Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

723results about "Refining by selective hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

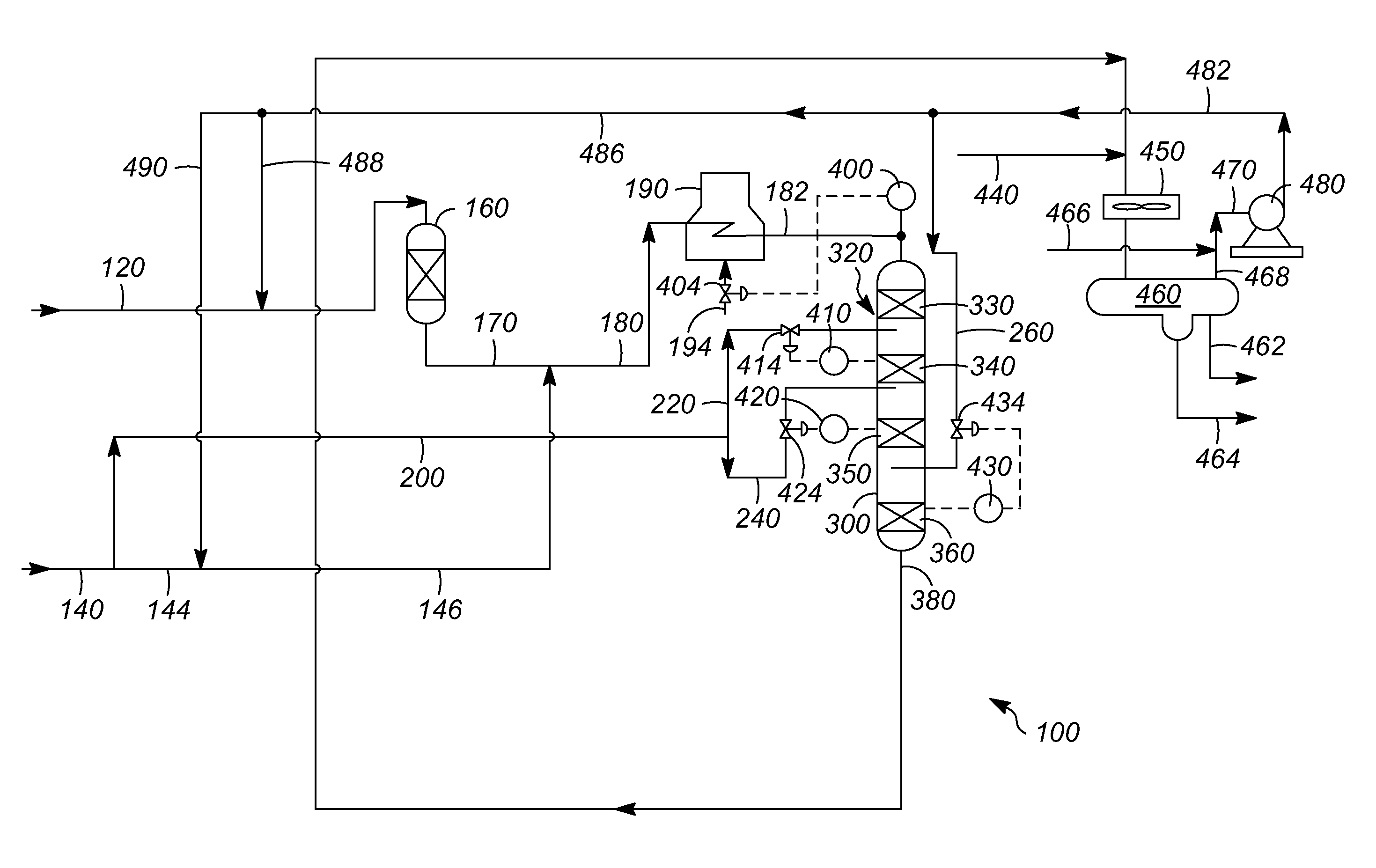

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

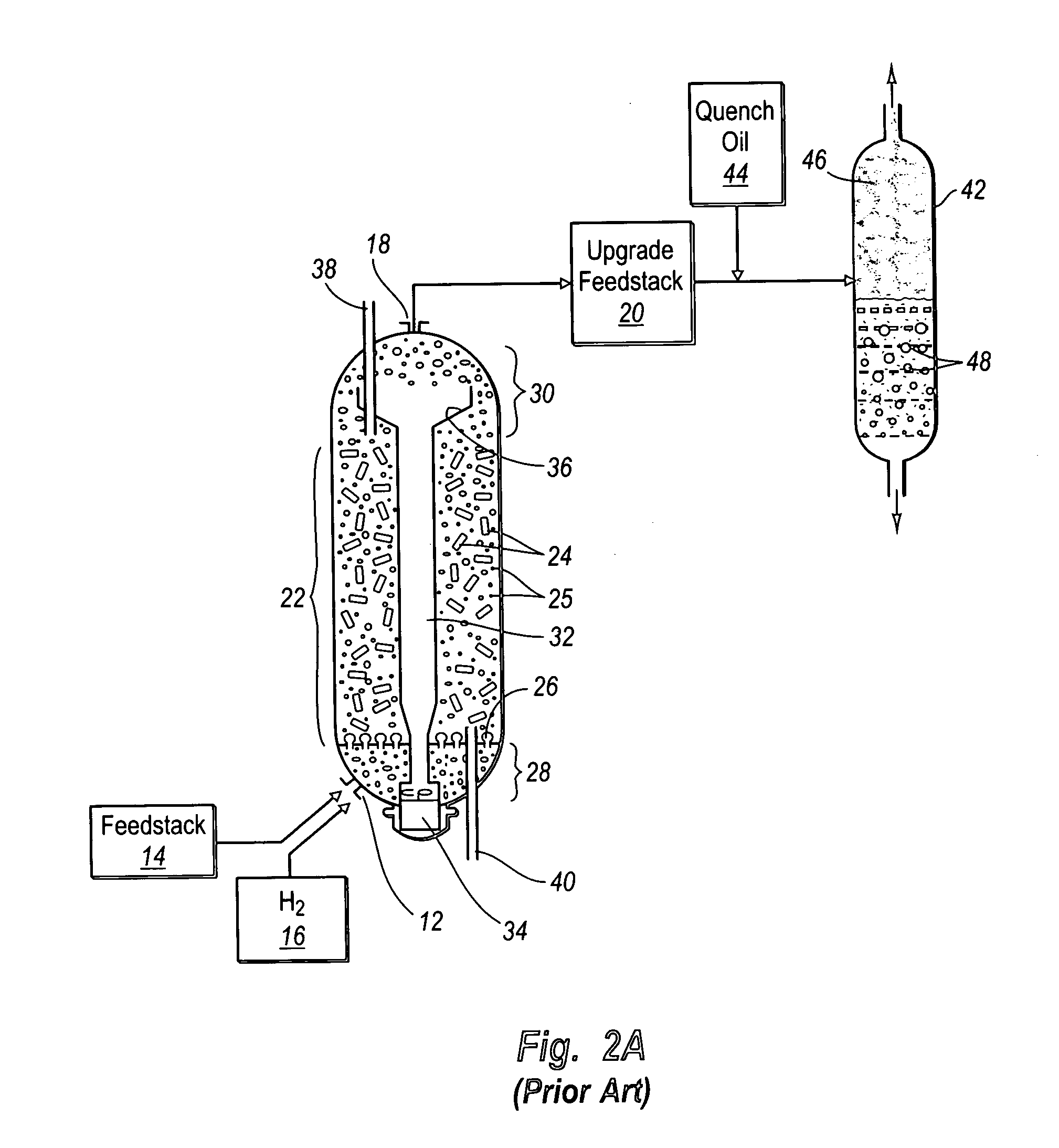

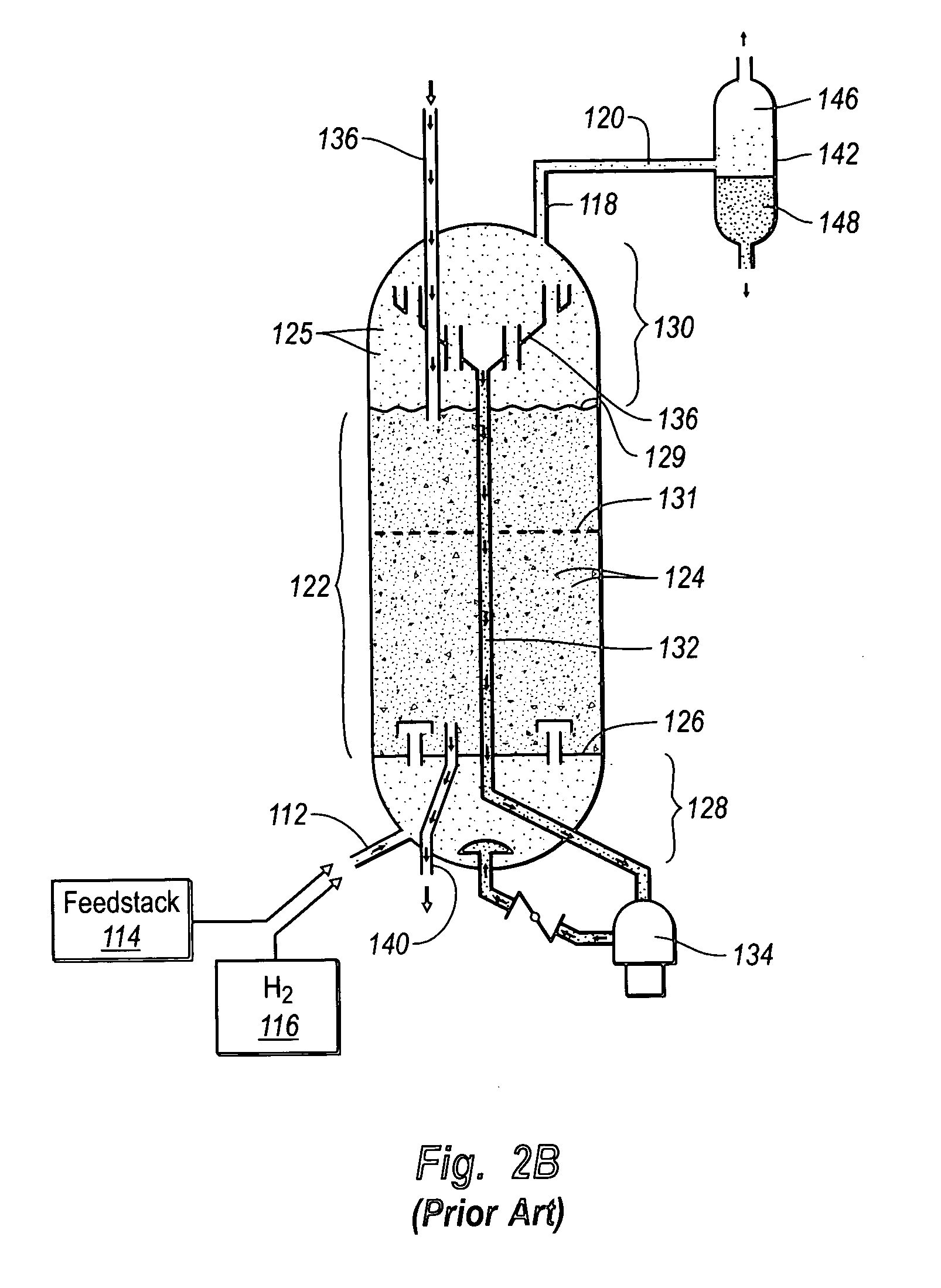

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS20050241991A1Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

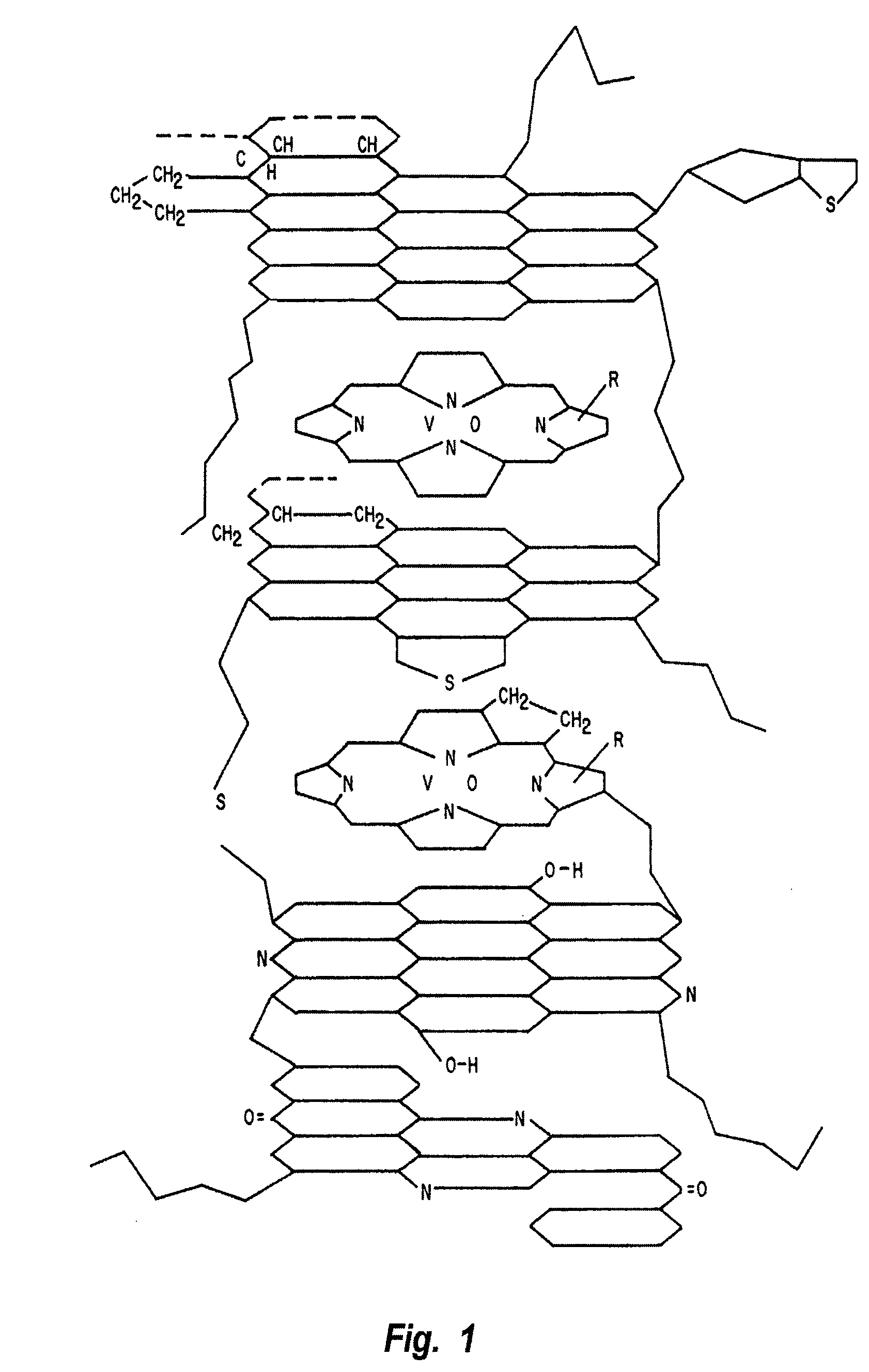

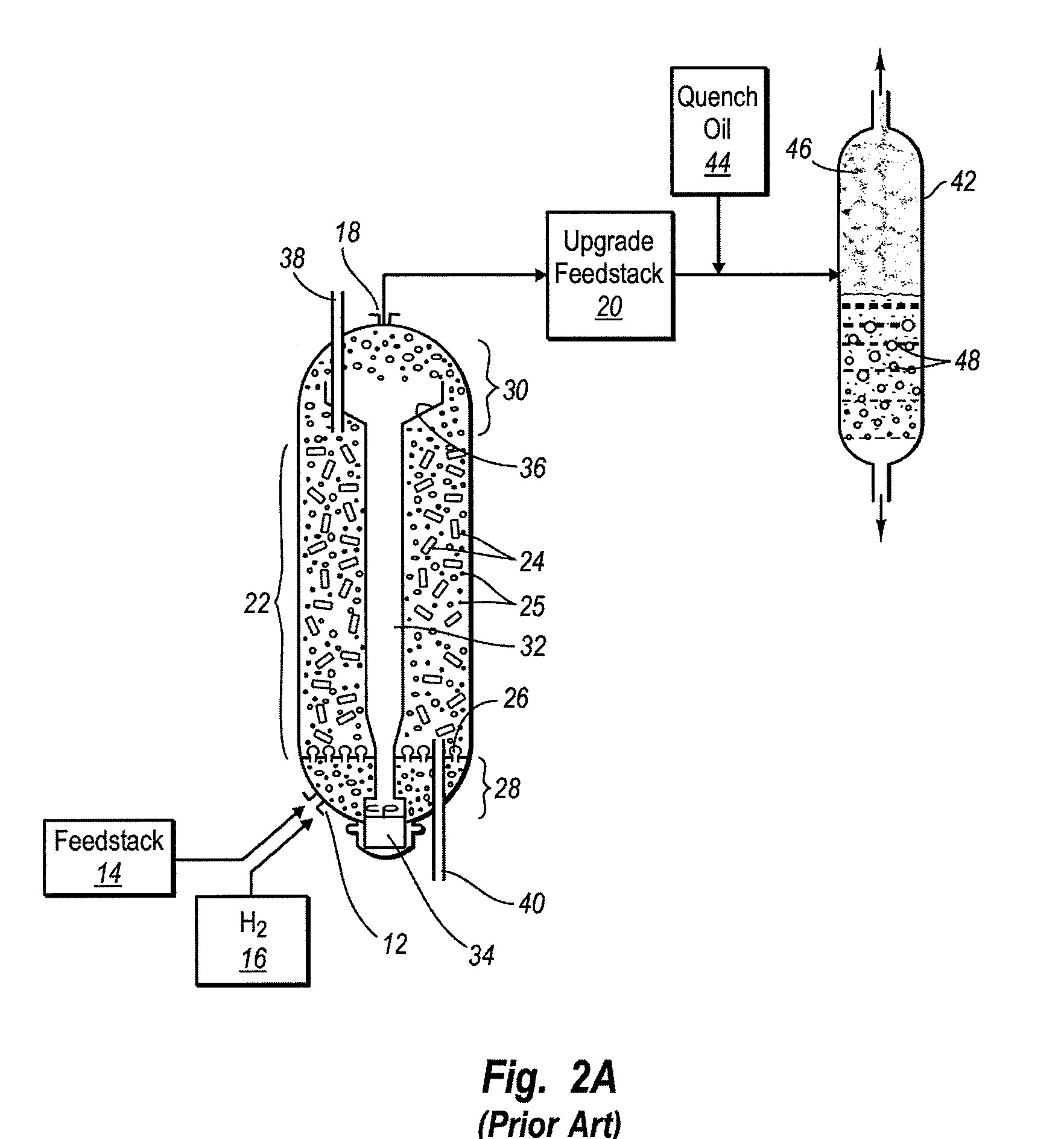

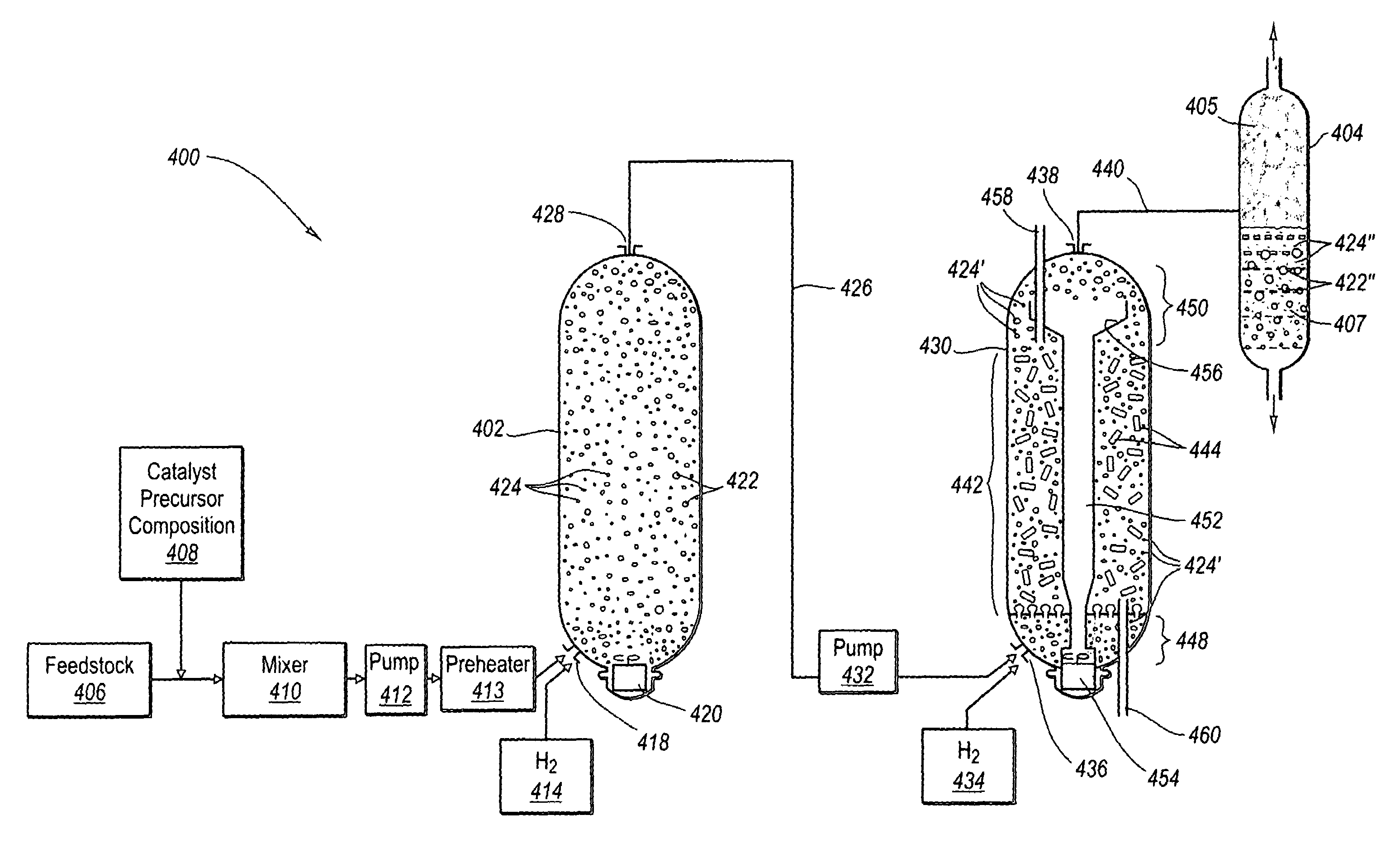

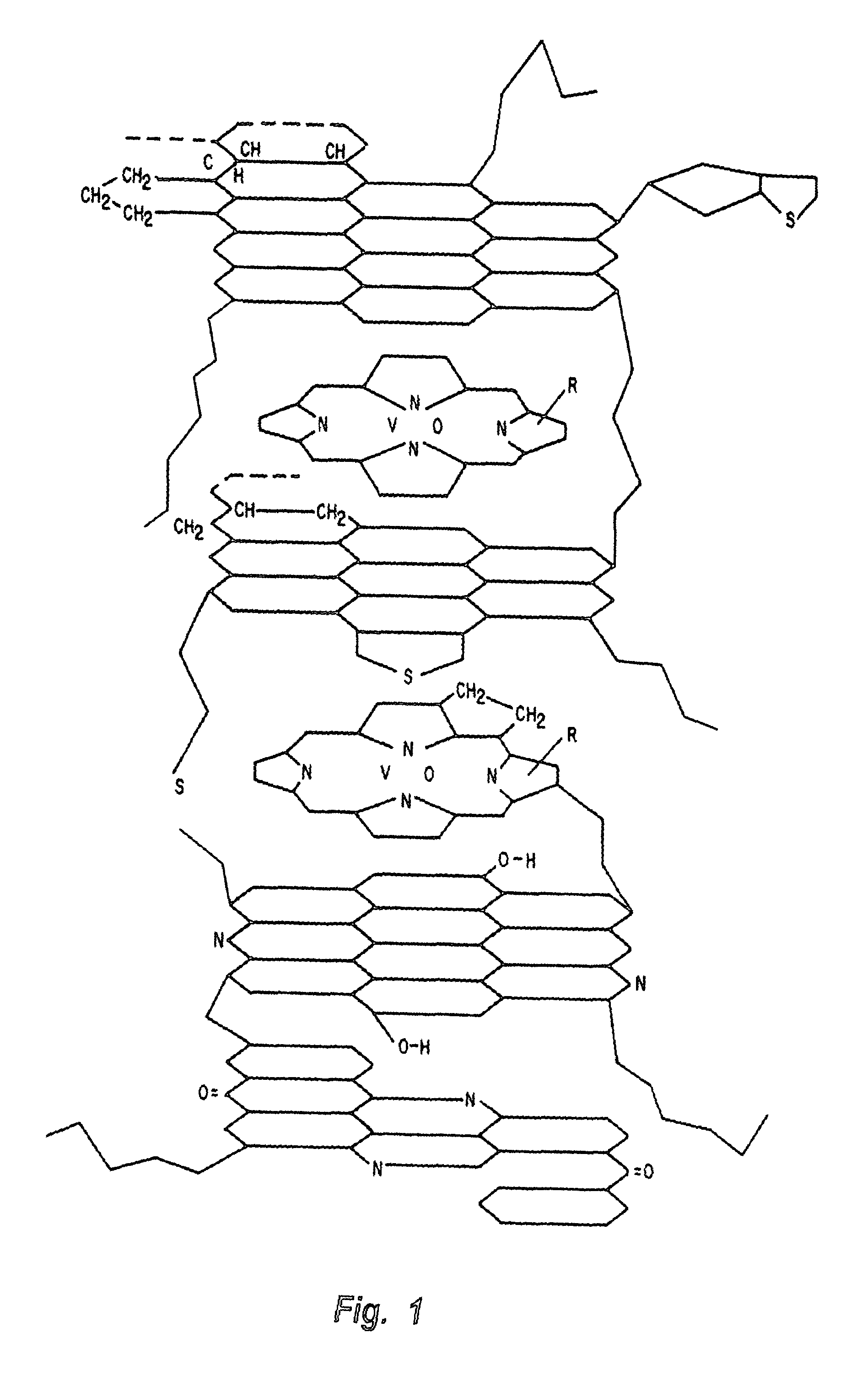

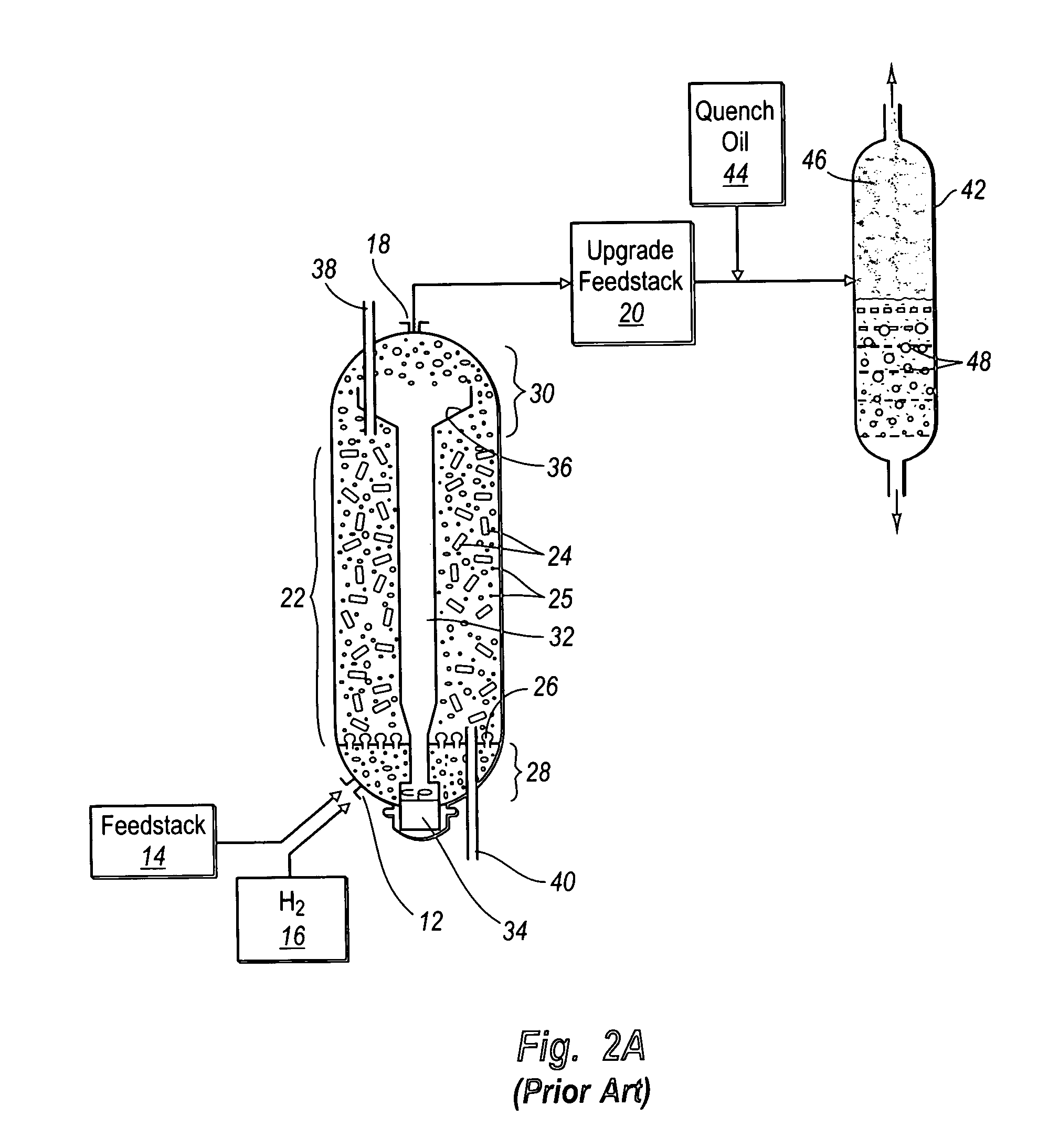

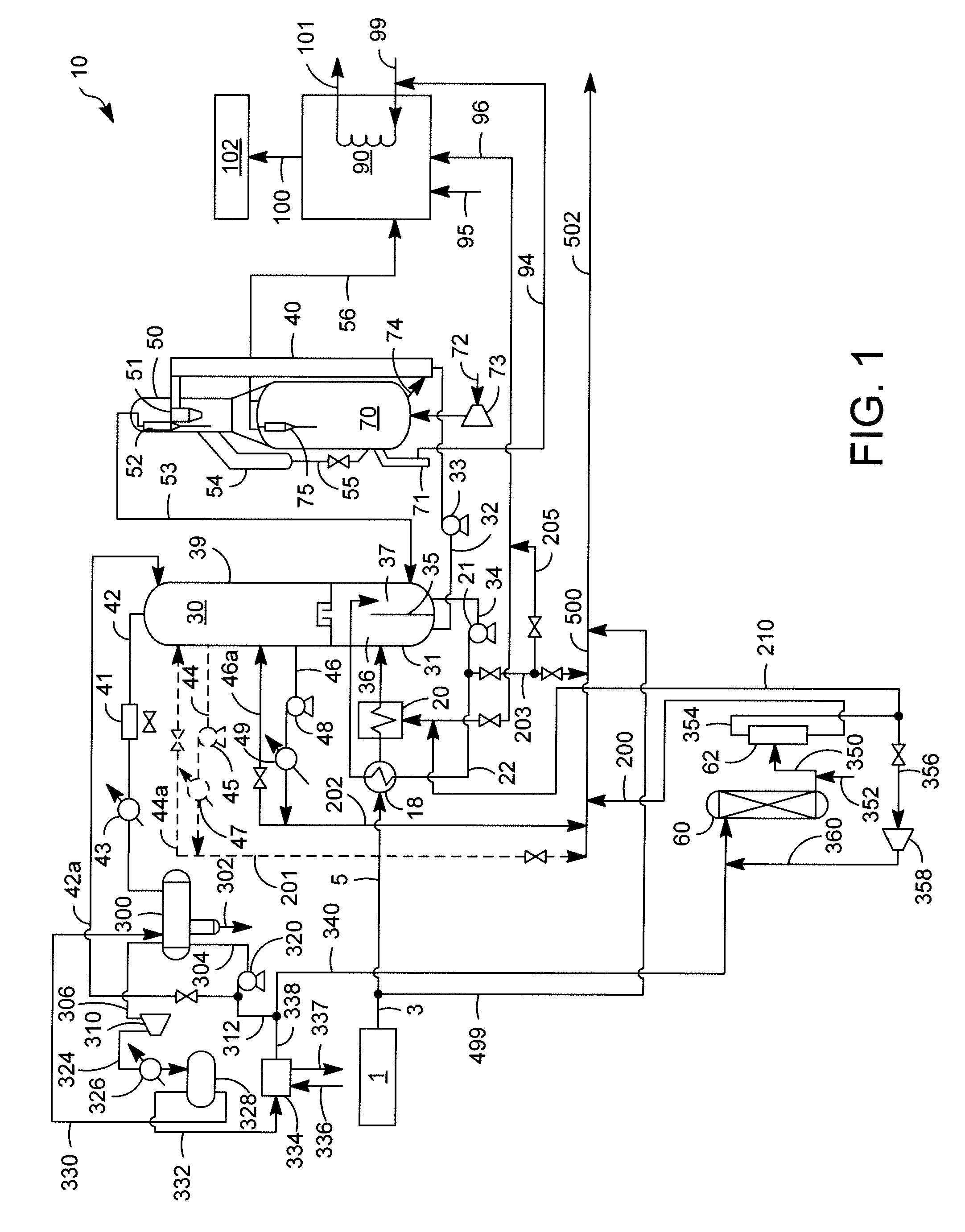

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

Process for BTX purification

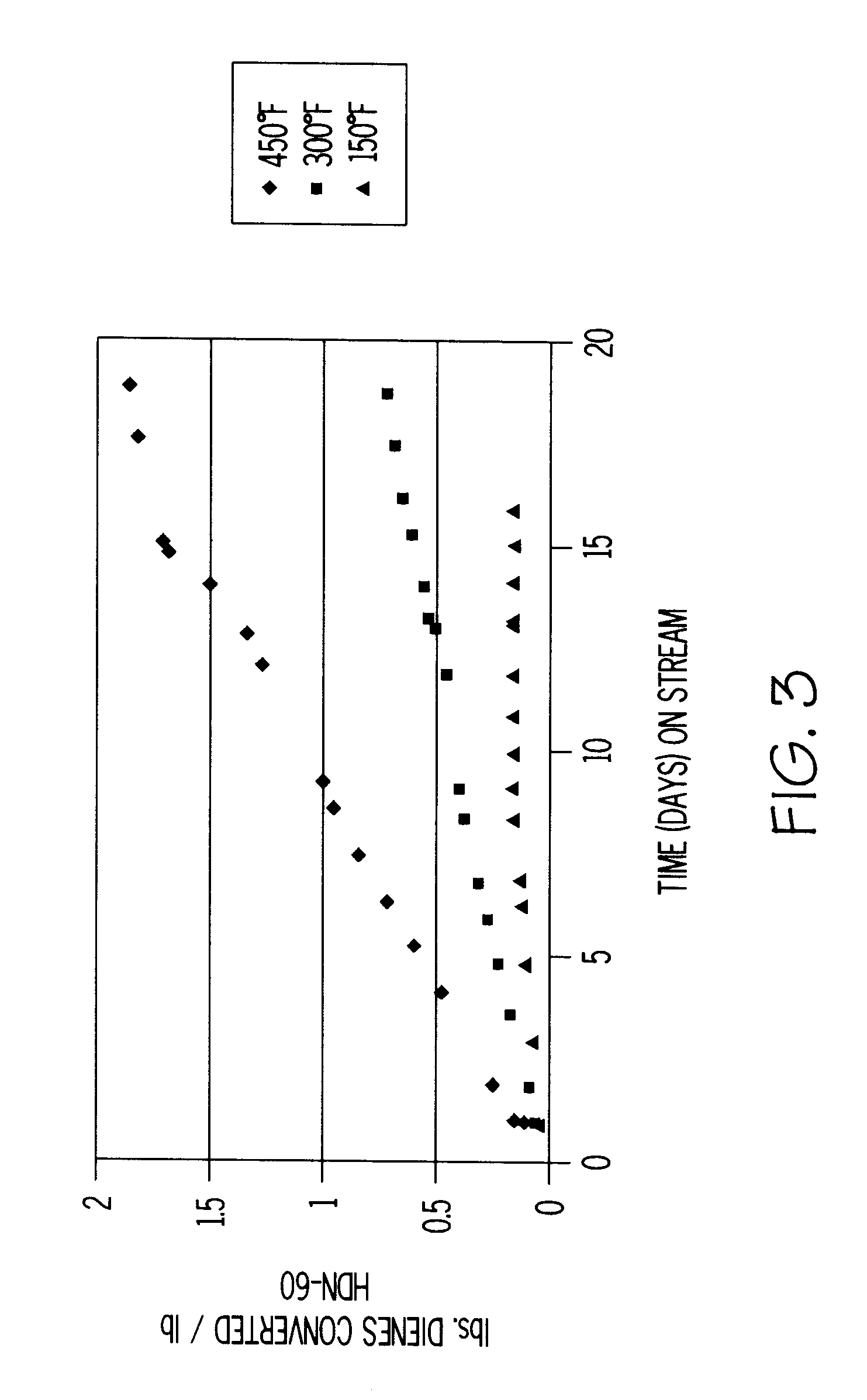

InactiveUS6500996B1Lowering indexEfficient executionOrganic chemistry methodsTreatment with plural serial refining stagesCobaltChromium

A process for the removal of hydrocarbon contaminants, such as dienes and olefins, from an aromatics reformate by contacting an aromatics reformate stream with a hydrotreating catalyst and / or a molecular sieve. The hydrotreating catalyst substantially converts all dienes to oligomers and partially converts olefins to alkylaromatics. The molecular sieve converts the olefins to alkylaromatics. The process provides an olefin depleted product which can be passed through a clay treater to substantially convert the remaining olefins to alkylaromatics. The hydrotreating catalyst has a metal component of nickel, cobalt, chromium, vanadium, molybdenum, tungsten, nickel-molybdenum, cobalt-nickel-molybdenum, nickel-tungsten, cobalt-molybdenum or nickel-tungsten-titanium, with a nickel molybdenum / alumina catalyst being preferred. The molecular sieve is an intermediate pore size zeolite, preferably MCM-22. The clay treatment can be carried out with any clay suitable for treating hydrocarbons.

Owner:EXXONMOBIL CORP (US)

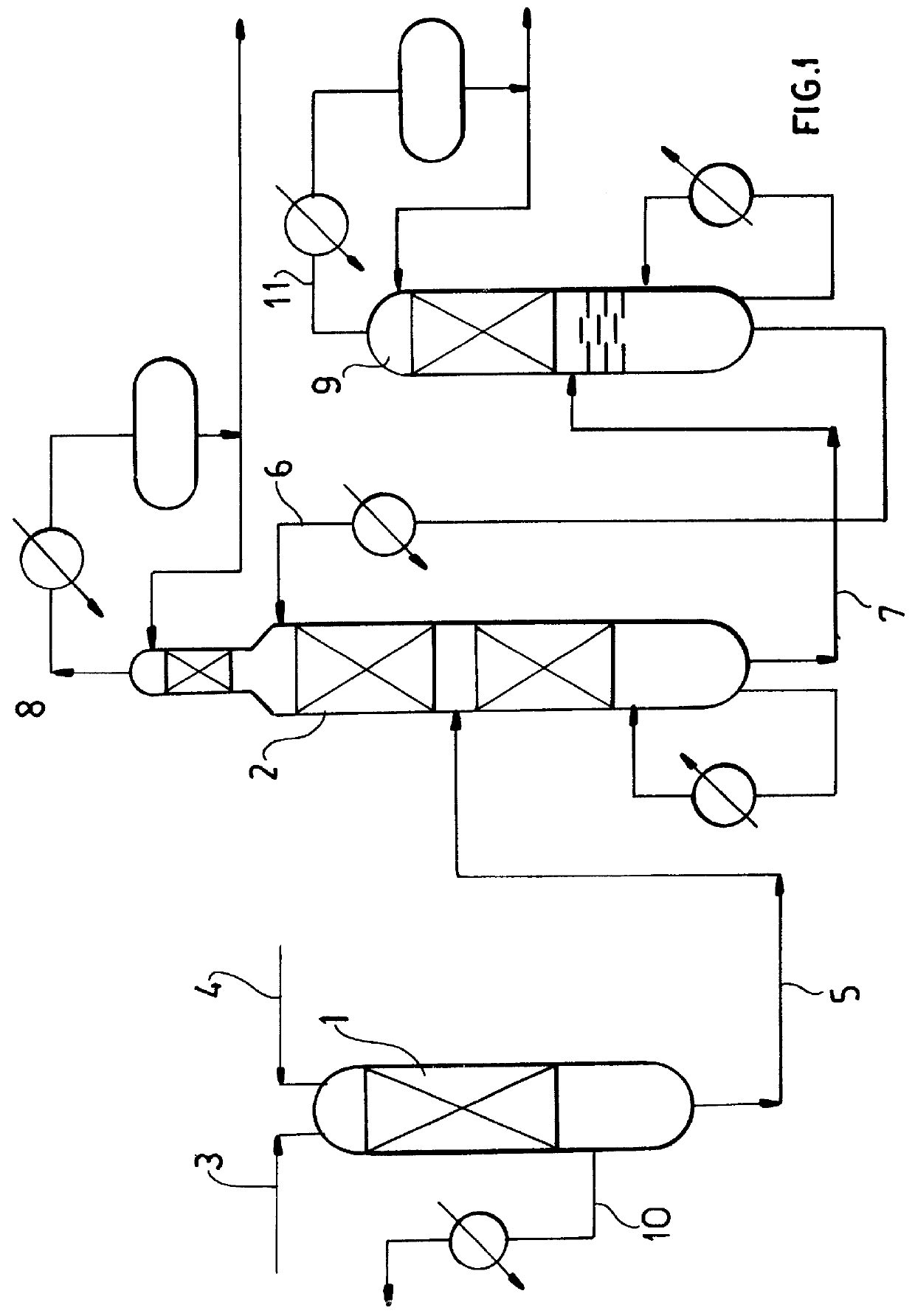

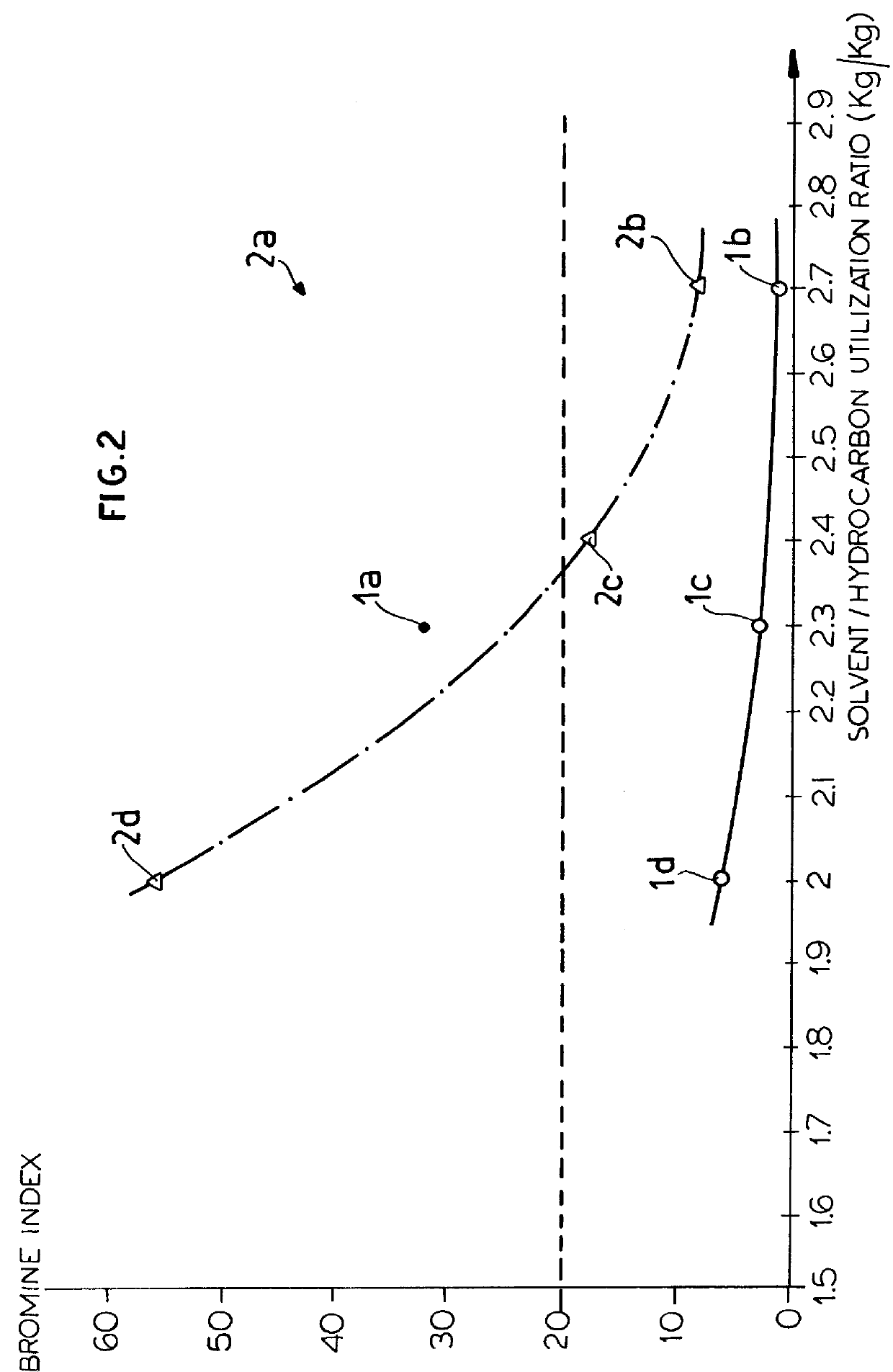

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

Selective hydrogenation catalyst and methods of making and using same

InactiveUS20070027030A1Hydrocarbon by hydrogenationCatalyst activation/preparationUnsaturated hydrocarbonCompound (substance)

A method for producing a selective hydrogenation catalyst for hydrogenating a highly unsaturated hydrocarbon to an unsaturated hydrocarbon comprising contacting an inorganic catalyst support with a chlorine-containing compound to form a chlorided catalyst support and adding palladium to the chlorided catalyst support to form a supported-palladium composition. A selective hydrogenation catalyst for hydrogenating a highly unsaturated hydrocarbon to an unsaturated hydrocarbon formed by the method comprising contacting an inorganic catalyst support with a chlorine-containing compound to form a chlorided catalyst support and adding palladium to the chlorided catalyst support to form a supported-palladium composition. A method of selectively hydrogenating a highly unsaturated hydrocarbon to an unsaturated hydrocarbon comprising contacting the highly unsaturated hydrocarbon with a selective hydrogenation catalyst composition produced by contacting an inorganic catalyst support with a chlorine-containing compound to form a chlorided catalyst support and adding palladium to the chlorided catalyst support to form a supported-palladium composition.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Hydrogenation catalyst, its process and use

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

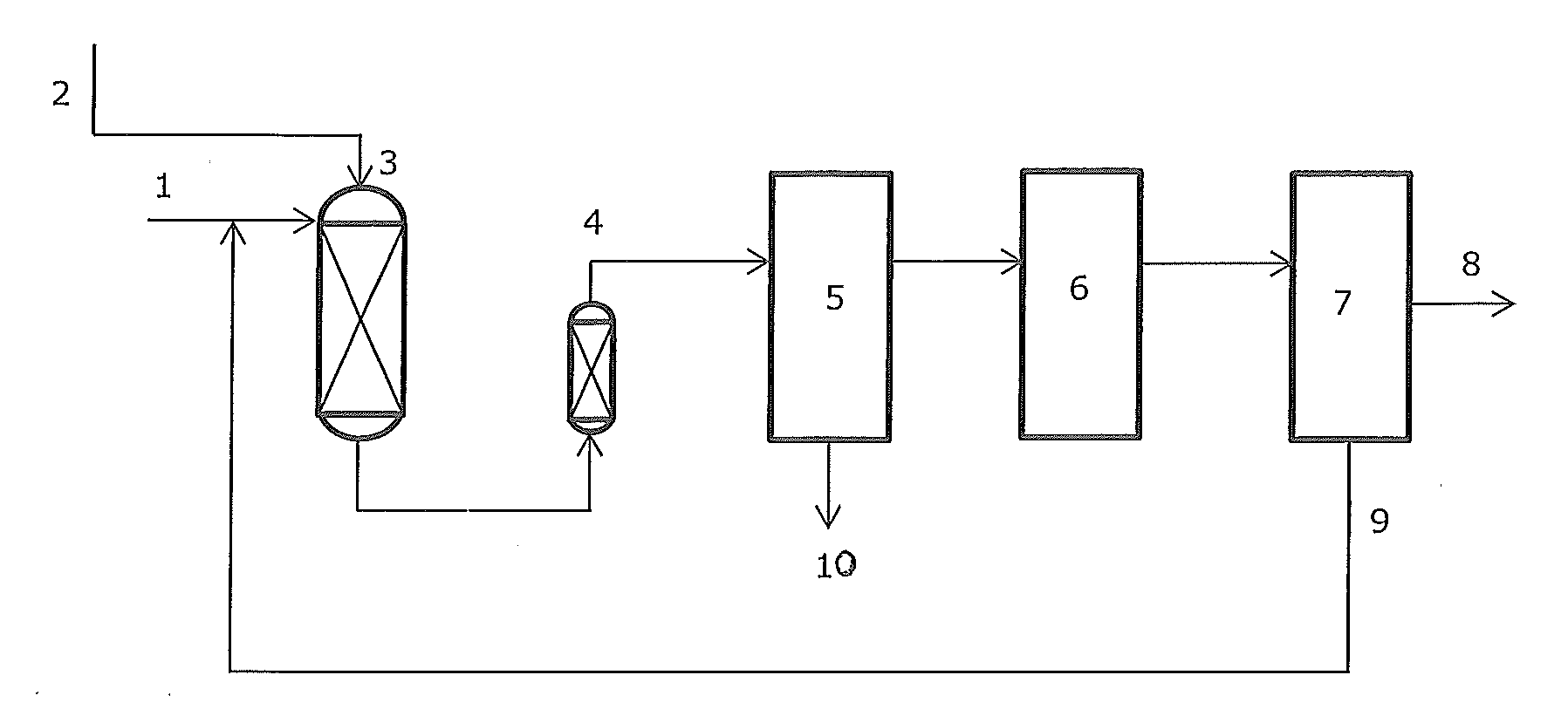

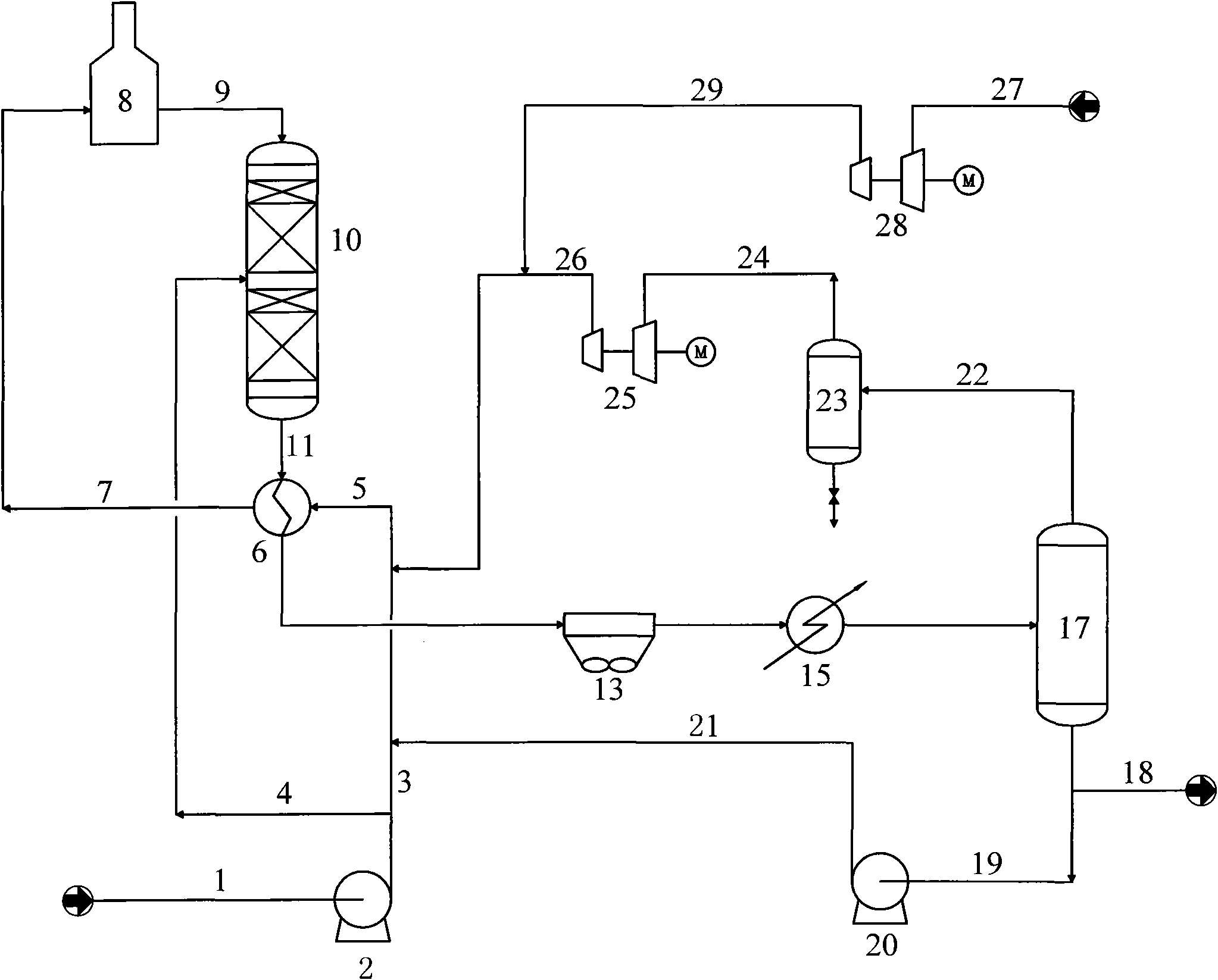

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

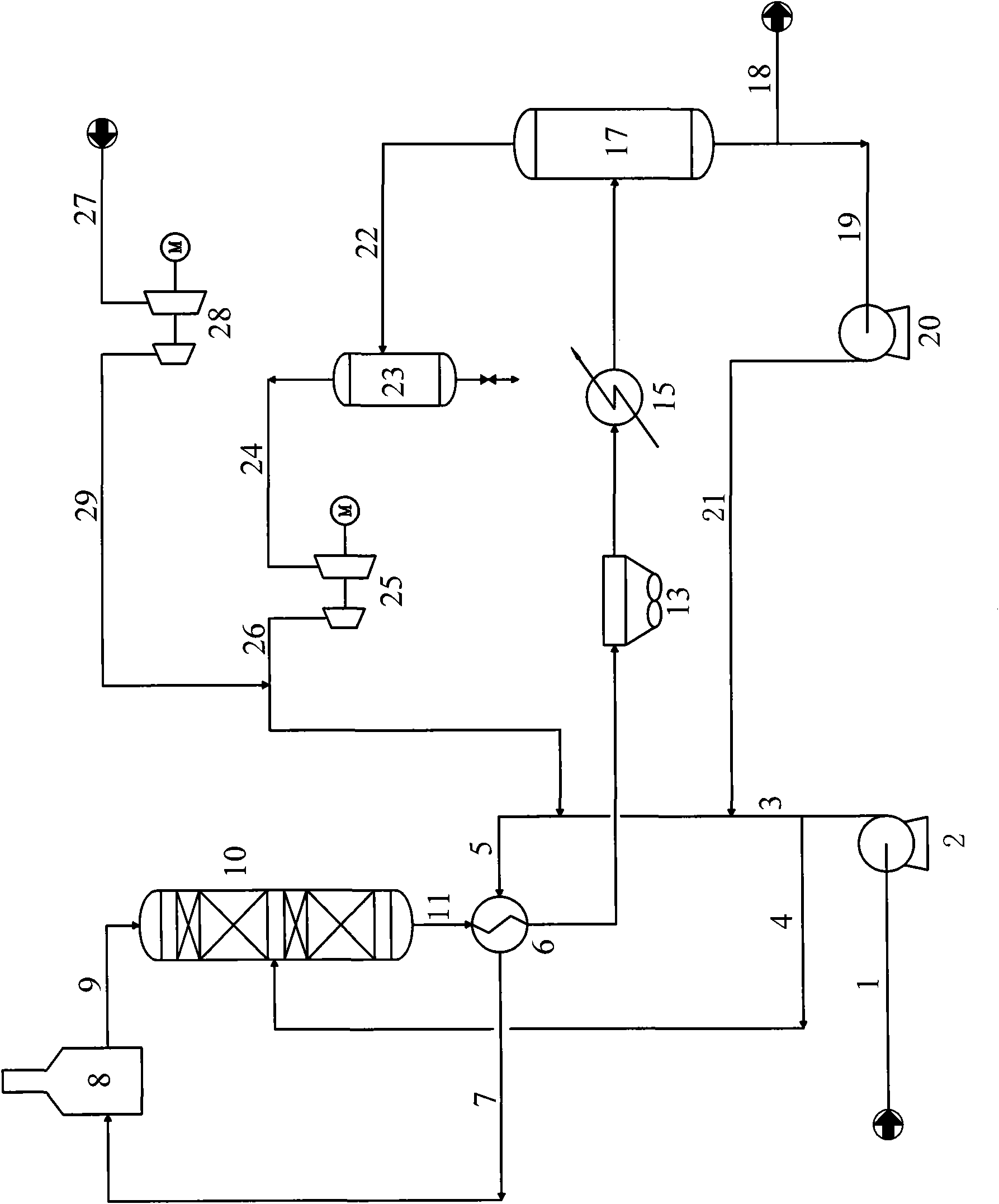

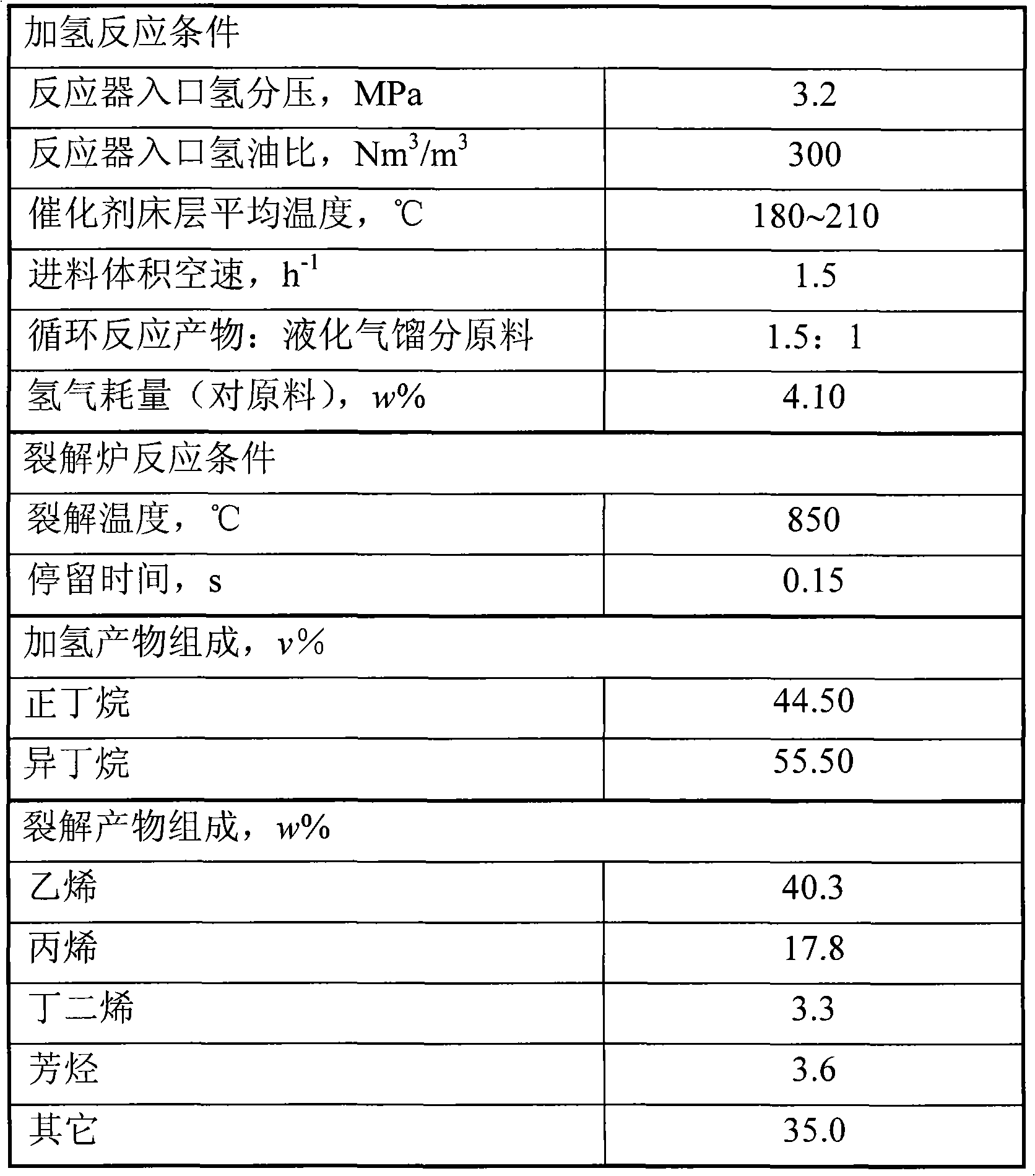

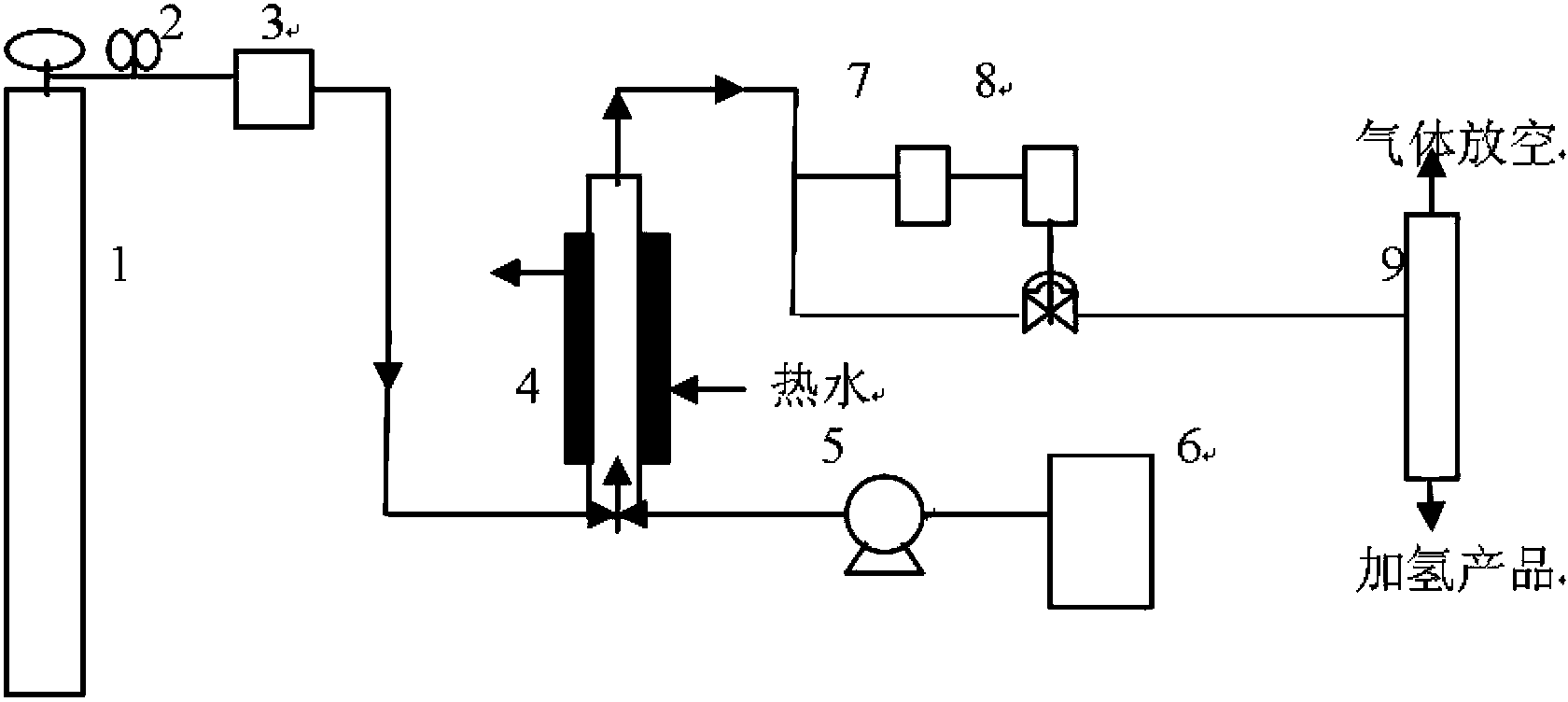

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

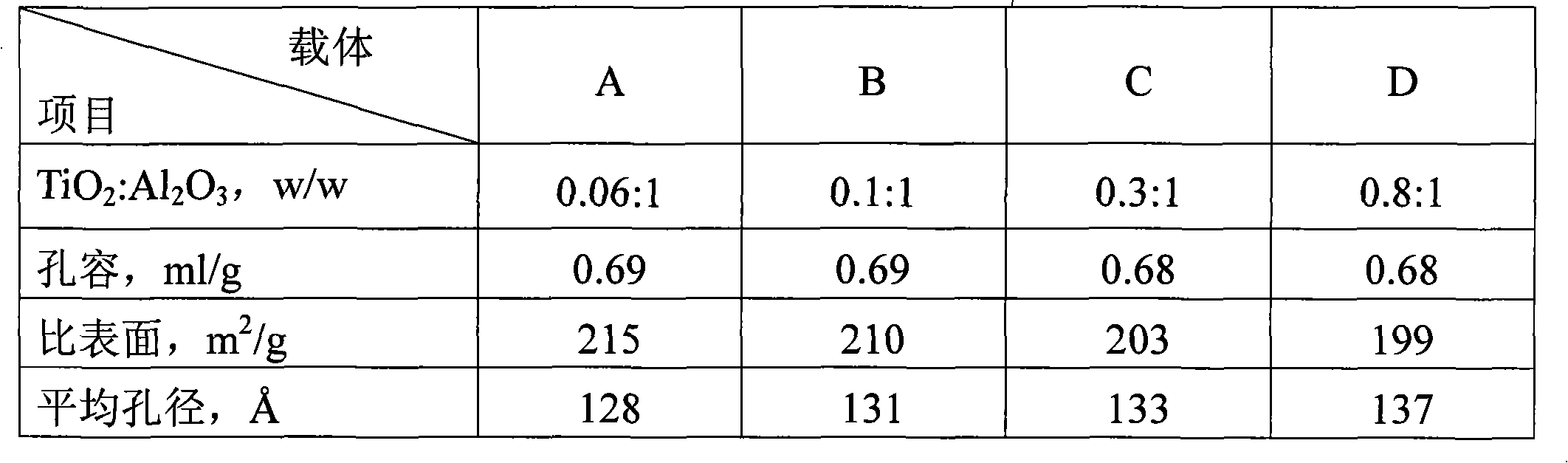

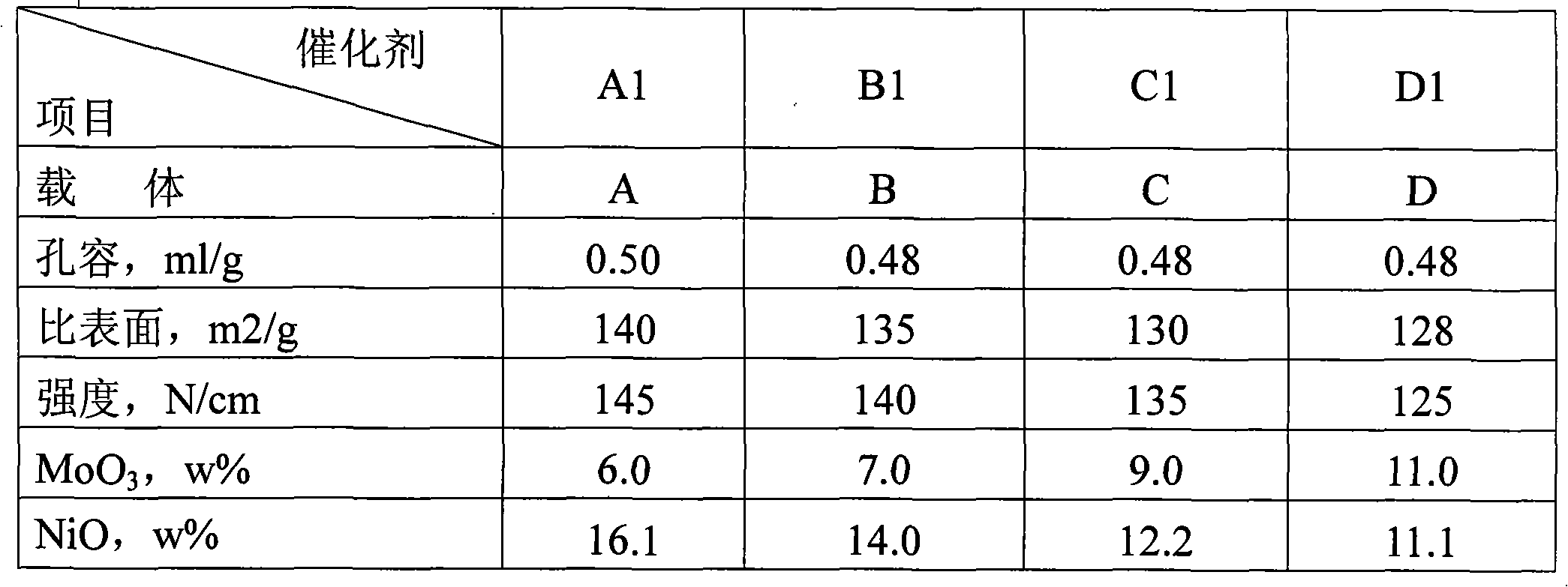

Selective hydrogenation catalyst for catalytic cracking gasoline and preparation method thereof

InactiveCN101869839AHigh selectivityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenGasoline

The invention relates to a selective hydrogenation catalyst for catalytic cracking gasoline and a preparation method thereof. The catalyst consists of AL2O3-TiO2 composite oxide carrier and active metal oxide; in percentage by the weight of the catalyst, the content of NiO in the active metal oxide is 10 to 20 w percent, and the content of MoO3 is 5 to 12 w percent, wherein the weight ratio of TiO2 to Al2O3 in the AL2O3-TiO2 composite oxide carrier is 0.01 to 1:1. When processing catalytic gasoline under the conditions of low temperature (100DEG C to 200DEG C), lower pressure (1MPa to 3.0MPa) and low hydrogen-oil ratio (hydrogen-oil volume ratio: 5:1 to 100:1), the selective hydrogenation catalyst shows high diolefin-removing and mercaptan-removing activities, selectivity and stability.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Ordered cobalt-aluminum and iron-aluminum intermetallic compounds as hydrogenation catalysts

InactiveCN102369074ALow costHigh selectivityPolycrystalline material growthHydrocarbon by hydrogenationPtru catalystUnsaturated hydrocarbon

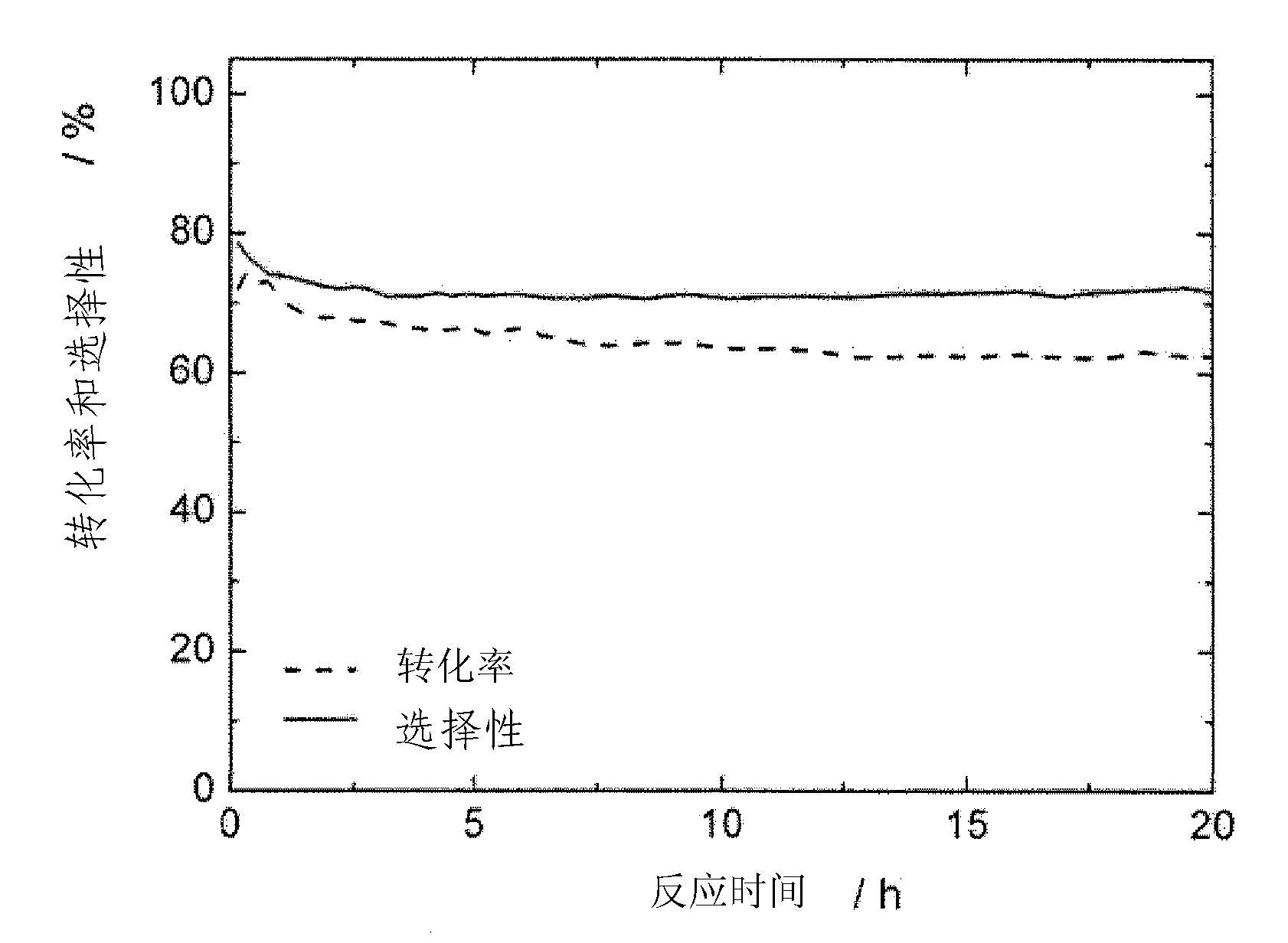

The present invention relates to a process for the hydrogenation, in particular the selective hydrogenation of unsaturated hydrocarbon compounds, such as the selective hydrogenation of acetylene to ethylene, using a hydrogenation catalyst comprising an ordered intermetallic compound, namely an ordered cobalt- aluminum or iron- aluminum intermetallic compound. According to another aspect, the present invention relates to a catalyst comprising a support and at least one specific ordered cobalt -aluminum and / or iron-aluminum intermetallic compound supported thereon, as well as to the use of specific ordered intermetallic cobalt-aluminum and iron -aluminum intermetallic compounds as catalysts. The ordered cobalt-aluminum and iron-aluminum intermetallic compounds proved to be highly selective and long-term stable catalysts, e.g. in the selective hydrogenation of acetylene to ethylene in a large excess of ethylene.

Owner:MAX PLANCK SOCIETY FOR THE ADVANCEMENT OF SCI +1

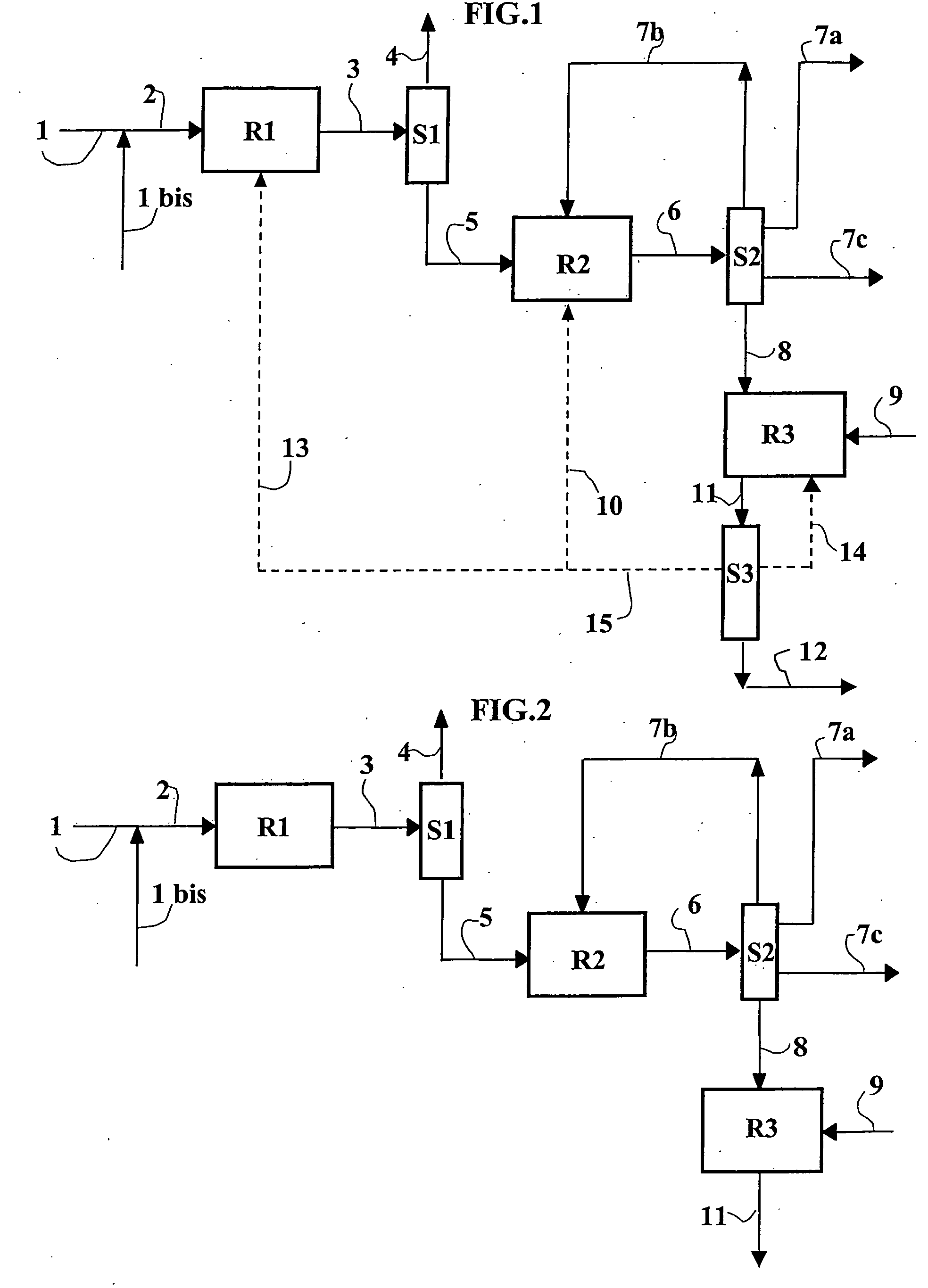

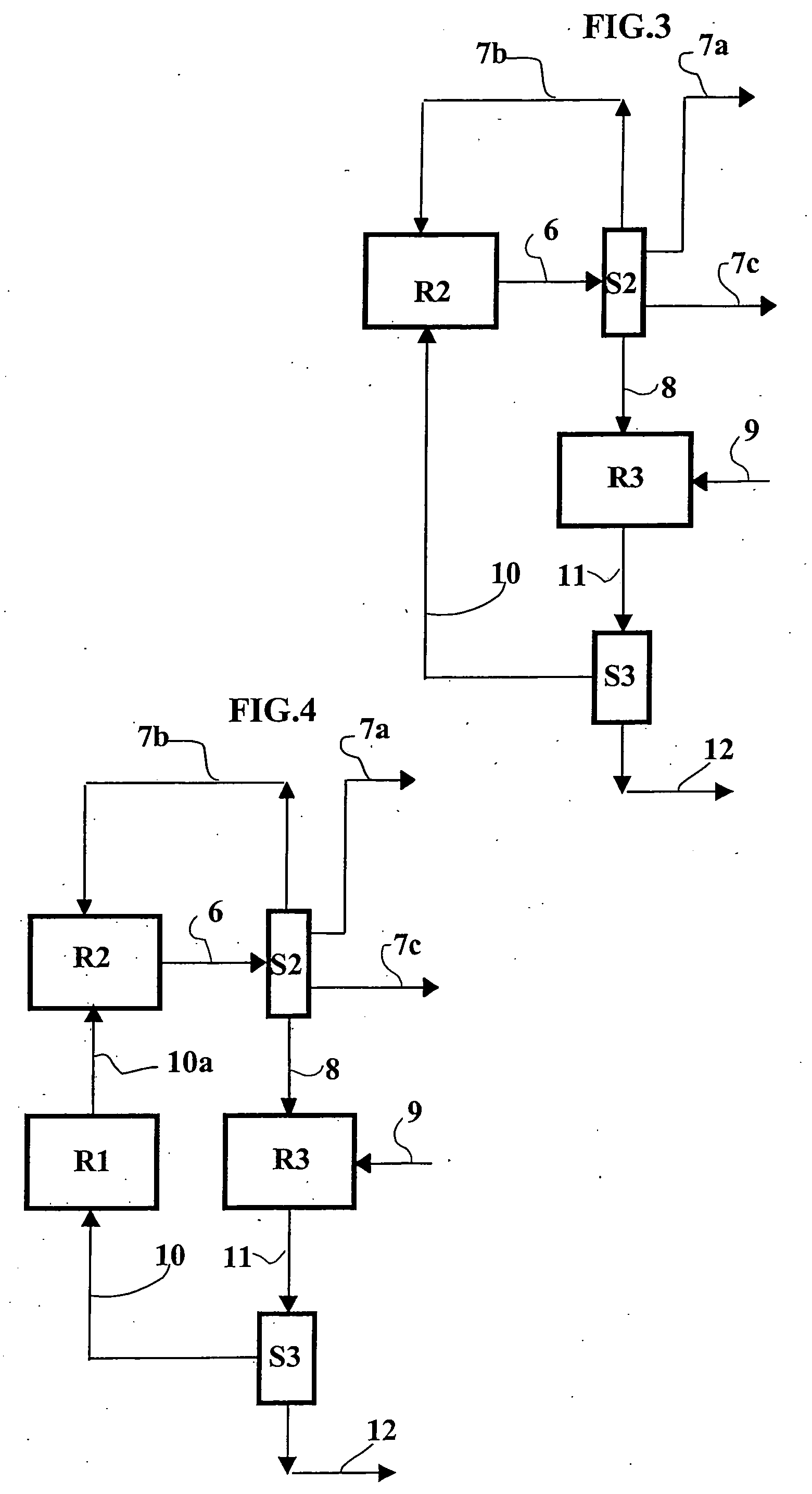

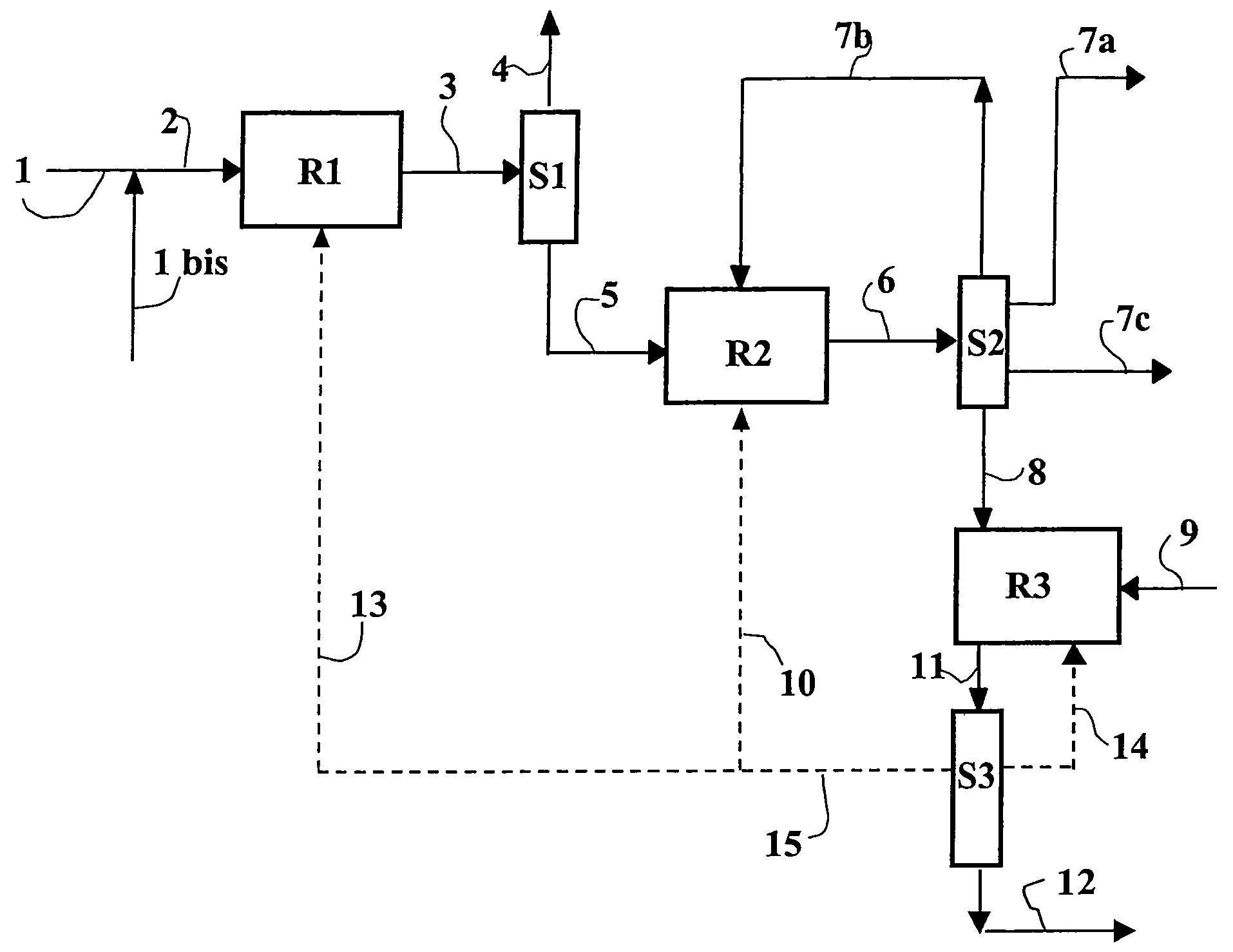

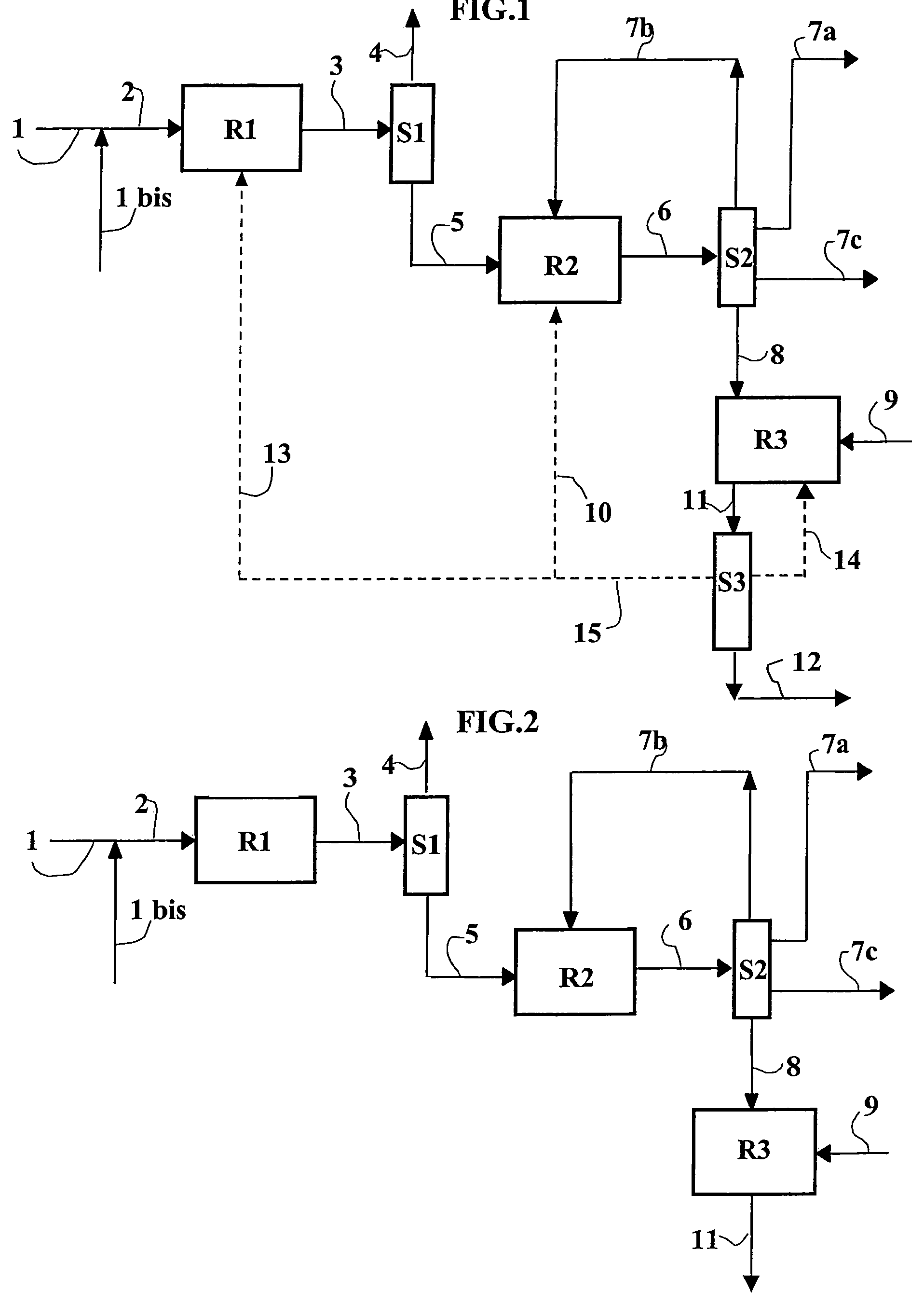

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

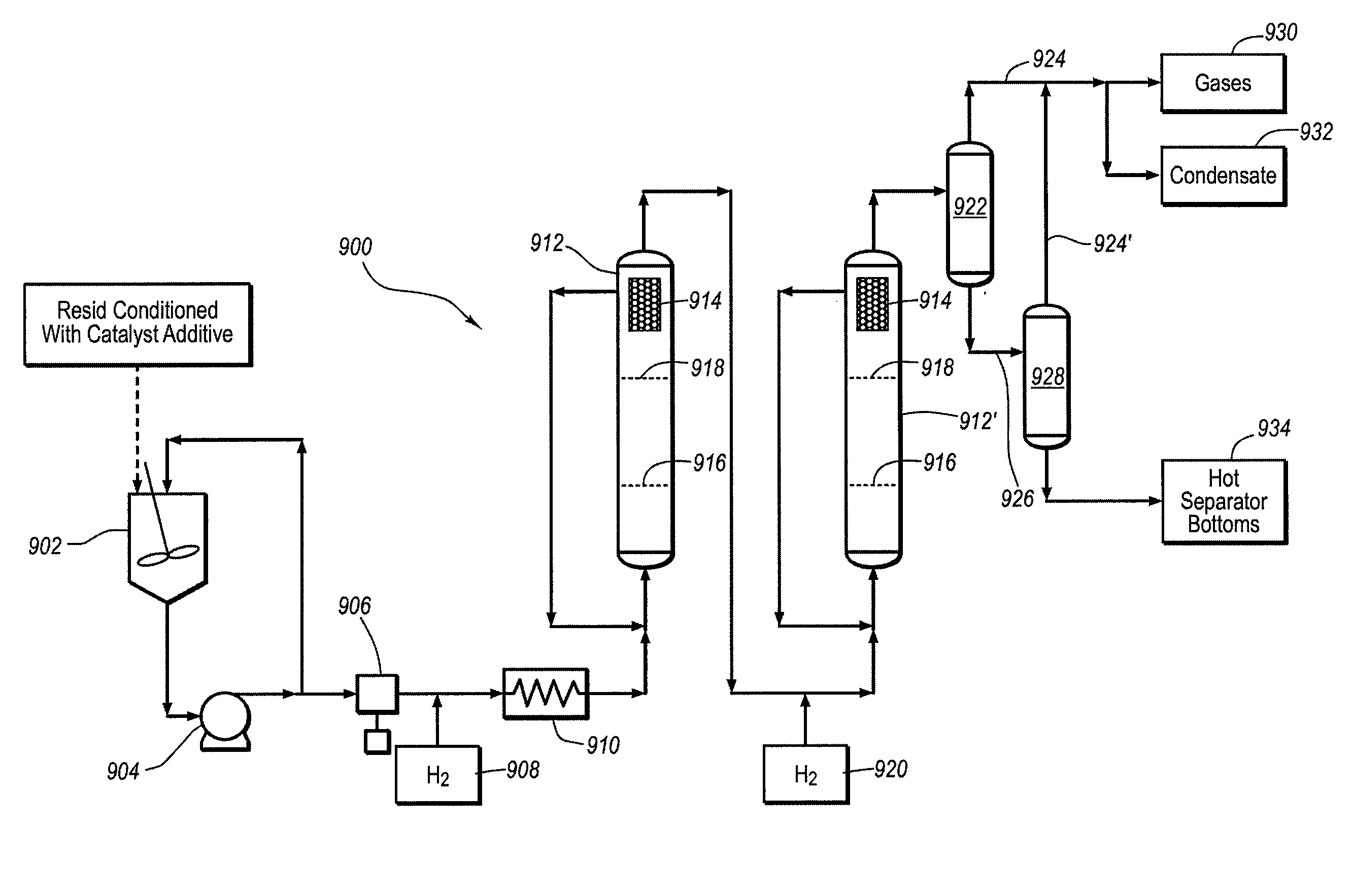

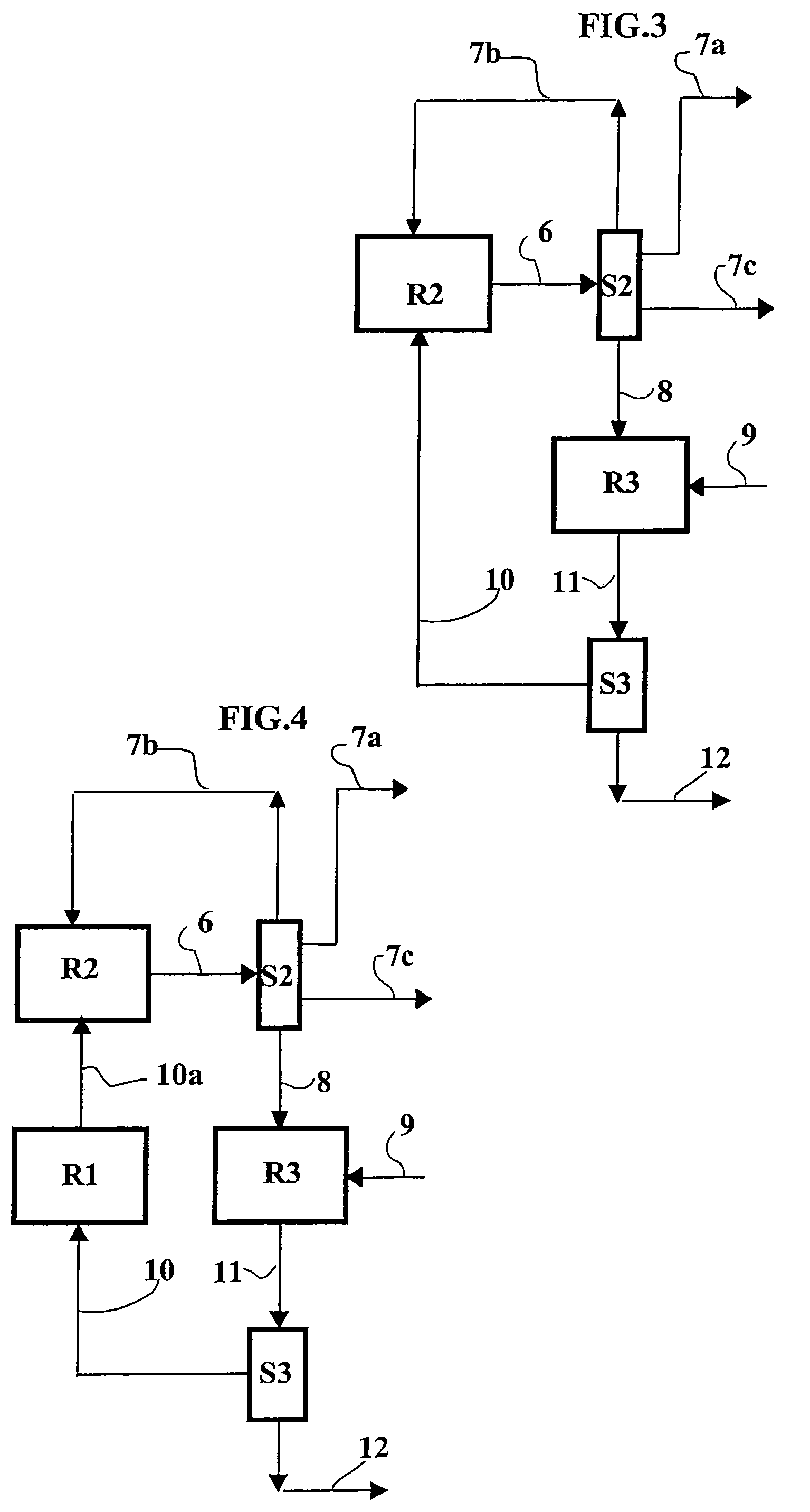

Ebullated bed hydroprocessing systems

ActiveUS20080193345A1Quality improvementReduce formationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

Catalyst formulation for hydrogenation

InactiveUS20050048658A1Satisfactory conversionSatisfactory selectivityChemical analysis using catalysisOther chemical processesParticulatesAlkyne

A composition and method for preparation of a catalyst for the liquid phase selective hydrogenation of alkynes to alkenes with high selectivity to alkenes relative to alkanes, high alkyne conversion, and sustained catalytic activity comprising a Group VIII metal and a Group IB, Group IIB, Group IIIA, and / or Group VIIB promoter on a particulate support.

Owner:SYNFUELS INT

Thermal treatment of triglycerides

A triglyceride or a triglyceride / hydrocarbon combination can be heated to produce thermally treated feeds. The thermally treated feeds can then be contacted with a hydrotreating catalyst in a reaction zone.

Owner:PHILLIPS 66 CO

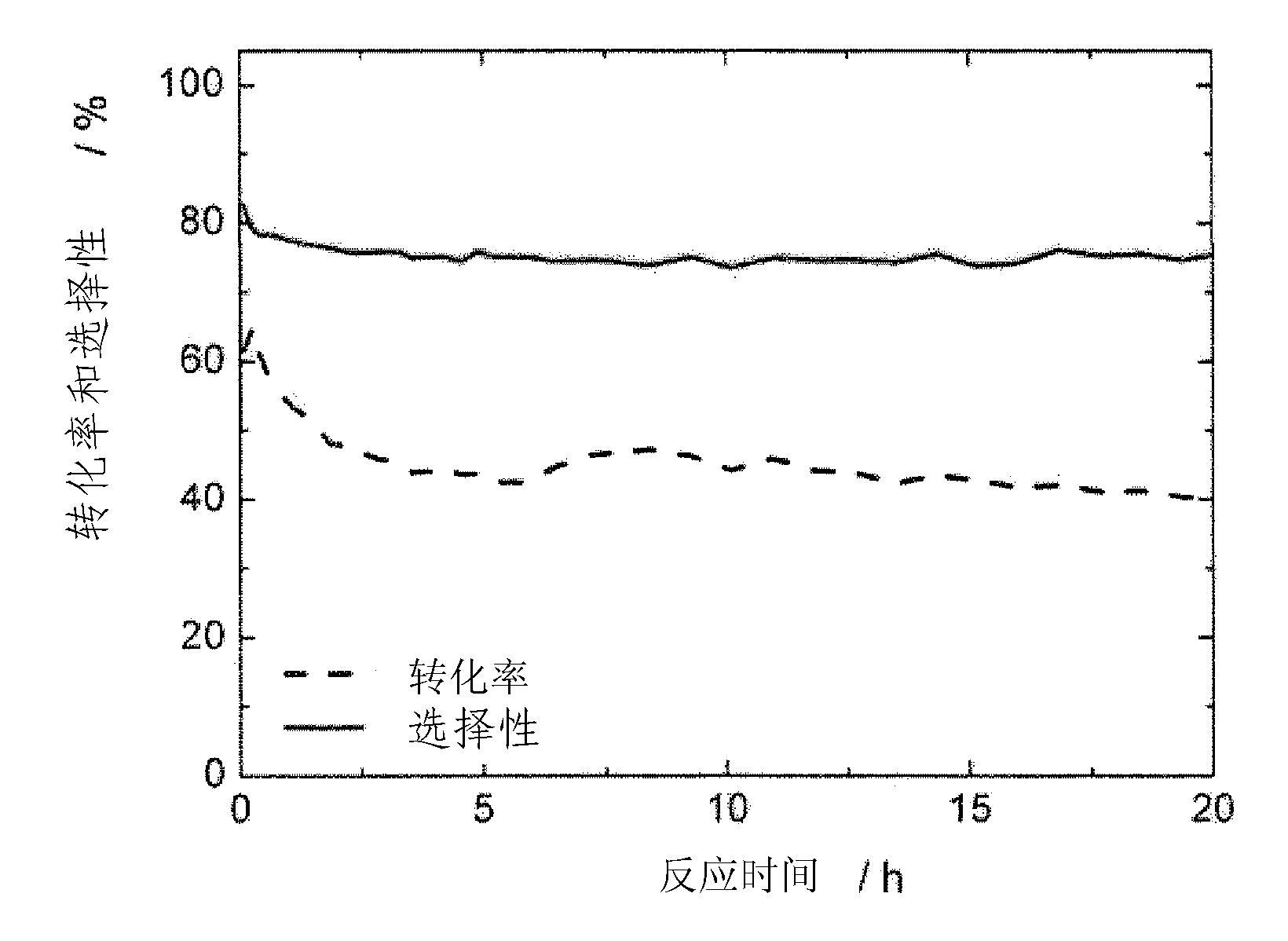

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

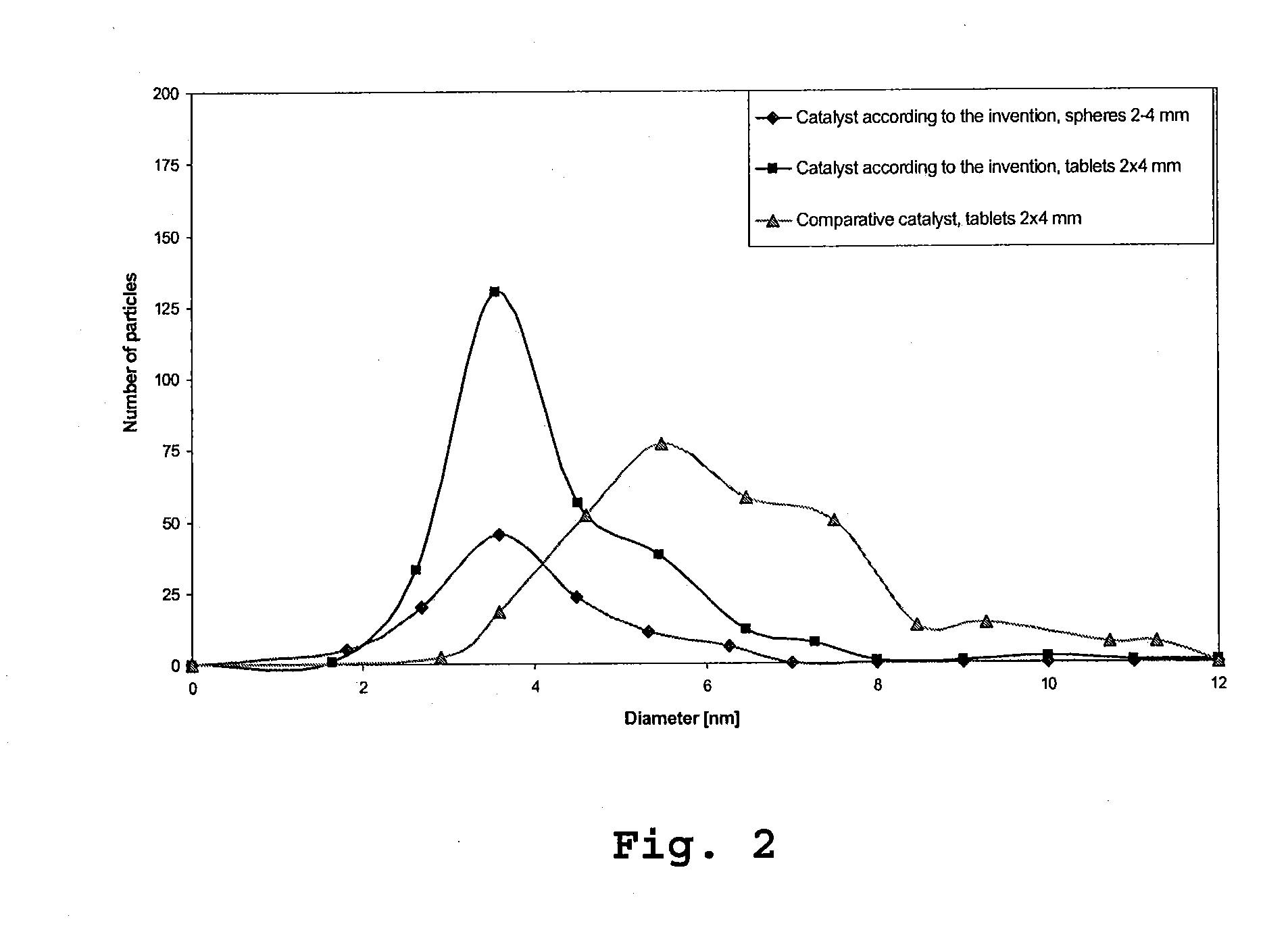

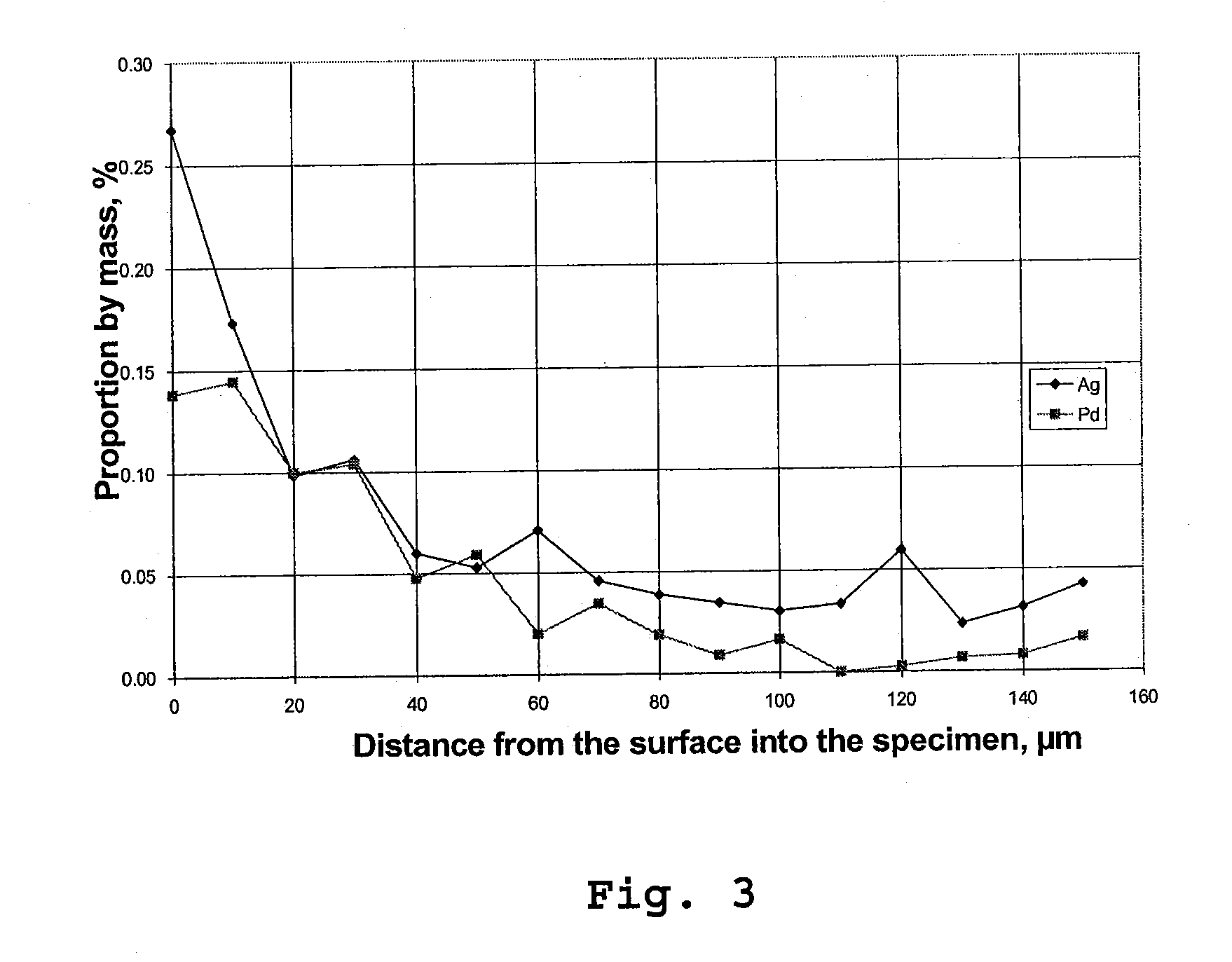

Catalyst For The Selective Hydrogenation Of Acetylenic Hydrocarbons And Method For Producing Said Catalyst

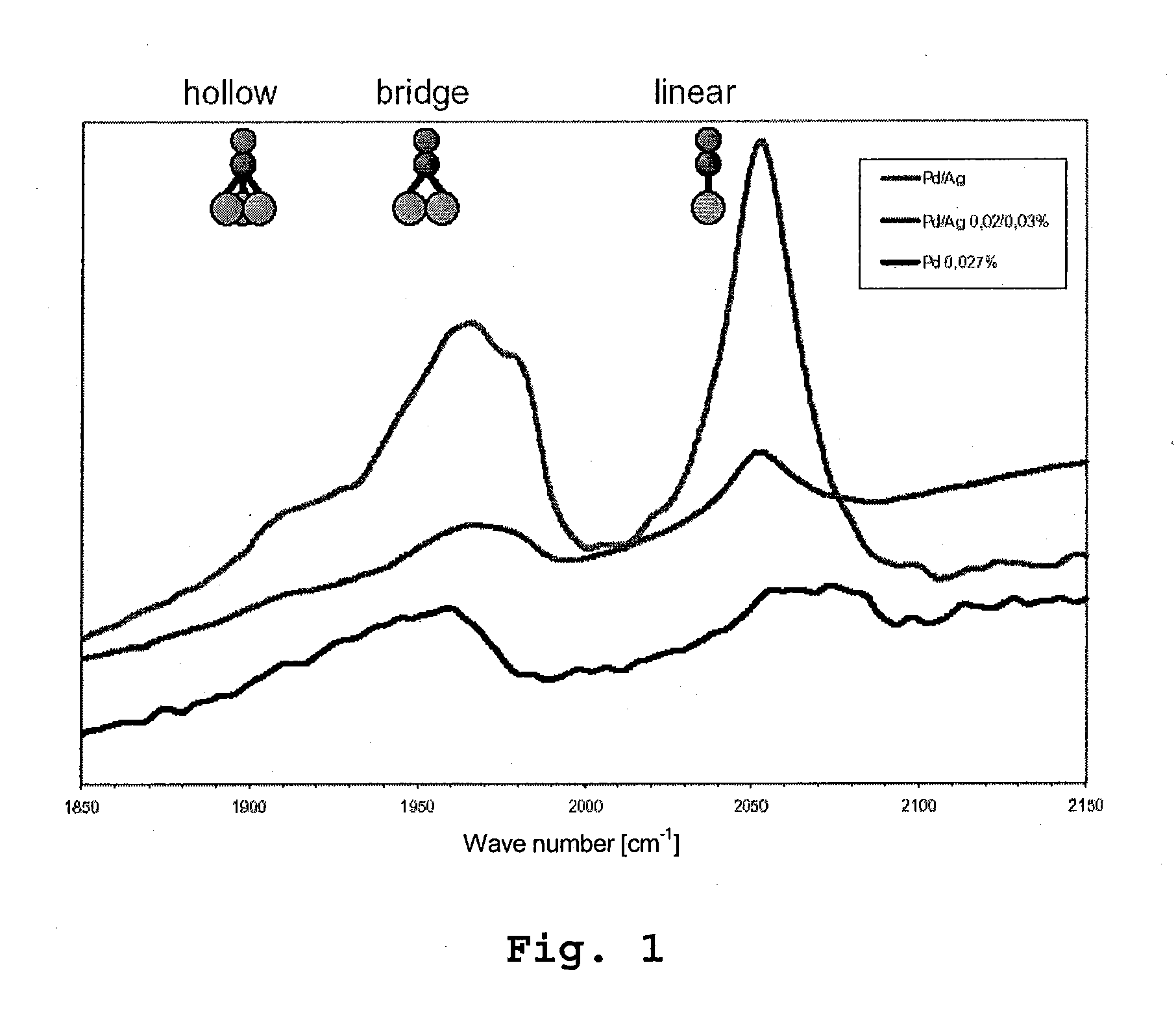

InactiveUS20100217052A1Narrow particle size distributionReduced tendency to form by-productOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationOrganic solventAcetylenic Compounds

A method for producing a catalyst, in particular for the selective reduction of acetylenic compounds in hydrocarbon streams. An impregnation solution is provided, which contains a mixture of water and at least one water-miscible organic solvent as solvent in which at least one active metal compound and also preferably at least one promoter metal compound is dissolved. A support is provided, the support is impregnated with the impregnation solution, and the impregnated support is calcined. Palladium is preferably used as active metal and silver is preferably used as promoter metal. Also, a catalyst as is obtained by the method and also its preferred use for the selective hydrogenation of acetylenic compounds.

Owner:SUED CHEM IP GMBH & CO KG

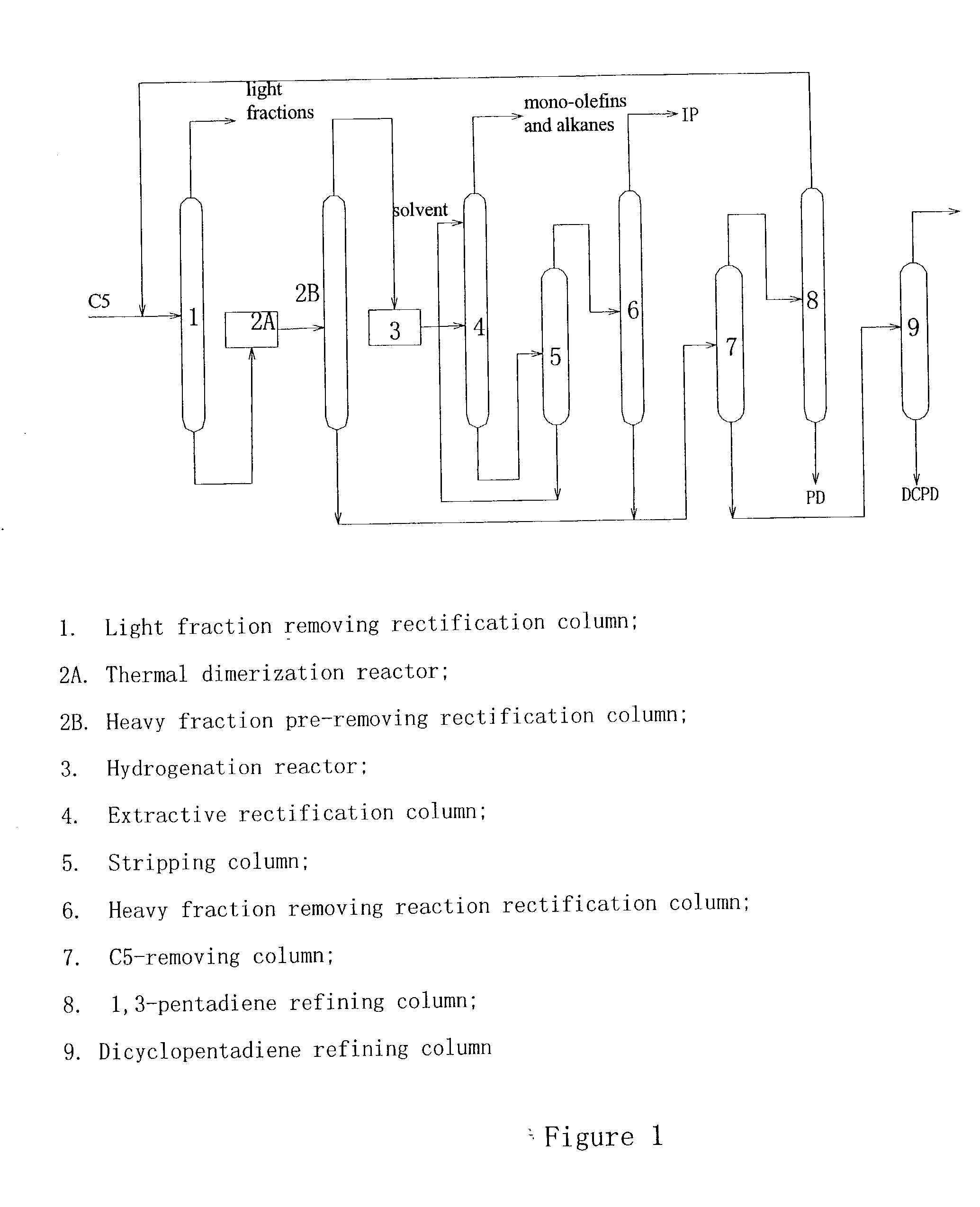

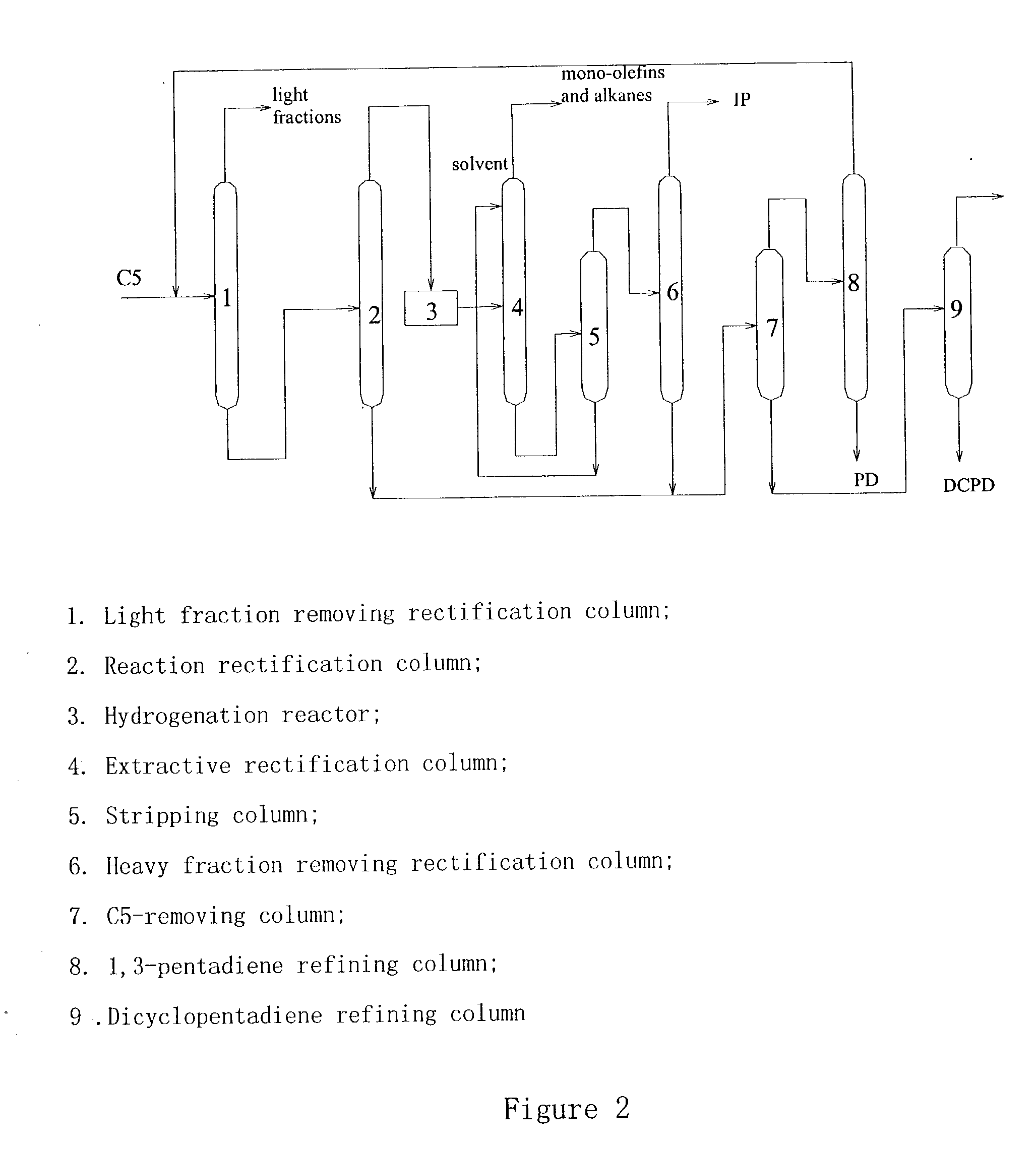

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Prepn process of vulcanized hydrogenation catalyst

ActiveCN101088619AFull and even contactEvenly mixedCatalyst activation/preparationRefining by selective hydrogenationSulfurNitrogen

The present invention relates to one kind of vulcanized hydrocarbon oil hydrogenating catalyst and its preparation process. The preparation process includes the first supporting certain amount of VI and VIII metal precursor oxide, the subsequent introducing sulfur and heat treatment in dynamic heating equipment, and final adding the residual VI and VIII metal precursor oxide and drying treatment. The present invention combines the pre-vulcanizing into the preparation process of catalyst, and the catalyst has raised reaction performance, and is suitable for hydrocarbon oil hydroprocessing, especially light fraction oil desulfurizing reaction, hydrodenitrogenation reaction, arene hydrogenating saturation and other catalytic reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cytalyst for reformed formation oil selective hydrogen removing olefin

The catalyst contains noble metal in 0.1-1.0 wt% as active component, alkali metal or alkali metal in 0.05-0.50 wt% as assistant and refractory inorganic oxide as carrier. It has specific surface area of 150-250 sq m / g and pore volume of 0.3-0.8 ml / g. It is used in the selective hydrogenation and oleine removing of gasoline fraction reformate in reaction temperature 150-250 deg.c, reaction pressure 1.5-3.0 MPa and volume space velocity 2.0-4.0 / hr. It may result in product bromine index less than 100 mg Br / 100 g, arene loss less than 0.5 wt% and satisfactory results.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for cracking gusoline selective hydrogenation, its preparation method and use

InactiveCN1429890ALow temperature hydrogenation activity is highLarge raw material handling capacityRefining by selective hydrogenationActive componentGasoline

A selective hydrocatalyst for cracking gasoline is composed of the titanium oxide-aluminium oxide compound as carrier and palladium as active component (0.25-0.35 wt.%). Its advantages are high spacespeed of liquid phase (in creased by 30-40 %), high selectivity (99% or more), and high activity stability.

Owner:RES INST OF BEIJING YANSHAN PETROCHEM

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS7449103B2Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Apparatus for Improving Flow Properties of Crude Petroleum

InactiveUS20100158764A1Low olefin concentrationTreatment with plural serial cracking stages onlyCatalytic crackingPetroleumChemistry

A process and apparatus for improving flow properties of crude may include processing a first crude stream, which may in turn include cracking the first crude stream with catalyst to form a cracked stream and spent catalyst, hydrotreating a portion of the cracked stream and then mixing the hydrotreated stream with an unprocessed second crude stream.

Owner:UOP LLC

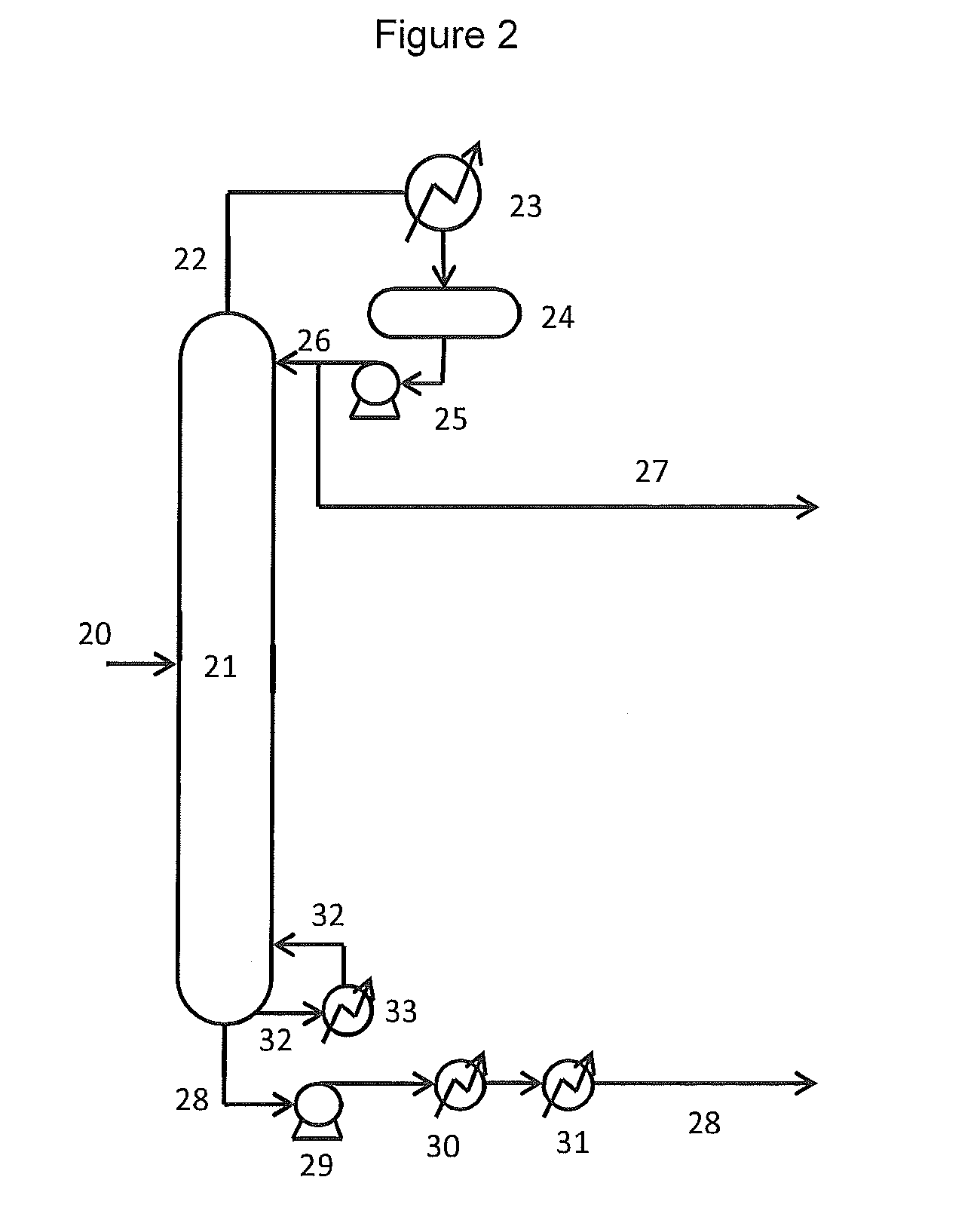

Selectivity hydrogenation method for whole fraction crack petroleum

ActiveCN101121899AGood activity at low temperatureGood choiceRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationPore distributionReaction temperature

The invention relates to a method for selective hydrogenation of full-run pyrolysis gasoline, which mainly solves the technical problem in the prior art that it is difficult to selectively hydrogenate full-run pyrolysis gasoline with high colloid and free water content. The present invention adopts the pyrolysis gasoline and hydrogen of the hydrocarbon compound fraction with C5 hydrocarbon to dry point of 204 DEG C as raw materials, the reaction temperature is 30 to 80 DEG C, the reaction pressure is 2.0 to 3.0 MPa, and the fresh oil space velocity is 2.5 to 5.0 hour-1, under the condition that the hydrogen / oil volume ratio is 60-120:1, the raw material is contacted with the catalyst and reacts to convert the diolefin and alkenyl aromatic components in the raw material into monoolefin and alkylaromatic. Including alumina support, active component metal palladium or its oxide, at least one element selected from IA or IIA in the periodic table or its oxide, at least one element selected from IVA or VA in the periodic table or its oxide Oxide, the specific surface area of the carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the carrier has a technical solution of composite pore distribution, which solves this problem well and can be used for full-run pyrolysis gasoline In the industrial production of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for multistage conversion of a charge comprising olefins with four, five or more carbon atoms, with the aim of producing propylene

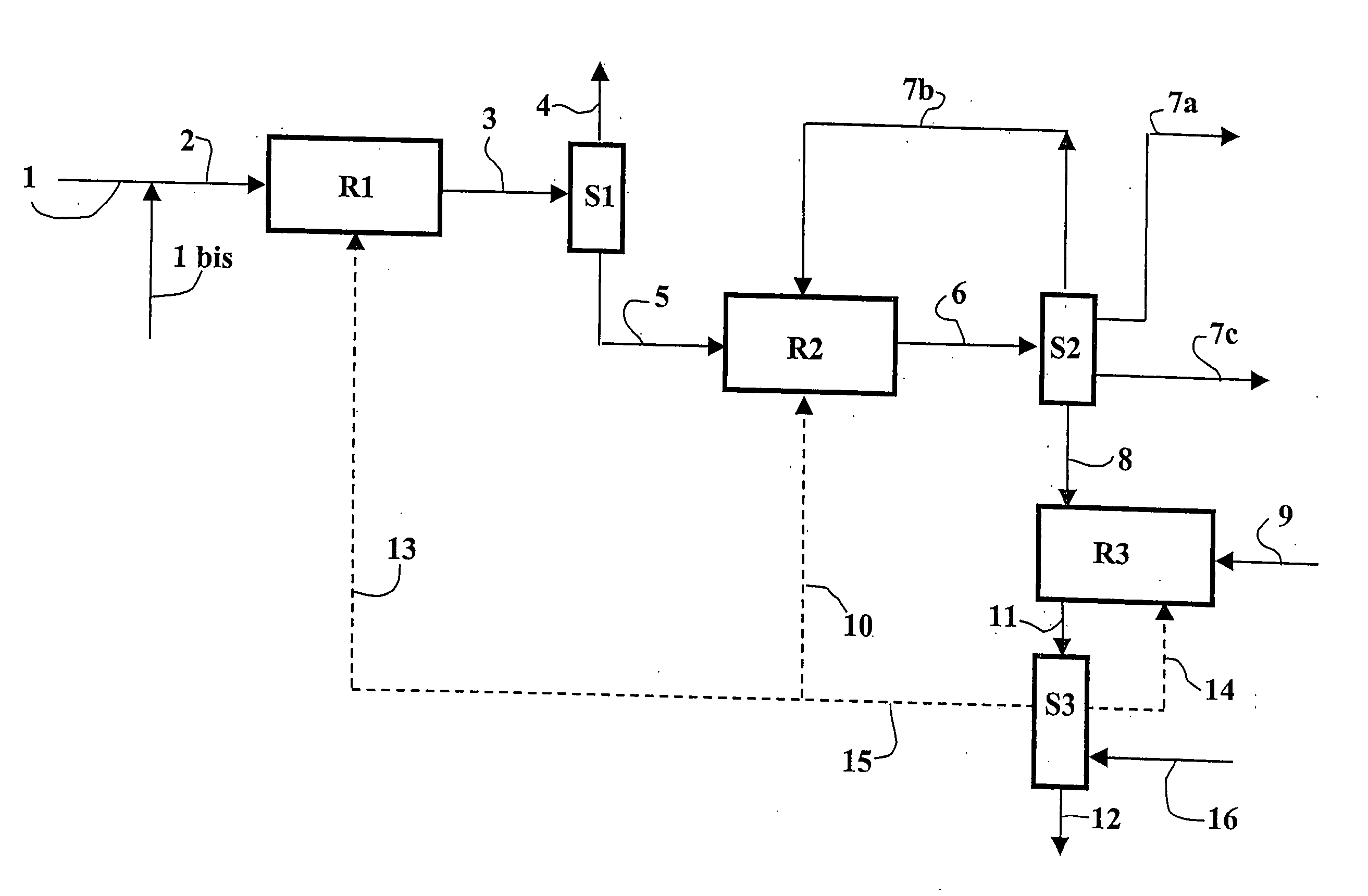

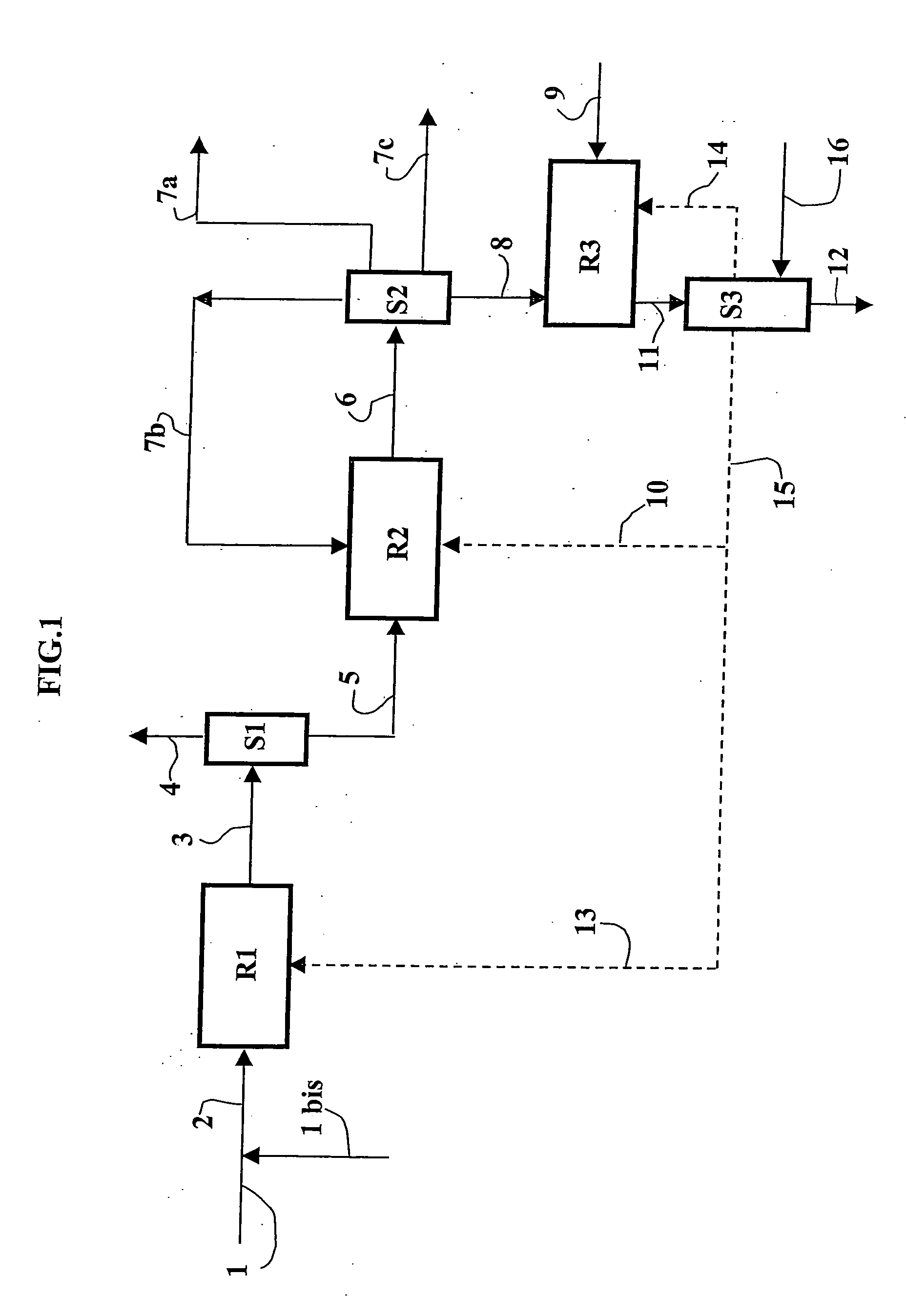

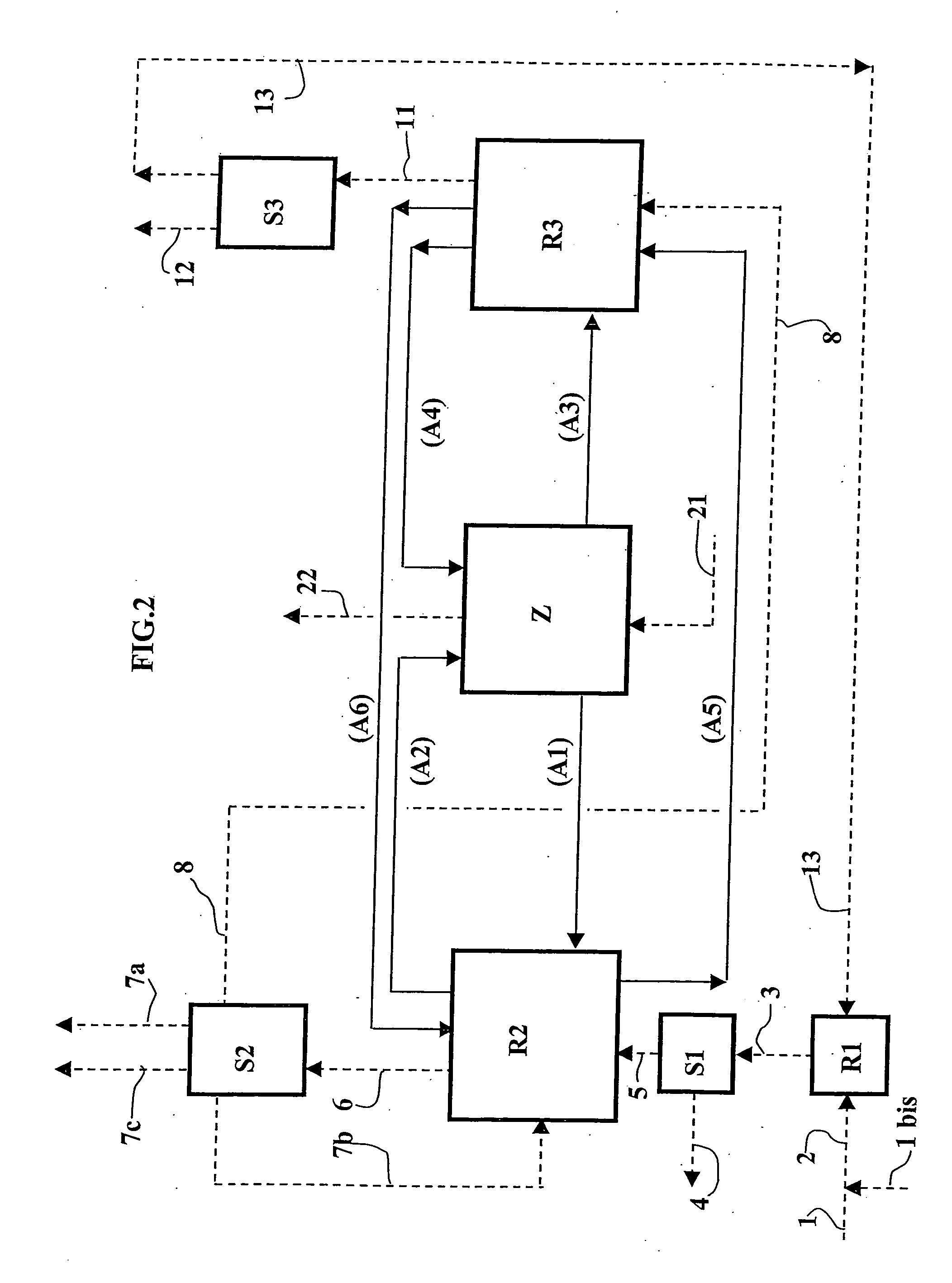

InactiveUS20050222475A1Improve propylene to ethylene ratioCatalytic crackingOrganic chemistry methodsButeneOligomer

The invention relates to a process for production of propylene in particular from a C4 and / or C5 cut from steam cracking and / or catalytic cracking, preferably comprising both butenes and pentenes, said process comprising at least one oligomerization stage, followed by a stage of catalytic cracking of the oligomers formed. Preliminary oligomerization, in particular of a wide fraction of the charge, makes it possible to optimize the yields, the conversion, and the selectivity for propylene, relative to direct cracking. It also makes it possible for cracking to be carried out in a fixed, moving, or fluidized bed, optionally with co-production of oligomers for uses other than the production of propylene.

Owner:INST FR DU PETROLE

Selective hydrogenation catalyst designed for raw gas feed streams

ActiveUS20060025302A1Hydrocarbon purification/separationCatalyst activation/preparationPtru catalystPhysical chemistry

A catalyst for selective hydrogenation of acetylenes and diolefins, particularly in a raw gas feed stream for front end selective hydrogenation. The catalyst contains a low surface area carrier with a surface area from about 2-20 m2 / g, wherein the pore volume of the pores of the carrier is greater than about 0.4 cc / g, wherein at least 90 percent of the pore volume of the pores is contained within pores having a pore diameter greater than about 500 Å and wherein from about 1 to about 2 percent of the total pore volume is contained in pores with a pore diameter from about 500 to about 1,000 Å, palladium, wherein the palladium comprises from about 0.01 to about 0.1 weight percent of the catalyst, and a Group IB metal, wherein the Group IB metal comprises from about 0.005 to about 0.06 weight percent of the catalyst.

Owner:CLARIANT INT LTD

Catalyst for hyrogenating deoxidating and olefine saturating of Feather synthesizing oil and its mfg. process and application

ActiveCN1597859AImprove hydrogenation activityRefining by selective hydrogenationPtru catalystCopper oxide

The invention is a hydro-deoxidation and alkene-saturation catalyst of Fischer-Tropsch oil product and its components in weight percent: nickel oxide 5.0-18.0%, cobalt oxide 0-11.0%, copper oxide 0-6.0%, iron oxide 0-12.0%, titanium oxide 0-12.0%, lanthanum oxide 0-8.0% and carrier 46.0-85.0%. Its preparing method includes in turn carrier preprocessing and after-processing of supported active component and catalyst. It has higher activity to hydro-deoxidation and alkene saturation of the oil product, especially applied to the hydrofining process of the iron-base paste Fischer-Tropsch oil product with higher content of oxygen-containing compound and alkene.

Owner:SYNFUELS CHINA TECH CO LTD

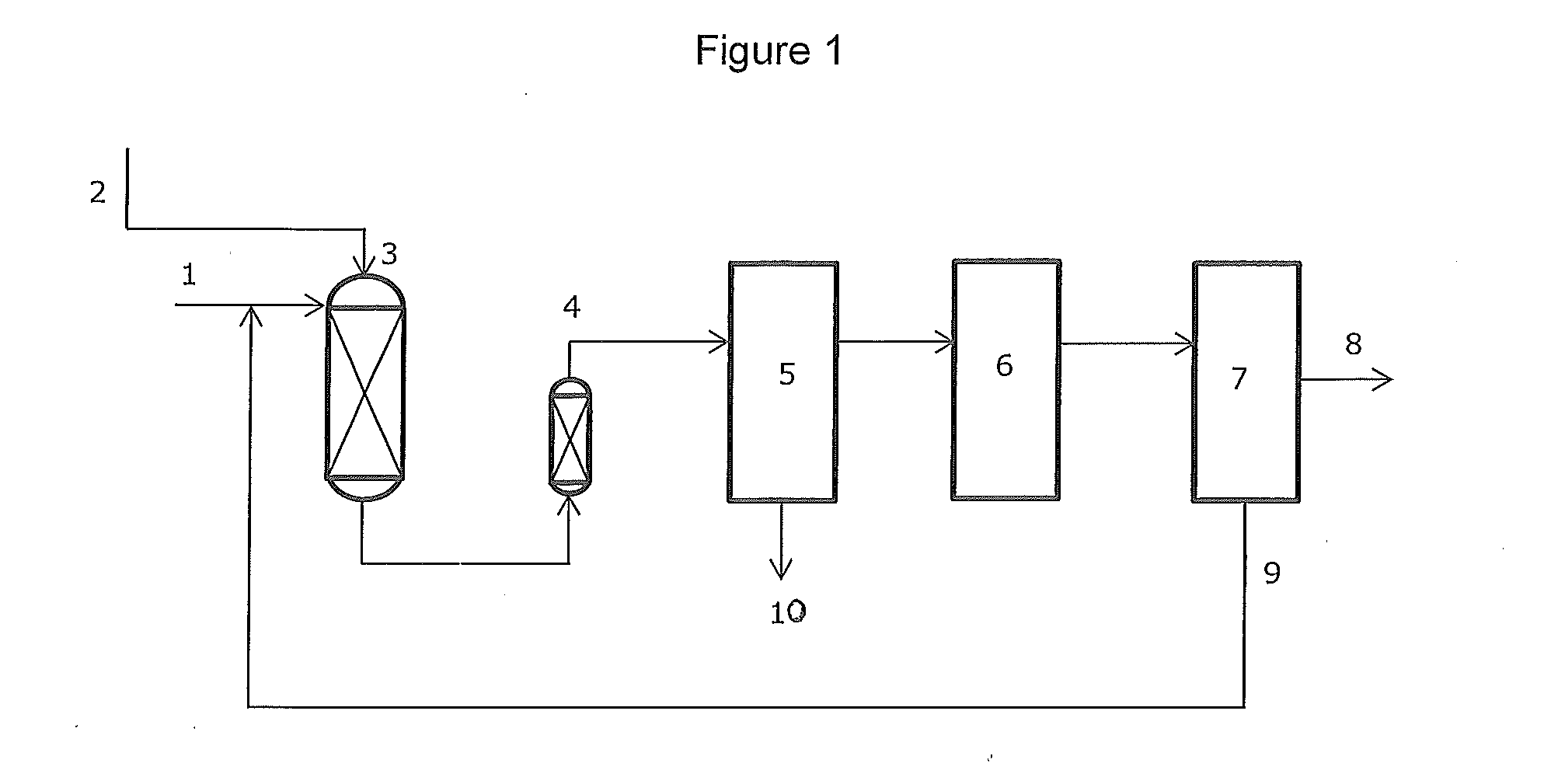

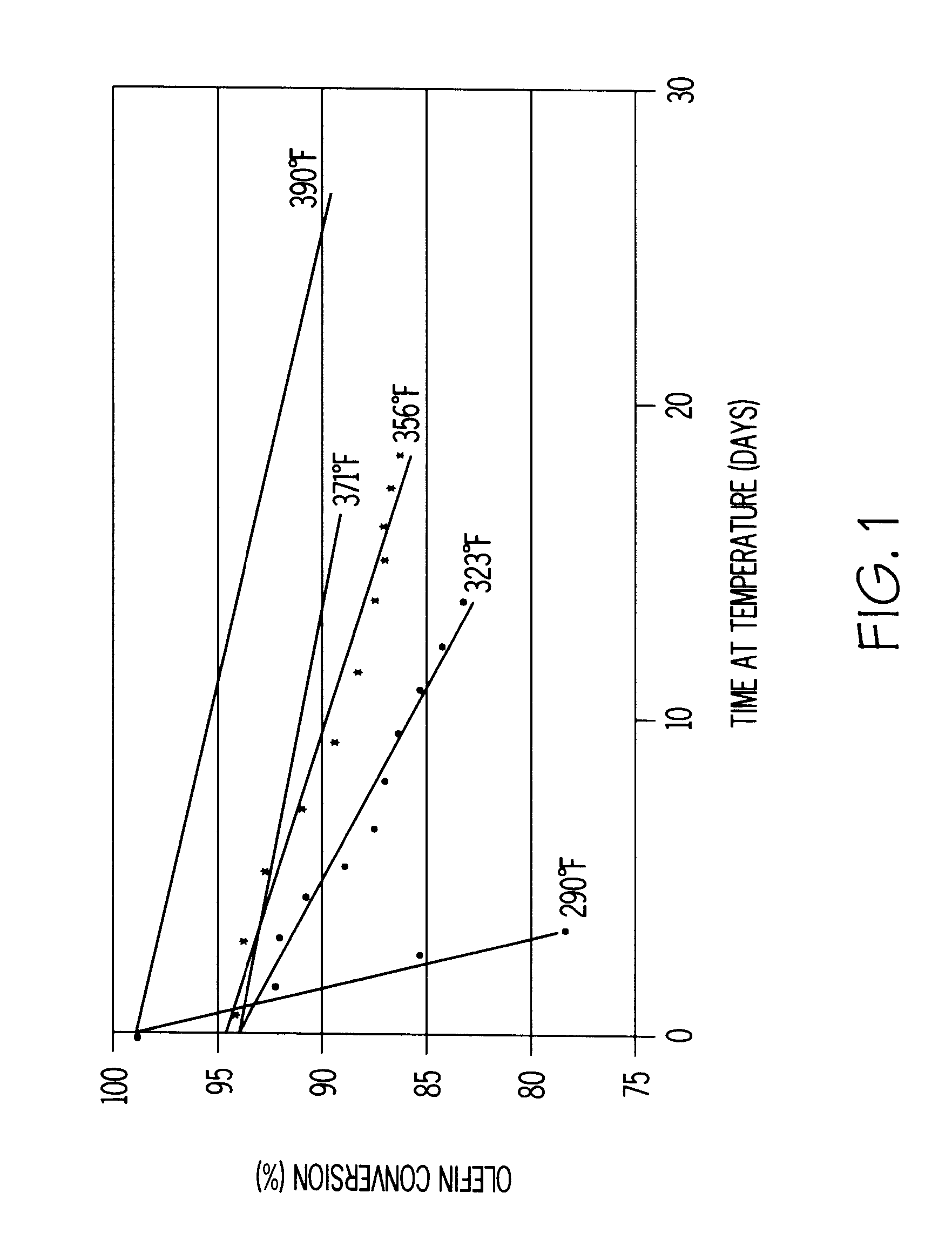

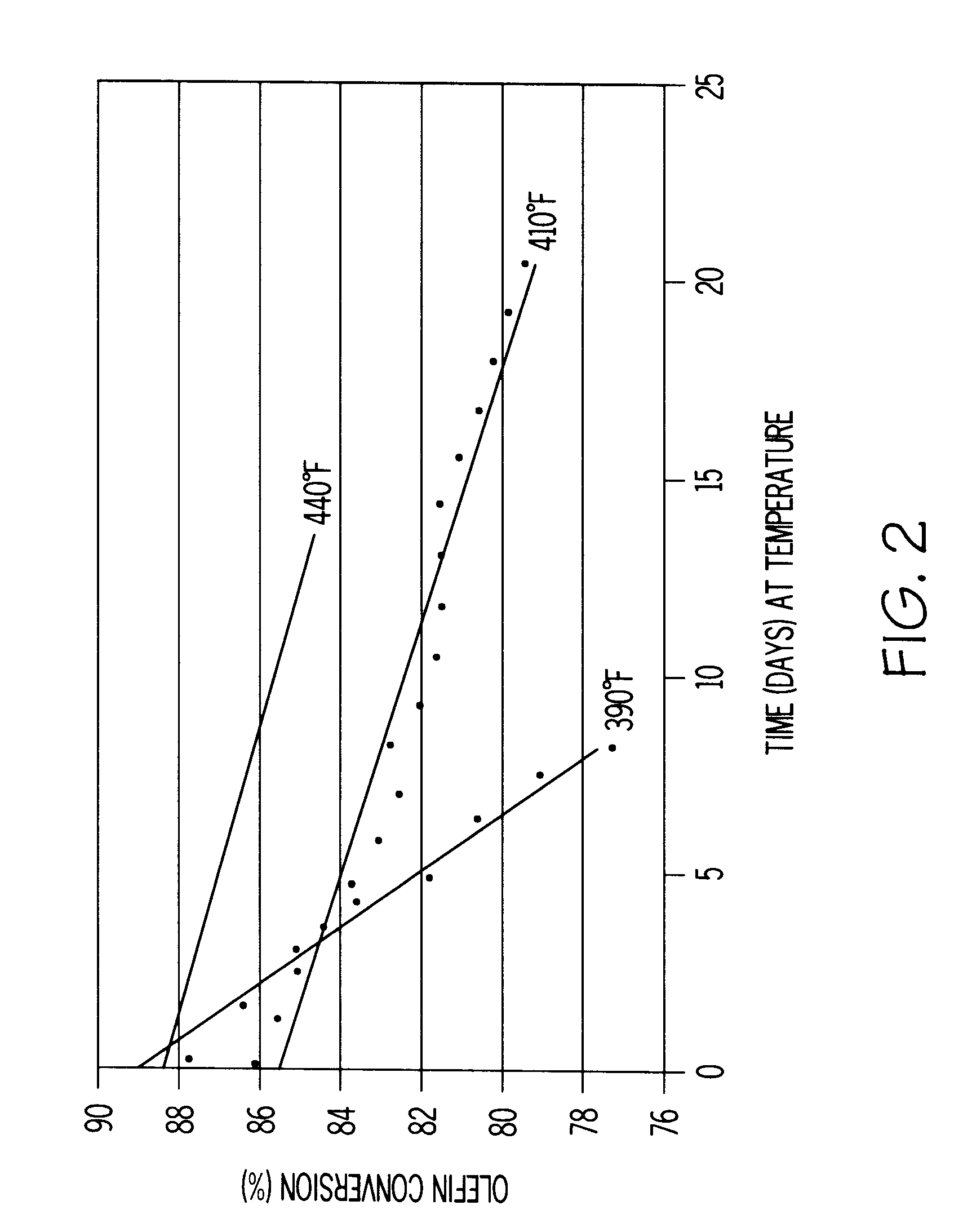

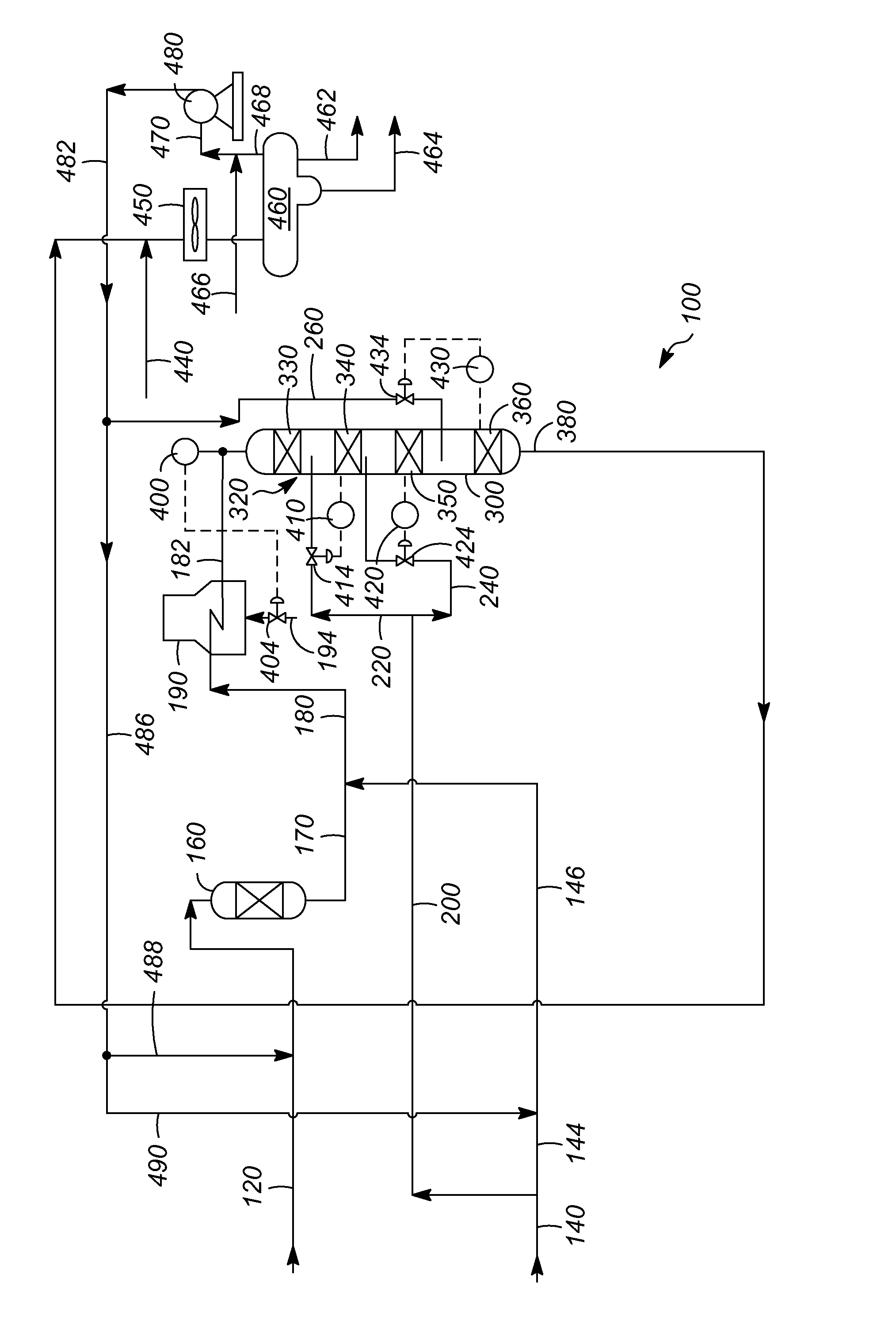

Hydrotreating process and controlling a temperature thereof

ActiveUS20120273394A1Reduce the amount requiredTreatment with hydrotreatment processesRefining by selective hydrogenationBromine numberNaphtha

One exemplary embodiment can be a hydrotreating process. The hydrotreating process can include providing a first feed stream having a coker naphtha with a bromine number of about 10-about 120, combining the first feed stream with a second feed stream having a straight run naphtha with a bromine number of less than about 10 to create a combined feed, providing the combined feed to a hydrotreating reactor having at least one catalyst bed, and separating a quench stream from the second feed stream and providing the quench stream after the at least one catalyst bed.

Owner:UOP LLC

Layered composition and processes for preparing and using the composition

A layered composition which can be used in various processes has been developed. The composition comprises an inner core such as a cordierite core and an outer layer comprising a refractory inorganic oxide, a fibrous component and an inorganic binder. The refractory inorganic oxide layer can be alumina, zirconia, titania, etc. while the fibrous component can be titania fibers, silica fibers, carbon fibers, etc. The inorganic oxide binder can be alumina, silica, zirconia, etc. The layer can also contain catalytic metals such as gold and platinum plus other modifiers. The layered composition is prepared by coating the inner core with a slurry comprising the refractory inorganic oxide, fibrous component, an inorganic binder precursor and an organic binding agent such as polyvinyl alcohol. The composition can be used in various hydrocarbon conversion processes.

Owner:UOP LLC

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurization process of gasoline

A process for desulfurizing gasoline includes such steps as reaction between thiol and diolefin in gasoline in fixed-bed reactor to generate S-contained compound with higher boiling point, separatingout low-sulfure light fraction from the gasoline in distilling tower, hydrodesulfurizing or selective hydrodesulfurizing in catalytic distilling tower to convert said S-contained compound and other sulfide to hydrogen sulfide, discharging the hydrogen sulfide, residual hydrogen and part of gasoline fraction from the tower top, and discharging the heavy components of gasoline from tower still. Itsadvantages are less consumption of hydrogen and high output rate of liquid.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com