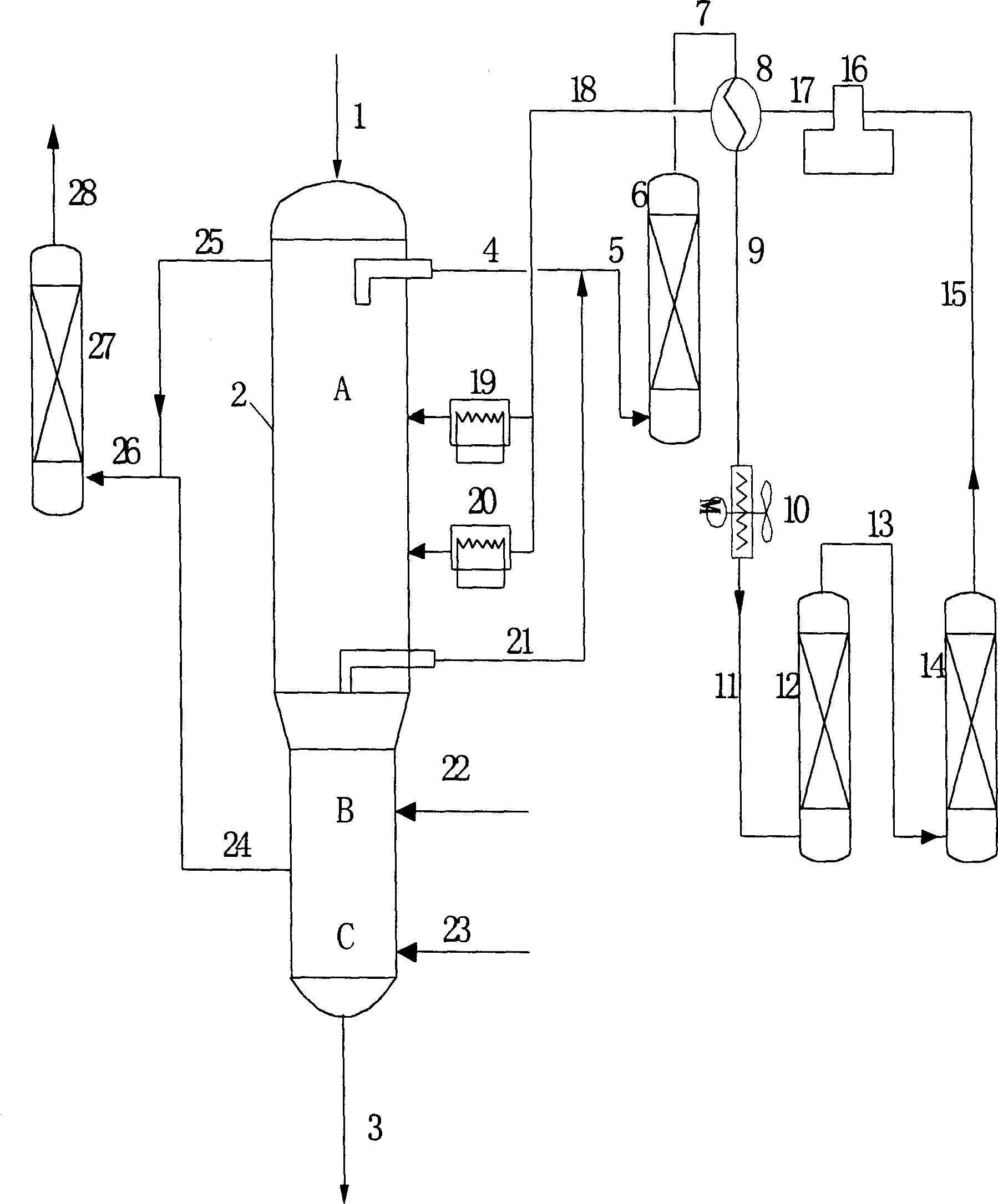

Method for purifying circulated gas regenerated continuously by reforming catalyst

A technology for reforming catalysts and circulating gases, applied in catalyst regeneration/reactivation, chemical instruments and methods, control/regulation of reforming operations, etc. Control, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The chlorine content of the charred regenerated gas and the dechlorinated gas was 1235 ppm. The gas is at a temperature of 400°C, a total pressure of 1.0MPa, and a volumetric space velocity of 1000h -1 Contact with the dechlorination agent in the dechlorination tank under certain conditions, and the gas after dechlorination is dried. The chlorine content of the purified gas is <1ppm.

Embodiment 2

[0029] The chlorine content of the charred regenerated gas and the dechlorinated gas was 4296ppm. The gas is at a temperature of 300°C, a total pressure of 1.0MPa, and a volumetric space velocity of 500h -1 Contact with the dechlorination agent in the dechlorination tank under certain conditions, and the gas after dechlorination is dried. The chlorine content of the purified gas is <1ppm.

Embodiment 3

[0031] The chlorine content of the gas after charring regeneration and the gas after dechlorination is 968ppm, and the water content is 5500 ppm. The gas is at a temperature of 300°C, a total pressure of 1.0MPa, and a volumetric space velocity of 500h -1 Contact with the dechlorination agent in the dechlorination tank under certain conditions, and the gas after dechlorination is dried. The chlorine content of the purified gas is <1ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com