

Owner:白龙浩

Narrow gap laser welding protective method and narrow gap laser welding protective device

ActiveCN104475987AAvoid gatheringImprove shielding effectLaser beam welding apparatusShielding gasCarbon Dioxide / Helium

The invention provides a narrow gap laser welding protective method and a narrow gap laser welding protective device. The method comprises the steps of: in a welding process, blowing shielding gas into a welding narrow gap in a side blowing mode; sucking smoke generated in a suction mode and plasma air mass wrapped above a molten pool. By the method, the welding smoke can be removed from a welding groove, and the smoke can be prevented from accumulating on the side wall of the welding groove; and moreover, a shielding effect of plasma to laser is improved, absorptivity of the laser is enhanced, and wettability between welding materials is improved, so that the stability of the narrow gap laser welding is improved, welding defects are avoided, and the method is easy to promote in the real industrial production.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

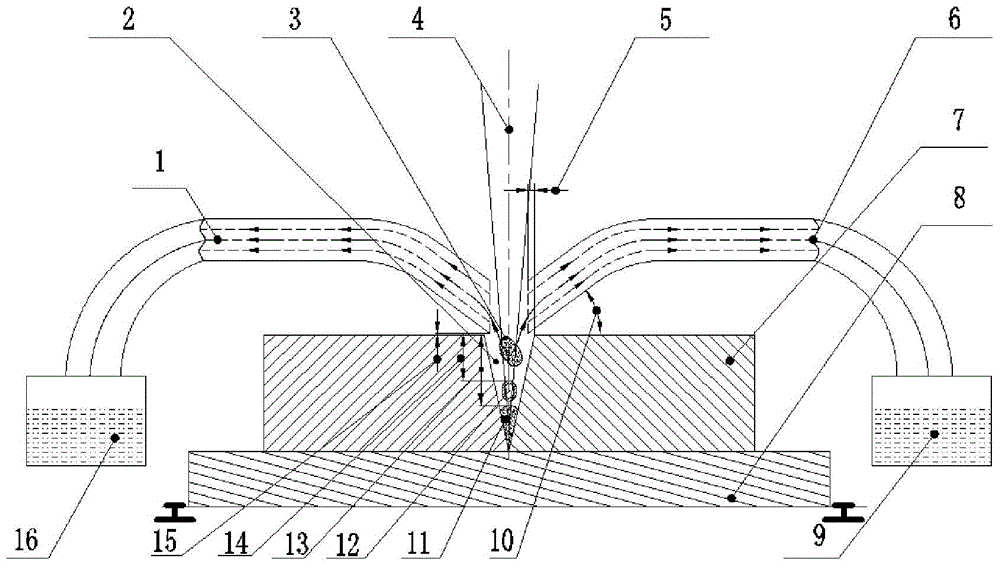

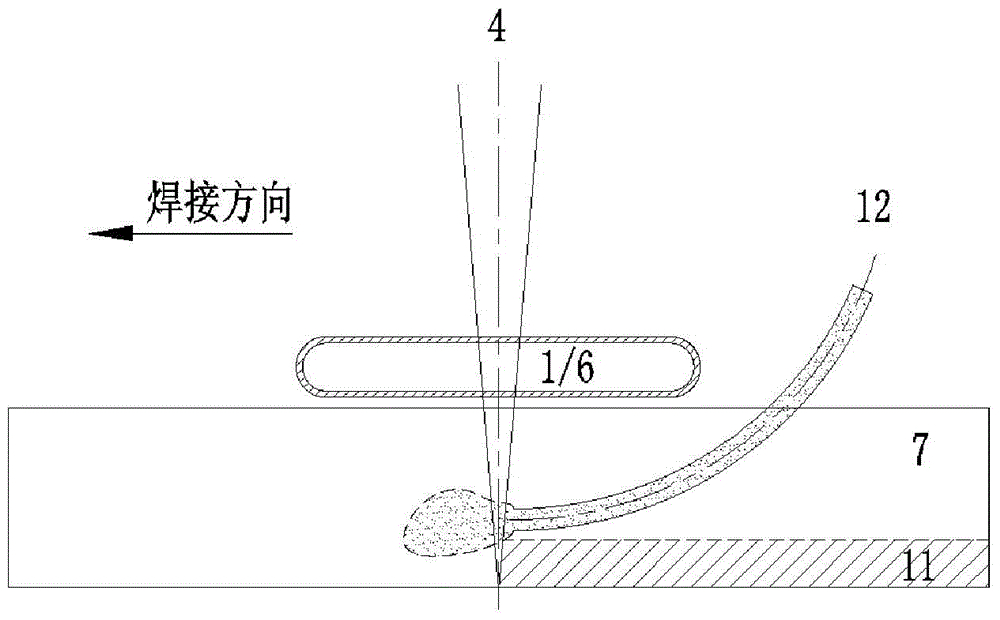

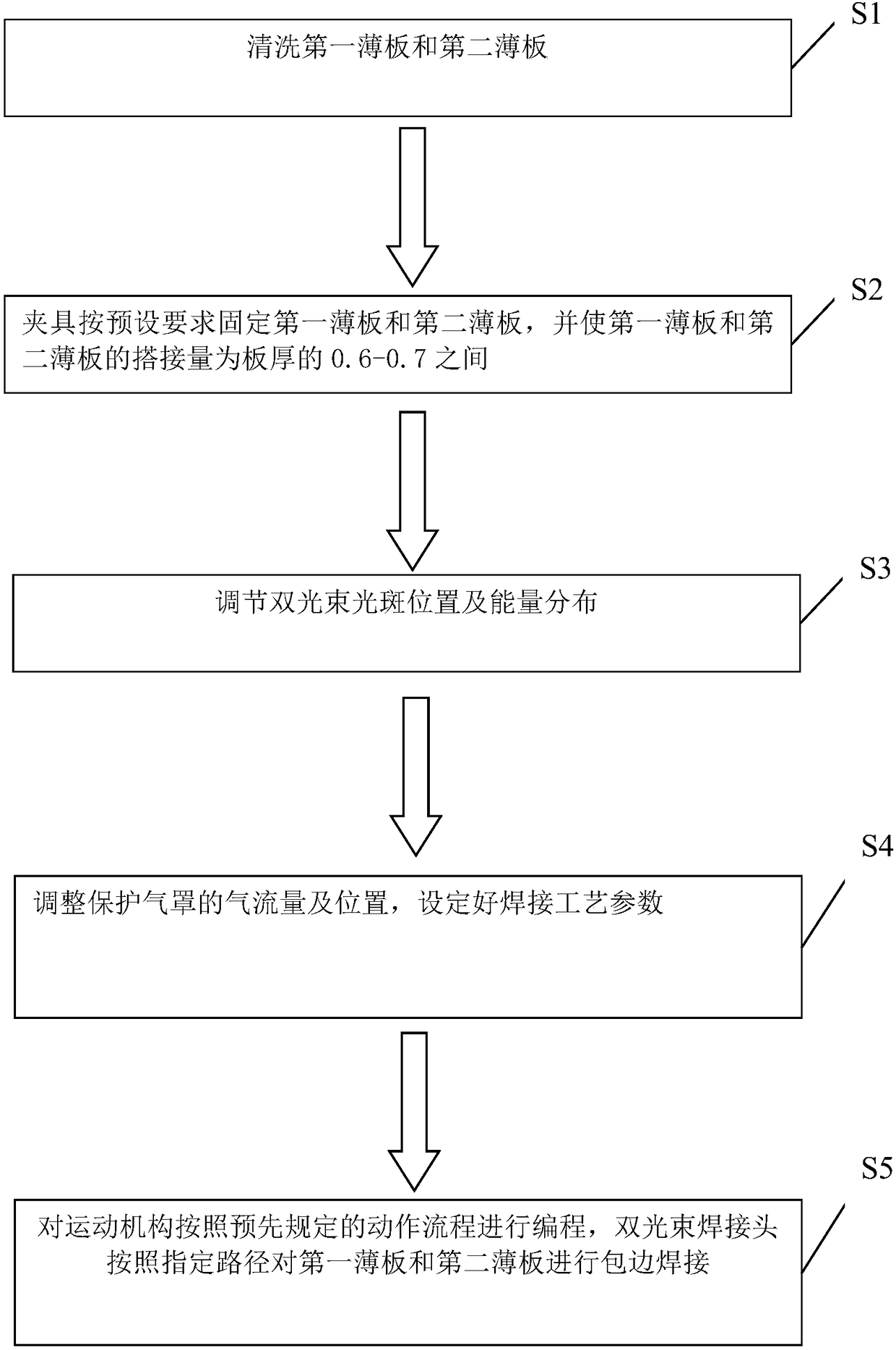

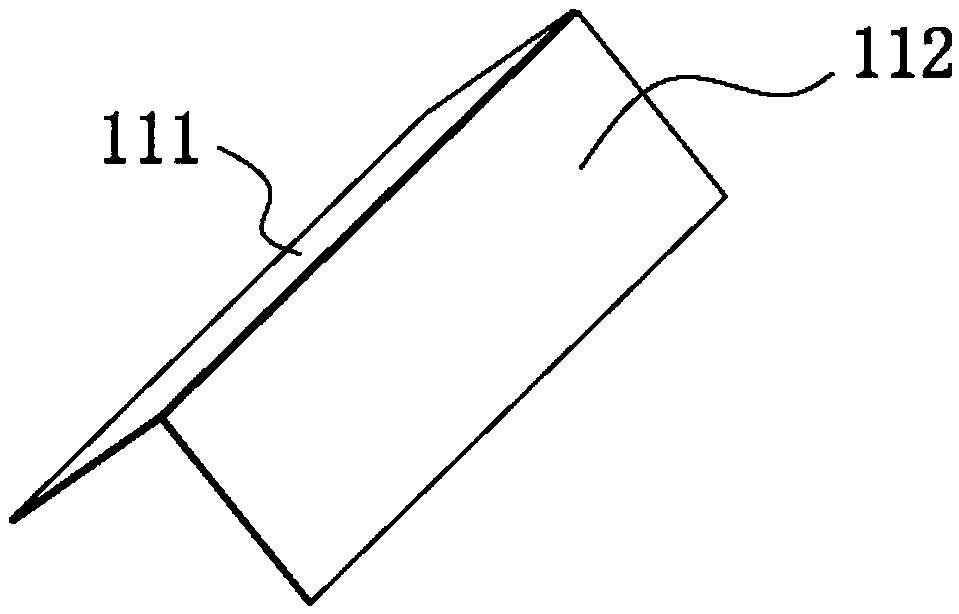

Double-beam laser welding machine and welding method thereof

ActiveCN108274121AAvoid Welding DefectsPrevent oxidationWelding/cutting auxillary devicesAuxillary welding devicesShielding gasLight beam

The invention provides a double-beam laser welding machine and a welding method thereof. The double-beam laser welding machine is used for carrying out binding welding on a first thin plate and a second thin plate. The double-beam laser welding machine comprises a fixture for the first thin plate and the second thin plate, a double-beam welding head which emits a first light spot and a second light spot, and a multifunctional gas hood which is located above the first thin plate and the second thin plate; and during welding, the first light spot and the second light spot are correspondingly distributed on the first thin plate and the second thin plate in parallel. Through selection on a laser light source and control on a double-beam light spot, the stability of a welding effect can be ensured effectively; through selection on the air supply mode of shielding gas and the gas, welding joint surface oxidization can be prevented effectively; through accurate control on technological parameters, the uniformity of weld penetration can be ensured; and by using the welding method, a thin plate binding welding joint can be a high-quality welding joint having the advantages of surface transition smoothness, no oxidization, and no welding defect.

Owner:HANS LASER TECH IND GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com