Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

638results about How to "Good strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

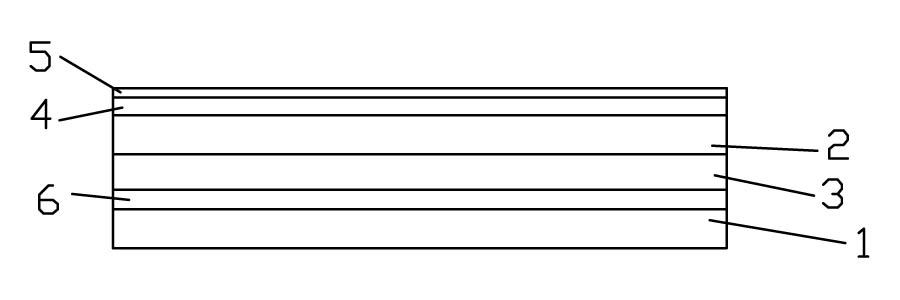

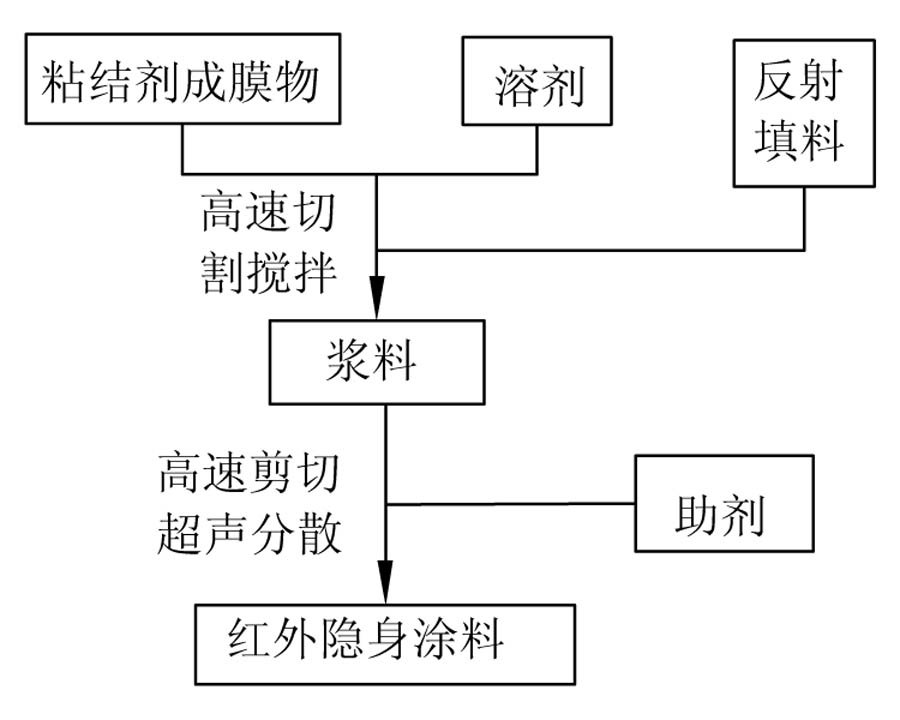

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

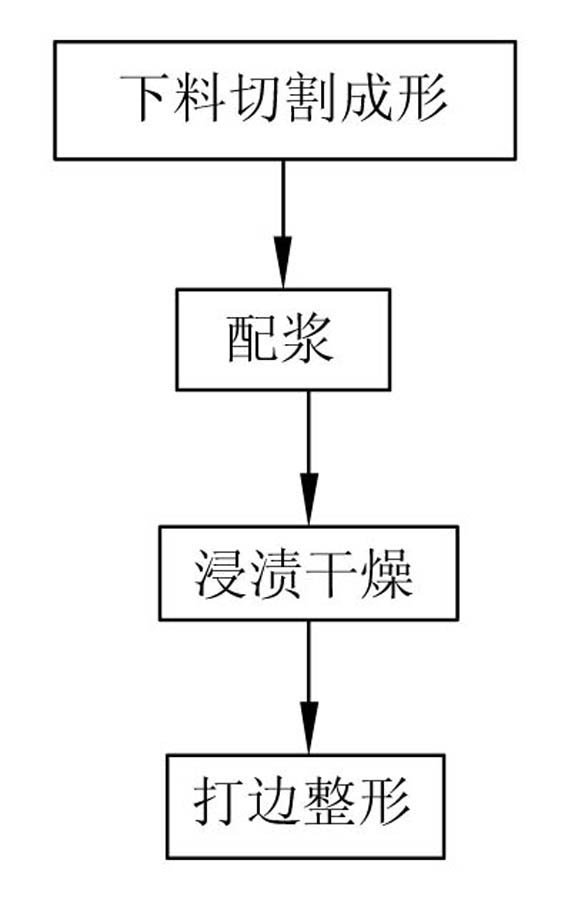

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

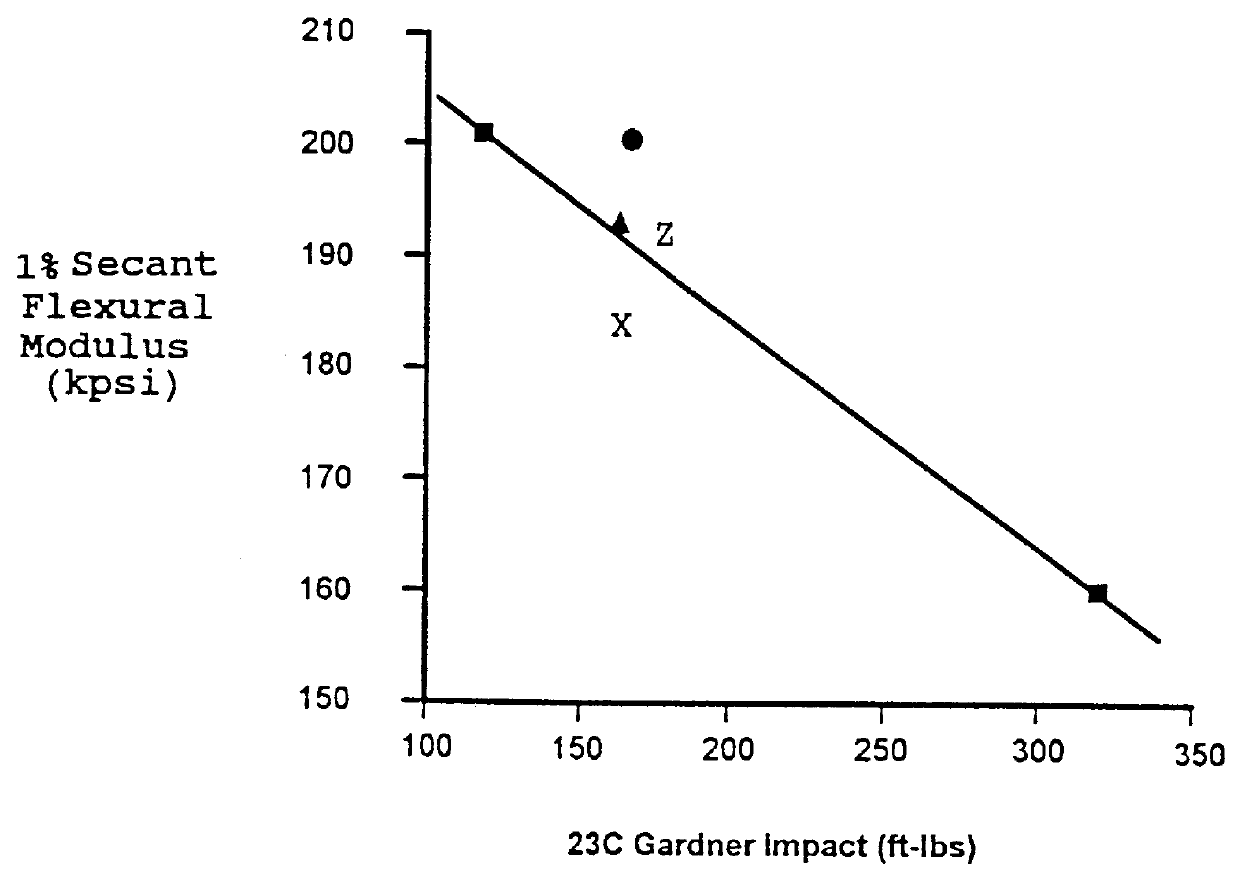

Thermosplastic vulcanizates from blends of a polypropylene and elastic alpha -olefin/cyclic olefin copolymers

Thermoplastic vulcanizate blends are prepared from a semi-crystalline polymer and a rubbery copolymer derived from copolymerizing at least one alpha-olefin monomer and at least one cyclic olefin copolymer. The rubbery copolymer also includes repeat units from at least one polyene monomer. The polyene monomer provides residual unsaturation for crosslinking of said rubbery copolymer. Crosslinking the rubbery copolymer of the blend generally reduces tension set, compression set and oil swell in aliphatic solvents. The cyclic olefin monomer reduces oil swell in aliphatic oils.

Owner:ADVANCED ELASTOMER SYST LP +1

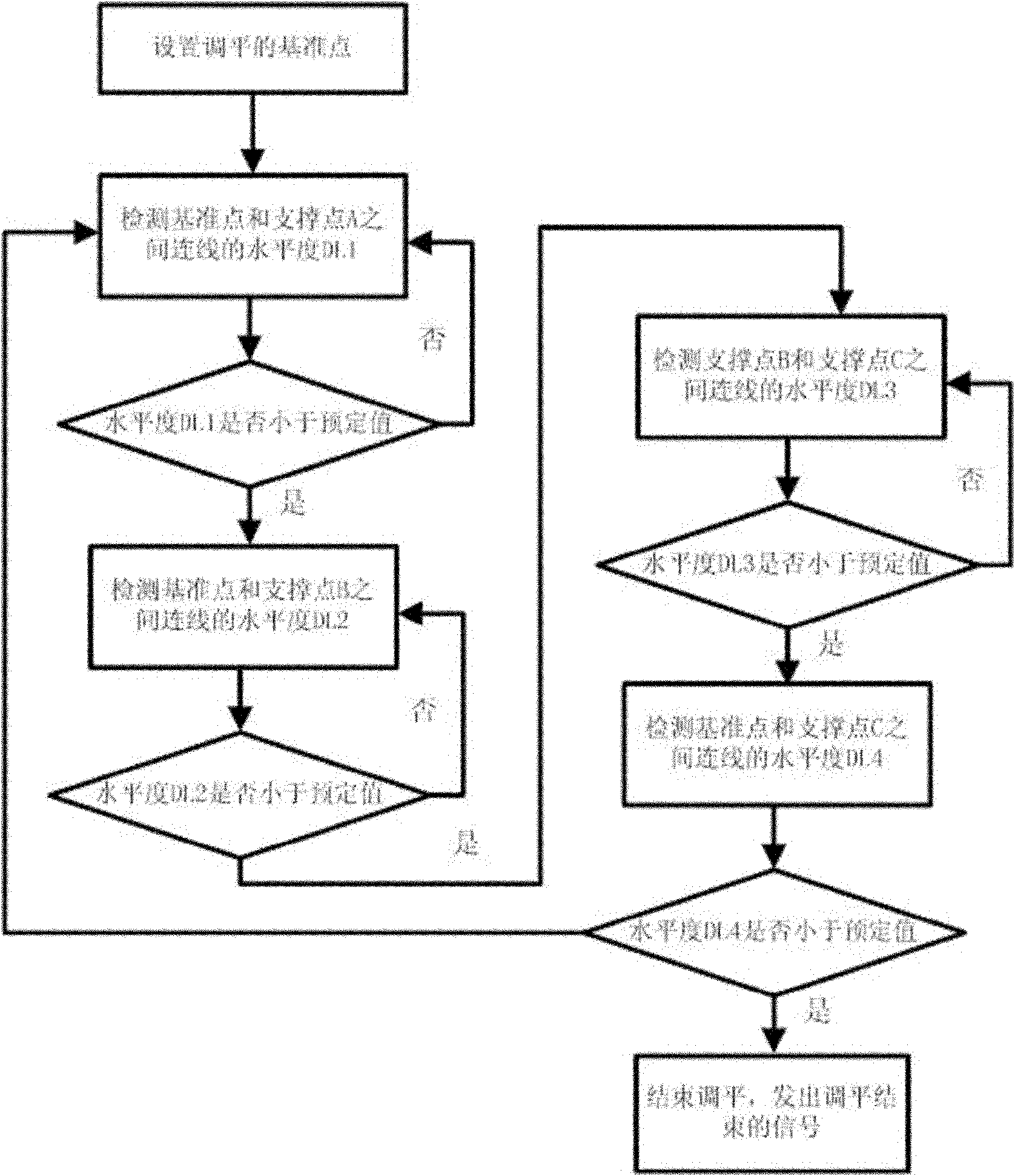

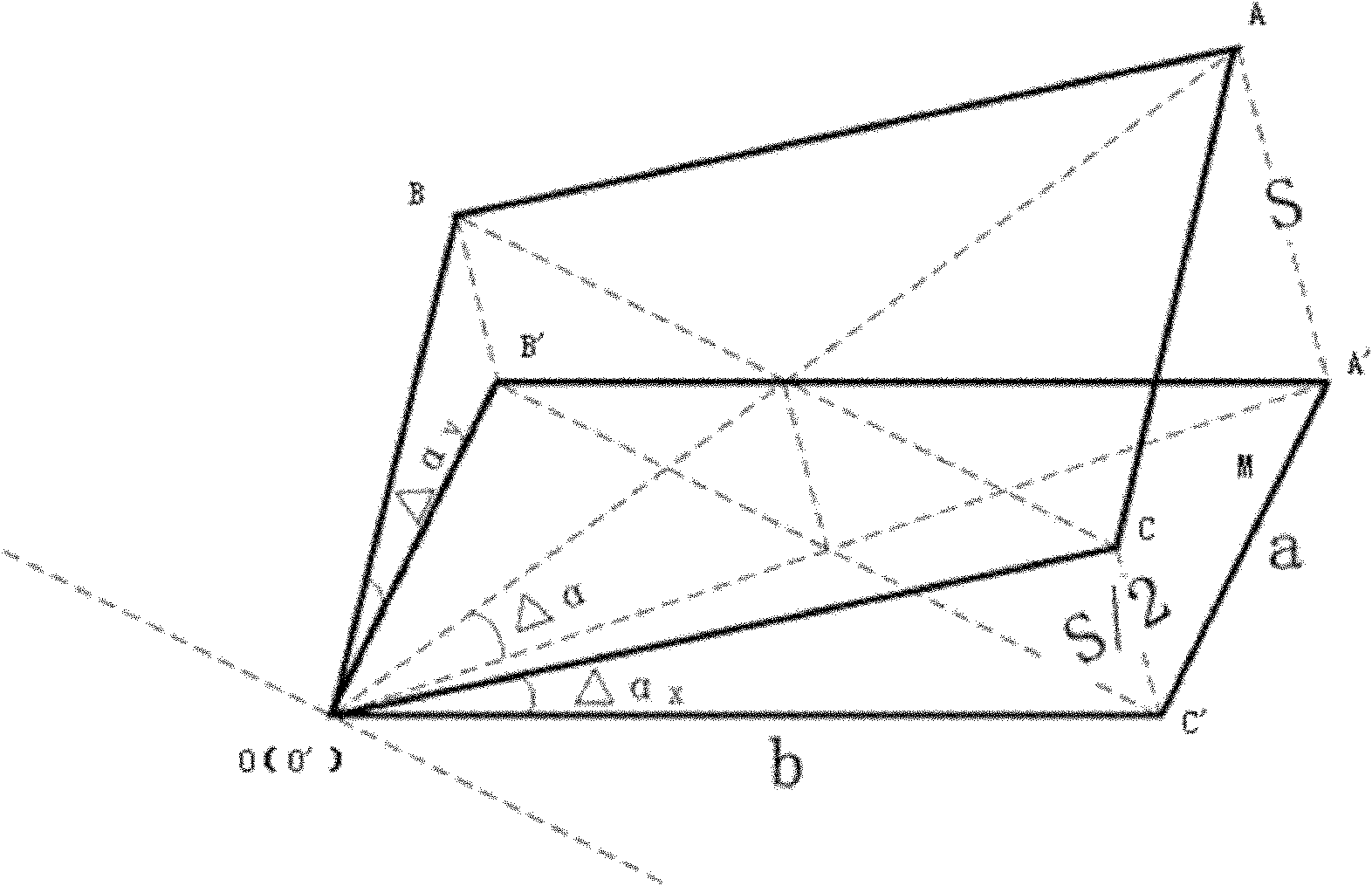

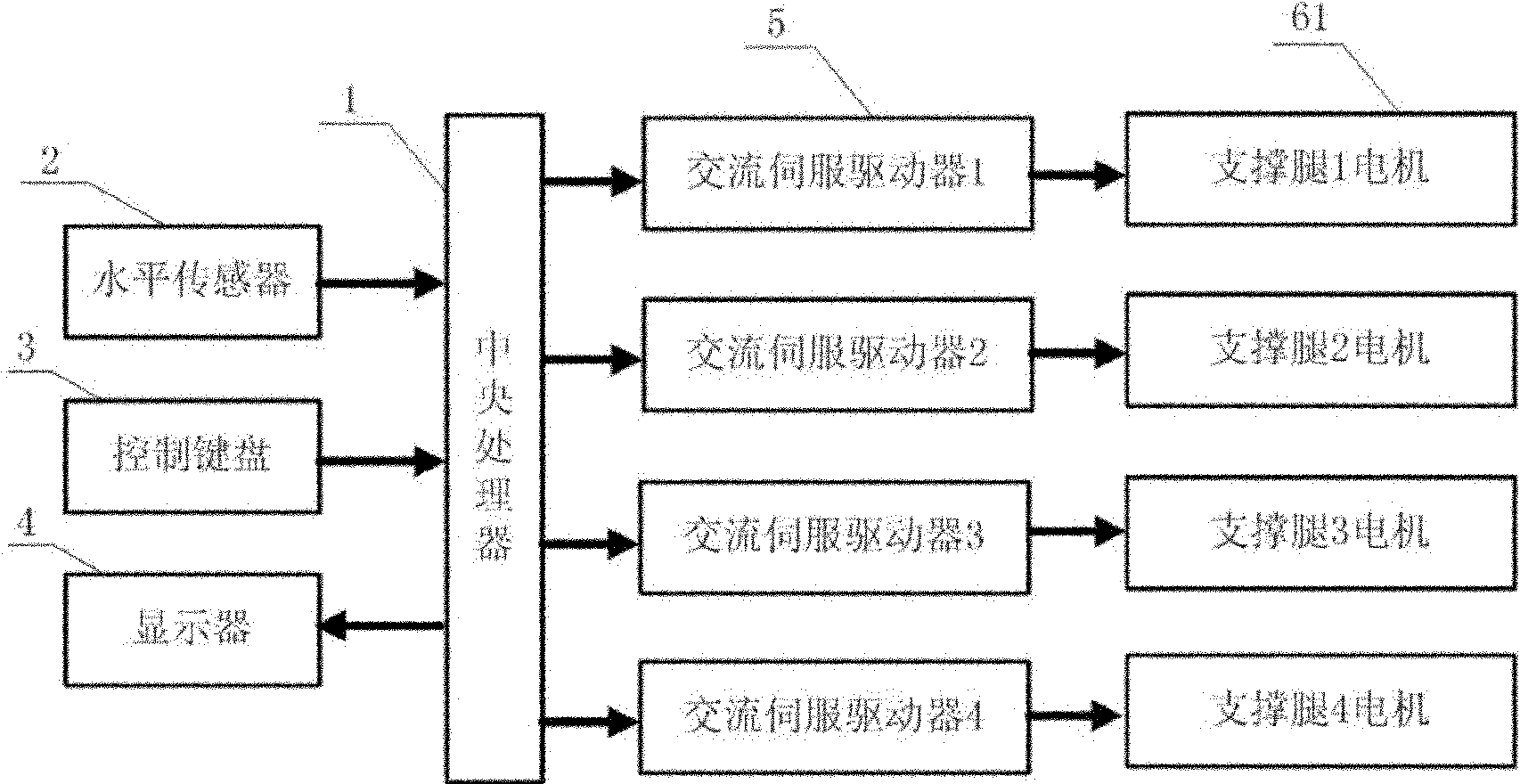

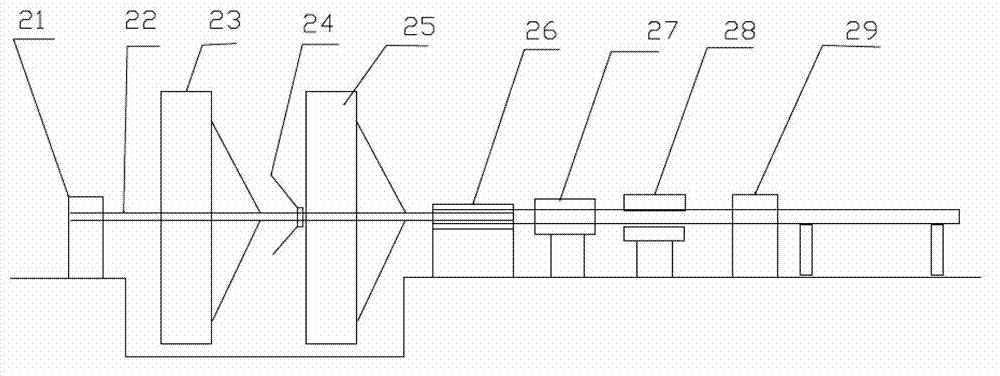

Leveling method based on four-point support and electromechanical automatic leveling system

InactiveCN102053624AImprove reliabilityStructural force change is reasonableAttitude controlDisplay deviceSimulation

The invention discloses a leveling method based on four-point support and an electromechanical automatic leveling system. In the leveling method, a symmetrical diagonal lifting and leveling strategy is adopted, and the leveling purpose is achieved mainly by regulating the levelness of the ligatures among supporting points on diagonal lines; and the leveling system comprises a central processor, a level sensor, a control keyboard, a display, four alternating-current servo drivers and four supporting legs; and each supporting leg comprises a motor, a speed reducer, a ball screw and a base. The invention is particularly suitable for large-medium-sized radar truck vehicle-mounted platforms, communication vehicles and various engineering vehicles for engineering machinery, the method has the advantages of high leveling efficiency, high leveling reliability and the like, and the leveling system has the advantages of high leveling precision, high intelligent degree, high speed, strong carrying capacity, good stability, high transmission efficiency, suitability for severe environments and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

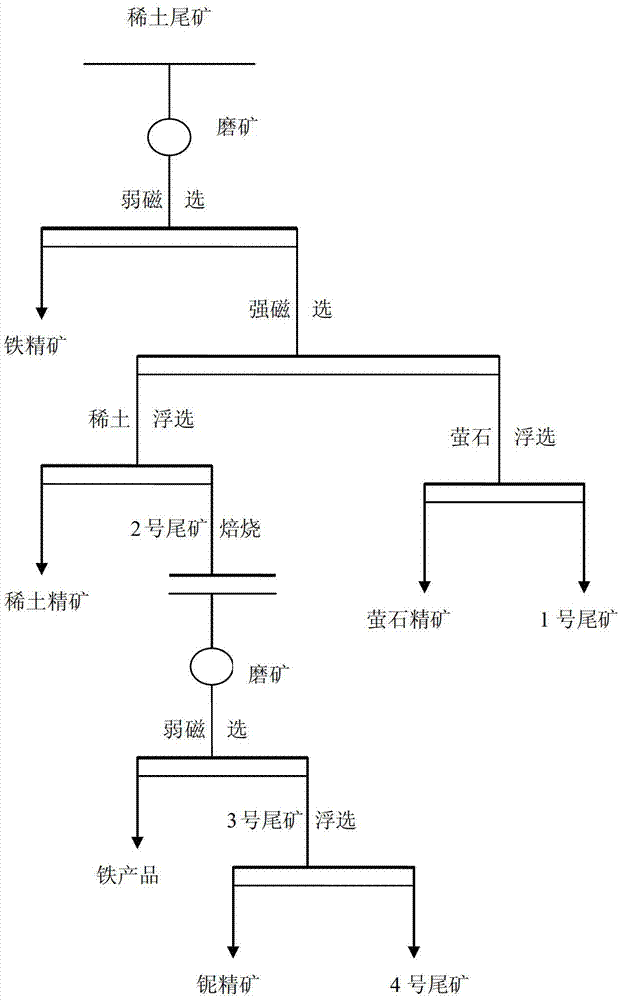

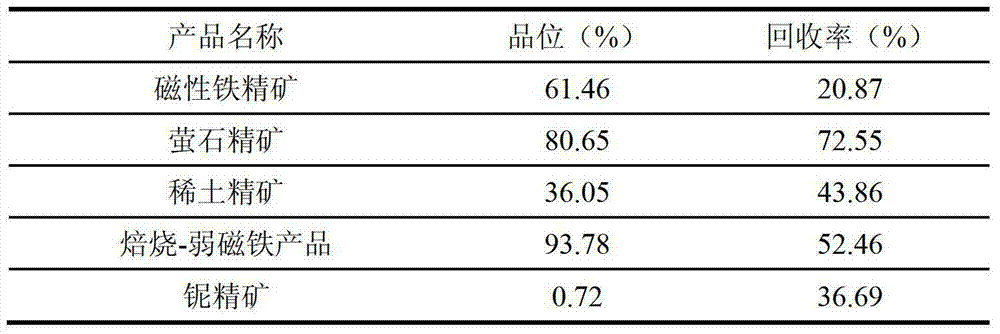

Method for comprehensively recycling valuable minerals in rare-earth tailings

InactiveCN103394408ATake advantage ofOptimized flotation collectionFlotationWet separationResource utilizationNiobium

The invention relates to a method for comprehensively recycling valuable compositions of rare earth, iron, niobium and fluorite in rare-earth tailings, and belongs to the fields of comprehensive resource utilization technologies and mineral processing engineering. The rare earth, the iron, the niobium and the fluorite in the rare-earth tailings are efficiently and comprehensively recycled by the method including 'grinding the rare-earth tailings, performing low-intensity magnetic separation, performing high-intensity magnetic separation on weak-intensity magnetic tailings, performing flotation on high-intensity magnetic tailings to obtain fluorite in the high-intensity magnetic tailings, performing flotation separation on high-intensity magnetic concentrates to obtain rare earth, iron and niobium in the high-intensity magnetic concentrates, reducing and roasting base flows, performing low-intensity magnetic separation to obtain iron and niobium in the base flows and performing flotation on low-intensity magnetic tailings to obtain niobium in the low-intensity magnetic tailings according to characteristics that the rare-earth tailings contain the various valuable compositions. Compared with a method for singly recycling one or two valuable compositions, the method has the advantages that the purpose of comprehensively recycling the valuable compositions in the rare-earth tailings can be effectively achieved, secondary resources can be sufficiently utilized, and the method has excellent economical and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Austenitic stainless steel medium-thick plate and manufacture method thereof

ActiveCN101724789AGood strengthGood corrosion resistance and ductilityMetal rolling arrangementsRare-earth elementAustenitic stainless steel

The invention relates to an austenitic stainless steel medium-thick plate which comprises the following components in percentage by weight: no more than 0.04 percent of C, 0.3-0.9 percent of Si, 1-2 percent of Mn, no more than 0.010 percent of S, no more than 0.04 percent of P, 16-22 percent of Cr, 8-14 percent of Ni, no more than 4 percent of Mo, 0.04-0.30 percent of N, 0.0010-0.0030 percent of B, smaller than 0.30 percent of one or more rare-earth elements, such as Ce, Dy, Y and Nd, 1-10 percent of high-temperature ferrite delta and the balance of ferrum and unavoidable impurities. The manufacture method of the austenitic stainless steel medium-thick plate comprises the following steps of: smelting; hot rolling; heating and preserving the temperature of the alloy and then carrying out 4-10 passes of rolling in a recrystallization area at 1,250-1,050 DEG C; water-cooling the recrystallization area by 20-40 DEG C / s to 700-950 DEG C, rolling 3-5 rounds in the temperature interval and water-cooling to room temperature; carrying out low-temperature annealing heat treatment at 900-1,050 DEG C; washing with acid and then obtaining the austenitic stainless steel medium-thick plate with excellent strength.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

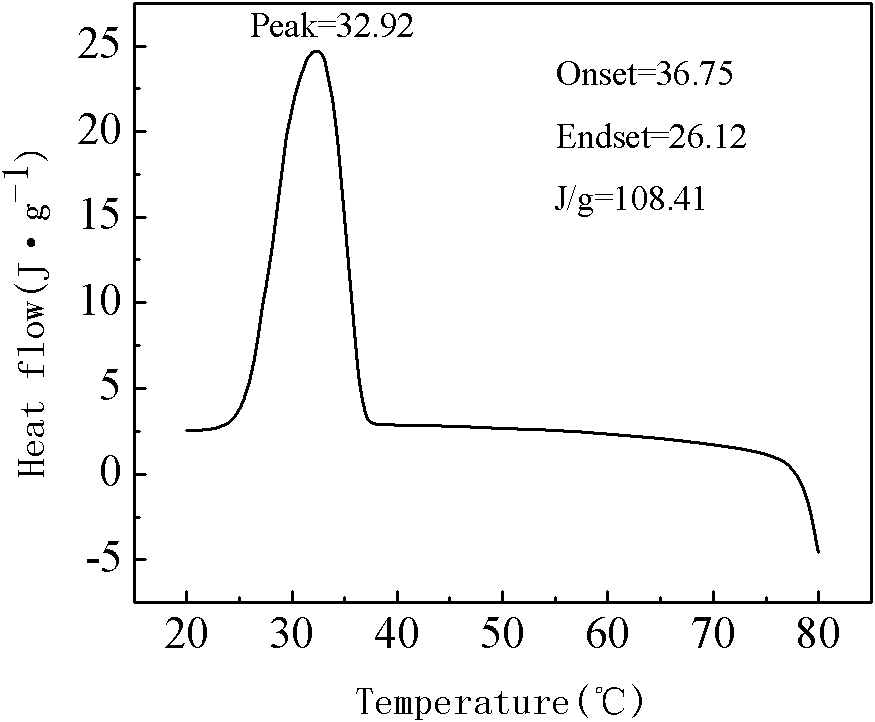

Preparation method of interpenetrating network formed phase-change material

InactiveCN102061148AGood shaping effectGood strengthHeat-exchange elementsConjugated synthetic polymer artificial filamentsTemperature resistanceMethylene bisacrylamide

The invention relates to a preparation method of an interpenetrating network formed phase-change material, comprising the following steps of: adding N-hydroxymethyl acrylamide as a network monomer, N, N-methylene-bisacrylamide as a cross linking agent, polyethylene glycol as a phase-change material and distilled water into a flask, ultrasonic-dispersing for 5 minutes after dissolving (the molar ratio of the cross linking agent to the network monomer is (1 / 7):(1 / 11), the mass ratio of the network monomer to the water is (1 / 6):(1 / 14), and the proportion of the polyethylene glycol accounts for 40-80 percent of the total mass); adding ammonium persulfate as an initiator and continuously ultrasonic-dispersing for 5 minutes, wherein the mass fraction of the initiator accounts for 1.5-3.5 percent of the network monomer; and reacting at a temperature of 70-80 DEG C for 3-4 hours to generate interpenetrating network hydrogel, and then drying to a constant weight to obtain the interpenetrating network formed phase-change material. The preparation method has a simple process and a low production cost and is friendly to environment. Moreover, the phase-change material has the advantages of high enthalpy (reaching over 108.41J / g), less loss, suitable phase-change temperature (32-42 DEG C) and good performance in high temperature resistance.

Owner:DALIAN POLYTECHNIC UNIVERSITY

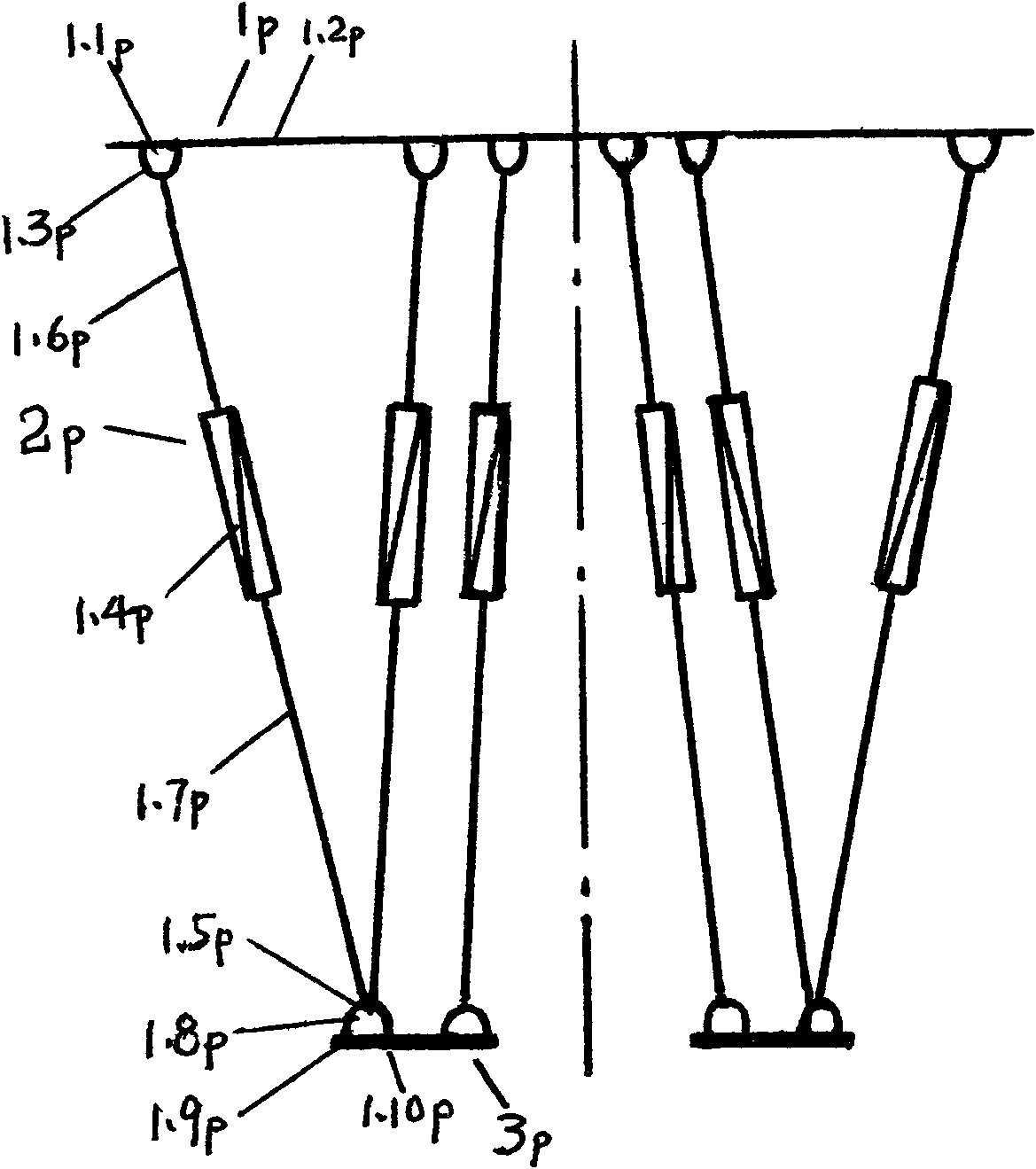

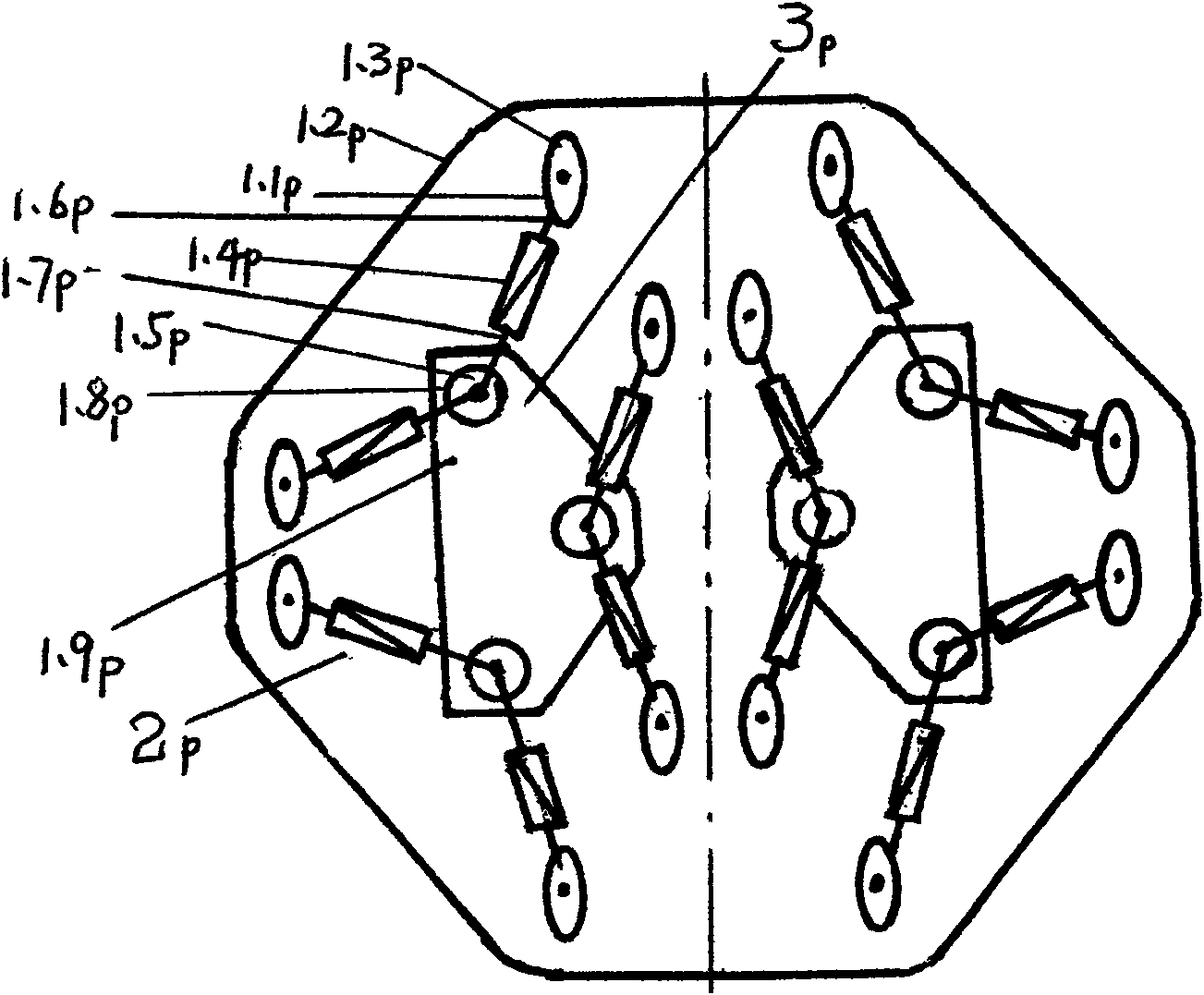

Method for connecting parallel connection walking robots and parallel connection walking robot thereof

The invention provides a method for connecting parallel connection walking robots and a parallel connection walking robot thereof. The parallel connection walking robot mainly comprises two parallel connection mechanisms, wherein each parallel connection mechanism also comprises an upper platform, a lower platform and three or more branch chains for connecting the upper platform with the lower platform. The parallel connection walking robot is characterized in that the two parallel connection mechanisms have specific freedom degree combinations, and the sum of freedom degrees is larger than or equal to 7; the upper platforms of the two parallel connection mechanisms are fixedly connected together, and the distance between projections of the hip joint polygonal centers of the two parallel connection mechanisms on the horizontal plane is smaller than or equal to 0.8 (Ra+Rb); and the lower platforms of the two mechanism respectively comprise two mutual independent foot arches. The robot can stably walk without adjusting the gravity center left and right in the advancing process, has the advantages of three-toe standing, high rigidity, high carrying capacity, flexible steering, high obstacle climbing capability, and the like, can be used for works, such as survey, rescue, exploration, and the like and can be also used for a manipulator.

Owner:韩方元

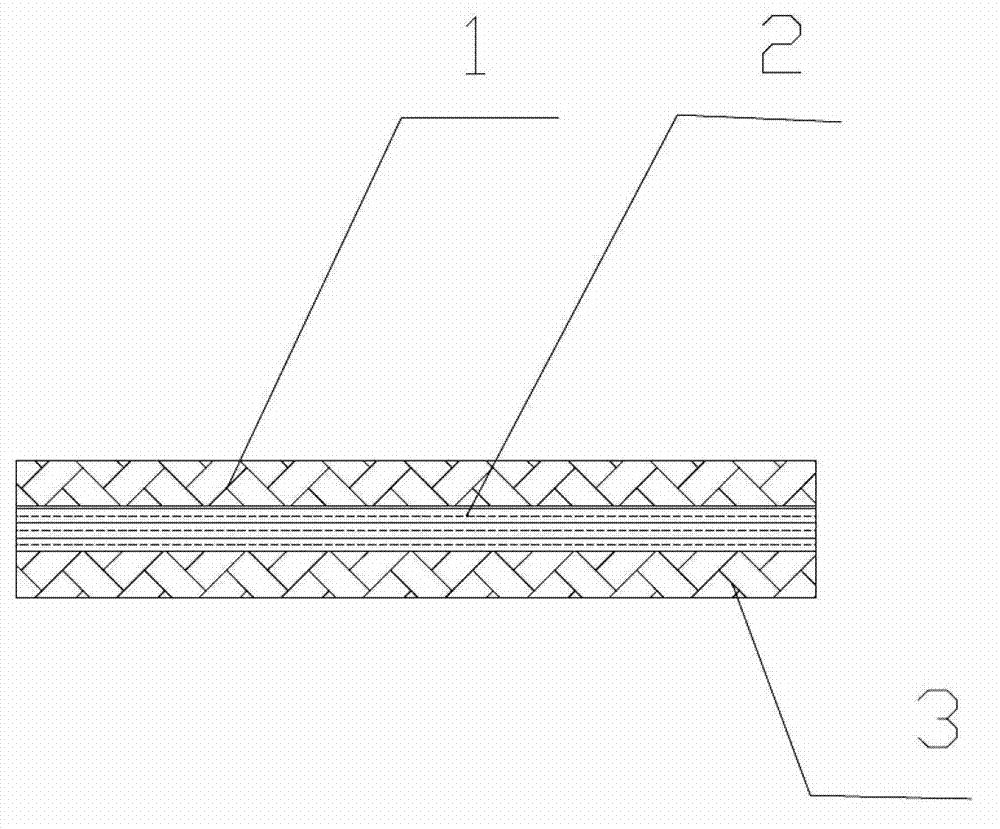

Fiber-woven pultrusion pipeline and production method

ActiveCN102777708AHigh strength and stiffness and impact resistanceGood strengthRigid pipesTubular articlesPolyresinHeat curing

The invention relates to a fiber-woven pultrusion pipeline and a production method, wherein shape of a pipe is like a cylinder; an inner wall and an outer wall of the pipe are smooth surfaces; inside diameter of the pipe is 20-400 mm; size and thickness of the pipe are determined according to a design requirement; the pipe is woven by a plurality of long fibers to form fiber layers; each fiber layer is provided with a layer of resin materials, and is formed by heat curing; and the fiber layers are composed of a plurality of fiber-woven layers. The production method comprises the following steps: weaving by a plurality of layers; dipping with glue in vacuum; solidifying; dragging; and cutting finished products. Compared with the prior art, the advantage that fiber composites have light weight and high strength is played, the defect that transverse strength and rigidity of normal pultrusion pipes are poor is overcome, and the problem that longitudinal strength of fixed length winding pipes is poor, labor force is more, and processes are fussy also are solved in the invention. Large-size fiber-woven pipelines are pulled and extruded under a state that moulds do not move at the first time; the pipelines can be produced continuously; and production efficiency is high.

Owner:深圳鑫宝通材料科技有限公司

Fire-resistant gravity flow pouring material and method for making same

The present invention relates to a preparation method for a fireproof self-flow pouring material. The technical scheme in the present invention is that: the fireproof self-flow pouring material is mixed and milled by the following components with the weight ratio that are: 35-55wt percent of bauxite grain, 5-20wt percent of bauxite powder, 5-25wt percent of corundum powder, 5-30wt percent of electrical-melting sand grain, 2-10wt percent of pure calcium aluminate cement, 2-6wt percent of silicon powder, 2-10wt percent of alpha -Al2O3 powder, 0.1-0.2wt percent of water reducer and so on. The fireproof and self-pouring material prepared by the present invention is characterized in non-segregation, good fluidity, easy to be constructed, higher density, better intension and much lower cost and so on. The present invention is widely adaptable to be used in the heat stove bushing including a heat stove bushing, steel enveloping persistent level and middle enveloping level and so on.

Owner:WUHAN UNIV OF SCI & TECH

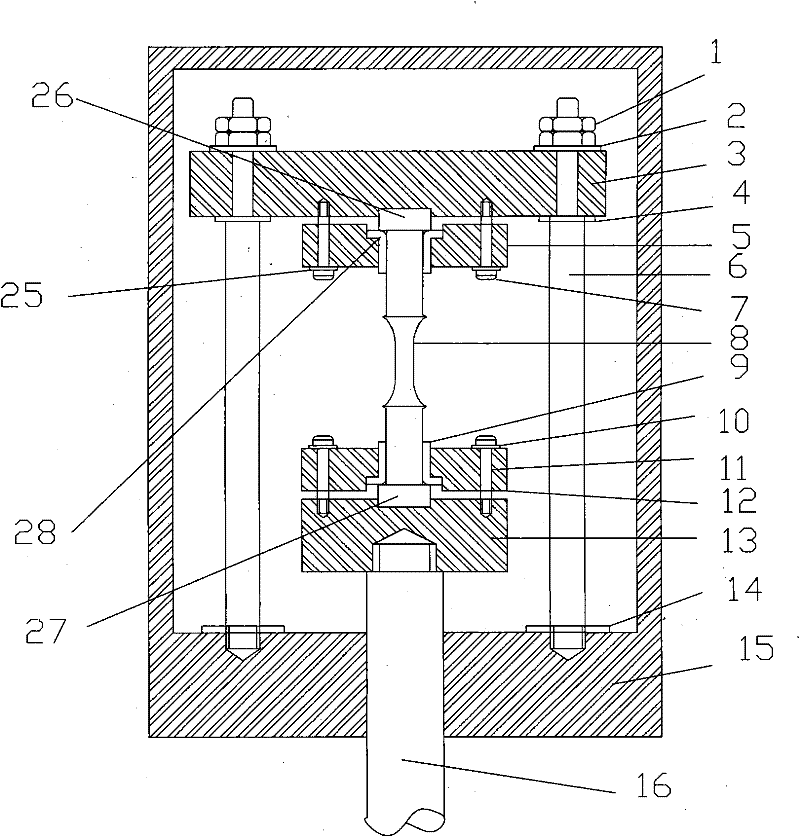

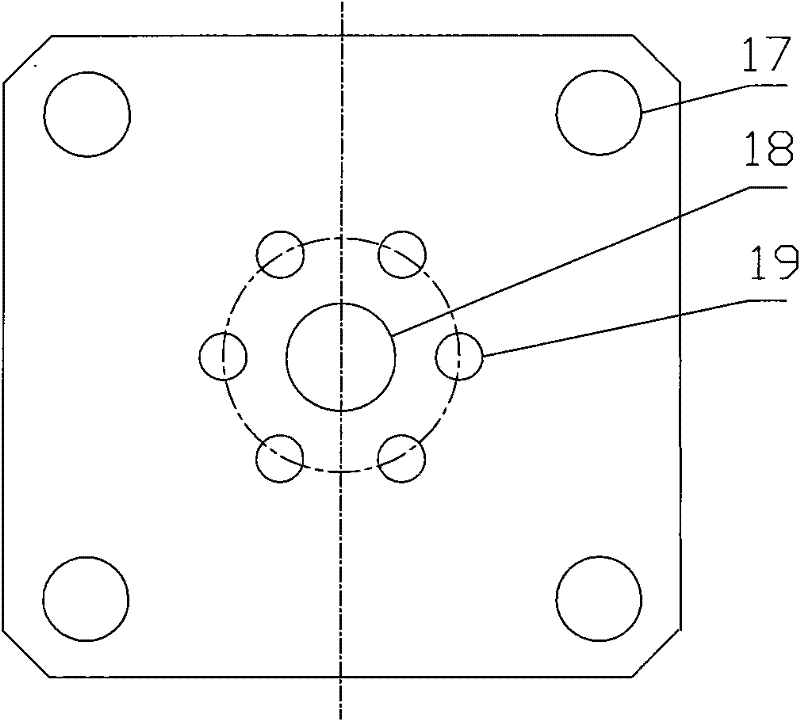

Fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and usage method thereof

ActiveCN102346113AGood strengthSimple structureWeather/light/corrosion resistanceStrength propertiesTemperature resistanceAqueous corrosion

The invention belongs to the material test technical field, to be more exactly, relates to a fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and an usage method thereof, which solves the problems of high temperature irresistance, high pressure irresistance, aqueous corrosion, large screw thread slit and poor centering in the current sample clamp. The clamp is provided with a column, a platform, an upper press cap, a lower press cap and a conversion adapter; the lower part of the column of the clamp is fixed on a cover of anautoclave, the upper part of the column of the clamp is fixed on the platform, and respectively and tightly pressed by lock nuts, the lower part of the conversion adapter is connected with a stretching shaft of a fatigue machine, through elevating the stretching shaft, an upper convex plate and a lower convex plate of the test sample are respectively placed in a platform groove and a conversion adapter groove, two dimidiate semirings are pressed on upper convex plate and the lower convex plate of the test sample, the upper press cap and the lower press cap are sleeved, the press cap bolts arescrewed for fixing two ends. The fatigue test sample clamp can be used in the autoclave for carrying out various fatigue tests (stress-stress, stress-tension, tension-tension and the like) under the high temperature high pressure solution environment, and has the advantages of simple structure and low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

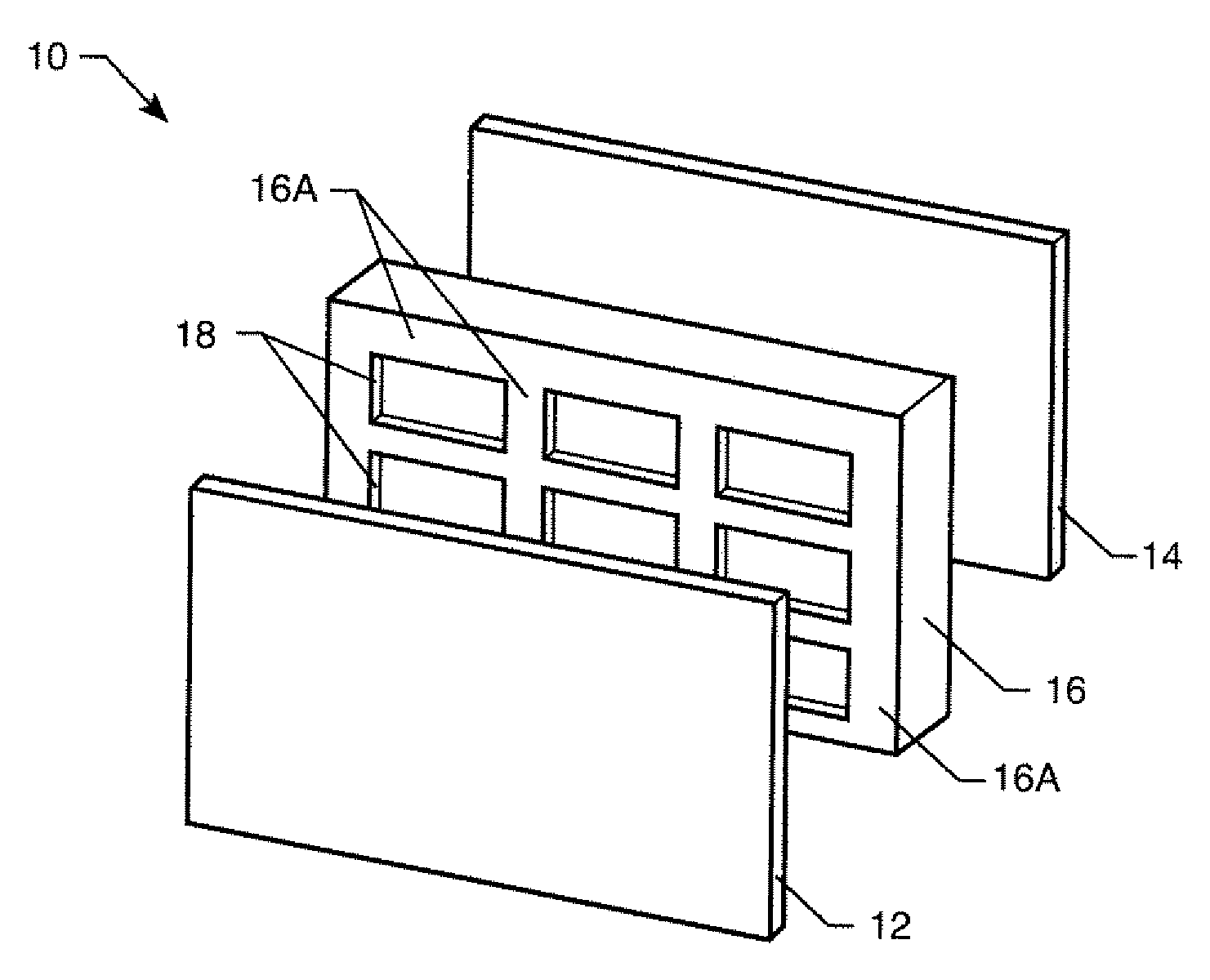

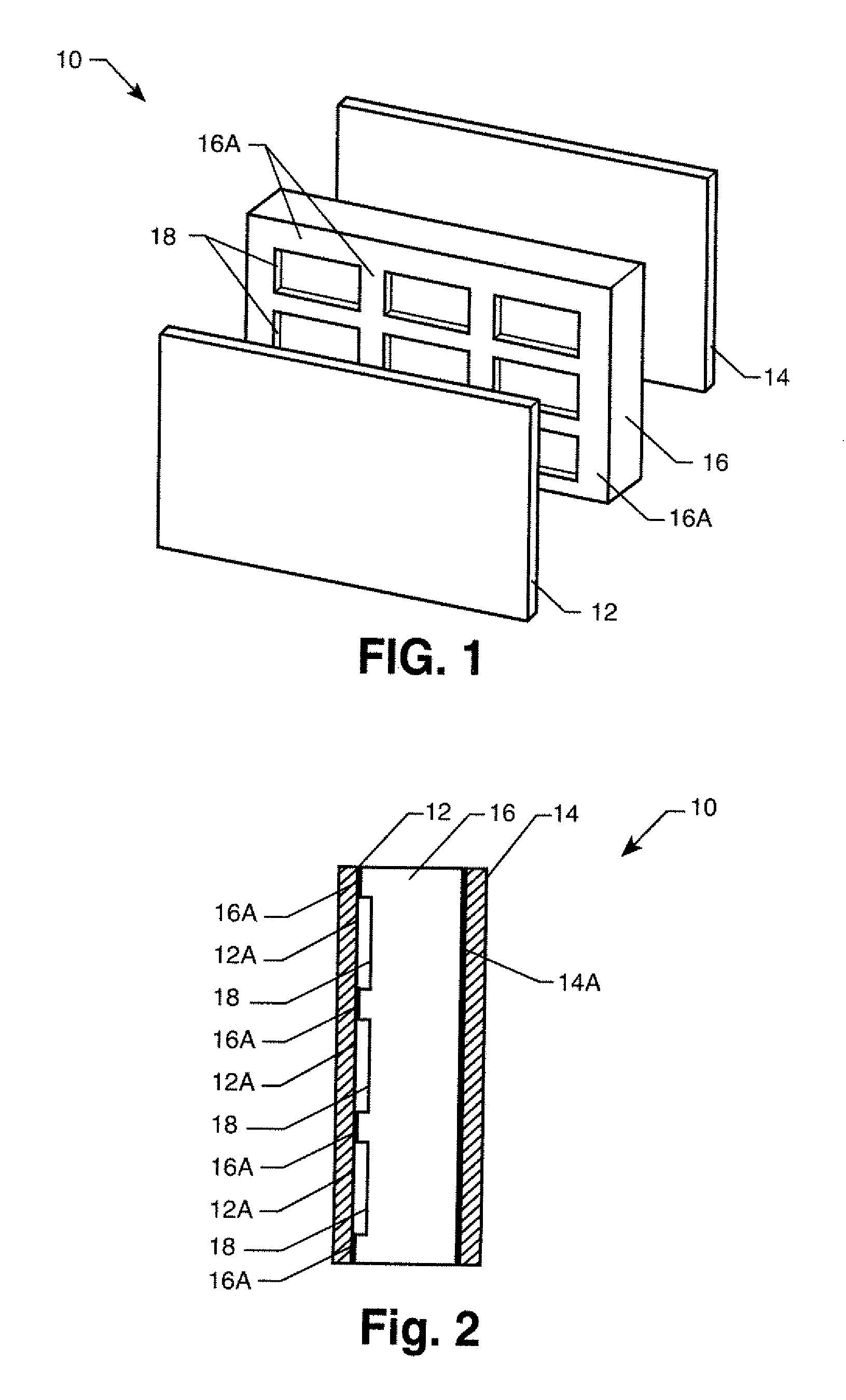

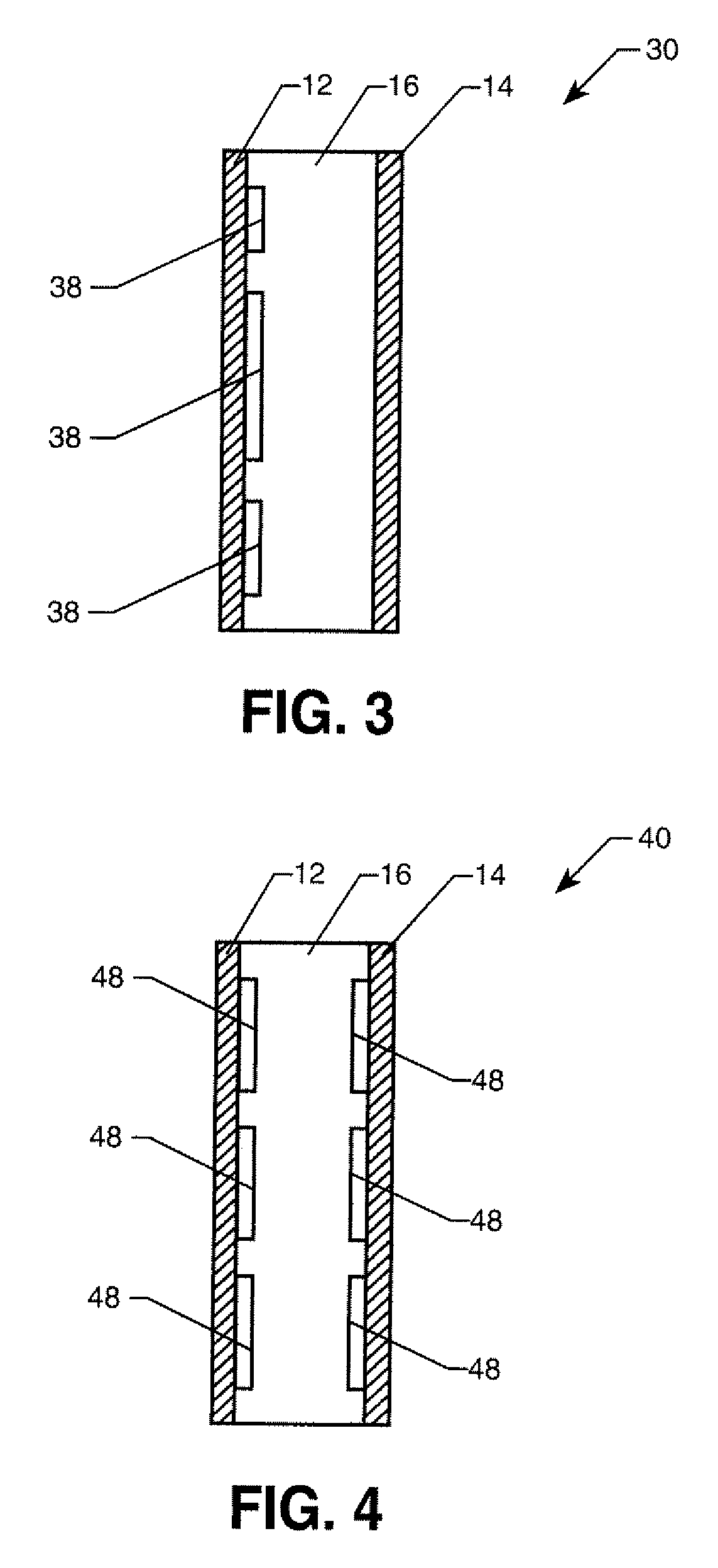

Composite Panel with Reinforced Recesses

InactiveUS20080128202A1Low noise transmissionGood strengthConstruction materialWallsElectrical and Electronics engineeringFace sheet

Owner:NASA

Continuously annealed or hot galvanized cold rolled transformation induced plasticity steel plate and preparation method thereof

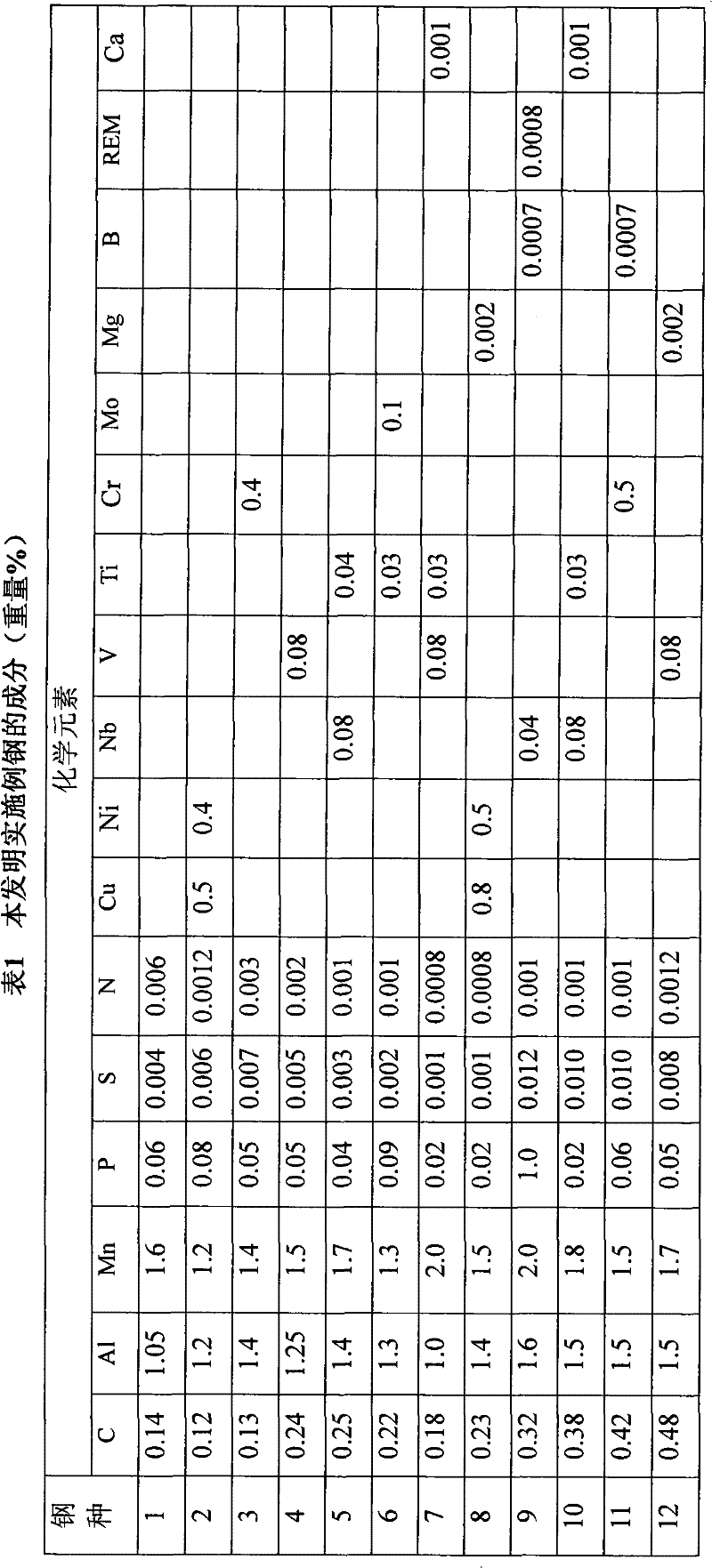

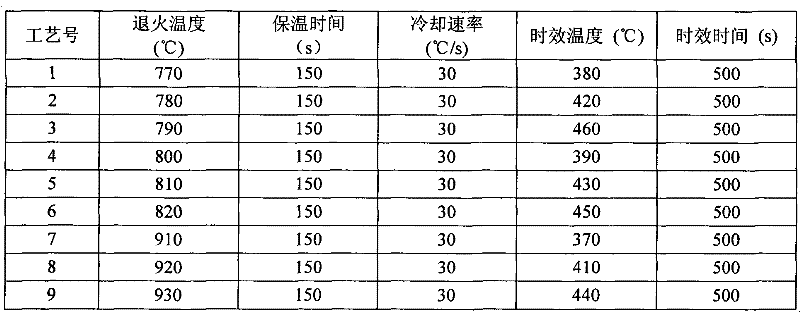

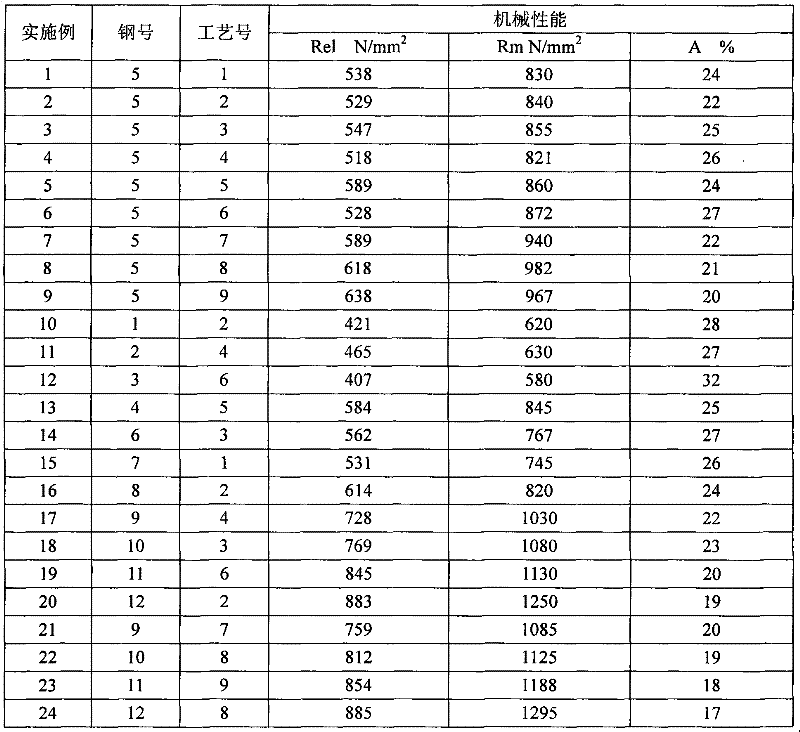

ActiveCN102409222AGood strengthHigh strengthTemperature control deviceFurnace typesSteel platesLiquid temperature

The invention provides a continuously annealed or hot galvanized cold rolled transformation induced plasticity steel plate and a preparation method thereof. The steel plate comprises the following components: 0.1-0.5% of C, 0.2-2.0% of Al, 0.5-2.5% of Mn, 0.02-0.12% of P, not more than 0.02% of S, not more than 0.01% of N and the balance of Fe. The method comprises smelting, rolling and continuous annealing or hot galvanizing and is characterized in that the hot rolling heating temperature is 1100-1250 DEG C; the heat is preserved for 1-4 hours; the initial rolling temperature is 1100 DEG C; the finish rolling temperature is 750-900 DEG C; the coiling temperature is less than 700 DEG C; accumulated cold rolled reduction is 40-80%; the continuous annealing temperature is 700-(Ac3+50) DEG C; the heat is preserved for 30-360 seconds; the cooling rate is 10-150 DEG C / s; the aging temperature is 250-600 DEG C; the aging time is 30-1200 seconds; the steel plate is cooled to the room temperature at a rate of 5-100 DEG C / s; the hot galvanizing and annealing temperature is 700-(Ac3+50) DEG C; the heat is preserved for 30-360 seconds; the cooling rate is 10-150 DEG C / s; the steel plate is cooled to 400-500 DEG C and enters into a zinc pot after the heat is preserved for 10-300 seconds; the zinc pot temperature is 450-500 DEG C; the impregnation time is 1-10 seconds; the steel plate is cooled to the zinc liquid temperature to be galvanized; the impregnation temperature is 450-500 DEG C; and the impregnation time is 1-10 seconds. The steel plate has good strength, plasticity, forming property, welding property and galvanizing property and is suitable for industrial production.

Owner:ANGANG STEEL CO LTD

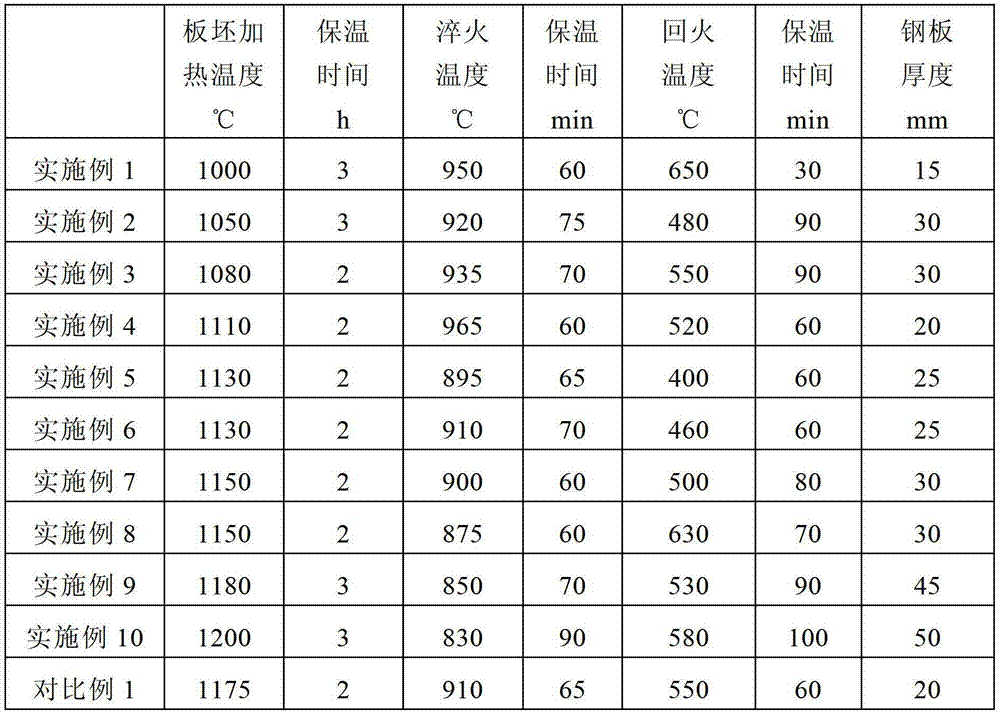

Steel plate with great heat and abrasion resistance and manufacturing method thereof

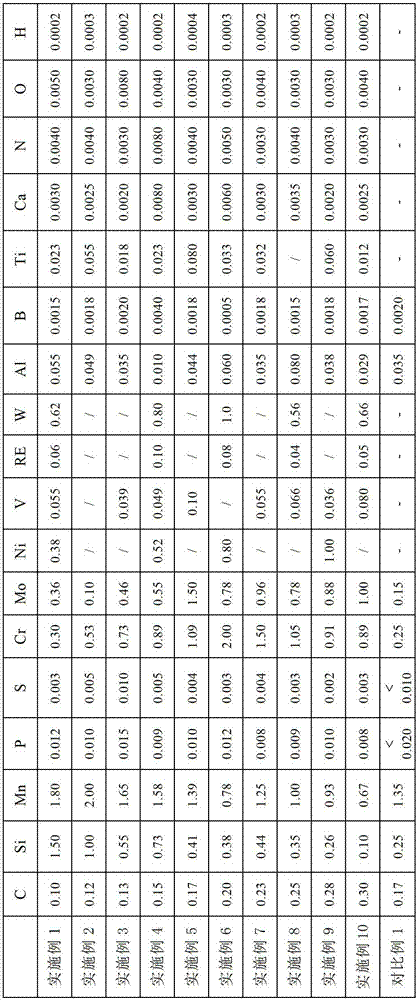

ActiveCN103205650AExcellent mechanical properties and wear resistanceImprove hardness and wear resistanceQuenchingSteel plates

The present invention provides a steel plate with great heat and abrasion resistance and a manufacturing method thereof. The steel plate comprises the following chemical composites, in percentage by weight: 0.10-0.30% of C, 0.10-1.50% of Si, 0.50-2.00% of Mn, 0-0.015% of P, 0-0.010% of S, 0.2-2.00% of Cr, 0.10-1.50% of Mo, 0-1.00% of Ni, 0-0.10% of V, 0-0.10% of RE, 0-1.00% of W, 0.010-0.080% of Al, 0.0005 -0.0040% of B, 0-0.080% of Ti, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0004% of H and the balance being Fe and inevitable impurities. The mechanical properties of the steel plate are that the Brinell hardness is greater than 360HB, and the 500 DEG C tensile strength is more than 1000MPa. The steel plate obtained by the various components through processes such as quenching and tempering has excellent mechanical properties and abrasion resistance, and is particularly suitable for various mechanical parts which are easy to wear while working under high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

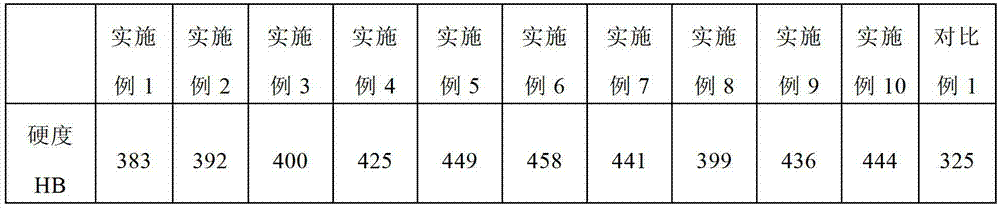

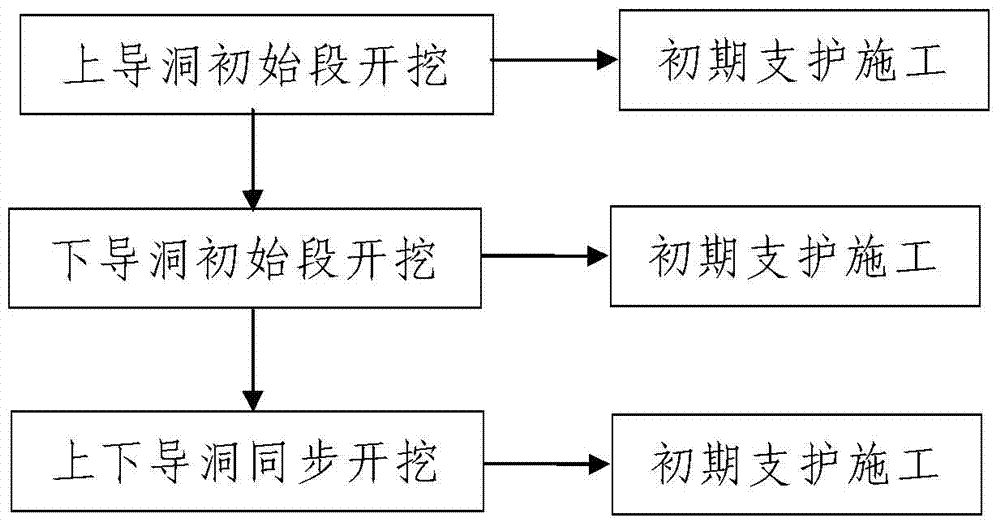

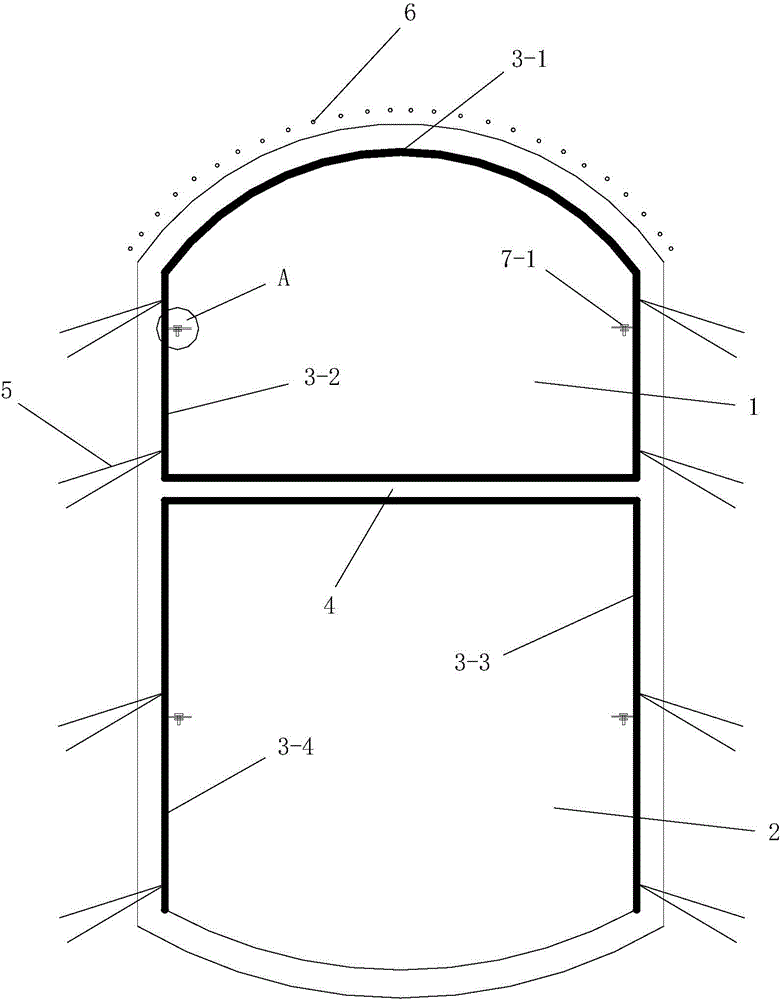

Construction method for enabling shallowly buried and darkly excavated tunnel to pass through cottage area

ActiveCN104500077AThe method steps are simpleReasonable designUnderground chambersTunnel liningRebarInitial segment

The invention discloses a construction method for enabling a shallowly buried and darkly excavated tunnel to pass through a cottage area. The construction method comprises the following steps: excavating a tunnel hole of the constructed shallowly buried and darkly excavated tunnel from back to front through a step excavation process, and performing preliminary bracing on the tunnel hole formed by excavating from back to front in an excavating process, wherein the tunnel hole consists of an upper guide hole and a lower guide hole positioned right below the upper guide hole, the rear part of the tunnel hole is connected with a vertical well, the preliminary bracing structure of the tunnel hole comprises a plurality of grating steel frameworks for supporting the tunnel hole from back to front, a layer of bar-mat reinforcement suspended on the inner wall of the tunnel hole and a concrete layer jetted on the inner wall of the tunnel hole. The process for excavating the tunnel hole of the shallowly buried and darkly excavated tunnel comprises the following steps: I, excavating the initial segment of the upper guide hole; II, excavating the initial segment of the lower guide hole; III, synchronously excavating the upper and the lower guide holes. The construction method disclosed by the invention is simple in step, reasonable in design, convenient in construction, good in construction effect, capable of simply completing the construction process of the shallowly buried and darkly excavated tunnel that passes through the cottage area, and safe and reliable in a construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

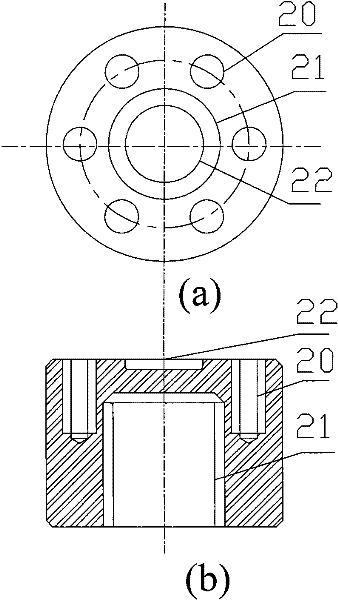

Battery pack

InactiveUS7160643B2Forestall shortingGood strengthPrimary cell to battery groupingCoupling device connectionsElectrical and Electronics engineeringBattery pack

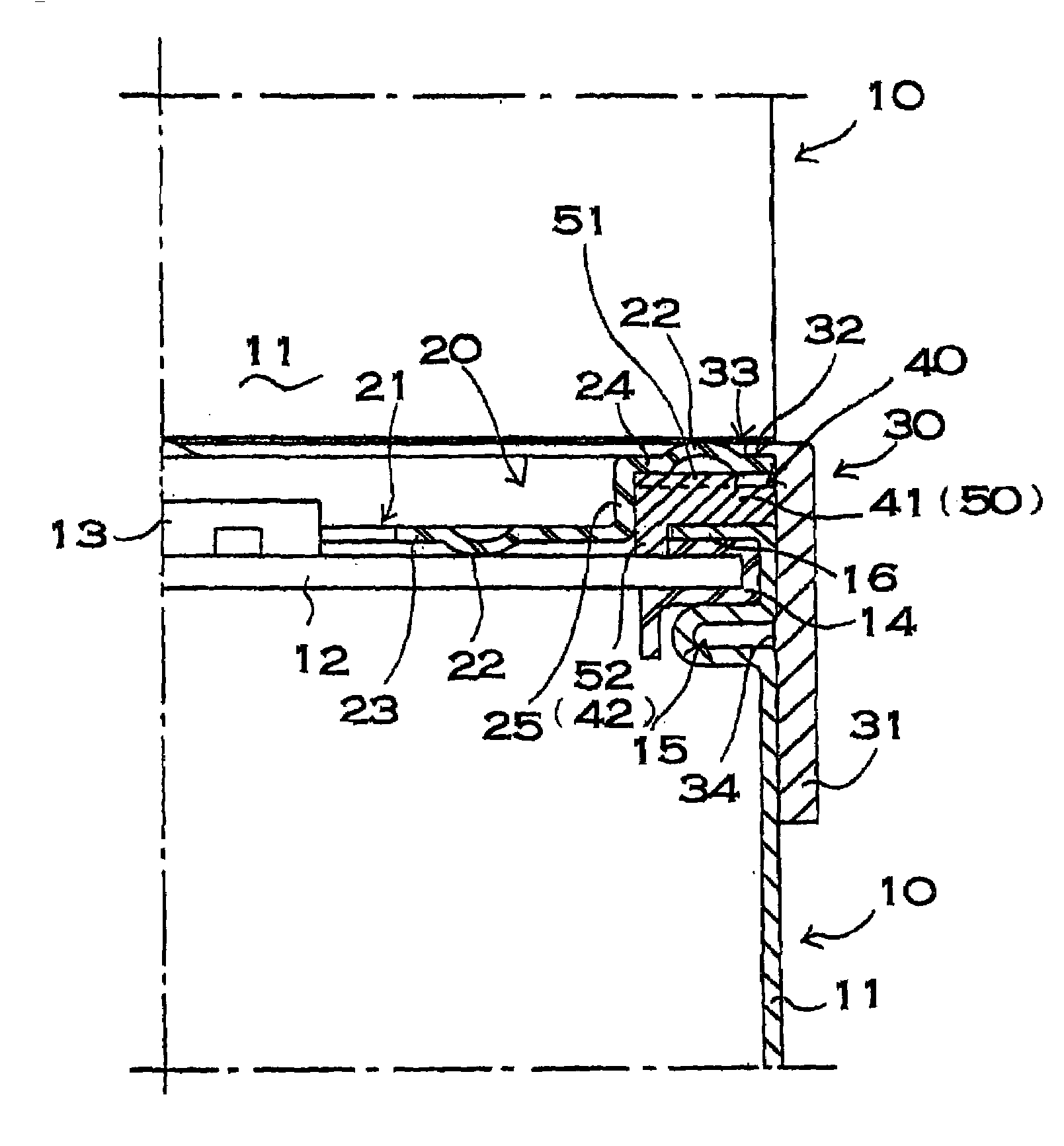

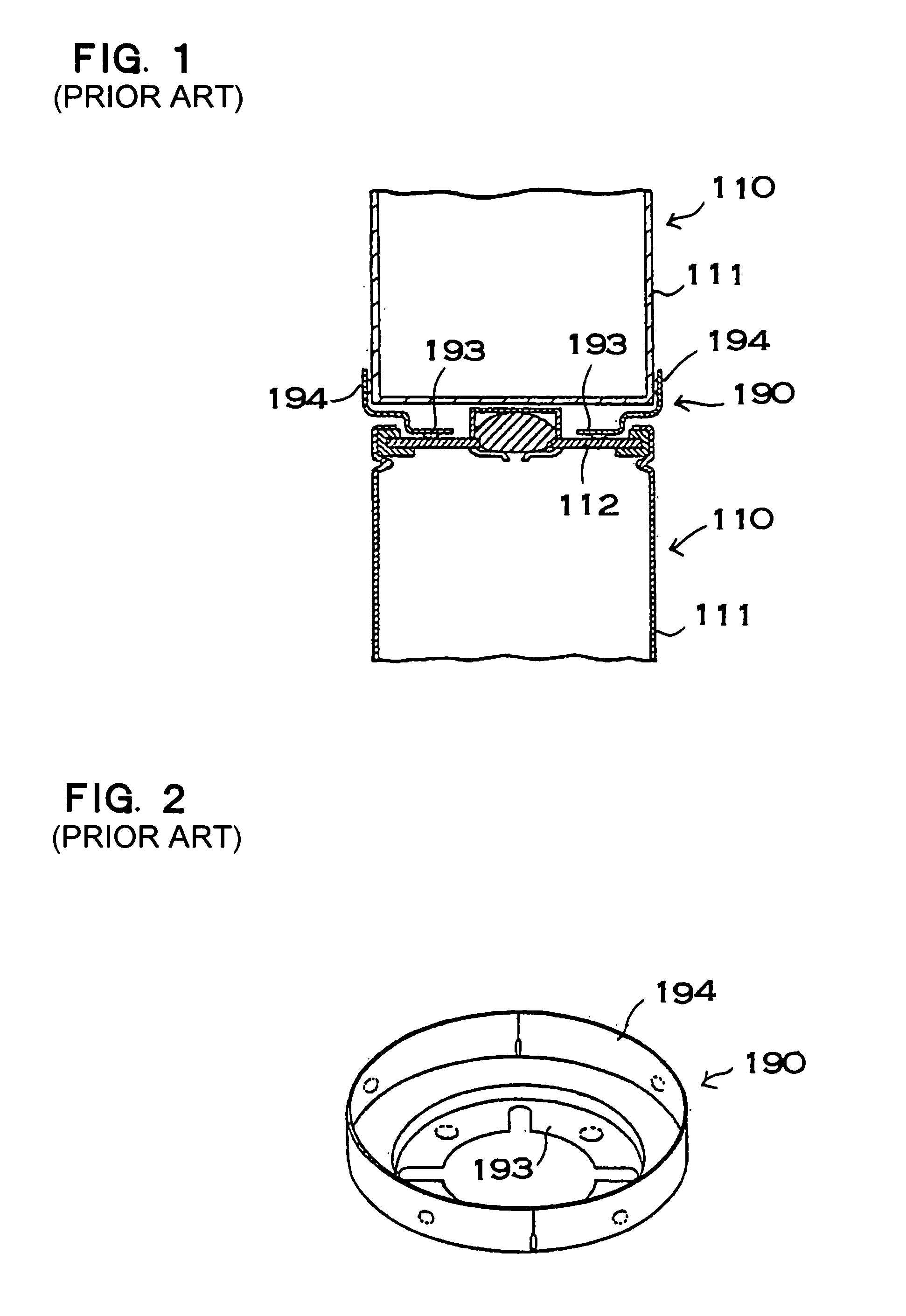

A battery pack includes a plurality of batteries interlocked linearly through a connector. The connector includes an inner peripheral portion to be welded to one battery, and an outer peripheral portion, provided outside the inner peripheral portion, to be welded to the other battery. The inner peripheral portion and the outer peripheral portion have a step in between, and the step places the inner peripheral portion in a concave portion of the connector. The inner peripheral portion of the connector is located interiorly of a caulking convex strip provided at an end face of one battery, and an inner peripheral portion is connected to the battery end face through welding without coming in contact with the caulking convex strip. The outer peripheral portion is connected to an outer peripheral portion of a battery end face of the other battery through welding.

Owner:SANYO ELECTRIC CO LTD

Biomass gasification tar cracking composite catalyst and preparation method thereof

InactiveCN101396660AHigh catalytic activityGood strengthMetal/metal-oxides/metal-hydroxide catalystsTar working-up by thermal treatmentTarCoal tar

The invention provides a preparation method of a biomass gasified tar cracking composite catalyst, comprising the following steps: first, the preparation of a binder: Ni(NO3)2.6H2O crystal and Al2O3 powder are weighed, the Al2O3 powder is added in the water solution of the Ni(NO3)2.6H2O crystal, immersed for 2h-4h at constant temperature water bath of 40 DEG C, dried into light green powder and calcinated; second, the pretreatment of dolomite: the dolomite is ground into powder of 200 meshes below; third, the preparation of a carrier of the composite catalyst: Fe2O3 and the dolomite powder are mixed uniformly and are added with the binder and 5-20mL of nitric acid to be mixed +-<*> uniformly, and the mixture is extruded to be molded, dried naturally, dried at 105 DGE C, calcinated under 400 DEG C and then calcinated at 900 DEG C; forth, the solution immersion of active components: Ni(NO3)2 ethanol solution is used for immersing the carrier of the composite catalyst, and after dried, the carrier is calcinated at 600-800 DGE C. the composite catalyst has the advantages of high catalytic activity, good strength, practical application and simple process.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

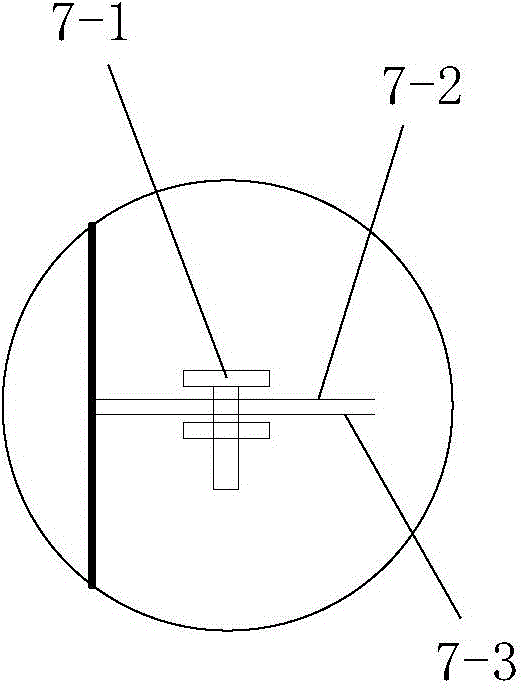

Deformation monitoring method for shallow-buried excavation tunnel construction

ActiveCN104564128AThe method steps are simpleReasonable designMining devicesUnderground chambersTunnel constructionCondition monitoring

The invention discloses a deformation monitoring method for shallow-buried excavation tunnel construction. The deformation monitoring method comprises the following steps: 1) digging a tunnel: digging a tunnel cavity for a constructed shallow-buried excavation tunnel from back to front, primarily supporting the dug tunnel cavity from back to front during the digging process, and forming a primary supporting structure, wherein the primary supporting structure comprises a plurality of grating steel frames for supporting the tunnel cavity from back to front, and each grating steel frame is composed of an arch supporting steel frame and left and right vertical supporting steel frames; 2) arranging monitoring points: arranging multiple sets of supporting state monitoring points on the primary supporting structure of the constructed tunnel cavity from back to front during the digging process, and meanwhile, arranging a plurality of ground surface settlement monitoring points in a construction area of the constructed shallow-buried excavation tunnel from back to front; 3) monitoring the deformation. The method provided by the invention has the advantages of simple steps, reasonable design, convenience in construction, good use effect and capability of effectively monitoring the stability of the constructed shallow-buried excavation tunnel and the ground surface settlement.

Owner:CHINA RAILWAY 20 BUREAU GRP

Polyester baling belt and process technique thereof

The invention relates to the technology field of a packing strap, in particular to a polyester strap and the processing technic. The invention solves the problems of easy deformation, poor intensity and short service life of the common plastic packing strap including the polypropylene and polyethylene packing straps. The packing strap utilizes the PET thermoplastic polyester as the raw materials, which is made through fused blending molding by an extruder, through at least twice stretching and tempering process and then through shaping. The packing strap has width of 9.5mm to 32mm, thickness of 0.55mm to 1.3mm and tensile strength of 400MPa to 550MPa. The processing procedure includes dehumidification drying the polyester raw materials such as slice, bottle flakes and reworked materials of the bottle flakes; extruding thick slice; stretching and heating the thick slice at least twice; embossing; tempering thermoforming; cooling forming and rolling, and the processing procedure above can be finished by arranged devices on each parts capable of realizing the processing procedure in turns.

Owner:朱富来

Multifunctional healthy cushion capable of producing far infrared ray and anion

The present invention relates to one kind of health care article, and is especially one kind of health care cushion artificially synthesized with tourmaline as main material. The product has material comprising tourmaline 20-25 wt%, Yiwangshi stone 15-20 wt%, Chinese medicinal stone 10-15 wt% and pottery clay 45-55 wt%. The said materials are superfine crushed to nano level and mixed with water, and the biscuit prepared with the mixture is sintered under 1060-1160 deg.c for 8 hr to form the product. The present invention may be further produced into mattress, pillow mat, etc. for directly contacting body to reach health care function.

Owner:陈民全 +1

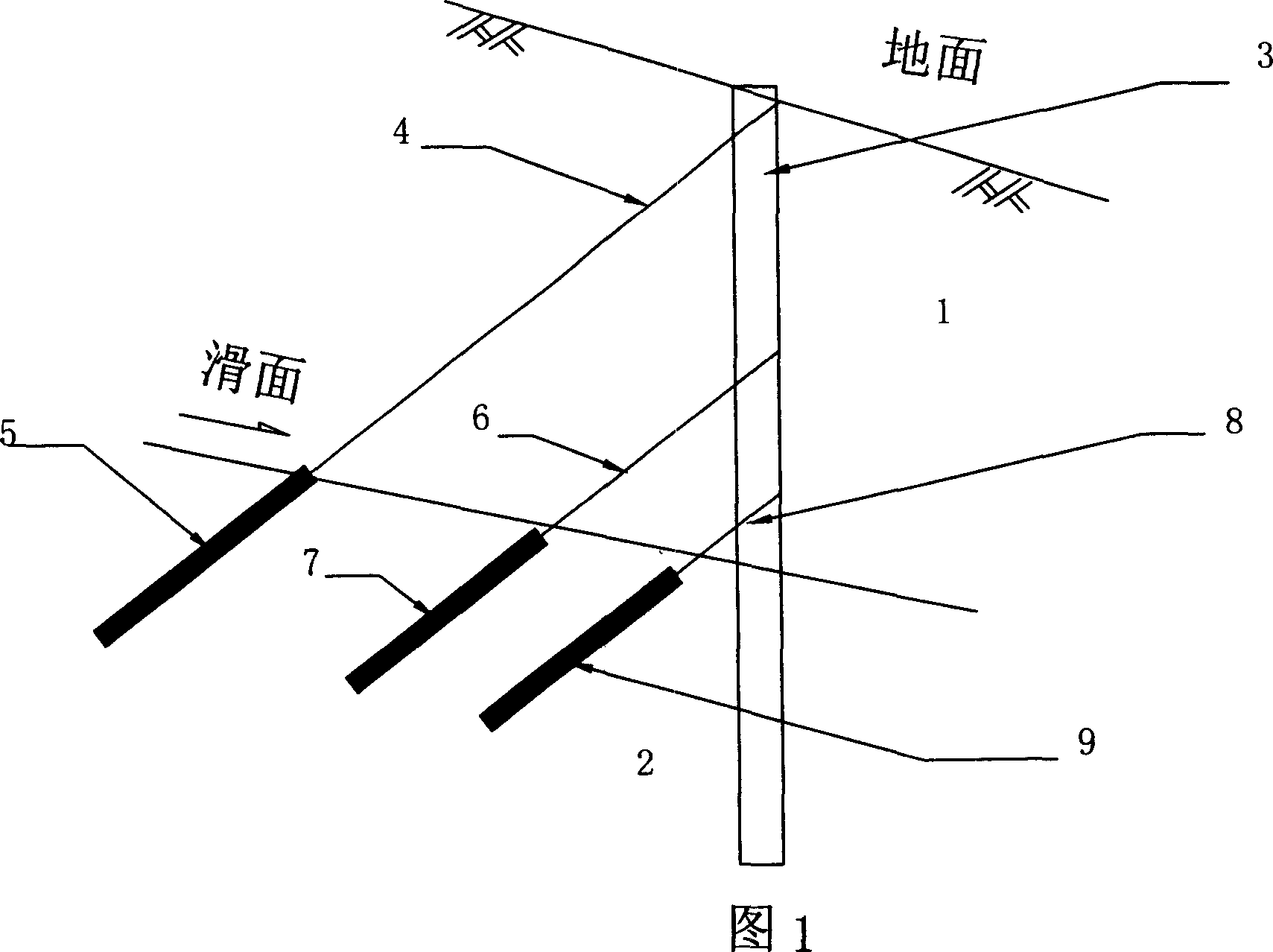

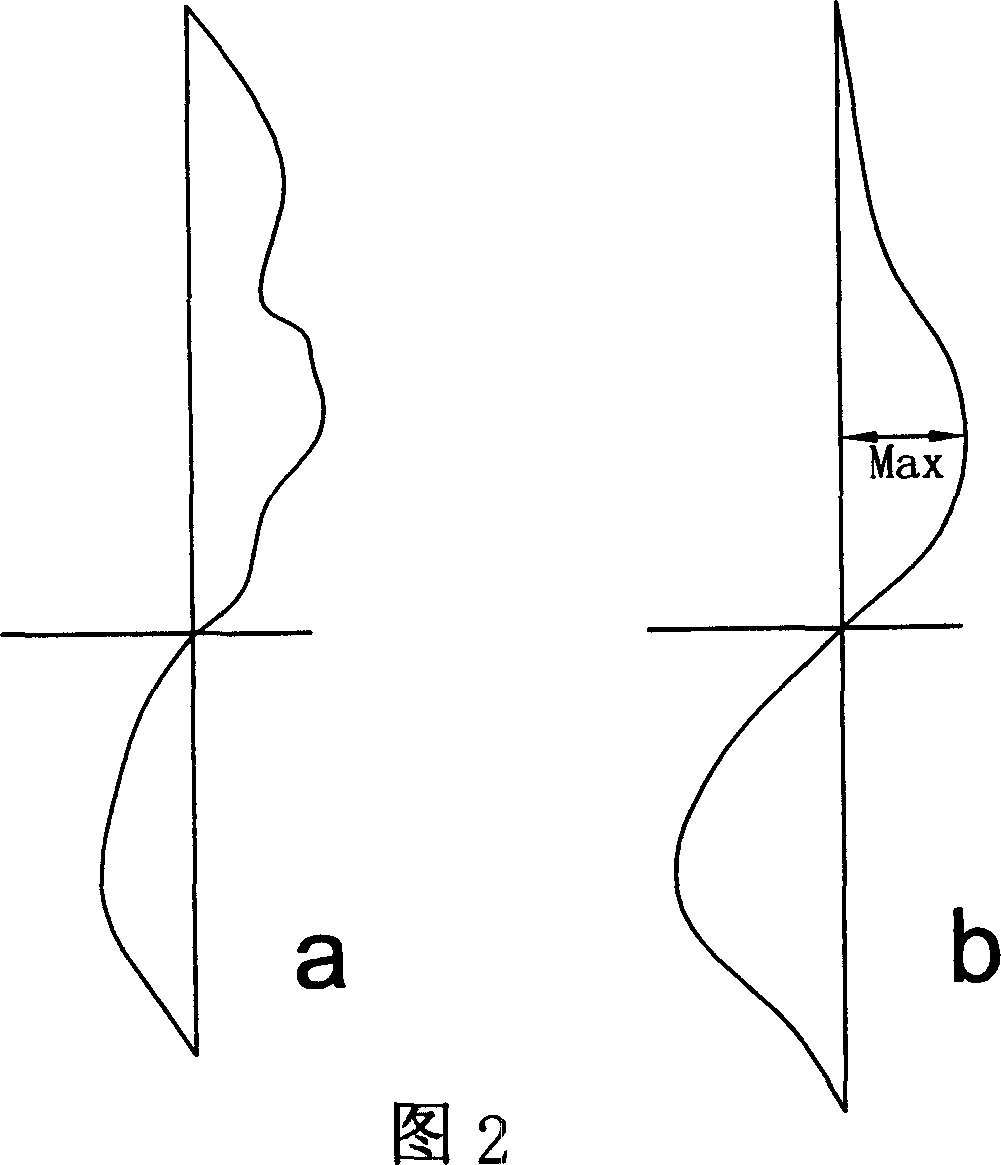

Multi-anchoring point antisliding pile adapted to multilayer slide surface and deep sliding face

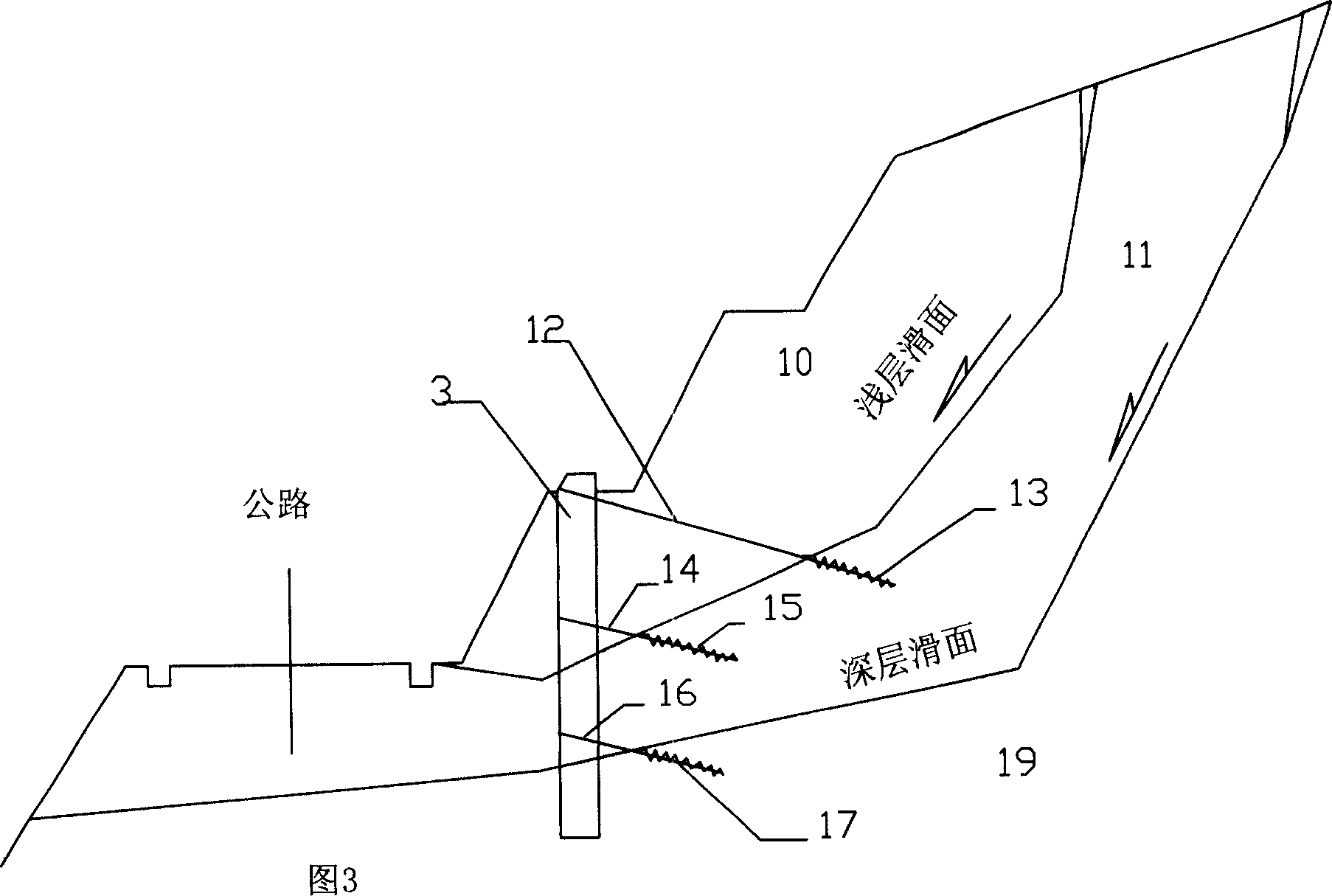

InactiveCN101067301AShorten the lengthBlock activityExcavationsBulkheads/pilesAnchor pointBuilding construction

The present invention discloses one kind of multiple anchor point anti-slide pile suitable for multiple slide plane condition and deep slide plane condition and its construction process. The construction process includes the following steps: excavating pile well and setting pile stem protecting wall in sections; boring hole in proper depth, installing anchor cable, grouting and tensing the anchor cable temporarily onto the protecting wall; further downward excavating and repeating the forgoing said steps until installing the lowest anchor cable; further excavating the pile well to designed depth; assembling reinforcing cage inside the pile well; tensing anchor cables and locking; and final pouring pile concrete to complete the pile construction.

Owner:NORTHWEST RES INST CO LTD OF C R E C

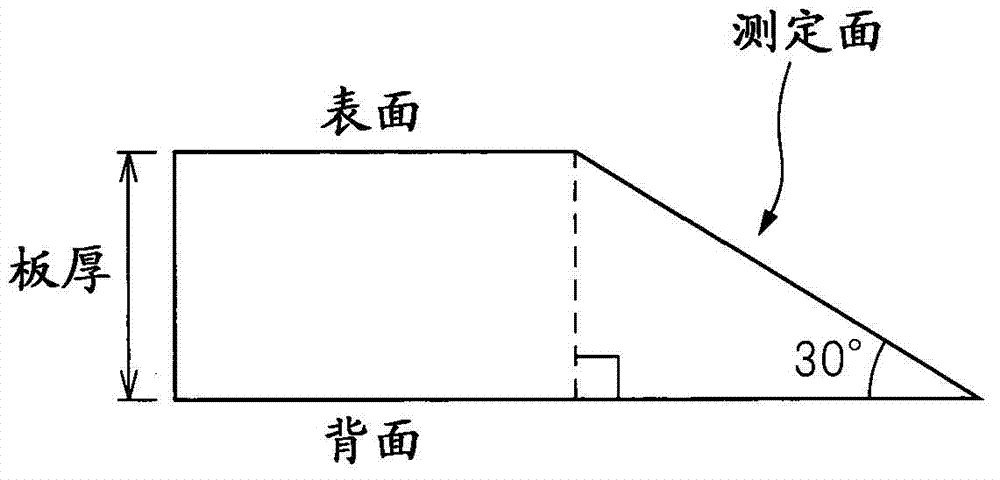

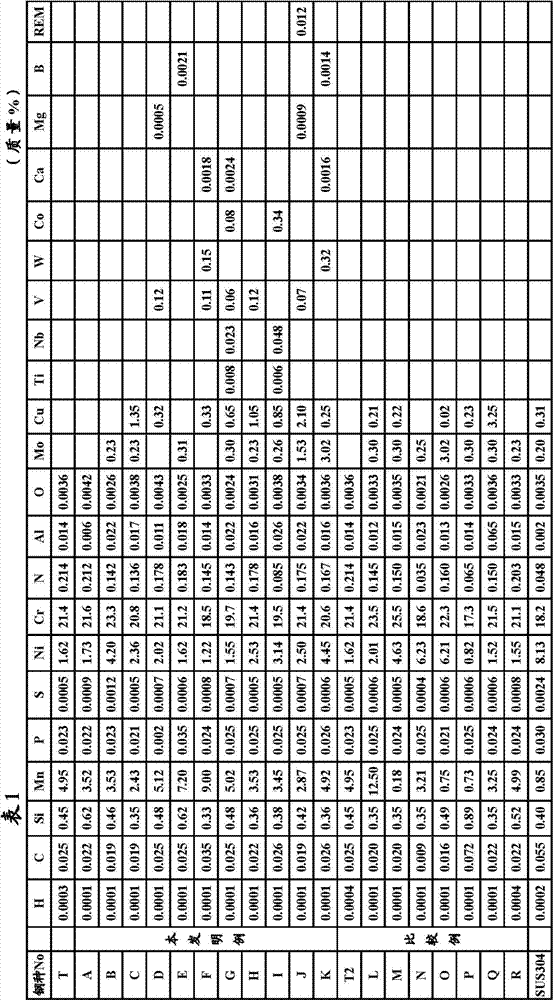

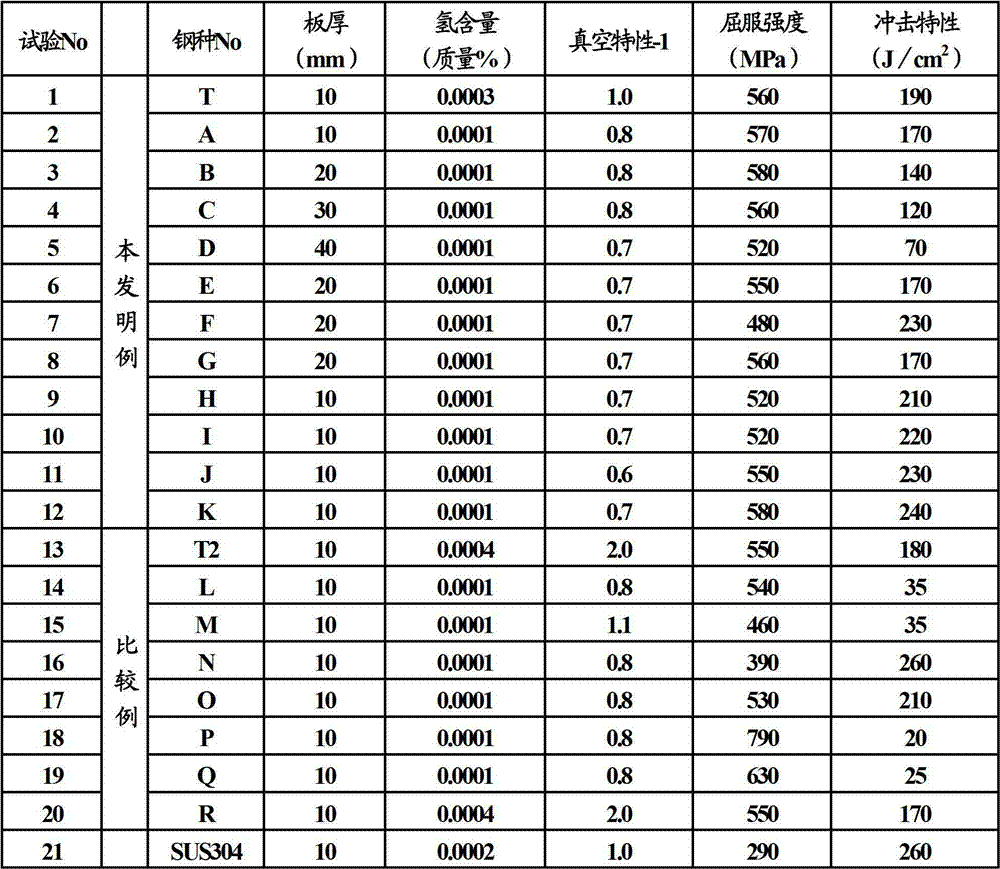

Duplex stainless steel material for vacuum vessels, and process for manufacturing same

ActiveCN102770572AGood strengthExcellent gas release characteristicsFurnace typesHeat treatment furnacesAustenitic stainless steelMetallurgy

Provided is an Ni-saving type duplex stainless steel material which exhibits excellent gas desorption characteristics and can substitute for austenitic stainless steel. The duplex stainless steel material is characterized by: containing, by mass, 0.06% or less of C, 0.05 to 1.5% of Si, 0.5 to 10.0% of Mn, 0.05% or less of P, 0.010% or less of S, 0.1 to 5.0% of Ni, 18.0 to 25.0% of Cr, 0.05 to 0.30% of N, and 0.001 to 0.05% of Al; and having a hydrogen content of 3ppm or less, the balance being Fe and unavoidable impurities.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

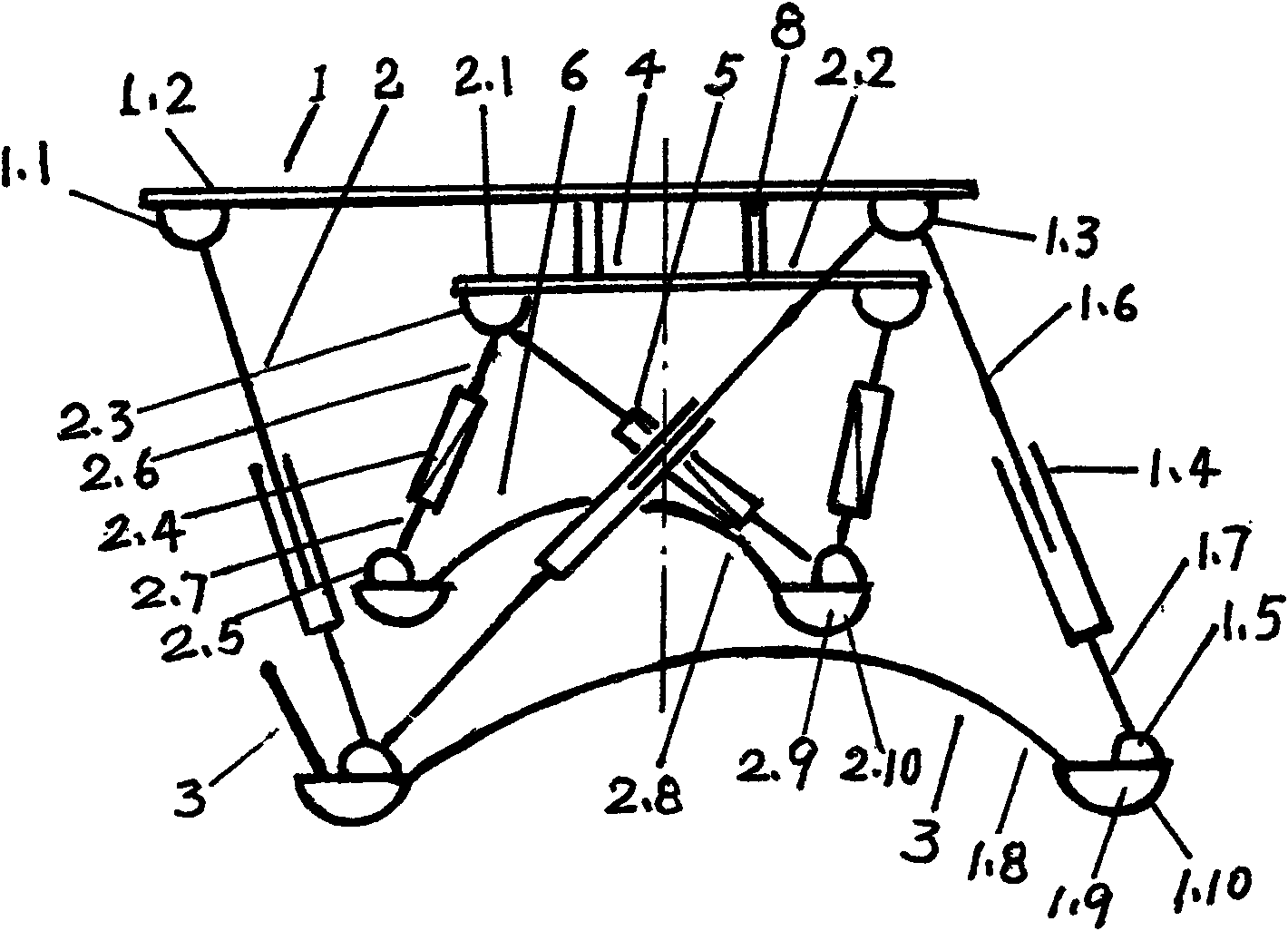

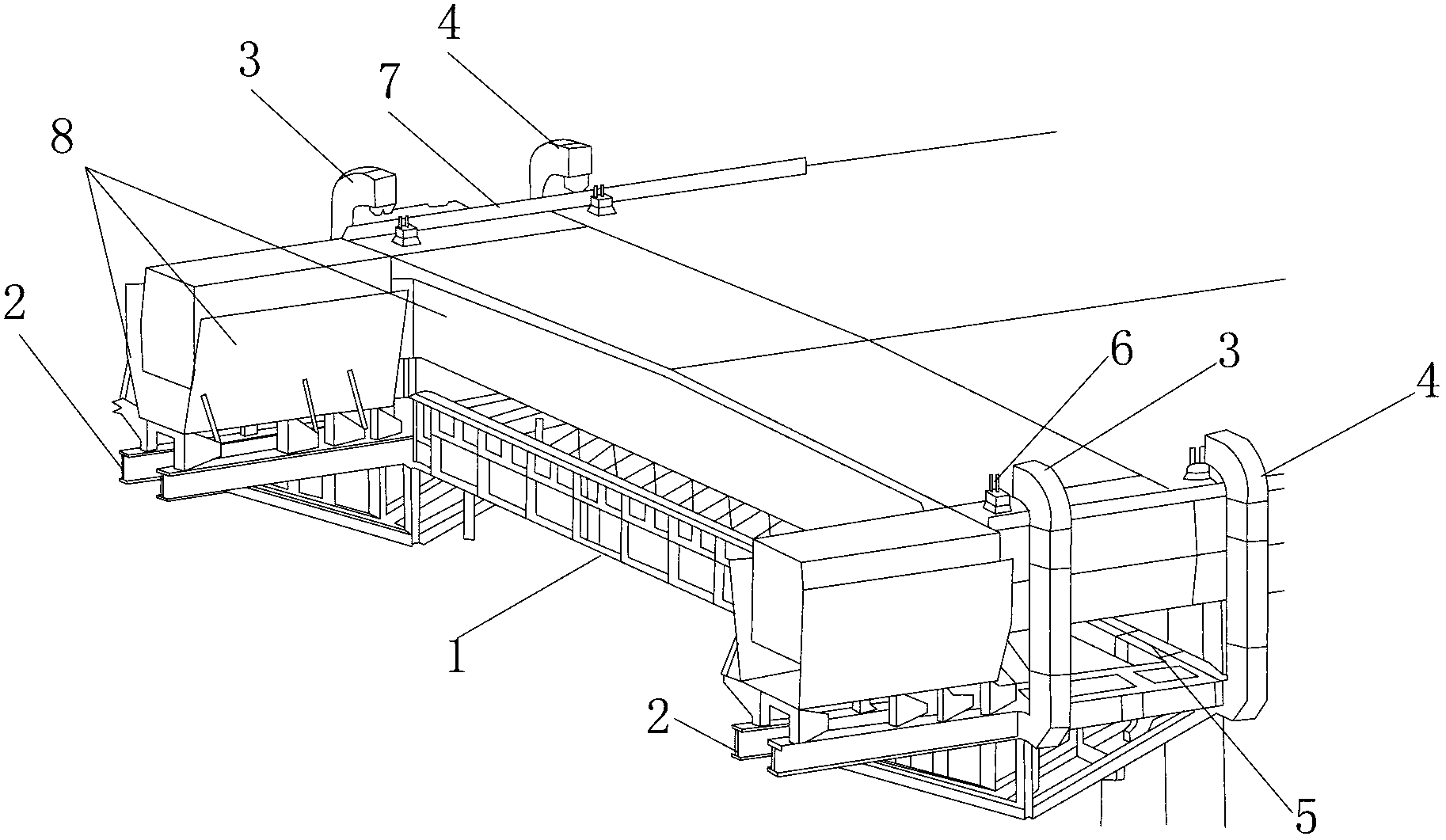

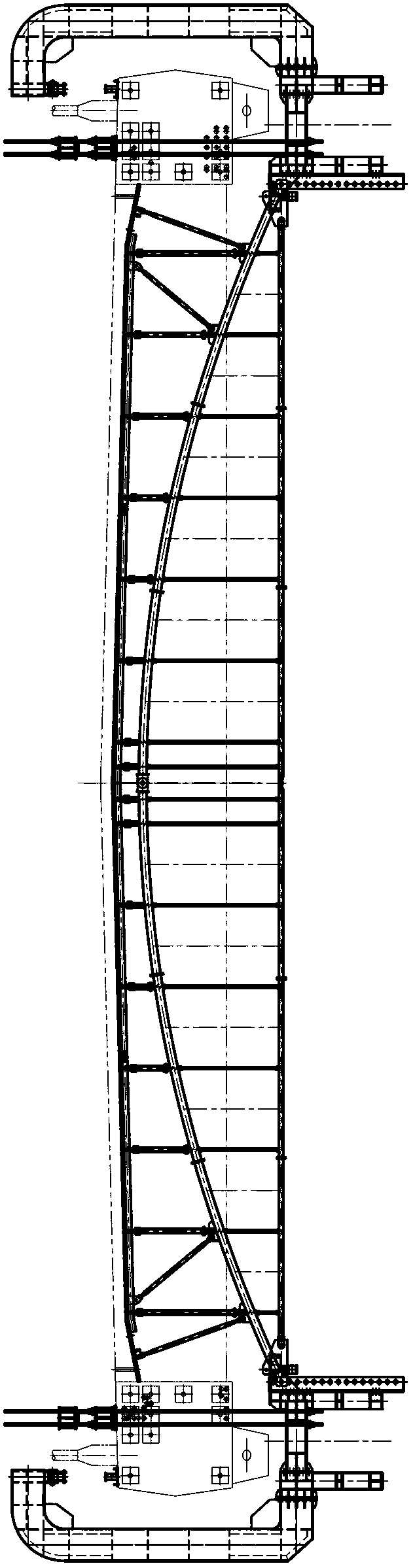

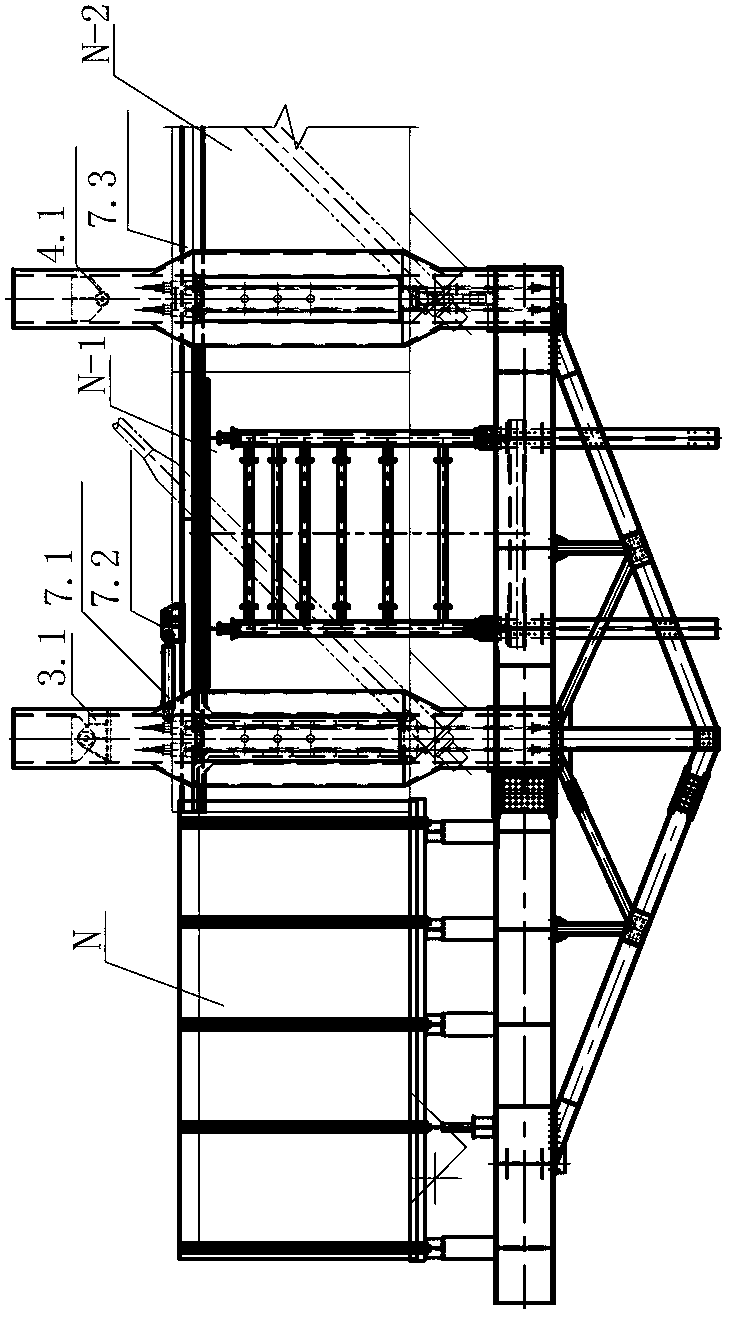

Rear supporting point triangular bracket hanging basket and bridge construction method using same

The invention discloses a rear supporting point triangular bracket hanging basket, which comprises (1) a bearing platform, (2) a suspension fixing system used for supporting and fixing the bearing platform on poured concrete; (3) a template system, and (4) a walking system. The rear supporting point triangular bracket hanging basket provide by the invention is supported and fixed on a poured edge main girder through hanging arms arranged at the middle part and the rear part of the hanging basket; the front part extending forwards is a suspension arm which can be used for bearing the pouring construction of the edge main girder, thus, a bridge guy cable does not need to bear forces, in such a way, the overall hanging basket system is stressed uniformly, the appearance of the hanging basket is more light, and the mobile construction operation can be carried out more conveniently; on the other hand, by adopting the triangular bracket hanging basket, a construction way of pouring the edge main girder firstly and then pouring a rear bridge top plate and a transverse partition plate can be adopted; the edge main girder, the top plate and the transverse plate are constructed separately in order, thus, the adverse influence of the edge main girder pretensioned force to the top plate is solved, the edge main girder pretensioned force can be ensured not being shared and weakened by the top plate, and moreover, the pretensioned force can be applied to the edge main girder more correctly.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AGood strengthImprove performanceWelding/cutting media/materialsSoldering mediaCorrosionSpot welding

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

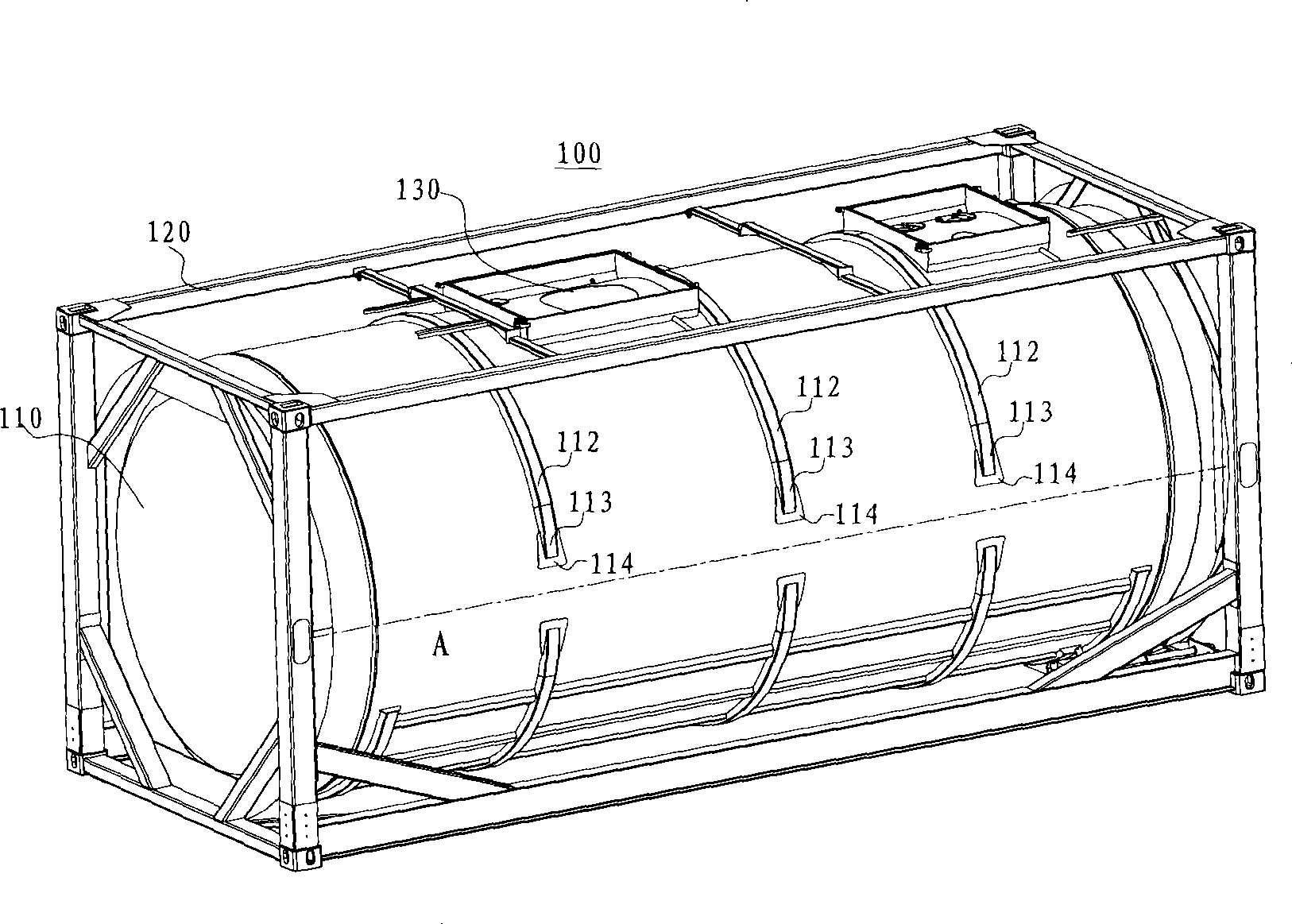

Large volume tank container

ActiveCN101362543ALose weightGuaranteed StrengthLarge containersBiochemical engineeringTank container

The invention relates to a high volume tank container, which comprises a framework, a tank body arranged in the framework, at least one reinforcing ring arranged on the periphery of the tank body and used for reinforcing the intensity of the tank body to better resist the external pressure; wherein, the reinforcing ring is broken in the position closed to the central line on the side of the tank body, and a wedge-shaped reinforcing ring is arranged at the broken end part of the reinforcing ring and connected with the tank on the both sides of the central line on the side of the tank body. A discharging system is installed at the bottom part at the rear end of the tank body, the lower beam corresponding to the position of the discharging system is disconnected into two sections, and a discharging bottom board is connected at the lower end of each lower beam in the disconnecting position. Simultaneously, the central line of the tank body is arranged lower than that of the framework, therefore, not only the dimension of the side surface of the high volume tank container is ensured to be within the ISO dimension, but also a larger operating space exists in the discharging positions at the top part and the bottom part, thus being convenient for the operation.

Owner:NANTONG CIMC TANK EQUIP CO LTD

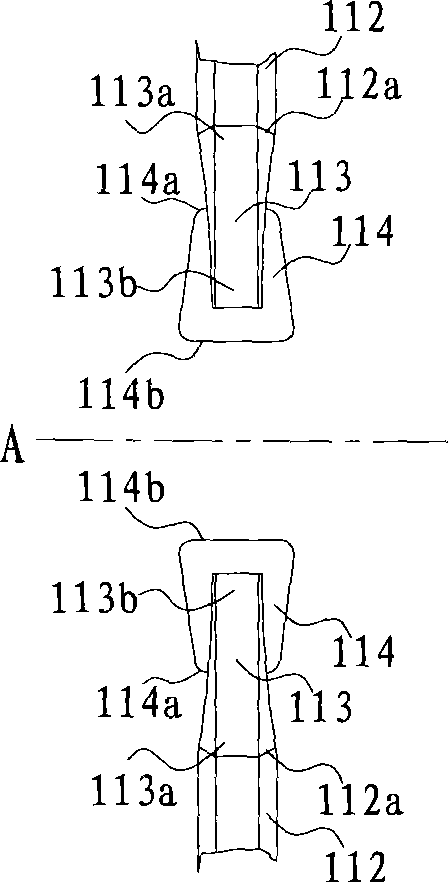

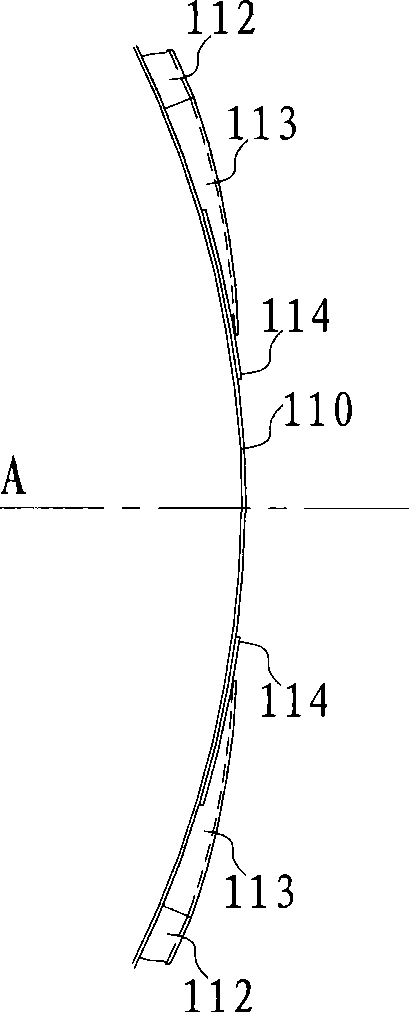

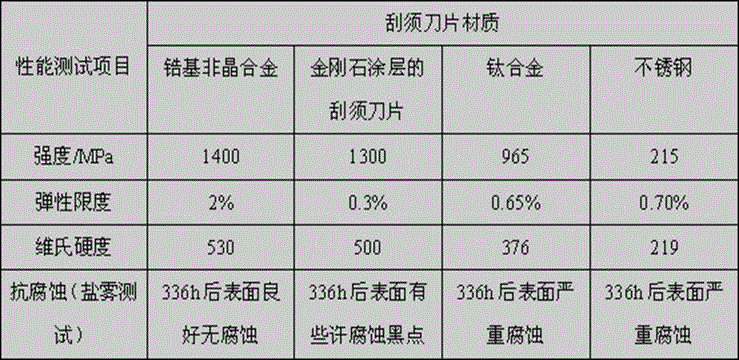

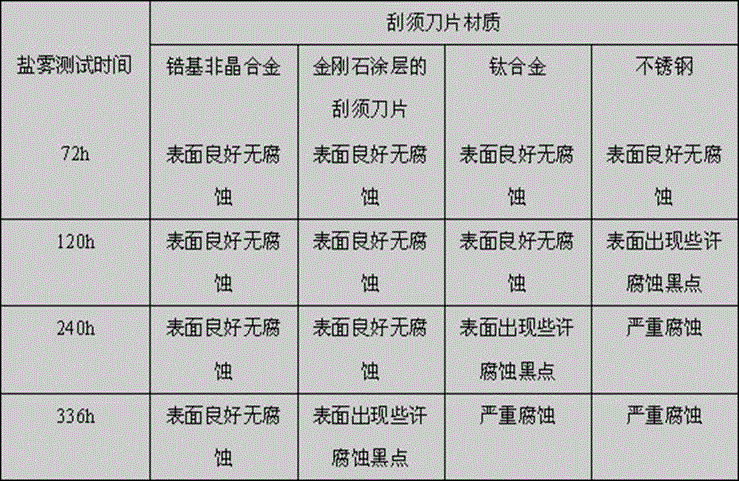

Application of amorphous alloy to preparation of razor blade and razor

The invention relates to the technical field of application of amorphous alloys and in particular relates to application of an amorphous alloy to preparation of a razor blade and a razor. The strength, elastic limit and Vickers hardness of the razor blade prepared by utilizing the amorphous alloy are respectively 1400-2300MPa, 2-2.5% and 530-600, and the surface of the razor blade is still good and corrosion-free after being subjected to salt spray test for 336-480 hours. The razor comprises a blade holder, a razor rest and the razor blade prepared in application of the amorphous alloy to preparation of the razor blade. Compared with the blades coated with coating materials or on which the coating materials are deposited and the razor blades directly cast by utilizing titanium alloys or stainless steel, the prepared razor blade and razor have excellent strength, elastic limit, Vickers hardness and corrosion resistance and have the advantages of simple production processes, high production efficiency and low production costs.

Owner:DONGGUAN PROMETAL TECH CO LTD

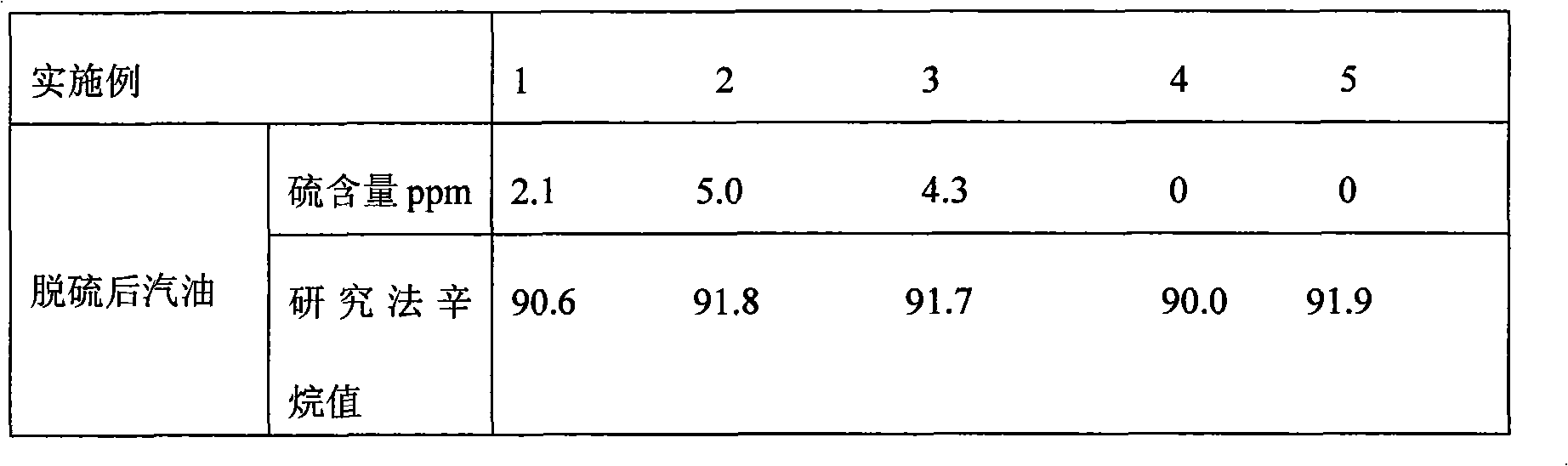

Catalytic gasoline absorbing desulfurization catalyst, preparation method and application thereof

ActiveCN101905161AGood strengthImprove wear resistanceCatalyst activation/preparationRefining with metal oxidesTitanium tetrachlorideCarbon black

The invention relates to a catalytic gasoline absorbing desulfurization catalyst, a preparation method and an application thereof. According to weight percentage, the catalyst contains 10 to 85% of activated zinc oxide, 5 to 80 % of white carbon black, 5 to 30 % of aluminum oxide and 4 to 45 % of nickel oxide. The preparation method comprises the following steps of: (1) decomposing titanium tetrachloride under hydrogen atmosphere at 1400 DEG C to obtain gaseous phase white carbon black, (2) mixing the activated zinc oxide, gaseous phase white carbon black, aluminum oxide and nickel salt into starch, (3) spraying the obtained mixture into ball or injecting into ball, (4) drying the balls formed in the step (3) at 110 to 150 DEG C, and (5) roasting the balls obtained from the step (4) at 300 to 550 DEG C. The prepared absorbing desulfurization catalyst has the advantages of strong intensity, excellent durability, excellent desulfurization activity, small octane number loss, low transportation cost, and application on mobile bed absorbing desulfurization technique.

Owner:PETROCHINA CO LTD

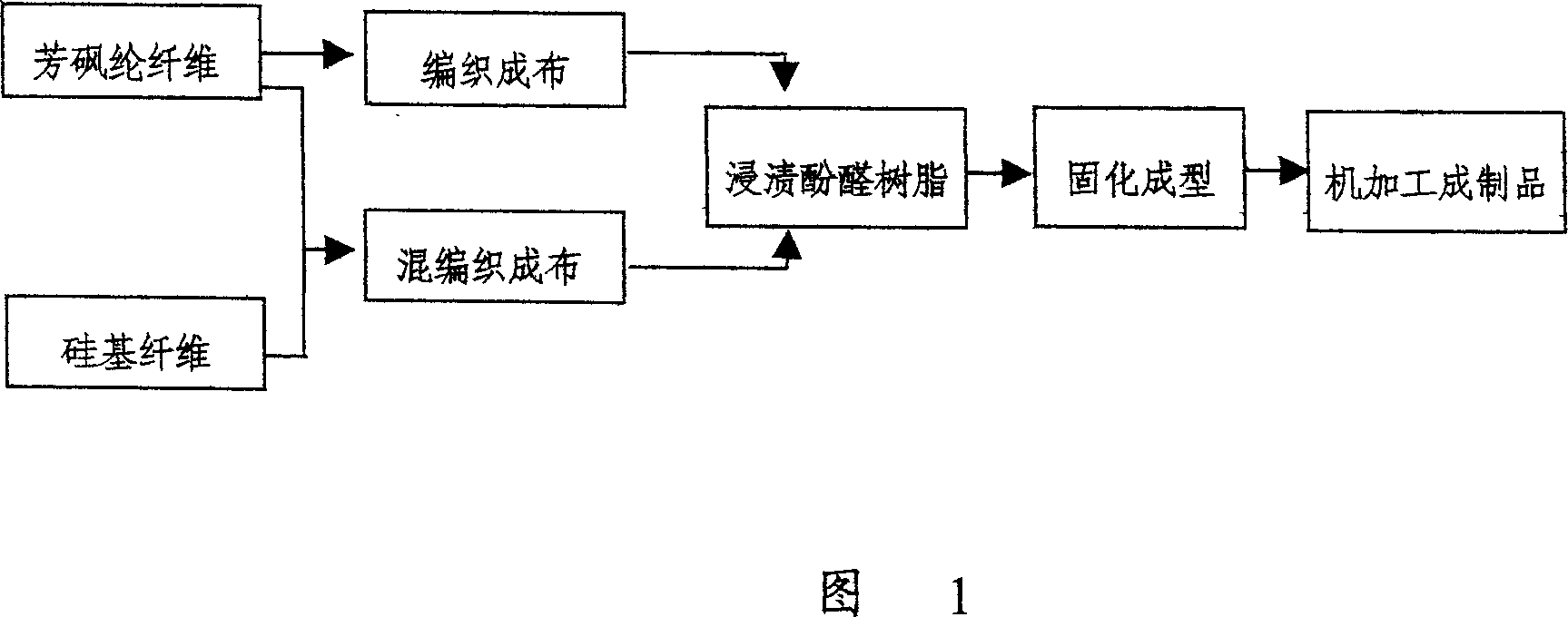

Enhancement ablation thermal protection composite material and preparation method thereof

ActiveCN1990920AGood strengthImprove heat resistanceFibre treatmentWoven fabricsThermal insulationFiber

The invention relates to a thermal protective composite with enhancing ablation and the manufacturing method. It is the novel heat insulation composite, whose manufacturing technology is that PSA fabric cloth or / and Si-based fiber mixed weaved cloth is dipped in phenolic resin and is solidified to mould. The composite in invention is widely applied in the structuring with heat insulation and protection and is provided with better intensity, stability of dimension and machining technology. It breaks through the demand that prior material can not be ablated for a long time and can not insulate heat. It finds a better solved path for realizing integration of ablative heat protection and heat insulation of material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

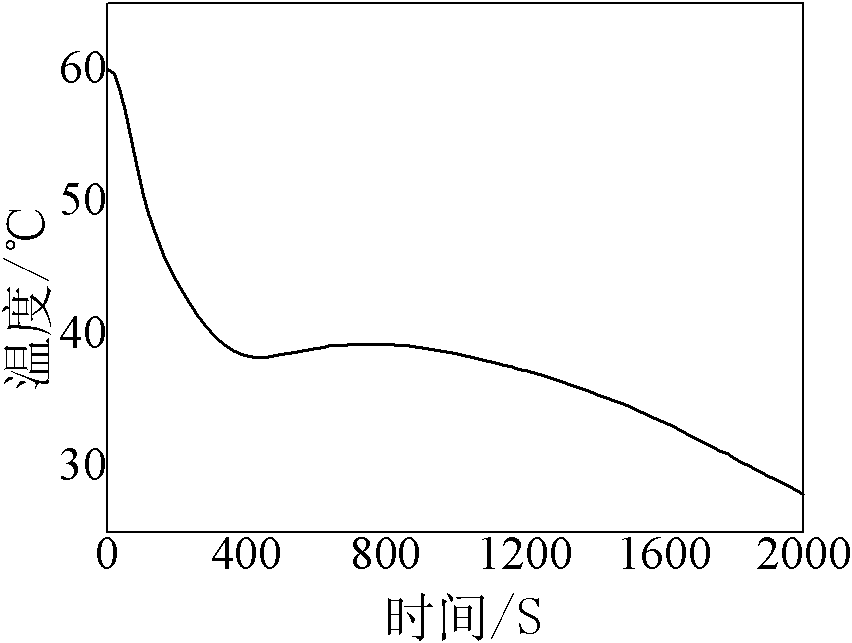

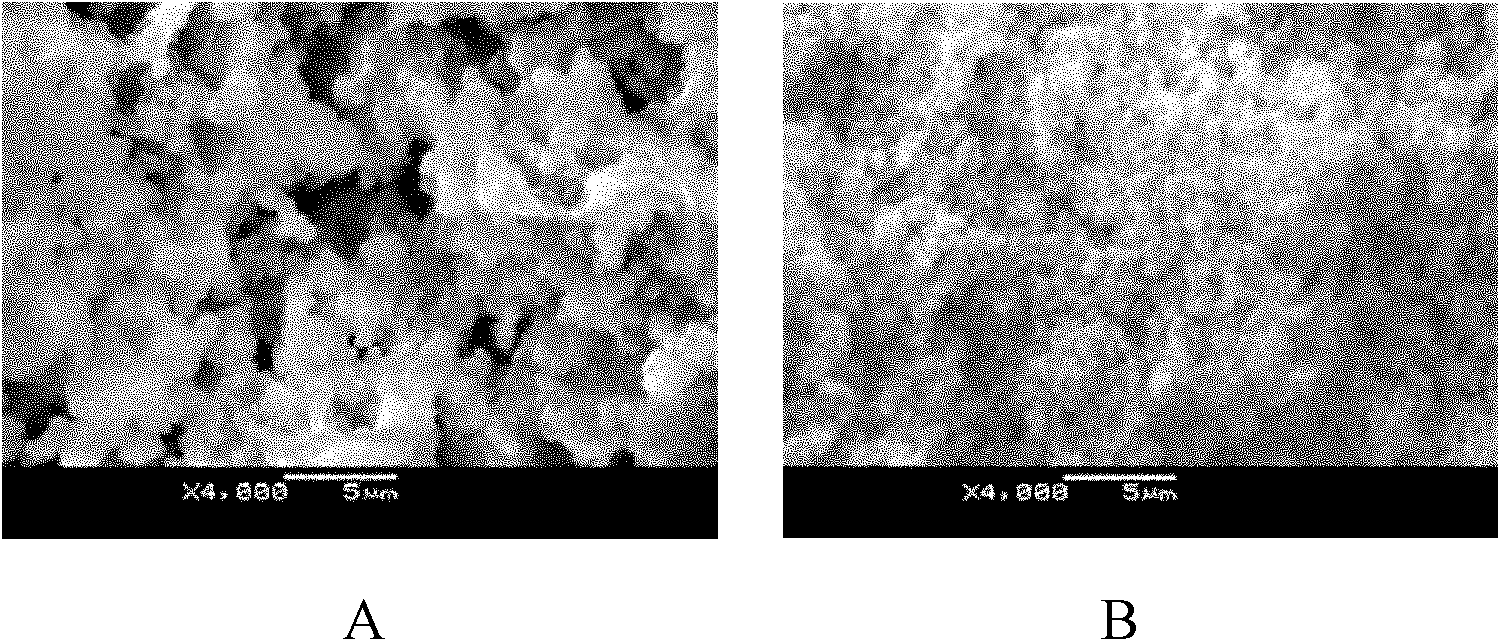

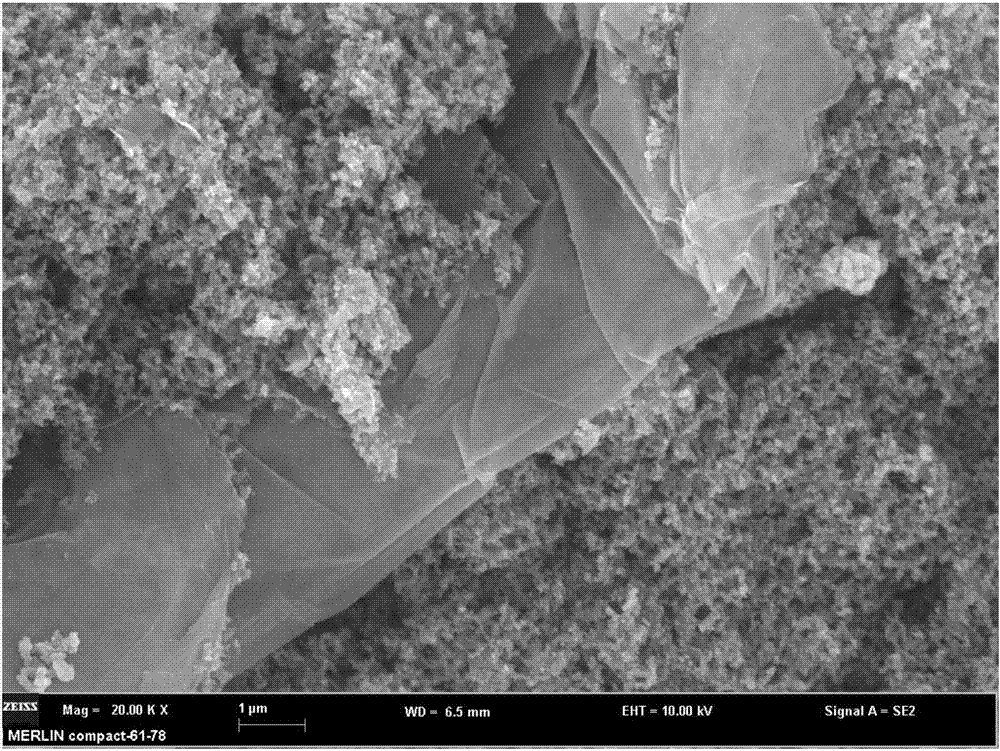

Graphene electroconductive macromolecular composite material and preparation method thereof, and electrothermal film obtained by graphene electroconductive macromolecular composite material

The invention provides a graphene electroconductive macromolecular composite material and a preparation method thereof, and an electrothermal film obtained by the graphene electroconductive macromolecular composite material, and belongs to the technical field of graphene. The electrothermal film has the advantages of high electric conductivity, high power, capability of working under the low-voltage condition and the like, and has a huge application prospect in the fields of winter heating and the like. The graphene electroconductive macromolecular composite material comprises the following components in parts by mass: 0.1 to 10 parts of graphene, 0.1 to 20 parts of electroconductive macromolecules, 5 to 40 parts of resin, 10 to 40 parts of electroconductive functional components and 0.07 to 21 parts of auxiliary functional components, wherein the graphene is prepared by a physical method. The graphene electroconductive macromolecular composite material can be applied to preparation of the electrothermal film for winter heating.

Owner:北京吉泰亿阳科技有限公司

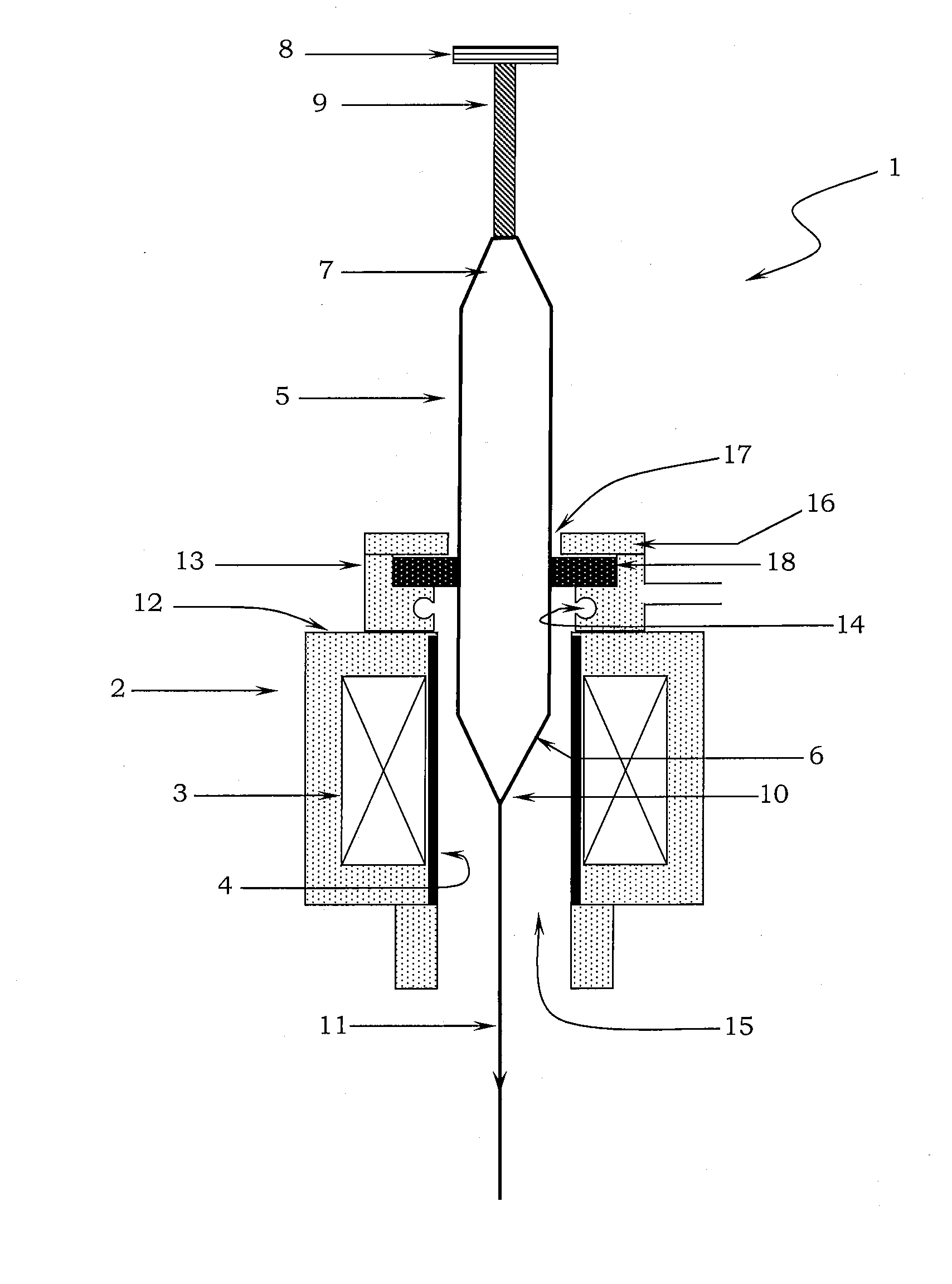

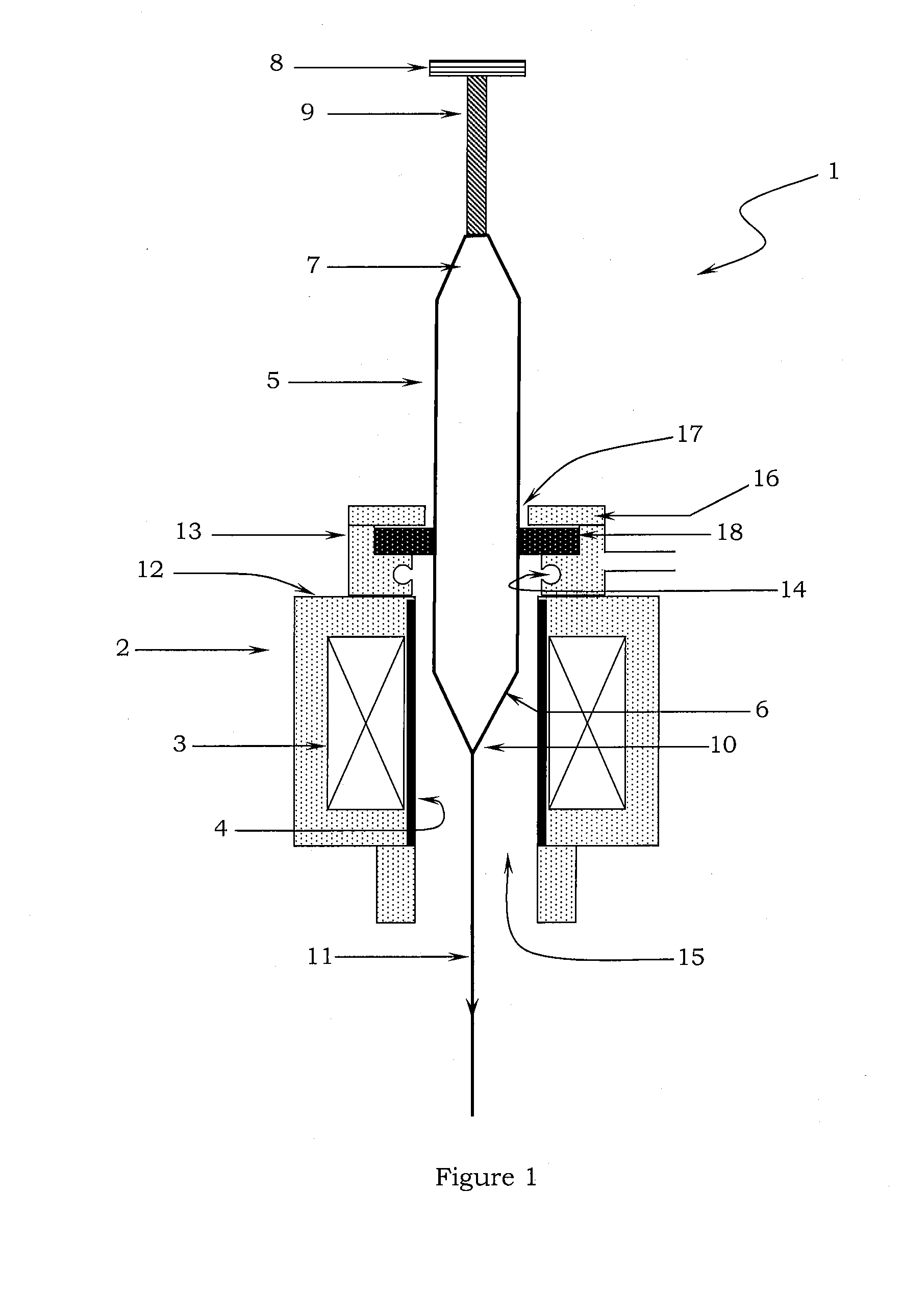

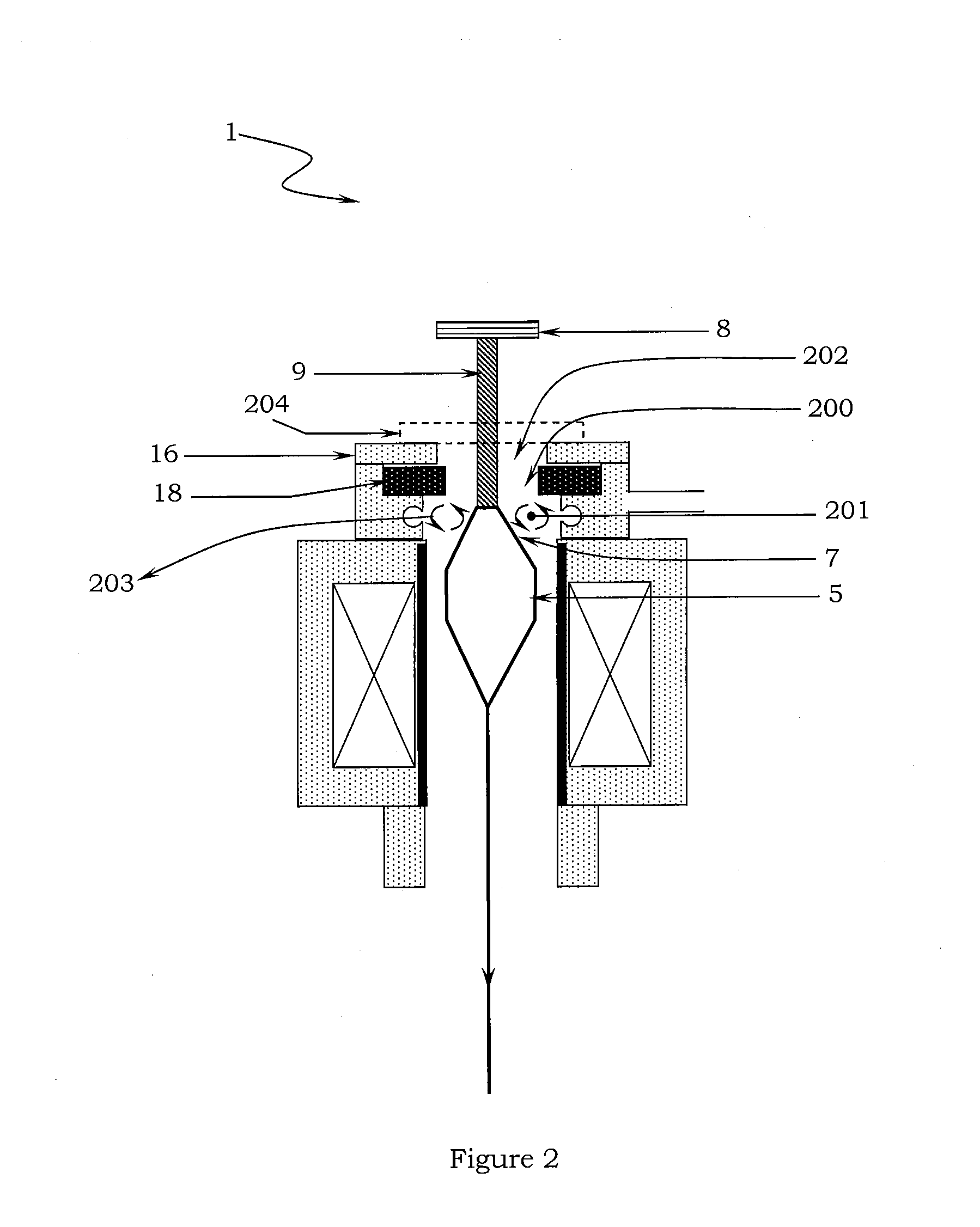

Apparatus and method for drawing an optical fiber having reduced and low attenuation loss, and optical fiber produced therefrom

InactiveUS20070283722A1Deterioration in strengthGood strengthCharging furnaceGlass fibre drawing apparatusAttenuation lossHeating element

An apparatus and method for drawing an optical fiber having reduced and low attenuation loss, and good strength are provided. The apparatus comprises a furnace comprising a furnace chamber provided with heating means having heating elements, wherein a preform is suitably suspended in core tube of the furnace so that its tip can be suitably heated to a temperature suitable for drawing a fiber, the top face of furnace chamber is provided with a diffuser having an orifice for pumping inert gas into core tube of furnace chamber so as to maintain positive pressure inside the core tube; an opening suitable for insertion of preform; a felt capable of sealing a gap between said preform and said diffuser so as to avoid entry of atmospheric gases in core tube of furnace chamber and allowing preform with variations in its diameter to enter core tube of furnace chamber; a diffuser plate on its top surface with aims for covering said felt from top and minimizing its contact with the atmospheric gases; characterized in that top end of preform is provided with a tubular member which is an opaque glass tube non-permeable to infrared [IR] radiations generated during heating of preform inside the core tube of furnace chamber and capable of stopping passing of IR radiations therethrough to said felt to avoid local elevation of temperature at joint between handle and optical fiber preform so as to avoid burning of felt provided at diffuser, and hence to avoid formation of gap between said felt and said tube, and creation of cavity in top part of said core tube of said furnace chamber.

Owner:STERLITE OPTICAL TECH

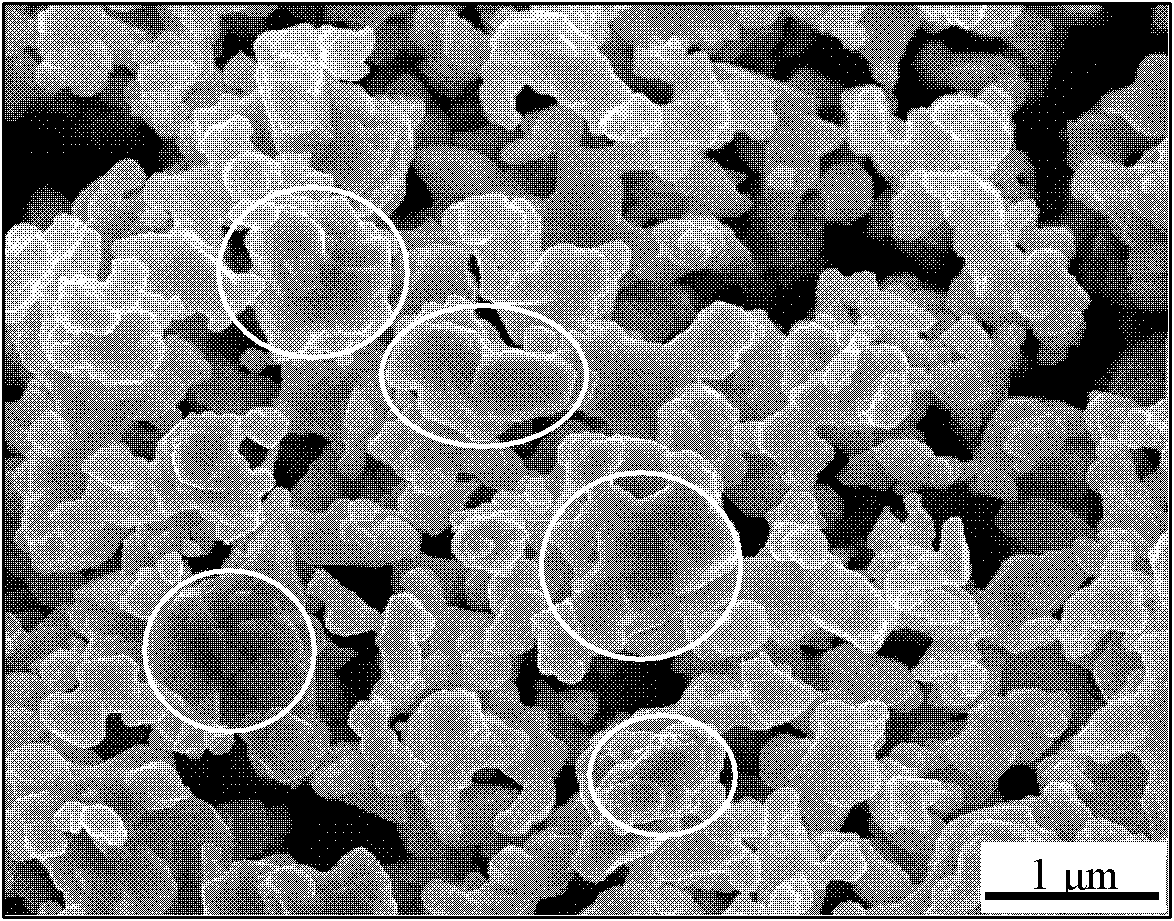

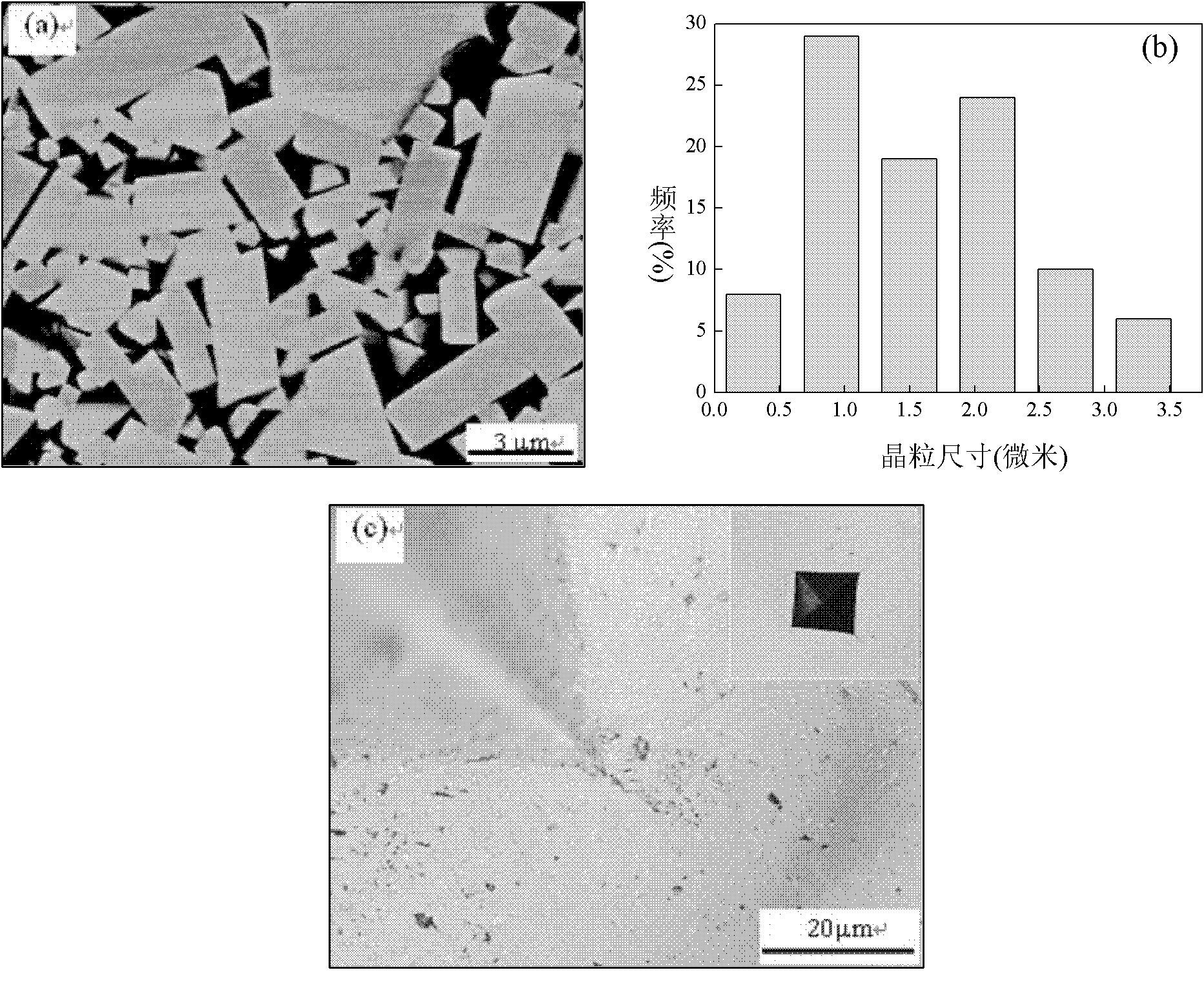

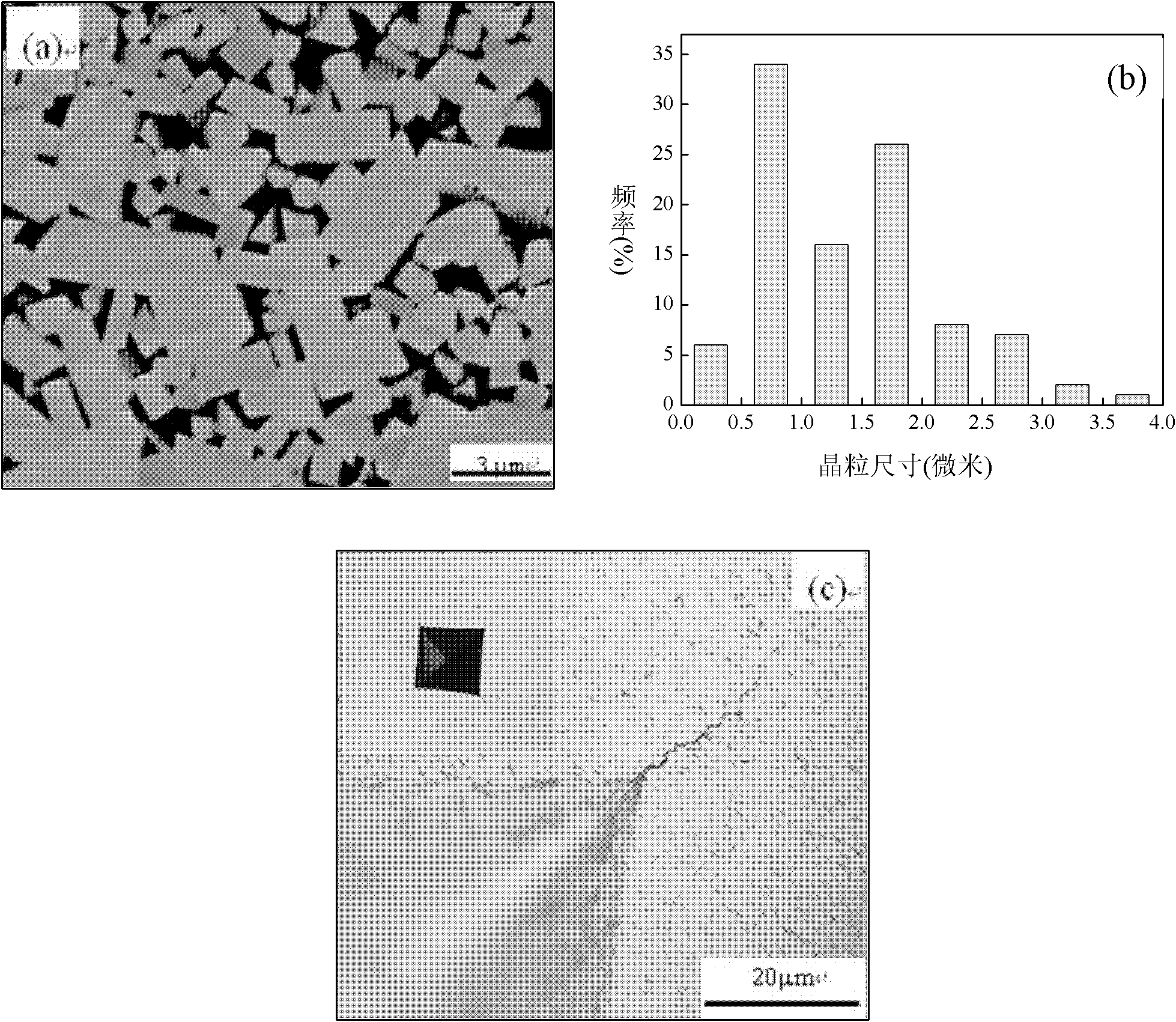

Method for industrially preparing dimorphic hard alloy with both high strength and high tenacity

The invention discloses a method for industrially preparing a dimorphic hard alloy with both high strength and high tenacity, belonging to the technical field of hard alloys. The method comprises the following steps of: according to the content of Co in the dimorphic hard alloy, ball-milling and mixing WO2.9, Co3O4 and carbon black; coldly pressing into a billet block; preparing WC-Co composite powder in a vacuum furnace; ball-milling by taking absolute ethyl alcohol or hexane as a medium; drying to obtain the WC-Co composite powder; under the protection of argon, performing powder aggregation pre-treatment; raising the temperature to 650-950 DEG C at a speed of 5-8 DEG C per minute; keeping the temperature for 30-60 min; adding 30-80 ml of polyethylene glycol forming agent to each kilogram of powder; moulding and forming; and sintering the moulded and formed powder billet in vacuum or at low pressure. The WC-Co dimorphic hard alloy prepared by the invention has both high strength andexcellent breakage tenacity. The method is an integral industrialization preparation technology route.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com