Production method of epoxy chloropropane

A technology of epichlorohydrin and its production method, which is applied in the direction of chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of reducing the cost of catalyst use, reducing catalyst activity, and low catalyst activity, so as to reduce the use of Cost and operating expenses, enhanced activity stability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

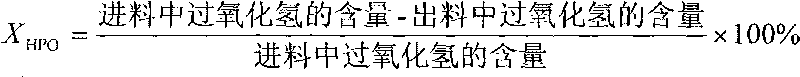

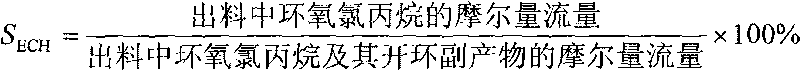

[0046] Add 0.036% ammonia of 3-chloropropene mass in the reaction raw material, and the reaction temperature starts from 50°C and gradually increases to 70°C at a heating rate of 0.044°C / hour. The result of the epoxidation reaction of 3-chloropropene and hydrogen peroxide See Table 1.

[0047] Table 1

[0048] Reaction time / h

Embodiment 2

[0050] Add 0.076% methylamine of 3-chloropropene quality in the reaction raw material, the reaction temperature starts from 55 DEG C and gradually raises to 75 DEG C with the heating rate of 0.052 DEG C / hour, the epoxidation reaction of 3-chloropropene and hydrogen peroxide The results are shown in Table 2.

[0051] Table 2

[0052] Reaction time / h

[0053] Reaction time / h

Embodiment 3

[0055] Add 0.11% ammonium carbonate of 3-chloropropene quality in the reaction raw material, the reaction temperature starts from 45 DEG C and gradually increases to 65 DEG C with the heating rate of 0.057 DEG C / hour, the epoxidation reaction of 3-chloropropene and hydrogen peroxide The results are shown in Table 3.

[0056] table 3

[0057] Reaction time / h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com