Continuous preparation method for ultra-fine electrostatic spinning fibre yarn

An electrospinning and electrospinning technology is applied in the field of preparation of nanofibers, which can solve the problems of difficult to obtain highly oriented fibers and fiber bundles, and difficult to continuously obtain single nanofibers or uniaxial fiber bundles, etc., to broaden the application field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 1.0 g of purified 3-hydroxybutyric acid and 3-hydroxyvaleric acid copolyester (PHBV) in 99 g (88 / 11) of chloroform / alcohol mixed solvent to obtain a transparent and uniform product with a mass fraction of 1 wt%. The solution;

[0029] (2) Benzyltriethylammonium chloride with a mass fraction of 0.3wt% is added in the solution to improve the spinning properties of the solution;

[0030] (3) Perform electrospinning with the prepared electrospinning dope. The spinning parameters are controlled at a voltage of 10kV, a nozzle aperture of 0.4mm, a solution flow rate of 1ml / h, an ambient temperature of 30°C, a relative air humidity of 65%, and a winding speed of 230r / min;

[0031] (4) Use the grounding needle tip to approach the nozzle to induce bundles of the electrospun fibers;

[0032] (5) Drag the bundled fiber bundle backwards through the twisting device for twisting;

[0033] (6) Winding the twisted continuous yarn on the bobbin through the winding device....

Embodiment 2

[0036] (1) Dissolving 10 g of purified PAN in N, N-dimethylformamide (DMF) (90 g) to obtain a transparent and uniform solution with a mass fraction of 10 wt % PAN;

[0037] (2) Benzyltriethylammonium chloride with a mass fraction of 0.3wt% is added in the solution to improve the spinning properties of the solution;

[0038] (3) Perform electrospinning with the prepared electrospinning dope. The spinning parameters are controlled at a voltage of 9kV, a nozzle aperture of 0.05mm, a solution flow rate of 1.5ml / h, an ambient temperature of 50°C, a relative air humidity of 50%, and a winding speed of 300r / min;

[0039] (4) Use the grounding needle tip to approach the nozzle to induce bundles of the electrospun fibers;

[0040] (5) Drag the bundled fiber bundle backwards through the twisting device for twisting;

[0041] (6) Winding the twisted continuous yarn on the bobbin through the winding device.

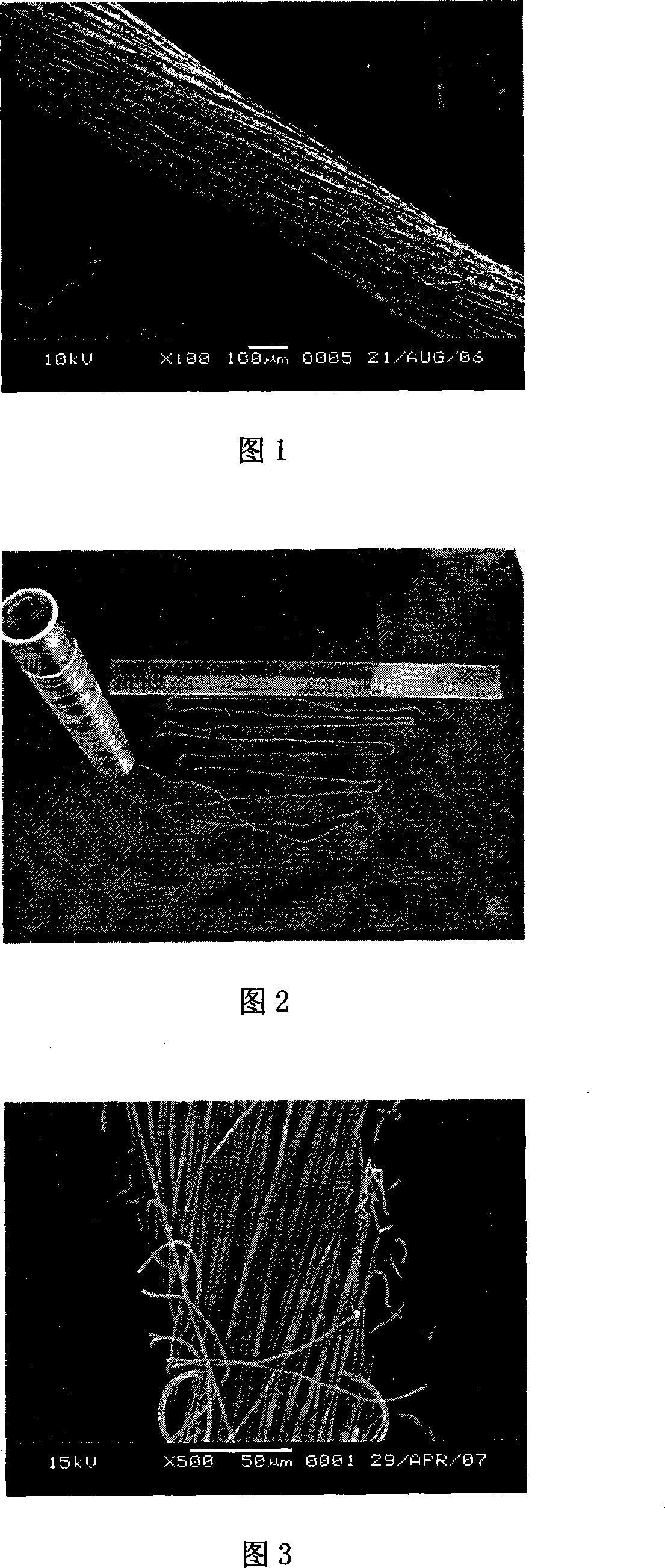

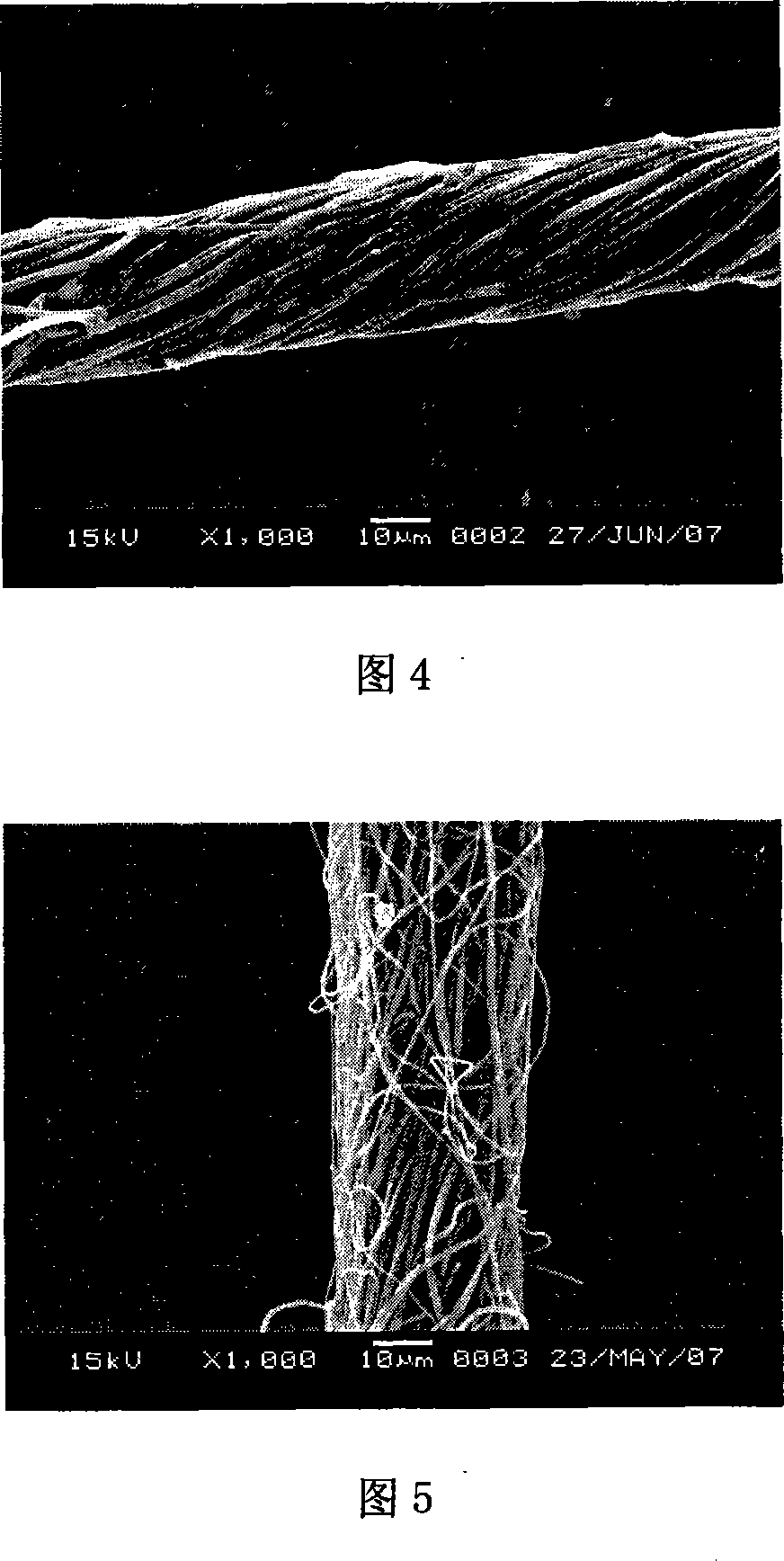

[0042] Figure 2 is a general photo of PAN electrospun fiber yarn, and Figure 3 ...

Embodiment 3

[0044] (1) 12 g of purified polylactic acid (PLA) was dissolved in 88 g (50 / 33) of dichloromethane / DMF mixed solvent to obtain a transparent and uniform solution with a mass fraction of 12 wt %;

[0045] (2) the sodium chloride that mass fraction is 0.5wt% is added in the solution, to improve the spinning characteristic of solution;

[0046] (3) Perform electrospinning with the prepared electrospinning dope. The spinning parameters were controlled at a voltage of 17kV, a nozzle aperture of 0.8mm, a solution flow rate of 3.6ml / h, an ambient temperature of 25°C, a relative air humidity of 70%, and a winding speed of 180r / min.

[0047] (4) Use the grounding needle tip to approach the nozzle to induce bundles of the electrospun fibers;

[0048] (5) Drag the bundled fiber bundle backwards through the twisting device for twisting;

[0049] (6) Winding the twisted continuous yarn on the bobbin through the winding device.

[0050] Figure 4 is a scanning electron micrograph of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com