Method for preparing denitrification catalyst with metatitanic acid as raw material in one step

A denitration catalyst, metatitanic acid technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. High temperature activity, simplified preparation process and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

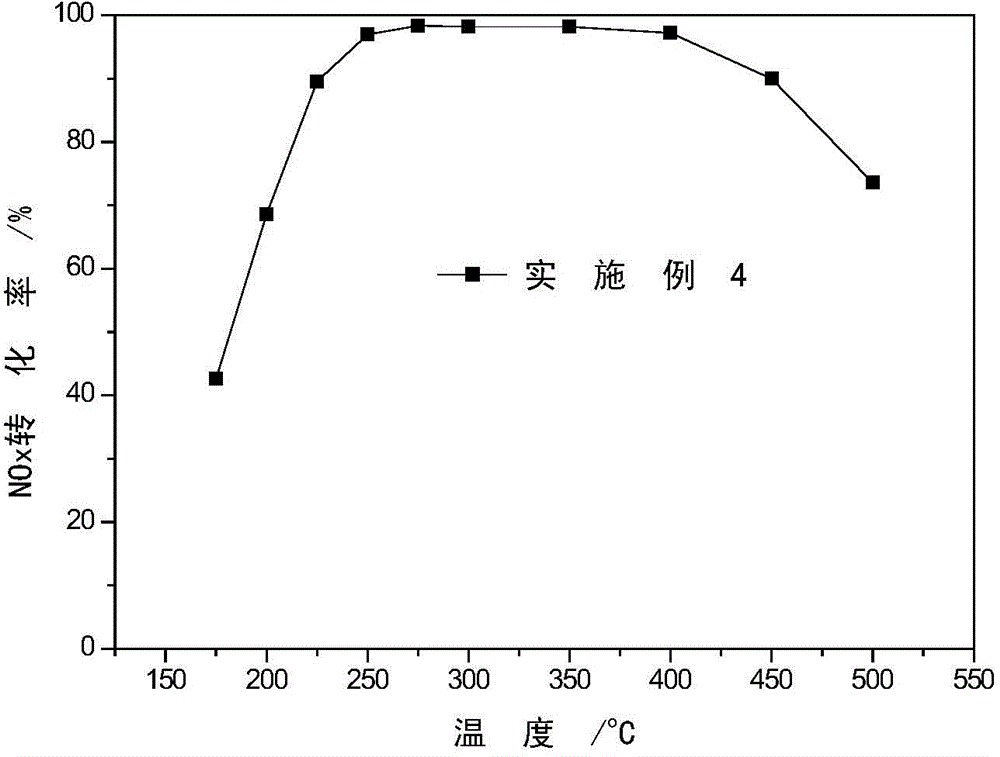

Examples

Embodiment 1

[0027] Ammonia washing treatment of metatitanic acid

[0028] Put 300g of metatitanic acid into a beaker, add 500mL of water and stir, then add 70mL of 25% concentrated ammonia water to adjust the pH to about 9.5. The mixture was transferred into a three-necked flask, and stirred under reflux at 95° C. for 3 hours. The mixture was separated from liquid to solid by filtration, and the filter cake was washed three times with 500 mL of deionized water each time, and then dried in an oven at 120° C. for 12 hours to obtain metatitanic acid after ammonia washing.

Embodiment 2

[0030] Take 3.2g of ammonium metavanadate, 1.16g of ethanolamine, and 4.4g of ammonium paratungstate and dissolve them in water to form a 45mL solution, mix them with 30g of ammonia-washed metatitanic acid, put them into a ball mill and mill them for 3 hours to obtain a catalyst slurry. Cut 400cpsi cordierite honeycomb ceramics into small pieces of Φ1.4×2.2cm, weigh them and immerse them in the obtained catalyst slurry, take them out after 30 seconds, blow off the remaining slurry in the channels with hot air, and then dry them in a microwave oven For 3 minutes, repeat this process once more to obtain a coated catalyst twice, and heat up to 500°C in a muffle furnace at a rate of 2°C / min for 2 hours to obtain a monolithic denitration catalyst. After taking out and weighing, the catalyst coating weight was measured to be 0.631g.

[0031] The method for testing the denitrification activity of the prepared catalyst is: put the monolithic coating catalyst into a quartz tube, and th...

Embodiment 3

[0033] The preparation of the catalyst slurry is the same as in Example 2. Cut 400cpsi cordierite honeycomb ceramics into small pieces of Φ1.4×2.2cm, weigh them and immerse them in the obtained catalyst slurry, take them out after 30 seconds, blow off the remaining slurry in the channels with hot air, and then dry them in a microwave oven For 3 minutes, repeat this process 2 more times to obtain a coated catalyst for 3 times, and heat up to 500°C in a muffle furnace at a rate of 2°C / min for 2 hours to obtain a monolithic denitration catalyst. After taking out and weighing, it is measured that the weight of the catalyst coating is 1.1938g.

[0034] The method for testing the denitrification activity of the prepared catalyst is: put the monolithic coating catalyst into a quartz tube, and the reaction atmosphere is: 500ppm NO+500ppm NH 3 +5%O 2 +N 2 , adjust the feed gas flow rate so that the reaction space velocity is 30000hr -1 . Separately detect NO and NO at import and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com