Catalytic reforming energy-saving system, catalytic reforming energy-saving method and catalytic reforming reaction system

A catalytic reforming, energy-saving system technology, applied in the direction of naphtha catalytic reforming, reforming operation control/regulation, petroleum industry, etc. Low temperature and other problems, to achieve the effect of lowering temperature, reducing cooling load, and reducing energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

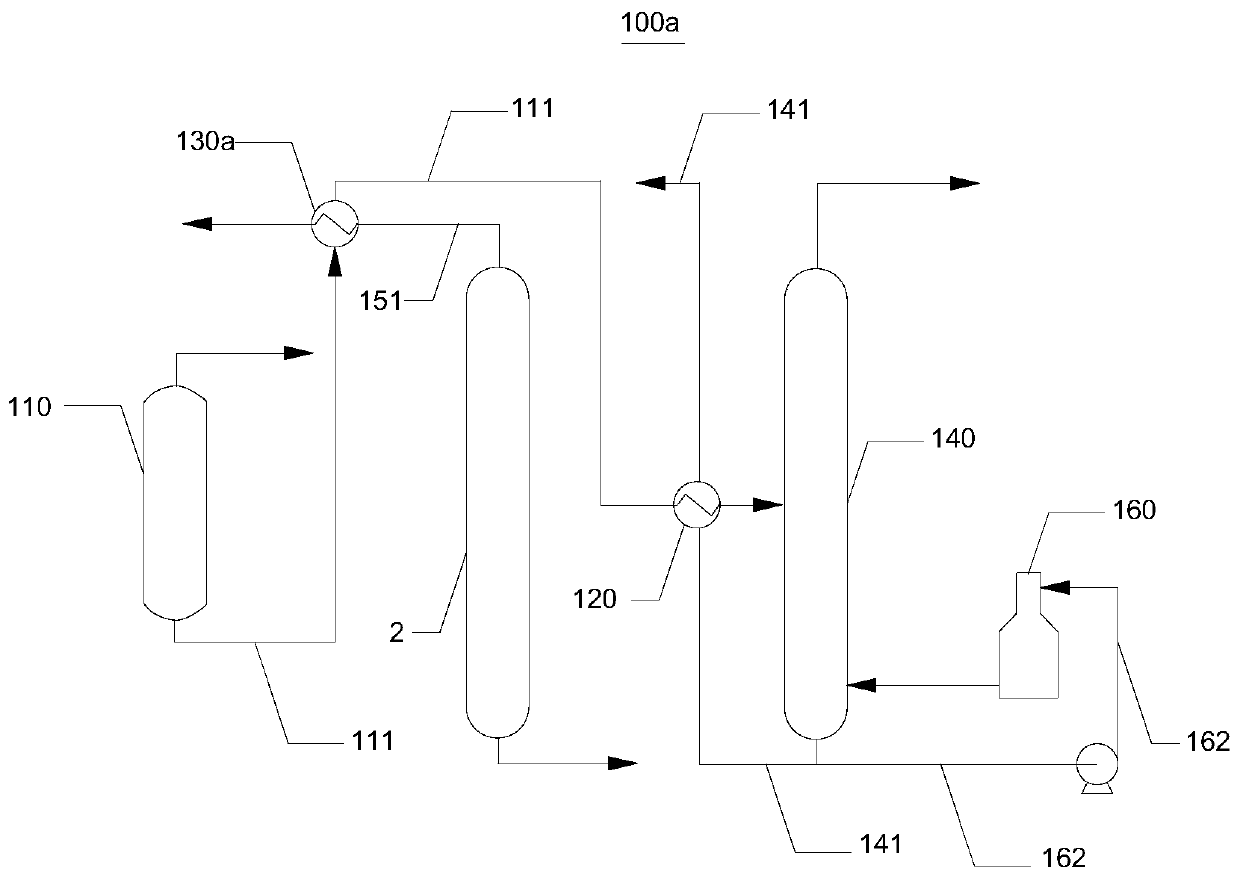

[0036] like figure 1 As shown, the catalytic reforming energy-saving system 100a provided in this embodiment includes a high-pressure absorption tank 110 , a reformed oil stabilization tower 140 and a first heat exchanger 120 .

[0037] Specifically, the high-pressure absorption tank 110 is connected with a bottom liquid output pipe 111, and the reformed oil stabilization tower 140 is connected with a bottom oil output pipe 141, and the bottom oil output pipe 141 communicates with the heat flow channel of the first heat exchanger 120 as a heat source pipeline, The bottom liquid output pipe 111 communicates with the cold flow channel of the first heat exchanger 120 as a cold source pipe, and the bottom liquid output pipe 111 communicates with the feed port of the reformed product oil stabilization tower 140 for transporting the bottom liquid to the reformed product. Oil stabilization tower.

[0038] Most of the gas at the top of the low-pressure gas-liquid separation tank ente...

Embodiment 1-1

[0048] This embodiment is implemented by using the catalytic reforming energy-saving system 100a provided in Embodiment 1 as a reforming energy utilization device.

[0049] Taking the 700,000-ton / year continuous reforming unit of a refinery as an example, the technology and method of energy saving and consumption reduction of this unit are explained. This device adopts the first-generation patented technology of IFP in France, and is aimed at producing high-octane gasoline components, and provides raw materials for aromatics complexes.

[0050] like figure 1 As shown, a kind of catalytic reforming energy-saving method described in this embodiment is specifically:

[0051] The tank bottom liquid (40°C) from the high-pressure absorption tank 110 and the oil gas at the top of the pre-fractionation tower 2 are heat-exchanged to 65°C through the newly added second heat exchanger 130a, and then heat-exchanged to 175°C through the first heat exchanger 120 After entering the reforme...

Embodiment 2

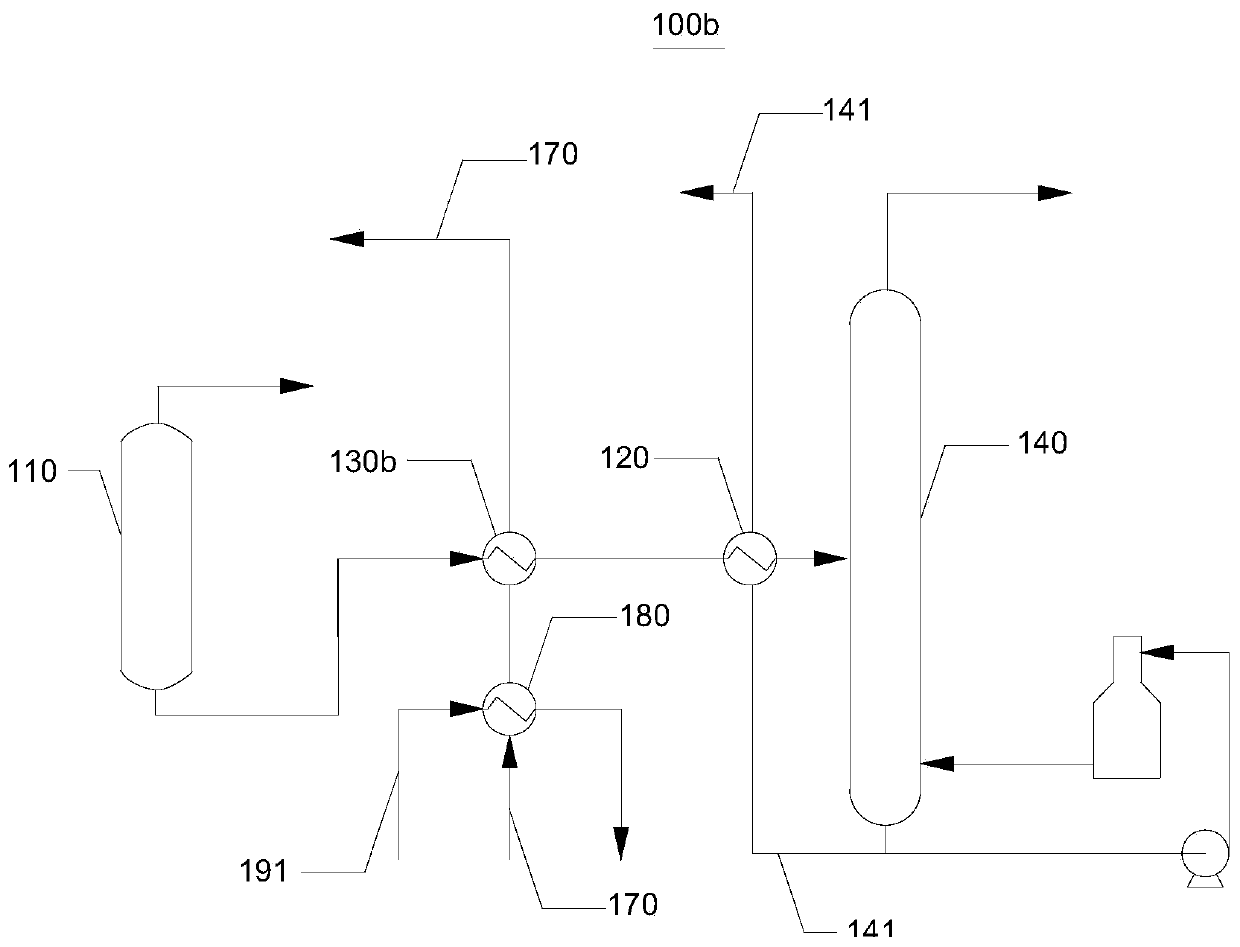

[0053] like figure 2 As shown, the catalytic reforming energy-saving system 100b provided by the embodiment of the present invention has the same realization principle and technical effect as that of Embodiment 1. For a brief description, the details not mentioned in this embodiment can be referred to in Embodiment 1. Corresponding content.

[0054] The catalytic reforming energy-saving system 100b provided in this embodiment includes a second heat exchanger 130b and a reformed product output pipe 170 communicated with the reforming reaction unit of the catalytic reforming reaction system. The reformed product output pipe 170 is used as a heat source pipe to connect with the second The heat flow channel of the second heat exchanger 130a is connected, and the bottom liquid output pipe 111 is connected with the cold flow channel of the second heat exchanger 130b as a cold source pipe.

[0055] The bottom liquid and the reformed product exchange heat, the temperature of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com