Coke-oven gas methanation catalyst and preparation method thereof

A technology of gas methane and catalyst, which is applied in the field of oxide catalyst in methanation reaction and its preparation, which can solve the problems of increased bed resistance, device inoperability, and large reaction temperature rise, etc., and achieves improved carbon resistance, good Low temperature activity and good carbon resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

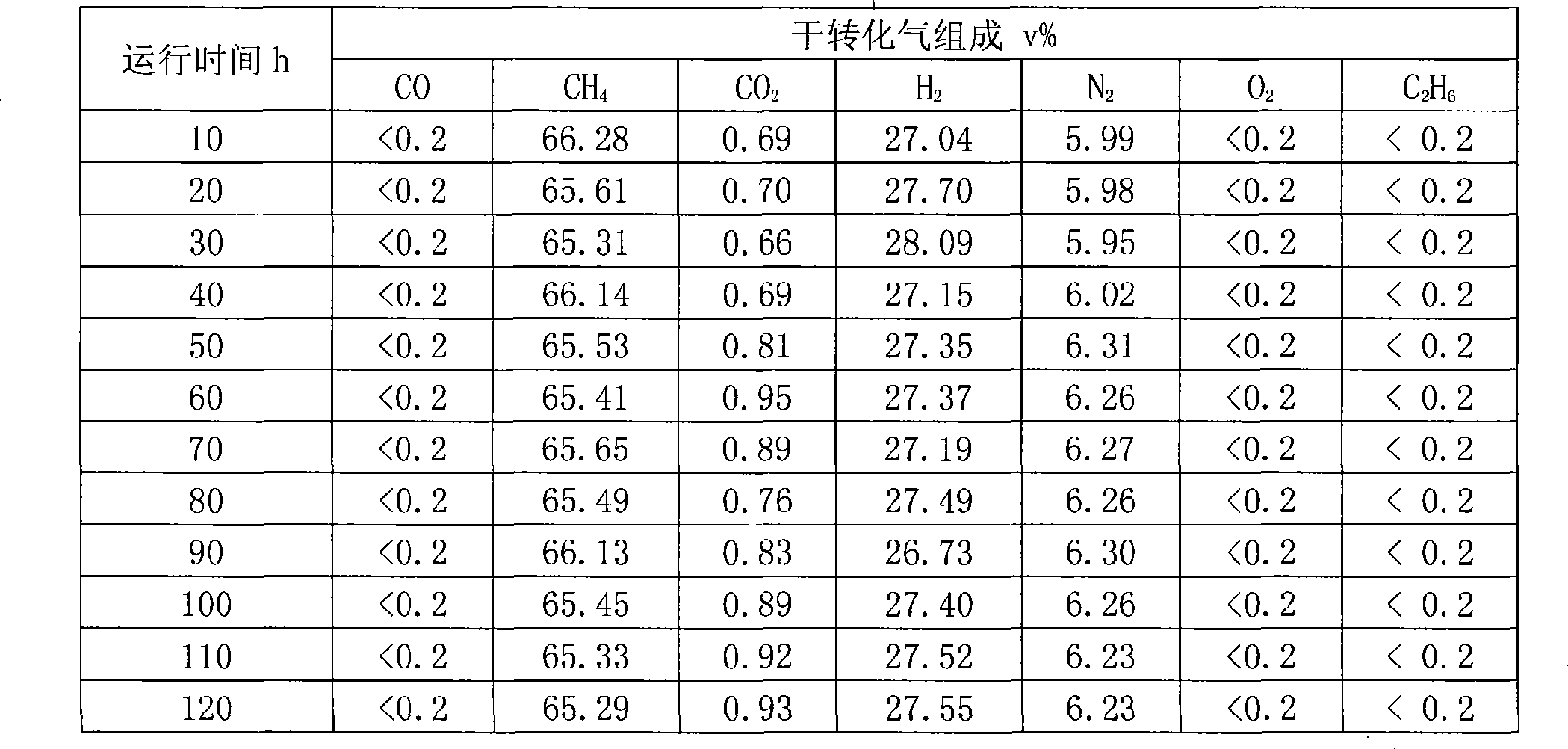

Examples

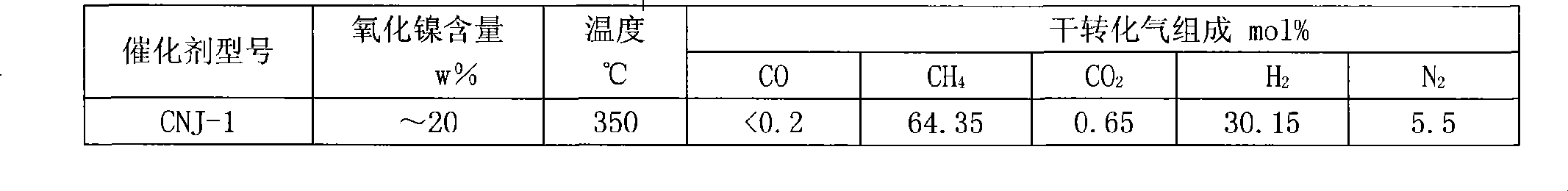

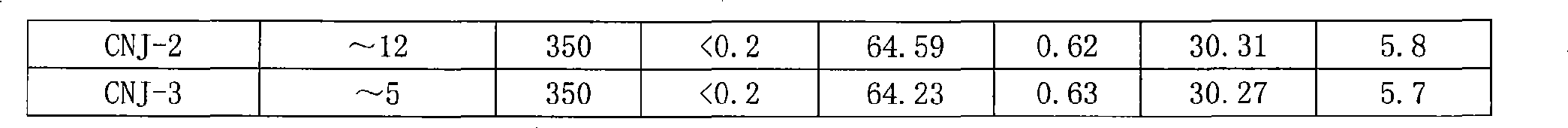

Embodiment 1

[0034] The coke oven gas methanation catalyst in this embodiment mainly includes a carrier, an active material and an auxiliary agent, etc., wherein:

[0035] Take Al 2 o 3 As the carrier, nickel is the main active component (nickel exists in the catalyst in the form of NiO), and MgO is the auxiliary agent; the carrier Al 2 o 3 The support structure of magnesium aluminum spinel is formed with the auxiliary agent MgO; the content of NiO is 20%, Al 2 o 3 The content of MgO is 70%, and the content of MgO is 10%.

[0036] The coke oven gas methanation catalyst of this embodiment is prepared by a method comprising the following main steps:

[0037] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 with MgO(Al 2 o 3 The mass ratio of MgO and MgO is 7:1) and mixed in a ball mill, and the grinding time is 2 hours; the material after ball milling is pre-pressed and granulated, and pressed into a columnar carrier green body with a pr...

Embodiment 2

[0044] The coke oven gas methanation catalyst in this embodiment mainly includes a carrier, an active material and an auxiliary agent, etc., wherein:

[0045] Take Al 2 o 3 As the carrier, nickel is the main active component (nickel exists in the catalyst in the form of NiO), and MgO is the auxiliary agent; the carrier Al 2 o 3 The support structure of magnesium aluminum spinel is formed with the auxiliary agent MgO; the content of NiO is 12%, Al 2 o 3 The content of MgO is 50%, and the content of MgO is 40%.

[0046] The coke oven gas methanation catalyst of this embodiment is prepared by a method comprising the following main steps:

[0047] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 with MgO(Al 2 o 3 The mass ratio of MgO and MgO is 5:4) in a ball mill, and the grinding time is 2 hours; the material after ball milling is pre-pressed and granulated, and pressed into a columnar carrier green body with a ring press m...

Embodiment 3

[0054] The coke oven gas methanation catalyst in this embodiment mainly includes a carrier, an active material and an auxiliary agent, etc., wherein:

[0055] Take Al 2 o 3 As the carrier, nickel is the main active component (nickel exists in the catalyst in the form of NiO), and MgO is the auxiliary agent; the carrier Al 2 o 3 The support structure of magnesium aluminum spinel is formed with the auxiliary agent MgO; the content of NiO is 5%, Al 2 o 3 The content of MgO is 45%, and the content of MgO is 50%.

[0056] The coke oven gas methanation catalyst of this embodiment is prepared by a method comprising the following main steps:

[0057] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 with MgO(Al 2 o 3 The mass ratio of MgO and MgO is 4.5:5) mixed in a ball mill, and the grinding time is 2 hours; the material after ball milling is pre-pressed and granulated, and pressed into a columnar carrier green body with a ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com