Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduced hydrothermal treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodesulfurization method of gasoline

InactiveCN106867576AAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

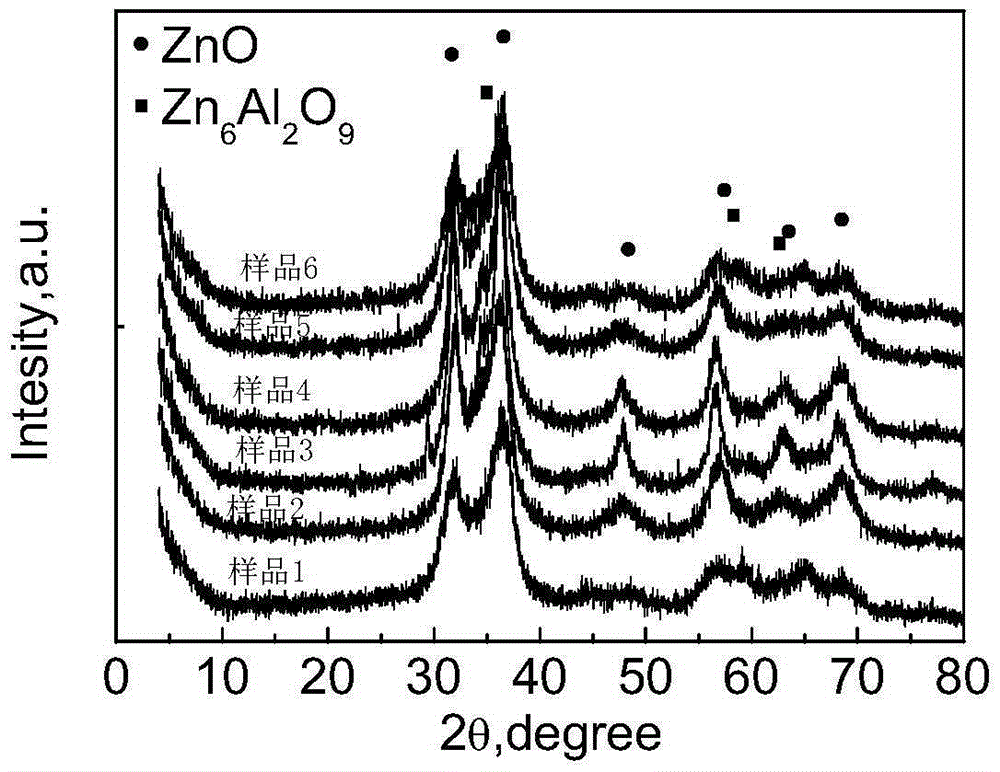

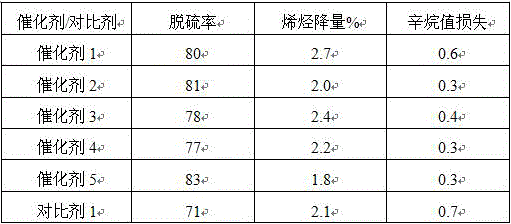

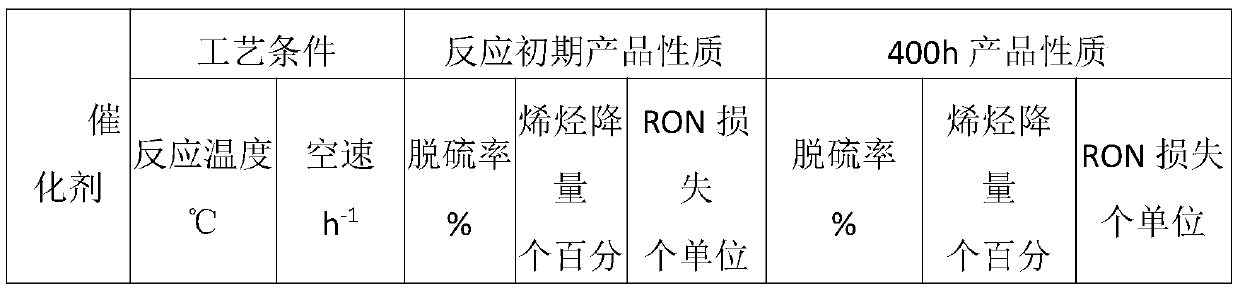

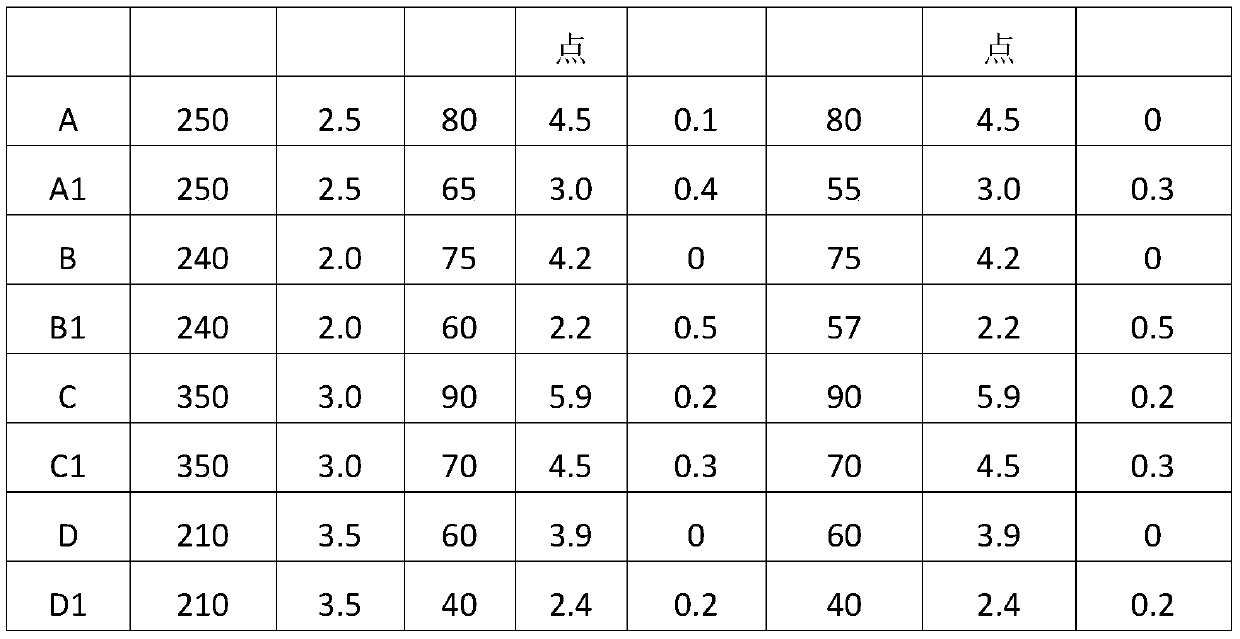

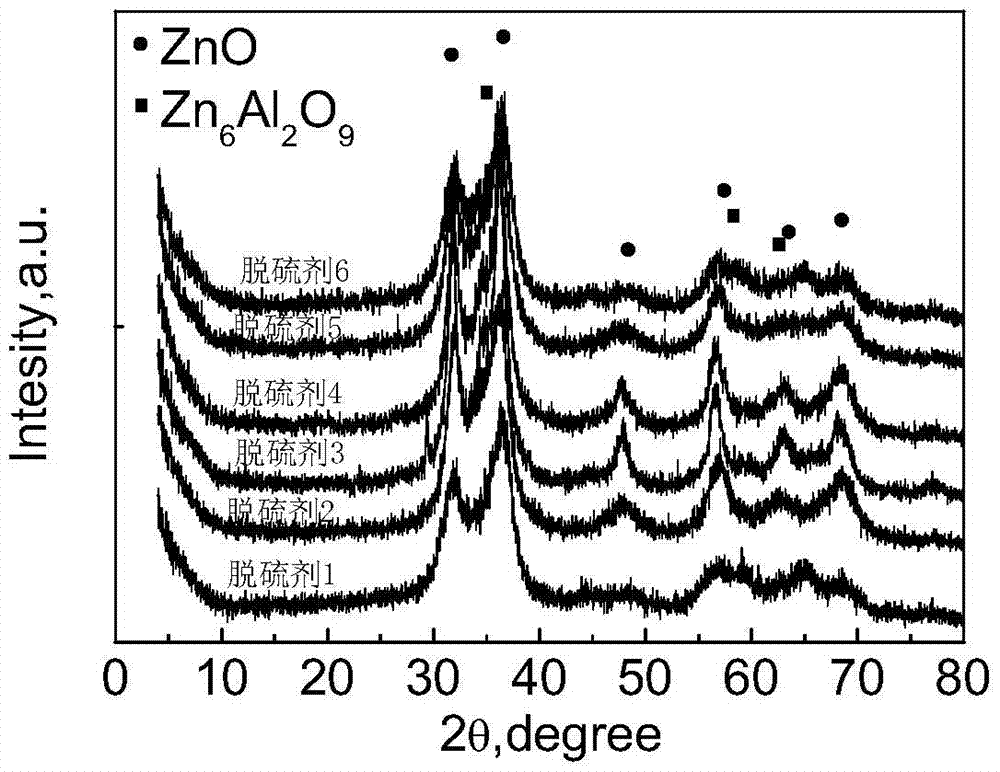

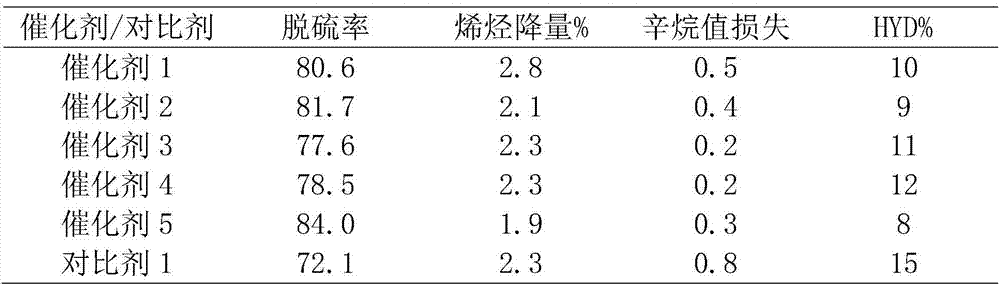

Selective hydrodesulfurization catalyst and preparation method thereof

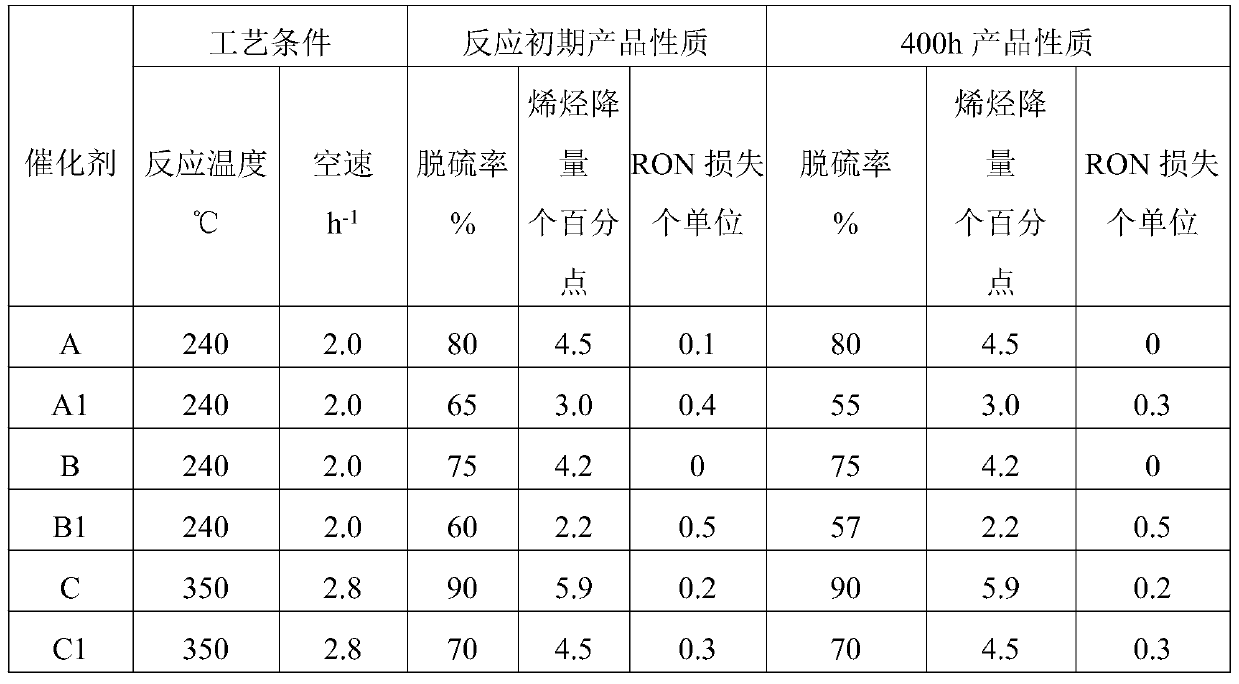

ActiveCN107583659AReduced hydrothermal treatment processHigh desulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryComposite oxide

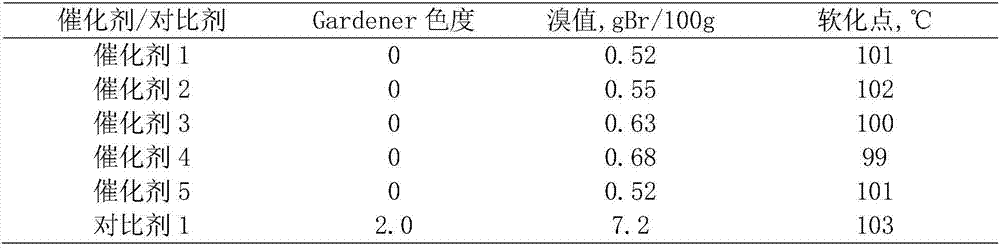

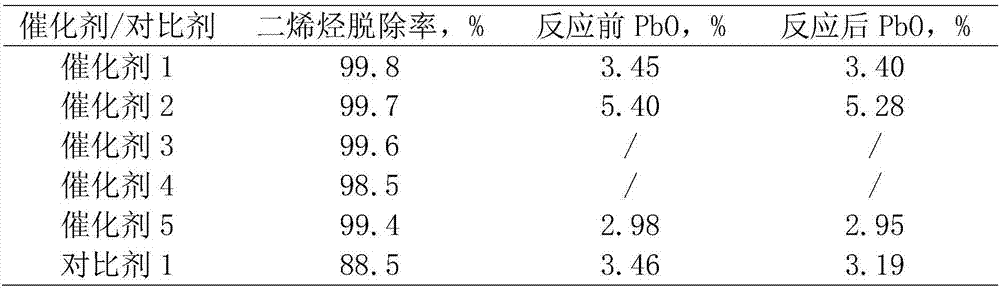

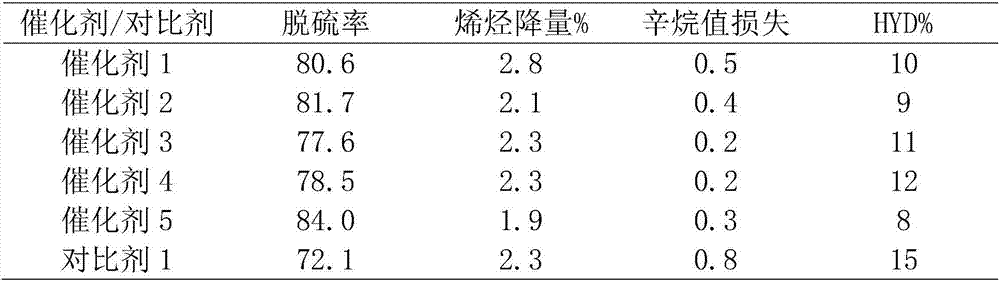

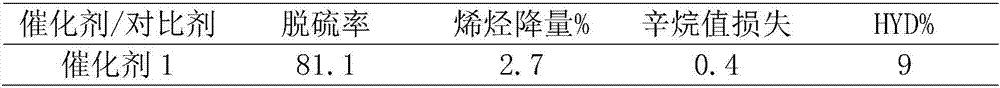

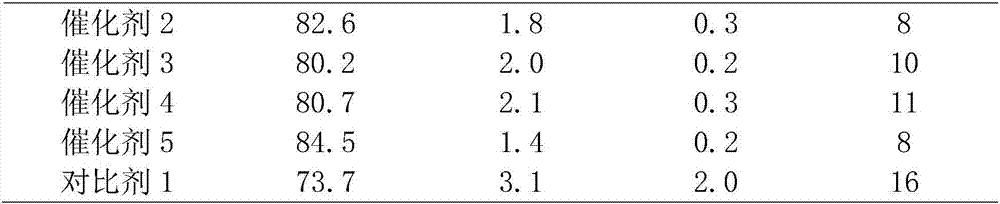

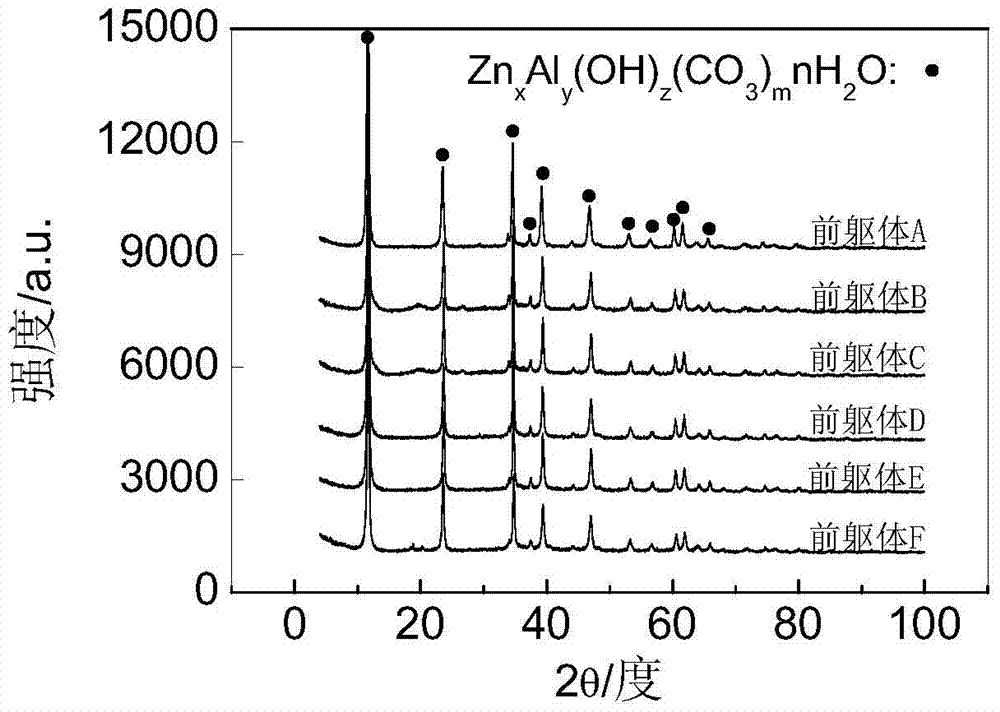

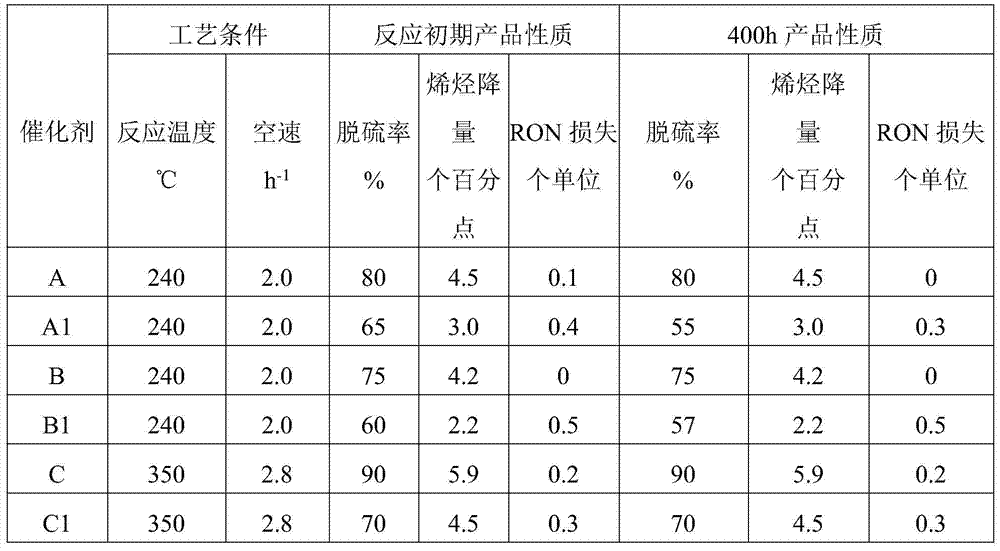

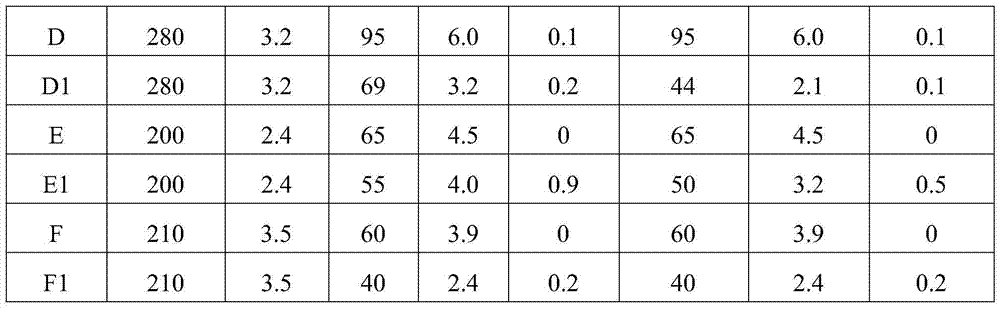

The invention relates to a selective hydrodesulfurization catalyst. The catalyst comprises, by mass, 3-5% of CoO as an active component, 10-13% of MoO3 as an active component, 2-3% of B203 as a carrier modification aid, 1-2% of P2O5 as a carrier modification aid, 1-1.5% of K2O as a carrier modification aid and 75.5-83% of a composite oxide carrier. The catalyst carriers comprise a zinc aluminate spinel-containing zinc oxide-alumina composite oxide prepared by nonconstant pH alternating titration. The catalyst has good desulfurization selectivity and stability.

Owner:PETROCHINA CO LTD

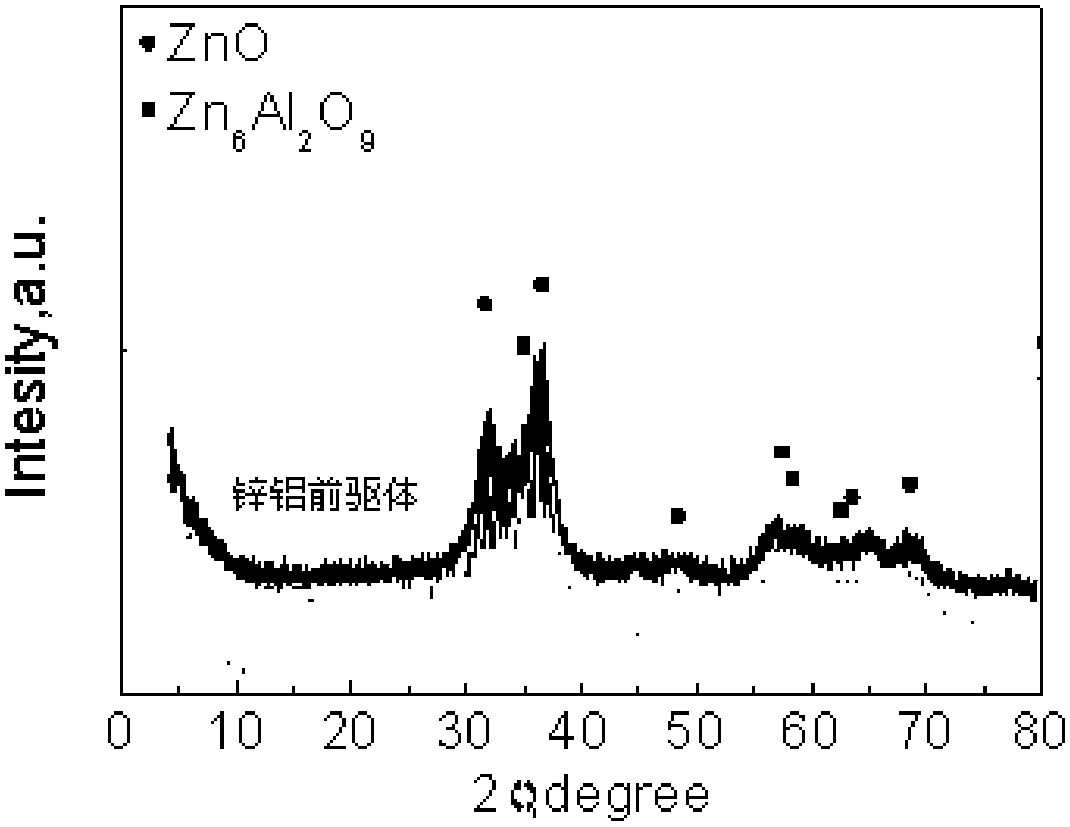

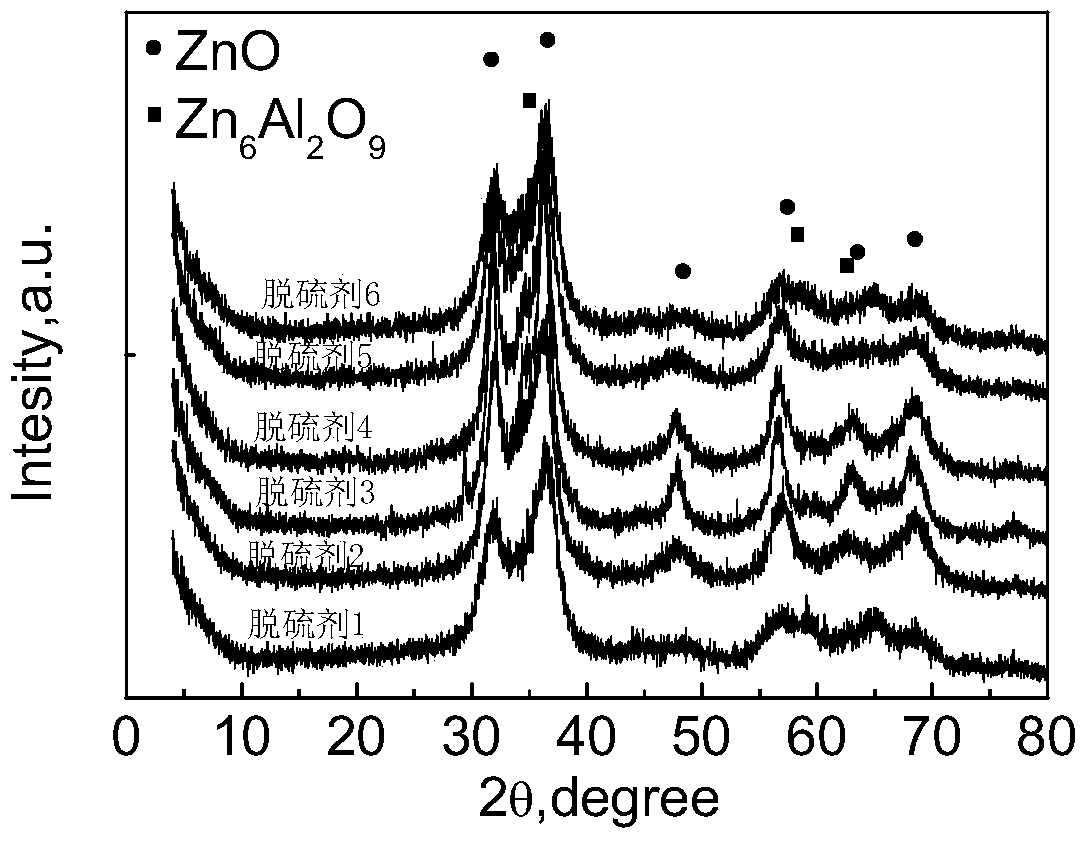

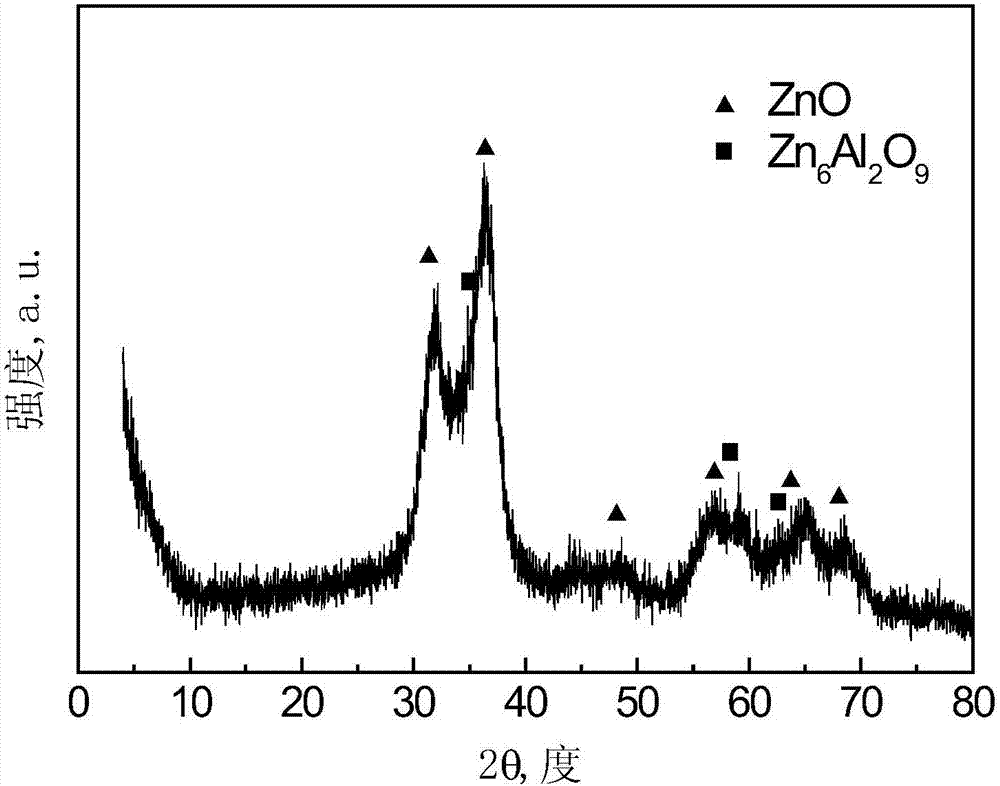

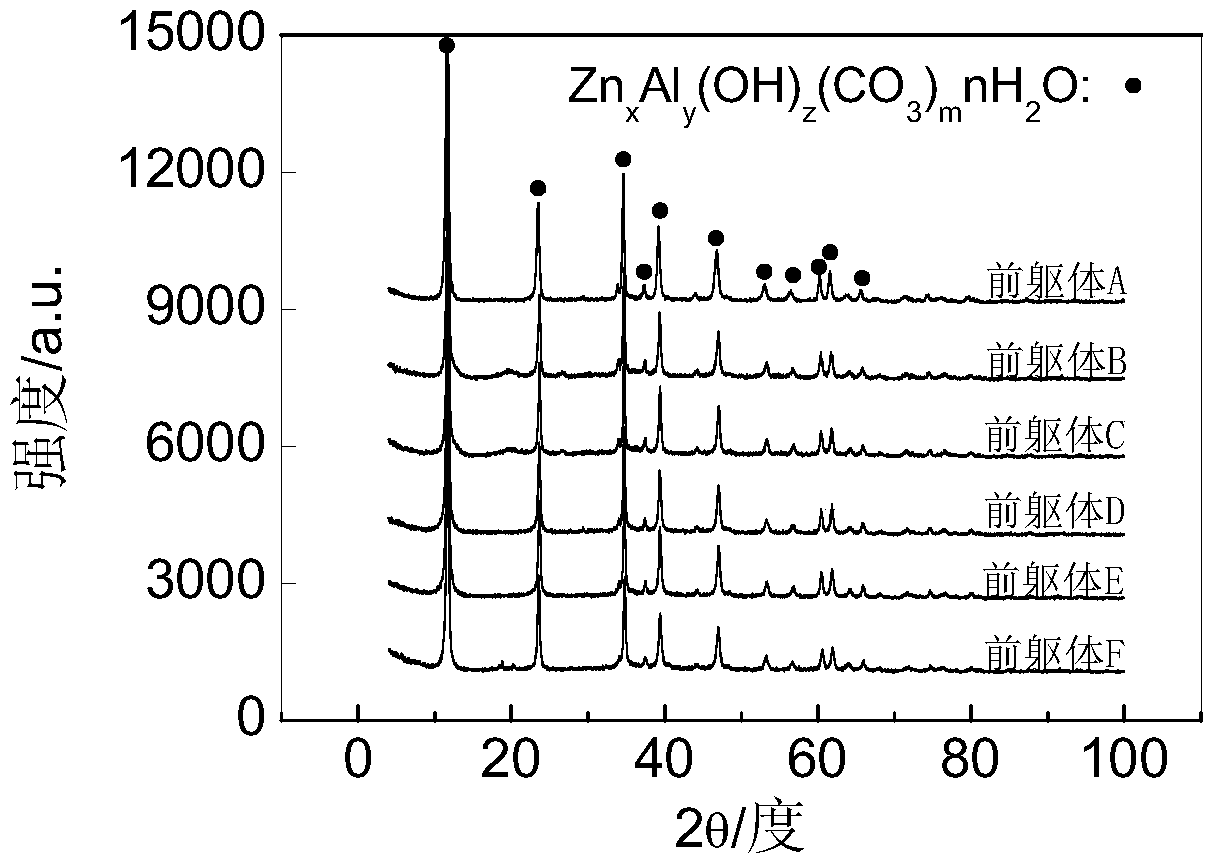

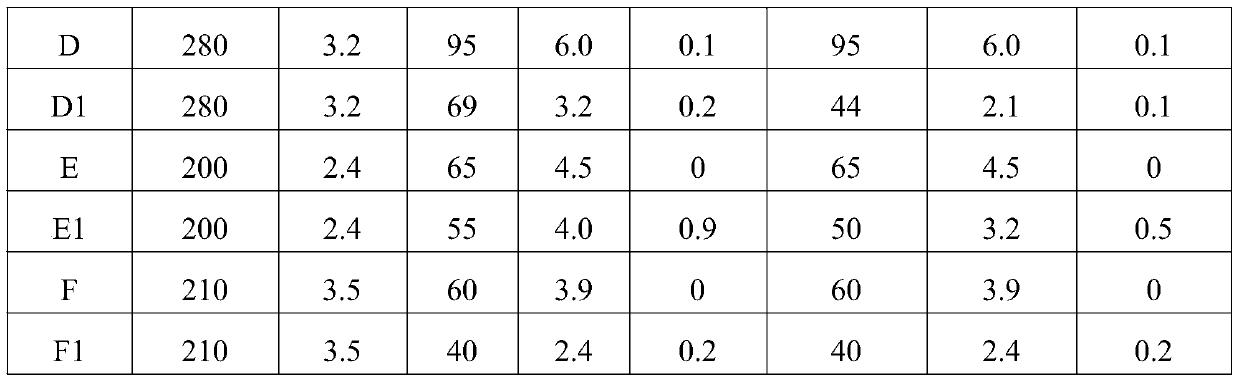

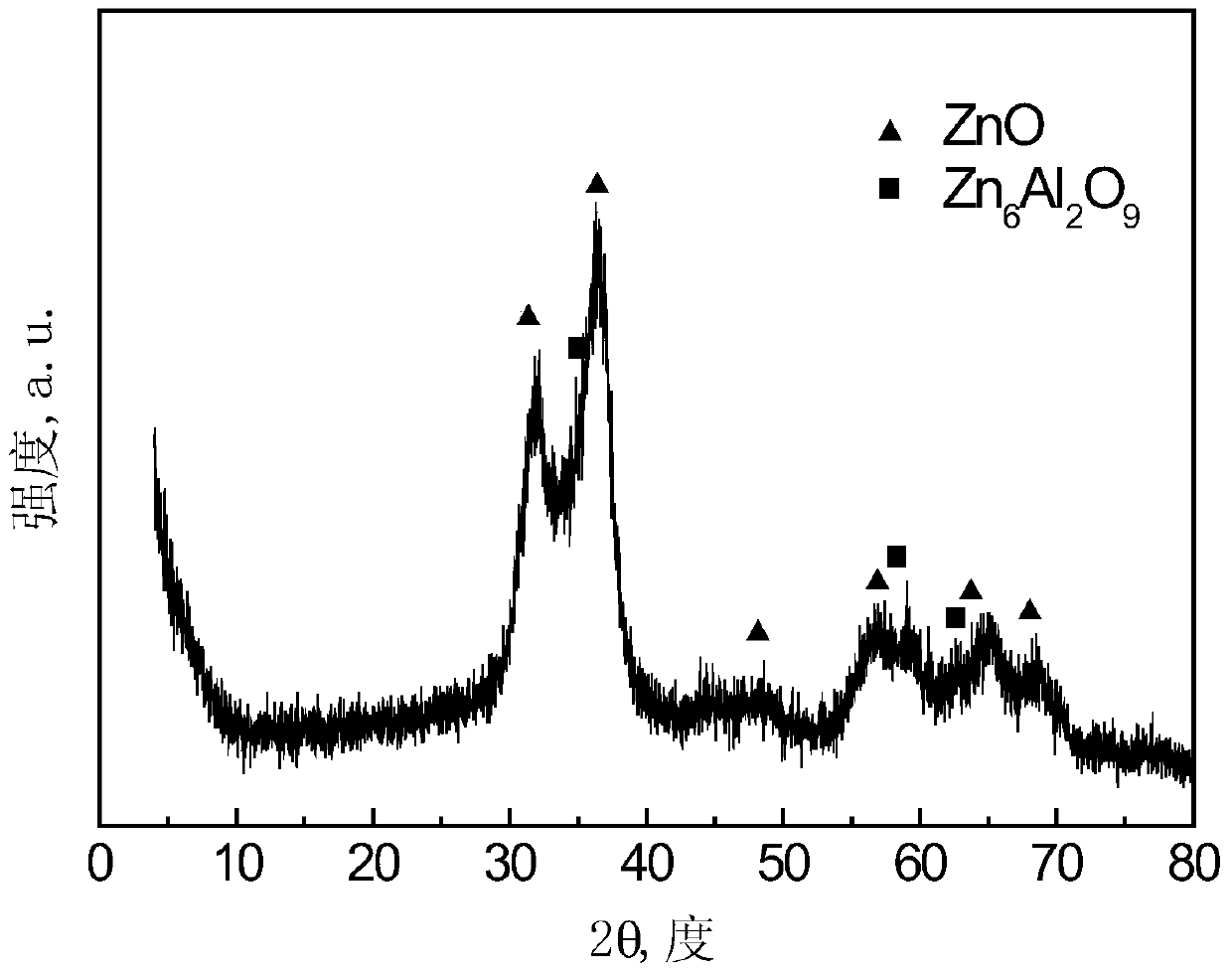

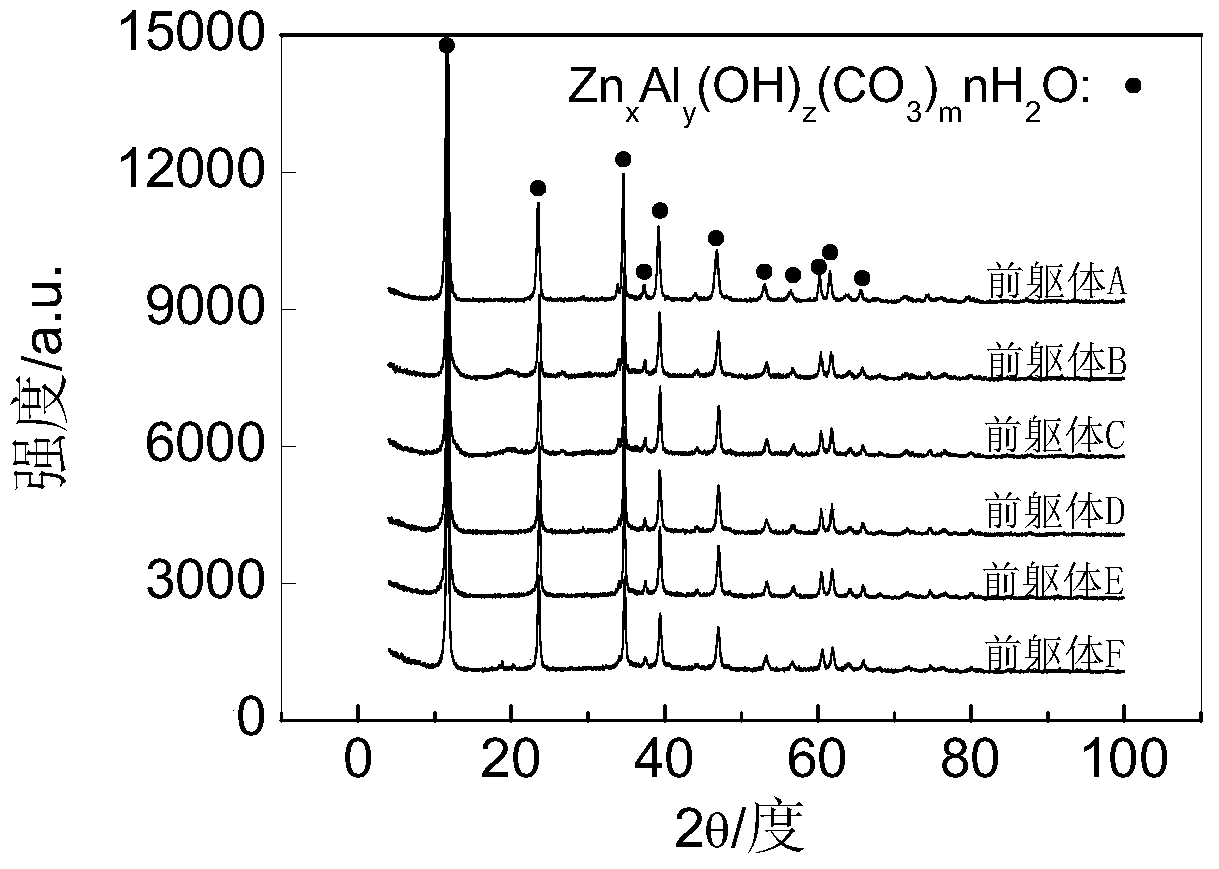

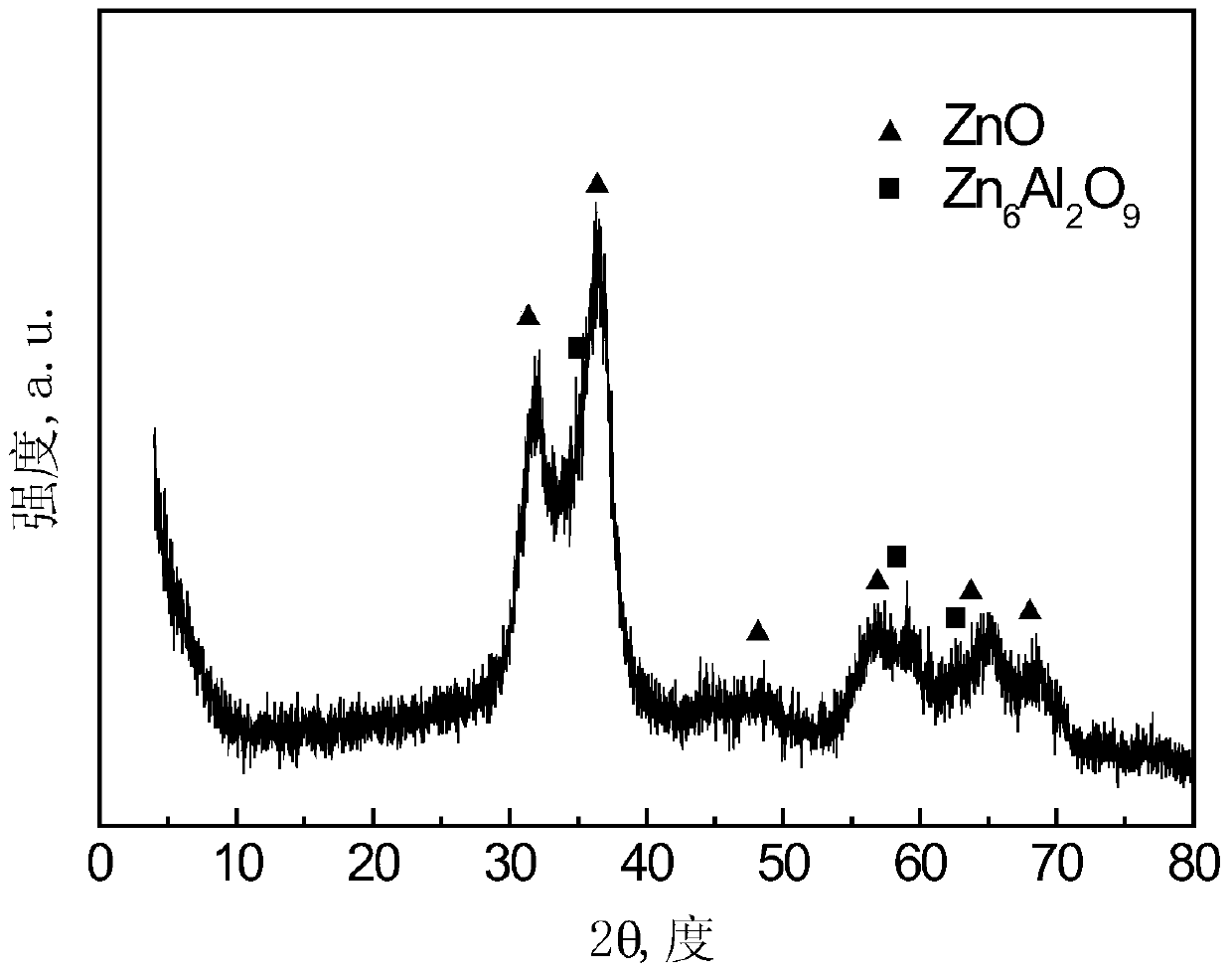

A zinc oxide material containing zinc-aluminate spinel and a preparing method thereof

ActiveCN106622204AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxideMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminateHydrodesulfurization

The invention relates to a zinc oxide material containing zinc-aluminate spinel. The zinc oxide content based on oxides is 55-90%, and the specific surface area of the zinc oxide material is 150-220 m<2> / g. The zinc oxide material is a zinc oxide material which contains the zinc-aluminate spinel, which is prepared by direct low-temperature calcination, which is uniformly dispersed, and the specific surface of which can be regulated in a range of 150-220 m<2> / g. The zinc oxide material is used for preparing adsorption desulphurization catalysts for gasoline or diesel oil treatment, can be added into an FCC catalyst as a desulphurization auxiliary agent, and can be adopted as a hydrodesulfurization catalyst carrier to load active components and then used for hydrodesulfurization of gasoline or diesel oil.

Owner:PETROCHINA CO LTD

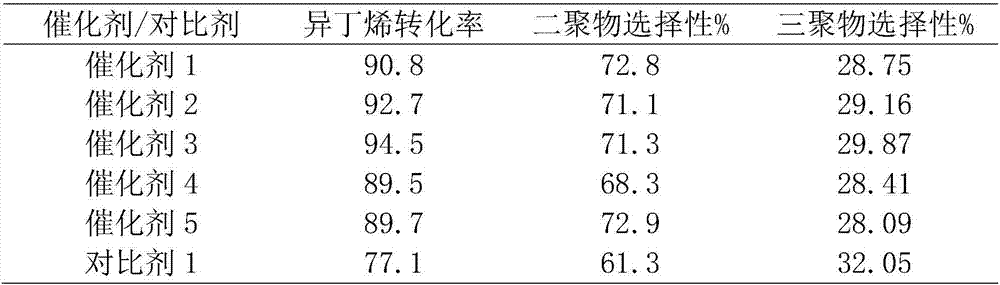

Catalyst for isobutene oligomerization and preparation method thereof

InactiveCN106861731AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxidePhysical/chemical process catalystsIron sulfatePtru catalyst

The invention relates to a catalyst for isobutene oligomerization and a preparation method thereof. The catalyst is composed of the following components in terms of oxide mass: 80.0-97.0wt% of a composite carrier containing zinc oxide-alumina, 4.0-15.0wt% of active component iron sulfate, and 1.0-6.0wt% of nickel sulfate. The catalyst has high oligomerization activity, the dimer selectivity is high, the trimer selectivity is low, and the catalyst operation cycle is long.

Owner:QINZHOU UNIV

Catalyst for C5 petroleum resin hydrogenation and preparation method thereof

InactiveCN106861730AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxidePhysical/chemical process catalystsPtru catalystHigh activity

The invention discloses a catalyst for C5 petroleum resin hydrogenation and a preparation method thereof. The catalyst comprises the following components by mass: 78.0-96.0wt% of a composite carrier containing zinc oxide-alumina, 1.0-8.0wt% of an active component, 1.0-15.0wt% of nickel phosphide, and 0.1-2.5wt% of lanthanum oxide. C5 petroleum resin has high hydrogenation activity and good activity stability, the catalyst active center loss rate is low, and the operation period is long.

Owner:QINZHOU UNIV

Hydrogenating and arsenic removing method of naphtha

ActiveCN106833731AHigh rate of hydrodearsenizationGood activity and stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentNaphthaActive component

The invention discloses a hydrogenating and arsenic removing method of naphtha. A catalyst used by the method comprises, by the mass of oxide, 72.0-90.0wt% of composite support containing zinc oxide-aluminum oxide, 6.0-16.0wt% active component nickel oxide, 2.0-6.0wt% of molybdenum oxide and 2.0-6.0wt% of tungsten oxide. The method is mild in reaction condition, wide in raw material application range, high in product arsenic removing, good in long-period reaction activity stability and long in operation period.

Owner:山东明成石化有限公司

Catalyst for dialkene hydrogenation and preparation method of catalyst

InactiveCN106881125AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxideHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsBULK ACTIVE INGREDIENTIron oxide

The invention discloses a catalyst for dialkene hydrogenation and a preparation method of the catalyst. The catalyst comprises the following ingredients in percentage by oxide mass: 91.0wt% to 97.5wt% of zinc oxide-aluminum oxide containing composite support, 1.5wt% to 5.5wt% of active ingredient, i.e., palladium oxide, 0.5wt% to 1.5wt% of auxiliary active ingredient, i.e., auric oxide and 0.5wt% to 2.0wt% of lanthanum oxide. According to the catalyst, the dialkene hydrogenation activity is high, the rate of loss of noble metal active ingredients is low, and the running cycle is long.

Owner:QINZHOU UNIV

Composite carrier containing zinc oxide-aluminum oxide and preparation method thereof

InactiveCN106955746AOrderly accumulationLarge specific surface areaCatalyst carriersHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention discloses a composite carrier containing zinc oxide-aluminum oxide and a preparation method thereof. The composite carrier contains zinc oxide containing zinc-aluminum spinel, aluminum oxide, auxiliary component phosphor, potassium and magnesium. The composite carrier is characterized by uniformly dispersed zinc aluminum and high specific surface area and can be used as a carrier for FCC catalyst sulfur-reducing auxiliary agent and FCC hydrogen desulfurization or hydrogenation catalyst.

Owner:QINZHOU UNIV

Catalyst for desulfurizing transforming of gasoline and preparation method

InactiveCN106881127AOrderly accumulationLarge specific surface areaPhysical/chemical process catalystsHydrodesulfurizationActive component

The invention discloses a catalyst for desulfurizing transforming of gasoline. A carrier of a hydrogenating and desulfurizing transforming catalyst is a zinc oxide-aluminum oxide composite carrier; active components comprise cobalt oxide, nickel oxide and molybdenum oxide. The composite carrier has the advantages that the zinc and aluminum are uniformly dispersed, and the specific surface area is high. The hydrogenating and desulfurizing transforming catalyst has the advantages that the saturating rate of olefin is low, the loss of octane value is little, the desulfurizing rate is high, and the stability is good.

Owner:QINZHOU UNIV

C5 petroleum resin hydrogenation method

InactiveCN106914259AHigh activityImprove performancePhysical/chemical process catalystsHydrocarbon oils refiningReaction temperatureFixed bed

The invention discloses a C5 petroleum resin hydrogenation method. According to the invention, a fixed bed reactor is employed, a catalyst is the supported catalyst taking palladium and nickel phosphide as active site, and the hydrogenation process condition is characterized in that the reaction temperature is 180-270 DEG C, the reaction pressure is 6.0-15.0 MPa, and the volume velocity is 0.2-7.0<-h>. The hydrogenation process condition is relatively mild, the performance of the hydrogenation petroleum resin product is good, and the active stability of the catalyst is good.

Owner:QINZHOU UNIV

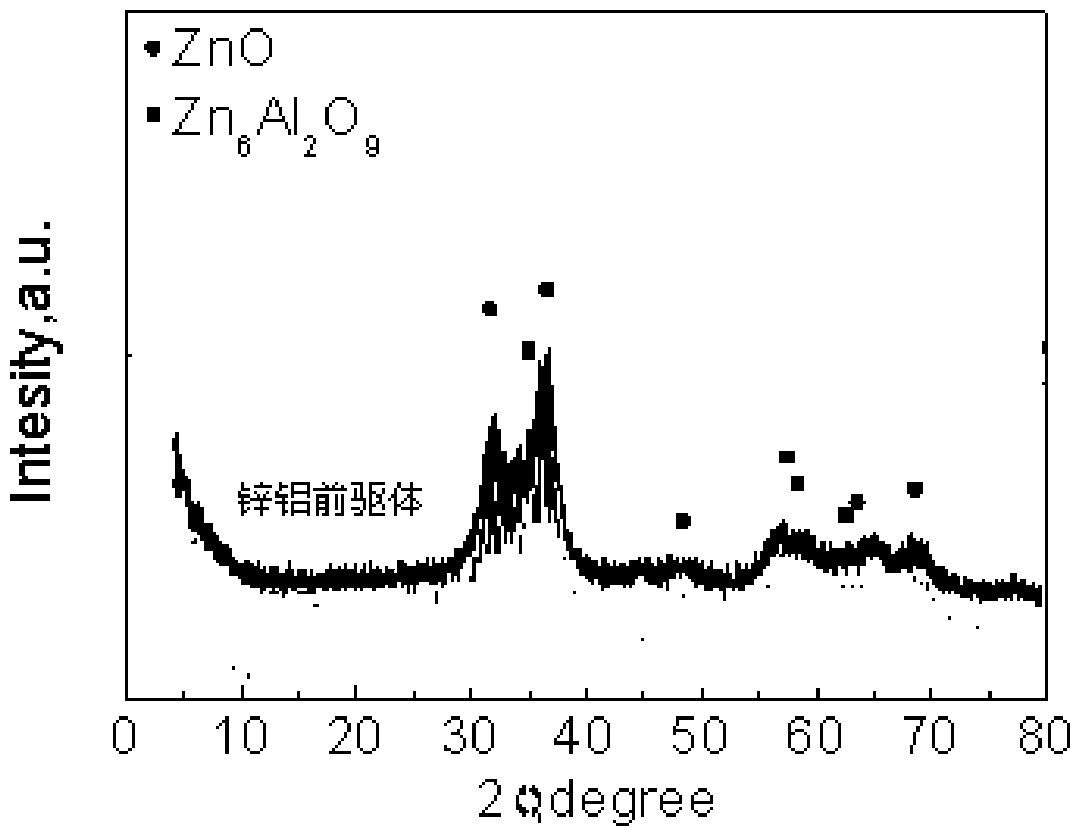

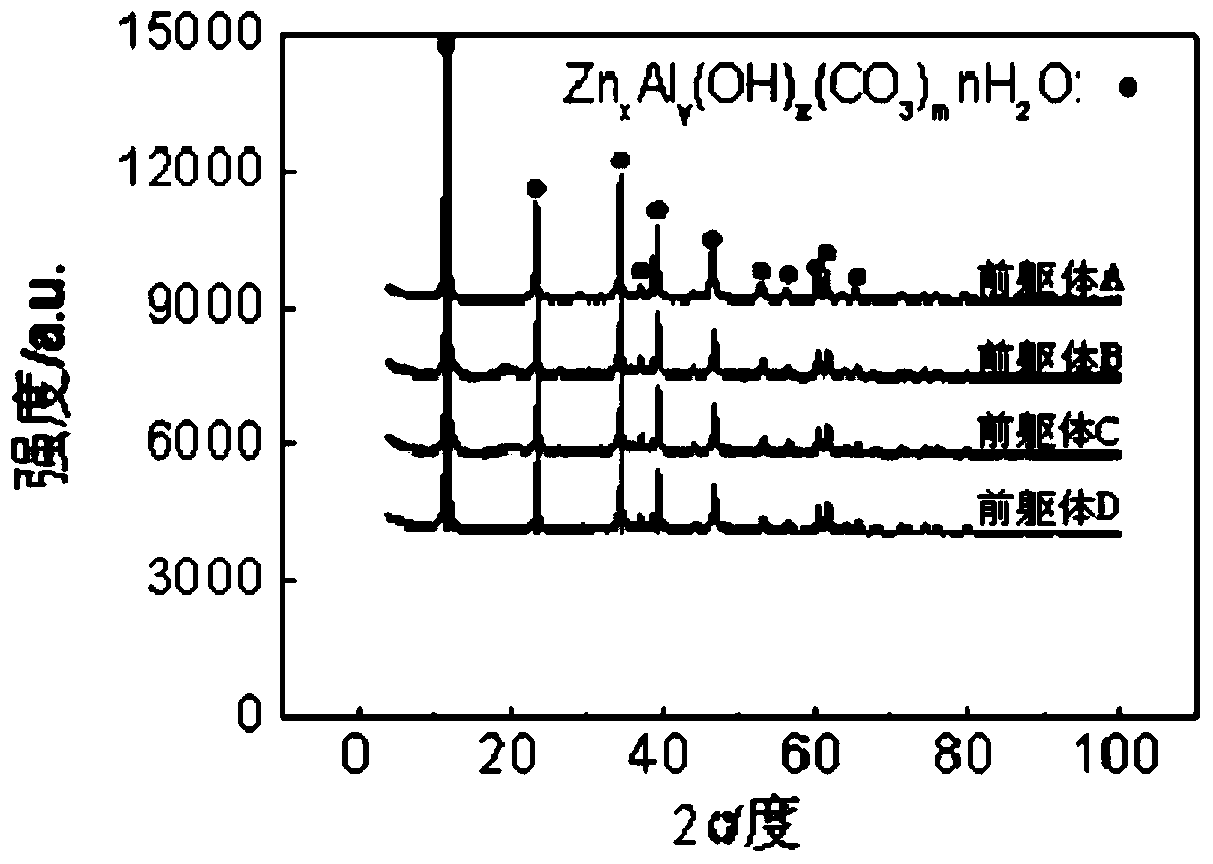

Sulfur-carrying hydrodesulfurization upgrading catalyst and preparation method

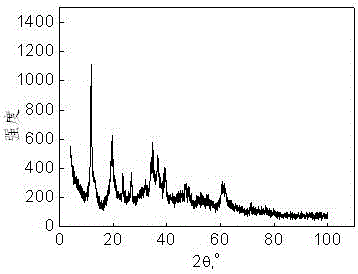

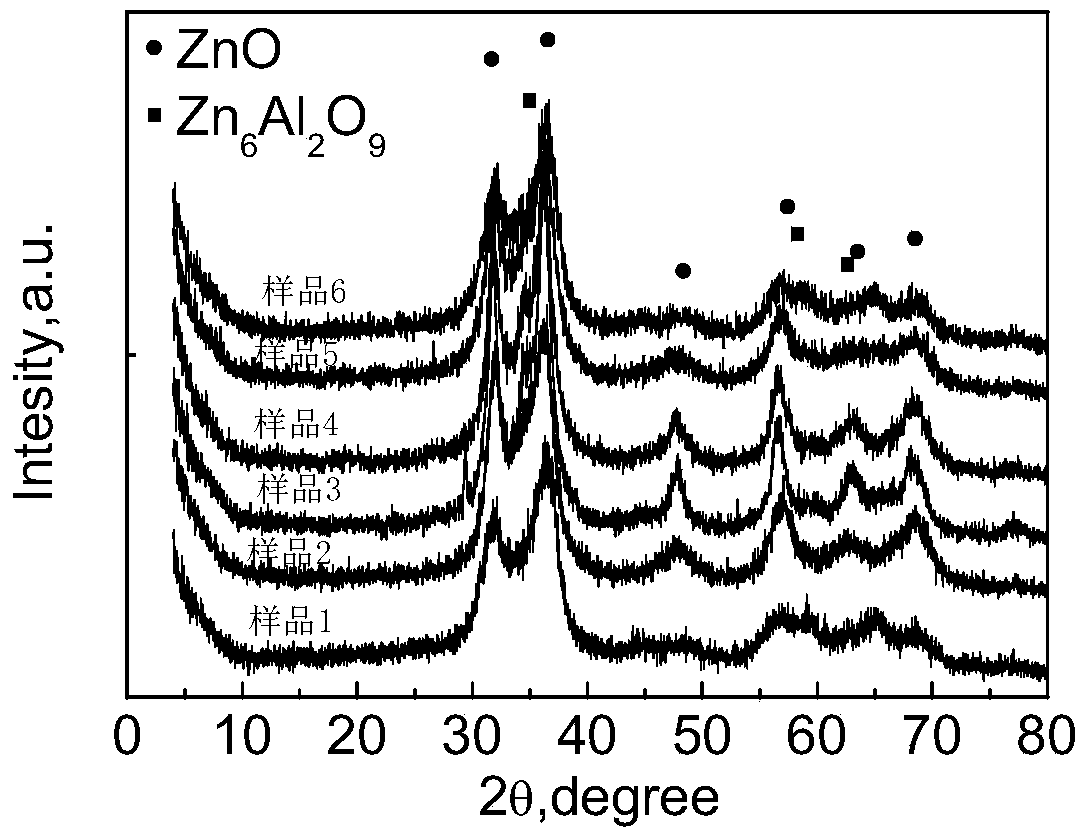

ActiveCN106925338AEvenly dispersedLarge specific surface areaMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveHydrodesulfurization

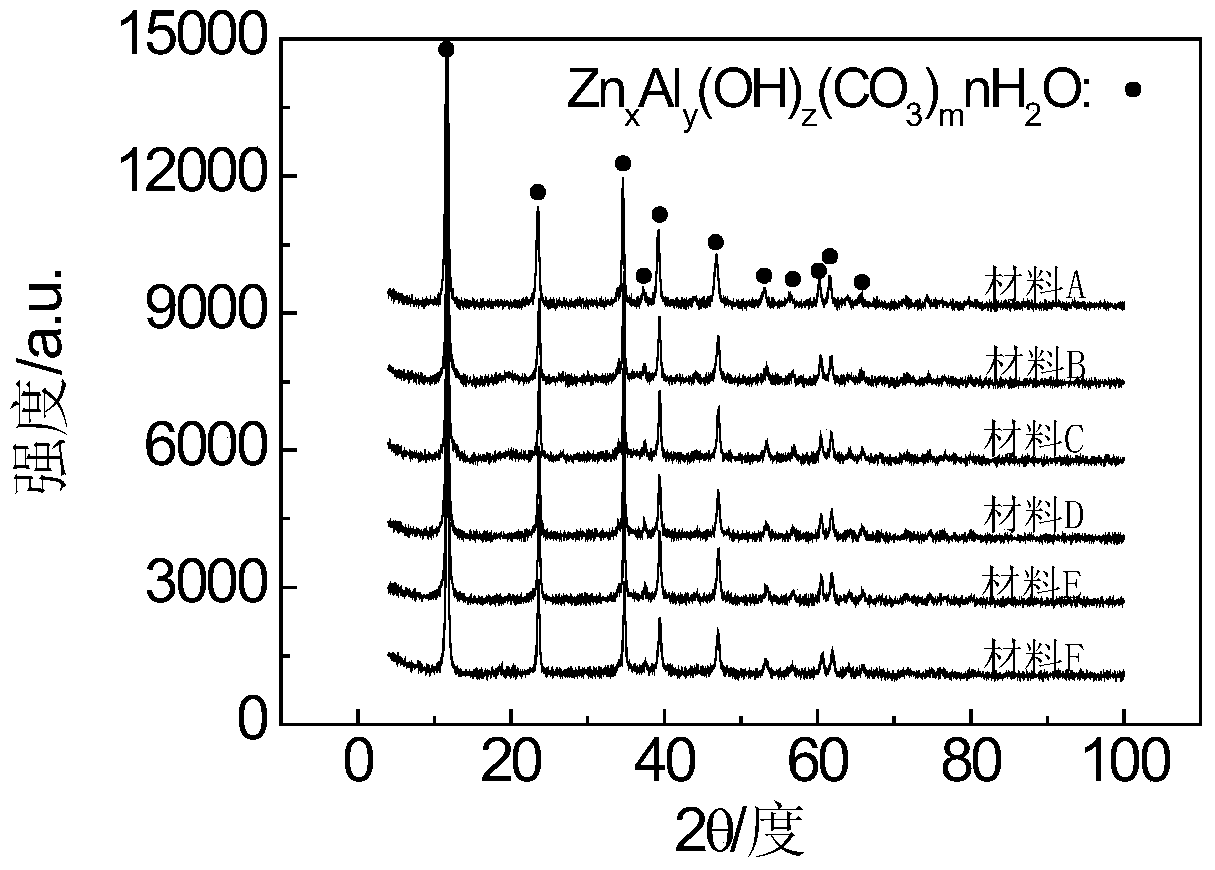

The invention relates to a sulfur-carrying hydrodesulfurization upgrading catalyst. On the basis of weight of the catalyst, content of a molecular sieve in the catalyst is 5-70wt%, VIB-family metal content is 2-10wt% calculated according to oxide, VIII-family metal content is 1-5wt% calculated according to oxide, sulfur content is 3-8wt%, content of a zinc-aluminum lamellar material prepared through non-constant pH alternate titration is 5-50%, and phosphorus content is 0-10wt% calculated according to oxide. The zinc-aluminum lamellar material in the catalyst has large specific surface area, and the sulfur-carrying hydrodesulfurization upgrading catalyst prepared by compositing the zinc-aluminum lamellar material with a molecular sieve material has good hydrodesulfurization and olefin-reducing performance.

Owner:PETROCHINA CO LTD

Additive-containing zinc oxide-aluminum oxide composite carrier and preparation method

InactiveCN106732516ALarge specific surface areaAvoid the problem of needing high temperature roasting to fix zinc oxideCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAluminatePotassium

The invention relates to an additive-containing zinc oxide-aluminum oxide composite carrier and a preparation method. The composite carrier is prepared from components such as zinc aluminate gahnite-containing zinc oxide, aluminum oxide, and additive components boron, potassium and strontium, wherein components of the composite carrier are counted by the weight of oxides as follows: the content of aluminate gahnite-containing zinc oxide is 5 to 40 percent by weight, the content of aluminum oxide is 65 to 85 percent by weight, and the content of the additive components boron, potassium and strontium is respectively as follows: 0.5 to 1.5 percent by weight of B2O3, 0.3 to 2.5 percent by weight of K2O, and 0.2 to 2.5 percent by weight of SrO. The composite carrier is uniform in dispersion of zinc and aluminum and high in specific surface area.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

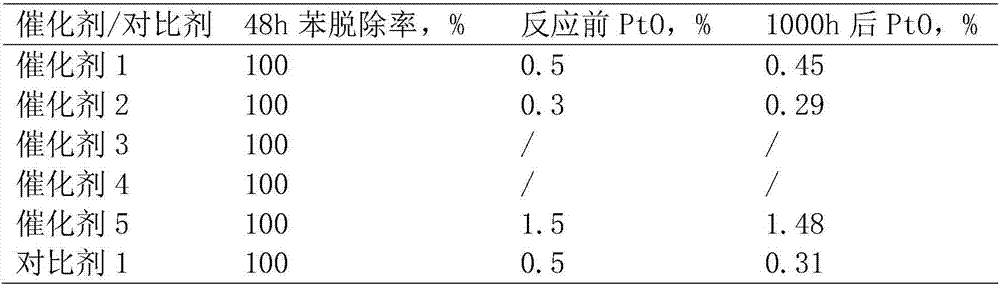

Method for producing cyclohexane through benzene hydrogenation

InactiveCN106927996AGood activity and stabilityMild reaction conditionsPhysical/chemical process catalystsHydrocarbon by hydrogenationBenzeneActive component

The invention discloses a method for producing cyclohexane through benzene hydrogenation. A catalyst contains the following components in the mass of oxides: 80-99wt% of a composite support containing zinc oxide-aluminum oxide, 0.1-5wt% of an active component platinum oxide and 0.1-5wt% of an active component palladium oxide; and the catalyst has high benzene hydrogenation activity, low loss rate of a precious metal active component and long running period.

Owner:QINZHOU UNIV

A kind of hydrogenation method of diene

ActiveCN106929092BHigh hydrogenation removal rateReduce lossesPhysical/chemical process catalystsRefining by selective hydrogenationMass ratioHydrogenation reaction

The invention discloses a hydrogenation method of dienes, which adopts a fixed bed reactor; the catalyst is a palladium-based supported catalyst, and the reaction process conditions are: reaction temperature 20-90°C, reaction pressure 1.0-4.0MPa, hydrogen The material quantity ratio of diene and diene is 1.0-3.0, and the volume space velocity is 1.0-10.0h-1. The hydrogenation reaction process conditions are mild. Under the high diolefin conversion rate, the monoolefin hydrogenation saturation rate is low, the catalyst's precious metal active center loss rate is low, and the activity stability is good.

Owner:五家渠市三江新能源科技有限公司

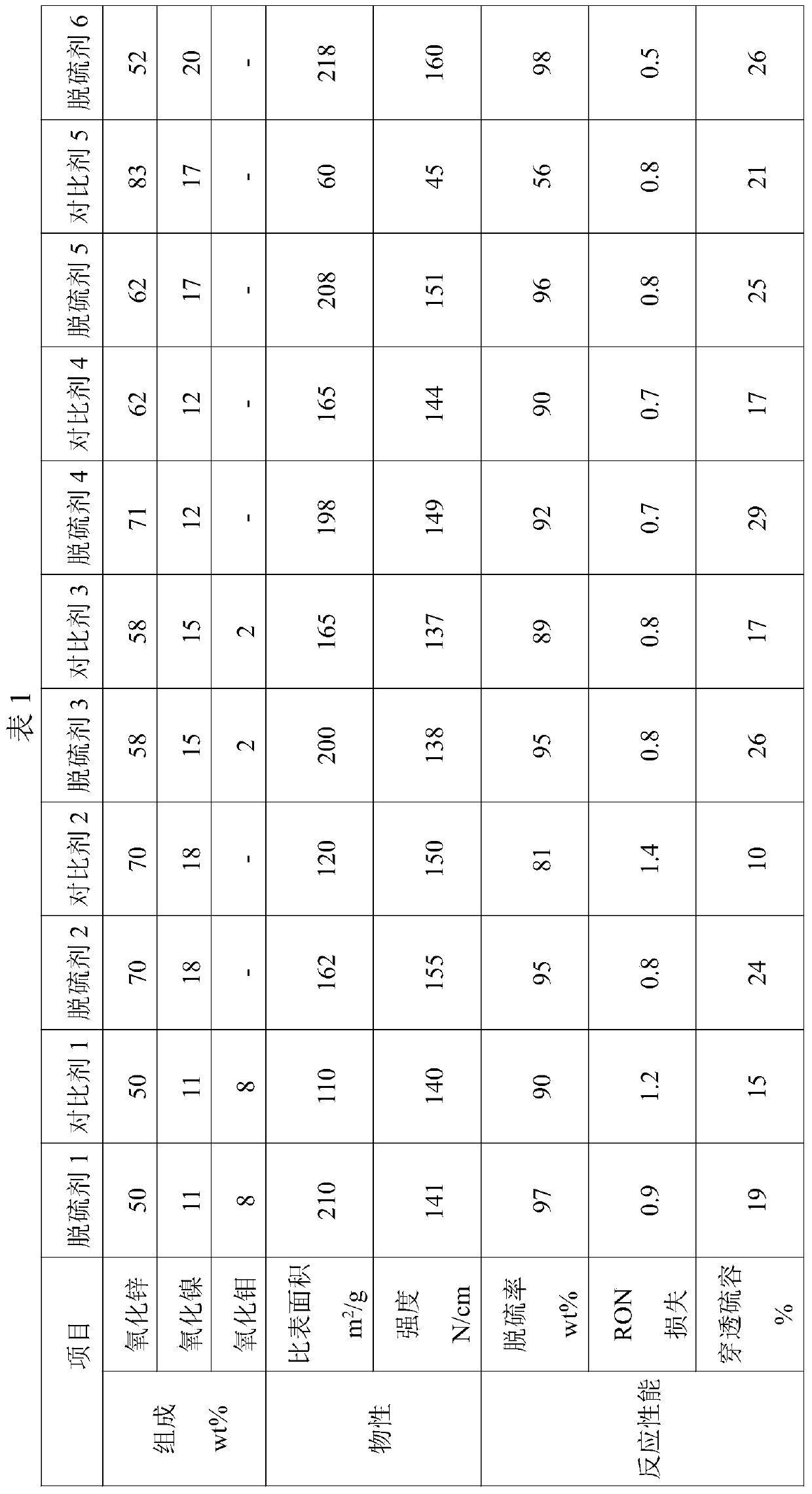

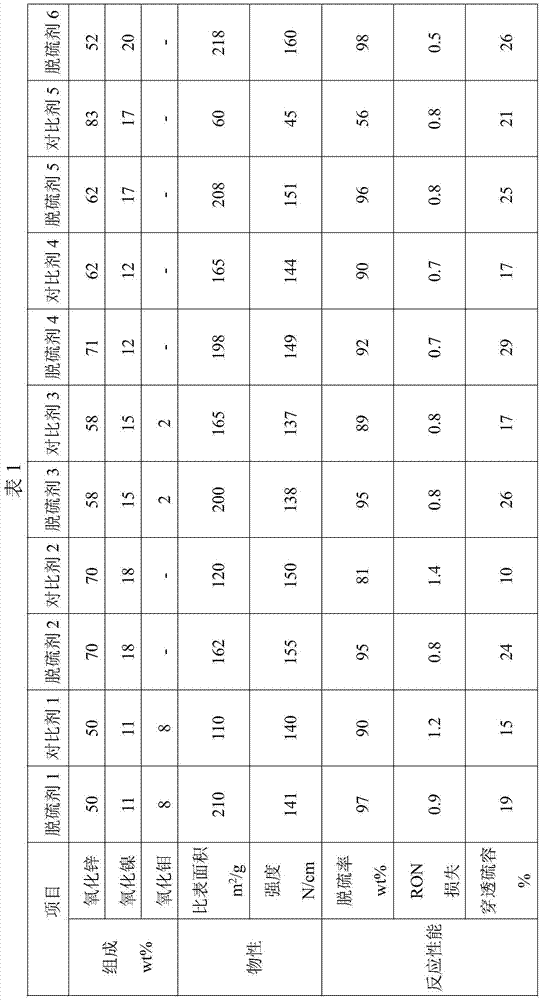

A zinc oxide desulfurizer containing zinc-aluminum spinel

ActiveCN106925249BHigh strengthIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentPtru catalystPhysical chemistry

The invention relates to a zinc aluminate gahnite contained zinc oxide desulphurizer. The zinc aluminate gahnite contained zinc oxide desulphurizer is prepared from, by weight of oxide, 30-80wt% of zinc oxide, 10-20wt% of nickel oxide, 0-10wt% of molybdenum oxide and 150-220m<2> / g. The desulphurizer applied to catalytic cracking of gasoline desulfurization treatment is low in octane loss.

Owner:PETROCHINA CO LTD

Pretreatment method for adsorptive desulfurizing agent

ActiveCN107511128AStrongIncrease the areaGas treatmentOther chemical processesPretreatment methodHydrogen atmosphere

The invention relates to a pretreatment method for an adsorptive desulfurizing agent. The method adopts a fixed bed reactor. The main components of the adsorptive desulfurizing agent are zinc oxide containing zinc-aluminum spinel, nickel oxide and molybdenum oxide. In terms of oxides, the adsorptive desulfurizing agent contains 40-85wt% of zinc oxide containing zinc-aluminum spinel, 10-35wt% of nickel oxide, and 0-25wt% of molybdenum oxide. And the specific surface area of the adsorptive desulfurizing agent is 150-220m<2> / g. The pretreatment technological conditions of the adsorptive desulfurizing agent are: in a hydrogen atmosphere or an atmosphere hydrogen-containing gas, a hydrogen / catalyst volume ratio of 150-500, a reduction temperature of 15-450DEG C, and a reduction pressure of 0.5-3.0MP. The pretreatment method has the characteristics of high desulphurization selectivity and high breakthrough sulfur capacity, and small octane number loss.

Owner:PETROCHINA CO LTD

A zinc oxide material containing zinc-aluminum spinel and its preparation method

ActiveCN106622204BOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxideMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminateHydrodesulfurization

The invention relates to a zinc oxide material containing zinc-aluminum spinel. Calculated as oxide, the zinc oxide content is 55-90% and the specific surface area is 150-220m 2 / g. The zinc oxide material of the present invention is uniformly dispersed and obtained by direct low-temperature roasting, and the specific surface area can be between 150-220m 2 Zinc oxide material containing zinc aluminum spinel regulated between / g. The zinc oxide material containing zinc aluminum spinel of the present invention is used to prepare an adsorption desulfurization catalyst to treat gasoline or diesel, is added to an FCC catalyst and used as a desulfurization aid, and is used as a carrier of a hydrodesulfurization catalyst to load active components. Hydrodesulfurization of gasoline or diesel.

Owner:PETROCHINA CO LTD

Sulfur-loaded hydrodesulfurization upgrading catalyst and preparation method

ActiveCN106925338BEvenly dispersedLarge specific surface areaMolecular sieve catalystsHydrocarbon oils treatmentMolecular sievePtru catalyst

The invention relates to a sulfur-carrying hydrodesulfurization upgrading catalyst. On the basis of weight of the catalyst, content of a molecular sieve in the catalyst is 5-70wt%, VIB-family metal content is 2-10wt% calculated according to oxide, VIII-family metal content is 1-5wt% calculated according to oxide, sulfur content is 3-8wt%, content of a zinc-aluminum lamellar material prepared through non-constant pH alternate titration is 5-50%, and phosphorus content is 0-10wt% calculated according to oxide. The zinc-aluminum lamellar material in the catalyst has large specific surface area, and the sulfur-carrying hydrodesulfurization upgrading catalyst prepared by compositing the zinc-aluminum lamellar material with a molecular sieve material has good hydrodesulfurization and olefin-reducing performance.

Owner:PETROCHINA CO LTD

Catalyst for selective hydrodesulfurization and preparation method thereof

ActiveCN107583659BHigh desulfurization activityExcellent hydrodesulfurization selectivityPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst. The catalyst comprises, by mass, 3-5% of CoO as an active component, 10-13% of MoO3 as an active component, 2-3% of B203 as a carrier modification aid, 1-2% of P2O5 as a carrier modification aid, 1-1.5% of K2O as a carrier modification aid and 75.5-83% of a composite oxide carrier. The catalyst carriers comprise a zinc aluminate spinel-containing zinc oxide-alumina composite oxide prepared by nonconstant pH alternating titration. The catalyst has good desulfurization selectivity and stability.

Owner:PETROCHINA CO LTD

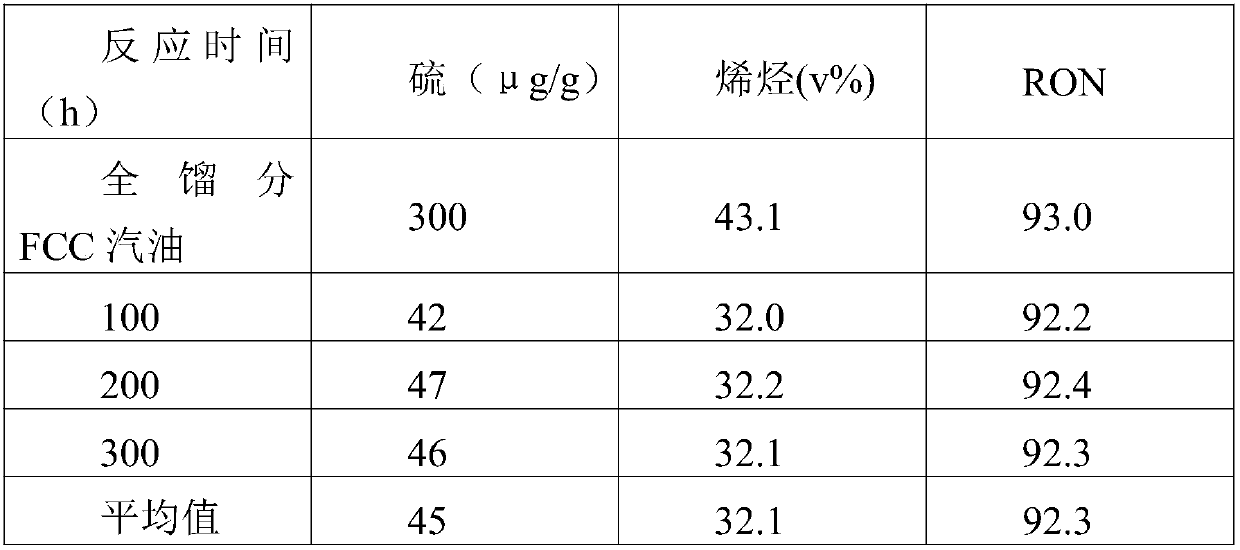

A kind of desulfurization treatment method of catalytic cracking gasoline

ActiveCN107511127BIncrease the areaAvoids the problem of requiring high temperature roasting to immobilize ZnOOther chemical processesHydrocarbon oils refiningFixed bedReaction temperature

The invention relates to a desulphurization treatment method for catalytic cracking gasoline. A fixed bed reactor is adopted; and an adsorption desulfurizer comprises 40-85 wt% of zinc oxide containing gahnite, 10-35 wt% of nickel oxide and 0-25 wt% of molybdenum oxide. The specific surface area of the adsorption desulfurizer is 150-220 m<2> / g, and reaction adsorption desulphurization technology conditions are as follows: the reaction temperature being 300-450 DEG C, the reaction pressure being 0.5-3.0 MPa, the volume hourly space velocity being 2-10 h<-1>, and the hydrogen / oil volume ratio being 0.1-1.0. The method has the advantages of high desulphurization selectivity, high breakthrough sulfur capacity and high octane number loss.

Owner:PETROCHINA CO LTD

A method for gasoline desulfurization

InactiveCN106867577BAdaptableHigh activityPhysical/chemical process catalystsHydrocarbon oils treatmentPtru catalystHydrodesulfurization

The invention discloses a gasoline desulfurization method. The method adopts a fixed bed reactor, the catalyst is a loaded nickel-cobalt-molybdenum catalyst, and the catalyst carrier is a composite carrier containing zinc oxide-alumina. The gasoline hydrodesulfurization process provided by the invention has the advantages of mild technological conditions, strong adaptability to different raw materials, low octane value loss and high desulfurization rate, and is suitable for deep desulfurization of high sulfur content and high olefin content gasoline.

Owner:QINZHOU UNIV

A kind of hydrodesulfurization method of gasoline

InactiveCN106867576BAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

A method for hydrodearsenication of naphtha

ActiveCN106833731BHigh rate of hydrodearsenizationGood activity and stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentNaphthaActive component

The invention discloses a hydrogenating and arsenic removing method of naphtha. A catalyst used by the method comprises, by the mass of oxide, 72.0-90.0wt% of composite support containing zinc oxide-aluminum oxide, 6.0-16.0wt% active component nickel oxide, 2.0-6.0wt% of molybdenum oxide and 2.0-6.0wt% of tungsten oxide. The method is mild in reaction condition, wide in raw material application range, high in product arsenic removing, good in long-period reaction activity stability and long in operation period.

Owner:山东明成石化有限公司

Hydrodesulfurization catalyst for zinc-aluminum layered material and preparation method thereof

ActiveCN107583660BEvenly dispersedLarge specific surface areaPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The invention relates to a hydrodesulfurization catalyst containing a zinc-aluminum layered material. The hydrodesulfurization catalyst comprises 30 to 74wt% of alumina, 4 to 15wt% of a group VIB metal on the basis of oxide, 1.5 to 5wt% of a group VIII metal on the basis of oxide, 20 to 70wt% of a zinc-aluminum layered material prepared through nonconstant pH alternant titration and 0 to 5wt% of phosphorus on the basis of oxide. The hydrodesulfurization modified catalyst prepared from the zinc-aluminum layered material and the alumina material has good hydrodesulfurization and olefin reductioneffects.

Owner:PETROCHINA CO LTD

A kind of hydrogenation method of raffinate oil

InactiveCN106833733BHigh hydrogenation removal rateGood activity and stabilityPhysical/chemical process catalystsRefining by selective hydrogenationPtru catalystReaction temperature

The invention discloses a hydrogenating method of raffinate oil. The method is characterized in that a fixed bed reactor is used, a palladium-based supported catalyst is used, reaction temperature is 165-200 DEG C, reaction pressure is 1.0-5.0MPa, hydrogen / oil volume ratio is (300-700):1, volume space velocity is 1.0-6.0h<-1>. The hydrogenating method is mild in hydrogenating reaction process condition, high in aromatic hydrocarbon and olefin removing rate and long in stable operation period.

Owner:QINZHOU UNIV

Hydrodesulfurization upgrading catalyst and preparation method thereof

ActiveCN106925337BEvenly dispersedLarge specific surface areaMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHydrodesulfurization

The invention relates to a hydrodesulfurization modification catalyst. Based on the weight of the catalyst, the molecular sieve content is 5-70wt%, the VIB group metal content is 2-10wt% in terms of oxides, and the VIII group metal content is 2-10wt% in terms of oxides. 1-5wt%, 5-50% zinc-aluminum layered material prepared by non-constant pH alternating titration, phosphorus content calculated as oxide is 0-10wt%. The zinc-aluminum layered material has a large specific surface area, and the zinc and aluminum are evenly dispersed. It is used to prepare a catalytic cracking hydrodesulfurization modification catalyst. The catalyst has good hydrodesulfurization and olefin reduction properties.

Owner:PETROCHINA CO LTD

Zinc aluminate gahnite contained zinc oxide desulphurizer

ActiveCN106925249AHigh strengthIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentAluminateGasoline

The invention relates to a zinc aluminate gahnite contained zinc oxide desulphurizer. The zinc aluminate gahnite contained zinc oxide desulphurizer is prepared from, by weight of oxide, 30-80wt% of zinc oxide, 10-20wt% of nickel oxide, 0-10wt% of molybdenum oxide and 150-220m<2> / g. The desulphurizer applied to catalytic cracking of gasoline desulfurization treatment is low in octane loss.

Owner:PETROCHINA CO LTD

Catalyst for hydrodesulfurization of gasoline and preparation method thereof

InactiveCN106925309AEvenly dispersedLarge specific surface areaPhysical/chemical process catalystsHydrocarbon oils treatment productsActive componentHydrodesulfurization

The invention discloses a catalyst for hydrodesulfurization of gasoline and a preparation method thereof. The catalyst comprises the following components in percentage by weight based on the weight of oxides: 1.0-9.5wt% of an active component cobalt oxide, 1.5-13.0wt% of molybdenum oxide and 78.0-94.0wt% of a composite carrier containing zinc oxide-aluminum oxide. The hydrodesulfurization catalyst is low in loss of octane number and high in desulfurization degree.

Owner:QINZHOU UNIV

A kind of regeneration method of adsorption desulfurization agent

ActiveCN107511143BIncrease the areaAvoids the problem of requiring high temperature roasting to immobilize ZnOOther chemical processesCatalyst regeneration/reactivationSulfurFixed bed

The invention relates to a regenerating method for an adsorption desulfurizer. A fixed bed reactor is adopted; and the adsorption desulfurizer comprises gahnite-containing zinc oxide, nickel oxide and molybdenum oxide, and the specific surface area of the adsorption desulfurizer is 150-220 m<2> / g. Regenerating technology conditions of the adsorption desulfurizer are as follows: the temperature rises to 260 DEG C from room temperature in a nitrogen atmosphere according to a heating rate of 15-30 DEG C / h, and stays at the 260 DEG C for 2-10 h, the temperature of a bed rises to 310 DEG C according to a heating rate of 5-20 DEG C / h, 10% air or an oxygen-containing gas is slowly introduced, and a cycle is established to regenerate a catalyst; and the regenerating pressure is 0.2-1.0 MPa. The regenerating method afresh recovers the desulfurization activity of the sulfur adsorption capacity-saturated inactivated catalyst in the desulfurization process through treatment in order to meet industrial operating requirements.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com