Preparation method of catalyst used in reaction of preparing methylacrolein by selective oxidation of isobutene/tertiary butanol

A technology of methacrolein and selective oxidation, which is applied in the preparation of oxygenated compounds by hydrocarbon oxidation, the preparation of organic compounds, the preparation of carbon-based compounds, etc. The problem of high reaction hot spot temperature of the catalyst can achieve the effect of prolonging the service life, reducing the reaction hot spot temperature and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1000 grams of ammonium paramolybdate tetrahydrate in 1 liter of distilled water, then add 494.5 grams of cobalt nitrate hexahydrate, 346.8 grams of ferric nitrate nonahydrate, 329.7 grams of bismuth nitrate pentahydrate, and 11.4 grams of potassium nitrate, and stir to dissolve into a mixed aqueous solution , then add 336.5 grams of silicon micropowder with a particle size of 1000-1500 nm to the above solution, continue to stir and mix at 60°C for 50 minutes, then transfer the above mixed slurry to an oven for 12 hours at 120°C, and take 300 grams of dry slurry Tablets are formed into hollow columnar particles with an outer diameter of 5mm, an inner diameter of 2mm, and a length of 5mm. The obtained catalyst particles are calcined at 550°C in air for 7 hours to obtain a composition of Mo 10 Bi 1.2 Fe 1.5 co 3 K 0.2 Si 10 catalyst.

[0021] Get 50 grams of catalyzer and pack in the fixed-bed tubular reactor, pass into the raw material isobutylene after preh...

Embodiment 2

[0023] The catalyst preparation method is the same as in Example 1, except that 336.5 grams of silicon micropowder with a particle diameter of 1000 to 1500 nm is changed to 3365 grams of white carbon black with a particle diameter of 30 to 50 nm in the catalyst preparation process, and the roasting temperature is changed from 550 ° C to 630 ° C. ℃, the catalyst composition is Mo 10 Bi 1.2 Fe 1.5 co 3 K 0.2 Si 100 . Catalyst activity evaluation conditions are also the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0025] 577.0 grams of cobalt nitrate hexahydrate, 462.3 grams of ferric nitrate nonahydrate, 549.5 grams of bismuth nitrate pentahydrate, and 2018.7 grams of white carbon black with a particle size of 100 to 200 nm were prepared as a mixed slurry, which was recorded as A; 1000 grams of paramolybdic acid tetrahydrate Dissolve ammonium and 17.1 grams of potassium nitrate in 1 liter of distilled water, and record it as B; add B to A under stirring, and continue to stir at 75°C for 2 hours, then transfer the above mixed slurry to an oven for 10°C and dry at 120°C hour, take 500 grams of dry slurry and mold it into hollow columnar particles with an outer diameter of 5 mm, an inner diameter of 2 mm, and a length of 5 mm; 10 Bi 2 Fe 2 co 3.5 K 0.3 Si 60 catalyst. Catalyst evaluation conditions are the same as in Example 1, and the results after 100 hours of reaction are listed in Table 1.

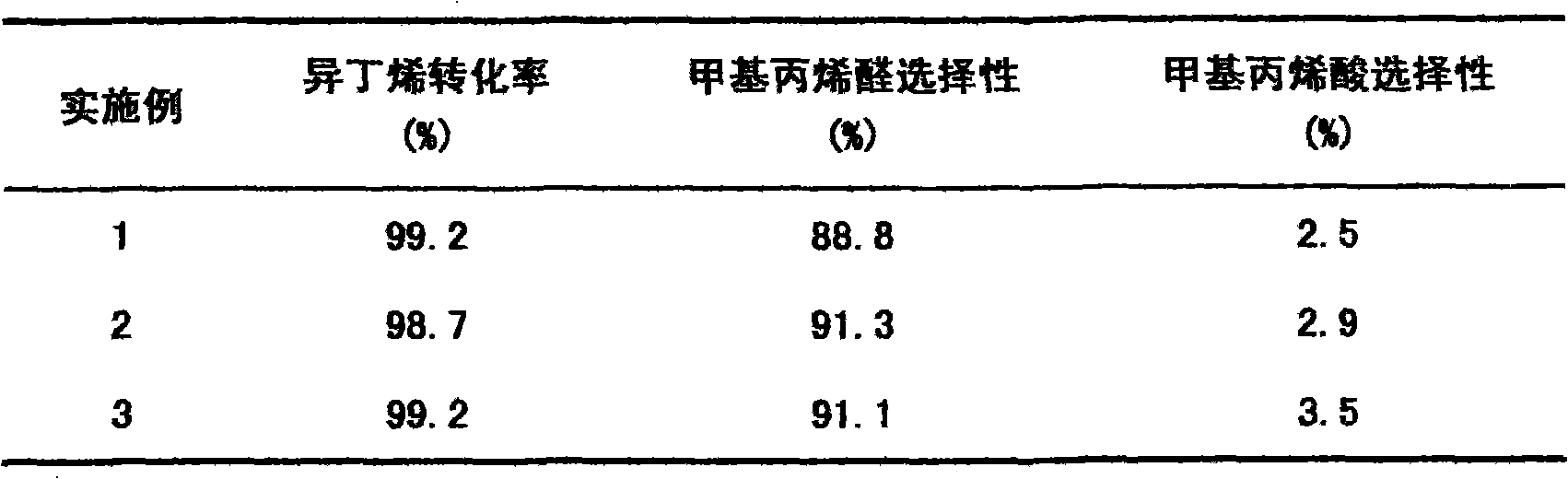

[0026] Oxidation reaction result in table 1 embodiment 1~3

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com