A method for preparing polyacrylonitrile carbon fiber precursors by dry jet wet spinning

A polyacrylonitrile carbon fiber, dry spray wet technology, applied in the direction of dry spinning, wet spinning, stretch spinning, etc., can solve the problem of poor operability and reproducibility, poor anti-aging performance, raw filament density and cross-section Difficult to meet the requirements and other problems, to achieve the effect of inhibiting the formation of large-scale pore structures and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

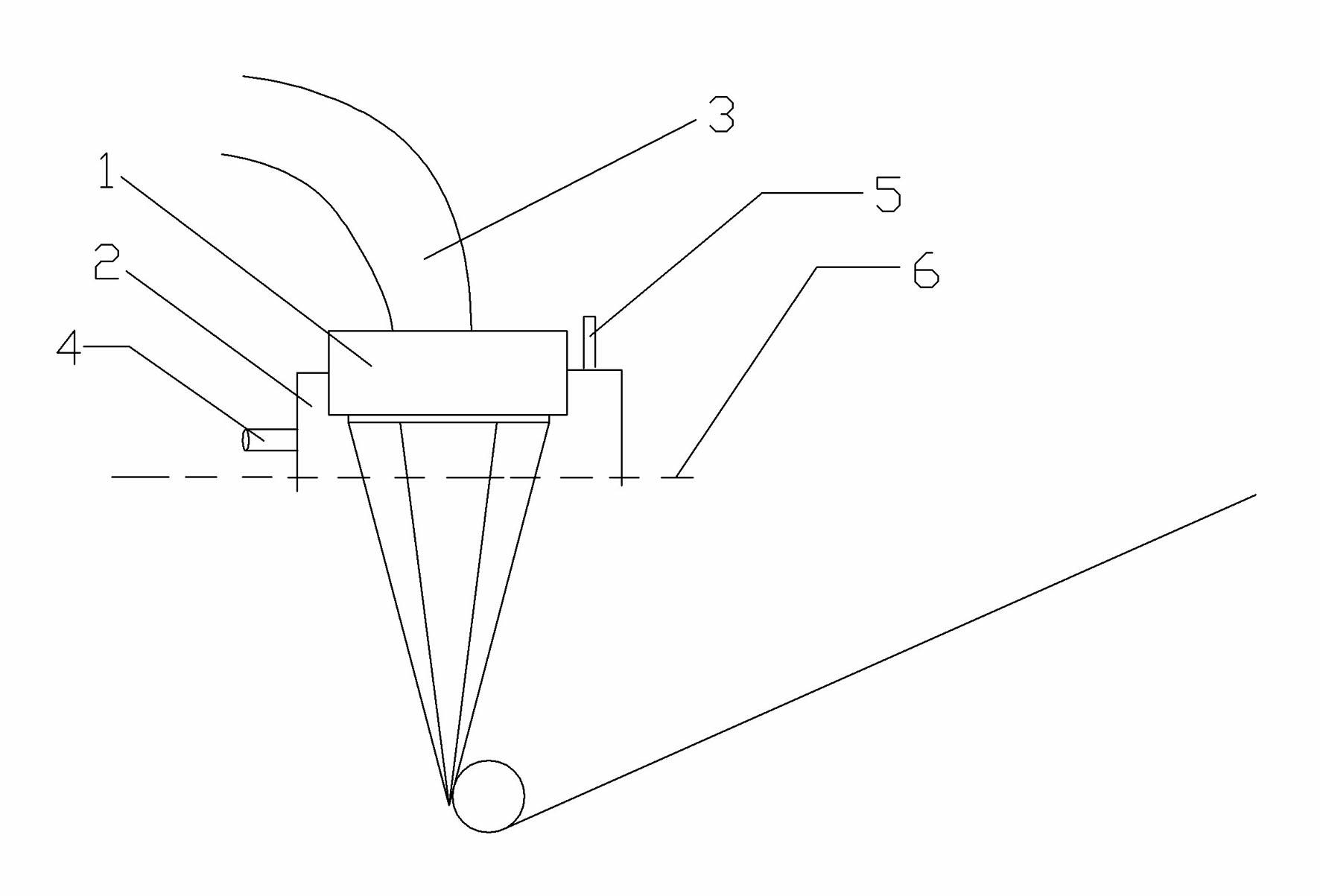

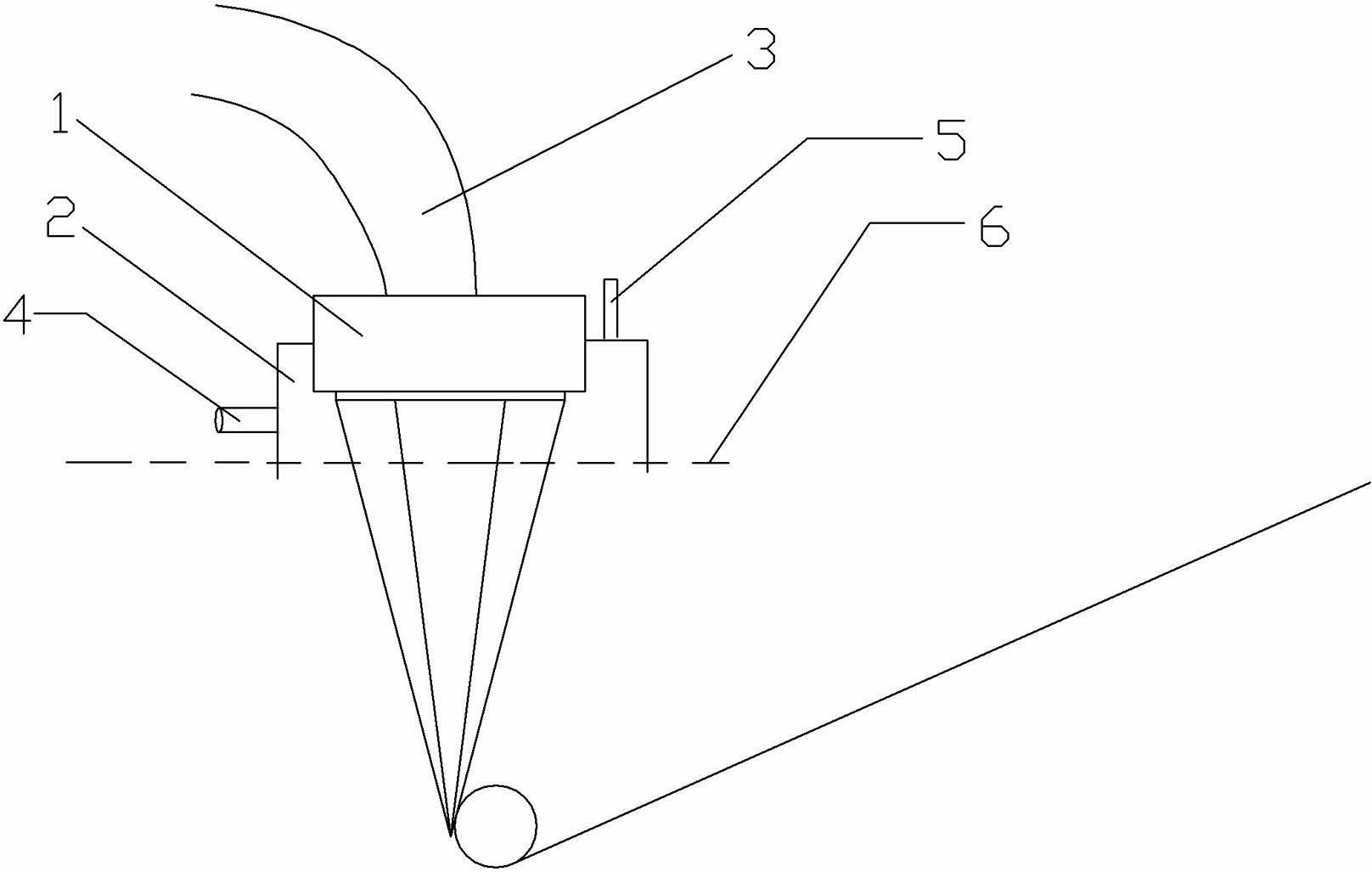

[0019] 10kg of acrylonitrile, 0.2kg of itaconic acid, 0.4kg of methyl acrylate, 0.07kg of azobisisoheptaonitrile and 36kg of dimethylsulfoxide were copolymerized at 50℃, and the viscosity average molecular weight of the binary copolymer obtained was 21 Ten thousand, dry and wet spinning after de-sizing, deaeration and filtration, the height of the dry section is 5mm, the ammonia flow in the air storage box is 20ml / min, the spinning speed is 7m / min, and the mass concentration of dimethyl sulfoxide in the coagulation bath is 70 %, the temperature is 30℃, after 4 water washing, 3 hot water drawing, oiling, drying and densification, first-level steam drawing and heat setting, the denier is 1.25dtex and the density is 1.189g / cm 3 Polyacrylonitrile fiber, which has been pre-oxidized and carbonized to obtain a density of 1.82g / cm 3 , Polyacrylonitrile carbon fiber with 5.15GPa strength and 278GPa elastic modulus. The said air storage box 2 is provided with a spinning assembly, on its s...

Embodiment 2

[0021] 10kg of acrylonitrile, 0.2kg of itaconic acid, 0.07kg of azobisisoheptanonitrile and 36kg of dimethylsulfoxide were copolymerized at 50°C to obtain a binary copolymer with a viscosity average molecular weight of 220,000. After defoaming and filtering, dry and wet spinning, the height of the dry section is 5mm, the ammonia flow in the air storage box is 5ml / min, the spinning speed is 7m / min, the mass concentration of dimethyl sulfoxide in the coagulation bath is 70%, and the temperature is 30℃. After 4 water washing, 3 hot water drawing, oiling, drying and densification, one-stage steam drawing and heat setting, the fineness is 1.25dtex and the density is 1.188g / cm 3 Polyacrylonitrile fiber, which is pre-oxidized and carbonized to obtain a density of 1.80g / cm 3 , Polyacrylonitrile carbon fiber with strength 4.98GPa and elastic modulus 285GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com