Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1474 results about "Butyraldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyraldehyde, also known as butanal, is an organic compound with the formula CH₃(CH₂)₂CHO. This compound is the aldehyde derivative of butane. It is a colourless flammable liquid with an unpleasant smell. It is miscible with most organic solvents.

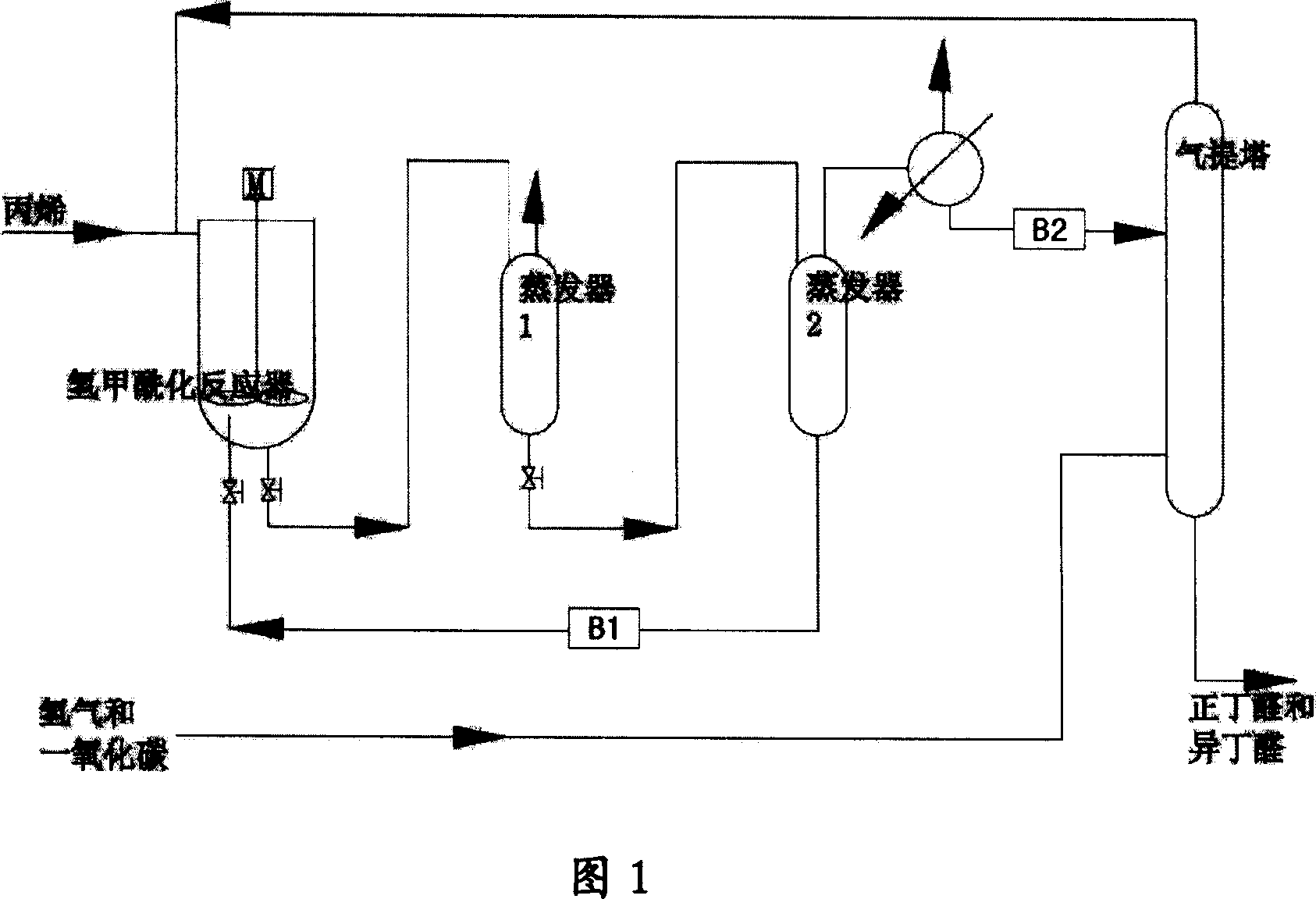

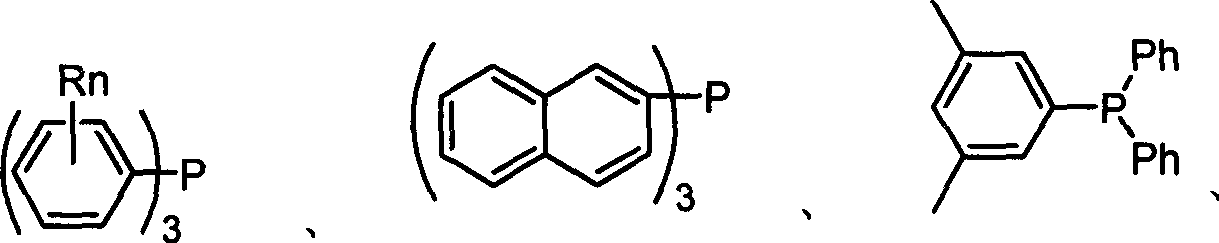

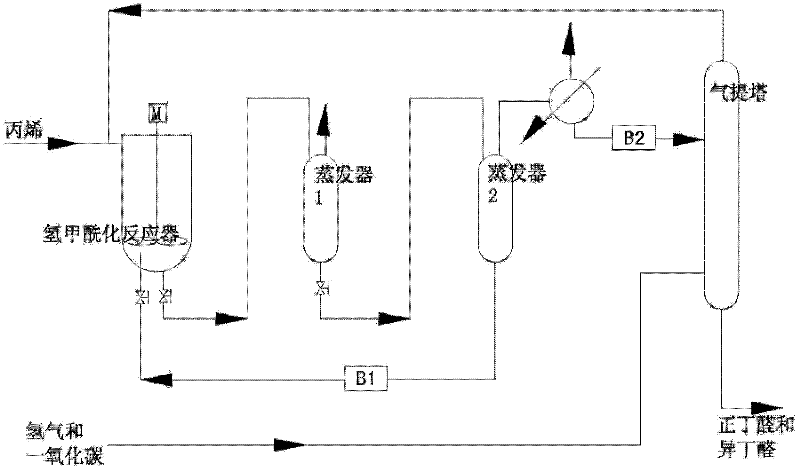

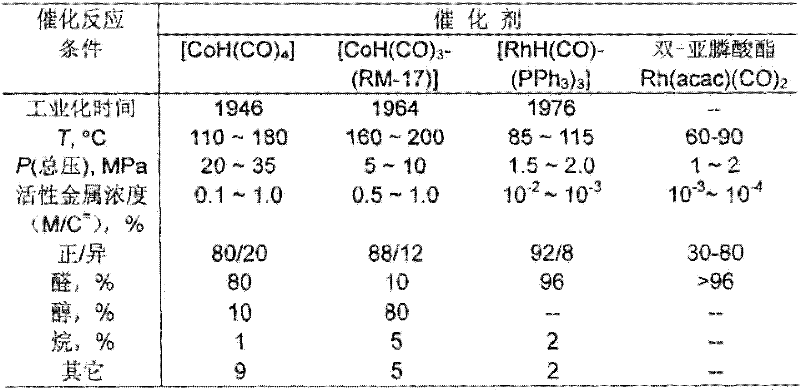

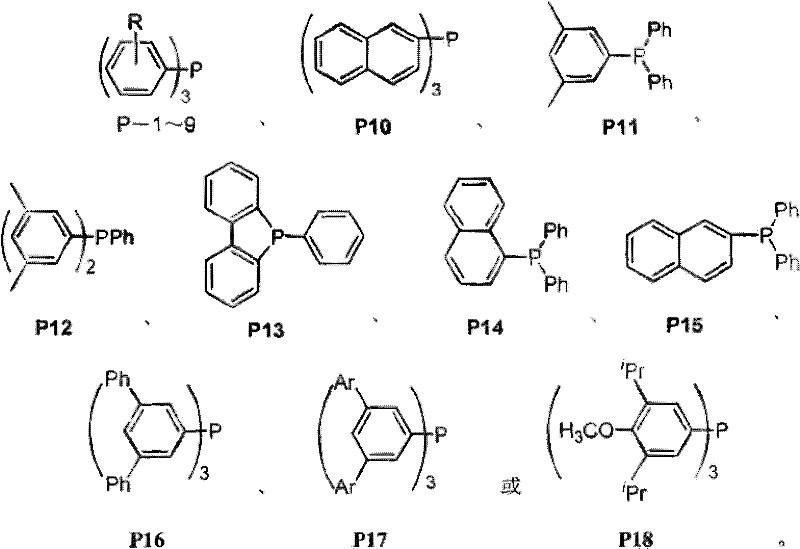

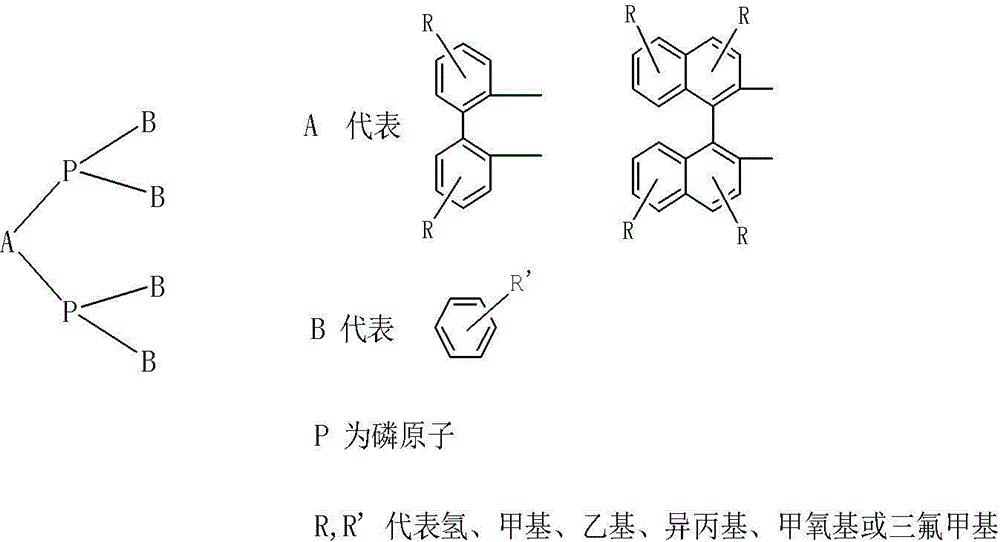

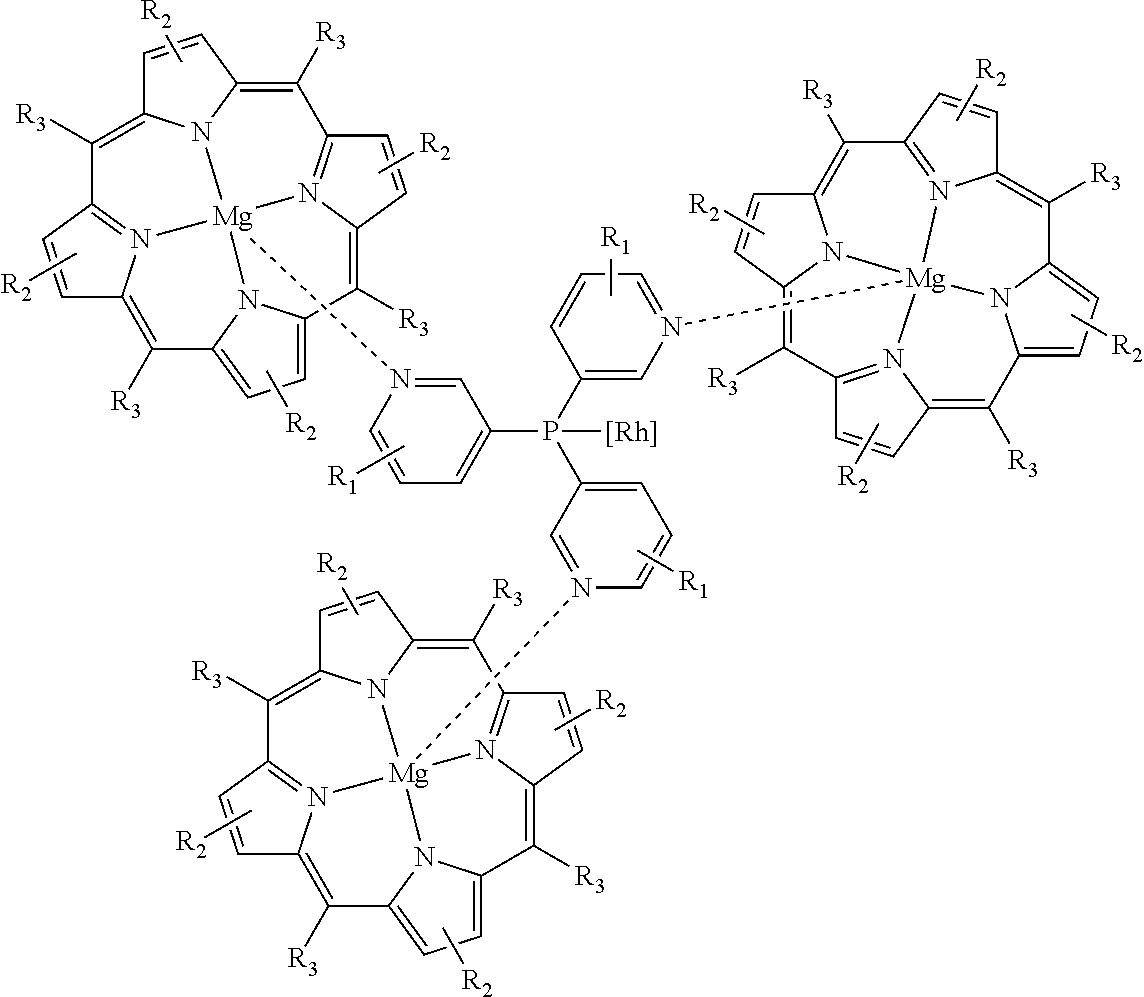

Catalyst system and catalyzing method of propylene hydrogenation and formylation

ActiveCN1986055AReduce dosageImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionTriphenylphosphine

The present invention relates to catalyst system for propylene hydrogenation and formylation and process of catalytically synthesizing butyl aldehyde. The catalyst system is triaryl phosphine-Rh(I) catalyst system with proper additive, such as bisphosphite ester, in proper amount. Compared with similar available catalyst, the catalyst system has obviously higher catalytic acitivity, higher selectivity, higher stability and raised n-butyl aldehyde / isobutyl aldehyde ratio in the catalytically synthesized product.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Intrusion resistant glass laminates

InactiveUS20050170160A1Increase stiffnessHigh stiffnessFilm/foil adhesivesSynthetic resin layered productsPolyvinyl butyralPolyethylene terephthalate

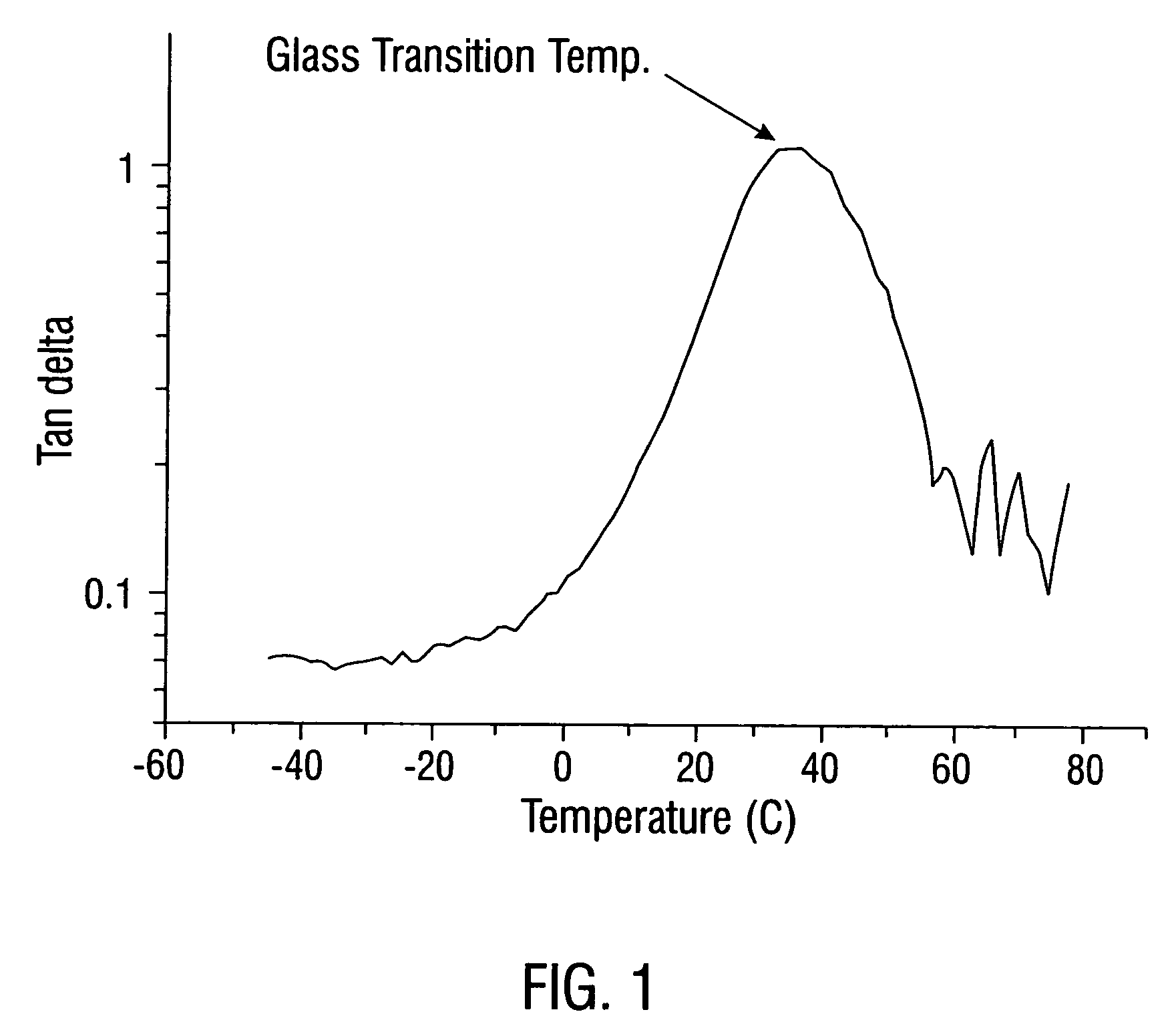

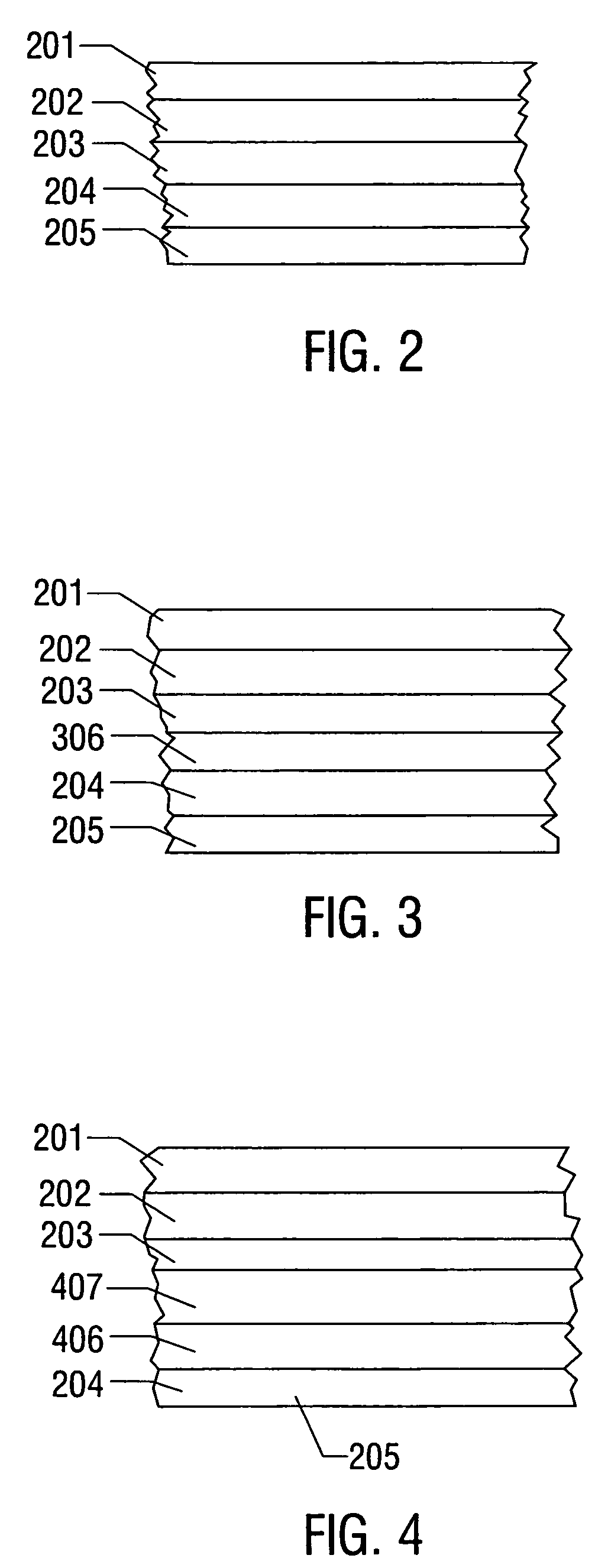

Composite laminate interlayers for adhering a glass laminate comprising a sheet of polyethylene terephthalate (PET) between layers of plasticized polyvinyl butyral (PVB) adhesive layers, wherein at least one of the PVB adhesive layers is stiffened, e.g. by reduction in the amount of plasticizer, and has a glass transition temperature greater than 35° C. The PET is preferably 0.075 to 0.25 mm (3-10 mils) thick and can have a functional coating for reducing radiation, e.g. UV or IR or visible light, transmission through the glass laminate. The laminate can also comprise at least one elastomeric layer adapted to reducing sound transmission through the glass laminate. The laminates exhibit enhanced maximum flexural modulus of greater than about 350 Newtons / centimeter.

Owner:SOLUTIA INC

Method for preparation of aviation kerosene and diesel oil from biomass derivative

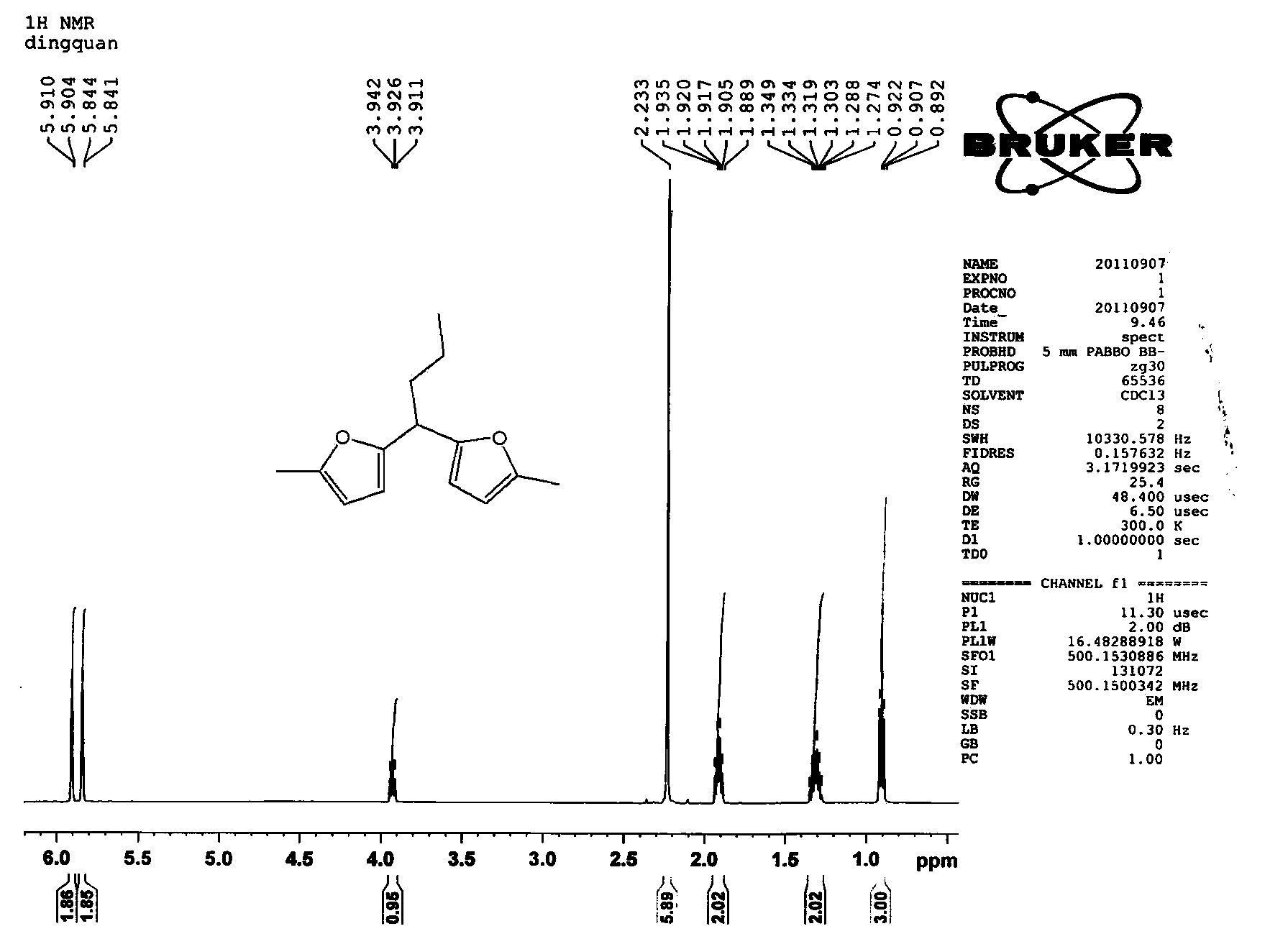

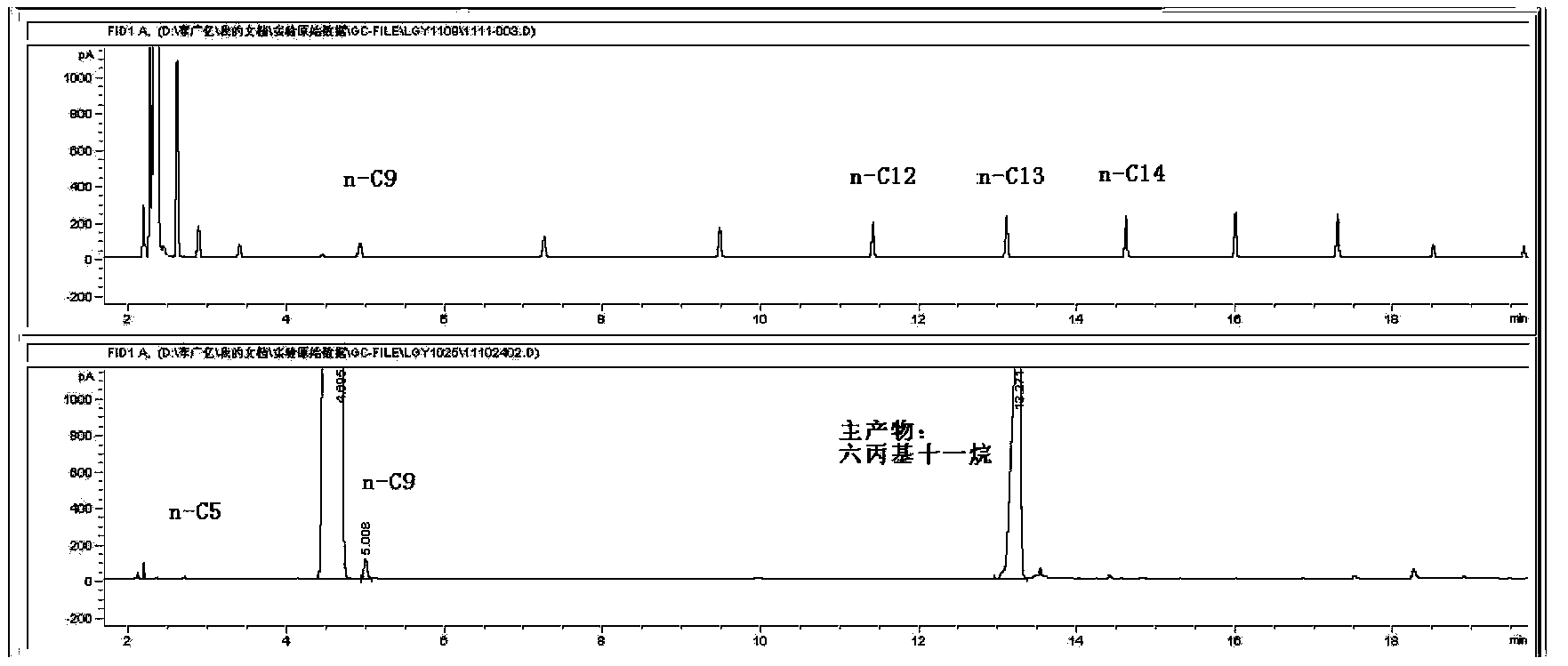

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Microorganisms for producing 1,4-butanediol and methods related thereto

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO), 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway comprising at least one exogenous nucleic acid encoding a BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway enzyme expressed in a sufficient amount to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine.

Owner:GENOMATICA INC

Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

InactiveCN101570090APromote environmental protectionThermographyInk transfer from master sheetPolyvinyl butyralAcrylic resin

The invention relates to a production method of an environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film. The production method comprises the following steps: a PET film of 6 to 15 micron is adopted as a carrier film; the carrier film is sequentially provided with four coatings such as a releasing layer, a color layer, an aluminum layer and an adhesive layer; wherein the releasing layer, the color layer and the adhesive layer coat the coating materials on a PET basal membrane substrate by a smooth roll or an anilox roll in a forward coating mode or backward coating mode; the aluminum layer is spray-plated in a vacuum spray-plating mode; the invention adopts the environment-friendly material and the production technique to produce the aluminothermic transfer printing film product, and the key points are as follows: solvent based acrylic resin, ethylene-vinyl acetate resin, ketone resin and cellulosic resin hot melt adhesive are changed into cellulose acetate and products made by cellulose acetate; and vinyl cellulose, polyvinyl butyral and powdery silicon dioxide are synthesized by water and a mixed solvent in a mode of wetting and dispersing. The production method has the characteristics of having no solvent residue harmful to human body and being beneficial to environmental protection and the like.

Owner:莫国平

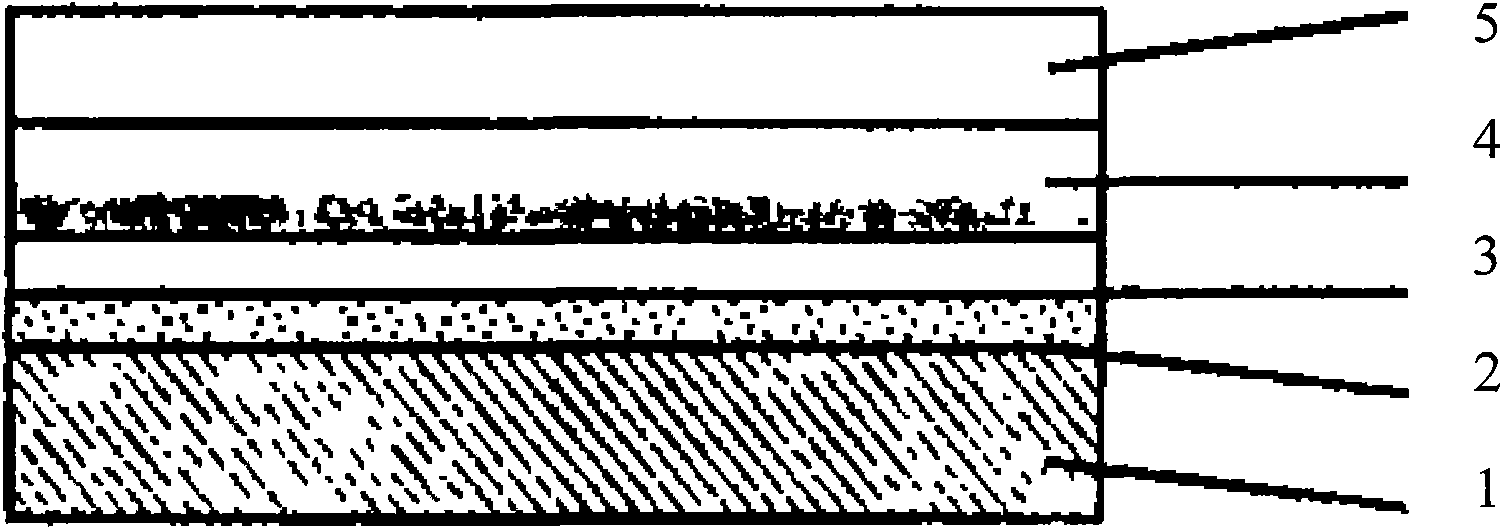

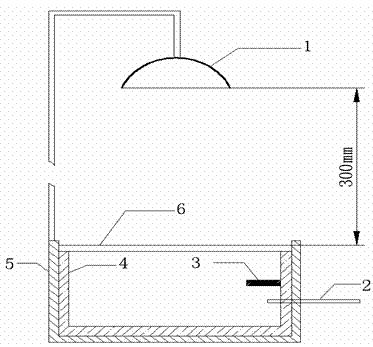

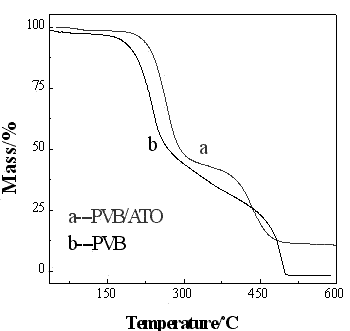

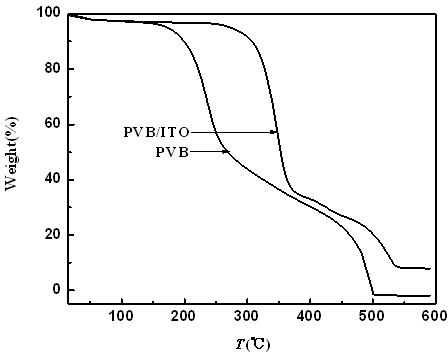

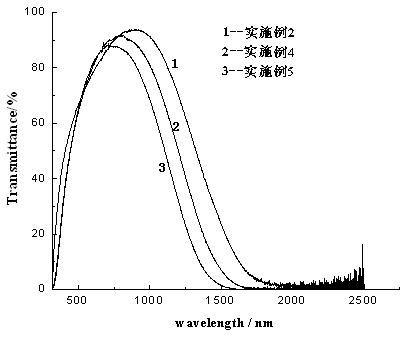

Polyvinyl butyral transparent film and preparation method thereof

ActiveCN102863917ANon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceComposite film

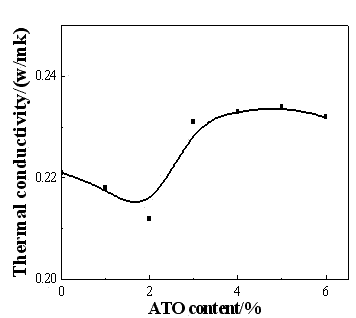

The invention belongs to the field of polymer / nanoparticle composite materials, and relates to an infrared thermal reflection and anti-ultraviolet polyvinyl butyral (PVB) transparent film for laminated safety glass and a preparation method thereof. According to the method, nano-indium stannum oxide (ATO) is selected as functional particles, is subjected to double processing through a coupling agent and a dispersing agent and is poured into a mold to be formed and compounded after being directly and uniformly mixed with purchased or self-made polyvinyl butyral, plasticizer, antioxidant and filming agent by means of ultrasonic wave to prepare a heat-insulating PVB nano composite film. The nano-ATO particles are subjected to the double processing and the special ultrasonic dispersion process, so that the problem of agglomeration of the ATO is effectively improved; and the prepared PVB nano composite film has superior mechanical property and higher infrared reflectivity and visible light transmittance, and can be directly used for processing and producing heat-insulating, sound-insulating, anti-ultraviolet, transparent and impact-resistant multi-functional safety glass.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

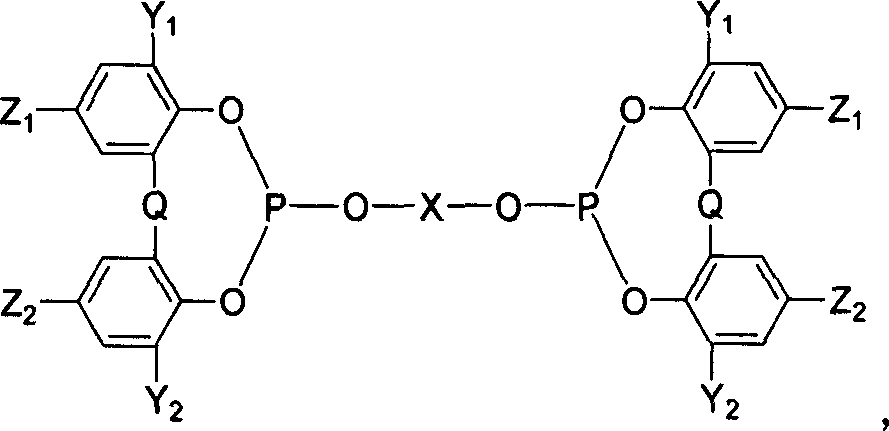

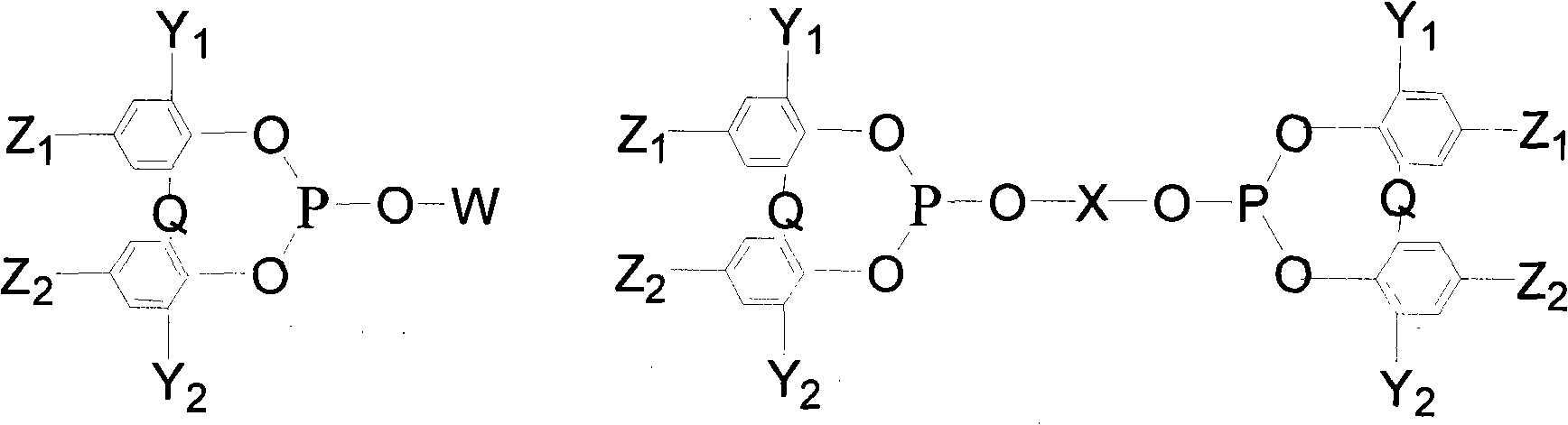

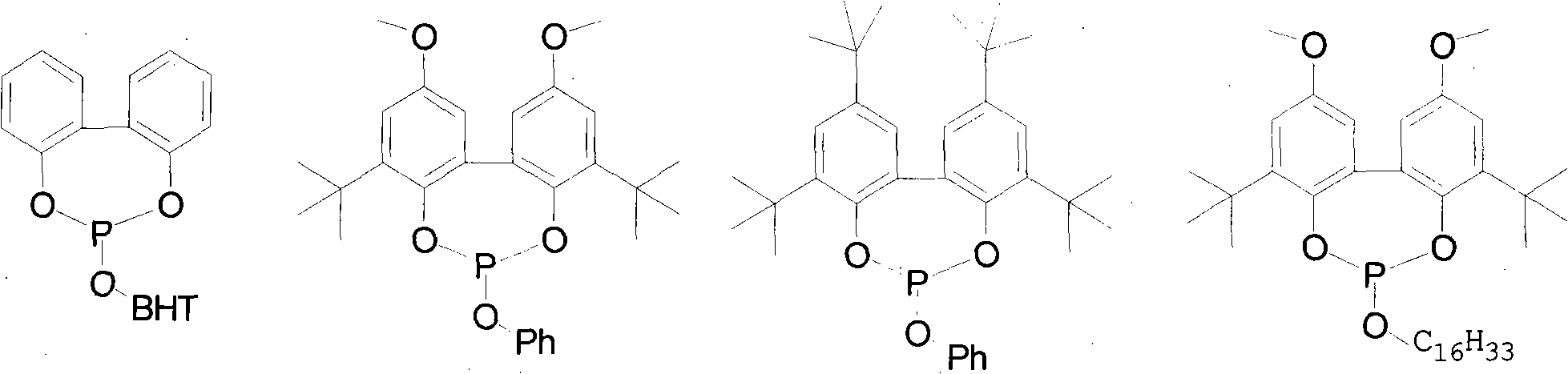

A kind of propylene hydroformylation catalytic system and method

InactiveCN102266796AReduce dosageImprove stabilityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsFormylation reactionTriphenylphosphine

The invention relates to a propylene hydroformylation catalyst system and a method for catalyzing synthesis of butyraldehyde. In the present invention, in the propylene hydroformylation reaction system catalyzed by triarylphosphine-Rh(I), by using appropriate types and quantities of additives, such as bisphosphite, the performance of the Rh(I) / triarylphosphine catalyst can be significantly improved The activity and the positive-iso ratio of butyraldehyde in the product (molar ratio of n-butyraldehyde / isobutyraldehyde>20), and significantly prolong the service life of the bisphosphite ligand, and significantly reduce the amount of triarylphosphine. This type of catalyst system is characterized by higher activity and selectivity than third-generation Rh(I) / triphenylphosphine catalysts and better stability than fourth-generation Rh(I) / bisphosphite catalysts, so The novel catalyst system provided by the present invention can overcome the shortcomings of the third and fourth generation catalysts, reduce the cost of industrialized production of propylene hydroformylation, and provide a new catalyst technology for its industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

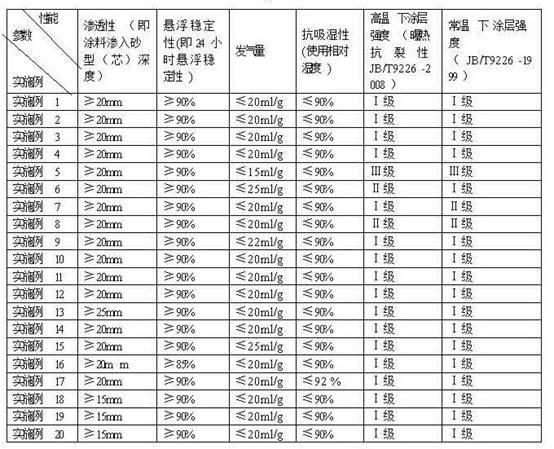

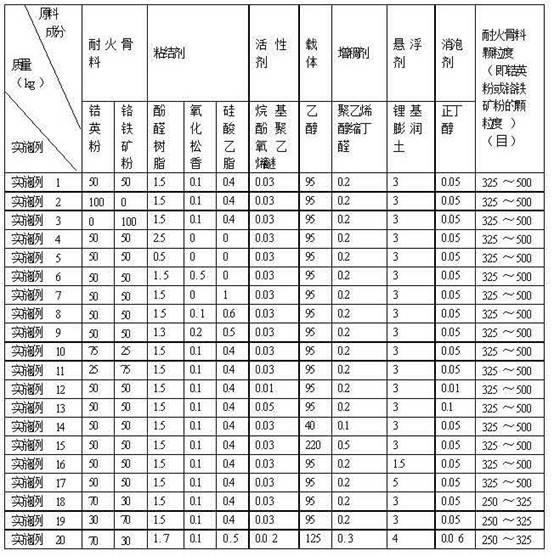

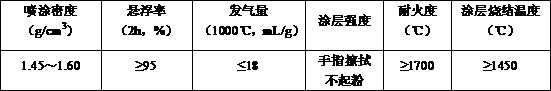

High-permeability sand-burning-preventing paint for casting and preparation method thereof

InactiveCN102139342AImprove permeabilityImprove high temperature strengthFoundry mouldsFoundry coresAlkylphenolSuspending Agents

The invention discloses high-permeability sand-burning-preventing paint for casting and a preparation method thereof. The high-permeability sand-burning-preventing paint is prepared from the following raw materials: refractory aggregate, a binding agent, an activating agent, a thickening agent, a suspending agent, a defoaming agent and a carrier, wherein the masses of the binding agent, the activating agent, the thickening agent, the suspending agent, the defoaming agent and the carrier respectively account for 0.5-2.5 percent, 0.01-0.05 percent, 0.1-0.5 percent, 1.5-5.0 percent, 0.01-0.1 percent and 40-220 percent of the mass of the refractory aggregate; the refractory aggregate is a mixture of one or two of zircon powder and chromite fines in any proportion; the binding agent is phenolic resin or a mixture of the phenolic resin and one or more than two of oxidized rosin and ethyl silicate; the activating agent is alkylphenol ethoxylates; the carrier is ethanol; the thickening agent is polyvinyl butyral; the suspending agent is lithium bentonite; and the defoaming agent is normal butanol.

Owner:衡阳中钢衡重铸锻有限公司

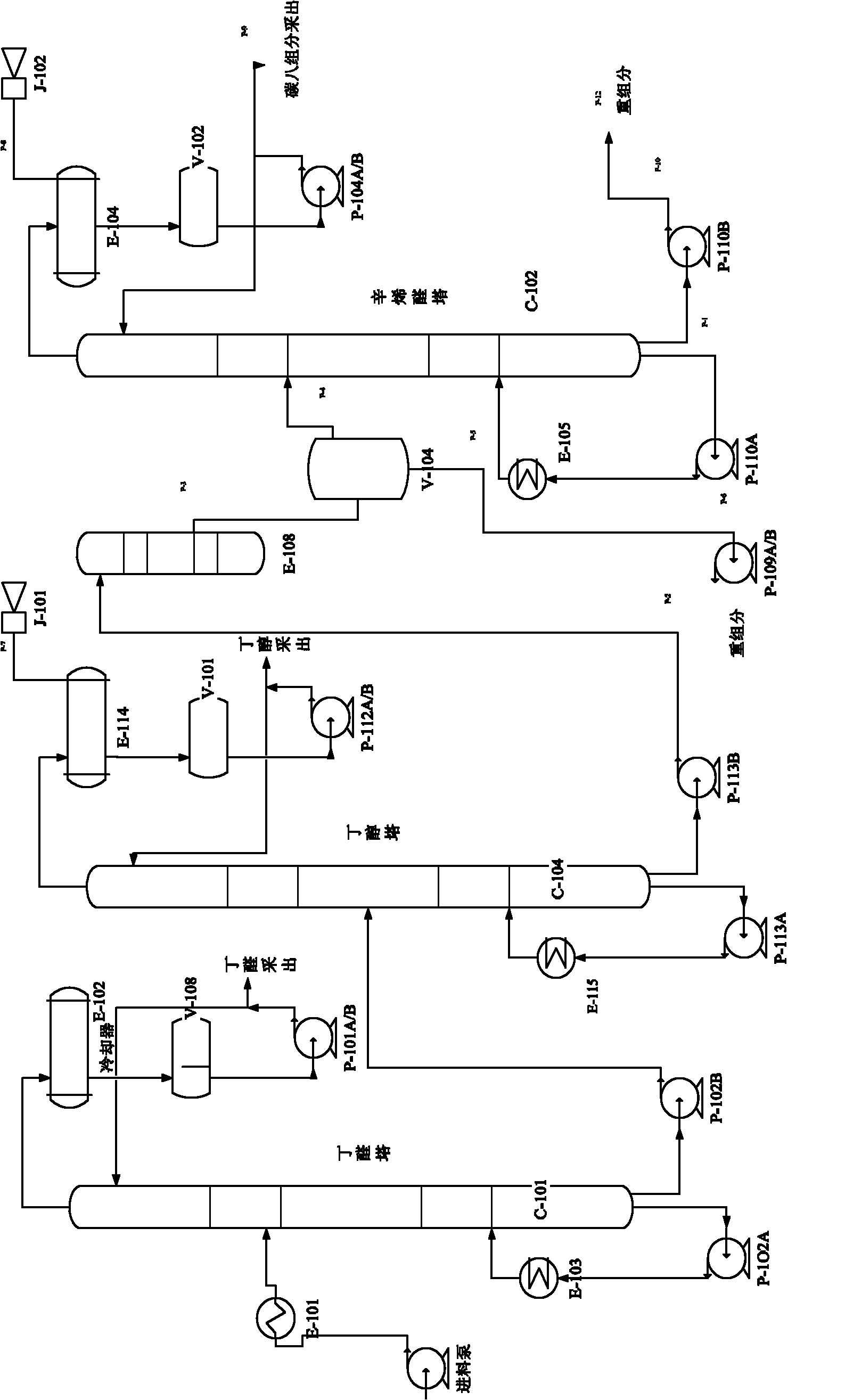

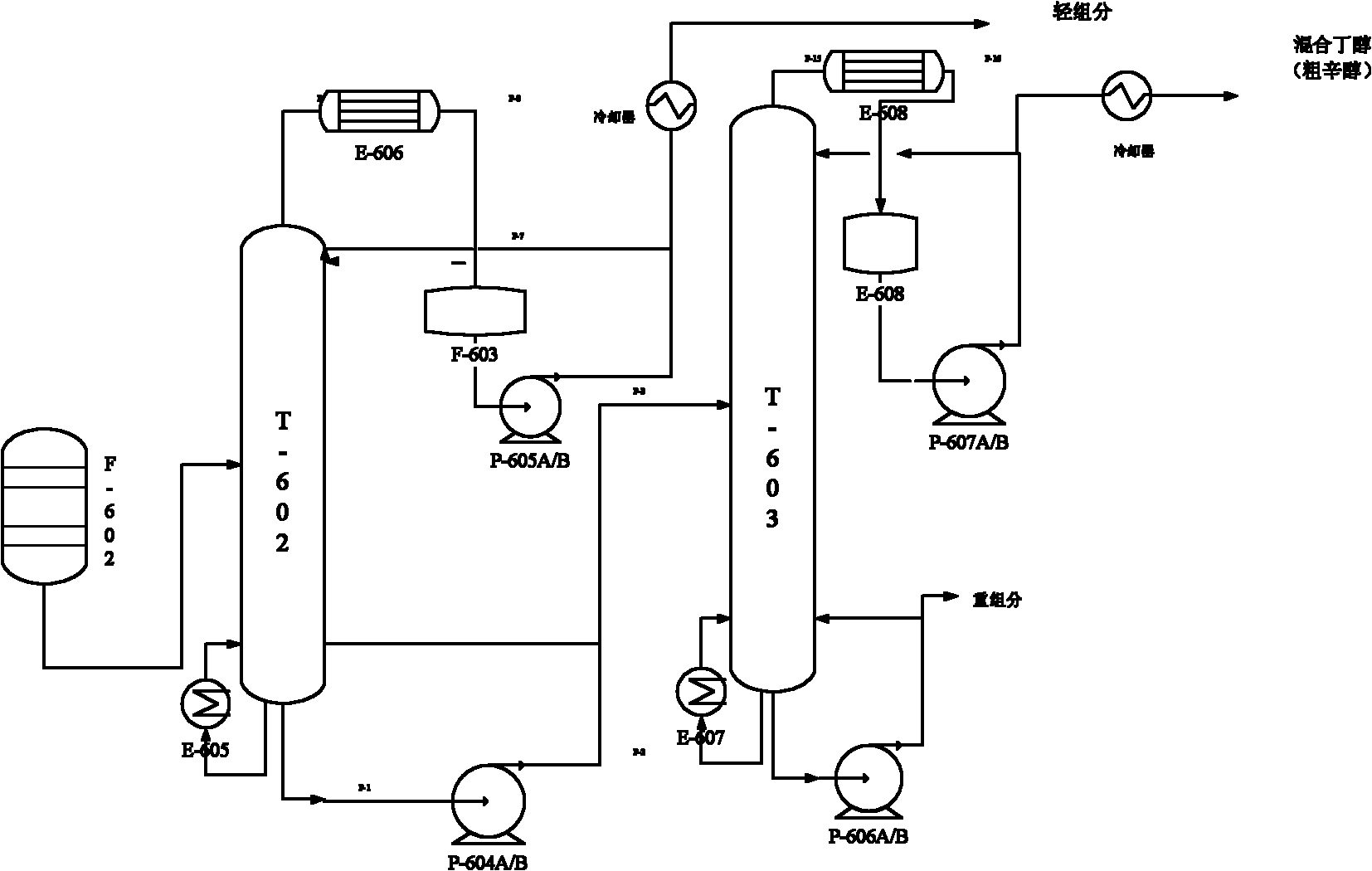

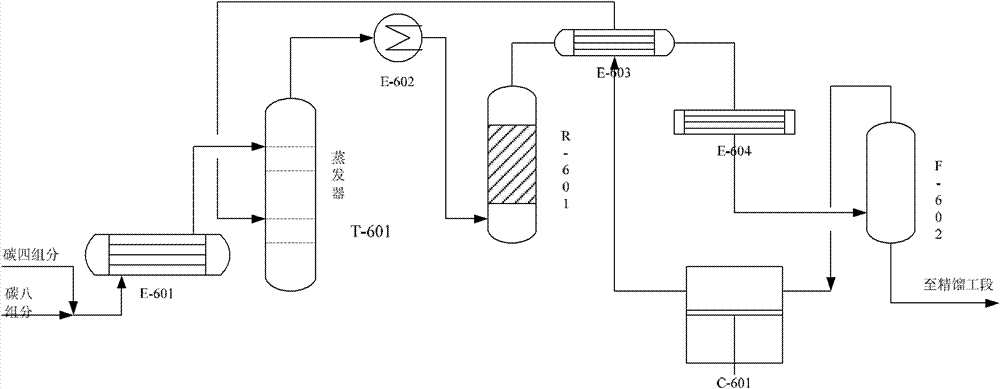

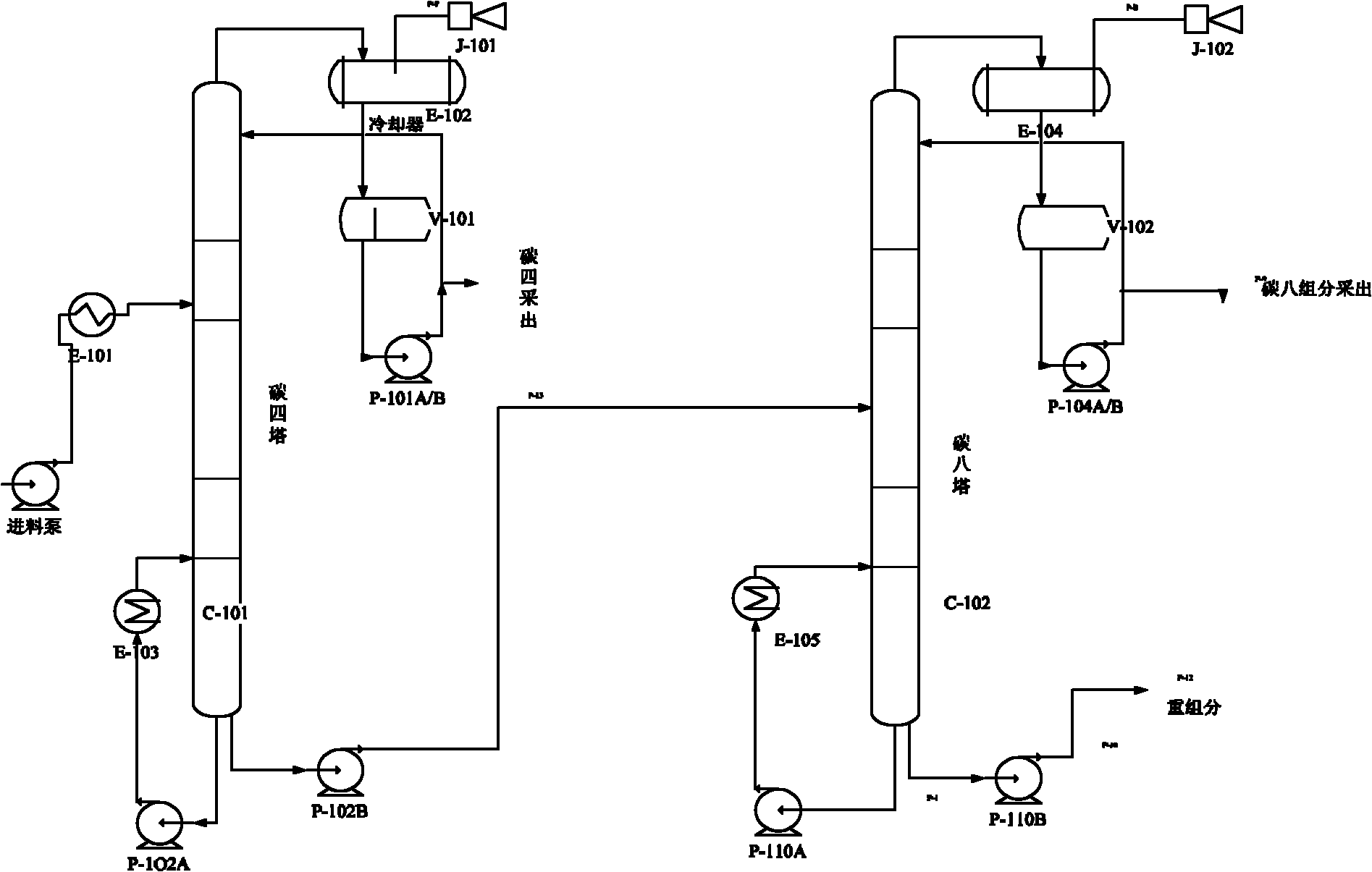

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846AReduce loadReduce processing costsOrganic compound preparationPreparation by hydrogenationLiquid wasteDistillation

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unit are suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

Composite comprising cellulose and thermoplastic polymer

Disclosed are composite compositions and articles prepared from such composites. The composition comprises or is produced from cellulose material, thermoplastic polymer, and a compatibilizing agent which is the reaction product of polyvinyl butyral, having hydroxyl functionality, and a second polymer which comprises or is produced from polyvinyl butyral and a second polymer wherein the polyvinyl butyral comprises a hydroxyl functionality and the second polymer reacts with at least a portion of the hydroxyl functionality.

Owner:DOW GLOBAL TECH LLC

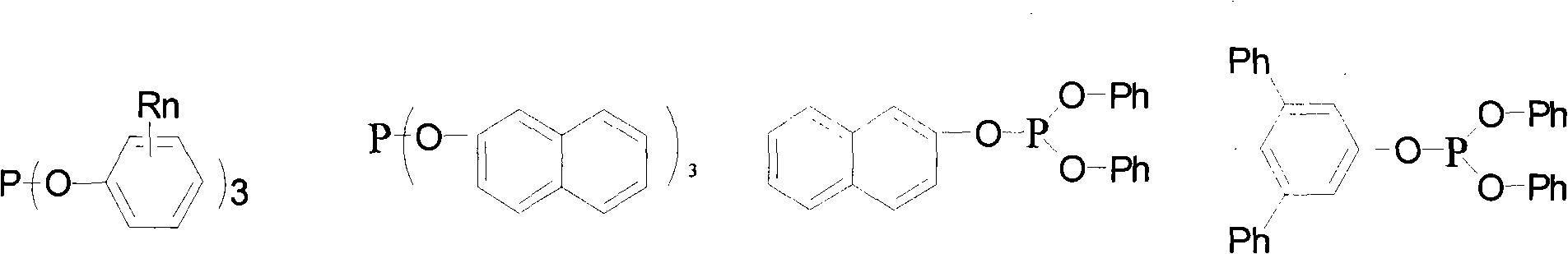

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

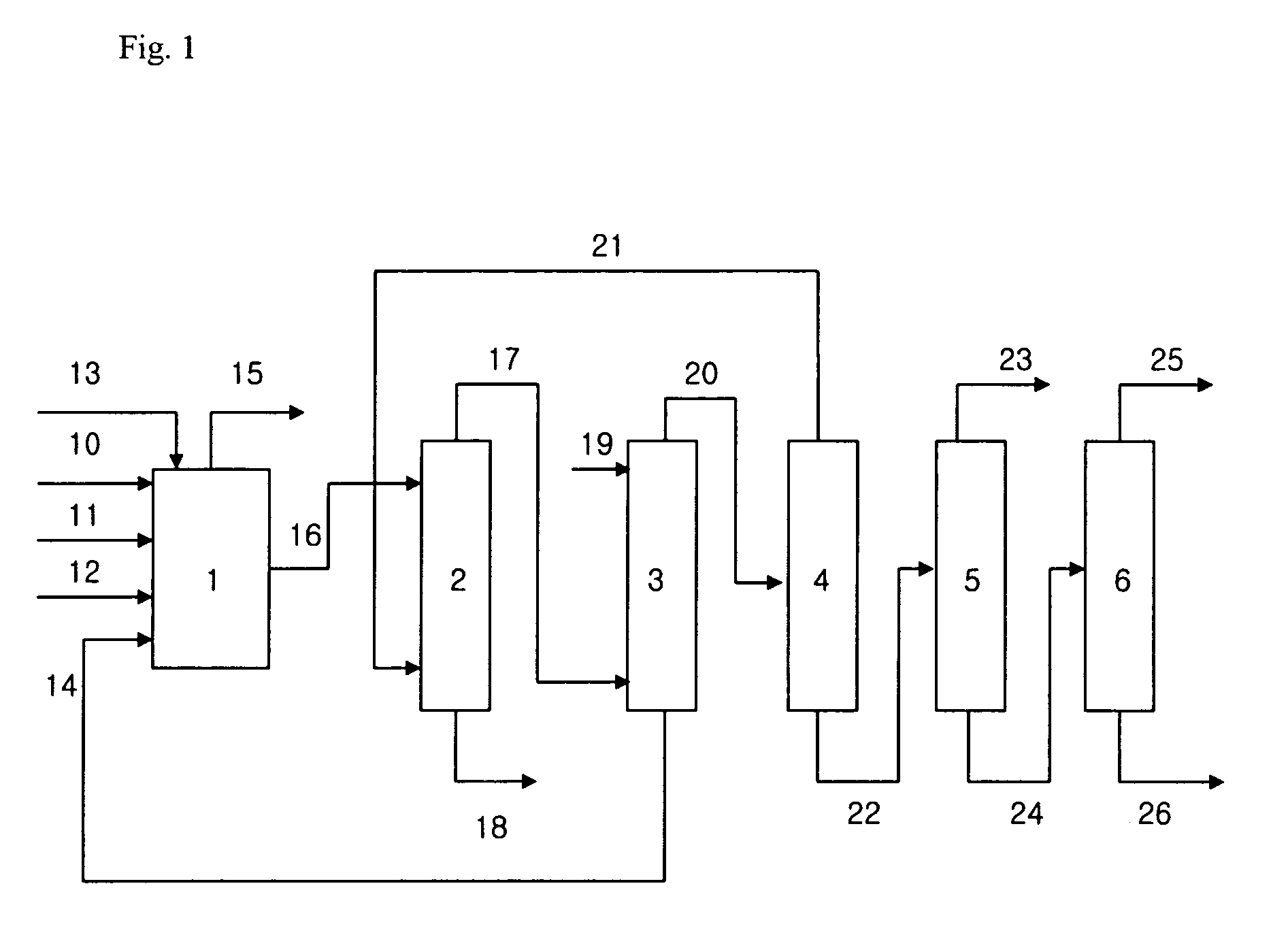

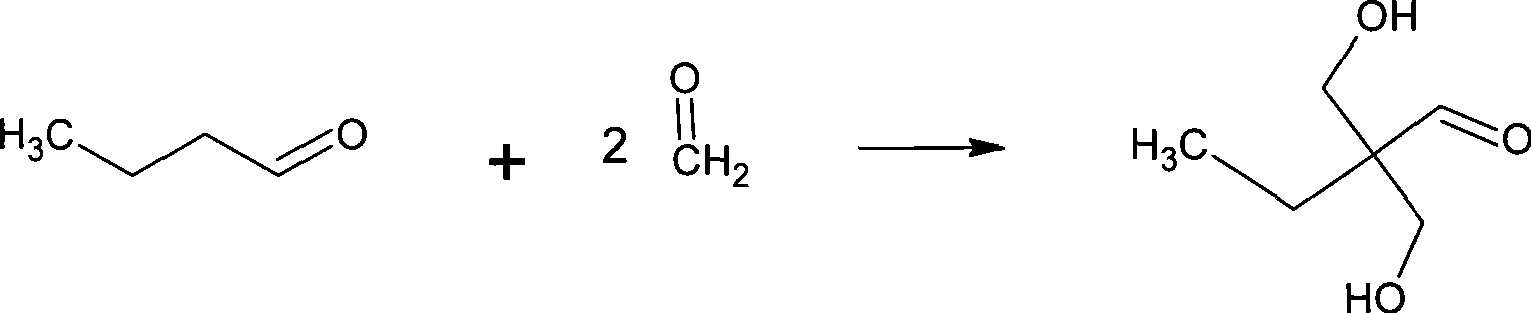

Method for preparing trimethylolproane

ActiveUS7253326B1Effective and economicalOrganic compound preparationOxygen compounds purification/separationAlcoholCannizzaro reaction

The present invention relates to a method for preparing trimethylolpropane (TMP) comprising the steps of: 1) synthesizing trimethylolpropane by using n-butyl aldehyde, an aqueous solution of formaldehyde and an aqueous solution of alkali metal hydroxide through aldol condensation reaction and Cannizzaro reaction; 2) extracting trimethylolpropane from a resultant mixture of the step 1) by contacting the resultant mixture with an alcohol having 6 to 10 carbons; 3) removing alkali metal ion from a resultant extract of the step 2) by contacting the resultant extract with water; and 4) distilling the alkali metal ion-removed extract obtained from the step 3). According to the present invention, a separate formaldehyde recovery process can be omitted, the extraction efficiency of TMP can be maximized with using a relatively small amount of extraction solvent, the separation and recovery processes for extraction solvent can be simplified since a mixture of solvents is not used for TMP extraction, and the yield of TMP can be maximized while the amount of generated waste water can be minimized, thereby producing TMP economically with good efficiency.

Owner:LG CHEM LTD

Method for processing cellulose by supercritical carbon dioxide, products and use thereof

The invention relates to a method for utilizing supercritical carbon dioxide to process cellulose; firstly, the cellulose and a cosolvent or an inorganic sol or a former body of the inorganic sol are arranged in a high pressure container; carbon dioxide is pumped by a pumping pressure; the reaction condition is 15 to 200 DEG C; the pressure is 4 to 40MPa; the reaction time is 0.5 to 24 hours; then the activated cellulose is manufactured; the cosolvent relates to carbinol, ethanol, normal butanol, isobutyl alcohol, acetone, tetrahydrofuran, formaldehyde, n-butyl aldehyde and isobutyraldehyde; the cellulose is a natural cellulose and a ramification thereof; the natural cellulose relates to chopped cotton fibers, cotton fabrics, bagasse, straws, paper products, bamboo, flax and wood. The method for utilizing the supercritical carbon dioxide to process the cellulose has the advantages that: the processing method is simply and easily operated; the supercritical carbon dioxide is adopted, thus having no burning, no pollution and no toxic action and being conveniently recycled and being repeatedly used; the content of the mixed inorganic oxide in a compound fiber material is high; the product is easily separated and purified; the characteristic is uniform and stable; the method for utilizing the supercritical carbon dioxide to process the cellulose has broad application prospects in the fields of catalyzing, chemical engineering, packaging, weaving, etc.

Owner:FUDAN UNIV

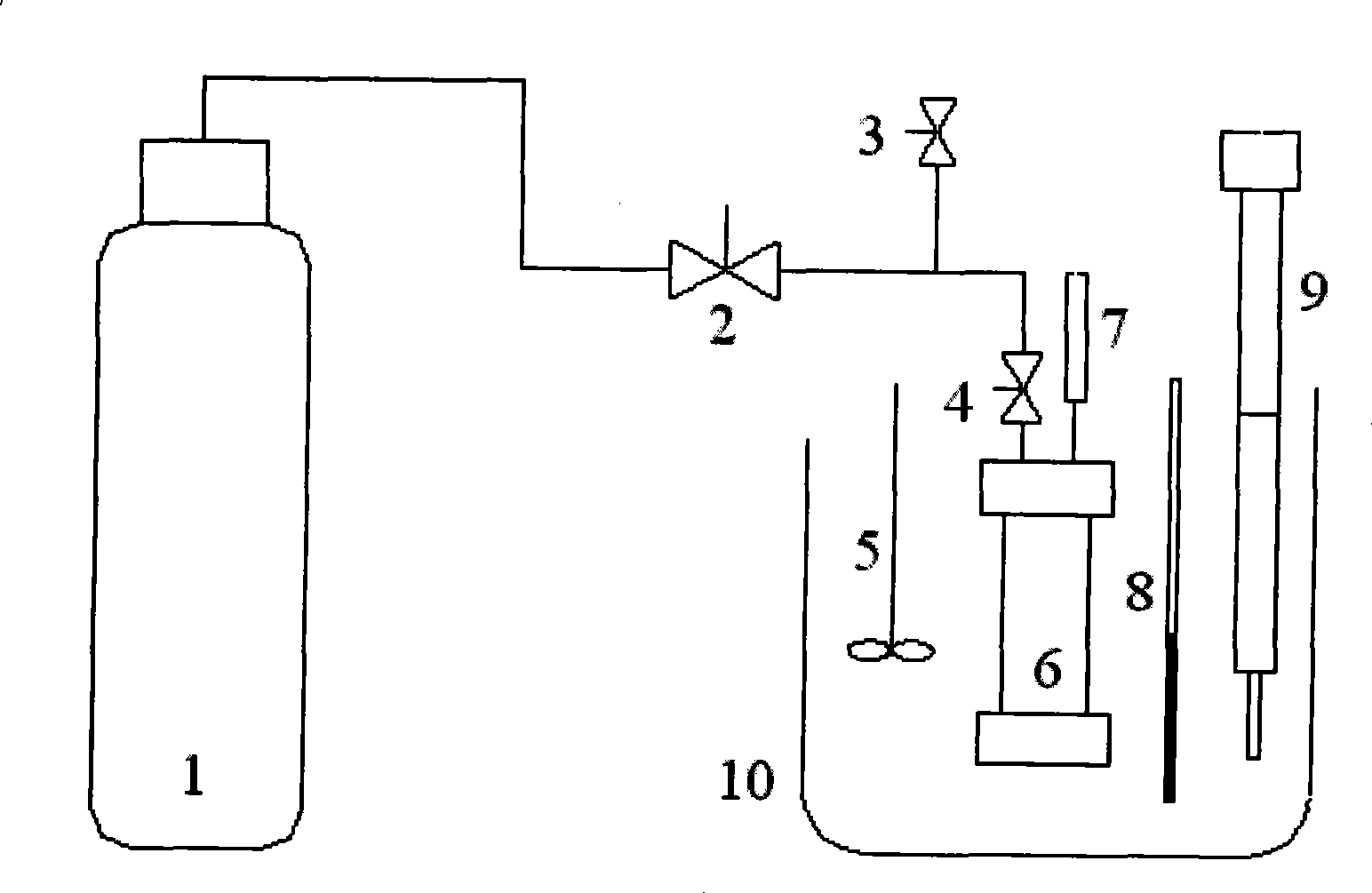

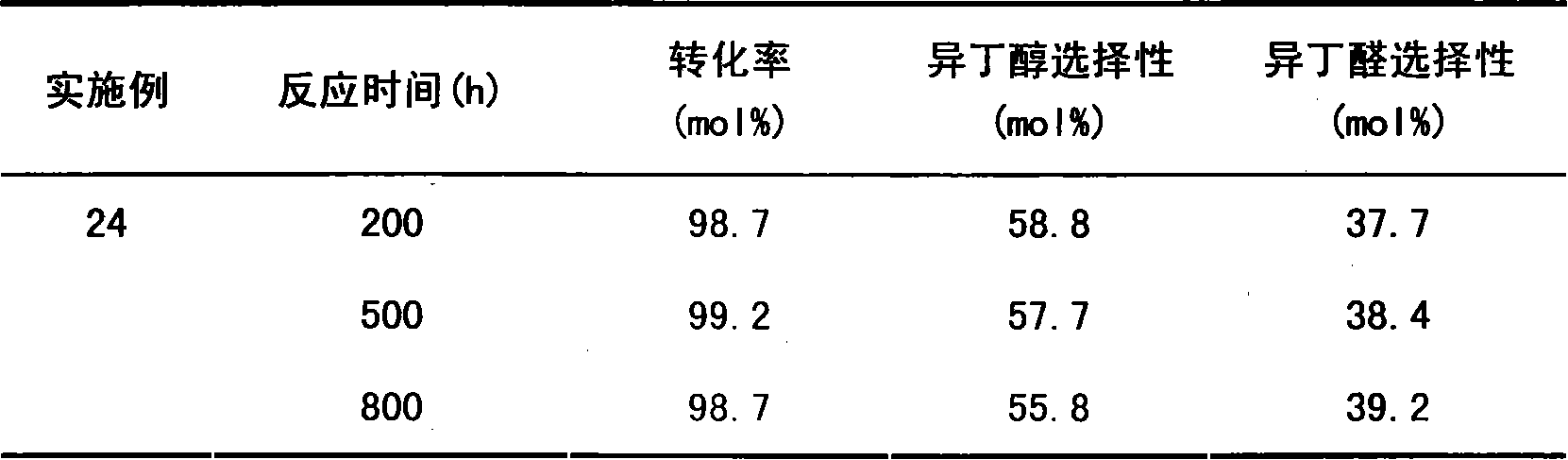

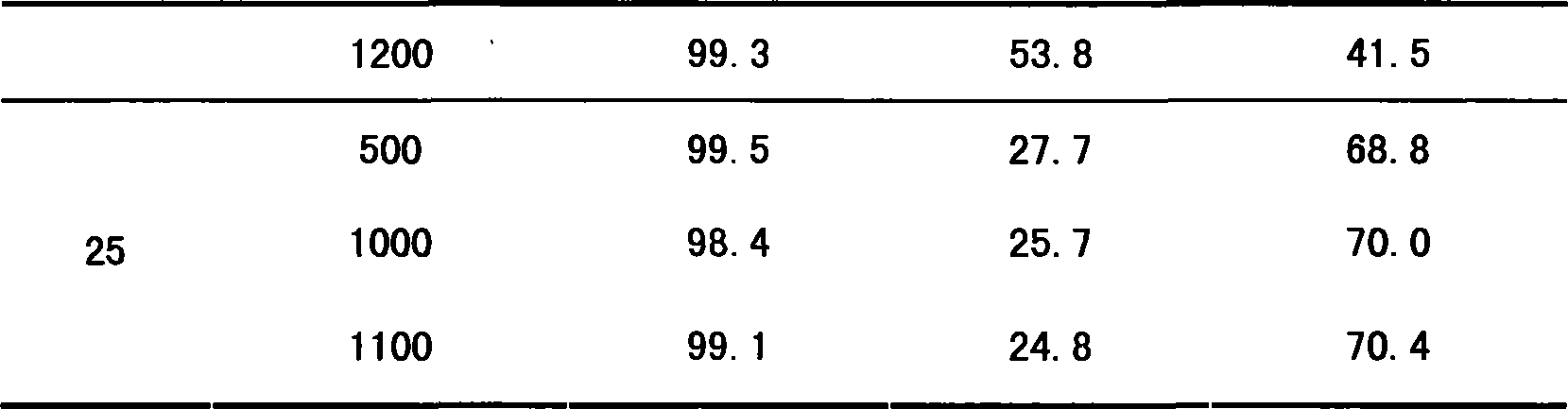

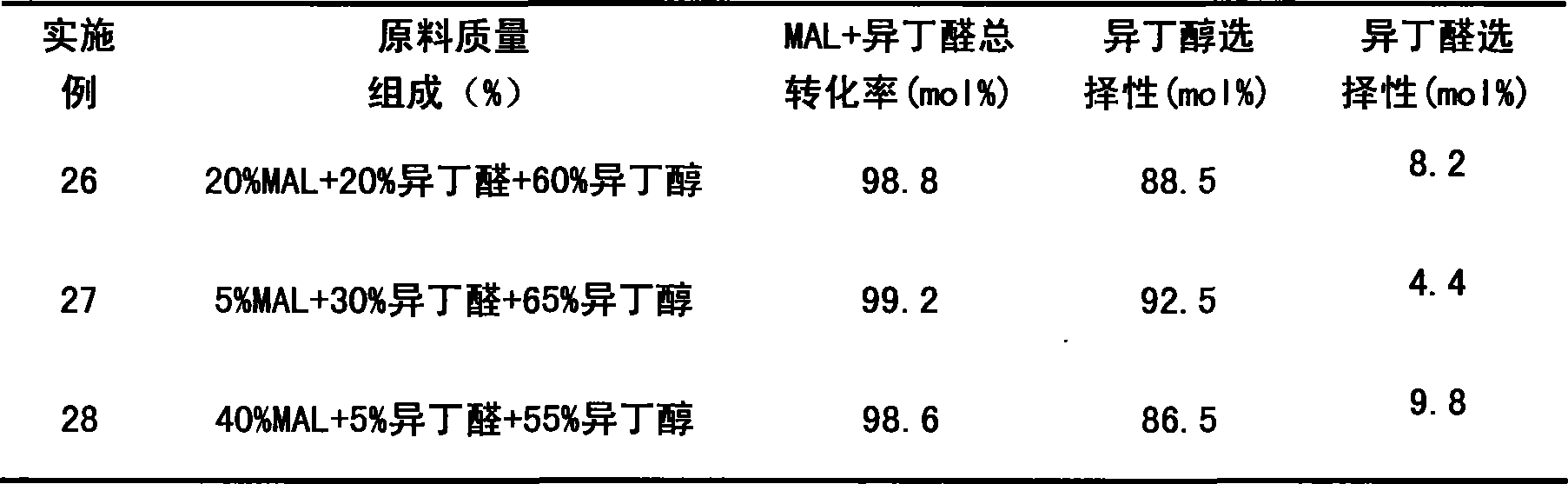

Method for preparing iso-butyraldehyde and isobutyl alcohol by methylacrolein hydrogenation

ActiveCN101239892ALow costHigh selectivityMolecular sieve catalystsOrganic compound preparationIsobutanolMetal catalyst

The invention relates to a method for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein. The method comprises using a supported metal catalyst, and hydrogenating methacrolein obtained by oxidating isobutene under gentle conditions. The invention provides a novel synthesis process for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein which is obtained by air-oxidating low-utilization C4 material isobutene or tert-butanol. The methacrolein conversion rate is larger than 98%, the total selectivity of isobutyraldehyde and isobutyl acohol is larger than 95%, the performance of the catalyst is stable even the reaction lasts more than 1000 hours. The invention has the advantages of high activity and high selectivity of catalyst, good stability of catalyst, cheap material isobutene, low productin cost of isobutene, environment-protecting process, and suitability of industrialisation production. The process is flexible, can change the proportion of isobutyraldehyde and isobutyl acohol through adjusting the reaction process condition, thereby cogenerating isobutyraldehyde and isobutyl acohol, or only generating isobutyl acohol by cycling and hydrogenating isobutyraldehyde.

Owner:SHANGHAI HUAYI NEW MATERIAL

Catalyst for the oxidation of a mixed aldehyde feedstock to methacrylic acid and methods for making and using same

InactiveUS20070021296A1Improve distributionOrganic compound preparationHeterogenous catalyst chemical elementsIndiumCerium

A heteropolyacid catalyst for oxidation of isobutyraldehyde, methacrolein or mixtures or combinations thereof to methacrylic acid is disclosed where the heteropolyacid catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), and a first component including bismuth (Bi) and / or boron (B). The heteropolyacid catalyst can also optionally include a second component including potassium (K), rubidium (Rb), cesium (Cs), and / or thallium (Tl) and optionally a third component including antimony (Sb), cerium (Ce), niobium (Nb), indium (In), iron (Fe), chromium (Cr), cobalt (Co), nickel (Ni), manganese (Mn), arsenic (As), silver (Ag), zinc (Zn), germanium (Ge), gallium (Ga), zirconium (Zr), magnesium (Mg), barium (Ba), lead (Pb), tin (Sn), titanium (Ti), aluminum (Al), silicon (Si), tantalum (Ta), tungsten (W), and / or lanthanum (La). The heteropolyacid catalyst can also include an ammonium-containing compound designed to increase a value of medium pores in the final heteropolyacid catalyst. A method for oxidizing isobutanal to methacrylic acid using the heteropolyacid catalyst is also disclosed.

Owner:SAUDI BASIC IND CORP SA

Catalyst composition for reaction of hydroformylation of propene,

ActiveCN101288852AHigh activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionHydrogenFormylation reaction

The invention relates to a catalyst combination used for propylene hydrogen formylation reaction, comprising the components: rhodium, bis-phosphite and single-phosphite. The effects that the activation of Rh / phosphite catalyst is kept and the normal / isomeric ratio of outcome butyraldehyde is suitably adjusted are achieved by adding single-phosphite or bis-phosphite in the propylene hydrogen formylation reaction system catalyzed by the phosphite / Rh; furthermore, highe normal / isomeric ratio and reaction rate are still remained on the basis that the dosage of bis-phosphite is reduced and sub-pressure CO: H2 is more than 1.

Owner:SHANGHAI HUAYI ENERGY CHEM

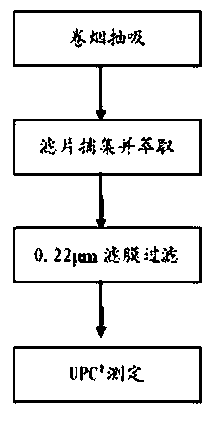

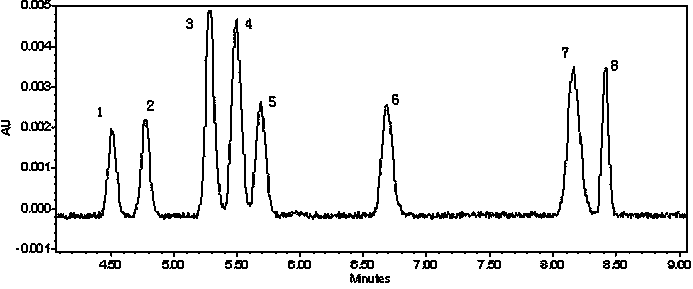

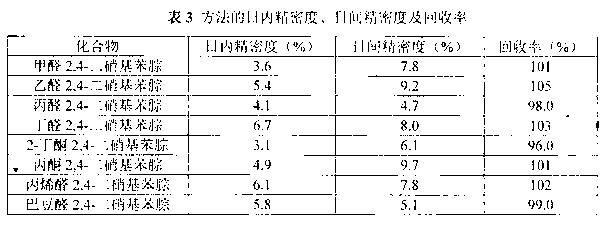

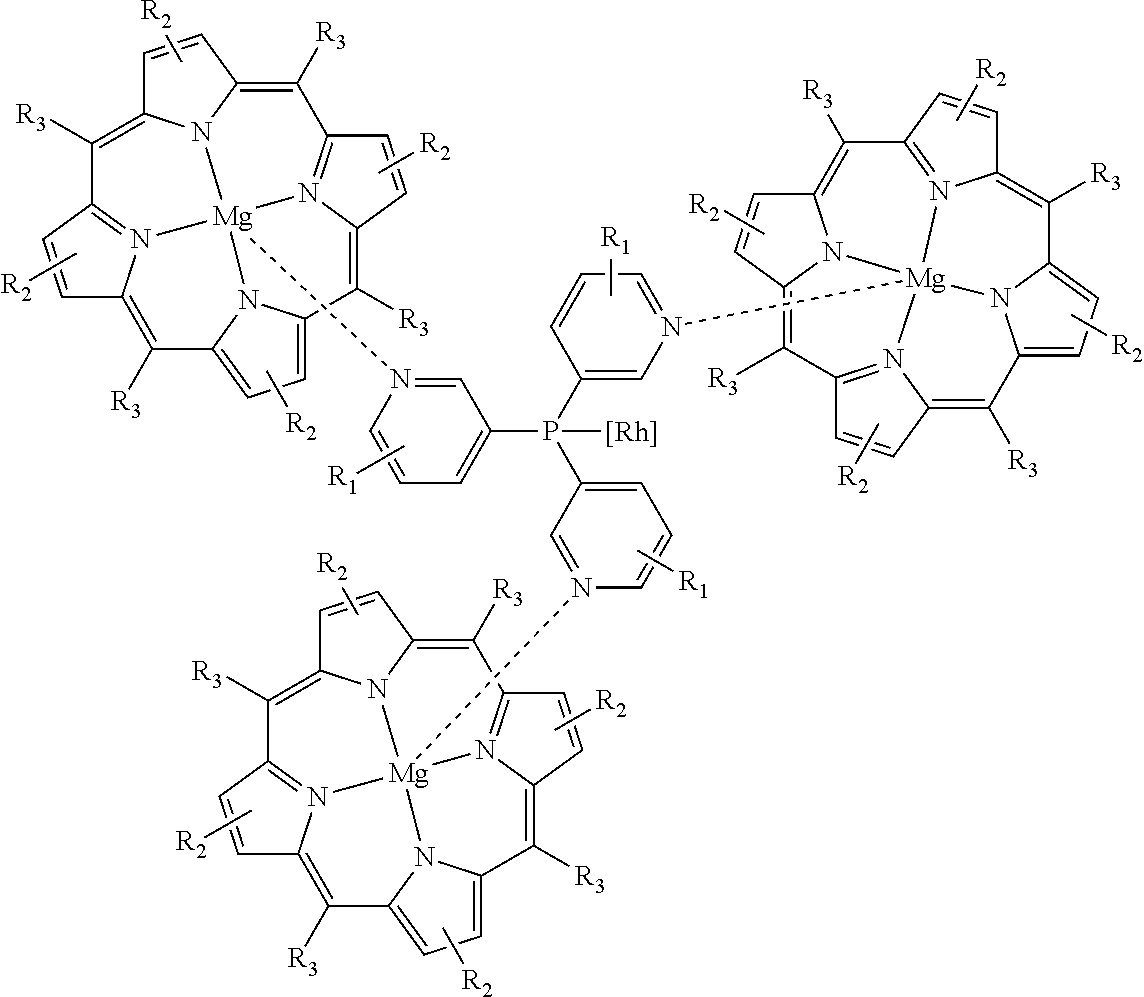

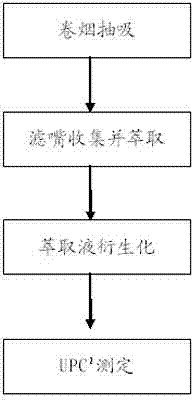

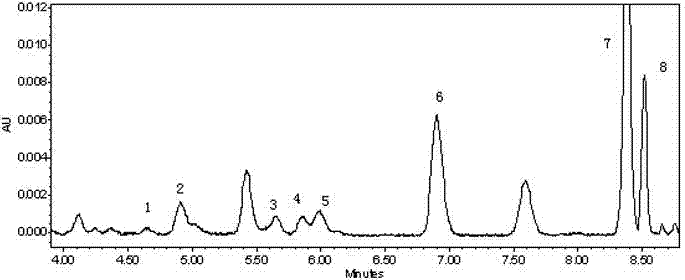

Method for measuring main carbonyl compounds in main stream smoke of cigarette through ultra high performance convergence chromatography

ActiveCN103698458AShort detection timeReduce consumptionComponent separationCrotonaldehydeDerivatization

A method for measuring main carbonyl compounds in a main stream smoke of a cigarette through ultra high performance convergence chromatography is a method for measuring butyraldehyde, 2-butanone, propionaldehyde, crotonaldehyde, acrolein, acetone, acetaldehyde and formaldehyde in the main stream smoke. The method is characterized in that a filter leaf processed with a derivatization reagent is used to gather the main carbonyl compounds in the main stream smoke of the cigarette, the analyzing and measuring method is used to obtain the contents of the eight carbonyl compounds in the main stream smoke through ultra high performance convergence chromatography (UPC2). When the method provided by the invention is used to detect the contents of the main carbonyl compounds in the main stream smoke of the cigarette rapidly and effectively, the pretreatment is simple, the average relative standard deviation is less than 7%, and the average recovery rate of various indexes is between 75%-94%. The method has the advantages of rapidness, accuracy, high flexibility and good repeatability.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

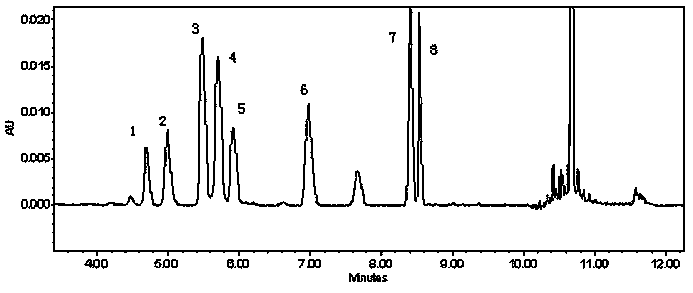

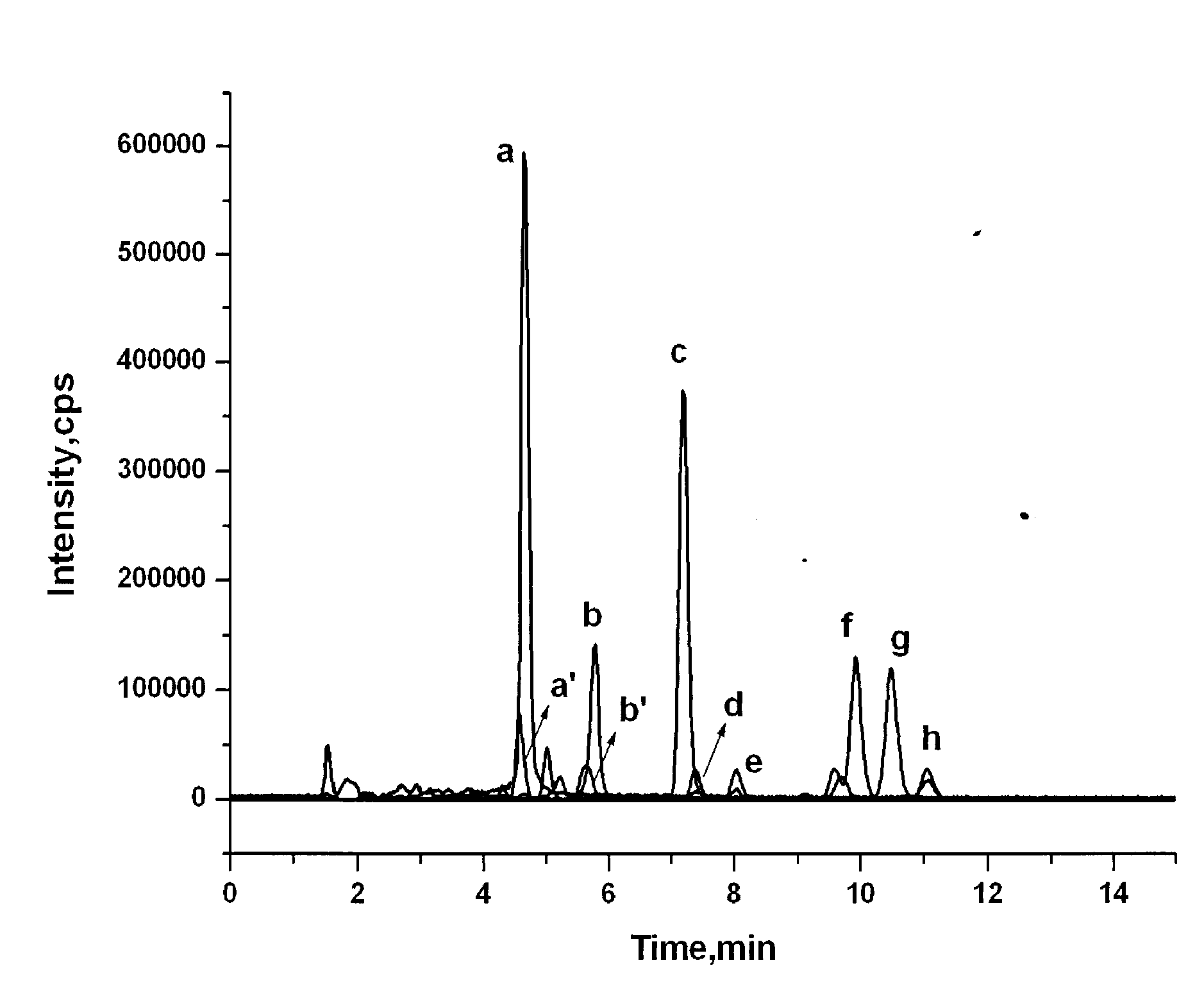

Method for detecting eight volatile carbonyl compounds in cigarette filter tip through liquid chromatography-tandem mass spectrometry

ActiveCN103163270AHigh sensitivityEfficient exclusionComponent separationCrotonaldehydeVapor phase chromatography

The invention relates to a method for detecting eight volatile carbonyl compounds in a filter tip through liquid chromatography-tandem mass spectrometry. The eight volatile carbonyl compounds are formaldehyde, acetaldehyde, propanal, acetone, acraldehyde, crotonaldehyde, butanal and 2-butanone. The method comprises the following steps: performing ultrasonic extraction on the carbonyl compounds in a filter tip by using an acetonitrile / water mixed solution, performing 2,4-dinitrophenylhydrazine derivatization reaction, and analyzing through a liquid chromatography-tandem mass spectrometer (LC-MS / MS). Compared with the original gas chromatography, the LC-MS / MS method used in the method has the following advantages: (1) the LC-MS / MS method is higher in sensitivity, and the two-stage mass spectrometry can more effectively eliminate the false positive result, thus ensuring that the qualitative analysis accuracy is higher; (2) separation is performed through liquid chromatography, and 2,4-dinitrophenylhydrazone of the carbonyl compounds has favorable stability; (3) the sample does not need to be purified, and the pretreatment is simple and efficient; and (4) the method can realize the simultaneous detection of the eight volatile carbonyl compounds.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

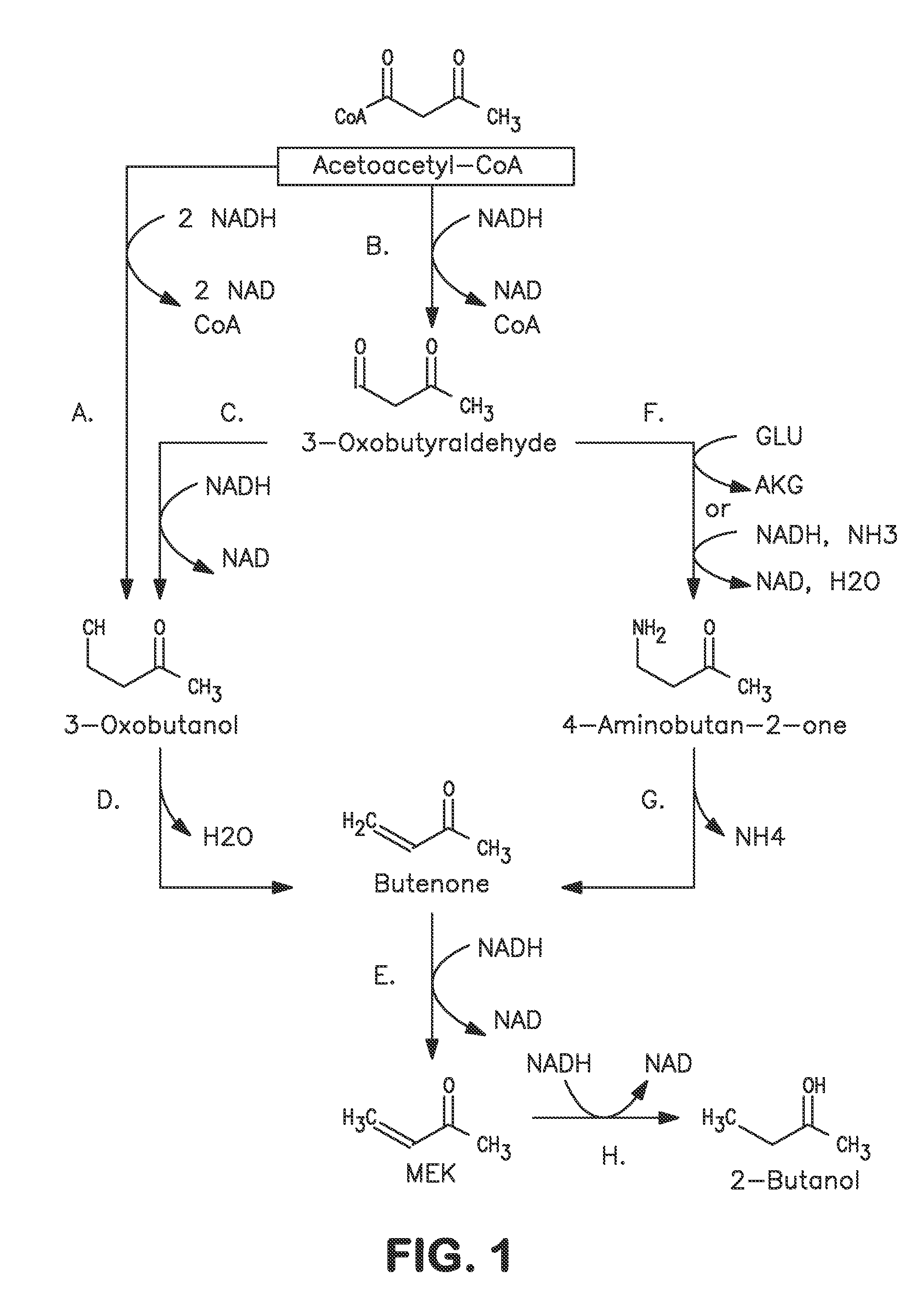

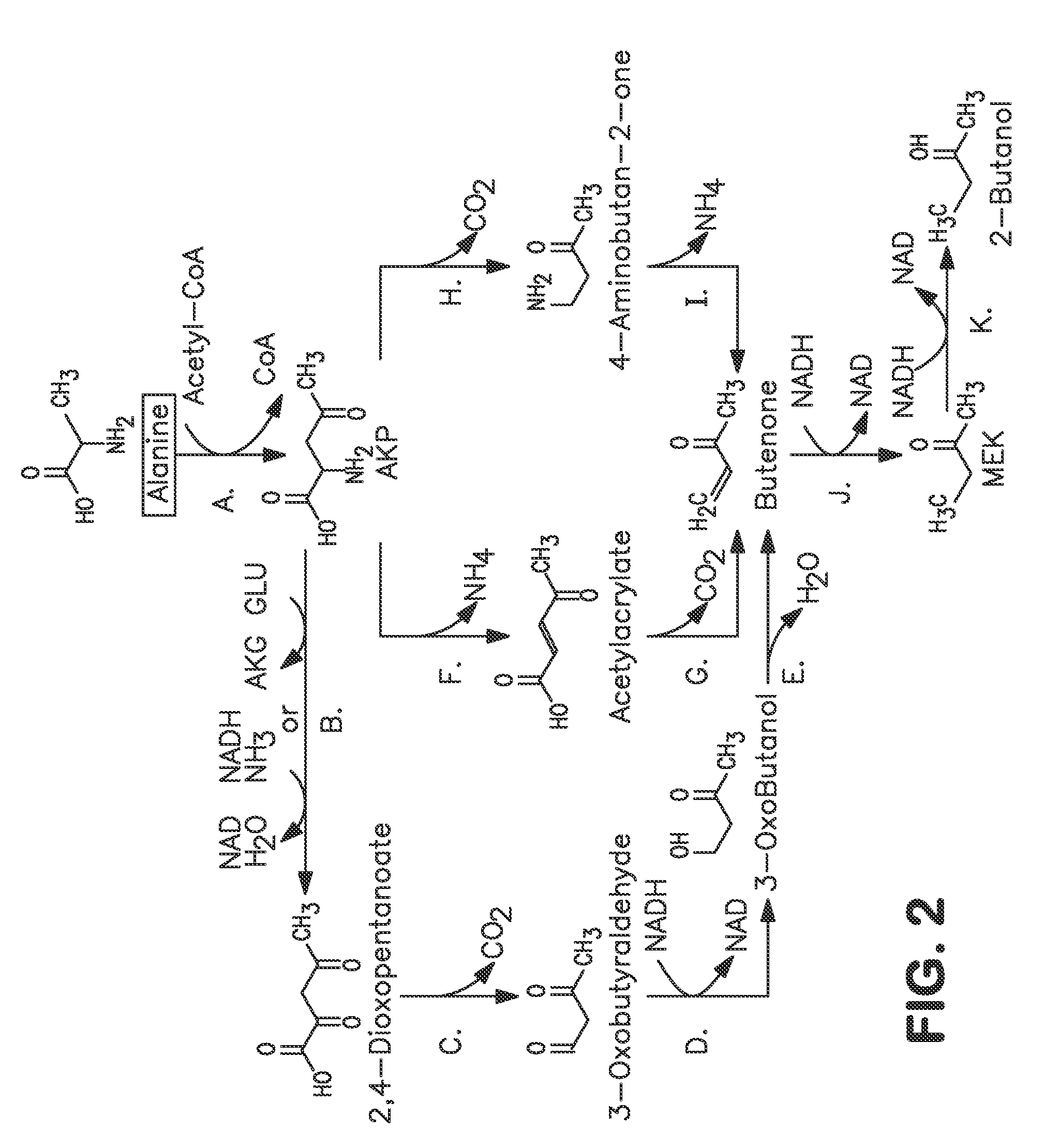

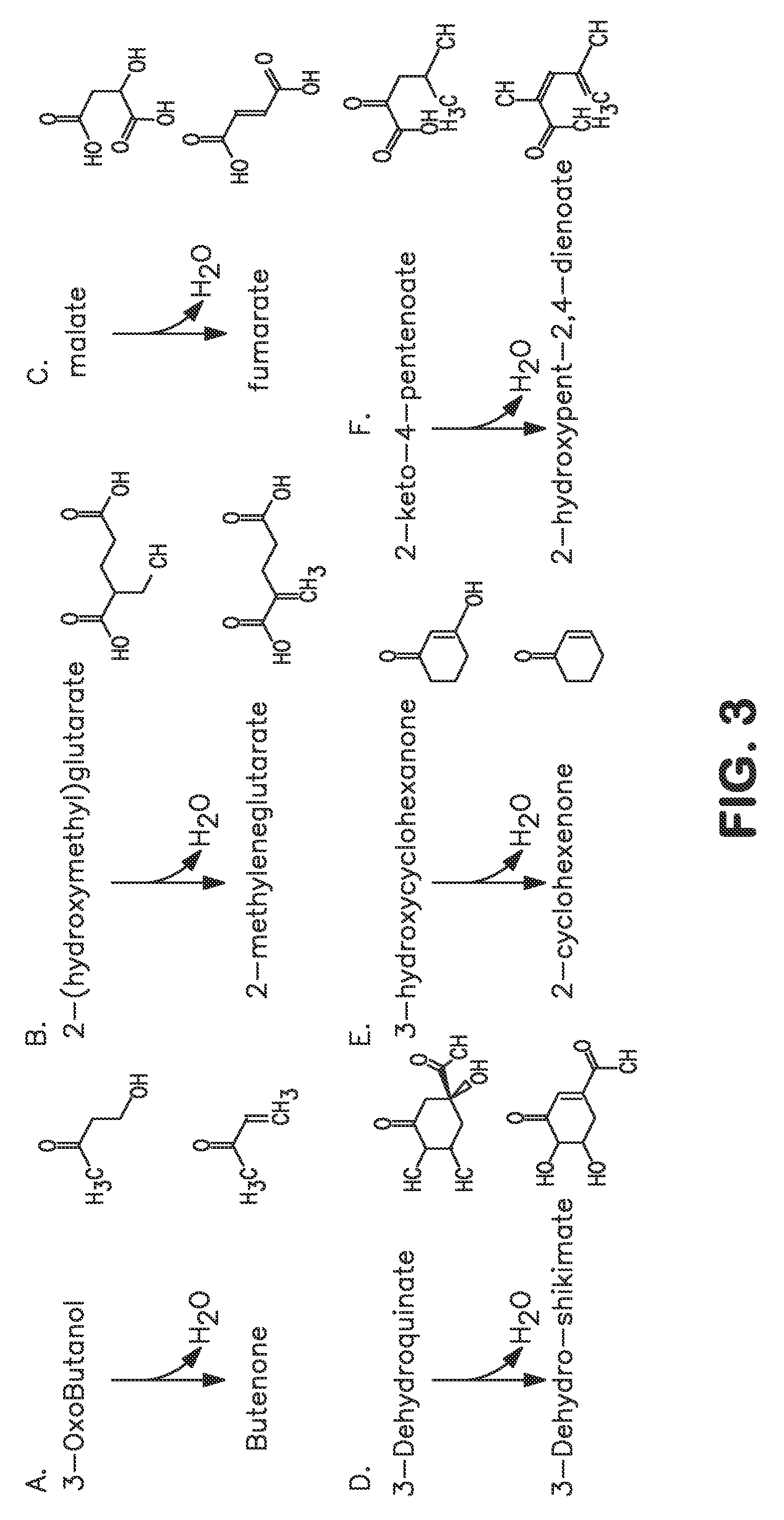

Microorganisms and methods for carbon-efficient biosynthesis of MEK and 2-butanol

A non-naturally occurring microbial organism has at least one exogenous nucleic acid encoding a MEK pathway enzyme expressed in a sufficient amount to produce MEK. The MEK pathway includes an enzyme selected from an acetoacetyl-CoA dehydrogenase (bifunctional), an acetoacetyl-CoA aldehyde dehydrogenase, a 3-oxobutyraldehyde reductase, a 3-oxobutanol dehydratase, an MEK oxidoreductase, a 3-oxobutyraldehyde aminotransferase, a 4-aminobutan-2-one deaminase, a 2-amino-4-ketopentanoate (AKP) thiolase, an AKP aminotransferase, a 2,4-dioxopentanoate decarboxylase, an AKP deaminase, an acetylacrylate decarboxylase, an AKP decarboxylase, a glutamate dehydrogenase, a 3-oxobutyraldehyde oxidoreductase (aminating) and an AKP oxidoreductase (aminating). A 2-butanol pathway further includes an MEK reductase. A method for producing MEK or 2-butanol includes culturing these organisms under conditions and for a sufficient period of time to produce MEK or 2-butanol.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol, 4-hydroxybutanal, 4-hydroxybutyryl-coa, putrescine and related compounds, and methods related thereto

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO), 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway comprising at least one exogenous nucleic acid encoding a BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway enzyme expressed in a sufficient amount to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine.

Owner:GENOMATICA INC

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846BSave energyReduce loadOrganic compound preparationPreparation by hydrogenationAlcoholDistillation

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unitare suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

Ocean epoxy zinc-rich anti-corrosion powder coating and preparation method thereof

ActiveCN104087125AImprove conductivityImprove thermal conductivityAnti-corrosive paintsPowdery paintsEpoxyPolyvinyl alcohol

The invention provides an ocean epoxy zinc-rich anti-corrosion powder coating and a preparation method thereof. The coating is prepared from the following raw materials: E-12 epoxy resin, novolac epoxy, trimethyl hexamethylenedi, polyvinyl butyral, dimethyl imidazole, aminopropyl triethoxy silane, zinc powder, aluminum powder, graphene, ethylene bis stearamide, polyethylene wax powder, an antioxidant DNP, and compound filler. The preparation method comprises the following steps: uniformly mixing zinc powder, aluminum powder and graphene, adding aminopropyl triethoxy silane, stirring to disperse so as to obtain a component A, mixing the E-12 epoxy resin, novolac epoxy, polyvinyl butyral and polyethylene wax powder, preheating, cooling down to room temperature, mixing the component A, the mixture and the rest raw materials, carrying out melt extrusion by virtue of an extruder, tabletting, carrying out air cooling, grinding into powder, and sieving. The coating can protect a steel structure from being corroded by various corrosive media for a long term, is non-toxic, pollution-free and salt mist resistant, and has strong adhesive force and shock resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Alcohol-based non-zirconium composite refractory aggregate spray paint for wet cast steel and preparation method thereof

ActiveCN103302236ALow costImprove suspension stabilityFoundry mouldsFoundry coresMetallurgyPolyvinyl alcohol

The invention discloses an alcohol-based non-zirconium composite refractory aggregate spray paint for wet cast steel and a preparation method thereof. The spray paint is prepared from the components in parts by weight: 65-70 parts of mullite powder, 30-35 parts of magnesium aluminum spinel powder, 8-10 parts of cordierite flour, 2-5 parts of forsterite powder, 2.0-2.5 parts of magnesium silicate aluminum powder, 1-1.5 parts of calcium bentonite, 4-5 parts of water, 3-5 parts of ludox, 2-3 parts of modified rosin ester, 0.3-0.5 part of butyral resin, 41-54 parts of methyl alcohol, 15-20 parts of grain ethanol, and 10-15 parts of isopropanol. The alcohol-based non-zirconium composite refractory aggregate spray paint disclosed by the invention is low in cost; and the alcohol-based non-zirconium composite refractory aggregate spray paint with high cost can be replaced for spraying green sand.

Owner:HUBEI UNIV OF TECH +1

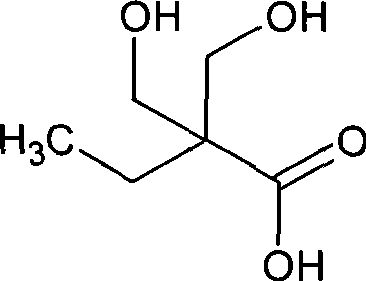

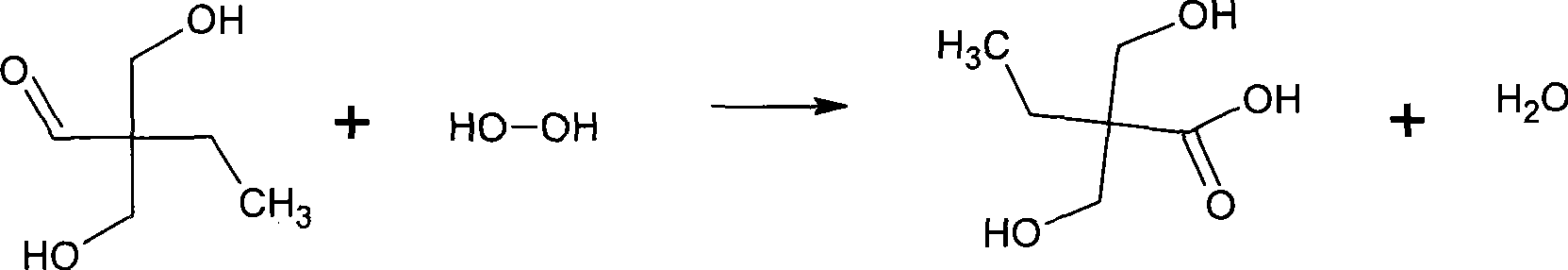

Method for synthesizing 2,2-bis(hydroxymenthyl)butyric acid

InactiveCN101381299AEasy to controlMild reaction conditionsCarboxylic preparation by oxidationOrganic synthesisOxygen

The invention belongs to the field of fine organic synthesis. The invention selects the mixture of NaCO3, Ba(OH)2, triethylamine and NaCO3, or the mixture of triethylamine and Ba(OH)2 as a catalyst, and makes use of butyraldehyde and formaldehyde to prepare 2, 2-hydroxymethyl butyric acid under the oxidation of hydrogen peroxide or oxygen through aldol condensation reaction. The invention prepares the 2, 2-hydroxymethyl butyric acid in the alkaline condition, thus the side reaction is less, the yield of the 2, 2-hydroxymethyl butyric acid is higher, and the industrialization of the invention is easy to realize.

Owner:QILU UNIV OF TECH

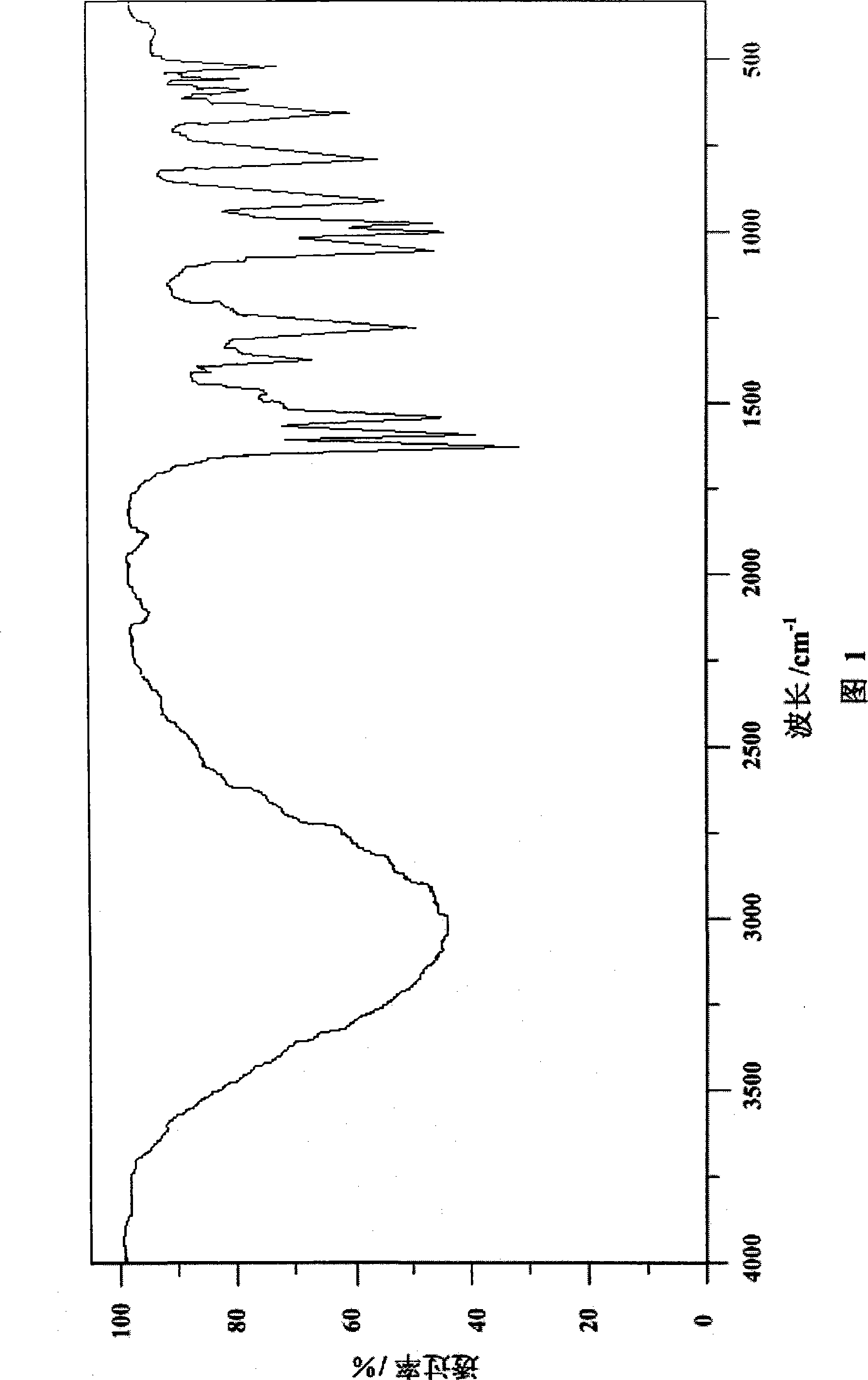

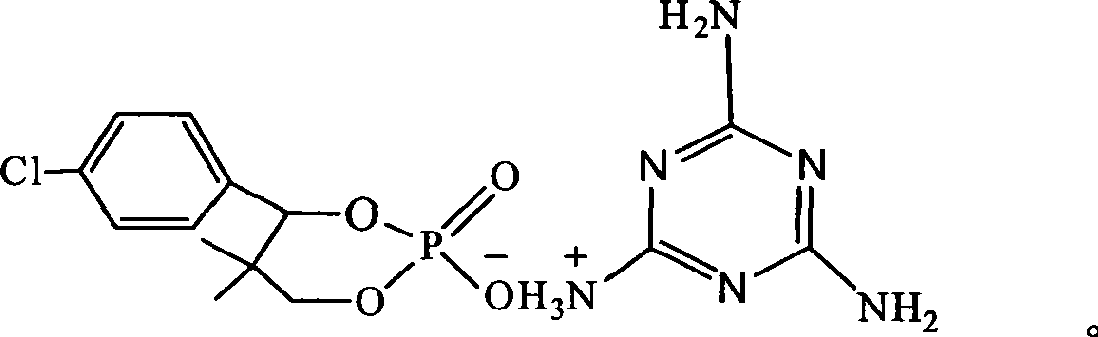

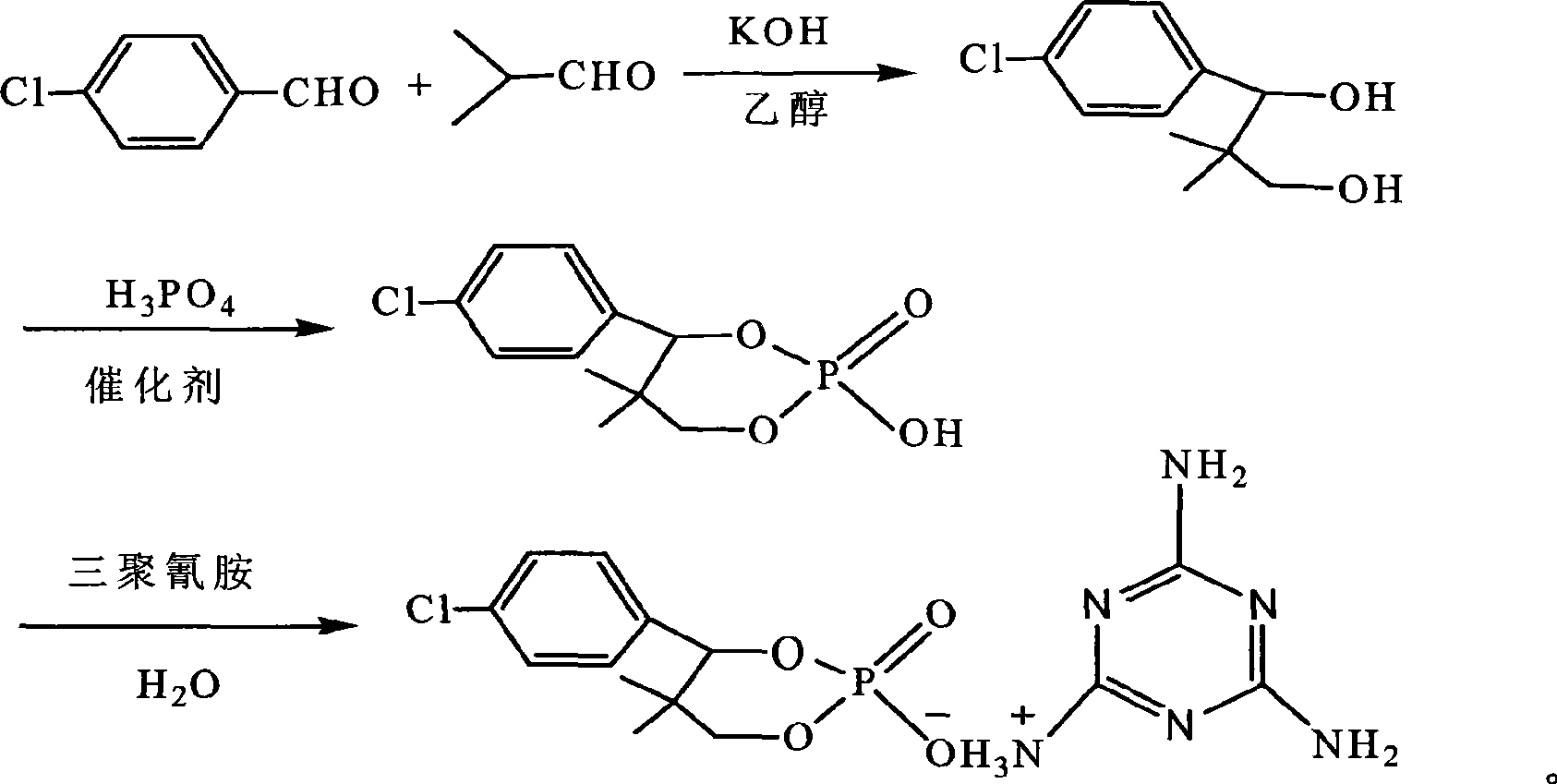

Phosphor-nitrogen expansion type combustion inhibitor and method of producing the same

InactiveCN101429438ALow viscosityReduce pollutionGroup 5/15 element organic compoundsBenzoic acidMelamine phosphate

The invention discloses a phosphorus-nitrogen swelling type fire retardant and a method for preparing the same. The chemical name of the fire retardant is 5, 5-dimethyl-4-p-chlorophenyl-1, 3, 2-dioxaphosphorinane phosphonate melamine salt. The preparation method comprises the following steps: (1) p-chlorobenzaldehyde and iso-butyraldehyde react with alkali ethanol solution, are cooled down and filtered to obtain an intermediate product (I); (2) the intermediate product (I) and phosphoric acid are added to solvent, and added with paratoluenesulfonic acid or benzoic acid or sodium salt of benzoic acid; and the mixing solution is distilled after reaction to reclaim the solvent to obtain an intermediate product(II); and (3) melamine and the intermediate product(II) are added to water for reaction, cooled down and filtered to obtain a filter cake; and the filter cake is dried to obtain phosphorus-nitrogen swelling type fire retardant. The phosphorus-nitrogen swelling type fire retardant has the advantages of high thermal stability, good compatibility, no halogen, less smoke and environmental protection. The preparation method has the advantages of materials available, simple process, mild reaction conditions, small viscosity of reaction liquid, low requirement on equipment and little environmental pollution.

Owner:SHANDONG TIANYI CHEM

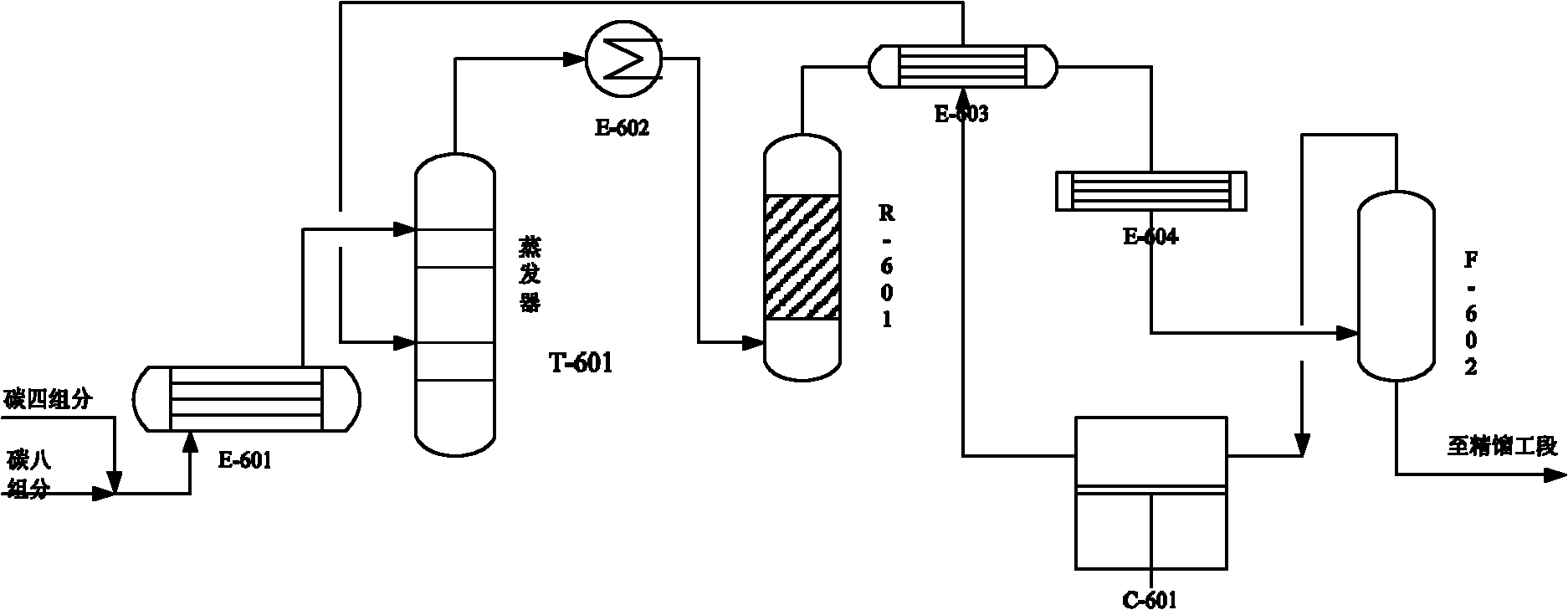

Method for extracting butyraldehyde and butanol mixture and octenal and octanol mixture from waste liquid discharged by butanol-octanol device

ActiveCN101973845BReduce processing loadSimple processOrganic compound preparationHydroxy compound preparationAlcoholResource utilization

The invention relates to a method for extracting a butyraldehyde and butanol mixture and an octenal and octanol mixture from waste liquid discharged by a butanol-octanol device, belonging to preparation methods of acyclic alcohol and acyclic aldehydes, particularly relating to the resource utilization and the treatment of the waste liquid discharged by the butanol-octanol device. The method is characterized by using a C4 fractionating tower system and a C8 fractionating tower system, wherein the butyraldehyde and butanol mixture is distilled off at the top of the C4 fractionating tower, and the octenal and octanol mixture is distilled off at the top of the C8 fractionating tower. The invention provides the method for extracting the butyraldehyde and butanol mixture and the octenal and octanol mixture from the waste liquid discharged by the butanol-octanol device, and the method lightens the wastewater treatment load of the butanol-octanol device, has the advantages of simple treatmentprocess, equipment investment saving and low operation cost and carries out the resource treatment of the waste liquid discharged by the butanol-octanol device so as to fully and effectively utilize the byproducts, such as butyraldehyde, butanol, octenal and octanol, The invention realizes the resource treatment of the waste liquid discharged by the butanol-octanol device.

Owner:淄博诺奥化工有限公司

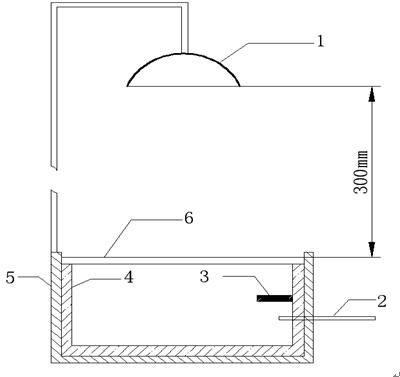

Transparent heat-insulation polyvinyl alcohol poly-butyraldehyde nanocomposite and preparation method thereof

The invention relates to a transparent heat-insulation polyvinyl alcohol poly-butyraldehyde nanocomposite and a preparation method thereof, belonging to the field of polymer-nano particle composite. Nano particles processed by coupling agent are dispersed in polyvinyl alcohol by ultrasonic wave and dispersing agent; under the action of catalyst, the nano particles and n-butanal are subjected to condensation reaction; nanocomposite is prepared with an in-suit dispersion one-step method; then, the nanocomposite and a proper quantity of antioxygen and film-forming solvent are stirred and mixed to obtain homogeneous solution; and then the homogeneous solution is poured into a mould to form the film. The film manufactured with the nanocomposite synthetized with the in-suit dispersion one-step method has even appearance, high transparency of a visible region and obvious heat-insulation effect of reflected infrared. The method is convenient to operate, and the production process route is simplified and shortened. Compared with other methods, the method can achieve same mechanical property and heat insulation effect, the adopted nano particle has small use amount, and therefore, production cost can be obviously lowered, which is favorable for industrial production. The transparent heat-insulation polyvinyl alcohol poly-butyraldehyde nanocomposite has wide application prospect in the safety glass industry of buildings and automobiles.

Owner:溧阳常大技术转移中心有限公司

Catalysts and process for producing aldehydes

ActiveUS8710275B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalysts1-OctenePorphyrin

Modification of a unique supramolecular assembly of a pyridylphosphine ligand and a metal centered porphyrin complex is shown to give unprecedented selectivities to branched aldehydes via rhodium catalyzed hydroformylation of propylene and 1-octene. Use of magnesium in the porphyrin center provides the highest reported concentrations of iso-butyraldehyde and 2-methyl-octanal.

Owner:EASTMAN CHEM CO

Method for measuring main carbonyl compounds in cigarette filter through ultra-performance convergence chromatography

ActiveCN103675153AShort detection timeReduce consumptionComponent separationCrotonaldehydeCigarette filter

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com