Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

294results about "Hydrocarbon distillation control/regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

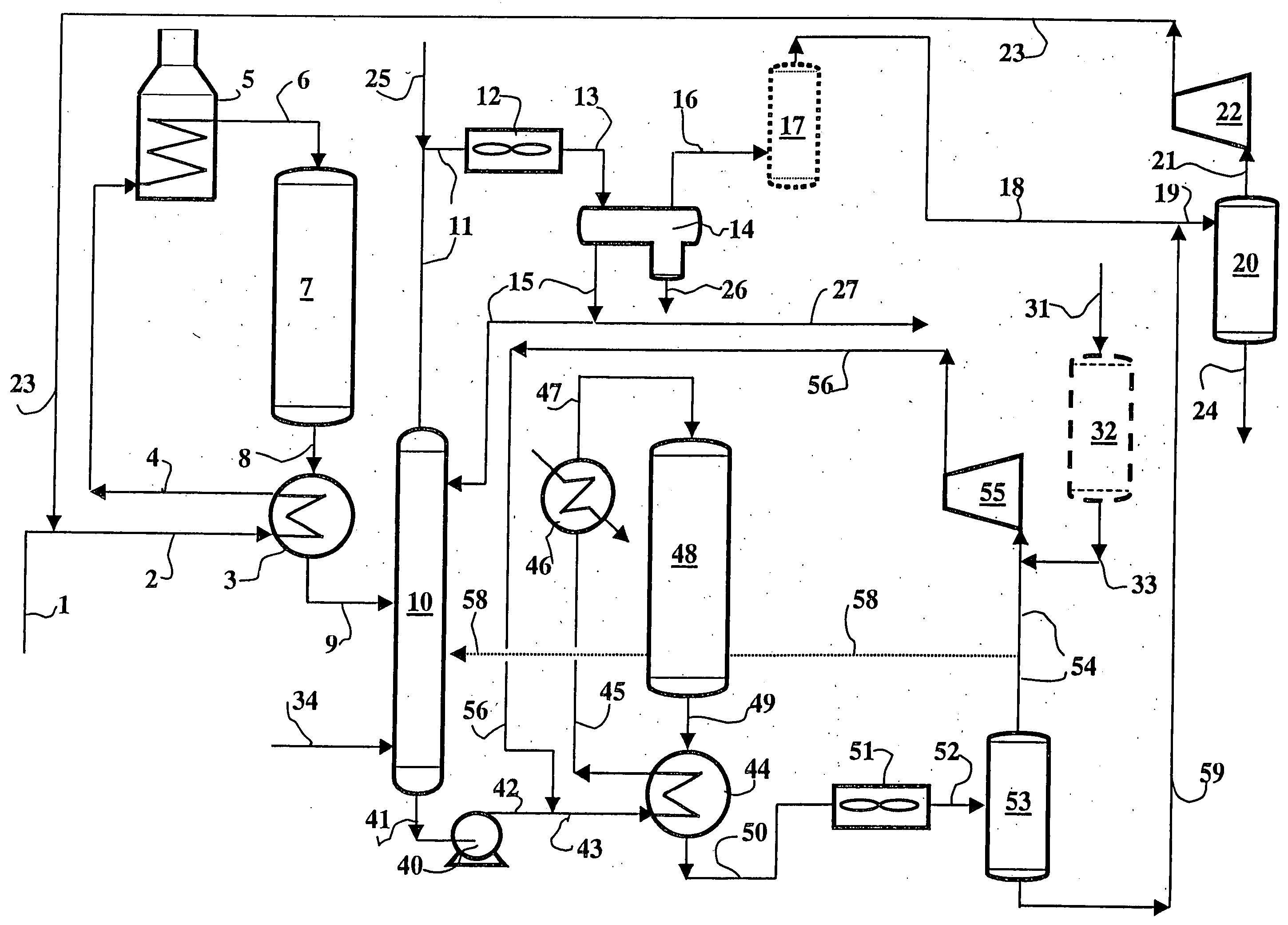

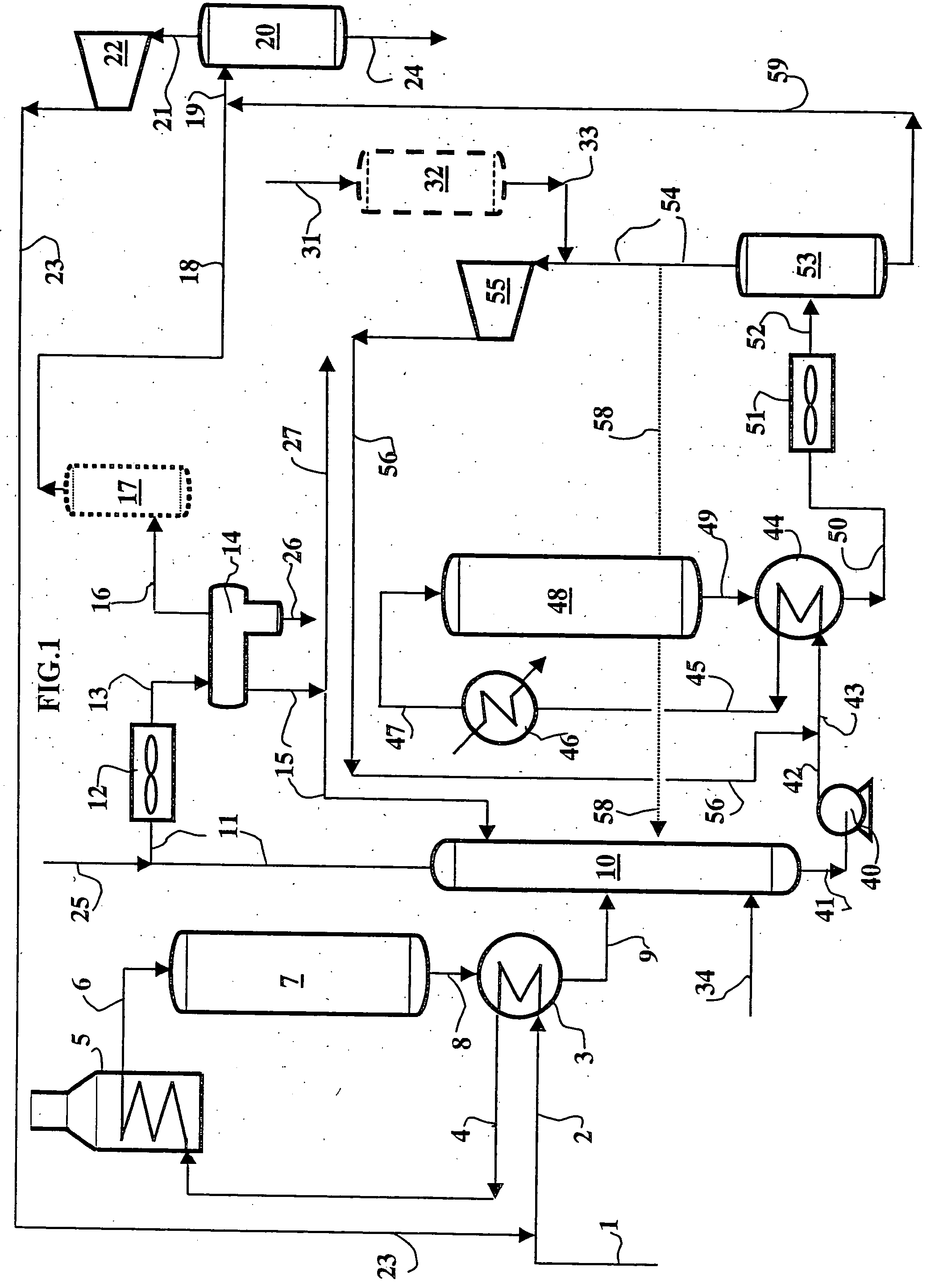

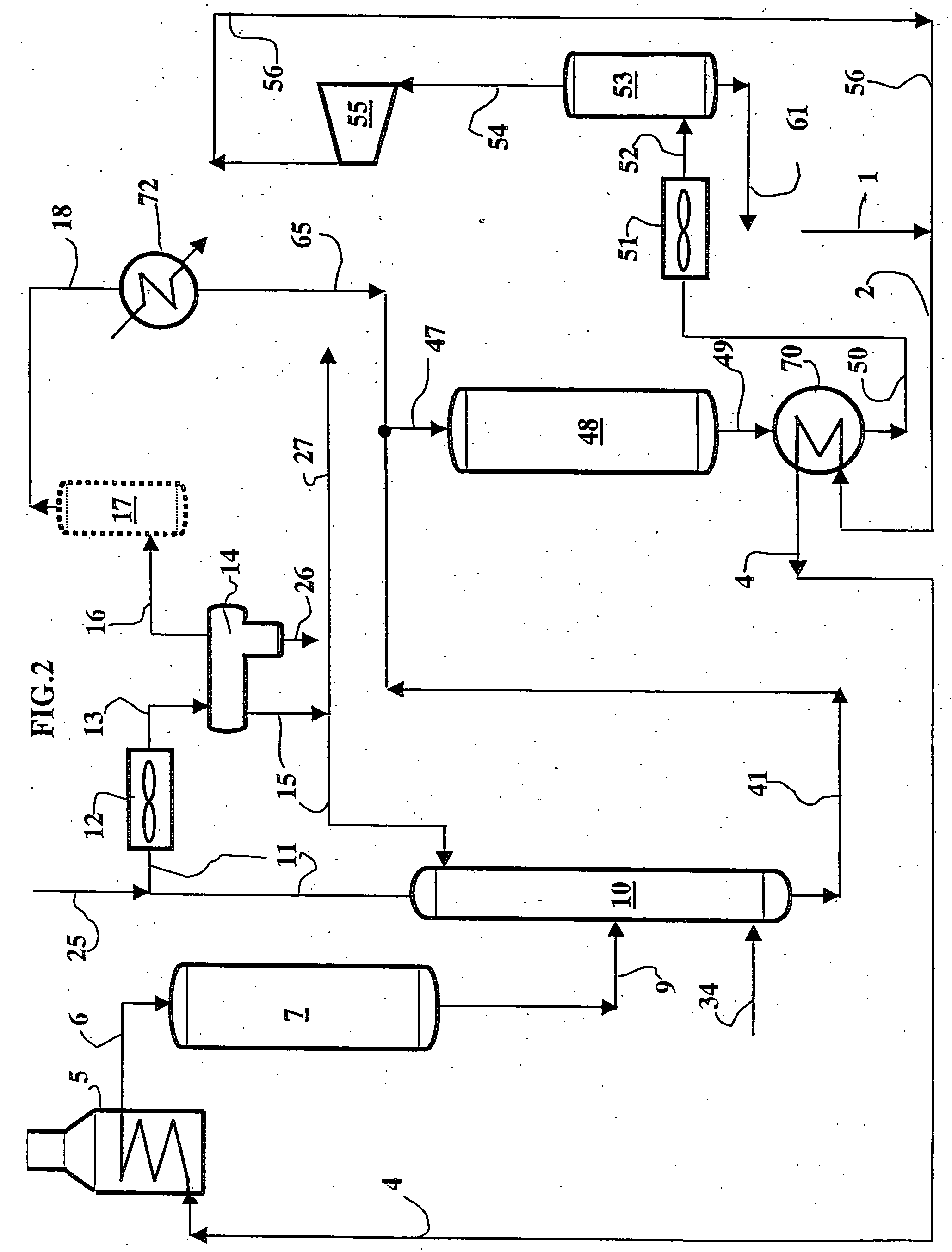

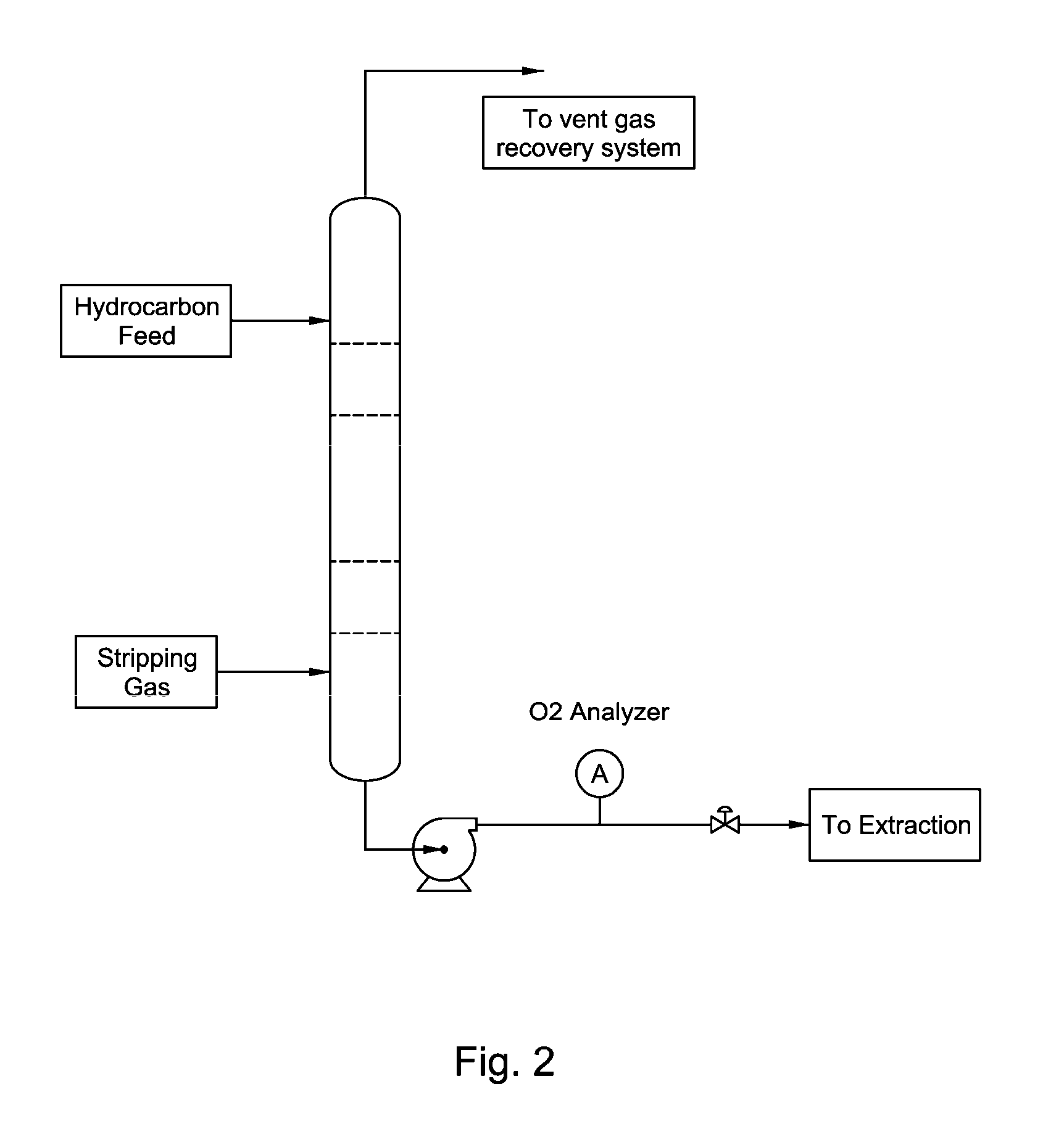

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

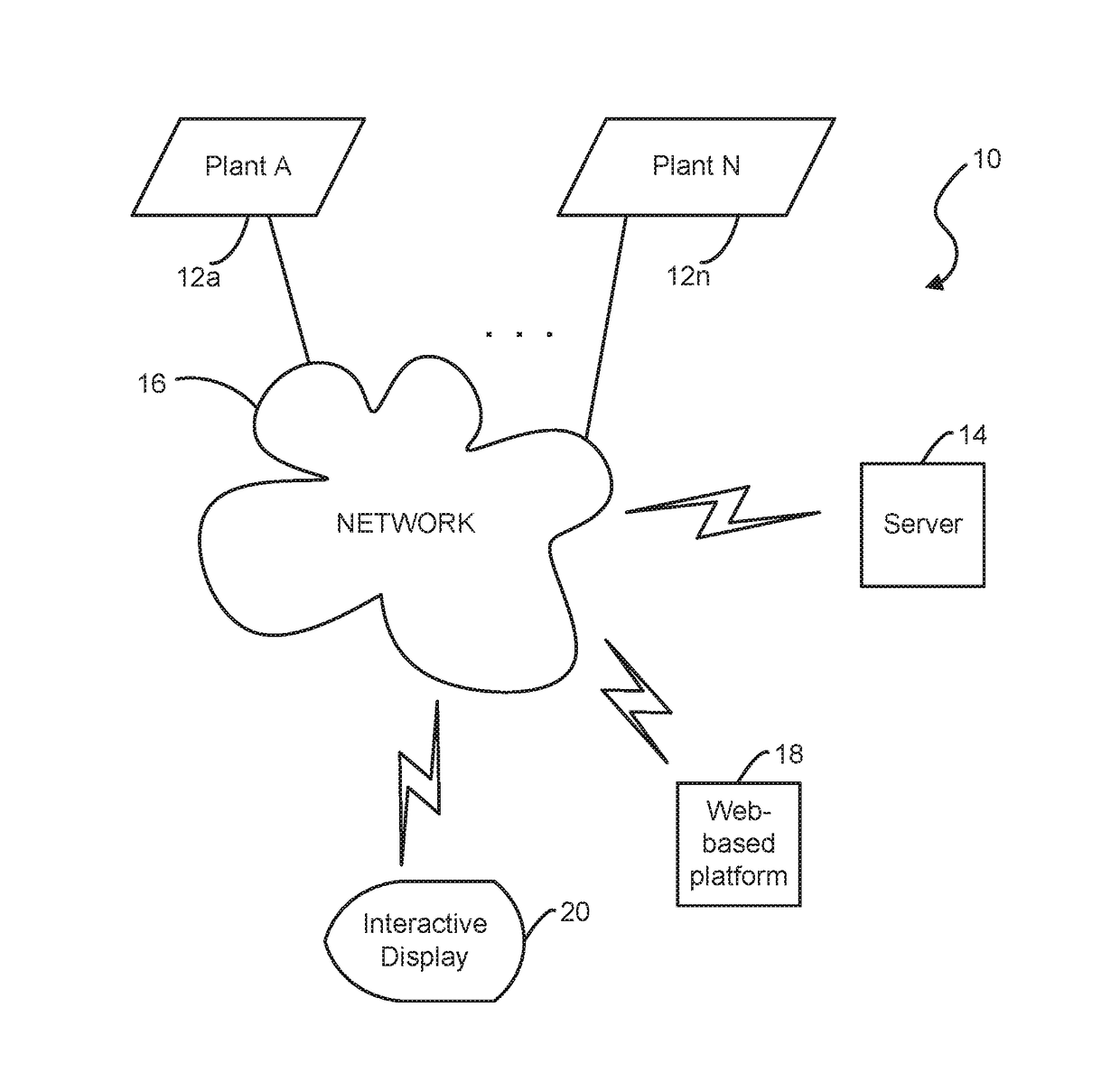

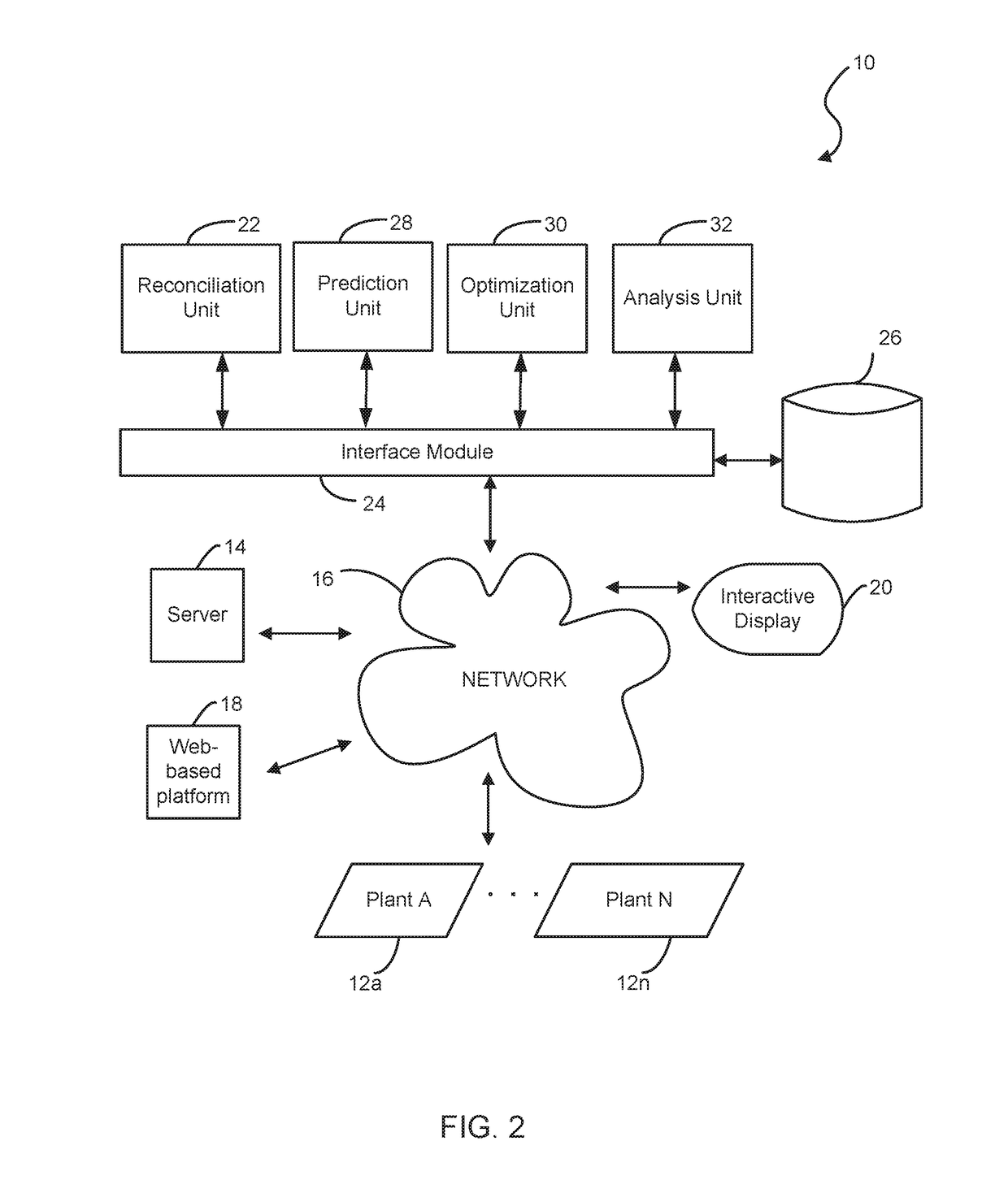

Identifying and implementing refinery or petrochemical plant process performance improvements

ActiveUS20180046155A1Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

System and method for improving performance of a chemical plant with a furnace

ActiveUS10095200B2Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

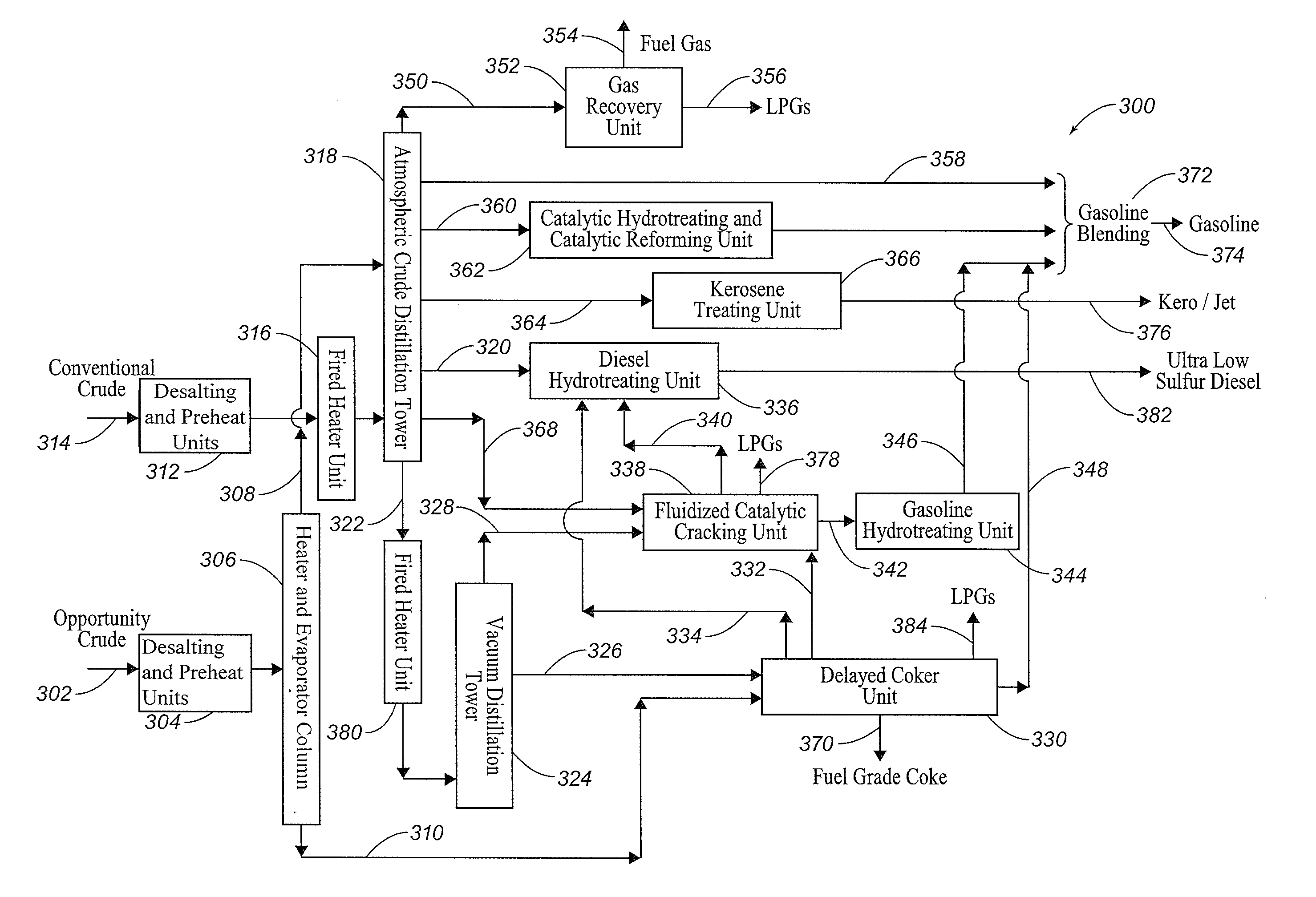

Systems and Methods for Refining Corrosive Crudes

ActiveUS20120261308A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationMaterials scienceCrude oil

Owner:BECHTEL ENERGY TECH & SOLUTIONS INC

Method for predicting fouling tendency of a hydrocarbon-containing feedstock

ActiveUS8492154B1Improve accuracyImprove efficiencyComponent separationHydrocarbon distillation control/regulationSolubilitySolvation

Disclosed herein is a method involving the steps of (a) precipitating an amount of asphaltenes from a liquid sample of a first hydrocarbon-containing feedstock having solvated asphaltenes therein with one or more first solvents in a column; (b) determining one or more solubility characteristics of the precipitated asphaltenes; (c) analyzing the one or more solubility characteristics of the precipitated asphaltenes; and (d) correlating a measurement of feedstock fouling tendency for the first hydrocarbon-containing feedstock sample with a mathematical parameter derived from the results of analyzing the one or more solubility characteristics of the precipitated asphaltenes.

Owner:WESTERN RES INST INC

Use of 13C NMR spectroscopy to produce optimum fischer-tropsch diesel fuels and blend stocks

InactiveUS6210559B1Optimize distillate fuel production processEasy to operateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonGasolineProcess engineering

The present invention is a process for producing a distillate fuel heavier than gasoline. The process is a Fischer-Tropsch (hydrocarbon synthesis) process that includes using 13C NMR to measure cetane number and a cold flow property in order to optimize the process. Cold flow properties include cold filter plugging point, cloud point and pour point.

Owner:EXXON RES & ENG CO

Refinery crude unit performance monitoring using advanced analytic techniques for raw material quality prediction

ActiveUS20060043004A1Hydrocarbon distillation control/regulationDistillation separationOil refineryChemistry

A method for the determination of optimal pipestill operation comprising the steps of: feeding a crude oil feedstream into the pipestill wherein the crude oil feedstream is separated into boiling range fractions, performing a virtual assay of the crude oil feedstream to determine predicted boiling range fraction yields, comparing the predicted boiling range fraction yields with the actual boiling range fraction yields from the pipestill to determine differences between these fraction yields, relating the difference between the fraction yields with the operation of the pipestill.

Owner:EXXON RES & ENG CO

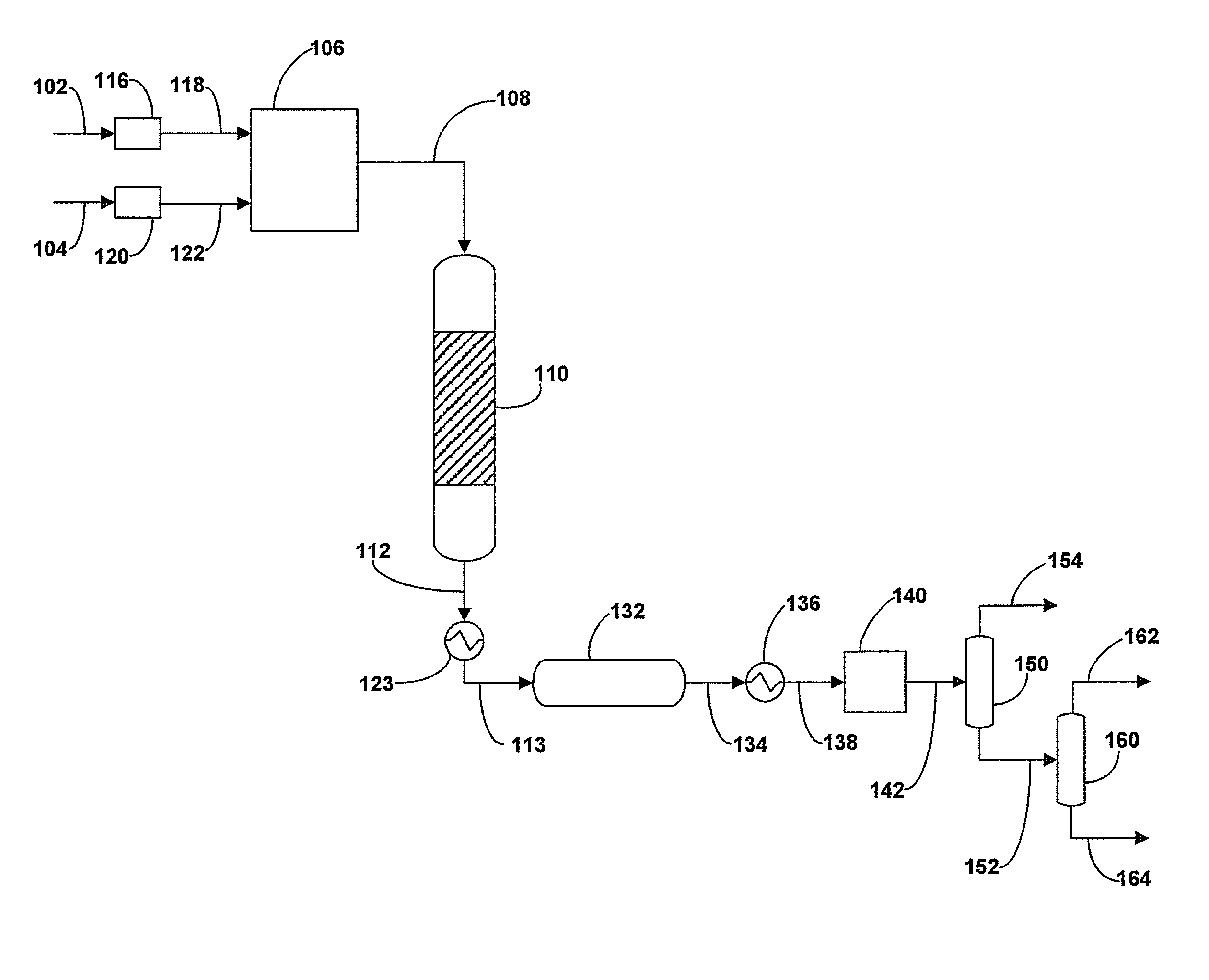

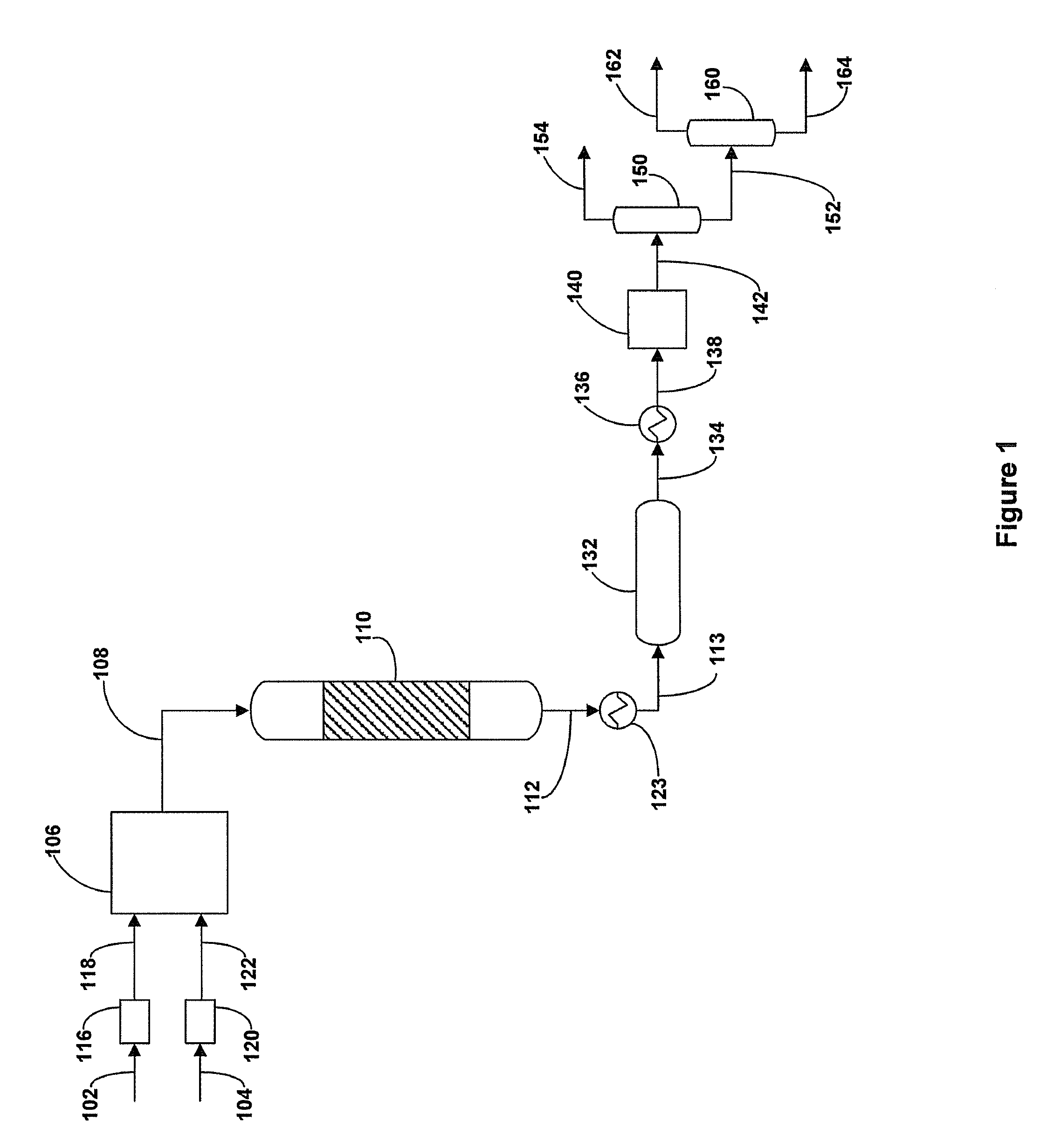

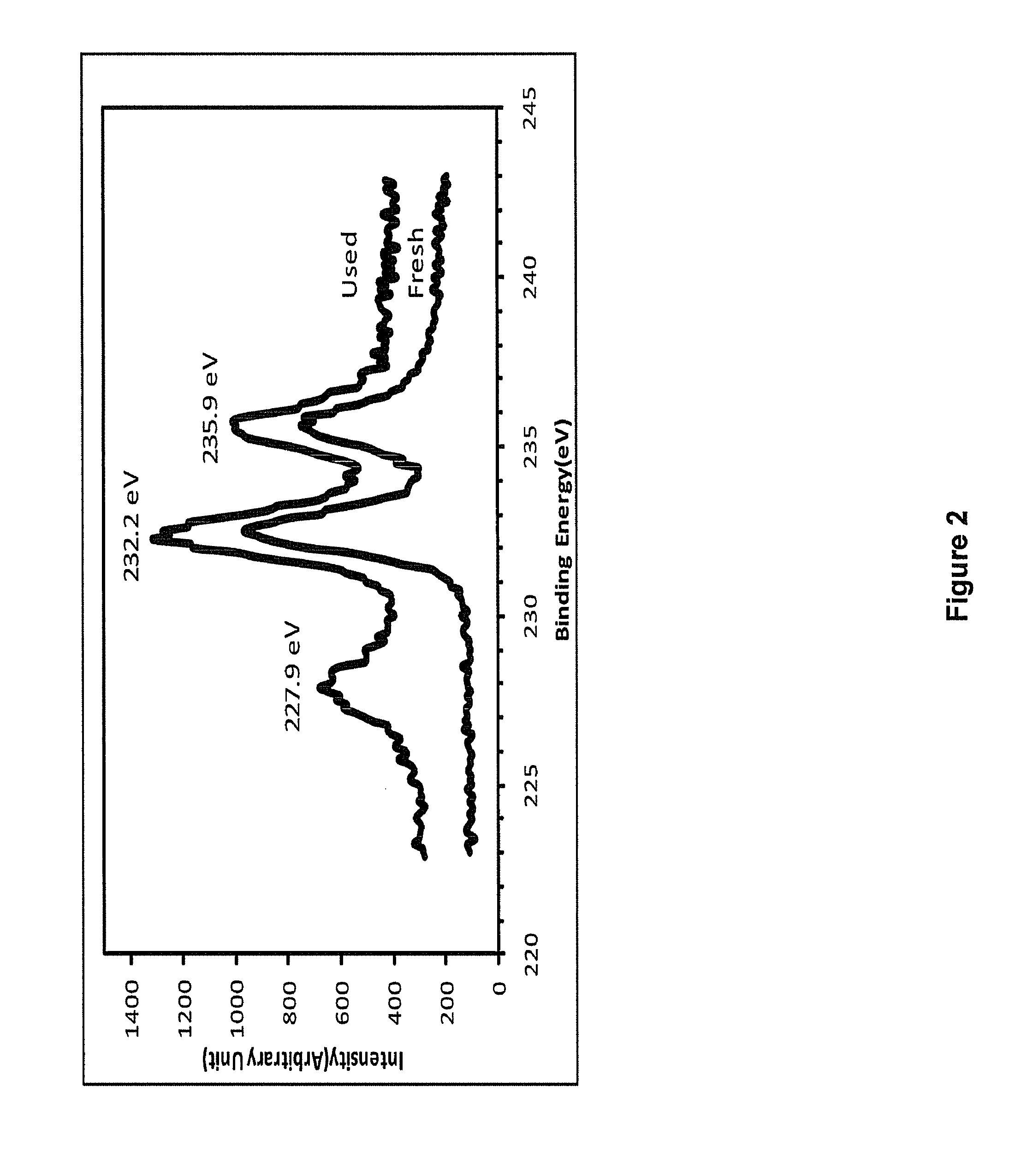

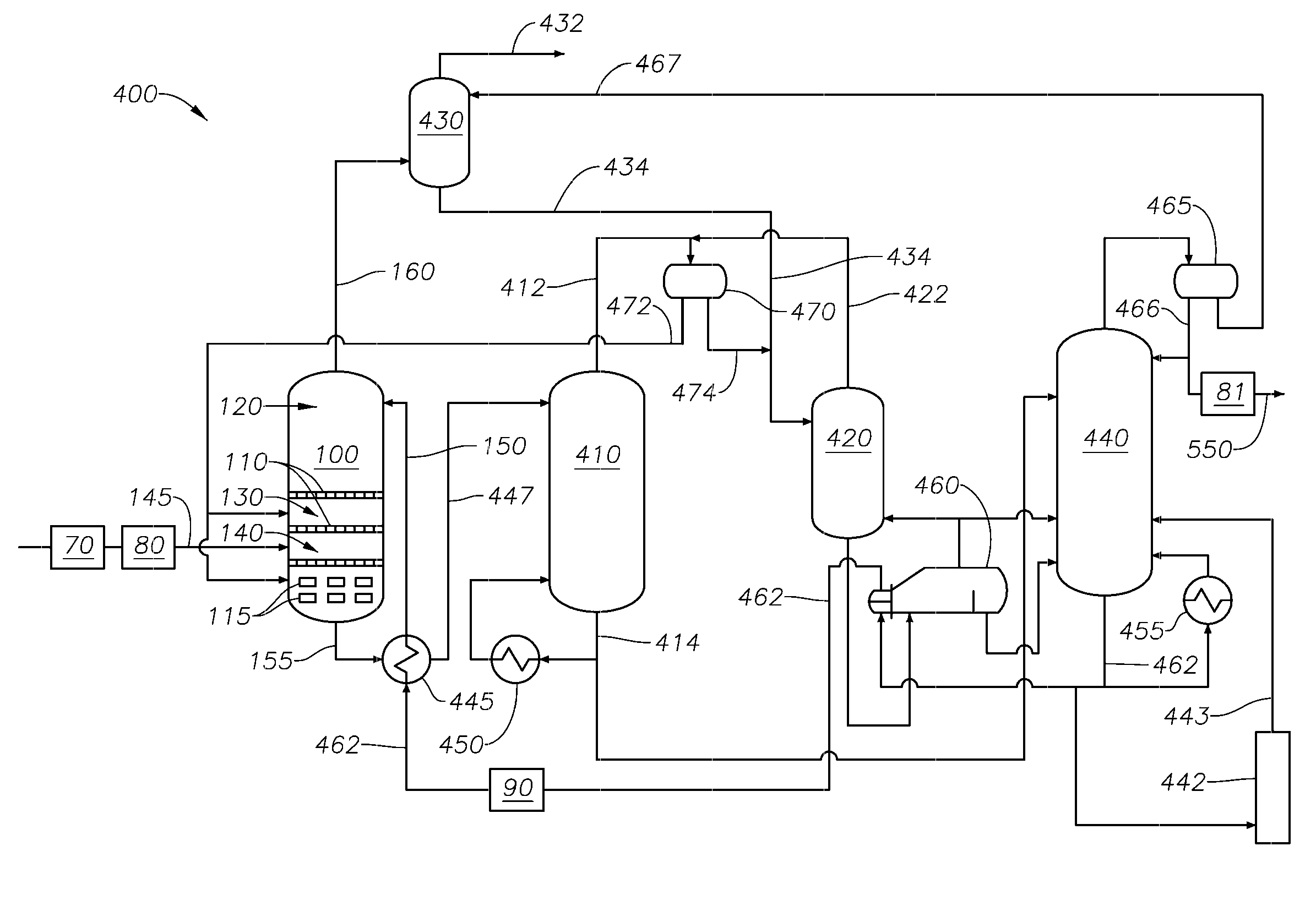

Petroleum upgrading and desulfurizing process

ActiveUS8535518B2Reduce dwell timeSmall sizeThermal non-catalytic crackingHydrocarbon distillation control/regulationSorbentWater flow

A petroleum feedstock upgrading method is provided. The method includes supplying a mixed stream that includes hydrocarbon feedstock and water to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream having an increased concentration of lighter hydrocarbons and / or concentration of sulfur containing compounds. The modified stream is then supplied to an adsorptive reaction stage charged with a solid adsorbent operable to remove at least a portion of the sulfur present to produce a trimmed stream. The trimmed stream is then separated into a gas and a liquid streams, and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

Method of refining tall oil

ActiveUS7208570B2Improve discriminationHigh precisionFatty oils/acids recovery from wasteWorking-up pitch/asphalt/bitumen by distillationCorrelation coefficientChemical composition

The present invention relates to a method of refining crude tall oil. According to the method, the crude tall oil is fed into a column distiller, where it is separated into desired fractions. The conditions of the column distiller are adjusted on the basis of the composition of the feed and the product flow. According to the present invention, the densities of the crude tall oil fed into the column distiller and of at least one product flow are measured accurately as a function of the temperature. The density values are compared with correlation coefficients derived from the chemical compositions of the flows, coefficients which are obtained on the basis of laboratory analyses made earlier from corresponding flows, by using temperature compensation to specify the correlations, and by taking account of the regular variation in the wood composition of fresh wood according to the annual cycle and, as a result, the compositions of the flows are achieved. The present invention decreases the number of chemical analyses and improves the uniformity of the products.

Owner:FORCHEM

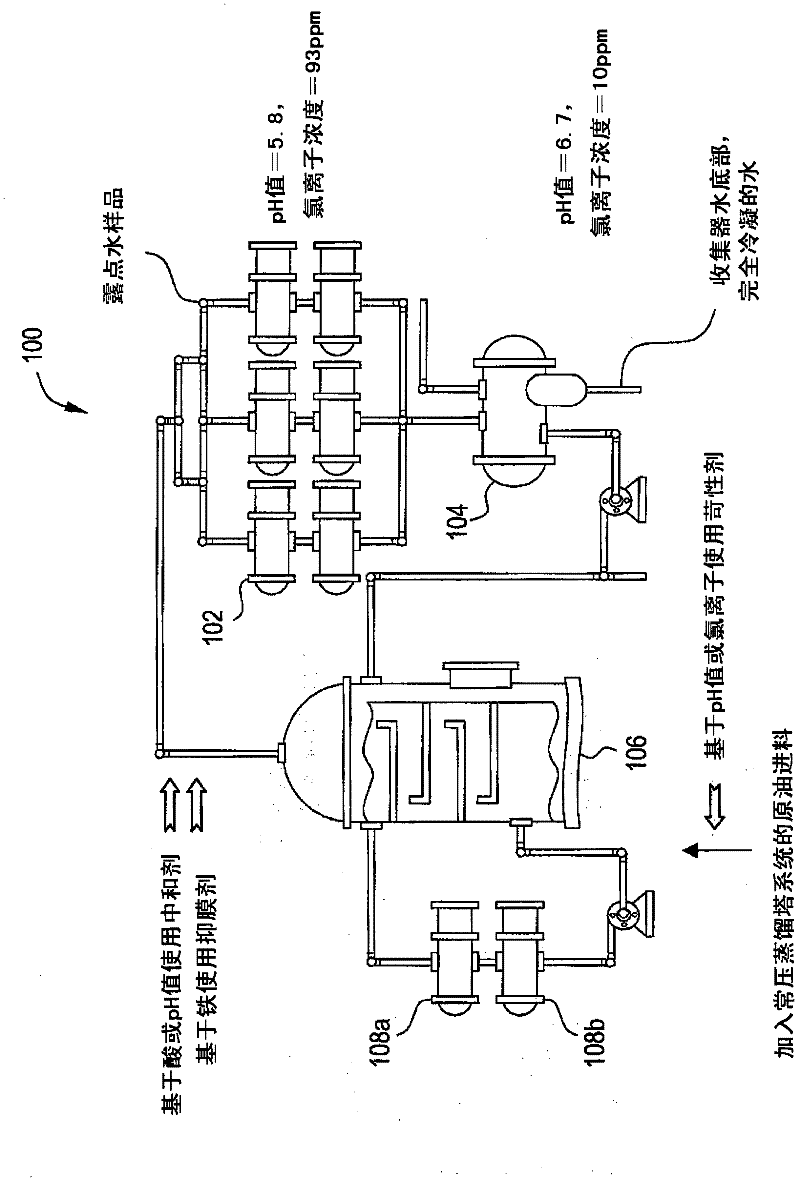

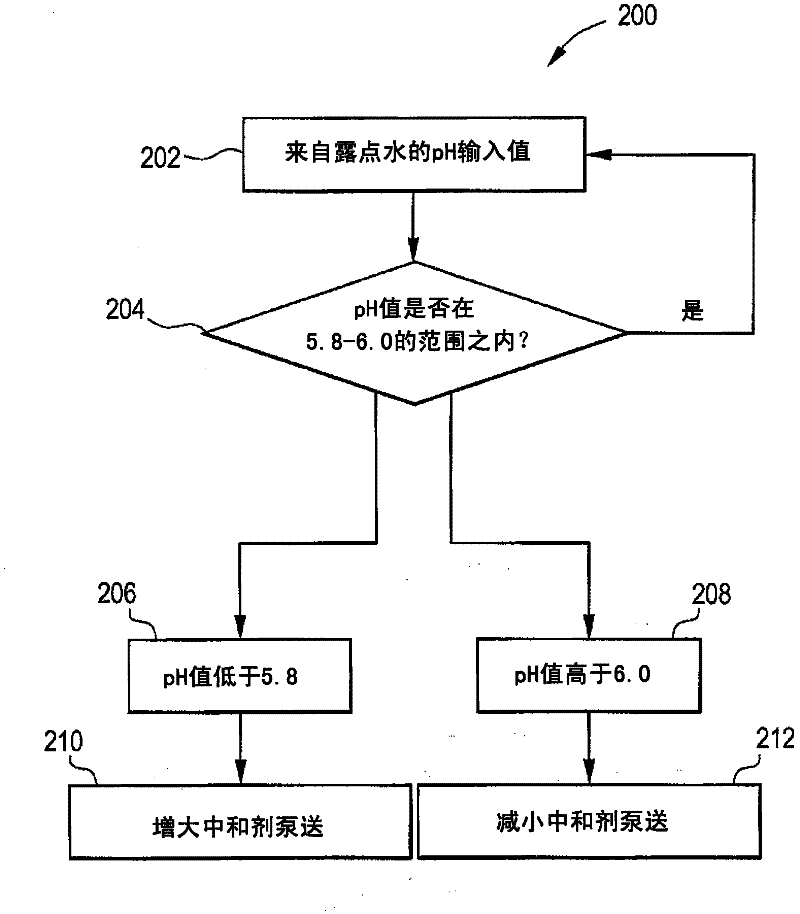

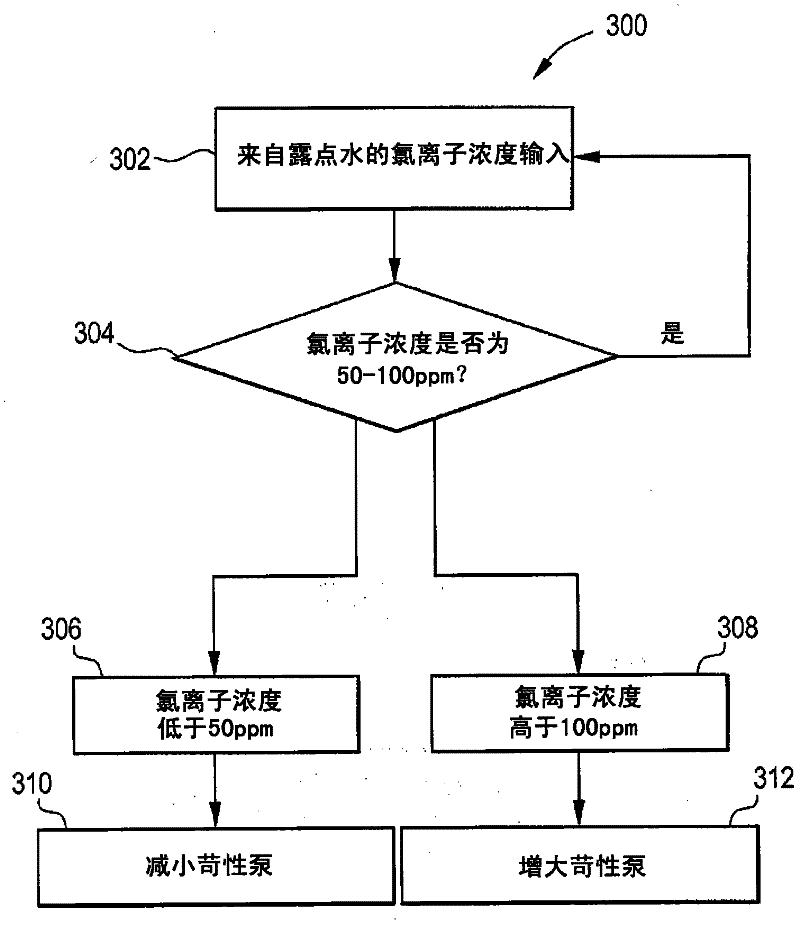

Method of reducing corrosion in a crude unit

ActiveCN102203219AReduce processing stepsReduce corrosionData processing applicationsDistillation corrosion inhibitionProcess engineeringProtection system

A method of optimizing system parameters in a crude unit to reduce corrosion and corrosion byproduct deposition in the crude unit is disclosed and claimed. The method includes measuring or predicting properties associated with the system parameters and using an automated controller to analyze the properties to cause adjustments in the chemical program to optimize the system parameters. Adjusting the system parameters effectively controls corrosion in the crude unit by reducing the corrosiveness of a fluid in the process stream and / or by protecting the system from a potentially corrosive substance. System parameter sensing probes are arranged at one or more locations in the process stream to allow accurate monitoring of the system parameters in the crude unit.

Owner:NALCO CO

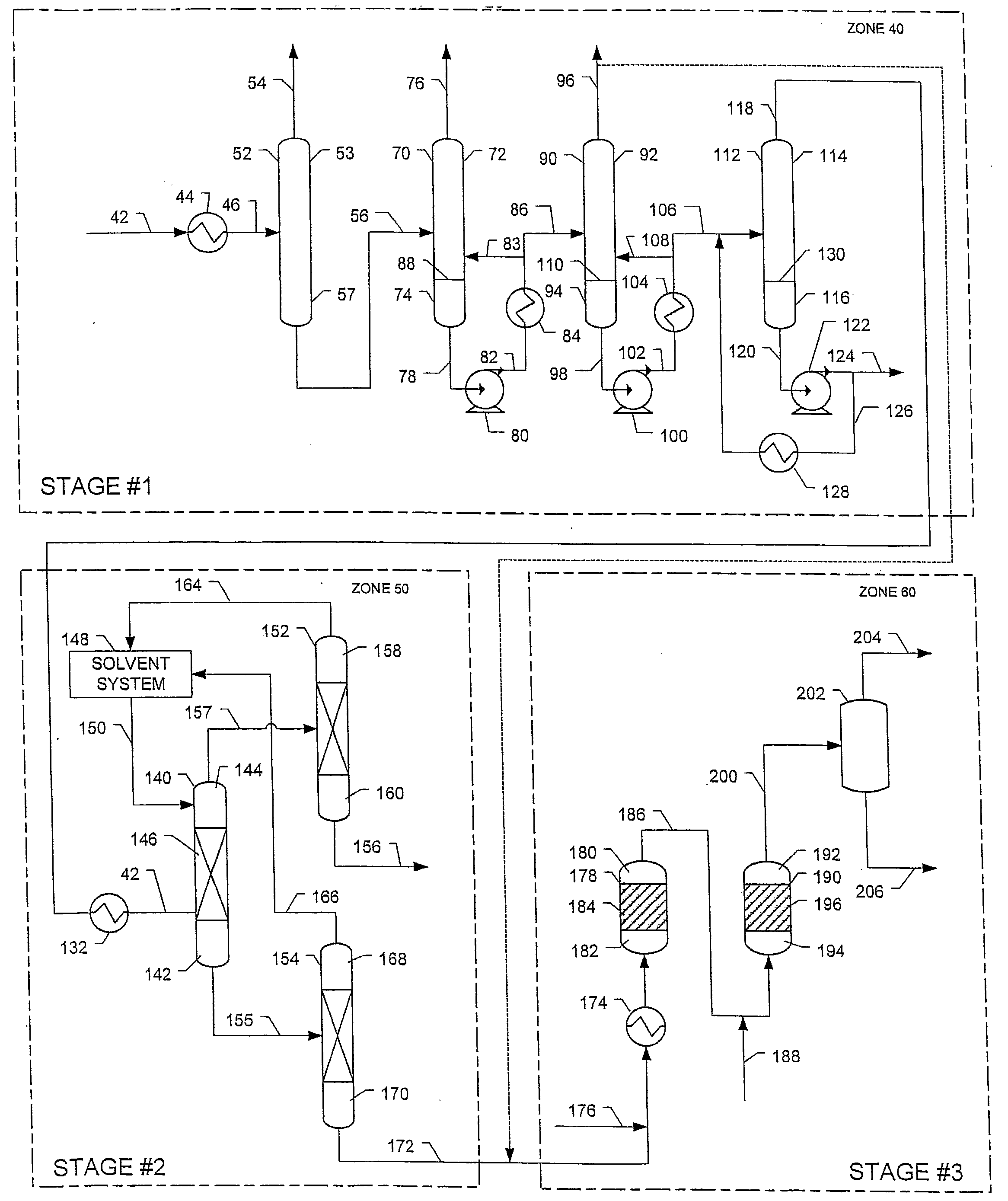

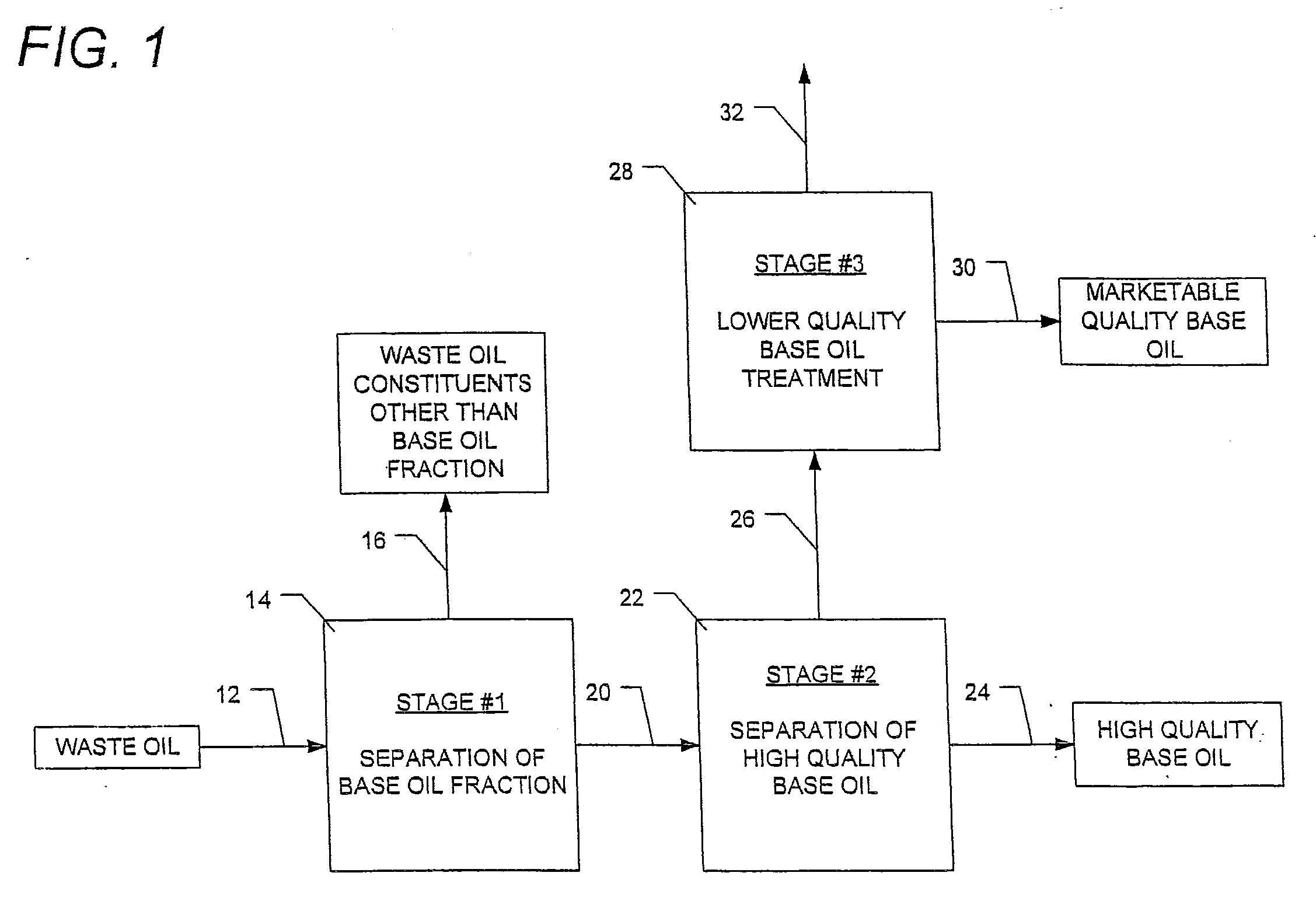

Method for producing base lubricating oil from waste oil

ActiveUS8366912B1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationWaste oilProduct base

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:GEN III OIL CORPORATION

Method for producing base lubricating oil from waste oil

InactiveUS20090223862A1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationProduct baseWaste oil

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:VEROLUBE

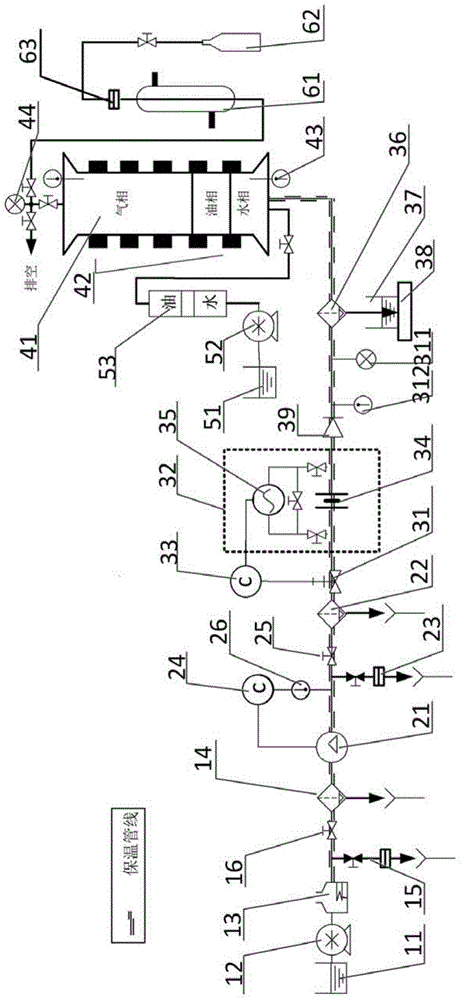

Method for recovering heat of quenching oil of ethylene unit

ActiveCN104673353AReduce wasteReduce workloadHydrocarbon distillation control/regulationFeed-water heatersReboilerDiluent

The invention relates to a method for recovering the heat of the quenching oil of an ethylene unit. A traditional quenching oil heat recovery process generally comprises the following steps: dividing the quenching oil into two branches, feeding one branch into a cracked fuel oil stripping tower, taking the other branch as a heat source of a diluent steam generator, injecting the heat-exchanged quenching oil into a cracked oil gas pipeline behind a cracking furnace for mixing with the cracked oil and then returning to a main fractioning tower. In the traditional process, the quenching oil is taken as the heat source of the diluent steam generator and then directly mixed with the high-temperature oil gas obtained from the cracking furnace, and therefore, the heat is not recovered thoroughly. The modification method comprises the following steps: (1) connecting a preheater with the existing gas bag feed water preheater in series for intensifying heat exchange between the gas bag feed water and the quenching oil to increase the temperature of the gas bag feed water; (2) additionally arranging a reboiler to the bottom of a process water stripping tower or replacing the existing reboiler by a reboiler with the quenching oil as the heat source. The modification method is capable of effectively recovering the superfluous heat of the quenching oil and reducing the energy waste, and is low in workload and cost.

Owner:SHANGHAI HUIDE ENERGY INTEGRATION TECH

System and method of predictive analytics for control of an overhead crude section of a hydrocarbon refining process

ActiveUS20180355258A1Maximize productionMinimizes operation riskProgramme controlDistillation corrosion inhibitionRisk indicatorProcess engineering

Described herein are systems and methods for control of an overhead crude section of a hydrocarbon refining process. In one aspect, the method comprises monitoring a plurality of operating conditions of an overhead crude section of a refinery; determining hydrogen chloride and amine conditions of the overhead crude section of the refinery at current operating conditions of the overhead crude section; determining a plurality of fields of action by simulating a variation of one or more of the plurality of conditions; determining a risk indicator of salting for each of the plurality of fields of action; and providing a recommended change in operation of the overhead crude section to one of the plurality of fields of action while adhering to one or more constraints.

Owner:BL TECH INC

System and Method for Auto Distilling Liquids at Strictly Defined Conditions Regardless of Composition

ActiveUS20180036648A1Good reproducibilityMinimizes human errorSamplingDistillation regulation/controlTemperature controlAtmospheric air

A system and method for distillation of a liquid sample at atmospheric pressure for the improved prediction of the heating necessary before the initial boiling point (IBP) of the sample is detected regardless of sample composition to ensure the IBP is observed within certain time constraints. A plurality of infrared (IR) sensors provides real-time temperature control in addition to a conventional measurement of vapor temperature. One IR-sensor monitors the liquid sample temperature in the distillation flask to obtain a corrected IBP time independent of the sample properties. Another IR-sensor monitors the temperature of the rising vapor column as the vapor rises up the neck of the distillation flask. Alternatively, an IR matrix may monitor the temperature of the rising vapor column. The system and method expand the scope of samples analyzed with improved signal, reproducibility, and test accuracy and still remain within the prescribed limits of a selected standard.

Owner:INSTR SCI DE LABORTOIRE ISL

Method for Producing Base Lubricating Oil from Waste Oil

ActiveUS20110278151A1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationBase oilComponents of crude oil

Owner:GEN III OIL CORPORATION

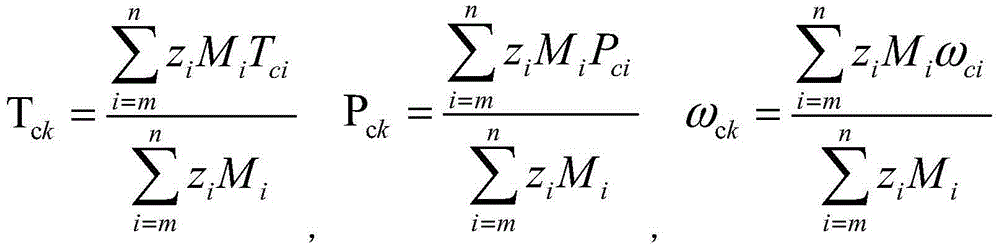

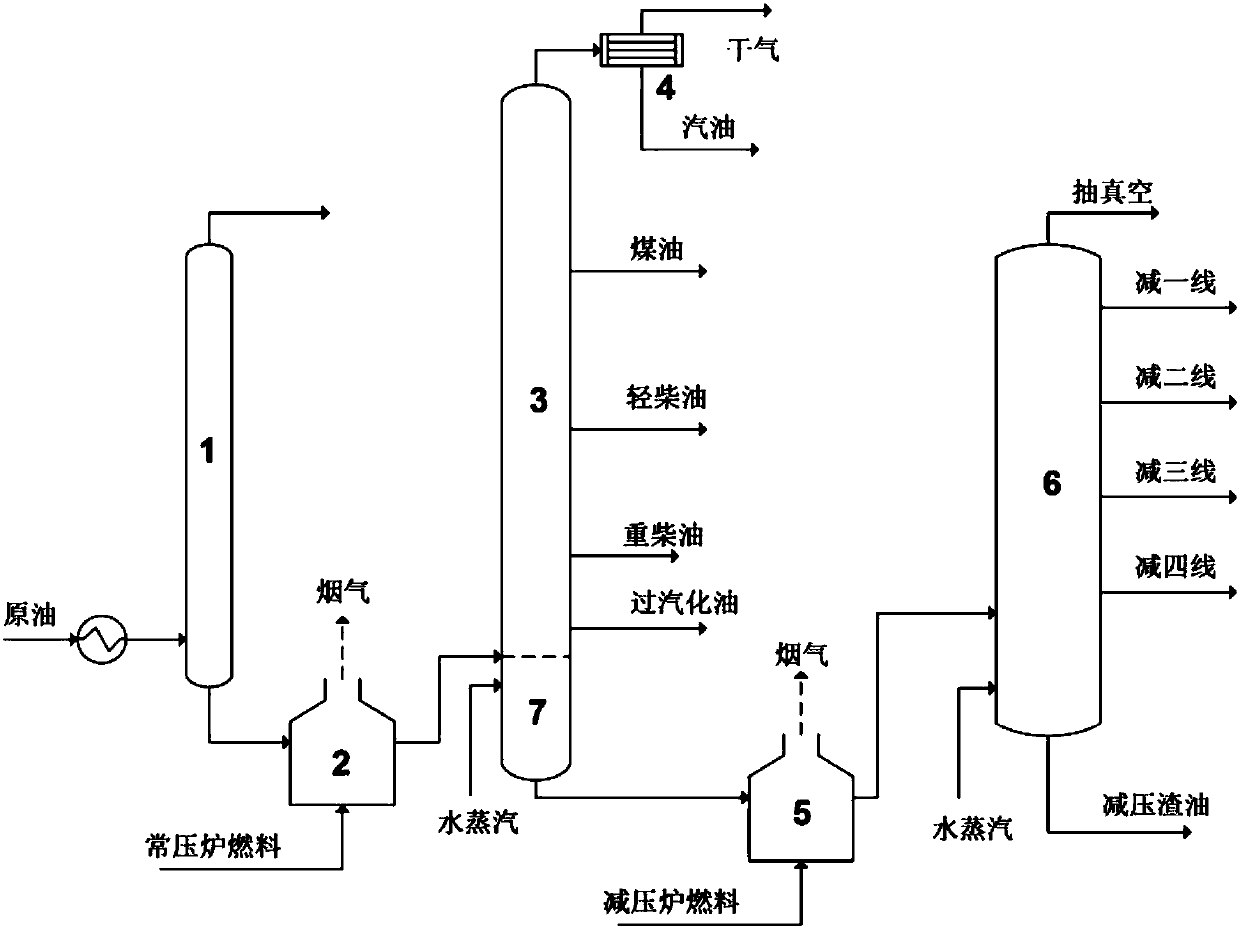

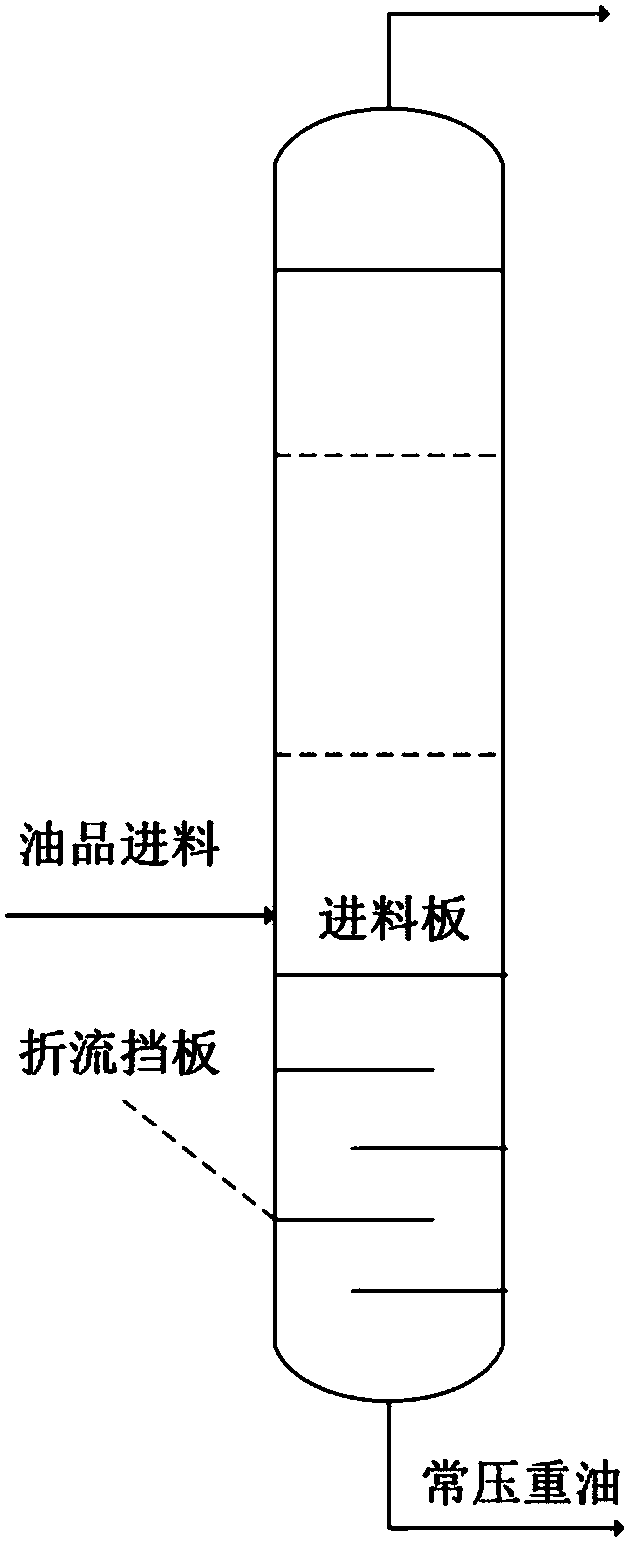

Highly-efficient energy-saving atmospheric and vacuum deep distillation process based on clear cut

ActiveCN107057747AHydrocarbon distillation control/regulationPetroleum wax recoveryBoiling pointDistillation

The invention provides a highly-efficient energy-saving atmospheric and vacuum deep distillation process based on clear cut. According to the invention, after first-section heat transfer of crude oil, the content of a fore-cut fraction with the temperature lower than the feeding temperature of primary distillation in primary distillation tower bottom oil is reduced to less than 1% to 3% through additional arrangement of a deep distillation stripper plate at the bottom of a primary distillation tower; after second-section heat transfer of the primary distillation tower bottom oil, the content of the fore-cut fraction with the temperature lower than the feeding temperature of primary distillation in the primary distillation tower bottom oil is reduced to less than 3% to 5% through additional arrangement of a flash tower at the front of an atmospheric furnace; flash oil enters an atmospheric tower for separation by pumping after being heated to 365 DEG C to 390 DEG C through the atmospheric furnace; through desuperheating rectification section and circulating reflux separation of partial hot heavy diesel, an initial boiling point of heavy diesel is controlled to be higher than 360 DEG C, and the gapping temperature of 5 DEG C or above is formed with 98% of second side stream of a diesel distillate, so the content of the fore-cut fraction with the temperature lower than 365 DEG C in atmospheric residual oil is reduced to less than 2% through additional arrangement of the deep distillation stripper plate at the bottom of the atmospheric tower; and by damp distillation of vacuum residual oil, the content of the fore-cut fraction with the temperature lower than a cut point in the vacuum residual oil is reduced to 5% or below through additional arrangement of the deep distillation stripper plate at the bottom of a vacuum tower.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

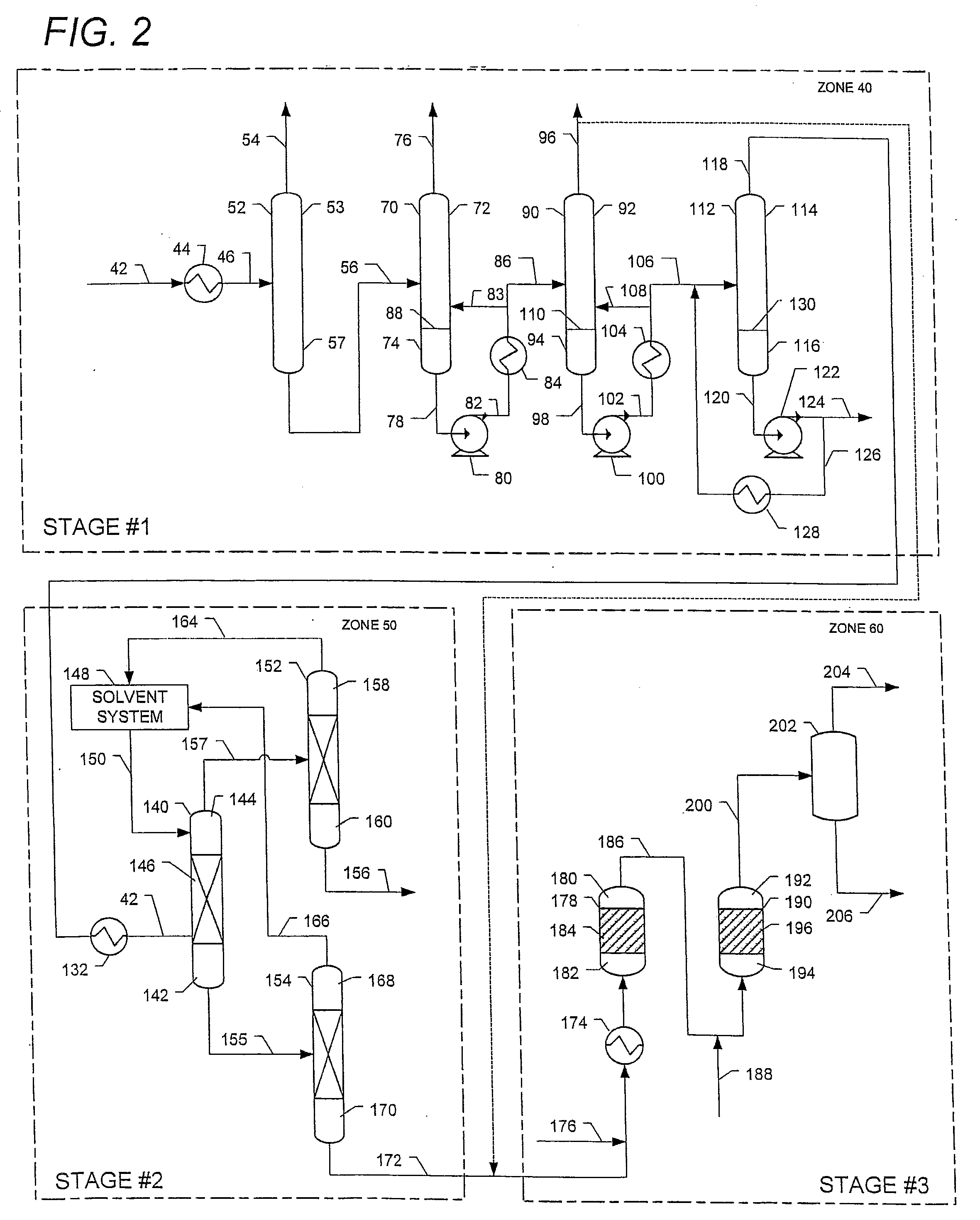

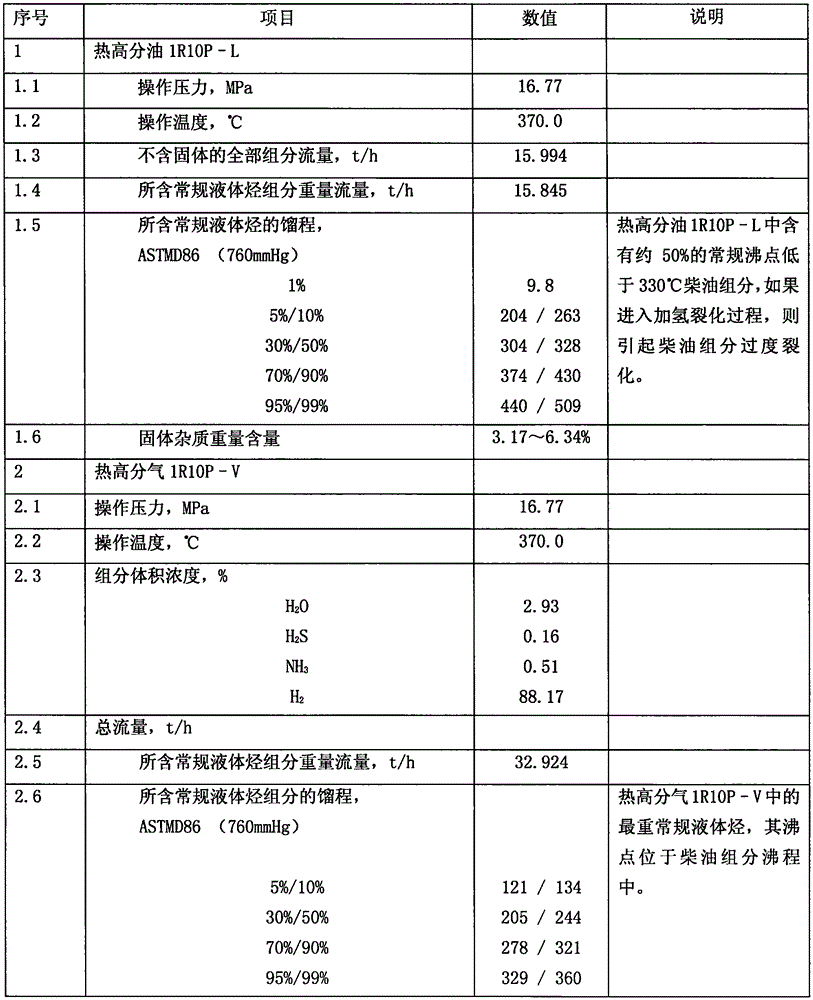

Hot high-pressure hydrogen gas stripping separation method of solid-containing hydrocarbon hydrogenated products

InactiveCN105567279AReduce volumeReduce gas volumeDistillation corrosion inhibitionHydrocarbon distillation control/regulationCavitationHigh pressure

The invention relates to a hot high-pressure hydrogen gas stripping separation method of solid-containing hydrocarbon hydrogenated products. The method is suitable for a separation process of reaction products of coal liquefication, oil-coal corefining, heavy oil suspension bed or fluidized bed hydrogenation, coal tar suspension bed or fluidized bed hydrogenation and the like, is capable of reducing the corrosive component quantity in oil S1L after the hot high-pressure separation and reducing the low-boiling-point component quantity, and can lower the temperature of the oil S1L and increase the viscosity of the oil S1L by utilizing the heat absorption during flash evaporation; and the properties of the hot high-pressure separated gas are changed due to more low-boiling-point hydrocarbon components contained in the gas. The changes of the properties of the hot high-pressure separated oil refer to S1L quantity reduction, corrosivity reduction, heavy component concentration increase and temperature reduction. When being used for separating the coal liquefication reactor products, the method enhances the oil product separation efficiency in the hot high-pressure separation process, reduces the cavitation and erosion speeds of the flow passage components in the oil S1L pressure reduction process, lowers the load and medium corrosivity in the oil S1L fractional distillation process, and enhances the solid removal efficiency.

Owner:何巨堂 +1

Catalytic cracking slurry oil solid content removal method

InactiveCN105802657ALow solid contentAdaptableHydrocarbon distillation control/regulationHydrocarbon oils treatmentHeat pretreatmentSolid particle

The invention discloses a catalytic cracking slurry oil solid content removal method.The method comprises the following steps that 1, heat pretreatment is conducted on catalytic cracking slurry oil; 2, vacuum distillation is conducted on the catalytic cracking slurry oil subjected to heat pretreatment, and solid removal slurry oil distillate oil is obtained.According to the catalytic cracking slurry oil solid content removal method, heat pretreatment is conducted on the slurry oil before distillation is conducted so as to enable micron or submicron solid particles in the slurry oil to aggregate and grow up, and the solid particles can stay in distillation residues more easily, so that the solid content in the slurry oil distillate oil is reduced, and the solid content of the slurry oil distillate oil is further reduced on the basis of simple distillation operation.The catalytic cracking slurry oil solid content removal method is easy to operate and high in removal efficiency, adaptability to raw materials is high, influence factors are few, the cost is low, and industrialization is easy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Alkylation reaction product separation device and separation method

PendingCN108211403ASimple equipmentSimple processDistillation corrosion inhibitionHydrocarbon distillation control/regulationRefluxAlkyl transfer

The invention discloses an alkylation reaction product separation device and separation method. The separation method comprises the following steps that (1) an alkylation reaction product from an alkylation reaction unit is introduced into a first fractionator, a gas-phase object which is educed from the top of the first fractionator is pressurized by a gas compressor as a hot source of a reboilerat the bottom of the first fractionator, and a part of a fractionator overhead stream after heat exchange and condensation returns to the fractionator top as a reflux of the first fractionator; (2) abottom liquid-phase stream of the first fractionator is introduced into a second fractionator for fractionation and separation; and (3) a bottom liquid-phase stream of the second fractionator is introduced into a third fractionator for fractionation and separation, and the bottom liquid-phase stream of the third fractionator is taken as an alkylation product. According to the separation method provided by the invention, by performing two-stage separation on isobutane fraction in the alkylation reaction product, the total energy consumption of an alkylation separation is greatly lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

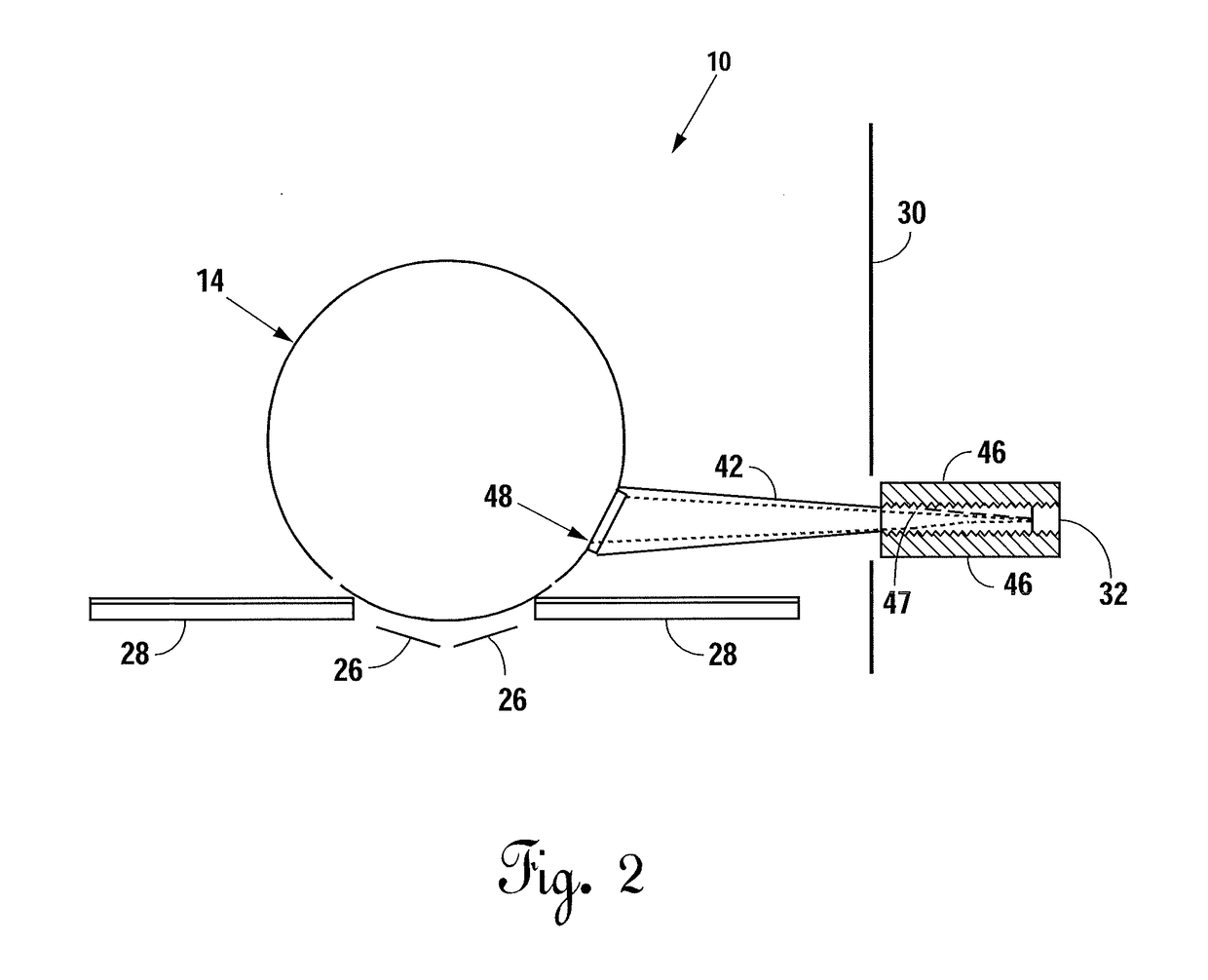

Adsorbing polynuclear aromatics from a reforming process at reaction temperatures

InactiveUS8518240B2Hydrocarbon distillation control/regulationCatalytic naphtha reformingActivated carbonReaction temperature

One exemplary embodiment can be a process for removing one or more polynuclear aromatics from at least one reformate stream from a reforming zone. The PNAs may be removed using an adsorption zone. The adsorption zone can include first and second vessels. Generally, the process includes passing the at least a portion of an effluent of the reforming zone through the first vessel containing a first activated carbon. The adsorption zone is operated at a temperature of at least 370° C.

Owner:UOP LLC

Experimental device and experimental method of superheated steam distillation of thickened oil

ActiveCN104650950AStable equilibrium distillationModified Equation of StateHydrocarbon distillation control/regulationHydrocarbon oils treatmentExperimental methodsGas phase

The invention provides an experimental device of superheated steam distillation of thickened oil. The experimental device comprises a steam generation unit, a heating unit, a metering unit, a distillation kettle, a liquid phase collecting unit and a gaseous phase collecting unit, wherein the steam generation unit is communicated with the heating unit; the heating unit is communicated with the metering unit; the distillation kettle is provided with a feeding hole, a liquid phase outlet and a gaseous phase outlet; the metering unit is communicated with the feeding hole of the distillation kettle; the liquid phase outlet of the distillation kettle is communicated with the liquid phase collecting unit; the gaseous phase outlet of the distillation kettle is communicated with the gaseous phase collecting unit. The invention also provides an experimental method of superheated steam distillation of thickened oil. The experimental device is adopted for the experimental method. The experimental device and the experimental method of the superheated steam distillation of the thickened oil are capable of realizing stable equilibrium distillation in a laboratory and accurately obtaining a distillation rate and a distillation product and also capable of correcting a state equation; as a result, the contribution of the distillation effect of water steam in the steam injection oil extraction process can be obtained.

Owner:PETROCHINA CO LTD

Polished turbine fuel

ActiveUS20190153942A1Low costMinimum operationCatalytic crackingHydrocarbon distillation control/regulationUnit operationLiquid fuel

Turbine fuel provided for large-scale land based turbines used by utilities for producing electricity and desalinated water, and for large mobile engines and turbines in marine and remote applications where only liquid fuels are available. Use results in less corrosion, ash formation and emissions (NOx, SOx, CO2 and noxious metals) than firing contaminated heavy crude, refinery residual oils or high sulfur fuel oils. Manufacture is by decontaminating crude oils, non-conventional crudes, and other highly contaminated feeds. Each fuel is produced as a single product of unit operations, not ex-plant blend of various refinery products, yet using an apparatus configuration less complex than conventional crude oil refining. These fuels can be fired by advanced high efficiency turbines of combined cycle power plants having hot flow paths and heat recovery steam generation systems susceptible to corrosion, which systems cannot otherwise risk contaminated heavy crudes or refinery residual oils feeds.

Owner:MAWETAL LLC

Method for deeply desulfurizing sulfur-containing raw material

ActiveCN108018066ANo lossHydrocarbon distillation control/regulationAzeotropic/extractive distillationDistillationKetone

The invention relates to the field of refining of hydrocarbon materials, and discloses a method for deeply desulfurizing a sulfur-containing raw material. The method is characterized in that solvent extraction of the sulfur-containing raw material and an extracting solvent is carried out through distillation to obtain a sulfur-containing solvent and a desulfurized product, wherein the extracting solvent contains a main extracting solvent and an assistant, the assistant is at least one substance of alcohols, ketones, organic acids and organic nitrides being intermiscible with the main extracting solvent and having a boiling point or a dry point being not more than the boiling point or the dry point of the main extracting solvent and / or water, and the organic nitrides are at least one of amines, carbamides and hydramines. The method can deeply remove sulfides from the sulfur-containing raw material, such as gasoline even under a hydrogen source-free or hydrogen source-deficient condition, and achieves basic no loss of the octane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid-containing heavy oil vacuum distillation apparatus and method

InactiveCN109181744AGuaranteed pullout rateReduce corrosion wearHydrocarbon distillation control/regulationEconomic benefitsSolid particle

The invention relates to a solid-containing heavy oil vacuum distillation apparatus and method. The method comprises: (1) performing vacuum flashing treatment on bottom oil containing solids under atmospheric pressure to obtain flash top gas and flash bottom oil, and (2) directly feeding the flash top gas into a vacuum tower, heating the flash bottom oil and feeding the flash bottom oil into the vacuum tower. The apparatus and method guarantee the extraction rate of the vacuum distillation tower, reduce the wear and corrosion of the solid particles in the oil component to the vacuum furnace and the furnace tube, improve the operation cycle of the vacuum furnace and improve the economic benefits.

Owner:胜帮科技股份有限公司

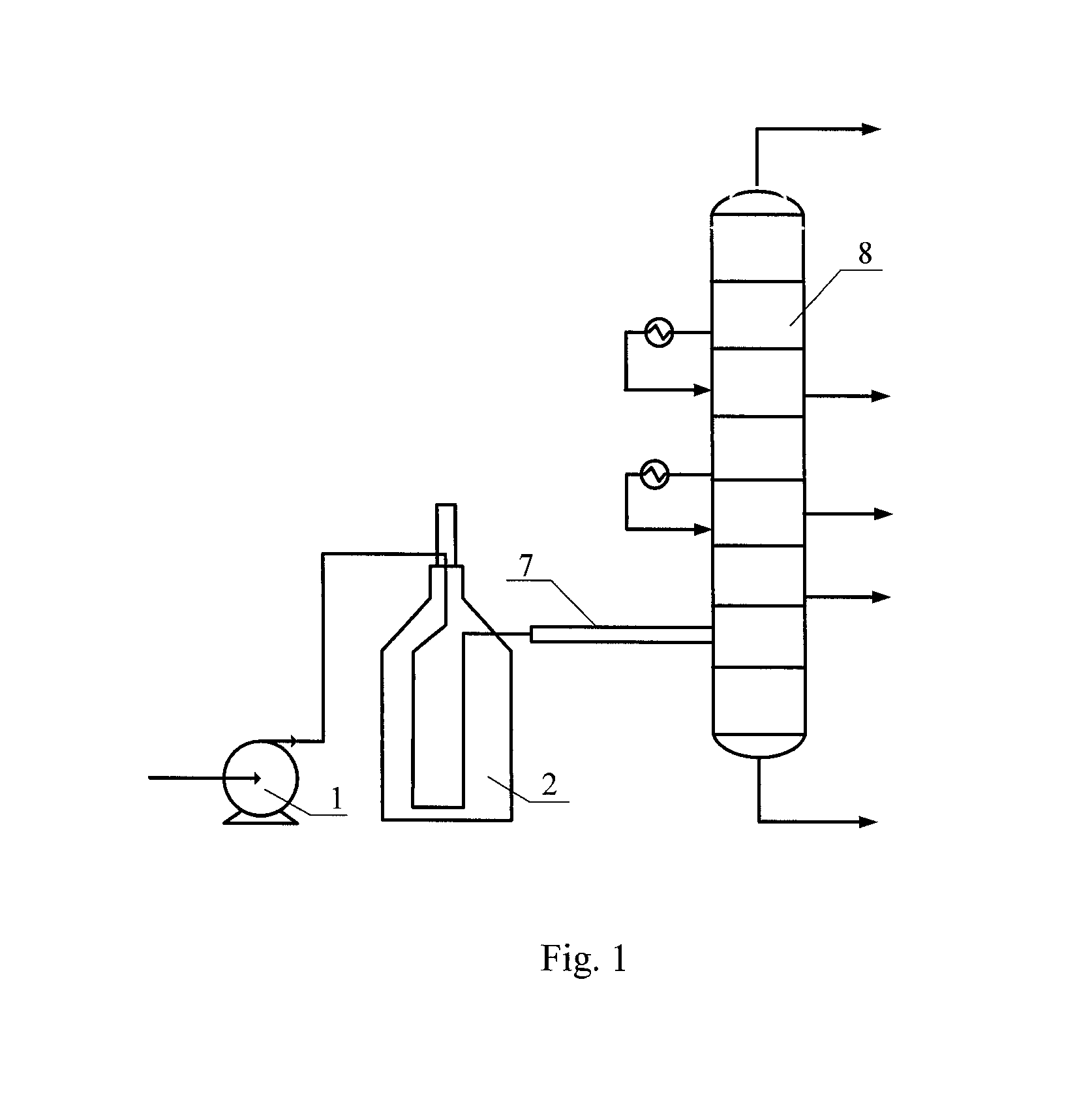

Distillation tower for improving yield of petroleum hydrocarbon distillate and feeding method thereof

ActiveUS20130220889A1Improve oil yieldThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationFractionating columnFractionation

A method for improving yield of petroleum hydrocarbon distillate in a distillation tower (6) comprises: preheating raw oil of petroleum hydrocarbon ready for fractionation; feeding it to a vaporization section (11) through a pressure feed system (3) under a pressure 100-1000 kPa higher than the vaporization section (11) of the distillation tower (6) for simultaneous atomizing and vaporizing; then feeding it to a fractionation section (13) for distillation-separation; and finally, discharging distillate product from the top and / or side of the tower and unvaporized heavy oil from the bottom. A distillation tower (6) for improving yield of petroleum hydrocarbon distillate comprises a vaporization section (11) and a fractionation section (13), and further comprises a pressure feed system (3) for feeding the raw oil of petroleum hydrocarbon ready for fractionation under a pressure 100-1000 kPa higher than that in the vaporization section (11) of the distillation tower (6).

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

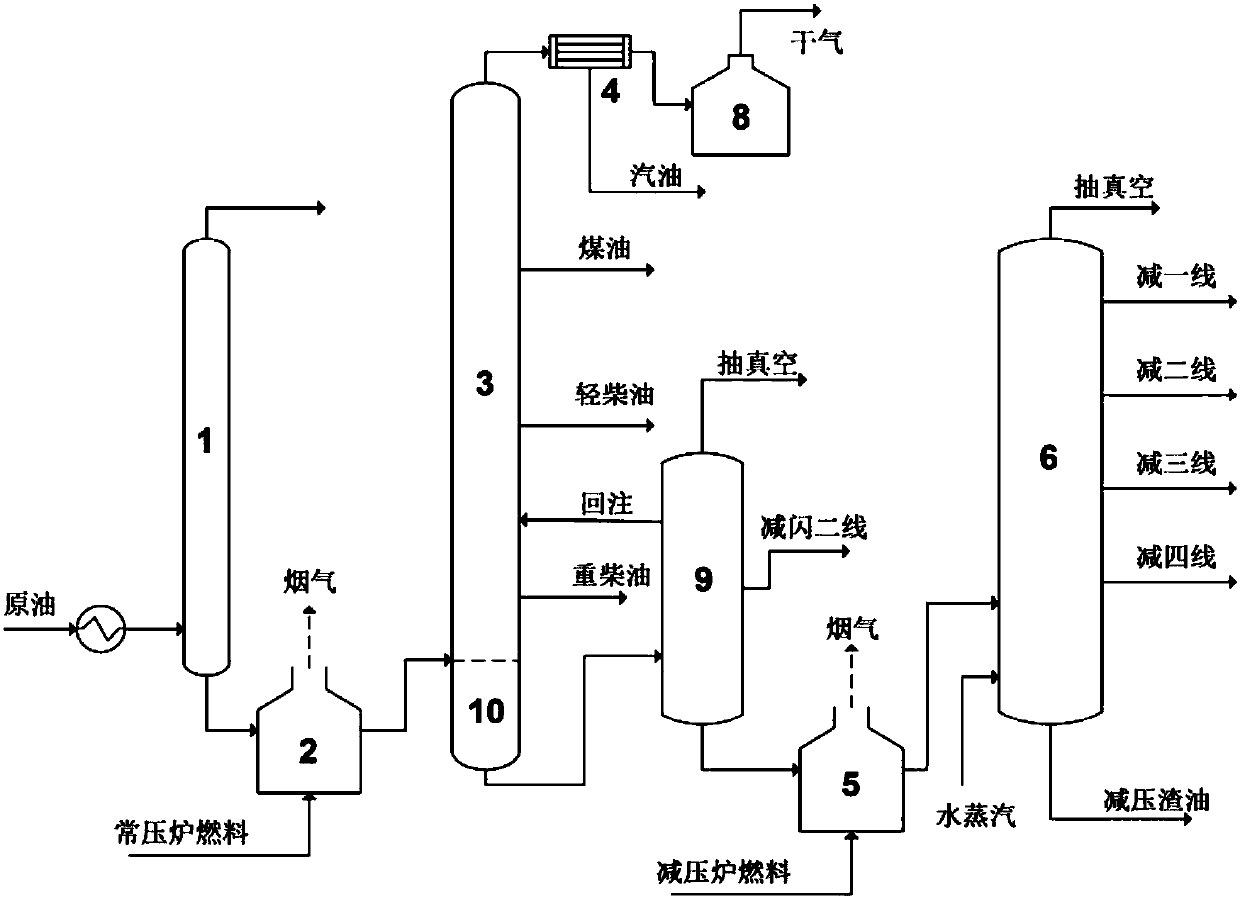

Water-free atmospheric vacuum distillation technology and device

ActiveCN107699273AEasy to separateSolve the problem of low temperature dew point corrosionHydrocarbon distillation control/regulationVacuum distillationReboilerFuel oil

The invention provides a water-free atmospheric vacuum distillation technology and device. The technology is characterized in that a normal-pressure tower and a vacuum tower adopt a four-time gasification and feeding manner; after crude oil is heated through a normal-pressure furnace, materials are fed from a tower kettle of the normal-pressure tower; water steam is not introduced into the tower kettle; each sideline product is heated by adopting a reboiler; alkali washing is carried out on tower top dry gas which is condensed and cooled at a tower top of the normal-pressure tower; a vacuum flashing tower is additionally arranged between the normal-pressure tower and a vacuum furnace; normal-pressure heavy oil from the tower kettle of the normal-pressure tower enters the vacuum flashing tower; the vacuum flashing tower is provided with a plurality of sidelines for drawing out products; the product drawn out from the first sideline is injected into the normal-pressure tower again; the heavy oil of the tower kettle enters the vacuum furnace and is further heated, and then enters the vacuum tower; pressure of the vacuum flashing tower is controlled between the pressure of the normal-pressure tower and the pressure of the vacuum tower. The invention further provides the water-free atmospheric vacuum distillation device. By adopting the device and the technology, provided by the invention, the low-temperature dew-point corrosion problem of the top of the normal-pressure tower can be solved, refinery wastewater is reduced and the diesel oil extraction rate of the normal-pressureheavy oil is improved; serious entrainment of the vacuum tower is alleviated and the decompression and deep drawing vacuum degree is reduced. The long-period, safe, stable and operation performance ofthe device is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for optimizing and controlling pressure in gas-oil separation plants

InactiveUS8805587B1Readily apparentSampled-variable control systemsHydrocarbon distillation control/regulationProduction rateGenetic algorithm

The method for optimizing and controlling pressure in gas-oil separation plants utilizes a genetic algorithm-based control method for controlling pressure in each stage of a multi-stage gas-oil separation plant to optimize oil production parameters. A neural network simulation model is used with an optimization procedure to provide on-line operation optimization of the multi-stage gas-oil separation plant. Pressure set points of each stage are automatically and continuously adjusted in the presence of fluctuating ambient temperatures and production rates to ensure optimal oil recovery and optimal quality of the produced oil.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method and system for analysing a blend of two or more hydrocarbon feed streams

ActiveUS20170023485A1Low costLow of opportunityAnalysis using chemical indicatorsDistillation corrosion inhibitionHydrocarbonMethod evaluation

The invention relates to a method for analysing a blend of two or more hydrocarbon feed streams such as crude oils. These crude oils are blended in a facility such as a refinery. The method assesses the compatibility of a hydrocarbon feed in a blend to calculate the blend stability such that organic deposition is minimised. The method uses all of a plurality of hydrocarbon feeds to be blended for analysis. The method either selects a neat hydrocarbon feed, from a plurality of the hydrocarbon feeds included in a blend, as a titrant, wherein the or each other hydrocarbon in the hydrocarbon feed are used to make a pseudo-blend and titrating the pseudo-blend with said selected neat hydrocarbon feed for a plurality of different blend ratios. Alternatively the method involves preparing a reference hydrocarbon and making a blend from the plurality of hydrocarbon feeds and titrating the blend with the reference hydrocarbon. Measurements associated with the change in characteristics of the titrated blend are made and data recorded. The method then calculates, using said data, the stability of the blend.

Owner:INTERTEK GRP

Solvent Quality Control in Extraction Processes

InactiveUS20120197057A1Improvement in quality and long-term reliabilityMaintain stabilityHydrocarbon distillation control/regulationDistillation purification/separationExtractive distillationQuality control

The invention concerns the control of solvent systems in processes and apparatus for the separation of aromatic hydrocarbons from non-aromatic hydrocarbons in liquid-liquid extraction, extractive distillation, and the combination thereof.

Owner:EXXONMOBIL CHEM PAT INC

Popular searches

Liquid-gas reaction processes Refining by aromatic hydrocarbon hydrogenation Refining to eliminate hetero atoms Reforming process control/regulation Total factory control Adaptive control Treatment with plural serial stages only Hydrocarbon oil cracking process Evaporation Liquid hydrocarbon mixture production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com