Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

377 results about "Gas liquid reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

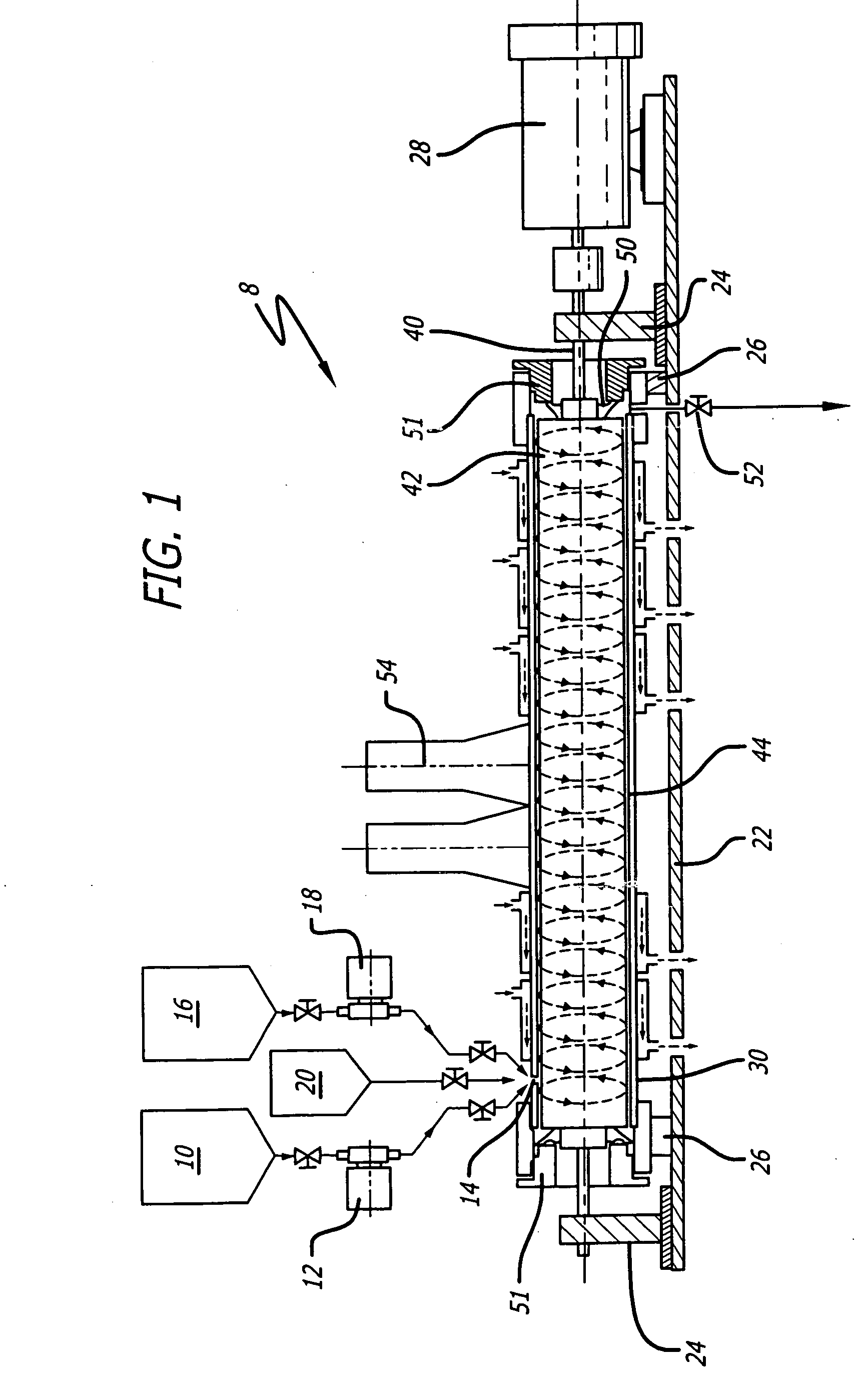

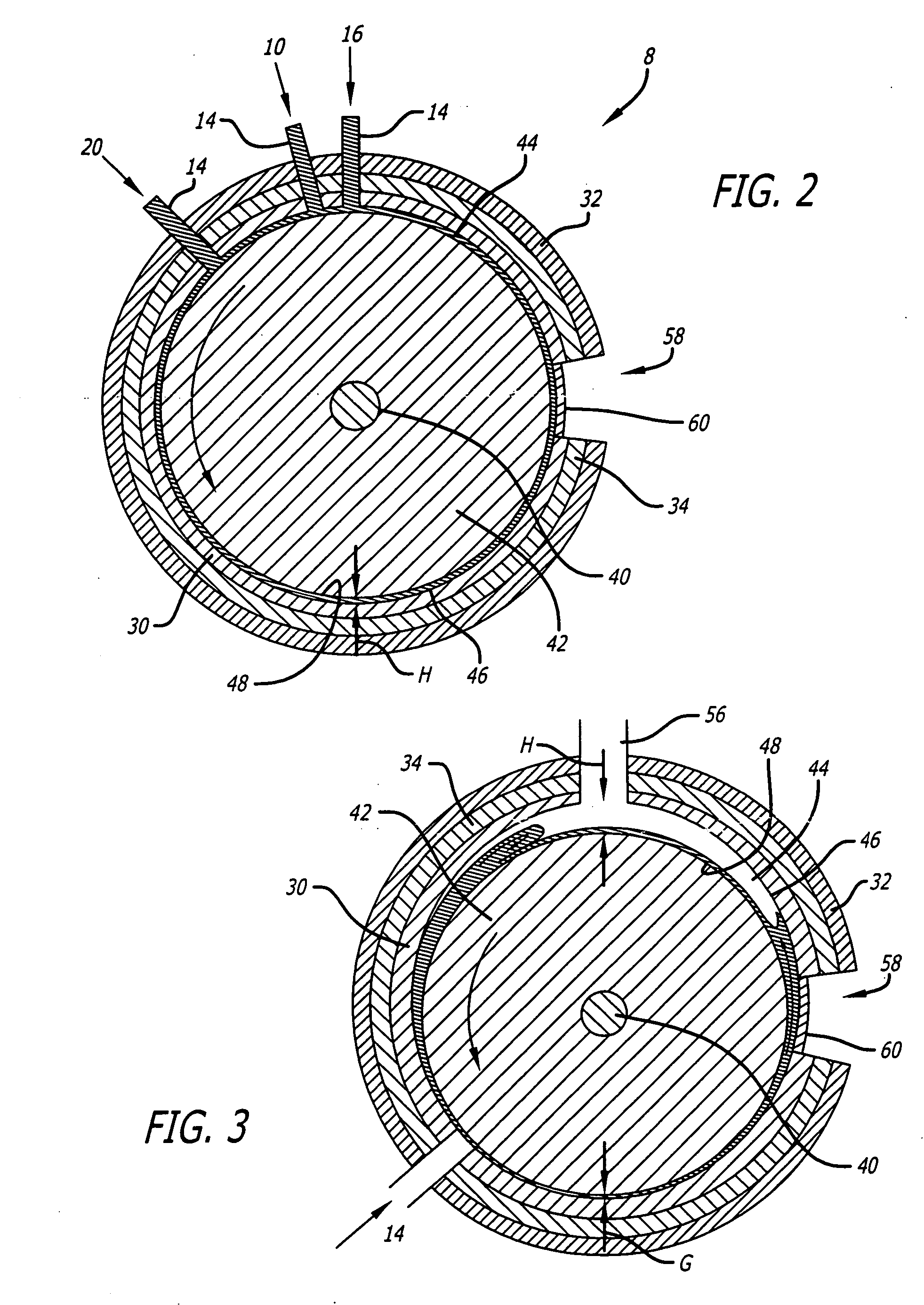

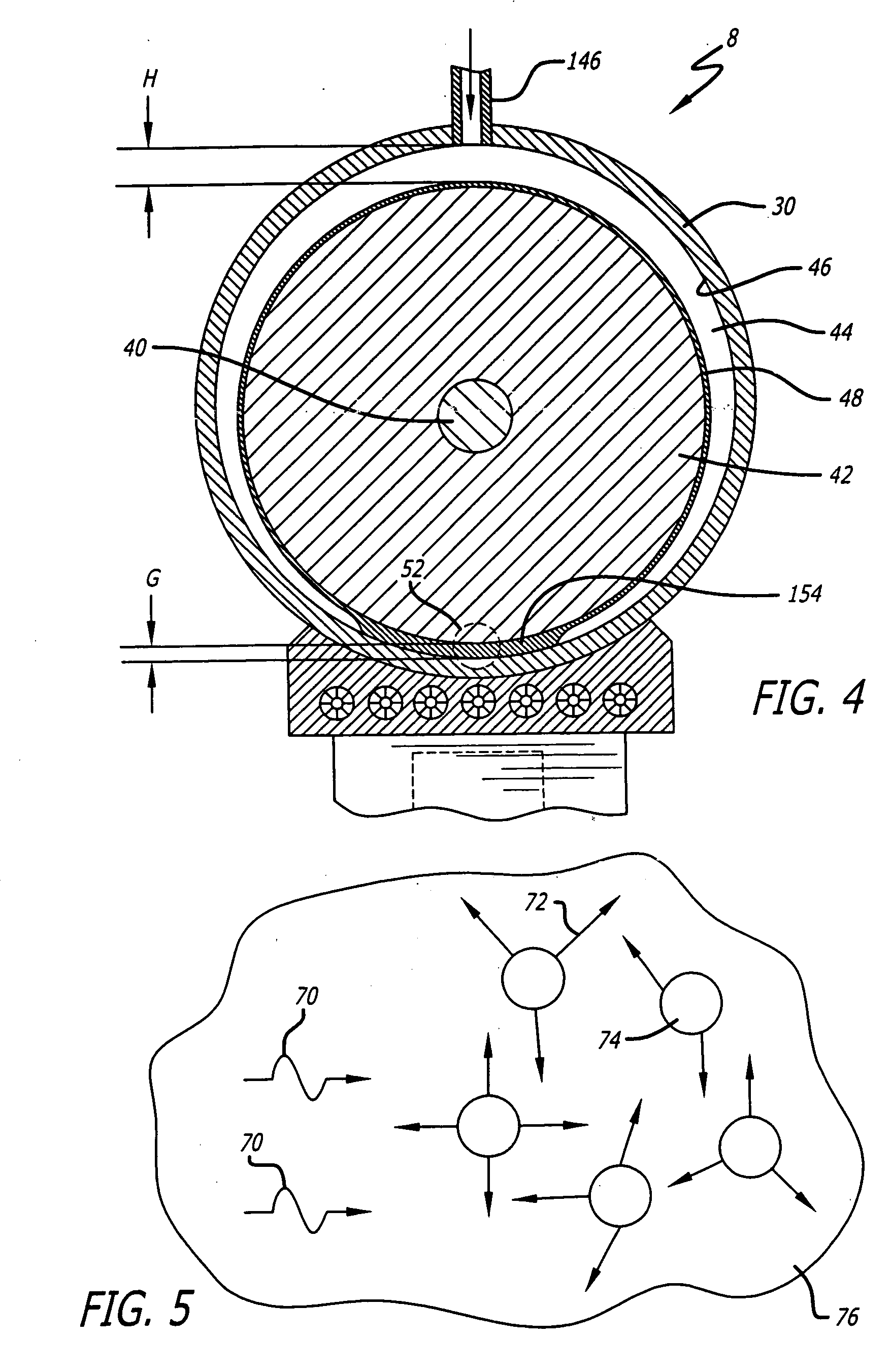

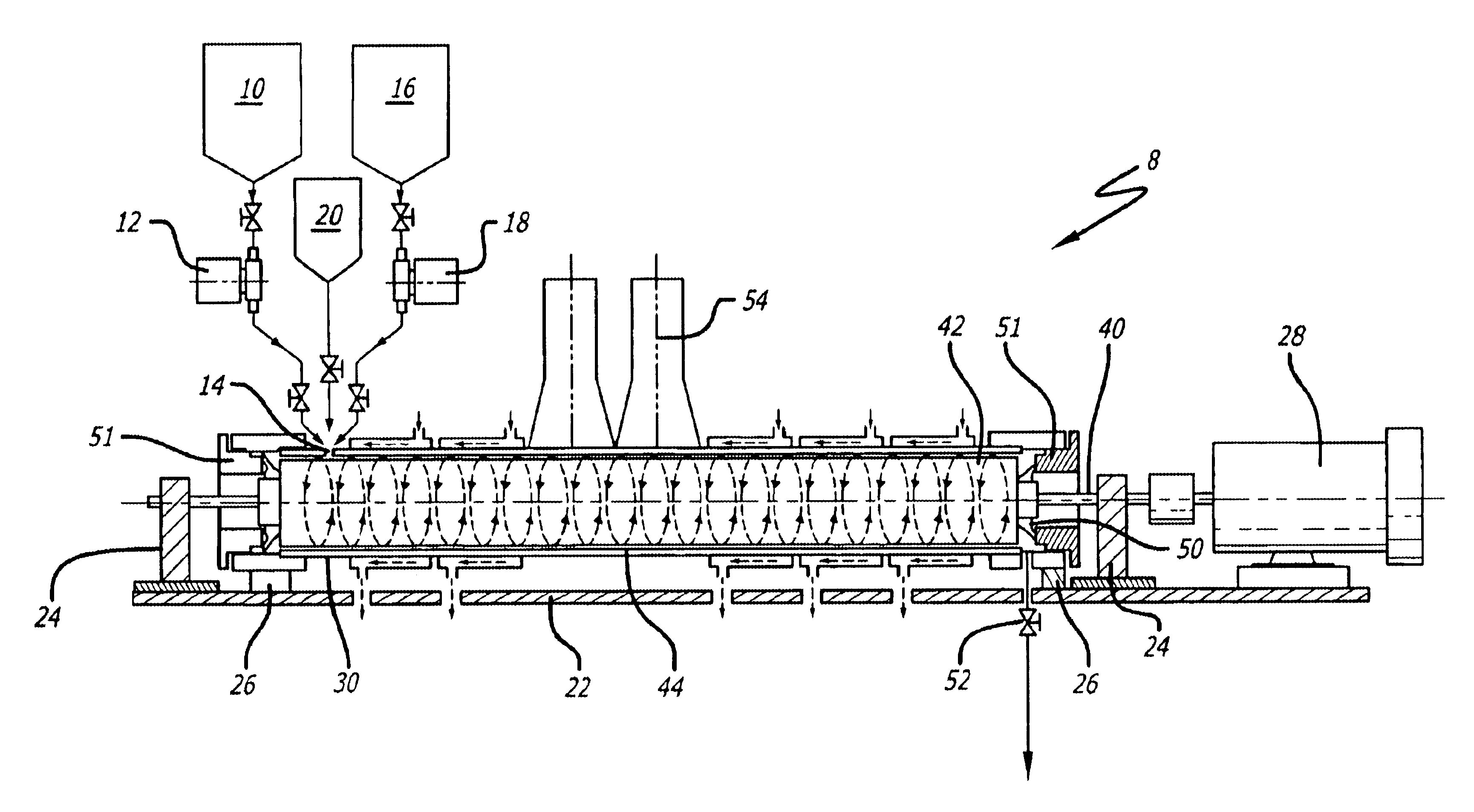

Process for high shear gas-liquid reactions

InactiveUS20050033069A1Superior and economical and efficientImprove responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

Process for high shear gas-liquid reactions

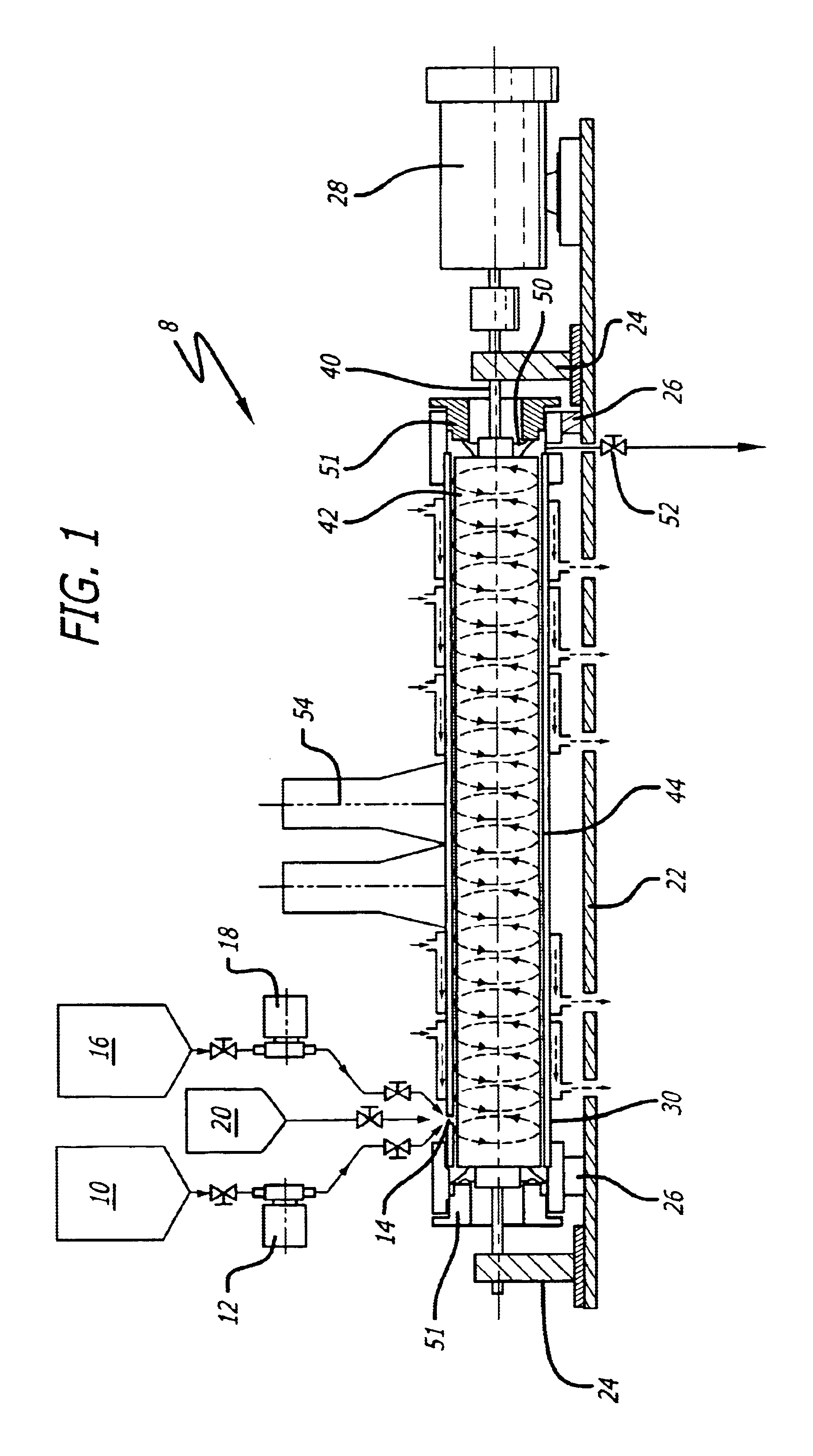

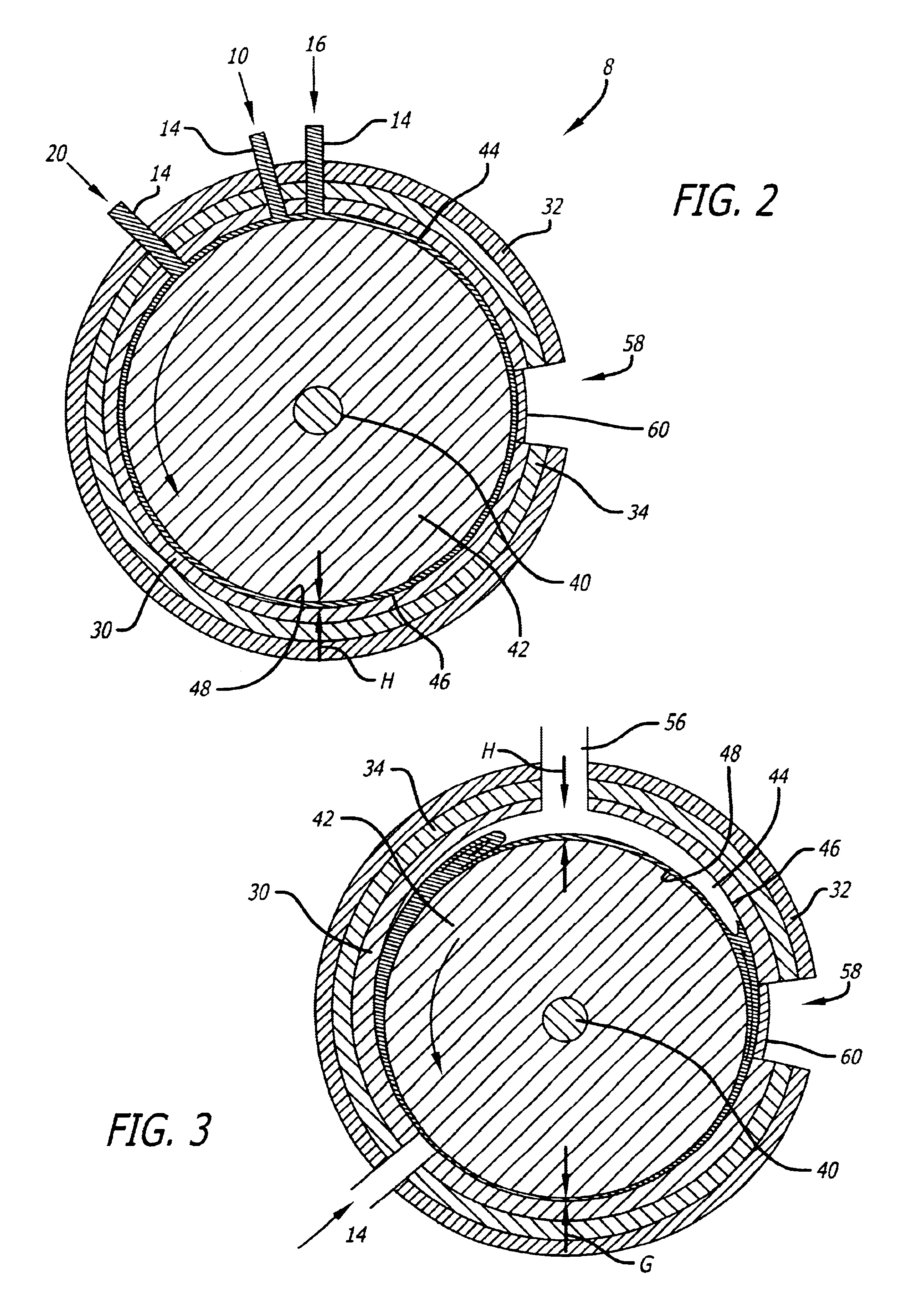

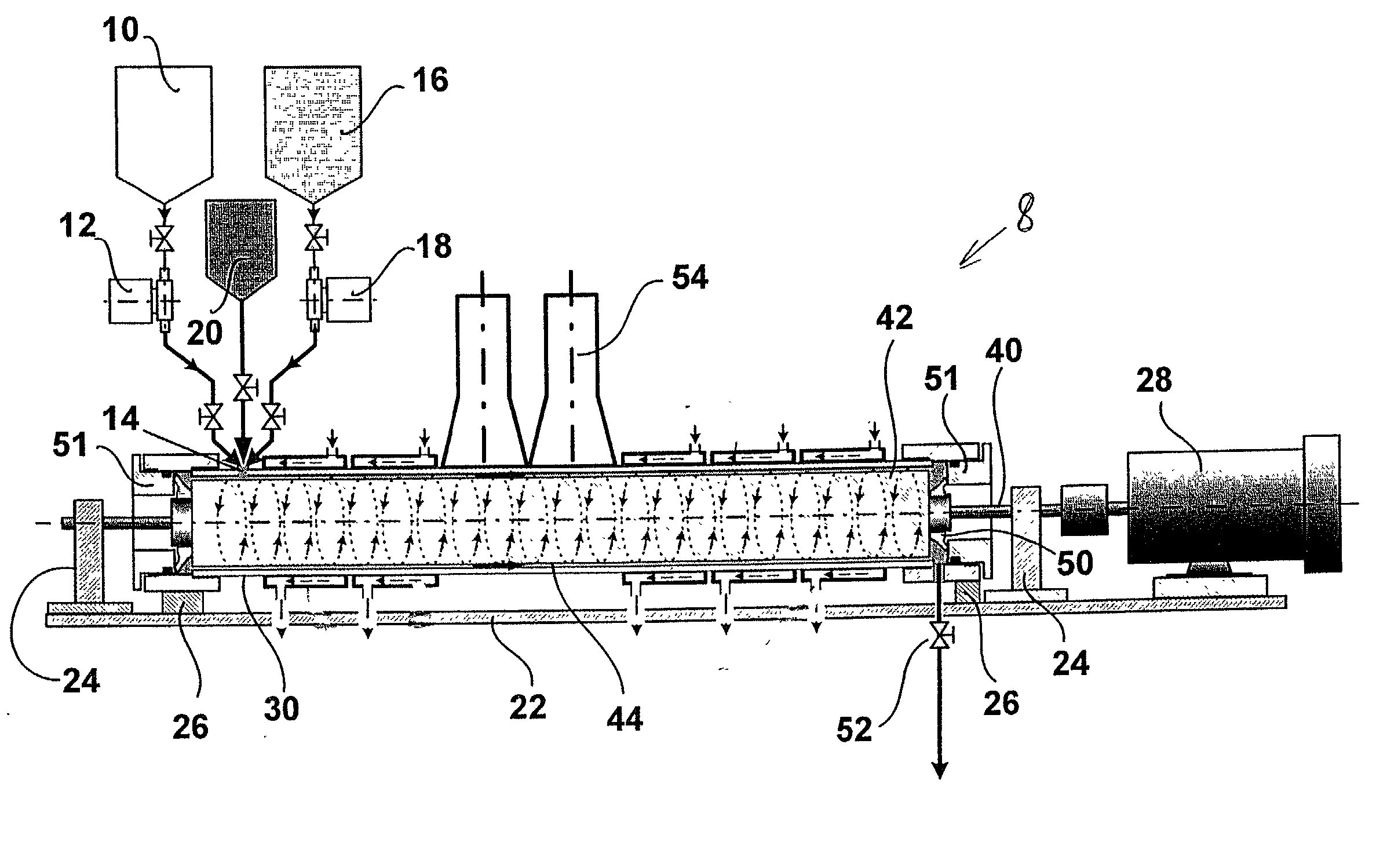

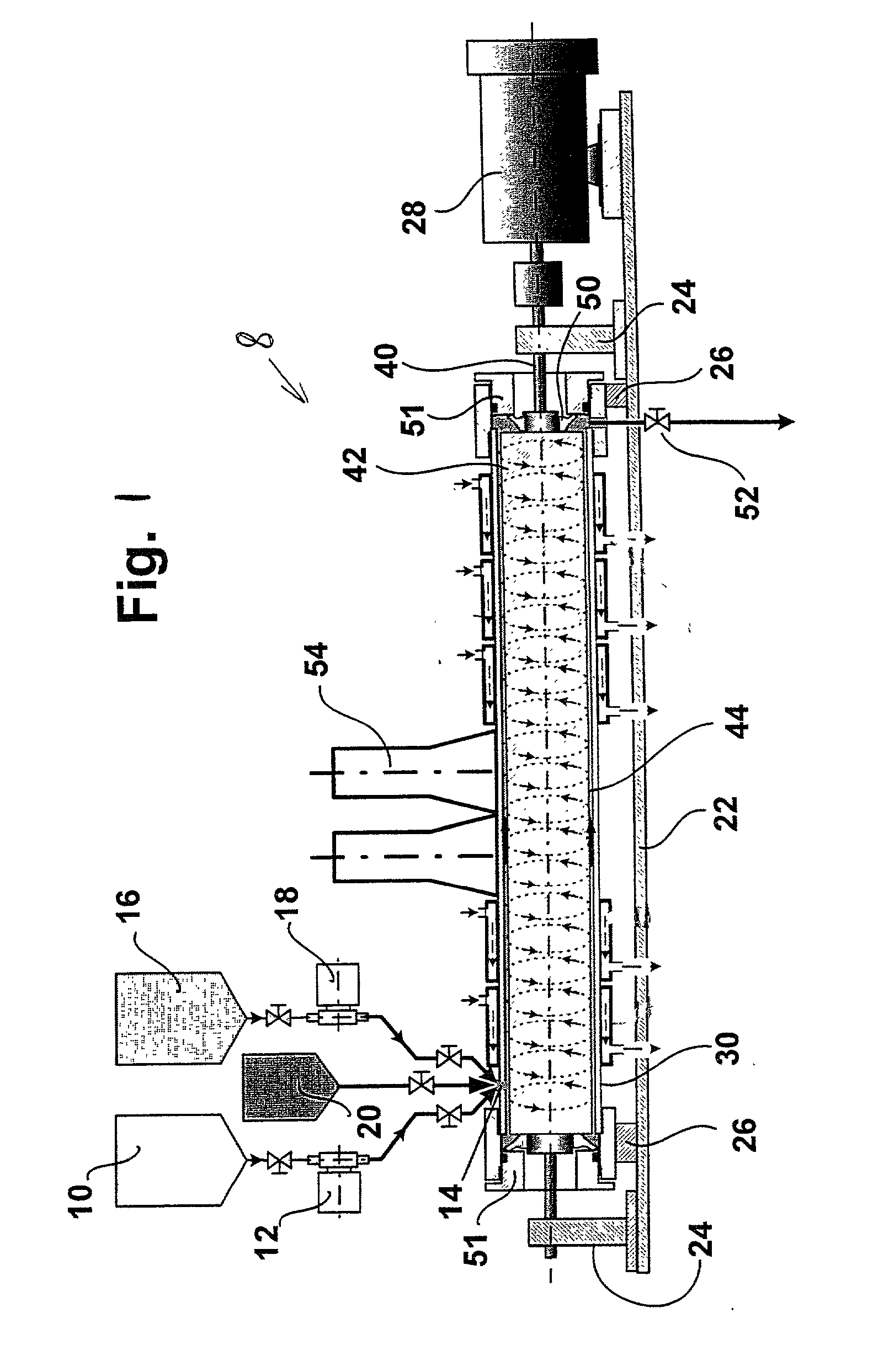

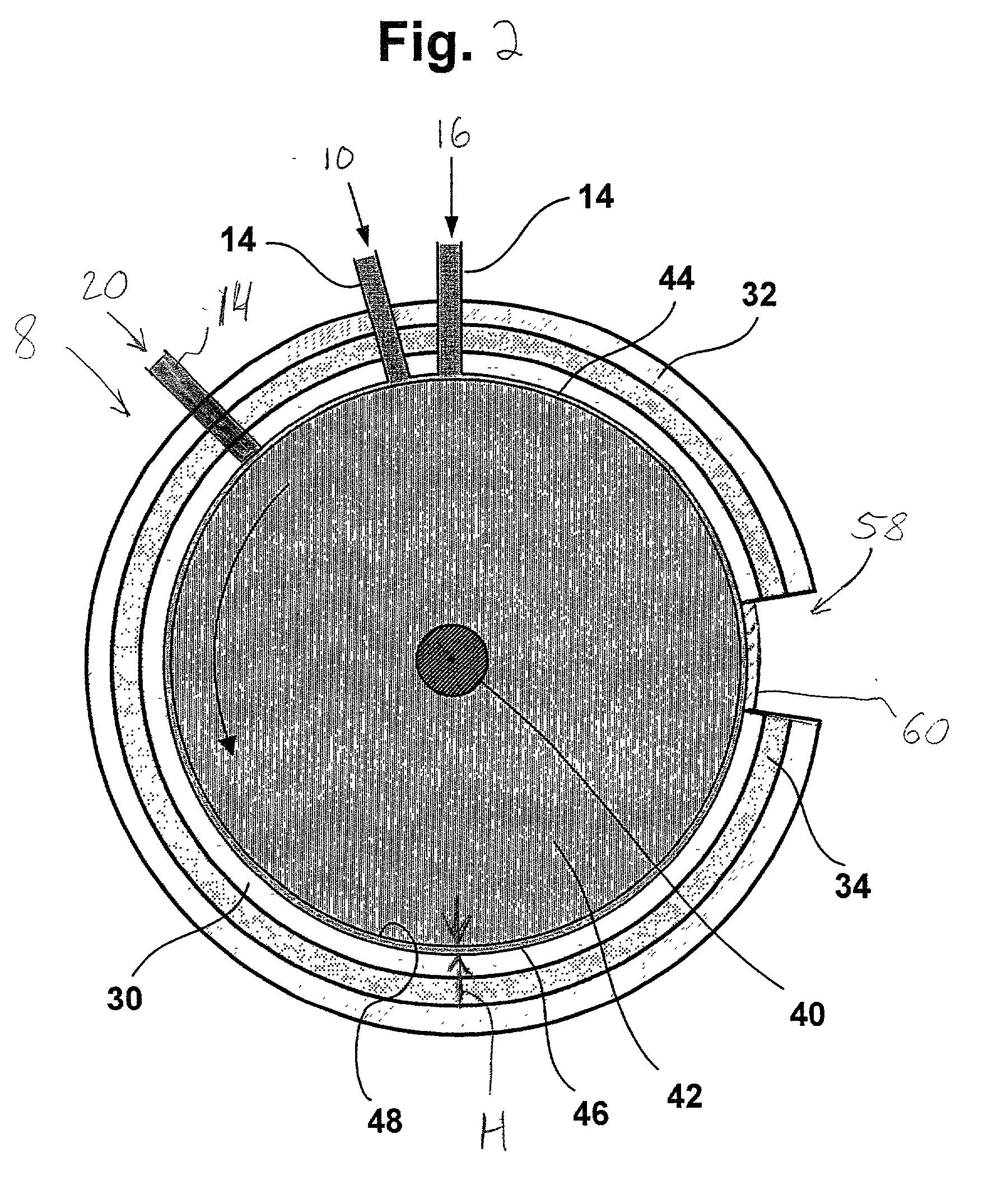

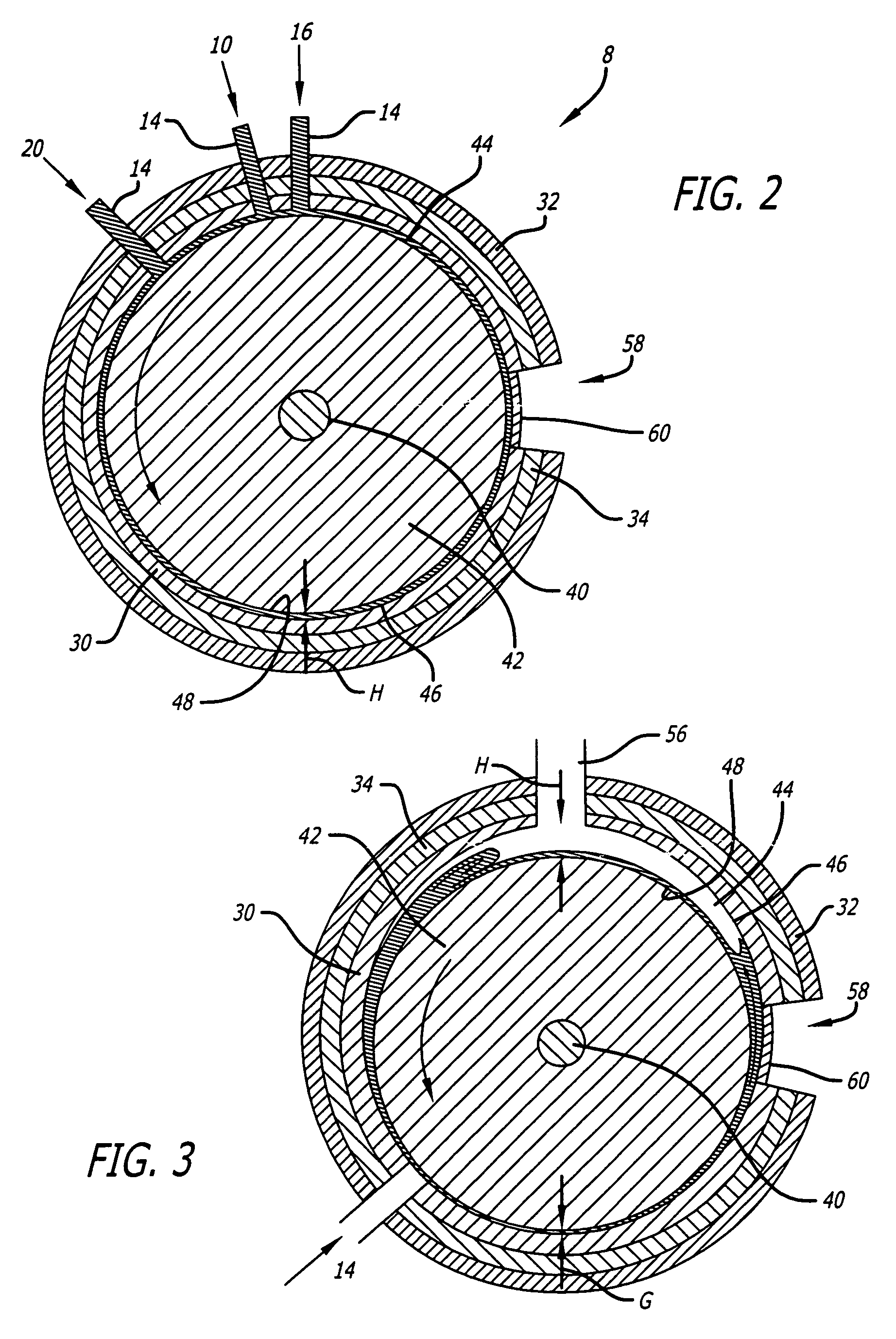

A reactor produces a gas-in-liquid emulsion for providing increased interfacial contact area between the liquid and the gas for improved reaction of the gas with the liquid, or more rapid solution or reaction of a difficulty soluble or immiscible gas in or with a liquid. The reactor is suitable for a continuous or batch type process. Rotor and stator cylindrical members are mounted for rotation relative to one another and have opposing surfaces spaced to form an annular processing passage. The gap distance between the opposing surfaces and the relative rotation rate of the cylindrical members are such as to form a gas-in-liquid emulsion of the gas in the liquid. The liquid and gas pass through the processing passage, changing into the gas-in-liquid emulsion.

Owner:323 TRUST

Process for high shear gas-liquid reactions

A reactor produces a gas-in-liquid emulsion for providing increased interfacial contact area between the liquid and the gas for improved reaction of the gas with the liquid, or more rapid solution or reaction of a difficulty soluble or immiscible gas in or with a liquid. The reactor is suitable for a continuous or batch type process. Rotor and stator cylindrical members are mounted for rotation relative to one another and have opposing surfaces spaced to form an annular processing passage. The gap distance between the opposing surfaces and the relative rotation rate of the cylindrical members are such as to form a gas-in-liquid emulsion of the gas in the liquid. The liquid and gas pass through the processing passage, changing into the gas-in-liquid emulsion.

Owner:323 TRUST

A method for preparing polyacrylonitrile carbon fiber precursors by dry jet wet spinning

ActiveCN102277629AFull and even contactInhibition formationArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentYarnGas liquid reaction

The invention relates to a method for preparing a polyacrylonitrile carbon fiber precursor. The method comprises the following steps of: copolymerizing acrylonitrile and copolymerization components in multicomponent solution so as to form polymer spinning stock solution which has a relatively uniform and controllable molecular structure, performing demonomerization on the spinning stock solution,defoaming, filtering, and preparing the polyacrylonitrile carbon fiber precursor by a dry-jet wet-spinning process. The key technology of the method is that: a gas storage box is arranged on a dry wet spinning pack, the gas storage box and the liquid level of coagulating bath fluid form a dry-jet wet-spinning air layer into a confined space, and ammonia is persistently aerated into the space to carry out gas-liquid reaction with spinning solution trickle in the air layer. The polyacrylonitrile precursor prepared by the method has regular sections and few defects, the density is not less than 1.187g / cm<3>, the density after carbonization is not less than 1.79g / cm<3>, the strength is not less than 5.1GPa, and the modulus of elasticity is 280 to 300GPa.

Owner:KINGFA SCI & TECH CO LTD +1

Process for high shear gas-liquid reactions

InactiveUS7538237B2Improve responseRapid responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

Method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater

ActiveCN103145273ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater contaminantsMultistage water/sewage treatmentOzone generatorGas liquid reaction

The invention belongs to the technical field of nitrobenzene wastewater, in particular relates to a method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater, and solves the problem of the existing method for degrading nitrobenzene wastewater. The method comprises the following steps of performing a reduction reaction on nitrobenzene wastewater in a micro-electrolysis bath; performing a sufficient contact reaction with ozone in gas-liquid reaction equipment; further degrading pollutants in the wastewater in the gas-liquid reaction equipment; and circularly treating the wastewater in the micro-electrolysis bath and the gas-liquid reaction equipment. The device comprises a rotary packed bed device, wherein a gas inlet is connected with an ozone generator; and a liquid inlet and a liquid outlet are connected with the micro-electrolysis bath. The method and the device have the beneficial effects that the process flow is simple and convenient to operate; the advantages of various technologies are given a full play by coupling the three technologies to reach the aim of treating waste by using waste, so that the treatment cost can be furthest reduced.

Owner:ZHONGBEI UNIV

Method for preparing nano material

InactiveCN102030352AThe method is scientific and reasonableImprove product qualityZinc oxides/hydroxidesNanotechnologyChemical reactionDecomposition

The invention relates to a method for preparing a nano material, which comprises the step of: preparing a nano material precursor and a nano material. The method for preparing the nano material precursor comprises the step of: placing reacting raw materials in a supergravity filed reactor for gas-liquid reaction or liquid-liquid reaction to obtain the nano material precursor. The method for preparing the nano material comprises the step of heating and roasting the nano material precursor with a microwave field to ensure that the nano material precursor generates decomposition or recrystallization to obtain the nano material. The method for preparing the nano material precursor also comprises the step of: in a process of accelerating and enhancing the mass transfer with the supergravity filed, enabling a metal salt water solution in the reactor to be uniformly mixed with a liquid precipitator or gas precipitator in a molecule size manner for chemical reaction to obtain the nano material precursor of carbonate materials or nano oxyhydrate materials or hydrous oxide materials of the metal, wherein the prepared nano material is used as a nano metal oxide. The method has the advantagesof scientific and reasonable structure, high quality of products, energy saving, no secondary pollution and the like.

Owner:XIANGTAN UNIV

Method for enhancing gas-liquid process in micro-reactor

ActiveCN104162395AImprove mass transfer coefficientImprove absorption rateEnergy based chemical/physical/physico-chemical processesMicroreactorGas liquid reaction

The invention relates to a method for enhancing a gas-liquid process in a micro-reactor. The method comprises the following steps: applying ultrasound of a specific frequency to a gas-liquid micro-reactor in which gas liquid two-phase flow is bubble flow, slug flow, slug annular flow, stirring flow or annular flow; and regulating and controlling the transverse equivalent diameter of a gas phase in the gas-liquid two-phase flow and the ultrasonic frequency till a product of the ultrasonic frequency and the transverse equivalent diameter of the gas phase is up to 1-40 mm.kHz. According to the method, disturbance and acoustic streaming are caused in liquid by using the ultrasound and the cavitation effect of the gas phase, so that gas-liquid mass transfer is enhanced; and meanwhile, agglomeration between a solid or a sticky substance in fluid or the adhesion to the wall surface of a micro channel can be broken, so that blockage is prevented and dredged. The method for enhancing the gas-liquid process disclosed by the invention is suitable for the fields of various gas-liquid reactions, gas absorption, gas separation and purification, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

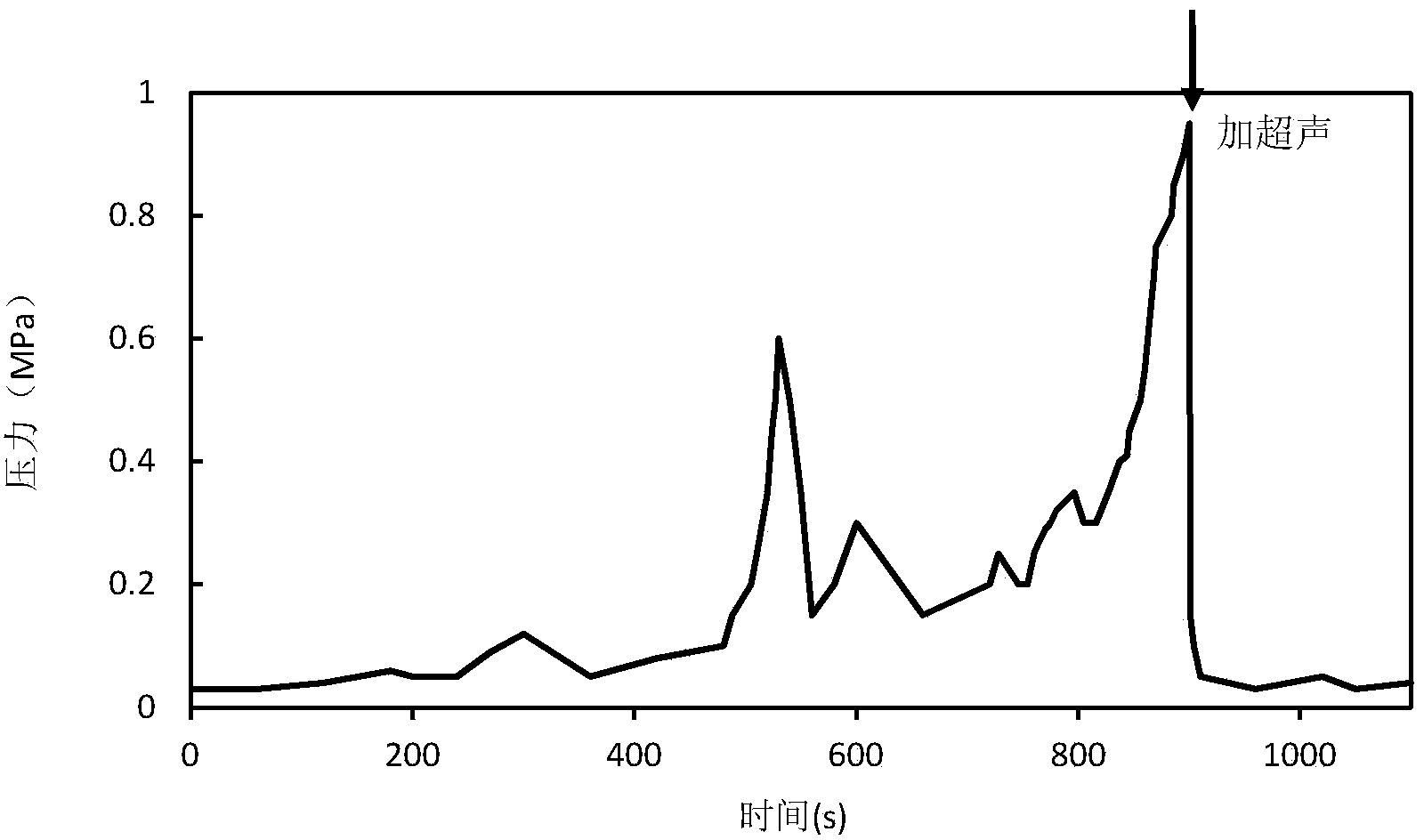

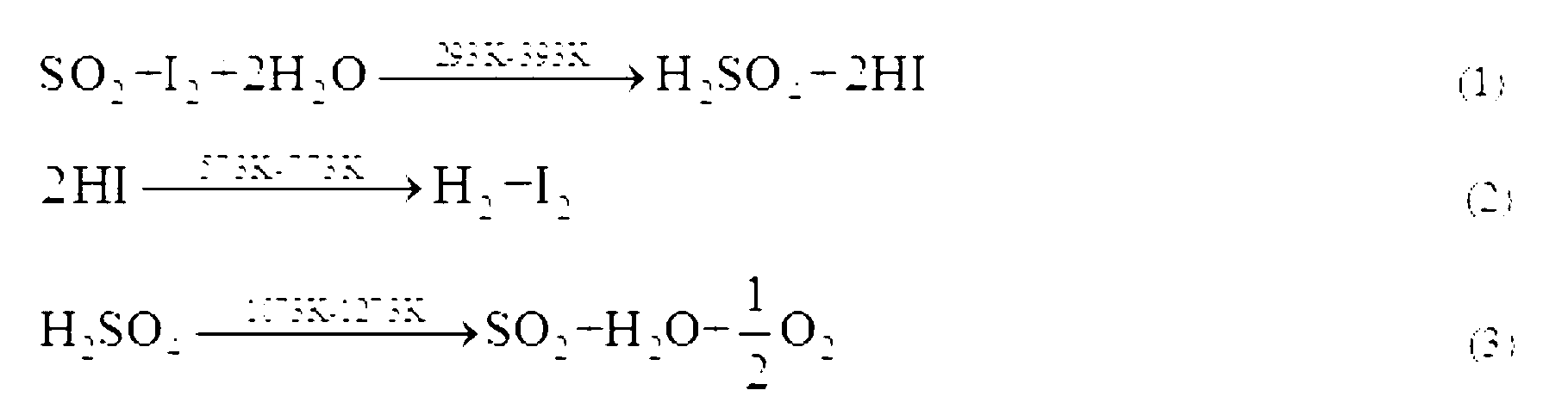

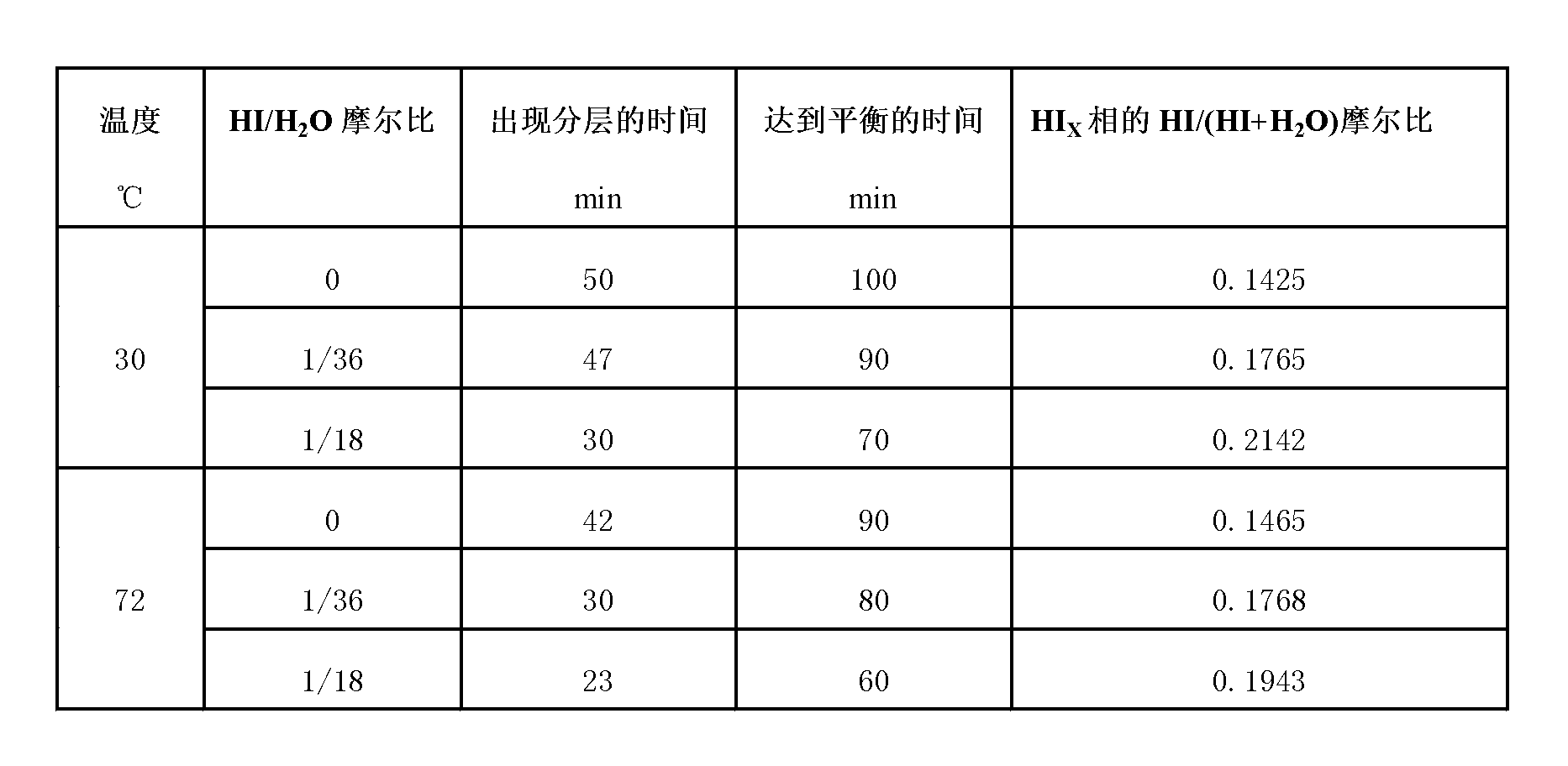

Method for promoting Bunsen reaction in thermochemical iodine-sulfur cycle for hydrogen manufacturing

ActiveCN103213945AOmit the concentration stepIncreased reaction kinetic rateHydrogen productionMass ratioDistillation

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

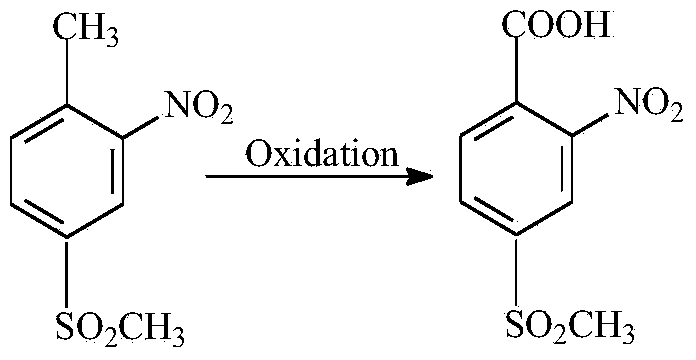

Preparation method of 2-nitro-4-methylsulphonylbenzoic acid

ActiveCN103787934AReduce pollutionEliminate pollutionOrganic chemistryOrganic compound preparationFiltrationSolvent

The invention relates to a preparation method of 2-nitro-4-methylsulphonylbenzoic acid. The preparation method comprises the steps of using 2-nitro-4-methyltolylsulfone as a raw material in a reactor under the 5-75 atmospheric pressure at the temperature of 110-450 DEG C, feeding air, oxygen-enriched air or oxygen which serves as oxidizing gas, using low-grade carboxylic acid as a solvent, adopting heteropolyacid, transition metal and halide to form a multi-element homogeneous catalysis system, producing gas-liquid reaction to convert 2-nitro-4-methyltolylsulfone in reaction liquid into the 2-nitro-4-methylsulphonylbenzoic acid; performing filtration to obtain a crystallized and sedimented 2-nitro-4-methylsulphonylbenzoic acid product after the reaction finishes; continuously recycling filtrate, namely supplementing the raw material and then performing oxidizing reaction. The defect that an existing 2-nitro-4-methylsulphonylbenzoic acid producing method causes large exhaust gas and wastewater pollution, severe corrosion, low selectivity, high production cost and the like is overcome, the selectivity is improved, the environmental pollution is reduced, and clean production of the 2-nitro-4-methylsulphonylbenzoic acid is achieved.

Owner:SINOCHEM AGRO +1

Method for removing sulfur trioxide from coal-fired flue gas

ActiveCN105477995AFully contactedReduce concentrationDispersed particle separationAir preheaterGas liquid reaction

The invention provides a method for removing sulfur trioxide from coal-fired flue gas. According to the concentration of sulfur trioxide in outlet flue gas of a selective catalytic reduction (SCR) denitration device, a prepared liquid absorbent is sprayed to flue gas in a flue gas passage between the outlet end of the SCR denitration device and an air preheater, and the spraying amount of the liquid absorbent per unit volume of the flue gas is 1-20 times of the mole number of sulfur trioxide required to be removed from the per unit volume of the flue gas. Through the gas-liquid reaction between the liquid absorbent and the sulfur trioxide in the flue gas, sulfur trioxide in the flue gas is removed. The liquid absorbent enters the flue duct in a spraying manner and is atomized into small droplets; the small droplets are evaporated in high-temperature flue gas to form tiny absorbent particles. The particles are large in relatively specific surface area and better in dispersion in the flue gas passage, and can be in contact with sulfur trioxide more fully to enable the reaction to be more fully, so that the concentration of sulfur trioxide in flue gas is greatly reduced, the generation of ammonium bisulfate is reduced, and corrosion and blockage of the air preheater are avoided.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

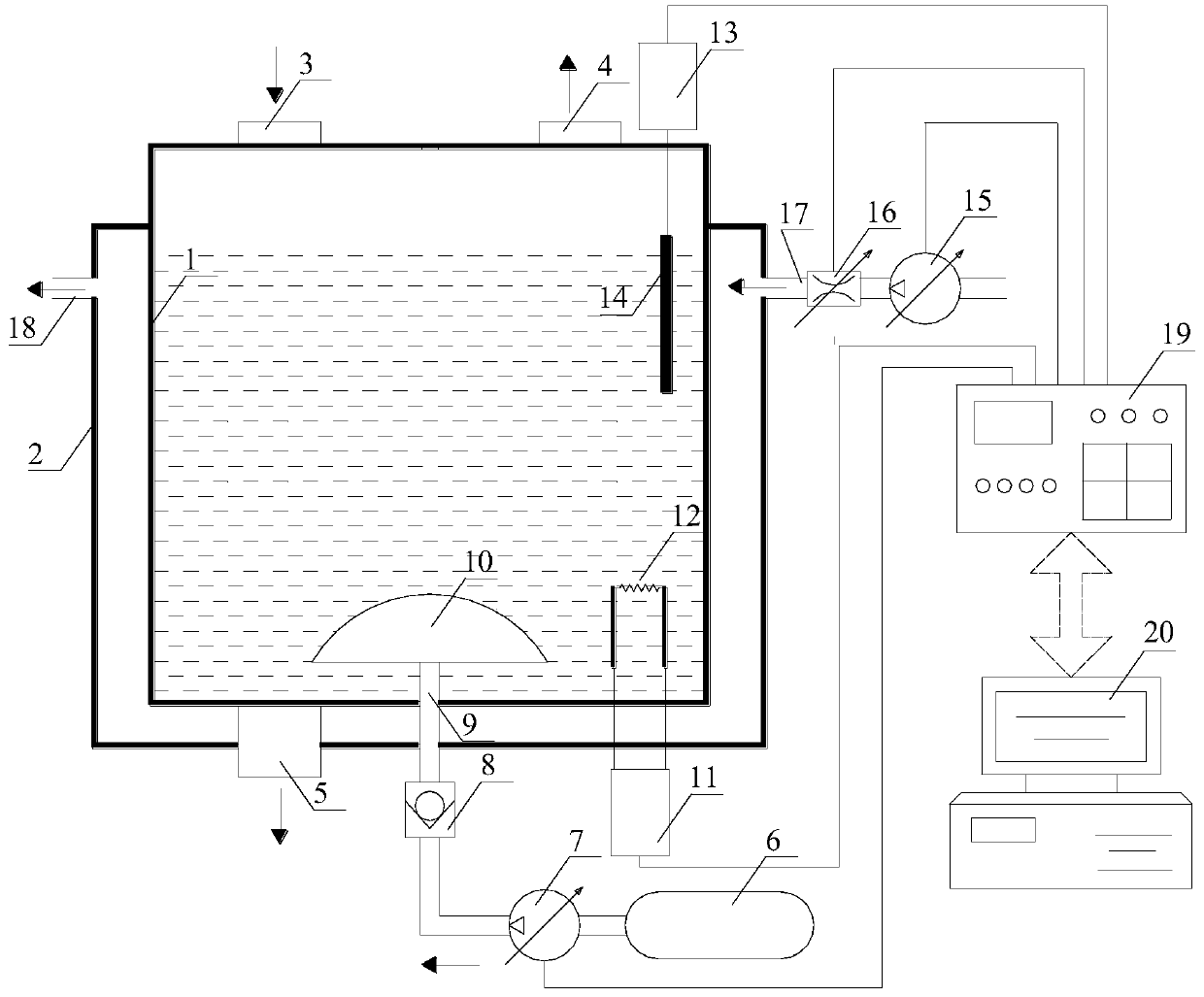

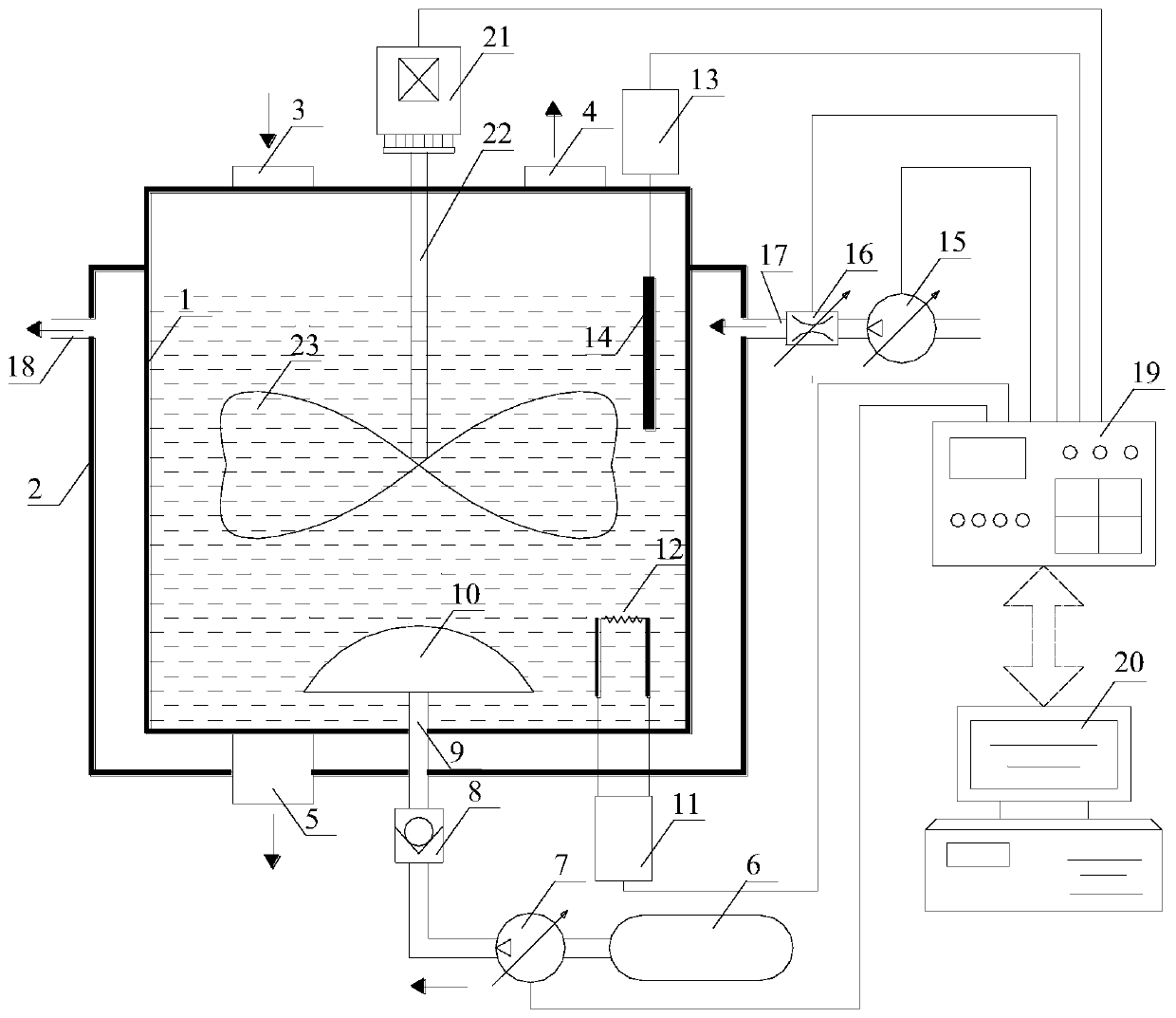

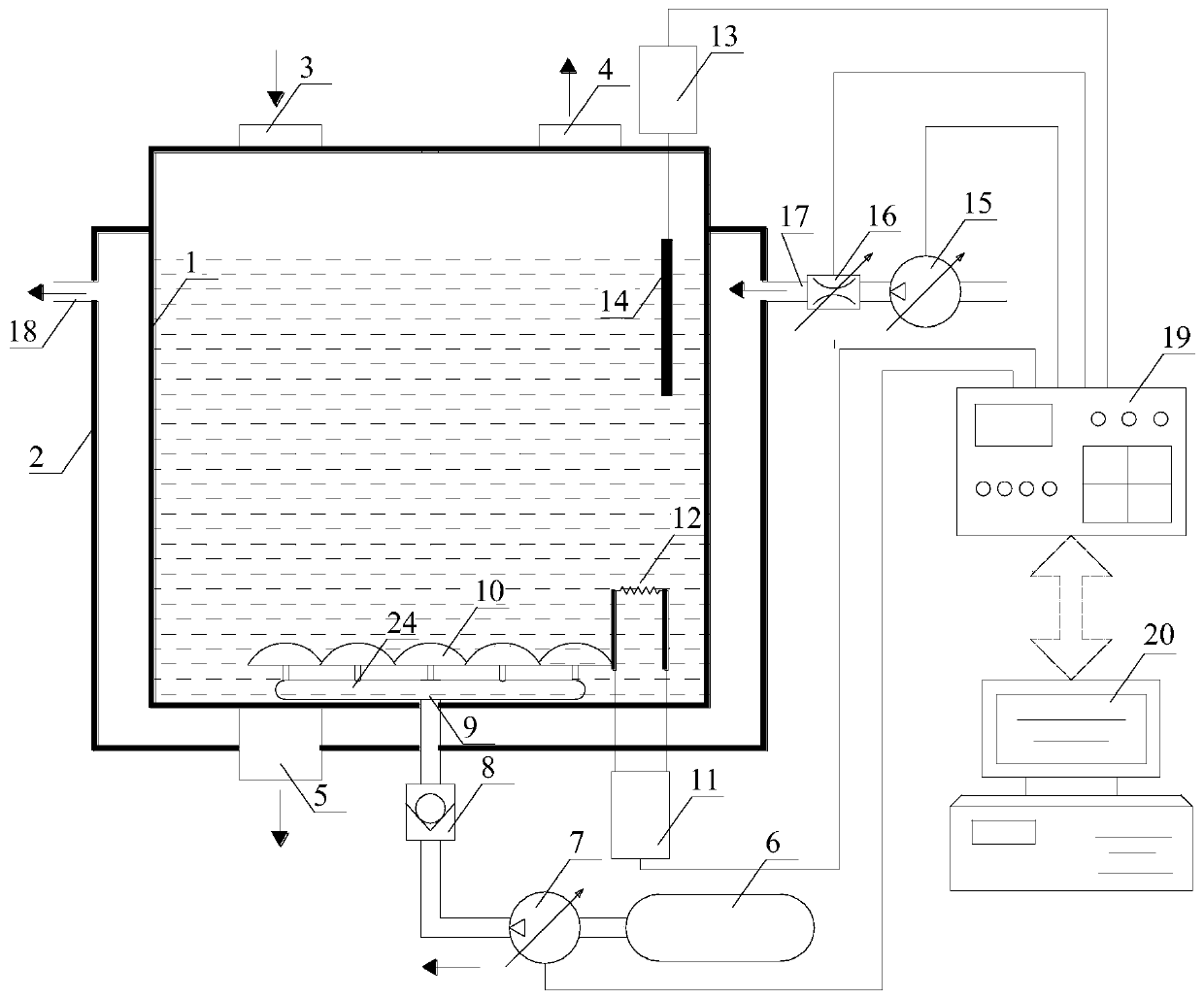

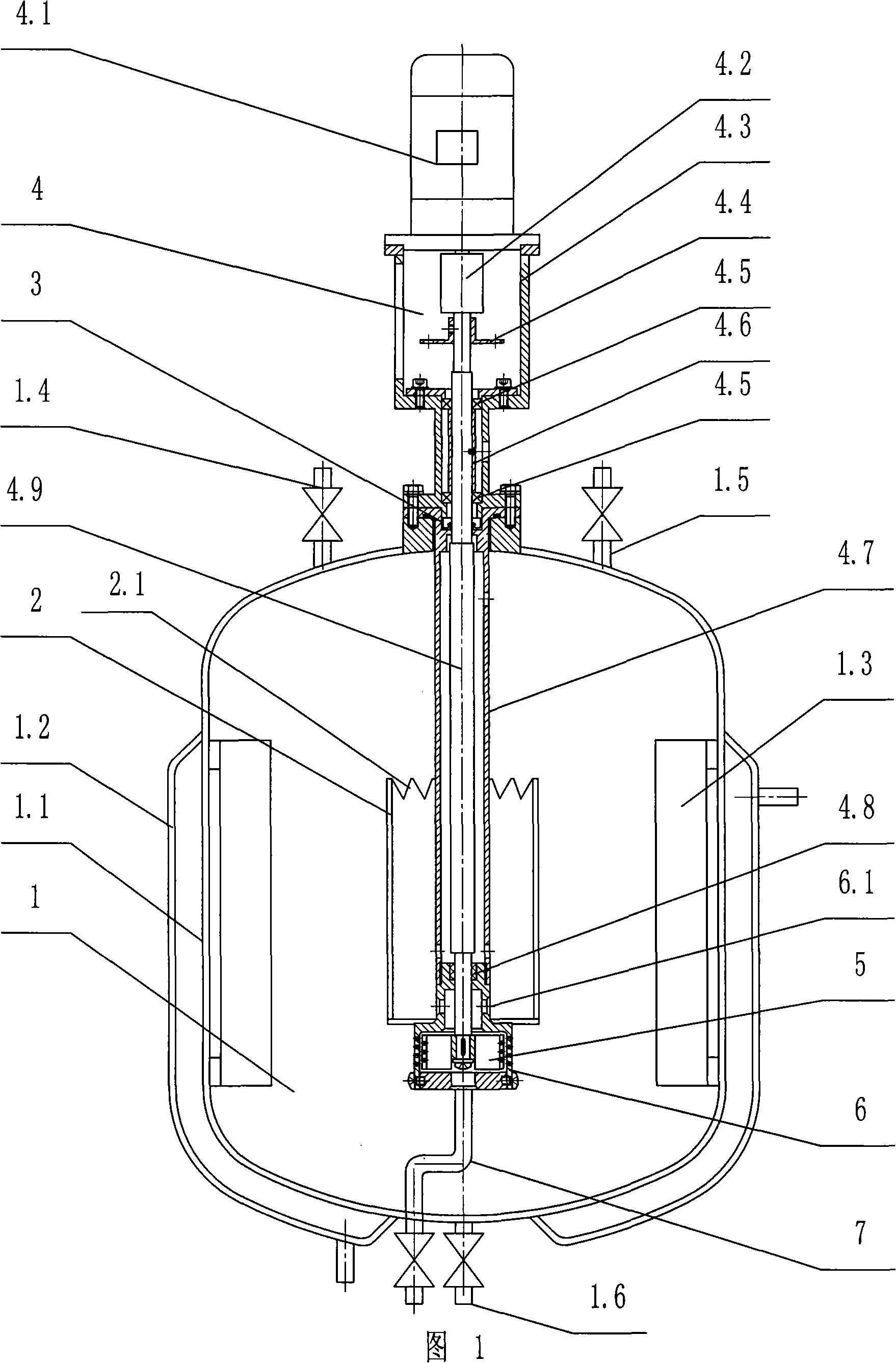

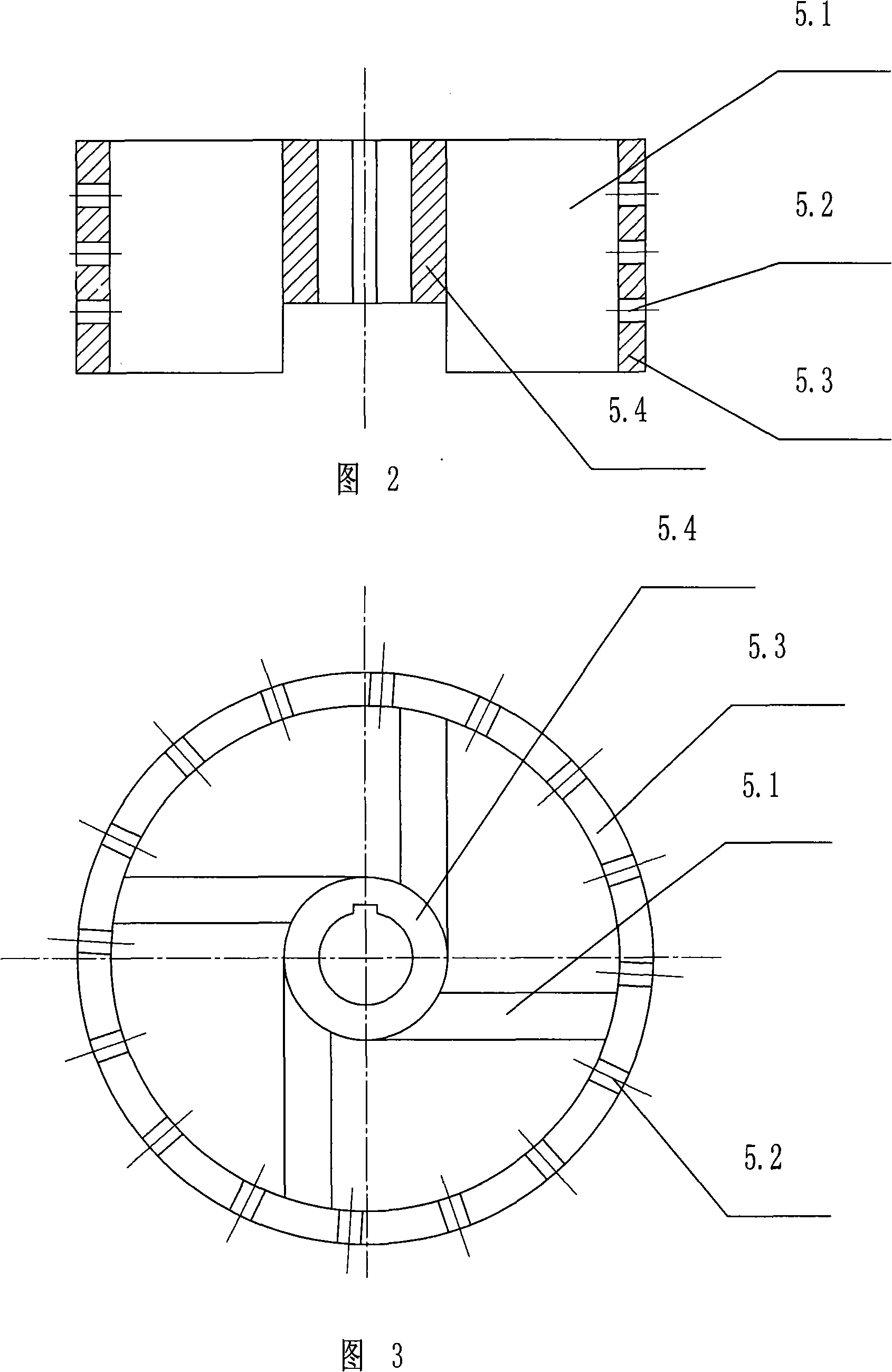

Gas liquid reaction kettle adopting spherical crown-shaped micropore corundum gas supply apparatus

PendingCN110404485ALarge air supplyStrong agitationLiquid-gas reaction as foam/aerosol/bubblesChemical/physical/physico-chemical stationary reactorsGas liquid reactionAging resistance

The invention relates to a gas liquid reaction kettle adopting a spherical crown-shaped micropore corundum gas supply apparatus. The gas liquid reaction kettle comprises a reaction kettle body and a gas supply device, the reaction kettle body comprises a main kettle body, the gas supply device comprises the gas supply apparatus, the gas supply apparatus is arranged in the main kettle body, and thetop surface of the gas supply apparatus is a spherical surface; the gas supply apparatus is in a spherical crown shape and is of an integrated structure, and upper and lower surfaces of the gas supply apparatus release gas simultaneously; the gas liquid reaction kettle has the advantages of a large gas supply amount, high stirring intensity, low resistance, high efficiency, low consumption, reliable operation, no blockage, ageing resistance, corrosion resistance, long service life and the like; in addition, the superficial area of contact between gas and liquid is greatly increased through alarge number of fine bubbles, the reaction speed is increased, and the reaction efficiency is improved; in addition, during gas supply, a high self-stirring effect of a large number of small bubbles is achieved, a stirring device of a conventional gas liquid reaction kettle does not need to be arranged, the structure can be simplified, the cost is reduced, and if the stirring device is arranged, the speed and efficiency of a gas liquid reaction can be further improved.

Owner:TONGLING UNIV

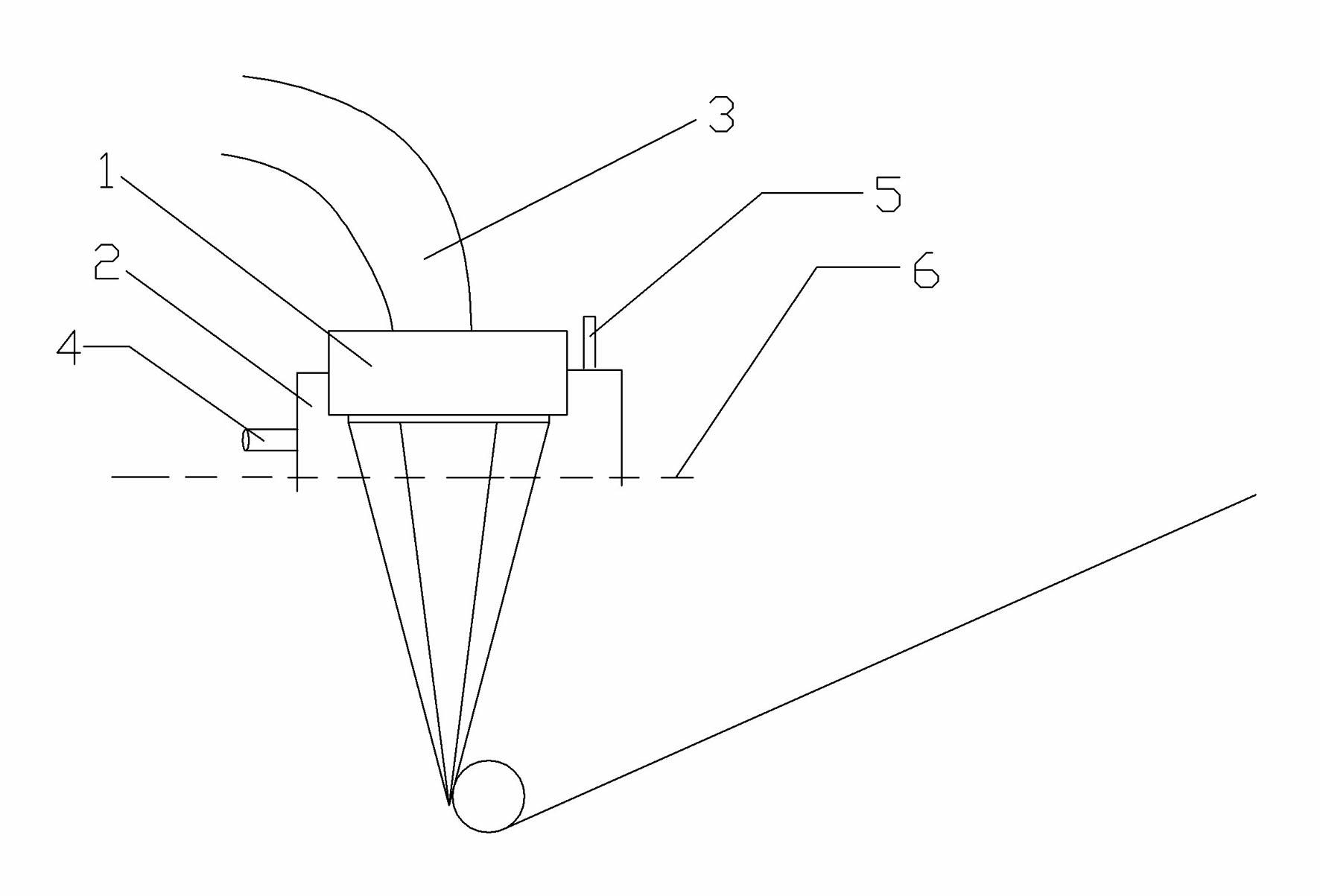

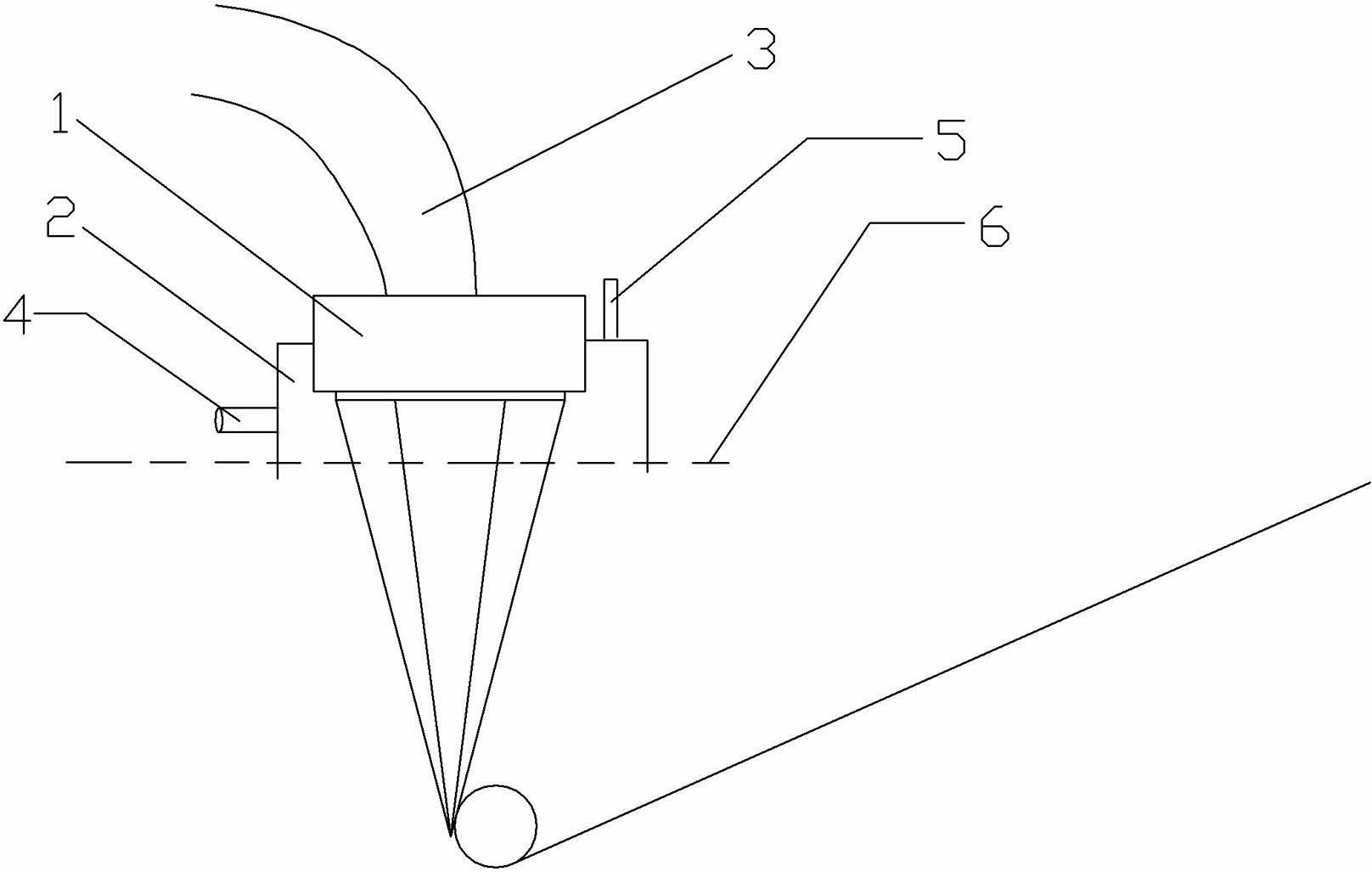

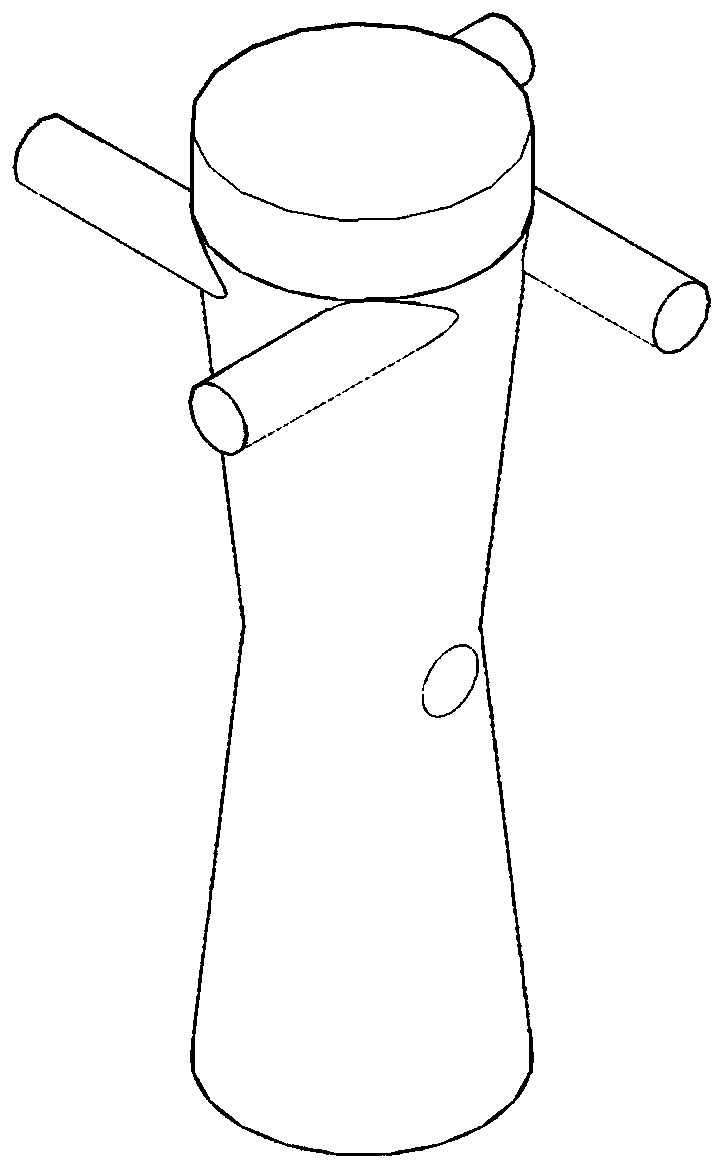

Venturi type micro-bubble generator and gas-liquid reactor

InactiveCN109966939AExtended stayImprove scoreFlow mixersTransportation and packagingGas liquid reactionMicro bubble

The invention discloses a Venturi type micro-bubble generator and a gas-liquid reactor, and belongs to the field of micro-bubble generators. The purpose of the invention is to overcome the disadvantages of large manufacturing difficulty, discrete bubble size and high energy consumption in the prior art. The Venturi type micro-bubble generator is composed of a swirling device, an air inlet hole anda Venturi tube, and the Venturi tube sequentially least comprises a converging section, a Venturi tube section and a diverging section from bottom to top. The Venturi type micro-bubble generator hasthe advantages of compact structure, low energy consumption, good micro-bubble generation effect, and convenience in maintenance. After the micro-bubble generator is used in the gas-liquid reactor, the gas-liquid mass transfer efficiency is greatly improved.

Owner:ZHEJIANG UNIV

Method for preparing isocyanate monomer

ActiveCN104945283AIncrease profitIncrease contact areaIsocyanic acid derivatives preparationOrganic compound preparationGas liquid reactionMixing effect

The invention discloses a method for preparing an isocyanate monomer. The method comprises the following steps: adding a first batch of solvents in a reaction kettle and circulating; compressing HCl, conveying HCl in a salt-forming reaction kettle through the outer tube of a mixer, carrying out gas-liquid separation and then circulating HCl in a system through a Venturi mixer; mixing diamine with the residual solvents in the inner tube of the mixer, then mixing the mixture with HCl in the outer tube, and then conveying the mixture in the salt-forming reaction kettle and reacting to obtain a diamine hydrochloride solution; reacting the diamine hydrochloride solution with phosgene under a pressurization condition to obtain an isocyanate photochemical solution. The mixer comprises the inner tube and the outer tube, wherein a spiral plate is installed in the thick-diameter part of the inner tube, a hole is formed in the tube wall of the thin-diameter part of the inner tube, and the bottom of the inner tube is a detachable bottom plate; the outer tube sleeves outside the inner tube, and the bottom of the outer tube is a mixer outlet. The method disclosed by the invention reinforces the mixing effect of the gas-liquid reaction, the obtained hydrochloride particles are uniform, the use efficiency of HCl is high, the energy consumption is low, and the purity of the photochemical solution after a phosgenation reaction is high.

Owner:WANHUA CHEM GRP CO LTD +1

Micro-bubble generation device

InactiveCN103041723AReduce energy consumptionSimple structureTreatment using aerobic processesFlow mixersGas liquid reactionMicro bubble

The invention discloses a micro-bubble generation device which aims at solving the defects of high energy consumption and few produced micro-bubbles in the existing device. The micro-bubble generation device comprises an outer sleeve and a core pipe arranged in the outer sleeve, wherein the core pipe comprises a water suction pipe section, at least one micro-bubble generation pipe section I and a micro-bubble injection pipe section; and the micro-bubble injection pipe section comprises a micro-bubble generation pipe section II at a water inlet end, and a loudspeaker-shaped injection pipe which is connected with the micro-bubble generation pipe section II and is positioned at a water outlet end side. The micro-bubble generation pipe sections I and II respectively comprise at least one gas introduction hole and at least one cutting groove. The micro-bubble generation device is used for providing a large number of micro-bubbles in water bodies in purifying tanks, baths, aquiculture pools, sewage treatment plants and the like or liquid in gas-liquid reaction tanks.

Owner:曾永芳

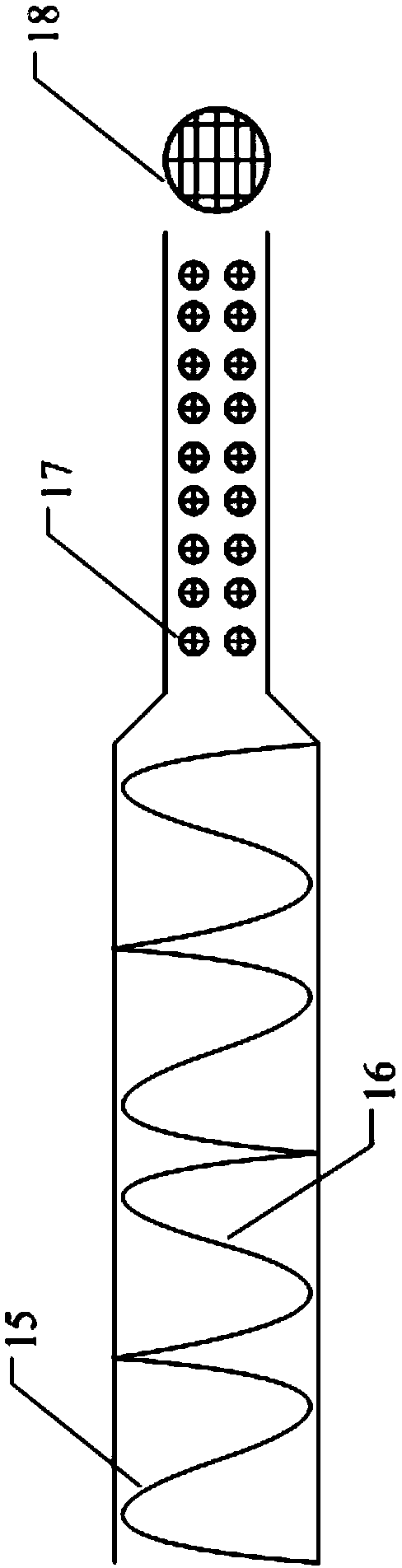

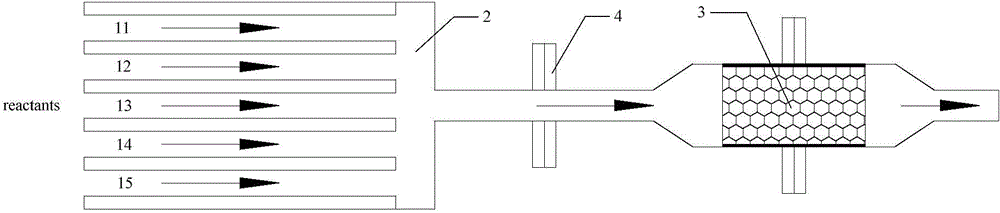

Tube bundle falling film microreactor for performing gas liquid reactions

ActiveUS8221708B2Widen meansAvoid disadvantagesOrganic compound preparationLiquid-gas reaction of thin-film typeVertical tubeMicroreactor

A tube bundle falling film microreactor for performing gas-liquid reactions, which has: a) at least one vertical tube with b) a device for distributing the liquid on the inside of the tube and c) a liquid collecting system, and d) a device for gas supply and removal, and use thereof.

Owner:DSM FINE CHEM AUSTRIA NFG GMBH & CO KG

Gas-liquid reaction device

InactiveCN103071444ATake advantage ofImprove mass transfer efficiency of chemical reactionsChemical/physical/physico-chemical stationary reactorsGas liquid reactionChemical reaction

The invention discloses a gas-liquid reaction device which comprises a reaction tank, wherein a gas-liquid mixing reactor is fixed inside the reaction tank; the reaction tank is communicated with the gas-liquid mixing reactor through a circulation pipe; a circulation pump is in series connection with a circulation pipeline; and the gas-liquid mixing reactor is a structure formed by connecting a gas chamber with a flow guide component through a gas-liquid mixing pipe. The device has the advantages that double circulation of gas-liquid materials can be realized; gas and liquid are fully mixed; the mass transfer efficiency of a chemical reaction is remarkably improved; raw materials are fully used; when a solid catalyst is needed, the liquid and the catalyst form a suspended solution with an agitator, so that the catalyst can circulate smoothly in the reaction device; the service life of the device is prolonged; and the maintenance cost of the device is lowered.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

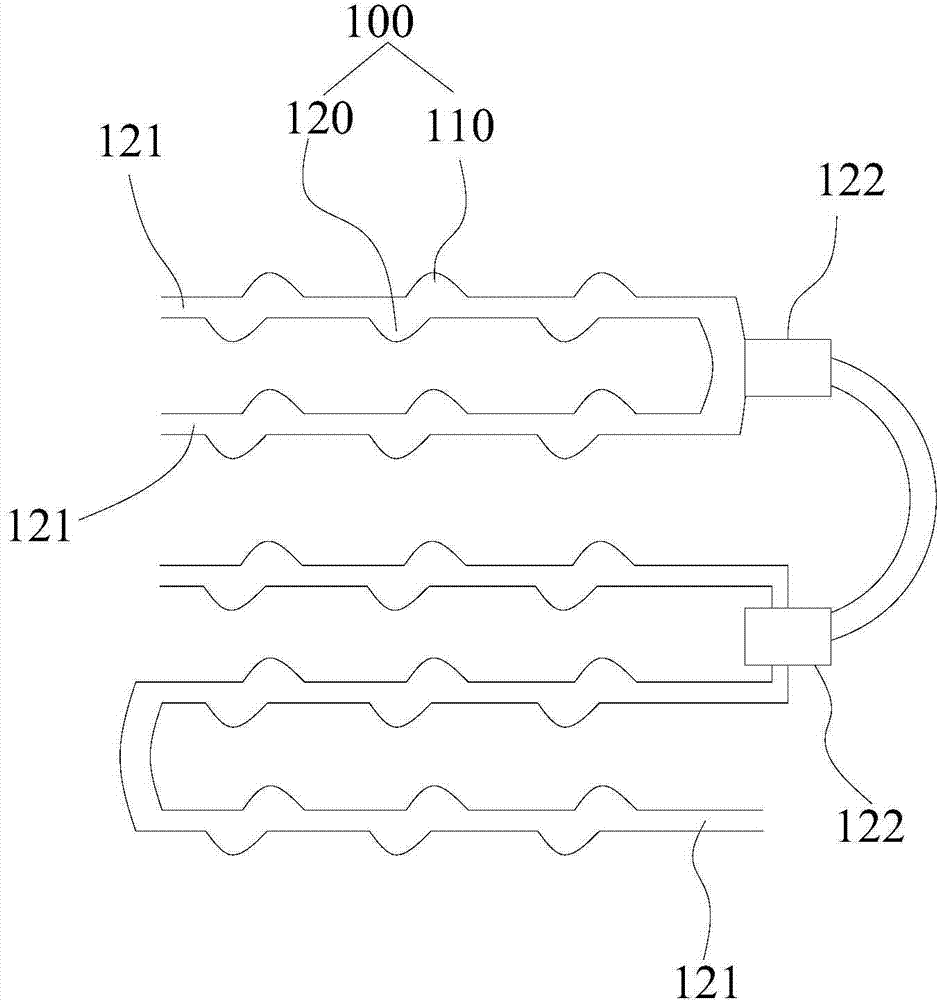

Micro-channel reaction system

ActiveCN104511264ASimple structureMeet the needs of the pilot testChemical/physical/physico-chemical microreactorsGas liquid reactionProcess development

The invention relates to the field of synthetic equipment and provides a micro-channel reaction system. The micro-channel reaction system comprises a micro-channel reaction device, a gas conveying device for introducing gas into the micro-channel reaction device, two or more liquid conveying devices for introducing liquid into the micro-channel reaction device, a gas-liquid separation device communicated with the micro-channel reaction device, and a sampling device. According to the micro-channel reaction device, different types of synthetic reactions such as gas-liquid reaction and liquid-liquid reaction can be produced; moreover, highly corrosive and strongly exothermal reactions of hydrogenation, oxidation, fluorination, bromination, nitration, sulfonation and the like can be produced by the micro-channel reaction device; in addition, the reaction system is simple in structure and easy to realize, and can meet the needs of small-amount process development research and pilot test.

Owner:SHENZHEN E ZHENG TECH

Method and device for the sulfonation or sulfation of sulfonatable or sulfatable organic substances and for performing faster, strongly exothermic gas/liquid reactions

InactiveUS7968742B2Rapid and highly exothermic gas/liquid reactionProcess control/regulationPhysical/chemical process catalystsSulfationGas liquid reaction

A method and a device for the sulfonation or the sulfation of organic liquid raw materials with an SO3 / air mixture and other reaction gases in order to perform rapid, highly exothermic gas-liquid reactions in conventional thin-layer falling-film reactors are disclosed. The introduction of the SO3 / air mixture occurs through several feed locations, which are located within (along) the reaction tube or reaction tubes or in the annular gap of annular-gap falling-film reactors. High peak temperatures, undesirable byproducts, worsening of the color and local oversulfation or oversulfonation, which leads to side reactions, are largely avoided.

Owner:CHEMITHON

New method of preparing tert-butyl phenol by alkylation of phenol and isobutene

InactiveCN1948247AIncrease profitReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferGas liquid reaction

The present invention relates to a new method for preparing tert-butyl phenol by utilizing phenols and isobutylene and making them produce alkylation reaction. Said method is characterized by that on the basis of gas-liquid reaction equipment a Venturi ejector or gas-liquid mixing pump and a feed liquor circulating pump are added, so that the unreacted isobutylene can be further absorbed and fed into reaction still, under the action of ejector and feed liquor circulating pump the isobutylene gas and liquid material can be continuously circulated in the system so as to make the gas-liquid reaction be more uniform.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Method for strengthening mixing and reaction of fluids in micro-reactor

ActiveCN105617957AAvoid structural optimization design processImprove absorption rateDispersed particle separationChemical/physical/physico-chemical processesMicroreactorGas liquid reaction

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel method and device for processing boat exhaust gas

ActiveCN101757846AConvenient sourceReduce energy consumptionDispersed particle separationRefluxElectricity

The invention relates to the technical field of environment protection and discloses a device for processing boat exhaust gas, which comprises a water pump, an electro-catalysis processing unit, a storage tank, an atomization device, a gas-liquid reaction device, a solid-liquid separation device, a condensation and reflux device, an exhaust gas inlet and a pump. The water outlet of the water pump is connected with the electro-catalysis processing unit which is connected with the storage tank; one end of the pump is connected with the storage tank, and the other end is connected with the atomization device which is connected with the liquid inlet end of the gas-liquid reaction device; the exhaust gas inlet is connected with the gas inlet end of the gas-liquid reaction device; the gas outlet end of the gas-liquid reaction device is connected with the condensation and reflux device which is provided with a gas exhaust port at the upper end; and the liquid output end of the gas-liquid reaction device is connected with the input end of the solid-liquid separation device which is provided with a solid discharge port and a liquid discharge port. The invention further discloses a method for processing the exhaust gas. The invention has the advantages of low energy consumption, high efficiency, convenient installation and simple operation, the resultants from the reaction are pollution-free, and the exhaust gas removal effect is better.

Owner:QINGDAO HEADWAY TECH

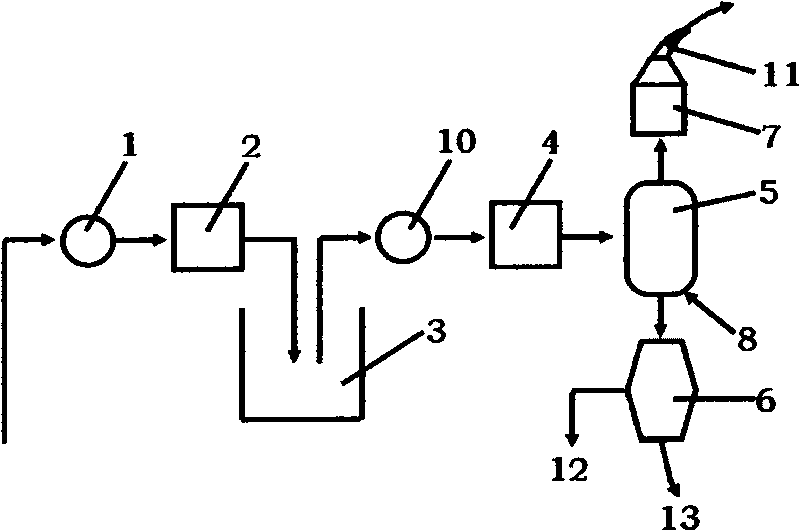

Process and apparatus for producing sodium hydrosulfide from acidic gas

ActiveCN104826463AIncreased depth of responseGuaranteed long-term operationSulfur compoundsDispersed particle separationPollutantGas pipeline

The invention discloses a process and apparatus for producing sodium hydrosulfide from acidic gas. The acidic gas treating process employs a two-stage gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, and the primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent; and a supplementary carrier gas pipeline is arranged between two-stage rotating packed bed reactors to introduce supplementary carrier gas, so the concentration of CO2 in the acidic gases is reduced and most CO2 is taken out of the apparatus together with the carrier gas, and thus, the contents of Na2CO3 and NaHCO3 are controlled, obstruction of the pipeline due to crystallization caused by production of a great amount of Na2CO3 is prevented, and long cycle operation of the apparatus is guaranteed. The rotating packed bed reactors are used as gas-liquid reactors which have high mass transfer and reaction efficiency. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and an acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting magnesium and lithium from brine

InactiveCN101905897ALow costIncrease valueMagnesium carbonatesLithium carbonates/bicarbonatesLithiumGas liquid reaction

The invention discloses a method for extracting magnesium and lithium from brine. The method comprises the steps of introducing brine containing magnesium into a gas-liquid reaction kettle or an absorption tower, reacting with gas containing carbon dioxide at the pressure of 1x105-1x107Pa and the temperature of 80 DEG C below zero to 200 DEG C so that the brine can absorb enough carbon dioxide to generate magnesium carbonate precipitate, filtering and separating mother liquor to obtain the crude product mainly containing the magnesium carbonate. The invention has the following characteristics: extra precipitator is not needed; the gas containing carbon dioxide can be tail gas and other secondary products after combustion of fuel; the cost of the reagent is low; the element of magnesium without high value is developed into the product so as to greatly increase the value of a salt lake and solve the pollution of the low-cost magnesium to the environment; the energy consumption is low and the tail gas after combustion of fuel is recycled, which is very environmental-friendly.

Owner:张慧媛

A kind of preparation method of low-cost cadmium phosphide quantum dot material

InactiveCN102268253AThe synthesis method is simpleContinuous operationLuminescent compositionsSynthesis methodsReaction temperature

The invention discloses a preparation method of a low-cost cadmium phosphide quantum dot material. The preparation method comprises the following steps: based on a cheap cadmium compound such as cadmium oxide, cadmium acetate or cadmium cetylacetonate and the like as a raw material, dissolving the cadmium compound and long-chain fatty acid in octadecylene at a high temperature so as to prepare a long-chain fatty acid salt of cadmium; or dissolving cadmium cetylacetonate in organic amine, and then carrying out a gas-liquid reaction based on hydrogen phosphide as a phosphorus source so as to prepare the high-quality cadmium phosphide quantum dot luminescent material. According to the invention, a cheap and continuously operable synthesis method is provided for the cadmium phosphide quantum dot material, and a solid foundation is provided for industrialized production of the cadmium phosphide quantum dot material; and through controlling factors such as reaction temperature, time and the like, the luminescence of the cadmium phosphide quantum dot material can be achieved in a wide region ranging from visible light (460nm) to infrared light (1500nm).

Owner:HEFEI UNIV OF TECH

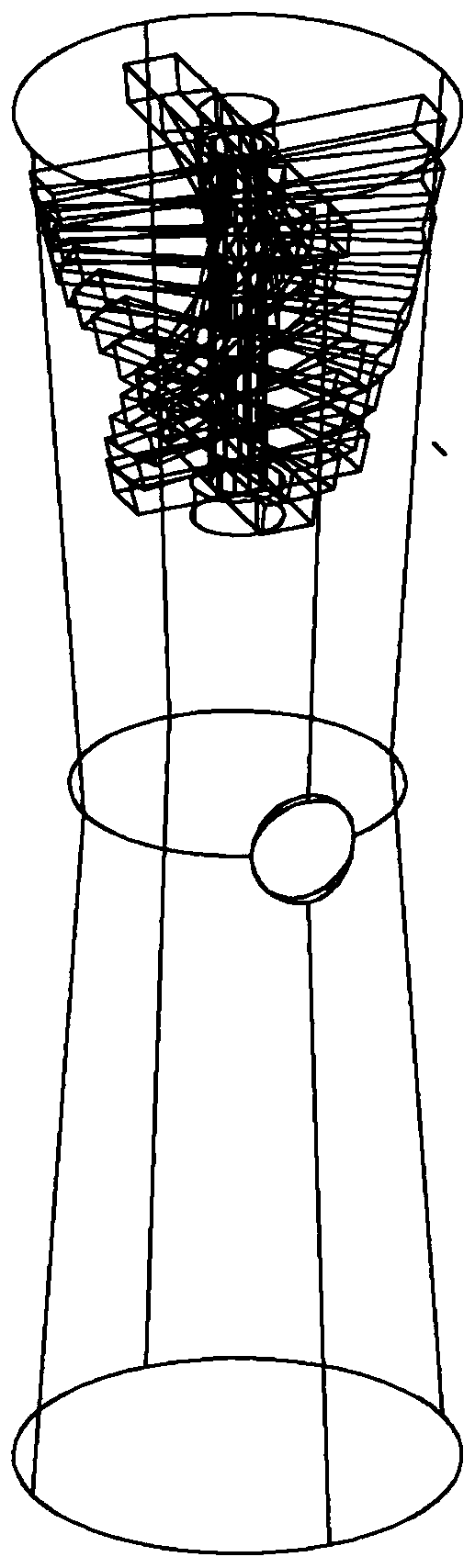

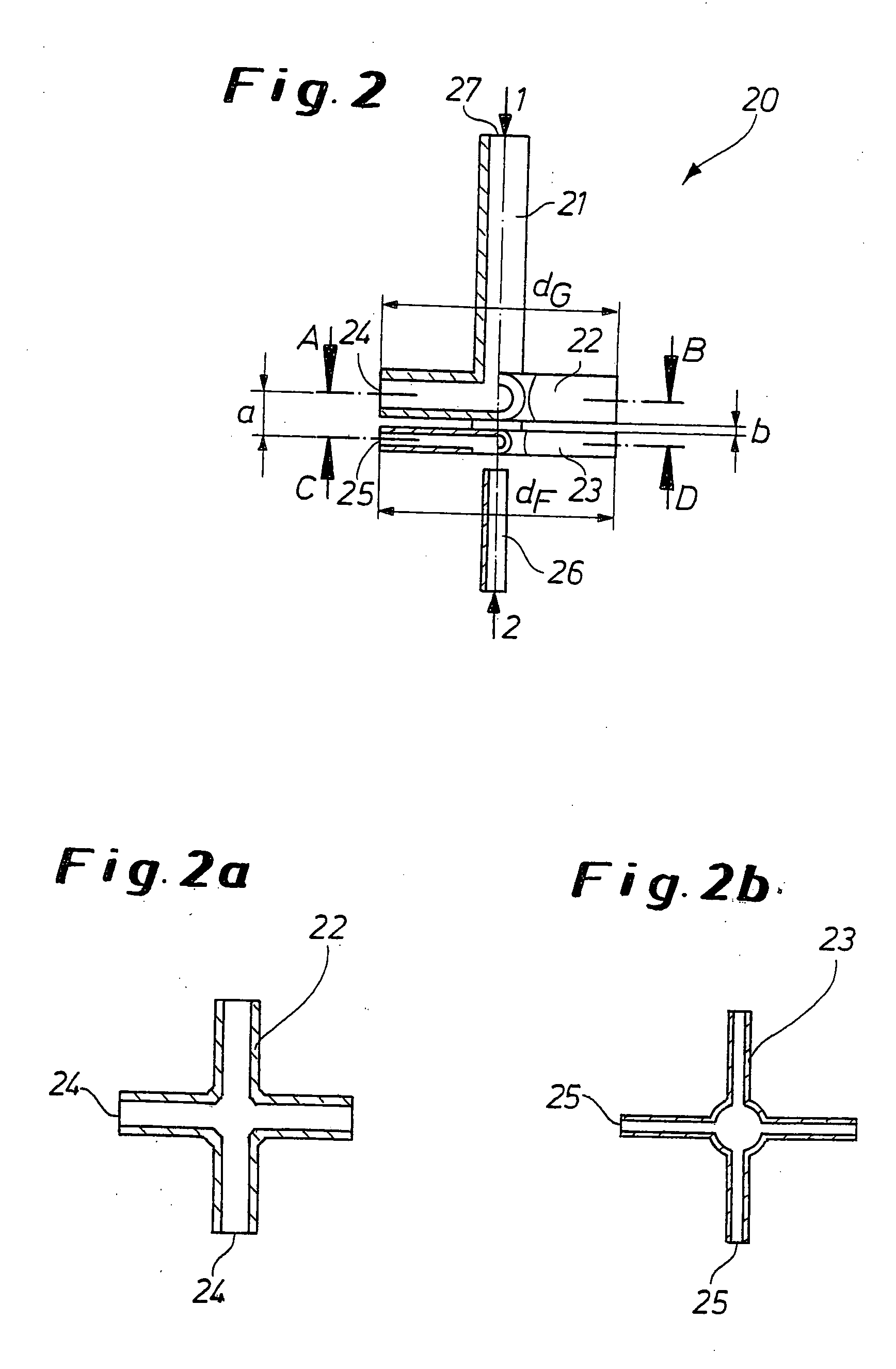

Stirring device and process for carrying out a gas-liquid reaction

InactiveUS20060038306A1Evenly distributedInherent disadvantageLighting and heating apparatusRotary stirring mixersGas liquid reactionEngineering

The invention describes a stirring device made from a gassing stirrer and a liquid mixer or two liquid mixers, which are arranged on a shaft and each have a feed and at least one exit opening, wherein the exit openings of the gassing stirrer and of the liquid mixer or the liquid mixers are at a distance from one another, the ratio, a / d, of the distance, a, between the exit openings to the diameter, d, of the gassing stirrer or liquid mixer being 0.02 to 0.5 and the ratio, b / d, of the distance, b, between the outer edges to the diameter, d, of the gassing stirrer or liquid mixer being 0.01 to 0.4.

Owner:COVESTRO DEUTSCHLAND AG

Self-suction type inner circulation overweight field gas-liquid reactor

InactiveCN101293190AReduce potential energyPrevent coalescenceLiquid-gas reaction processesChemical reactionGas phase

The present invention relates to a self-suction inner recycling super-gravity field gas-liquid reactor, which comprises a reactor container body, a dynamic rotor, a stator, a guide cylinder, a gas inlet pipe, a drive mechanism and a sealing mechanism. High-speed rotation produced by the drive mechanism drives the rotor to produce high centrifugal force, thus ensuring that the liquid in the container is thrown out by rapid centrifugation; the rotor center opposite to the air inlet pipe is vacuum, so that the gas is automatically suctioned from the lower part and the liquid is suctioned from the upper part at the same time; the gas phase and the liquid phase flow in the high turbulence in the rotor and are limited by the stator provided with small holes; the gas phase and the liquid phase carry out the super-gravity contact in a rotating chamber and are ejected out from the small holes of the stator after high-intensity physical mass transfer and chemical reaction are achieved; the two phases are mightily dispersed to form a large contacting area and further reacted in the container; the liquid at the proper position of the upper part of the container is suctioned into the rotor through the guide cylinder, thus forming the inner liquid recycling. The reactor can be widely applied in the fields of chemicals, petroleum chemicals, environment, pharmacy, light industry, etc. as well as gas-liquid reaction.

Owner:JIANGNAN UNIV +1

Stirring grinding reactor and method thereof for preparation of isocyanate

ActiveCN105126711AIncrease disturbanceImprove conversion rateIsocyanic acid derivatives preparationOrganic compound preparationTemperature controlGas liquid reaction

The invention discloses a stirring grinding reactor and a method thereof for preparation of isocyanate. The reactor is provided with dynamic rotation slices and static rotation slices in a mutual spacing manner; the dynamic rotating slices and the static rotation slices are provided with channel holes, the dynamic rotation slices each have a saucer-shaped structure having a serrated surface, and the static rotation slices have the structure complementary with that of the dynamic rotation slices. A special stirring structure of the reaction kettle can avoid hydrochloride caking, and increases the salifying concentration and the diamine conversion rate. A gas-liquid reaction effect is strengthened, the temperature control of the system is stable, obtained hydrochloride granules are exquisite, the reaction time can be shortened during a liquid phase phosgenation reaction, the product yield is improved, at the same time, blocking of salifying equipment can be reduced, the equipment can be allowed to perform long-term stable running, the equipment structure is concise, and large-scale industrialized application is convenient.

Owner:WANHUA CHEM GRP CO LTD

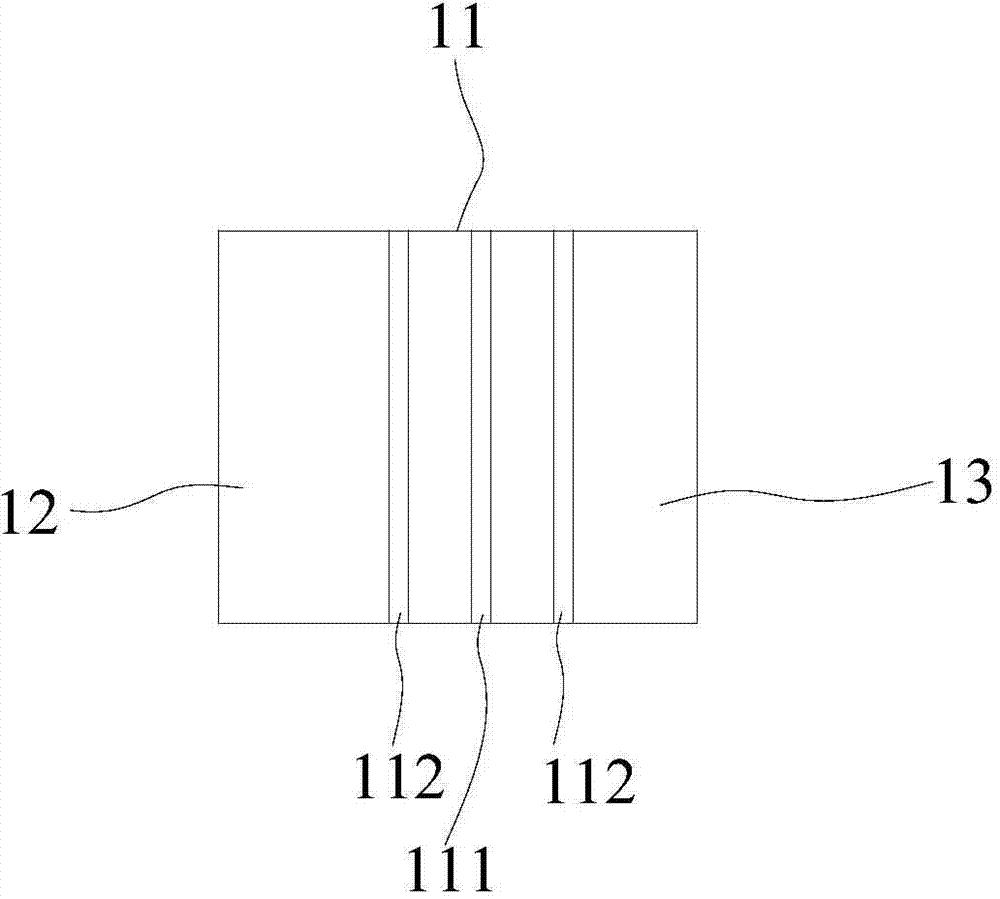

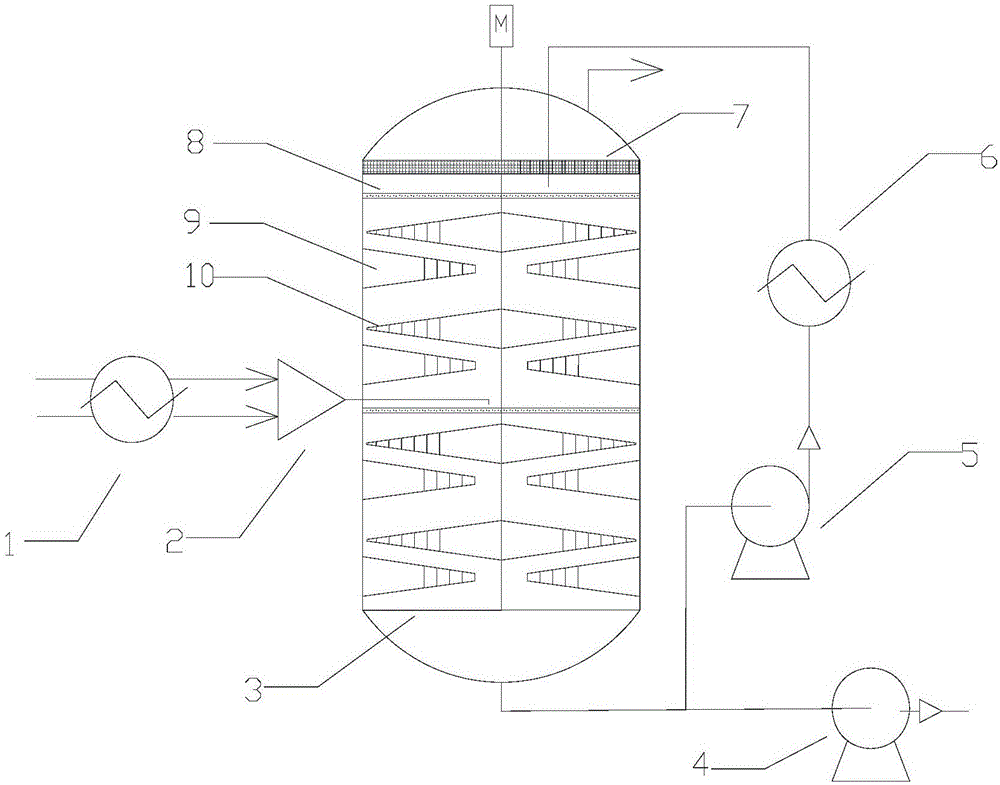

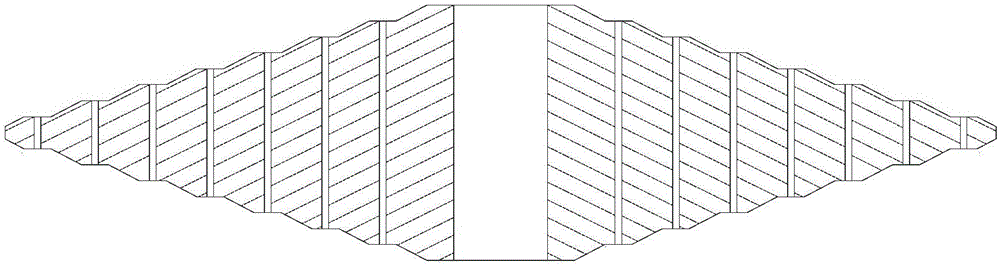

Reaction apparatus, reaction system, and liquid phase hydrogenation reaction method

ActiveCN107243299AImprove the efficiency of the hydrogenation reactionGood hydrogenation reaction effectTreatment with hydrotreatment processesChemical/physical processesGas liquid reactionHydrogenation reaction

The present invention discloses a gas-liquid reaction apparatus, which comprises a reactor and a mixer, wherein the internal space of the reactor is provided with n catalytic reaction zones for filling a catalyst, n is an integer of more than 2, the m-th catalytic reaction zone and the (m+1)-th catalytic reaction zone are connected through a separation member, m is any integer selected from an interval [1, n-1], and the separation member is used for dividing the radial cross section of the catalytic reaction zone of the separation member into a plurality of sub-zones, and making the material output from the m-th catalytic reaction zone enter the (m+1)-th catalytic reaction zone through the plurality of the sub-zones. The invention further discloses a liquid phase hydrogenation reaction system using the reaction apparatus and a liquid phase hydrogenation treatment method. According to the present invention, with the application of the reaction apparatus to perform liquid phase hydrogenation on hydrocarbon oil, the hydrocarbon oil can be subjected to liquid phase hydrogenation without application of the circulating oil and the diluent, and the efficiency of the hydrogenation reaction can be effectively improved so as to achieve the good hydrogenation reaction effect.

Owner:湖南长科诚享石化科技有限公司

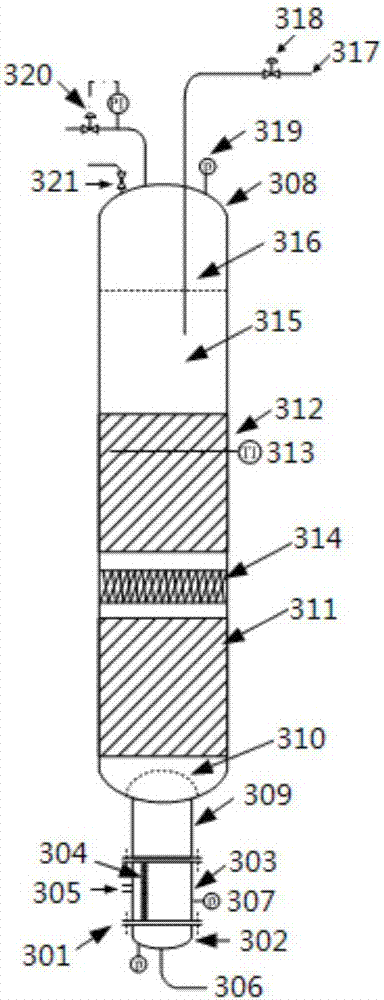

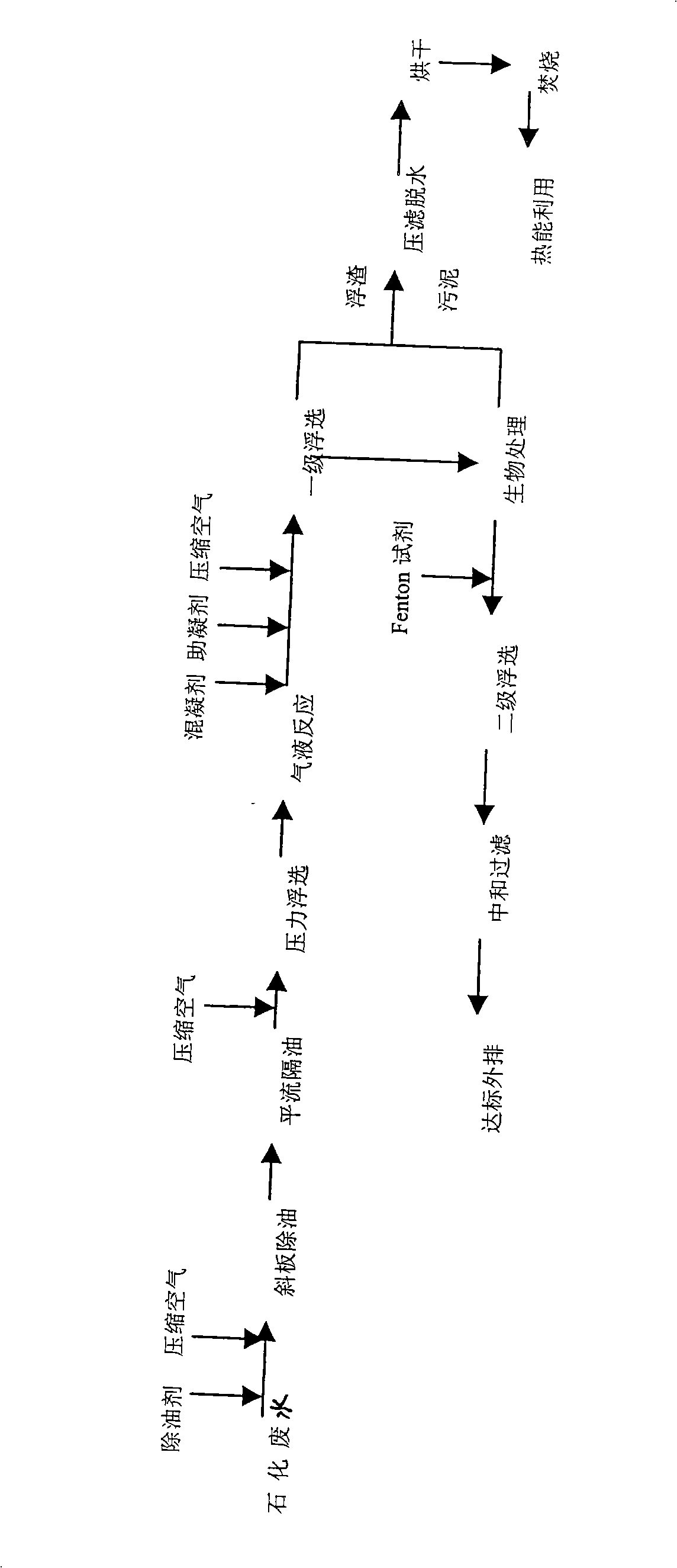

Petrified waste water treatment process

InactiveCN101318754ASimple technologyLow running costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentOil processingSocial benefits

The invention relates to a process for treating petrochemical wastewater. The process comprises a plurality of working procedures and implementation steps such as oil removal by a sloping plate, advection oil separation, pressure floatation, primary floatation by a gas-liquid reaction, biotreatment, secondary floatation, neutralization and filtration and scum and sludge treatment. The process has simple equipment technology, easy implementation and low operating expense; and the process is utilized to rapidly treat wastewater produced in the process of petroleum processing with high efficiency and recycle oil products, thereby effectively reducing environmental pollution and achieving good economical and social benefits.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com