Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "Allyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl acetate is an organic compound with formula C₃H₅OC(O)CH₃. This colourless liquid is a precursor to especially allyl alcohol, which is a useful industrial intermediate. It is the acetate ester of allyl alcohol.

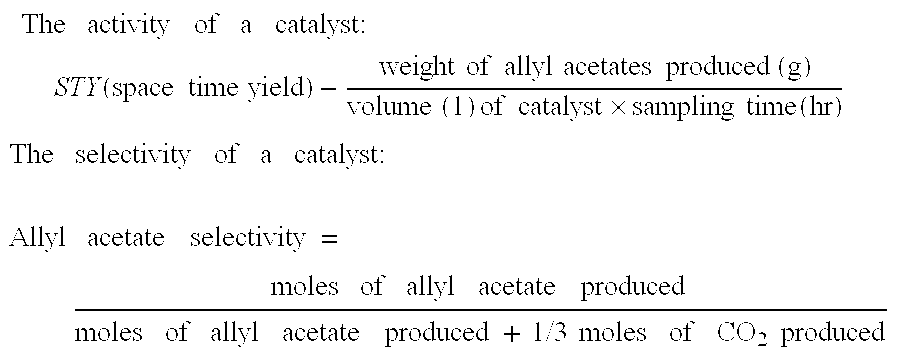

Process for production of allyl acetate production catalyst

ActiveCN101657259AEfficient productionReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationAllyl acetateAcetic acid

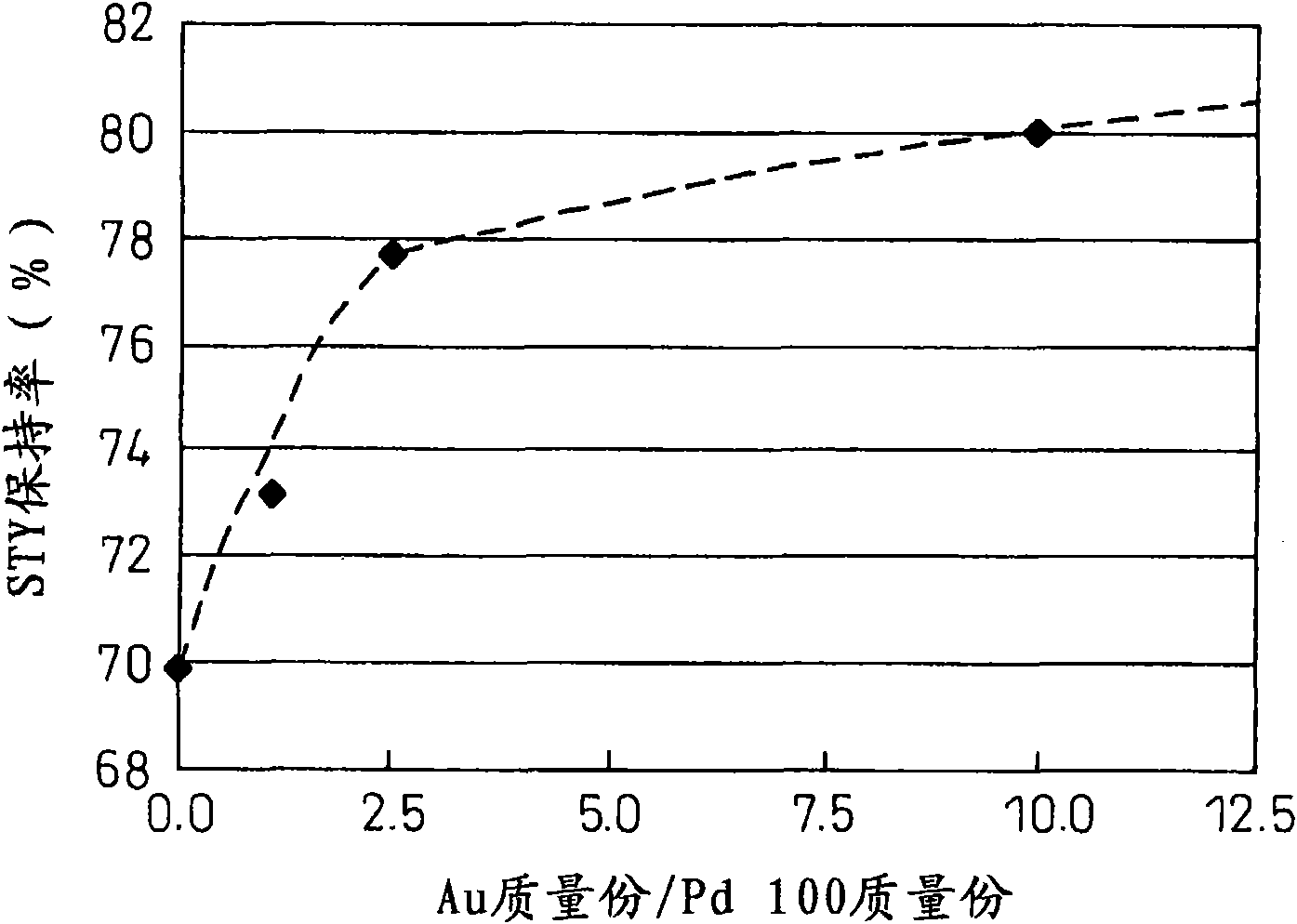

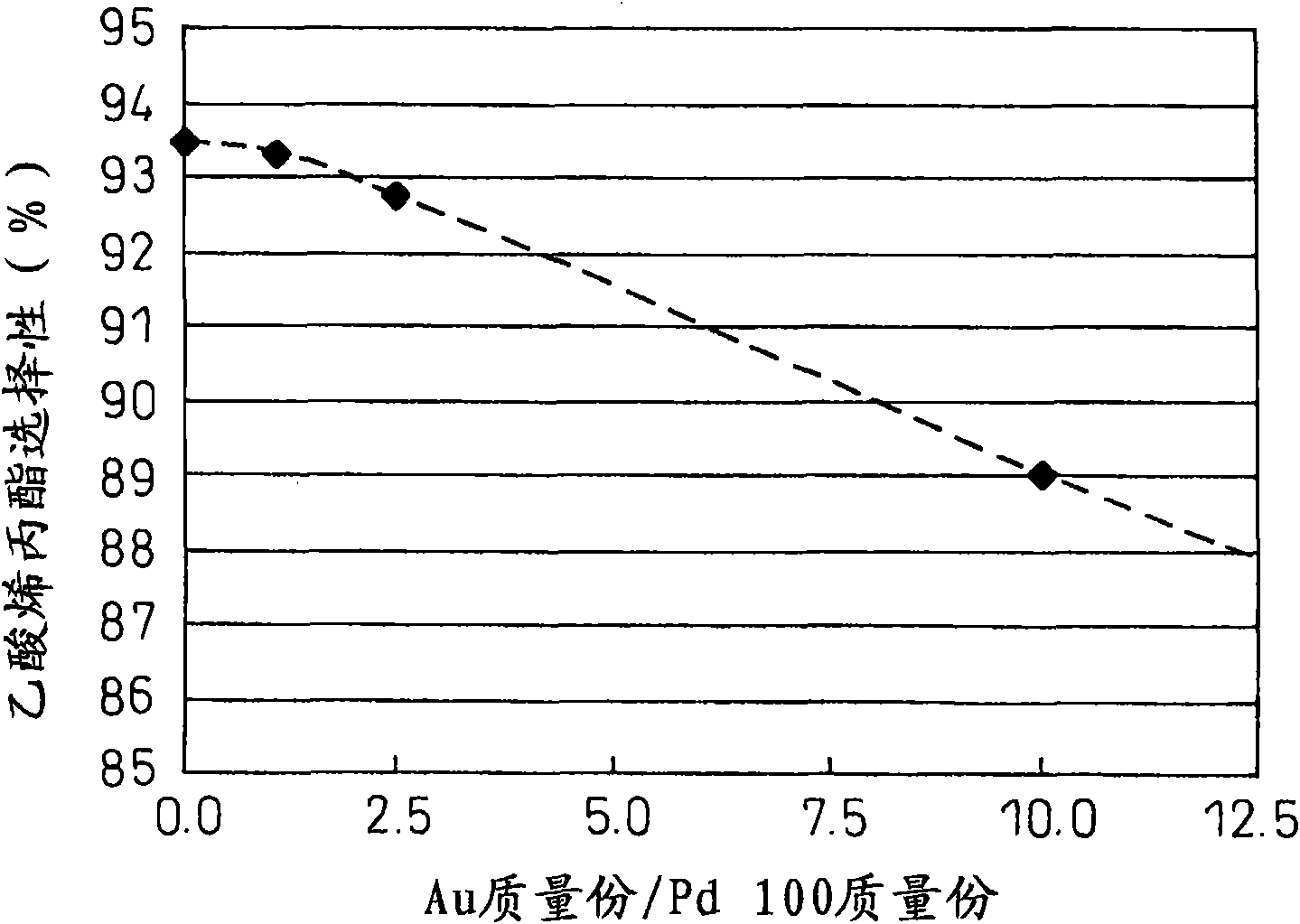

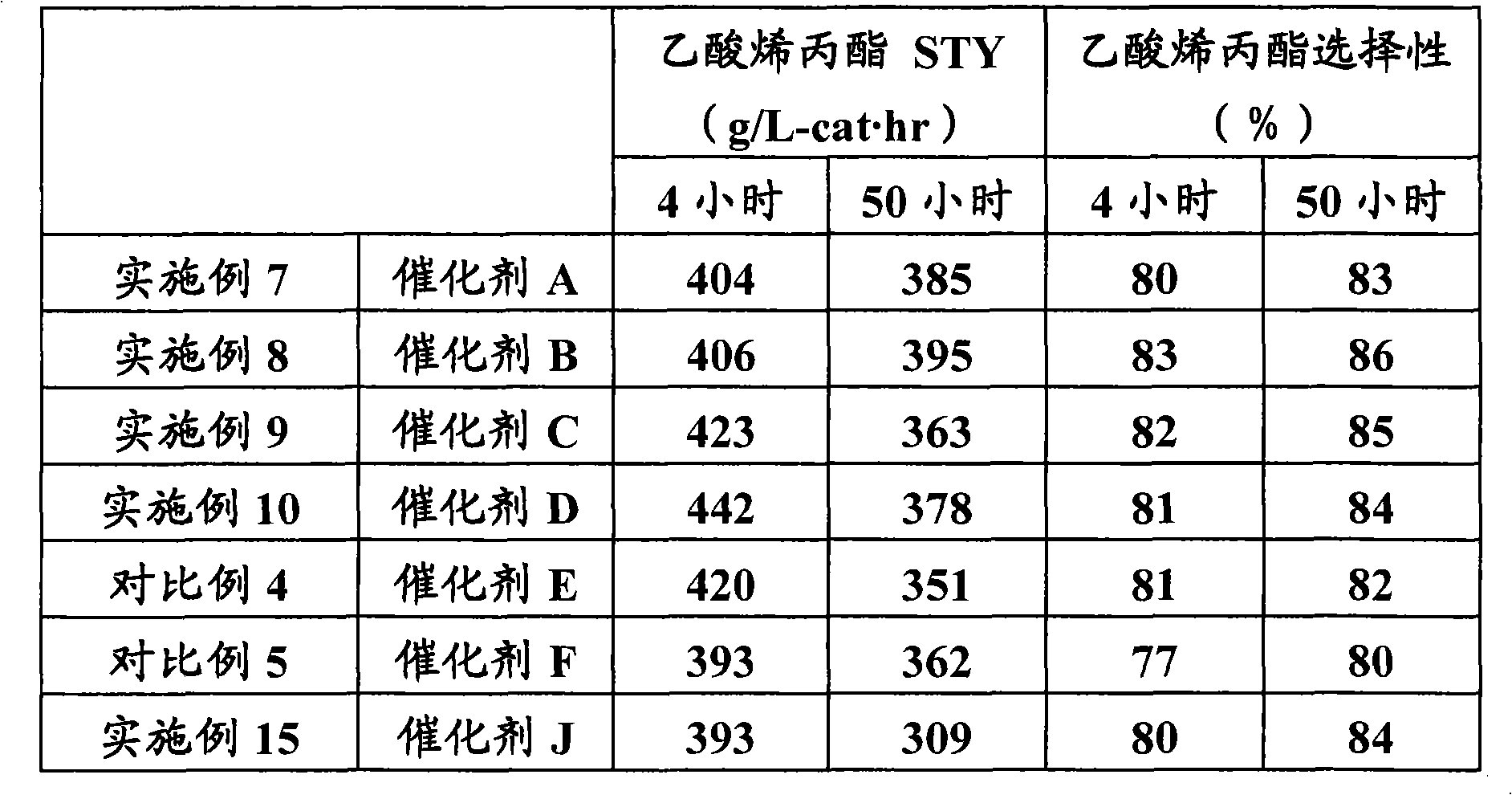

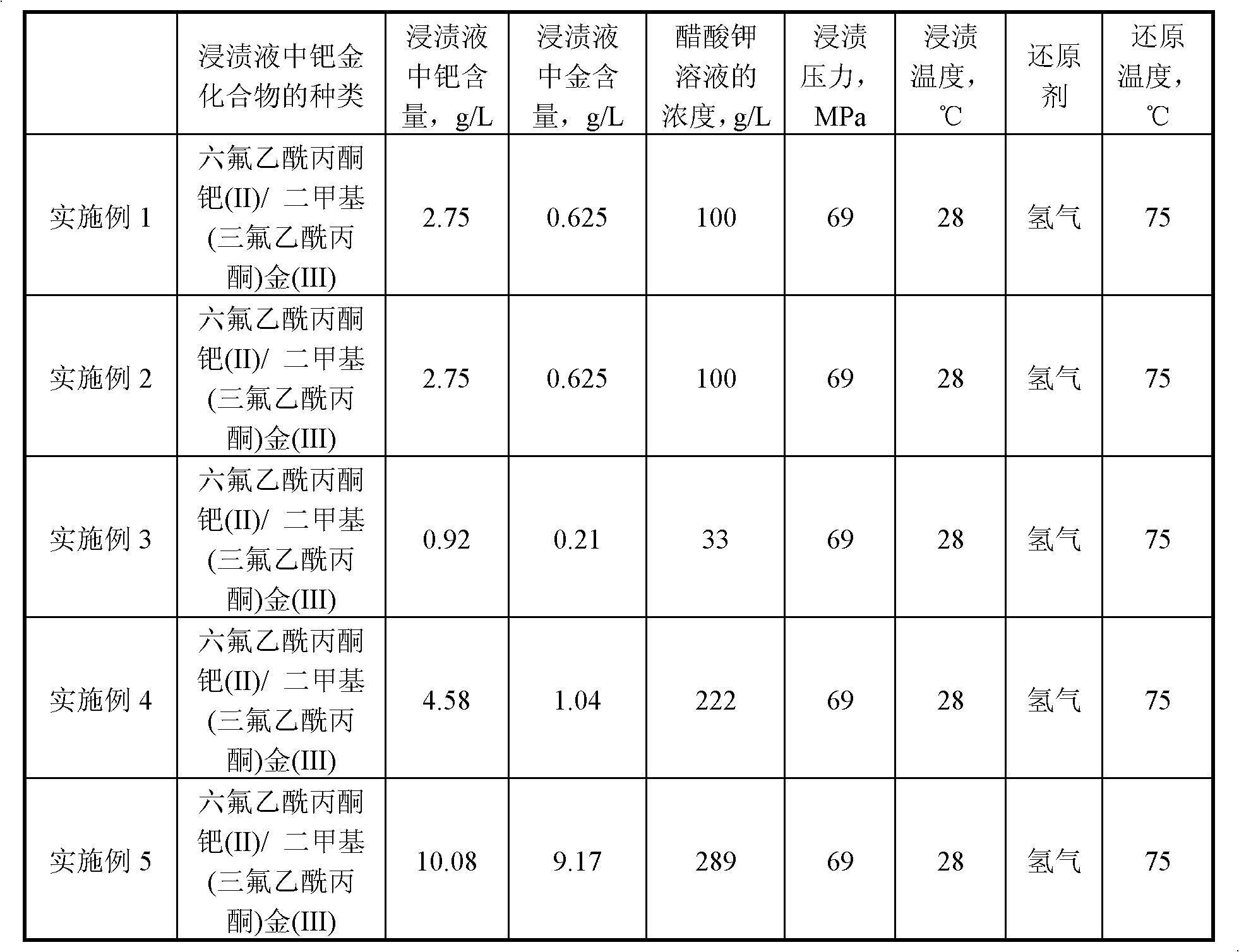

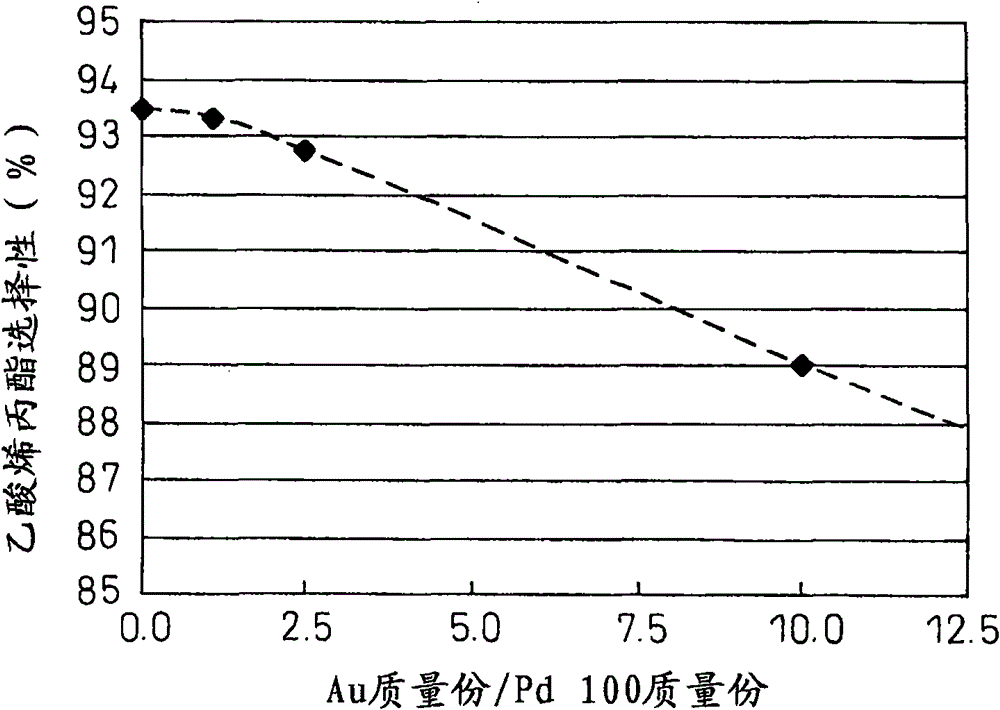

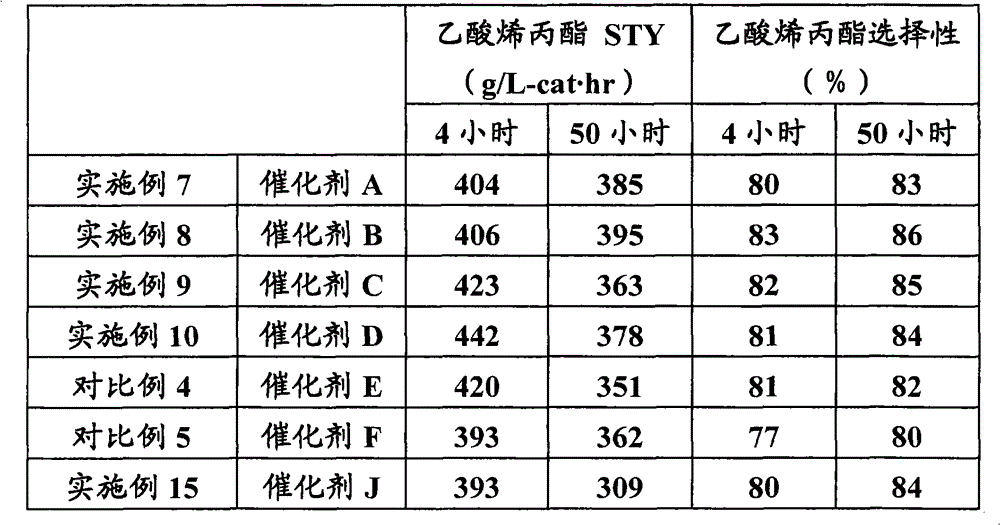

An allyl acetate production catalyst comprising at least (a) palladium, (b) gold, (c) a compound containing at least one element selected from copper, nickel, zinc and cobalt, (d) an alkali metal saltcompound and (e) a carrier, is produced by a process comprising step 1 in which a homogeneous solution of a palladium-containing compound and a gold-containing compound is supported on a carrier by contact therewith, step 2 in which the carrier obtained in step 1 is contacted with an alkali solution for impregnation, step 3 in which the carrier obtained in step 2 is subjected to reduction treatment, and step 4 in which a compound containing at least one element selected from copper, nickel, zinc and cobalt and an alkali metal salt compound are supported onto the carrier obtained in step 3. The obtained allyl acetate production catalyst has minimal reduction in activity and improved selectivity, when used for production of allyl acetate from propylene, oxygen and acetic acid.

Owner:株式会社力森诺科

Vinyl acetate preparation method

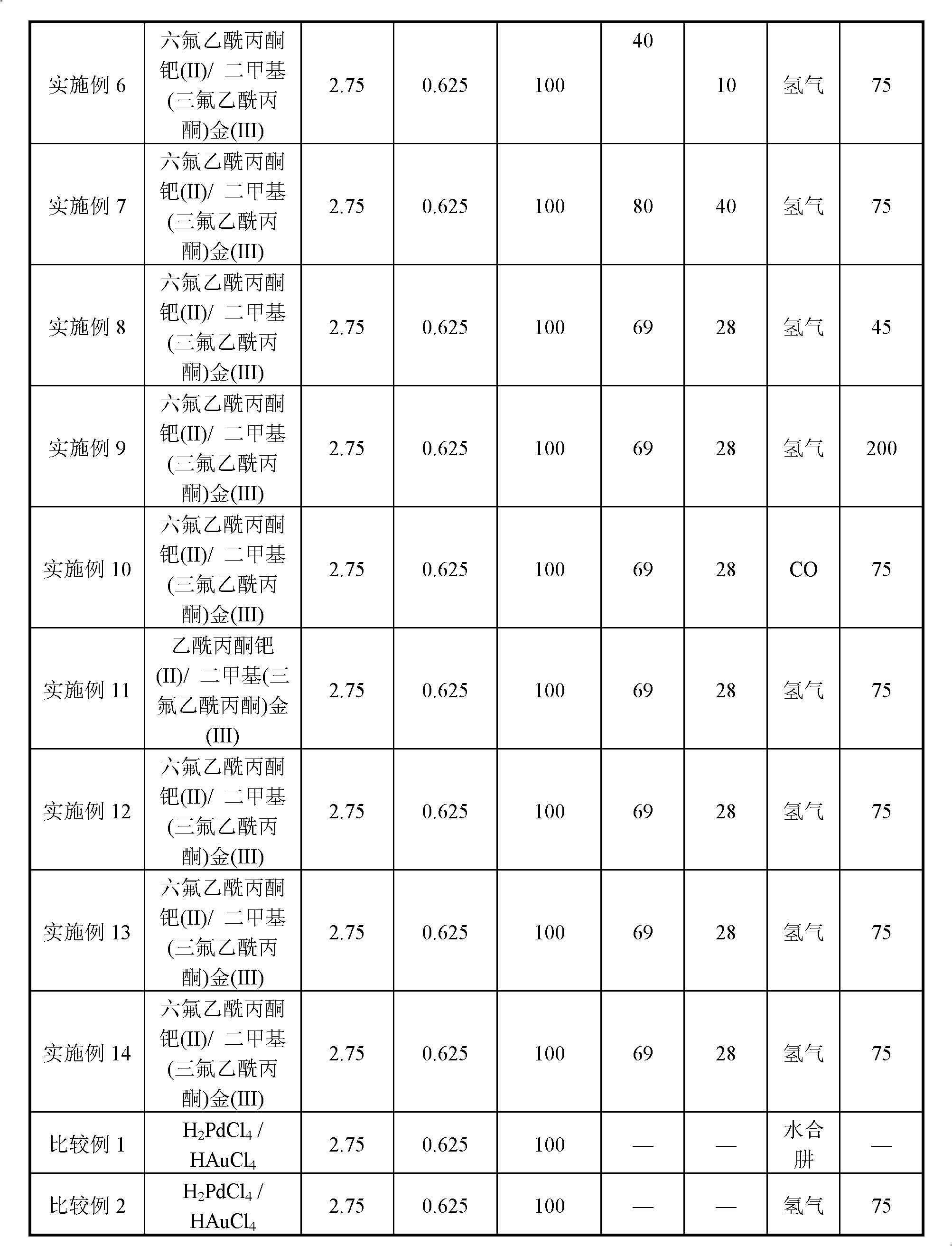

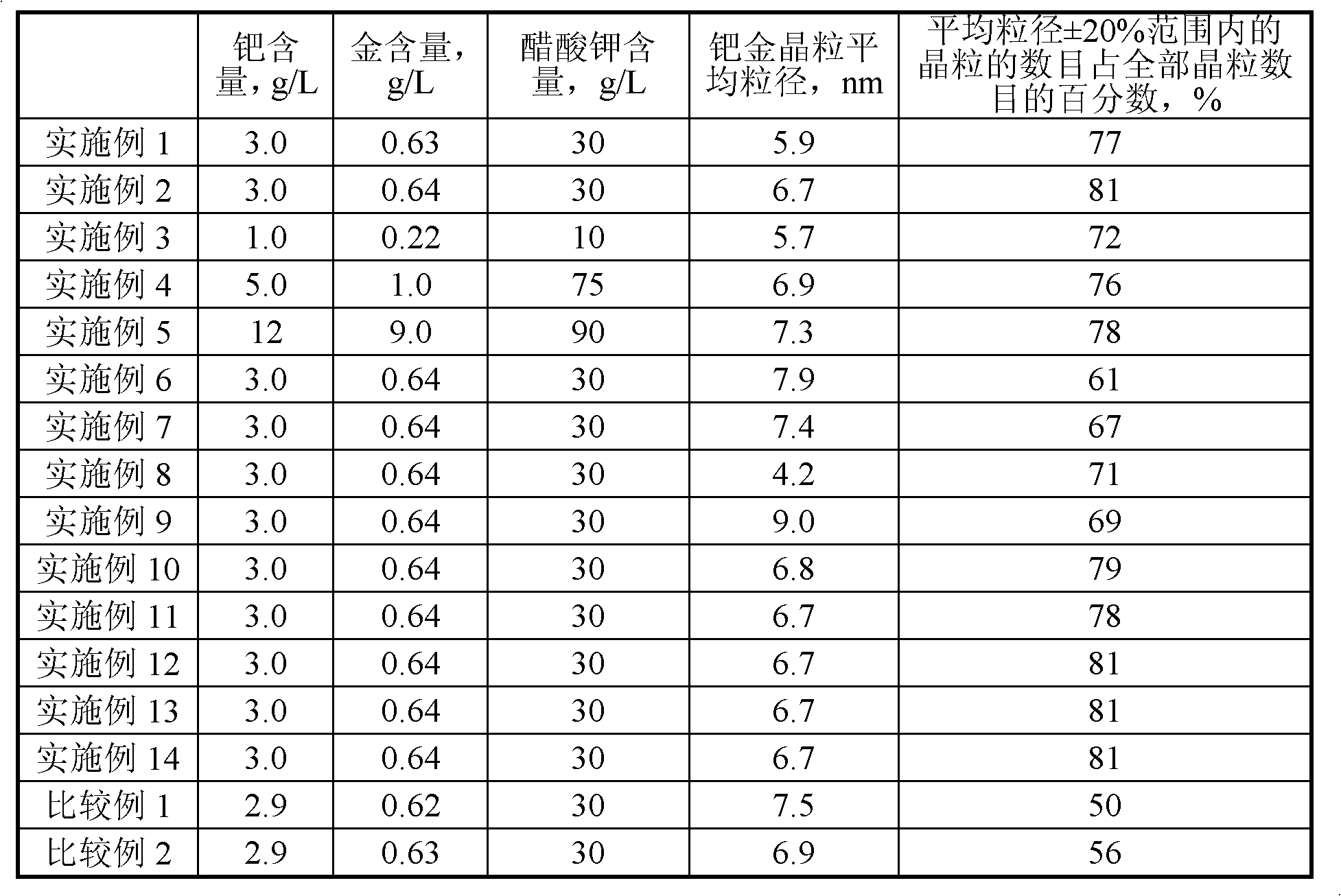

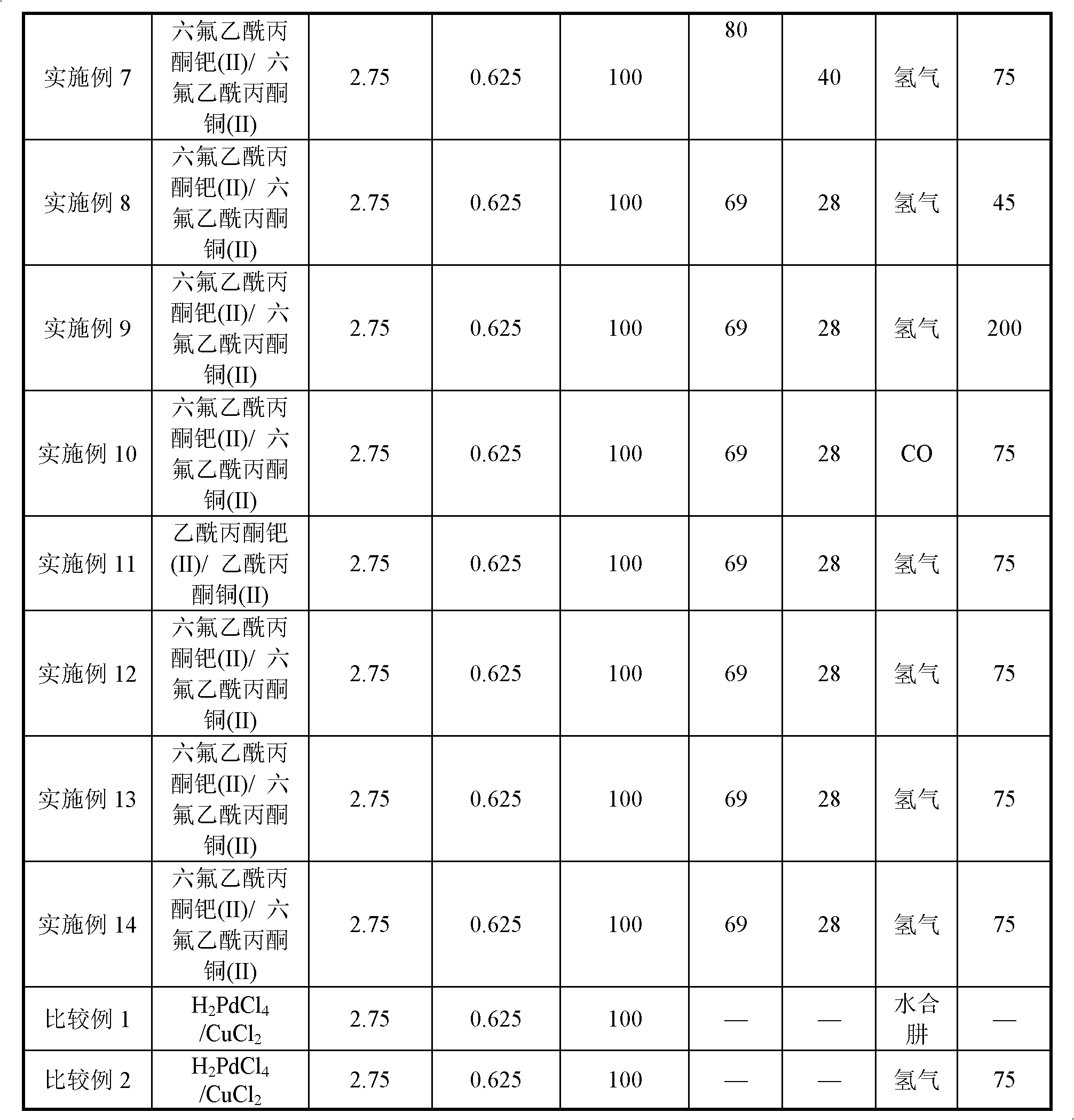

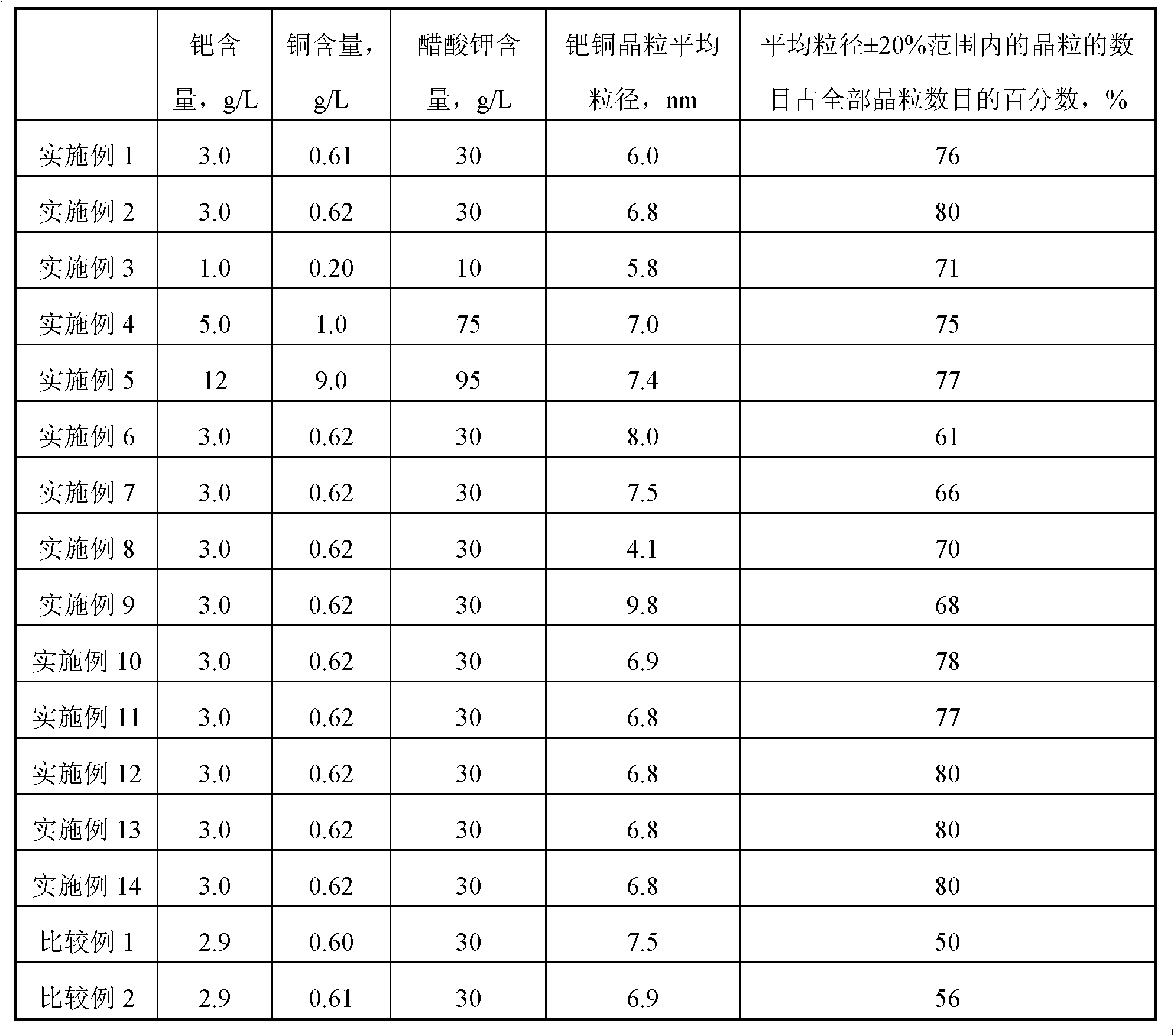

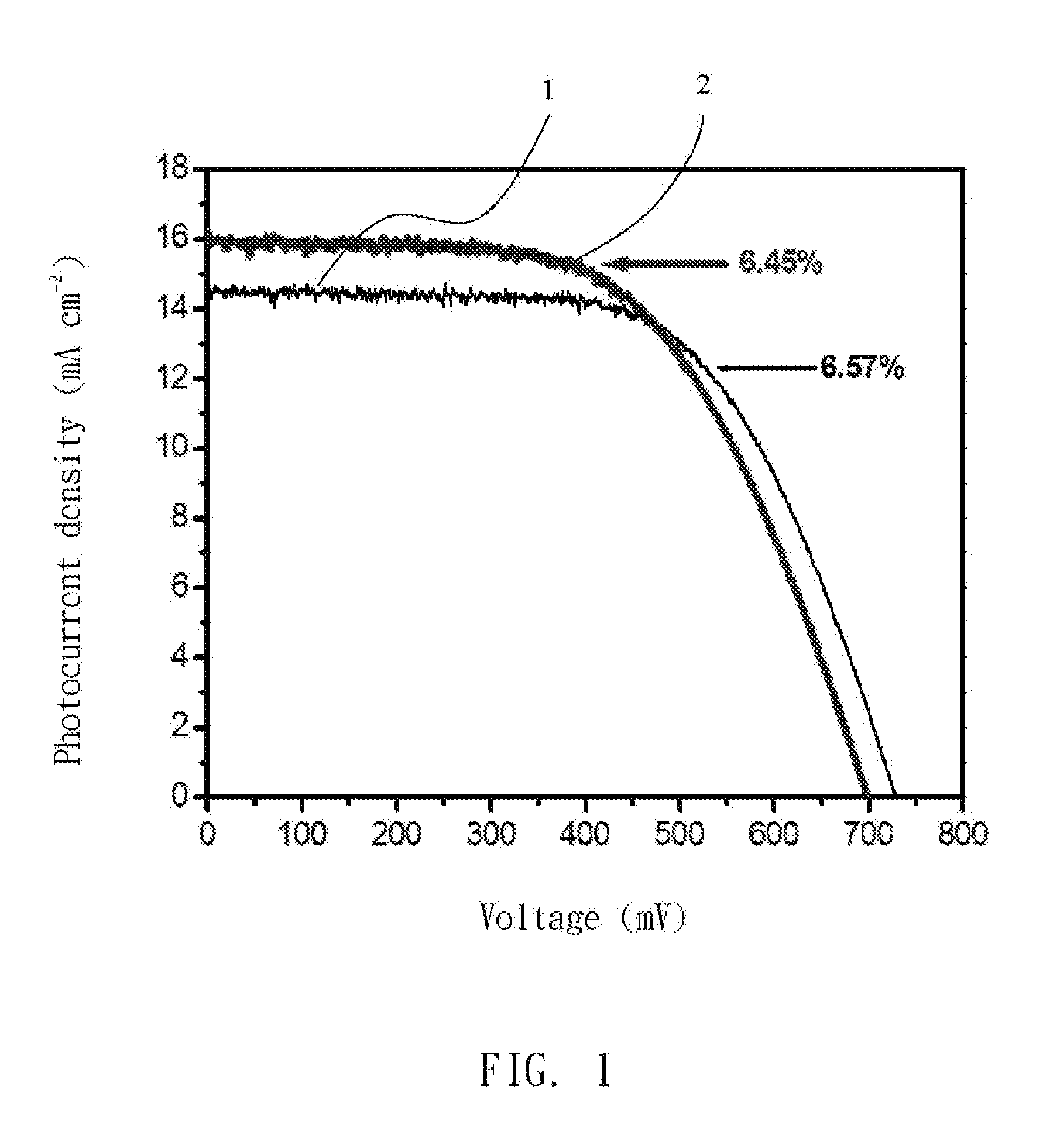

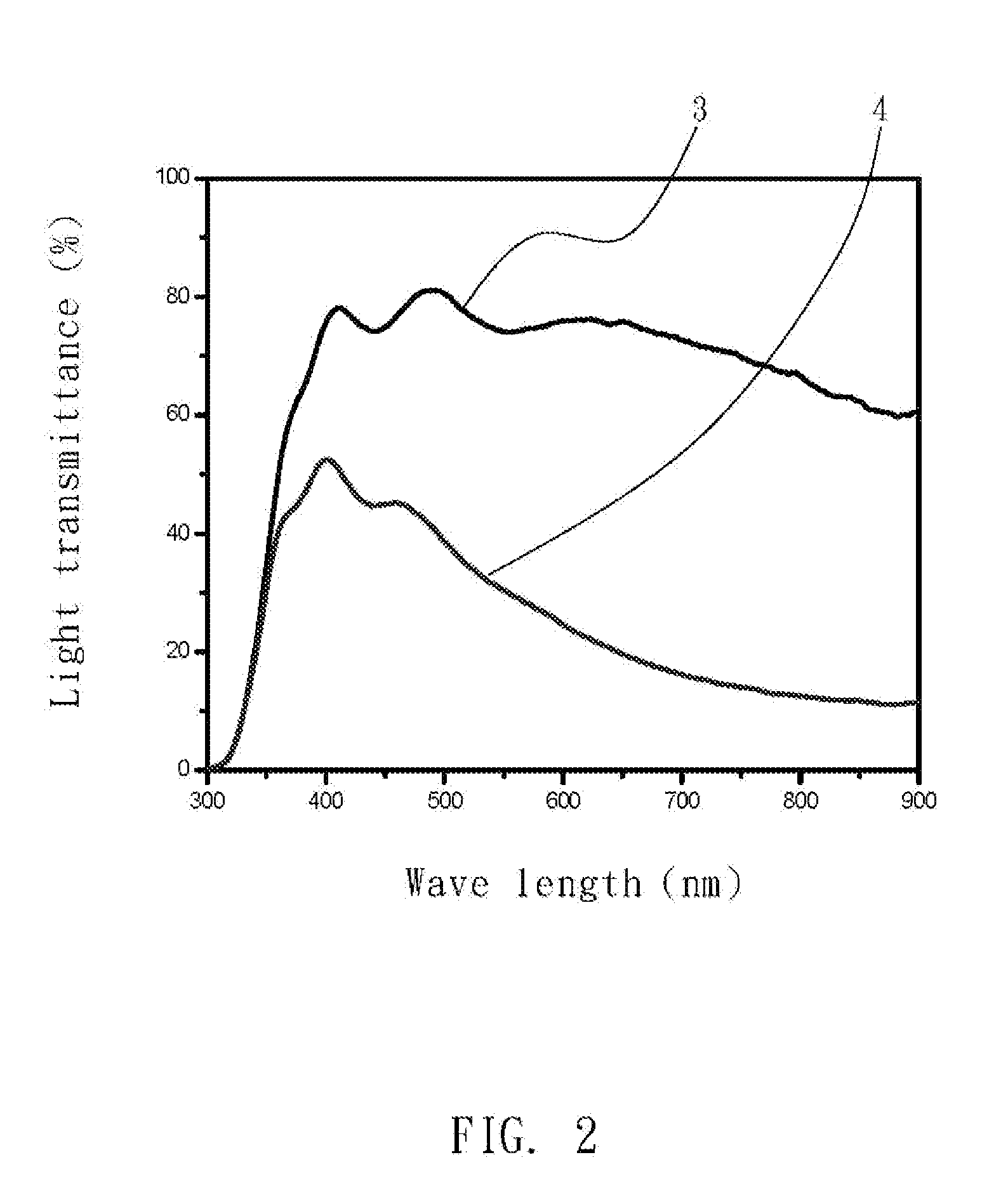

ActiveCN103121952AUniform particle size distributionHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateOxygen

The invention relates to a vinyl acetate preparation method which is mainly used for solving the problems of space time yield and low selectivity of the prior art. The method for preparing allyl acetate is adopted, reaction raw materials which consist of ethylene, acetic acid, oxygen and water are contacted with a catalyst so as to obtain a reaction product containing allyl acetate, wherein the catalyst takes SiO2, Al2O3 or a mixture thereof as a carrier, and load active components comprise metal palladium, metal gold and alkali metal acetate; and the catalyst comprises 1-12g / L of palladium, 0.1-9g / L of gold and 10-90g / L of alkali metal acetate. The method is characterized in that the average crystal grain diameters of palladium and gold are between 4 and 9nm, and crystal grains with the average crystal grain diameters within a scope of plus or minus 20% account for 60-81% of the whole crystal grains. The method can be utilized for better solving the problems and used for allyl acetate industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

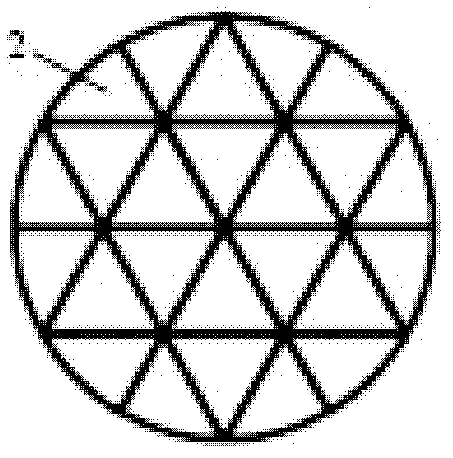

Allyl acetate catalyst and preparation method thereof

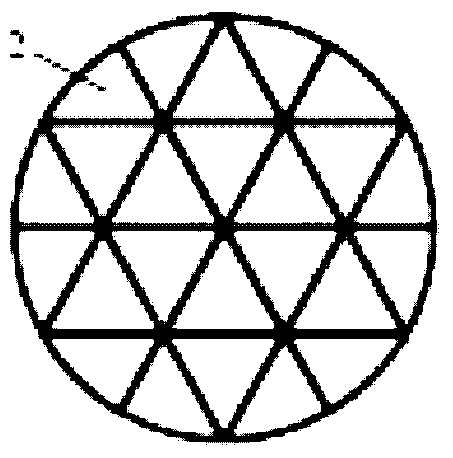

ActiveCN103055941ALarge stacking porosityLarge particle surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateResidence time

The invention relates to a catalyst for synthesizing allyl acetate and a preparation method thereof. The catalyst and the preparation mainly solve the problems that the residence time yield is low and the reaction selectivity is bad in the prior art. The problems are solved by adopting the catalyst for synthesizing the allyl acetate and the preparation method thereof provided by the invention, wherein a catalyst carrier consists of SiO2 or a mixture of the SiO2 and Al2O3 and is in a columnar type, a cylinder is 3-8mm long, and the ratio of the length to the diameter is 0.78-1.0; and a cross section in the cylinder is in a latticed type and gridding holes are in a triangular or square type. Therefore, the catalyst for synthesizing the allyl acetate and the preparation method thereof can be applicable to the industrial production of an allyl acetate catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic oxacylation vapor phase process

InactiveUS7265243B2High catalytic activityIncreases economic utilityOrganic compound preparationOrganic chemistry methodsAllyl acetateAcetic acid

This invention relates to a catalyst which comprises palladium metal as the main catalyst, tin metal or a mixture of tin and additional metals as the promoter, in combination with an alkali or alkaline earth metal compound, supported on the outer surface of a porous carrier. The catalyst is used in the process for producing allyl acetate through the oxacylation of propylene, acetic acid and oxygen in a vapor phase. The catalyst of the present invention exhibits high catalytic activity, high catalytic selectivity and high catalytic life, which greatly increases the economic utility of the oxacylation process.

Owner:DALIAN CHEM IND CO LTD

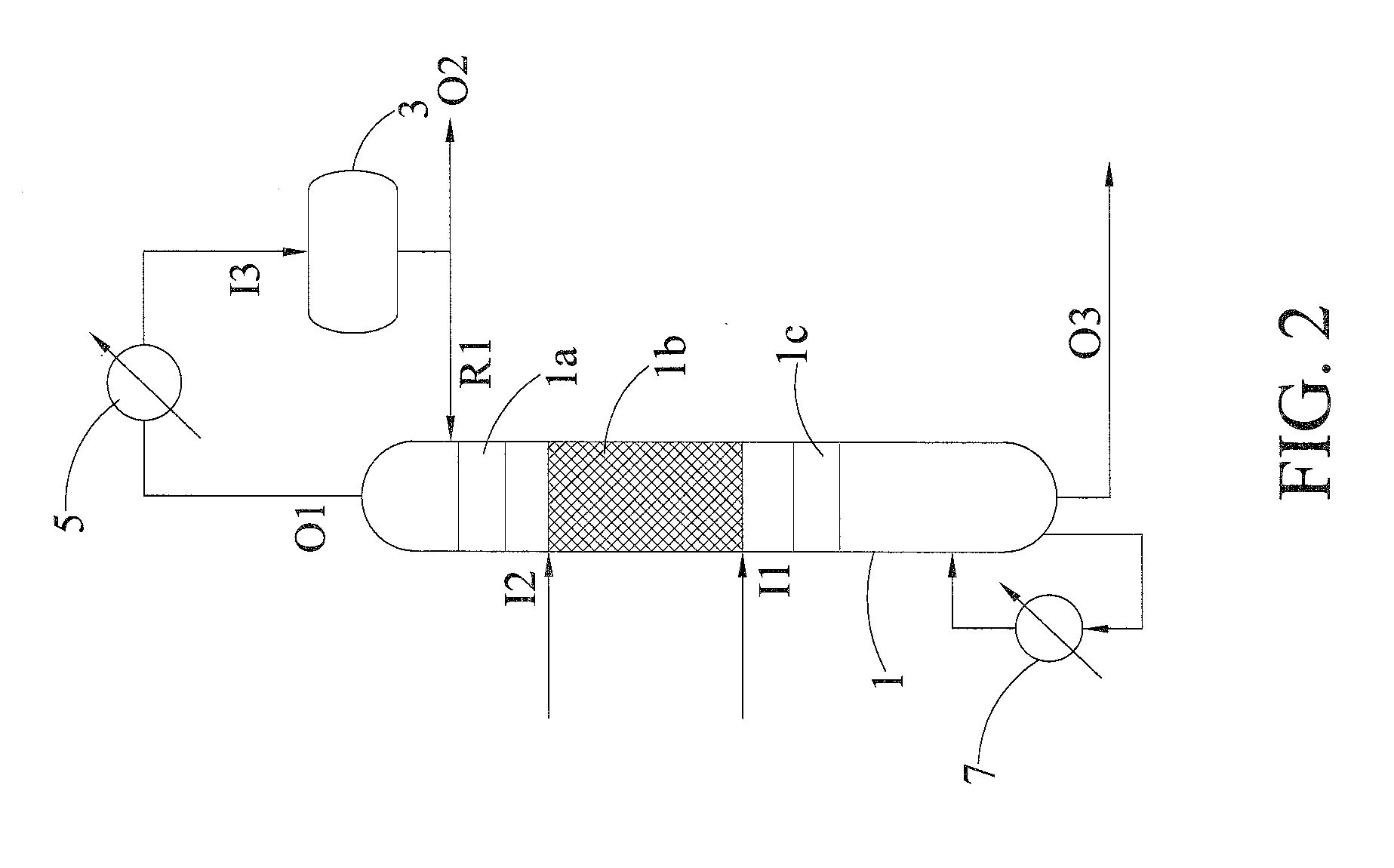

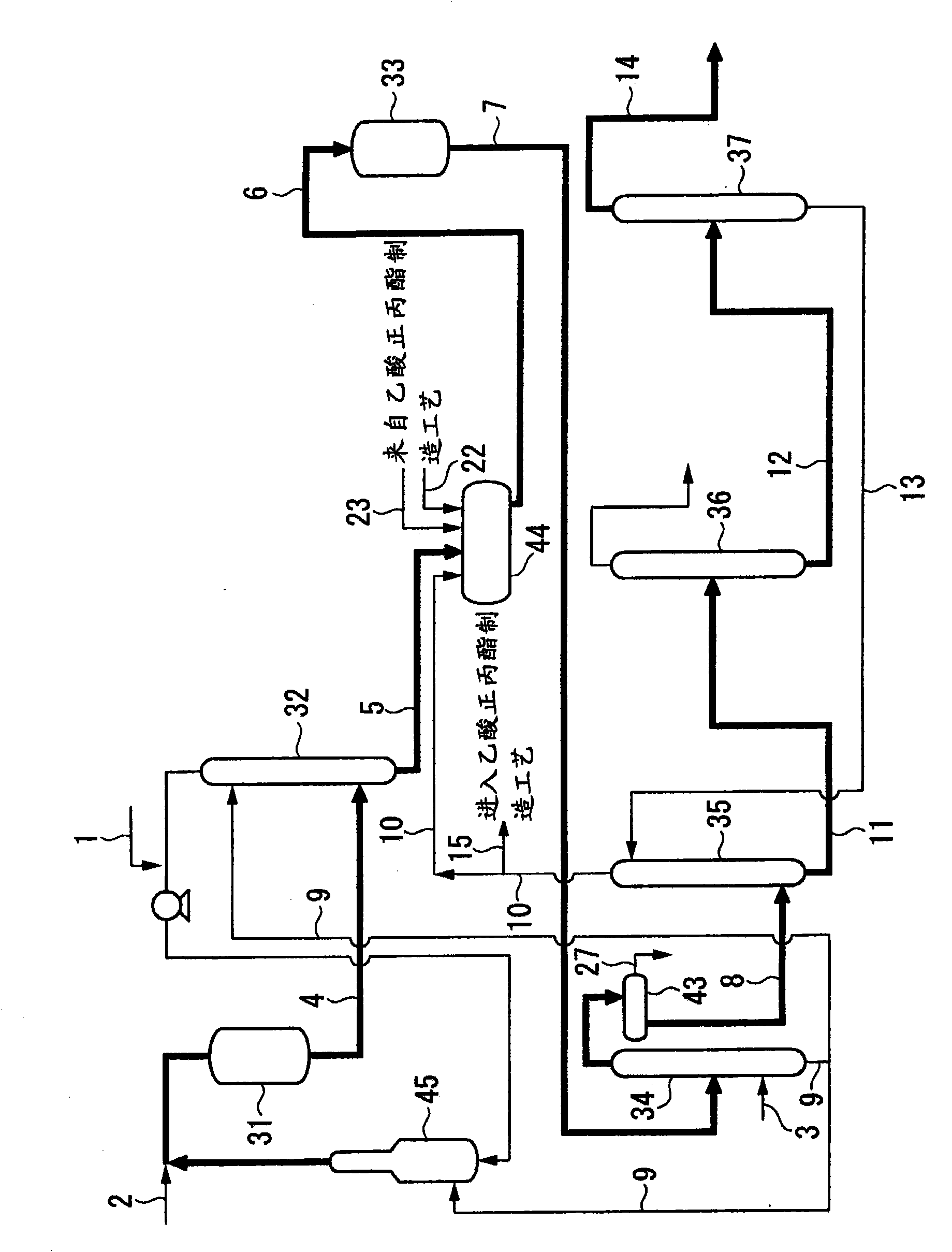

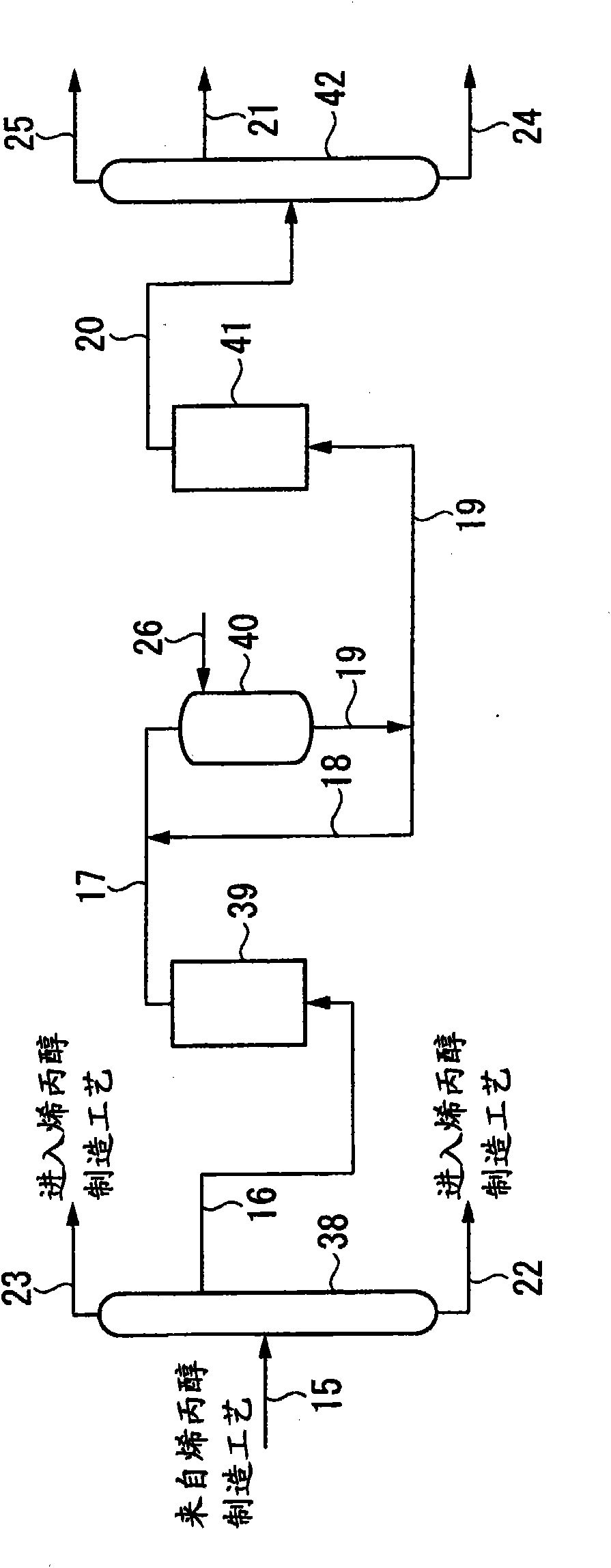

Process and device for hydrolytically obtaining a carboxylic acid alcohol from the corresponding carboxylate

InactiveUS7041199B1Raise the ratioConvenience to workSolvent extractionOrganic chemistry methodsAllyl acetateAlcohol

A process and a device for the catalytic hydrolysis of a carboxylate, e.g., methyl acetate, ethyl acetate, i- or n-propyl acetate, i- or n-butyl acetate, allyl acetate and methyl formate, into the corresponding carboxylic acid and alcohol, by a combination of a pre-reactor and a reactive distillation column are disclosed. By the combination of a pre-reactor and a reactor distillation column, the conversion ratio can be substantially improved. The device can compensate for fluctuations in the supply quantity or in the composition of the feed flow. The product composition can also be controlled in a wide range.

Owner:SULZER CHEMTECH AG +1

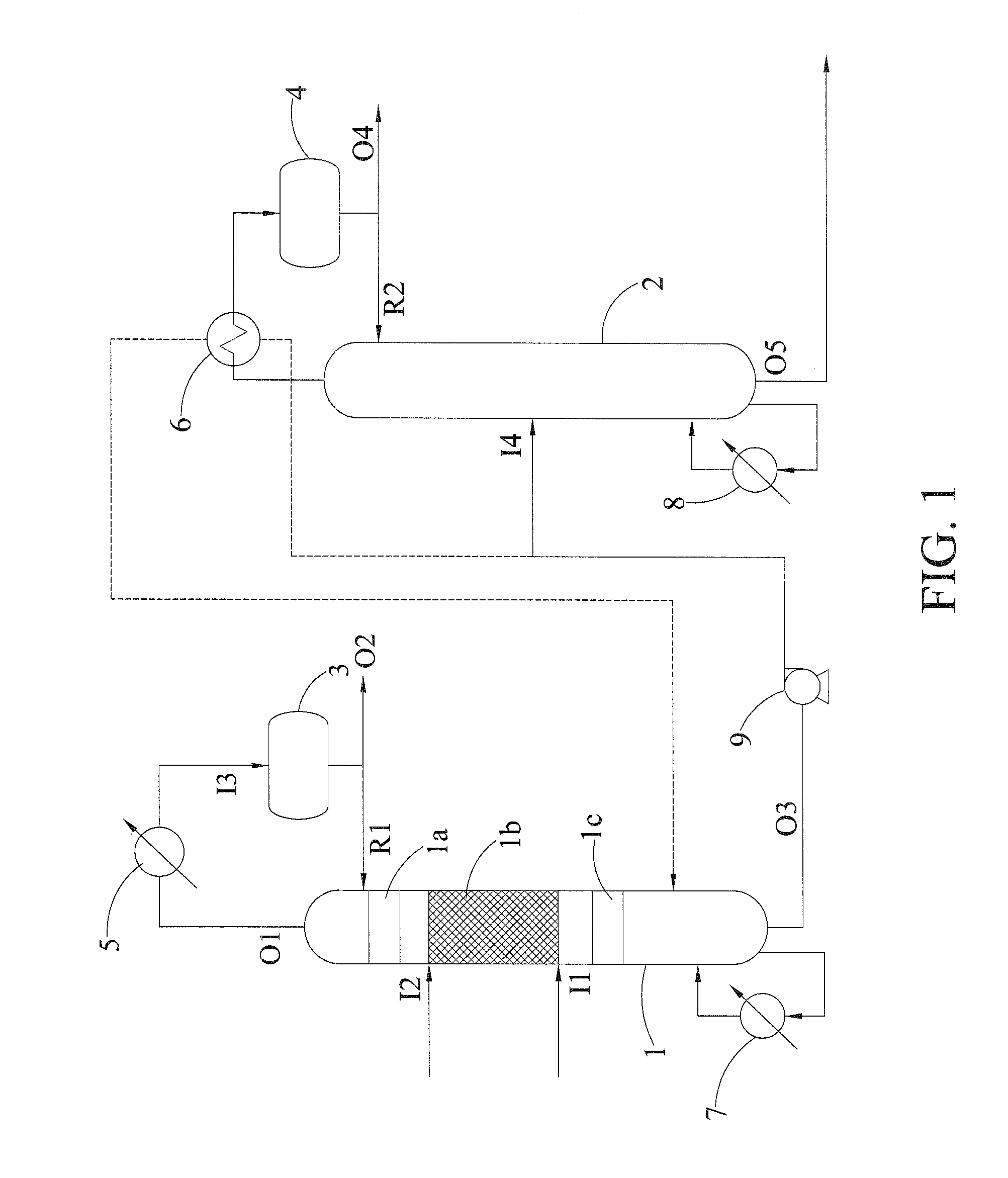

Method for producing allyl alcohol

ActiveUS20140364655A1Low costAvoid corrosionOxygen-containing compound preparationOrganic compound preparationAllyl acetateAcetic acid

A method for producing allyl alcohol is disclosed. The method includes steps of feeding allyl acetate and water into a reactive distillation column; performing a reaction in a reaction zone and separating a product containing allyl alcohol, acetic acid and water from the reactive distillation column. Accordingly, the method effectively enhances a conversion rate of hydrolysis for allyl acetate, simplifies the process and reduces energy consumption.

Owner:DALIAN CHEM IND CO LTD

Pineapple flavor essence

InactiveCN101760317AConvenient sourceAnti-mildewEssential-oils/perfumesAllyl acetateCinnamyl acetate

The invention discloses a pineapple flavor essence. The raw materials of the pineapple flavor essence comprise 300.0 weight permillage of allyl caproate, 200.0 weight permillage of cyclohexyl allyl propionate, 30.0 weight permillage of ethyl acetate, 50.0 weight permillage of cyclohexyl allyl acetate, 30.0 weight permillage of geranyl hexanoate, 10.0 weight permillage of benzyl propionate, 5.0 weight permillage of petit grain oil, 2.0 weight permillage of acetic leaf alcohol ester, 10.0 weight permillage of vanillic aldehyde, 3.5 weight permillage of cinnamyl acetate, 100.0 weight permillage of ethyl butyrate, 20.0 weight permillage of ethyl oenanthate, 30.0 weight permillage of pentyl acetate, 30.0 weight permillage of cyclohexyl allyl butyrate,10.0 weight permillage of geranyl butyrate, 10.0 weight permillage of linalool, 10.0 weight permillage of citral dimethyl acetal, 0.5 weight permillage of dimethyl hydroxyl furanone, and 150.0 weight permillage of diethyl phthalate. The pineapple flavor essence of the invention is fit for perfuming products such as grease, emulsion, shampoo, and the like, and has the advantages of pure flavor, strong endurance, less dosage, and the like.

Owner:刘新光

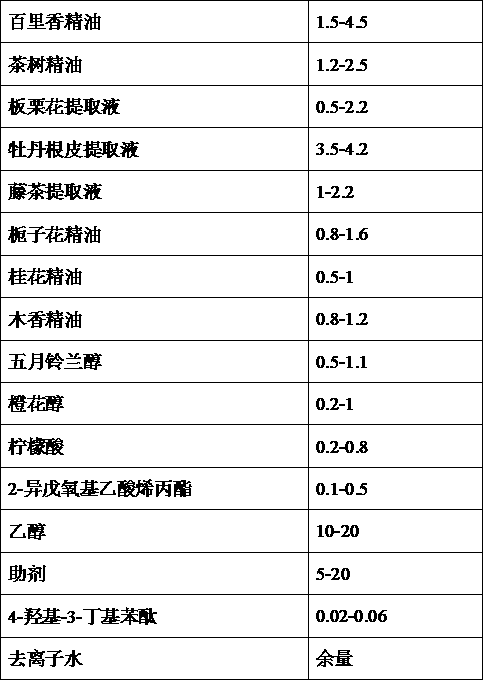

Compound air cleaning agent and preparing method and application thereof

InactiveCN103239745ARich fragranceImprove mosquito repellent effectBiocidePest repellentsBiotechnologyAllyl acetate

The invention provides a compound air cleaning agent and a preparing method and application thereof. The compound air cleaning agent is formed by compounding multiple components of thyme essential oil, tea tree essential oil, castanea mollissima flower extracting solution, peony root and skin extracting solution, vine tea extracting solution, gardenia essential oil, osmanthus fragrans essential oil, costustoot essential oil, may lily of the valley alcohol, nerol, citric acid, 2-isopentyloxy allyl acetate, alcohol, assistant, 4-hydroxy-3-butylphthalide and deionized water. The air cleaning agent has the advantages of better sterilizing, mosquito repelling and aroma enhancing performances due to proper selecting of component and proportion and the coordinated action among the components, less using amount, long time effectiveness, and is more saved and fast in the aspect of life and use of people.

Owner:清远市立道精细化工有限公司

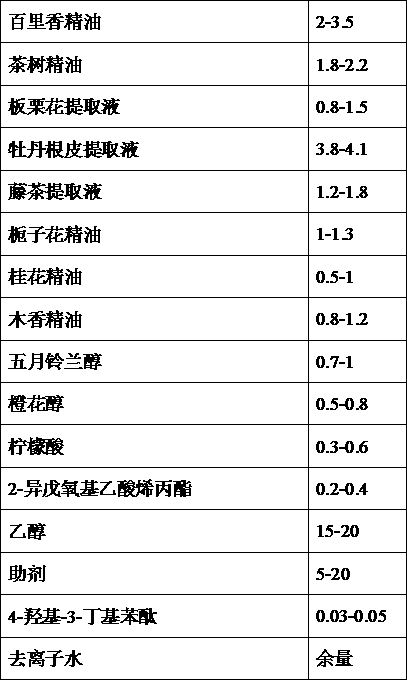

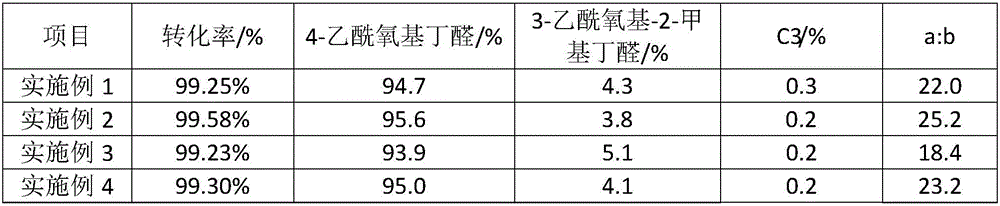

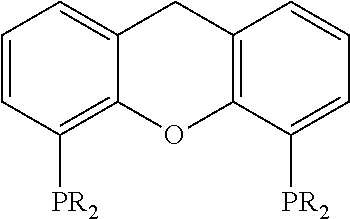

Allyl acetate hydroformylation method

InactiveCN106518677AHigh selectivityEasy to synthesizeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionAllyl acetateBenzene

The invention discloses an allyl acetate hydroformylation method. The method includes the step that with the existence of a solvent and a catalyst system, a hydroformylation reaction happens to allyl acetate, carbon monoxide and hydrogen, butyraldehyde acetate is generated. The catalyst system comprises a rhodium complex and 6,6'-(3,3',5,5'-4-tert-butylbiphenyl-2,2'-biradical)bis(oxy)bisdibenzo[d,f][1,3,2] dioxaphospholane heterocyclic heptylene . By the adoption of the method, the butyraldehyde acetate is prepared through the allyl acetate in a hydroformylation manner with higher efficiency, and the method has the beneficial effects that the process is simple, the straight-chain product selectivity is high, and catalyst ligands are easy to synthesized.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Process for producing allyl acetate

ActiveUS20110077425A1Organic compound preparationPreparation by transesterificationAcetic acidAllyl acetate

A process for producing allyl acetate is disclosed. The process comprises reacting a feed comprising propylene, acetic acid, oxygen, and carbon dioxide in the presence of a supported palladium catalyst. The feed comprises from 2 to 6 mole percent carbon dioxide, which improves the selectivity to allyl acetate.

Owner:LYONDELL CHEM TECH LP

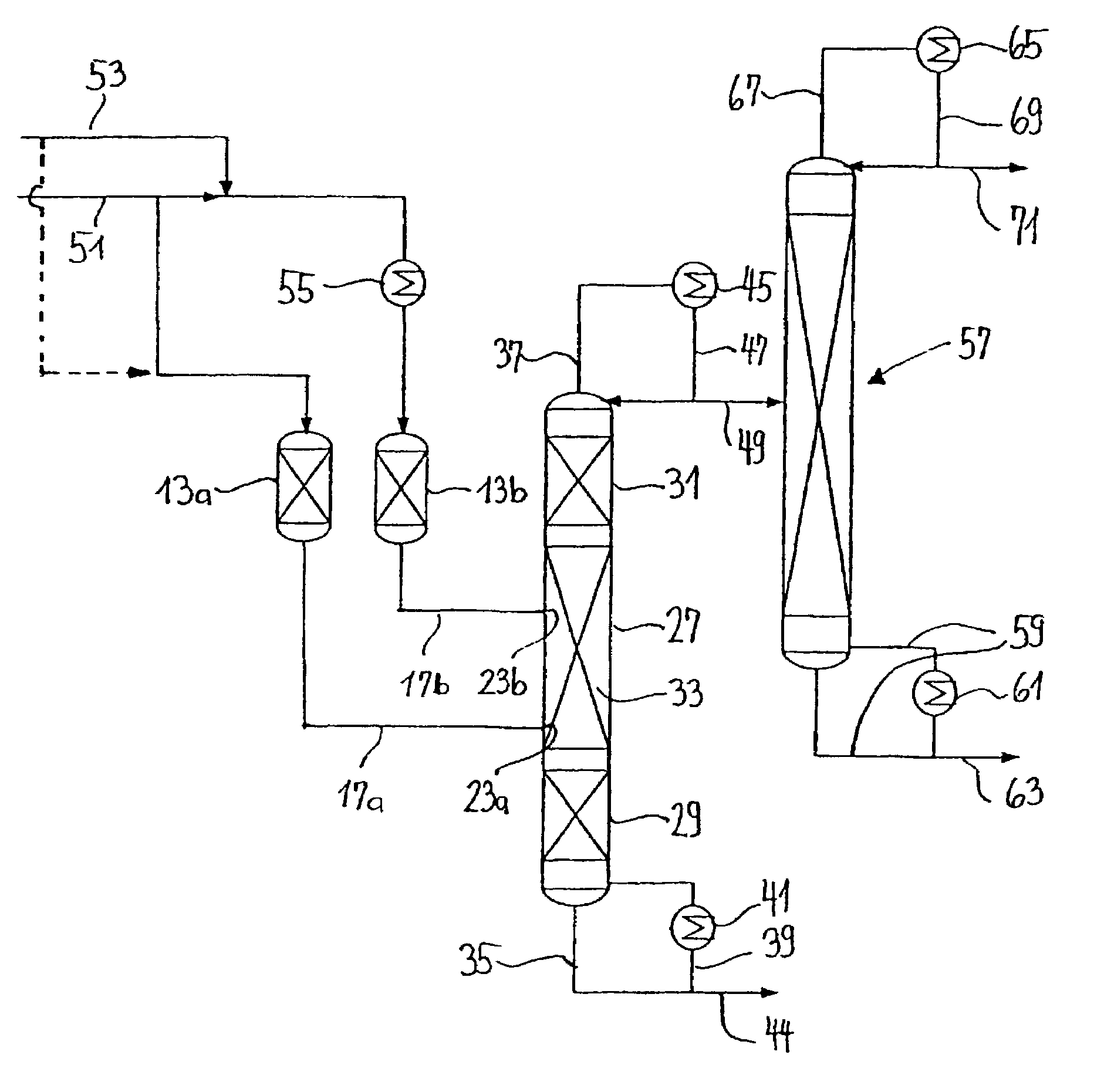

Production process of allyl alcohol, and allyl alcohol obtained by the production processes

InactiveUS20060084829A1Efficiently obtainedPreparation by oxidation reactionsOxygen-containing compound preparationAcetic acidAllyl acetate

A process for producing allyl alcohol, comprising a step (1) of producing allyl acetate from propylene, acetic acid and oxygen in a gas phase in the presence of a catalyst comprising a support having supported thereon a catalyst component containing a compound containing alkali metal and / or alkaline earth metal, an element belonging to Group 11 of the Periodic Table or a compound containing at least one of these elements, and palladium, and a step (2) of hydrolyzing the ally acetate obtained in the step (1) using an acid catalyst to produce allyl alcohol, wherein the conversion of the starting material acetic acid in the step (1) is 60% or more.

Owner:SHOWA DENKO KK

Allyl diacetate decomposition

InactiveUS20100197977A1Oxygen-containing compound preparationOrganic compound preparationAllyl acetateAcetic acid

A process for purifying an acetoxylation mixture is disclosed. Allyl acetate, water, acetic acid, and from 0.1 to 10 wt. % allyl diacetate are contacted in the vapor phase with a solid acidic catalyst under conditions effective to decompose the allyl diacetate and generate an intermediate stream comprising allyl acetate, water, acetic acid, and acrolein. Acrolein is then removed from the intermediate stream, preferably by distillation, to give an allyl acetate-containing product stream. Usually, this product stream is then hydrolyzed to produce allyl alcohol. The invention includes processes in which propylene first reacts with oxygen and acetic acid in the presence of a noble metal catalyst to generate the acetoxylation mixture.

Owner:LYONDELL CHEM TECH LP

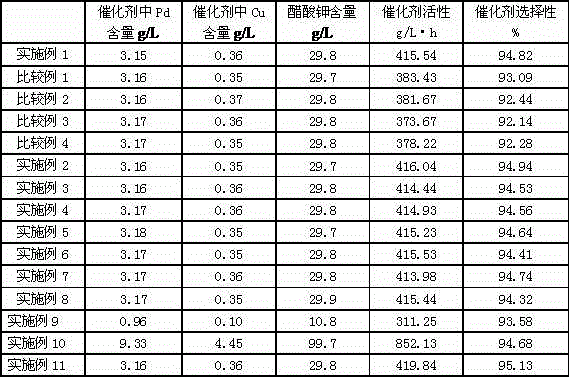

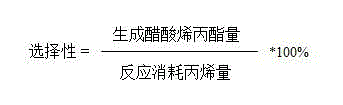

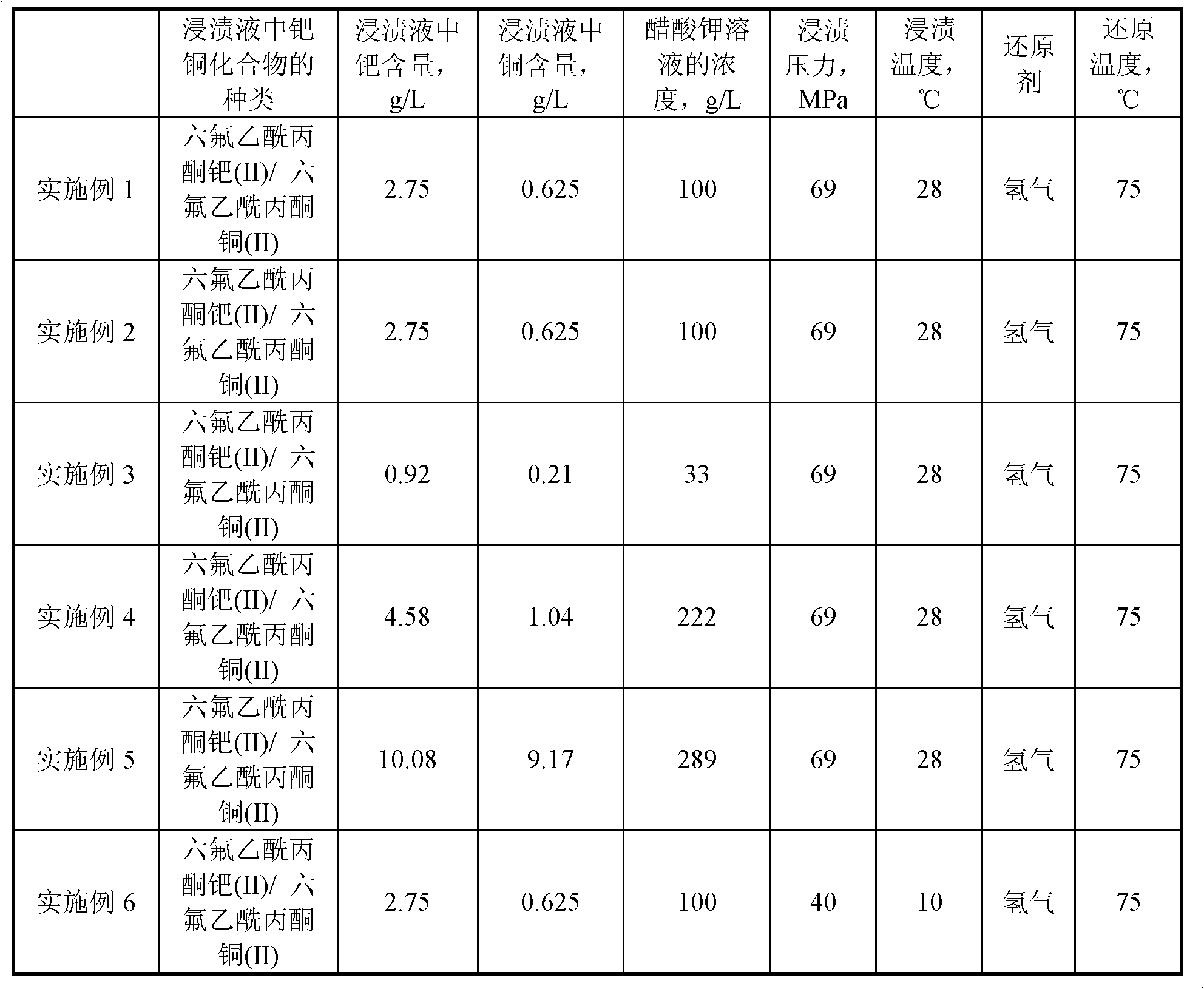

Allyl acetate catalyst and preparation method of allyl acetate catalyst

ActiveCN104437622AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetatePtru catalyst

The invention relates to an allyl acetate catalyst, a preparation method of the allyl acetate catalyst, and a synthesis method of allyl acetate, which mainly solve the problem that a catalyst is low in activity and selectivity in the prior art. According to the adopted technical scheme, the allyl acetate catalyst comprises a carrier, active components and a cocatalyst; active components comprise metal Pd and metal Cu; the cocatalyst is potassium acetate; the carrier is selected from at least one of the following oxides: SiO2 or Al2O3 which are subjected to ultrasonic treatment in the presence of organic amine, the problem is relatively well solved, and the allyl acetate catalyst and the preparation method of the allyl acetate catalyst can be used for industrial production of the allyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing allyl acetate

InactiveCN103121955AHigh yieldHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateOxygen

The invention relates to a method for preparing allyl acetate, and the method is mainly used for solving the problems of space time yield and low selectivity of the prior art. The method for preparing allyl acetate is adopted, reaction raw materials which consist of propylene, acetic acid, oxygen and water are contacted with a catalyst so as to obtain a reaction product containing allyl acetate, wherein the catalyst takes SiO2, Al2O3 or a mixture thereof as a carrier, and load active components comprise metal palladium, metal copper and alkali metal acetate; and the catalyst comprises 1-12g / L of palladium, 0.1-10g / L of copper and 10-100g / L of alkali metal acetate, wherein the average crystal grain diameters of palladium and copper are between 4 and 10nm, and crystal grains with the average crystal grain diameters within a scope of plus or minus 20% account for 60-80% of the whole crystal grains. The method can be utilized for better solving the problems and used for allyl acetate industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

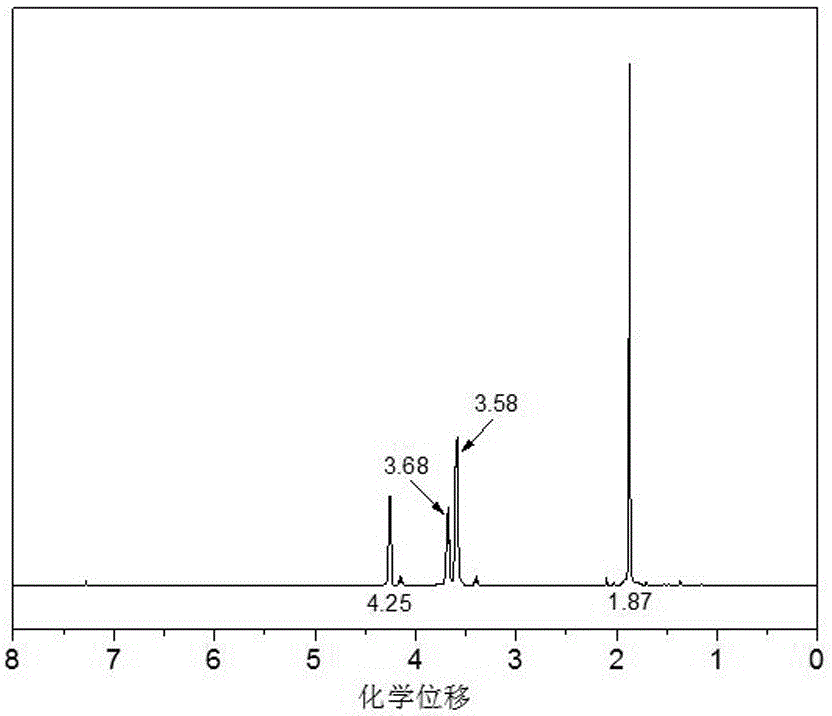

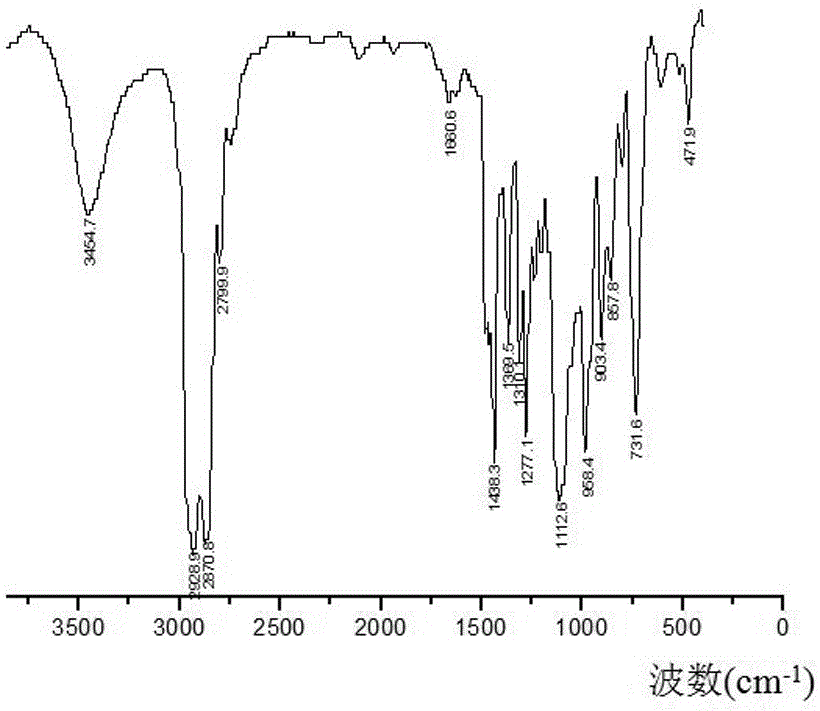

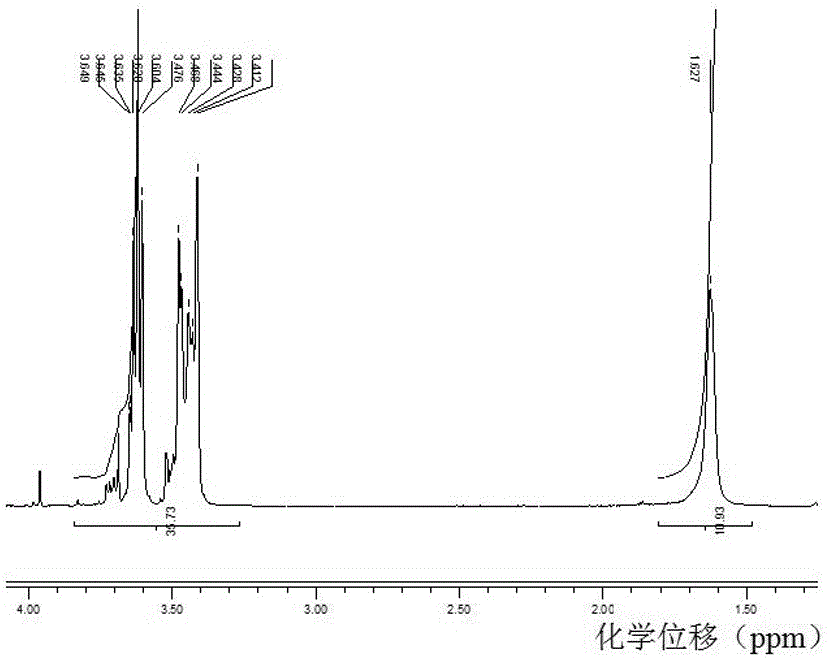

Gelator for producing a gel electrolyte

InactiveUS20100267849A1Acceptable ionic conductivityNot easilyCation exchanger materialsIon-exchanger regenerationAllyl acetateLithium

A gelator for producing a gel electrolyte is a copolymer and comprises multiple major monomeric units, multiple minor monomeric units and multiple optional components. The major monomeric units comprise acrylonitrile (AN) monomeric units that have good ionic conductivity and coordinating sites for lithium ions to be dissolved with a liquid-electrolytic solvent. The minor monomeric units are a combination of at least one type monomeric unit, and the combination of at least one type monomeric unit is selected from a group consisting of vinyl acetate (VA), allyl acetate (AA), styrene, acrylamide and at least one reactive compound. A gel electrolyte is a mixture of a gelator and a liquid-electrolytic solvent.

Owner:NAT CHENG KUNG UNIV

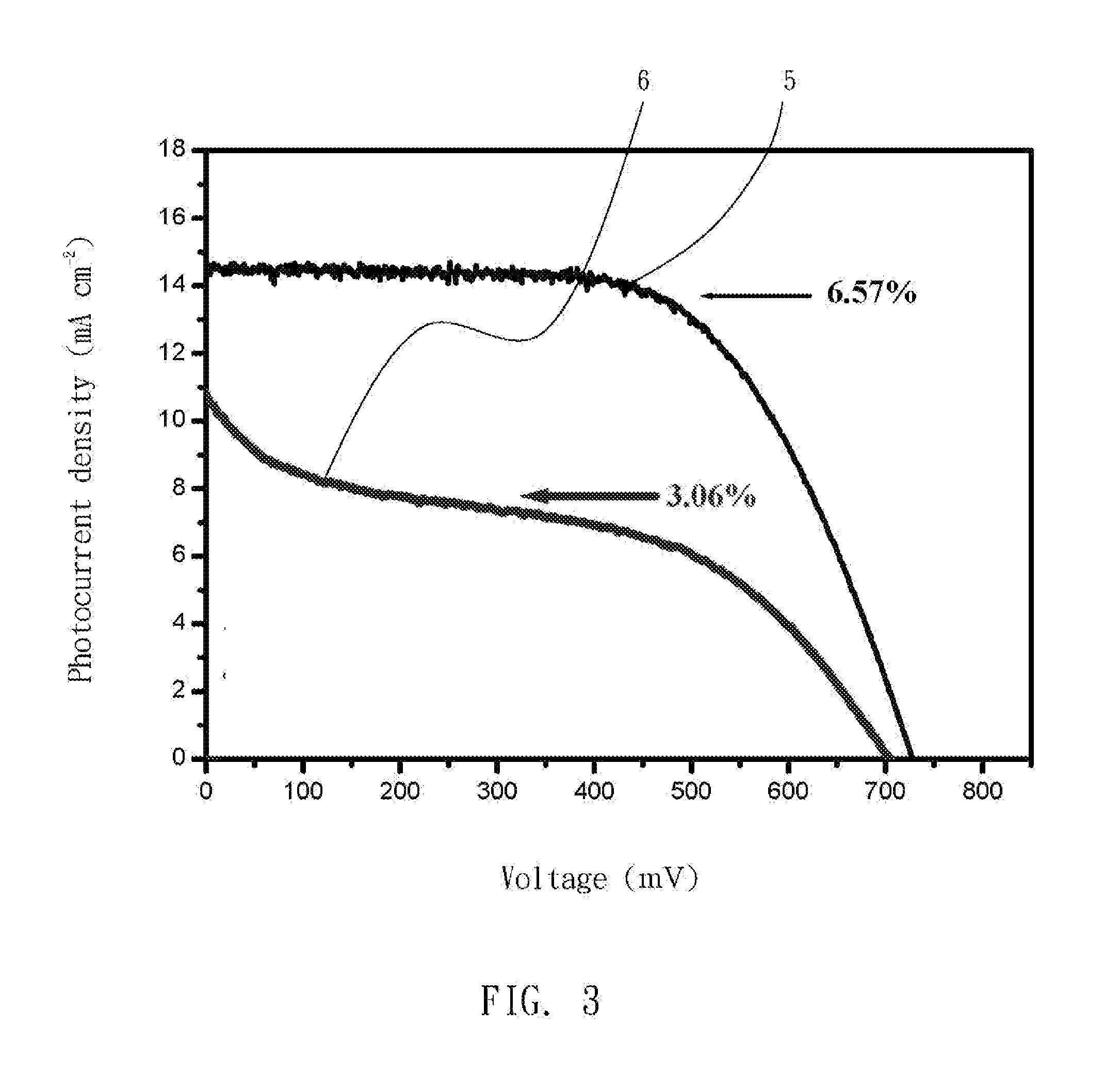

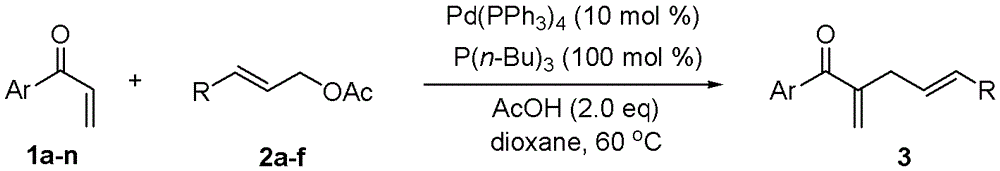

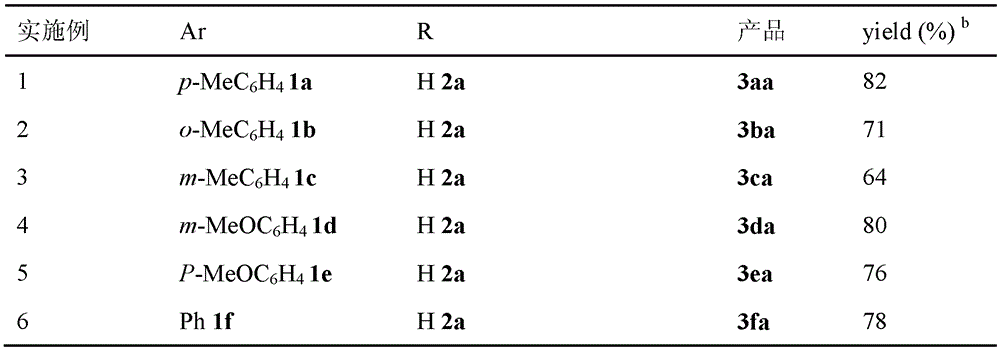

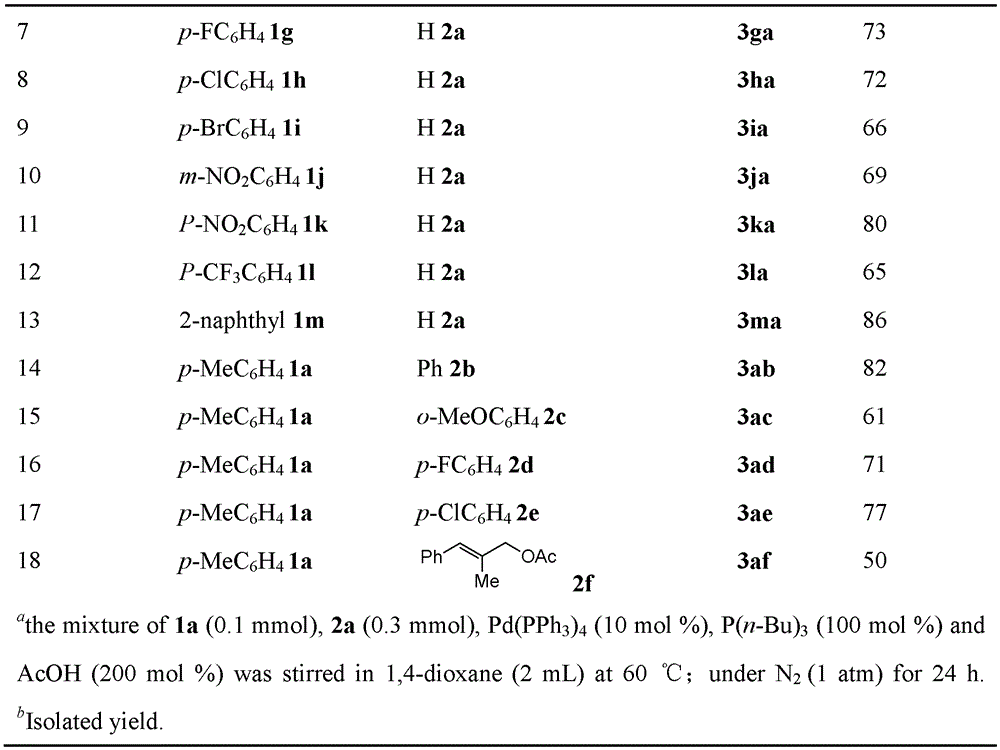

MBH reaction of alpha, beta-unsaturated ketone and allyl acetate

InactiveCN105541582AEasy to manufactureAvoid MBH reactionsOrganic compound preparationCarbonyl compound separation/purificationAcetic acidAllyl acetate

The invention discloses an MBH reaction of alpha, beta-unsaturated ketone and allyl acetate. The reaction comprises the following steps that 1, alpha, beta-unsaturated ketone, acetic acid and a catalyst are added into solvent and stirred, then Pd(PPh3)4 and allyl acetate are added, and the mixture reacts for 22-26 hours in a stirred mode at the temperature of 50 DEG C-70 DEG C; 2, a reaction product obtained in the step 1 is decompressed, the solvent is steamed away, and residues are subjected to column chromatography separation to obtain alpha-allyl substituted alpha, beta-unsaturated ketone. Adopted allyl acetate is easier to prepare, and alpha, beta-unsaturated ketone with the open chain is used. Because acetic acid is added, alpha, beta-unsaturated ketone is prevented from generating the MBH reaction by itself.

Owner:ZHEJIANG UNIV

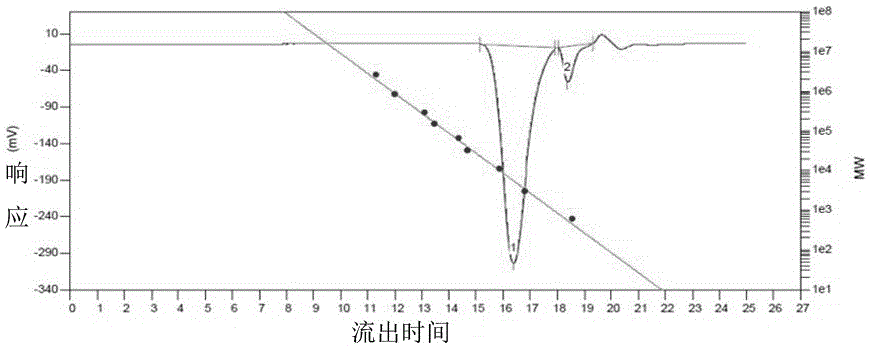

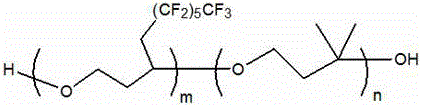

Fluoroalkyl-containing copolyether and preparation method thereof

ActiveCN106750236AHigh fluorine contentSurface properties are easy to controlAntifouling/underwater paintsPaints with biocidesAllyl acetateIodide

Owner:SUZHOU UNIV

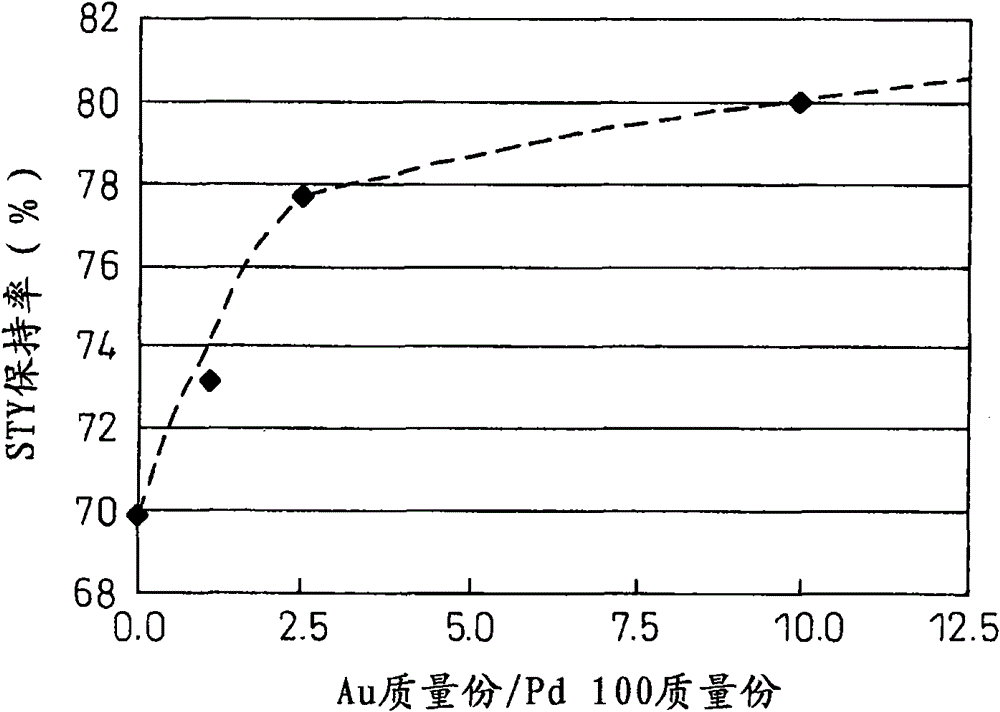

Process for production of allyl acetate production catalyst

ActiveCN101657259BEfficient productionReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationAllyl acetateAcetic acid

An allyl acetate production catalyst comprising at least (a) palladium, (b) gold, (c) a compound containing at least one element selected from copper, nickel, zinc and cobalt, (d) an alkali metal salt compound and (e) a carrier, is produced by a process comprising step 1 in which a homogeneous solution of a palladium-containing compound and a gold-containing compound is supported on a carrier by contact therewith, step 2 in which the carrier obtained in step 1 is contacted with an alkali solution for impregnation, step 3 in which the carrier obtained in step 2 is subjected to reduction treatment, and step 4 in which a compound containing at least one element selected from copper, nickel, zinc and cobalt and an alkali metal salt compound are supported onto the carrier obtained in step 3. The obtained allyl acetate production catalyst has minimal reduction in activity and improved selectivity, when used for production of allyl acetate from propylene, oxygen and acetic acid.

Owner:RESONAC CORPORATION

Allyl acetate purification

ActiveUS20110152568A1Oxygen-containing compound preparationOrganic compound preparationAcetic acidAllyl acetate

A process for purifying allyl acetate is disclosed. An acetoxylation mixture is distilled at elevated pressure to remove propylene and generate a first bottoms mixture comprising allyl acetate, acetic acid, acrolein, allyl diacetate, and 3-acetoxypropionaldehyde. The first bottoms mixture is flash vaporized, and the resulting vapor is contacted with a solid acidic catalyst under conditions effective to decompose allyl diacetate and 3-acetoxypropionaldehyde. The flashed product, which comprises allyl acetate, acetic acid, and acrolein, is then distilled to remove acrolein and generate a second bottoms mixture comprising allyl acetate and acetic acid. The second bottoms mixture can be used to manufacture allyl alcohol.

Owner:LYONDELL CHEM TECH LP

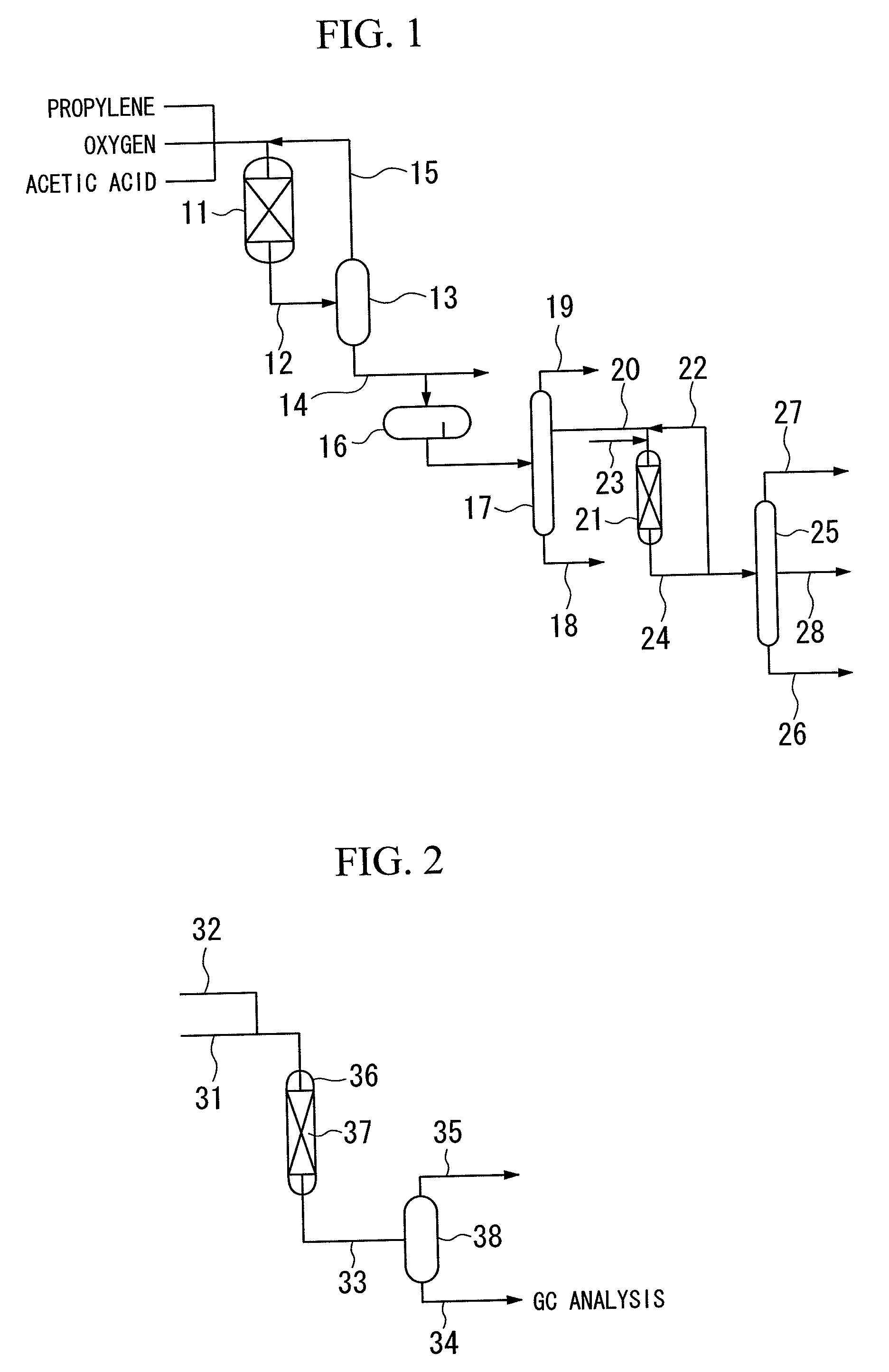

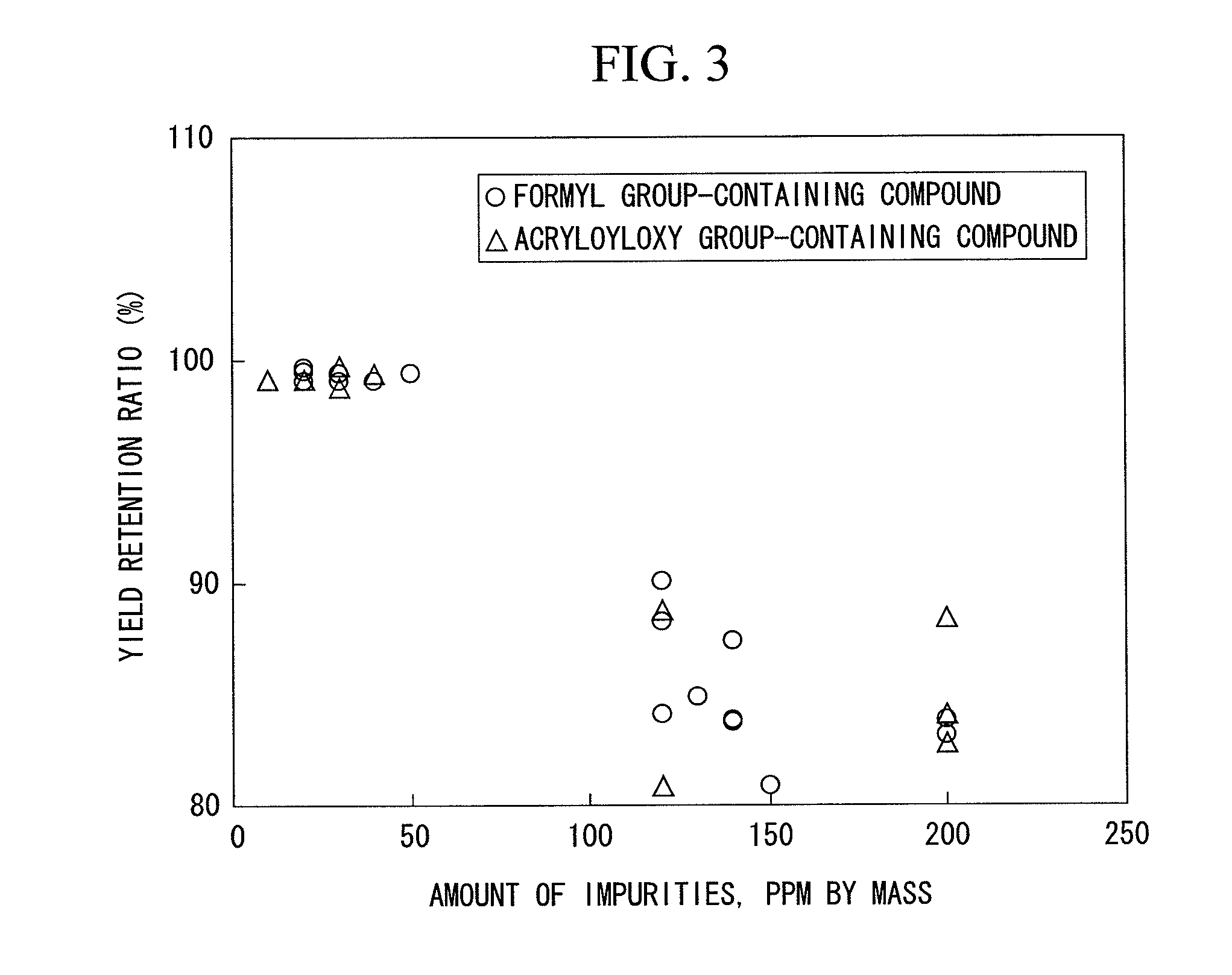

METHOD FOR PRODUCING n-PROPYL ACETATE

ActiveUS20110065951A1Deterioration can be suppressedReduce frequencyOrganic compound preparationPreparation by transesterificationAllyl acetatePurification methods

Provided is a method for producing n-propyl acetate capable of suppressing the deterioration of a hydrogenation catalyst to such an extent that the catalyst can be industrially used, for example, in the case where n-propyl acetate is produced by performing a hydrogenation reaction in the presence of the hydrogenation catalyst using, as a raw material liquid, a liquid containing allyl acetate or the like which has been produced from propylene, oxygen and acetic acid and obtained using a purification process such as distillation. In such a method for producing n-propyl acetate, the concentration of a formyl group-containing compound (such as acrolein, propionaldehyde or 2-methylcrotonaldehyde) and the concentration of an acryloyloxy group-containing compound (such as acrylic acid or allyl acrylate) in the raw material liquid are respectively set to 100 ppm by mass or less. As a result, the deterioration of the hydrogenation catalyst can be suppressed to such an extent that the catalyst can be industrially used.

Owner:RESONAC CORP

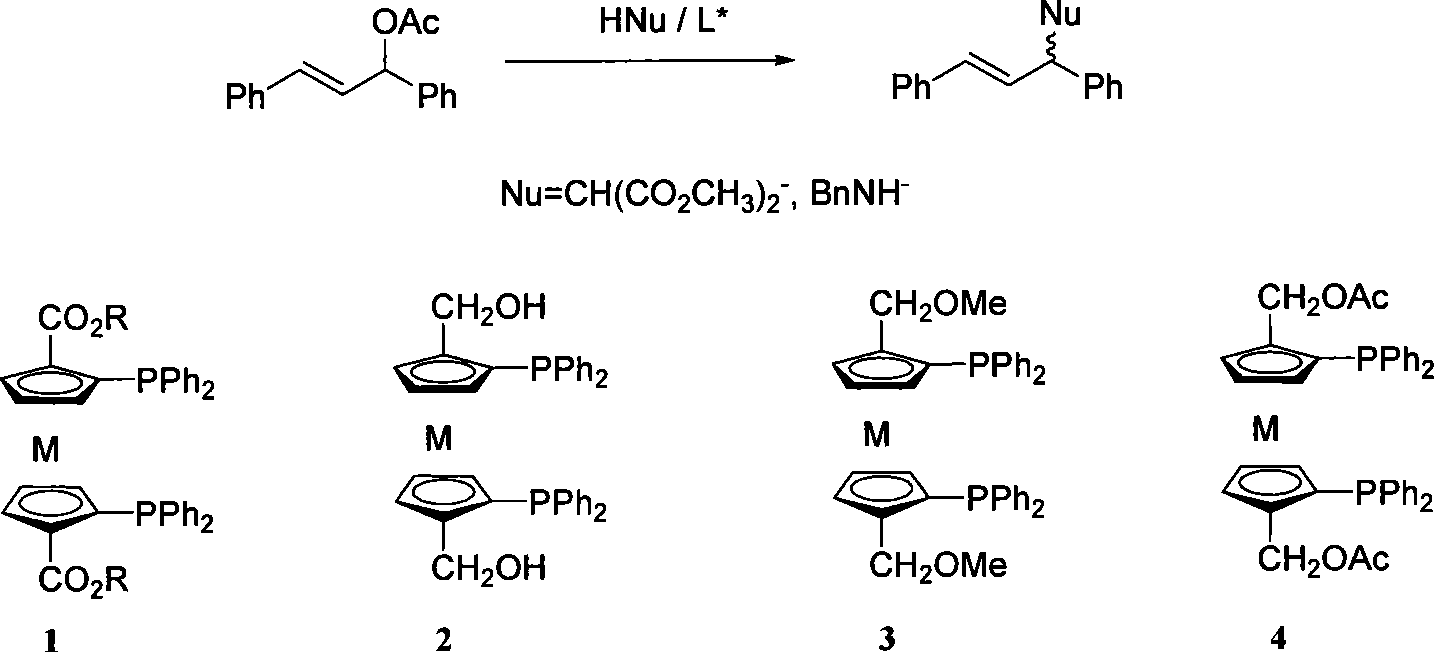

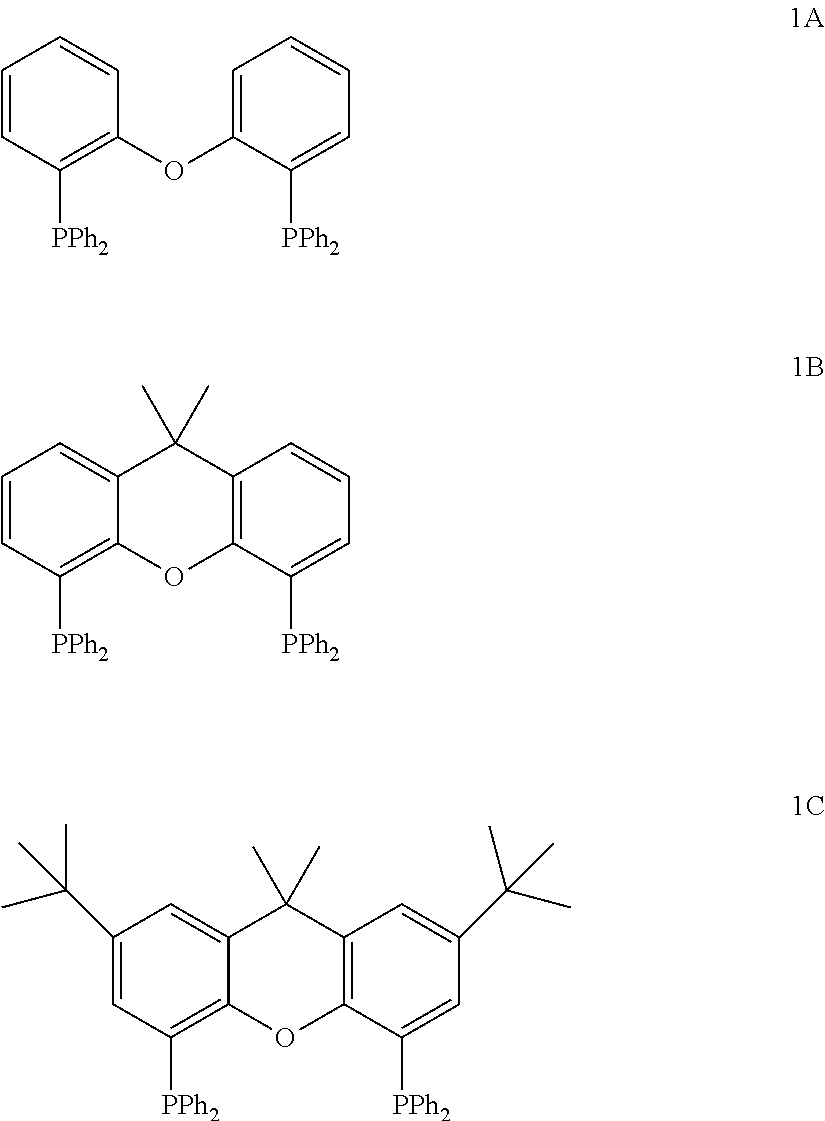

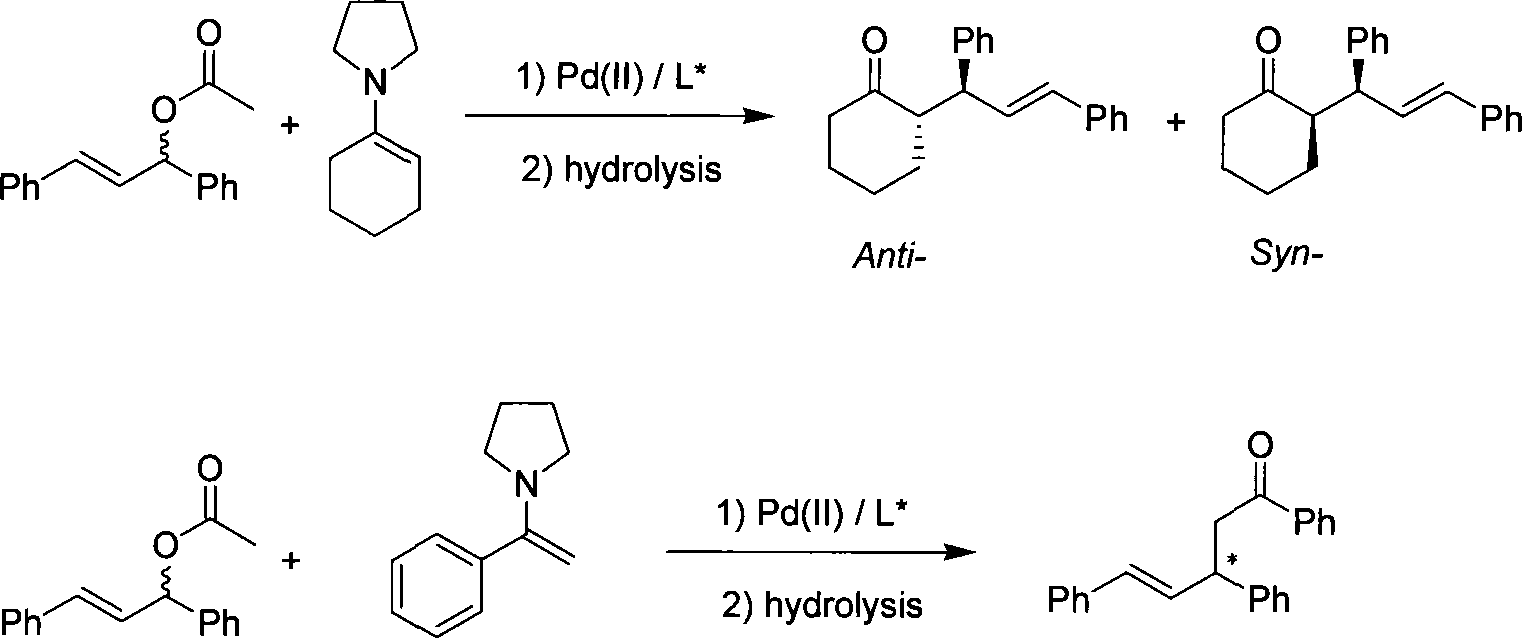

Enantioselectivity reversion method for allyl substitution reaction catalyzed by Pd

InactiveCN101143818AEasy to predict stereo configurationSimple and fast operationOrganic compound preparationOrganic chemistry methodsAllyl acetateOrtho position

The invention relates to a method of enantioselective reversion in the Pd-catalyzed allylic substitution reaction in the field of chemical technique. Metallocene diphosphine ligand with the same chiral skeleton is applied to the Pd-catalyzed allylic asymmetric substitution reaction of 1, 3-diphenyl allyl acetate, and the used nucleophile is dimethyl malonate or benzylamine. When the group at the ortho position of diphenylphosphine is ester group, a S-shaped product is produced by catalysis. If the ester group is reduced into hydroxymethyl group, then a R-shaped product is induced, and the etherified or esterified hydroxyl group has the same inductive function. The method has the advantages of convenient operation, convenient spatial configuration of predicted products and wide screenable range.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparation method of allyl acetate

ActiveCN103058863ALarge stacking porosityLarge particle surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateAcetic acid

The invention relates to a preparation method of allyl acetate, and the method is mainly used for solving the technical problems that the allyl acetate catalyst has the defects of low space-time yield and poor reaction selectivity in an allyl acetate synthesis method in the prior art. The technical scheme adopted by the invention is as follows: according to the method, a catalyst of allyl acetate is synthetized through gas-phase reaction of propylene, acetic acid and oxygen-containing gas, the carrier of the catalyst is SiO2 or a mixture of SiO2 and Al2O3, the carrier is cylindrical and the length of the cylinder is 3-8mm, the ratio of the length to the diameter is 0.78-1.0, the inner cross section of the cylinder is latticed, and the shape of grid holes is triangle or square, so that the problems in the prior art are better solved, and the method can be used in the industrial production of allyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

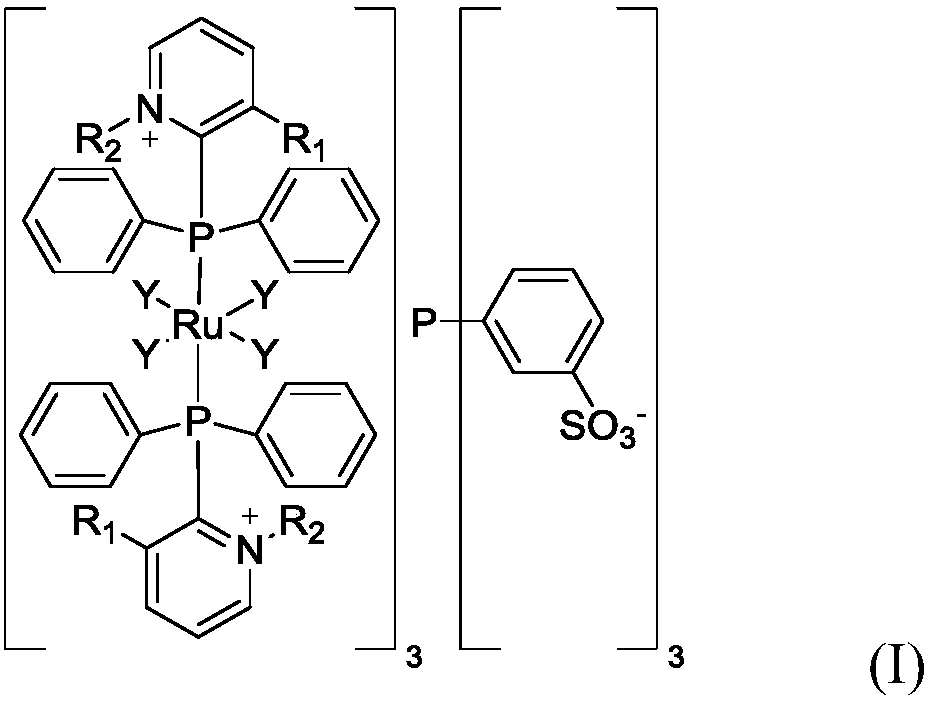

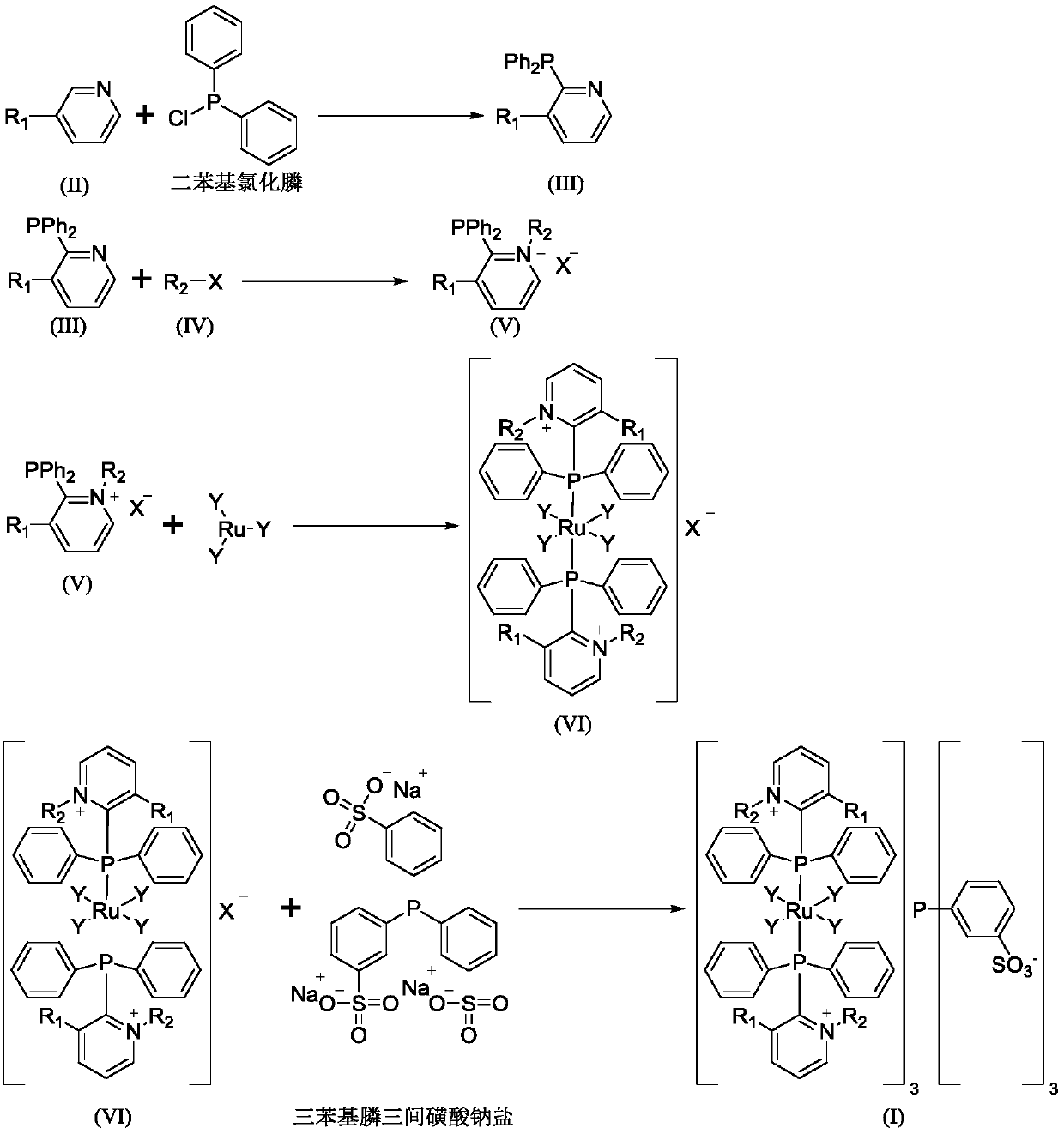

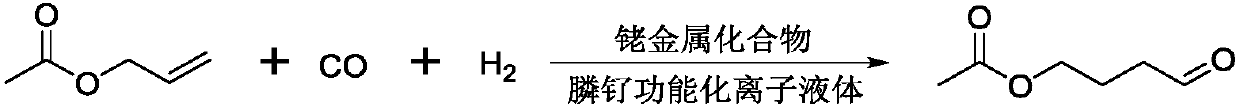

Phosphine-ruthenium functionalized ionic liquid and preparation method thereof, catalyst and preparation method for 4-acetoxybutyraldehyde

ActiveCN109550519ASuppress generationImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateRuthenium

The invention relates to a phosphine-ruthenium functionalized ionic liquid and a preparation method thereof, a catalyst and a preparation method for 4-acetoxybutyraldehyde. The catalyst containing thephosphine-ruthenium functionalized ionic liquid is utilized to catalyze a hydroformylation reaction of allyl acetate to generate the 4-acetoxybutyraldehyde, wherein the conversion rate of the reaction is up to 99%, and the yield of the 4-acetoxybutyraldehyde is up to 95.17% to 98.57%. The catalyst provided by the invention can be separated from a product only with the need of simple extraction and phase separation, can be directly used for a next reaction, and still can maintain high reaction conversion rate (larger than 99%) and high yield (larger than 95%) after being separated and reused for a plurality of times.

Owner:WANHUA CHEM GRP CO LTD

Method for synthesizing cis-alpha-allyl-beta, gamma-unsaturated carboxylic acid ester

InactiveCN101318896AEasy to separate and purifyEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetatePlatinum

The invention relates to a cis-alpha-allyl-belta, gamma-unsaturated carboxylic ester and a method for synthesizing the same. The method comprises the following steps that: a1,4-addition of a Grignard reagent and an allenoic ester, is conducted to give a 1,3-conjugated diene magnesia salt at a temperature of below 78 DEG C under the catalytic action of ferric acetylacetonate. The 1,3-conjugated diene magnesia salt reacts with allyl acetates under the catalytic action of tetrakis(triphenylphosphine)platinum to give a series of cis-alpha-allyl-belta, gamma-unsaturated carboxylic ester compounds. The synthetic method has the advantages that the operation is simple, the raw materials and reagents are readily available, the reaction has high regional and vertical selectivity and can substitute two groups at the same time, the products can be separated and purified easily, and can be used to synthesize various cis-alpha-allyl-belta, gamma-unsaturated carboxylic esters.

Owner:ZHEJIANG UNIV

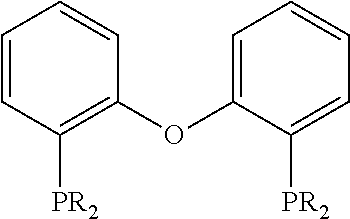

Allyl acetate hydroformylation process

ActiveUS20110124904A1Raise the ratioOrganic compound preparationPreparation by transesterificationAllyl acetateDiphenyl ether

A process for the production of 4-acetoxybutyraldehyde is described. The process comprises reacting allyl acetate with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst comprising a rhodium complex and a diphosphine. The diphoshine is a substituted or unsubstituted 2,2′-bis(dihydrocarbylphosphino)diphenyl ether. The process gives a high ratio of 4-acetoxybutyraldehyde:3-acetoxy-2-methylpropionaldehyde.

Owner:LYONDELL CHEM TECH LP

Method for application of enamine in palladium catalytic asymmetry allyl group alkylated reaction

InactiveCN101139270ASimple and safe operationHigh reactivityOrganic compound preparationCarbonyl compound preparationAllyl acetateEnamine

The present invention relates to a method in the chemical technological field wherein the enamine is used in the palladium-catalyzed asymmetric allyl alkylation; the chiral ligand and the palladium catalyst are dissolved in the solvent first and react at the room temperature; the substituted allyl acetate is added; the mixture is stirred; then the enamine category compounds are added in the reaction; the cold saturated ammonium chloride solution is used for hydrolysis after the reaction is finished; thus, the product can be made. The enamine is a quite convenient and quite promising pro-nuclear reagent and overcomes the trouble of the unstable enol ether caused by the replacement of the alkali with the simple ketone; the operation is simple and safe; and the catalytic reaction has the high activity and selectivity of the reaction.

Owner:SHANGHAI JIAO TONG UNIV

Industrial synthesis method for acetoxylpropyltrimethoxysilane

ActiveCN108059639AHigh yieldThe synthesis process is simpleGroup 4/14 element organic compoundsAllyl acetateSynthesis methods

The invention relates to an industrial synthesis method for acetoxylpropyltrimethoxysilane, which belongs to the technical field of fine chemical engineering. According to the industrial synthesis method, trichlorosilane and allyl acetate first undergo hydrosilylation under catalyst, so that acetoxylpropyltrichlorosilane is obtained, and methanol is then used for esterifying acetoxylpropyltrichlorosilane so that acetoxylpropyltrimethoxysilane and hydrochloric acid are obtained. The yield of acetoxylpropyltrimethoxysilane disclosed by the invention is high, the synthesis process is simple and safe, and the environment is not polluted.

Owner:JINGZHOU JIANGHAN FINE CHEM

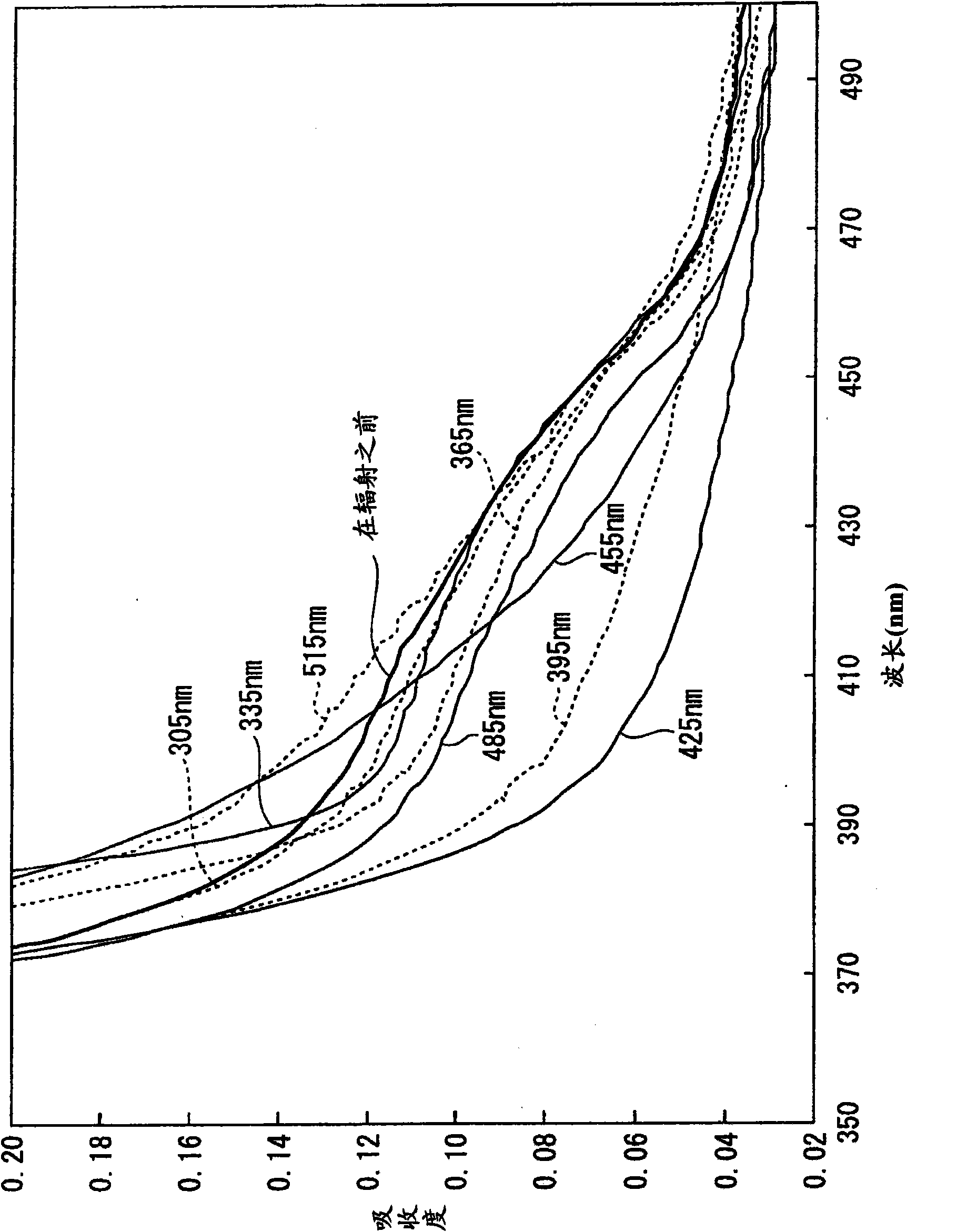

Method of producing n-propyl acetate and allyl acetate

InactiveCN101855195AOrganic compound preparationCarboxylic acid esters preparationAllyl acetateHydrogenation reaction

The present invention provides a method of producing n-propyl acetate comprising producing allyl acetate by using propylene, oxygen and acetic acid as raw materials, and subsequently carrying out a hydrogenation reaction by using the allyl acetate as raw material that is an intermediate of a process for producing allyl alcohol by hydrolyzing the allyl acetate; wherein, the method comprises a photoirradiation treatment step and / or ozone treatment step, hi addition, the present invention provides a method of producing allyl acetate comprising producing allyl acetate by using propylene, oxygen and acetic acid as raw materials, and subsequently carrying out photoirradiation treatment on allyl acetate that is an intermediate of a process for producing allyl alcohol by hydrolyzing the allyl acetate.

Owner:SHOWA DENKO KK

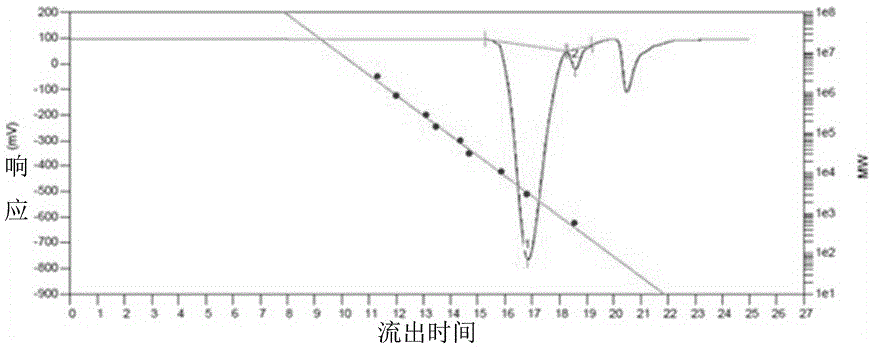

Fluorine-containing polyether glycol and preparation method thereof

The invention relates to fluorine-containing polyether glycol and a preparation method thereof. According to the preparation method, single electron addition reaction is carried out on perfluoroalkyl iodine serving as an initial raw material with allyl acetate butyl ester, and fluorine-containing oxetane is prepared by cyclization reaction; when fluorine-containing oxetane and dimethyl oxetane are copolymerized, a polyether product of fluoroalkyl, which is uniformly distributed on the main chain of a polyether macromolecule can be obtained due to close polymerization of the two epoxy monomers; the proportion of copolymer monomers is regulated to obtain polyether glycol with different fluorine contents, and the fluorine-containing high-polymer products with various performances can be prepared favorably; and the production cost of the fluorine-containing polyether product can be reduced by adding non-fluorine-containing oxetane monomer for copolymerizing. When the side-radical fluorine-containing alkyl polyether glycol is used for preparing a high-polymer material, the side-chain fluorine alkyl can be used for supplying strong hydrophobicity; and furthermore, the preparation process of the fluorine-containing polyether glycol is simple and convenient, is mild in reacting condition, only requires conventional equipment during production, and is suitable for industrial production.

Owner:SUZHOU UNIV

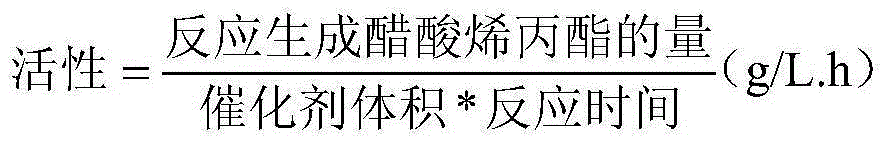

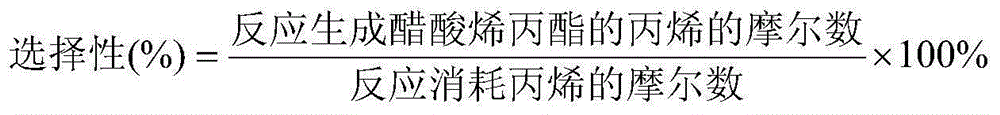

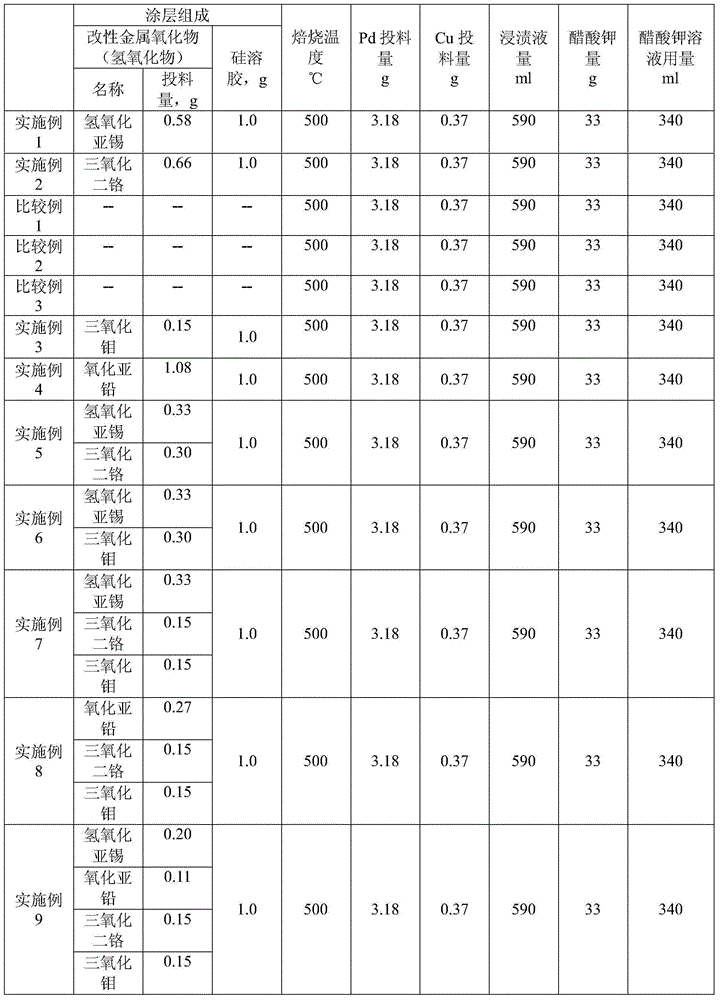

Allyl acetate catalyst and application thereof

ActiveCN106582854AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateActive component

The invention relates to an allyl acetate catalyst and an application thereof. The problems of poor activity and low selectivity of catalysts in the prior art are mainly solved in the invention. The catalyst comprises a carrier, an active component and a cocatalyst; the active component comprises metal Pd and metal Cu; the cocatalyst is alkali metal acetate; the carrier comprises a carrier substrate and a surface coating; the substrate is porous silica; the coating comprises a modified metal element and a silica binder for binding the modified metal element to the surface of the substrate; the content of the modified metal element is 0.1-1.00 g / L; and the modified metal element is selected from at least one of group IVA metal elements and group VIB metal elements. The allyl acetate catalyst well solves the problems, and can be used in industrial production of allyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com