Catalytic gasoline absorbing desulfurization catalyst, preparation method and application thereof

A catalytic cracking gasoline, adsorption desulfurization technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of adsorbent running loss and production cost increase , to achieve good desulfurization activity, high wear resistance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Mix 40g of active zinc oxide with 30g of fumed white carbon black, 10g of aluminum hydroxide and 20g of NiO, add water and make a slurry. Spray into balls Φ0.5~1.5mm, and dry at 120°C for 3 hours. 500 ° C × 4 roasting.

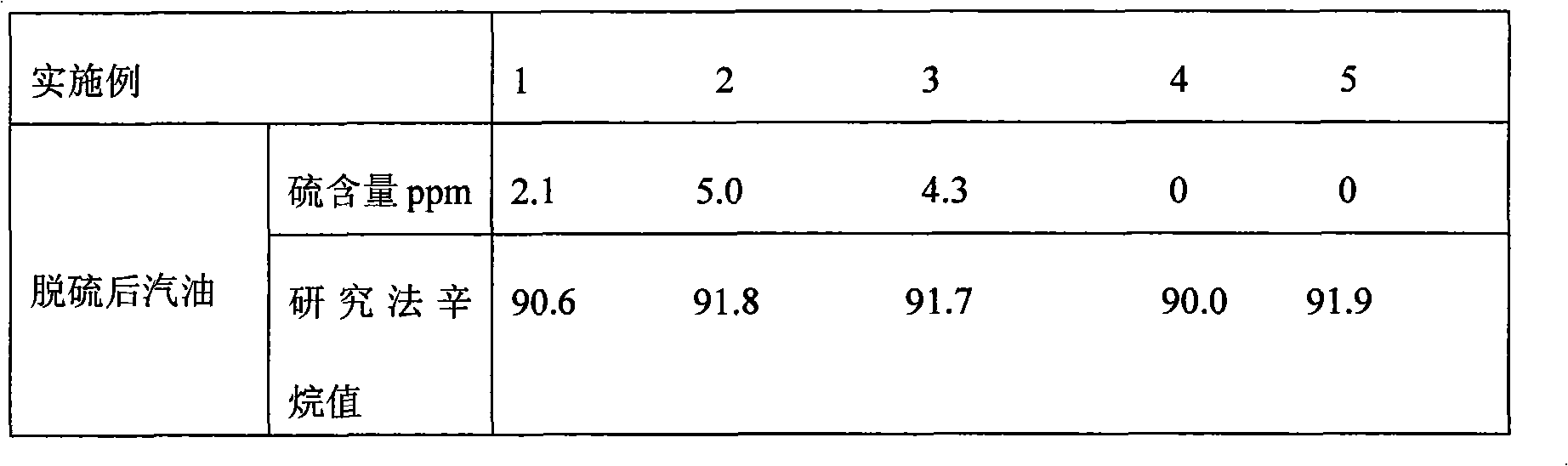

[0028] Adsorption desulfurization performance evaluation conditions: The reduction conditions of the adsorbent are: reduction temperature 450°C, pressure 0.15MPa, and hydrogen as the medium. Adsorption desulfurization reaction conditions are: reaction temperature 380°C, reaction pressure 2.0MPa, volumetric space velocity 7h-1, hydrogen flow rate 150ml / min, and adsorbent loading 30ml. The sulfur content of catalytic cracking gasoline is 2000ppm, and the research octane number is 92. The results of the sulfur in the desulfurized gasoline and the research octane number after the moving bed activity evaluation is stable for 2 hours are shown in Table 1.

Embodiment 2

[0030] 10% active zinc oxide; 80% fumed white carbon black; 5% alumina; 5% NiO nickel nitrate mixed with water, oil injection molding; 120 ° C × 6 hours drying, 550 ° C × 6 hours roasting to get finished catalyst.

Embodiment 3

[0032] Add 60% active zinc oxide, 15% fumed white carbon black, 15% aluminum oxide and 10% NiO or nickel carbonate with water to make slurry, spray into balls, and dry at 140°C for 6 hours. Calcined at 500°C for 4 hours to obtain the finished catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com