Welding technique for base plate of LNG low-temperature tank

A welding process and low-temperature tank technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve problems such as easy burn-through, poor formation of lap fillet welds, welding thermal cracks, etc., achieve good mechanical properties, reduce welding Effects of heat input and pressure-bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiments 1 to 4 are specific implementations of the welding process of the bottom plate of the LNG low-temperature tank of the present invention, wherein embodiment 1 is the best embodiment.

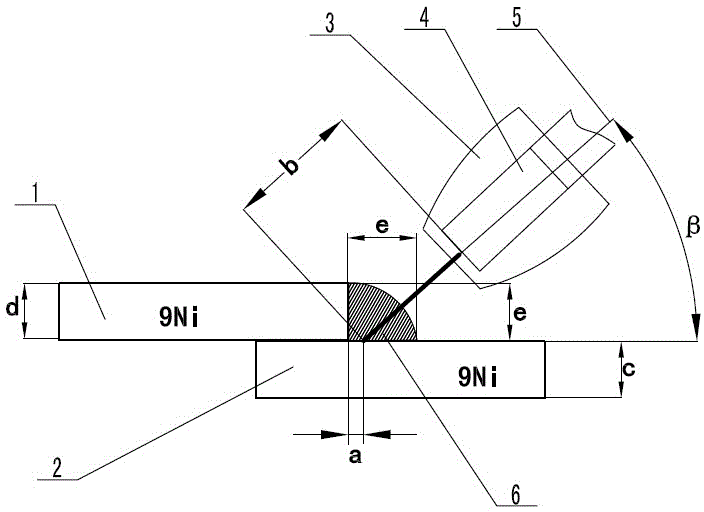

[0030] refer to figure 1 The contact tip 3 of the welding trolley is fixed with a welding wire 5, which is used as the base material to weld the upper 9Ni steel plate 1 and the lower 9Ni steel plate 2 of the bottom plate of the LNG low-temperature storage tank to overlap each other to form a lap joint, and the lap joint does not open a groove. The bottom plate of the LNG low-temperature storage tank is composed of multiple sets of overlapping upper 9Ni steel plates 1 and lower 9Ni steel plates 2, the thickness c of the upper 9Ni steel plates is 6~9mm, and the thickness d of the lower 9Ni steel plates is 6~9mm. The welding root is the junction of the overlapping area of the upper 9Ni steel plate 1 and the lower 9Ni steel plate 2 on the back of the fillet weld 6 , that is, the ...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] 1) Form a lap joint: lap two 9Ni steel plates with a thickness of 7 mm horizontally, and form a lap joint at the overlap;

[0040] 2) Clean the end face: Use an angle grinder to clean and polish the end face of the lap joint until the end face appears metallic luster; clean the surface of the 9Ni steel plate within 60mm from the lap joint, and remove moisture, oil and dust within this range ;The grinding machine uses black silicon carbide as the abrasive and rubber as the adhesive grinding wheel;

[0041] 3) Preparatory welding: place the welding trolley in parallel with the reserved fillet weld area at the end face of the lap joint, aim the welding torch at the fillet weld area before welding, and keep the distance between the end of the welding wire and the welding root at 0 ~5mm, the welding trolley walks along the weld seam in advance, planning the path of the welding trolley during the welding process;

[004...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] 1) Form a lap joint: lap two 9Ni steel plates with a thickness of 8 mm horizontally, and form a lap joint at the overlap;

[0046] 2) Clean the end face: Use an angle grinder to clean and polish the end face of the lap joint until the end face appears metallic luster; clean the surface of the 9Ni steel plate within 60mm from the lap joint, and remove moisture, oil and dust within this range ;

[0047] The grinding machine uses black silicon carbide as the abrasive and rubber as the adhesive grinding wheel;

[0048] 3) Preparatory welding: place the welding trolley in parallel with the reserved fillet weld area at the end face of the lap joint, aim the welding torch at the fillet weld area before welding, and keep the distance between the end of the welding wire and the welding root at 0 ~5mm, the welding trolley walks along the weld seam in advance, planning the path of the welding trolley during the welding proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com