Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1759results about "Carboxylic preparation by oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

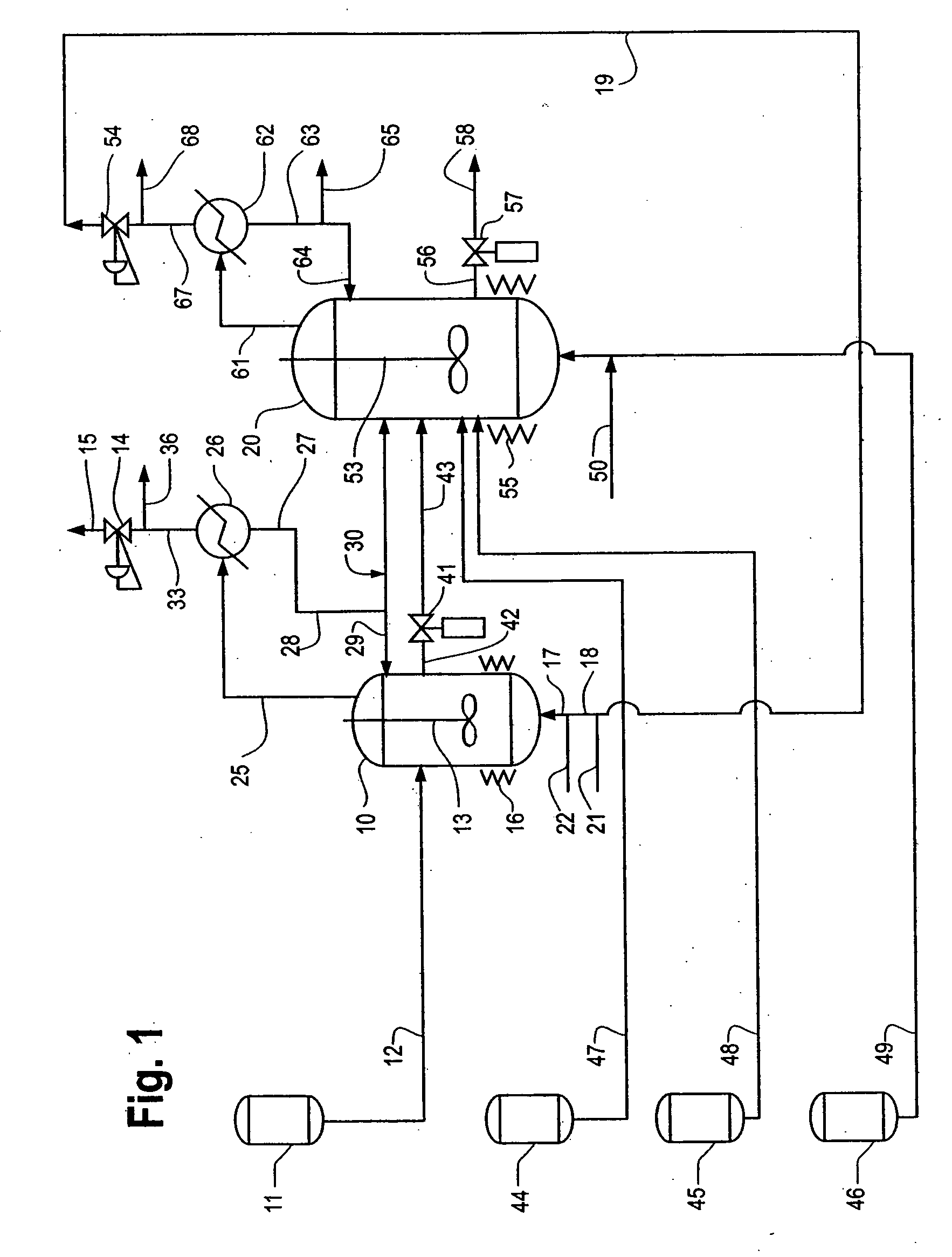

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

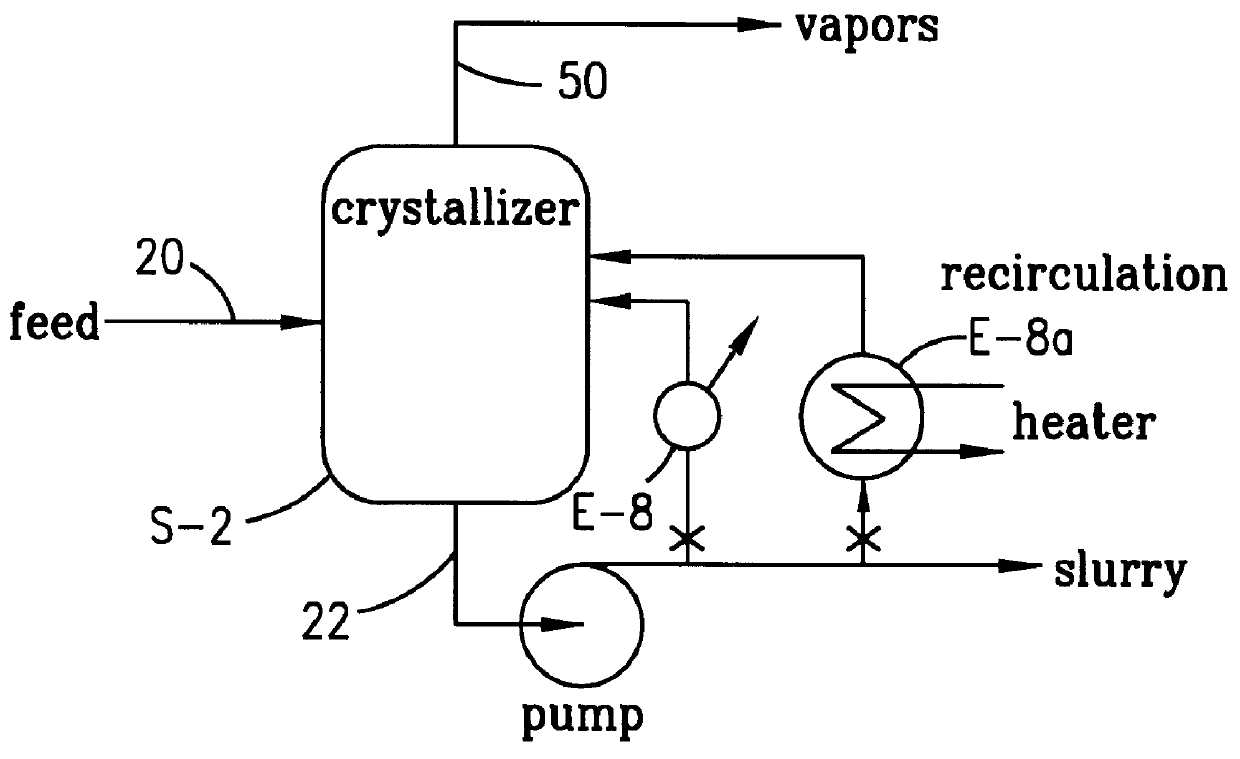

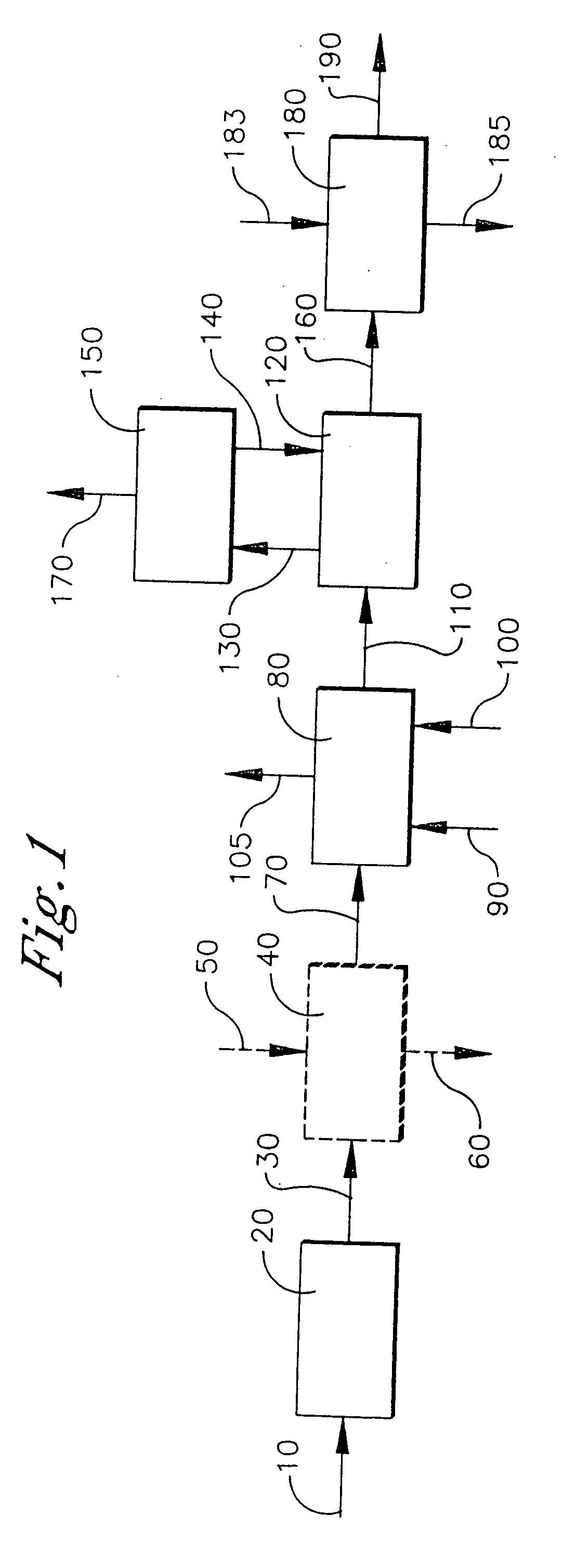

Process for the purification of a crude carboxylic acid slurry

InactiveUS20050065373A1Organic compound preparationCarboxylic preparation by oxidationFiltrationCarboxylic acid

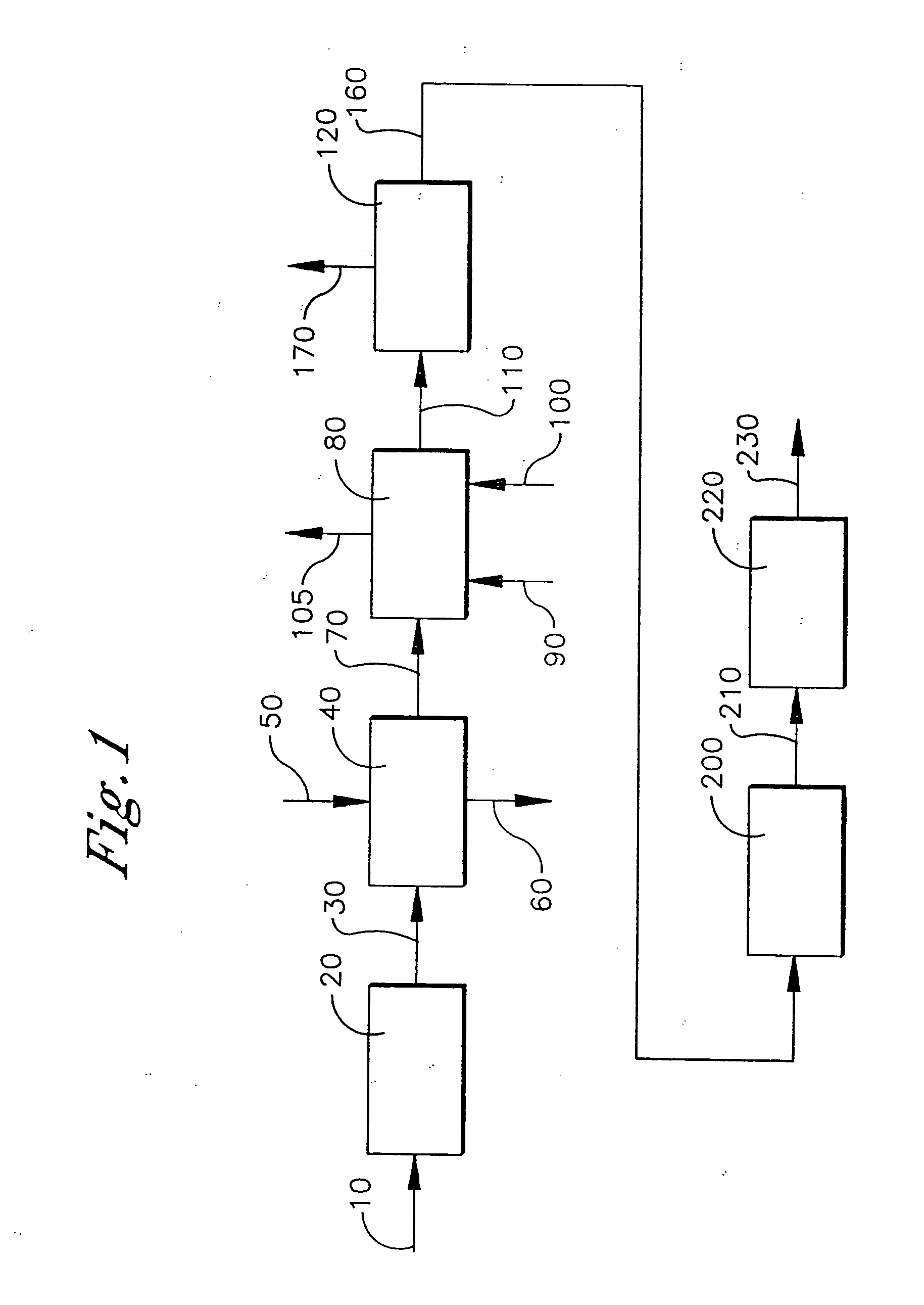

Disclosed is a process to produce a purified carboxylic acid product. The process comprises removing impurities from a crude carboxylic acid slurry in a solid-liquid displacement zone to form a slurry product. The slurry product if further treated in a staged oxidation zone and a crystallization zone to from a crystallized product. The crystallized product is further cooled in a cooling zone and subsequently filtered and dried in a filtration and drying zone. The process produces purified carboxylic acid product having good color and low impurity levels without the use of purification steps like hydrogenation.

Owner:ALPEK POLYESTER SA DE CV

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

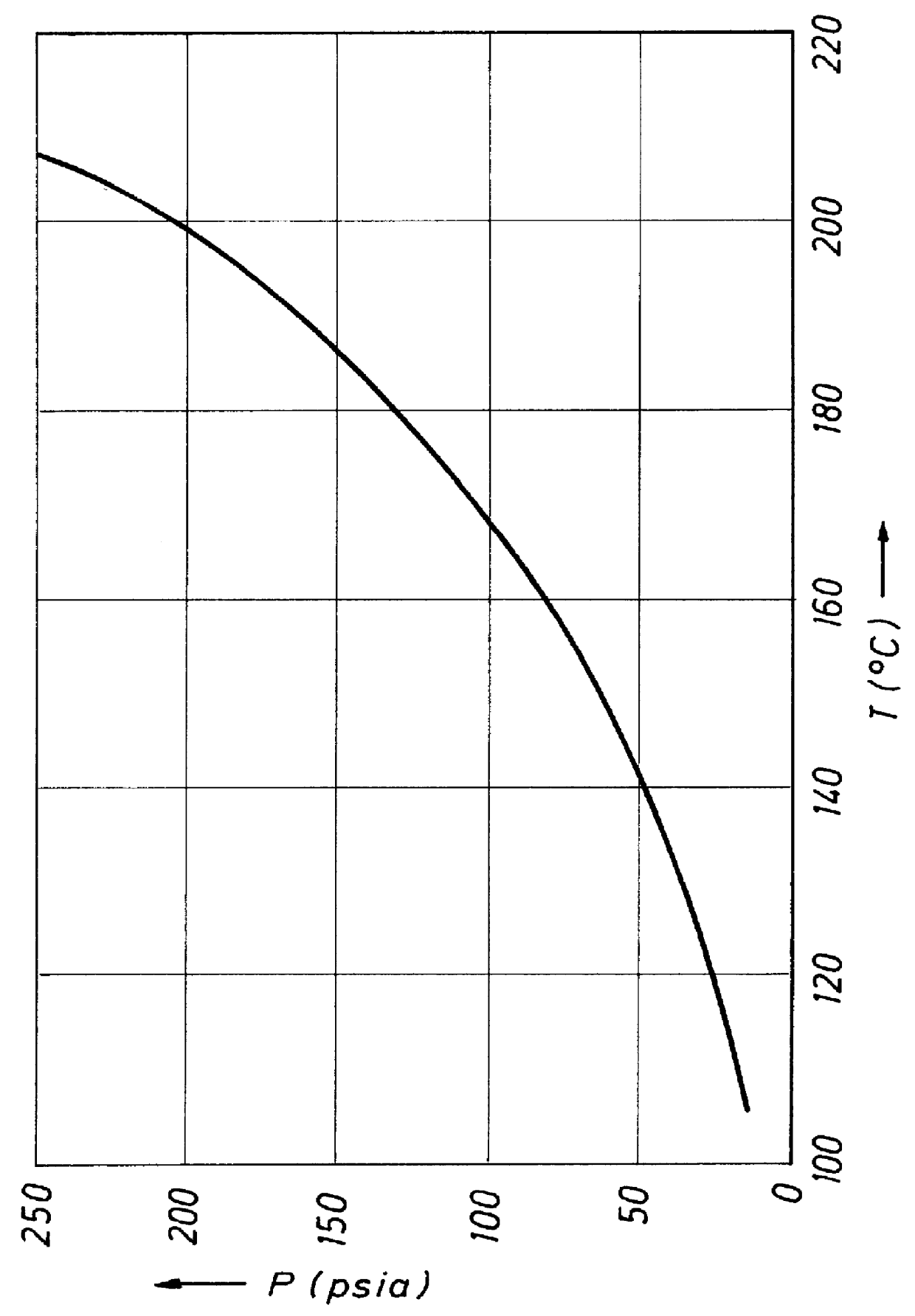

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

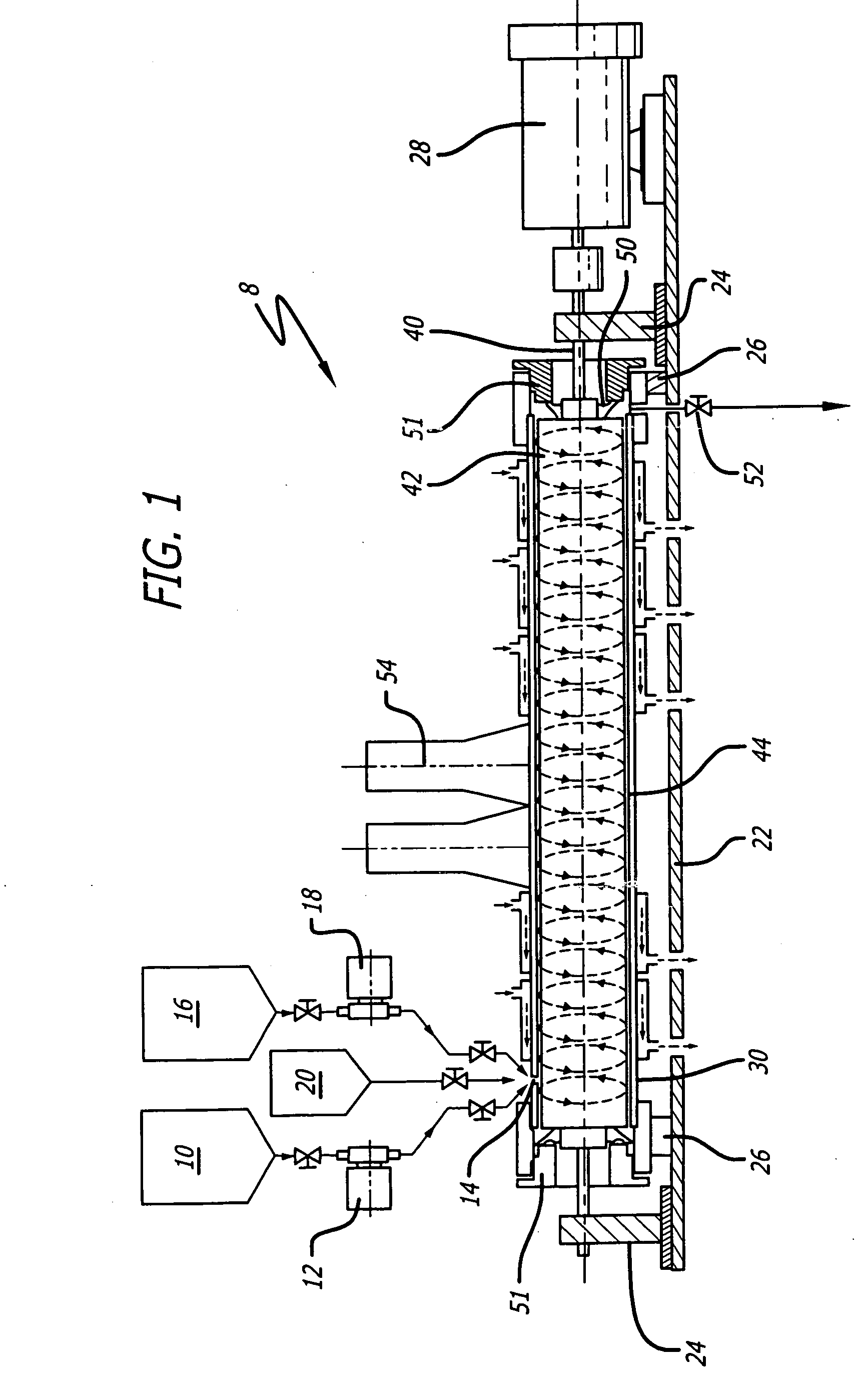

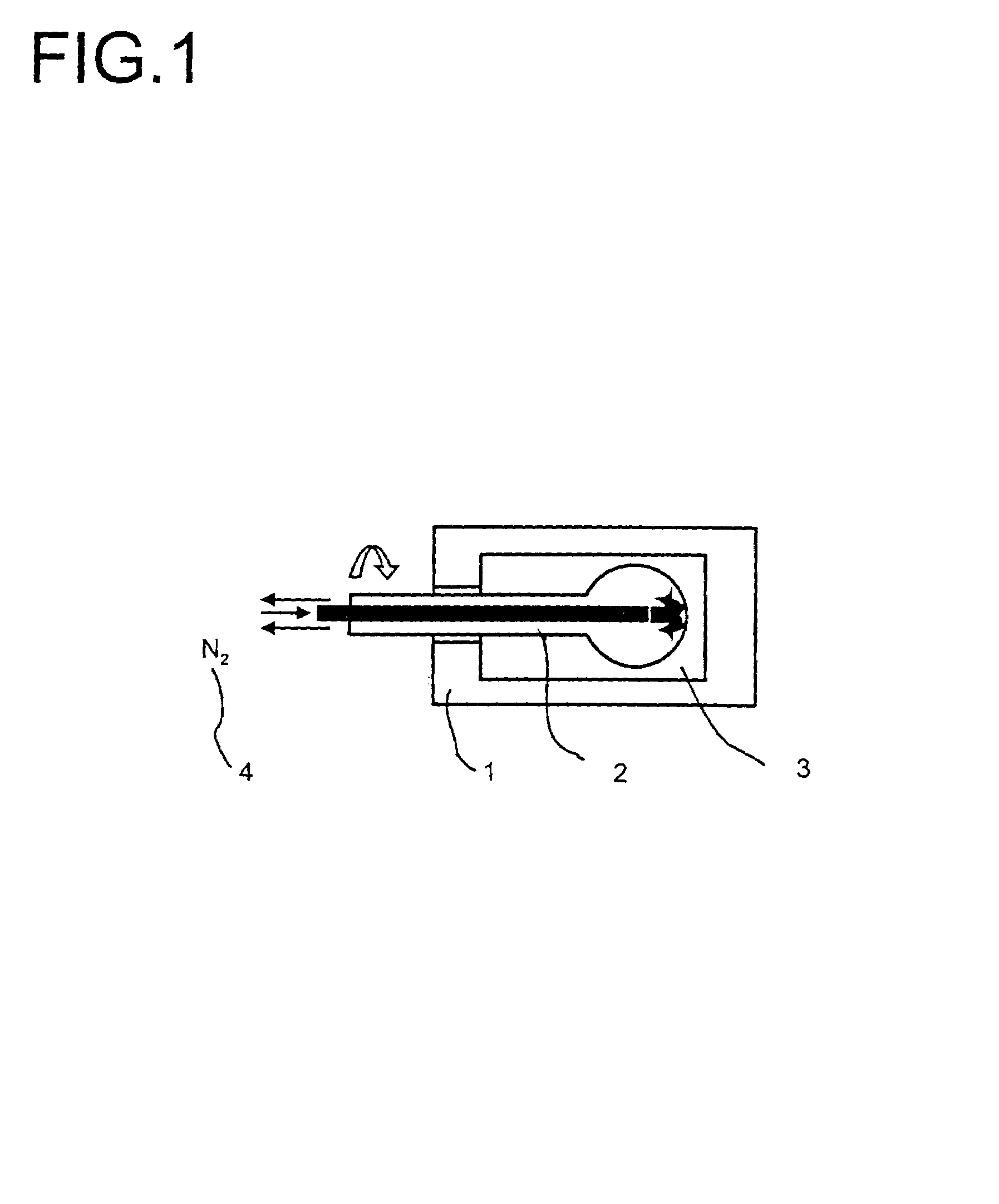

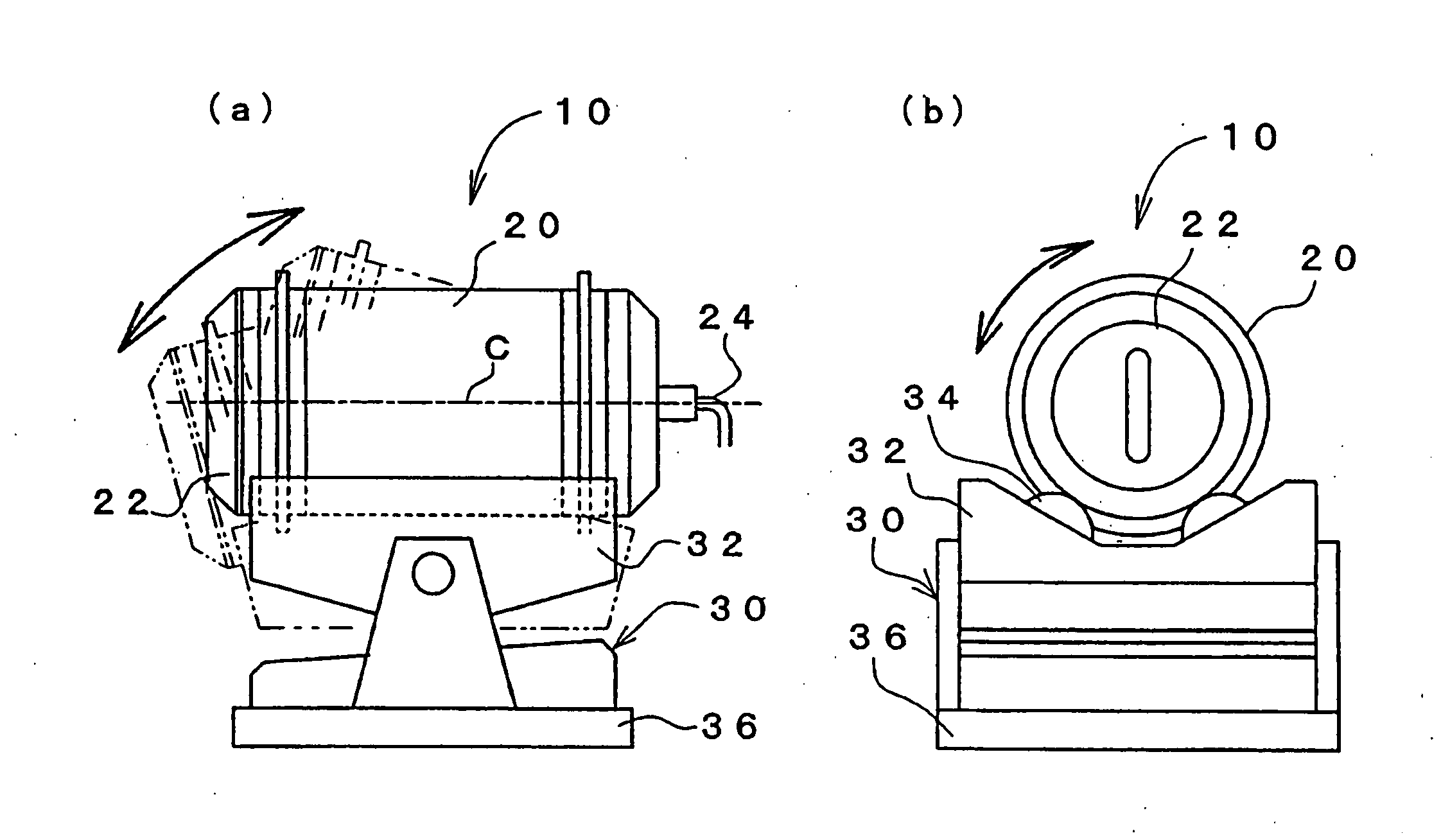

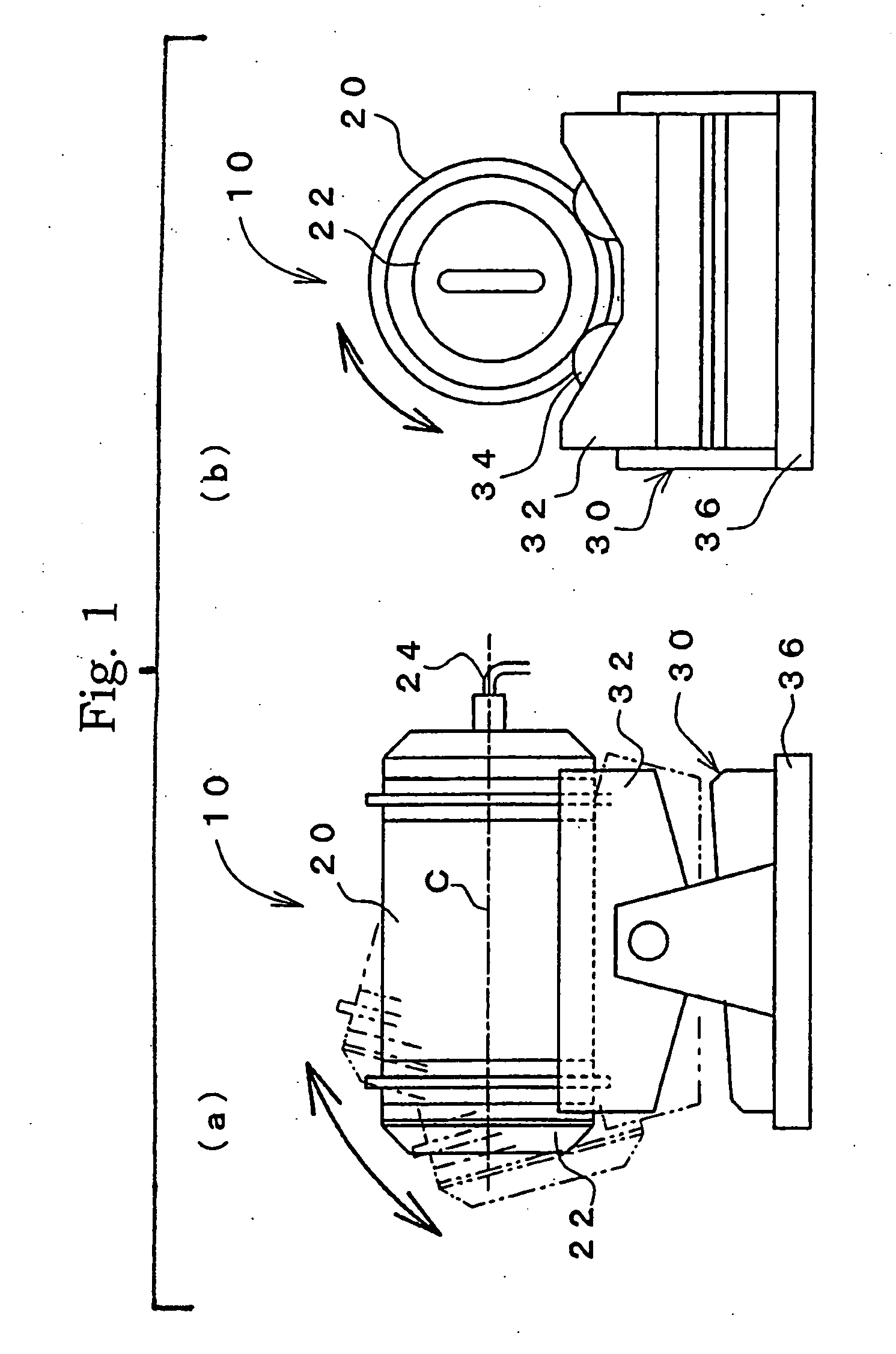

Process for high shear gas-liquid reactions

InactiveUS20050033069A1Superior and economical and efficientImprove responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

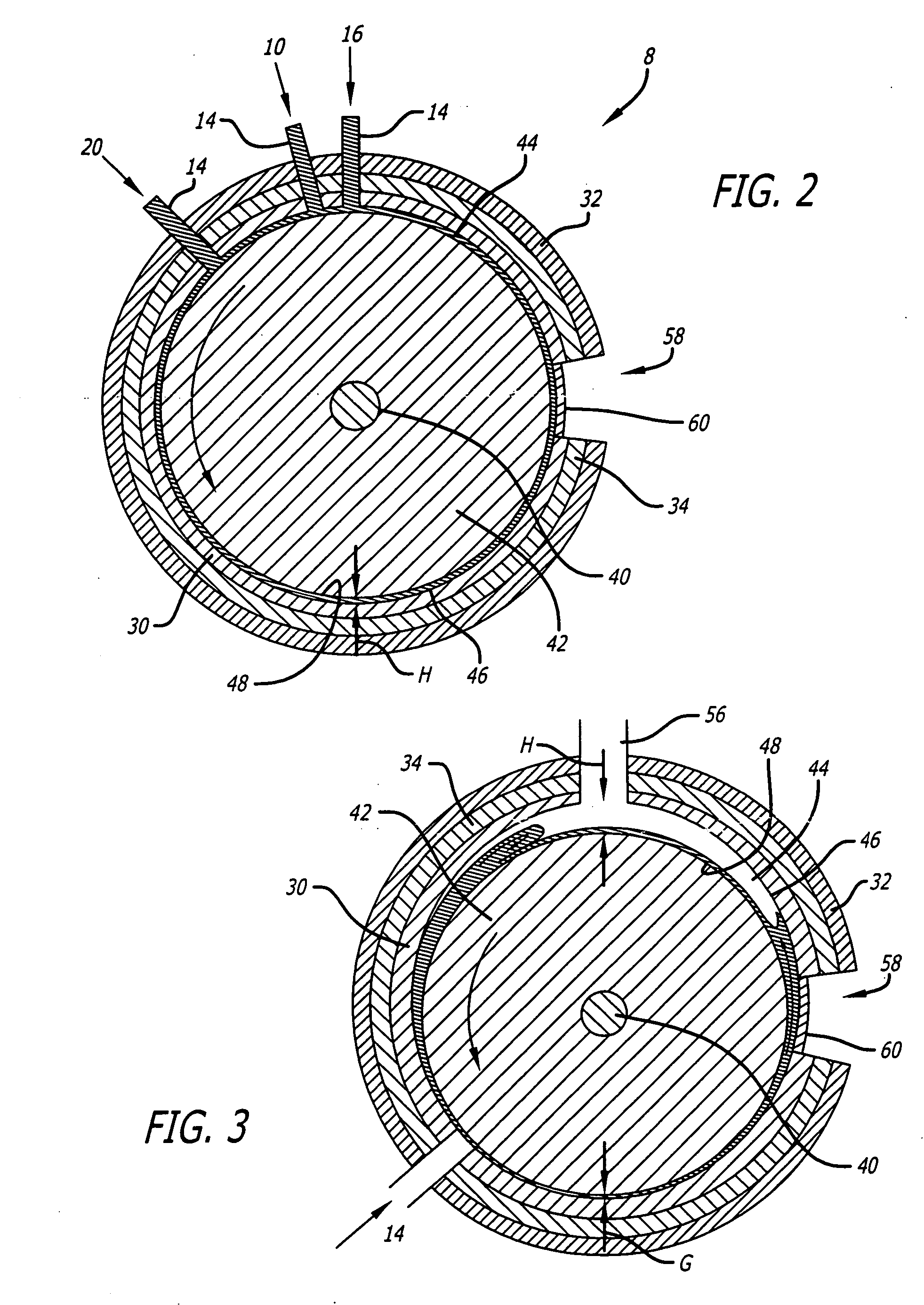

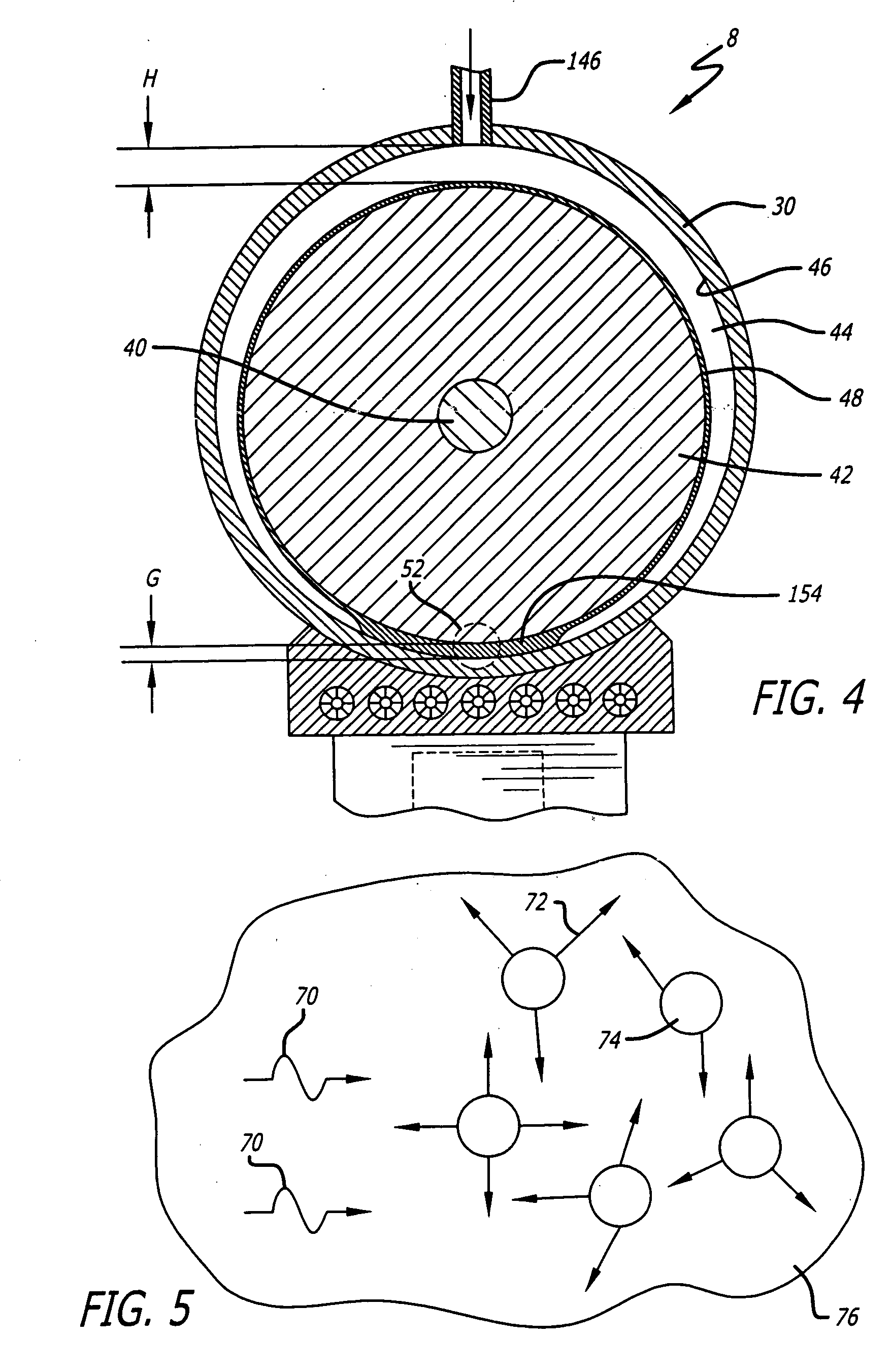

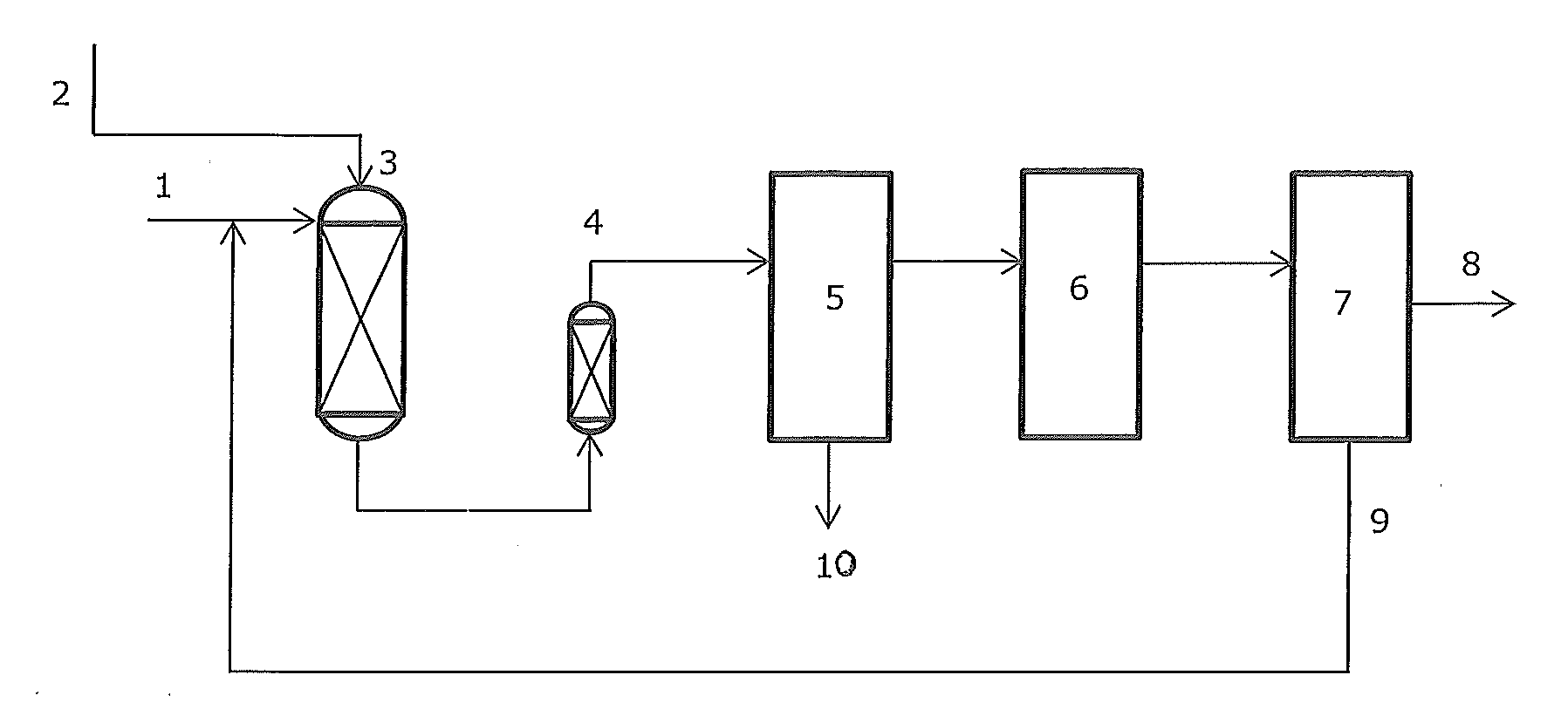

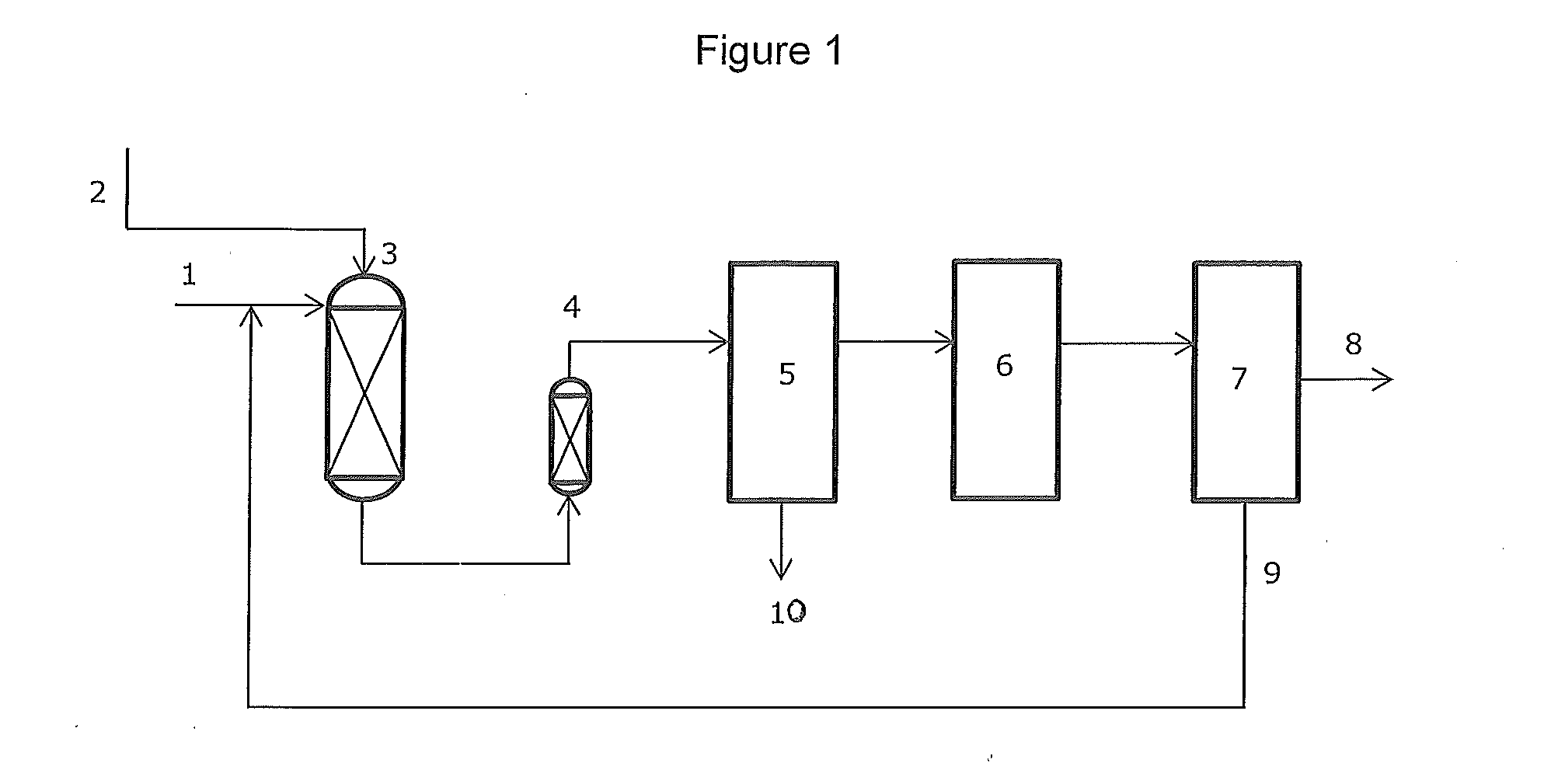

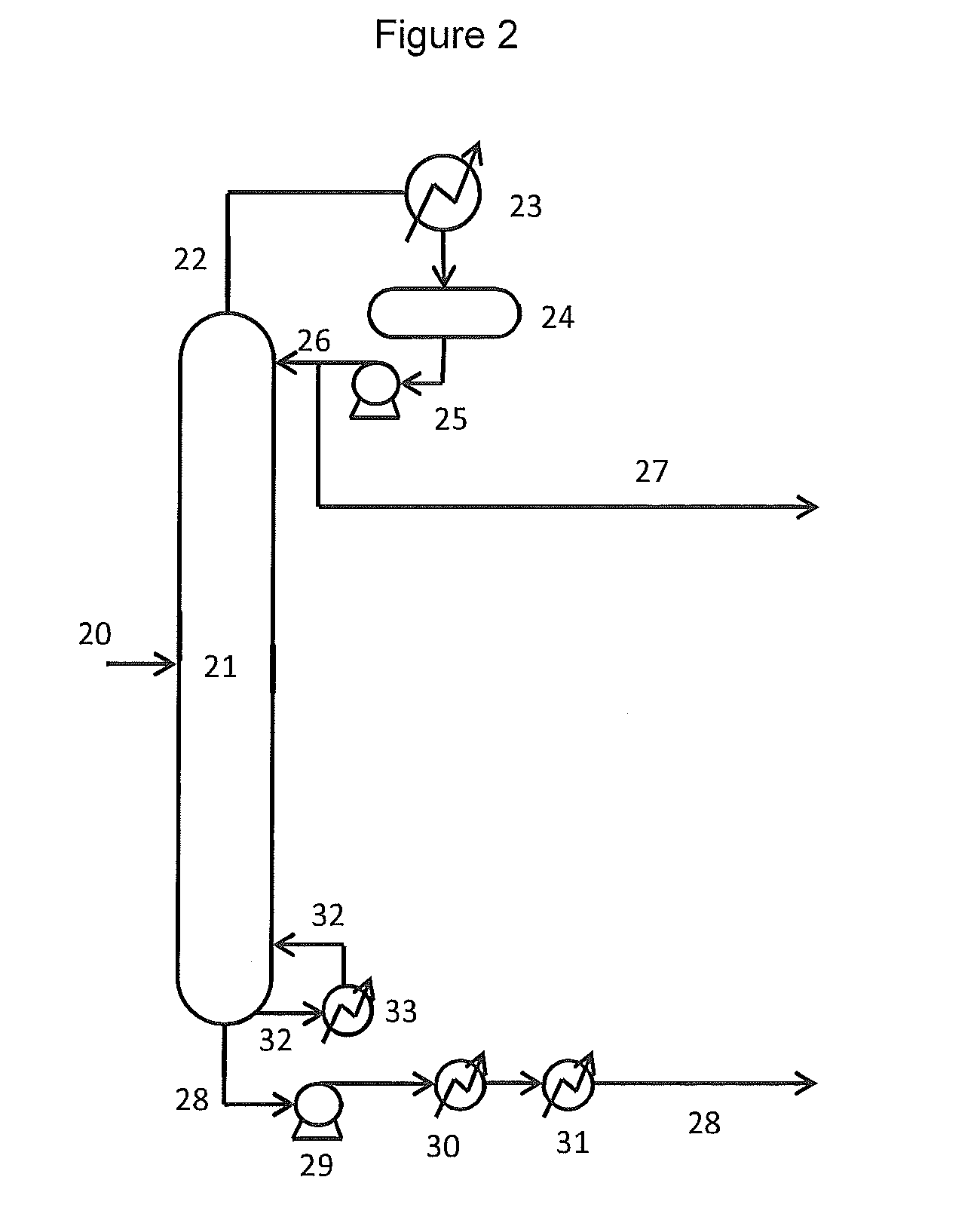

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

Multimetal oxide materials

Owner:BASF SE

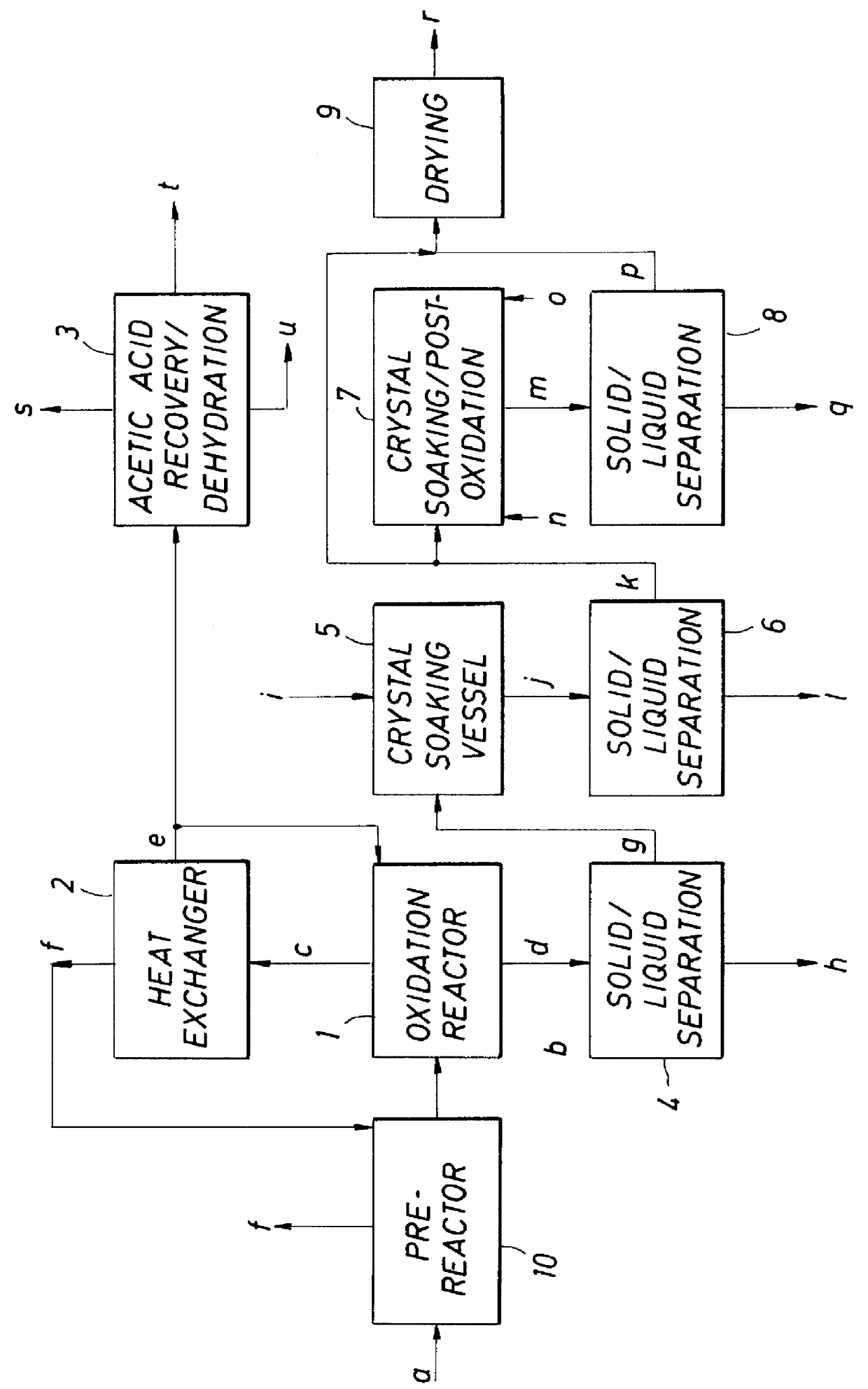

Process for the oxidative purification of terephthalic acid

InactiveUS20040110980A1Organic compound preparationCarboxylic preparation by oxidationSlurryCarboxylic acid

Disclosed is a process to produce a purified carboxylic acid slurry. The process comprises removing impurities from a crystallized product in a solid liquid displacement zone to form the purified carboxylic acid slurry. The process produces purified carboxylic acid slurry having good color and low impurity levels without the use of purification steps like hydrogenation or an impurity removal process.

Owner:ALPEK POLYESTER SA DE CV

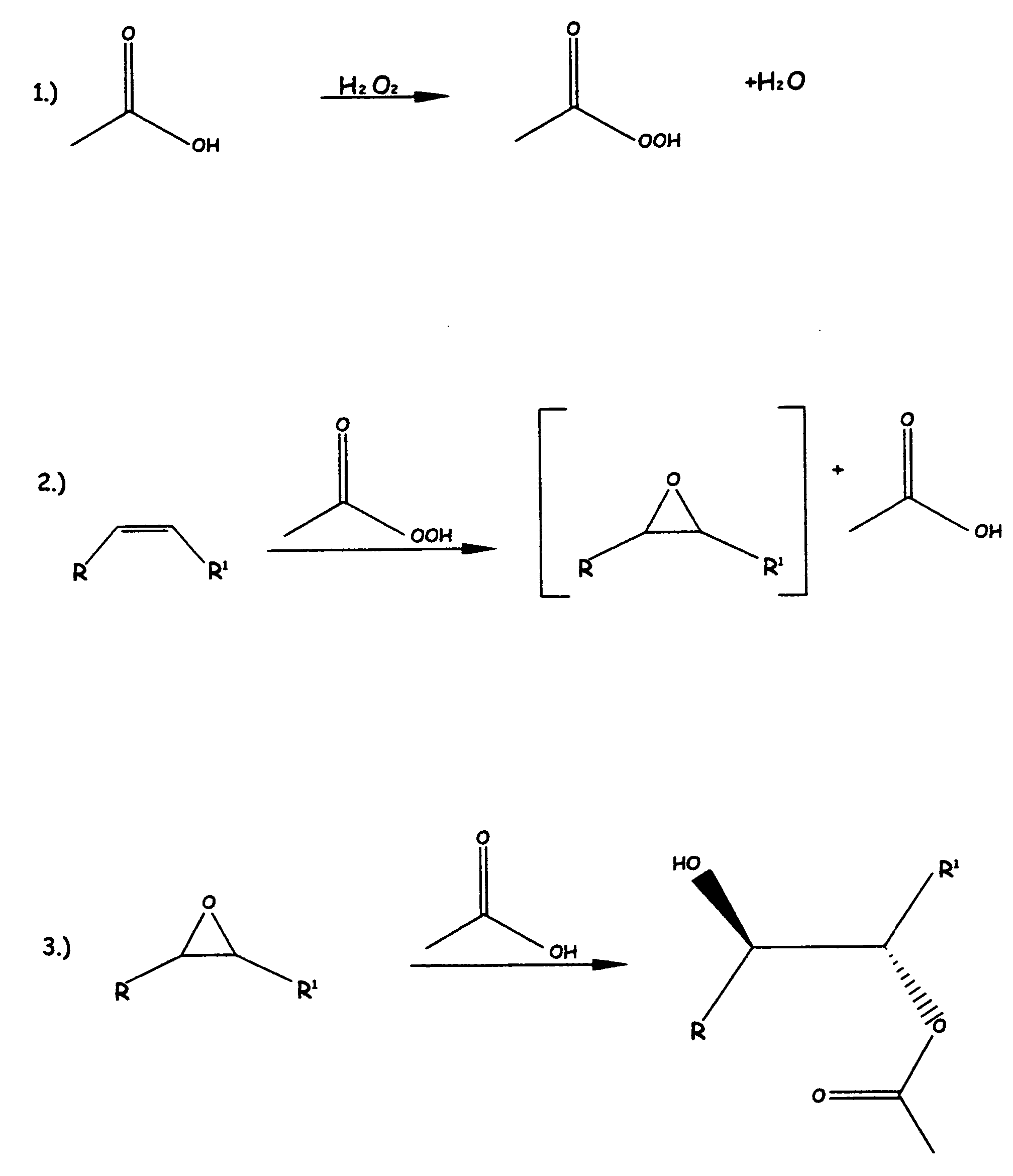

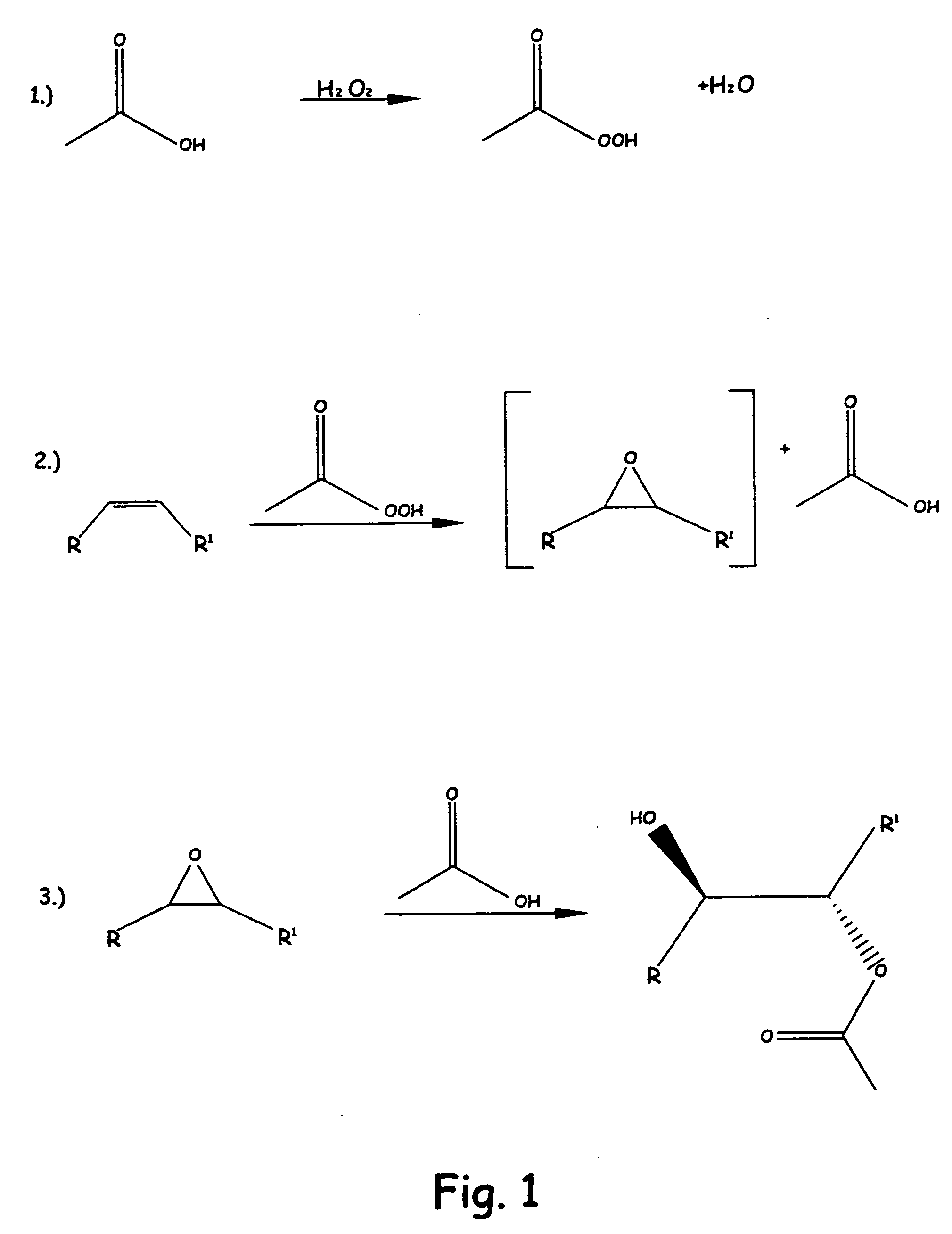

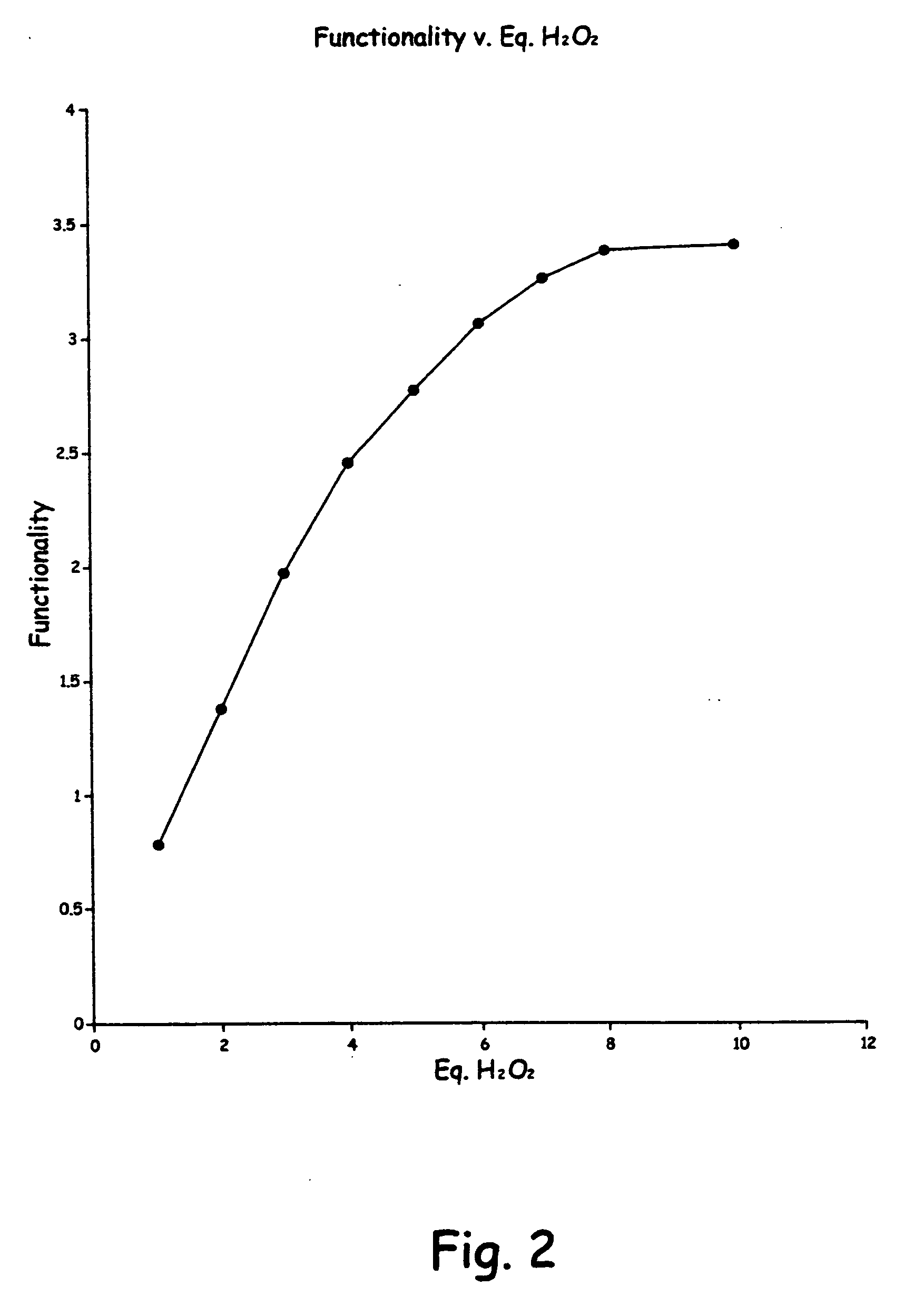

Methods of preparing hydroxy functional vegetable oils

Simple, economical preparative processes for the provision of pure hydroxyl functional materials that are derived by converting the alkene groups of the unsaturated molecules found in vegetable oils, into hydroxyl groups.

Owner:CARGILL INC

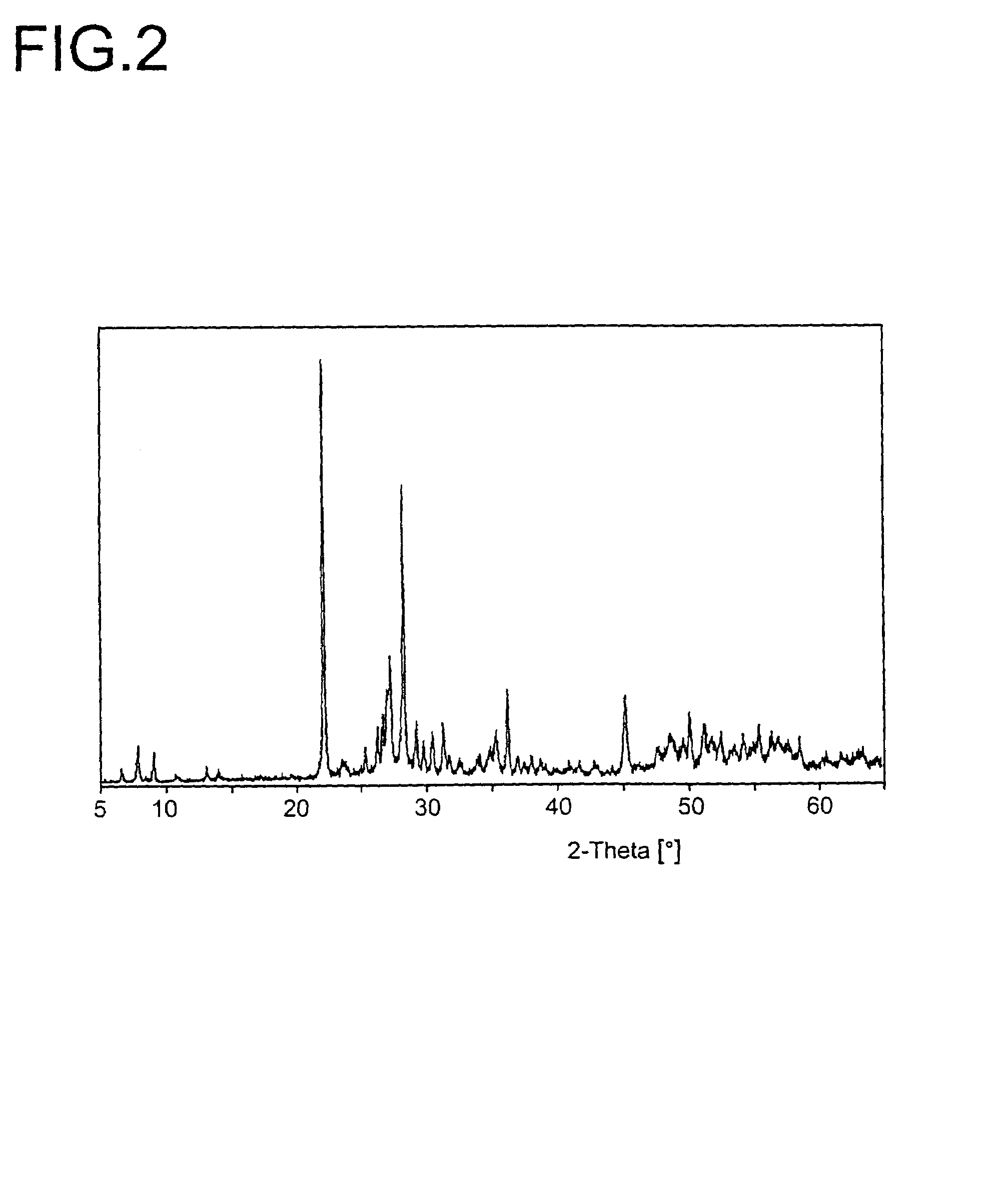

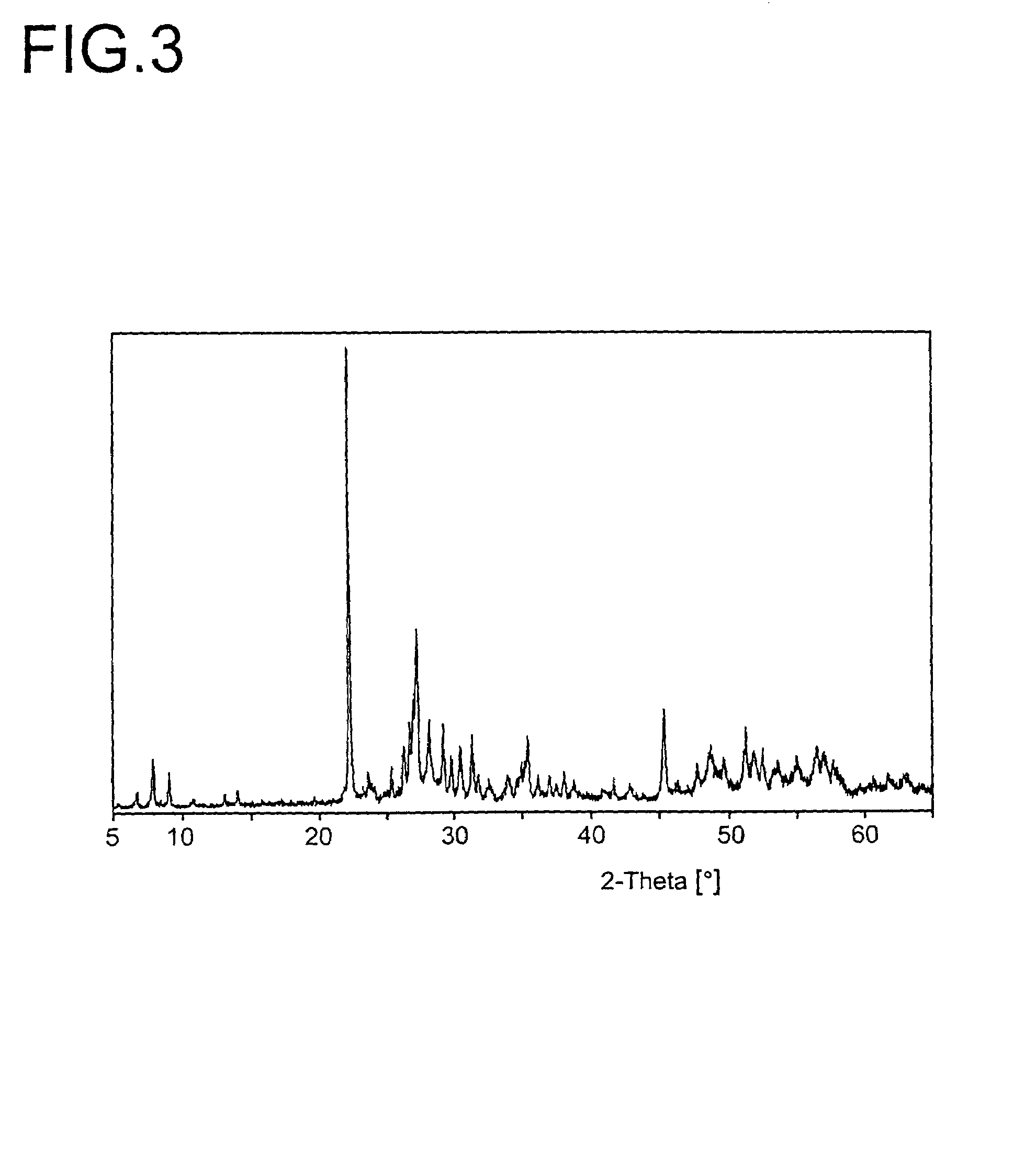

Oxide catalyst composition

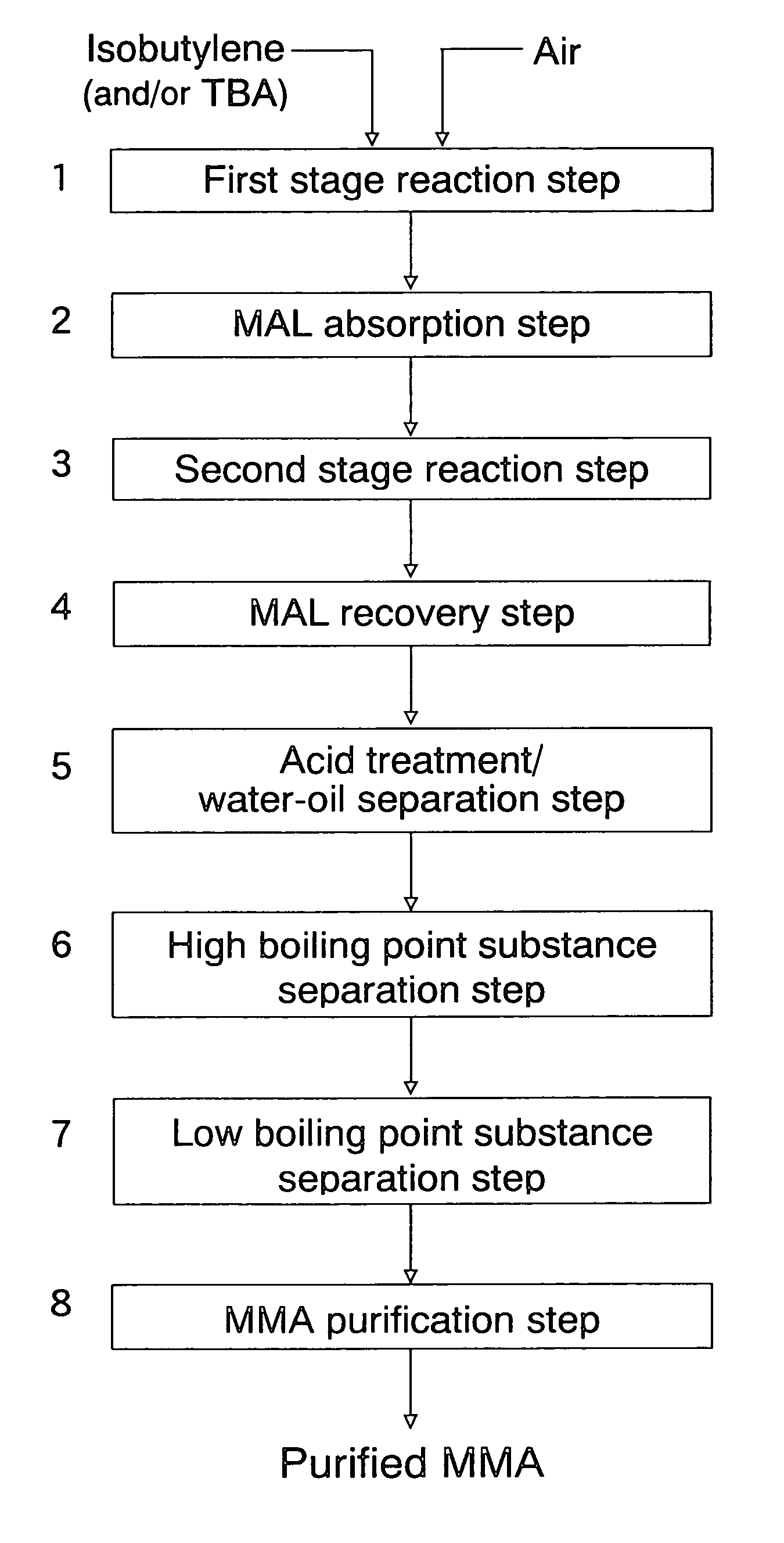

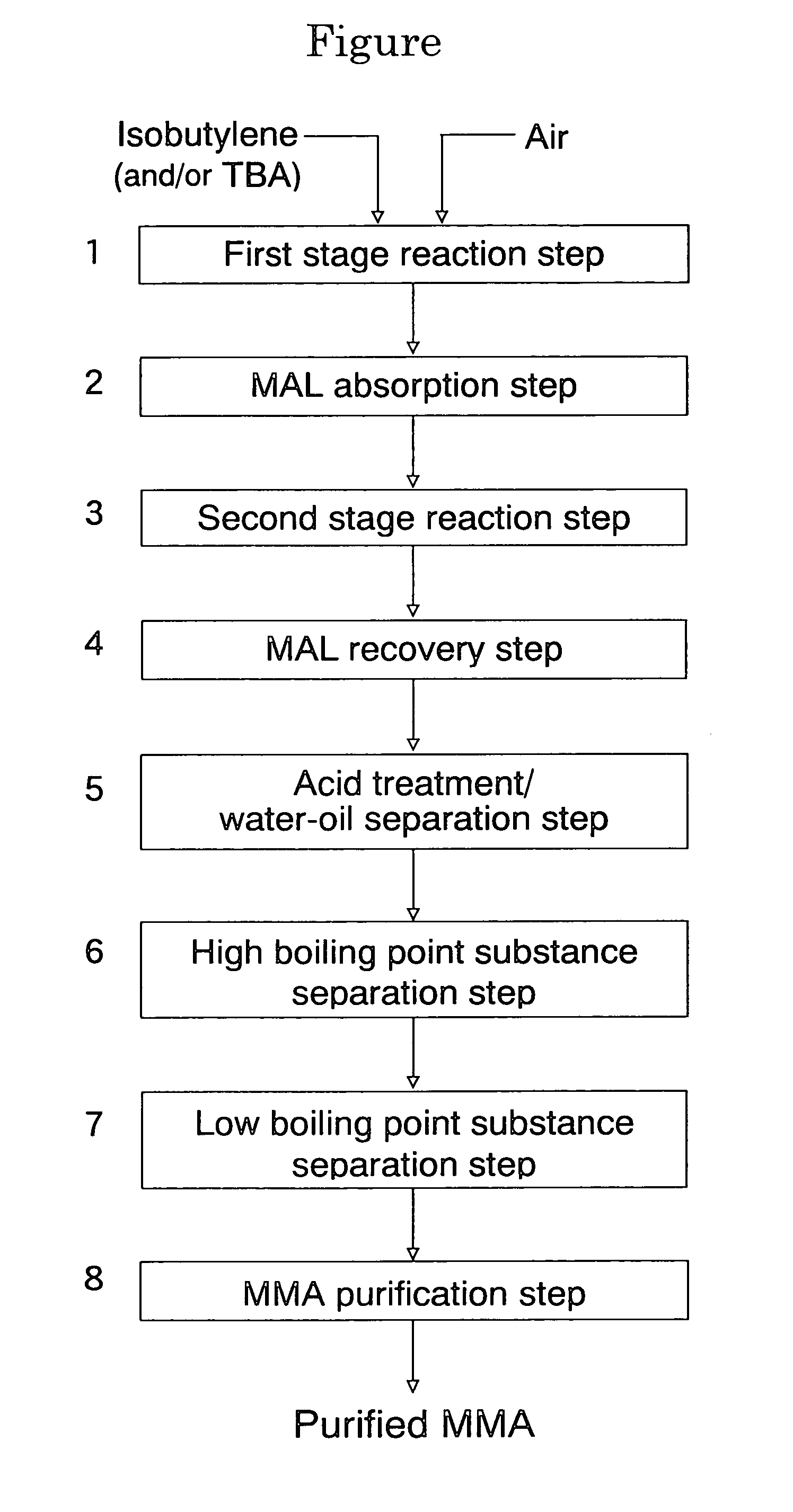

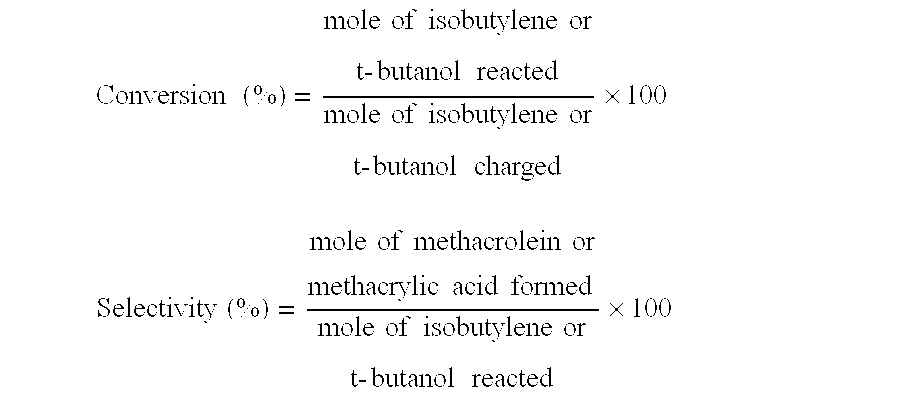

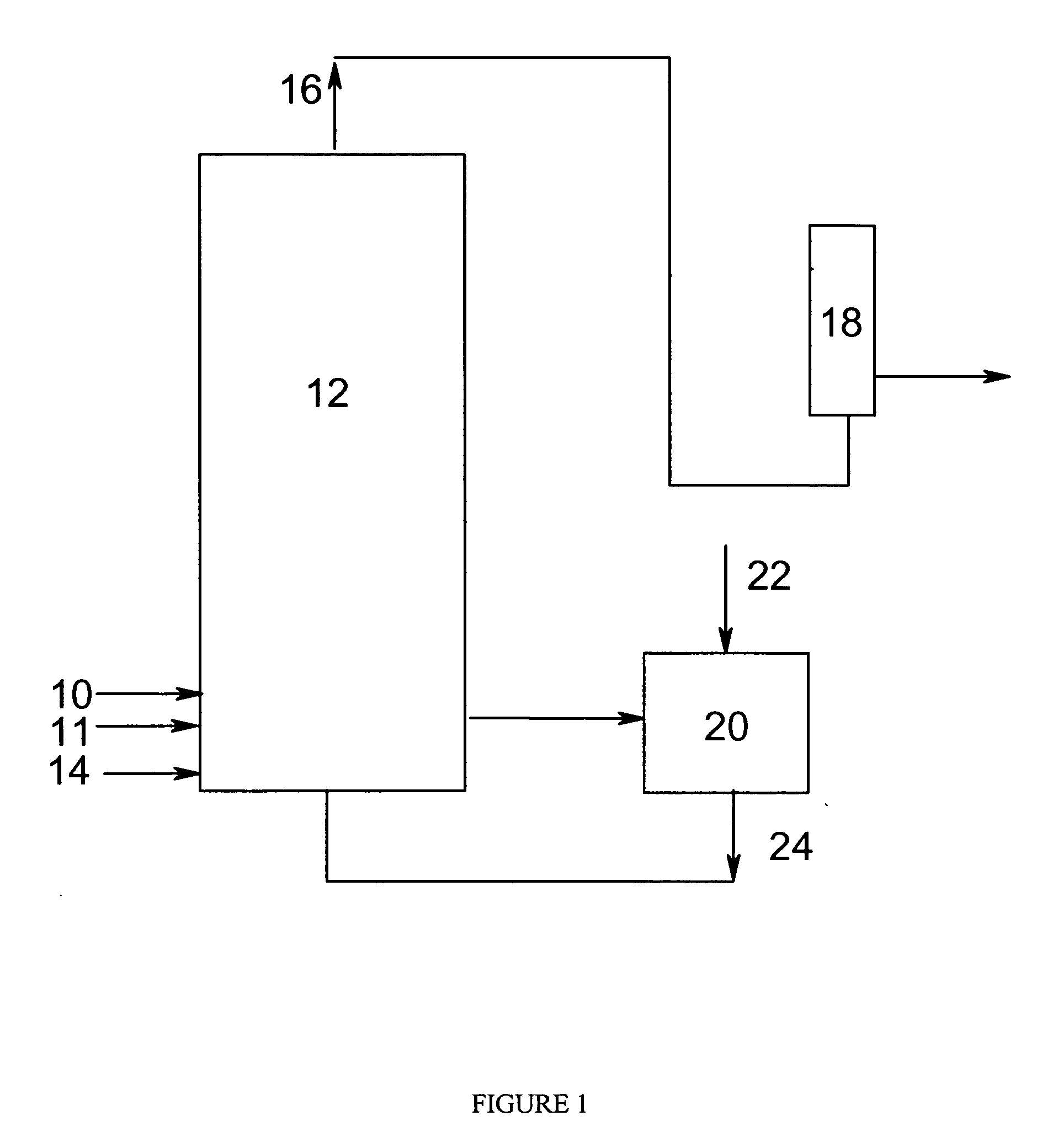

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

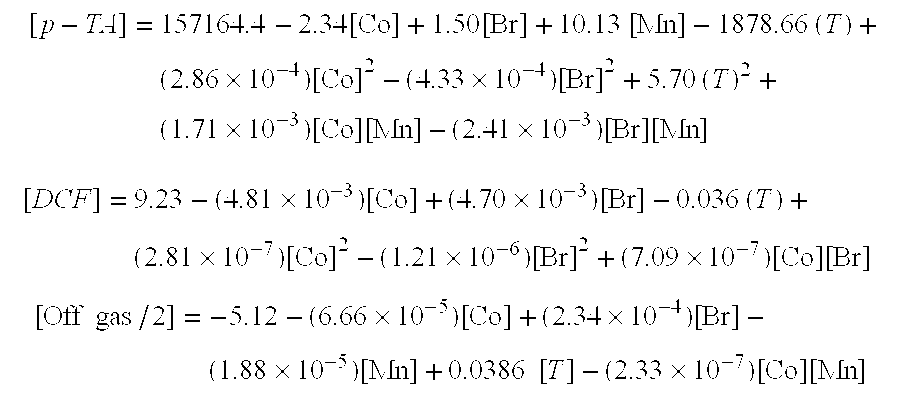

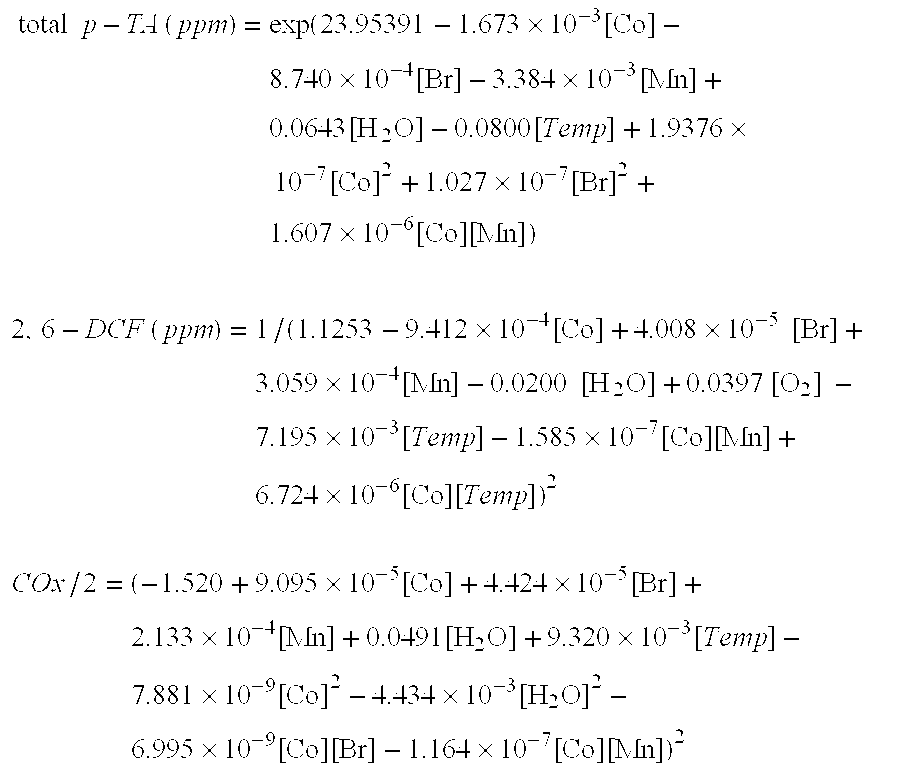

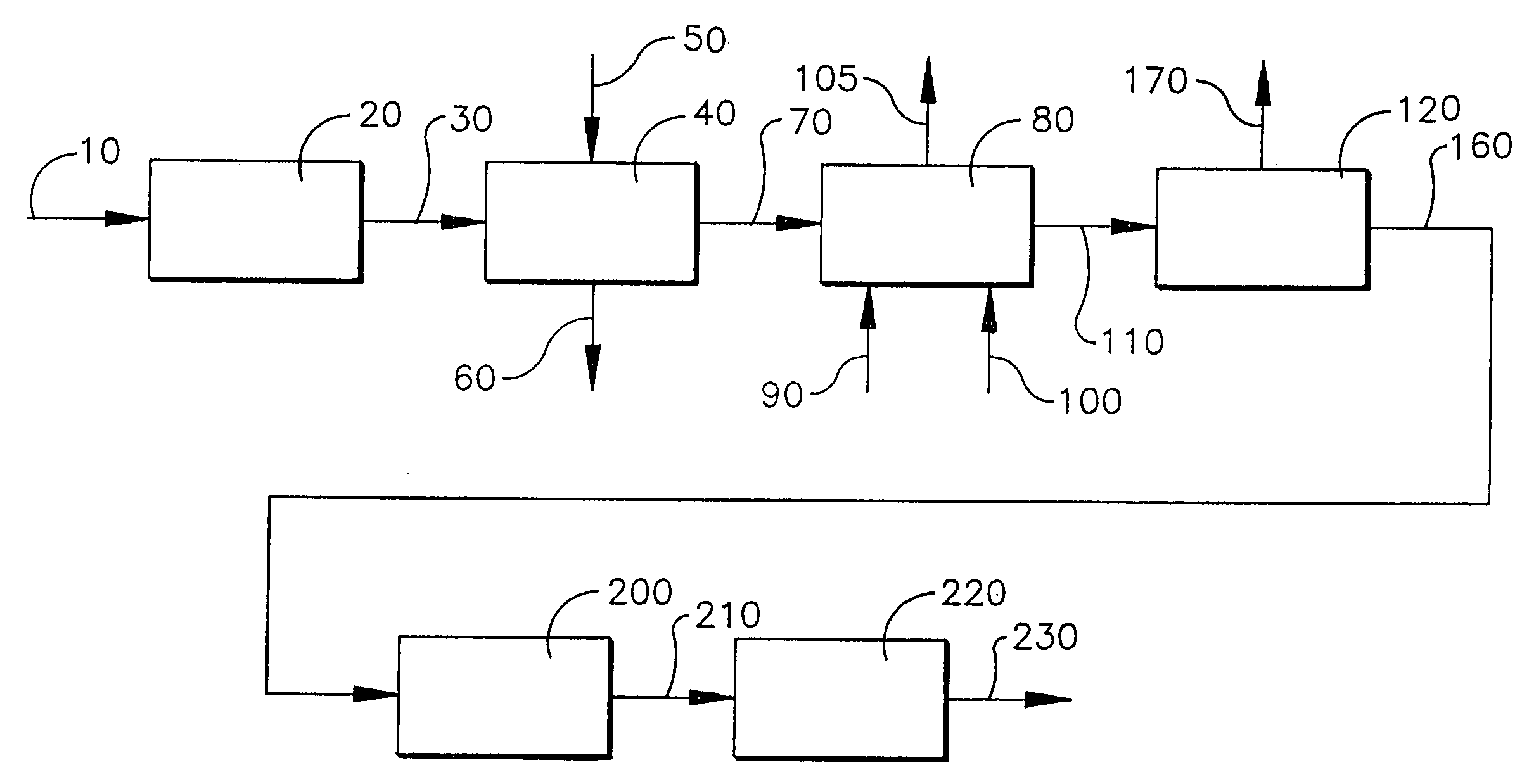

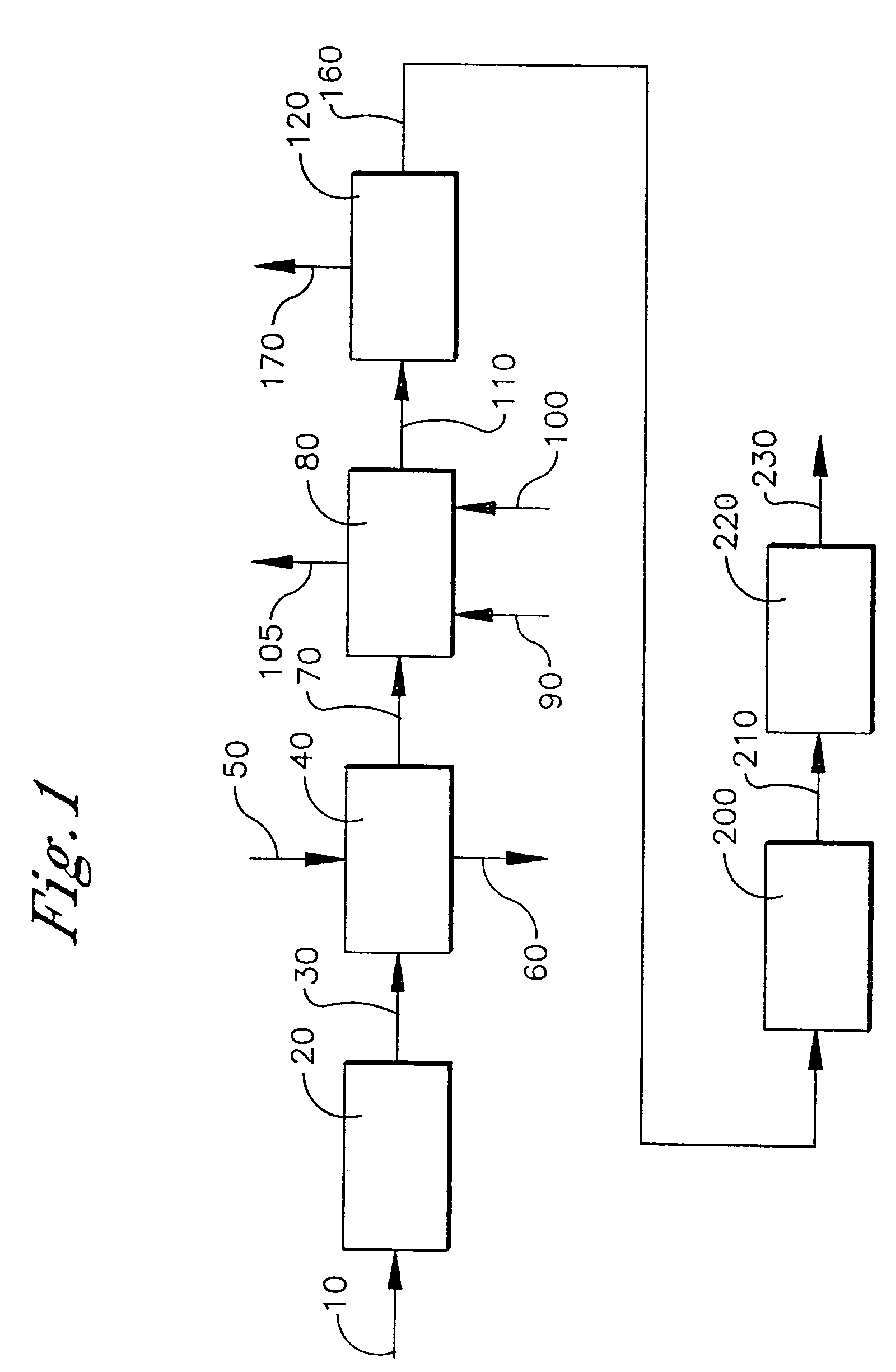

Processes for producing terephthalic acid

InactiveUS20060205977A1Organic compound preparationCarboxylic preparation by oxidationSolventBromine

Processes for producing terephthalic acid are disclosed, the processes comprising combining in a reaction medium p-xylene, a solvent comprising water and one or more saturated organic acids having from 2-4 carbon atoms, and an oxygen-containing gas, at a temperature from about 135° C. to about 165° C., in the presence of a catalyst composition comprising cobalt atoms and manganese atoms, with bromine atoms provided as a promoter. The amount of cobalt used may be from about 1,800 ppm to about 6,000 ppm, with respect to the total weight of the liquid in the reaction medium, and the weight ratio of cobalt to manganese may be from about 40 to about 400. The processes according to the invention produce terephthalic acid as a precipitated reaction product, with typically no more than about 10 ppm 2,6-dicarboxyfluorenone produced, with respect to the weight of the terephthalic acid produced, or no more than about 20 ppm 2,6-dicarboxyfluorenone, with respect to the total weight of the reaction medium, per batch or upon one pass through a reactor. The terephthalic acid so produced may be further purified by one or more additional oxidation reactions, without the need for expensive hydrogenation purification processes.

Owner:EASTMAN CHEM CO

Process for the purification of a crude carboxylic acid slurry

Disclosed is a process to produce a purified carboxylic acid product. The process comprises removing impurities from a crude carboxylic acid slurry in a solid-liquid displacement zone to form a slurry product. The slurry product if further treated in a staged oxidation zone and a crystallization zone to from a crystallized product. The crystallized product is further cooled in a cooling zone and subsequently filtered and dried in a filtration and drying zone. The process produces purified carboxylic acid product having good color and low impurity levels without the use of purification steps like hydrogenation.

Owner:ALPEK POLYESTER SA DE CV

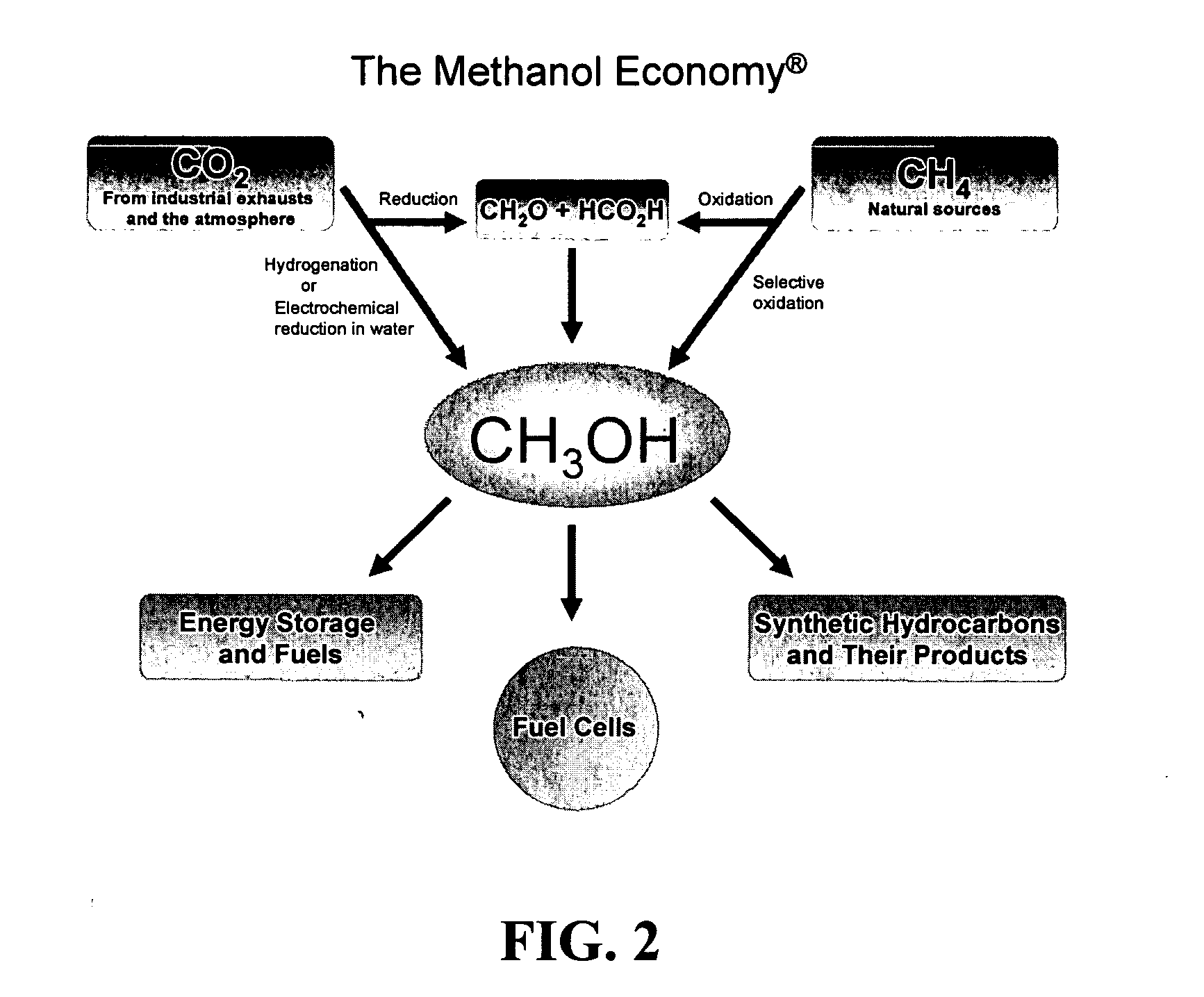

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20060235091A1Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

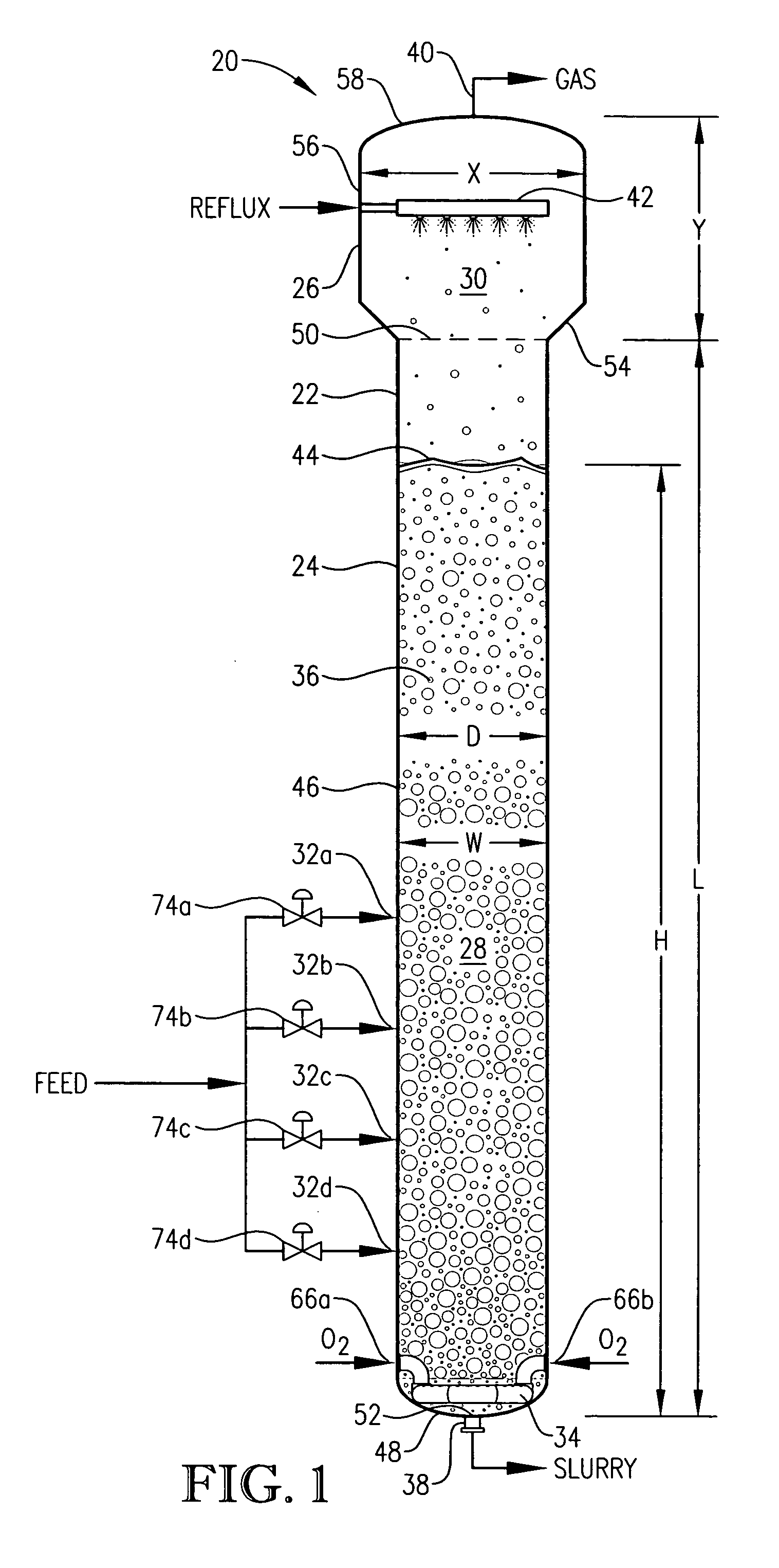

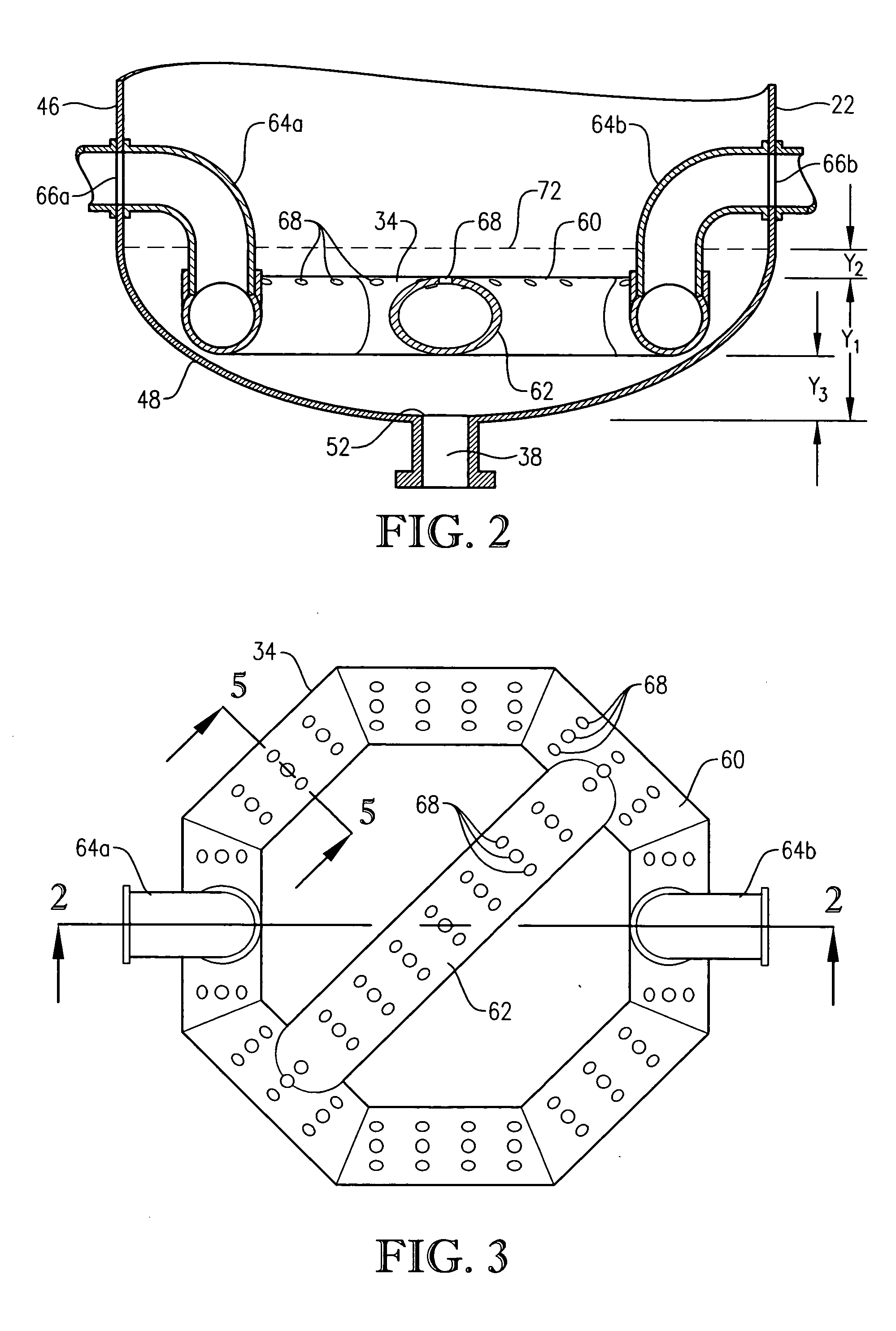

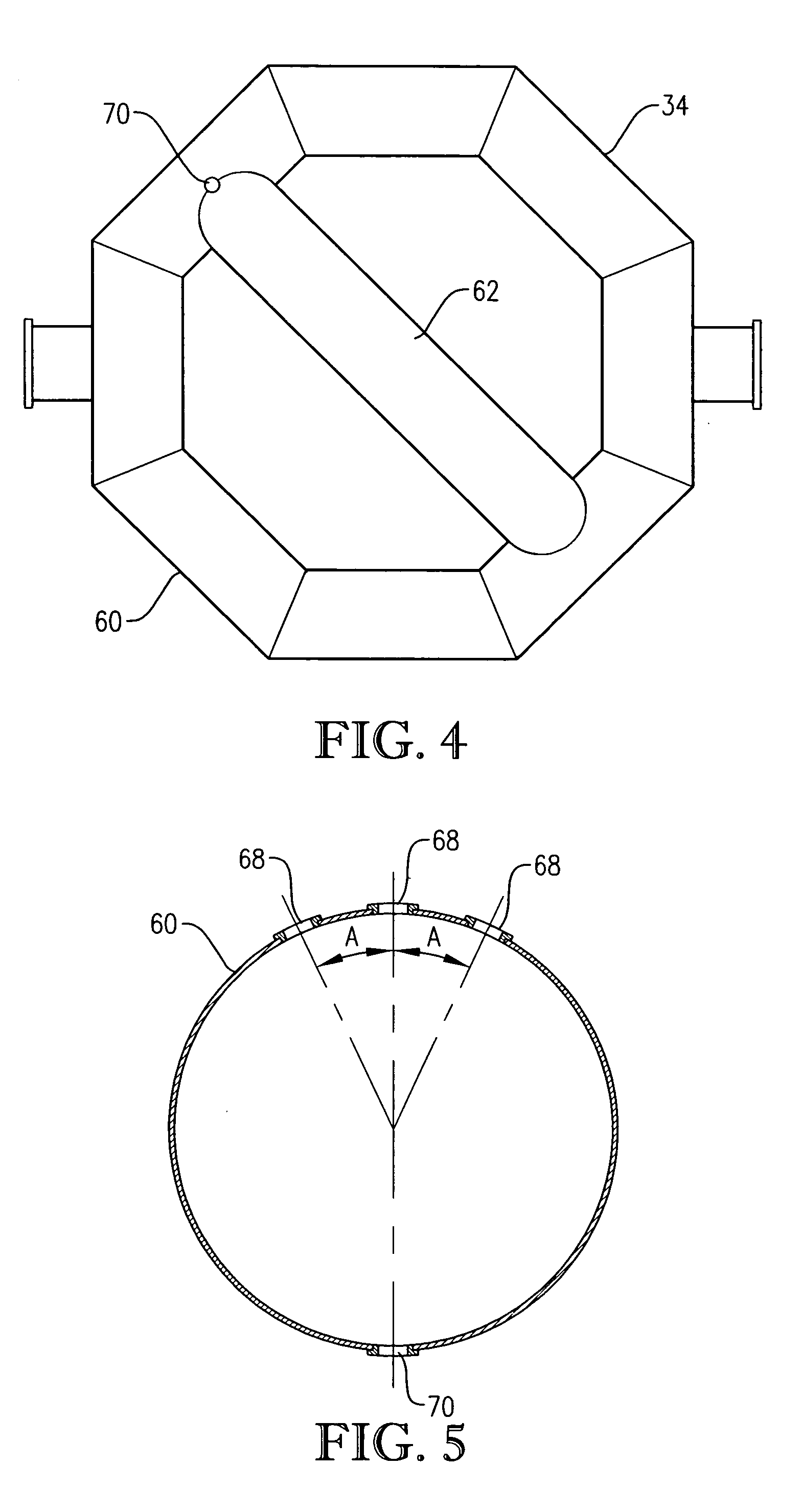

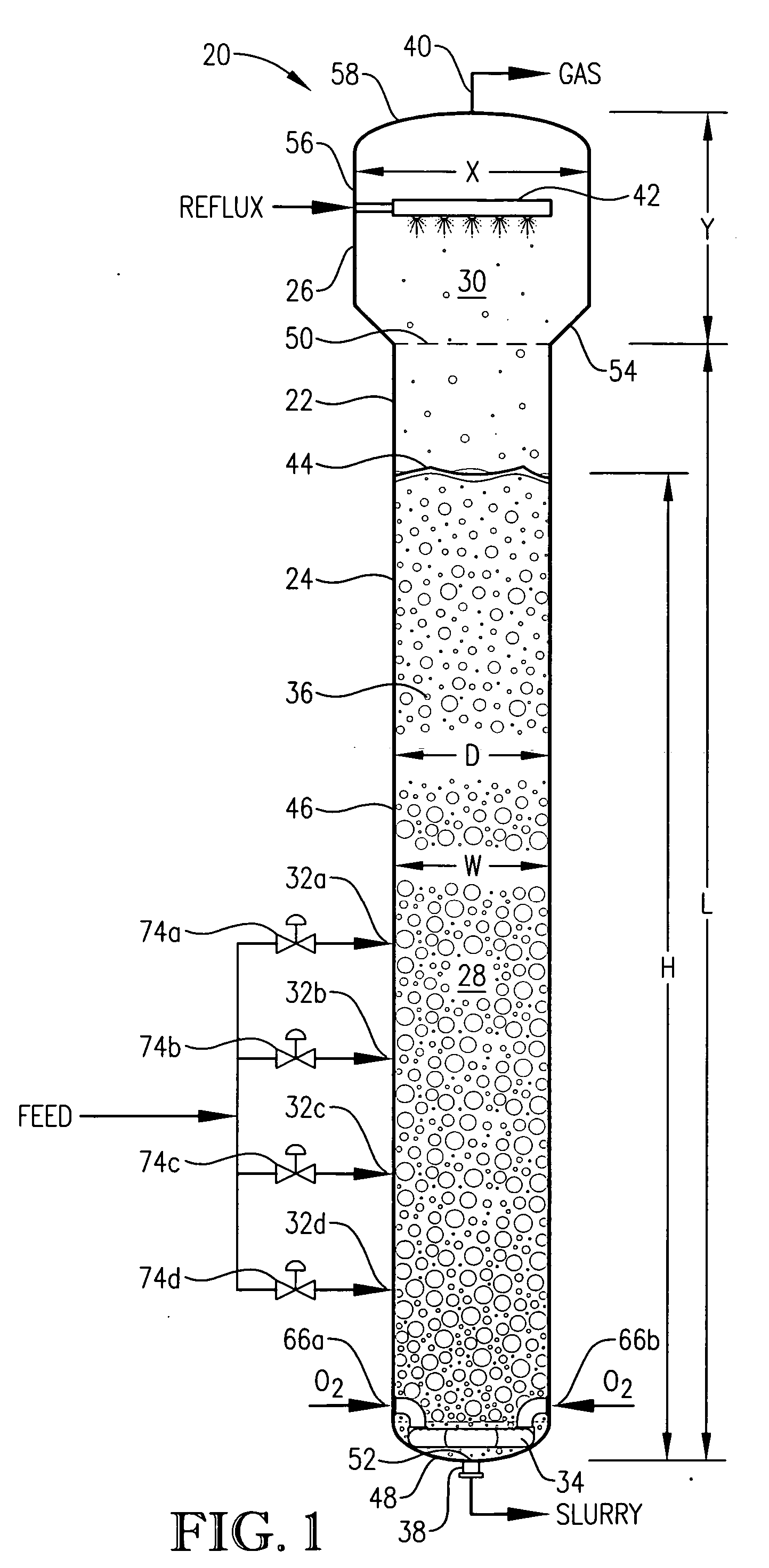

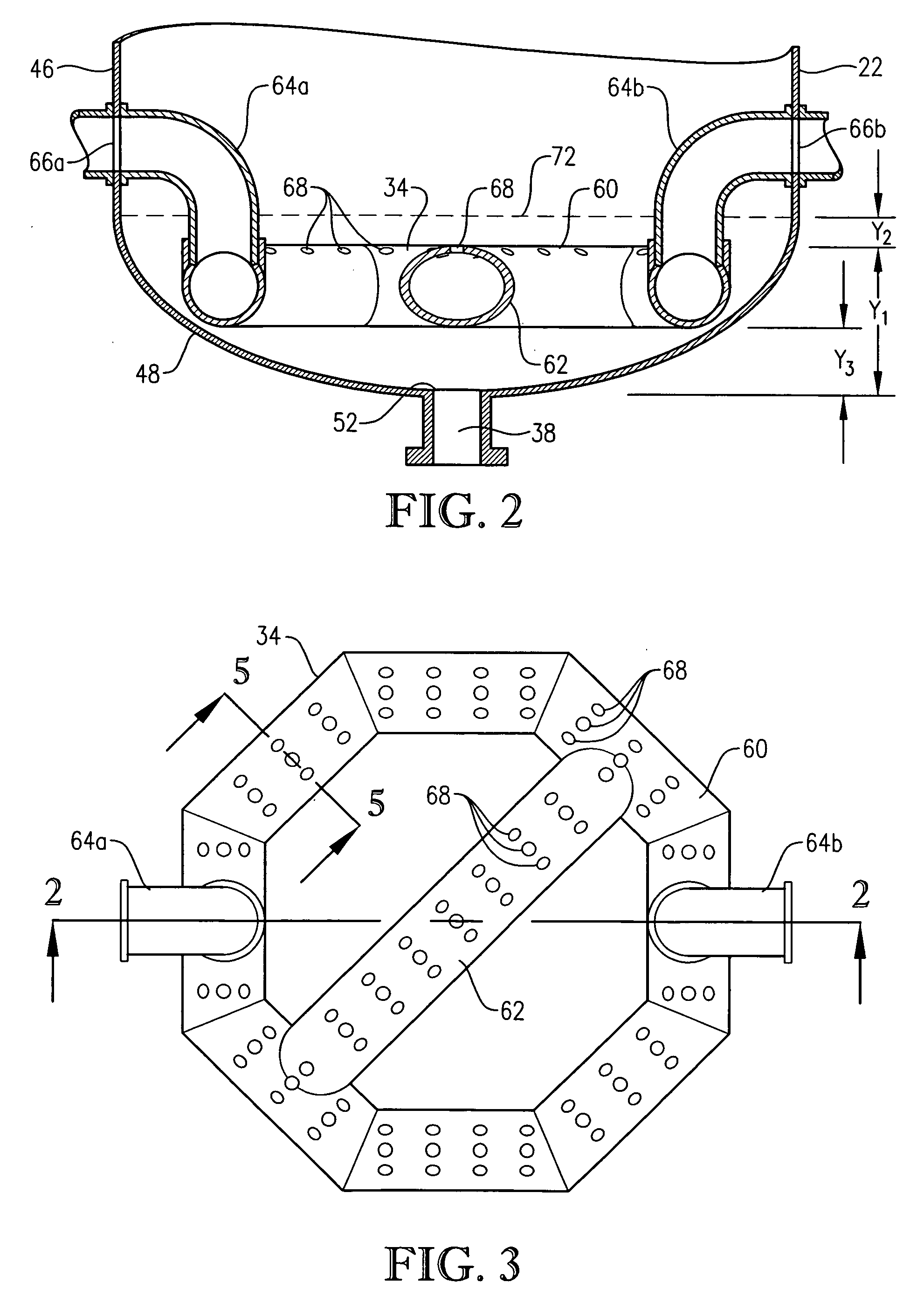

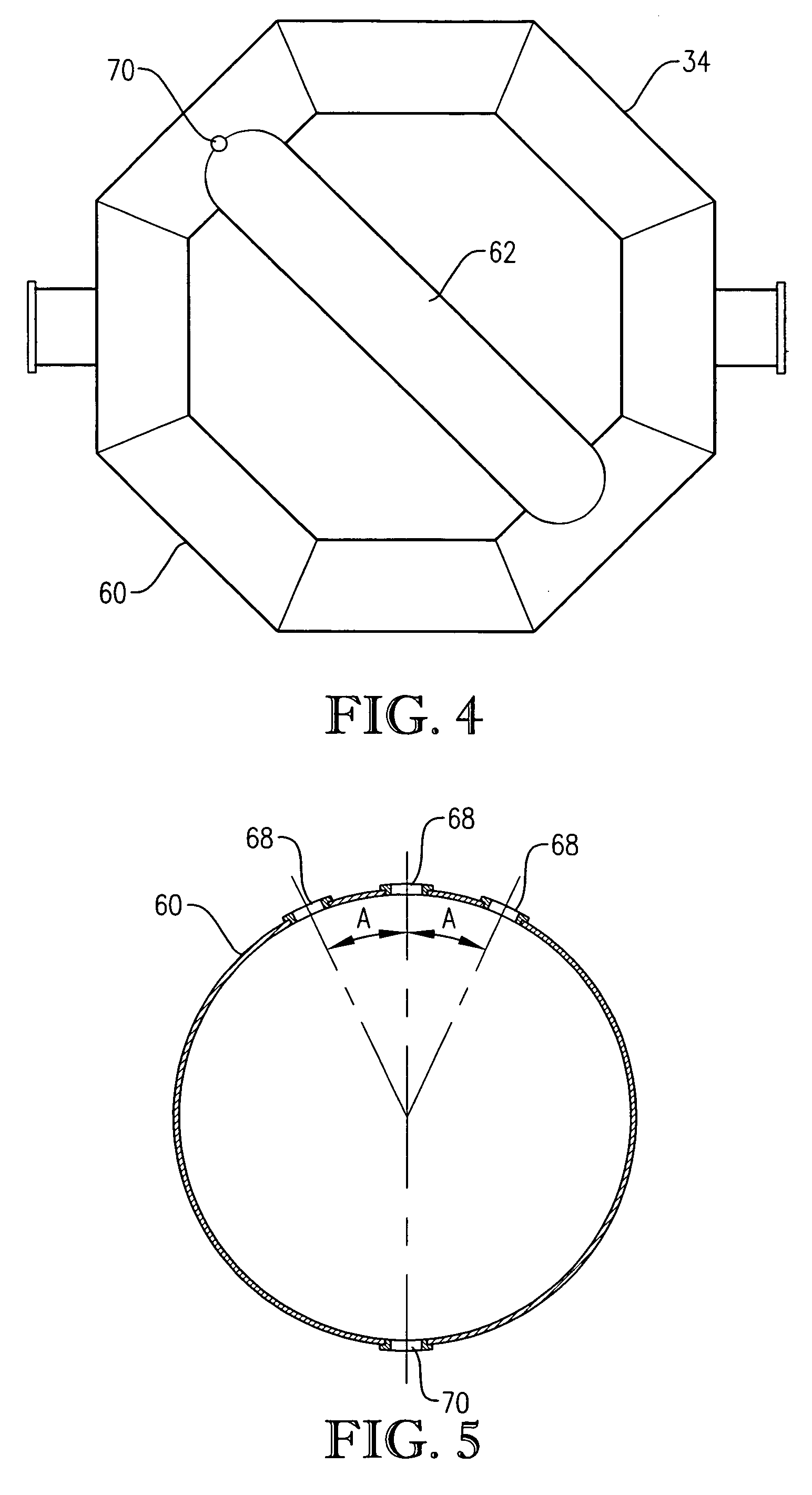

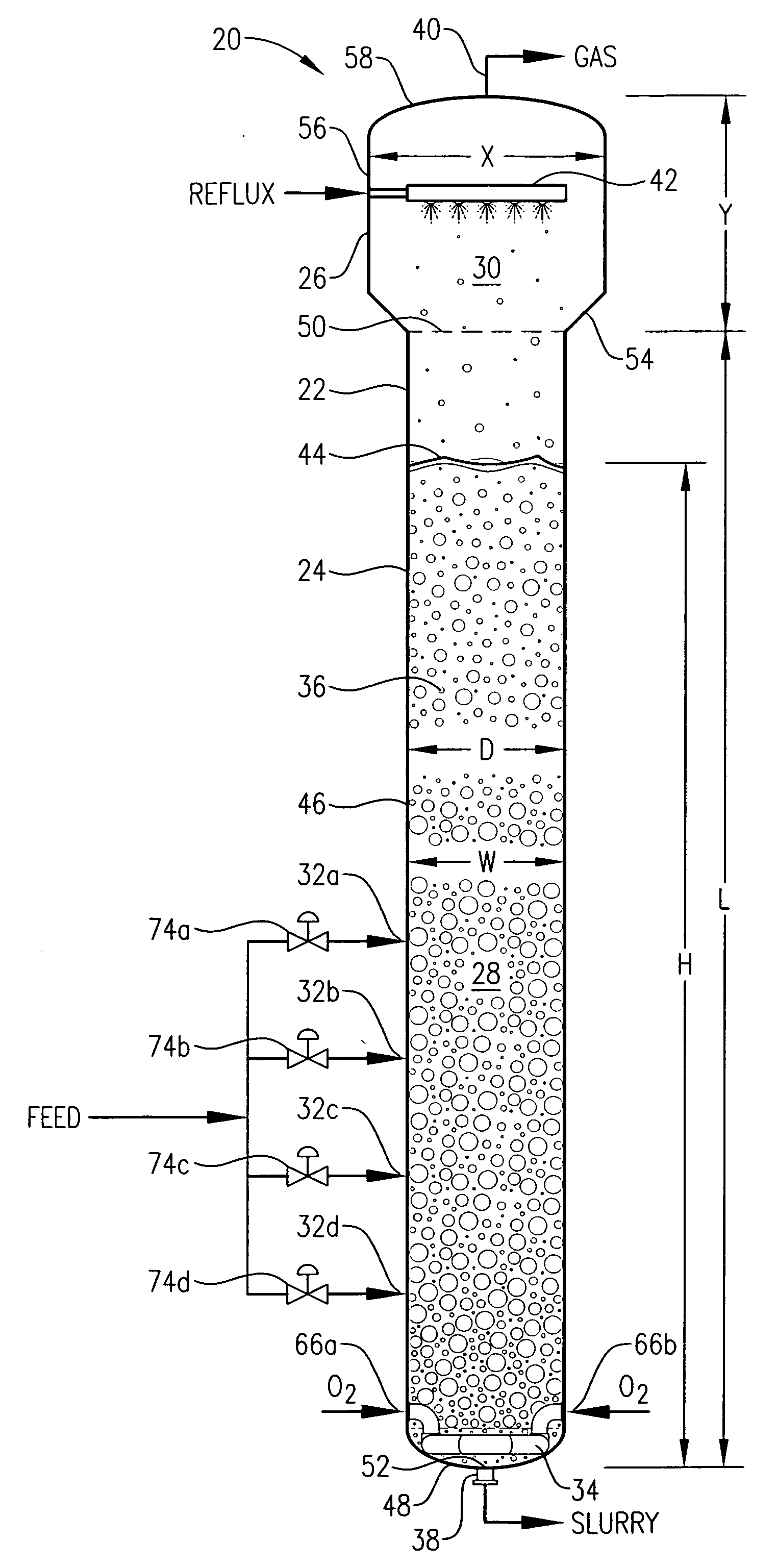

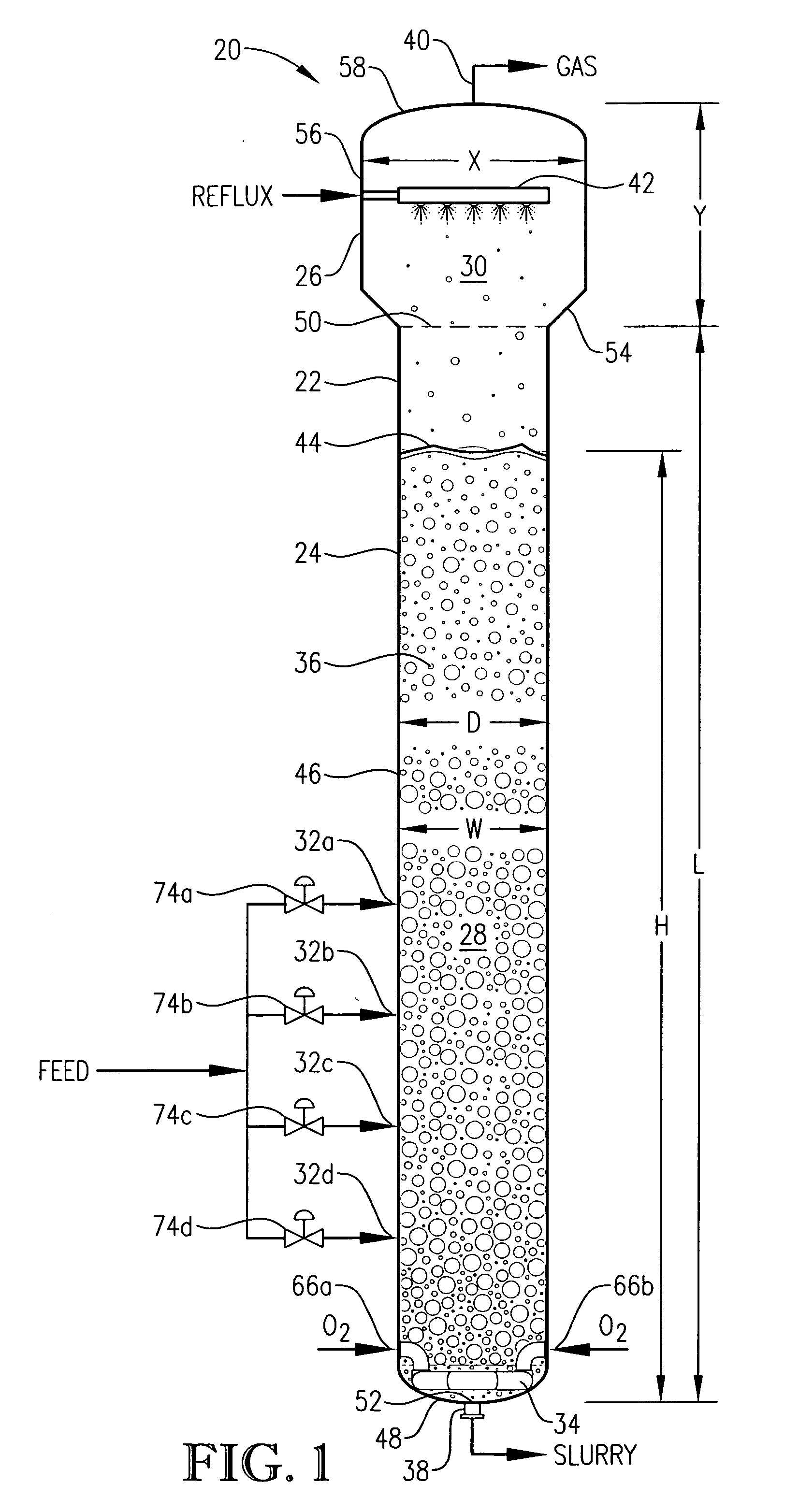

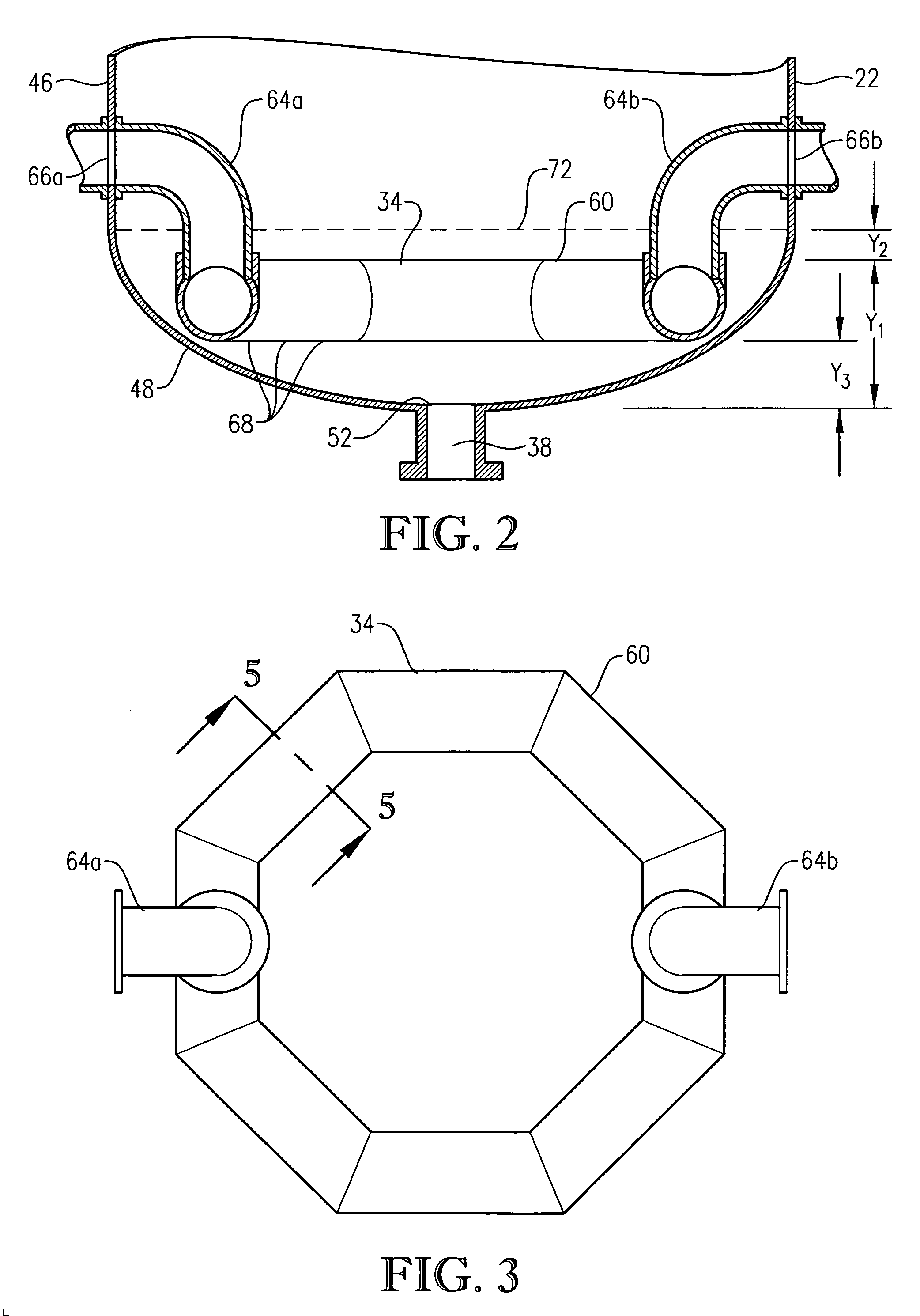

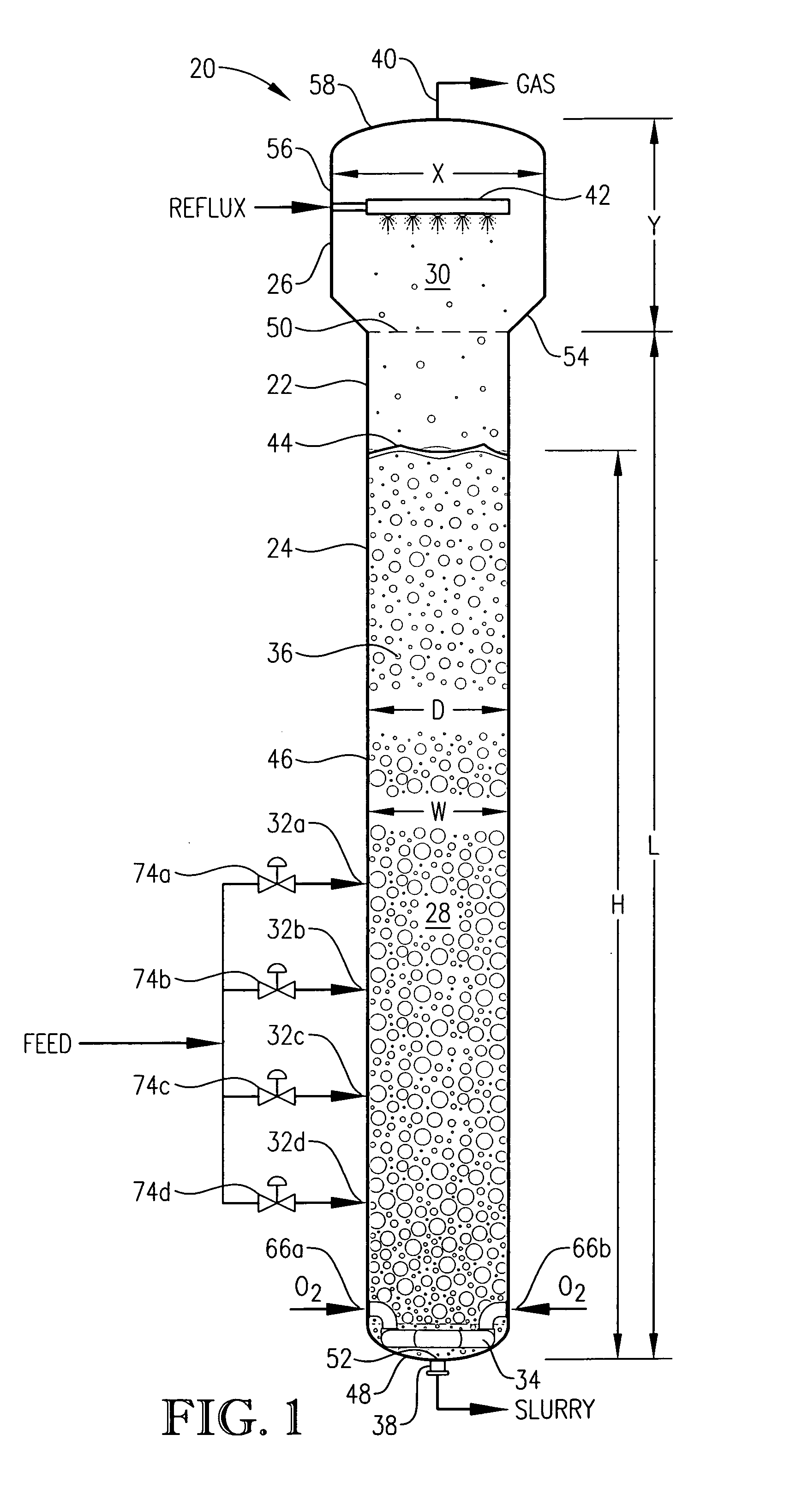

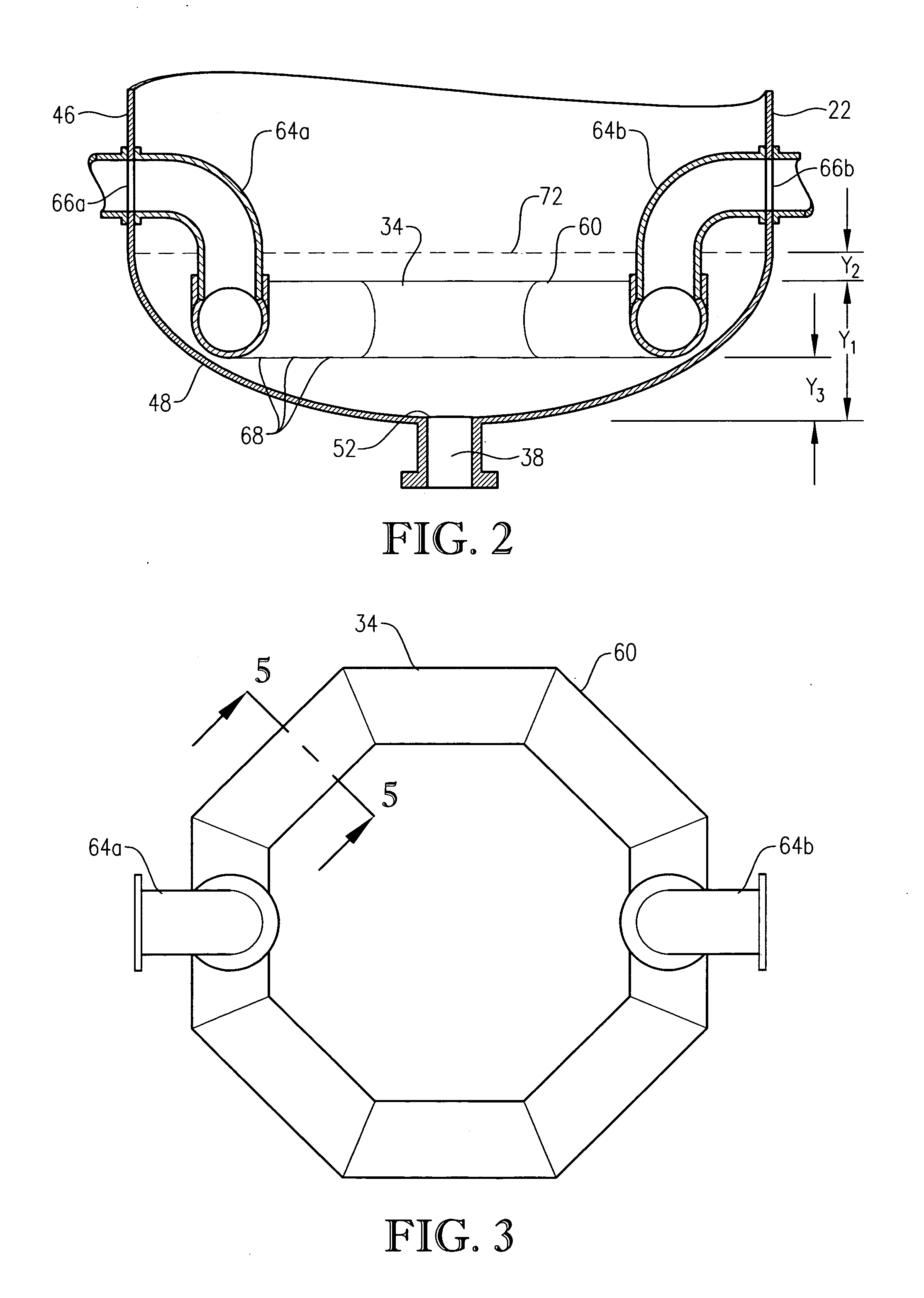

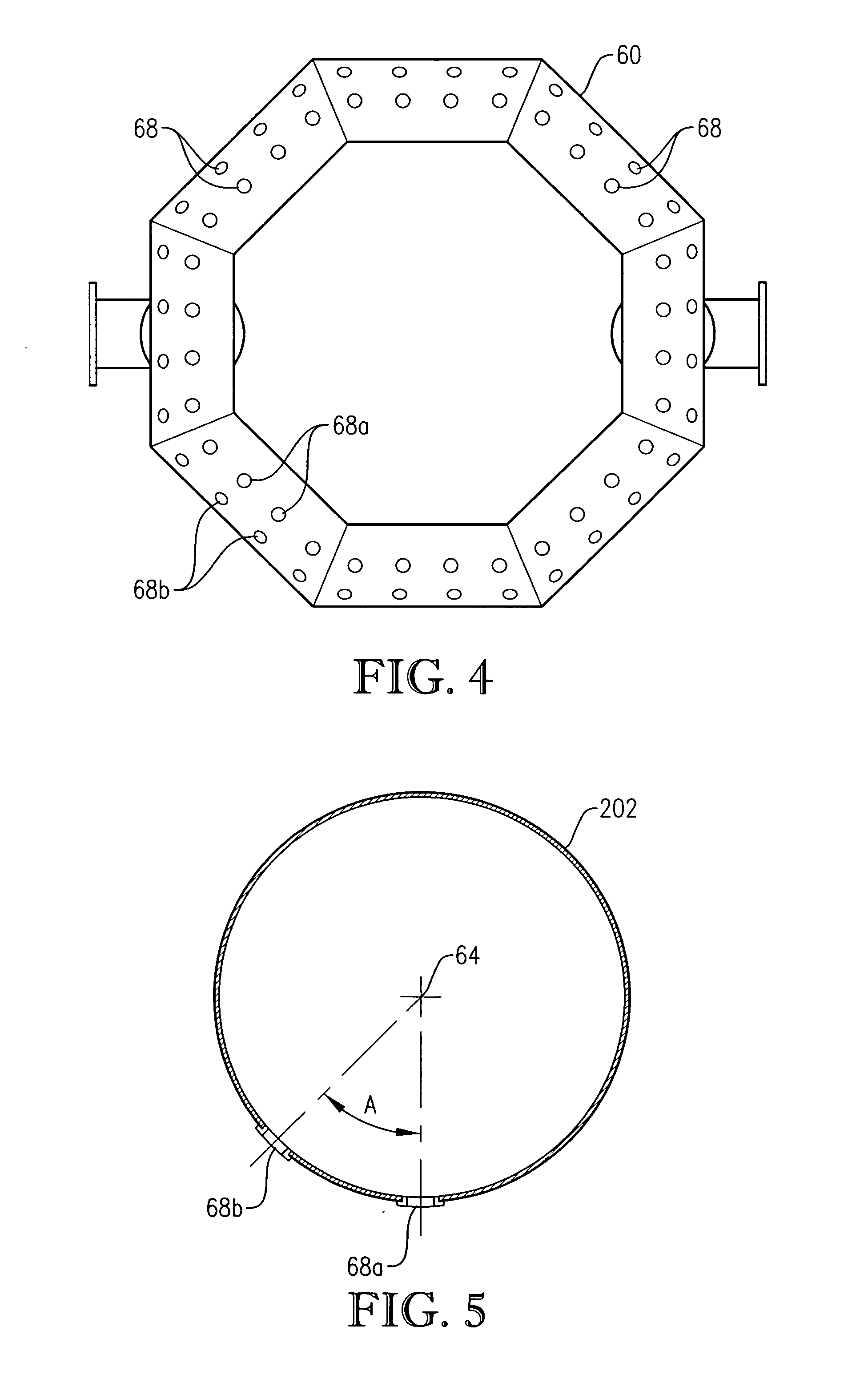

Optimized liquid-phase oxidation

ActiveUS20060047163A1Effective and economicalReduce formationOrganic oxidationOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

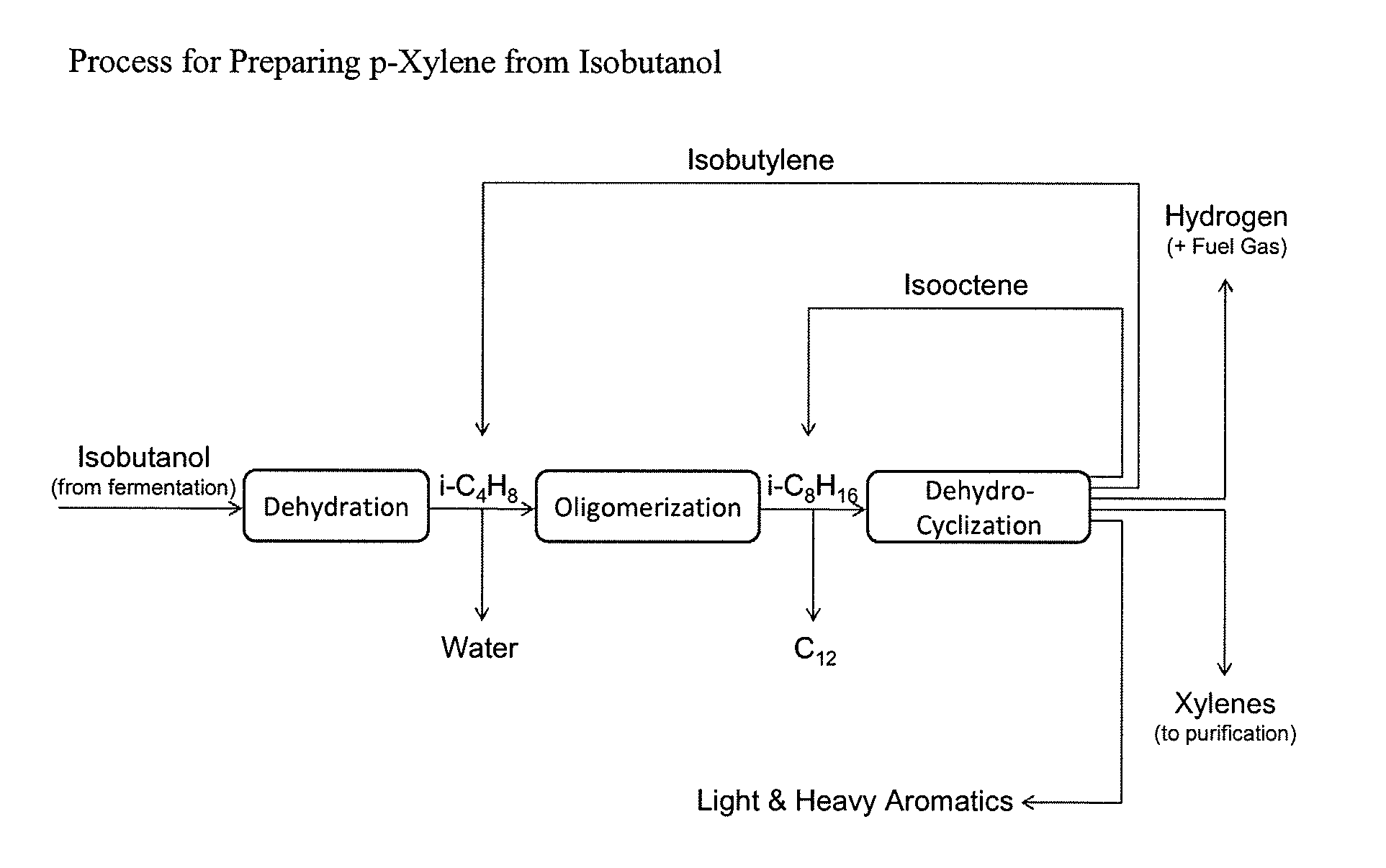

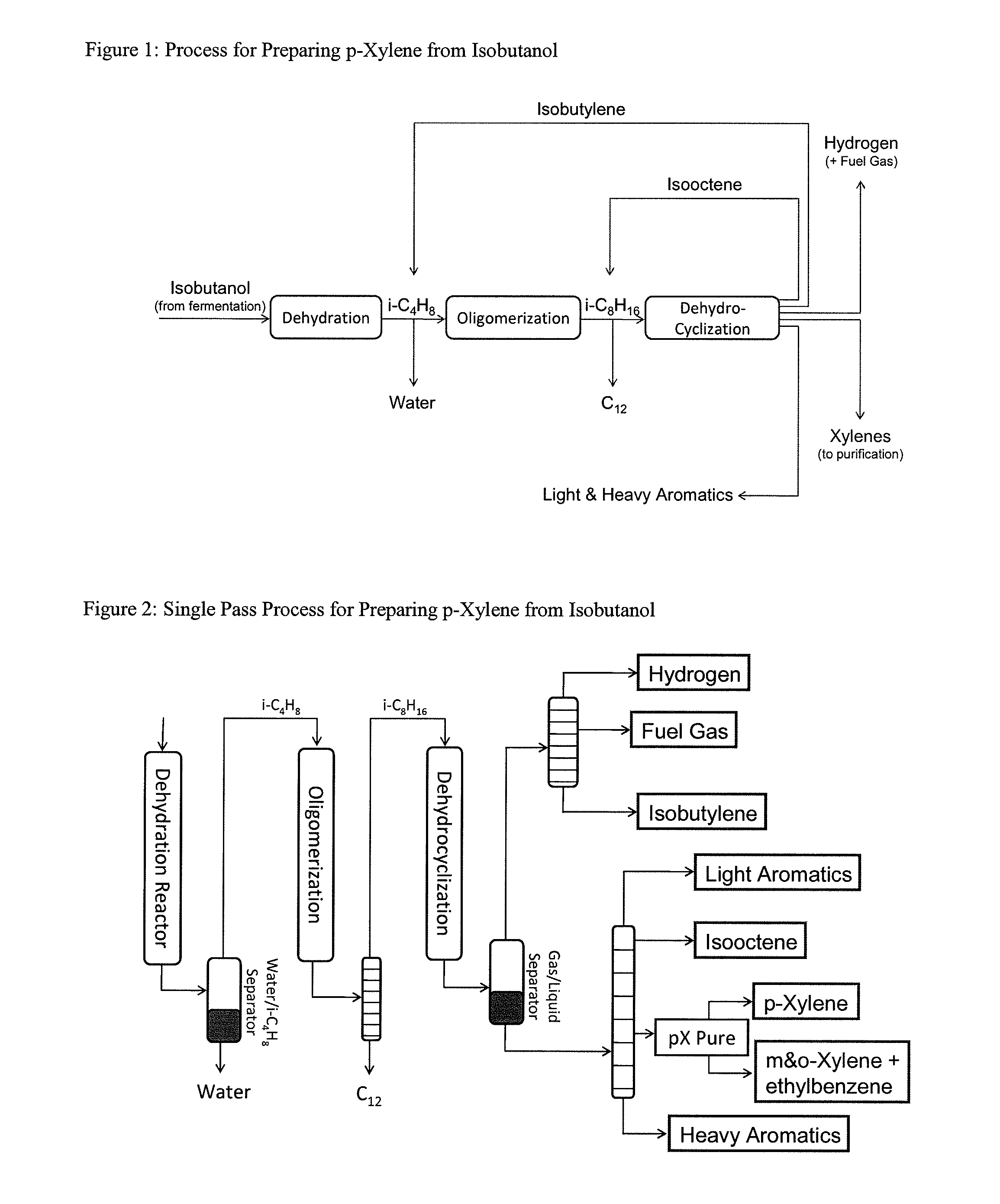

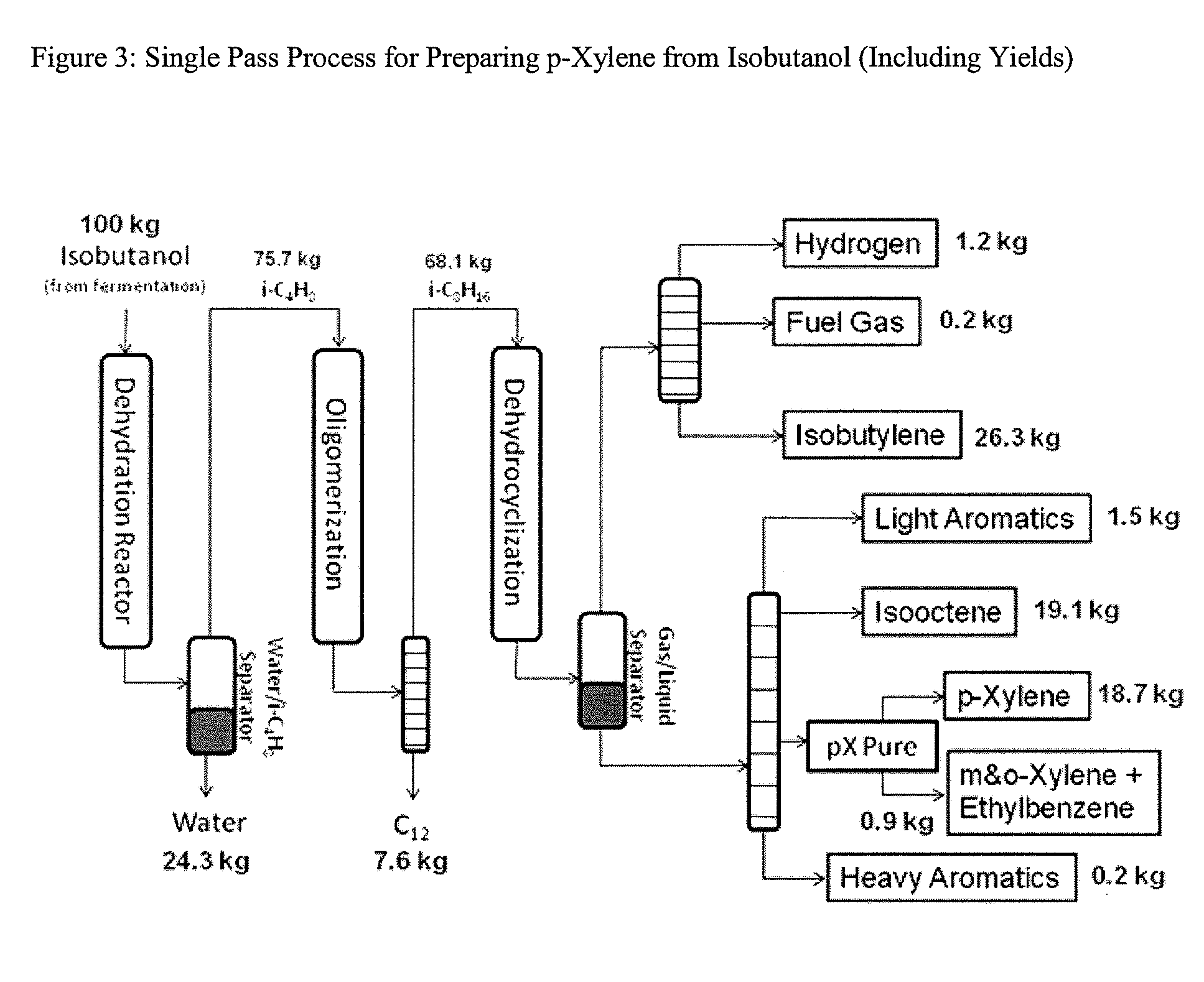

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Process for the production of polyols based on natural oils

InactiveUS20070123725A1Wide range of valuesOrganic oxidationOrganic compound preparationPolyolUnsaturated Oils

The present invention relates to a process for the production of polyols based on natural unsaturated oils.

Owner:BAYER MATERIALSCIENCE AG

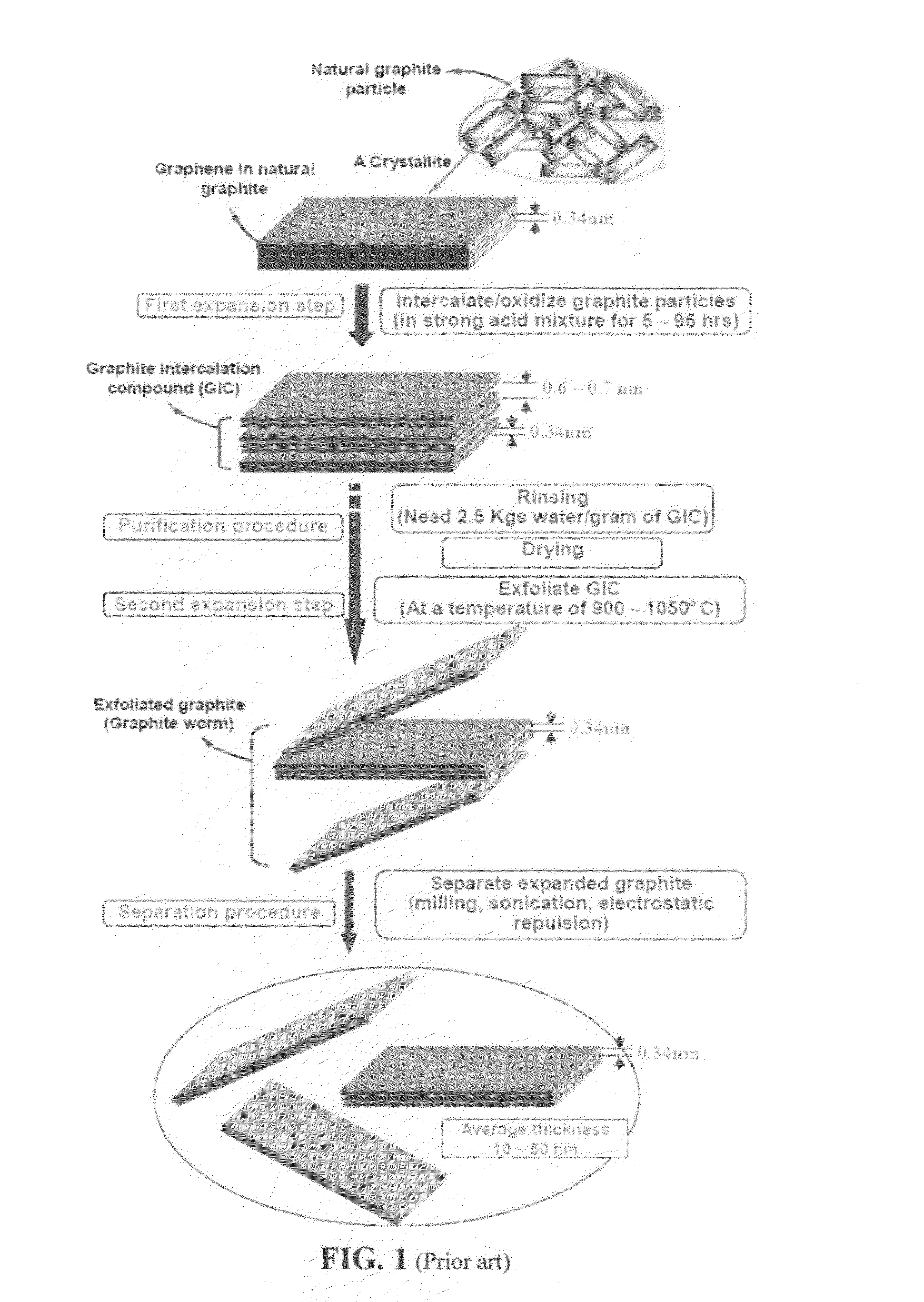

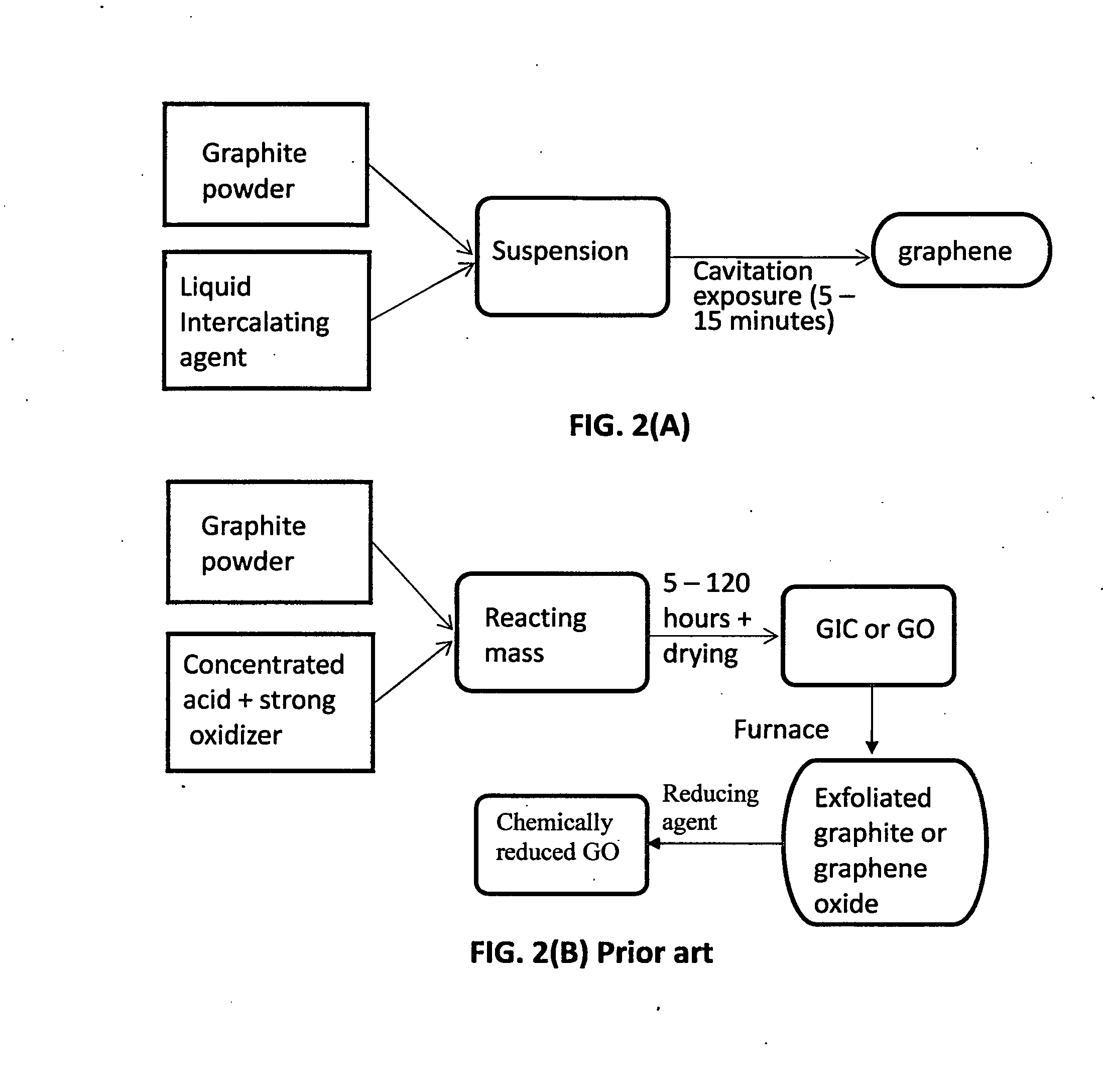

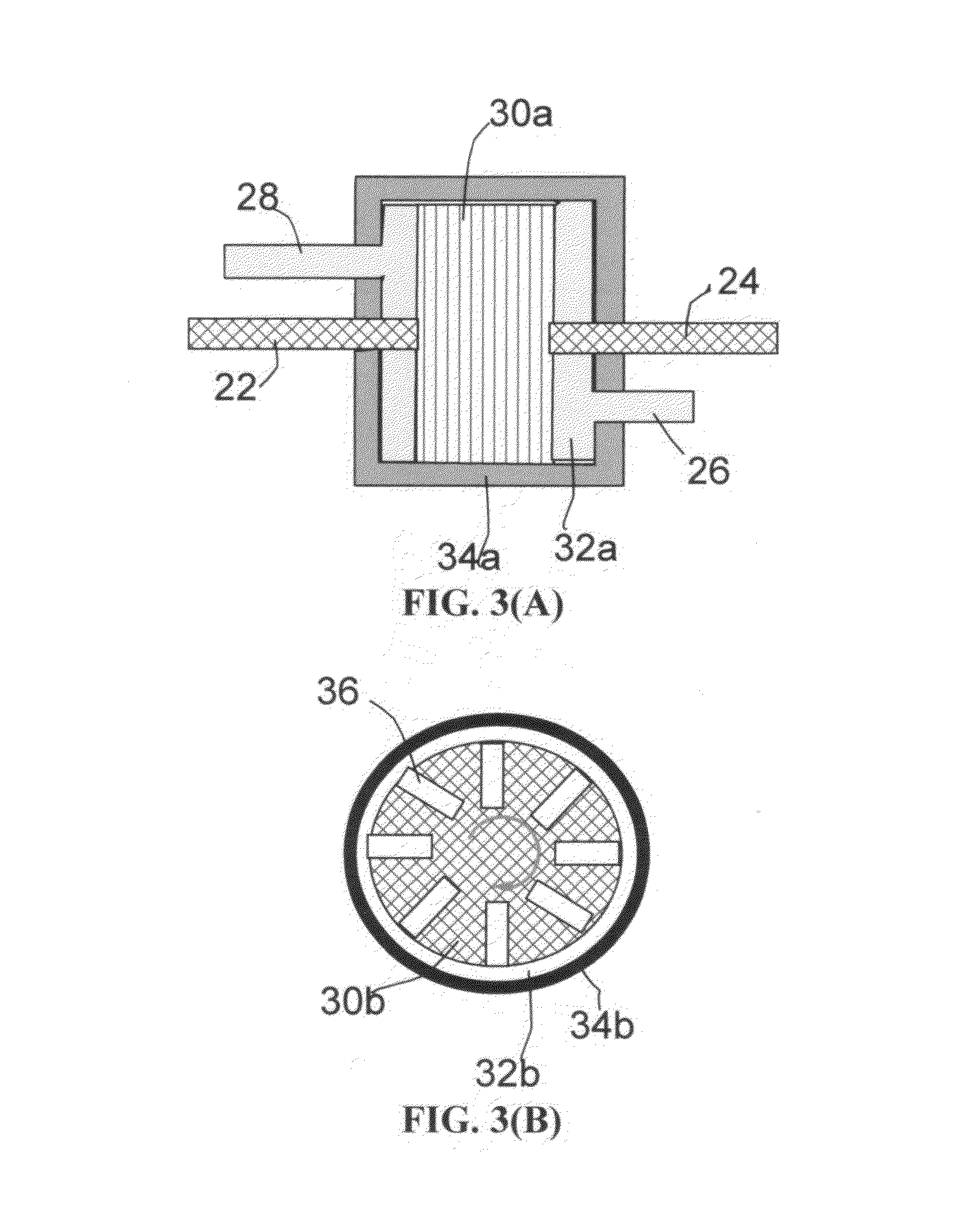

Production of graphene materials in a cavitating fluid

ActiveUS20150239741A1Shorten the timeReduce lossesCarboxylic acid nitrile preparationGraphiteCavitationLiquid medium

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

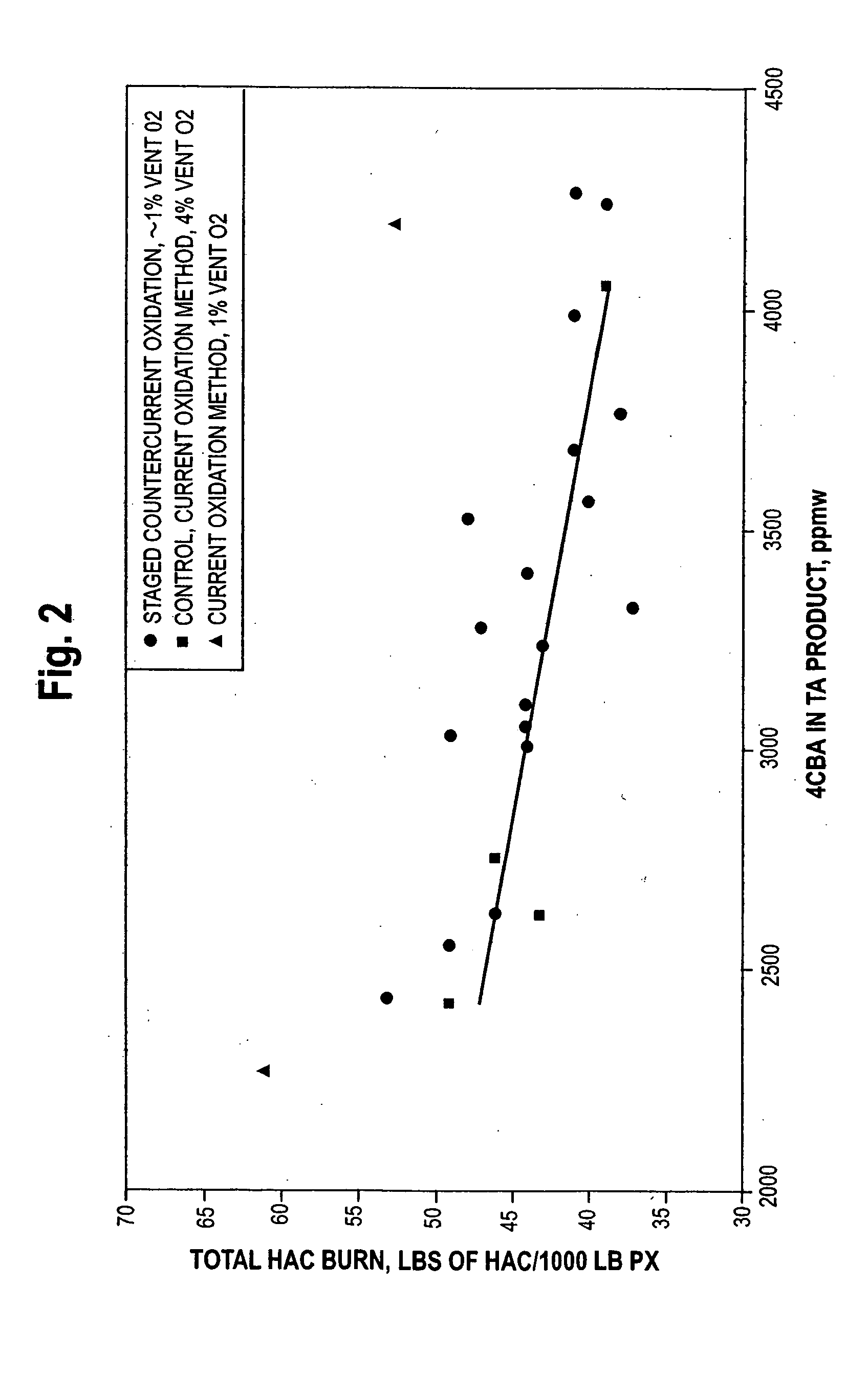

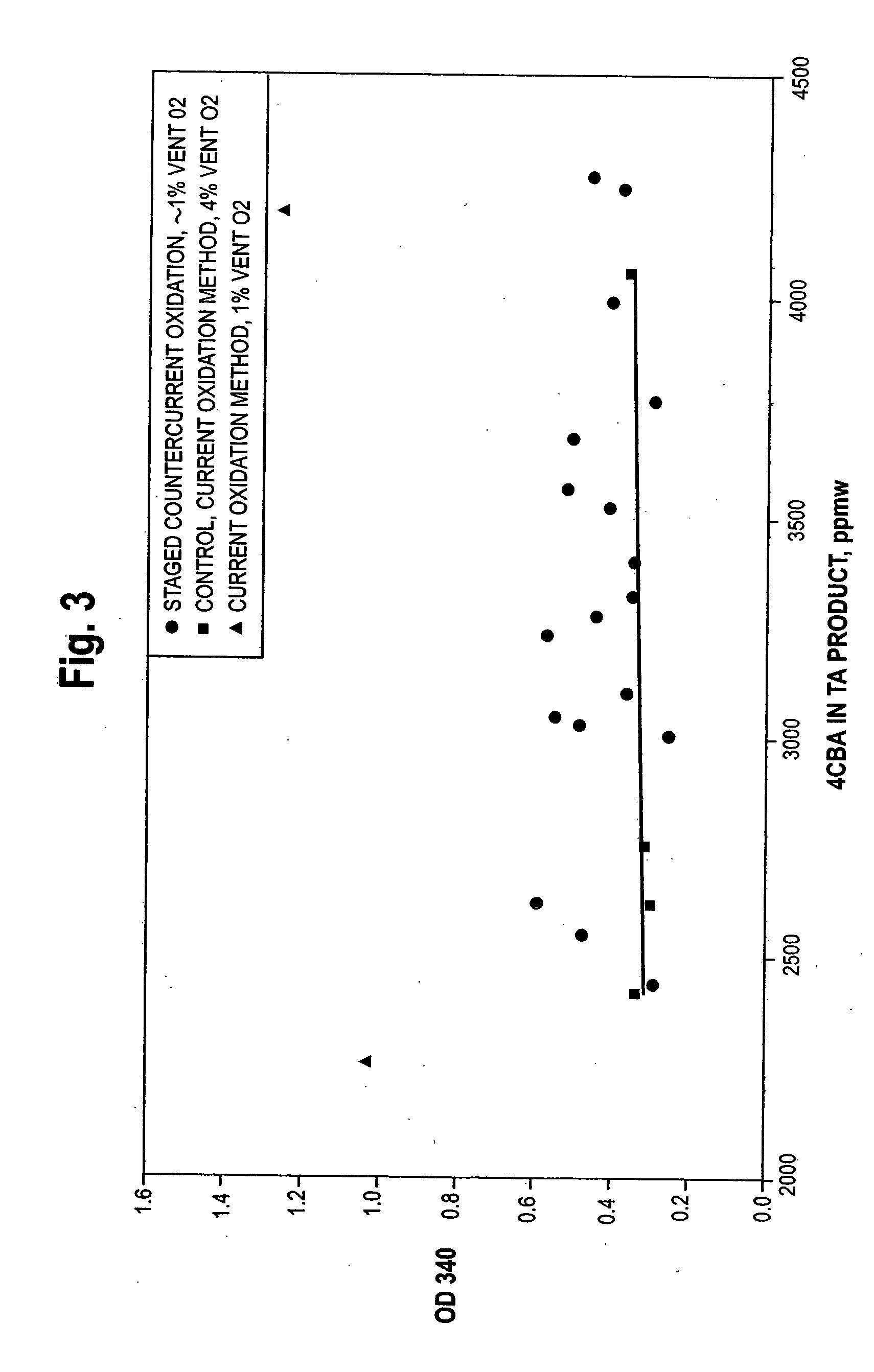

Staged countercurrent oxidation

InactiveUS20050107630A1Continuous processingOrganic compound preparationOrganic chemistry methodsCarboxylic acidOxygen

Owner:BP CORP NORTH AMERICA INC

Optimized liquid-phase oxidation

ActiveUS20060047147A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

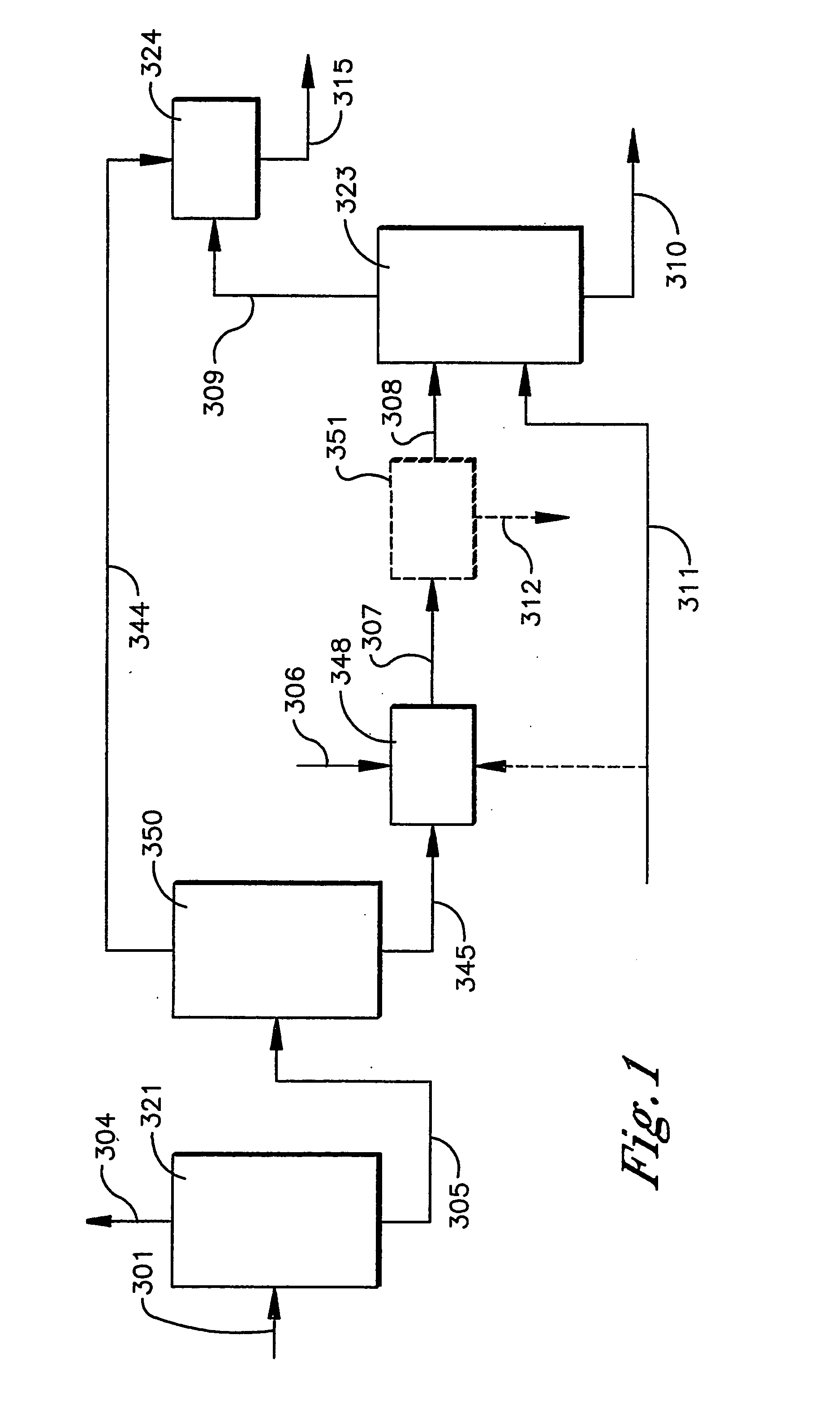

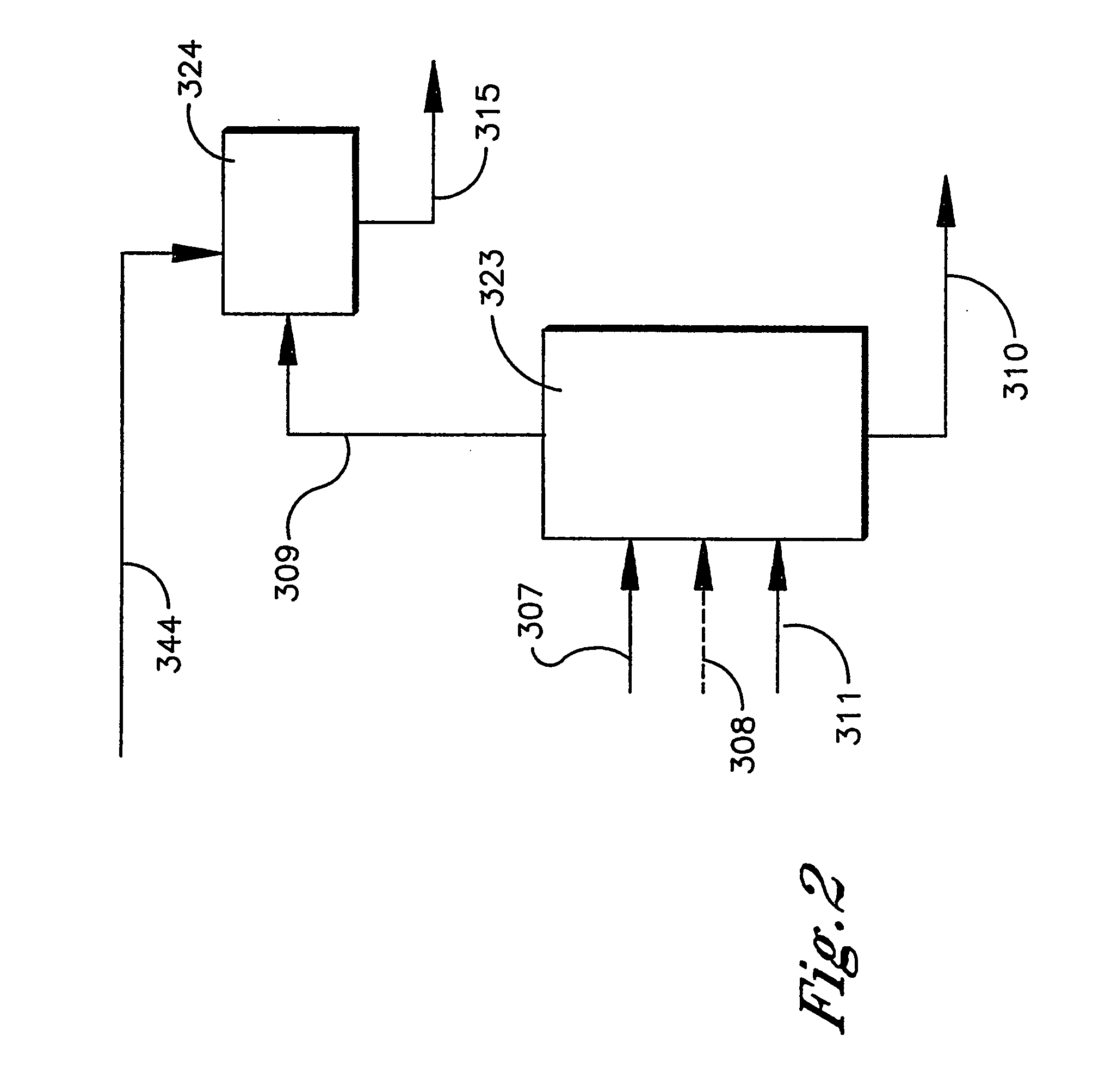

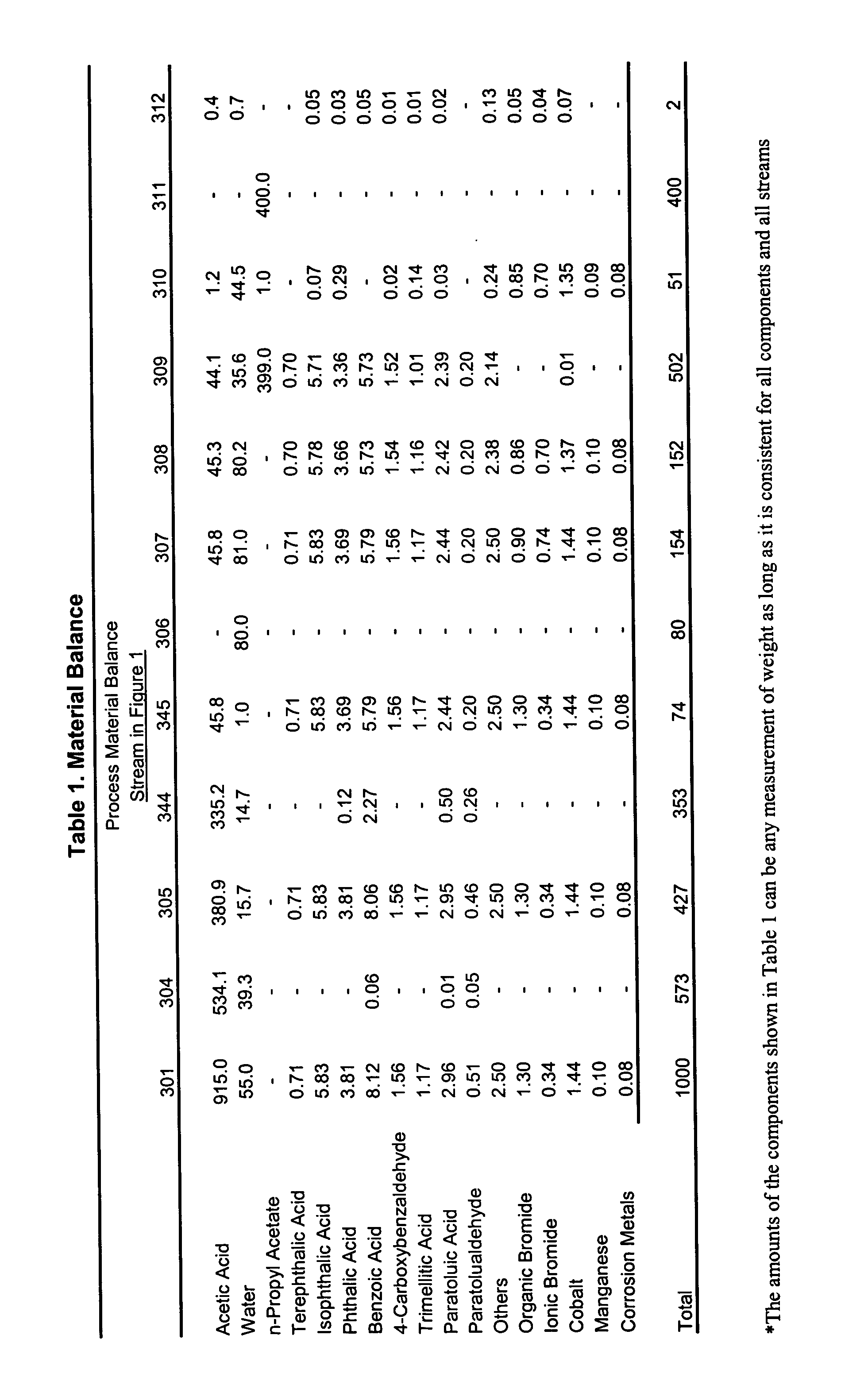

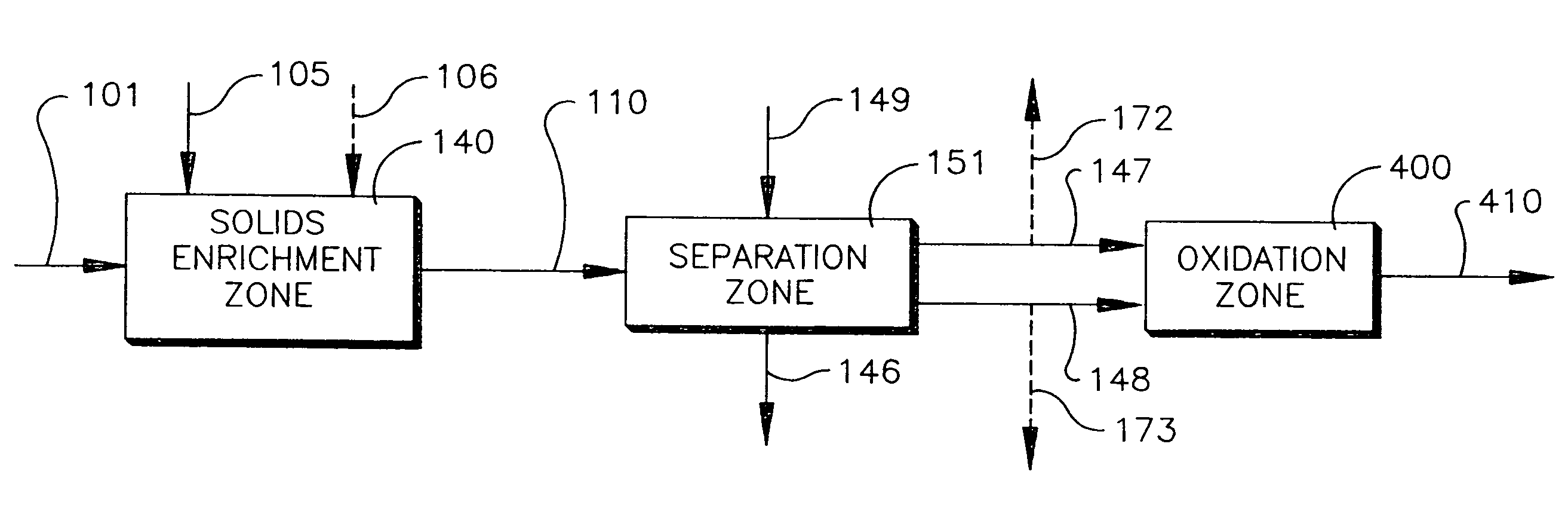

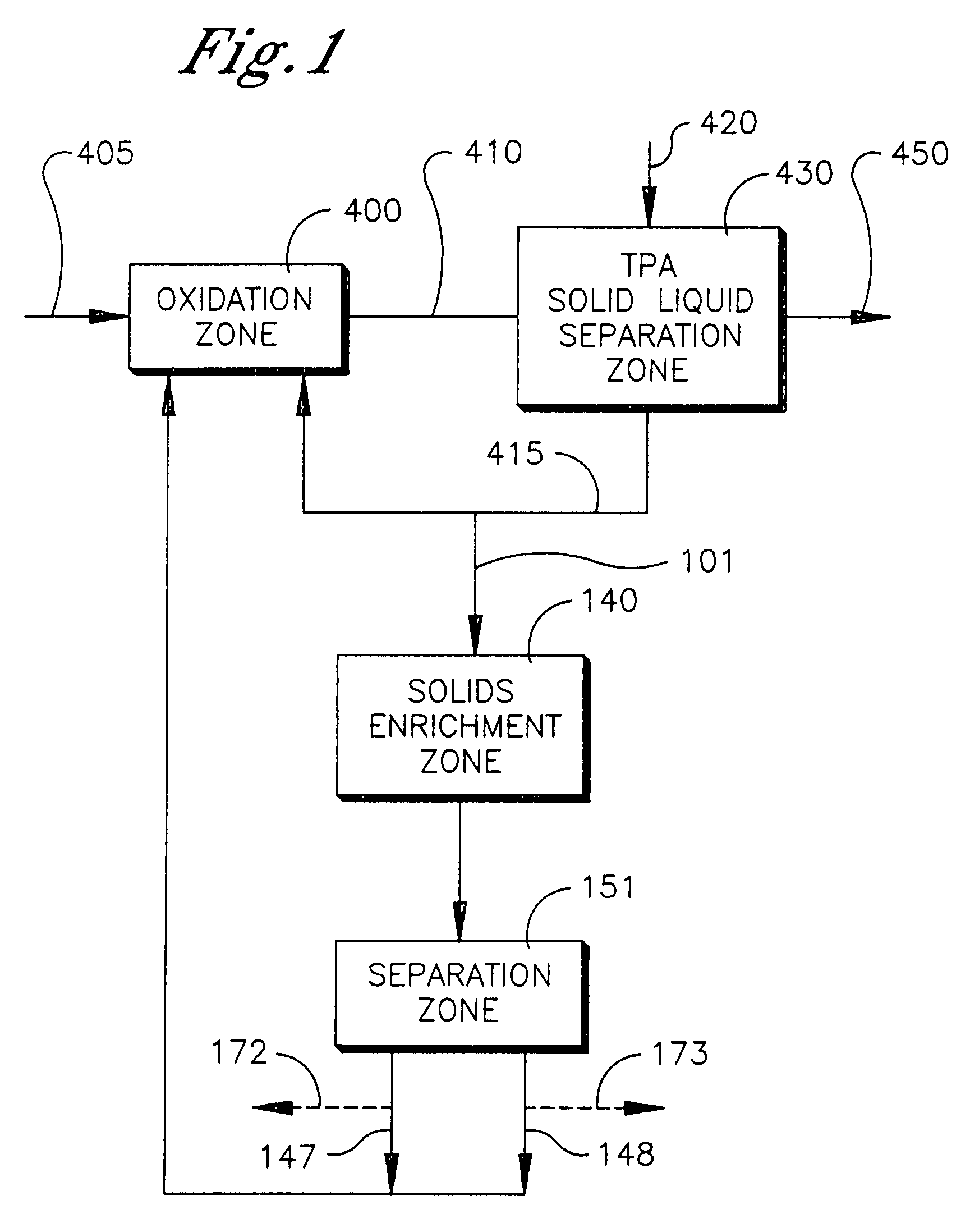

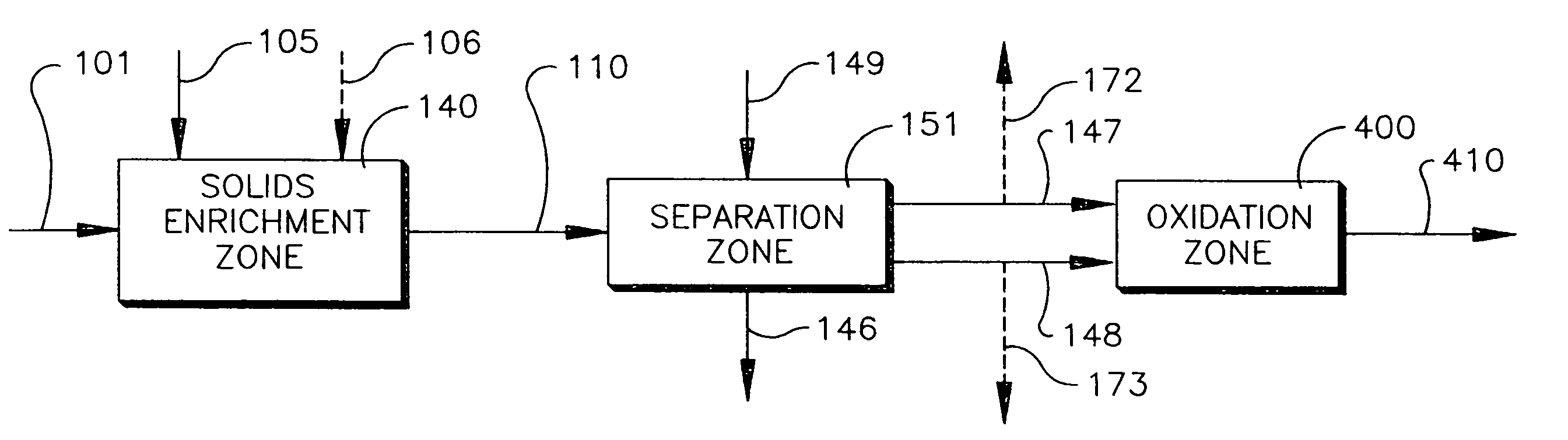

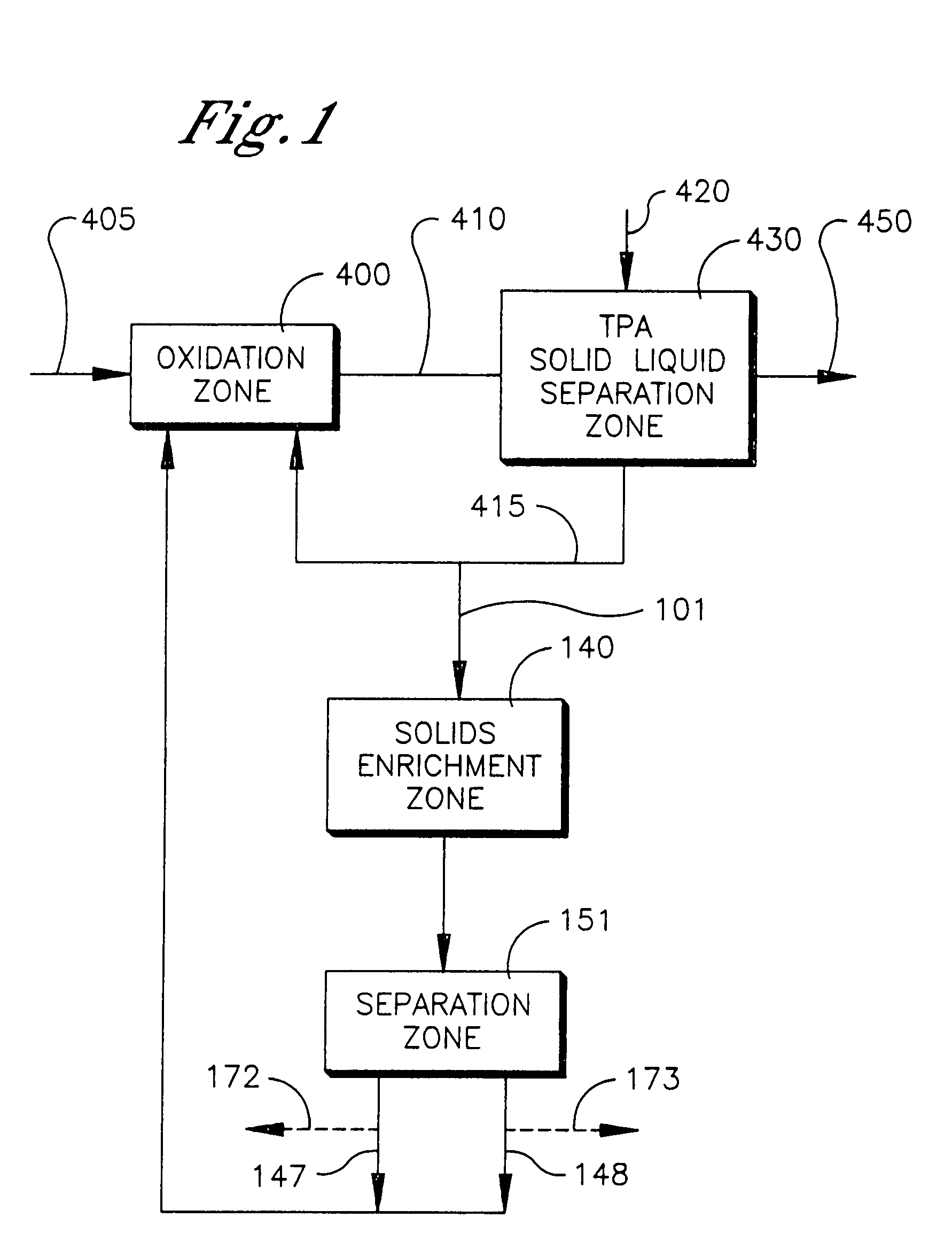

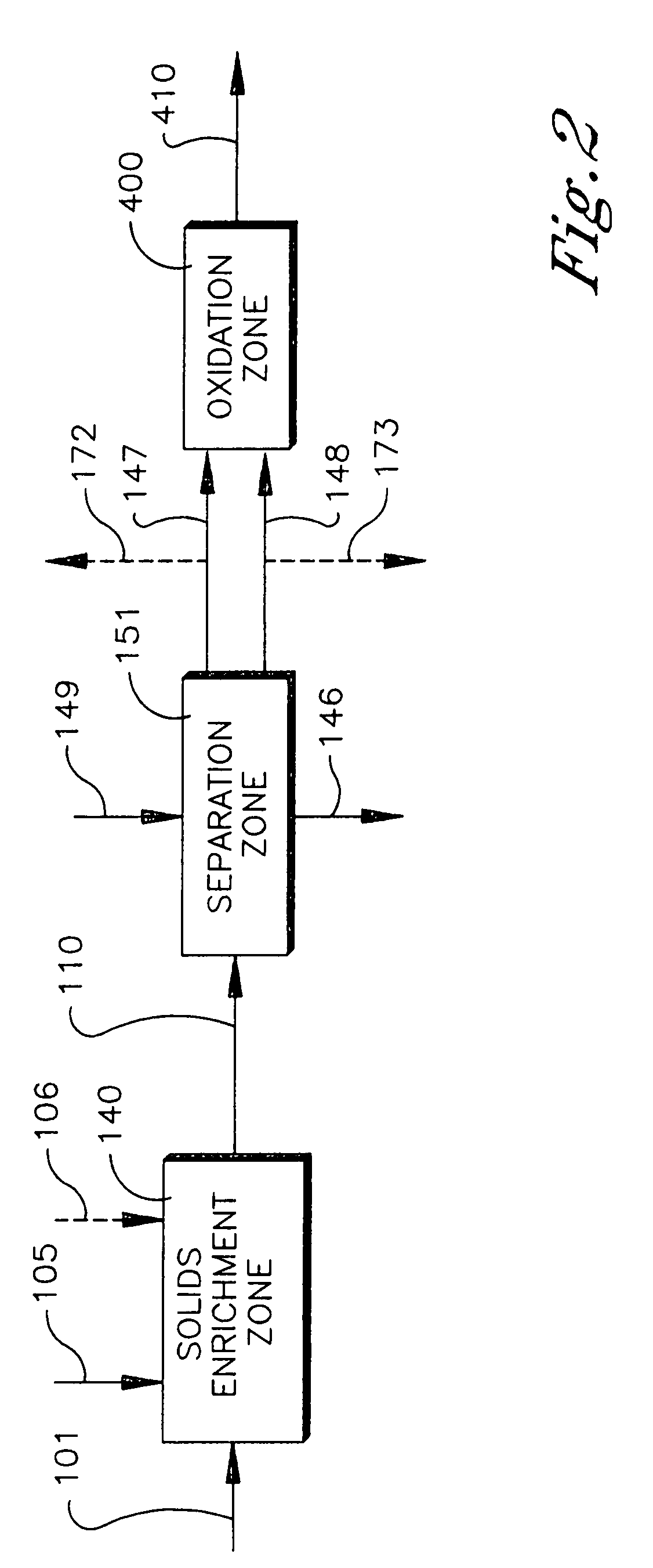

Process for removal of impurities from an oxidizer purge stream

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

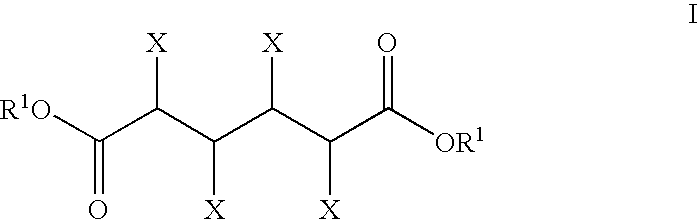

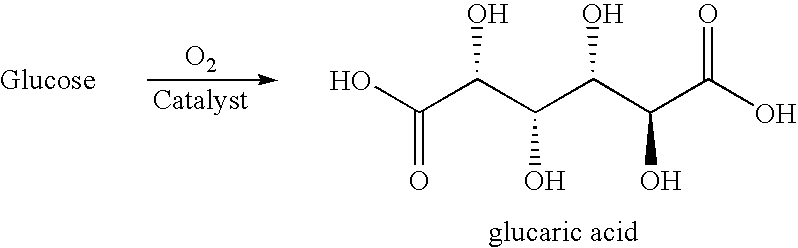

Production of adipic acid and derivatives from carbohydrate-containing materials

ActiveUS8669397B2Low costLactams preparationCarboxylic acid nitrile preparationCatalytic oxidationHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Oxidation system with internal secondary reactor

ActiveUS20070155985A1Effective and economicalReduce formationLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Method for producing vinyl acetate monomer from ethane or ethylene oxidation

Methods for the catalytic production of vinyl acetate monomer from ethane, ethylene or an ethane / ethylene mixture using a first catalyst containing MoVNbPd, MoVLaPdNbX (where X is Al, Ga, Ge or Si) or MoVNbX (where X is P, B, Hf, Te, As or mixtures thereof) in the first step of oxidation and using a conventional VAM catalyst for the second step. The method produces high yields to acetic acid and vinyl acetate without the coproduction of carbon monoxide. Further-more, the ethylene and acetic acid produced in the first step may be utilized in the second step for VAM production

Owner:SAUDI BASIC IND CORP SA

Production process for catalyst

InactiveUS20060205978A1Efficiently and uniformlyHigh strengthOrganic compound preparationHeterogenous catalyst chemical elementsParticulates

Owner:NIPPON SHOKUBAI CO LTD

Transition metal-containing catalysts and catalyst combinations including transition metal-containing catalysts and processes for their preparation and use as oxidation catalysts

ActiveUS20060229466A1Organic compound preparationGroup 5/15 element organic compoundsCatalytic oxidationNitrogen

This invention relates to the field of heterogeneous catalysis, and more particularly to catalysts including carbon supports having compositions which comprise one or more transition metals in combination with nitrogen and / or carbon formed on or over the surface of the carbon support. The present invention also relates to catalyst combinations comprising catalysts including carbon supports having compositions which comprise one or more transition metals in combination with nitrogen and / or carbon formed on or over the surface of a carbon support and a secondary catalyst or, co-catalyst, including a secondary transition metal. The invention further relates to the field of catalytic oxidation reactions, including the preparation of secondary amines by the catalytic oxidation of tertiary amines.

Owner:MONSANTO TECH LLC

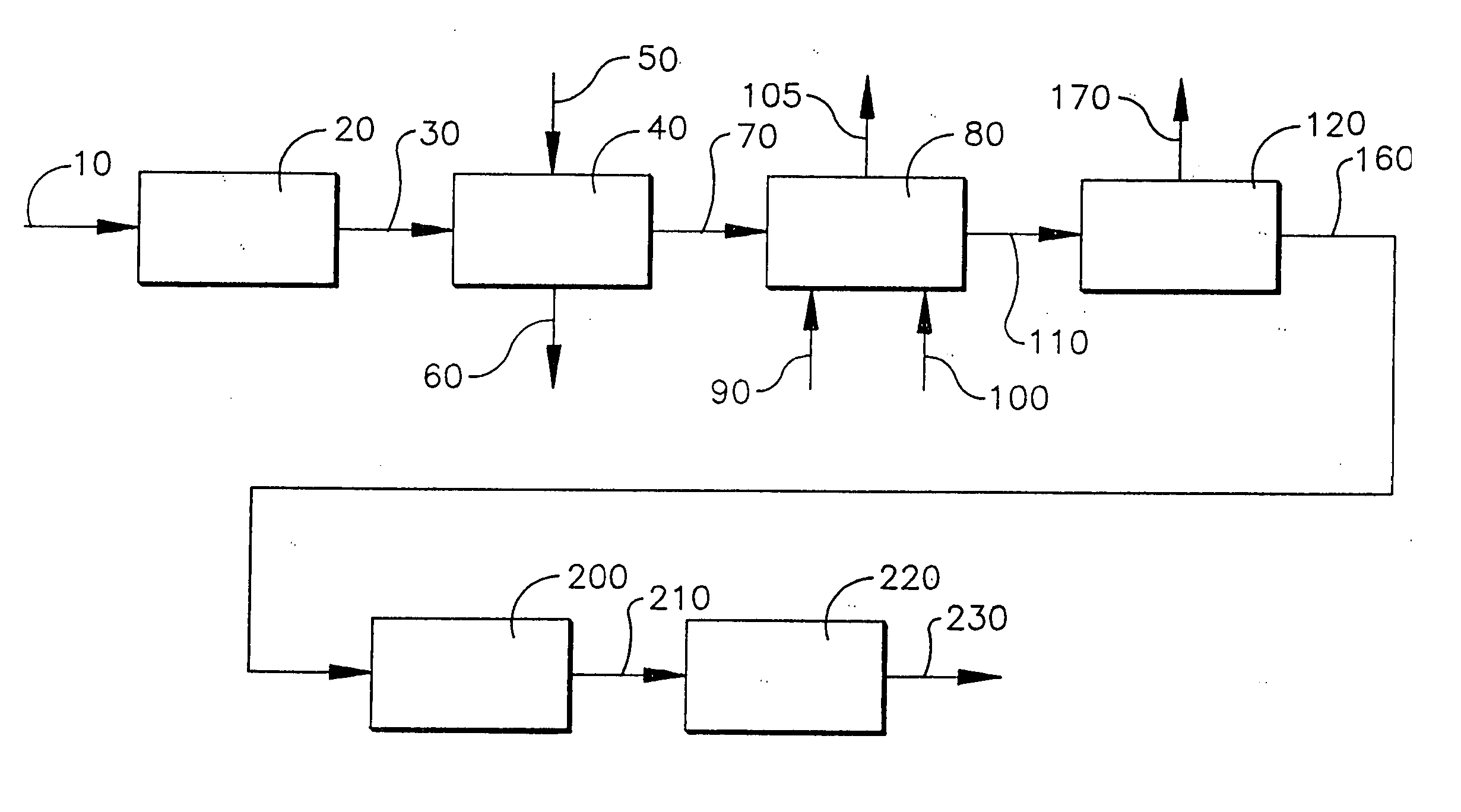

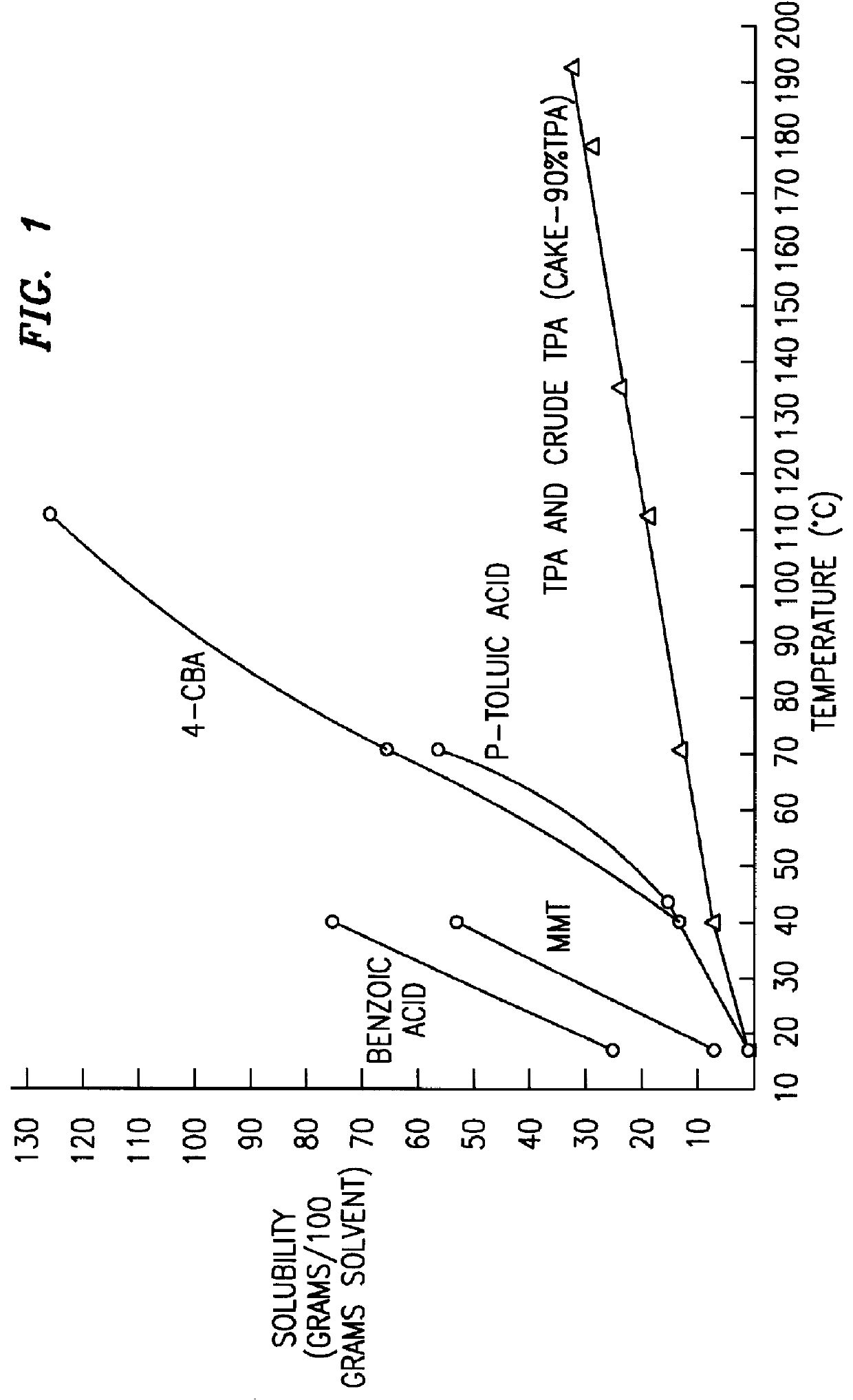

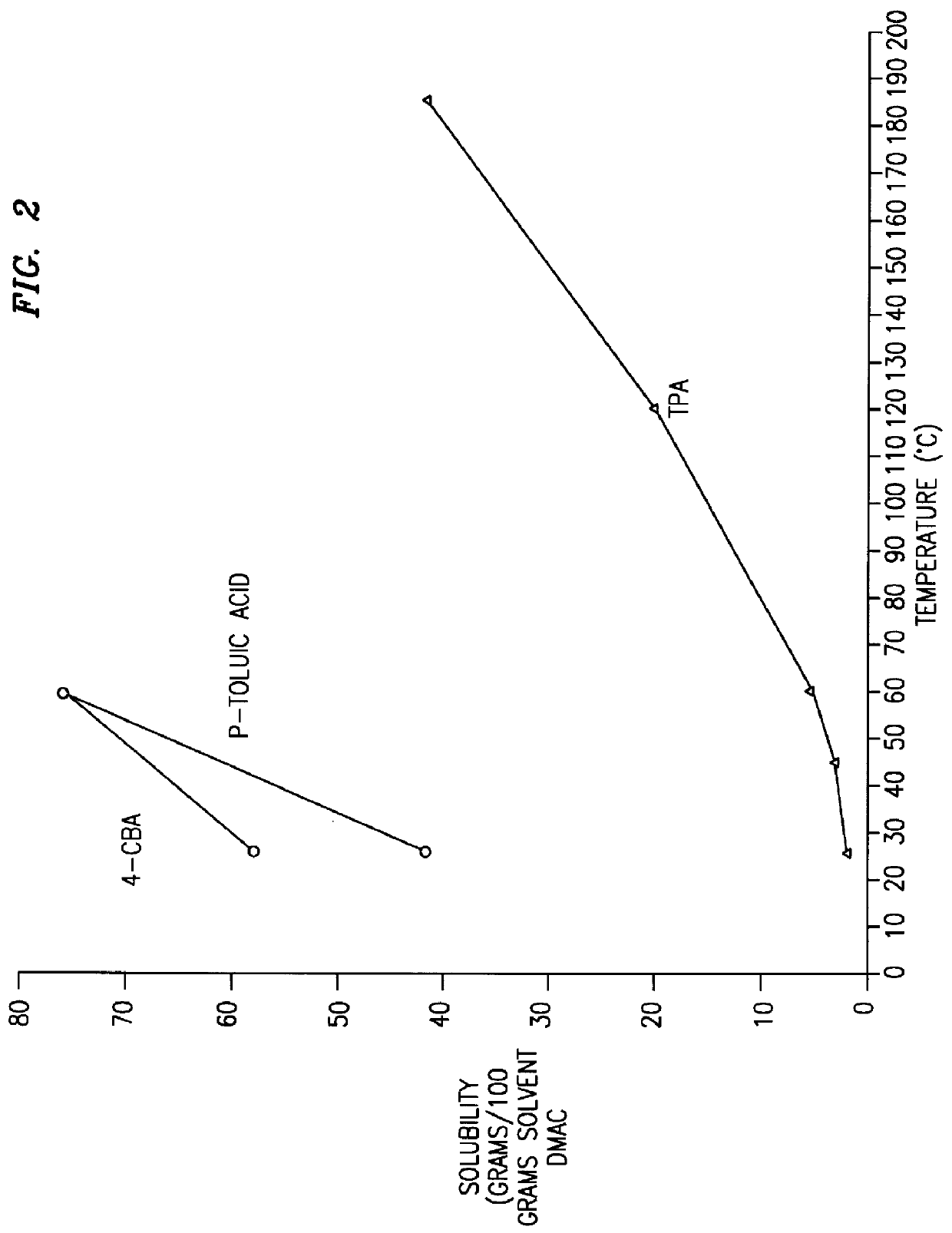

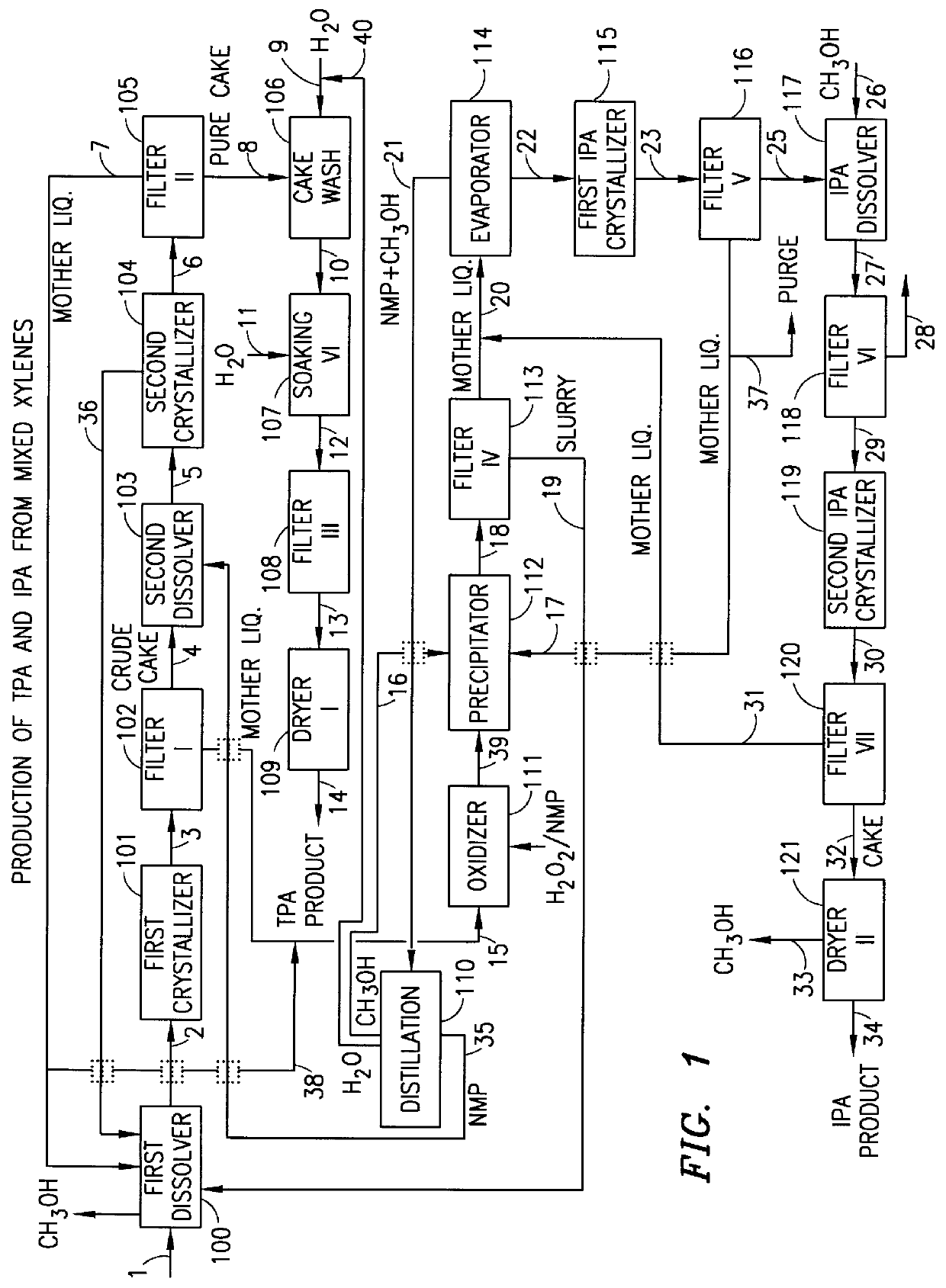

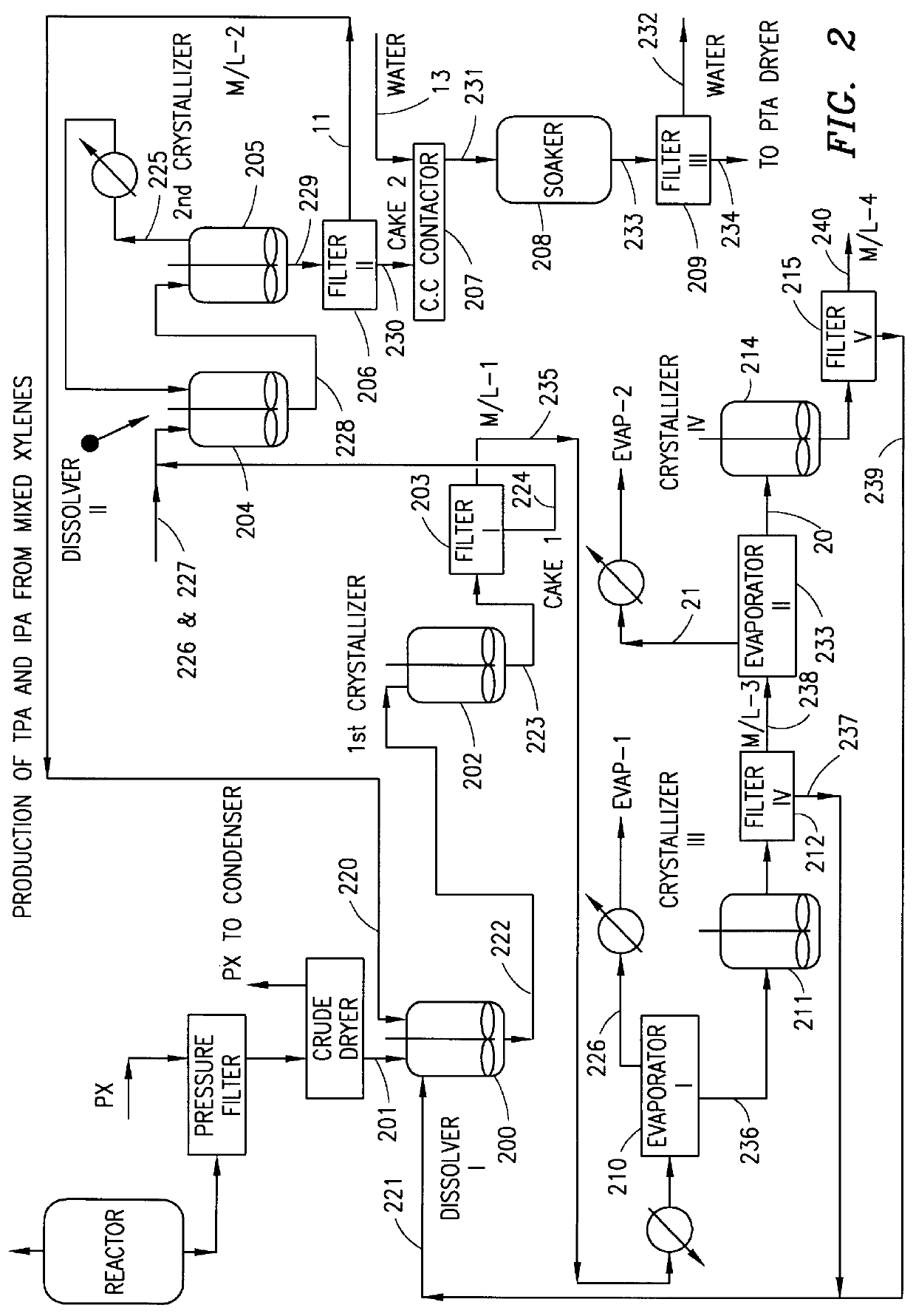

Method and apparatus for preparing purified terephthalic acid and isophthalic acid from mixed xylenes

InactiveUS6054610AReduce pressureReduce the temperatureOrganic compound preparationChemical industryIsophthalic acidXylene

A method and apparatus for preparing purified terephthalic acid and, optionally, isophthalic acid from mixed xylenes. The method of the present invention purifies the oxidation reactor effluent containing a mixture of terephthalic acid and isophthalic acid as well as minor amounts of 4-carboxybenzaldehyde (4-CBA), 3-carboxybenzaldehyde (3-CBA), and toluic acid isomers, to produce purified terephthalic acid and, optionally, purified isophthalic acid in an integrated process.

Owner:GTC TECHNOLOGY INC

Process and Catalyst for Oxidizing Aromatic Compounds

InactiveUS20090088585A1Reduce conversionShifting selectivityOrganic oxidationOrganic compound preparationPtru catalystCarboxylic acid

Catalytic compositions for conversion of substituted aromatic feed materials to oxidized products comprising aromatic carboxylic acid derivatives of the substituted aromatic feed materials comprise a combination comprising a palladium component, an antimony component and / or a bismuth component, and one or more Group 4, 5, 6 or 14 metal or metalloid components. A process for oxidizing substituted aromatic feed materials comprises contacting the feed material with oxygen in the presence of such a catalytic composition in a liquid reaction mixture.

Owner:BP CORP NORTH AMERICA INC

Polycarboxylic acid production system employing oxidative digestion with reduced or eliminated upstream liquor exchange

ActiveUS20070208190A1Reduce formationPromote oxidationOrganic compound preparationCarboxylic preparation by oxidationCarboxylic acidSlurry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system minimizes or eliminates the need for liquor exchange upstream of oxidative digestion and / or upstream of substantial cooling of the TPA-containing slurry.

Owner:ALPEK POLYESTER SA DE CV

Oxidative reactions using membranes that selectively conduct oxygen

InactiveUS6730808B2Eliminate the problemNot possibleAlkali metal oxides/hydroxidesFunctional group formation/introductionLanthanideOxygen

Reactor membranes for used in oxidation reactions of hydrocarbons involving oxygen comprising a selective oxidation catalyst on a mixed conducting, oxide ion selective ceramic membrane of the composition (Sr1-xCax)1-yAyMn1-zBzO3-delta, whereA is Ba, Pb, Na, K, Y, an element of the lanthanide group or a combination thereof,B is Mg, Al, Ga, In, Sn, an element of the 3d or 4d period or a combination thereof,x is from 0.2 to 0.8,y is from 0 to 0.4,z is from 0 to 0.6, anddelta is a number, dependent on x, y and z, that renders the composition charge neutral.

Owner:BASF AG

Process for removal of impurities from an oxidizer purge stream

ActiveUS7273559B2Organic compound preparationSedimentation separationEnvironmental engineeringCarboxylic acid

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com