Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

652 results about "Aviation kerosene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aviation kerosene, also known as QAV-1, is the fuel used by airplanes and helicopters equipped with turbine engines, such as pure jet, turboprops, or turbofans.

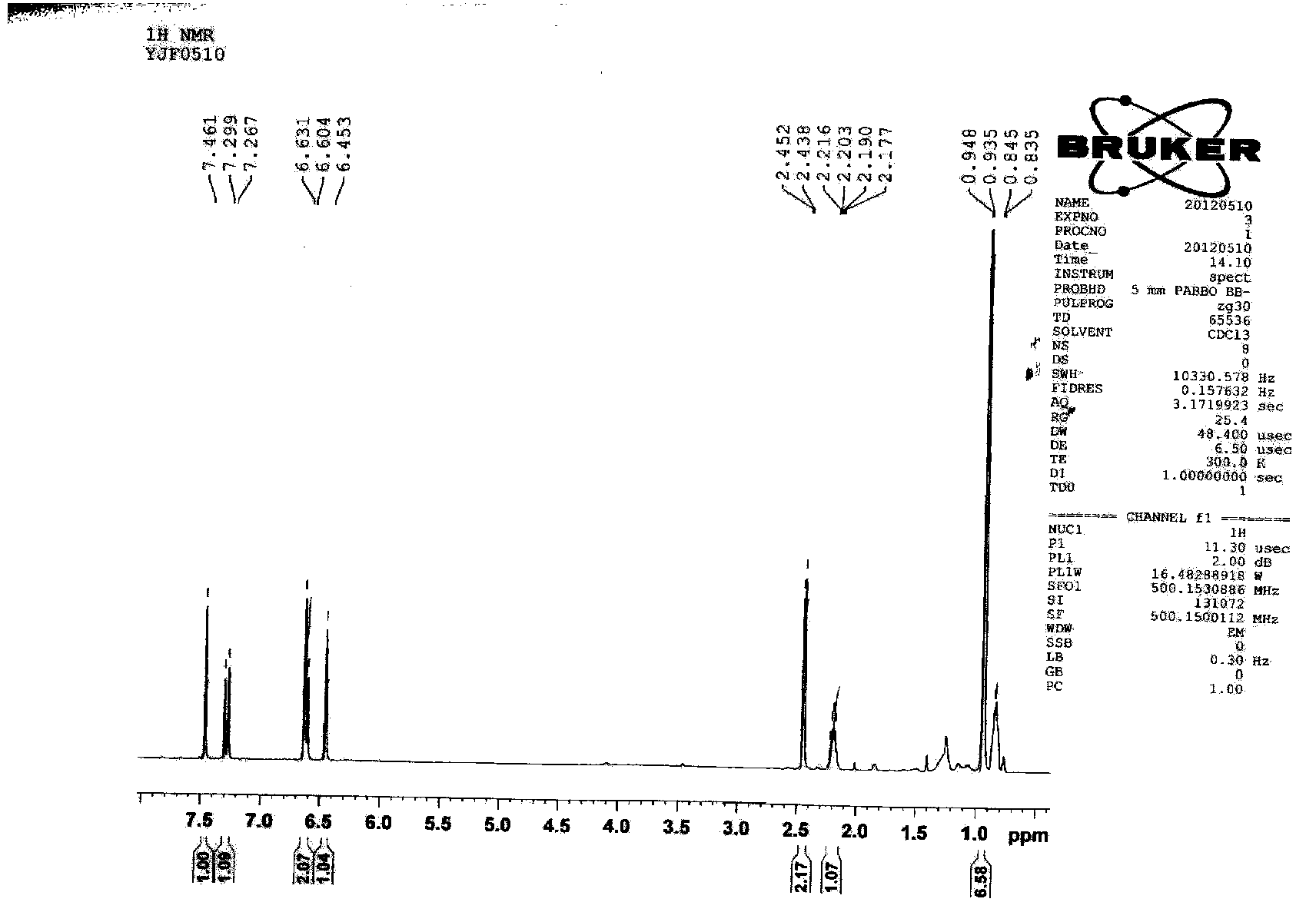

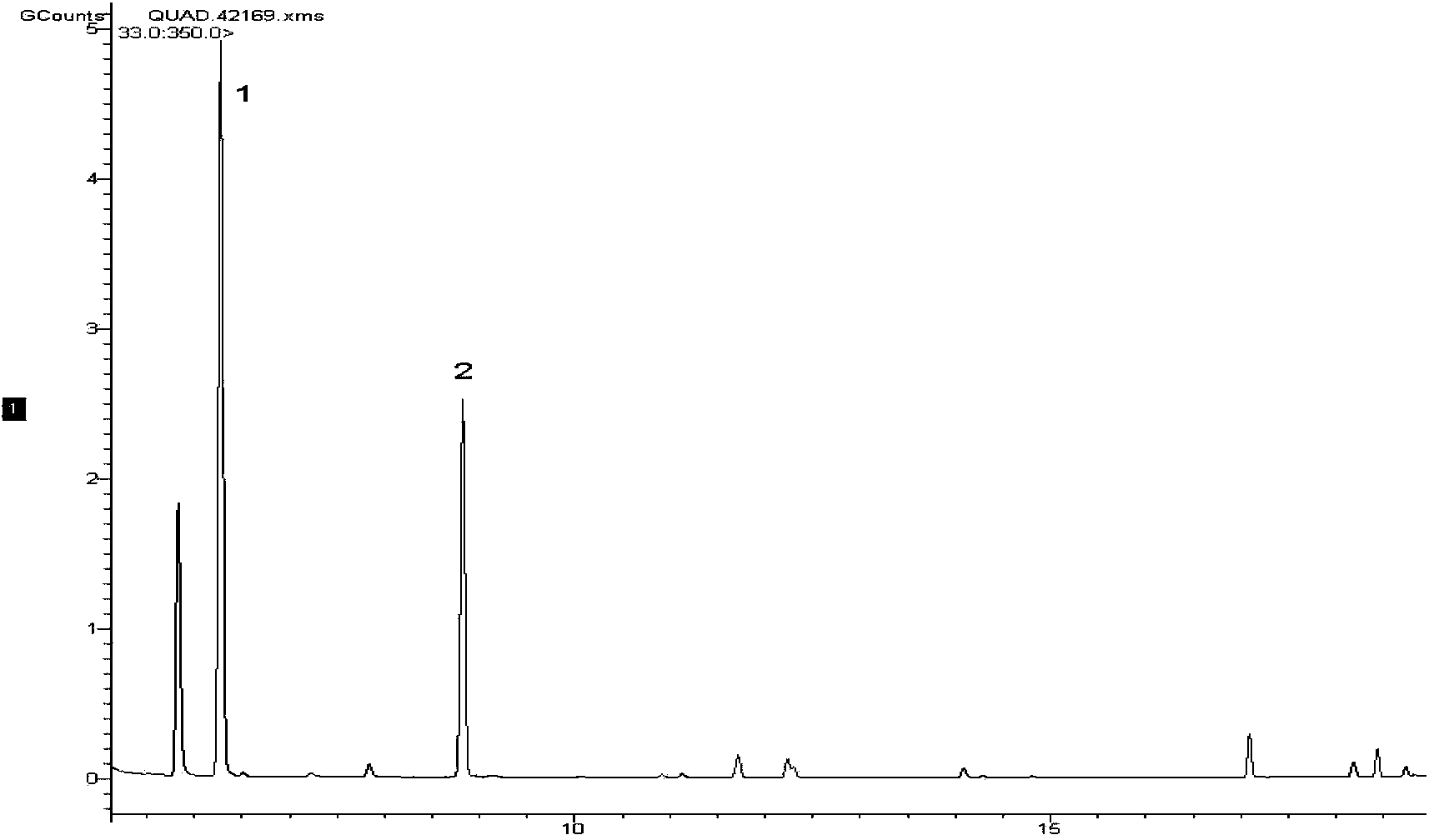

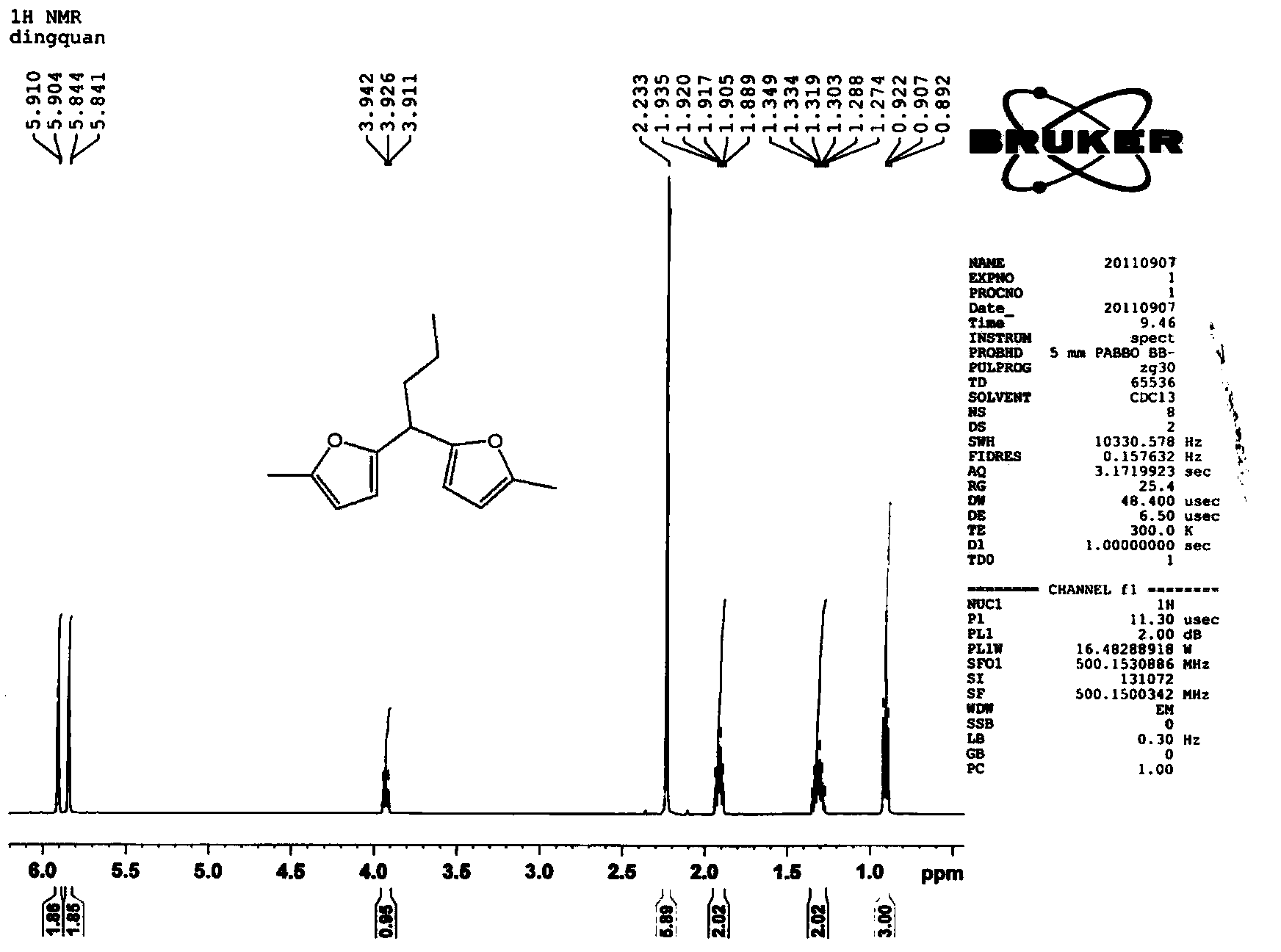

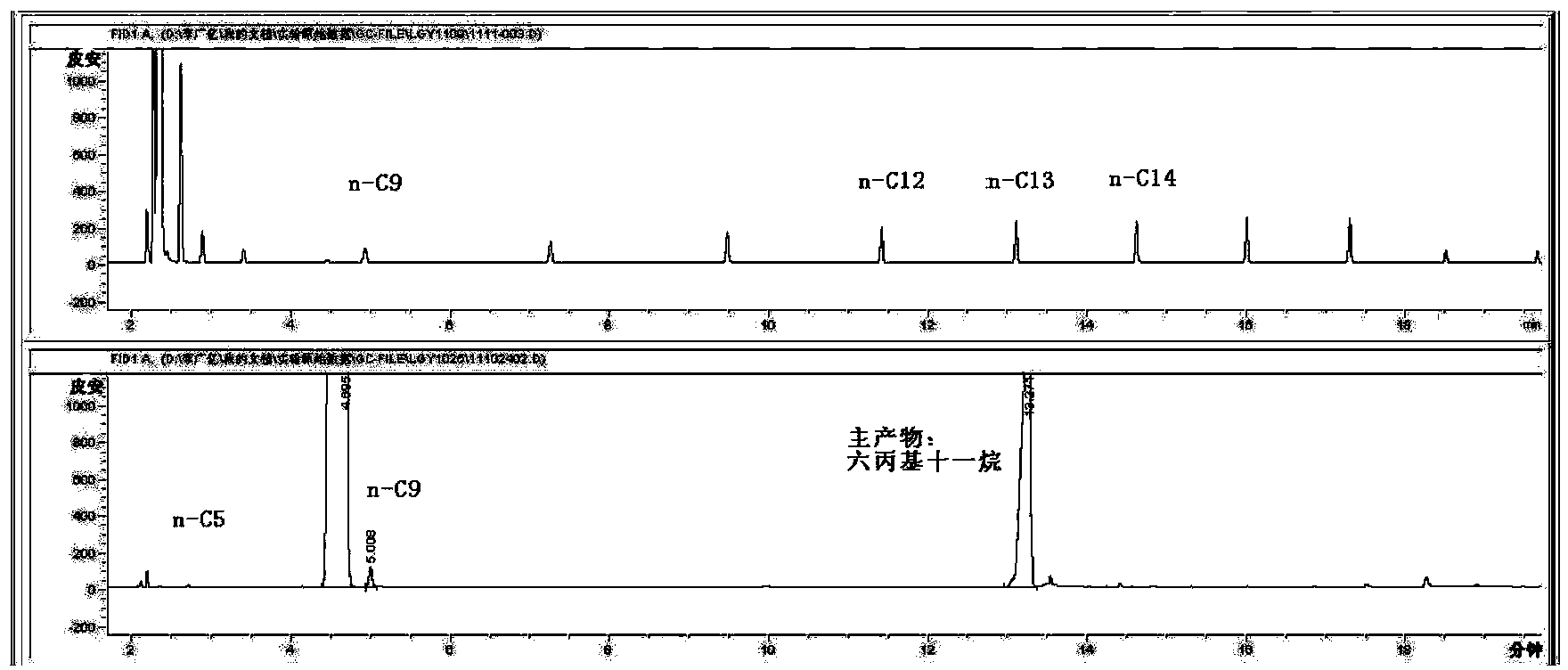

Preparation method of aviation kerosene or diesel

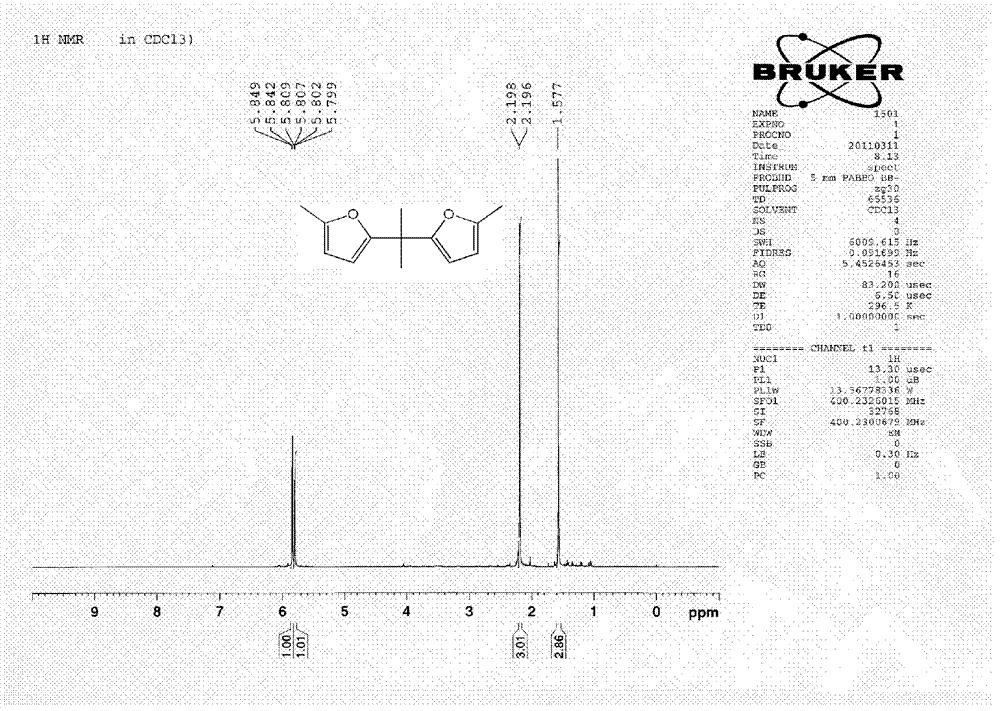

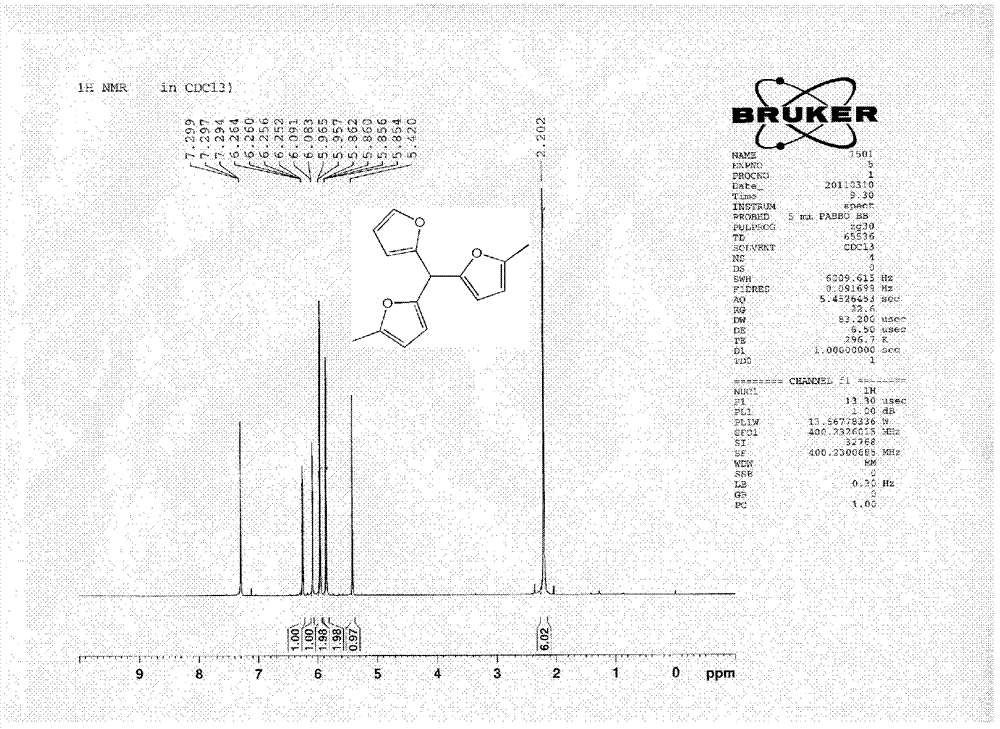

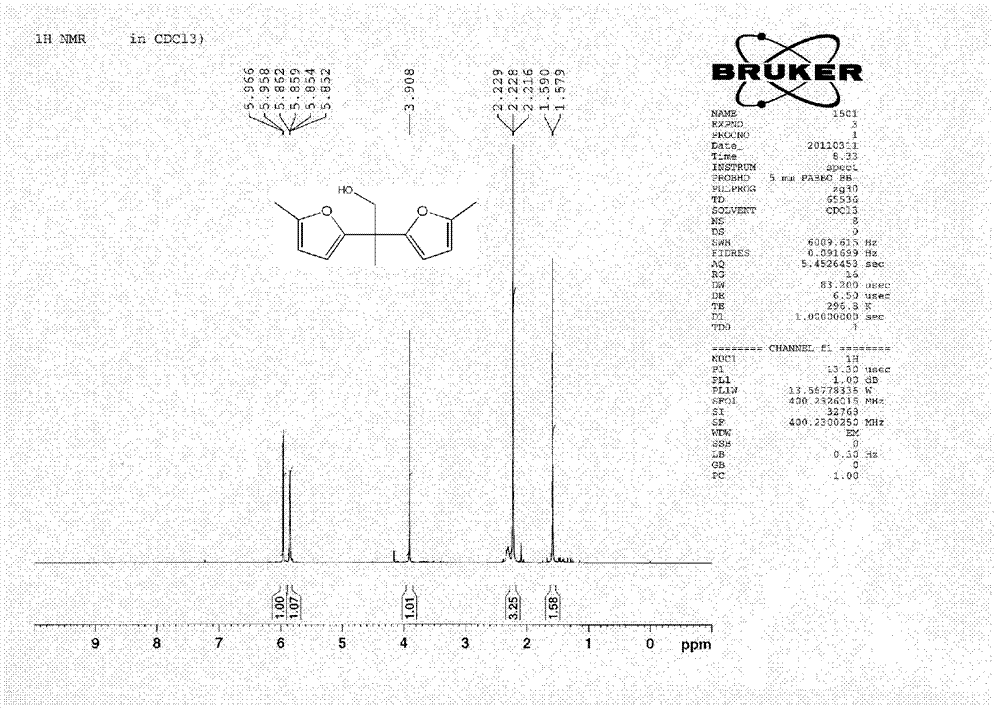

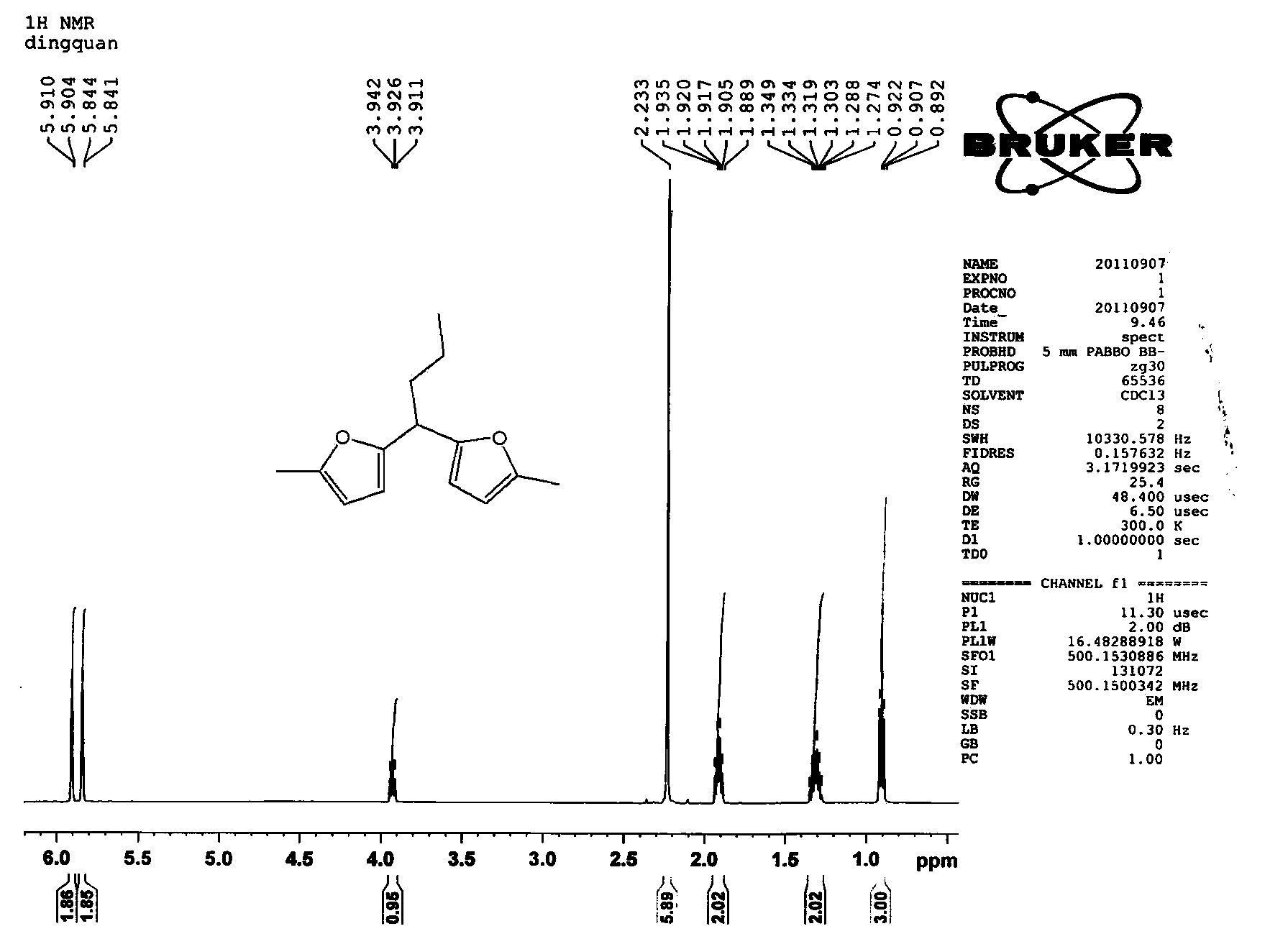

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

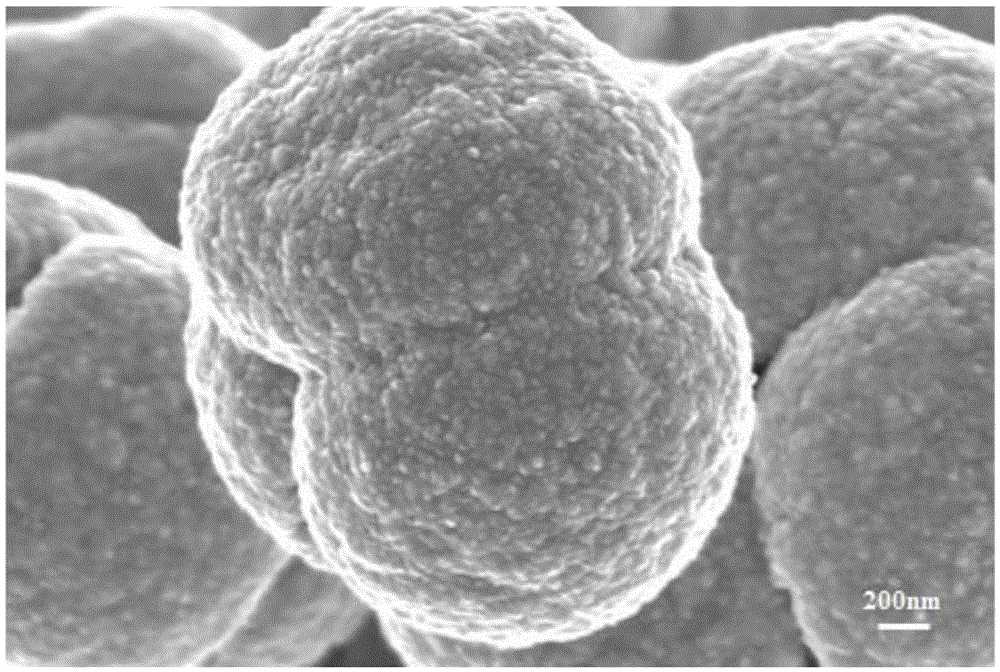

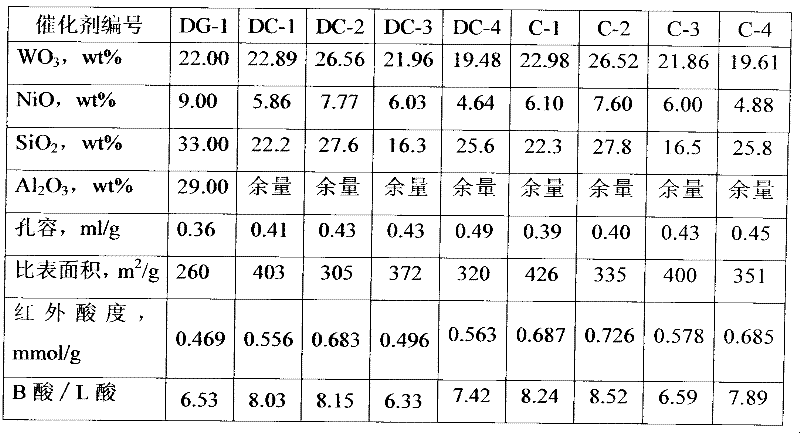

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing aviation kerosene from furyl oxygen-containing organic compounds by hydrogenation deoxidation

ActiveCN104119943AReduce energy consumptionSimple operation processMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneFuran

The invention relates to a new method for preparing hydrocarbons in the scope of aviation kerosene from C8-C16 furyl oxygen-containing organic compounds as raw materials by hydrogenation deoxidation reaction, wherein the C8-C16 furyl oxygen-containing organic compounds are obtained by C-C coupling of lignocellulose based platform chemical compounds; low temperature direct hydrogenation deoxidation under the condition of no solvent of the furyl oxygen-containing organic compounds can be realized by use of a metal-solid acid dual-functional catalyst to obtain a series of low freezing point branched alkanes having the chain in the length range of the aviation kerosene in high yield. The catalyst is composed of two parts of an active metal A and an acid vector X. The catalyst related in the method ahs the characteristics of being in no need of a solvent, simple in operation process, mild in reaction conditions, good in aviation kerosene (or diesel) selectivity, and the like, and is an ideal hydrogenation deoxidation catalyst for preparing liquid fuels from the furyl oxygen-containing organic compounds by the hydrogenation deoxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

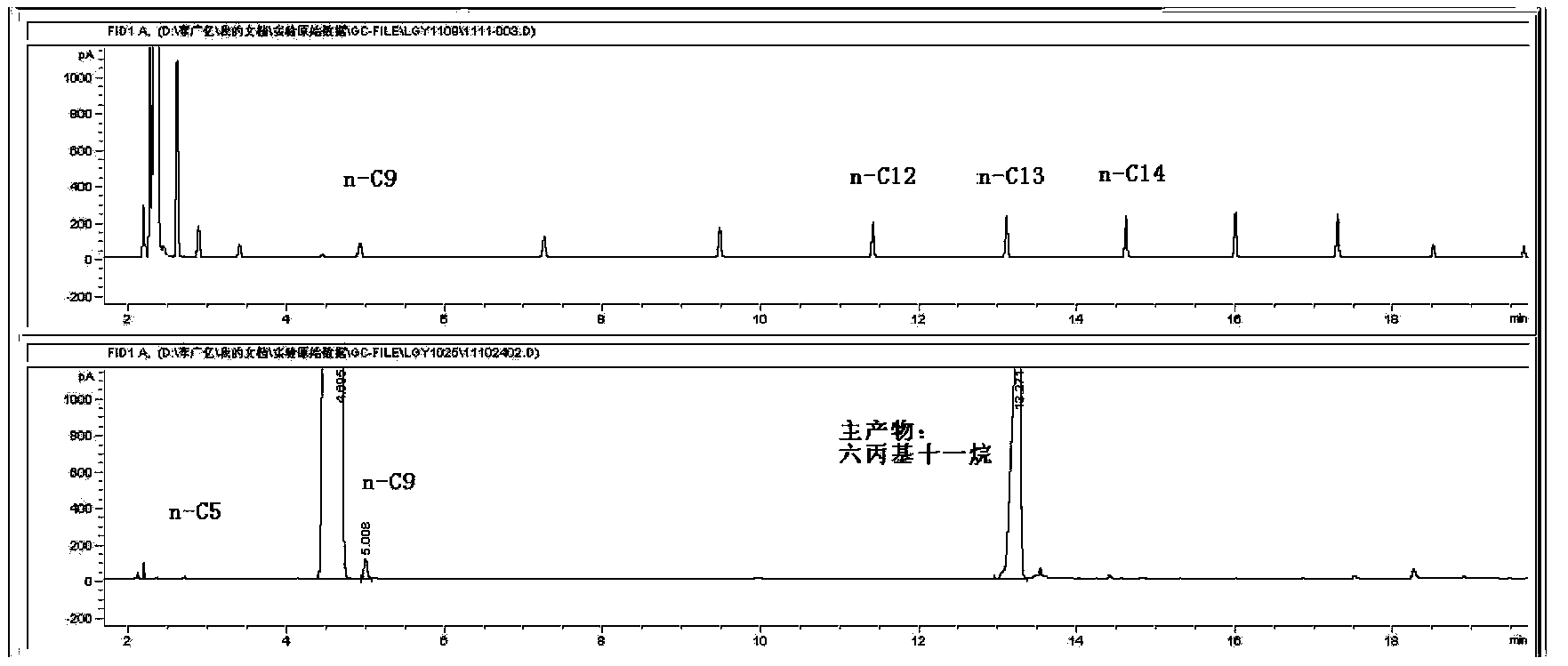

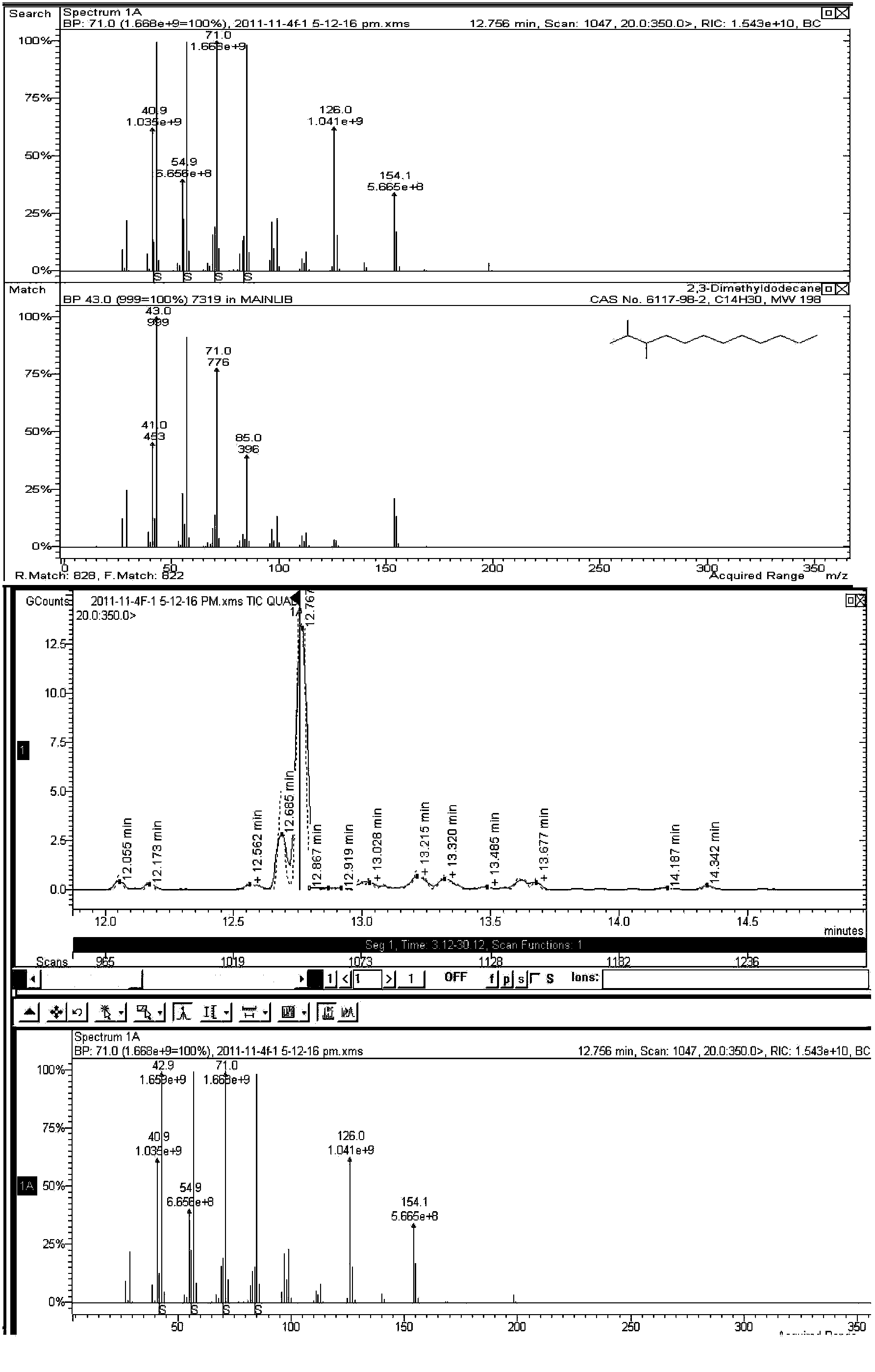

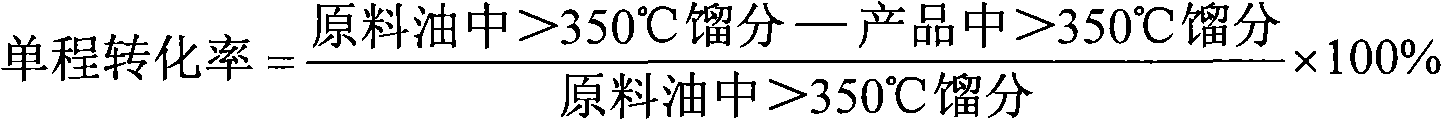

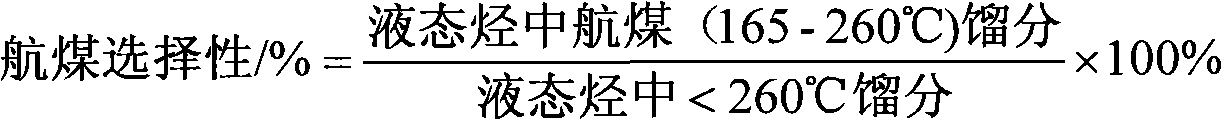

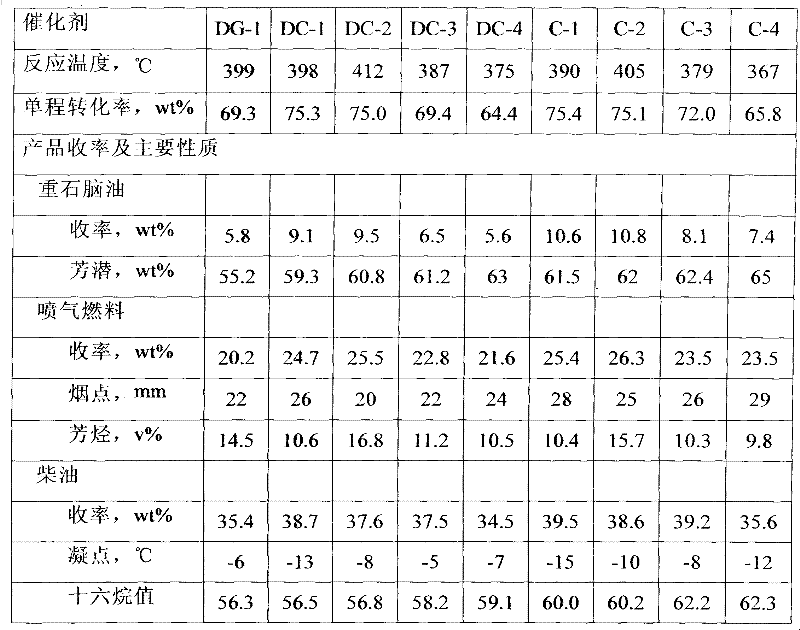

Hydrocracking method for selective increasing of aviation kerosene yield

ActiveCN103013559AGuaranteed selectivityQuality improvementTreatment with hydrotreatment processesHydrogenSmoke point

The invention discloses a hydrocracking method for selective increasing of an aviation kerosene yield. The hydrocracking method comprises that raw oil and hydrogen are mixed and then orderly undergo a hydrofinishing reaction and a hydrocracking reaction; a reaction effluent is cooled and is subjected to separation so that a heavy diesel fraction is obtained; and the heavy diesel fraction having the content of 10 to 100% and a temperature of 320 to 370 DEG C is fed back to a raw material tank and then undergoes a reaction sequentially, wherein the heavy diesel fraction has low aromatic hydrocarbon content and naphthenic hydrocarbon content and is an appropriate fraction for selective increasing of aviation kerosene yield. The hydrocracking method realizes high selectivity of an aviation kerosene fraction. The recycle heavy diesel fraction is fed into the raw material tank and undergoes a hydrofinishing reaction in a hydrofinishing reactor and a hydrocracking reaction in a hydrocracking reactor so that an aromatic hydrocarbon further undergoes a hydrogenation saturation reaction. Therefore, the hydrocracking method is conducive to improvement of a smoke point of aviation kerosene and reduction of aromatic hydrocarbon content of aviation kerosene.

Owner:CHINA PETROLEUM & CHEM CORP +1

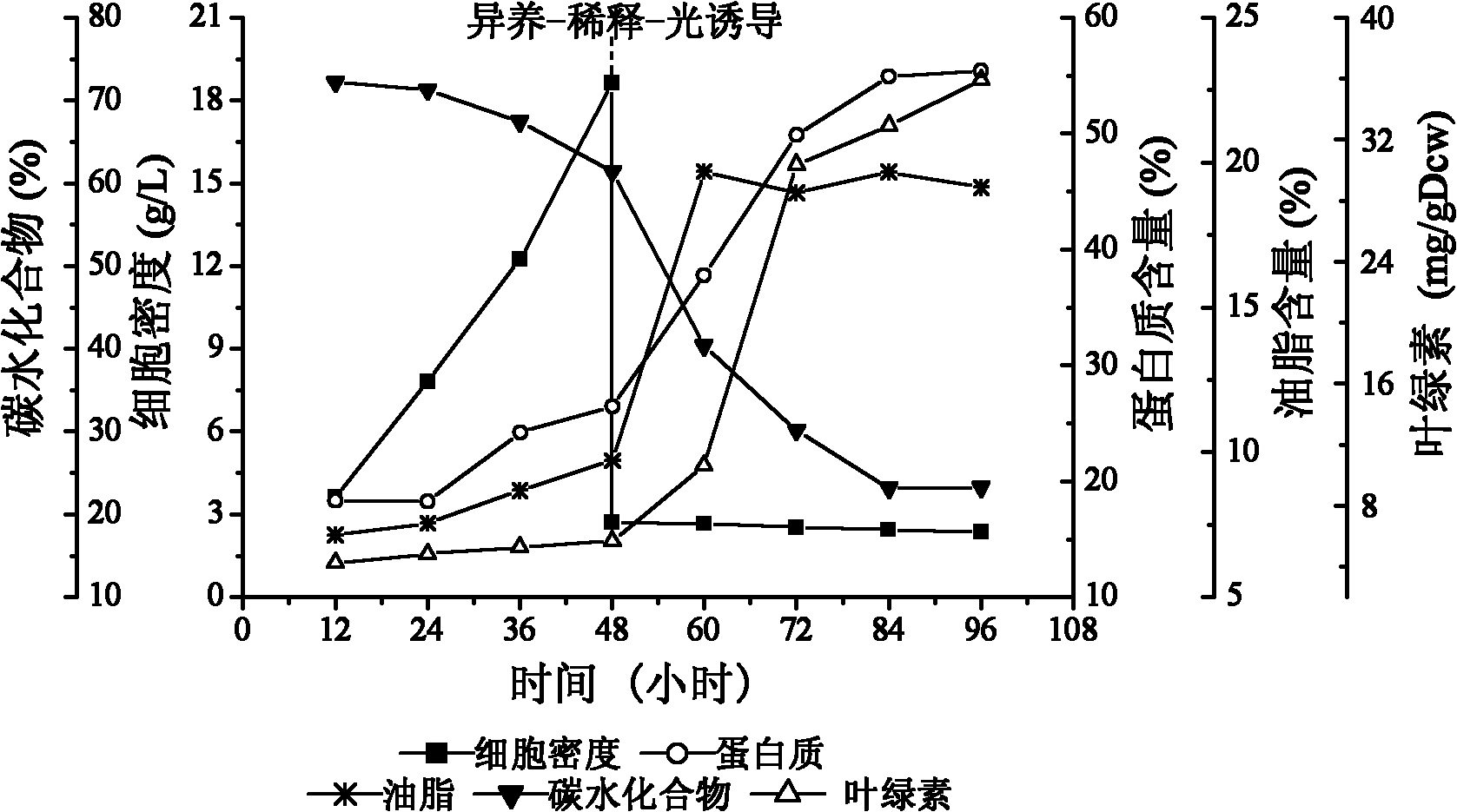

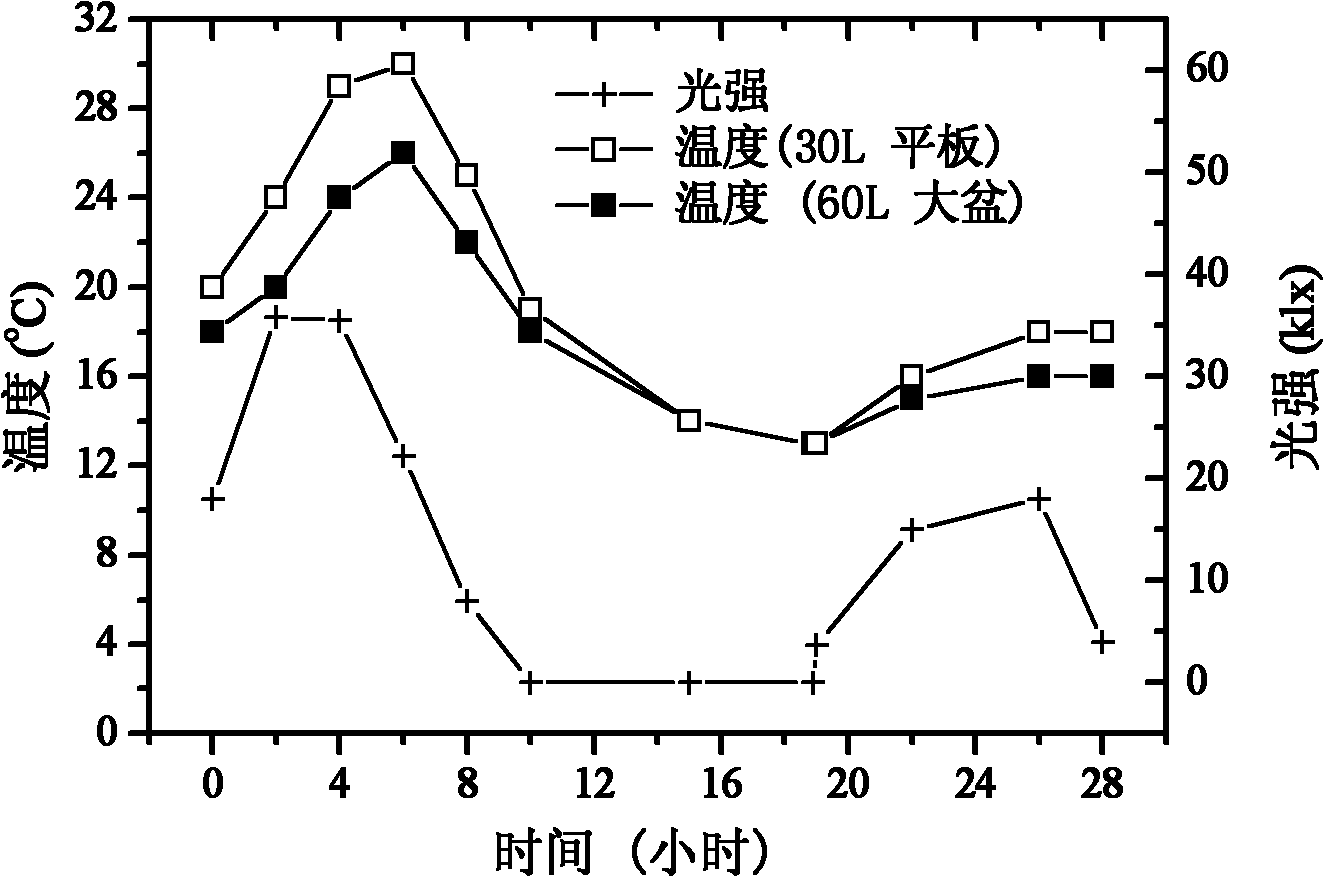

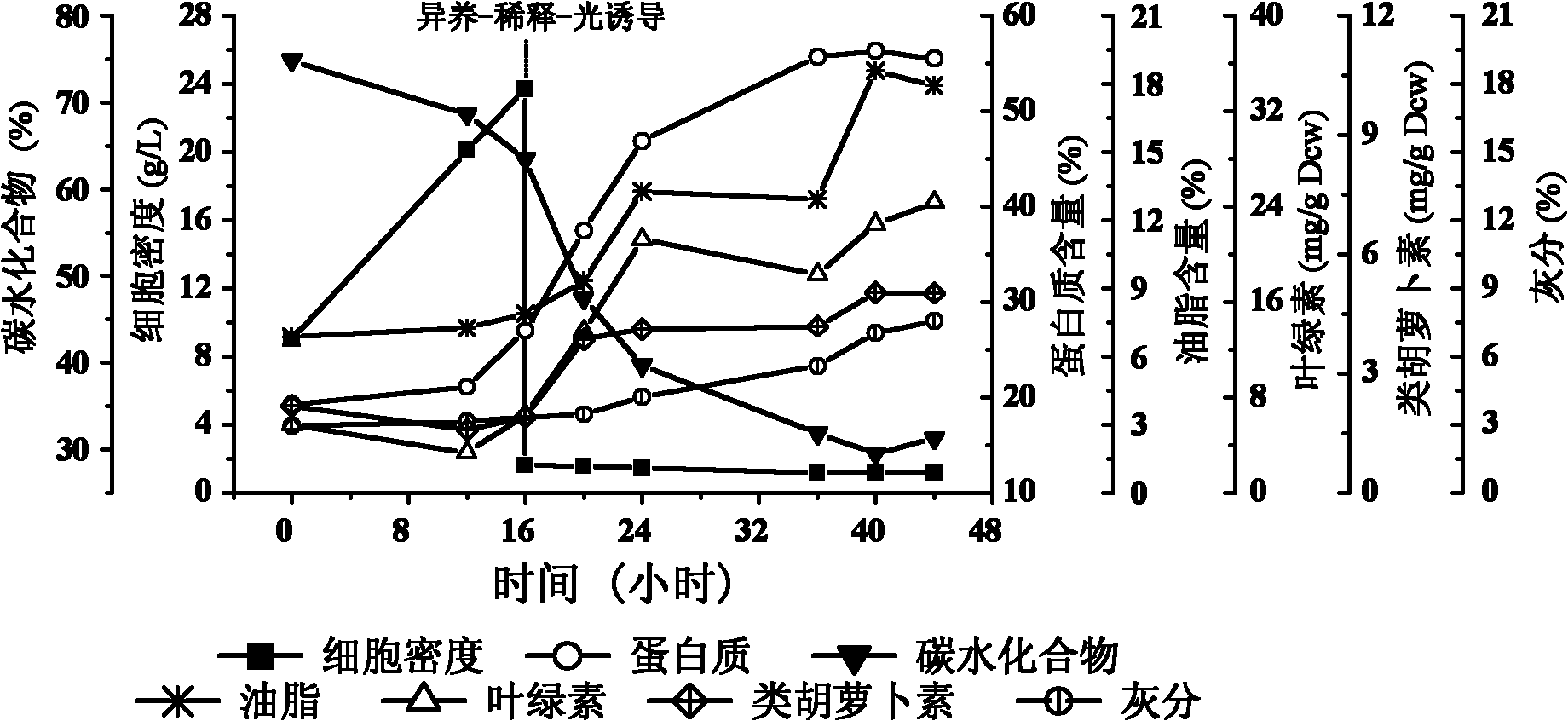

Method for rapidly accumulating micro-algae intracellular grease

InactiveCN102021208APromote rapid accumulationUnicellular algaeMicroorganism based processesIntracellularKerosene

The invention relates to a method for rapidly accumulating micro-algae intracellular grease, which comprises steps of heterotrophic culturing, dilution, photo-inductive culturing, micro-algae collection and grease extraction and the like. By using the method, advantages of rapid micro-algae intracellular grease accumulation in the photo-inductive stage are brought into full play so as to provide significant technical means for solving the problem of exceeded cost caused by insufficient raw materials in process of preparing biological fuels (such as diesel oil, aviation kerosene and the like) in a large scale.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Ultra-deep absorption desulfurizer for light oil and application thereof

InactiveCN101940908AGood dispersionEfficient removalOther chemical processesHydrocarbon oils refiningNaphthaAdhesive

The invention relates to an ultra-deep absorption desulfurizer for light oil and an application thereof. The desulfurizer comprises 10.0-80.0% of zinc oxide, 5.0-75.0% of VIII metal oxide, 1.0-50.0% of adsorption assistant, 1.0-10.0% of pore-expanding agent and 10.0-35.0% of adhesive. The method for making the desulfurizer comprises the following steps: uniformly mixing, pressing to obtain sheets or squeezing to obtain strips, drying and roasting. The absorption desulfurizer does not use noble metals, thereby having the advantage of low price; the invention adopts mixed roasting technique, thereby having the advantages of simple preparation method and easy operation; the desulfurizer has the advantages of high desulfurization activity and favorable regeneration effect, and can be used for processing low-sulfur light oil; the content of sulfides in the processed light oil can be reduced to below 0.5 ppm; and the desulfurizer is suitable to be used in the low-temperature fine desulfurization process of naphtha, gasoline, diesel, aviation kerosene and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization

ActiveCN102504866AHigh activityConcentration effective controlBiofuelsEfficient propulsion technologiesOil and greaseVegetable oil

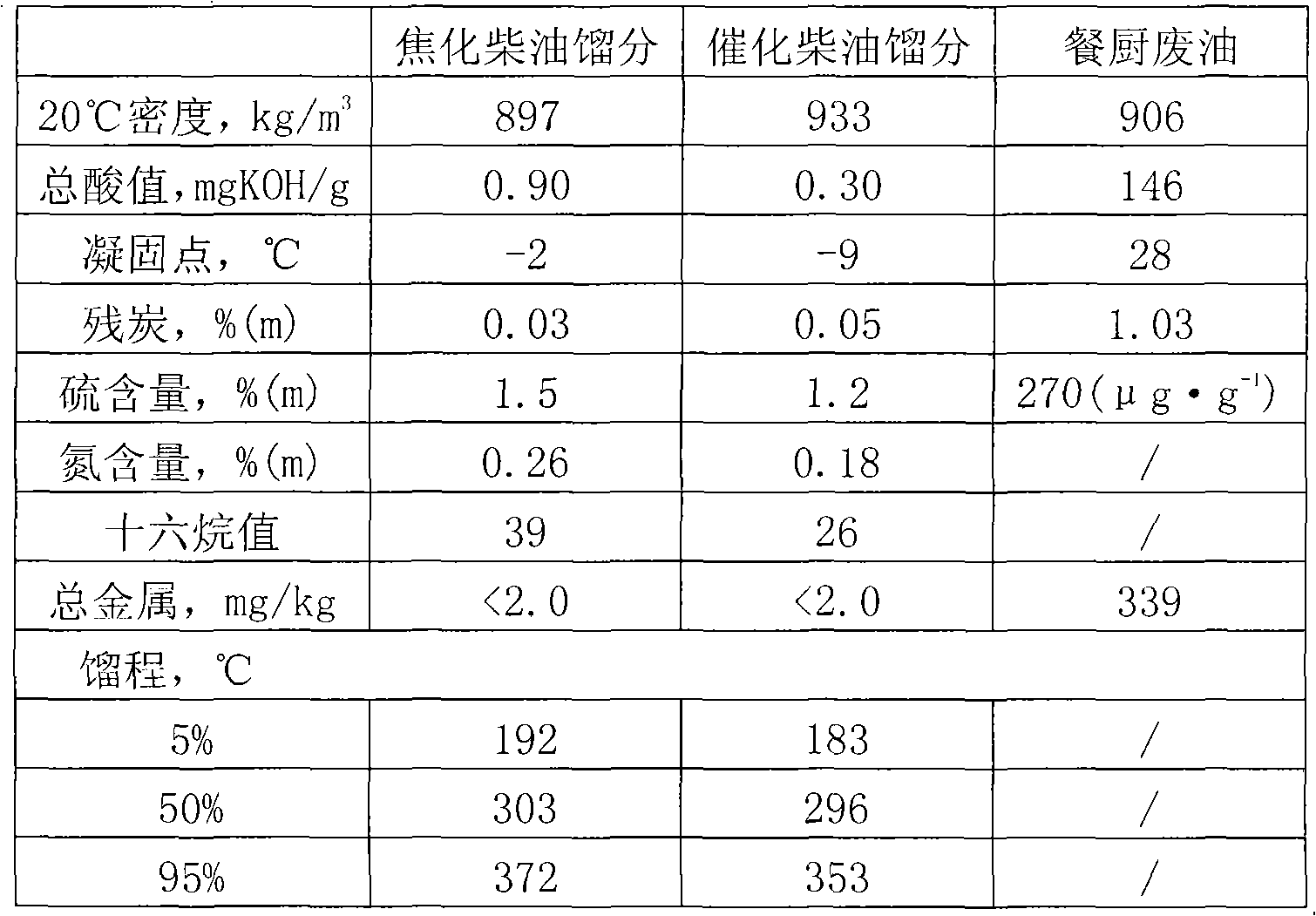

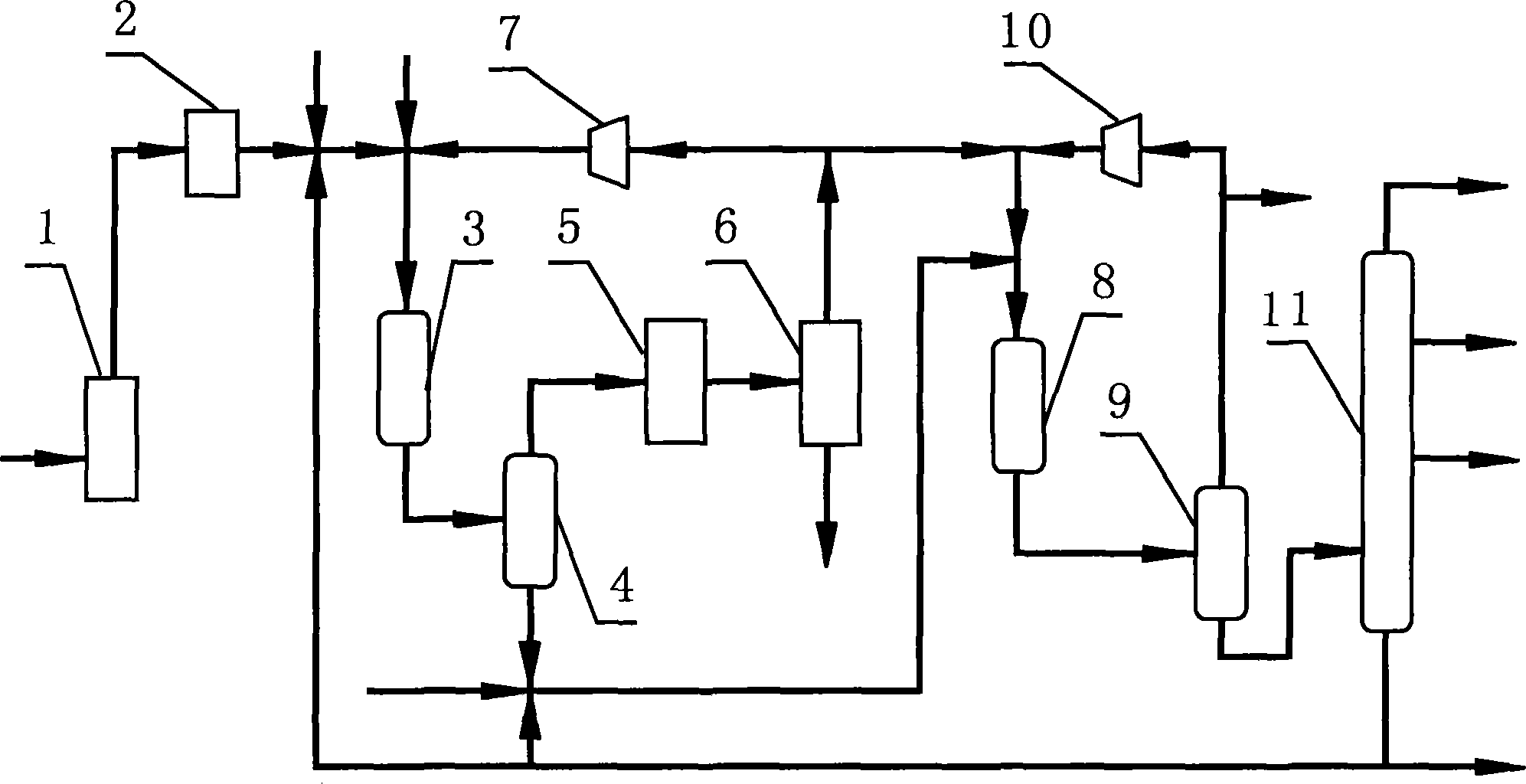

The invention relates to a method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization. The method comprises the steps as follows: pretreatment of waste edible oil, a first stage of hydrogenization process, a second stage of hydrogenization process, and a product fractionation process. The method adopts the waste edible oil and the mineral diesel oil as raw materials for preparing high-quality biodiesel and biological aviation kerosene components which have low polycyclic aromatic hydrocarbon contents, high cetane values, low sulfur contents and low nitrogen contents, effectively solves the problems of blockage of a catalyst bed caused by the settlement of metal and gelatine in the animal and vegetable hydrogenization process, influence on the activity of catalyst from H2O, CO2 and CO produced in reaction, sulfur supplement of a hydrogenization system, and influence on the service life of the catalyst caused by centralized release of reaction heat, can realize the continuous hydrogenization and industrial production of materials containing animal and vegetable oils, and has practical significance.

Owner:海南环宇新能源有限公司

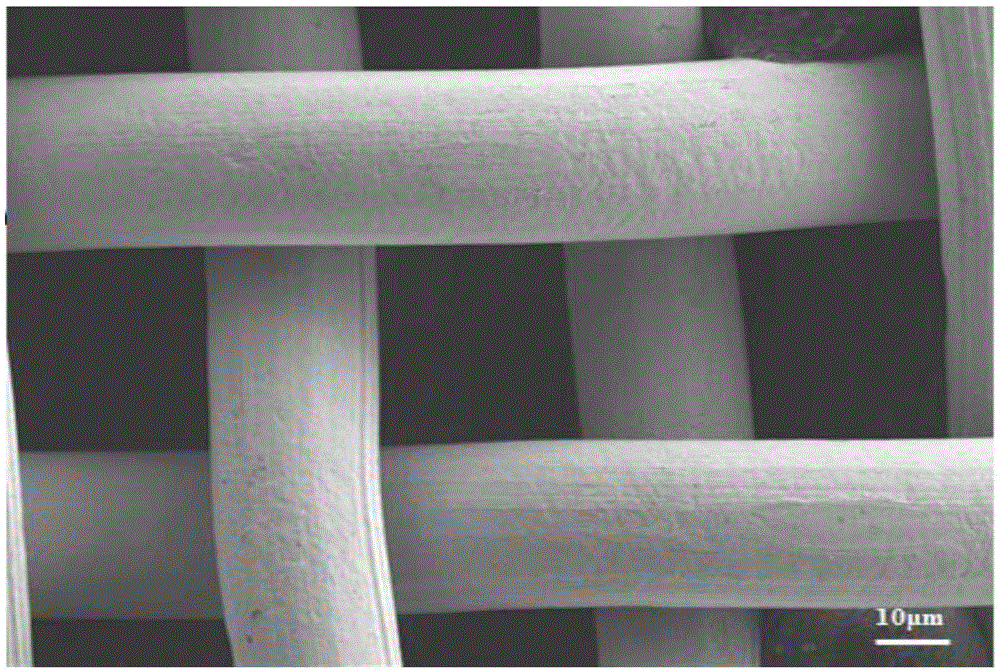

Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

ActiveCN105536296AImprove separation efficiencyEfficient separationNon-miscible liquid separationKeroseneCopper sulfate

The invention discloses a super-hydrophobic / super-oleophilicity copper wire mesh for oil and water separation and a preparation method and application thereof. The preparation method comprises the steps that firstly, the copper wire mesh is ultrasonically cleaned through diluted hydrochloric acid, absolute ethyl alcohol and deionized water respectively and dried through nitrogen; chemical deposition liquid of copper sulfate and a sodium thiosulfate solution is prepared; the cleaned copper wire mesh is placed into the chemical deposition liquid for a deposition reaction; the copper wire mesh is taken out and cleaned through the deionized water and dried in the air; the dried copper wire mesh is placed in a solution of a curing agent and polydimethylsiloxane with hydroxyl sealed end, and the copper wire mesh is taken out and heated. No expensive fluorine-containing substance is needed, the copper wire mesh has the advantages that the preparation technology is simple, reaction conditions are mild, no strong acidity or strong basicity or corrosivity reagents are needed, and no harm is caused to the environment, separation of oily wastewater can be achieved rapidly and efficiently, the good separation effect on chloroform, normal hexane, petroleum ether, plant oil, diesel oil, aviation kerosene and the like is achieved, and separation of strong acidity, strong basicity and high salinity oily wastewater can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of hydrogenation catalyst

ActiveCN102451743AReduce roasting stepsEasy to manufactureMolecular sieve catalystsHydrocarbon oil crackingAmorphous silica-aluminaCoal

The invention discloses a preparation method of a hydrogenation catalyst. According to the catalyst, a cracking molecular sieve, amorphous silica-alumina and alumina are used as carriers, and VIII and VIB metals are used as hydrogenation active components. The preparation process comprises the following steps of: mixing the cracking molecular sieve, amorphous silica-alumina and alumina for molding, drying, loading the active metals by an immersion method, drying and roasting to obtain the catalyst. In comparison with the routine immersion method, the method provided by the invention can be used to prepare the molded carriers without roasting, simplify time and energy, minimize strong interaction, help uniform distribution of the metals as well as performance of the metal activity, and avoid specific surface area loss caused by multi-step roasting. The catalyst prepared by the method is especially applicable to be used as a hydrogenation catalyst for high-yield high-quality heavy naphtha, aviation kerosene and diesel oil. By the adoption of the preparation method, activity and selectivity of the catalyst are raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

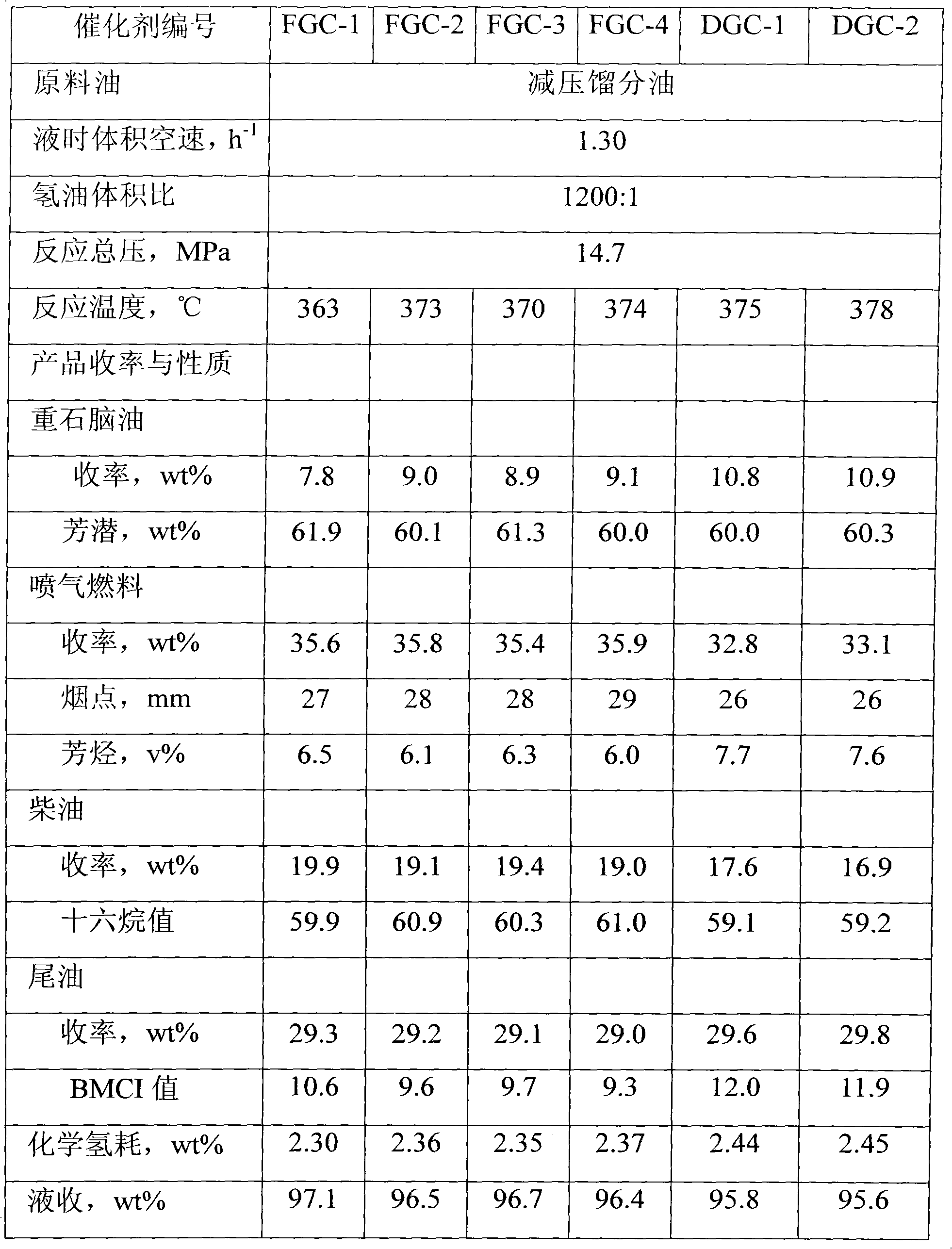

Hydrocracking method

ActiveCN1955260ALow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesHexadecaneCatalytic reforming

This invention discloses a hydrocracking method.It includes that the heavy distillate oil and poor quality catalytic cracking diesel refining separately by hydrogenation, and the mixture enters into hydrocracking reactivator, then its cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce High aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

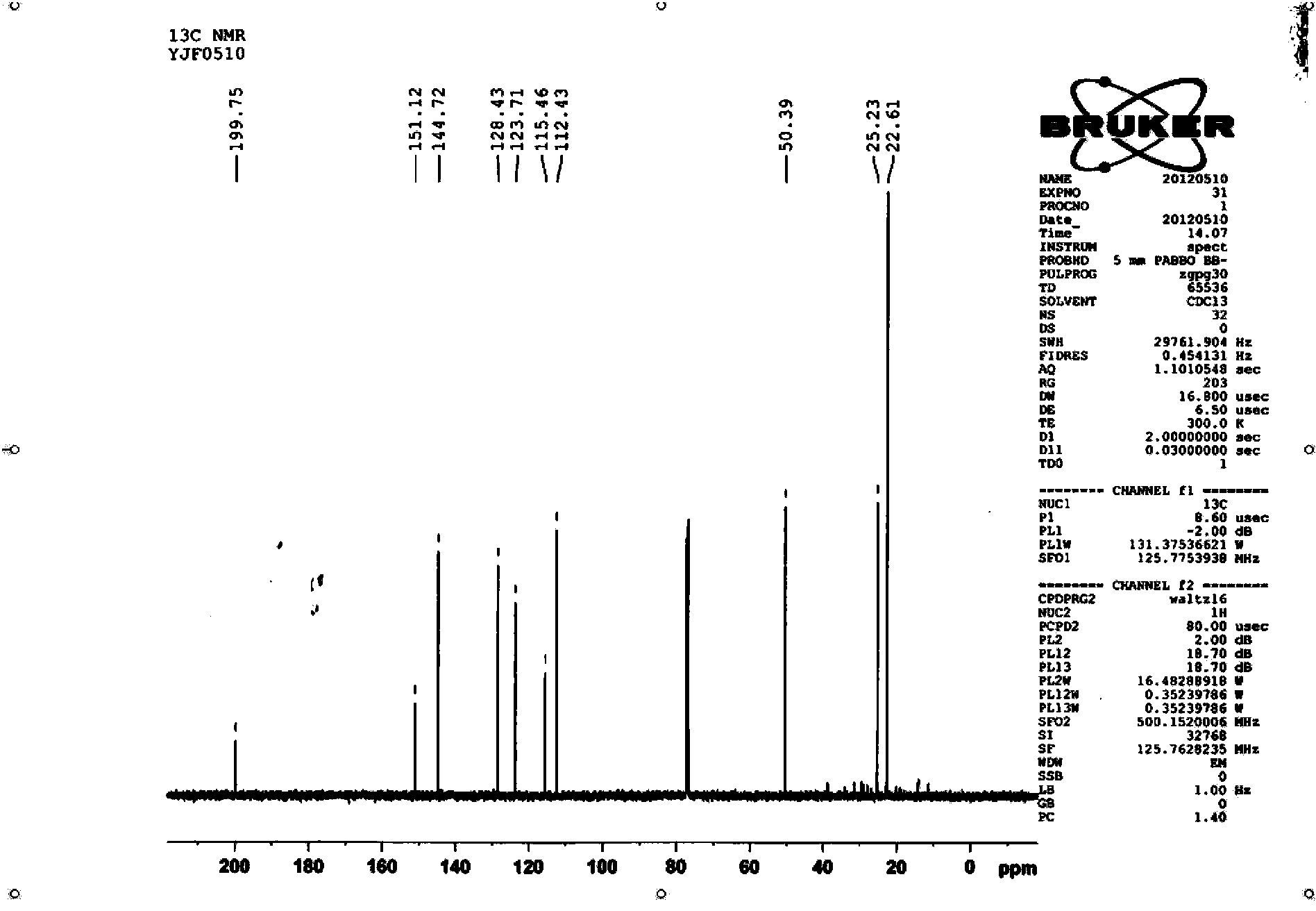

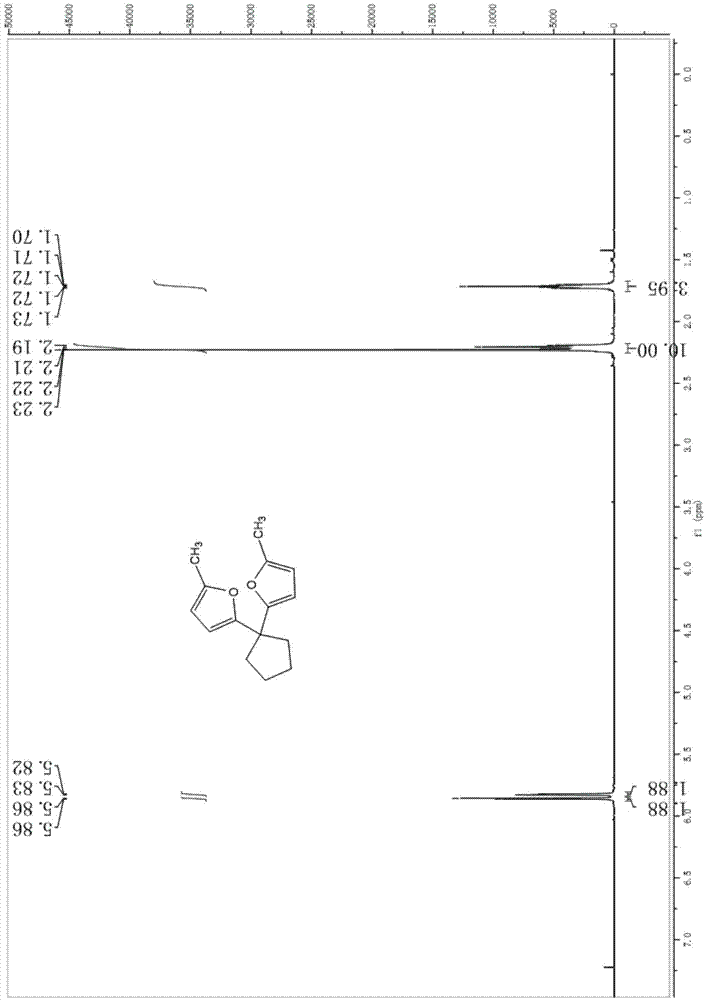

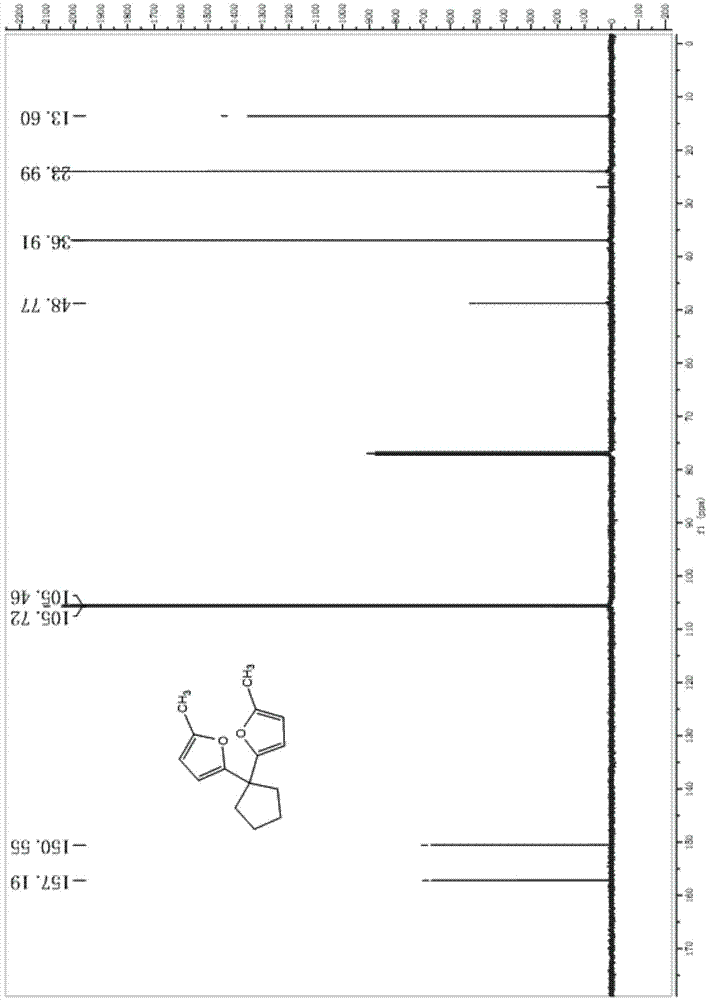

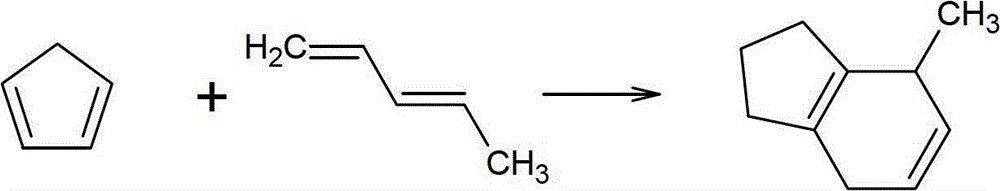

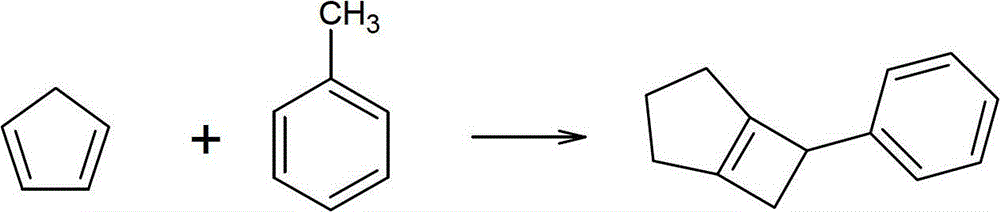

Method for preparing cycloparaffin as aviation kerosene or diesel oil by biomass route

ActiveCN104711021AGood choiceSimple operation processTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneCellulose

The invention relates to a novel cycloparaffin fuel synthesis route which utilizes a platform chemical compound raw material prepared from lignocellulose and is completely independent of fossil energy. The liquid fuel produced by the method can be used as an aviation kerosene or diesel oil substitute or as an additive for improving fuel cetane number and cold resistance so that through the liquid fuel, a degree of dependence on liquid fuel import is reduced. The method comprises that 1, on a novel solid acid catalyst, cyclopentanone and a furan platform chemical compound (such as fura, methyl furan and hydroxyl methyl furan) prepared from lignocellulose are used as raw materials and undergo an acid catalytic alkylation reaction to produce an oxygen-containing organic compound with carbon chain length of 8-21, and 2, the alkylation product is subjected to hydrogenation deoxidation by a metal-solid acid double function catalyst so that the cycloparaffin which has carbon chain length of 8-21, has high energy density and stability and is suitable as biomass aviation kerosene or high-grade diesel oil is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for reaction of preparing aviation kerosene by castor oil and a preparation method of catalyst

ActiveCN103801295AExpand sourceEase the crisisMolecular sieve catalystsLiquid hydrocarbon mixture productionKeroseneActive component

The invention provides a catalyst for reaction of preparing aviation kerosene by castor oil through hydrogenation and a preparation condition of the catalyst. Modified MCM-41, SBA-15 and the like are used as the carrier of a hydro-de-oxygenation catalyst, and one selected from Ni, Ni2P, Co, CoP and Pt is used as an active component; modified SAPO-11, SAPO-34 and the like are used as the carrier of a hydrogenation isomerism catalyst, and one or two selected from Ni, Ag, Pd and Ru is / are used as the active component; the catalyst for the action of preparing the aviation kerosene by the castor oil through a one-step method is characterized in that with one or more selected from modified USY, a beta-type molecular sieve, an X-type molecular sieve and ZSM-5 as the carrier and Ni and Cu as active components or Ni2P and Cu3P as the active components, under a proper reaction condition, the aviation kerosene which meets the need of the operation conditions is prepared.

Owner:NANKAI UNIV +1

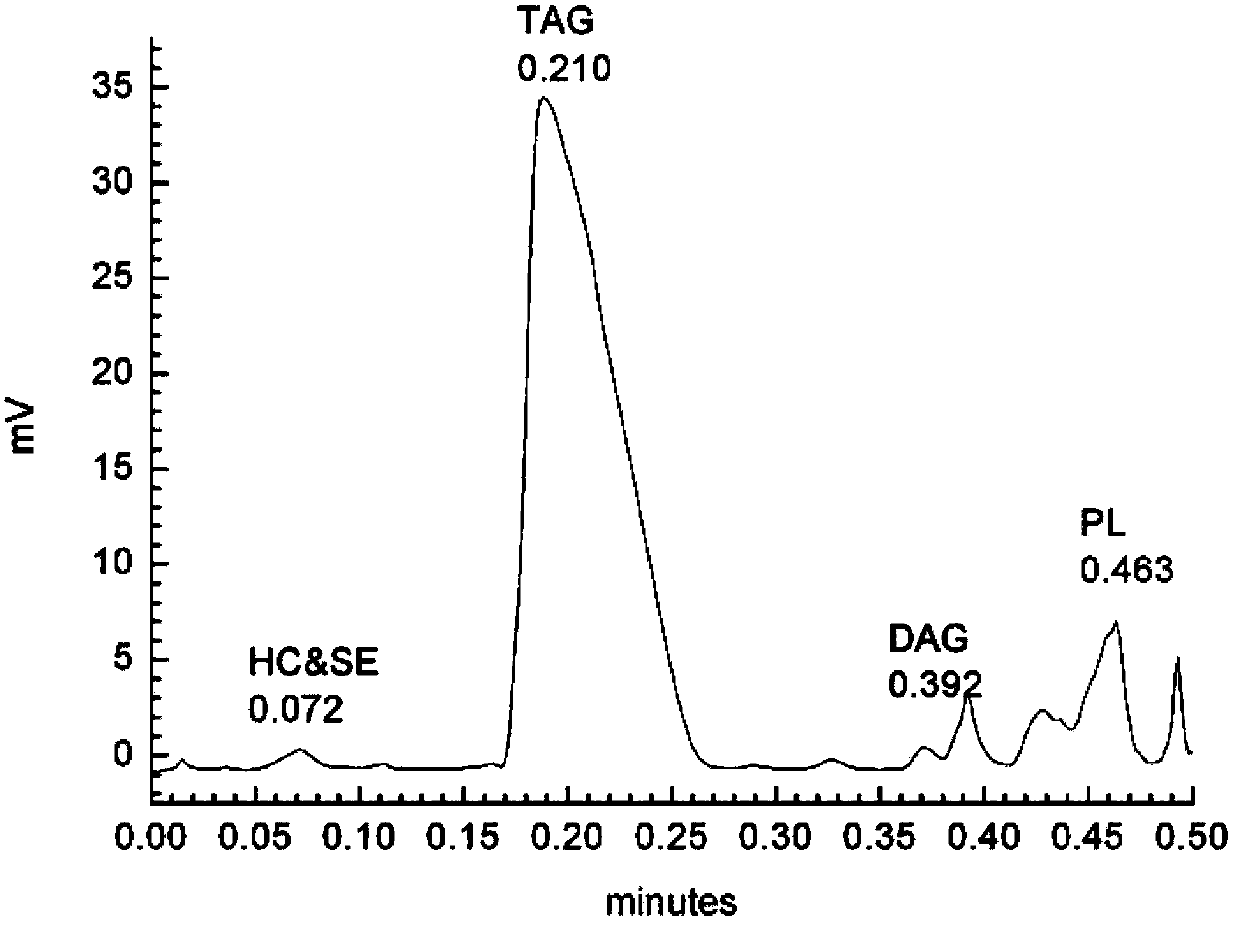

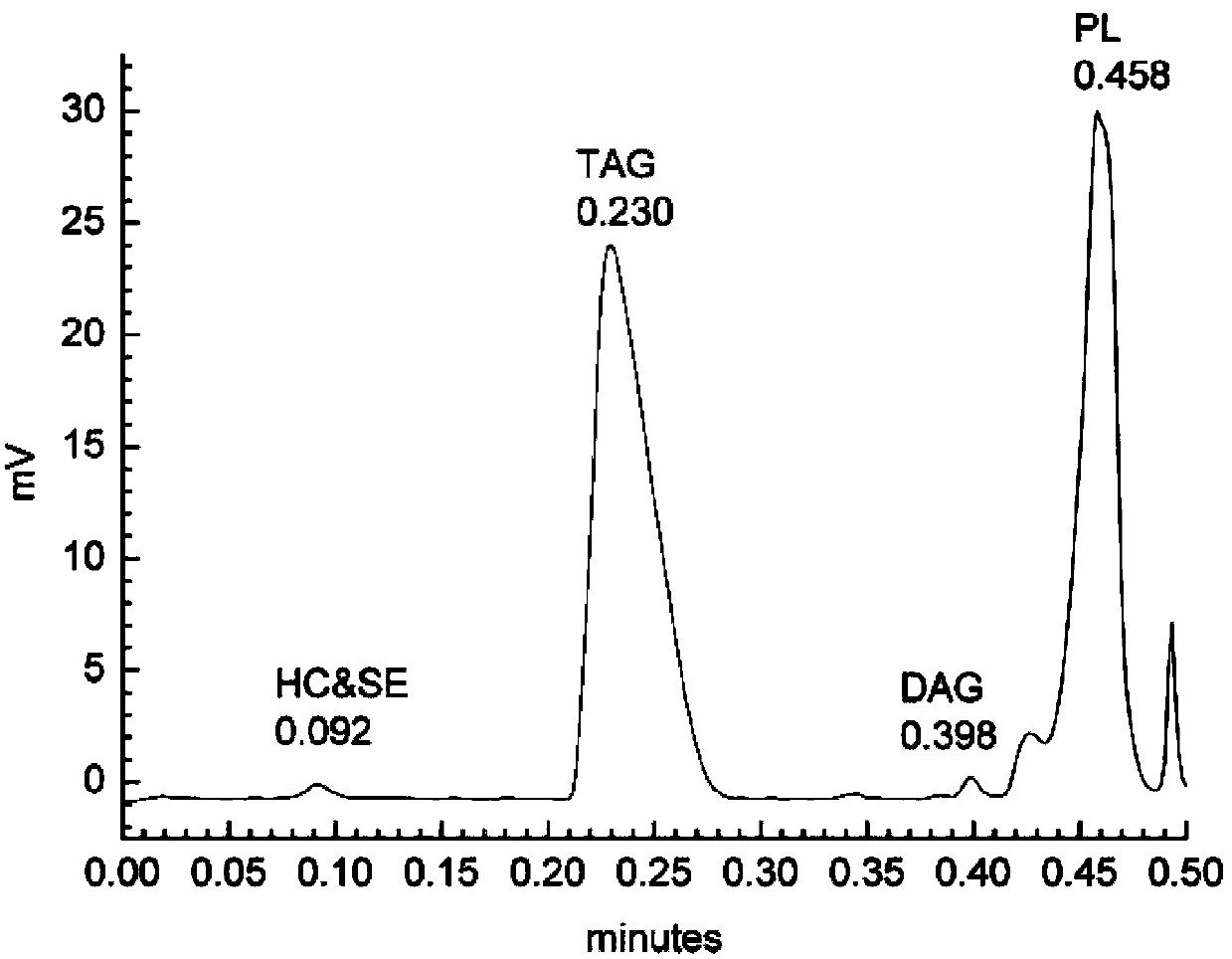

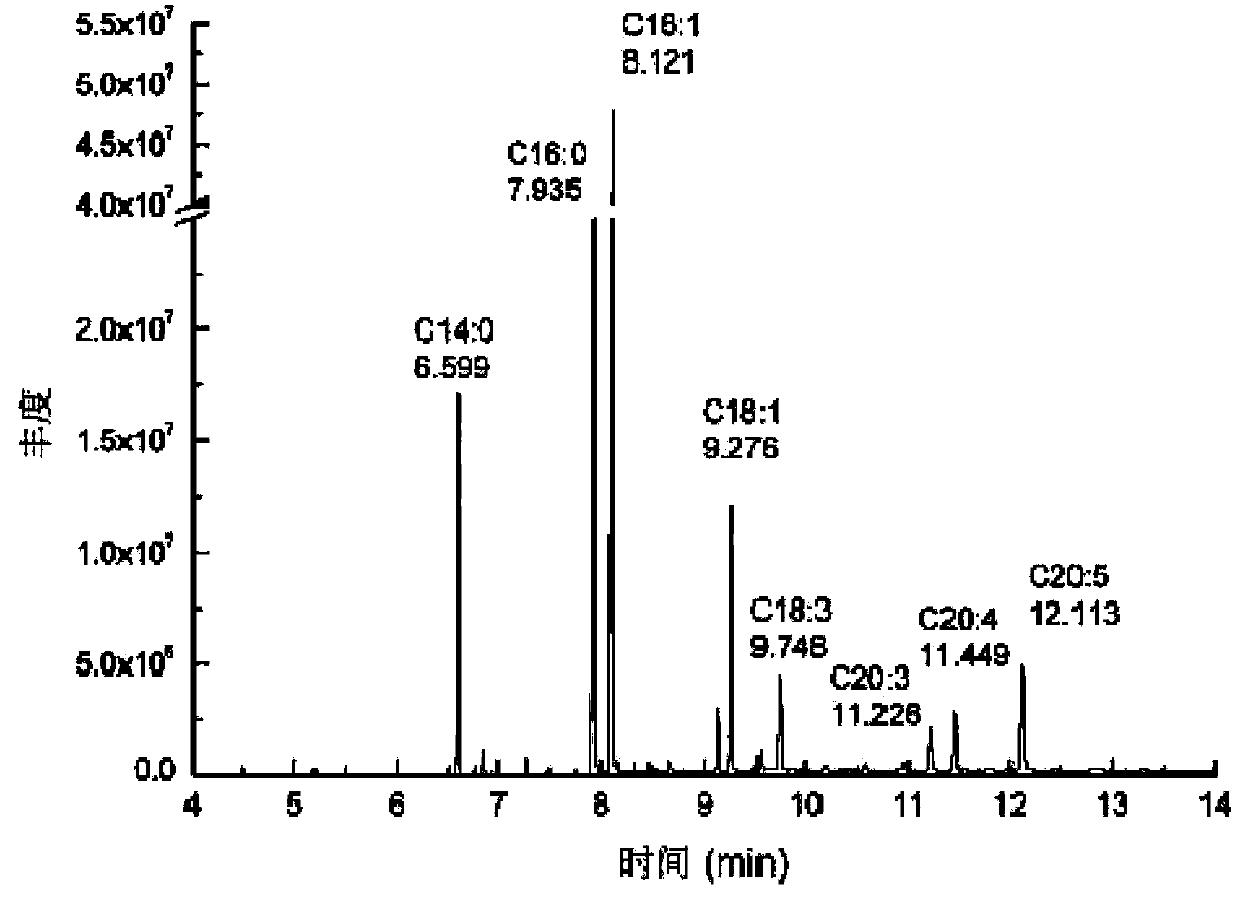

Method for preparing tribonema biological oil and tribonema biological oil prepared by method

ActiveCN103960117AIncrease cetane numberImprove low temperature performanceClimate change adaptationBiofuelsBiodieselOrganic solvent

The invention related to a method for preparing tribonema biological oil, the tribonema biological oil prepared through the method and biodiesel, aviation kerosene, food or feed prepared from the tribonema biological oil. Particularly, one or two of isomorphous tribonema, common tribonema, small-size tribonema, pseudo-silk tribonema and cystic tribonema or a mixture of more algae is subjected to scale culture on an open culture device or a closed culture device or a culture device on which the tribonema grows in a biofilm form and an attaching manner to obtain oil-containing tribonema biomass. The tribonema biomass is extracted with an organic solvent, or squeezed or prepared by adopting an extracting and squeezing combined method to obtain biological oil containing 40-80wt% of triglyceride, 65-85wt% of hexadecenoic fatty acid in the fatty acid and 6-15wt% of eicosatetraenoic polyunsaturated fatty acid.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

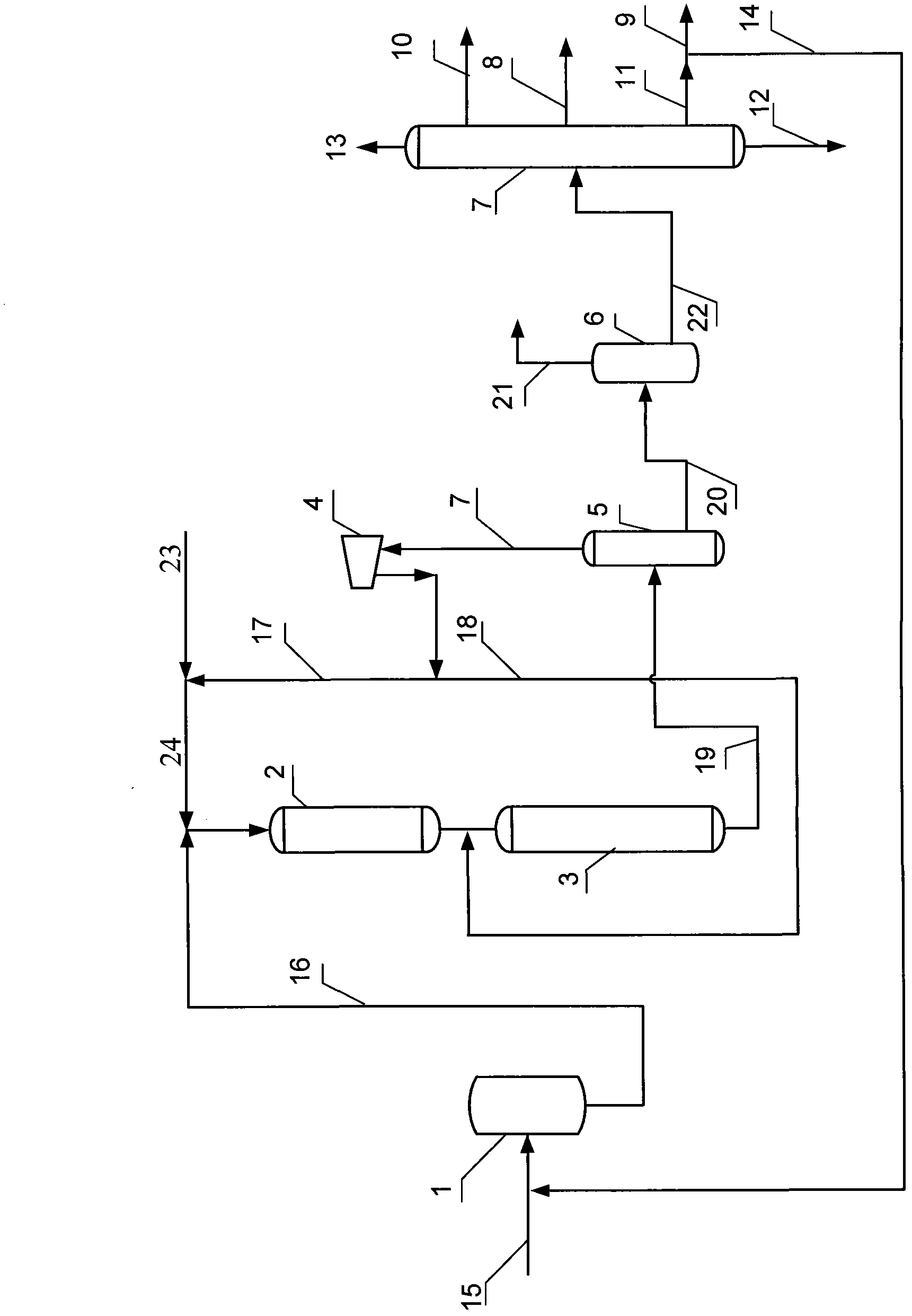

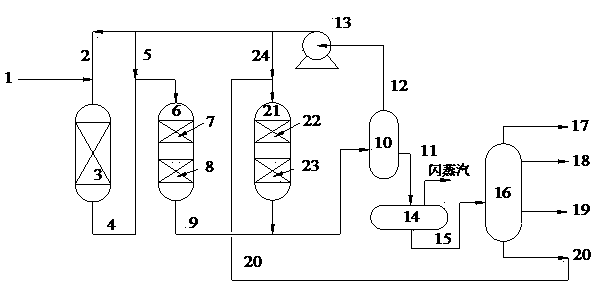

Middle-pressure hydrocracking method for producing aviation kerosene and low-freezing point diesel

ActiveCN103059985AThe method flow is simpleLow investment costTreatment with hydrotreatment processesDistilled oilMixed materials

The invention discloses a middle-pressure hydrocracking method for producing aviation kerosene and low-freezing point diesel. The method comprises the steps that a single-section serial one-time passing flow is adopted under a middle pressure condition; the heated material and hydrogen enter a hydrotreatment reactor; reaction effluent enters a hydrocracking reactor without separation, and reacts under the existence of a hydrocracking catalyst; the generated reaction effluent is subjected to oil-gas separation and then cyclically used after being compressed by the obtained hydrogen-rich gas; the obtained liquid is distilled to obtain a little of pyrolytic naphtha; and a large part of product is middle distilled oil fraction. By adopting the method provided by the invention, 3# aviation kerosene and low-freezing point diesel meeting the GC6537-2006 standard are prepared from light wax oil or a mixed material of the light wax oil and FCC light cycle oil under the middle pressure condition. The method disclosed by the invention is simple in flow, low in operating cost, and low in device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method of productive high-quality jet fuel

ActiveCN103773464AQuality improvementHigh smoke pointTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention discloses a hydrocracking method of a productive high-quality jet fuel. Raw material oil and hydrogen successively pass through a hydrofining zone and a first cracking reaction zone to obtain tail oil to get into a second cracking reaction zone for cracking; two cracking catalysts exist in the first cracking reaction zone, the upstream of the first cracking reaction zone is loaded with a catalyst I, and the downstream of the first cracking reaction zone is loaded with a catalyst II; the catalyst I contains 15%-50% of a modified Y molecular sieve, the catalyst II contains 3%-30% of the modified Y molecular sieve, and the content of the Y molecular sieve in the catalyst I is 10%-25% higher than the content of the Y molecular sieve in the catalyst II. The catalyst I has strong aromatic conversion ability, can convert aromatic hydrocarbons in heavy components into smaller molecules to distribute into the heavy naphtha fractions and aviation kerosene fractions, the catalyst II has strong alkane cracking ability, by synergy of the catalyst II and the catalyst I, the quality of the jet fuel is obviously improved. The hydrocracking method can maximumly produce the high quality jet fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

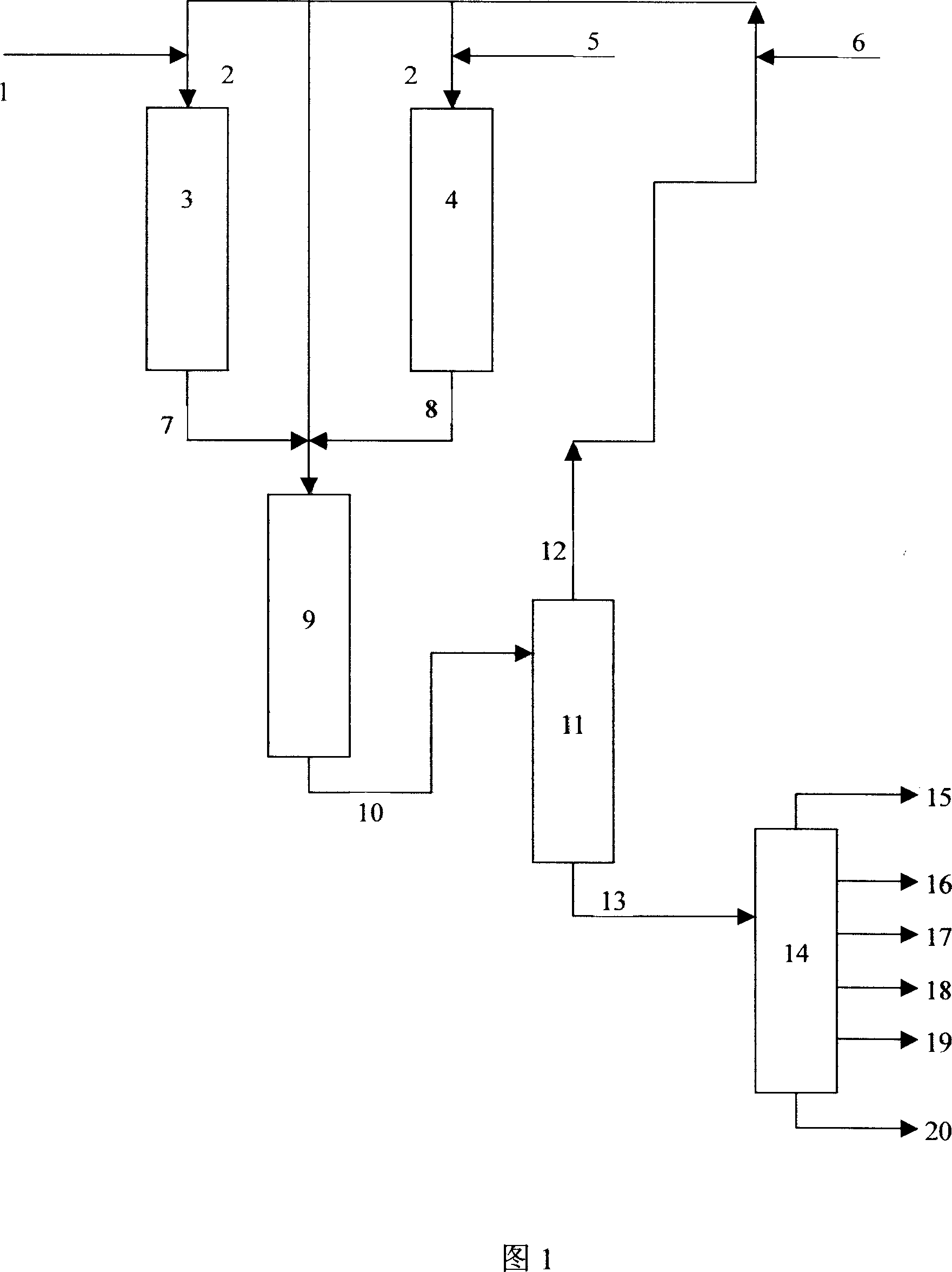

Hydrogenation conversion method for poor ignition quality fuel distillate

ActiveCN101280221ASave investment costsSave operating costsTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrogenation transformation method of poor quality diesel distillate. The poor quality diesel distillate and hydrogen pass the reaction area which contains hydrorefining catalyst; the obtained material is separated to obtain hydrogen-rich gas and diesel distillate; the hydrogen-rich gas and the diesel distillate is fed into the hydrogenation cracking reaction area; the separated aviation kerosene distillate is fed into the aviation kerosene hydrorefining reaction area; the gas obtained in the hydrogenation cracking area through the separation of the material stream is for recycle use; naphtha and diesel product are obtained; the obtained aviation kerosene distillate is fed into the aviation kerosene hydrorefining reaction area; the gas obtained through the separation of aviation kerosene hydrorefining material steam is for recycle use and the aviation kerosene product is obtained. The hydrogenation transformation method of poor quality diesel distillate adopts the combination process of hydrorefining and hydrogenation cracking to transform the diesel distillate into high quality naphtha, aviation kerosene and diesel products directly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low fluorescence lubricant for well drilling liquid and its producing method

InactiveCN1944570AInhibits hydration swellingAvoid stuck pipe accidentsDrilling compositionFluorescenceKerosene

The present invention relates to one kind of low fluorescence lubricant for well drilling fluid and its production process. The low fluorescence lubricant is produced through adding aviation kerosene in 50-90 weigh portions and industrial white oil in 15-75 weigh portions into reaction kettle, heating in water jacket furnace to 70-90 deg.c and stirring for 30-60 min, adding sulfur powder in 0.5-2.5 weigh portions, stirring and further heating to 90-100 deg.c, adding oleic acid in 3.5-8.5 weigh portions, stirring for 30-60 min, cooling to 70-80 deg.c, adding polyoxyethylene ether in 3.5-8.5 weigh portions and Span-80 in 0.5-2.5 weigh portions, and further stirring for 30- 60 min. It is used in drilling well and can inhibit the hydrating expansion of clay shale, consolidate well wall and avoid bit freezing. Compared with available technology, the present invention has the advantages of low fluorescence level and no influence on geological logging.

Owner:HENGXIANG SCI & TECH KELAMAYI CITY

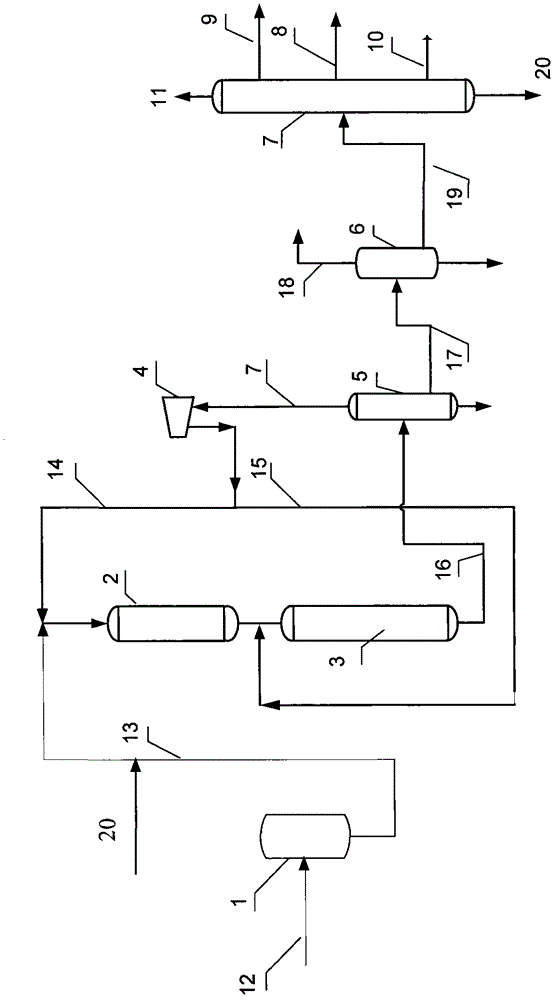

Method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene

ActiveCN103789034AImprove featuresExcellent carbon deposition performanceTreatment with hydrotreatment processesKeroseneFractionation

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 140-290DEG C kerosene fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the large-specific weight aviation kerosene. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to maximumly produce the large-specific weight aviation kerosene with the advantages of high density, volume, high volume calorific value, low aromatic hydrocarbon content, and good low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetized diesel oil

This invention relates to synthetic diesel oil, which is produced by: (1) mixing isooctyl nitrate 30 wt.%, cyclohexylamine 30 wt.%, ferrocene 30 wt.%, and zinc peroxide 10 wt.% to obtain composite additive; (2) mixing fossil-grade diesel oil 10-40 parts and the composite additive 0.3-2 parts to obtain mother diesel oil; (3) mixing 200# solvent oil 10-30 parts and lightweight aviation kerosene 5-20 parts to obtain modified 200# solvent oil; (4) mixing fatty acid methyl ester or C9 10-60 parts, the mother diesel oil and the modified 200# solvent oil to obtain the synthetic diesel oil. The synthetic diesel oil has such advantages as low cost, simple process and abundant raw materials, and can be used for replacing standard fossil-grade diesel oil.

Owner:固安中德利华石油化学有限公司

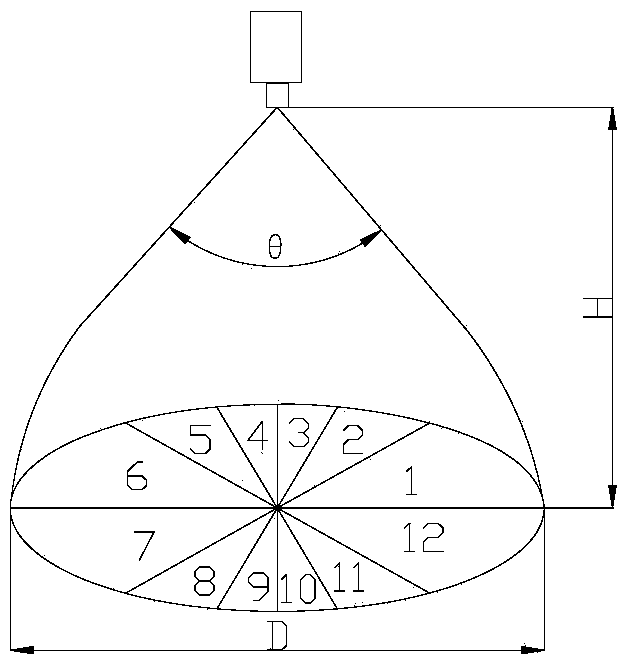

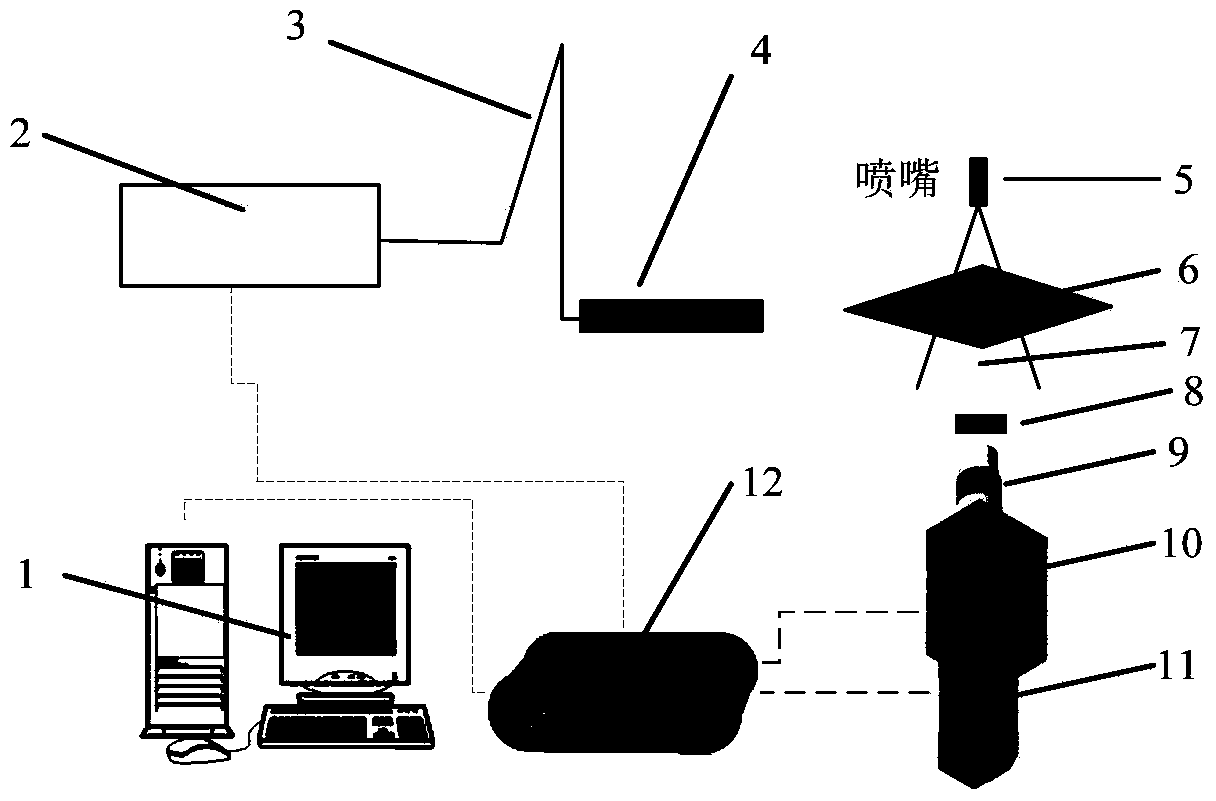

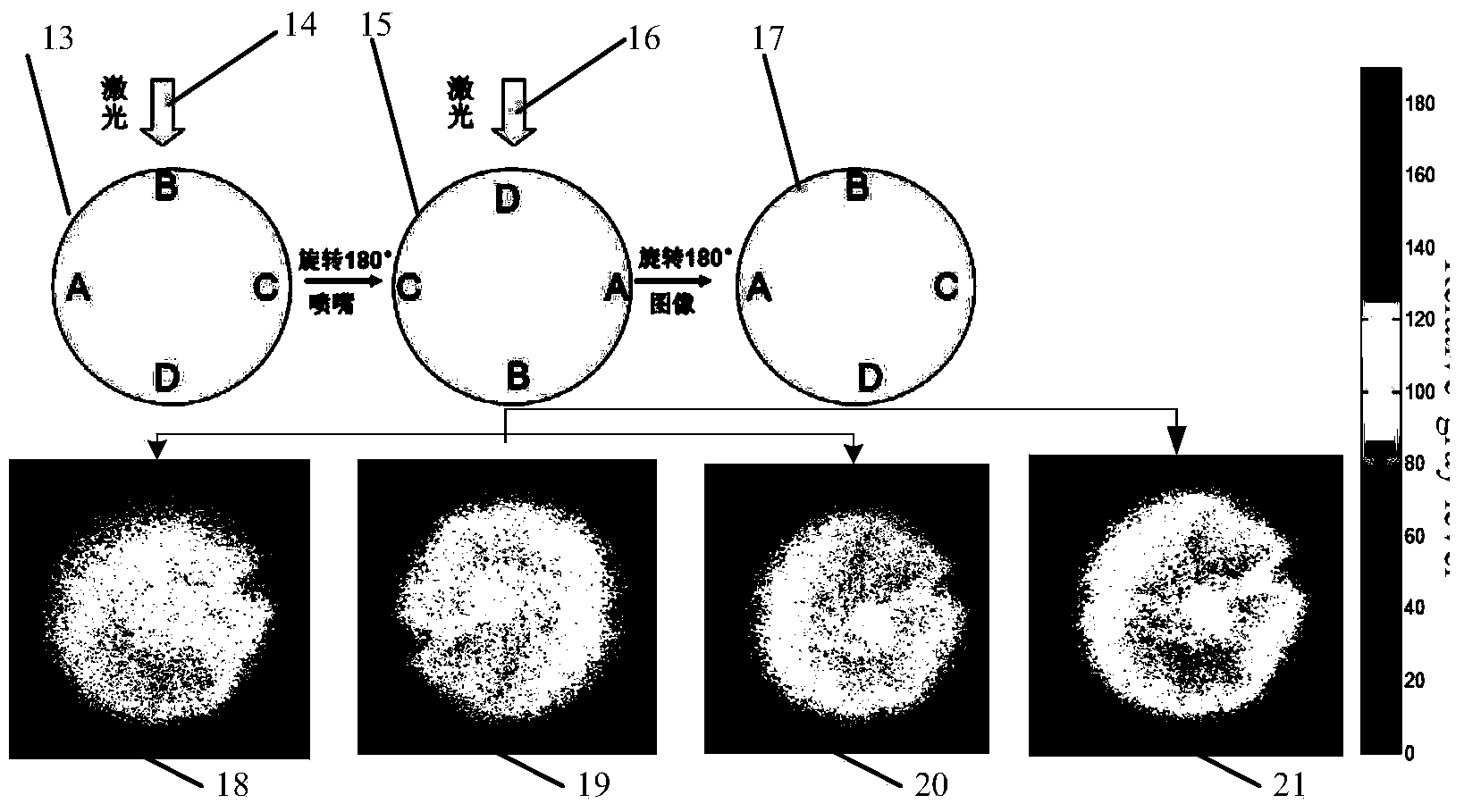

Optical measuring method and device for spatial distribution of liquid droplets of fuel nozzle

InactiveCN103760142AHigh measurement accuracySolve the problem of laser energy attenuationMachine part testingFluorescence/phosphorescenceKeroseneFluorescence

The invention discloses an optical measuring method and device for the spatial distribution of liquid droplets of a fuel nozzle. By using a characteristic that aromatic compounds in aviation kerosene can emit red-shift fluorescence signals under the excitation of ultraviolet light with a wavelength of 266 nm, a correction scheme for solving the problem that the measurement errors of spatial distribution of fuel are caused due to the attenuation of laser energy in a droplet cone is designed. The method and device disclosed by the invention are characterized in that the spatial distribution of the liquid droplets in the fuel droplet cone can be quickly and accurately measured, and have an advantage of flow field noninterference, transient and time average results can be obtained, and a deficiency that only an average result can be obtained by a fuel accumulation method is solved. The optical measuring method for the spatial distribution of liquid droplets of a fuel nozzle disclosed by the invention can be used for measuring the spatial distribution characteristics of the liquid droplets in the droplet cone of the fuel nozzle of an aero-engine or an internal combustion engine, and for fuel which does not contain fluorescent components, a tracer agent is required to be added.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Parallel hydrocracking method

ActiveCN1955259ALow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesHexadecaneCatalytic reforming

This invention discloses a hydrocracking method, and this invention is used for producing high aromatic hydrocarbon heavy naphtha and high quality end oil.It includes that heavy distillate oil and poor quality catalytic cracking diesel hydrocracks separately, and the mixture of the cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce high aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

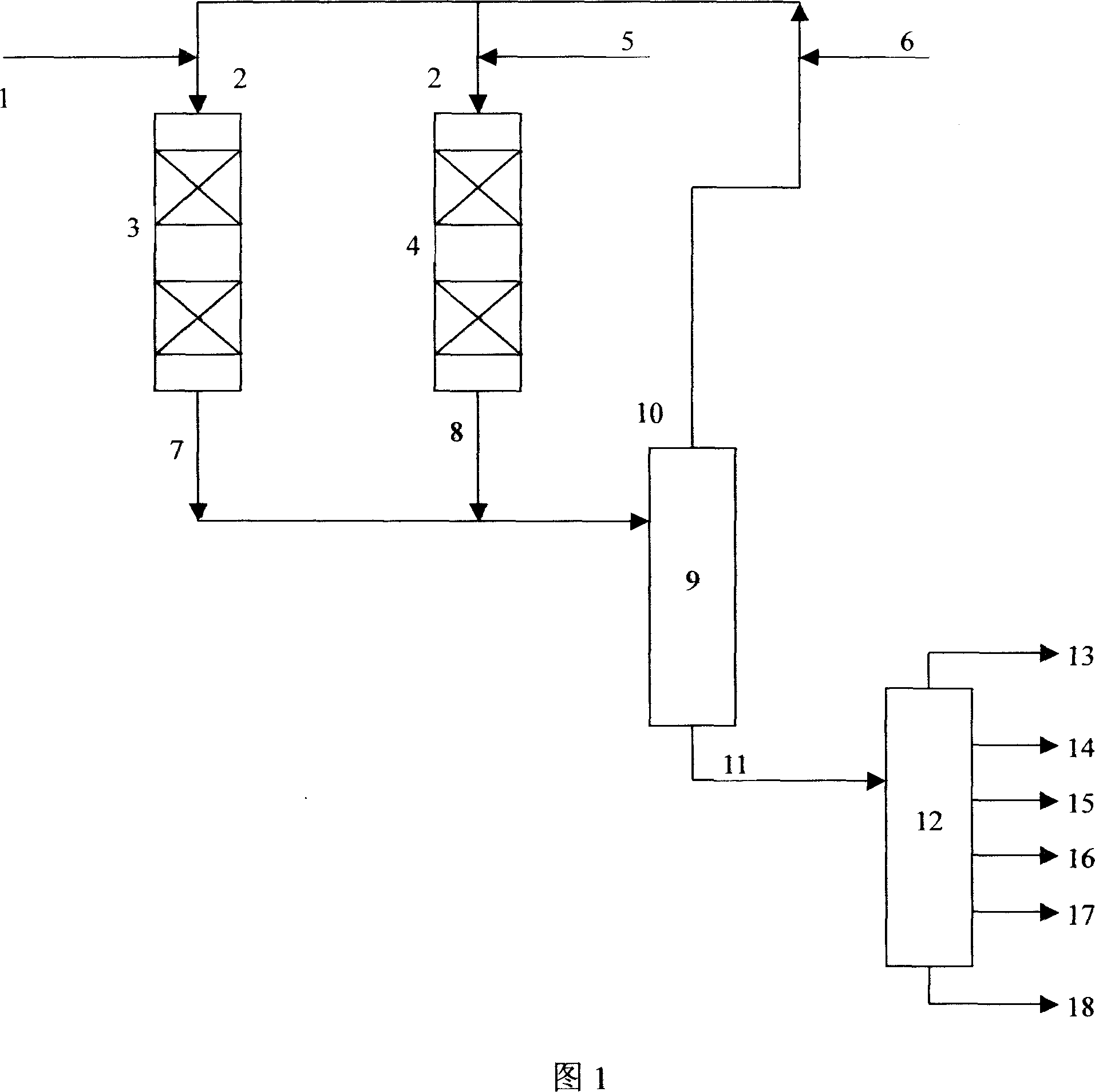

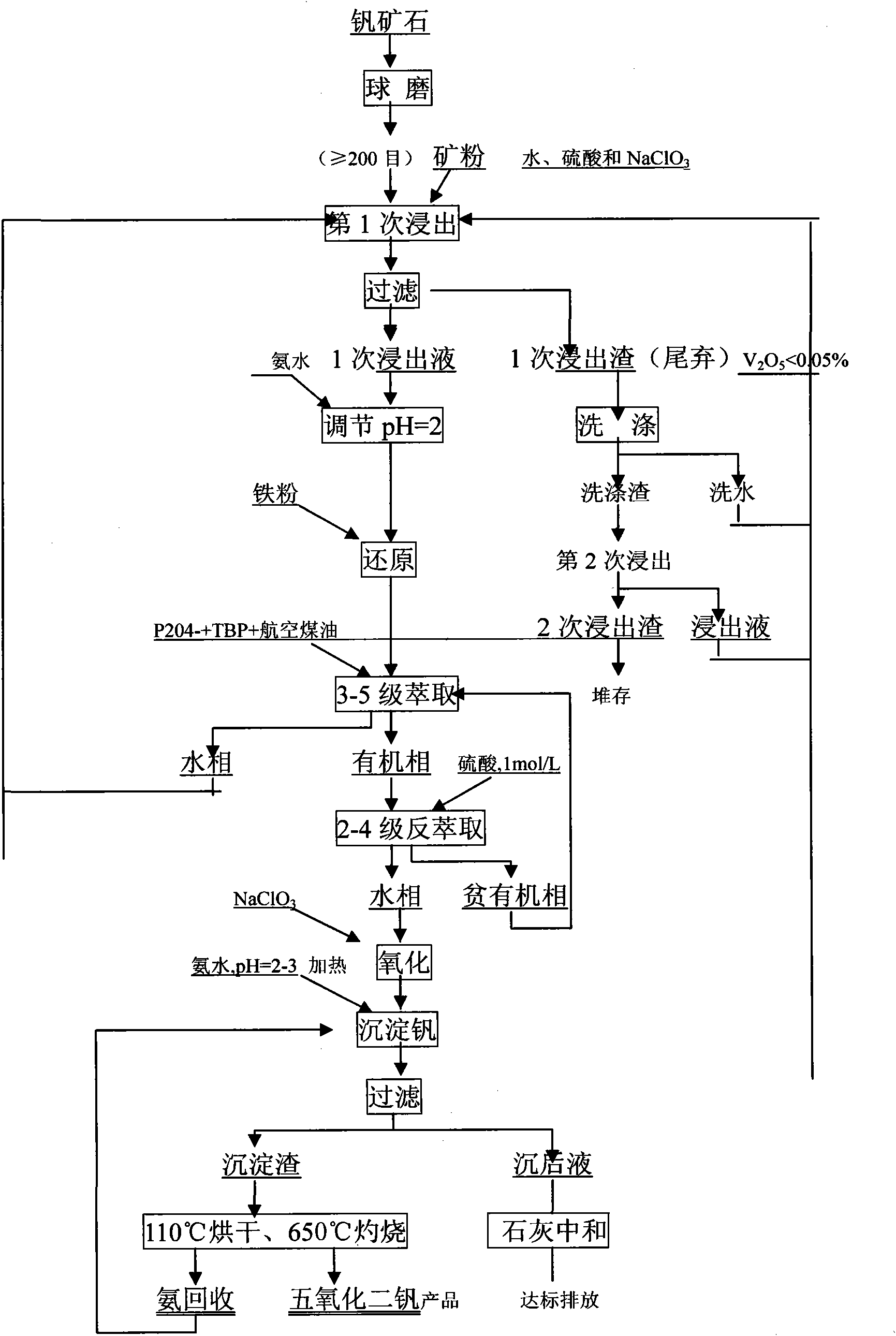

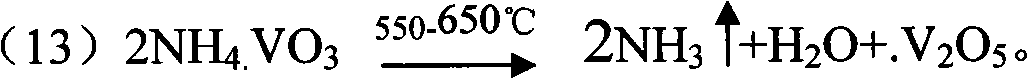

Method for recycling vanadium from vanadium ore containing high silicon and high carbon via wet process

InactiveCN101914695ANo pollution in the processHigh recovery rateProcess efficiency improvementHigh carbonPhosphate

The invention provides a method for recycling vanadium from a vanadium ore containing high silicon and high carbon via a wet process, belonging to the technical field of wet-process metallurgy. For a low-quality vanadium ore containing high silicon and high carbon as well as impurities such as aluminum, sulphur, calcium, iron, magnesium and potassium, and the like, the method adopts the following steps to recycle vanadium: ball-milling the ore, oxidizing and leaching with sulphuric acid, separating the leached liquor and leached residue and washing the leached residue to be neutral, adding magnesium powder to reduce the pentavalent vanadium in the leached liquor to tetravalent vanadium, taking mixed liquor of P204 with mass percent of 15%, TBP (Tri-Butyl-Phosphate) with mass percent of 7.5% and aviation kerosene with mass percent of 77.5% as extracting agents to extract the tetravalent vanadium in the once sulphuric acid leached liquor, using 1mol / L of sulphuric acid solution to re-extract vanadium-rich organic extraction phase, oxidizing the re-extracted liquor by sodium chlorate so as to oxidize the reduced tetravalent vanadium in the solution to pentavalent vanadium, depositing the vanadium with ammonia water, and drying and roasting the vanadium deposited residue so as to obtain a product with vanadium pentoxide content above 98%.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

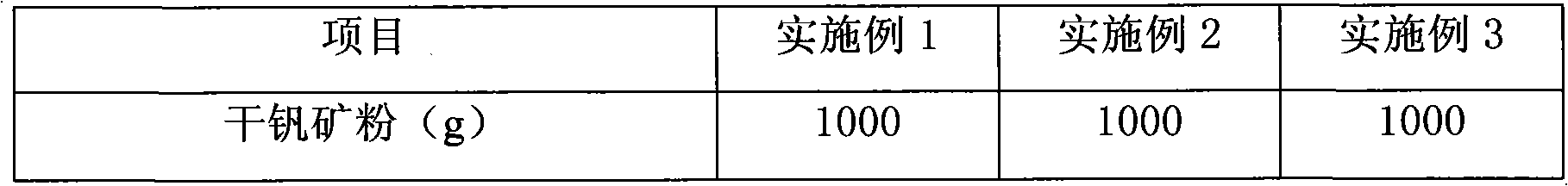

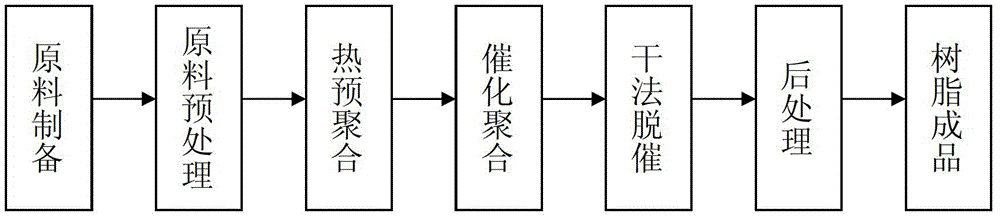

Method for preparing C5/C9 copolymerized petroleum resin

The invention relates to a method for preparing C5 / C9 copolymerized petroleum resin. The method comprises the following steps of: mixing crude m-pentadiene, crude cyclopentadiene and selectively hydrogenated and pretreated C9 material D uniformly, performing pre-polymerization at the temperature of between 180 and 230 DEG C to obtain a dimmer mixture F of C10 and C15, blending hydro-cracking aviation kerosene serving as a solvent, performing catalytic polymerization for 2 to 5 hours at the temperature of between 30 and 65 DEG C by using gaseous boron trifluoride as a catalyst to obtain deep yellow to brown polymerization solution, rectifying under reduced pressure to remove the solvent and oligomers, and thus obtaining the C5 / C9 copolymerized petroleum resin. The prepared C5 / C9 resin is good in compatibility and light in color; the preparation method is reasonable and strong in pertinence; the hue, the compatibility and the thermal stability of the resin are remarkably improved; and the resin can be widely applied in the fields of ink, coating, papermaking, plastics and the like.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

One-pot or one-step method for preparing diesel oil or aviation kerosene

ActiveCN108130112AImprove efficiencyEnhanced inhibitory effectLiquid hydrocarbon mixture productionBio-feedstockKeroseneHigh energy

The invention relates to a novel synthesis route of liquid chain hydrocarbon fuel from platform compounds obtained on the basis of lignocellulose as a raw material completely independent of fossil energy. A reported method comprises two-step reactions as follows: 1) lignocellulose-based carbonyl-containing platform compounds (such as levulinic acid, levulinate, acetone, hydroxyacetone, furfural and the like) and furan platform compounds (such as furan, methylfuran, hydroxymethyl furfuran and the like) are taken as raw materials on a solid acid catalyst and subjected to an acid catalysis alkylation reaction, and oxygen-containing organic compounds with the carbon chain length ranging from 8 to 16 are prepared; 2) hydrogenation and hydrodeoxygenation are performed on an alkylation product byuse of a metal-solid acid dual-function catalyst, so that biomass aviation kerosene or high-grade diesel which has the carbon chain length ranging from 8 to 16 and has higher energy density and stability is obtained. The two steps are integrated into one step innovatively in the invention, the reaction course is shortened, and the production efficiency is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

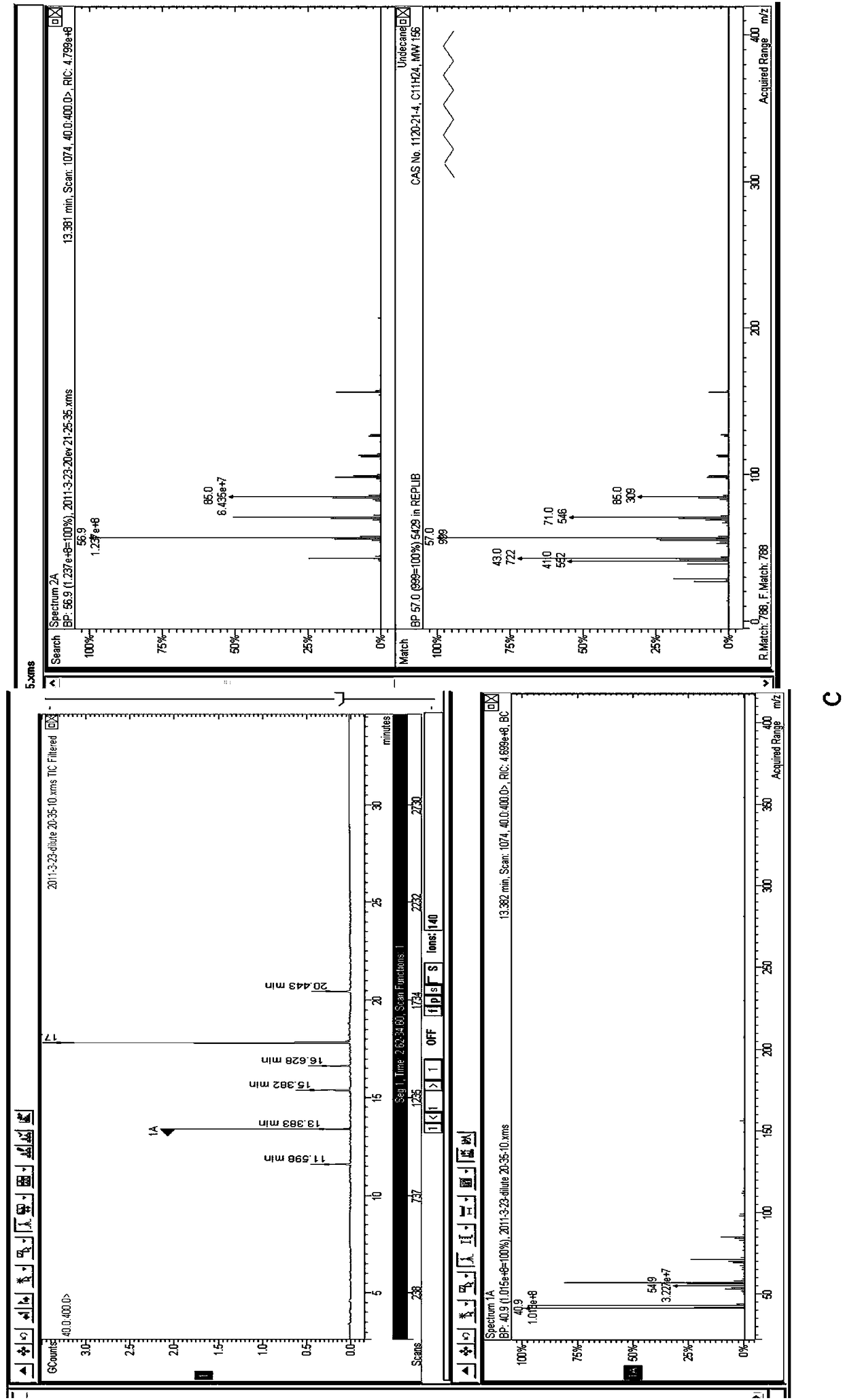

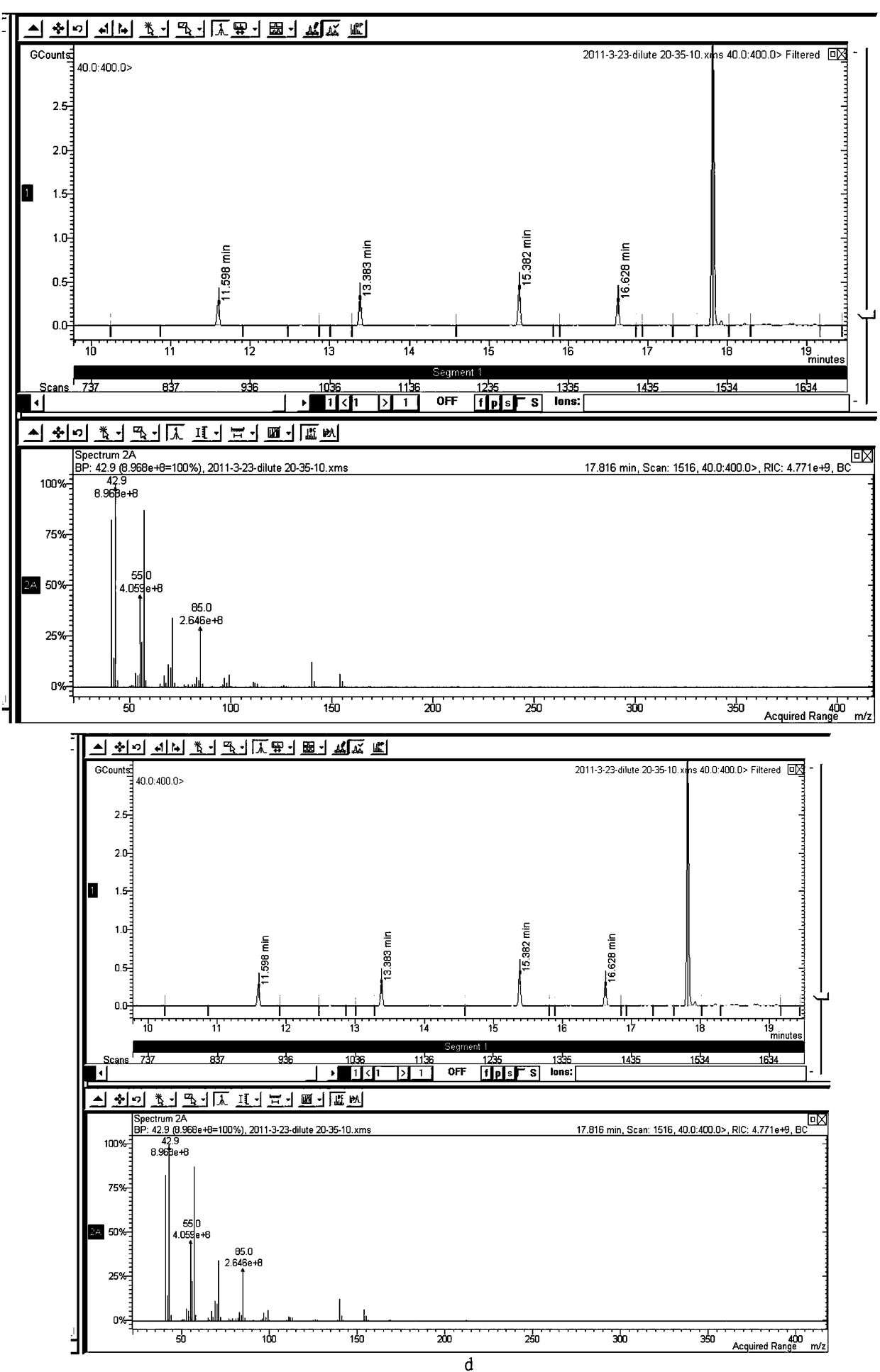

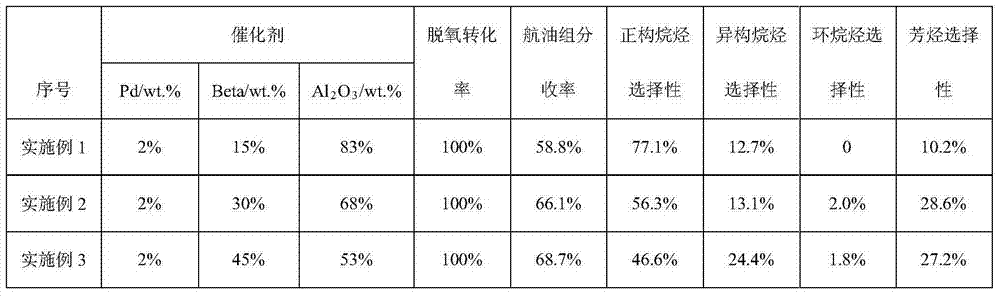

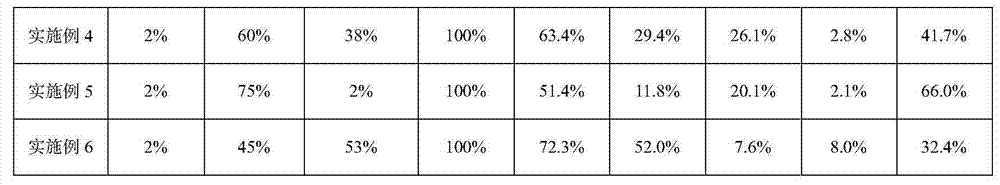

Catalyst for preparing aviation kerosene components through one-step hydrodeoxygenation cracking isomerization of grease and preparation method of catalyst

InactiveCN103920528AHigh calorific valueModerate densityMolecular sieve catalystsLiquid hydrocarbon mixture productionIsomerizationKerosene

The invention relates to a catalyst for preparing aviation kerosene components through one-step hydrodeoxygenation cracking isomerization of grease and a preparation method of the catalyst. The catalyst is mainly used for the process of preparing new-generation ultra-clean aviation fuel oil substitution components through one-step catalytic hydrogenation of grease model compounds, grease and derivatives of the grease. The catalyst provided by the invention is loading noble metal / composite solid acid carrier catalyst which is composed of 0.2-5.0% of Pd, 5-85% of a bata molecular sieve, 10-94.8% of Al2O3. With the adoption of the catalyst, the grease and the grease model compounds can be converted into the biological aviation kerosene components (C8-C16) through hydrogenation, deoxygenation, cracking and isomerization. The catalyst obtained by the preparation method has the advantages of high activity, high selectivity, low hydrogen consumption and the like, and has great significance in promoting development of biological aviation kerosene and reduction of carbon emission; in evaluation for the catalytic activity of the catalyst, the hydrodeoxygenation conversion rate of grease is 100%, and the yield of the aviation kerosene components is 72.3%.

Owner:KUNMING INST OF PRECIOUS METALS

Powder metallurgy aviation brake material for large-scale airplane and producing method thereof

InactiveCN101195898AGuaranteed densificationComponent response is sufficientFriction liningAviationJet aeroplane

The invention relates to powder metallurgy aviation brake material used for a large scale aircraft. The brake material comprises the following components calculated according to the mass percent: 8 to 18 percent of ferrum, 8 to 16 percent of graphite, 4 to 10 percent of dune sand, 1 to 5 percent of tin, 1 to 3 percent of nickel, 1 to 10 percent of SiC+Al2O3, 1 to 5 percent of molybdenum disulphide, and 50 to 75 percent of copper. The components are mixed evenly and then aviation kerosene is added, the compression sintering process is as follows: the temperature is elevated for two to four hours and held for two to three hours, the holding temperature is 950 to 1020 DEG C, the thermal insulated pressure is 1.5 to 3.0 MPa, and the sintering is protected under the hydrogen atmosphere. The average friction coefficient mu is equal to 0.20 to 0.30, the attrition performance, the system compatibility and the service life, etc. reach or exceed in the performance indexes of an import brake pair.

Owner:CENT SOUTH UNIV +1

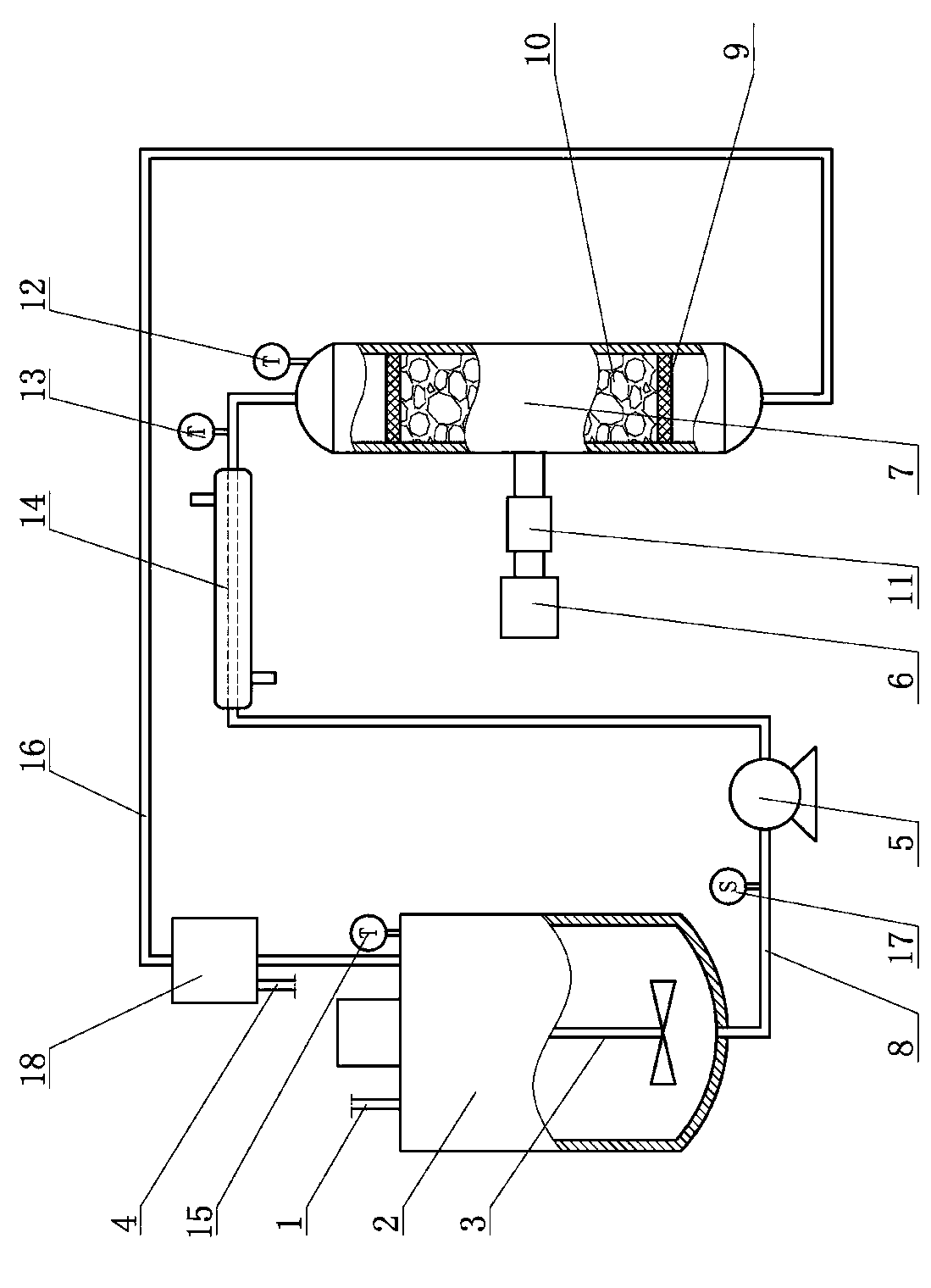

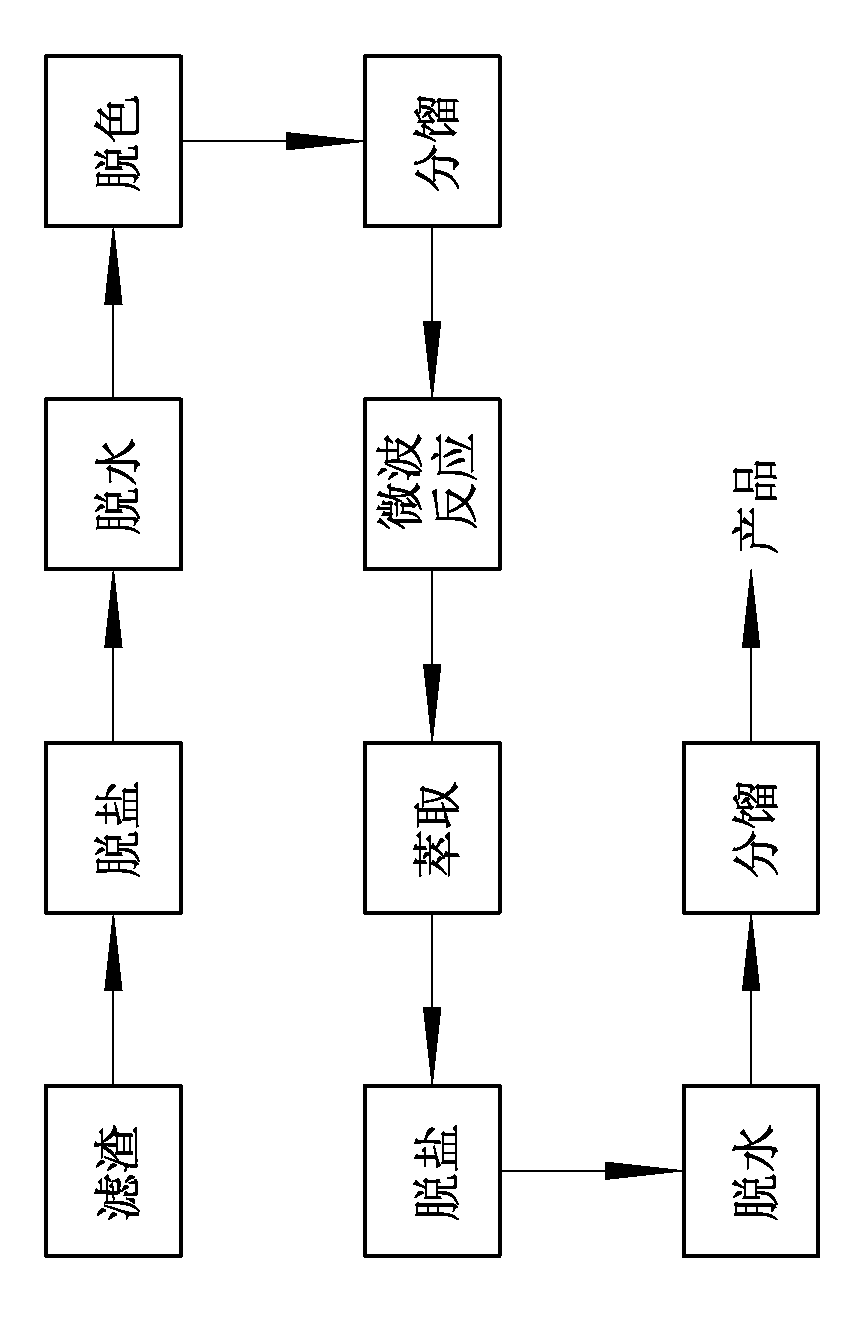

Method for preparing biological aviation kerosene by using swell-cooked dirty oil

InactiveCN102994138AResolve tensionAvoid pollutionLiquid hydrocarbon mixture productionBio-feedstockSlagKerosene

The invention relates to a method for preparing biological aviation kerosene by using swell-cooked dirty oil. The method comprises the following steps: filtering out slag, desalting, dewatering and decoloring, then conducting fractional distillation, circulating three to five times together with ammonium formate in circulating type microwave reaction equipment under the action of a Pd / Al2O3 catalyst, extracting together with ethyl acetate, then desalting and dewatering, adding into a fractionating tower for fractionating to obtain biological aviation kerosene. The biological aviation kerosene prepared by adopting the method reaches the existing biological aviation kerosene standard, the shortage of biological aviation kerosene can be effectively overcome, the recovered swell-cooked dirty oil can avoid polluting the environment, and the resources can be saved.

Owner:陈秀海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com