Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2599results about How to "Low operating cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

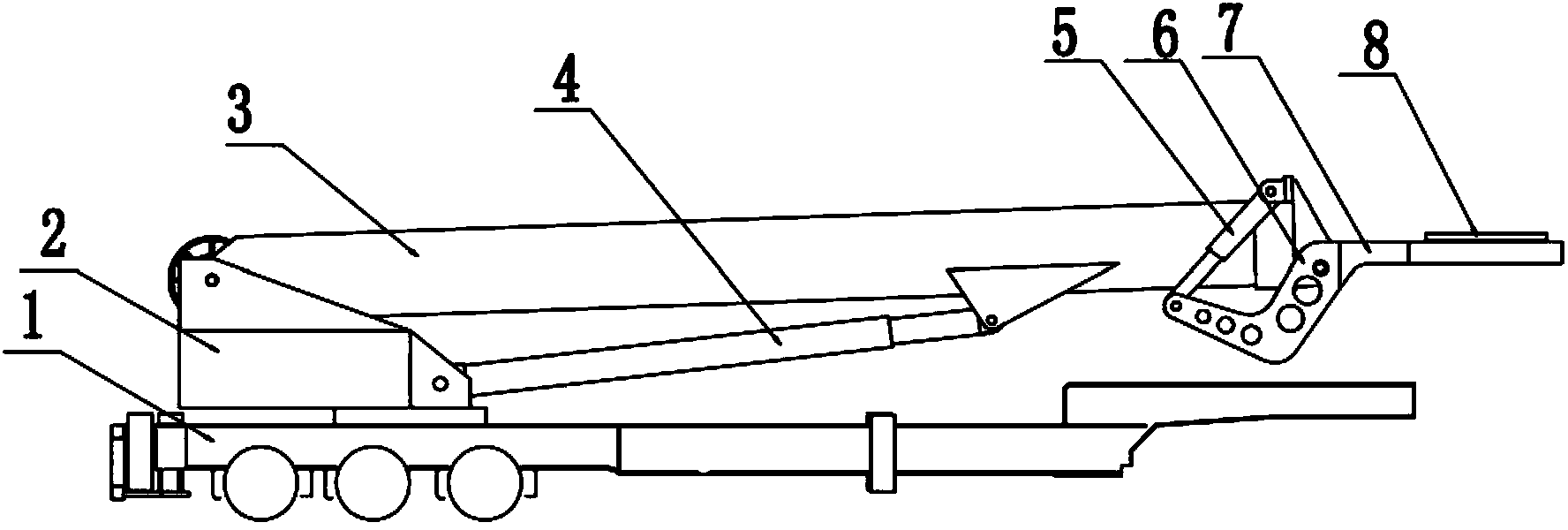

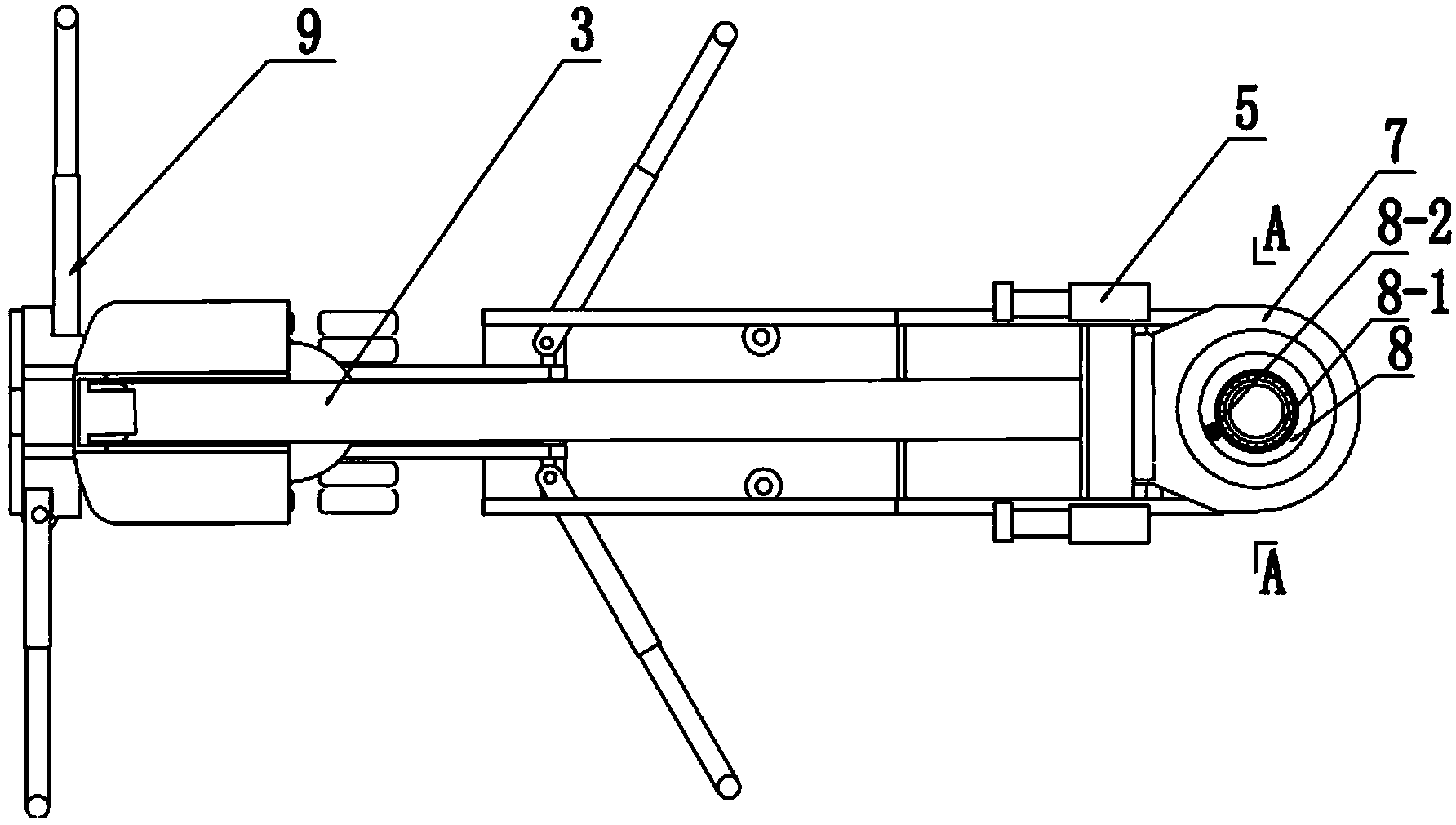

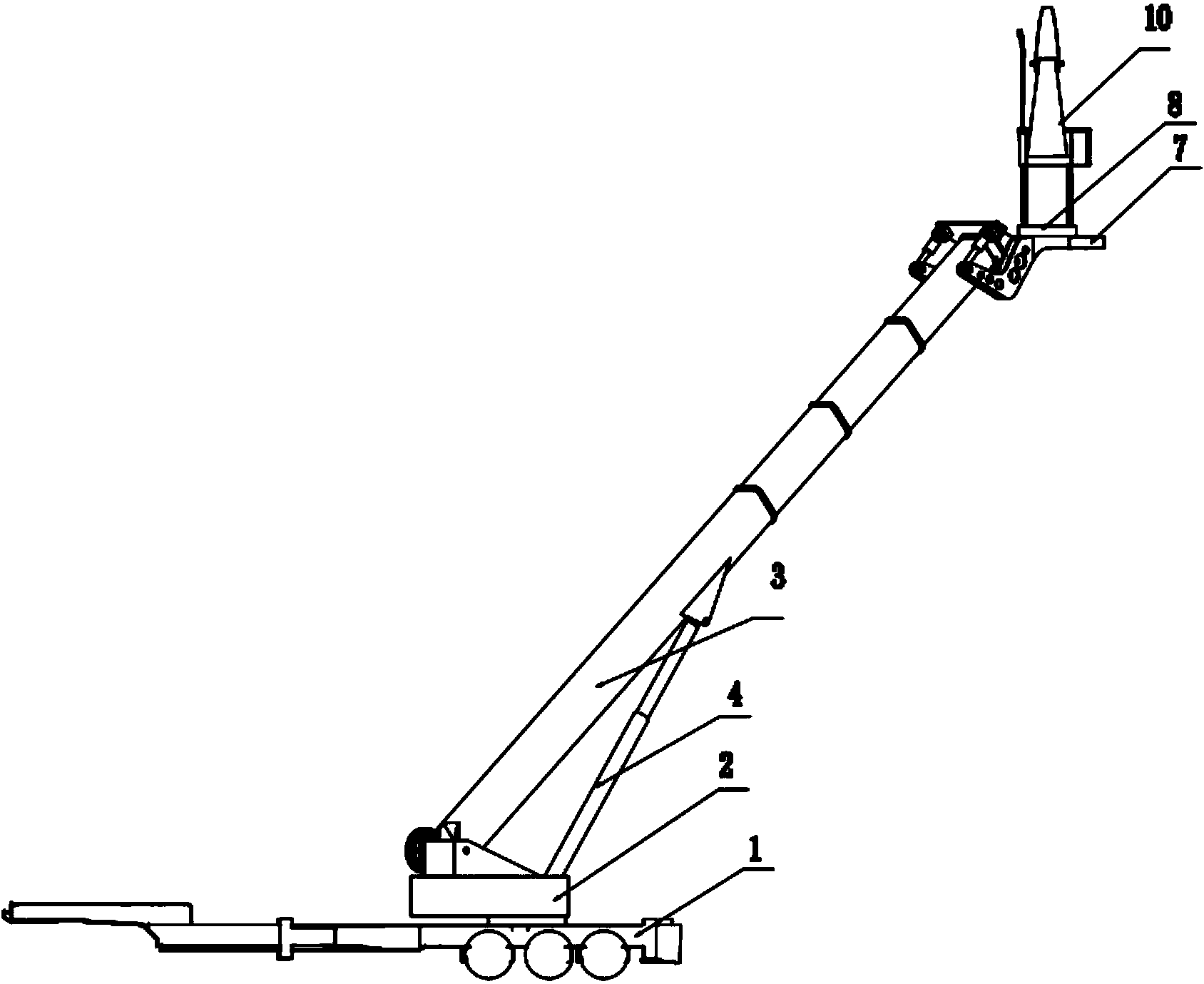

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

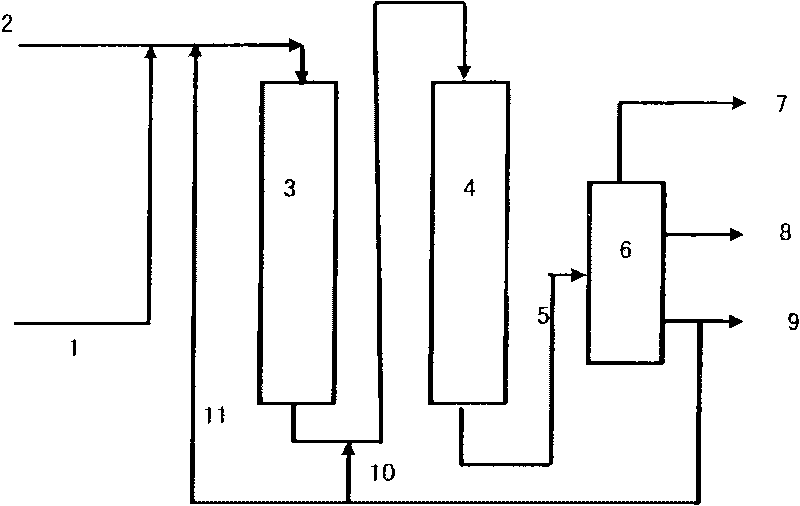

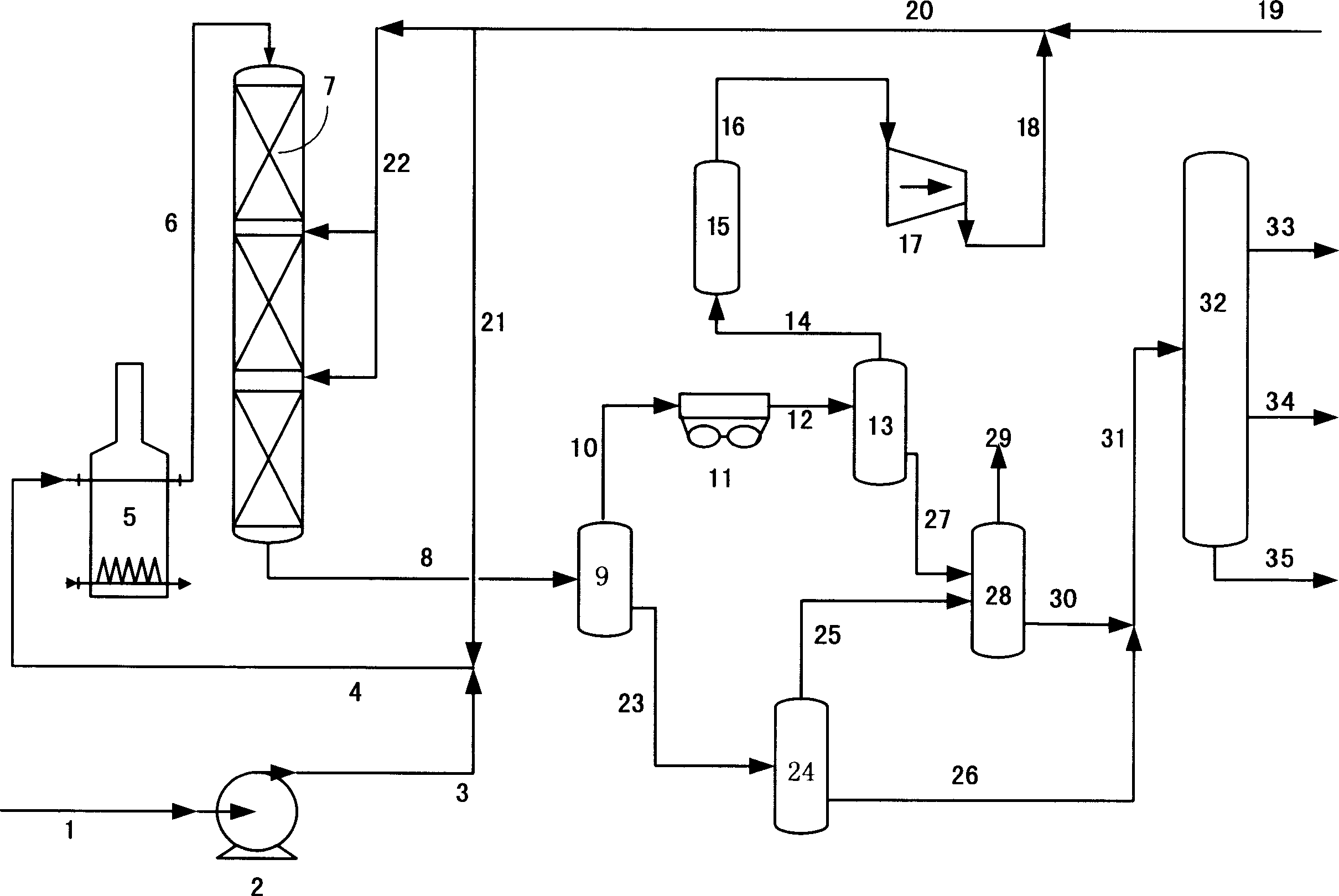

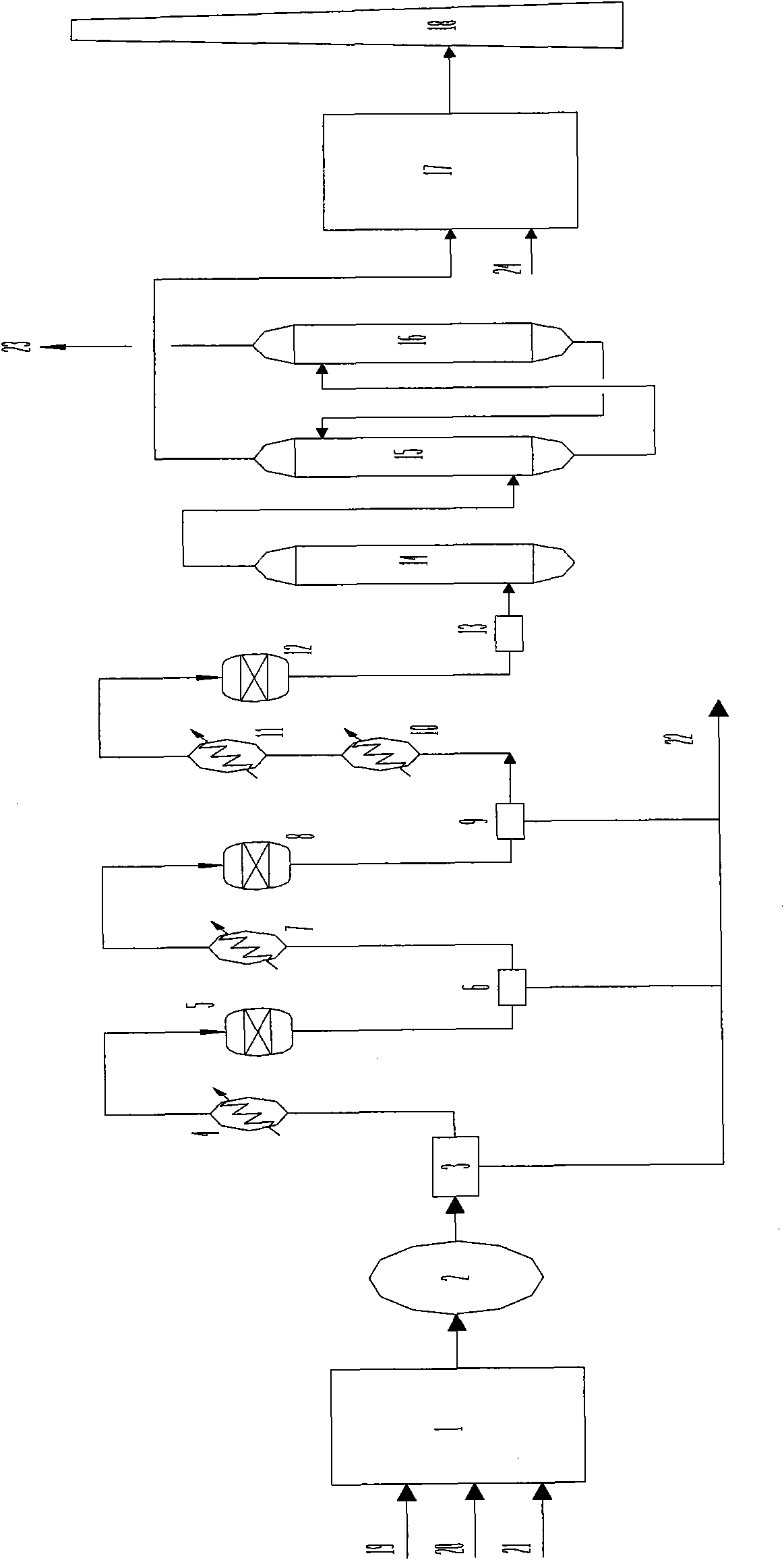

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

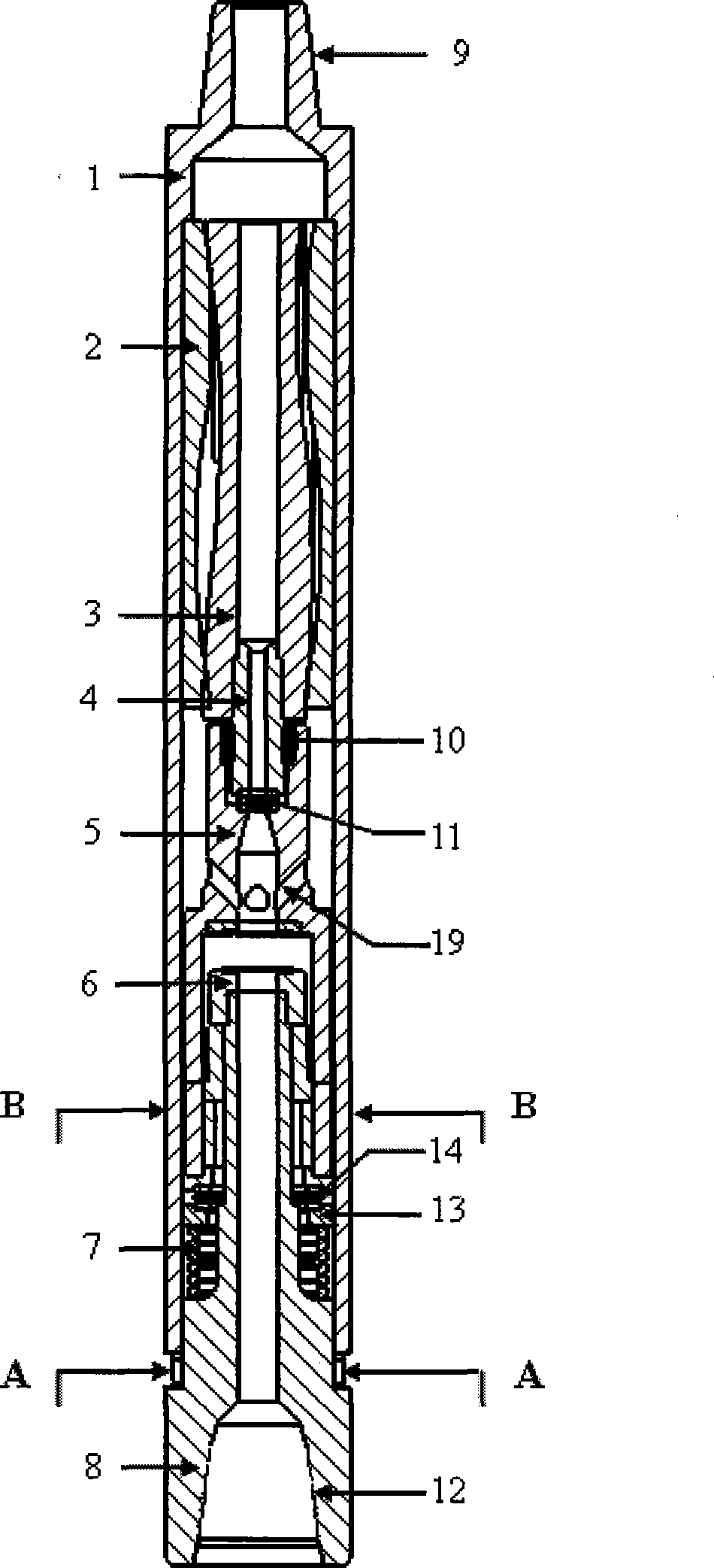

Torsional impact drilling tool

ActiveCN101463709AReduce stick-slipReduce the possibility of failureVibration drillingRate of penetrationDrive shaft

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

Hydrocracking method for producing high-octane petrol

ActiveCN101724454AWide applicabilitySimple methodTreatment with hydrotreatment processesHydrogenGasoline

The invention discloses a hydrocracking method for producing high-octane petrol, which comprises the following steps that: raw oil and hydrogen gas are mixed and then enter a first reactor for impurity removal reaction; and reaction effluent enters a second reactor for hydrocracking reaction which uses an appropriate catalyst and is performed under a certain content of nitrogen. Compared with the prior art, the method has the characteristics of machining poorer raw materials and having long running period of the catalyst, good quality of a hydrocracking product and the like. The method is mainly used for the hydrocracking technological process for producing the high-octane petrol by using diesel fractions with various high arene contents as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

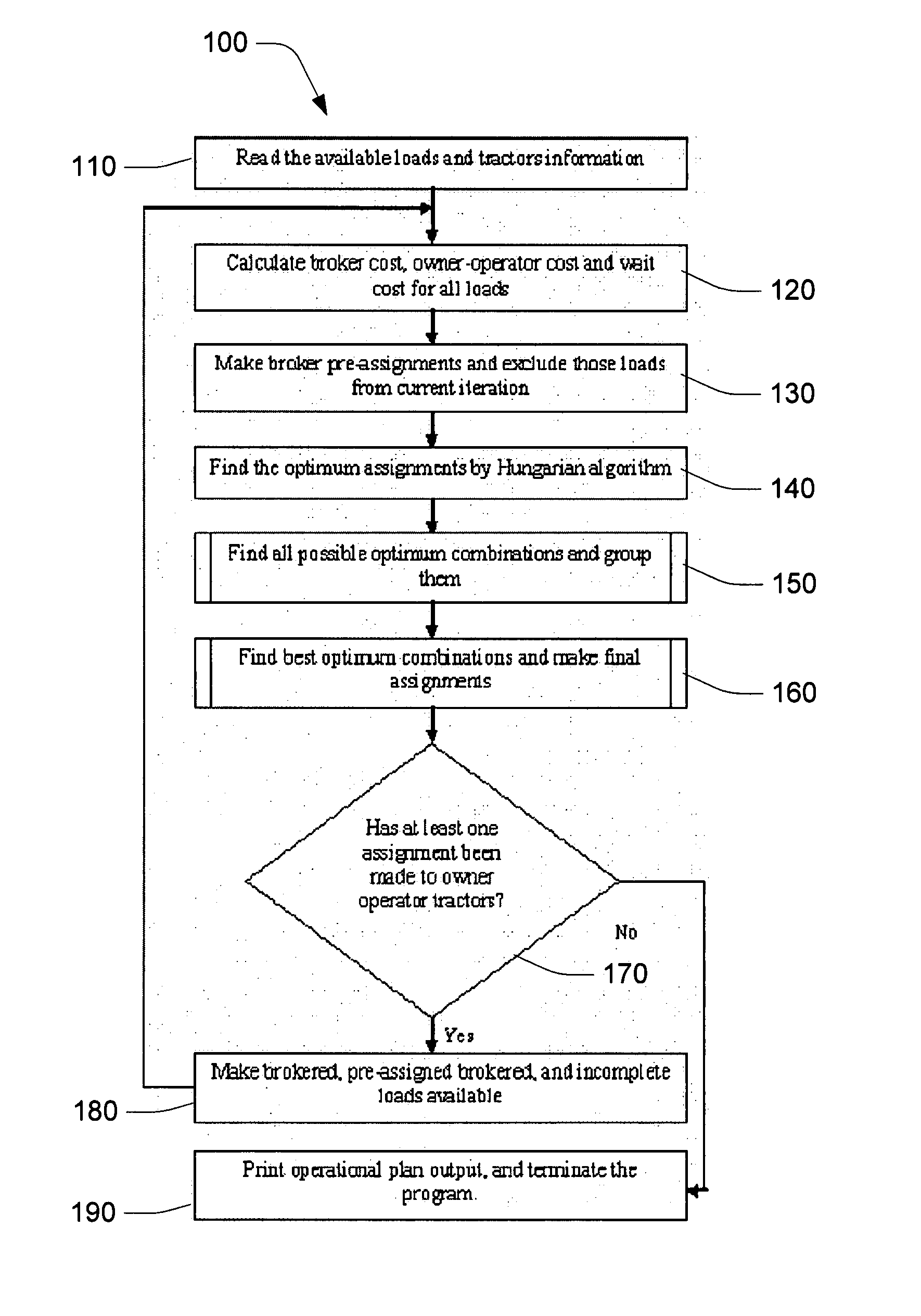

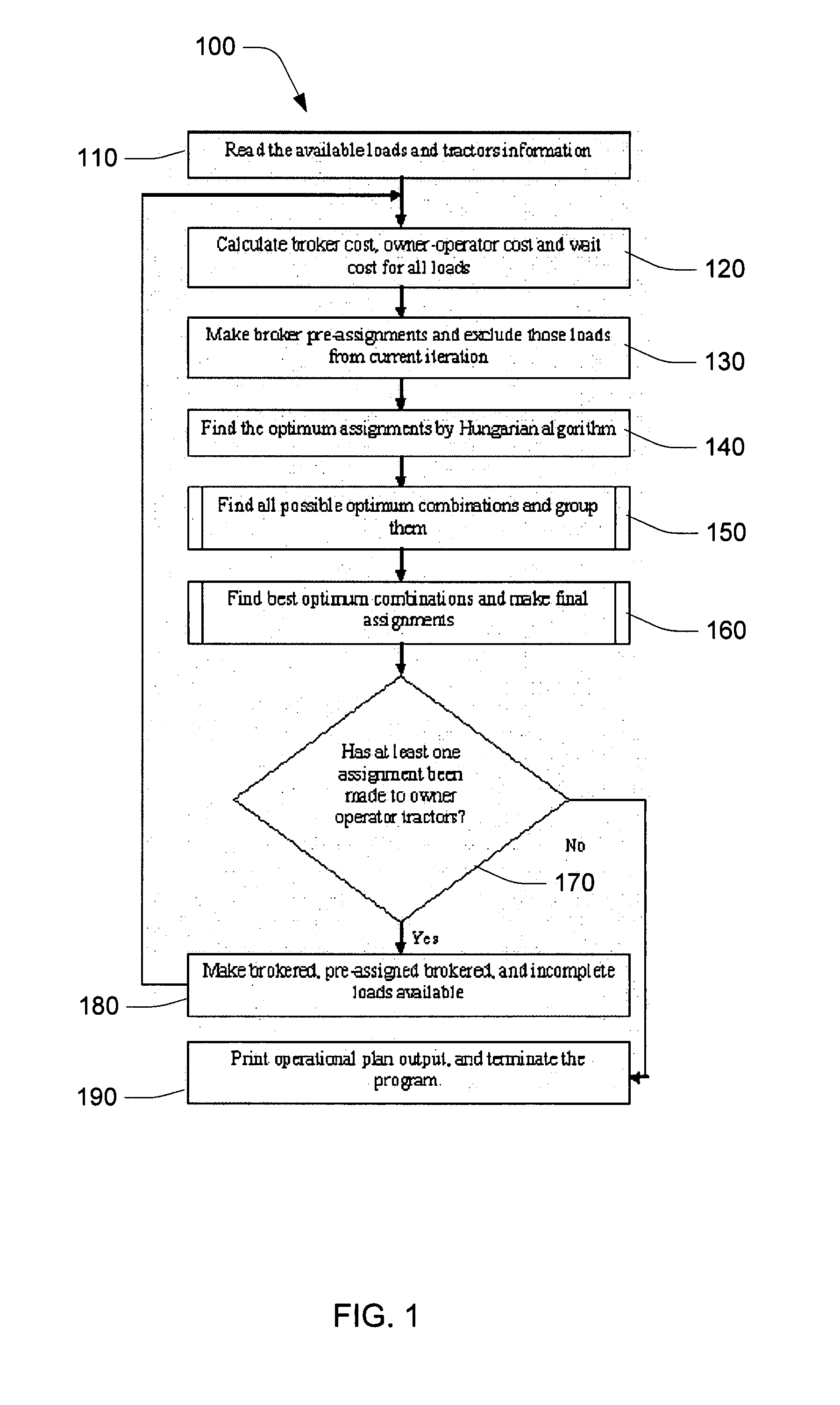

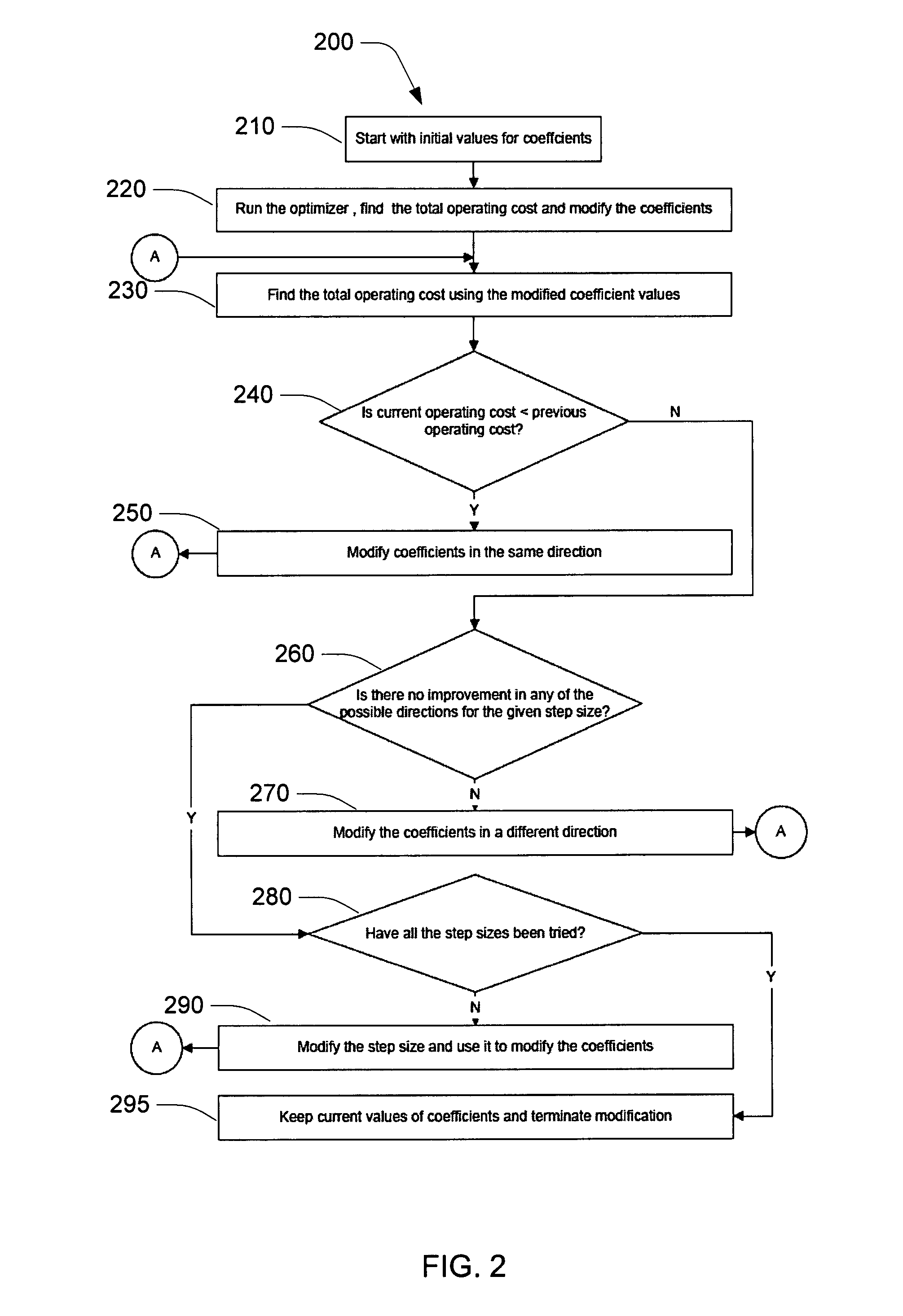

System and method suitable for optimizing linehaul operations

InactiveUS20080140597A1Low operating costEfficiency gainForecastingKnowledge representationIteration processHybrid algorithm

Owner:UNIVERSITY OF NEW BRUNSWICK

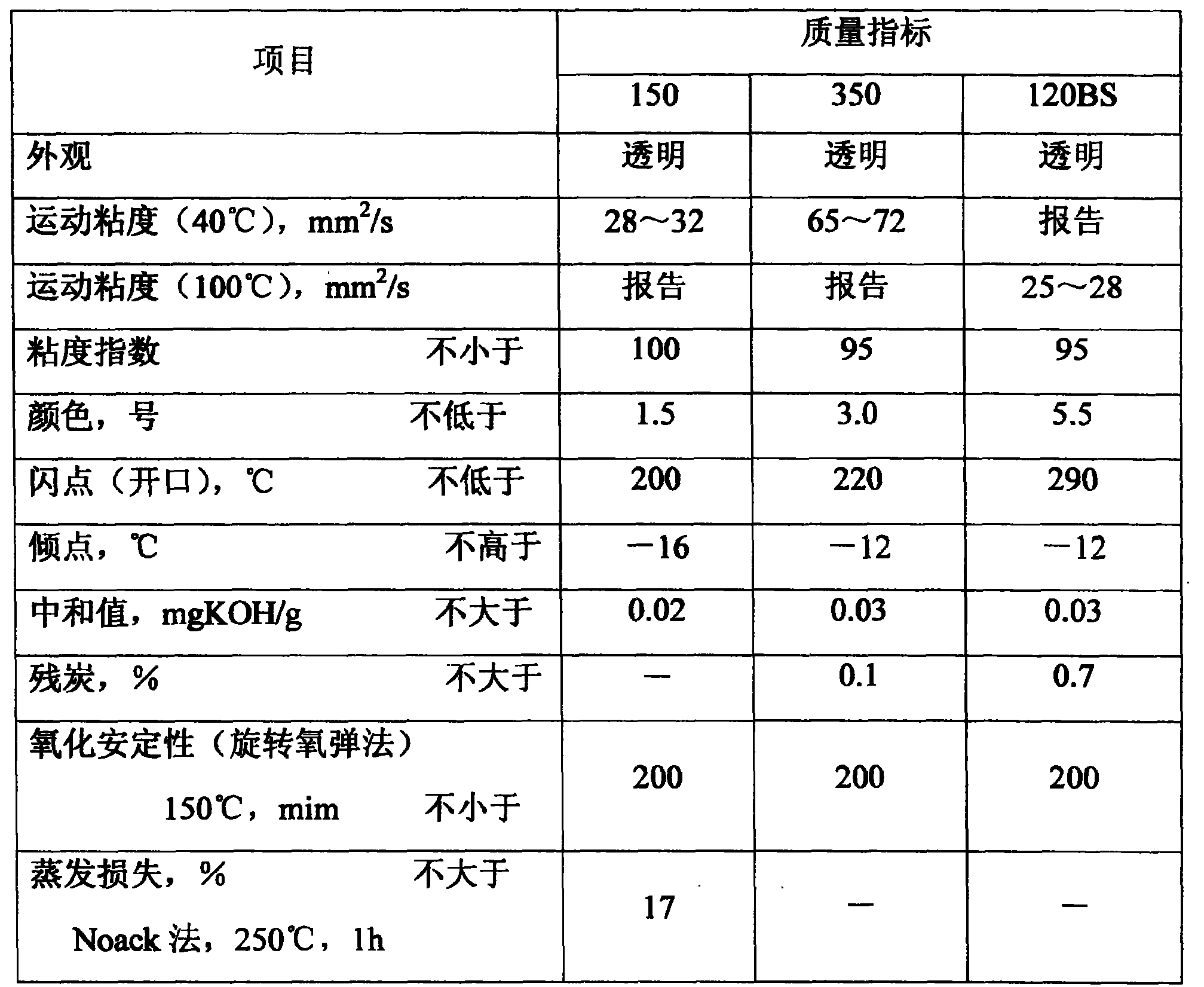

Method for producing lubricating oil basic oil

ActiveCN101173191AMeet the indicator requirementsLow pour pointTreatment with hydrotreatment processesBase-materialsBase oilPour point

The invention discloses a method for producing lube base oil, which is characterized in that low-pressure hydroisomerization and adsorption treatment are adopted and organically combined, and the lube base oil meeting the standard of HVIW is obtained; the raw material firstly enters a low-pressure hydroisomerizing reactor, and the pour point is lowered; after gas-liquid separation of the heterogeneous product, adsorption treatment is done to the separated lube fraction for color enhancement and stability improvement. The invention has the advantages that adaptability of the raw oil is strong; operating condition is mild; investment and operating cost is low; and the prepared lube base oil meeting the standard of HVIW can be applied to blinding with various brands of high-grade lube.

Owner:CHINA PETROLEUM & CHEM CORP +1

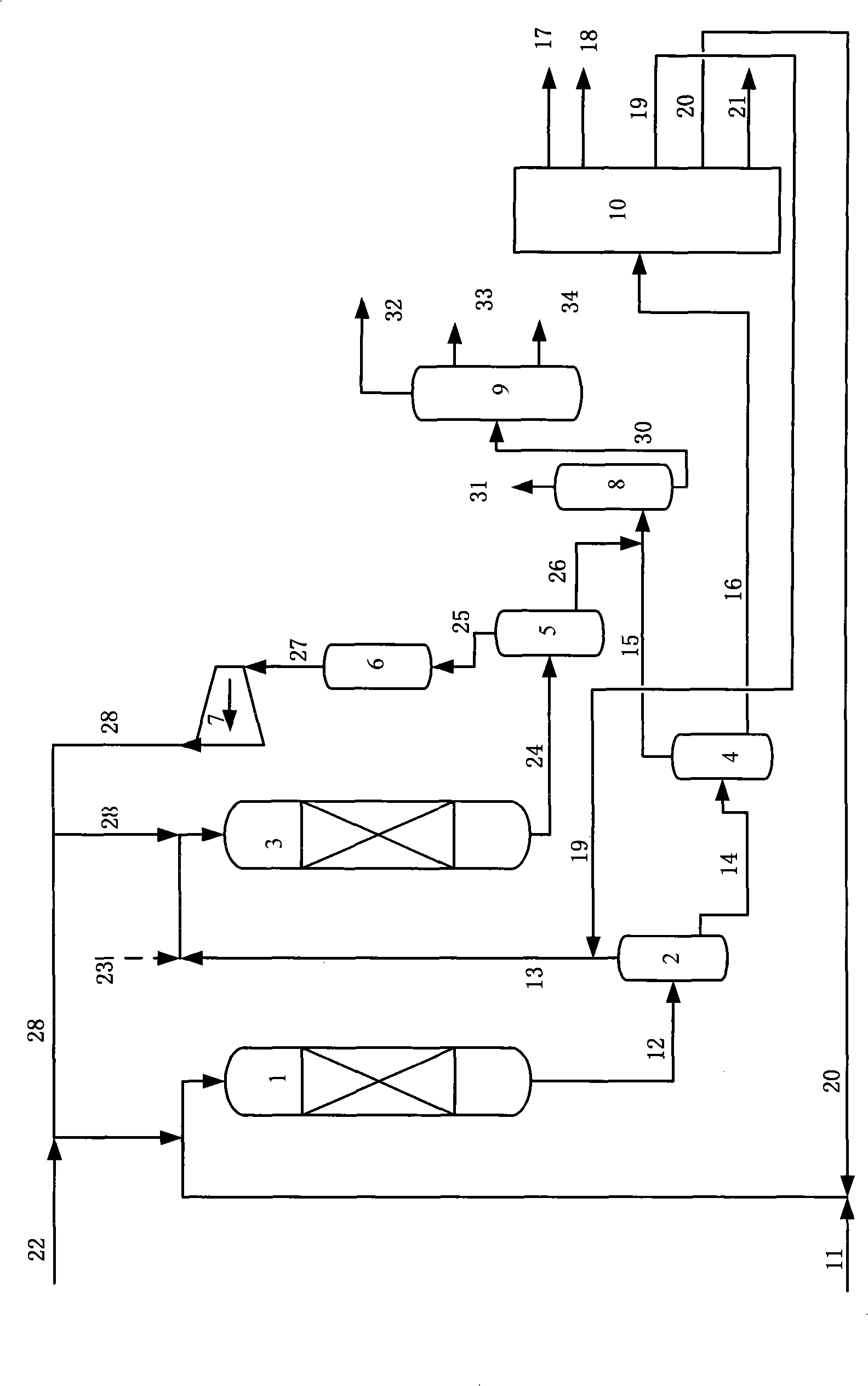

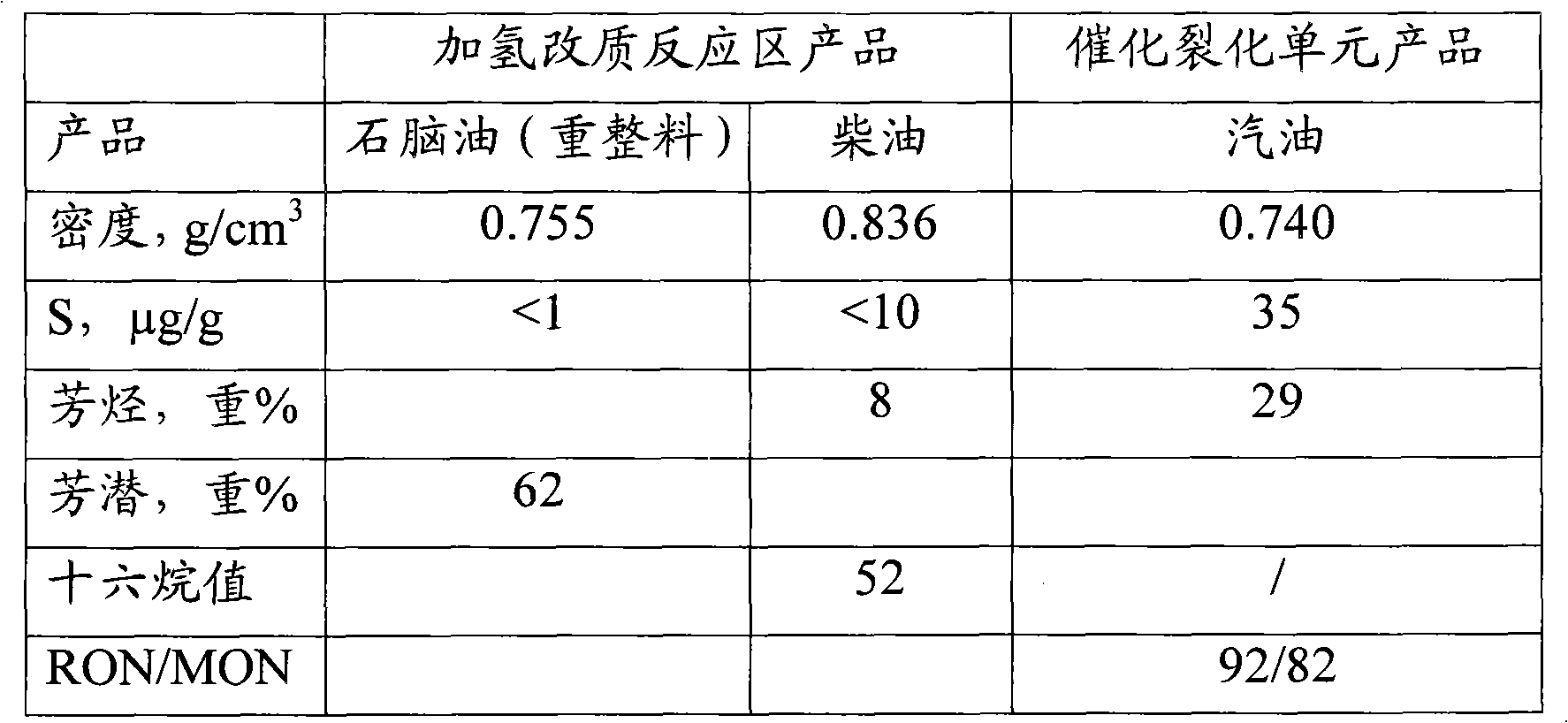

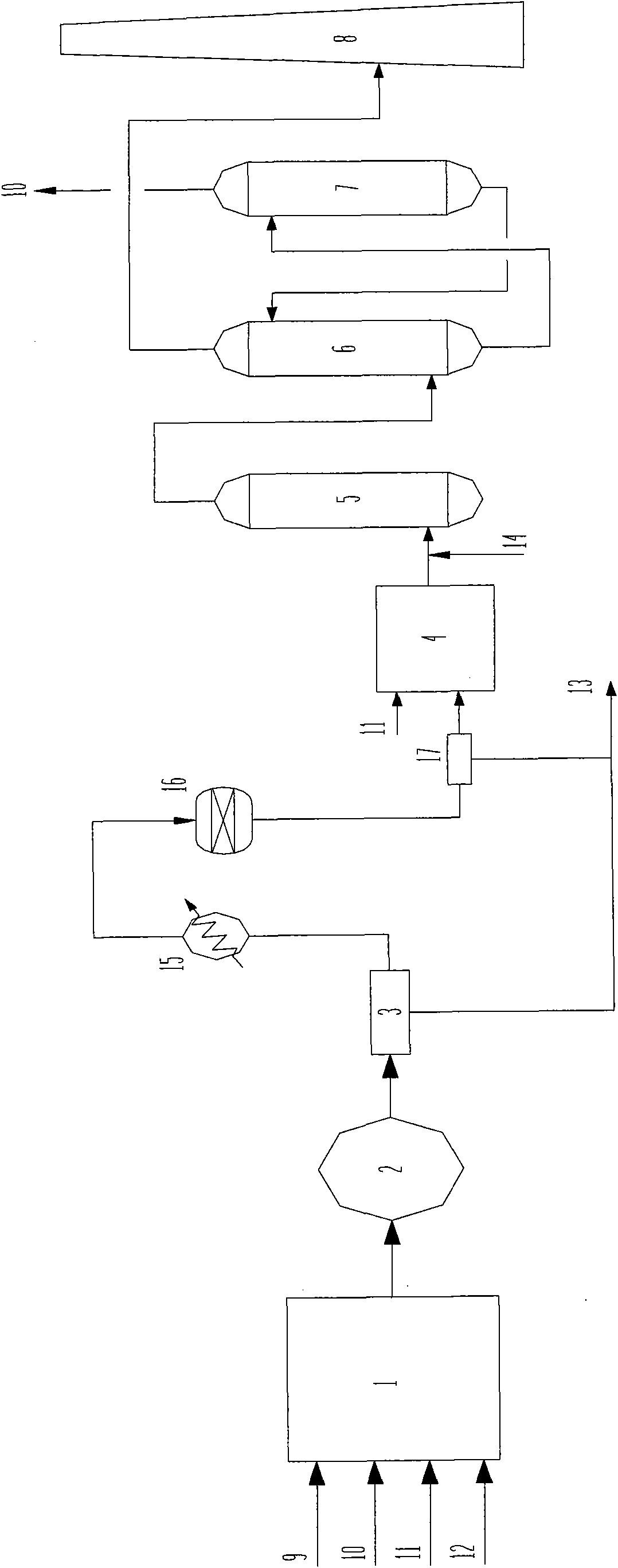

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing modified aqueous adhesion agent of polyurethane

InactiveCN101003715AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyPolyester

This invention discloses a method for preparing modified aqueous polyurethane adhesive. The method comprises: (1) modifying epoxy resin with modifier to obtain modified epoxy resin; (2) reacting polyisocyanate with polyester or polyol polyether, and adding chain extender to obtain polyurethane with prepolymer; (3) modifying polyurethane prepolymer with modified epoxy resin to obtain modified polyurethane prepolymer; (4) adding water, dispersing by a high-speed disperser, and adding neutralizer and crosslinking agent to obtain modified aqueous polyurethane adhesive. This invention introduces epoxy resin into the modification of aqueous polyurethane adhesive, thus combines high modulus, high strength and good chemical resistance of epoxy resin with the advantages of polyurethane resin. The modified aqueous polyurethane adhesive can meet the needs of automobile inner decoration materials. The method has such advantages as simple process, and low cost.

Owner:SOUTH CHINA UNIV OF TECH

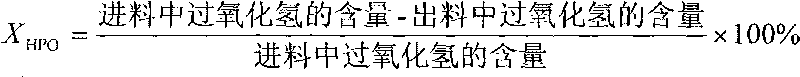

Production method of epoxy chloropropane

ActiveCN101747296AImprove activity stabilityReduce usage and operating costsOrganic chemistryMolecular sieve catalystsSolventMolecular sieve

The invention relates to a production method of epoxy chloropropane. The method provided in the invention comprises contacting 3-chloropropene with hydrogen peroxide with existence of titanium silicalite molecular sieve catalyst, alkaline additive and solvent, wherein, the temperature of contact between 3-chloropropene and hydrogen peroxide is raised from 10-55 DEG C to 65-100 DEG C, and the temperature raising velocity is 0.02-1 DEG C / h. Compared with the prior art, the method for producing epoxy chloropropane provided in the invention greatly enhances activity stability of catalyst, obviously reduces use cost and operation expenditure of catalyst; the technique process is simple and the implementation is convenient.

Owner:CHINA PETROLEUM & CHEM CORP +1

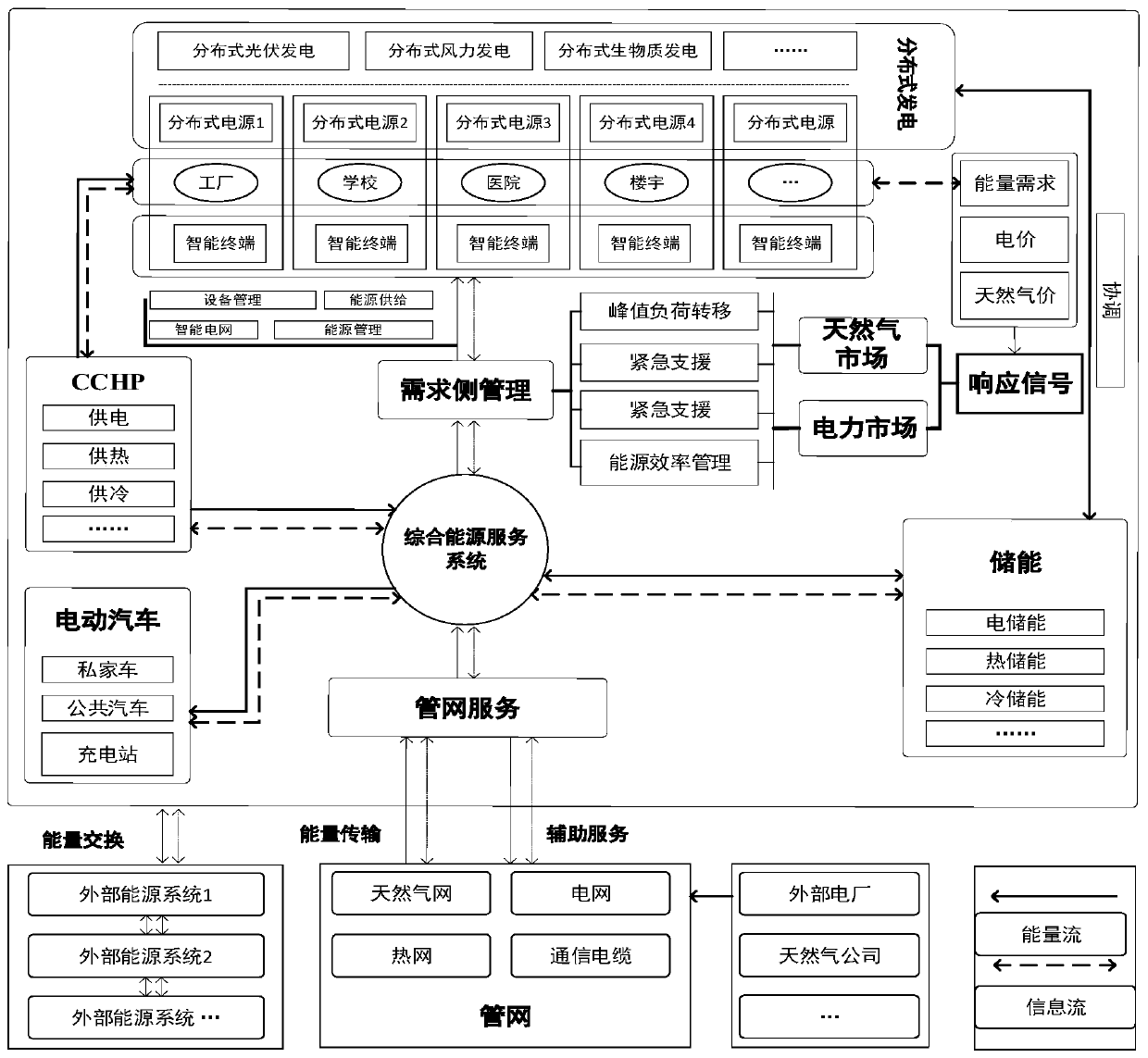

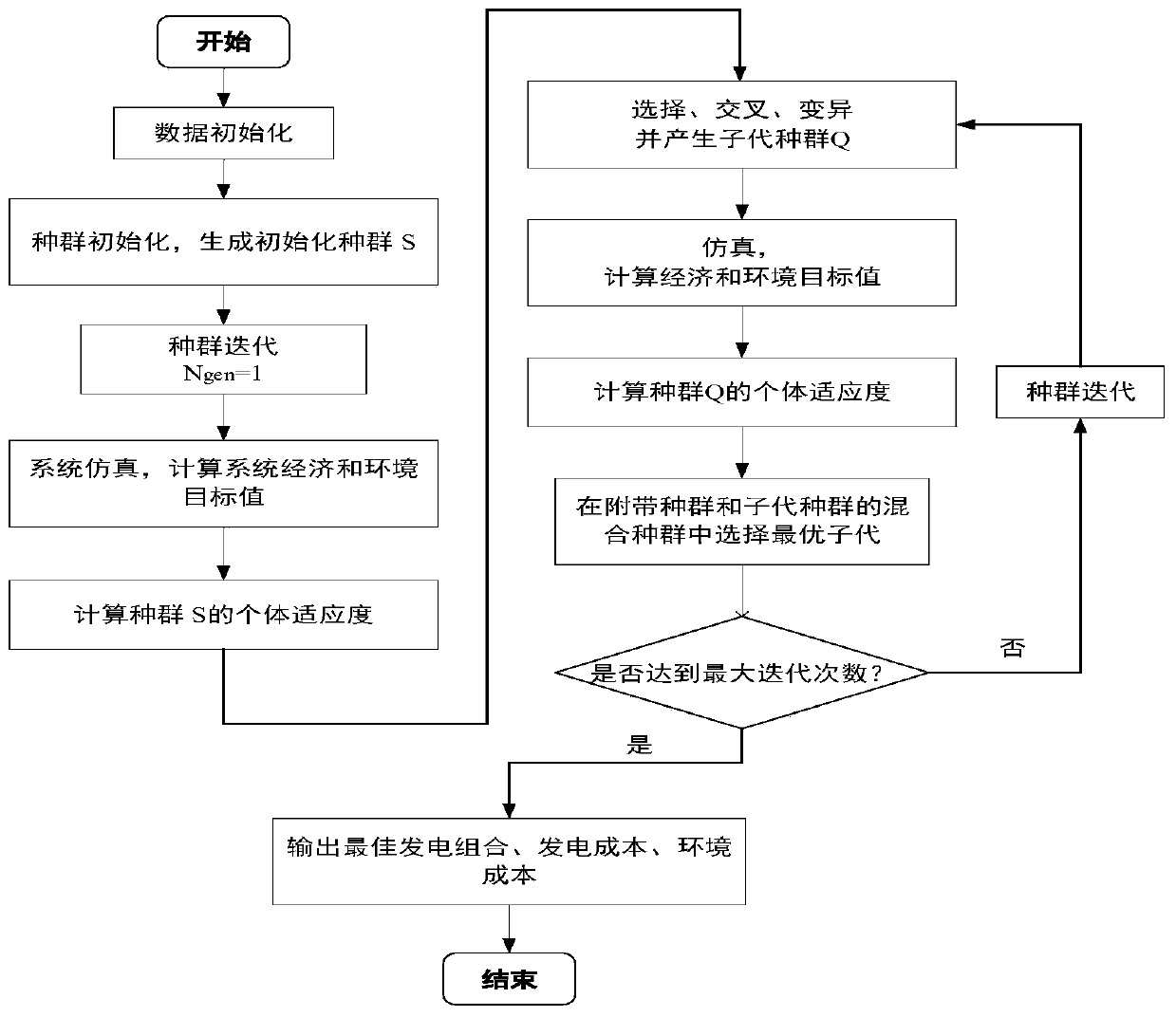

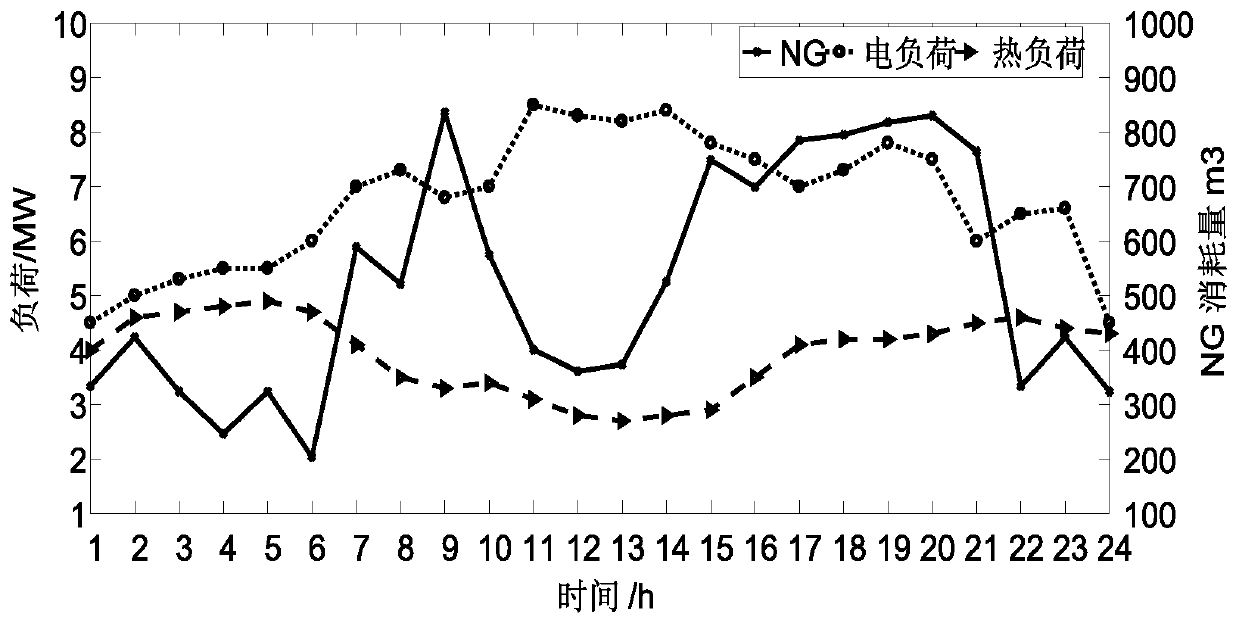

Regional integrated energy system optimization control method

InactiveCN109784569ALow operating costImprove reliabilityForecastingSystems intergating technologiesReduction rateEnergy system optimization

The invention discloses a regional integrated energy system optimization control method. The method comprises the following steps: S1, optimizing a control objective function of the regional integrated energy system; The purposes of the lowest total operation cost and the highest reliability and system emission reduction rate of the regional comprehensive energy system are achieved, and the objective function is divided into an operation cost model, an environment cost model and a system reliability model; including S11, constructing an objective function based on an operation cost model; S12,constructing an objective function based on an environment cost model; S13, constructing an objective function based on the system reliability model; S2, analyzing optimization control constraint conditions of the regional comprehensive energy system; S21, energy balance constraint analysis; S22, performing energy balance constraint analysis; And S23, system operation constraint. The control method aims at achieving the purposes that the total operation cost of the system is lowest, and reliability and system emission reduction rate are highest.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

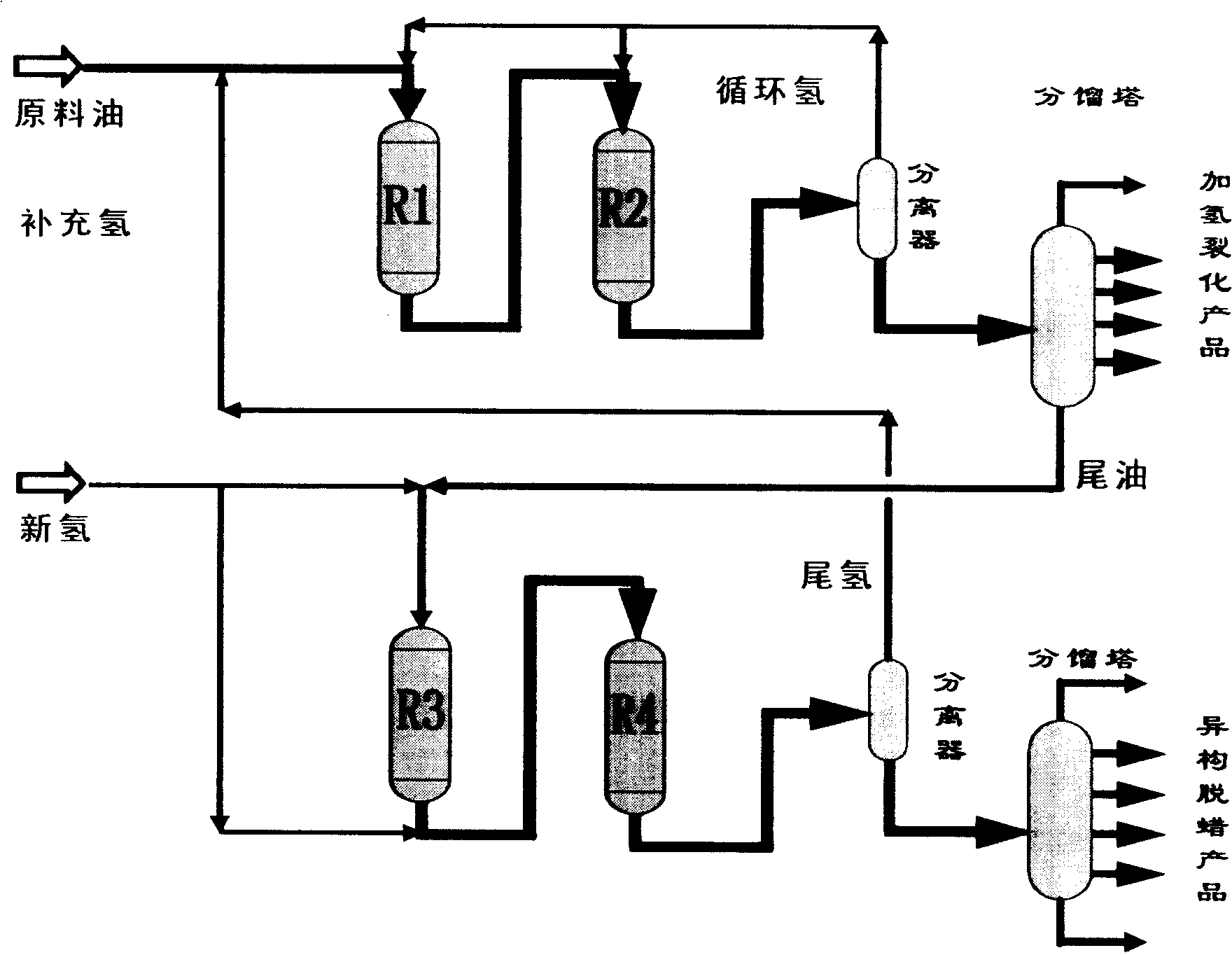

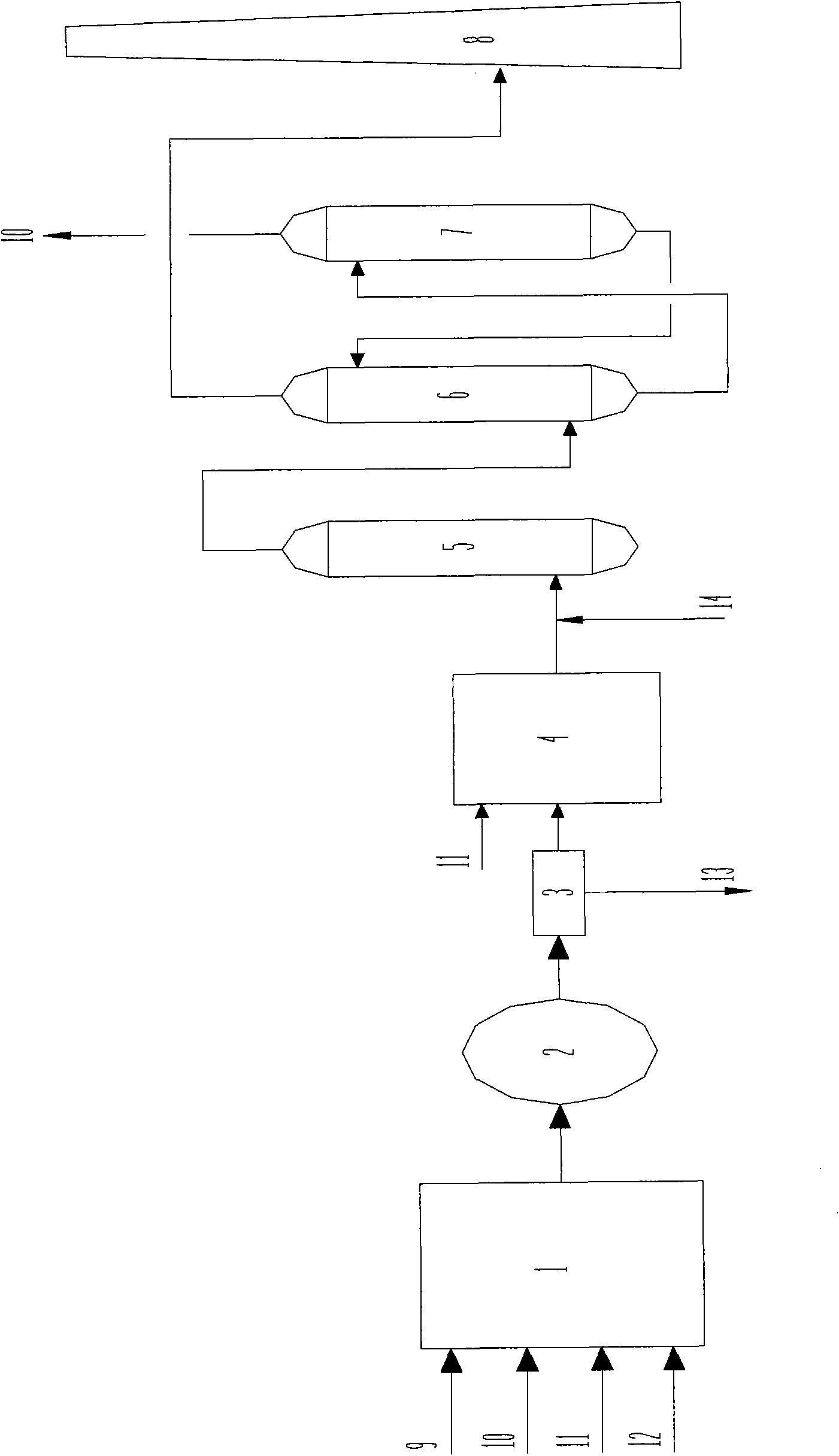

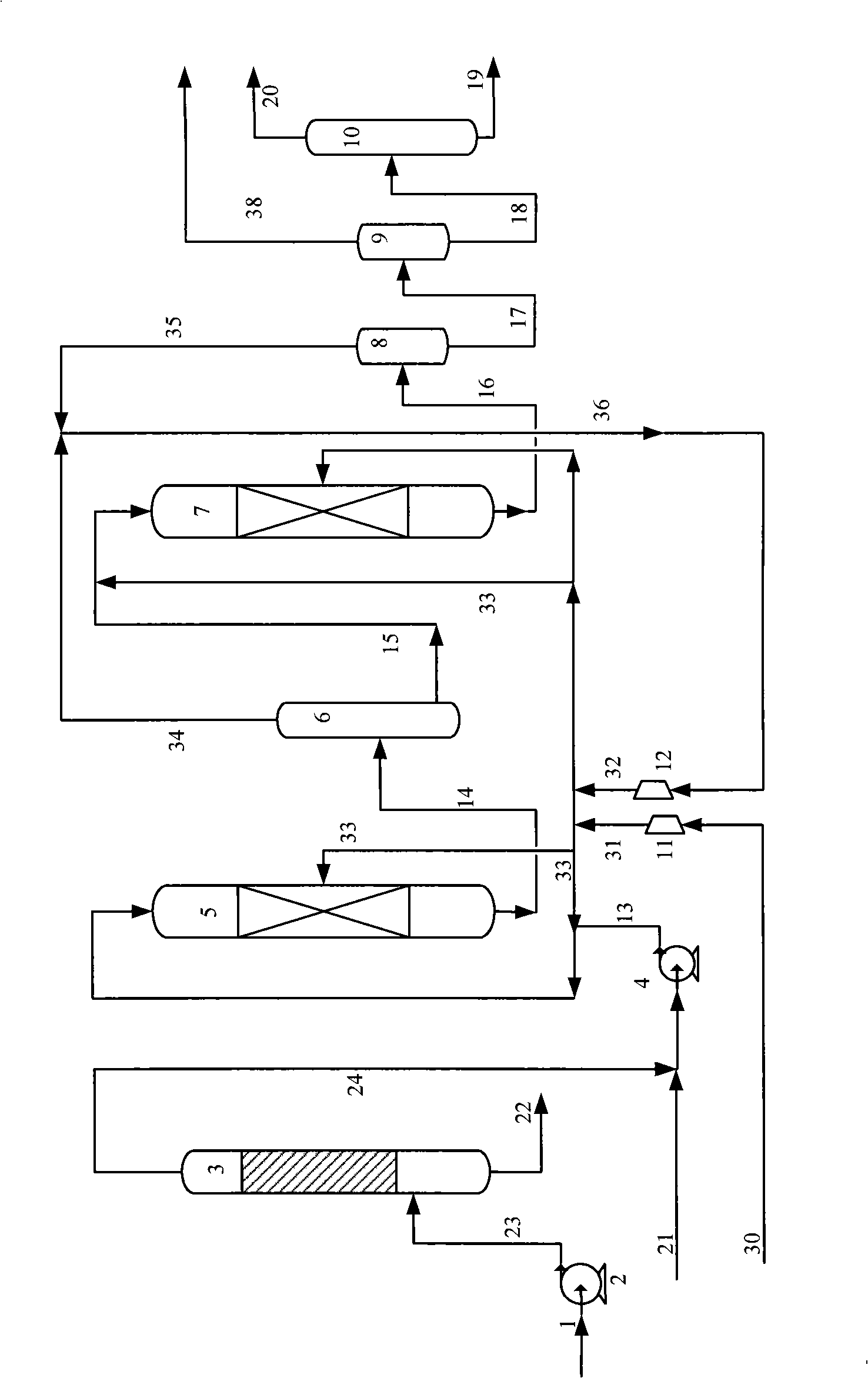

Combined technological process for producing lube oil base stock

ActiveCN101333460ASimple processLow operating costTreatment with hydrotreatment processesPetroleum wax recoveryHydrogenIsomerization

The invention discloses a production method of lubricating oil basic oil. The method takes distillate oil or refined oil, etc. as raw materials, and adopts the combined process of hydrogen cracking-isomerization dewaxing to produce the lubricating oil basic oil. The tail oil of a hydrogen cracking unit is directly supplied to a tail oil isomerization dewaxing unit for serving as a raw material, the new hydrogen passes through the tail oil isomerization dewaxing unit at a time, and the tail hydrogen directly returns to the hydrogen cracking unit for serving as compensation hydrogen. Only one hydrogen circulation system is arranged due to the deep combination of the two units, the construction investment of apparatus and the operating cost are obviously reduced, and the product quality is somewhat improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method for acid gas containing H2S

InactiveCN102205202AReduce the overall heightReduce the overall diameterSulfur compoundsDispersed particle separationSulfateProduct gas

The invention provides a processing method for an acid gas containing H2S. The method comprises the following steps that: H2S in the acid gas is transformed into SO2 through burning; the SO2 is subjected to a reaction to generate SO3 in the presence of a catalyst; the SO3 reacts with an alkaline solution to produce a sulfate solution; at last the sulfate solution is processed to obtain a sulfate product. With the method provided by the present invention, the acid gas can be removed so as to meet discharge requirements of environmental protection, and operation difficulty and operation cost are reduced.

Owner:BEIJING FUNGHAN ENG CONSULTING

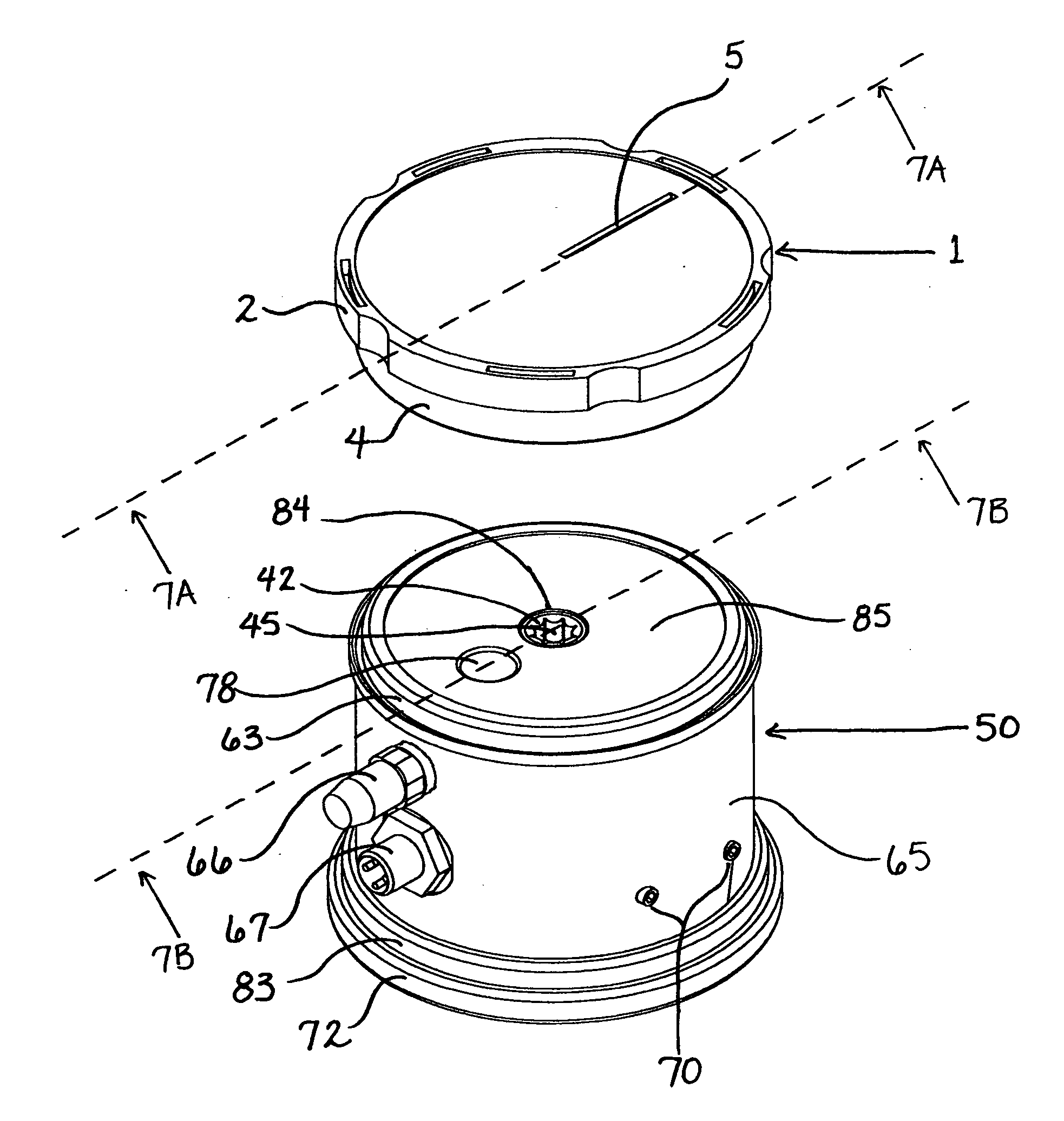

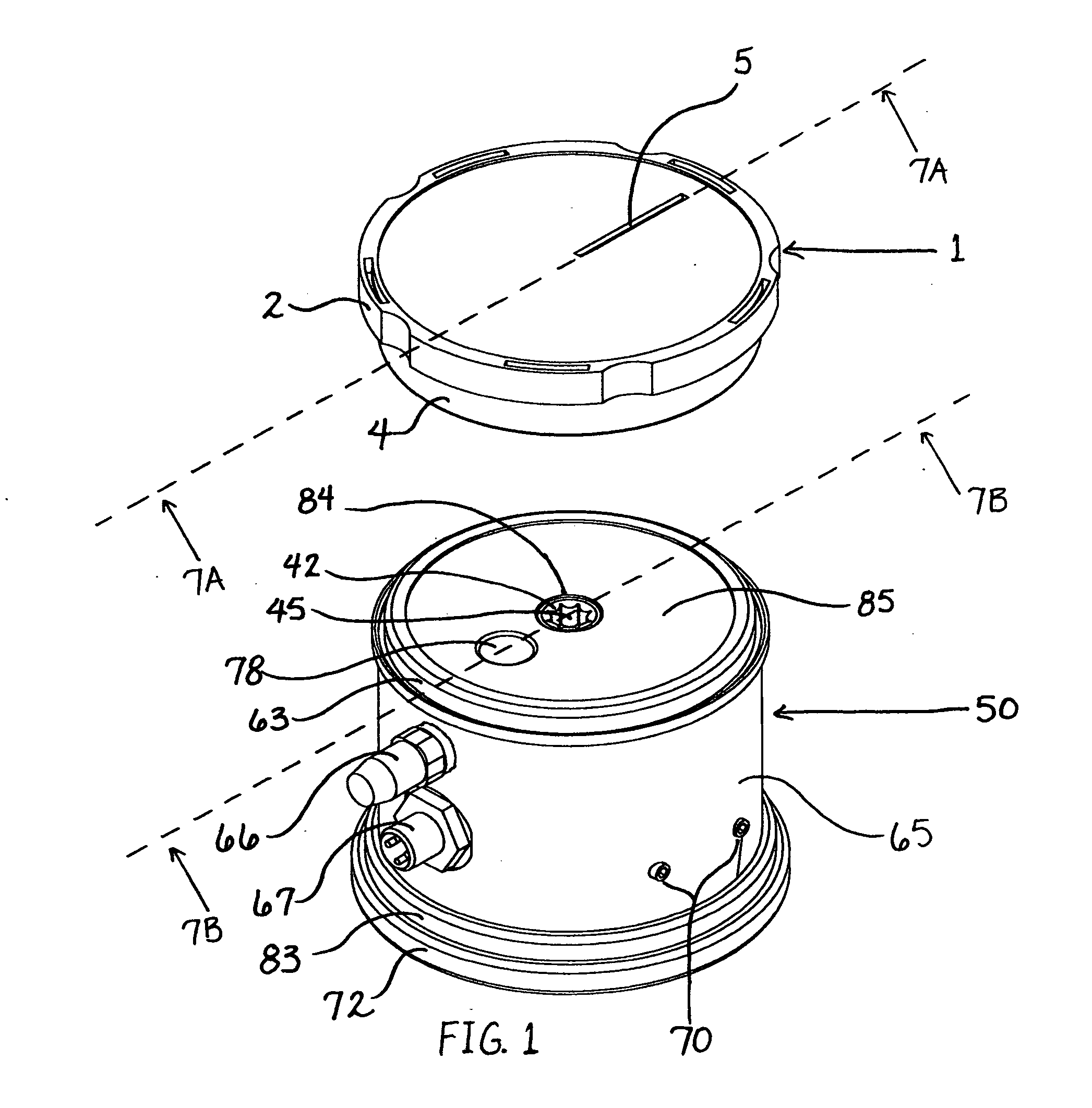

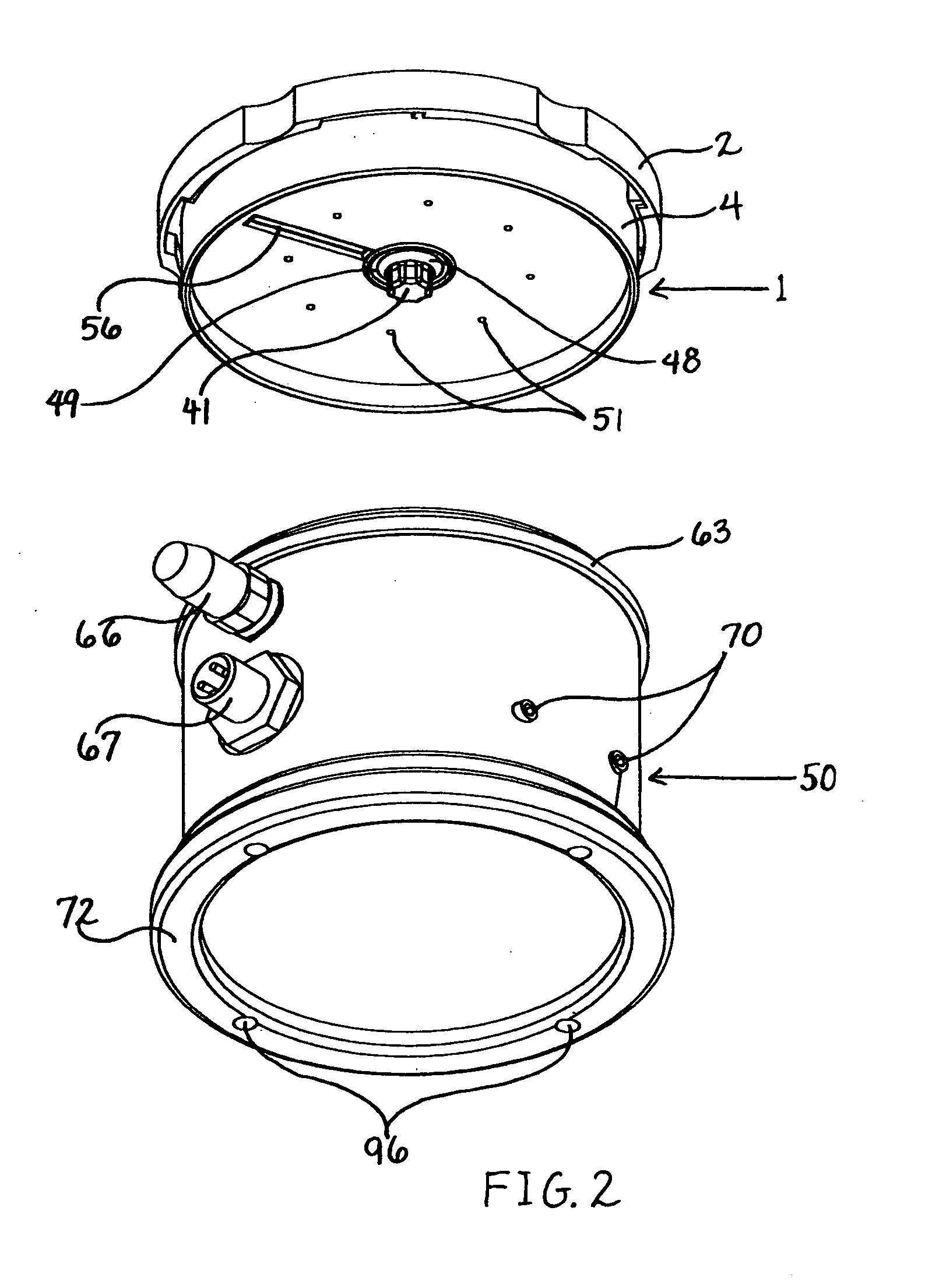

Single use sterile slit impact sampling cassette with rotatable capture tray

A single use sterile slit impact sampling cassette with rotatable capture tray for recovering particulate matter from ambient air, having a lid with a slit shaped air inlet, dish with an air outlet, and capture tray. The dish and lid assemble to form a sealed sample chamber, which houses the capture tray. The assembled cassette is sterile packaged with its inlet and outlet covered before use. The cassette is placed on a base for operation, which supplies the required vacuum for sampling, and rotational means for the capture tray. Air drawn into the air inlet is accelerated to a velocity that ensures impingement, or entrainment of particulate matter from the sampled air volume onto, or within the capture media. The sampled air volume is evacuated from the sample chamber through an air outlet. The cassette is then removed from the operative base, and then may be analyzed for the target contaminants.

Owner:SWENSON ERIK AXEL +1

Hydrogenation method for producing good quality catalytic cracking material

ActiveCN101007964AReduced activityDelay pressure drop riseRefining to eliminate hetero atomsHydrogenNaphtha

The invention relates to a hydrogenation method for high- quality catalytic cracking material. It comprises: carrying out hydrogenation and modifying reaction for mixture of raw oil and hydrogen gas in hydrogenation preservative, any hydrogenation demetalation catalyst and hydrogenation treating catalyst in turn; and the filling volumetic percentage of mentioned preservative and catalyst are 2- 15%, 0- 30% and 55-95%, cooling reactant and separating and getting a large amount of refined gas oil fraction, part of low-sulphur diesel fraction and little amount of benzine naphtha fraction, and the refined gas oil fraction is the catalytic cracking material. The invention can prolong the operation cycle for device under high percentage of desulfurization, the activity of employed catalyst is high, and the rational packing method ensures better catalyst activity, and reduces production cost. The invention is characterized by simple process, low operation pressure, low device investment and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

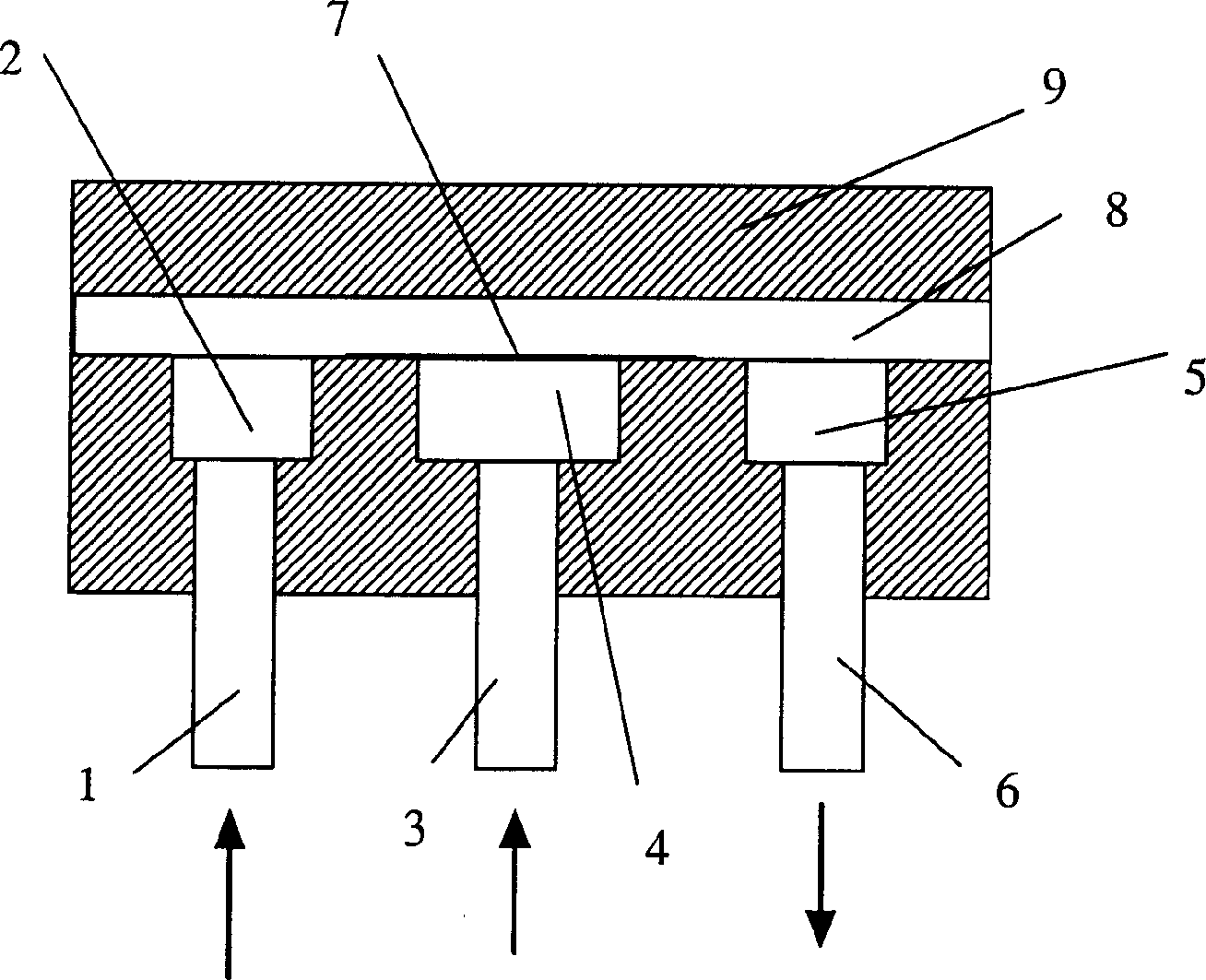

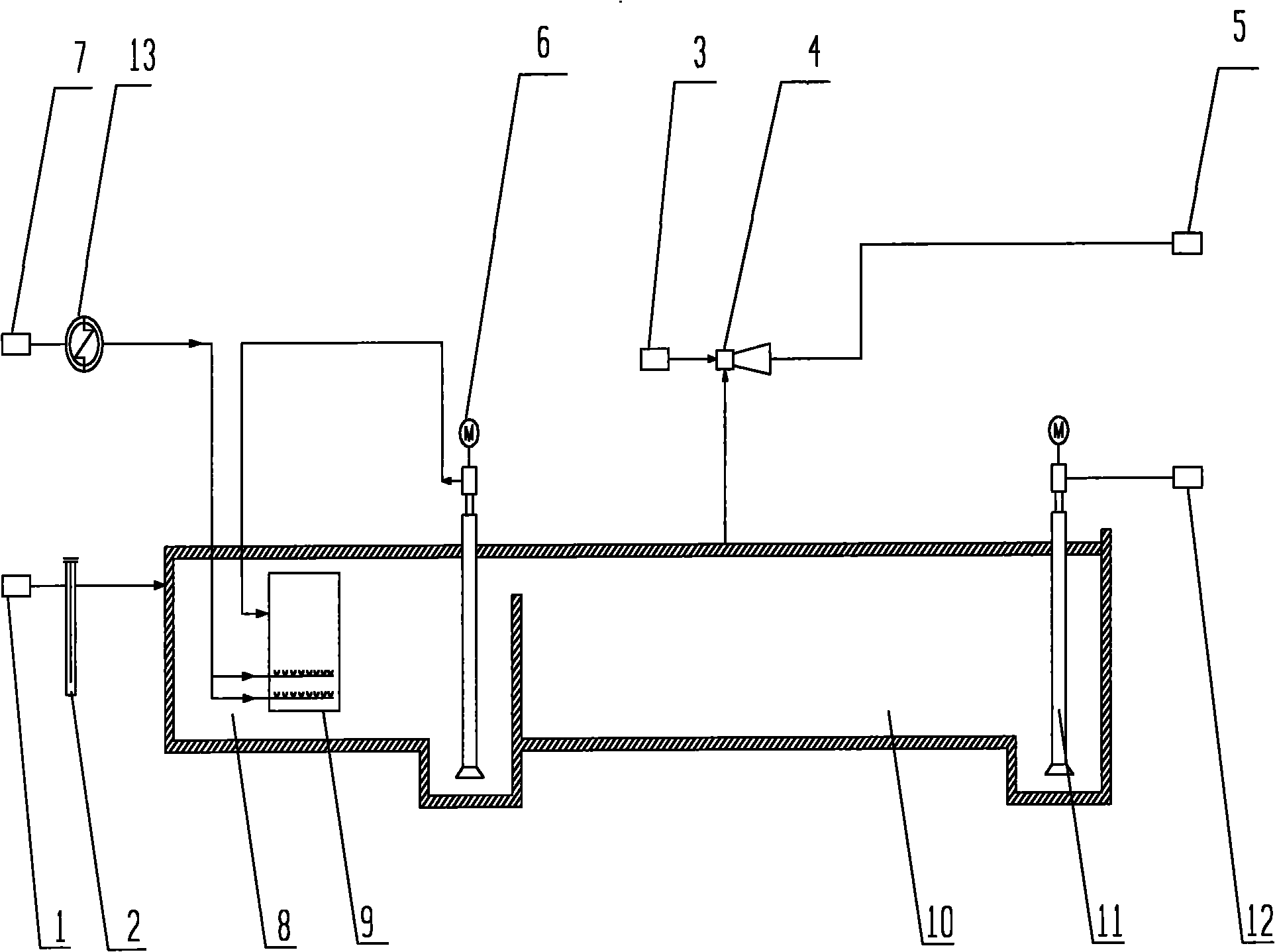

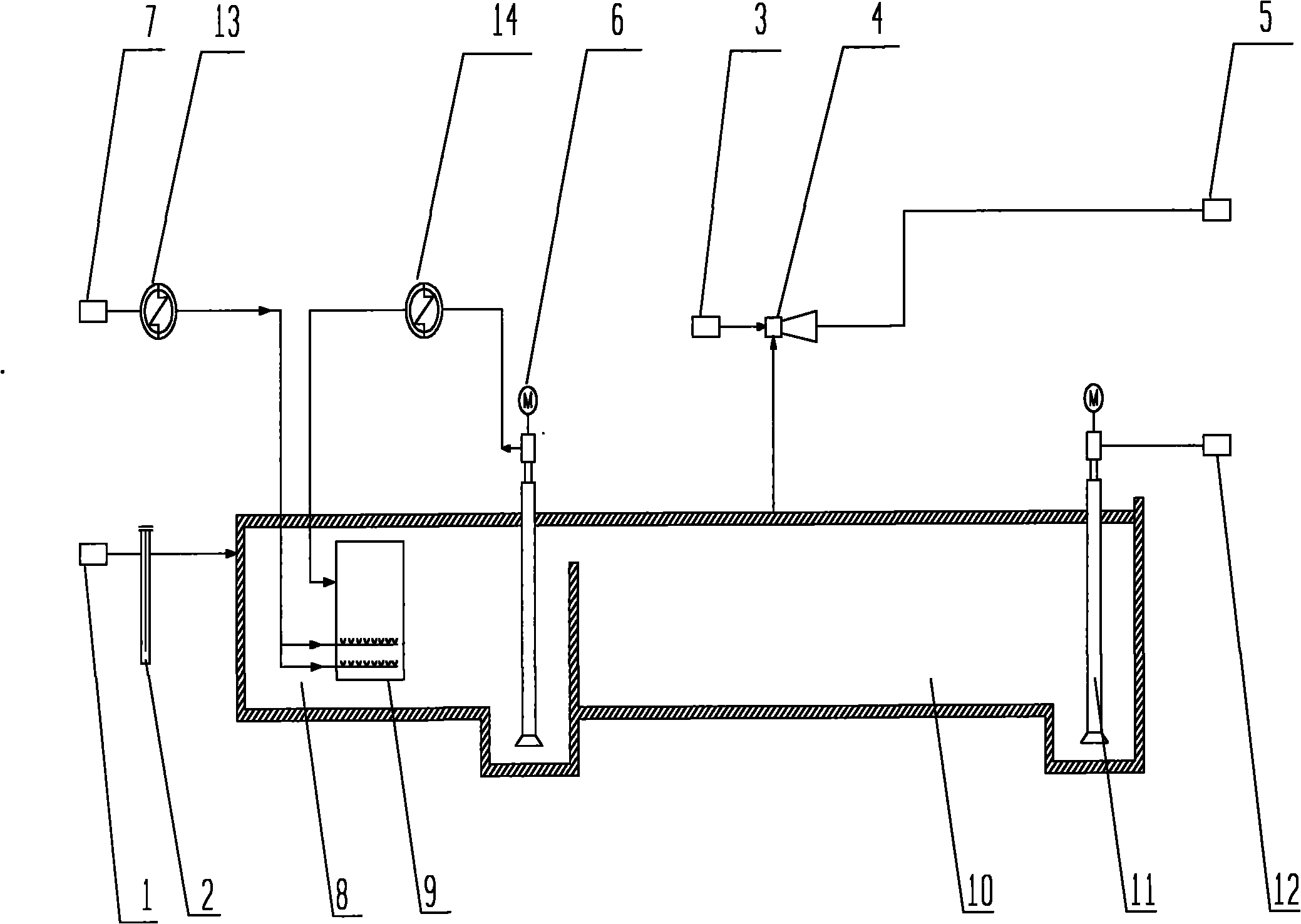

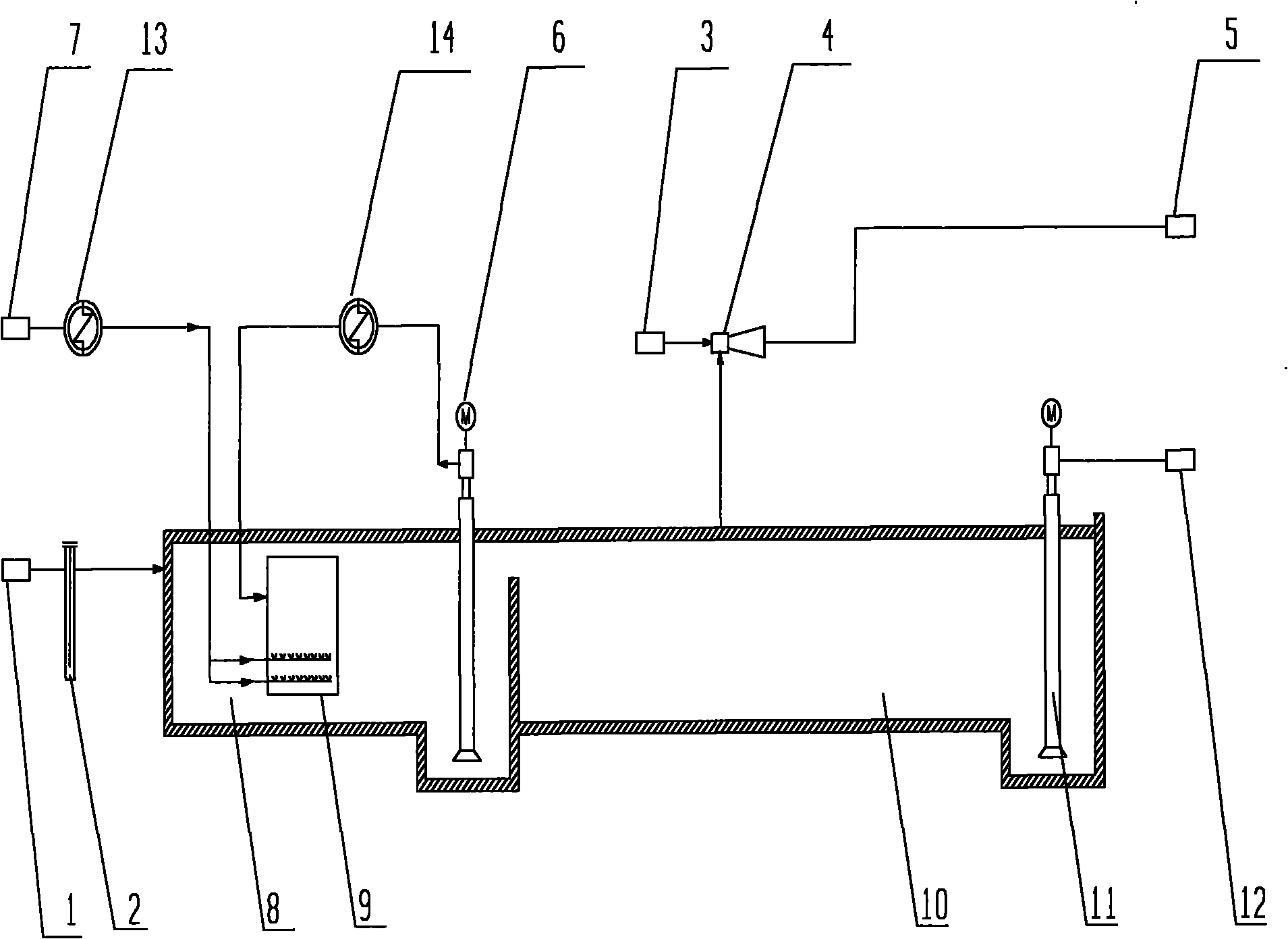

Multi-channeled micro-structured reactor

ActiveCN1736577AHigh selectivityIncrease throughputChemical/physical/physico-chemical processesLiquid-gas reaction processesEngineeringParallel channel

Disclosed is amultichannel reactor with microstructure. Continuous phase inlet pipe and distribution chamber, discontinuous phase inlet pipe and distribution chamber, mixture phase buffer chamber and fluid outlet pipe connects separately, and they compose the lower cavity. Porous distribution medium is sealed in the upper distribution chamber of discontinuous phase. A parallel channel plate of continuous phase is located above the lower cavity and the upper is sealed. The continuous phase liquid flows into the reactor from the distribution chamber of inlet pipe; the discontinuous liquid flows into the parallel channel of continuous phase following through the distribution medium, distributes into minute drop or air bubble with the floating shearing force of continuous phase liquid, and then connects with the continuous phase liquid to realize the rapid mixture and reaction of the two- phase liquid; then the liquid flows out of the reactor. With the invention, the area of mass transfer is big, the reaction conversion rate is high, and large scale production can be realized.

Owner:TSINGHUA UNIV

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

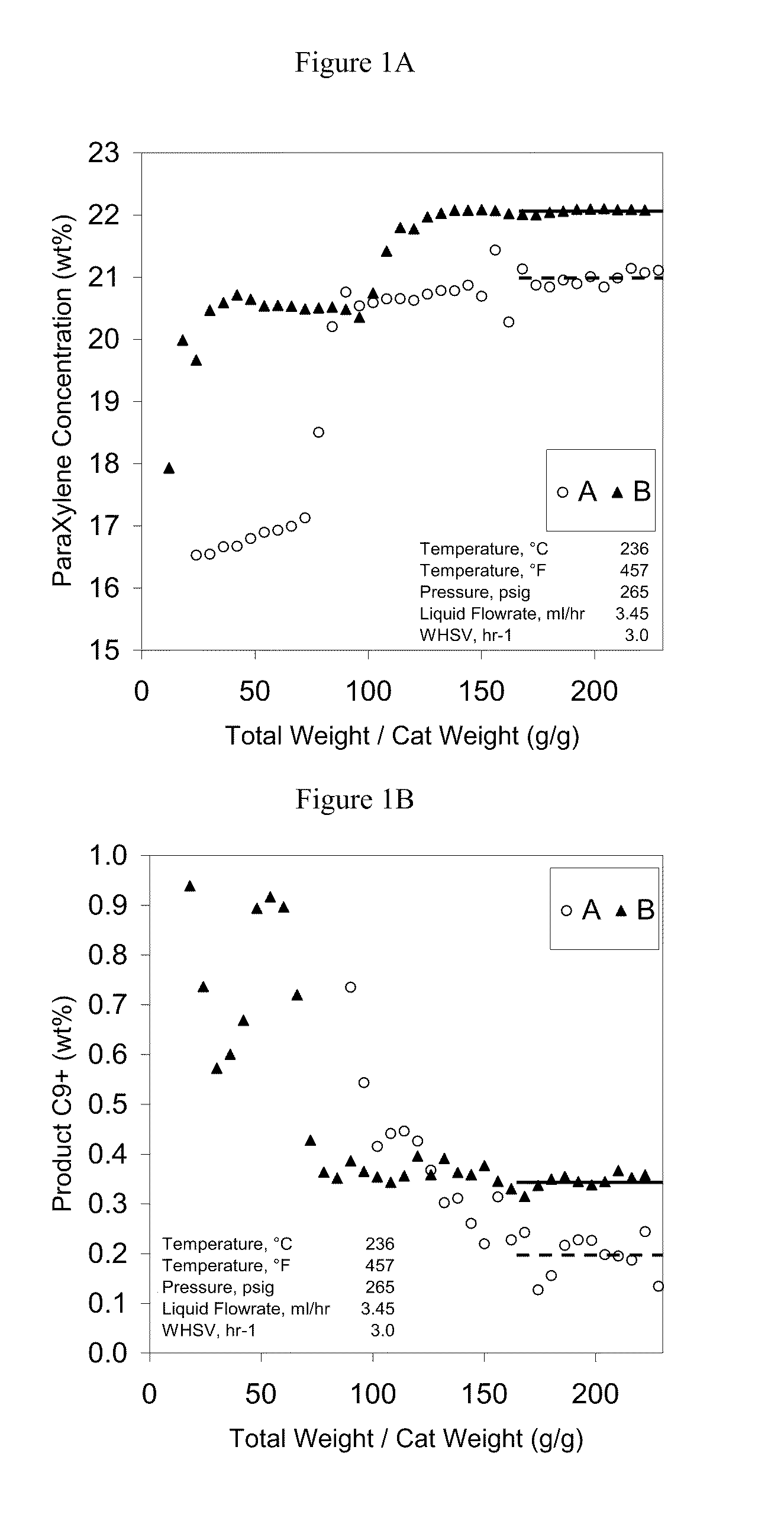

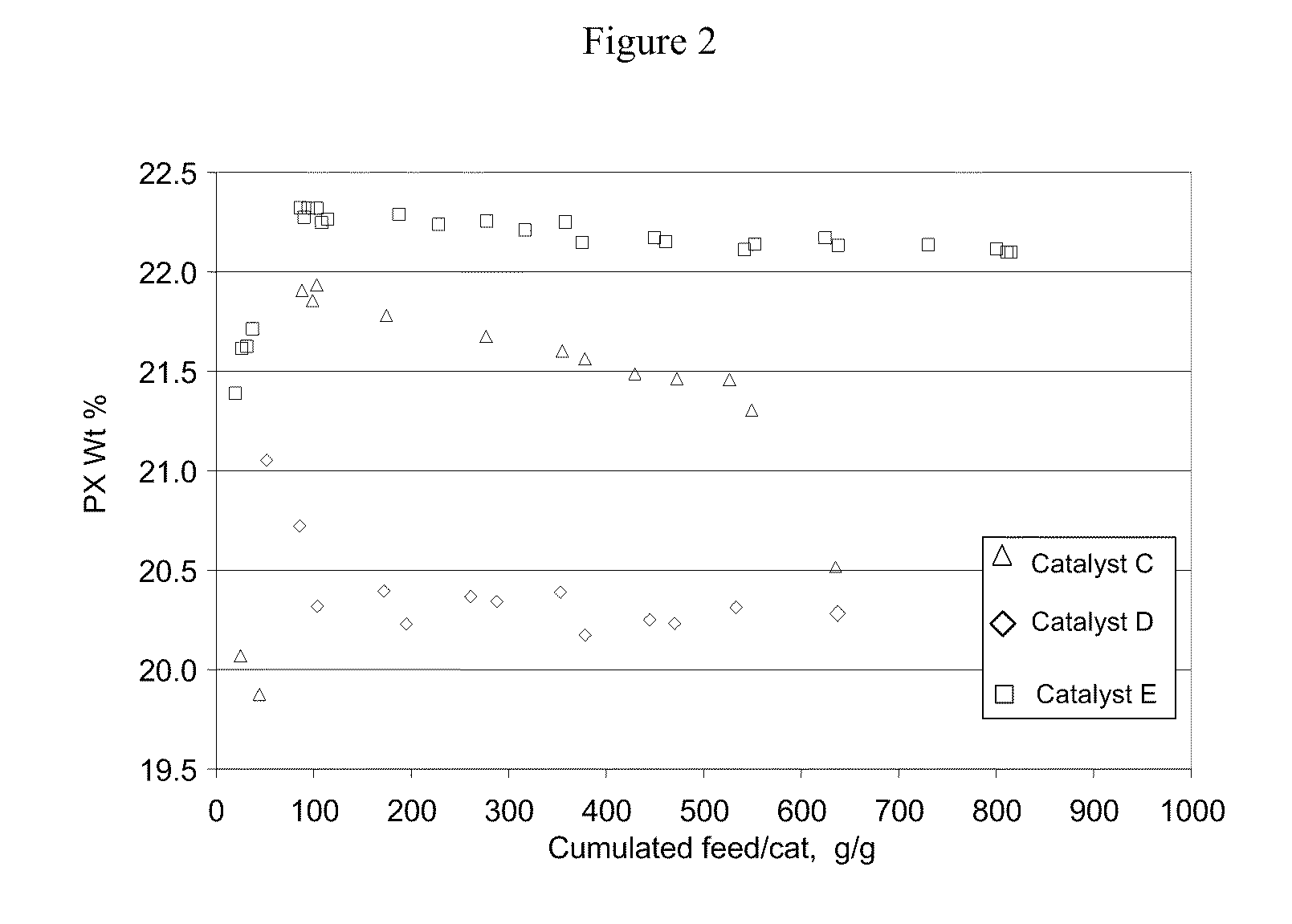

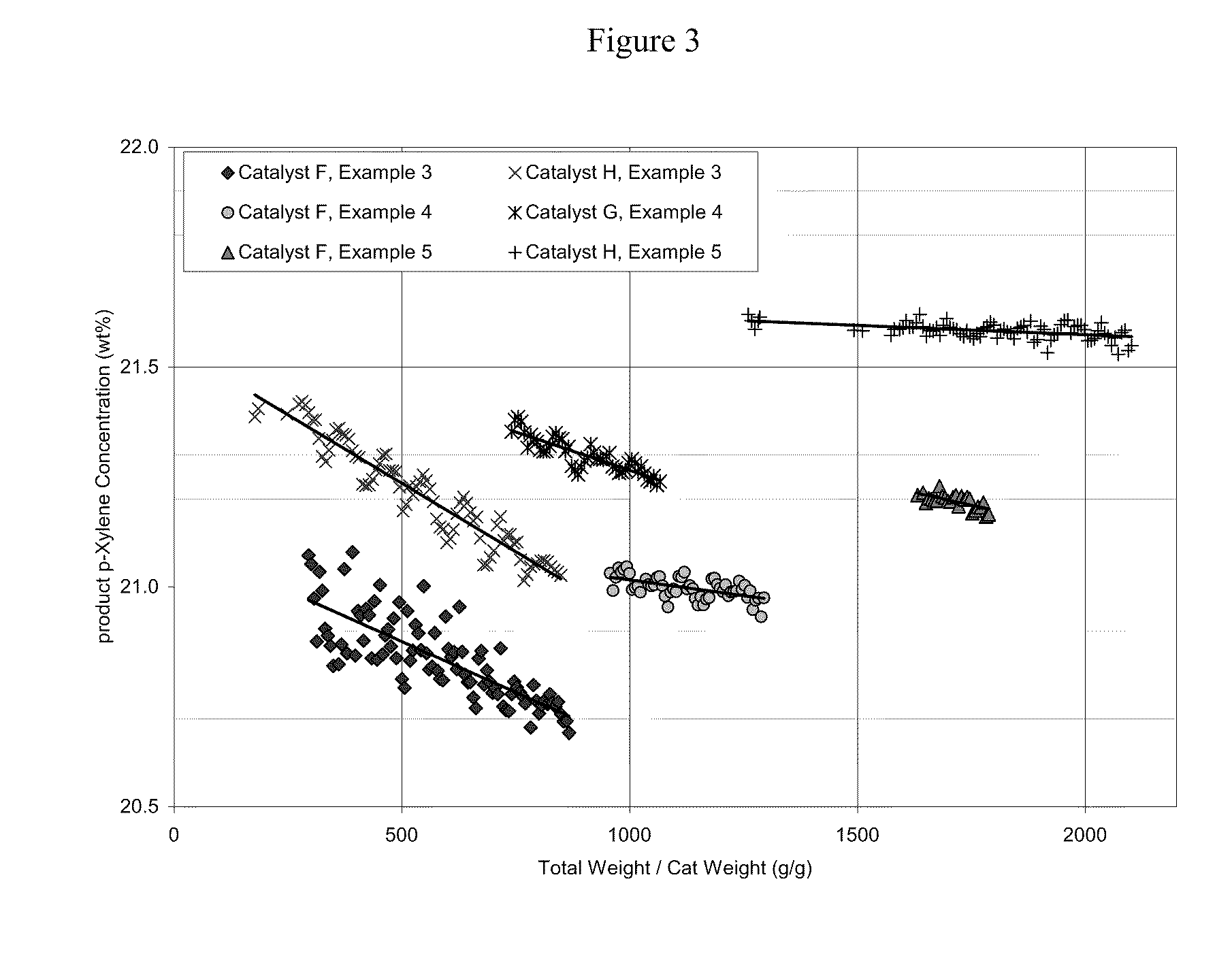

Xylene Isomerization Process and Catalyst Therefor

InactiveUS20110263918A1Low investmentLow operating costHydrocarbon by isomerisationAluminium compoundsContinuous modeIsomerization

The invention concerns a xylenes isomerization process for the production of equilibrium or near-equilibrium xylenes. The process utilizes a catalyst comprising HZSM-5 or MCM-49 and process conditions including a temperature of less than 295° C. and a pressure sufficient to maintain the xylenes in liquid phase. In embodiments, the process can be operated in a continuous mode with ppm levels of dissolved H2 in the feed and in other embodiments in a cyclic mode without the H2 in feed but with periodic regenerations using a feed having low ppm levels of H2.

Owner:EXXONMOBIL CHEM PAT INC

Degassing technique for liquid sulfur

InactiveCN102381685ALess investmentLow operating costSulfur preparation/purificationExhaust gasChemistry

The invention provides a degassing technique for liquid sulfur. The degassing technique can be used for solving the technical problems of the prior art that local condensation easily occurs in a bubbler, the bubbler is easily blocked and a degassing effect is unstable. The degassing technique comprises the following steps: A) entering into a degassing section after sealing the liquid sulfur, utilizing a liquid sulfur degassing pump to pressurize and send the liquid sulfur into a gas-stripping degassing column arranged in the degassing section, and circulating the liquid sulfur inside and outside the gas-stripping degassing column; B) heating compressed air and then introducing the compressed air into a bubbling device on the lower part of the gas-stripping degassing column, contacting the compressed air with the liquid sulfur in the gas-stripping degassing column, removing H2S dissolved in the liquid sulfur and burning the removed H2S after sending the removed H2S to a tail gas incinerator or an acid gas combustion furnace; and C) after overflowing the degassed liquid sulfur from the degassing section to a storage section, sending the liquid sulfur by a liquid sulfur end product pump. The degassing technique can be used for reducing the content of H2S in the liquid sulfur, preventing the bubbling device from being blocked, promoting the liquid sulfur degassing effect and achieving the content of the H2S in the liquid sulfur being less than 10ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur recycling technique

InactiveCN101585511ALow investment costLow operating costEnergy inputSulfur preparation/purificationHigh concentrationCombustion

The present invention discloses a sulfur recycling technique which comprises the following steps: 1) supplying the acid gas, the high-concentration SO2 gas and equivalent of wind into a combustion furnace for combusting and generating a CLAUS reaction, recovering the heat and reducing the temperature through a waste heat boiler, cooling for obtaining the liquid sulfur, supplying the uncooled gas into a step 2); 2) supplying the gas from the step 1) into an end gas incinerator and adding equivalent of wind for obtaining the gas containing SO2 into a step 3); and 3) directly mixing the gas which comes from the step 2) and includes SO2 gas with the gas that comes from the outside of the device and includes SO2, after quench cooling and washing for eliminating the dust, absorbing and de-absorbing, and returning the obtained high-concentration SO2 gas to the step 1), wherein the gas after absorbing is discharged. The method of the invention has the advantages of short flow path, 15%-35% of investment reduction, and 20%-40% of operating cost reduction.

Owner:CHINA PETROCHEMICAL CORP +1

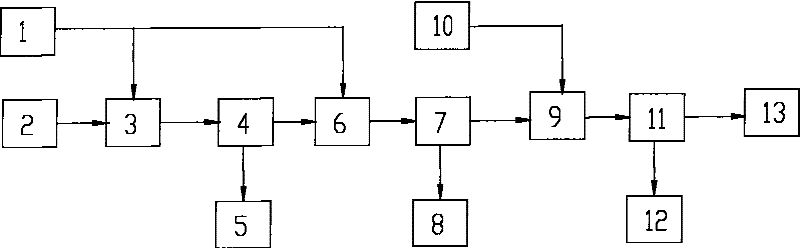

A combined hydrogenation process

ActiveCN102268293ALess investmentLow operating costTreatment with hydrotreatment processesHigh pressureChemistry

The invention discloses a hydrogenation combined process. In the process, a reaction effluent from a middle-high pressure hydrogenation device with a pressure of more than 4.0MPa is subjected to gas-liquid separation in a high pressure separator, wherein the gas obtained by separation is used as circular hydrogen, and the liquid obtained by separation enters into a low pressure separator for further gas-liquid separation; and the liquid obtained by further separation is used as a product, and the gas obtained by further separation is used as hydrogen for a low pressure hydrogenation with an operation pressure of 2.0-3.0MPa. The reaction effluent is subjected to gas-liquid separation, the gas obtained by separation is discharged out of the device, and the liquid obtained by separation is the product.

Owner:CHINA PETROCHEMICAL CORP +1

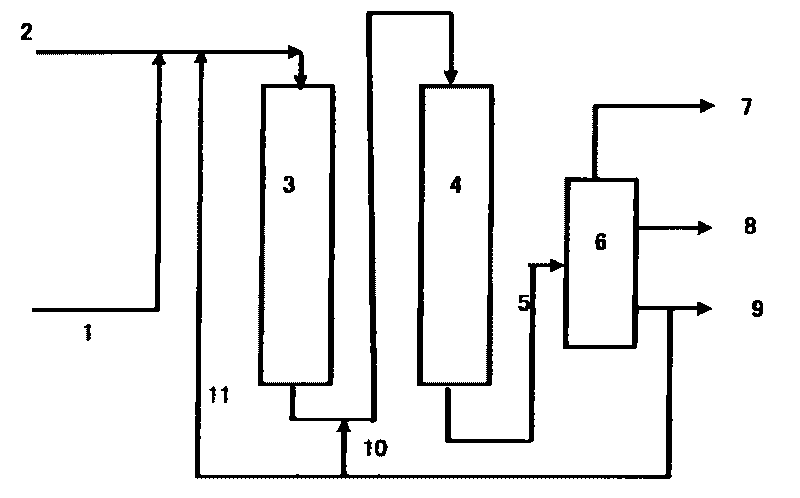

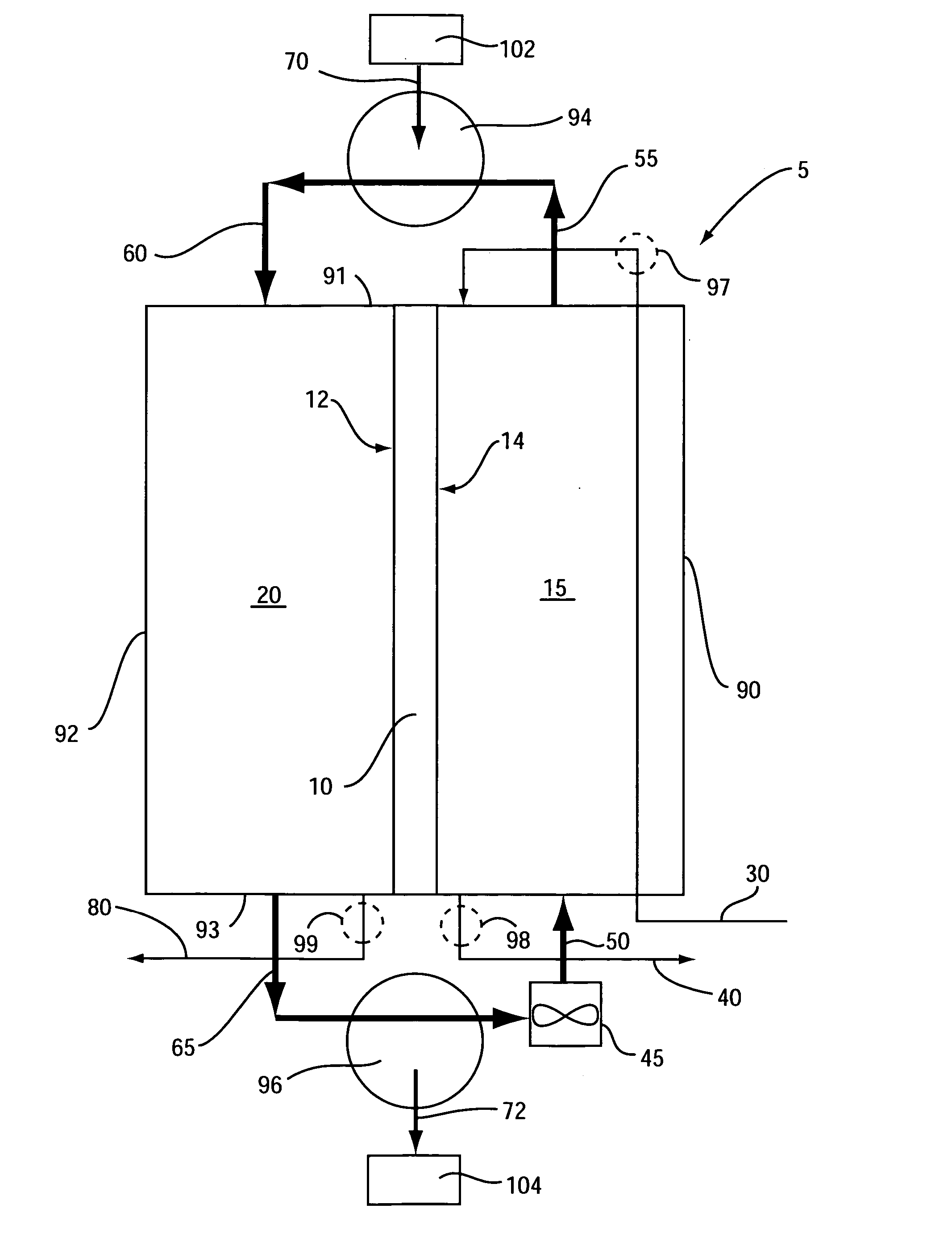

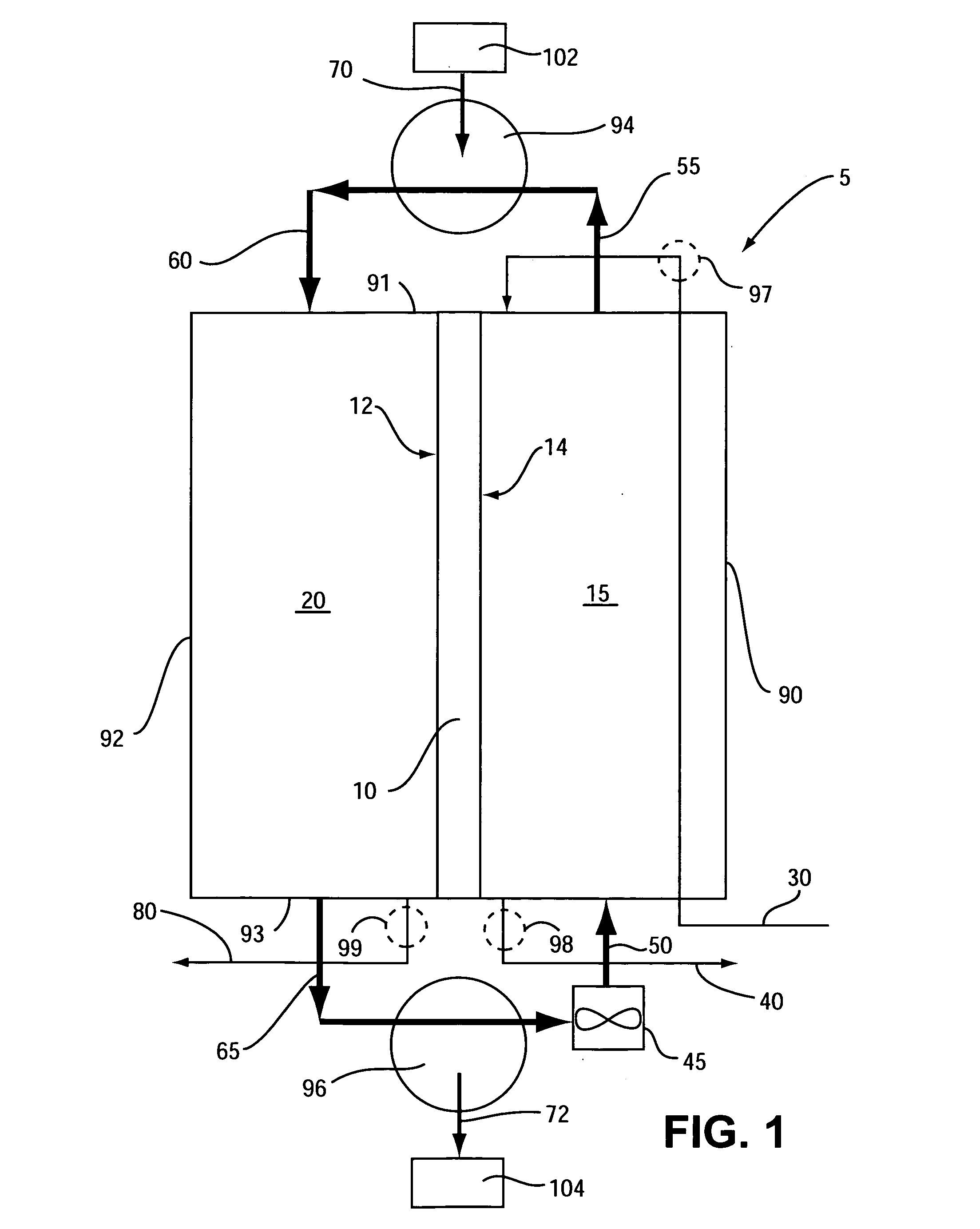

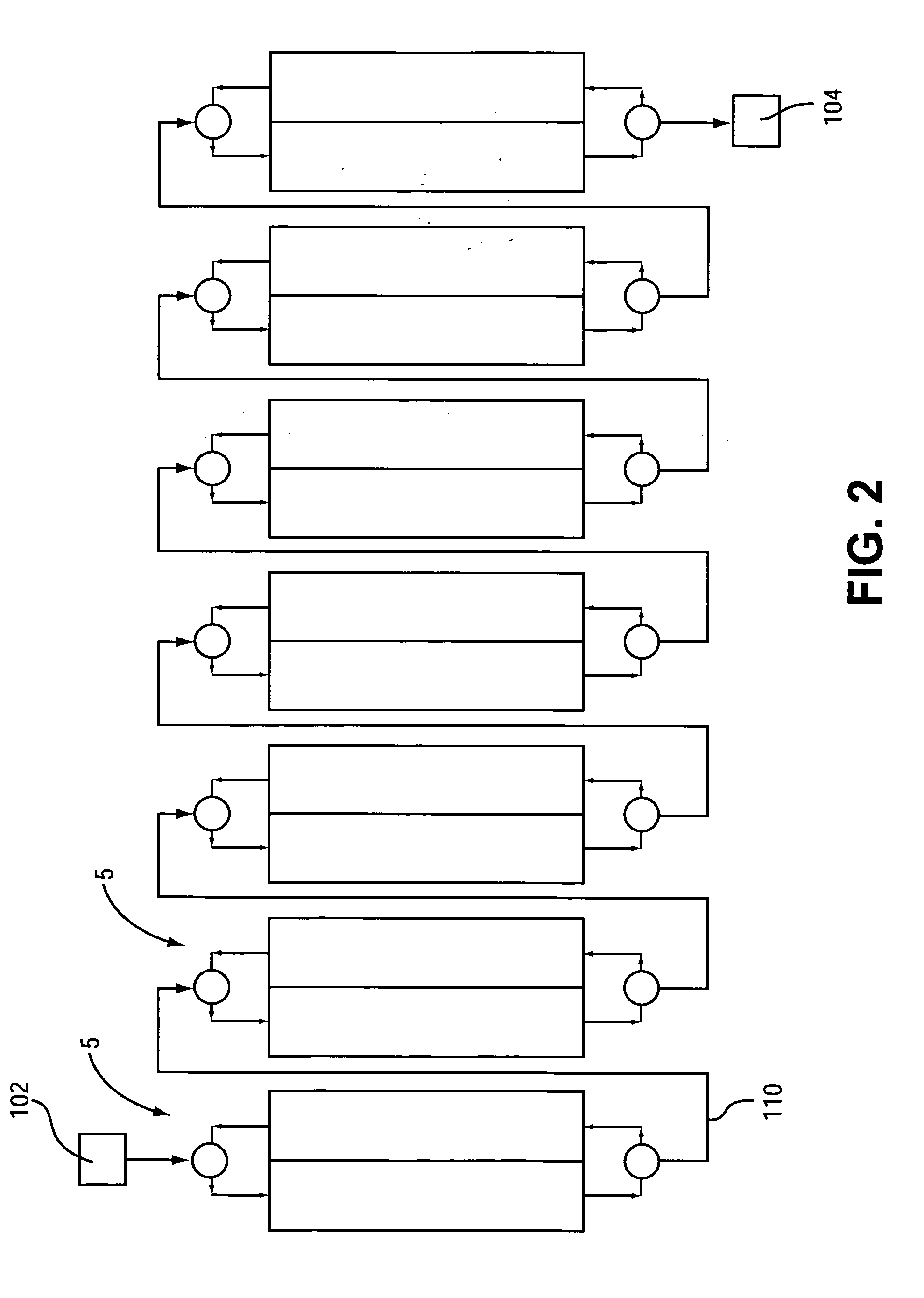

Method and apparatus for simultaneous heat and mass transfer utilizing a carrier-gas at various absolute pressures

ActiveUS20050121304A1Improve energy efficiencyLow operating costSpace heating and ventilationDistillation regulation/controlMass transferEngineering

A method, system, and apparatuses for simultaneous heat and mass transfer utilizing a carrier-gas at various absolute pressures are described. A method may include: thermally coupling at least two continuous contacting apparatuses together; varying the pressure between the at least two continuous contacting apparatuses; allowing heat removed from the first continuous contacting apparatus to be the heat delivered to the second continuous contacting apparatus. A system may include: at least two continuous contacting apparatuses thermally coupled together and operating at different absolute pressures. A continuous contacting apparatus may include: an evaporation chamber and a dew-formation chamber both operating at an absolute pressure in a vacuum range. A continuous contacting vapor recompression apparatus may include: an evaporation chamber operating at a first absolute pressure; and a dew-formation chamber operating at a second absolute pressure higher than the first absolute pressure.

Owner:ARIZONA STATE UNIVERSITY

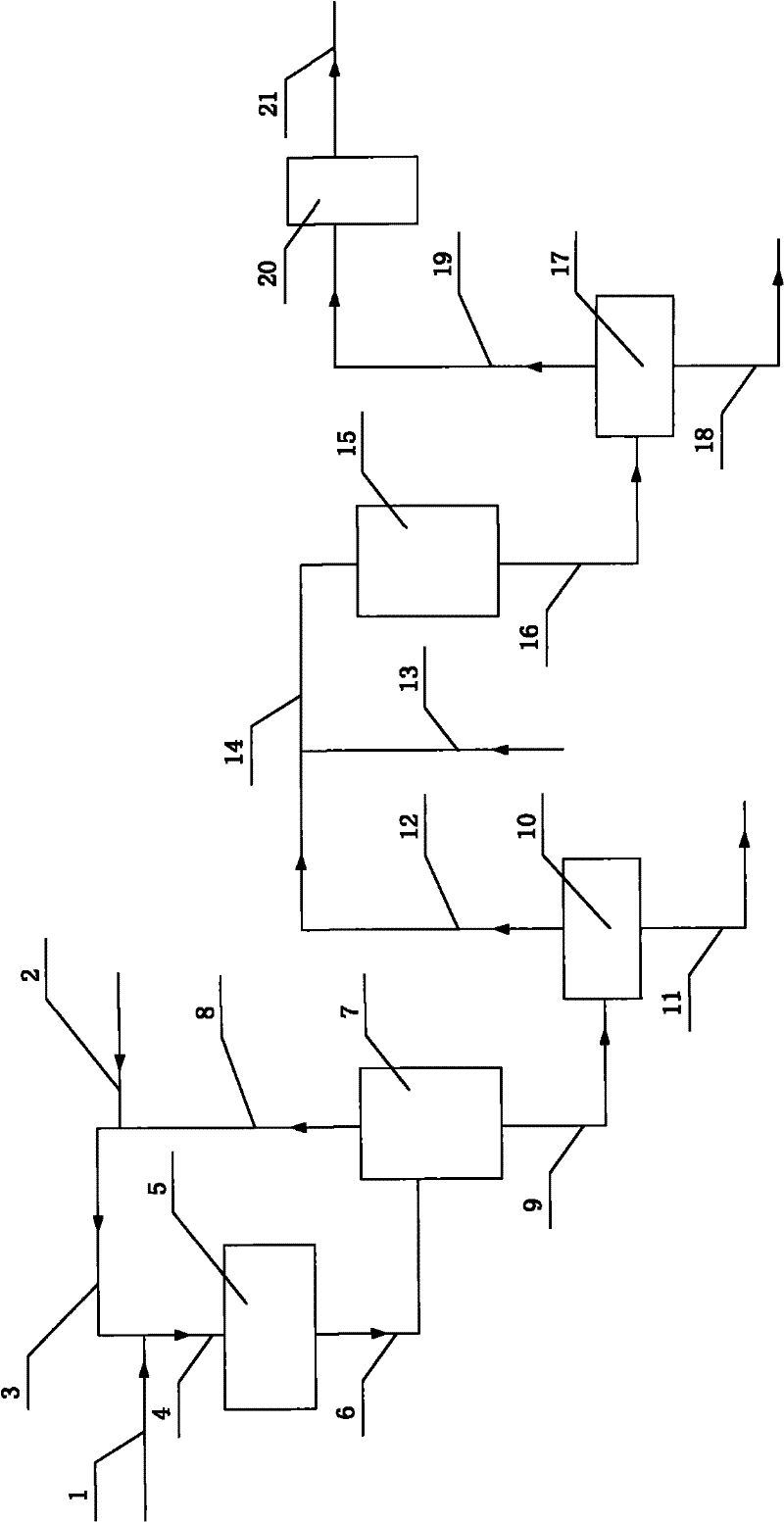

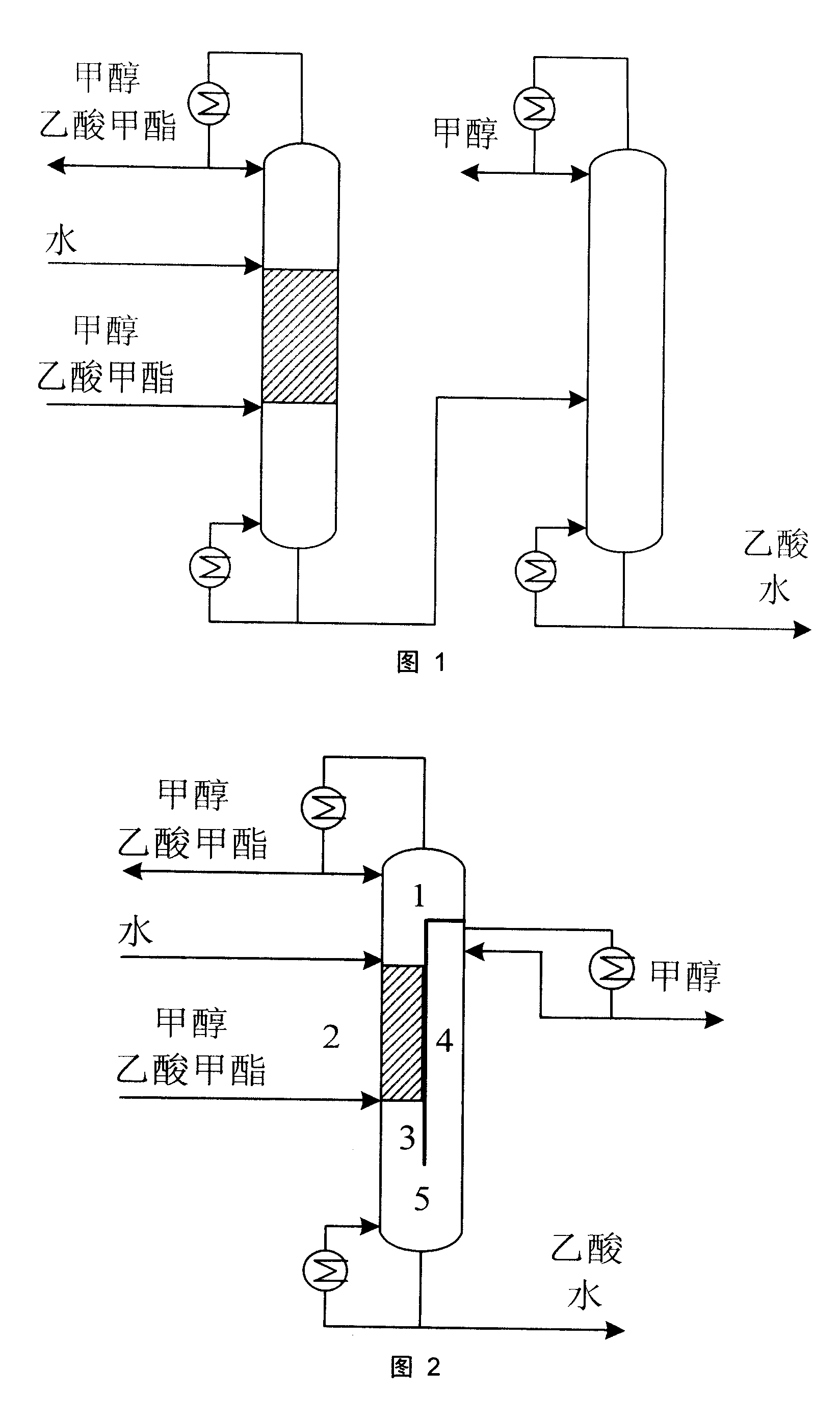

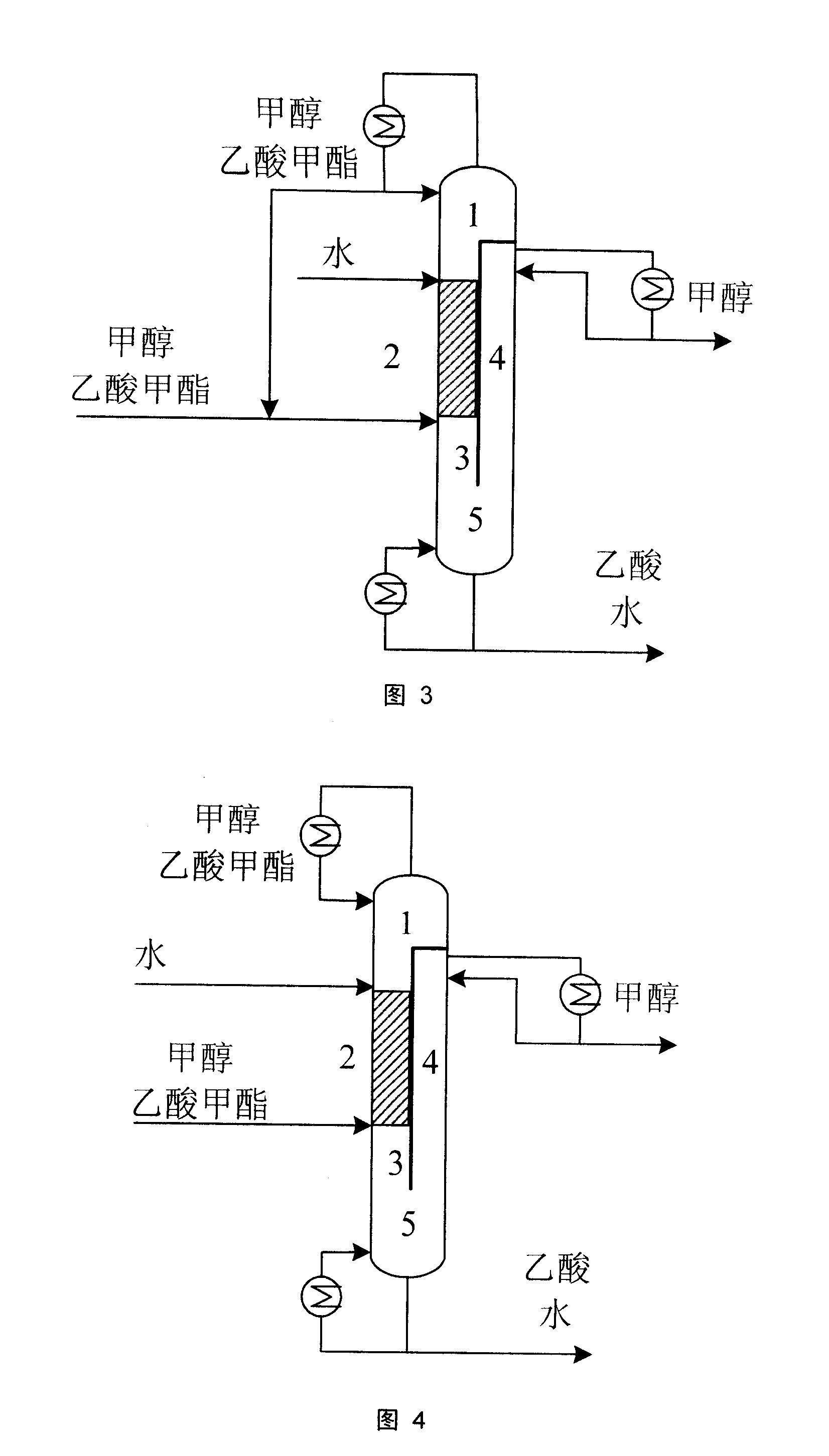

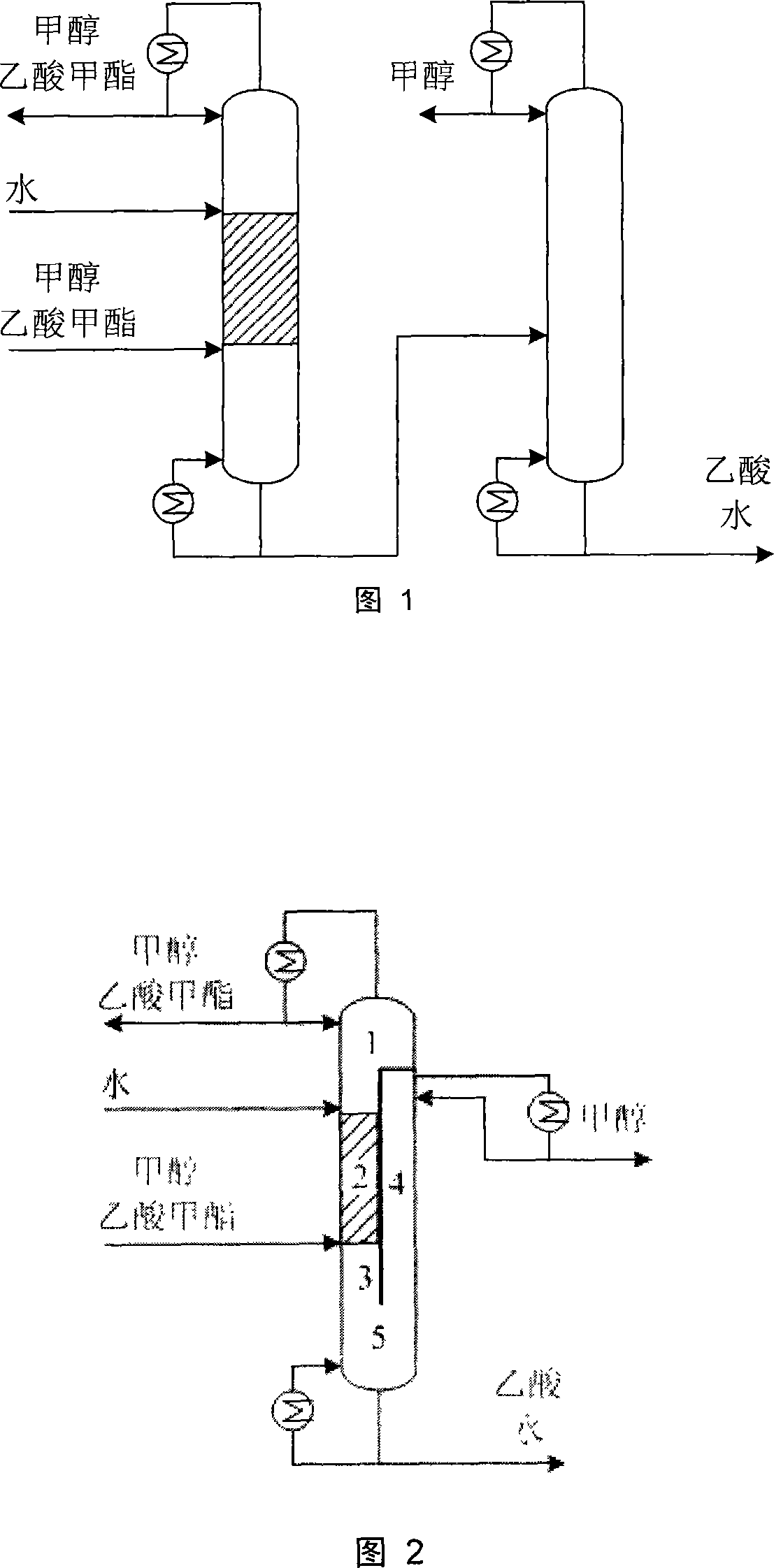

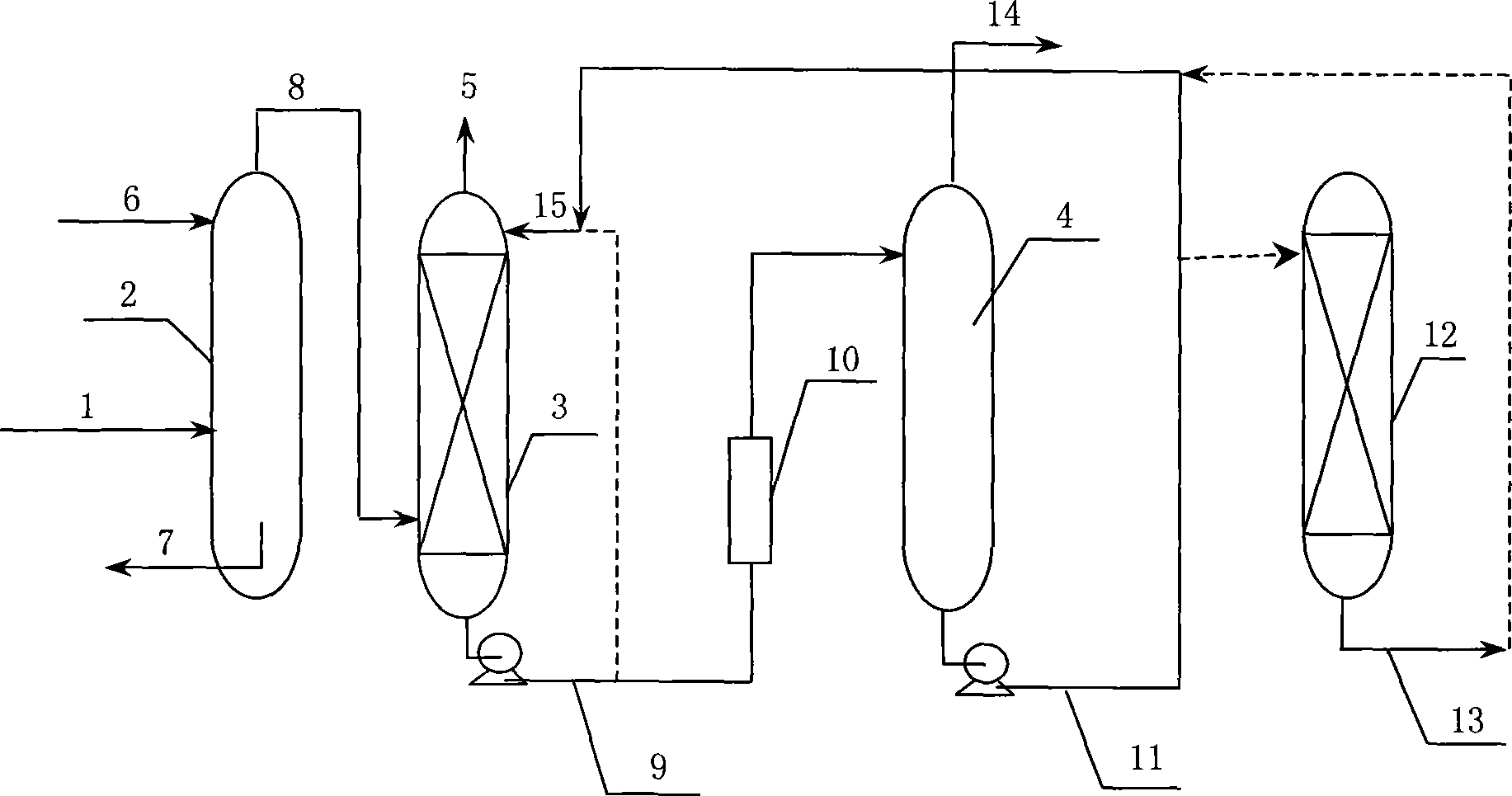

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for coking full fraction oil hydrogenation refining

InactiveCN1458233AImprove product propertiesDiesel properties improvedHydrocarbon oils refiningProcess engineeringHeating energy

The present invention is one process of hydrofining coked full fraction oil. Based on available process of hydrofining coked full fraction oil, new hydrogen of the system is used in further refining of diesel oil, so that diesel oil is refined under ideal thermodynamic and dynamic conditions. This results in high product quality, flexible, economic and practical technological process, less investment increment, fully utilization of heat energy and low operation cost. The present invention is suitable for reforming and constructing coked full fraction oil hydrofining apapratus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regeneratable wet fuel gas desulfurizing technology

InactiveCN101185838AReduce lossesLarge absorption capacityDispersed particle separationLoss rateFlue gas

The invention discloses a reproducible wet flue gas desulfurization technique, which solves the problems of the prior art of high operation cost and high loss rate when absorbent is in use. The invention is characterized in that after going through a washing tower, flue gas containing gas SO< X > is then connected with the absorbent in a reverse flow in an absorption tower; the purified flue gas is discharged into the atmosphere; a portion of pregnant solution absorbent directly returns to the absorption tower for circular application, wherein SO2 of the flue gas is absorbed by the pregnant solution; a portion of air stripping is used circularly after a regeneration. The invention has the advantages that the energy consumption and operation cost of the technique are low, and loss of the absorbent is small.

Owner:CHINA PETROCHEMICAL CORP +1

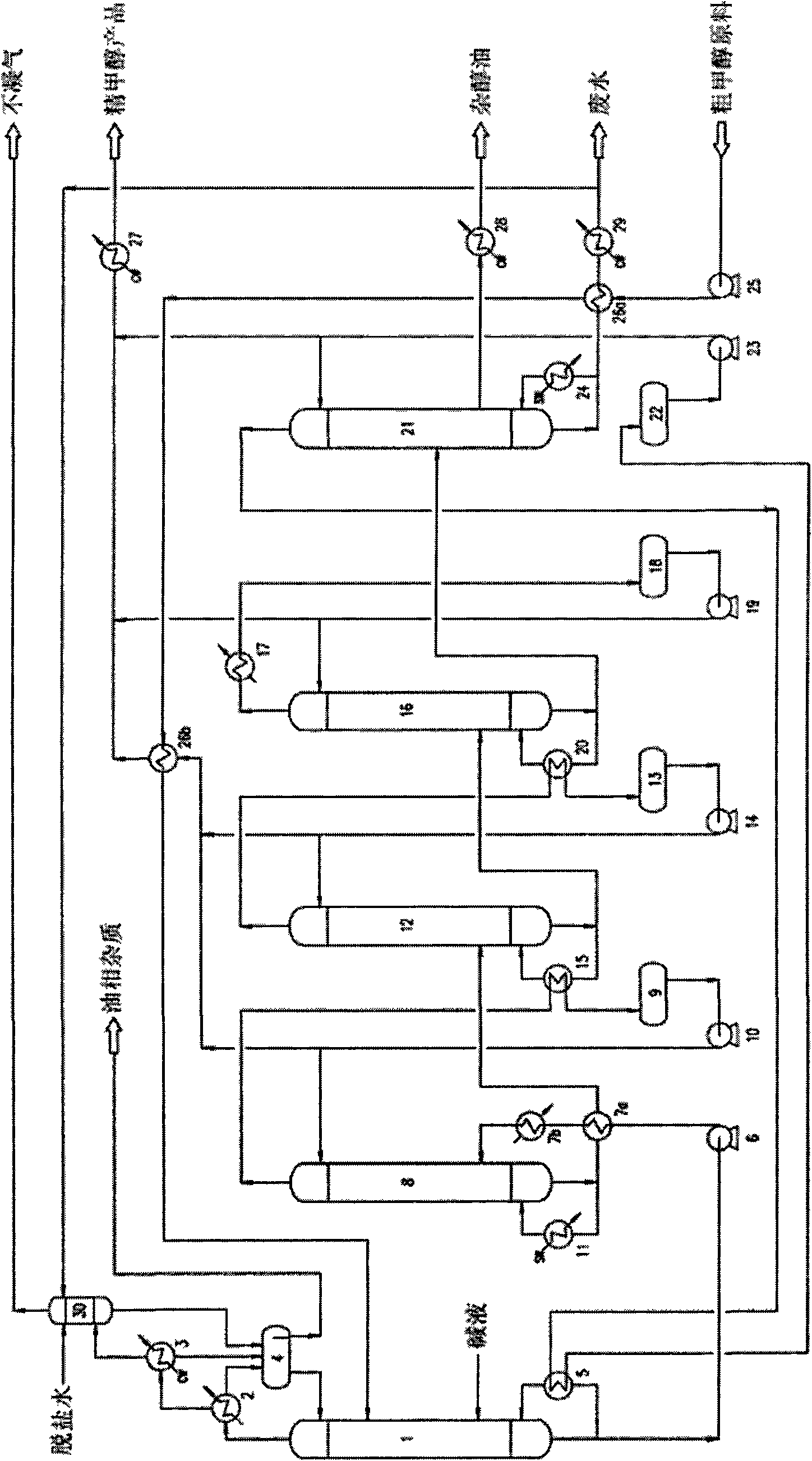

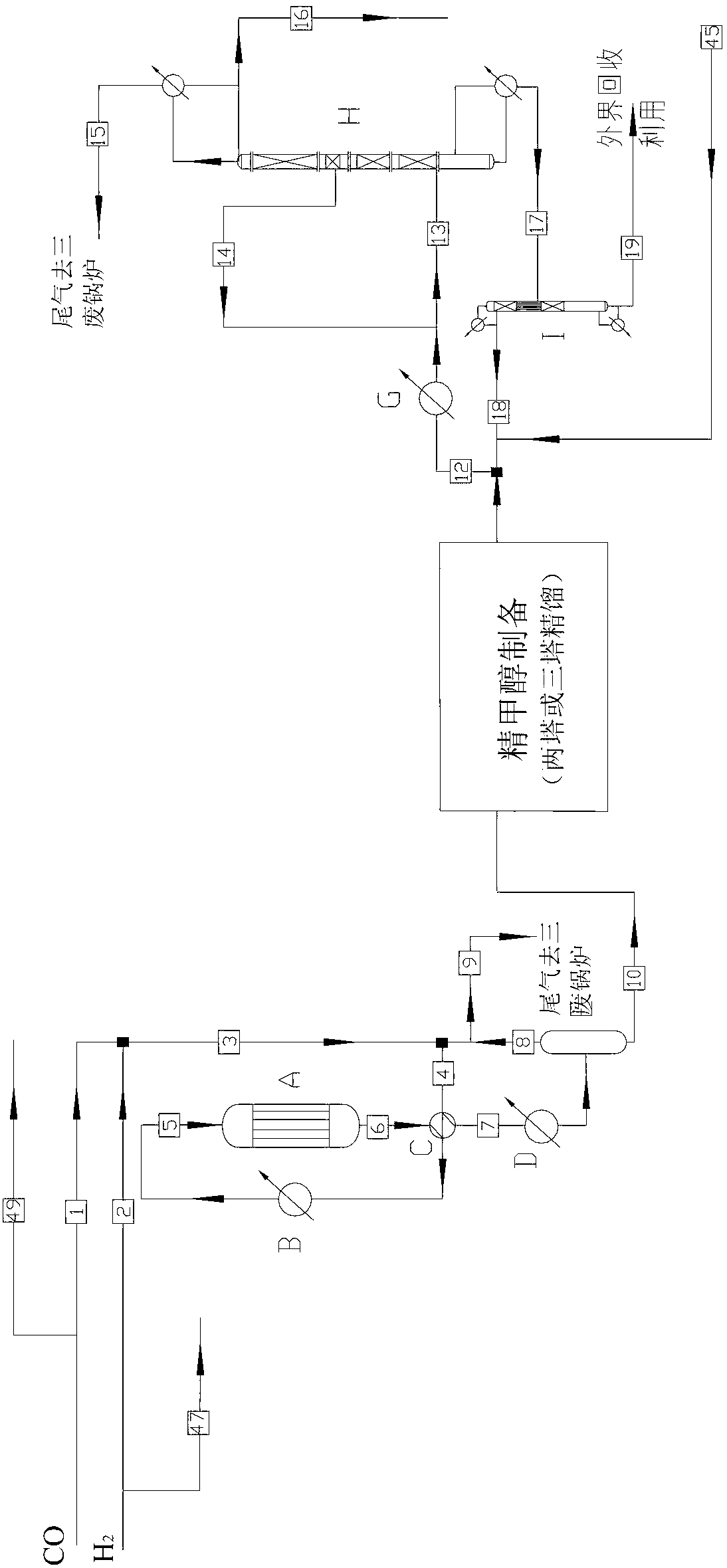

Multi-effect rectifying process of methanol

InactiveCN101570466AIncrease operating pressureIncrease productionOrganic compound preparationChemical industryChemistryReboiler

The invention relates to a multi-effect rectifying process of methanol, which belongs to the technical field of separation and purification of chemical products. In the process, a crude methanol raw material of coal-to-methanol is rectified by a pre-rectifying tower, a pressurizing tower I, a pressurizing tower II, an atmospheric tower and a recovery tower in turn at appropriate temperature and pressure so as to obtain a high-purity refined methanol product according with quality requirements. In the flow, methanol steam on the top of the pressurizing tower I is used for providing heat for a reboiler at the bottom of the pressurizing tower II, the methanol steam on the top of the pressurizing tower II is used for providing heat for a reboiler at the bottom of the atmospheric tower, and the pressurizing tower I, the pressurizing tower II and the atmospheric tower form multi-effect rectification; and simultaneously, the methanol steam on the top of the recovery tower is used for providing heat for a reboiler at the bottom of the pre-rectifying tower, and the recovery tower and the pre-rectifying tower form double-effect rectification. The invention provides an energy-saving methanol multi-effect rectifying process method which has the advantages of greatly reduced energy consumption, more stable production process, more easily controlled product quality, higher methanol recovery rate and basically equivalent investment compared with a three-tower rectifying process.

Owner:XI'AN PETROLEUM UNIVERSITY

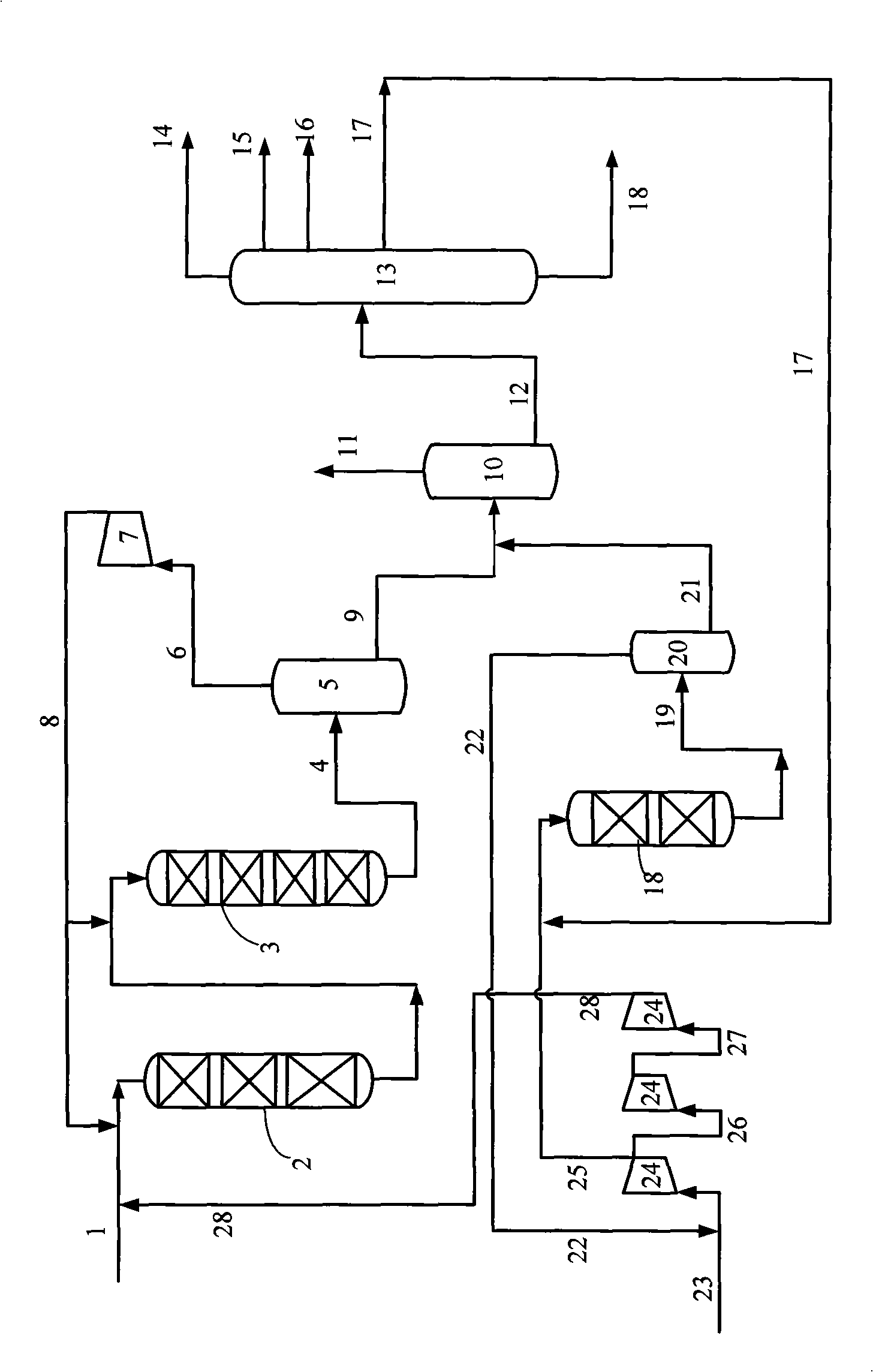

Hydrocracking method for producing chemical materials to maximum with low cost

ActiveCN101684415AReduce hydrogen consumptionLow investment costHydrocarbon oil crackingNaphthaFractionation

The invention relates to a hydrocracking method for producing chemical materials to the maximum with low cost, comprising the following steps: mixing raw oil and hydrogen gas , entering a first reaction area, sequentially contacting with hydrofining catalyst and hydrocracking catalyst, reacting under the pressure of 6.0-16.0 MPa; carrying out oil-gas separation and fractionation on the reaction products thereof to obtain liquefied gas, light naphtha fractions, heavy naphtha fractions, middle fractions and tail oil fractions; mixing the middle fractions and the hydrogen gas and enteringa second reaction area, contacting with the hydrocracking catalyst under the pressure of 1.0-5.5 MPa to react; and carrying out oil-gas separation on the reaction products thereof and entering a fractionation system . By adopting the method, heavy raw materials such as vacuum gas oil, coking gas oil and the like are treated to obtain more than 98 weight percent chemical materials. In the invention, themiddle fractions are wholly converted into the chemical materials in the low pressure condition, and low hydrogen consumption, low investment cost and low operation cost are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

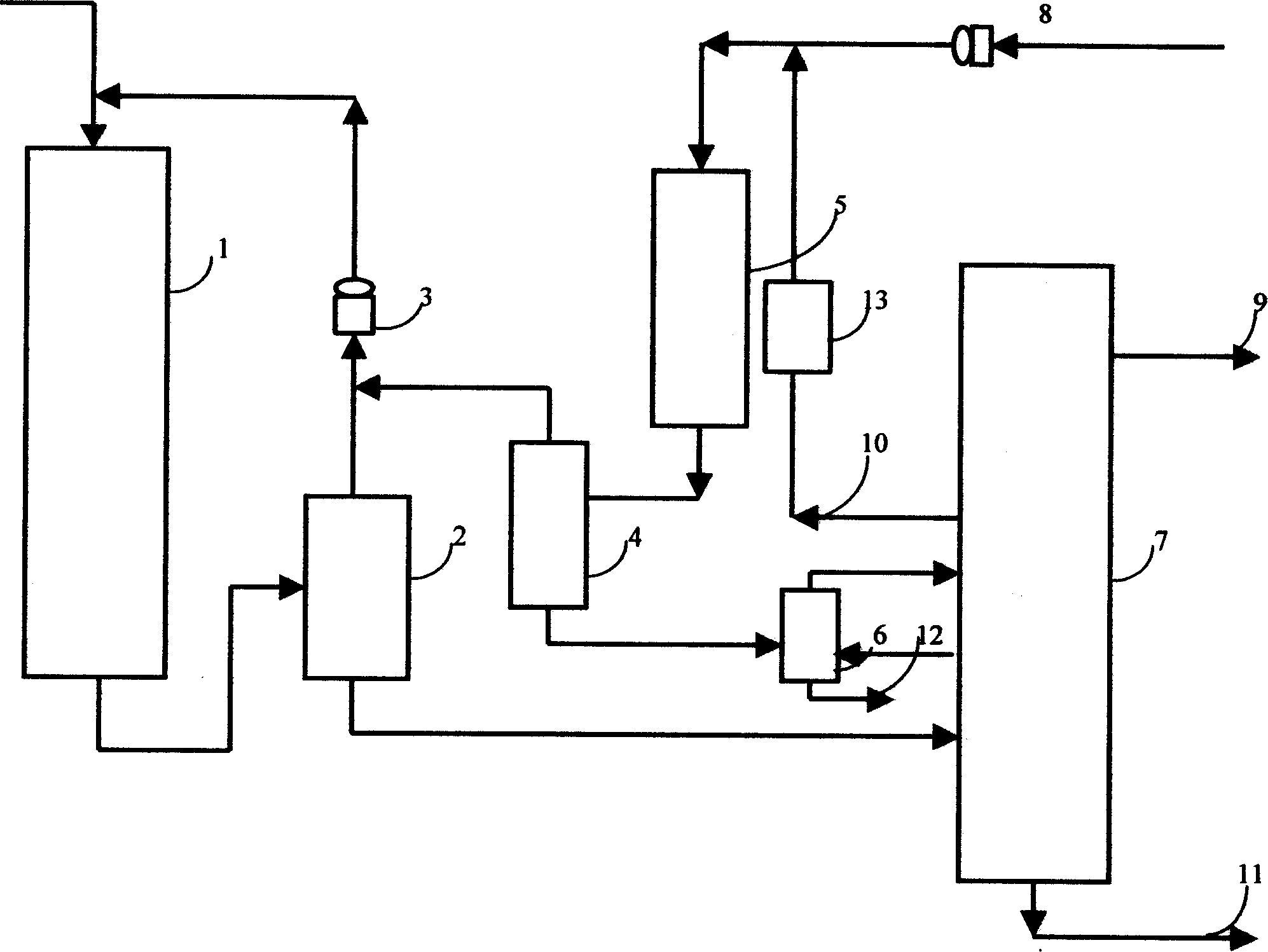

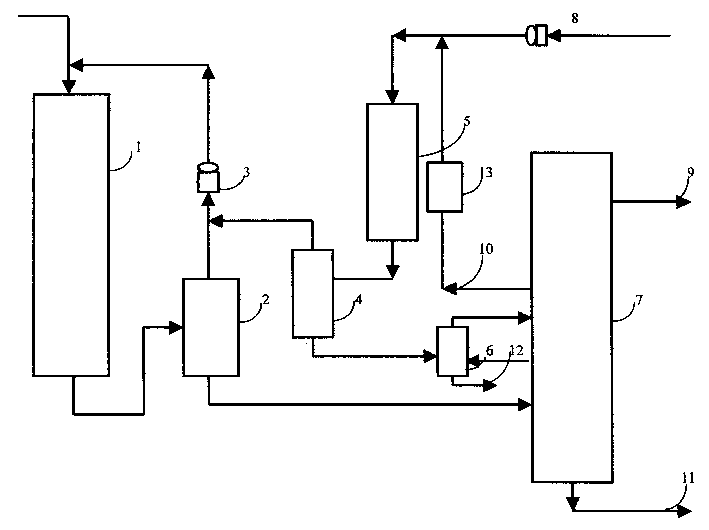

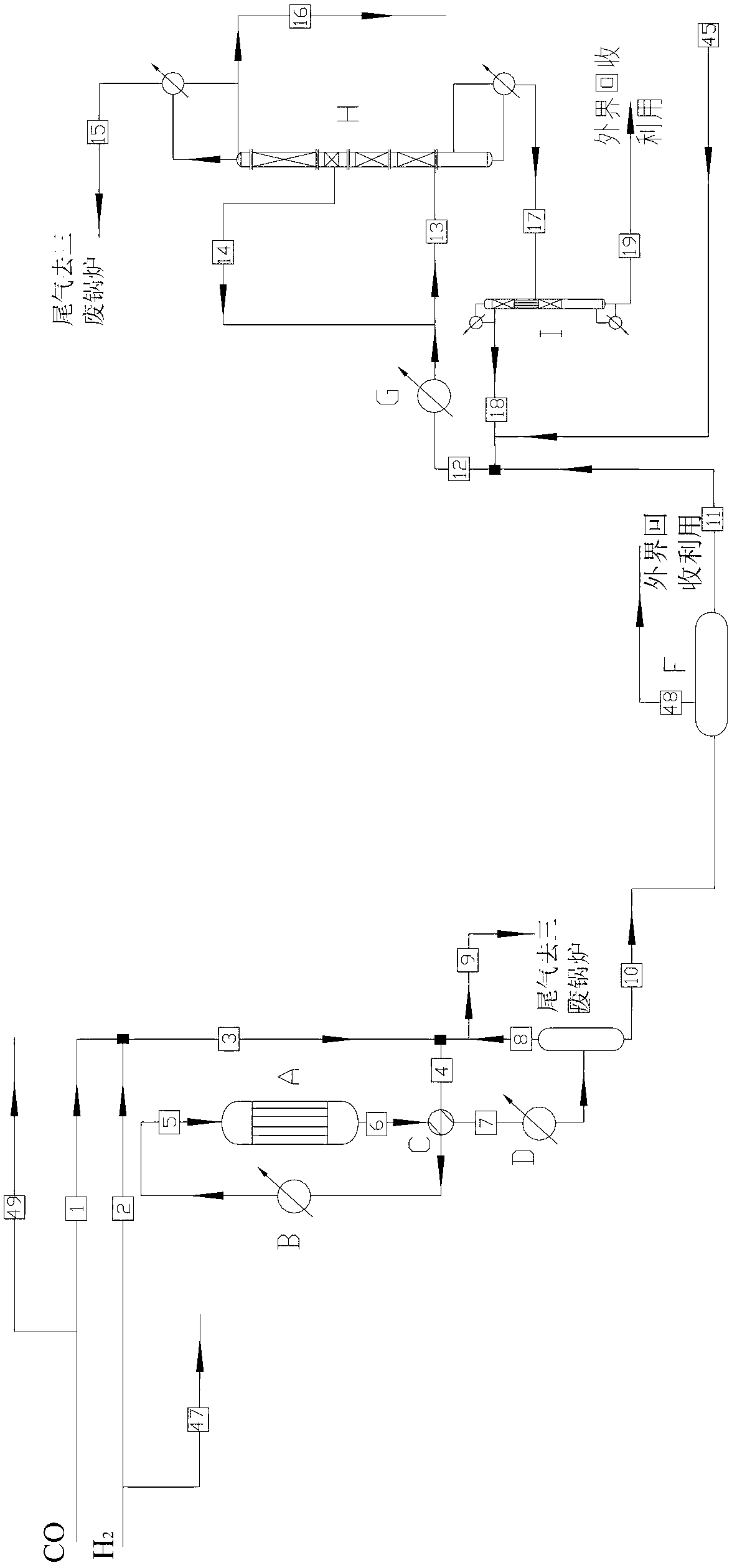

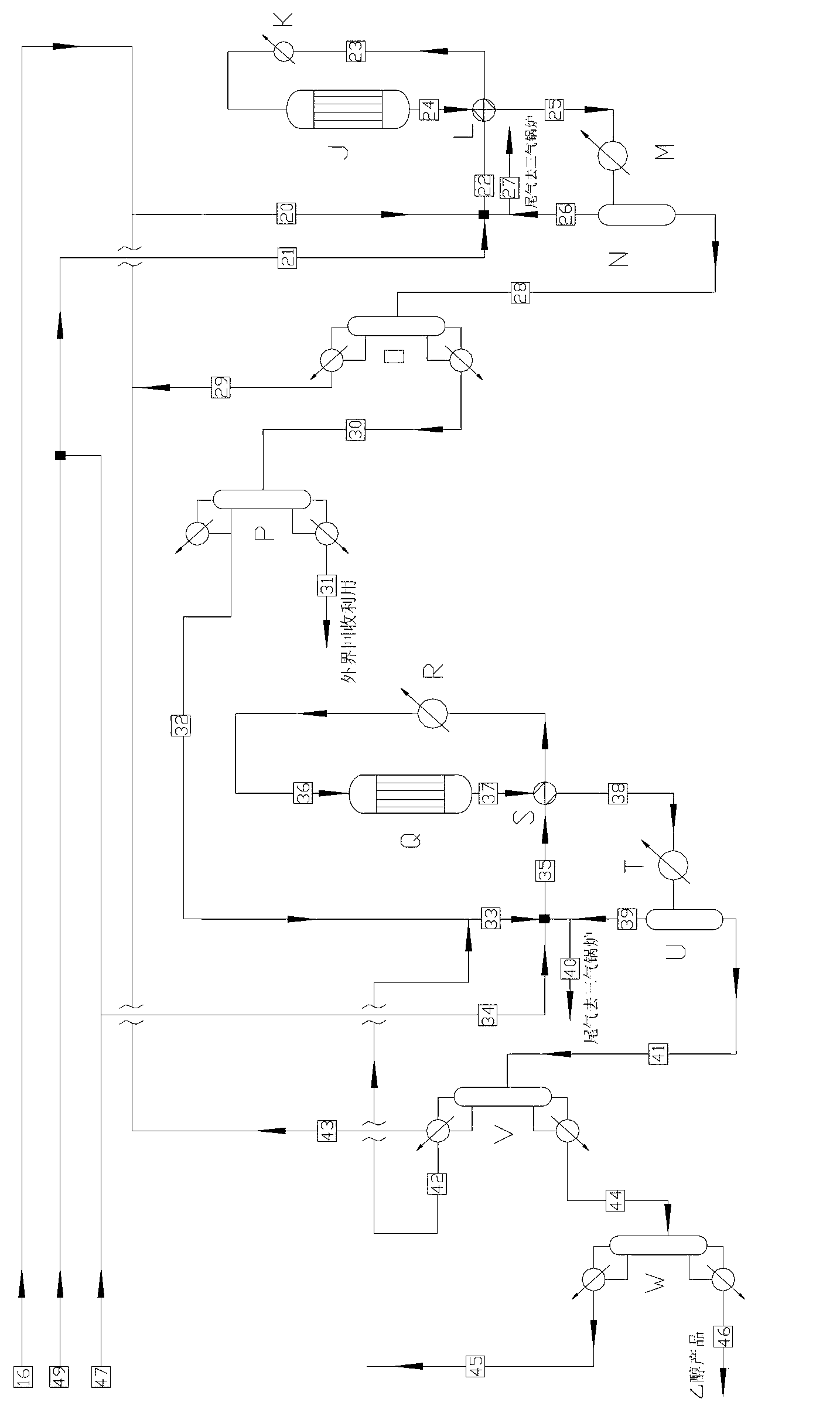

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

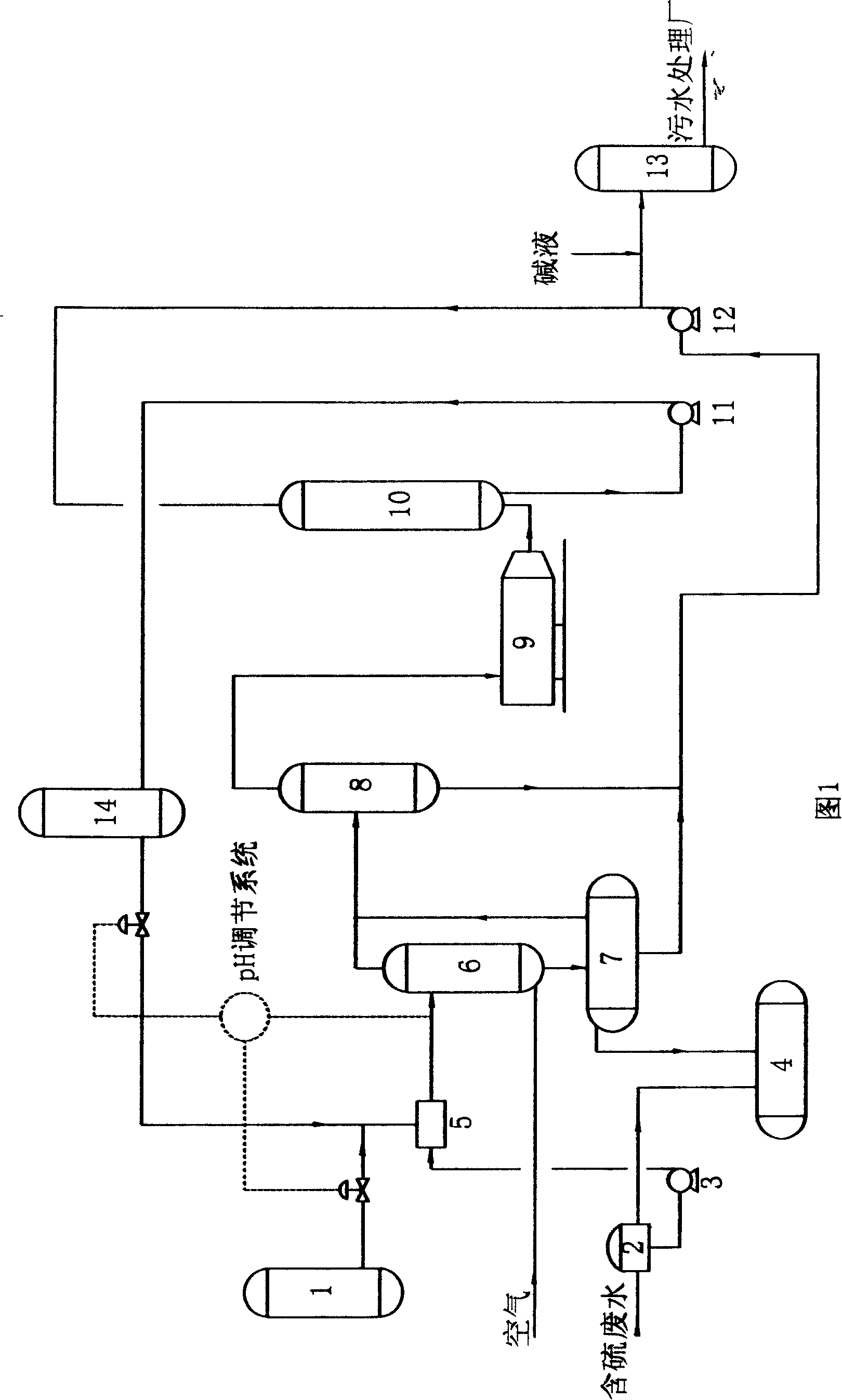

Method for treating sulfur-containing waste water

ActiveCN101239758ALess quantityLow costFatty/oily/floating substances removal devicesWater contaminantsWastewaterSewage

The present invention relates to a method for treating the sulfur-containing sewage. The industrial process of the invention is firstly adding sulfuric acid into the sulfur-containing sewage, adjusting pH value to 4-6, aerating with appropriate amount of air, facilitating the escaping of the H2S along with the air, and discharging the discharged water to the sewage treatment plant after adding alkali for neutralization. The aeration end gas containing H2S enters the incineration furnace or catalyzing burning reactor to generate SO2 and SO3, the SO2 and SO3 are absorbed by the absorption liquid to form a diluted acid. The generated diluted acid can be used back for adjusting pH to the sulfur-containing sewage, when the system operates normally basically no fresh sulfuric acid is added into the sulfur-containing sewage, the entire technique forms a closed system for treating the sulfur-containing sewage, the application range is broad and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com