Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about "Reforming process control/regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

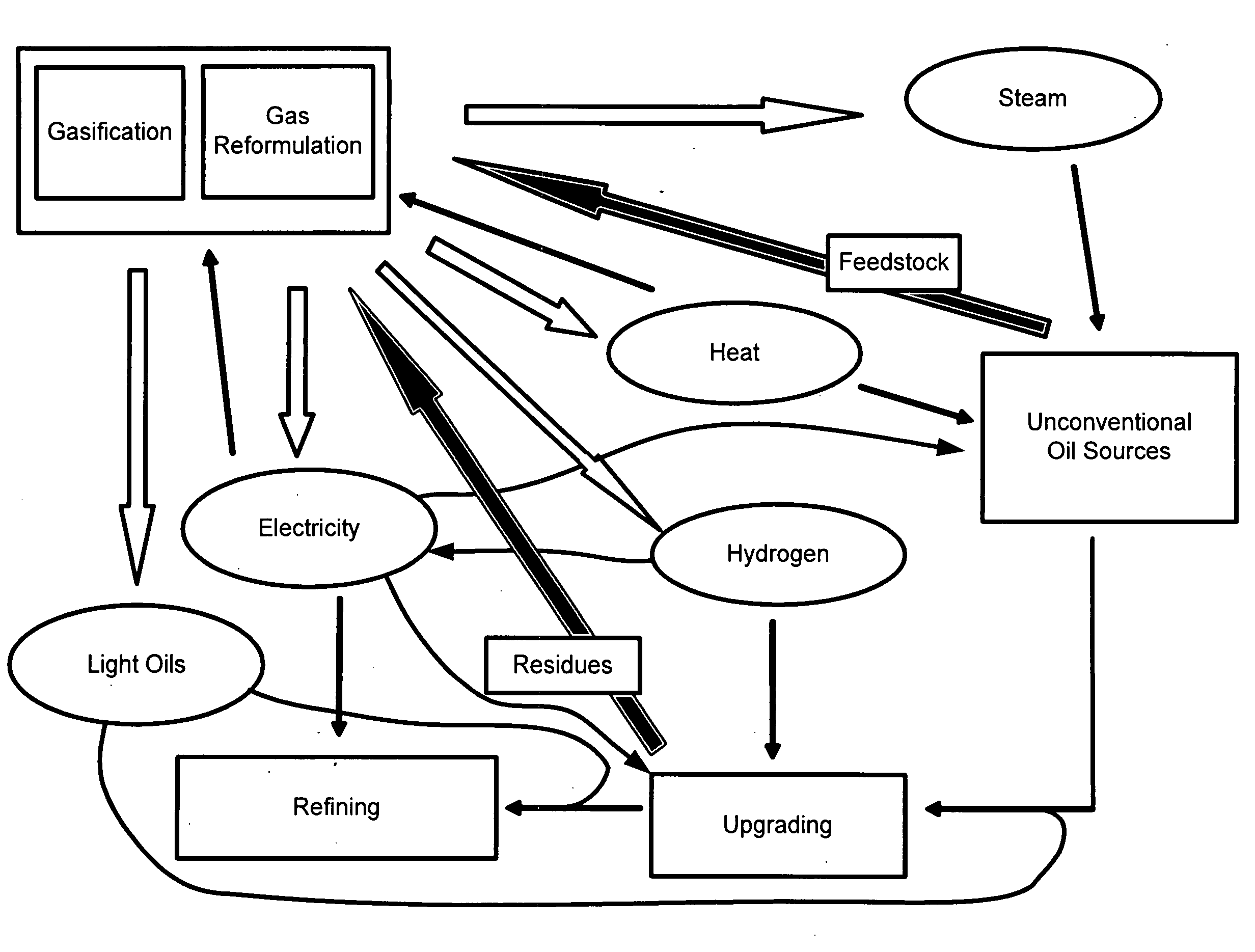

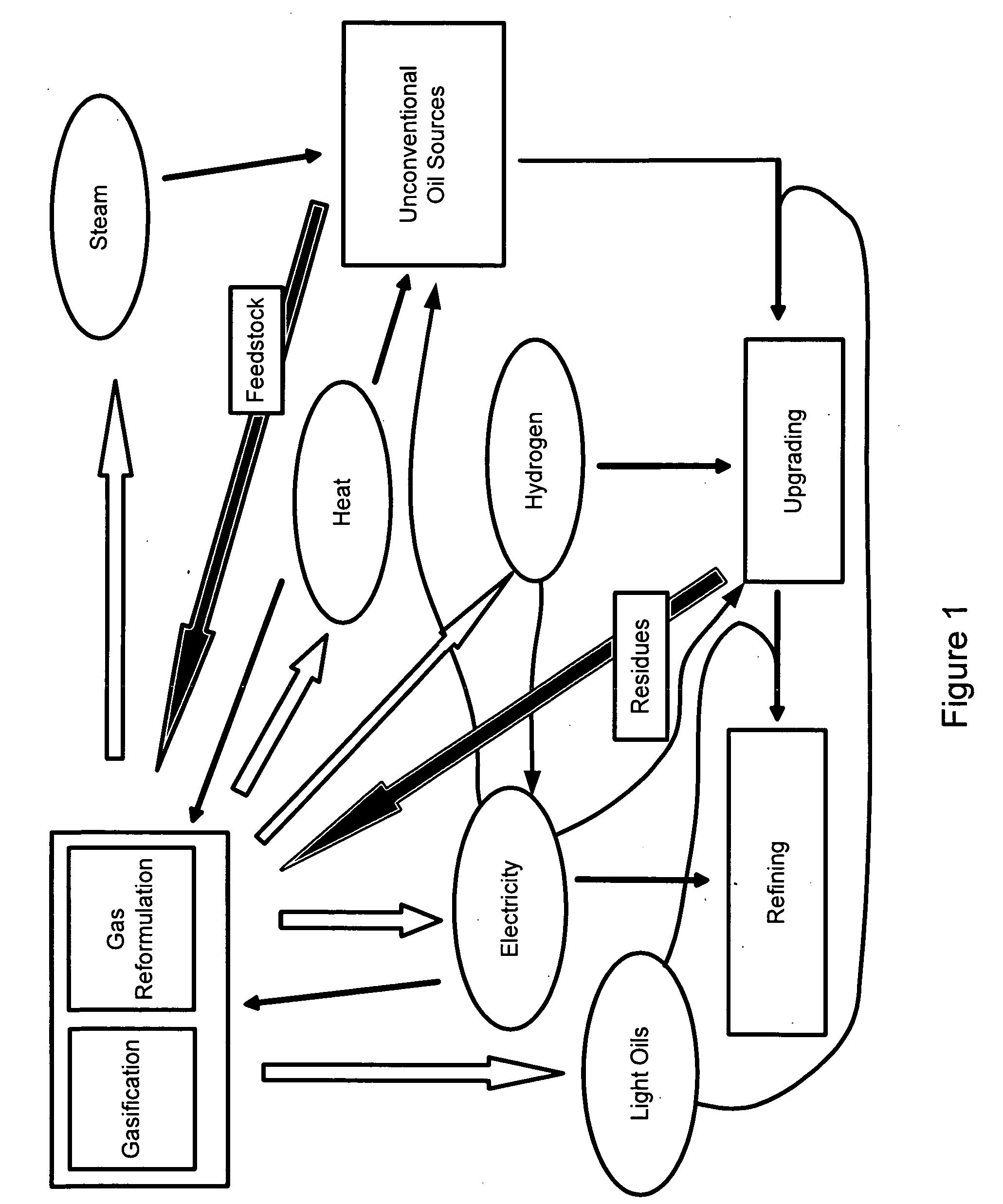

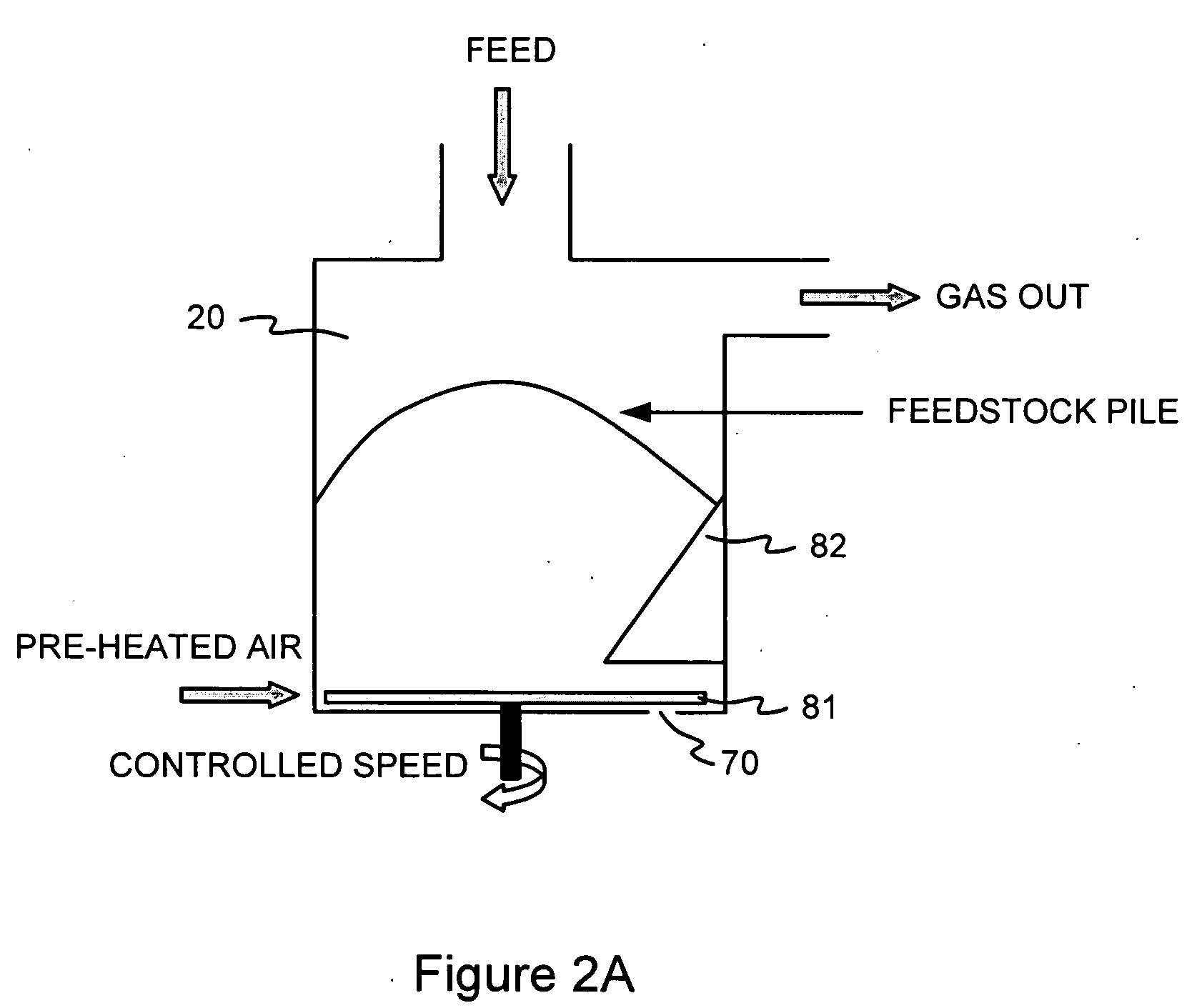

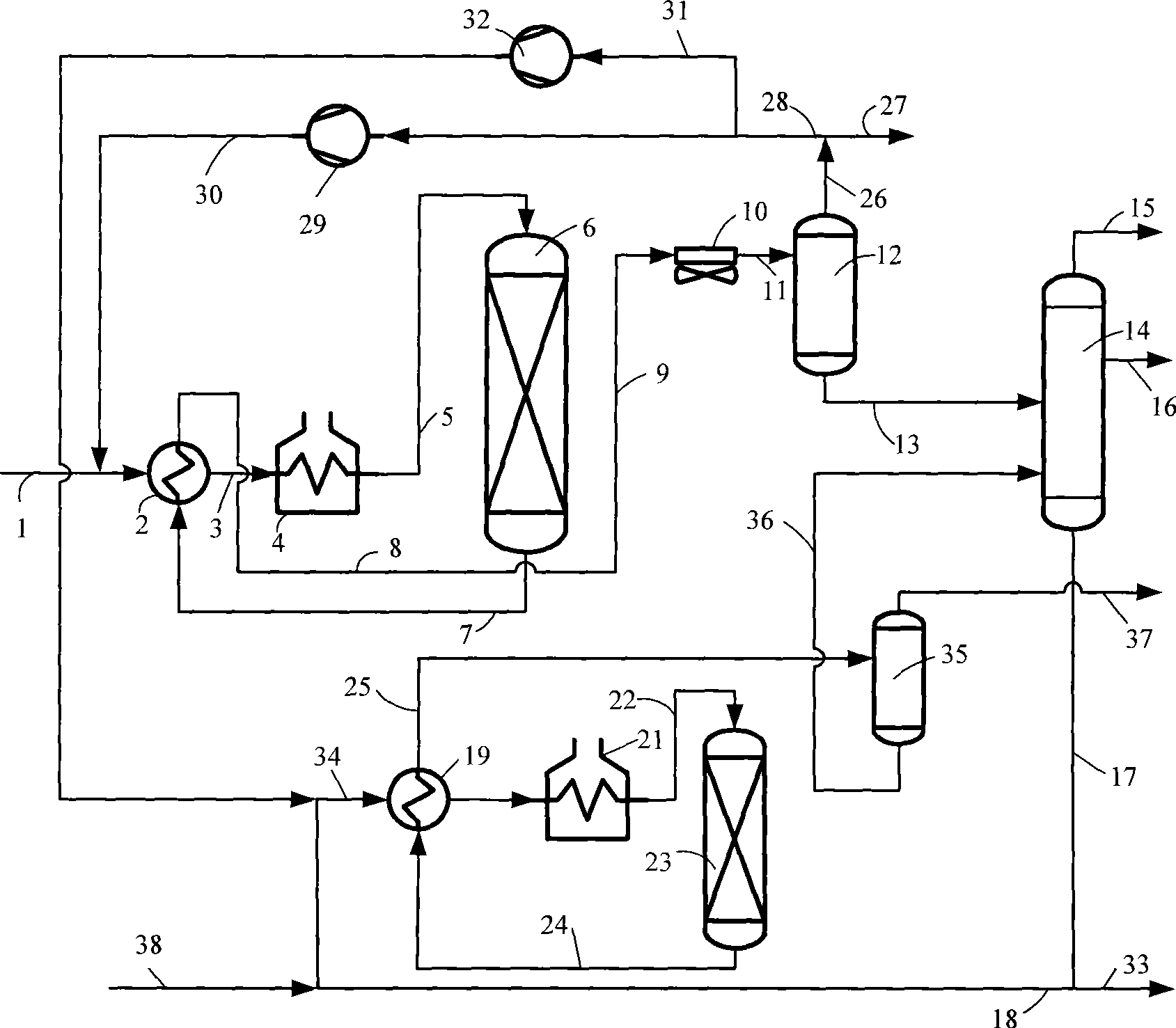

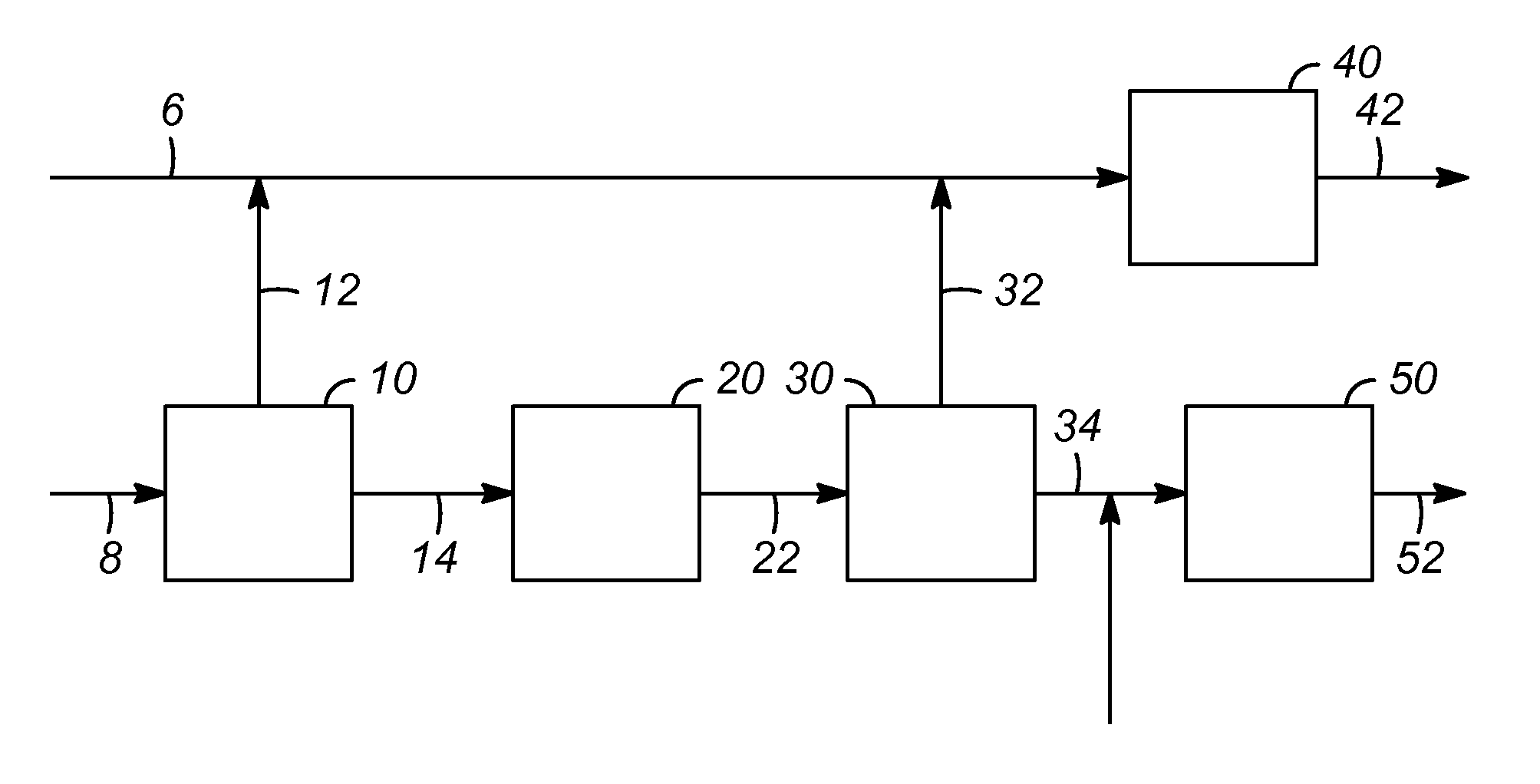

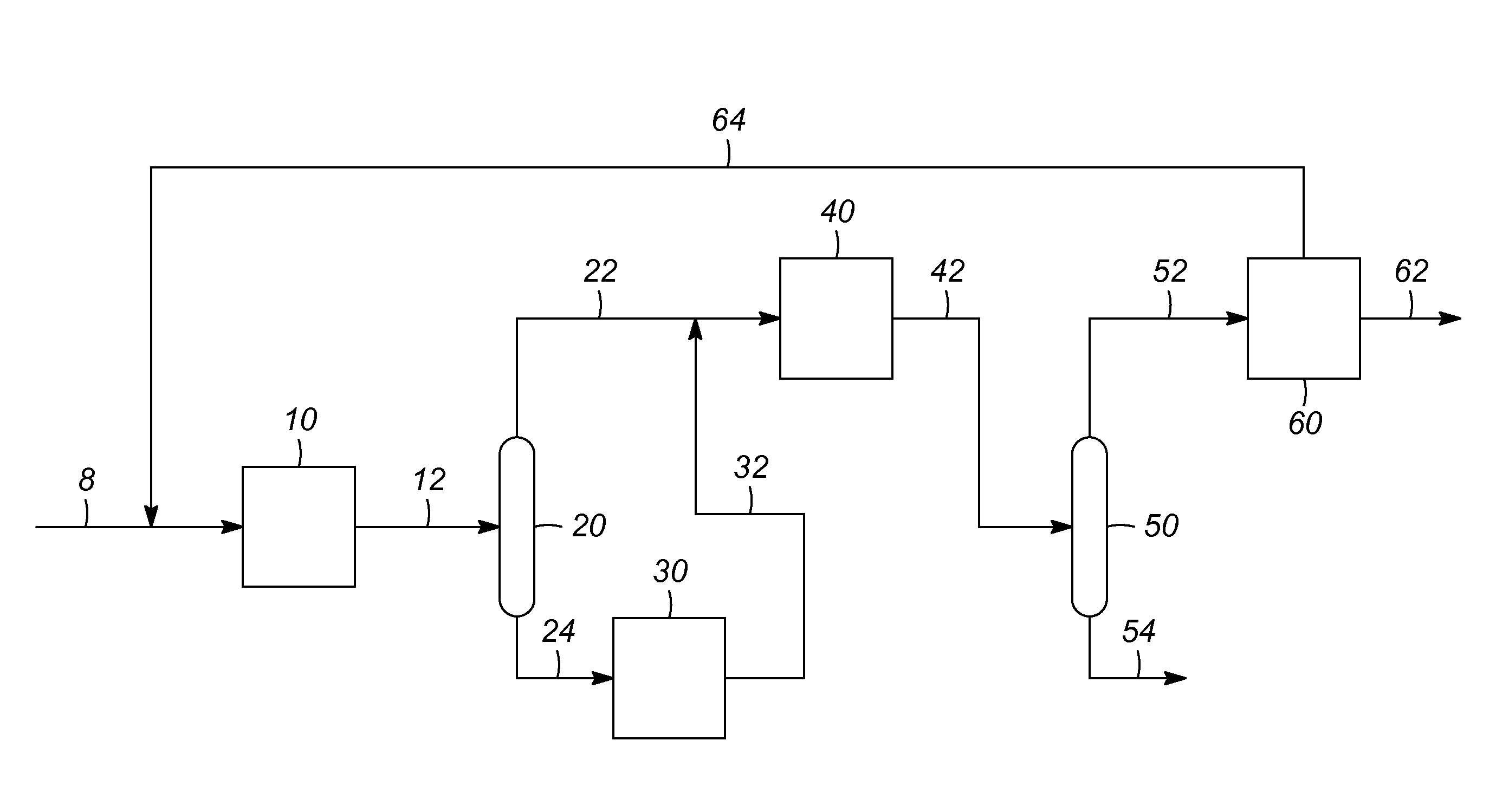

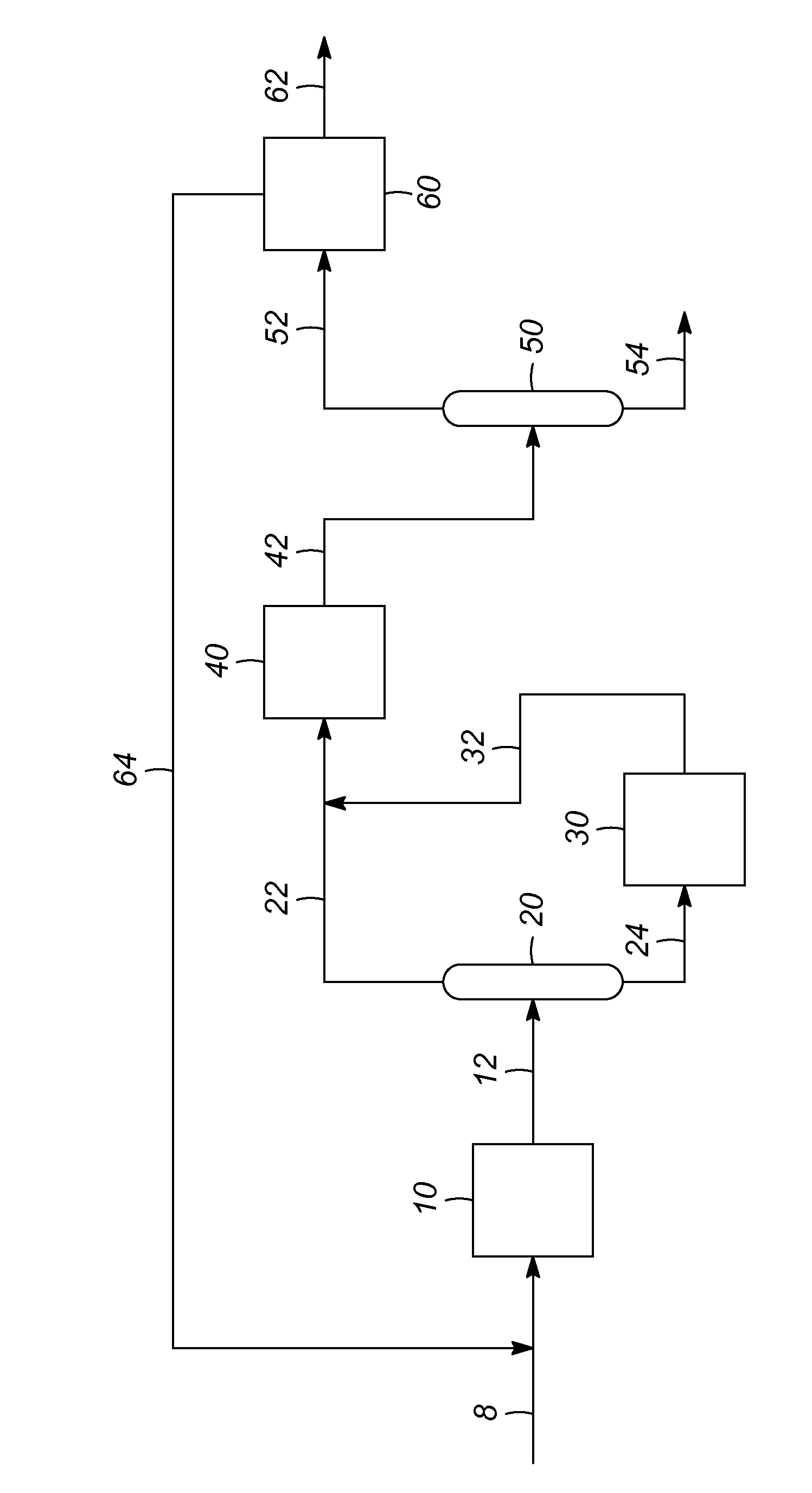

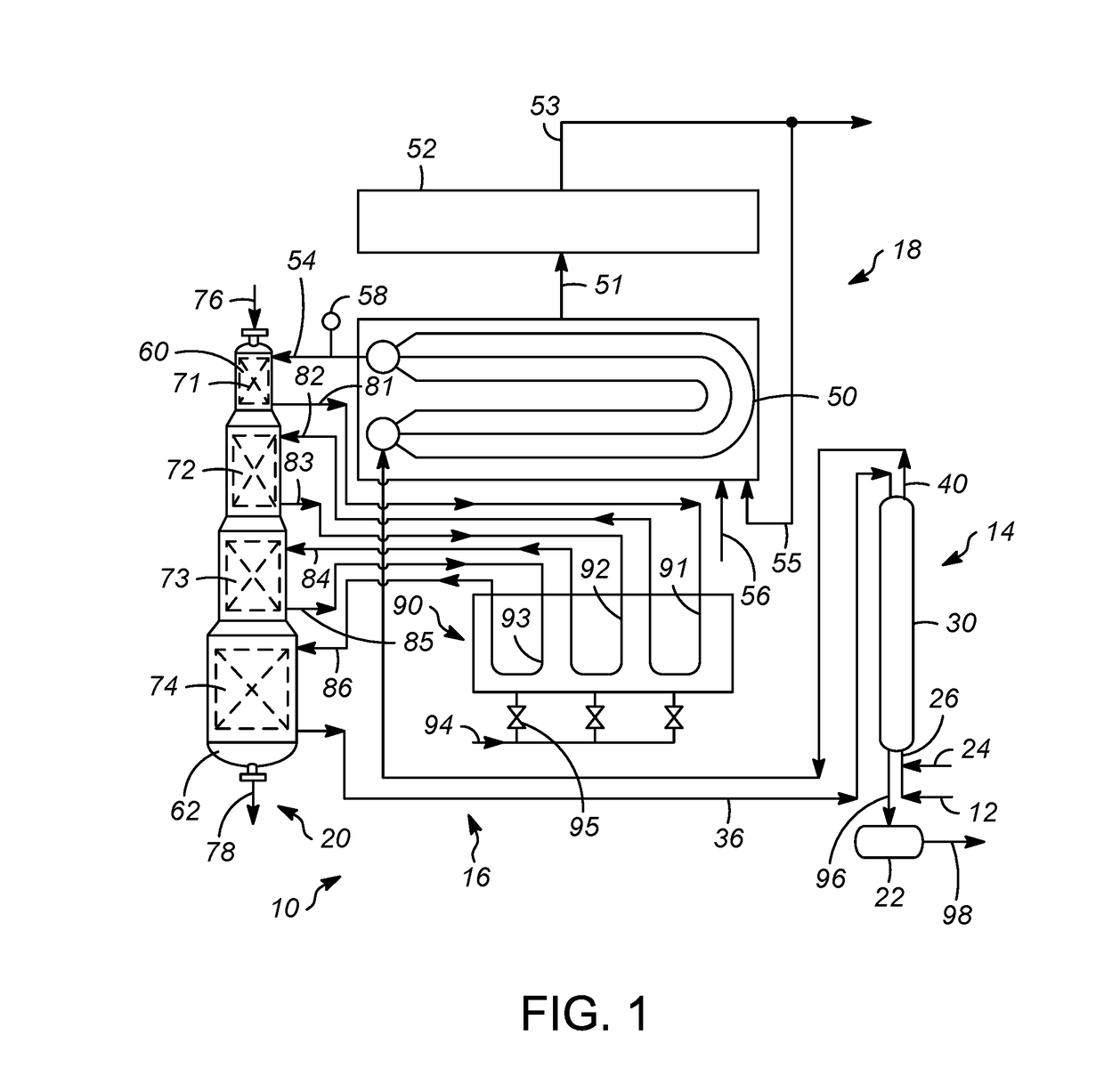

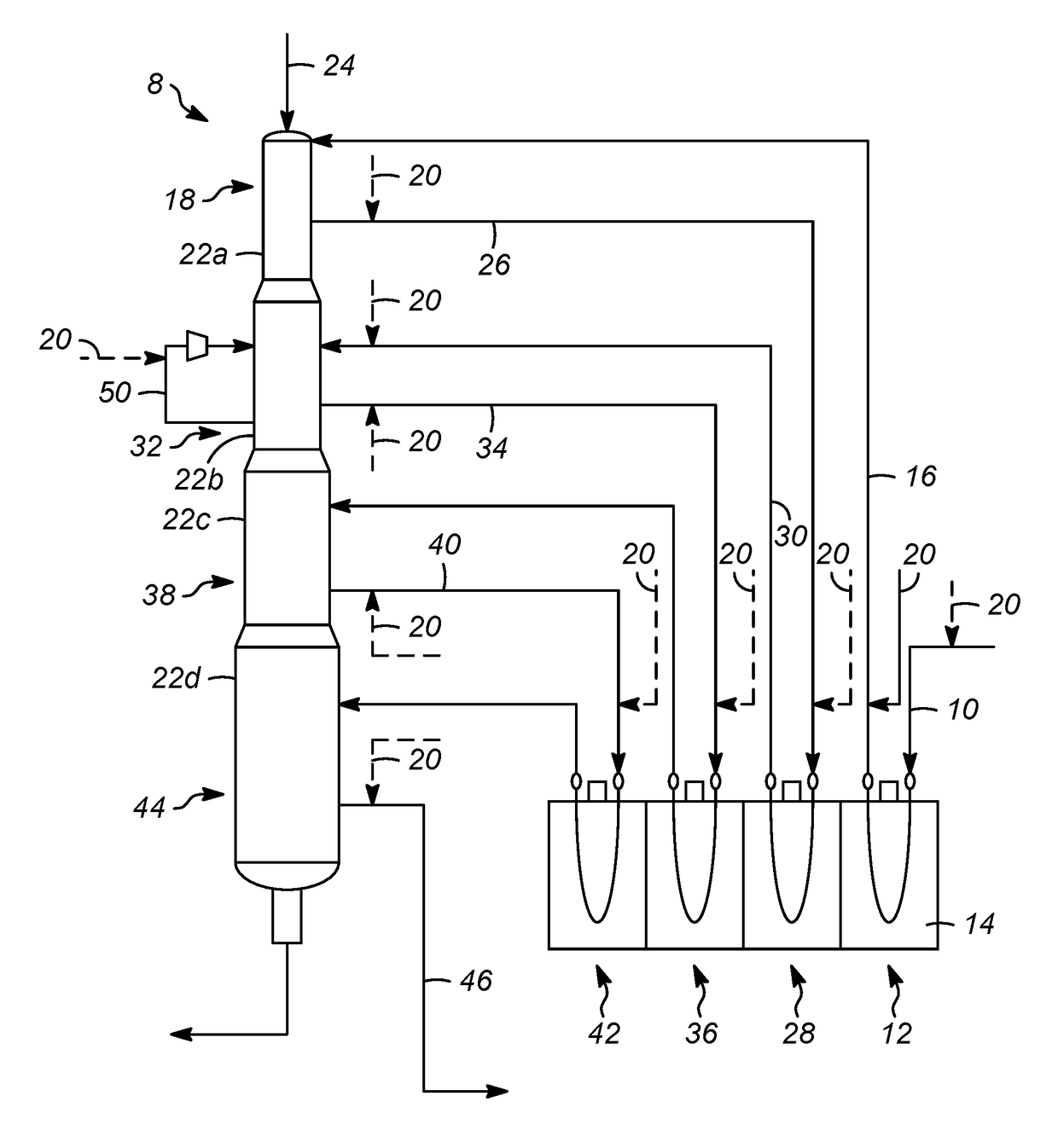

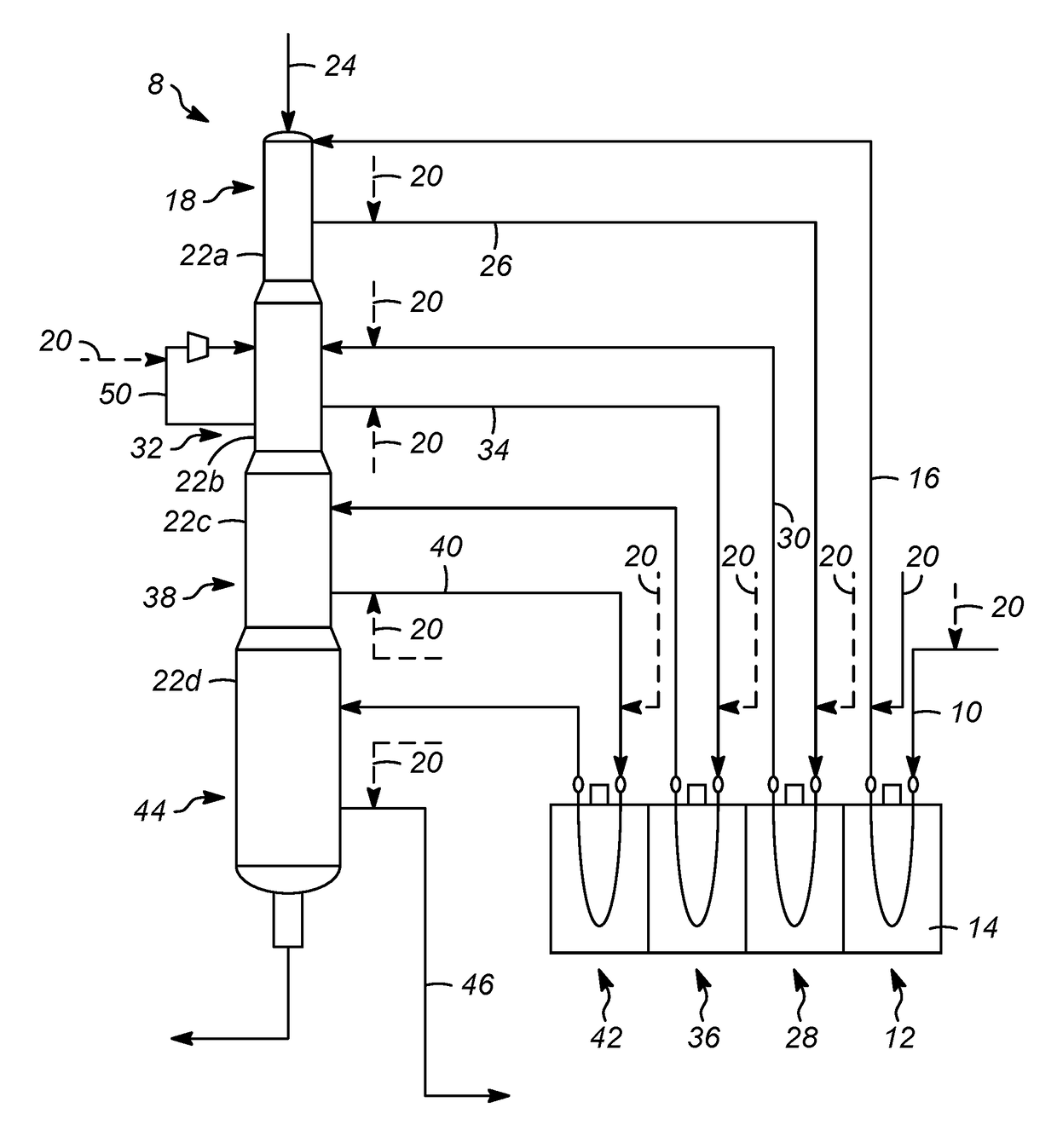

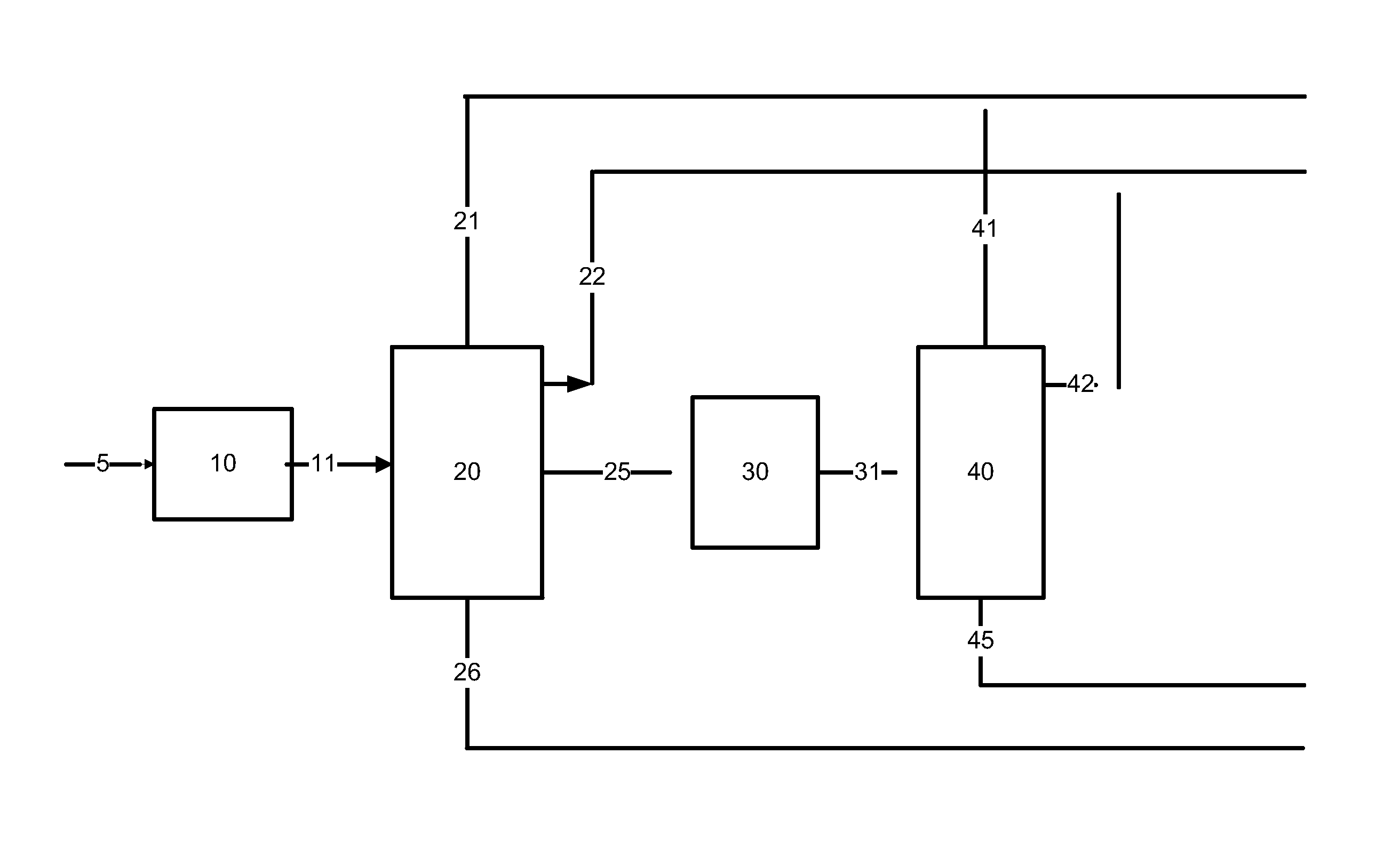

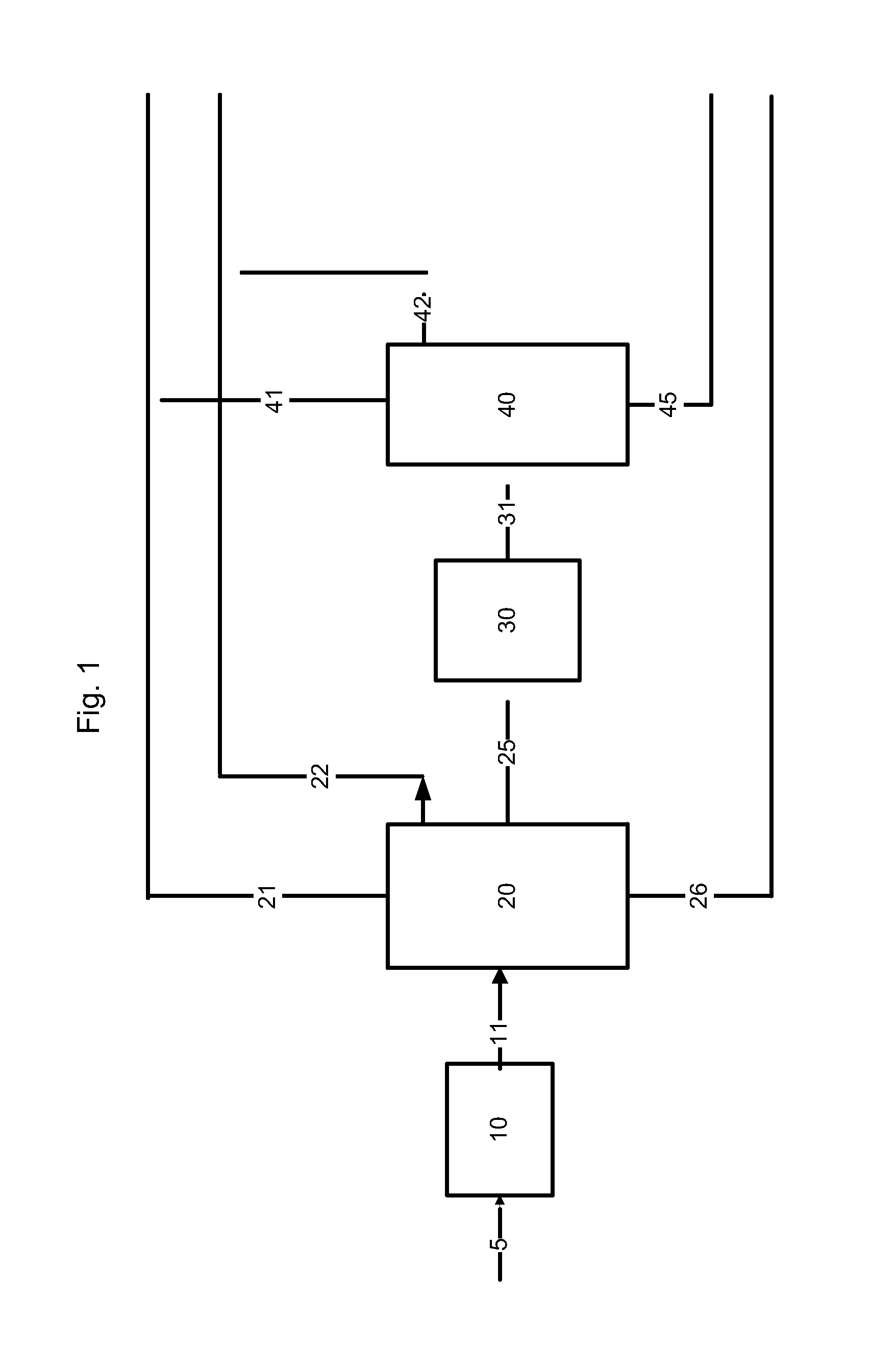

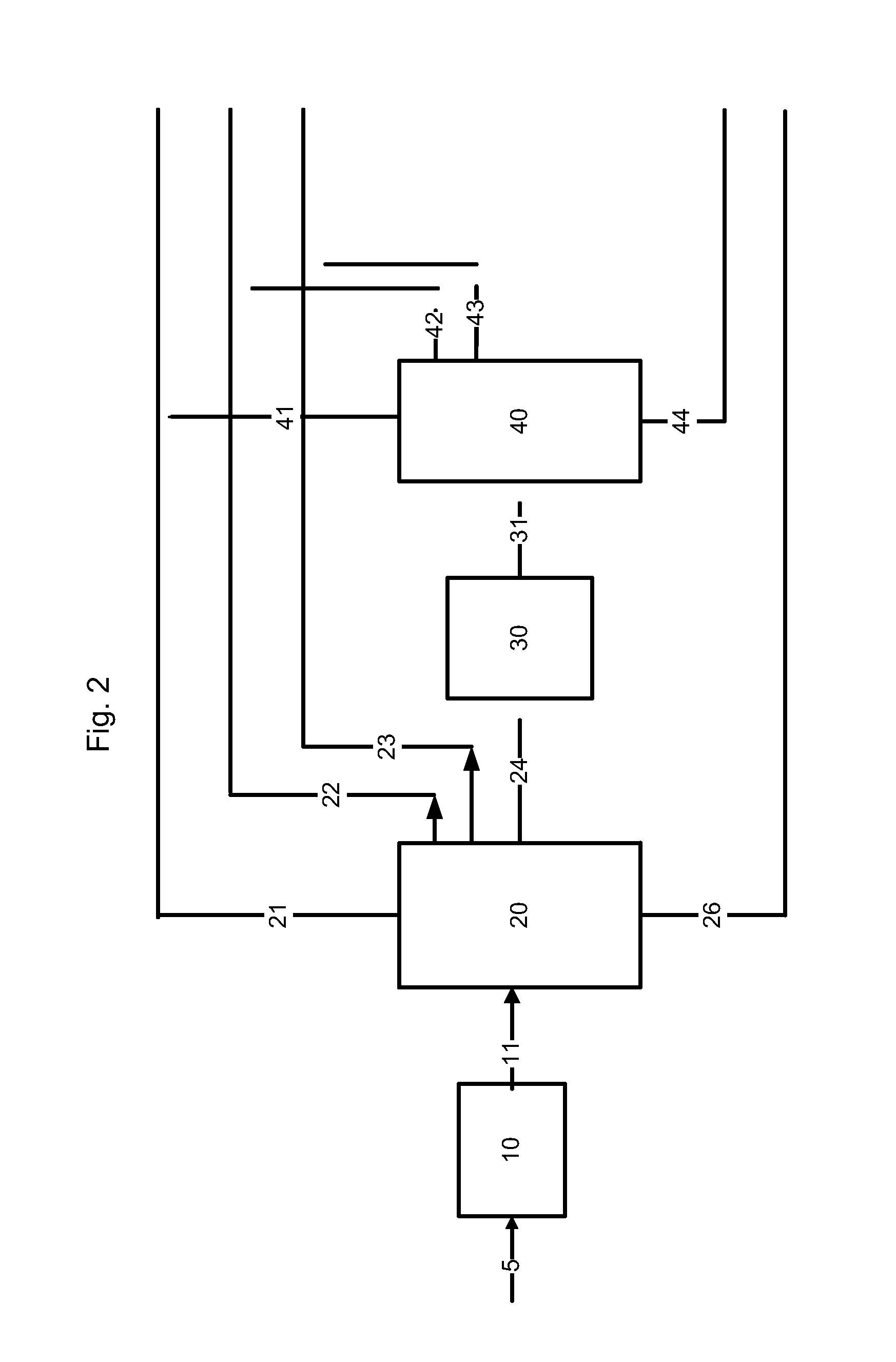

System comprising the gasification of fossil fuels to process unconventional oil sources

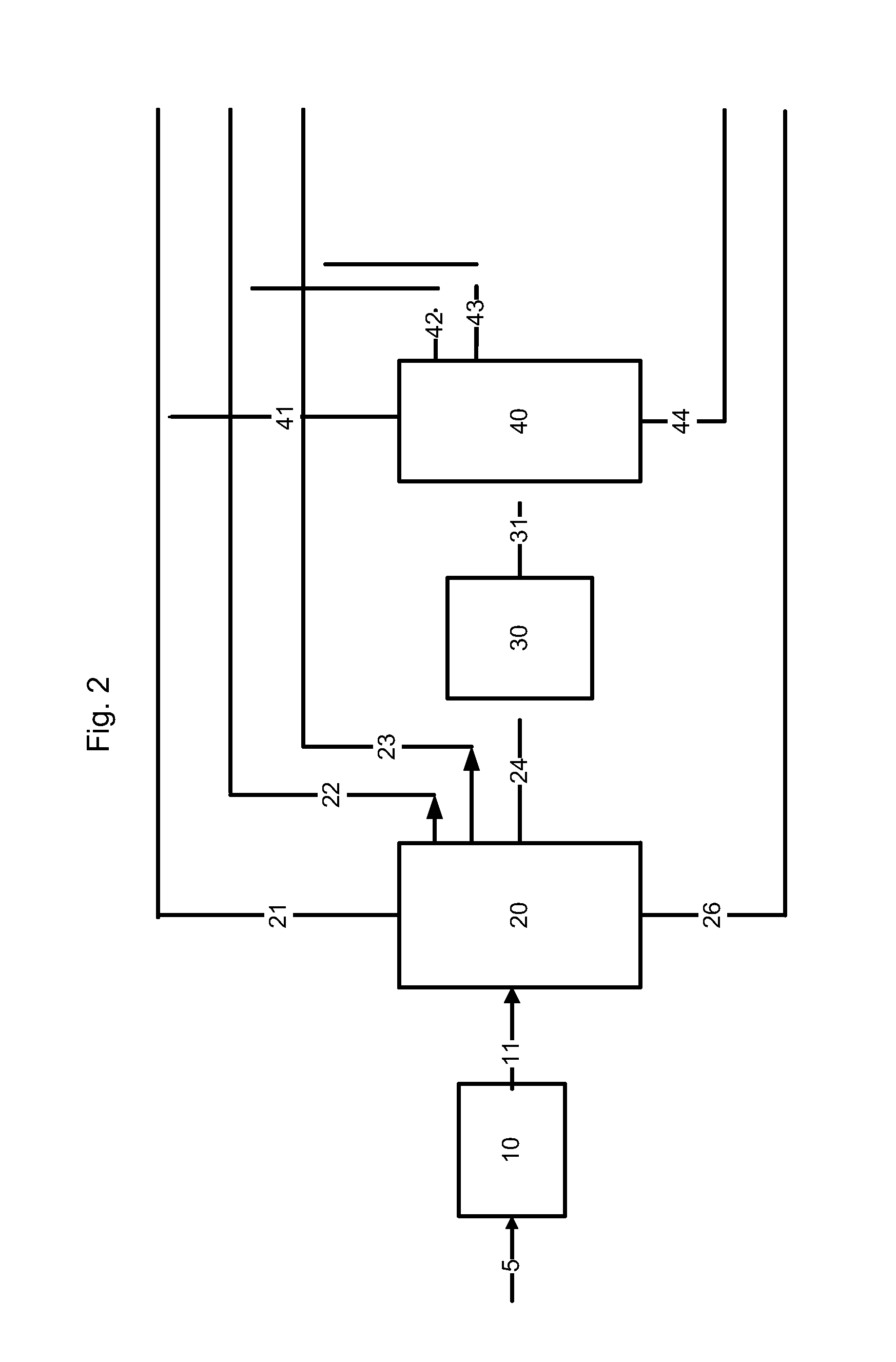

A facility comprising integrated systems for the extraction, and optionally upgrading and / or refinement, of unconventional oil sources, using fossil fuels as a primary source of energy. In particular, this facility provides a means to gasify one or more fossil fuels in an efficient manner, converting it into intermediate products such as heat, steam and electricity, which are then used by the system to obtain useful fuel products from unconventional oil sources such as tar sands and oil shale. The design of the components of this facility is optimized such that the overall costs are competitive with an equivalent unconventional oil source processing facility that uses natural gas as a source of processing energy. The facility can be used on its own, may use supplemental natural gas energy sources, or may be used in conjunction with an existing facility that uses natural gas as an energy source in order to improve the overall cost effectiveness of the processing and / or reduce the requirement for other energy sources, such as natural gas.

Owner:PLASCO ENERGY GROUP INC

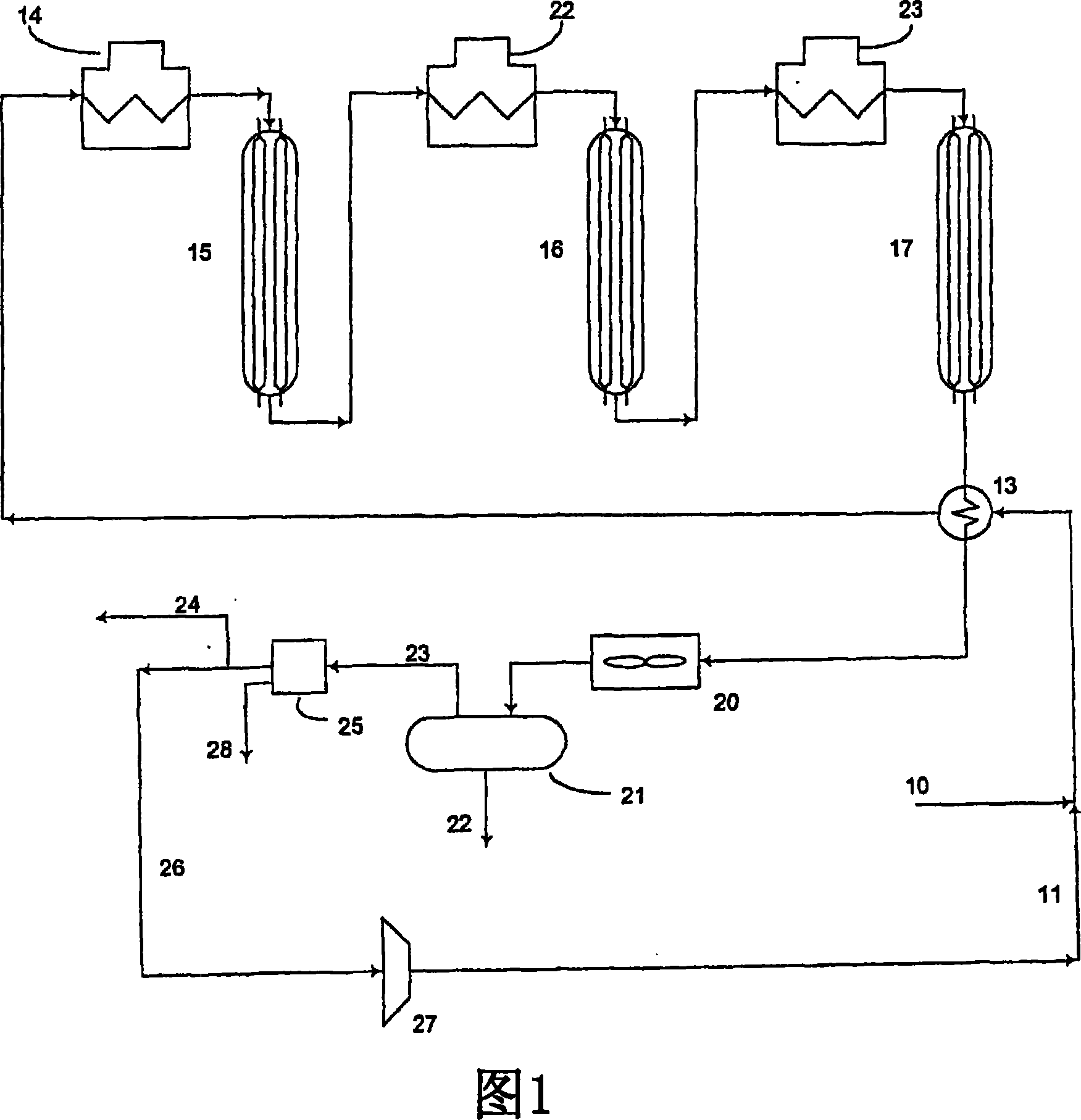

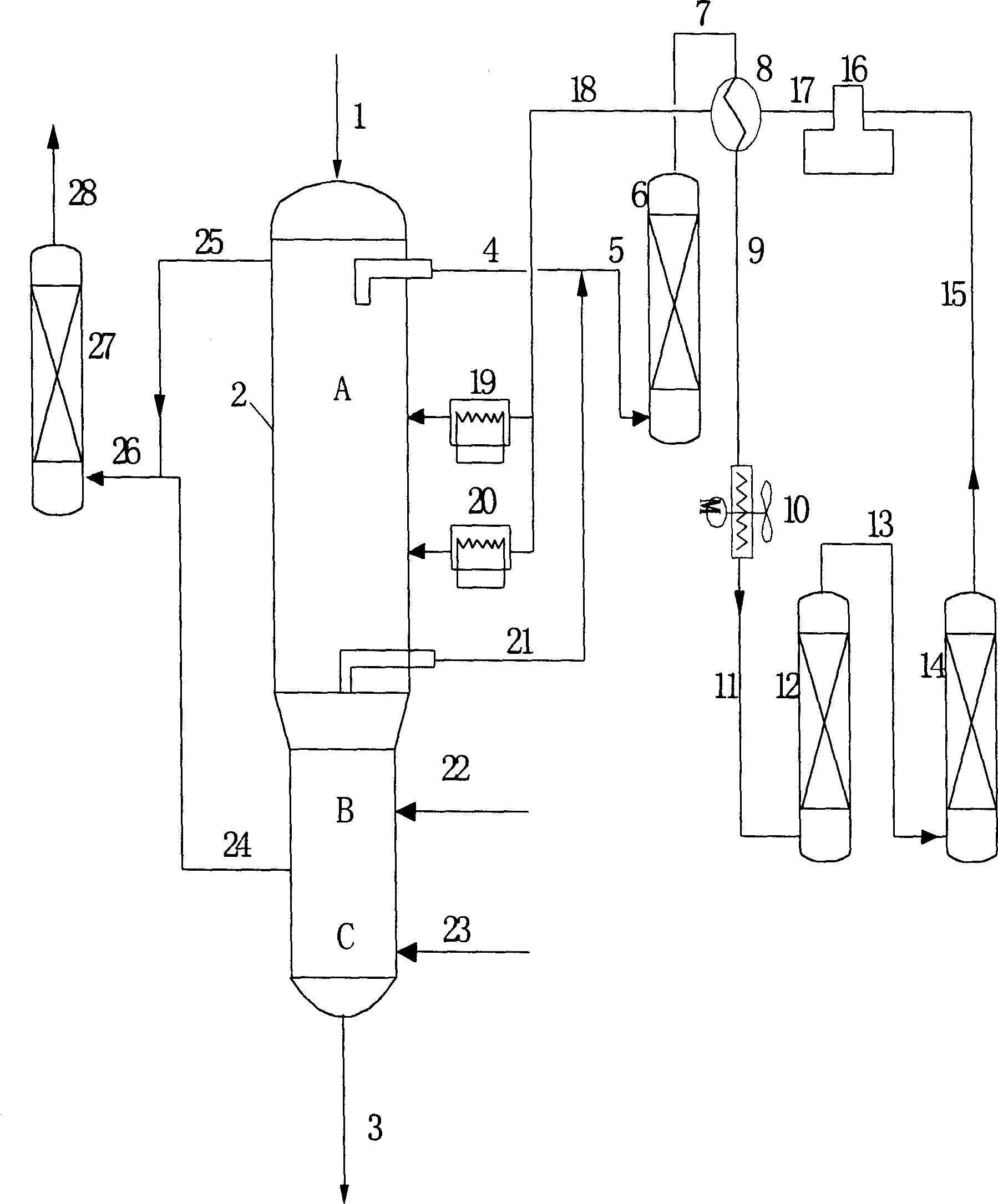

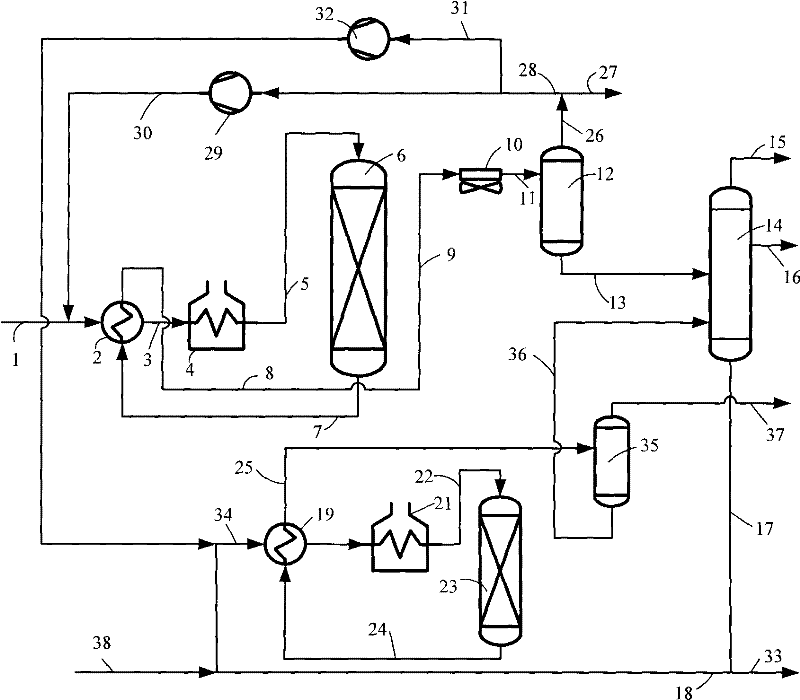

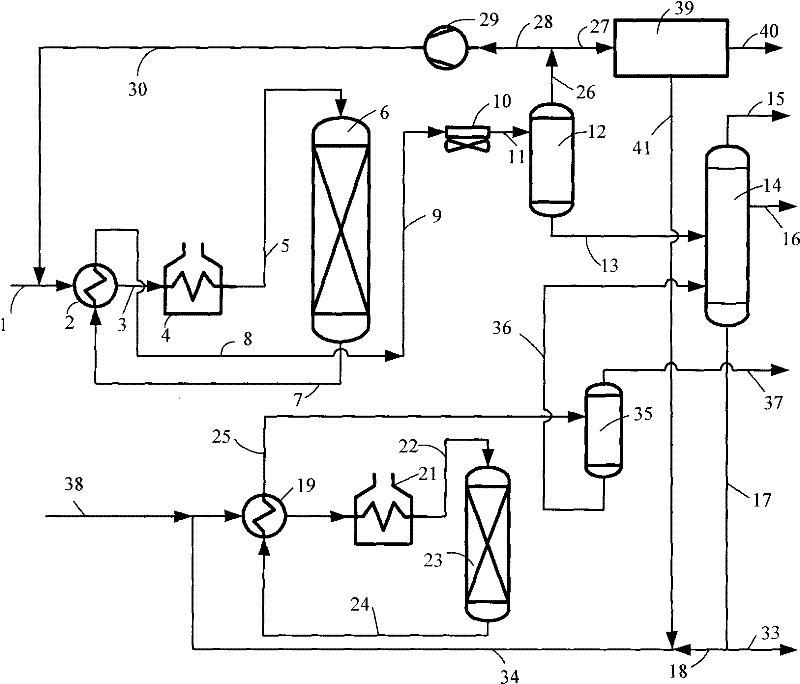

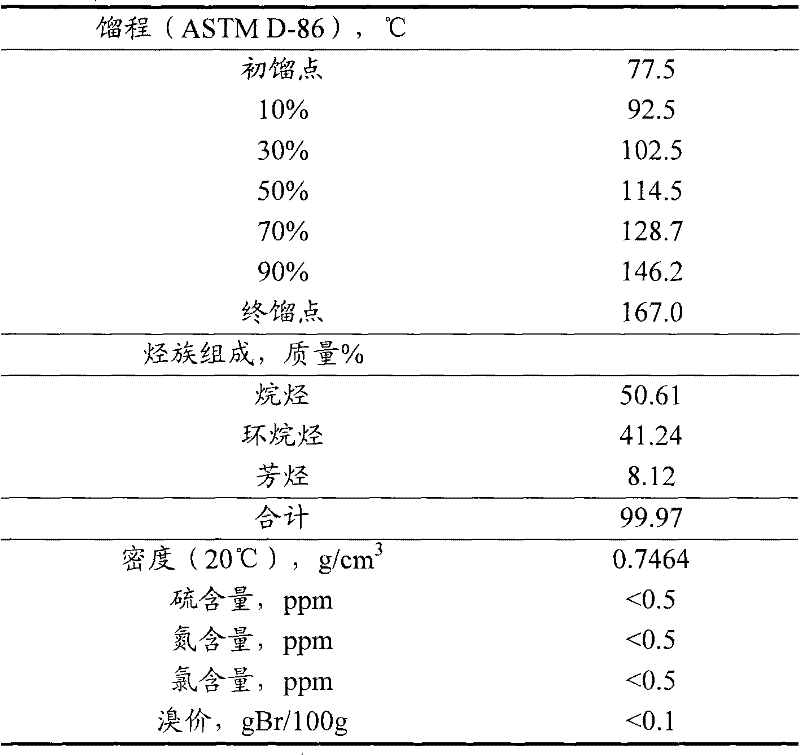

Benzin naphtha catalytic reforming method

ActiveCN101376823AImprove conversion rateGood choiceCatalytic naphtha reformingReforming process control/regulationLiquid productCatalytic reforming

The invention relates to a naphtha catalytic reforming method which includes the steps as follows: the naphtha is pumped into the reactor of a catalytic reforming device; gas-liquid separation is carried out on the reformed product for separating gas components, the light component of C8<-> as well as the heavy component of C9<+>; then a light aromatics reaction is carried out on the heavy component of C9<+> under the existence of a light aromatics catalyst; the hydrogen used by the light aromatics reaction is from the circulated hydrogen generated from a reforming device; then gas-liquid separation is carried out on the product after the light aromatics reaction; the liquid returns to the liquid product distilling system of the reforming device. The method can fully utilize the heavy component of C9<+> and convert the heavy component into light aromatic hydrocarbon, improve the aromatic hydrocarbon yield or the yield of the reformed gasoline during the whole process and improve the character of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

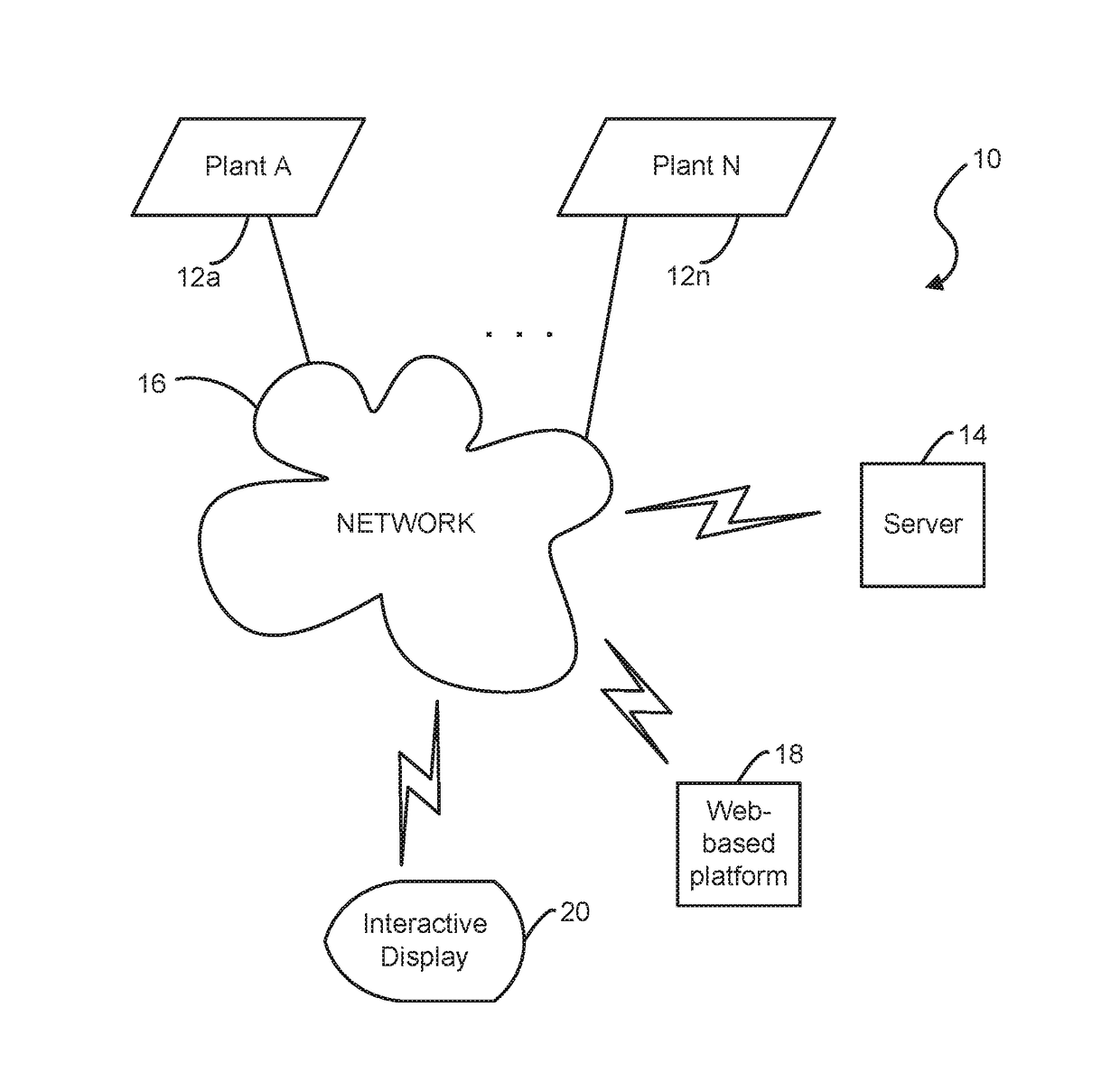

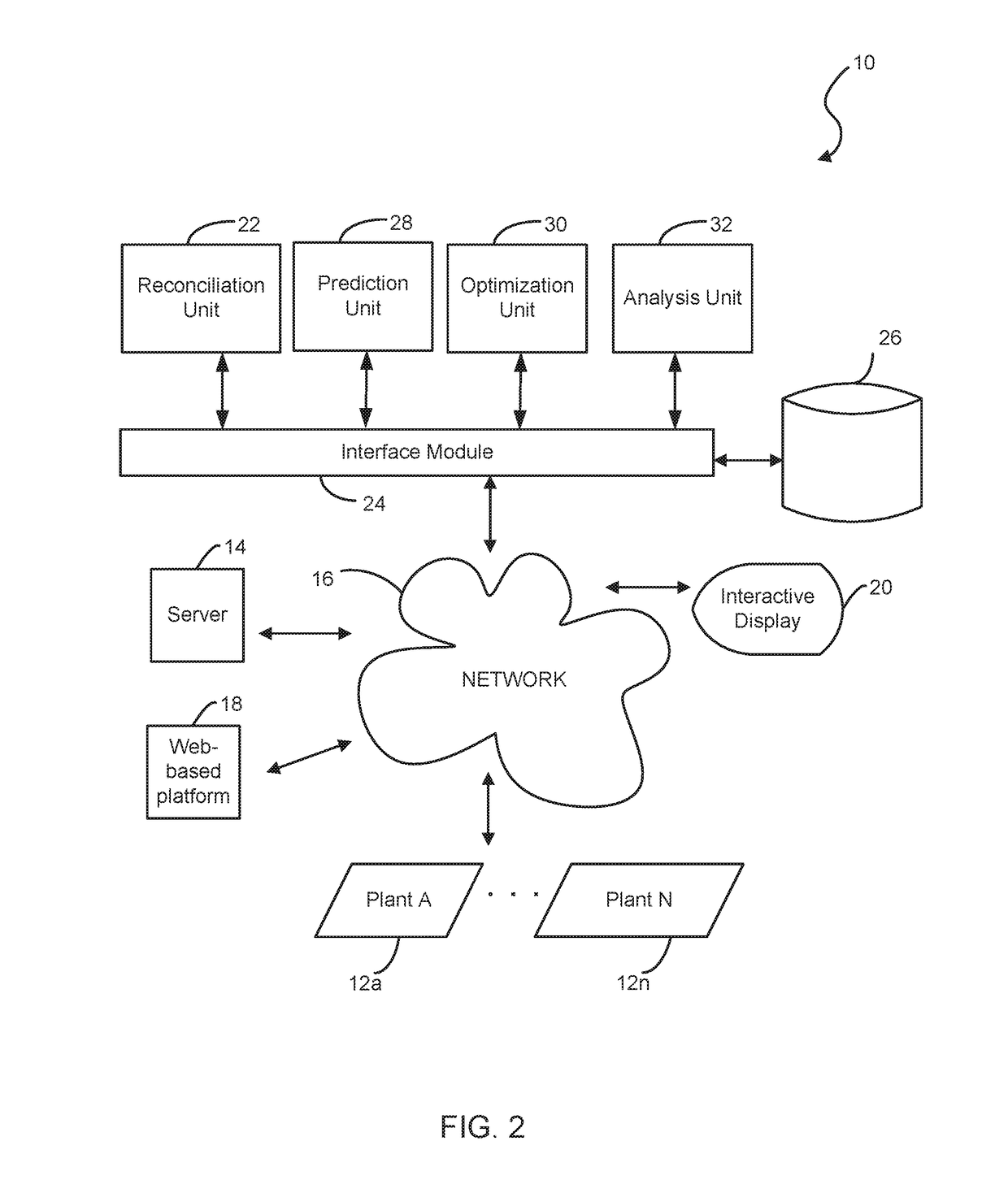

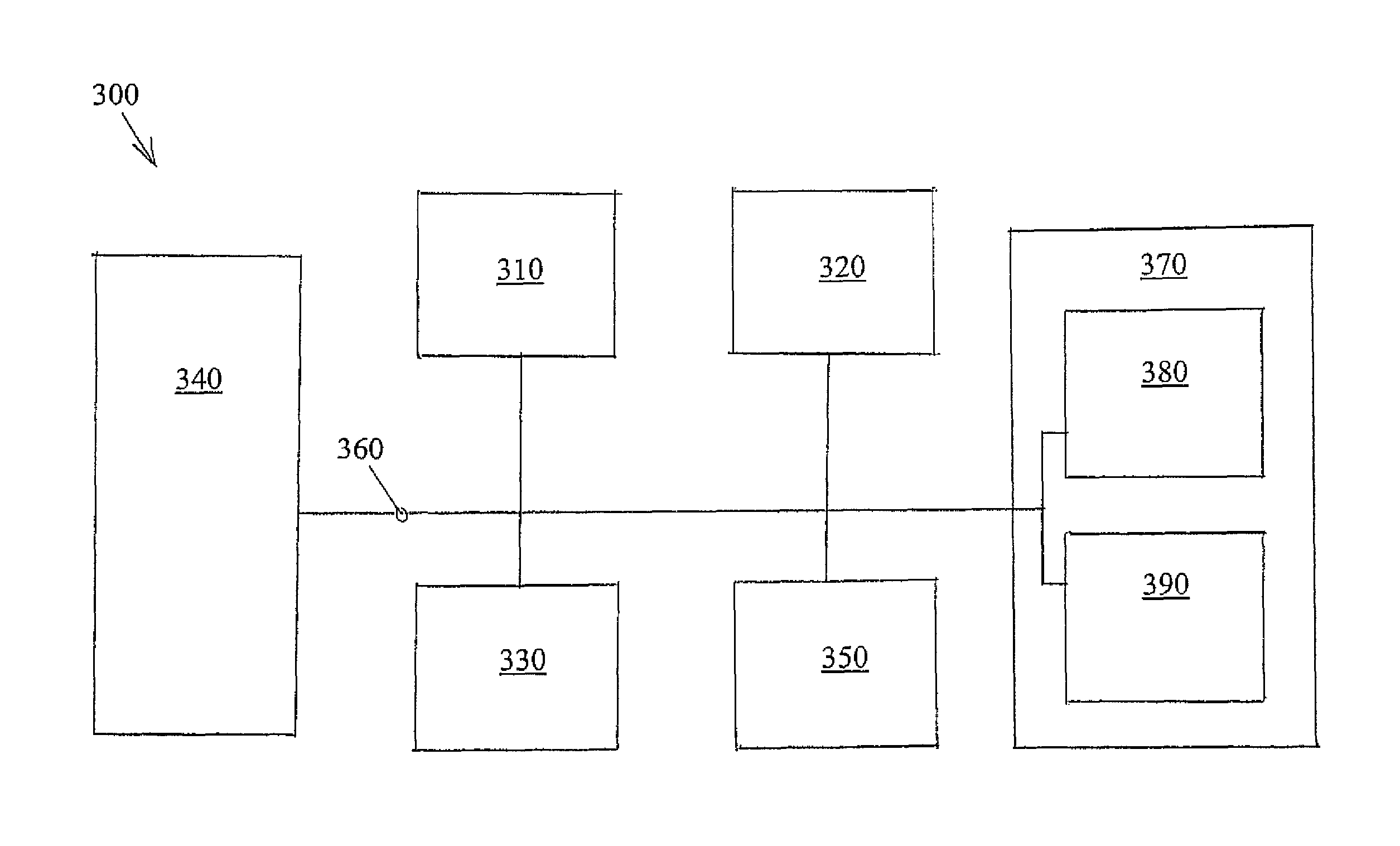

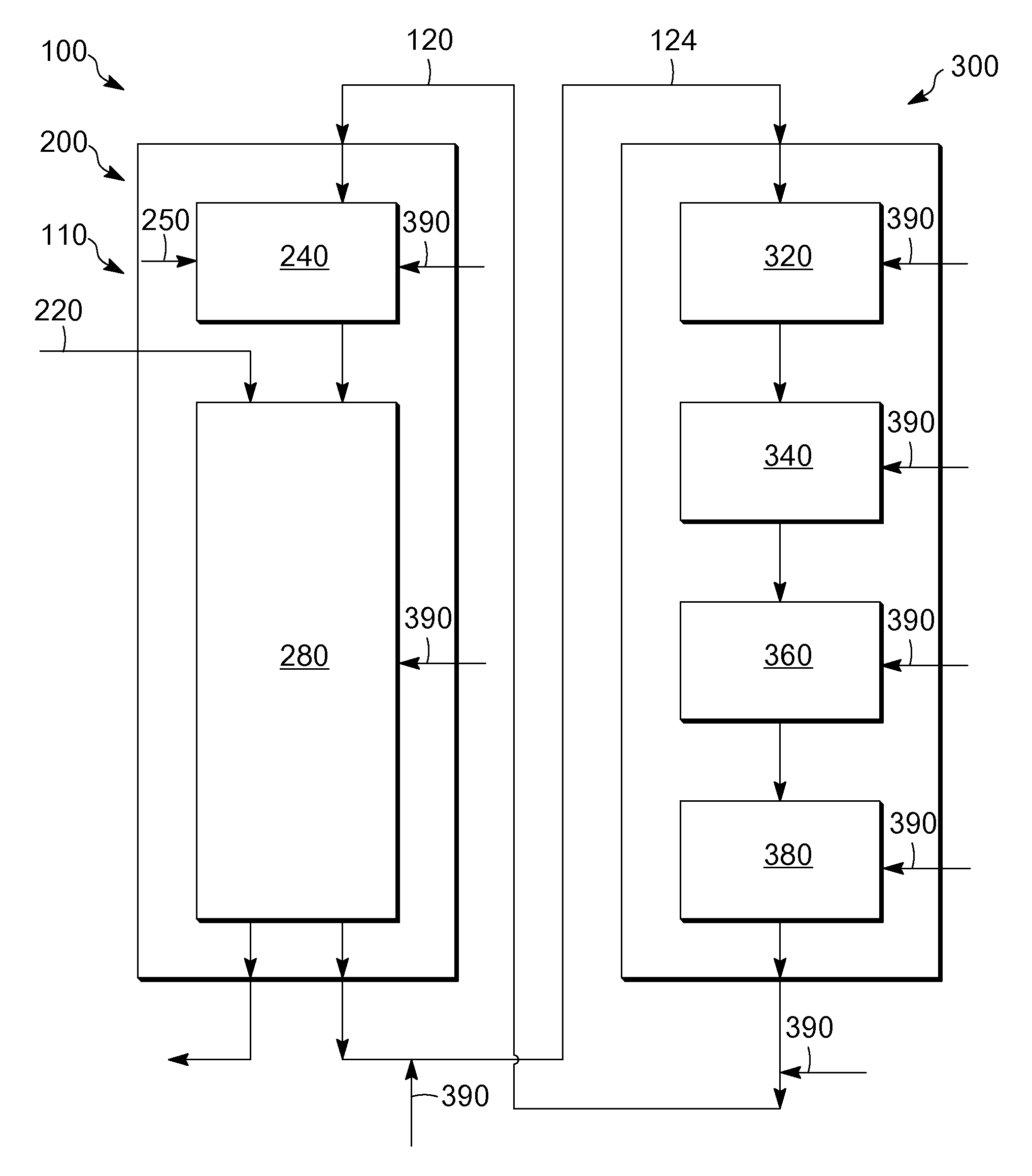

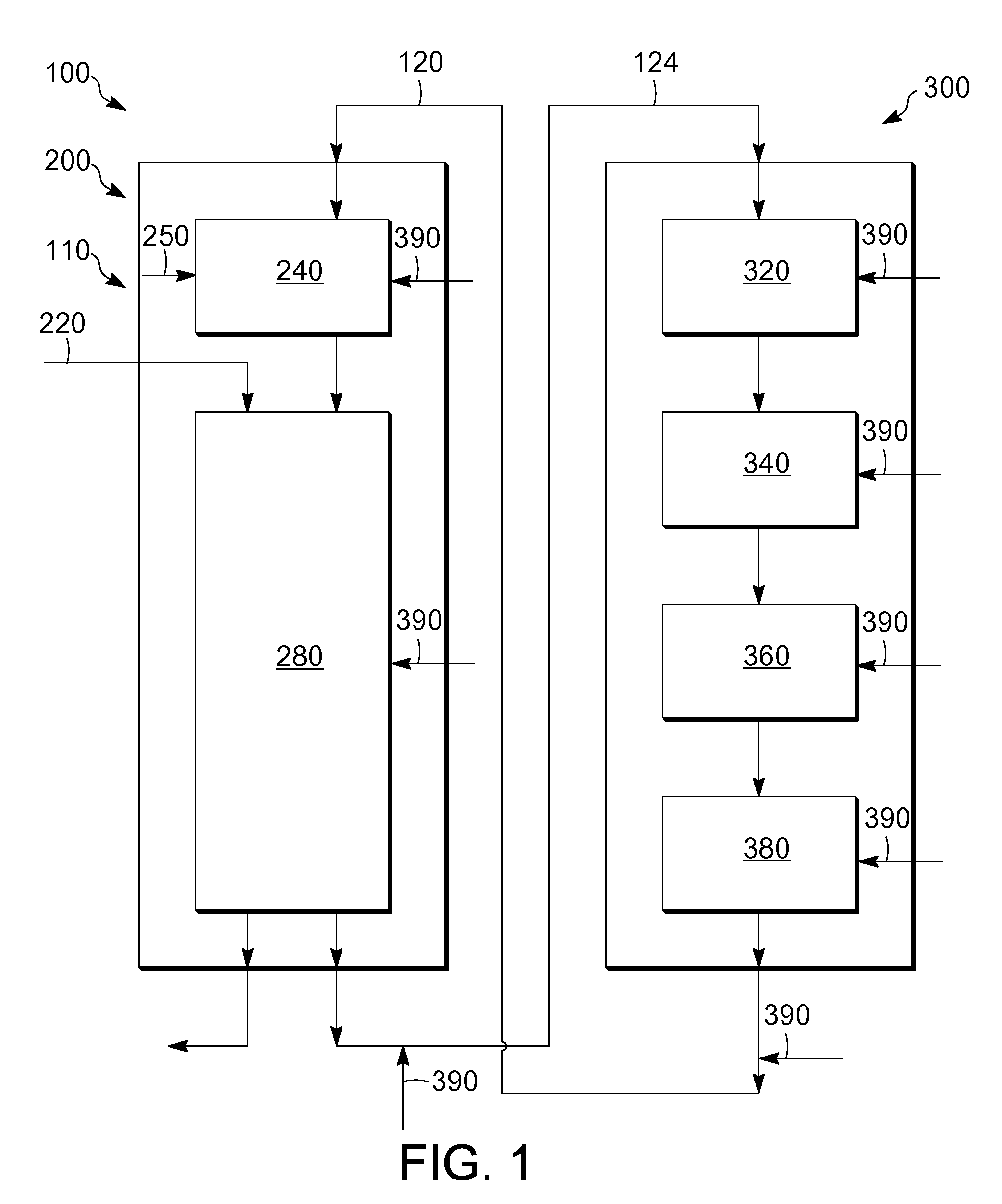

Identifying and implementing refinery or petrochemical plant process performance improvements

ActiveUS20180046155A1Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

System and method for improving performance of a chemical plant with a furnace

ActiveUS10095200B2Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

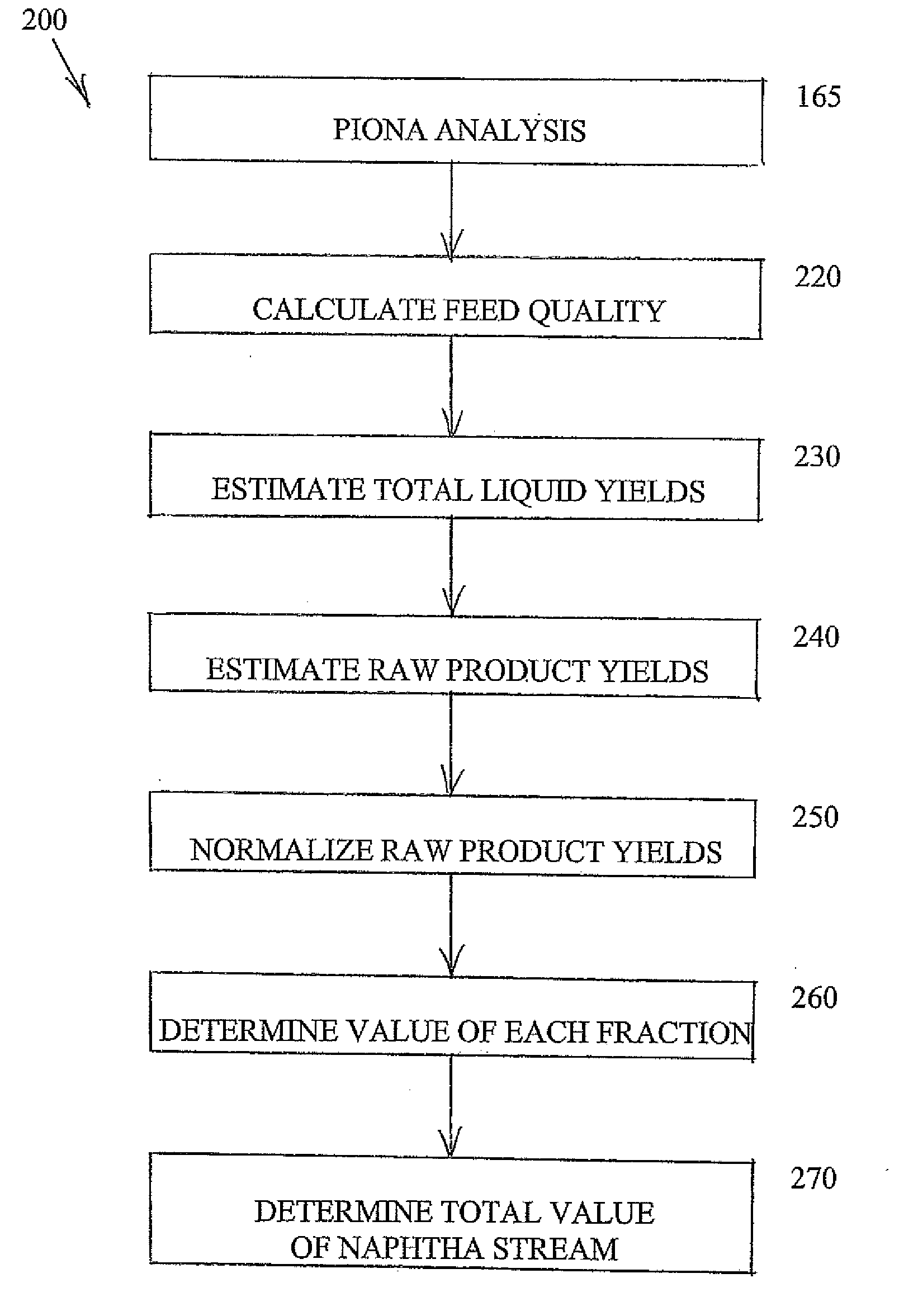

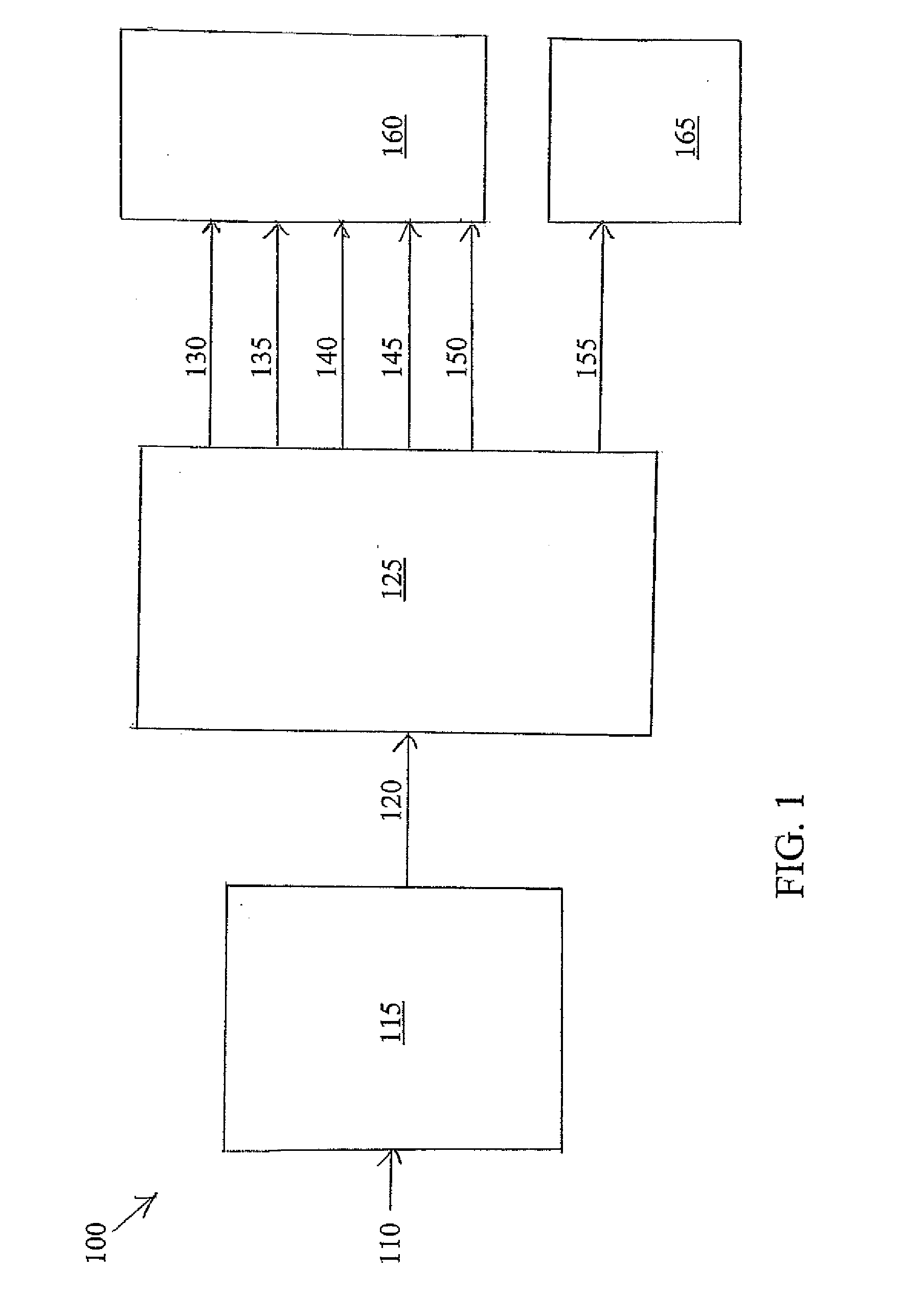

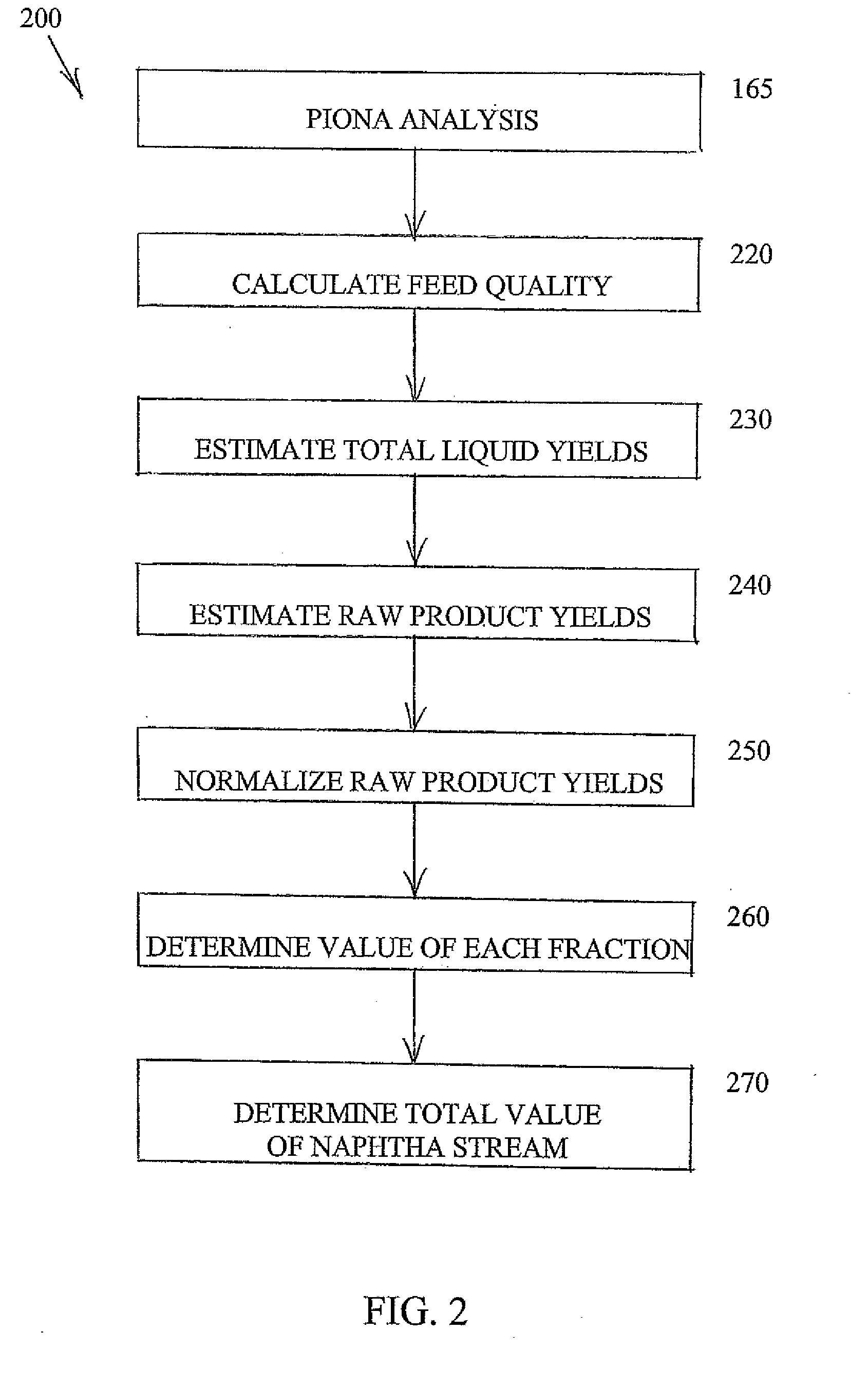

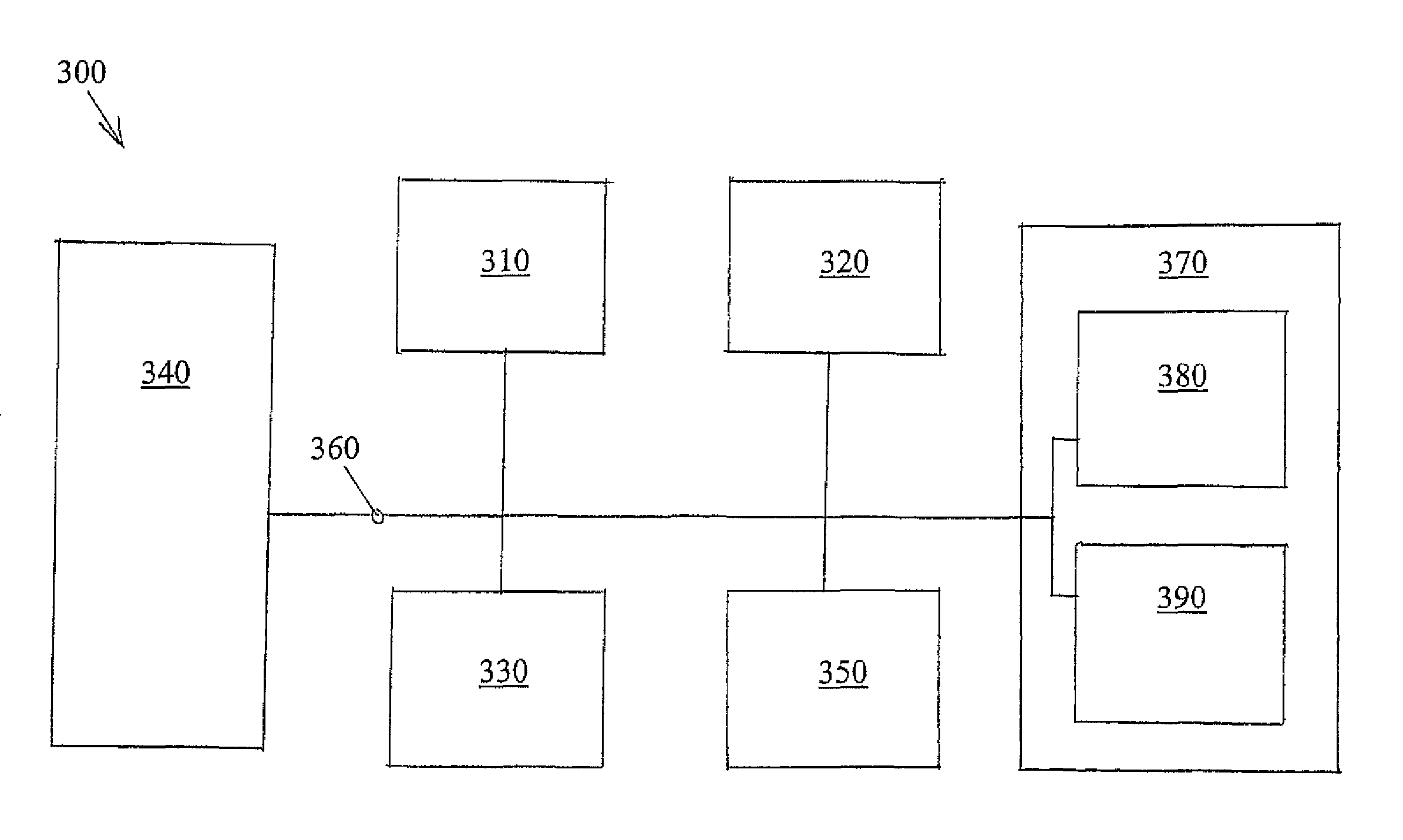

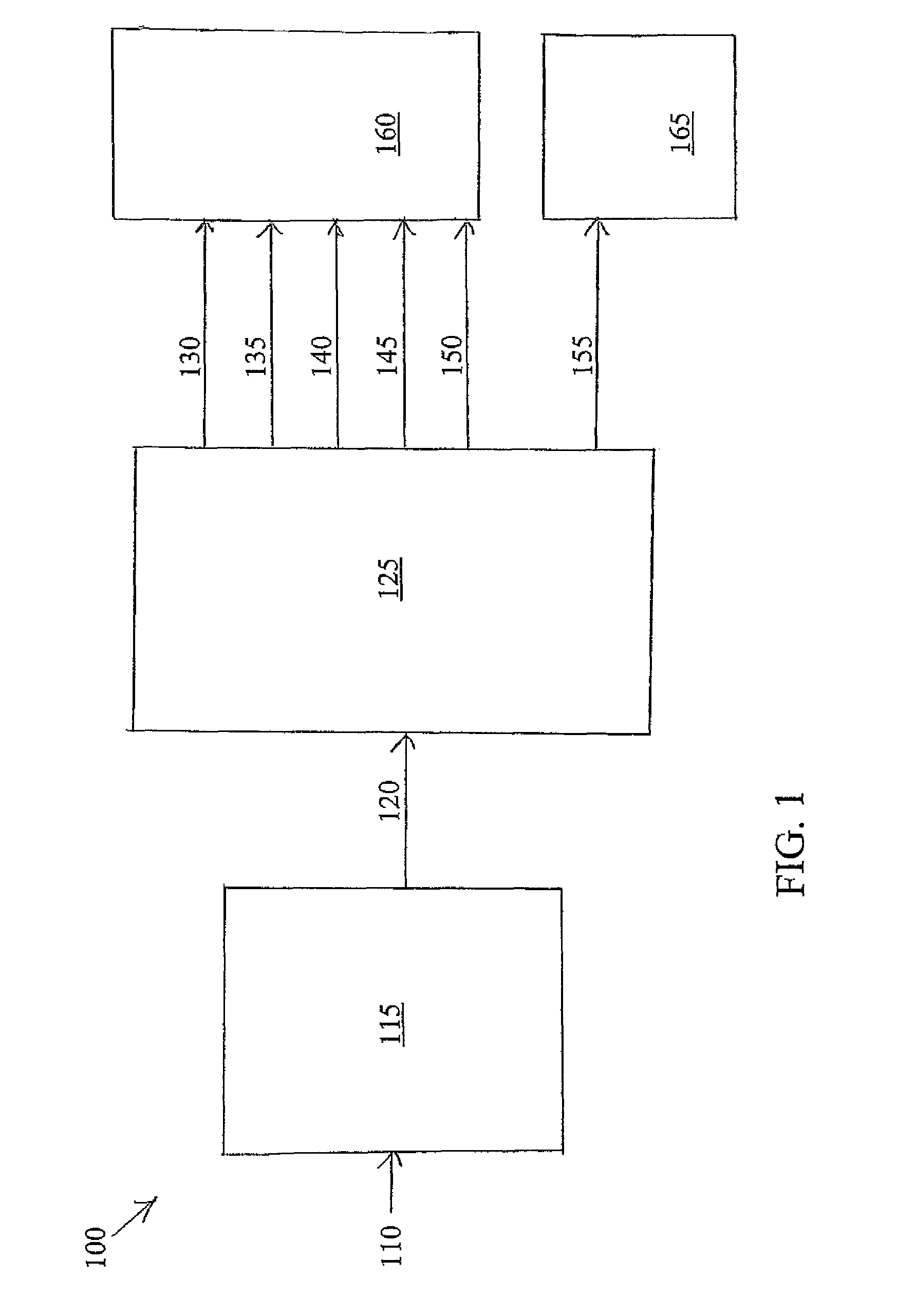

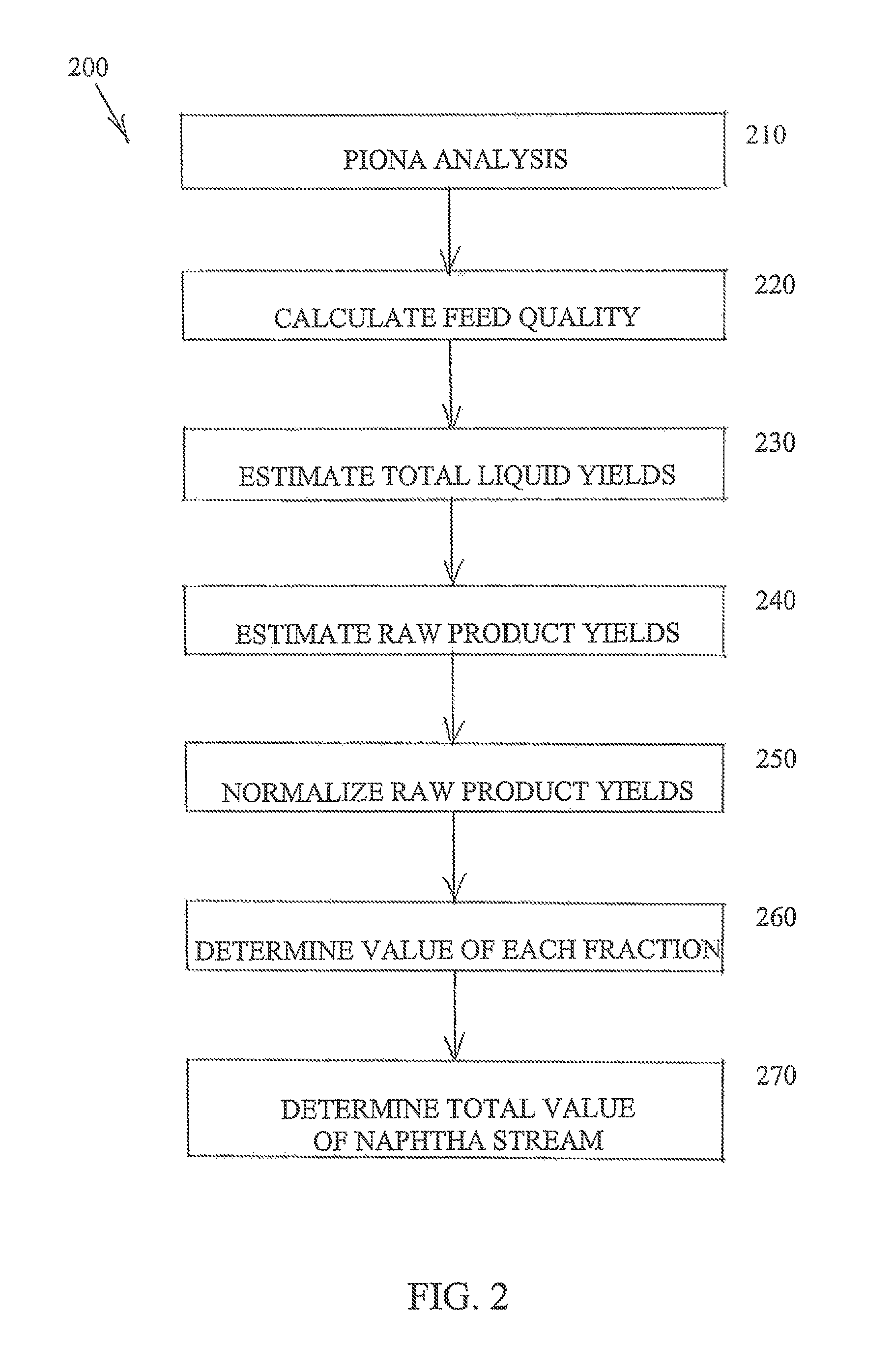

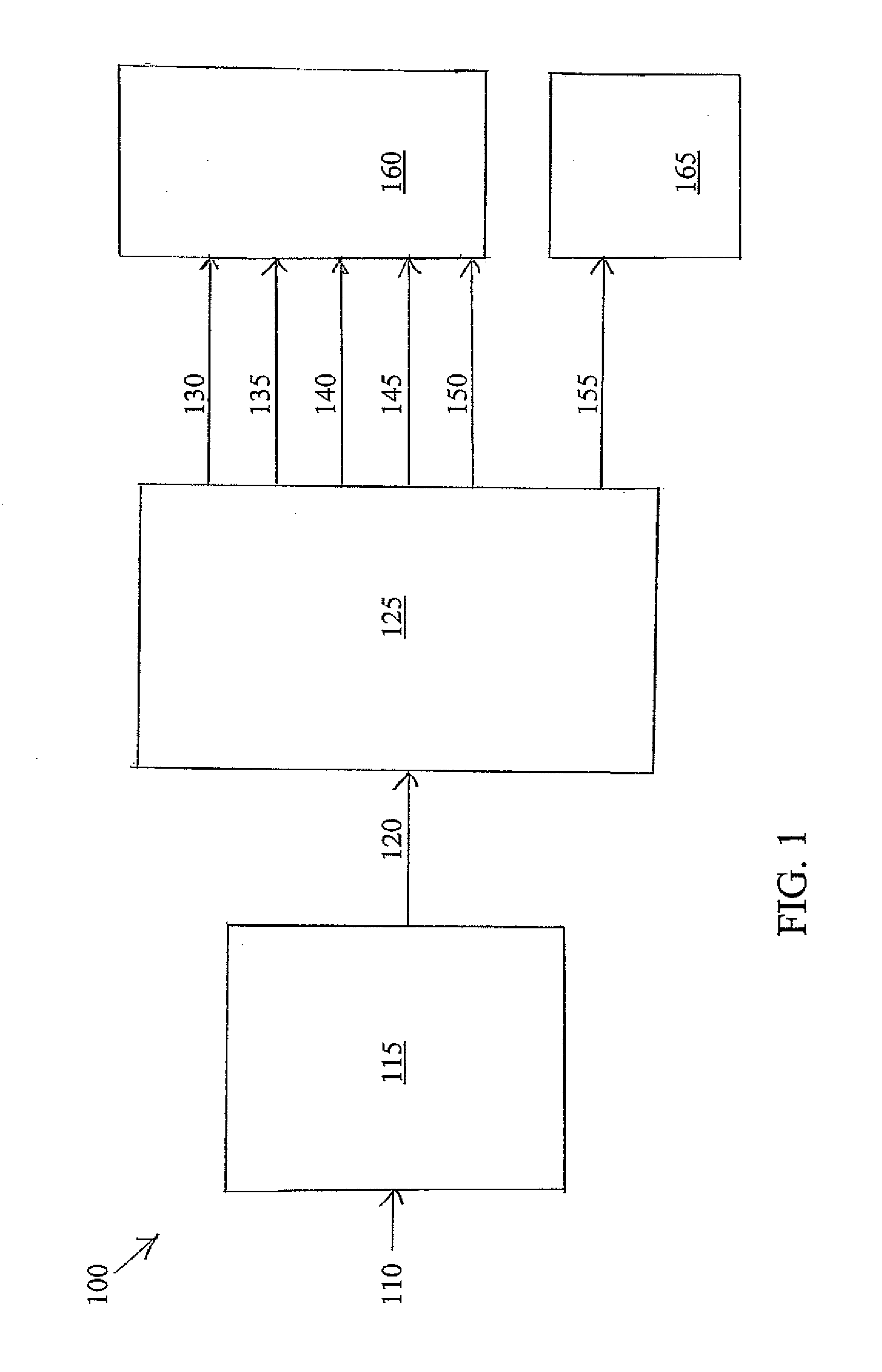

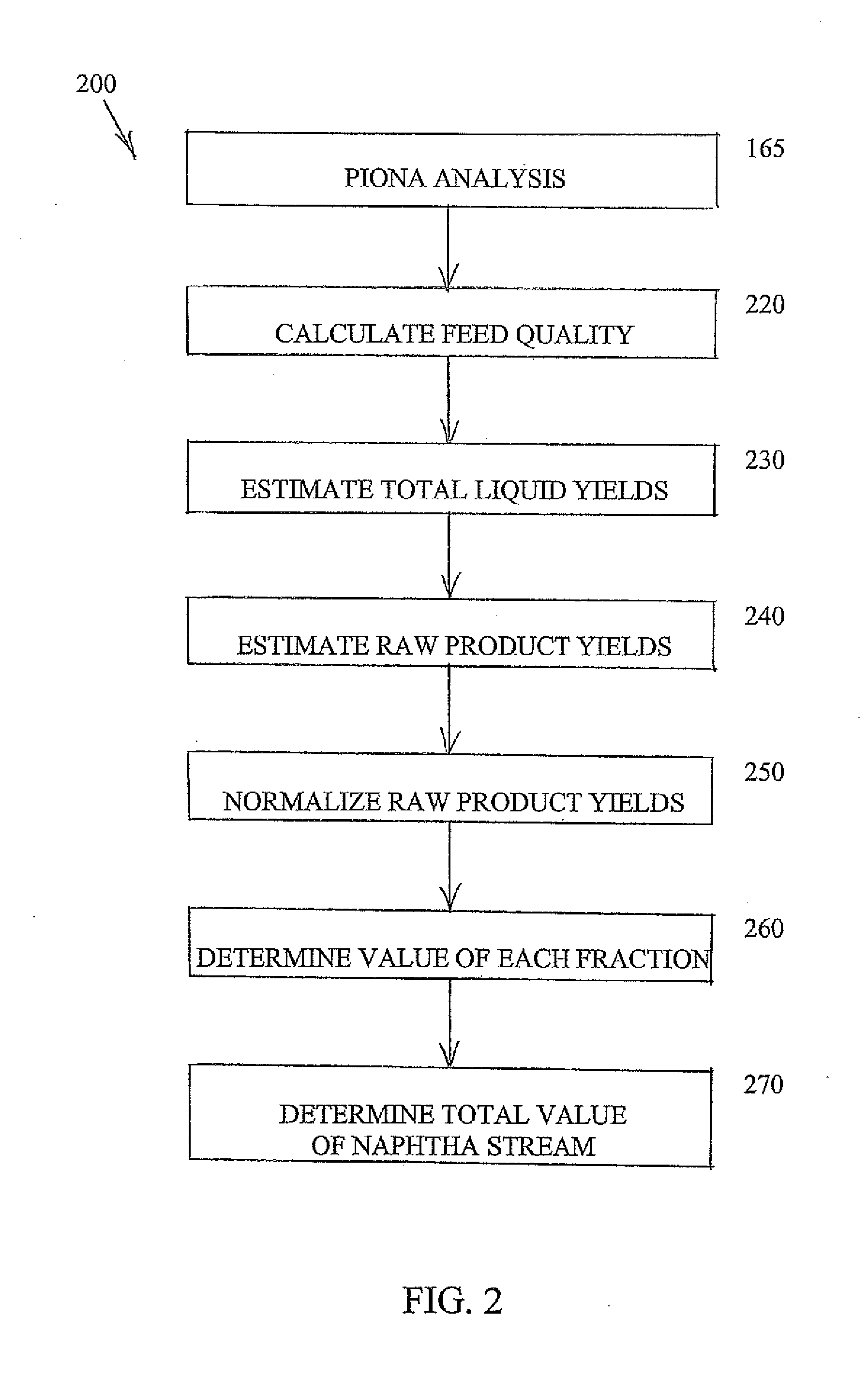

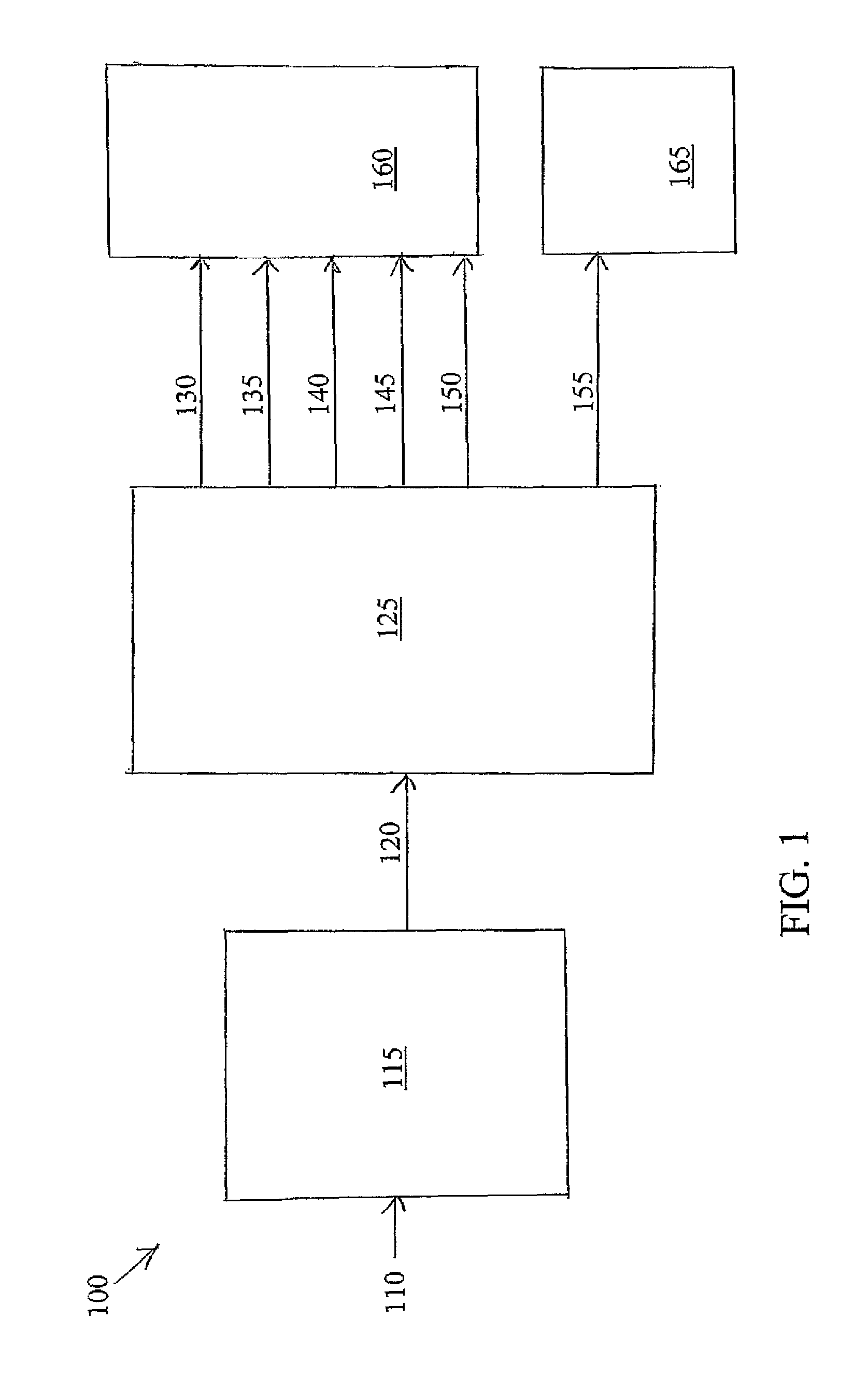

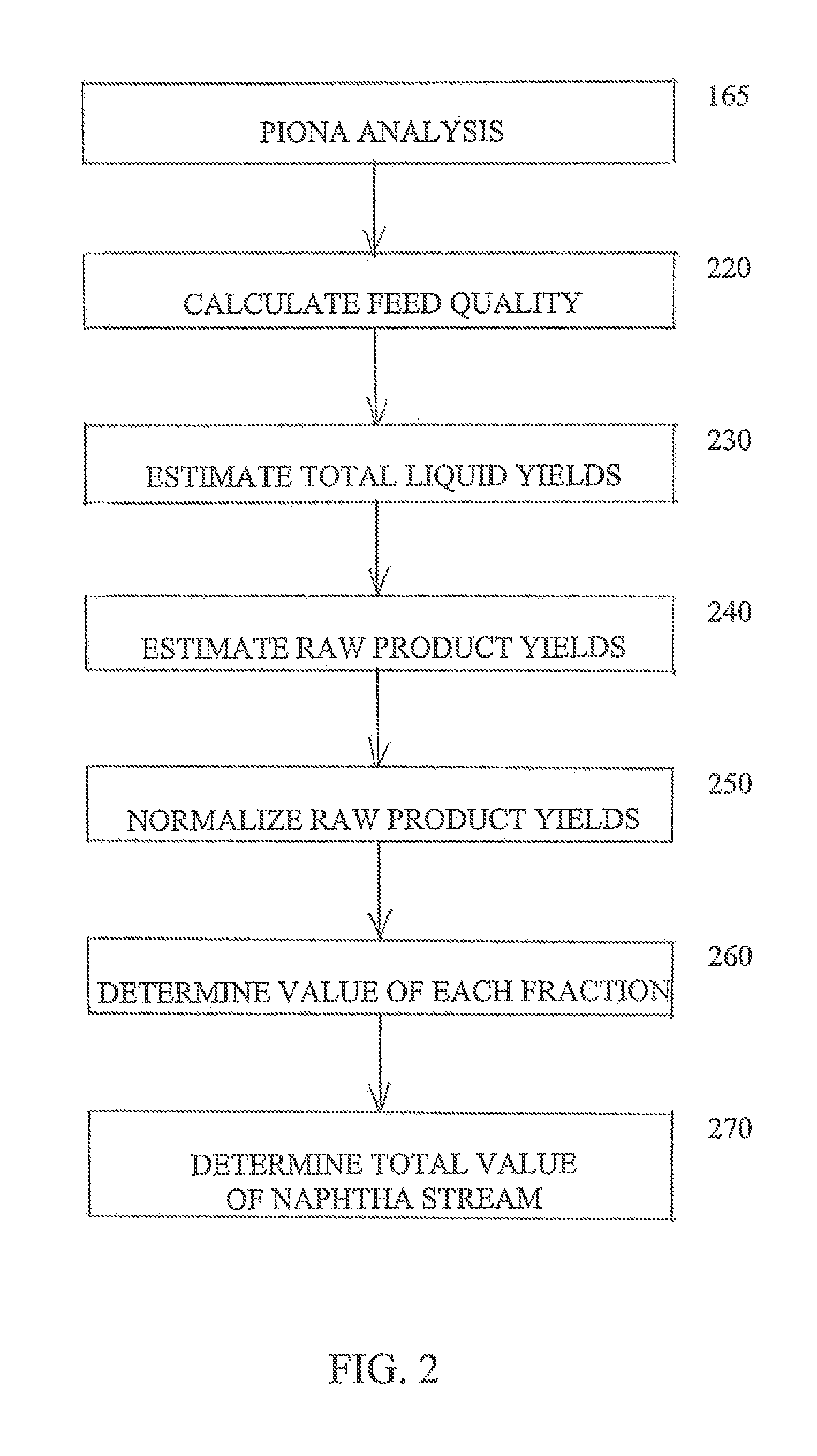

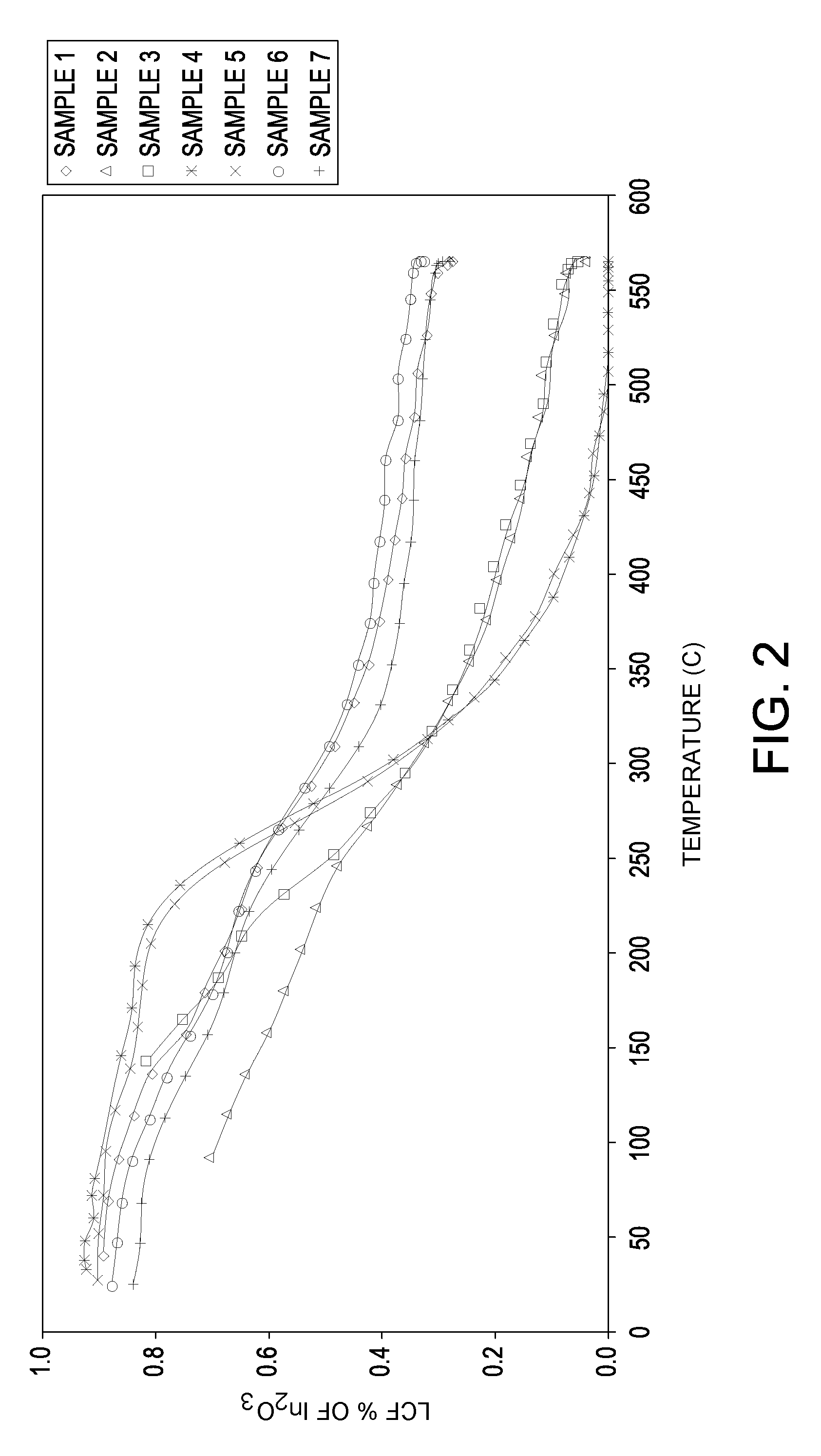

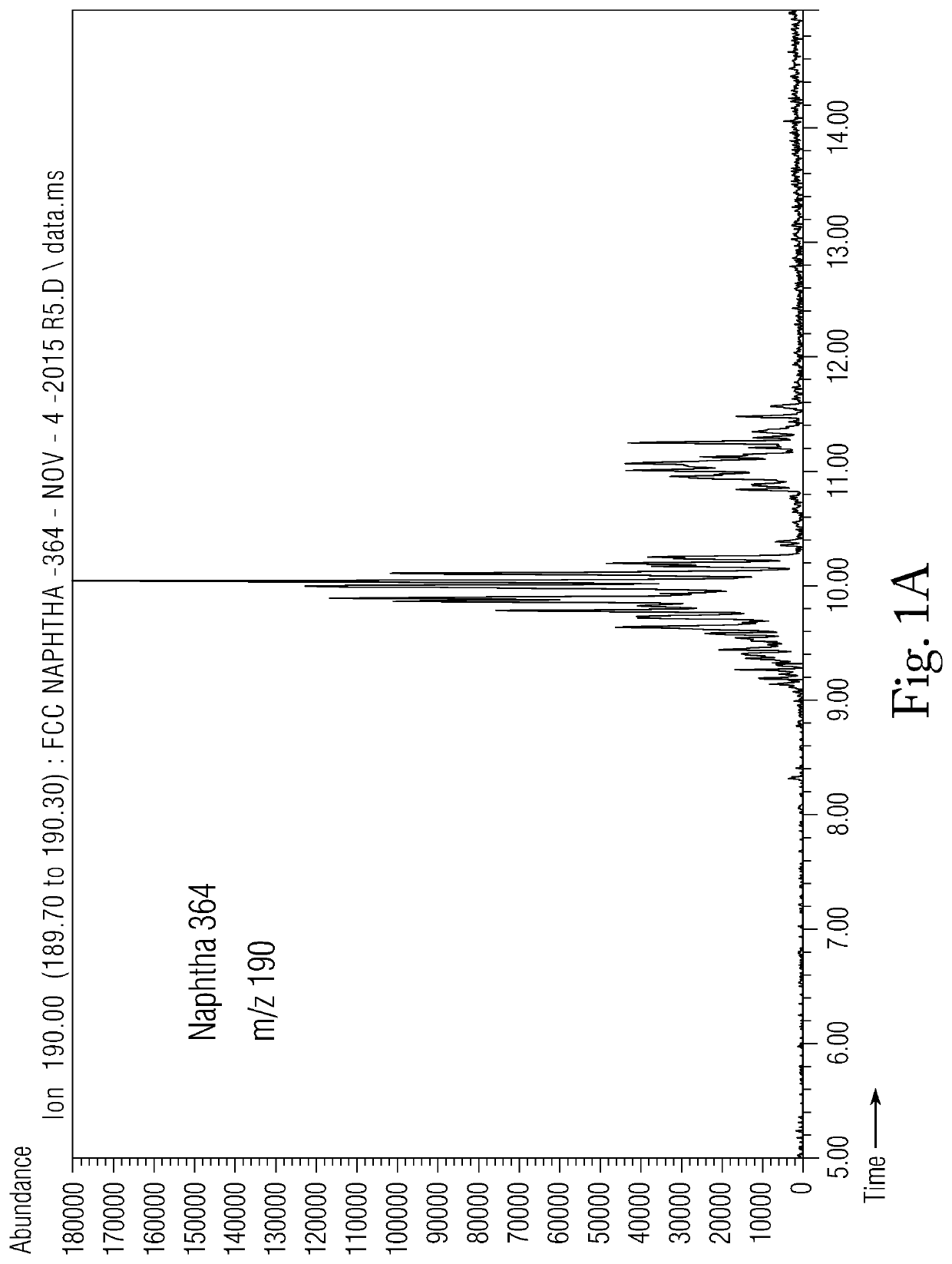

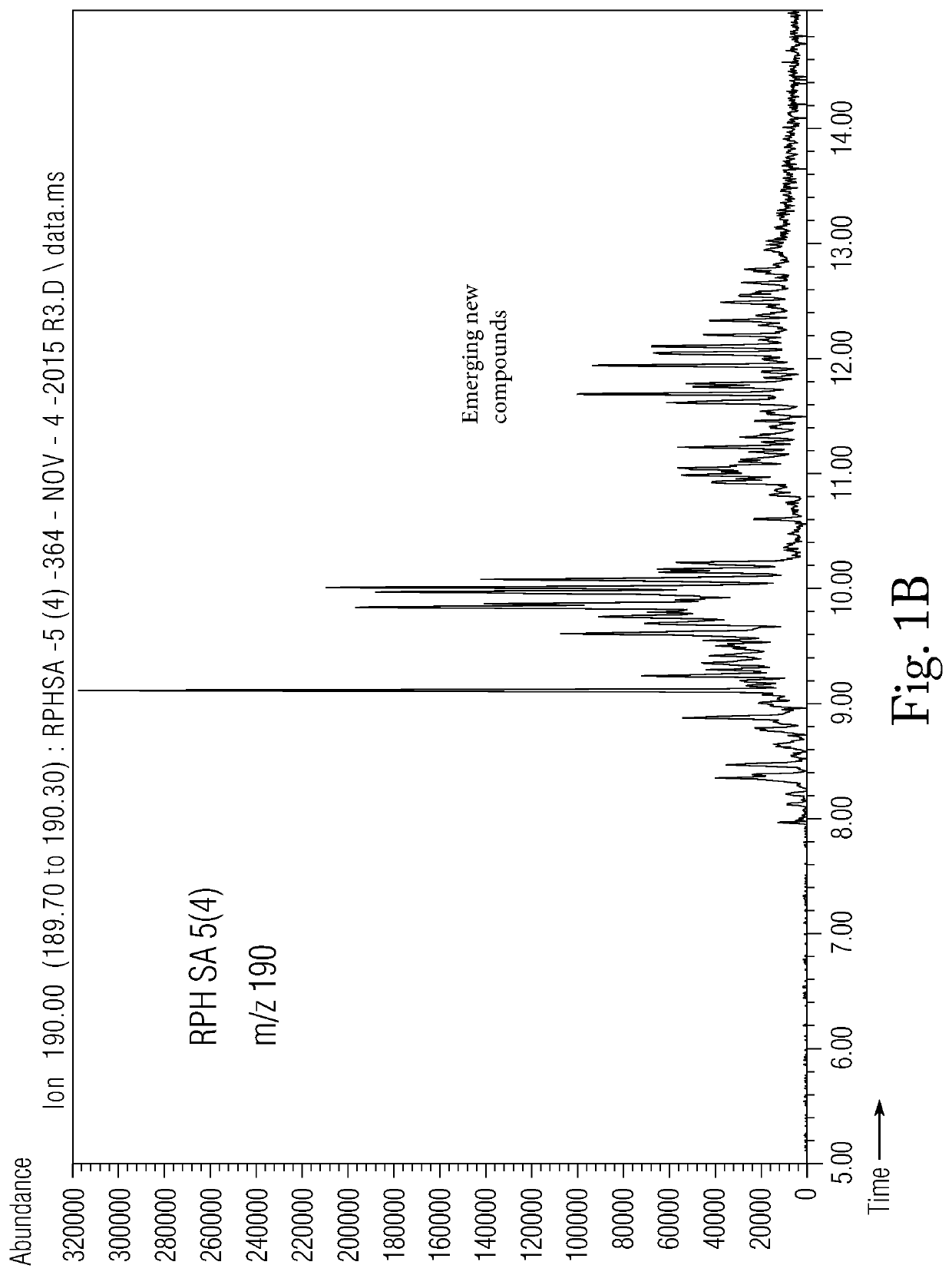

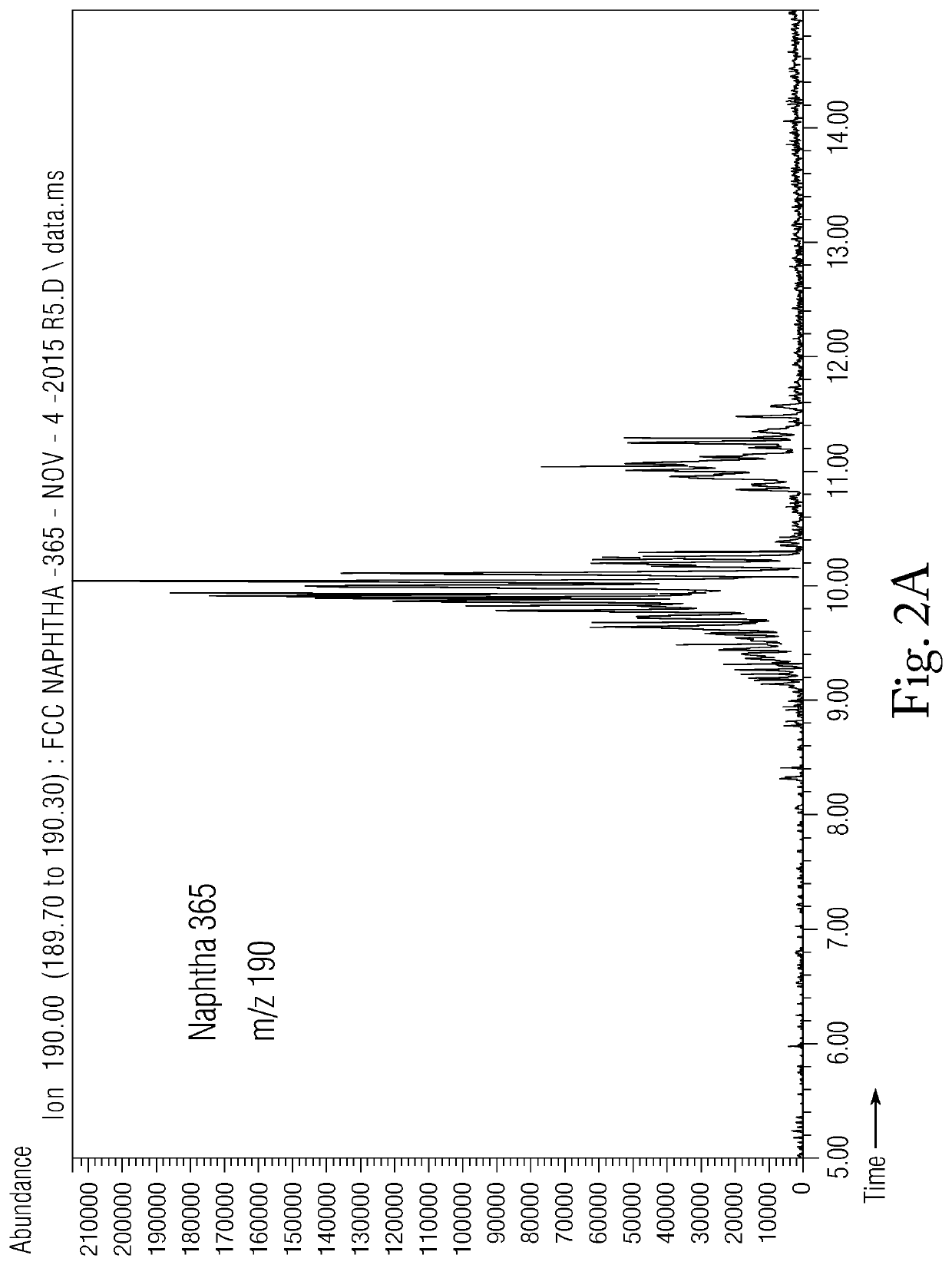

Relative valuation method for naphtha streams

ActiveUS20150112611A1Weighing by removing componentRaman/scattering spectroscopyNaphthaStandardization

A system and a method for determining the relative value of a naphtha stream is provided, by conducting analysis on the crude oil sample, after which modules or steps are performed to estimate the total liquid yields, estimate raw product yields, normalize raw product yields, determine the value of each fraction based on predetermined values, and calculate the total value of the naphtha stream. The method is repeated on samples from different crude oils in order to provide relative values for comparison purposes at a predetermined RON.

Owner:SAUDI ARABIAN OIL CO

Relative valuation method for naphtha streams

A system and a method for determining the relative value of a naphtha stream is provided, by conducting analysis on the crude oil sample, after which modules or steps are performed to estimate the total liquid yields, estimate raw product yields, normalize raw product yields, determine the value of each fraction based on predetermined values, and calculate the total value of the naphtha stream. The method is repeated on samples from different crude oils in order to provide relative values for comparison purposes at a predetermined RON.

Owner:SAUDI ARABIAN OIL CO

Relative valuation method for naphtha streams

A system and a method for determining the relative value of a naphtha product includes reforming the naphtha into fractions at a predetermined constant research octane number (RON), conducting PIONA analysis on the reformate, after which modules or steps are performed to assign the feed quality, assign the total liquid yields, assign raw product yields, normalize the assigned raw product yields, assign a value to one or more fractions, and calculate a total value of the naphtha stream. The method is repeated on samples of different crude oils in order to provide relative values at the predetermined RON for comparison purposes.

Owner:SAUDI ARABIAN OIL CO

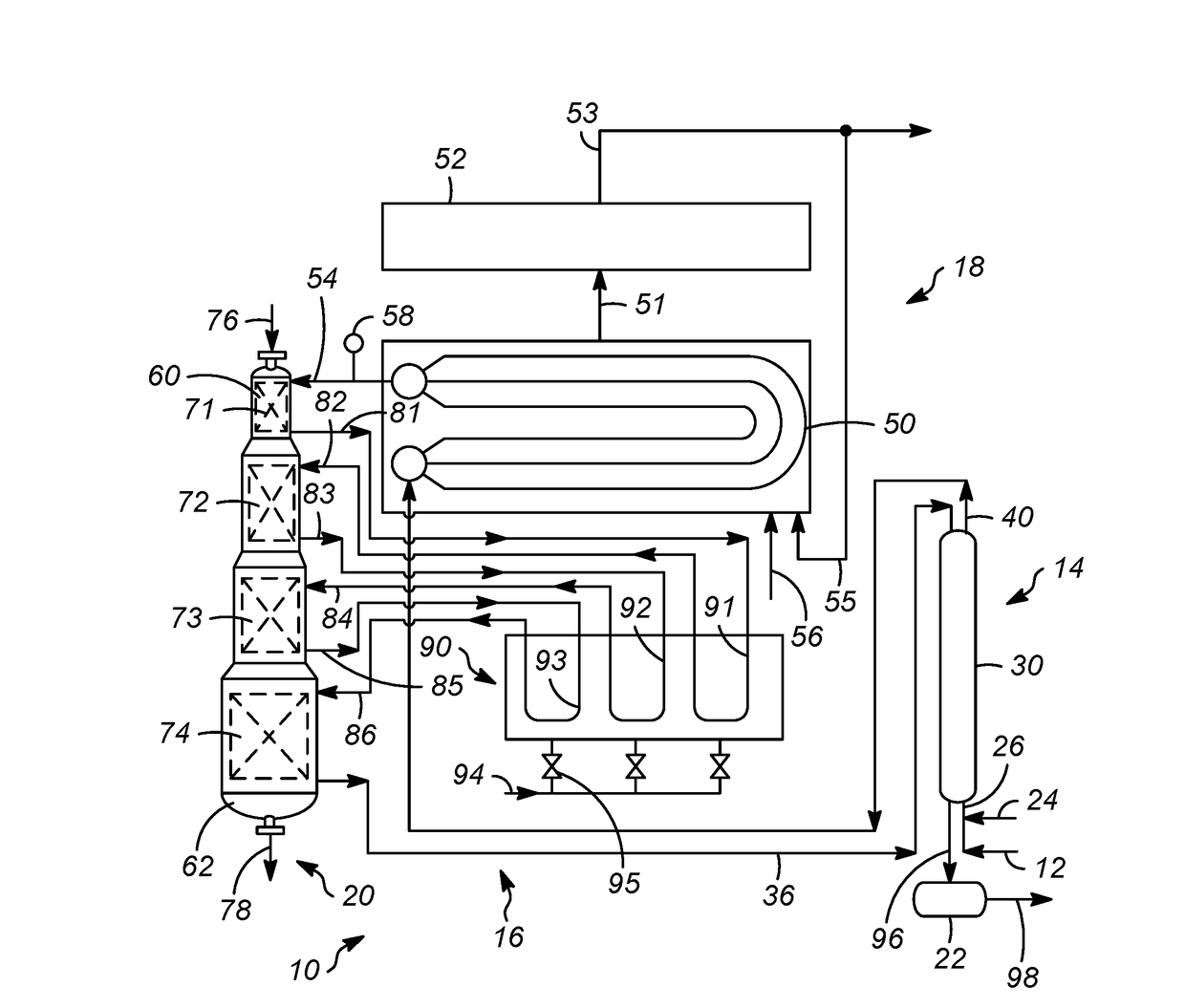

Improved catalytic reformer unit and unit operation

InactiveCN101107055AHigh purityImprove reforming performanceDispersed particle separationCatalytic naphtha reformingCatalytic reformingPhysical chemistry

The management of hydrogen in hydrogen-containing streams associated with petrochemical process units wherein the hydrogen-containing stream is subjected rapid cycle pressure swing adsorption to increase the concentration of hydrogen therein.

Owner:EXXON RES & ENG CO

Relative valuation method for naphtha streams

A system and a method for determining the relative value of a naphtha product includes reforming the naphtha into fractions at a predetermined constant research octane number (RON), conducting PIONA analysis on the reformate, after which modules or steps are performed to assign the feed quality, assign the total liquid yields, assign raw product yields, normalize the assigned raw product yields, assign a value to one or more fractions, and calculate a total value of the naphtha stream. The method is repeated on samples of different crude oils in order to provide relative values at the predetermined RON for comparison purposes.

Owner:SAUDI ARABIAN OIL CO

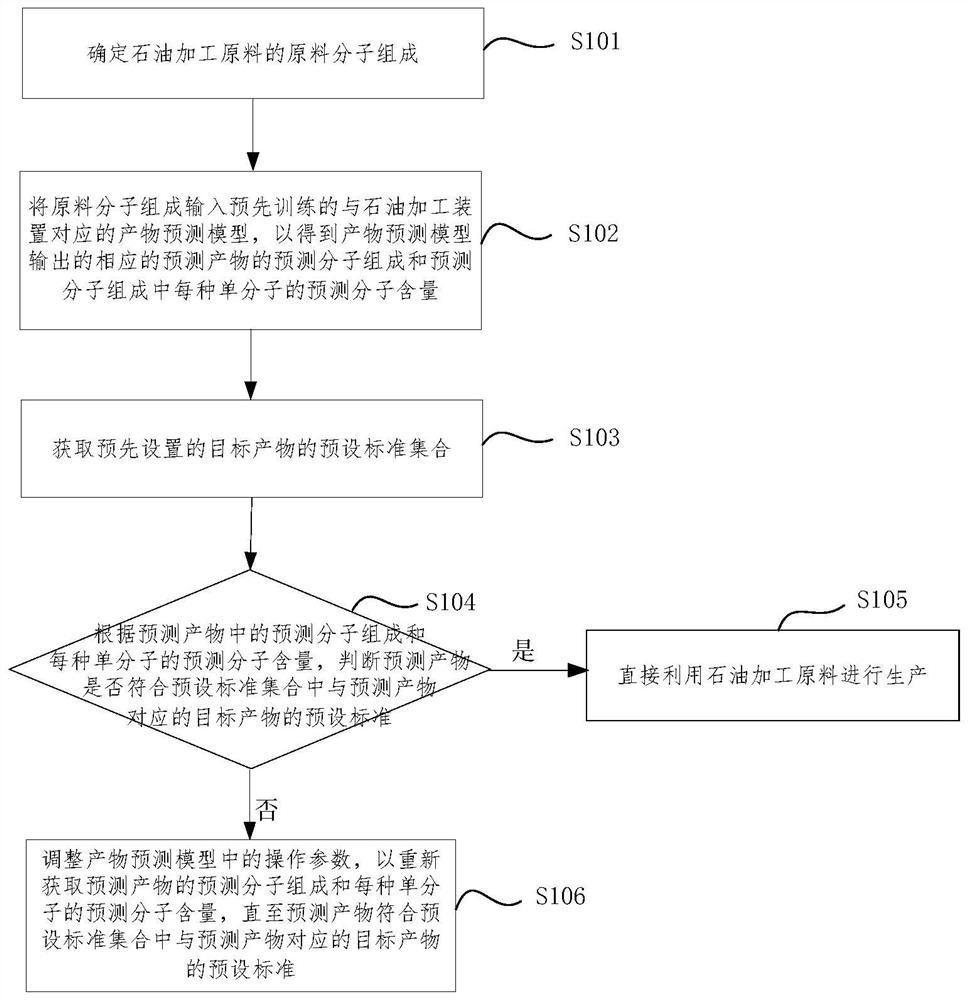

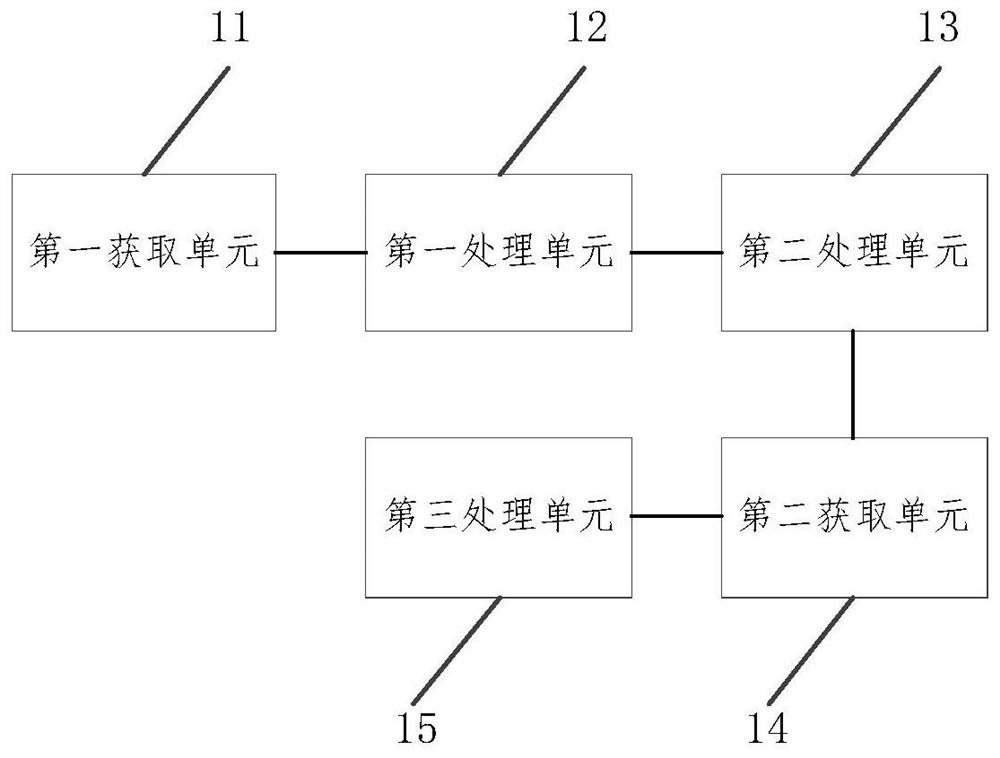

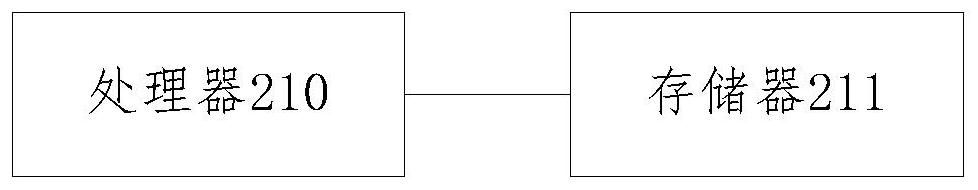

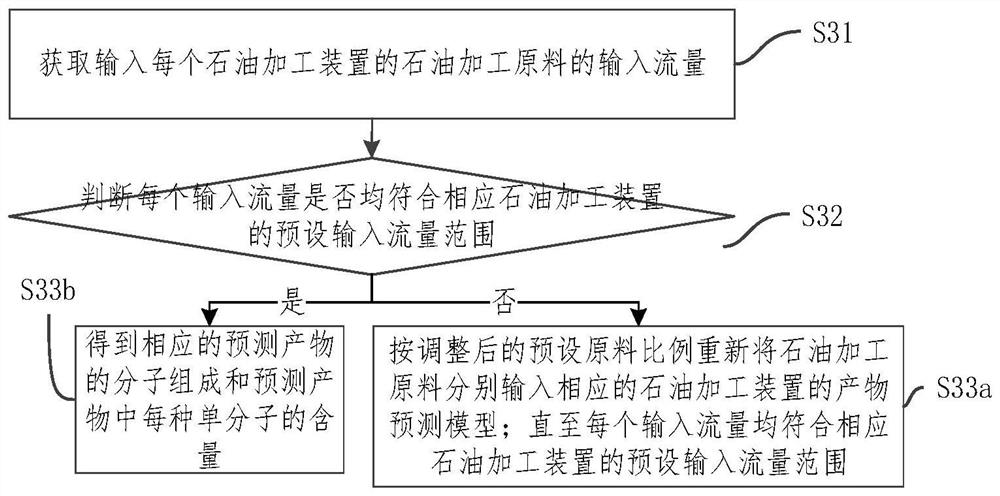

Real-time optimization method, device and system of molecular-level device, and storage medium

PendingCN111899793ARealize simulationHigh precisionChemical property predictionMolecular entity identificationPhysicsProcess engineering

The invention relates to a real-time optimization method, device and system of a molecular-level device, and a storage medium. The method comprises the following steps: determining raw material molecular composition of a petroleum processing raw material; inputting the raw material molecular composition into a pre-trained product prediction model to obtain the predicted molecular composition of acorresponding predicted product and the predicted molecular content of each single molecule; acquiring a preset standard set of a preset target product; according to the predicted molecular composition and the predicted molecular content of each single molecule, judging whether the predicted product meets a preset standard of a target product, corresponding to the predicted product, in the presetstandard set or not; and if any preset standard of the corresponding target product is not met, adjusting operation parameters in a product prediction model to obtain the predicted molecular composition of the predicted product and the predicted molecular content of each single molecule again until the preset standard is met. According to the invention, molecular-level overall simulation and real-time optimization of the molecular-level device from raw materials to product processing are achieved, and precision and production benefits are improved.

Owner:PETROCHINA CO LTD

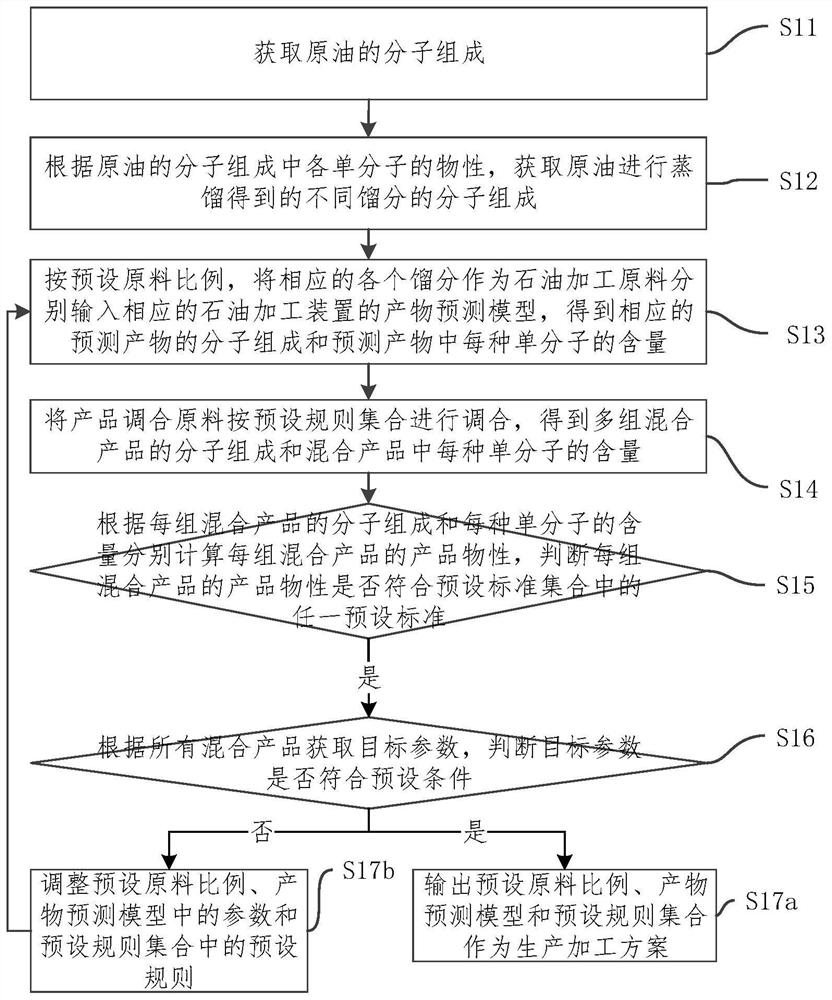

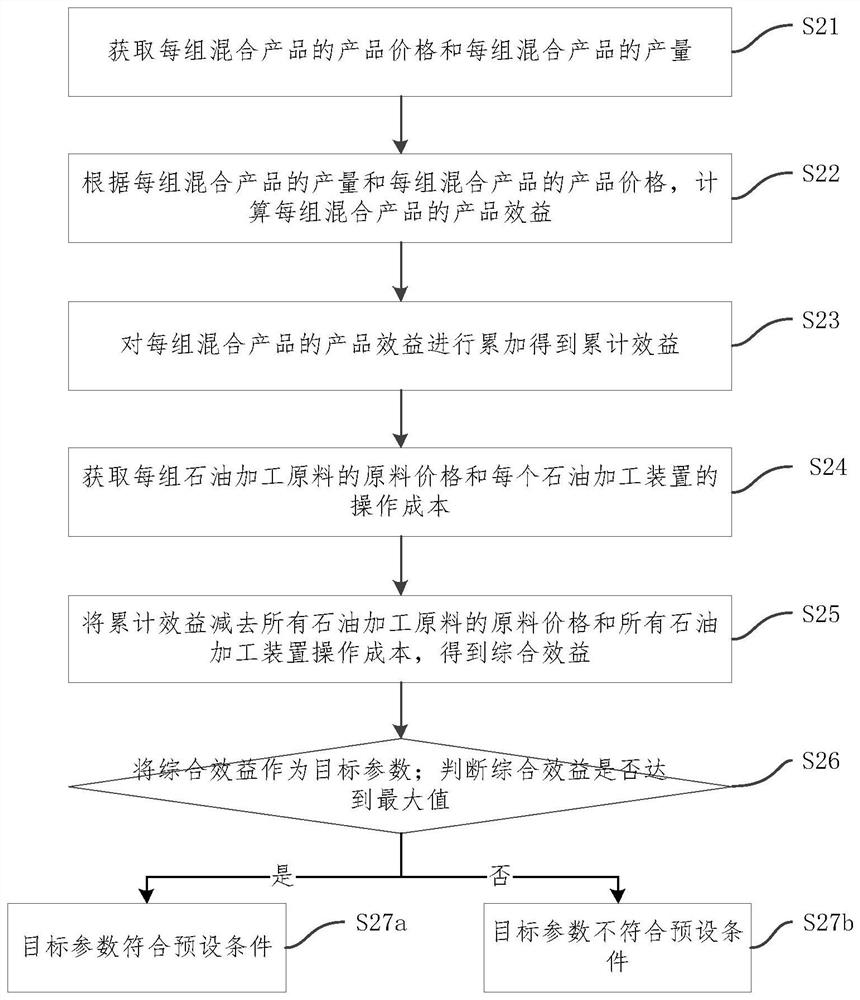

Method, device and system for full-process optimization of molecular-grade oil refining processing, and storage medium

PendingCN111899795AImprove production efficiencyChemical property predictionThermal non-catalytic crackingOil processingProcess engineering

The invention relates to a method, device and system for full-process optimization of molecular-grade oil refining processing, and a storage medium. According to embodiments of the invention, mixed products are obtained by simulating and predicting the molecular-grade crude oil processing flow; when the physical property of any mixed product does not conform to any preset standard, or the target parameters of the mixed products do not meet preset conditions, the proportions of different fractions entering corresponding petroleum processing devices are adjusted, the operation parameters in a product prediction model are adjusted, and mixing rules for mixing predicted products are adjusted so as to obtain mixed products again; and the above operations are repeated until the physical properties of all the mixed products meet any preset standard and the target parameters of all the mixed products meet the preset conditions, and a final predicted product is predicted by adjusting the proportion of fractions subjected to secondary treatment. A production process is simulated and optimized, so production benefits are improved.

Owner:PETROCHINA CO LTD

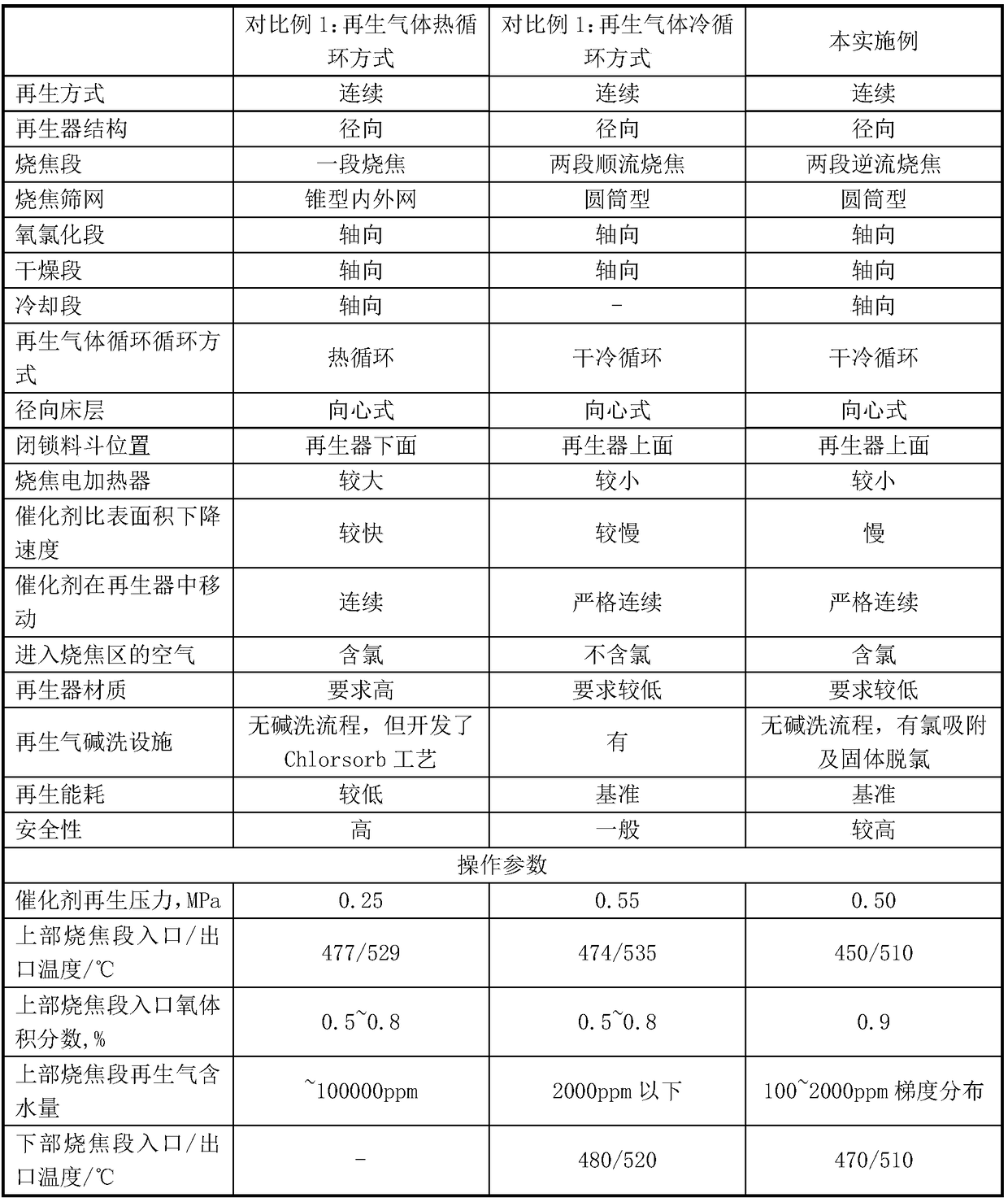

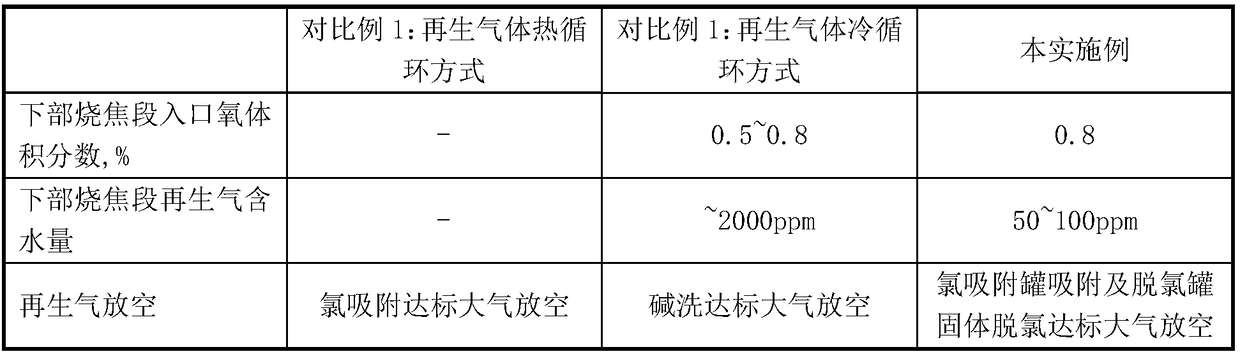

Method for purifying circulated gas regenerated continuously by reforming catalyst

InactiveCN1461675AOvercoming Chlorine Corrosion ProblemsCatalytic naphtha reformingCatalyst regeneration/reactivationEngineeringProduct gas

Owner:CHINA PETROLEUM & CHEM CORP +1

Rapid cycle reforming process

InactiveUS20110147267A1Reduce sulfur contentCatalytic naphtha reformingCatalyst regeneration/reactivationGasolineHydrogen content

This invention relates to process for producing a reformate or gasoline product. The process involves a rapid cycle of reacting hydrocarbon feedstock to form the product and then regenerating the catalyst used in the reaction. The process can be carried out at relatively high liquid hourly space velocities and preferably at relatively low hydrogen to hydrocarbon ratios to produce a reformed product having relatively high liquid yield and hydrogen content.

Owner:EXXON RES & ENG CO

Oil-refining chemical production balancing system

ActiveCN101515170AAccurately understand the production situationHydrocarbon oils treatment control/regulationHydrocarbon oil crackingData acquisitionStreamflow

The invention relates to an oil-refining chemical production balancing system, which comprises an oil-refining production device, an oil tank, a lateral line for connecting the oil-refining production device and the oil tank, and a data acquisition unit for connecting an oil tank volume data acquisition device and a lateral line flow conjecture data acquisition device, wherein the data acquisition unit is connected with an estimation calculating device which can calculate out lateral line flow conjecture data according with oil tank volume data. The oil-refining chemical production balancing system can calculate out the lateral line flow conjecture data which are in consistent with the oil tank volume data and accords with actual situations better through the oil tank volume data, so thata production manager can accurately know the production condition of the oil-refining production device. The oil-refining chemical production balancing system can feed back on-site production information in time and make adjustments according with the actual situation aiming at the production condition of the device.

Owner:石化盈科信息技术有限责任公司

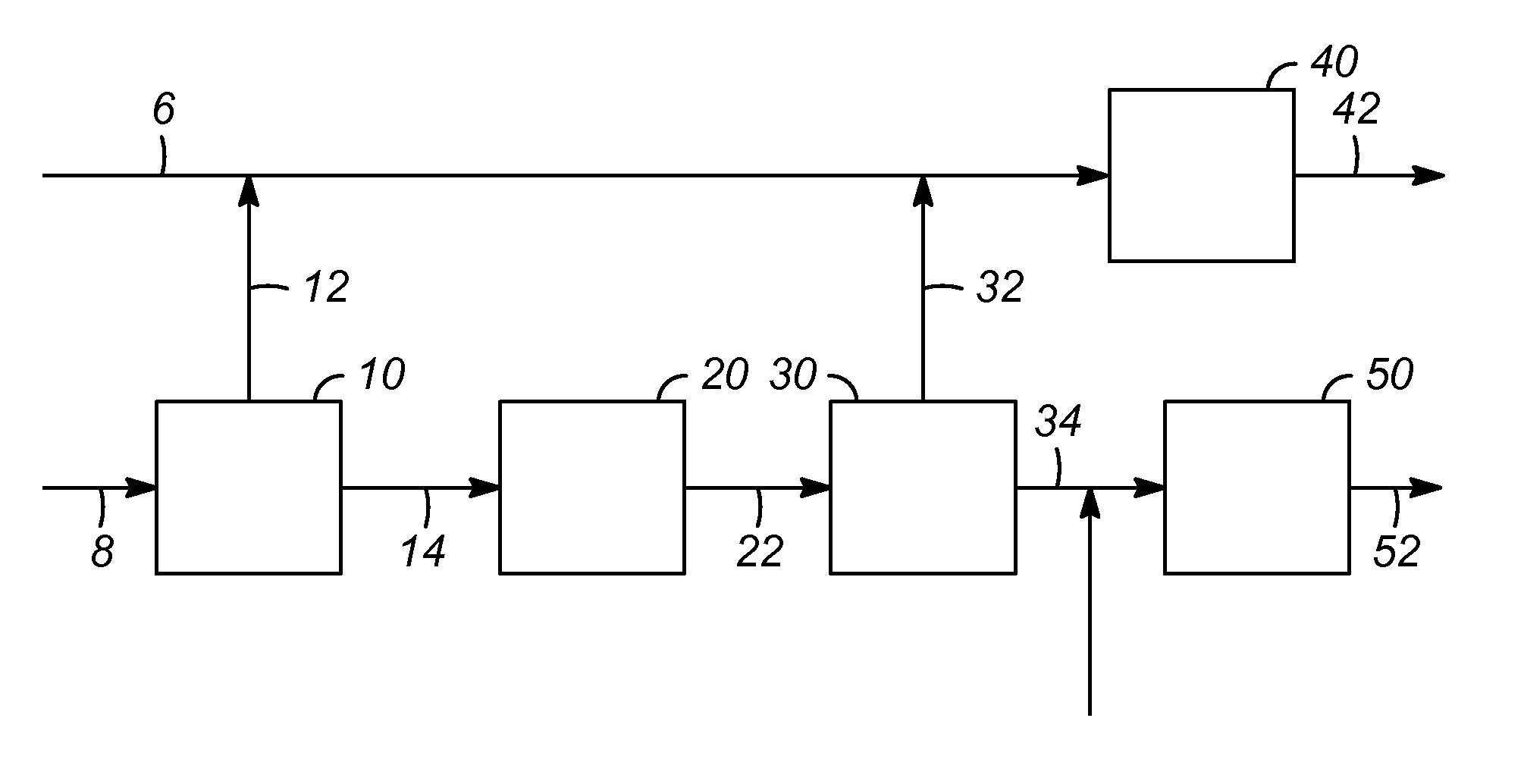

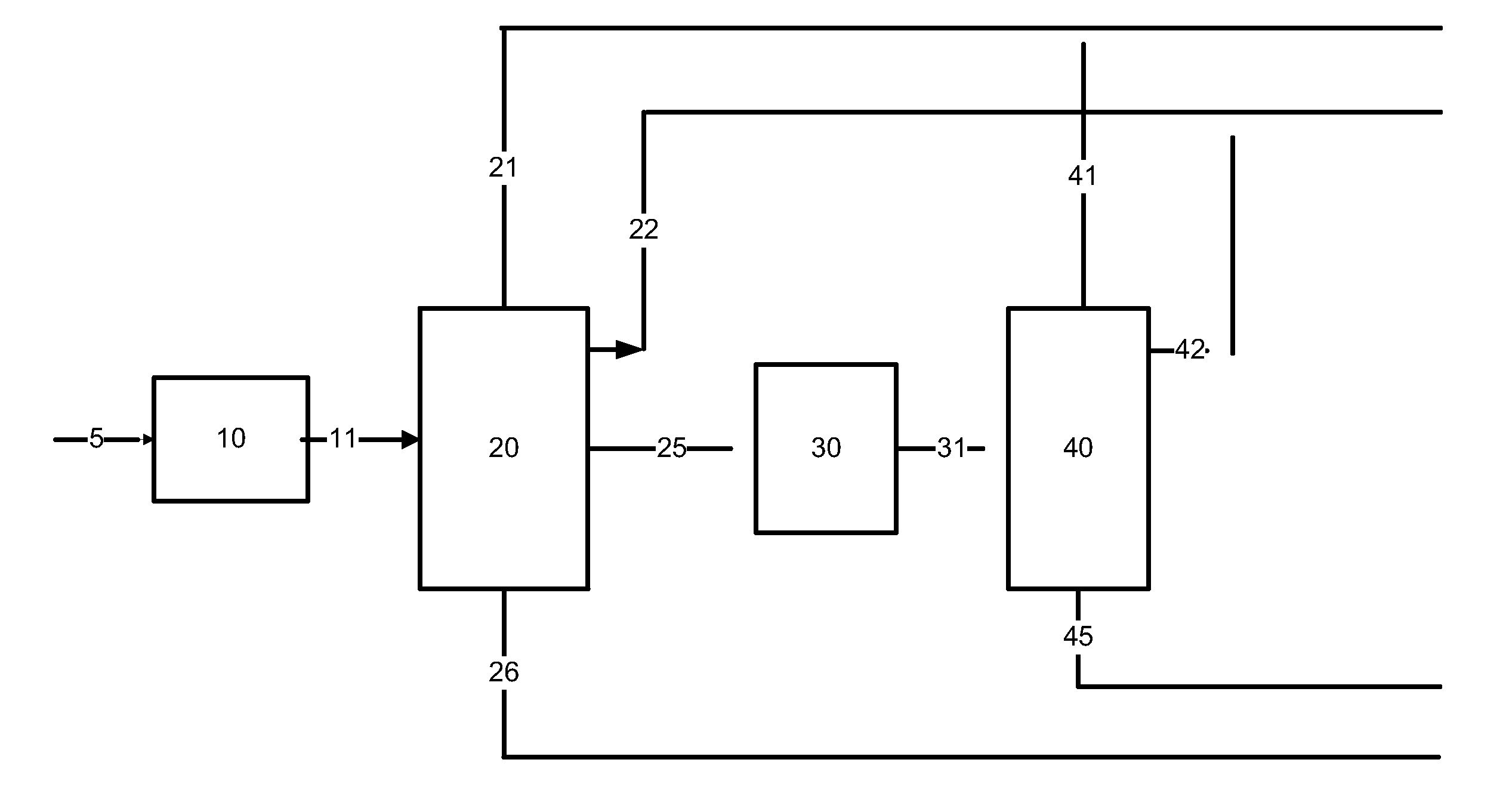

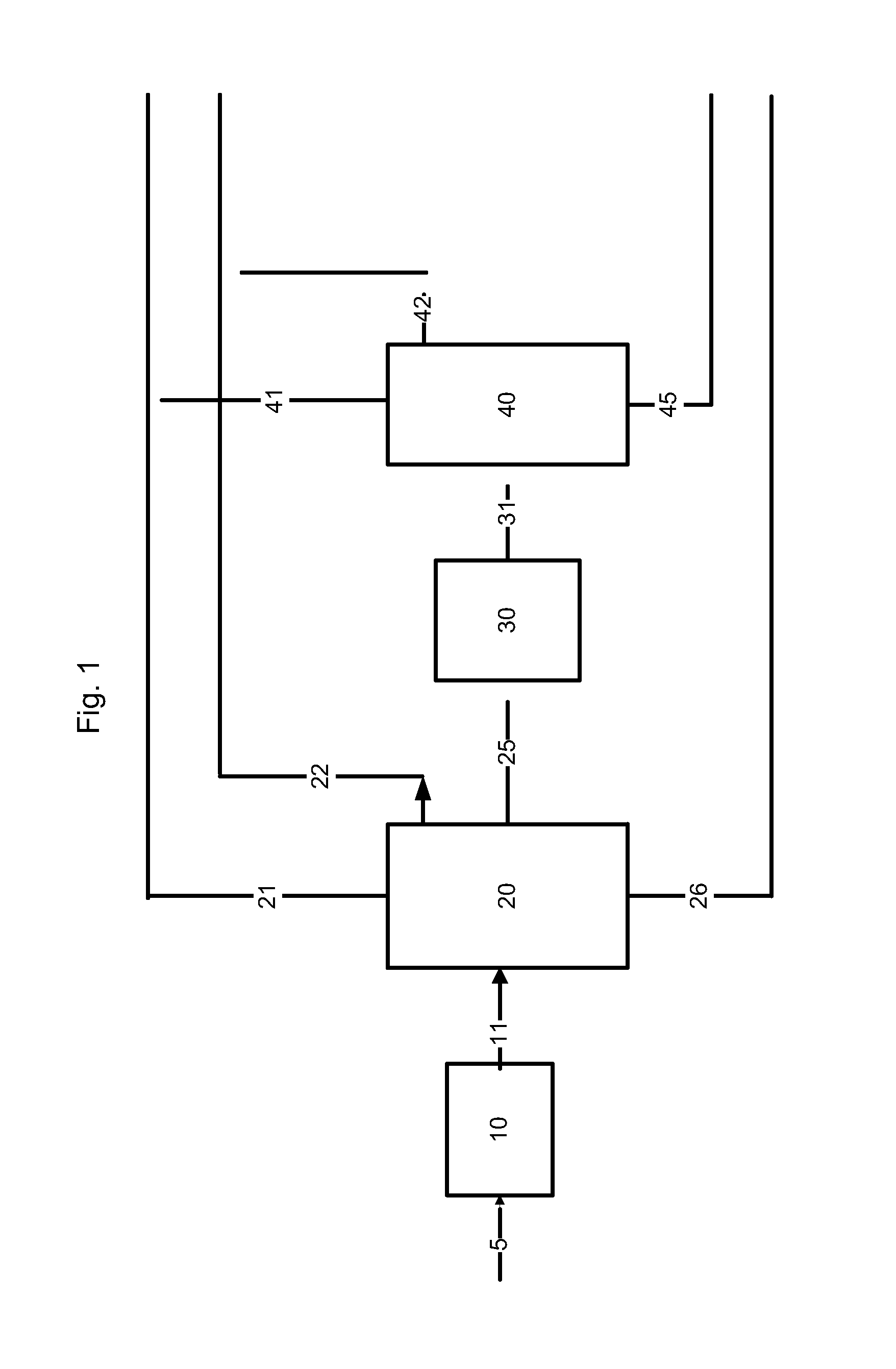

Naphtha cracking

ActiveUS9328299B2Increase productionEasy to crackTreatment with plural serial cracking stages onlyTreatment with hydrotreatment processesNaphthaNormal component

A process for increasing the yields of light olefins and the yields of aromatics from a hydrocarbon stream is presented. The process includes a first separation to direct the light components that are not reformable to a cracking unit, with the remainder passed to a second separation unit. The second separation unit extracts normal components from the hydrocarbon stream to pass to the cracking unit. The resulting hydrocarbon stream with reduced light ends and reduced normals is passed to a reforming unit.

Owner:UOP LLC

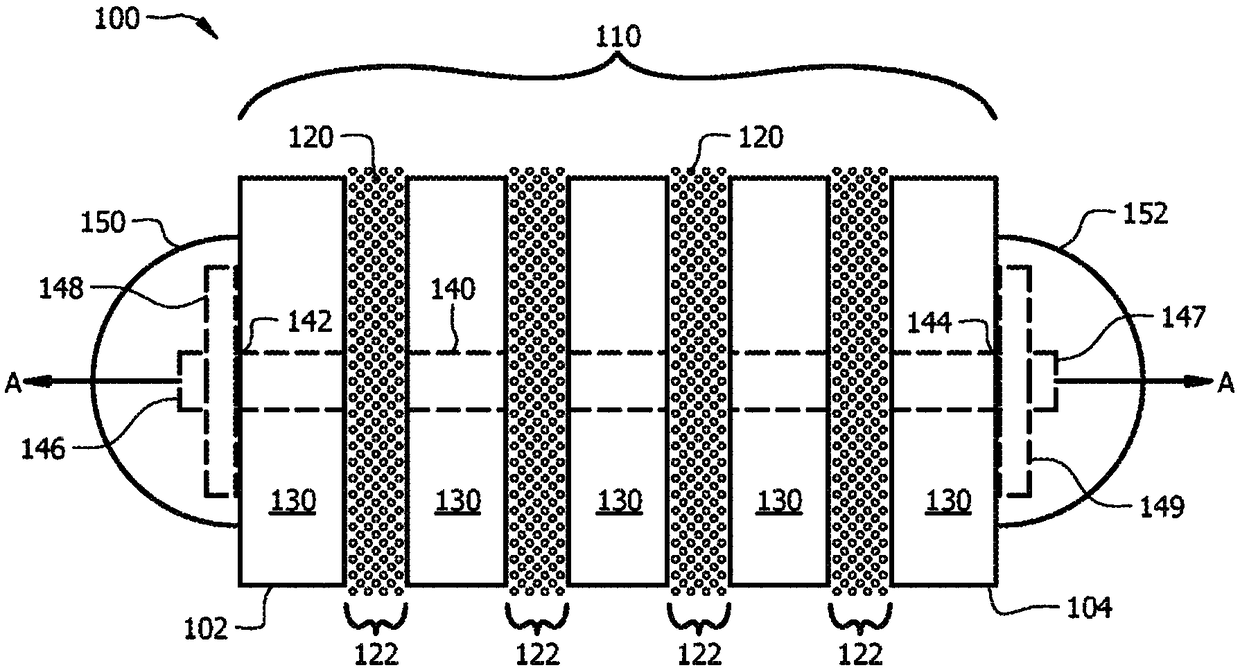

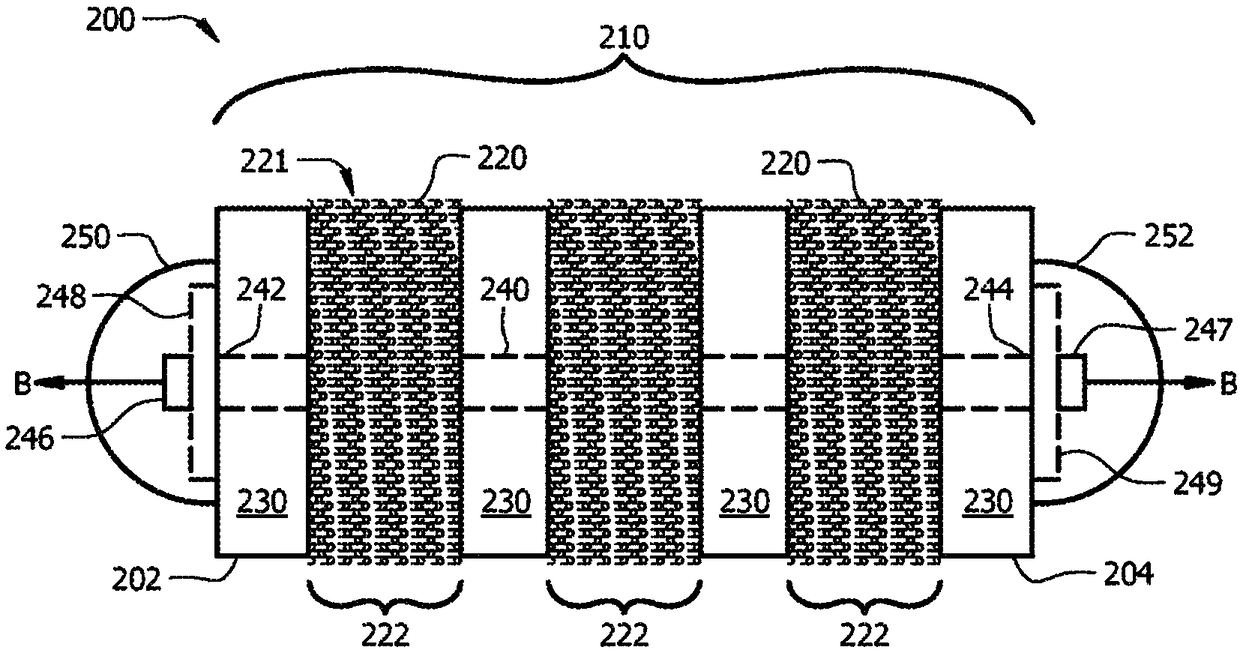

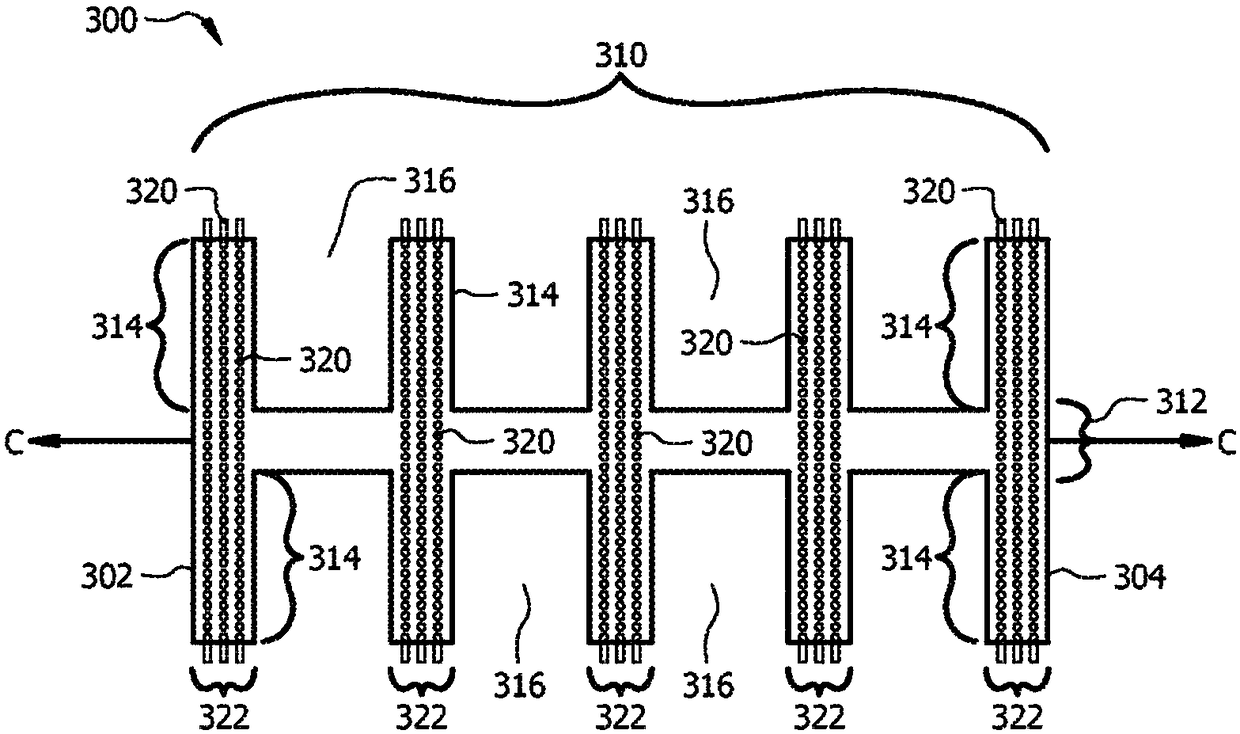

Cleaning coke deposits from process equipment

A method for cleaning a coke deposit from an internal surface of process equipment comprises removing at least a portion of the coke deposit from the internal surface using a flexible pig comprising aplurality of bristles, without damaging a metal protective layer of the internal surface of the process equipment. A flexible pig (100) for cleaning a coke deposit from an internal surface of processequipment without damaging a metal protective layer of the internal surface comprises a flexible body (110) formed of a polymeric material (130), and a plurality of bristles (120) partially encapsulated by the polymeric material of the flexible body.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Integrated hydrogenation/dehydrogenation reactor in a catalytic reforming process configuration for improved aromatics production

ActiveUS9024097B2Hydrocarbon by hydrogenationHydrocarbon purification/separationCatalytic reformingReaction temperature

A process for reforming hydrocarbons is presented. The process involves applying process controls over the reaction temperatures to preferentially convert a portion of the hydrocarbon stream to generate an intermediate stream, which will further react with reduced endothermicity. The intermediate stream is then processed at a higher temperature, where a second reforming reactor is operated under substantially isothermal conditions.

Owner:UOP LLC

Multi-stage reforming process to produce high octane gasoline

ActiveUS20120024753A1Improve performanceCatalytic naphtha reformingTreatment with hydrotreatment processesNaphthaStaged reforming

The present invention relates to a multistage reforming process to produce a high octane product. A naphtha boiling range feedstock is processed in a multi-stage reforming process, in which said process involves at least 1) a penultimate stage for reforming the naphtha feedstock to produce a penultimate effluent 2) a final stage for further reforming at least a portion of the penultimate effluent 3) a regeneration step for the final stage catalyst. The severity of the penultimate stage can be increased during final stage catalyst regeneration in order to maintain the target RON of the reformate product and avoid reactor downtime.

Owner:CHEVROU USA INC

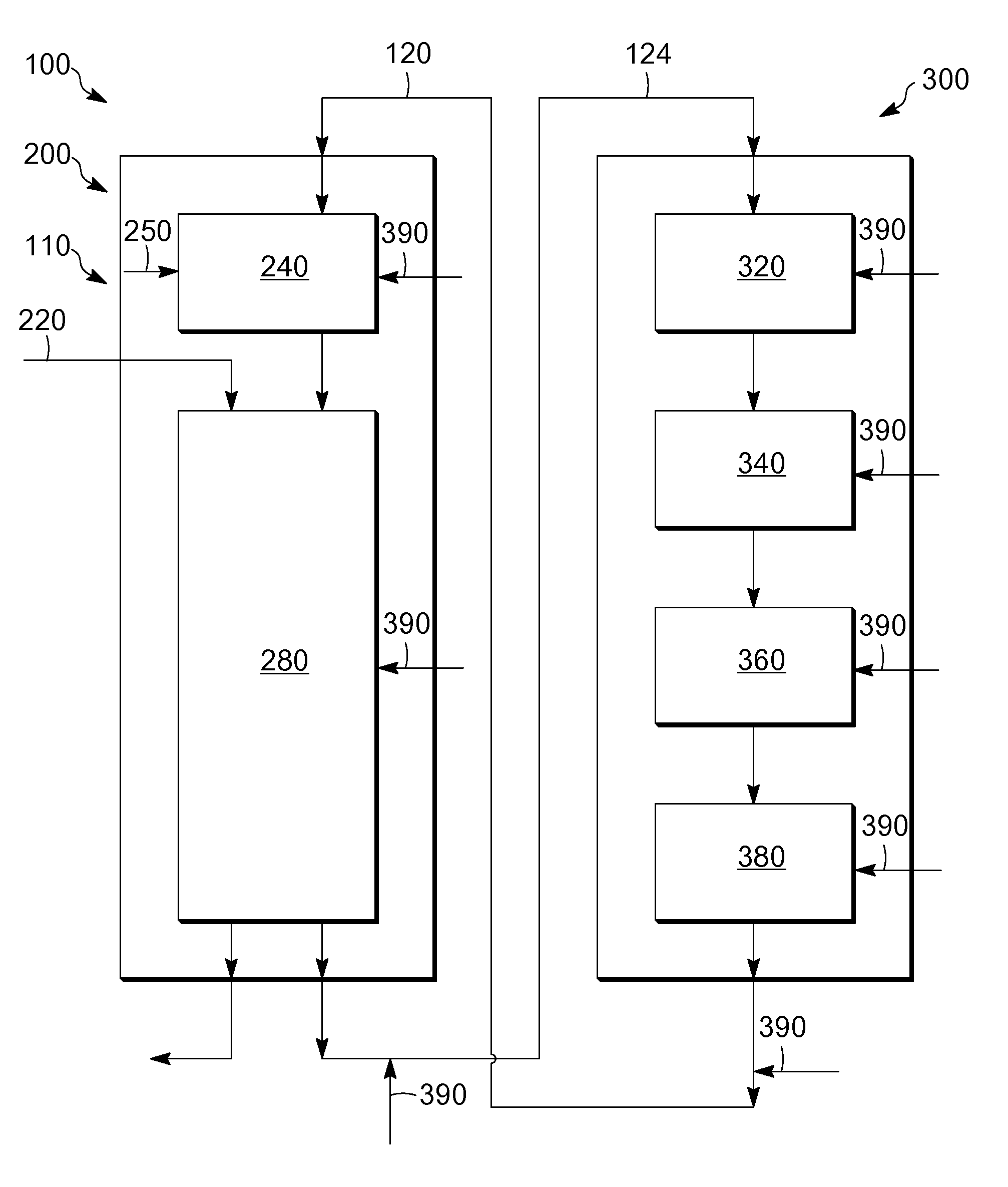

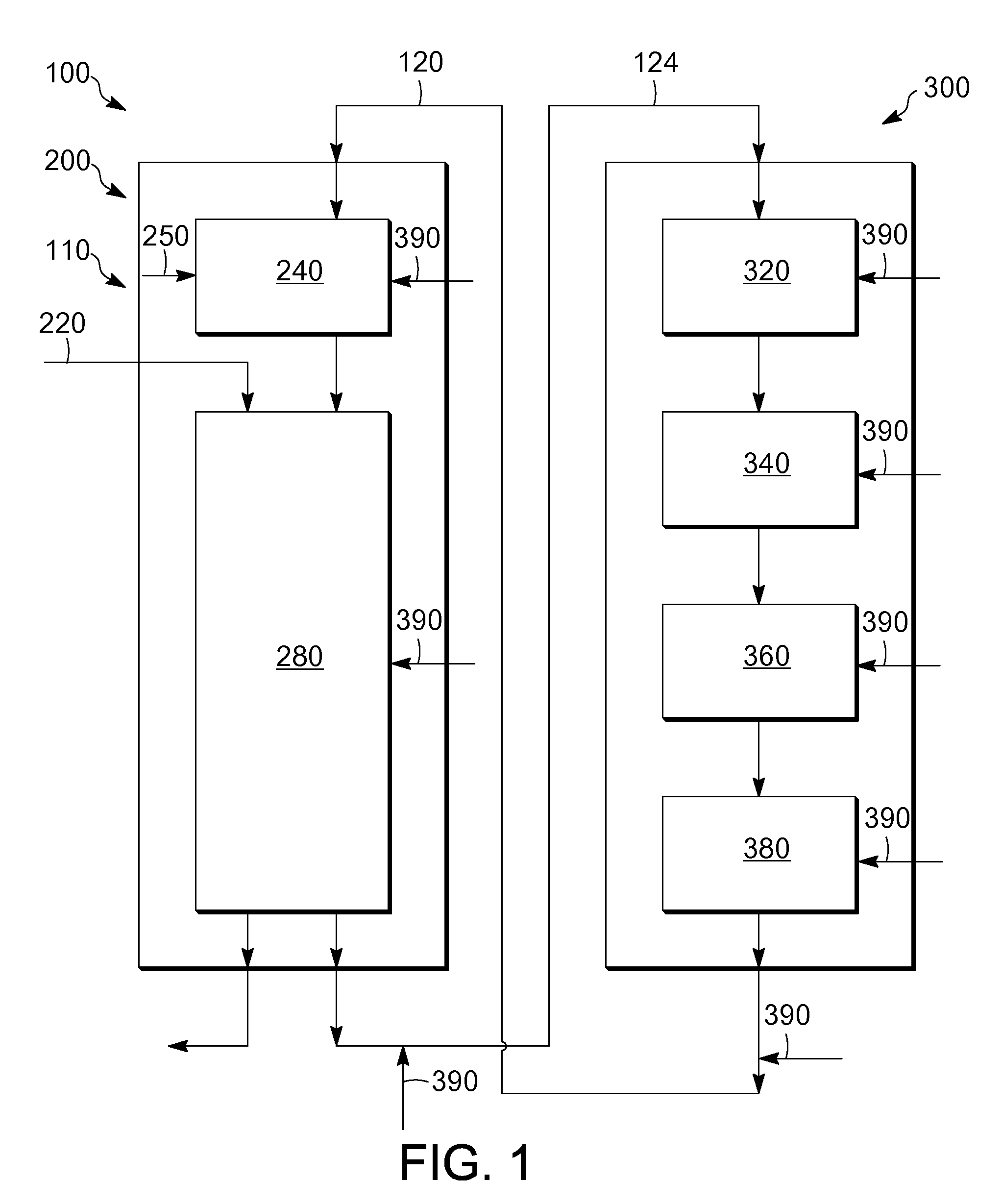

Process and system for the transfer of a metal catalyst component from one particle to another

InactiveUS20090261018A1Improve conversion of hydrocarbonEasy transferCatalytic naphtha reformingReforming process control/regulationNaphthaMetal catalyst

One exemplary embodiment can be a process for facilitating a transfer of a metal catalyst component from at least one donor particle to at least one recipient particle in a catalytic naphtha reforming unit. The process can include transferring an effective amount of the metal catalyst component from the at least one donor particle to the at least one recipient particle under conditions to effect such transfer to improve a conversion of a hydrocarbon feed.

Owner:UOP LLC

Modified ultra-stable Y (USY) zeolite catalyst for deolefinization of hydrocarbon streams

The present disclosure relates to a process for the deolefinization of hydrocarbon streams through an aromatic alkylation reaction by olefins, using a catalyst containing a framework-substituted zirconium and / or titanium and / or hafnium-modified ultra-stable Y (USY) type zeolite.

Owner:SAUDI ARABIAN OIL CO +2

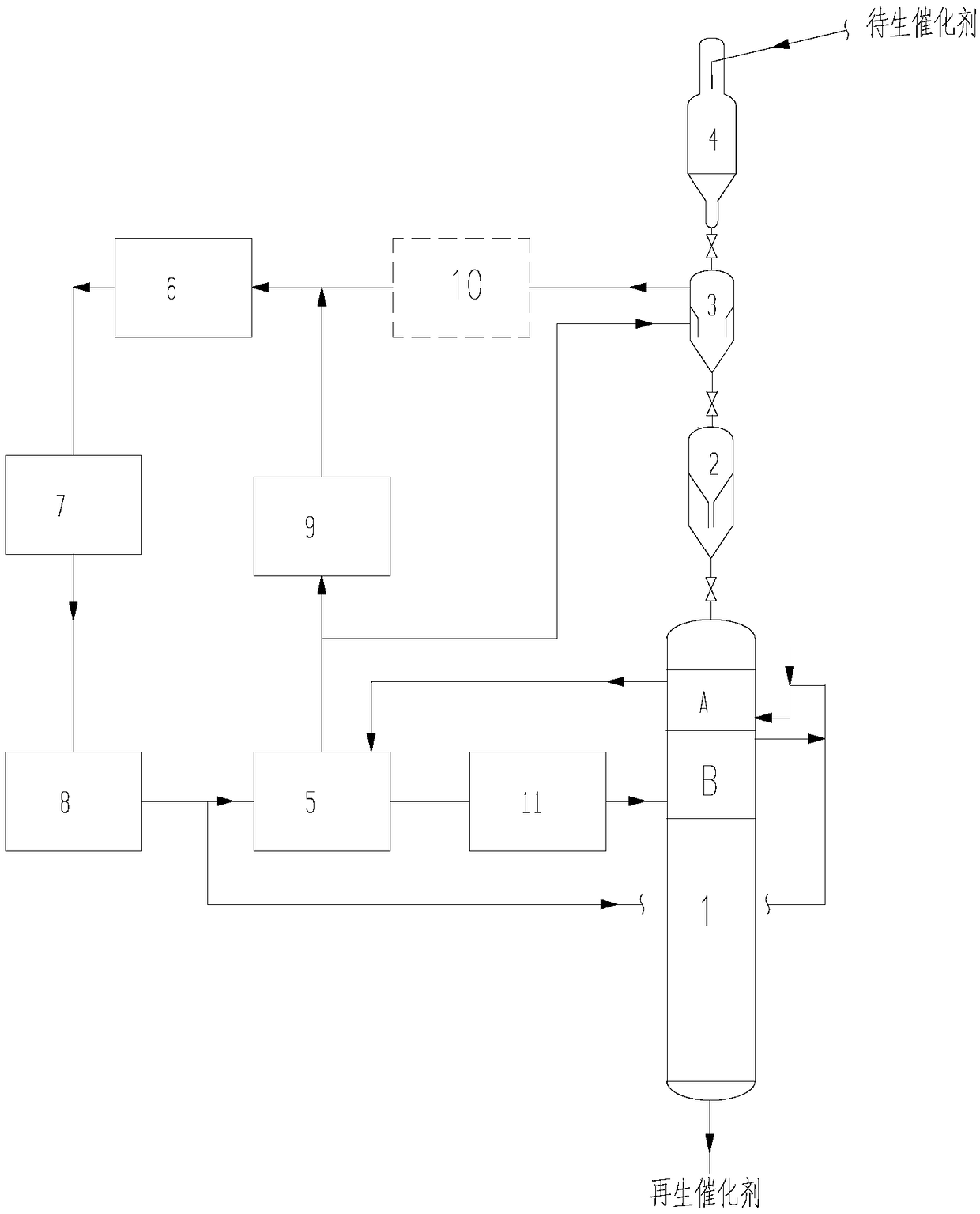

Continuous catalytic reforming method capable of achieving upflow regeneration of catalyst and adsorption and recovery of chlorine in coke-burning gas

ActiveCN108998078AReduce injectionGuaranteed activityCatalytic naphtha reformingReforming process control/regulationCatalytic reformingWater content

The invention relates to a continuous catalytic reforming method capable of achieving upflow regeneration of a catalyst and adsorption and recovery of chlorine in coke-burning gas. Upflow contact of the to-be-regenerated catalyst with the coke-burning gas is performed through a regenerator so as to achieve regeneration, so that the water content of the coke-burning gas in an upper coke burning section and a lower coke burning section is reduced to a very low level, and the water content of the coke-burning gas in the upper coke burning section is decreased gradually in the direction of catalyst movement. When the method is compared with the prior art, reduction of the specific surface area loss of the catalyst, prolonging of the service life of the catalyst and reduction of the loss of thechlorine component in the catalyst can be achieved in the regeneration process relative to a dry coke burning environment, so that the usage amount of a chlorinating agent needed to be supplemented in the oxychlorination process is reduced, and corrosion of the coke burning gas to devices and pipelines in a circulation loop is slowed down; and the chlorine in the coke burning gas is adsorbed by the to-be-regenerated catalyst, so that the chlorine injection amount in the oxychlorination section is reduced, investment is saved, and the environment is protected.

Owner:SHANGHAI HOTO PETROCHEM ENG

Process and system for the transfer of a metal catalyst component from one particle to another

InactiveUS7909988B2Easy transferImprove efficiencyCatalytic naphtha reformingReforming process control/regulationNaphthaMetal catalyst

One exemplary embodiment can be a process for facilitating a transfer of a metal catalyst component from at least one donor particle to at least one recipient particle in a catalytic naphtha reforming unit. The process can include transferring an effective amount of the metal catalyst component from the at least one donor particle to the at least one recipient particle under conditions to effect such transfer to improve a conversion of a hydrocarbon feed.

Owner:UOP LLC

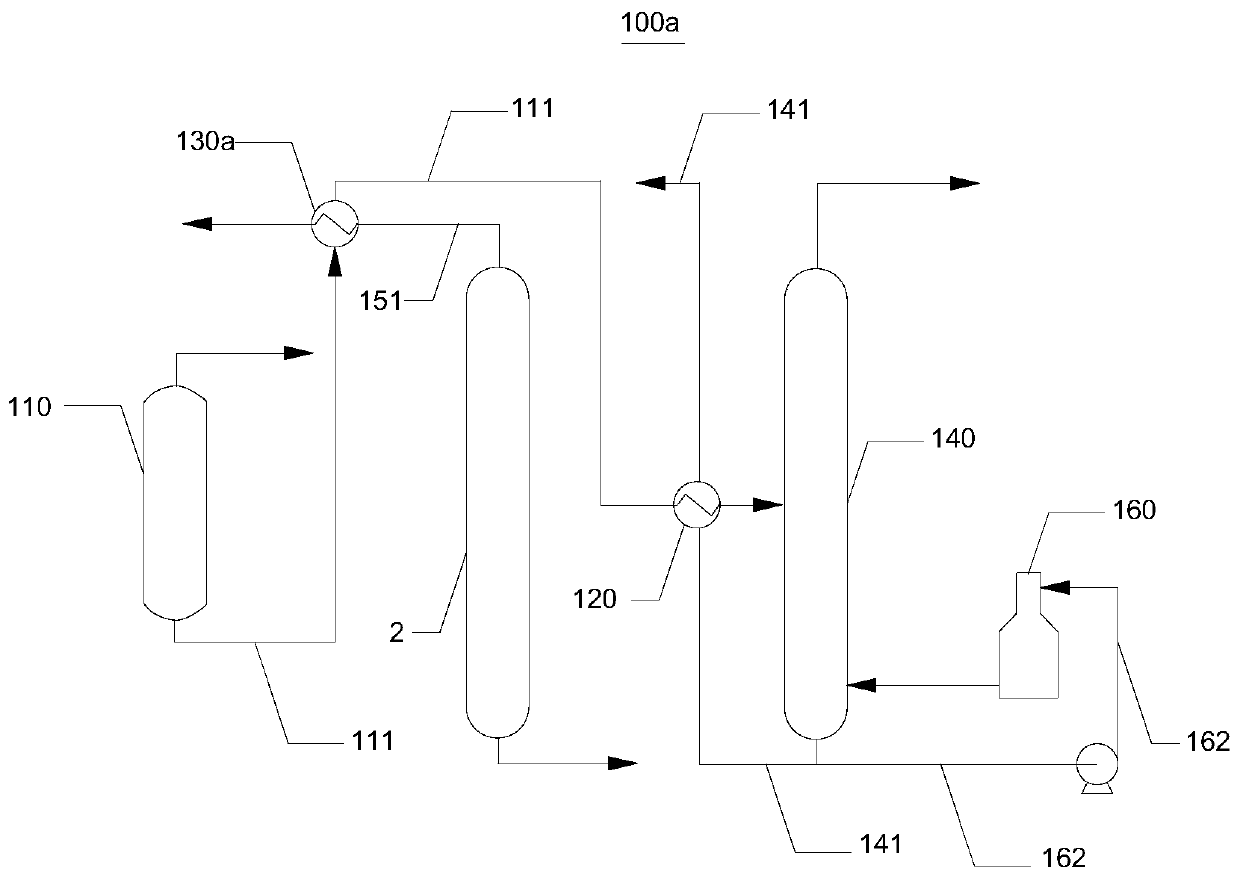

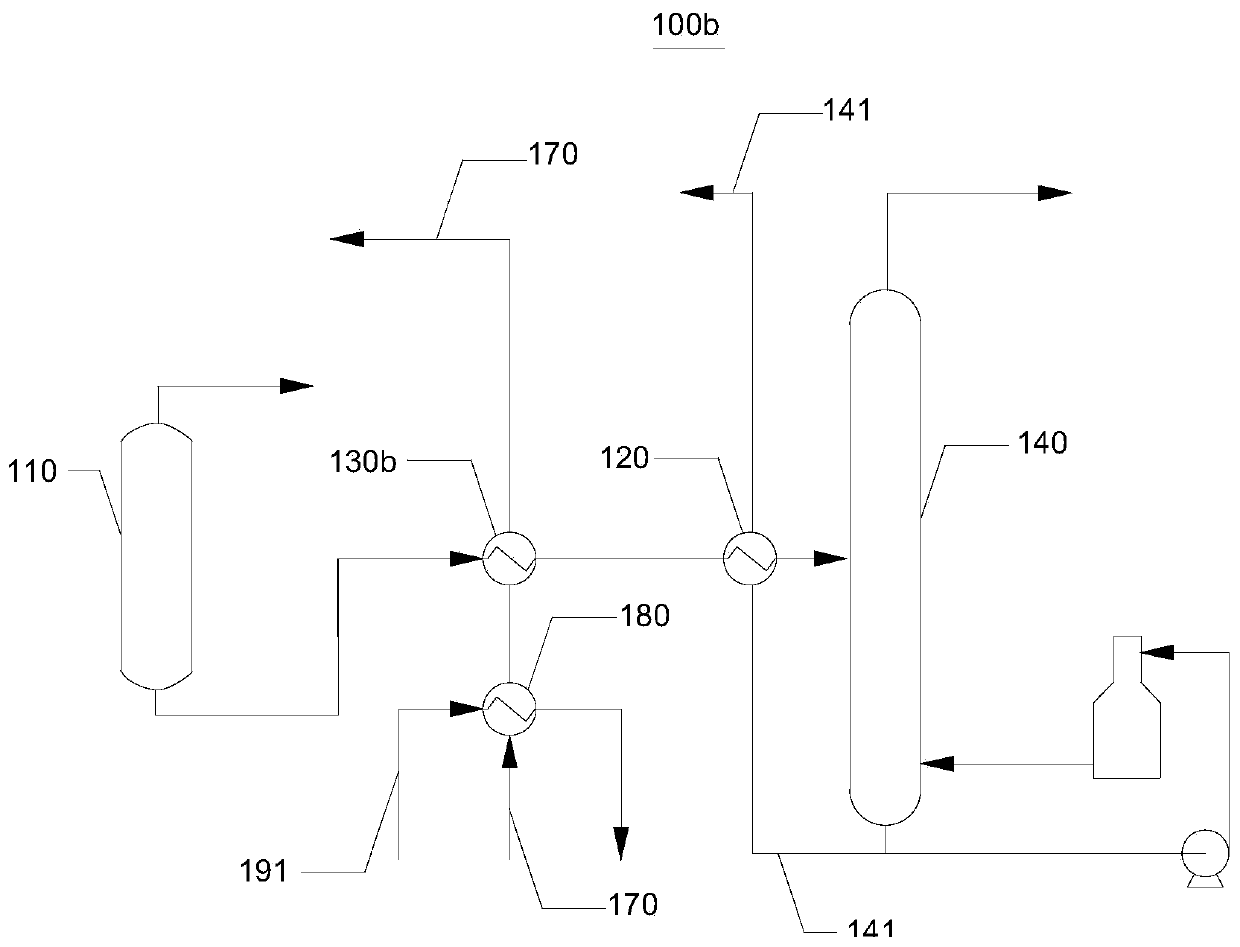

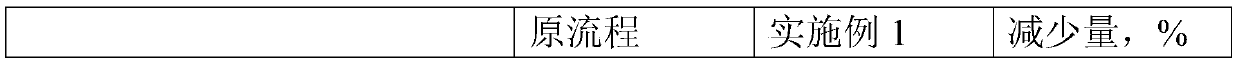

Catalytic reforming energy-saving system, catalytic reforming energy-saving method and catalytic reforming reaction system

InactiveCN110776947AIncrease temperatureReduce the temperatureCatalytic naphtha reformingReforming process control/regulationCatalytic reformingProcess engineering

The invention relates to the technical field of catalytic reforming, and discloses a catalytic reforming energy-saving system, a catalytic reforming energy-saving method and a catalytic reforming reaction system. The catalytic reforming energy-saving system comprises a high-pressure absorption tank, a reformed oil stabilizing tower and a first heat exchanger, wherein the high-pressure absorption tank is communicated with a base solution output pipe; the base solution output pipe is communicated with the feed port of a reformate stabilizing tower; the reformate stabilizing tower is communicatedwith a base oil output pipe; the base oil output pipe serves as a heat source pipeline; and the base solution output pipe serves as a cold source pipeline and is connected with the first heat exchanger. The catalytic reforming energy-saving method comprises a step of performing heat exchange on a base solution generated by the high-pressure absorption tank with base oil generated by the reformatestabilizing tower as a heat source. The catalytic reforming reaction system comprises the catalytic reforming energy-saving system. According to the catalytic reforming energy-saving system, the catalytic reforming energy-saving method and the catalytic reforming reaction system, system load can be reduced, system energy consumption is reduced, and resource conservation is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

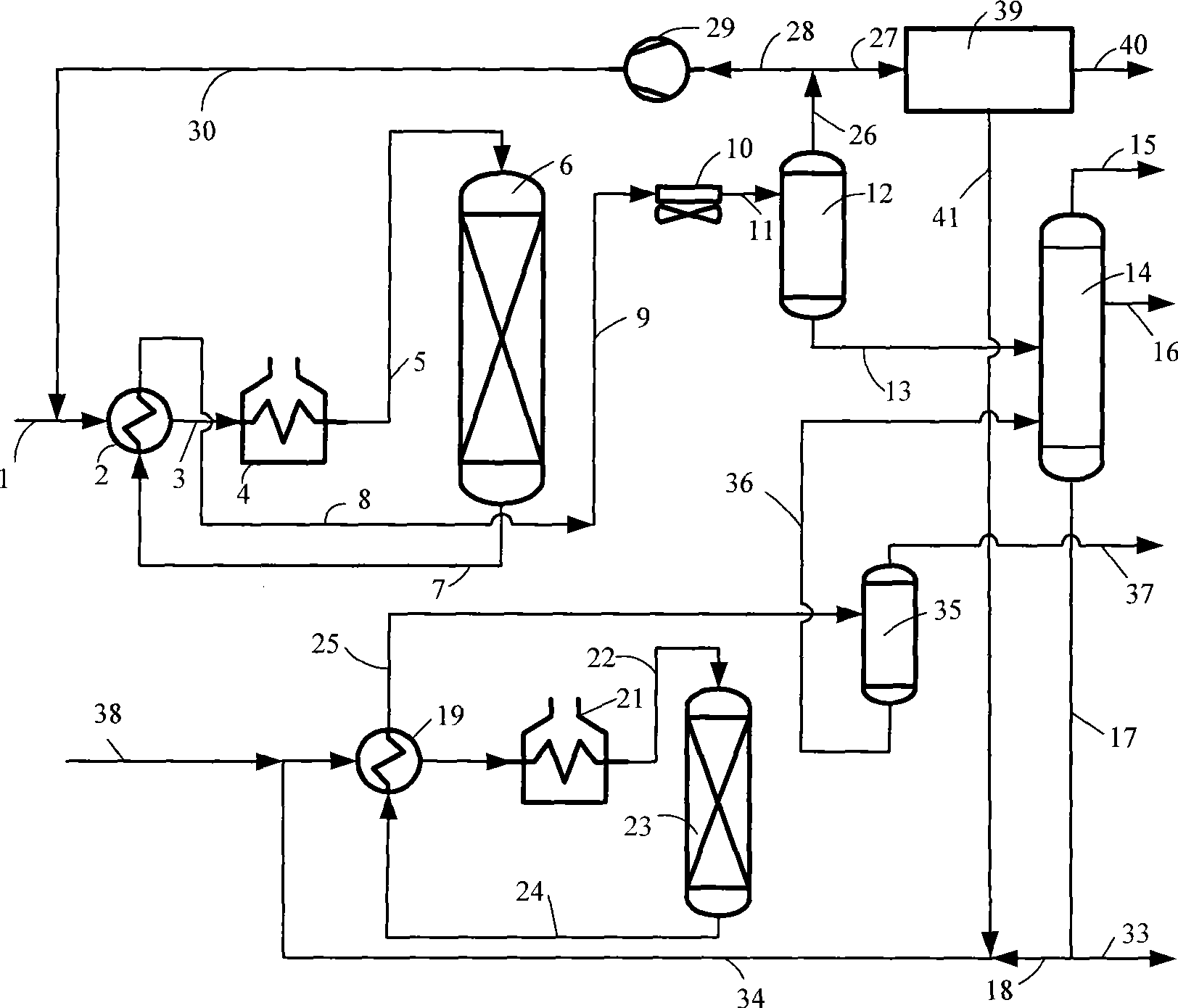

Benzin naphtha catalytic reforming method

ActiveCN101376823BImprove conversion rateGood choiceCatalytic naphtha reformingReforming process control/regulationCatalytic reformingLiquid product

The invention relates to a naphtha catalytic reforming method which includes the steps as follows: the naphtha is pumped into the reactor of a catalytic reforming device; gas-liquid separation is carried out on the reformed product for separating gas components, the light component of C8- as well as the heavy component of C9+; then a light aromatics reaction is carried out on the heavy component of C9+ under the existence of a light aromatics catalyst; the hydrogen used by the light aromatics reaction is from the circulated hydrogen generated from a reforming device; then gas-liquid separation is carried out on the product after the light aromatics reaction; the liquid returns to the liquid product distilling system of the reforming device. The method can fully utilize the heavy component of C9+ and convert the heavy component into light aromatic hydrocarbon, improve the aromatic hydrocarbon yield or the yield of the reformed gasoline during the whole process and improve the character of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

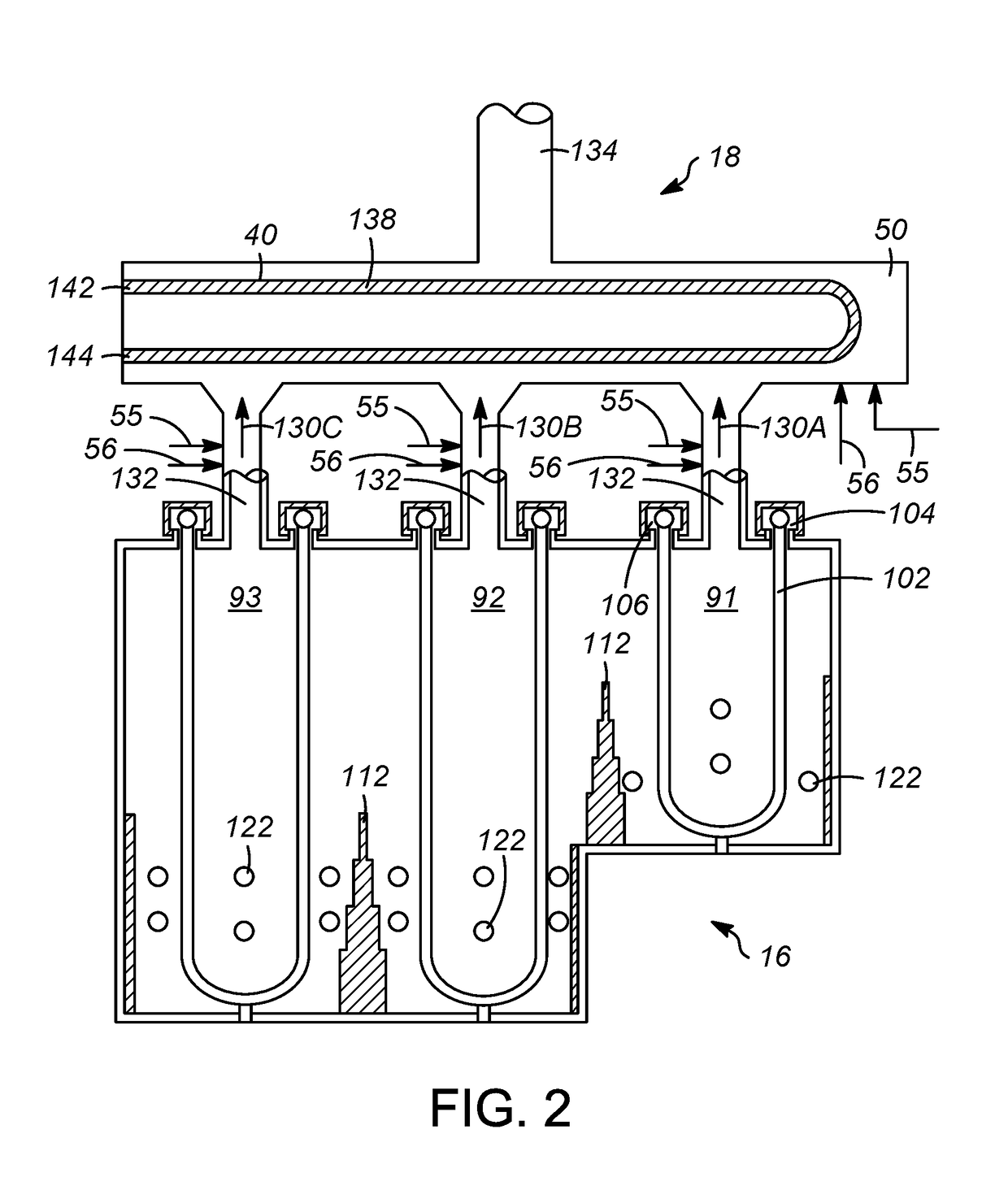

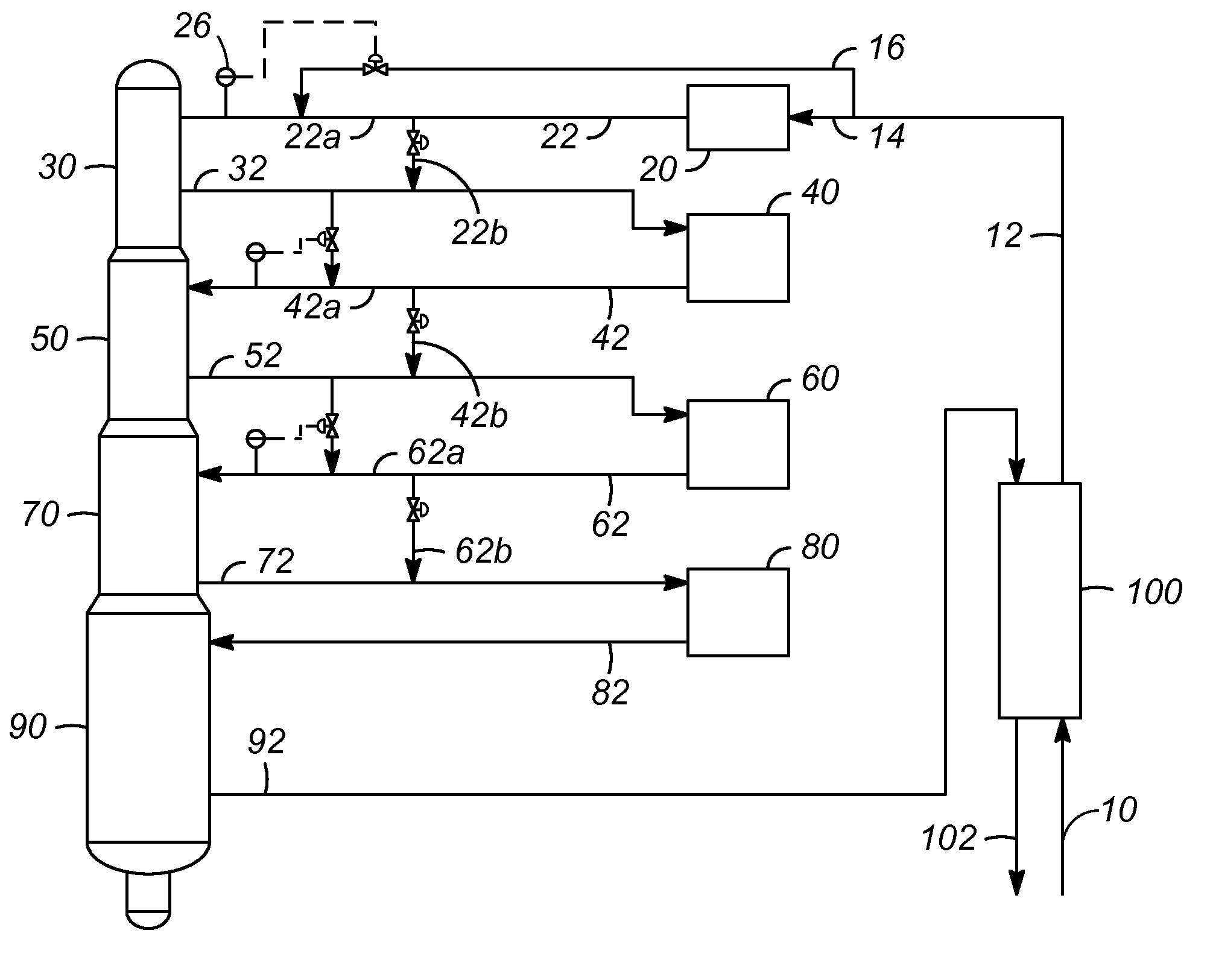

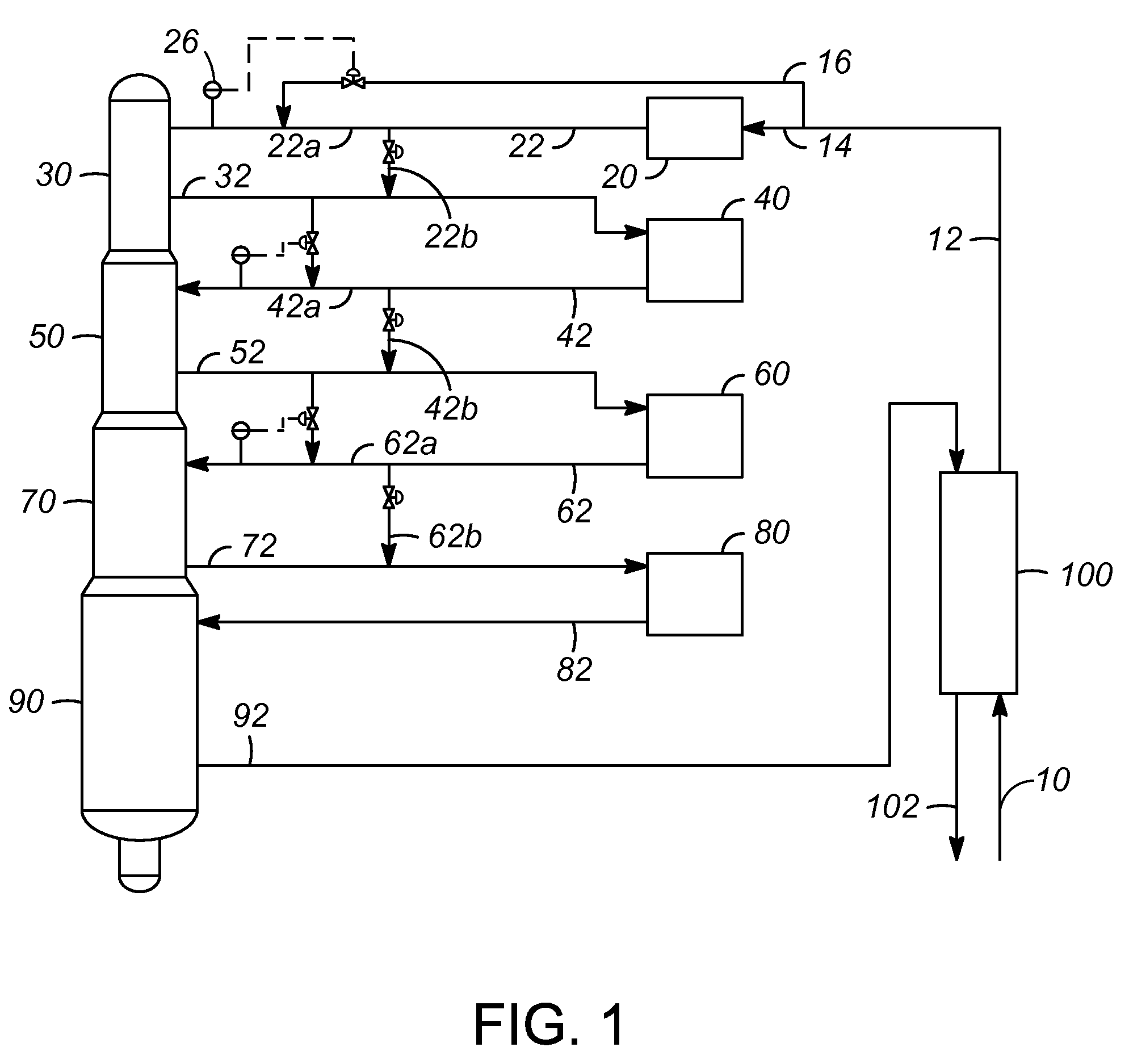

Reforming process with improved heater integration

ActiveUS20170327755A1Thermal non-catalytic crackingThermal naphtha reformingRadiant heaterProcess engineering

A method and apparatus for processing a hydrocarbon stream are described. The method includes heating a feed stream in a convective bank. The heated feed stream is reacted in a first reaction zone to form a first effluent, which is heated in a first radiant cell. The first radiant cell combusts fuel to heat the first effluent and forms a first exhaust gas. The first exhaust gas is contacted with the convective bank to heat the feed stream. The outlet temperature the heated feed stream from the convective bank is controlled by introducing an additional gas stream into the convective bank. There can be additional reaction zones and radiant heaters.

Owner:UOP LLC

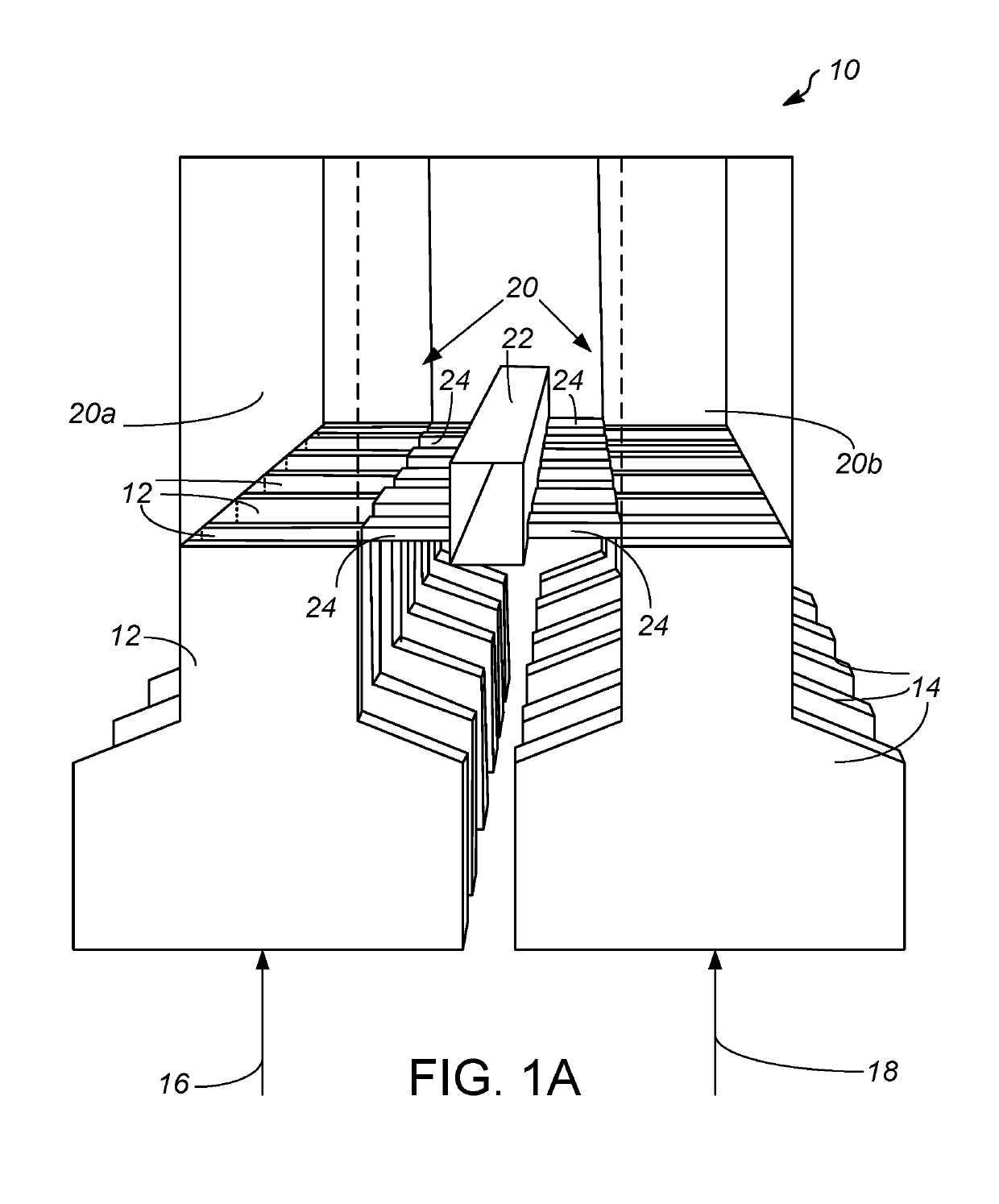

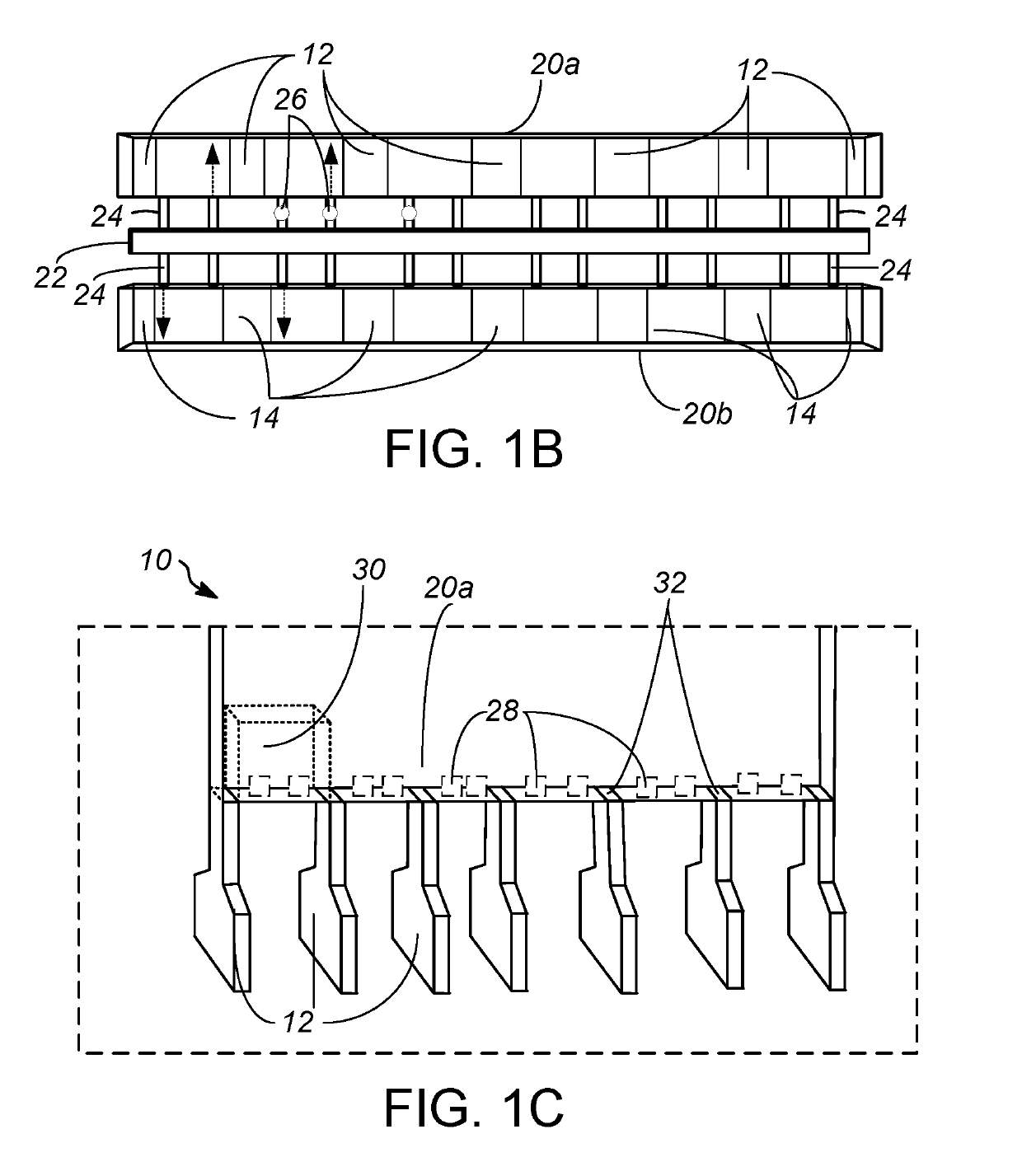

Process and apparatus for a convection charge heater having a recycle gas distributor

ActiveUS20190330538A1Uniform and consistent temperature profileHigh densityThermal non-catalytic crackingTemperatue controlFlue gasProcess engineering

Processes and apparatuses for relocating a reforming process heater service into the convection section rely on combining a flue gas recycle quench stream with the radiant section off gases entering the convection section. The uniformity of mixing influences the effectiveness of that quench stream. The more effective the quench stream is, the lower the equipment size required to manage the recycle design.

Owner:UOP LLC

Catalytic reforming processes

ActiveUS9683179B2Reduce the amount requiredYield minimizationCatalytic naphtha reformingReforming process control/regulationCatalytic reformingHydrocarbon

Processes for catalytic reforming in which a cracking inhibitor, such as an olefin, or a light olefin, is used to inhibit thermal cracking of larger hydrocarbons in non-reactive zones. The cracking inhibitor may be added at various positions through the processes, such as in the recycle gas stream, before a heater, before a stream is passed into a reforming zone, after an effluent stream is recovered from a reforming zone. A molar ratio of cracking inhibitor to hydrocarbons in stream may be between 0.01 and 0.2.

Owner:UOP LLC

High temperature CCR process with integrated reactor bypasses

A process is presented for increasing the aromatics content in a reformate process stream. The process modifies existing processes to change the operation without changing the reactors or heating units. The process includes bypasses to utilize heating capacity of upstream heating units, and passes the excess capacity of the upstream heating units to downstream process streams.

Owner:UOP LLC

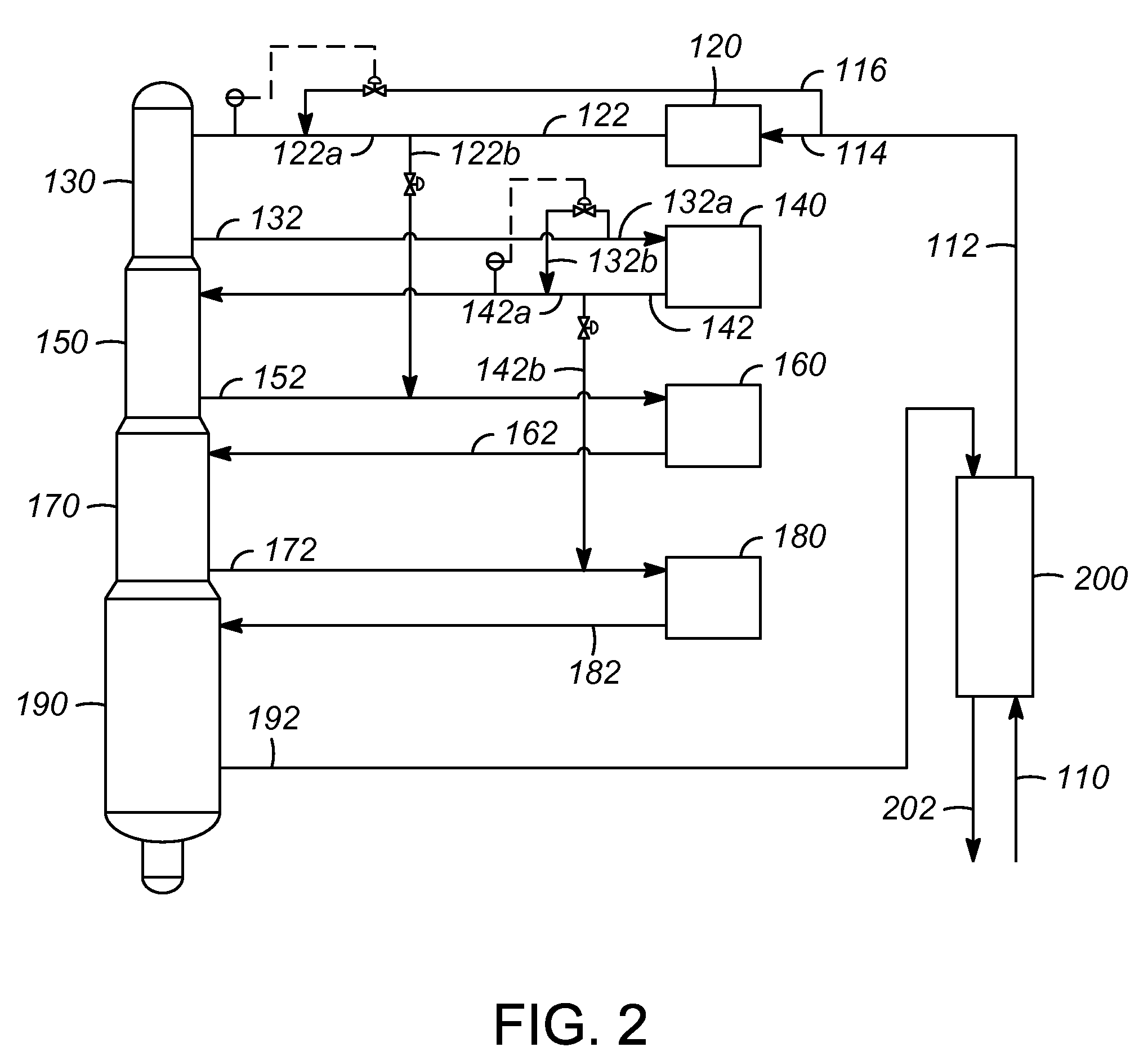

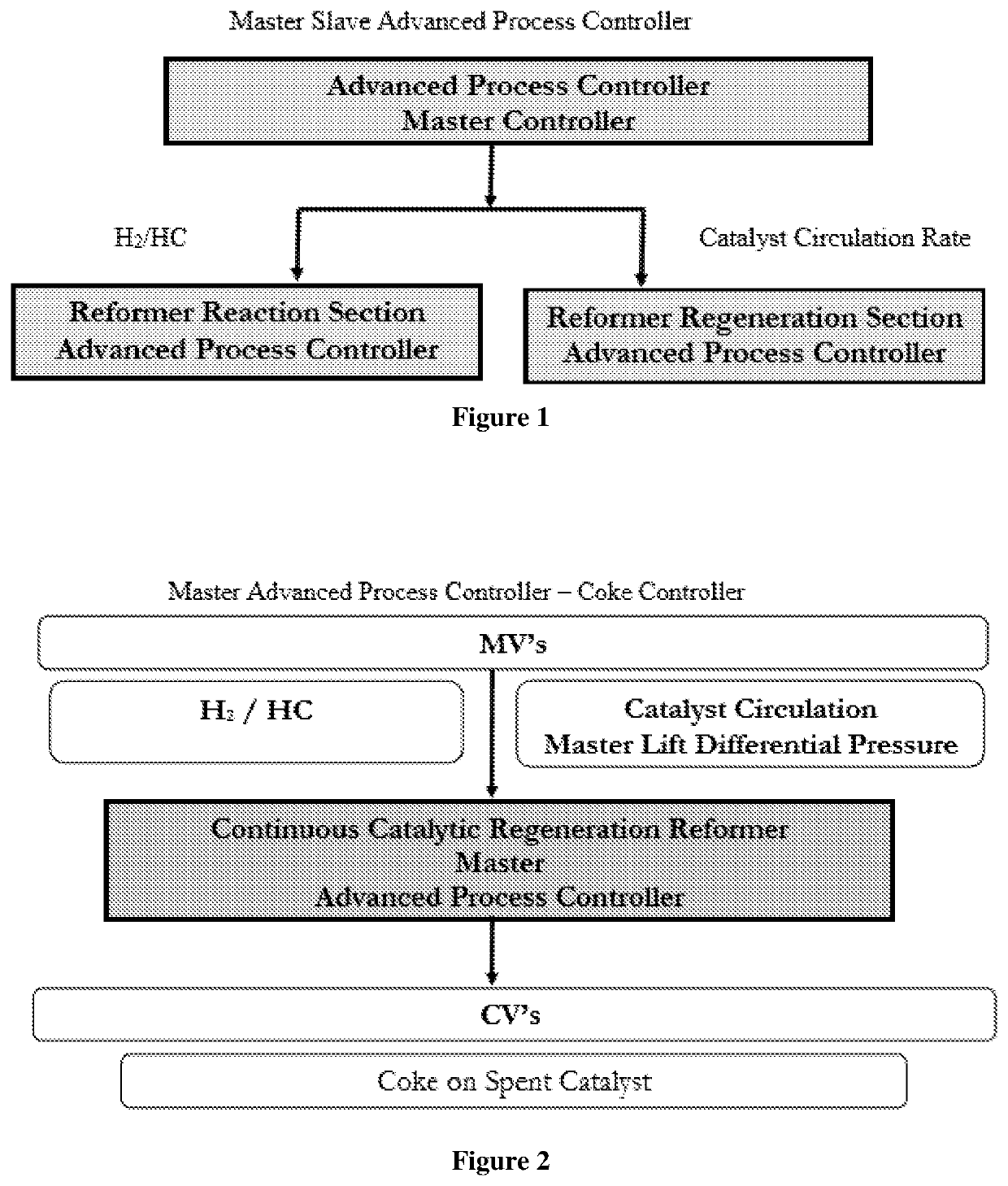

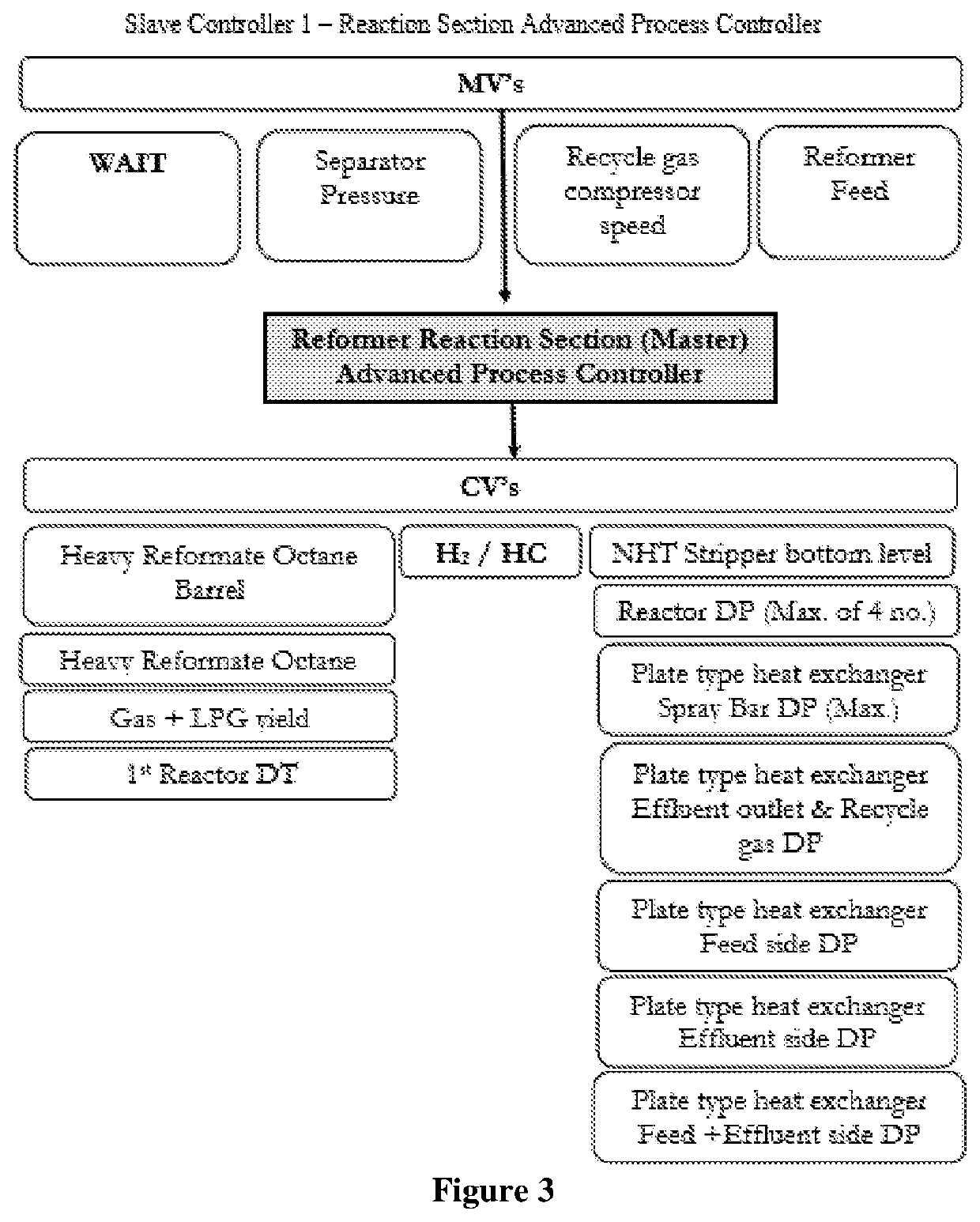

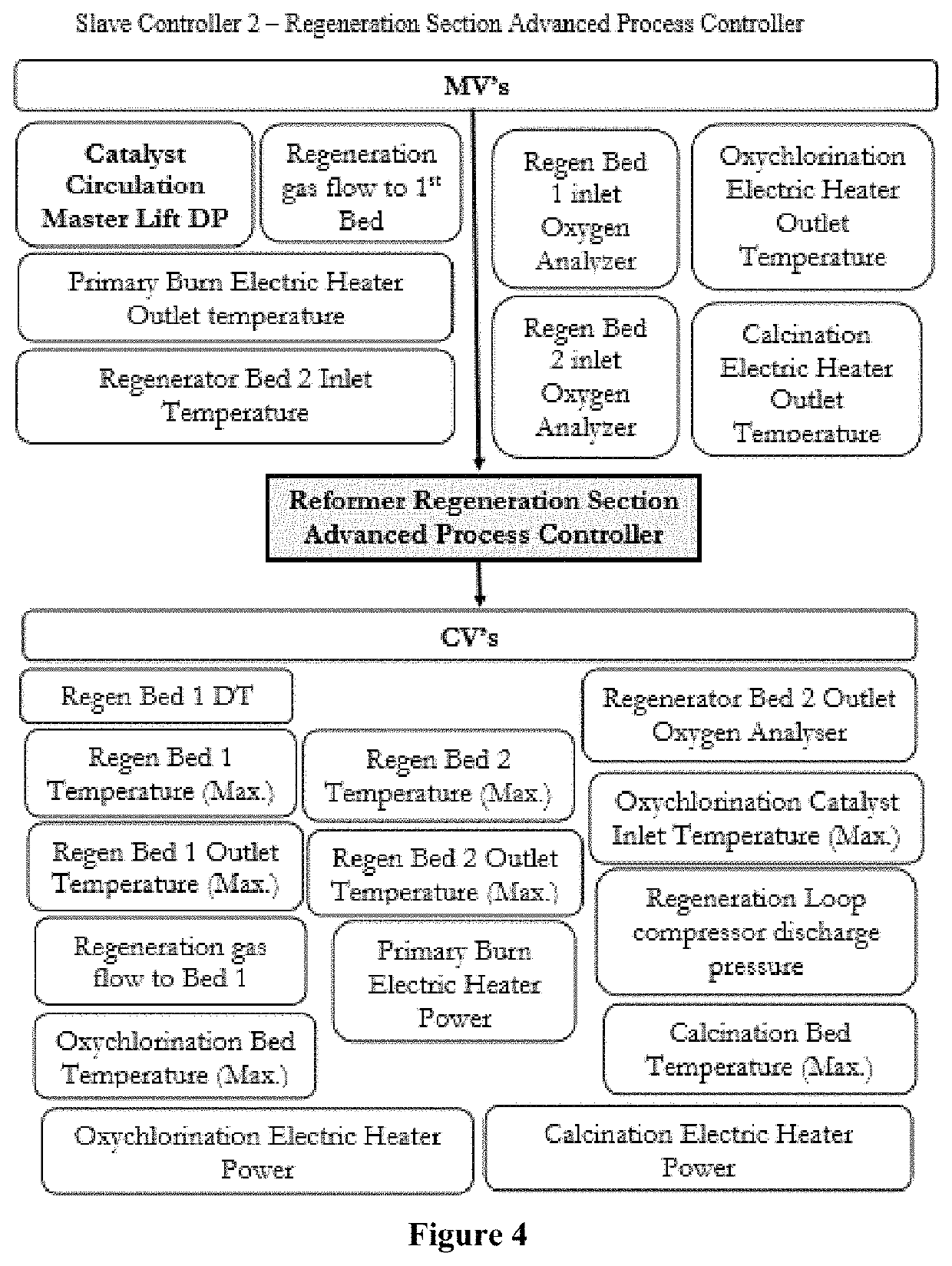

Advanced process control in a continuous catalytic regeneration reformer

ActiveUS11318438B2Change controlProcess control/regulationCatalytic naphtha reformingPtru catalystProcess engineering

The present invention relates to an advanced process control system (APC) for a continuous catalytic regeneration reformer with master-slave configuration to control coke on spent catalyst while maximizing heavy reformate octane barrel using online inferential, both for coke content of spent catalyst and octane of heavy reformate. Further, the present invention relates to provide an APC system for a continuous catalytic regeneration reformer with master-slave configuration, which comprises of a master APC, a reactor APC, and a regenerator APC, wherein, the reactor APC and the regenerator APC are linked to the master APC.

Owner:BHARAT PETROLEUM CORP LTD

Multi-stage reforming process to produce high octane gasoline

ActiveUS8658021B2Improve performanceCatalytic naphtha reformingTreatment with hydrotreatment processesNaphthaGasoline

The present invention relates to a multistage reforming process to produce a high octane product. A naphtha boiling range feedstock is processed in a multi-stage reforming process, in which the process involves at least 1) a penultimate stage for reforming the naphtha feedstock to produce a penultimate effluent 2) a final stage for further reforming at least a portion of the penultimate effluent 3) a regeneration step for the final stage catalyst. The severity of the penultimate stage can be increased during final stage catalyst regeneration in order to maintain the target RON of the reformate product and avoid reactor downtime.

Owner:CHEVROU USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com