Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1071results about "New-spun product collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength activated polyester industry yarn and preparation method thereof

ActiveCN104499080AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsPolyesterChemistry

The invention relates to a high-strength activated polyester industry yarn and a preparation method thereof. The high-strength activated polyester industry yarn is a modified polyester industry yarn of which the surface is coated with an activating agent and the high-strength activated polyester industry yarn is prepared from modified polyesters through spinning; the modified polyester is composed of polyester and aminoadipic acid gylcol ester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume of the fiber is increased when the high-strength activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced into the polyester molecules, a firm resinoid coating is formed on the surface of a polyester cord thread and the reactivity of the polyester fiber is improved; and the high-strength activated polyester industry yarn can be applied to triangular belt cords, radial tire cord fabrics and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Figured sea-island super-fine fiber, and preparation method thereof and synthetic leather preparing process method using same

ActiveCN102071495AGood mechanical propertiesImprove dyeing effectNew-spun product collectionFilament/thread formingPhospholambanPolyolefin

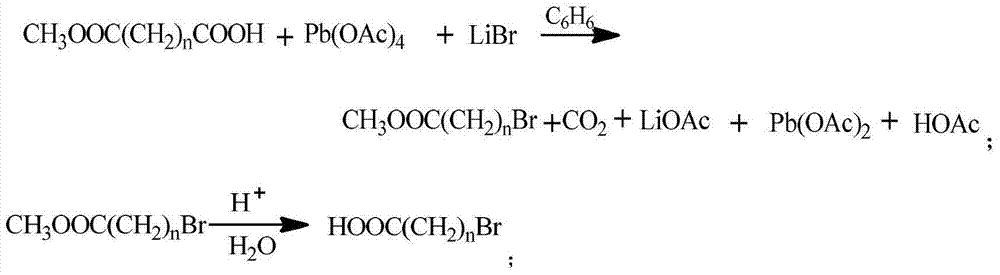

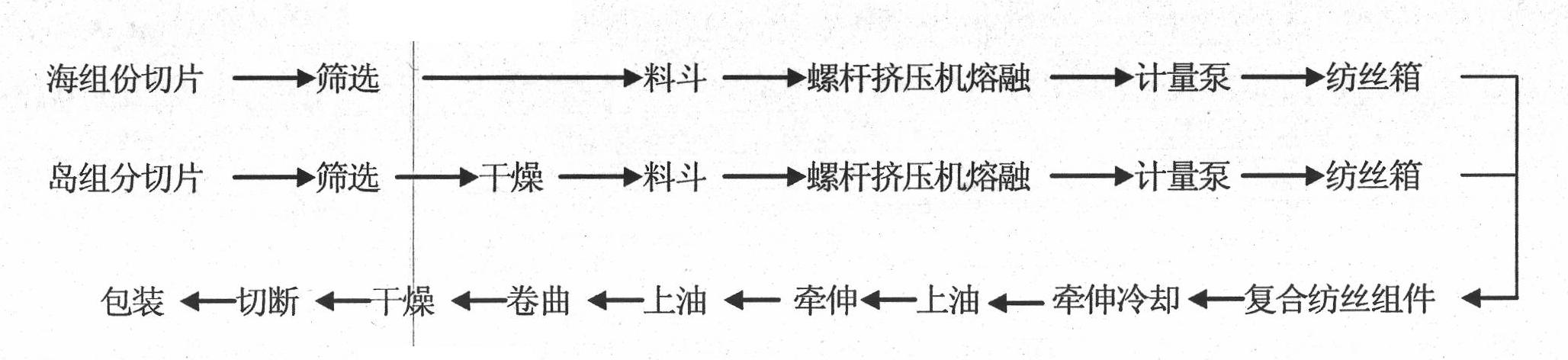

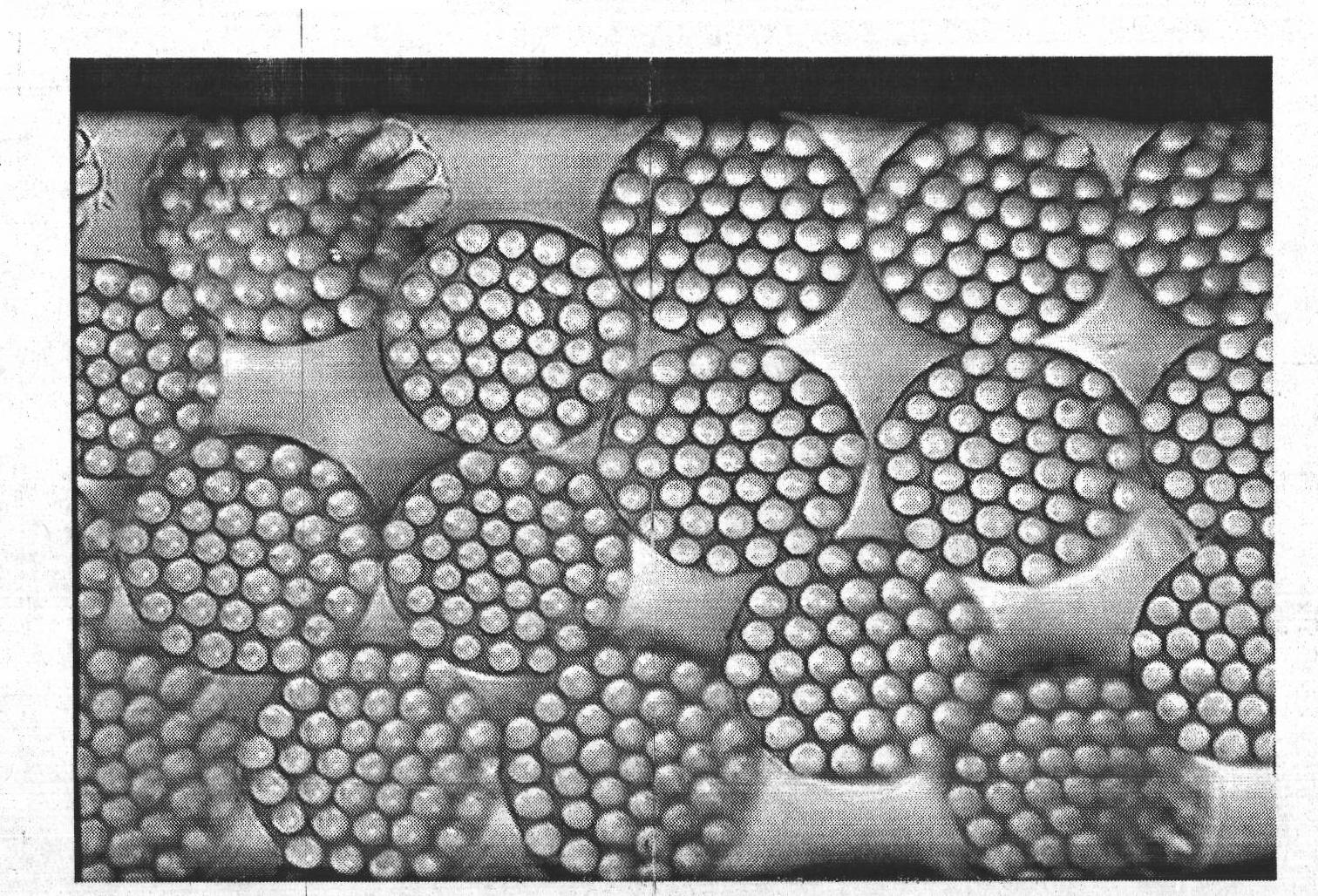

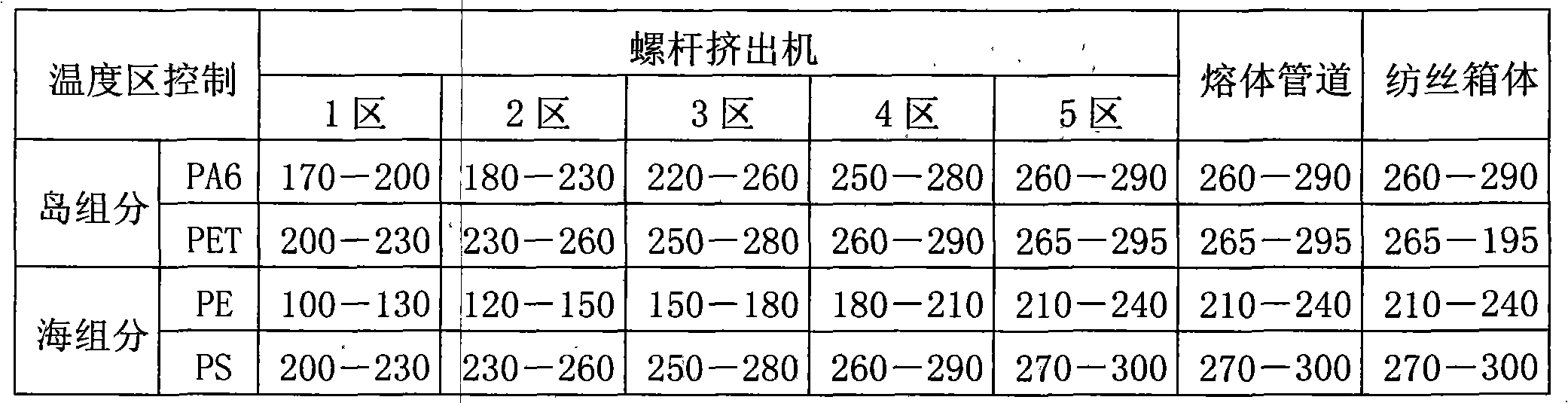

The invention relates to a figured sea-island super-fine fiber, and a preparation method and a synthetic leather preparing process method using the same, which belong to the technical field of leather and leather manufacture methods. The figured sea-island super-fine fiber is characterized in that the weight percentage ratio of island components of the fiber to sea components of the fiber is 50 percent to 80 percent / 50 percent to 20 percent, wherein the island components are polyamide (PA) 6 or polyethylene terephthalate (PET), and the sea components are polyolefins or phospholamban (PLB) or polyvinyl alcohol (PVOH). The preparation method comprises the steps of slice drying and melting, composite spinning, oiling and falling into a barrel, drafting curling and drying cutting. The synthetic leather preparing method comprises the following steps that: 1. the components are sequentially prepared into a single-layer fiber net, a composite layer fiber net, needle-punched non-woven cloth and needle-punched non-weaving cloth; 2.soakage and coagulation are sequentially carried out on the non-weaving cloth, the non-weaving cloth is washed, so that a synthetic leather impregnated substrate is formed, repeated soaking squeezing, azeotropic distillation and drying are sequentially carried out, so the synthetic leather is obtained. The synthetic leather produced by the invention has the advantages of excellent mechanical performance, excellent dyeing performance, excellent dyefastness, better production controllability, economy and environment protection. Compared with natural leather and products of the natural leather, the synthetic leather has the advantages that use performance such as durability, weatherability, antibacterium mothproofing, dyefastness and the like of products is much superior to that of the natural leather and the products of the natural leather.

Owner:烟台万华超纤股份有限公司

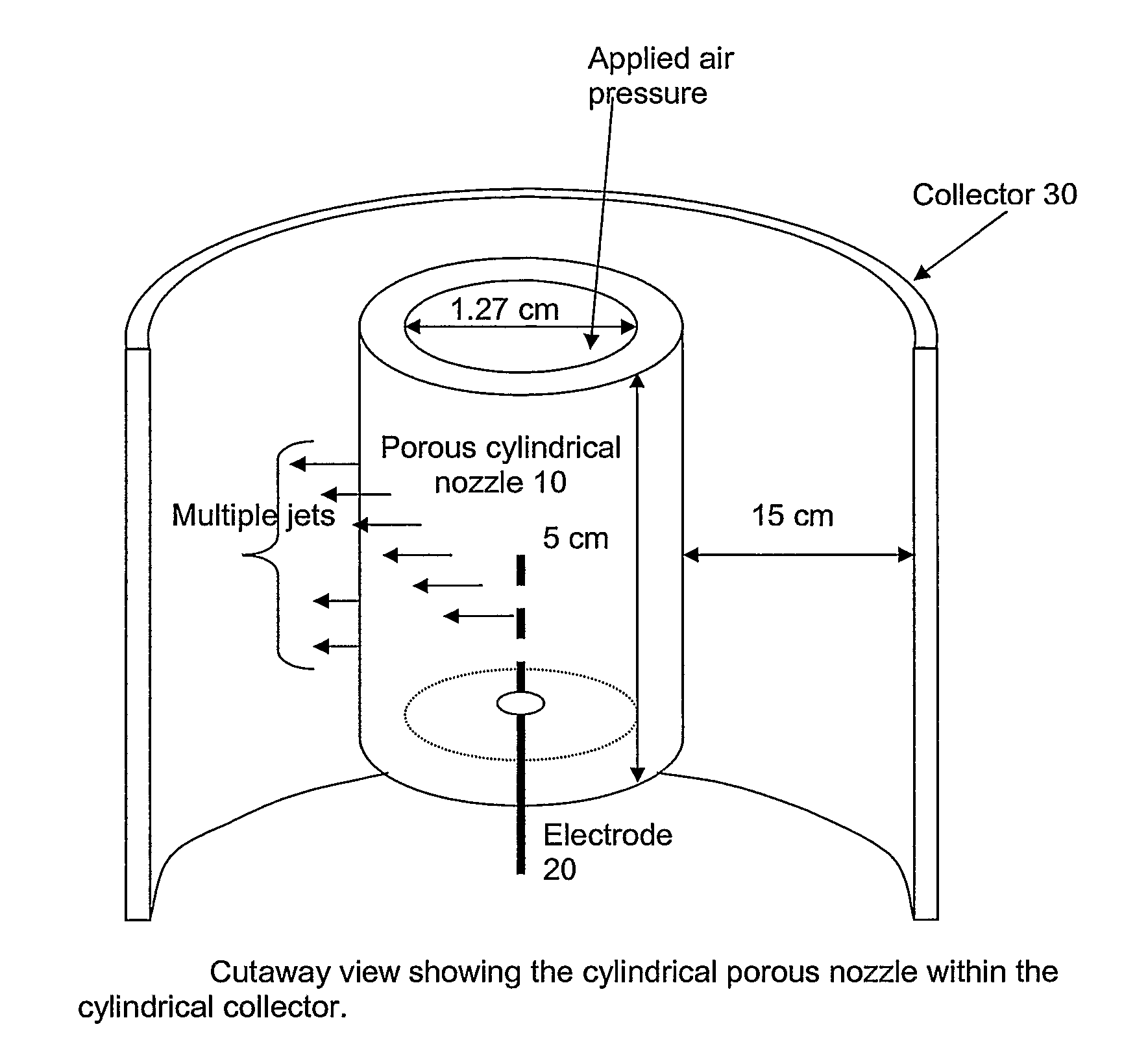

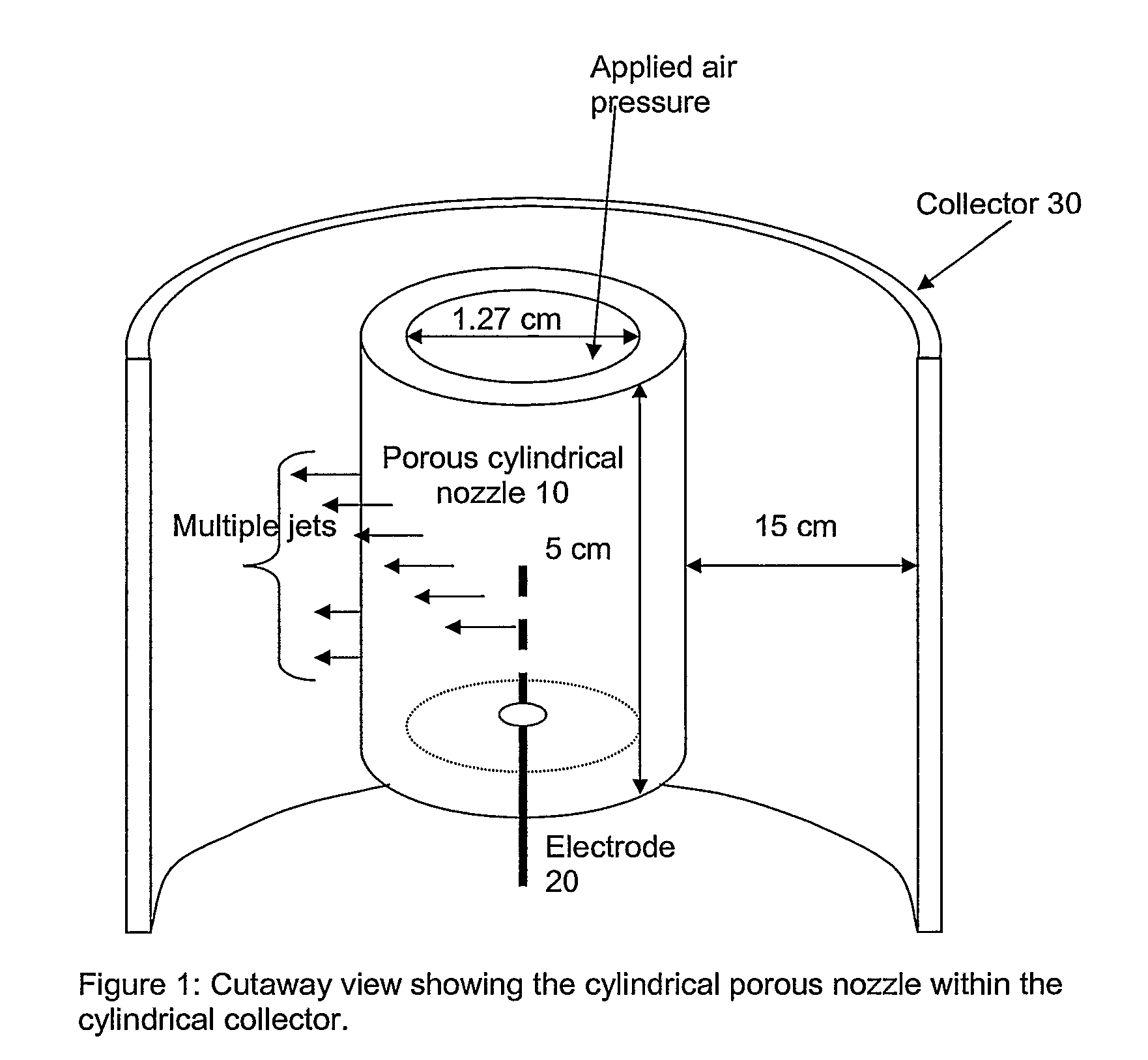

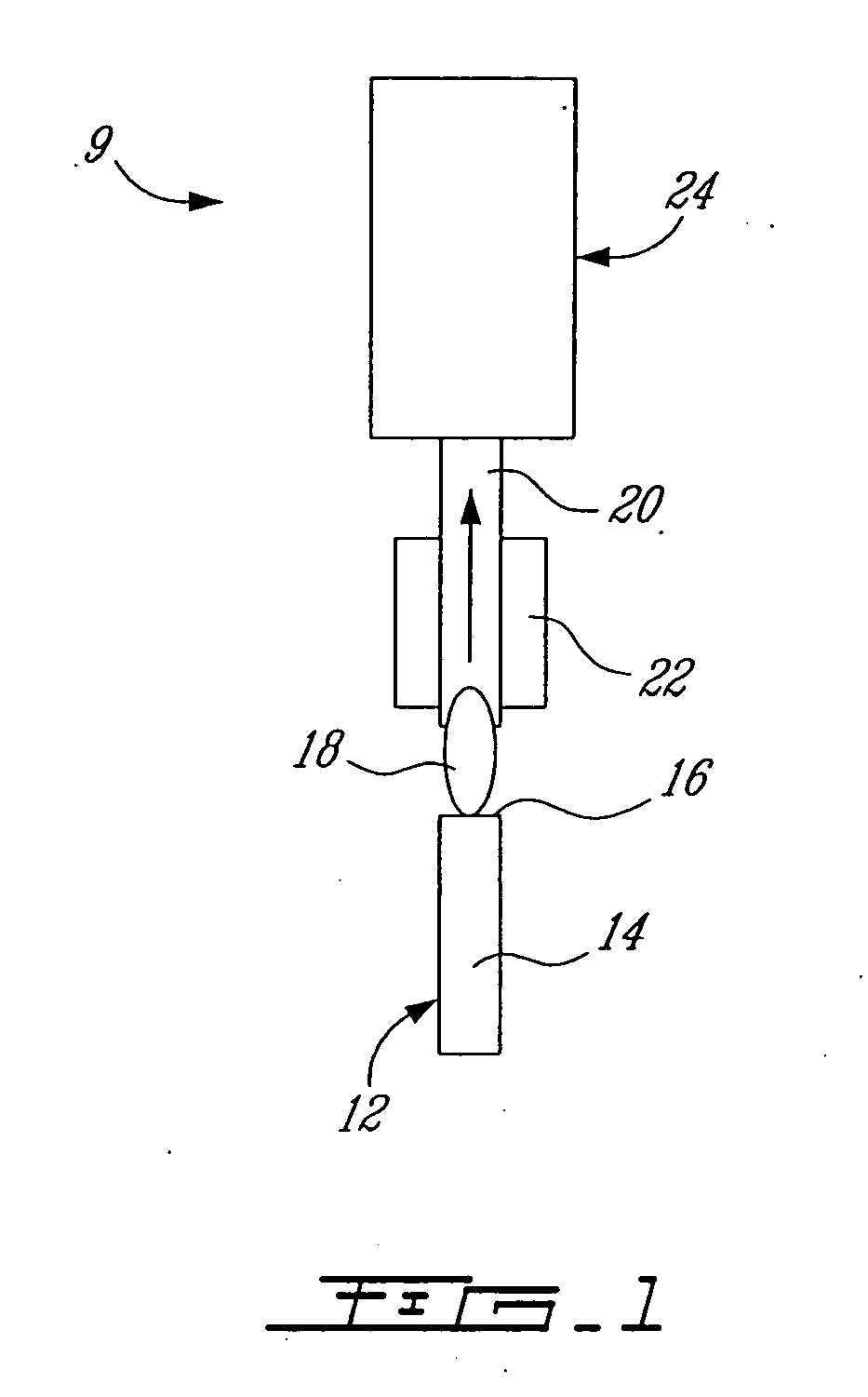

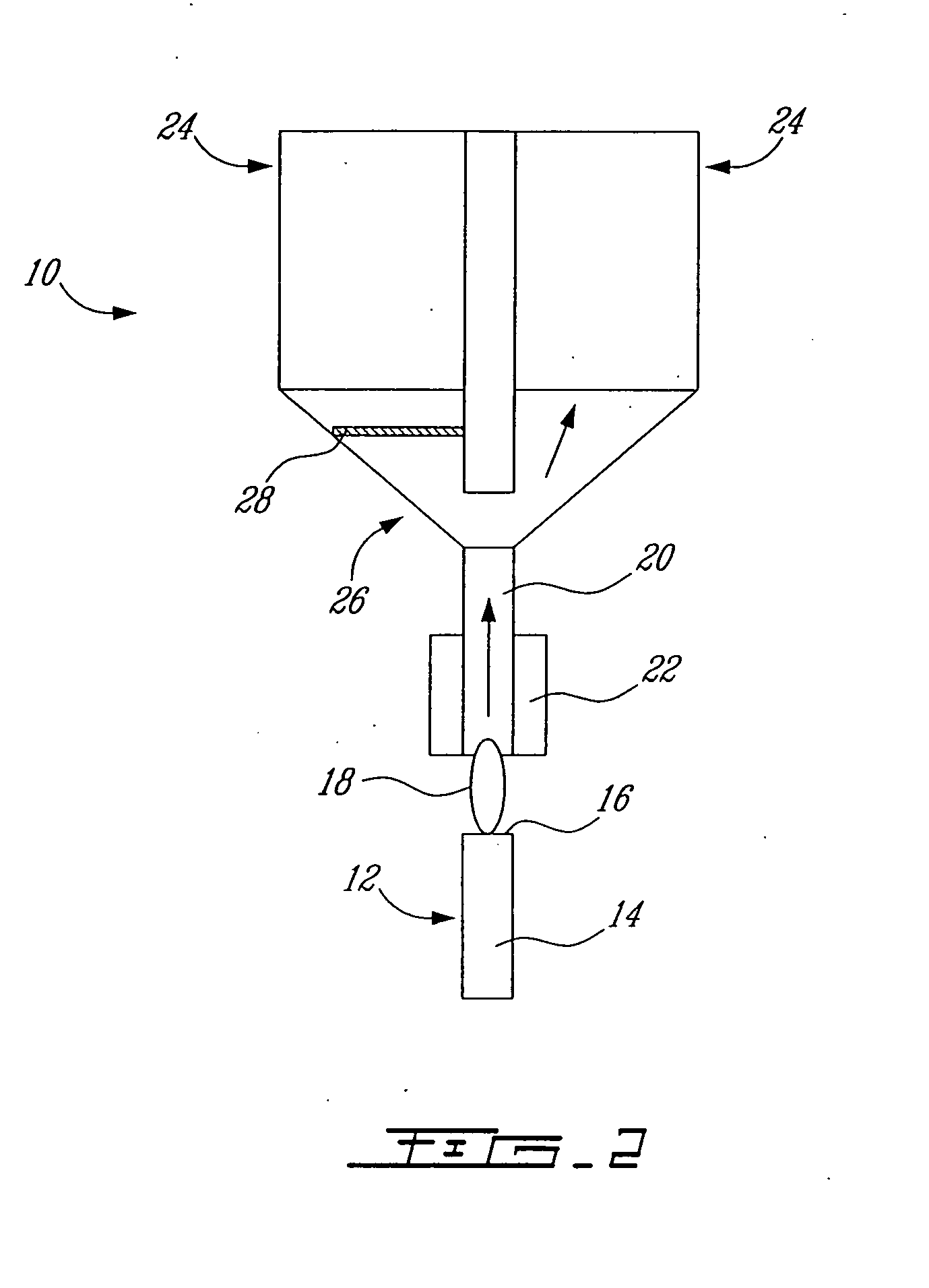

Method and device for producing electrospun fibers

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

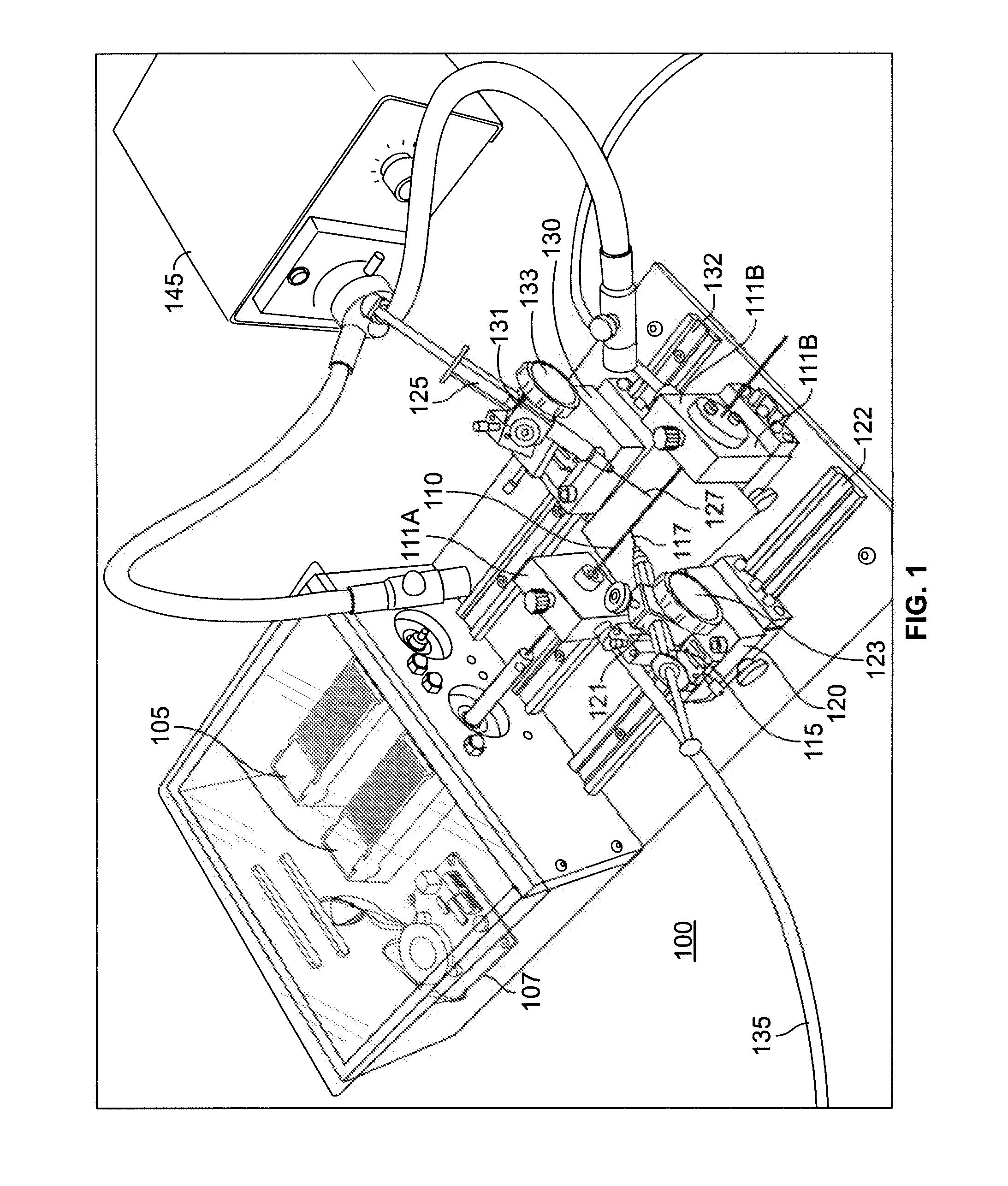

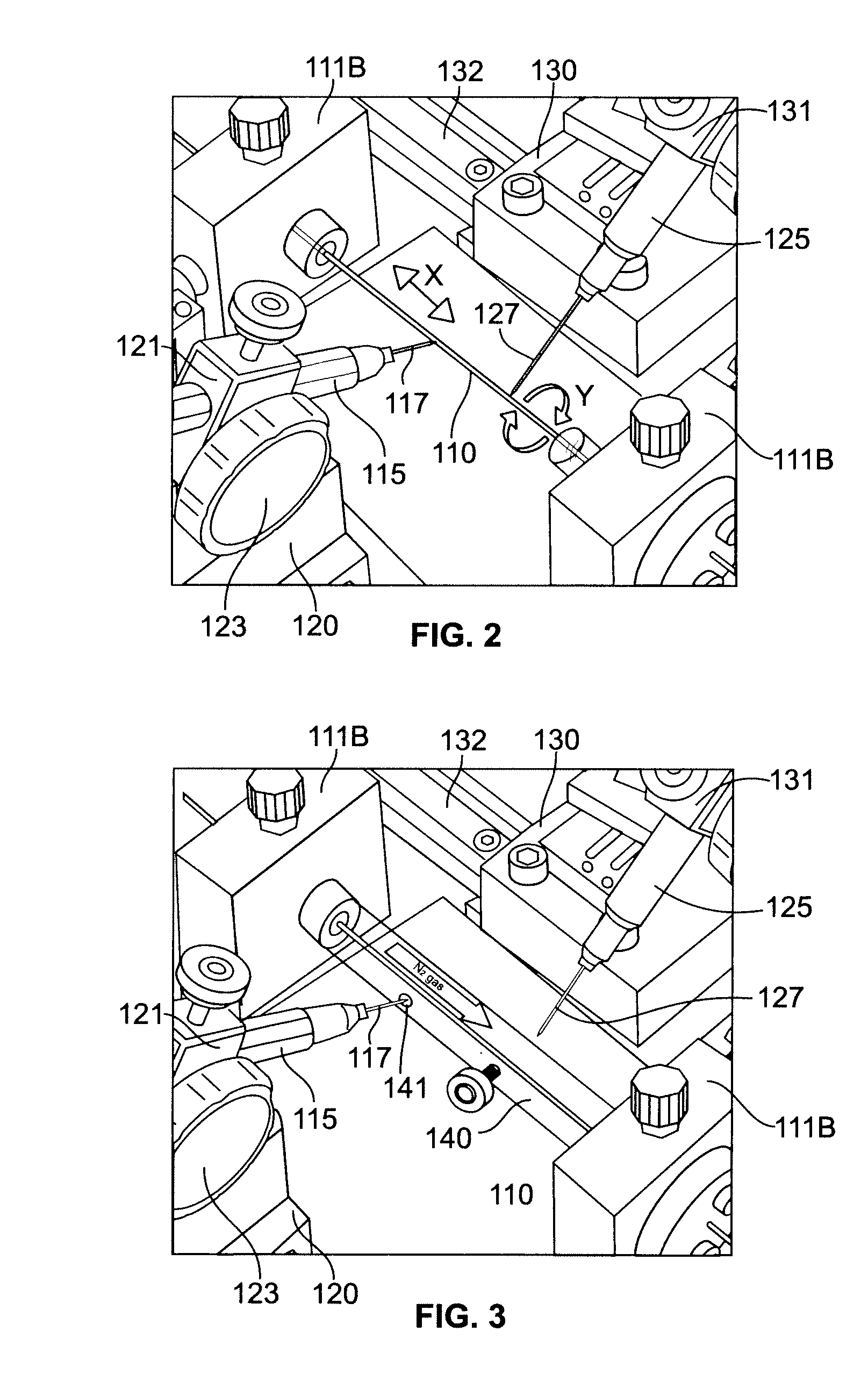

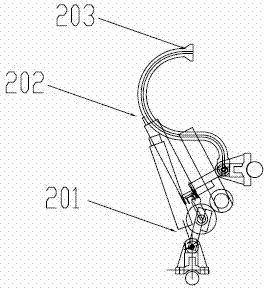

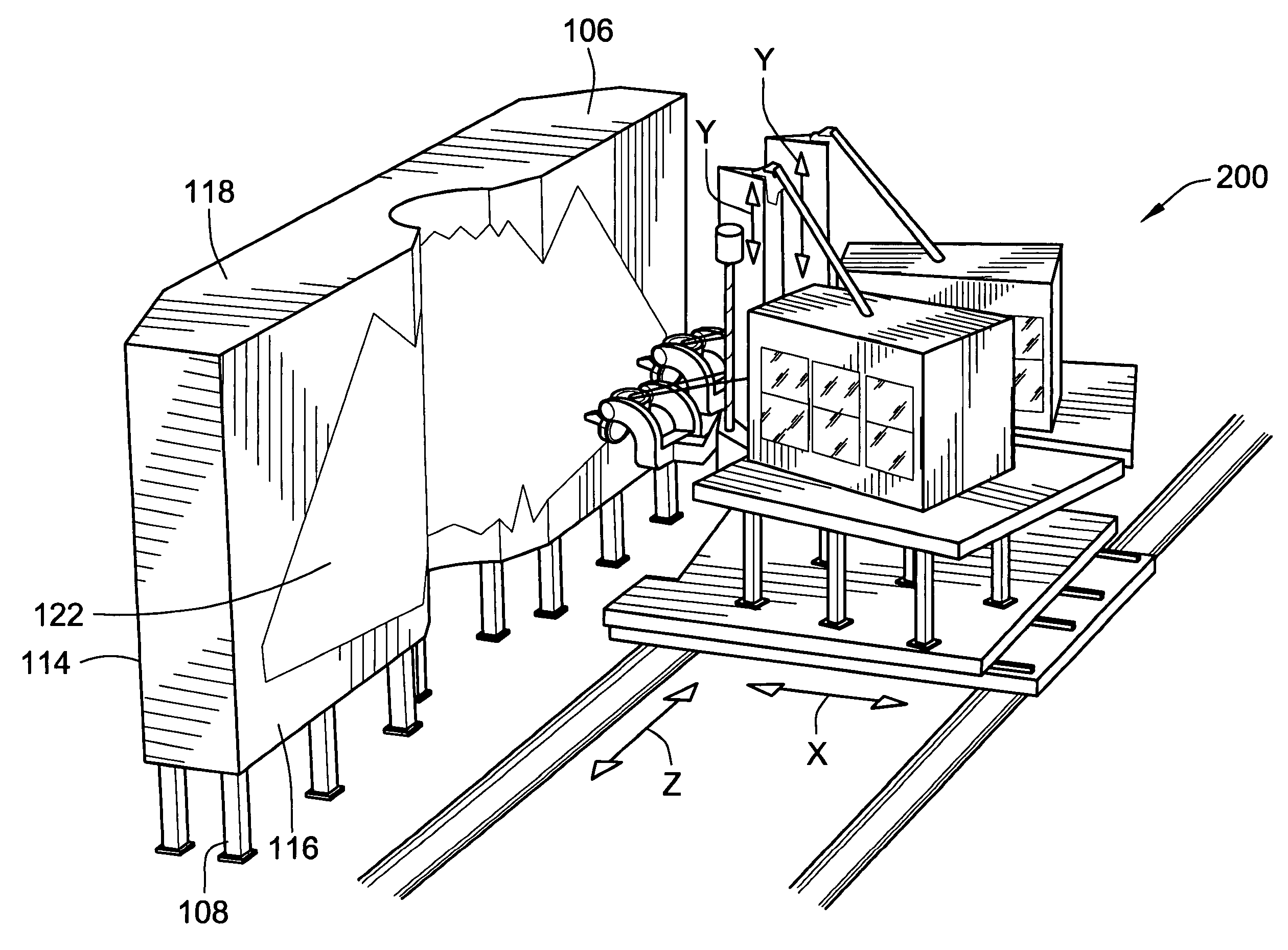

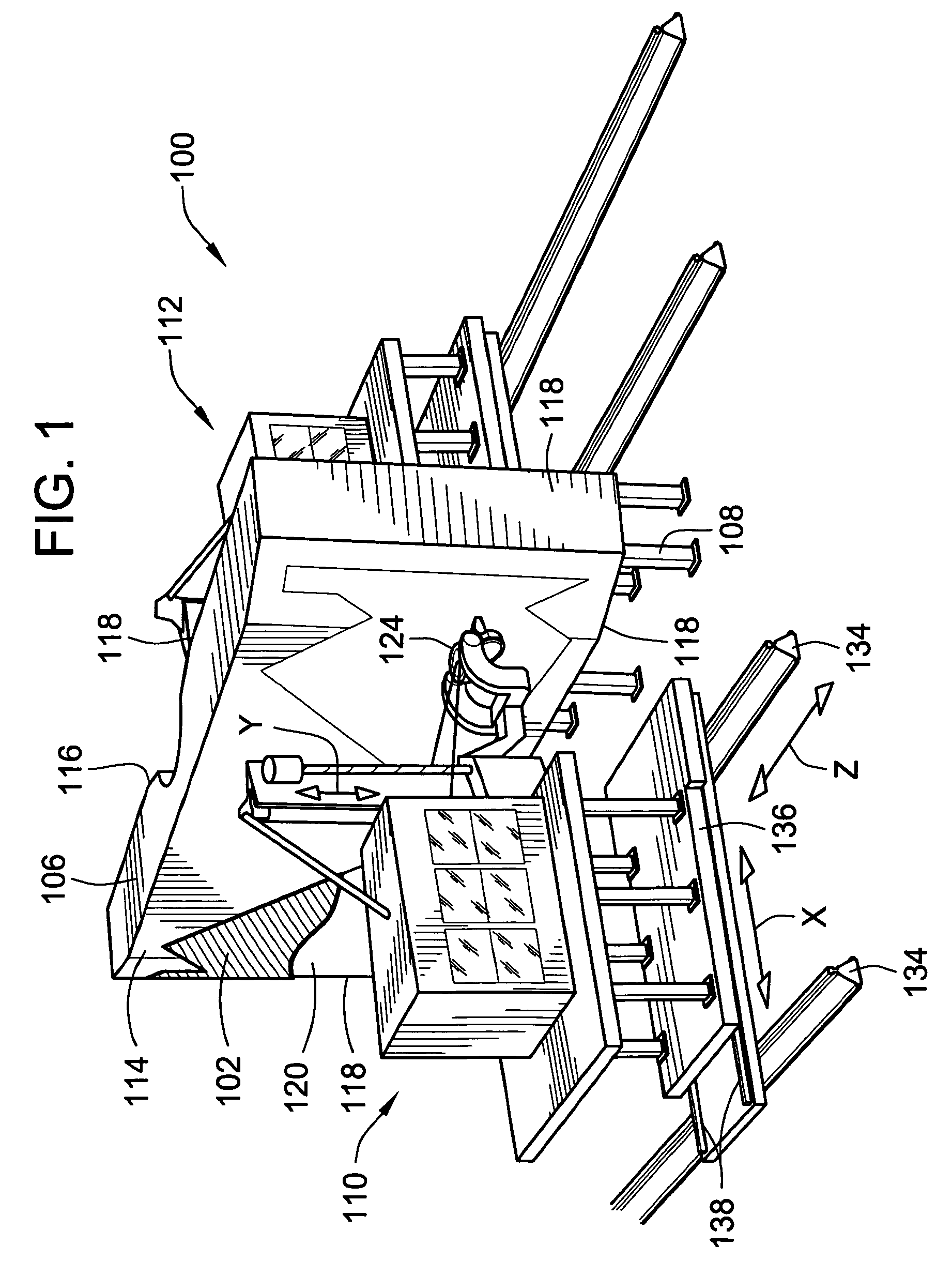

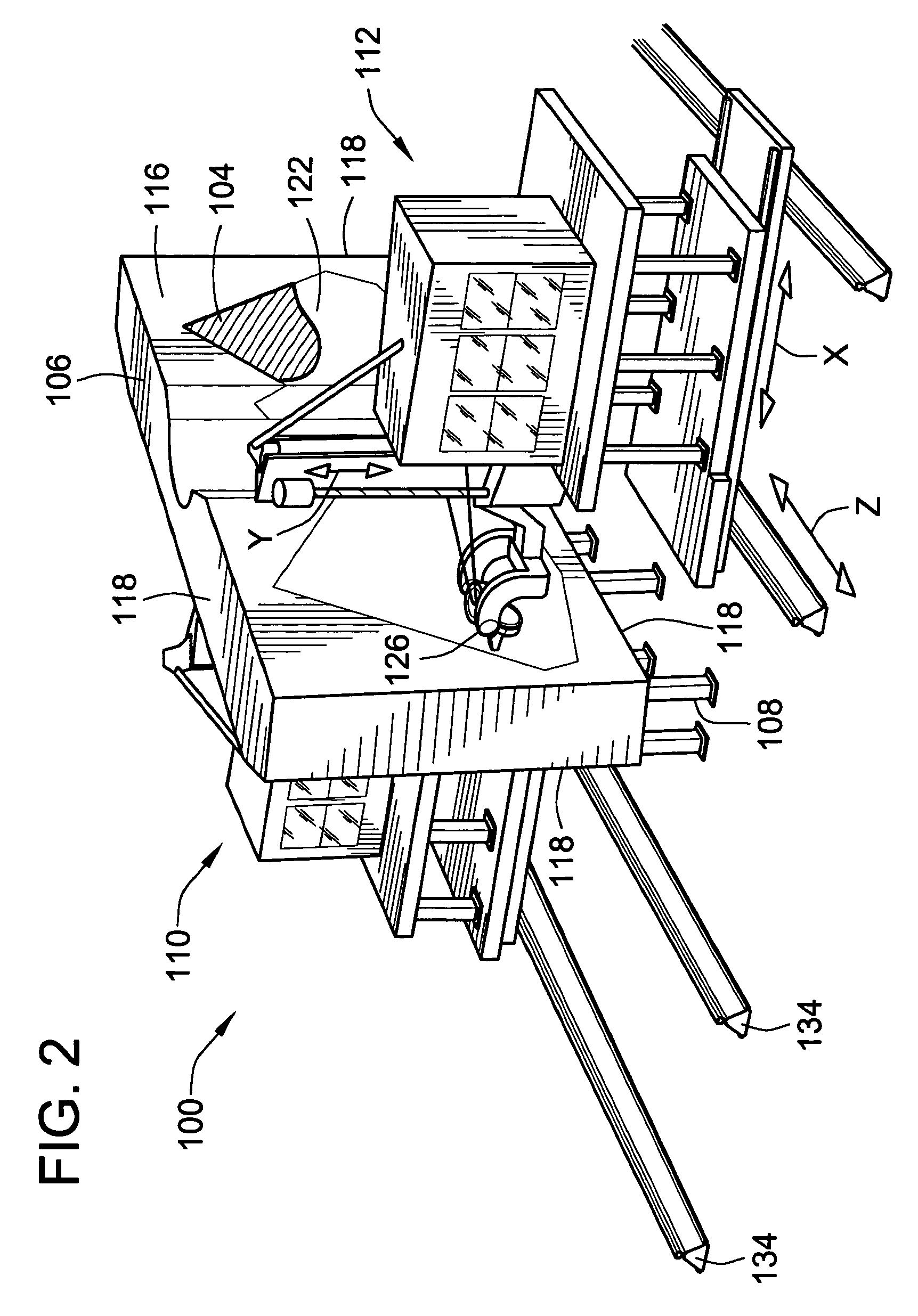

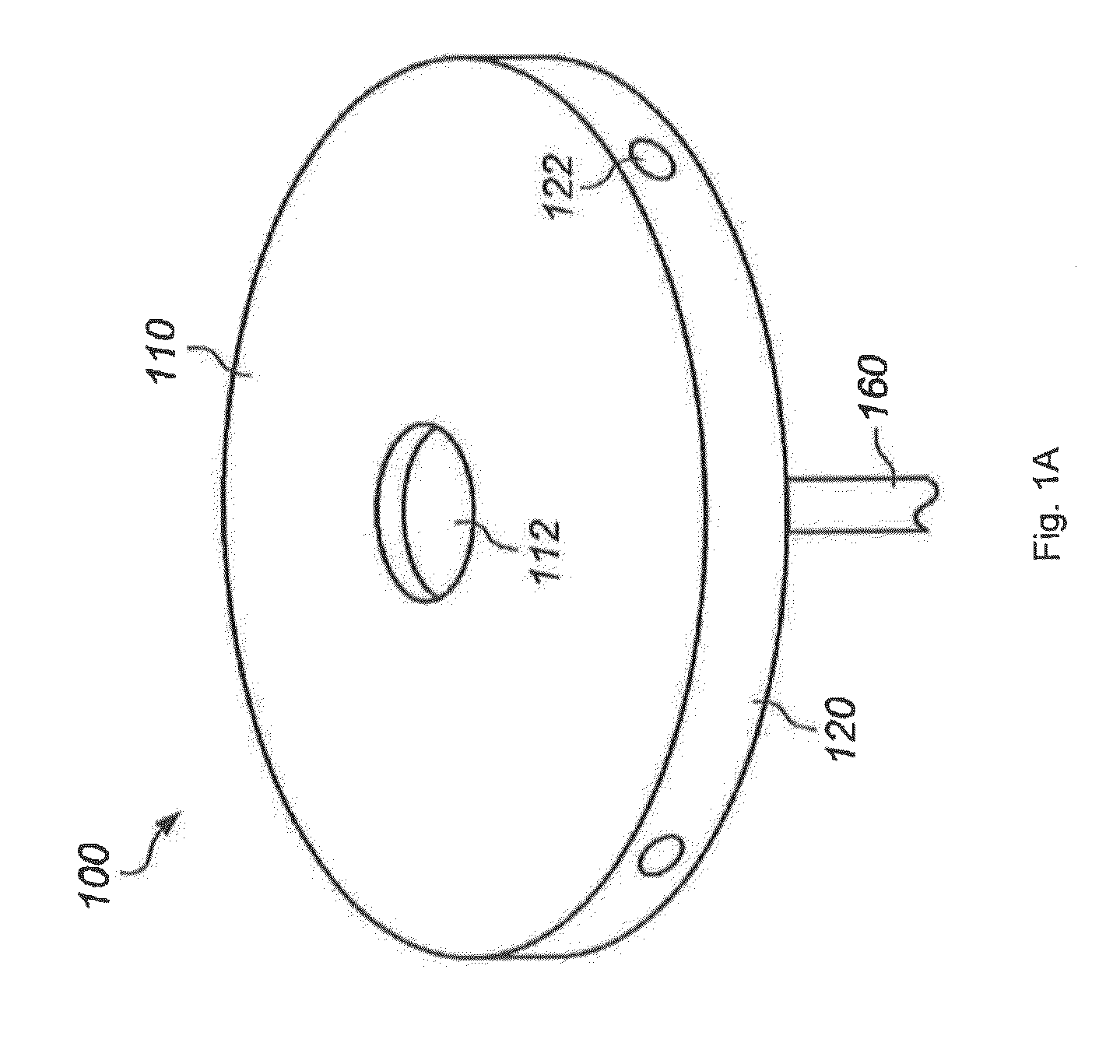

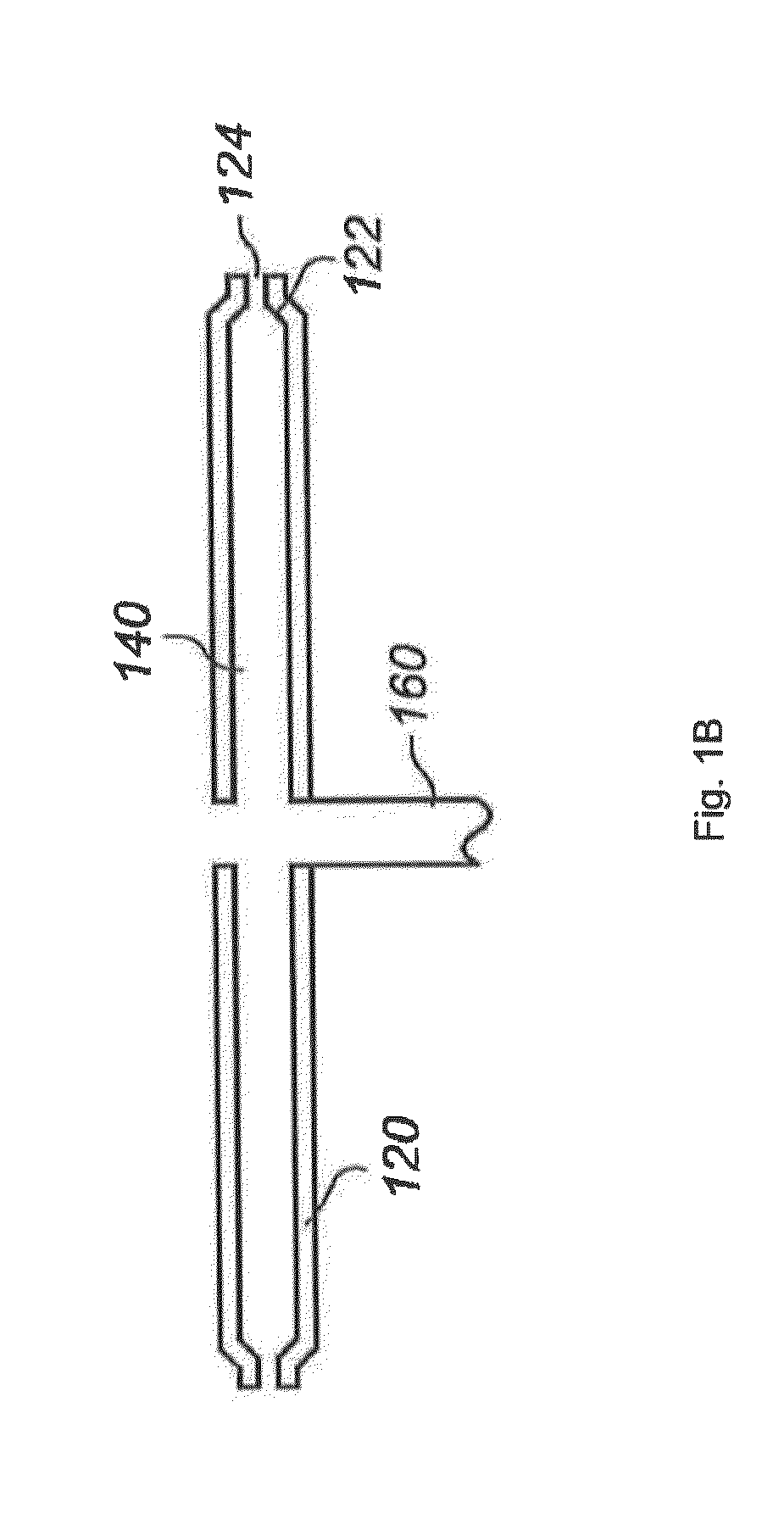

System and method for making biomaterial structures

ActiveUS20110076384A1Unique and robust mechanical propertyProperty is limitedNew-spun product collectionMonocomponent fibroin artificial filamentFiberMaterials processing

A system and method for making a biomaterial device includes a support structure providing a shape for a biomaterial device. At least one applicator has a supply of biomaterial solution and is positioned along the support structure. The at least one applicator forms a biomaterial fiber by applying shear force to the biomaterial solution and delivering the biomaterial fiber to the support structure. A controller causes relative movement between the support structure and the at least one applicator, and the biomaterial fiber is arranged on the support structure according to the relative movement to form the biomaterial device. The biomaterial may be silk fibroin which may be wound onto a reciprocating and rotating mandrel. Control over the properties of the biomaterial device is achieved through appropriate selection of material processing, winding strategy, and post-winding processing.

Owner:TRUSTEES OF TUFTS COLLEGE +1

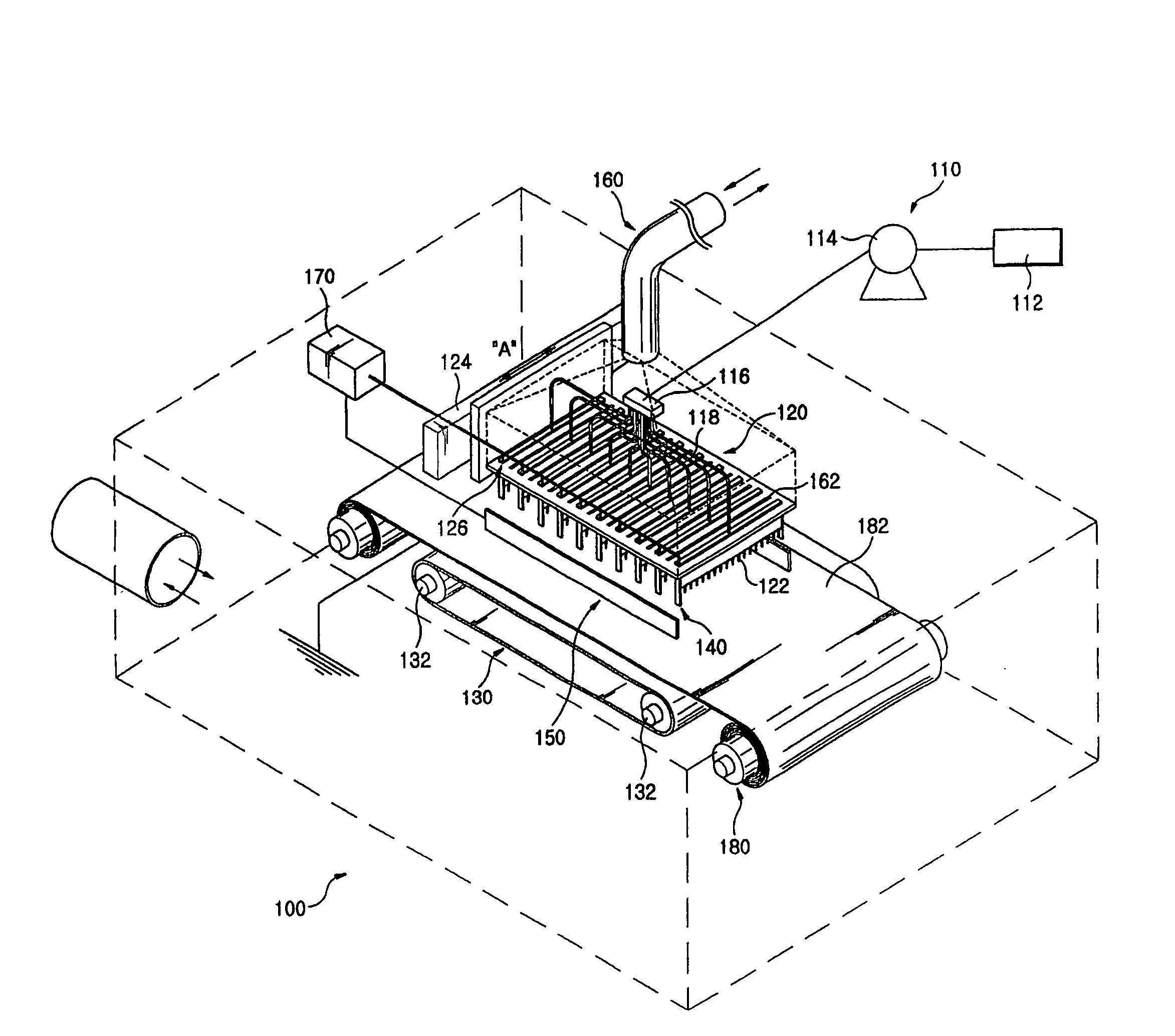

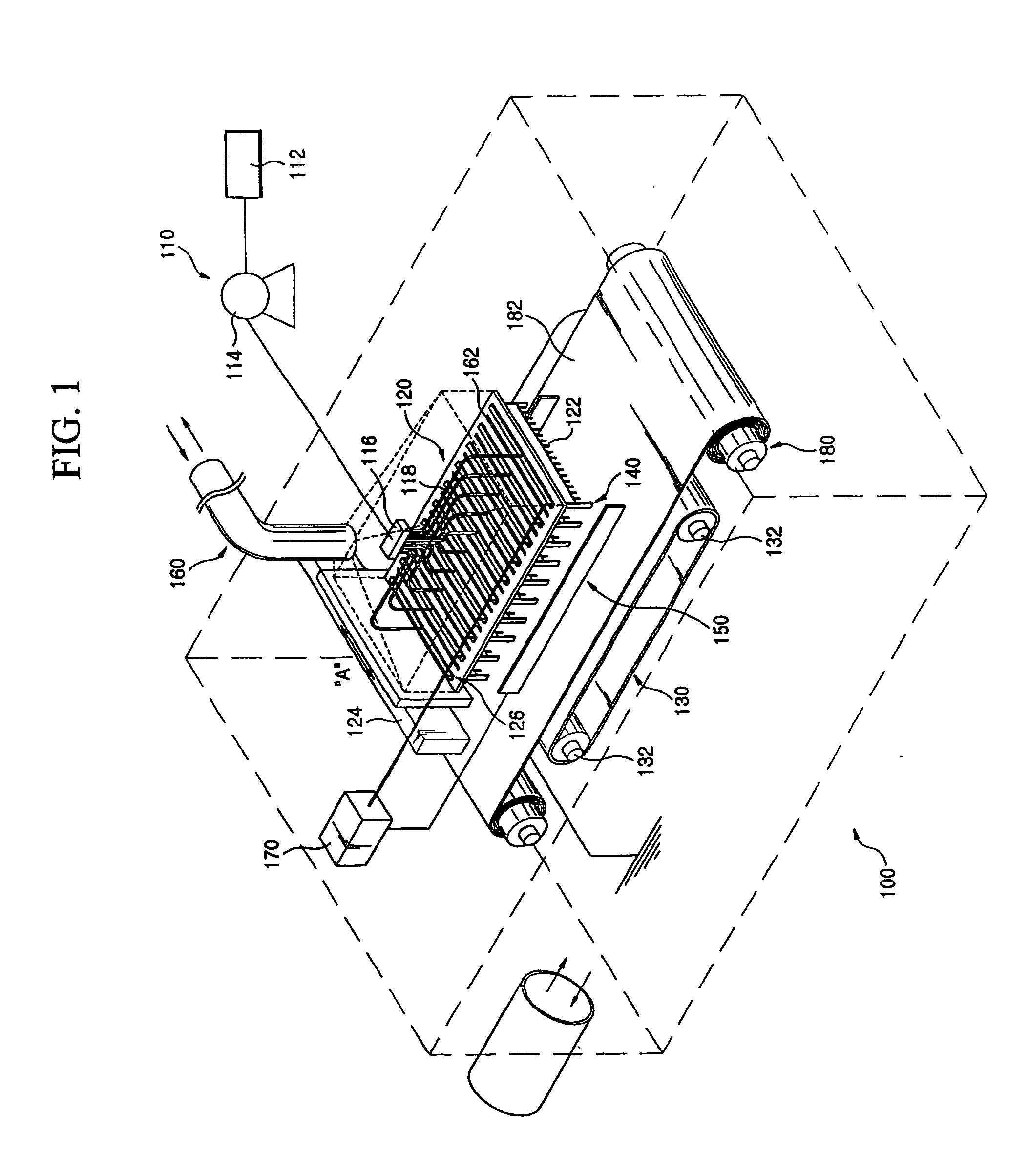

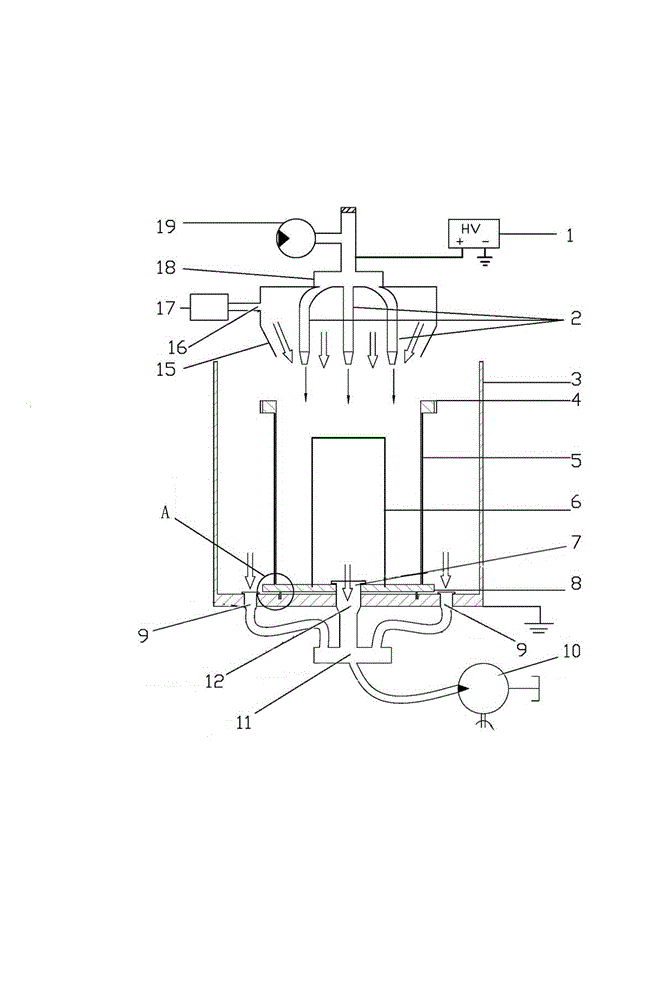

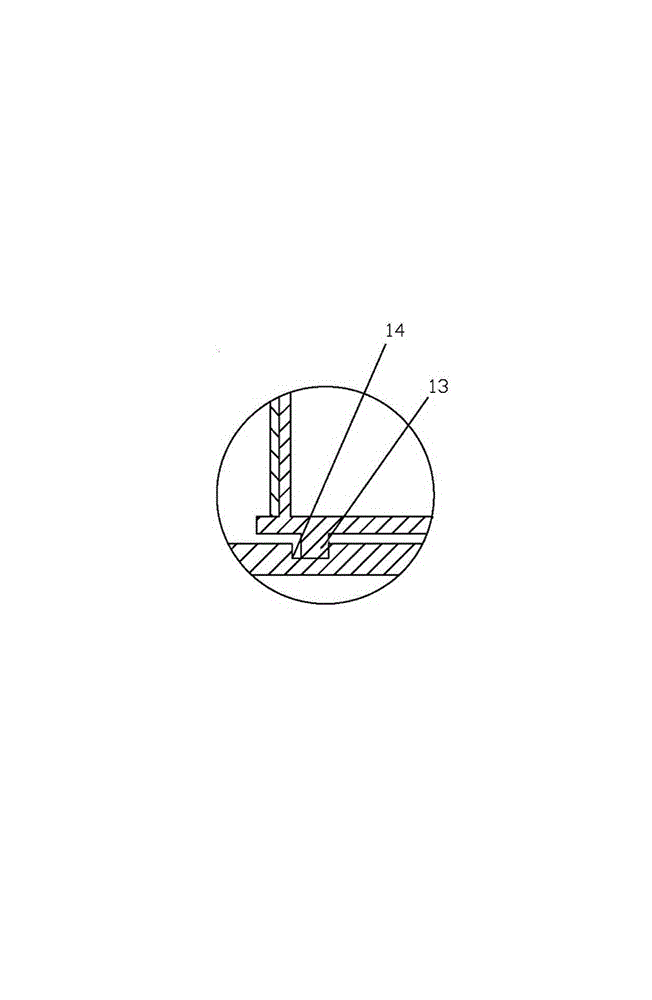

Apparatus for producing nanofiber utilizing electospinning and nozzle pack for the apparatus

The apparatus for producing a nanofiber includes a supply unit (110) for supplying melted polymer for fiber material, a spinning unit (122) having several radiation nozzles (122) to which first voltage having a polar is applied to discharge the polymer solution supplied from the supply unit in a filament form, a collector (130) spaced apart form the spinning nozzles in order to pile the filament from the spinning unit and applied to second voltage having opposite polar to the first voltage, and a control unit (140) applied to the first voltage having the same polar as the charged filament and extended from an end of the spinning nozzle toward the collector at least at both sides of the spinning unit in order to prevent repulsion and dispersion of the filament stream radiated from each spinning nozzle.

Owner:NANOPHIL

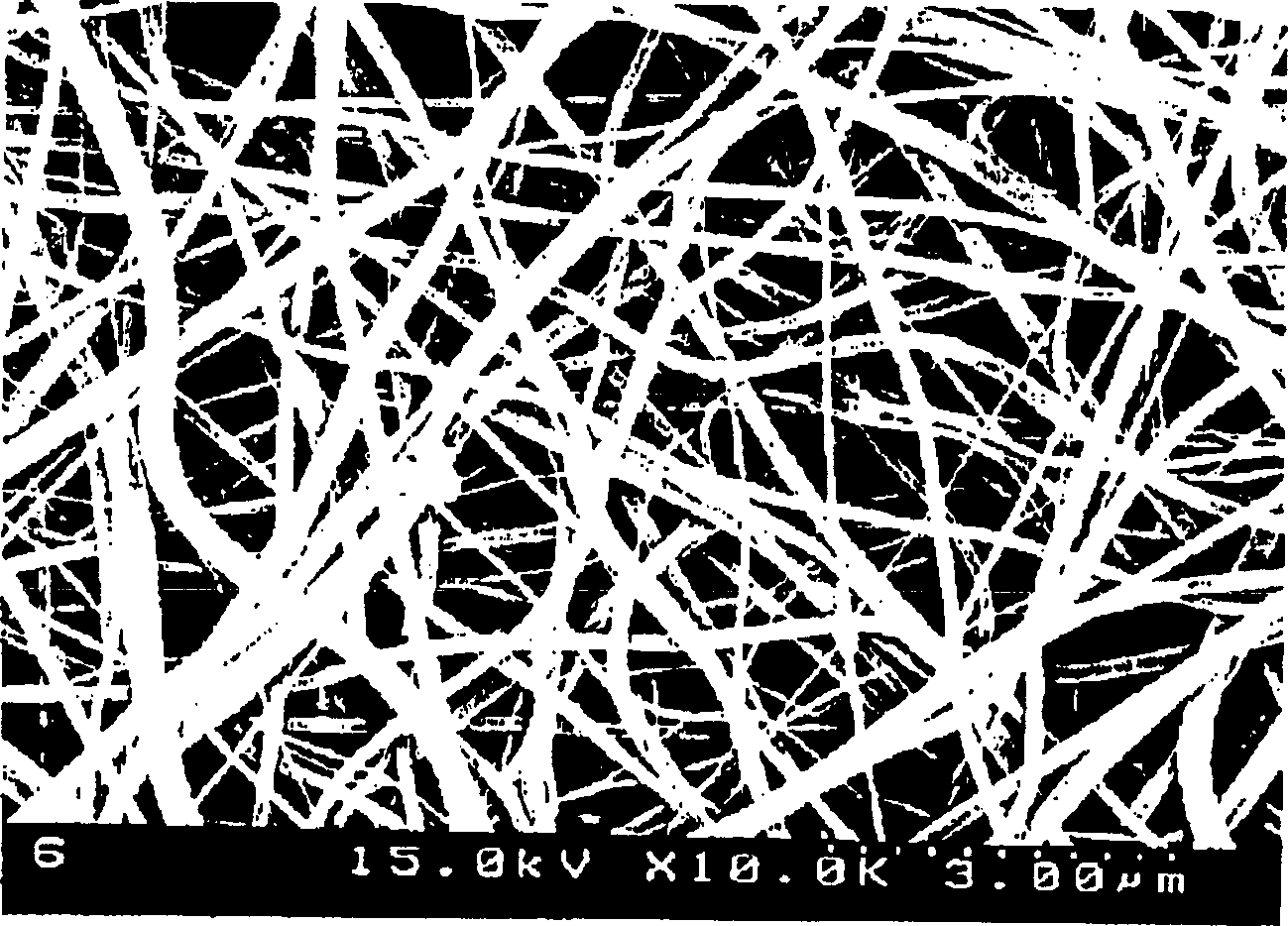

Graphene fiber non-woven fabric and preparation method thereof

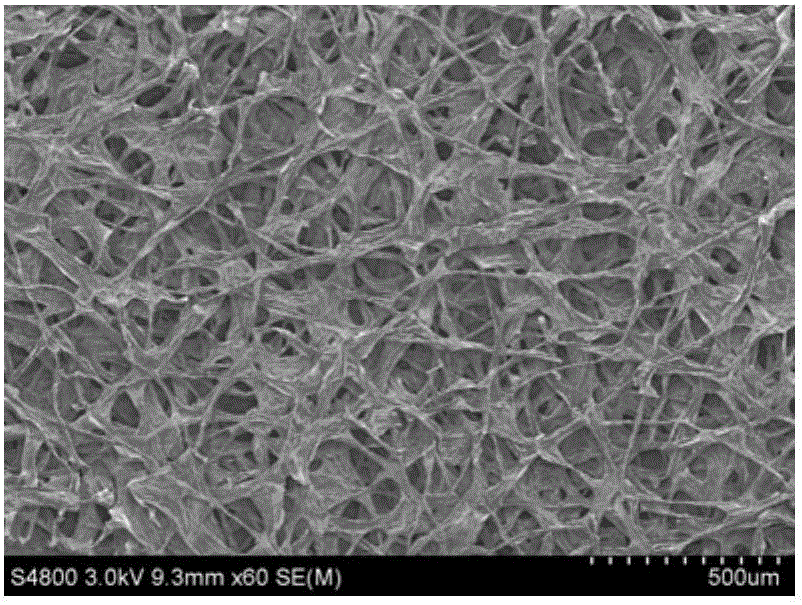

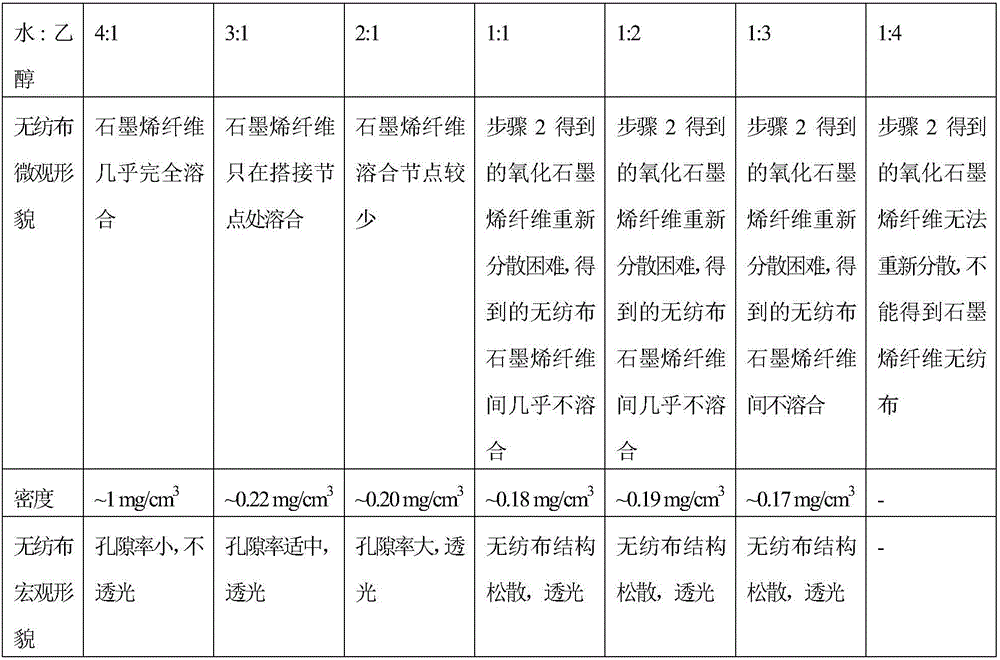

ActiveCN106192201AGood electrical and thermal conductivitySimple methodNew-spun product collectionGrapheneElectricityPolymer science

The invention discloses a graphene fiber non-woven fabric and a preparation method thereof. The non-woven fabric is obtained by filtering and depositing a graphene short-fiber dispersion solution through a filter net and performing drying and reduction, so that the structural unit of the non-woven fabric is disorderly-stacked and bonded graphene short fiber, and fiber is overlapped to form a large number of holes through which liquid of gas can pass. The graphene fiber non-woven fabric has the good mechanical strength and tenacity, is completely composed of graphene fiber, does not contain high polymer materials as a skeleton or adhesives, the electricity and heat conducting performance of the reduced network structure overlapped by the graphene fiber is excellent, and the non-woven fabric can be used as a multifunctional high-performance fabric.

Owner:杭州德烯科技集团有限公司

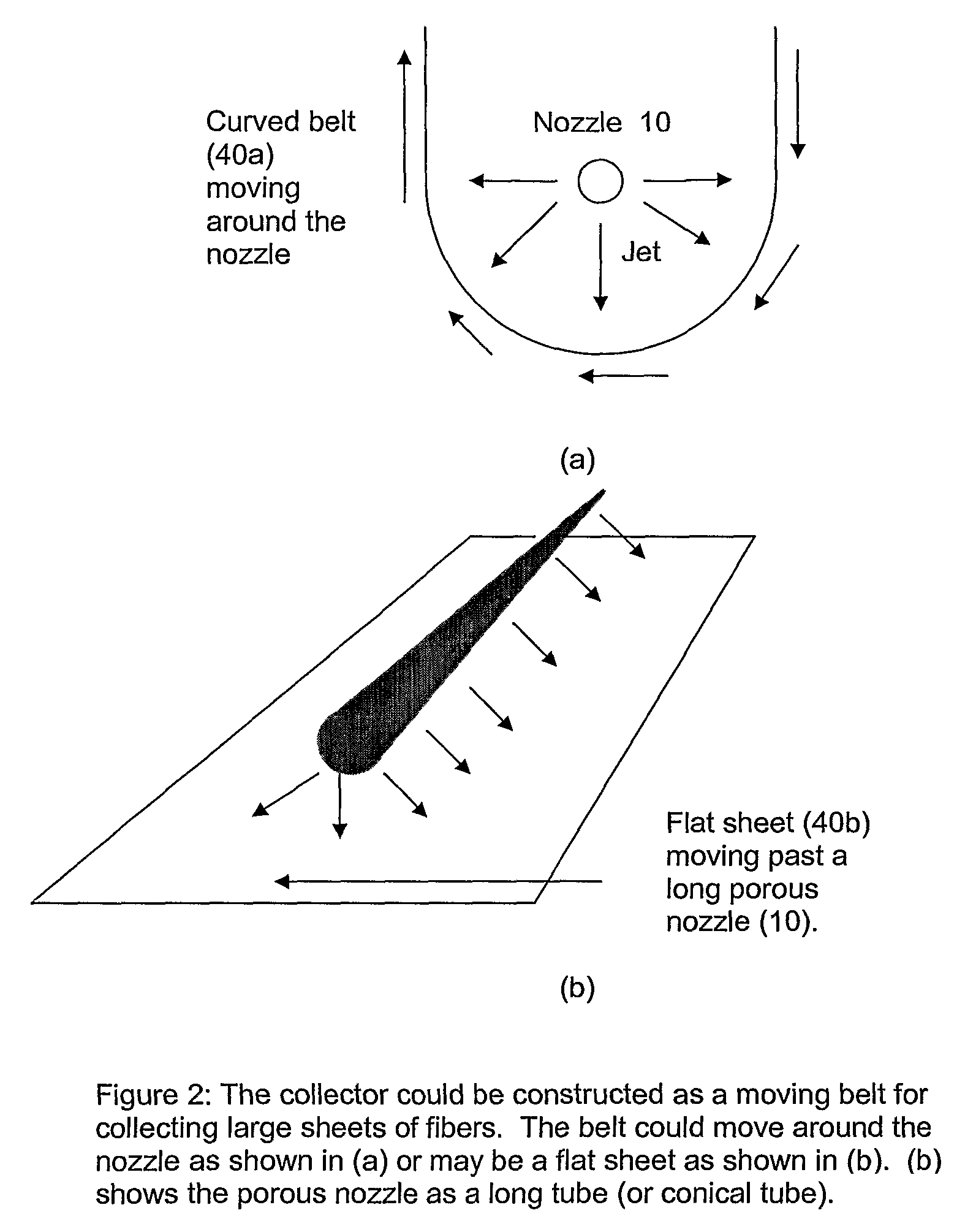

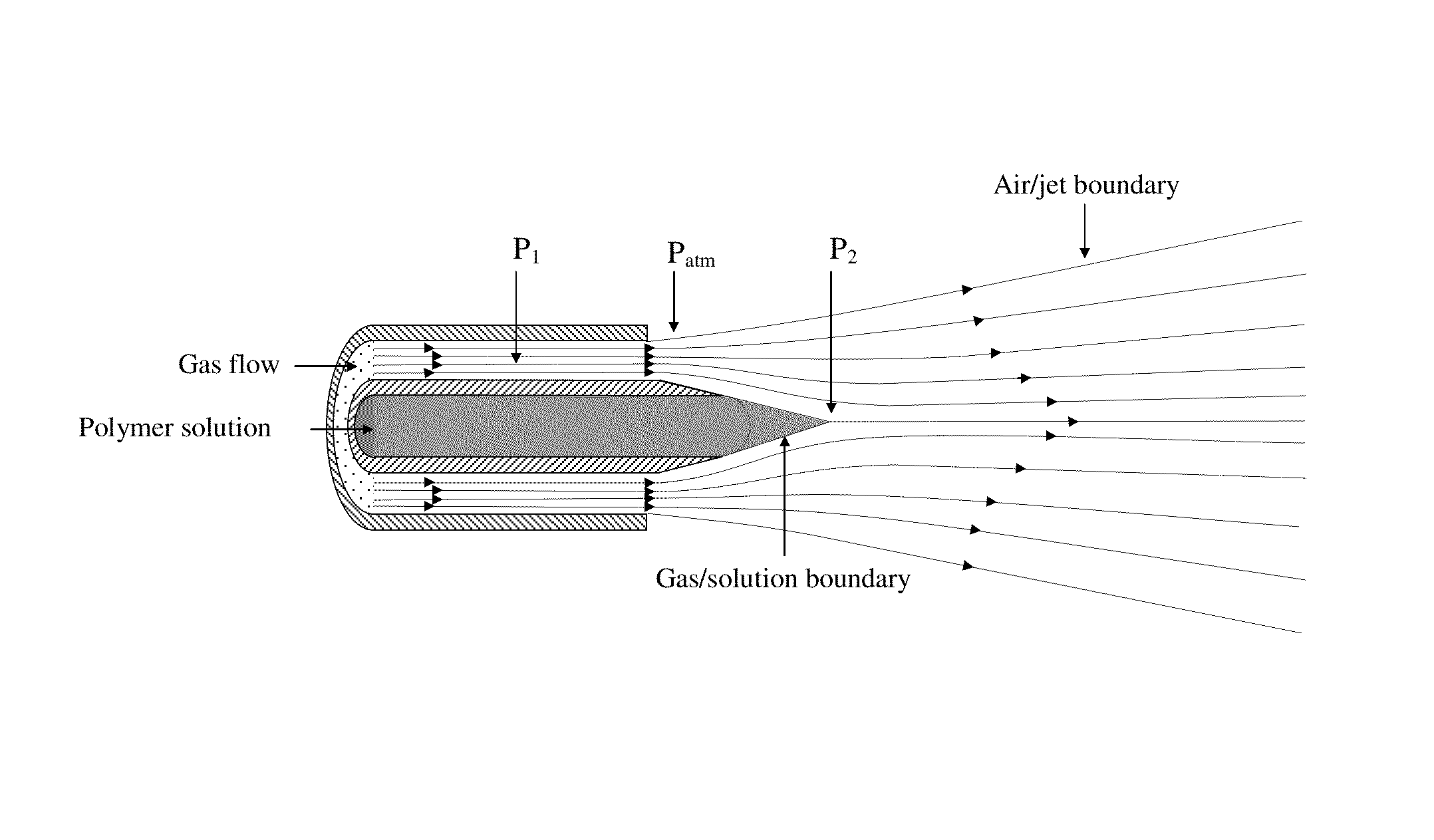

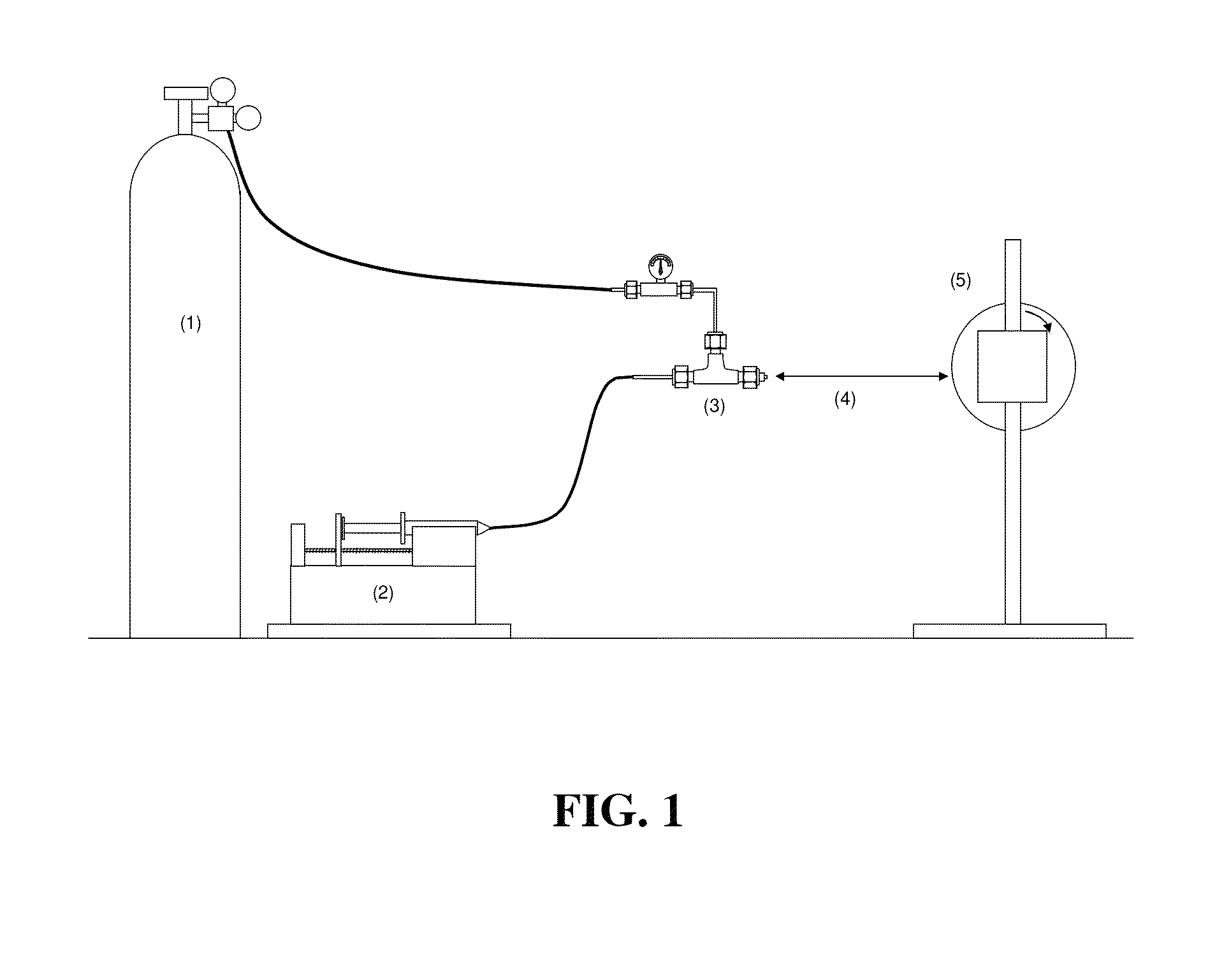

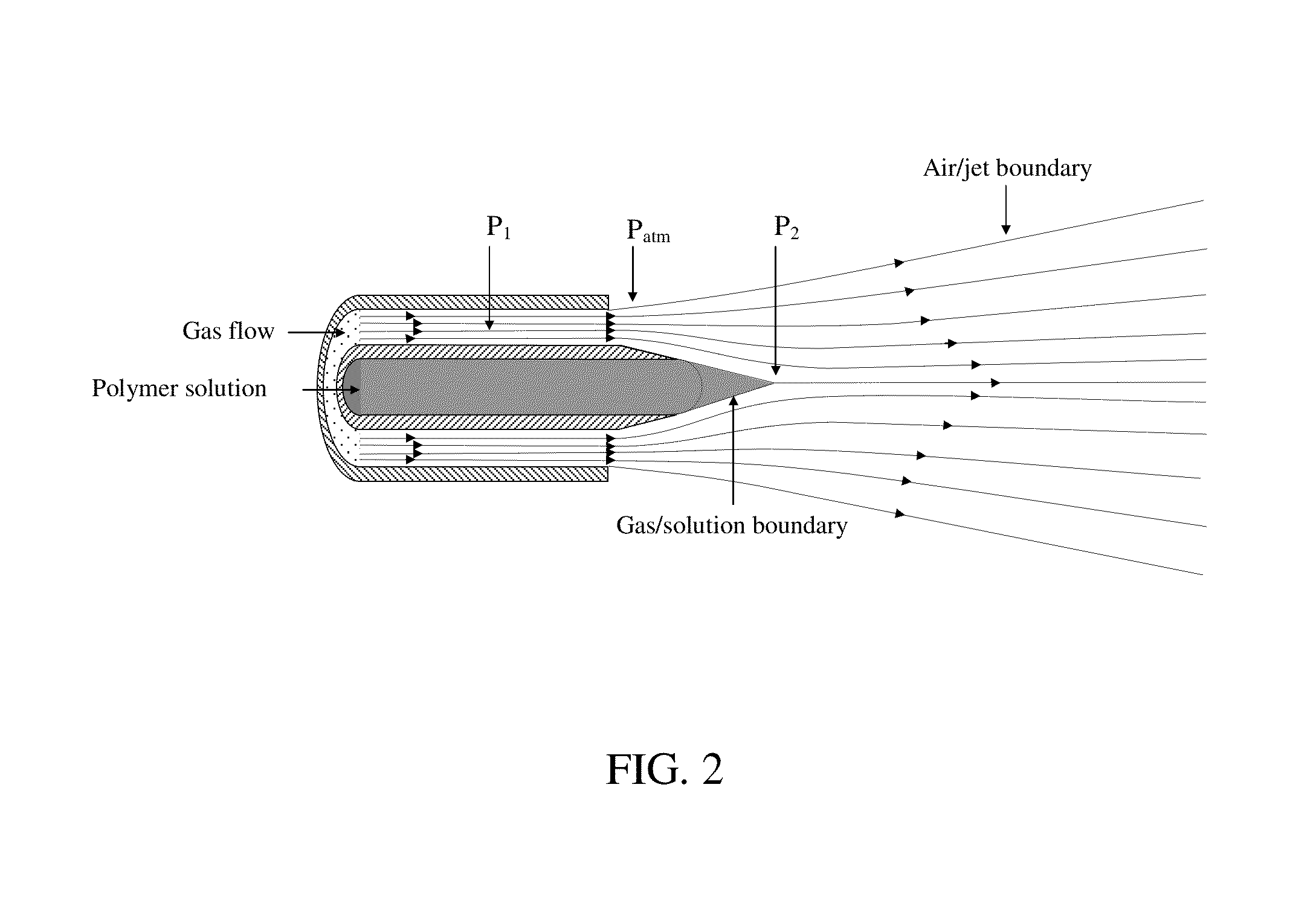

Solution blow spinning

InactiveUS8641960B1Reducing fiber diameterScalable for commercial productionNew-spun product collectionMelt spinning methodsEngineeringNanofiber

The present invention relates to a solution blow spinning method for the production of nonwoven webs of micro and nanofibers.

Owner:US SEC AGRI

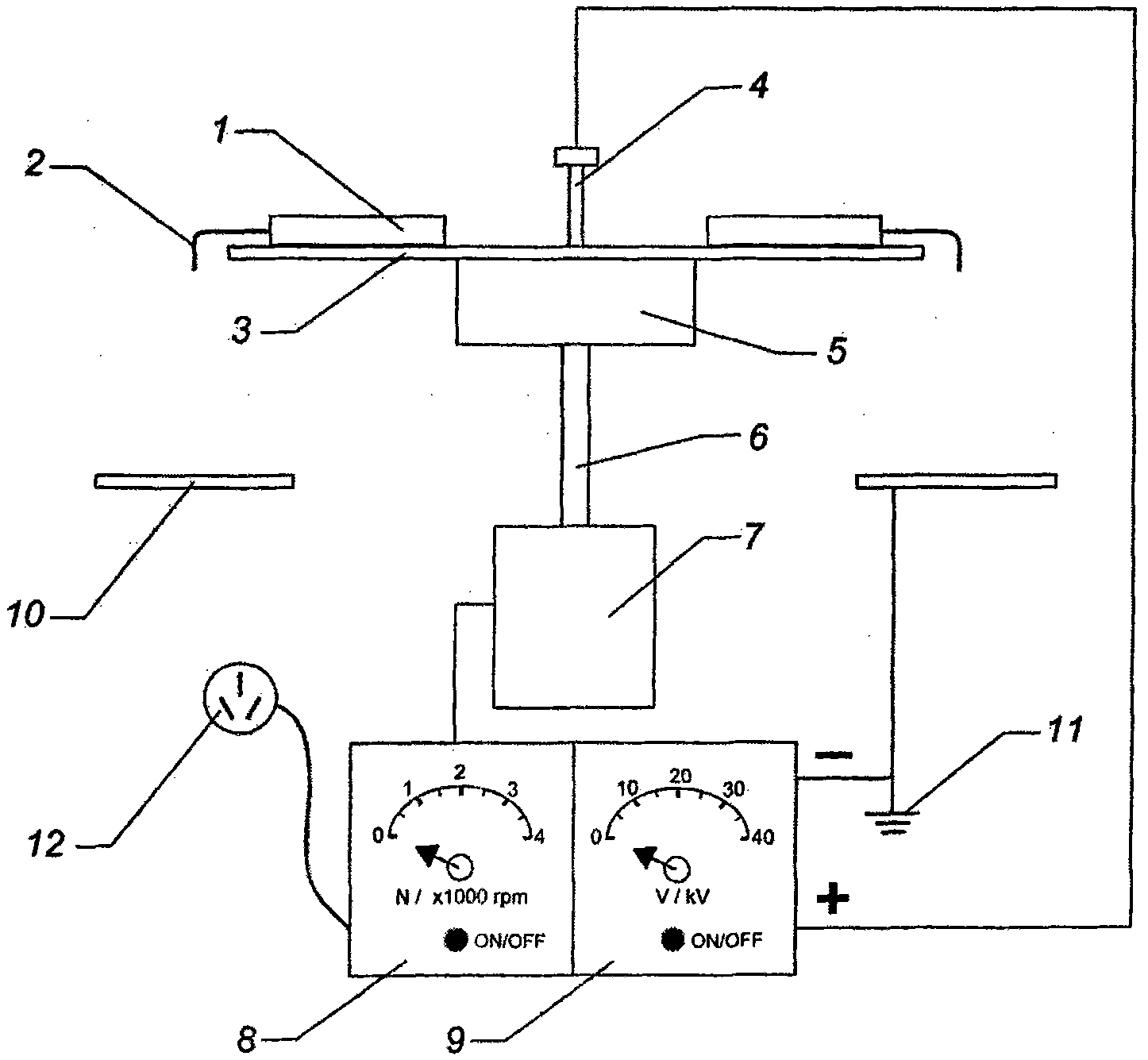

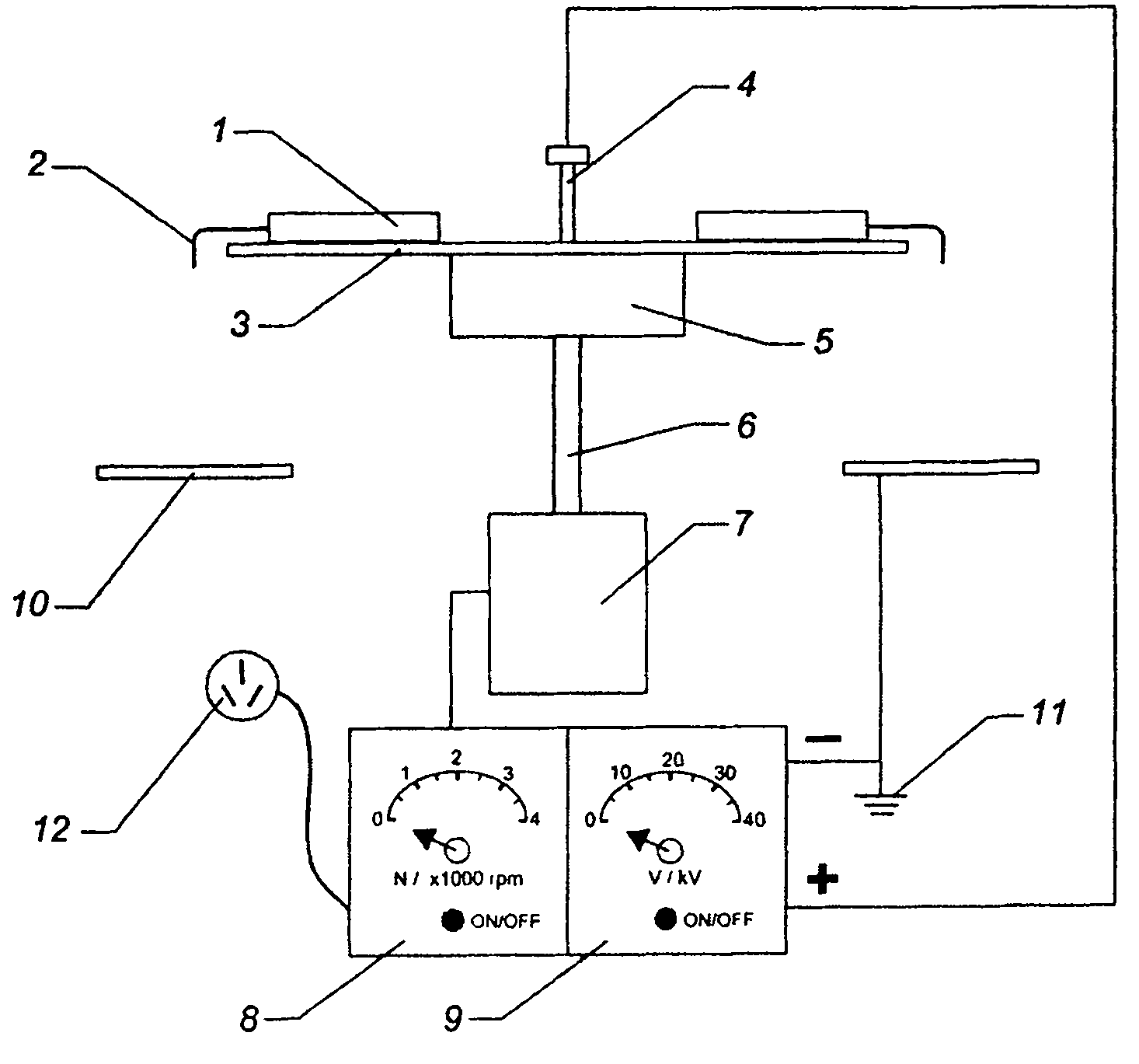

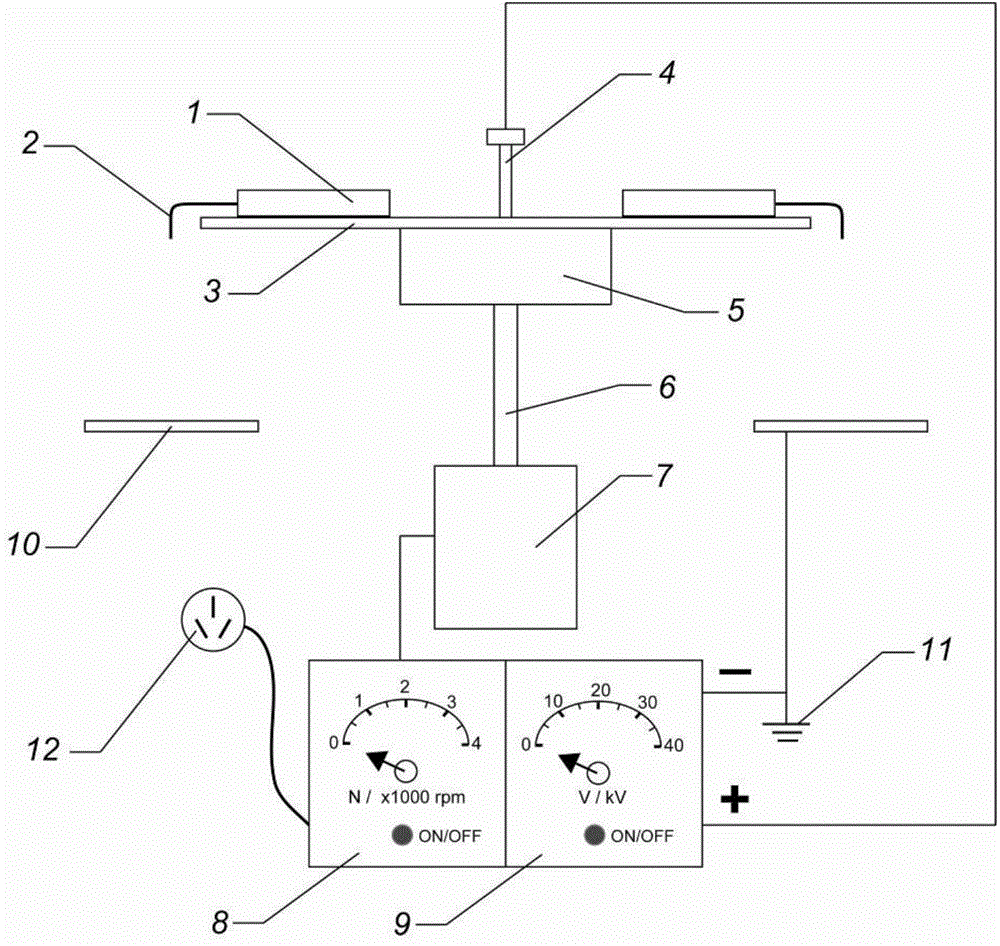

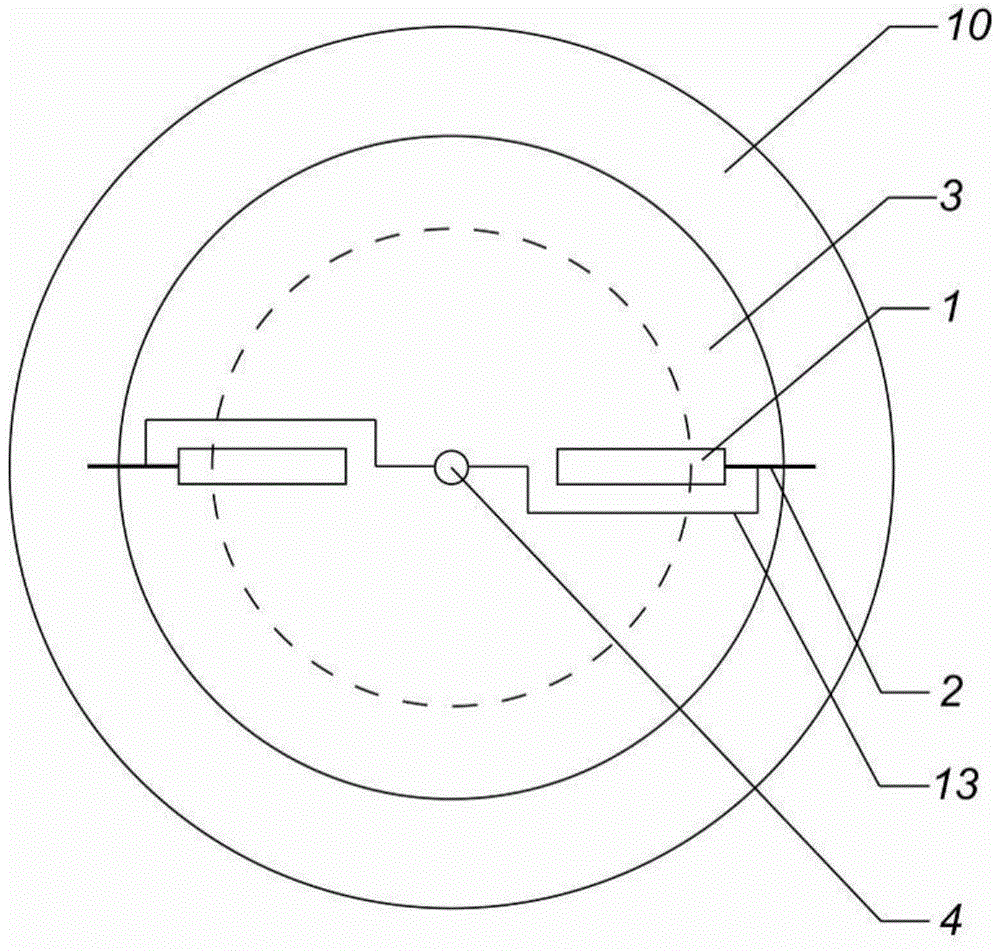

Device for preparing nano fibers with ordered arrangement and cross structures

InactiveCN101857976ASmall and uniform diameterGood lookingNew-spun product collectionFilament/thread formingFiberElectric machine

The invention belongs to the technical field of electrostatic spinning, and relates to a low-pressure centrifugal electrostatic spinning device for preparing nano fibers with ordered arrangement and cross structures for nano electronic devices and optical devices. A spinning solution container with a processed hollow stainless steel needle is fixed on the upper side of an insulating rotary table, a rotary shaft of a rotary motor is connected with the insulating rotary table together through an insulating support body and drives the insulating rotary table to rotate, the processed hollow stainless steel needle is connected with an anode of a high-voltage power supply, a metal rod coaxial with the rotary shaft is fixed at the circle center of the insulating rotary table, and the metal rod is communicated with the processed hollow stainless steel needle through a metal lead; both a rotational speed control panel of the motor and the high-voltage power supply or a voltage control panel have a power supply switch and an adjusting knob; and the cathode of the high-voltage power supply is connected with an annular metal collector and grounded. The device has the advantages of simple structure, reliable principle, low working voltage and good safety; and the prepared nano fibers have high order degree and attractive appearance.

Owner:QINGDAO UNIV

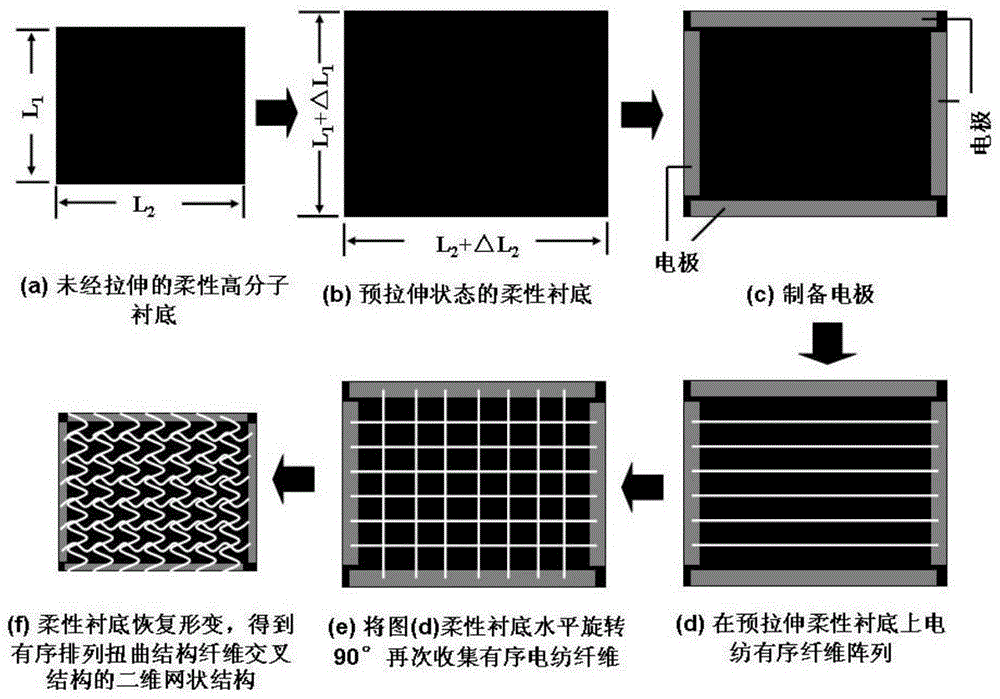

Method for manufacturing flexible stretchable device based on ordered arrangement torsion structure

InactiveCN104153128AAccurate realization of pre-strain controlAchieve pre-strain controlNew-spun product collectionFilament/thread formingPre strainElectrospinning

The invention belongs to the technical field of flexible device manufacturing, and relates to a method for manufacturing a flexible stretchable device based on an ordered arrangement torsion structure. The method includes the steps that firstly, a flexible macromolecule substrate is pre-stretched to be fixed to a glass sheet, and electrodes are manufactured at the four edges of the pre-stretched flexible macromolecule substrate; secondly, the flexible macromolecule substrate is placed on an annular metal collector connected with the negative electrode of a power source to serve as a collecting substrate, and a machined hollow stainless steel needle serves as a spinning spraying head; a spinning solution is injected into a spinning solution container for electrospinning; the flexible macromolecule substrate is horizontally rotated by 90 degrees for continuous electrospinning and then taken down from the glass sheet, and the flexible stretchable device based on an ordered arrangement torsion structure is obtained. The method is simple in manufacturing process and convenient to operate; the manufactured flexible stretchable device can be stressed and tensioned in one or two of the two-dimensional directions respectively, pre-strain control over materials in the two directions can be accurately achieved, and the application range is wide.

Owner:QINGDAO UNIV

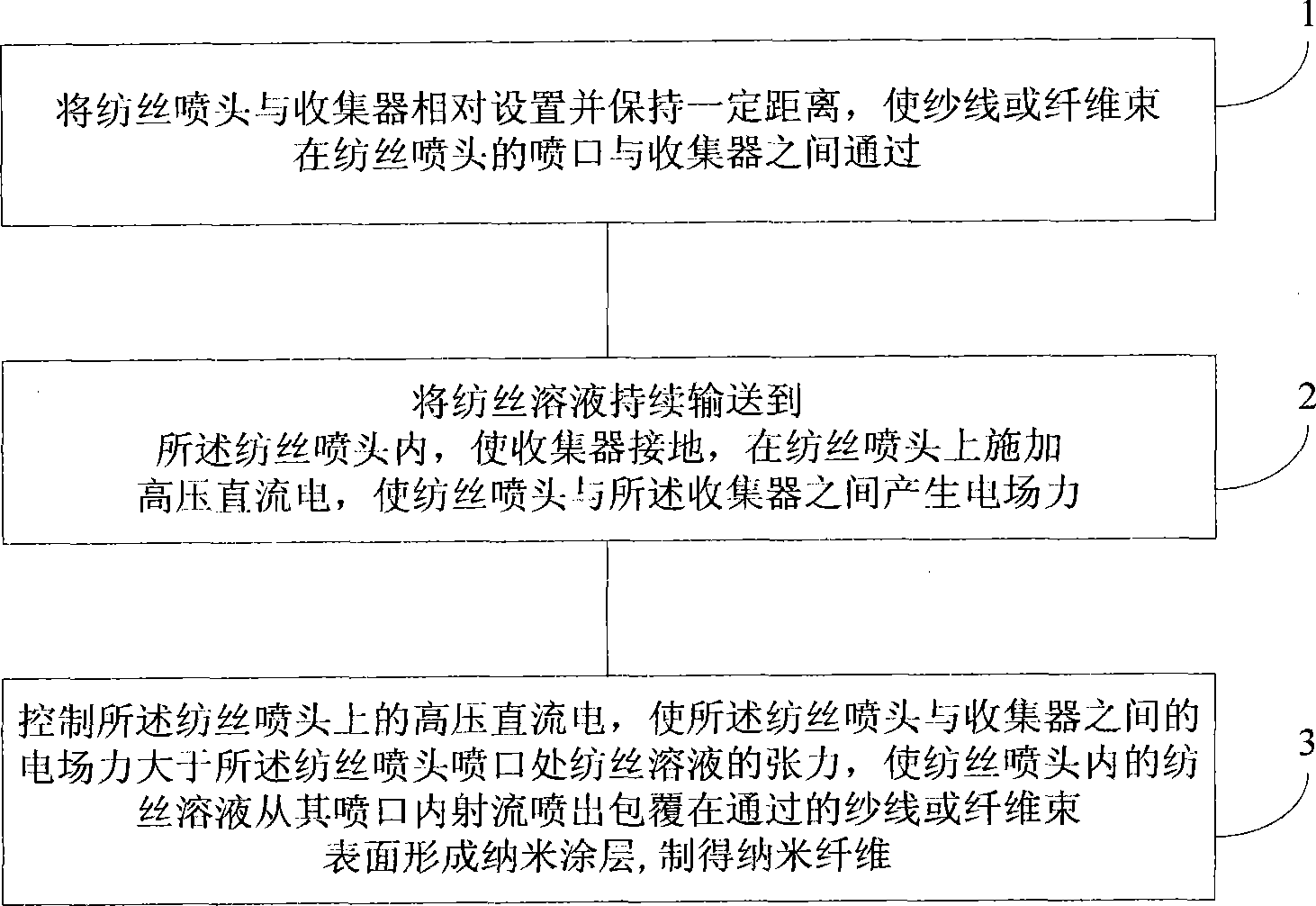

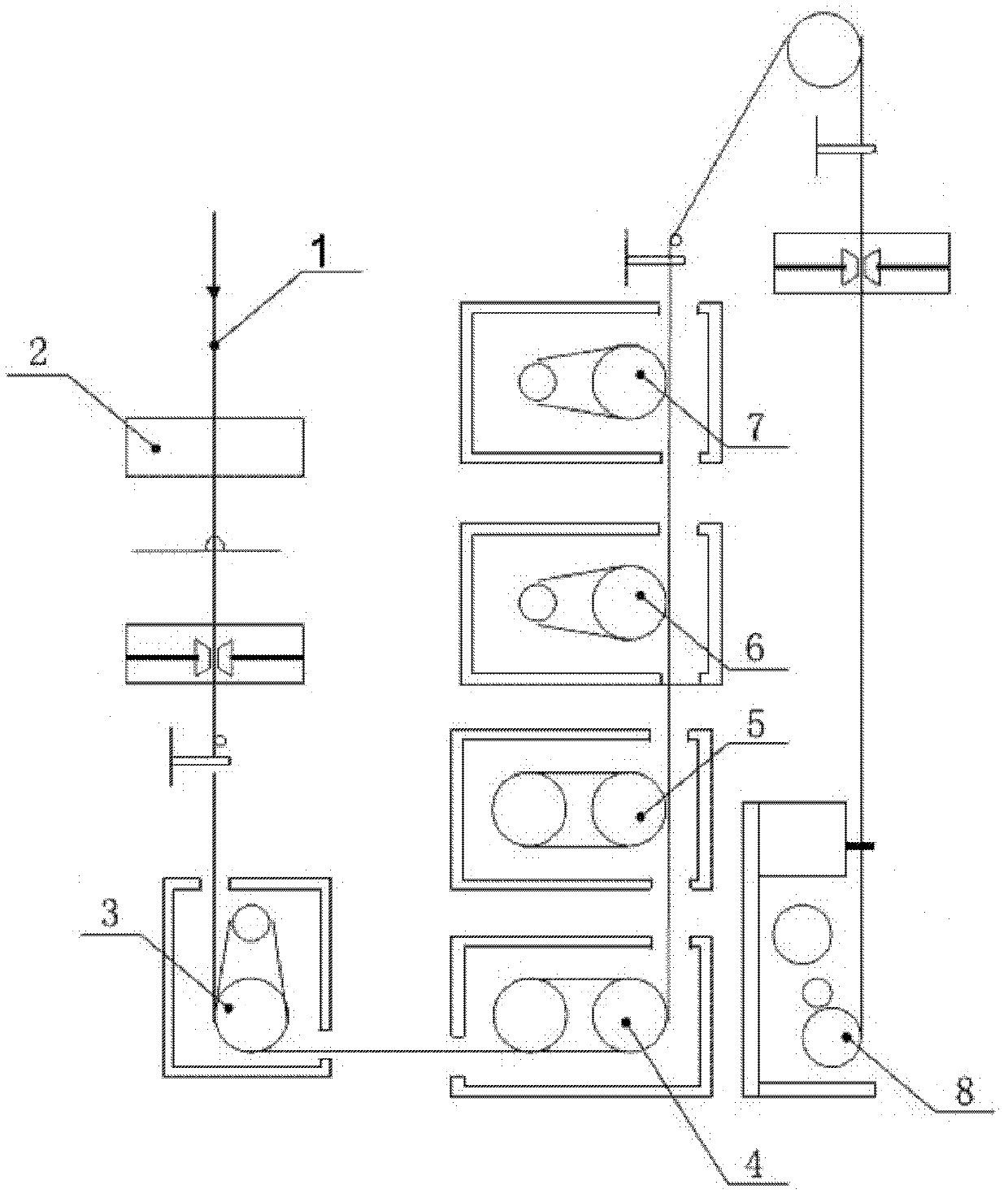

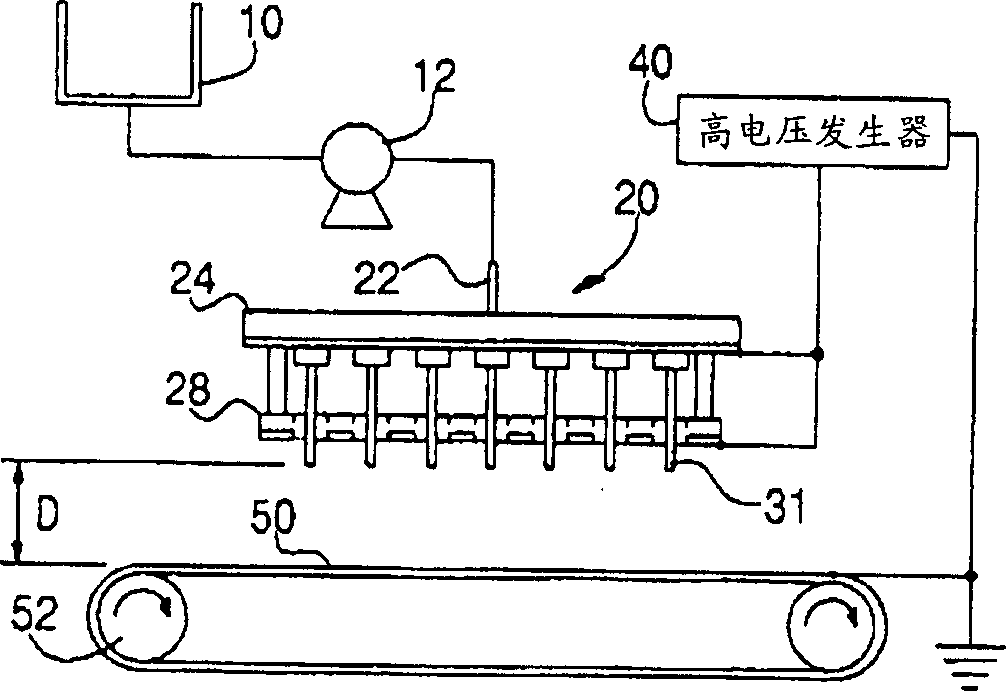

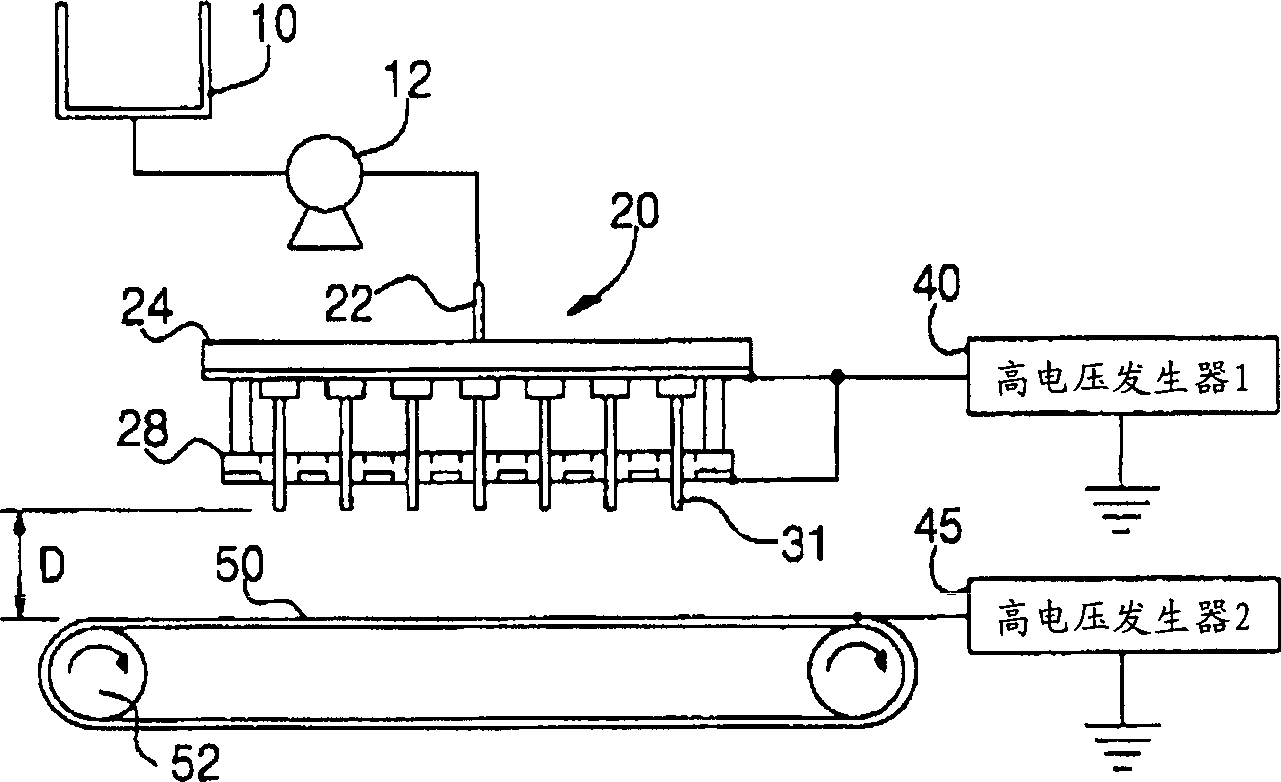

Method and system for preparing nanofiber coating on surface of yarn or fiber bundle

InactiveCN102912456AUniform diameter distributionImprove performanceLiquid surface applicatorsSpinnerette packsYarnFiber bundle

The invention discloses a method and a system for preparing a nanofiber coating on the surface of a yarn or a fiber bundle and belongs to the field of the textile industry. The method includes: arranging a spinning sprayer and a collector oppositely by a certain distance so that the yarn or the fiber bundle passes through between a nozzle of the spinning sprayer and the collector; continuously supplying spinning solution into the spinning sprayer by the aid of an automatic solution delivery device, enabling the collector to be grounded, applying high-voltage direct current on the spinning sprayer, and generating electric field force between the spinning sprayer and the collector; and controlling the high-voltage direct current on the spinning sprayer, enabling the electric field force between the spinning sprayer and the collector to be larger than surface tension of the spinning solution at the nozzle of the spinning sprayer, and enabling the spinning solution in the spinning sprayer to be sprayed out of the nozzle of the same by jet flow to be coated on the surface of the passing yarn or the passing fiber bundle so that a nano coating is formed, and the yarn with the nano coating formed on the surface is a prepared nano fiber. The method is simple in process steps, good in controllability and capable of producing nano fibers uniform in diameter distribution and excellent in performance with low cost.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Preparation method of continuous filament of asphalt-based carbon fiber

InactiveCN103046165ASmall diameterIncrease the number of filamentsNew-spun product collectionArtificial thread manufacturing machinesFiber bundleCarbonization

The invention discloses a preparation method of a continuous filament of an asphalt-based carbon fiber, and belongs to the field of carbon fiber production. The preparation method solves the problems that the existing spinning speed is lower, the fiber bundle damage is large, the infusibility efficiency is low, and doubling and embrittlement are easy. The preparation method comprises the specific process steps that a, spinning asphalt is extruded into fines by spinning position fusion, humidified, oiled and bundled to form a protogenic asphalt fiber bundle; b, double roller stranding and tensioning are conducted; c, the asphalt fiber bundle is wound on a spinning roller sleeve; d, an asphalt fiber reel is immersed in an oxidability liquid phase, and a liquid-phase oxidized fiber bundle reel is obtained; e, the reel is immersed in a high-temperature-resistant oil solution; the filament is unreeled and rollers are removed at a low speed; the oxidized fiber bundle continuously enters a continuous infusible furnace and a continuous low-temperature pre-carbonization furnace to form a pre-carbonization fiber bundle reel; and f, drawing heat treatment is conducted through a continuous carbon-fiber high-temperature carbonization furnace and a graphitization furnace, and then the continuous filament of the asphalt-based carbon fiber is obtained.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

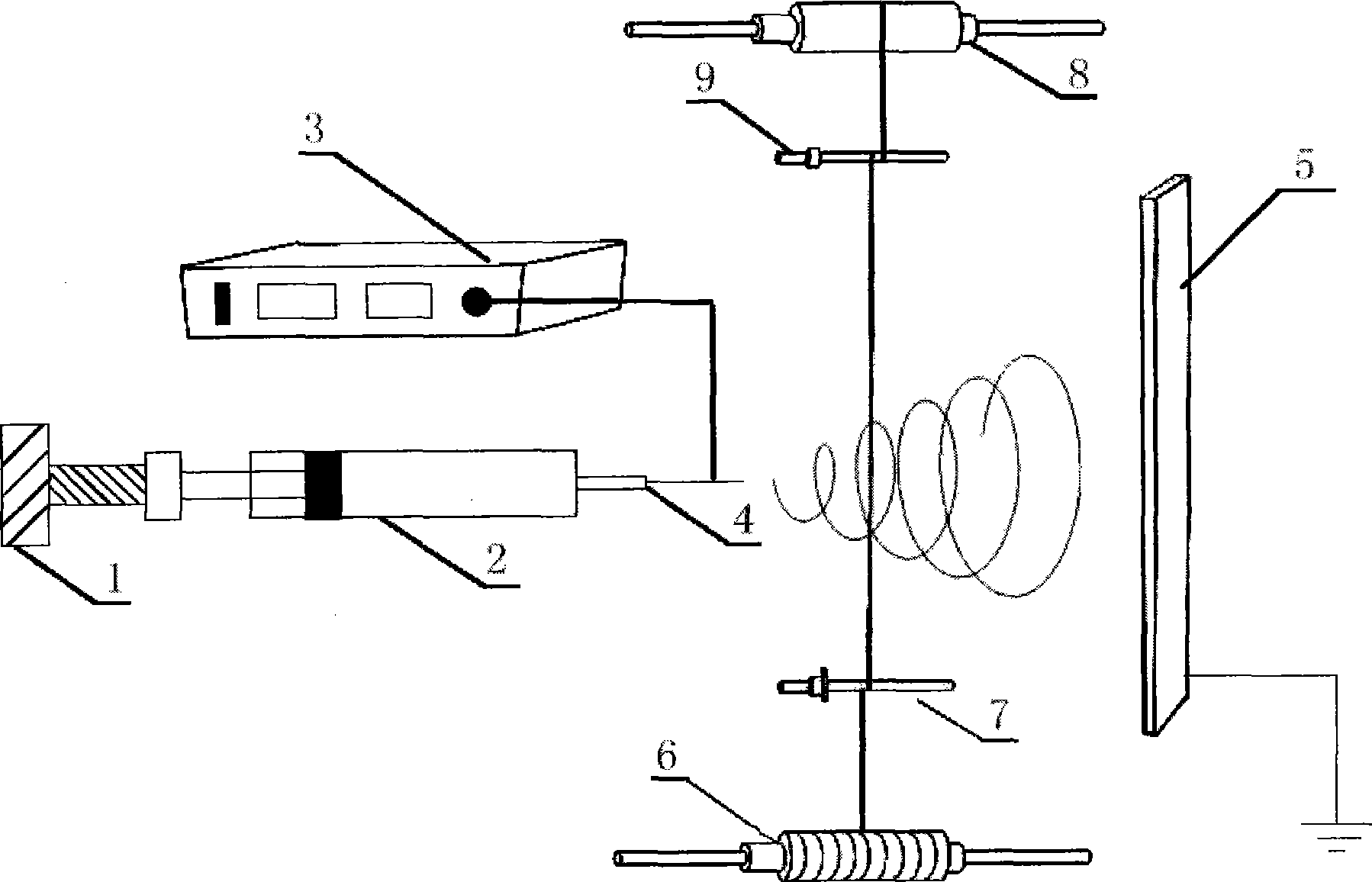

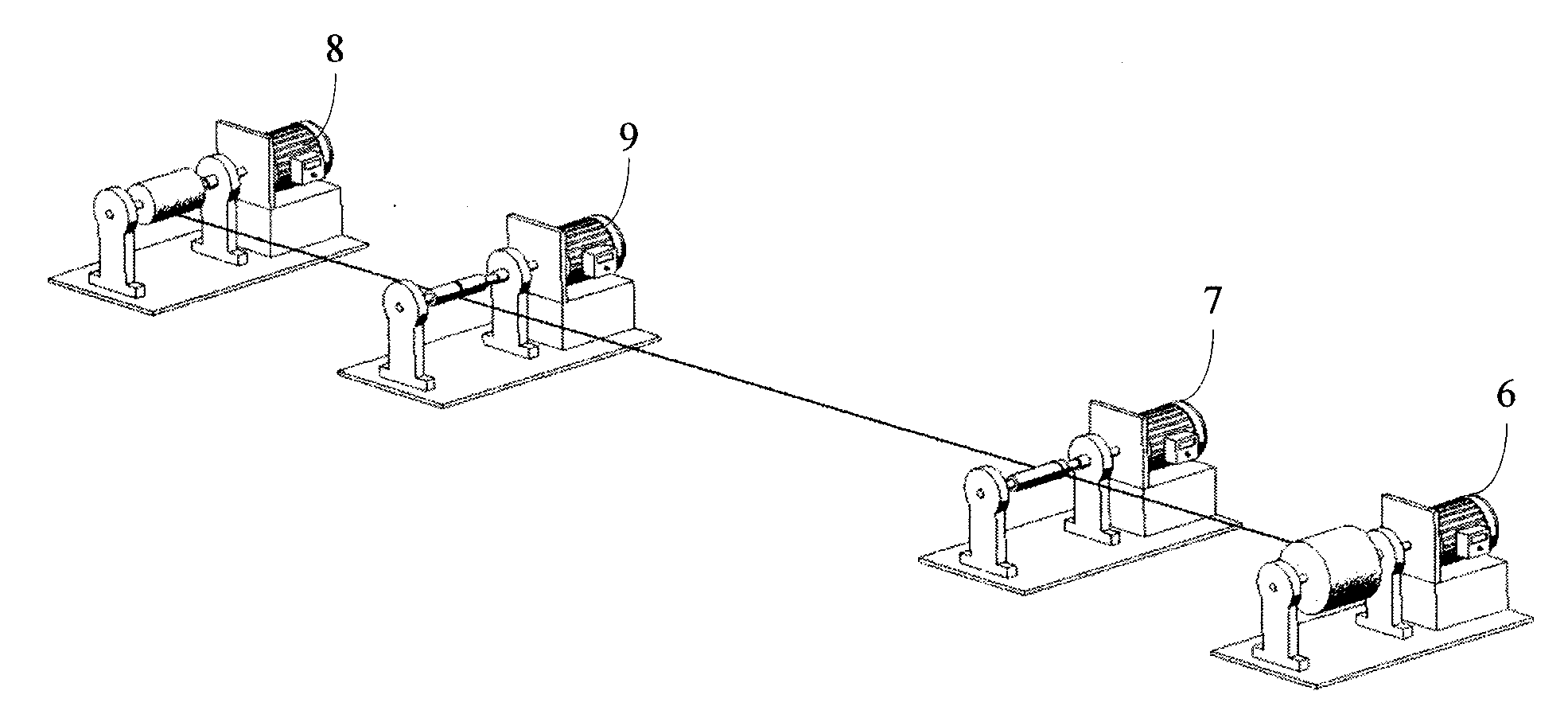

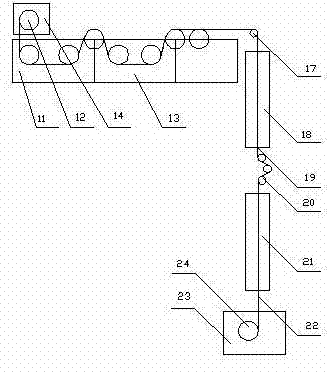

Continuous preparation method for ultra-fine electrostatic spinning fibre yarn

ActiveCN101104970AMonocomponent polyurethanes artificial filamentNew-spun product collectionYarnUltra fine

The invention relates to a continuous preparation method of superfine electrostatic-spinning fiber yarn, which comprises the following steps: (1) dissolving a polymer in a solvent to obtain a homogenous solution; (2) adding additives into the solution; (3) electrostatic spinning: feeding the spinning stock solution into a container, and extruding from a nozzle connected with a high-voltage anode under the control of a microinjection pump while controlling various electrostatic spinning parameters to keep a stable spinning state; (4) approaching a grounded needle tip to the nozzle to induce the electrostatic-spinning fibers to form bundles; (5) dragging the fiber bundles and twisting by a twisting machine; and (6) winding the twisted continuous yarns around a barrel by using a winding machine. The superfine electrostatic-spinning fiber yarn produced by the inventive method has wide application range.

Owner:DONGHUA UNIV

Industrial functional chinlon 66 fibre and preparation method thereof

ActiveCN103290497ASmall shrinkageHigh strengthNew-spun product collectionMelt spinning methodsYarnDry heat

The invention discloses industrial functional chinlon 66 fibre and a preparation method thereof, and belongs to the technical field of fibre production. The method comprises the following steps: adopting chinlon 66 slices, tackifying through solid-phase polymerization, adopting a one stage process route of spinning, drafting and forming, and producing the industrial functional chinlon 66 FDY (Fully Drawn Yarn) fibre with middle low denier, high strength and low shrink on a spin-draft integrated device with an unique structure, wherein the total denier of a tow is 50 to 300 tex; the single silk fineness dpf is 1 to 5; the strength is larger than or equal to 8.5 g / d; and the dry heat shrinking percentage is less than or equal to 3%.

Owner:LIAONING YINZHU CHEMTEX GROUP

Method for preparing micro-nano-scale patterned electrospun fiber membrane

InactiveCN102260963AEasy to processHigh degree of automationNew-spun product collectionFilament/thread formingFiberMicro nano

The invention relates to a method for preparing a micro-nano-scale patterned electrospun fiber membrane. The method comprises the following steps: A) using a computer to draw a required pattern through layout design software; B) inputting the pattern into a micro-electrical mechanical system and using the micro-electrical mechanical system to deposit metal onto a non-metal base material according to the input pattern so as to get a receiving plate with the micro-nano-scale pattern; and C) taking the receiving plate with the micro-nano-scale pattern as the receiving plate of an electrospinning device and performing electrostatic spinning so as to get the micro-nano-scale patterned electrospun fiber membrane. By adopting the method, the patterned electrospun fiber membrane with micro-nano-scale minimal unit size of the pattern can be prepared, and the patterned electrospun fiber membrane has good application prospects in repair and manufacturing of micro-electronic devices, sensors, ultrafine filters and human tissues. Furthermore, the preparation process is simple and convenient, the degree of automation is high and the processed pattern is precise, controllable and good in repeatability.

Owner:SOUTHWEST JIAOTONG UNIV

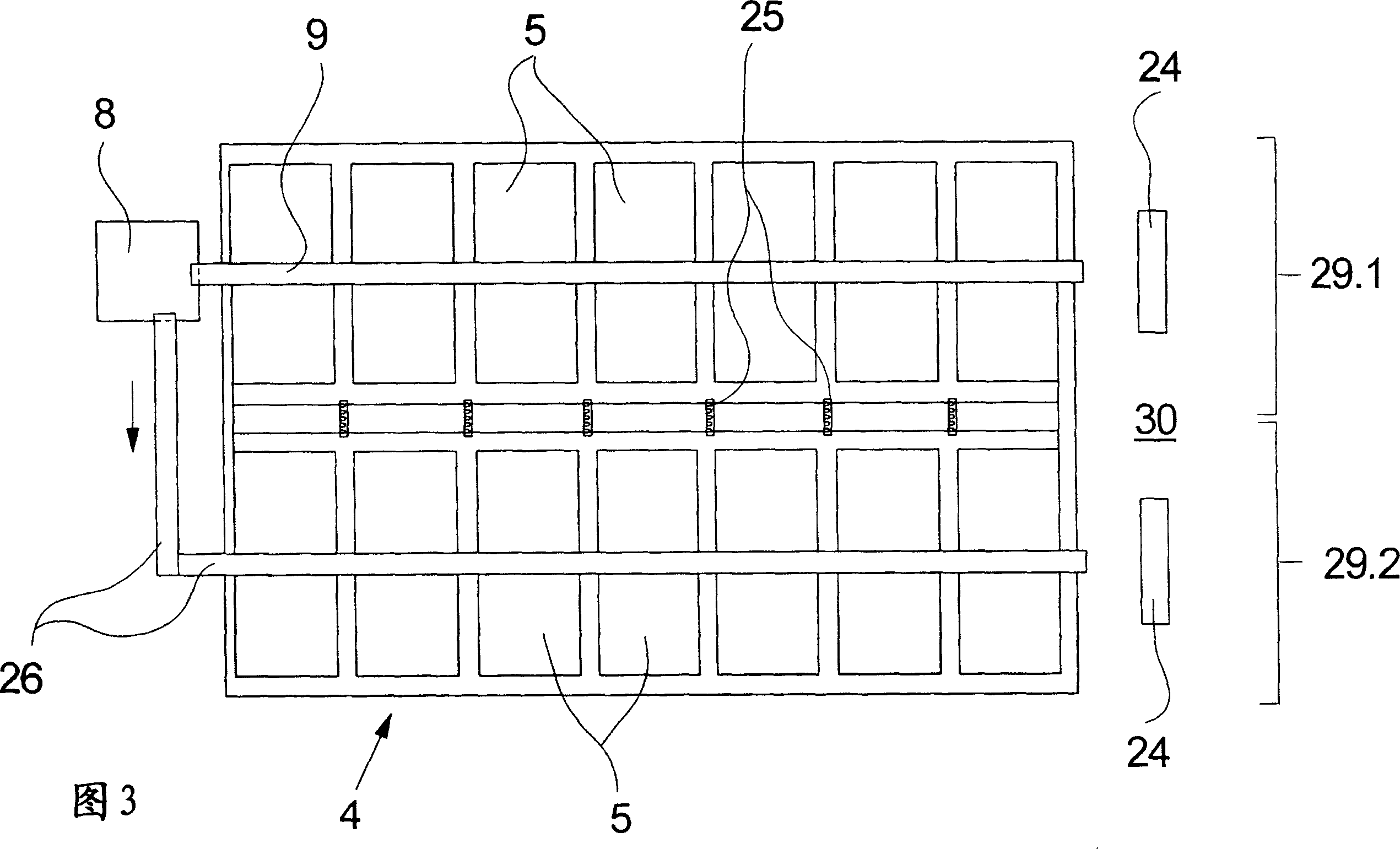

Polymer fibre web mfg. device and method

InactiveCN1435515AHigh porosityImprove productivityNew-spun product collectionWet spinning methodsFiberLiquid state

An apparatus and method for preparing high-molecular fibre net is disclosed. Said method includes preparing a liquid-state high-molecular substance, passing it through more than one electrically charged nozzles until it reaches the lower part of said nozzle while charging it by different electric polarity, and spraying it onto a moving collector.

Owner:KOREA INST OF SCI & TECH

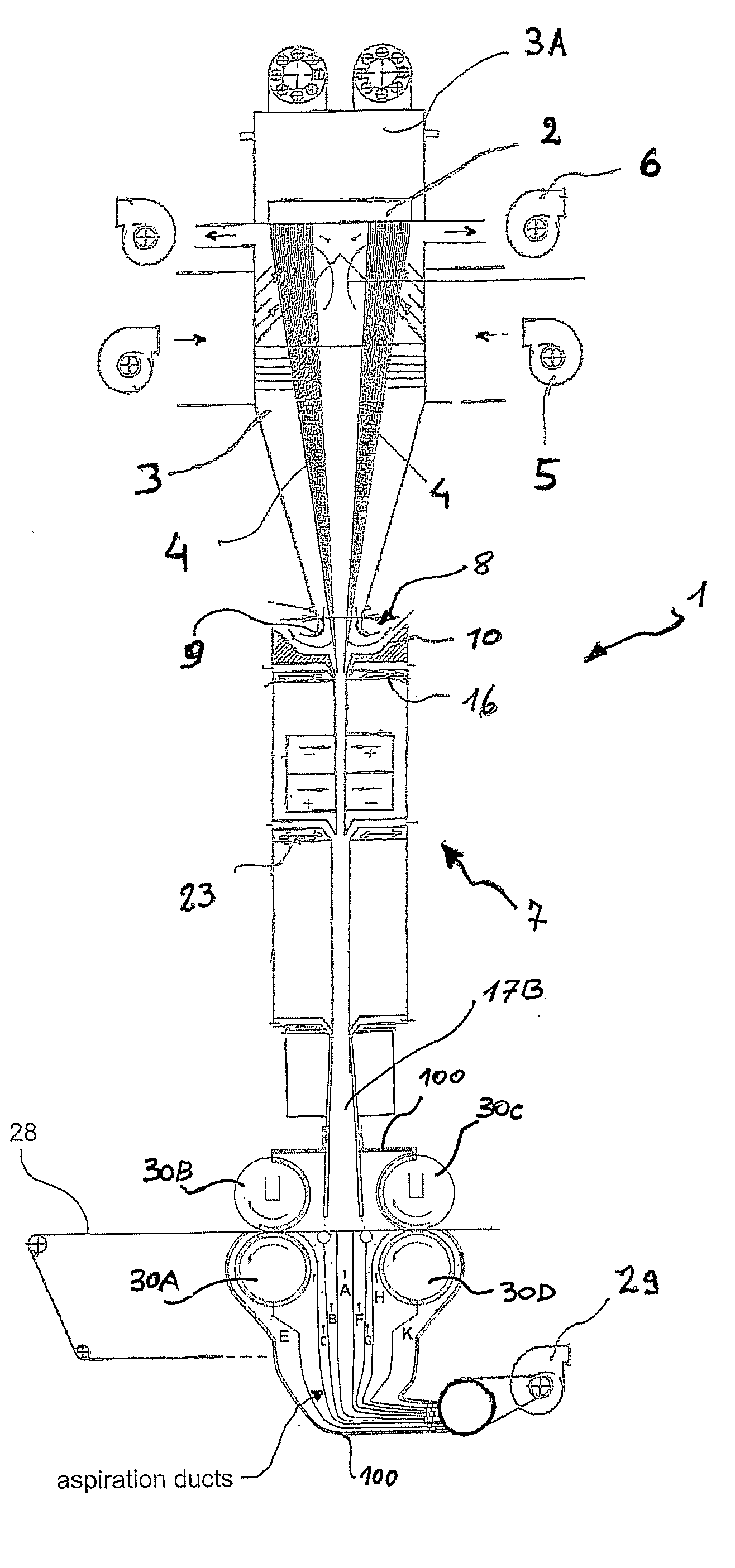

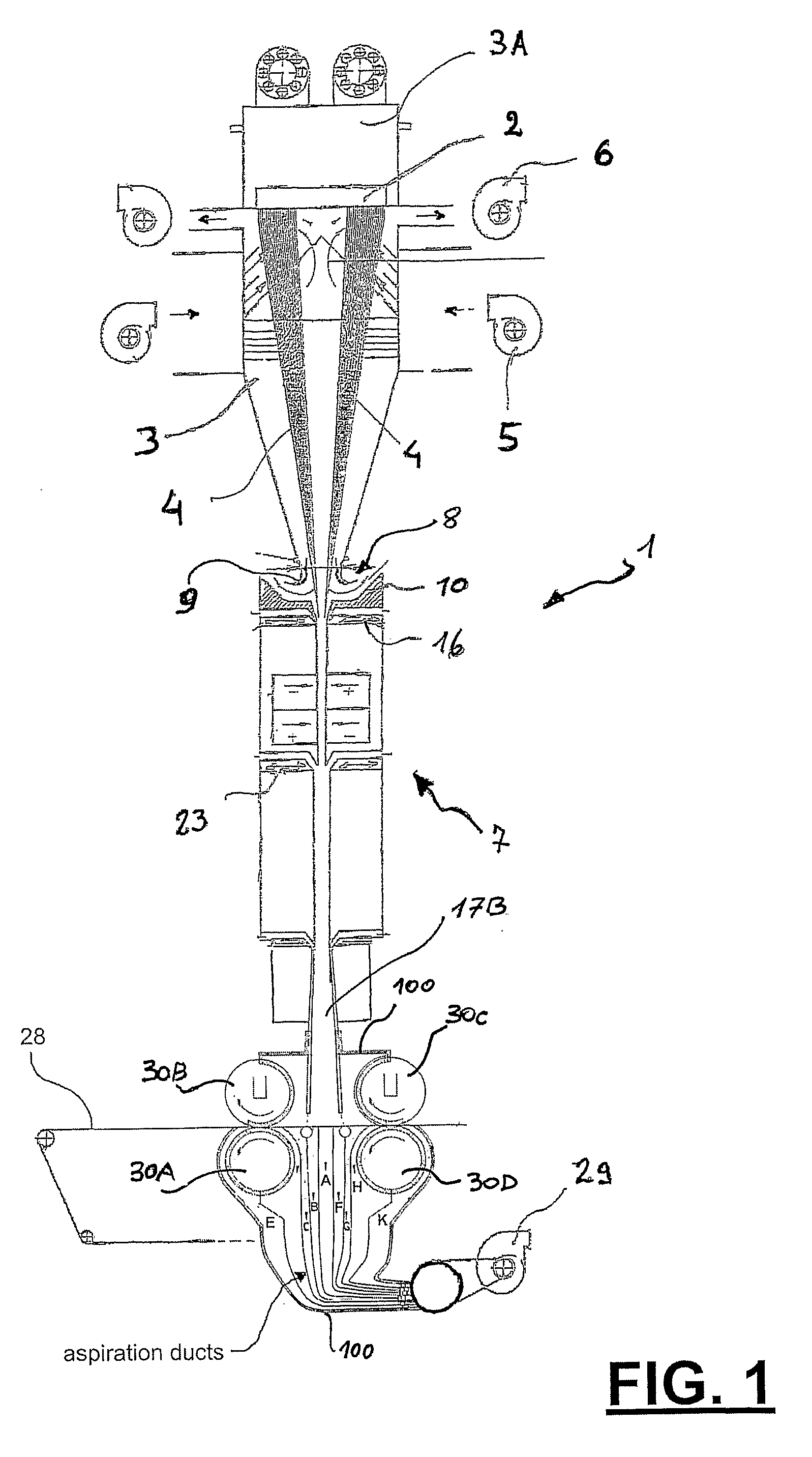

Apparatus and process for the production of a non-woven fabric

ActiveUS20100062672A1Minimize air inflow from external environmentUniform depositionEngine sealsNew-spun product collectionEngineeringNonwoven fabric

In an apparatus for the production of a non-woven fabric of filaments, where a plurality of filaments are extruded, cooled, stretched and collected on a mobile support, the means of collecting the filaments include furthermore, a gas permeable mobile support element (28), an aspirator (29) and one or more aspiration ducts (33C-36C), the collecting means being insulated from the environment air.

Owner:FARE

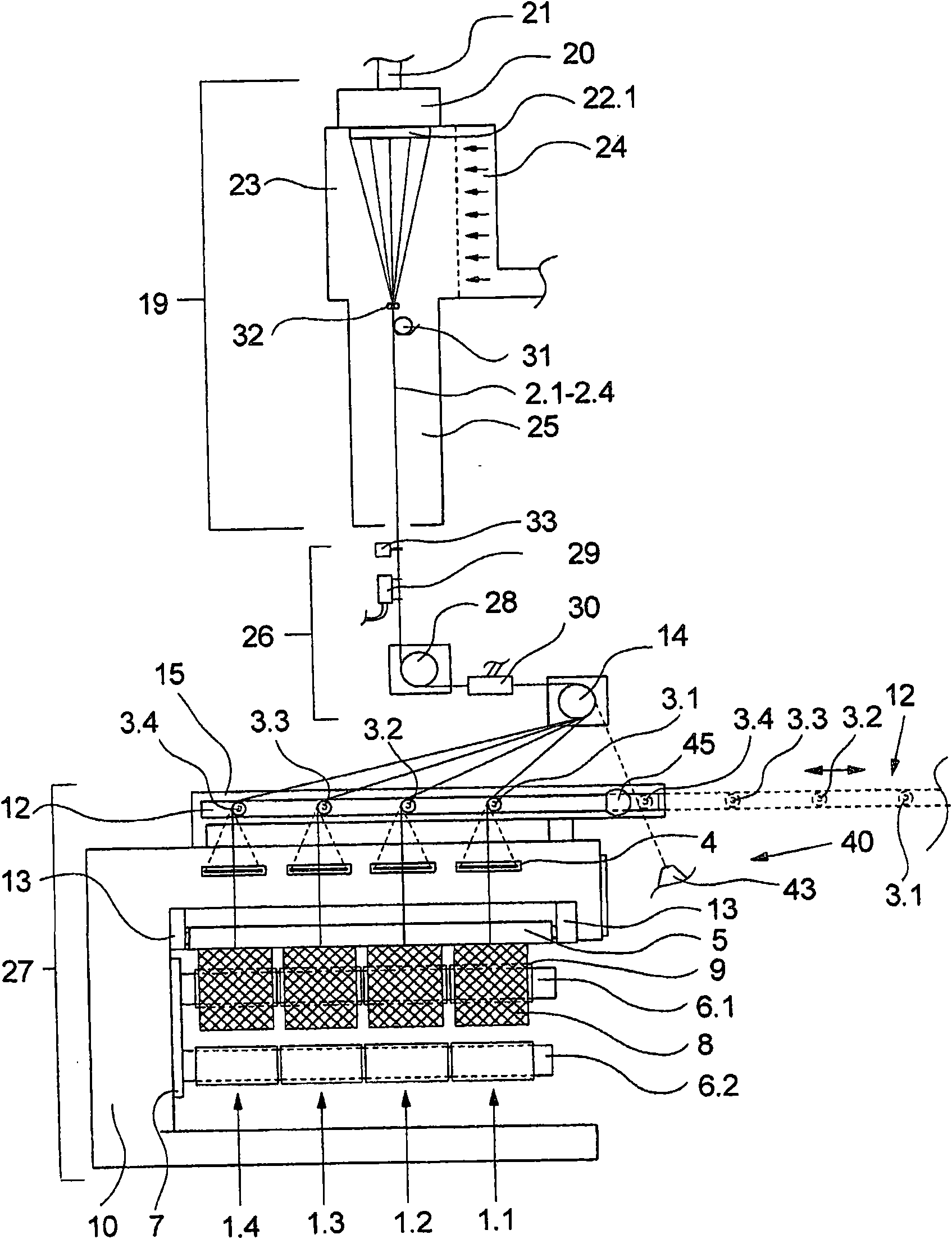

Process for producing polyester industrial yarns by liquid-phase tackified melts in multi-end direct spinning manner

ActiveCN102605444AShort turnaround timeReduce energy consumptionFilament forming substance formingNew-spun product collectionWinding machineYarn

The invention discloses a process for producing polyester industrial yarns by liquid-phase tackified melts in a multi-end direct spinning manner, which belongs to the technical field of polyester industrial yarns and includes the following steps: liquid-phase tackifying; obtaining high-viscosity polyester melts with intrinsic viscosity ranging from 0.90dl / g to 1.10dl / g by tackifying low-viscosity polyester melts in a liquid phase; double-end spinning; directly conveying the polyester melts after being subjected to liquid-phase tackifying to different spinning positions capable of spinning in 16-24 ends; drafting and thermal-forming; winding and forming; and utilization of a twin winding machine to perform high-speed winding of 16-24 spindle spinning cakes. In the process, 16-end direct spinning of high-strength or low-shrinkage polyester industrial yarns with a single end ranging from 800D to 1300D and 24-end direct spinning of low-denier polyester industrial yarns with a single end ranging from 100D to 500D can be realized on the same spinning position, and product production efficiency is high, performance is stable, production energy consumption and equipment investment cost are low.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Macroscopic assembly of nanometric filamentary structures and method of preparation thereof

InactiveUS20060216602A1Efficient separationPrevent reduce risk of expositionMaterial nanotechnologyNanomagnetismEngineeringVolumetric Mass Density

The invention relates to a macroscopic assembly of nanometric filamentary structures. The macroscopic assembly comprises a plurality of microscopic assemblies substantially aligned in a same direction and connected together. Each of the microscopic assemblies comprises a plurality of members defining a plurality of spaces therebetween. Each of the members comprises a nanometric filamentary structure or a bundle of nanometric filamentary structures, wherein the macroscopic assembly has a density of less than 8 mg / cm3. The is also provided a method for prerparing such a macroscopic assembly.

Owner:INST NAT DE LA FLECHERCHE SCI

Nylon 56 short fiber and melt direct spinning preparation method thereof

InactiveCN105887230AShort processImprove efficiencyNew-spun product collectionSpinning head liquid feederWinding machineInternal pressure

The invention discloses a melt direct spinning preparation method of nylon 56 short fibers. The method includes steps: (1) allowing reaction of bio-based pentamethylene diamine and adipic acid in water under nitrogen protection to obtain a nylon 56 salt solution; (2) adding the nylon 56 salt solution and a molecular weight regulator into a reactor, and keeping the pressure under the condition that the temperature is 210-240 DEG C and the pressure is 1.7-1.85MPa; releasing the internal pressure of the reactor, and heating to 280-290 DEG C; vacuumizing and stirring to obtain nylon 56 polymer melt; (3) feeding the nylon 56 polymer melt into a spinning manifold; subjecting the nylon 56 polymer melt to spinning through a spinneret, cooling, leading to a winding machine to realize finishing and conditioning, and sequentially performing drafting, crimping, finishing, relaxed heat setting and cutting to obtain the nylon 56 short fibers. The melt direct spinning preparation method has advantages of short process, high efficiency and product stability and provides guidance for industrial direct spinning of bio-based nylon and nylon polymers.

Owner:优纤科技(丹东)有限公司 +2

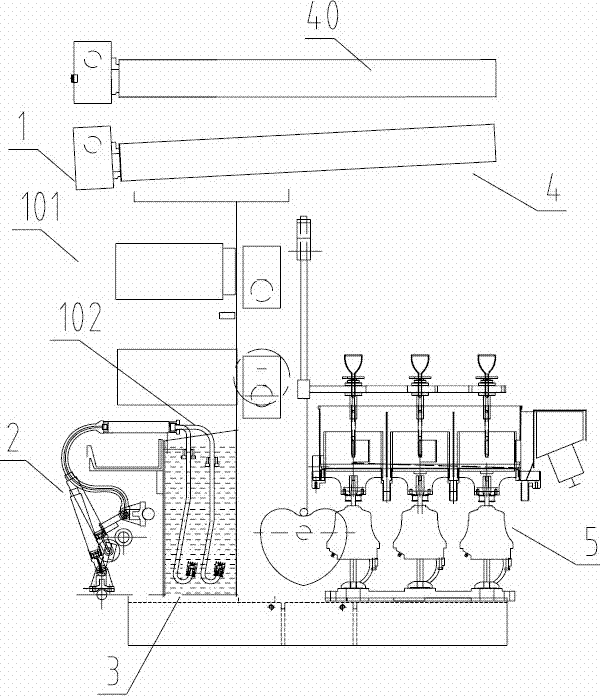

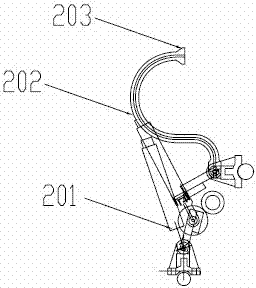

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

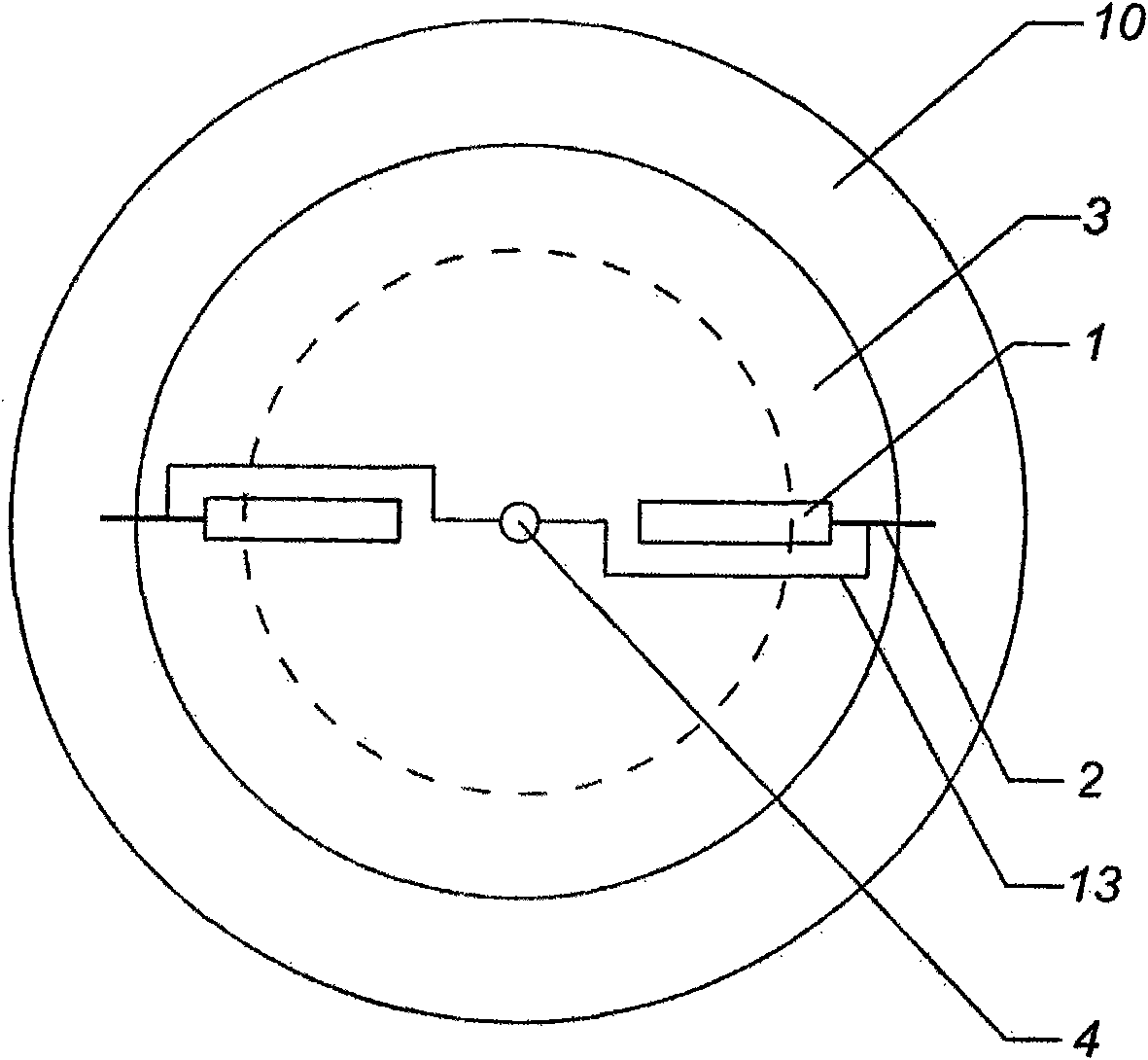

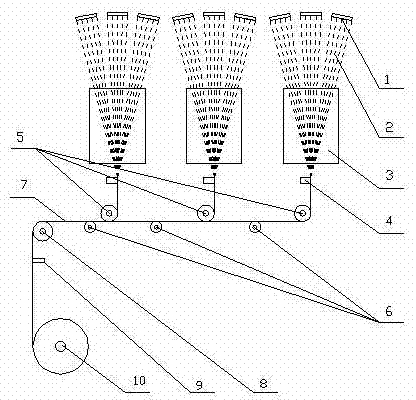

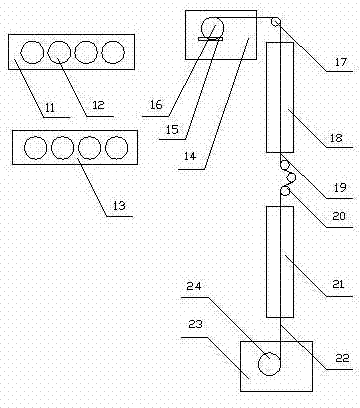

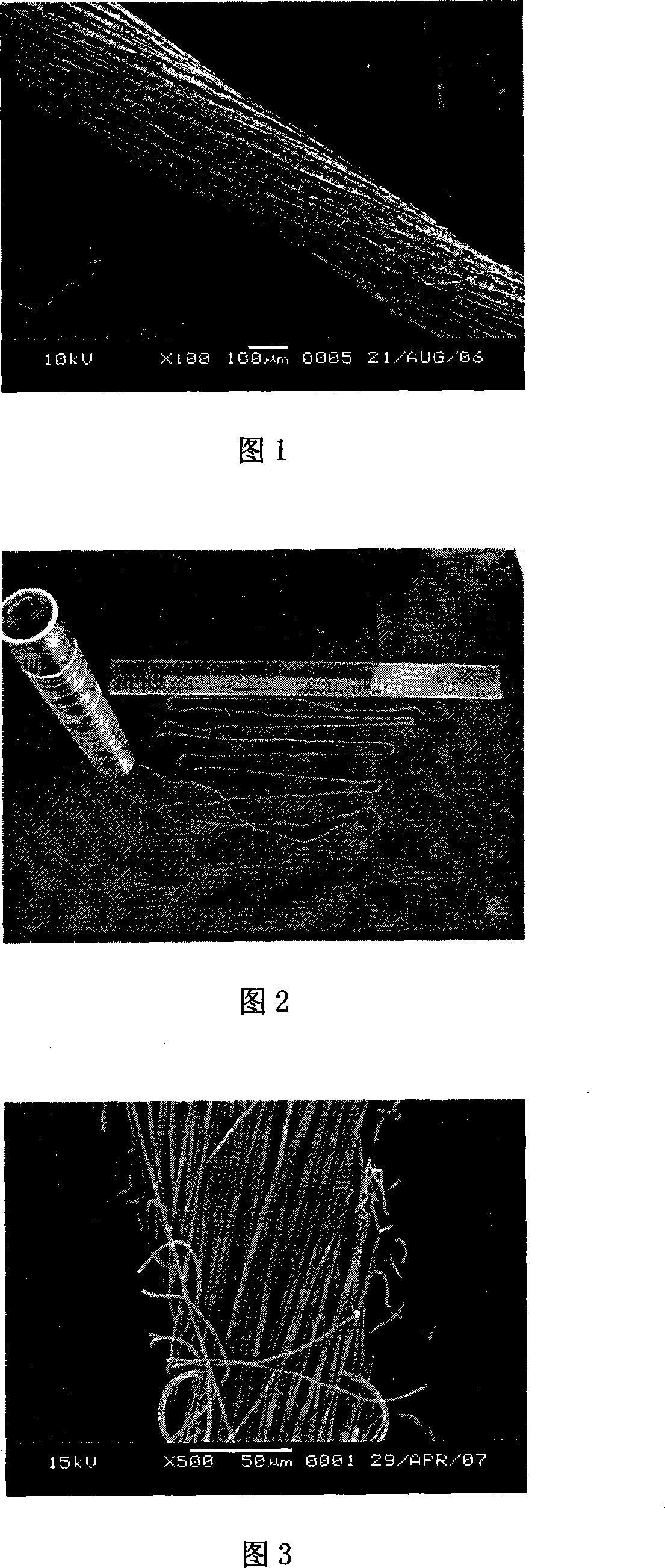

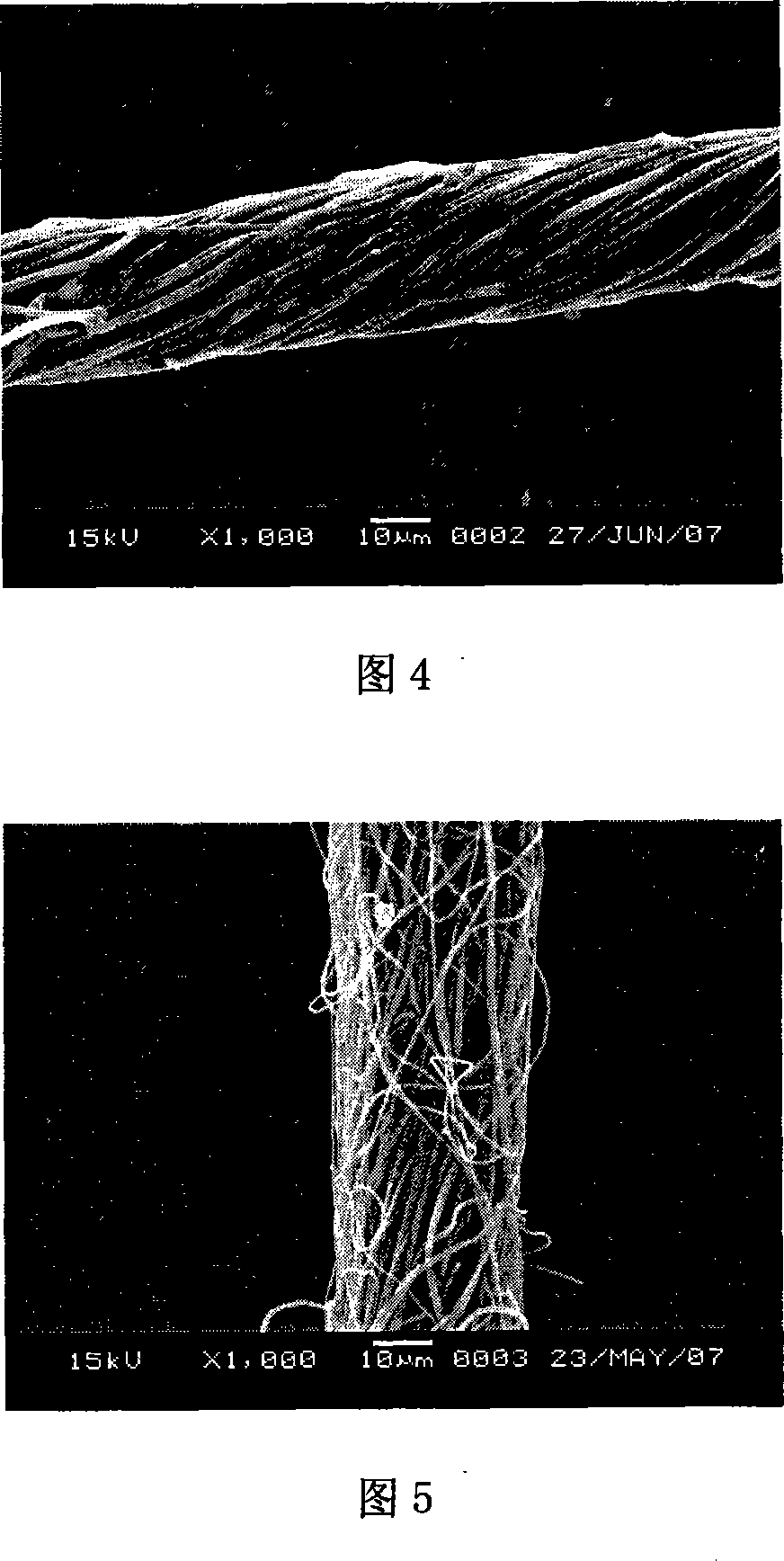

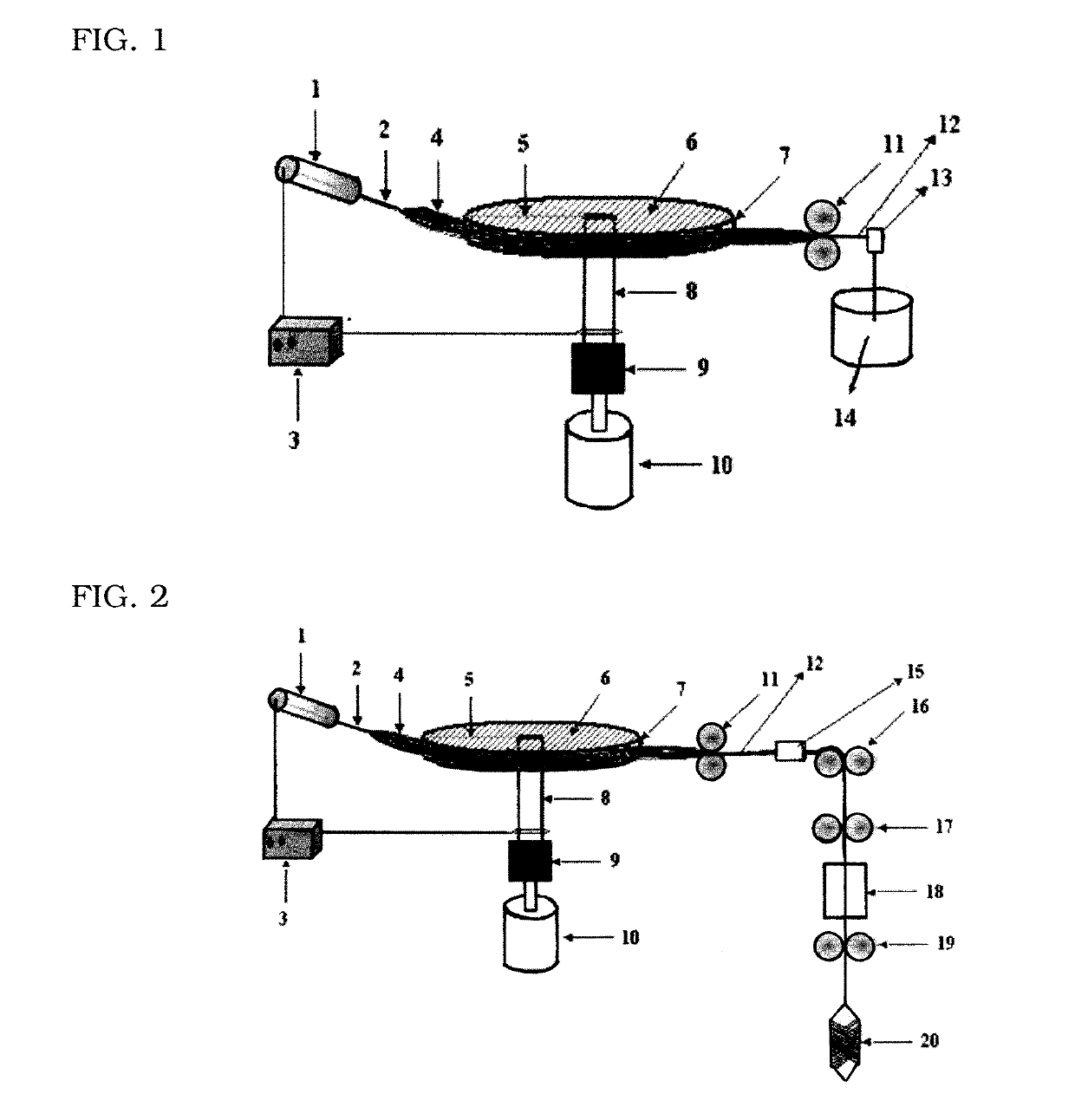

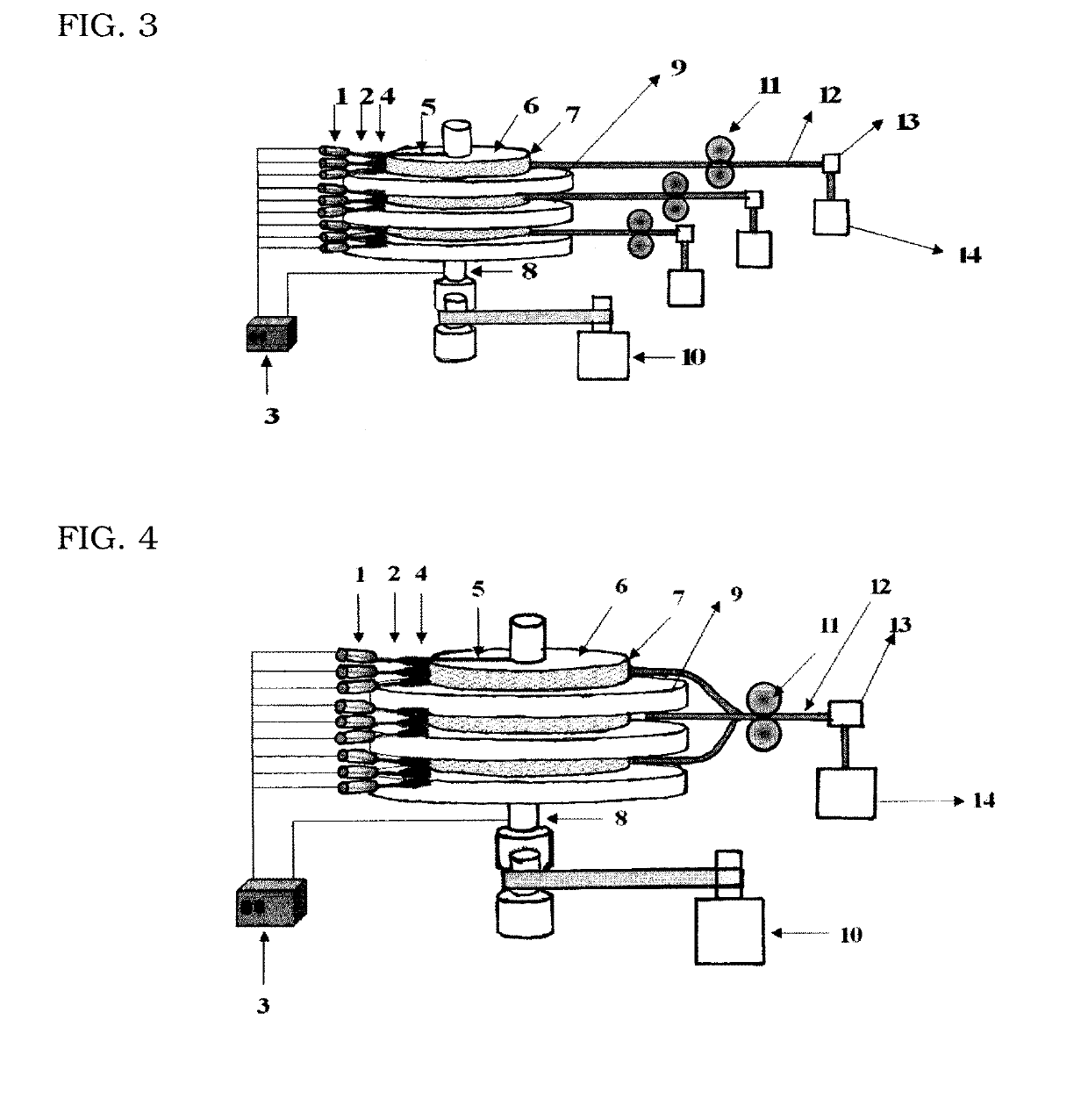

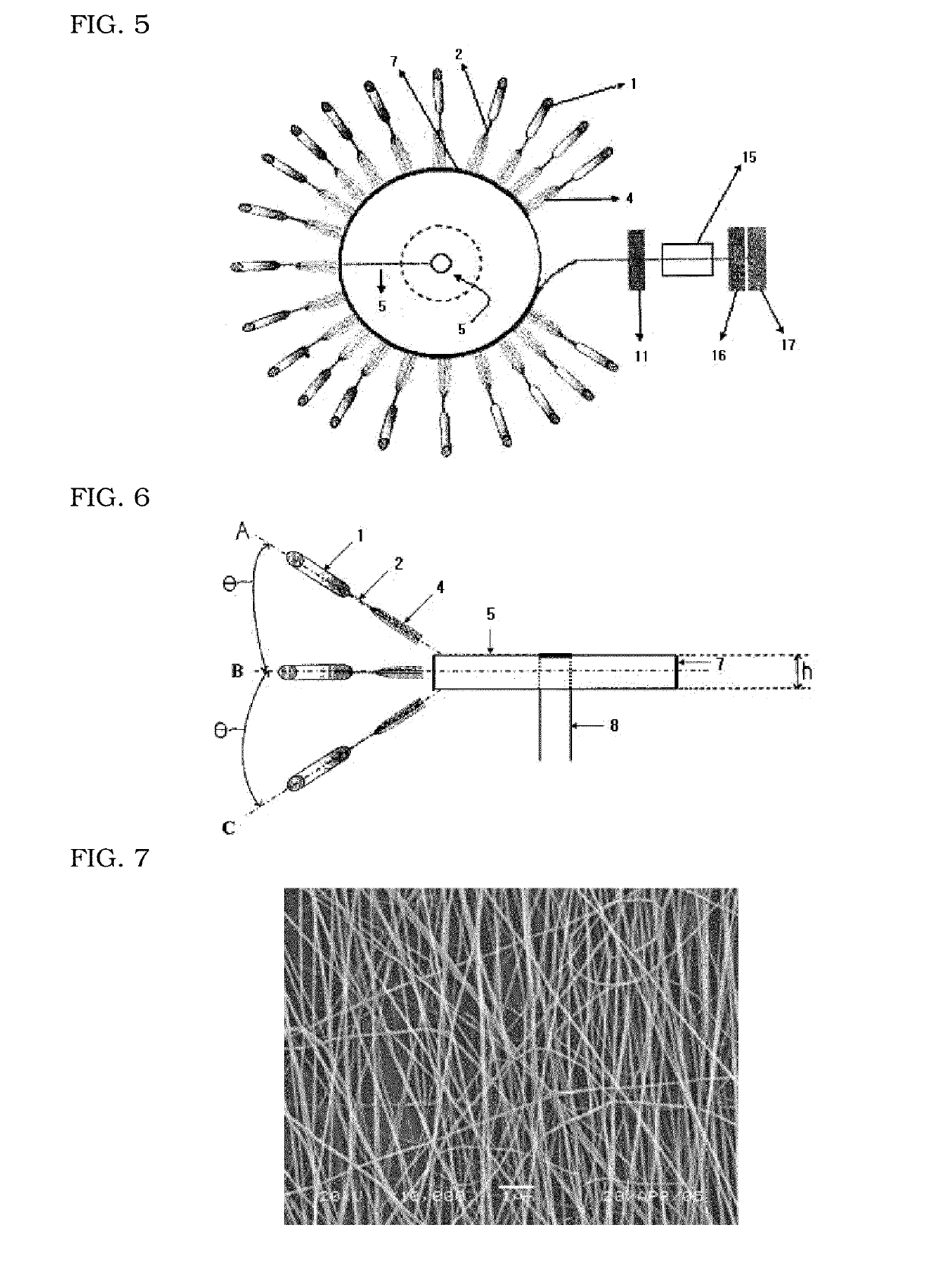

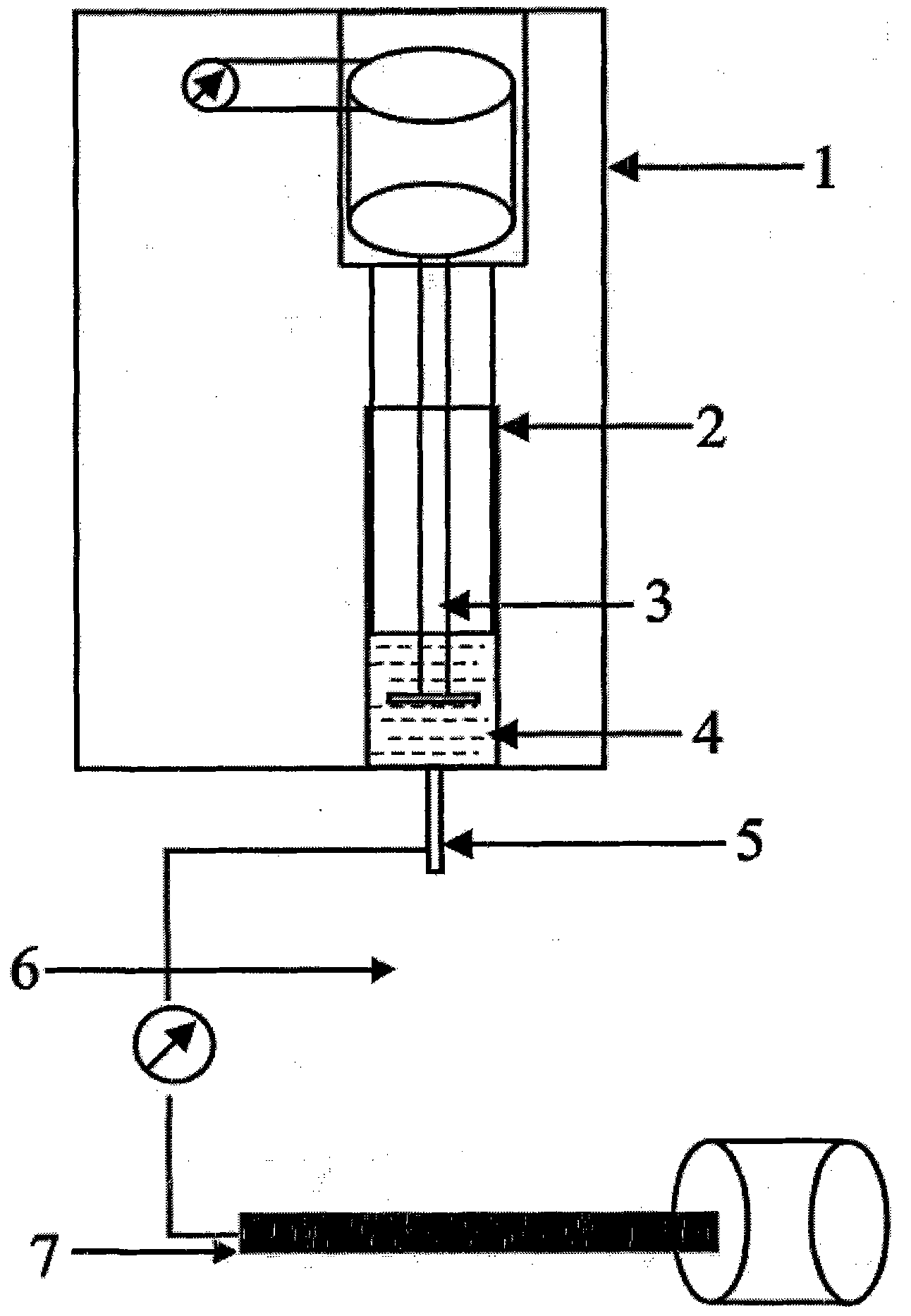

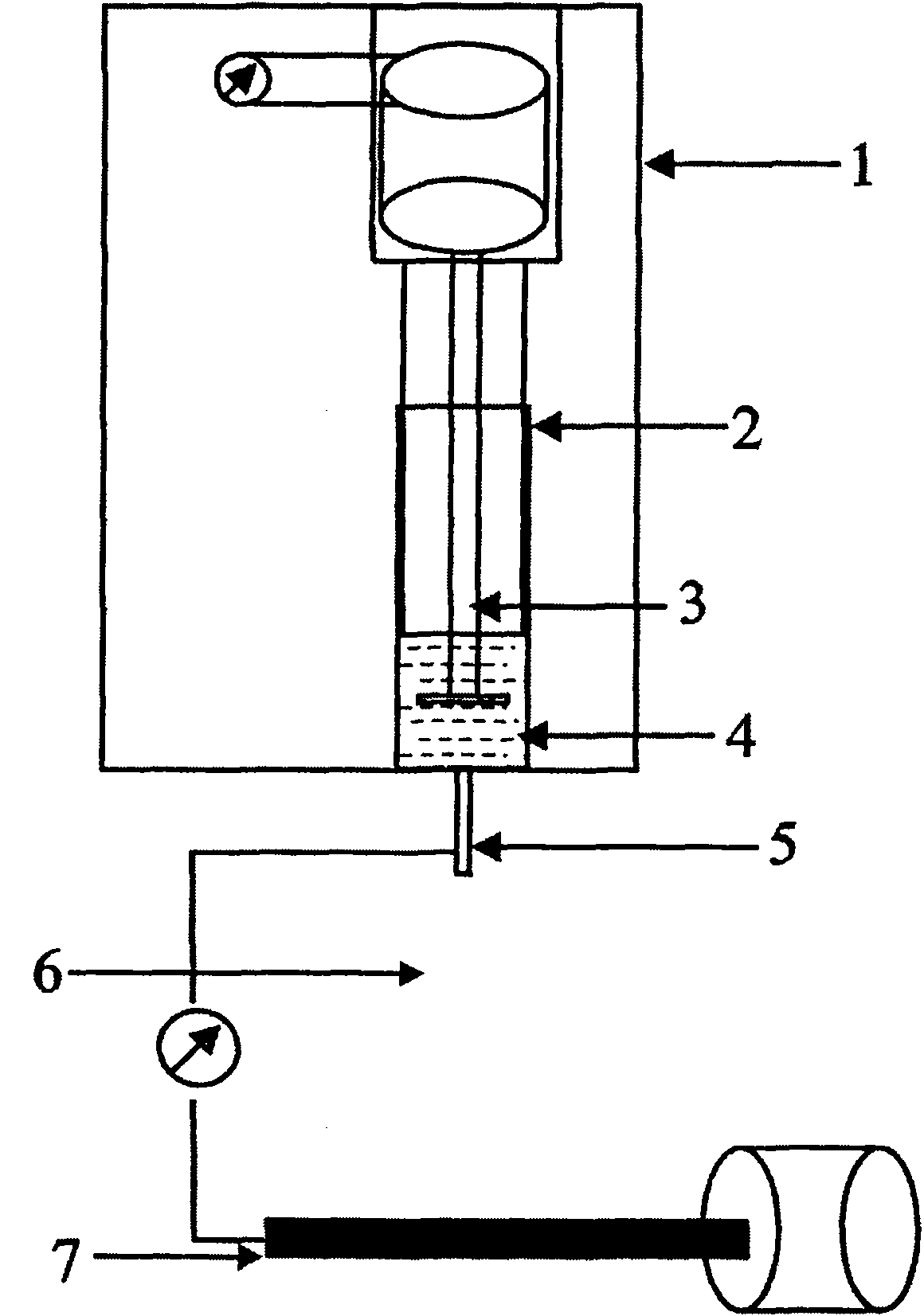

Method of manufacturing a continuous filament by electrospinning and continuous filament manufactured thereby

InactiveUS20090324950A1Good physical propertiesContinuous filamentNew-spun product collectionYarnElectrospinningEngineering

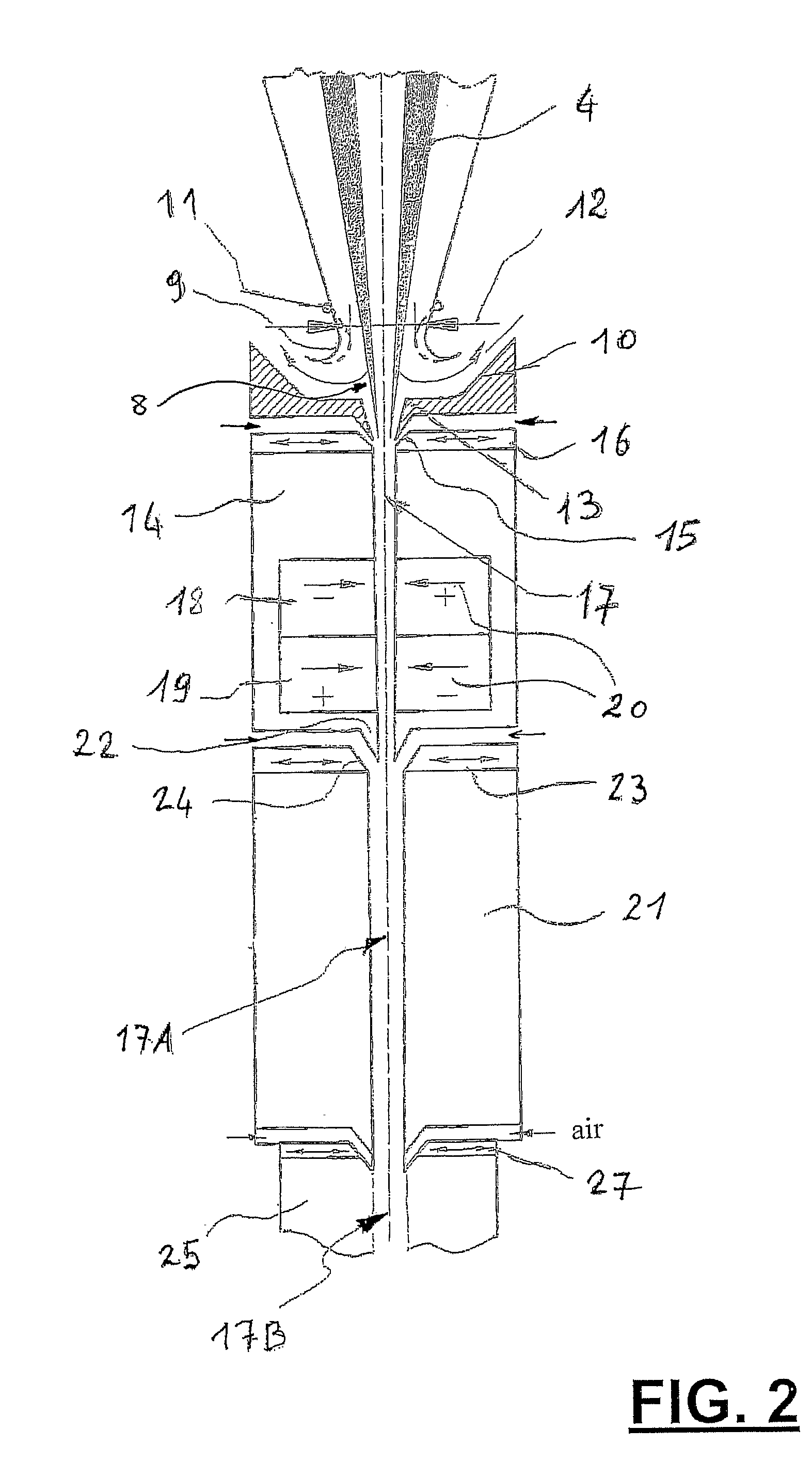

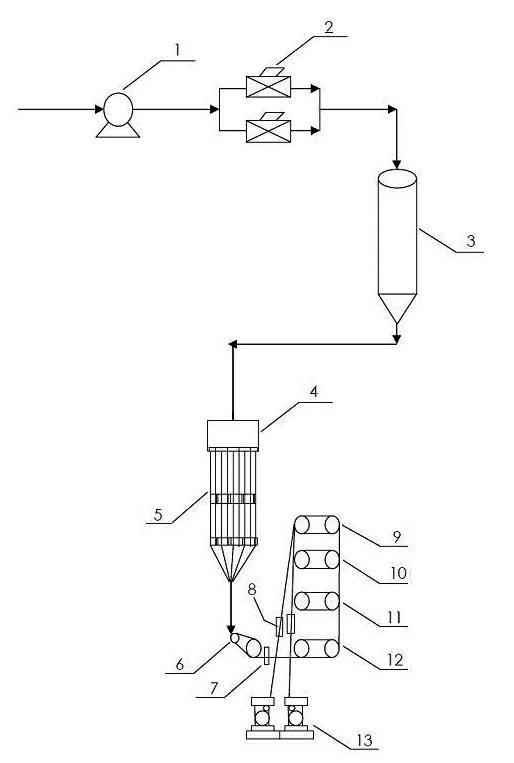

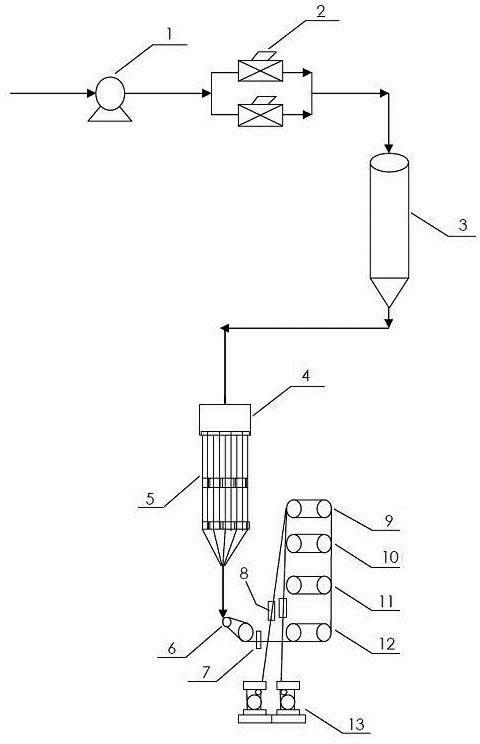

Disclosed are a method of manufacturing a continuous filament by electrospinning, and a continuous filament manufactured thereby. Electrospun nano fibers 4 are collected on a collector 7 by electrically spinning a polymer spinning dope in a spinning dope main tank 1 onto the collector 7, which is a disk-shaped conductive material with a high voltage applied thereto and which rotates at a rotational linear velocity of 5 m / sec or more, through nozzles 2 having a high voltage applied thereto, and then the nano fiber 4 collected on the collector 7 are prepared in the form of a continuous filament by use of a collecting roller 11, and then the nano fibers 4 are (I) put in a canvas 14 through a traverse 13, or (II) dried, drawn, and wound consecutively.The continuous filament is superior in terms of drawing properties because nano fibers are arranged well in a filament axis direction, the continuous filament composed of nano fibers can be prepared by a continuous procedure, and the prepared continuous filament is useful as materials for various industrial fields, such as artificial leather, filters, and so on.

Owner:KIM EE

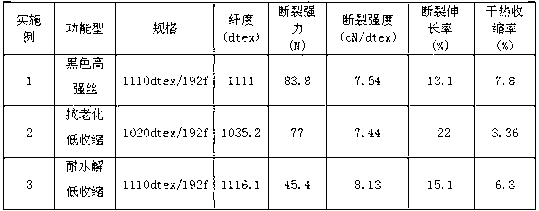

Process for producing melt direct-spinning multifunctional PET (Polyester) industrial yarns

ActiveCN102787376AImprove flexibilityShort turnaround timeFilament forming substance formingNew-spun product collectionYarnPolyester

The invention discloses a process for producing melt direct-spinning multifunctional PET (Polyester) industrial yarns and belongs to the technical field of preparation of PET industrial yarns. The process is characterized by comprising the following steps of: (1) melt tackification, i.e., tackifying low-viscosity PET melt obtained by condensation polymerization by a melt tackifying reactor to obtain high-viscosity PET melt; (2) mixing of functional melt, i.e., conveying the high-viscosity PET melt to a spinning manifold through a melt pipeline to carry out spinning and mixing the functional melt and the high-viscosity PET melt in the melt pipeline according to a certain ratio; and (3) spinning, i.e., directly conveying the mixed functional high-viscosity PET melt to each spinning positions to carry out spinning; (4) drafting heat setting, i.e., carrying out two-stage drafting one-stage loosening heat setting on functional high-tenacity PET industrial yarns and carrying out two-stage drafting two-stage loosening heat setting on functional low-shrink PET industrial yarns; and (5) winding formation, i.e., carrying out winding formation after carrying out network processing on fibers subjected to drafting heat setting. According to the invention, the aim of producing the multifunctional PET industrial yarns by adopting the melt to carry out direct spinning is fulfilled; and the process has the advantages of low cost, high efficiency, uniformity and stability.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

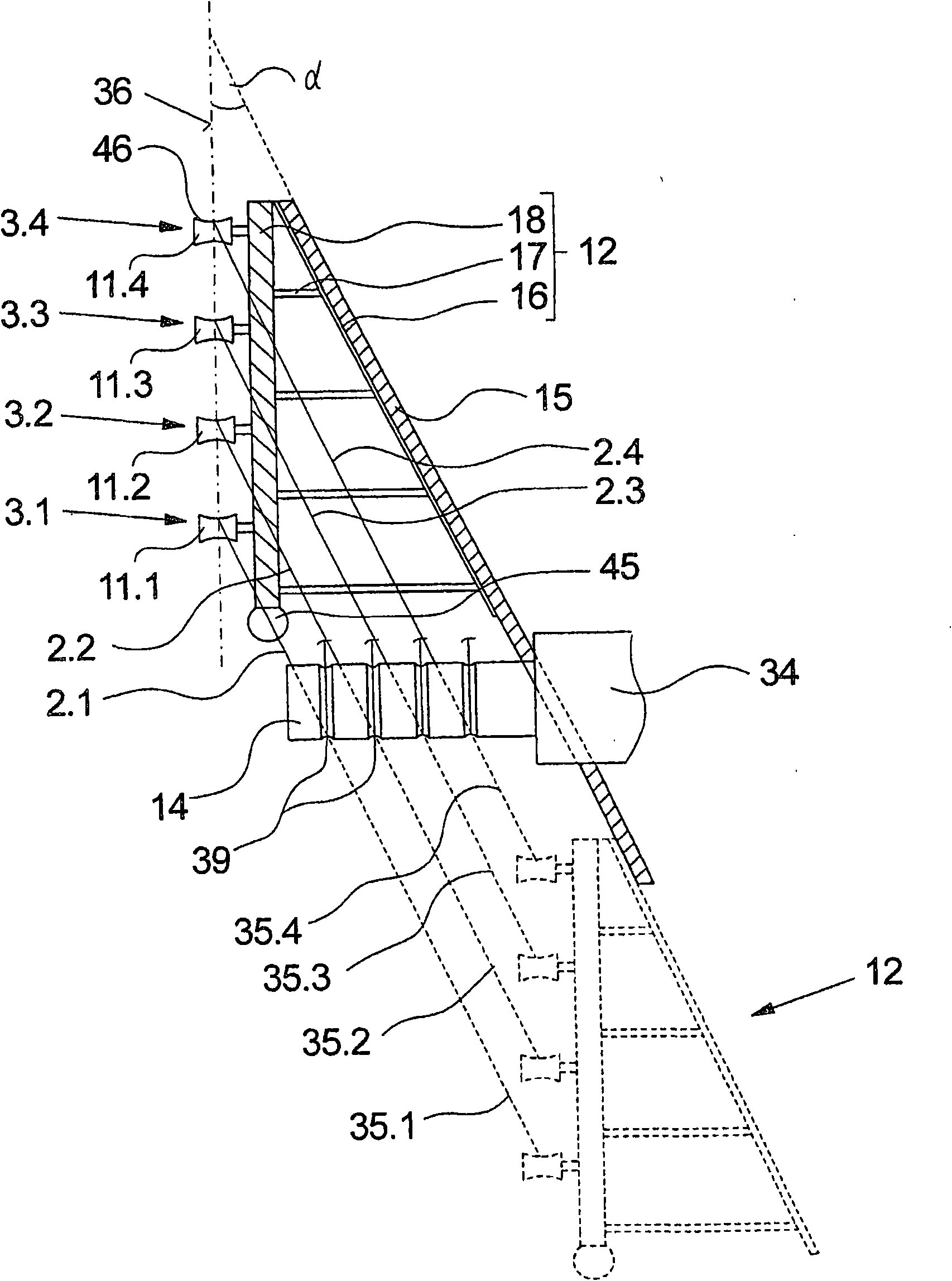

Device for melt-spinning and winding synthetic threads

ActiveCN101680119AFully automatedCompact structureNew-spun product collectionArtificial thread manufacturing machinesWinding machineEngineering

The invention relates to a device for melt-spinning and winding synthetic threads, comprising a spinning device, a treatment device and a winding machine. The treatment device is provided with a take-off godet for guiding the threads before the threads are fed and distributing the threads to a plurality of winding points in the winding machine. The take-off godet is disposed above the winding machine and guides the threads on the circumference such that the threads run parallel next to each other. The take-off godet is arranged transversely to a winding spindle, above the winding machine. Thewinding machine is equipped with a plurality of top thread guides, which are mounted upstream of the winding points and are located in a feeding plane. In order to improve the application process regarding the distribution of the filaments on the individual winding points when starting the process or pausing the process, the take-off godet and the group of the top thread guides for applying the threads into the winding points of the winding machine are designed to be moveable relative to each other according to the invention.

Owner:OERLIKON TEXTILE GMBH & CO KG

Electrostatic spinning device

ActiveCN103334165APromote stretch refinementIncreased Jet Jet VelocityNew-spun product collectionFilament/thread formingFiberFiltration

The invention relates to the technical field of preparation of polymer electrospun fibers by adopting an electrostatic spinning technique, and provides an electrostatic spinning device which comprises a liquid supply device, a liquid distribution device, a plurality of electrostatic spinning nozzles, a high-voltage power supply, an auxiliary gas generating device, a cylindrical guiding device and a double-net-cylinder collector, wherein the auxiliary gas generating device comprises an air feed pump, an air tube and a vent hood, and the vent hood is communicated with the air feed pump through the air tube, so as to form an auxiliary airflow channel; the plurality of electrostatic spinning nozzles are uniformly distributed in the vent hood; the cylindrical guiding device is arranged below the auxiliary gas generating device; the double-net-cylinder collector is arranged inside the cylindrical guiding device. The electrostatic spinning device introduces auxiliary airflow to promote jetting and stretching of jet flow, and utilizes the squeezing effect of the airflow to guide spinning nanofibers to perform multilayered three-dimensional deposition in the double-net-cylinder collector, so as to realize quick manufacturing of a columnar nano-fiber filter, and promote the application of the electrostatic spinning technique in the field of filtration.

Owner:XIAMEN UNIV

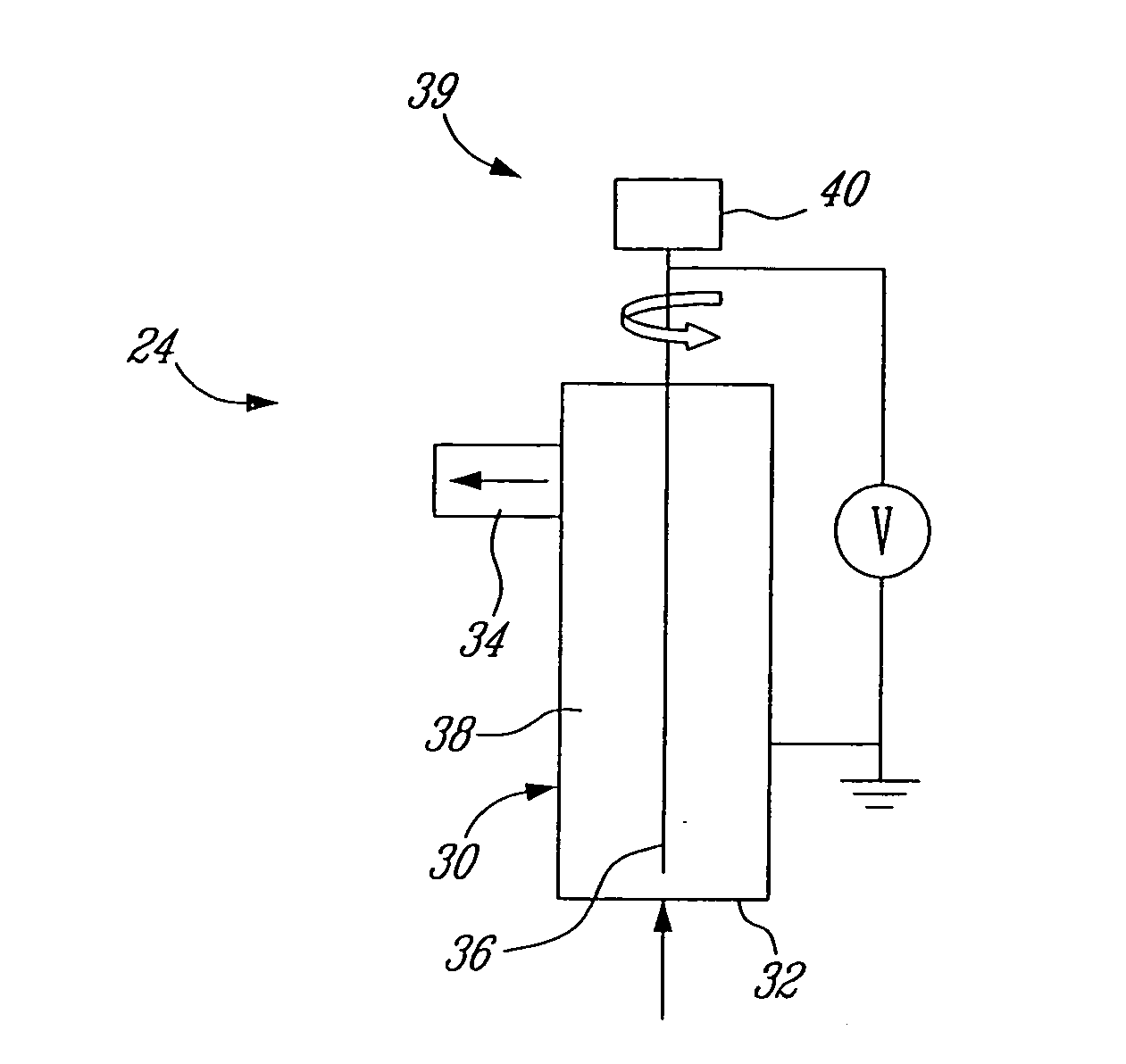

Polyethylene terephthalate and polyurethane composite artificial blood vessel and preparation thereof

ActiveCN102008755AIncrease elasticityImprove mechanical propertiesNew-spun product collectionFilament/thread formingCell adhesionPolyethylene terephthalate glycol

The invention discloses a polyethylene terephthalate and polyurethane composite artificial blood vessel and a preparation method thereof, belonging to the field of biomedical engineering. The artificial blood vessel is prepared from polyethylene terephthalate and polyurethane by means of an electrostatic spinning device with a stirrer. The prepared artificial blood vessel is a tubular object witha microporous structure. The polyurethane added in the artificial blood vessel can improve the elasticity of the blood vessel under the condition of not damaging the strength of the polyethylene terephthalate material, increase the compliance of the artificial blood vessel and achieve the requirements of clinical use. The polyethylene terephthalate and polyurethane composite artificial blood vessel has the advantages of high strength, large elasticity and compliance, good biocompatibility, strong anticoagulant property and large cell adhesion, and can meet the requirements of the clinical useof the artificial blood vessels with large diameter and small diameter. The preparation process is simple and practical, and applicable to preparing the artificial blood vessels with various different requirements on mechanical properties.

Owner:宁波贝昂生物材料有限公司

Forming a composite structure by filament placement on a tool surface of a tablet

ActiveUS8003034B2Large massComplexity of and and reduced eliminatedNew-spun product collectionFilament/thread formingFiberEngineering

A method and apparatus are provided for forming a composite structure with an automatic placement head, through the use of a non-rotating tooling tablet having first and second substantially oppositely facing surfaces thereof, joined around the peripheries thereof by a side surface of the tablet, with at least one of the first or second surfaces forming a tool surface of the tablet. Layers of pre-impregnated fiber or tape are applied to the tool surface of the tablet by the automated fiber placement head.

Owner:INGERSOLL MACHINE TOOLS

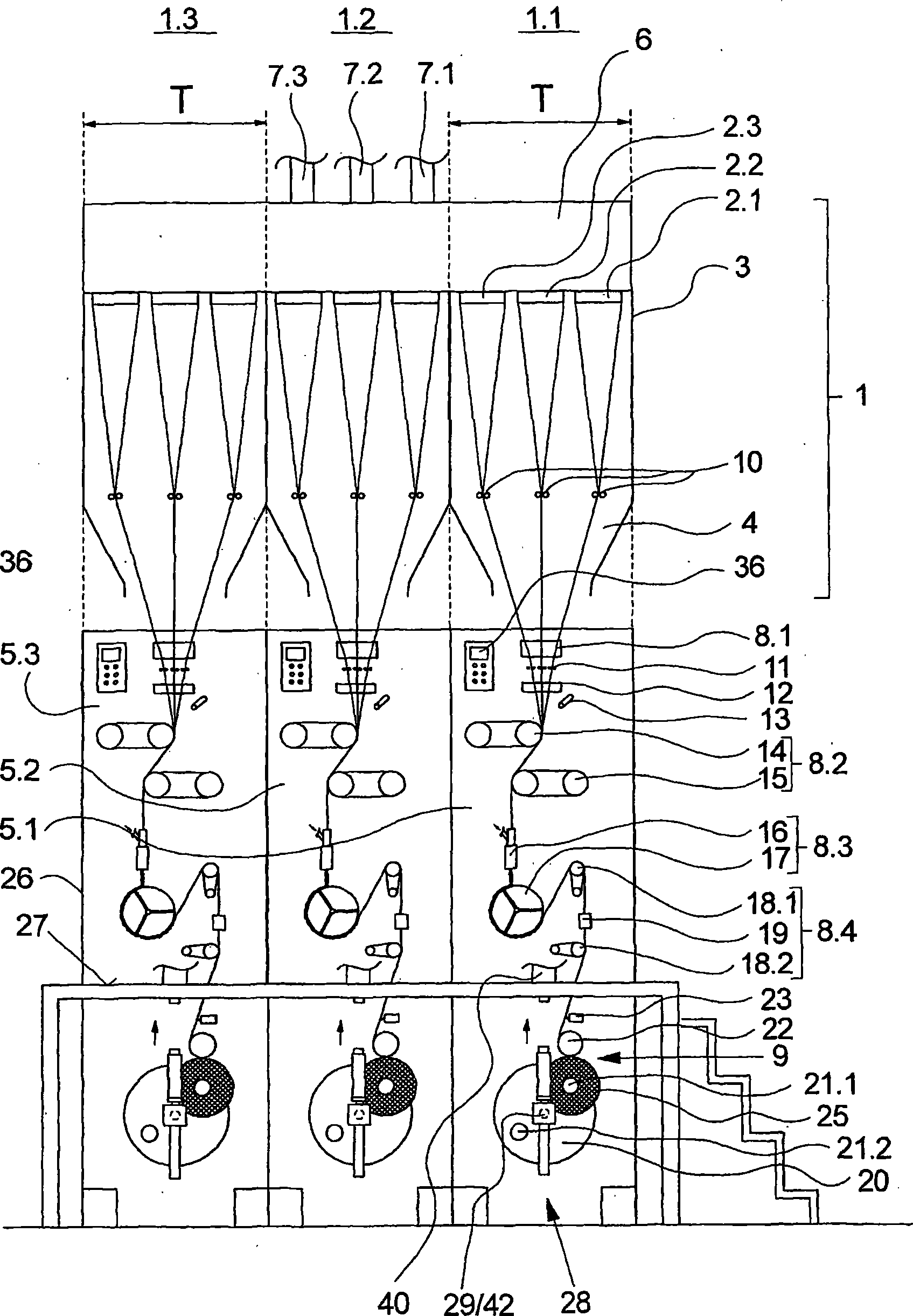

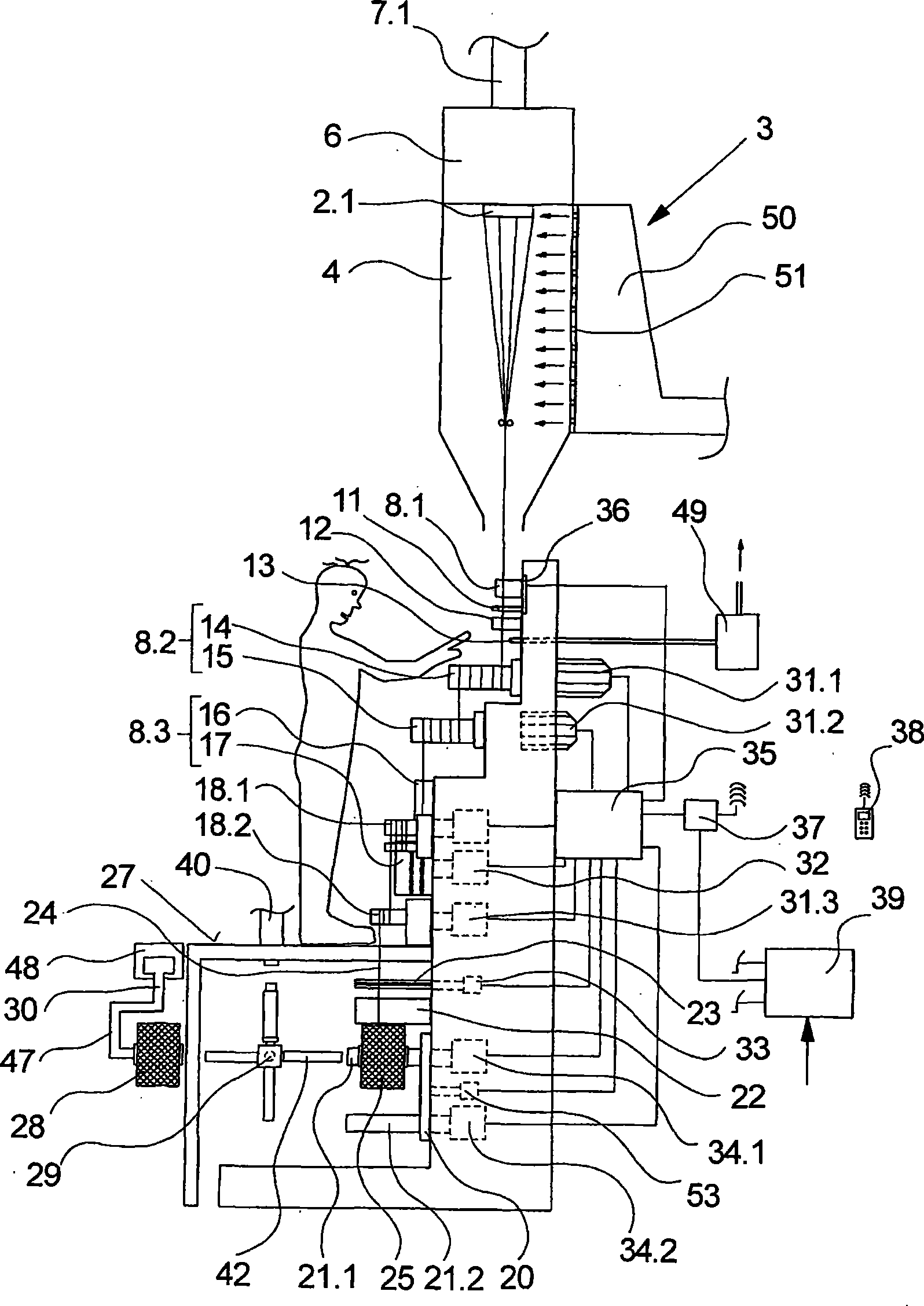

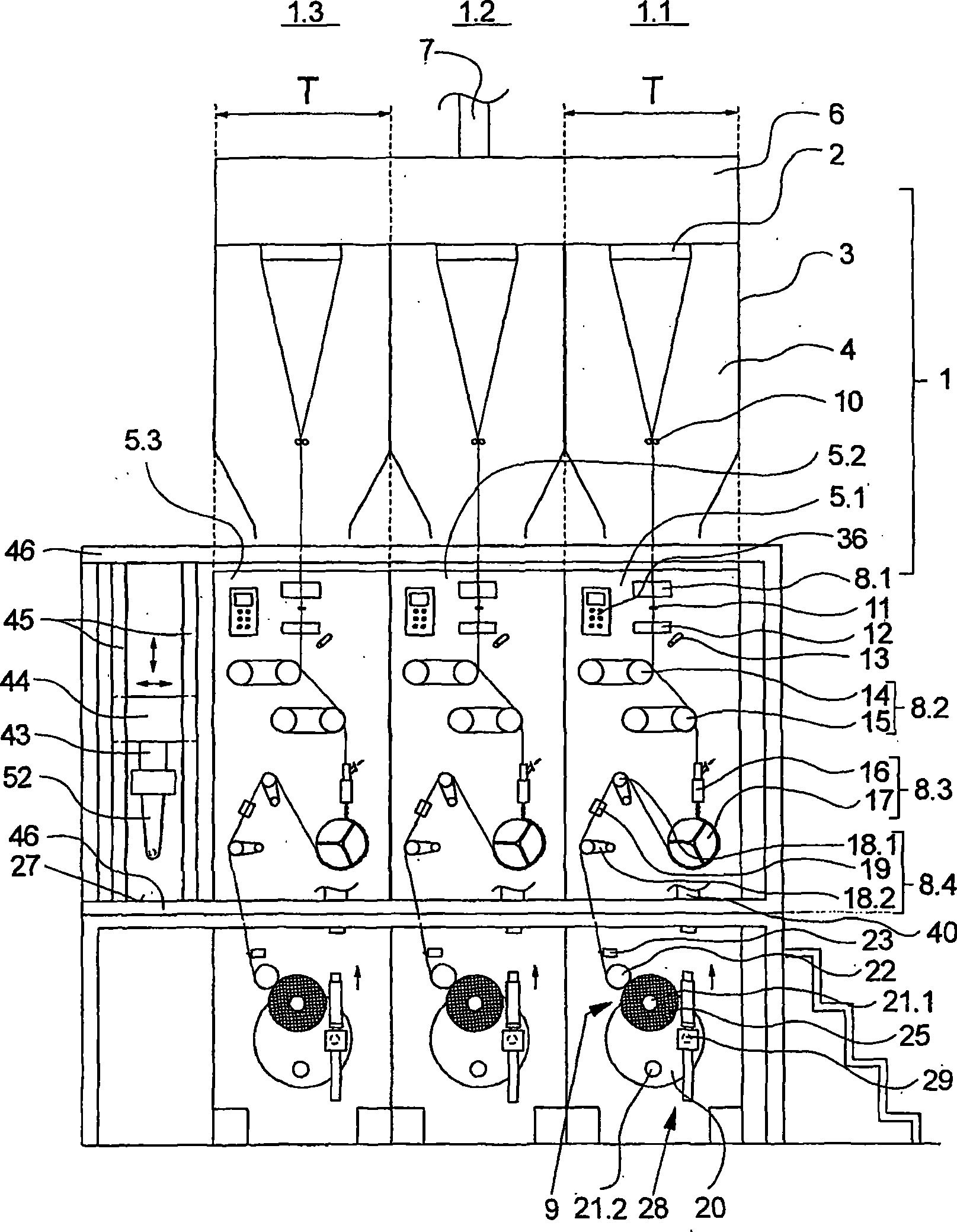

Device for melt spinning, treating and winding synthetic threads

InactiveCN101437990AEliminate interactive broken wiresImprove practicalityNew-spun product collectionArtificial thread manufacturing machinesComputer moduleEngineering

The invention relates to a spinning, drawing and texturing machine for producing curled threads, said machine comprising a spinning unit and several machine modules that are allocated to the spinning unit. Each of said machine modules has several processing assemblies for drawing and curling one of the threads and a spooling unit for winding the thread. The machine modules are arranged next to one another to form a longitudinal side of the machine, the processing assemblies and spooling units being held in relation to one another on the machine modules in such a way that a narrow machine partition of approximately <800 mm occurs on the longitudinal side of the machine. The spinning unit has one or more spinnerets and a spinning duct within the machine partition, said spinnerets being held in rows parallel to the longitudinal side of the machine. Respective spinning positions that combine to produce a thread are thus obtained for each machine module.

Owner:OERLIKON TEXTILE GMBH & CO KG

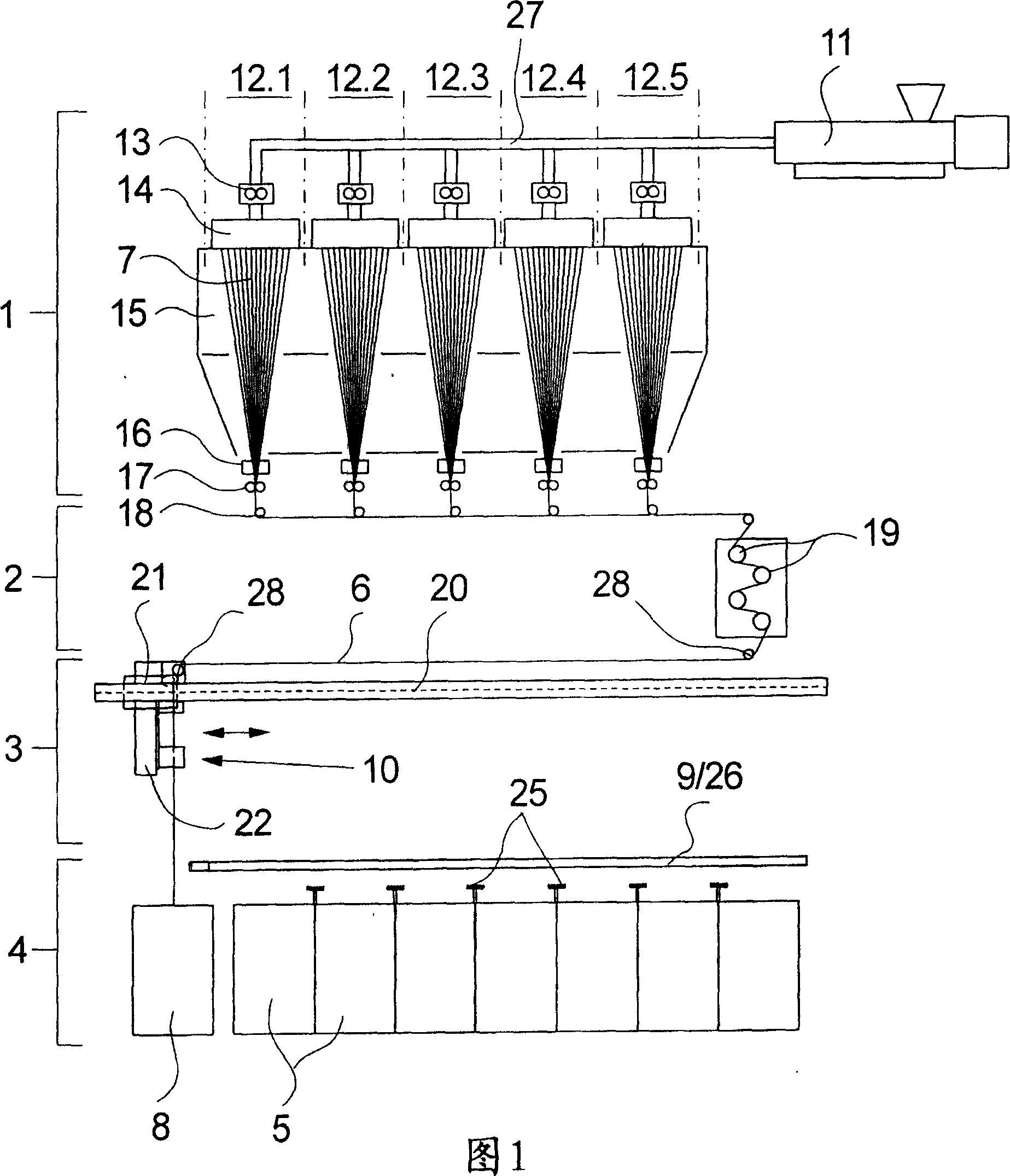

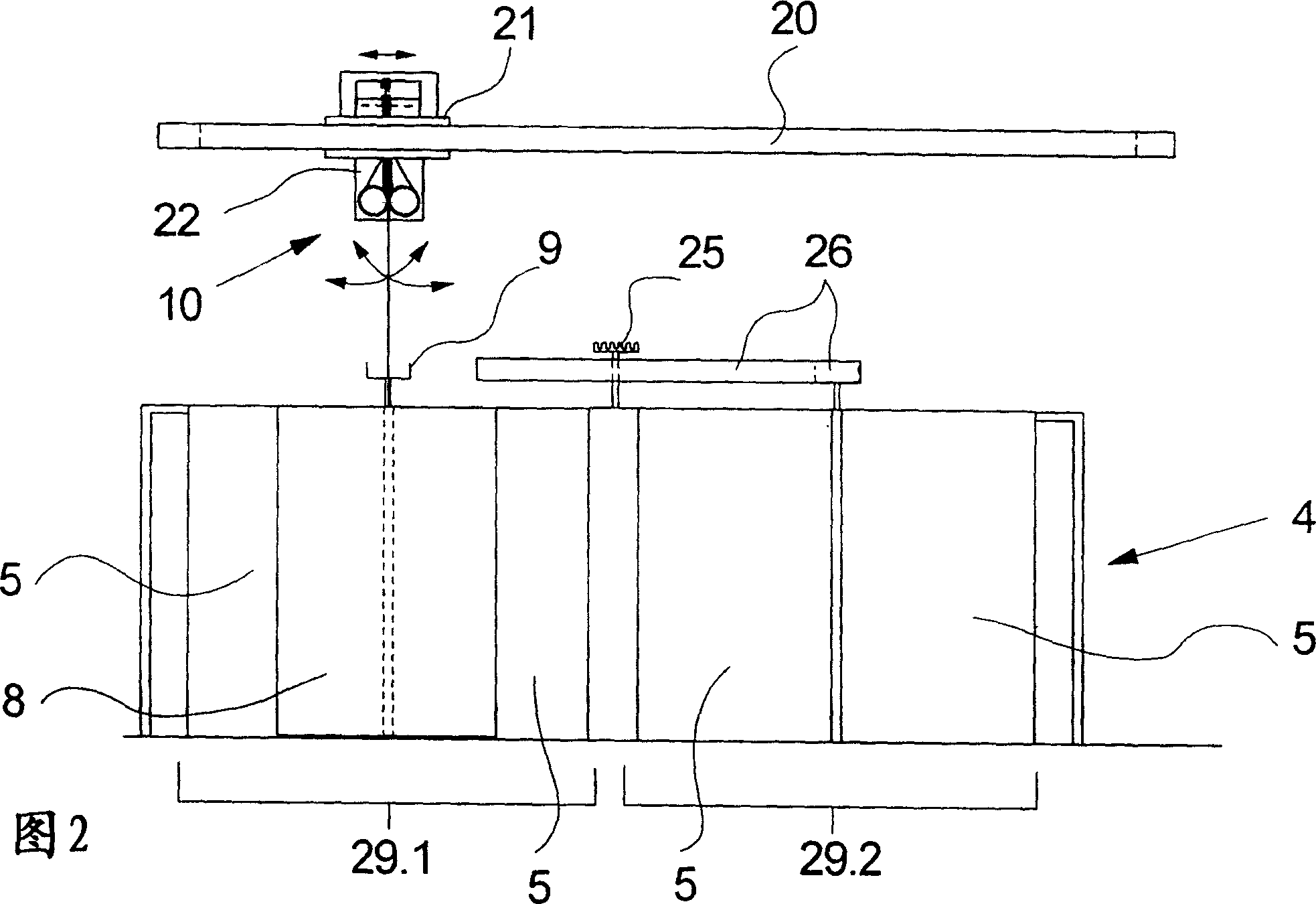

Method and device for producing and storing tows

InactiveCN101016656AAvoid clearingMaximum loadingProgramme-controlled manipulatorNew-spun product collectionPolymer meltMechanical engineering

The invention relates to a method and device to manufacture and store wire beams. Plenty of single wire beams are manufactured by parallel abreast spinning and pumping of polymer melts and form wire beams. The wire beams are continuously located in canisters of frame by transportation mechanism, and fills the canisters in order. In order to reliably received unqualified wire beams in beginning or ending of the process, a waster canister is located on the frame.

Owner:SAURER GMBH & CO KG

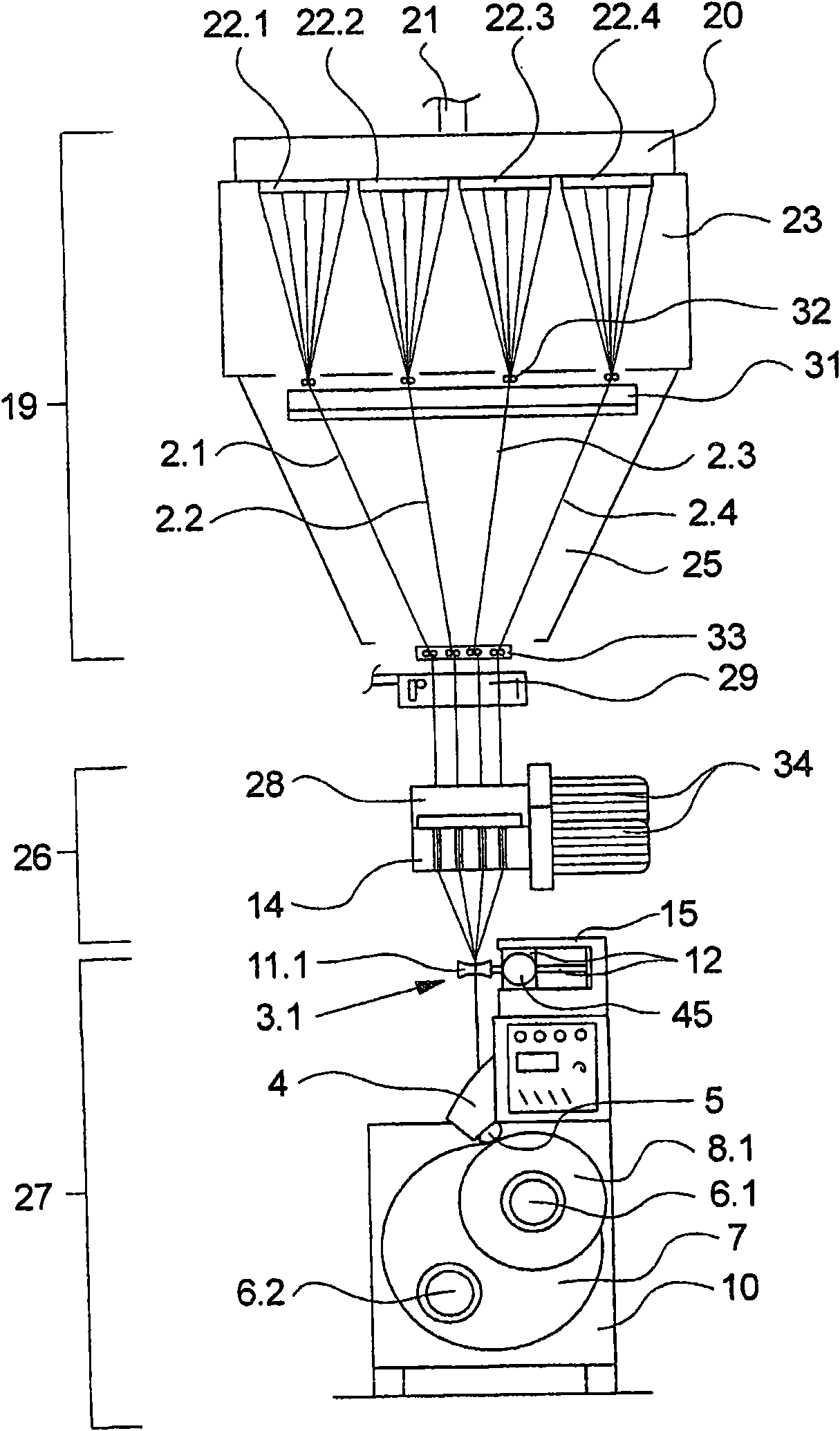

Manufacturing technique of melt direct spinning polyester activate industrial yarns

ActiveCN103088453AShort turnaround timeReduce energy consumptionNew-spun product collectionFilament forming substance formingYarnPolyester

The invention discloses a manufacturing technique of melt direct spinning polyester activate industrial yarns, and specifically belongs to the field of fiber manufacturing in polyester industry. The manufacturing technique is used for rubber framework materials and comprises melt liquid tackifying, melt direct spinning, draft heat shaping and winding molding. A vertical type liquid phase tackifying reactor is used for tackifying, a spinning technique, multi-stage draft, multi-stage relaxation heat shaping, activating treatment of oil applying on an oil nozzle, and unique high speed winding of a winder are matched, and therefore yarn activation of the melt direct spinning polyester activate industrial yarns is achieved. The manufacturing technique of the melt direct spinning polyester activate industrial yarns has the advantages of being low in energy consumption, high in the rate of production, short in production cycle and the like. Manufactured activation yarns can be used for rubber framework materials such as a conveying belt, a triangle belt, canvas, ropes and the like.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

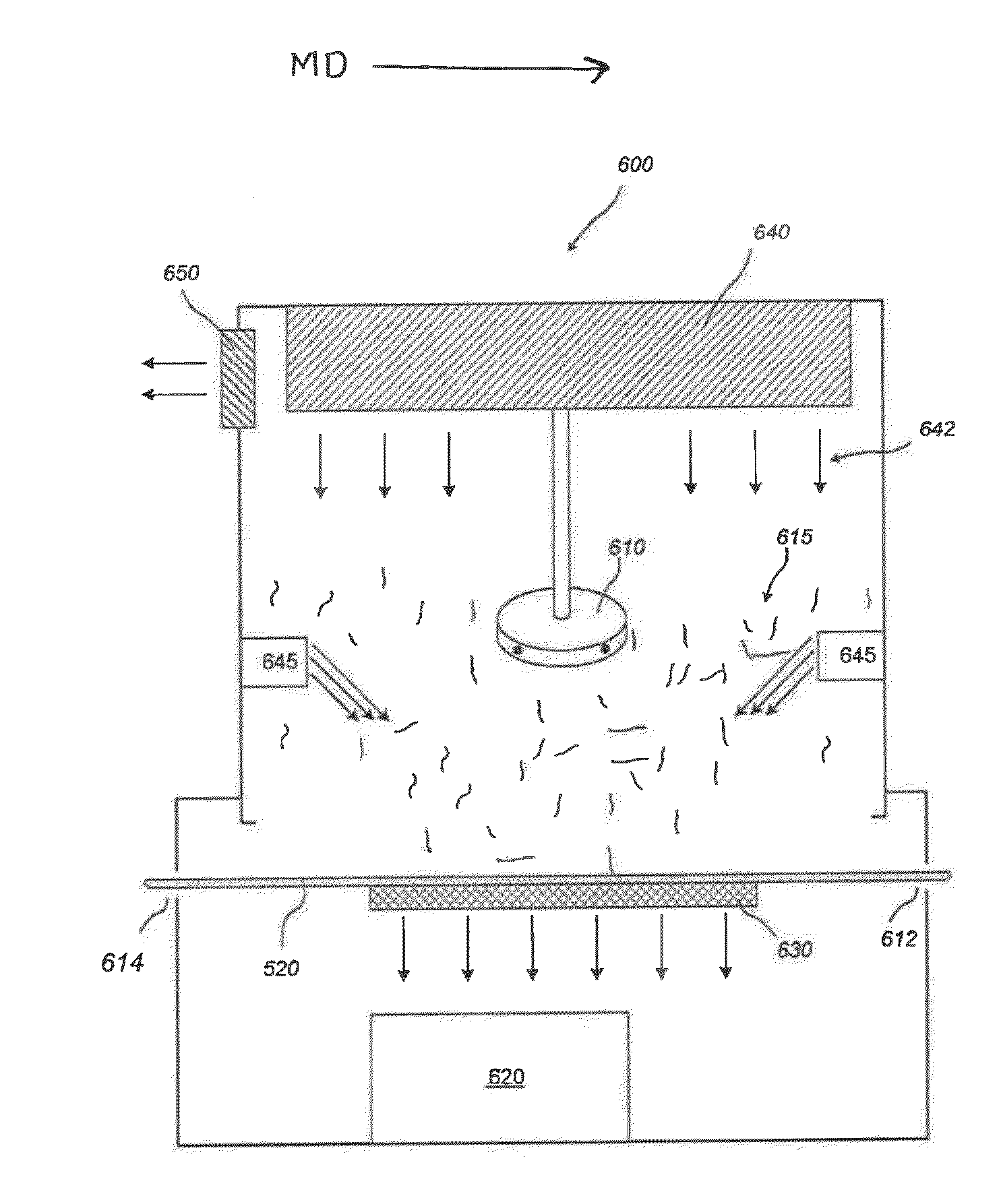

Negative Polarity on the Nanofiber Line

A centrifugal spinning system and method for forming a fibrous web containing nanofibers, microfibers, or a combination thereof from a molten polymer composition or an aqueous spinning solution is provided. Through careful control over the arrangement of the system, a fibrous web can be formed that is relatively defect free. To help accomplish this feature, at least two centrifugal spinning chambers, each containing a charged forming plate, are utilized. To minimize the present of defects in the fibrous web, the charge applied to the first spinning chamber has a polarity that is opposite the polarity of the charge applied to the second spinning chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com