Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

382results about How to "Good activity at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

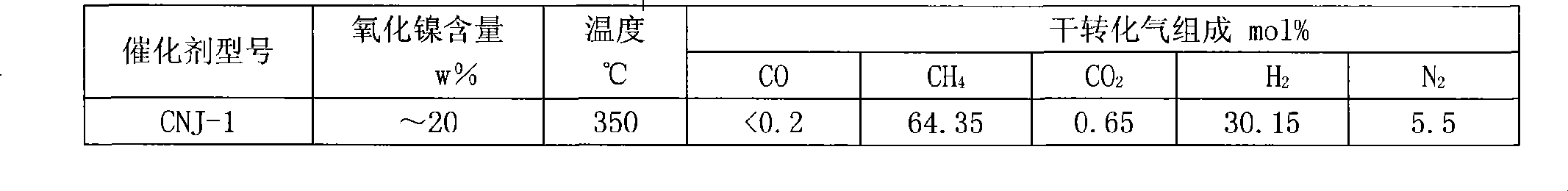

Coke-oven gas methanation catalyst and preparation method thereof

ActiveCN101391218AHigh activityImprove carbon resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

The invention discloses a coke oven gas methanation catalyst, which takes Al2O3 as a carrier, nickel as a main active component, and MgO as an auxiliary agent; wherein: the active component nickel exists in the catalyst in the form of NiO, and the carrier Al2O3 and the auxiliary agent MgO form a carrier structure of magnesia-alumina spinel; the main components respectively include, by weight percentage: 5 percent to 20 percent of NiO, 30 percent to 80 percent of Al2O3, and 1 percent to 50 percent of MgO. The catalyst has the advantages of high strength, good activity, good thermal stability, excellent anti-coking performance and good low temperature activity, and also has the properties of transforming high hydrocarbon and good anti-oxidation. The invention also discloses a preparation method of the coke oven gas methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Integral supported carbon molecular sieve catalyst, preparing method and applications thereof

InactiveCN101224432AReduce the number of growthSave raw materialsMolecular sieve catalystsEther preparation by compound dehydrationGas phaseCarbon nanotube

A catalyst for an integrated supported carbon modular sieve comprises an integrated beehive cordierite, a carbon-nano tube and an HZSM-5 modular sieve, wherein the carbon-nano tube takes 7-20 proportions, HZSM-5 takes 10-30 proportions, and cordierite tales 60-80 proportions. The preparation method is that: carbon-nano tube is produced in situ on the integrated beehive cordierite by using chemical vapor deposition firstly, and the carbon-nano tube is taken as carrier, then the ZSM-5 modular sieve is developed on the carrier by using a secondary growth method. The catalyst for an integrated supported carbon-modular sieve can be used for the gas-phase synthesis of dimethyl ether DME by the dehydration of methanol.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

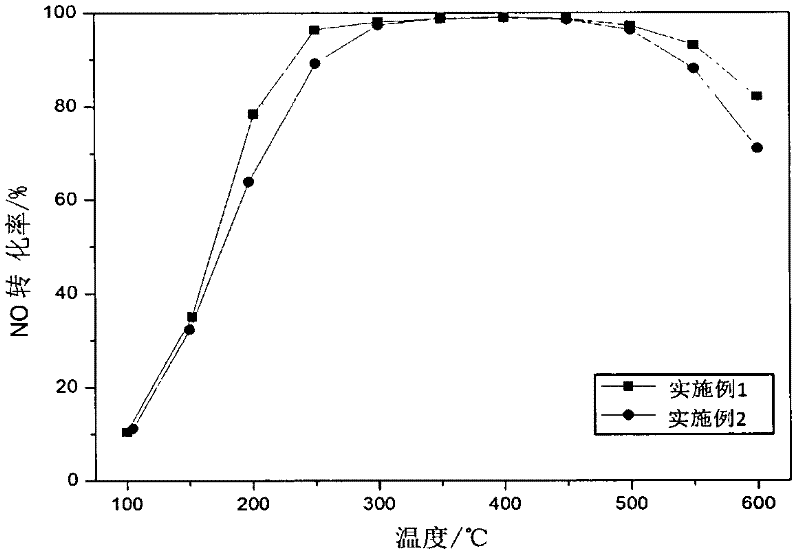

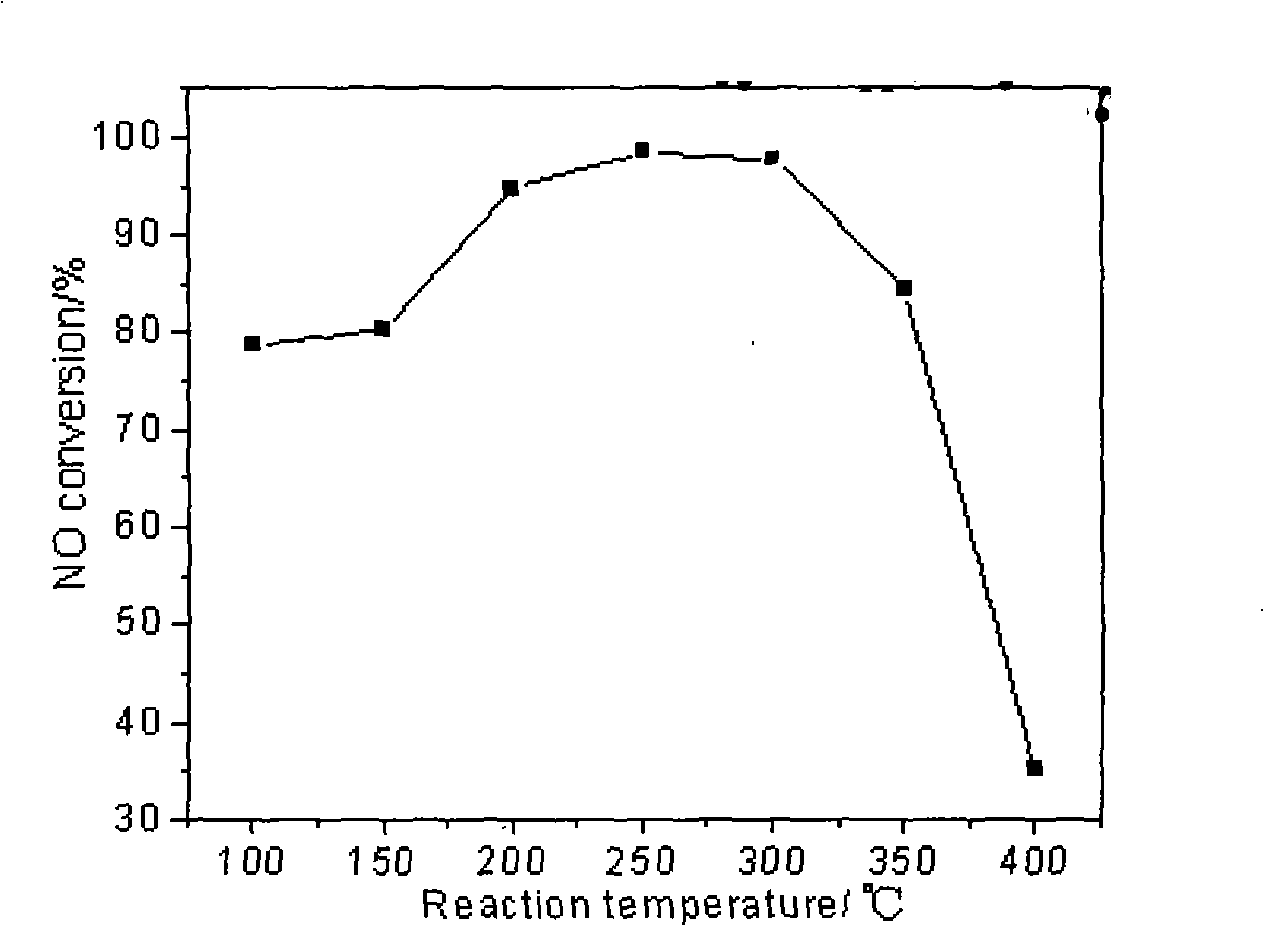

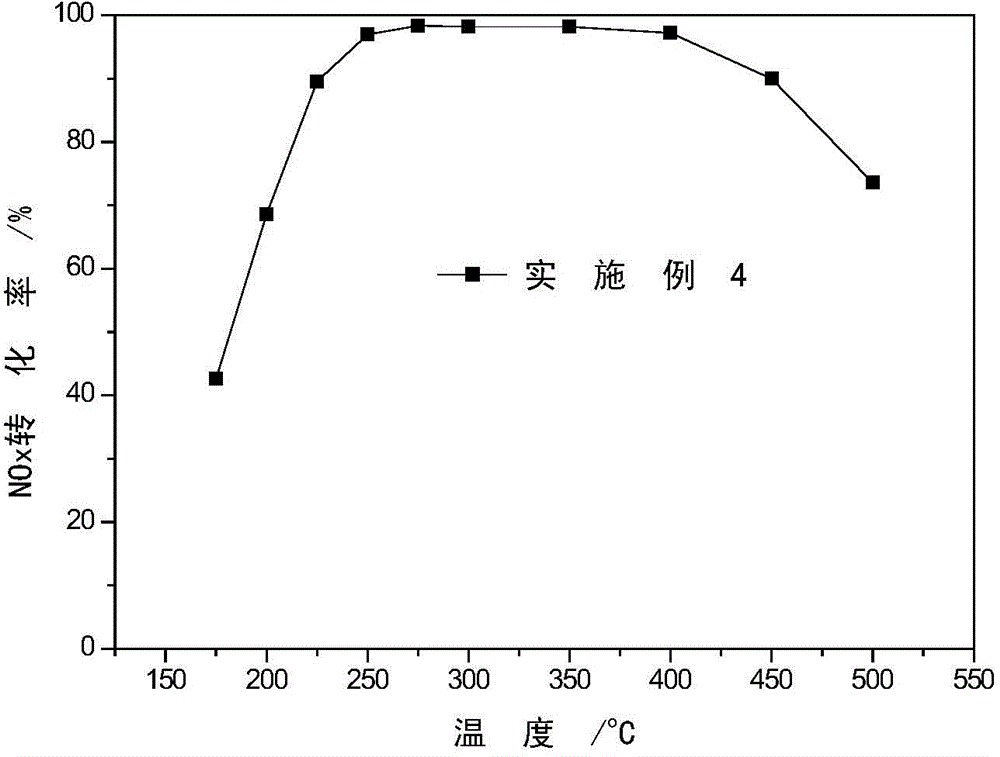

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

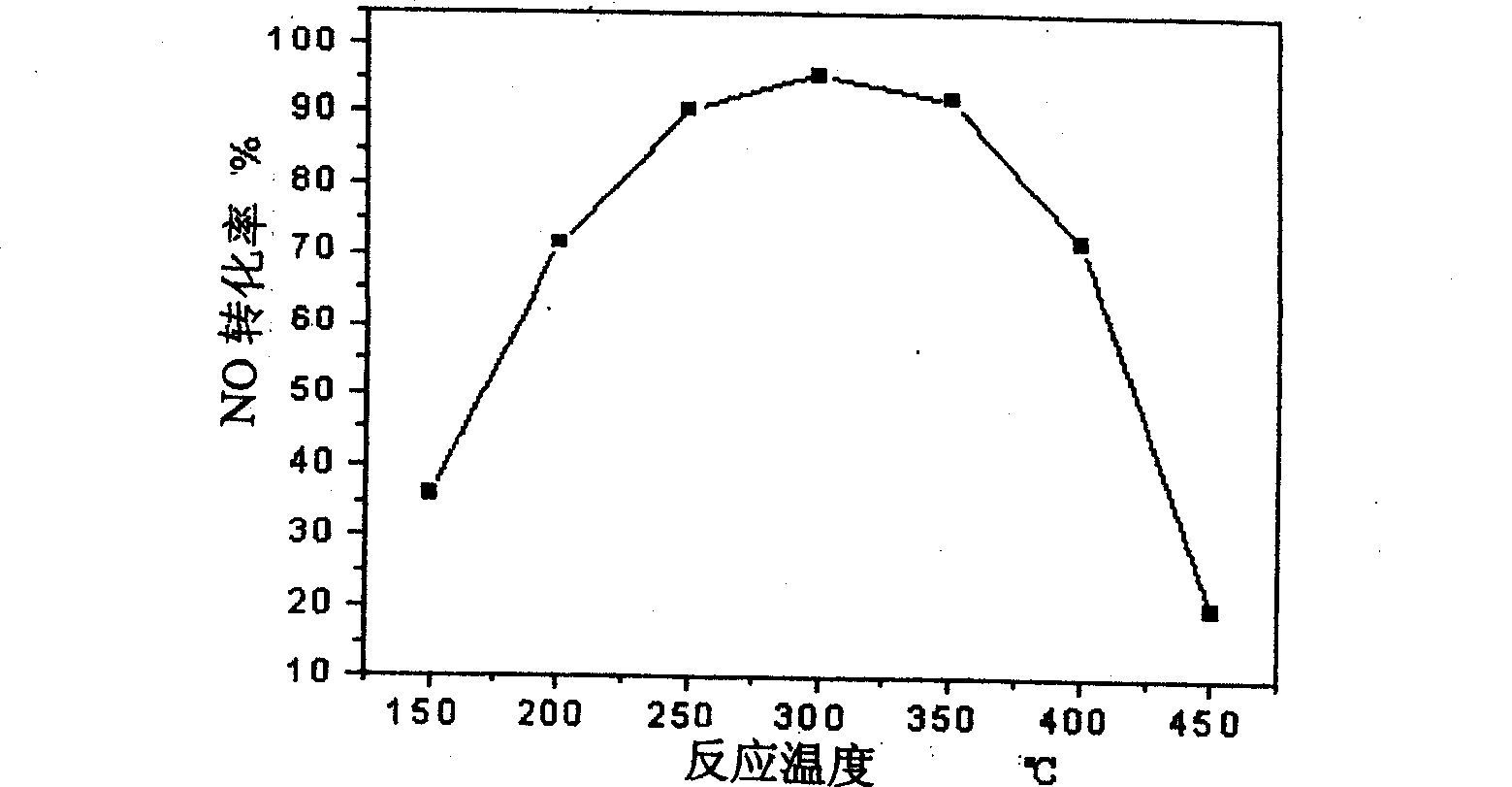

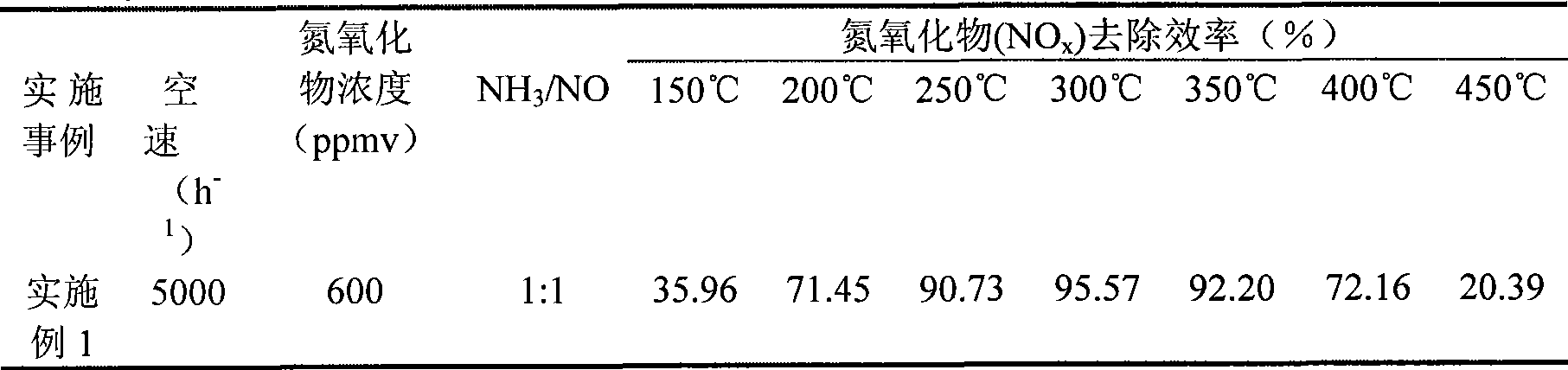

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

Hydrogenation modification process for low grade gasoline

ActiveCN1621495AGood activity at low temperatureLow reaction temperatureRefining by aromatic hydrocarbon hydrogenationRefining to eliminate hetero atomsPre treatmentLow graded

The inferior gasoline hydrogenating modification process includes cutting the material gasoline at 60-90 deg.c into light fraction and heavy fraction; mixing the heavy fraction with hydrogen, reacting with hydrogenating and desulfurizing catalyst via contact, and reacting the effluent with aromatizing modification catalyst for aromatizing modification to obtain high octane number and low sulfur gasoline fraction; and mixing the modified heavy gasoline fraction with the light fraction or the light fraction after mercaptol eliminating pre-treatment to obtain the product gasoline. The said process makes the gasoline product possess S content not more than 150 ppm, olefin content not more than 20 %, arene content not more than 40 % and 1-3 unit raised RON.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

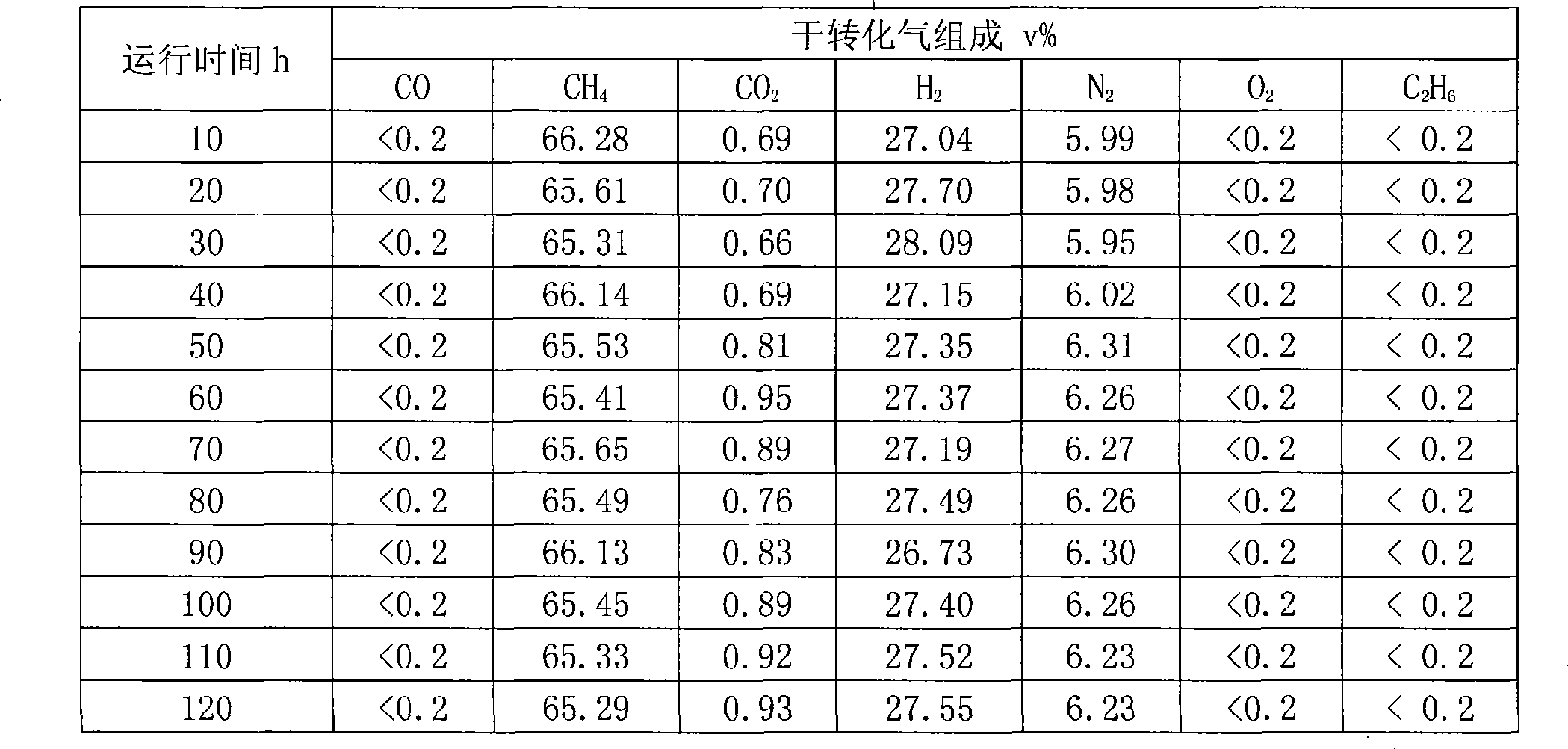

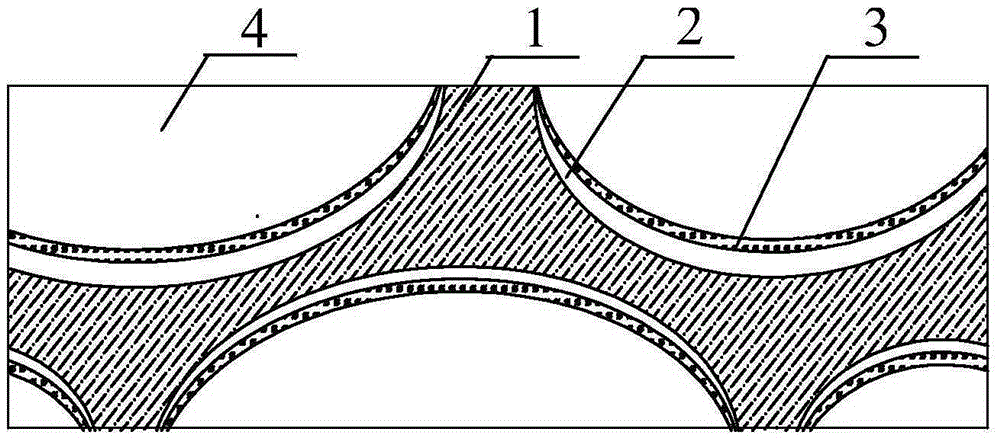

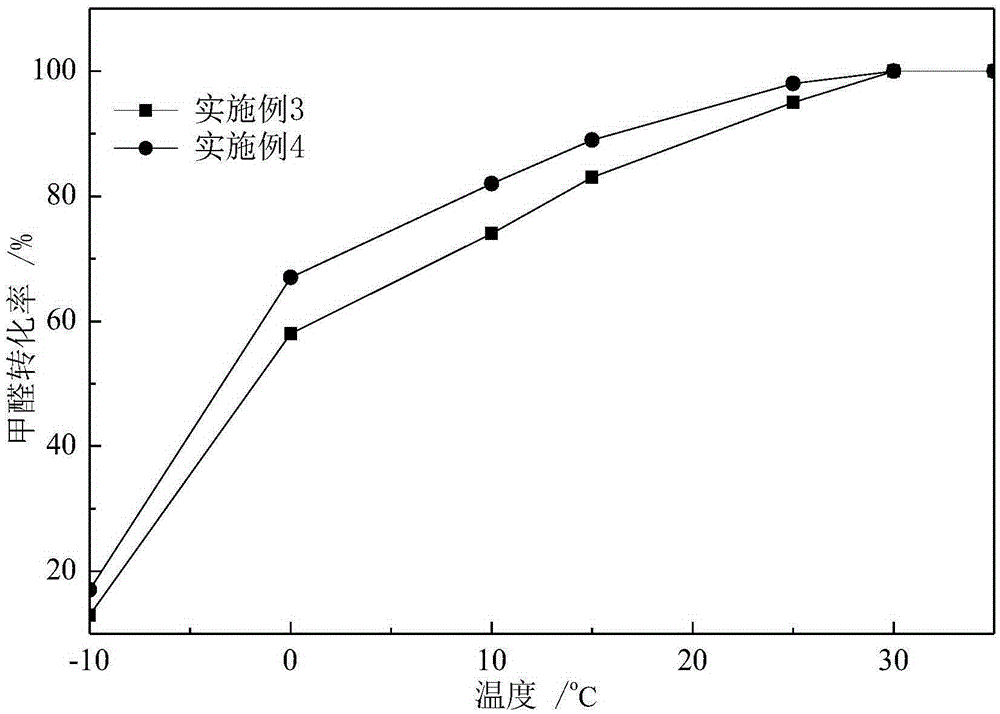

Catalytic module capable of removing formaldehyde at room temperature and preparation method thereof

ActiveCN105289298AImprove catalytic activity and purification efficiencyExcellent low temperature activity and removal efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryLight source

The invention discloses a catalytic module capable of removing formaldehyde at room temperature and a preparation method thereof. The catalytic module comprises a skeleton carrier, coatings and catalyst layers, the skeleton carrier is a foam ceramic structure with three-dimensional pore channels, and the foam ceramic structure is internally provided with multiple pore channels which are interwoven into a net-shaped structure and arranged in any one of the X direction, the Y direction and the Z direction; the coatings are evenly coated on the surfaces of the pore channels in the foam ceramic structure and the other surface of the foam ceramic structure, and the catalyst layers are highly dispersed on the coatings. By means of the catalytic module capable of removing the formaldehyde at the room temperature and the preparation method thereof, at the room temperature and environment humidity, low-concentration formaldehyde can be oxidized into H2O and CO2, excellent low-temperature activity and removing efficiency are achieved, and the formaldehyde removing efficiency can be kept above 98 percent at the airspeed SV equal to 50,000 h<-1>. The preparation process is simple, the precious metal load is low, and accessory equipment such as light sources and heating are not needed. The catalytic module is suitable for air purification of closed and semi-closed spaces such as living rooms, office buildings, schools, dormitories, shopping malls, furniture markets and automobiles.

Owner:展宗城

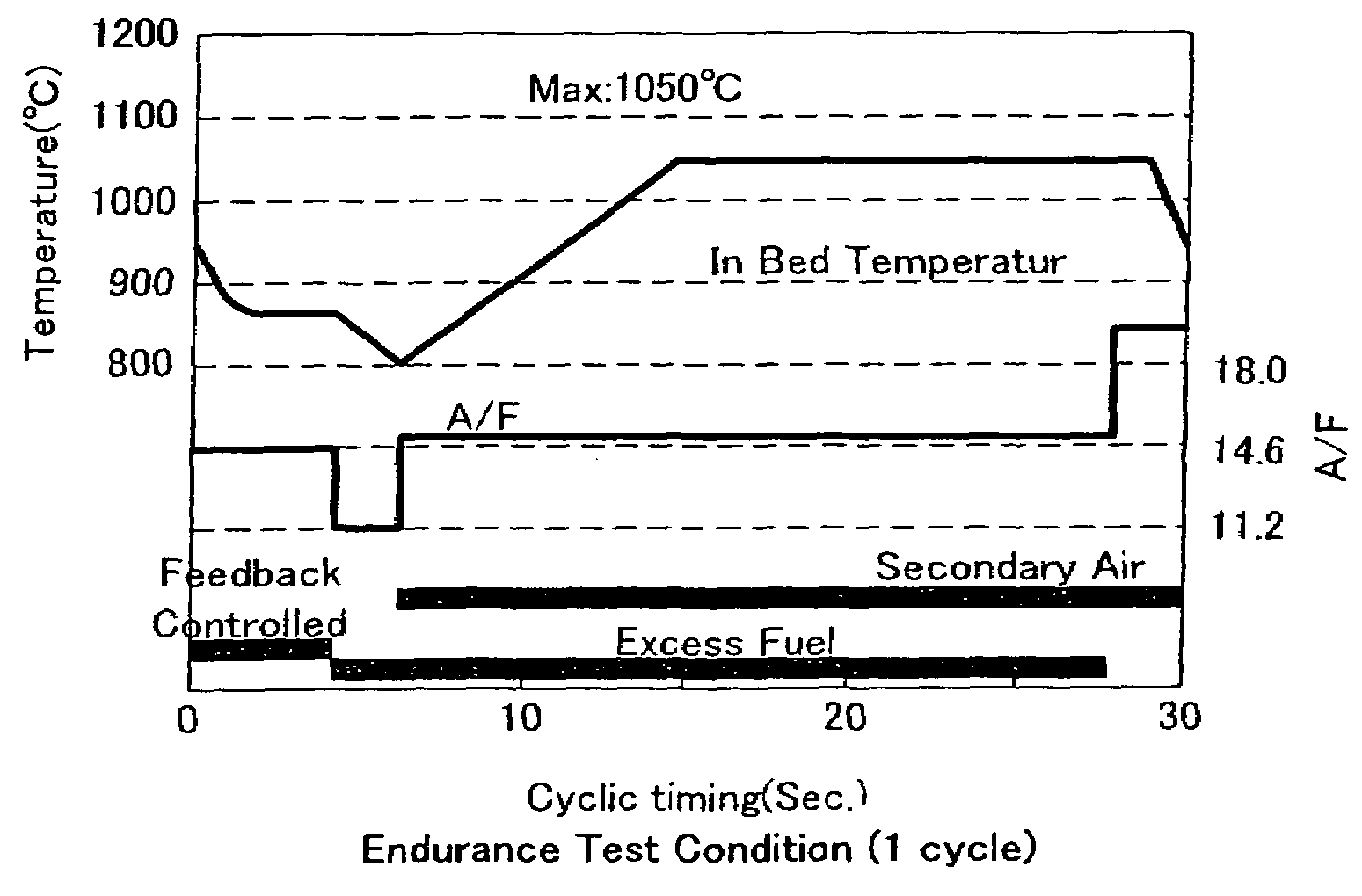

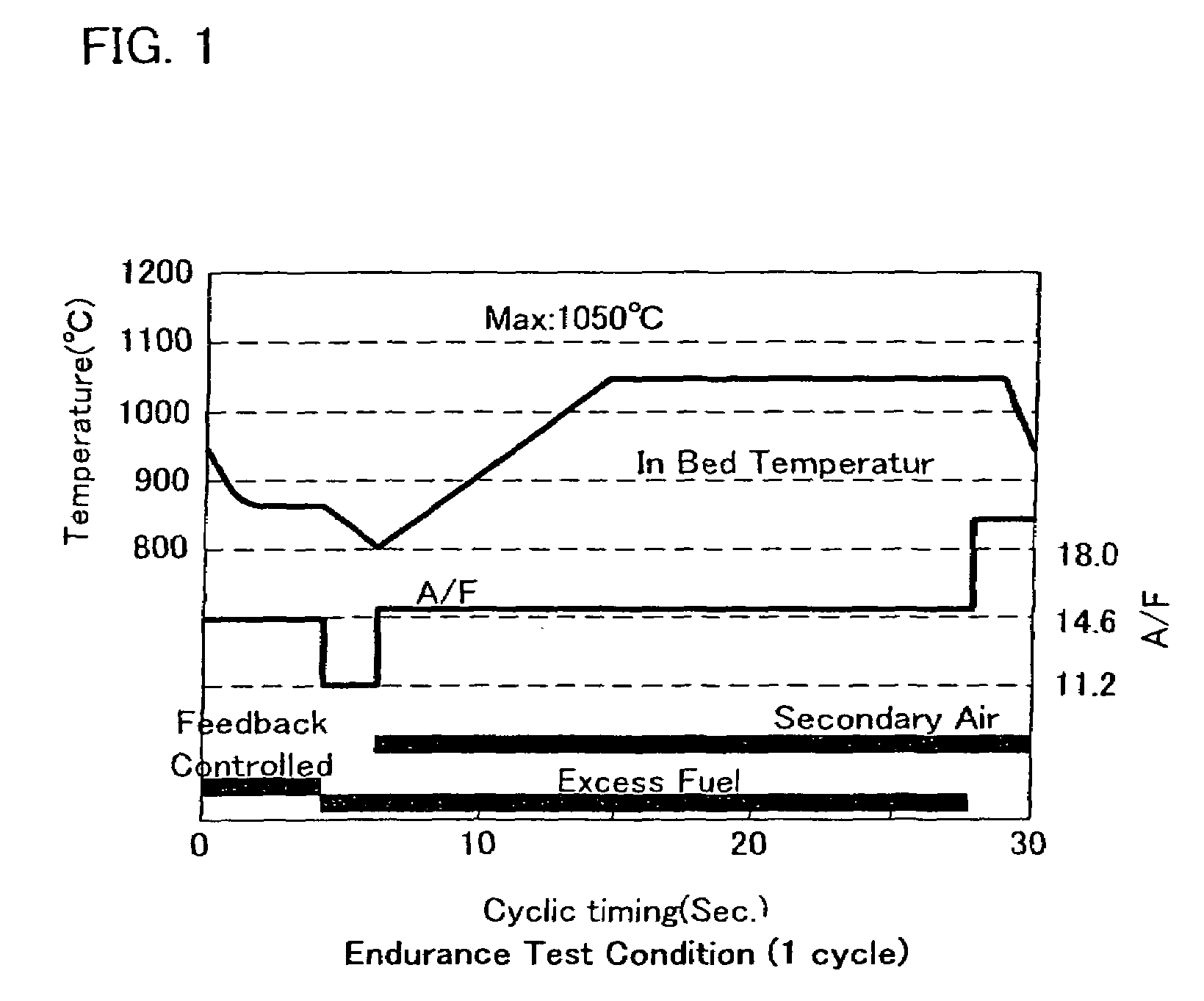

Exhaust gas purifying catalyst

InactiveUS7081430B2High activityGood activity at low temperatureInternal combustion piston enginesOther chemical processesPlatinumCerium

An exhaust gas purifying catalyst that provides the excellent low-temperature activity and also develops the good catalytic activity of rhodium to produce a good purifying performance economically. The exhaust gas purifying catalyst comprises an alumina on which rhodium and platinum are previously supported; a zirconium complex oxide on which rhodium and platinum are previously supported; and a cerium complex oxide on which platinum is previously supported.

Owner:DAIHATSU MOTOR CO LTD

Flue gas denitrating integral catalyst with aluminium base ceramic as carrier and preparation thereof

InactiveCN101234345AGood activity at low temperatureImprove thermal stabilityDispersed particle separationCatalyst activation/preparationFlue gasThermal stability

The invention relates to a flue gas denitration integral type catalyst using an aluminum-based ceramic as a carrier and a preparation method thereof. The invention uses the aluminum-based ceramic as a first carrier, an alumina is used as a second carrier, and CeO2 which is added with proper amounts of doped metal oxides is used as an active constituent. The first carrier is used as a benchmark, the content mass percentage of the alumina is 3 to 40wt percent and the load content mass percentage of the CeO2 and the doped metal oxides which is used as the active constituent is 1 to 26wt percent. The adopted preparation method is to impregnate the Ce salt and the doped metal salt composite solution to prepare an active catalytic component coating after impregnating the aluminum-based ceramic with an alumina sol and being roasted driedly to prepare an alumina coating. Compared with the prior art, the flue gas denitration integral type catalyst and the preparation method thereof not only improve the mechanicalness and the heat stability of the catalyst carrier and reduce the loading amount of the active constituent, but also are environmental protection without a secondary pollution, improve the activity of the catalyst and expand a window of activity temperature in a low temperature.

Owner:NANJING UNIV OF TECH

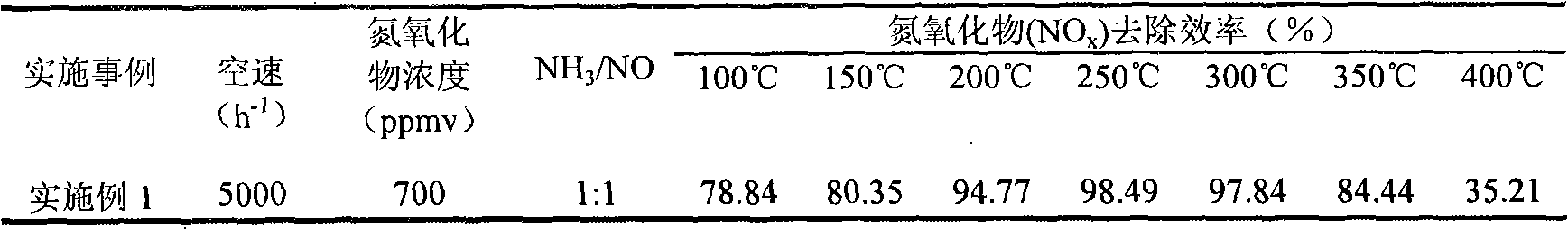

Integrated honeycomb SCR (selective catalytic reduction) catalyst for low-temperature smoke denitration and preparation method of catalyst

ActiveCN102824922AGood activity at low temperatureImprove water resistanceMolecular sieve catalystsDispersed particle separationHoneycombSmoke

The invention discloses an integrated honeycomb SCR (selective catalytic reduction) catalyst for low-temperature smoke denitration and a preparation method of the catalyst, wherein the integrated honeycomb SCR catalyst comprises substrates, active elements and additives; the substrates are TiO2 and ZSM-5 molecular sieve powder; the active elements comprise ZrO2, MnO2, Fe2O3 and CeO2. The catalyst provided by the invention not only has higher catalytic activity at a low temperature (120 DEG C), but also has a good waterproof property and a higher practical application value in engineering.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Fume denitration composite catalyst using titanium-base ceramics as carrier and preparation method thereof

ActiveCN101380543AGood chemical stabilityExtend your lifeCatalyst carriersDispersed particle separationCeriumChemical stability

The invention relates to a flue gas denitration composite catalyst and the preparation method thereof and pertains to the technical field of environment-friendly catalytic material and air pollution treatment. The invention is characterized in that aluminum-based or silicon-based ceramics is taken as a first carrier, aluminum-silicon composite oxide is taken as a second carrier, and cerium-zirconium composite metal oxide is taken as the catalyst active component. The aluminum-based or silicon-based ceramics is infused in the aluminum-silicon composite sol, after preparing a carrier coating by drying and baking, then the carrier coating is infused in cerium-zirconium composite solution for preparing the coating of active catalyst components. Compared with the prior art, the invention not only improves the activity and the chemical stability of the catalyst and enlarges the catalysis activity temperature window, but also improves the mechanical performance and thermal stability of the catalyst carrier, is environment-friendly and cheap, has no secondary pollution and lowers the loading quantity of the active components.

Owner:NANJING UNIV OF TECH

Selectivity hydrogenation method for whole fraction crack petroleum

ActiveCN101121899AGood activity at low temperatureGood choiceRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationPore distributionReaction temperature

The invention relates to a method for selective hydrogenation of full-run pyrolysis gasoline, which mainly solves the technical problem in the prior art that it is difficult to selectively hydrogenate full-run pyrolysis gasoline with high colloid and free water content. The present invention adopts the pyrolysis gasoline and hydrogen of the hydrocarbon compound fraction with C5 hydrocarbon to dry point of 204 DEG C as raw materials, the reaction temperature is 30 to 80 DEG C, the reaction pressure is 2.0 to 3.0 MPa, and the fresh oil space velocity is 2.5 to 5.0 hour-1, under the condition that the hydrogen / oil volume ratio is 60-120:1, the raw material is contacted with the catalyst and reacts to convert the diolefin and alkenyl aromatic components in the raw material into monoolefin and alkylaromatic. Including alumina support, active component metal palladium or its oxide, at least one element selected from IA or IIA in the periodic table or its oxide, at least one element selected from IVA or VA in the periodic table or its oxide Oxide, the specific surface area of the carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the carrier has a technical solution of composite pore distribution, which solves this problem well and can be used for full-run pyrolysis gasoline In the industrial production of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxidation Catalyst for NH3 and an Apparatus for Treating Slipped or Scripped NH3

InactiveUS20090126353A1Inhibition formationGood activity at low temperatureCombination devicesGas treatmentPlatinumIn vehicle

Disclosed herein are an ammonia oxidation catalyst and a system for treating slipped ammonia or waste ammonia using the oxidation catalyst. More specifically, disclosed are an ammonia oxidation catalyst comprising either Cu-containing zeolite impregnated with platinum or Cu-containing alumina impregnated with platinum, which has improved low-temperature activity to oxidize ammonia generated in a mobile source or fixed source system and is used to inhibit the formation of nitrogen oxides, as well as a system for treating ammonia contained in vehicle exhaust gas, a chemical reactor system and an environmental device and system, which include the oxidation catalyst.

Owner:HEESUNG CATALYSTS CORP

Nickel catalyst for selective hydrogenation

ActiveCN101147871AGood activity at low temperatureGood choiceHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNickel catalyst

The present invention relates to a nickel catalyst for selective hydrogenation. The catalyst composition includes the following components: (by wt%) (a), 5.0-40.0% of metal nickel or its oxide; (b), 0.01-20.0% of at least one element selected from molybdenum or tungsten or its oxide; (c), 0.01-10.0% of at least one element selected from rare earth elements or its oxide; (d), 0.01-2.0% of at least one element selected from IA or IIA of periodic table of chemical elements or its oxide; (e), 0-15.0% of at least one element selected from Si, P, B or F or its oxide; (f), 0-10.0% of at least one element selected from IVB of periodic table of chemical elements or its oxide; and (g), the rest is aluminium oxide. Said catalyst can be used for pyrolysis gasoline hydrotreating production.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Methane oxidation coupling catalyst and preparation method thereof

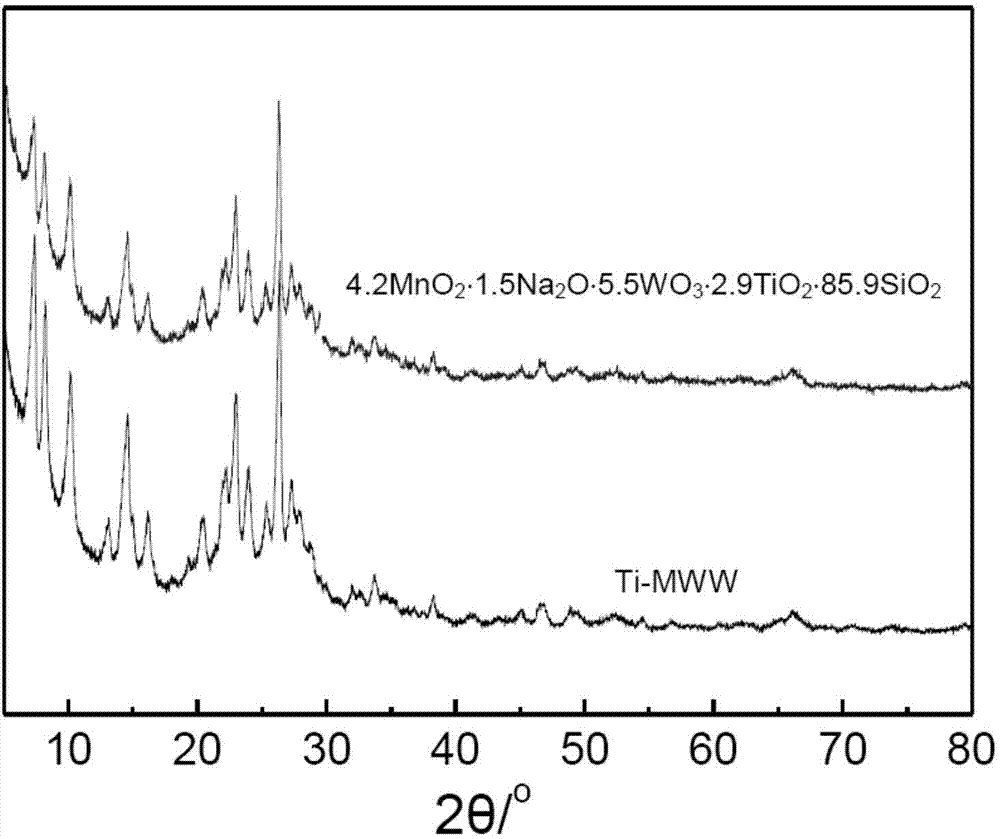

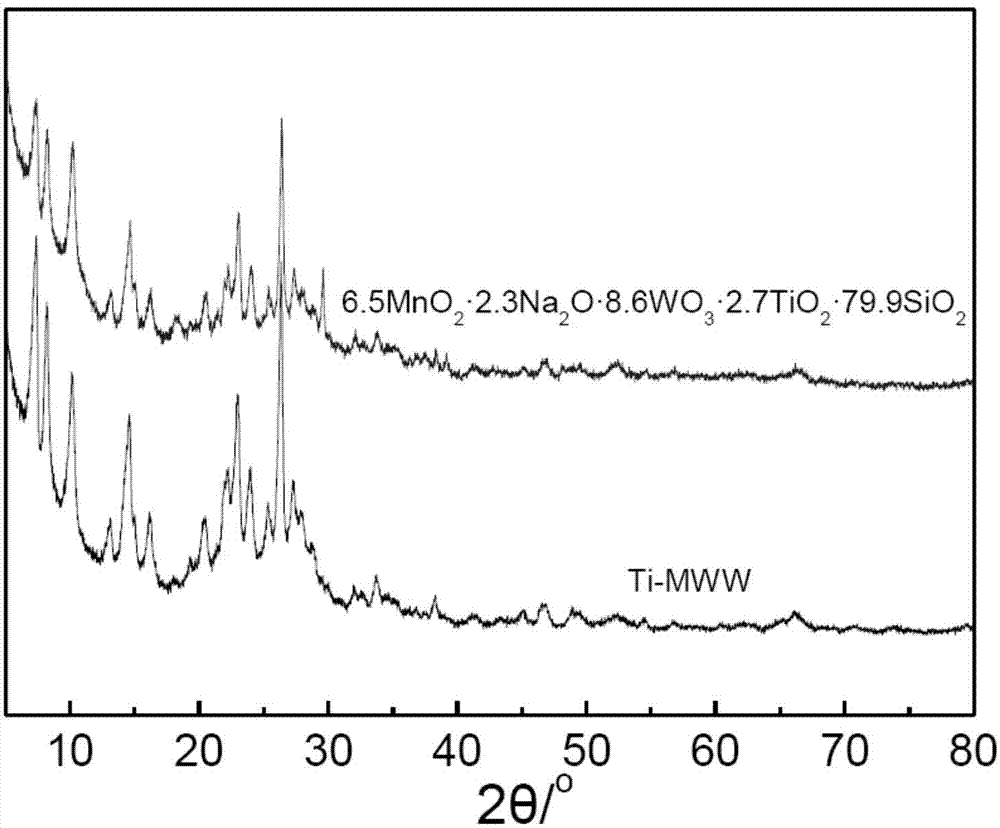

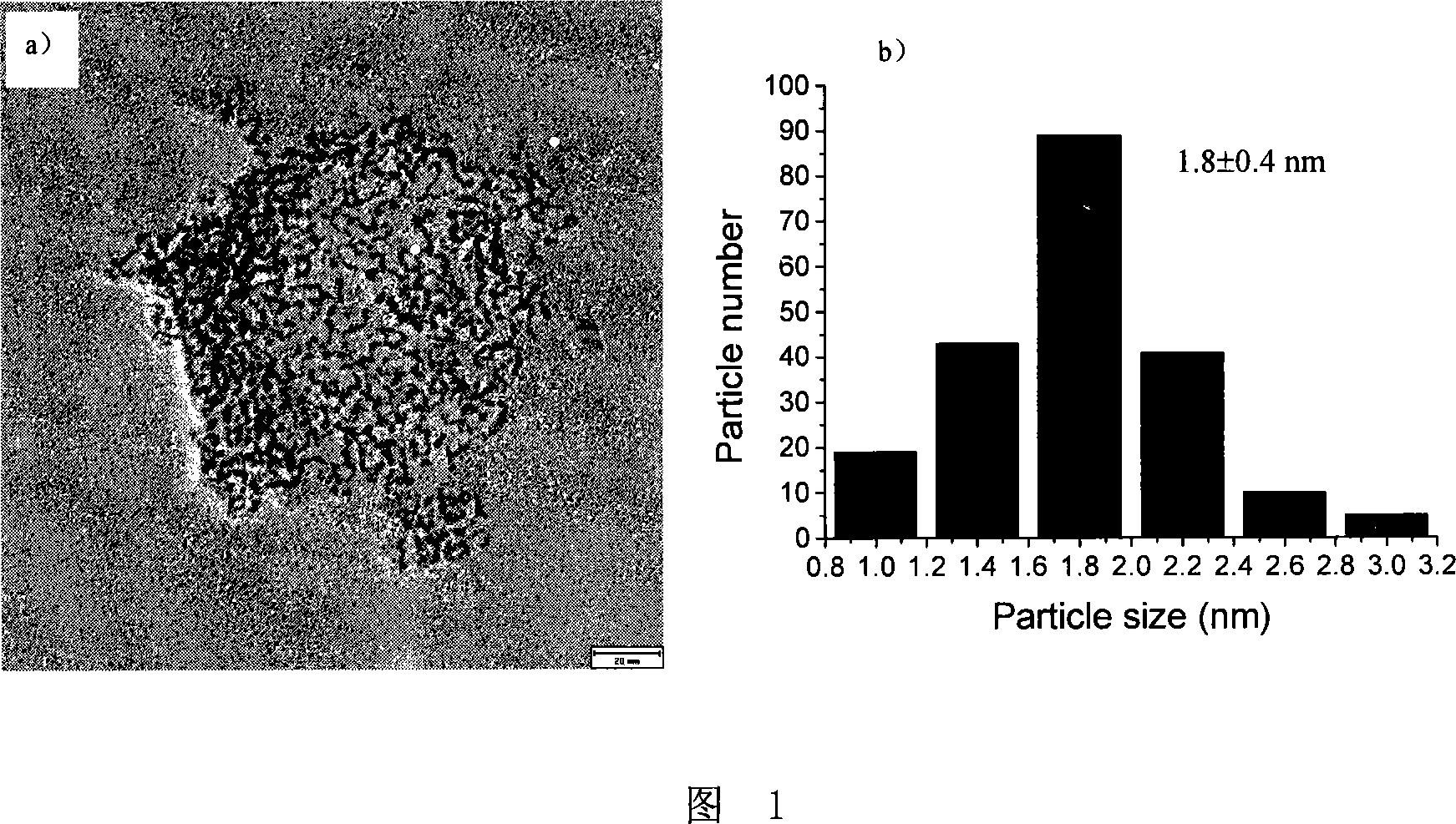

ActiveCN104759291AGood activity at low temperatureHigh selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsManganese oxideStructural formula

The present invention discloses a manganese-sodium-tungsten-silicon composite oxide oxidative coupling of methane catalyst containing or not containing titanium, obtained by loading manganese-sodium-tungsten onto a titanium-silicon molecular sieve or a pure silicon molecular sieve by means of a step-by-step impregnation method and calcination. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium has the following structural formula: vMnO2·xNa2O·yWO3·zTiO2·(100-v-x-y-z)SiO2, the v, x, y, and z respectively representing the fractional quality occupied by metal manganese oxide, sodium oxide, tungsten oxide and titanium oxide, 0.3≤v≤16, 0.1≤x≤5, 0.6≤y≤21, 0.0≤z≤4. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium set forth in the present invention is used for oxidative coupling of methane reactions, having excellent low-temperature catalytic activity and ethylene / propylene selectivity generation and reaction stability.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

Method for proceeding Feituo Synthesizing reaction and catalyst specially for the same

ActiveCN101045206ASmall particle sizeNarrow distributionHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystLiquid medium

Owner:SYNFUELS CHINA TECH CO LTD

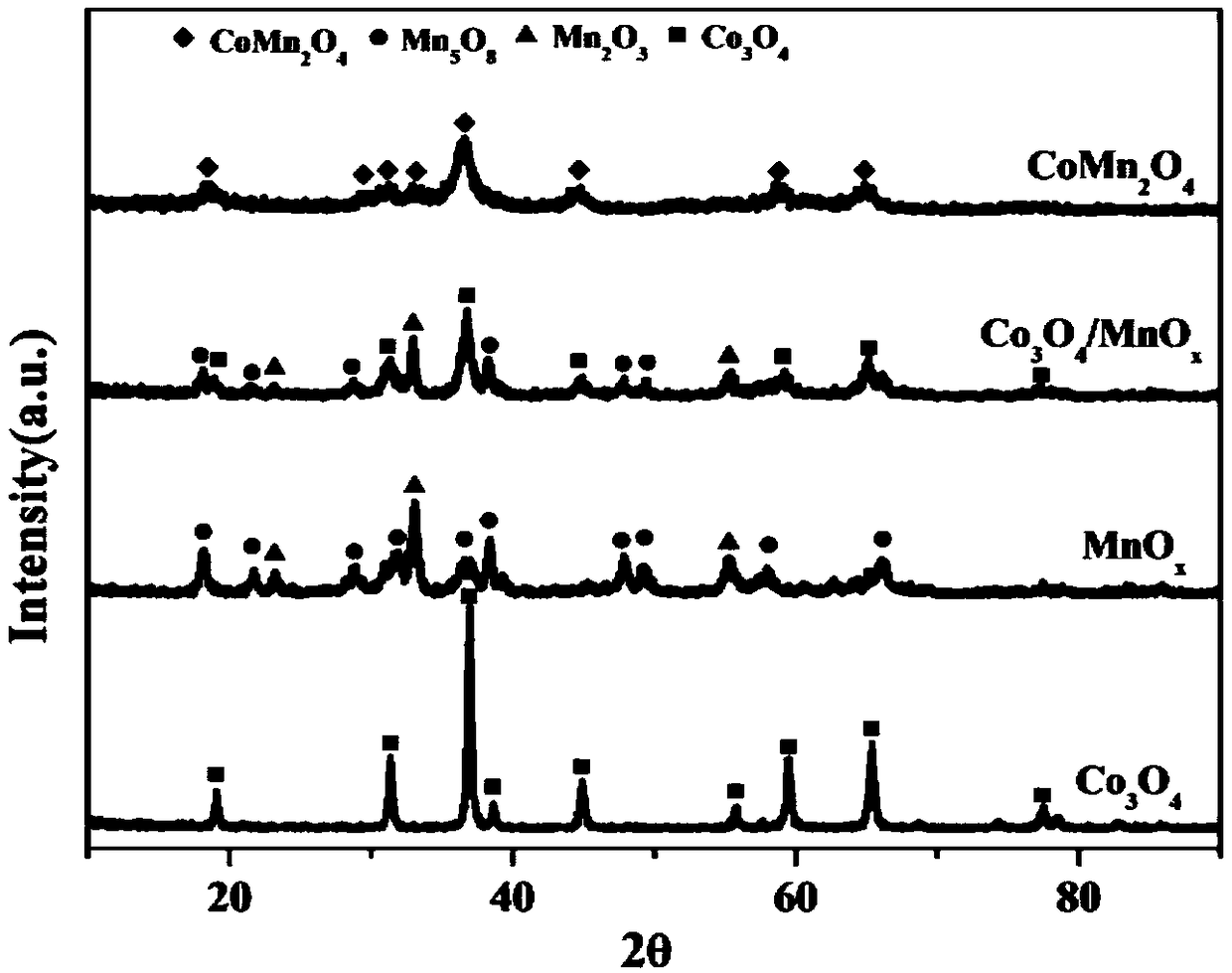

Nanoflower spinel CoMn2O4 catalyst for catalytic oxidation of VOCs (Volatile Organic Compounds), preparation method and application

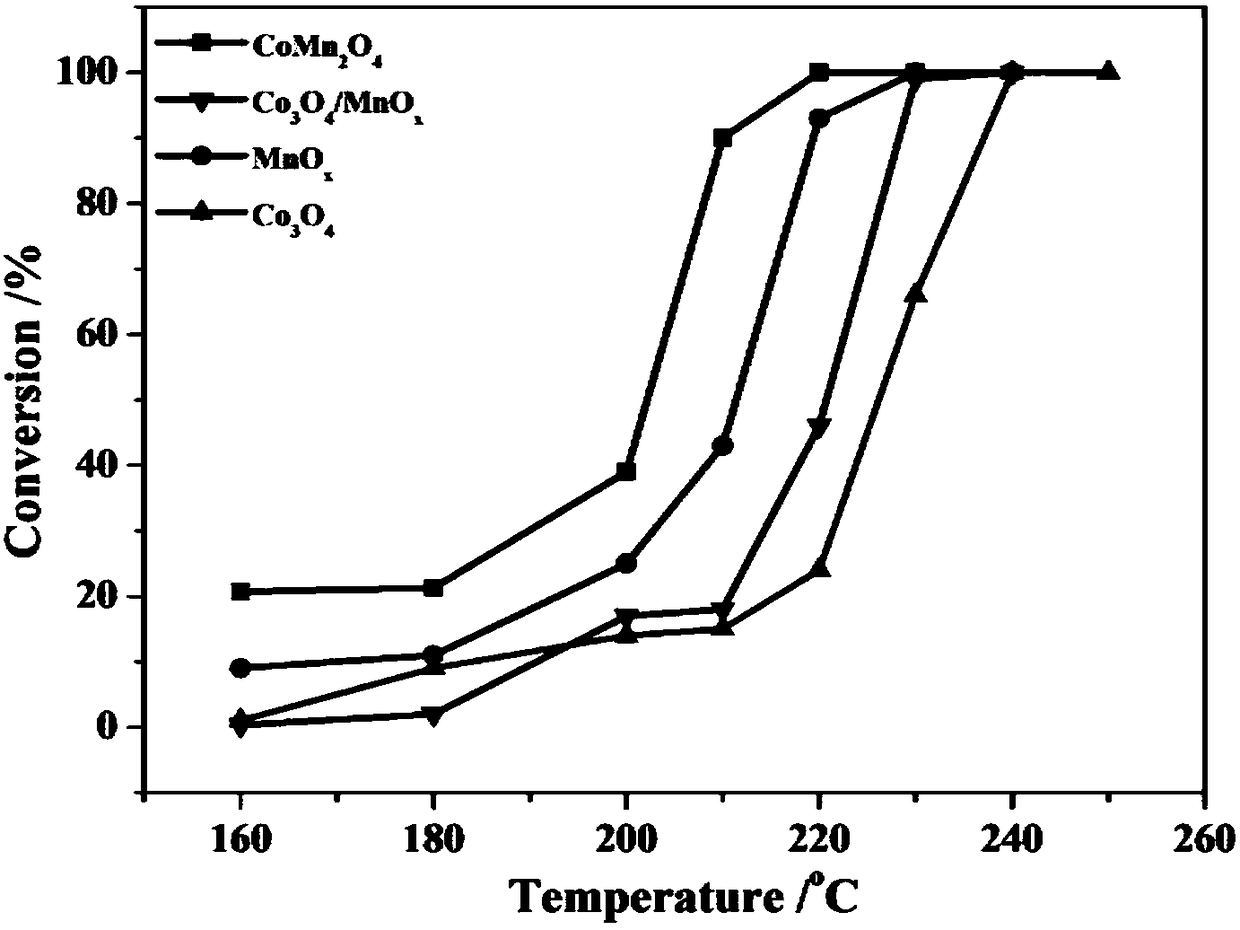

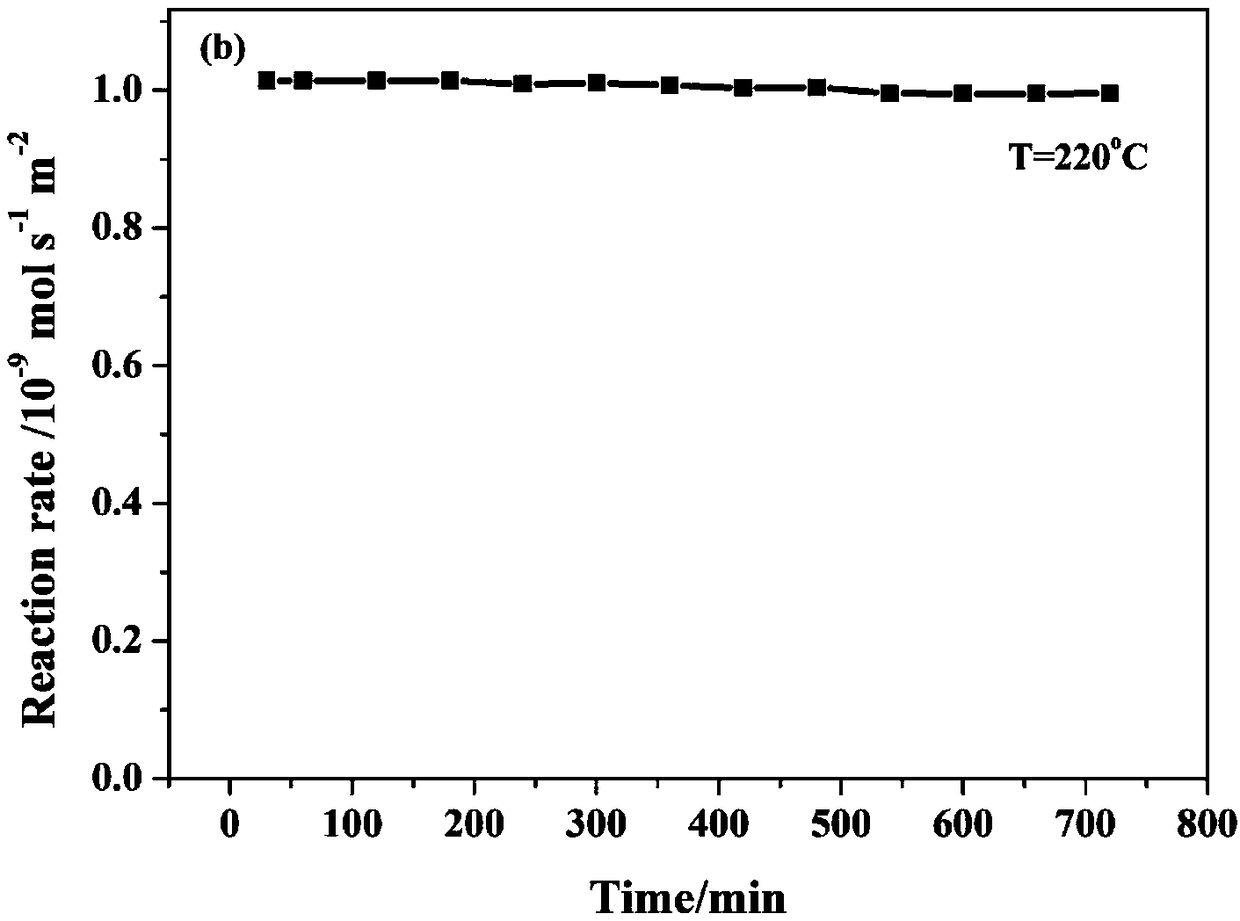

ActiveCN108295866AHigh activityAchieve complete oxidationGas treatmentDispersed particle separationCatalytic oxidationSpinel

The invention belongs to the technical field of the catalytic purification of environments, and provides a nanoflower spinel CoMn2O4 catalyst for the catalytic oxidation of VOCs (Volatile Organic Compounds), a preparation method and application thereof. Oxalic acid is used as a precipitator; the pinel CoMn2O4 catalyst is obtained by washing, drying and calcination. The CoMn2O4 catalyst prepared bythe preparation method exhibits that nanosheets form a nanoflower-shaped structure through self-assembly. Compared with oxides Co3O4 and MnOx, a mixed phase Co3O4 / MnOx and a spinel CoMn2O4 catalyst reported by current literature, the spinel CoMn2O4 catalyst prepared by the preparation method shows better activity and stability in removal of the VOCs, can reach 99 percent of the toluene removal rate at 220 DEG C, is used for realizing 100 percent conversion of formaldehyde at 90 DEG C, meanwhile, can have the acetone removal rate reaching 100 percent at 170 DEG C, and has a better industrial application prospect.

Owner:DALIAN UNIV OF TECH

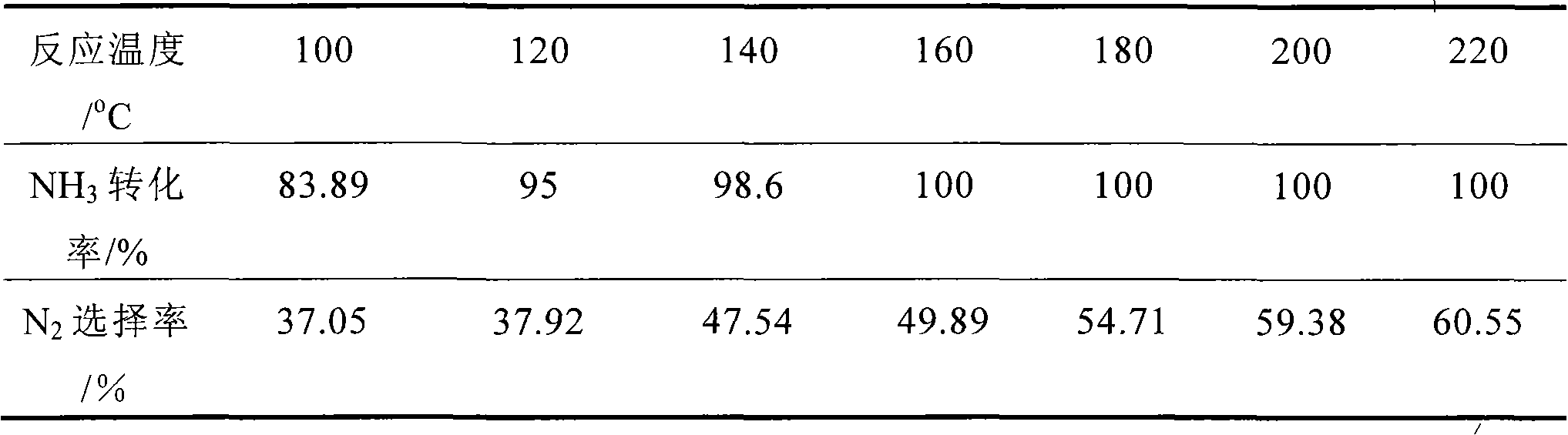

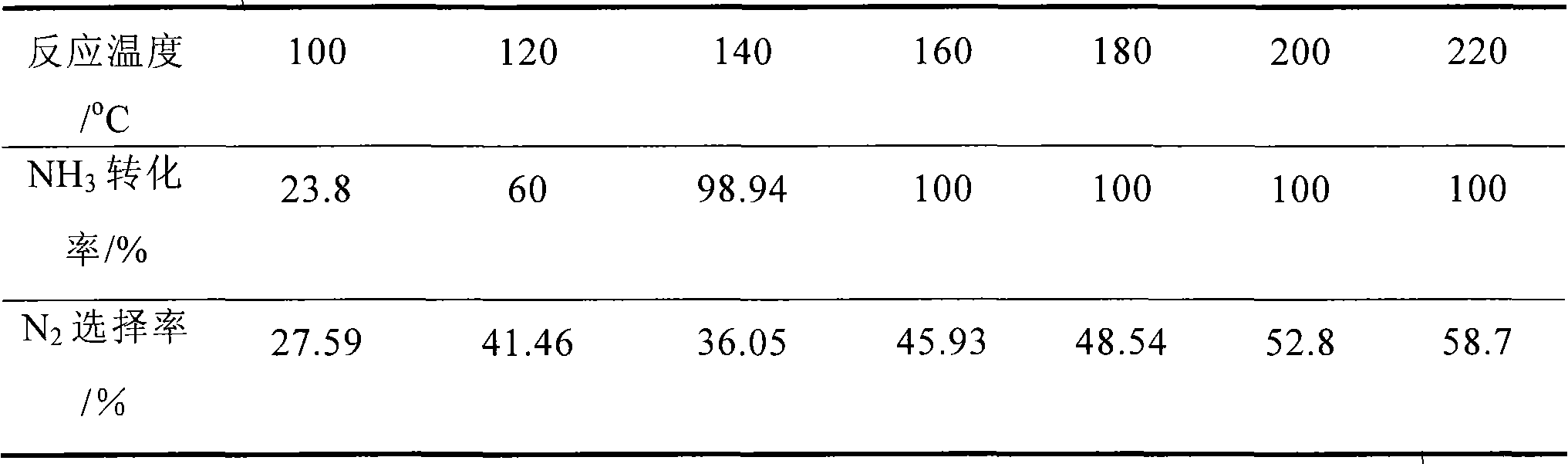

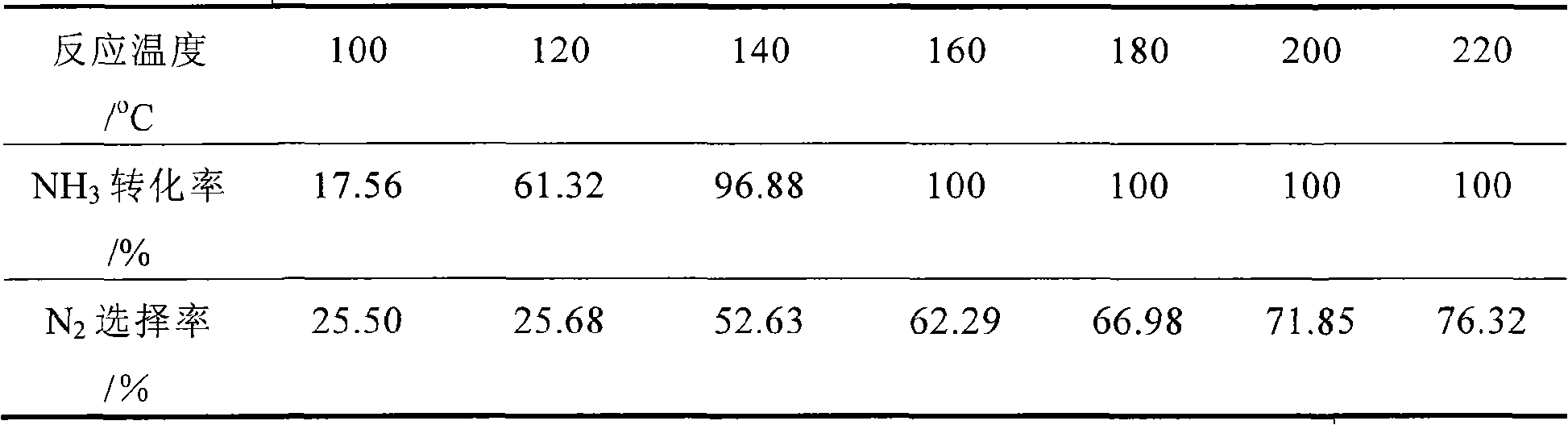

Low-temperature ammonia selective oxidation catalyst

ActiveCN101554587ARaw materials are readily availableEasy to prepareNitrogen preparationDispersed particle separationCeriumNitrogen gas

The invention provides a low-temperature ammonia selective oxidation catalyst which is used for eliminating ammonia gas pollution generated in the field of industry, agriculture, traffic, architecture, and the like, and selectively catalyzing and oxidizing the ammonia into pollution-free nitrogen and water under lower temperature. The oxidation catalyst can completely convert the ammonia under the temperature above 160 DEG C, and has the nitrogen selectivity of nearly 80 percent, good low-temperature oxidbillity, high catalytic efficiency and high stability. The oxidation catalyst contains porous inorganic oxide carrier, silver as an active component and cerium as an accessory ingredient, wherein the porous inorganic oxide carrier can be silicon dioxide, aluminium oxide, zirconia, lanthana, zinc oxide or titanium dioxide or the mixture of more than one of the oxide; the active component is formed by loading silver which a metal element with the weight conversion value of 1-15 percent on the inorganic oxide carrier; and the accessory ingredient is formed by simultaneously loading cerium and silver with the metal element weight conversion value of 5-50 percent on the inorganic oxide carrier.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Catalyst for selective oxidation of sulfureted hydrogen into elemental sulfur and reaction process thereof

InactiveCN101380582AGood activity at low temperatureImprove conversion rateSulfur preparation/purificationMetal/metal-oxides/metal-hydroxide catalystsSesquioxideReaction temperature

A selective oxidation catalyst and process which converts the hydrogen sulphide into the element sulphur, wherein, the catalyst comprising a catalyst carrier and active components which are selected from the trioxide iron and / or trioxide chromium is characterized in that the carrier is the mixed oxides of the titanium dioxide and aluminum sesquioxide, in which the content of the titanium dioxide is 60-95%. The catalyst is used in the reaction which selectively oxidizes the mixed gas containing the hydrogen sulphide into the element sulphur. Reaction conditions are as follows: reaction temperature is 160-280 DEG C, reaction pressure is 0.02-10.0MPa, gas space velocity is 400-2000h<-1>, H2S is less than or equal to 3.0% (Vol%), the molar ratio of O2 and H2S is 0.6-3.0. The catalyst shows excellent activity at low temperature and has selective oxidation activity at 160 DEG C. The yield of the sulfur is high and is more than or equal to 90%.

Owner:淄博海川精细化工有限公司 +1

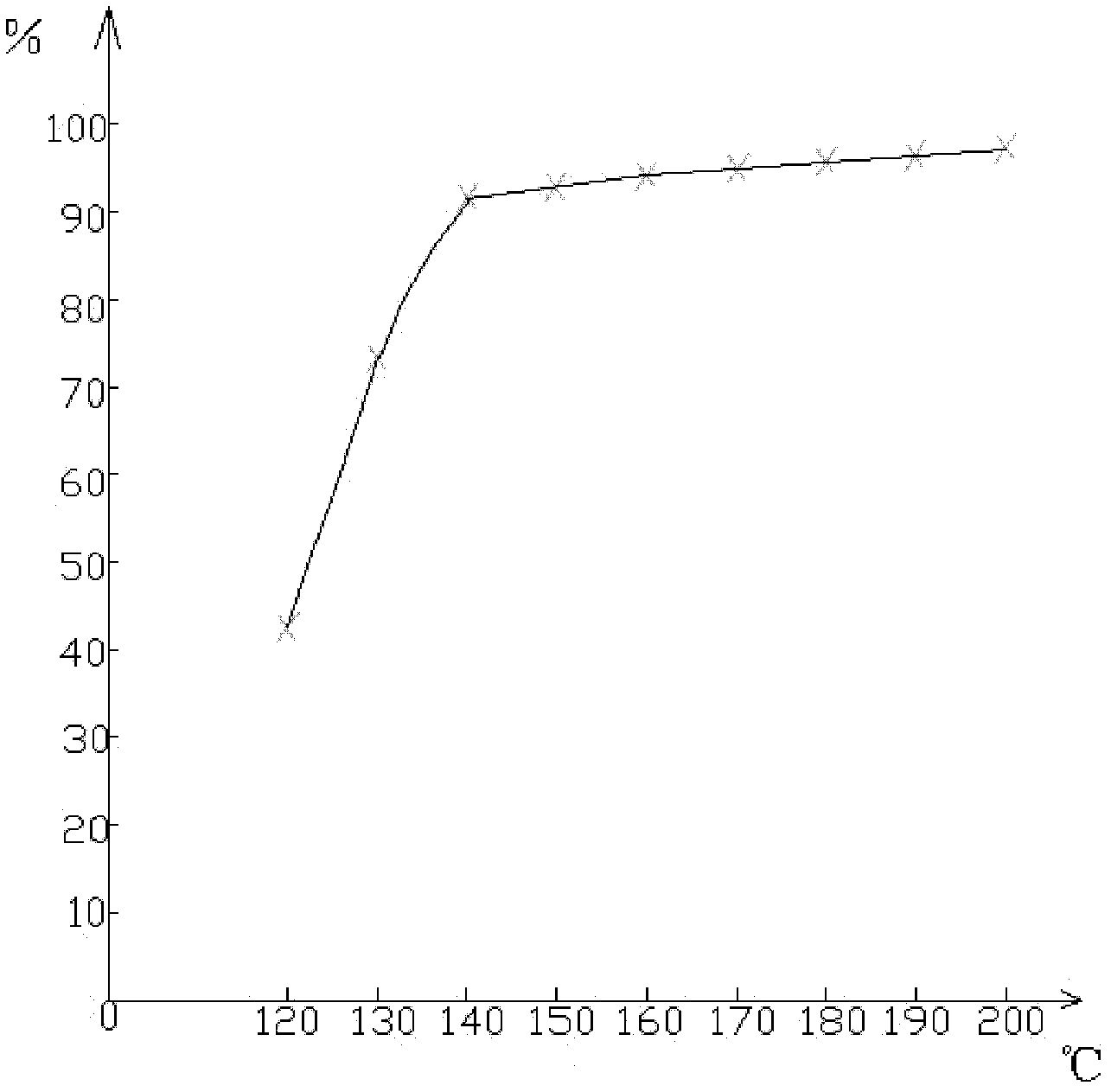

SCR (selective catalytic reduction) nitrogen oxide catalyst, and preparation method and application thereof

ActiveCN102764645AWide operating temperature windowGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOperating temperatureComposite oxide

The invention relates to an SCR (selective catalytic reduction) nitrogen oxide catalyst, and a preparation method and application thereof, belonging to the field of catalysis. The SCR nitrogen oxide catalyst is a composite oxide catalyst composed of manganese and at least one transition metal. The SCR nitrogen oxide catalyst is prepared from non-poisonous raw materials through a method which is simple and easy to operate, and has the advantages of wide operating temperature window, good low-temperature activity and excellent N2 generation selectivity. Thus, the catalyst is very suitable for the purification of nitrogen oxide in flue gas from coal-fired power plants representative of stationary sources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

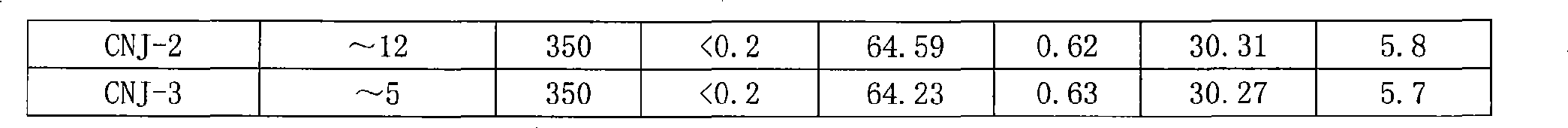

Catalyst for methanating coke oven gas and preparation method thereof

InactiveCN102513124AImprove thermal stabilityGood activity at low temperatureHydrocarbon from carbon oxidesGaseous fuelsRare-earth elementMethanation

The invention relates to a technology for manufacturing artificial natural gas by methanating oxycarbide and provides a catalyst for methanating coke oven gas and a preparation method thereof. The catalyst is a gamma-aluminum oxide or a TiO2 carrier for carrying an active component and an addition agent, wherein the active component is Ni and the addition agent is composed of a first addition agent and a second addition agent; the first addition agent is a rare-earth element and the second addition agent is one or combination of more of Sr, Mn, V, Zr, Ce and Cr. The catalyst provided by the invention has good coke oven gas methanation activity and selectivity, and has the advantages of good high-temperature resistance, low-temperature activity and higher use space velocity; and the catalyst can be applied to various coke oven gas methanation processes including heat-insulating circulation, heat-insulating non-circulation, heat-exchange reactors and the like, and operation space velocities in the processes are more than 5000 per hour.

Owner:DALIAN CATALYTIC ENG TECH

Hydrogenation modification process for low grade gasoline

ActiveCN1283761CExtended service lifeGood activity at low temperatureTreatment with hydrotreatment processesRefining by aromatic hydrocarbon hydrogenationHydrogenHydrodesulfurization

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

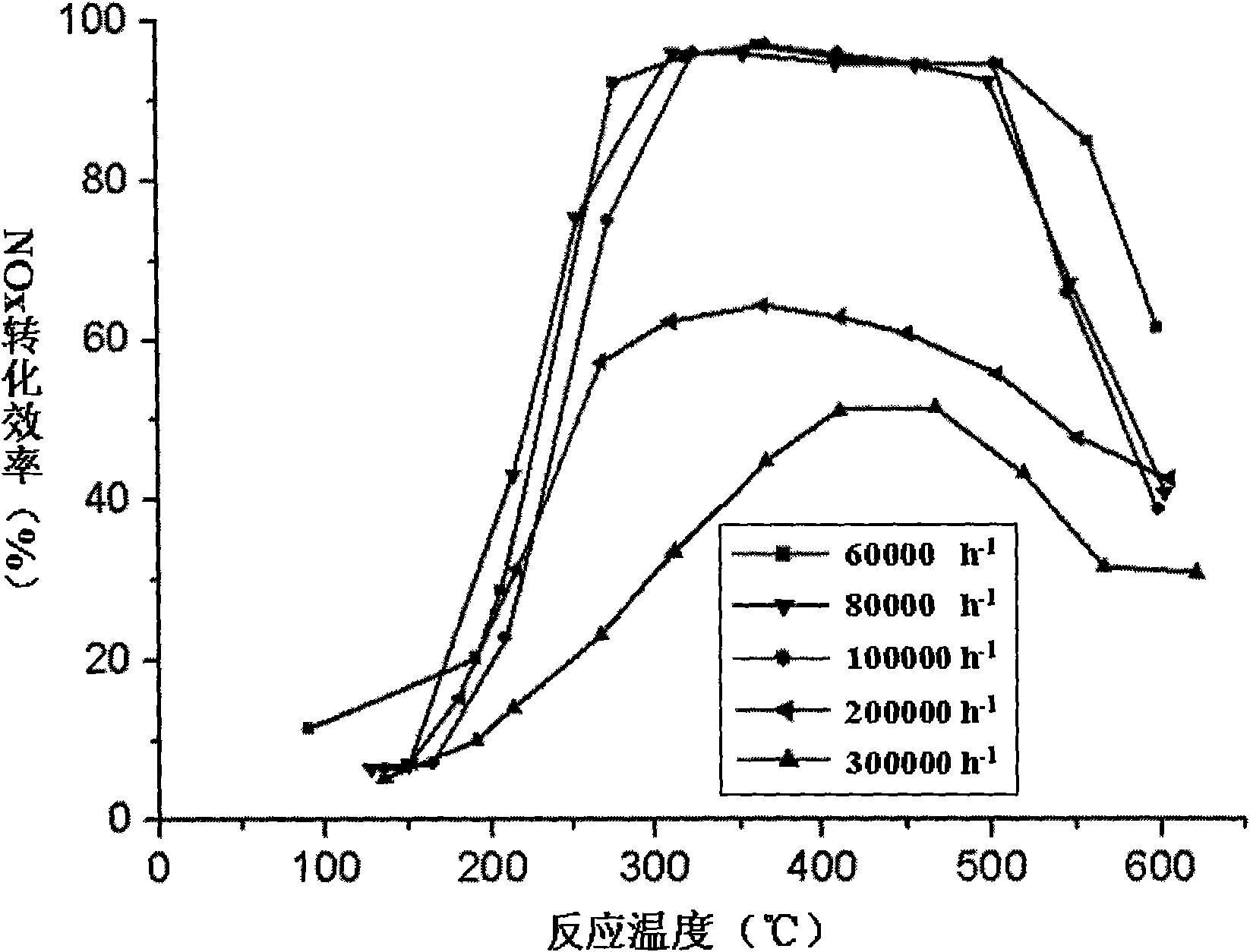

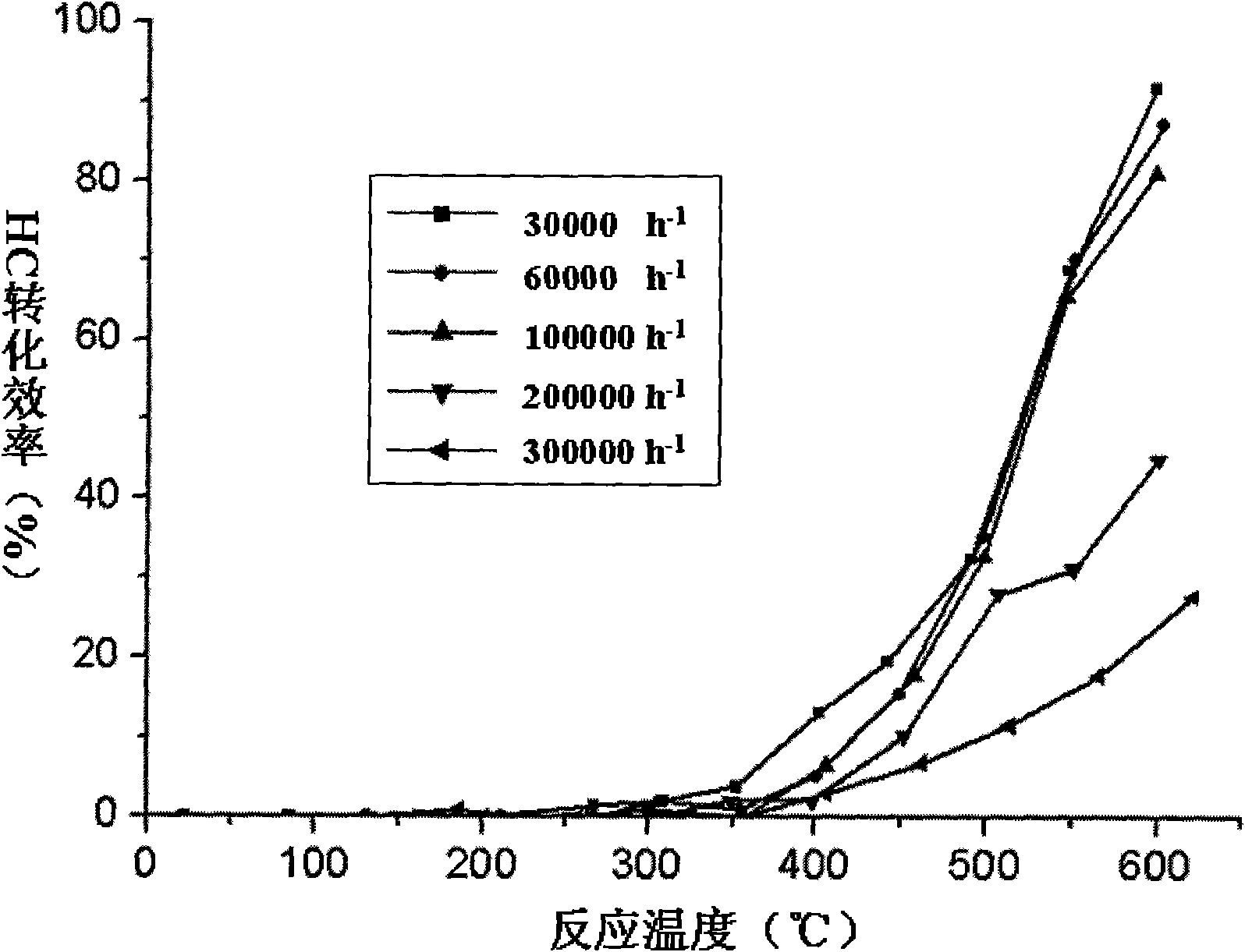

Transition metal doped cerium and titanium compound oxide catalyst for selective catalytic reduction of nitric oxide by ammonia

ActiveCN102302930ACause harmWide operating temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumSodium hydroxide

The invention relates to a transition metal doped cerium and titanium compound oxide catalyst for selective catalytic reduction of nitric oxide by ammonia, and a preparation method thereof. The catalyst in the invention is a transition metal (iron, tungsten and molybdenum) doped cerium and titanium compound oxide catalyst. The preparation method of the catalyst is a co-precipitation method, which comprises the following steps of: preparing mixed solution from cerium salt, titanium salt and salt corresponding to one or more transition metals of iron, tungsten and molybdenum, and continuously stirring for 3 to 15 hours at the temperature of between 50 and 150 DEG C by using one of ammonia water, sodium hydroxide, sodium carbonate, ammonium bicarbonate or urea; and filtering, washing, baking and calcining. In the invention, the adopted raw materials are non-toxic and harmless, the preparation method is simple and easy, the prepared catalyst has the characteristics of high catalytic activity, excellent N2 generation selectivity, broad operation temperature window, high space velocity reaction condition adaptability and the like, and is suitable for mobile sources represented by tail gas of diesel vehicles, as well as stationary source nitric oxide catalytic purification device represented by flue gas of coal fired power plants.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Fe molecular sieve catalyst for purifying NOx in acrylonitrile oxidization tail gas and preparation method of Fe molecular sieve catalyst

InactiveCN102513145AEfficient removalEasy to handleMolecular sieve catalystsDispersed particle separationActive componentIon exchange

The invention relates to a Fe molecular sieve SCR (Selective Catalytic Reduction) catalyst for purifying NOx in acrylonitrile oxidization tail gas and a preparation method of the Fe molecular sieve SCR catalyst. A commercial ZSM-5 molecular sieve, a Y type molecular sieve, ferrierite or a beta molecular sieve is used as a carrier, 0.3-10.0 percent by mass of Fe<3+> is introduced to be used as an active component by adopting an immersion method or ion exchange method, and 0.5-8.0 percent by mass of M (lanthanum La or cobalt Co) is introduced to be used as a modification component. The SCR catalyst prepared by adopting the preparation method furthest realizes NO transformation and efficient catalysis removal of the NOx in the acrylonitrile oxidization tail gas under an oxygen enrichment condition. The preparation method provided by the invention has the advantages of simple process and good repeatability, and is beneficial to industrialized production.

Owner:TIANJIN UNIV

Cerium-titanium solid solution and its preparing method

InactiveCN1565724AImprove stabilityHigh oxidation-reductionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrateCerium

The invention provides a CeTi#-[2]O#-[6] solid solution and its preparing method. The molecular formula is CeTi#-[2]O#-[6]. The process includes the following steps : the precursor of the cerous nitrate and titanium tetrachloride solution is served as raw material, the raw material is mixed and added into strong aqua ammonia, after depositing, aging, centrifuge washing, washing away Cl#+[-], vacuum freeze drying and baking, CeO#-[2]-TiO#-[2] powder is obtained, CeO#-[2]-TiO#-[2] powder is roasted at 650,750 and 800 degrees C., and crystallization of CeTi#-[2]O#-[6] is finished.The invention is suitable for removing NO#-[x] and SO#-[x] catalyst carrier.

Owner:ZHEJIANG UNIV

Catalyst for removing nitrogen oxide through selective catalytic reduction for Ce2O3 and V2O5 double active composition diesel truck

InactiveCN101559363ALow biological toxicityFacilitate catalytic reactionsInternal combustion piston enginesDispersed particle separationTraffic conditionsDiesel engine

The invention relates to a catalyst for removing nitrogen oxide through selective catalytic reduction for an automobile diesel engine adopting Ce2O3 and V2O5 double active compositions. The catalyst adopts scordierite honeycomb ceramics as a framework material, the Ce2O3 and the V2O5 as main active compositions, WO3 or MoO3 as an auxiliary catalyst composition, and TiO2 as a coating substrate, wherein the mass fraction of the main active compositions, namely the Ce2O3 and the V2O5, to the auxiliary catalyst composition WO3 or MoO3 to the coating substrate TiO2 is 1-3:6:12:85-93. The specific process comprises the following steps: preparing a TiO2 precursor solution; coating a TiO2 coating; coating an auxiliary catalyst; determining the loading of active compositions of oxides; and coating the main active compositions, namely the Ce2O3 and the V2O5. The catalyst replaces the V2O5 with high toxicity with the Ce2O3 with low toxicity, and reduces the environmental hazards of the catalyst, and the replaced catalyst has wider active temperature range, particularly greatly improves the low-temperature activity, and is particularly suitable for the traffic conditions of urban highways of China.

Owner:TIANJIN UNIV

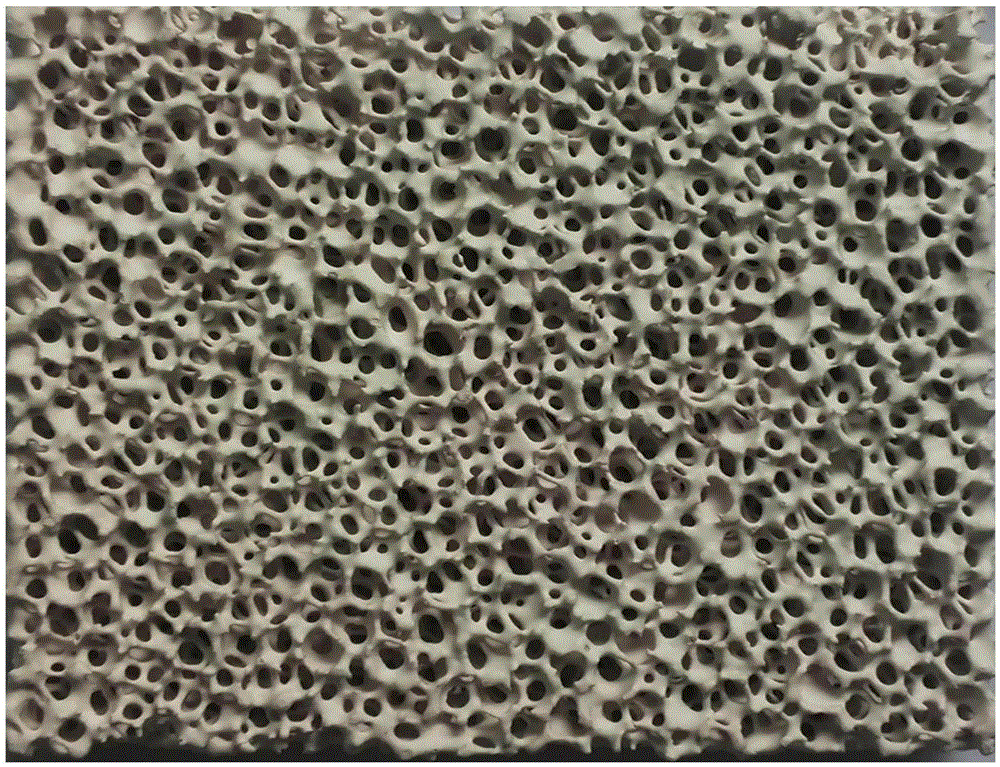

Methanation catalyst for synthesizing substitute natural gas and preparation method thereof

ActiveCN103191749ASimple structureImprove stabilityCatalyst carriersGaseous fuelsMethanationSpace velocity

The invention relates to a methanation catalyst for synthesizing substitute natural gas and a preparation method thereof. The methanation catalyst comprises Al2o3, MgO, NiO, La2O3, TiO2, CeO2 or ZrO2 and the mixture thereof. Compared with the existing methanation catalyst, the methanation catalyst prepared by using the method disclosed by the invention has high conversion ratio, great space velocity, high activity and good thermostability, so that the methanation catalyst and the preparation method thereof are suitable for the adiabatic non-circulation process and the adiabatic cycle process for synthesizing the substitute natural gas through the tail gas in hydrocarbon industries.

Owner:XIAN ORIGIN CHEM TECH

Flue gas denitrification catalyst with wide activity temperature interval as well as preparation method thereof

InactiveCN103894182AWide active temperature rangeGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

The invention discloses a flue gas denitrification catalyst with a wide activity temperature interval as well as a preparation method thereof. The flue gas denitrification catalyst comprises 65%-99.8% of carrier TiO2, 0.1%-10% of active component V2O5, 0.1%-10% of active component WO3 and 0.1%-15% of valence-variation metallic oxide. According to the invention, a ball mill is adopted for enabling the VWTiO2 catalyst and the valence-variation metal element oxide to be fully mixed mechanically, simplifies the technological process, reduces the energy consumption, and prevents the environment pollution; the prepared flue gas denitrification catalyst has a wide activity temperature interval and high capability of NOx removing activity and SO2 and H2O toxication resistance.

Owner:北京宏庚环保科技有限公司

SCR flue gas denitration composite catalyst and preparation method thereof

ActiveCN101352678AGood chemical stabilityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumCerium

The invention relates to a compound catalyst for SCR flue gas denitration and a preparation method thereof, pertaining to the technical fields of environmental protection catalytic materials and atmosphere pollution controlling. The compound catalyst takes aluminum-based, titanium-based or zirconium-based ceramics as a carrier and titanium-zirconium-aluminum-cerium complex metal oxide as an active ingredient of the compound catalyst. The preparation method adopted includes: the aluminum-based, titanium-based or zirconium-based ceramics is impregnated in a titanium-zirconium-aluminum-cerium complex colloidal sol, and then dried and roasted to prepare compound catalyst active coatings. Compared with the prior art, the compound catalyst not only promotes the activity and the chemical stability of the catalyst and extends the temperature window of the catalytic activity, but also enhances the mechanical and thermal stability of a catalyst carrier, is environment protective and cheap without secondary pollution, prolongs the service life of the catalyst and lowers the load of the active ingredient.

Owner:NANJING UNIV OF TECH

Acid-modified CeO2-based SCR (Selective Catalytic Reduction) catalyst for denitration and preparation method of acid-modified CeO2-based SCR catalyst

ActiveCN103203243ASimple preparation processEase of industrial productionPhysical/chemical process catalystsDispersed particle separationWorking temperatureCordierite

The invention belongs to the field of posttreatment and purification of NOx and in particular relates to an acid-modified CeO2-based SCR (Selective Catalytic Reduction) catalyst for denitration and a preparation method of the acid-modified CeO2-based SCR catalyst. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier, an active coating is loaded on the carrier, and a modified coating is loaded on the active coating. The cordierite carrier plays a framework loading role; the active coating of the catalyst mainly plays a role of activating NOx and NH3; and the modified coating mainly plays a role of cooperating with active components and can be used for promoting the catalytic activity of the catalyst, avoiding advanced oxidation on the surface of the catalyst which is applied at high temperature and improving the anti-hydrothermal and anti-aging performances of the catalyst. The catalyst is prepared with a simple process and is easy for industrial production. The working temperature window (the denitration efficiency is more than 80 percent) of the optimized catalyst can reach 200-500 DEG C. The catalyst does not contain V2O5, is free of toxicity and excellent in N2 generation selectivity, can be suitable for high-airspeed reaction conditions and has favorable thermal stability.

Owner:TSINGHUA UNIV +1

Catalyst for low-temperature SCR (Selective Catalytic Reduction) denitration and preparation method of catalyst

ActiveCN103170344AGood activity at low temperatureAvoid abrasionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsVanadium(V) oxideTreatment costs

The invention relates to a catalyst for low-temperature SCR (Selective Catalytic Reduction) denitration. The catalyst is composed of titanium dioxide, vanadium pentoxide, molybdenum trioxide and an assistant, wherein the assistant is one or more of transition metal silicates. The invention further relates to a preparation method of the catalyst. The low-temperature SCR denitration catalyst provided by the invention is excellent in low temperature activity, and is capable of performing the denitration reaction at a low temperature, reducing the reaction energy consumption and lowering the treatment cost. Furthermore, the raw materials of the catalyst provided by the invention are easily available and low in cost, and the preparation process is simple.

Owner:TIANJIN RENDE SCI

Method for preparing denitrification catalyst with metatitanic acid as raw material in one step

ActiveCN104415796ASimple preparation processHigh catalytic activityDispersed particle separationCatalyst activation/preparationIonTungsten

A method for preparing a denitrification catalyst with metatitanic acid as a raw material in one step. In the method, with the metatitanic acid as the raw material and through desulfuration by ammonia water, a catalyst slurry material is prepared with addition of a mixed solution containing vanadium and tungsten, a silicon sol and deionized water after grinding, and then the catalyst slurry material is used for impregnating a honeycomb ceramic supporter and a drying and roasting process is carried out to obtain the denitrification catalyst. In the method of the denitrification catalyst, only one roasting step is included so that the method is simple and environmental-protective. A prepared monolithic catalyst is excellent in denitrification activity and is greatly reduced in production cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com