Gas liquid reaction kettle adopting spherical crown-shaped micropore corundum gas supply apparatus

A gas-liquid reaction, spherical crown technology, applied to the reaction of liquid and gas under foam/aerosol/bubble, chemical method for reacting liquid and gas medium, chemical/physical/physicochemical stationary reactor, etc. Direction, can solve the problems of not being able to give full play to the gas-liquid reaction speed and efficiency, the size of the bubbles is not small enough, the number is not enough, etc., to achieve the effects of small resistance, increased surface area, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

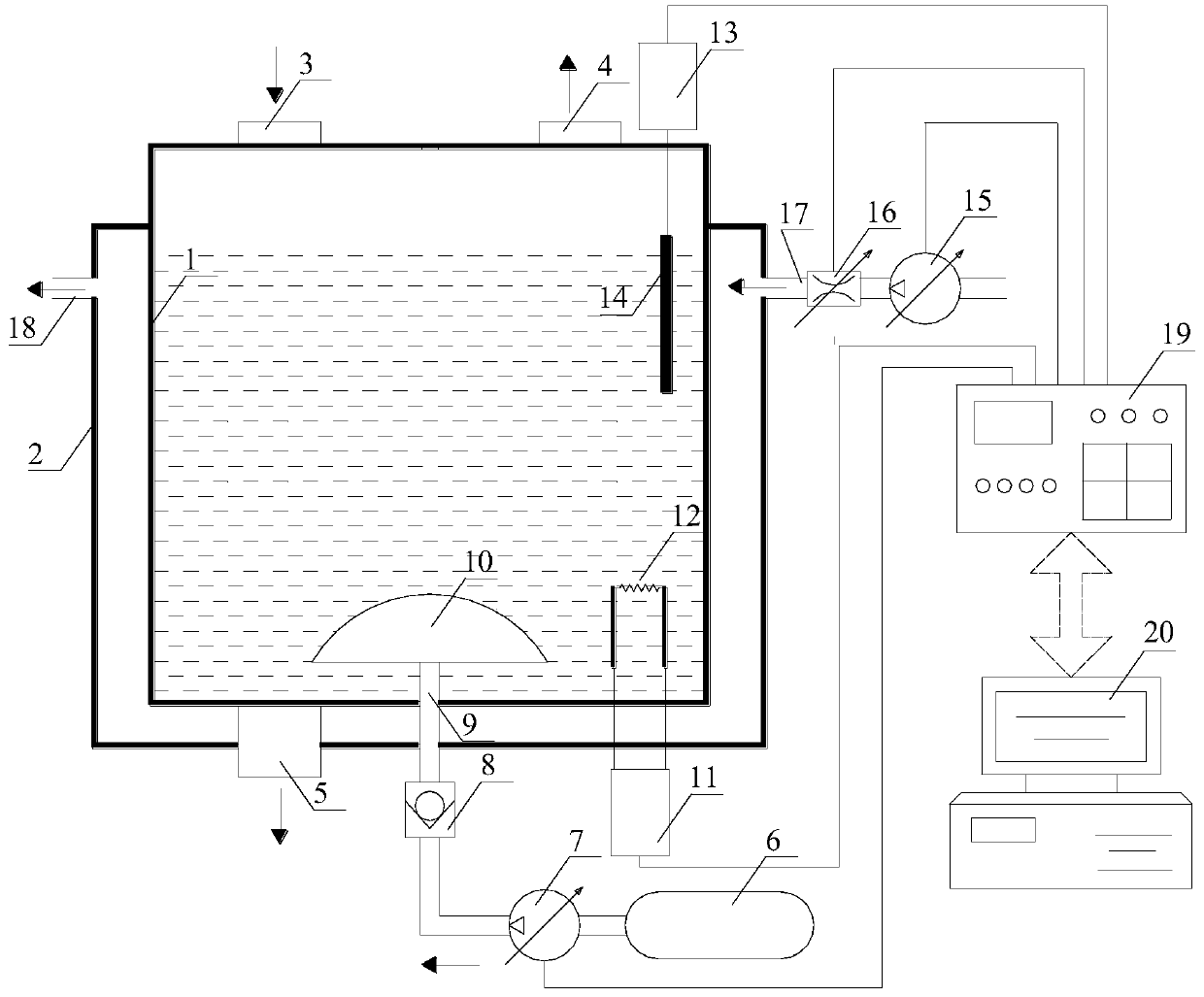

[0032] Such as figure 1 As shown, a gas-liquid reactor adopting a spherical microporous corundum gas supply device includes a reactor body, a gas supply device, a heating device, a temperature measuring device, a cooling device and a control device; the reactor body is connected to a supply Gas device, heating device, temperature measuring device and cooling device, gas supply device, heating device, temperature measuring device, cooling device connection control device;

[0033] The reaction kettle body includes a kettle body 1, the top of the kettle body 1 is provided with a feed port 3 and an exhaust port 4, and the bottom is provided with a discharge port 5; the gas supply device includes an air storage tank 6, an air pump 7 , check valve 8, air intake pipe 9 and air supply device 10, the air tank 6 is connected to the inlet of the air pump 7, and the outlet of the air pump 7 is connected to the air supply device 10 through the air intake pipe 9, and the air intake pipe 9 ...

Embodiment 2

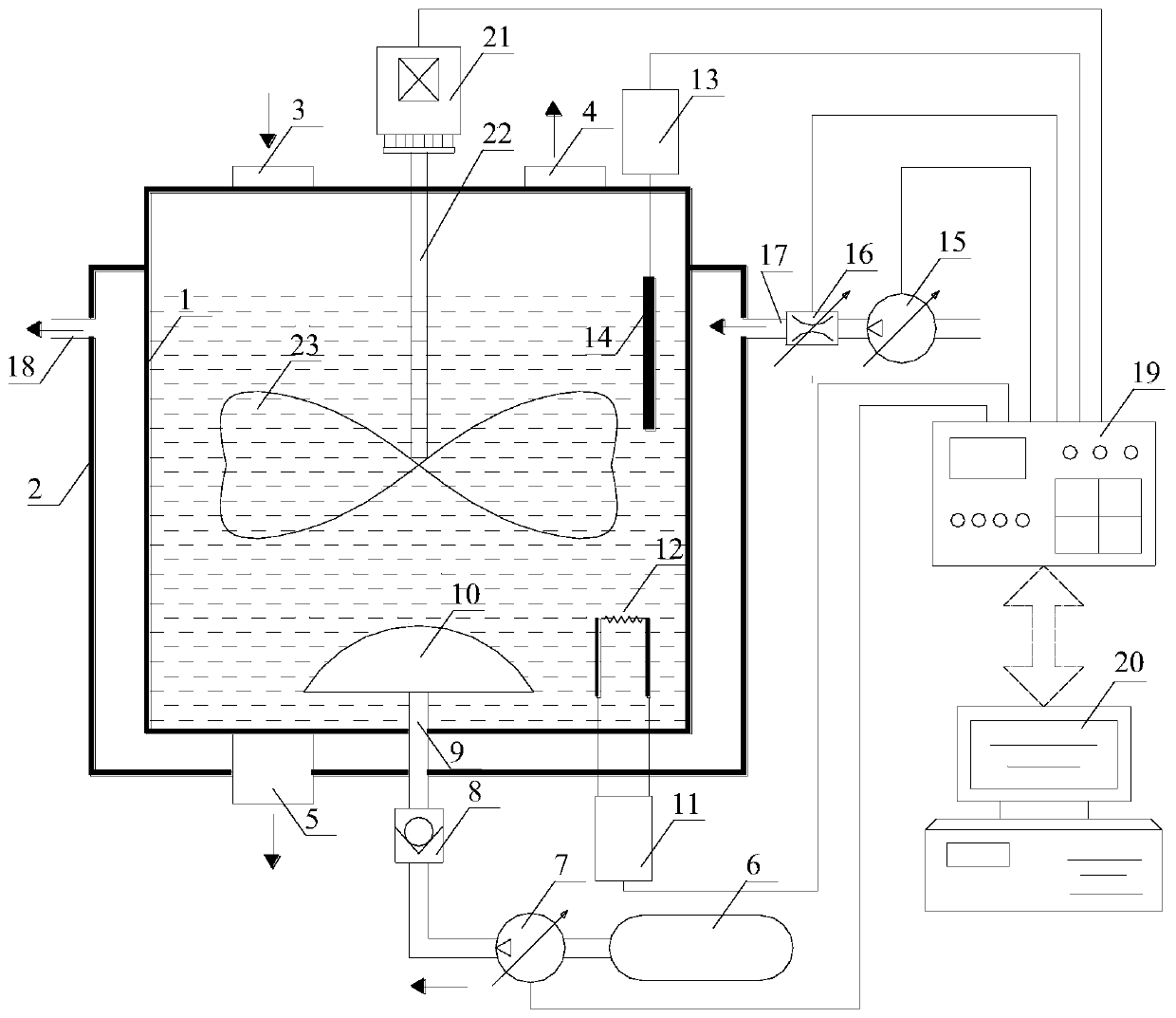

[0056] Such as figure 2 As shown, a gas-liquid reactor adopting a spherical microporous corundum gas supply device includes a reactor body, a gas supply device, a heating device, a temperature measuring device, a cooling device, a control device and a stirring device; the reactor The main body is connected to the gas supply device, heating device, temperature measuring device and cooling device, and the gas supply device, heating device, temperature measuring device and cooling device are connected to the control device;

[0057] The reaction kettle body includes a kettle body 1, the top of the kettle body 1 is provided with a feed port 3 and an exhaust port 4, and the bottom is provided with a discharge port 5; the gas supply device includes an air storage tank 6, an air pump 7 , check valve 8, air intake pipe 9 and air supply device 10, the air tank 6 is connected to the inlet of the air pump 7, and the outlet of the air pump 7 is connected to the air supply device 10 throu...

Embodiment 3

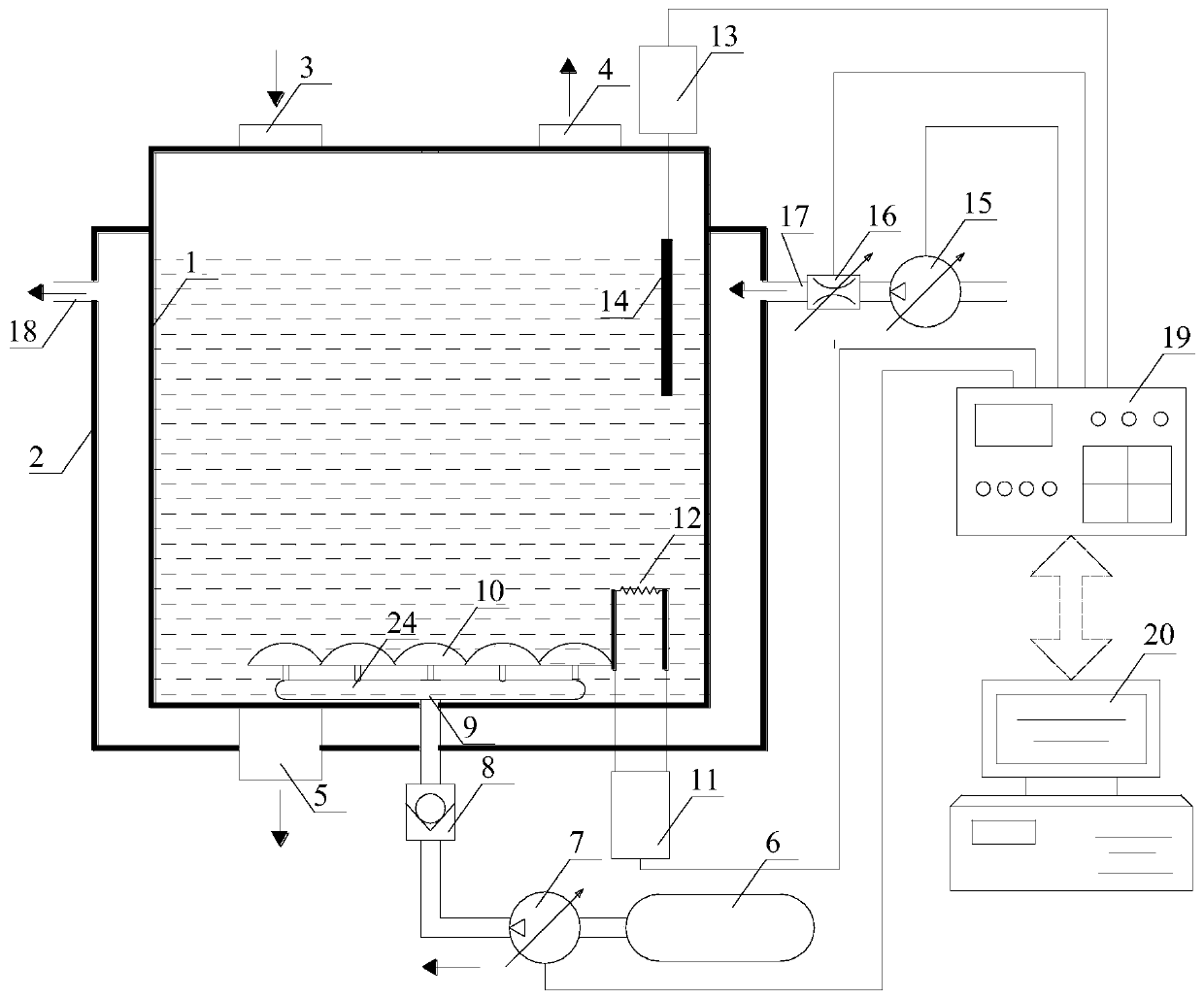

[0082] Such as image 3 , 4 As shown, a gas-liquid reactor adopting a spherical microporous corundum gas supply device includes a reactor body, a gas supply device, a heating device, a temperature measuring device, a cooling device and a control device; the reactor body is connected to a supply Gas device, heating device, temperature measuring device and cooling device, gas supply device, heating device, temperature measuring device, cooling device connection control device;

[0083] The reaction kettle body includes a kettle body 1, the top of the kettle body 1 is provided with a feed port 3 and an exhaust port 4, and the bottom is provided with a discharge port 5; the gas supply device includes an air storage tank 6, an air pump 7 , check valve 8, air intake pipe 9 and air supply device 10, the air tank 6 is connected to the inlet of the air pump 7, and the outlet of the air pump 7 is connected to the air supply device 10 through the air intake pipe 9, and the air intake pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com