Ni based-flux-cored wire and method for preparing copper-steel base gradient composite

A technology of flux-cored welding wire and composite material, applied in welding/cutting medium/material, welding equipment, welding equipment, etc., can solve the problem that parts are prone to generate welding thermal stress, cannot obtain fusion welding joints, and have relatively different thermal physical parameters. It can improve the utilization rate of materials, facilitate the operation, and optimize the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

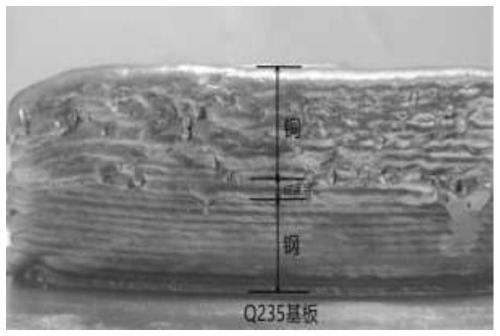

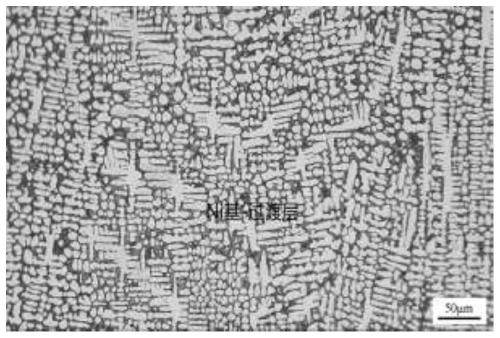

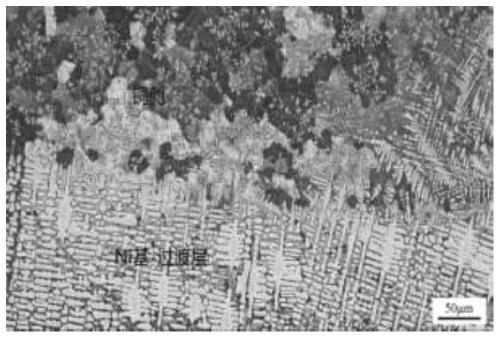

Embodiment 1

[0048] Step 1: Firstly, according to Ni powder 86%, Mn powder 5%, Si powder 7%, Cu powder 2%, weigh the metal powder whose mass percentage sum is 100%. Put the weighed metal powder into an automatic powder mixer and mix it. After mixing, place it in a vacuum ring furnace and heat it to 200°C to keep it warm. Then place the pure copper strip on the wire drawing machine, fill the mixed metal powder into the copper strip, go through the drawing process, and finally reduce the diameter to 1.2mm for use; the filling rate of the flux core powder in the flux cored wire is 22wt%;

[0049] Step 2: Surface-treat the low-carbon steel welding wire, transition layer Ni-based-flux-cored welding wire and pure copper welding wire, that is, wipe it with anhydrous ethanol cloth, and put it into a vacuum tube furnace for drying. The drying temperature is: 40°C;

[0050] Step 3: Mechanically clean the surface of the carbon steel plate with a size of 200mm×50mm×5mm, and then put it into an ultras...

Embodiment 2

[0054] Step 1: Firstly, according to Ni powder 87%, Mn powder 4%, Si powder 6%, Cu powder 3%, weigh the metal powder whose mass percentage sum is 100%. Put the weighed metal powder into an automatic powder mixer and mix it. After mixing, place it in a vacuum ring furnace and heat it to 200°C to keep it warm. Then the pure copper strip is placed on the wire drawing machine, the mixed metal powder is filled into the copper strip, and after the drawing process, the diameter is finally reduced to 1.2mm for use; the filling rate of the flux core powder in the flux cored wire is 25wt%;

[0055] Step 2: Surface-treat the low-carbon steel welding wire, transition layer Ni-based-flux-cored welding wire and pure copper welding wire, that is, wipe it with anhydrous ethanol cloth, and put it into a vacuum tube furnace for drying. The drying temperature is: 42°C;

[0056] Step 3: Mechanically clean the surface of the carbon steel plate with a size of 200mm×50mm×5mm, and then put it into a...

Embodiment 3

[0060] Step 1: Firstly, according to Ni powder 88%, Mn powder 4%, Si powder 6%, Cu powder 2%, weigh the metal powder whose mass percentage sum is 100%. Put the weighed metal powder into an automatic powder mixer and mix it. After mixing, place it in a vacuum ring furnace and heat it to 200°C to keep it warm. Then the pure copper strip is placed on the wire drawing machine, the mixed metal powder is filled into the copper strip, and after the drawing process, the diameter is finally reduced to 1.2mm for use; the filling rate of the flux core powder in the flux cored wire is 23wt%;

[0061] Step 2: Surface-treat the low-carbon steel welding wire, transition layer Ni-based-flux-cored welding wire and pure copper welding wire, that is, wipe it with anhydrous ethanol cloth, and put it into a vacuum tube furnace for drying. The drying temperature is: 50°C;

[0062] Step 3: Mechanically clean the surface of the carbon steel plate with a size of 200mm×50mm×5mm, and then put it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com