Method of manufacturing a continuous filament by electrospinning and continuous filament manufactured thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0099]A polymer spinning dope was prepared by dissolving nylon 6 resin, which has a relative viscosity of 3.2 in a 96% sulfuric acid solution, in formic acid at a concentration of 15% by weight. The polymer spinning dope had a surface tension of 49 mN / m, a solution viscosity of 40 centipoise at an ambient temperature, and an electrical conductivity of 420 mS / m.

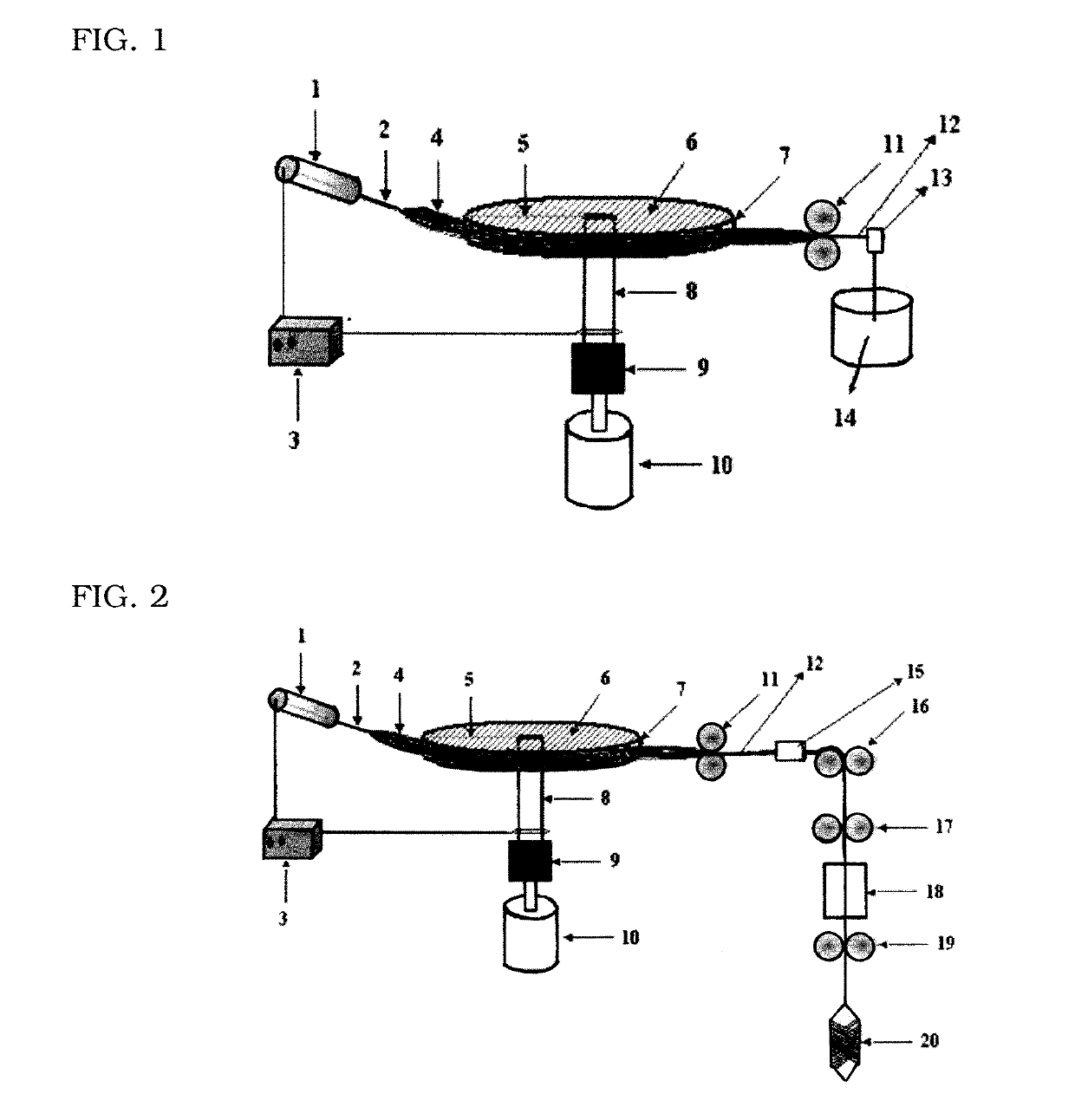

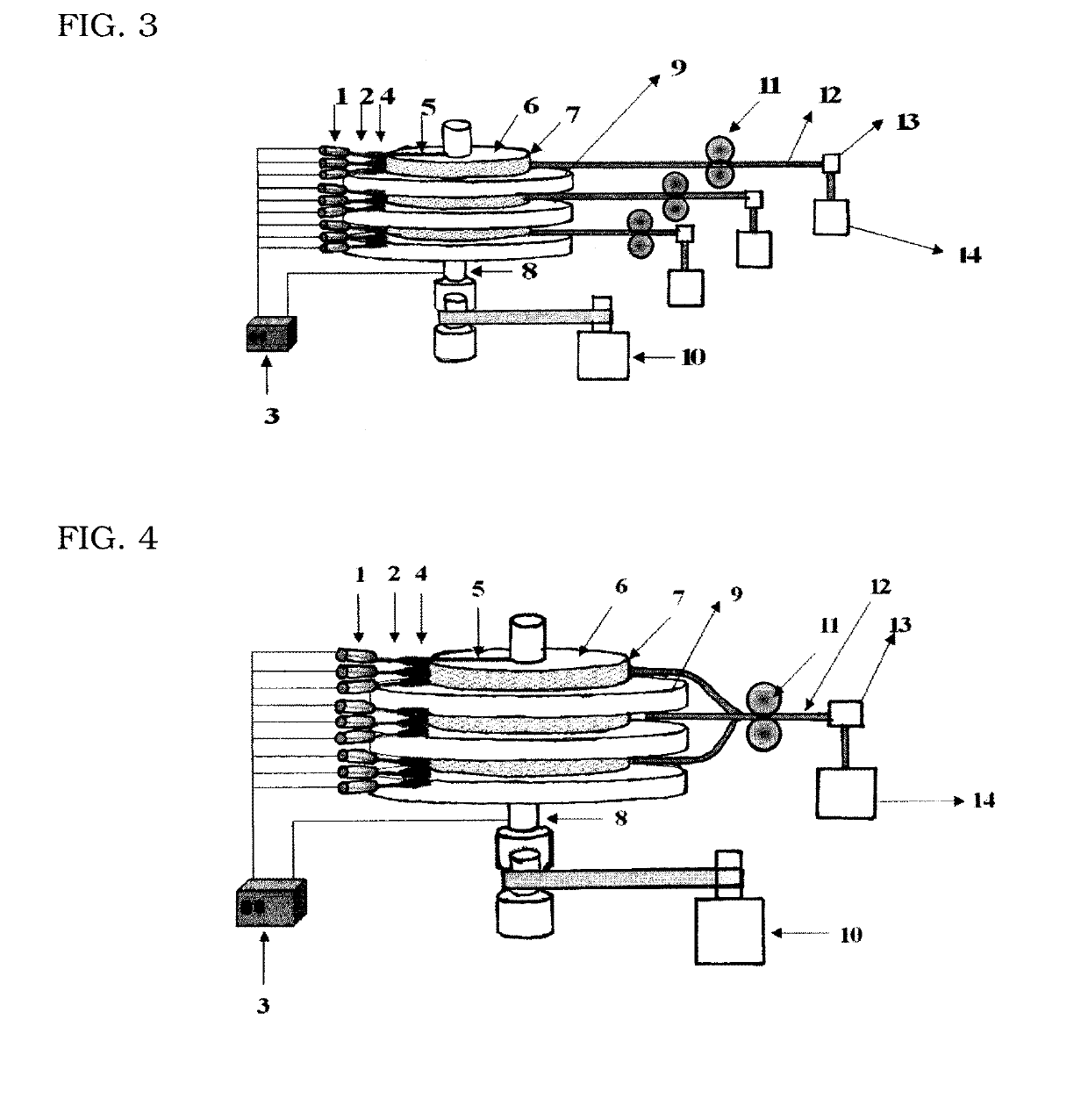

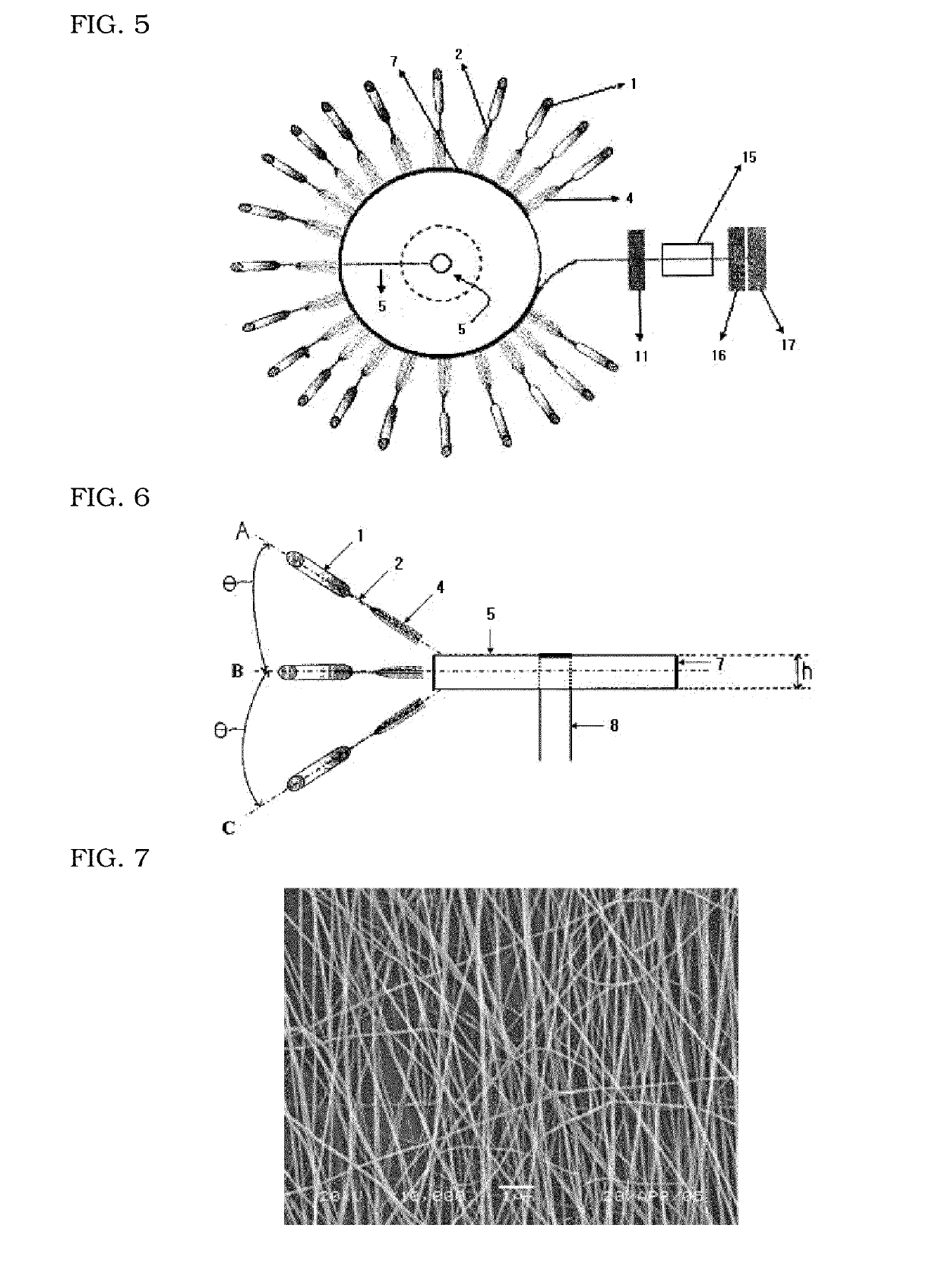

[0100]The prepared spinning dope was electrically spun onto a collector 7, which is a disk-shaped stainless steel plate having a high voltage applied thereto and rotating at a rotational linear velocity of 20 m / sec, through nozzles 2 with a high voltage applied thereto in the electrospinning method as shown in FIG. 1, thereby collecting electrospun nano fibers 4 on the collector 7.

[0101]The collector rotates by being connected to a rotary motor 10 by connecting rods 8 and 9, and has a diameter of 1.5 m. The height (h) of the collector is 25 mm.

[0102]The total number of the nozzles 2 is 900. They are arranged in 300 matrices in...

example 2

[0107]A continuous filament was prepared under the same procedure and conditions as in Example 1 except that the rotational linear velocity of the collector 7 and the surface velocity of the collecting roller 11 were changed to 10 m / sec, respectively. As a result of evaluating the physical properties of the prepared continuous filament, the strength was 140 MPa, the degree of elongation was 32%, and the nano fibers were arranged at an arrangement angle of 2.8° in the axis direction of the filament.

[0108]FIG. 8 is an electron micrograph of the surface of the prepared continuous filament. A stress-strain curve graph of the prepared continuous filament was as shown in b of FIG. 9.

example 3

[0109]A polymer spinning dope was prepared by dissolving a poly(ε-caprolactone) polymer (purchased from Aldrich Chemical Company) having a number average molecular weight of 80,000 in a mixed solvent of methylene chloride / N,N′-dimethyl form amide (volume ratio: 75 / 25) at a concentration of 13% by weight. The polymer spinning dope had a surface tension of 35 mN / m, a solution viscosity of 250 centipoise at an ambient temperature, an electrical conductivity of 0.02 mS / m and a permittivity constant of 90.

[0110]The prepared spinning dope was electrically spun onto a collector 7, which is a disk-shaped stainless steel plate having a high voltage applied thereto and rotating at a rotational linear velocity of 10 m / sec, through nozzles 2 with a high voltage applied thereto in the electrospinning method as shown in FIG. 1, thereby collecting electrospun nano fibers 4 on the collector 7.

[0111]The collector rotates by being connected to a rotary motor 10 by connecting rods 8 and 9, and has a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com