Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329 results about "Methacrolein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methacrolein, or methacrylaldehyde, is an unsaturated aldehyde. It is a clear, colorless, flammable liquid. Methacrolein is one of two major products resulting from the reaction of isoprene with OH in the atmosphere, the other product being Methyl vinyl ketone (MVK, also known as butenone). These compounds are important components of the atmospheric oxidation chemistry of biogenic chemicals, which can result in the formation of ozone and/or particulates.

Composite metal oxide for unsaturated aldehyde selective oxidation and preparing method thereof

A composite metallic oxide as catalyst for selective oxidization of unsaturated aldehyde, especially the acrylaldehyde or methyl acrylaldehyde to obtain acrylic acid or methyl acrylic acid, is composed of active components (Mo, V and Cu), stabilizer (at least Sb and Ti) and the composite oxide of Ni, Fe, Si, Al, alkali metal and alkali-earth metal. Its preparing process is also disclosed.

Owner:兰州金润宏成新材料科技有限公司

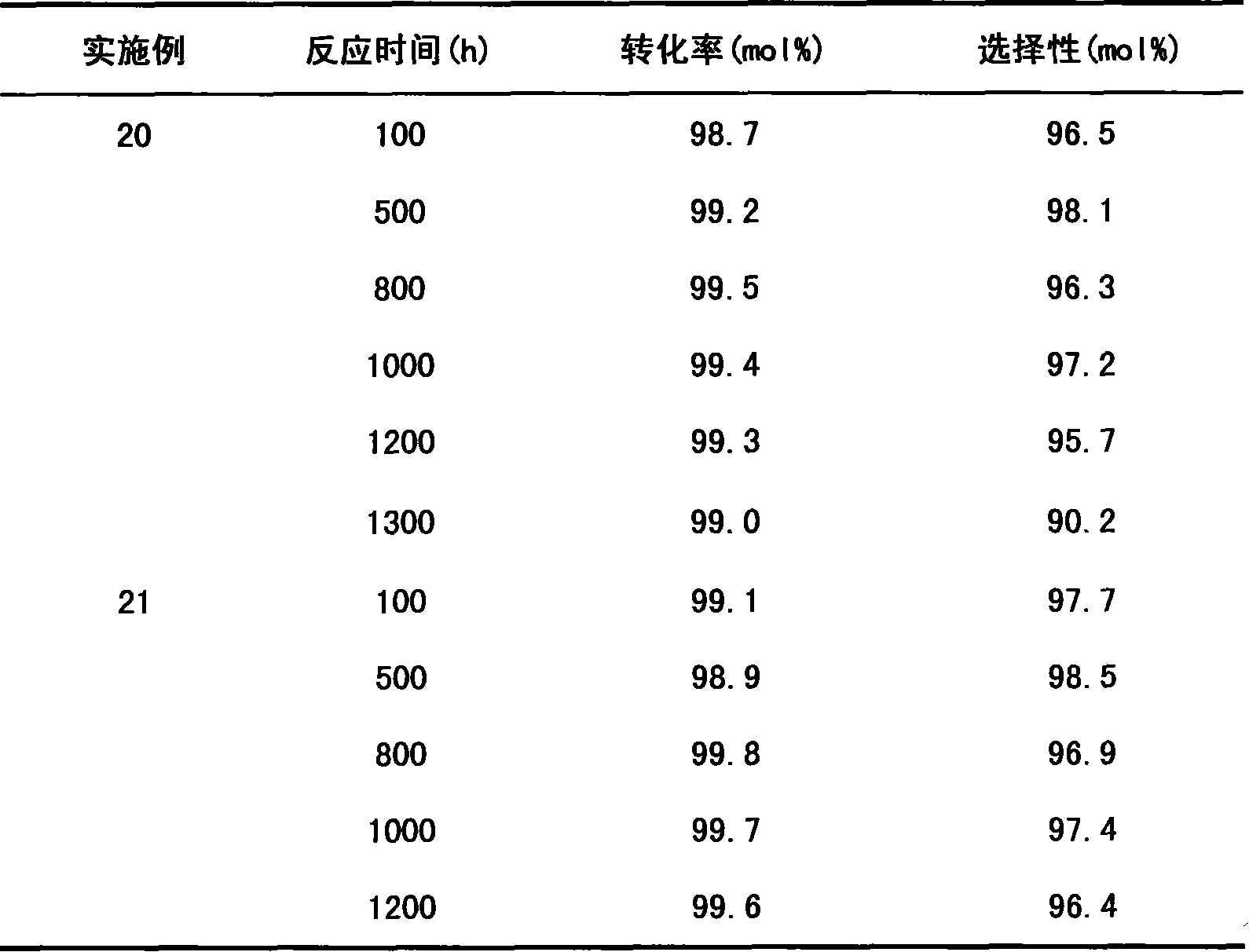

Oxide catalyst composition

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

Production of methyl a-methacrylate with methanal as raw material

InactiveCN101074192AImprove conversion rateReduce manufacturing costPreparation by aldehyde oxidation-reductionMethacrylateDivinylbenzene

Production of methyl-methyl acrylate from methanal is carried out by reacting methanal with propanal in diethylamine muriate solution at 40-45 degree to obtain methyl-acryl, mixing methyl-acryl with methanol in proportion of 30-50:1, adding them into reactor, adding into 2.0-4.0% catalyst, inducing into oxygen at 40-60 degree and flow 10 ml / min, reacting for 4-6 hrs and synthesizing to obtain final product. The catalyst carrier is styrene-divinylbenzene polymer organic resin, which consists of palladium 2-5 wt%, bismuth 0-3 wt%, lead 0.3-1 wt% and iron 0.3-1 wt%. It's cheap, has friendly reactive environment, better selectivity and conversion rate.

Owner:TIANJIN UNIV

Process for preparing a catalyst for use in production of methacrylic acid and process of preparing methacrylic acid

InactiveUS6498270B1Lower performance requirementsHigh selectivityOrganic compound preparationOrganic chemistry methodsGas phaseDehydrogenation

The present invention provides a process for preparing a catalyst and the same for use in production of methacrylic acid, which is characterized by molding a raw material including a powder containing phosphorus and molybdenum at the specific pressure. The invention also provides a process for preparing methacrylic acid by gas phase oxidation and / or oxidative dehydrogenation of at least one compound selected from the group consisting of methacrolein, isobutyraldehyde and isobutyric acid in the presence of the catalyst.

Owner:SUMITOMO CHEM CO LTD

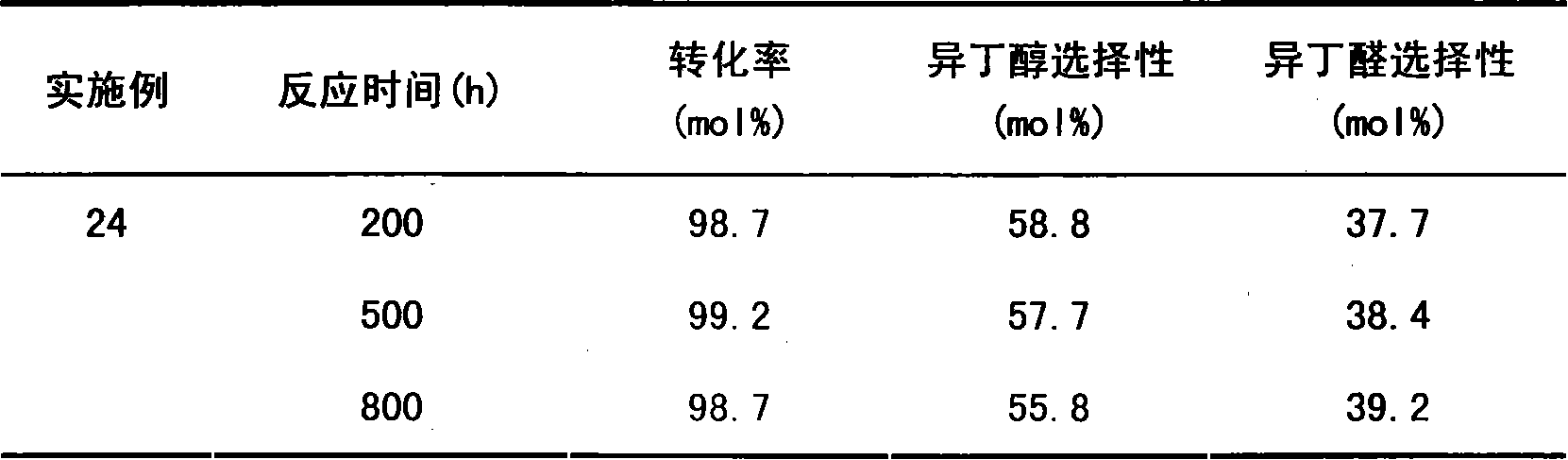

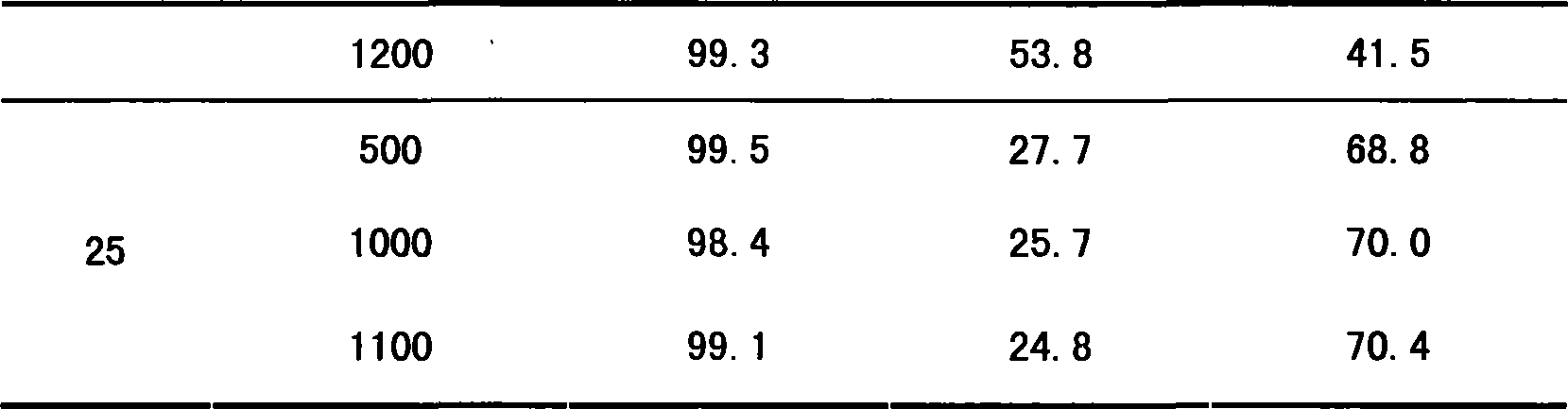

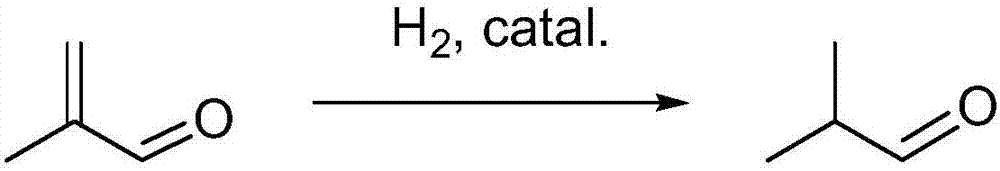

Method for preparing isobutyl alcohol by methylacrolein hydrogenation

ActiveCN101239888ALow costHigh activityMolecular sieve catalystsOrganic compound preparationIsobutanol synthesisMetal catalyst

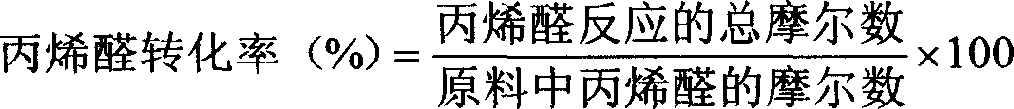

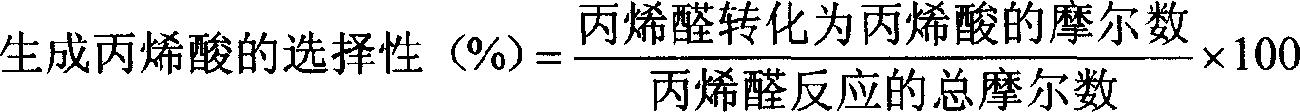

The invention relates to a method for hydrogenation preparing isobutyl acohol from methacrolein, which comprises selecting a supported metal catalyst, and hydrogenating methacrolein obtained by oxidating isobutene under gentle conditions. The invention proposes a novel isobutyl acohol synthesis process, i.e., a process of hydrogenation preparing isobutyl acohol from methacrolein which is obtained by air-oxidating low-utilization C4 material isobutene. The methacrolein conversion rate is larger than 97.8%, the total selectivity of isobutyl acohol is larger than 95.9%, the performance of the catalyst is stable even the reaction lasts more than 1200 hours. The invention has the advantages of high activity and high selectivity of catalyst, good stability of catalyst, cheap material isobutene, low productin cost of isobutene, environment-protecting process, and suitability of industrialisation production.

Owner:SHANGHAI HUAYI NEW MATERIAL

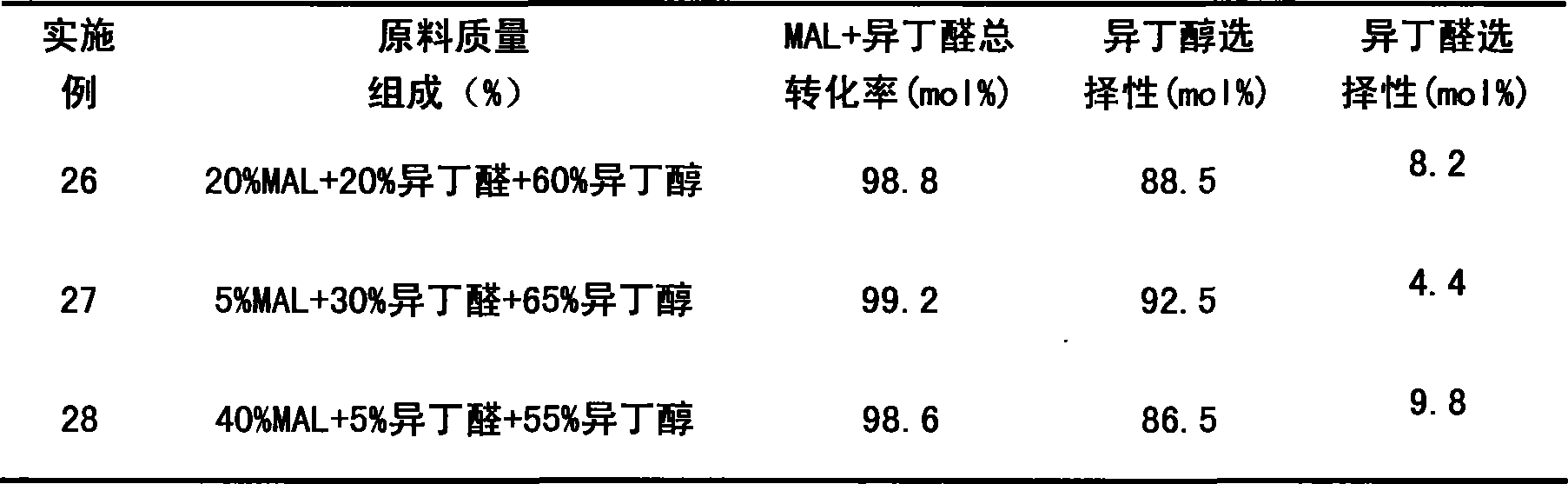

Method for preparing iso-butyraldehyde and isobutyl alcohol by methylacrolein hydrogenation

ActiveCN101239892ALow costHigh selectivityMolecular sieve catalystsOrganic compound preparationIsobutanolMetal catalyst

The invention relates to a method for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein. The method comprises using a supported metal catalyst, and hydrogenating methacrolein obtained by oxidating isobutene under gentle conditions. The invention provides a novel synthesis process for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein which is obtained by air-oxidating low-utilization C4 material isobutene or tert-butanol. The methacrolein conversion rate is larger than 98%, the total selectivity of isobutyraldehyde and isobutyl acohol is larger than 95%, the performance of the catalyst is stable even the reaction lasts more than 1000 hours. The invention has the advantages of high activity and high selectivity of catalyst, good stability of catalyst, cheap material isobutene, low productin cost of isobutene, environment-protecting process, and suitability of industrialisation production. The process is flexible, can change the proportion of isobutyraldehyde and isobutyl acohol through adjusting the reaction process condition, thereby cogenerating isobutyraldehyde and isobutyl acohol, or only generating isobutyl acohol by cycling and hydrogenating isobutyraldehyde.

Owner:SHANGHAI HUAYI NEW MATERIAL

Catalyst for preparing unsaturated acid from unsaturated aldehyde by oxidization and preparation method of catalyst

ActiveCN102039141AHigh yieldGood choiceOrganic compound preparationCatalyst activation/preparationAlkaline earth metalActive component

The invention relates to a catalyst for preparing an unsaturated acid from an unsaturated aldehyde by oxidization and a preparation method of the catalyst. The invention mainly solves the problems of low reaction yield and low selectivity of unsaturated acid in the catalyst in the prior art. The technical scheme is as follows: at least one of SiO2, Al2O3 and TiO2 is selected as a carrier; and the catalyst contains the active component illustrated by the general formula Mo12VaCubXcYdZeOx, wherein X is selected from at least one of W, Cr and Nb, Y is selected from at least one of Fe, Bi, Sb, Ce, La, Zr and Th, and Z is selected from at least one of alkali metals or alkaline earth metals. By using the technical scheme of the invention, the problems are solved. The catalyst can be used for industrially producing acrylic acid or methacrylic acid from acrolein or methacrolein by oxidization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for the oxidation of a mixed aldehyde feedstock to methacrylic acid and methods for making and using same

InactiveUS20070021296A1Improve distributionOrganic compound preparationHeterogenous catalyst chemical elementsIndiumCerium

A heteropolyacid catalyst for oxidation of isobutyraldehyde, methacrolein or mixtures or combinations thereof to methacrylic acid is disclosed where the heteropolyacid catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), and a first component including bismuth (Bi) and / or boron (B). The heteropolyacid catalyst can also optionally include a second component including potassium (K), rubidium (Rb), cesium (Cs), and / or thallium (Tl) and optionally a third component including antimony (Sb), cerium (Ce), niobium (Nb), indium (In), iron (Fe), chromium (Cr), cobalt (Co), nickel (Ni), manganese (Mn), arsenic (As), silver (Ag), zinc (Zn), germanium (Ge), gallium (Ga), zirconium (Zr), magnesium (Mg), barium (Ba), lead (Pb), tin (Sn), titanium (Ti), aluminum (Al), silicon (Si), tantalum (Ta), tungsten (W), and / or lanthanum (La). The heteropolyacid catalyst can also include an ammonium-containing compound designed to increase a value of medium pores in the final heteropolyacid catalyst. A method for oxidizing isobutanal to methacrylic acid using the heteropolyacid catalyst is also disclosed.

Owner:SAUDI BASIC IND CORP SA

Catalyst for methacrylic acid production, coated catalyst, and process for producing the same

InactiveCN1461236AHas industrial application valueHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsCatalytic oxidationHigh load

A catalyst for producing methacrylic acid from methacrolein through vapor-phase catalytic oxidation which comprises as essential active ingredients molybdenum, vanadium, phosphorus, and copper, characterized by being one obtained using copper acetate as all or part of the copper material necessary for the catalyst preparation. By using the catalyst, methacrolein can be reacted at a high conversion and methacrylic acid can be produced with high selectivity. The catalyst is usable also in reactions under high-load conditions.

Owner:NIPPON KAYAKU CO LTD

Catalyst for methacrolein oxidation and method for making and using same

InactiveUS7851397B2Reduce the amount of solutionIncrease the amount addedOrganic compound preparationHeterogenous catalyst chemical elementsOrganic acidRubidium

Owner:SAUDI BASIC IND CORP SA

Process for producing catalyst for methacrylic acid production

InactiveUS20070010394A1High yieldHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsGas phaseWater insoluble

The object of the present invention is to provide a method for preparing a catalyst for producing methacrylic acid by subjecting methacrolein, isobutyl aldehyde or isobutyric acid to gas phase catalytic oxidation with high yield and high selectivity. A method for preparing a catalyst for producing methacrylic acid by subjecting methacrolein, isobutyl aldehyde or isobutyric acid to gas phase catalytic oxidation, the method comprising: (a) a step of blending compounds each containing any one of Mo, V, P, Cu, Cs or NH4 with water to prepare an aqueous solution or dispersion of the compounds (hereinafter referred to, both included, as a slurry); (b) a step of drying the slurry obtained in the step (a) to obtain a dried slurry; (c) a step of calcining the dried slurry obtained in..the step (b) to obtain a calcined body; (d) a step of filtering a mixture obtained by blending the calcined body obtained in the step (c) with water to separate an aqueous solution and water-insoluble matter; and (e) a step of drying the water-insoluble matter obtained in the step (d) to obtain a dried water-insoluble body.

Owner:NIPPON KAYAKU CO LTD

Unsaturated aldehyde catalyst produced by an oxidation method and preparation method thereof

ActiveCN102039144AImprove responseImprove technical effectOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationAcroleinMethacrolein

The invention relates to an unsaturated aldehyde catalyst prepared by oxidizing olefin and a preparation method thereof, and mainly solves the problems of low reaction yield and selectivity of target products unsaturated aldehyde and unsaturated acid in the prior art. The catalyst takes at least one of SiO2 and Al2O3 as a carrier, and contains active ingredients shown as a formula Mo12BiaFebNicXdYeZfQqOx, wherein X is at least one of Mg, Co, Ca, Be, Cu, Zn, Pb and Mn; Y is at least one of Zr, Nb and Ti; Z is at least one of K, Rb, Na, Li, Cr, Tl and Cs; and Q is at least one of La, Ce, Sm andTh. Through the technical scheme, the catalyst and the preparation method thereof well solve the problems and can be used for the industrial production of acrolein or methacrolein prepared by oxidizing propylene or isobutylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

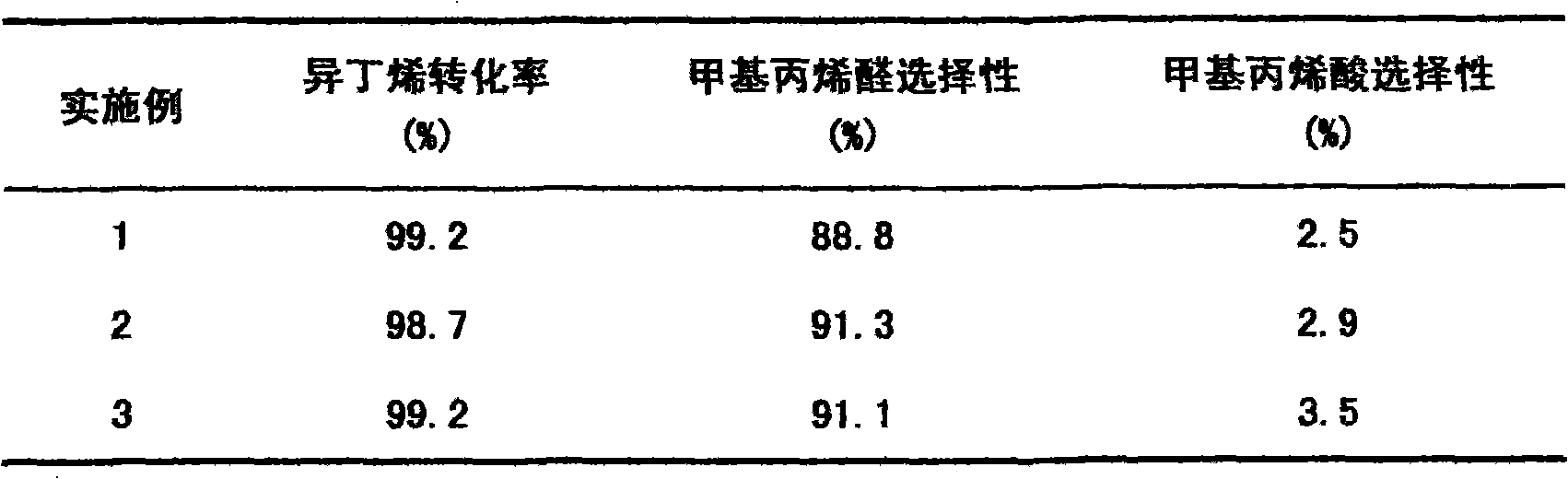

Catalyst and preparation method thereof as well as method for preparing methylacrolein with catalyst

ActiveCN102211027AHigh selectivityHigh activityOrganic compound preparationCarbonyl compound preparationMethacroleinHigh activity

The invention discloses a catalyst for preparing methylacrolein, a preparation method thereof as well as a method for preparing methylacrolein by catalyzing tert butyl alcohol or isobutene with the catalyst. The catalyst comprises a composite metal oxide which is expressed by the following general formula: (Mo12BiaFebCocCudCseVfNbiWjPbk): n carriers. The catalyst disclosed by the invention has the characteristics of high activity, high methylacrolein selectivity, high yield and the like. Finally, the conversion rate of the tert butyl alcohol or isobutene can be bigger than 95%, the methylacrolein selectivity can be bigger than 90%, and the single period yield of the methylacrolein can exceed 90%. The catalyst has the advantages of simple preparation technology and low production cost and is suitable for large-scale industrial application.

Owner:WANHUA CHEM GRP CO LTD +1

Method for the production of nanocrystalline bismuth-molybdenum mixed oxide

InactiveUS8480998B2High activityHigh selectivityOrganic compound preparationMolybdeum compoundsMixed oxideAcrolein

A method for the production of a nanocrystalline bismuth-molybdenum mixed oxide, the use of the bismuth-molybdenum mixed oxide as catalyst for chemical conversions, in particular for a conversion of propylene to acrolein and / or acrylic acid or of isobutylene to methacrolein and / or methacrylic acid, as well as a catalyst that contains the bismuth-molybdenum mixed oxide.

Owner:SUED CHEM IP GMBH & CO KG

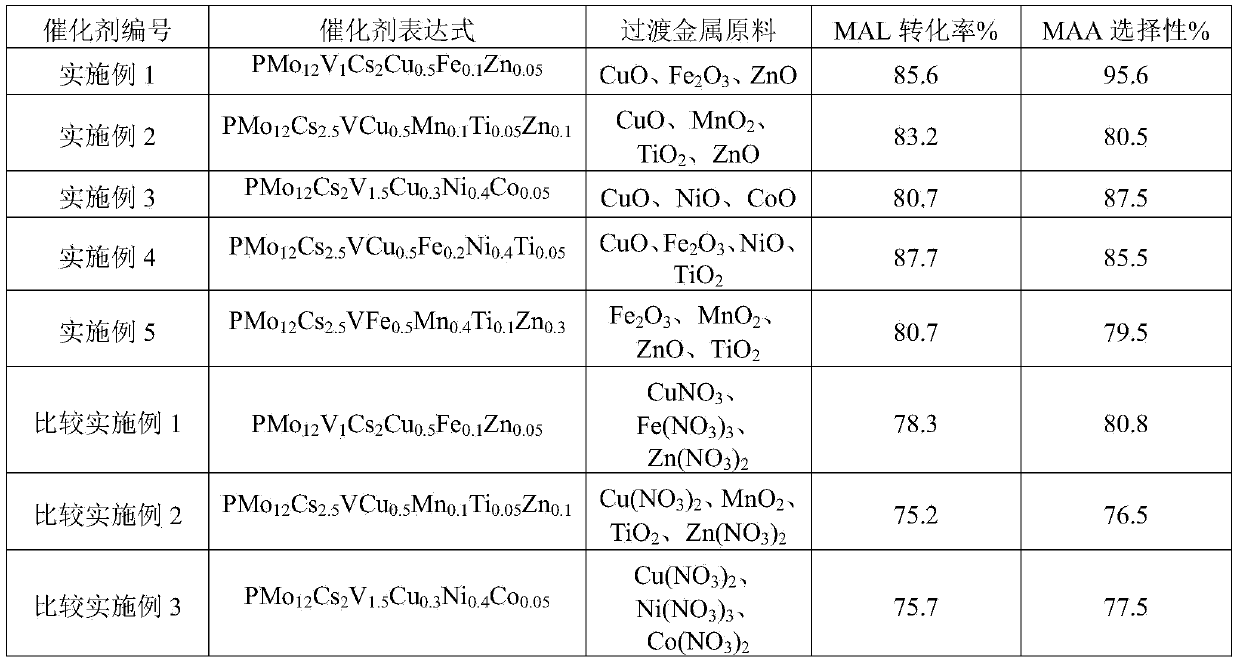

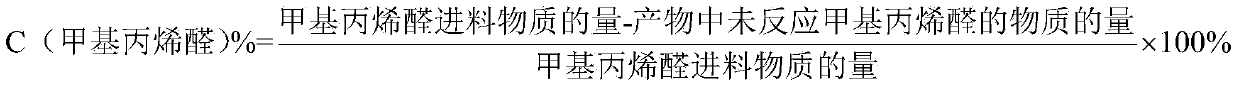

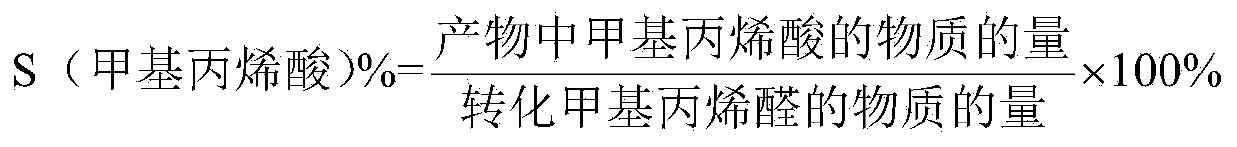

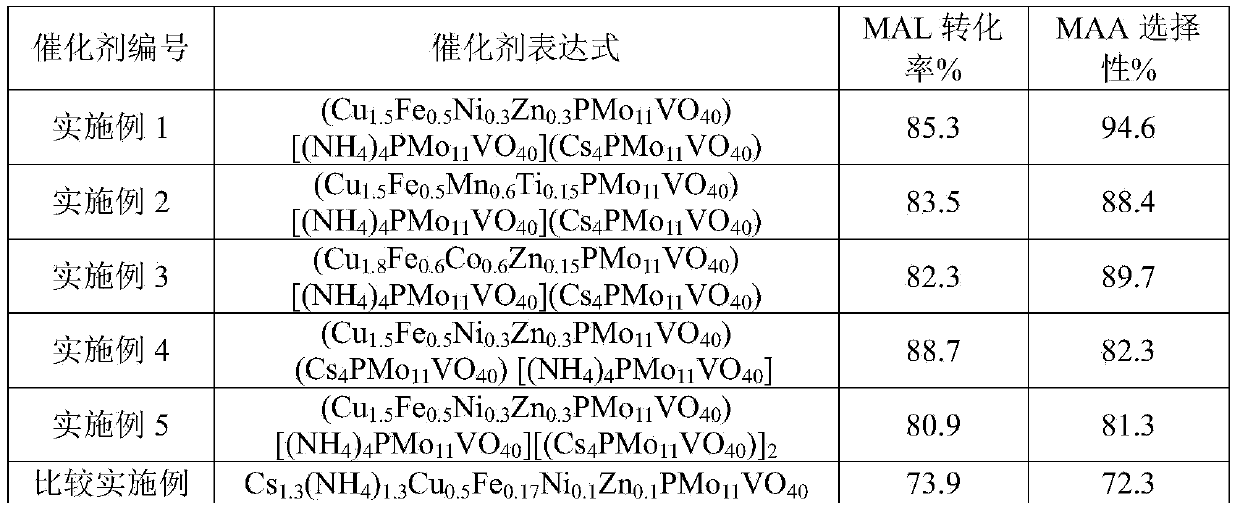

Preparation method of catalyst for preparing methacrylic acid through oxidation of methylacrolein

InactiveCN104001542AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidHeteropoly acid

The invention discloses a heteropolyacid and oxide compound catalyst for preparing methacrylic acid through oxidation of methylacrolein. The preparation method of the catalyst comprises the following steps: mixing phosphomolybdic acid and metallic oxide (such as vanadium pentoxide, ferric oxide, cupric oxide, nickel oxide, manganese dioxide, cobaltous oxide, titanium dioxide and zinc oxide) in a liquid phase step by step so as to form relatively large amount of active sites on the surface of heteropolyanion; adding caesium to obtain the catalyst. The catalyst has high catalytic activity for preparing methacrylic acid through oxidation of methylacrolein and has a long catalyst service life.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

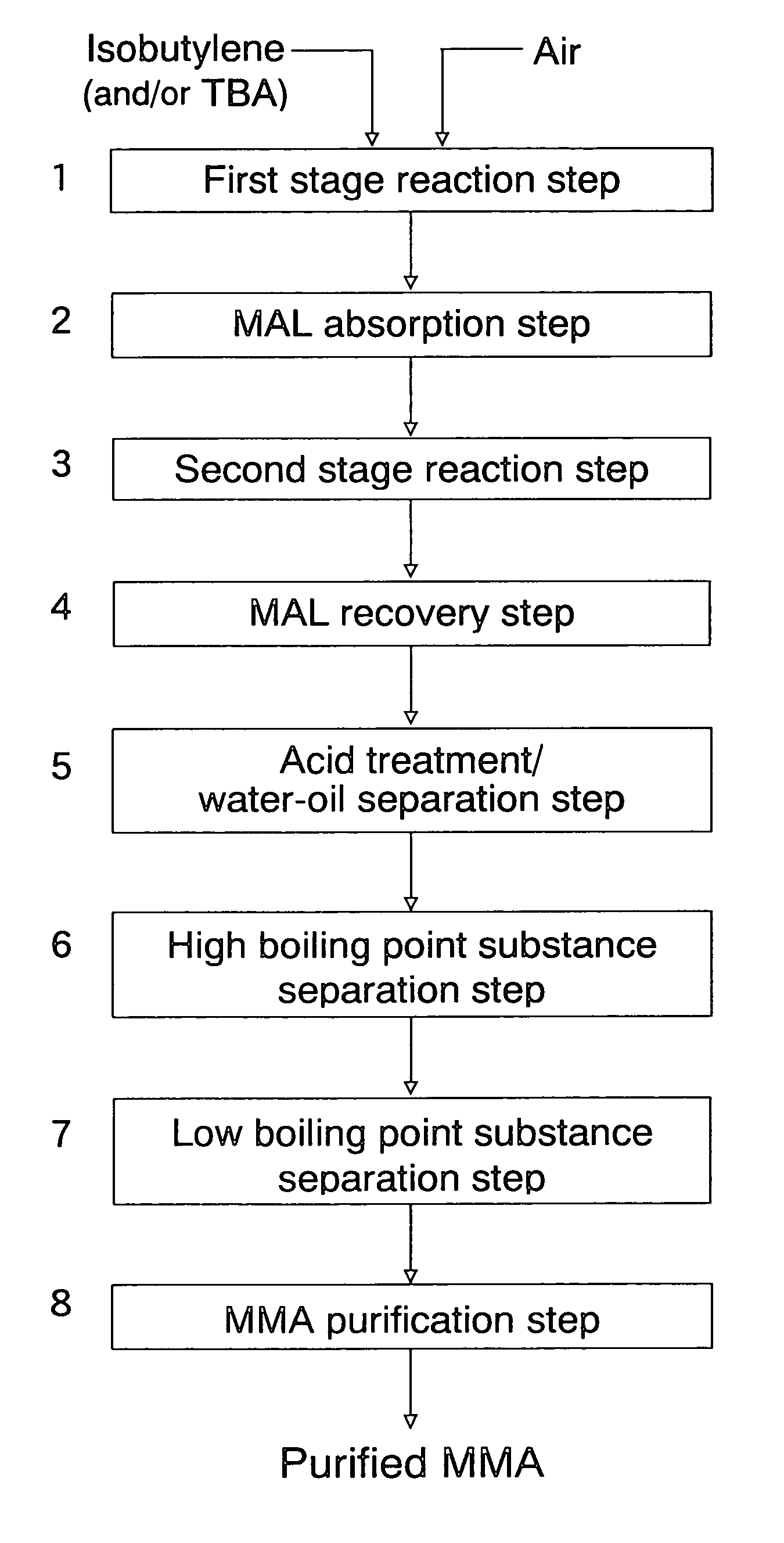

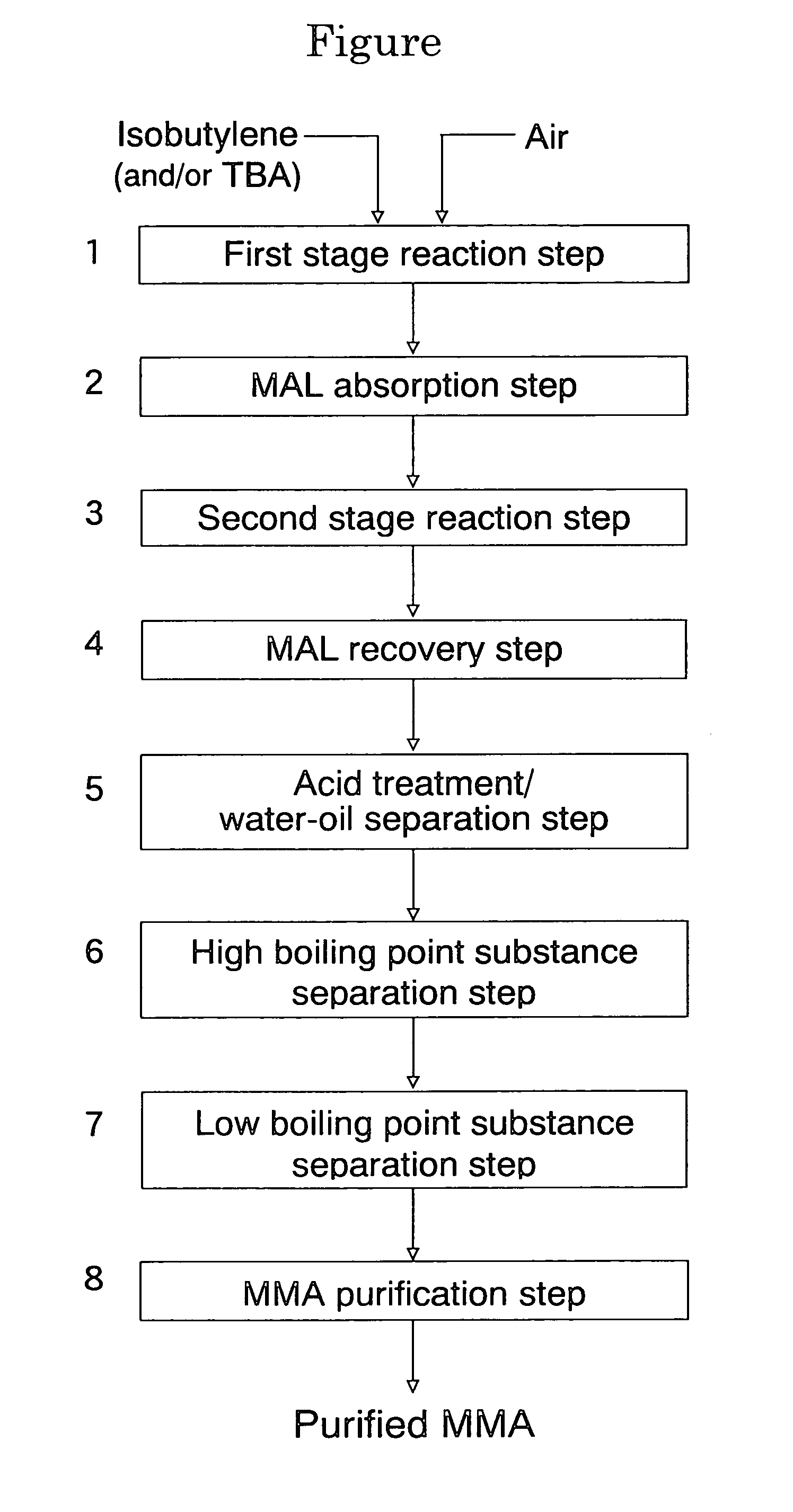

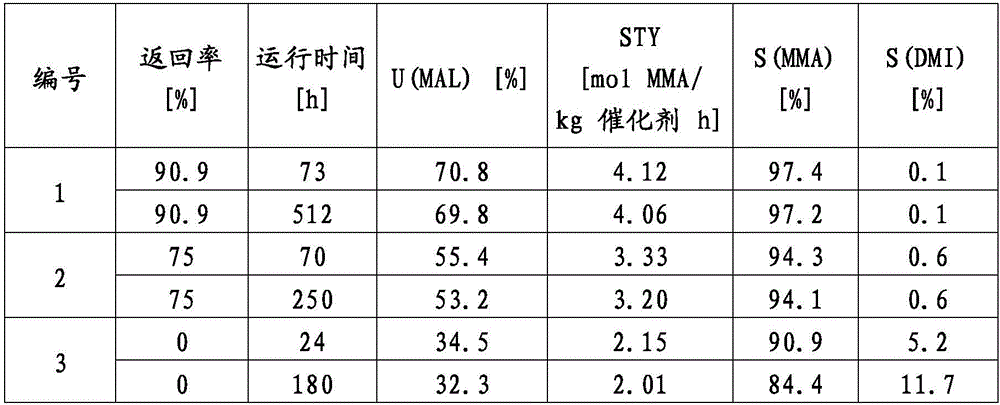

Process for producing methyl methacrylate

ActiveUS20160280628A1High yieldHigh selectivityOrganic compound preparationCarboxylic acid esters preparationEsterification reactionMethacrolein

The present invention relates to a catalytic continuous process for producing methyl methacrylate, said process comprising the step of reacting methacrolein with oxygen and methanol in the presence of a heterogeneous noble-metal-containing catalyst in an oxidative esterification reaction to give methyl methacrylate, characterized in that the stationary concentration of the starting material methacrolein is equal to or less than 12% by weight based on the total weight of the reaction mixture in the reactor, and the ratio F between the total liquid volume within the reactor expressed in litres divided by the total weight of catalyst in the reactor expressed in kilograms is equal to or less than 4.

Owner:ROHM GMBH

Catalyst for preparing methacrylic acid by oxidation of methylacrolein and preparation method of catalyst

ActiveCN104001543AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseReactive site

The invention relates to a heteropolyacid catalyst for preparing methacrylic acid by oxidation of methylacrolein and a preparation method of the catalyst. According to the catalyst, phosphorus molybdenum cesium metavanadate or phosphorus molybdenum ammonium metavanadate with high thermal stability serves as a kernel; phosphorus molybdenum ammonium metavanadate or phosphorus molybdenum cesium metavanadate serves as a secondary outer layer; phosphorus molybdenum vanadate with a catalytic active site coats the outermost layer. The catalyst has high catalytic activity and long catalytic life in preparation of the methacrylic acid by gas-phase oxidation of the methylacrolein.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

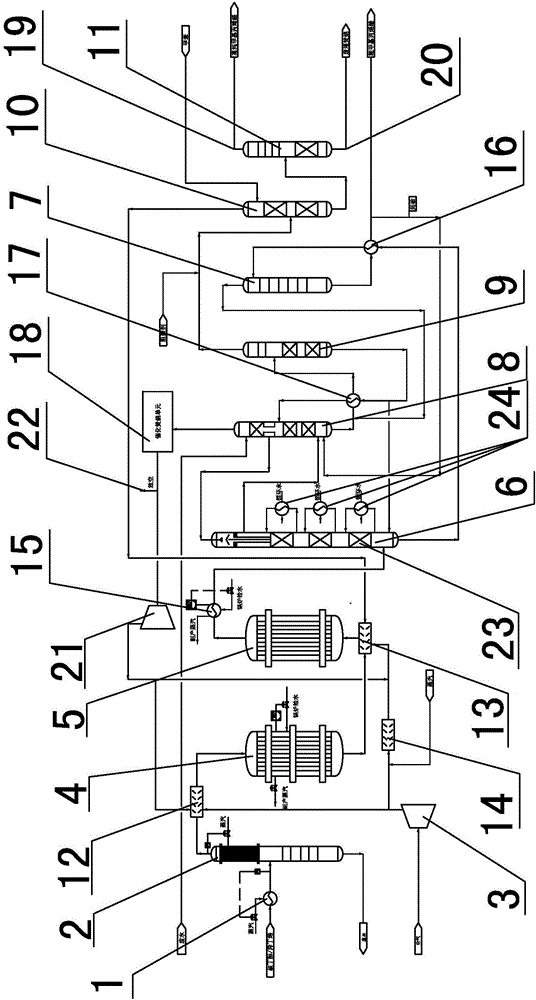

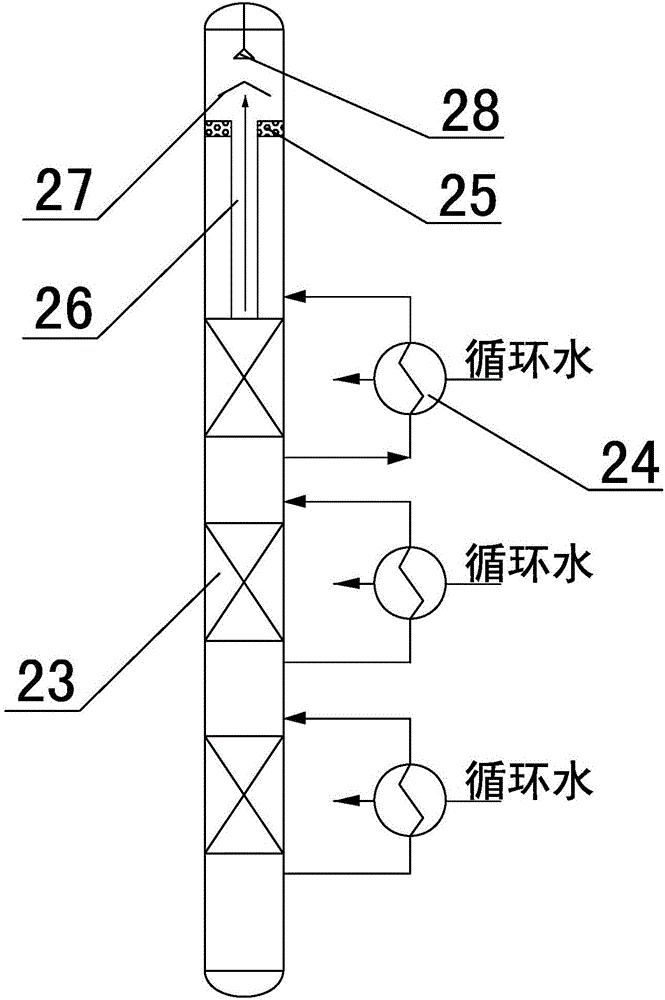

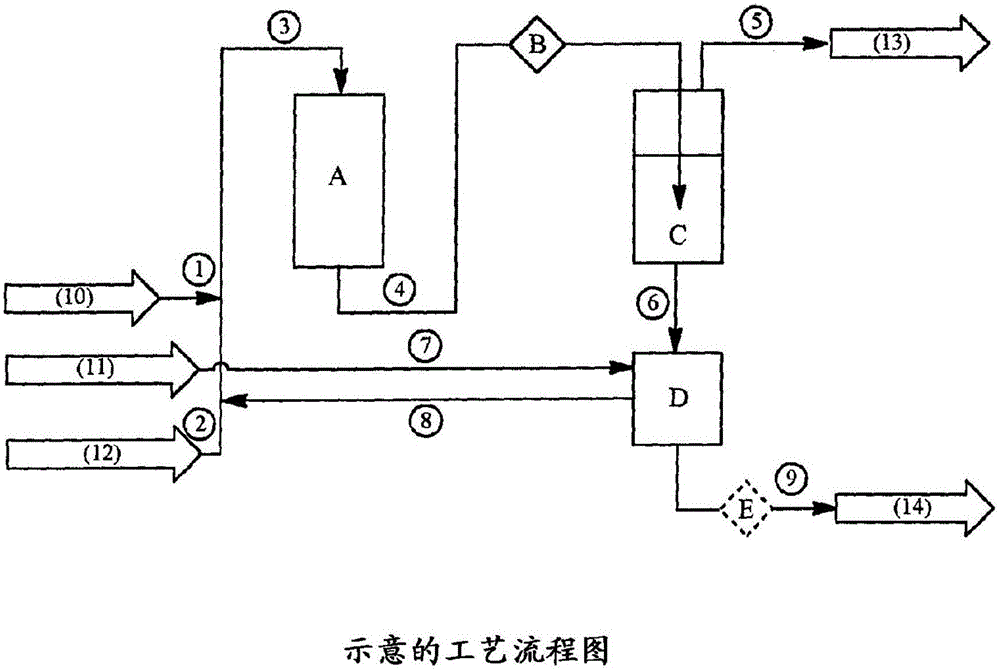

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

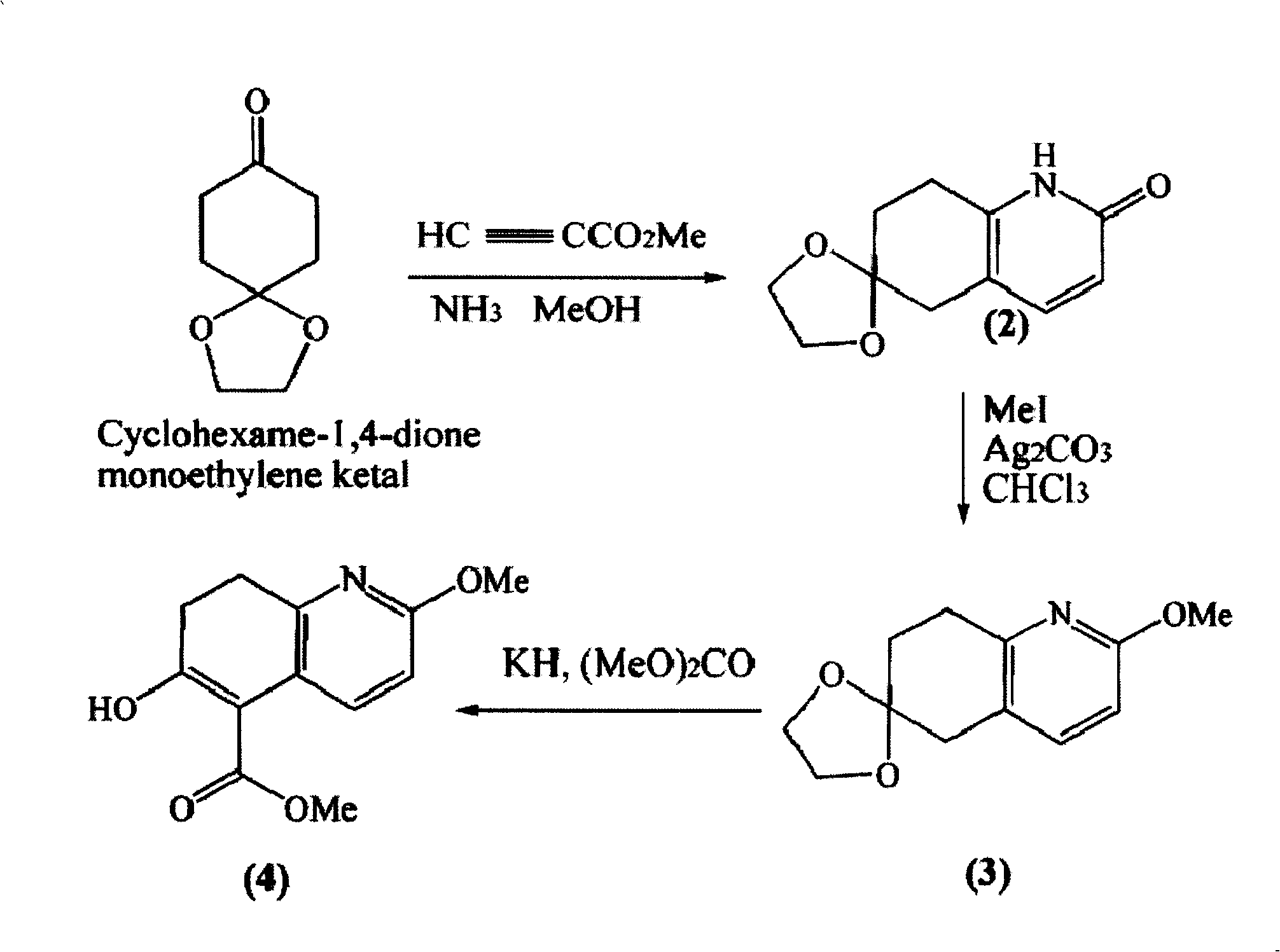

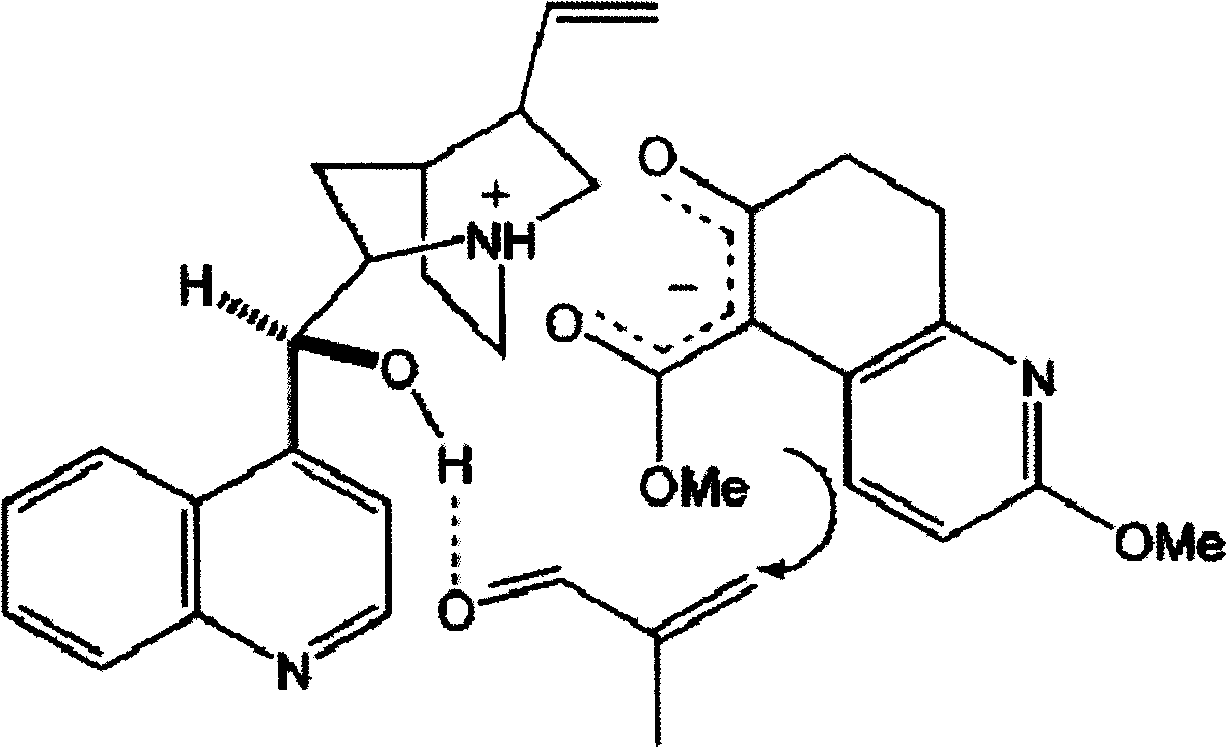

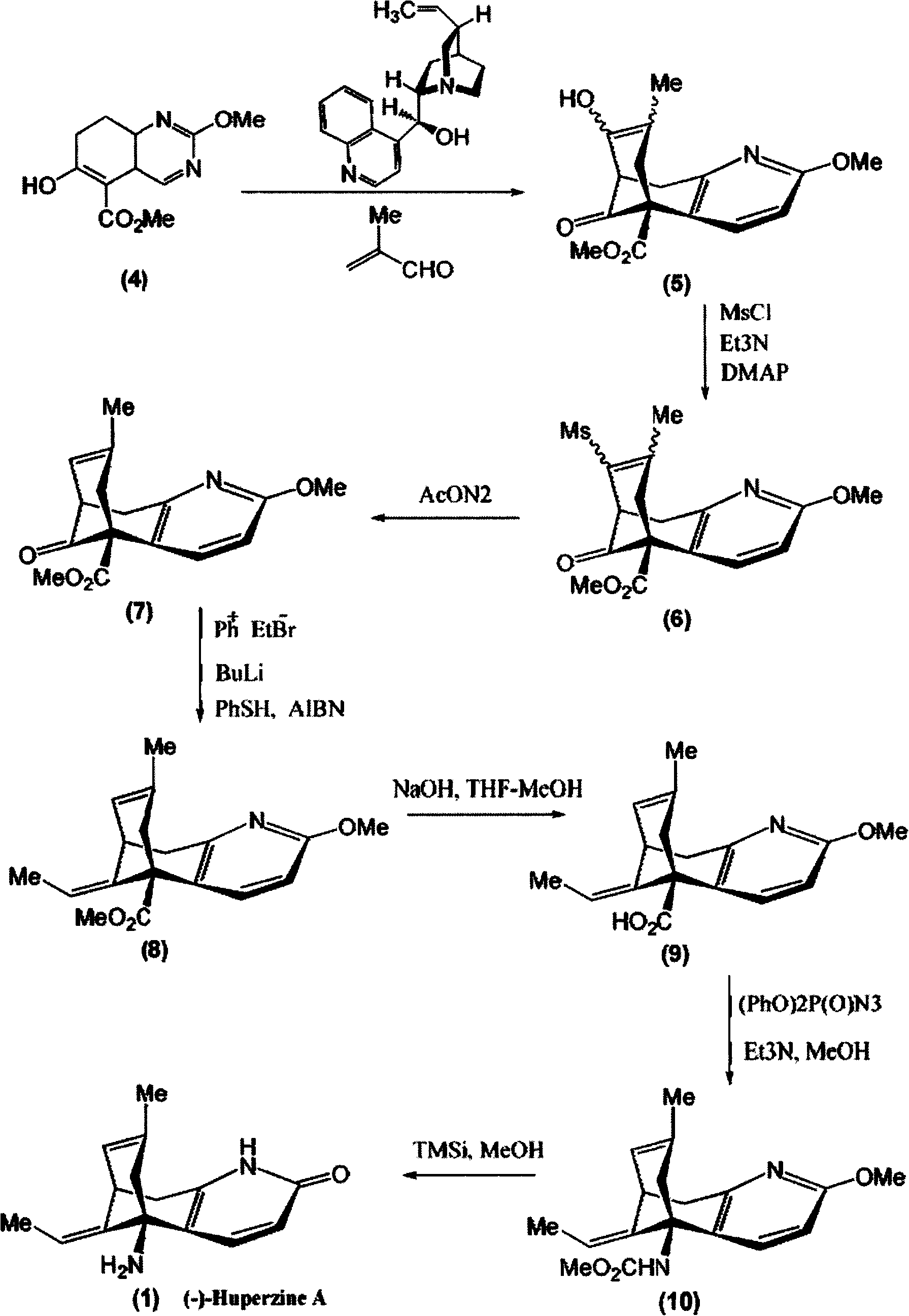

Asymmetric synthesis for chiral huperzine A

Disclosed is an asymmetric total-synthesis method for chiral huperzine a. The method takes 1,4-dihydro-spiro (4,5) -8 -decanone as starting material to get benzoate through hydroxymethylation and the treatment of benzoyl chloride and K2CO3; the benzoate is reacted with hydrogen sulfate O-methyl iso urea to get quinazoline; after the ketal is eliminated, Mander reagent is used for methyl esterification reaction so as to obtain beta-keto ester. Chiral ammonia, such as cinchona alkaloid, is used to promote the tandem asymmetric Michael addition / aldol condensation reaction of beta-keto esters and methyl acrolein. The compound carboxylate of diastereoisomer is reacted with MsCl, triethylamine and DMAP to get transformed. Through TMSI and MeOH processing, the protective group is removed so as to obtain optically pure-chiral huperzine a.

Owner:京山瑞生制药有限公司 +1

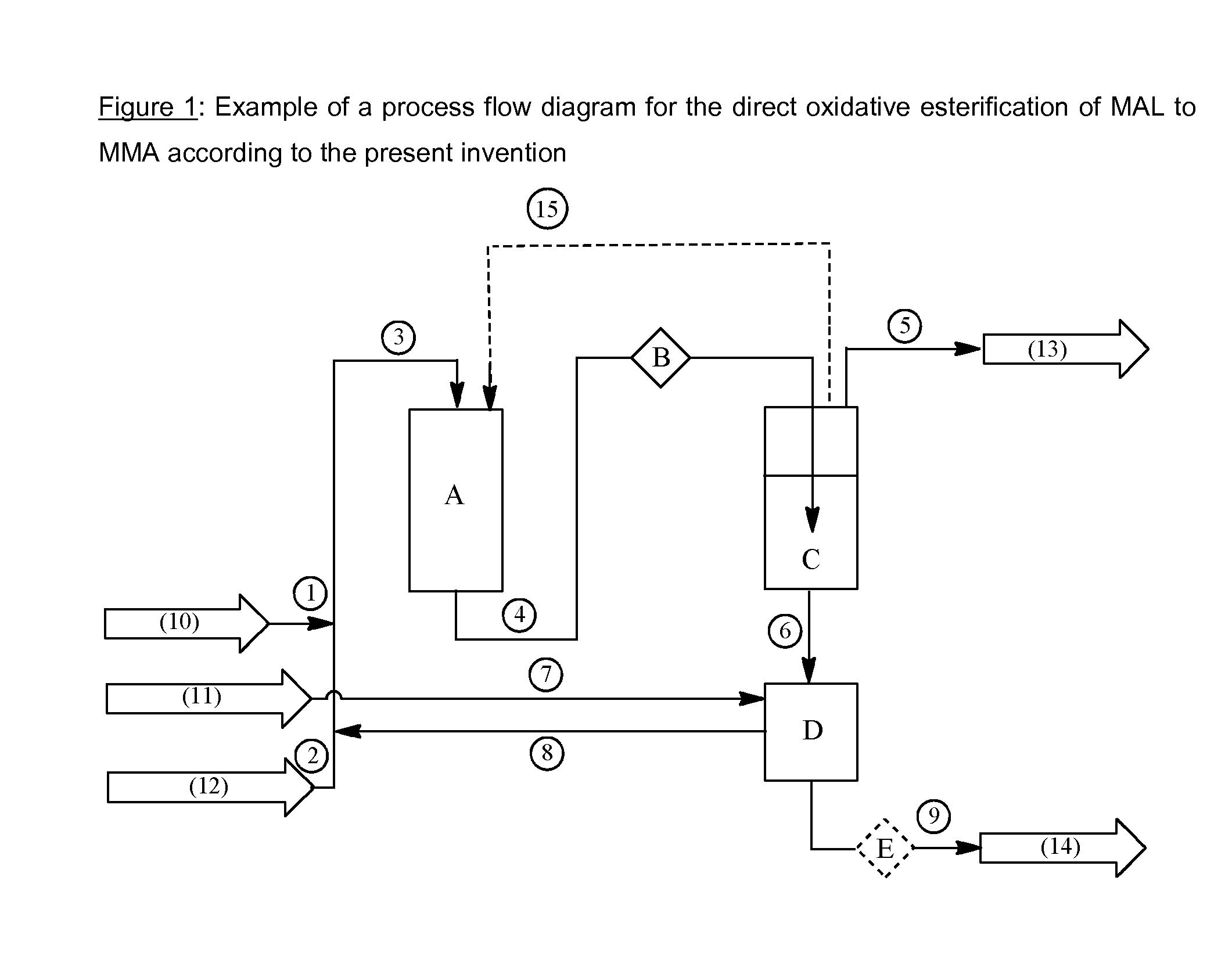

Process for preparing unsaturated esters proceeding from aldehydes by direct oxidative esterification

ActiveCN105722816ACheap implementationReduce maintenance costsOrganic compound preparationCarboxylic acid esters preparationOxygenMethacrolein

The present invention relates to a process for preparing methyl methacrylate by a direct oxidative esterification of methacrolein with oxygen and methanol, which is conducted in the liquid phase at a pressure of 2 to 100 bar with a gold catalyst. According to the invention, the liquid phase is withdrawn continuously from the reactor and optionally enriched with oxygenous gas, the pH, after the withdrawal, is adjusted to a pH between 5 and 9 by means of addition of a basic solution and this liquid phase is conducted back into the reactor again to an extent of at least 50%.

Owner:ROHM G M B H

Catalyst for methacrolein oxidation and method for making and using same

InactiveUS20070021630A1Reduce the amount of solutionIncrease the amount addedOrganic compound preparationHeterogenous catalyst chemical elementsOrganic acidRubidium

A catalyst for oxidation of unsaturated and / or saturated aldehydes to unsaturated acids is disclosed where the catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), bismuth (Bi), and a first component selected from the group consisting of potassium (K), rubidium (Rb), cesium (Cs), thallium (Tl), or mixtures or combinations thereof, where the bismuth component was dissolved in an organic acid solution prior to adding the bismuth containing solution to a solution of the other components. Methods for making and using the catalysts are also disclosed.

Owner:SAUDI BASIC IND CORP SA

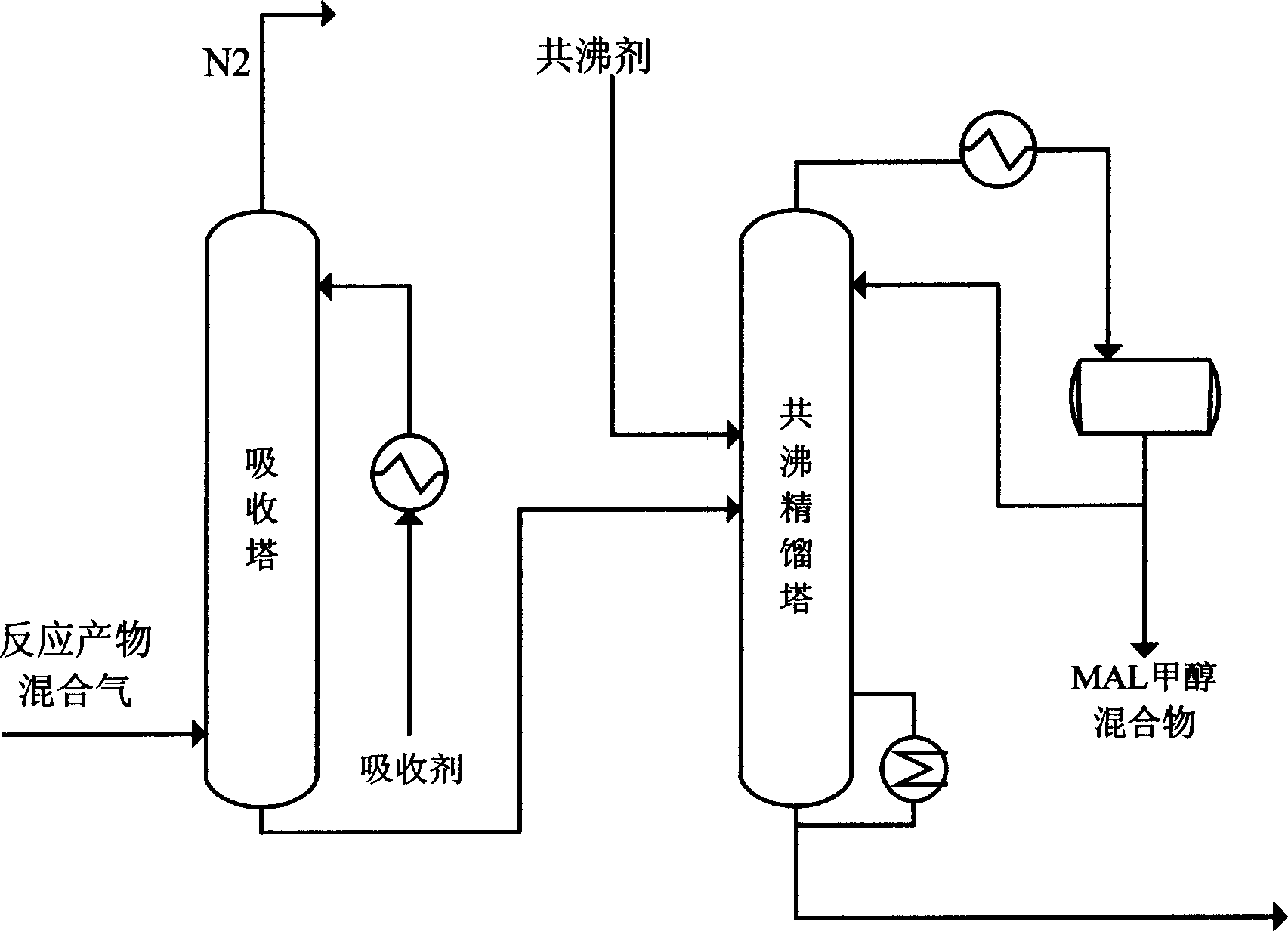

Method for separating methyl-acrolein in methyl-methyl acrylate

ActiveCN1817844AEasy to removeReduce water contentOrganic compound preparationCarboxylic acid esters preparationZeotropic mixtureAcrolein

Separation of methylacrolein in methyl methacrylate production is carried out by reacting to obtain mixed gas containing MAL, cooling and absorbing for MAL by 0~60 degrees C water, azeotropic rectifying with methanol as azeotropic agent, and separating MAL from mixed gas to obtain azeotropic mixture of MAL and methanol with water content lower 500pp. It is simple.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

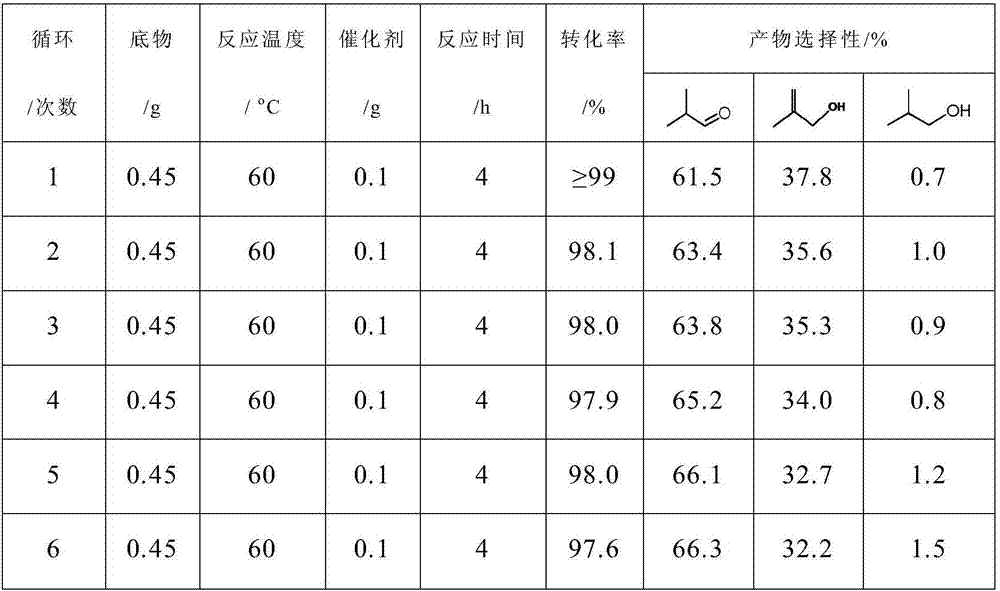

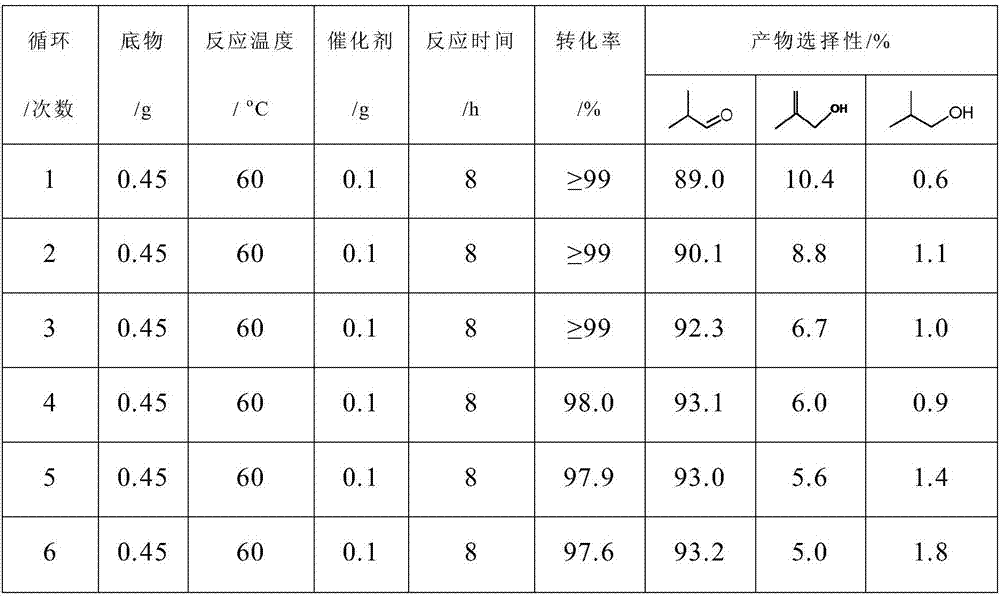

Selective hydrogenation catalyst, preparation method and catalyzing evaluation method on generation of isobutyraldehyde by the selective hydrogenation catalyst

InactiveCN106925267ALow costEasy to prepareOrganic compound preparationCarbonyl compound preparationIridiumRhenium

The invention relates to a selective hydrogenation catalyst, a preparation method and a catalyzing evaluation method for isobutyraldehyde by the selective hydrogenation catalyst. The selective hydrogenation catalyst comprises a carrier and active components, wherein the active components include a noble metal material and a non-noble metal material; the carrier is selected from one of fumed silica, precipitated silicon dioxide, aluminum oxide, carbon nitride and titanium dioxide; the noble metal material is noble metal, namely Ir (iridium); the non-noble metal material is selected from one of non-noble metals, namely Mo (molybdenum), W (tungsten), Ni (nickel), Co (cobalt), Sm (samarium), Ce (cerium) and Re (rhenium); the atom ratio of non-noble metal material to noble metal material is 0.8 to 5. The selective hydrogenation catalyst has the advantage that the methylacrolein can be selectively hydrogenated to generate the isobutyraldehyde in environment-friendly green solvent water under the milder reaction condition.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

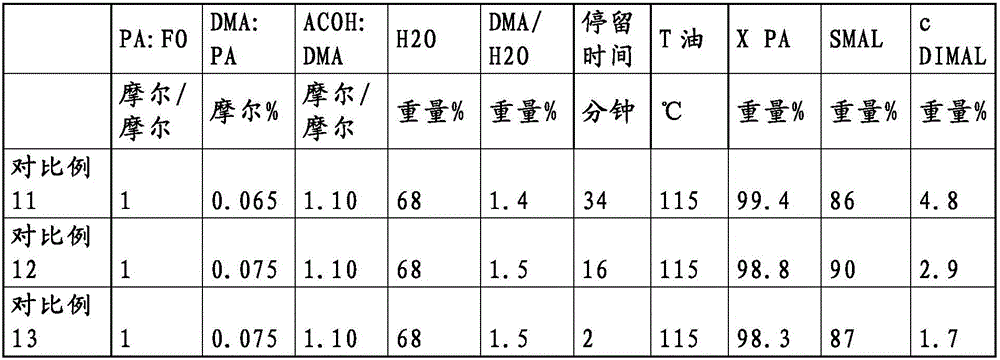

Optimized method for producing methacrolein

ActiveUS20170275227A1Reduced form requirementsReduce the ratioOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBULK ACTIVE INGREDIENT

Owner:ROHM GMBH

Optimized method for producing methacrolein

ActiveCN106687437AAvoid formingHigh purityOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethacrolein

The invention relates to an optimized method for producing methacrolein. Methacrolein is used in chemical synthesis, in particular as an intermediate product for producing methacrylic acid, methylmethacrylate or also active substances, odorous substances or flavourings. The invention also relates to the optimization of process parameters, as a result of which, the content of harmful dimer methacrolien in the end product can be reduced.

Owner:ROHM G M B H

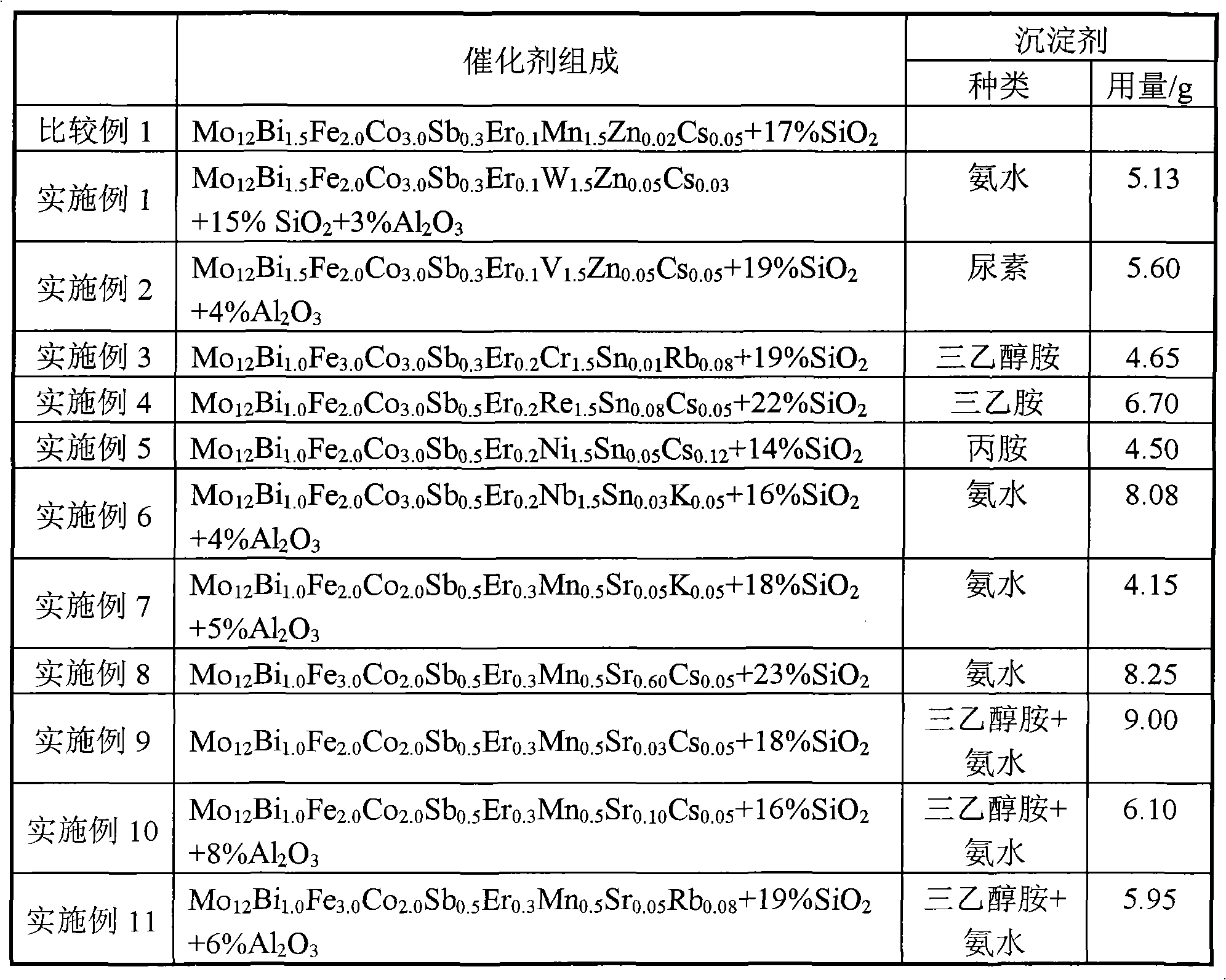

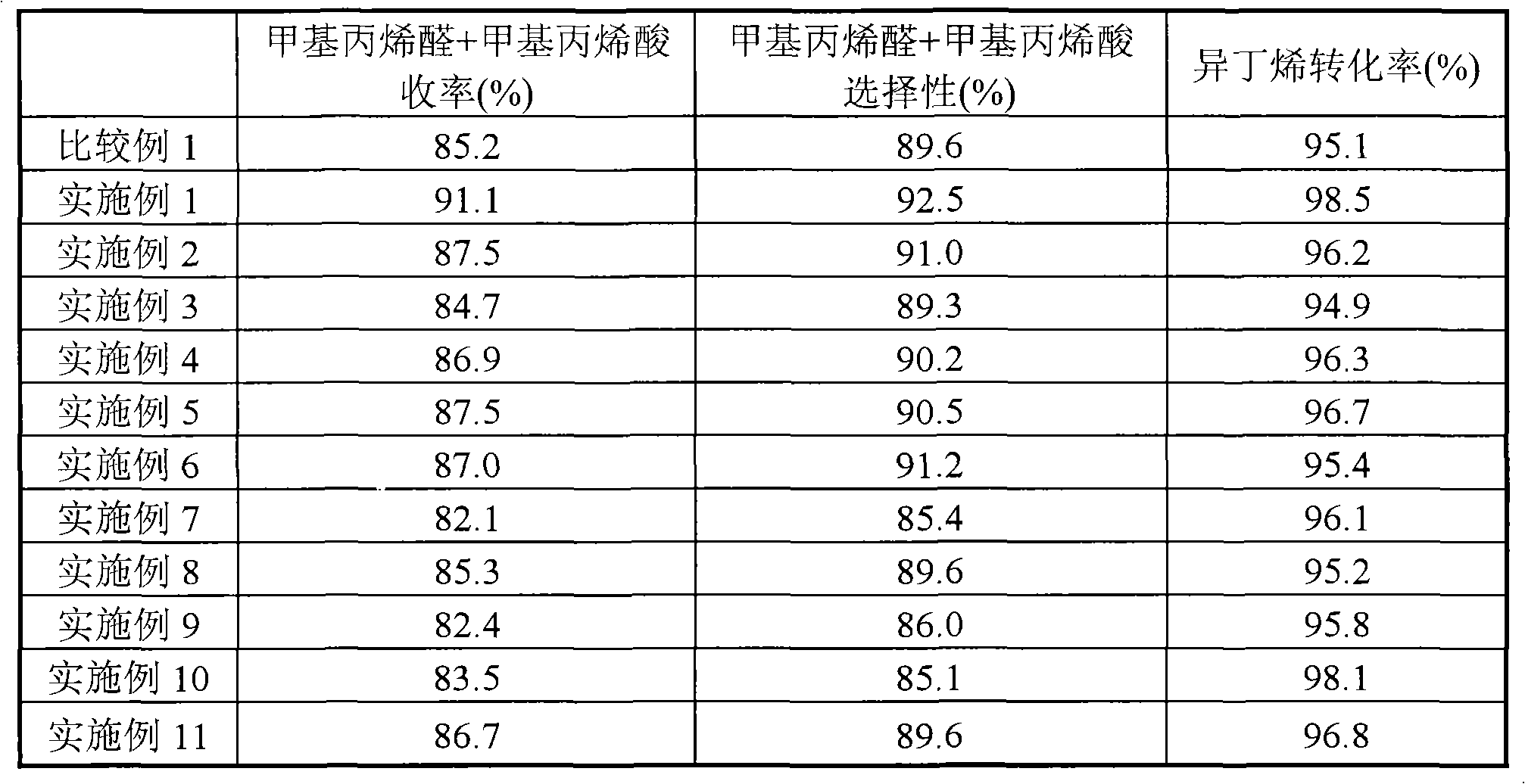

Catalyst for oxidizing isobutene of tert-butyl alcohol to prepare methy acraldehyde and preparation method thereof

ActiveCN102371159AImprove responseImprove technical effectOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationAcroleinBULK ACTIVE INGREDIENT

The invention relates to a catalyst for oxidizing isobutene of tert-butyl alcohol to prepare methy acraldehyde and a preparation method thereof, mainly solving the problems of low yield and low selectivity of the catalyst in the prior art. The catalyst comprises at least one selected from SiO2 or Al2O3 as a carrier and an active ingredient represented as Mo12BiaFebCocSbdEreXfYgZhOx, wherein, X isat least one selected from W, V, Ni, Cr, Mn, Nb or Re, Y is at least one selected from Sn, Sr, Zn, Ti or Zr, and Z is at least one selected from K, Rb, Na, Li, Tl or Cs. The invention can be applied in the industrial production of methy acraldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

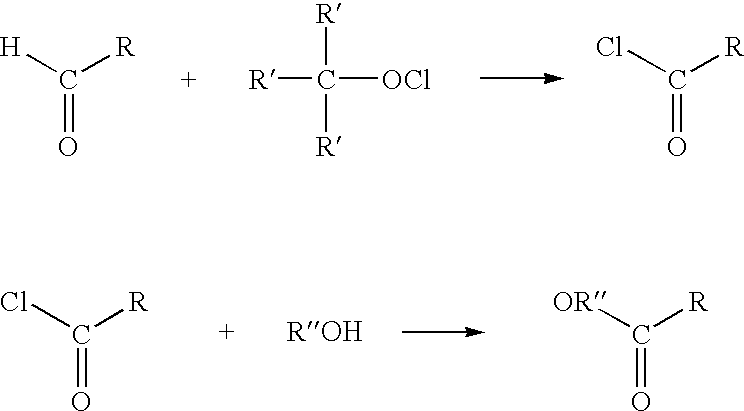

Process for the conversion of aldehydes to esters

InactiveUS20030216587A1Organic compound preparationCarboxylic acid esters preparationHypochloriteReaction temperature

A process for the conversion of aldehydes to esters, specifically acrolein or methacrolein to methyl acrylate or methyl methacrylate, respectively. Essentially in the absence of water, an aldehyde is contacted with an oxidizing agent to form an intermediate and then the intermediate is contacted with a diol or an alcohol to form an ester or diester. Preferably, the oxidizing agent is also a chlorinating agent. Specifically, acrolein or methacrolein is contacted with an oxidizing / chlorinating agent, such as t-butyl hypochlorite, and the chlorinated compound is contacted with an alcohol, such as methanol, to form methyl acrylate or methyl methacrylate, respectively. Generally, the order of addition is for the oxidizing agent to be added to the aldehyde, specifically for t-butyl hypochlorite to be added to acrolein or methacrolein, and for the diol or alcohol to be added to the intermediate, specifically for the methanol to be added to the reaction product of acrolein or methacrolein and t-butyl hypochlorite. The process of the present invention can be carried out in the absence or in the presence of solvent. Generally, better methyl acrylate or methyl methacrylate yields are obtained at lower reaction temperatures.

Owner:SAUDI BASIC IND CORP SA

Catalyst for the oxidation of a mixed aldehyde feedstock to methacrylic acid and methods for making and using same

A heteropolyacid catalyst for oxidation of isobutyraldehyde, methacrolein or mixtures or combinations thereof to methacrylic acid is disclosed where the heteropolyacid catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), and a first component including bismuth (Bi) and / or boron (B). The heteropolyacid catalyst can also optionally include a second component including potassium (K), rubidium (Rb), cesium (Cs), and / or thallium (Tl) and optionally a third component including antimony (Sb), cerium (Ce), niobium (Nb), indium (In), iron (Fe), chromium (Cr), cobalt (Co), nickel (Ni), manganese (Mn), arsenic (As), silver (Ag), zinc (Zn), germanium (Ge), gallium (Ga), zirconium (Zr), magnesium (Mg), barium (Ba), lead (Pb), tin (Sn), titanium (Ti), aluminum (Al), silicon (Si), tantalum (Ta), tungsten (W), and / or lanthanum (La). The heteropolyacid catalyst can also include an ammonium-containing compound designed to increase a value of medium pores in the final heteropolyacid catalyst. A method for oxidizing isobutanal to methacrylic acid using the heteropolyacid catalyst is also disclosed.

Owner:SAUDI BASIC IND CORP SA

Preparation method of catalyst used in reaction of preparing methylacrolein by selective oxidation of isobutene/tertiary butanol

InactiveCN102091634AHigh activityExtended service lifeOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationReaction temperatureSlurry

The invention provides a preparation method of a catalyst used in reaction of preparing methylacrolein by selective oxidation of isobutene / tertiary butanol, wherein the catalyst is a composite oxide containing Mo, Bi, Fe, Co, K and Si. The preparation method comprises the steps of: stirring and mixing one or two of precursor compound silicon micro powder of Si and white carbon black with precursor compounds of other active components except for the Si to obtain mixed slurry, and then drying, forming and roasting the mixed slurry to obtain the catalyst. The catalyst has high activity and lower required reaction temperature when used in the reaction of preparing unsaturated aldehyde through selective oxidation of isobutene / tertiary butanol; better methylacrolein can be obtained, and the selectivity is high; and the reaction hot point is lower and the stability of the catalyst is good.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

Prepn process of catalyst for selective oxidation of isobutene to produce methyl acraldehyde

InactiveCN101088608AGood dispersionReduce energy consumptionCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsAcroleinMethacrolein

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com