A kind of desulfurization treatment method of catalytic cracking gasoline

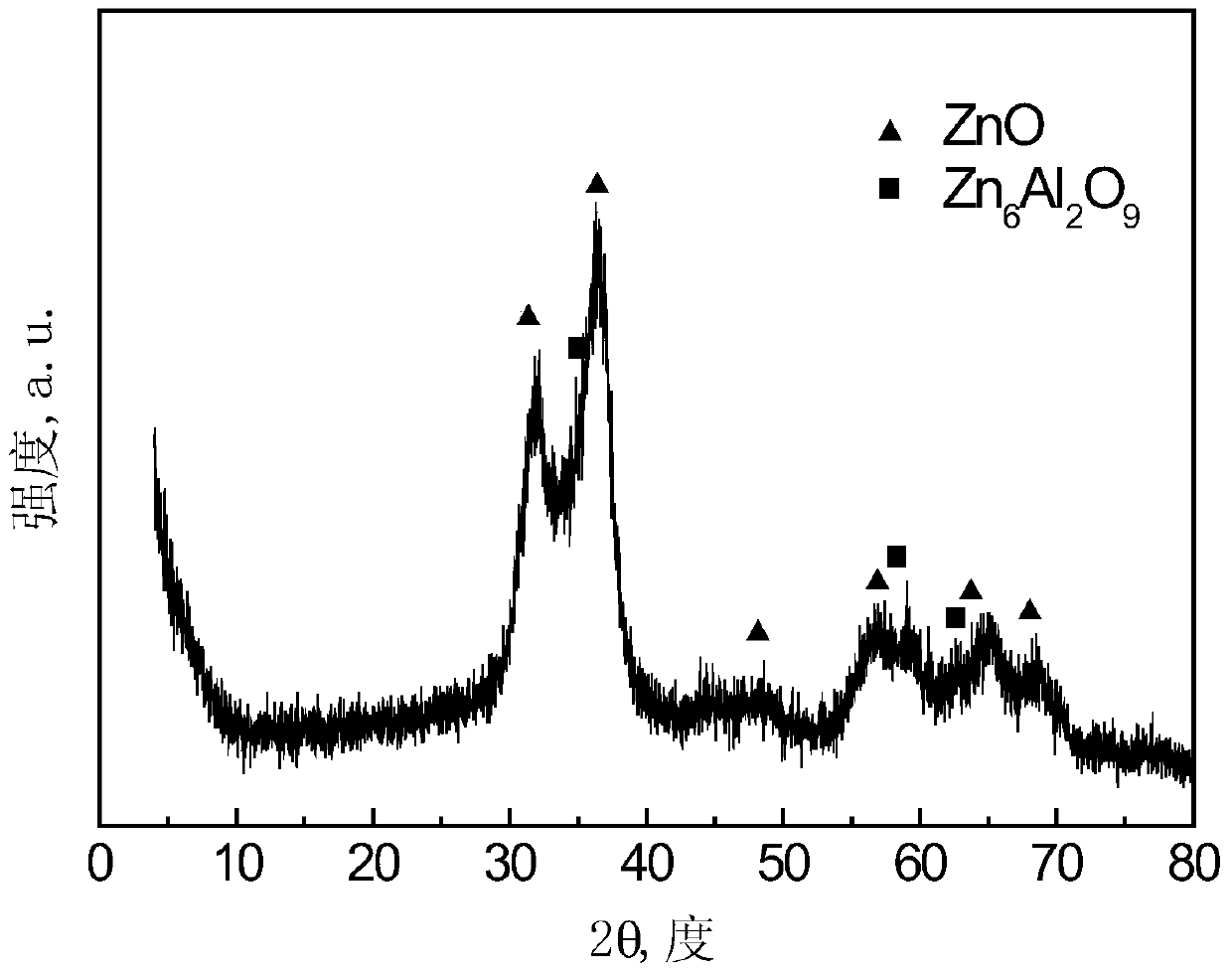

A technology of catalytic cracking gasoline and treatment method, which is applied in the field of adsorption desulfurization process of various fractions of catalytic cracking gasoline, can solve the problems of large octane number loss, low desulfurization selective breakthrough sulfur capacity, etc., and achieve high strength and specific surface area, Reduces the effect of the hydrothermal treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]Put the adsorption desulfurizer 1 into a 500mL fixed-bed adiabatic reactor. When the pressure is 0.8MPa, under the hydrogen atmosphere, the volume ratio of hydrogen to catalyst is 200:1 to establish a cycle, and the temperature is raised to 260 at a heating rate of 10°C / h. Stay at ℃ for 3 hours, raise the temperature to 300℃ and stay for 1h, raise the temperature to 350℃ and stay for 5h, raise the temperature to 410℃ and stay for 2h. The reaction process conditions are: reactor temperature 410°C, reaction pressure 1.2MPa, volume space velocity 6.5h -1 , the volume ratio of hydrogen to oil is 0.8; the desulfurization rate of the product is 93%, the octane number loss is 0.8 units, and the breakthrough sulfur capacity is 28%.

Embodiment 2

[0056] Put the adsorption desulfurizer 2 into a 1L fixed-bed adiabatic reactor. When the pressure is 0.8MPa, under the atmosphere of hydrogen-containing gas, the volume ratio of hydrogen to catalyst is 200:1 to establish a cycle, and the temperature rise rate is 10°C / h Raise the temperature to 260°C and stay for 3 hours, raise the temperature to 300°C and stay for 1 hour, raise the temperature to 350°C and stay for 5 hours, raise the temperature to 410°C and stay for 2 hours. The reaction process conditions are: reactor temperature 370°C, reaction pressure 0.8MPa, volume space velocity 5.8h -1 , the volume ratio of hydrogen to oil is 0.3; the desulfurization rate of the product is 96%, the octane number loss is 0.8 units, and the breakthrough sulfur capacity is 32%.

Embodiment 3

[0058] Put the adsorption desulfurizer 3 into a 200mL fixed-bed isothermal reactor. When the pressure is 0.8MPa, under the hydrogen atmosphere, the volume ratio of hydrogen to catalyst is 200:1 to establish a cycle, and the temperature is raised to 260 at a heating rate of 10°C / h. Stay at ℃ for 3 hours, raise the temperature to 300℃ and stay for 1h, raise the temperature to 350℃ and stay for 5h, raise the temperature to 410℃ and stay for 2h, after the pretreatment process is completed, adjust to the reaction process conditions, and enter the raw material 2 for reaction. The reaction process conditions are: reactor temperature 385°C, reaction pressure 0.8MPa, volume space velocity 7h -1 , the volume ratio of hydrogen to oil is 0.4; the desulfurization rate of the product is 90%, the octane number loss is 0.5 units, and the breakthrough sulfur capacity is 37%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com