Method for preparing C5/C9 copolymerized petroleum resin

A technology for copolymerizing petroleum resin and raw materials, which is applied in the field of preparation of C5/C9 copolymerized petroleum resin, and can solve the problem of low comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

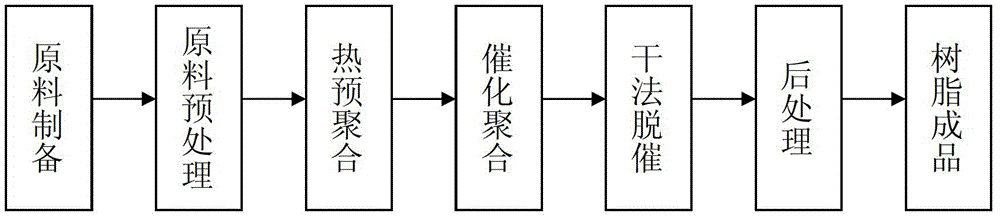

Image

Examples

Embodiment 1~6

[0081] The following table 9 is the embodiment of preparing C5 / C9 petroleum resin, raw material C is Pd / Al 2 o 3 The processes of catalyst selective hydrogenation, Friedel-Crafts catalyst pretreatment and subsequent catalyst removal, raw material rectification to remove oligomers, solvent dilution, and resin polymerization liquid catalyst removal are as follows:

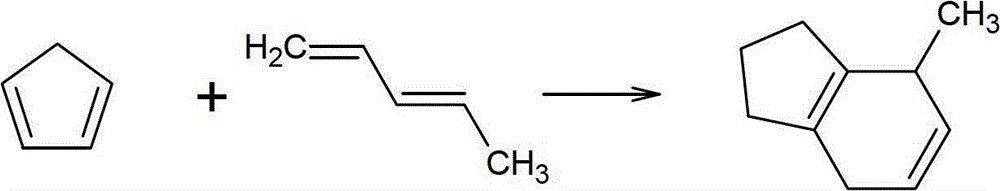

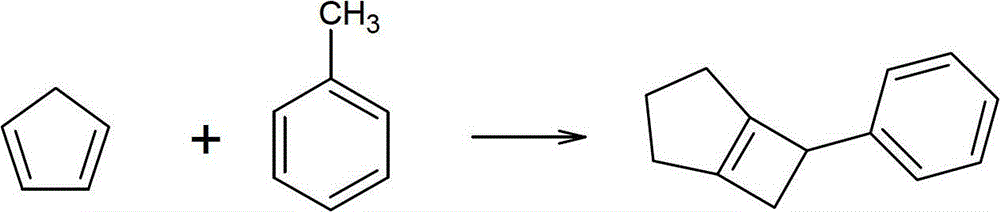

[0082] (1) Thermal prepolymerization

[0083] Mix the raw materials A, B, and D to obtain the polymerization raw material E, and then transport it to a high-pressure reactor with stirring for thermal prepolymerization to obtain the dimerization product F of carbopentaolefins and styrene or methylstyrene;

[0084] (2) Catalytic polymerization

[0085] The above-mentioned dimerization product F is used as raw material, mixed with a solvent at a mass ratio of 1:0.1~1.0, and a gaseous boron trifluoride catalyst is added to catalyze polymerization to obtain a dark yellow to brown polymerization liquid, which is a mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com