Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

373results about How to "High desulfurization activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation catalyst of containing phosphor with alumina being as carrier, and preparation

ActiveCN1872960AHigh activityHigh desulfurization activityRefining to eliminate hetero atomsPhosphorMolybdenum

This invention provides a method for preparing hydrogenation catalyst containing phosphorus supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, phosphorus oxide 1-10 wt.%, and aluminum oxide. The molar ratio of tungsten oxide to molybdena oxide is 2.6-30. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and phosphorus oxide into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

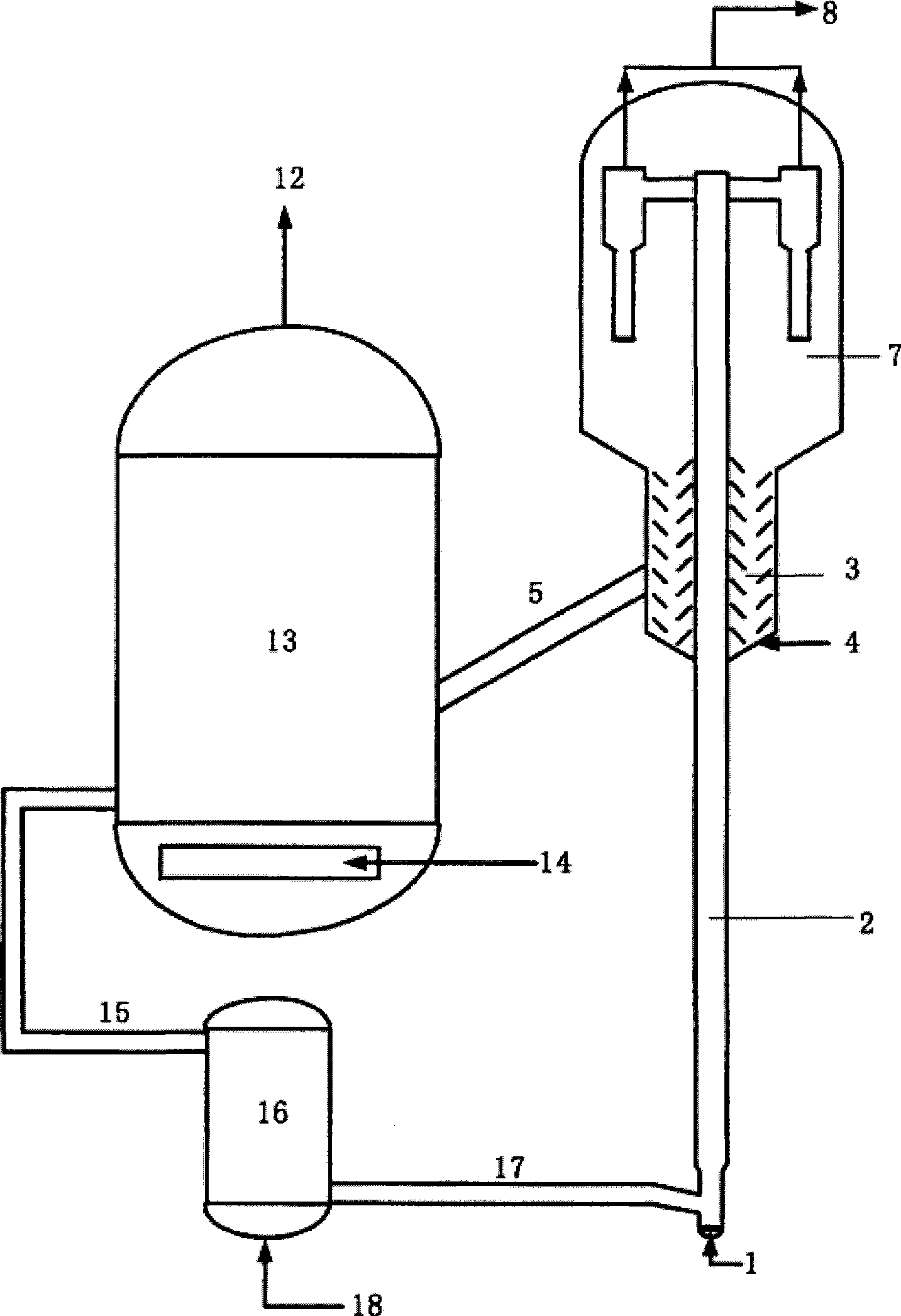

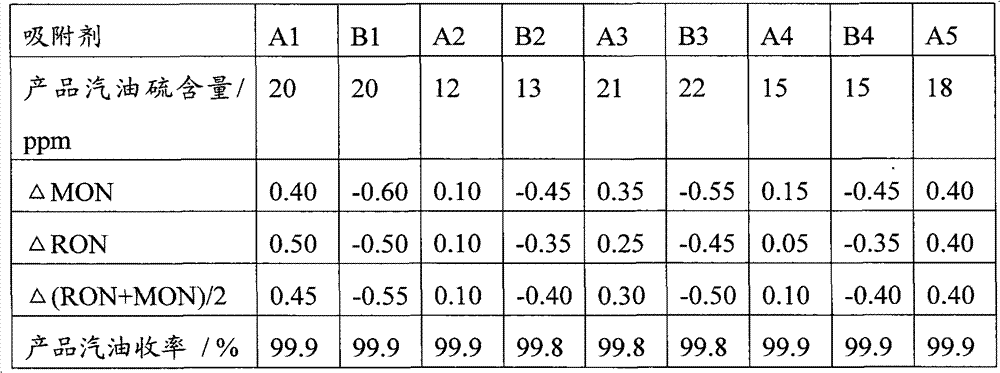

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

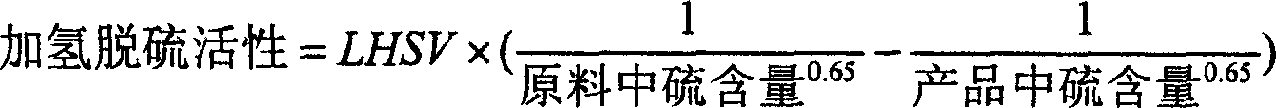

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst and processes for hydrotreating hydrocarbon oil with the same

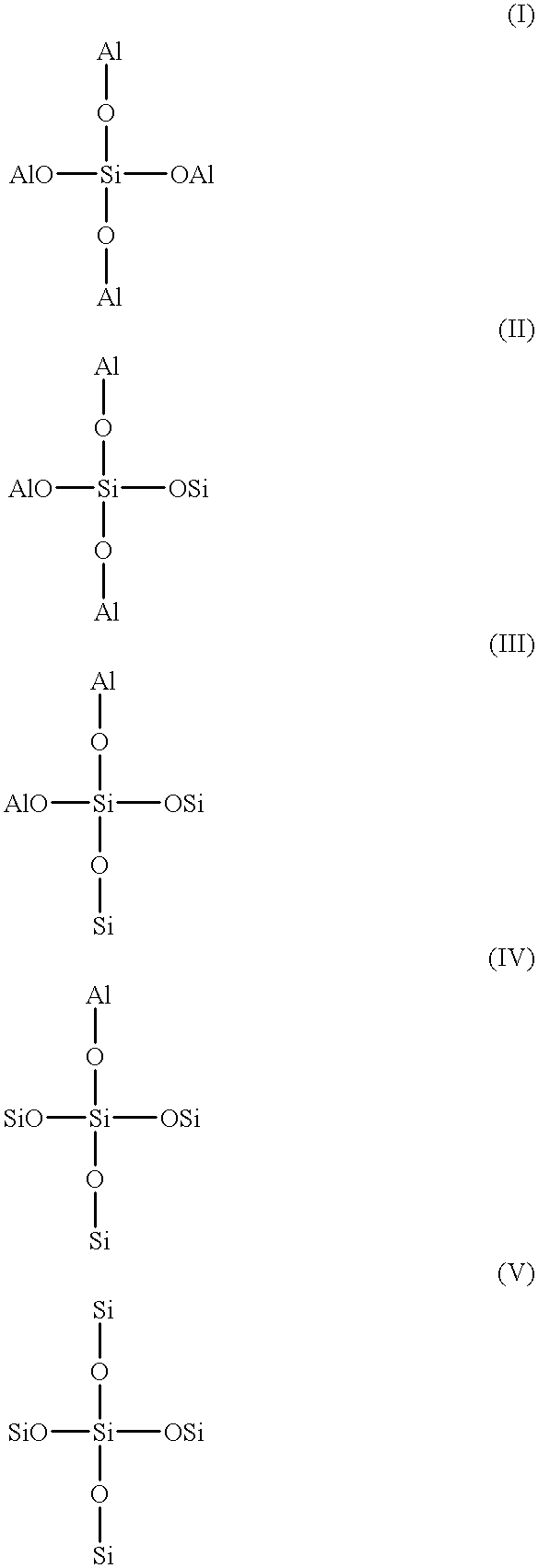

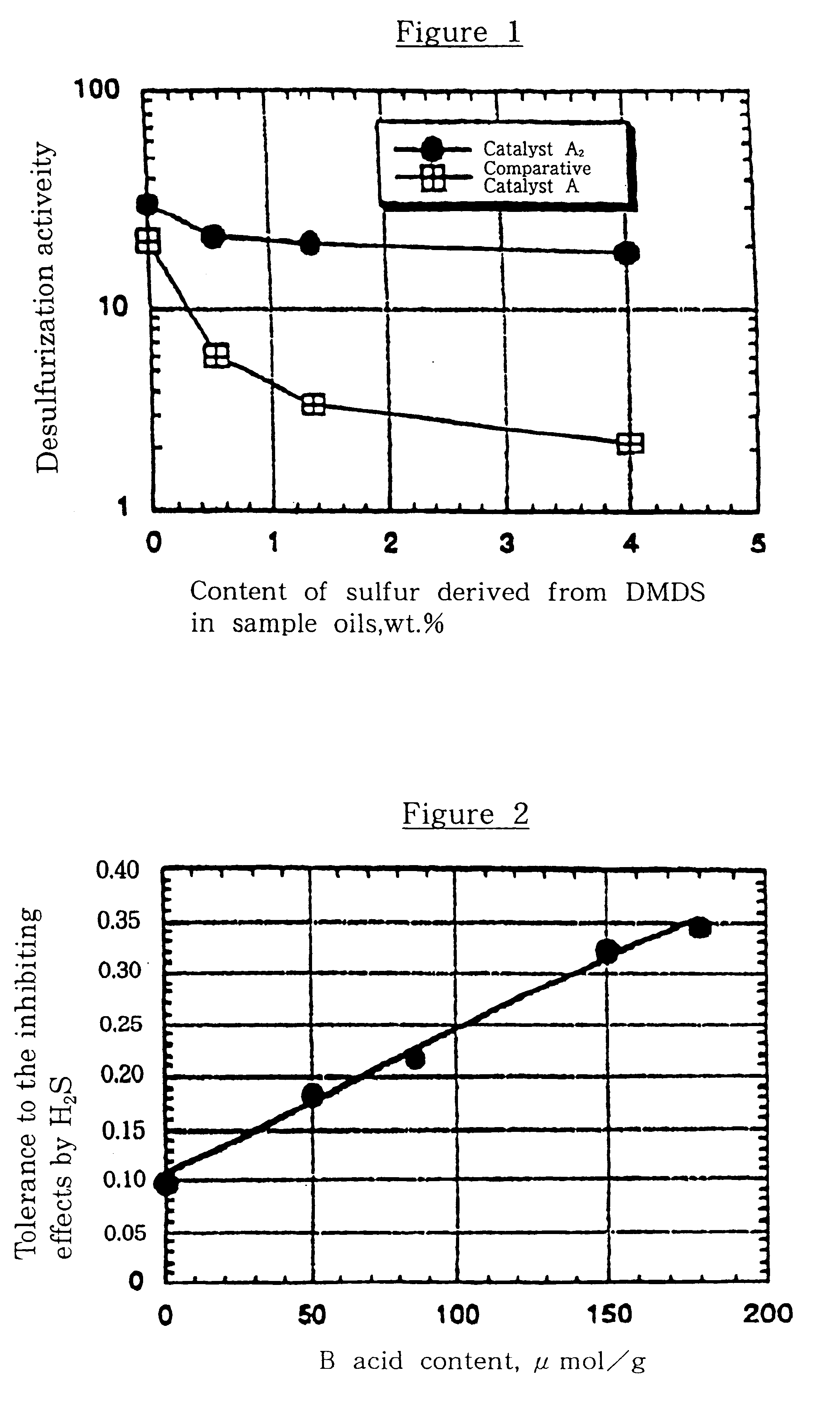

InactiveUS6267874B1Improve toleranceEfficient removalHydrocarbon oil crackingTreatment with hydrotreatment processesActive componentSilicon dioxide

The present invention relates to a hydrotreating catalyst composed of a carrier having a Brønsted acid content of at least 50 mumol / g such as a silica-alumina carrier or a silica-alumina-third component carrier, in which the silica is dispersed to high degree and a Brønsted acid content is at least 50 mumol / g, and at least one active component (A) selected from the elements of Group 8 of the Periodic Table and at least one active component (B) selected from the elements of Group 6 of the Periodic Table, supported on said carrier. The present invention also relates to a method for hydrotreating hydrocarbon oils using the same. The hydrotreating catalyst of the present invention provides excellent tolerance to the inhibiting effect of hydrogen sulfide, high desulfurization activity, and exhibits notable effects for deep desulfurization of hydrocarbon oils containing high contents of sulfur, in particular gas oil fractions containing difficult-to-remove sulfur compounds. The hydrotreating catalyst of the present invention is also very effective for hydrodenitrogenation, hydrocracking, hydrodearomatization, hydroisomerization, hydrofining and the like of hydrocarbon oils.

Owner:TONENGENERAL SEKIYU

Boron containing hydrodesulphurization catalyst and preparation method thereof

ActiveCN101314130AHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationBoron containing

The invention discloses a boron-bearing hydrodesulfurization catalyst and a preparation method thereof. The boron-bearing hydrodesulfurization catalyst contains a carrier, at least one VIB hydrogenative reactive metal composition and at least one VIII hydrogenative reactive metal composition and boron; the catalyst is calculated by oxide and a catalyst is taken as a reference, the content of the VIB metal composition is between 0.5 and 35 weight percent, the content of the VIII metal composition is between 0.1 and 10 weight percent, the content of the boron is between 0.2 and 6 weight percent, and the content of the carrier is between 49 and 99.2 weight percent, wherein, the carrier contains alumina provided with a delta and / or theta structure. Compared with the prior catalyst, the catalyst has higher hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst of catalytic cracking gasoline

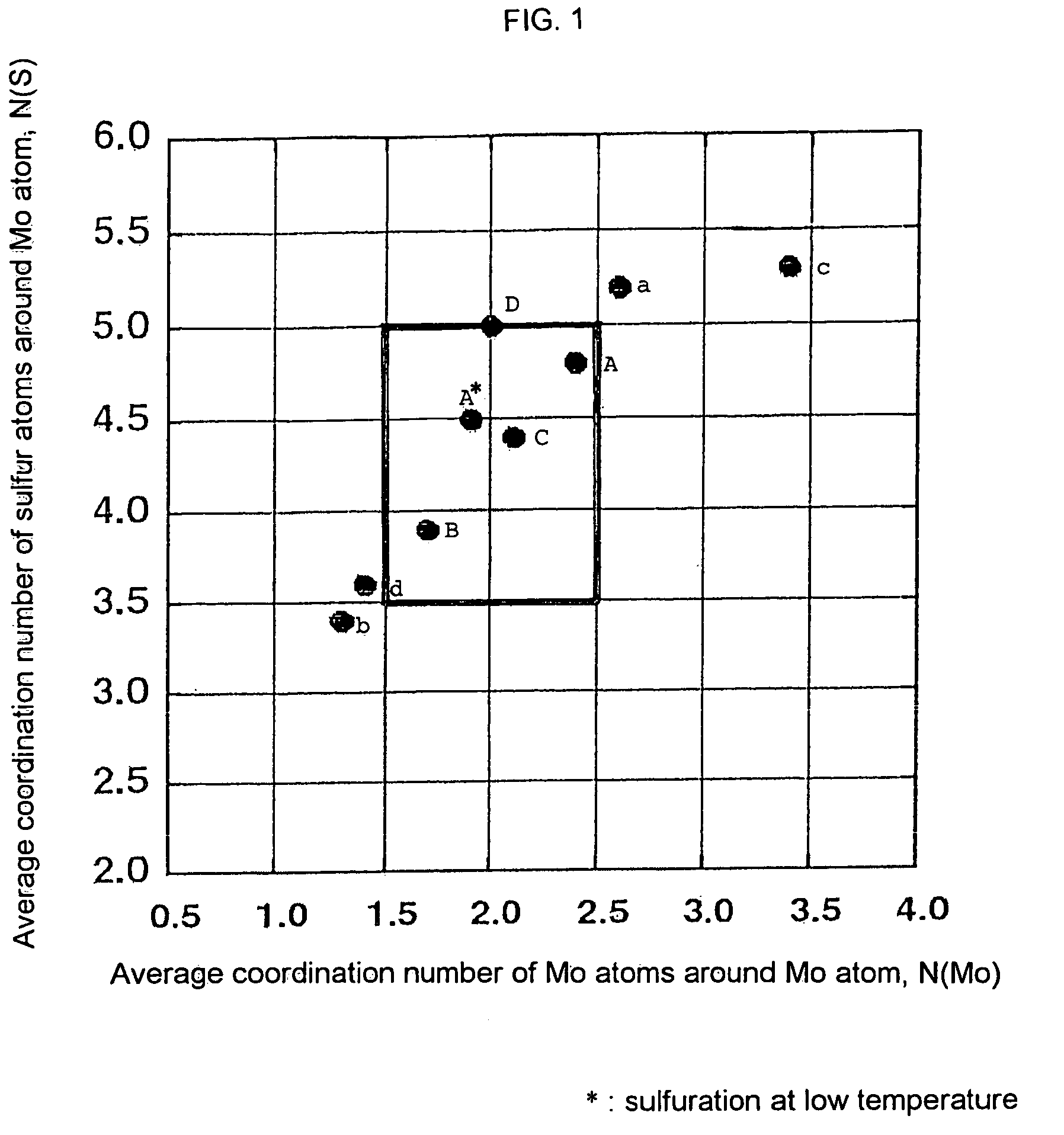

InactiveUS20050261124A1High degreeHigh desulfurization activityInorganic chemistryCatalyst activation/preparationXANES SpectroscopyStructure analysis

A hydrotreating catalyst comprising a Group 8 metal of the periodic table, molybdenum (Mo), phosphorus and sulfur, wherein the average coordination number [N(Mo)] of the molybdenum atoms around the molybdenum atom is from 1.5 to 2.5 and the average coordination number [N(S)] of the sulfur atoms around the molybdenum atom is from 3.5 to 5.0 when MoS2 structure in the catalyst is measured in accordance with extended X-ray absorption fine structure (EXAFS) analysis.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Diesel fuel fraction hydrotreating method

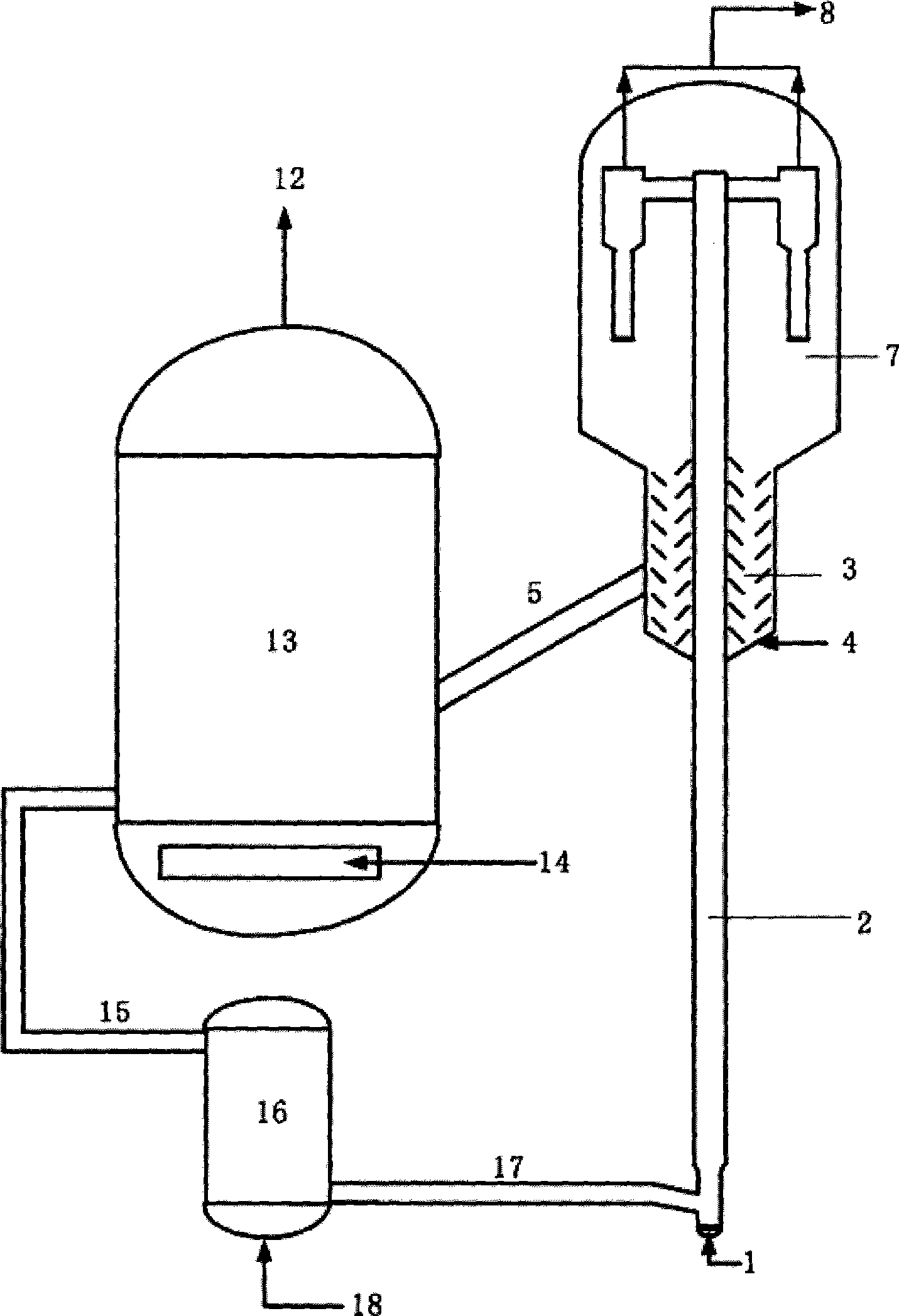

ActiveCN1769387AHigh gross airspeedImprove efficiencyTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses the diesel oil distillate hydrotreating method. The method comprises the following steps: dividing the raw oil into light cut and heavy cut, entering the light cut into the first reaction area to touch the hydrofining catalyst, entering the heavy cut into the second reaction area to touch the hydrofining catalyst, mixing the liquid product of the two reaction areas to prepare the refined distillate oil. The first reaction area uses the hydrogenation catalyst which possesses high desulfurizing activity, and the second reaction area uses hydrogenation catalyst which possesses the high hydrogenation activity. Comparaed with the general diesel oil refined process, the said method can realize the deep hydrogenation and desulfuration. The method possesses the characteristics of simple process flow and easy operation. The said method can be used for various hydrotreating processes containing the diesel oil fraction raw oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkali metal-containing desulfurization adsorbent and preparation method and application thereof

ActiveCN101816918AHigh strengthHigh desulfurization activityOther chemical processesHydrocarbon oils refiningSulfurSorbent

The invention provides an adsorbent for removing sulfur from cracked gasoline and diesel fuel, which has high abrasion strength resistance and desulfurization activity. Based on the total weight of the adsorbent, the desulfurization adsorbent comprises the following components in percentage by weight: 1) 5 to 35 percent of alumina; 2) 3 to 30 percent of silicon oxide; 3) 10 to 80 percent of metallic oxide which is at least one of IIB, VB and VIB group; 4) 3 to 30 percent of promoter metal which is at least one of VIIB and VIII group; and 5) 0.5 to 10 percent of alkali metal oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for hydrogenation treatment and method for hydrogenation treatment of hydrocarbon oil

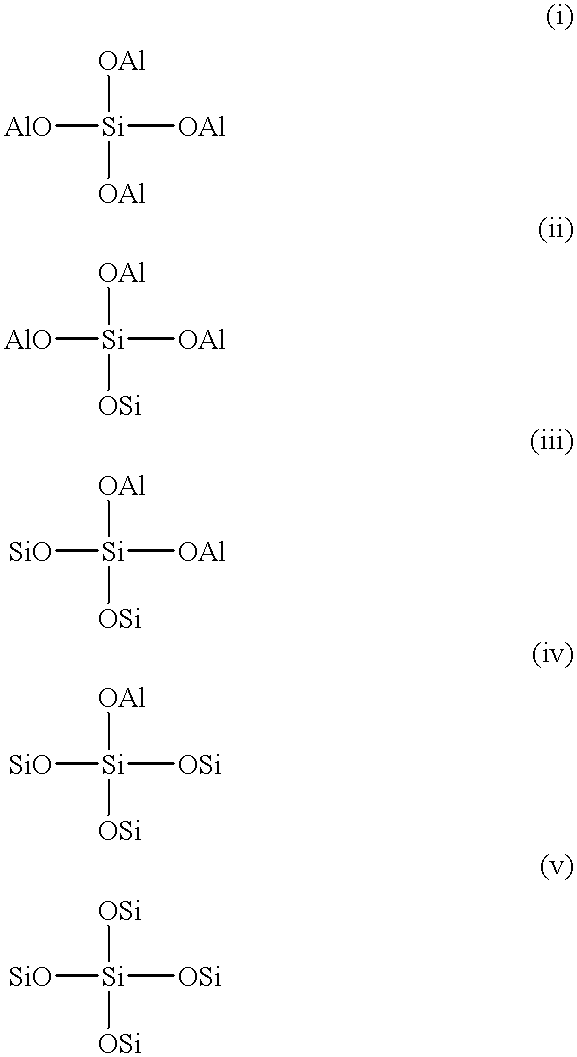

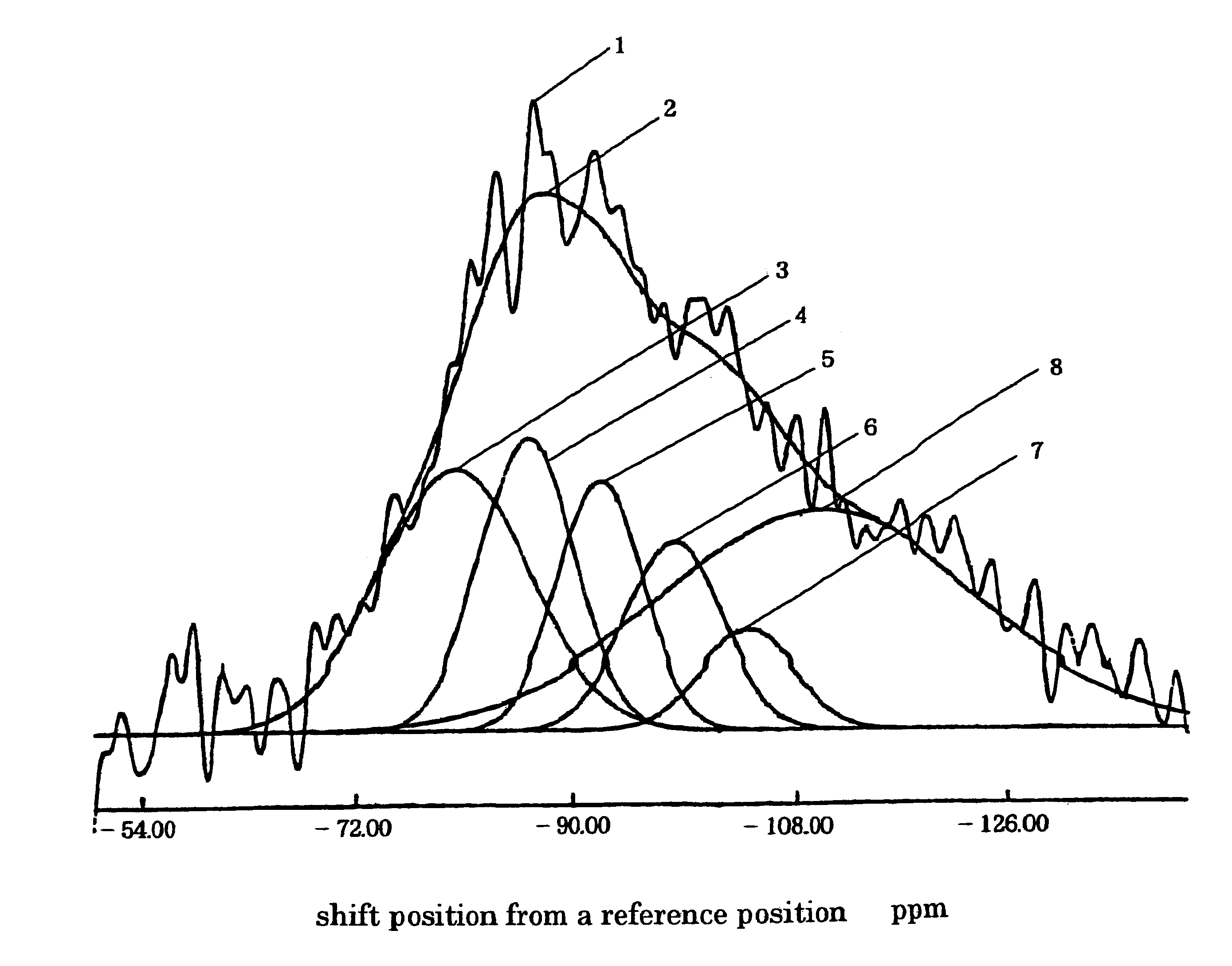

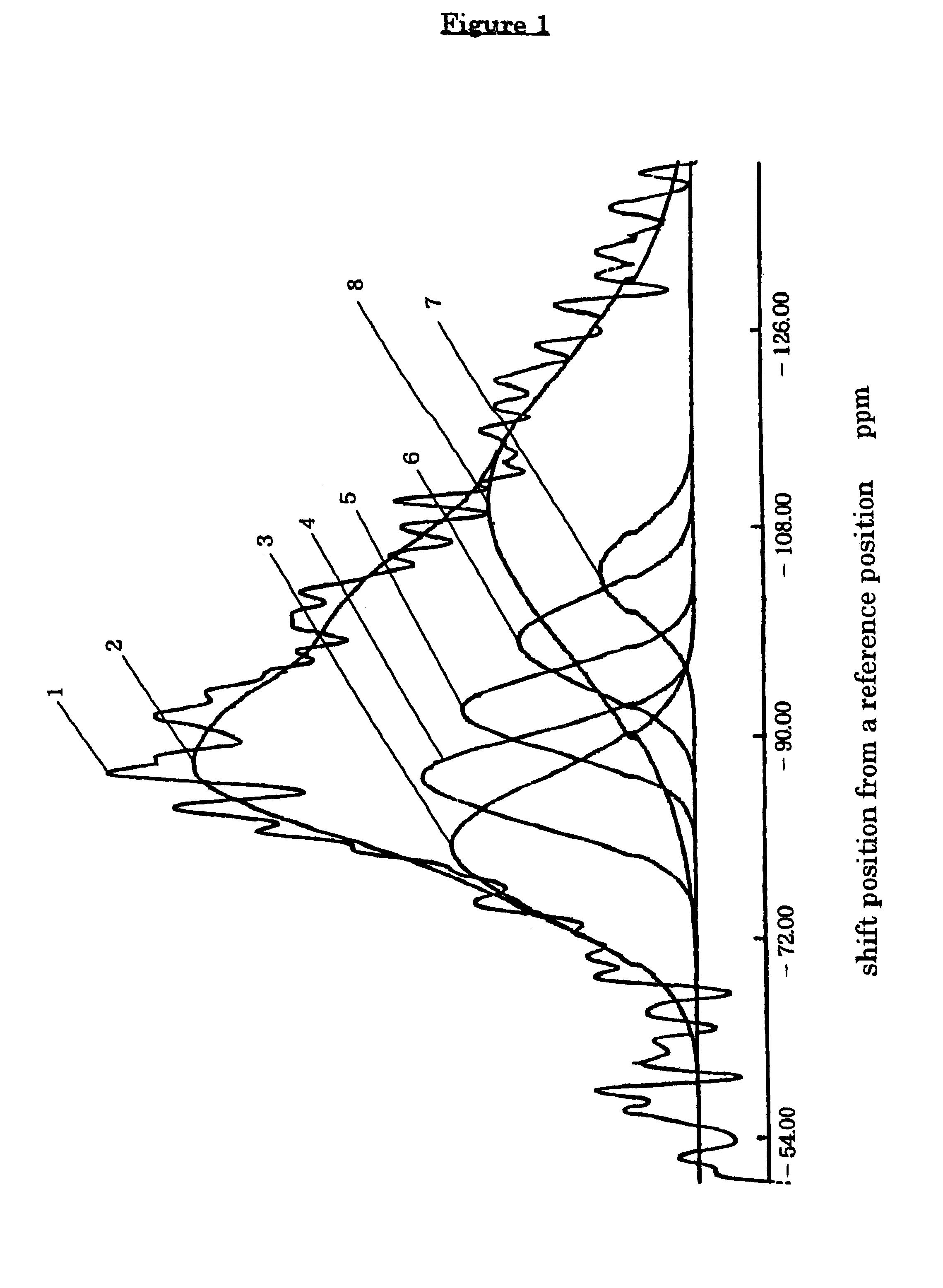

InactiveUS6306289B1High desulfurization activityHigh activityCatalyst activation/preparationTreatment with hydrotreatment processesComponent LoadNMR - Nuclear magnetic resonance

A hydrotreating catalyst having both a high desulfurization activity and a denitrogenation activity and a method of hydrotreating a hydrocarbon oil using the same is provided.A hydrotreatment catalyst comprising a silica-alumina carrier loaded with at least one hydrogenation-active component; wherein (1) the silica content is in the range of 2 to 40% by weight based on the total weight of the carrier; and (2) in the spectrum obtained by nuclear magnetic resonance analysis (29Si-NMR), (i) the area of the peak at -80 ppm is 10% or more of the combined area of all the peaks; and (ii) the combined area of peaks at -80 ppm, -86 ppm and -92 ppm is 20% or more of the combined area of all peaks; a hydrotreating catalyst comprising a silica-alumina carrier containing a specific amount of a third component loaded with at lest one hydrogenation-active metal component and having a specific pore structure; and a method of hydrotreating a hydrocarbon oil comprising contacting a hydrocarbon oil with hydrogen in the presence of said hydrotreating catalyst.

Owner:TONENGENERAL SEKIYU

Hydrodesulfurization method of gasoline

InactiveCN106867576AAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

Hydrogenation catalyst for hydrocarbon oil, carrier for it, and method of hydrogenation of hydrocarbon oil

InactiveUS20070135300A1Convenient introductionHigh desulfurization activityOther chemical processesCatalyst activation/preparationNitrogenHydrocarbon

Provided are a hydrogenation catalyst for hydrocarbon oil, having markedly improved desulfurization activity, denitrogenation activity, and dearomatization activity; a carrier for the catalyst and its production; and a method of hydrogenation of hydrocarbon oil with the catalyst.

Owner:IDEMITSU KOSAN CO LTD

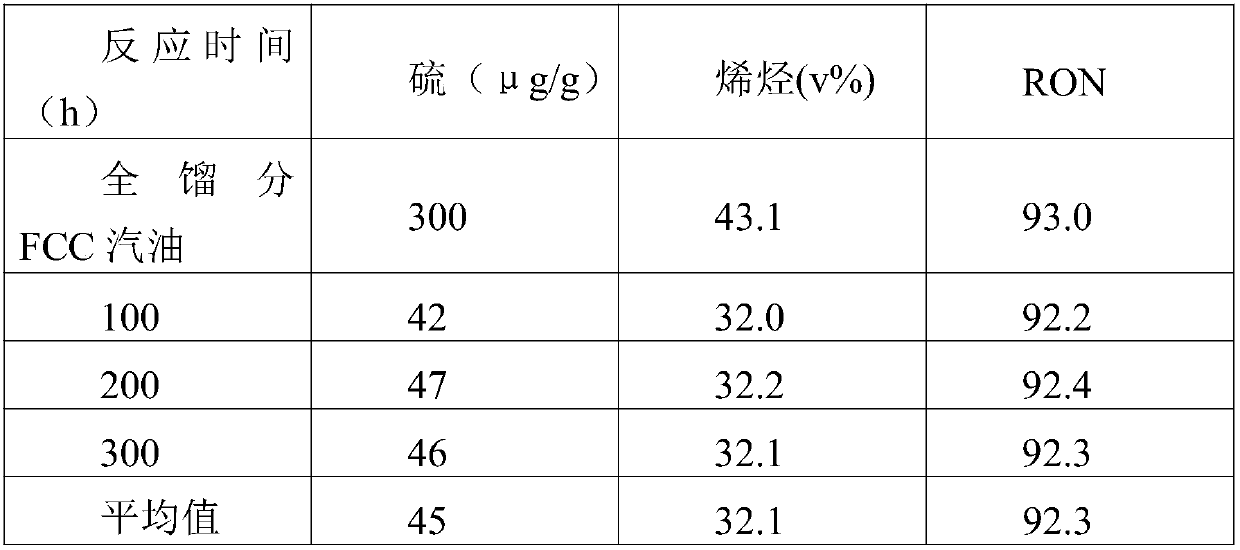

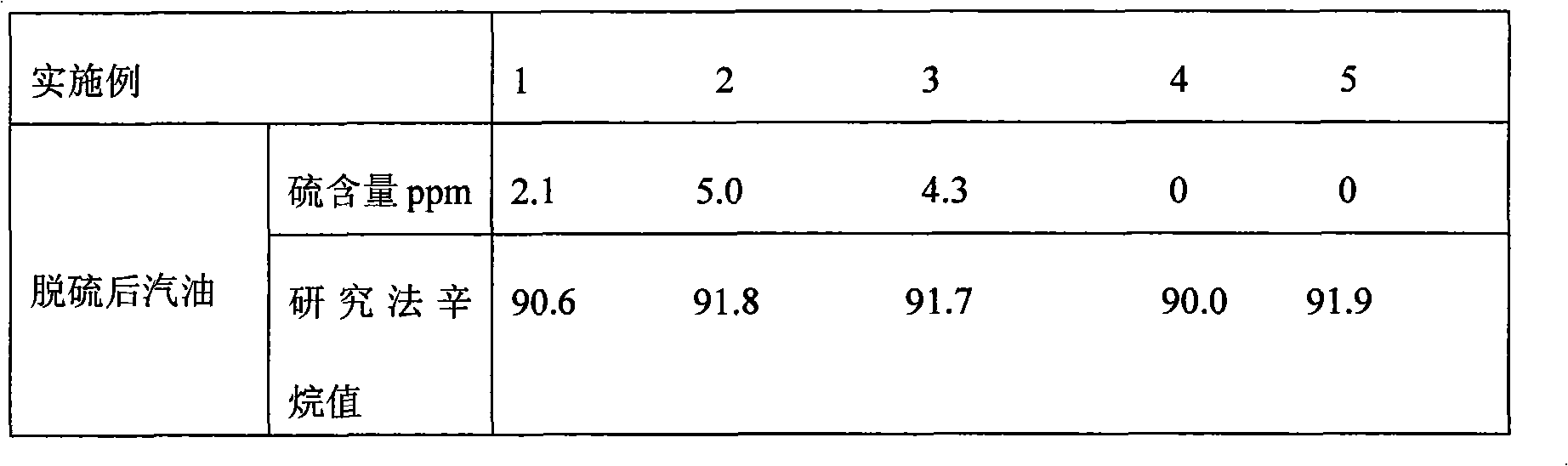

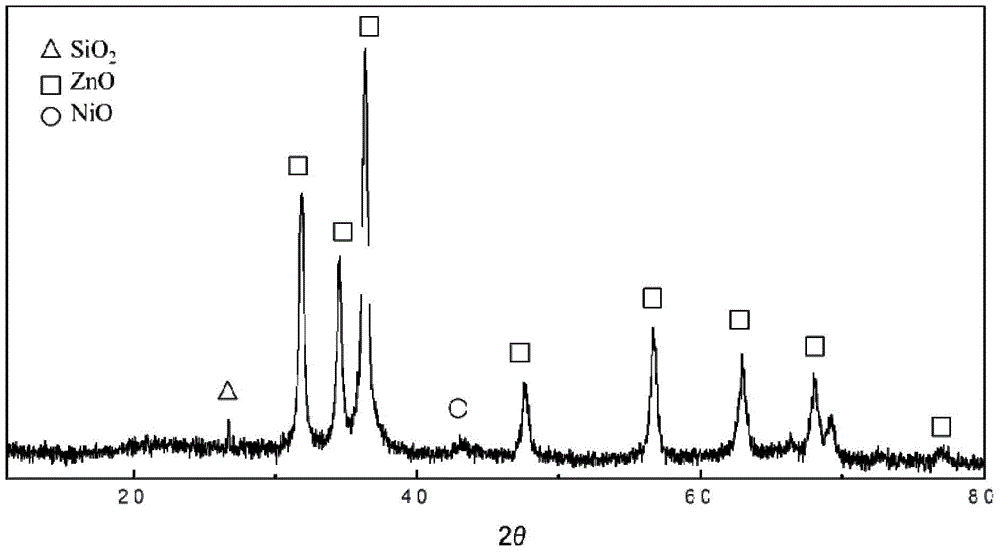

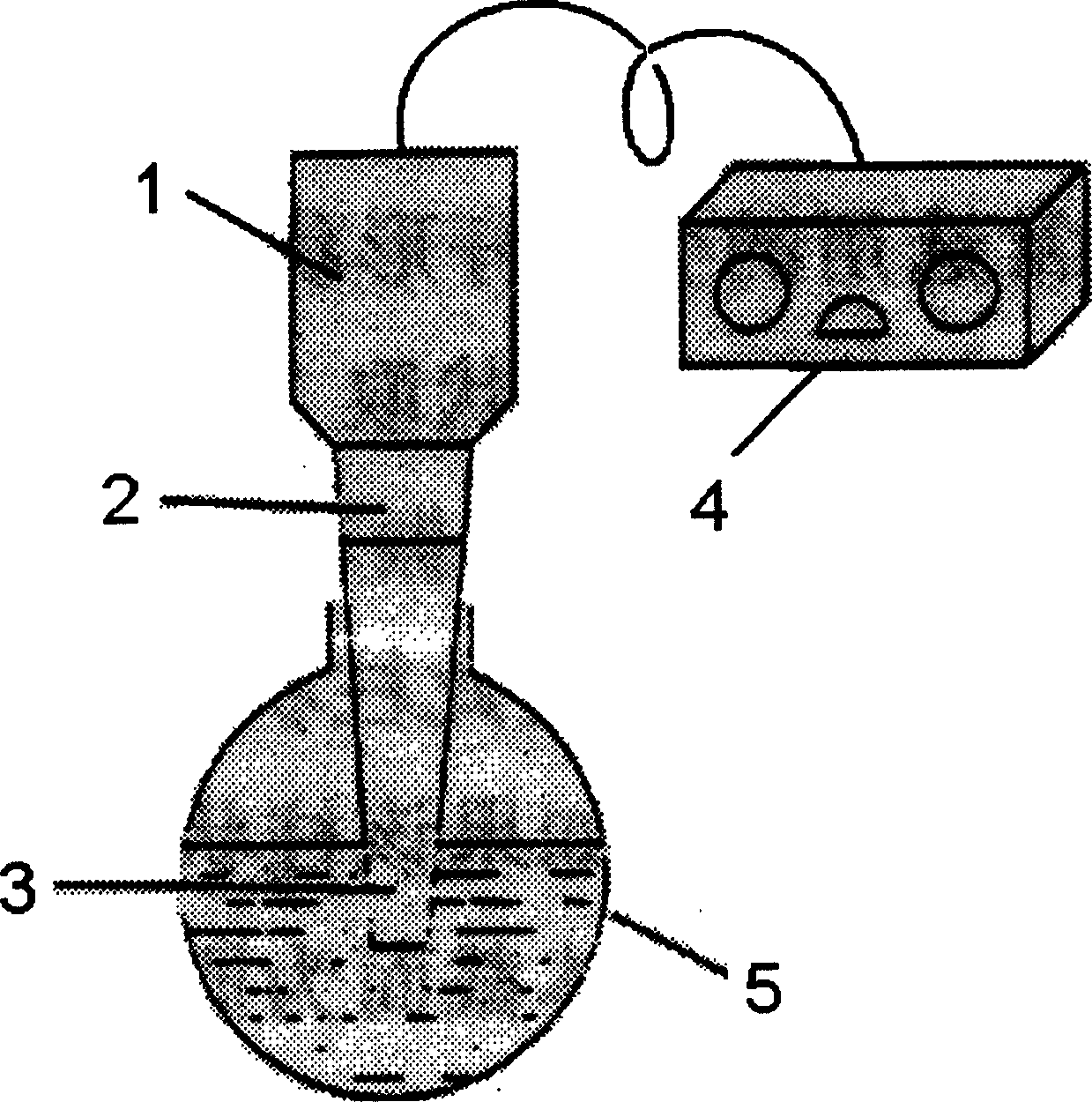

Absorbing desulfurizing catalyst for catalytic cracking petroleum and preparing method thereof

InactiveCN1583962ASuitable for desulfurizationOctane has little effectHydrocarbon oils refiningNano zinc oxidePetroleum

A kind of catalyst for Fcc gasoline's adsorption desulfuration contains in weight percent: 10-85% nano zinc oxide, the atomic diameter of which is 100-500 mu m, 5-80% silica oxide, 5-30% alumina oxide, and 4-45% nickel oxide. The method of preparation is: (1) Mix evenly the nano zinc oxide, silica oxide, alumina oxide, and nickel oxide; dry the particle of step (b); roast the dry particle of step(c); deoxidize the particle of step(d) by proper reductant. The portions of this catalyst remain mixed, and the method adopts the technology of roasting. The catalyst has a good strength, high desulfuration activity, and effective regeneration. Because of the adoption of nano zinc oxide, it causes little to octane number and applies to desulfuration of FCC gasoline. Moreover, the method of preparation is simple and the operation is easy.

Owner:SINOPEC QILU CO

A kind of hydrocarbon oil desulfurization adsorbent and its preparation method and application

InactiveCN102294222AHigh desulfurization activityBoost octaneOther chemical processesAluminium silicatesSorbentManganese

The invention provides a hydrocarbon oil desulfurization adsorbent, a preparation method and an application method of the adsorbent. The adsorbent provided by the present invention, based on the total weight of the adsorbent, at least includes the following composition: 1) SAPO molecular sieve, with a content of 1-20wt%; 2) alumina binder, with a content of 3-35wt%; 3) oxidation 5-40wt% silicon source; 4) zinc oxide, 10-80wt% content; 5) at least one metal promoter selected from cobalt, nickel, iron and manganese, 5-30wt% content. The adsorbent of the invention has high desulfurization activity, and also has the advantage of obviously increasing the gasoline octane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurizing sorbent and preparation method and application thereof

ActiveCN101766985AHigh strengthHigh desulfurization activityOther chemical processesHydrocarbon oils refiningSulfurSorbent

The invention provides a sorbent for desulfurizing cracked spirit and diesel engine fuel. The sorbent has good abrasion resistance and desulfurizing activity. With reference of the gross weight of sorbent, the desulfurizing sorbent includes the following components: 5-35wt percent of alumina; 3-30wt percent of monox; 10-80wt percent of metal oxide, at least one type selected from the families of IIB, VB and VIB; 3-30wt percent of accelerant metal, at least one type selected from the families of VIIB and VIII; and 0.5-10wt percent of metal oxide from the IIA family.

Owner:CHINA PETROLEUM & CHEM CORP +1

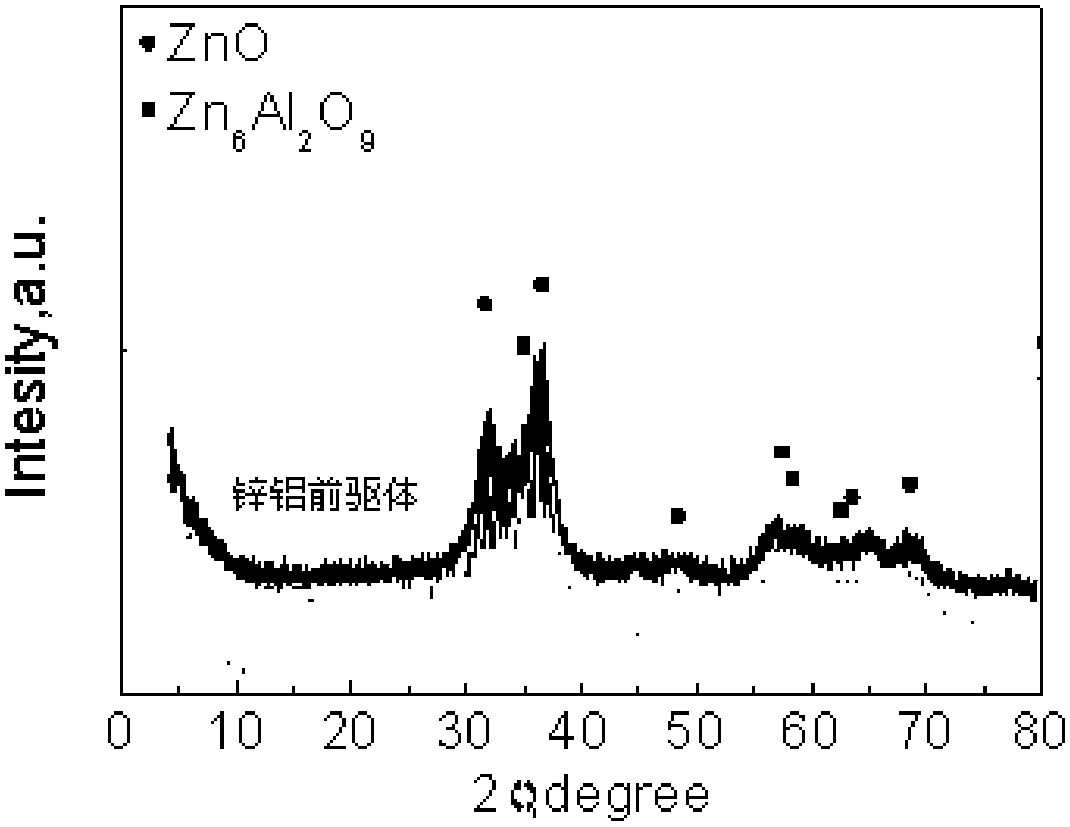

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN107583659AReduced hydrothermal treatment processHigh desulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryComposite oxide

The invention relates to a selective hydrodesulfurization catalyst. The catalyst comprises, by mass, 3-5% of CoO as an active component, 10-13% of MoO3 as an active component, 2-3% of B203 as a carrier modification aid, 1-2% of P2O5 as a carrier modification aid, 1-1.5% of K2O as a carrier modification aid and 75.5-83% of a composite oxide carrier. The catalyst carriers comprise a zinc aluminate spinel-containing zinc oxide-alumina composite oxide prepared by nonconstant pH alternating titration. The catalyst has good desulfurization selectivity and stability.

Owner:PETROCHINA CO LTD

Desulphurization sorbent

ActiveCN101433817AEvenly distributedHigh strengthOther chemical processesHydrocarbon oils refiningAdditive ingredientSorbent

The invention discloses a desulfurization adsorbent, which comprises 1 to 30 weight percent of rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; the rare earth-zeolite mixture and a carrier mixture are preformed into porous heat-resistant solid particles, and then active metal ingredients are introduced on the solid particles to obtain the adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic gasoline absorbing desulfurization catalyst, preparation method and application thereof

ActiveCN101905161AGood strengthImprove wear resistanceCatalyst activation/preparationRefining with metal oxidesTitanium tetrachlorideCarbon black

The invention relates to a catalytic gasoline absorbing desulfurization catalyst, a preparation method and an application thereof. According to weight percentage, the catalyst contains 10 to 85% of activated zinc oxide, 5 to 80 % of white carbon black, 5 to 30 % of aluminum oxide and 4 to 45 % of nickel oxide. The preparation method comprises the following steps of: (1) decomposing titanium tetrachloride under hydrogen atmosphere at 1400 DEG C to obtain gaseous phase white carbon black, (2) mixing the activated zinc oxide, gaseous phase white carbon black, aluminum oxide and nickel salt into starch, (3) spraying the obtained mixture into ball or injecting into ball, (4) drying the balls formed in the step (3) at 110 to 150 DEG C, and (5) roasting the balls obtained from the step (4) at 300 to 550 DEG C. The prepared absorbing desulfurization catalyst has the advantages of strong intensity, excellent durability, excellent desulfurization activity, small octane number loss, low transportation cost, and application on mobile bed absorbing desulfurization technique.

Owner:PETROCHINA CO LTD

Desulfuration adsorbent for catalytic gasoline as well as preparation method and application of adsorbent

ActiveCN103551107AHigh selectivityHigh strengthOther chemical processesHydrocarbon oils treatmentManganeseCobalt

The invention relates to a desulfuration adsorbent for catalytic gasoline as well as a preparation method and an application of the adsorbent. The desulfuration adsorbent based on the total weight of the adsorbent which is 100% comprises the following components in percent by weight: 2-15wt% of a dealuminized ferrierite molecular sieve, 8-20wt% of an aluminum oxide binder, 10-30wt% of silicon source clay, 40-65wt% of zinc oxide, 10-25wt% of at least one metal accelerants selected from cobalt, nickel, copper and manganese and 0.1-2wt% of a metal assistant selected from metals in IA group and IIA group, wherein preferably, the at least one metal selected from cobalt, nickel, copper and manganese is Ni and / or Co. The adsorbent provided by the invention has high desulfuration activity, and meanwhile further has the advantage of remarkably increasing the octane number of gasoline. The adsorbent can be applicable to a desulfurization process of catalytic gasoline or hydrogenated gasoline.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for preparing molybdenum nitride and use thereof as hydrogenation and desulfurizing catalyst

InactiveCN1401580AUniform crystal phaseHigh desulfurization activityMolybdenum halidesRefining to eliminate hetero atomsHydrodesulfurizationOxygen

A process for preparing molybdenum nitride from MoO3 includes multi-stage thermal reaction in the mixed atmosphere of N2 and H2, cooling in inert gas and purifying in oxygen. Said product can be used as hydrodesulfurizing catalyst for hdyrodesulfurizing at 250-450 deg.C and 0.2-20 MPa. Its advantages are simple process and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrofining catalyst containing molybdenum and/or tungsten and nickel and/or cobalt and its preparation process

InactiveCN1566280AImprove hydrodesulfurization activityHigh desulfurization activityRefining to eliminate hetero atomsHydrodesulfurizationUltrasound Radiation

The invention discloses a hydrofining catalyst containing molybdenum and / or tungsten and nickel and / or cobalt, wherein the catalyst comprises a heat-proof inorganic oxide carrying agent and molybdenum and / or tungsten or tungsten and nickel and / or cobalt loaded on the carrying agent, wherein the catalyst is prepared through immersing the heat-proof inorganic oxide carrying agent with dipping solution containing molybdenum and / or tungsten and nickel and / or cobalt compound. The catalyst prepared by the process provided by the present invention has higher hydrogenation desulfurization activity than the conventional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Medium temperature iron-manganese desulfurizing agent and preparation method thereof

InactiveCN102039086AGood desulfurization effectHigh breakthrough sulfur capacityDispersed particle separationManganese oxideBrown iron oxide

The invention relates to an iron-manganese desulfurizing agent. The desulfurizing agent consists of 10 to 85 weight percent of iron oxide, 10 to 85 weight percent of manganese oxide and 5 to 20 weight percent of inorganic adhesive. The invention further discloses a preparation method for the iron-manganese desulfurizing agent. The iron-manganese desulfurizing agent is prepared by extruding and molding with a dry method and roasting at a specific temperature. The iron-manganese desulfurizing agent prepared by using the preparation method has optimal desulfurizing effect and high penetrating sulfur capacity. The test shows that the penetrating sulfur capacity of the desulfurizing agent can reach 25.1 percent. Moreover, the desulfurizing agent has high mechanical strength, can be widely applied in a chemical refining and desulfurizing process, and can be prevented from being broken to cause loss and affect the desulfurizing effect; and the test shows that the mechanical strength of the iron-manganese desulfurizing agent can reach 100N / cm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Desulphurization sorbent composition

ActiveCN101433819AHigh desulfurization activityEvenly distributedOther chemical processesHydrocarbon oils refiningSorbentRare earth

The invention discloses a desulfurization adsorbent composition, which comprises 1 to 30 weight percent of phosphorus-modified rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; a rare earth-zeolite mixture is modified by phosphorus and then is preformed with a carrier mixture into porous heat-resistant solid particles, and then active metal components are introduced on the solid particles to obtain an adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon oil desulphurization adsorbent, and preparation method and application thereof

ActiveCN102895948AHigh desulfurization activityIncrease gasoline octane ratingOther chemical processesHydrocarbon oils refiningMolecular sieveAdhesive

The invention provides a hydrocarbon oil desulphurization adsorbent, and a preparation method and an application thereof. With a total weight of the adsorbent as a standard, The adsorbent provided by the invention at least comprises the components of, by weight: (1) 1-20% of an aluminosilicate molecular sieve with a duodenary-ring pore-channel structure, (2) 3-35% of an alumina adhesive, (3) 5-40% of a silicon oxide source, (4) 10-80% of zinc oxide, and (5) 5-30% of at least one metal accelerating agent selected from cobalt, nickel, iron and manganese. The absorbent provided by the invention has high desulphurization activity, and has an advantage of a capacity for substantially increasing gasoline octane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon oil desulfurization catalyst and preparation method thereof, and hydrocarbon oil desulfurization method

ActiveCN105289701AGood wear resistanceLow catalyst lossMolecular sieve catalystsHydrocarbon oils refiningChemistryMolecular sieve

The invention discloses a hydrocarbon oil desulfurization catalyst and a preparation method thereof, and a hydrocarbon oil desulfurization method. Based on the total weight of the hydrocarbon oil desulfurization catalyst as the reference, the hydrocarbon oil desulfurization catalyst comprises 10-80 wt% of at least one of metal oxides of IIB, VB, and VIB group elements, 3-35 wt% of aluminium oxide, 5-40 wt% of silicon nitride, 5-30 wt% of a metal accelerant selected from at least one of cobalt, nickel, iron and manganese, and 1-20 wt% of a molecular sieve with an FAU and / or BEA structure. The hydrocarbon oil desulfurization catalyst is excellent in stability, higher in desulfurization activity, better in wear resistance and longer in service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation treatment catalyst for heavy hydrocarbon oil, and method for hydrogenation treatment of heavy hydrocarbon oil

ActiveUS9908107B2Not easy to produceHigh desulfurization activityHeterogenous catalyst chemical elementsTreatment with hydrotreatment processesActive componentPore diameter

A hydrogenation treatment catalyst is provided for heavy hydrocarbon oil, in which a hydrogenation-active component is supported on a silica-containing porous alumina carrier containing 0.1% to 1.5% by mass of silica based on the carrier. The total pore volume is 0.55 to 0.75 mL / g. Of the total volume of pores having a pore diameter of 3 to 30 nm (1) 30% to 45% have a pore diameter of 5 to 10 nm, (2) 50% to 65% have a pore diameter of 10 to 15 nm, and (3) the total volume of pores having a pore diameter in a range of ±1 nm from the average pore diameter is 25% or more. The total volume of pores having a pore diameter of 30 nm or more is 3% or less. The average pore diameter of pores having a pore diameter of 10 to 30 nm is 10.5 to 13 nm.

Owner:COSMO OIL CO LTD

Desulfuration adsorbent containing phosphorus and preparation method and application thereof

ActiveCN101766984AHigh strengthHigh desulfurization activityOther chemical processesHydrocarbon oils refiningChemistryWear resistant

The invention provides a phosphorus-containing adsorbent for removing sulfur from cracked gasoline and diesel fuel, which has good wear resistant strength and desulfuration activity. On the basis of the total weight of the adsorbent, the desulfuration adsorbent comprises the following components: 1) 5-35wt% of alumina, 2) 3-30wt% of monox, 3)10-80wt% of at least one metal oxide which is selected from IIB, VB and VIB group, 4) 3-30wt% of at least one accelerator metal which is selected from VIIB and VIII group and 5) 0.3-5wt% of phosphorus oxide calculated on the basis of phosphorus.

Owner:CHINA PETROLEUM & CHEM CORP +1

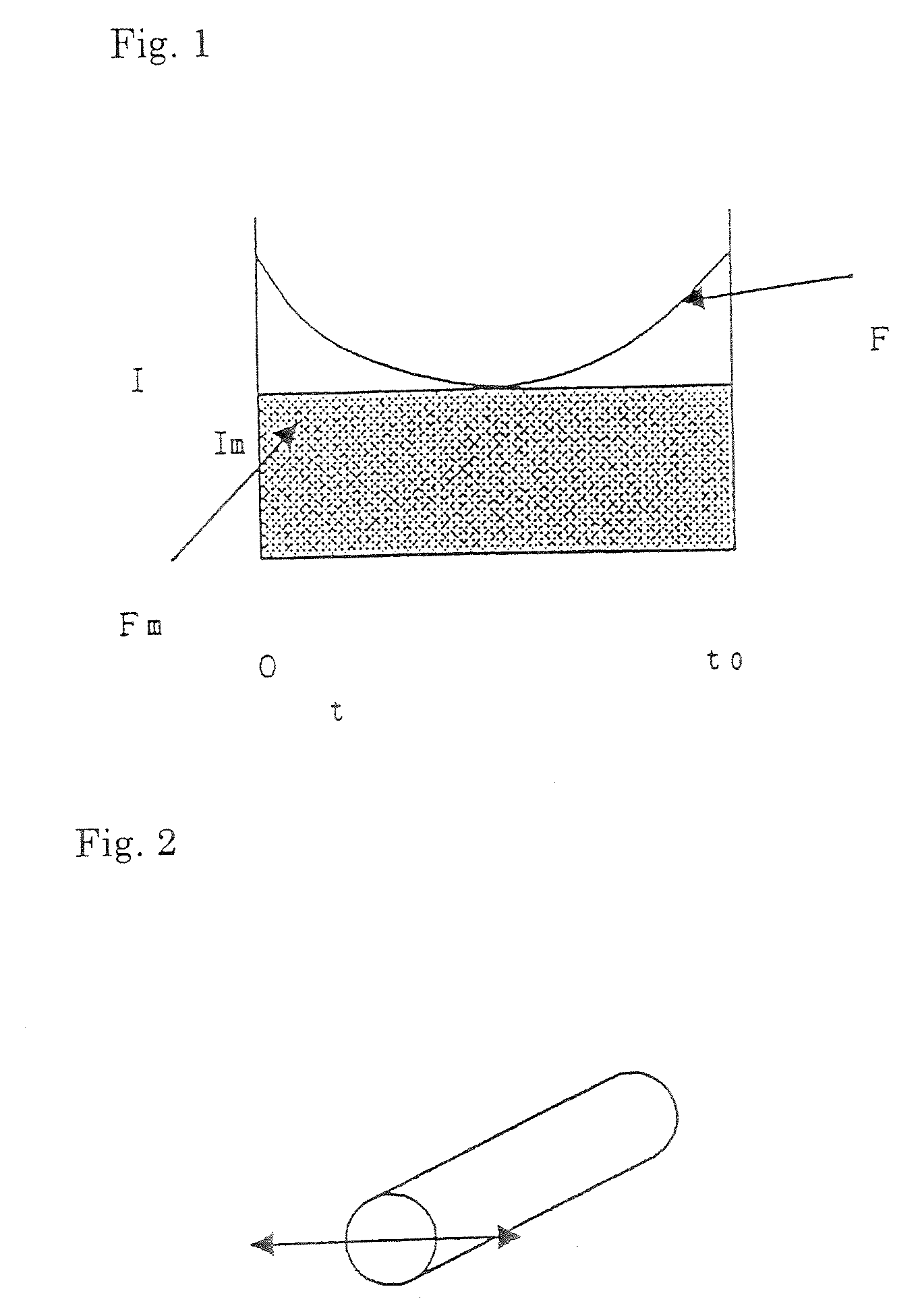

Porous inorganic oxide support and hydrotreating catalyst of catalytic cracking gasoline using the same

InactiveUS20090258780A1High desulfurization activityExcellent function of suppressing hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOxygenOrganic compound

A porous inorganic oxide support comprising an oxygen-containing carbonaceous material supported thereon, preferably a porous inorganic oxide support wherein the oxygen-containing carbonaceous material is a carbide of an oxygen-containing organic compound, wherein the ratio of the supported carbon amount with respect to the mass of the support for preparing the catalyst is from 0.05 to 0.2, the atomic ratio of the supported hydrogen amount with respect to the supported carbon amount is from 0.4 to 1.0, and the atomic ratio of the supported oxygen amount with respect to the supported carbon amount is from 0.1 to 0.6; and a hydrotreating catalyst of catalytic cracking gasoline which comprises the support and a catalyst containing a Group 8 metal of the periodic table, molybdenum (Mo), phosphorus and sulfur which is supported on the support are useful as a desulfurization catalyst of, for example, catalytic cracking gasoline at a hyperdesulfurized level, because of having functions of suppressing the hydrogenation activity of olefins and minimizing the decrease in the octane number even under reaction conditions with a high desulfurization ratio.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Hydroprocessing catalyst for heavy hydrocarbon oil, method for manufacturing hydroprocessing catalyst for heavy hydrocarbon oil, and hydroprocessing method for heavy hydrocarbon oil

ActiveUS20160230102A1Easily produce sedimentHigh desulfurization activityCatalyst activation/preparationTreatment with hydrotreatment processesSilicon dioxideHydrocarbon

The hydroprocessing catalyst for a heavy hydrocarbon oil, includes, as a carrier, a phosphorus-silica-containing alumina carrier containing 0.1% by mass to 4% by mass of phosphorus in terms of oxide based on the carrier, and 0.1% by mass to 1.5% by mass of silica based on the carrier, the carrier supporting 8% by mass to 20% by mass of at least one selected from metals in Group 6 of the periodic table in terms of oxide based on the catalyst and 2% by mass to 6% by mass of at least one selected from metals in Groups 8 to 10 of the periodic table in terms of oxide based on the catalyst.

Owner:COSMO OIL CO LTD

Catalyst for removing H2S from gas by catalytic oxidation, preparation method and application

InactiveCN102500362AEasy to prepareHigh desulfurization activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonSulfur

A catalyst for removing H2S from gas by catalytic oxidation contains a metal oxide as active component, and active carbon as carrier, wherein the weight percentages of the two components are as follows: active carbon 95.0% to 99.9%, and metal oxide 0.1% to 5%; active carbon has a specific surface area of 850 to 900 m<2> / g, total pore volume of 0.45 cm<3> / g, and micro-pore volume of 0.154 cm<3> / g; and the metal oxide is oxide of Fe, V, Mn, Cu, Ce or Co. The catalyst provided by the invention has a simple preparation method, and can remarkably improve the desulfurization activity and selectivity of active carbon and greatly improve breakthrough sulfur capacity of desulfurizer.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrogenation catalyst for heavy hydrocarbon oil, production method for hydrogenation catalyst for heavy hydrocarbon oil, and hydrogenation method for heavy hydrocarbon oil

ActiveUS20160220986A1Easily produce sedimentHigh desulfurization activityHeterogenous catalyst chemical elementsCatalyst activation/preparationZincHydrocarbon

The hydrogenation catalyst for heavy hydrocarbon oil, includes: as a carrier, phosphorous-zinc-containing alumina that contains 0.1% by mass to 4% by mass, in terms of oxide based on the carrier, of phosphorous and 1% by mass to 12% by mass, based on the carrier, of zinc oxide particles, and supporting, on the carrier, 8% by mass to 20% by mass, in terms of oxide based on the catalyst, of at least one selected from metals in Group 6 of the periodic table and 2% by mass to 6% by mass, in terms of oxide based on the catalyst, of at least one selected from metals in Groups 8 to 10 of the periodic table, and the average particle diameter of the zinc oxide particles being 2 μm to 12 μm.

Owner:COSMO OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com