Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce the proportion of micropores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

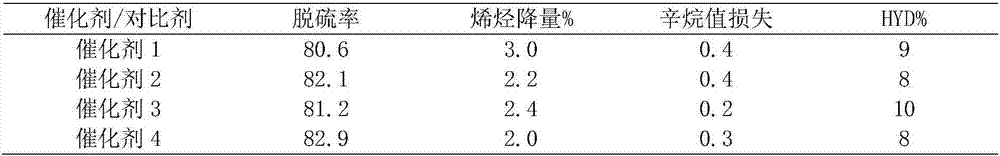

Hydrodesulfurization method of gasoline

InactiveCN106867576AAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

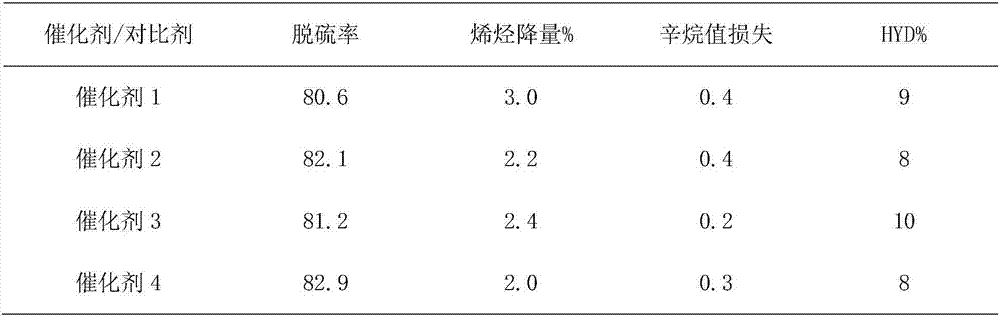

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

Method for selective hydrogenation through cracking of C5-C9 distillate

InactiveCN107159283AAperture size adjustableGood adhesive performancePhysical/chemical process catalystsRefining by selective hydrogenationPtru catalystHydrogenation reaction

The present invention relates to a method for selective hydrogenation through cracking of a C5-C9 distillate. According to the method, the catalyst comprises an alumina carrier having a macroporous structure and metal active components comprising nickel and tungsten and supported on the carrier, the nickel oxide content is 12-22 wt% based on the total weight of the catalyst, the tungsten oxide is 1.5-8 wt% based on the total weight of the catalyst, and the hydrogenation reaction process conditions are that the reaction inlet temperature is 40-55 DEG C, the reaction pressure is 2.0-3.5 MPa, the hydrogen oil volume ratio is 60-150, and the liquid volume space velocity is 3.0-5.5 h<-1>. According to the present invention, the catalyst has characteristics of good glue capacity, strong arsenic resistance, strong sulfur resistance, strong coking inhibition and low temperature activity; and the method provides strong adaptability for the cracking gasoline raw materials having different arsenic contents and different sulfur contents.

Owner:QINZHOU UNIV

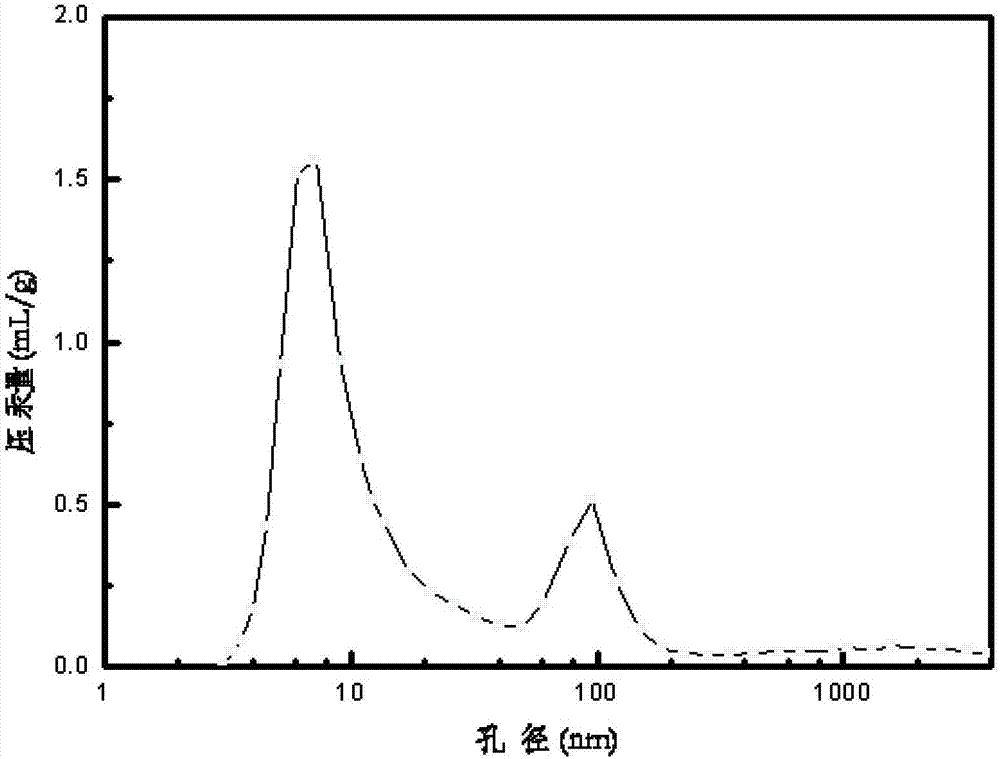

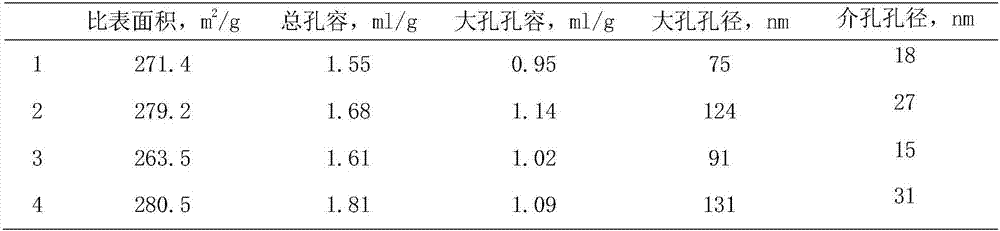

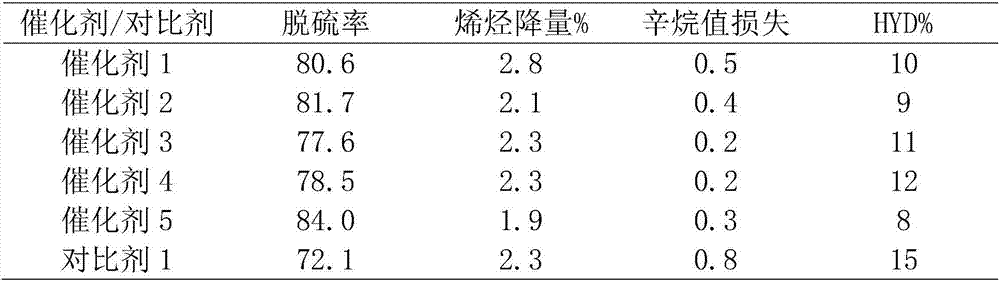

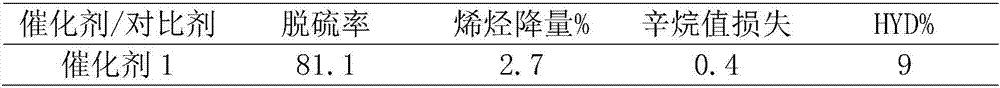

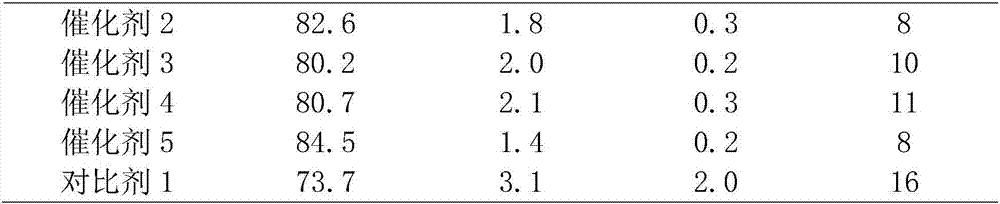

Catalyst for hydrogen desulfurization of catalytic cracking gasoline and preparation method of catalyst

ActiveCN107081155AAperture size adjustableLow priceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

The invention discloses a catalyst for hydrogen desulfurization of catalytic cracking gasoline and a preparation method of the catalyst. The catalyst comprises the following components based on mass of oxides: 78.0-94.0wt% of an alumina supporter of a macroporous structure, 2.0-10.5wt% of an active ingredient cobalt oxide and 2.5-15.0wt% of molybdenum oxide, wherein the supporter takes chitosan as a pore-enlarging agent. The hydrogen desulfurization catalyst is low in octane loss and high in desulfurization rate.

Owner:廊坊高科广大科技有限公司

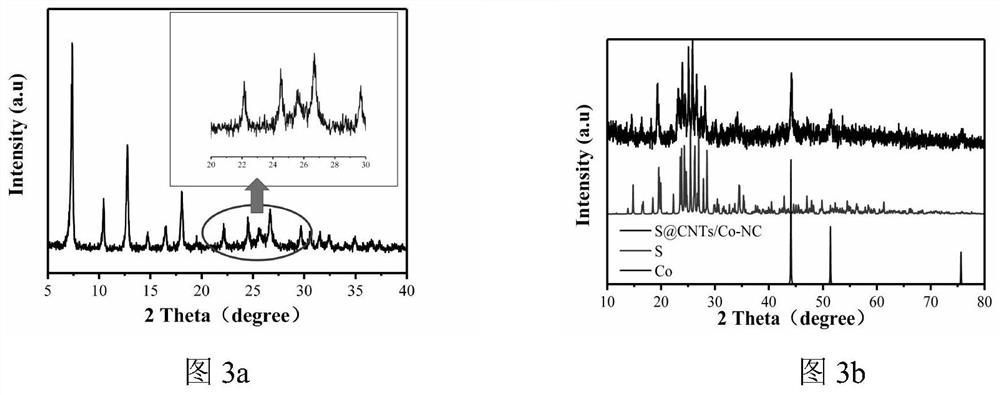

Lithium-sulfur battery positive electrode material containing three-dimensional interpenetrating composite carbon material and preparation method thereof, positive electrode plate containing lithium-sulfur battery positive electrode material, and lithium-sulfur battery

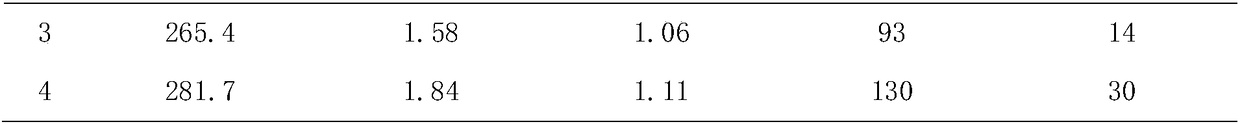

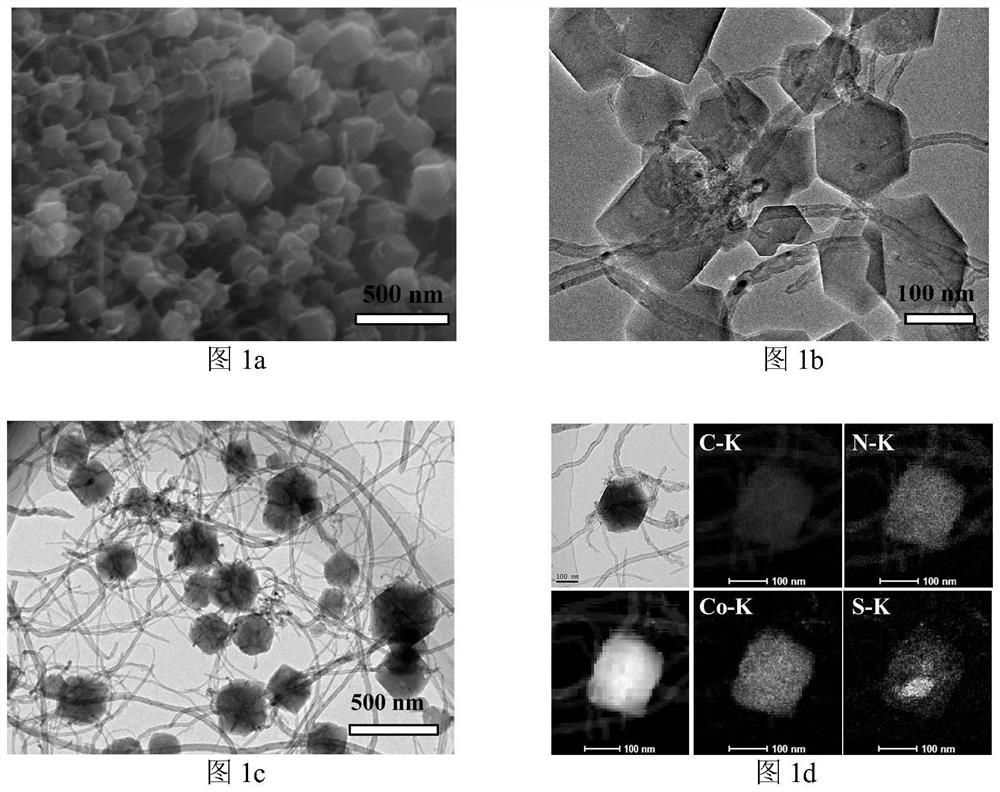

ActiveCN110729463AFacilitate conductionIncrease profitElectrode collector coatingNon-aqueous electrolyte accumulator electrodesActivated carbonLithium–sulfur battery

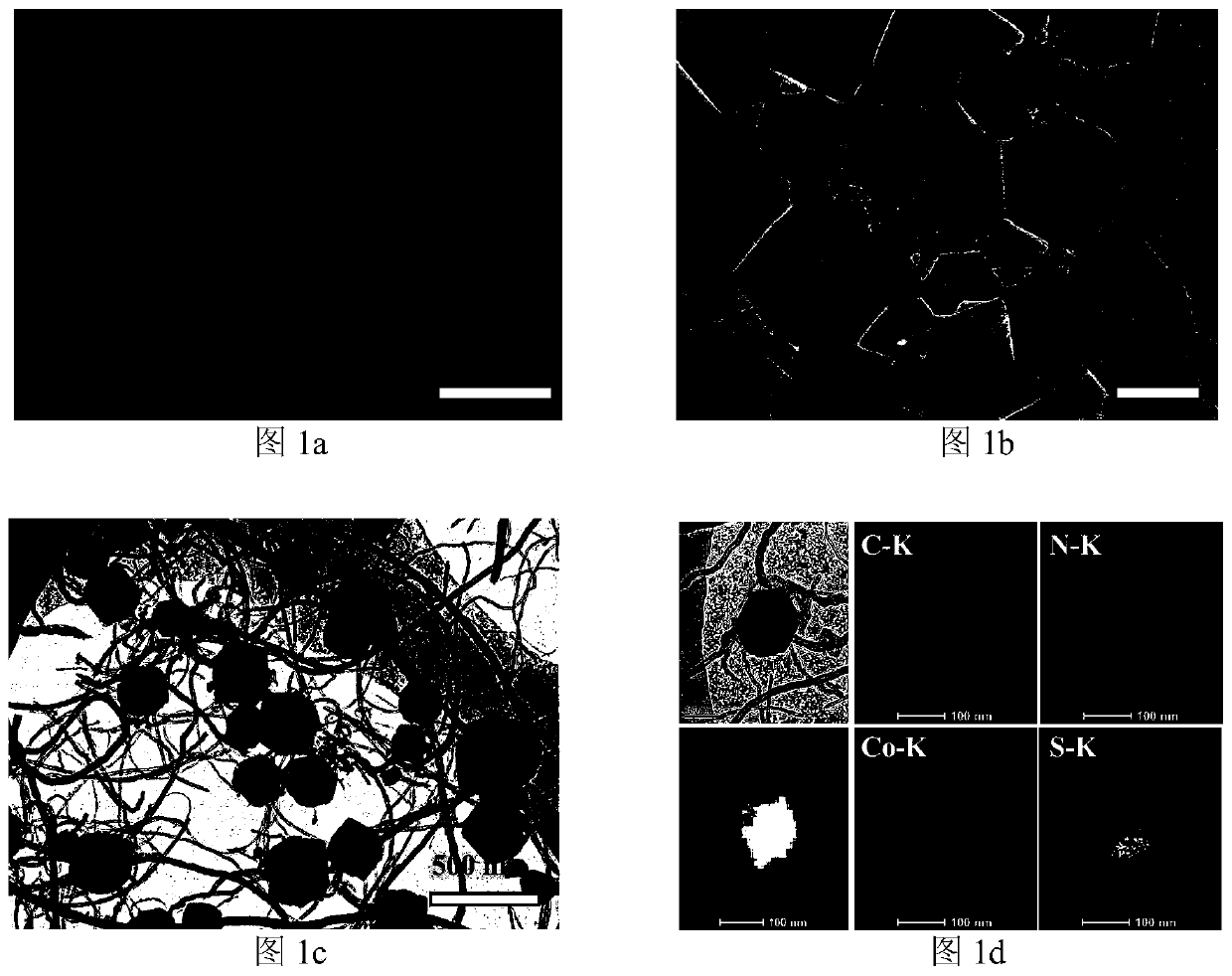

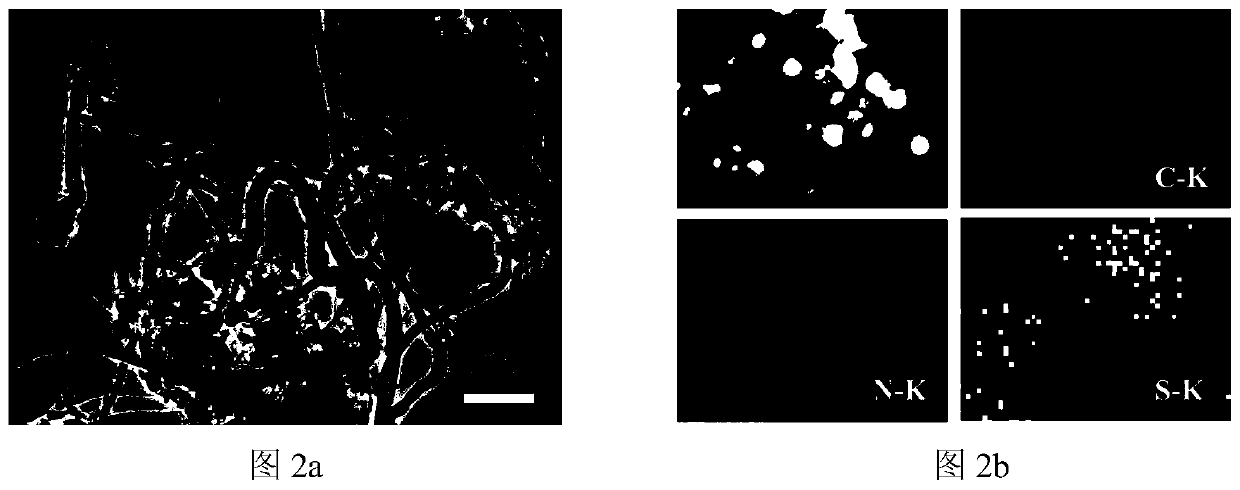

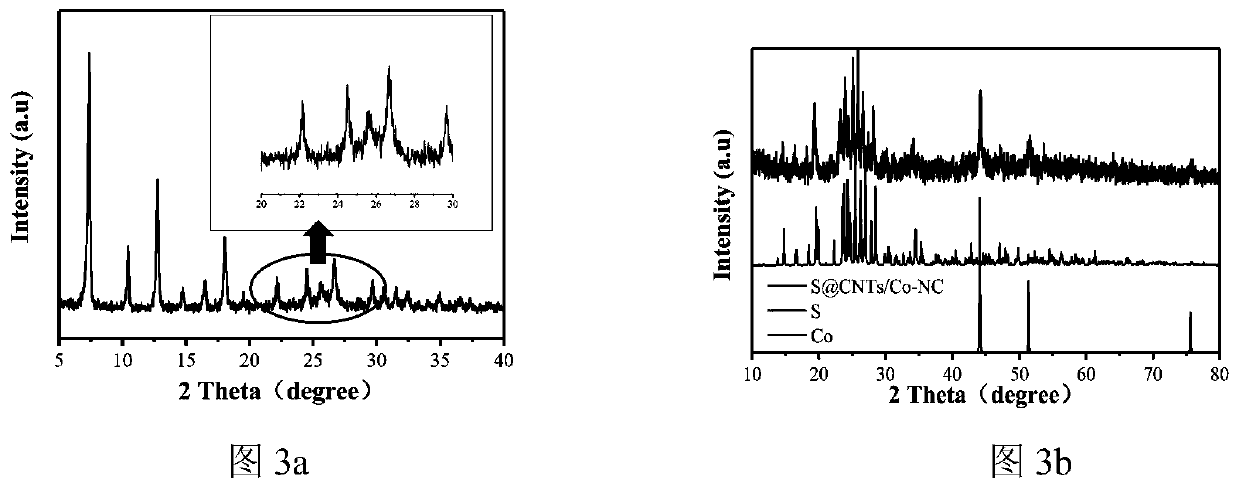

The invention discloses a lithium-sulfur battery positive electrode material containing a three-dimensional interpenetrating composite carbon material and a preparation method thereof, a positive electrode plate containing the lithium-sulfur battery positive electrode material, and a lithium-sulfur battery. The composite carbon material has a three-dimensional interpenetrating network structure and is formed from carbon nanotubes and ZIF-67 derived hierarchical porous carbon polyhedrons by interpenetrating. ZIF-67 is grown on the surface of activated carbon nanotubes used as a framework, and the ZIF-67 is carbonized into hierarchical porous carbon polyhedrons through high-temperature sintering. The preparation method of the lithium-sulfur battery positive electrode active material comprises the following steps: weighing the composite carbon material and elemental sulfur according to a mass ratio of 1: 4; uniformly dispersing the composite carbon material and the elemental sulfur in a CS2 solution; carrying out stirring until the solvent is completely volatilized; and infiltrating the elemental sulfur in the mixture into a carbon structure by using a melting method. The positive electrode plate is composed of the positive electrode active material, superconducting carbon and a binder in a mass ratio of 8: 1: 1. The lithium-sulfur battery is mainly composed of the positive electrode plate, a diaphragm, an electrolyte and a lithium metal negative electrode.

Owner:NAT UNIV OF DEFENSE TECH

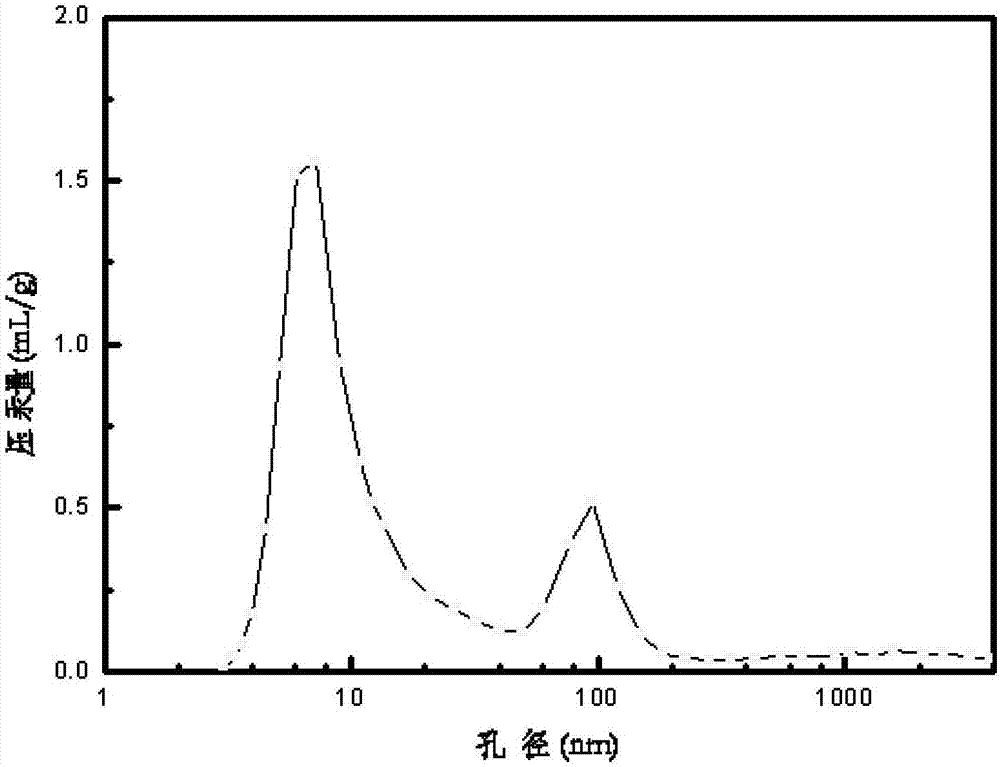

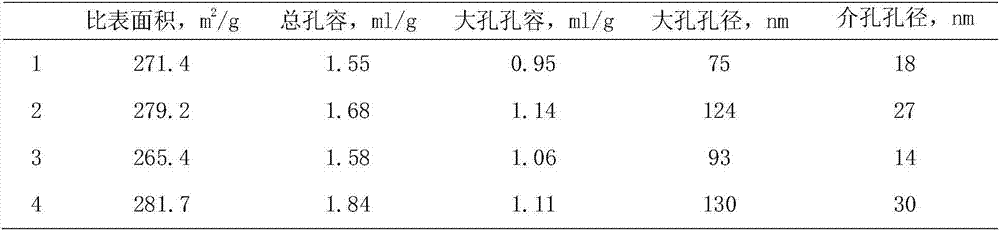

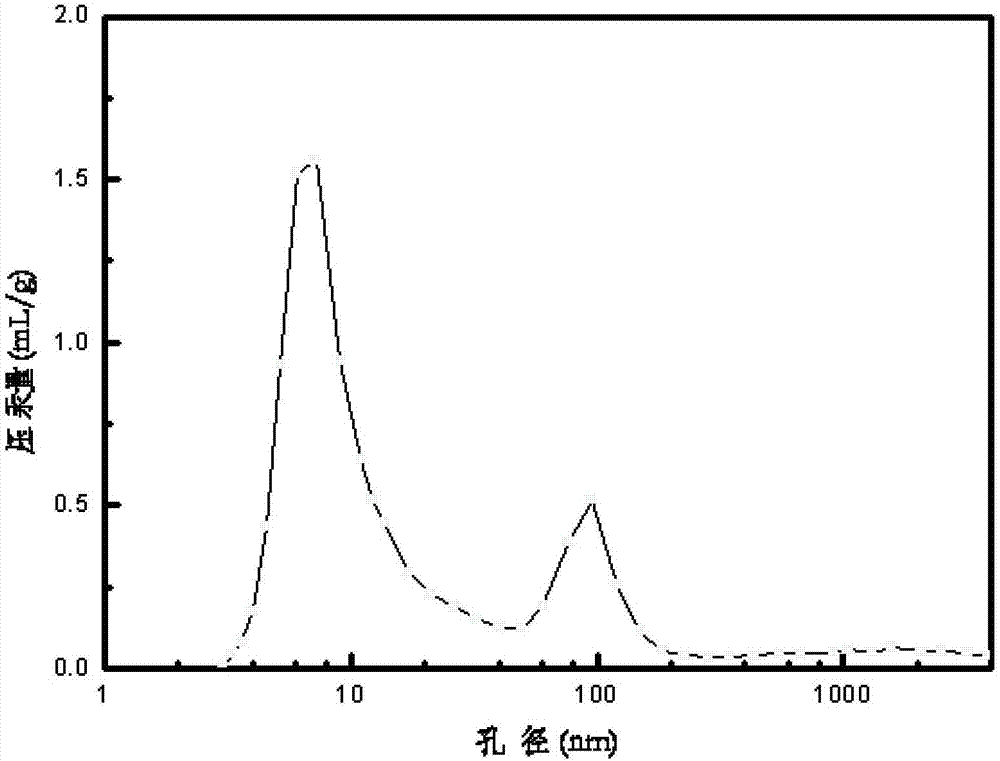

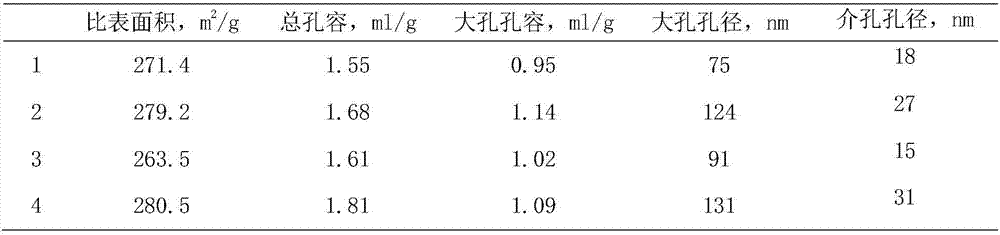

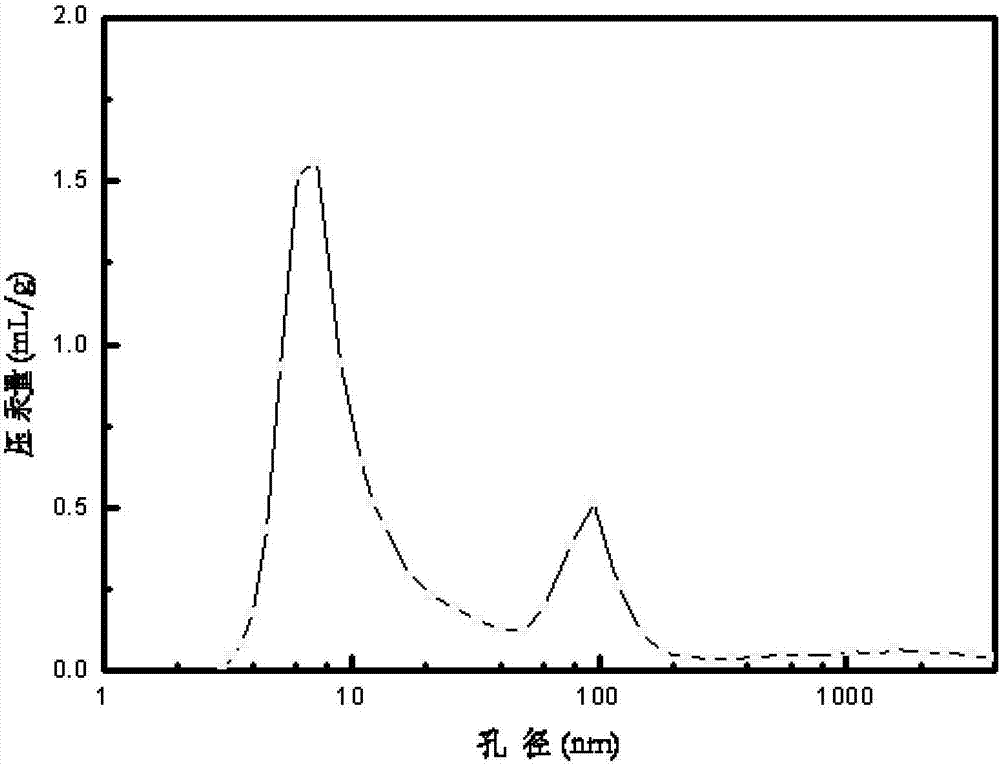

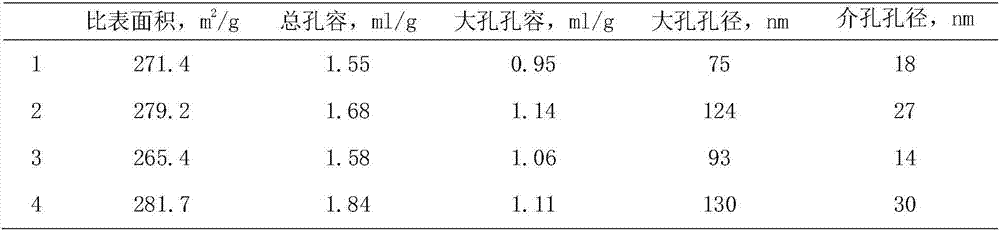

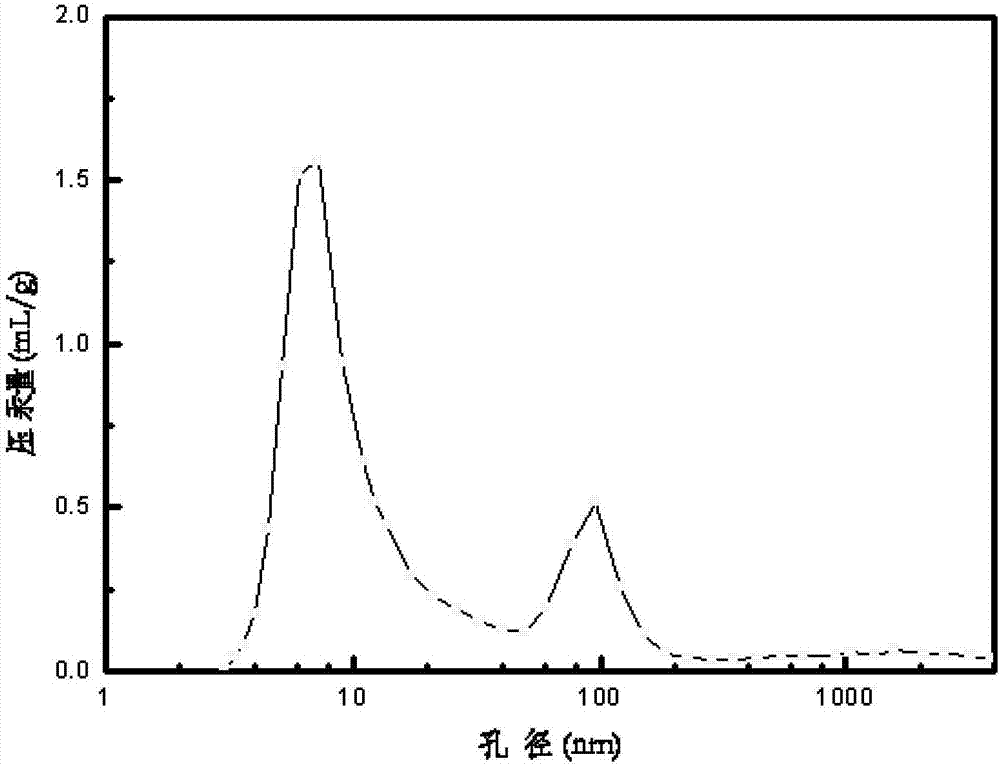

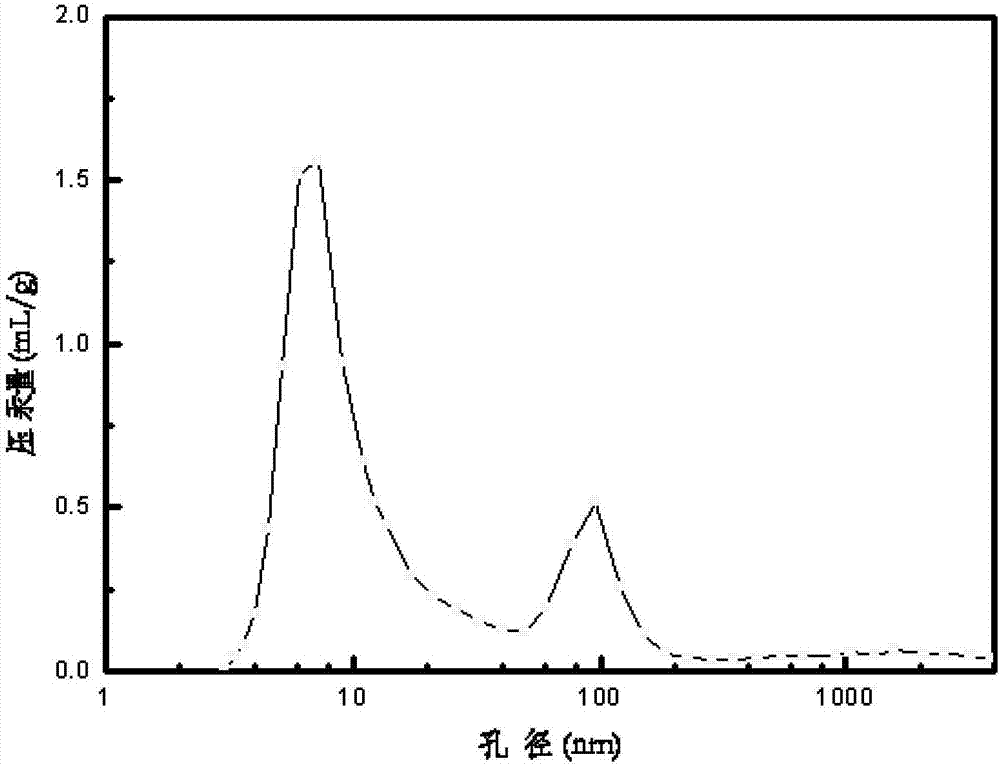

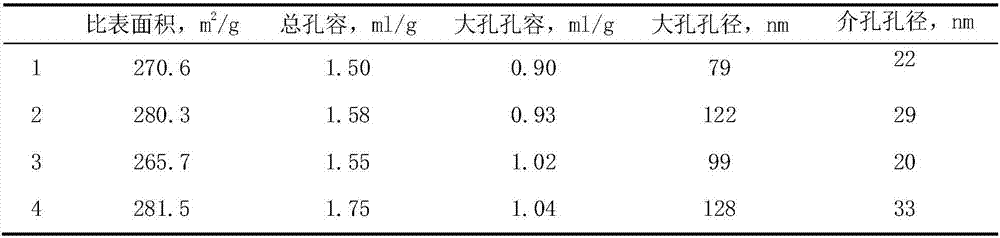

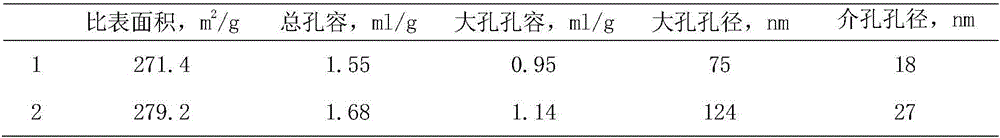

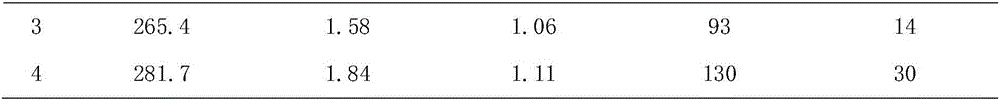

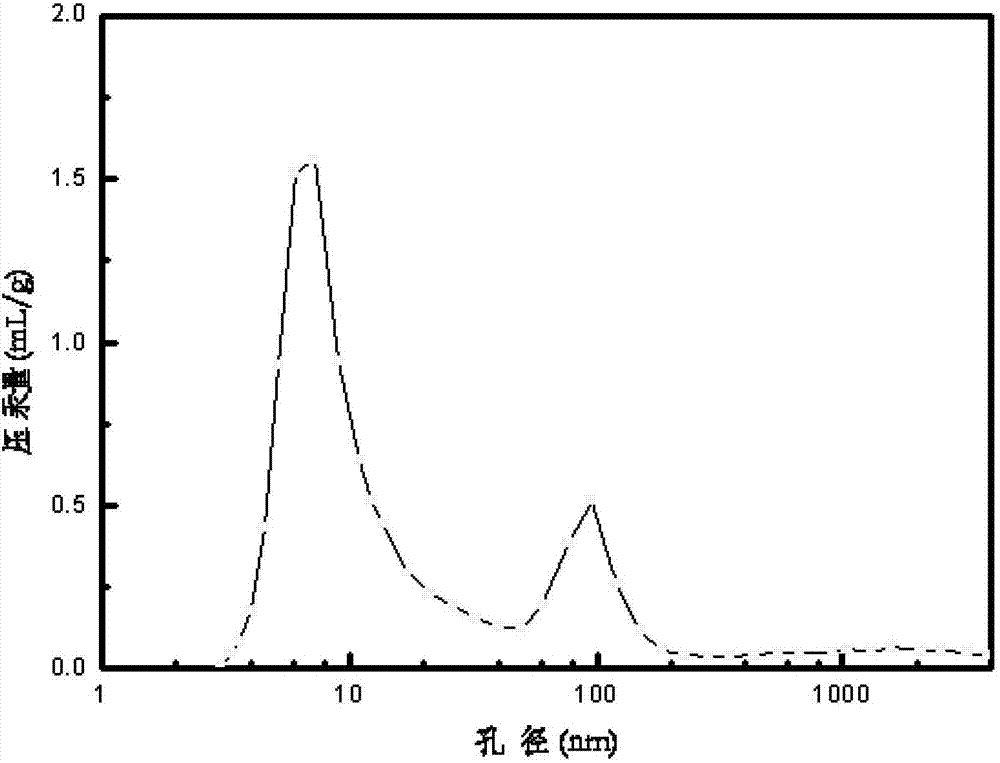

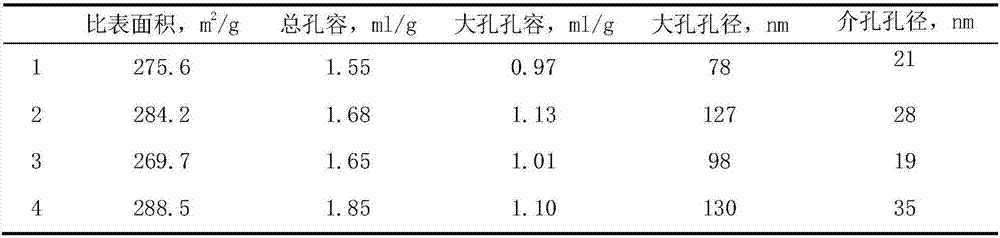

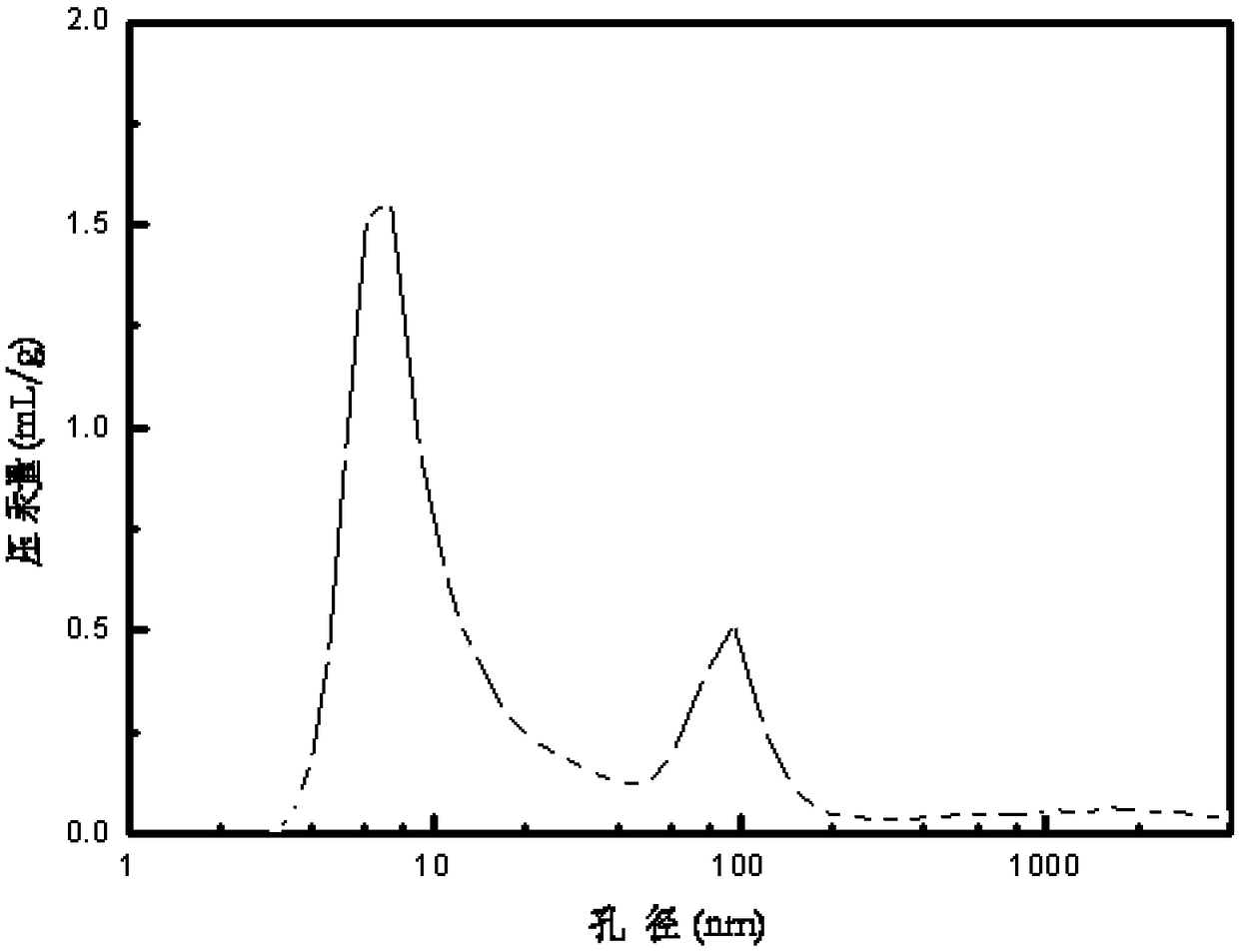

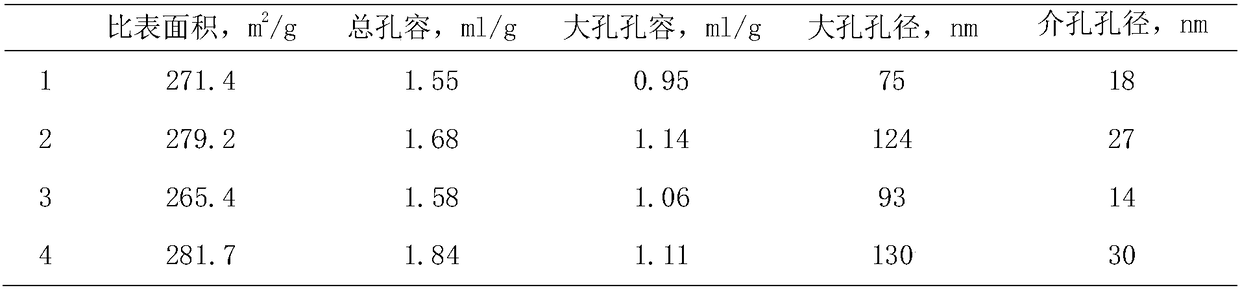

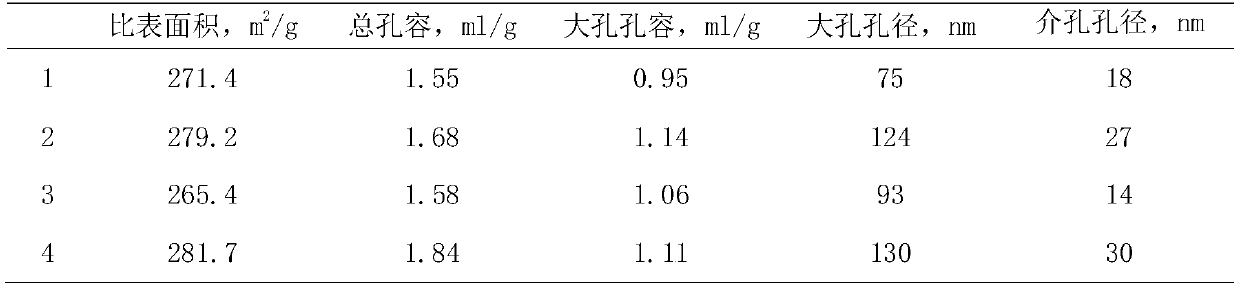

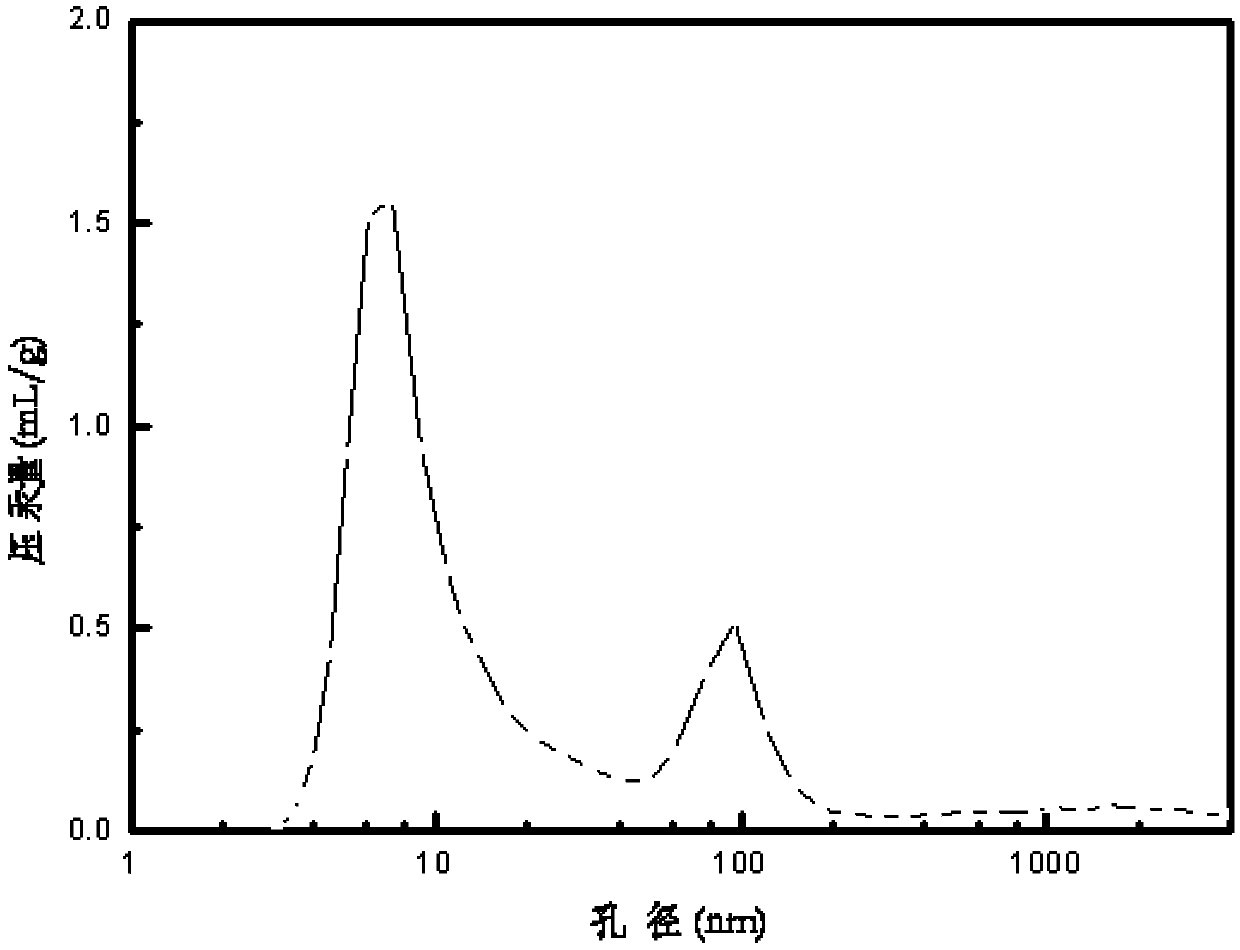

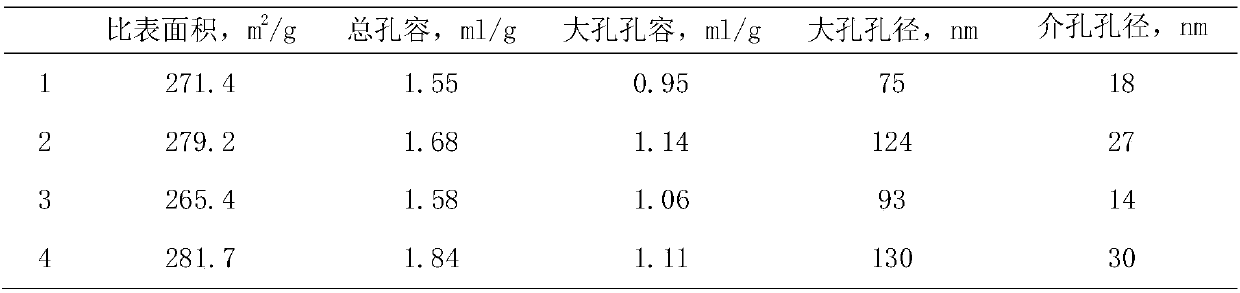

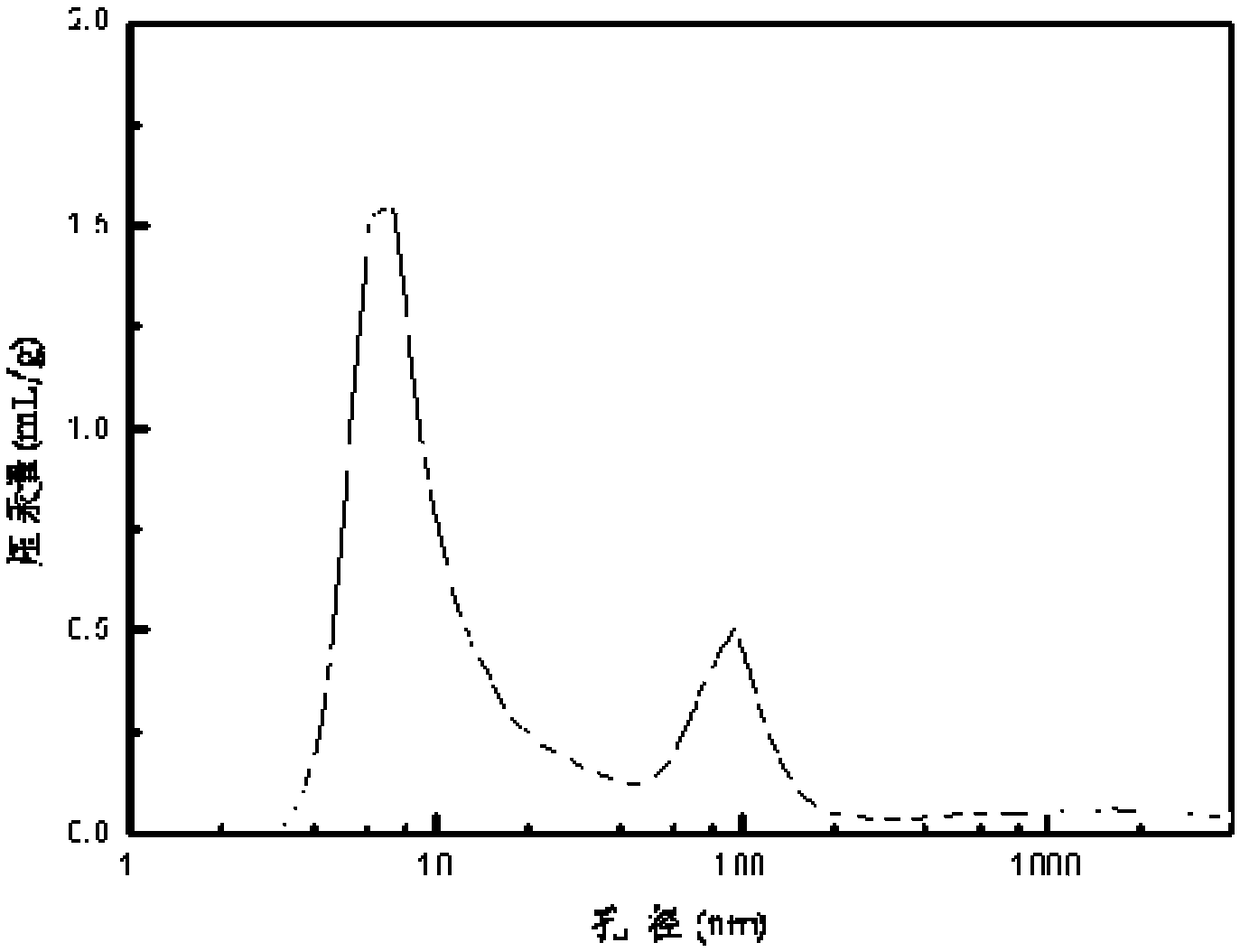

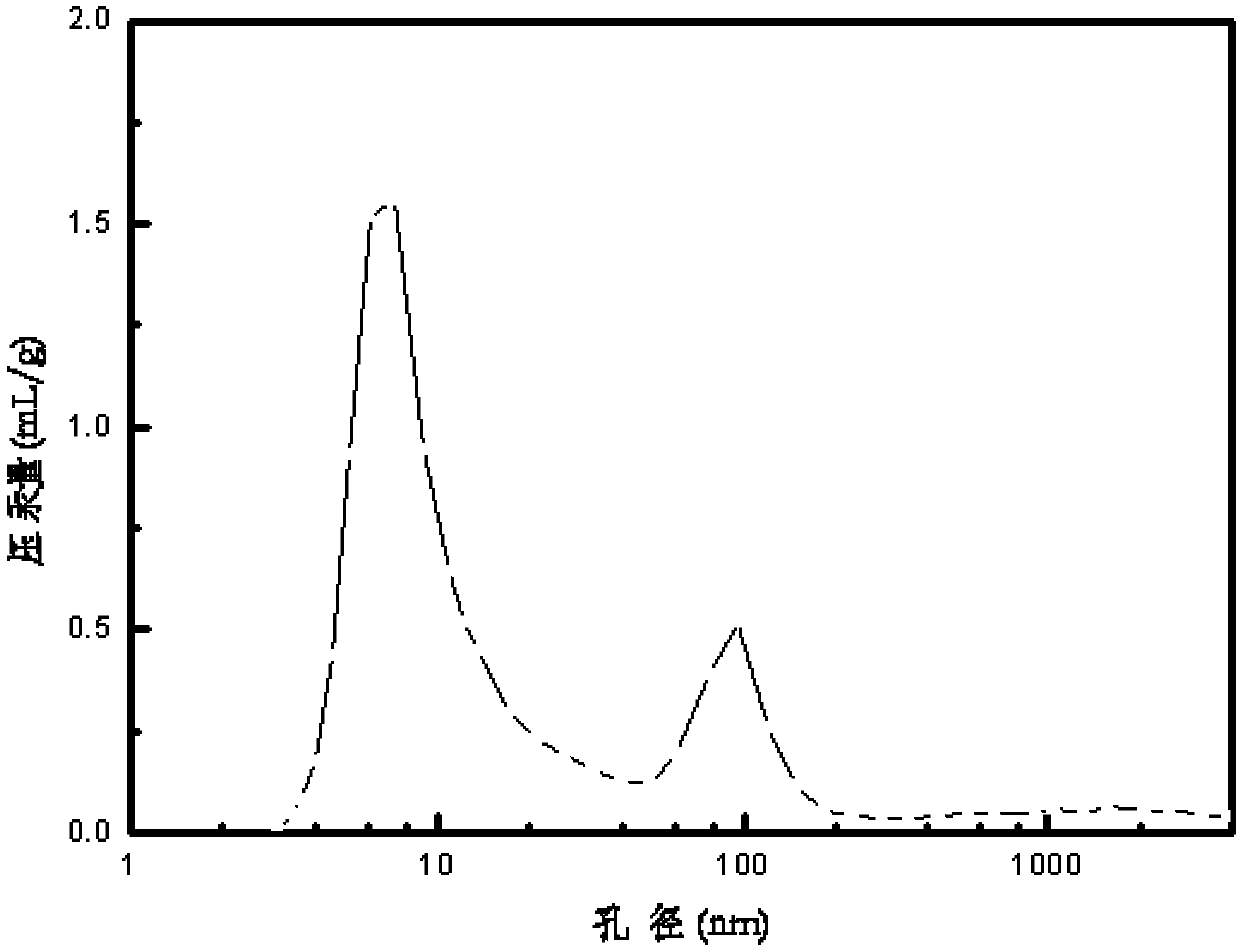

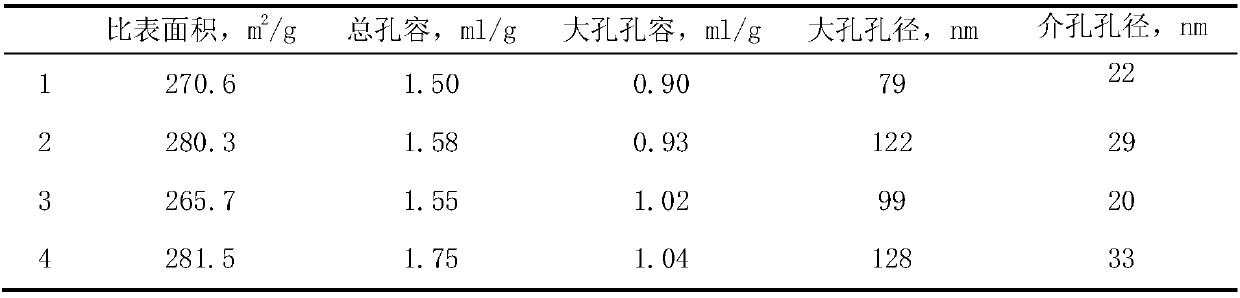

Aluminum oxide carrier with macro-porous structure and preparation method

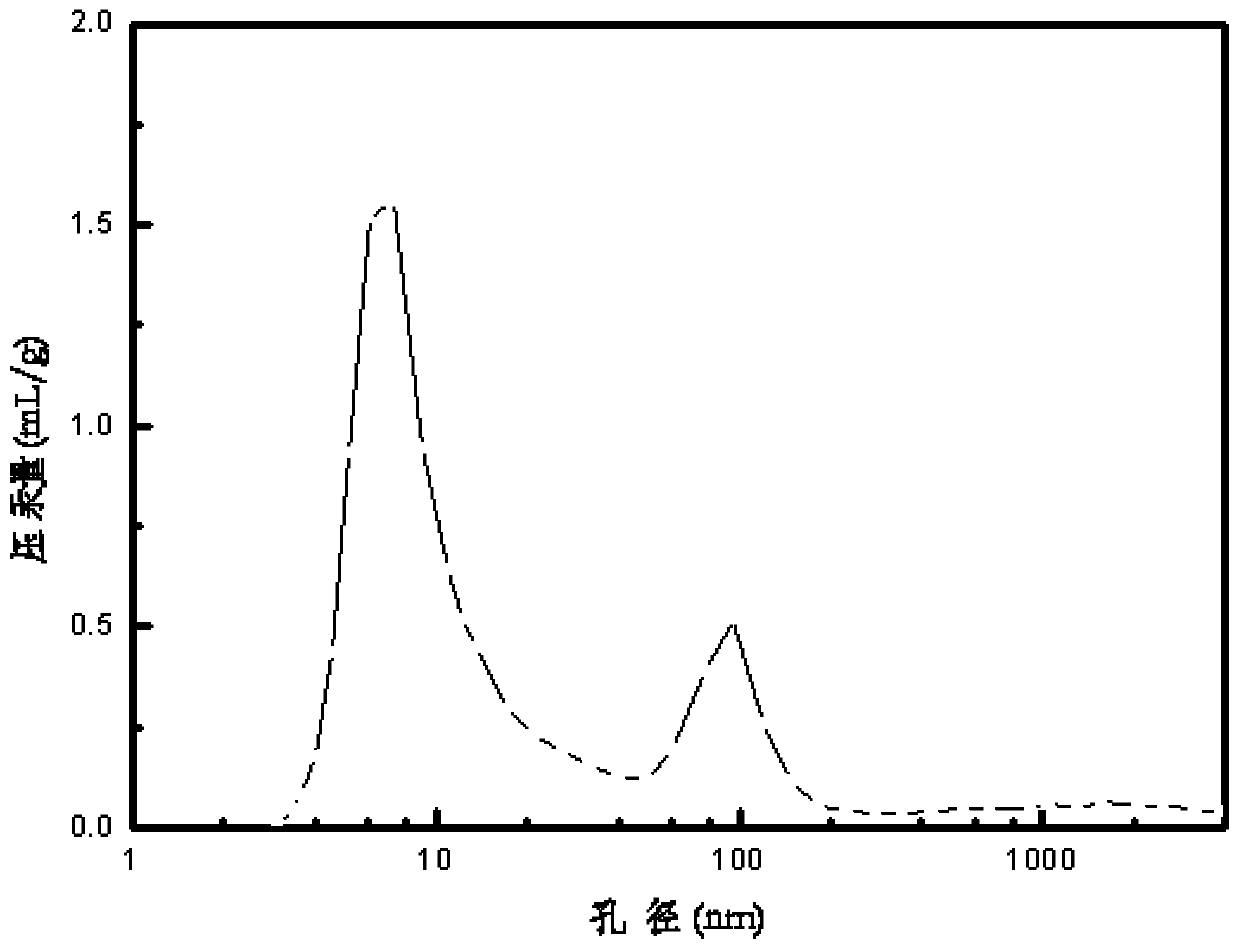

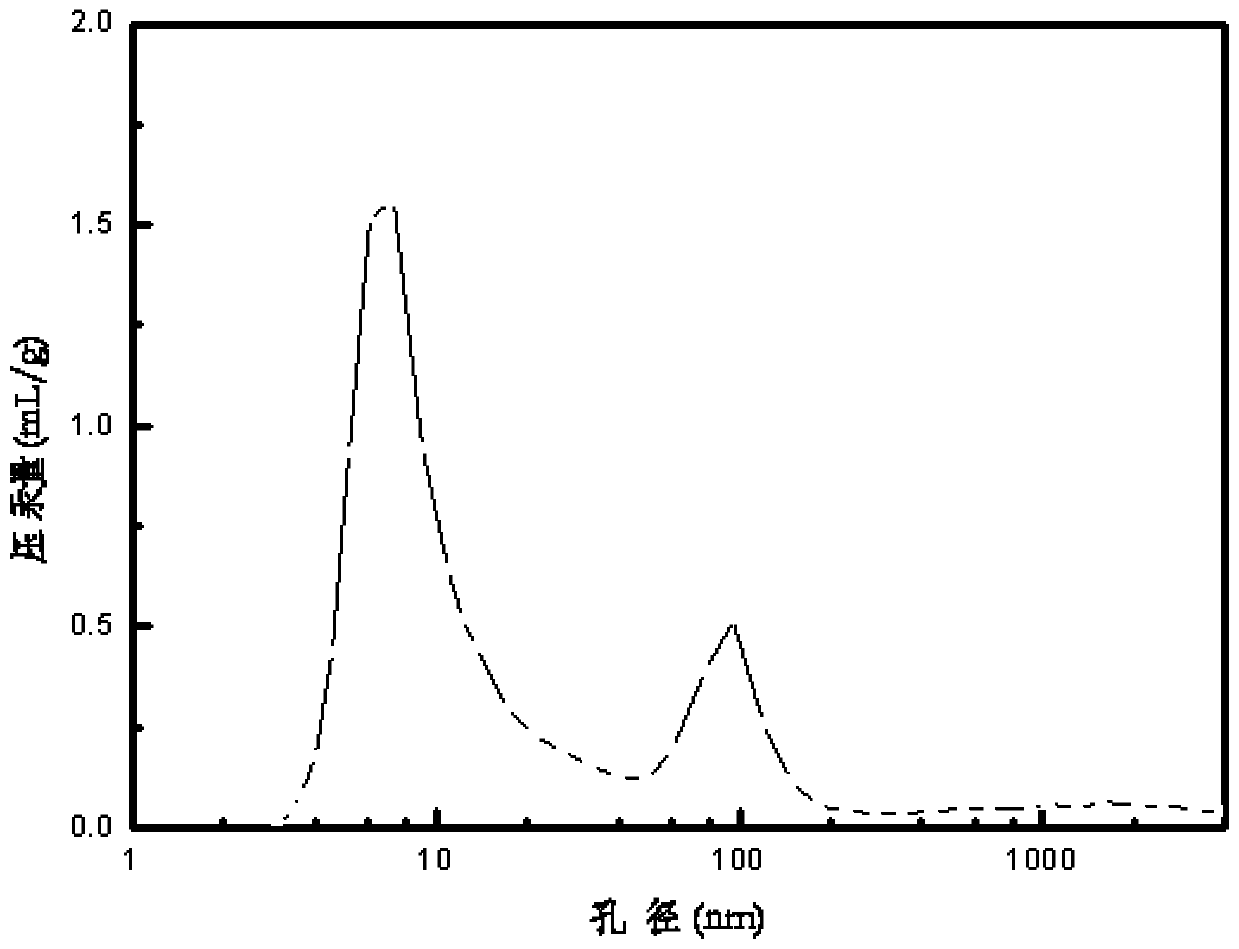

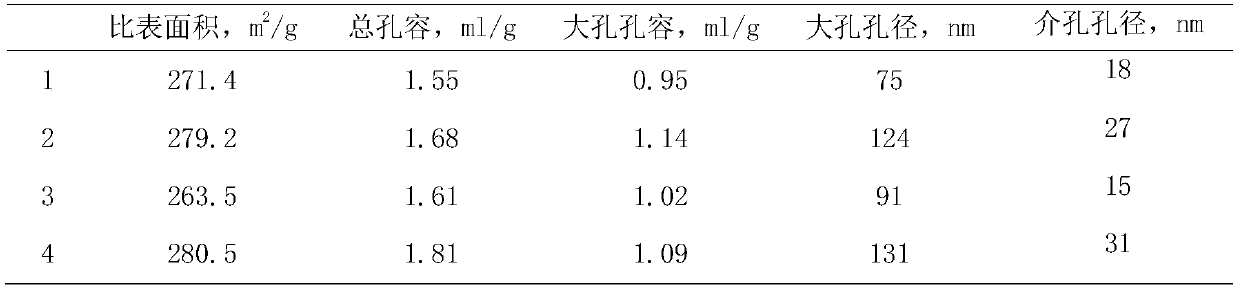

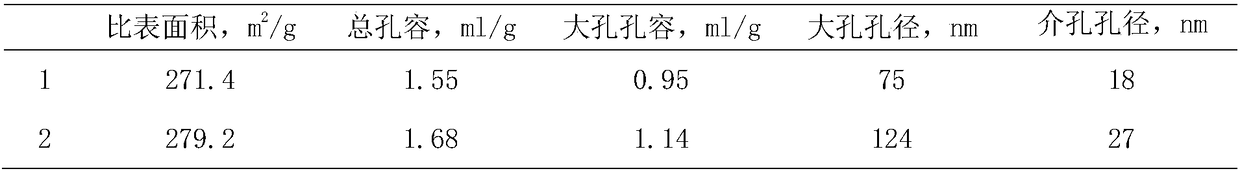

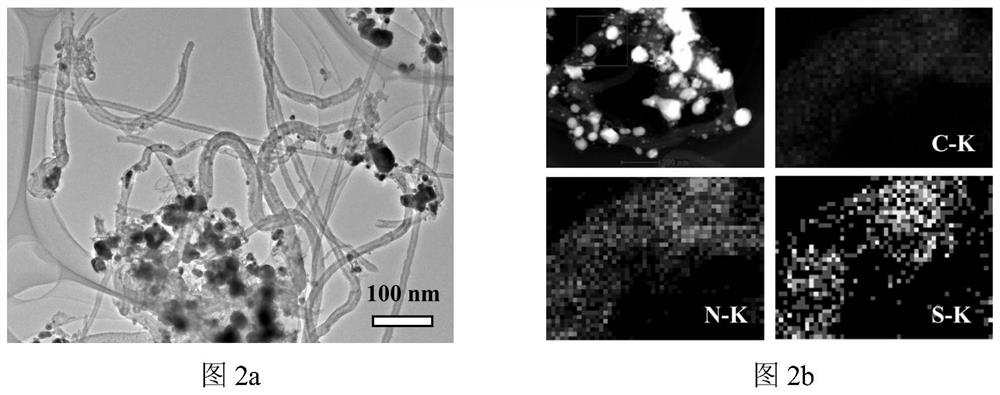

ActiveCN106994361AAperture size adjustableEffective control of macropore ratioCatalyst carriersPetrochemicalPore diameter

The invention relates to an aluminum oxide carrier with a macro-porous structure. The carrier contains auxiliary agent components phosphorus and magnesium, wherein the content of the auxiliary agent components phosphorus and magnesium in the carrier is as follows in percentage by mass: 0.1 weight percent to 2.5 weight percent of P2O5 and 0.1 weight percent and 2.5 weight percent of MgO; the pore diameter distribution is 60nm to 180nm, the macro-pore ratio is 2 percent to 75 percent, the pore capacity is 0.8ml / g to 2.0ml / g and the specific surface area is 250m<2> / g to 300m<2> / g; macro-porous aluminum oxide has the characteristics of adjustable pore diameter size and capability of effectively controlling the macro-pore ratio. The aluminum oxide carrier with the macro-porous structure can be used for the fields including petrochemical industry and fine chemical engineering.

Owner:QINZHOU UNIV

Method for hydrogenation and arsenic removal of distillate oil

InactiveCN107011939AAperture size adjustableLow pricePhysical/chemical process catalystsHydrocarbon oils treatmentReaction temperatureFixed bed

The invention discloses a method for hydrogenation and arsenic removal of distillate oil. The active centers of a catalyst are nickel and molybdenum; an alumina carrier with a macroporous structure is used as a catalyst carrier and accounts for 70.0 to 96.0 wt%; the active component nickel oxide accounts for 2.0 to 20.0 wt%; and the active component nickel oxide accounts for 2.0 to 10.0 wt%. A fixed-bed reactor is used in a reaction. Process conditions are that reaction temperature is 120 to 220 DEG C; reaction pressure is 1.0 to 4.0 MPa; a hydrogen-oil volume ratio is 100-300: 1; and volume space velocity is 1.0 to 10.0 / h. The method has the following advantages: reaction conditions are mild; raw materials are widely available; the arsenic removal rate of a product is high; and the catalyst has long-period reaction activity, good stability and a long operation period.

Owner:QINZHOU UNIV

Preparation method of flue gas denitration catalyst

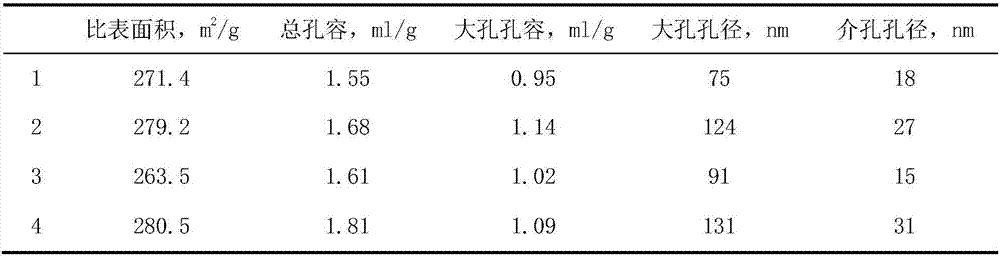

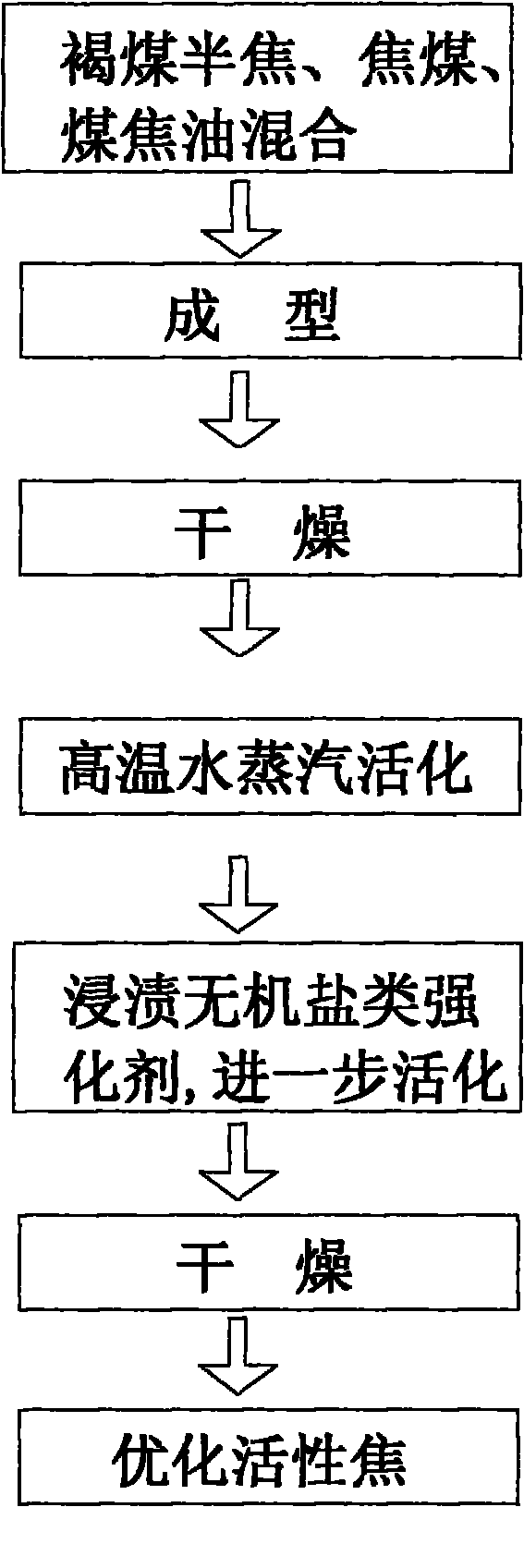

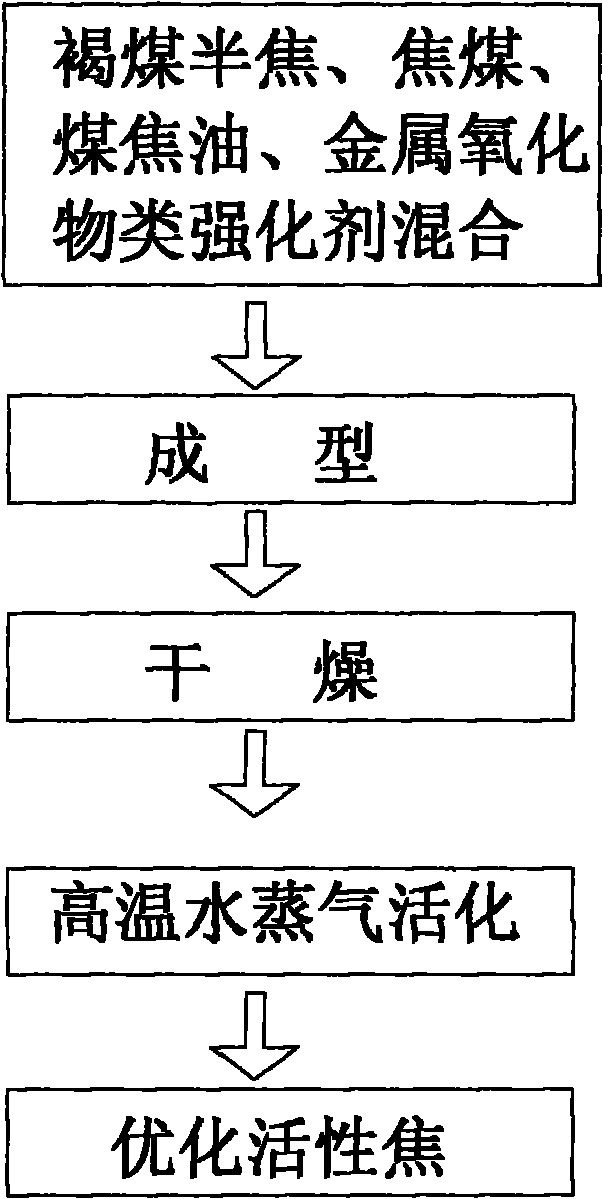

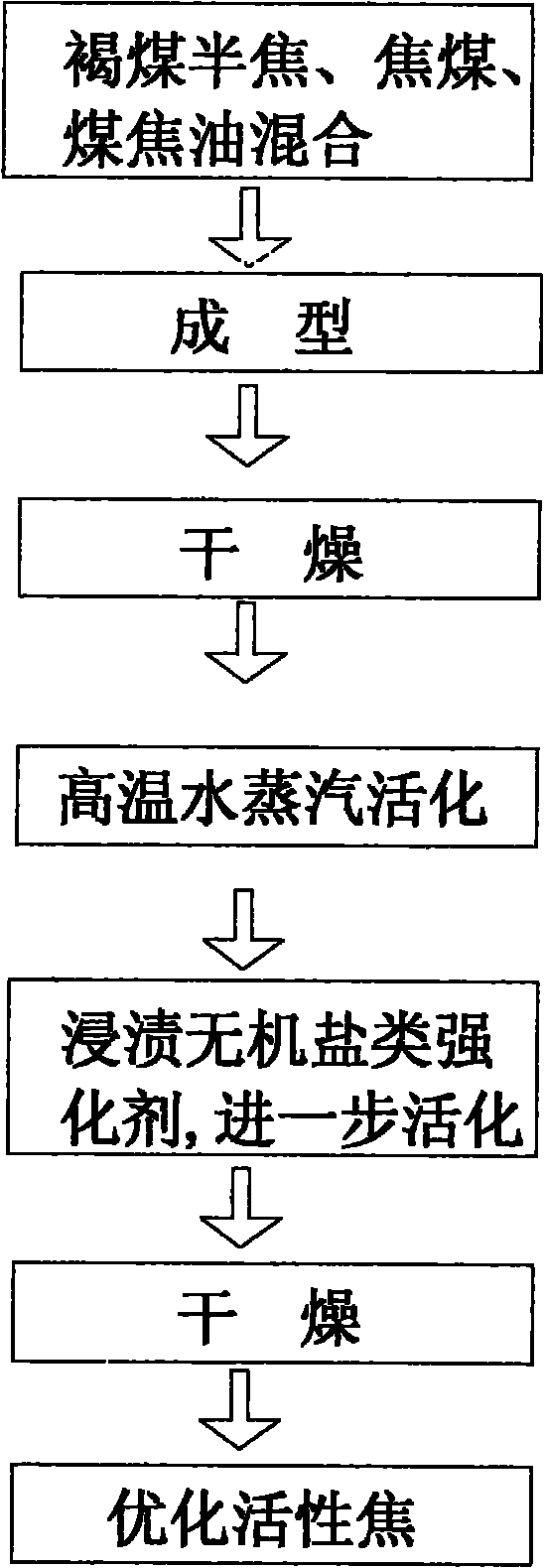

InactiveCN101767041AIncrease oxygen contentLow degree of coalificationDispersed particle separationCatalyst activation/preparationInorganic saltsFlue gas

The invention discloses a preparation method of flue gas denitration catalyst, which solves the problem of expensive denitration catalyst and low denitration efficiency in the prior art. The adopted technical scheme is as follows: the method comprises the processing process and method of lignite char, which comprise the following steps and sequence: preparing the lignite char through using lignite as raw material, according to weight percentage of 47-75% :10-35%:5-24%, mixing, forming, drying the lignite char, the lignite, and the coal tar to prepare active coke, adding the enhancer to the active coke for further activation, in order to prepare the optimized active coke. The invention uses the lignite as main raw material, uses the inorganic salt or metal oxide as the enhancer; the advantages of the invention are as follows: the manufacturing cost is low, and the product catalytic effect is good.

Owner:王向明

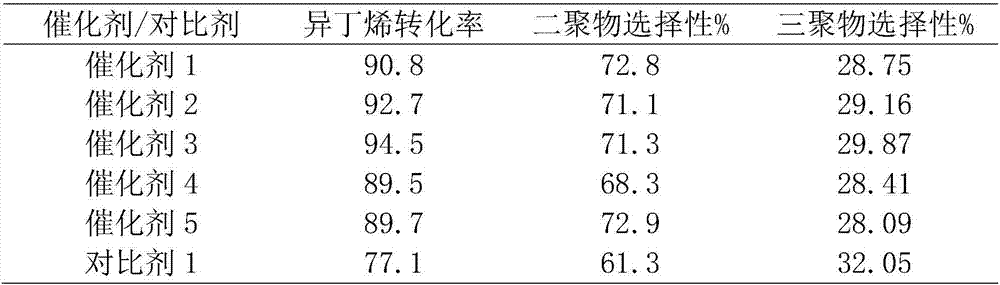

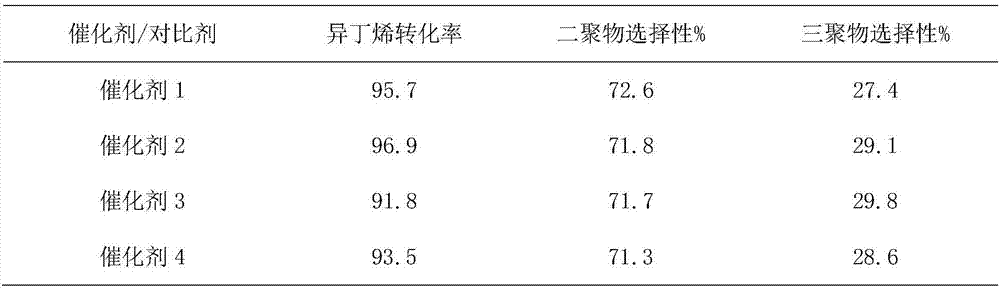

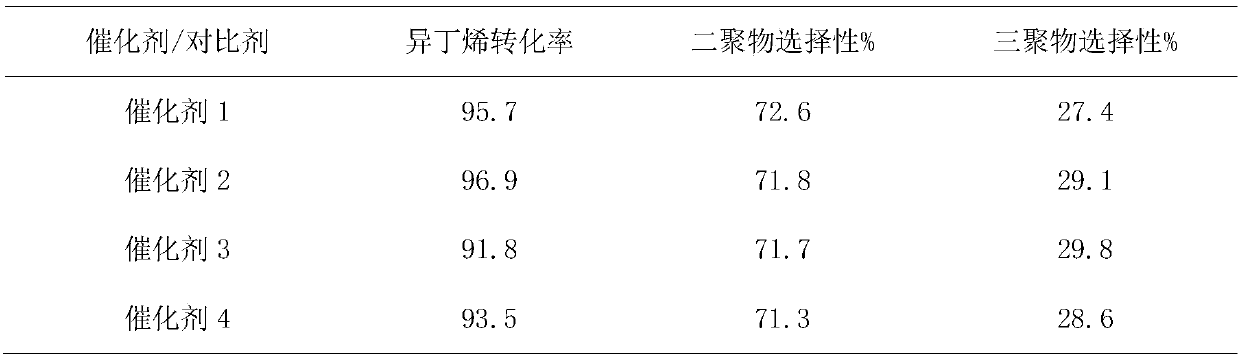

Catalyst for isobutene oligomerization and preparation method thereof

InactiveCN106861731AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxidePhysical/chemical process catalystsIron sulfatePtru catalyst

The invention relates to a catalyst for isobutene oligomerization and a preparation method thereof. The catalyst is composed of the following components in terms of oxide mass: 80.0-97.0wt% of a composite carrier containing zinc oxide-alumina, 4.0-15.0wt% of active component iron sulfate, and 1.0-6.0wt% of nickel sulfate. The catalyst has high oligomerization activity, the dimer selectivity is high, the trimer selectivity is low, and the catalyst operation cycle is long.

Owner:QINZHOU UNIV

First-stage selective hydrogenation method for pyrolysis gasoline

InactiveCN107057757AGood choiceHigh activityCatalyst activation/preparationRefining by selective hydrogenationRaw materialChemistry

The invention relates to a first-stage selective hydrogenation method for pyrolysis gasoline. The pyrolysis gasoline is C6-C8 fraction, a catalyst comprises an alumina supporter with a macroporous structure and metal active components including nickel and tungsten which are supported on the supporter, wherein the content of nickel oxide is 12wt%-22wt% of total weight of the catalyst, the content of tungsten oxide is 1.5wt%-8wt% of the total weight of the catalyst, and technological conditions of the hydrogenation reaction are shown as follows: the reaction inlet temperature is 60-100 DEG C, the reaction pressure is 2.0-3.5 MPa, a volume ratio of hydrogen to oil is 60-180, and volume space velocity of a liquid is 3.0-5.5 h<-1>. The catalyst is better in colloid tolerance capacity, is arsenic-resistant and sulfur-resistant, has high coking inhibition capacity and is well-adapted to pyrolysis gasoline raw materials with different arsenic content and different sulfur content.

Owner:QINZHOU UNIV

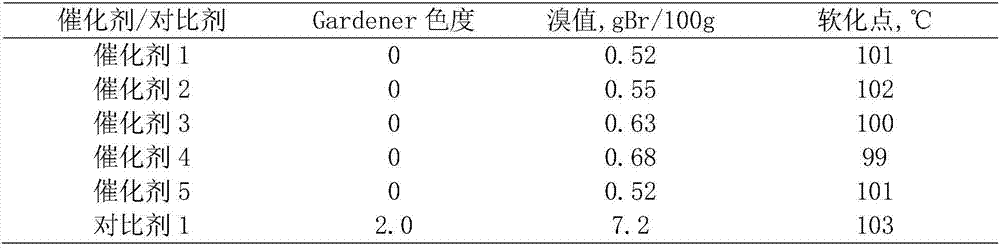

Catalyst for C5 petroleum resin hydrogenation and preparation method thereof

InactiveCN106861730AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxidePhysical/chemical process catalystsPtru catalystHigh activity

The invention discloses a catalyst for C5 petroleum resin hydrogenation and a preparation method thereof. The catalyst comprises the following components by mass: 78.0-96.0wt% of a composite carrier containing zinc oxide-alumina, 1.0-8.0wt% of an active component, 1.0-15.0wt% of nickel phosphide, and 0.1-2.5wt% of lanthanum oxide. C5 petroleum resin has high hydrogenation activity and good activity stability, the catalyst active center loss rate is low, and the operation period is long.

Owner:QINZHOU UNIV

Hydrogenating and arsenic removing method of naphtha

ActiveCN106833731AHigh rate of hydrodearsenizationGood activity and stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentNaphthaActive component

The invention discloses a hydrogenating and arsenic removing method of naphtha. A catalyst used by the method comprises, by the mass of oxide, 72.0-90.0wt% of composite support containing zinc oxide-aluminum oxide, 6.0-16.0wt% active component nickel oxide, 2.0-6.0wt% of molybdenum oxide and 2.0-6.0wt% of tungsten oxide. The method is mild in reaction condition, wide in raw material application range, high in product arsenic removing, good in long-period reaction activity stability and long in operation period.

Owner:山东明成石化有限公司

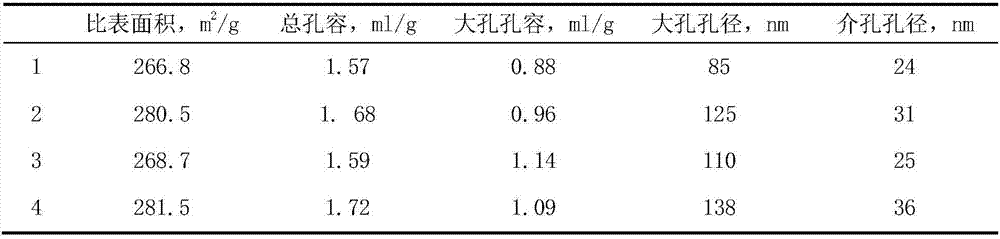

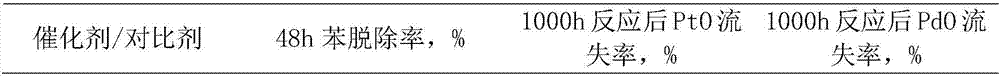

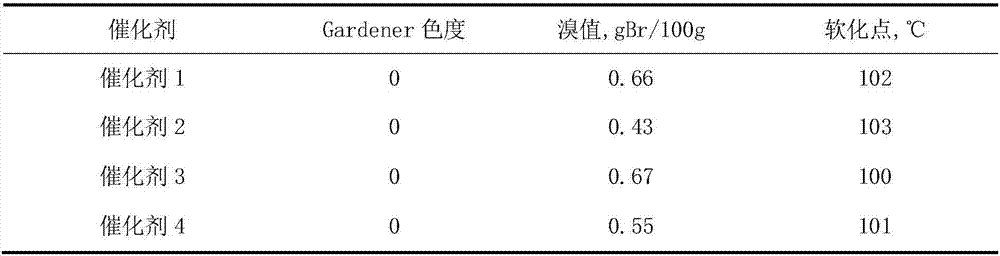

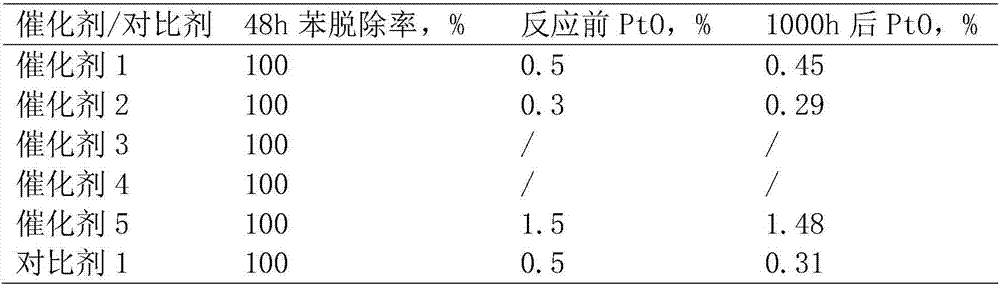

A benzene hydrogenation catalyst and a preparing method thereof

InactiveCN107096533AAperture size adjustableGood resistance to impuritiesHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsBenzeneActive component

A benzene hydrogenation catalyst and a preparing method thereof are disclosed. The catalyst includes, based on mass of oxides, 90.3-97 wt% of an alumina carrier having a macroporous structure and adopting chitosan as a pore-enlarging agent, 0.2-4.9 wt% of an active component that is platinum oxide and 0.2-4.8 wt% of an active component that is palladium oxide. The macroporous alumina carrier comprises auxiliary components which are tin, lanthanum and potassium. The catalyst has high benzene hydrogenation activity, the rate of loss of precious metal active components is low, and an operation cycle is long.

Owner:QINZHOU UNIV

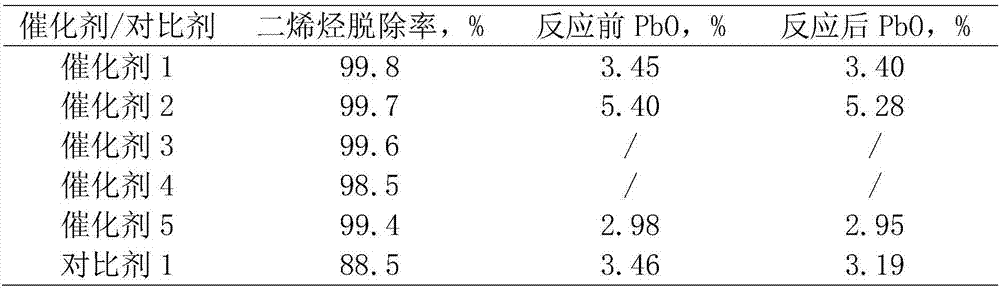

Catalyst for dialkene hydrogenation and preparation method of catalyst

InactiveCN106881125AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxideHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsBULK ACTIVE INGREDIENTIron oxide

The invention discloses a catalyst for dialkene hydrogenation and a preparation method of the catalyst. The catalyst comprises the following ingredients in percentage by oxide mass: 91.0wt% to 97.5wt% of zinc oxide-aluminum oxide containing composite support, 1.5wt% to 5.5wt% of active ingredient, i.e., palladium oxide, 0.5wt% to 1.5wt% of auxiliary active ingredient, i.e., auric oxide and 0.5wt% to 2.0wt% of lanthanum oxide. According to the catalyst, the dialkene hydrogenation activity is high, the rate of loss of noble metal active ingredients is low, and the running cycle is long.

Owner:QINZHOU UNIV

Olefin oligomerization catalyst and preparation method thereof

InactiveCN107185560AAperture size adjustableGood resistance to impuritiesPhysical/chemical process catalystsHydrocarbonsAdditive ingredientSulfate

The invention discloses an olefin oligomerization catalyst and a preparation method thereof. The catalyst is prepared from the following ingredients through being metered by the mass of oxides: 81.0 to 96.0 weight percent of aluminum oxide carriers with macroporous structures (carriers use chitosan as pore-enlarging agents), 2.5 to 11.5 weight percent of active ingredients of ferric sulfate and 1.5 to 7.5 weight percent of nickel sulfate. The olefin oligomerization catalyst has the advantages that the oligomerization activity is high; the dioolymer selectivity is high; the trimer selectivity is low; the operation period of the catalyst is long.

Owner:QINZHOU UNIV

Composite carrier containing zinc oxide-aluminum oxide and preparation method thereof

InactiveCN106955746AOrderly accumulationLarge specific surface areaCatalyst carriersHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention discloses a composite carrier containing zinc oxide-aluminum oxide and a preparation method thereof. The composite carrier contains zinc oxide containing zinc-aluminum spinel, aluminum oxide, auxiliary component phosphor, potassium and magnesium. The composite carrier is characterized by uniformly dispersed zinc aluminum and high specific surface area and can be used as a carrier for FCC catalyst sulfur-reducing auxiliary agent and FCC hydrogen desulfurization or hydrogenation catalyst.

Owner:QINZHOU UNIV

Catalyst for hydrodesulfurization of catalytic cracking gasoline and preparation method thereof

ActiveCN107081155BAperture size adjustableLow priceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

The invention discloses a catalyst for hydrogen desulfurization of catalytic cracking gasoline and a preparation method of the catalyst. The catalyst comprises the following components based on mass of oxides: 78.0-94.0wt% of an alumina supporter of a macroporous structure, 2.0-10.5wt% of an active ingredient cobalt oxide and 2.5-15.0wt% of molybdenum oxide, wherein the supporter takes chitosan as a pore-enlarging agent. The hydrogen desulfurization catalyst is low in octane loss and high in desulfurization rate.

Owner:廊坊高科广大科技有限公司

Method for FCC (fluid catalytic cracking) gasoline sweetening

InactiveCN107177370ANot easy to coke and deactivateImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentReaction temperatureFixed bed

The invention relates to a method for FCC (fluid catalytic cracking) gasoline sweetening. The method adopts a fixed bed reactor, a used catalyst comprises, in weight percentage, 66-91wt% of alumina support with a macro-porous structure, 5-19wt% of metal active component nickel oxide and 2-15wt% of metal active component molybdenum oxide, the metal active component nickel and the metal active component molybdenum are loaded on the support, the alumina support takes chitosan as a pore-expanding agent, the support comprises additive component phosphorus and additive component molybdenum, and the reaction process conditions include that reaction temperature ranges from 110 DEG C to 220 DEG C, reaction pressure ranges from 1.1MPa to 3.5MPa, volume space velocity ranges from 1.2h<-1> to 4.0h<-1>, and hydrogen oil volume ratio is (7-25):1. The sweetening method has strong adaptability to oil products with different sulfur contents, mercaptan sulfur contents and olefin contents.

Owner:QINZHOU UNIV

Catalyst for desulfurizing transforming of gasoline and preparation method

InactiveCN106881127AOrderly accumulationLarge specific surface areaPhysical/chemical process catalystsHydrodesulfurizationActive component

The invention discloses a catalyst for desulfurizing transforming of gasoline. A carrier of a hydrogenating and desulfurizing transforming catalyst is a zinc oxide-aluminum oxide composite carrier; active components comprise cobalt oxide, nickel oxide and molybdenum oxide. The composite carrier has the advantages that the zinc and aluminum are uniformly dispersed, and the specific surface area is high. The hydrogenating and desulfurizing transforming catalyst has the advantages that the saturating rate of olefin is low, the loss of octane value is little, the desulfurizing rate is high, and the stability is good.

Owner:QINZHOU UNIV

Petroleum resin hydrogenation catalyst and preparation method thereof

InactiveCN107051430AAperture size adjustableLow priceCatalyst carriersCatalyst activation/preparationActive componentPalladium oxide

The invention discloses a petroleum resin hydrogenation catalyst and a preparation method thereof. In terms of oxide mass, the catalyst comprises components as follows: 75.0wt%-96.0wt% of an alumina supporter with a macroporous structure, 1.0wt%-10.0wt% of an active component palladium oxide and 3.0wt%-15.0wt% of nickel phosphide, wherein chitosan is adopted as a pore-expanding agent of the supporter. The petroleum resin hydrogenation activity is high, the activity stability is good, the loss rate of an active center of the catalyst is low, and the operating cycle is long.

Owner:QINZHOU UNIV

C5 petroleum resin hydrogenation method

InactiveCN106914259AHigh activityImprove performancePhysical/chemical process catalystsHydrocarbon oils refiningReaction temperatureFixed bed

The invention discloses a C5 petroleum resin hydrogenation method. According to the invention, a fixed bed reactor is employed, a catalyst is the supported catalyst taking palladium and nickel phosphide as active site, and the hydrogenation process condition is characterized in that the reaction temperature is 180-270 DEG C, the reaction pressure is 6.0-15.0 MPa, and the volume velocity is 0.2-7.0<-h>. The hydrogenation process condition is relatively mild, the performance of the hydrogenation petroleum resin product is good, and the active stability of the catalyst is good.

Owner:QINZHOU UNIV

Method for producing cyclohexane through benzene hydrogenation

InactiveCN106927996AGood activity and stabilityMild reaction conditionsPhysical/chemical process catalystsHydrocarbon by hydrogenationBenzeneActive component

The invention discloses a method for producing cyclohexane through benzene hydrogenation. A catalyst contains the following components in the mass of oxides: 80-99wt% of a composite support containing zinc oxide-aluminum oxide, 0.1-5wt% of an active component platinum oxide and 0.1-5wt% of an active component palladium oxide; and the catalyst has high benzene hydrogenation activity, low loss rate of a precious metal active component and long running period.

Owner:QINZHOU UNIV

A method for selective hydrogenation of cracked C6-C8 cuts

InactiveCN107189812BAperture size adjustableGood adhesive performanceCatalyst carriersHeterogenous catalyst chemical elementsChemistryRaw material

Owner:QINZHOU UNIV

A kind of hydrogenation method of diene

ActiveCN106929092BHigh hydrogenation removal rateReduce lossesPhysical/chemical process catalystsRefining by selective hydrogenationMass ratioHydrogenation reaction

The invention discloses a hydrogenation method of dienes, which adopts a fixed bed reactor; the catalyst is a palladium-based supported catalyst, and the reaction process conditions are: reaction temperature 20-90°C, reaction pressure 1.0-4.0MPa, hydrogen The material quantity ratio of diene and diene is 1.0-3.0, and the volume space velocity is 1.0-10.0h-1. The hydrogenation reaction process conditions are mild. Under the high diolefin conversion rate, the monoolefin hydrogenation saturation rate is low, the catalyst's precious metal active center loss rate is low, and the activity stability is good.

Owner:五家渠市三江新能源科技有限公司

A kind of catalyst and preparation method for fcc gasoline sweetening

InactiveCN107096552BNot easy to coke and deactivateImprove stabilityCatalyst activation/preparationHydrocarbon oils treatment productsPtru catalystHydrogen selectivity

The invention relates to a catalyst for demercaptanization of FCC gasoline. The catalyst includes an alumina carrier with a macroporous structure and metal active components nickel and molybdenum loaded on the carrier. In terms of weight percentage, the alumina with a macroporous structure The carrier is 66-91wt%. The carrier contains additive components phosphorus and magnesium. The pore size distribution is 60-180nm, the macropore ratio is 2-75%, the pore volume is 0.8-2.0ml / g, and the specific surface area is 250-300m 2 / g. The nickel oxide content is 5-19wt%, and the molybdenum oxide content is 2-15wt%. The catalyst has high mercaptan removal activity, high diolefin hydrogenation selectivity, and low octane number loss.

Owner:QINZHOU UNIV

Catalyst for selective hydrogenation of pyrolysis gasoline and use method thereof

InactiveCN109603850AReduce the proportion of microporesIncrease profitHeterogenous catalyst chemical elementsRefining by selective hydrogenationActive componentPalladium

The invention discloses a catalyst for selective hydrogenation of pyrolysis gasoline. The catalyst comprises an alumina supporter with a pore-expanding structure, wherein the alumina supporter is supported with metal palladium and nickel oxide, the content of the metal palladium is 0.1-0.15% of total weight of the catalyst, and the content of the nickel oxide is 8-10% of the total weight of the catalyst. The surface of the obtained alumina supporter with the pore-expanding structure is modified by using calcium, and the surface of the supporter is further modified by combining with impregnation way, and part of micropores formed in the surface of the supporter can be effectively peptized, so that reduction of the proportion of micropores in the surface of the supporter is facilitated, thegeneration of more active site supporting centers on the surface of the supporter is promoted, the utilization rate of the active component nickel is effectively improved, and the selective hydrogenation activity of the pyrolysis gasoline is improved. In addition, the inner and outer components of the supporter are different in concentration, so that the phenomenon is avoided that alkyne and alkadiene easily enter pore channels cause polymerization reaction and the pore channels are blocked.

Owner:GUANGDONG XINHUAYUE HUADE TECH

One-stage selective hydrogenation catalyst for pyrolysis gasoline and preparation method thereof

InactiveCN107159279BAperture size adjustableGood adhesive performancePhysical/chemical process catalystsRefining by selective hydrogenationActive componentSulfur

Owner:QINZHOU UNIV

A method for sweetening fcc gasoline

InactiveCN107177370BNot easy to coke and deactivateImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentFixed bedReaction temperature

The invention relates to a method for demercaptanization of FCC gasoline, which adopts a fixed-bed reactor. The catalyst used includes an alumina carrier with a macroporous structure and metal active components nickel and molybdenum loaded on the carrier, in weight percent. The alumina carrier with macroporous structure is 66-91wt%. The alumina carrier uses chitosan as the pore expander. The carrier contains auxiliary components phosphorus and magnesium. The nickel oxide content is 5-19wt%, and the molybdenum oxide content is 2‑15wt%; the reaction process conditions are: reaction temperature 110‑220°C, reaction pressure 1.1‑3.5MPa, volume space velocity 1.2‑4.0h‑1, hydrogen to oil volume ratio 7‑25:1. The mercaptan removal method of the present invention has strong adaptability to oil products with different sulfur contents, mercaptan sulfur contents and olefin contents.

Owner:QINZHOU UNIV

Lithium-sulfur battery positive electrode material containing three-dimensional interpenetrating composite carbon material, preparation method, positive electrode sheet containing same, and lithium-sulfur battery

ActiveCN110729463BFacilitate conductionIncrease profitElectrode collector coatingNon-aqueous electrolyte accumulator electrodesActivated carbonLithium–sulfur battery

The invention discloses a lithium-sulfur battery positive electrode material containing a three-dimensional interpenetrating composite carbon material and a preparation method thereof, a positive electrode plate containing the lithium-sulfur battery positive electrode material, and a lithium-sulfur battery. The composite carbon material has a three-dimensional interpenetrating network structure and is formed from carbon nanotubes and ZIF-67 derived hierarchical porous carbon polyhedrons by interpenetrating. ZIF-67 is grown on the surface of activated carbon nanotubes used as a framework, and the ZIF-67 is carbonized into hierarchical porous carbon polyhedrons through high-temperature sintering. The preparation method of the lithium-sulfur battery positive electrode active material comprises the following steps: weighing the composite carbon material and elemental sulfur according to a mass ratio of 1: 4; uniformly dispersing the composite carbon material and the elemental sulfur in a CS2 solution; carrying out stirring until the solvent is completely volatilized; and infiltrating the elemental sulfur in the mixture into a carbon structure by using a melting method. The positive electrode plate is composed of the positive electrode active material, superconducting carbon and a binder in a mass ratio of 8: 1: 1. The lithium-sulfur battery is mainly composed of the positive electrode plate, a diaphragm, an electrolyte and a lithium metal negative electrode.

Owner:NAT UNIV OF DEFENSE TECH

A kind of olefin oligomerization catalyst and preparation method thereof

InactiveCN107185560BAperture size adjustableGood resistance to impuritiesPhysical/chemical process catalystsHydrocarbonsIron sulfatePolymer science

The invention discloses an olefin oligomerization catalyst and a preparation method. The composition of the catalyst includes the following components in terms of oxide mass: 81.0-96.0wt% alumina carrier with macroporous structure, and chitosan is used as the carrier to expand the pores. The active components are iron sulfate 2.5-11.5wt% and nickel sulfate 1.5-7.5wt%; the catalyst has high oligomerization activity, high dimer selectivity, low trimer selectivity, and long catalyst operation cycle.

Owner:QINZHOU UNIV

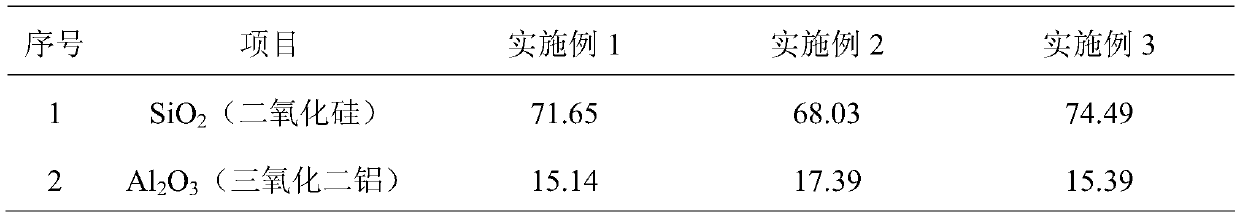

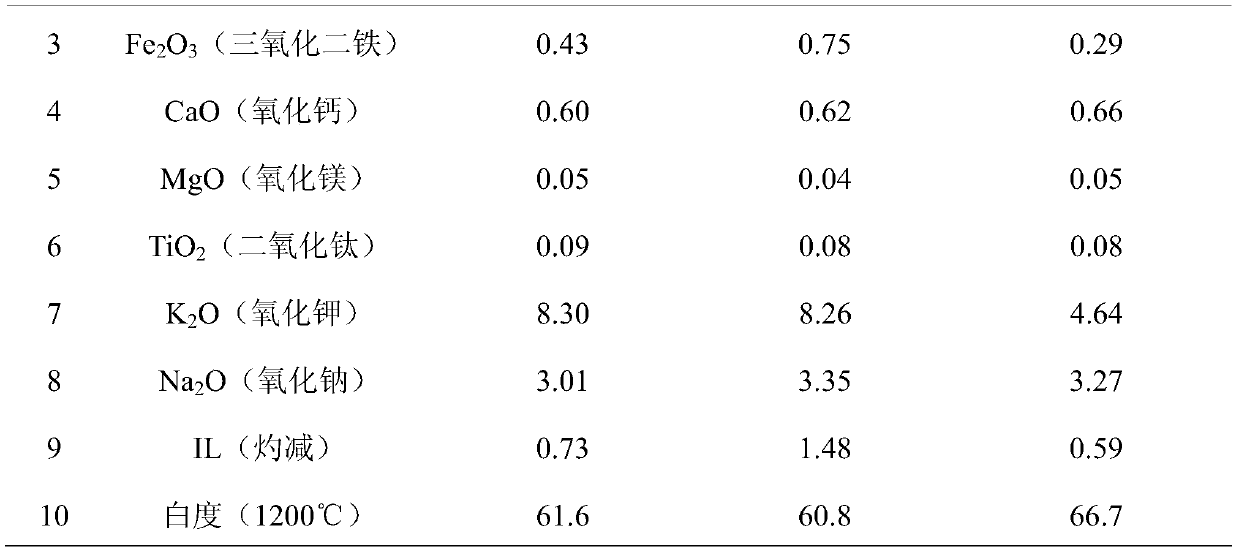

Method for preparing environment-friendly brick from potassium feldspar tailings

InactiveCN111574194AIncrease viscosityStable stateCeramic materials productionClaywaresCompression moldingBrick

The invention discloses a method for preparing an environment-friendly brick from potassium feldspar tailings. The method comprises the following technical steps: 1) treatment of the potassium feldspar tailings; 2) primary mixing: fully mixing the potassium feldspar tailings with sludge to obtain sandy clay; 3) secondary mixing: mixing 60-70% by mass of the sandy clay obtained in the previous stepwith 30-40% by mass of fly ash, and carrying out uniform stirring to form a mixture; 4) digestion: adding the stirred secondary mixture into a continuous digestion bin for digestion; 5) compression molding: carrying out compression molding on the digested second mixture under a vacuum condition to obtain a green brick, and naturally airing the green brick until a water content is 15-19% to obtainan aired green brick; 6) sintering of the green brick: putting the aired green brick into a kiln for firing; and 7) sealing of the kiln for cooling: sealing the kiln and conducting water seepage cooling. The environment-friendly brick prepared by using the method disclosed by the invention conforms to the MU25 grade in the national standard 5101-2003 in China, and has obvious advantages.

Owner:贺州市骏鑫矿产品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com