Method for preparation of aviation kerosene and diesel oil from biomass derivative

A technology for aviation kerosene and biomass, which is applied in the petroleum industry, processing hydrocarbon oil, and liquid carbon-containing fuels, etc., and can solve the problems of hydrogenation or hydrodeoxygenation catalyst poisoning, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

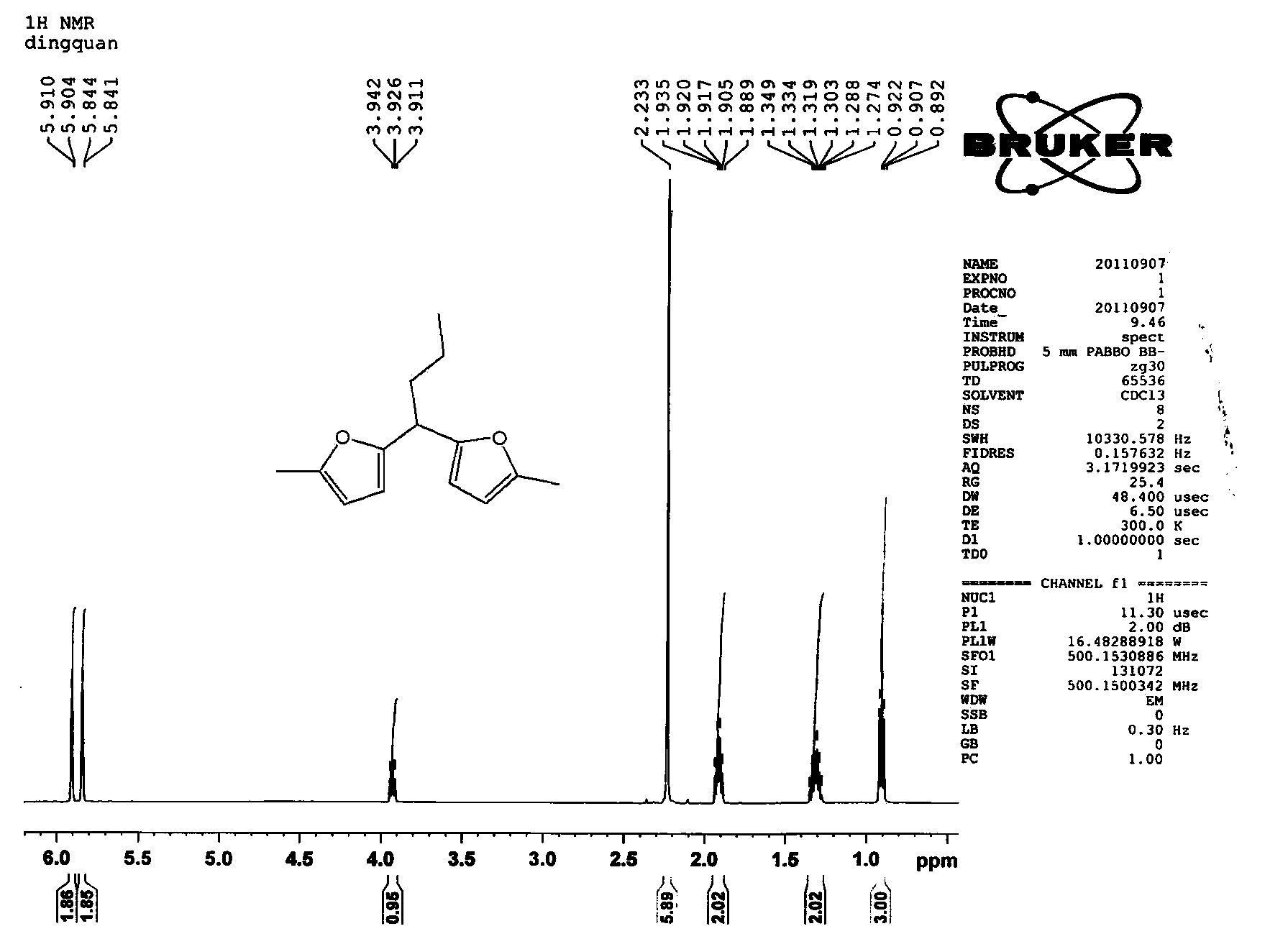

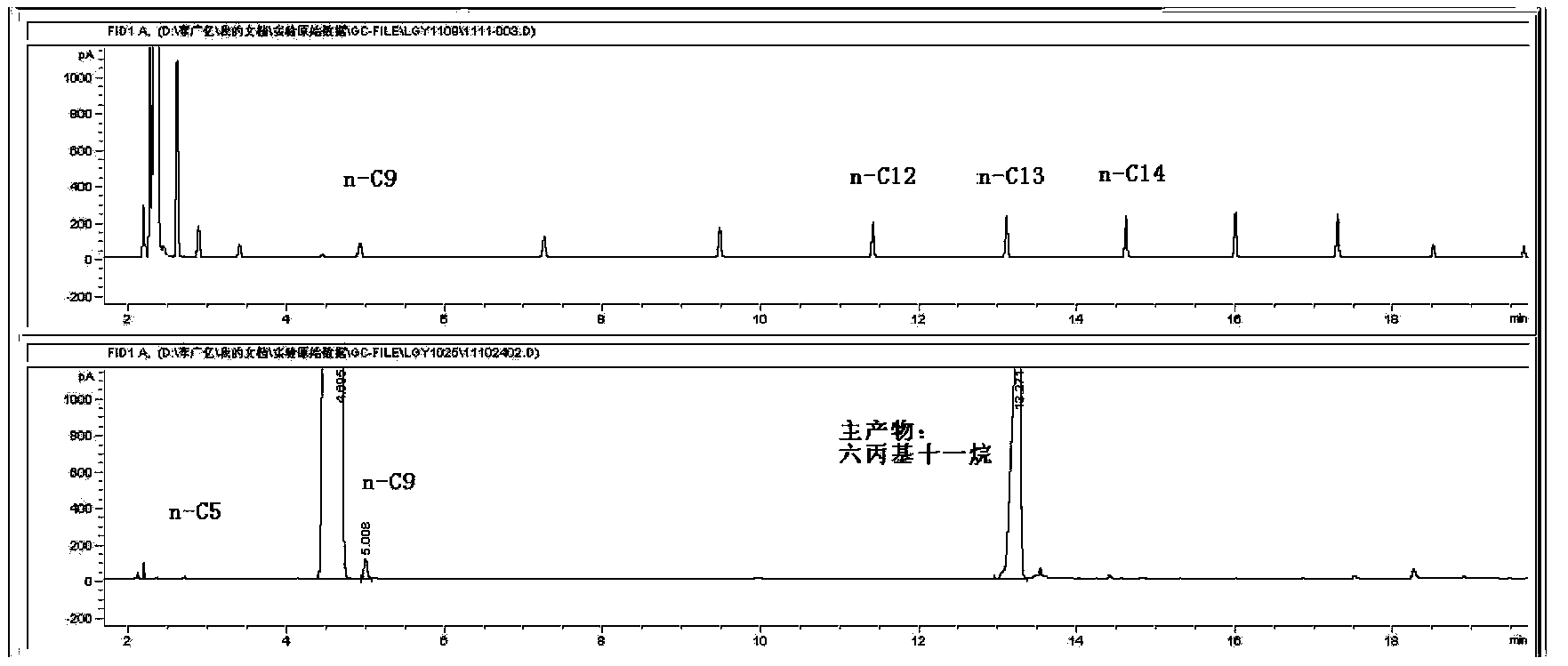

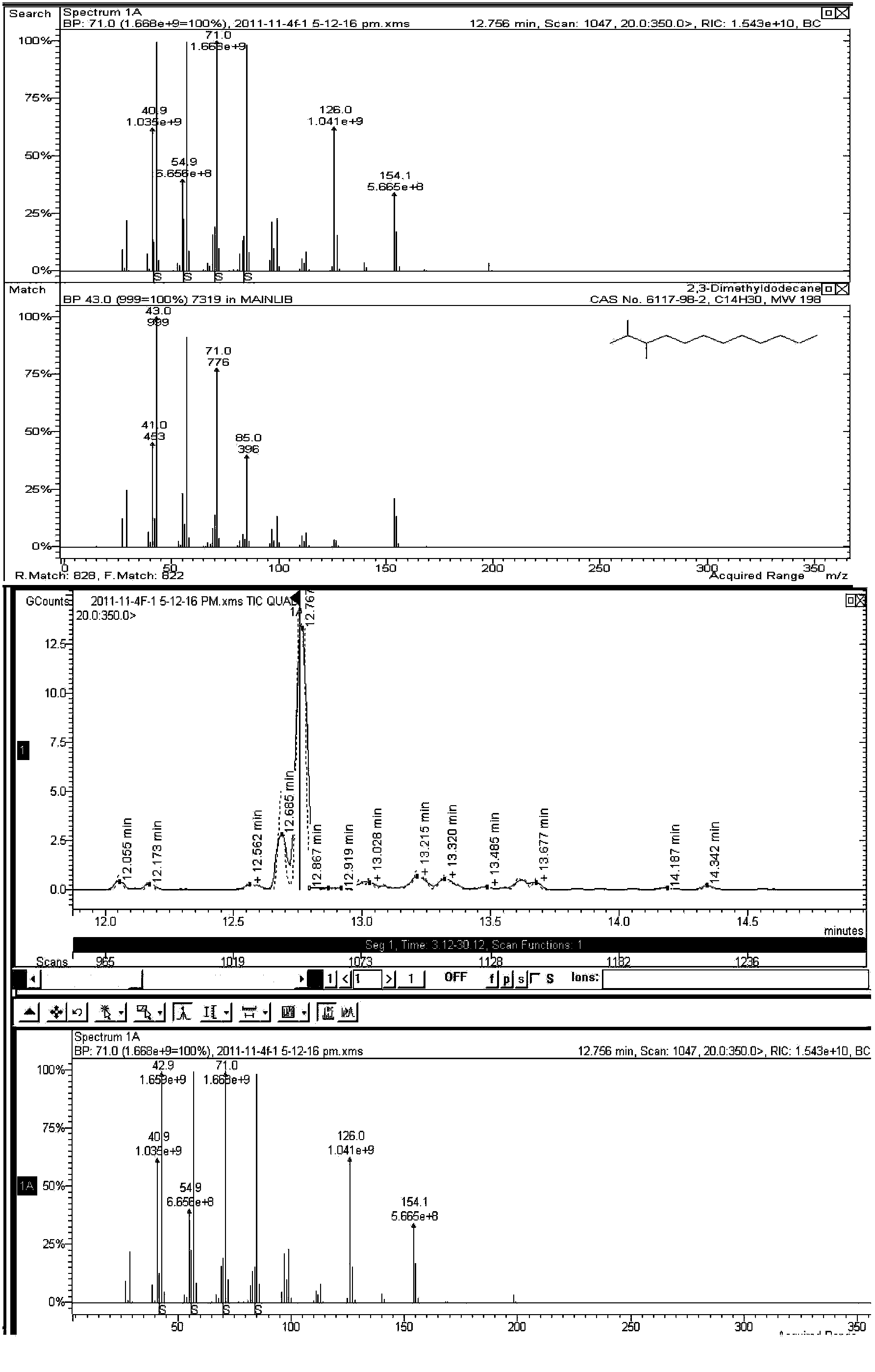

Image

Examples

Embodiment

[0032] 1. Catalyst preparation:

[0033] 1) Preparation of solid acid catalyst: Nafion and Amberlyst resins are commercial catalyst products purchased directly.

[0034] The activated carbon used in the present invention is pretreated by immersing in nitric acid with a mass concentration of 20-50% at 80° C. for 24 hours. Mix activated carbon (AC) or mesoporous carbon (MC) with concentrated sulfuric acid (95%) at a mass ratio of 1:15, raise the temperature to 250°C under nitrogen protection, keep it for 24h, filter it, and wash it with 80°C hot water several times, then washed with deionized water until neutral, and dried overnight at 120°C. Zirconium phosphate (ZrP) catalyst is mixed with 1mol / L zirconium oxychloride and ammonium dihydrogen phosphate aqueous solution at a volume ratio of 2:1, and the obtained precipitate is washed and filtered repeatedly, dried at 120°C for 10h, and then dried at 400°C Under roasting 4h. Sulfonated alumina is γ-Al 2 o 3 Mix with 2.5mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com