Method for strengthening mixing and reaction of fluids in micro-reactor

A micro-reactor, internal fluid technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of incomplete reaction, short residence time, high space velocity of micro-reactor, and achieve simplified operation, The effect of avoiding the design process and reducing the resistance of the system

Active Publication Date: 2016-06-01

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF10 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Even for a liquid-liquid process, in order to achieve a better distribution, the microreactor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

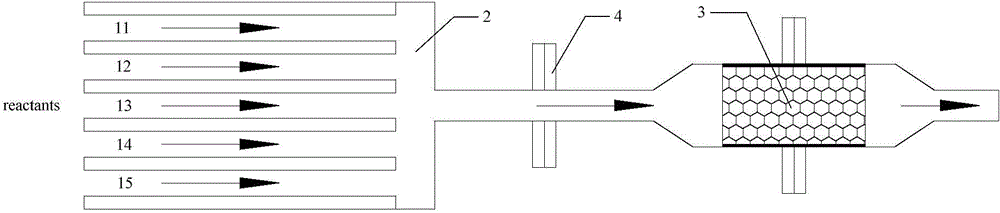

A method for strengthening mixing and reaction of fluids in a micro-reactor includes that various fluids flow through a micro-reactor firstly, are mixed in the micro-reactor and complete partial reaction, a mixed fluid including reactants and products is formed, and the mixed fluid flows out of the micro-reactor and then further flows through a tubular reactor filled with an internal component; the micro-reactor has a stacked type parallel structure and has channels with the characteristic scale of 0.1-2 mm; the tubular reactor is directly connected with the micro-reactor, and the internal component is a mesh-structural foam metal, foam ceramic or quartz filler. The additional resistance formed by the tubular reactor is used for strengthening mixing of the fluids in the micro-reactor, and at the same time, the internal component in the tubular reactor can make the mixed fluid further subjected to reaction. The method is suitable for a gas-liquid reaction process and a liquid-liquid reaction process.

Description

technical field [0001] The invention relates to a method for enhancing fluid mixing and reaction, and more particularly, relates to a method for combining a microreactor and a tubular reactor containing internal components for fluid mixing and reaction. Background technique [0002] Microreactor is a kind of chemical process intensification equipment, which has a microchannel structure with a characteristic scale of several microns to several millimeters. According to the mass and heat transfer mechanism of conventional scale, under laminar flow, the mass and heat transfer coefficient is inversely proportional to the characteristic scale. The process is reinforced. The reduction of the characteristic scale also increases the internal specific surface area of the microreactor. When the depth of the microchannel is 1mm, the specific surface area value is 1000m 2 / m 3 , when the depth is 0.1mm, the specific surface area can reach 10000m 2 / m 3 . [0003] The characteris...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J19/00B01D53/78B01D53/62

Inventor 陈光文焦凤军

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com