Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1073 results about "Chemical plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical plant is an industrial process plant that manufactures (or otherwise processes) chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

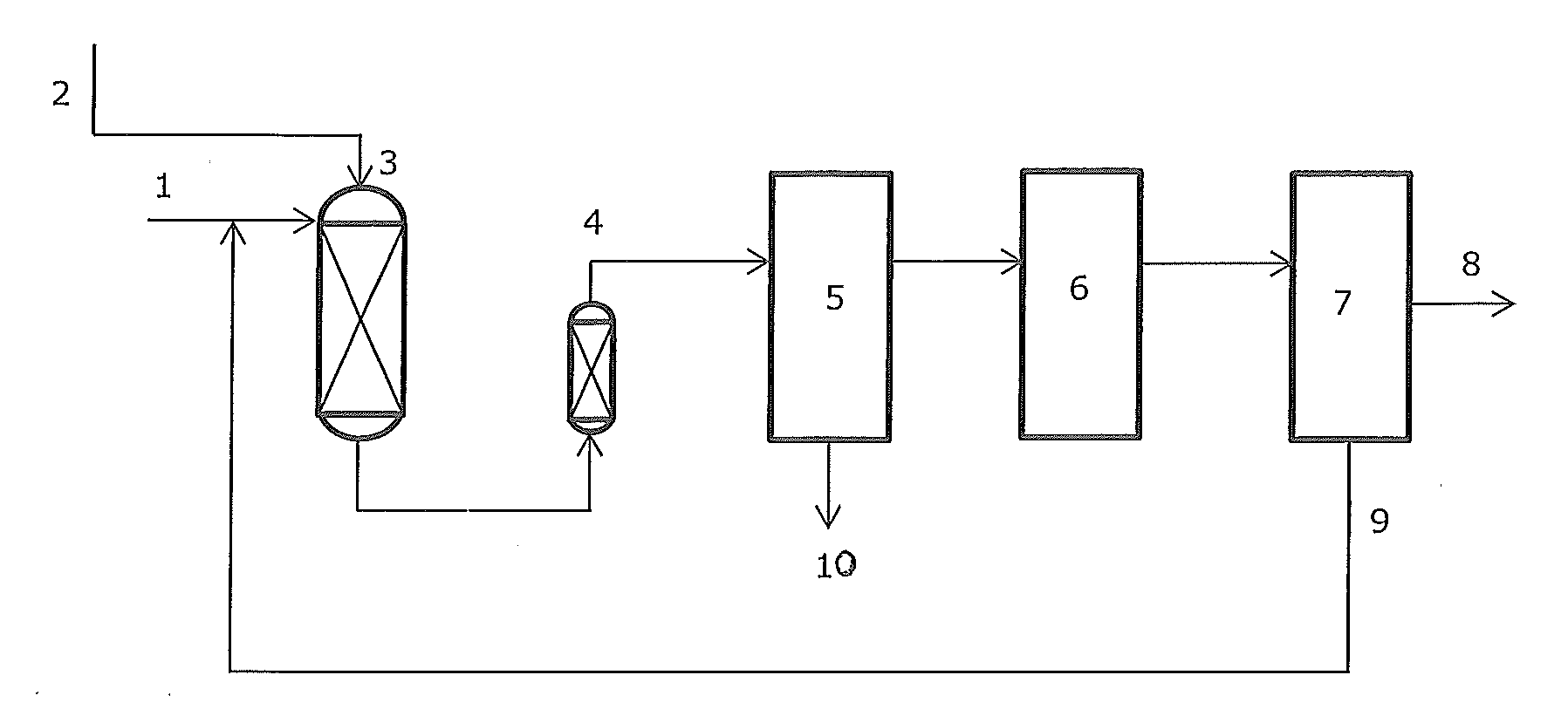

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

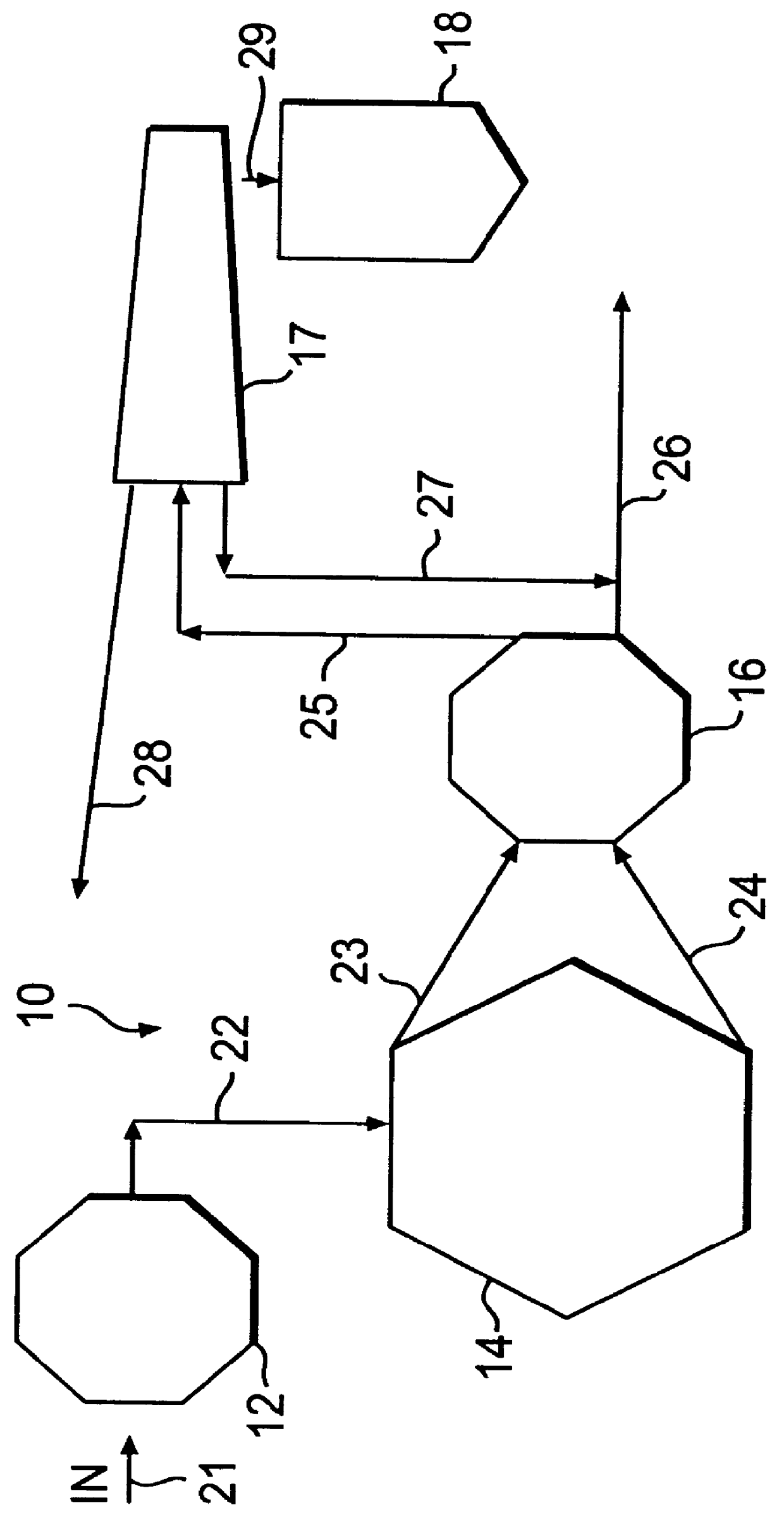

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

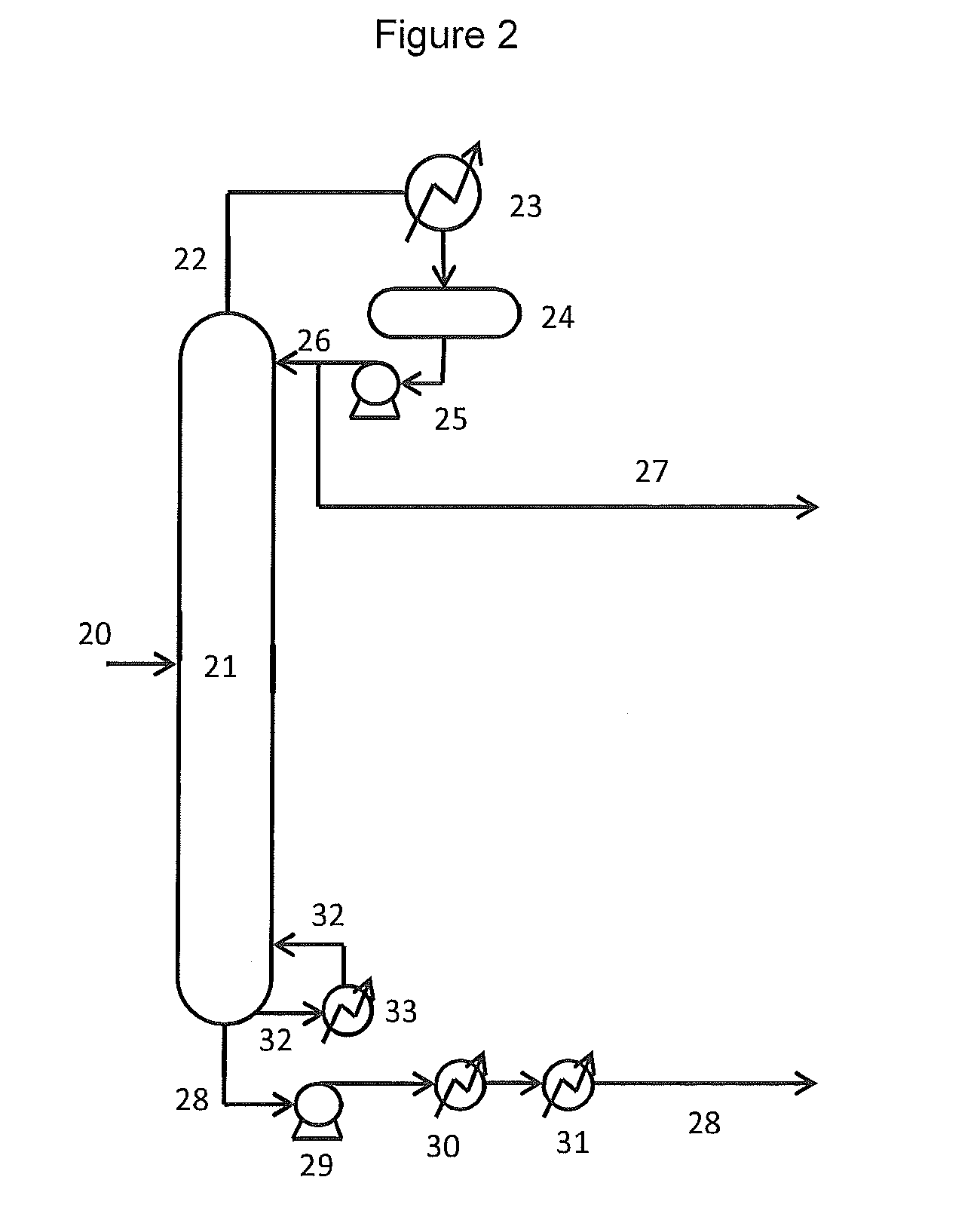

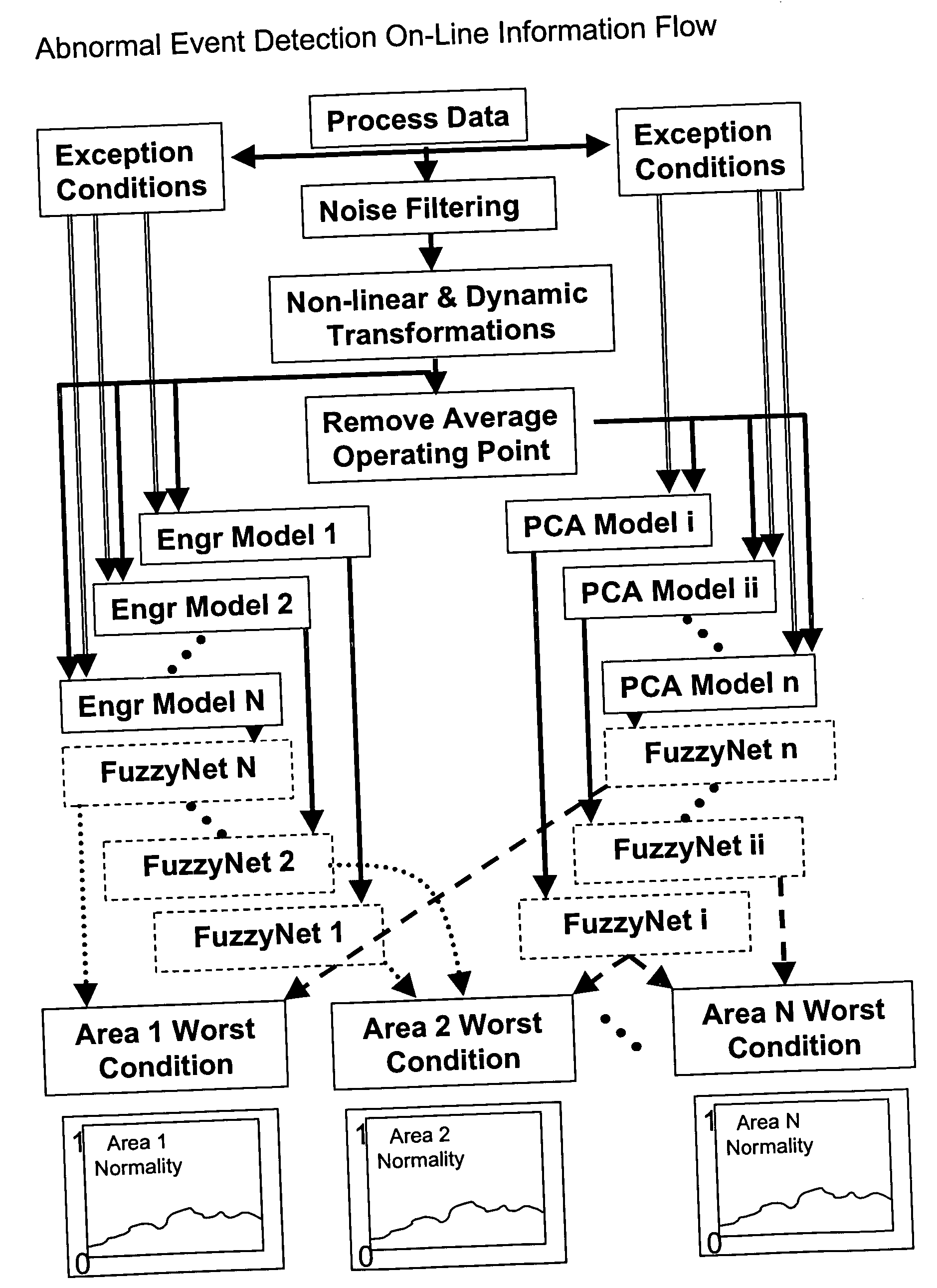

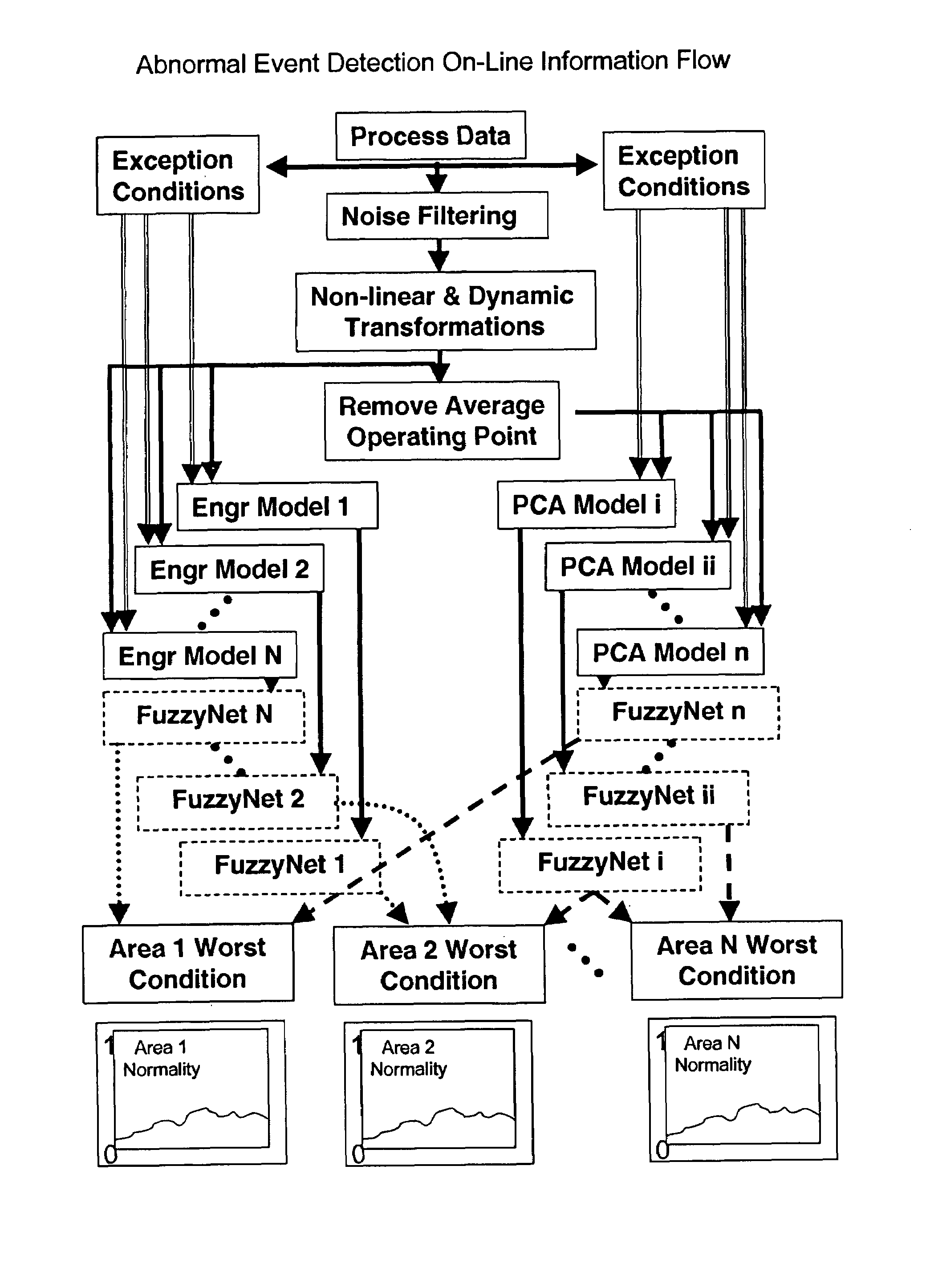

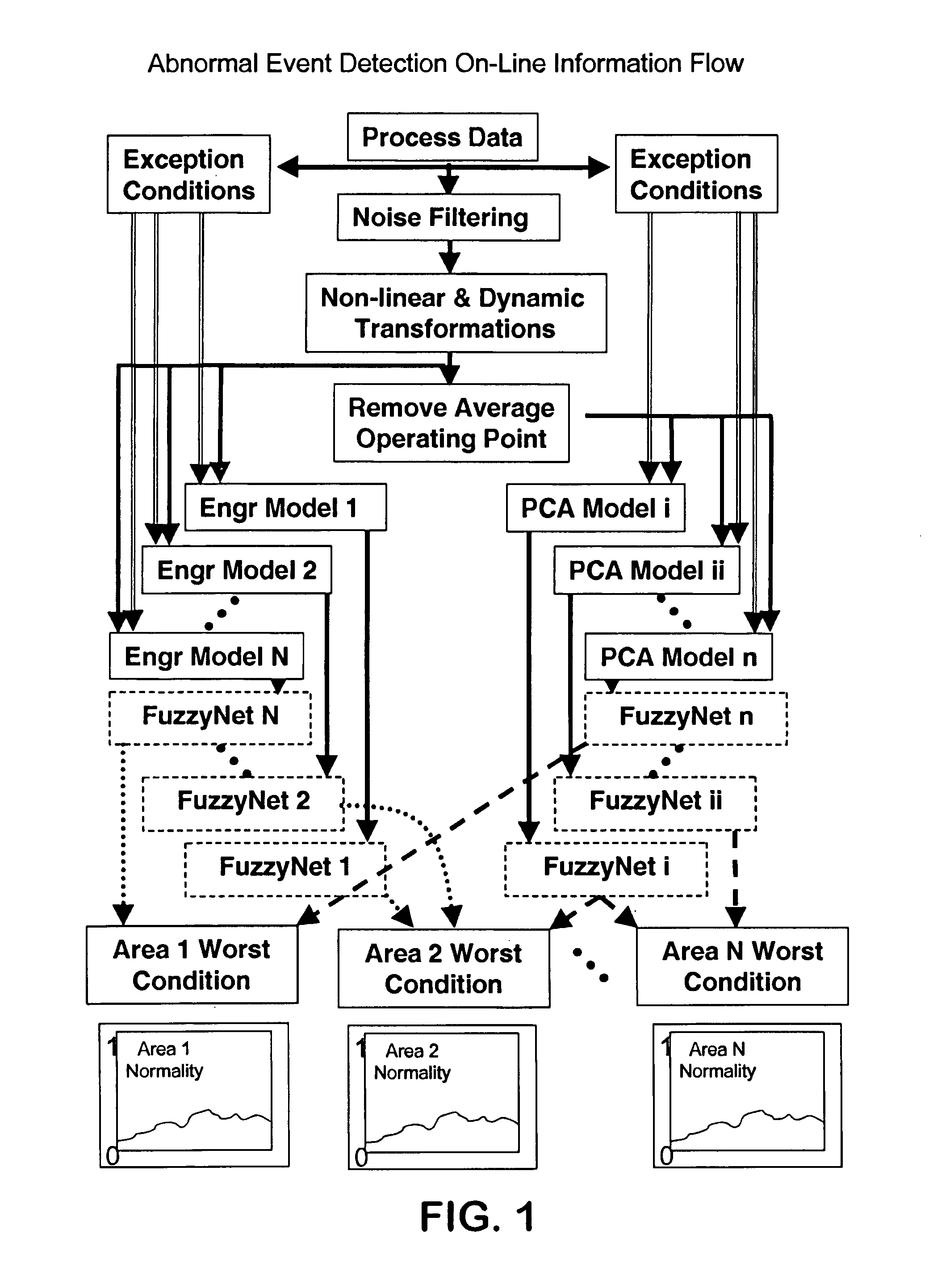

System and method for abnormal event detection in the operation of continuous industrial processes

ActiveUS20060058898A1Eliminate the effects ofEasy to monitorCatalytic crackingTesting/monitoring control systemsMultivariate statisticsPrincipal component analysis

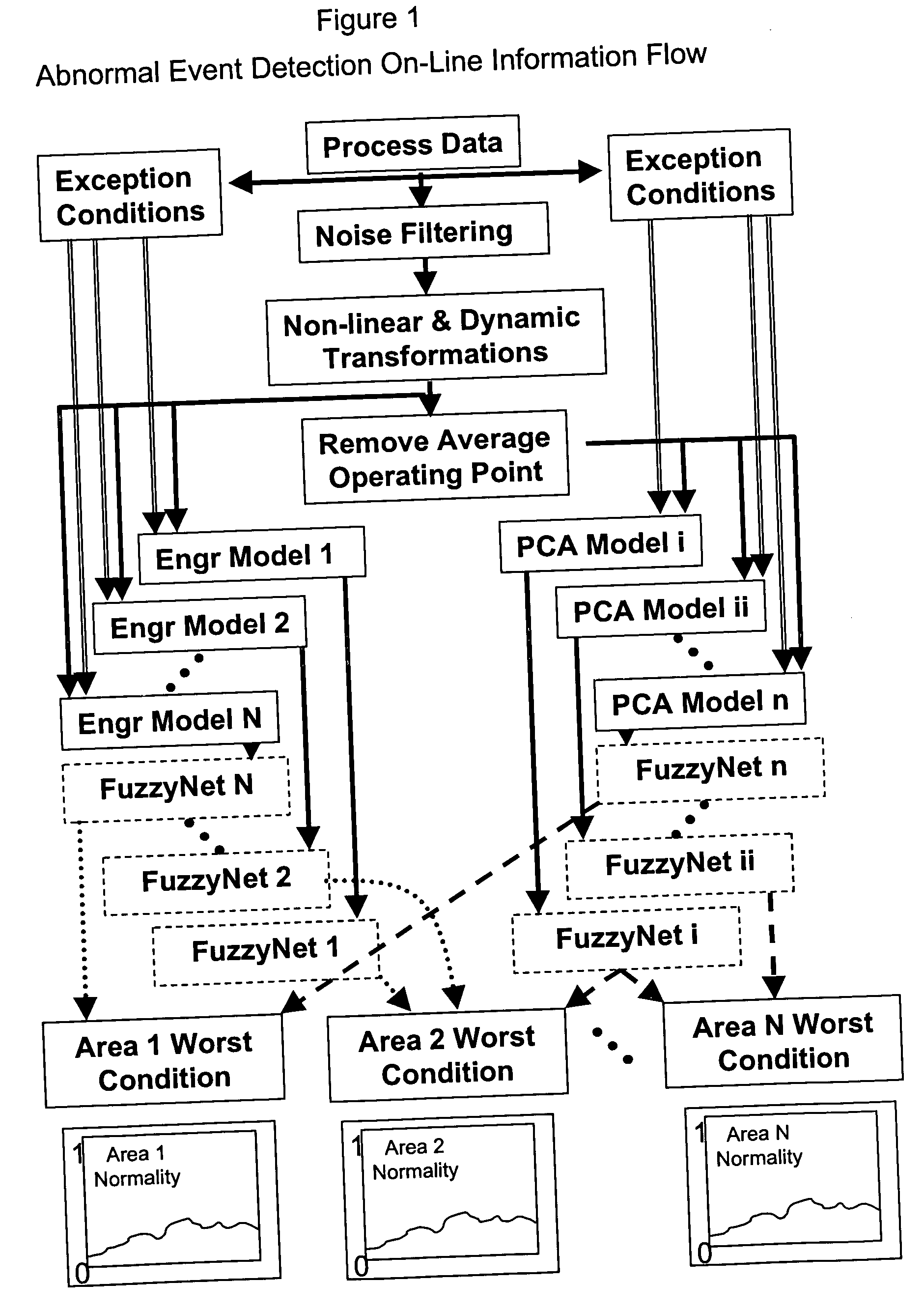

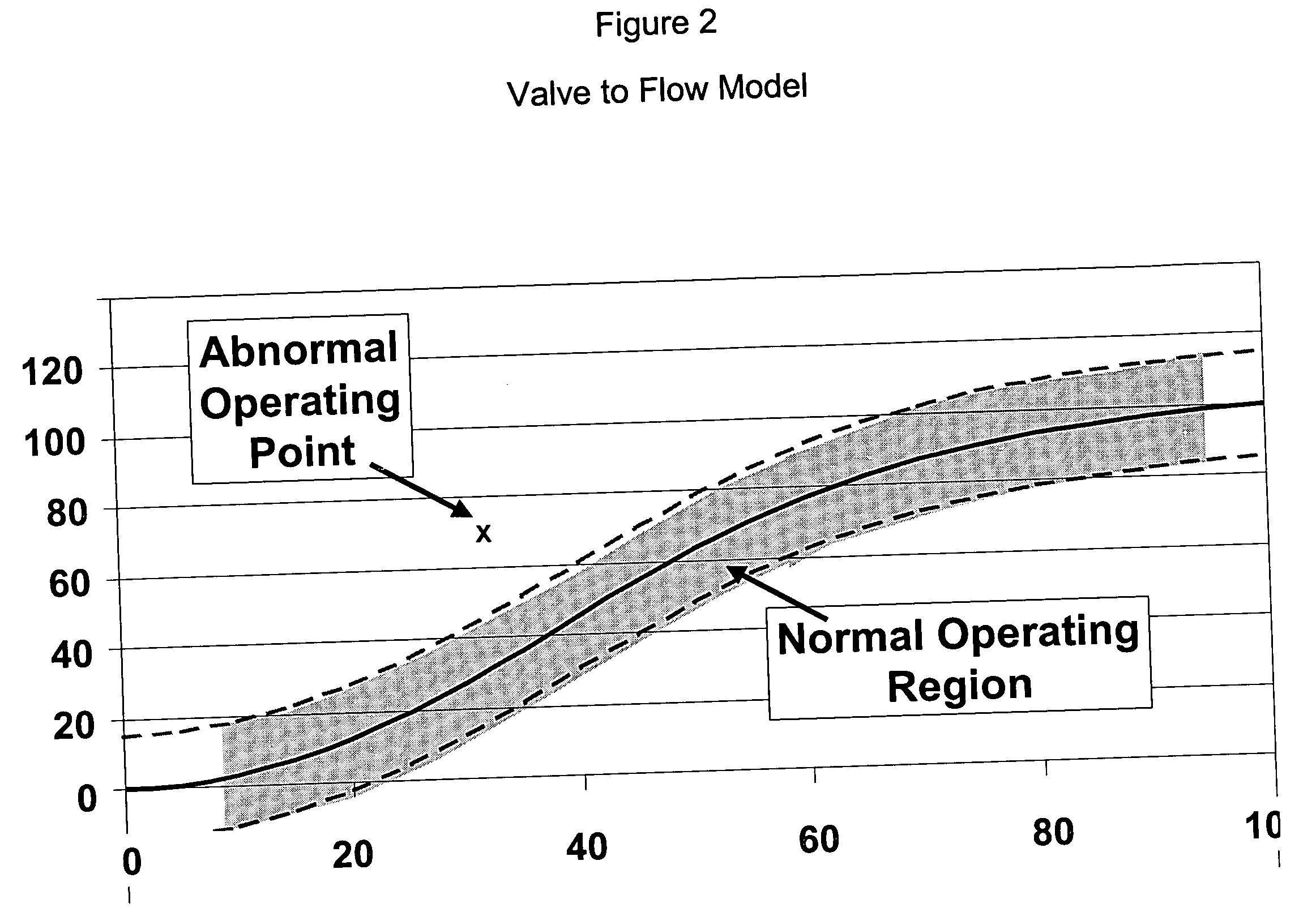

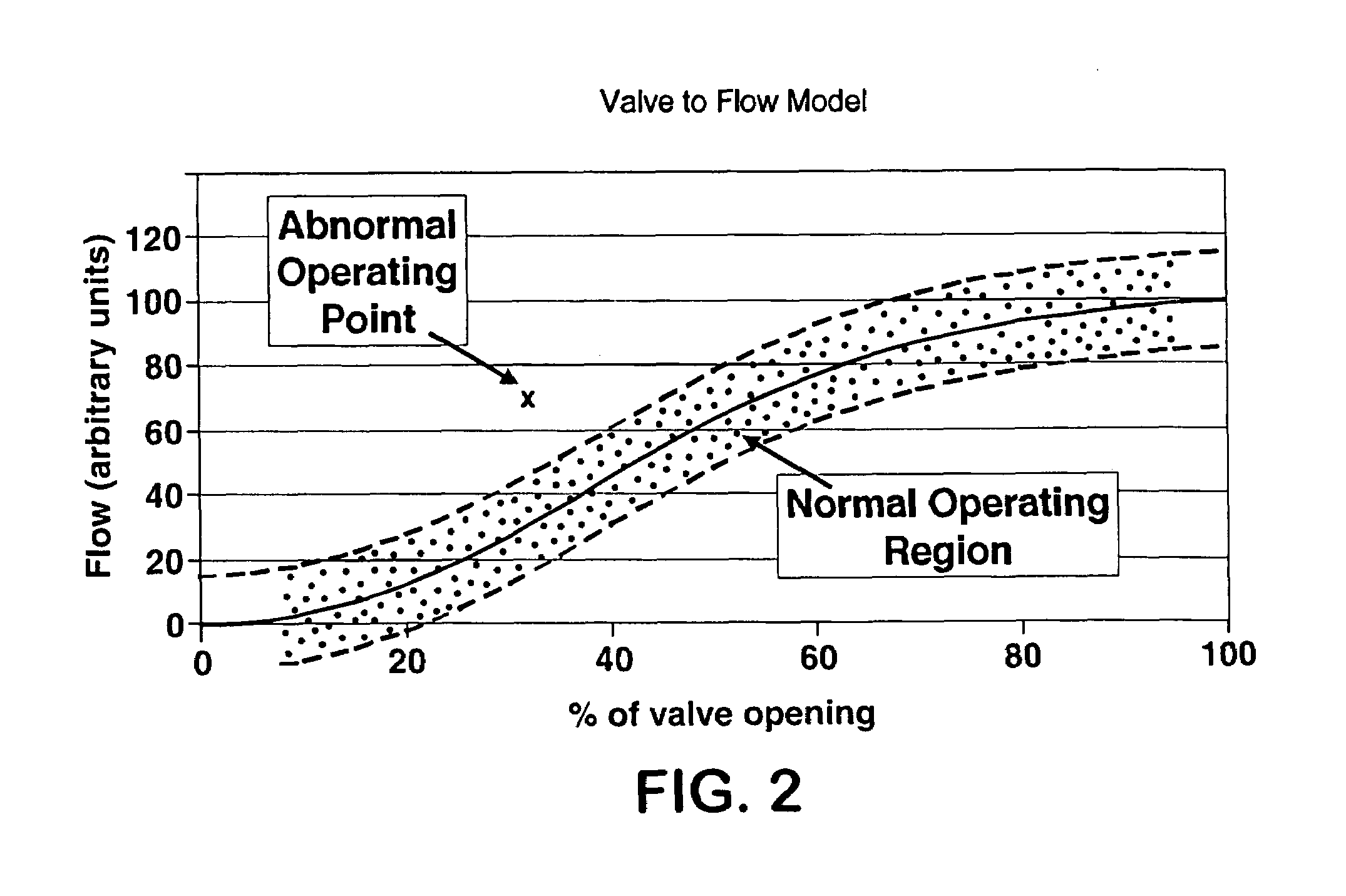

Thousands of process and equipment measurements are gathered by the modern digital process control systems that are deployed in refineries and chemical plants. Several years of these data are historized in databases for analysis and reporting. These databases can be mined for the data patterns that occur during normal operation and those patterns used to determine when the process is behaving abnormally. These normal operating patterns are represented by sets of models. These models include simple engineering equations, which express known relationships that should be true during normal operations and multivariate statistical models based on a variation of principle component analysis. Equipment and process problems can be detected by comparing the data gathered on a minute by minute basis to predictions from these models of normal operation. The deviation between the expected pattern in the process operating data and the actual data pattern are interpreted by fuzzy Petri nets to determine the normality of the process operations. This is then used to help the operator localize and diagnose the root cause of the problem.

Owner:EXXON RES & ENG CO

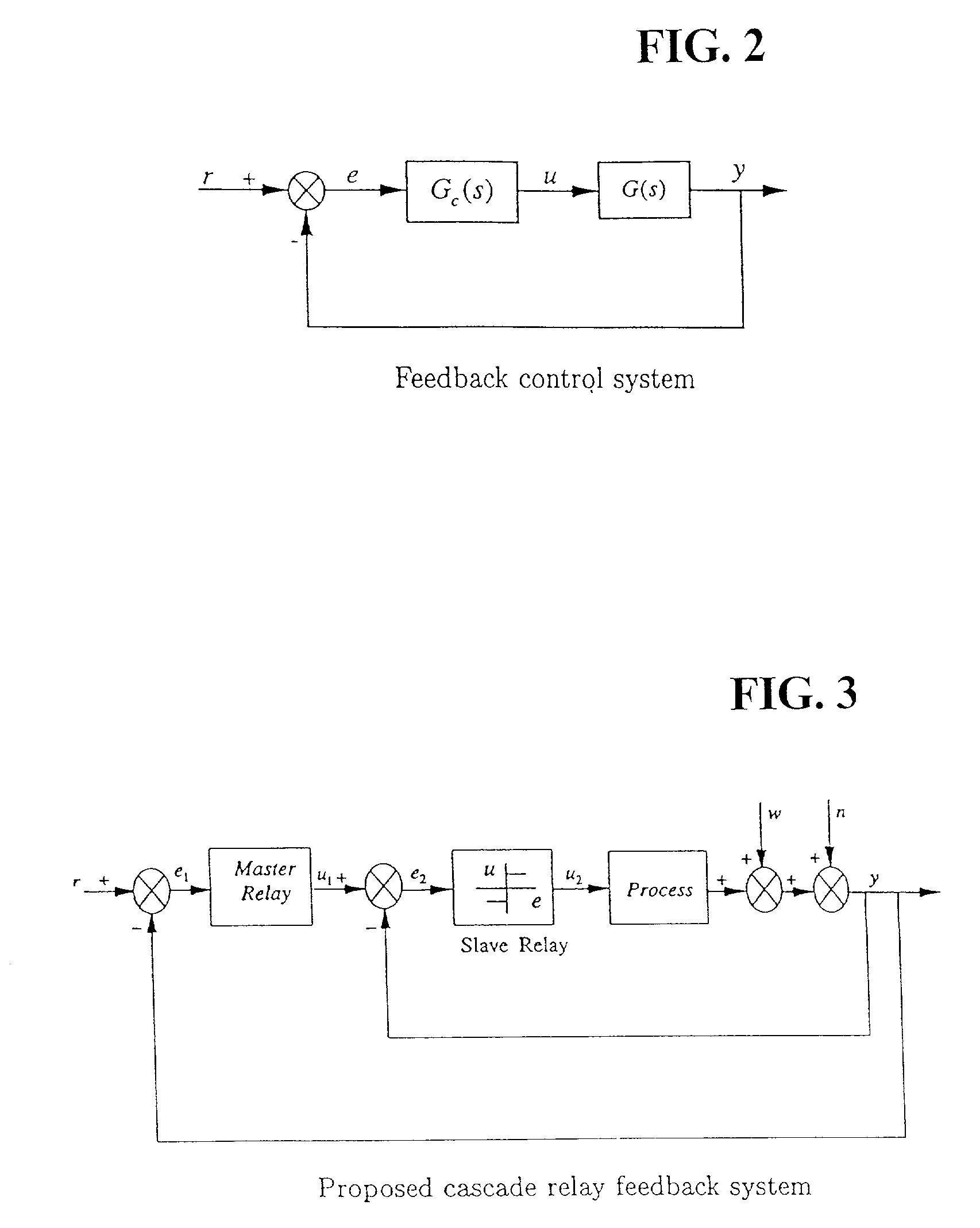

Robust process identification and auto-tuning control

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

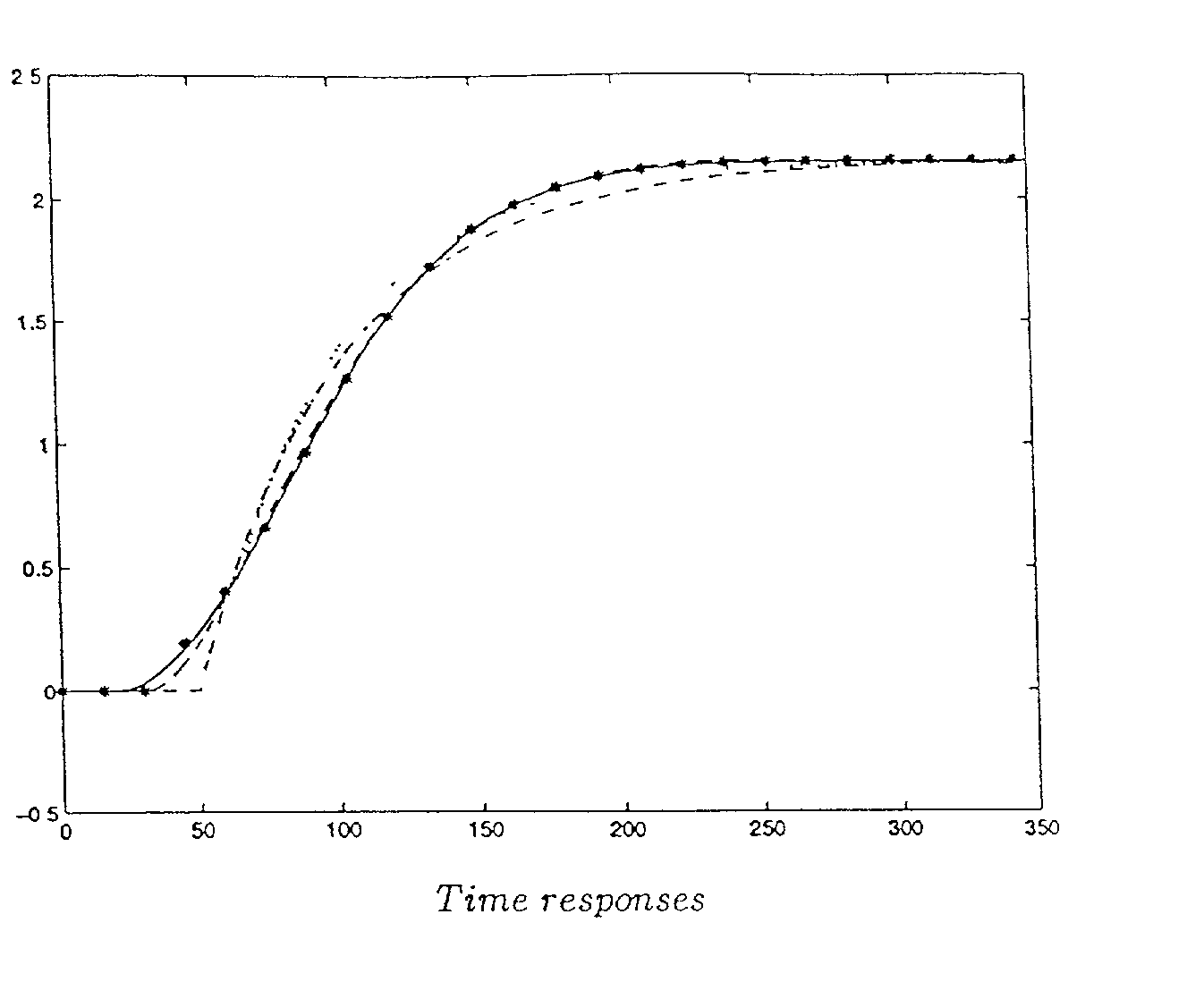

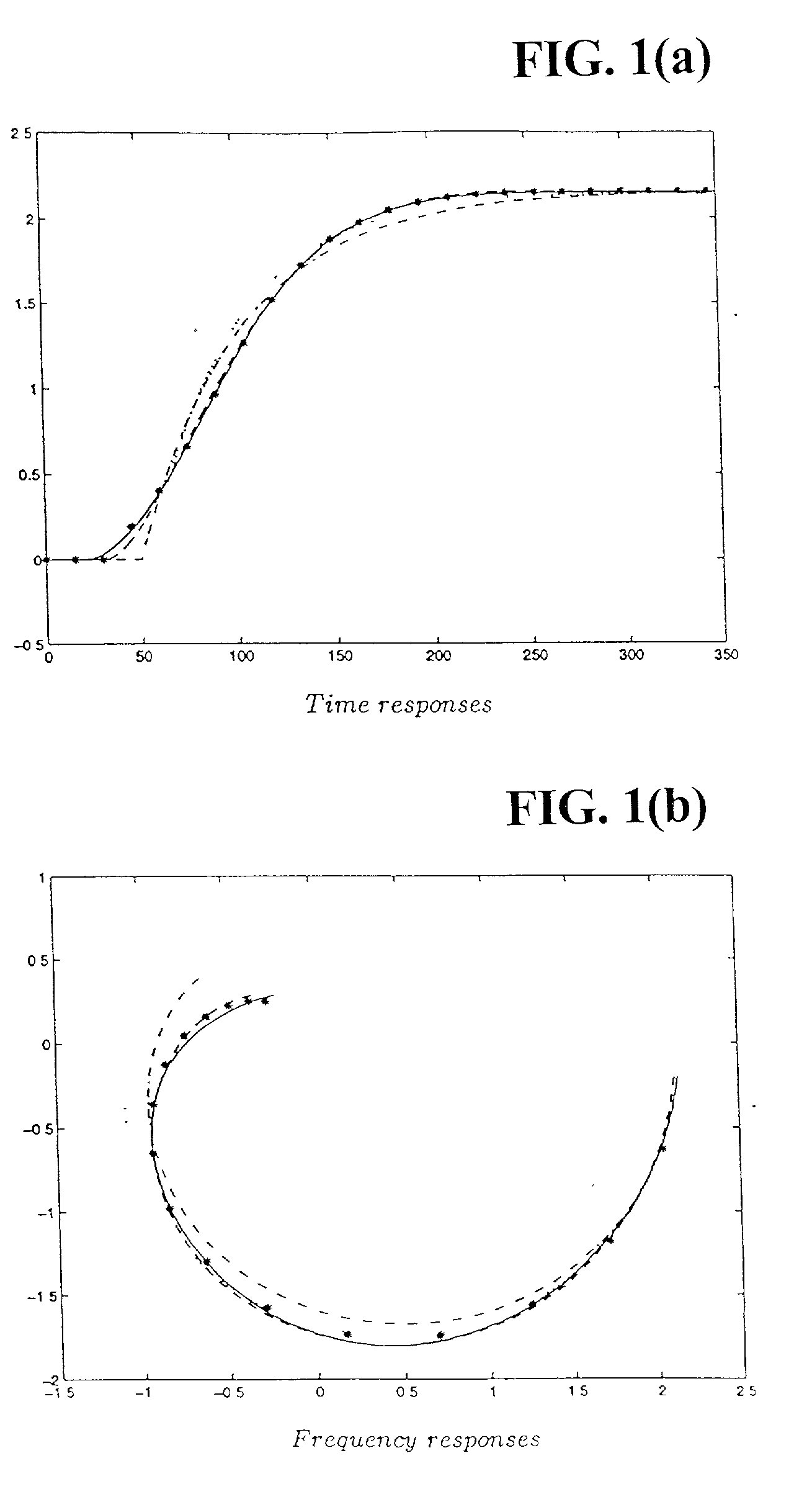

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

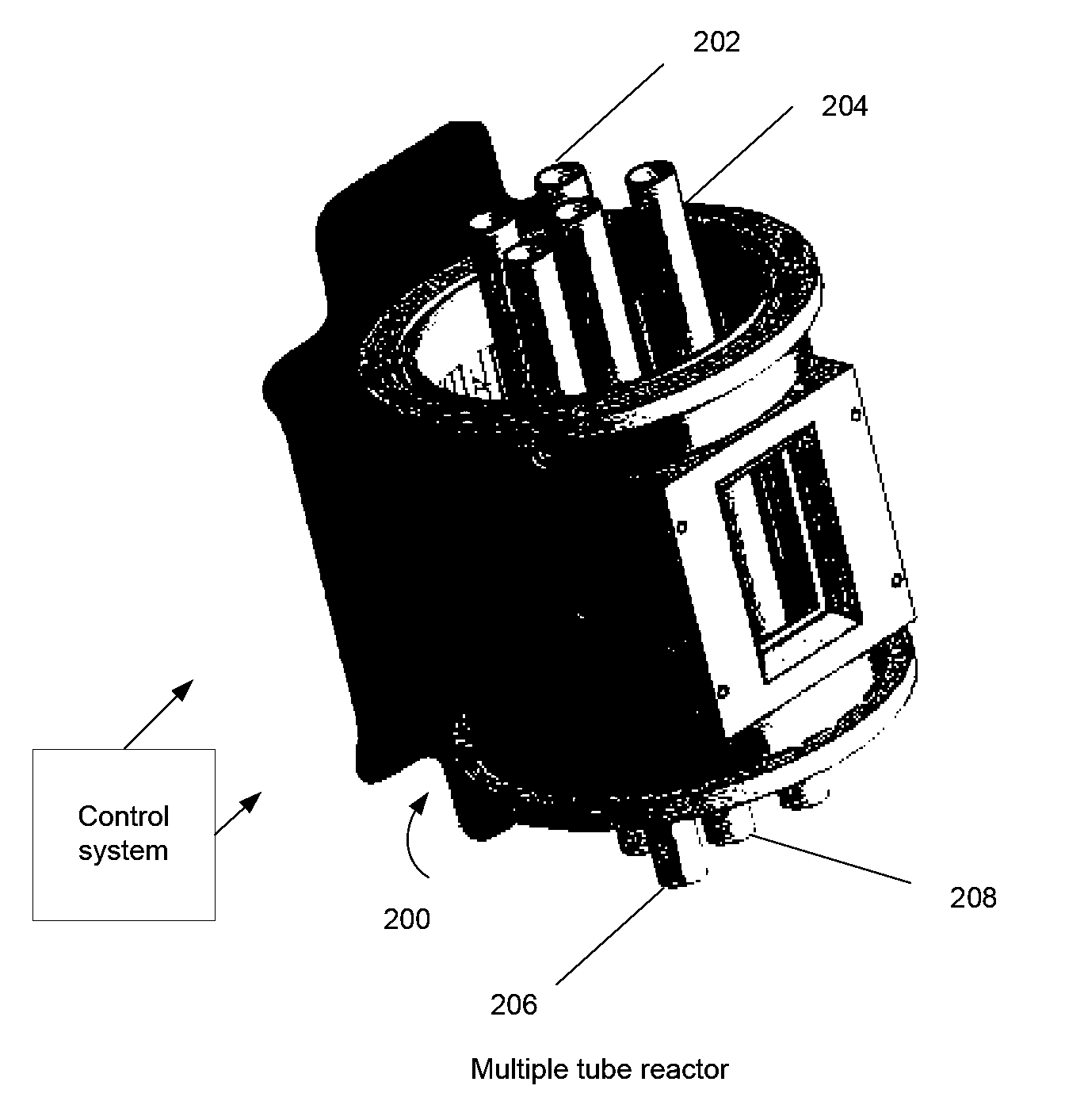

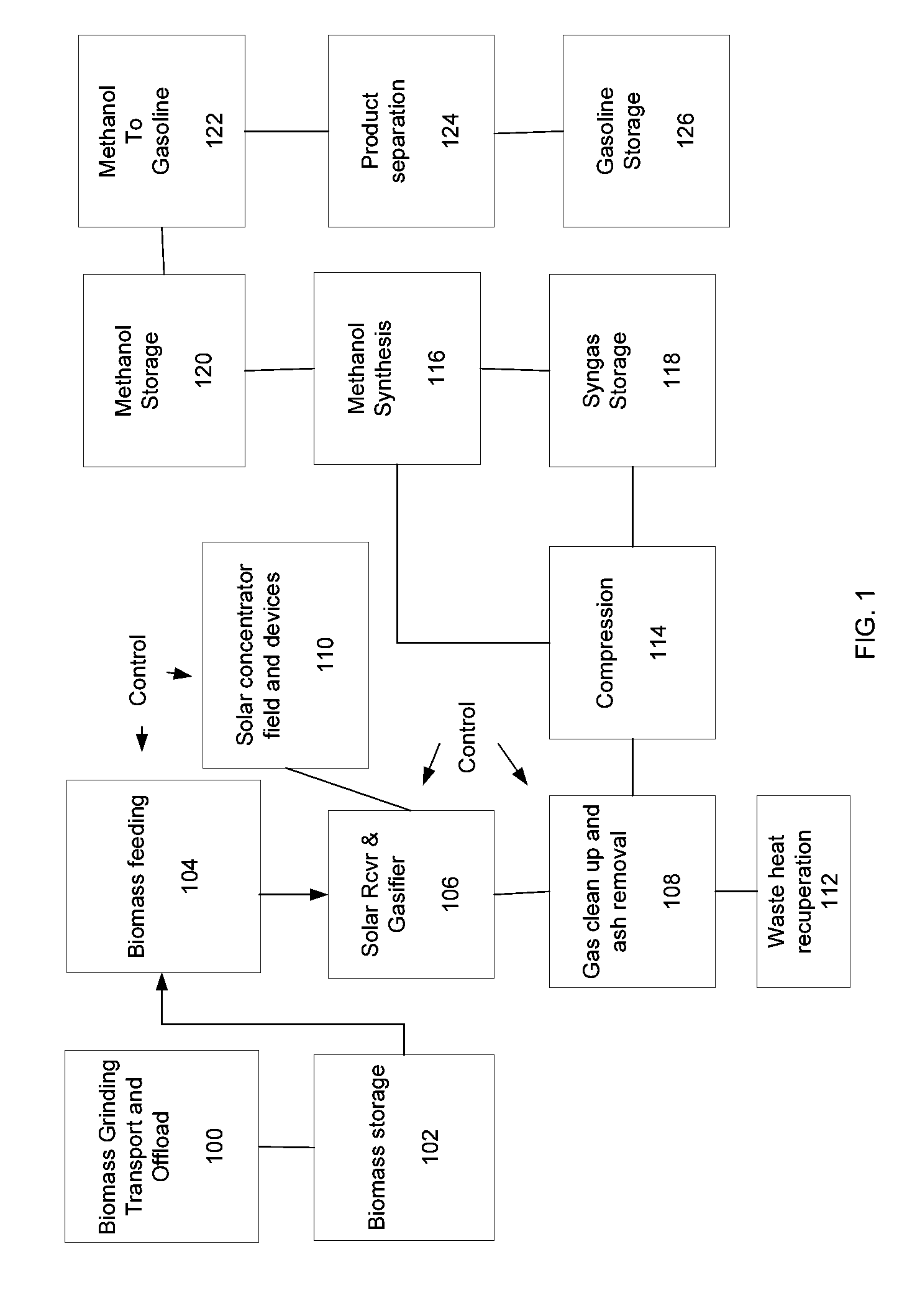

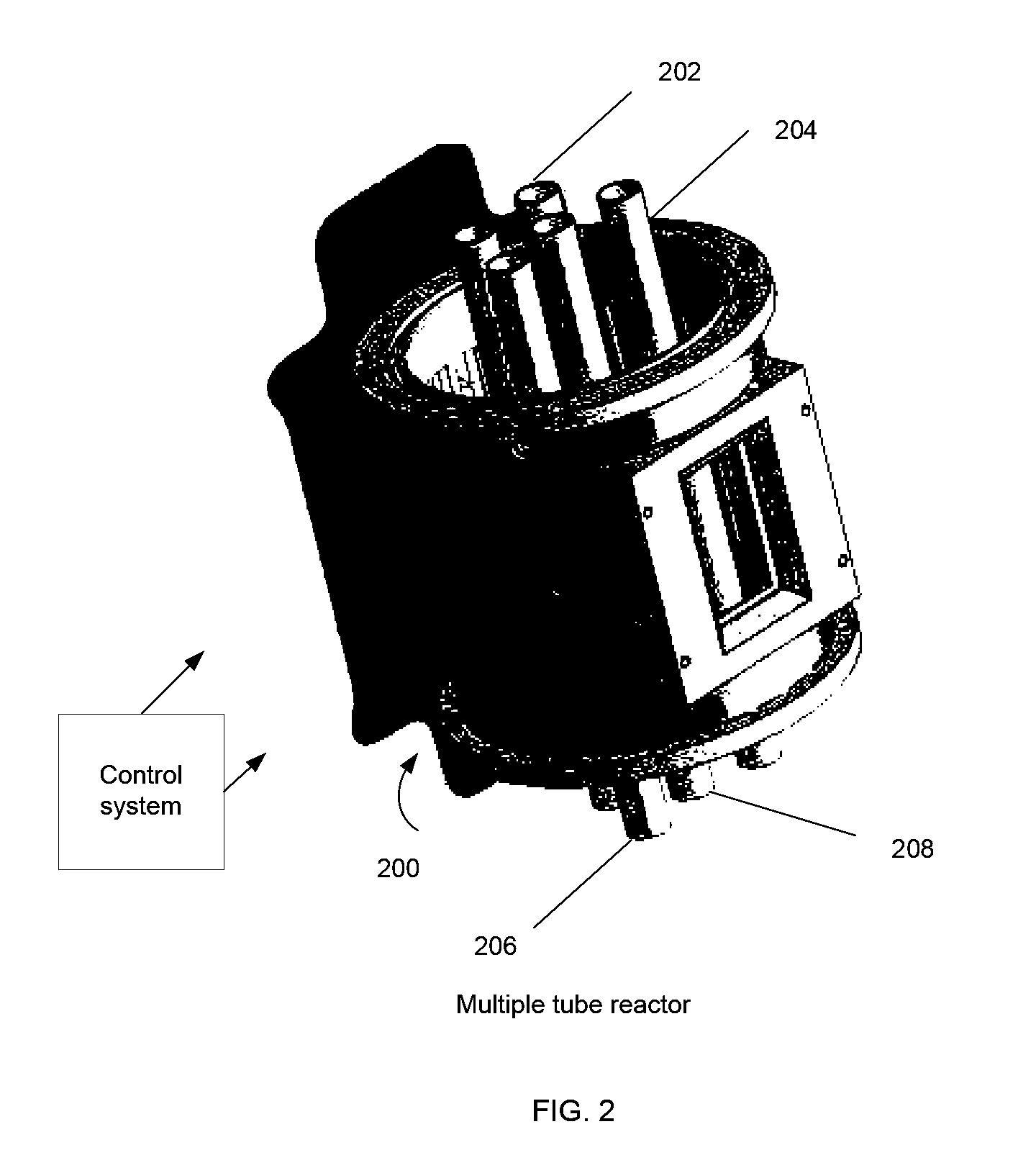

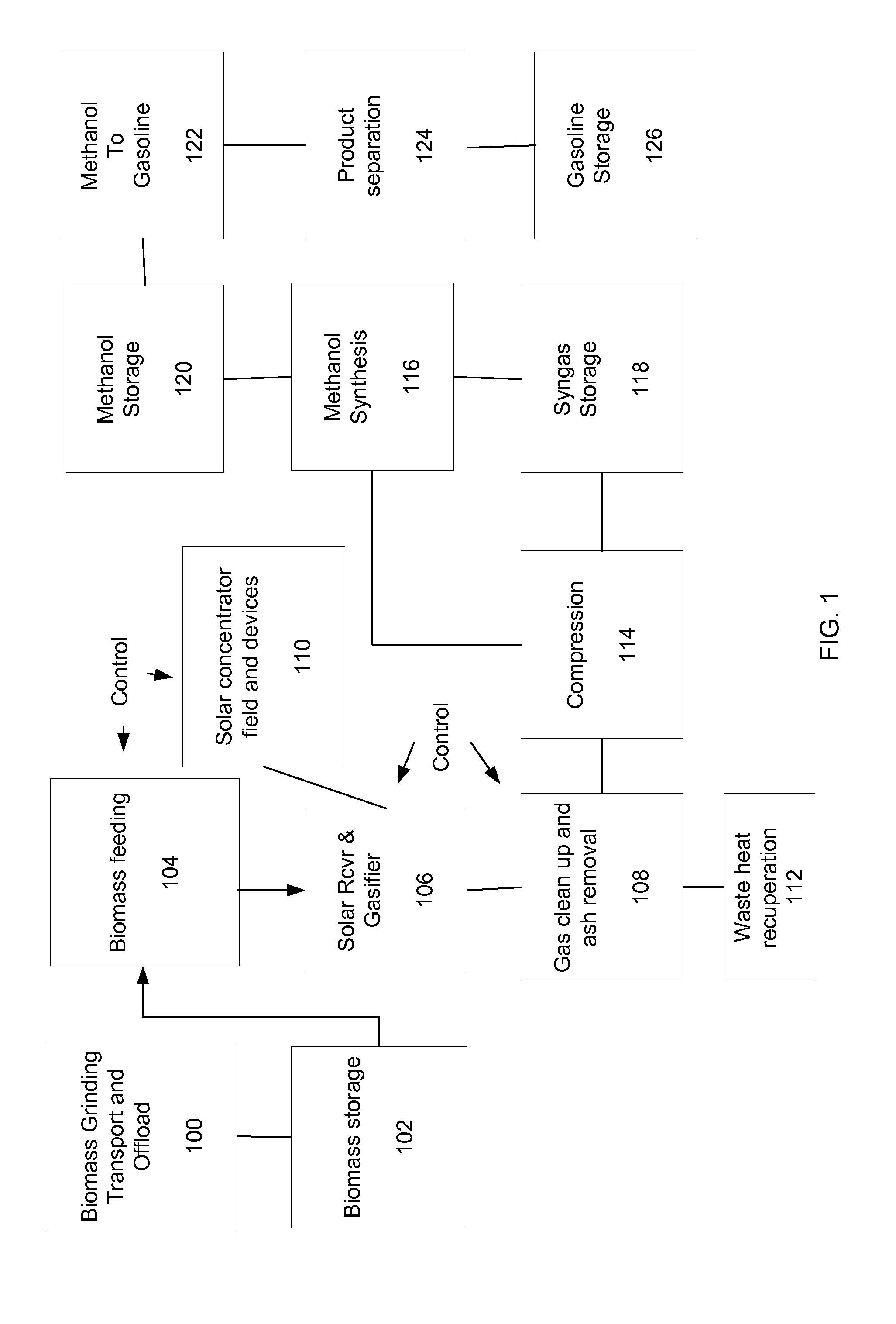

Systems and methods for solar-thermal gasification of biomass

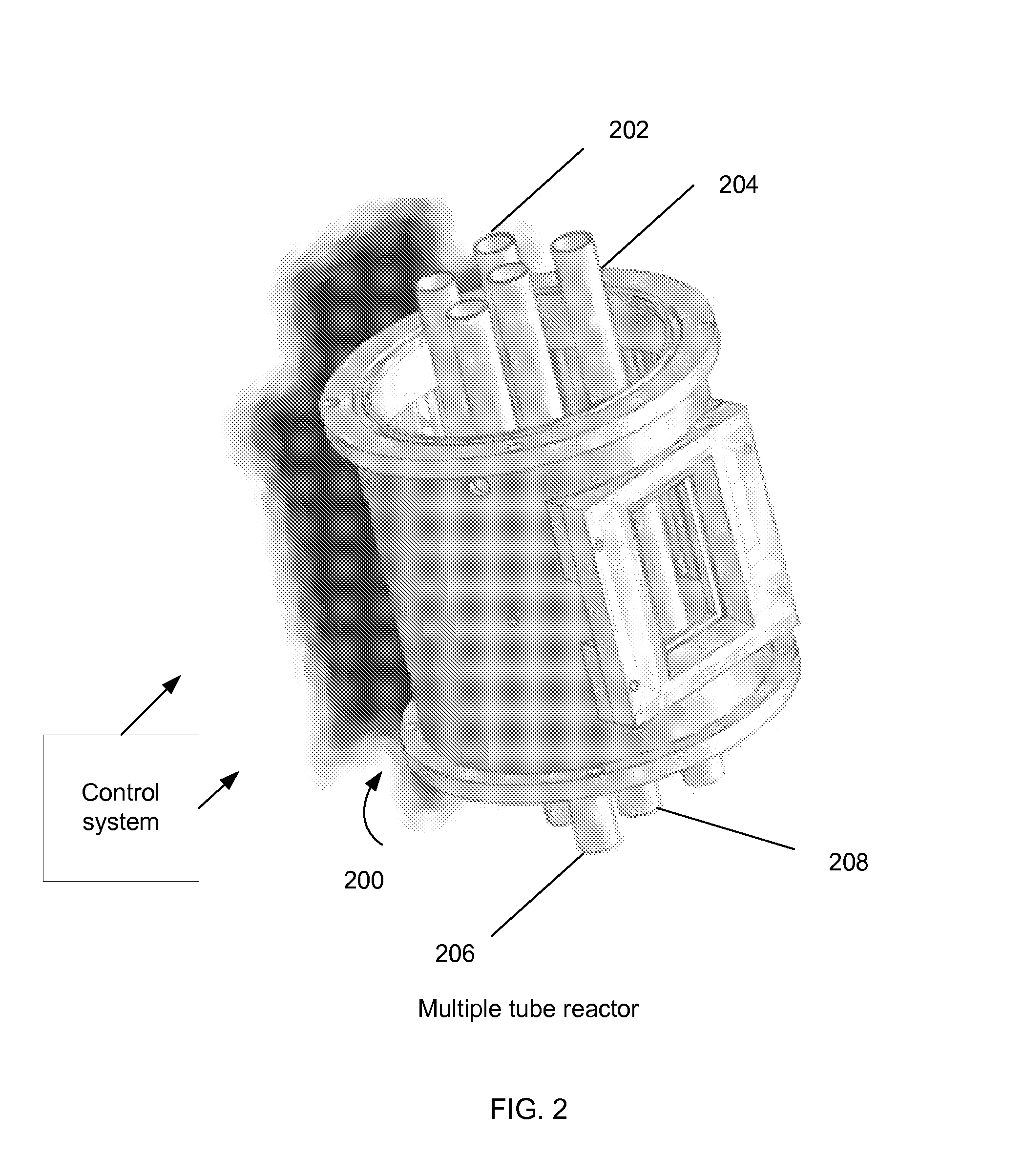

InactiveUS20100237291A1Process control/regulationSolar heating energySteam reformingChemical reaction

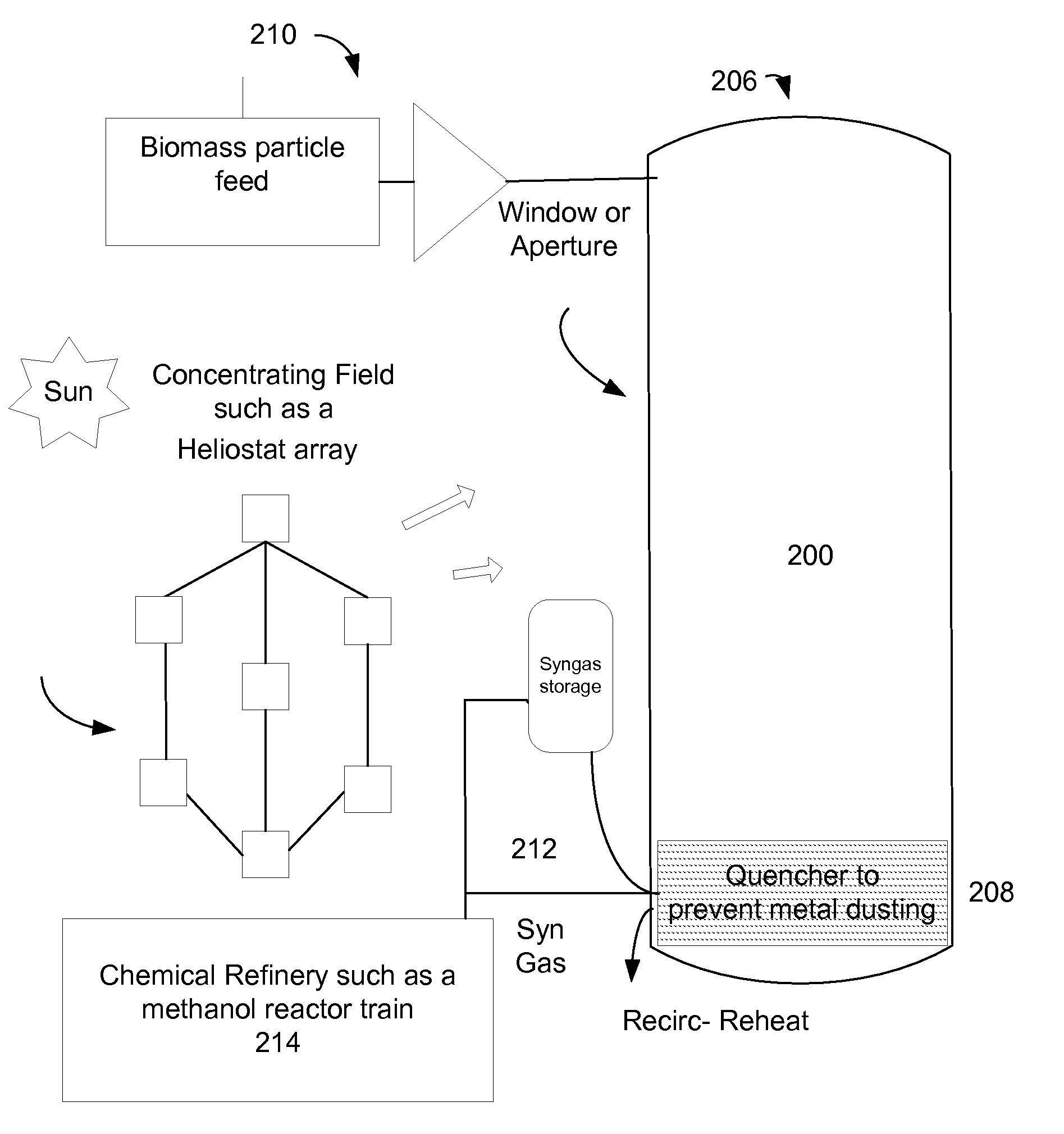

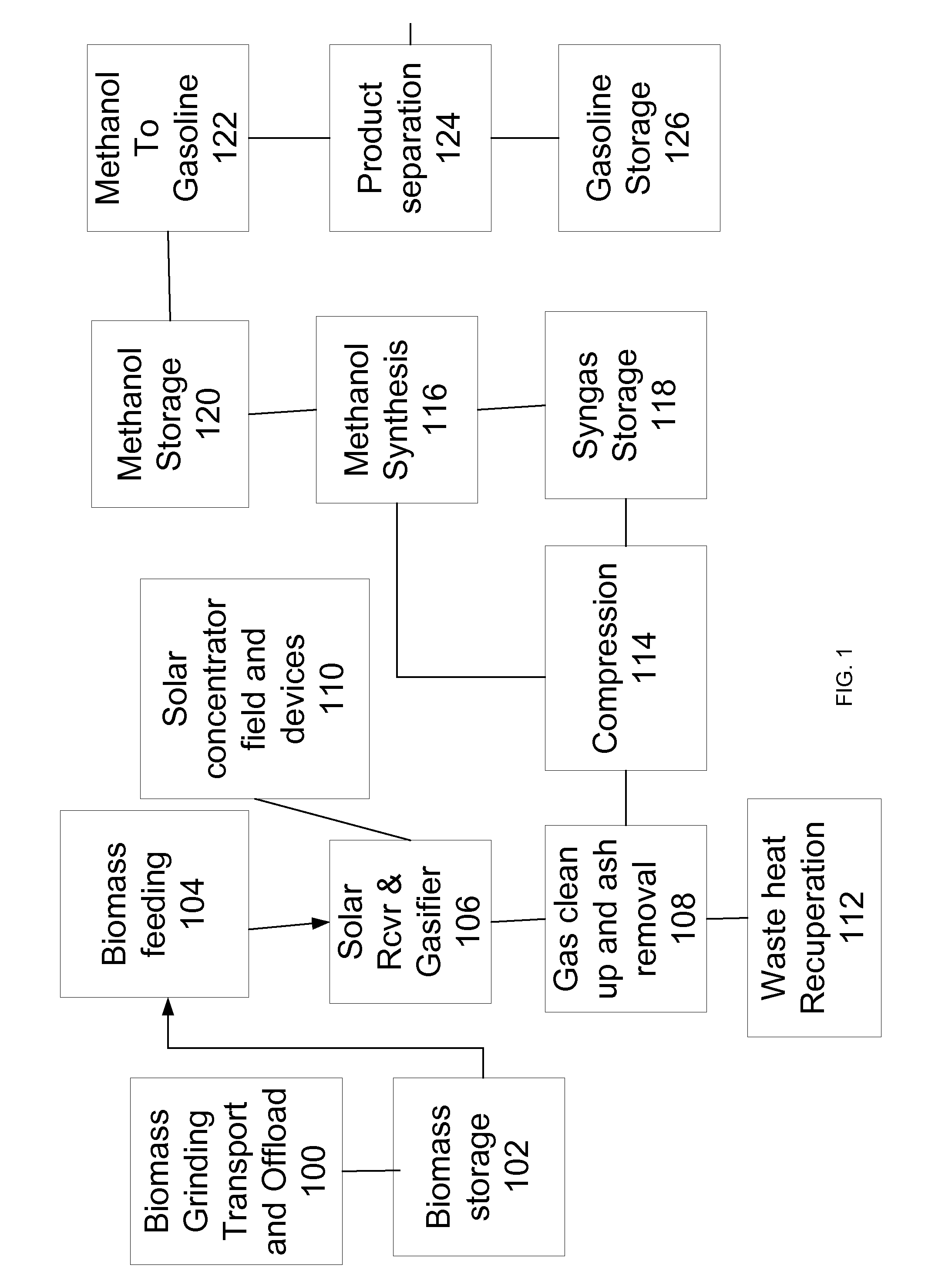

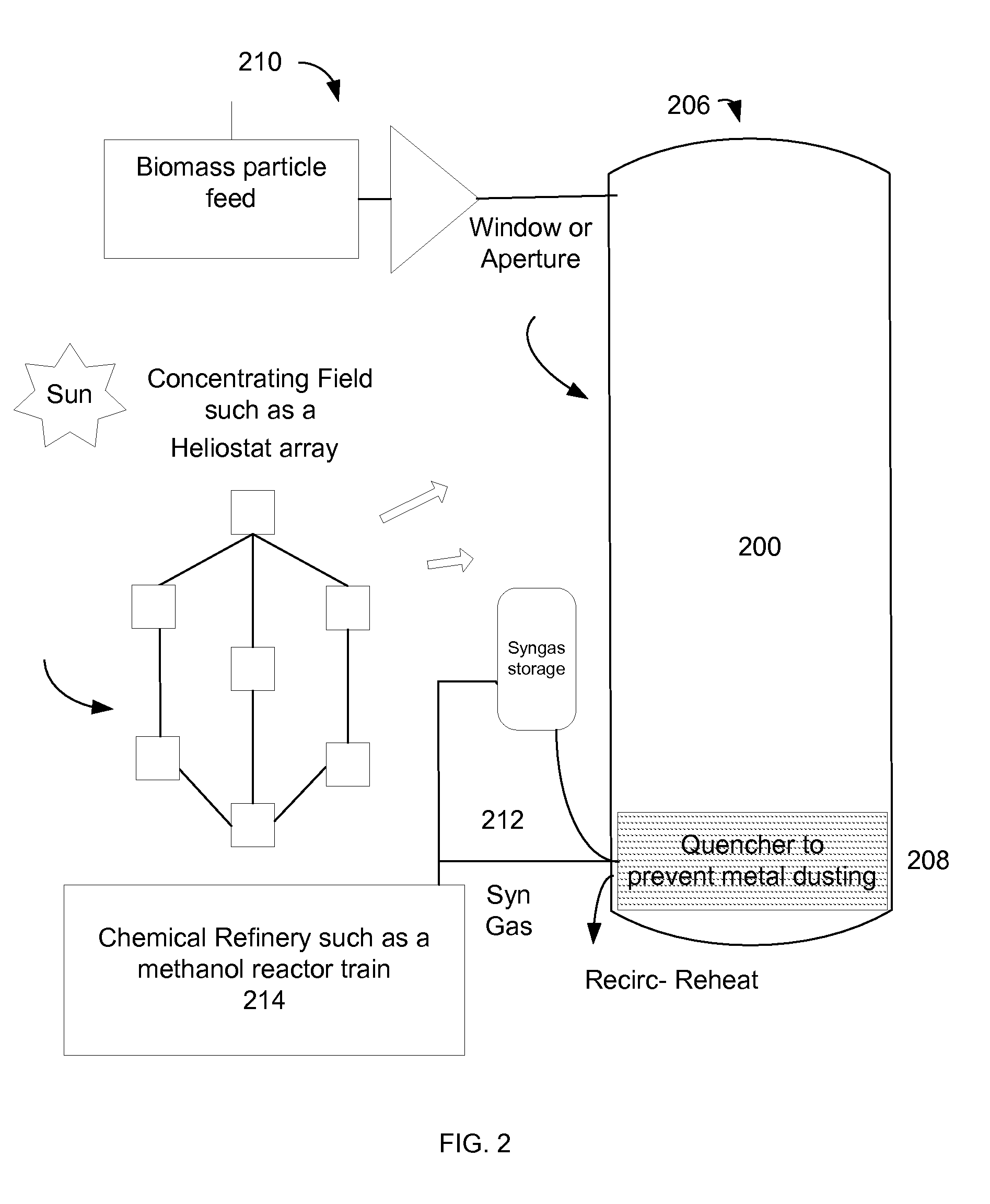

A method, apparatus, and system for a solar-driven chemical plant that may include a solar thermal receiver having a cavity with an inner wall, where the solar thermal receiver is aligned to absorb concentrated solar energy from one or more of 1) an array of heliostats, 2) solar concentrating dishes, and 3) any combination of the two. Some embodiments may include a solar-driven chemical reactor having multiple reactor tubes located inside the cavity of solar thermal receiver, wherein a chemical reaction driven by radiant heat occurs in the multiple reactor tubes, and wherein particles of biomass are gasified in the presence of a steam (H2O) carrier gas and methane (CH4) in a simultaneous steam reformation and steam biomass gasification reaction to produce reaction products that include hydrogen and carbon monoxide gas using the solar thermal energy from the absorbed concentrated solar energy in the multiple reactor tubes.

Owner:SUNDROP IP HLDG LLC

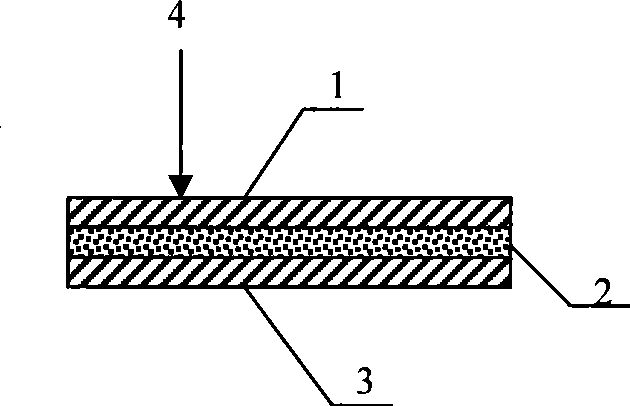

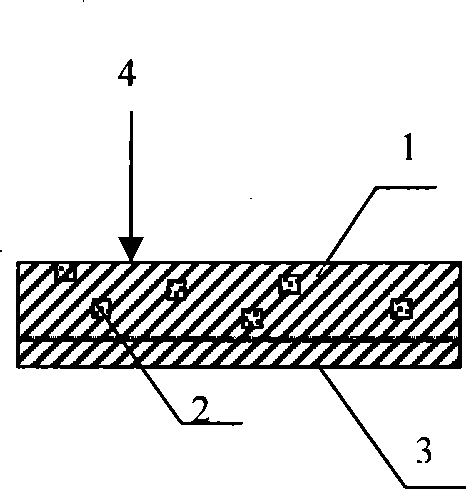

Functional filter felt for eliminating harmful constituents of fume, preparation method and application method thereof

ActiveCN101518718AExtended service lifePrevent penetrationPhysical/chemical process catalystsDispersed particle separationNonwoven fabricHigh heat

The invention pertains to the technical field of fume purification. The provided functional filter felt for eliminating harmful constituents of fume can realize the desulfurization or denitration of fume when removing dust; the filter felt is made from fiber materials and a functional catalyst in a compound manner; when purifying the harmful constituents of fume, the filter felt filters the dusts in the fume with nonwoven fabrics made from high temperature-resistant fiber material and carries out a catalytic reaction to eliminate nitrogen oxides (NOX) and / or sulfur oxides (SOX) through the functional catalyst contained in the filter felt. The provided filter felt is applicable to fume dedusting devices, fume desulfurization devices and fume denitration devices in power plants, metallurgical plants and chemical plants, in particular to the manufacturing of bag type fume filter. Compared with the prior art, the invention simplifies the fume purifying processes, improves processing efficiency, effectively saves the investment and reduces operational expenses, thus being suitable for the modification of the existing fume dedusting device.

Owner:CHINESE TEXTILE ACAD

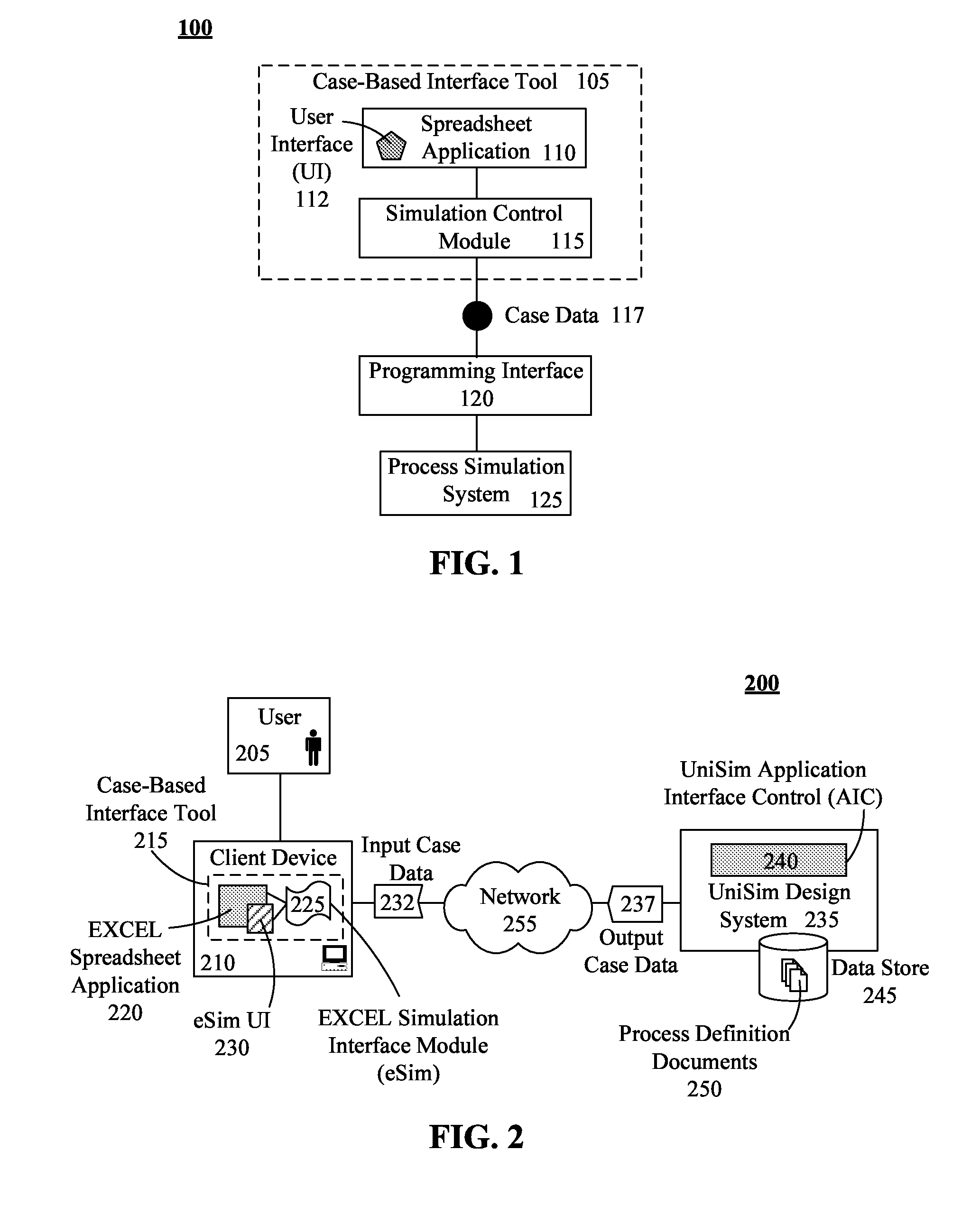

Utilizing spreadsheet user interfaces with flowsheets of a cpi simulation system

InactiveUS20100262900A1Shorten the timeSimulator controlAnalogue computers for chemical processesElectronic formParallel computing

A simulation system includes at least one processor configured to execute a computer program product, stored upon a storage medium. The computer program product includes a spreadsheet application, a process simulation application, and an integration tool (e.g., eSim), where the spreadsheet application and the process simulation application are discrete, stand alone products. The process simulation application can simulate chemical processes using at least one flowsheet, which models a general flow of chemical plant processes and equipment. The integration tool can map process simulation application objects and properties to spreadsheet application objects, can convey information between mapped objects, can perform case management functions, and can perform orchestrated calculation functions.

Owner:HONEYWELL INT INC

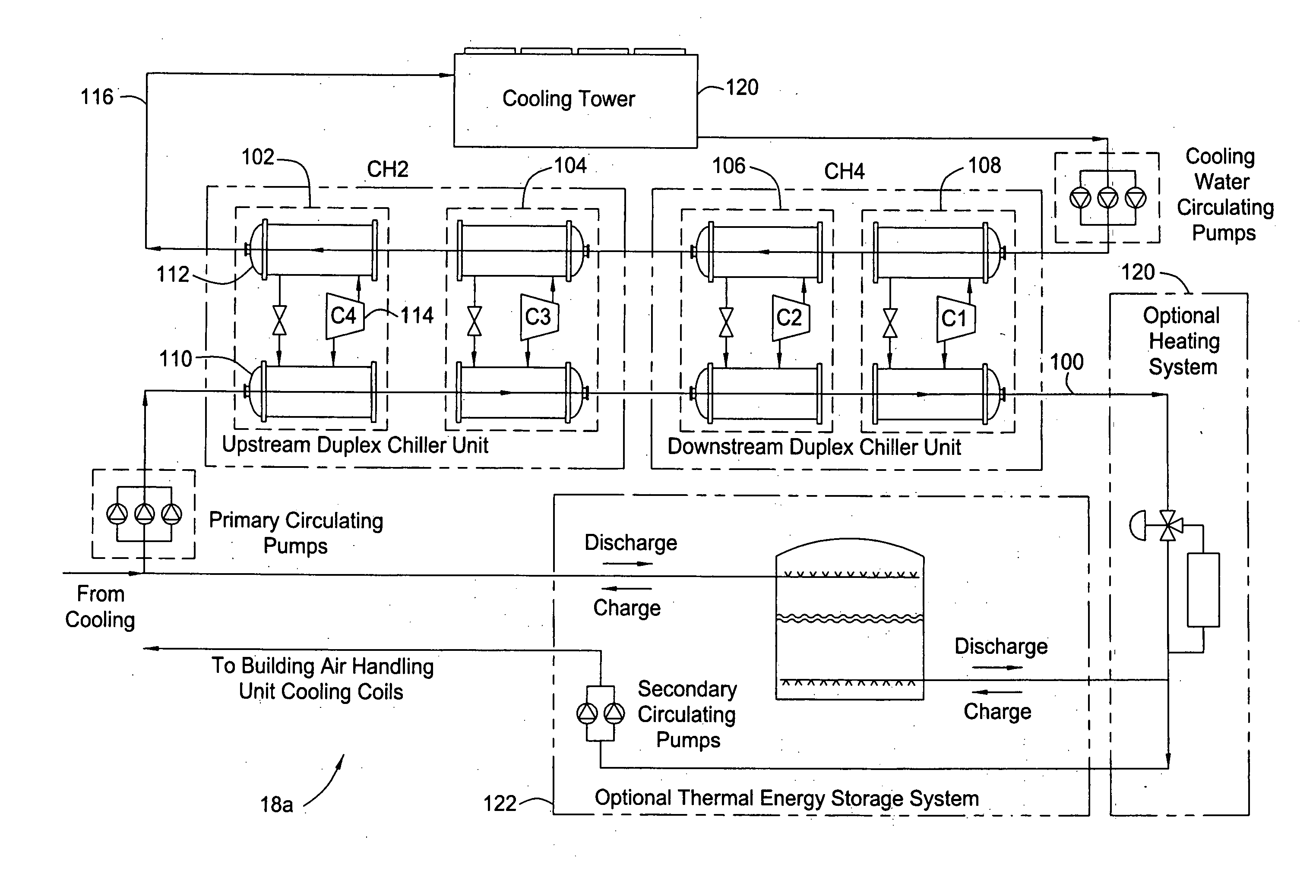

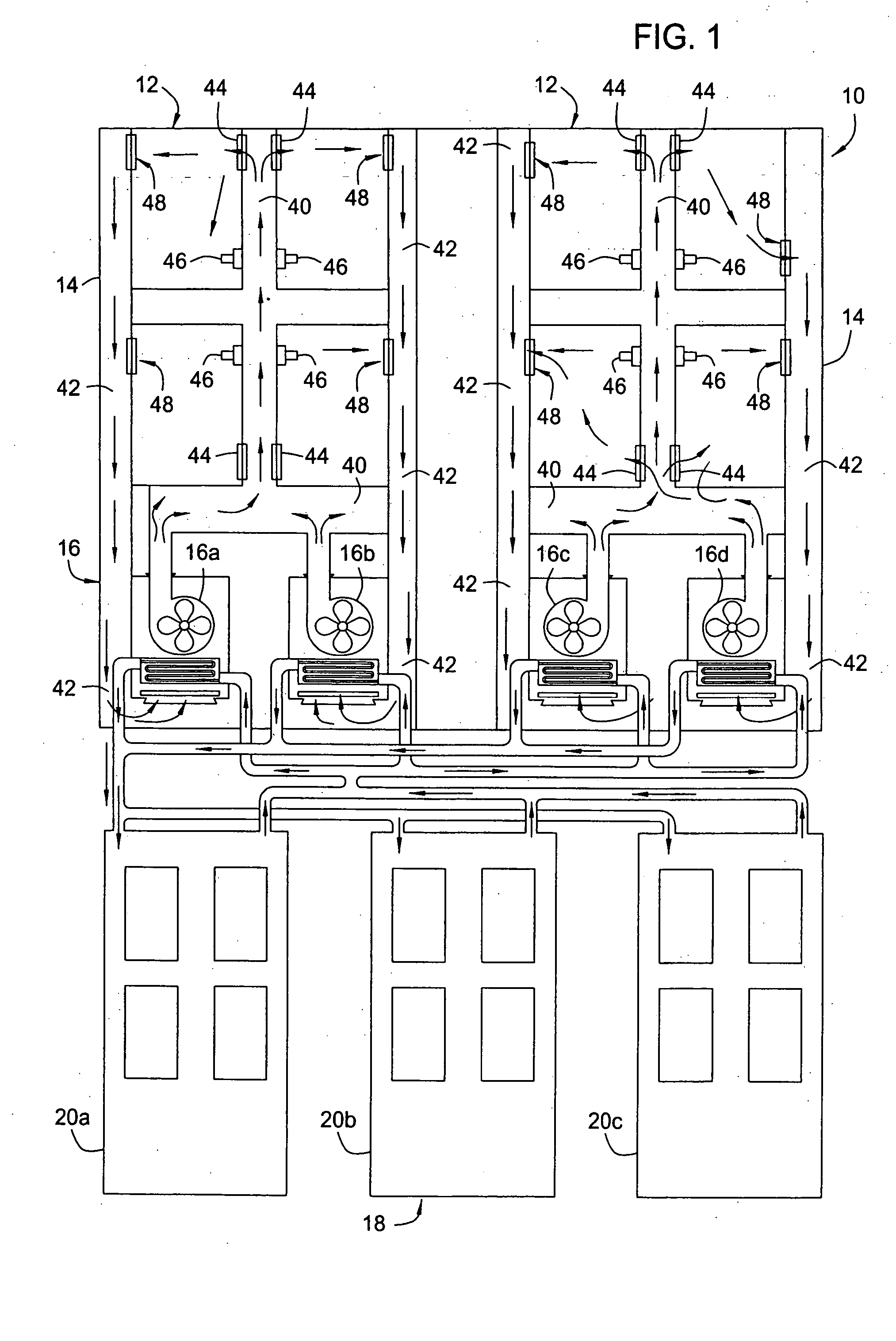

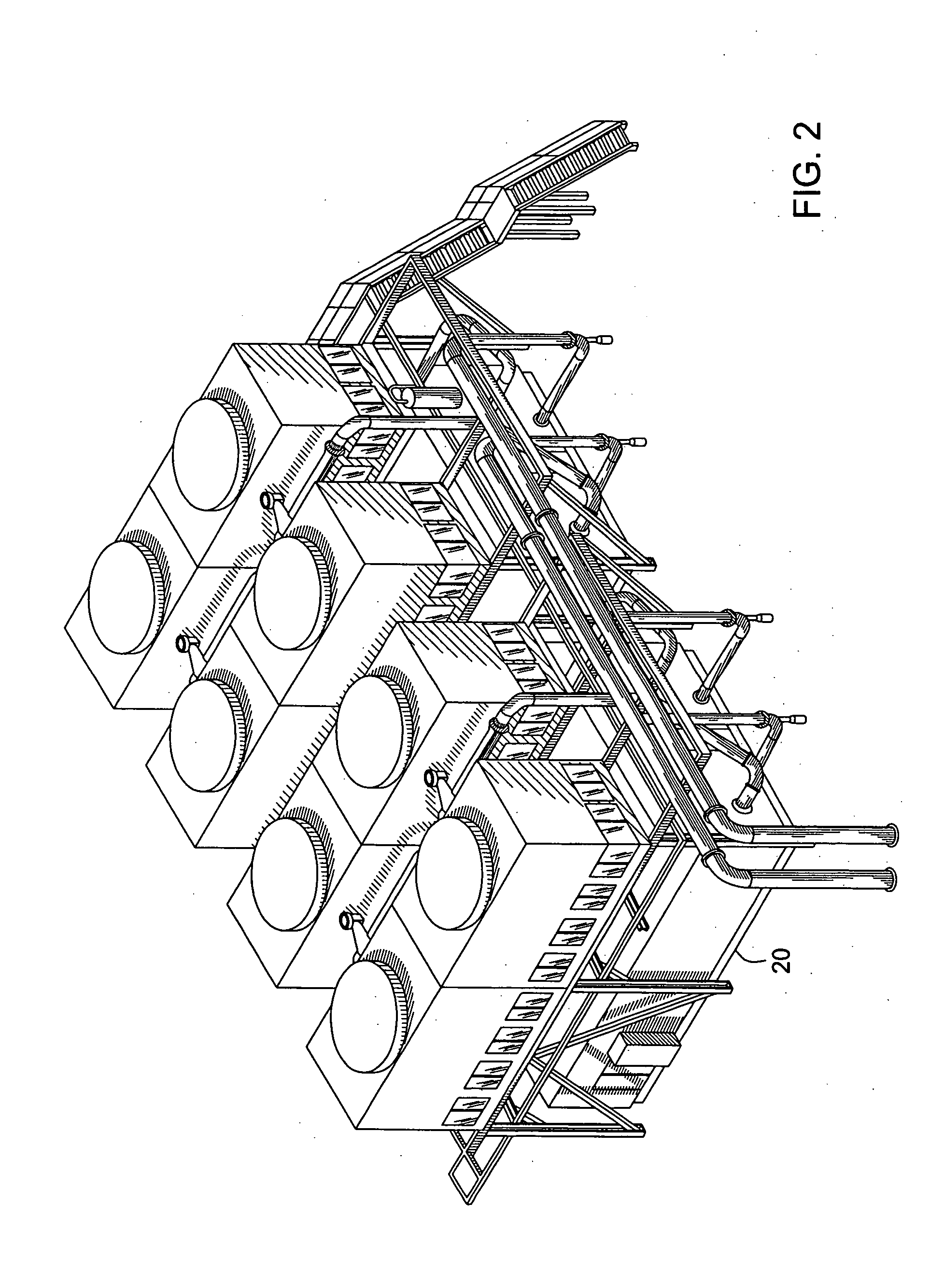

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

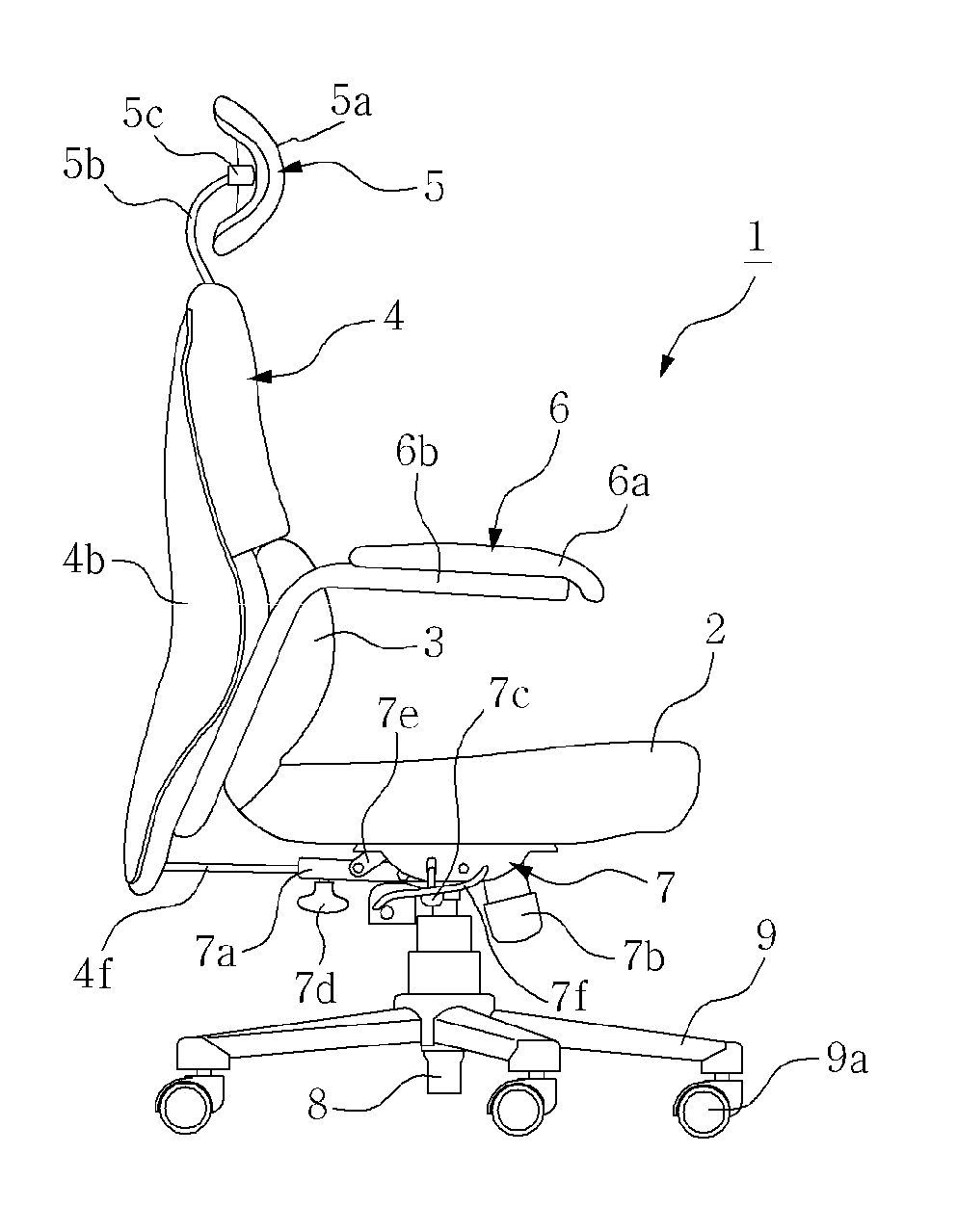

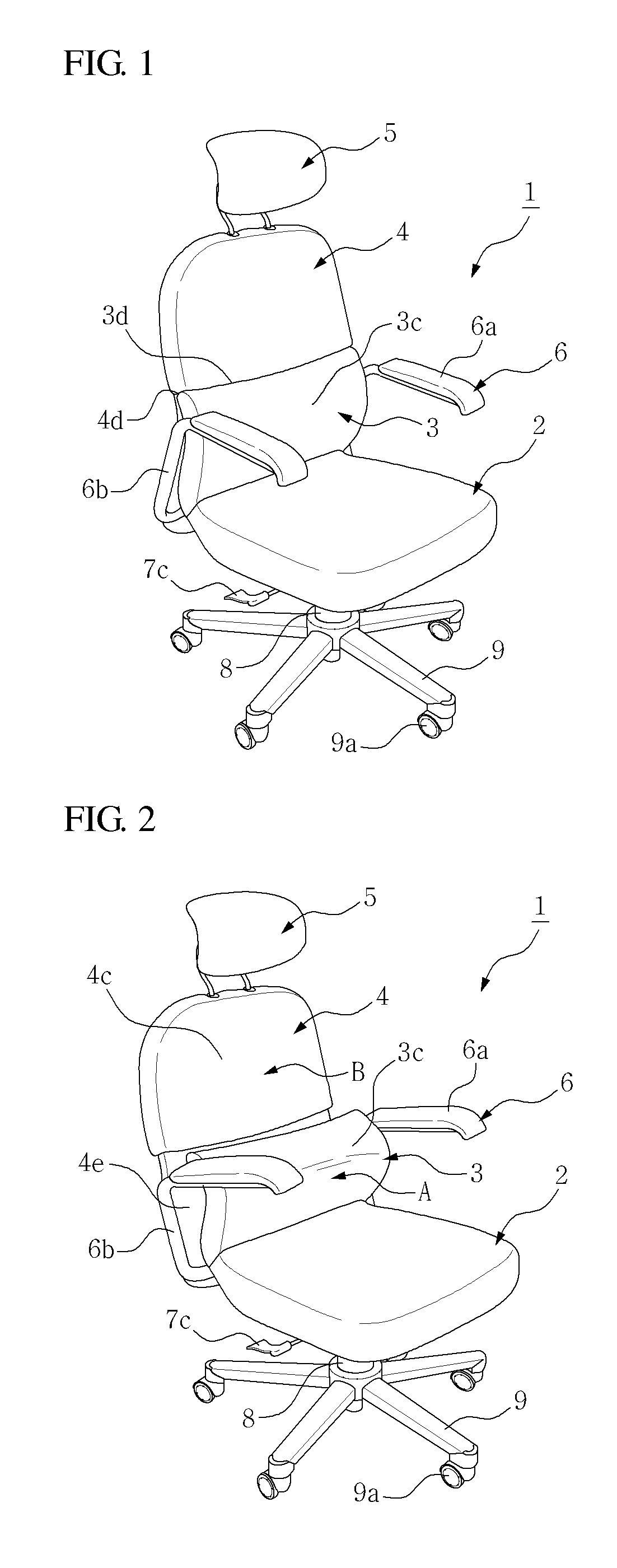

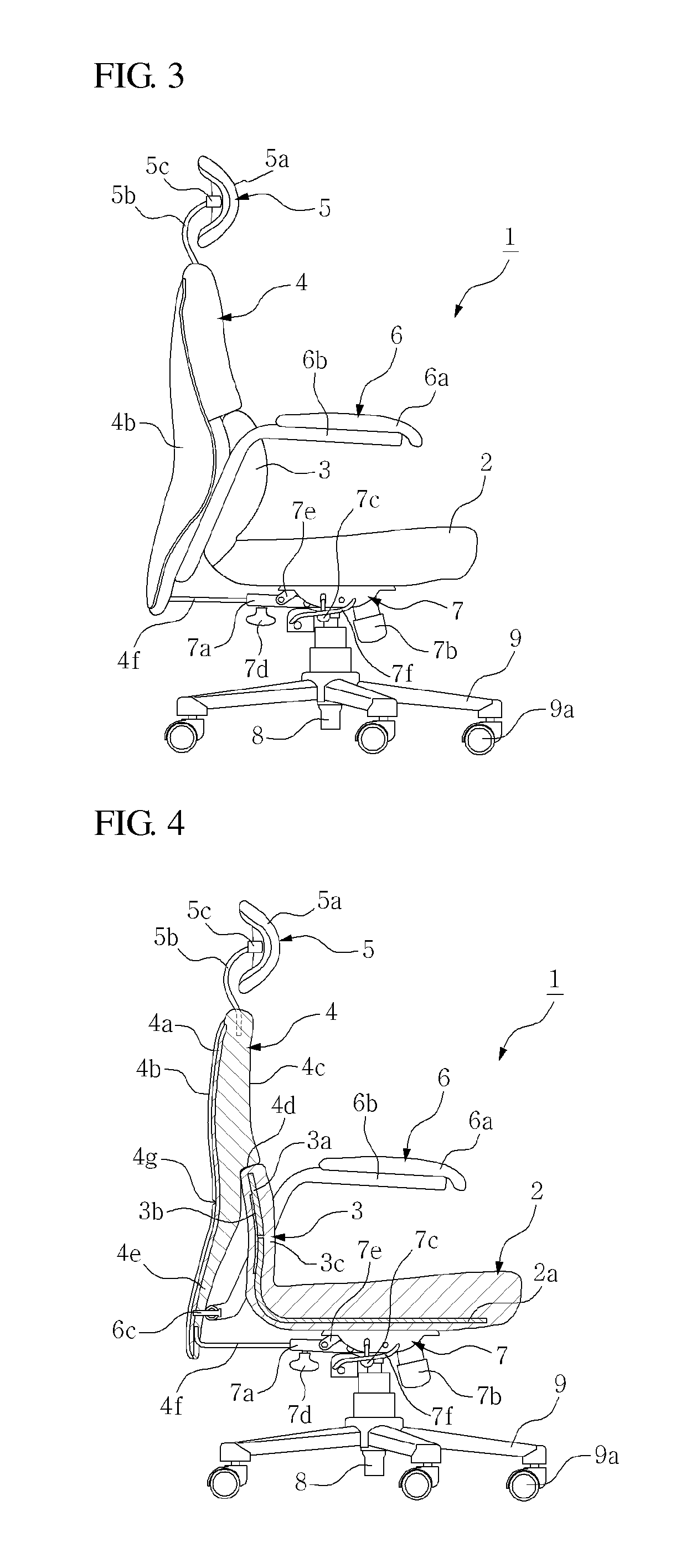

Chair with separate and interconnecting type lumbar and thoracic supports

The present invention relates to an apparatus for effectively purifying and neutralizing toxic gases such as odors, fumes or various volatile organic compounds generated by research laboratories, chemical processing factories or hospitals where medicinal products are handled. The apparatus according to the present invention comprises: a main body having an intake, an exhaust and a control panel; a pre-filter, a first filter, first and second neutralizing pellet beds, and a second filter which are mounted in the apparatus main body and are placed from the intake to the exhaust in that order; and a blower and a driving device placed between the first and second neutralizing pellet beds. The apparatus effectively purifies and neutralizes toxic gases and collects fine particles or dust. Thus, the apparatus helps to maintain health of researchers, people who perform experiments, workers in chemical factories, or medical workers, since the filter and neutralizing pellet bed are configured in a cartridge form, the apparatus is low-maintenance. Also, additional connection of other facilities or pipes is not required. Therefore, the apparatus has high usability due to the independent compact form and function thereof, and can be driven with less noise.

Owner:CHAIRO

System and method for abnormal event detection in the operation of continuous industrial processes

ActiveUS7349746B2Easy to monitorImprove isolationCatalytic crackingResistance/reactance/impedencePrincipal component analysisMultivariate statistical

Thousands of process and equipment measurements are gathered by the modern digital process control systems that are deployed in refineries and chemical plants. Several years of these data are historized in databases for analysis and reporting. These databases can be mined for the data patterns that occur during normal operation and those patterns used to determine when the process is behaving abnormally.These normal operating patterns are represented by sets of models. These models include simple engineering equations, which express known relationships that should be true during normal operations and multivariate statistical models based on a variation of principle component analysis. Equipment and process problems can be detected by comparing the data gathered on a minute by minute basis to predictions from these models of normal operation. The deviation between the expected pattern in the process operating data and the actual data pattern are interpreted by fuzzy Petri nets to determine the normality of the process operations. This is then used to help the operator localize and diagnose the root cause of the problem.

Owner:EXXON RES & ENG CO

Systems and methods for quenching, gas clean up, and ash removal

A method, apparatus, and system for a solar-driven chemical plant are disclosed. An embodiment may include a solar thermal receiver aligned to absorb concentrated solar energy from one or more solar energy concentrating fields. A solar driven chemical reactor may include multiple reactor tubes located inside the solar thermal receiver. The multiple reactor tubes can be used to gasify particles of biomass in the presence of a carrier gas. The gasification reaction may produce reaction products that include hydrogen and carbon monoxide gas having an exit temperature from the tubes exceeding 1000 degrees C. An embodiment can include a quench zone immediately downstream of an exit of the chemical reactor. The quench zone may immediately quench via rapid cooling of at least the hydrogen and carbon monoxide reaction products within 0.1-10 seconds of exiting the chemical reactor to a temperature of 800 degrees C. or less.

Owner:SUNDROP IP HLDG LLC

Methods for wastewater treatment

InactiveUS6132630ALow cost of treatmentOptimize present wastewater treatment plantWater/sewage treatment by centrifugal separationWater contaminantsFuel oilOil and natural gas

A method has been invented for separating components of a wastewater stream, the stream containing water, oil (e.g. heavy oil and / or light oil), undesirable organic material (solid and / or liquid), and contaminating solids, the method including feeding a wastewater stream to a first pre-treatment unit producing a first pretreated stream, feeding the first pretreated stream to a first centrifuge for centrifugal separation, producing a first liquid centrifuged stream, and a second liquid stream, and feeding the first liquid centrifuged stream to a second centrifuge producing a resultant centrifuged stream of recoverable oil and a water phase centrifuged stream which can be treated further or fed back to a source for re-use. The source may be a facility from the group including refineries, chemical plants, paper mill plants, and oil and gas processing facilities.

Owner:TUBOSCOPE VETCO INT +1

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

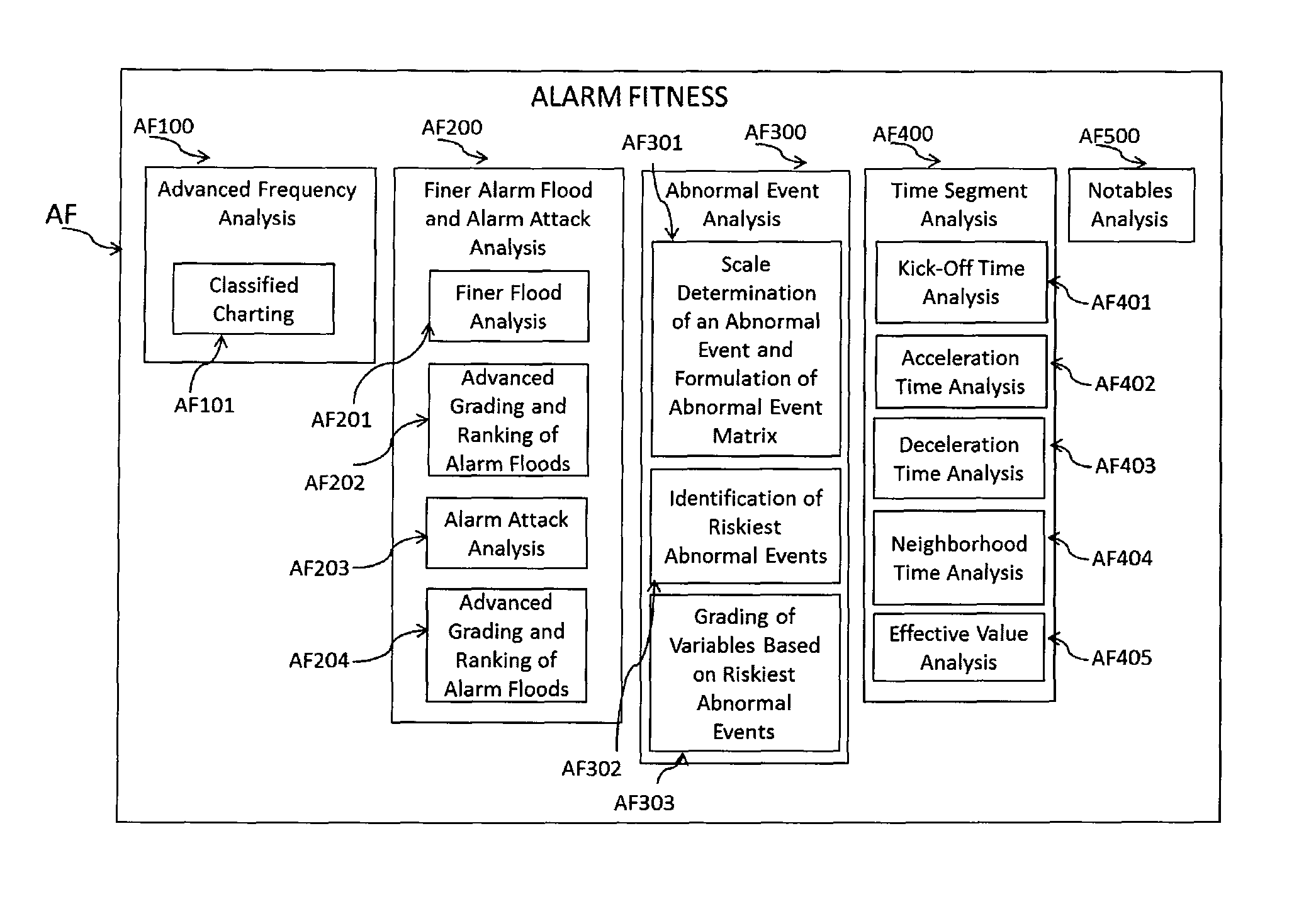

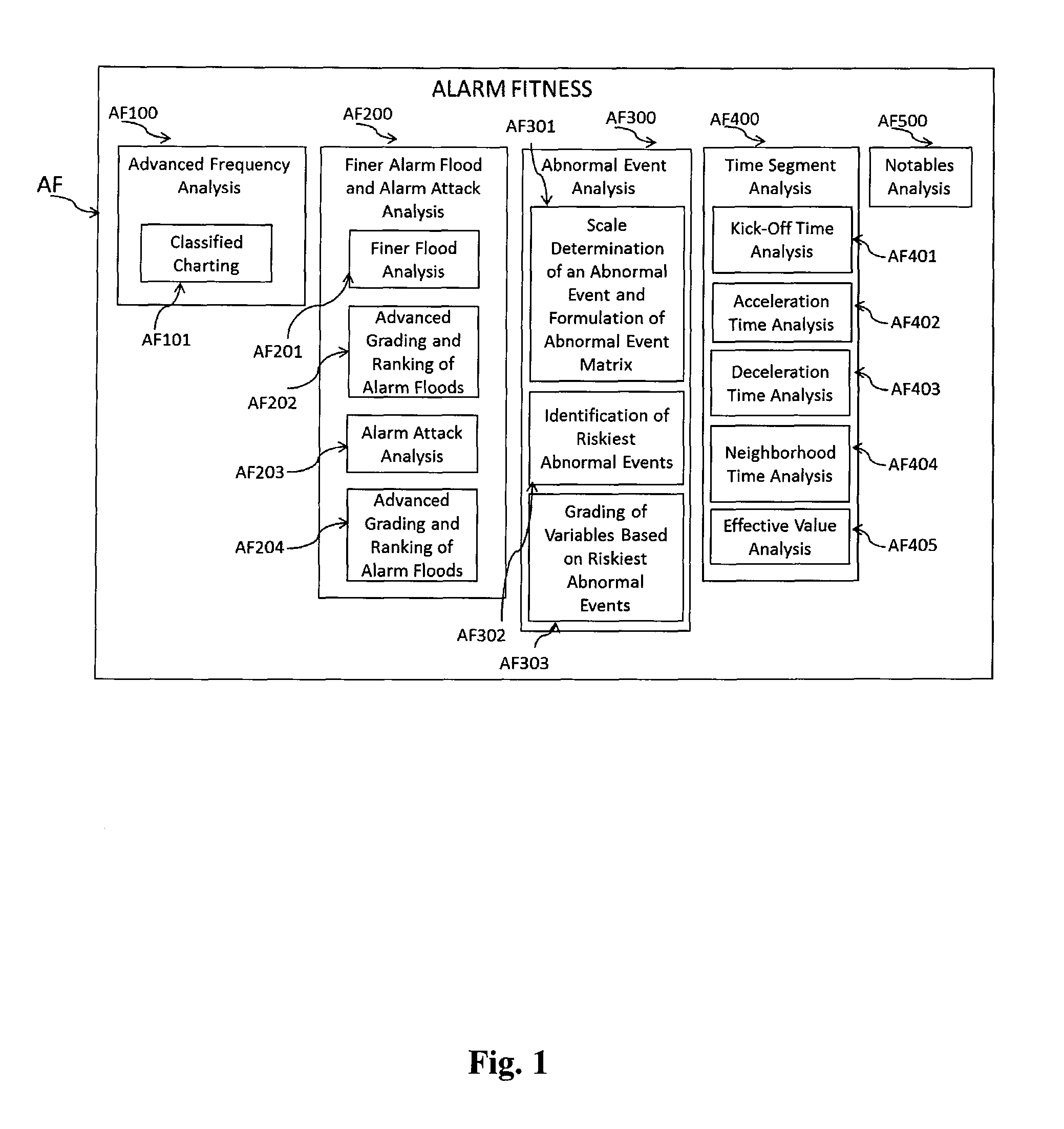

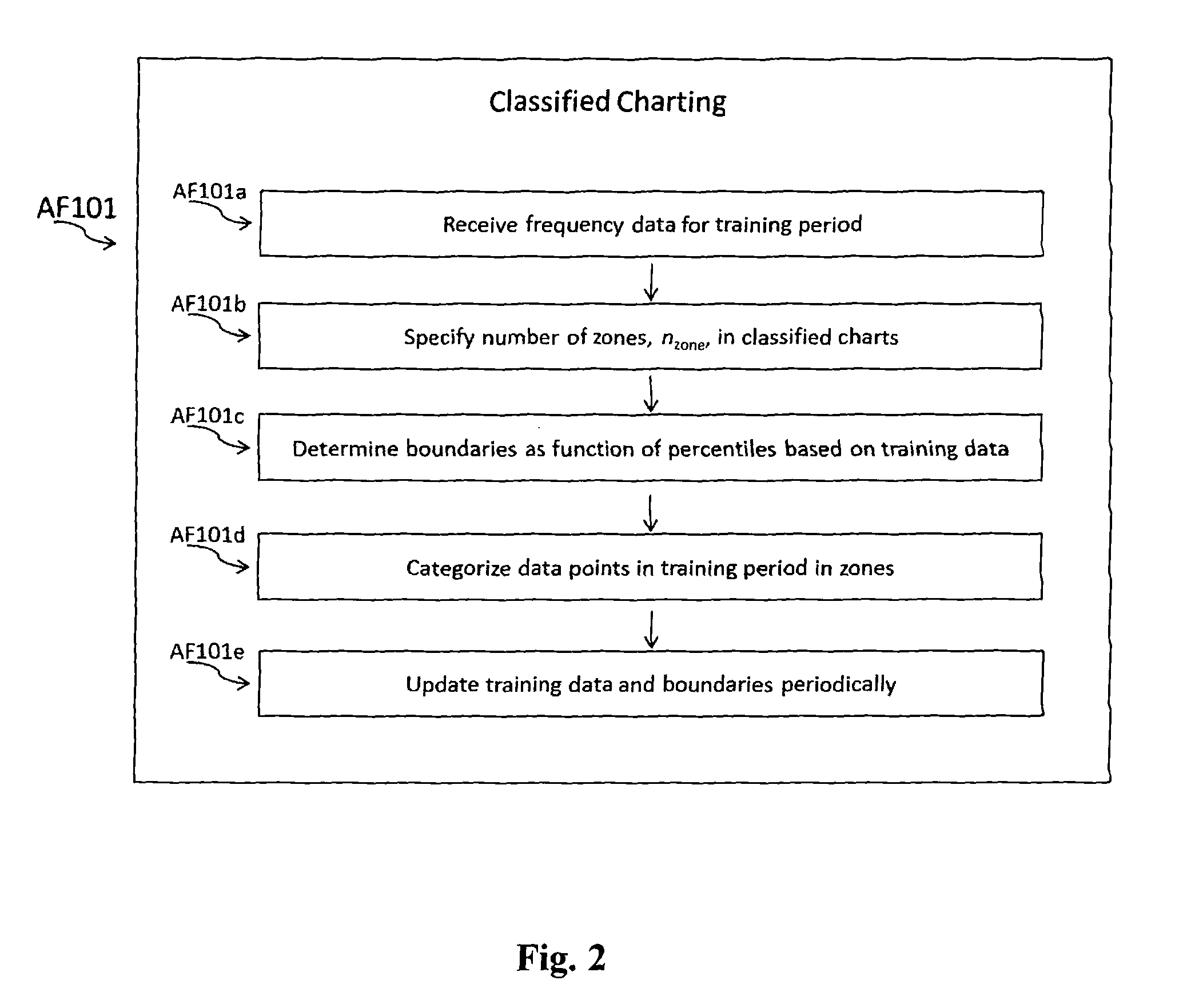

Dynamic prediction of risk levels for manufacturing operations through leading risk indicators

ActiveUS20130063264A1Raise the possibilityImprove securityTesting/monitoring control systemsAlarmsRisk levelDisposal waste

Provided are methodologies to properly assess and manage operational risks at operations sites, e.g., a manufacturing, production or processing facility, such as a refinery, chemical plant, fluid-catalytic-cracking units, or nuclear energy plant, or a biological or waste management facility, airport or even financial institutions, or at any facility in which operations are often accompanied by risk associated with many high-probability, low-consequence events, often resulting in near-misses. In some operations, processes are monitored by alarms, but the invention operates on either process data or alarm data. The methods are based upon measurement of one or more variables, and / or utilization and management of the concept of “hidden process near-miss(es)” to identify a change or escalation, if any, in probability of occurrence of an adverse incident. The methodologies combine a plurality of subsets (also useful independently) of dynamically calculated leading risk indicators for dynamic risk management.

Owner:NEAR MISS MANAGEMENT

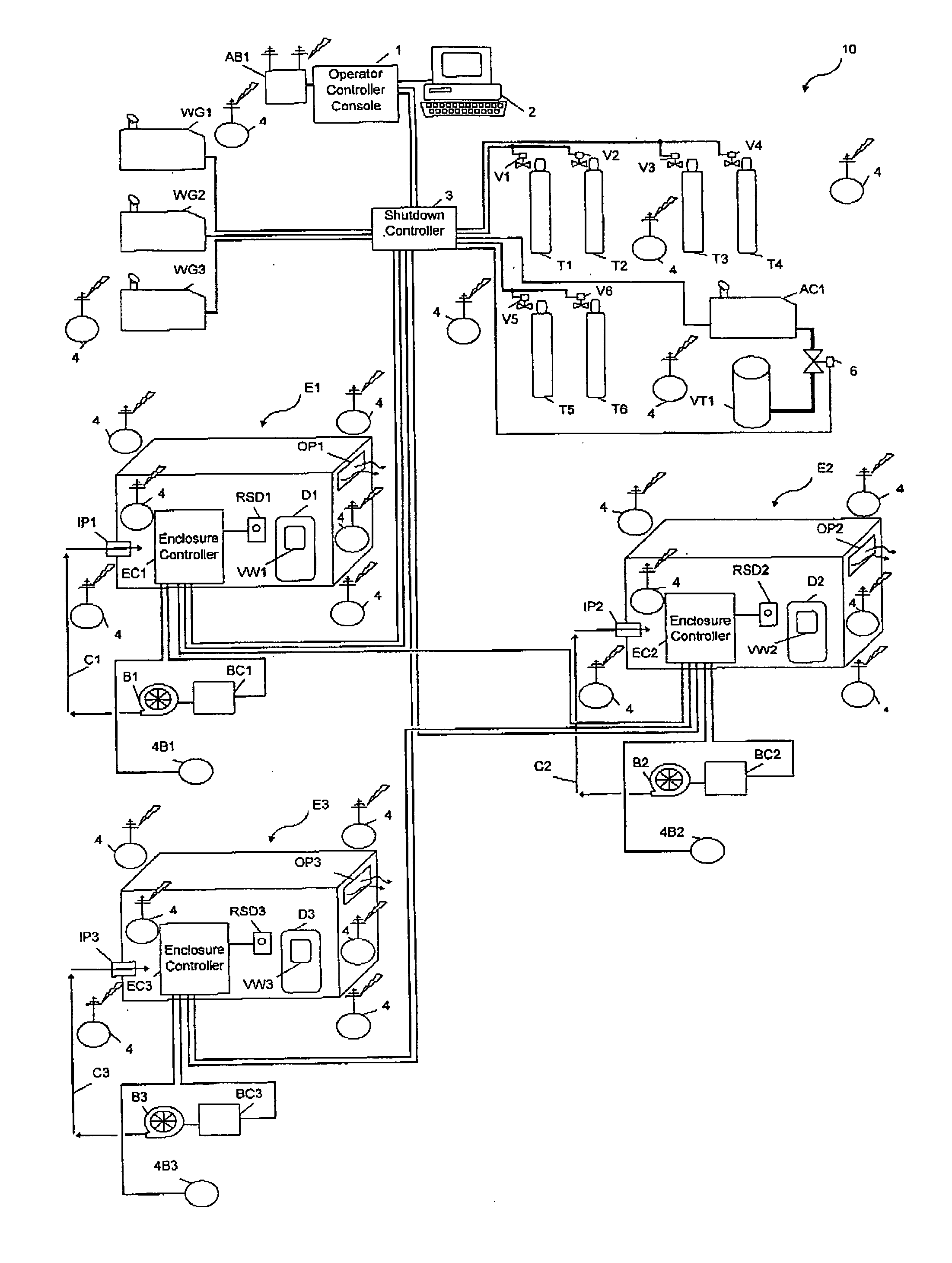

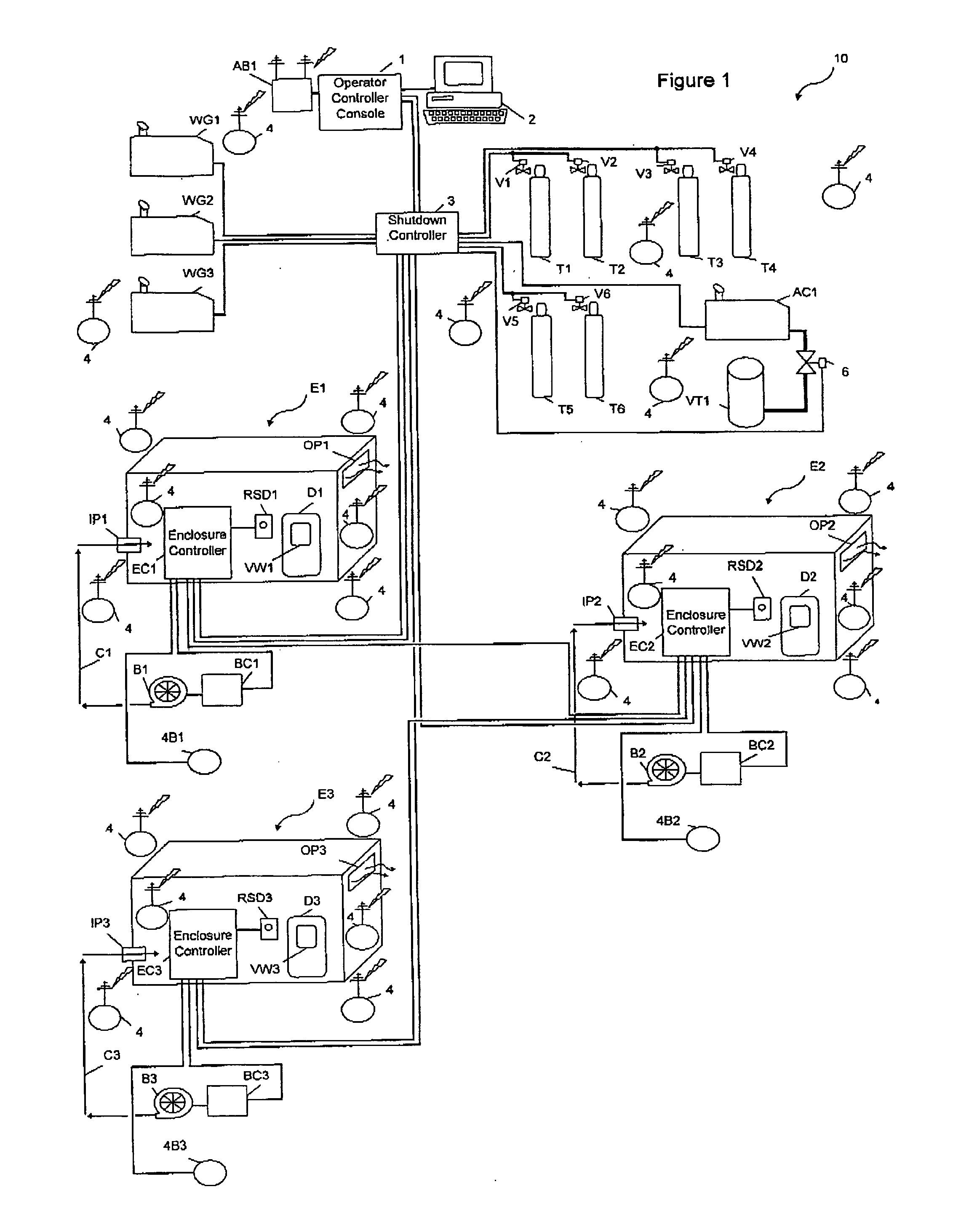

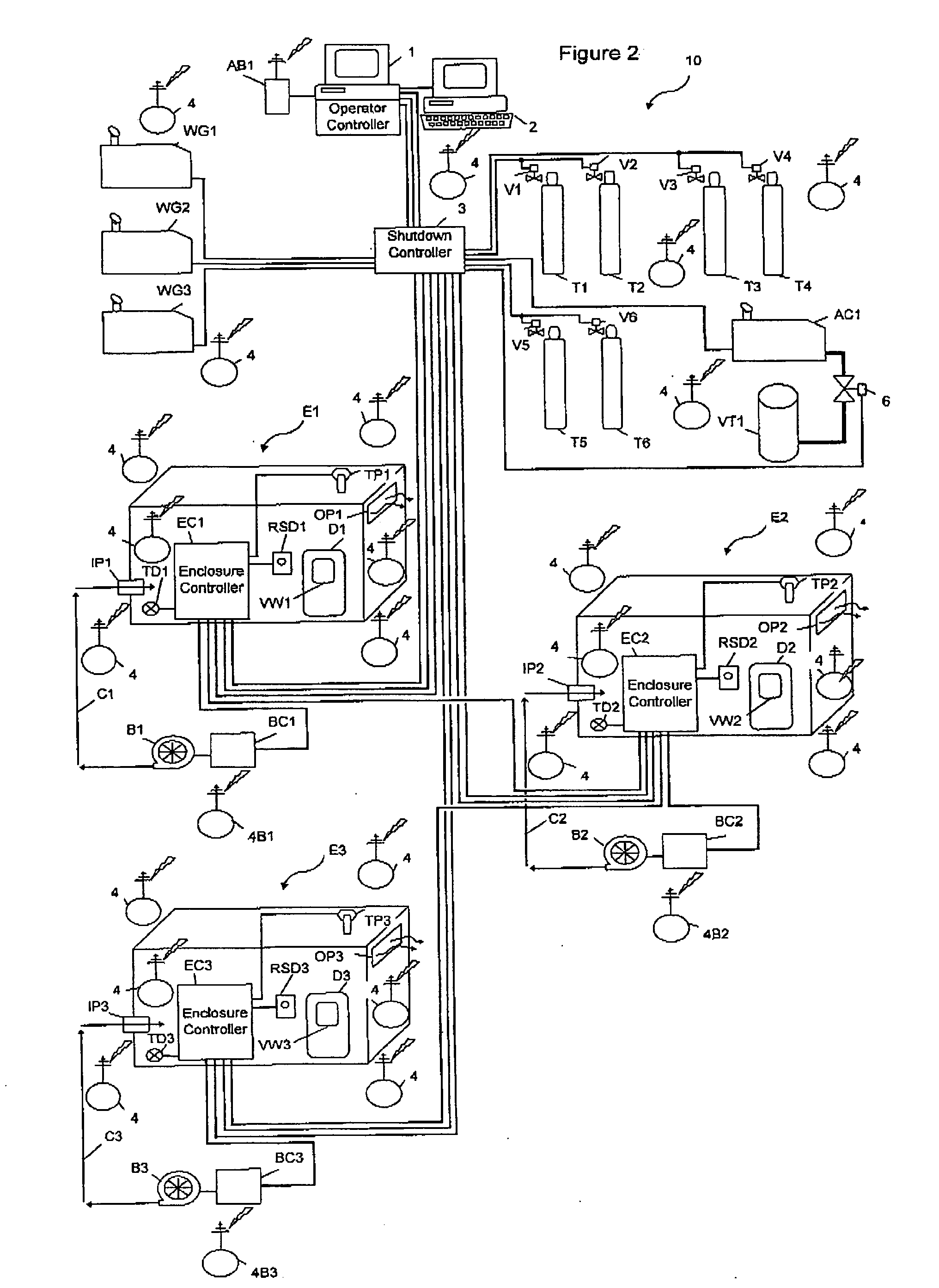

Enclosure system allowing for hot work within the vicinity of flammable and combustible material

InactiveUS20070052543A1Welding/cutting auxillary devicesElectric testing/monitoringCompound (substance)Hot work

An enclosure constructed around an area at which hot work is to be performed at a facility containing flammable or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like. Facilities include petroleum drilling and production platforms, oil tankers, petroleum and chemical plants, and petroleum tank farms. Gas detection monitoring apparatuses are used with the enclosure which will automatically simultaneously shutdown one or more enclosures.

Owner:ALFORD SAFETY SERVICES

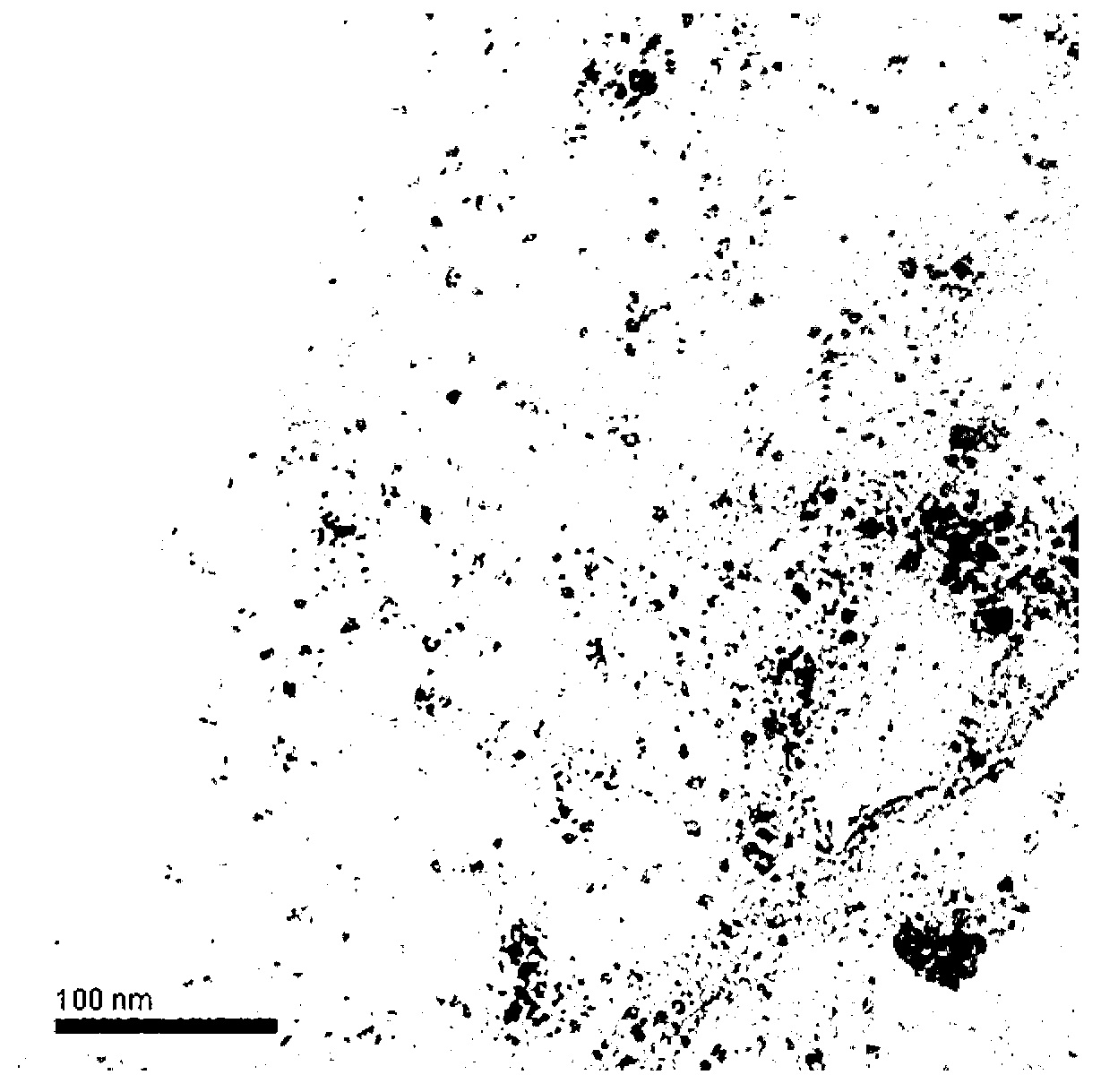

Sulfonylation graphene oxide magnetic adsorbent, and preparation method and application thereof

InactiveCN102989420AWide variety of sourcesLow priceOther chemical processesAlkali metal oxides/hydroxidesSorbentAniline

The invention relates to a sulfonylation graphene oxide magnetic adsorbent, and a preparation method and application thereof. The adsorbent uses graphene oxide nanosheet as a substrate; the substrate surface is loaded with magnetic ferrite nanoparticles, and contains a large amount of sulfonic acid. The method comprises the following specific steps: first subjecting a graphite powder to pre-oxidation and deep oxidation, and conducting ultrasonic separation to obtain a graphene oxide solution; then adding a mixed solution of iron ions and ferrous ions; rapidly adding ammonia solution while stirring to obtain magnetic graphene oxide; and finally grafting aminobenzene sulfonic acid to magnetic graphene oxide matrix, washing and determining a constant volume to obtain a final product. The product has good adsorption effect on the heavy metals, copper and cadmium, and organic aniline. The product has the advantages of low cost, large specific surface area, high adsorption capacity and easy separation and recovery. The invention can be used for treating wastewater from smelting factory, electronics factory, chemical plant and electroplating plant.

Owner:HUNAN UNIV

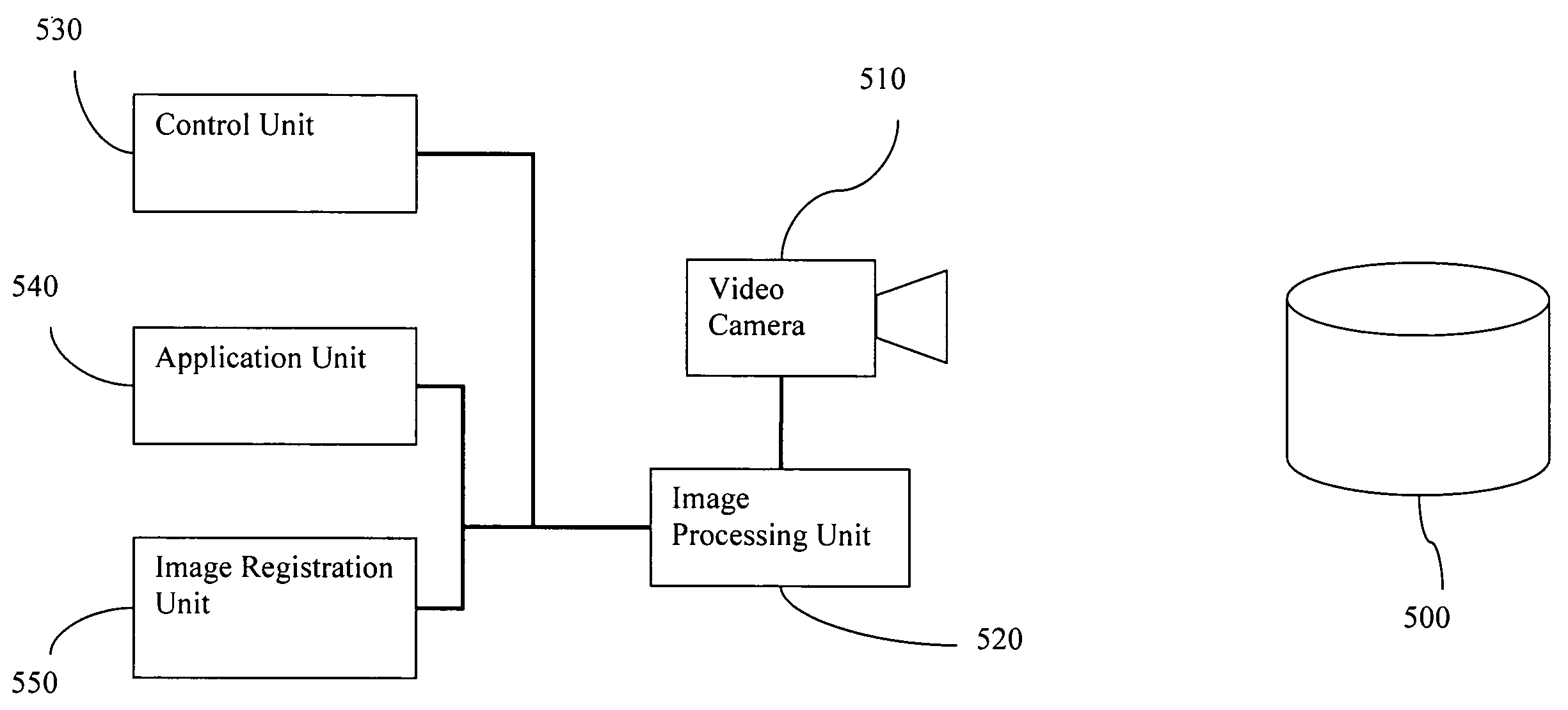

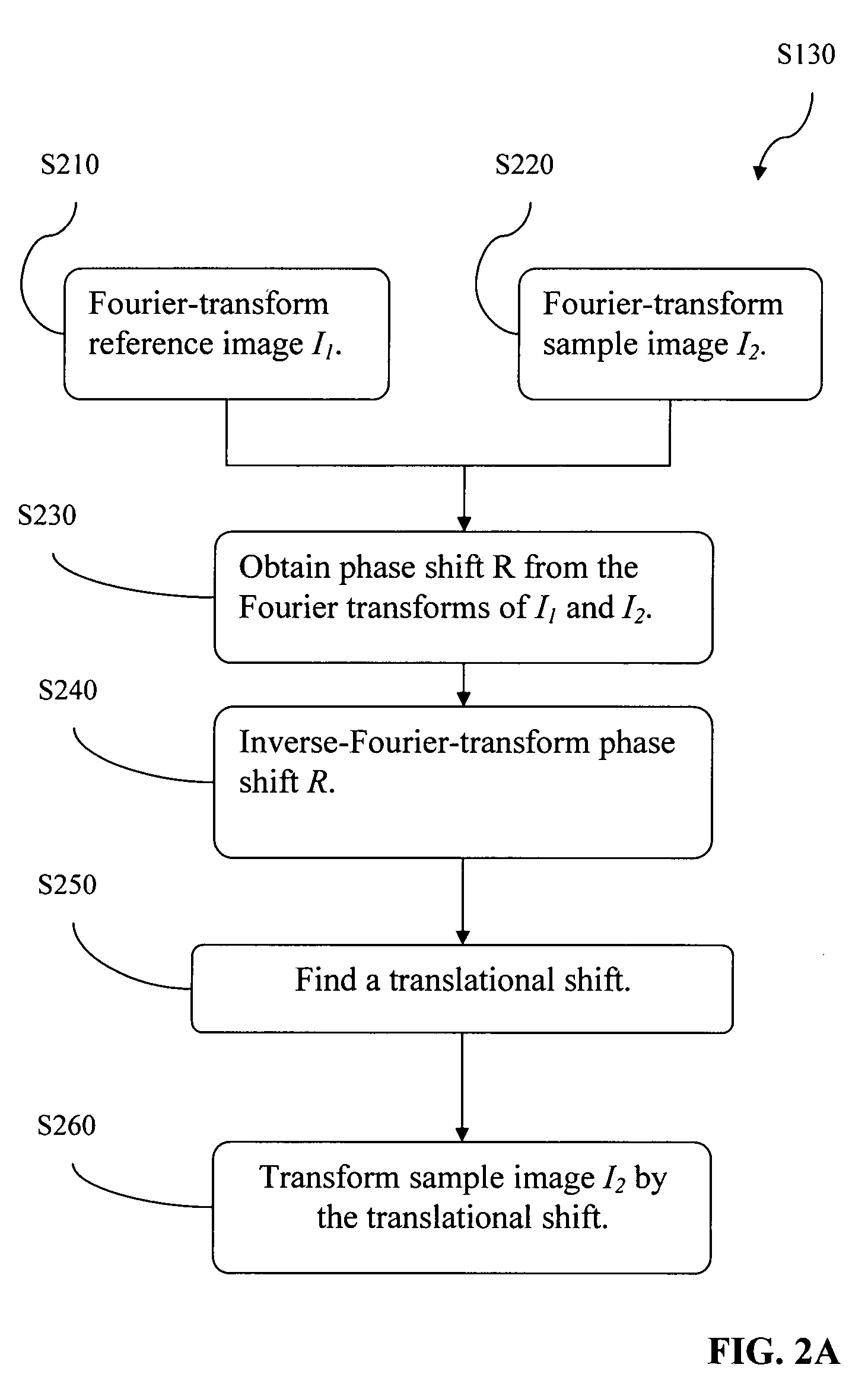

Automatic alignment of video frames for image processing

InactiveUS20080063298A1Reduce errorsImprove stabilityImage enhancementImage analysisProcess equipmentConfocal

The provided is a method that can automatically align image frames in recorded video clips. Individual frames in video may shift and rotate due to shaking or vibration of a video camera. Unaligned frames make some imaging processing techniques difficult or infeasible. One example of image processing techniques is to isolate, recognize, and / or quantitatively analyze vapor plume images captured by an Infrared (IR) camera. Such techniques have a great potential to be used to automatically detect volatile organic compounds (VOC) leaked from process equipment at refineries and chemical plants. This invention is a technique for various subsequent image processing techniques. The invention uses spatially based Fast Fourier Transforms (FFT) to determine amount of shift, rotation, and scaling to align image frames, and uses a digital filtering technique to improve the alignment.

Owner:PROVIDENCE PHOTONICS

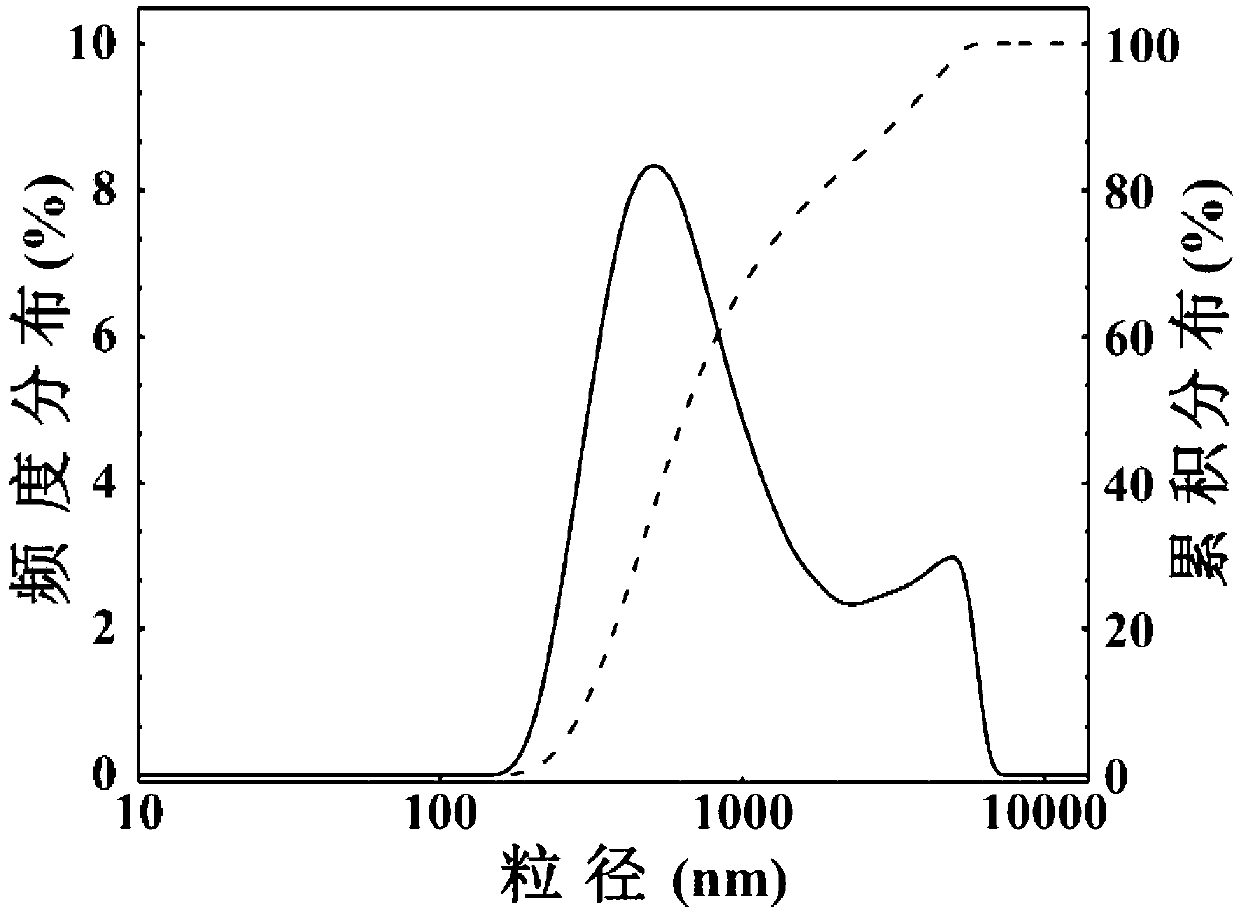

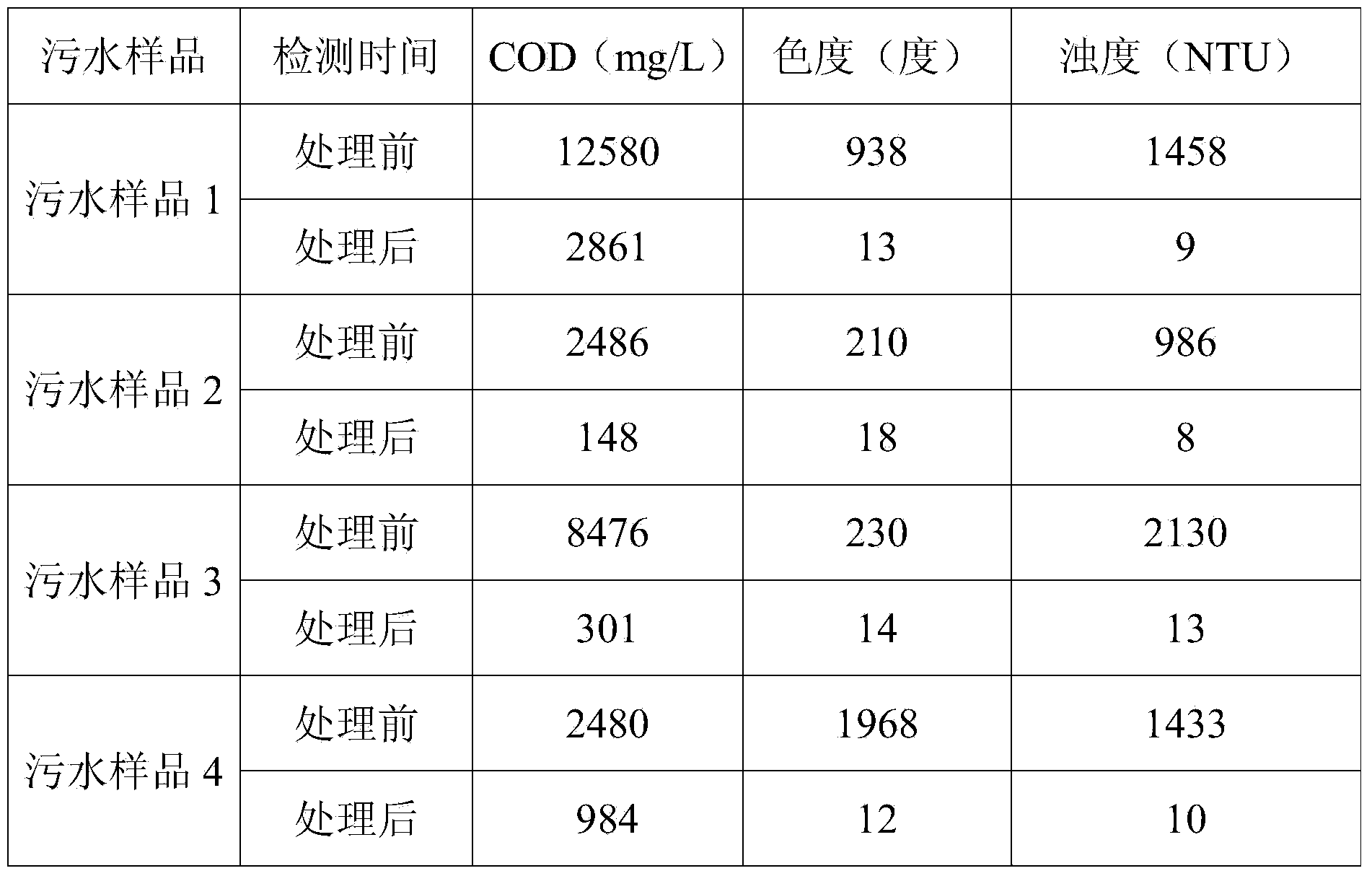

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

Utilizing spreadsheet user interfaces with flowsheets of a CPI simulation system

InactiveUS9053260B2Simulator controlAnalogue computers for chemical processesParallel computingApplication object

Owner:HONEYWELL INT INC

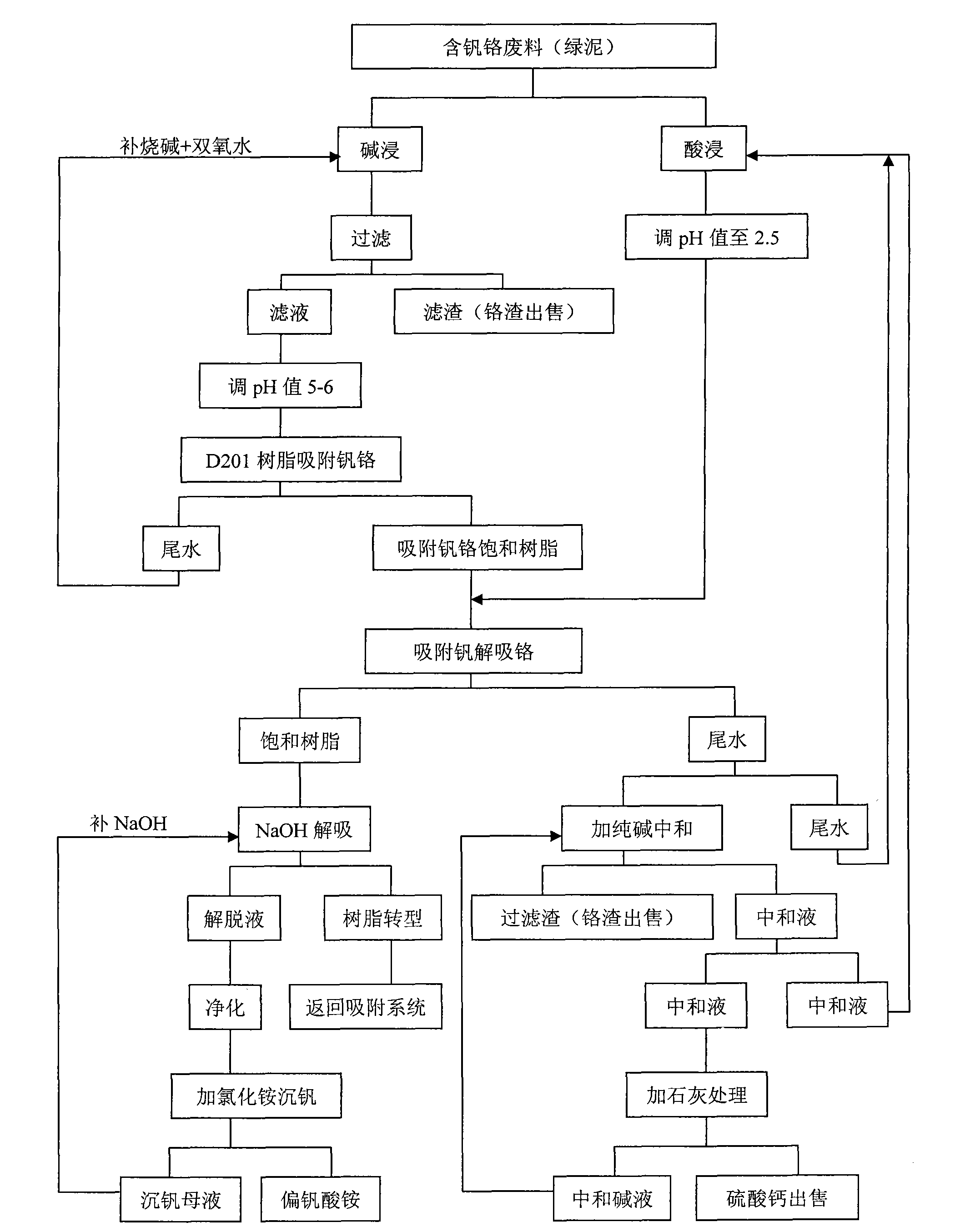

Method for separating and recovering vanadium and chrome from vanadium and chrome-containing waste

InactiveCN101538652ALess investmentMature production processProcess efficiency improvementDesorptionIon exchange

The invention relates to the field of chemical hydrometallurgy, in particular relates to a method for separating and recovering vanadium and chrome from a vanadium and chrome-containing waste. The method comprises the following steps: (1) alkaline leaching; (2) adsorption of alkaline leaching liquid; (3) acid leaching; (4) ion exchange; (5) desorption and devanadation; and (6) vanadium precipitation. The method has the advantages that: (1) the method has lower cost than a primary and secondary compound amine extraction process; (2) the method has short process flow, convenient operation, easy control, easy mastering and mature production process of recovering vanadium and chrome once the vanadium and chrome are separated; (3) the method has low production cost, and excluding sales revenue from chrome residues and calcium sulphate, the cost of fine vanadium is only 50000-60000 yuan / t; (4) the vanadium and the chrome are completely separated by the method; and (5) the method produces no secondary pollution, all the production processes are performed at normal temperature and has no roasting fume, and industrial water is recycled and subject to zero discharge; produced neutralization residues are of high-quality chrome residues and calcium sulphate and can be sold to chemical plants and cement plants as a raw material.

Owner:杨秋良 +1

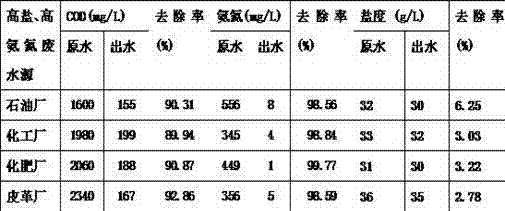

Method for treating high-salinity high-concentration ammonia-nitrogen wastewater

InactiveCN102849857AOvercoming processingOvercome the shortcomings of wastewater resistant to high ammonia nitrogenBacteriaBiological water/sewage treatmentHigh concentrationActivated sludge

The invention discloses a method for treating high-salinity high-concentration ammonia-nitrogen wastewater, characterized by: adopting sequencing batch reactor, accumulating nitrification sludge by alternately increasing the concentration of a nutrient solution or ammonia-nitrogen concentration, and domesticating to obtain high salinity-resisting high ammonia nitrogen-resisting nitrobacteria. According to the invention, the nitrobacteria can treat high-salinity wastewater having ammonia-nitrogen concentration of 500mg / L and having the salt content of no larger than 35g / L to make the effluent have the ammonia-nitrogen concentration of no larger than 10mg / L, thus the effluent achieve national level of discharging standard; the method has good effect on treating high-salinity high ammonia-nitrogen wastewater in chemical plant, leather factory, oil refinery and the like, can overcome the shortage that the nitrobacteria cannot simultaneously treat high-salinity and high ammonia-nitrogen wastewater existing in the prior art, and has important economic benefits and social benefits.

Owner:NANJING UNIV

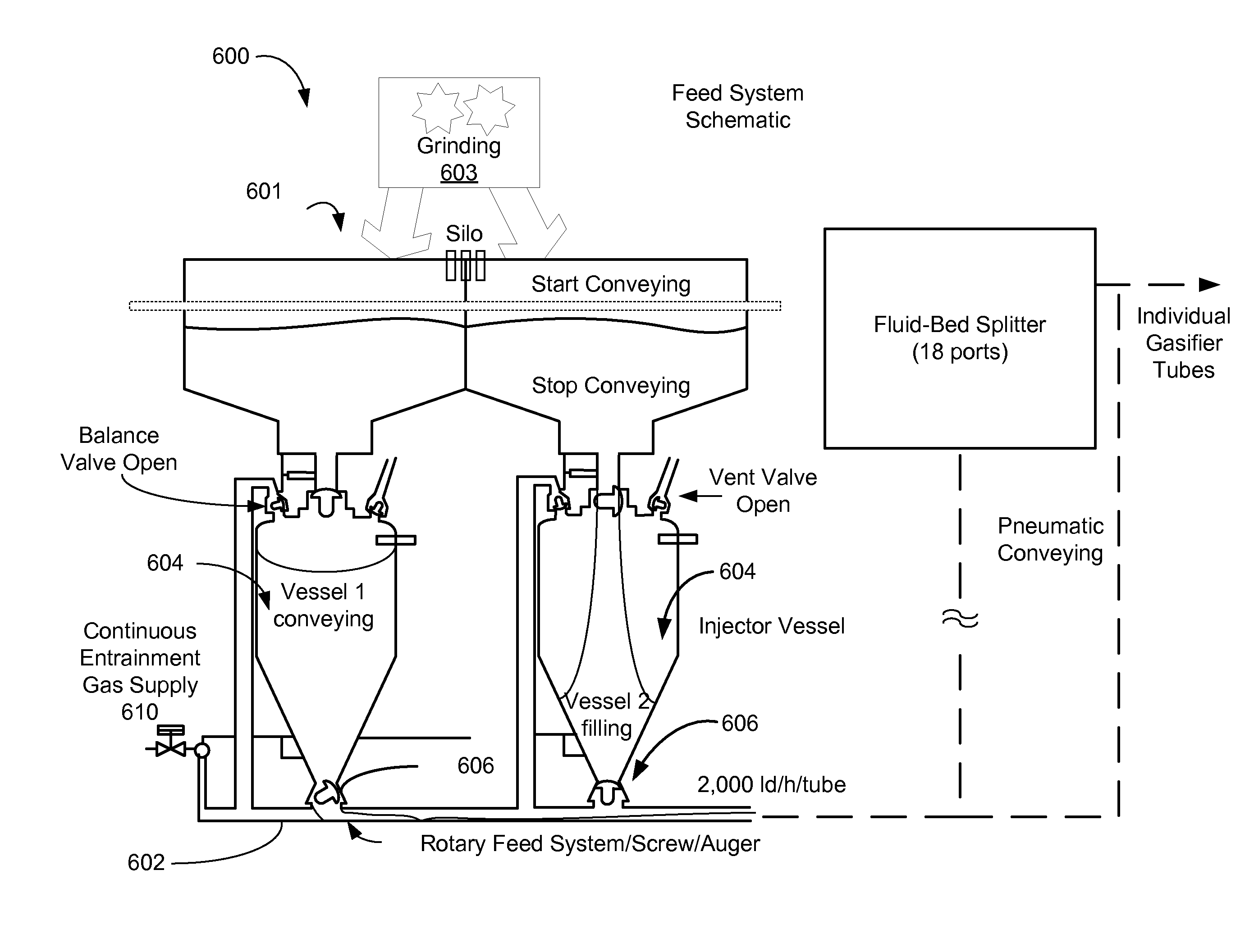

Systems and methods for reactor chemistry and control

InactiveUS20100242354A1Process control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical plant that manages variations in solar energy are disclosed. Some embodiments include a solar thermal receiver to absorb concentrated solar energy, a solar driven chemical reactor contained within the solar thermal receiver, and an entrained gas biomass feed system that uses an entrainment carrier gas and supplies a variety of biomass sources fed as particles into the solar driven chemical reactor. Inner walls of the solar thermal receiver and the chemical reactor can be made from materials selected to transfer energy. Some embodiments include a control system that may be configured to balance the gasification reaction of biomass particles with the available concentrated solar energy and additional variable parameters including, but not limited to, a fixed range of particle sizes, temperature of the chemical reactor, and residence time of the particles in a reaction zone in the chemical reactor.

Owner:SUNDROP FUELS

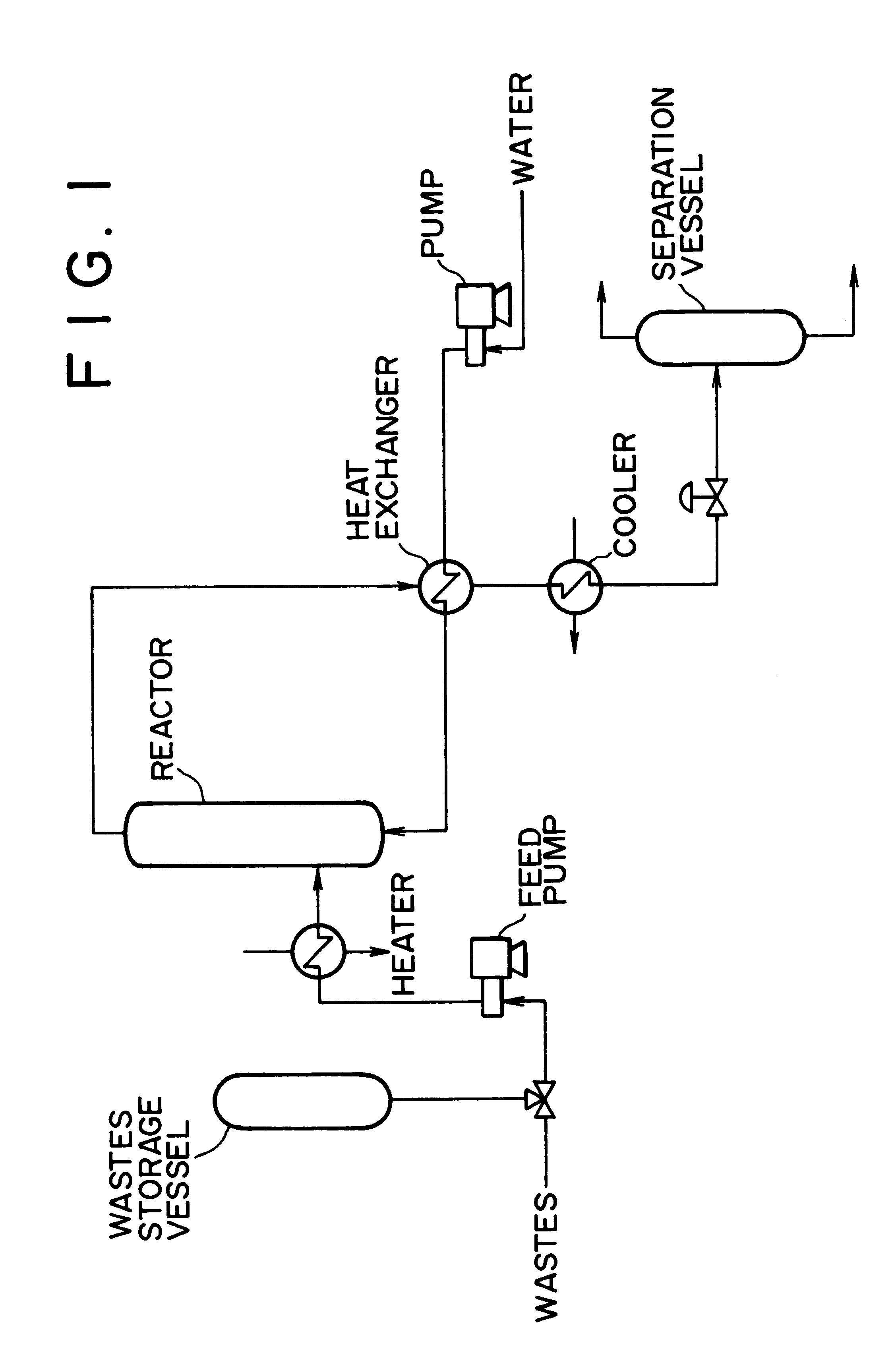

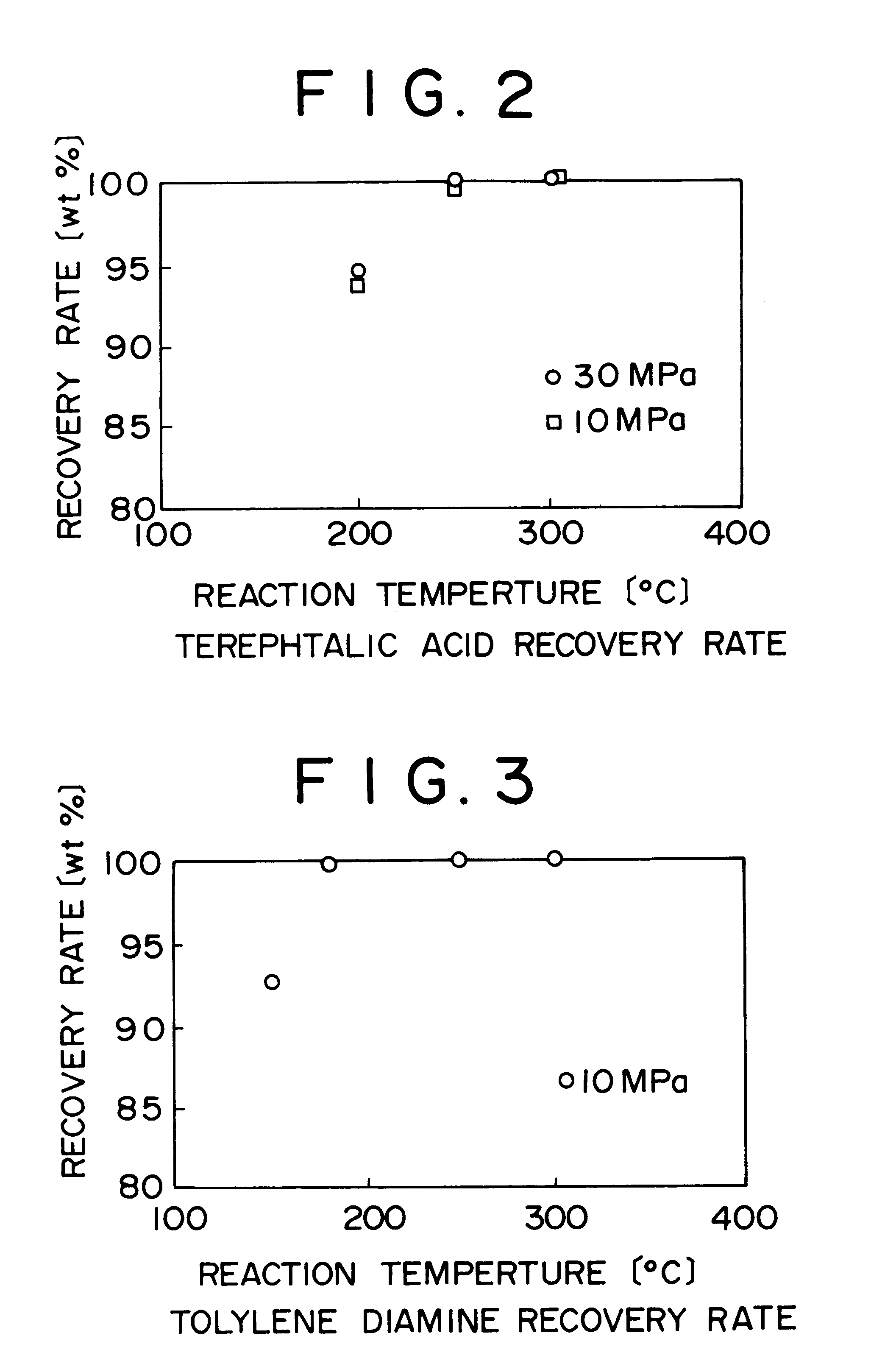

Method of and apparatus for decomposing wastes

InactiveUS6255529B1Useful operationResultant decomposition products can be utilized effectivelySolid waste disposalIndirect heat exchangersMolten stateLiquid state

A method of decomposing wastes containing target compounds having one or more of hydrolyzable bonds of ether bond, ester bond, amide bond and isocyanate bond wherein the method comprises continuously supplying the wastes in a molten state or liquid state to a reactor, continuously supplying super-critical water or high pressure / high temperature water to the reactor, bringing the water into contact with the wastes, thereby decomposing the target compounds and then recovering them as raw material compounds or derivatives thereof for the target compounds. Target compounds contained in wastes in chemical plants which could not be utilized but merely incinerated or discarded so far are continuously decomposed into raw material compounds or derivatives thereof for the aimed compound and can be reutilized effectively.

Owner:TAKEDA CHEM IND LTD 50

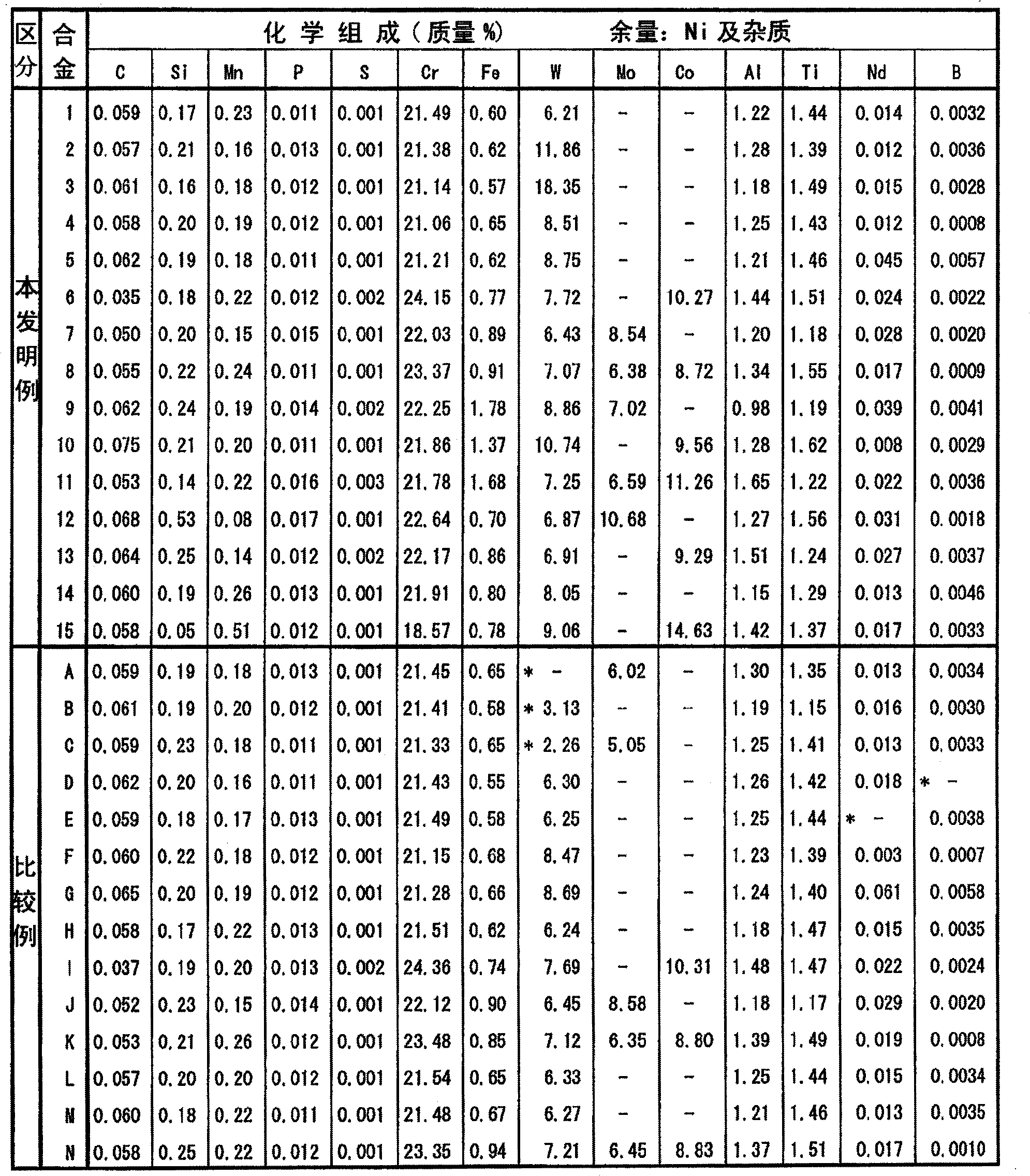

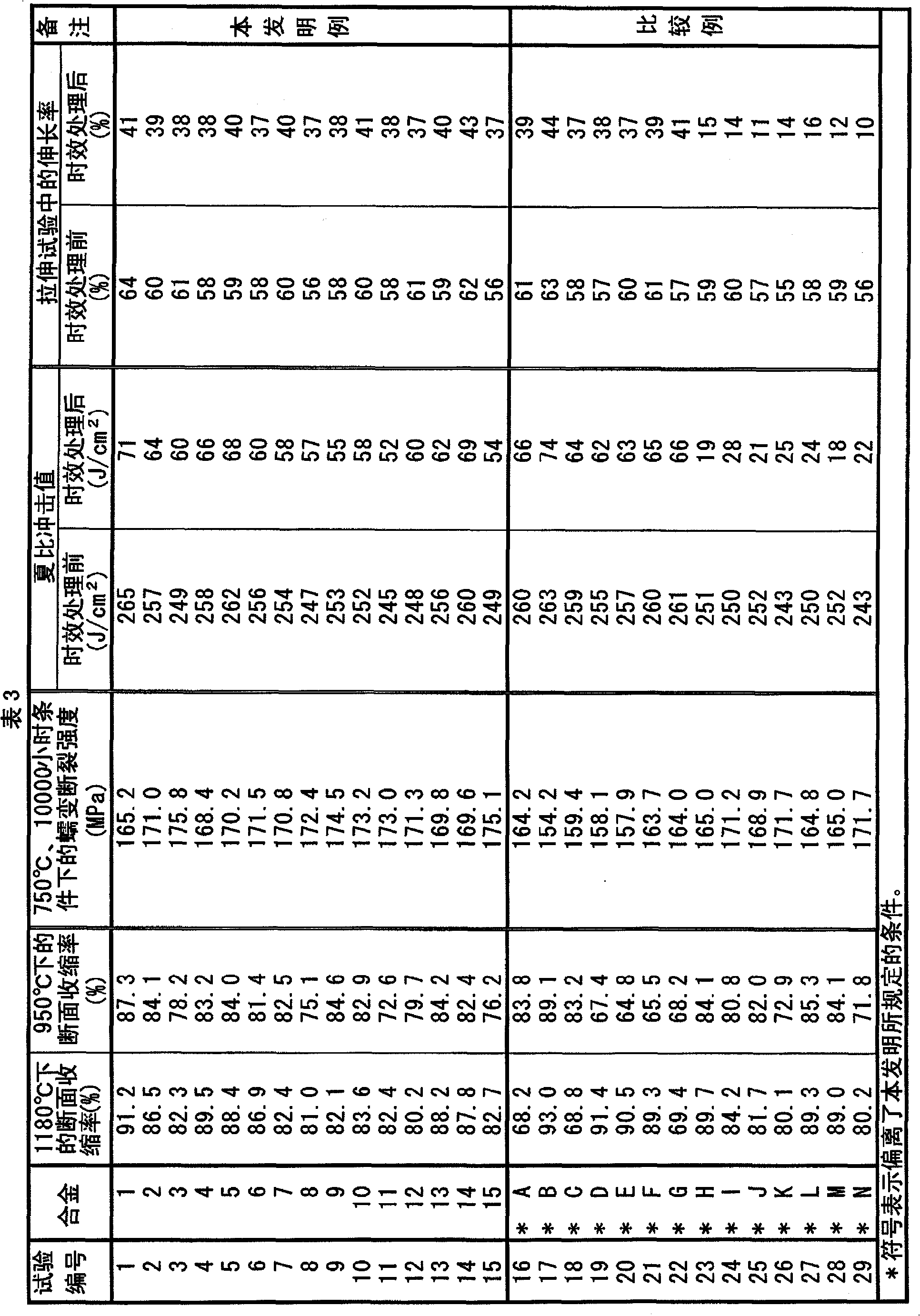

Ni-based heat-resistant alloy

Disclosed is a Ni-based heat-resistant alloy that contains C <= 0.1%, Si <= 1%, Mn <= 1%, Cr more than 15% and less than 28%, Fe <= 15%, W more than 5% to 20%, Al more than 0.5% to 2%, Ti more than 0.5% to 2%, Nd 0.001% to 0.1%, B 0.0005% to 0.01%, and the remainder comprising Ni and impurities, wherein the impurities P, S, Sn, Pb, Sb, Zn and As are such that P <= 0.03%, S <= 0.01%, Sn <= 0.020%,Pb <= 0.010%, Sb <= 0.005%, Zn <= 0.005%, and As <= 0.005%, and in addition, satisfy the three equations [0.015 <= Nd + 13.4*B <= 0.13], [Sn + Pb <= 0.025] and [Sb + Zn + As <= 0.010]. With the alloy, an even higher level of strength than with conventional Ni-based heat-resistant alloys can be achieved, while the ductility and toughness after long-term use at high temperature are significantly improved, and the zero ductility temperature and hot processing characteristics are even further improved. Thus, the alloy can be favorably used as a pipe material, a thick sheet for heat-resistant and compression-resistant members, a rod material, and cast articles such as in power generating boilers or industrial chemical plants. The alloy could also contain a specified quantity of at least one ofMo, Co, Nb, V, Zr, Hf, Mg, Ca, Y, La, Ce, Ta or Re.

Owner:NIPPON STEEL CORP

Method for preparing silicon dioxide and aluminum oxide from coal ash

ActiveCN101993084AMild desilication reactionWeak corrosiveSilicaSolid waste disposalFoam concreteHigh pressure

Owner:CHINACOAL PINGSHUO GRP

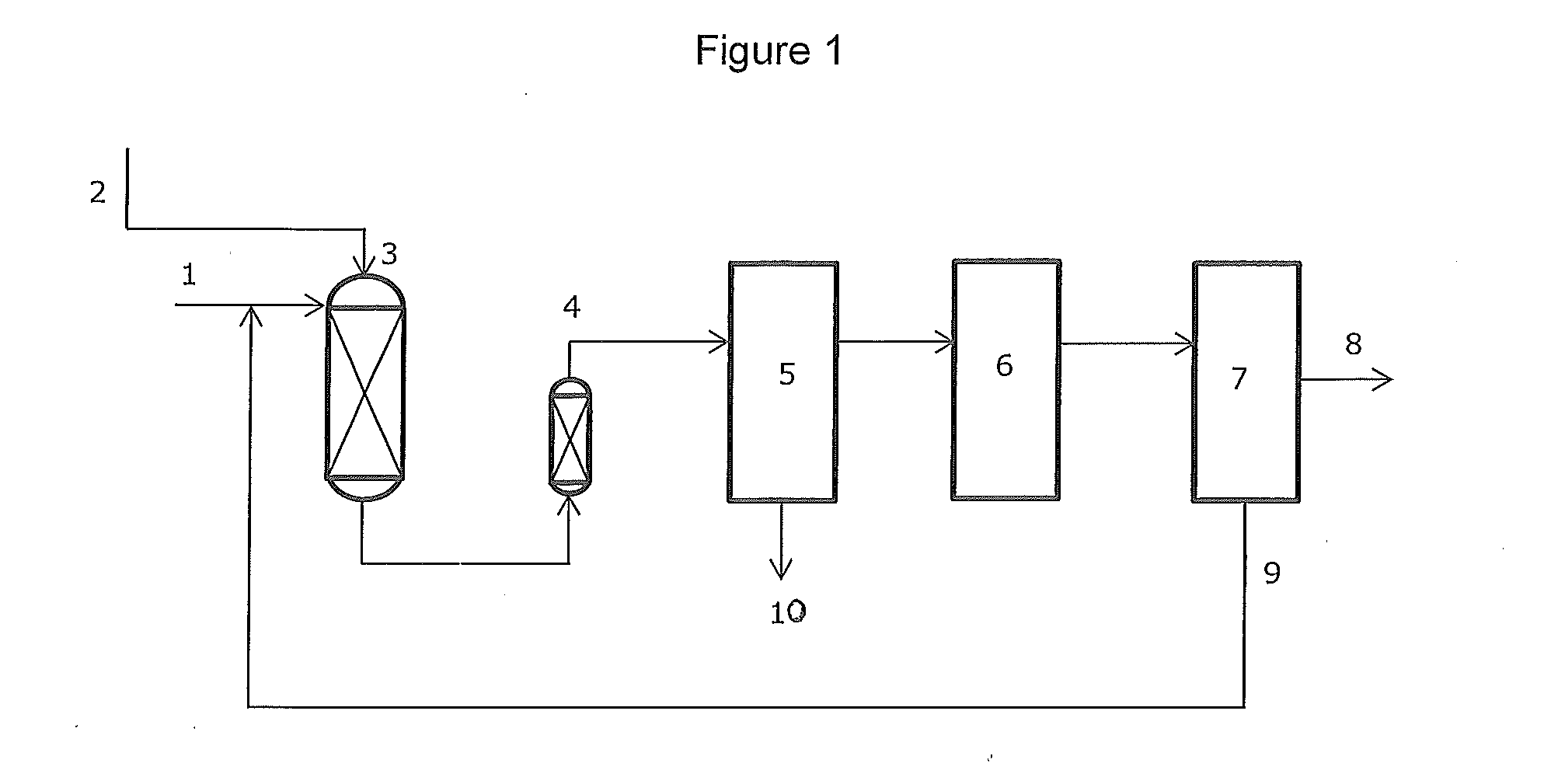

System and method for improving performance of a chemical plant with a furnace

ActiveUS10095200B2Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

Method of treating organic wastewater and sludge and treatment apparatus therefor

InactiveUS20050016919A1Reduce the amount requiredImprove and stabilize removal ratioWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningHigh concentrationHuman waste

The present invention has an object to provide a process and an apparatus for efficiently recovering magnesium ammonium phosphate (hereinafter referred to as “MAP”) crystals of high purity and good quality in the technique of removing phosphorus and the like as MAP crystals from wastewater containing high concentration organic substance, phosphorus and nitrogen such as a digested supernatant liquor of human waste sewage and septic tank sludge, a digested liquor of sludge, chemical plant wastewater, and simultaneously recovering the MAP crystals. As the means to achieve such an object, the present invention provides a sludge treatment process comprising treating a sludge mixed liquor formed in the biological treatment system for organic wastewater in an anaerobic digestion tank to effect the digestion of sludge, simultaneously adding a magnesium source to the anaerobic digestion tank to allow crystals particles of MAP to form and grow in the anaerobic digestion tank, withdrawing a sludge mixed liquor containing the crystals of MAP from the anaerobic digestion tank, separating and recovering solids containing MAP crystal particles from the withdrawn sludge mixed liquor, and returning part of the sludge mixed liquor after separation and recovery of MAP crystal particles to the anaerobic digestion tank.

Owner:EBARA ENG SERVICE

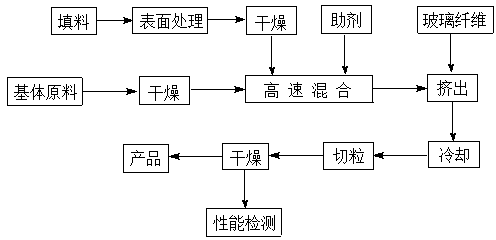

Multi-component compound modified nylon 6 composite material for carrier roller and preparation method thereof

The invention belongs to the field of high-molecular composite materials, and provides a high-performance multi-component compound modified nylon 6 composite material for a conventional carrier roller. The composite material consists of 100 parts of mixed nylon 6, 10-40 parts of alkali-free glass fiber, 5-30 parts of talcum powder, 0.01-1 part of nano silicon dioxide, 1-5 parts of solid lubricant, 0.01-3 parts of wear-resistant agent, 0.05-1 part of anti-aging agent, 0.2-1 part of dispersing agent and 0.01-0.5 part of silane coupling agent. After being uniformly mixed, the material system is extruded by a twin-screw extruder and granulated to obtain a high-performance composite material. By adopting the composite material provided by the invention, the prepared carrier roller has the characteristics of high strength, abrasion resistance, high-temperature resistance, light weight, low noise, long service life, appropriate price, convenience in maintenance and the like, and can be widely applied to the places such as mines except coal mines, wharfs, grain depots, cement plants, power plants, chemical plants, salt fields and the like.

Owner:HUNAN UNIV OF TECH

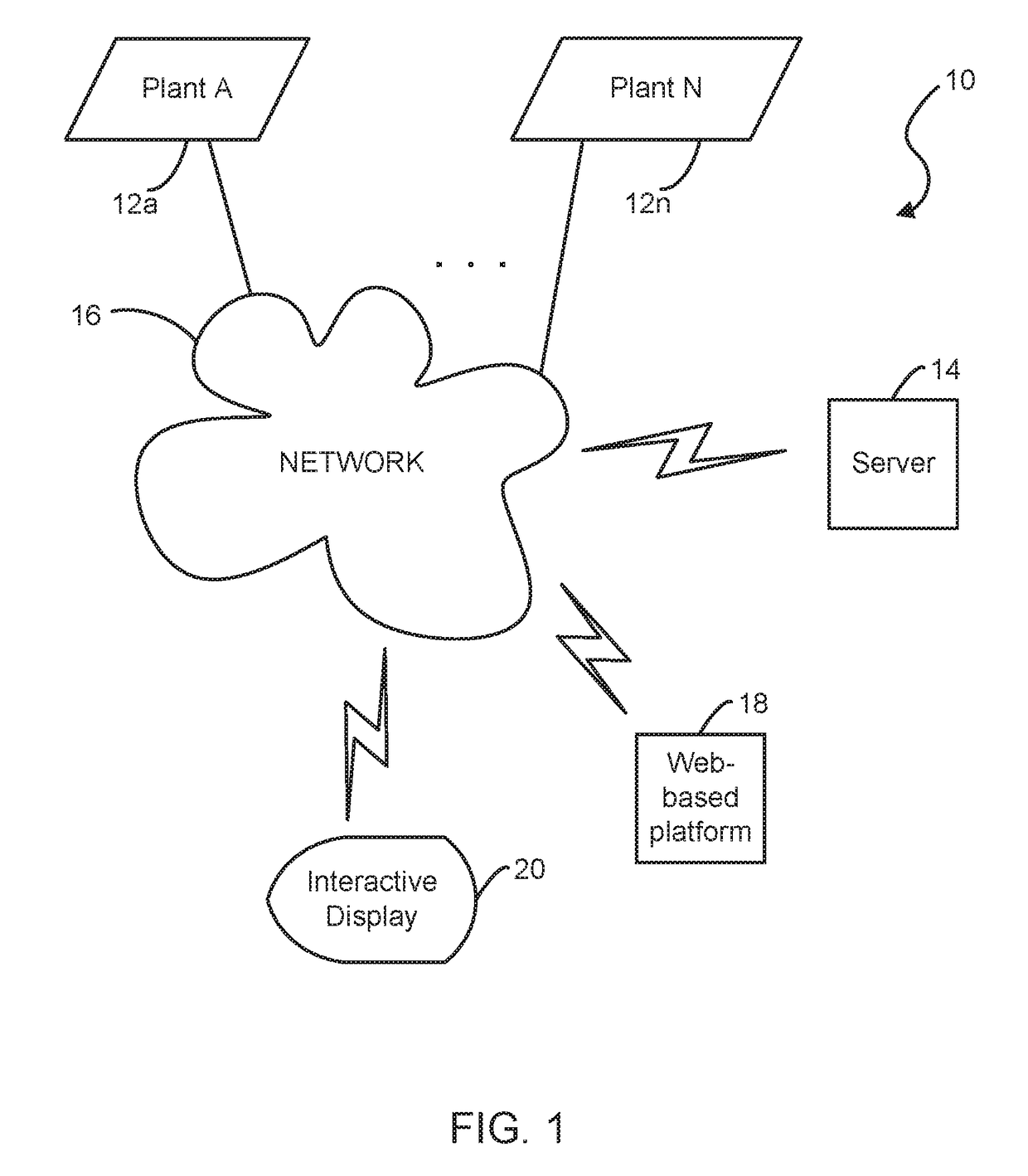

Tuning system and method for improving operation of a chemical plant with a furnace

ActiveUS10180680B2Operation efficiency can be improvedEasy to operateDigital computer detailsTotal factory controlDisplay deviceComputerized system

A tuning system for improving operation of a plant. A server is coupled to the tuning system for communicating with the plant via a communication network. A computer system has a web-based platform for receiving and sending plant data related to the operation of the plant over the network. A display device interactively displays the plant data. A reconciliation unit is configured for reconciling actual measured data from the plant in comparison with a performance process model result from a simulation engine based on a set of predetermined reference or set points. The reconciliation unit performs a heuristic analysis against the actual measured data and the performance process model result using a set of predetermined threshold values.

Owner:UOP LLC

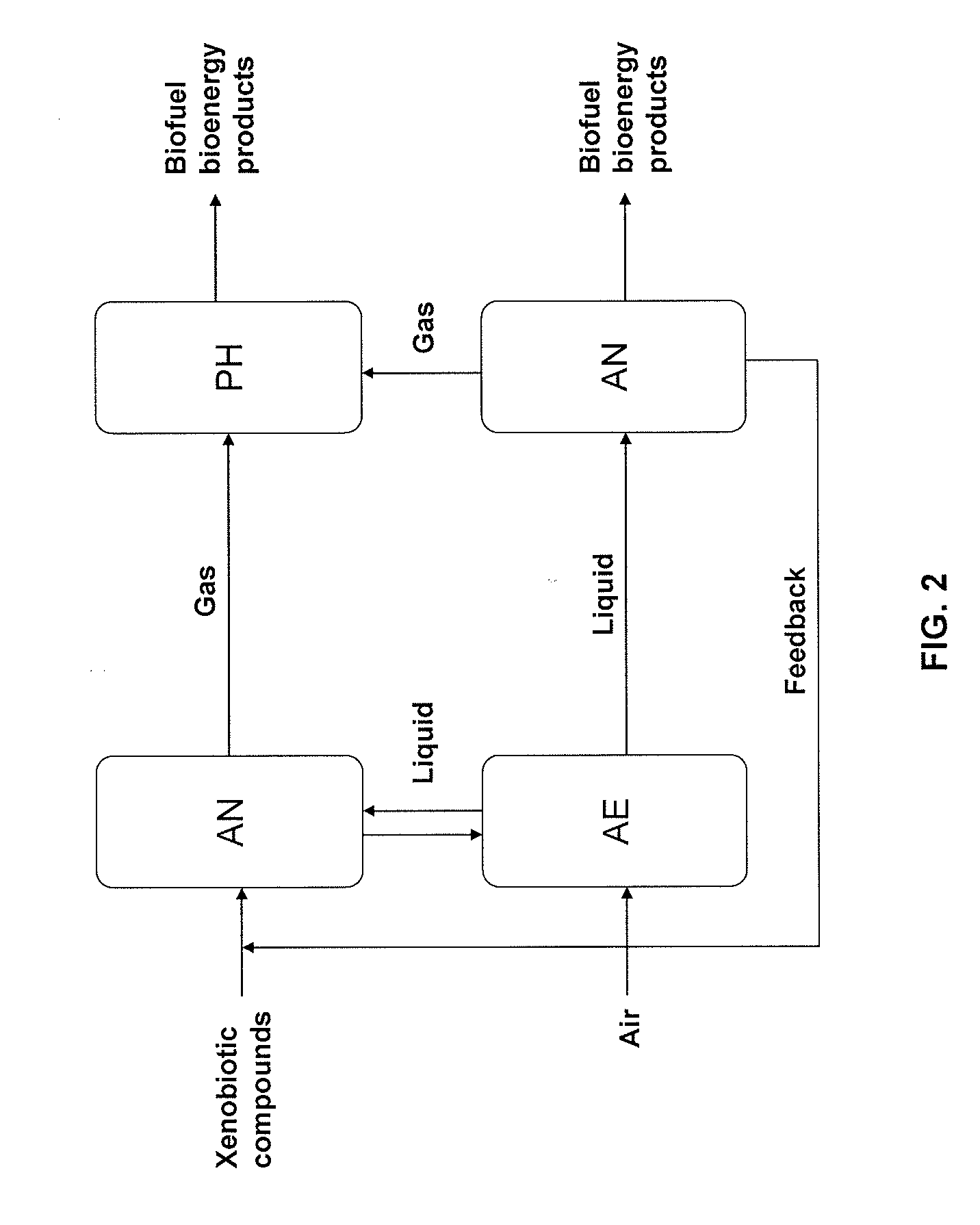

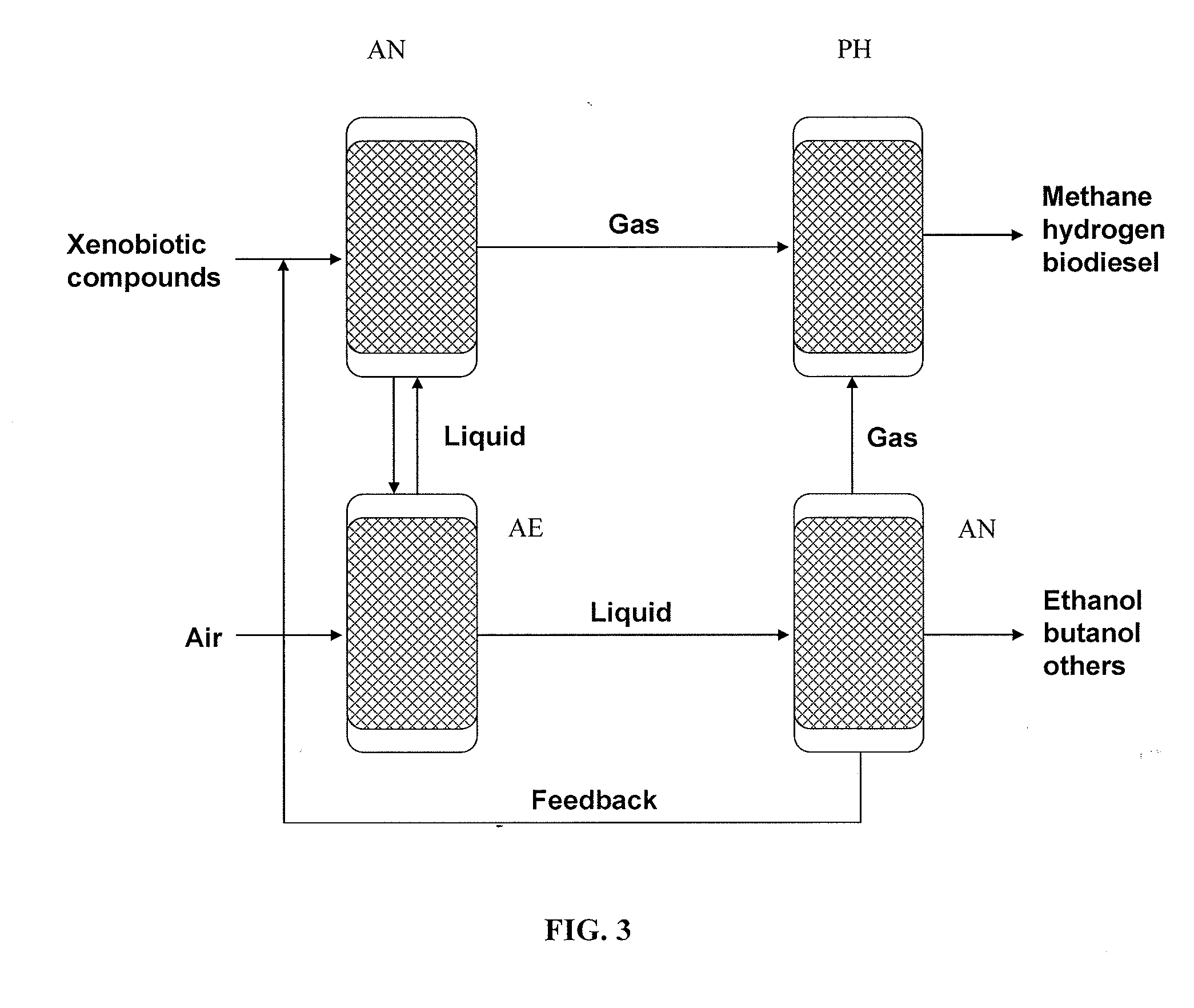

Methods and systems for producing biofuels and bioenergy products from xenobiotic compounds

InactiveUS20100159539A1Reduce contaminationReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselDecomposition

The present invention provides methods and systems for producing biofuel and bioenergy products using, as starting raw material, xenobiotic materials or compounds. The xenobiotic materials or compounds may originate from industrial or chemical plants, municipal waste, pharmaceutical products, cosmetic and personal care products, or other sources, and may include aliphatic and aromatic hydrocarbons, chlorinated organic solvents and other halogenated hydrocarbons, as well as heteroaromatic compounds. In accordance with the invention, these materials act as a carbon source to support the metabolism of xenobiotic-degrading microorganisms, thereby producing biomass and / or biogas that may be converted to bioenergy products by microbial synthesis. For example, the biomass may be converted to products such as ethanol, methanol, butanol, and methane, among others. The biogas may be converted to hydrogen gas and biodiesel, among others. Thus, the present invention couples the microbial breakdown (decomposition) of xenobiotic materials with the microbial synthesis of biofuel, thereby supplying needed (inexpensive) energy products, while reducing environmental pollution and contamination, and reducing the costs associated with disposal of hazardous waste.

Owner:ASCON MIGUEL +1

Preparation method, product and application of catalytic activity nano particle loaded absorbent

InactiveCN102151543AThe preparation method is simple and easyRaw materials are cheap and easy to getOther chemical processesWater contaminantsDesorptionSorbent

The invention discloses a preparation method of a catalytic activity nano particle loaded absorbent, which comprises the step of: with a plurality of kinds of absorbing agents as carriers, surface-loading metal oxide nano particles with catalytic activity to obtain the efficient catalytic activity absorbent in sewage treatment. The invention also discloses an absorbent prepared by using the method and application thereof in the posttreatment of organic phosphorus containing sewage. The absorbent achieves the purpose of synergism of catalysis and absorption through carrying out catalytic oxidization reaction on the surface-loaded nano particles, thereby overcoming the problems of low capacity and difficult desorption of the traditional physical absorbing process and easy loss of components of catalysts in the high-grade oxidization technology in the sewage treatment, remarkably improving efficiency of removing the absorbent, and reducing process links and steps. The absorbent has wide application prospect on the aspects of domestic sewage purification, chemical plant sewage treatment, catalytic degradation of toxic substances in the sewage, and the like.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com